Patents

Literature

63 results about "Hexachlorodisilane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hexachlorodisilane is the inorganic compound with the chemical formula Si₂Cl₆, It is a colourless liquid that fumes in moist air. It has specialty applications in as a reagent and as a volatile precursor to silicon metal.

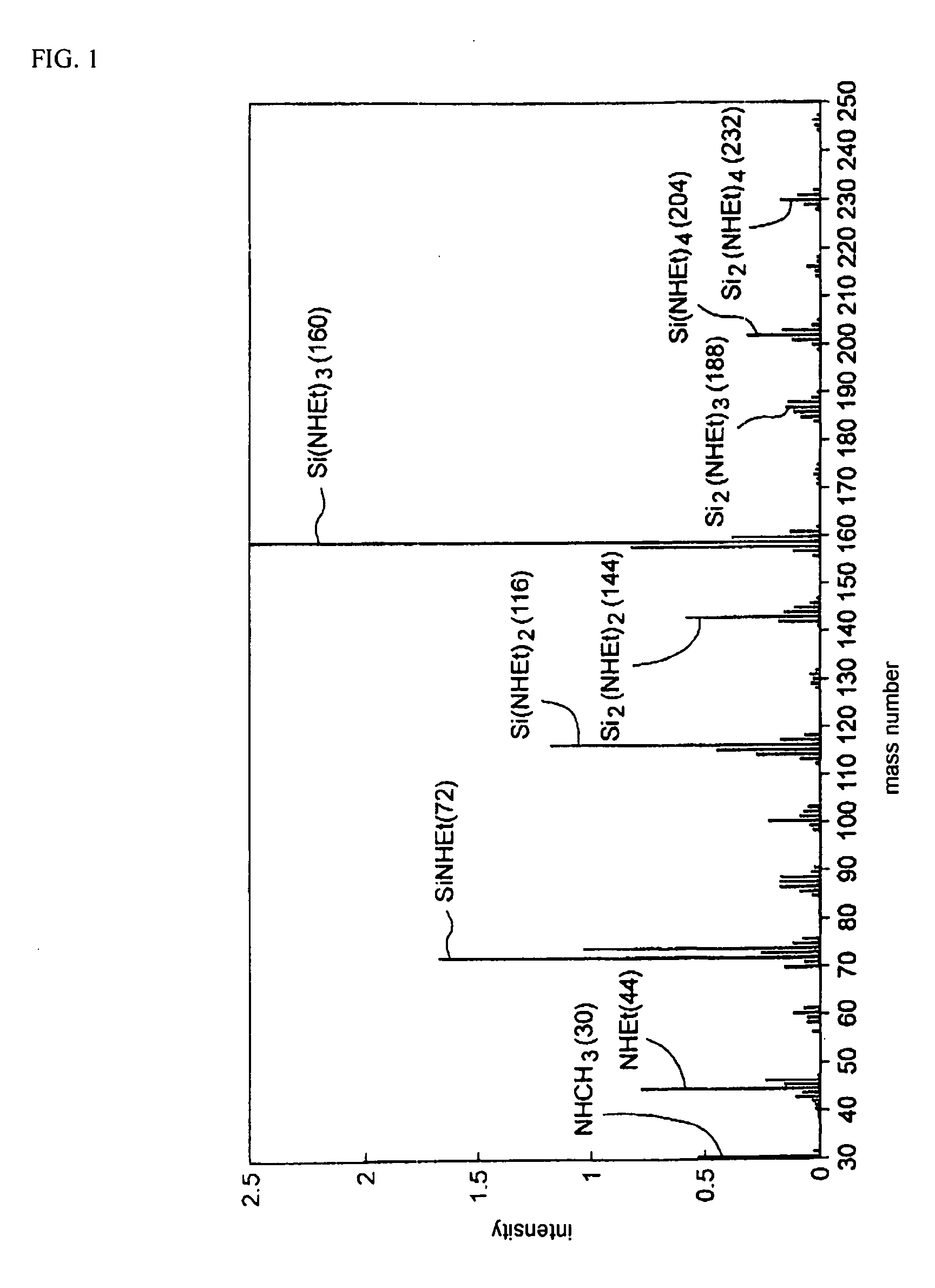

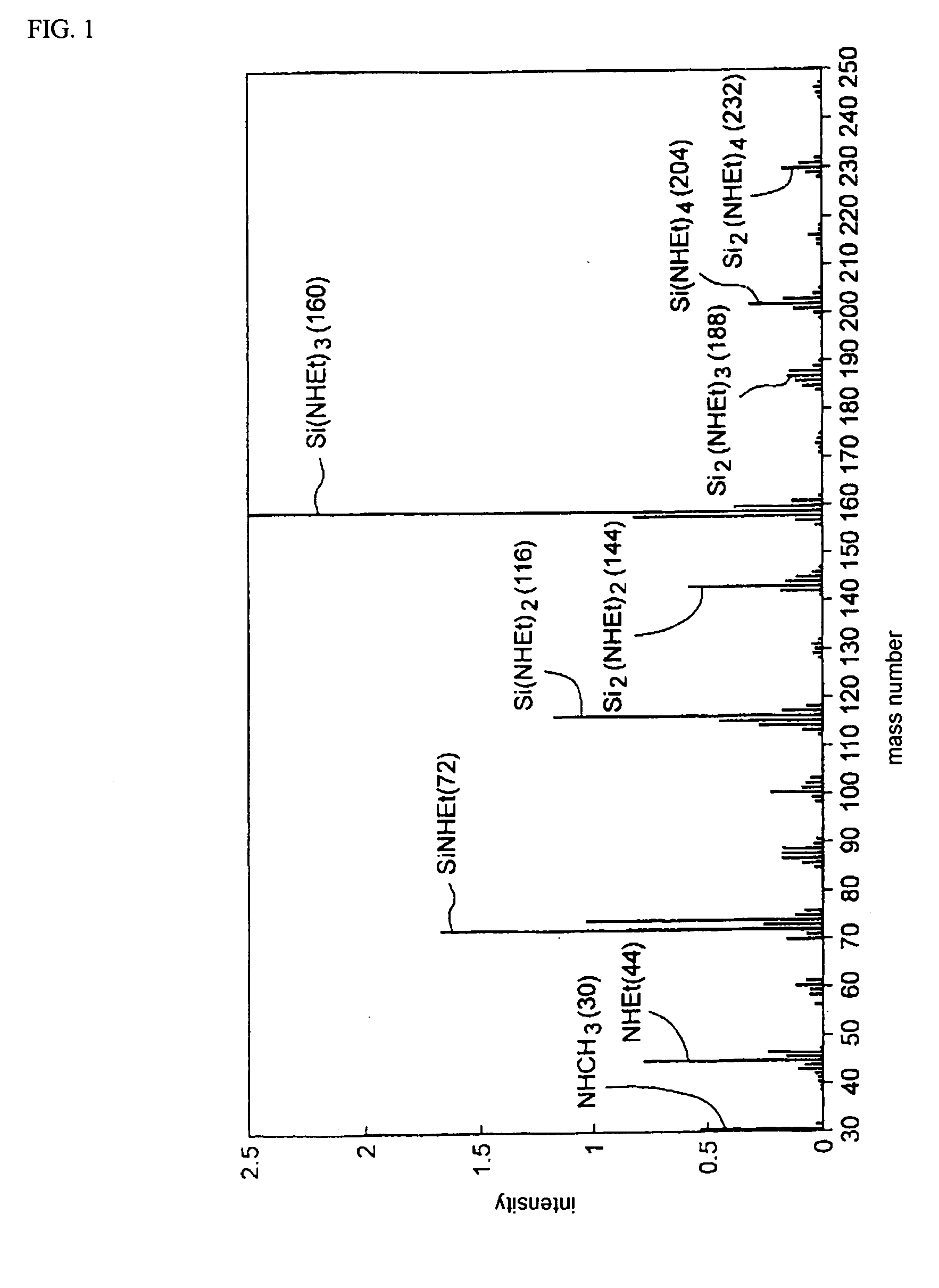

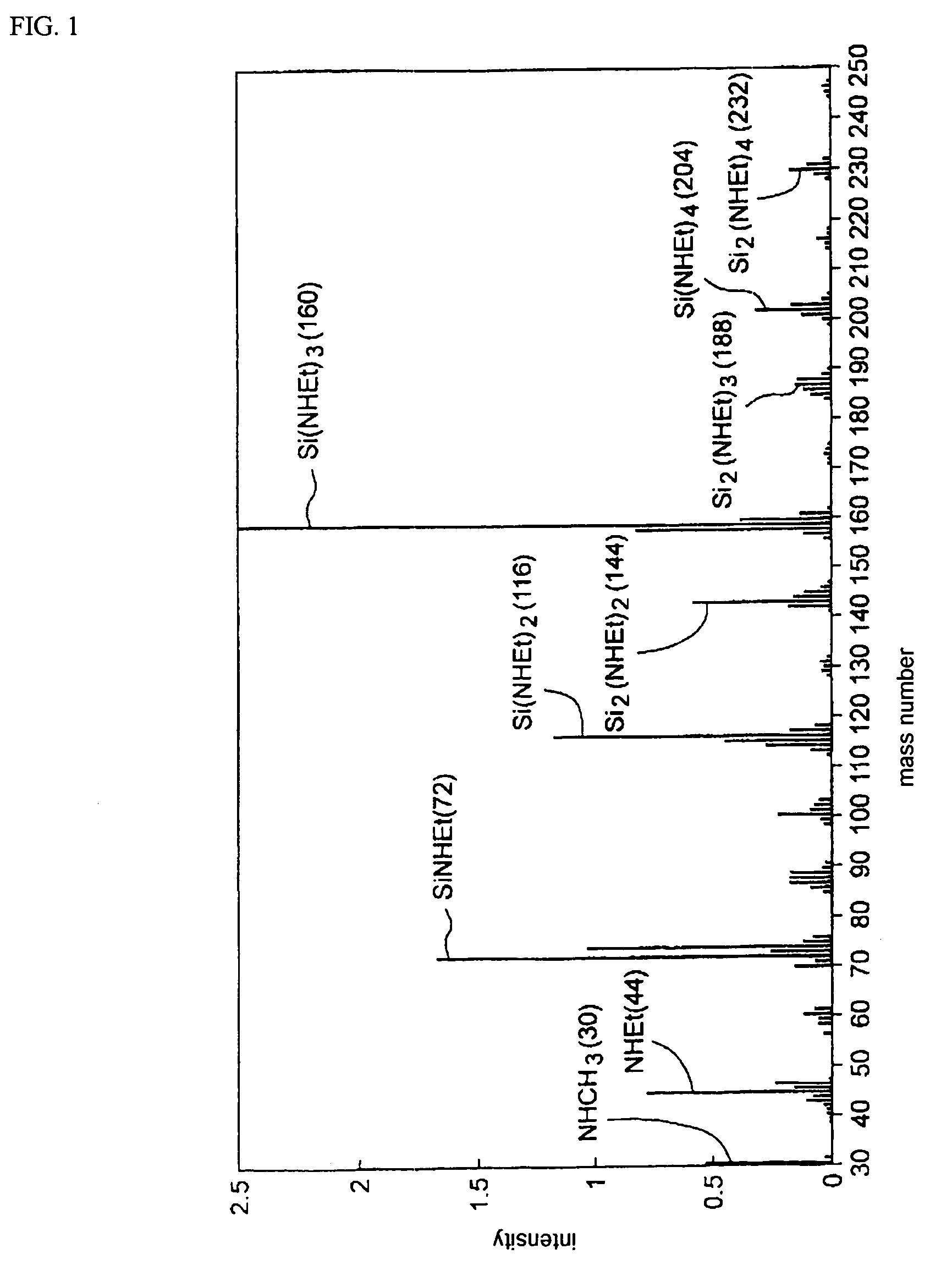

Hexakis(monohydrocarbylamino) disilanes and method for the preparation thereof

InactiveUS20050107627A1Improve featuresSilicon organic compoundsSemiconductor/solid-state device manufacturingSilane compoundsOrganic solvent

A composition and method of preparation, to provide silane compounds that are free of chlorine. The compounds are hexakis(monohydrocarbylamino)disilanes with general formula (I) ((R)HN)3—Si—Si—(NH(R))3 (I) wherein each R independently represents a C1 to C4 hydrocarbyl. These disilanes may be synthesized by reacting hexachlorodisilane in organic solvent with at least 6-fold moles of the monohydrocarbylamine RNH2 (wherein R is a C1 to C4 hydrocarbyl). Such compounds have excellent film-forming characteristics at low temperatures. These films, particularly in the case of silicon nitride and silicon oxynitride, also have excellent handling characteristics.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Low temperature silicon nitride films using remote plasma CVD technology

ActiveUS9583333B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingCelsius DegreeRemote plasma

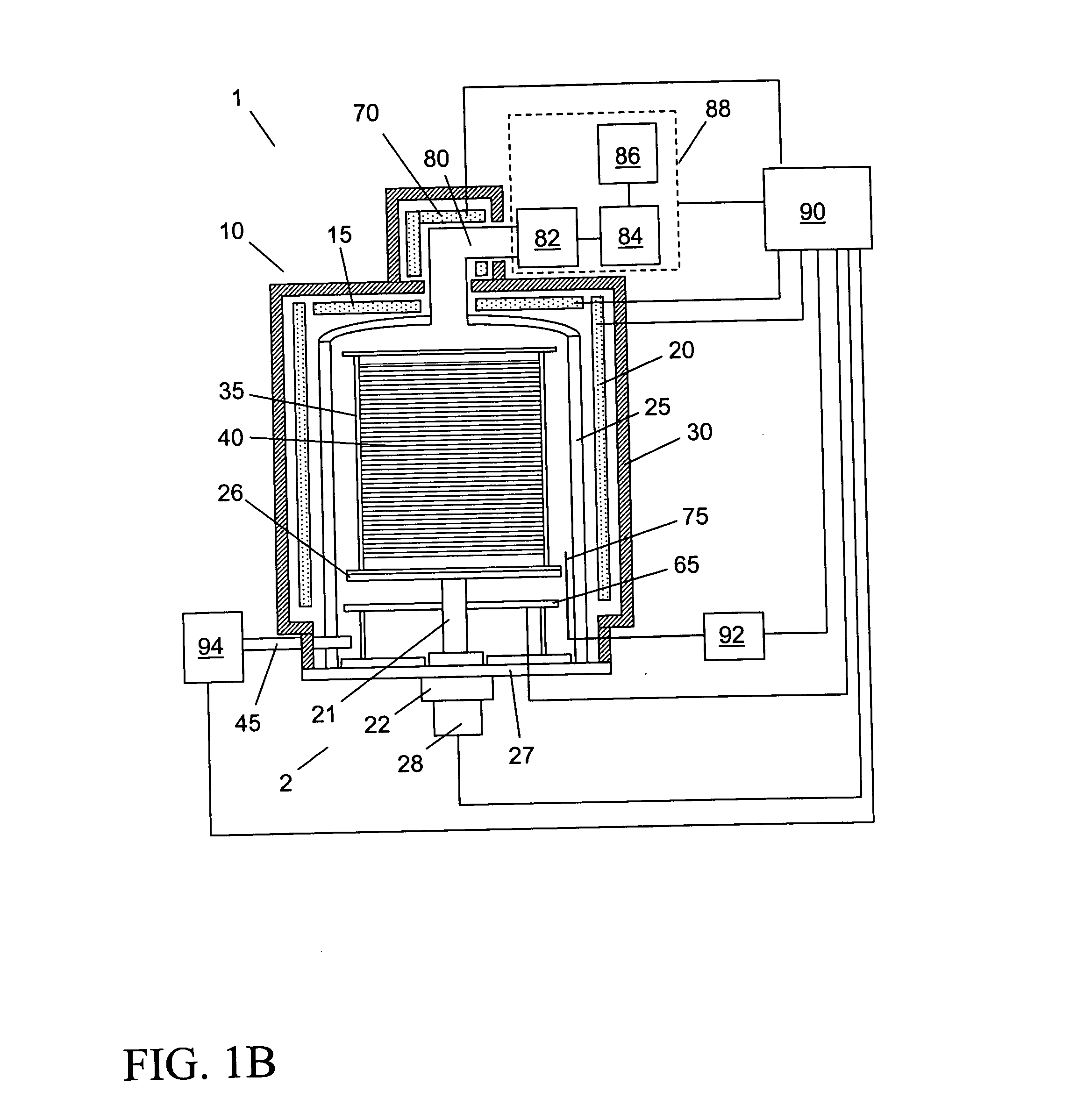

Embodiments of the present invention generally provide methods for forming a silicon nitride layer on a substrate. In one embodiment, a method of forming a silicon nitride layer using remote plasma chemical vapor deposition (CVD) at a temperature that is less than 300 degrees Celsius is disclosed. The precursors for the remote plasma CVD process include tris(dimethylamino)silane (TRIS), dichlorosilane (DCS), trisilylamine (TSA), bis-t-butylaminosilane (BTBAS), hexachlorodisilane (HCDS) or hexamethylcyclotrisilazane (HMCTZ).

Owner:APPLIED MATERIALS INC

Hexakis(monohydrocarbylamino) disilanes and method for the preparation thereof

InactiveUS7019159B2Silicon organic compoundsSemiconductor/solid-state device manufacturingSilane compoundsOrganic solvent

A composition and method of preparation, to provide silane compounds that are free of chlorine. The compounds are hexakis(monohydrocarbylamino)disilanes with general formula (I)((R)HN)3—Si—Si—(NH(R))3 (I)wherein each R independently represents a C1 to C4 hydrocarbyl. These disilanes may be synthesized by reacting hexachlorodisilane in organic solvent with at least 6-fold moles of the monohydrocarbylamine RNH2 (wherein R is a C1 to C4 hydrocarbyl). Such compounds have excellent film-forming characteristics at low temperatures. These films, particularly in the case of silicon nitride and silicon oxynitride, also have excellent handling characteristics.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

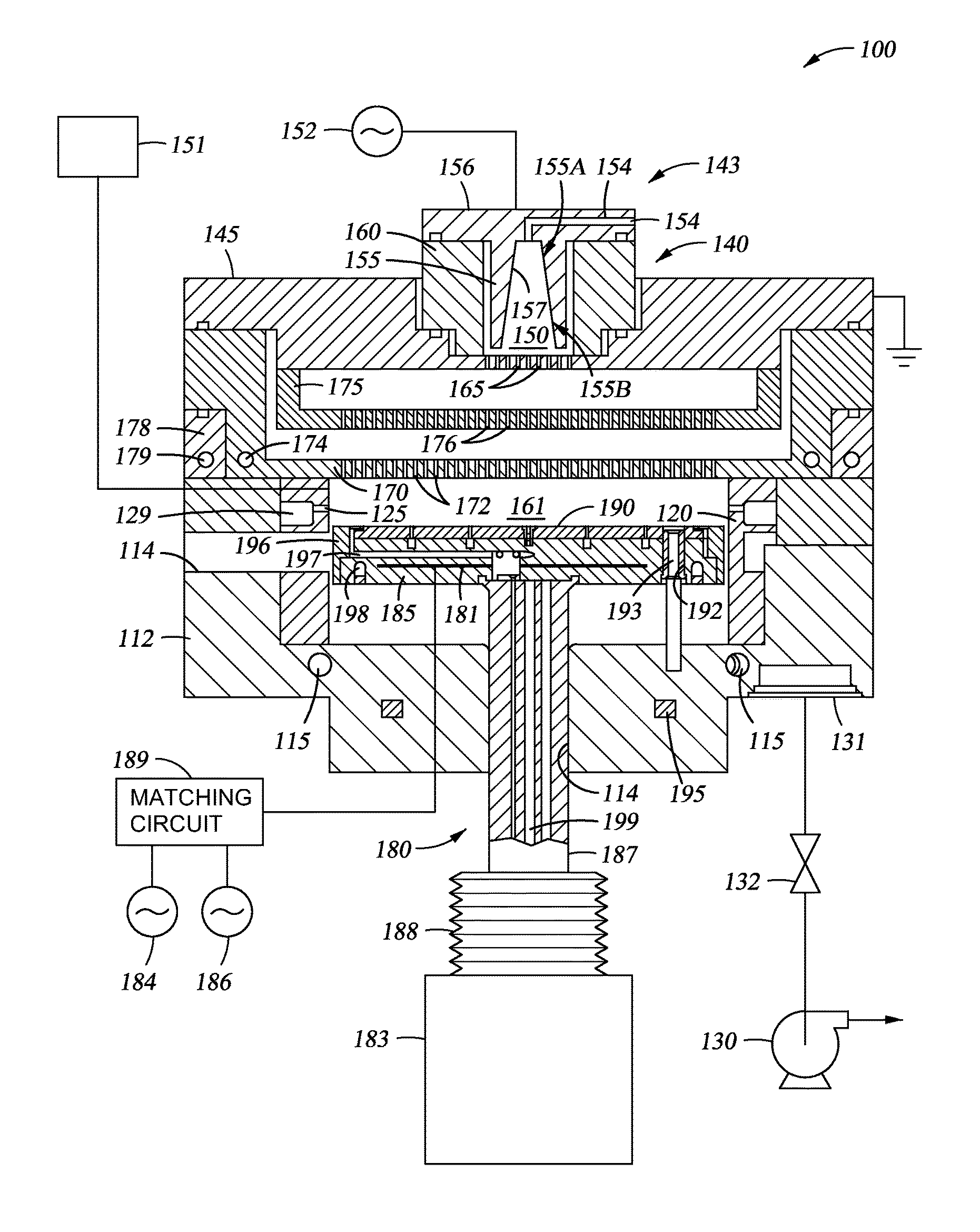

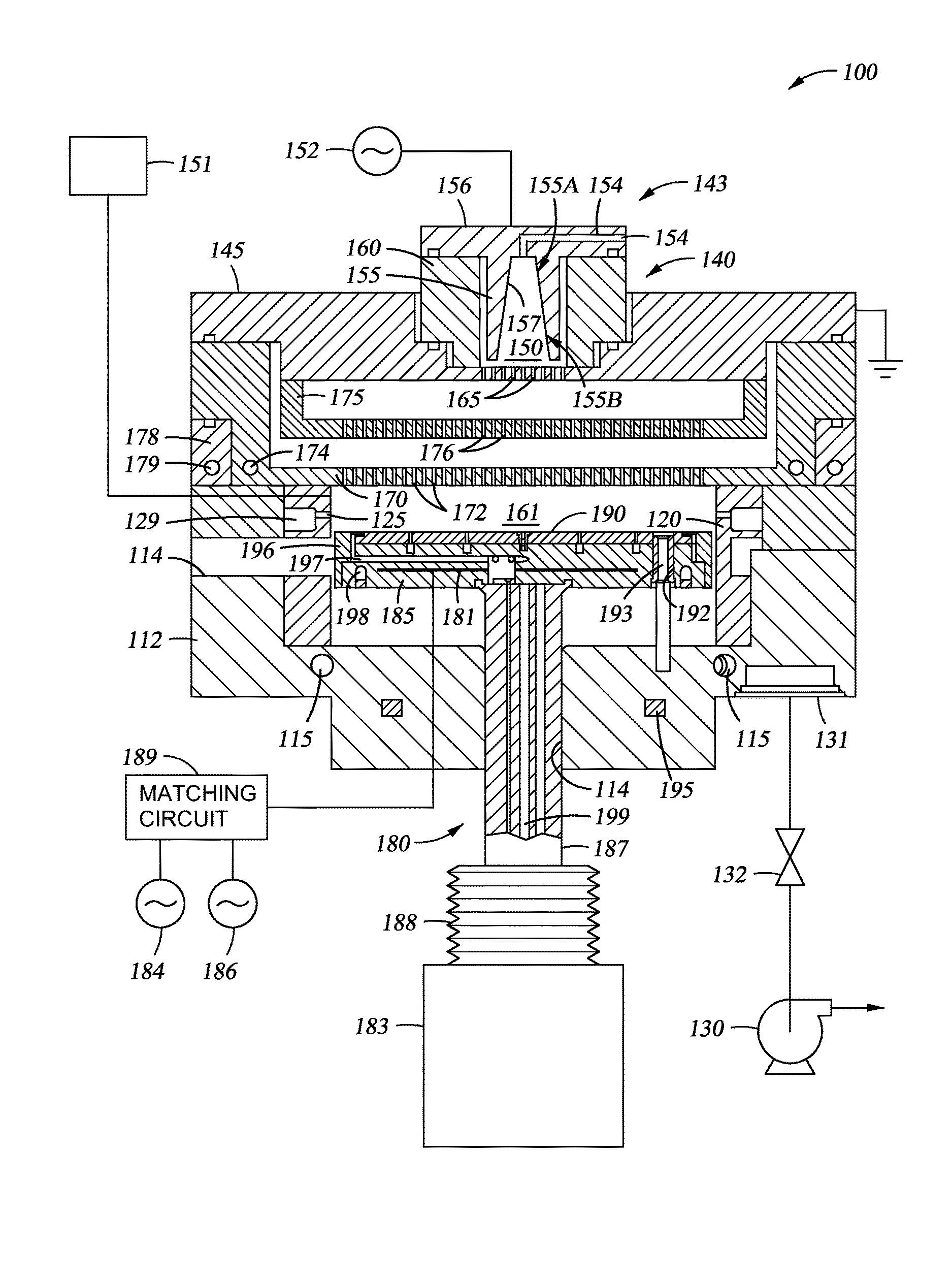

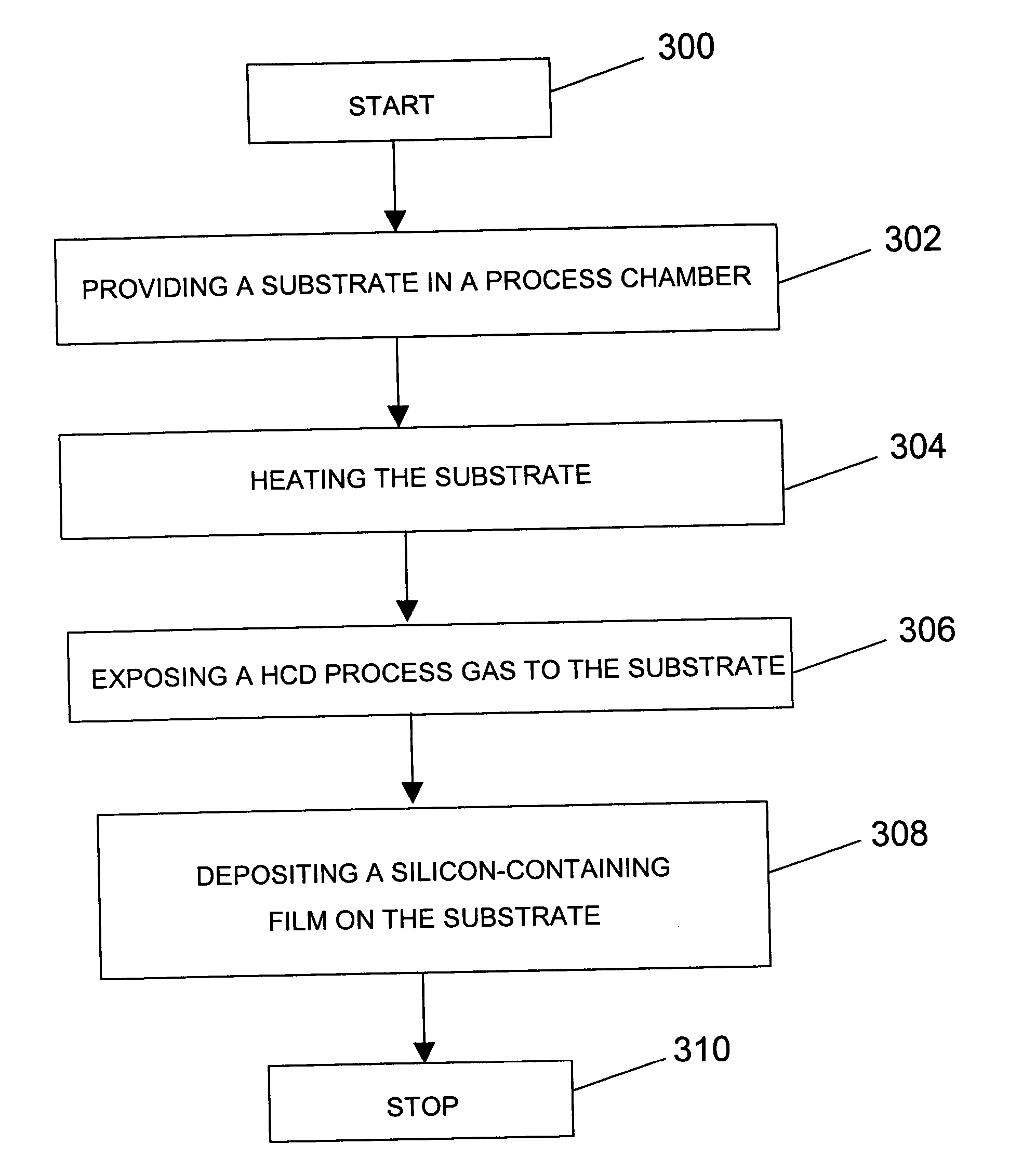

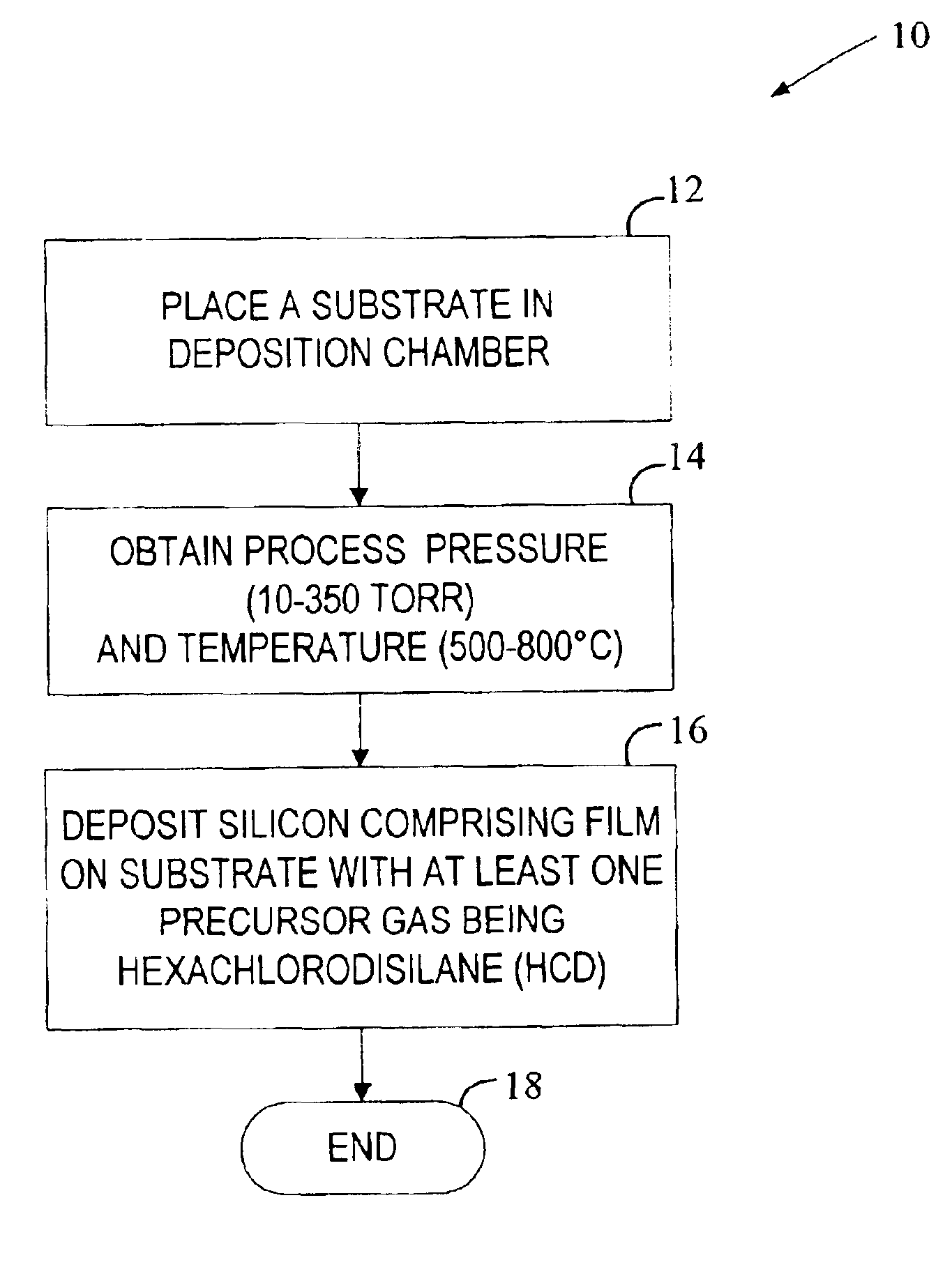

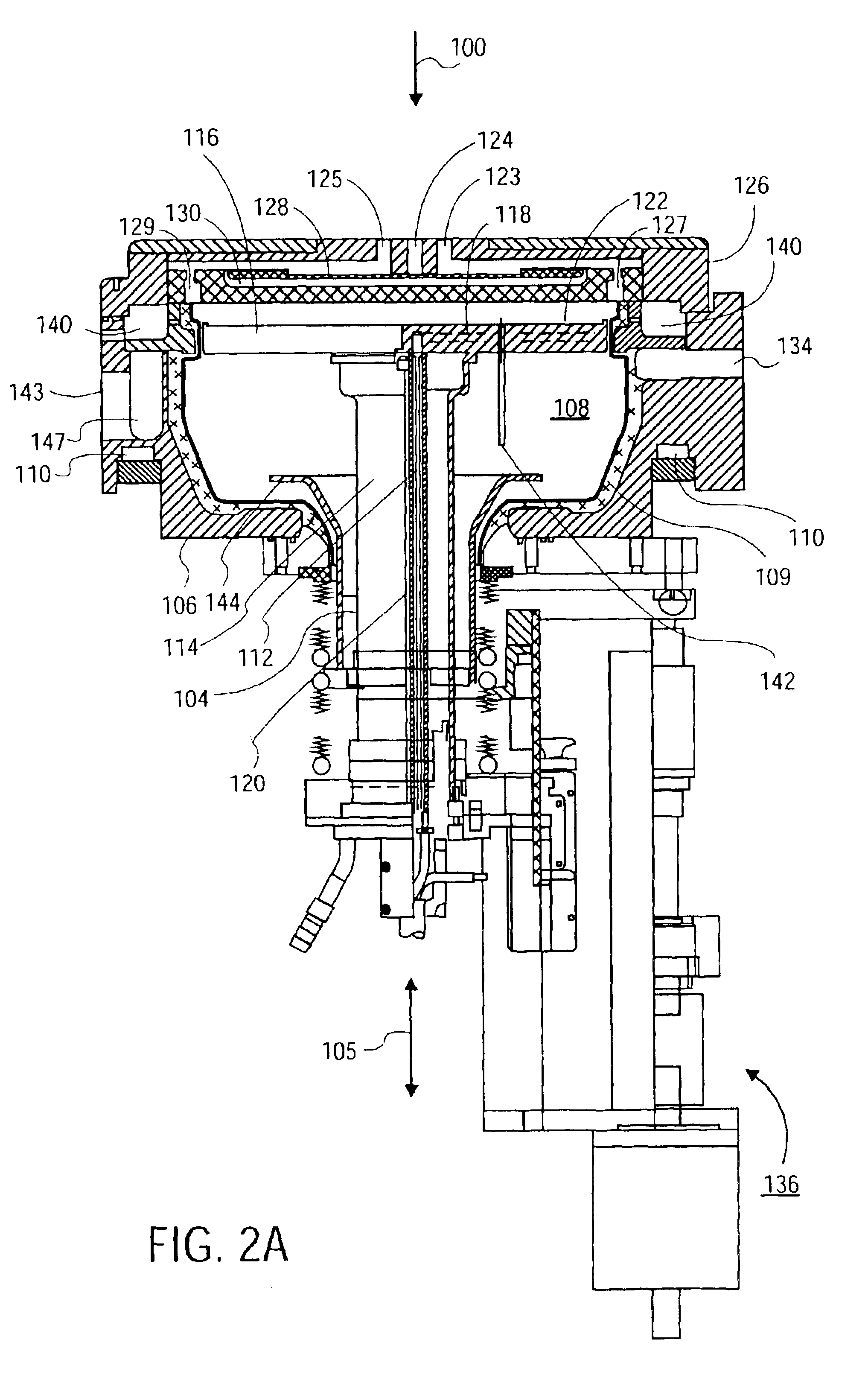

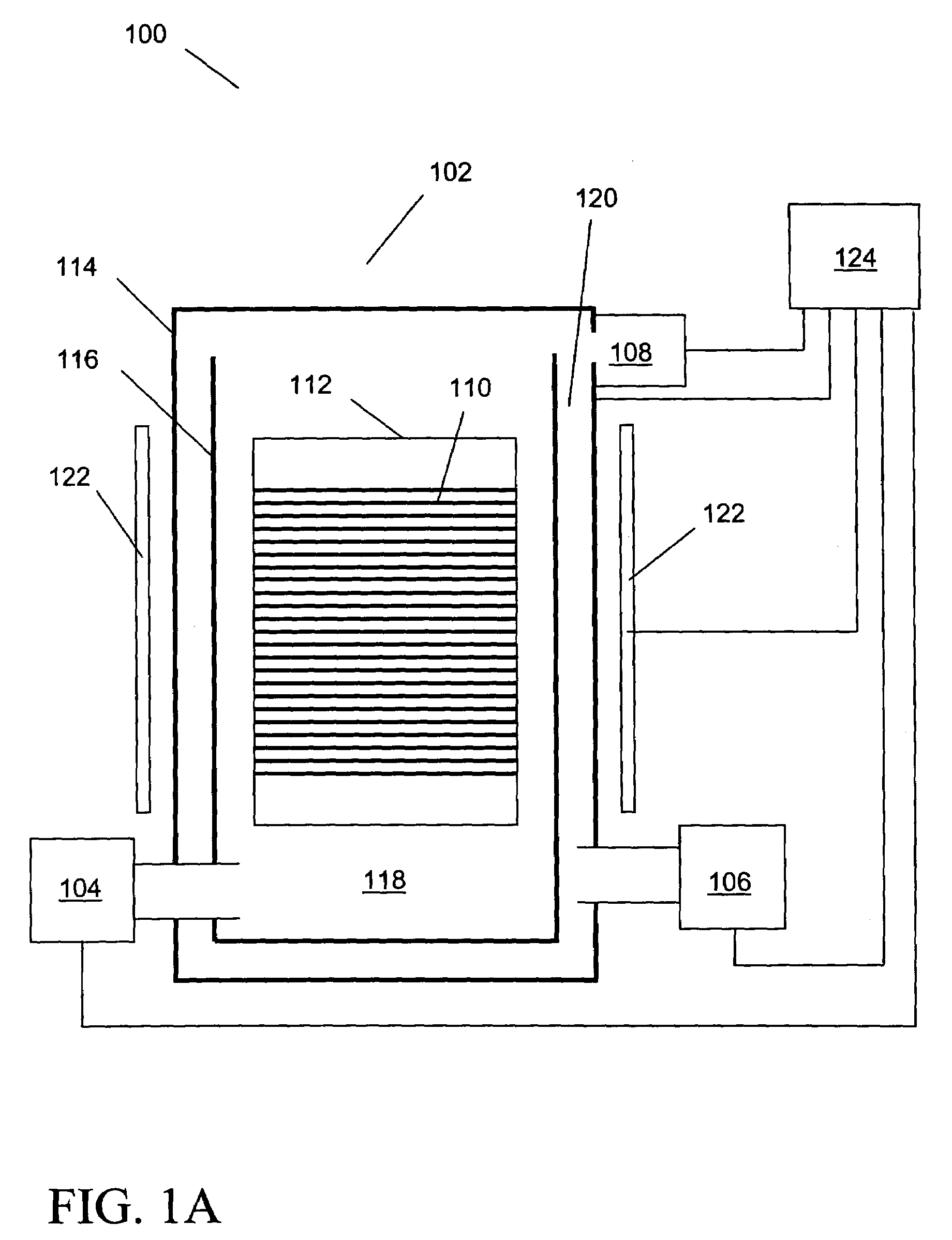

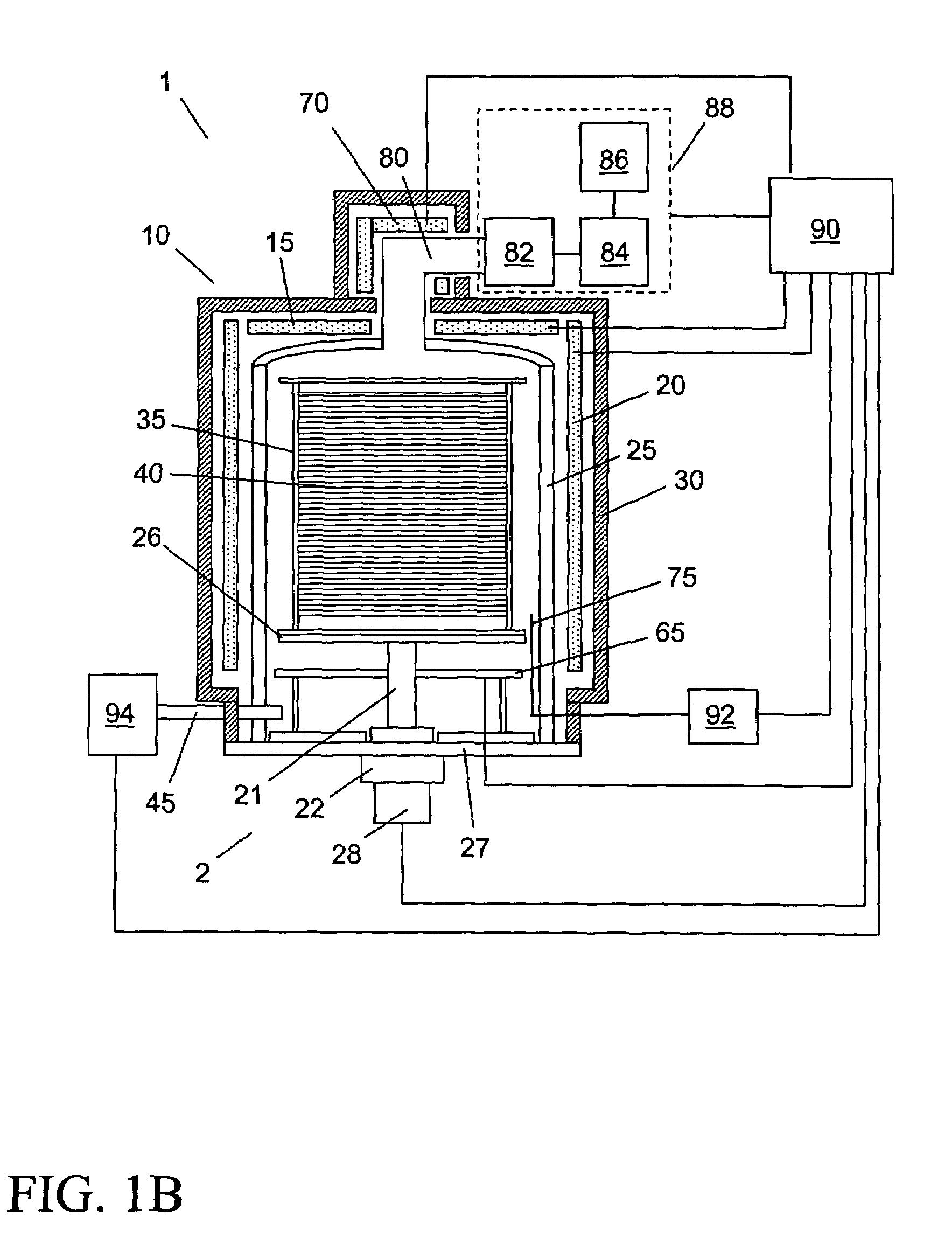

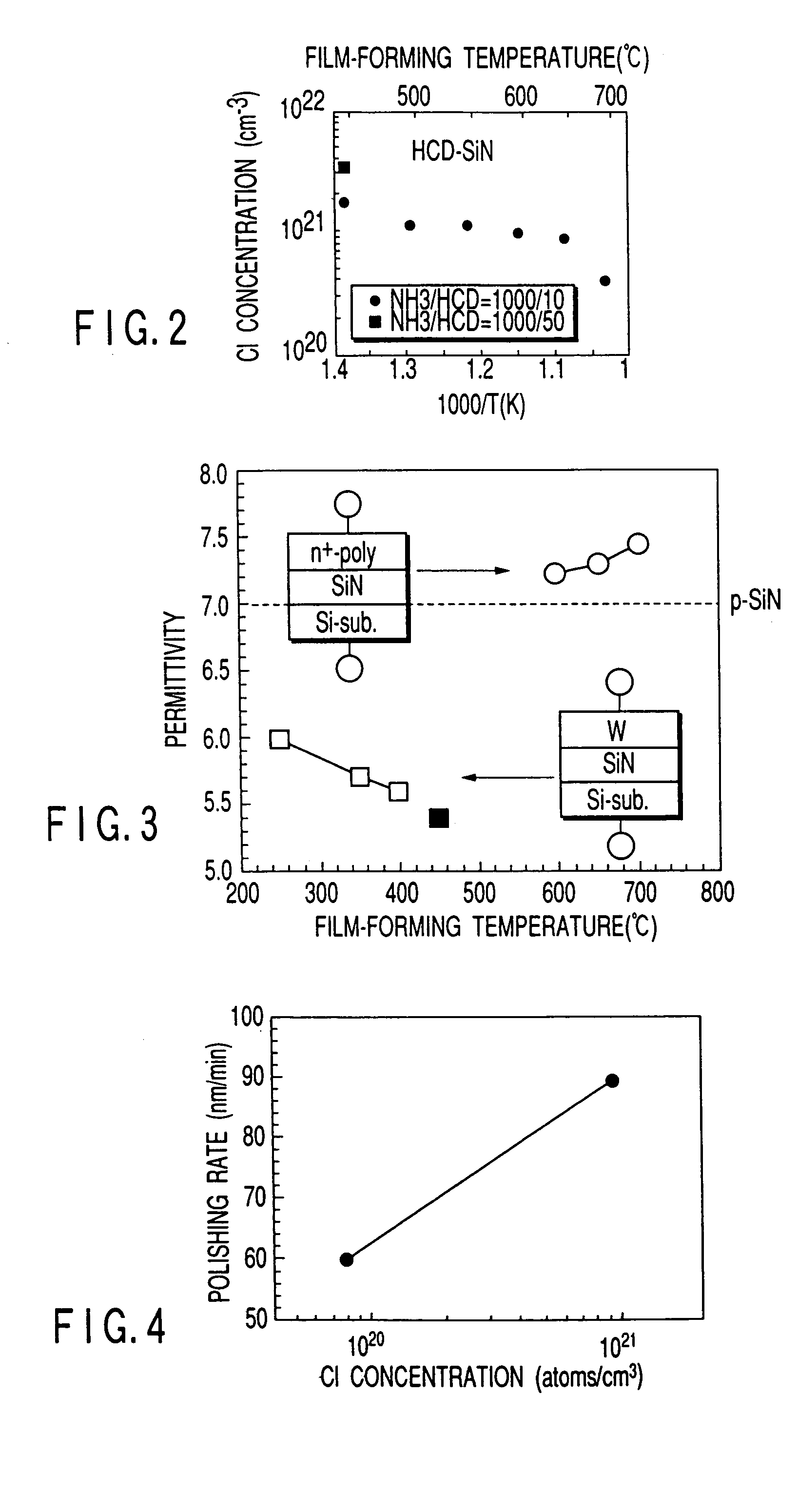

Deposition of silicon-containing films from hexachlorodisilane

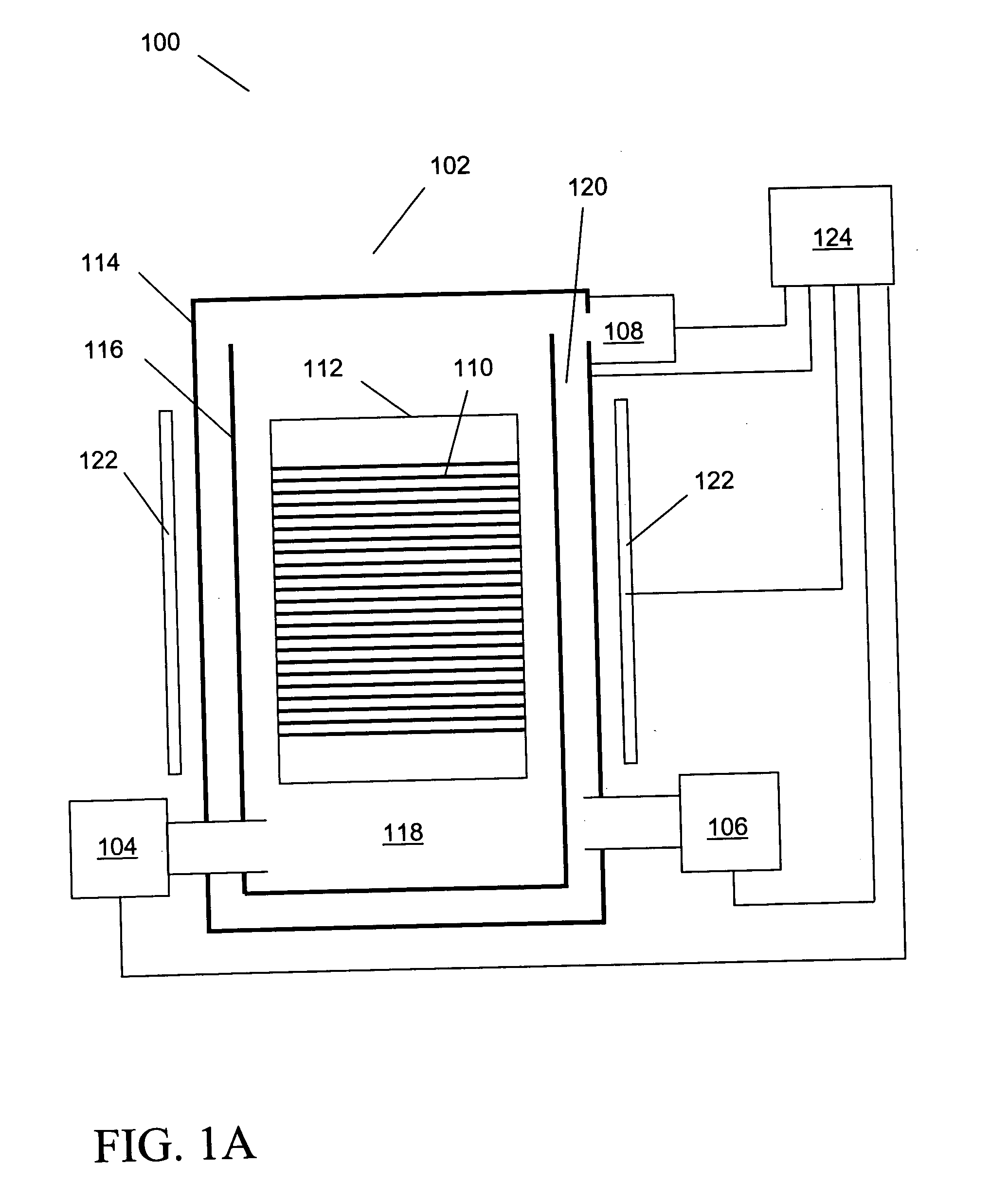

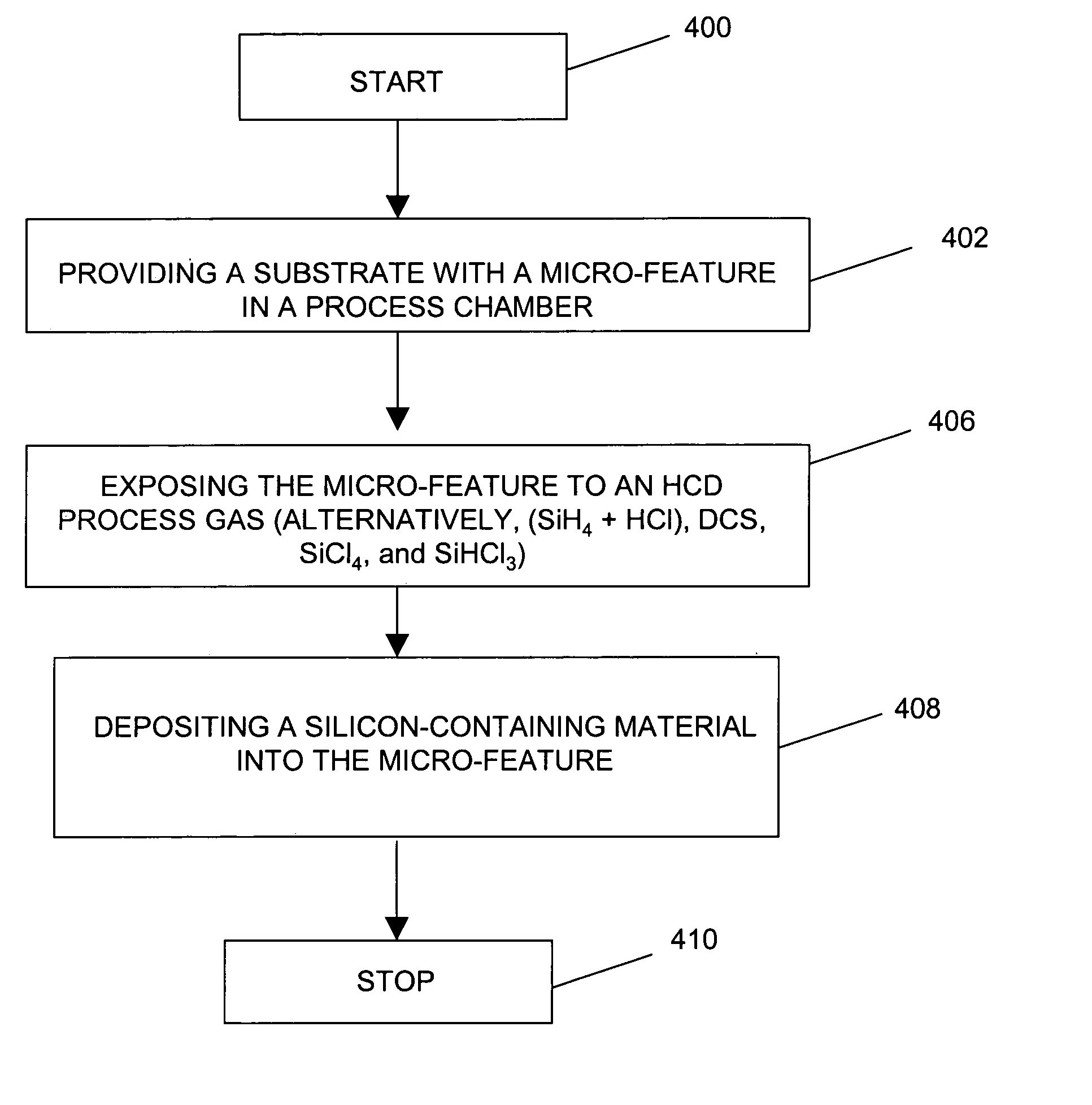

InactiveUS20050066892A1Cost effectiveIntegrated cost-effectivelyPolycrystalline material growthFrom solid stateDeposition processHandling system

A method is provided for depositing a silicon-containing film on a substrate by a low pressure deposition process in a processing system. A silicon-containing film can be formed on a substrate by providing a substrate in a process chamber of a processing system, heating the substrate, and exposing a hexachlorodisilane (HCD) process gas to the substrate. The method can selectively deposit an epitaxial silicon-containing film on a silicon surface of a substrate or, alternately, non-selectively deposit a silicon-containing film on a substrate. A processing tool containing a processing system for forming a silicon-containing film on s substrate using a HCD process gas is provided.

Owner:TOKYO ELECTRON LTD

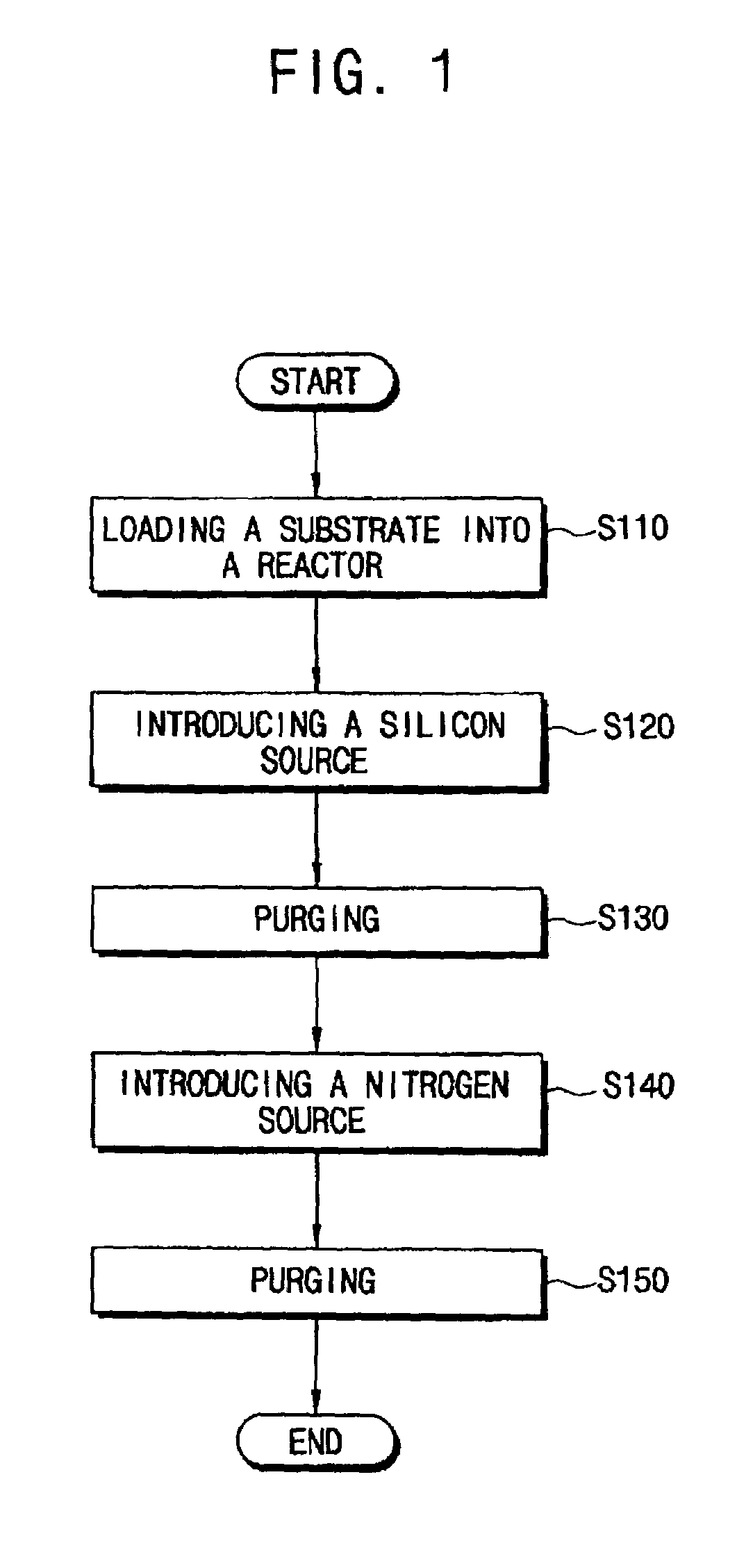

Methods of forming silicon nitride layers using nitrogenous compositions

The present invention provides nitrogenous compositions for forming a silicon nitride layer, wherein the nitrogenous composition comprises a hydrazine compound, an amine compound or a mixture thereof. The present invention further provides source compositions for forming a silicon nitride layer, wherein the source composition comprises a nitrogenous composition comprising a hydrazine compound, an amine compound or a mixture thereof, and a silicon source comprising hexachlorodisilane. Methods for forming silicon nitride layers are further provided. The silicon nitride layers provided herein may be formed on a substrate at a low temperature and may further exhibit improved breakdown voltage and an enhanced etch resistance.

Owner:SAMSUNG ELECTRONICS CO LTD

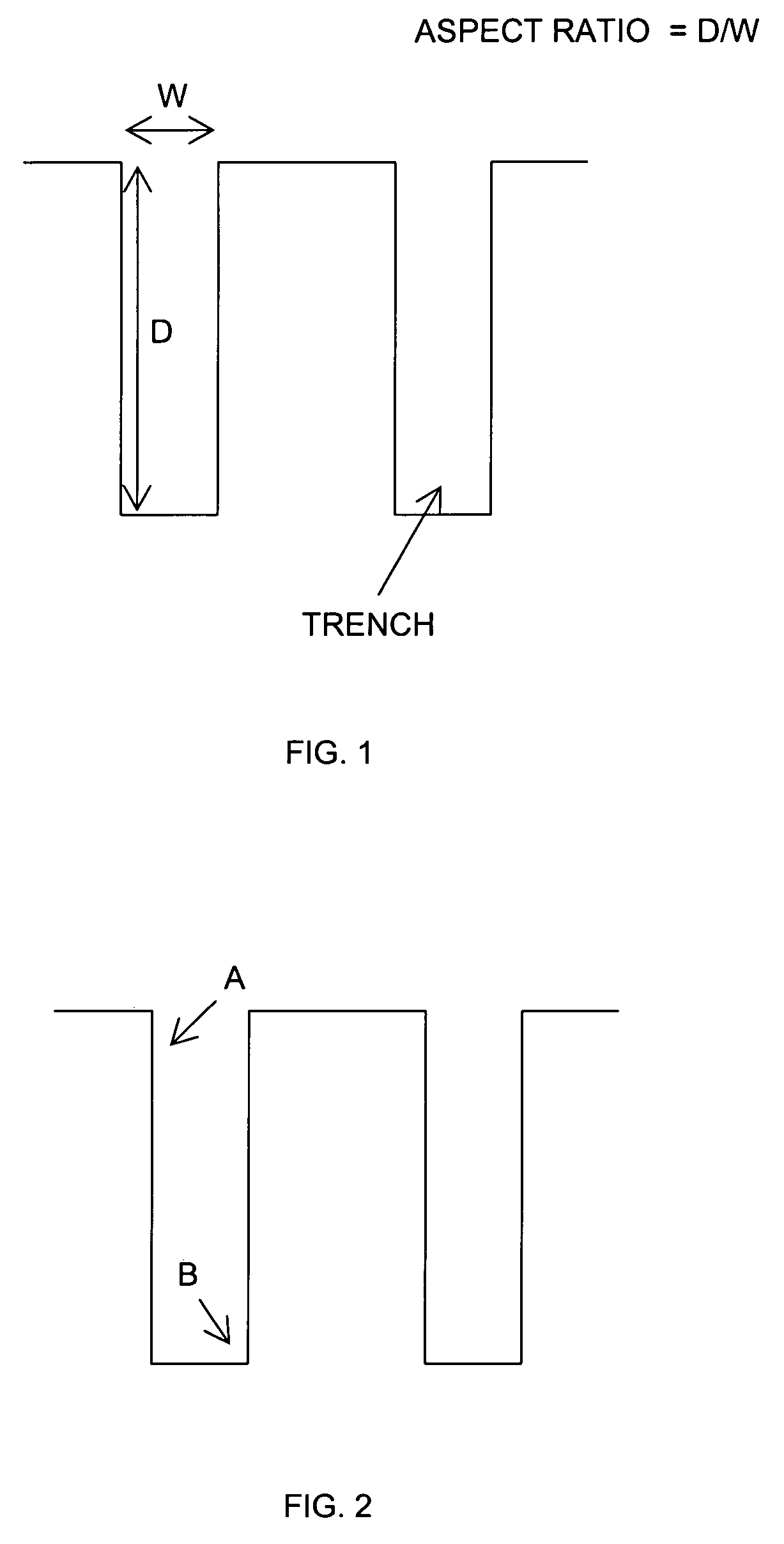

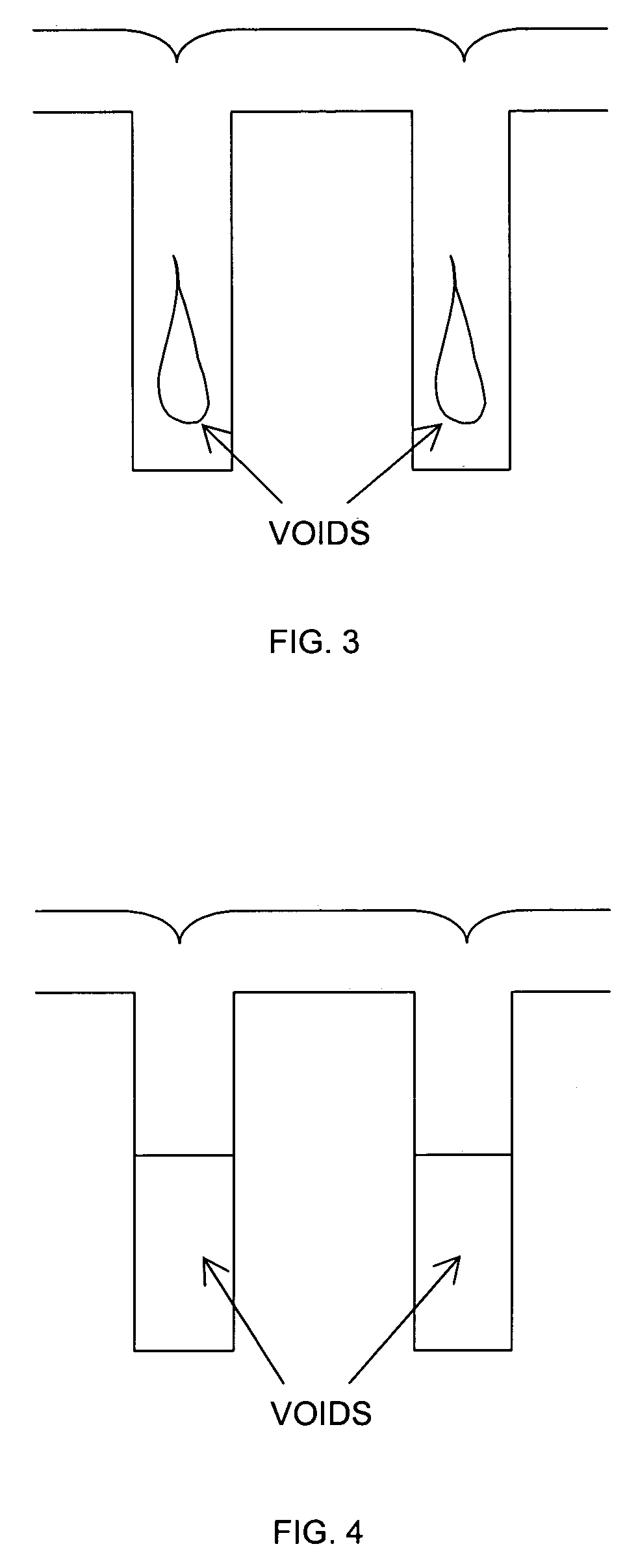

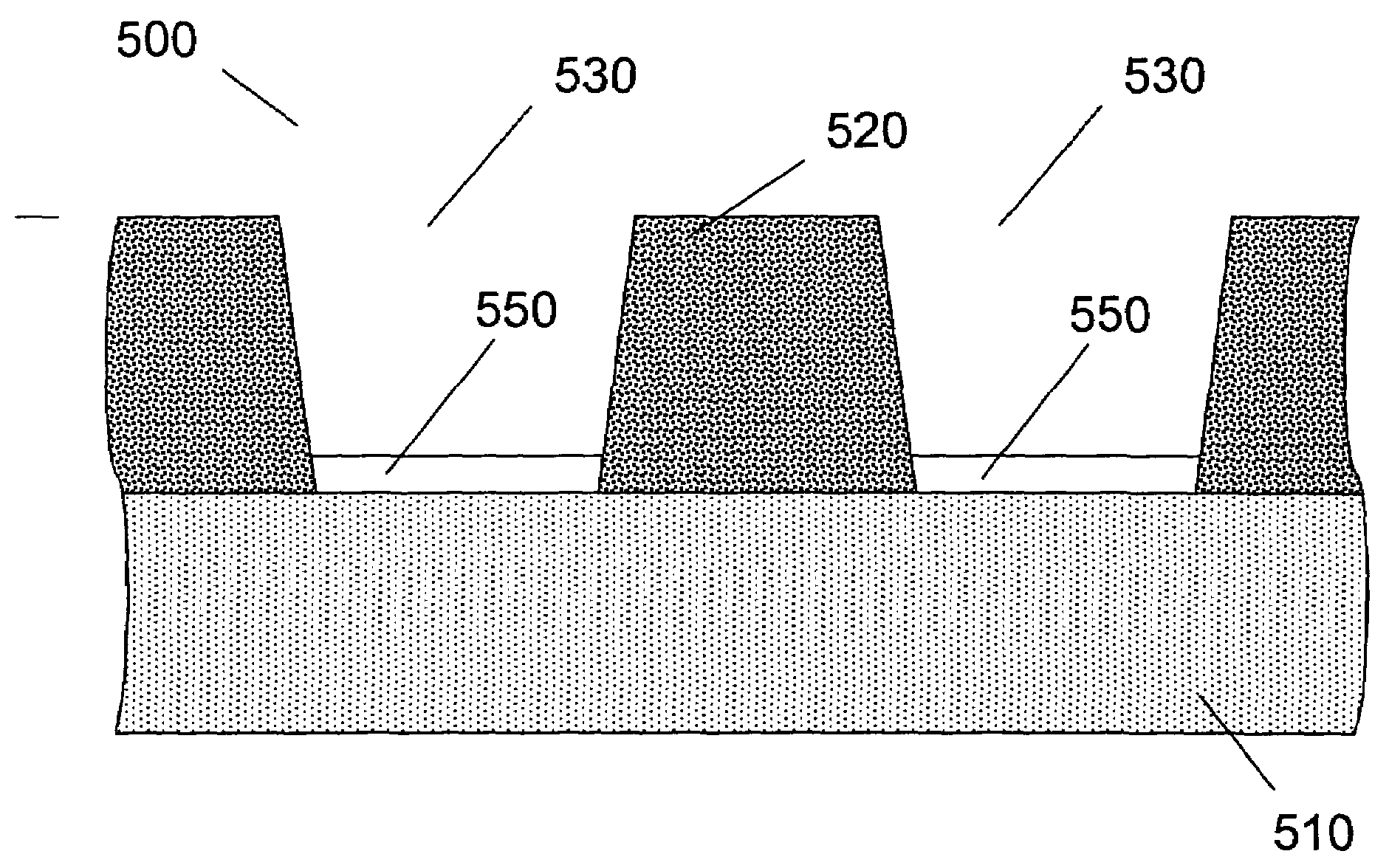

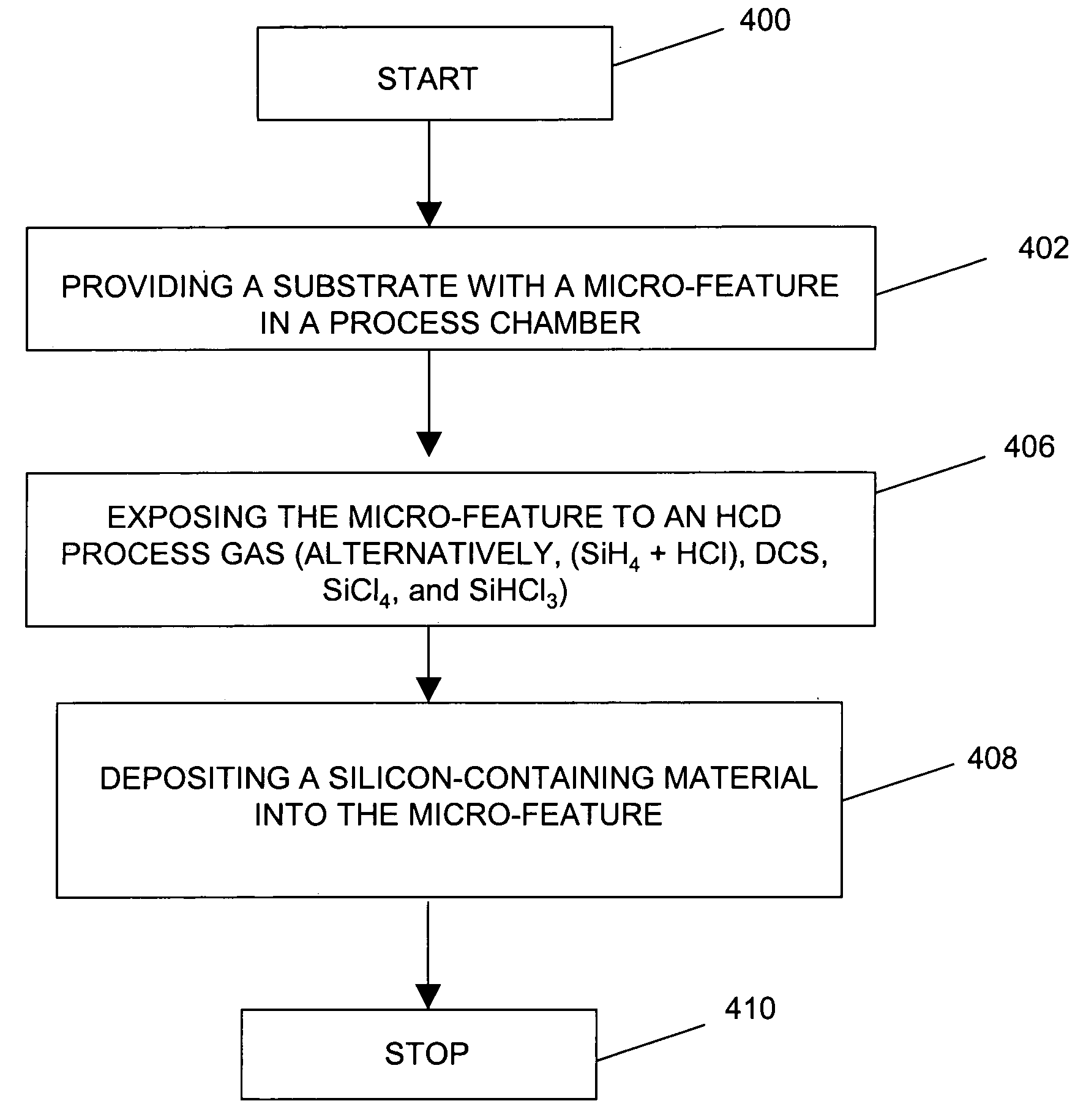

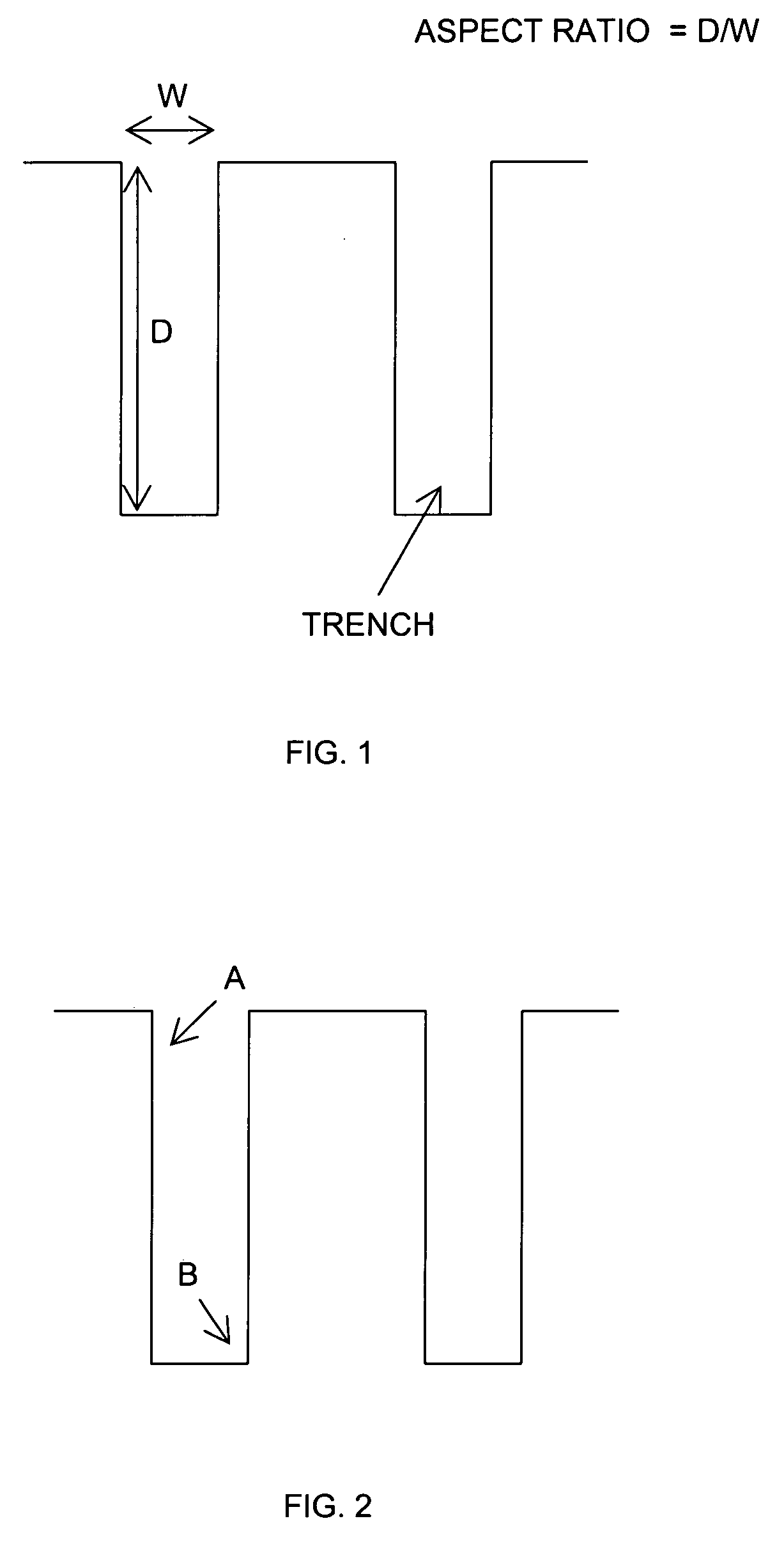

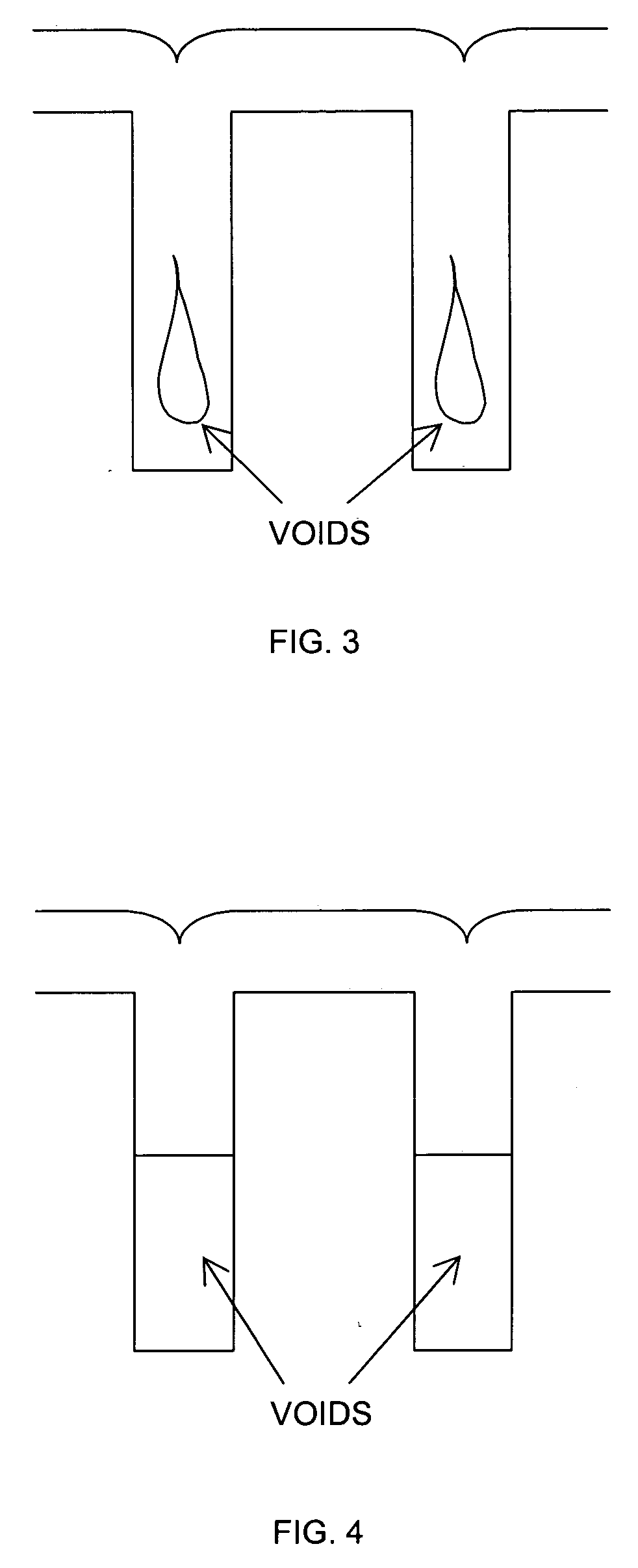

Micro-feature fill process and apparatus using hexachlorodisilane or other chlorine-containing silicon precursor

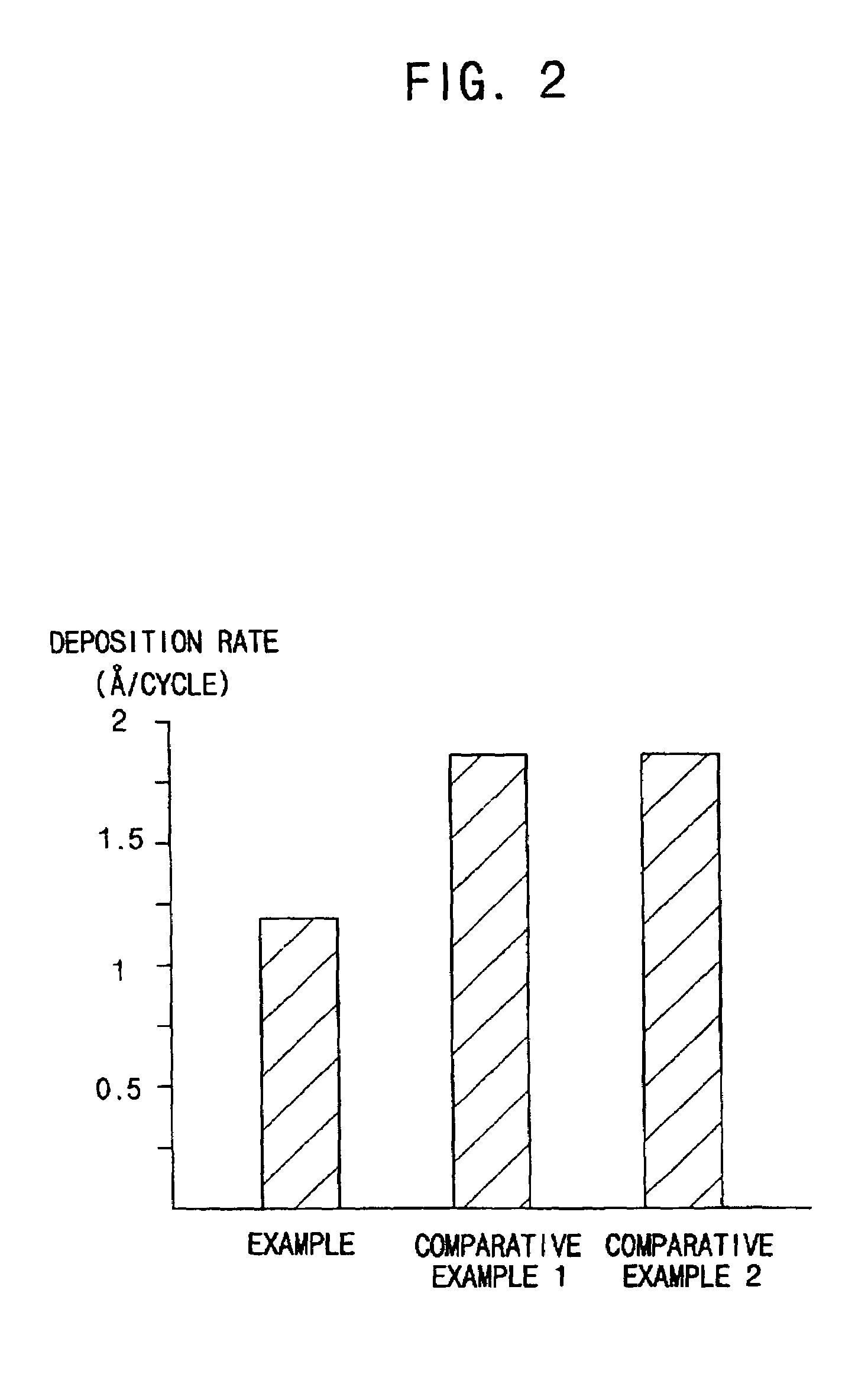

ActiveUS7205187B2Inhibition formationIncrease deposition rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon membraneDeposition process

A method is provided for depositing a silicon-containing film in a micro-feature on a substrate by a low pressure deposition process in a processing system. A silicon-containing film can be formed in a micro-feature by providing a substrate in a process chamber of a processing system, and exposing a hexachlorodisilane (HCD) process gas to the substrate. A processing tool containing a processing system for forming a silicon-containing film in a micro-feature using a silicon and chlorine-containing gas such as a HCD process gas is provided. Alternatively, the micro-feature can be exposed to DCS, SiCl4, and SiHCl3 gases. Alternatively, the micro-feature can be exposed to (SiH4+HCl).

Owner:TOKYO ELECTRON LTD

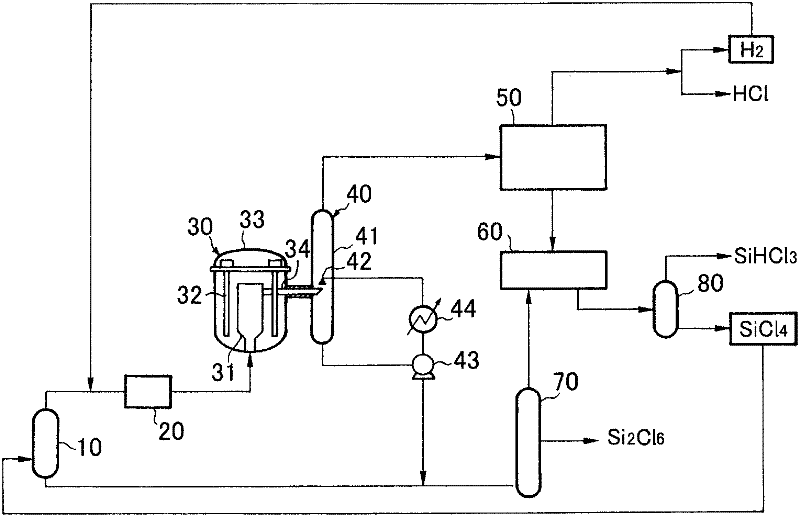

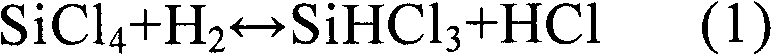

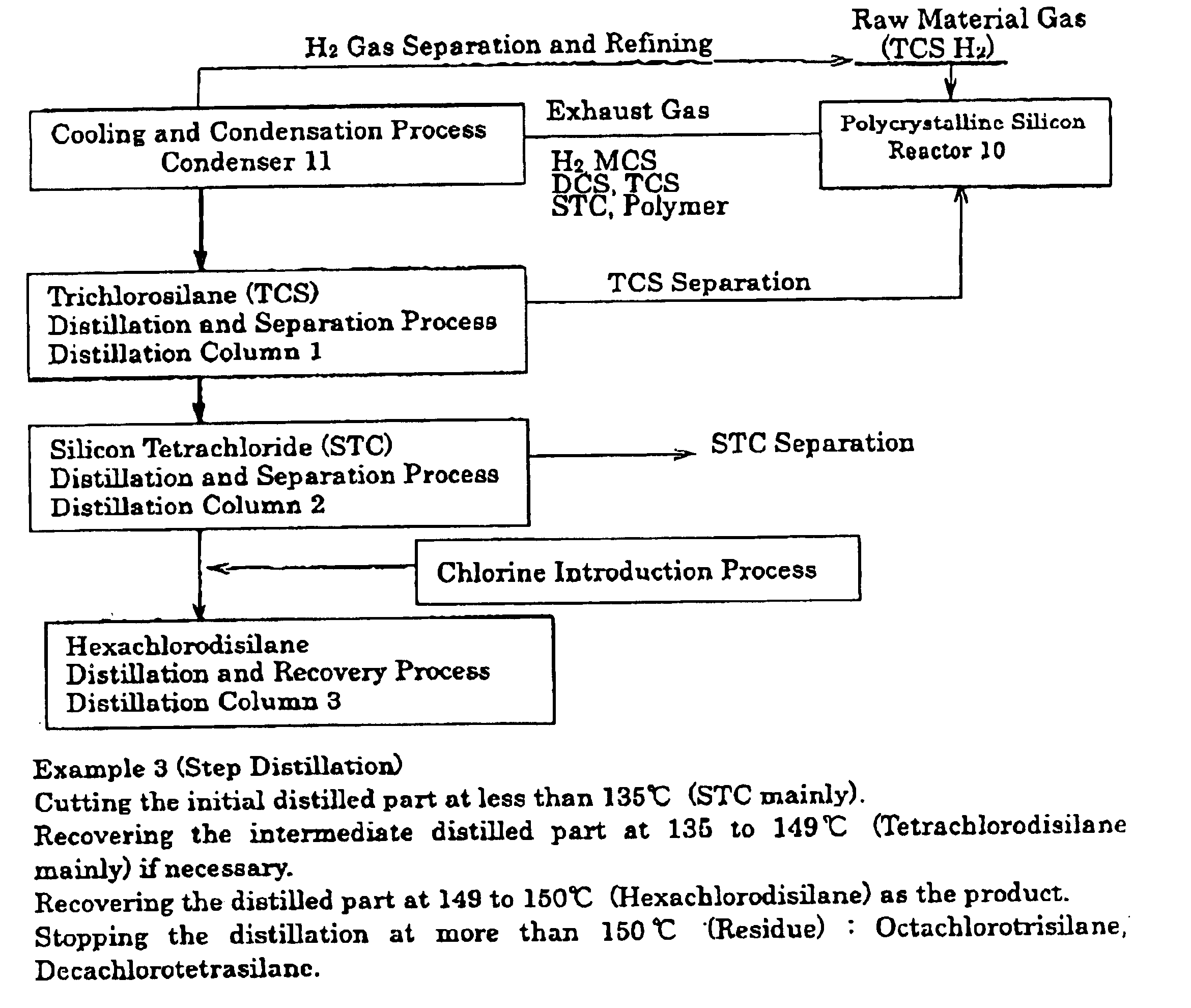

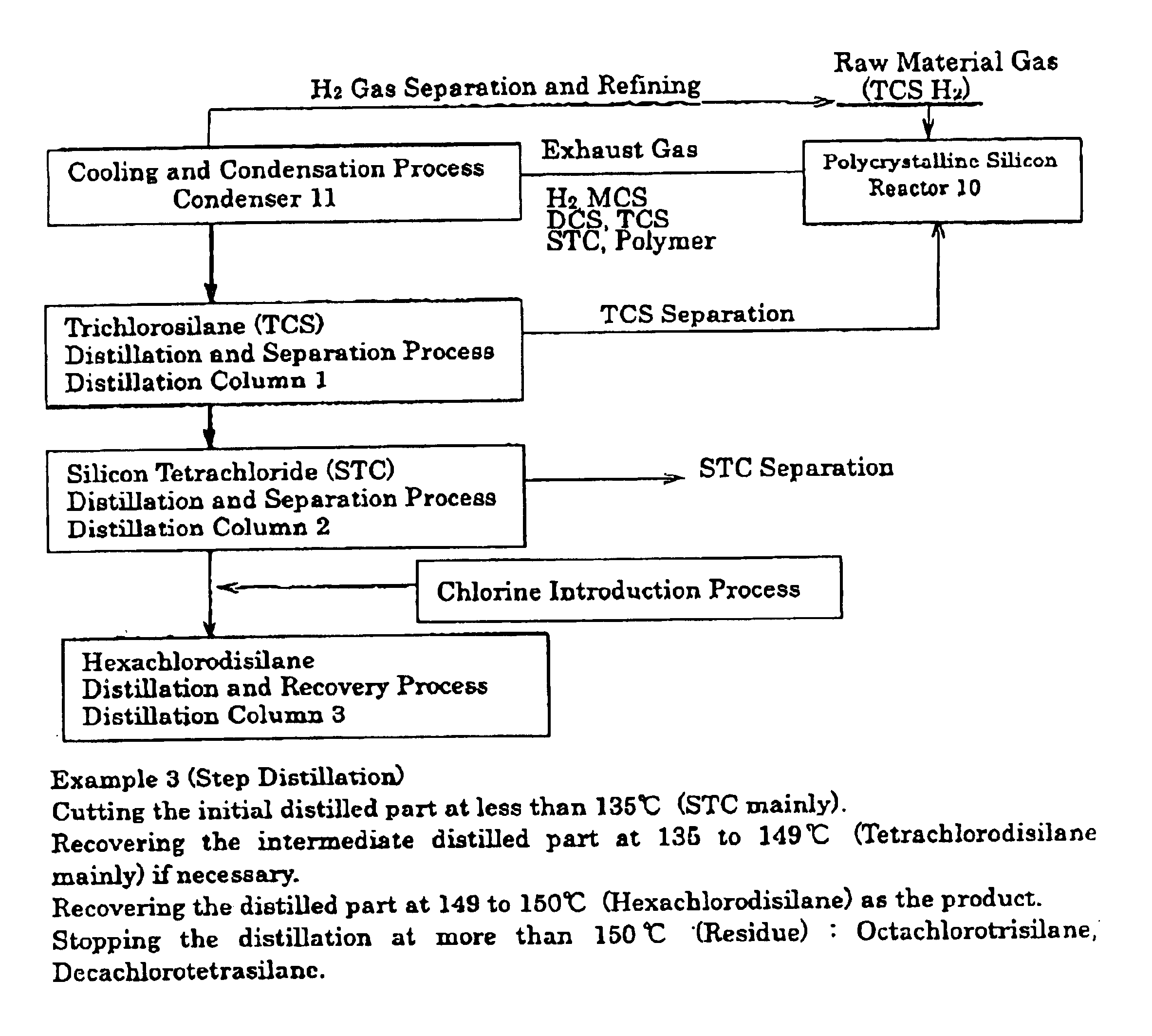

Process for producing hexachlorodisilane

InactiveUS6846473B2High purityEffective recoverySiliconDistillation separationHydrogenSilicon tetrachloride

A process for producing hexachlorodisilane comprising, condensing an exhaust gas discharged from a reactor for producing polycrystalline silicon from a chlorosilane and hydrogen to separate the hydrogen, distilling the resultant condensate to separate the unreacted chlorosilane and by-product silicon tetrachloride, and then further distilling to recover hexachlorodisilane, wherein tetrachlorodisilane can be recovered together with the hexachlorodisilane, and the hexachlorodisilane and tetrachlorodisilane recovered have a far higher purity than the conventional ones produced from metallic silicon.

Owner:MITSUBISHI MATERIALS CORP

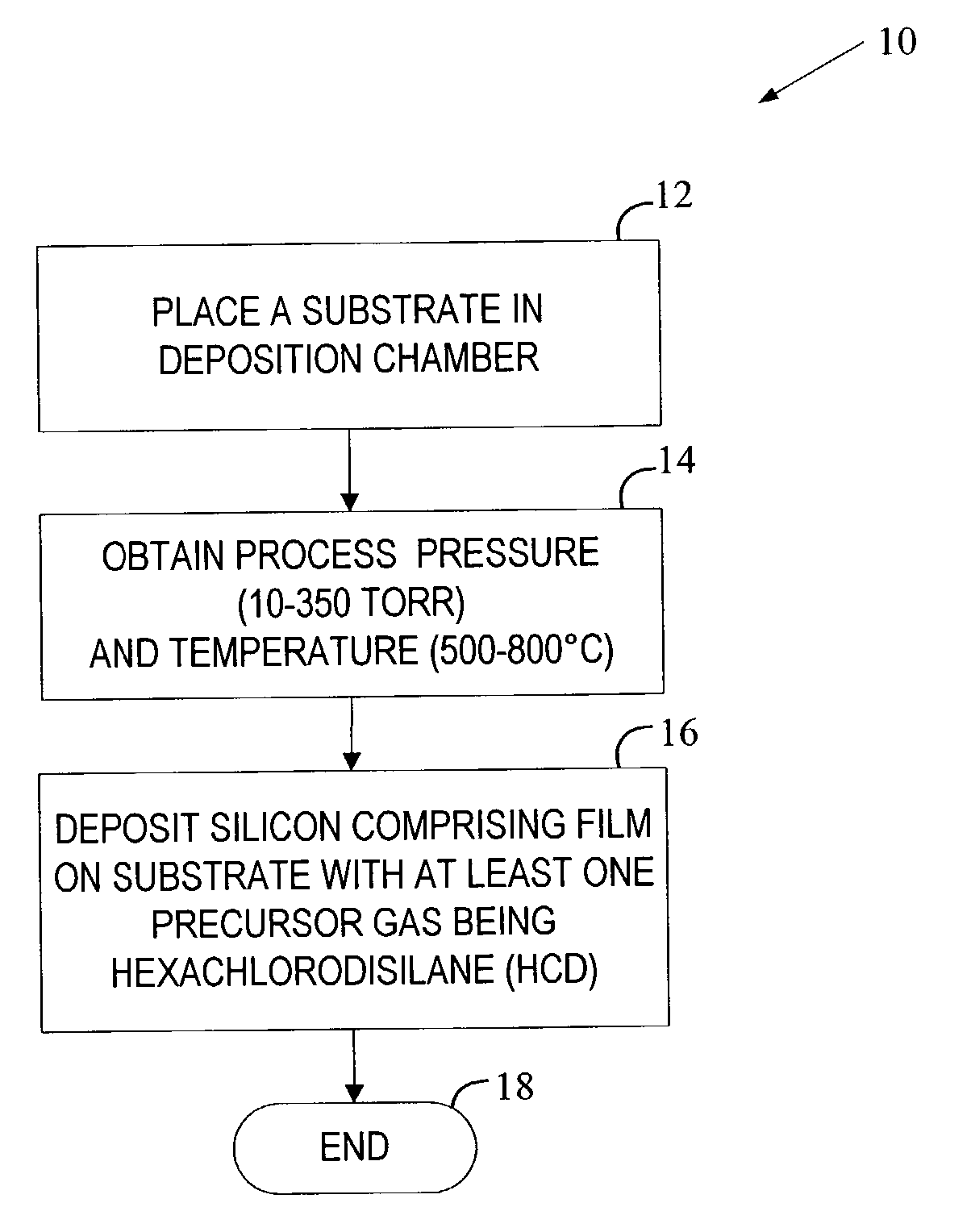

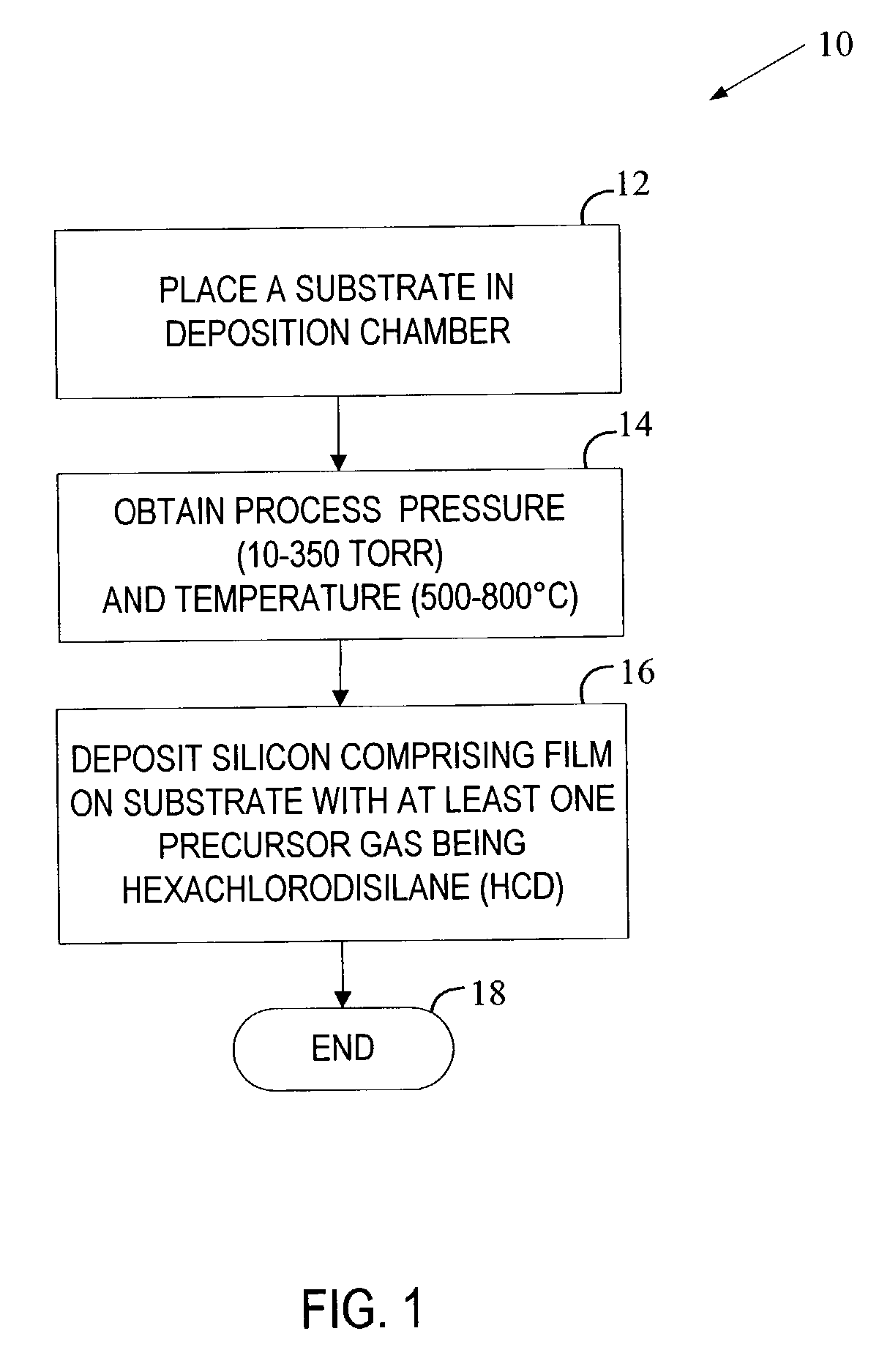

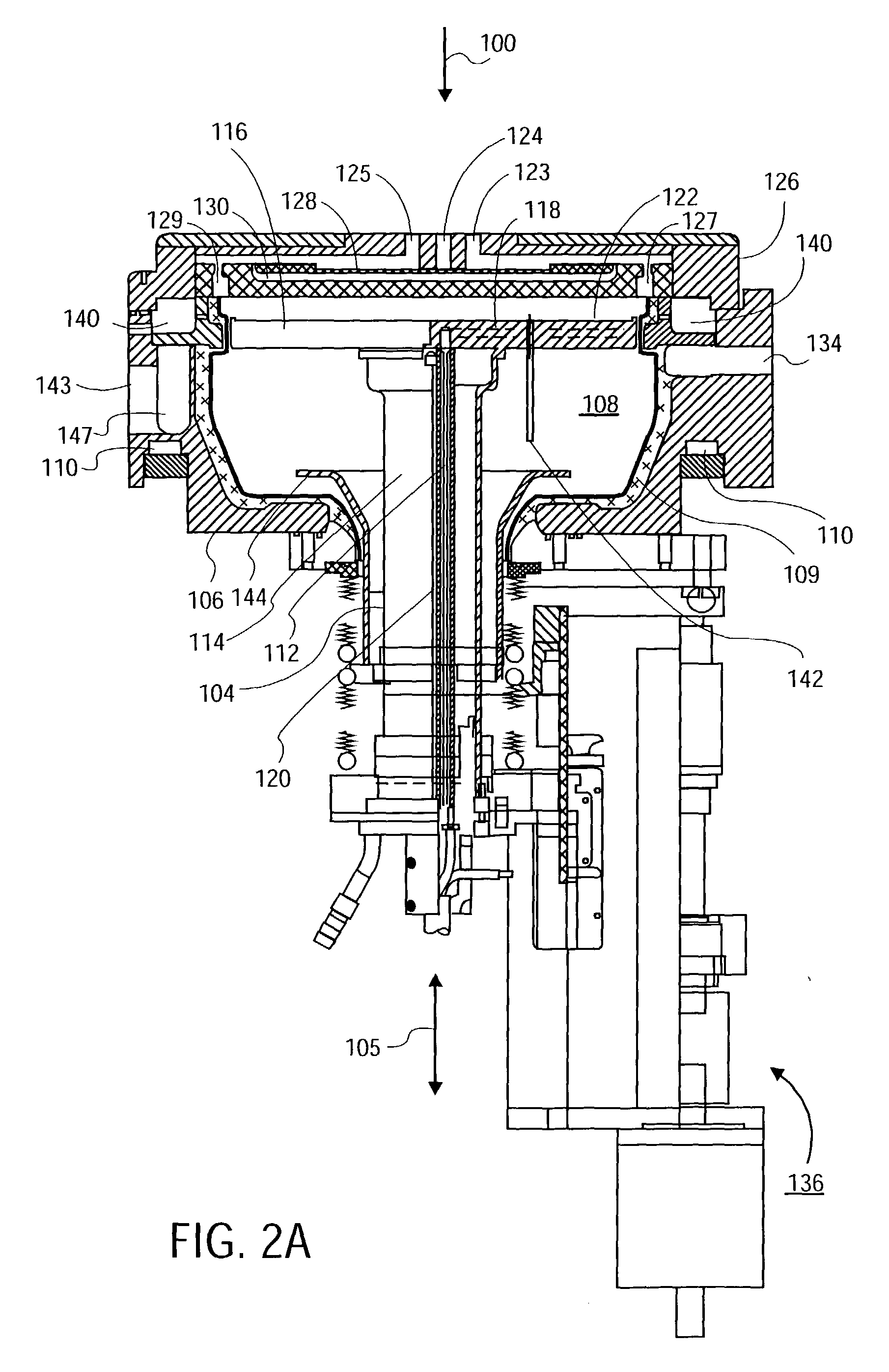

Methods for forming silicon comprising films using hexachlorodisilane in a single-wafer deposion chamber

InactiveUS20040086640A1Pretreated surfacesSemiconductor/solid-state device manufacturingSilicon membraneTorr

A silicon comprising film and its method of fabrication is described. The silicon comprising film is grown on a substrate. A hexachlorodisilane (HCD) source gas is one of the reactant species used to form the silicon comprising film. The silicon comprising film is formed under a pressure between 10 Torr and 350 Torr.

Owner:APPLIED MATERIALS INC

Method for preparing substrate material with multilayer composite protective film

InactiveCN101974734APrecise thickness controlPrecise control ratioChemical vapor deposition coatingChemisorptionNitrogen gas

The invention relates to a method for preparing a substrate material with a multilayer composite protective film, which comprises the following steps: putting the substrate material into a reaction chamber, and heating the substrate material until the temperature thereof is 100 to 500 DEG C; introducing trimethyl aluminum or Al (CH3) N (CH2) 5CH3 precursor into the reaction chamber within 0.2 to 0.5 seconds under the pressure of 0.1 to 10 Torr; introducing nitrogen or inert gas into the reaction chamber so as to remove the trimethyl aluminum or Al (CH3) N (CH2) 5CH3 residual gas which is not subjected to chemisorption by a substrate; under the pressure of 0.1 to 10 Torr, introducing ozone or vapor reactive gas into the reaction chamber within 0.2 to 0.5 seconds so as to deposit an alumina atom layer on the substrate, wherein the thickness of the alumina atom layer on the substrate is 2 to 100nm; and replacing the trimethyl aluminum or Al (CH3) N (CH2) 5CH3 precursor by using chlorosilane, hexachlorodisilane or tetraethyl orthosilicate as silicon source, then repeating the steps above, and covering a silicon dioxide layer on an alumina layer, wherein the thickness of the alumina layer is 2 to 100nm; and finally, obtaining the substrate material with a composite inorganic protective film in a Al2O3 / SiO2 double-layer structure, wherein the thickness of the substrate material is 5 to 120nm. The method can precisely control the thickness of the film, wherein the thickness of the film can directly and precisely be controlled within a range of 1 to 100nm, and the film has excellent oxidation resistance and gas permeation resistance, and can control the ratio of Al2O3 to SiO2.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Methods for forming silicon comprising films using hexachlorodisilane in a single-wafer deposion chamber

InactiveUS6884464B2Pretreated surfacesSemiconductor/solid-state device manufacturingSilicon membraneTorr

A silicon comprising film and its method of fabrication is described. The silicon comprising film is grown on a substrate. A hexachlorodisilane (HCD) source gas is one of the reactant species used to form the silicon comprising film. The silicon comprising film is formed under a pressure between 10 Torr and 350 Torr.

Owner:APPLIED MATERIALS INC

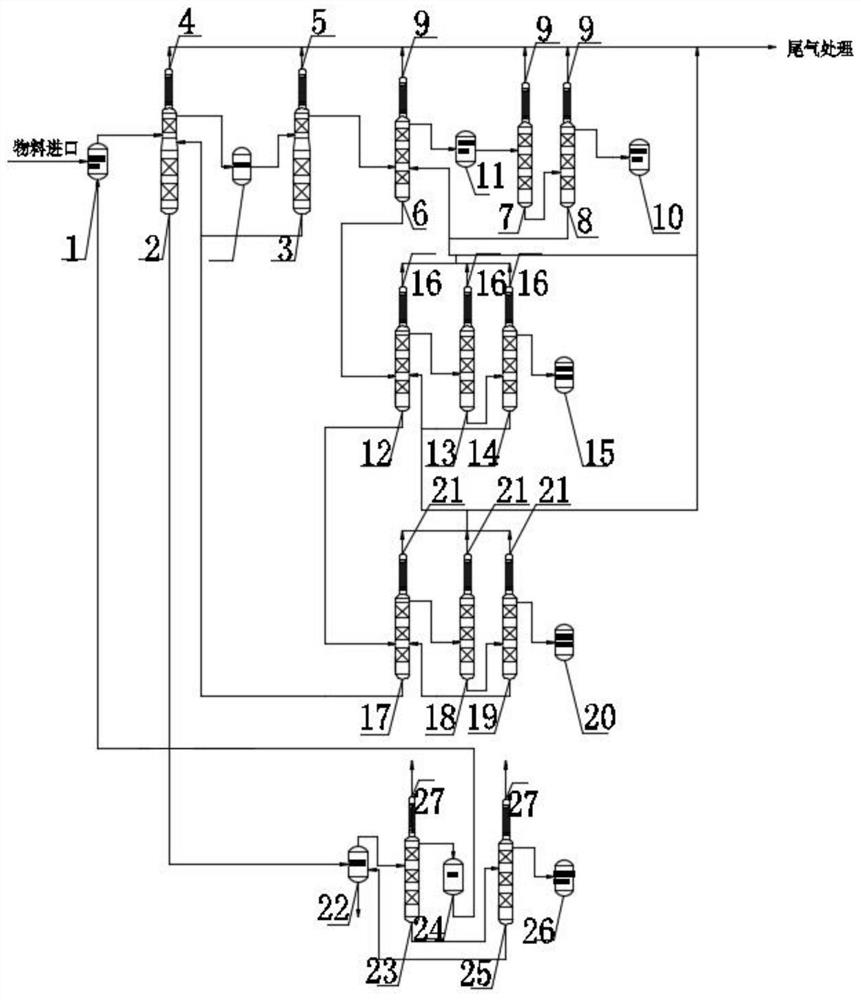

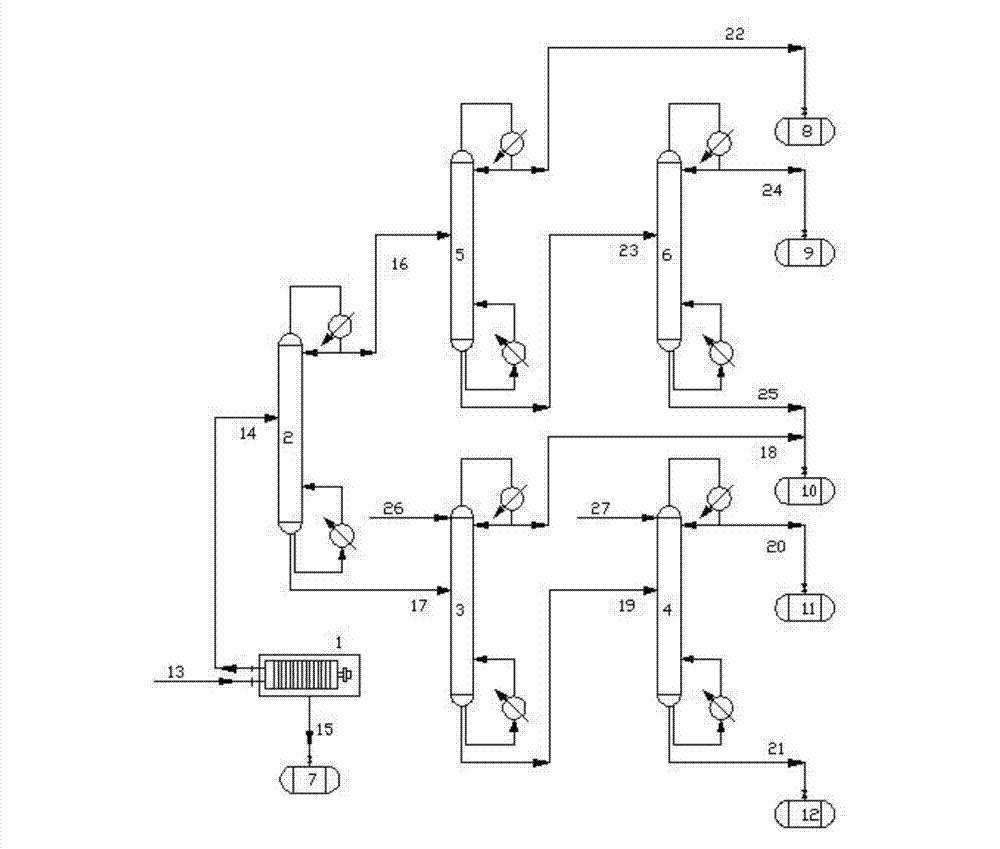

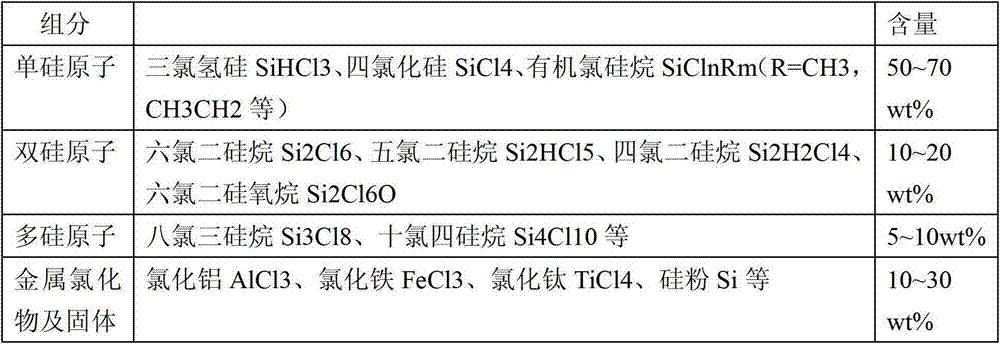

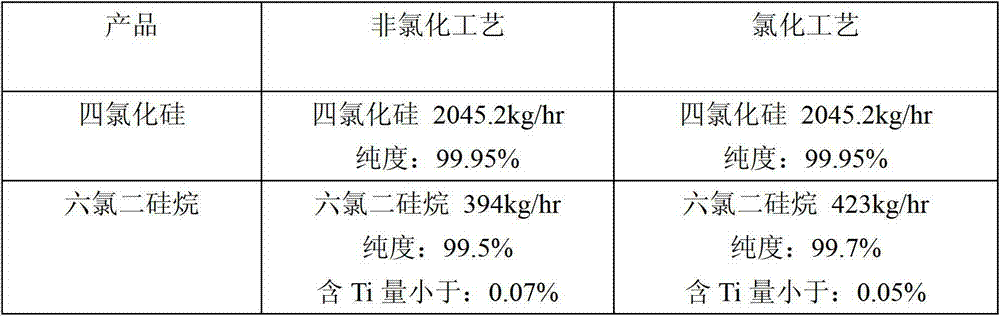

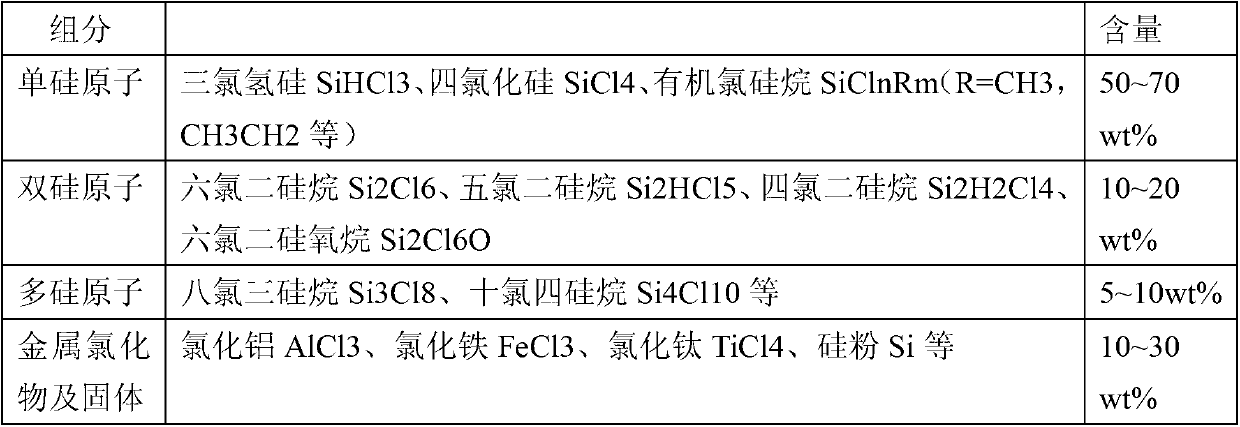

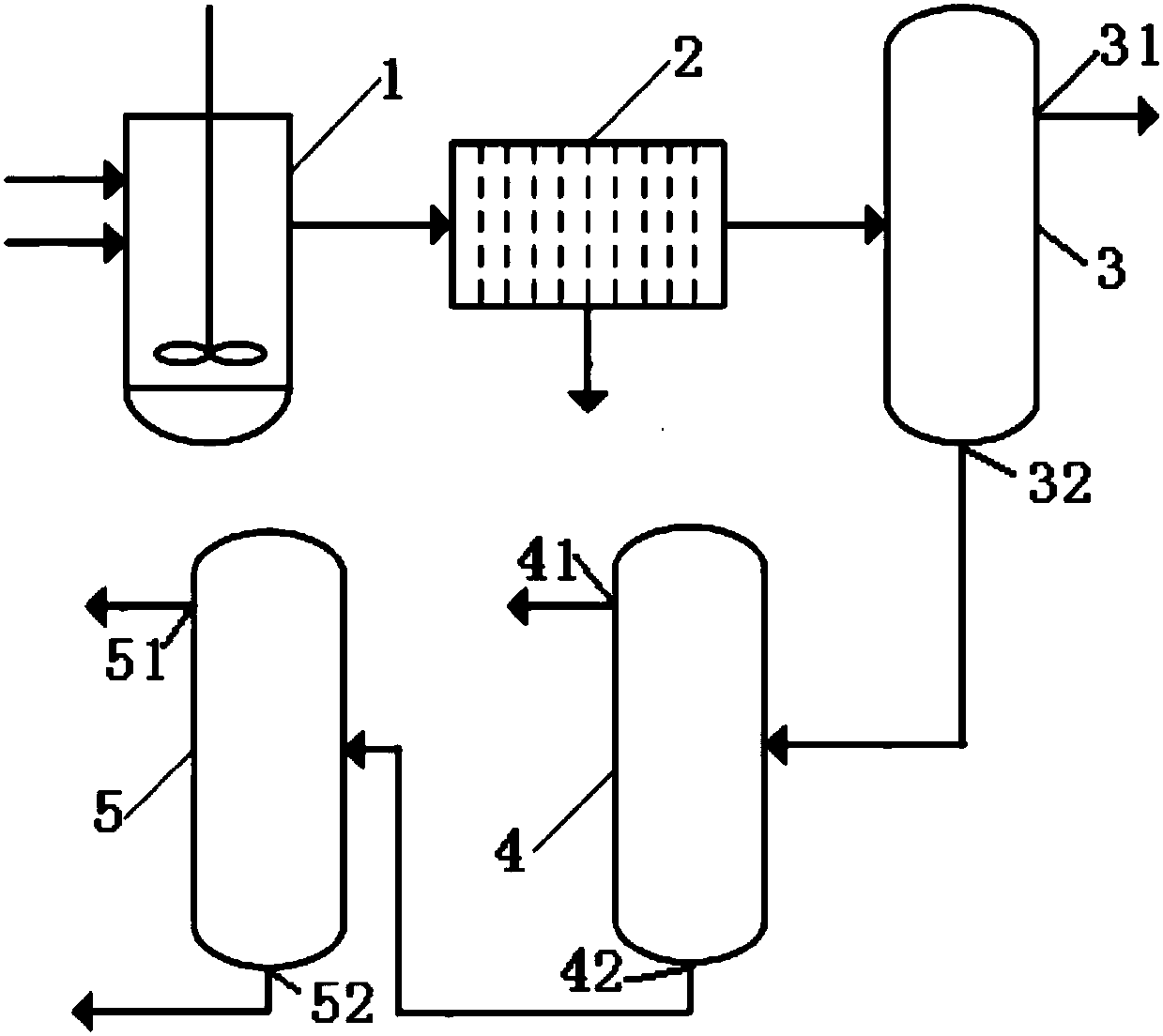

Device and method for continuous recovery treatment of chlorosilane residual liquid

InactiveCN103112859AIncrease added valueMaximize resource utilizationHalogenated silanesReduction procedureDistillation

The invention relates to a device and a method for continuous recovery treatment of chlorosilane residual liquid, and particularly relates to a method and a device for recovering hexachlonxlisilane with extremely high value. According to the method, a filter, a primary tower, a hexachlonxlisilane light-component removal column, a hexachlonxlisilane heavy-component removal column, a silicon tetrachloride light-component removal column and a silicon tetrachloride heavy-component removal column are mainly included. The device and the method are especially applicable to treatment of dirt residual liquids such as cold hydrogenation slurry, distillation residues and distillation residues of synthesis procedures during production of polycrystalline silicon as well as treatment of residual liquids such as distillation residues of reduction procedures, distillation residues of thermal hydrogenation procedures or the mixture of both; and based on the device and the method, organic chlorosilane difficultly separating from silicon tetrachloride and titanium tetrachloride difficultly separating from hexachlonxlisilane can be removed, and hexachlonxlisilane with the purity of 99.7 percent can be recovered according to the method.

Owner:TIANJIN UNIV

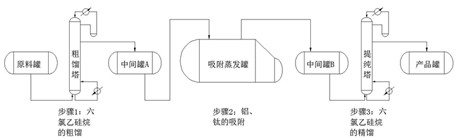

Intermittent operation method and device for recovery and purification of hexachlorodisilane from chlorosilane residual liquid

ActiveCN103101914AIncrease added valueMaximize resource utilizationHalogenated silanesSlagHydrogenation process

The invention aims to provide an intermittent technology and a device for treatment and recovery of chlorosilane residual liquid and residue thereof, especially a method and a device for recovering hexachlorodisilane with very high value. The invention puts forward an intermittent technical scheme for the circumstance of a small residual liquid treatment amount. The technology mainly involves a primary rectification tower and an intermittent rectification tower. The method and the device provided in the invention are particularly applicable to treatment of the cold hydrogenation slag slurry and rectification residual liquid in polysilicon production, the rectification residual liquid and other dirty residual liquids in a synthesis process, and are also applicable to the rectification residual liquid in a reduction process and the rectification residual liquid in a thermal hydrogenation process or mixed type residual liquids, etc. With the treatment technology disclosed in the invention, hexachlorodisilane with purity above 98% can be recovered.

Owner:TIANJIN UNIV

Deposition of silicon-containing films from hexachlorodisilane

InactiveUS7468311B2Cost effectiveIntegrated cost-effectivelyPolycrystalline material growthSemiconductor/solid-state device manufacturingHandling systemDeposition process

Owner:TOKYO ELECTRON LTD

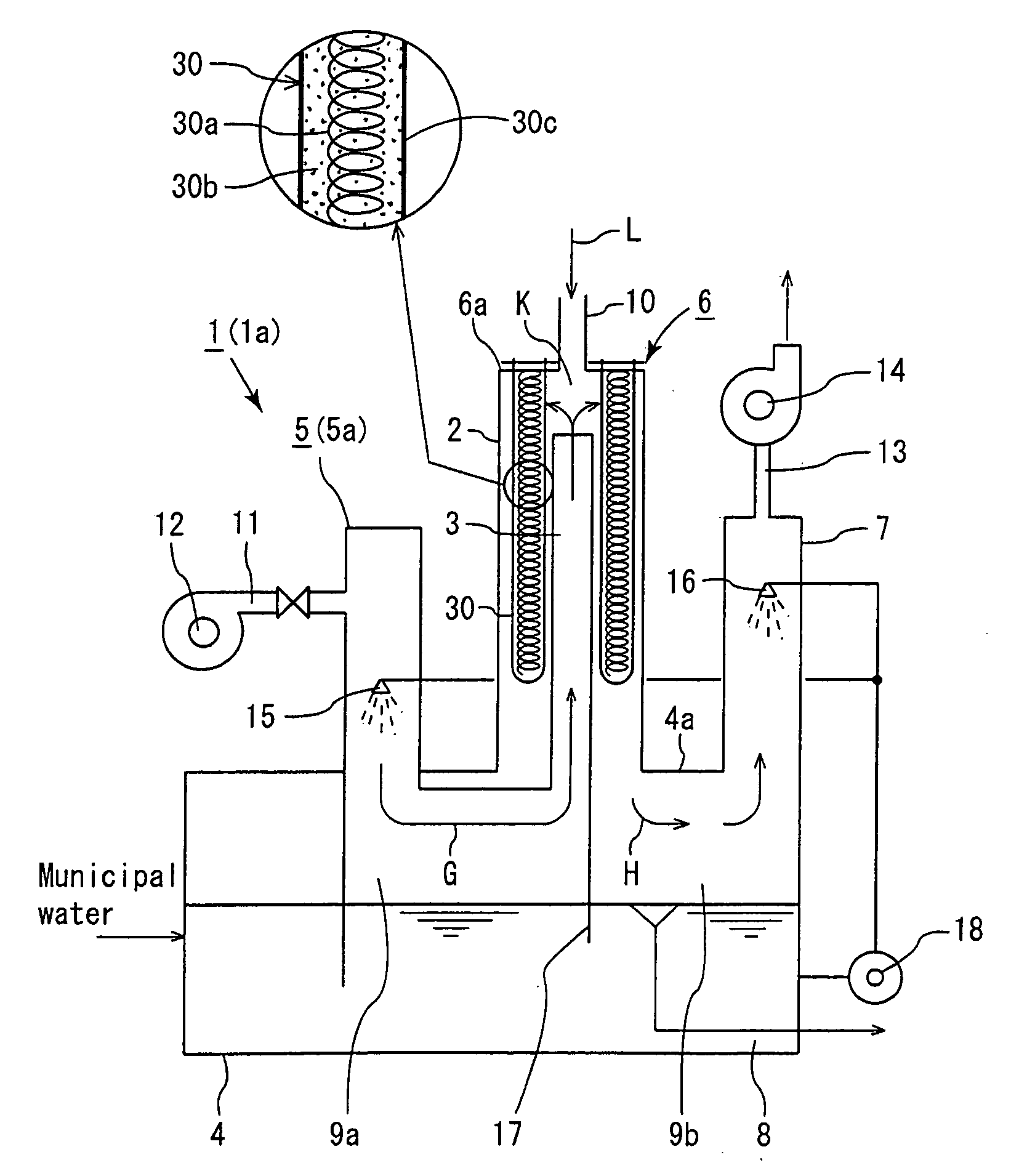

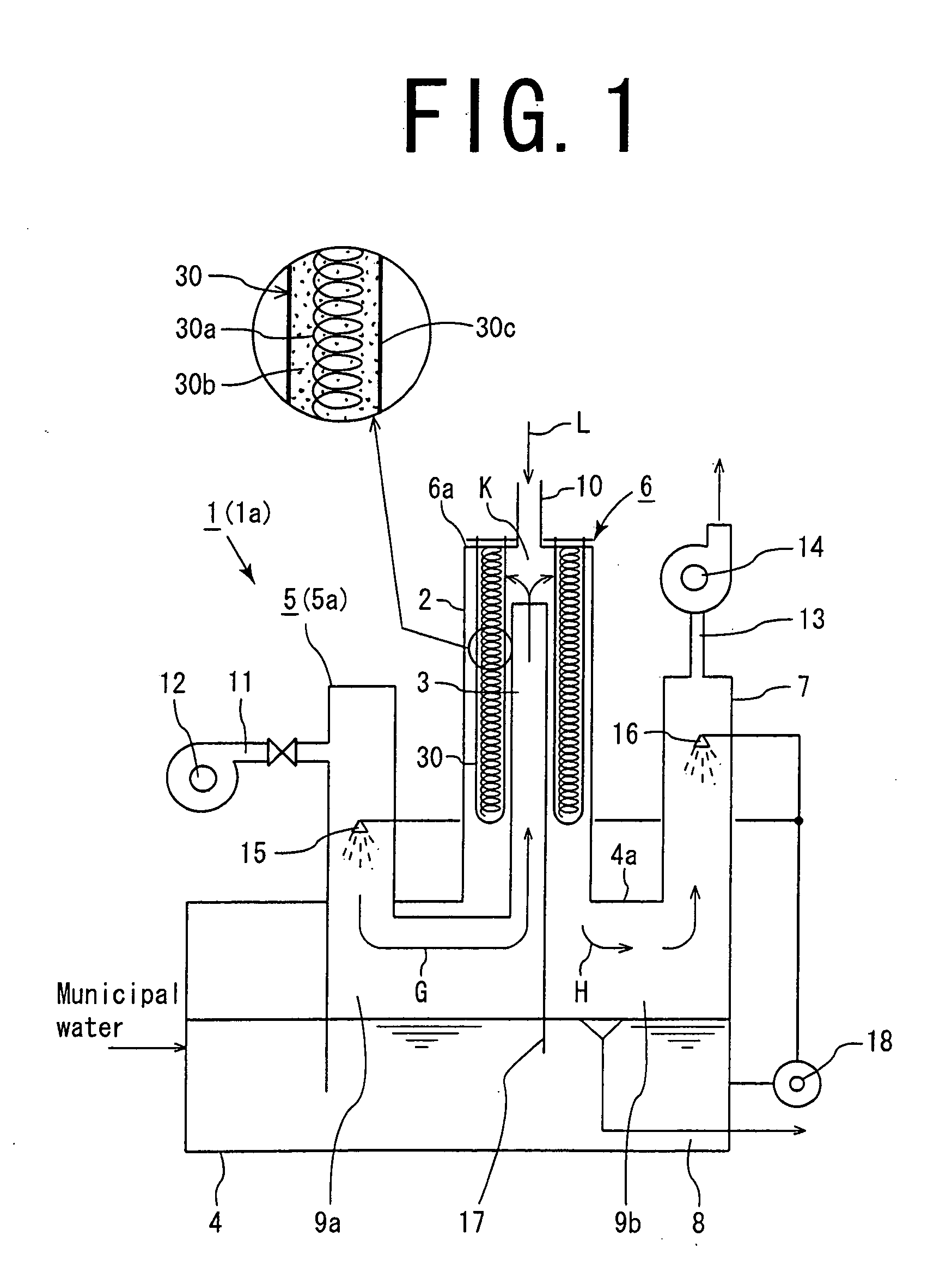

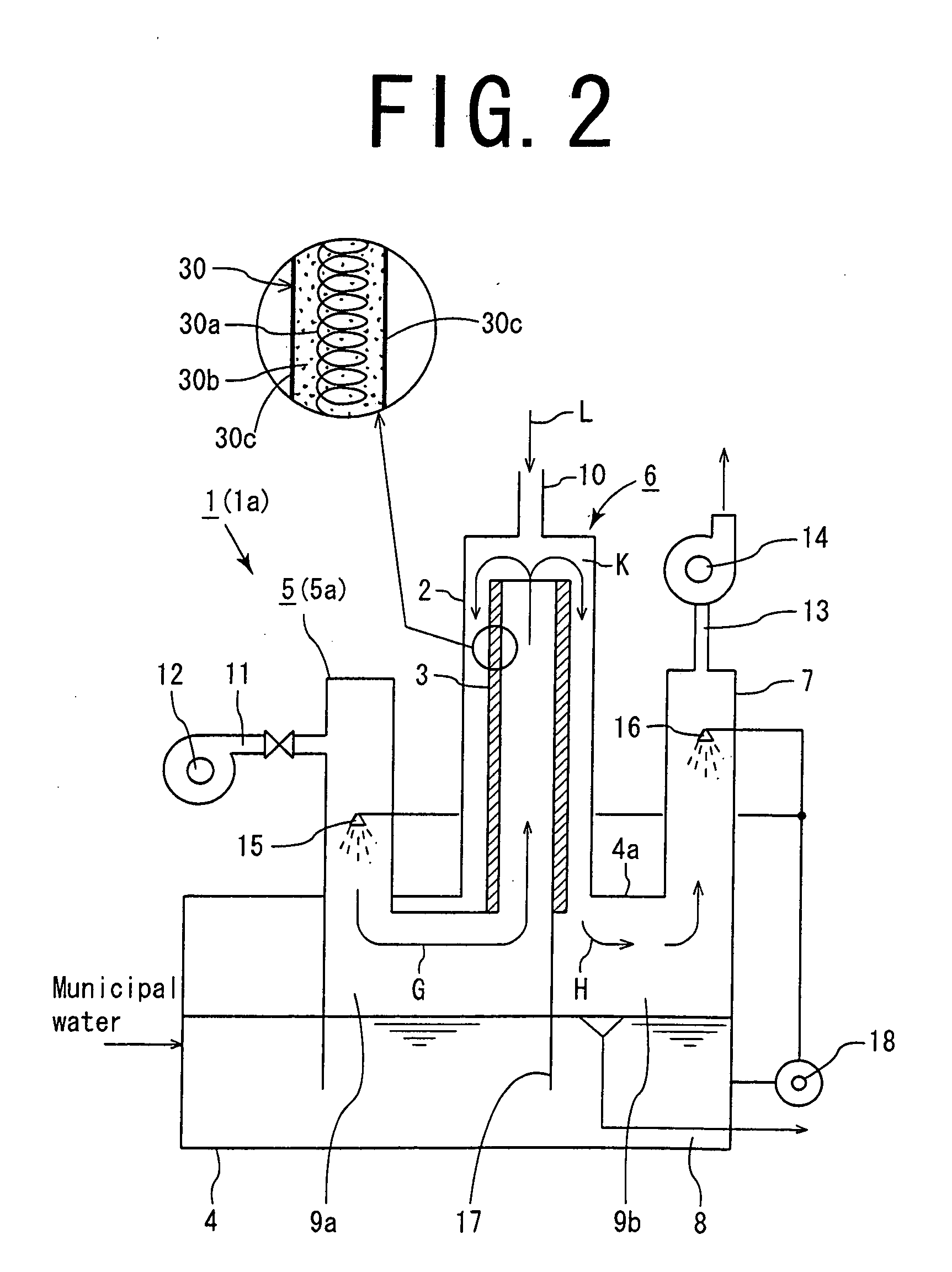

Method for detoxifying hcd gas and apparatus therefor

ActiveUS20090104100A1Carry-out safelyCombination devicesChlorine/hydrogen-chloride purificationFlue gasOxygen

Hexachlorodisilane is decomposed into hydrochloric acid, silicon dioxide and water by introducing hexachlorodisilane-containing flue gas into a reaction region without moistening the flue gas and by supplying oxygen-containing gas that also contains a small amount of moisture to the reaction region maintained at a temperature at which hexachlorodisilane decomposes.

Owner:KANKEN TECHNO +1

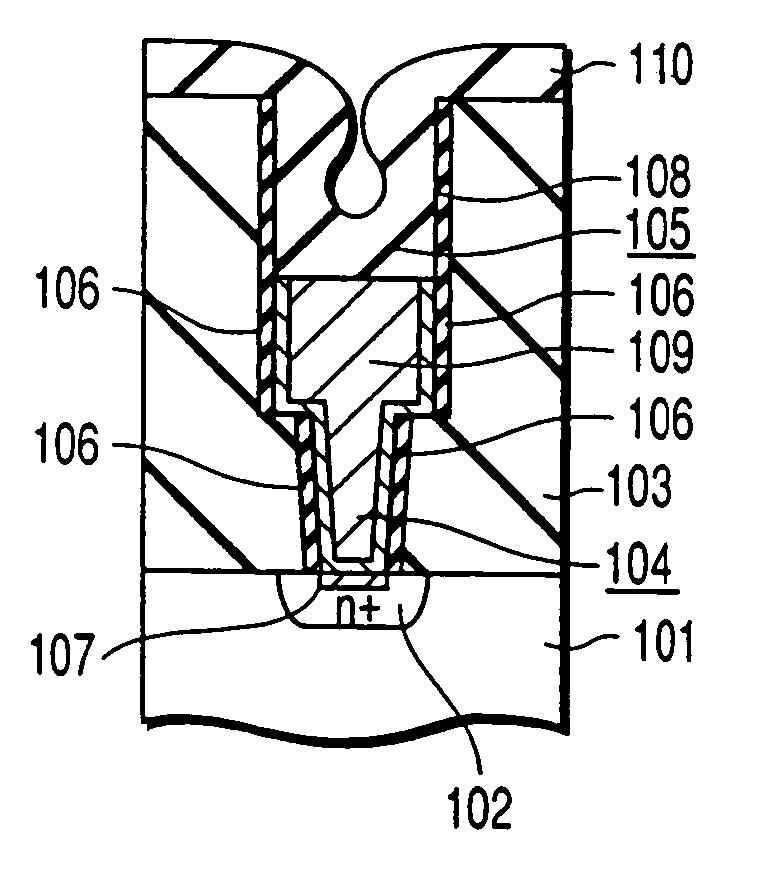

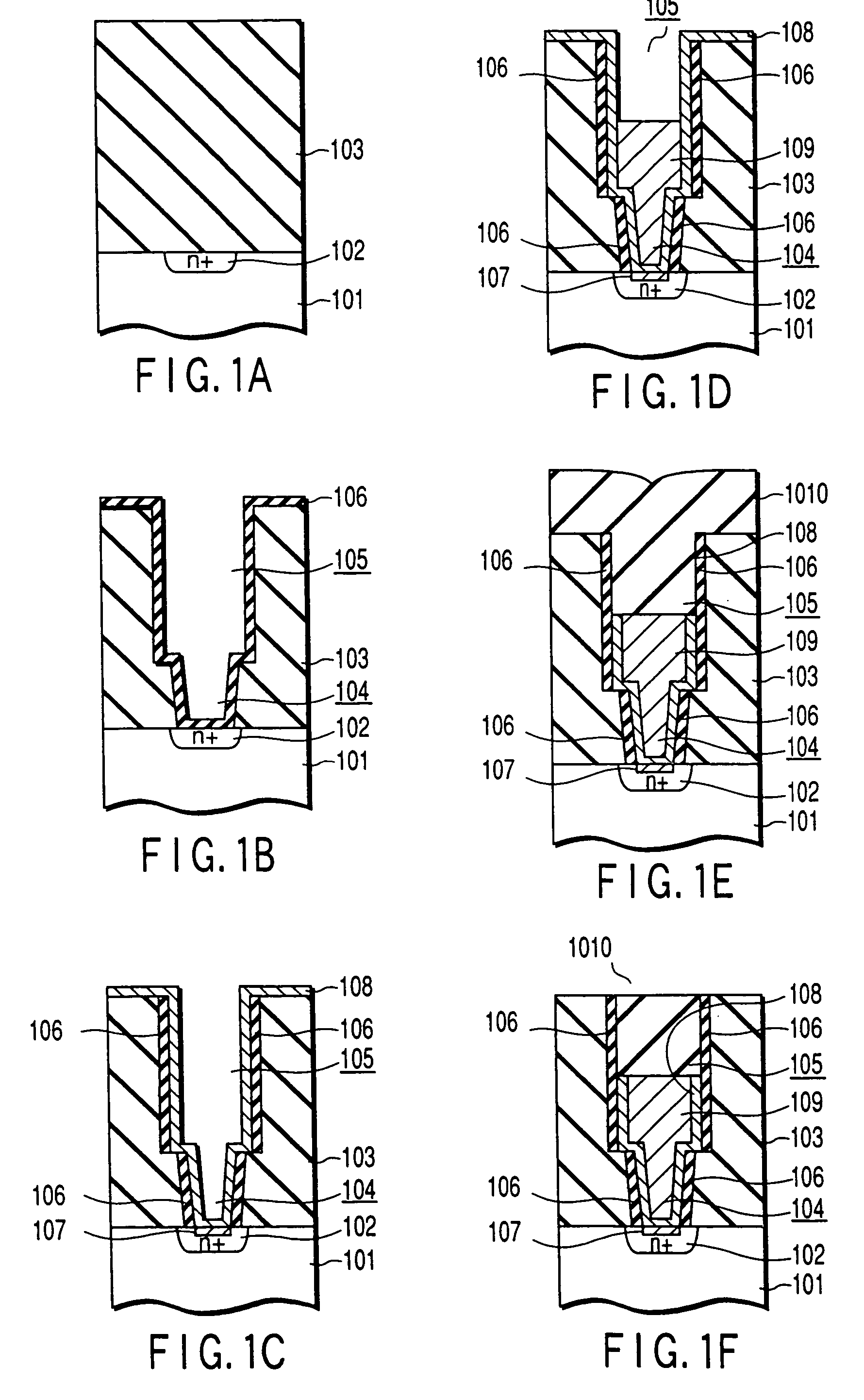

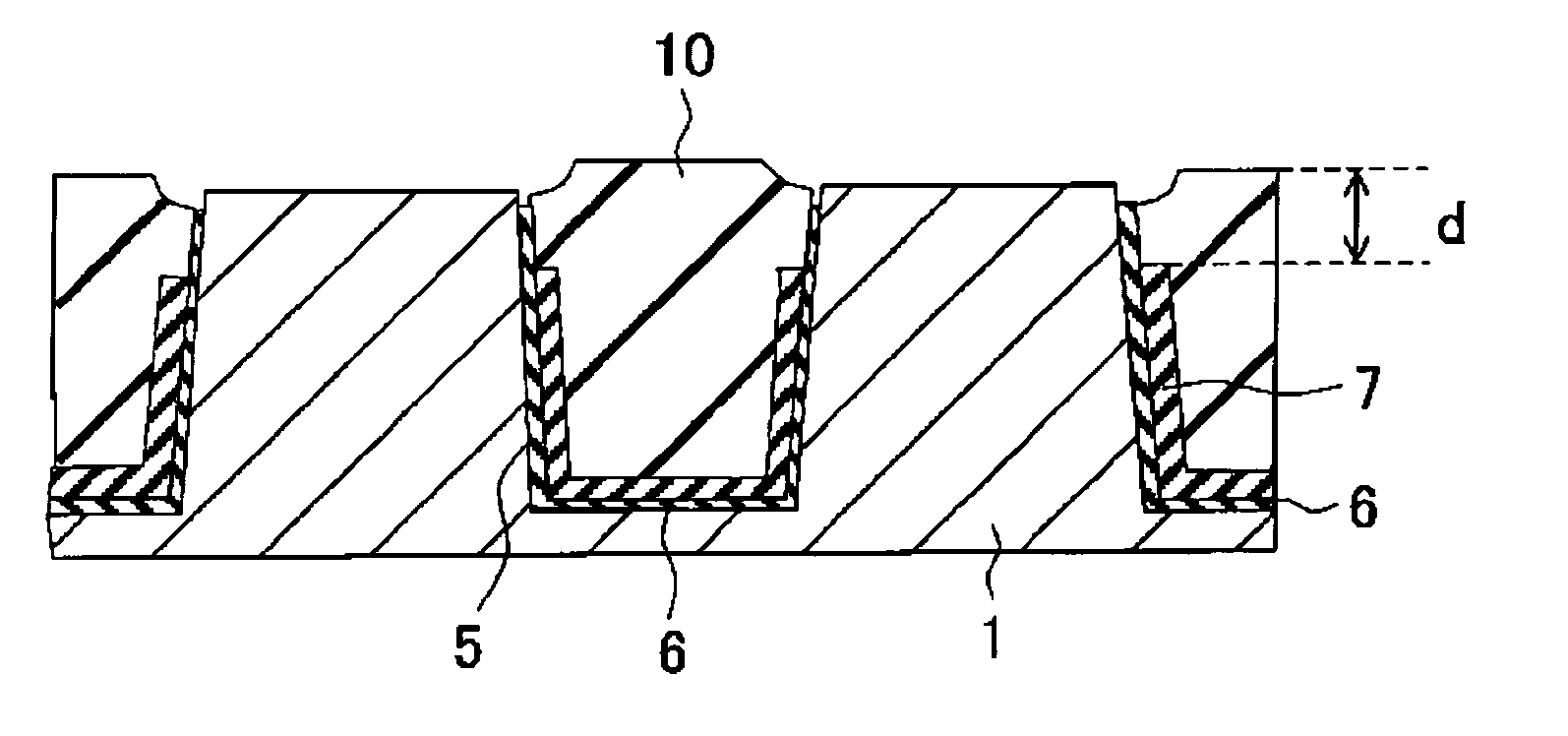

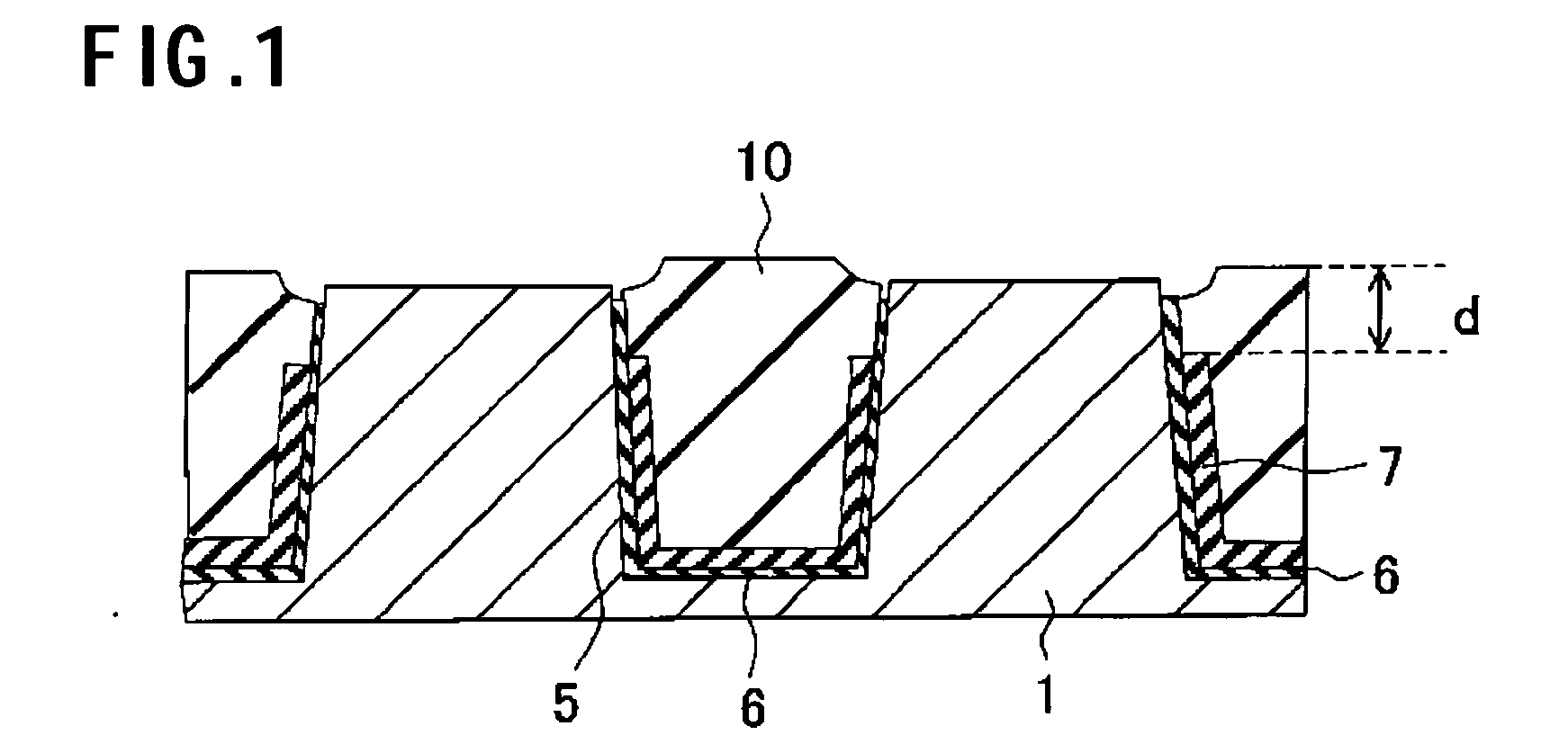

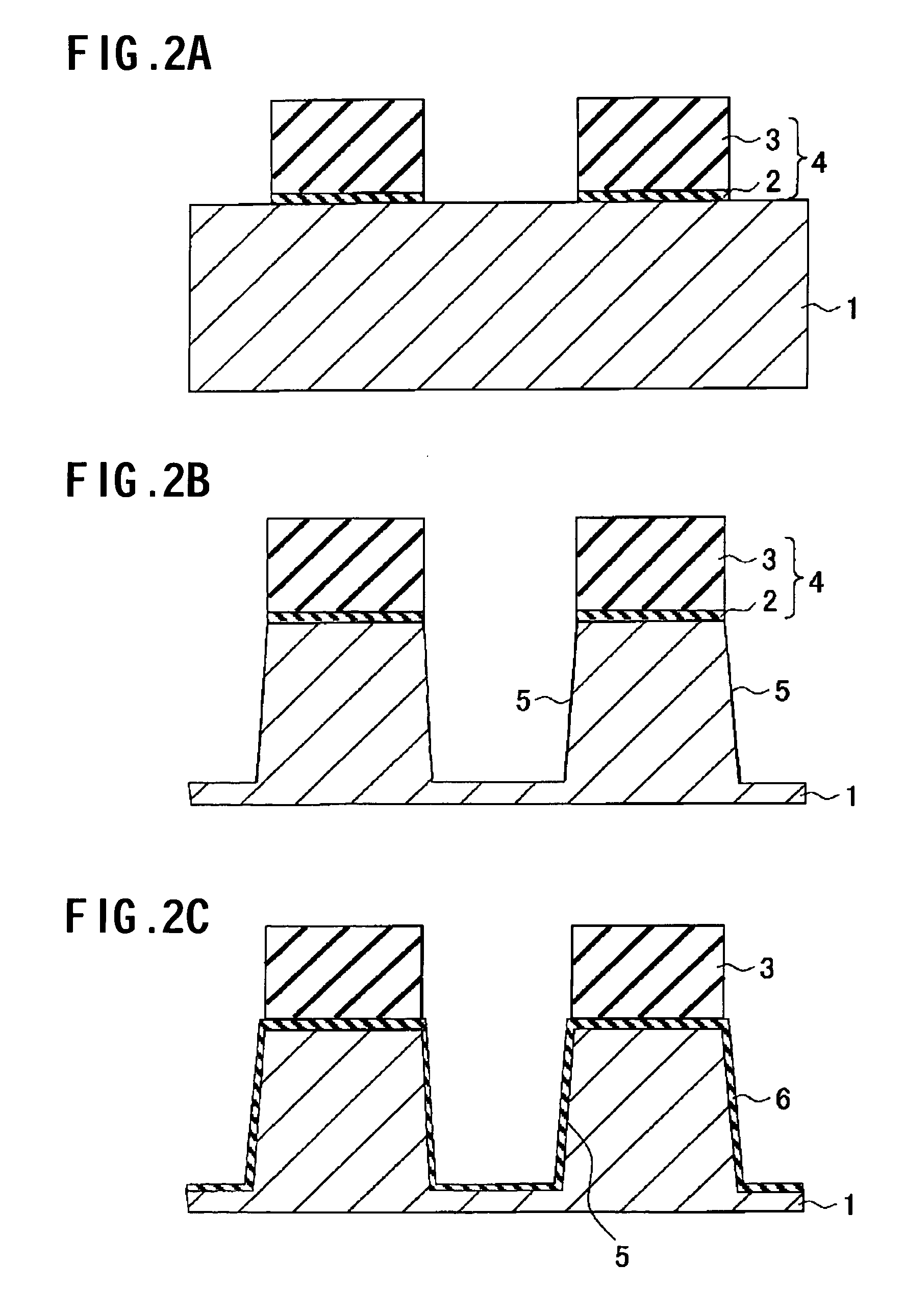

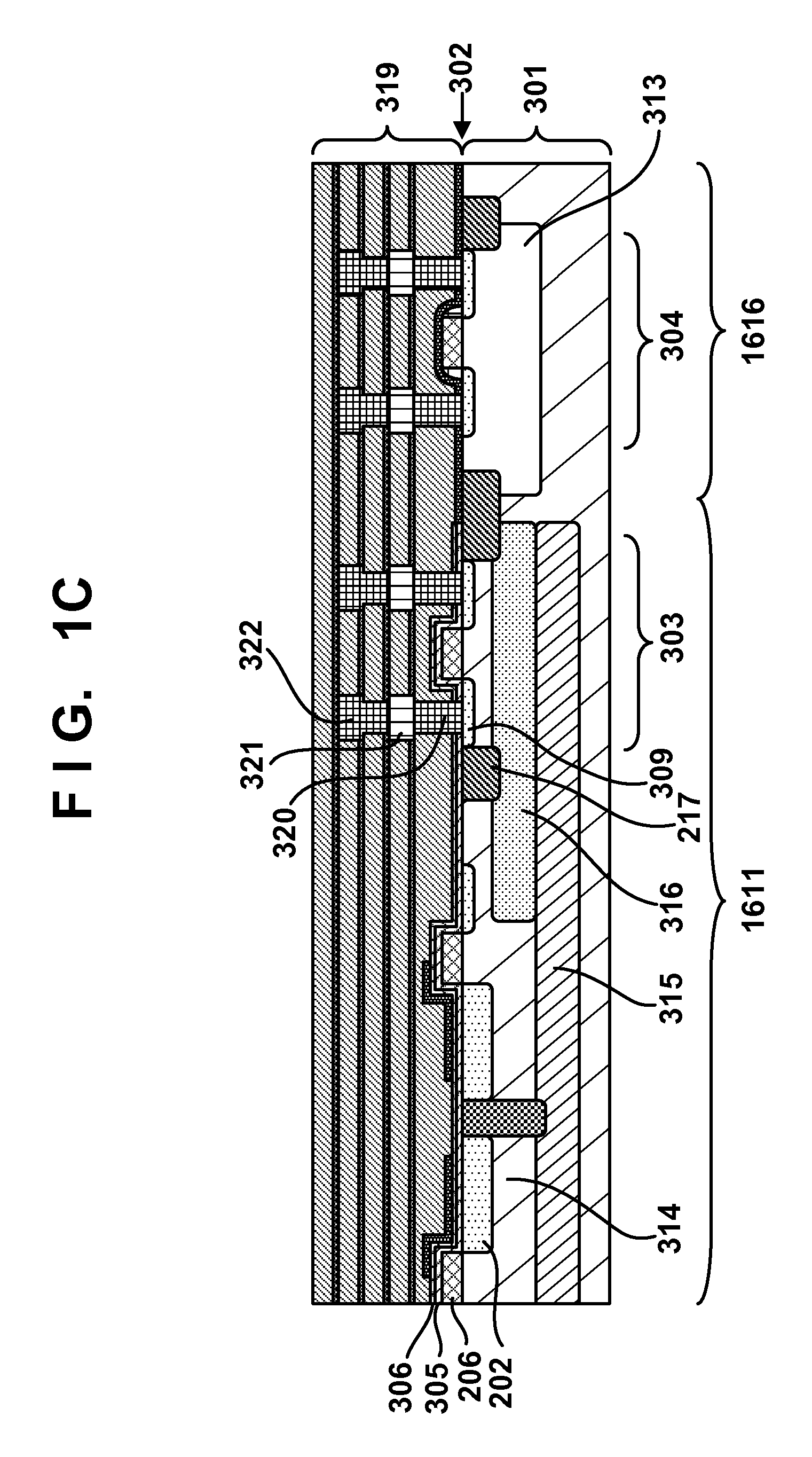

Semiconductor device and manufacturing method thereof

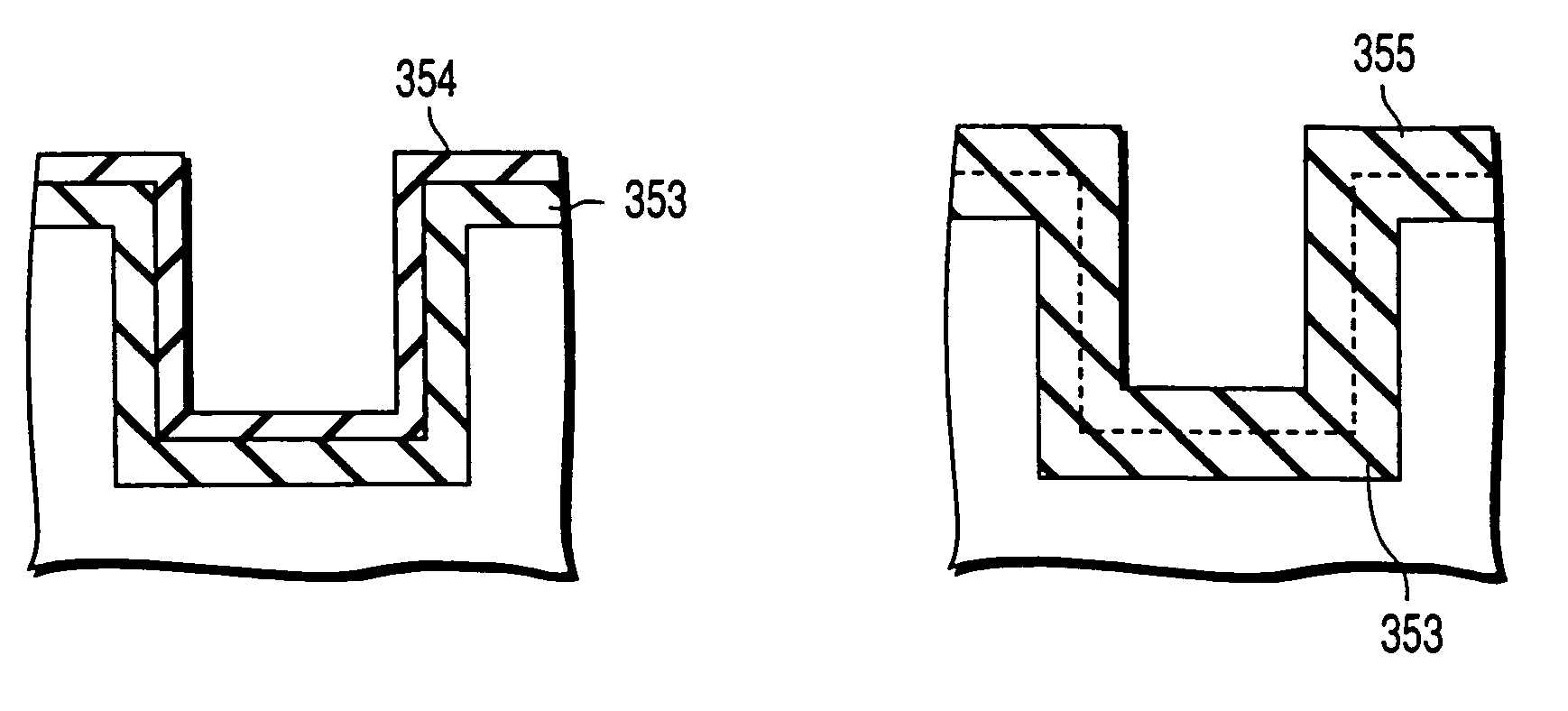

InactiveUS20050253199A1Good embedding effectEasy to embedSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialEngineering

In order to improve embeddability of an embedded insulating film to a filling portion to have a preferable embedded structure, the present invention provides a semiconductor device having an embedded structure in which an embedded insulating film is embedded in a filling portion formed in or on a substrate. The embedded structure includes an underlying insulating film containing a silicon nitride film formed on an inner wall of the filling portion by a chemical vapor deposition method using material gas containing hexachlorodisilane, and an embedded insulating film formed by filling in the filling portion via the underlying insulating film.

Owner:SONY CORP

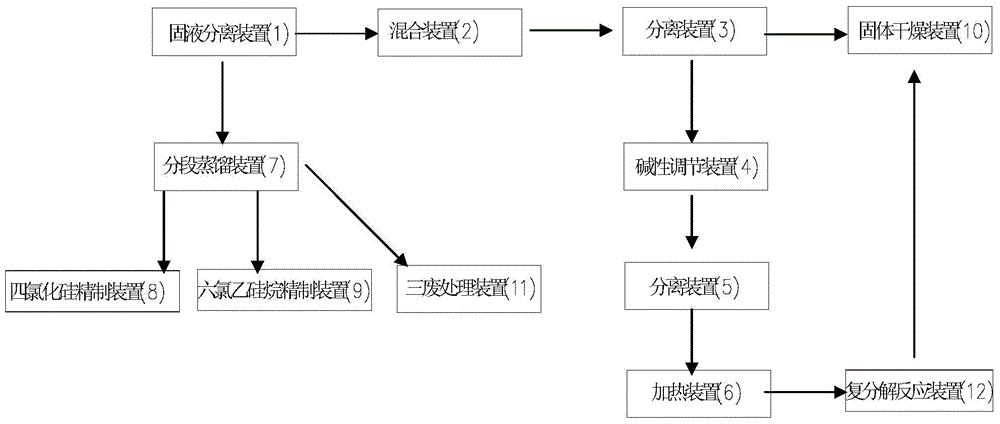

Treatment system and treatment method of chlorosilane slurry raffinate

InactiveCN104909400ARelieve pressureSimple processing methodCopper oxides/halidesChemical recyclingDistillationSlurry

The invention provides a treatment system and a treatment method of chlorosilane slurry raffinate. The treatment method comprises the following steps: carrying out solid-liquid separation on chlorosilane slurry raffinate to obtain a first filtrate and a first solid phase solid phase; carrying out subsection distillation on the first filtrate to obtain a silicon tetrachloride crude product and a hexachlorodisilane crude product; mixing the first solid phase and water, and filtering to obtain a second filtrate and a silicon powder; mixing the second filtrate and an alkaline substance containing an amino group, and filtering to obtain a third filtrate and a second solid phase; and heating the third filtrate to obtain copper hydroxide. In comparison with the prior art, chlorosilane is separated from the silicon powder and a metal chloride impurity through solid-liquid separation, silicon tetrachloride and hexachlorodisilane are separated due to different boiling points, and simultaneously, copper ion in the metal chloride is separated from other metals by forming cuprammonium-ion so as to recycle a catalyst. The treatment method is simple and low-cost. In addition, consumption of lye and water resources for treating raffinate are also minimized, and environmental stress is greatly reduced.

Owner:SICHUAN RENESOLA SILICON MATERIAL

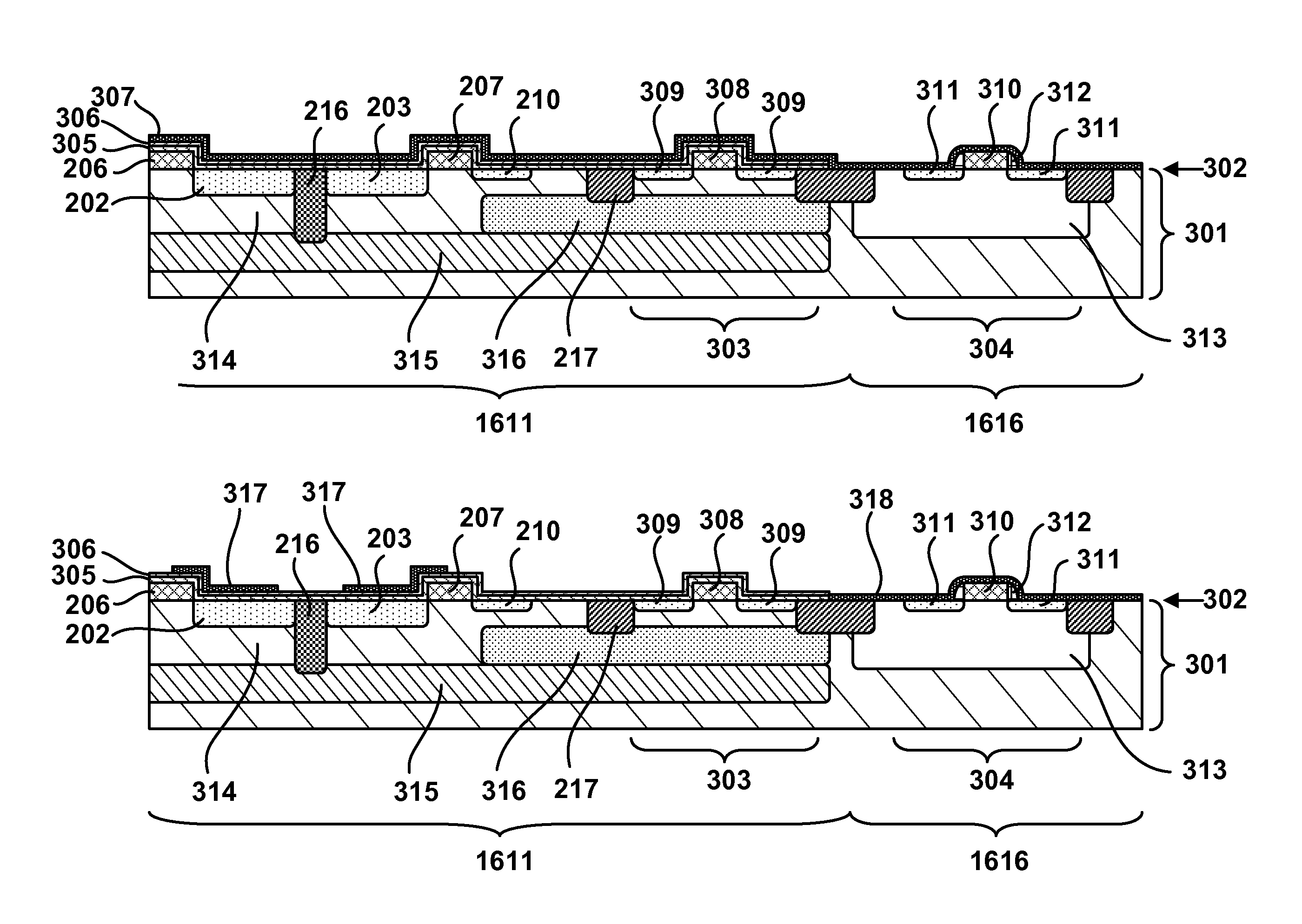

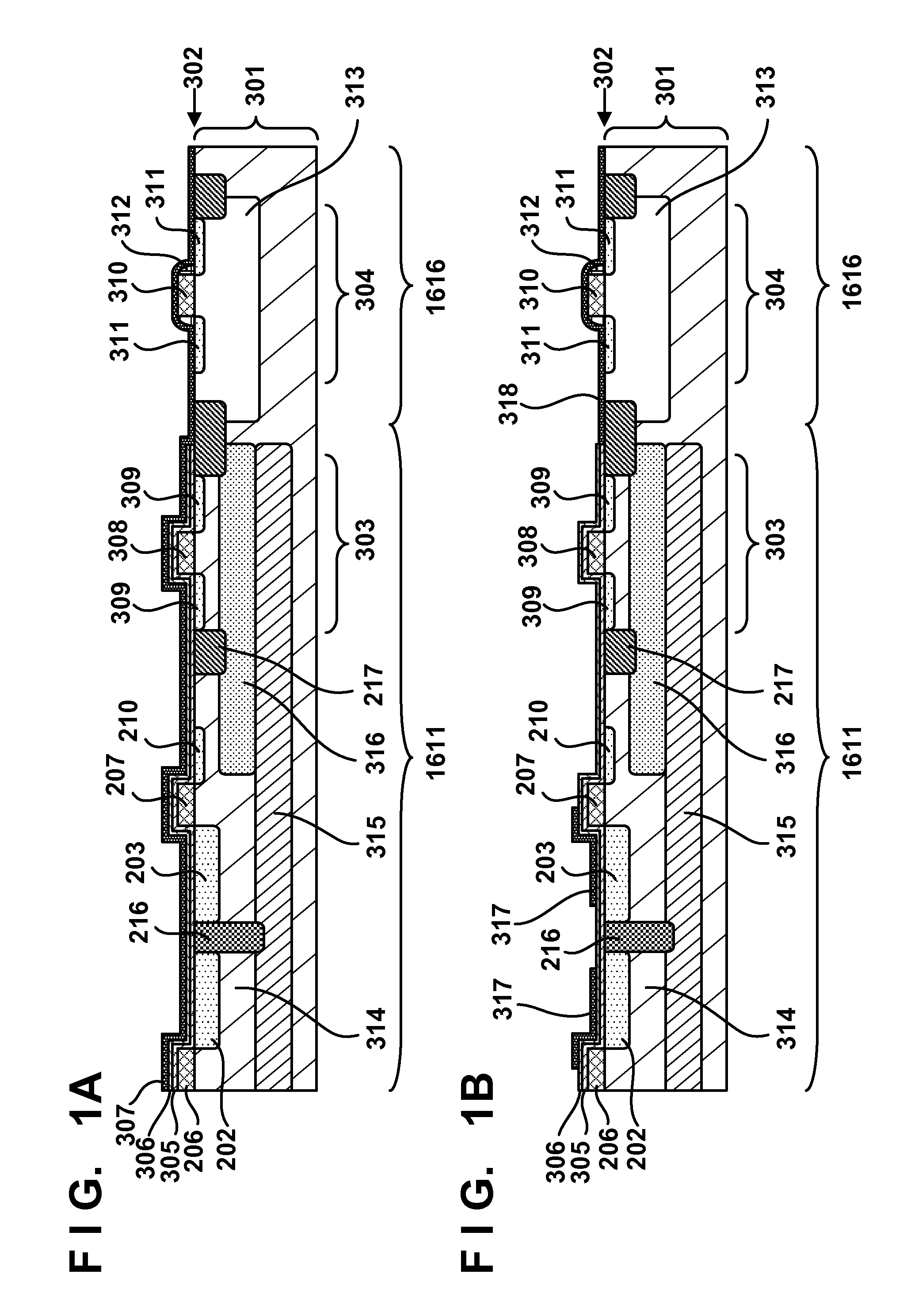

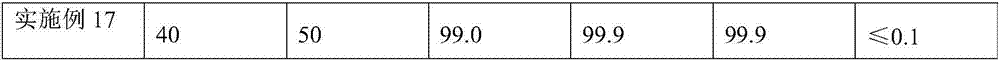

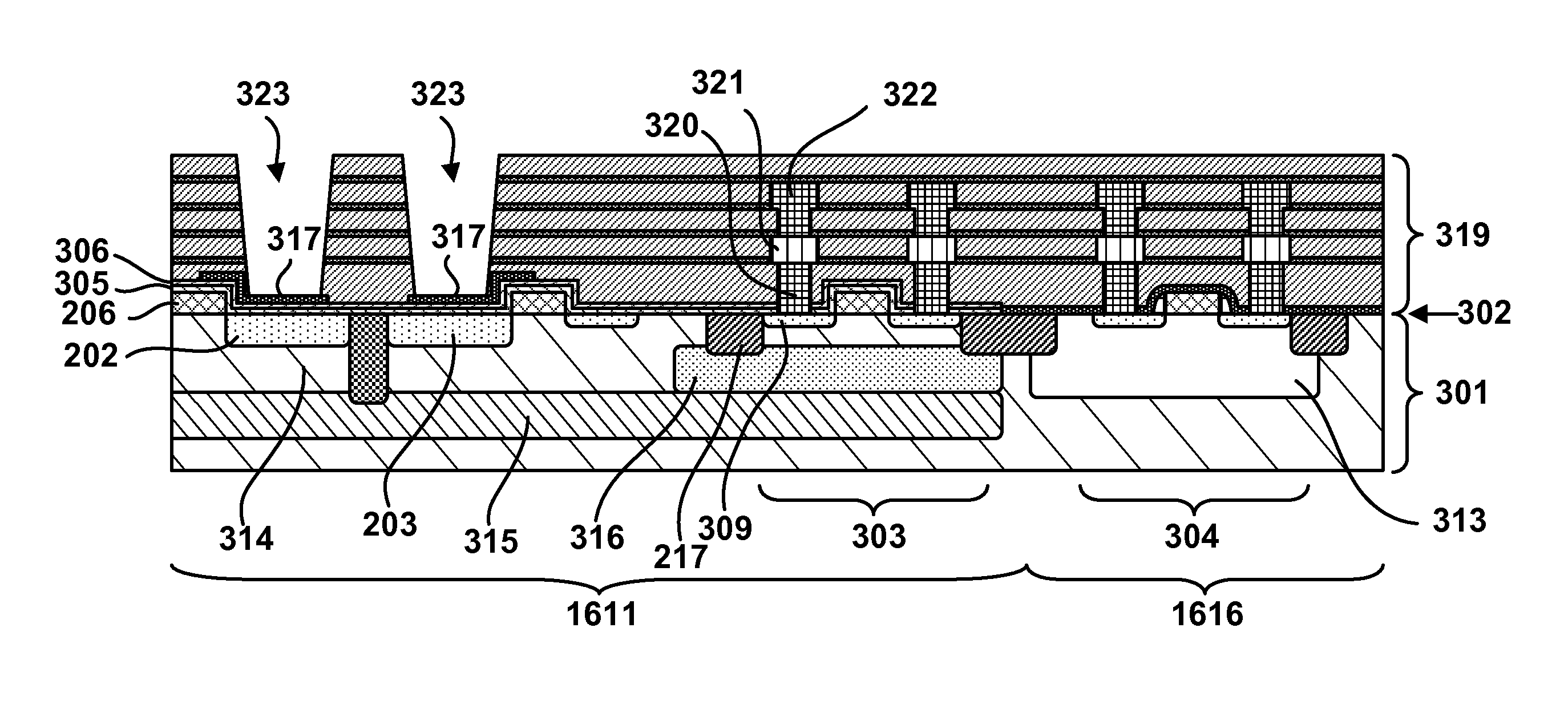

Solid-state image sensor and manufacturing method thereof, and camera

InactiveUS8982254B2Reduce dark currentTelevision system detailsTelevision system scanning detailsGas phasePhotoelectric conversion

A method of manufacturing a solid-state image sensor having a photoelectric conversion portion includes forming a silicon nitride film by a low-pressure chemical vapor deposition method using hexachlorodisilane (Si2Cl6) as a material gas such that the silicon nitride film covers at least a part of the photoelectric conversion portion.

Owner:CANON KK

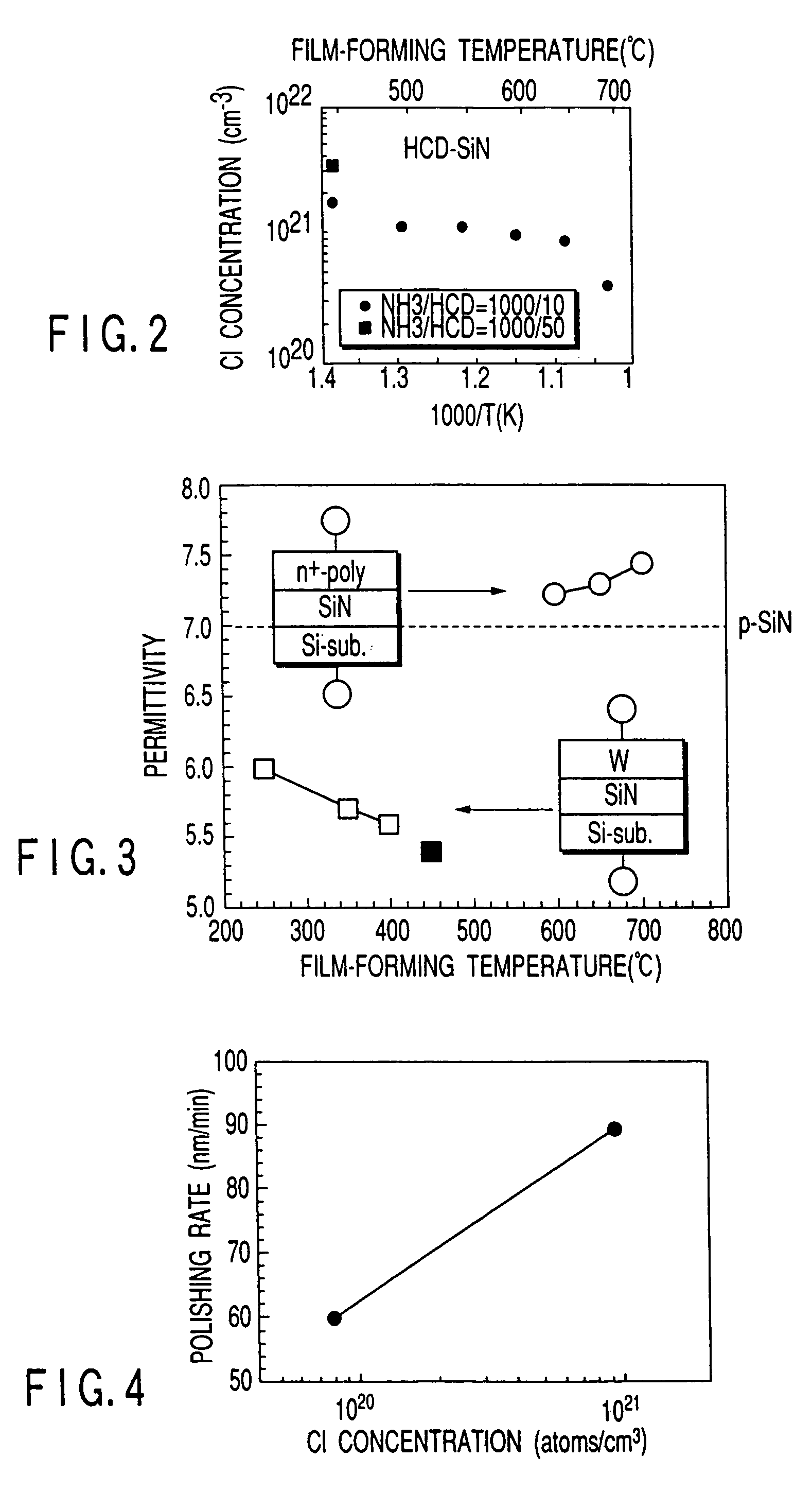

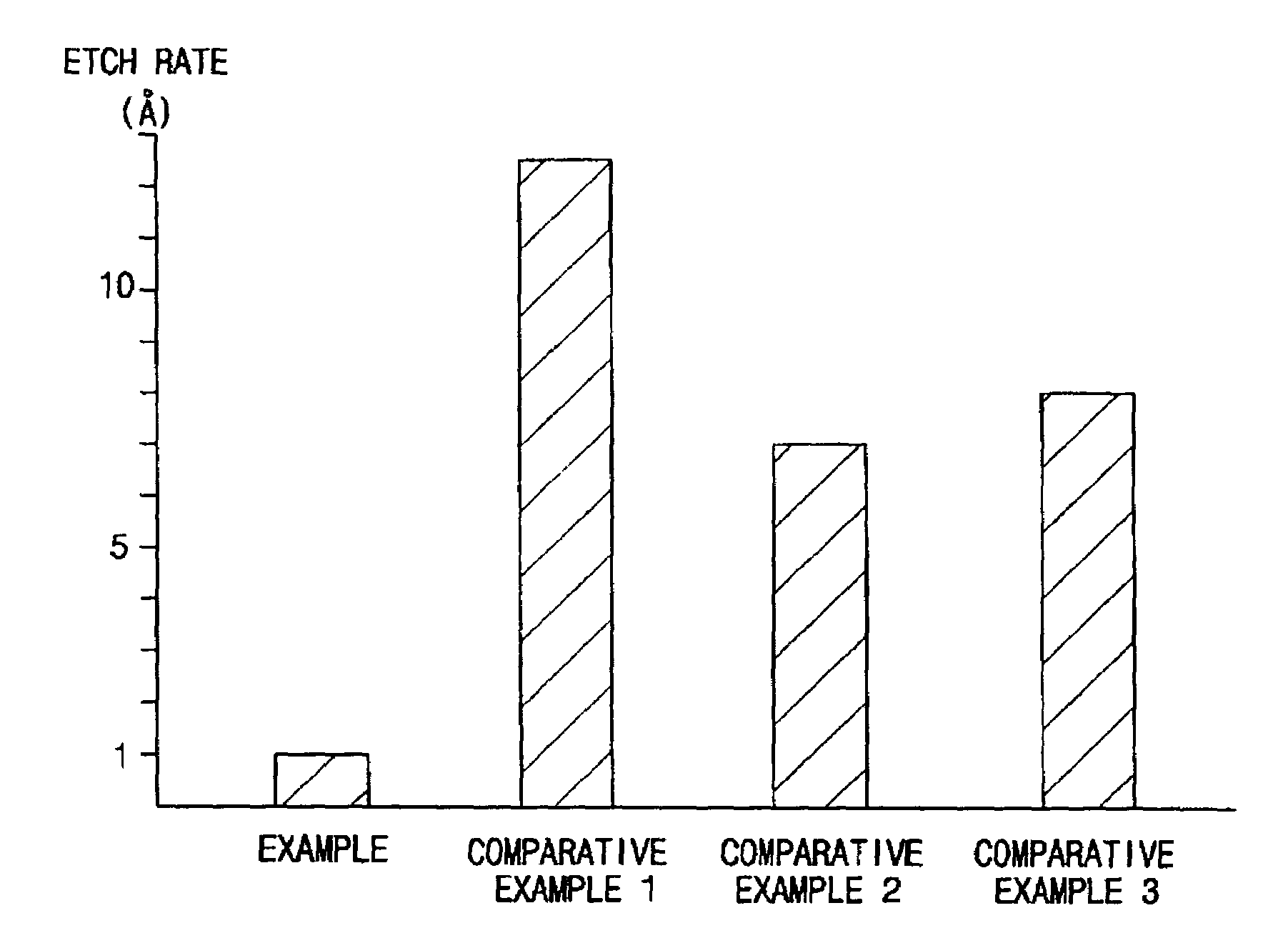

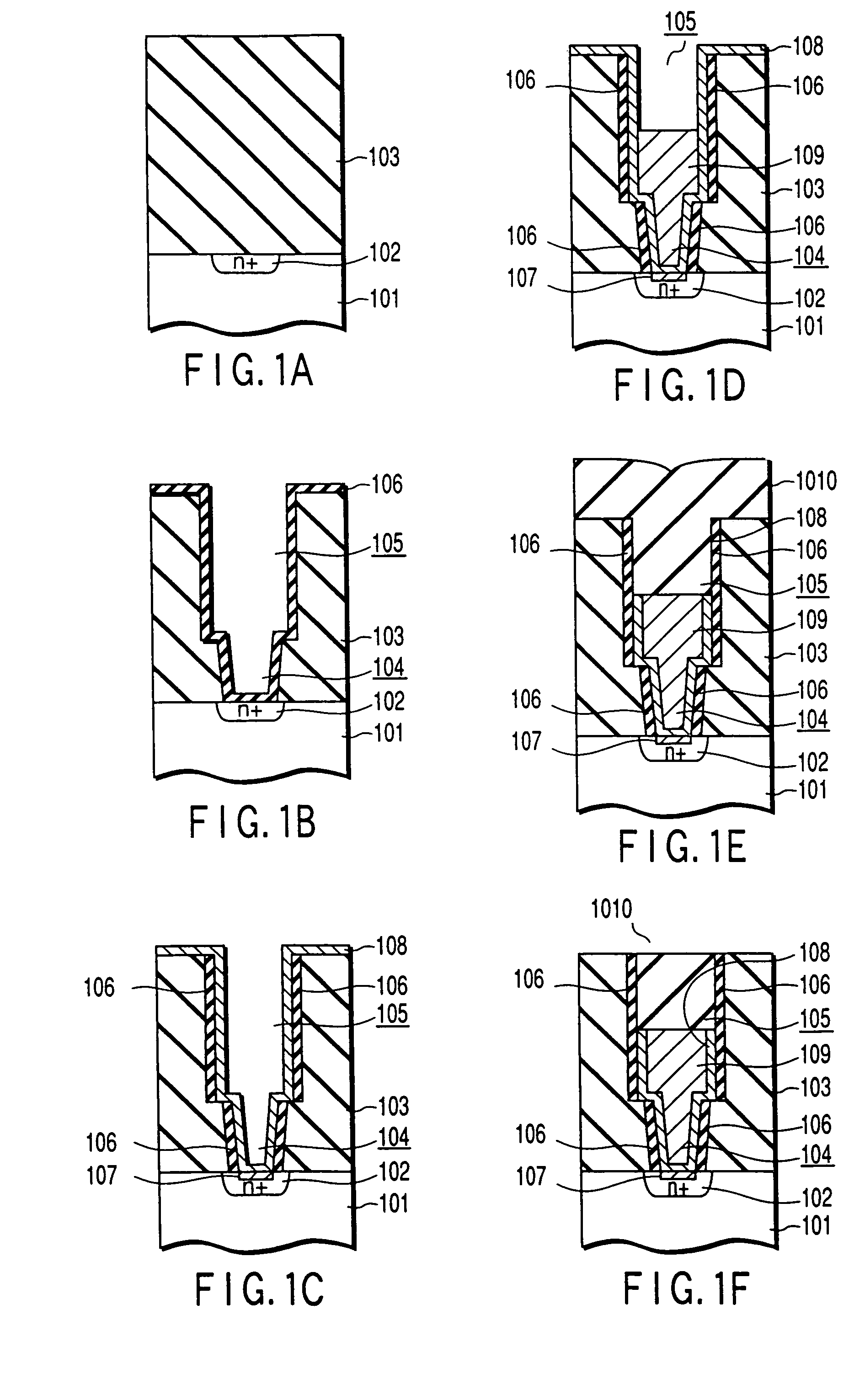

Semiconductor device and method of manufacturing the same

InactiveUS7098115B2Improve leakage currentTransistorSemiconductor/solid-state device detailsMetallurgySilicon oxide

Hexachlorodisilane (Si2Cl6) is used as a Si raw material for forming a silicon nitride film that can be widely different in the etching rate from a silicon oxide film. The silicon nitride film is formed by an LPCVD method.

Owner:TOSHIBA MEMORY CORP

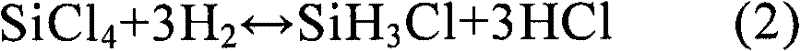

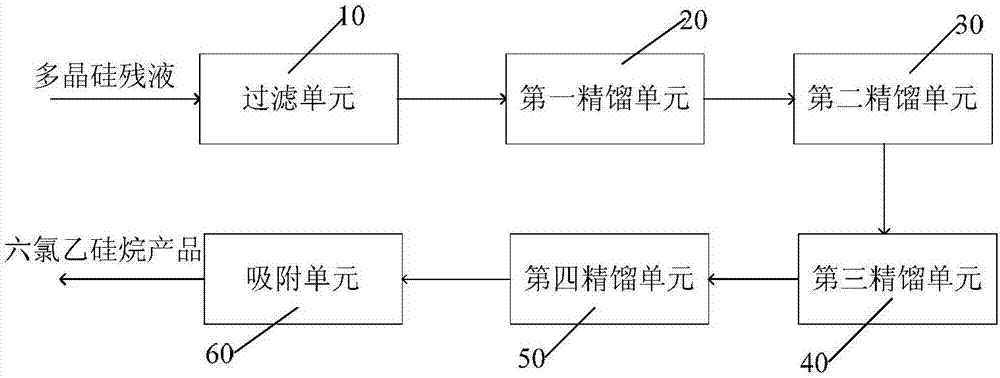

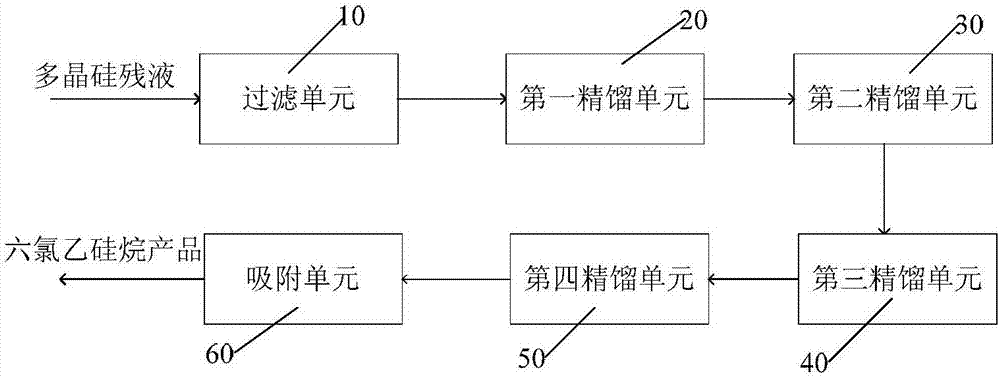

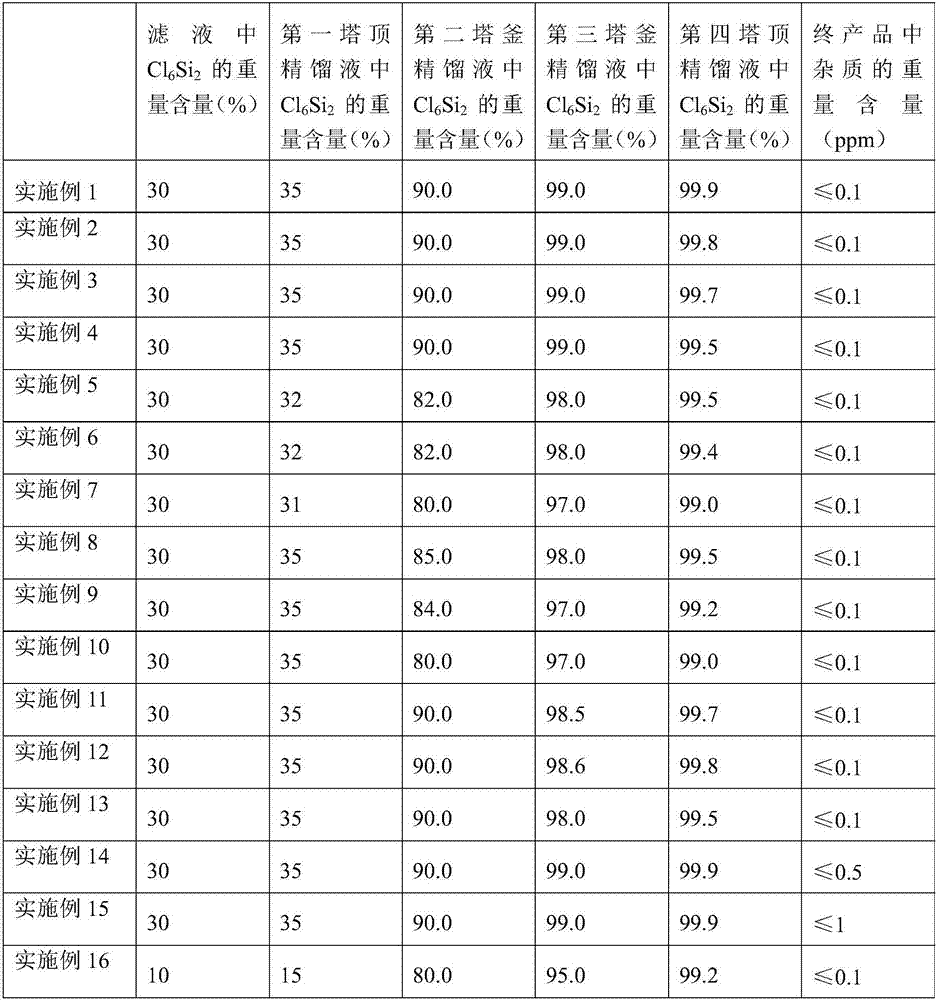

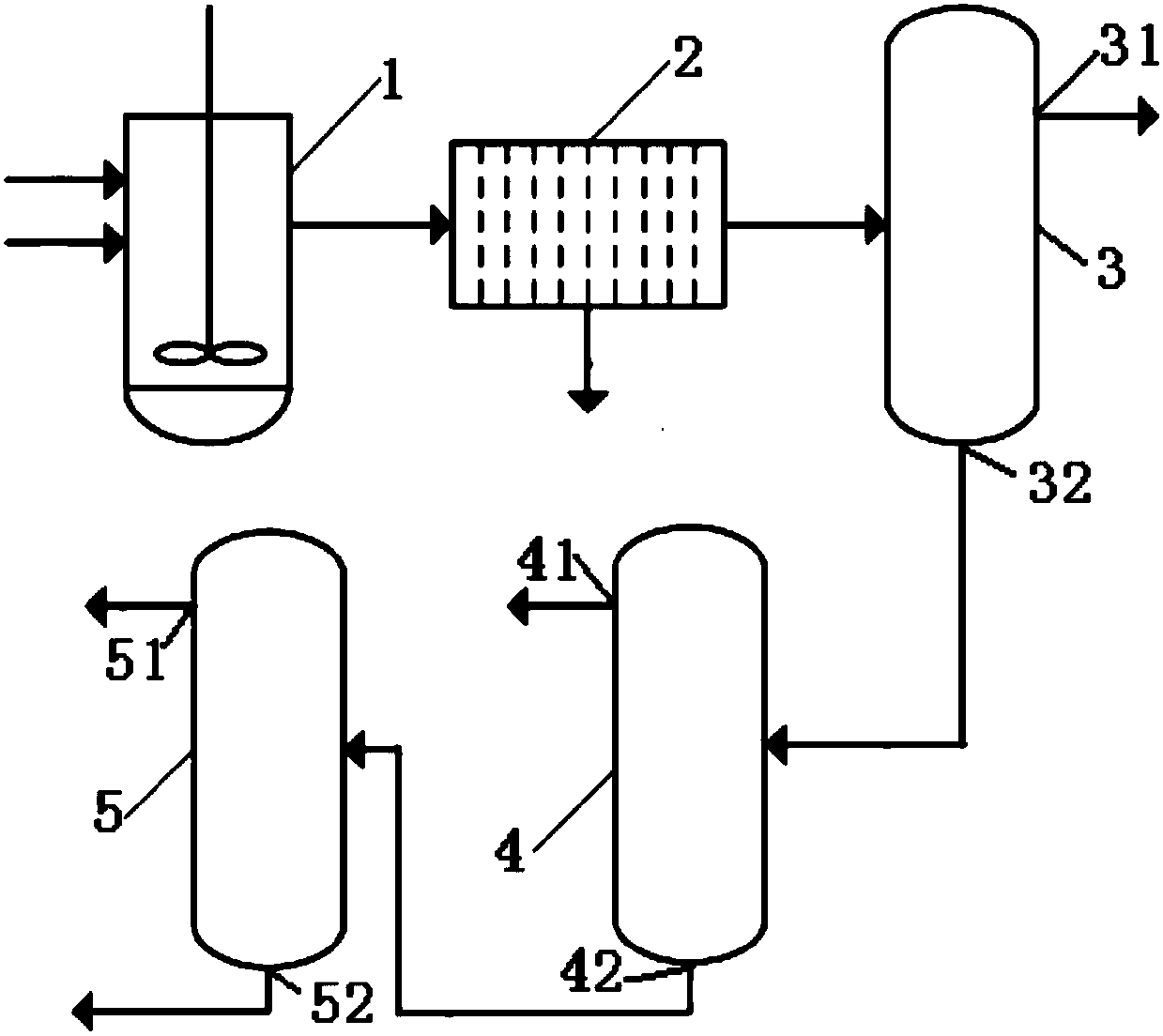

Method for recycling hexachlorodisilane

The invention provides a method for recycling hexachlorodisilane. The method includes steps of S1, filtering polycrystalline silicon residual liquid to obtain filtrate and filter residues with solid particles and metal polymer impurities; S2, primarily rectifying the filtrate and removing impurities with amorphous silicon and metal to obtain first tower top rectification liquid; S3, secondarily rectifying the first tower top rectification liquid and removing low-boiling substances with trichlorosilane and silicon tetrachloride to obtain second tower kettle rectification liquid; S4, rectifying the second tower kettle rectification liquid for the third time and removing silicon tetrachloride and hexachlorodisiloxane to obtain third tower kettle rectification liquid mainly with the hexachlorodisilane. The method has the advantages that the polycrystalline silicon residual liquid is filtered, and accordingly the solid particles and the metal polymer impurities in the polycrystalline silicon residual liquid can be removed; the filtrate obtained by means of filtering is rectified for the third time, and accordingly the silicon tetrachloride, the hexachlorodisiloxane and the third tower kettle rectification liquid mainly with the hexachlorodisilane can be obtained on tower tops.

Owner:CHINA SILICON CORP LTD +1

Solid-state image sensor and manufacturing method thereof, and camera

InactiveUS20130088626A1Reduce dark currentTelevision system detailsTelevision system scanning detailsPhotoelectric conversionChemical vapor deposition

A method of manufacturing a solid-state image sensor having a photoelectric conversion portion includes forming a silicon nitride film by a low-pressure chemical vapor deposition method using hexachlorodisilane (Si2Cl6) as a material gas such that the silicon nitride film covers at least a part of the photoelectric conversion portion.

Owner:CANON KK

Micro-feature fill process and apparatus using hexachlorodisilane or other chlorine-containing silicon precursor

ActiveUS20060160288A1Integrated cost-effectivelyInhibition formationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon membraneDeposition process

A method is provided for depositing a silicon-containing film in a micro-feature on a substrate by a low pressure deposition process in a processing system. A silicon-containing film can be formed in a micro-feature by providing a substrate in a process chamber of a processing system, and exposing a hexachlorodisilane (HCD) process gas to the substrate. A processing tool containing a processing system for forming a silicon-containing film in a micro-feature using a silicon and chlorine-containing gas such as a HCD process gas is provided. Alternatively, the micro-feature can be exposed to DCS, SiCl4, and SiHCl3 gases. Alternatively, the micro-feature can be exposed to (SiH4+HCl).

Owner:TOKYO ELECTRON LTD

Treating method for residual liquid and slag slurry produced in polysilicon production

InactiveCN106698441AProduction environmental protectionReduce processing costsHalogenated silanesLiquid wasteSlag

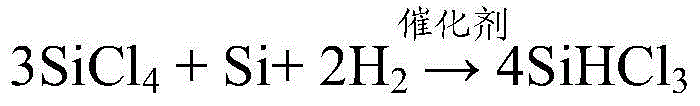

The invention discloses a treating method for residual liquid and slag slurry produced in polysilicon production, wherein the residual liquid and slag slurry contains silicon and silicon tetrachloride. The method comprises a step of adding a catalyst into the residual liquid and slag slurry so as to allow silicon to react with silicon tetrachloride so as to produce hexachlorodisilane. According to the treating method, through a synthesis reaction for hexachlorodisilane, the content of hexachlorodisilane in the residual liquid and slag slurry is increased, so residual liquid and slag slurry with high added value are obtained, and the economic performance of a hexachlorodisilane recovery process is improved; both solid waste and liquid waste produced in polysilicon production are reasonably converted and recycled, so treating cost for the residual liquid and slag slurry is lowered, and recovery of high-added-value products are realized; bottleneck problems in treating of the residual liquid and slag slurry during polysilicon production are overcome, and products of polysilicon production are diversified; and the discharge amounts of waste gas, waste water and industrial residues during polysilicon production are greatly reduced, and polysilicon production becomes environment-friendlier.

Owner:XINTE ENERGY

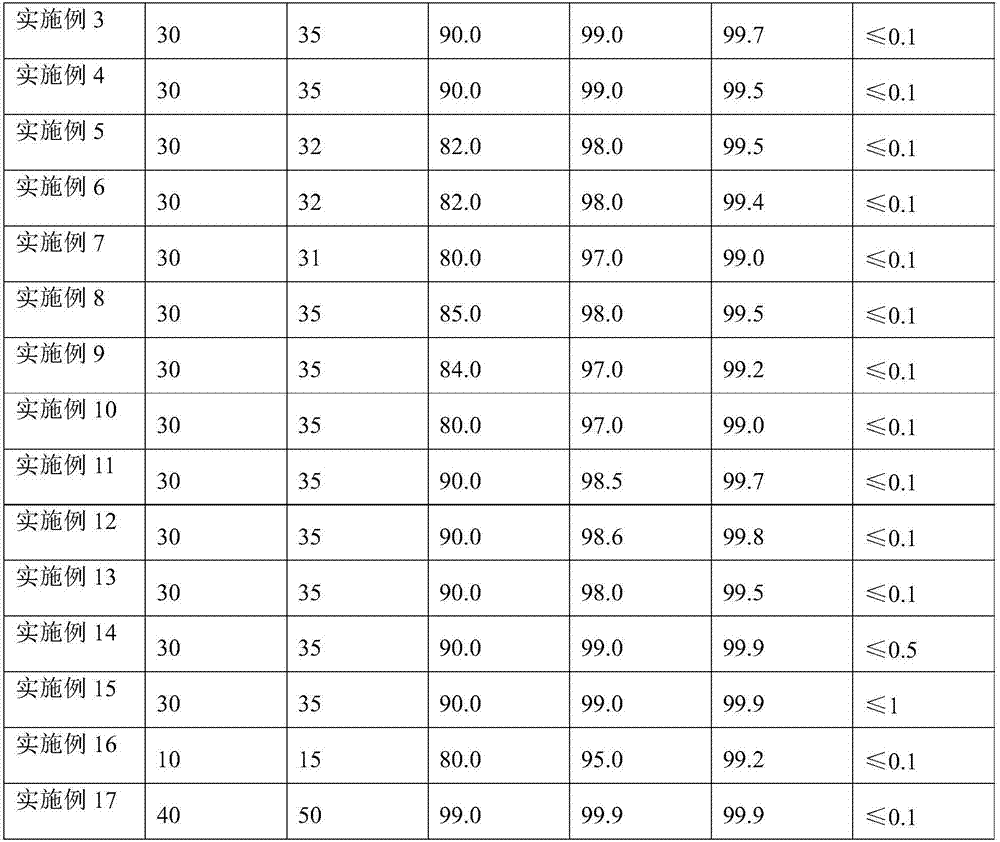

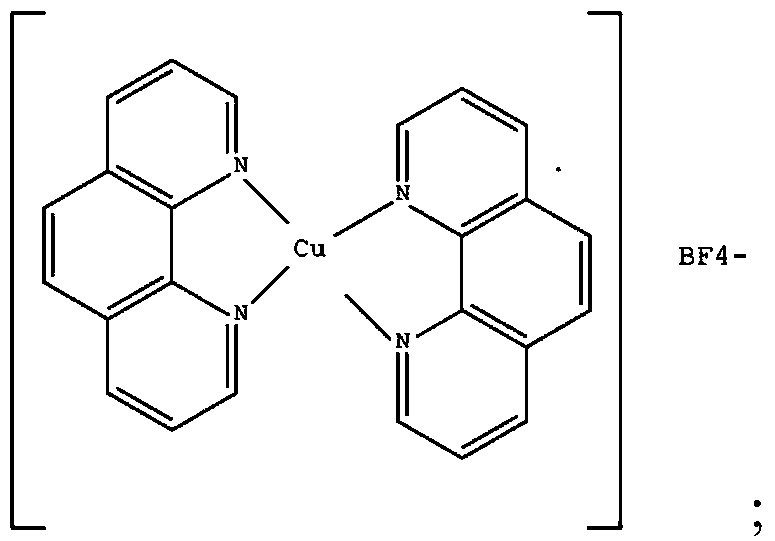

Novel process for preparation of 1-[2-(2,4-dimethylphenylsulphanyl)phenyl] piperazine

InactiveCN105461656AReduce usageRaw materials are cheap and easy to getOrganic chemistryBenzenesulfonic acidProtic solvent

The present invention discloses a novel process for the preparation of 1-[2-(2,4-dimethylphenylsulphanyl)phenyl] piperazine. The process uses o-halogenated benzenesulfonic acid and m-xylene as raw materials, which are subjected to dehydration condensation with methylsulfonic acid and phosphorus pentoxide as condensing agents to generate halogenated diarylsulfone. Halogenated diarylsulfone and piperazine are subjected to a substitution reaction in an aprotic solvent to produce piperazine ring substituted diarylsulfone; the piperazine ring substituted diarylsulfone is reduced by hexachlorodisilane in an aprotic solvent to obtain a product with high yield. This method has the advantages of cheap and easily available raw materials, avoidance of the usage of a noble metal catalyst and treatment of residual palladium, simple operation, mild reaction conditions, simple post-treatment, and potential application values.

Owner:BEIJING VENTUREPHARM BIOTECH

Semiconductor device and method of manufacturing the same

InactiveUS7060555B2Reduce leakage currentImprove leakage currentTransistorSemiconductor/solid-state device detailsMetallurgySilicon oxide

Hexachlorodisilane (Si2Cl6) is used as a Si raw material for forming a silicon nitride film that can be widely different in the etching rate from a silicon oxide film. The silicon nitride film is formed by an LPCVD method.

Owner:TOSHIBA MEMORY CORP

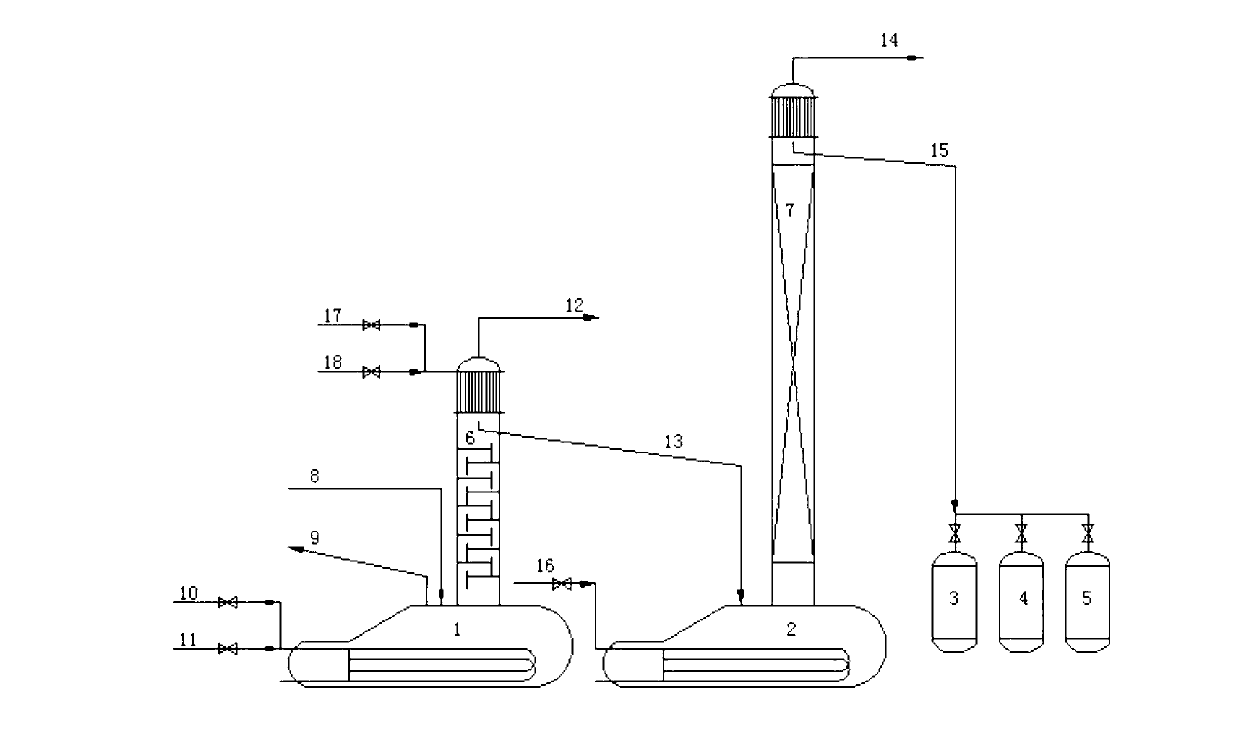

Method for collection of hexachlorodisilane and plant for the method

Disclosed is a method for collecting hexachlorodisilane which is produced as a by-product in the production of trichlorosilane from tetrachlorosilane and hydrogen. The method comprises the steps of: reacting a raw material gas composed of vaporized trichlorosilane and hydrogen at a temperature ranging from 700 to 1400 DEG C to yield a reaction product gas; cooling the reaction product gas to a temperature ranging from 30 to 60 DEG C to yield a cooled condensate solution containing hexachlorodisilane; and concentrating and collecting a high-boiling-point material containing hexachlorodisilane from the cooled condensate solution.

Owner:DENKA CO LTD

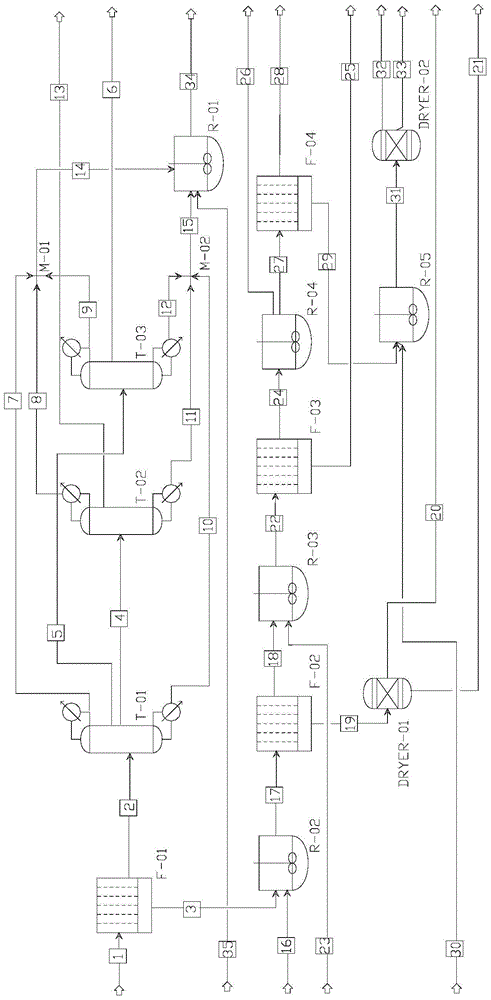

Recovery device of hexachlorodisilane

The invention provides a recovery device of hexachlorodisilane. The recovery device of hexachlorodisilane comprises: a filtering unit having a polysilicon raffinate inlet and a filtrate outlet; a first rectifying unit connected with the filtrate outlet of the filtering unit to rectify a filtrate obtained by the filtering unit and having a first tower top rectification liquid outlet; a second rectifying unit connected with the tower top rectification liquid outlet of the first rectifying unit to rectify the tower top rectification liquid of the first rectifying unit and having a second tower bottom rectification liquid outlet; and a third rectifying unit connected with the tower bottom rectification liquid outlet of the second rectifying unit to rectify the second tower bottom rectification liquid of the second rectifying unit. A polysilicon raffinate is filtered to remove solid particles and metal polymer impurities; and the filtrate obtained after the filtration undergoes first-stage rectification, second-stage rectification and third-stage distillation to obtain silicon tetrachloride, hexachlorodisiloxane and a hexachlorodisilane-based third tower bottom rectification liquid at the tower top.

Owner:CHINA SILICON CORP LTD +1

System for producing silane, monochlorosilane, dichlorosilane and hexachlorodisilane

The invention discloses a system for producing silane, monochlorosilane, dichlorosilane and hexachlorodisilane. The system comprises a raw material synthesis system, a silane synthesis system, a monochlorosilane synthesis system, a dichlorosilane synthesis system and a hexachlorodisilane synthesis system, wherein the raw material synthesis system comprises a hydrogenation system, a disproportionation tower I, a disproportionation tower II, a condenser I and a condenser II; the condenser I is fixed at the top end of the disproportionation tower I and is communicated with the disproportionation tower I; the condenser II is fixed at the top end of the disproportionation tower II and is communicated with the disproportionation tower II; an inlet of the hydrogenation system is communicated with the hexachlorodisilane synthesis system; the top outlet is communicated with the inlet of the disproportionation tower I; the top outlet of the disproportionation tower I is communicated with an inlet of the disproportionation tower II, and a bottom outlet of the disproportionation tower I is communicated with an inlet of the hexachlorodisilane synthesis system; a bottom outlet of the disproportionation tower II is communicated with an inlet of the disproportionation tower I, and a top outlet of the disproportionation tower II is communicated with an inlet of the silane synthesis system.

Owner:内蒙古兴洋科技股份有限公司

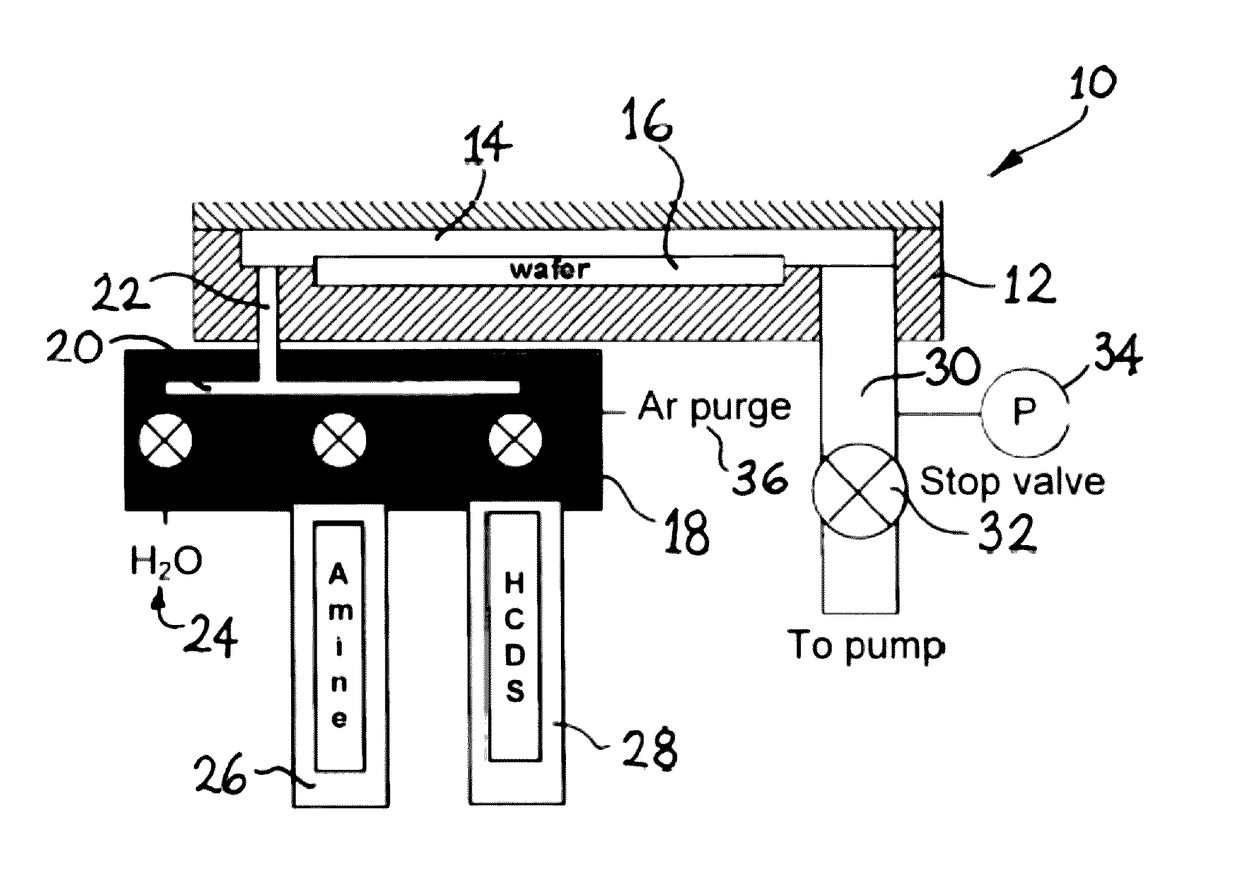

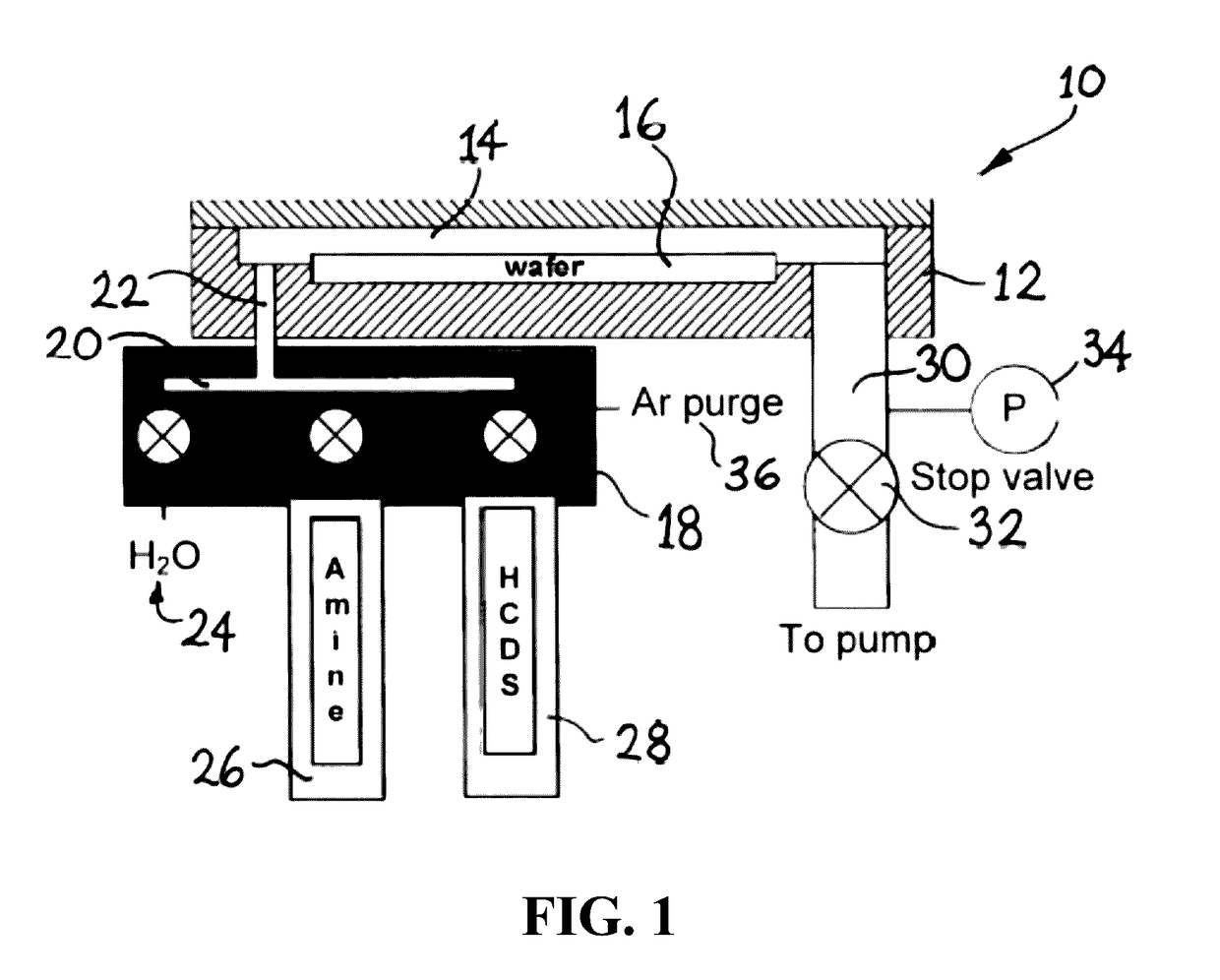

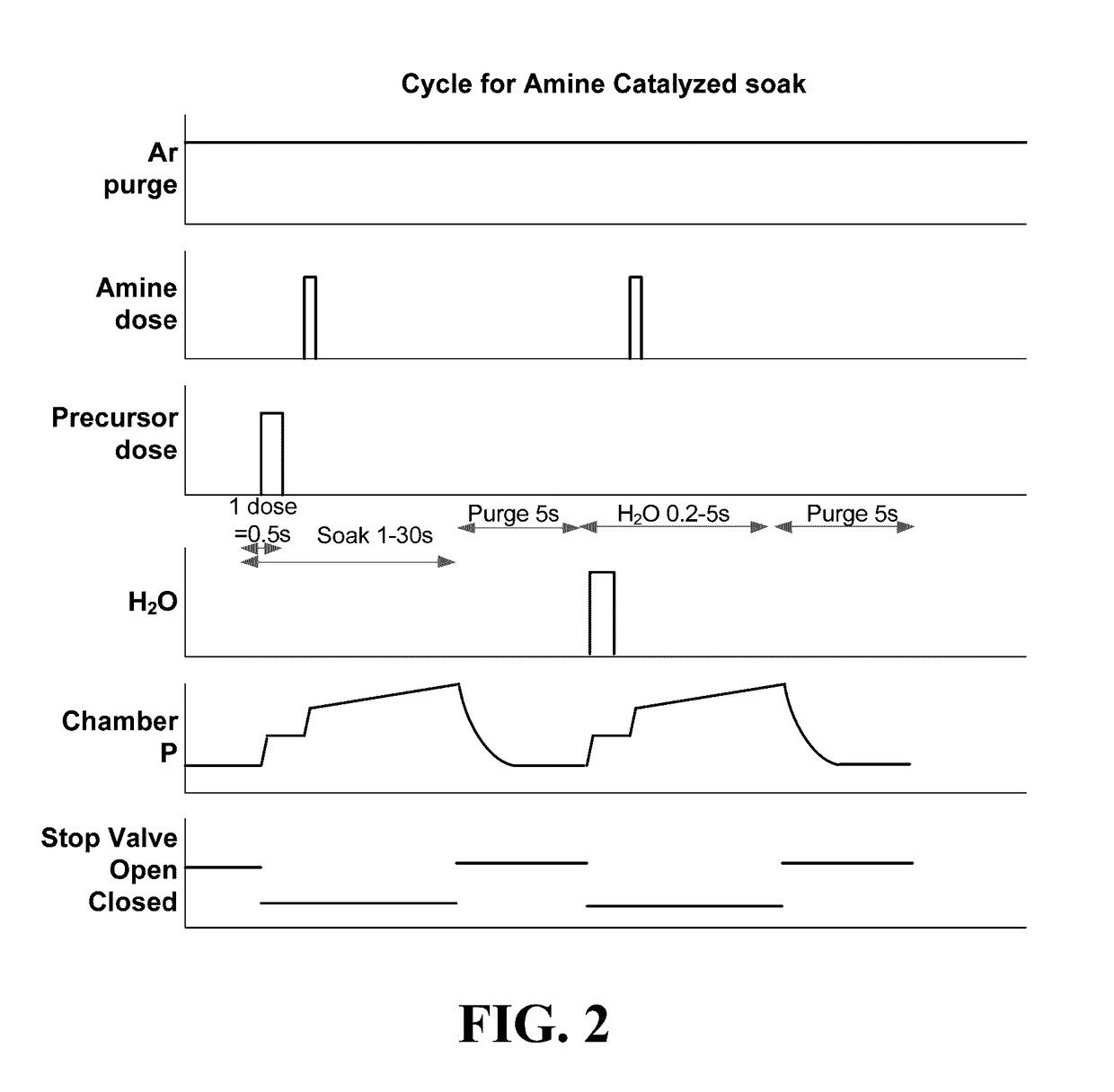

AMINE CATALYSTS FOR LOW TEMPERATURE ALD/CVD SiO2 DEPOSITION USING HEXACHLORODISILANE/H2O

InactiveUS20170103888A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingLow temperature depositionN dimethylformamide

A precursor composition is described, useful for low temperature (<150° C.) vapor deposition of silicon dioxide. The precursor composition includes hexachlorodisilane, water, and nitrogenous catalyst including an amide compound selected from the group consisting of N-ethylacetamide and N,N-dimethylformamide. Compositions and processes for forming silicon dioxide at a low temperature with alternative chemistries are also described, e.g., a precursor composition of chloroaminosilane and water, or a precursor composition of chlorosilane and ethanolamine, which may be utilized in pulsed chemical vapor deposition or atomic layer deposition processes.

Owner:ENTEGRIS INC

Process for preparing high-purity hexachlorodisilane

ActiveCN111643916AAvoid heat deteriorationStir wellFractional distillationHalogenated silanesMetallurgyDistillation

The invention relates to the field of preparation of high-purity hexachlorodisilane, in particular to a process for preparing high-purity hexachlorodisilane. According to the method, sorbitol is adopted to replace chelate resin to adsorb metal impurities, nitrogen is added in the purification process for accompanying as inert gas for protection and rectification, the introduced nitrogen mainly hasthe effects of reducing the distillation temperature and enhancing stirring of liquid in the tower kettle to prevent local overheating of the liquid in the kettle, therefore hexachlorodisilane is prevented from being heated to deteriorate. The process is high in rectification efficiency and low in process cost.

Owner:HUBEI JINGXING SCI & TECH INC CO LTD

Hexakis(monohydrocarbylamino)disilanes and method for the preparation thereof

InactiveUS20060030724A1Silicon organic compoundsChemical vapor deposition coatingSilane compoundsOrganic solvent

A composition and method of preparation, to provide silane compounds that are free of chlorine. The compounds are hexakis(monohydrocarbylamino)disilanes with general formula (I) ((R)HN)3—Si—Si—(NH(R))3 (I) wherein each R independently represents a C1 to C4 hydrocarbyl. These disilanes may be synthesized by reacting hexachlorodisilane in organic solvent with at least 6-fold moles of the monohydrocarbylamine RNH2 (wherein R is a C1 to C4 hydrocarbyl). Such compounds have excellent film-forming characteristics at low temperatures. These films, particularly in the case of silicon nitride and silicon oxynitride, also have excellent handling characteristics.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Novel process for preparation of 1-[2-(2,4-dimethylphenylsulphanyl)phenyl] piperazine Novel process for preparation of 1-[2-(2,4-dimethylphenylsulphanyl)phenyl] piperazine](https://images-eureka.patsnap.com/patent_img/622853fd-3ecb-4807-b9c0-ea6b7d2cc5a1/2015107619750100002DEST_PATH_IMAGE001.PNG)

![Novel process for preparation of 1-[2-(2,4-dimethylphenylsulphanyl)phenyl] piperazine Novel process for preparation of 1-[2-(2,4-dimethylphenylsulphanyl)phenyl] piperazine](https://images-eureka.patsnap.com/patent_img/622853fd-3ecb-4807-b9c0-ea6b7d2cc5a1/365486DEST_PATH_IMAGE004.PNG)

![Novel process for preparation of 1-[2-(2,4-dimethylphenylsulphanyl)phenyl] piperazine Novel process for preparation of 1-[2-(2,4-dimethylphenylsulphanyl)phenyl] piperazine](https://images-eureka.patsnap.com/patent_img/622853fd-3ecb-4807-b9c0-ea6b7d2cc5a1/572979DEST_PATH_IMAGE002.PNG)