Patents

Literature

1230 results about "Silicon oxynitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon oxynitride is a ceramic material with the chemical formula SiOₓNy. While in amorphous forms its composition can continuously vary between SiO₂ (silica) and Si₃N₄ (silicon nitride), the only known intermediate crystalline phase is Si₂N₂O. It is found in nature as the rare mineral sinoite in some meteorites and can be synthesized in the laboratory.

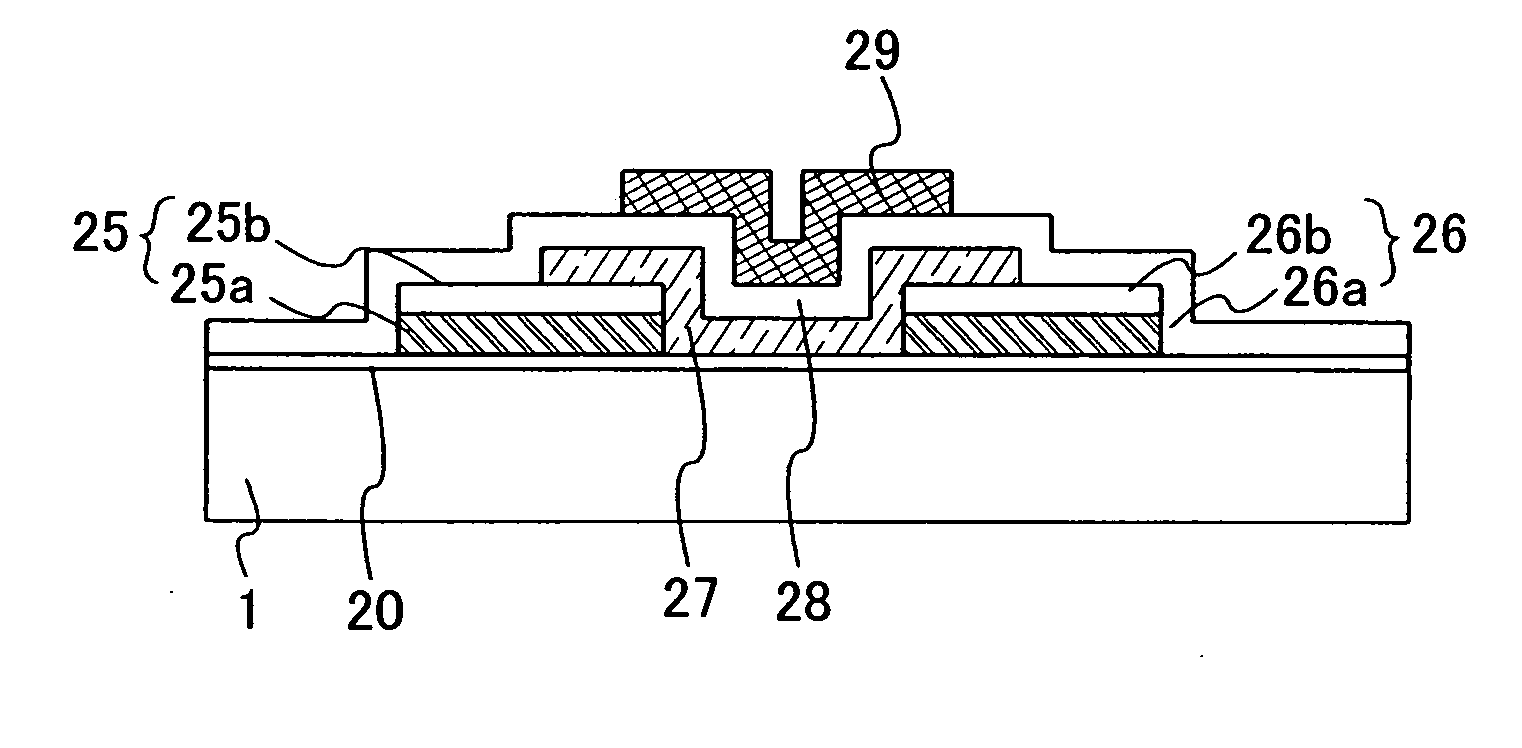

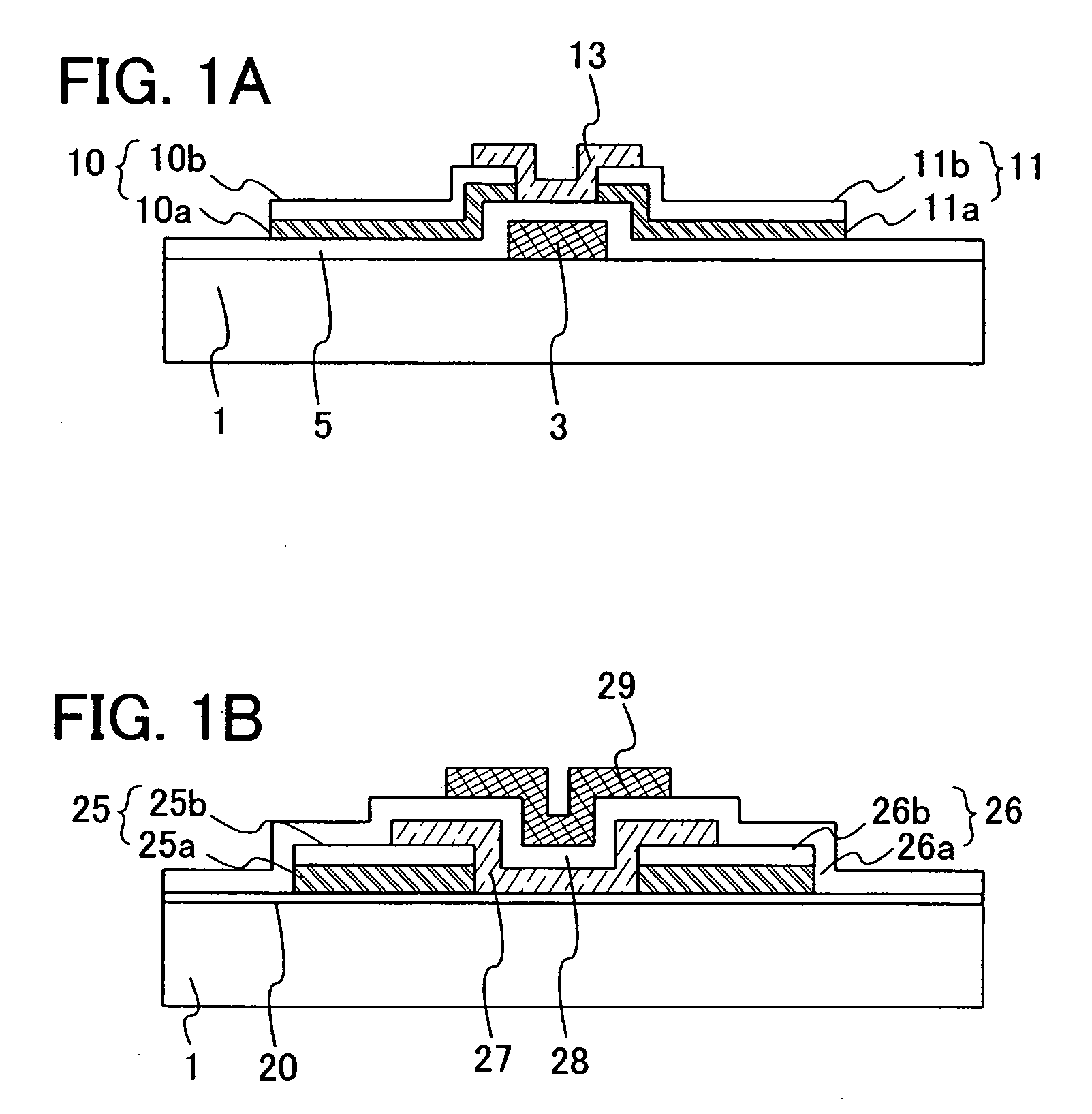

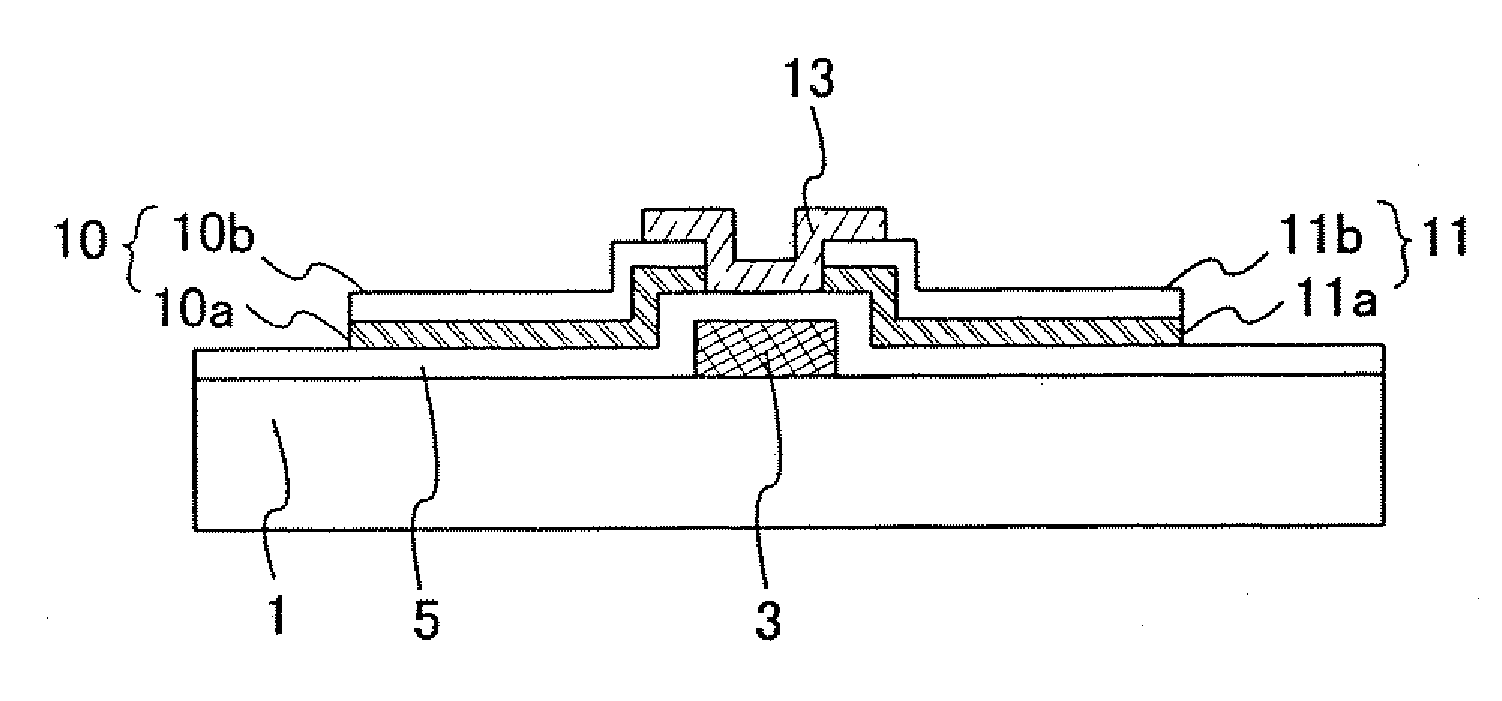

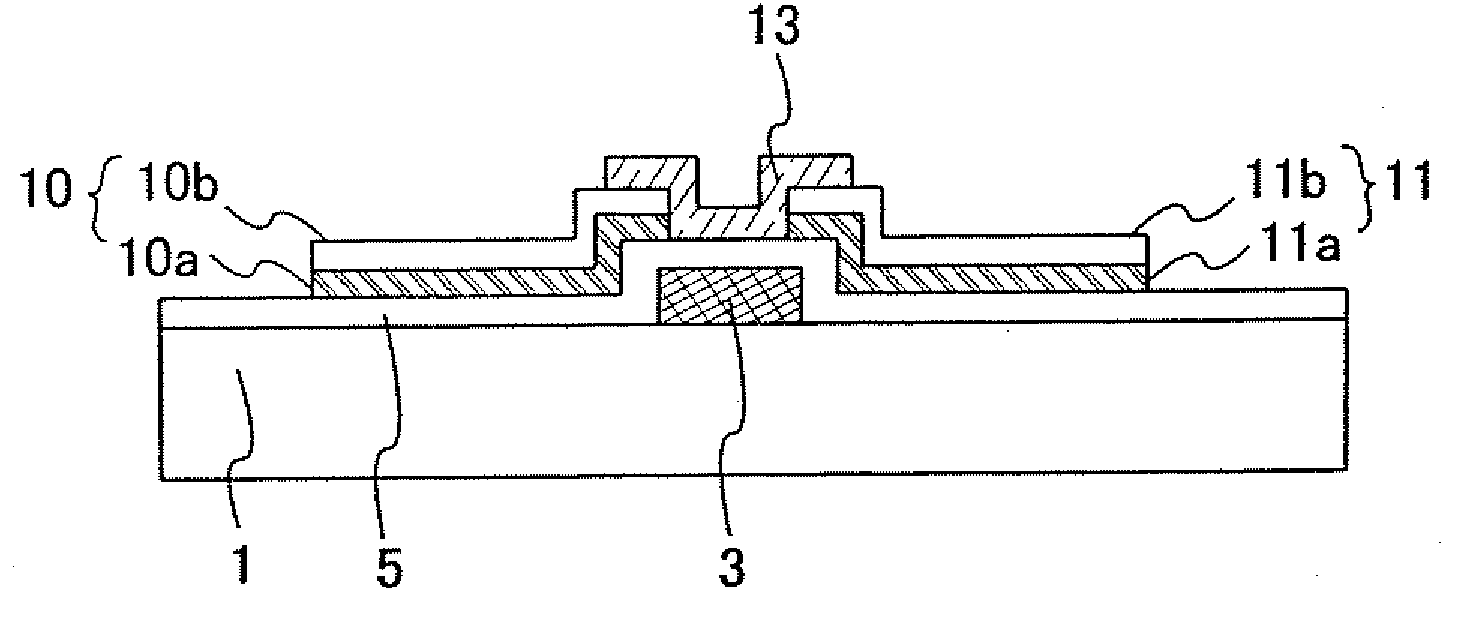

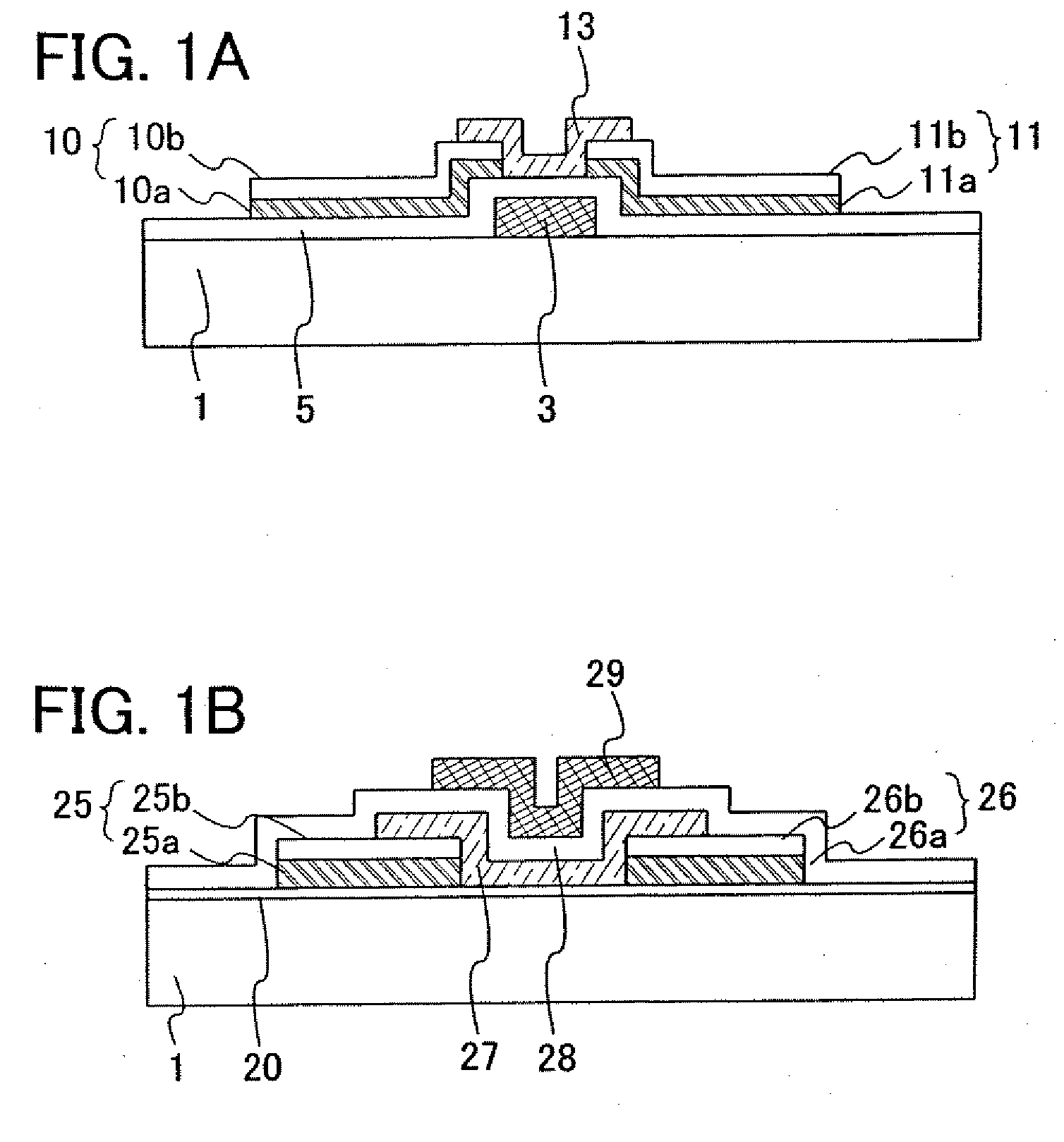

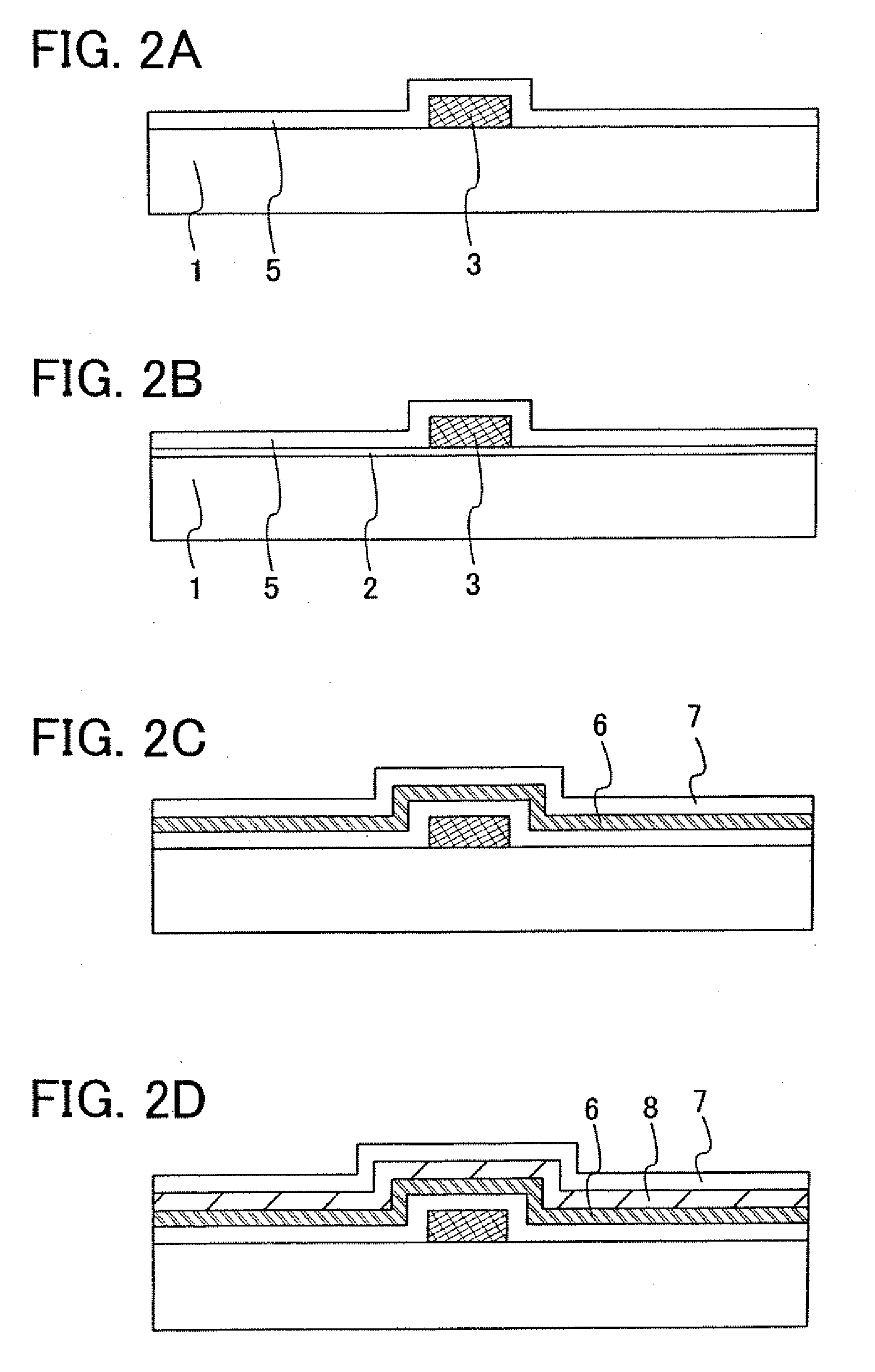

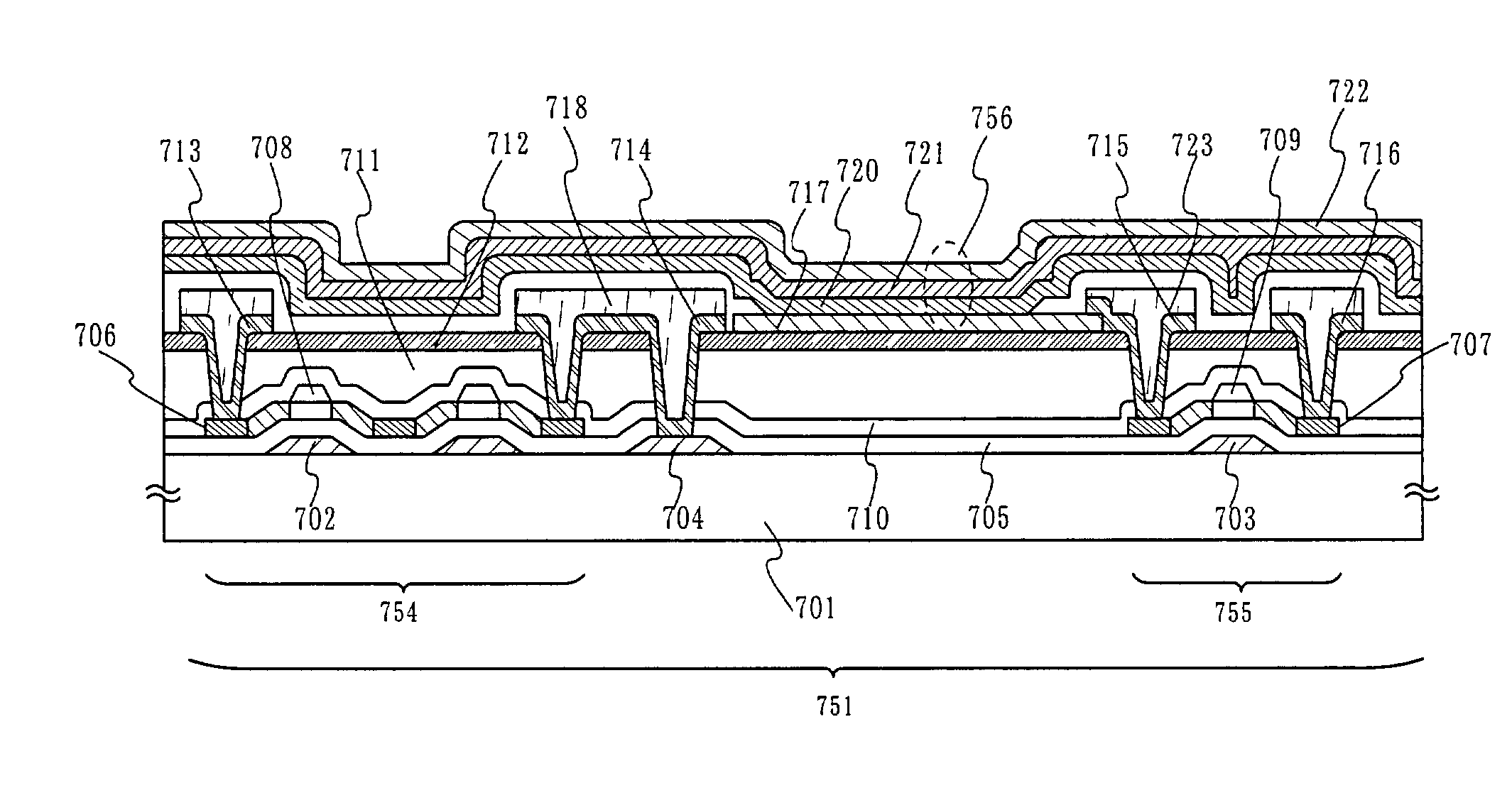

Semiconductor device and manufacturing method thereof

ActiveUS20070108446A1Low resistance of wireLower resistanceTransistorElectroluminescent light sourcesAlloySilicon oxide

To provide a semiconductor device in which a defect or fault is not generated and a manufacturing method thereof even if a ZnO semiconductor film is used and a ZnO film to which an n-type or p-type impurity is added is used for a source electrode and a drain electrode. The semiconductor device includes a gate insulating film formed by using a silicon oxide film or a silicon oxynitride film over a gate electrode, an Al film or an Al alloy film over the gate insulating film, a ZnO film to which an n-type or p-type impurity is added over the Al film or the Al alloy film, and a ZnO semiconductor film over the ZnO film to which an n-type or p-type impurity is added and the gate insulating film.

Owner:SEMICON ENERGY LAB CO LTD

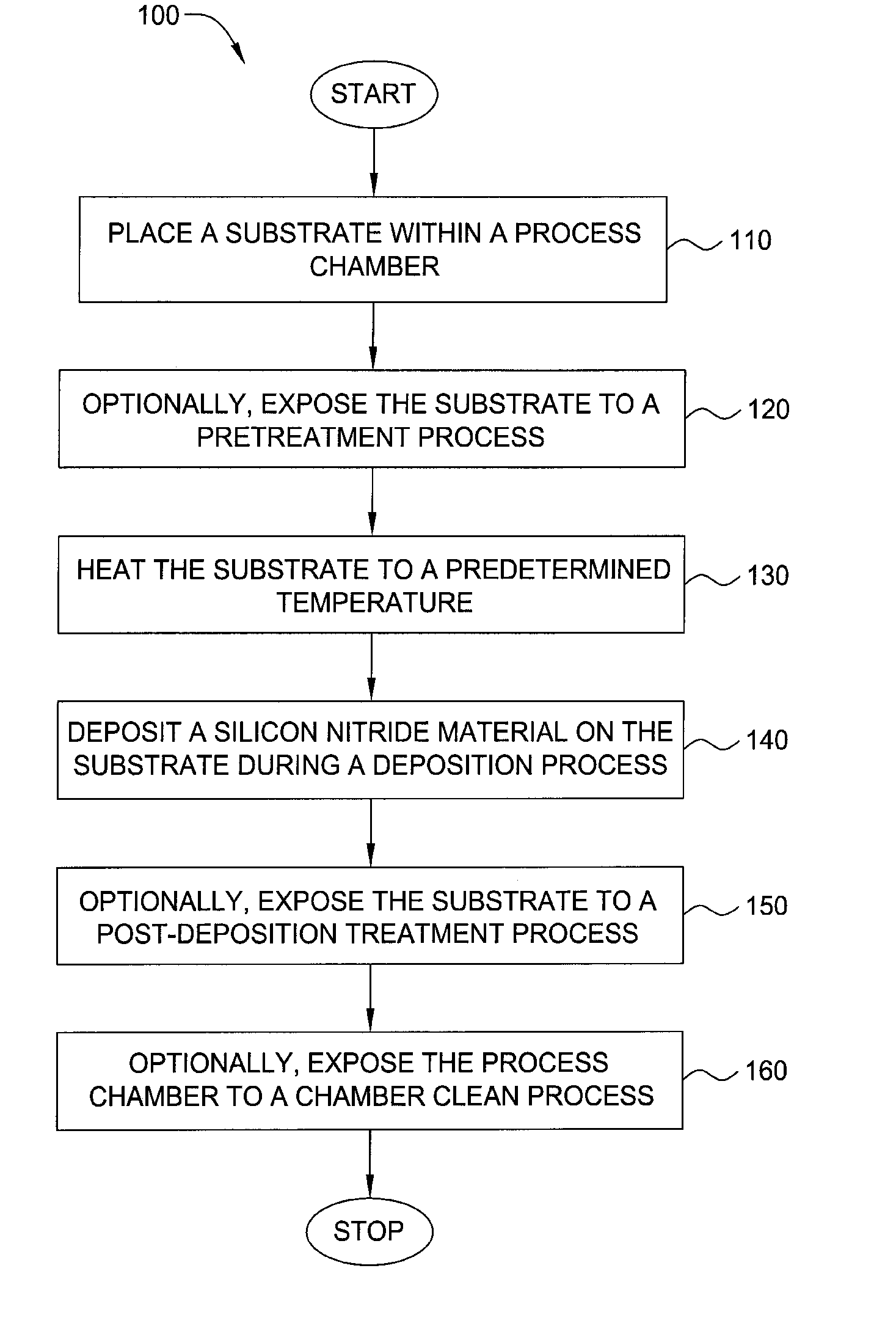

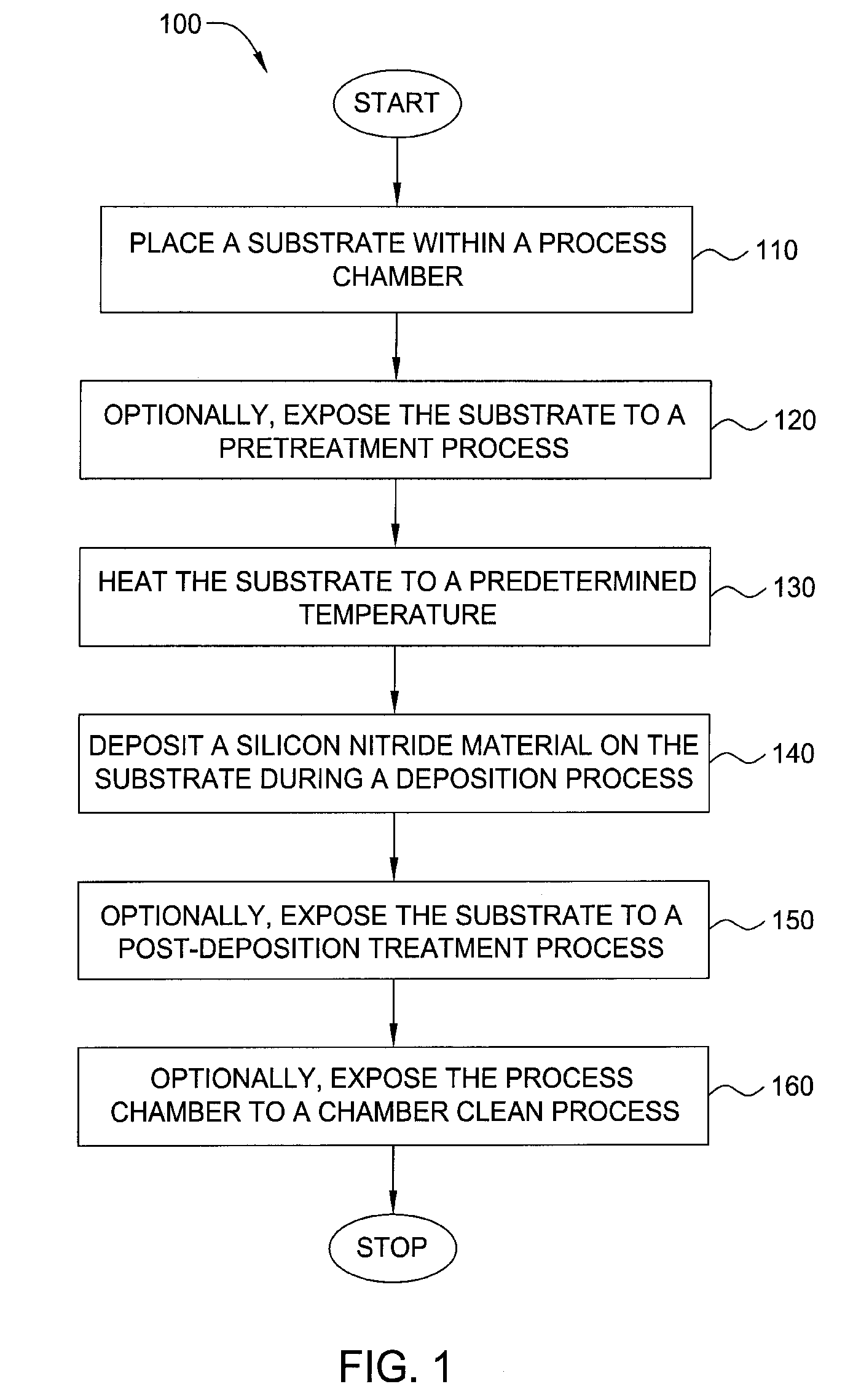

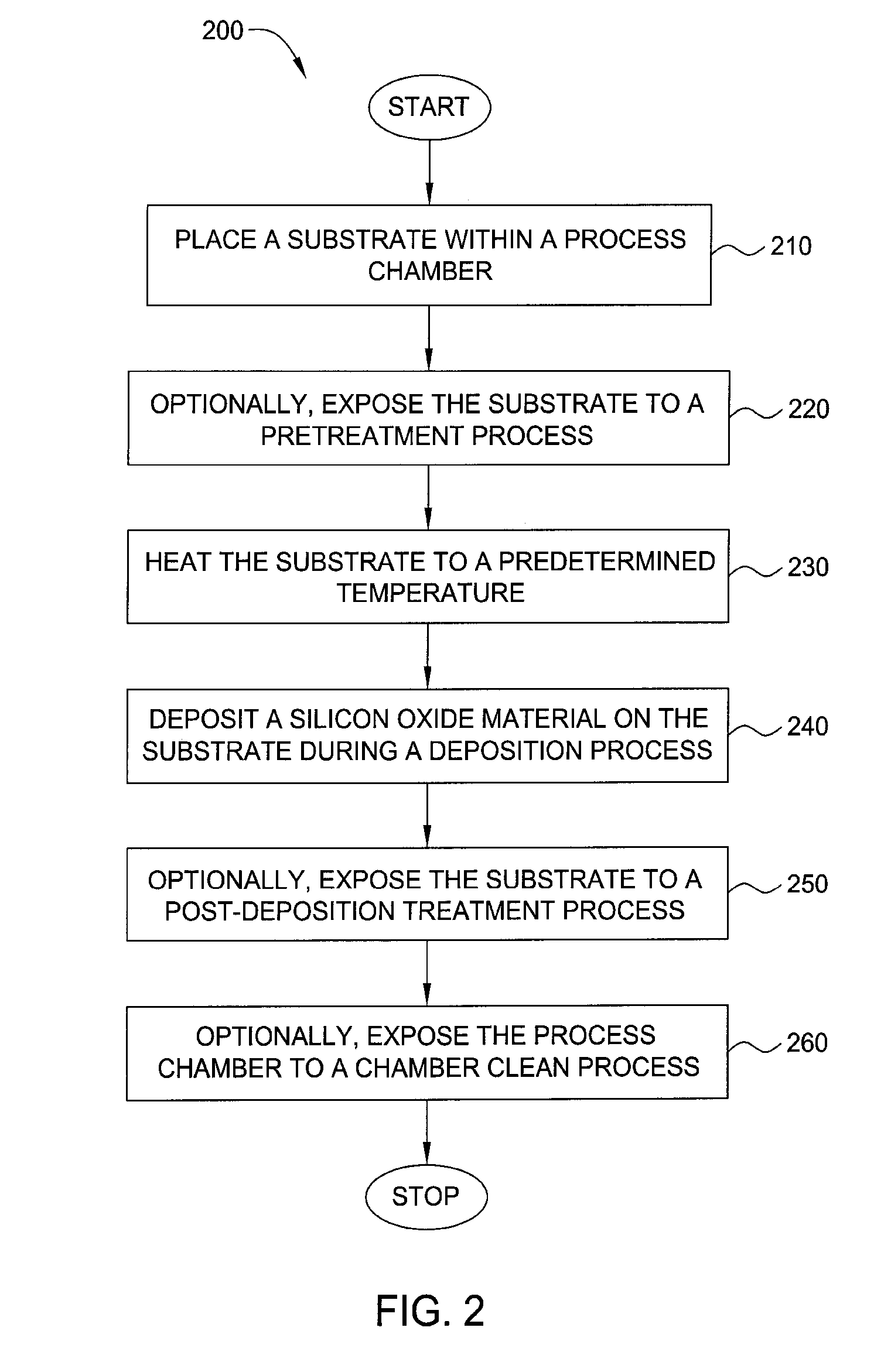

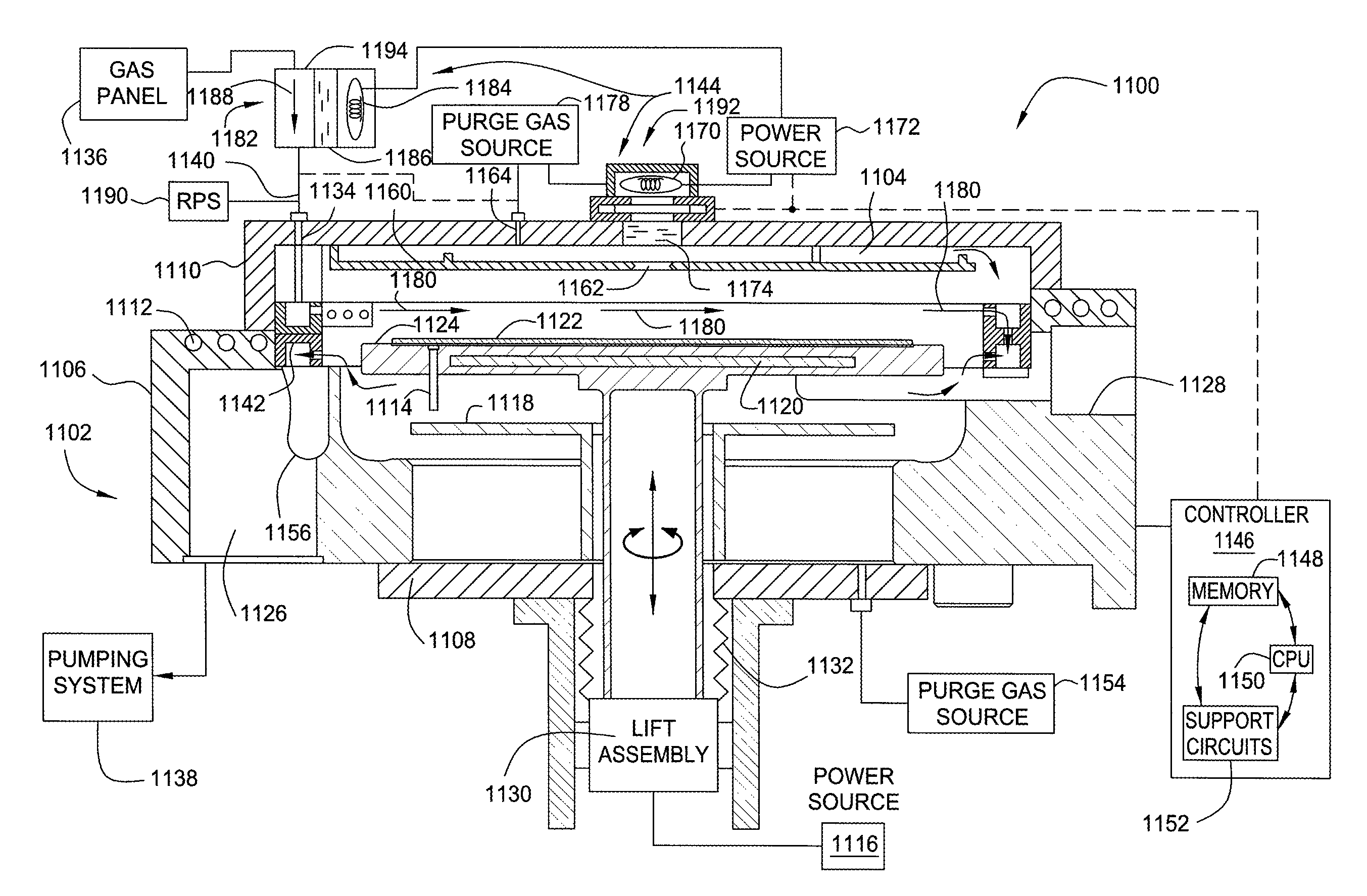

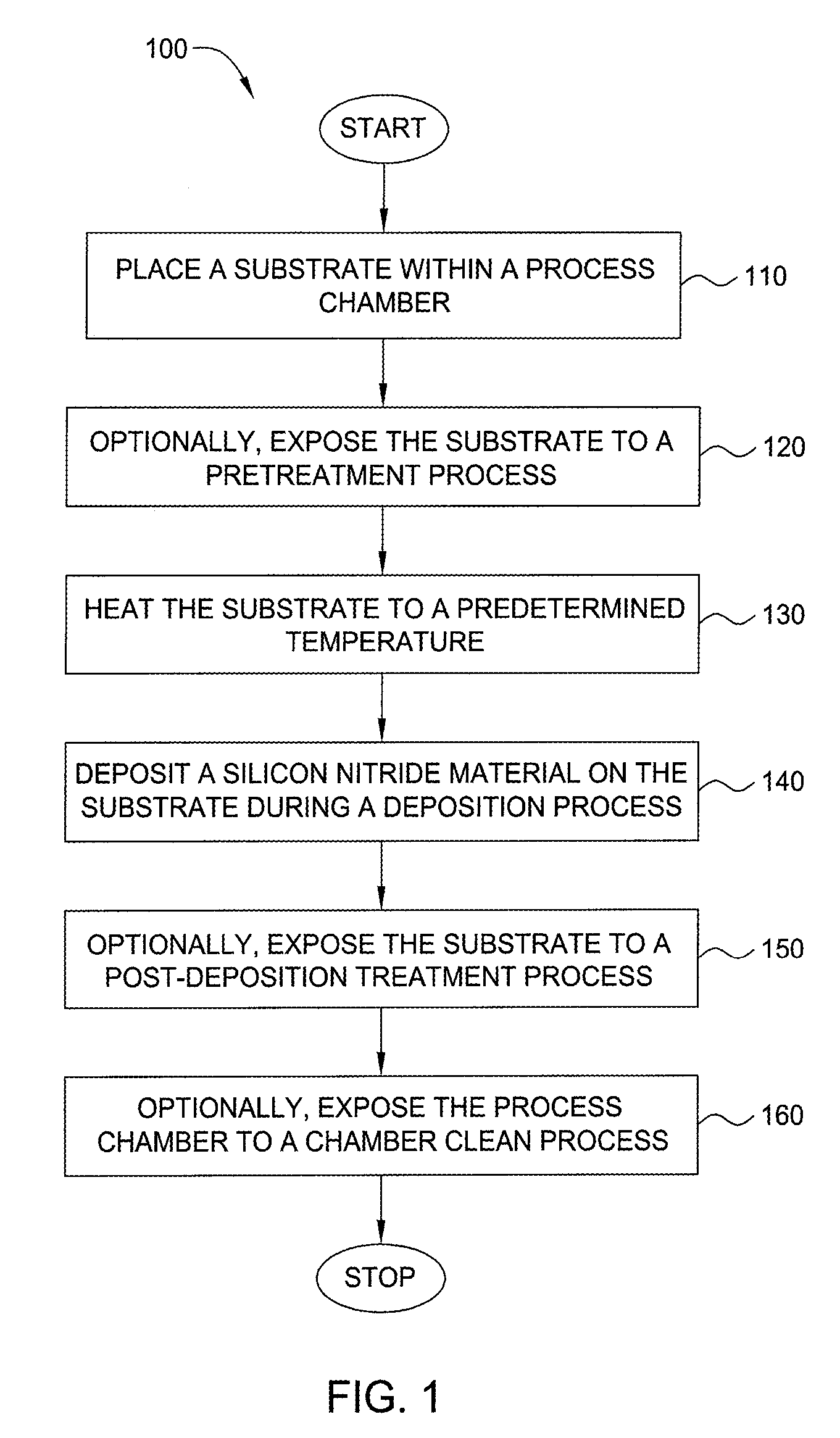

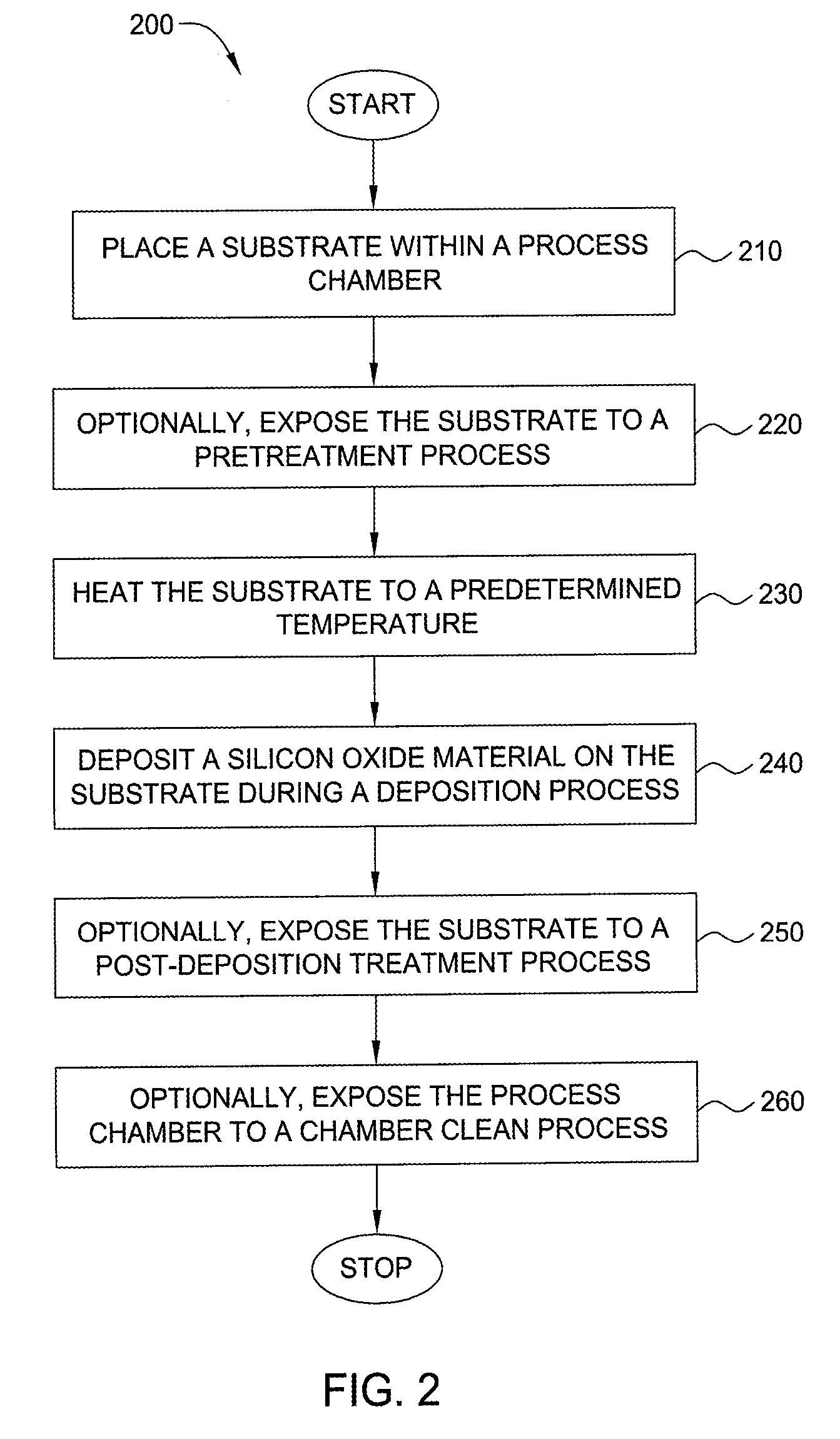

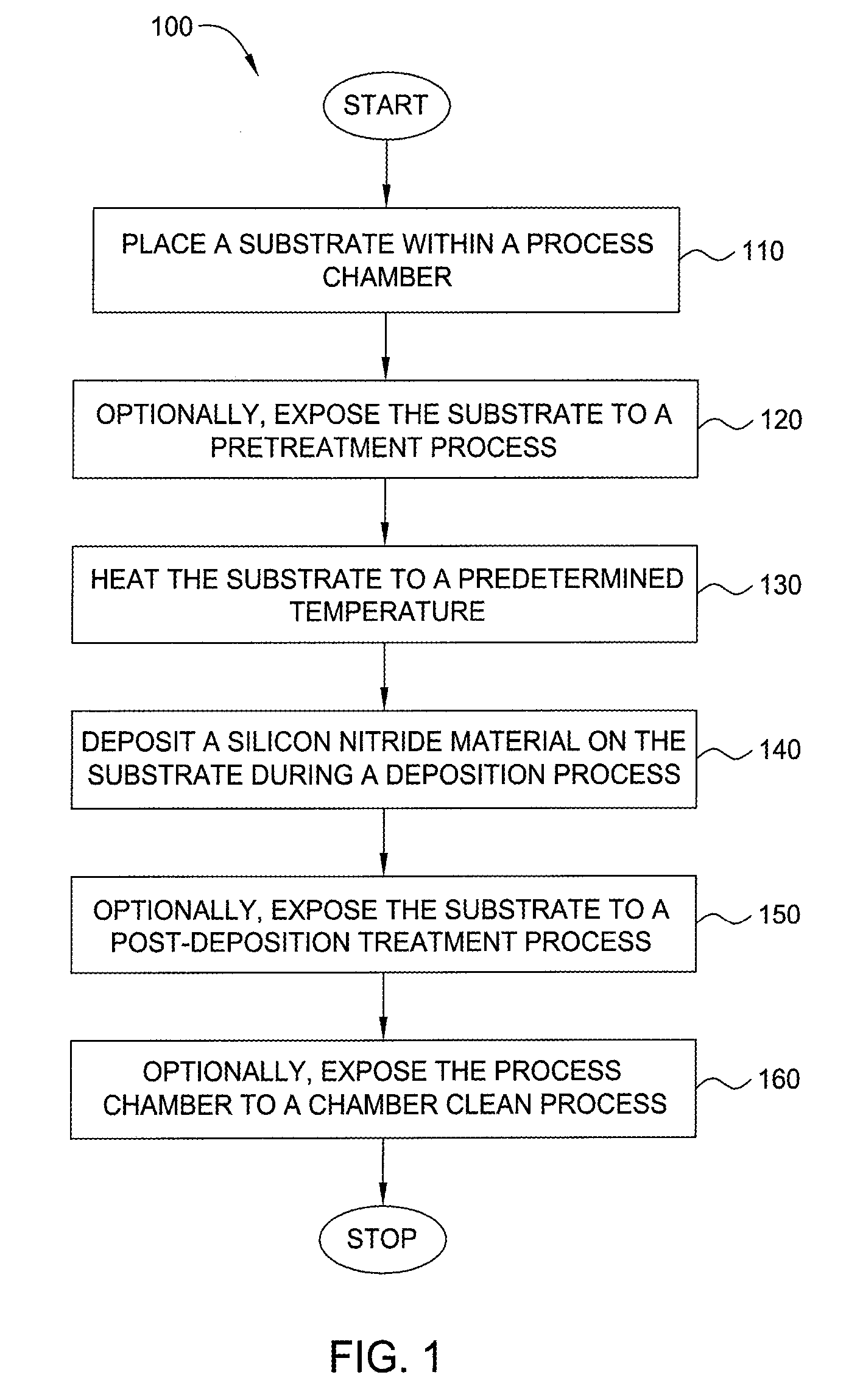

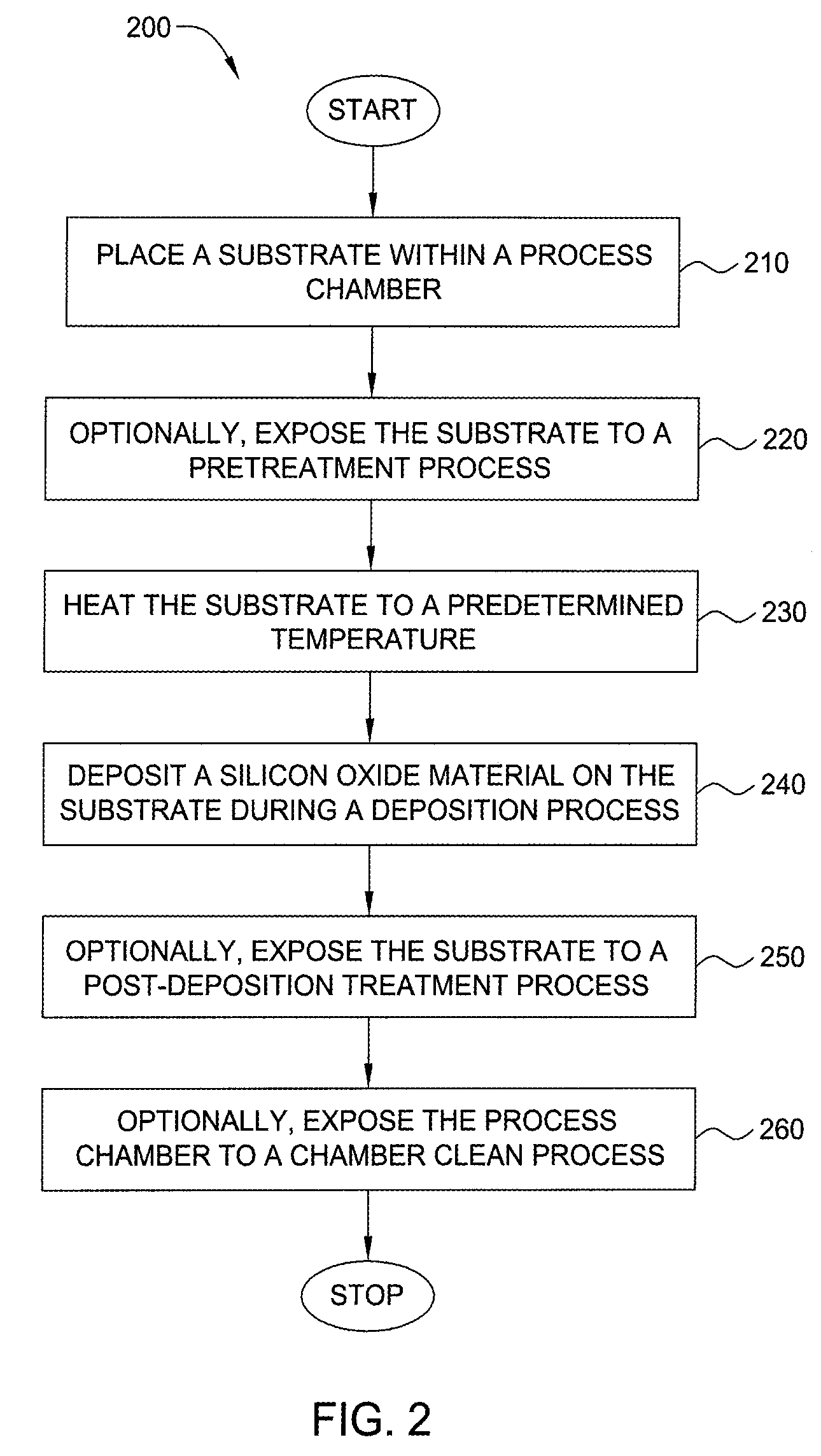

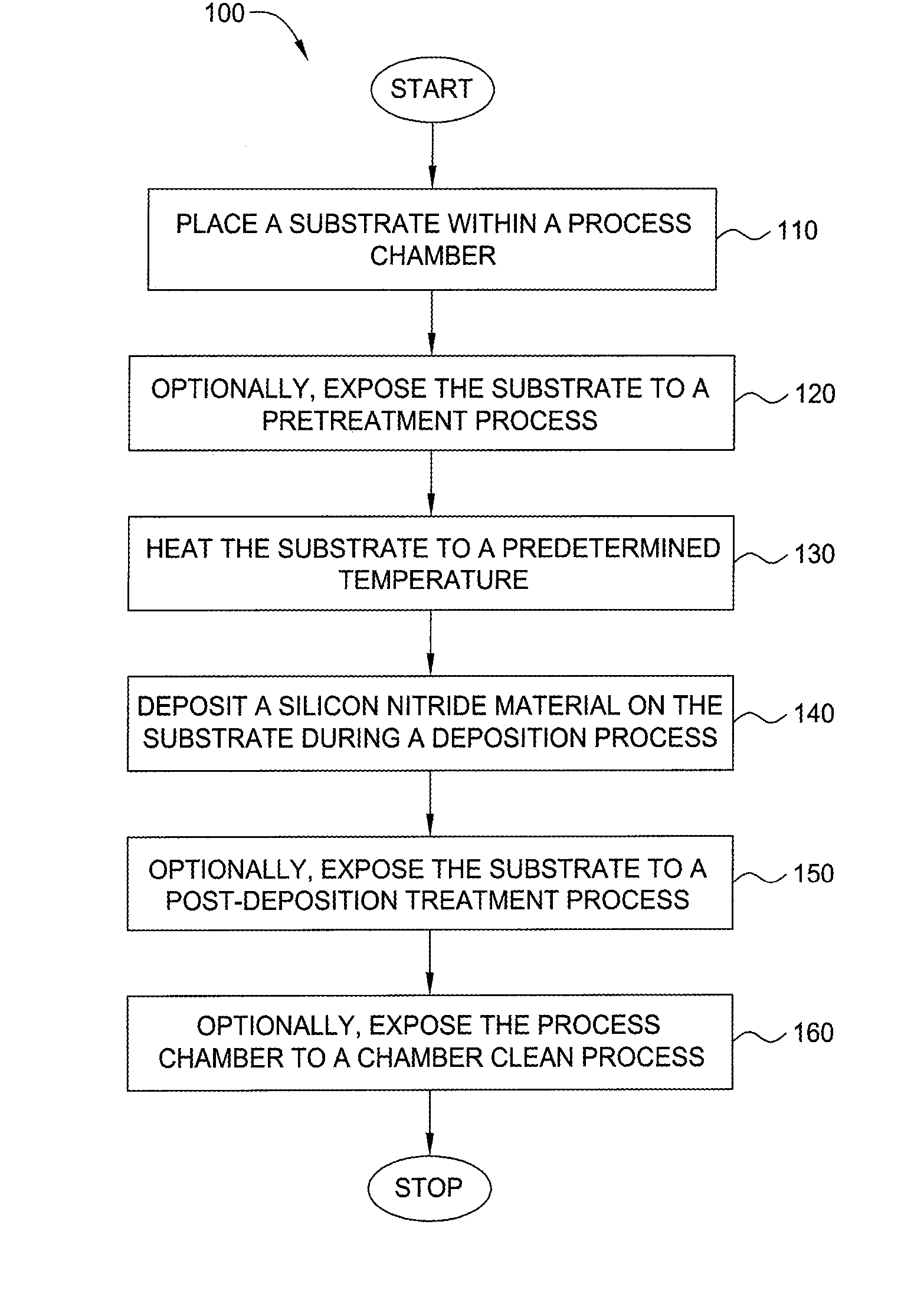

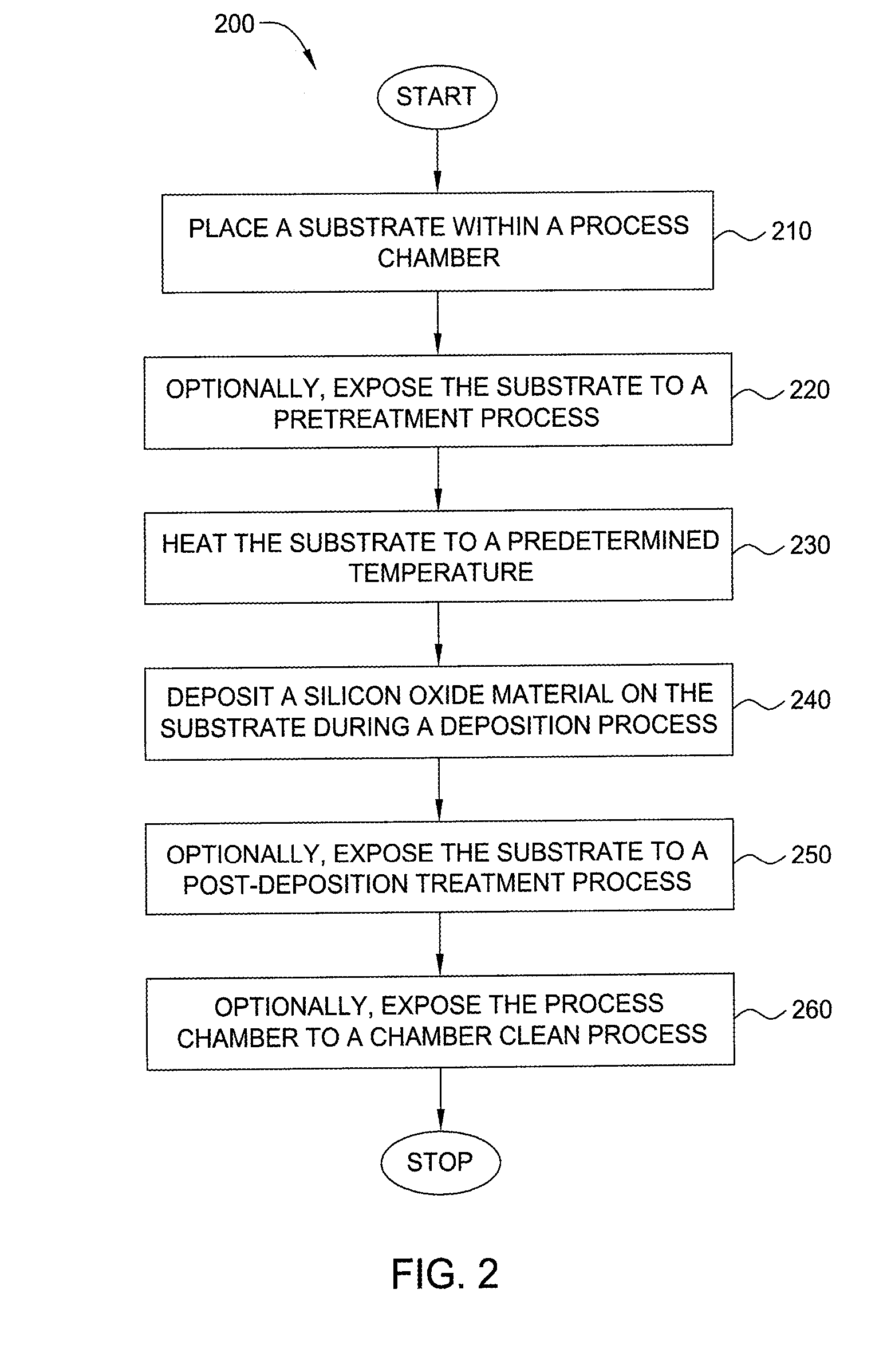

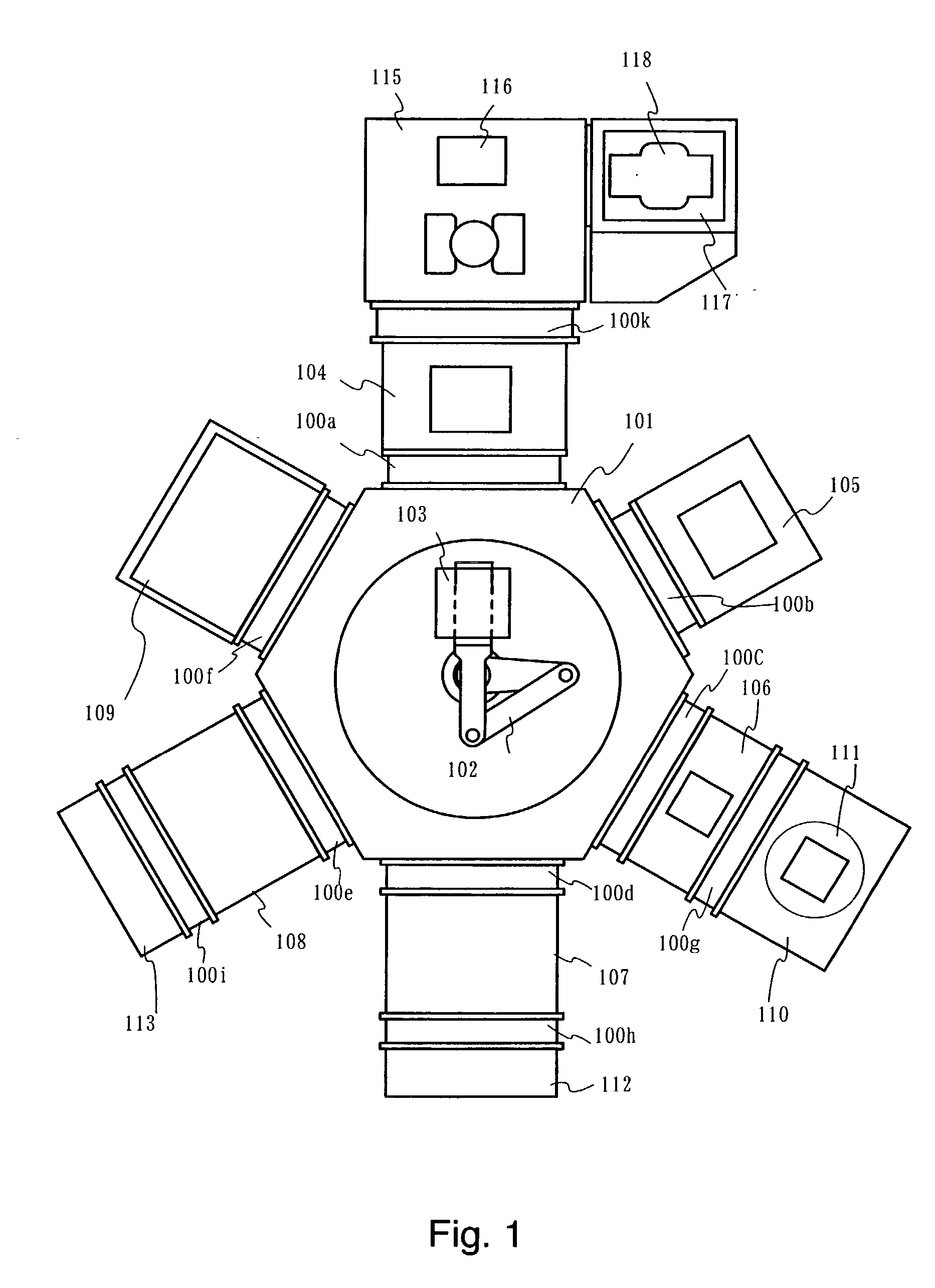

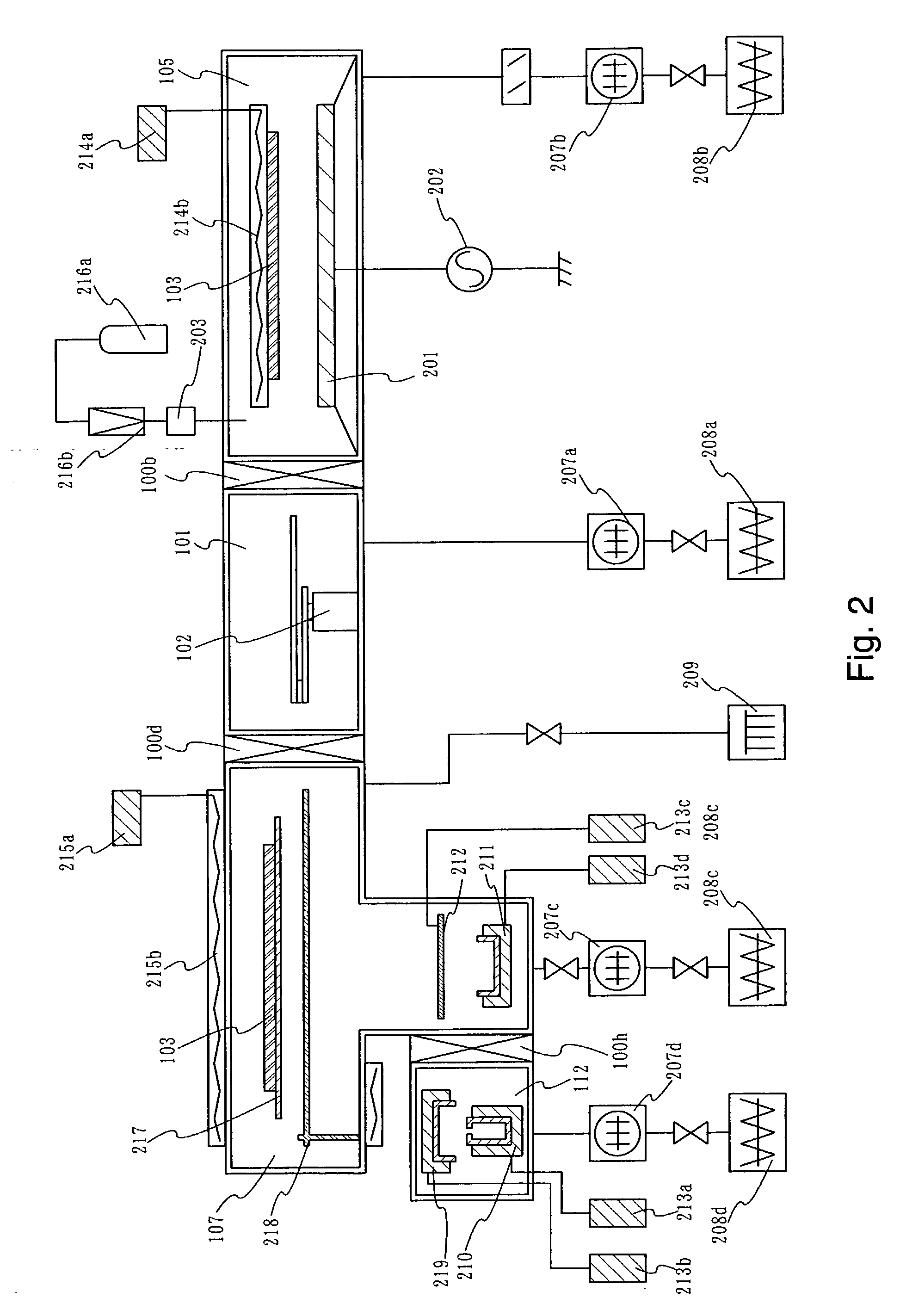

Method for forming silicon-containing materials during a photoexcitation deposition process

InactiveUS20060286774A1Enhance chamber cleaning processHigh surface energyPolycrystalline material growthSemiconductor/solid-state device manufacturingVolatilesSilicon oxide

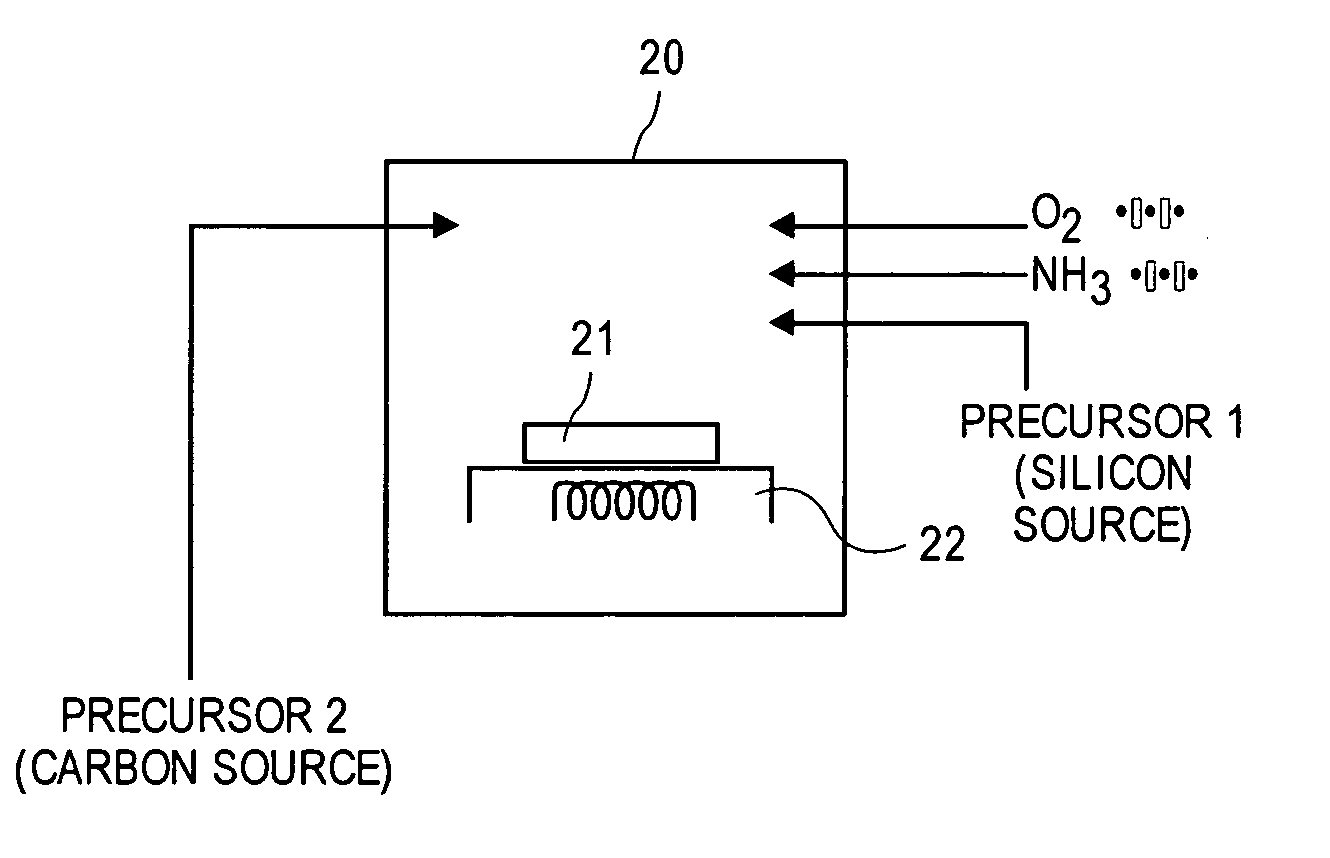

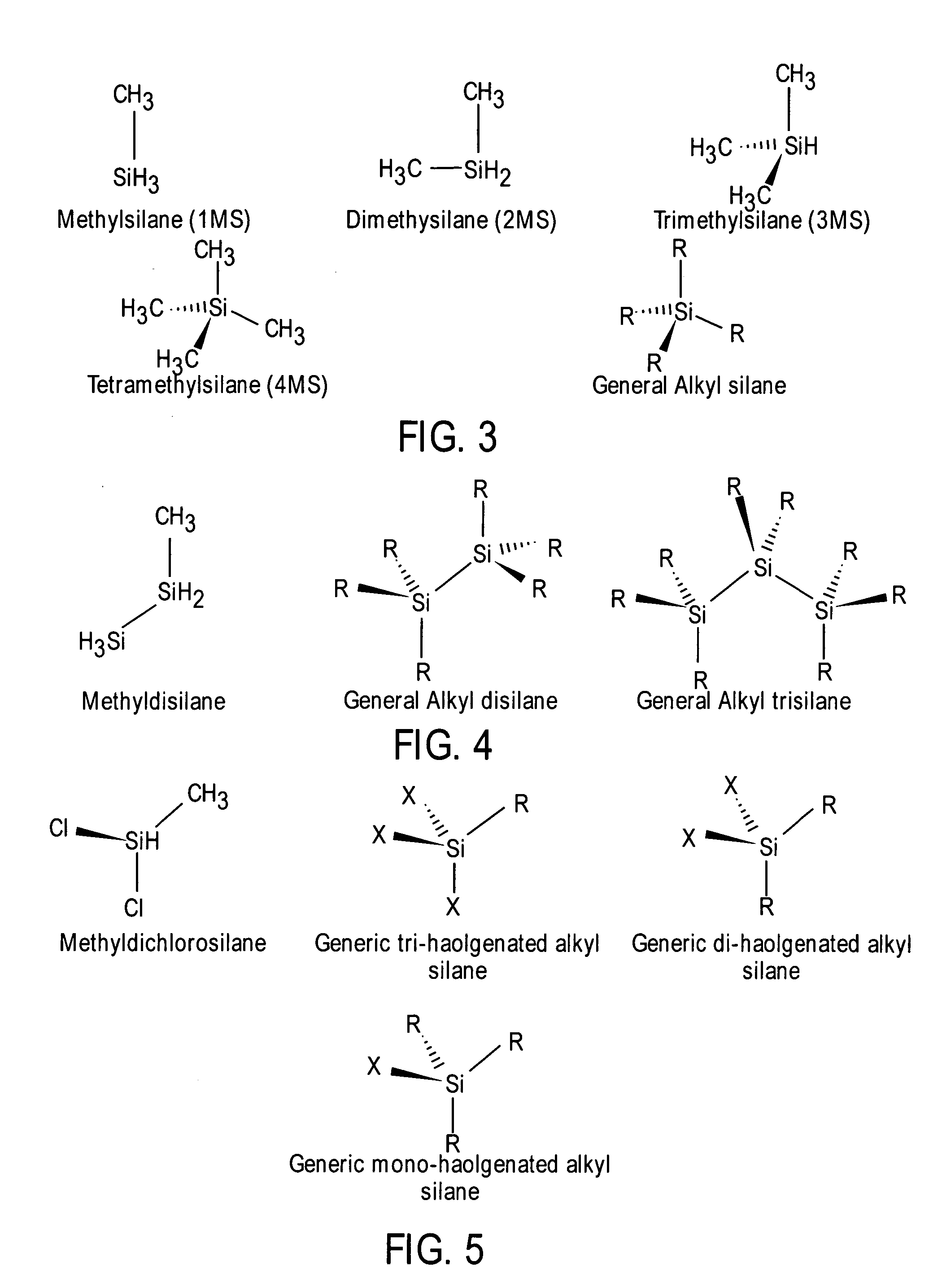

Embodiments of the invention generally provide a method for depositing films or layers using a UV source during a photoexcitation process. The films are deposited on a substrate and usually contain a material, such as silicon (e.g., epitaxy, crystalline, microcrystalline, polysilicon, or amorphous), silicon oxide, silicon nitride, silicon oxynitride, or other silicon-containing materials. The photoexcitation process may expose the substrate and / or gases to an energy beam or flux prior to, during, or subsequent a deposition process. Therefore, the photoexcitation process may be used to pre-treat or post-treat the substrate or material, to deposit the silicon-containing material, and to enhance chamber cleaning processes. Attributes of the method that are enhanced by the UV photoexcitation process include removing native oxides prior to deposition, removing volatiles from deposited films, increasing surface energy of the deposited films, increasing the excitation energy of precursors, reducing deposition time, and reducing deposition temperature.

Owner:APPLIED MATERIALS INC

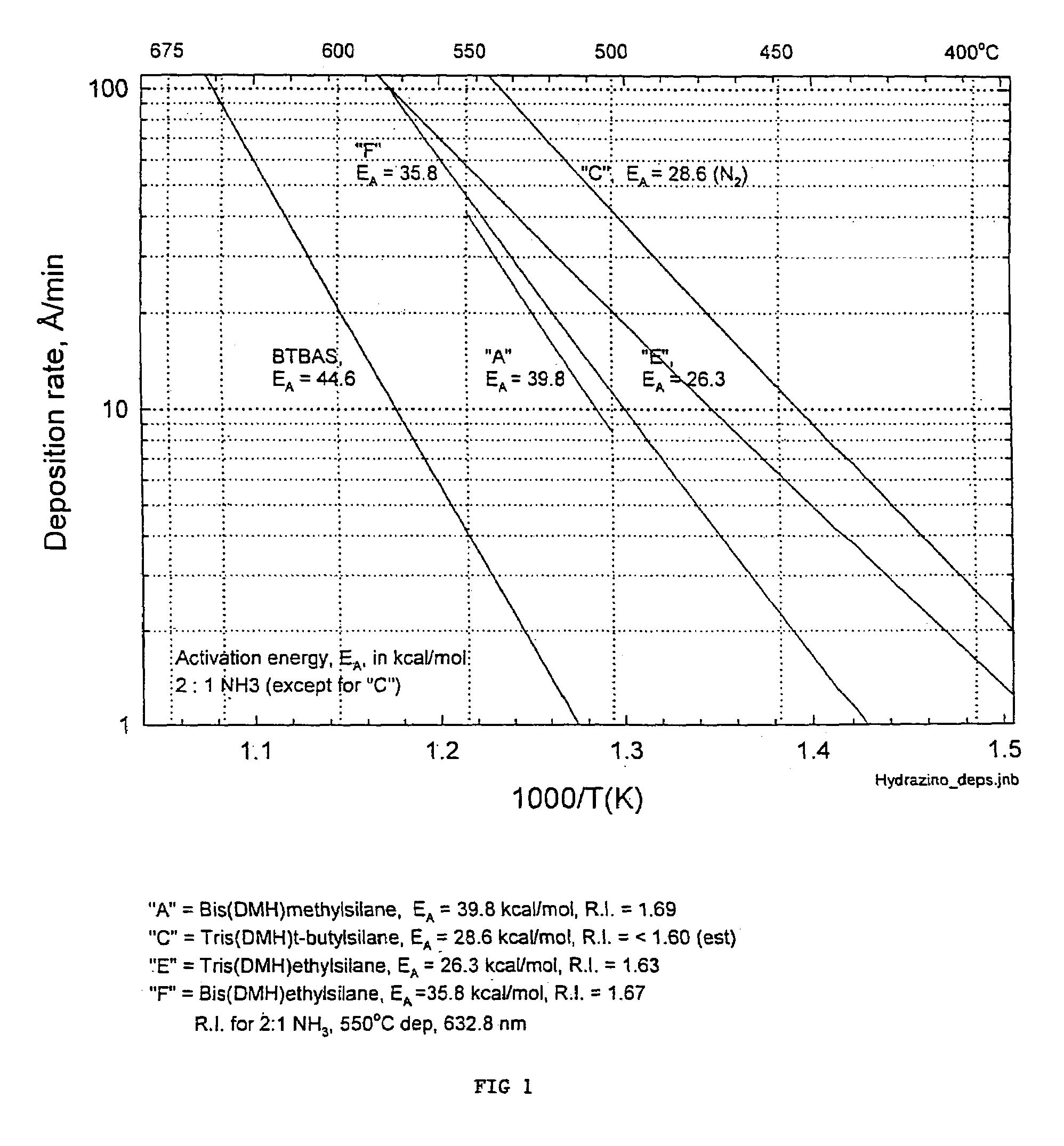

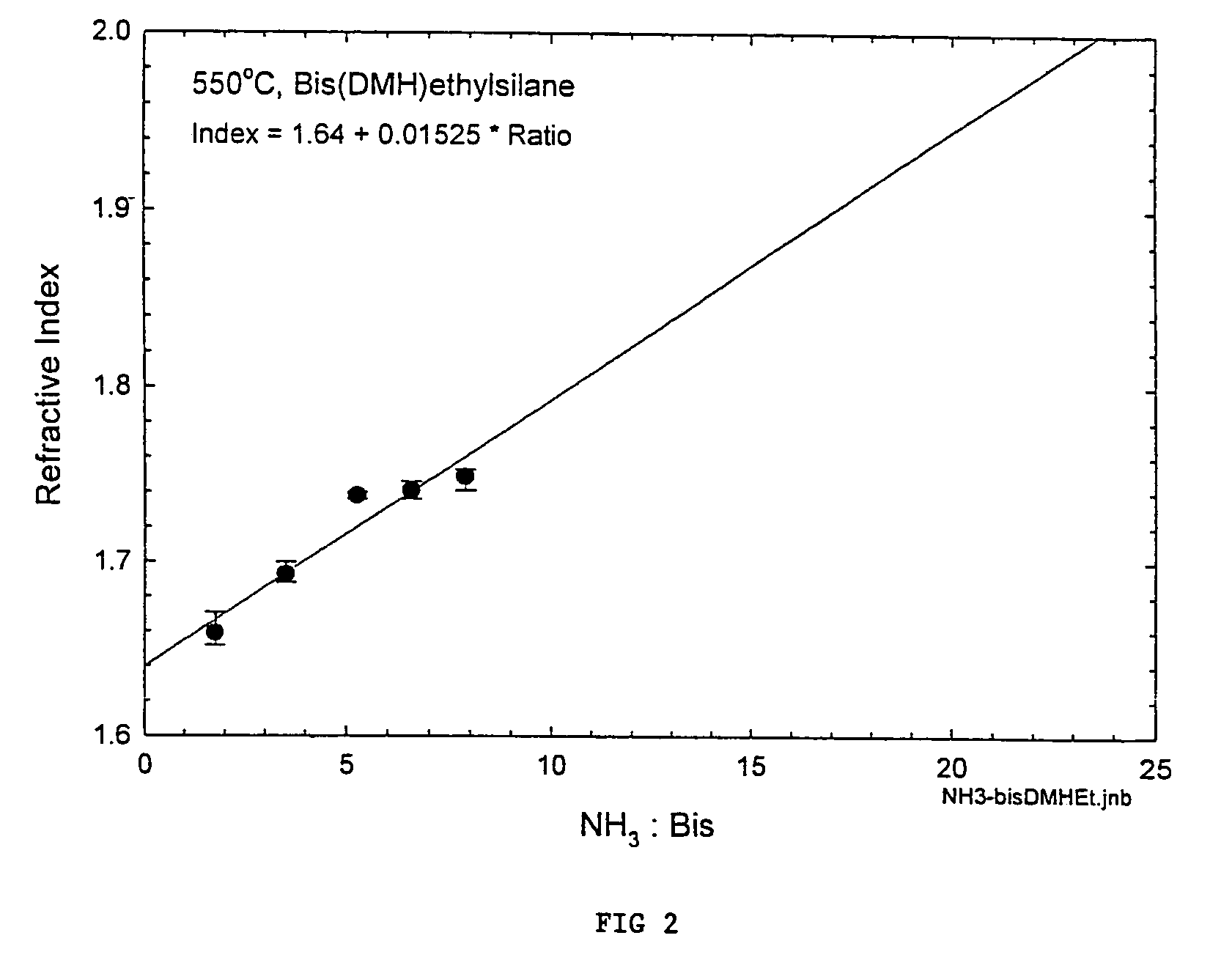

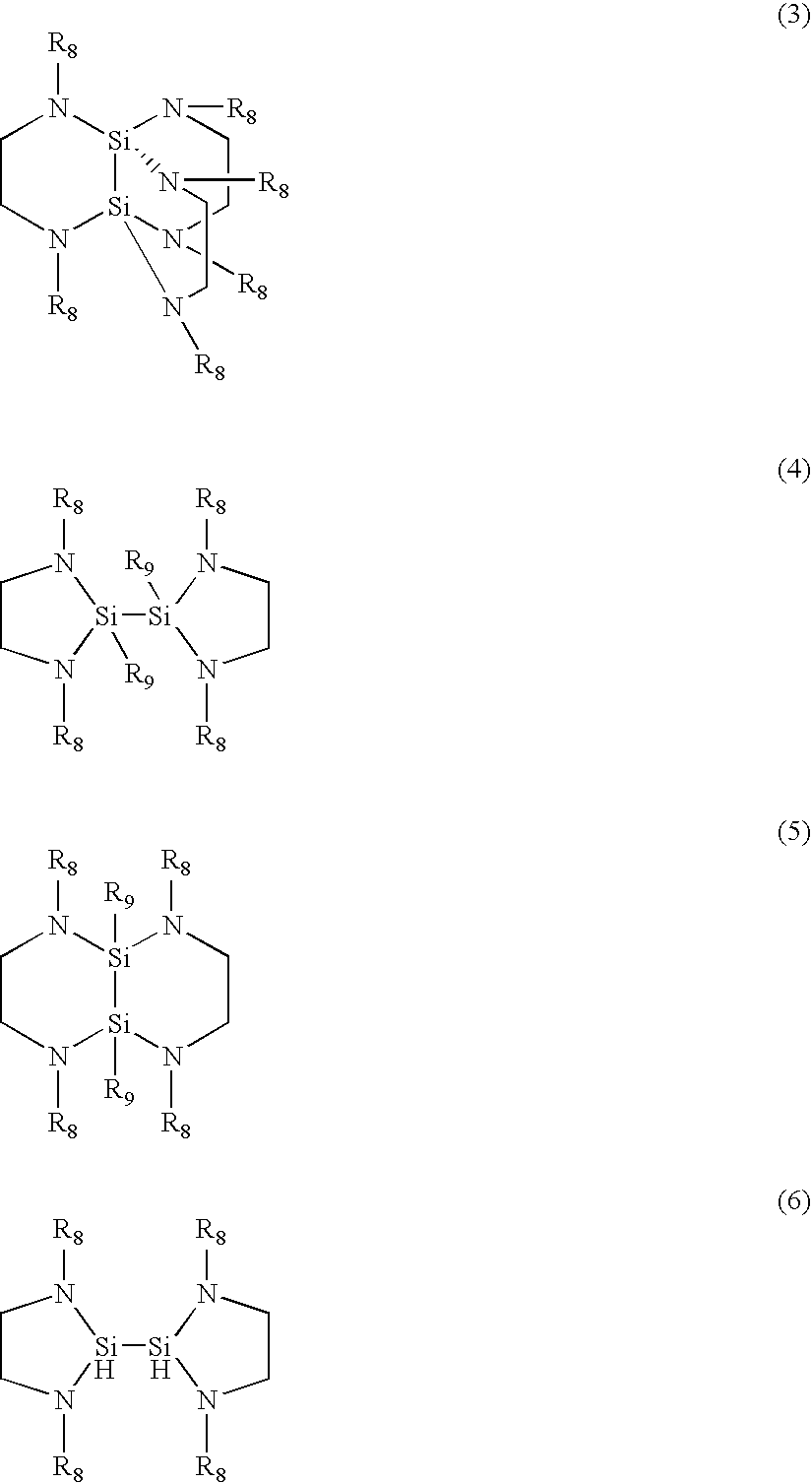

Precursors for depositing silicon containing films and processes thereof

Processes for precursors for silicon dielectric depositions of silicon nitride, silicon oxide and silicon oxynitride on a substrate using a hydrazinosilane of the formula:[R12N—NH]nSi(R2)4−nwhere each R1 is independently selected from alkyl groups of C1 to C6; each R2 is independently selected from the group consisting of hydrogen, alkyl, vinyl, allyl, and phenyl; and n=1–4. Some of the hydrazinosilanes are novel precursors.

Owner:VERSUM MATERIALS US LLC

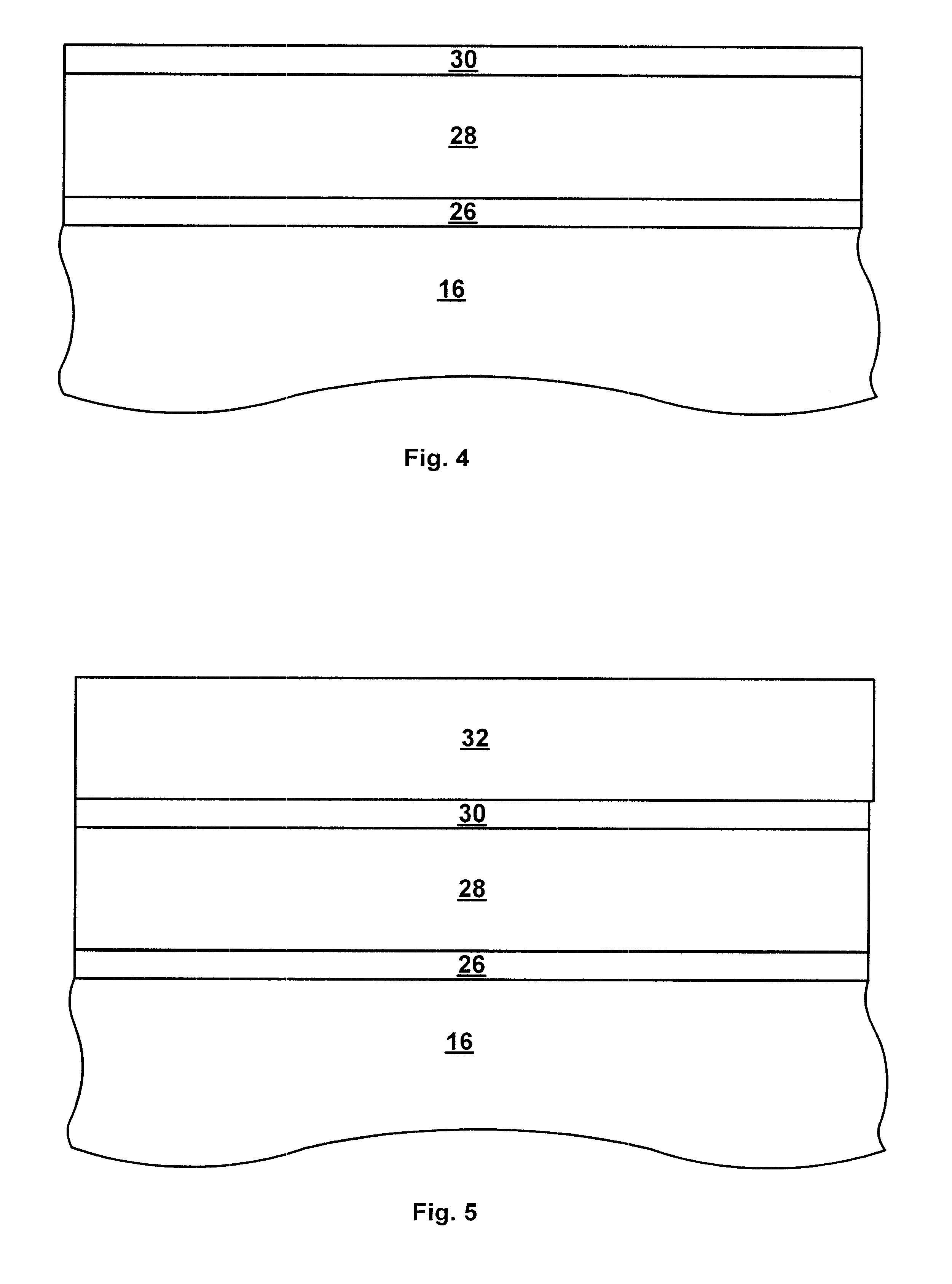

Formation of well-controlled thin SiO, SiN, SiN, SiON layer for multilayer high-K dielectric applications

A process for fabricating a semiconductor device having a high-K dielectric layer over a silicon substrate, including steps of growing on the silicon substrate an interfacial layer of a silicon-containing dielectric material; and depositing on the interfacial layer a layer comprising at least one high-K dielectric material, in which the interfacial layer is grown by laser excitation of the silicon substrate in the presence of oxygen, nitrous oxide, nitric oxide, ammonia or a mixture of two or more thereof. In one embodiment, the silicon-containing material is silicon dioxide, silicon nitride, silicon oxynitride or a mixture thereof.

Owner:ADVANCED MICRO DEVICES INC

Low Temperature Deposition of Silicon-Containing Films

ActiveUS20100304047A1Low deposition temperatureSemiconductor/solid-state device manufacturingSpecial surfacesLow temperature depositionDeposition temperature

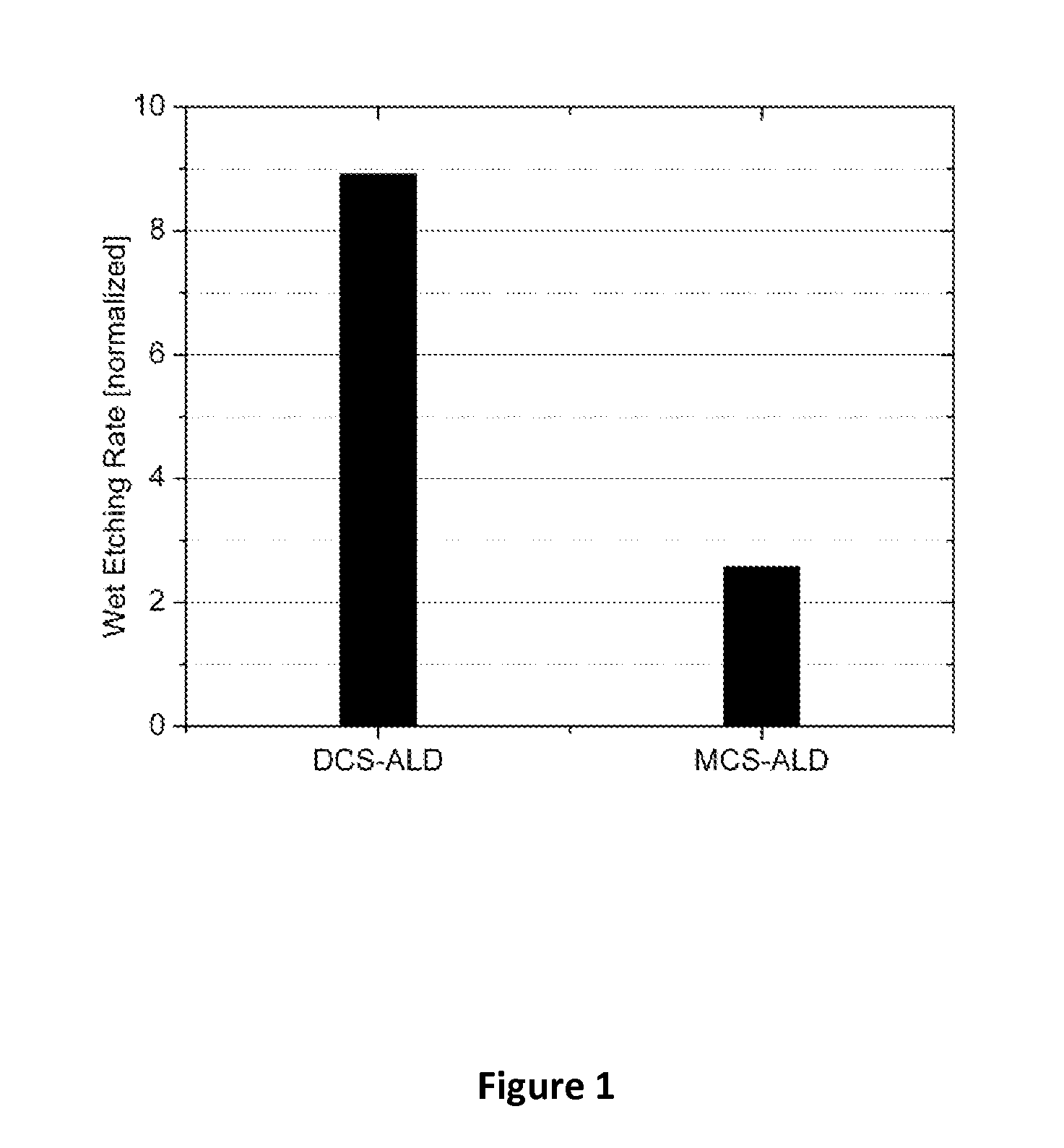

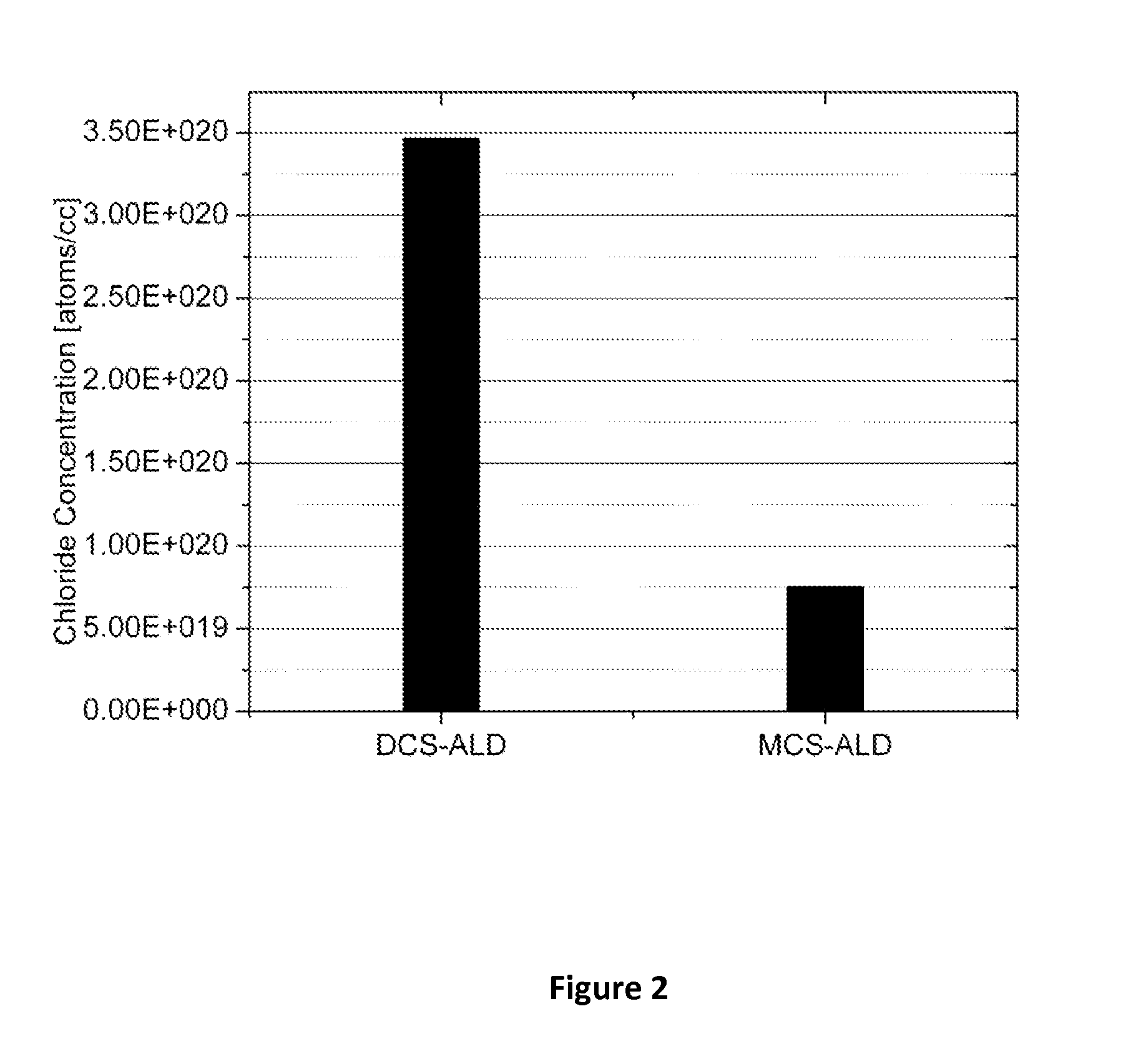

This invention discloses the method of forming silicon nitride, silicon oxynitride, silicon oxide, carbon-doped silicon nitride, carbon-doped silicon oxide and carbon-doped oxynitride films at low deposition temperatures. The silicon containing precursors used for the deposition are monochlorosilane (MCS) and monochloroalkylsilanes. The method is preferably carried out by using plasma enhanced atomic layer deposition, plasma enhanced chemical vapor deposition, and plasma enhanced cyclic chemical vapor deposition.

Owner:TOKYO ELECTRON LTD +1

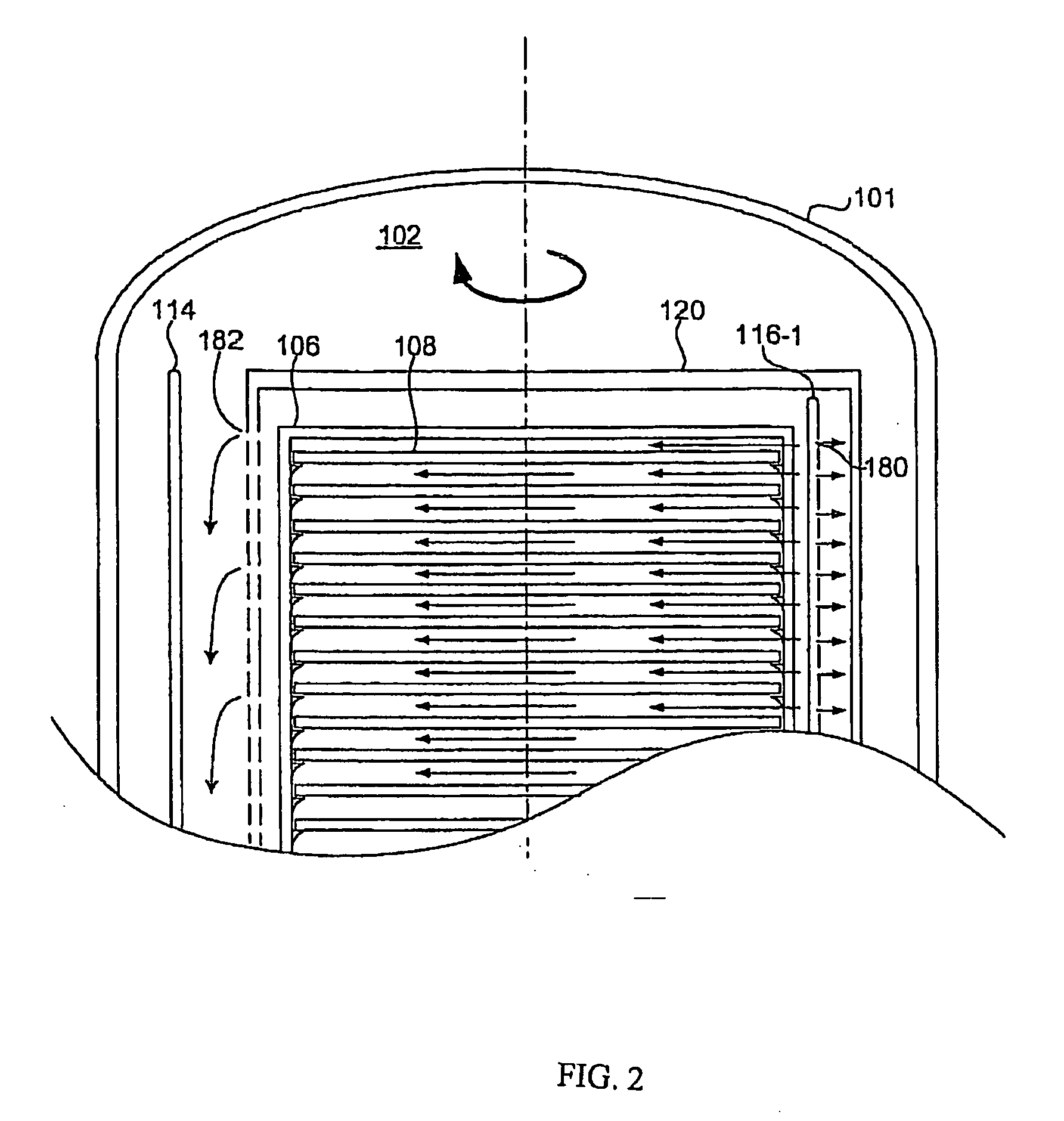

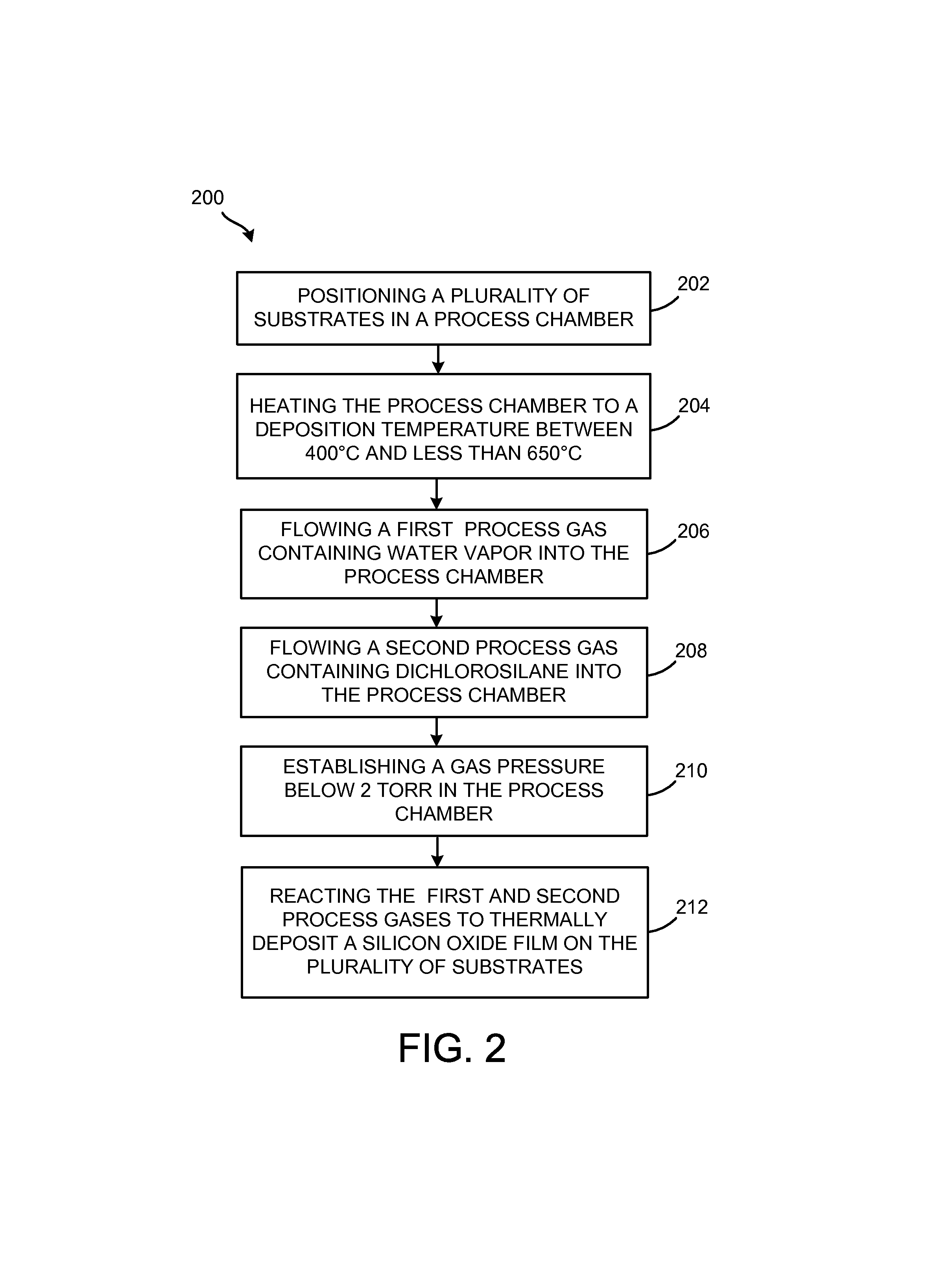

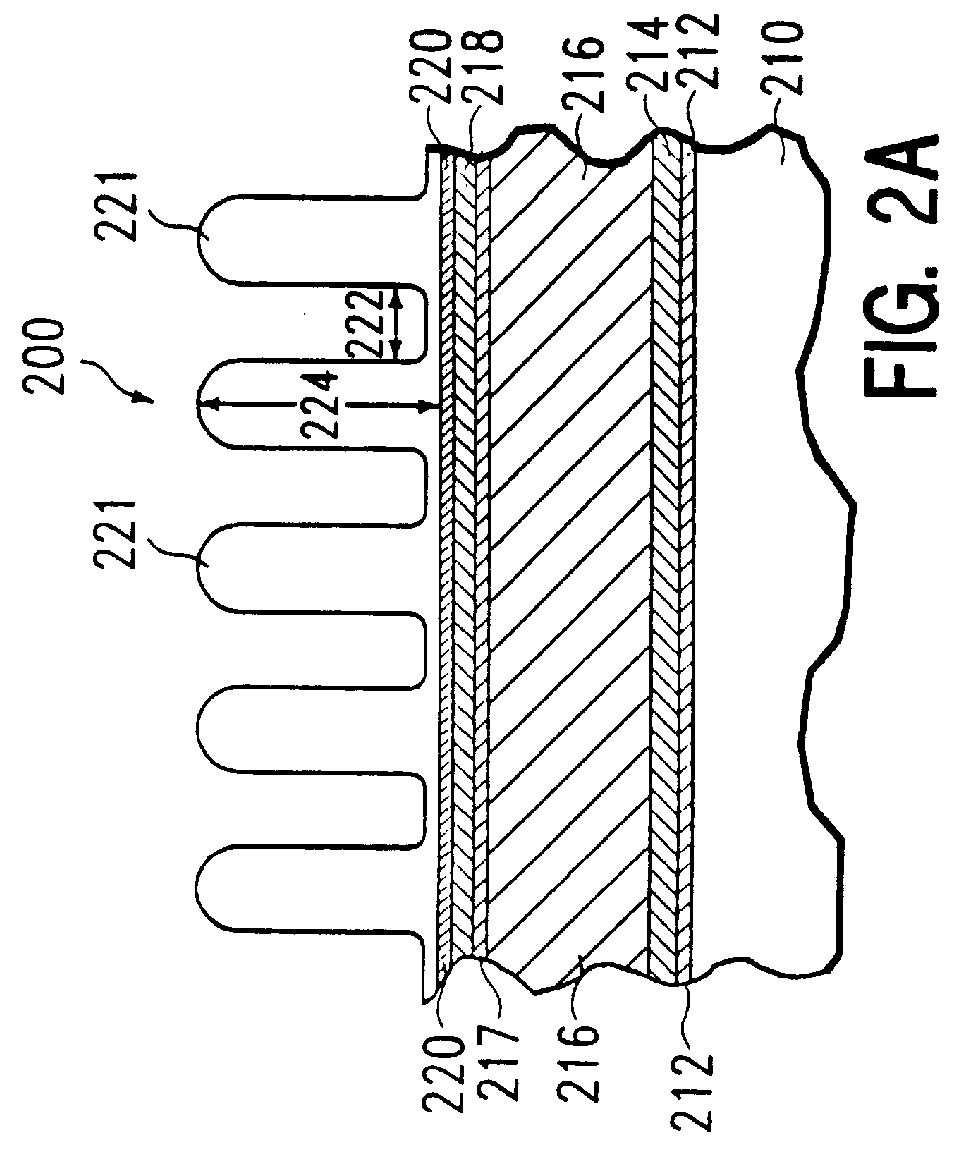

Uniform batch film deposition process and films so produced

InactiveUS20070010072A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingVertical tubeSilicon oxide

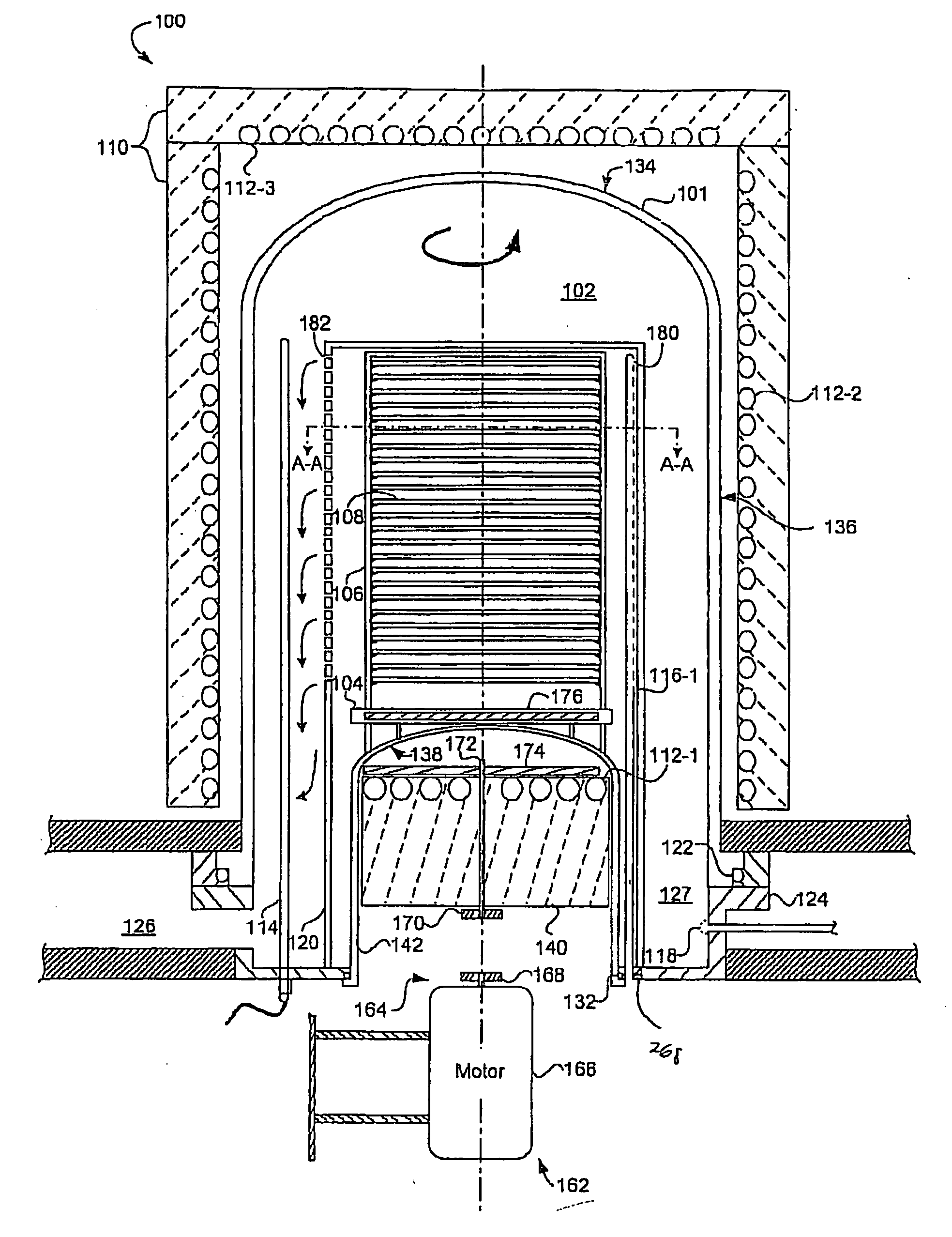

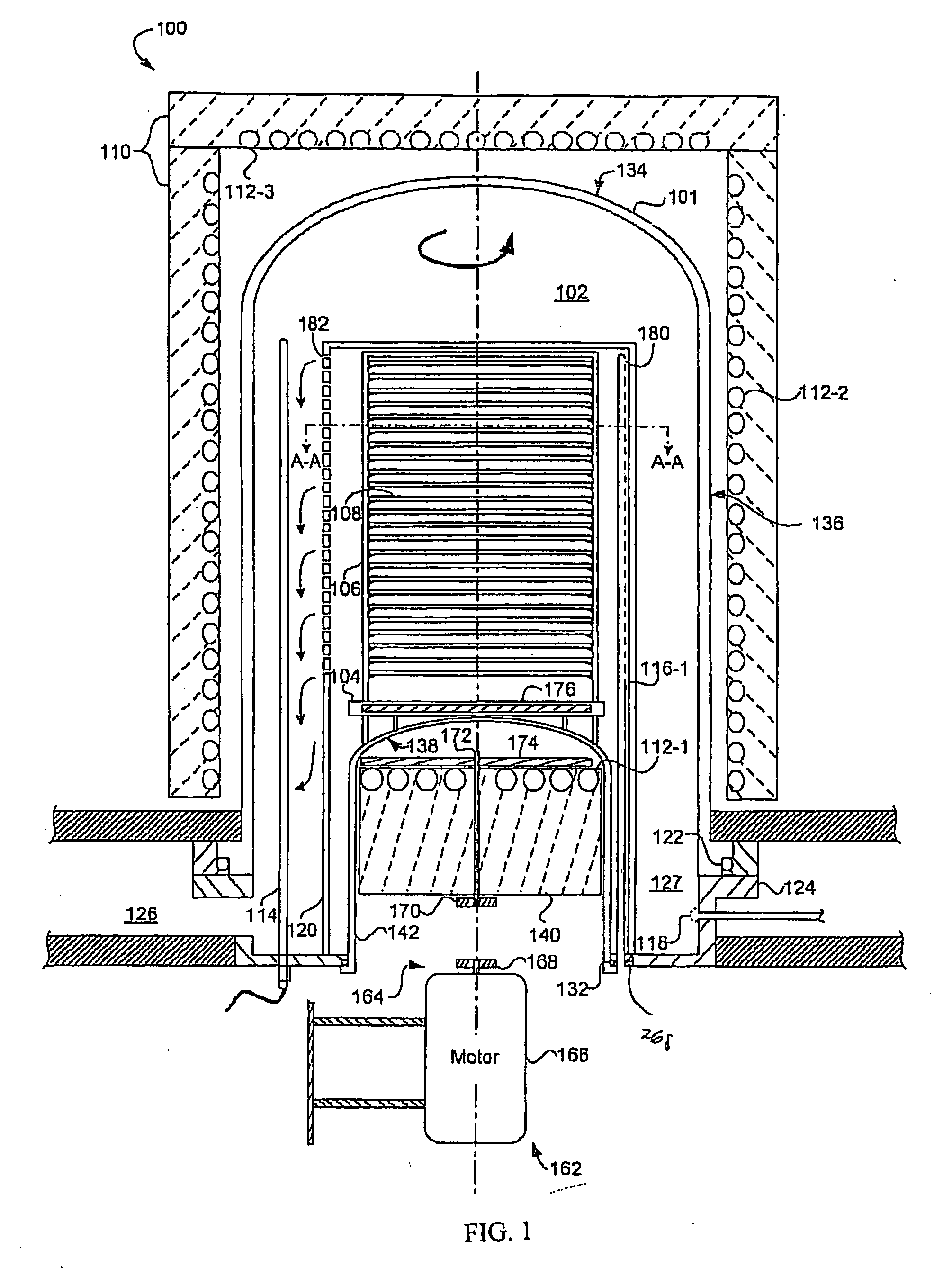

A batch of wafer substrates is provided with each wafer substrate having a surface. Each surface is coated with a layer of material applied simultaneously to the surface of each of the batch of wafer substrates. The layer of material is applied to a thickness that varies less than four thickness percent across the surface and exclusive of an edge boundary and having a wafer-to-wafer thickness variation of less than three percent. The layer of material so applied is a silicon oxide, silicon nitride or silicon oxynitride with the layer of material being devoid of carbon and chlorine. Formation of silicon oxide or a silicon oxynitride requires the inclusion of a co-reactant. Silicon nitride is also formed with the inclusion of a nitrification co-reactant. A process for forming such a batch of wafer substrates involves feeding the precursor into a reactor containing a batch of wafer substrates and reacting the precursor at a wafer substrate temperature, total pressure, and precursor flow rate sufficient to create such a layer of material. The delivery of a precursor and co-reactant as needed through vertical tube injectors having multiple orifices with at least one orifice in registry with each of the batch of wafer substrates and exit slits within the reactor to create flow across the surface of each of the wafer substrates in the batch provides the within-wafer and wafer-to-wafer uniformity.

Owner:AVIZA TECHNOLOGY INC

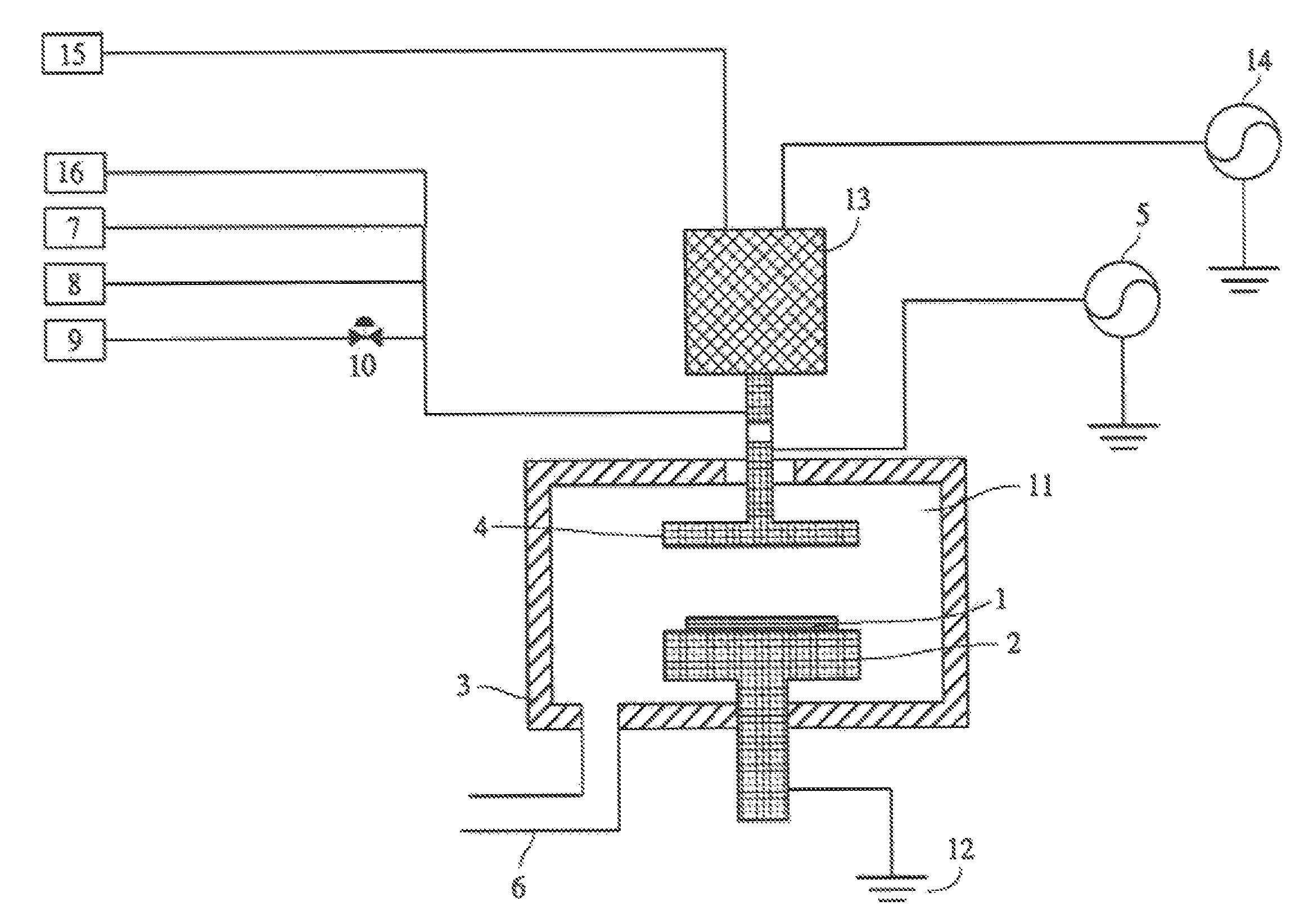

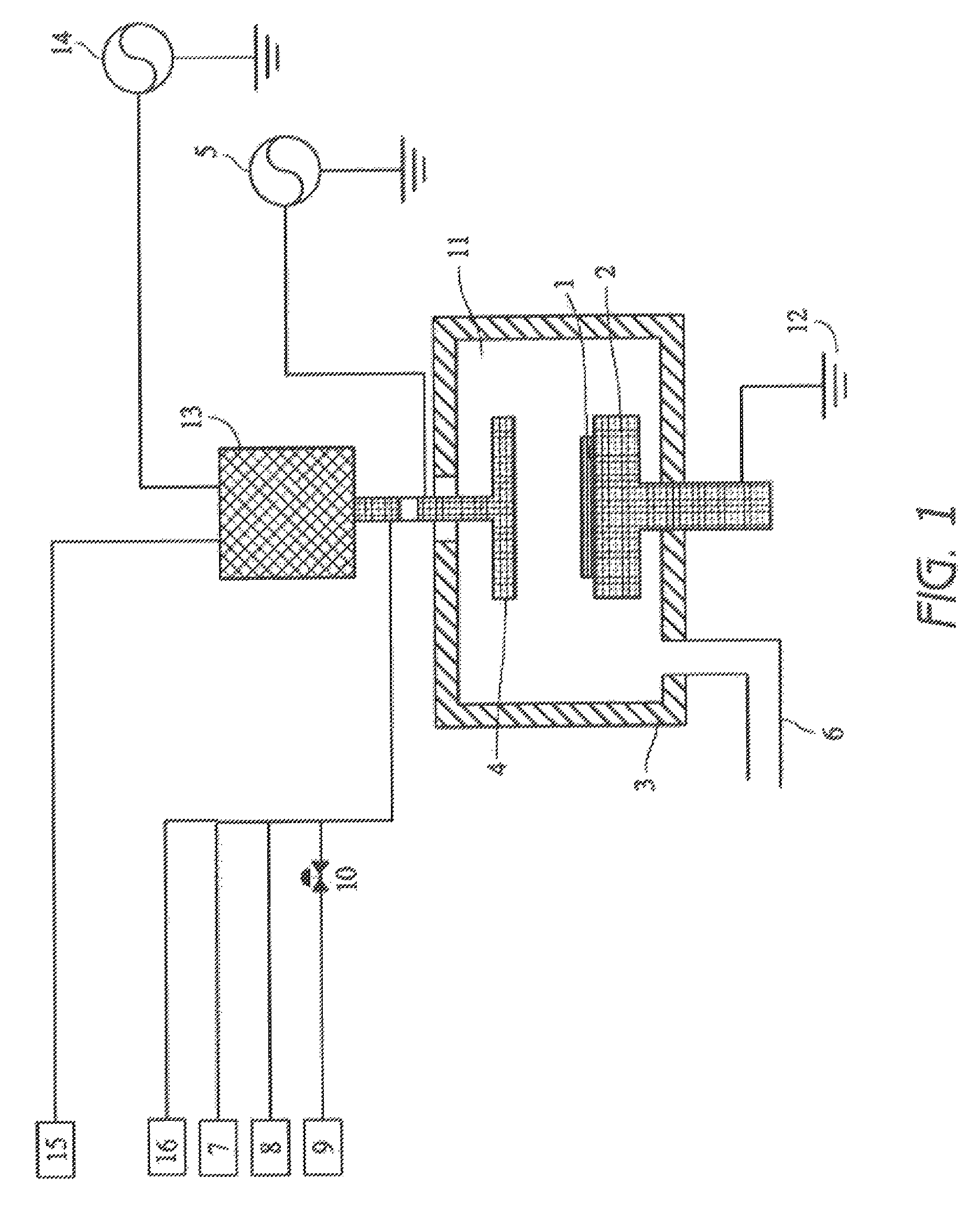

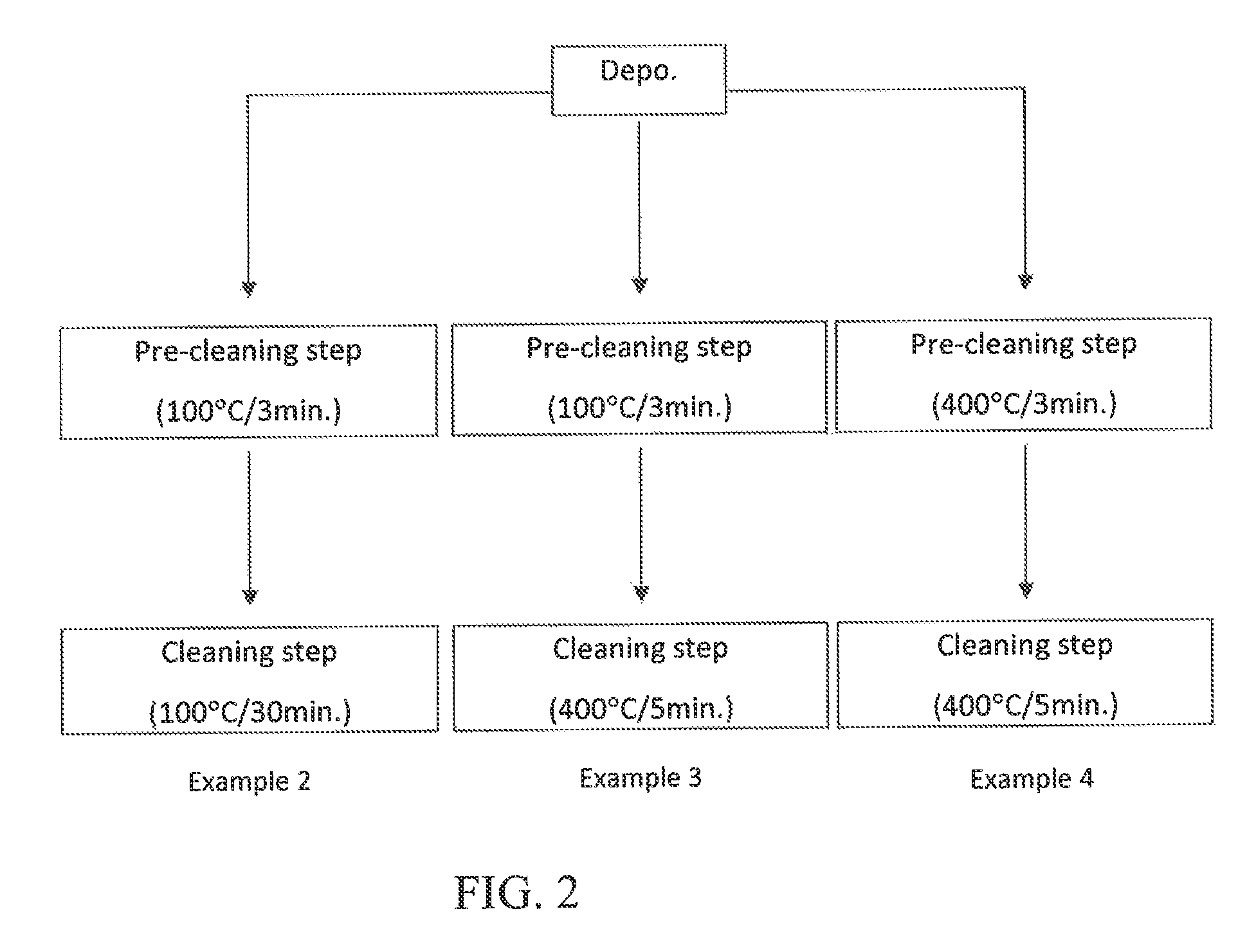

Method for cleaning reaction chamber using pre-cleaning process

ActiveUS9142393B2Improve efficiencyElectric discharge tubesHollow article cleaningNitrogenSilicon oxide

Owner:ASM IP HLDG BV

Method for forming silicon-containing materials during a photoexcitation deposition process

InactiveUS7651955B2Easy to cleanHigh surface energyPolycrystalline material growthSemiconductor/solid-state device manufacturingAutoxidationDeposition temperature

Embodiments of the invention generally provide a method for depositing films or layers using a UV source during a photoexcitation process. The films are deposited on a substrate and usually contain a material, such as silicon (e.g., epitaxy, crystalline, microcrystalline, polysilicon, or amorphous), silicon oxide, silicon nitride, silicon oxynitride, or other silicon-containing materials. The photoexcitation process may expose the substrate and / or gases to an energy beam or flux prior to, during, or subsequent a deposition process. Therefore, the photoexcitation process may be used to pre-treat or post-treat the substrate or material, to deposit the silicon-containing material, and to enhance chamber cleaning processes. Attributes of the method that are enhanced by the UV photoexcitation process include removing native oxides prior to deposition, removing volatiles from deposited films, increasing surface energy of the deposited films, increasing the excitation energy of precursors, reducing deposition time, and reducing deposition temperature.

Owner:APPLIED MATERIALS INC

Method for forming silicon-containing materials during a photoexcitation deposition process

InactiveUS7648927B2Easy to cleanHigh surface energyPolycrystalline material growthSemiconductor/solid-state device manufacturingAutoxidationDeposition temperature

Embodiments of the invention generally provide a method for depositing films or layers using a UV source during a photoexcitation process. The films are deposited on a substrate and usually contain a material, such as silicon (e.g., epitaxy, crystalline, microcrystalline, polysilicon, or amorphous), silicon oxide, silicon nitride, silicon oxynitride, or other silicon-containing materials. The photoexcitation process may expose the substrate and / or gases to an energy beam or flux prior to, during, or subsequent a deposition process. Therefore, the photoexcitation process may be used to pre-treat or post-treat the substrate or material, to deposit the silicon-containing material, and to enhance chamber cleaning processes. Attributes of the method that are enhanced by the UV photoexcitation process include removing native oxides prior to deposition, removing volatiles from deposited films, increasing surface energy of the deposited films, increasing the excitation energy of precursors, reducing deposition time, and reducing deposition temperature.

Owner:APPLIED MATERIALS INC

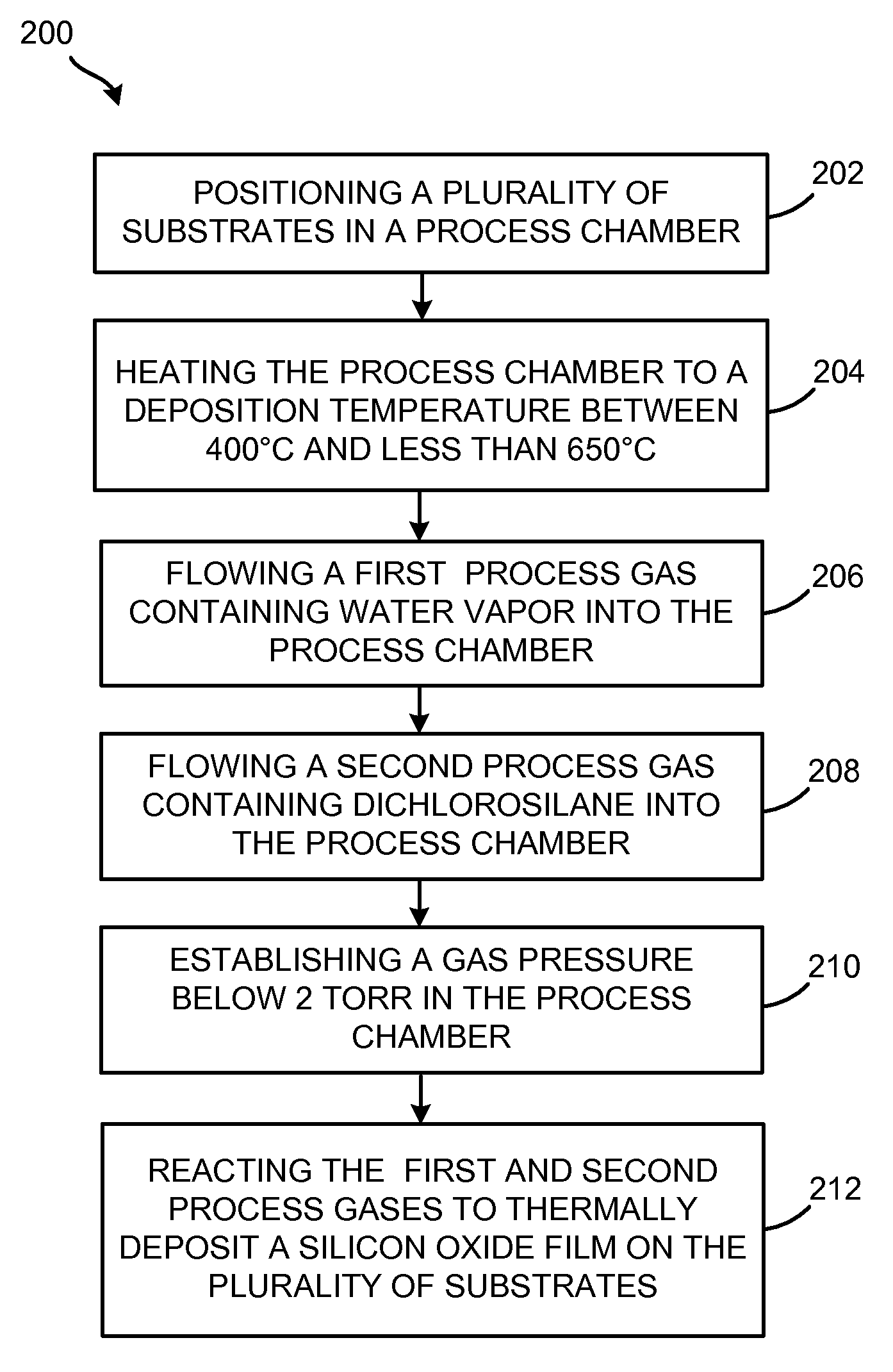

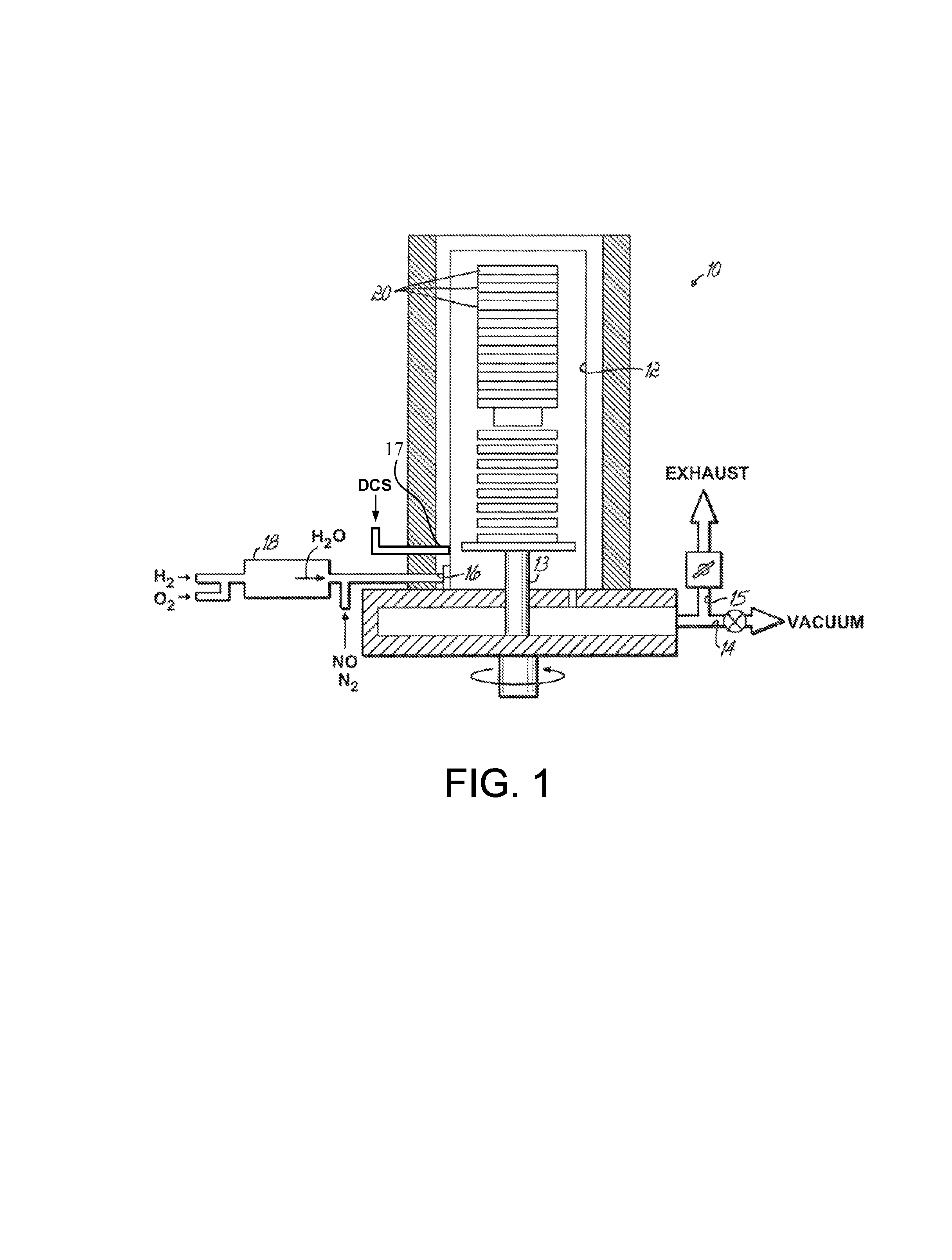

Low-temperature dielectric film formation by chemical vapor deposition

InactiveUS7994070B1Semiconductor/solid-state device manufacturingSemiconductor devicesDielectricWater vapor

A method for depositing a dielectric film on a substrate includes positioning a plurality of substrates in a process chamber, heating the process chamber to a deposition temperature between 400° C. and less than 650° C., flowing a first process gas comprising water vapor into the process chamber, flowing a second process gas comprising dichlorosilane (DCS) into the process chamber, establishing a gas pressure of less than 2 Torr, and reacting the first and second process gases to thermally deposit a silicon oxide film on the plurality of substrates. One embodiment further includes flowing a third process gas comprising nitric oxide (NO) gas into the process chamber while flowing the first process gas and the second process gas; and reacting the oxide film with the third process gas to form a silicon oxynitride film on the substrate.

Owner:TOKYO ELECTRON LTD

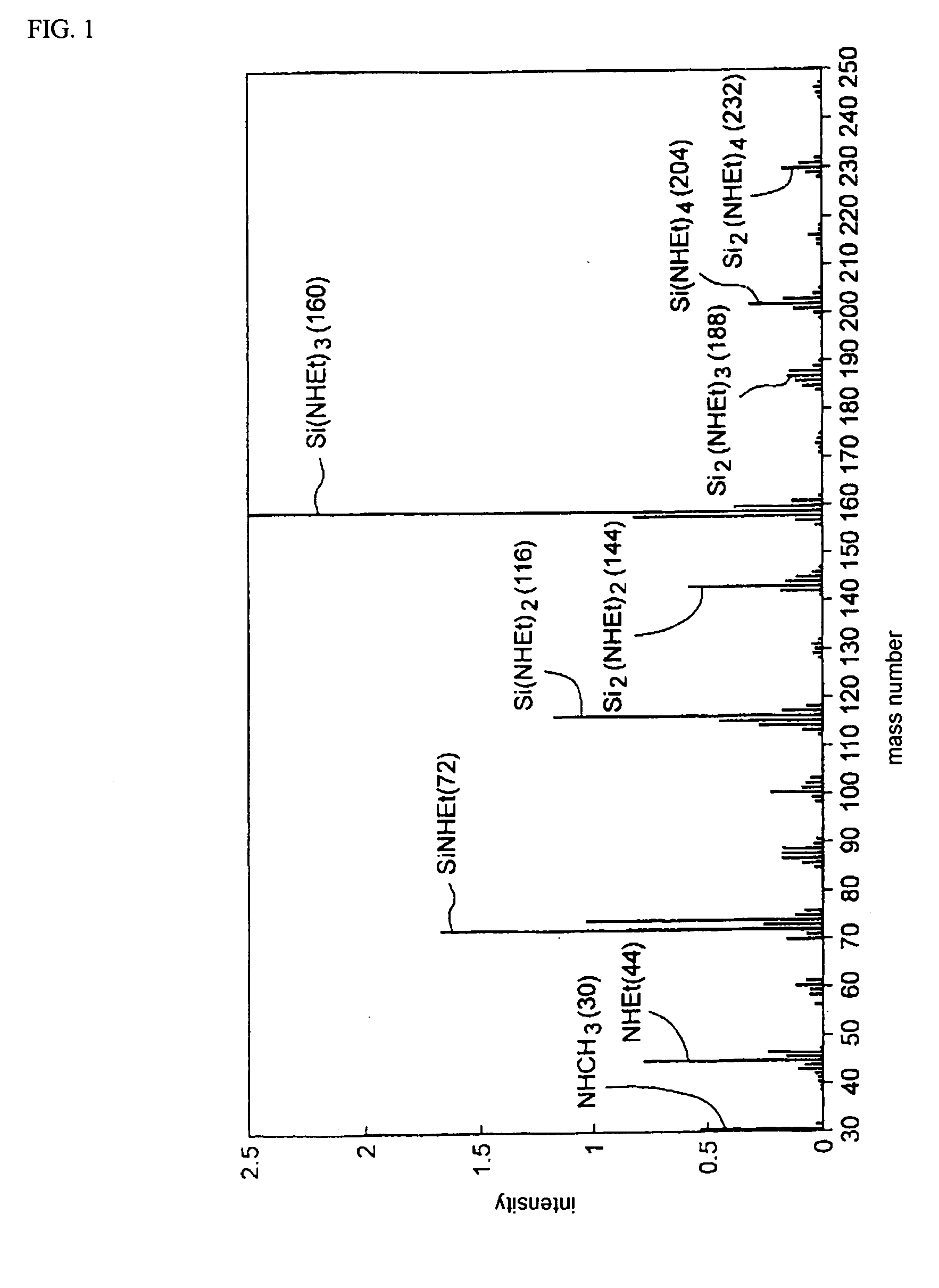

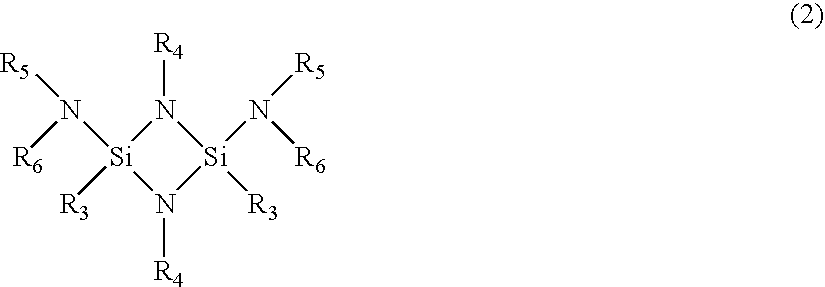

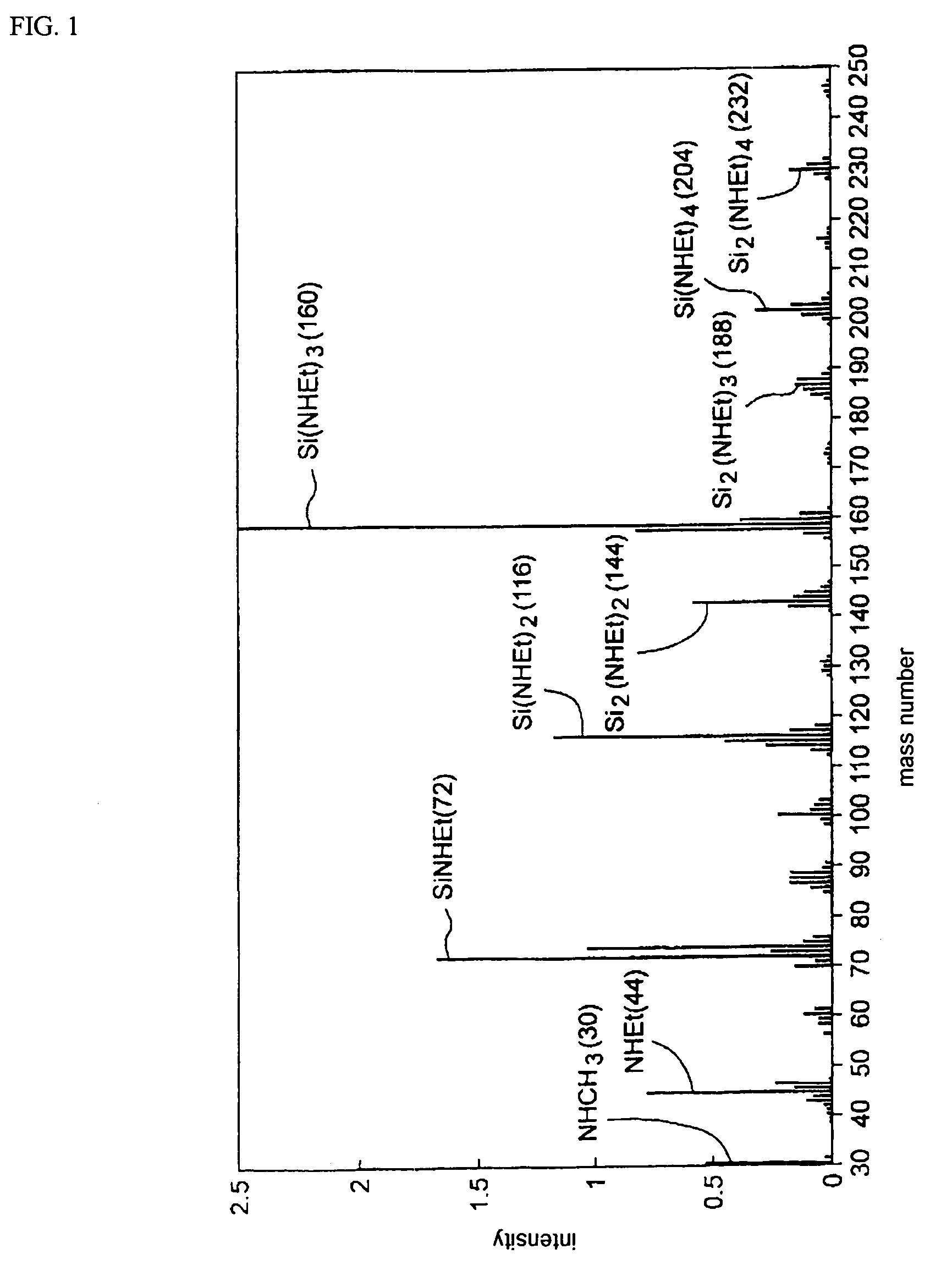

Hexakis(monohydrocarbylamino) disilanes and method for the preparation thereof

InactiveUS20050107627A1Improve featuresSilicon organic compoundsSemiconductor/solid-state device manufacturingSilane compoundsOrganic solvent

A composition and method of preparation, to provide silane compounds that are free of chlorine. The compounds are hexakis(monohydrocarbylamino)disilanes with general formula (I) ((R)HN)3—Si—Si—(NH(R))3 (I) wherein each R independently represents a C1 to C4 hydrocarbyl. These disilanes may be synthesized by reacting hexachlorodisilane in organic solvent with at least 6-fold moles of the monohydrocarbylamine RNH2 (wherein R is a C1 to C4 hydrocarbyl). Such compounds have excellent film-forming characteristics at low temperatures. These films, particularly in the case of silicon nitride and silicon oxynitride, also have excellent handling characteristics.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

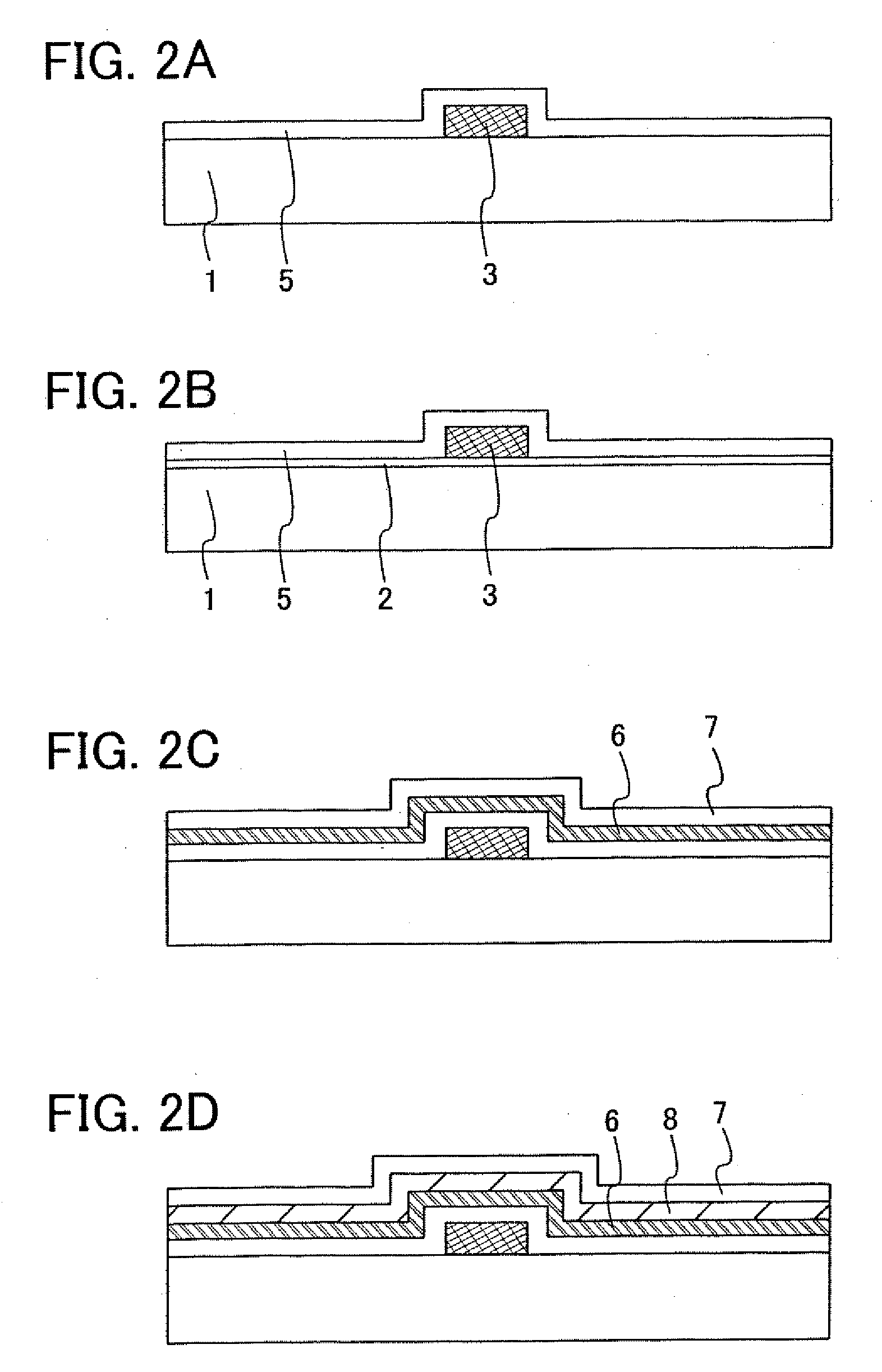

Semiconductor device and manufacturing method thereof

To provide a semiconductor device in which a defect or fault is not generated and a manufacturing method thereof even if a ZnO semiconductor film is used and a ZnO film to which an n-type or p-type impurity is added is used for a source electrode and a drain electrode. The semiconductor device includes a gate insulating film formed by using a silicon oxide film or a silicon oxynitride film over a gate electrode, an Al film or an Al alloy film over the gate insulating film, a ZnO film to which an n-type or p-type impurity is added over the Al film or the Al alloy film, and a ZnO semiconductor film over the ZnO film to which an n-type or p-type impurity is added and the gate insulating film.

Owner:SEMICON ENERGY LAB CO LTD

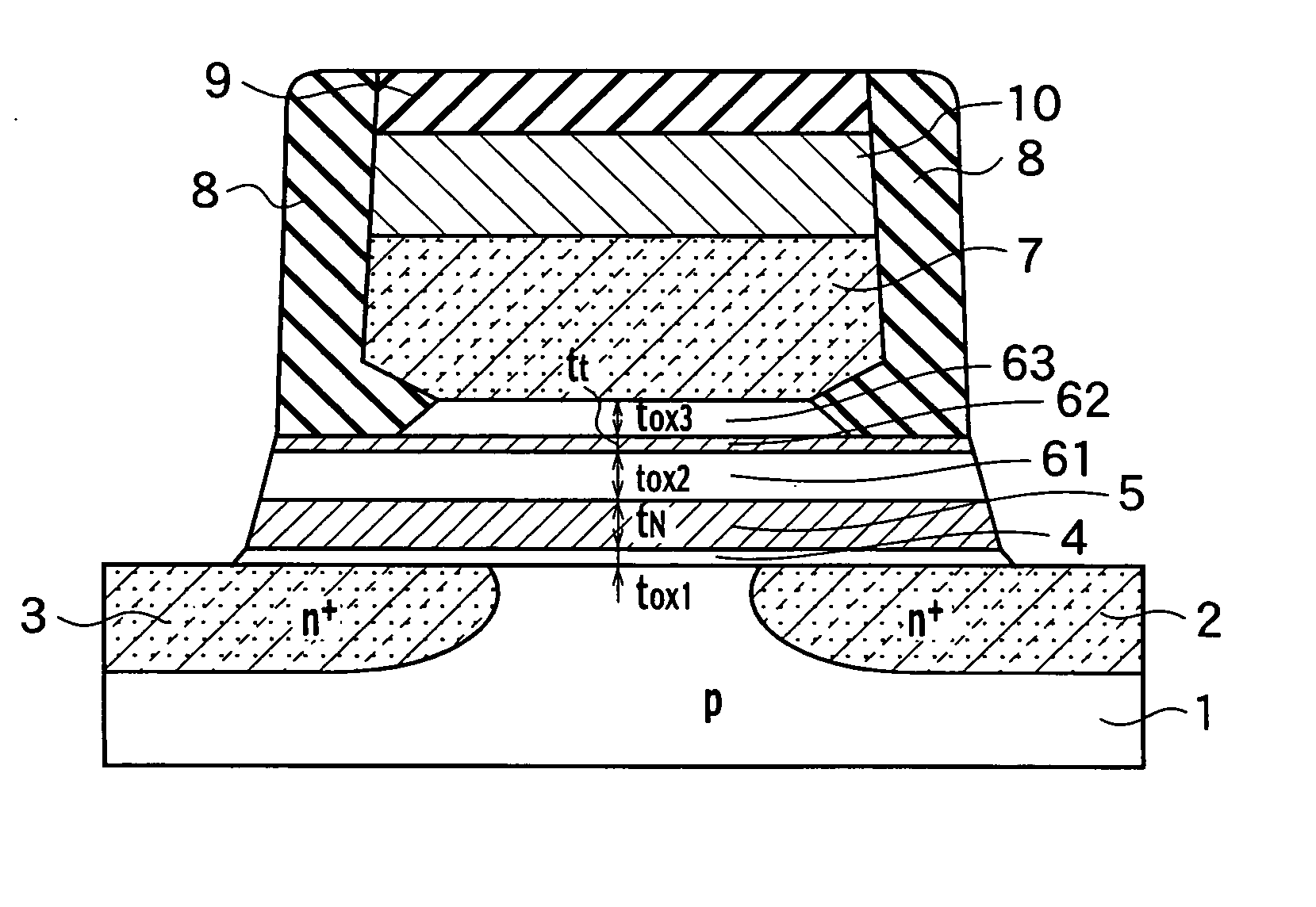

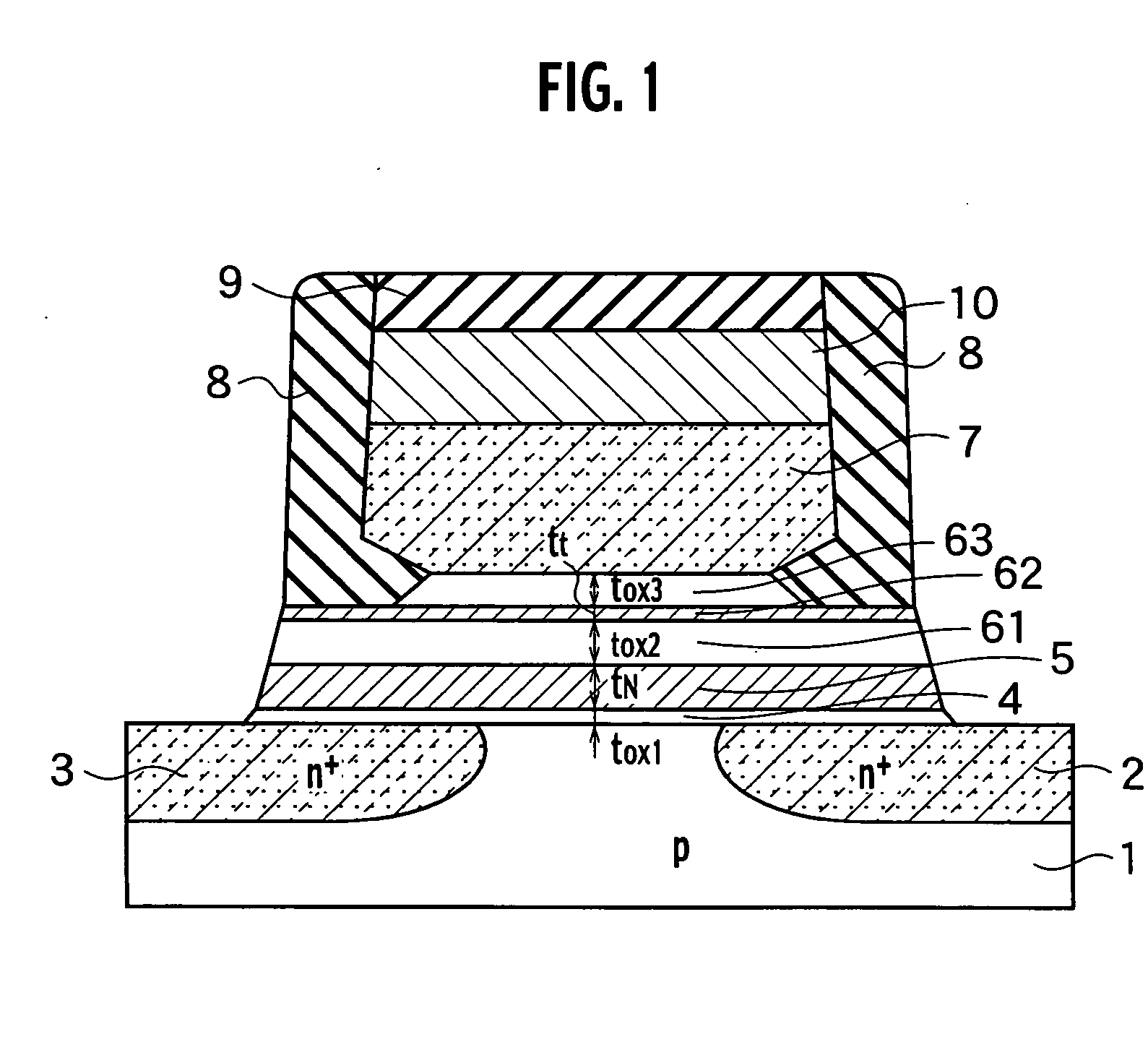

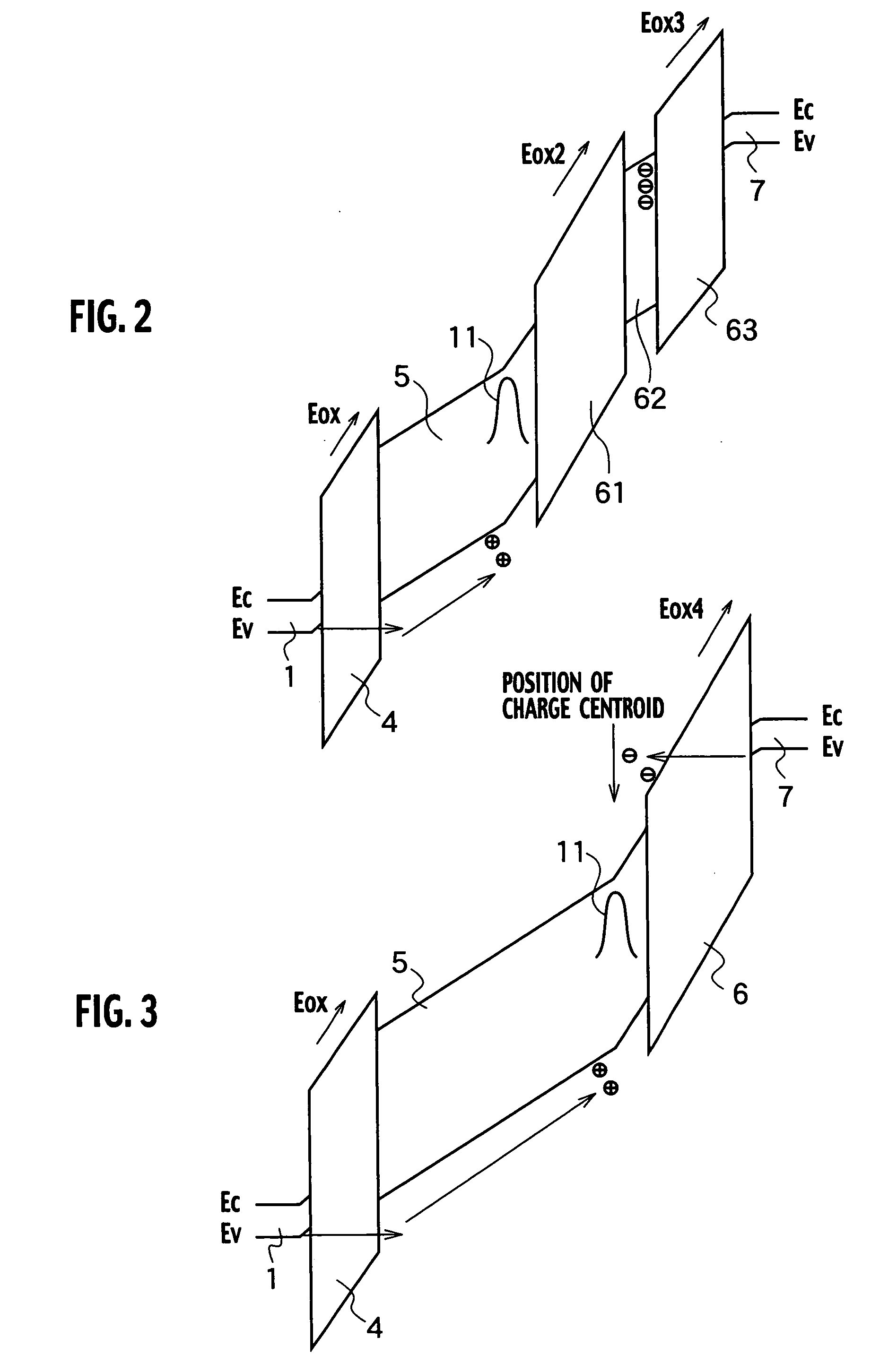

Semiconductor memory

A semiconductor memory having an electrically writable / erasable memory cell includes a first gate insulating layer made from a compound containing silicon and oxygen; a first charge-storage layer being in contact with the first gate insulating layer made from a silicon nitride film, a silicon oxynitride film, or an alumina film; a second insulating layer thicker than the first gate insulting layer; a second charge-storage layer being in contact with the second insulating layer; a third insulating layer thicker than the first gate insulating layer being in contact with the second charge-storage layer; and a control electrode upon the third insulating layer.

Owner:KK TOSHIBA

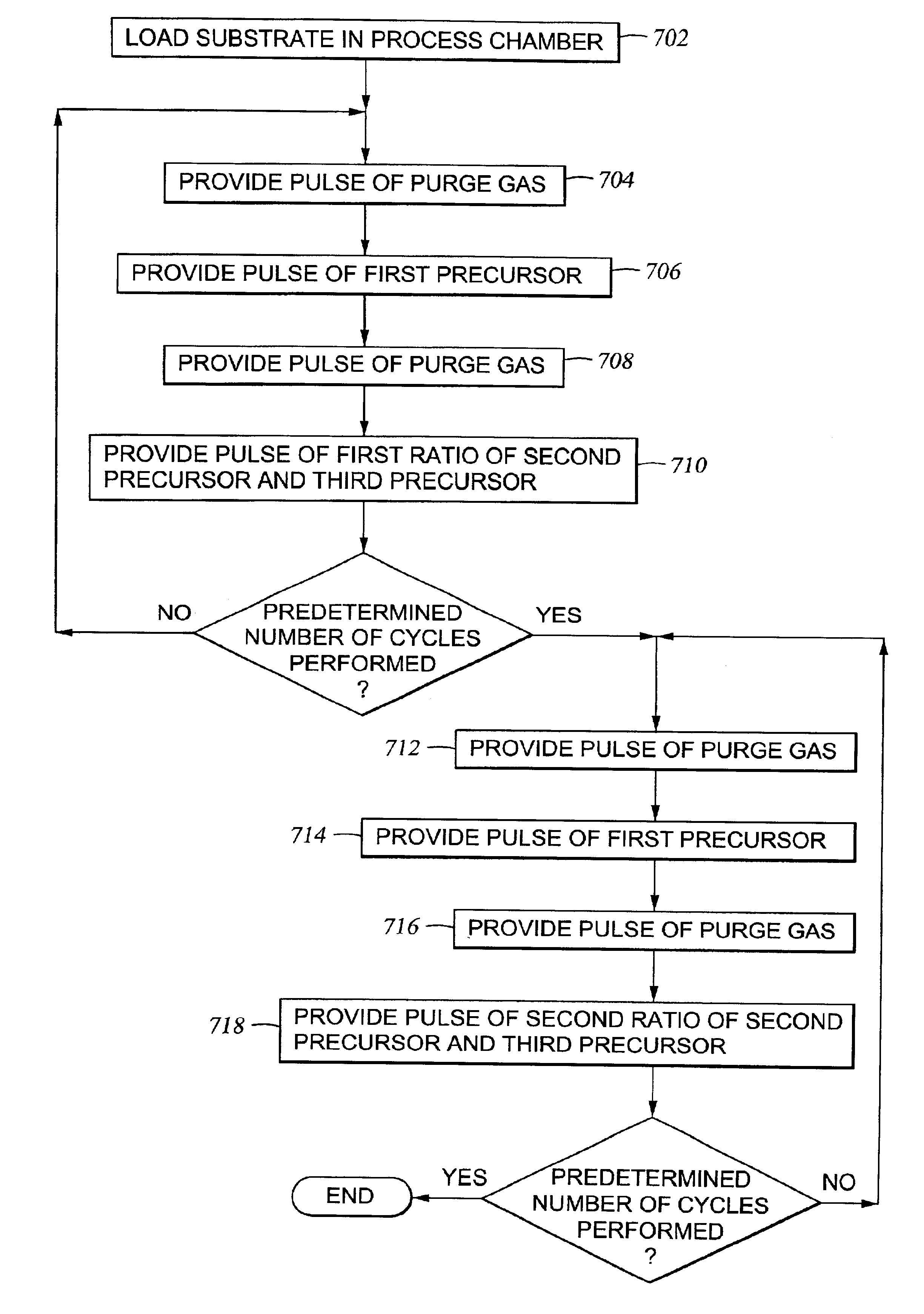

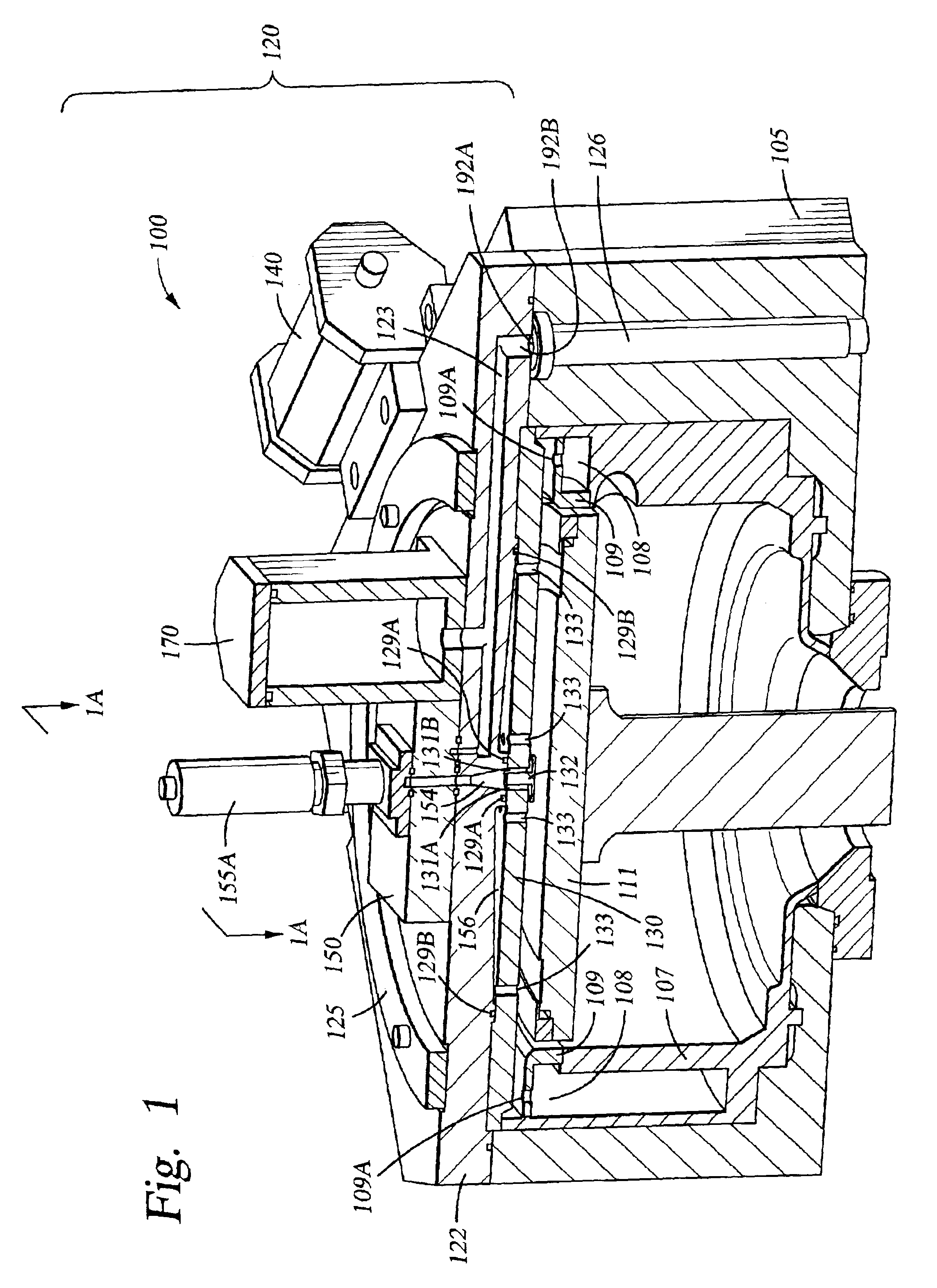

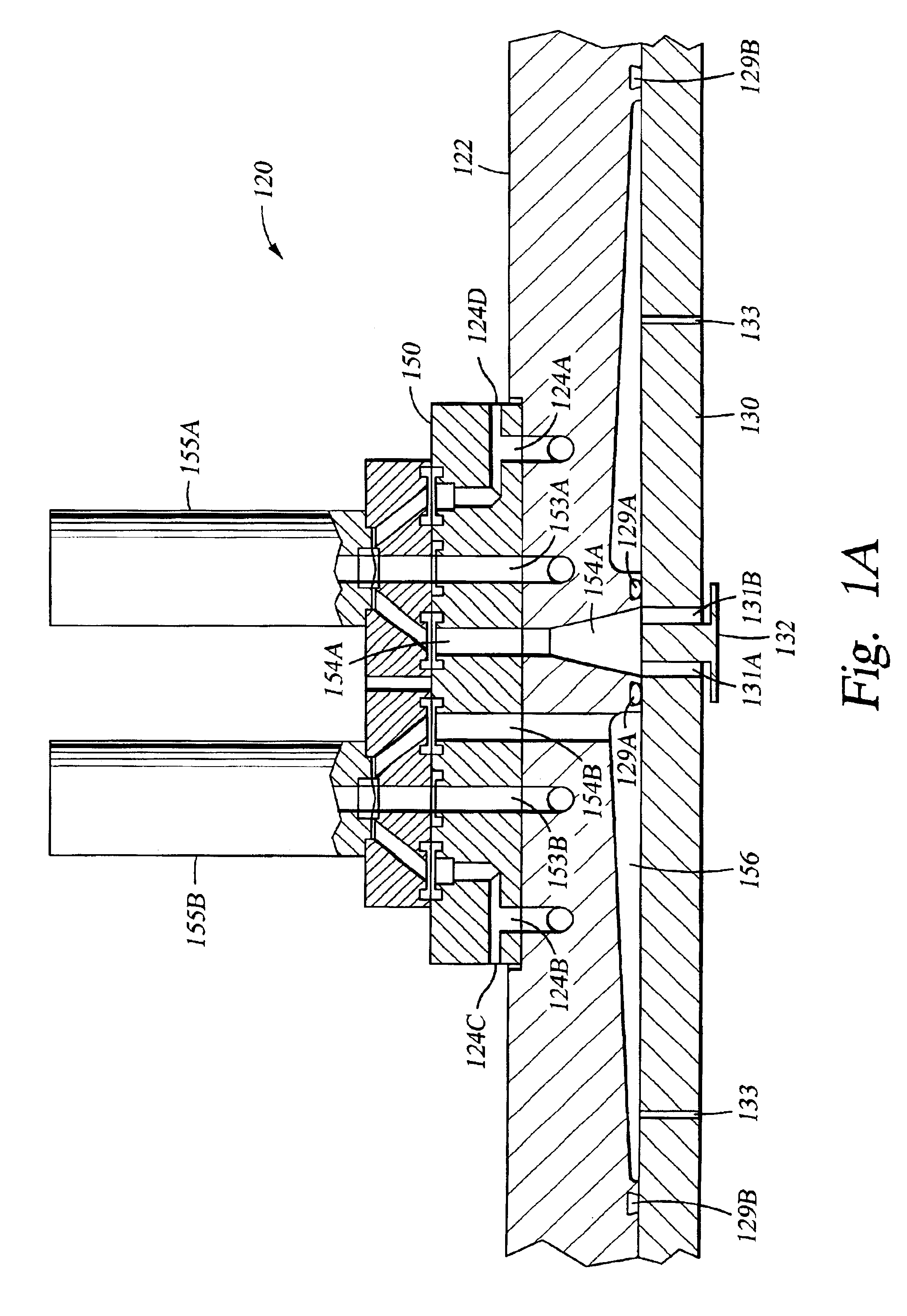

Multiple precursor cyclical deposition system

Embodiments of the present invention relate to an apparatus and method of cyclical deposition utilizing three or more precursors in which delivery of at least two of the precursors to a substrate structure at least partially overlap. One embodiment of depositing a ternary material layer over a substrate structure comprises providing at least one cycle of gases to deposit a ternary material layer. One cycle comprises introducing a pulse of a first precursor, introducing a pulse of a second precursor, and introducing a pulse of a third precursor in which the pulse of the second precursor and the pulse of the third precursor at least partially overlap. In one aspect, the ternary material layer includes, but is not limited to, tungsten boron silicon (WBxSiy), titanium silicon nitride (TiSixNy), tantalum silicon nitride (TaSixNy), silicon oxynitride (SiOxNy), and hafnium silicon oxide (HfSixOy). In one aspect, the composition of the ternary material layer may be tuned by changing the flow ratio of the second precursor to the third precursor between cycles.

Owner:APPLIED MATERIALS INC

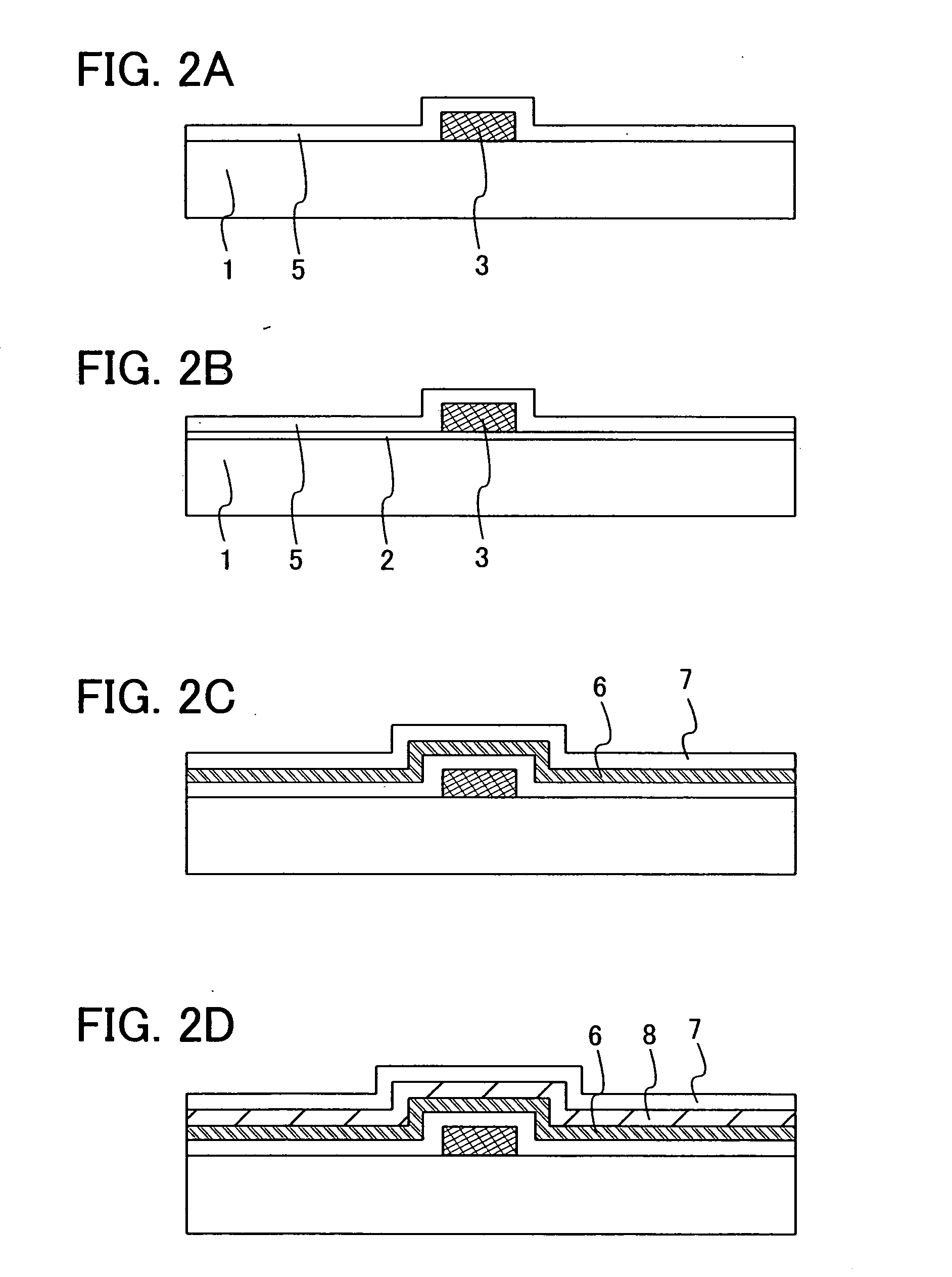

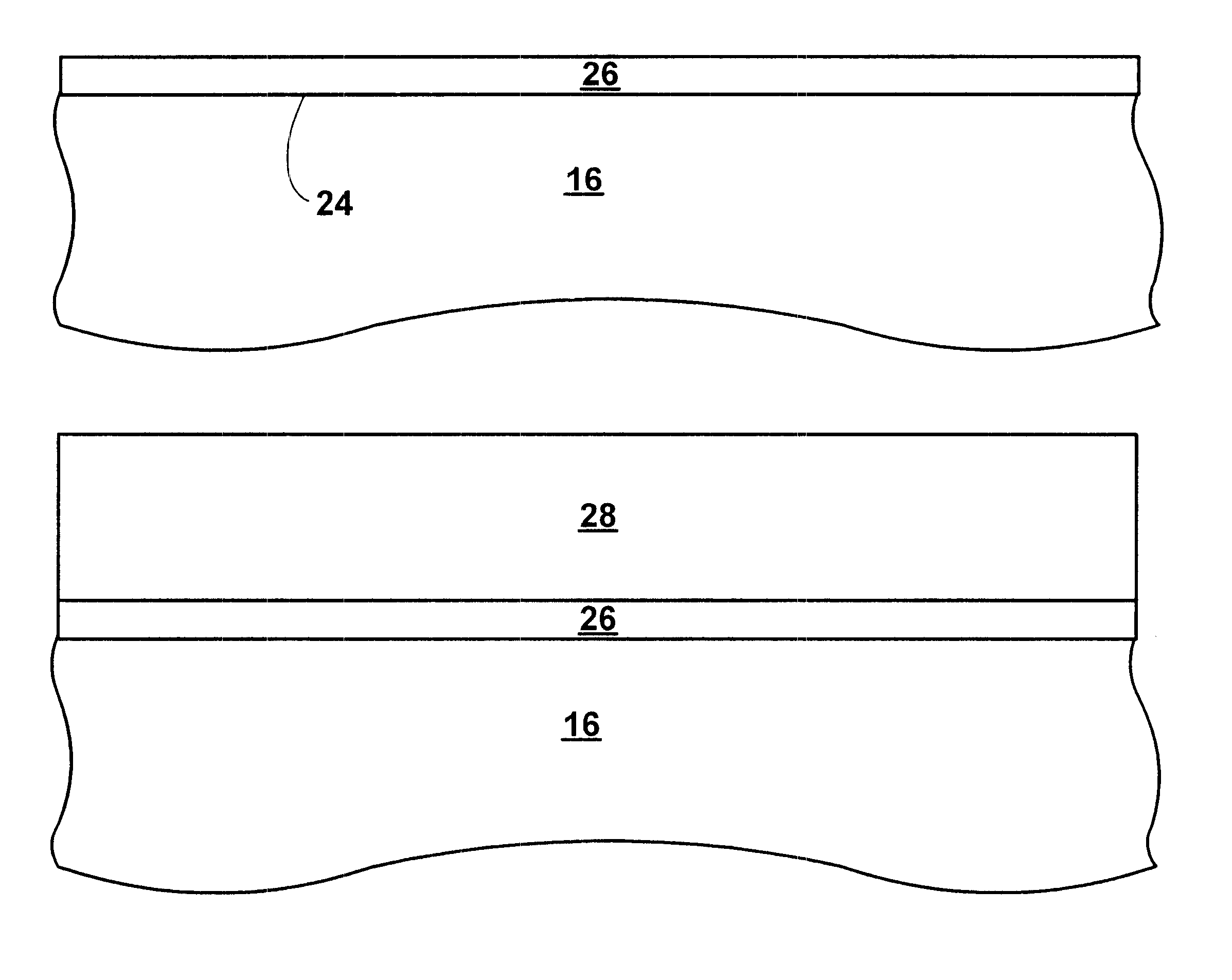

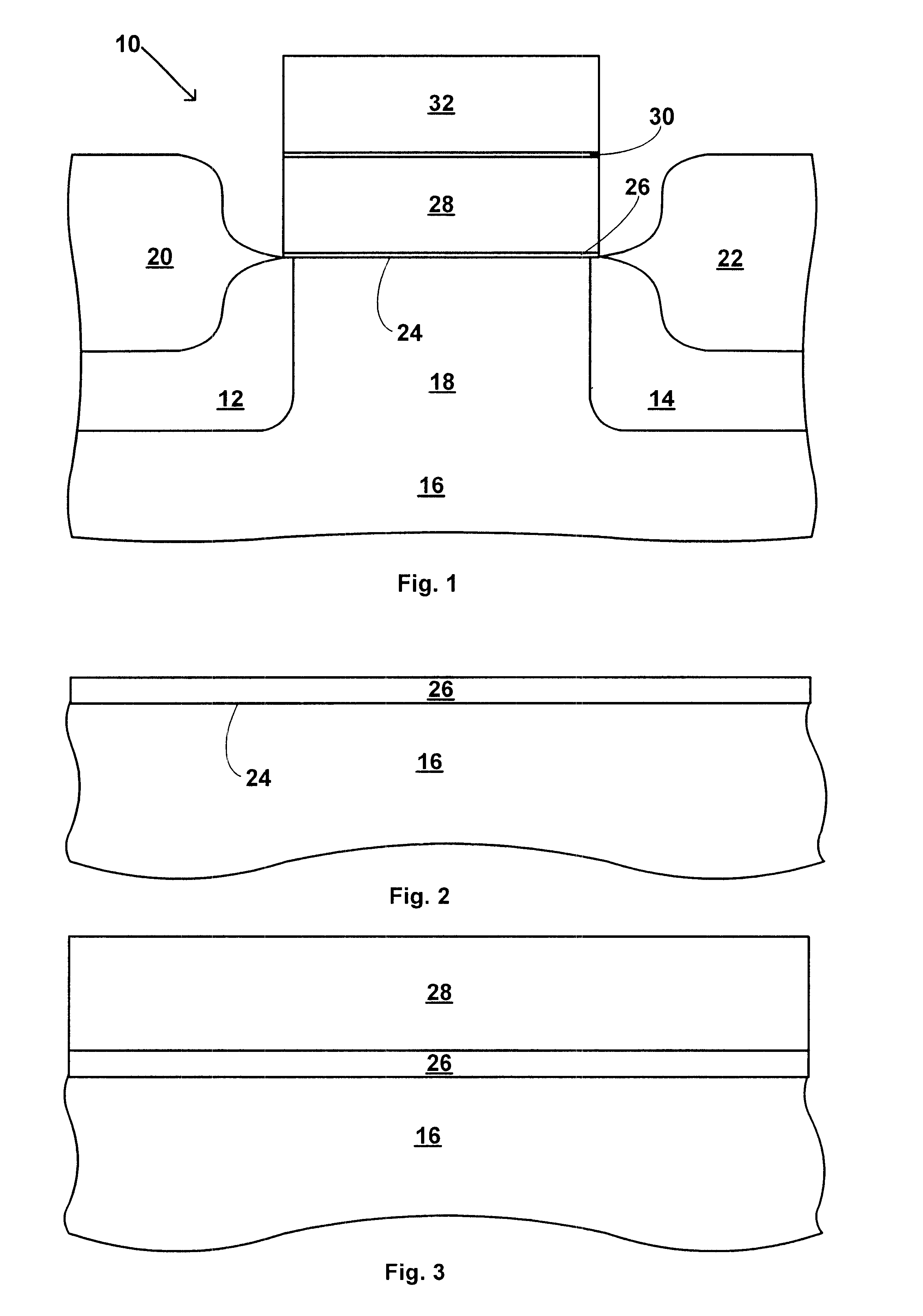

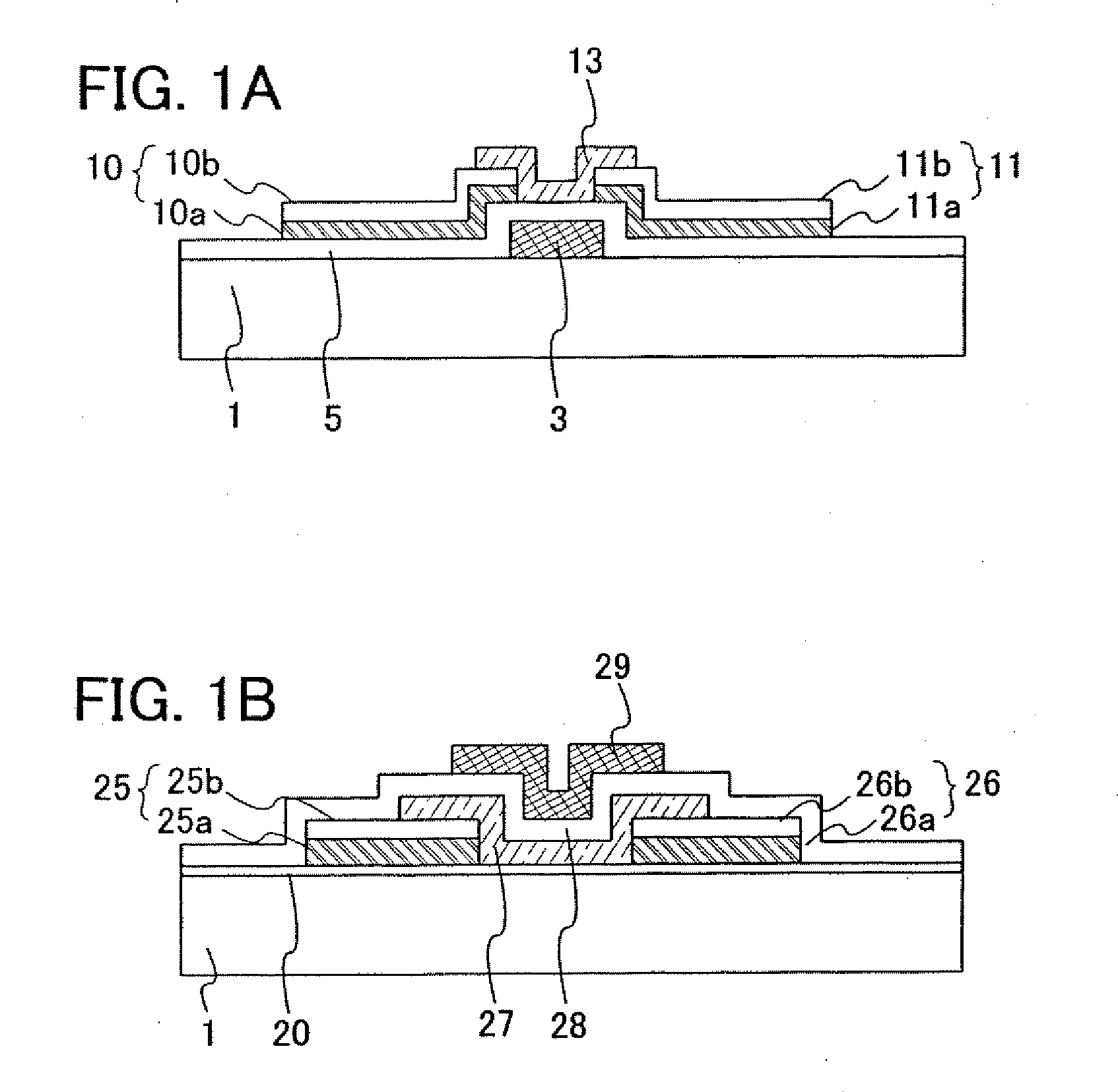

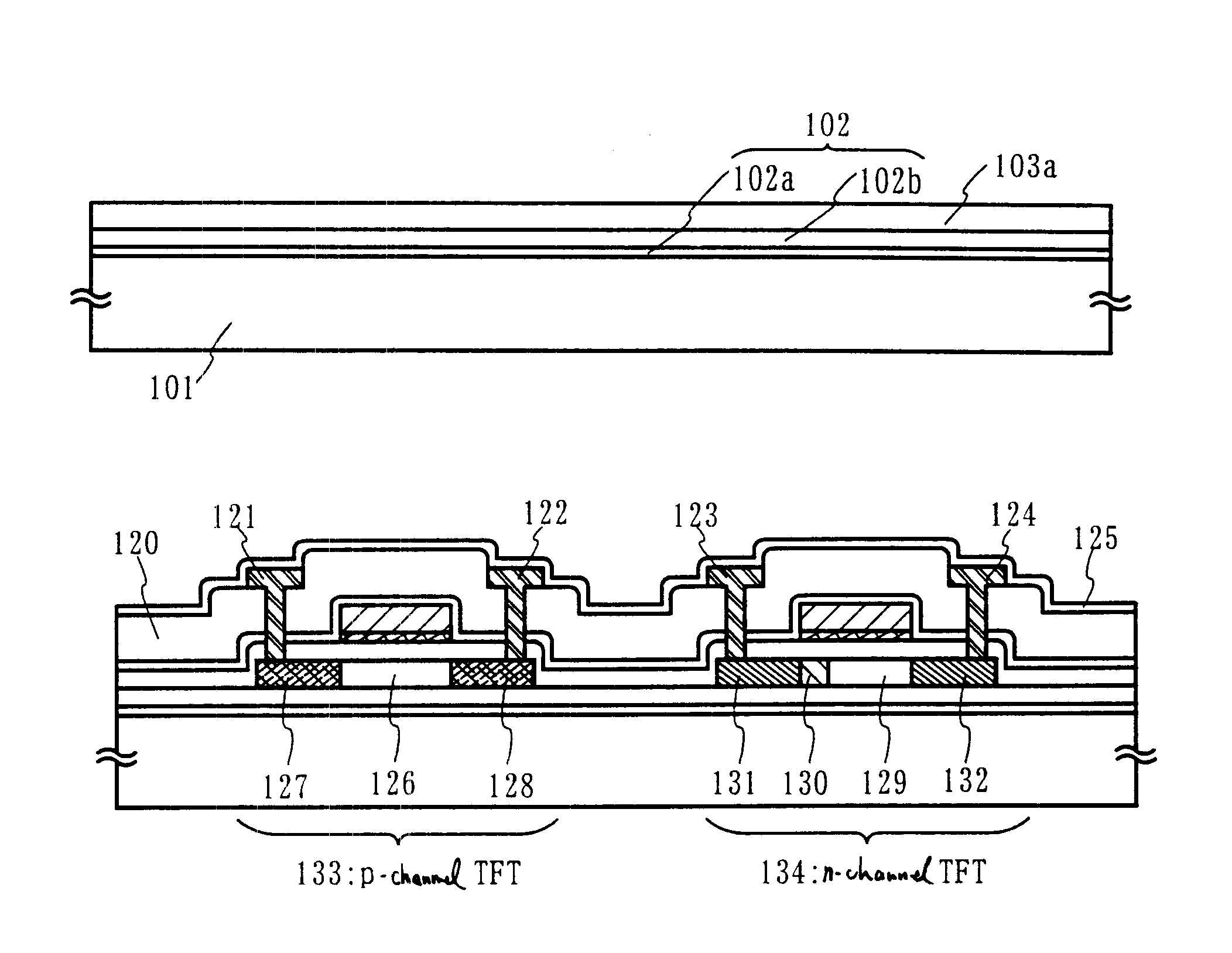

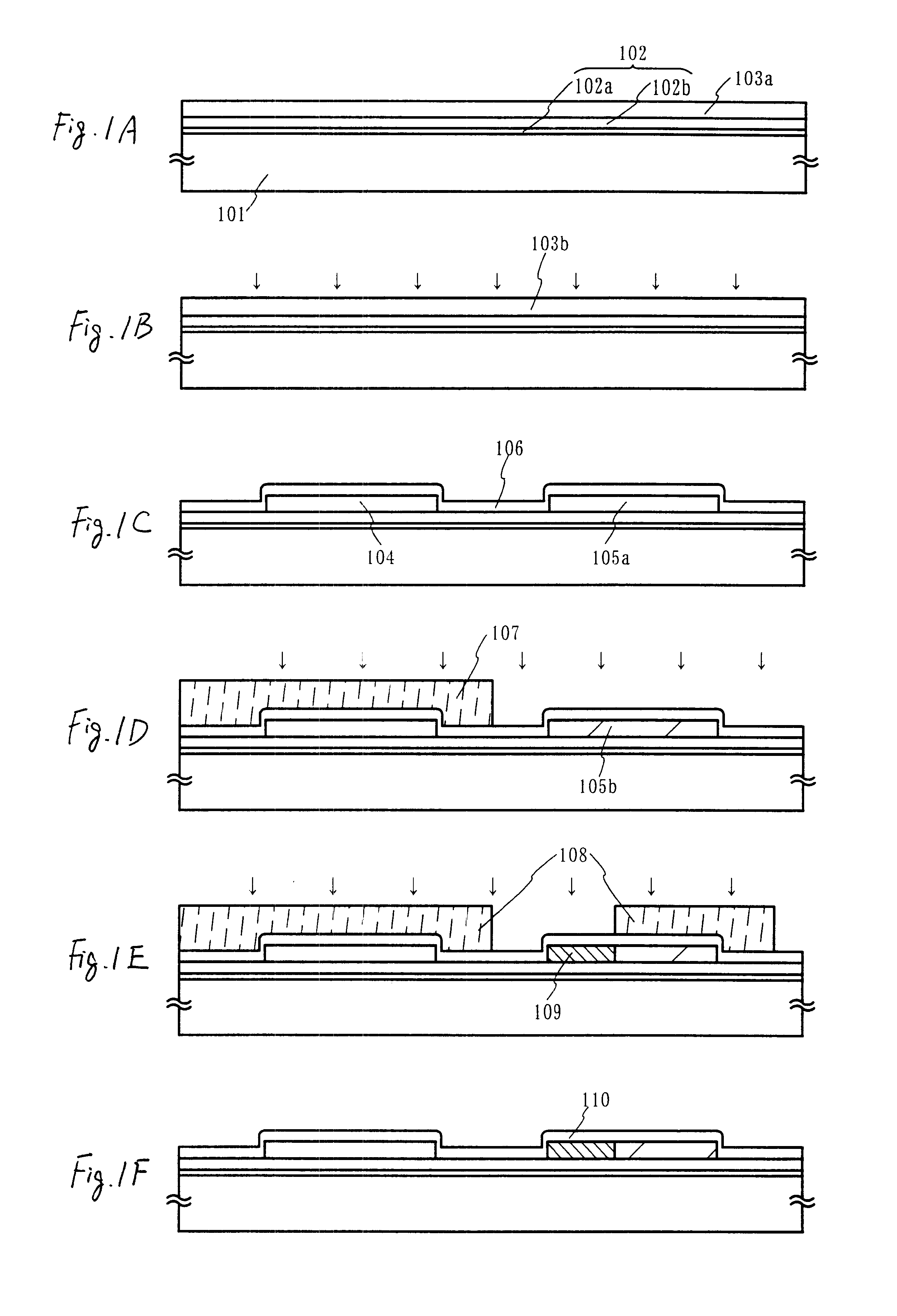

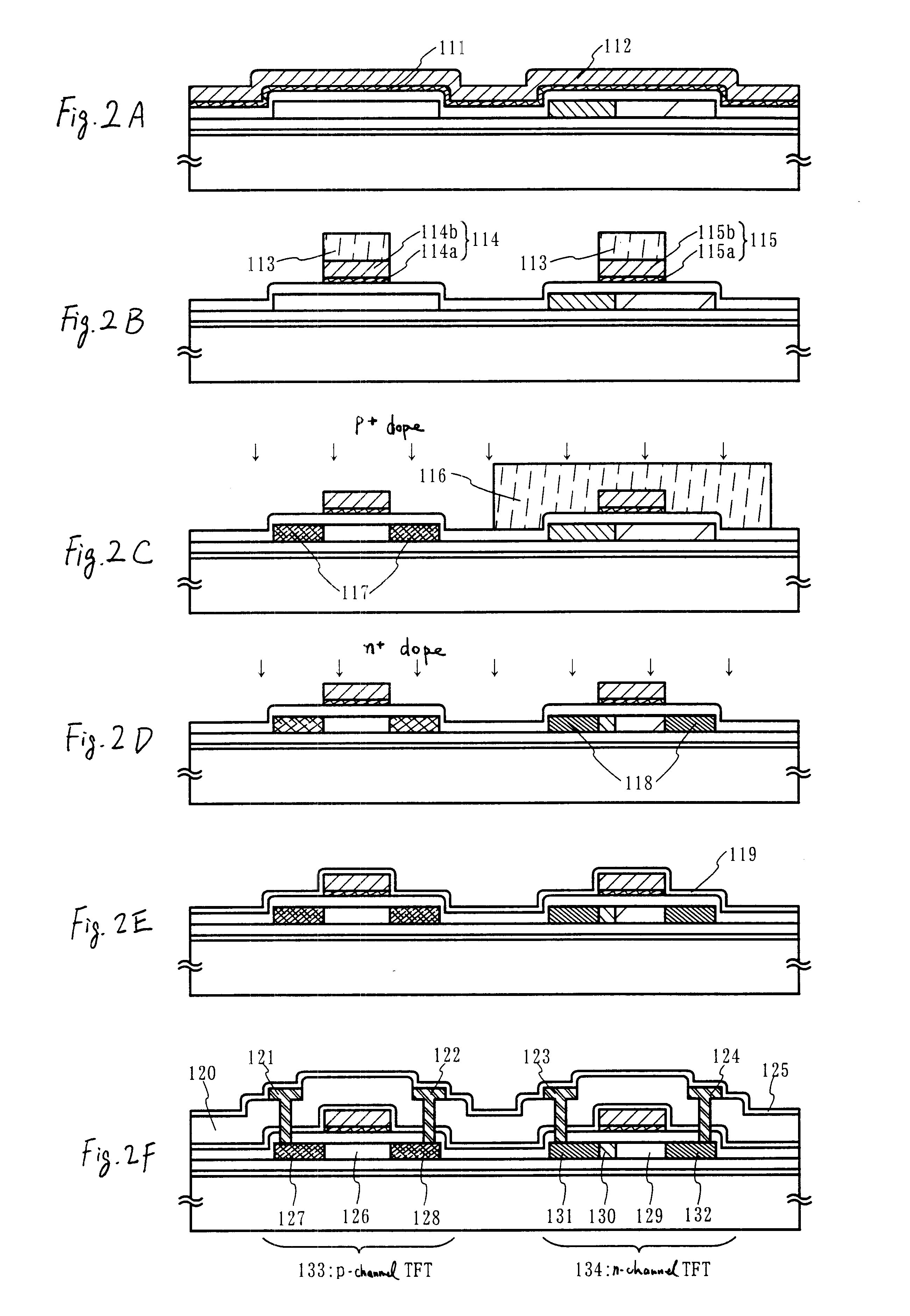

Oxynitride laminate "blocking layer" for thin film semiconductor devices

Channel doping is an effective method for controlling Vth, but if Vth shifts to the order of -4 to -3 V when forming circuits such as a CMOS circuit formed from both an n-channel TFT and a P-channel TFT on the same substrate, then it is difficult to control the Vth of both TFTs with one channel dope. In order to solve the above problem, the present invention forms a blocking layer on the back channel side, which is a laminate of a silicon oxynitride film (A) manufactured from SiH4, NH3, and N2O, and a silicon oxynitride film (B)manufactured from SiH4and N2O. By making this silicon oxynitride film laminate structure, contamination by alkaline metallic elements from the substrate can be prevented, and influence by stresses, caused by internal stress, imparted to the TFT can be relieved.

Owner:SEMICON ENERGY LAB CO LTD

Method for forming silicon-containing materials during a photoexcitation deposition process

InactiveUS20060286776A1Enhance chamber cleaning processHigh surface energyPolycrystalline material growthSemiconductor/solid-state device manufacturingVolatilesSilicon oxide

Embodiments of the invention generally provide a method for depositing films or layers using a UV source during a photoexcitation process. The films are deposited on a substrate and usually contain a material, such as silicon (e.g., epitaxy, crystalline, microcrystalline, polysilicon, or amorphous), silicon oxide, silicon nitride, silicon oxynitride, or other silicon-containing materials. The photoexcitation process may expose the substrate and / or gases to an energy beam or flux prior to, during, or subsequent a deposition process. Therefore, the photoexcitation process may be used to pre-treat or post-treat the substrate or material, to deposit the silicon-containing material, and to enhance chamber cleaning processes. Attributes of the method that are enhanced by the UV photoexcitation process include removing native oxides prior to deposition, removing volatiles from deposited films, increasing surface energy of the deposited films, increasing the excitation energy of precursors, reducing deposition time, and reducing deposition temperature.

Owner:APPLIED MATERIALS INC

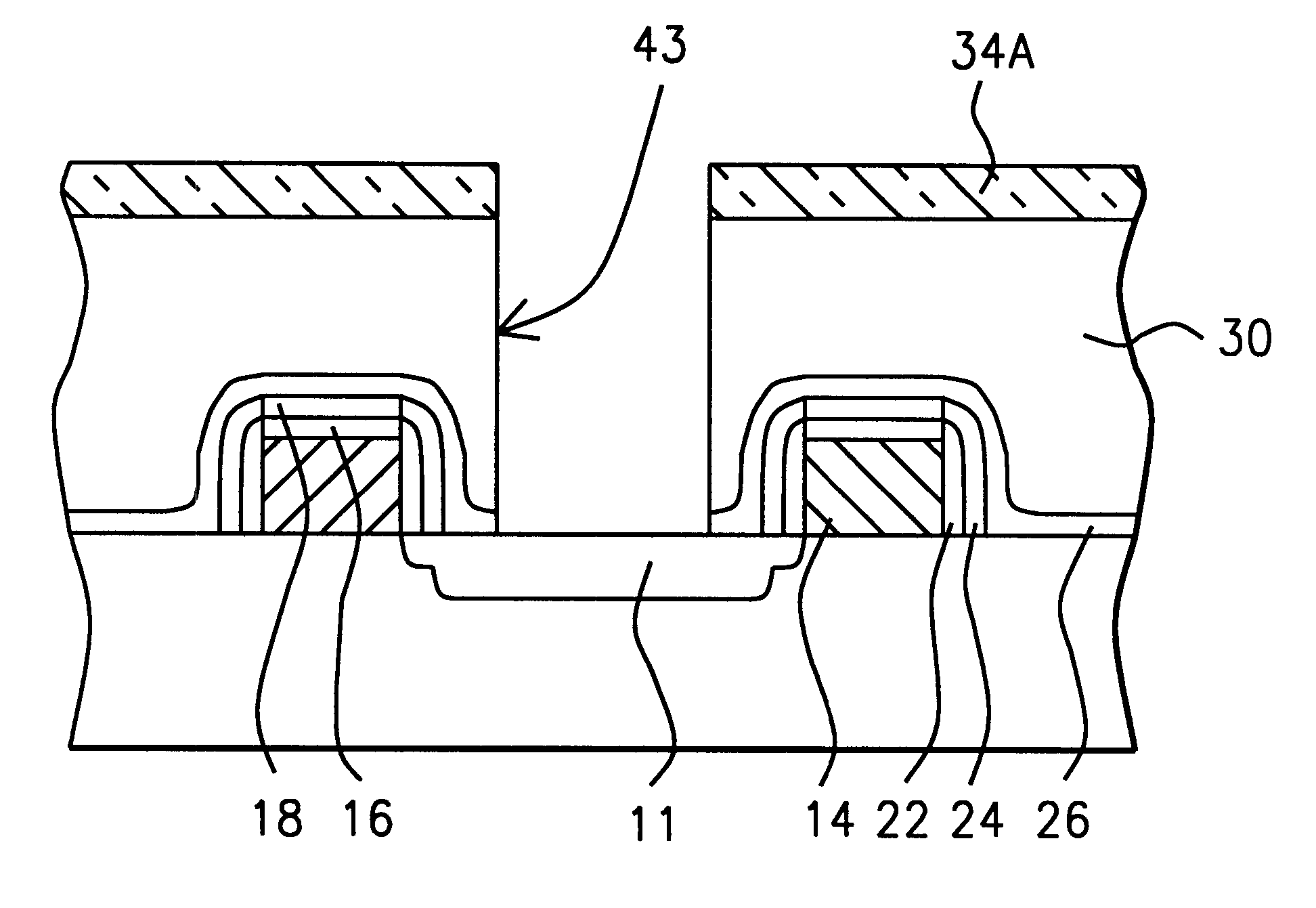

High selectivity Si-rich SiON etch-stop layer

The present invention provides an anti-reflective Si-Rich Silicon oxynitride (SiON) etch barrier layer and two compatible oxide etch processes. The Si-Rich Silicon oxynitride (SiON) etch barrier layer can be used as a hard mask in a dual damascene structure and as a hard mask for over a polysilicone gate. The invention has the following key elements: 1) Si rich Silicon oxynitride (SiON) ARC layer, 2) Special Silicon oxide Etch process that has a high selectivity of Si-Rich SiON to silicon oxide or SiN; 3) Special Si Rich SiON spacer process for a self aligned contact (SAC).A dual damascene structure is formed by depositing a first dielectric layer. A novel anti-reflective Si-Rich Silicon oxynitride (SiON) etch barrier layer is deposited on top of the first dielectric layer. A first opening is etched in the first insulating layer. A second dielectric layer is deposited on the anti-reflective Si-Rich Silicon oxynitride (SiON) etch barrier layer. A second dual damascene opening is etched into the dielectric layers. The anti-reflective Si-Rich Silicon oxynnitride (SiON) etch barrier layer can also serve as an ARC layer during these operations to reduce the amount of reflectance from conductive region to reduce distortion of the photoresist pattern.

Owner:TAIWAN SEMICON MFG CO LTD

Semiconductor device and manufacturing method thereof

Owner:SEMICON ENERGY LAB CO LTD

Composition and method for low temperature deposition of silicon-containing films such as films including silicon nitride, silicon dioxide and/or silicon-oxynitride

ActiveUS20040096582A1Silicon organic compoundsPolycrystalline material growthLow temperature depositionGas phase

Silicon precursors for forming silicon-containing films in the manufacture of semiconductor devices, such as low dielectric constant (k) thin films, high k gate silicates, low temperature silicon epitaxial films, and films containing silicon nitride (Si3N4), siliconoxynitride (SiOxNy) and / or silicon dioxide (SiO2). The precursors of the invention are amenable to use in low temperature (e.g., <500° C.) chemical vapor deposition processes, for fabrication of ULSI devices and device structures.

Owner:ENTEGRIS INC

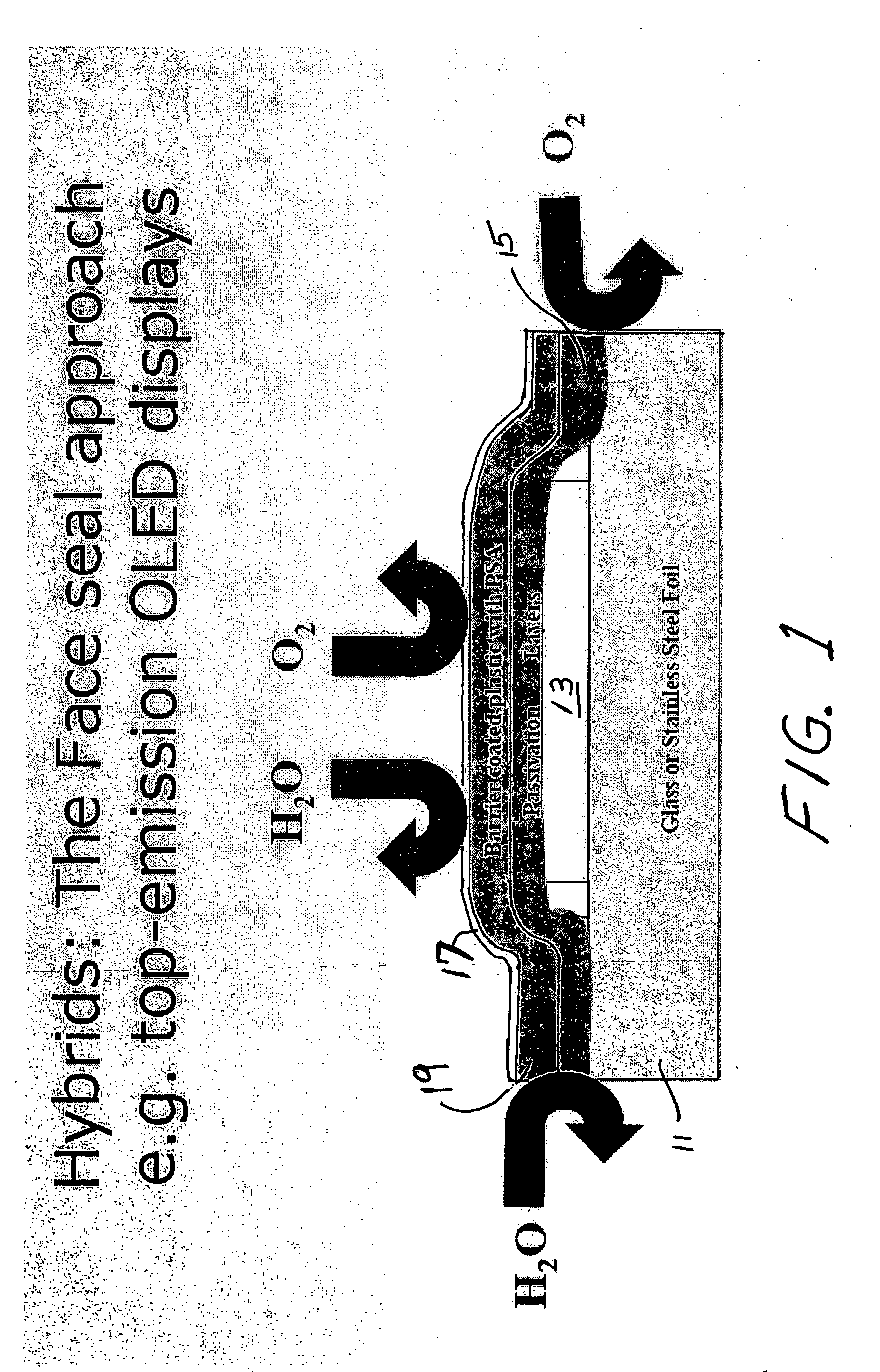

Gas barrier

InactiveUS20070135552A1Improved resistance to water vapor transmissionSmall sizeMaterial nanotechnologyPolymer scienceSealant

Nanoparticles of amorphous aluminum oxynitride or silicon oxynitride having a very high aspect ratio are used to fill polymeric materials to provide products that have an extremely low WVTR / OTR. Such products are particularly effective for incorporation into organic light-emitting devices or the like which are susceptible to degradation from moisture and / or oxygen. Pressure sensitive and / or thermosetting adhesives filled with such particles create excellent sealants. Polymeric sheets or films made from resin in which these nanoparticles are dispersed, or intimately associated with, before extrusion exhibit very low WVTR / OTR.

Owner:GENERAL ATOMICS

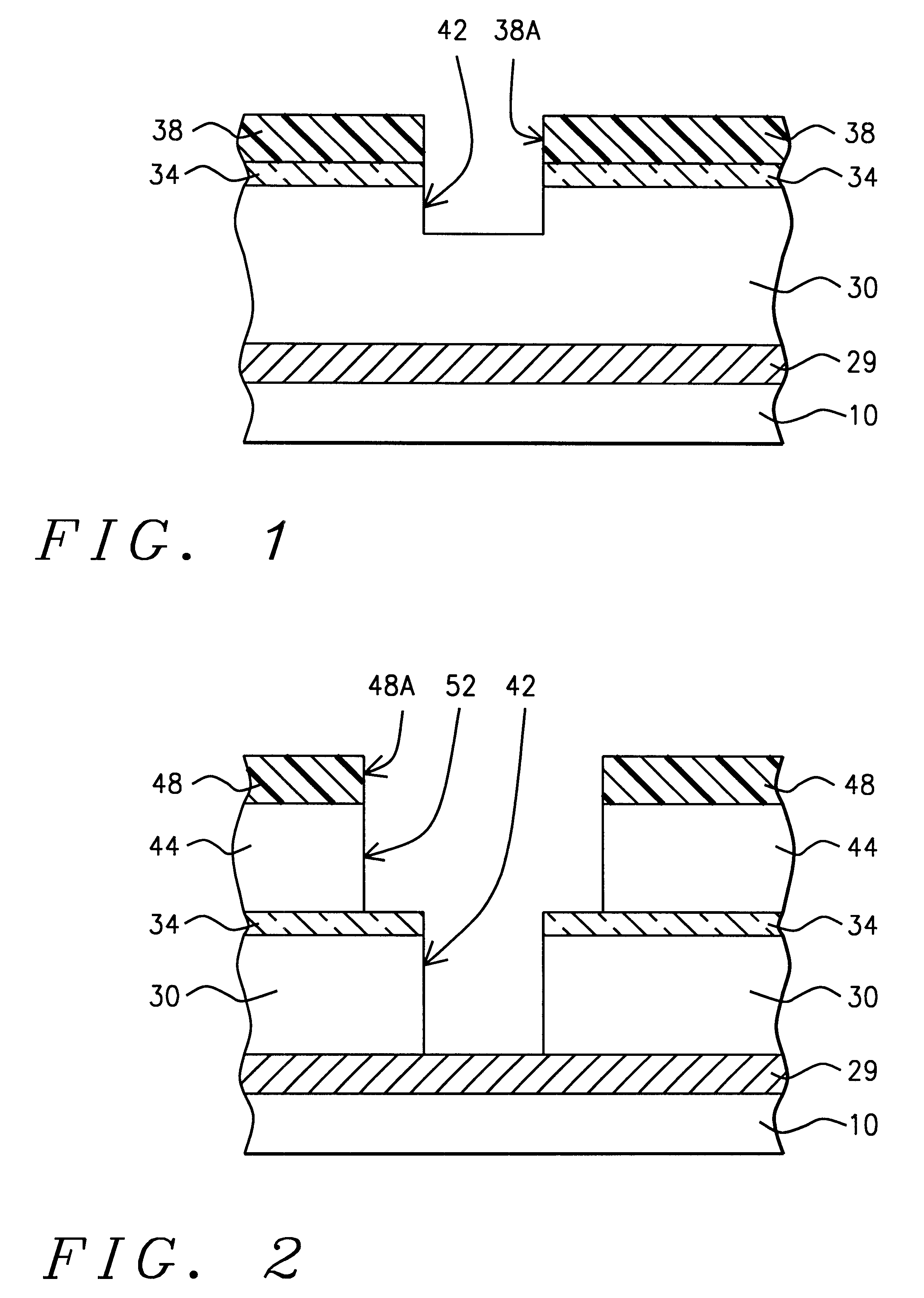

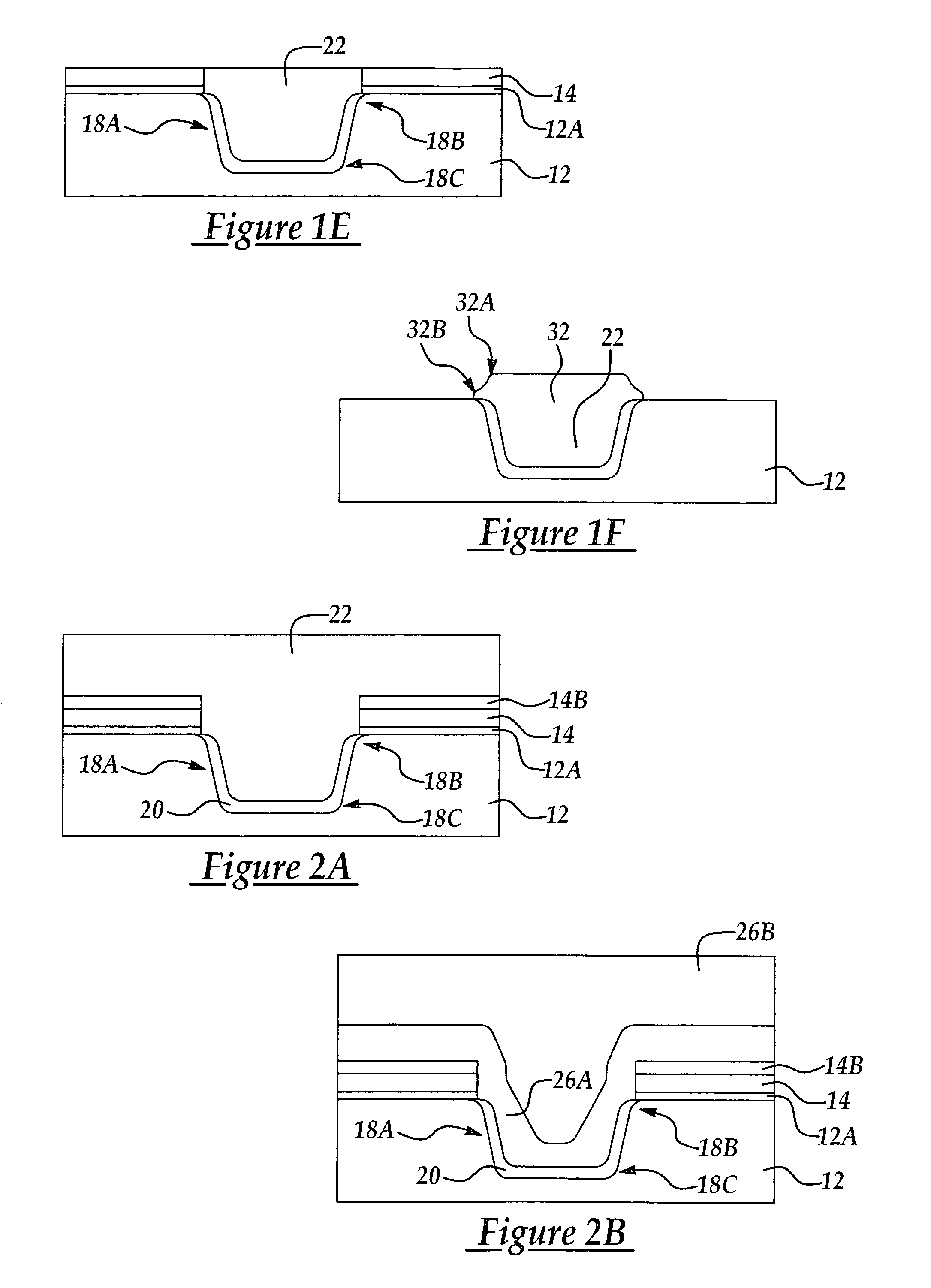

Method of achieving improved STI gap fill with reduced stress

InactiveUS7118987B2Relieve pressureIncrease charge mobilityStentsBalloon catheterEngineeringSilicon dioxide

A shallow trench isolation (STI) structure and method of forming the same with reduced stress to improve charge mobility the method including providing a semiconductor substrate comprising at least one patterned hardmask layer overlying the semiconductor substrate; dry etching a trench in the semiconductor substrate according to the at least one patterned hardmask layer; forming one or more liner layers to line the trench selected from the group consisting of silicon dioxide, silicon nitride, and silicon oxynitride; forming one or more layers of trench filling material comprising silicon dioxide to backfill the trench; carrying out at least one thermal annealing step to relax accumulated stress in the trench filling material; carrying out at least one of a CMP and dry etch process to remove excess trench filling material above the trench level; and, removing the at least one patterned hardmask layer.

Owner:TAIWAN SEMICON MFG CO LTD

Precursors for the deposition of carbon-doped silicon nitride or silicon oxynitride films

InactiveUS20060228903A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingEtchingMetallurgy

Owner:INTEL CORP

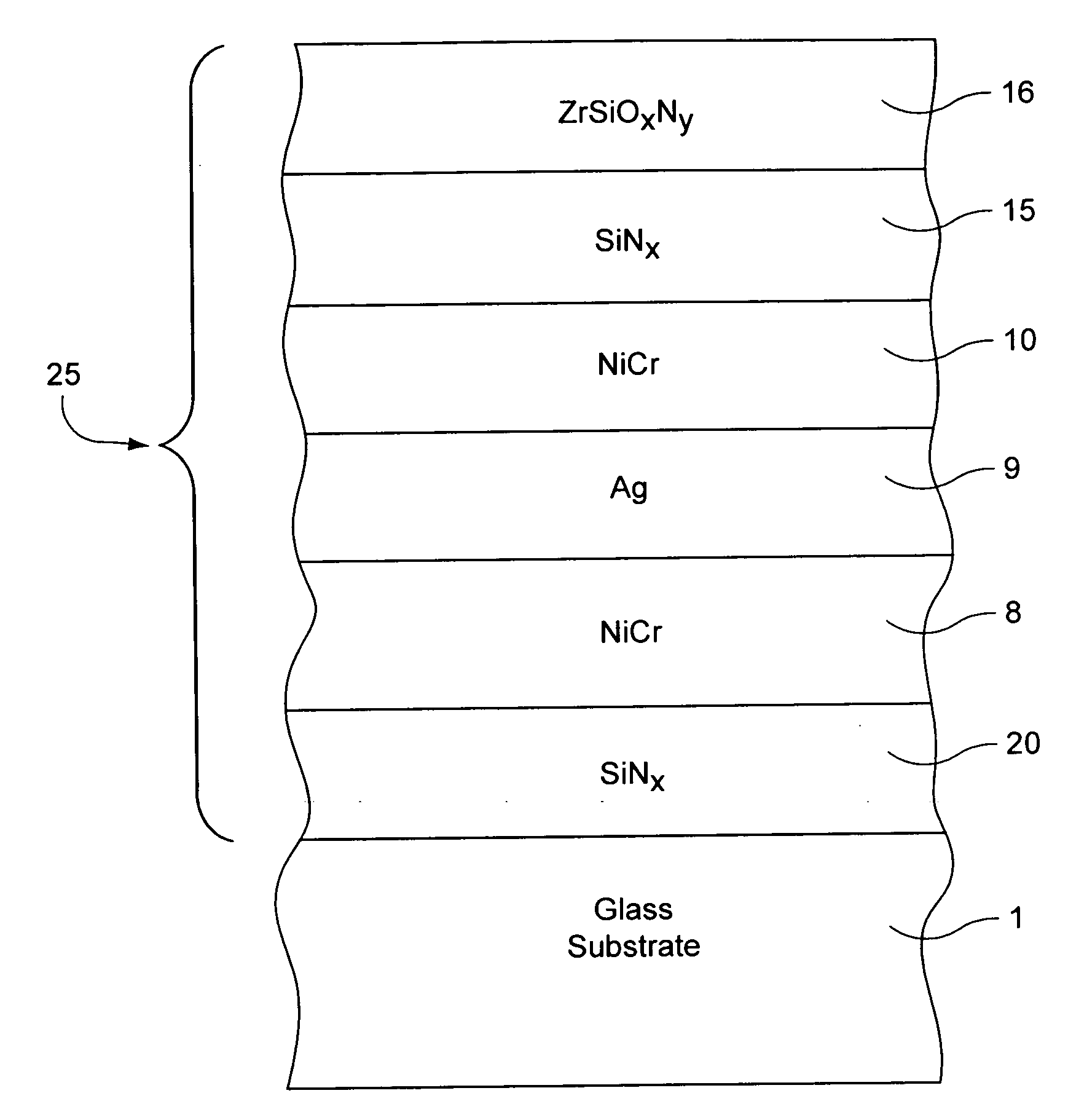

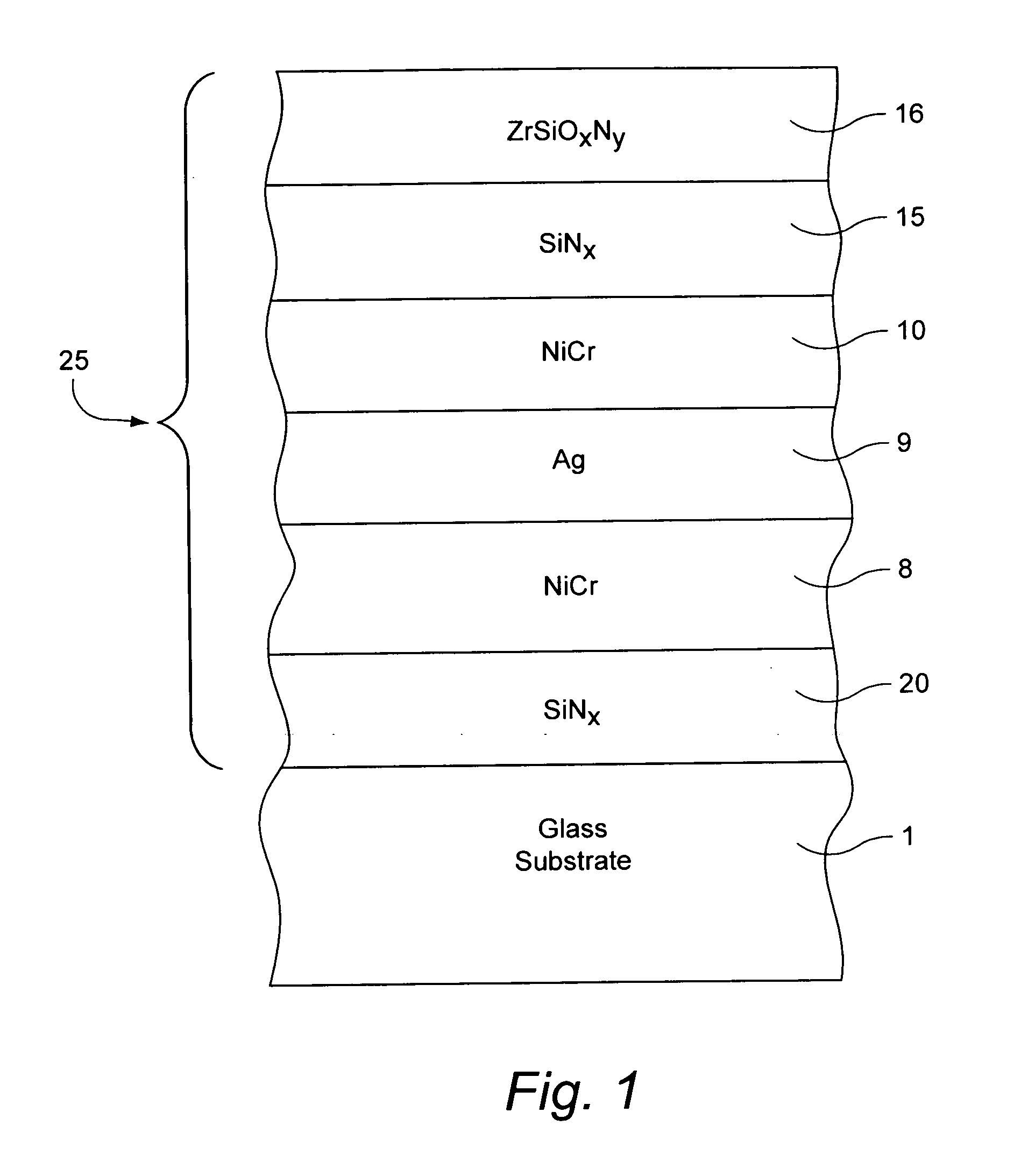

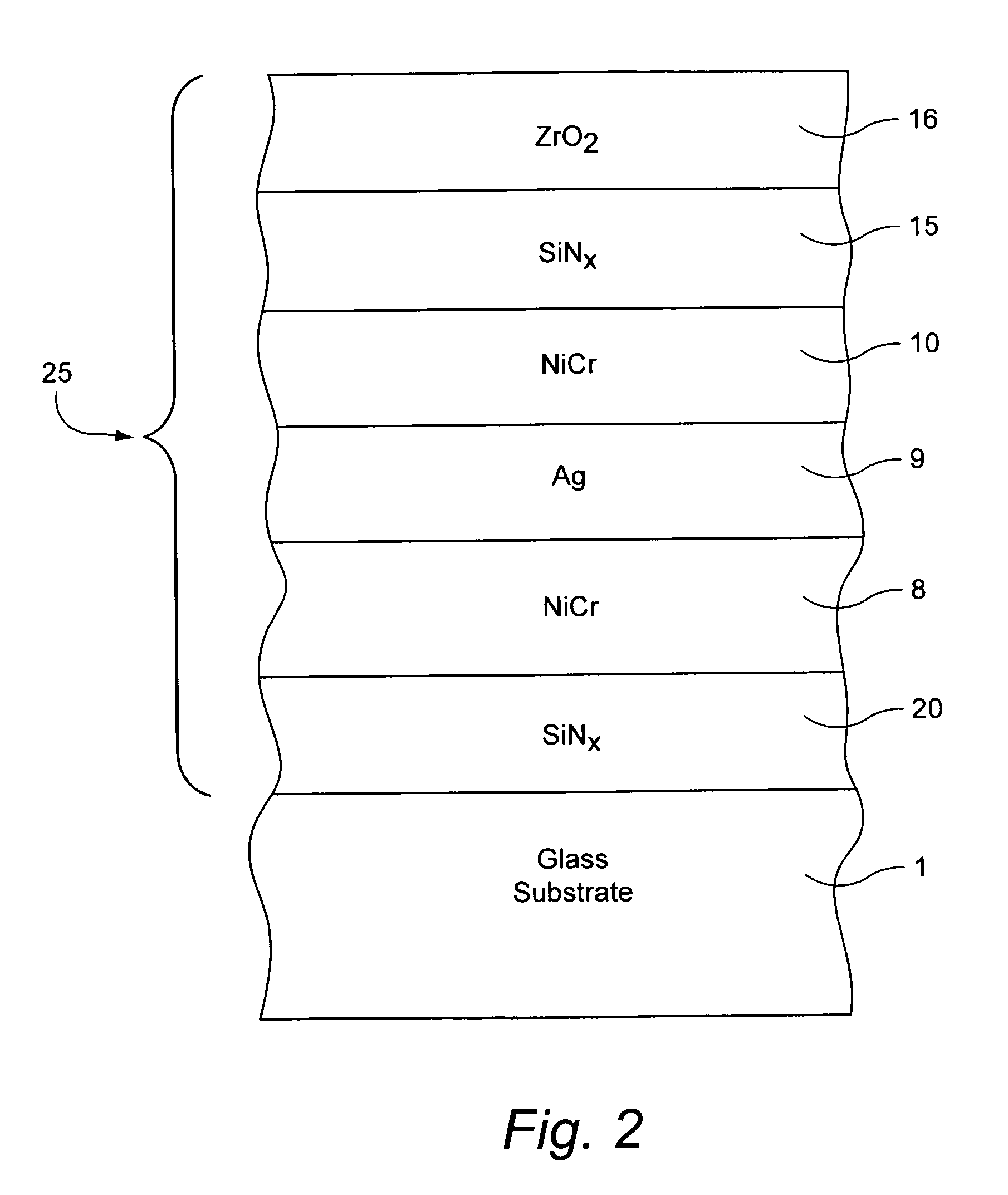

Coated article with low-E coating including zirconium oxide and/or zirconium silicon oxynitride and methods of making same

InactiveUS20090324967A1Reduce sheet resistanceImprove transmittanceGlass/slag layered productsCoatingsZirconium hydrideHeat stability

This application relates to a coated article including at least one infrared (IR) reflecting layer of a material such as silver or the like in a low-E coating. In certain embodiments, at least one layer of the coating is of or includes zirconium oxide (e.g., ZrO2) or zirconium silicon oxynitride (e.g., ZrSiOxNy). When a layer comprising zirconium oxide or zirconium silicon oxynitride is provided as the uppermost or overcoat layer of the coated article (e.g., over a silicon nitride based layer), this results in improved chemical and heat stability in certain example embodiments. Coated articles herein may be used in the context of insulating glass (IG) window units, vehicle windows, or in other suitable applications such as monolithic window applications, laminated windows, and / or the like.

Owner:GUARDIAN GLASS LLC

Hexakis(monohydrocarbylamino) disilanes and method for the preparation thereof

InactiveUS7019159B2Silicon organic compoundsSemiconductor/solid-state device manufacturingSilane compoundsOrganic solvent

A composition and method of preparation, to provide silane compounds that are free of chlorine. The compounds are hexakis(monohydrocarbylamino)disilanes with general formula (I)((R)HN)3—Si—Si—(NH(R))3 (I)wherein each R independently represents a C1 to C4 hydrocarbyl. These disilanes may be synthesized by reacting hexachlorodisilane in organic solvent with at least 6-fold moles of the monohydrocarbylamine RNH2 (wherein R is a C1 to C4 hydrocarbyl). Such compounds have excellent film-forming characteristics at low temperatures. These films, particularly in the case of silicon nitride and silicon oxynitride, also have excellent handling characteristics.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

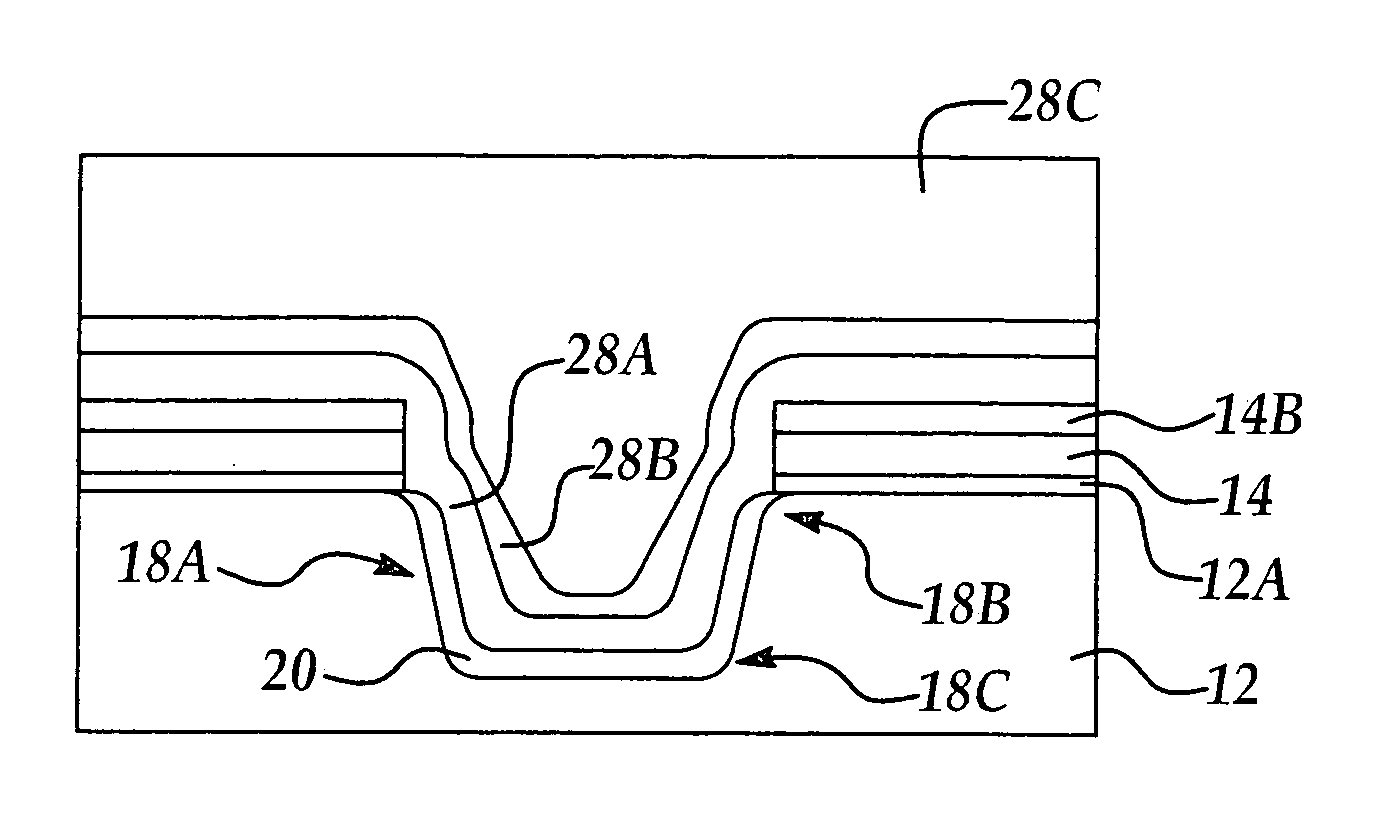

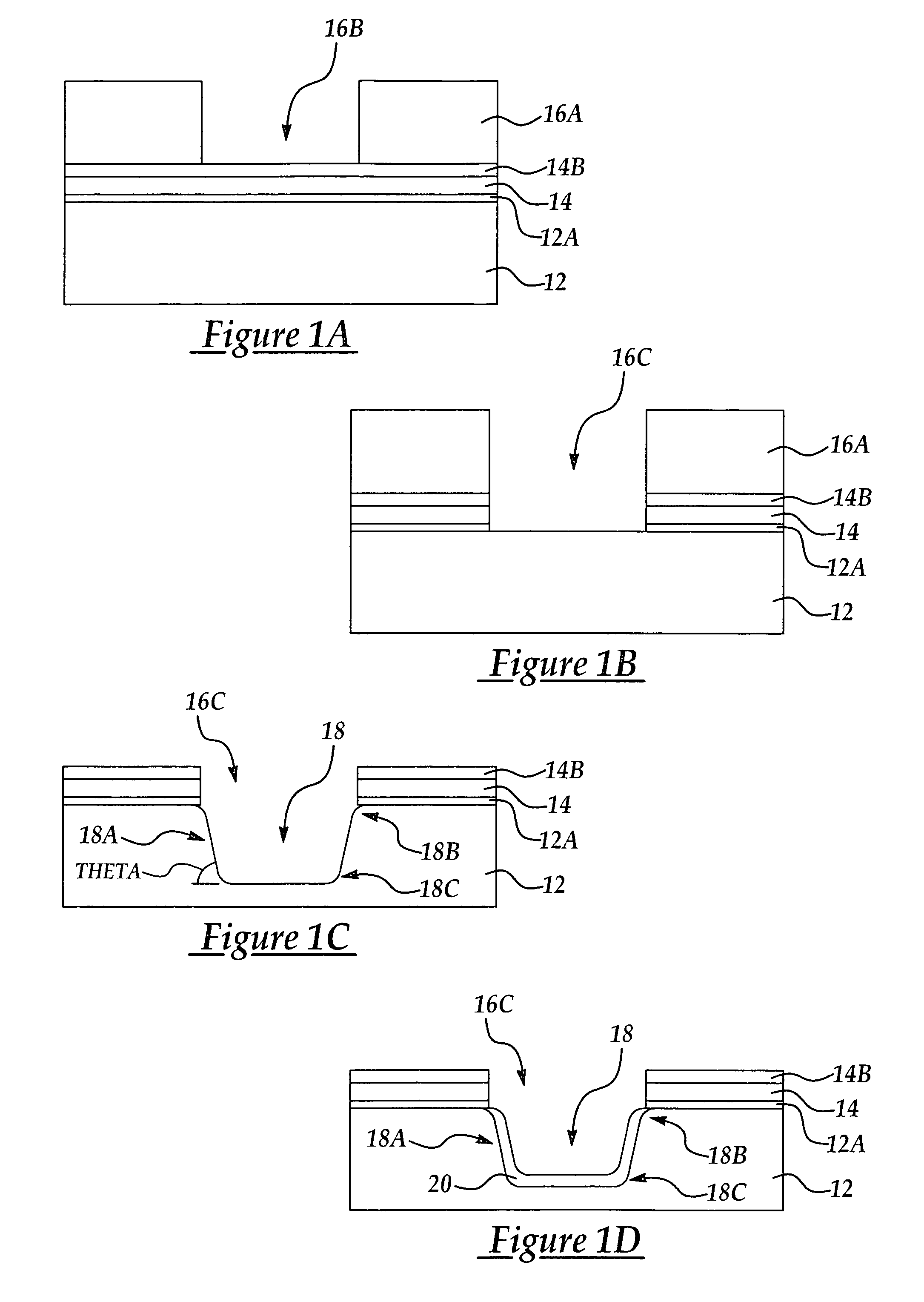

Light emitting device

InactiveUS20030146439A1Avoid contaminationPrevent penetrationFinal product manufactureElectroluminescent light sourcesStructuring elementAluminum oxynitride

An objective is to increase the reliability of a light emitting device structured by combining TFTs and organic light emitting elements. A TFT (1201) and an organic light emitting element (1202) are formed on the same substrate (1203) as structuring elements of a light emitting device (1200). A first insulating film (1205) which functions as a blocking layer is formed on the substrate (1203) side of the TFT (1201), and a second insulating film (1206) is formed on the opposite upper layer side as a protective film. In addition, a third insulating film (1207) which functions as a barrier film is formed on the lower layer side of the organic light emitting element (1202). The third insulating film (1207) is formed by an inorganic insulating film such as a silicon nitride film, a silicon oxynitride film, an aluminum nitride film, an aluminum oxide film, or an aluminum oxynitride film. A fourth insulating film (1208) and a partitioning layer (1209) formed on the upper layer side of the organic light emitting element (1202) are formed using similar inorganic insulating films.

Owner:SEMICON ENERGY LAB CO LTD

Method for etching silicon oxynitride and inorganic antireflection coatings

InactiveUS6013582ADecorative surface effectsSemiconductor/solid-state device manufacturingMetallurgyOxygen

The present disclosure pertains to a method for plasma etching a semiconductor patterning stack. The patterning stack includes at least one layer comprising either a dielectric-comprising antireflective material or an oxygen-comprising material. In many instances the dielectric-comprising antireflective material will be an oxygen-comprising material, but it need not be limited to such materials. In one preferred embodiment of the method, the chemistry enables the plasma etching of both a layer of the dielectric-comprising antireflective material or oxygen-comprising material and an adjacent or underlying layer of material. In another preferred embodiment of the method, the layer of dielectric-comprising antireflective material or oxygen-comprising material is etched using one chemistry, while the adjacent or underlying layer is etched using another chemistry, but in the same process chamber. Of particular interest is silicon oxynitride, an oxygen-comprising material which functions as an antireflective material. A preferred embodiment of the method provides for the use of a source of carbon and an appropriate halogen-comprising plasma, to achieve selective etch of one oxygen-containing material compared with another material which contains a more limited amount of oxygen.

Owner:APPLIED MATERIALS INC

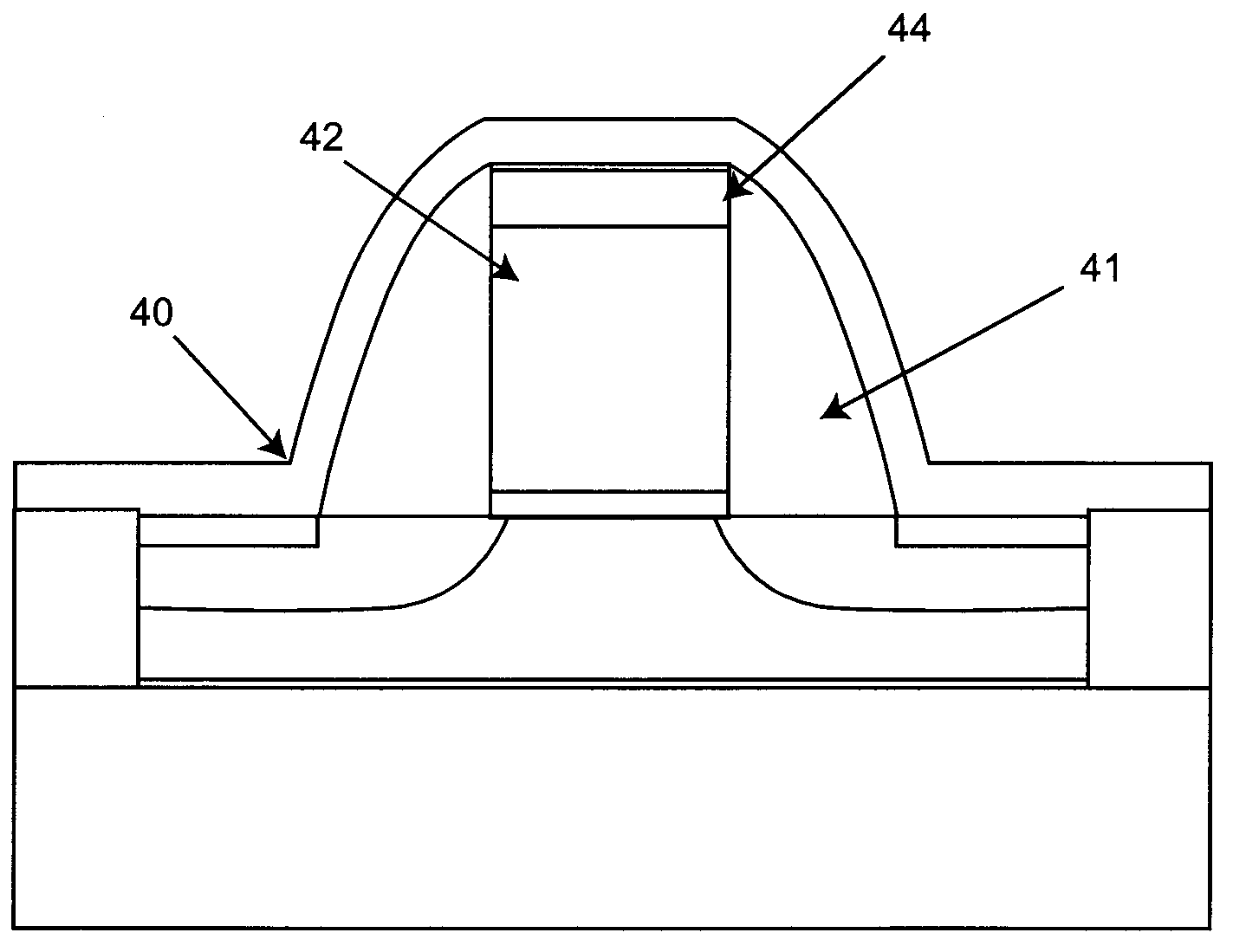

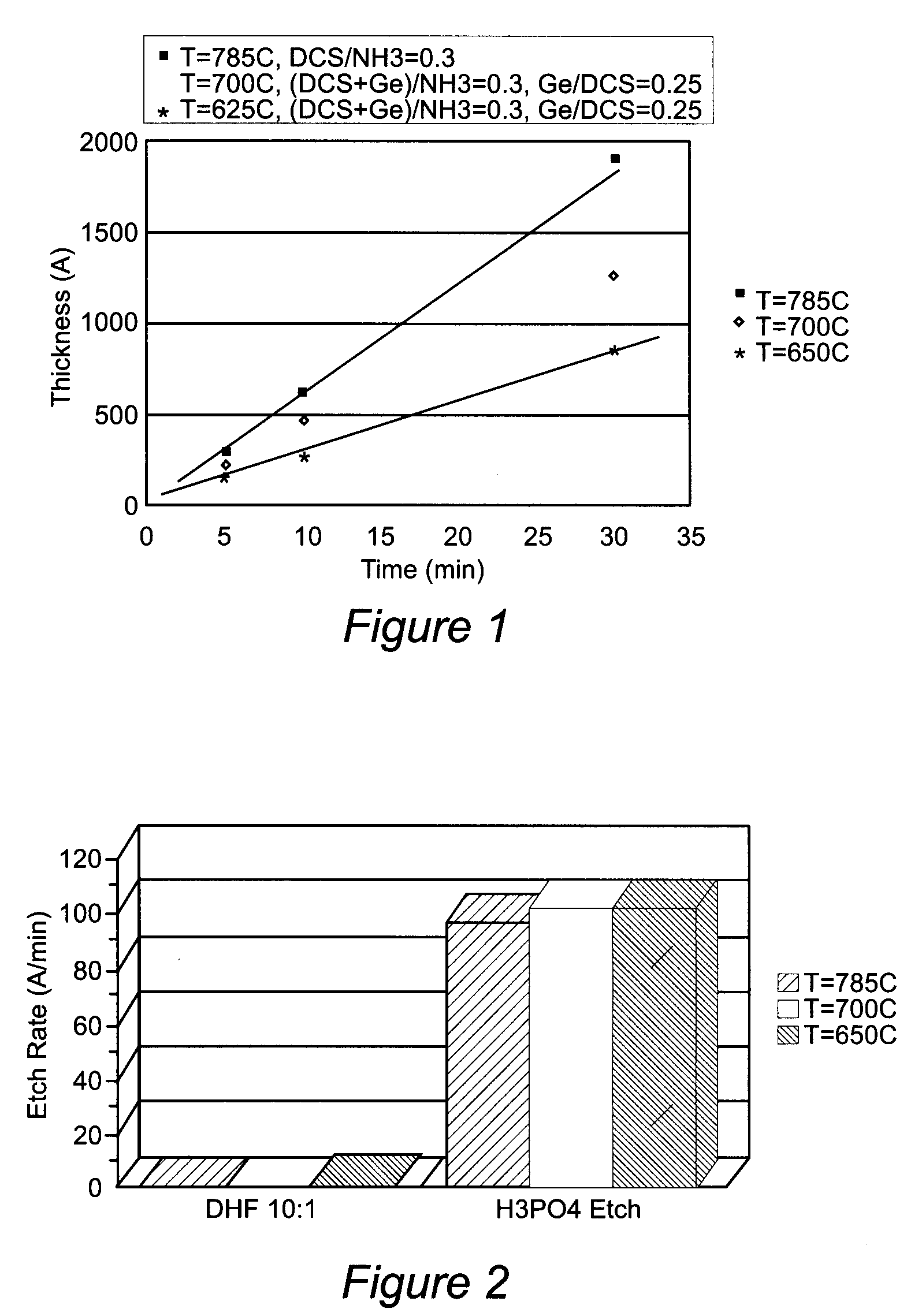

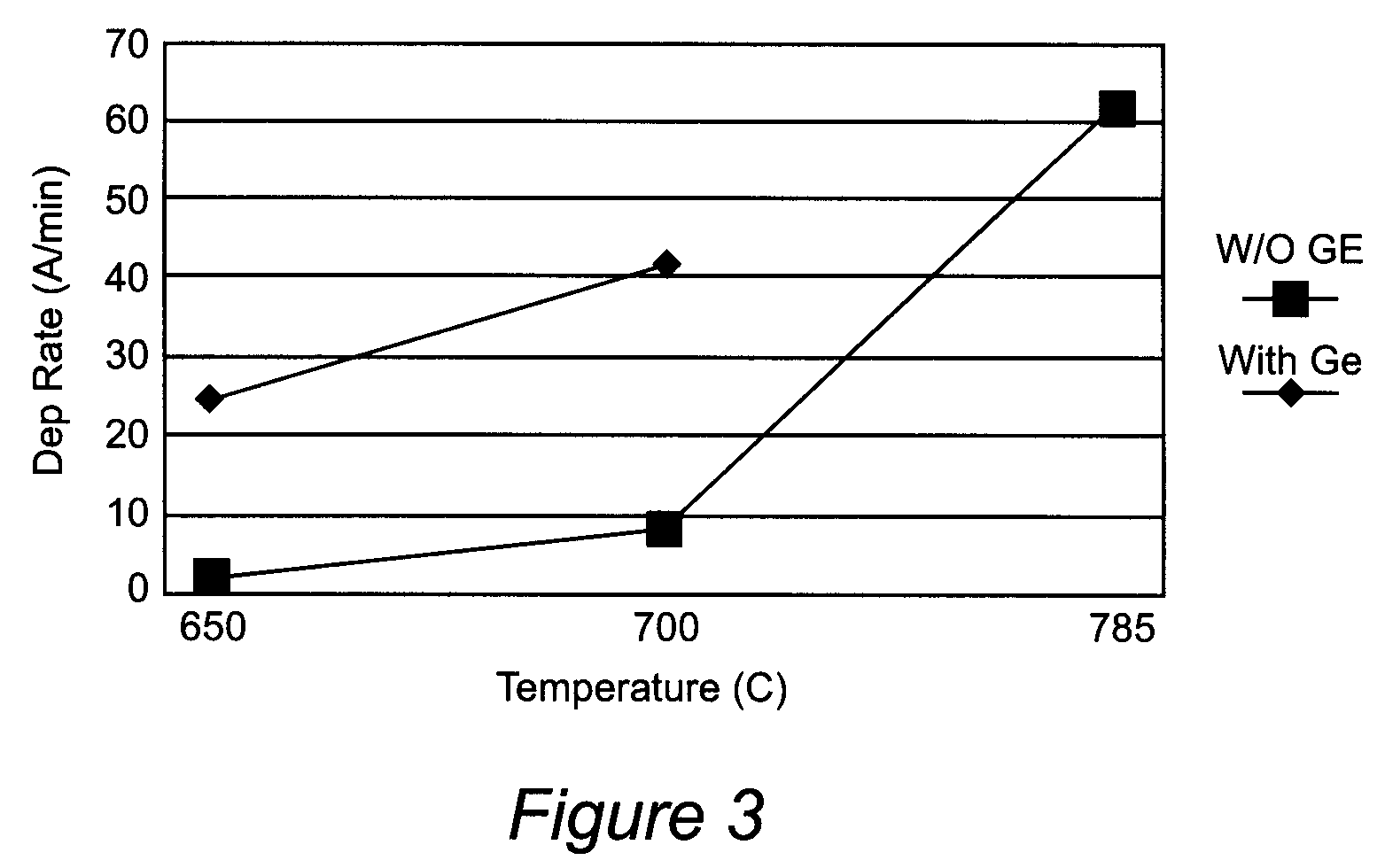

Doped nitride film, doped oxide film and other doped films

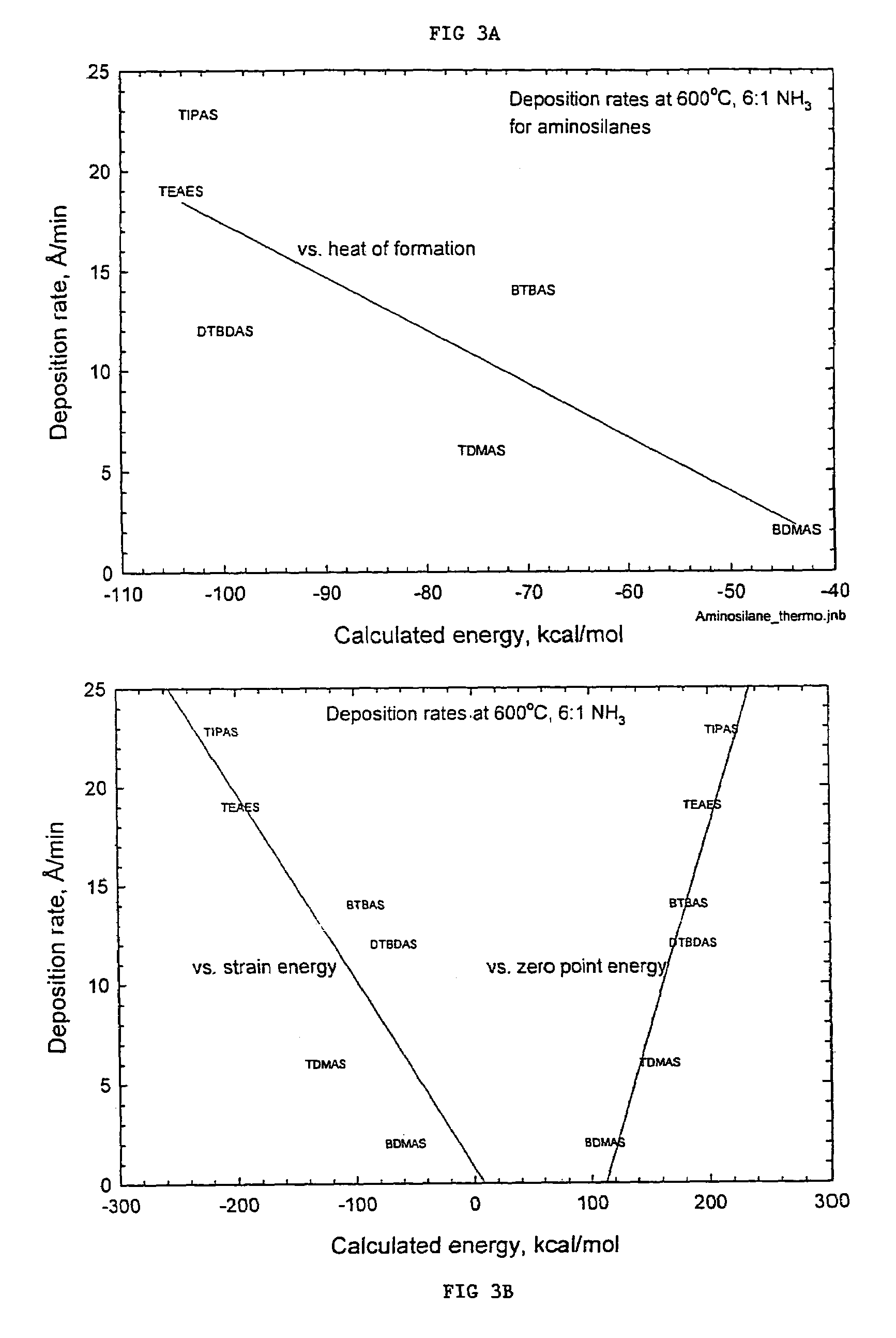

InactiveUS20050287747A1Increase deposition rateImprove device performanceTransistorSemiconductor/solid-state device manufacturingDopantSilicon oxide

Adding at least one non-silicon precursor (such as a germanium precursor, a carbon precursor, etc.) during formation of a silicon nitride, silicon oxide, silicon oxynitride or silicon carbide film improves the deposition rate and / or makes possible tuning of properties of the film, such as tuning of the stress of the film. Also, in a doped silicon oxide or doped silicon nitride or other doped structure, the presence of the dopant may be used for measuring a signal associated with the dopant, as an etch-stop or otherwise for achieving control during etching.

Owner:GLOBALFOUNDRIES INC

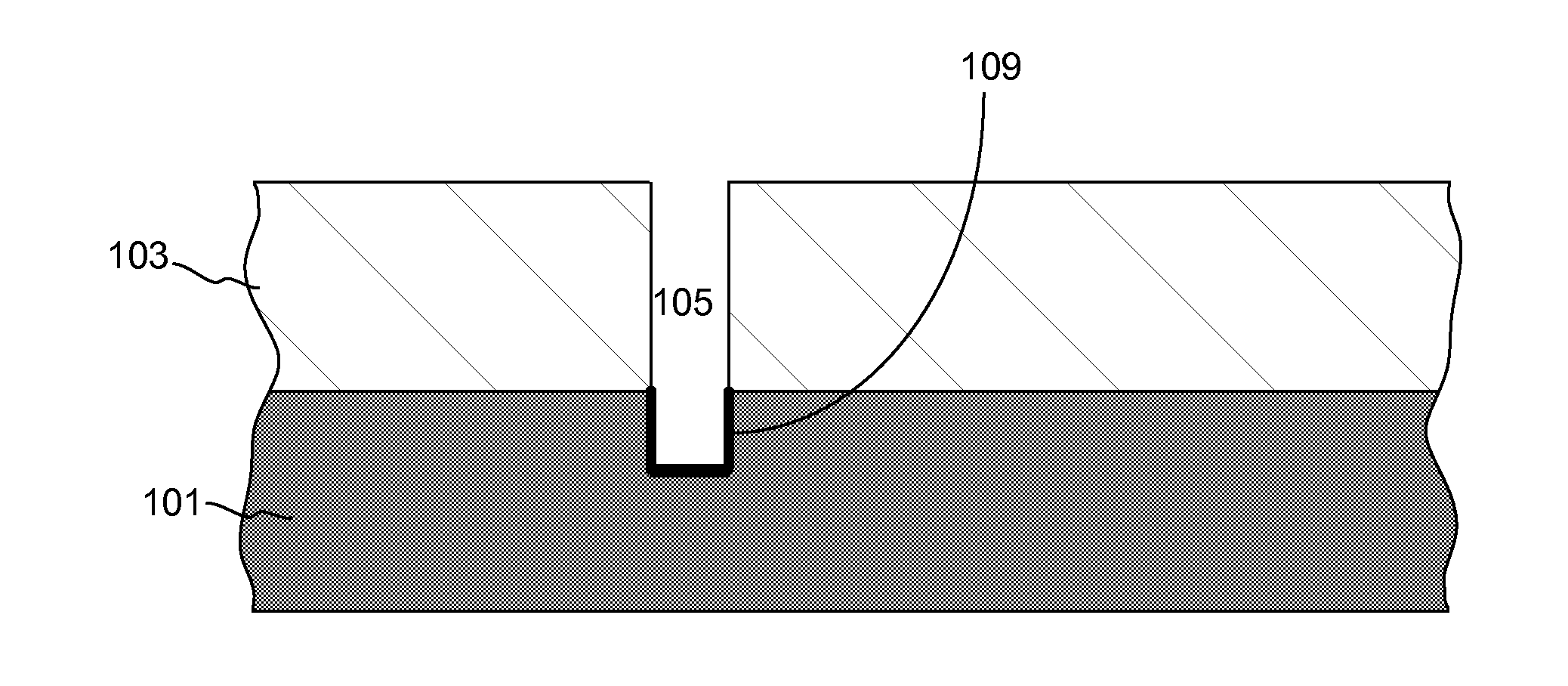

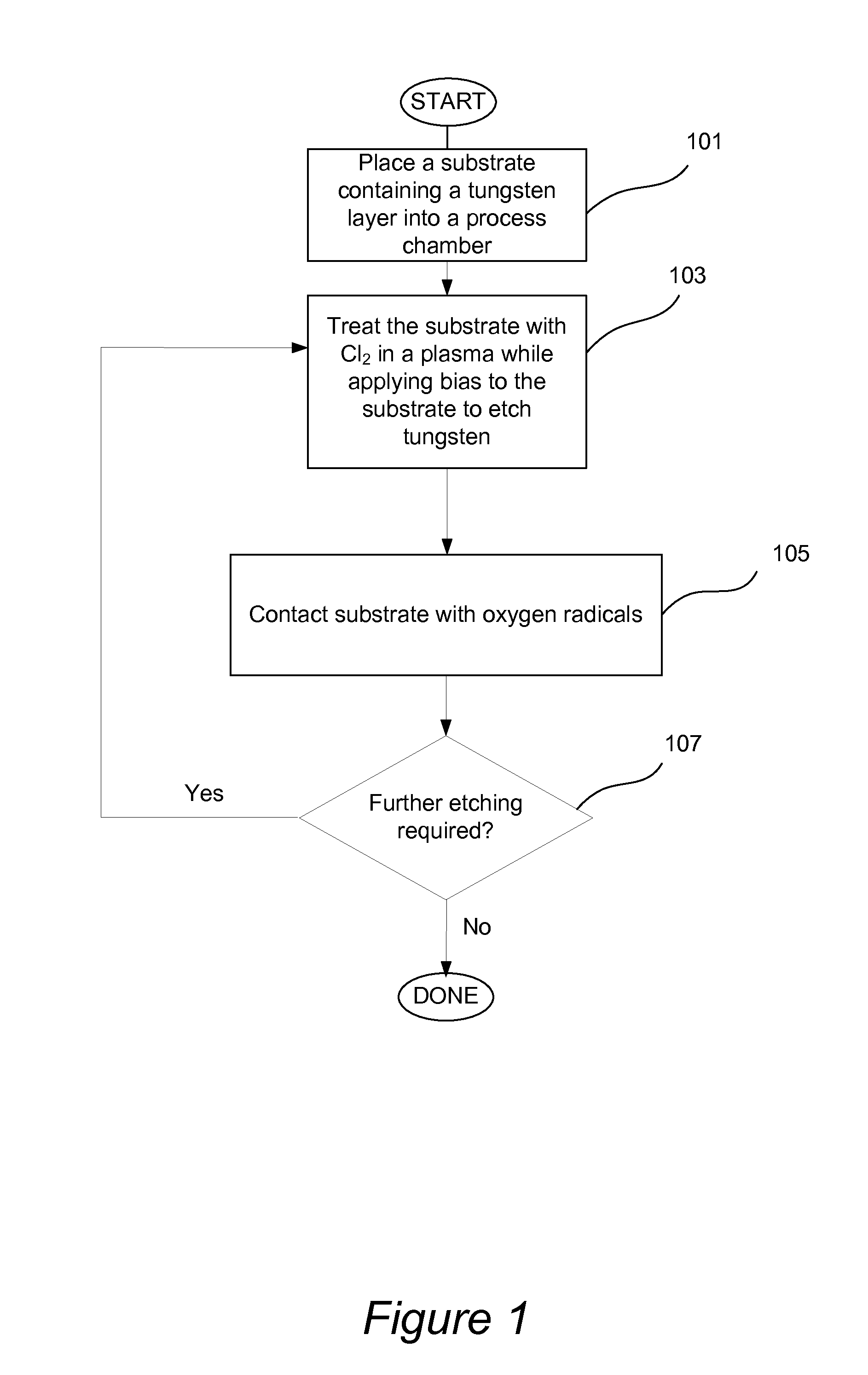

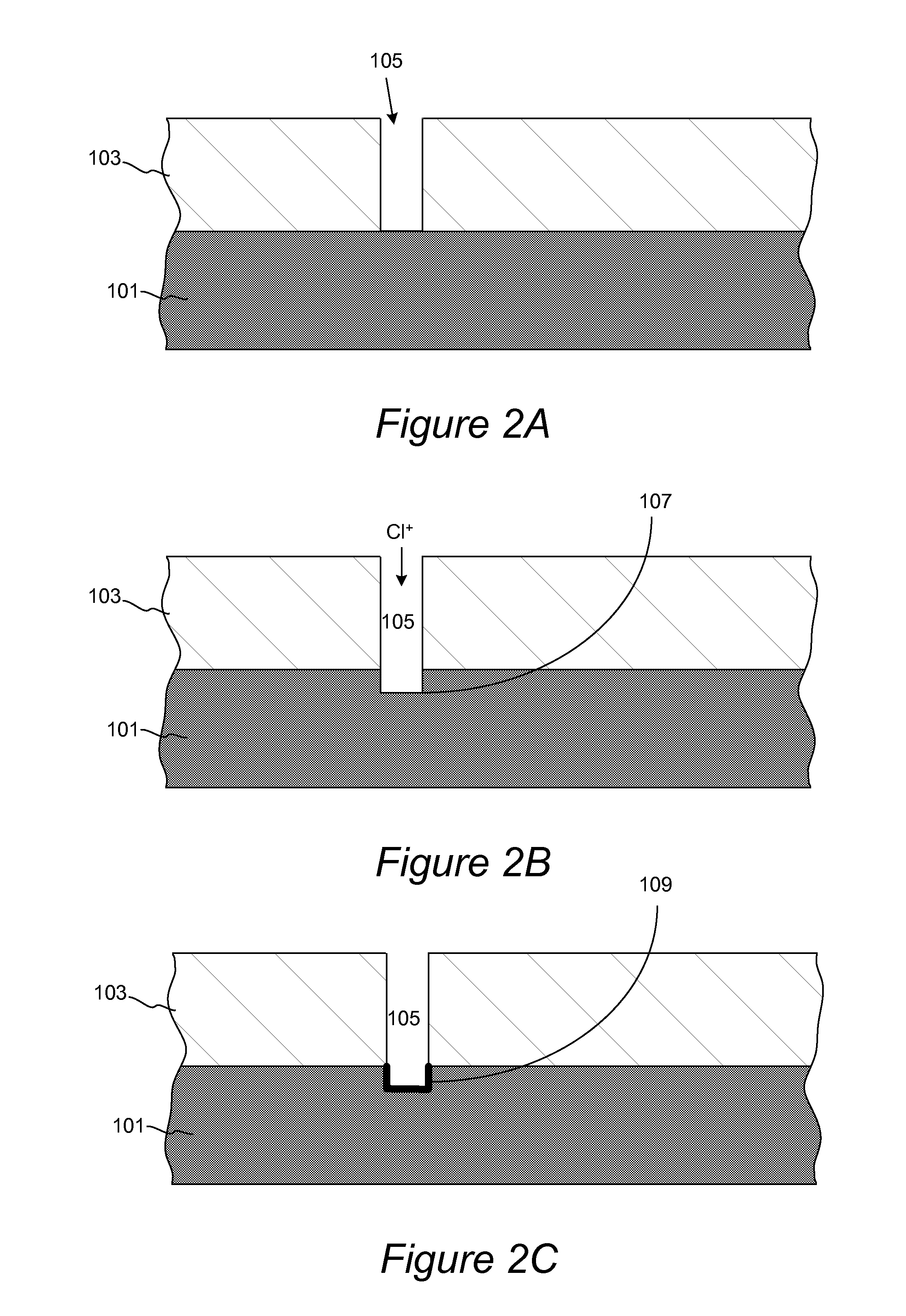

Method and apparatus for anisotropic tungsten etching

ActiveUS20160196985A1Electric discharge tubesSemiconductor/solid-state device manufacturingSilicon oxideOxygen

Methods for anisotropically etching a tungsten-containing material (such as doped or undoped tungsten metal) include cyclic treatment of tungsten surface with Cl2 plasma and with oxygen-containing radicals. Treatment with chlorine plasma is performed while the substrate is electrically biased resulting in predominant etching of horizontal surfaces on the substrate. Treatment with oxygen-containing radicals passivates the surface of the substrate to etching, and protects the vertical surfaces of the substrate, such as sidewalls of recessed features, from etching. Treatment with Cl2 plasma and with oxygen-containing radicals can be repeated in order to remove a desired amount of material. Anisotropic etching can be performed selectively in a presence of dielectric materials such as silicon oxide, silicon nitride, and silicon oxynitride.

Owner:LAM RES CORP

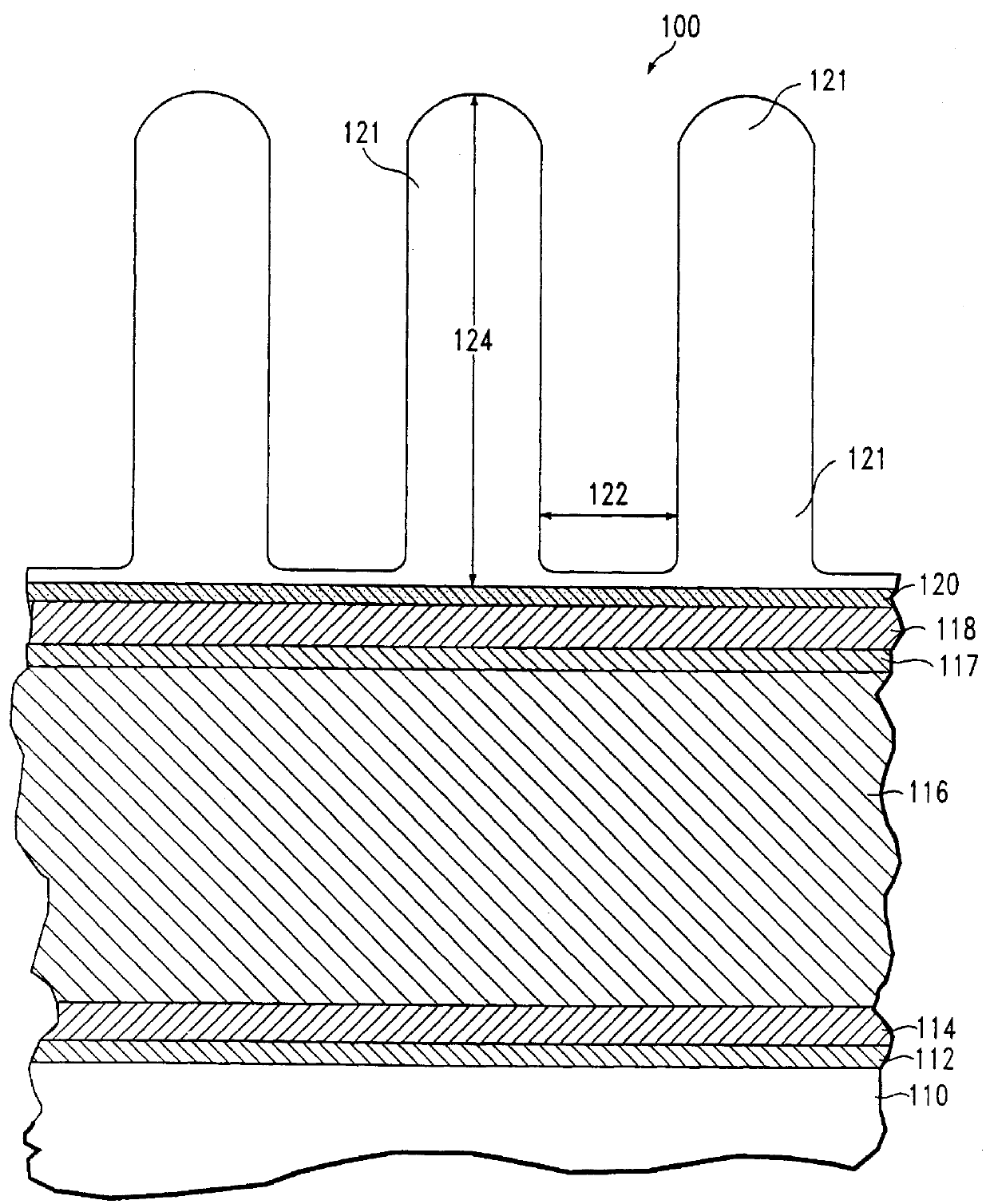

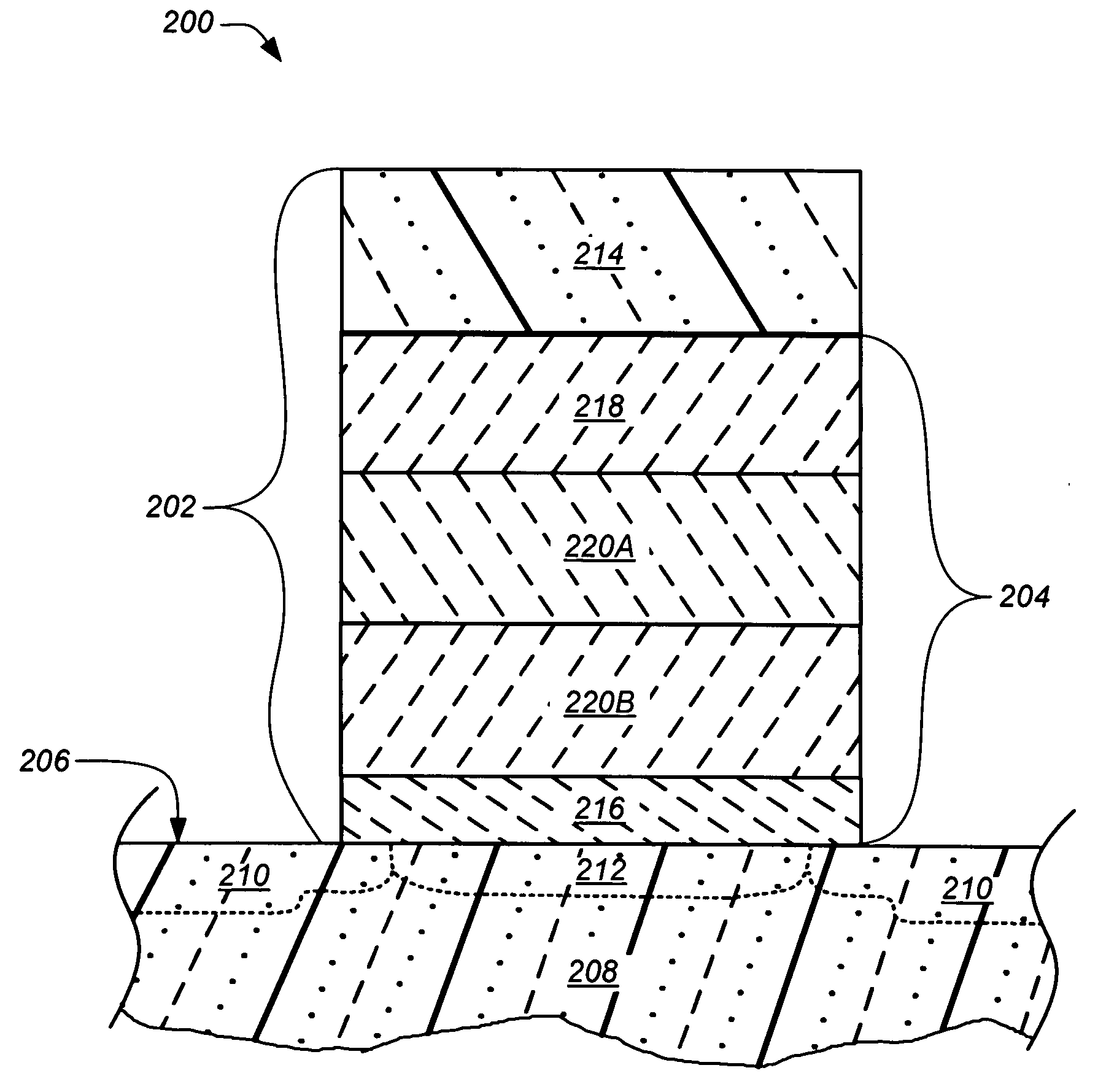

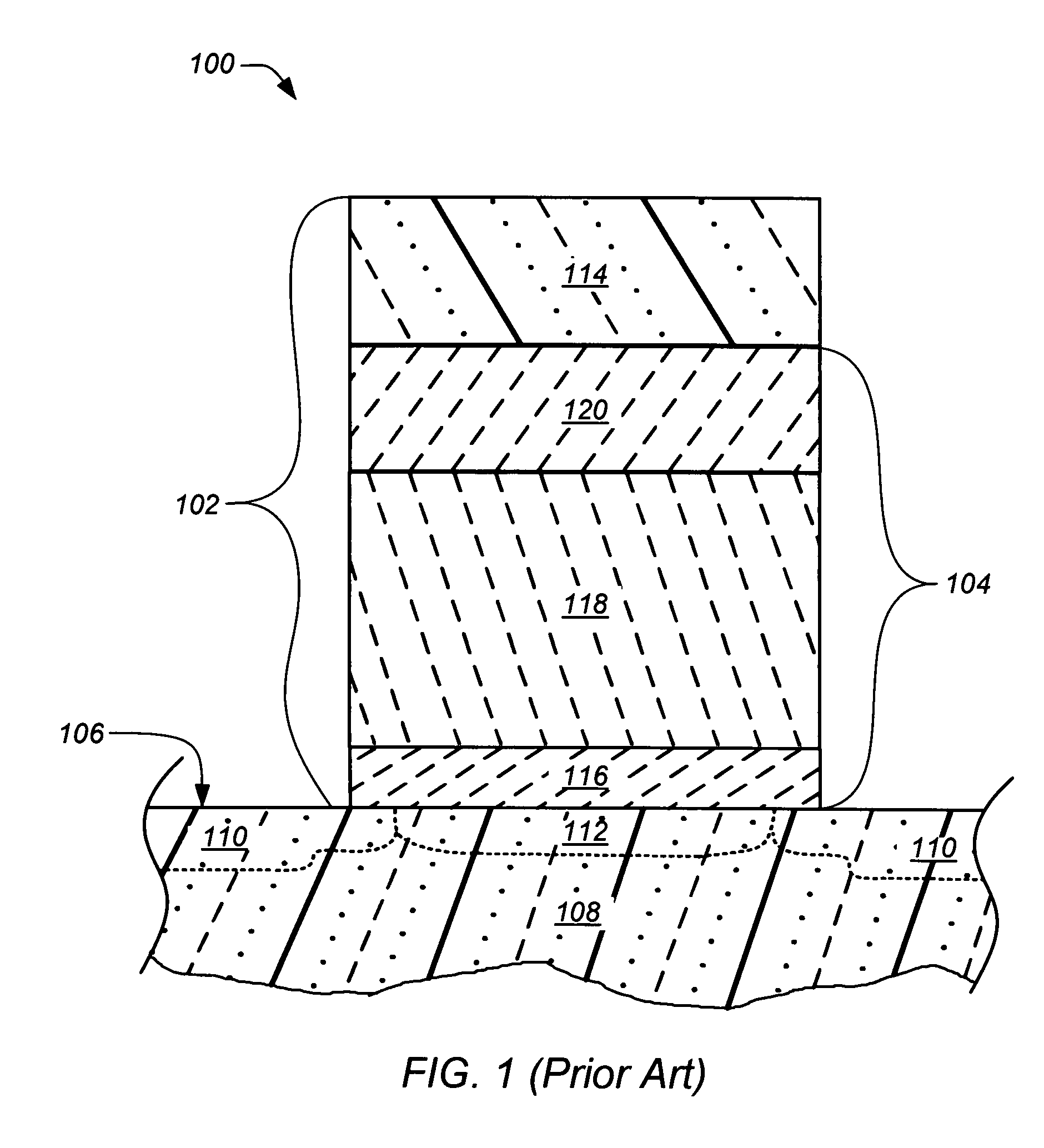

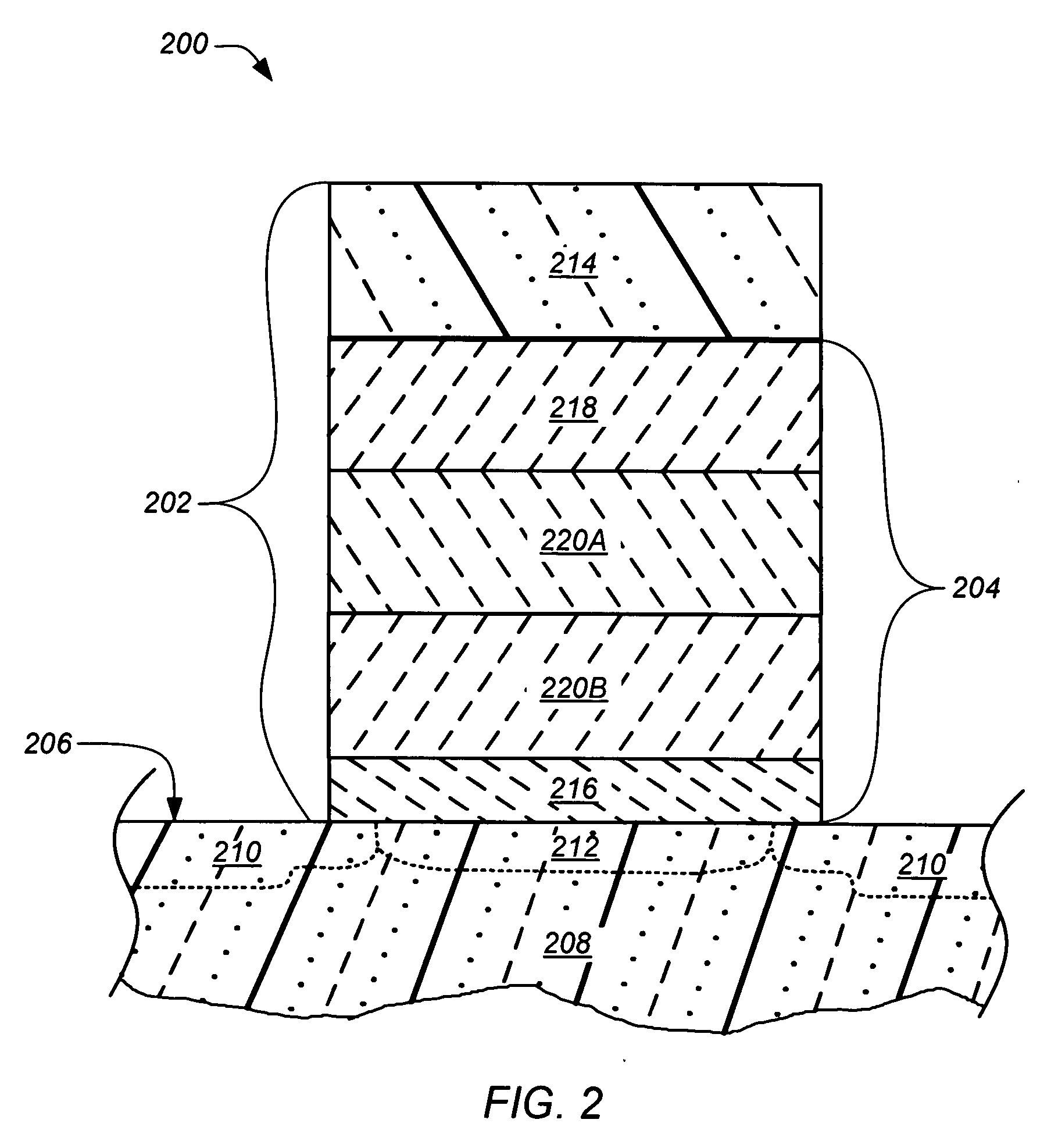

Oxide-nitride-oxide stack having multiple oxynitride layers

InactiveUS20090179253A1Read-only memoriesSemiconductor/solid-state device manufacturingNitrogenSilicon oxide

A semiconductor device including an oxide-nitride-oxide (ONO) structure having a multi-layer charge storing layer and methods of forming the same are provided. Generally, the method involves: (i) forming a first oxide layer of the ONO structure; (ii) forming a multi-layer charge storing layer comprising nitride on a surface of the first oxide layer; and (iii) forming a second oxide layer of the ONO structure on a surface of the multi-layer charge storing layer. Preferably, the charge storing layer comprises at least two silicon oxynitride layers having differing stoichiometric compositions of Oxygen, Nitrogen and / or Silicon. More preferably, the ONO structure is part of a silicon-oxide-nitride-oxide-silicon (SONOS) structure and the semiconductor device is a SONOS memory transistor. Other embodiments are also disclosed.

Owner:LONGITUDE FLASH MEMORY SOLUTIONS LTD

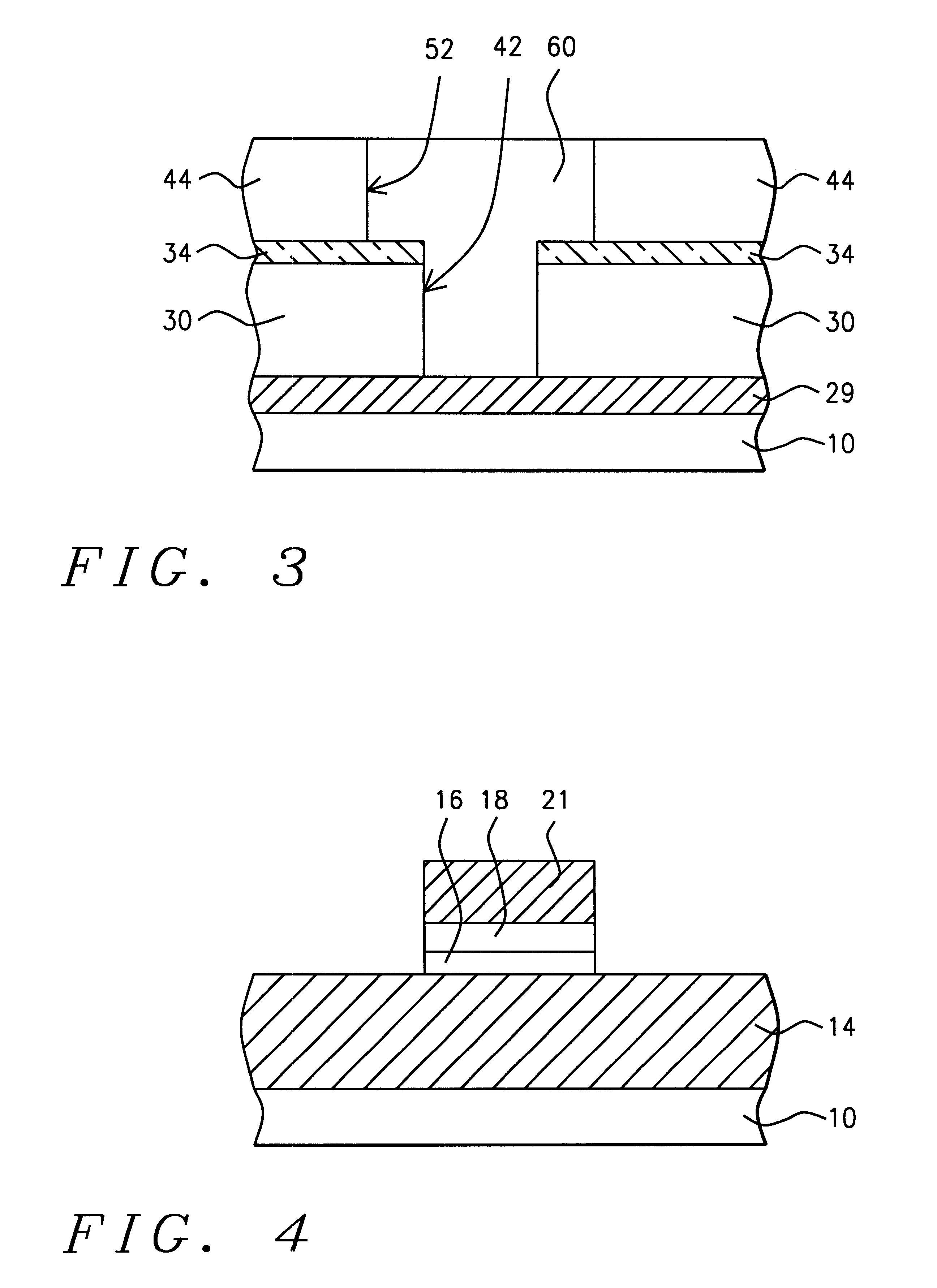

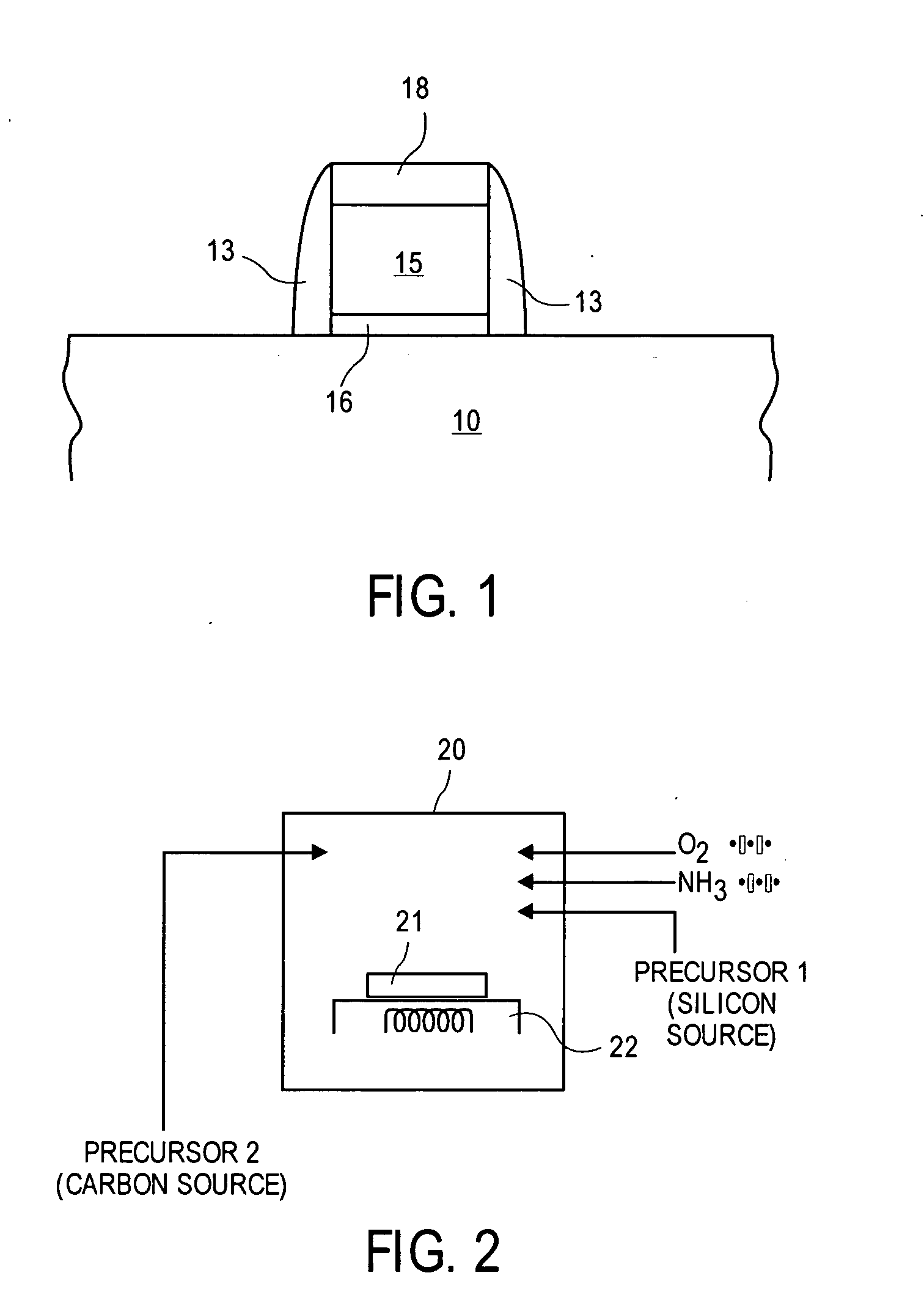

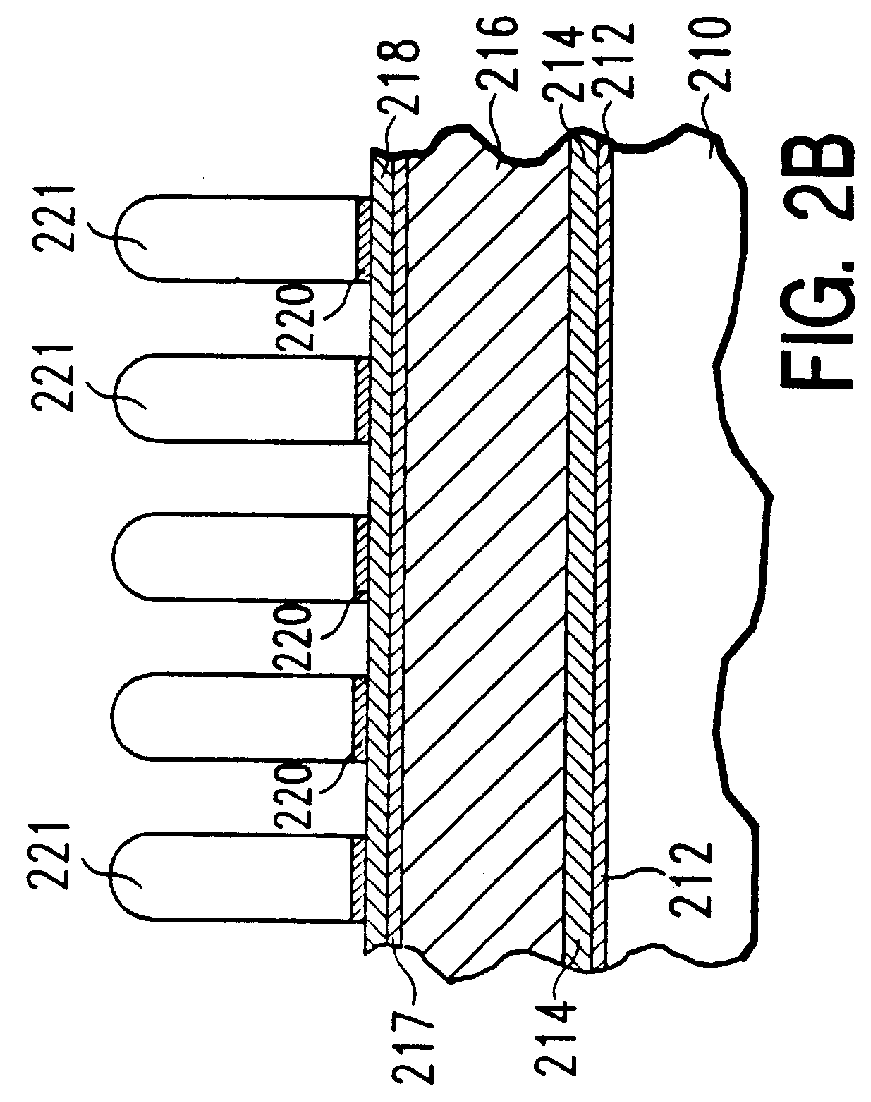

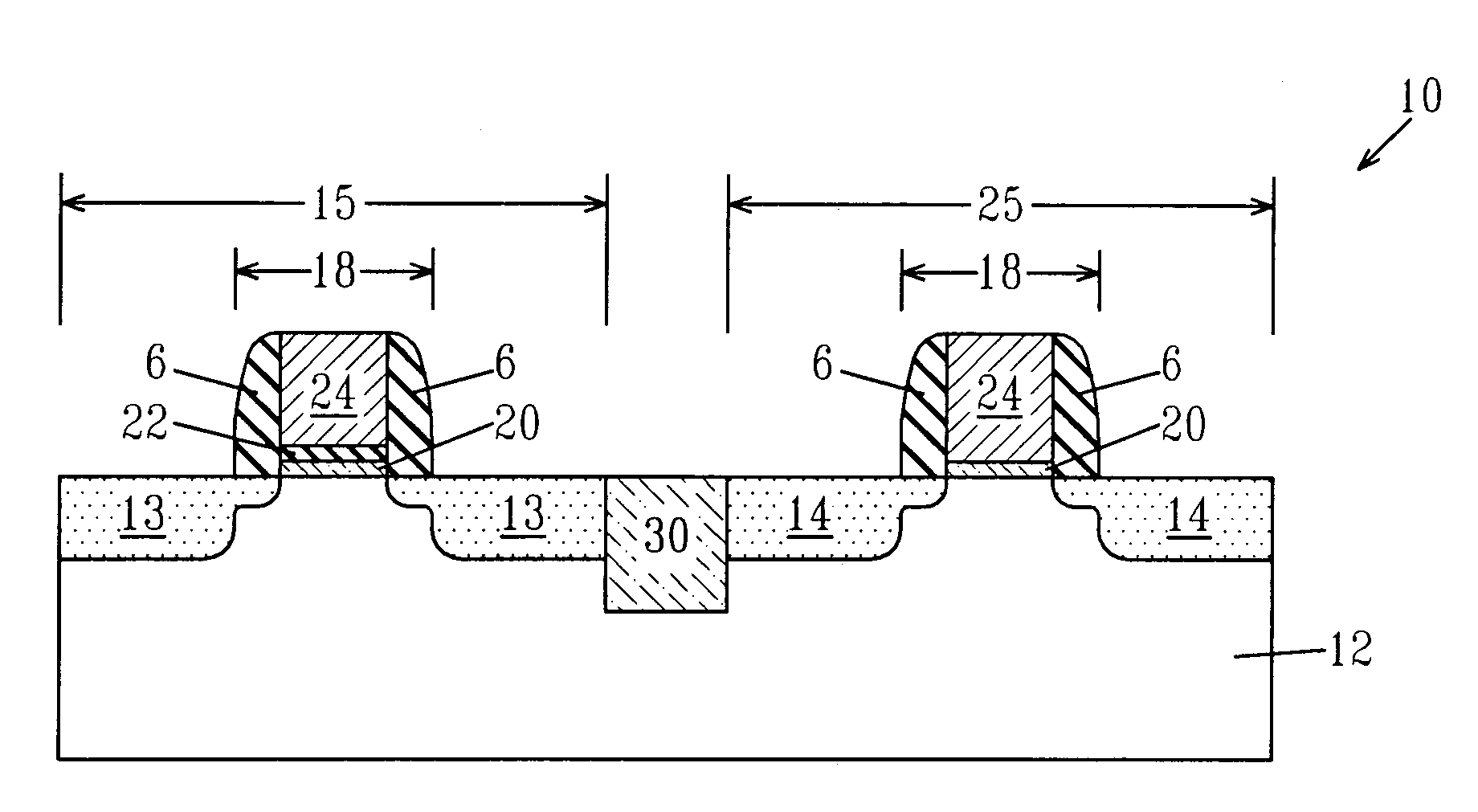

Selective implementation of barrier layers to achieve threshold voltage control in CMOS device fabrication with high k dielectrics

ActiveUS7105889B2Avoid interactionReduce capacitanceSemiconductor/solid-state device manufacturingSemiconductor devicesDielectricCMOS

A method of forming a CMOS structure, and the device produced therefrom, having improved threshold voltage and flatband voltage stability. The inventive method includes the steps of providing a semiconductor substrate having an nFET region and a pFET region; forming a dielectric stack atop the semiconductor substrate comprising an insulating interlayer atop a high k dielectric; removing the insulating interlayer from the nFET region without removing the insulating interlayer from the pFET region; and providing at least one gate stack in the pFET region and at least one gate stack in the nFET region. The insulating interlayer can be AlN or AlOxNy. The high k dielectric can be HfO2, hafnium silicate or hafnium silicon oxynitride. The insulating interlayer can be removed from the nFET region by a wet etch including a HCl / H2O2 peroxide solution.

Owner:AURIGA INNOVATIONS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com