Multiple precursor cyclical deposition system

a cyclical deposition and precursor technology, applied in chemical vapor deposition coating, coating, metallic material coating process, etc., can solve the problems of large amount of ongoing effort, many traditional deposition processes have difficulty filling sub-micron structures,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Process Chamber Adapted for Cyclical Deposition

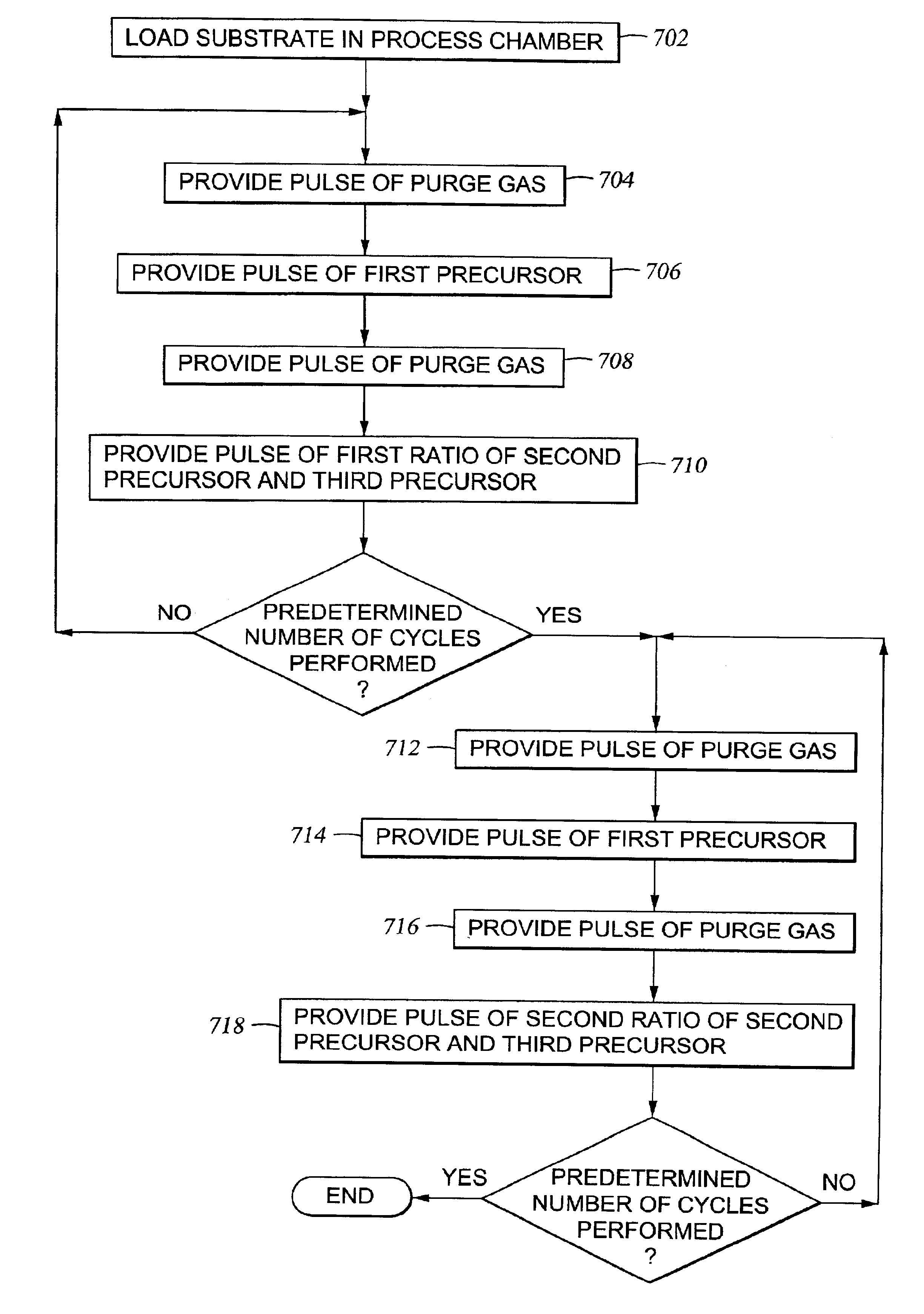

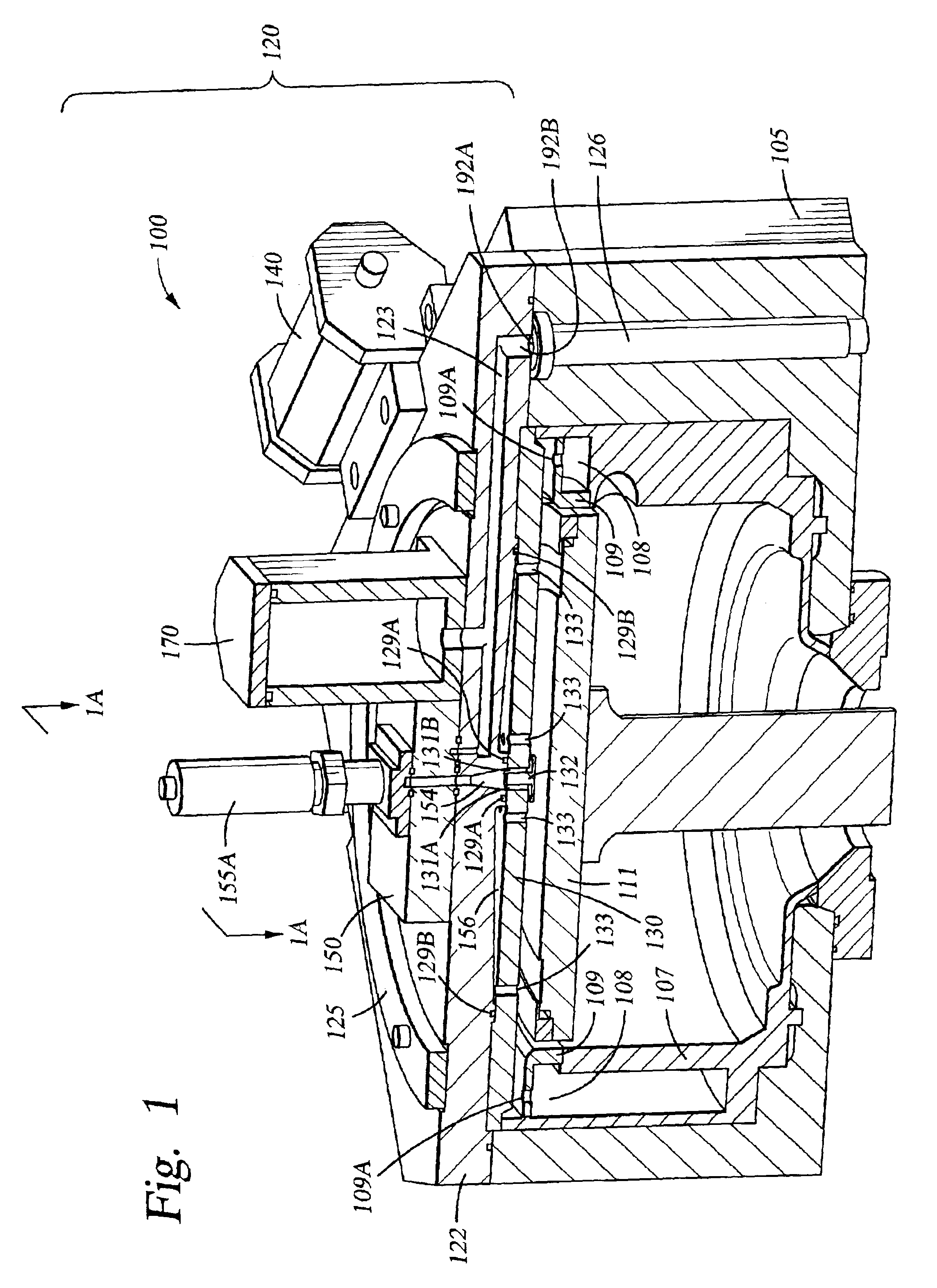

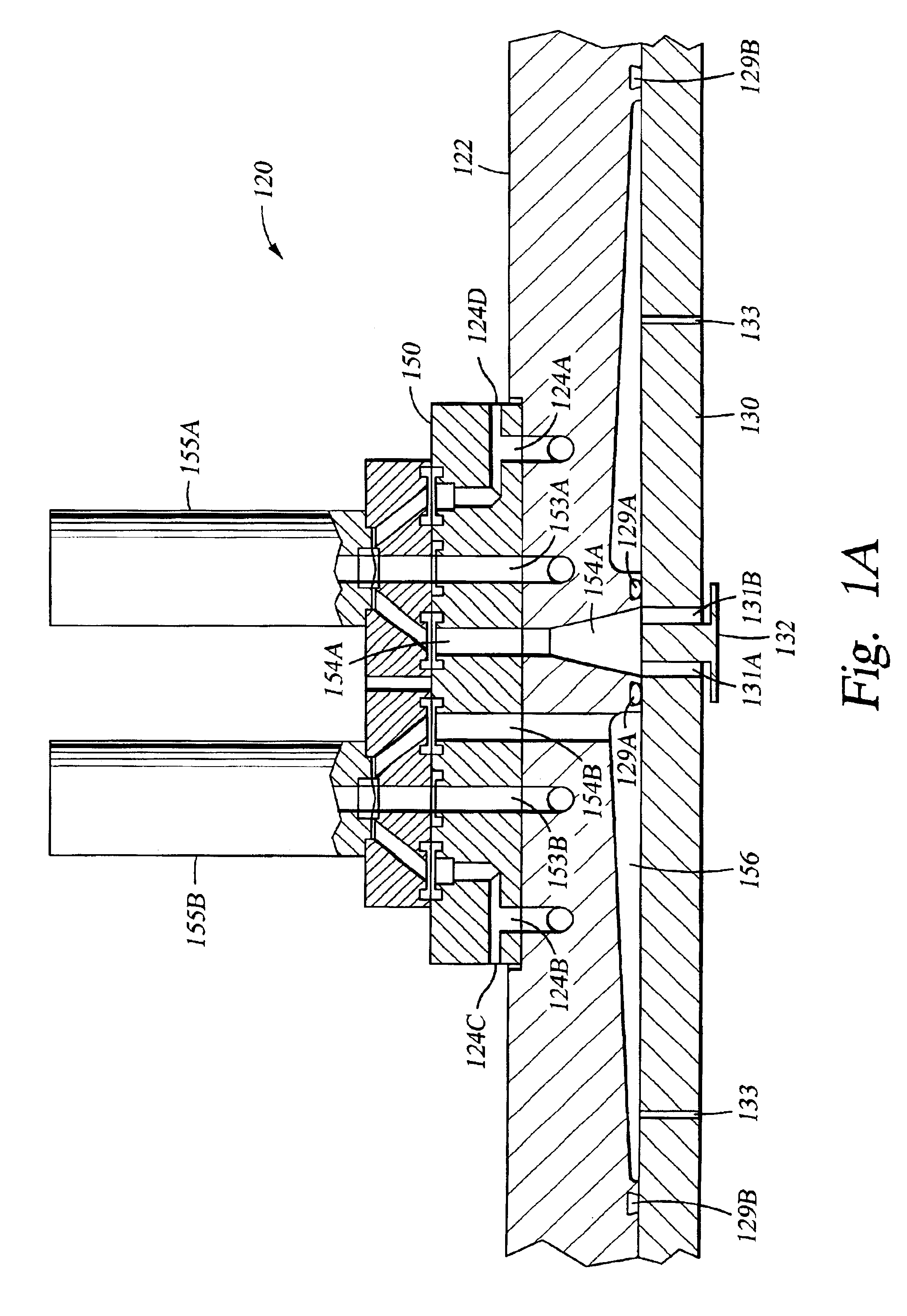

FIGS. 1, 1A, and 2 are drawings of exemplary embodiments of a processing system that may be used to perform cyclical deposition. The term “cyclical deposition” as used herein refers to the sequential introduction of reactants to deposit a thin layer over a structure and includes processing techniques such as atomic layer deposition and rapid sequential chemical vapor deposition. The sequential introduction of reactants may be repeated to deposit a plurality of thin layers to form a layer to a desired thickness. Not wishing to be bound by theory, it is believed that the mode of deposition of cyclical deposition provides conformal coverage over substrate structures.

FIG. 1 is a partial cross-sectional perspective view of one embodiment of a processing system 100. The processing system 100 comprises a lid assembly 120 includes a lid plate 122, a manifold block 150, one or more valves (one valve 155A is shown in FIG. 1), one or more reservoi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| circuit density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com