Process for preparing high-purity hexachlorodisilane

A hexachlorodisilane, high-purity technology, applied in the directions of halosilanes, silicon compounds, halogenated silicon compounds, etc., can solve the problems that hexachlorodisilane cannot meet the needs of semiconductor production, strict process control parameters, and complex resin components. , to achieve the effect of avoiding heat deterioration, low process cost, and preventing stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

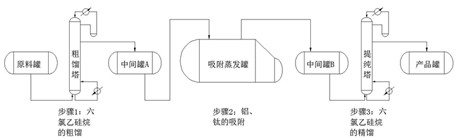

[0018] see figure 1 , the hexachlorodisilane raw material enters the crude distillation tower through the raw material tank to carry out the crude distillation operation of step 1—hexachlorodisilane, and the hexachlorodisilane obtained after the crude distillation is stored in the intermediate tank A. The hexachlorodisilane in the intermediate tank A is sent to the adsorption evaporation tank for step 2—the adsorption operation of metal aluminum and titanium in the hexachlorodisilane, and the adsorbed hexachlorodisilane is stored in the intermediate tank B. The hexachlorodisilane in the intermediate tank B enters the purification tower for step 3—hexachlorodisilane rectification operation. After rectification and purification, more than 99.99% of the hexachlorodisilane product can be obtained and stored in the product tank. The detailed steps are as follows:

[0019] 1) Crude distillation of hexachlorodisilane:

[0020] a. Feeding: Open the valve at the top of the crude dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com