Patents

Literature

322results about How to "Smooth meshing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

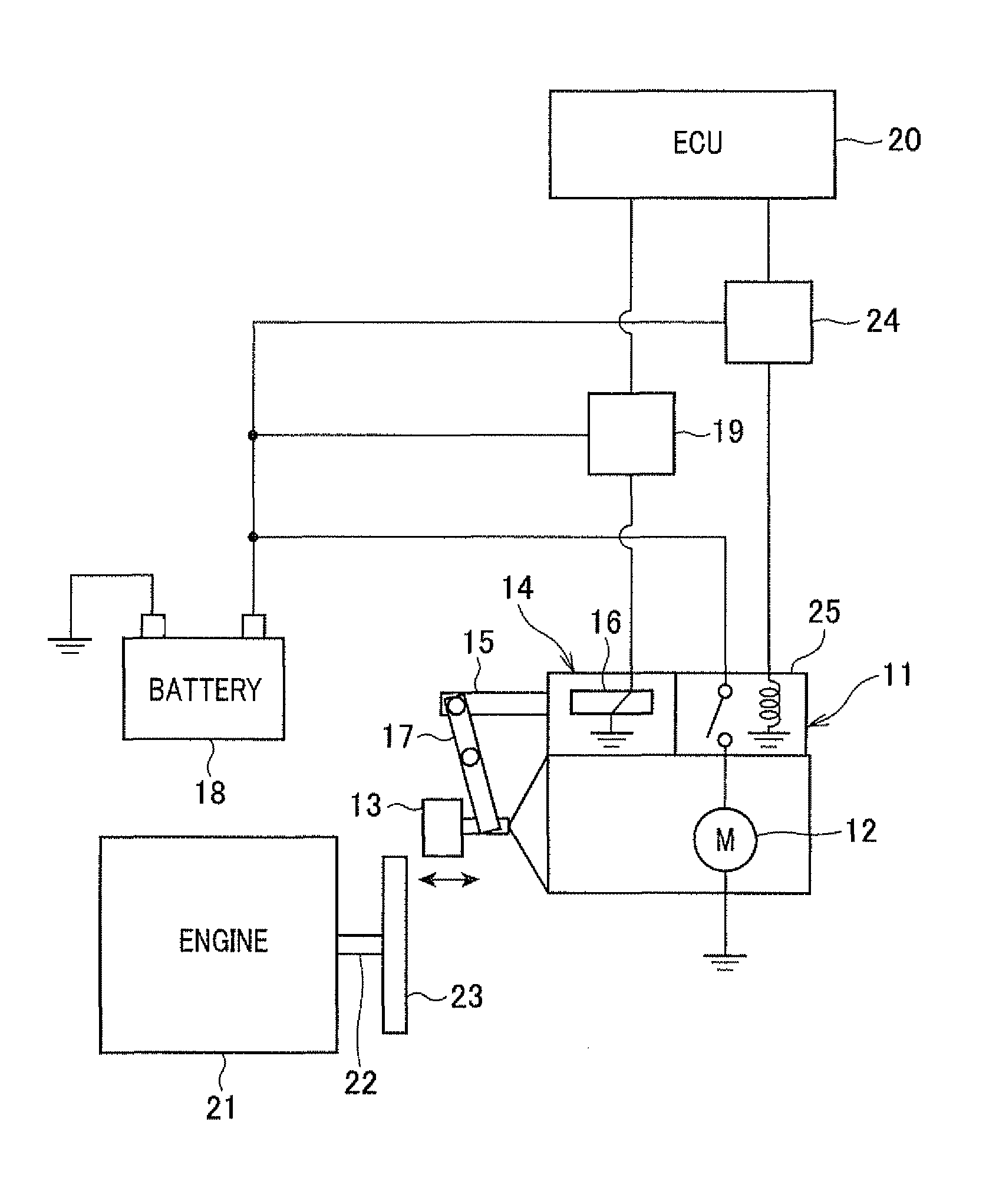

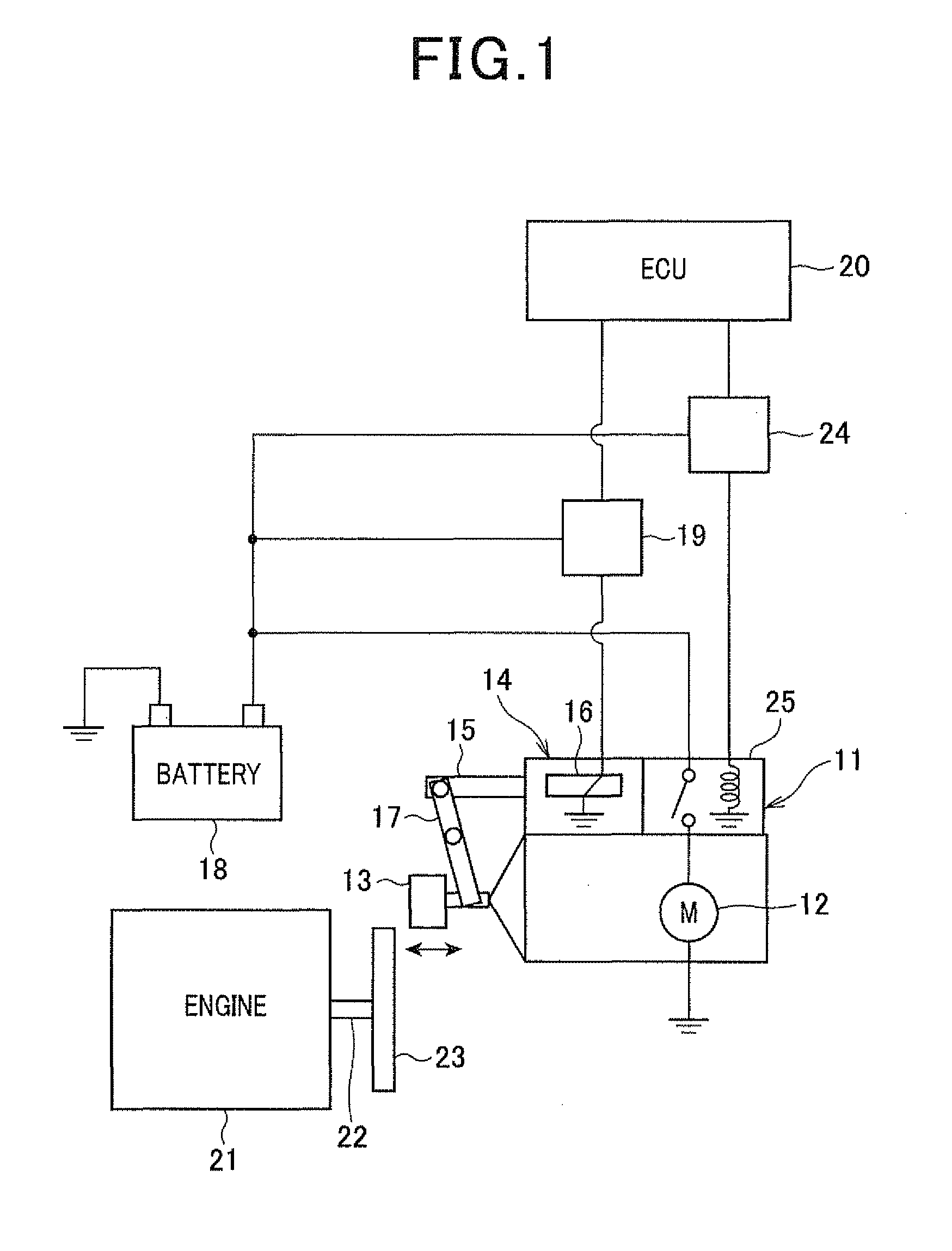

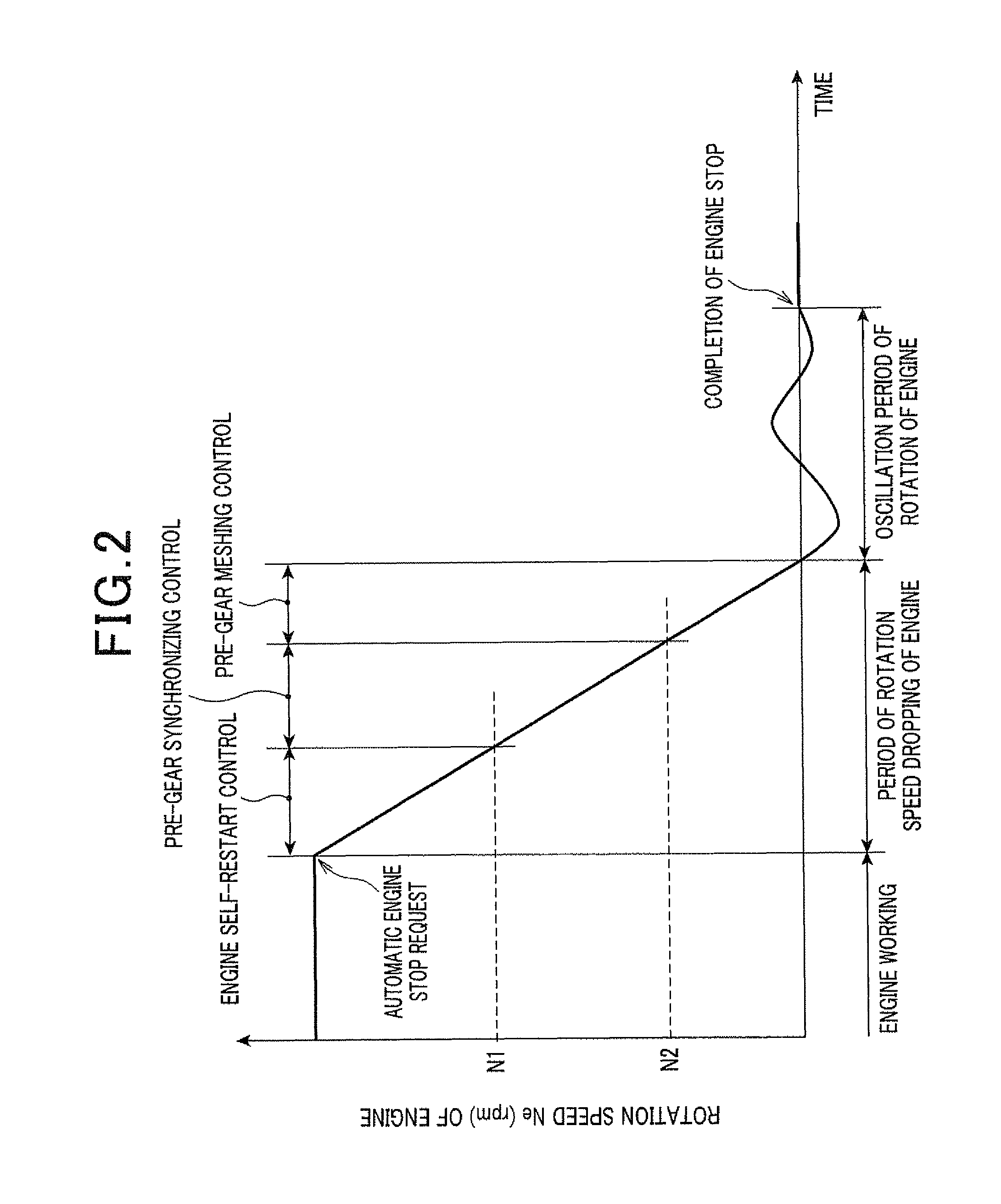

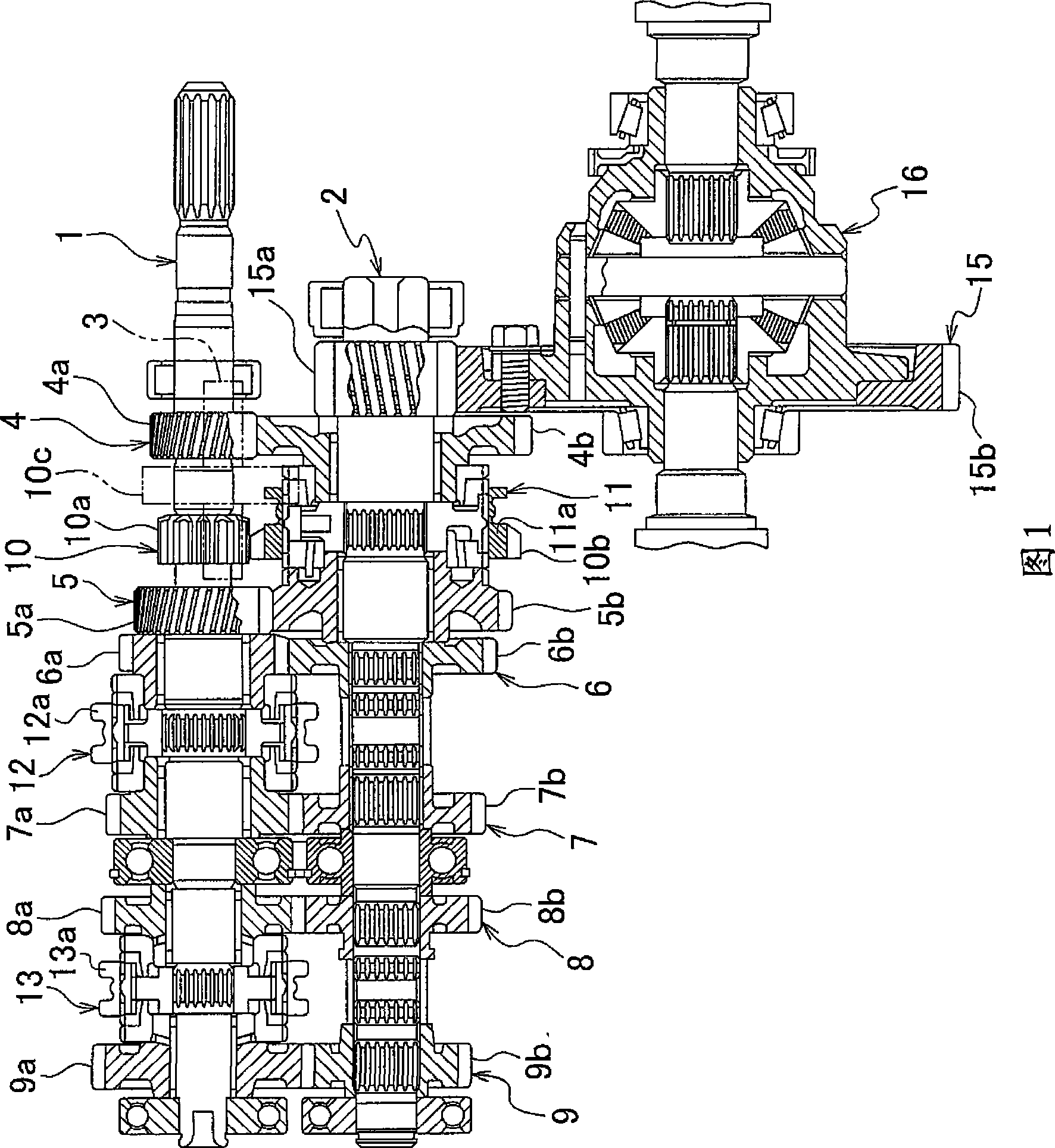

Control device of automatic engine stop and start

ActiveUS20110178695A1Improve accuracySmooth meshingAnalogue computers for vehiclesElectrical controlAerospace engineeringRate control

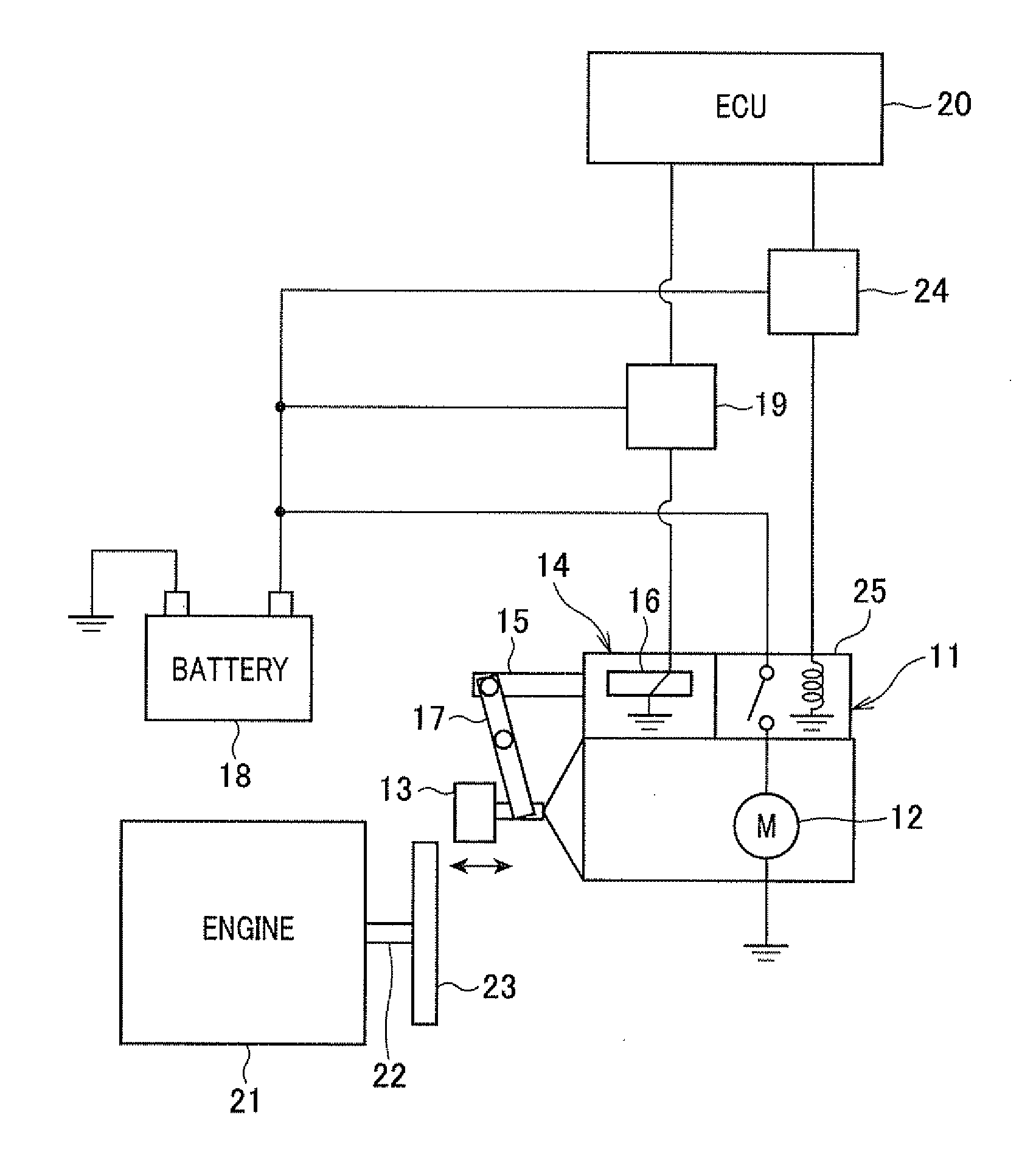

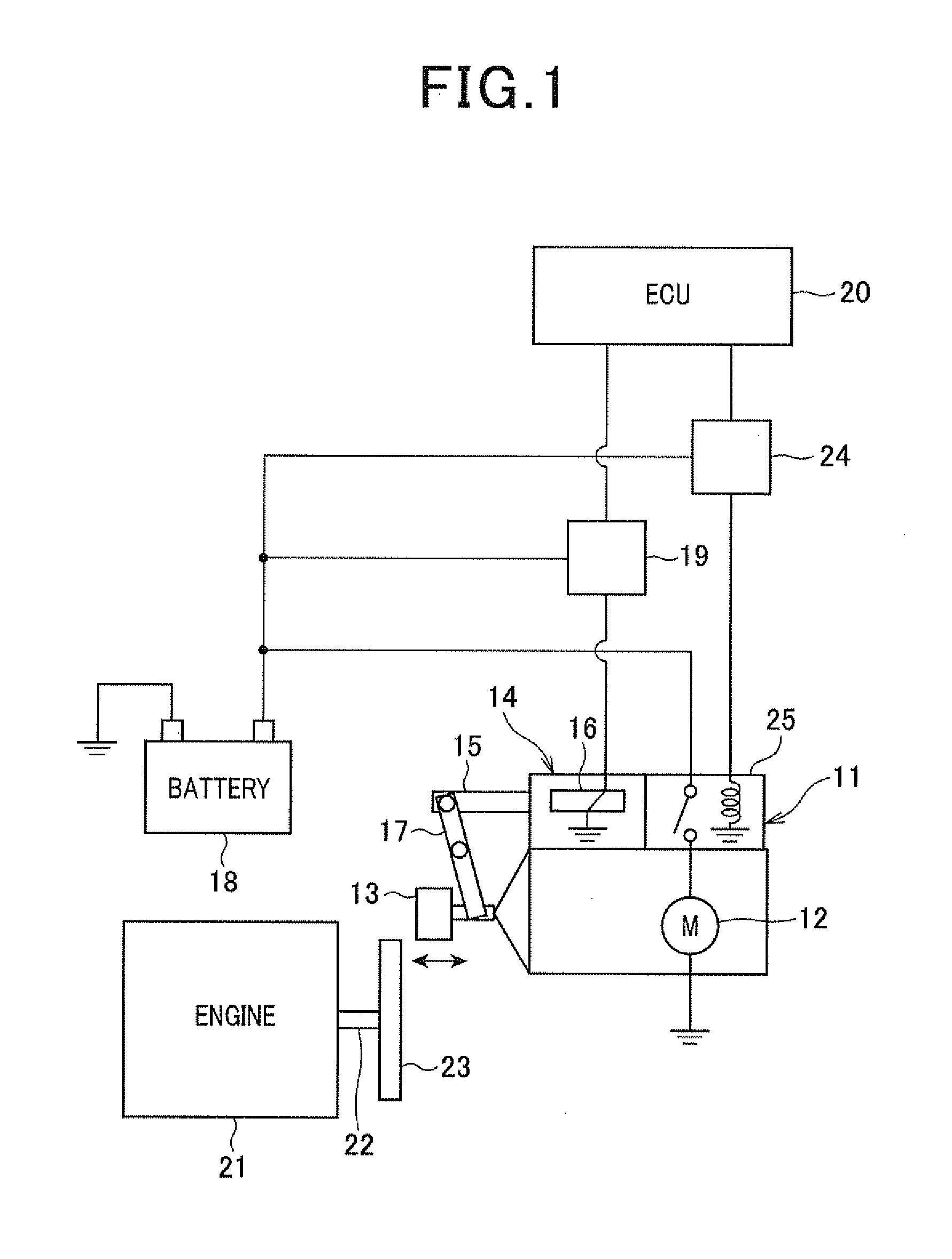

In a control device, an engine self-restart means tries the engine restart when an engine restart request is issued while the engine rotation speed is within a first rotation speed range. A pre-gear synchronizing control means executes gear rotation speed synchronization between pinion and ring gears, and then retries the engine restart when the engine restart request is issued while the engine rotation-speed is within a second rotation speed range. A pre-gear meshing control means executes gear-meshing between the pinion and ring gears and then retries the engine restart when the engine restart request is issued while the engine rotation speed is within a third rotation speed range. On detecting the engine-restart failure of the engine self-restart control, the control device prohibits the execution of pre-gear synchronizing control until a predetermined time counted form the failure detection time is elapsed, and executes the pre-gear meshing control after the predetermined time period is elapsed.

Owner:DENSO CORP

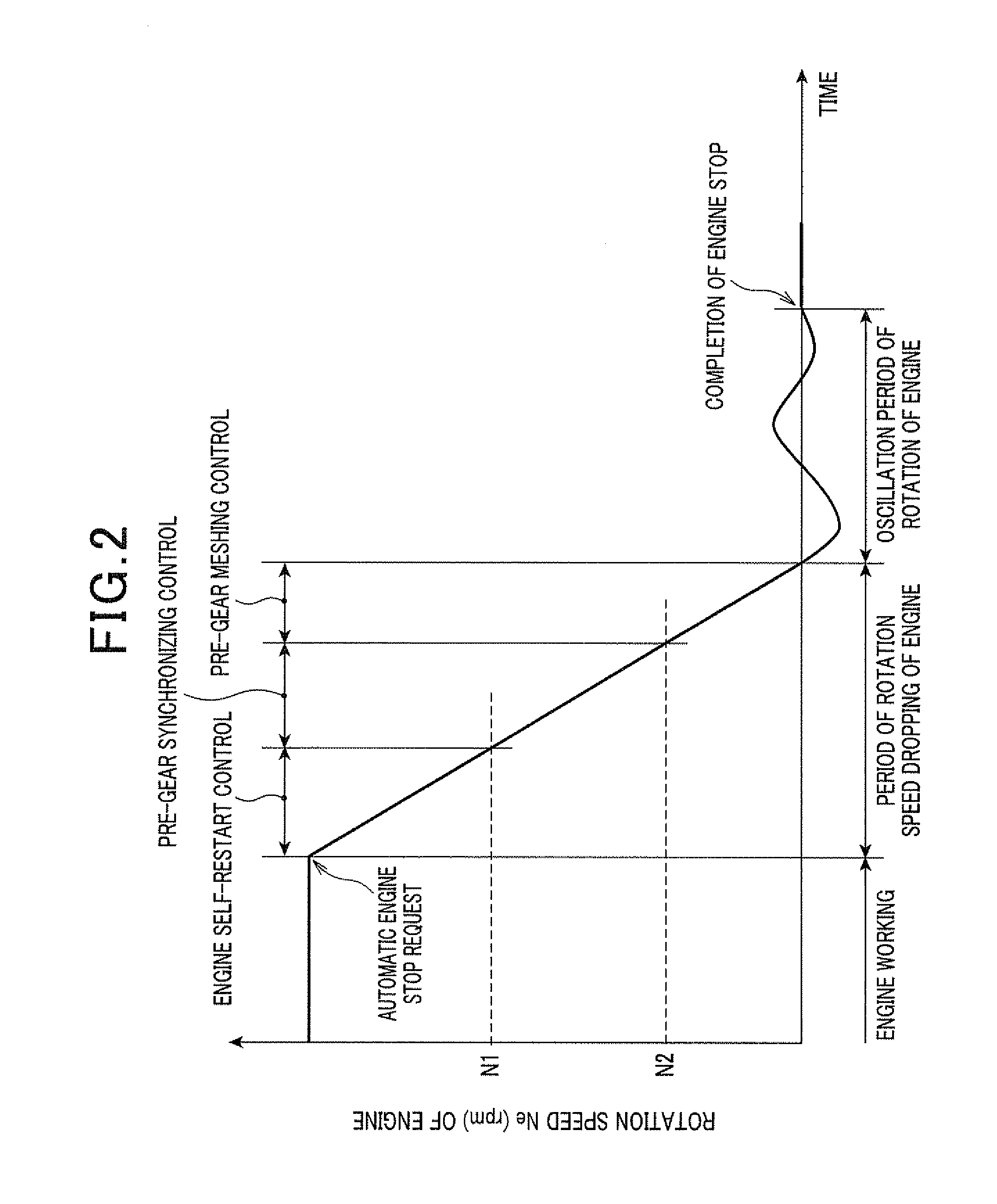

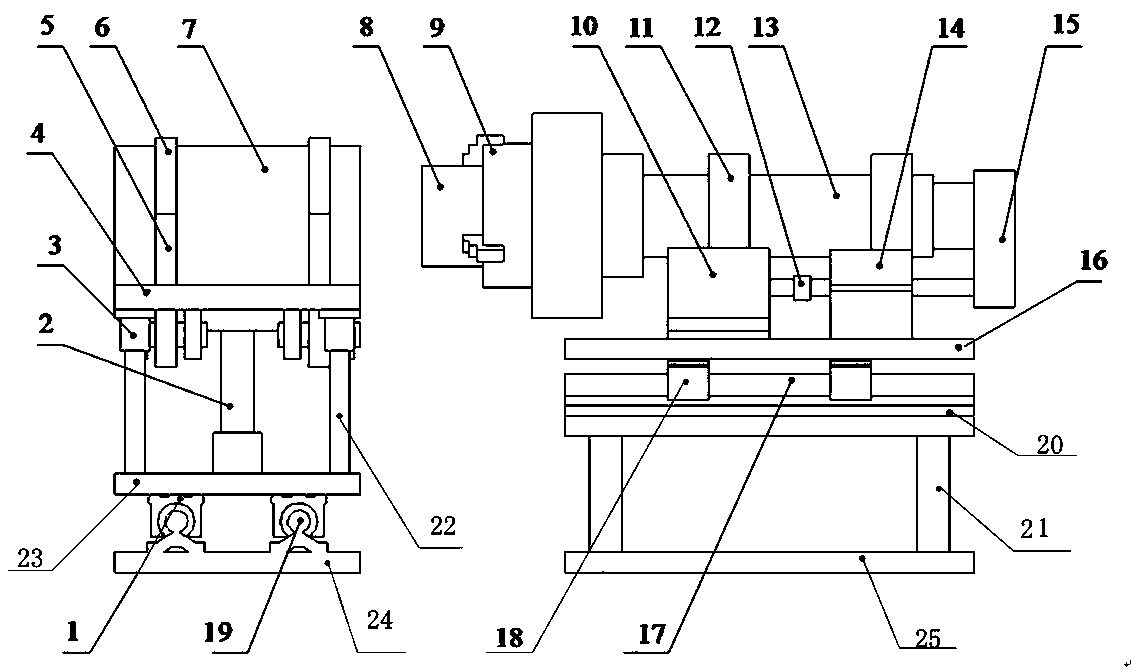

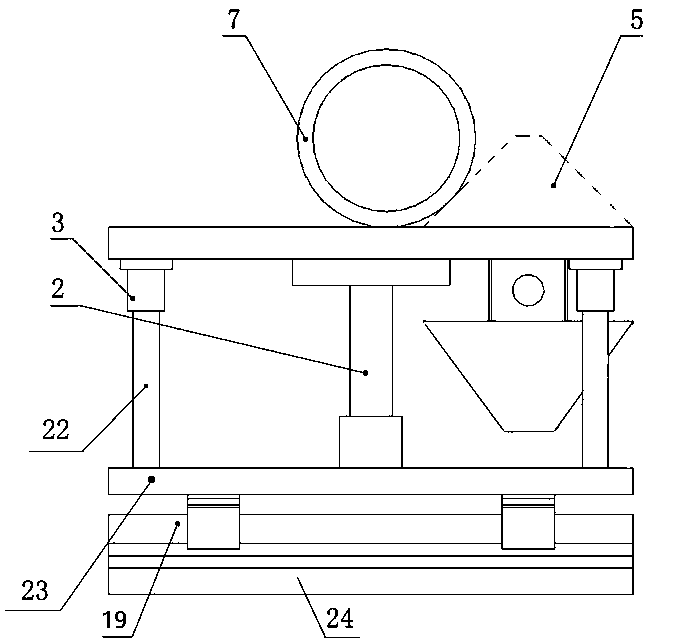

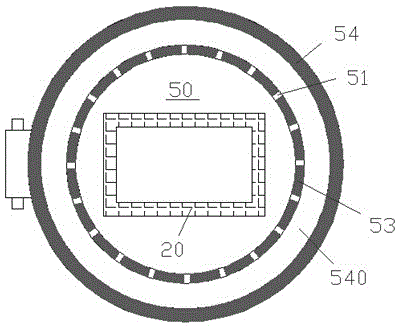

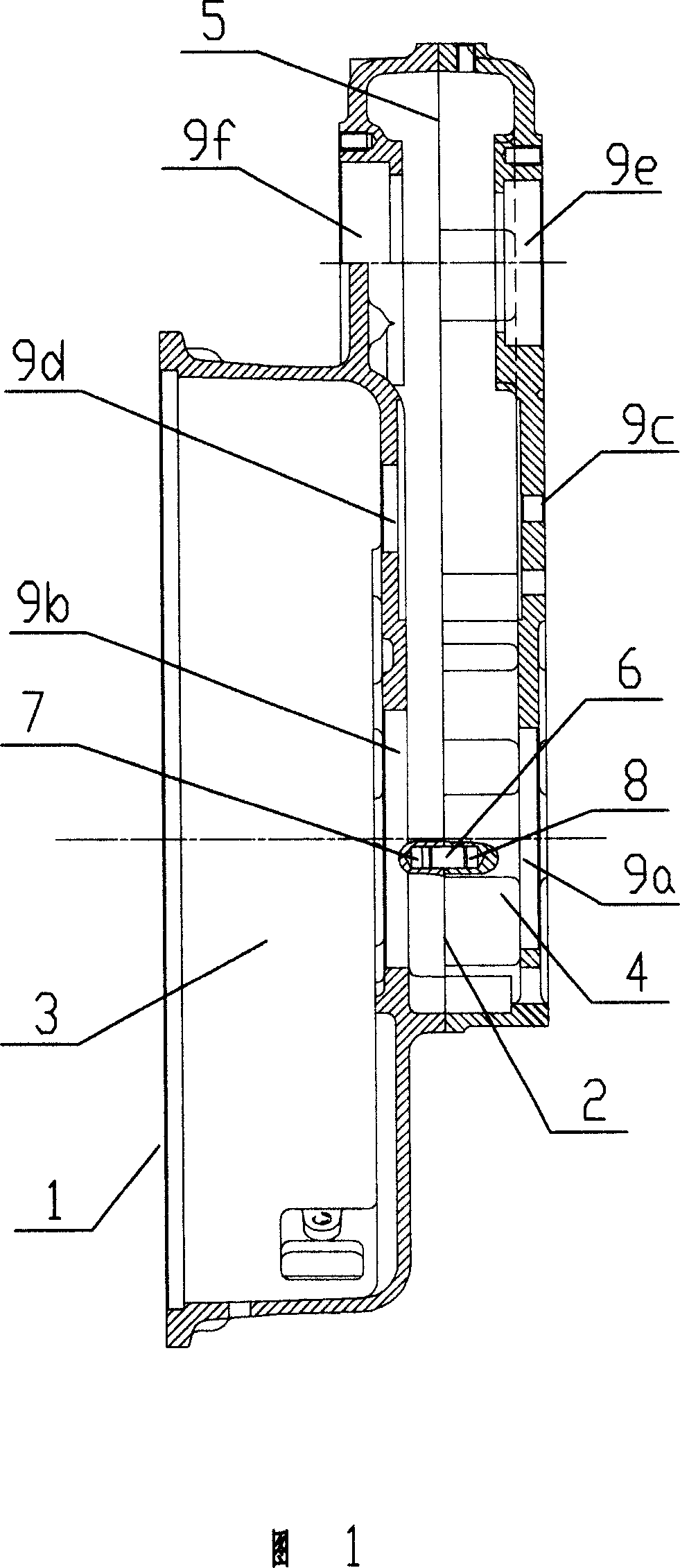

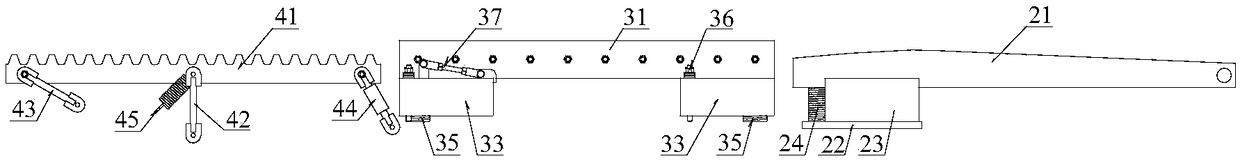

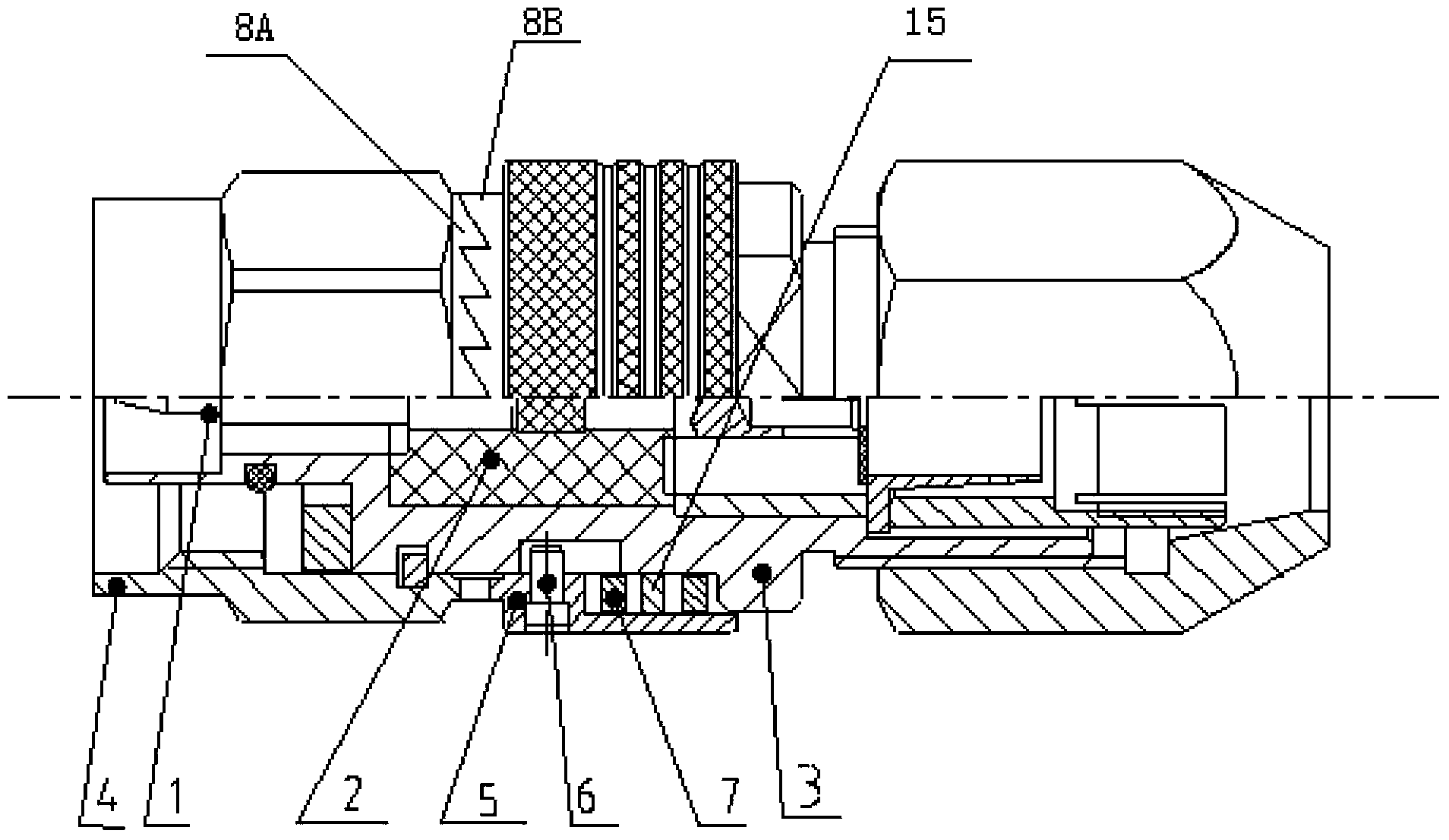

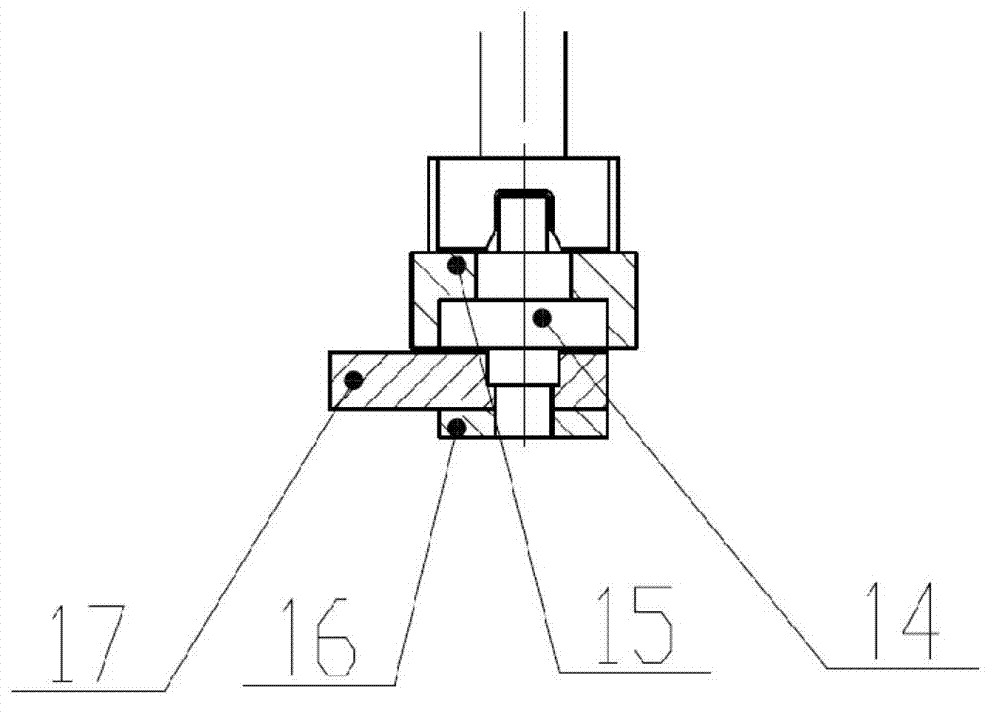

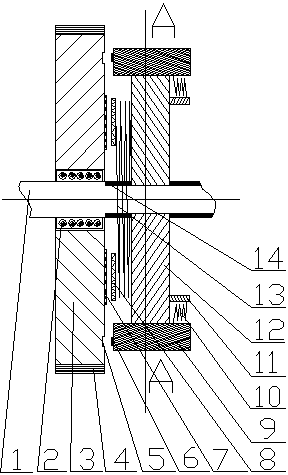

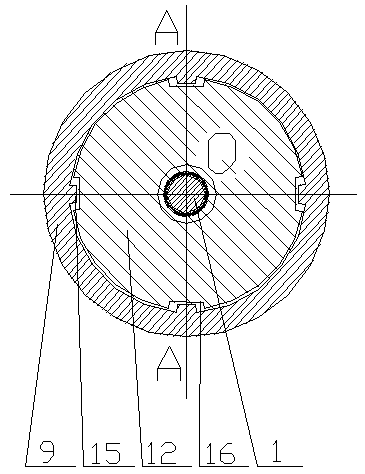

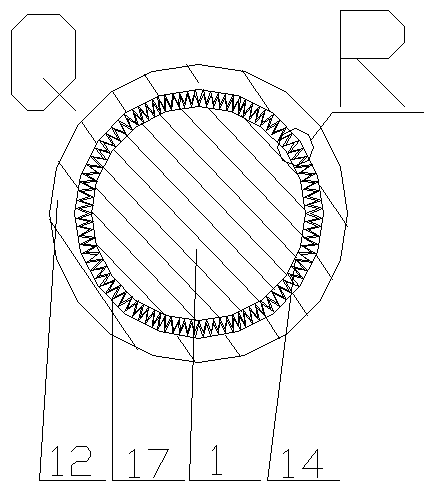

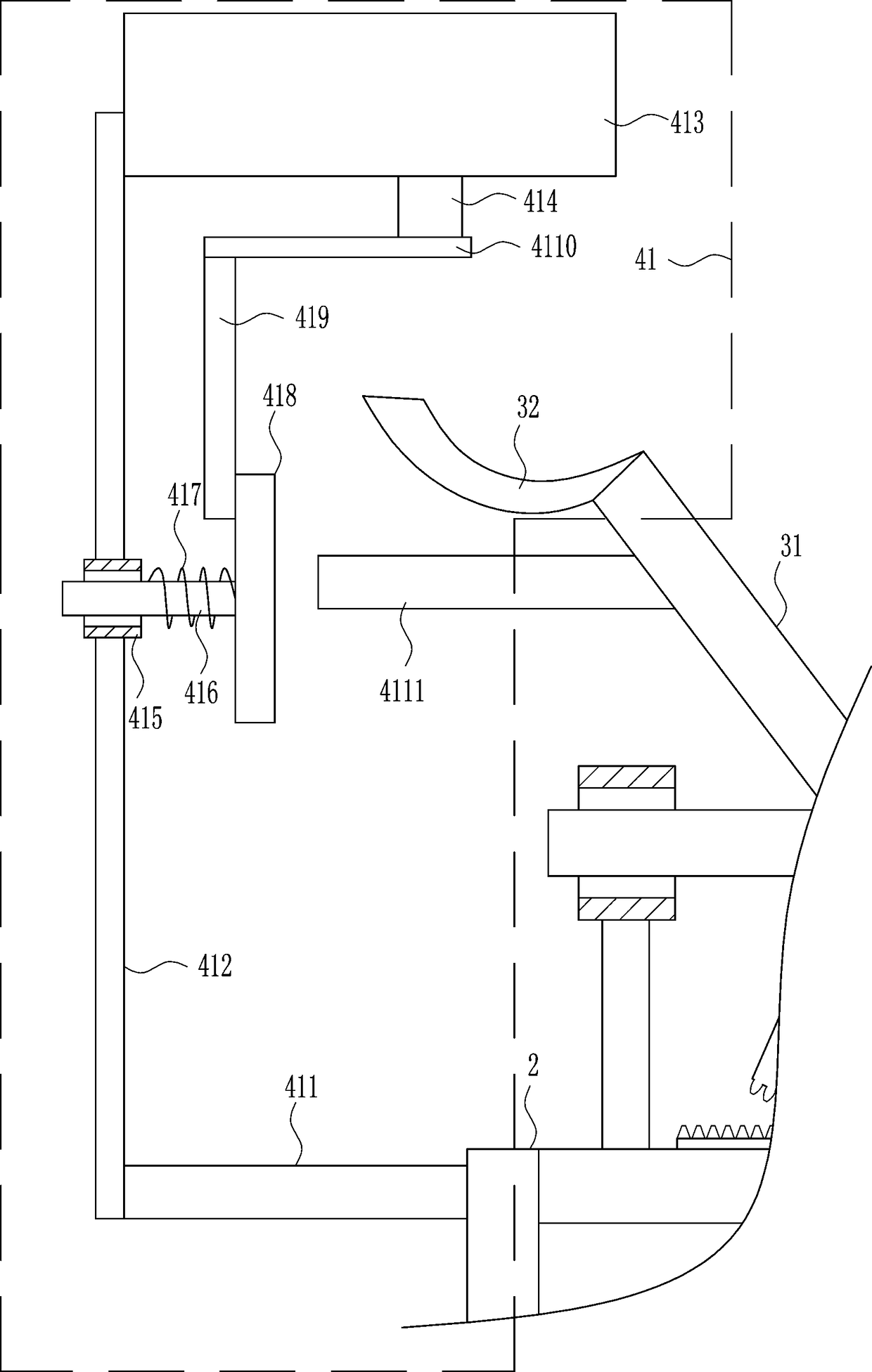

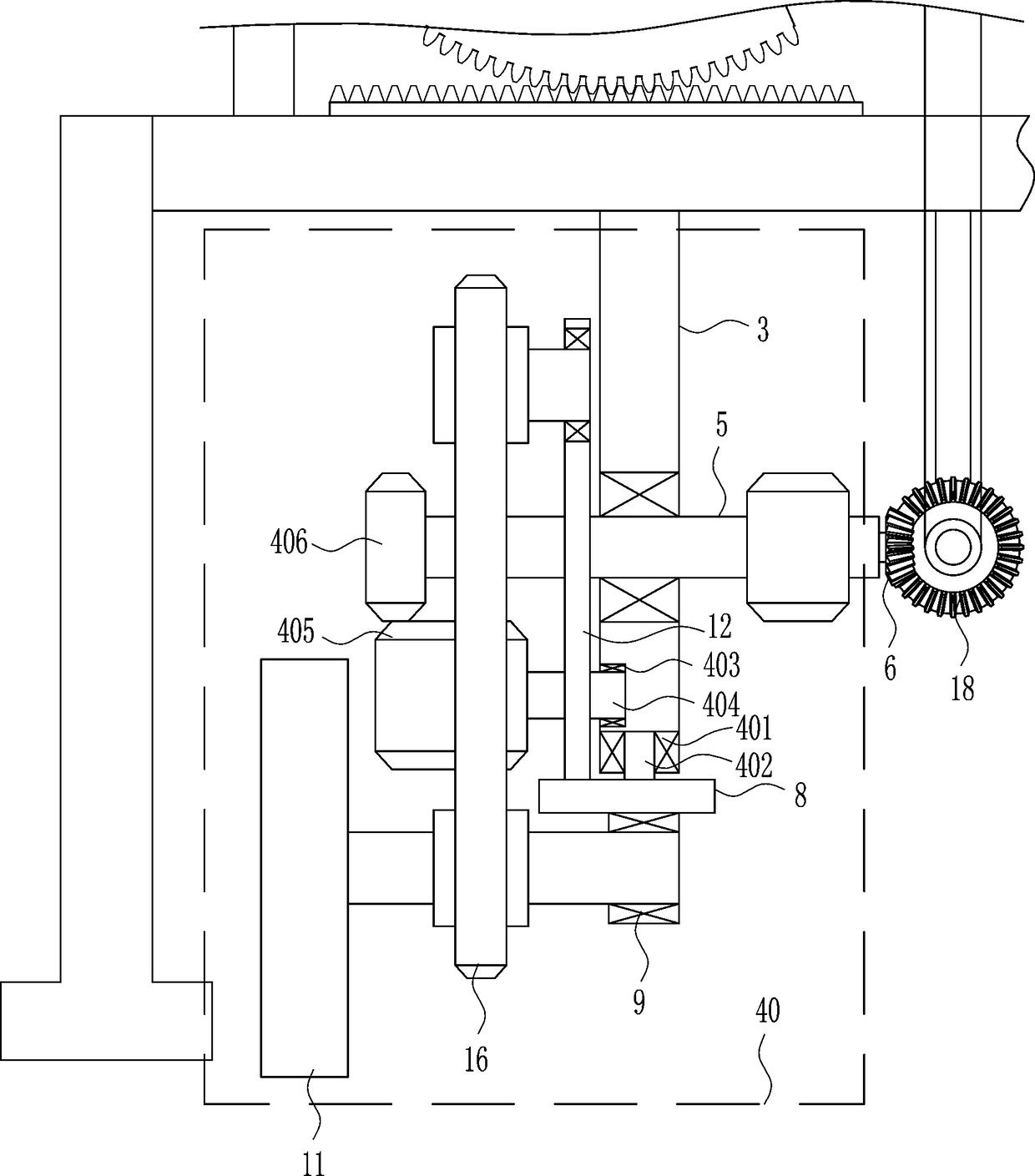

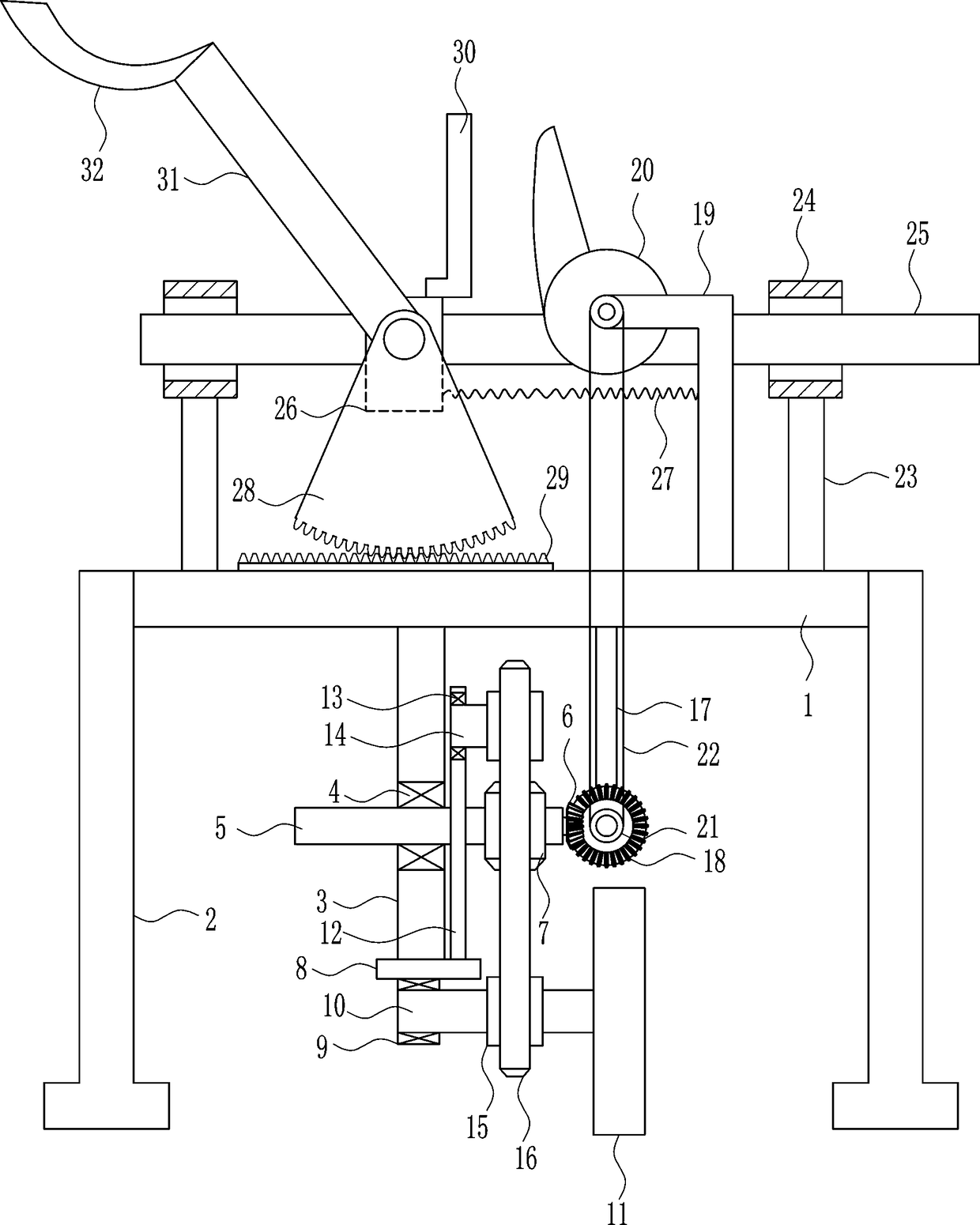

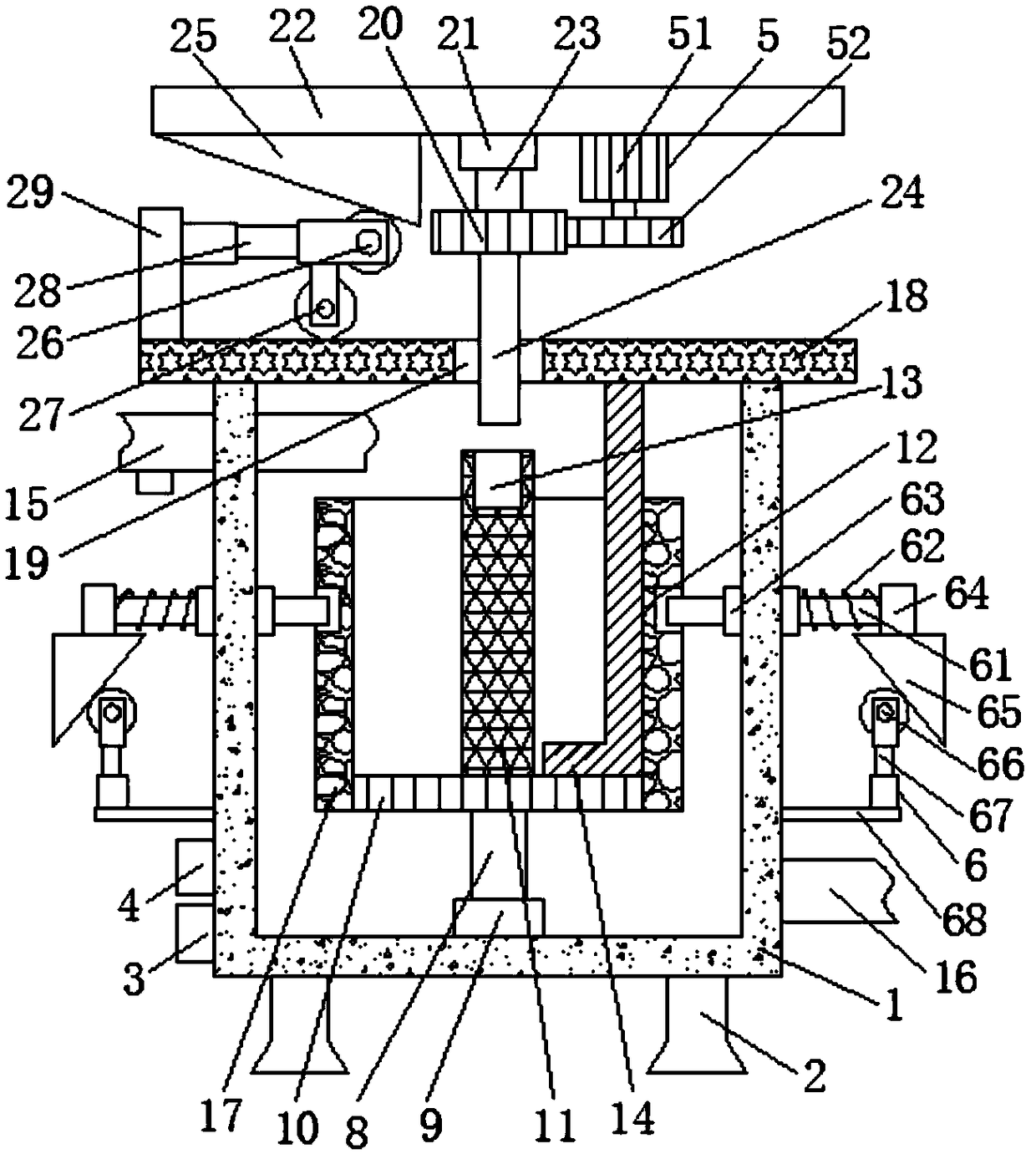

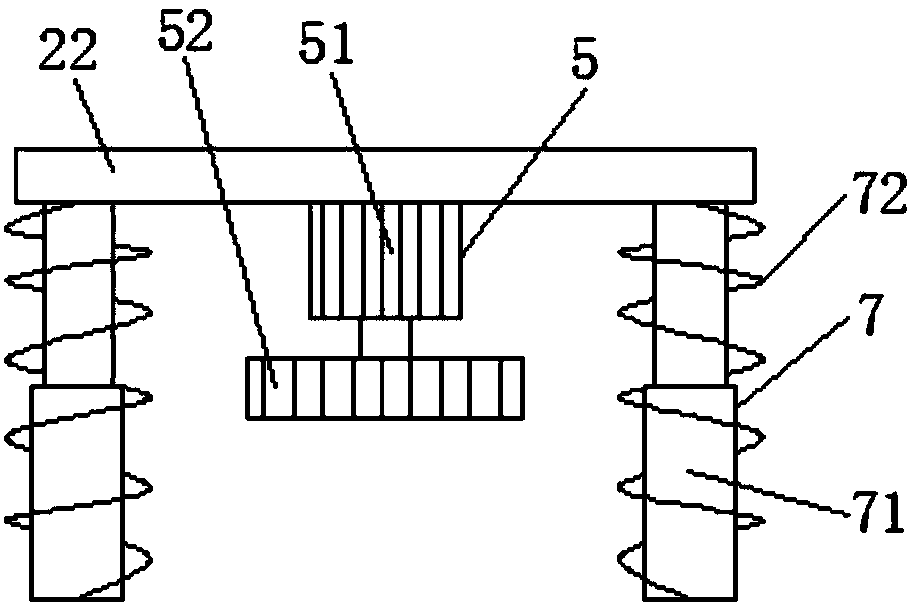

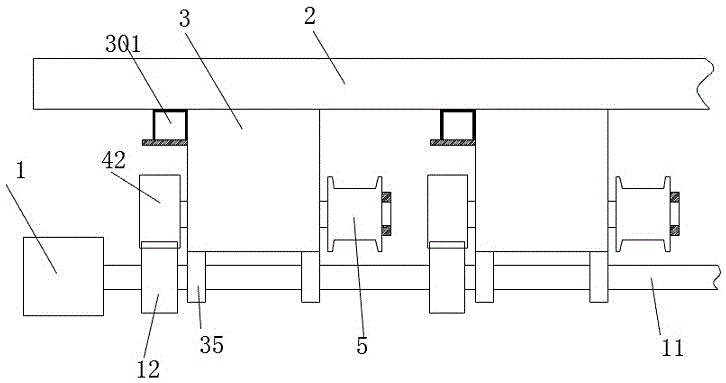

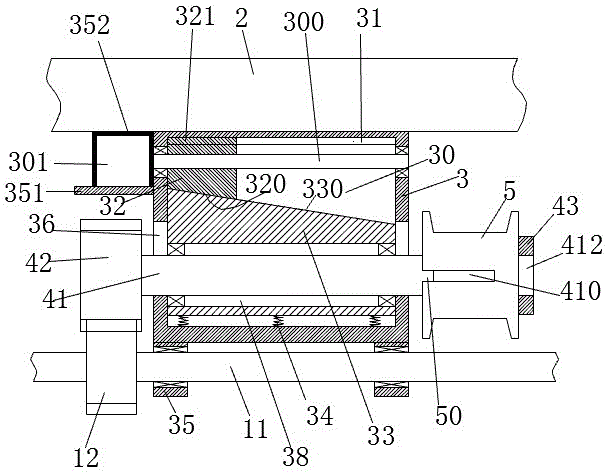

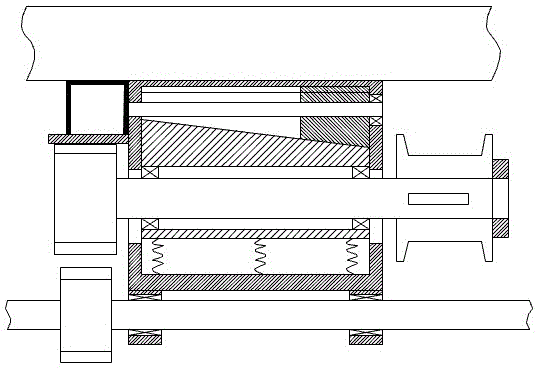

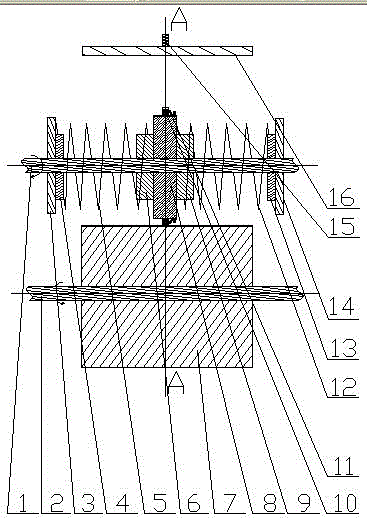

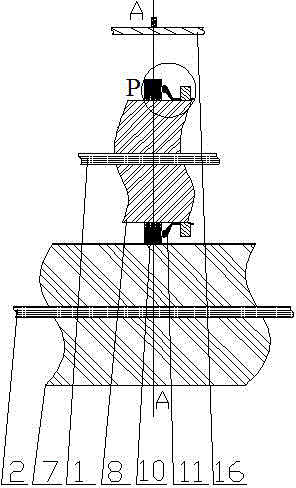

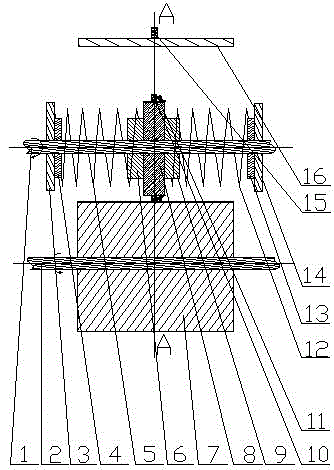

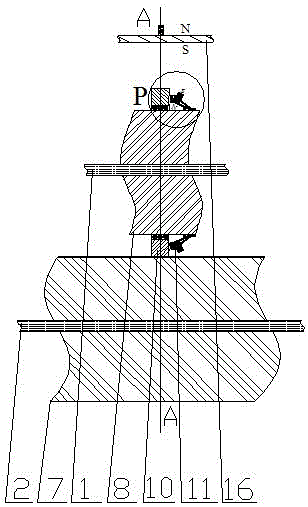

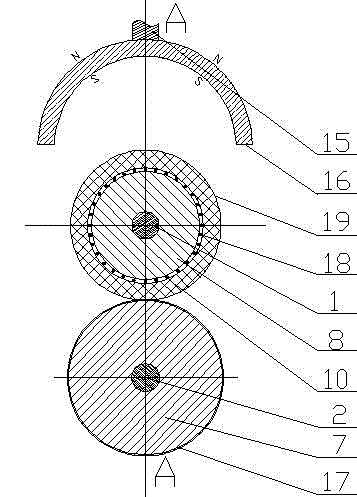

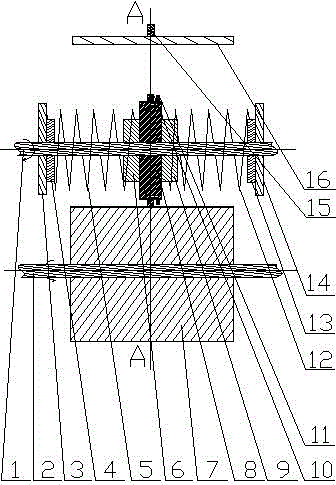

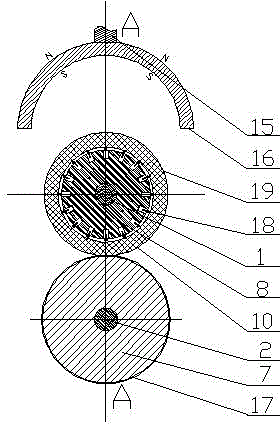

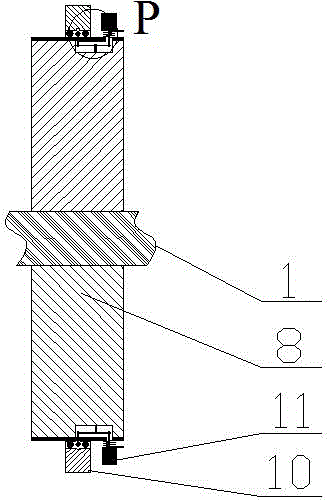

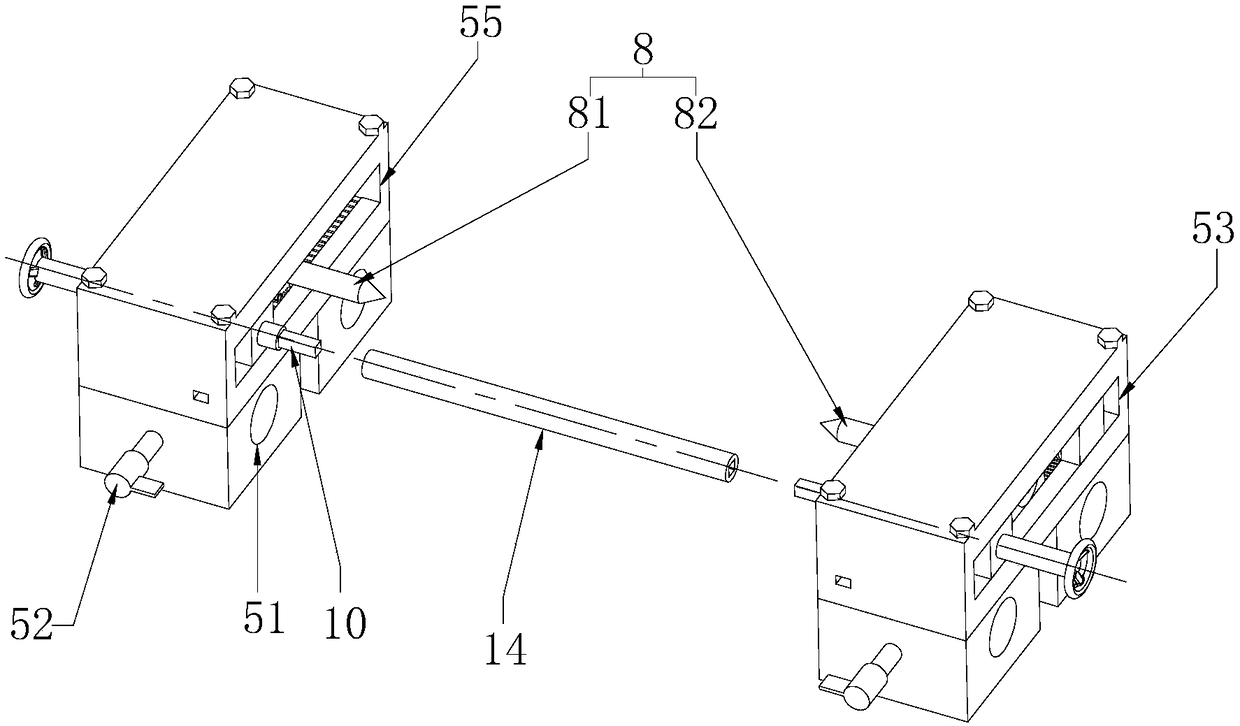

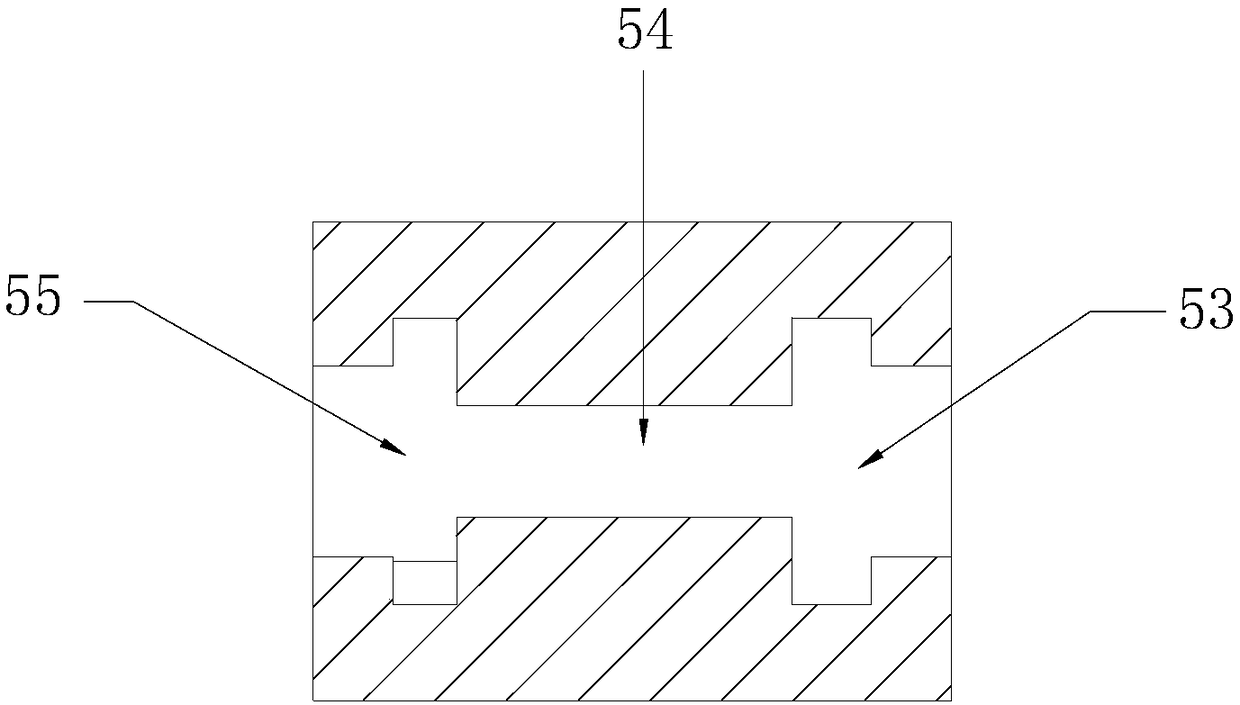

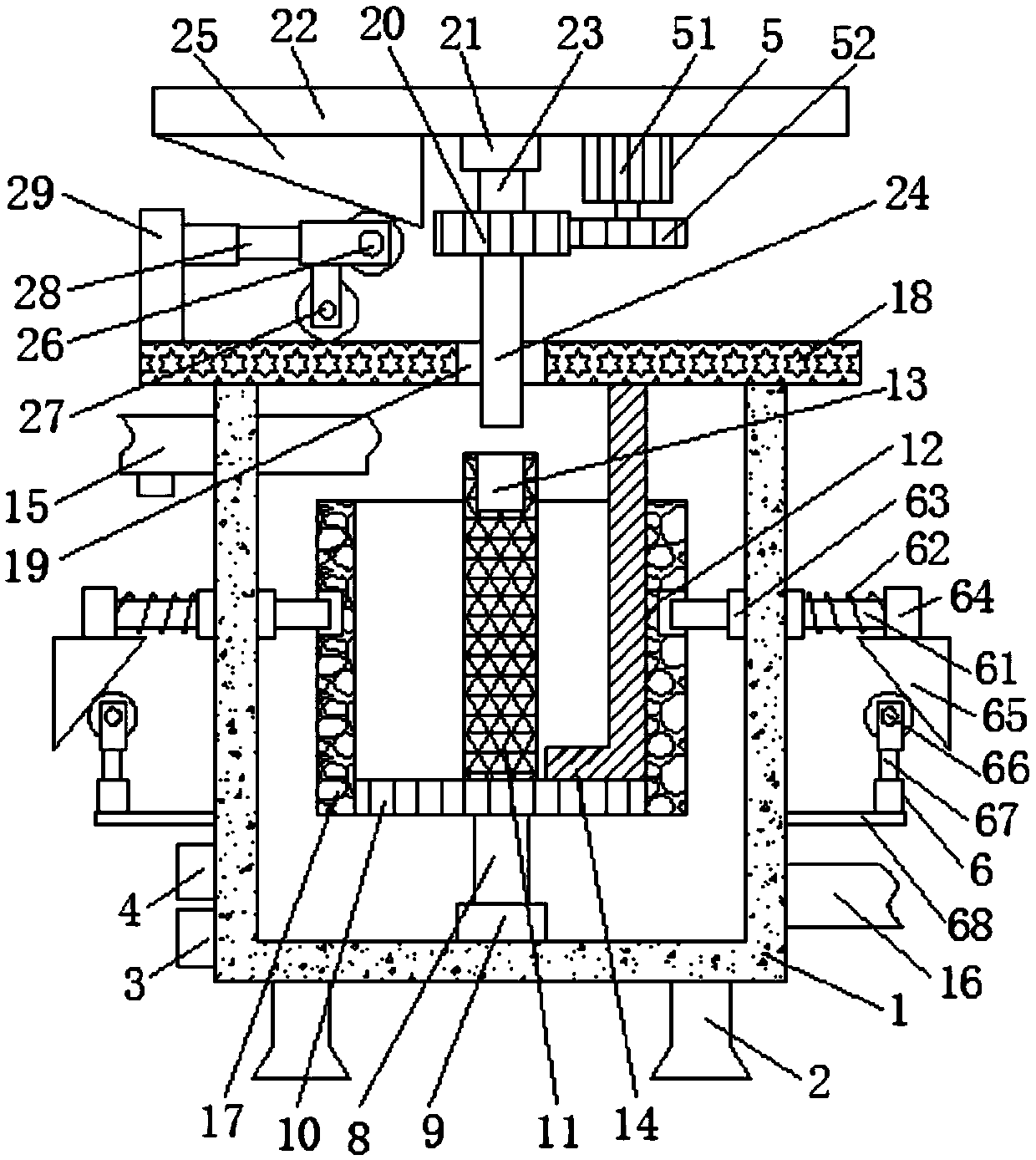

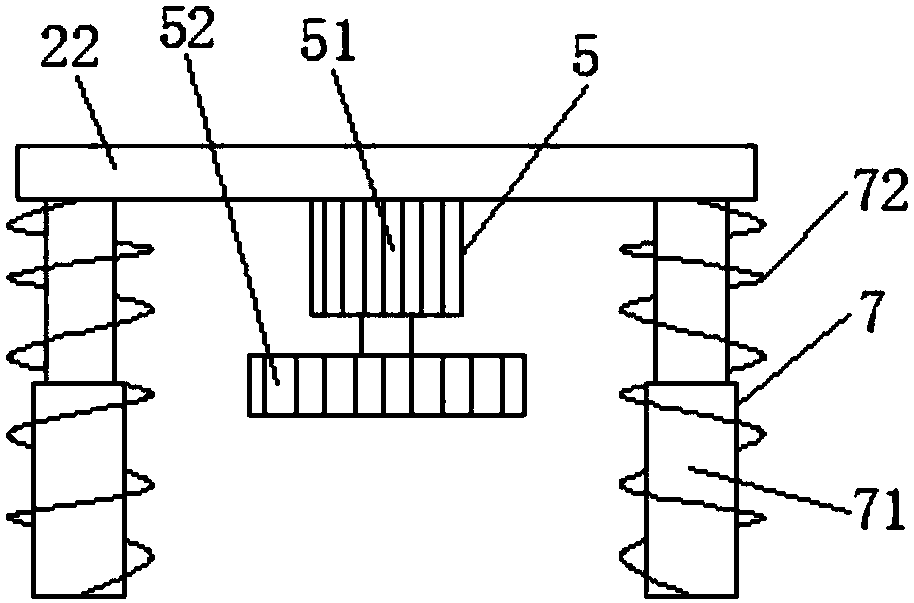

Self-adaptation flexible assembling device for hydraulic cylinder head body

InactiveCN109015468AFast and accurate vertical liftingQuick dockingWork holdersMetal working apparatusHydraulic cylinderCylinder head

The invention relates to the technical field of automatic machine assembling, in particular to a self-adaptation flexible assembling device for a hydraulic cylinder head body. The technical problem ofassembling of a cylinder barrel and a cylinder head body of a large multistage hydraulic cylinder is solved. The self-adaptation flexible assembling device comprises a cylinder barrel flexible clamping platform and a cylinder head body flexible clamping platform which are independent from each other and need to be used in cooperation with each other. The cylinder barrel flexible clamping platformis used for fixing a cylinder barrel, and the cylinder barrel flexible clamping platform can do perpendicular lifting motion and horizontal motion in the radial direction of the cylinder barrel. Thecylinder head body flexible clamping platform is used for fixing a cylinder head body, the cylinder head body flexible clamping platform can do horizontal motion along the axis of the cylinder barrel,the cylinder head body flexible clamping platform drives the cylinder head body to move towards the cylinder barrel and rotate synchronously, and finally the cylinder head body and the cylinder barrel can be assembled through thread connection. By means of the self-adaptation flexible assembling device, the historic problems that operation is complex, the assembling efficiency is low, the surface, making contact with a lifting clamp, of the cylinder barrel is likely to be damaged, and even the cylinder barrel is disengaged in the traditional cylinder barrel and cylinder head body assembling process can be effectively solved.

Owner:SHANXI UNIV

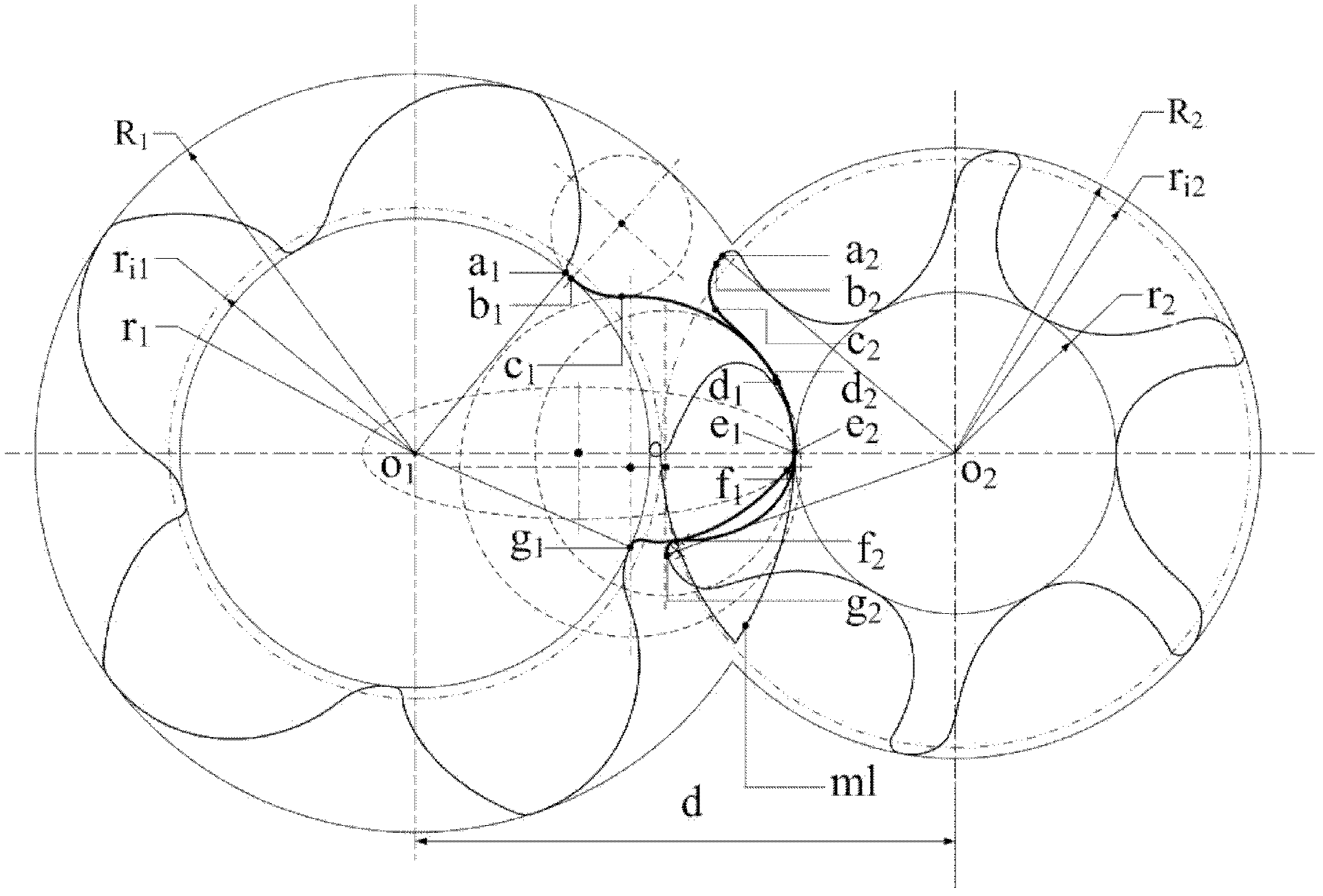

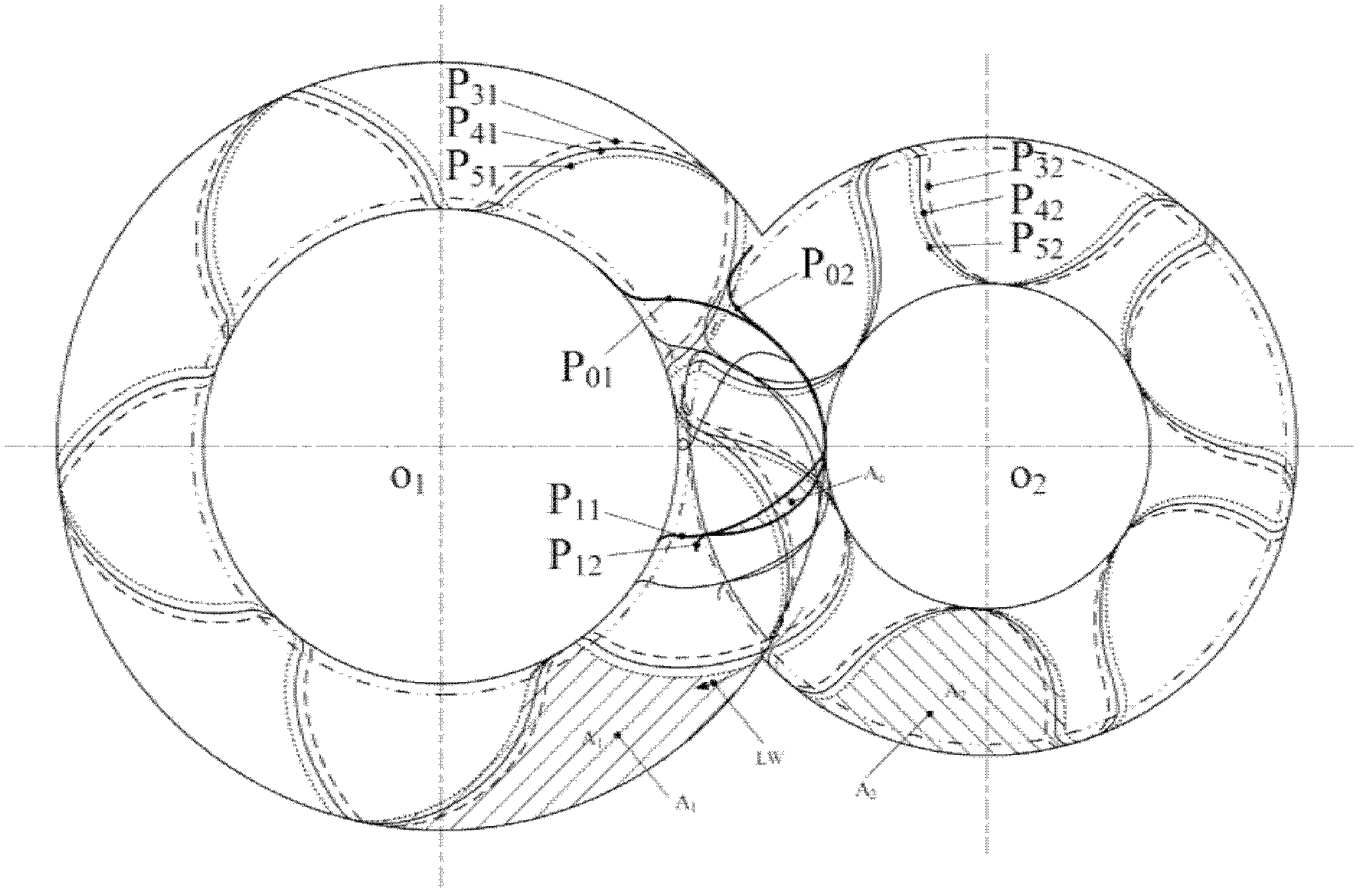

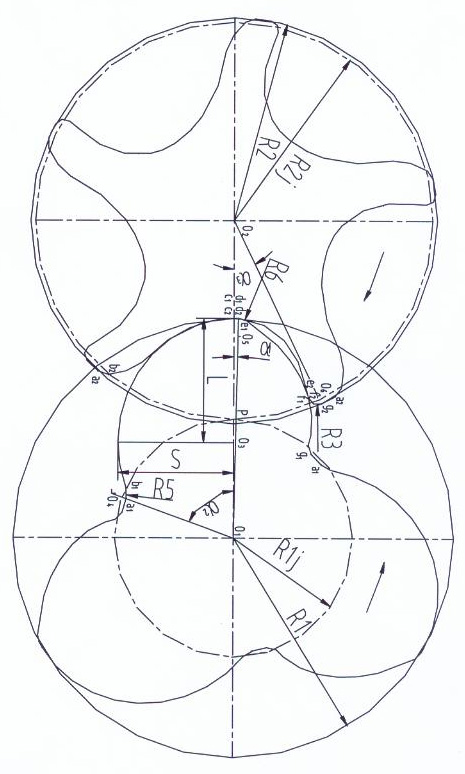

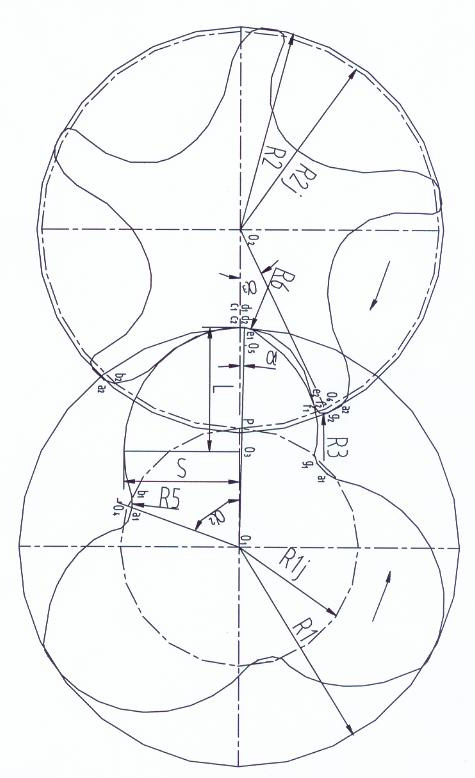

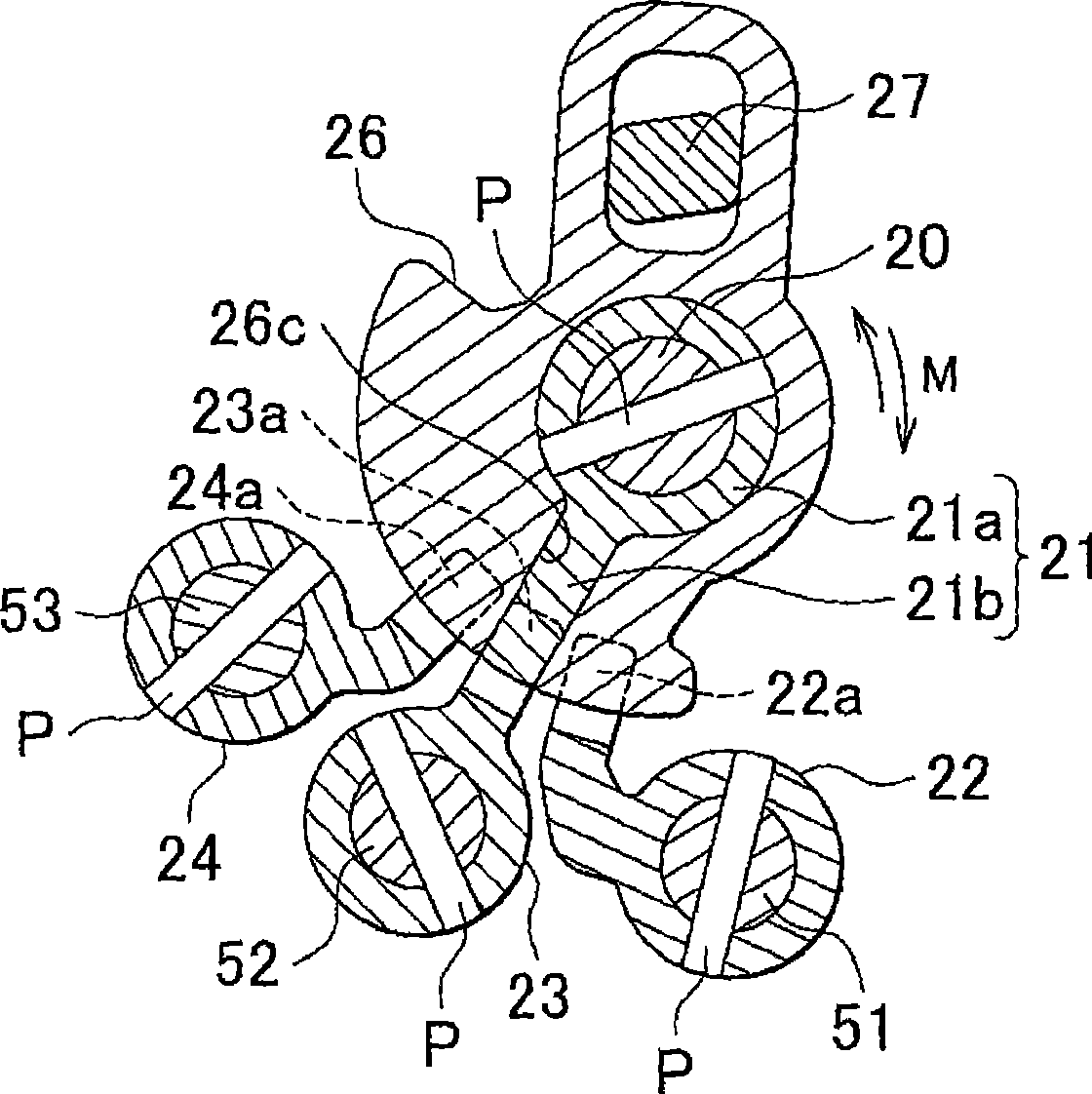

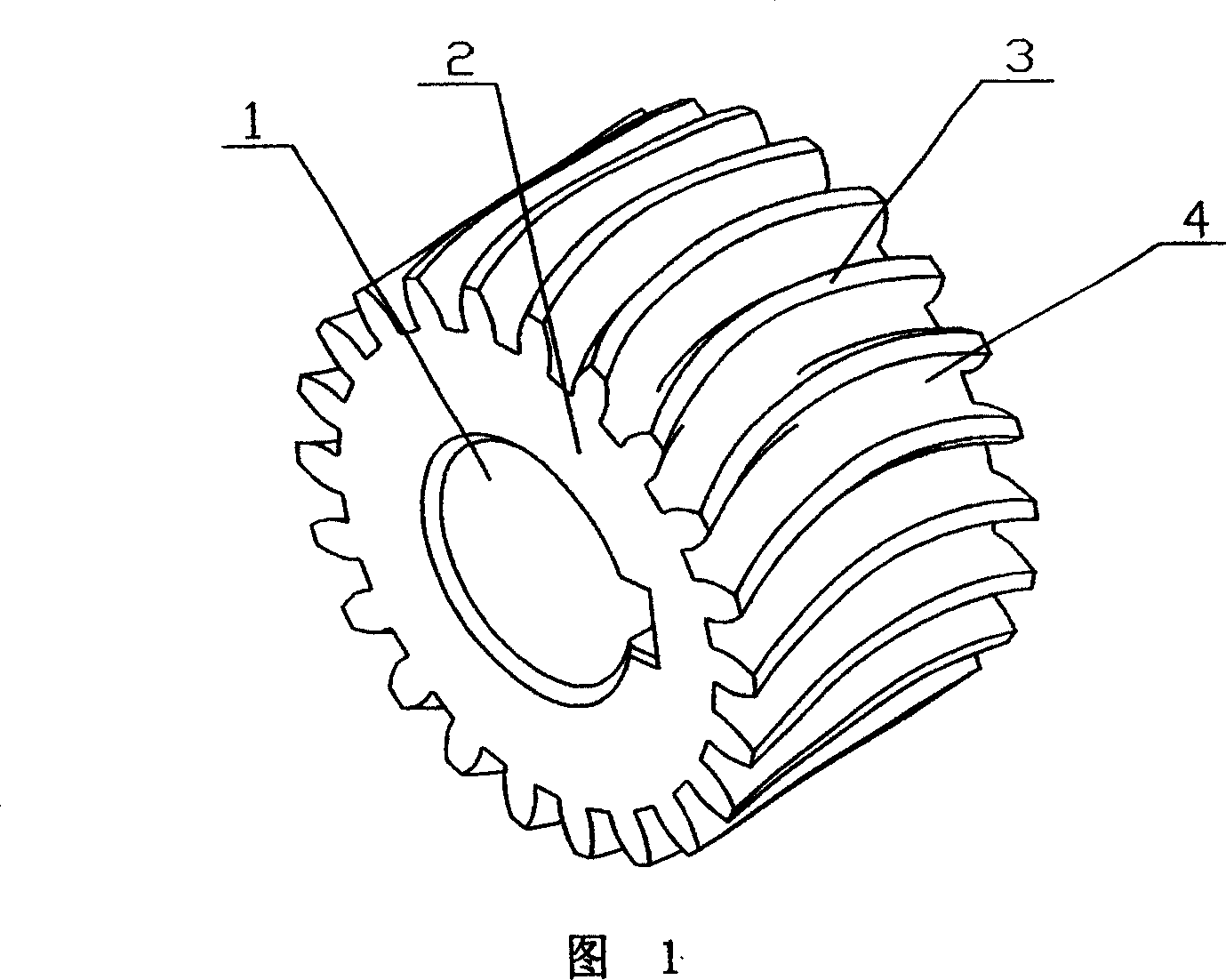

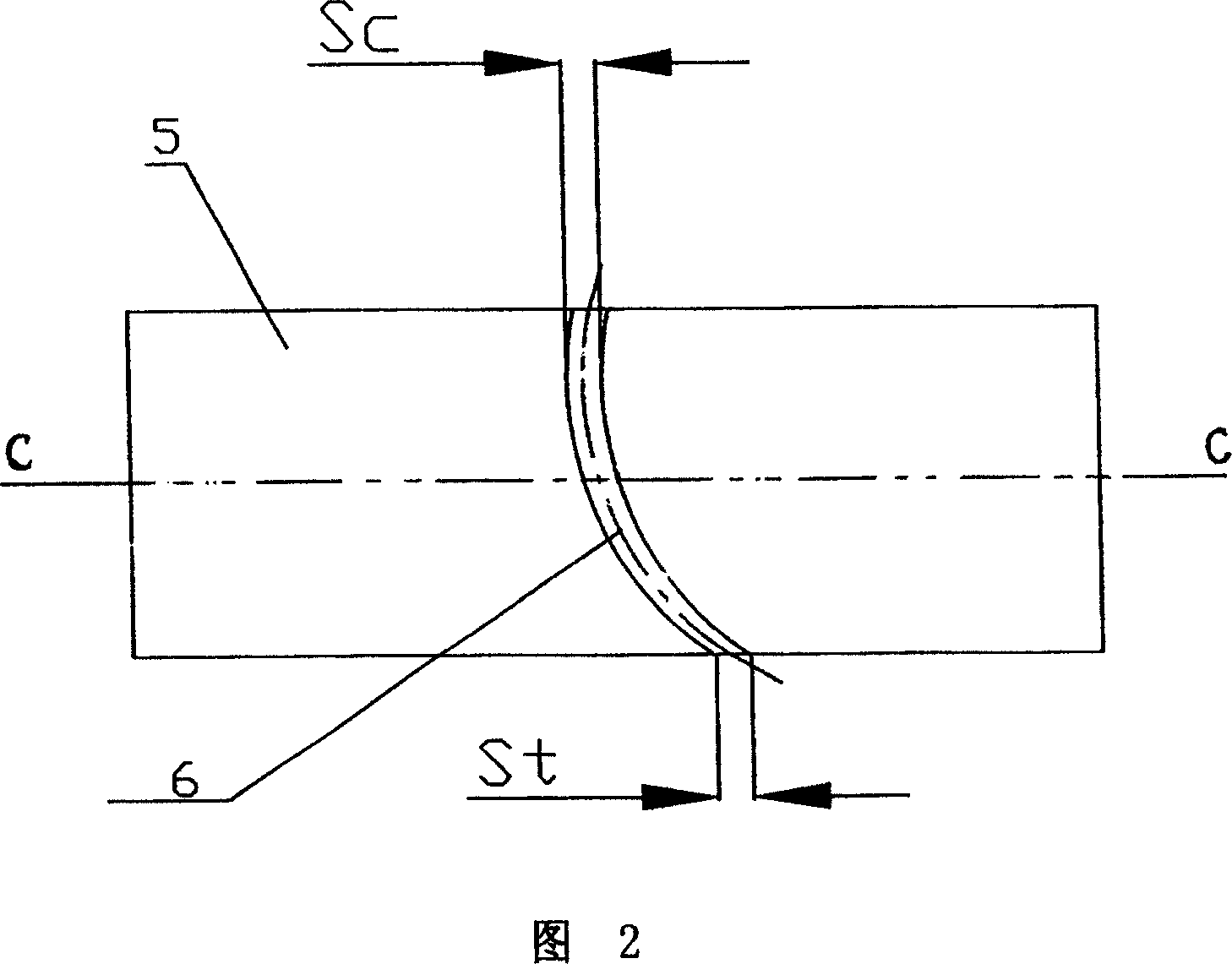

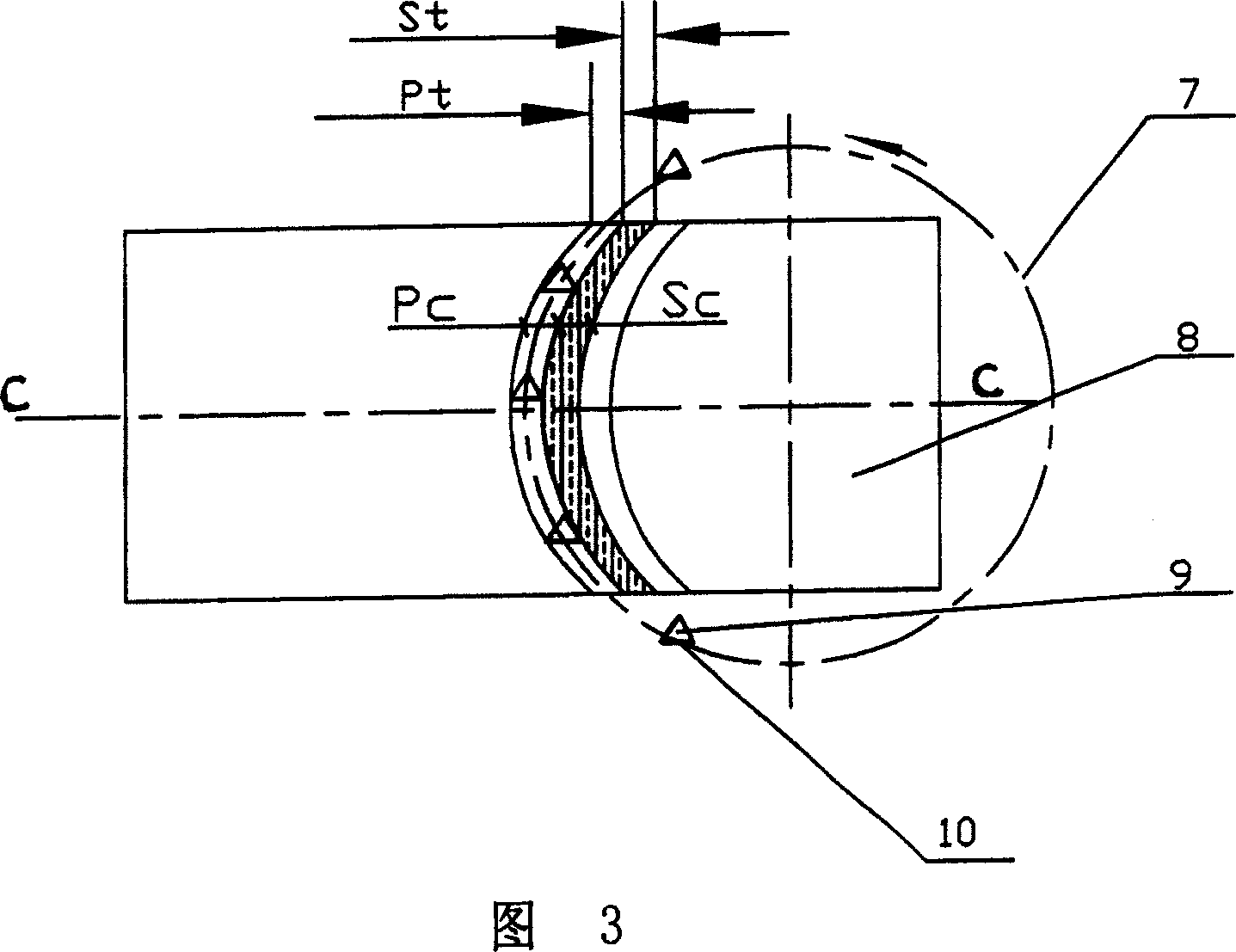

Screw rotor end face profile pair and construction method thereof

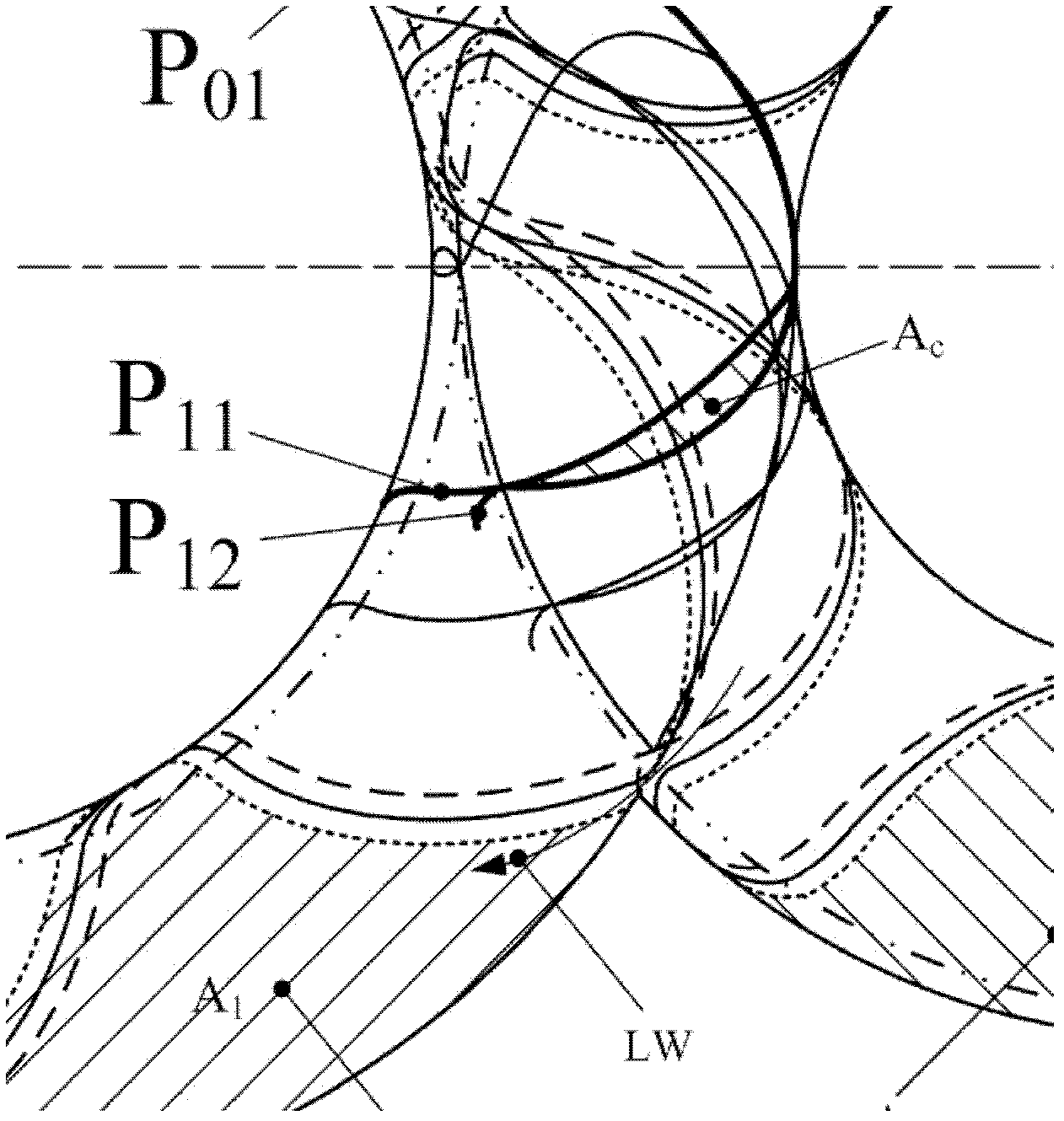

ActiveCN102352840AImprove machinabilitySmooth meshingRotary piston pumpsRotary piston liquid enginesEllipseMechanical engineering

The invention provides a screw rotor end face profile pair and a construction method thereof. The screw rotor end face profile pair comprises a pair of conjugated male rotor profile and female rotor profile, wherein each tooth profile in the male rotor profile and the female rotor profile is formed by six curves in a smooth connection mode; segmented curves of the male and female rotors are first-order continuous, rotor profiles formed by the segmented curves and envelope curves of the segmented curves are not interfered each other; and each curve comprises four segments of elliptical arcs, two segments of arcs and envelope curves of the arcs. According to the invention, tooth crests of driven edges of the male and female rotors are in an elliptical arc transition, and the tooth root and the tooth crest of a driving edge of the male rotor are in an elliptical arc transition, so that the construction of the profile is flexible, the machinable performance of the rotor can be improved, more importantly, the torque generated by the gas pressure on the driven edge of the female rotor can be adjusted, thus the smooth mesh of the rotors can be ensured; no pin tooth arcs are used, thus the meshing stability can be improved; the adjustable construction parameters are more, thus different performance requirements can be satisfied; the combination of the rotor tooth profile pair is diversified, thus the tooth profile pair can be applied to different occasions.

Owner:SHAANXI FENGZE ELECTROMECHANICAL TECH

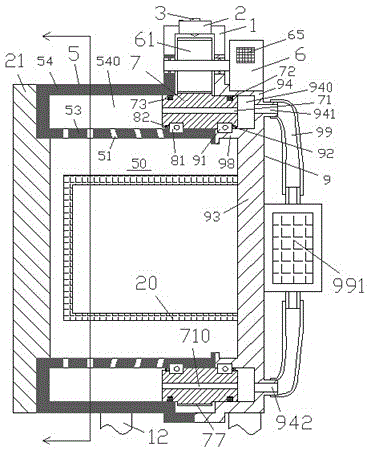

Speed-adjustable medical ozone disinfection cabinet device stable in operation

The invention provides a speed-adjustable medical ozone disinfection cabinet device stable in operation. The speed-adjustable medical ozone disinfection cabinet device comprises an ozone airflow ejection device (5). The ozone airflow ejection device (5) comprises an annular inner-layer part (53) internally provided with a cylindrical disinfection chamber (50) and an annular shell part (54) surrounding the annular inner-layer part (53), wherein the annular inner-layer part (53) and the annular shell part (54) are integrally formed. The annular inner-layer part (53) is internally provided with a plurality of circles of blowing air passage sets distributed in the axial direction. A plurality of blowing air passages (51) in the radial direction are evenly distributed in each circle of blowing air passage sets in the peripheral direction to input airflow in the radial direction of the cylindrical disinfection chamber (50), and an annular airflow distribution cavity (540) is formed between the annular shell part (54) and the annular inner-layer part (53).

Owner:沁瀚(浙江)医疗器械有限责任公司

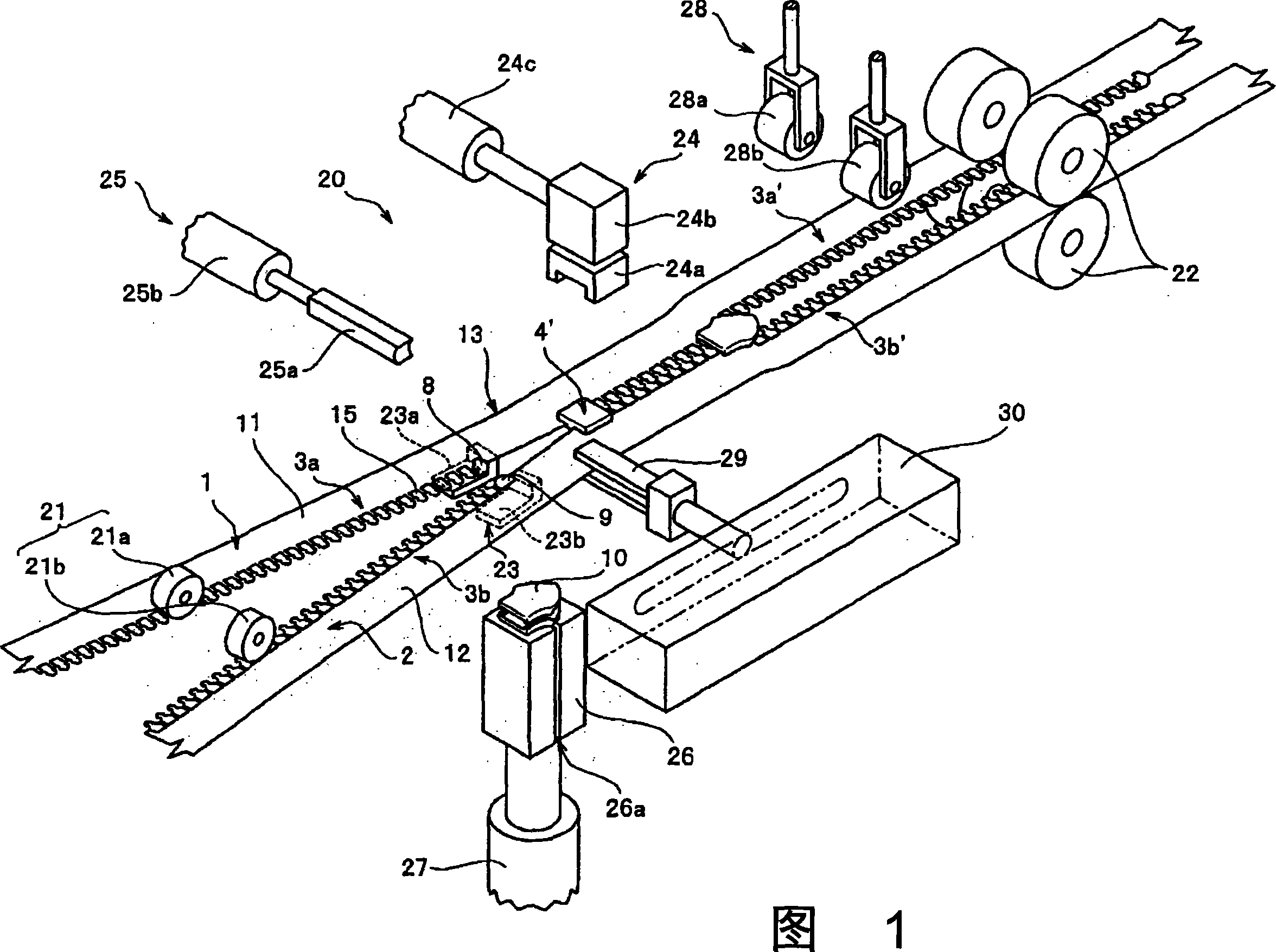

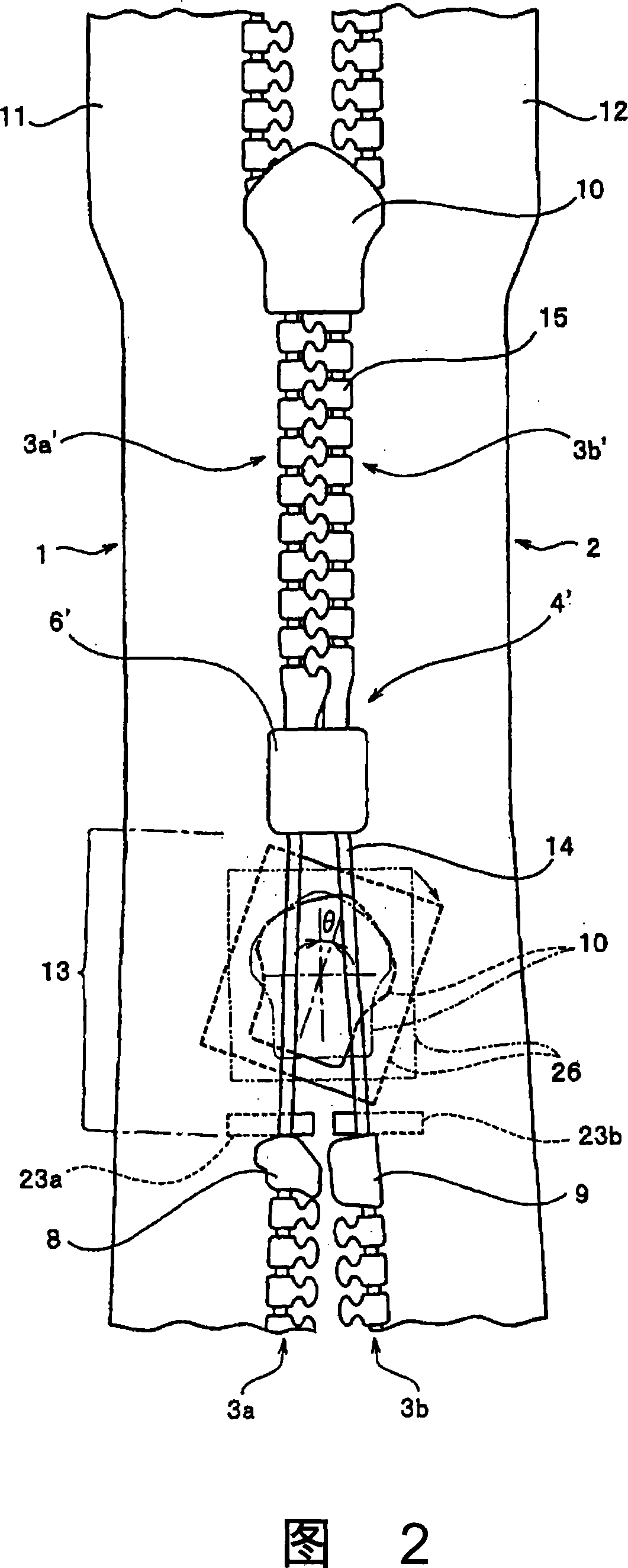

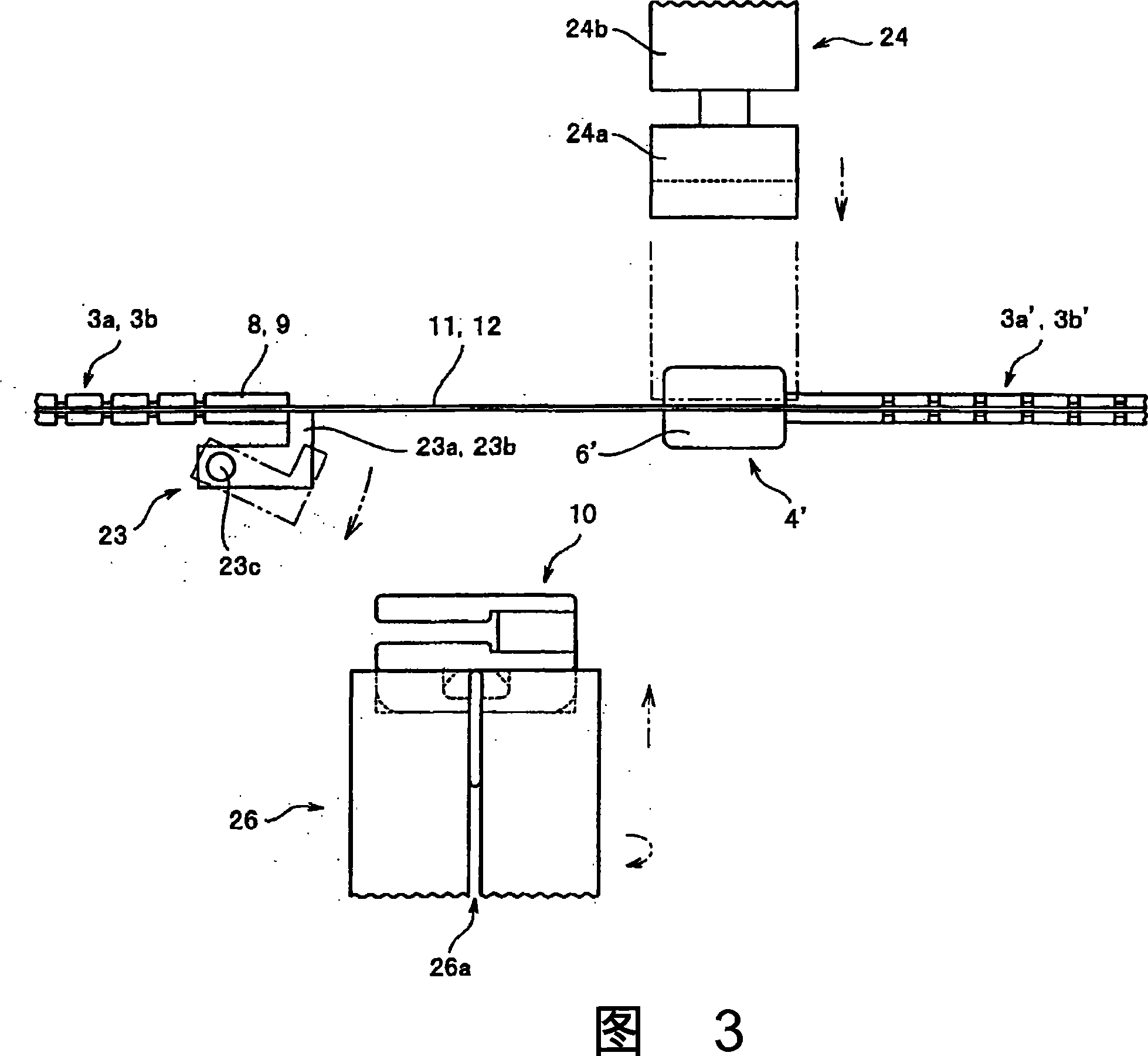

Fastener head covered method and fastener head covered device

The present invention provides a method of setting a set of left-and-right slide fastener's vertical-line slider,making one end which is automatically set at the chain tooth line possess detachable bottom stop block,and making the other side of the slide fastener possess top stop block.Following the present invention the method of setting the slide fastener's slider is setting the slider(10) on the chain tooth lines(3a,3b) between the first and second vertical strip(1,2),includes: the first working procedure of orienting the direction of the chain tooth lines(3a,3b) to make the first and the second vertical line of the slide fastener(1,2) in a right-and-left curving state;the second woking procedure of moving the slider(10) to make the first vertical strip(1) located on the side of the slider(10) and make the second vertical strip(2) linking to the below wing board(18);the third woking procedure of jointing the first vertical strip(1) to the slider(10);the fourth working procedure of moving the first and the second vertical strip ahead to joint the box-shaped pin(5) to the slider(10);and the fifth working procedure of countermarching the inserted pin(7) when it has moved to the frontage of the slider(10) to make the slider(10) setting on the right-and-left chain tooth line.

Owner:YKK CORP

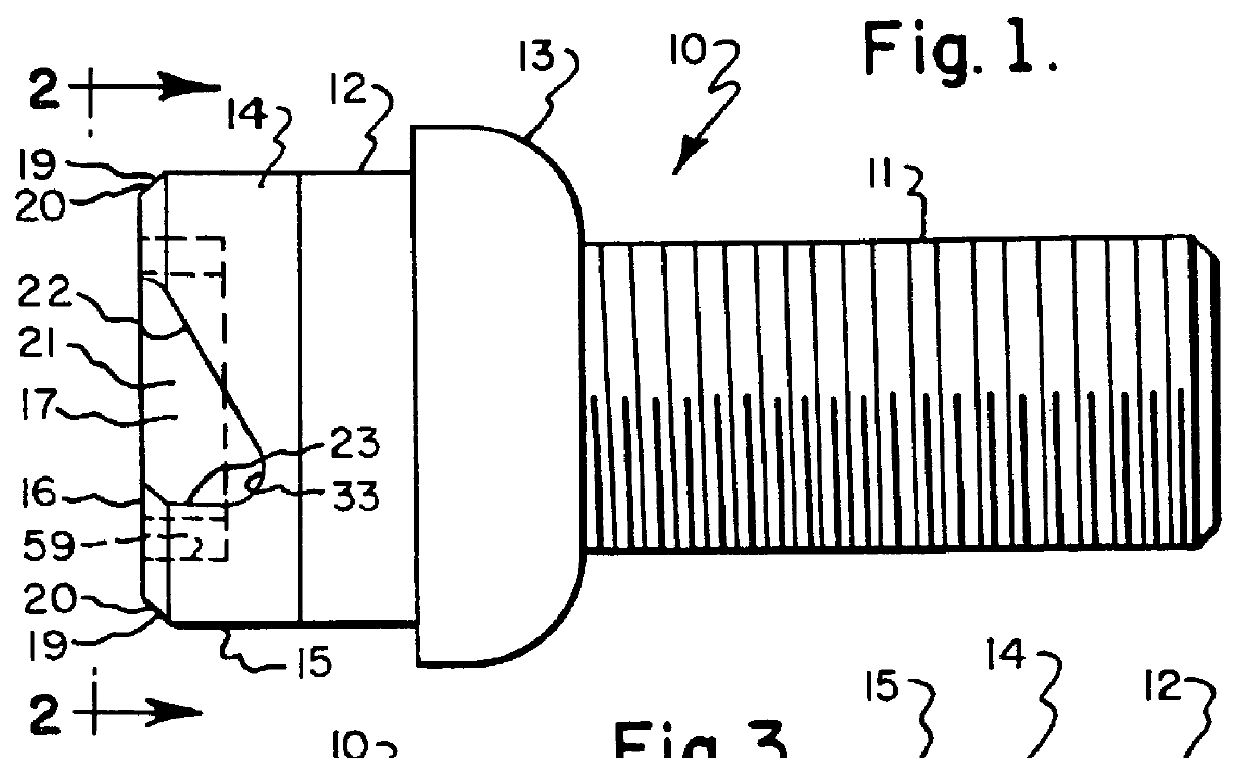

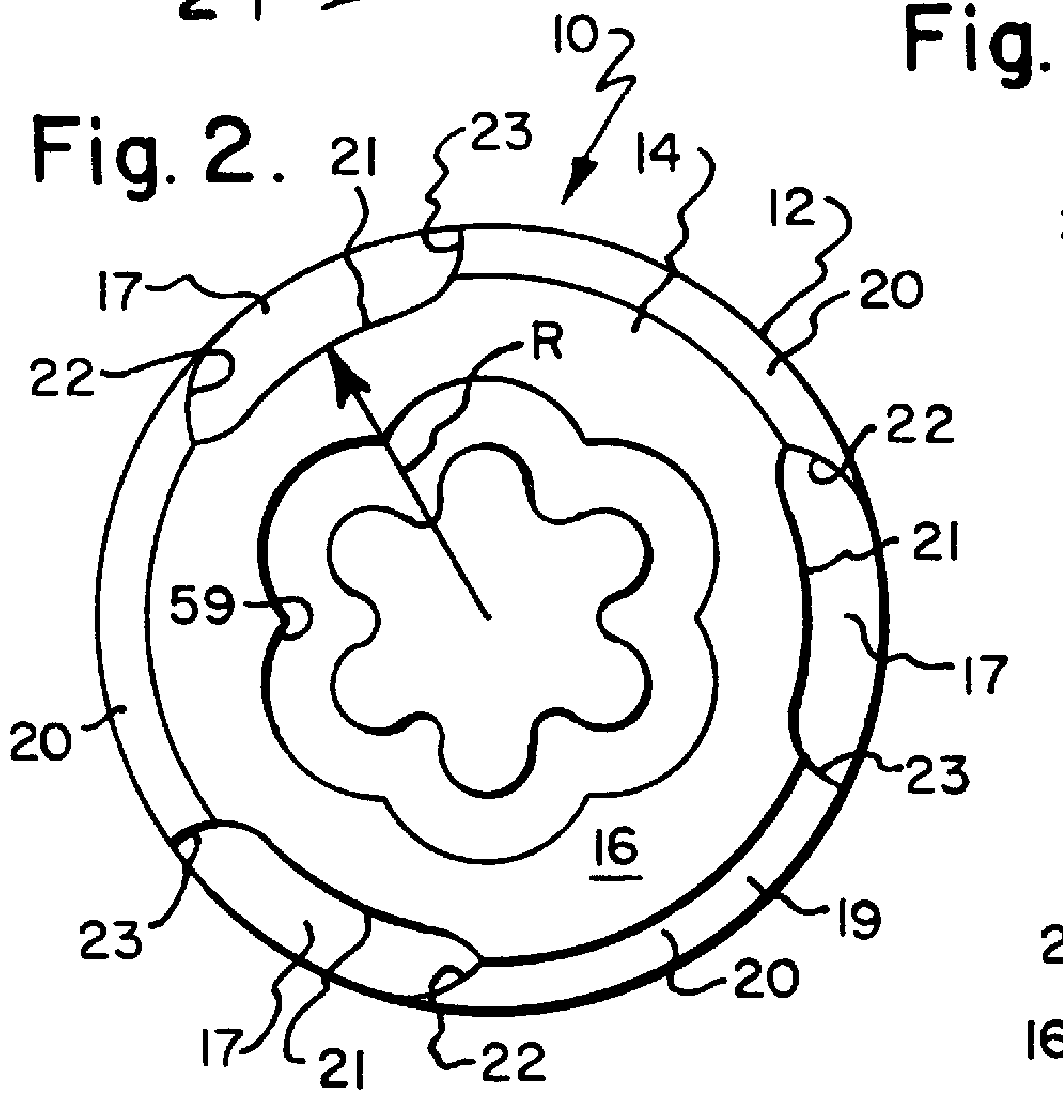

Security fastener and drive tool for driving both security fasteners and conventional fasteners

A security fastener including a body having a circumferential periphery and an end wall, a curvilinear groove in the end wall, a plurality of circumferentially spaced depressions extending inwardly into said circumferential periphery from said end wall and having a bottom wall and first and second side walls, junctions having radii between the bottom wall and the side walls. One of the side walls extends at a greater angle to the axis of the fastener than the other side wall, which is engaged by the driving tool. A driving tool for driving both the foregoing security fastener and a conventional hexagonal fastener including a body having a bore with a plurality of axially extending splines for selectively engaging either the above-mentioned side wall of the depression of the security fastener or a plurality of sides of the hexagonal fastener.

Owner:MCGARD

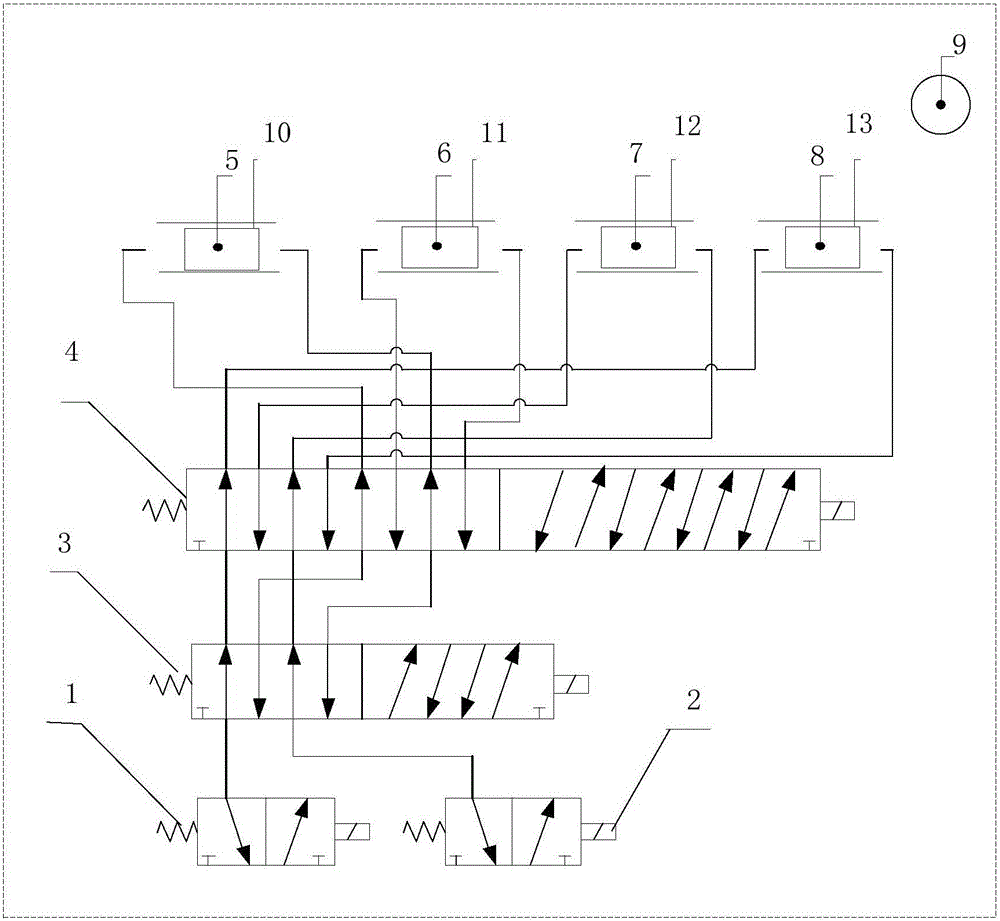

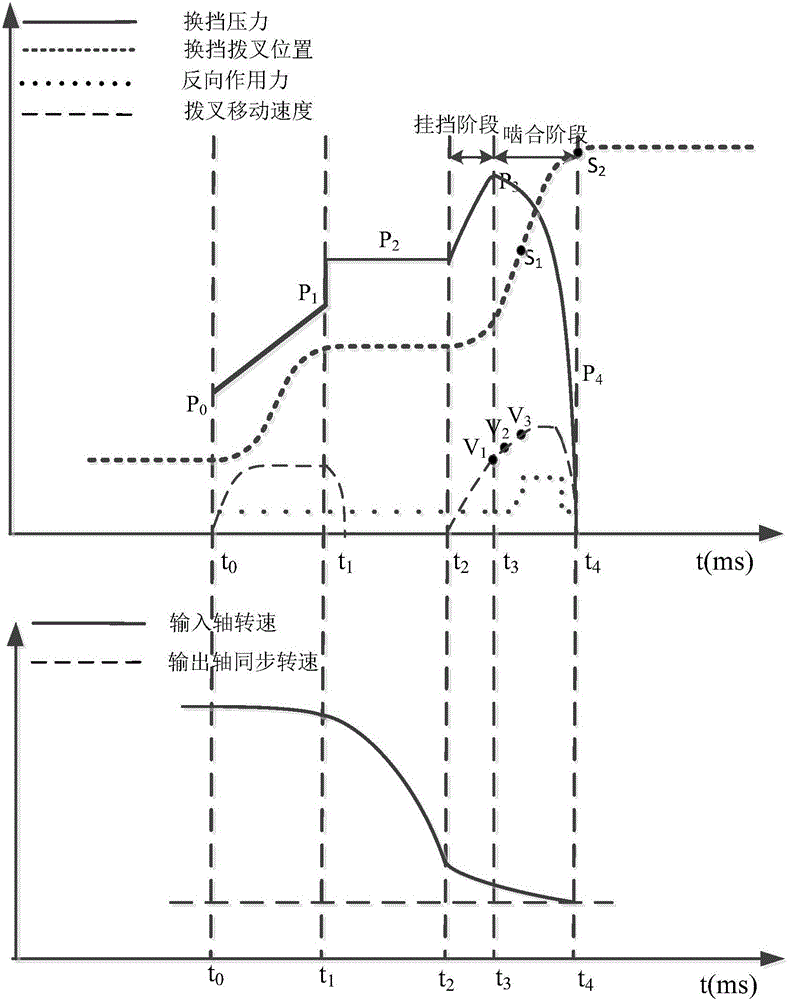

Gear engaging control method for dual-clutch automatic transmission with synchronizer

The invention provides a gear engaging control method for a dual-clutch automatic transmission with a synchronizer. According to the method, gear shifting is divided into two stages from synchronization to engagement, i.e., the gear engaging stage and the engaging stage. A closed-loop control mode is provided, smooth engaging of a gear sleeve and a connection gear is achieved by means of the control method that positive gear shifting force is controlled through a curve path mode and negative acting force is regulated in real time according to the position of a gear shifting fork and the moving speed of the gear shifting fork, and therefore gear shifting impact is reduced.

Owner:CHINA FIRST AUTOMOBILE

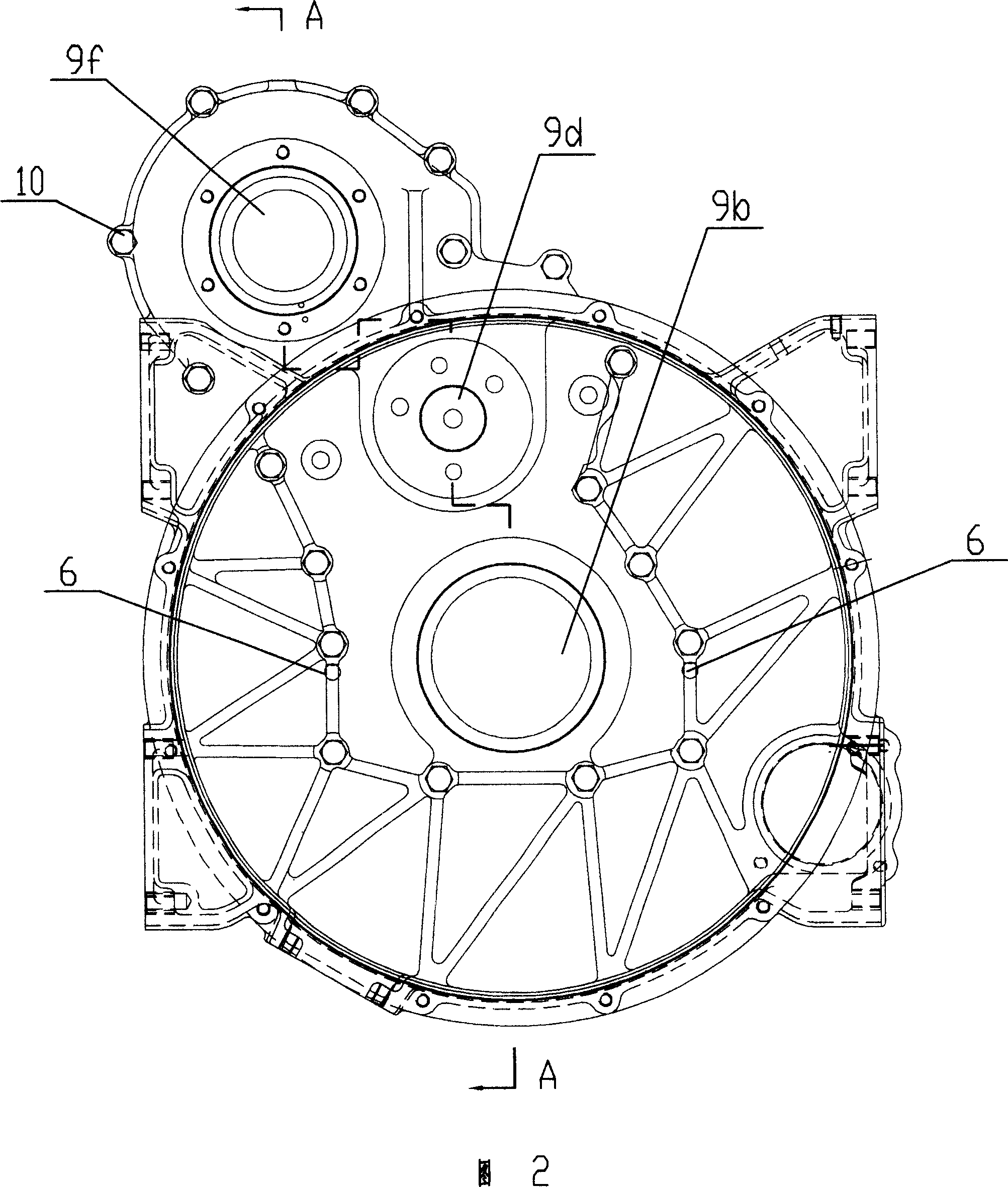

Method for processing output end tank of double-power output engine

InactiveCN1963262ASolve difficult clampingGuaranteed concentricity requirementsMachine framesGearboxesGear wheelEngineering

The processing method for a dual power outlet case of an engine is like this: fastening the flywheel cover to the special flywheel clippers, locating the rear casing and the flywheel housing through the locating pin, then, using the screw fastening the rear case on the end face of the flywheel housing through connecting holes. It solves the difficulty of clamping of rear cases with accurate location, complete same with the using status. With one time clamping, one time processing, it ensures the concentricity requirement of the side outlet gearbox gear shaft or bearing holes, with stable teething, low rotating noise and long durability.

Owner:SHENGRUI TRANSMISSION

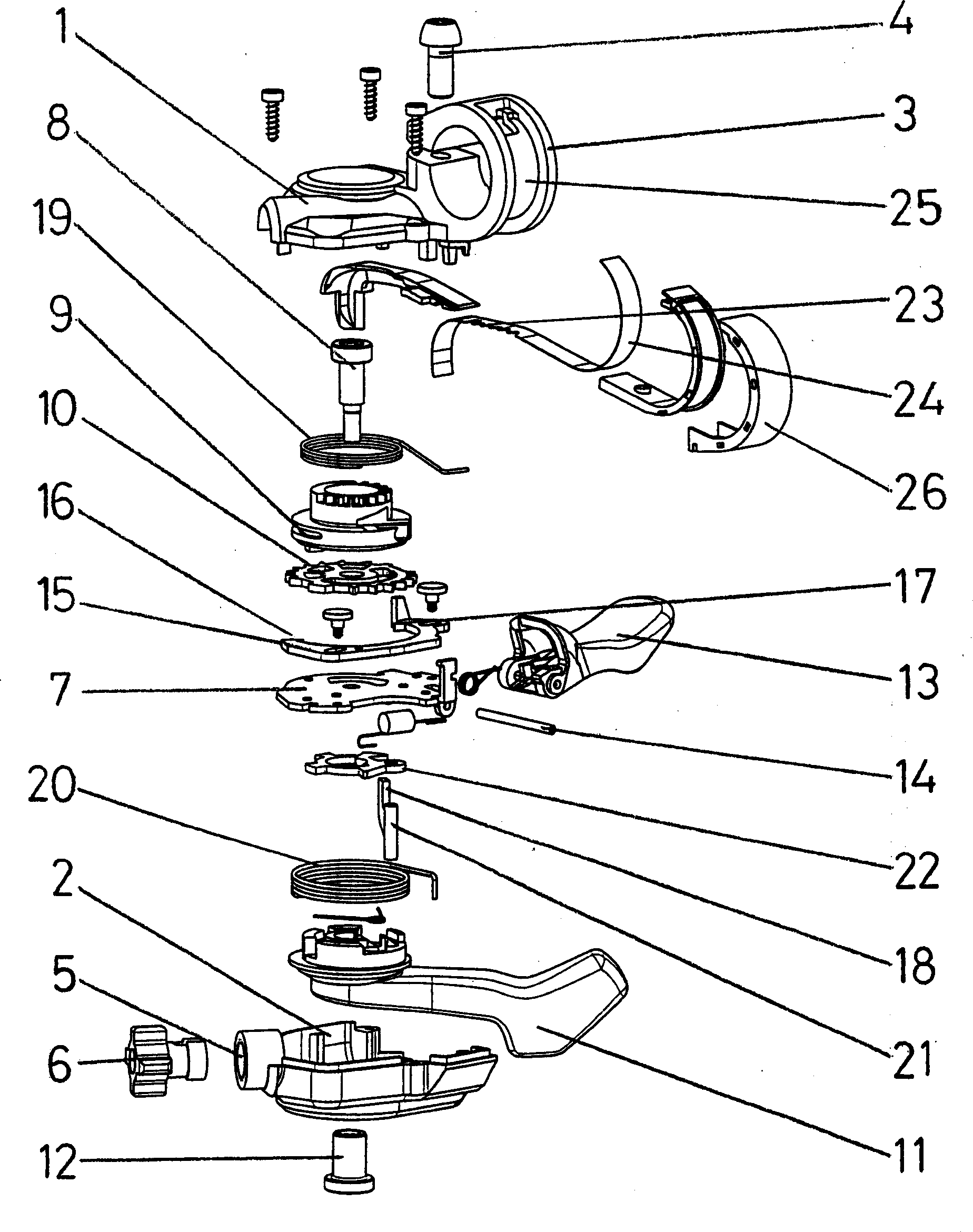

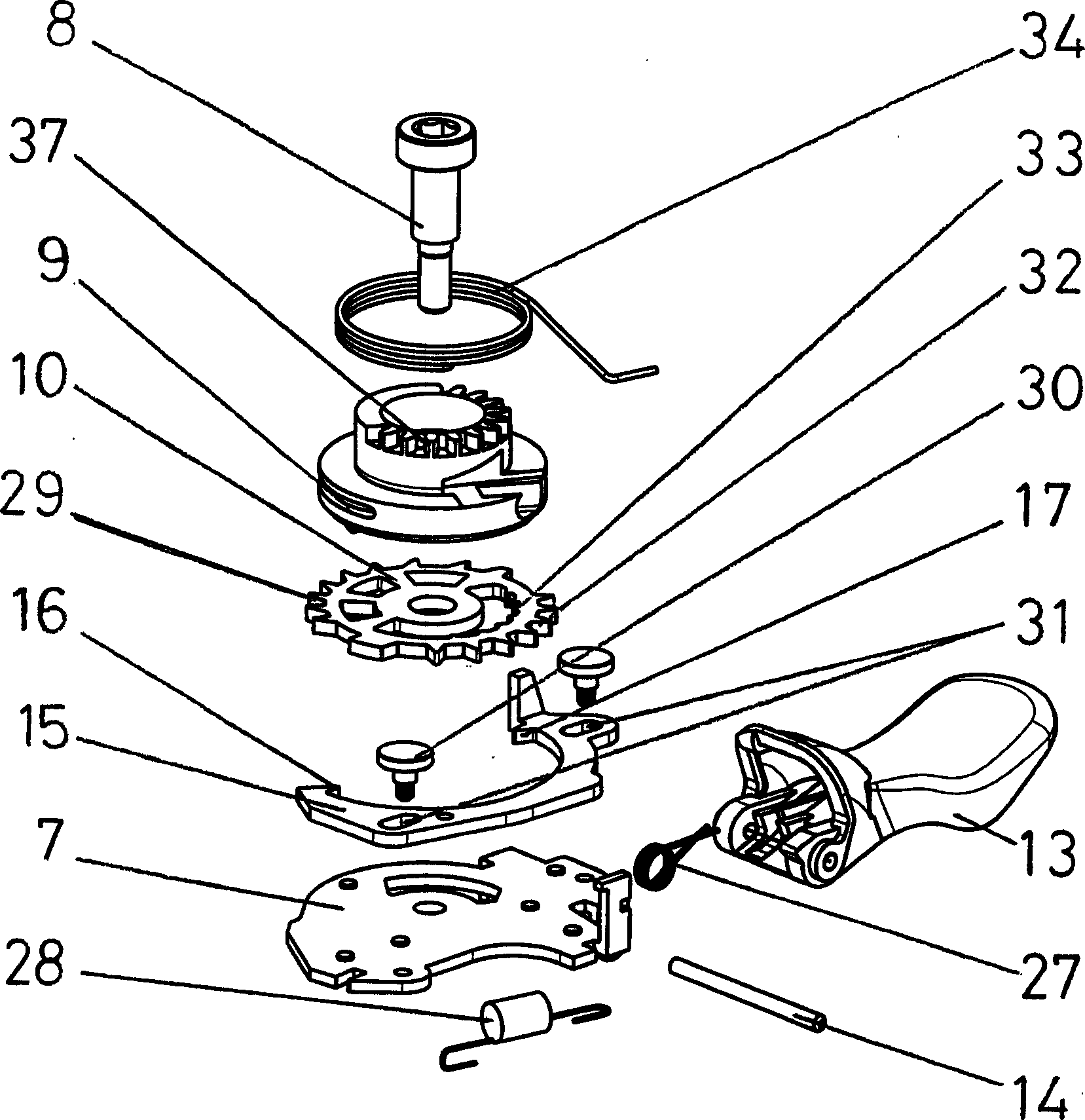

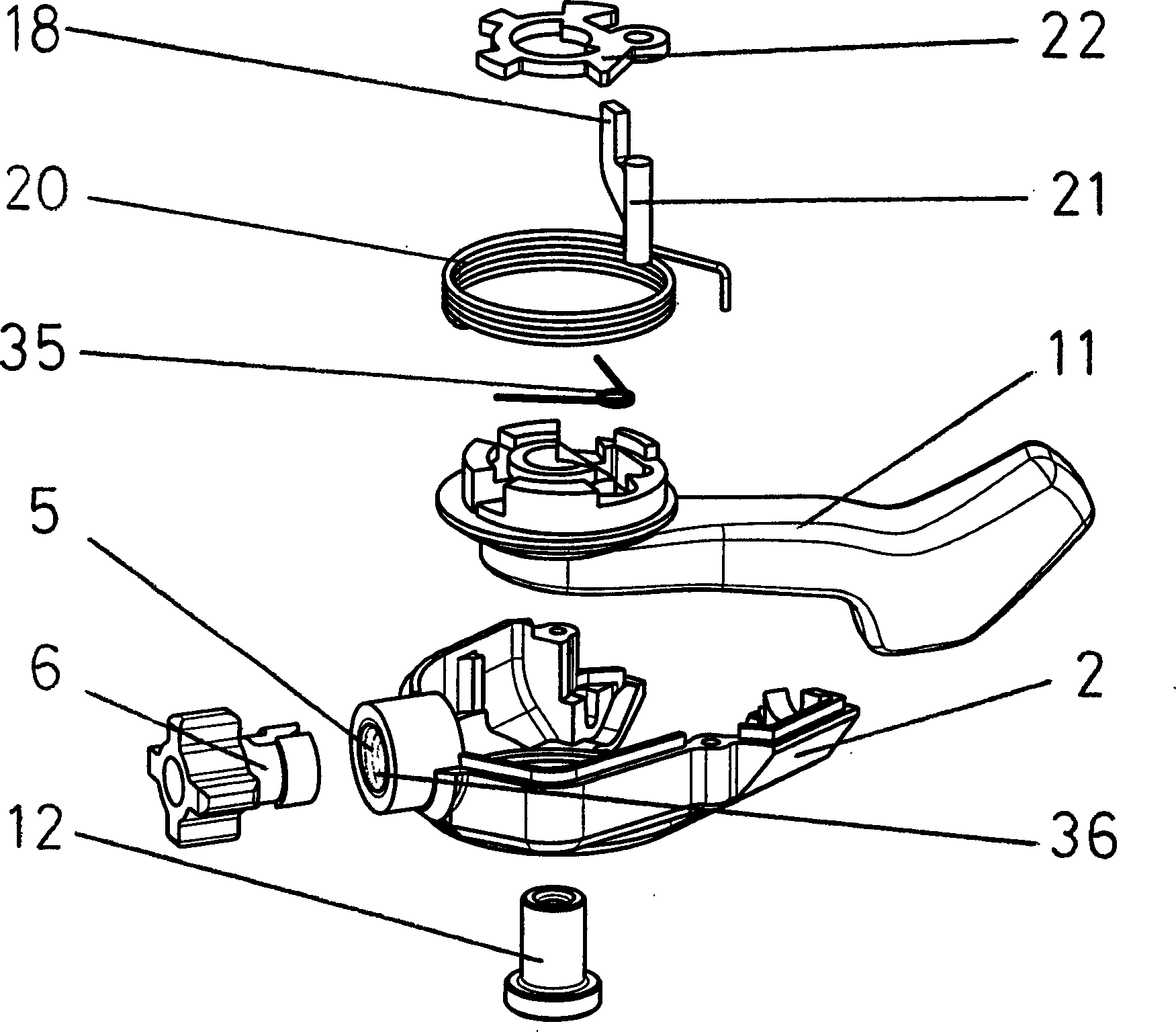

Steel cable tension mechanism for handle-type gear changer

This invention relates to a trigger-switch with a pull-up, holding and release mechanism in level or rotation-grasp-switches to operate the bicycle gear-shifter. The switch is composed of a housing with integrated handle-bar-clamp and a pull-up-, holding, release and display mechanism. The tooth-segments, in which a pull-up-, holding and stop-claw is engaged respectively, necessary for the pull-up, holding and release-process are mounted in only one dish-shaped member. Thus a tooth-segment, preferably with inner tooth, is arranged inside of the circumference in an opening of the dish-element. The pull-up-movement is transferred over a slim pull-up-claw of the operation-element through the carrier-plate to the pull-up-tooth segment located inside of the dish-element. The actual gear-state is transferred over an elastic display-band, which combs in a tooth of the rope-spool, from there out around the handle-bar, along the handle-bar-clamp into the visible region of the rider. In order to improve the display-discrimination, a transparent cover of the display-band is formed as lens or amplifying glass. The switch mechanism is surrounded by a switch-housing and a casing-element composed of plastics. The receptacle of the adjusting-bolt for the gear-traction stress exists on this casing-element.

Owner:SRAM

Twin-screw compressor rotor profile

InactiveCN102052322AContact wire shortLeaky triangle smallRotary piston pumpsRotary piston liquid enginesBilateral asymmetryEllipse

The invention relates to a twin-screw compressor rotor profile, wherein a two-side asymmetric profile is adopted, six sections of profiles are combined to form end face profiles of a female rotor and a male rotor, and the female rotor and the male rotor which are identical in central distance A and different in size are combined to a form a female / male rotor profile series of a screw compressor. An arc f2g2 with a certain radius and an arc envelope d2e2 at the addendum circle on the passive side of the female rotor end face profile are in smooth connection through taking a straight line e2f2 as a common tangent. The elliptic arc b1c1 on the male rotor end face profile is different from the ordinary arc pin tooth curve or the envelope and can enable the engagement and releasing of the male and female rotors to be more stable through properly adjusting the length ratio of the major and minor axes of the ellipse, so as to reduce noise and vibration. The included angle of the addendum arc c1d1 on the male rotor end face profile can be adjusted, and the addendum arc c1d1 is in tangent and smooth connection with both the elliptic arc b1c1 and an arc d1e1. The invention endows the rotors with the advantages of short contact line, small disclosed triangle, big flow passage area, streamlined rotor profile, reduced aerodynamic resistance and the like.

Owner:南通永力液压设备有限公司

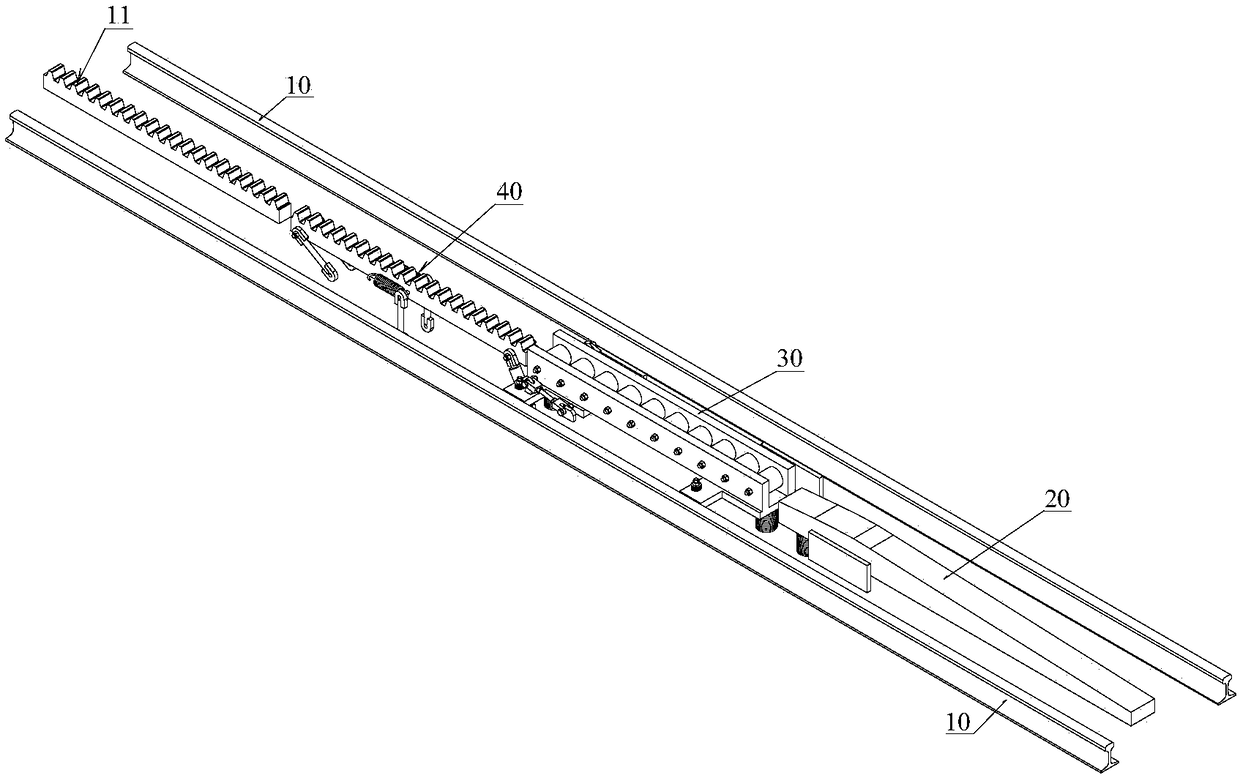

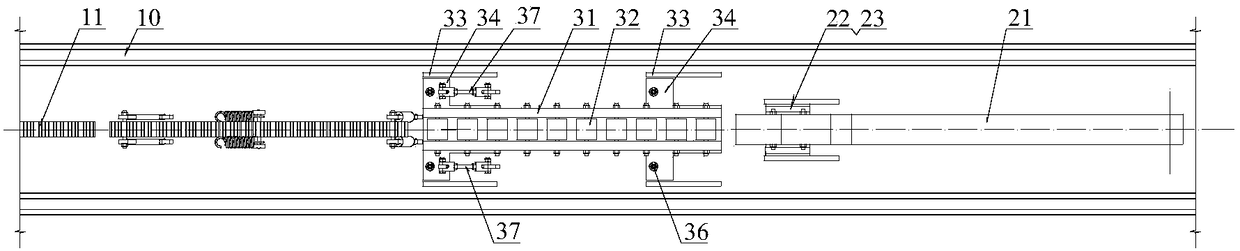

Non-stop three-section wheel rail-rack rail transition device for rack rail traffic system

ActiveCN108149529AAvoid top teethSmooth meshingRailway tracksRailway transportDrive wheelEngineering

A non-stop three-section wheel rail-rack rail transition device for a rack rail traffic system is used for enabling smooth transition of a rack-rail vehicle from a wheel-rail section to a rack rail section to guarantee stability and safety in operation of the vehicle. The non-stop three-section wheel rail-rack rail transition device comprises a rack rail mounted between steel rails on two sides, arack transition device, a roller transition device and a slope transition device are sequentially arranged in front of a driving-in end of the rack rail, the slope transition device, the roller transition device and the rack transition device sequentially act on driving gears passing through the rail-rack vehicle to enable relative slide between driving wheels of the rail-rack vehicle and the steel rails by vertical force, and the driving gears and the rack rail are effectively meshed when the vehicle enters the driving-in end of the rack rail.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

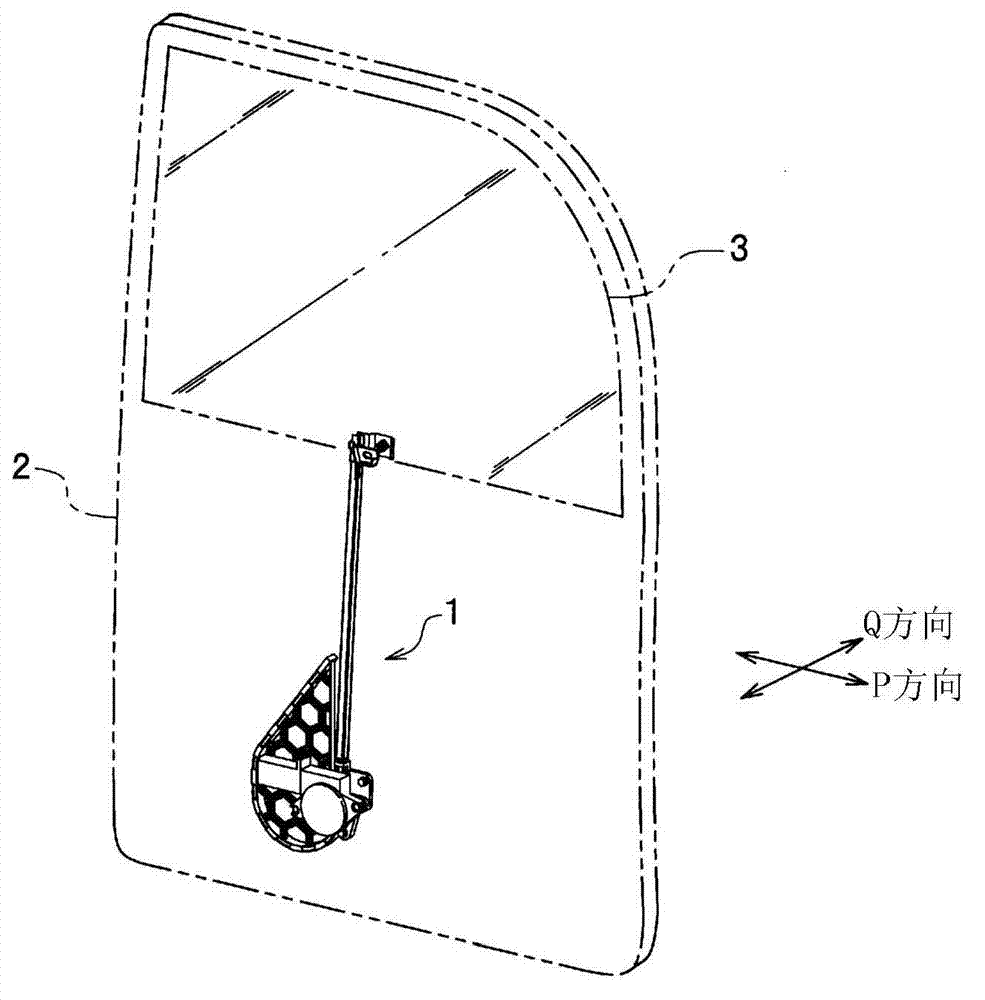

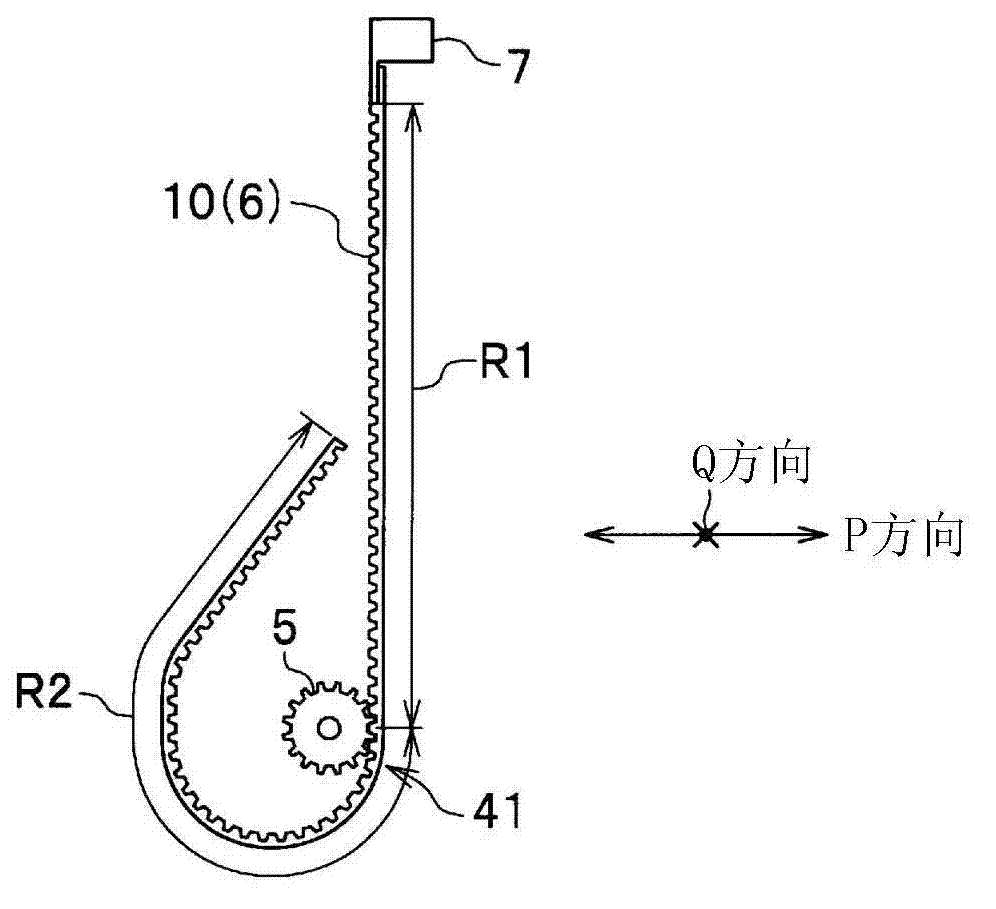

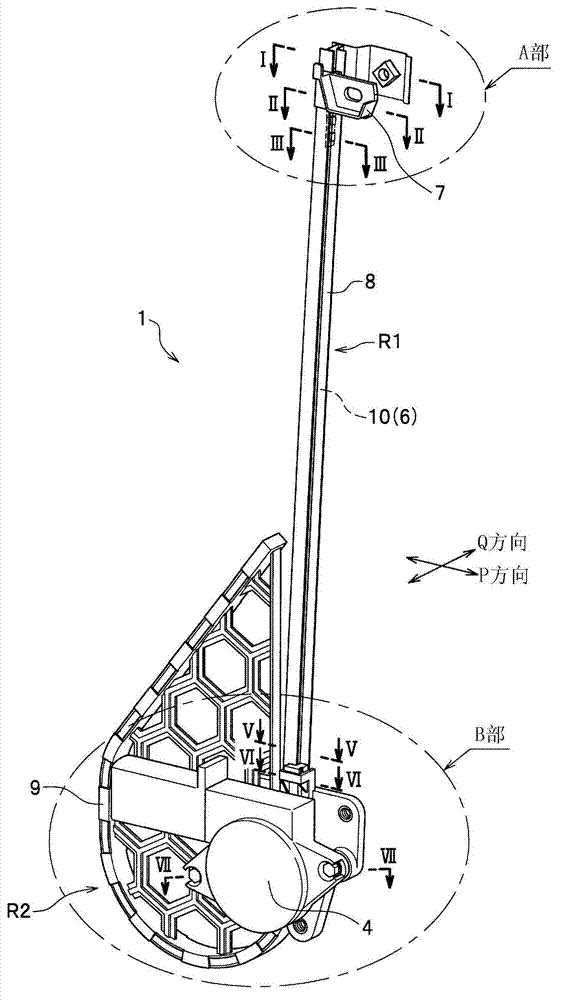

Window regulator

ActiveCN103201447AReduce the formation rangeAchieve compactnessWindowsWindscreensPush pullDrive motor

A window regulator (1) comprises a drive gear that is attached to a drive motor (4), a pliable push-pull member (6) with an open end that engages with the drive gear and is push-pulled by the two-way rotation of the drive gear, a carrier (7) that connects to one end side of the push-pull member (6) and connects to a window pane, and a guiderail (8) that guides the push-pull member (6) and the carrier (7) in a drive route (R1), wherein a frame (9) is provided in which a means of fixedly supporting the drive motor (4), a means of fixedly supporting the guiderail (8), a means of retaining the path of the push-pull member (6) in an idling route (R2), and a means of attaching to an object to be attached, are integrally formed.

Owner:YACHIYO IND CO LTD

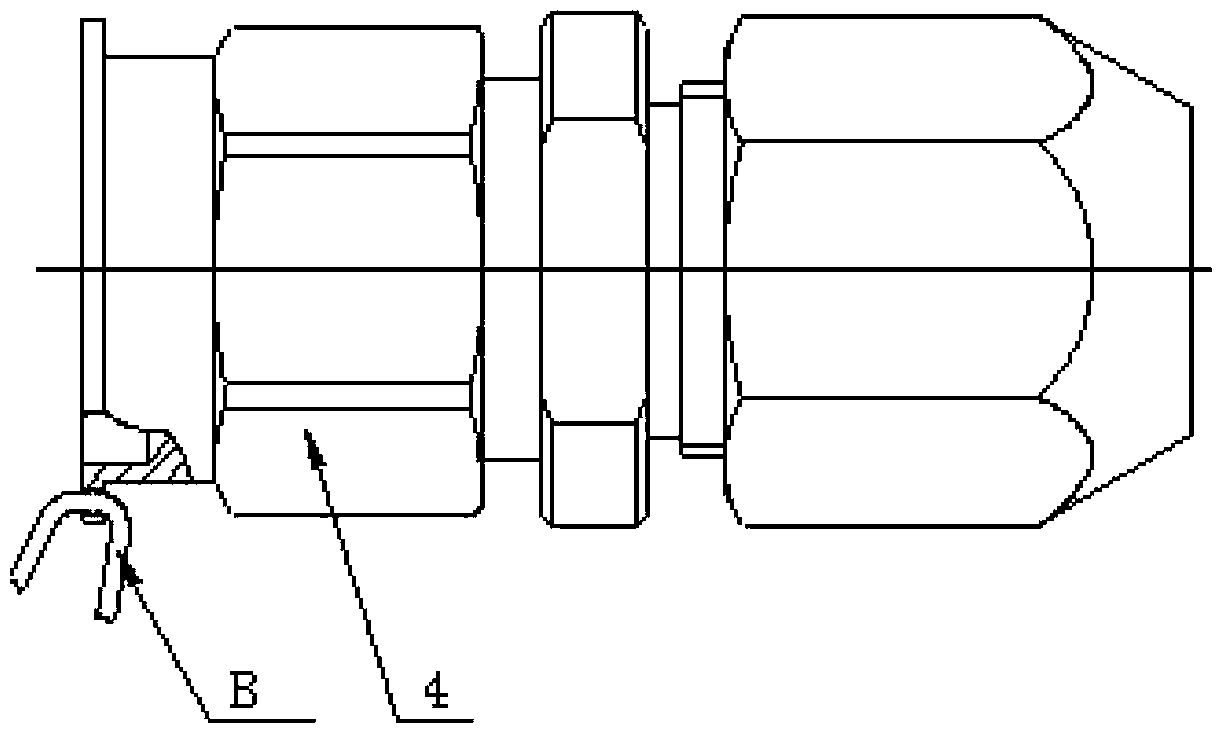

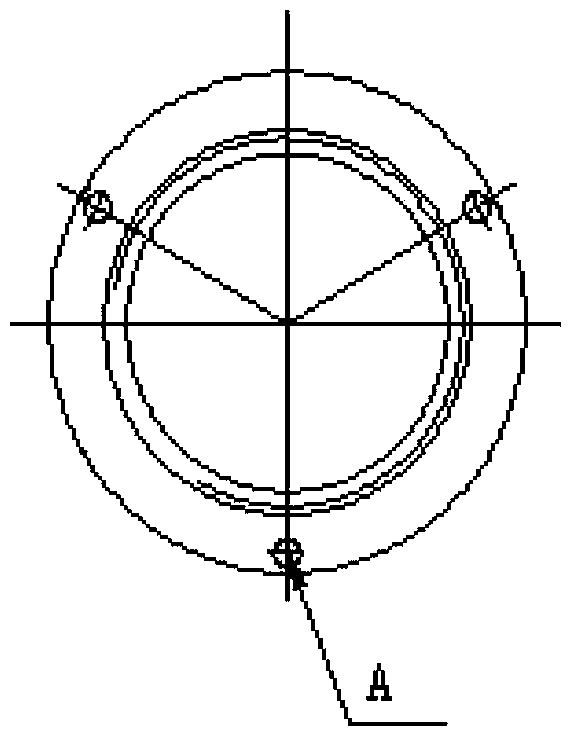

Ratchet wheel locking type thread coaxial connector

InactiveCN103457117AReliable anti-loosening functionSmooth meshingCoupling device detailsTwo-part coupling devicesElectrical conductorEngineering

The invention discloses a ratchet wheel locking type thread coaxial connector. The ratchet wheel locking type thread coaxial connector comprises an outer conductor, an inner conductor arranged in the outer conductor, an insulating medium arranged between the outer conductor and the inner conductor and a threaded sleeve which is arranged at the butt-joint end of the outer conductor and is connected with the outer conductor through a clamping ring. Because a looseness preventing sleeve is additionally arranged on a traditional thread connector, the contact ends of the looseness preventing sleeve and the thread sleeve are provided with ratchets respectively, when the two groups of ratchets are meshed, the threaded sleeve can rotate towards the screwing direction instead of the loosening direction, and accordingly the ratchet wheel locking type thread coaxial connector has a reliable looseness preventing function.

Owner:SHAANXI JINBO COMM TECH

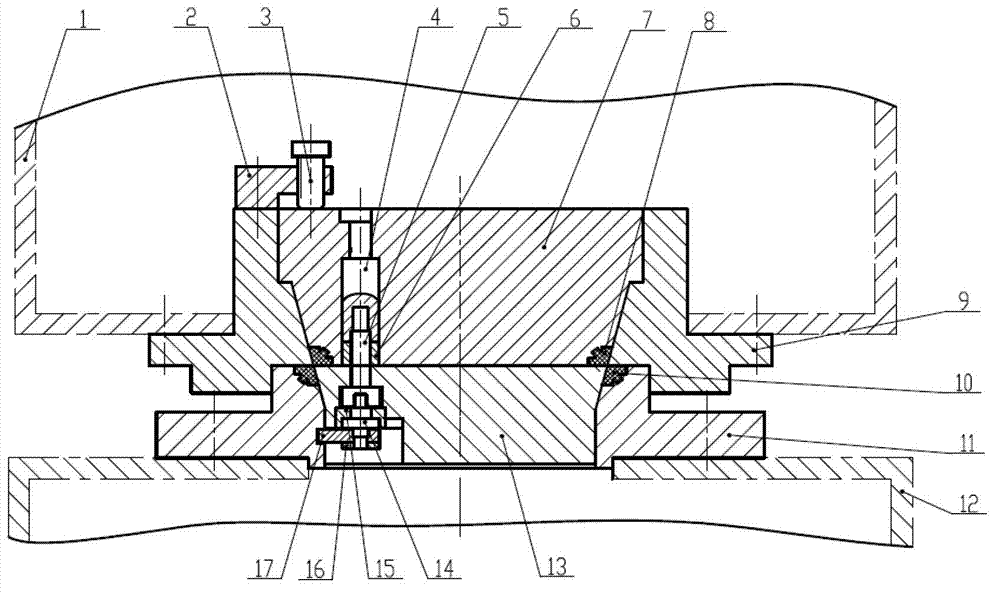

Multi-point locked double-cover sealing device

ActiveCN102881345AGuaranteed reliabilityImprove reliabilityPortable shielded containersRadioactive gasEngineering

The invention relates to a multi-point locked double-cover sealing device and belongs to the field of design of sealing transfer devices. The multi-point locked double-cover sealing device comprises an upper door component, a lower door component and a special tool, wherein each of the upper door component and the lower door component comprises a round door plate, a door seat and multiple sets of locking and unlocking devices; the door plate is arranged in the door seat; the multiple sets of locking and unlocking devices are arranged around the center of the door plate uniformly; a groove is formed at the lower end of a latch of the upper door locking and unlocking device; the latch passes through the lower door plate and is matched with a lock shaft of the lower door locking and unlocking device; the lower end of the lock shaft is connected with a clamping plate which rotates together with the lock shaft; the lock shaft is rotated by the special tool, so that the clamping plate is screwed in or out of the groove in the lower door seat and the lower door seat is separated from the lower door plate; and the latch is connected with the lower door plate, so that the upper door plate and the lower door plate are meshed with each other, sealing reliability in any state is guaranteed, and radioactive gas does not enter a personnel operating region.

Owner:CHINA NUCLEAR POWER ENG CO LTD

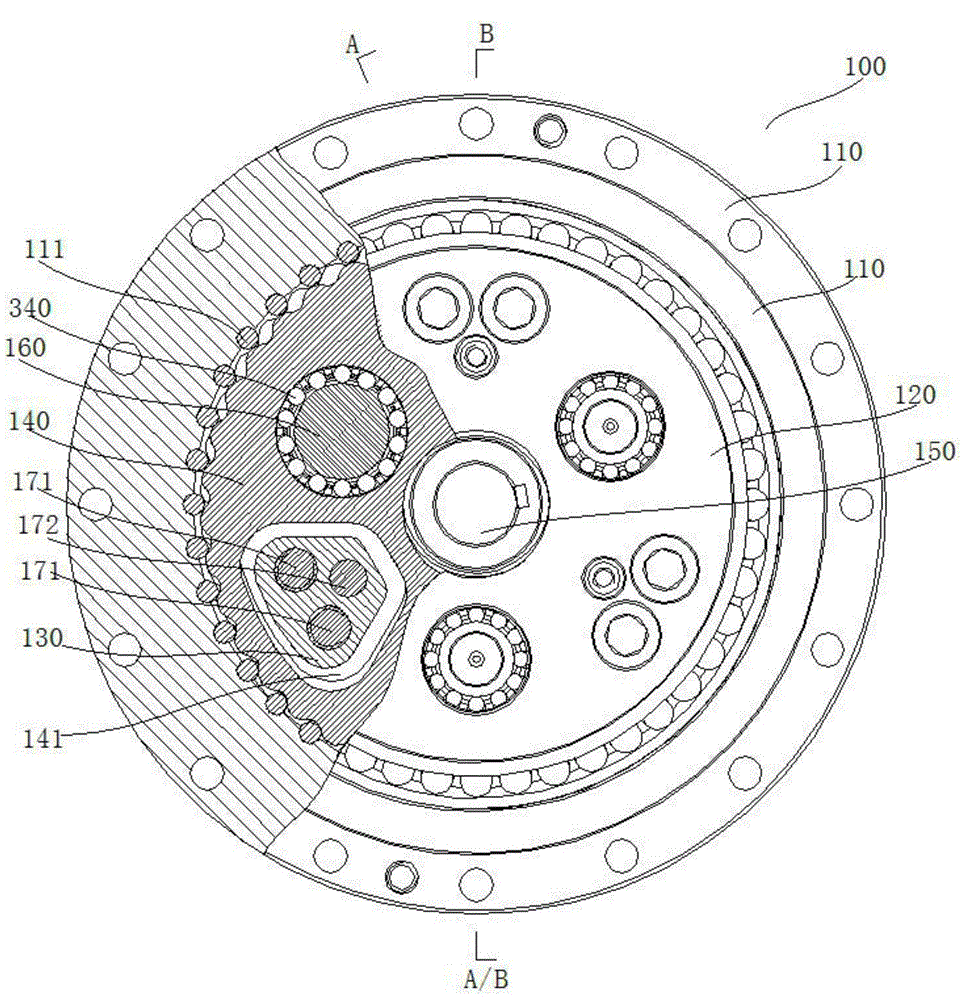

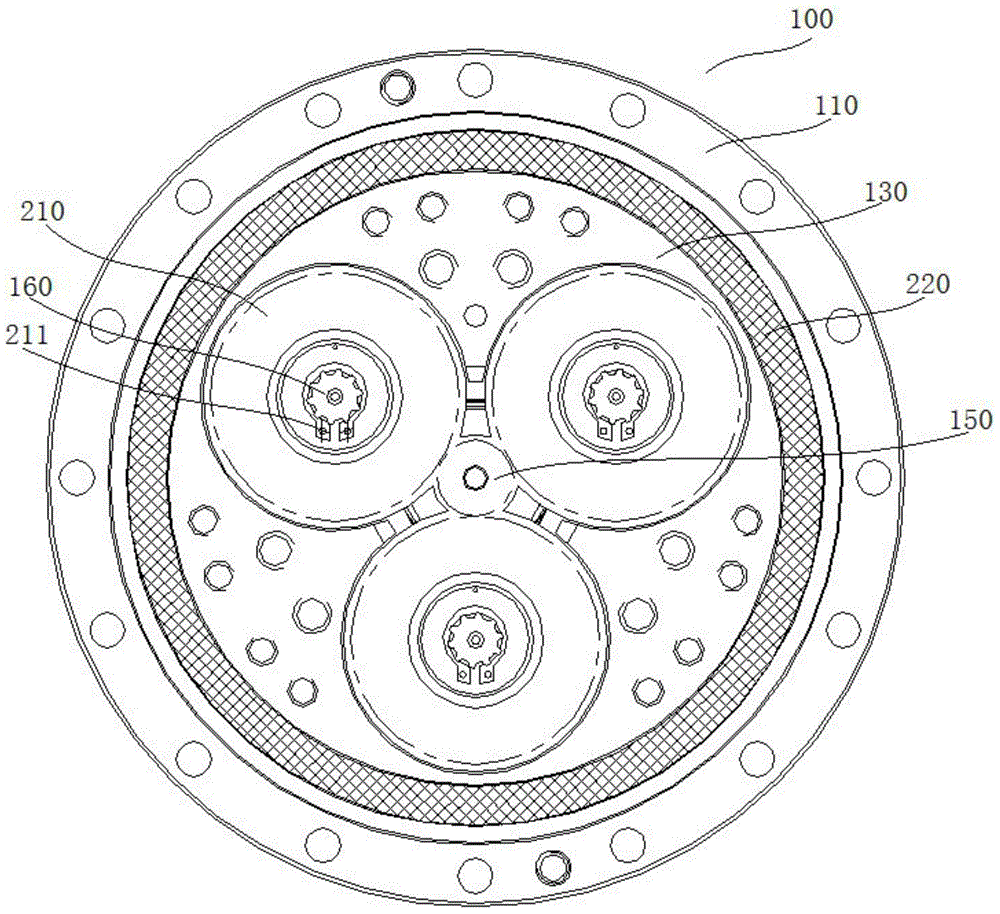

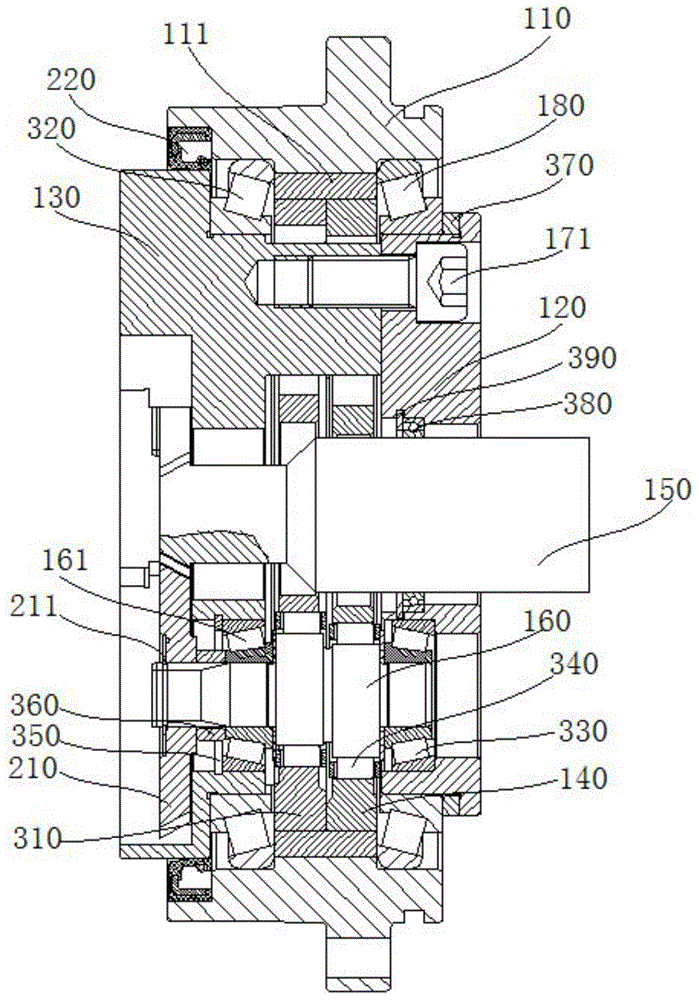

RV reducer comprising constant-depth tooth spiral bevel gear

InactiveCN104482130AReasonable structureCompact structureToothed gearingsGearing detailsReduction driveControl theory

The invention relates to a reducer, in particular to an RV reducer comprising a constant-depth tooth spiral bevel gear. One end of a pin gear casing is provided with an input planet carrier and the other end is provided with an output planet carrier; the input planet carrier and the output planet carrier are constructed to rotate within the pin gear casing after being fixedly connected; the internal wall of the pin gear casing is provided with a rolling pin; a pair of cycloidal gears are arranged between the input planet carrier and the output planet carrier and are constructed to be engaged with the rolling pin; a planetary gear is arranged on the output planet carrier; the center of the output planet carrier is provided with an input shaft which is engaged with the planet gear; the central shaft of the planet gear is provided with a crank shaft; the crank shaft is constructed to rotate on the input planet carrier and the output planet carrier; the pair of cycloidal gears are hinged to the crank shaft; the input shaft drives the crank shaft through the planet gear; the crank shaft drives the pair of cycloidal gears; the pair of the cycloidal gears drive the output planet carrier. The RV reducer comprising the constant-depth tooth spiral bevel gear is small in noise, high in first-level transmission contact ratio, stable in transmission, uniform in stress, compact in structure and can obtain small elasticity backlash.

Owner:ZHEJIANG SHUANGHUAN DRIVELINE

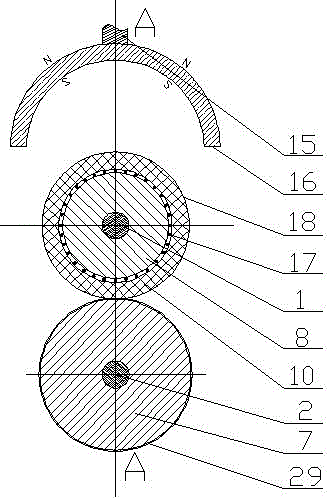

Spring pressure friction gear mesh clutch

ActiveCN103925310APower transmission efficiency is lowImprove transmission efficiencyFriction clutchesDrive shaftClutch

A spring pressure friction gear mesh clutch comprises a driving shaft, a set of driving gears and a set of driven gears, wherein the driving shaft is sleeved with the driving gears and the driven gears. The spring pressure friction gear mesh clutch is characterized in that driving shaft spline teeth are arranged on the right segment of the driving shaft, the driving shaft spline teeth are sleeved with the driving gears, and spline teeth in the driving gears are meshed with the driving shaft spline teeth; driving gear outer gears are installed on the periphery of the driving gears, a plurality of driving gear outer spline grooves are arranged in the periphery of the driving gears and matched with a plurality of driving gear outer gear inner spline teeth on the inner circle of the driving gear outer gears in a sleeved mode, and the width of the driving gear outer spline grooves is larger than the width of the driving gear outer gear inner spline teeth; a powerful high-strength spring is fixedly installed on the left side of the driving gears, and a circle of side gears are arranged on the left end face of the driving gear outer gears; the driven gears are installed on the left segment of the driving shaft and connected with the driving shaft through inner bearings of the driven gears; a friction ring on the right side of the driven gears is installed on the right side face of the driven gears, and a circle of driven gear right teeth are arranged on the right side face, close to the periphery of the driven gears, of the driven gears.

Owner:重庆尚平机械有限公司

Farmland fertilizer throwing equipment used for different water flow directions for water-conservancy projects

ActiveCN108235850ASmooth meshingSave energyFertiliser distributersRenewable energy machinesAgricultural engineeringWater flow

The invention relates to water-conservancy agricultural equipment, and particularly relates to farmland fertilizer throwing equipment used for different water flow directions for water-conservancy projects. The technical problem to be solved by the invention is to provide the farmland fertilizer throwing equipment used for different water flow directions for water-conservancy projects, wherein theequipment is used by adopting an automatic device and is time-saving and labor-saving. The invention provides the farmland fertilizer throwing equipment used for different water flow directions for water-conservancy projects, and the equipment comprises a mounting plate, support frames, a first fixing plate, a first bearing seat, a first rotating rod, a first conical gear, a first gear, a mounting block and the like; the left end and the right end of the mounting plate are both connected with one bracket; and the first fixing plate is connected to the left side of the lower side of the mounting plate. According to the equipment provided by the invention, the effects of saving time, saving labor and adopting the automatic device are achieved. A used mode is as the follows that water flow power is adopted to drive a rotating plate to rotate, then a material hopper is driven to rotate, and a material is thrown out, so that pollution-free power can be used, energy can be saved, the use oflabor force is avoided, and thus time and labor are saved.

Owner:NANTONG HISIN INFORMATION TECH CO LTD

Sewage filtering device capable of facilitating clearing sludge

InactiveCN108273310AEasy to cleanConvenience to workStationary filtering element filtersSludgeEngineering

The invention discloses a sewage filtering device capable of facilitating clearing sludge. The sewage filtering device comprises a shell; the shell is internally provided with a filter cartridge; filter holes are formed in the lower surface of the filter cartridge; the lower surface of the filter cartridge is fixedly connected with a first rotating shaft; the outer surface of the first rotating shaft is connected with a bearing in a clamping way; and a first bearing is connected to the lower surface of the inner wall of the shell in a clamping way. According to the sewage filtering device capable of facilitating clearing sludge, the filter cartridge rotates under the matching of a first gear and a second gear, so that sludge residues at the side of the filter cartridge are cleared by a theleft side of a scraping plate; and the sludge residues on the lower surface of the inner wall of the filter cartridge are cleared by the lower surface of the scraping plate, but it is not needed thatthe sludge residues on the inner wall of the filter cartridge are cleared by a worker by using a manual method, so that the time and physical power of the worker are saved, meanwhile, the phenomenonthat hands and clothes of the worker are polluted by the sludge residues is also avoided, convenience is brought for the work of the worker, and the sewage filtering device is beneficial for the workof the worker.

Owner:杨文武

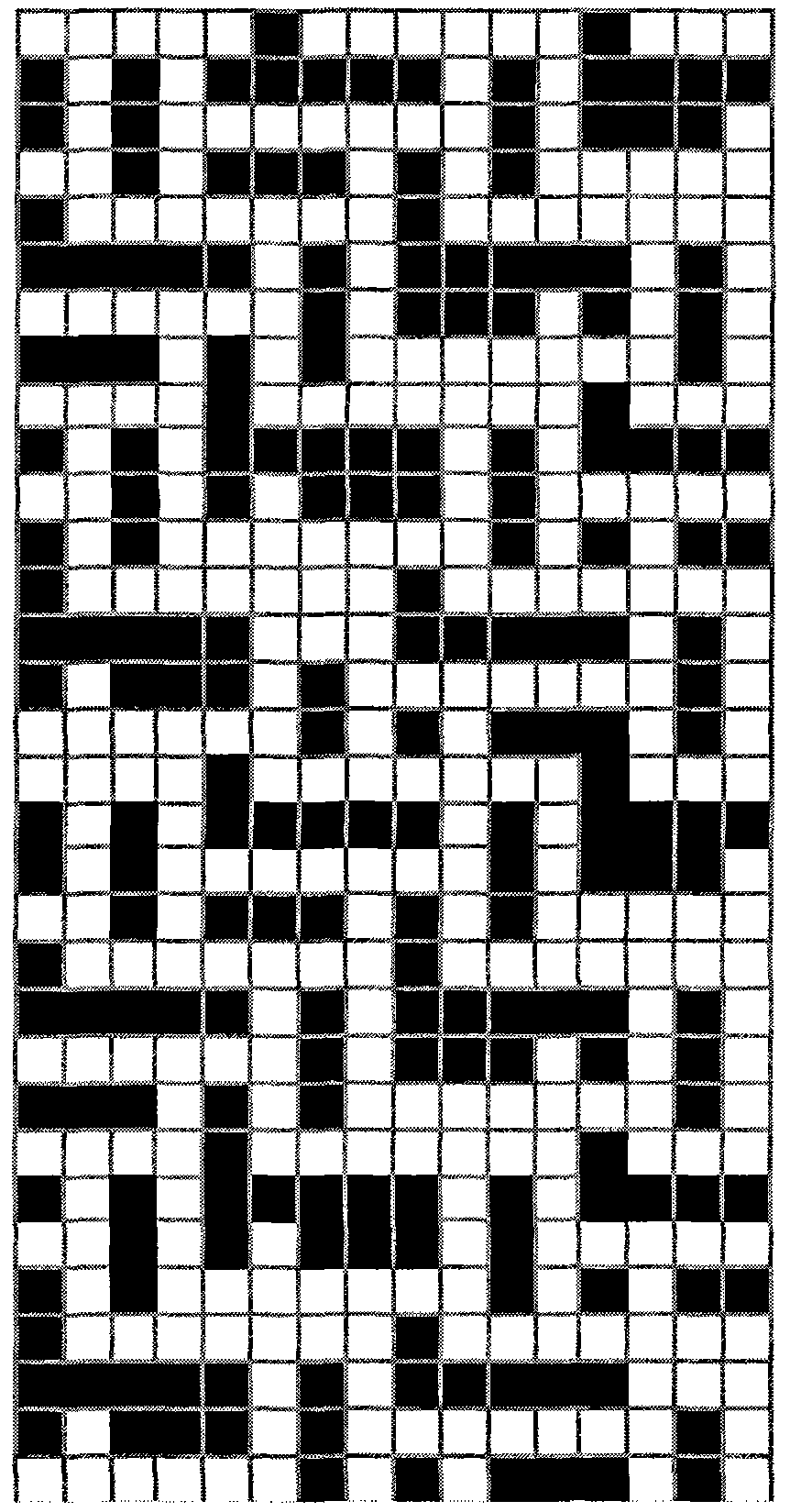

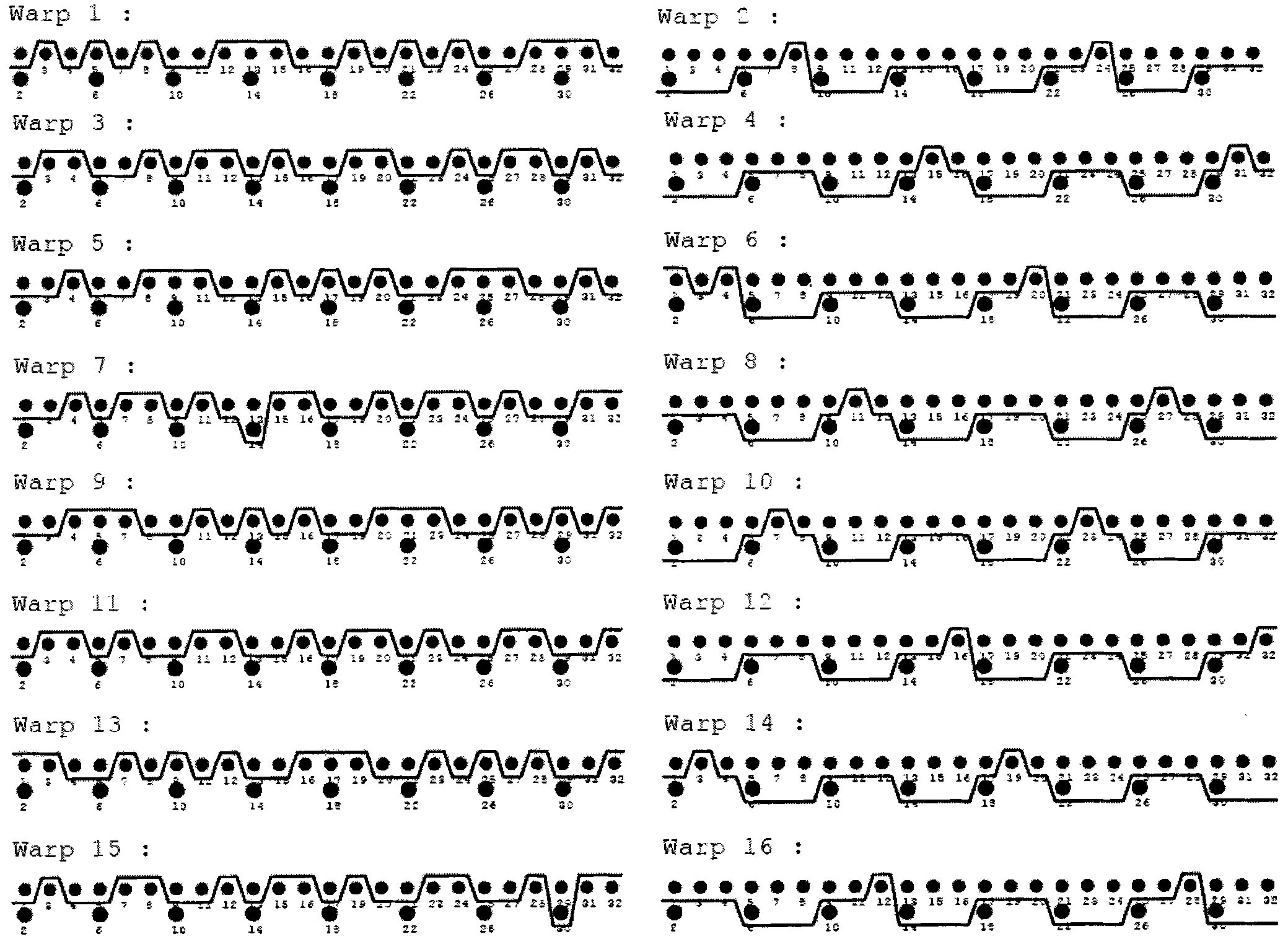

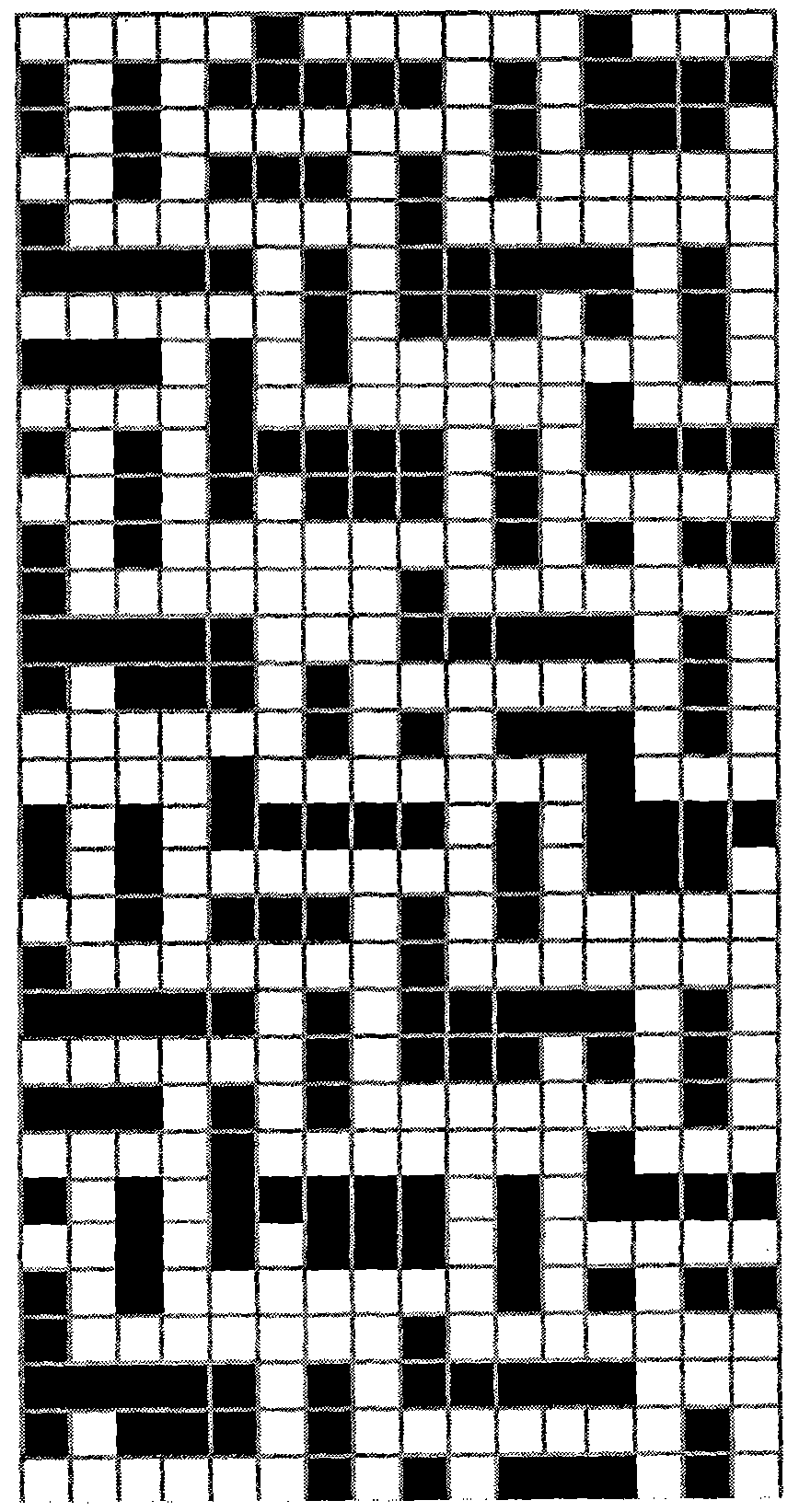

Manufacture method of secondary-seaming ternary-papermaking forming net

The invention discloses a manufacture method of a secondary-seaming ternary-papermaking forming net. Sixteen heald frames are adopted to interweave polyester or nylon monofilaments into three layers of different weaving structures into a whole, the three layers of different weaving structures comprise a paper-forming layer, an intermediate connecting layer and a machine layer, the minimum tissue unit comprising sixteen polyester monofilaments as warps and thirty-two polyester or nylon monofilaments as wefts, the warp number ratio of the paper-forming layer to the machine layer is 1:1, the weft number ratio of the paper-forming layer to the machine layer is 2:1, and the intermediate connecting layer comprises one half of total wefts and is characterized by being formed by the secondarily seaming of the self warp seaming and the self weft seaming of the paper-forming layer. The invention has the advantages of smooth papermaking surface, firm interlayer binding force, no internal abrasion or net elongation and compact and even net structure, and the machine layer has wear resistance, small thickness, long service life and strong dewatering performance.

Owner:JIANGSU JINNI ENGINEERED FABRIC CO LTD

Bobbin winding device for spinning

InactiveCN106829638AAvoid sudden rotationImprove winding efficiencyFilament handlingBobbinEngineering

The invention discloses a bobbin winding device for spinning. The bobbin winding device for spinning comprises a first motor, a rotation shaft which is in power connection with the first motor, a fixed support and multiple winding assemblies which are fixedly installed at the lower end of the fixed support, the rotation shaft is fixedly provided with multiple fixed gears, each winding assembly comprises an installation shell which is fixedly installed at the lower end of the fixed support, the interior of the installation shell is provided with a sliding cavity, the sliding cavity is internally provided with a sliding block which is capable of sliding up and down, the interior of the sliding block is provided with an installation groove which is cut-through left and right, the installation groove is rotatably provided with a rotation straight shaft through a bearing, the left end of the rotation straight shaft is fixedly provided with mobile gears which can be meshed with the fixed gears, the right end of the rotation straight shaft is provided with a winding cylinder through the coordination of a bar-type key and a bar-type key groove, the top wall of the sliding cavity is provided with a guide groove which extends left and right, the upper ends of the left and right side walls of the installation shell are rotatably provided with mobile threaded rods, and the mobile threaded rods are provided with mobile extrusion blocks in a screw-thread fit mode.

Owner:惠安县蓝普欣日用品有限公司

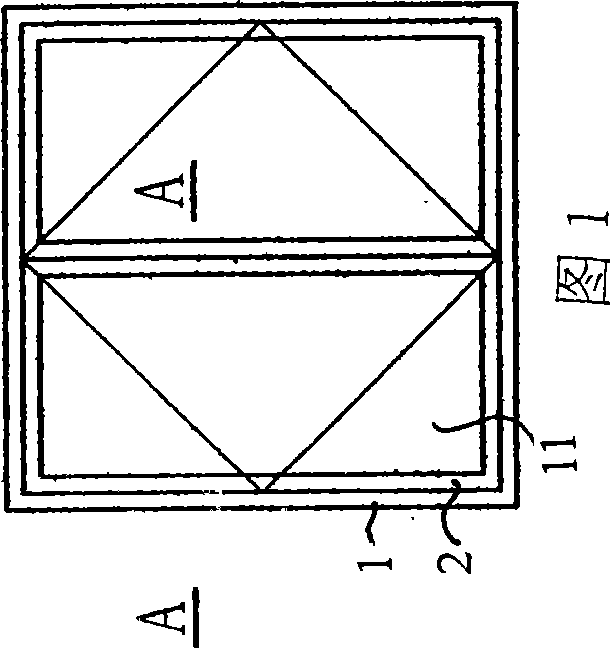

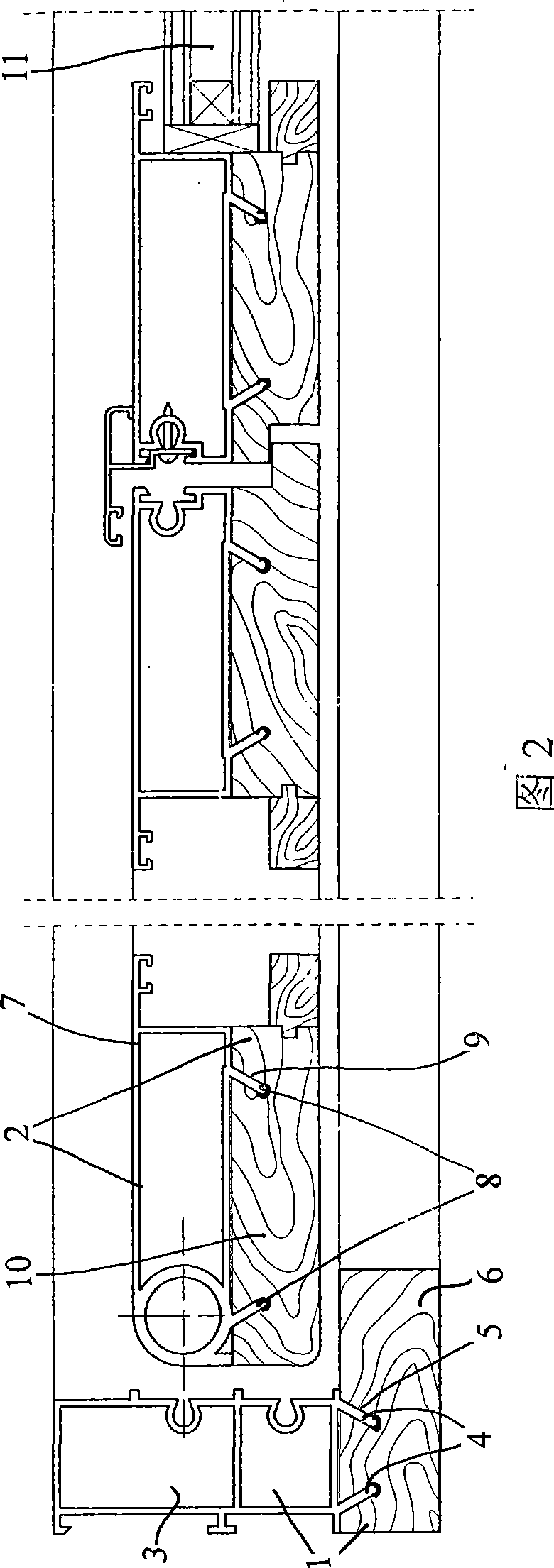

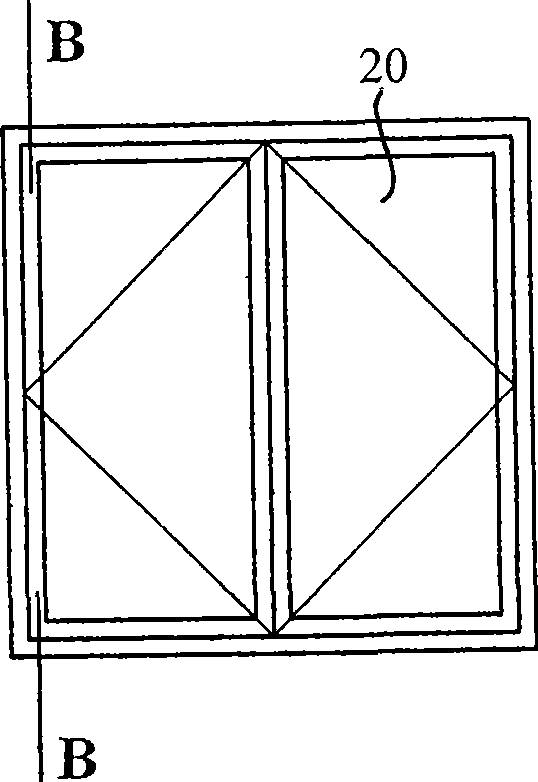

Assembling aluminium-wood energy saving door and window

InactiveCN101387178ASmooth meshingEasy to assembleHingesWing arrangementsEngineeringMechanical engineering

The invention provides an assembled aluminum wood energy-saving door and window, which is provided with an outer frame and a sash frame, and is characterized in that the outer frame is provided with an aluminum sash layer, aluminum sash connecting strip components which are integrated into a whole with the aluminum sash layer and arranged in the shape of inverted V and / or V, solid wooden frame connecting groove components which are matched with the aluminum sash connecting strip components and arranged in the shape of the V and / or the inverted V, and a solid wooden frame layer which is assembled into a whole with the aluminum sash layer through the solid wooden frame connecting groove components and the aluminum sash connecting strip components; the sash frame comprises an aluminum sash frame layer, aluminum sash frame connecting strip components which are integrated into a whole with the aluminum sash frame layer and arranged in the shape of the inverted V and / or the V, solid wooden sash frame connecting groove components which are matched with the aluminum sash frame connecting strip components and arranged in the shape of the V and / or the inverted V, and a solid wooden sash frame layer which is assembled into a whole with the aluminum sash frame layer through the solid wooden sash frame connecting groove components and the aluminum sash frame connecting strip components. The assembled aluminum wood energy-saving door and window is heat-insulated, heat-preserved, vibration-absorbed and noiseproof.

Owner:詹庆富

Spring clutch of laterally controlled screw

ActiveCN104595377ASmooth meshingIncrease elasticityMechanical actuated clutchesGearingDrive wheelDrive shaft

The invention discloses a spring clutch of a laterally controlled screw. The clutch comprises a driven shaft with a strip of outer thread and a driven shaft wheel screwed on the driven shaft, wherein a driven free wheel sleeves the center of the periphery of the driven shaft wheel; the periphery of the driven shaft wheel at one side of the driven free wheel is symmetrically provided with a plurality of clutch crank arm wheels; the left side of the driven shaft wheel is provided with a left auxiliary wheel, a left buffer wheel, a left blocking wheel and a left spring; the right side of the driven shaft wheel is provided with a right auxiliary wheel, a right buffer wheel, a right blocking wheel and a right spring, and a semicircular barrel magnetic shoe is arranged at one side, far away from a driving wheel, of the driven free wheel; the clutch is characterized in that the driven free wheel is installed in the center of the periphery of the driven shaft wheel; a plurality of driven free wheel side slots are formed in one side of the driven free wheel symmetrically, and one sides of the driven free wheel side slots are symmetrically provided with the plurality of clutch crank arm wheels; one end of each clutch crank arm is provided with a small roller shaft of the clutch crank arm and a small roller wheel of the clutch crank arm, and the other end of each clutch crank arm is provided with a clutch crank arm rail rod; the left side of each clutch crank arm rail rod is provided with a left tail fin of the clutch crank arm, and the right side of each clutch crank arm rail rod is provided with a right tail fin of the clutch crank arm.

Owner:徐州雅居乐环保科技有限公司

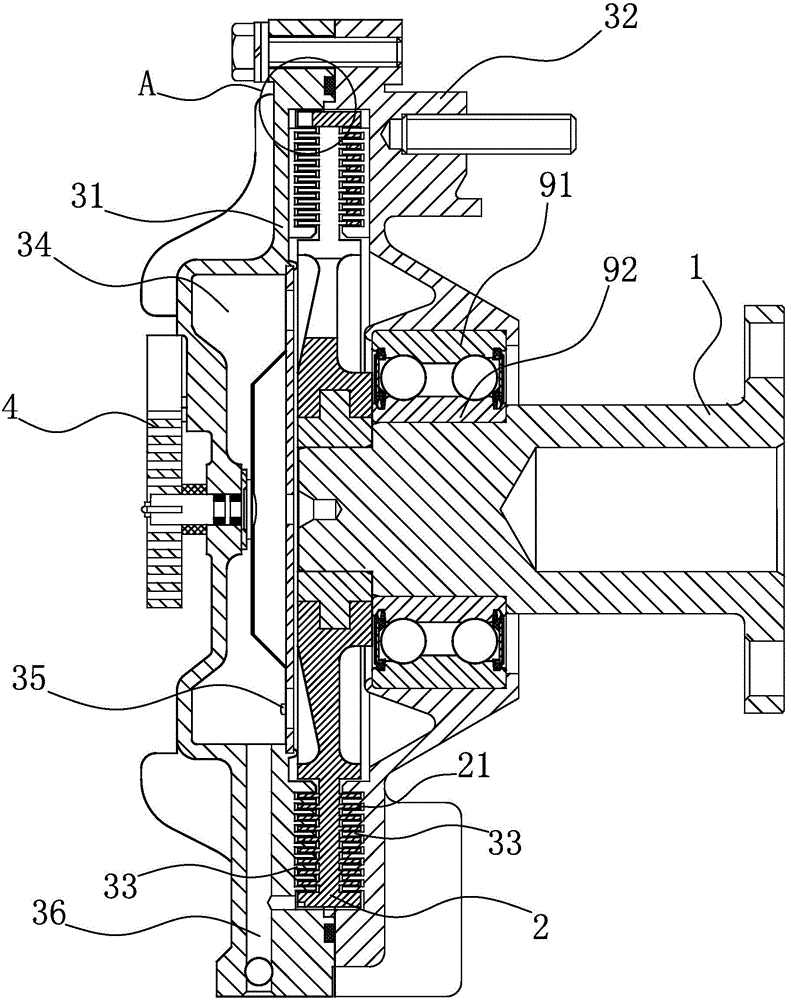

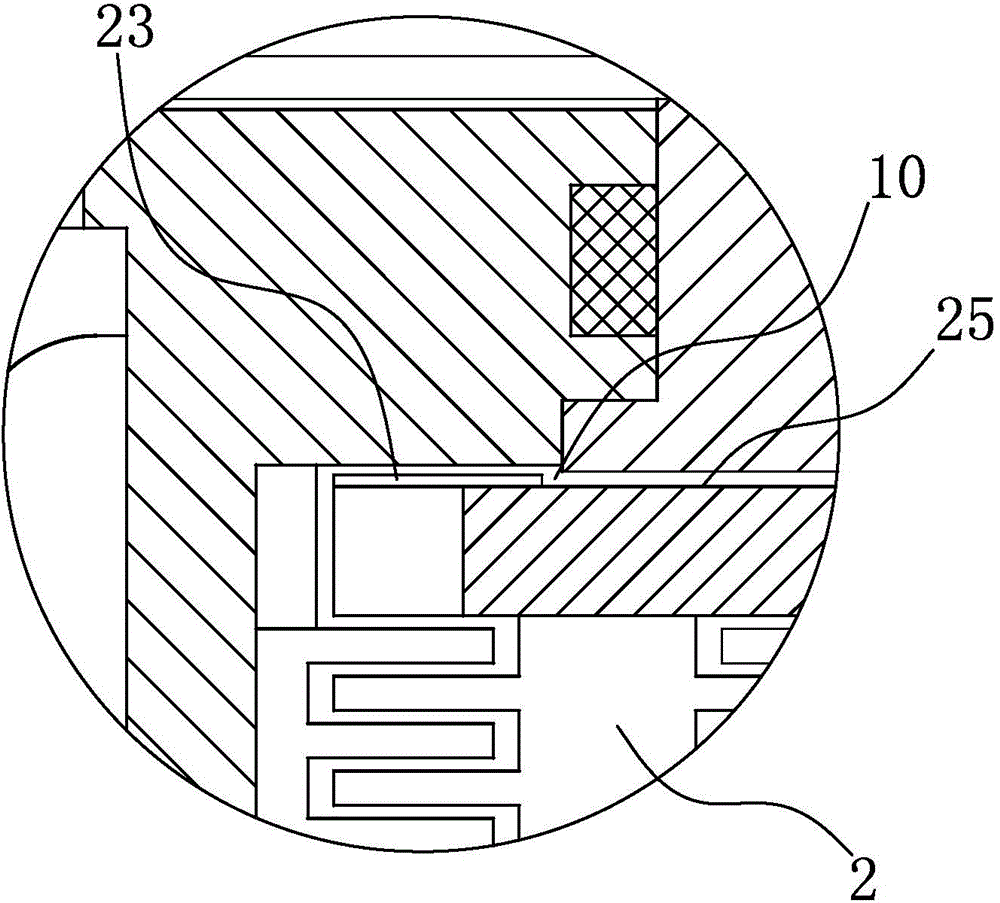

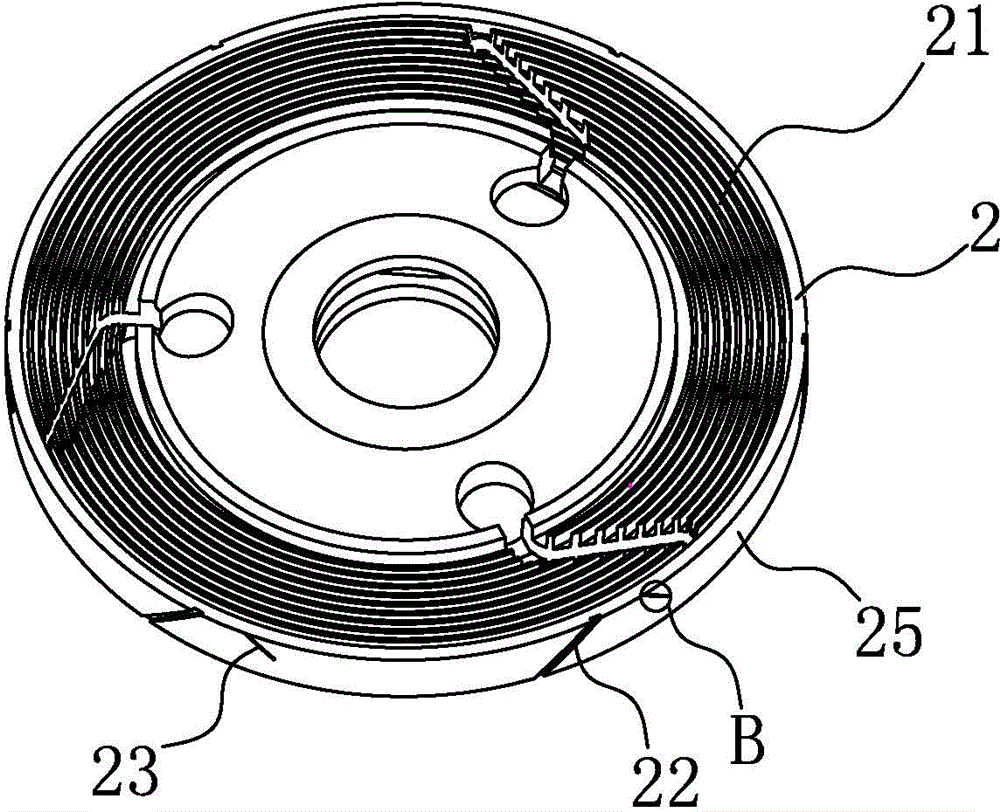

Silicone oil fan clutch with controllable separation speed

ActiveCN104632929AIncrease separation speedSmooth meshingCoolant flow controlMachines/enginesSeparated stateDrive shaft

The invention relates to a silicone oil fan clutch with controllable separation speed. The silicone oil fan clutch with controllable separation speed comprises a sealed bearing, a shell arranged on an outer ring of the sealed bearing and a driving shaft arranged on the inner ring of the sealed bearing. A driving disc is arranged on the driving shaft, the driving disk is arranged in the shell, and an oil storage cavity is formed in the shell. An oil-guiding groove is formed in an outer cylindrical surface of the driving disc, and a raised rib strip is also arranged on the outer cylindrical surface of the driving disc. The silicone oil fan clutch with controllable separation speed provided by the invention has the advantages that a raised rib strip is further arranged on the outer cylindrical surface of the driving disc, when the silicone oil fan clutch transforms from a meshed mode into a separated mode, the rib strip can guide a fraction of silicone oil into a clearance between the outer cylindrical surface of the driving disc and the shell from a clearance between the upper portion of the driving disc and the shell, an oil pressure zone with certain pressure is formed on one side of the rib strip, the additional transmission function is generated in this way, and the separation speed of the silicone oil fan clutch is improved.

Owner:XUELONG GRP

Control device of automatic engine stop and start

ActiveUS8510019B2Smooth meshingProcess stabilityAnalogue computers for vehiclesElectrical controlSynchronous controlPinion

In a control device, an engine self-restart means tries the engine restart when an engine restart request is issued while the engine rotation speed is within a first rotation speed range. A pre-gear synchronizing control means executes gear rotation speed synchronization between pinion and ring gears, and then retries the engine restart when the engine restart request is issued while the engine rotation-speed is within a second rotation speed range. A pre-gear meshing control means executes gear-meshing between the pinion and ring gears and then retries the engine restart when the engine restart request is issued while the engine rotation speed is within a third rotation speed range. On detecting the engine-restart failure of the engine self-restart control, the control device prohibits the execution of pre-gear synchronizing control until a predetermined time counted form the failure detection time is elapsed, and executes the pre-gear meshing control after the predetermined time period is elapsed.

Owner:DENSO CORP

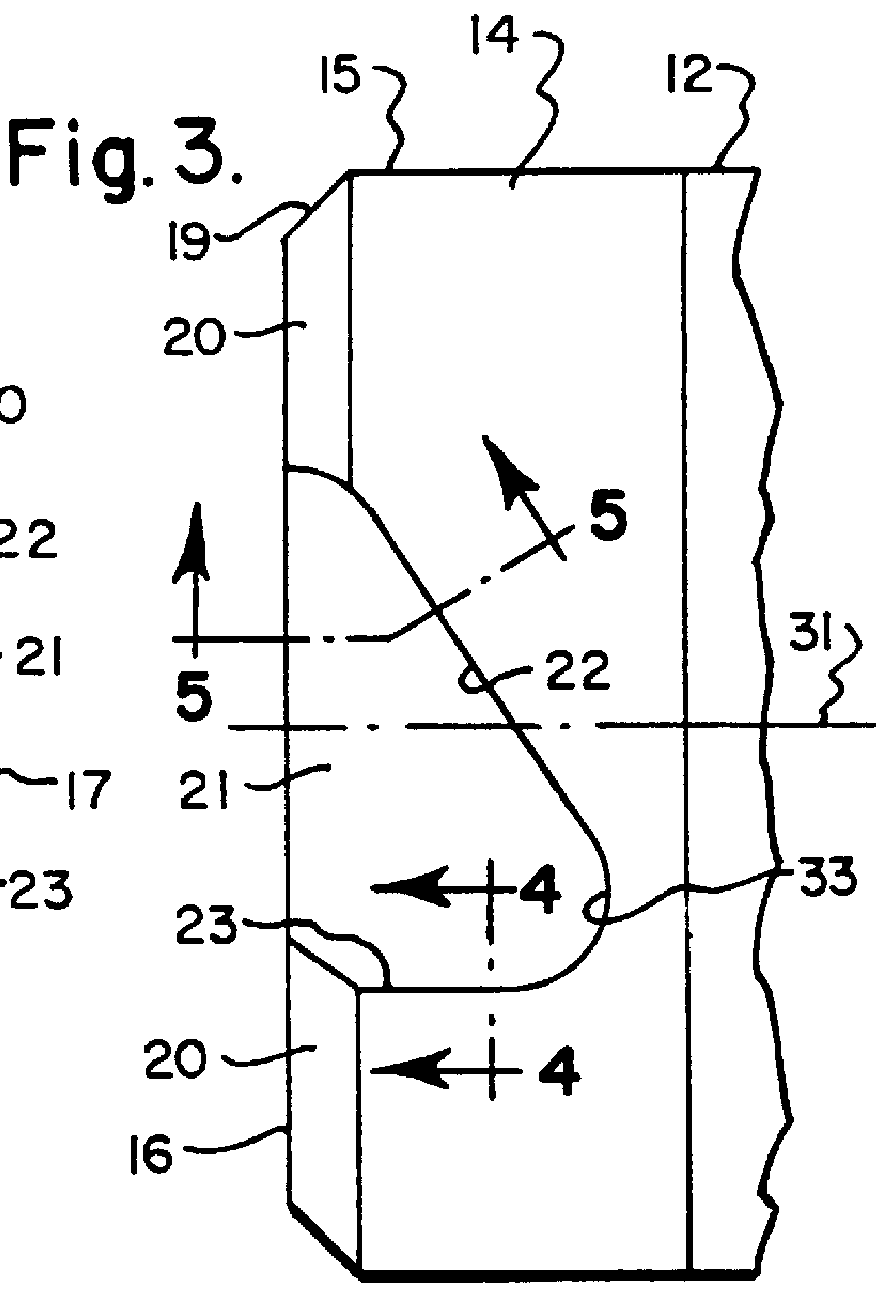

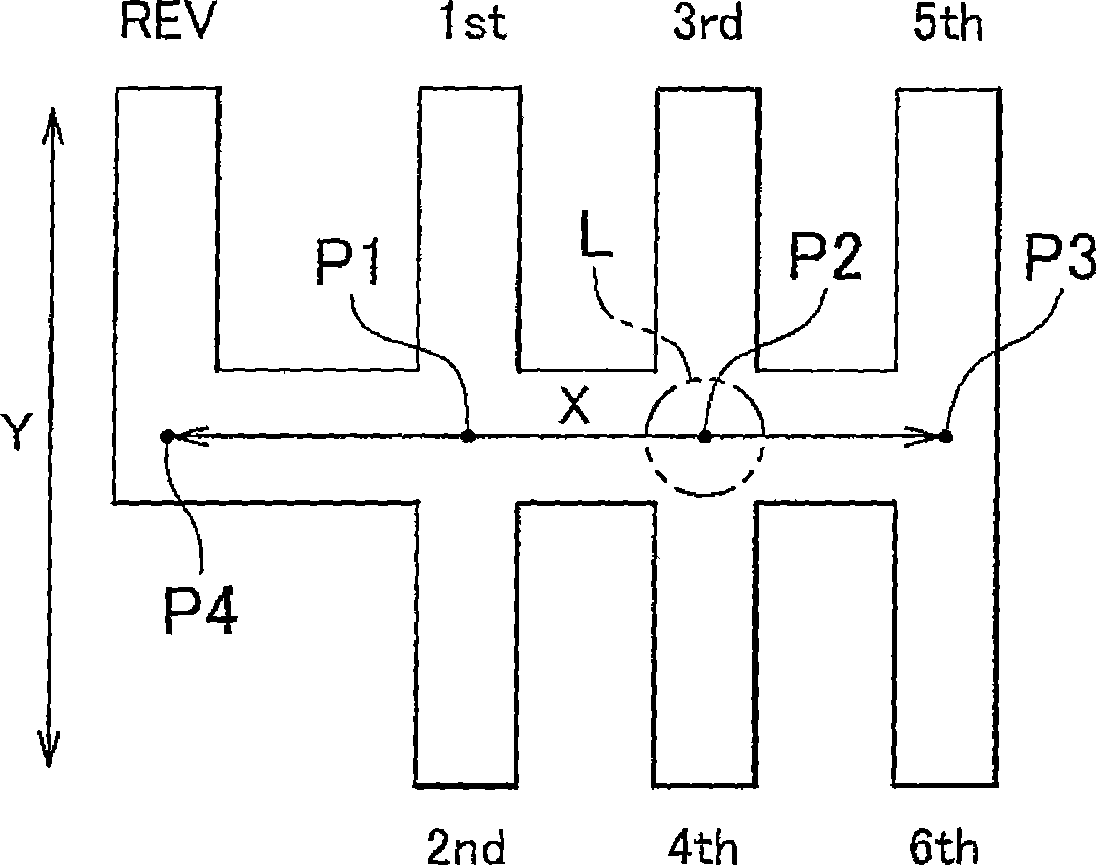

Gear noise preventing system for manual transmission

During a reverse shift operation, in accordance with a select operation performed on a shift lever, a first head (61) that rotates together with a shift select shaft (20) rotates a second head (62) that is supported by a third gear-fourth gear fork shaft (52). A rotational force of the second head (62) is transferred to a third head (63) that is provided integrally onto a fifth gear-sixth gear fork shaft (53) and the fifth gear-sixth gear fork shaft (53) moves in the axial direction. Thus, a synchromesh mechanism operates and the rotation of an input shaft slows down. Then, in accordance witha shift operation performed on the shift lever, the first head (61) retracts from the second head (62) and the operation of the synchromesh mechanism is terminated. During a reverse shift select operation, the synchromesh mechanism for forward gear is operated for a sufficiently long period and by a sufficient amount to reliably prevent gear noise.

Owner:AISIN AI CO LTD

Magnetically-controlled side pressing type screw rod and spring clutch

InactiveCN104653653ASmooth meshingIncrease elasticityMechanical actuated clutchesGearingClutchEngineering

The invention relates to a magnetically-controlled side pressing type screw rod and spring clutch, which comprises a driven shaft and a driven shaft wheel, wherein the driven shaft is provided with external threads, the driven shaft wheel is screwed onto the driven shaft, a driven movable wheel sleeves the exterior of the center of the outer circumference of the driven shaft wheel, a plurality of clutch crank arm wheels are symmetrically arranged at the outer circumference of the driven shaft wheel at one side of the driven movable wheel, a left auxiliary wheel, a left buffering wheel, a left retaining wheel and a left spring are arranged at the left side of the driven shaft wheel, a right auxiliary wheel, a right buffering wheel, a right retaining wheel and a right spring are arranged at the right side of the driven shaft wheel, and a semicircular bucket magnetic bearing is arranged at one side, away from a driving wheel, of the driven movable wheel. The magnetically-controlled side pressing type screw rod and spring clutch is characterized in that the driven movable wheel is arranged at the center of the outer circumference of the driven shaft wheel, a group of bearings are arranged at an inner ring of the driven movable wheel and are connected with the driven shaft wheel, the driven movable wheel side grooves are symmetrically formed in one side of the driven movable wheel, each clutch crank arm wheel is provided with a clutch crank arm lower spring, a clutch crank arm small roller shaft and a clutch crank arm small roller are arranged at one side surface, near the driven movable wheel, of each clutch crank arm, and the number of the clutch crank arm small rollers is matched with the number of the driven movable wheel side grooves in the side surface of the driven wheel.

Owner:魏伯卿

Magnetic side pressure internal control screw spring clutch

A magnetic side pressure internal control screw spring clutch comprises a driven shaft with an external thread and a driven shaft wheel screwed on the driven shaft. The outer portion of the center of the outer circumference of the driven shaft wheel is sleeved with a driven free wheel, a plurality of clutch magnetic blocks are symmetrically installed on the outer circumference of the driven shaft wheel on one side of the driven free wheel, each clutch magnetic block is connected with a clutch seesaw device through a clutch seesaw cross rod, each clutch seesaw device is provided with a clutch seesaw wheel in an inner ring surface area of the driven free wheel, and a plurality of driven free wheel inner grooves matched with the clutch seesaw wheel are formed in the inner ring surface of the driven free wheel. Auxiliary wheels, buffer wheels, blocking wheels and springs are positioned on the left side and the right side of the driven shaft wheel, and a semicircular barrel magnetic shoe is installed on one side of the driven free wheel far away from a driving wheel. The magnetic side pressure internal control screw spring clutch is characterized in that the inner diameters, the number and the distribution of the driven free wheel inner grooves correspond to and are matched with the outer diameters, the number and the distribution of the clutch seesaw wheels.

Owner:嘉兴美茵钛传动科技有限公司

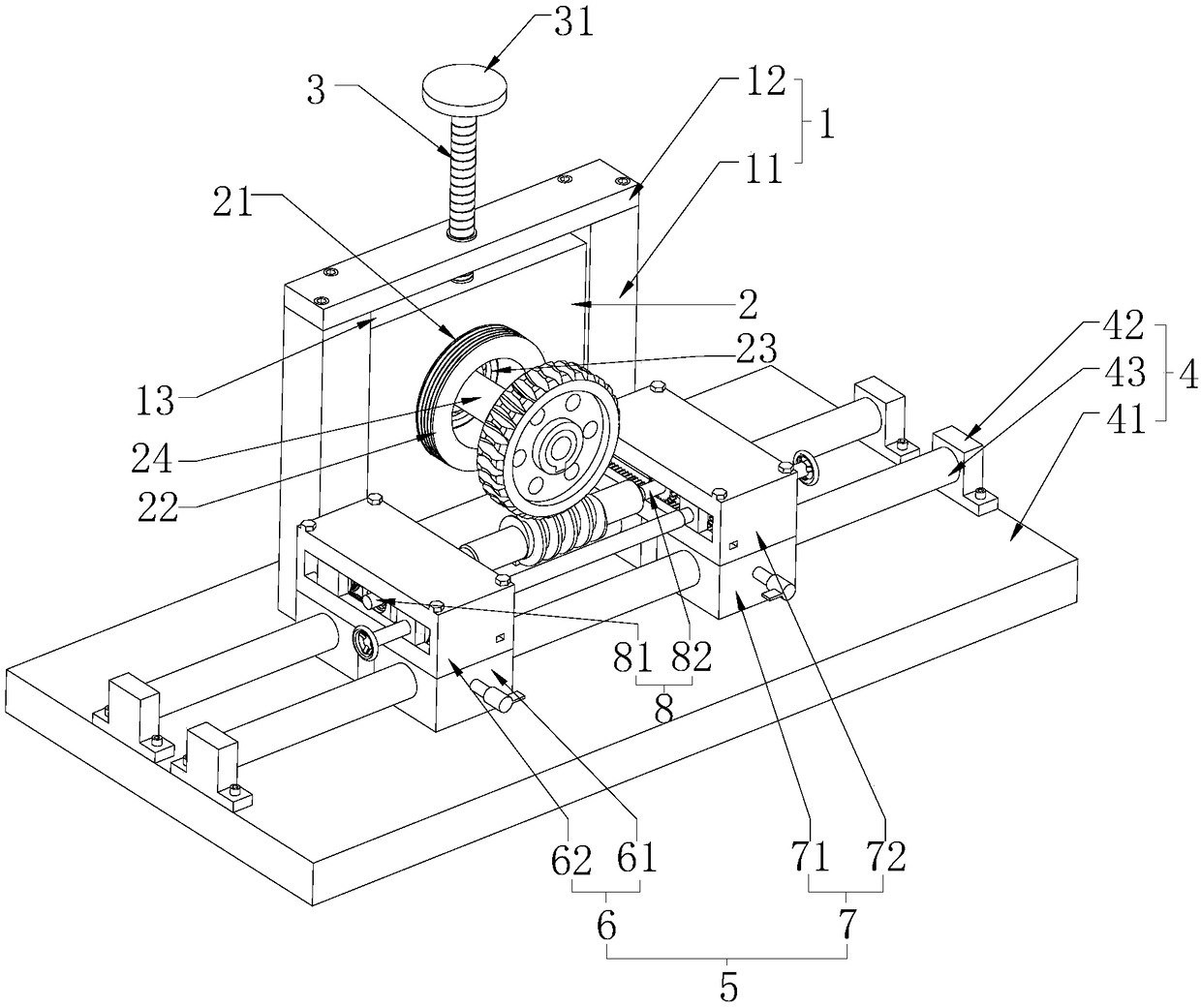

Worm gear and worm matching detection device

ActiveCN109506930ARealize positioning rotationImprove adaptabilityMachine gearing/transmission testingEngineeringMechanical engineering

Owner:浙江神腾科技有限公司

Curved teeth cylindrical gear, machining method and apparatus thereof

InactiveCN100335821CSmooth meshingReduce noisePortable liftingGear teeth manufacturing toolsLow noiseEngineering

Owner:宋爱平

Sewage filtering robot capable of being used for conveniently cleaning sludge

InactiveCN108031165AEasy to cleanConvenience to workTreatment involving filtrationMoving filtering element filtersSludgeBiochemical engineering

The invention discloses a sewage filtering robot capable of being used for conveniently cleaning sludge. The sewage filtering robot comprises a casing, wherein a filter tube is arranged in the casing;a filter hole is formed in the lower surface of the filter tube; a first rotating shaft is fixedly connected with the lower surface of the filter tube; a bearing is clamped and connected onto the outer surface of the first rotating shaft; the first bearing is clamped and connected onto the lower surface of the inner wall of the casing. The sewage filtering robot capable of being used for conveniently cleaning silt has the advantages that under the matching of a first gear and a second gear, the filter tube rotates, so that the left side surface of a scraping plate is used for cleaning the sludge residue on the side surface of the filter tube; the lower surface of the scraping plate is used for cleaning the sludge residue on the inner wall of the filter tube, the cleaning on the sludge residue on the inner wall of the filter tube by workers by using a manual method is not needed, so that the time and the physical strength of workers can be saved; meanwhile, the hand and the clothes ofworkers can be prevented from getting dirty by the sludge residue; therefore convenience is brought to the work of workers; the work of workers is facilitated.

Owner:HUZHOU CHUANGSHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com