Patents

Literature

132results about How to "Small shift shock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric motor zero torque control bisynchronous shifting method for hybrid vehicle

InactiveCN101830221AReduce wearImprove acceleration performanceHybrid vehiclesElectric machineryHybrid vehicle

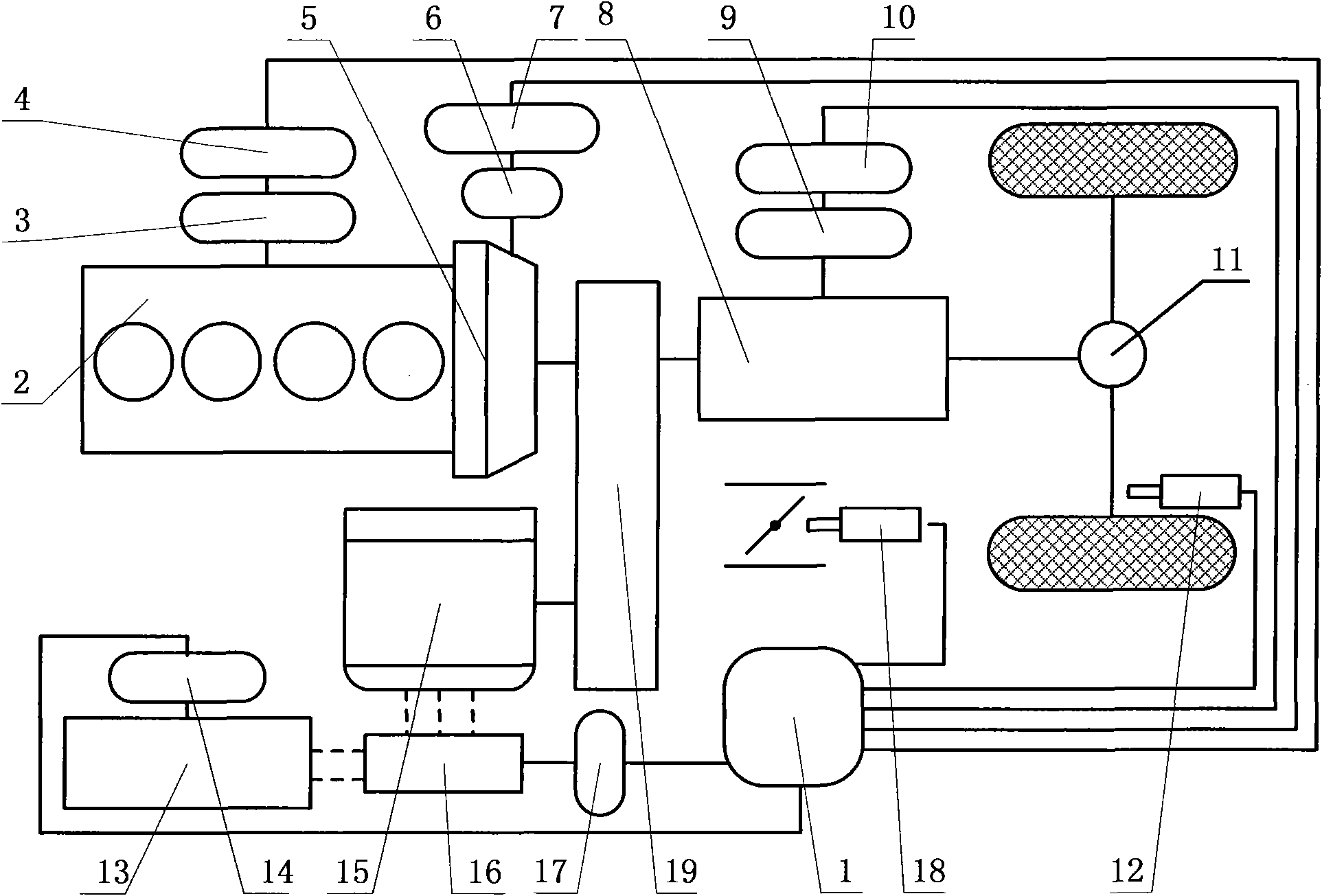

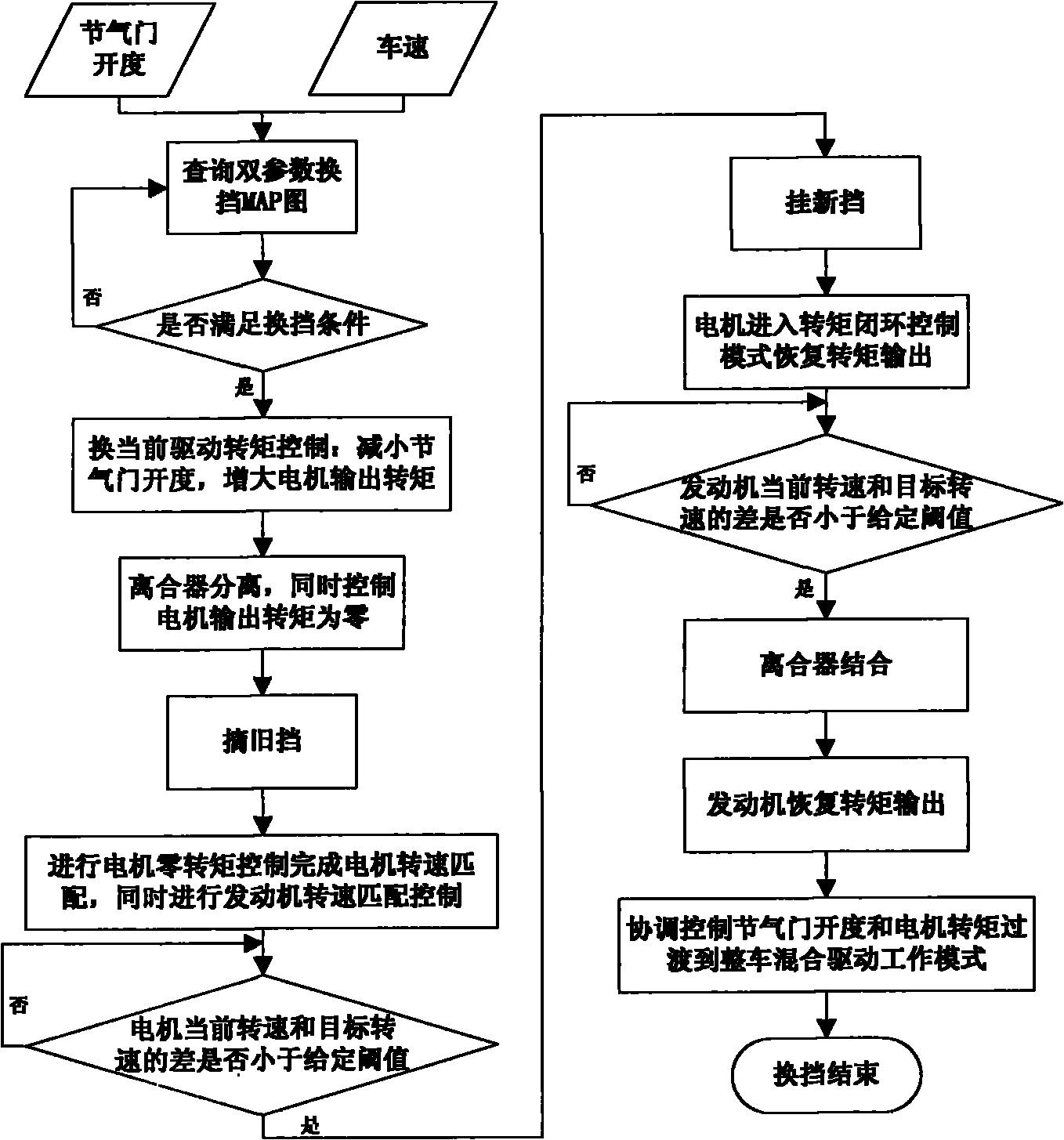

The invention relates to an electric motor zero torque control bisynchronous shifting method for hybrid vehicles, belonging to the technical field of modern transportation. The method is characterized in that vehicle speed ua and throttle valve alpha are monitored to identify shifting points; throttle percentage is reduced and the electric motor torque is increased; when throttle percentage is less than the given threshold value, a clutch is separated and the electric motor torque is controlled to be zero and original shift is restored; engine speed is adjusted to matched target speed ne, meanwhile zero torque control is performed on the electric motor and a zero torque control map, input voltage Uin and input current Iin corresponding to the given inverter matched target speed nm are inquired and the electric motor speed is controlled to reach the matched target speed nm; when the deviation between the electric motor speed nm and the matched target speed nm of the electric motor is less than the given threshold value, a new shift is moved to; electric motor torque output is restored; when the deviation between the engine speed ne and the matched target speed ne is less than the given threshold value, the clutch is combined; finally, engine torque output is restored. The invention has the effects and benefits of reducing shifting impact, shortening power interruption time and improving shifting comfort.

Owner:DALIAN UNIV OF TECH

Non-clutch non-synchronizer AMT gear changing control method of short-distance blade electric vehicle

The invention discloses a non-clutch non-synchronizer AMT gear changing control method of a short-distance blade electric vehicle, and relates to a non-clutch non-synchronizer AMT gear changing control method of a blade electric vehicle. According to the control method, when the vehicle needs to change gears during traveling process, a direct-current brushless driving motor is braked by matching two forms of electric braking and PI control, the time needed in speed reduction of the driving motor is shortened, on this basis, and a gear changing motor similarly adopts electric braking, so that the motion of a gear changing execution mechanism and the speed regulation of the driving motor can be conducted simultaneously, the position control error of a shifting fork is less than 0.04mm, the fastest motion speed of the shifting fork can be guaranteed, the needed time is shortest, and the gear changing time is shortened. The gear changing time is basically the same as that in static state, smooth gear changing effect can be simultaneously guaranteed, the difference of rotating speed in gear engaging is less than 50r / min, and people basically cannot feel gear changing shock during gear changing. The gear changing speed is fast, the gear changing impact degree is low, and the dynamic performance of the electric vehicle can be improved.

Owner:HARBIN INST OF TECH AT WEIHAI

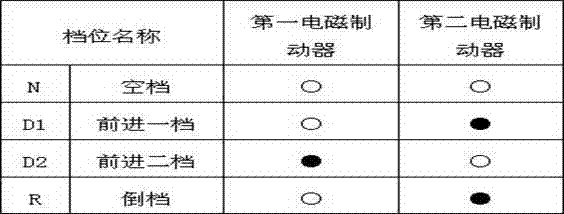

Three-gear wire control automatic transmission of electric vehicle

ActiveCN104389999ASmall sizeReduce power consumptionToothed gearingsGearing controlVariatorElectric vehicle

The invention discloses a three-gear wire control automatic transmission of an electric vehicle. one end of an input gear is connected with an input shaft of the transmission, and the other end of the input gear is frequently engaged to a first-gear high speed gear, a second-gear high speed gear, a third-gear high speed gear and a reverse-gear idle gear along the peripheral outer side of the gear; the first-gear high speed gear, the second-gear high speed gear, the third-gear high speed gear and a reverse-gear high speed gear are respectively connected with a first-gear main shaft, a second-gear main shaft, a third-gear main shaft and a reverse-gear main shaft through a first-gear electromagnetic clutch, a second-gear electromagnetic clutch, a third-gear electromagnetic clutch and a reverse-gear electromagnetic clutch; the first-gear main shaft, the second-gear main shaft, the third-gear main shaft and the reverse-gear main shaft are distributed at the periphery of an intermediate shaft of the transmission; an electric control unit controls the joint and the separation of all gears of high speed gears and a driving gear through all gears of electromagnetic clutches to realize the wire control gear shifting control of the three-gear wire control automatic transmission of the electric vehicle. The three-gear wire control automatic transmission of the electric vehicle has such advantages as compact structure, wire control power gear shifting and no mechanical or hydraulic gear shifting parts.

Owner:SHANDONG UNIV OF TECH

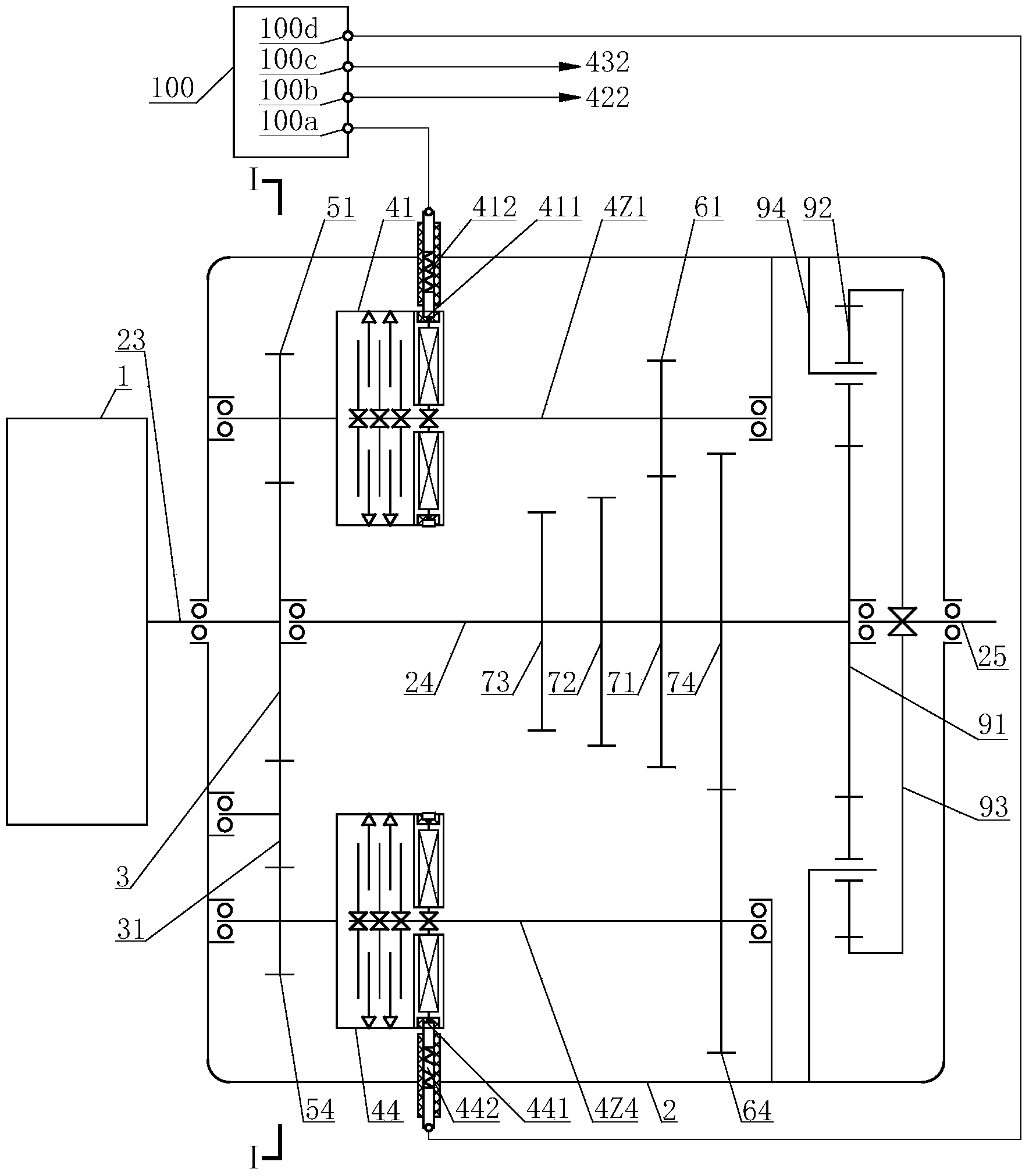

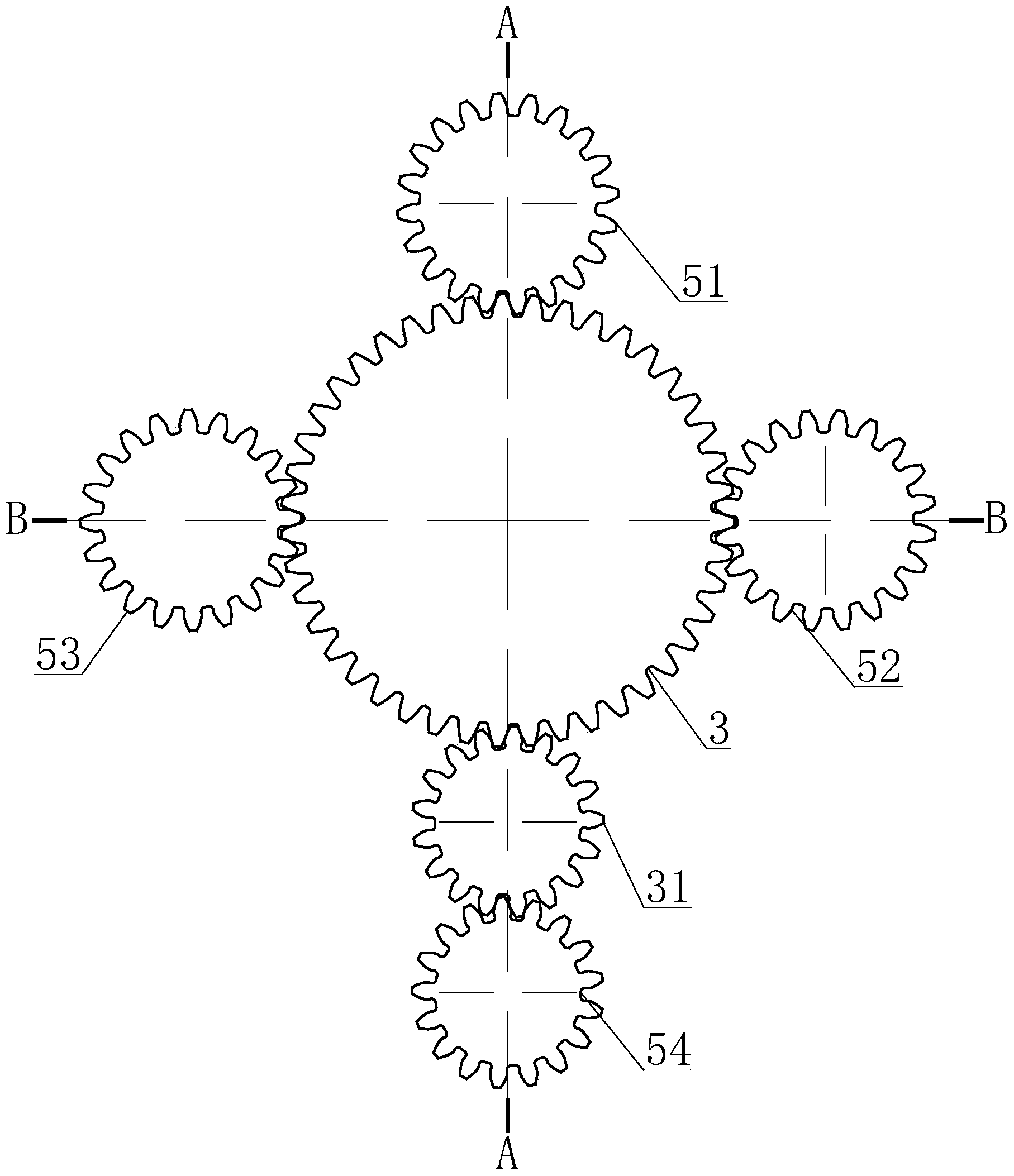

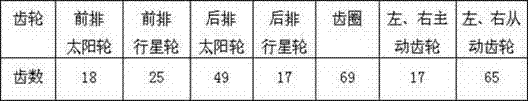

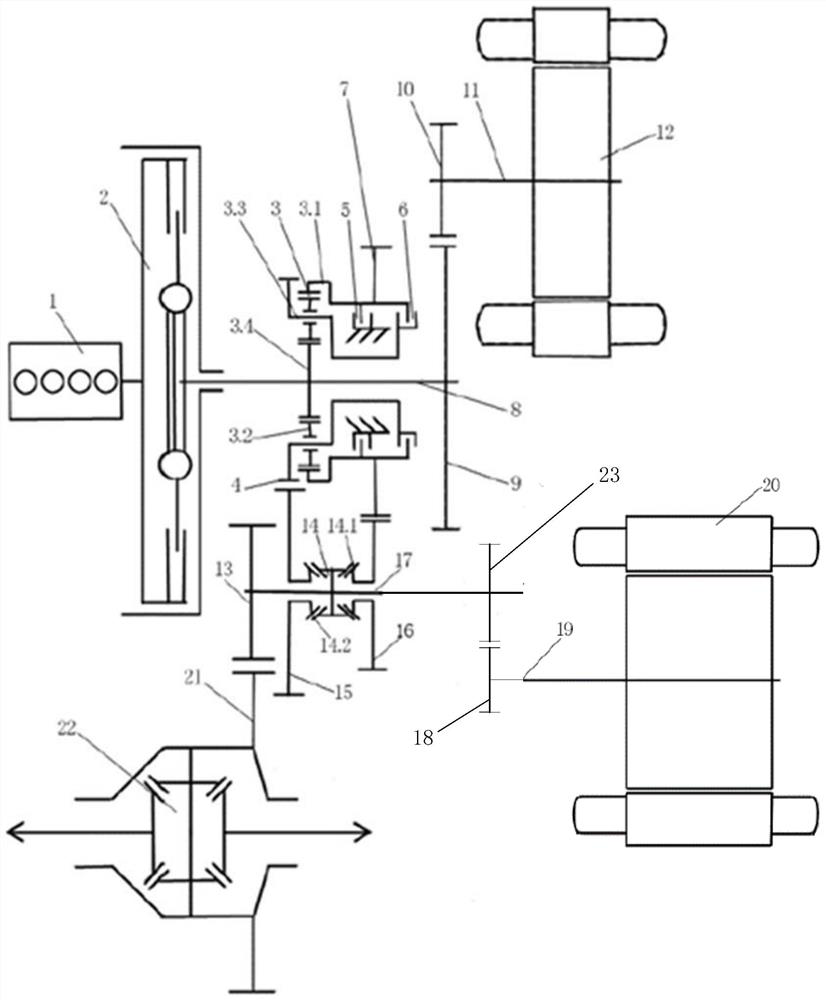

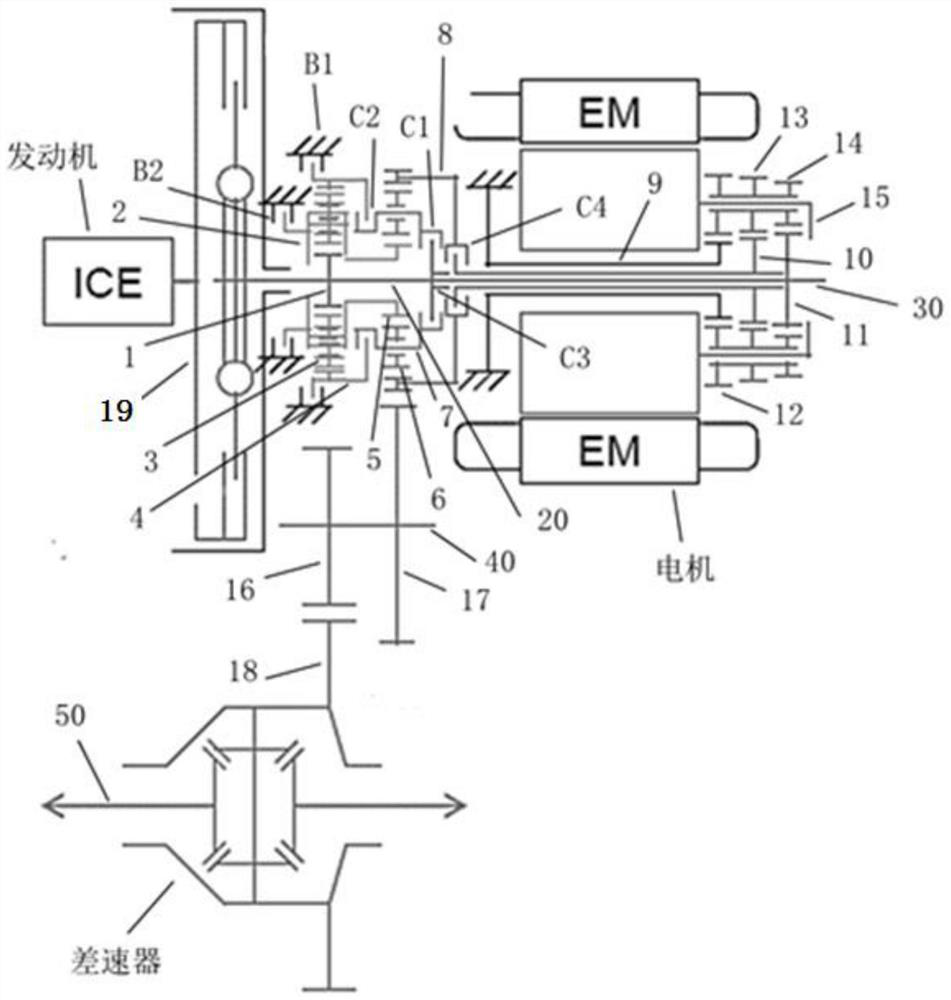

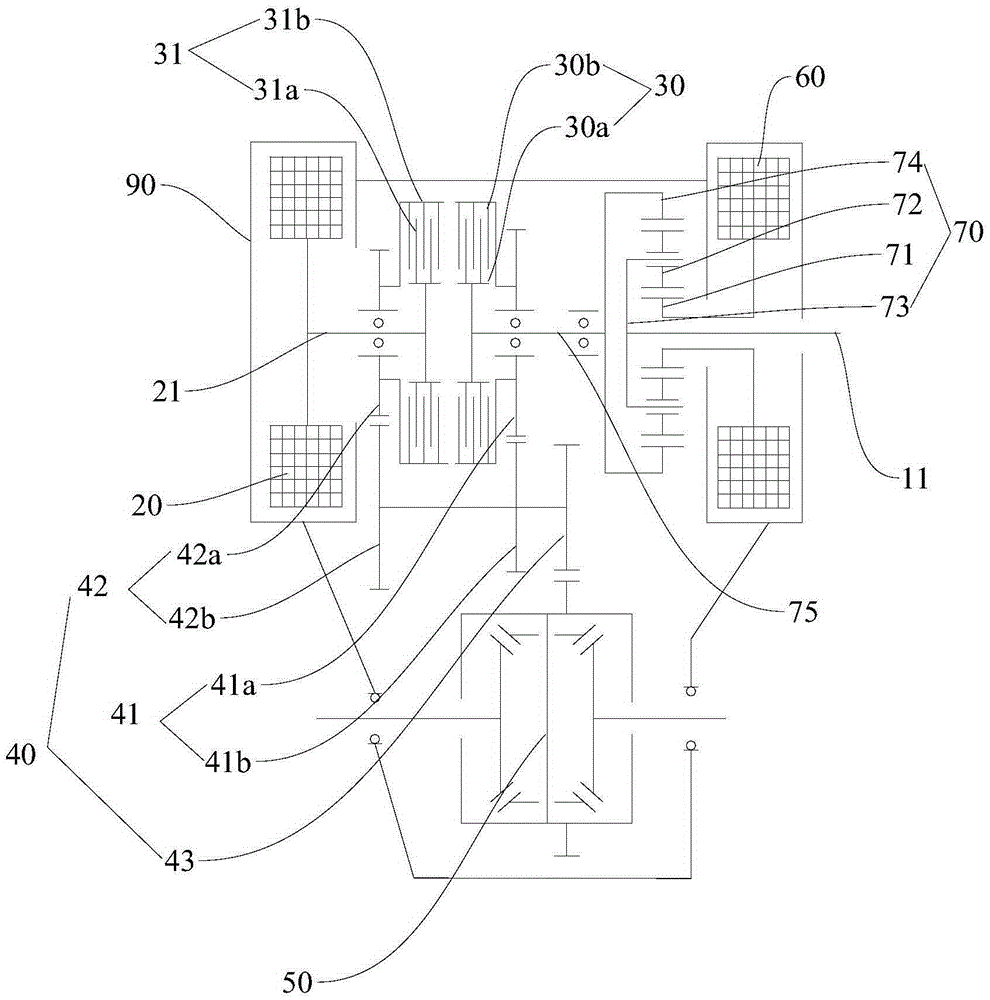

Four-gear mechanical automatic transmission power assembly system based on planetary gear mechanisms

ActiveCN105402334ASmall sizeReduce processing difficultyToothed gearingsAutomatic transmissionGear wheel

The invention discloses a four-gear mechanical automatic transmission power assembly system based on planetary gear mechanisms. The four-gear mechanical automatic transmission power assembly system comprises an engine, a main clutch, a motor, a first planet row, a second planet row, two engagement devices, three auxiliary clutches, an electromagnetic brake, two brakes, a gear ring, and a transmission input shaft as well as a transmission output shaft; the first planet row, the second planet row and a splined hub are orderly arranged on the transmission input shaft; the splined hub is engaged with an engagement sleeve; and switching of four forward gears, a neutral gear and a reverse gear is realized by means of mutual cooperation of the engagement sleeve, the electromagnetic brake and the clutches. Compared with a traditional mechanical transmission, the four-gear mechanical automatic transmission power assembly system based on the planetary gear mechanisms is provided with no synchronizer, and instead, the motor is adopted for accurate speed regulation to realize smooth gear shifting, and two planetary gear mechanisms are used to take the place of traditional a plurality of pairs of gear mechanism; as a result, the overall mechanism is simple, small in volume, low in cost and easy to manufacture.

Owner:包头北奔重汽桥箱有限公司

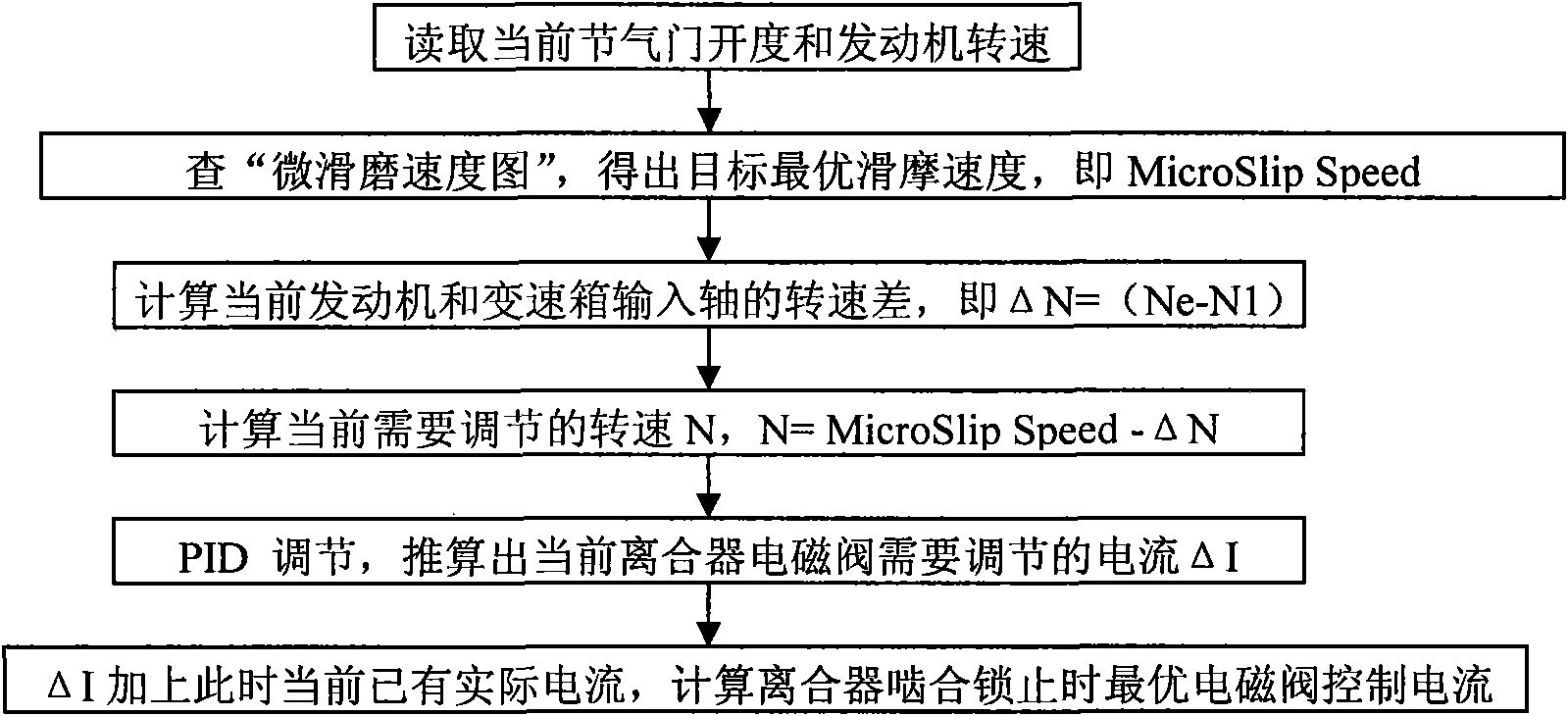

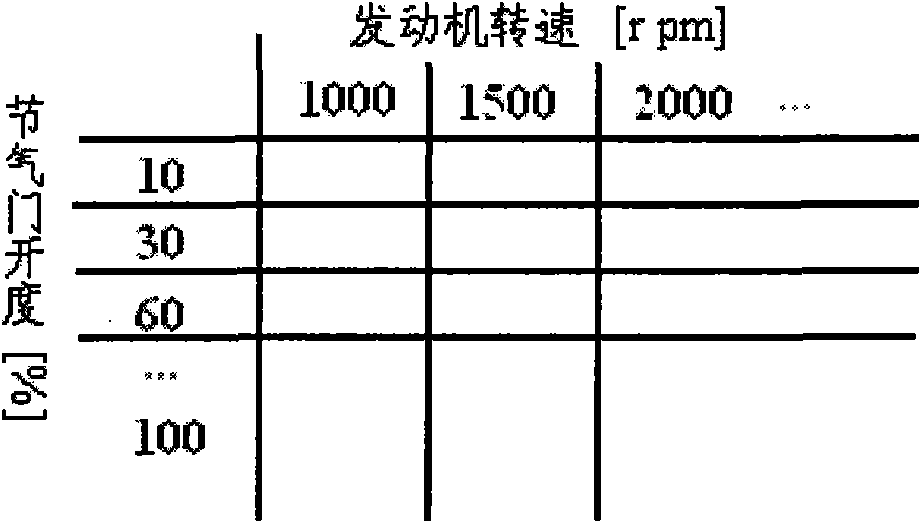

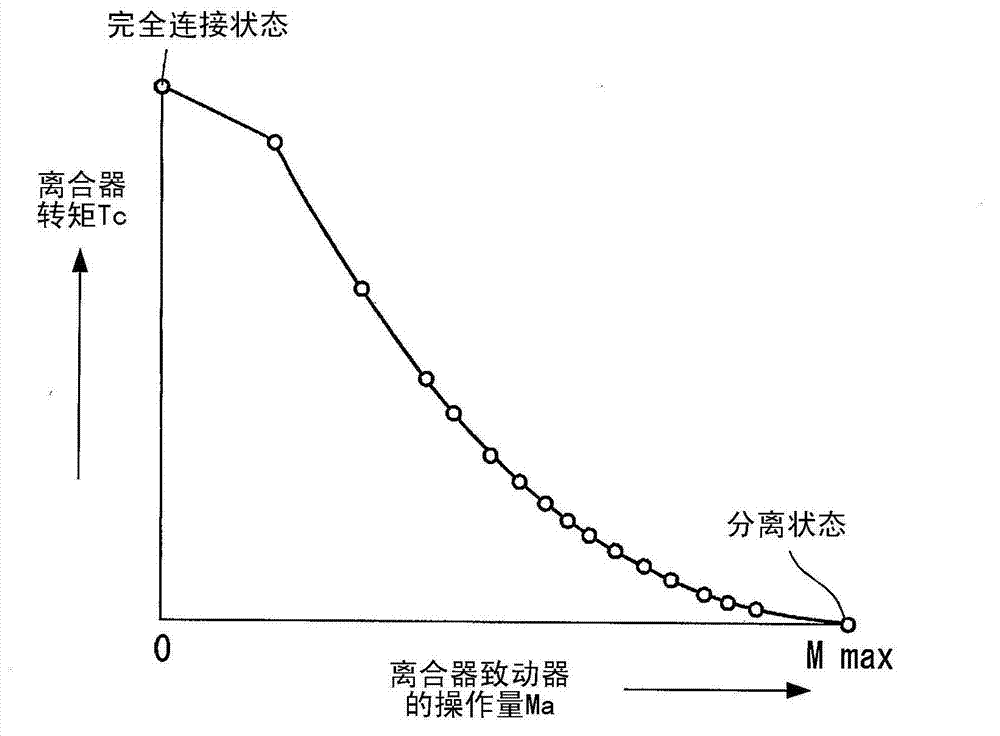

Micro slip control method during lock-up meshing of wet clutch

The invention discloses a micro slip control method during lock-up meshing of a wet clutch, including: firstly, reading current throttle percentage and engine speed; secondly, looking up a micro slip speed diagram to obtain optimal micro slip speed namely MicroSlip Speed; thirdly, calculating the current rotating speed difference between the engine and the input shaft of a gear reducer; fourthly, calculating the current rotating speed N required to be regulated; fifthly, converting the rotating speed difference into corresponding current variation value, namely the current delta I required to be regulated to control relevant solenoid valve of the clutch, through appropriate PID regulation; sixthly, adding the current delta I of solenoid valve required to be regulated the clutch with the current existing effective current and calculating optimal control current of the solenoid valve during micro slip lock-up meshing of the clutch. The invention can effectively reduce shift impact, reduce oil consumption in frequent shift process and can obviously improve operation reliability of the clutch and prolong the service life of the clutch.

Owner:SAIC MOTOR +1

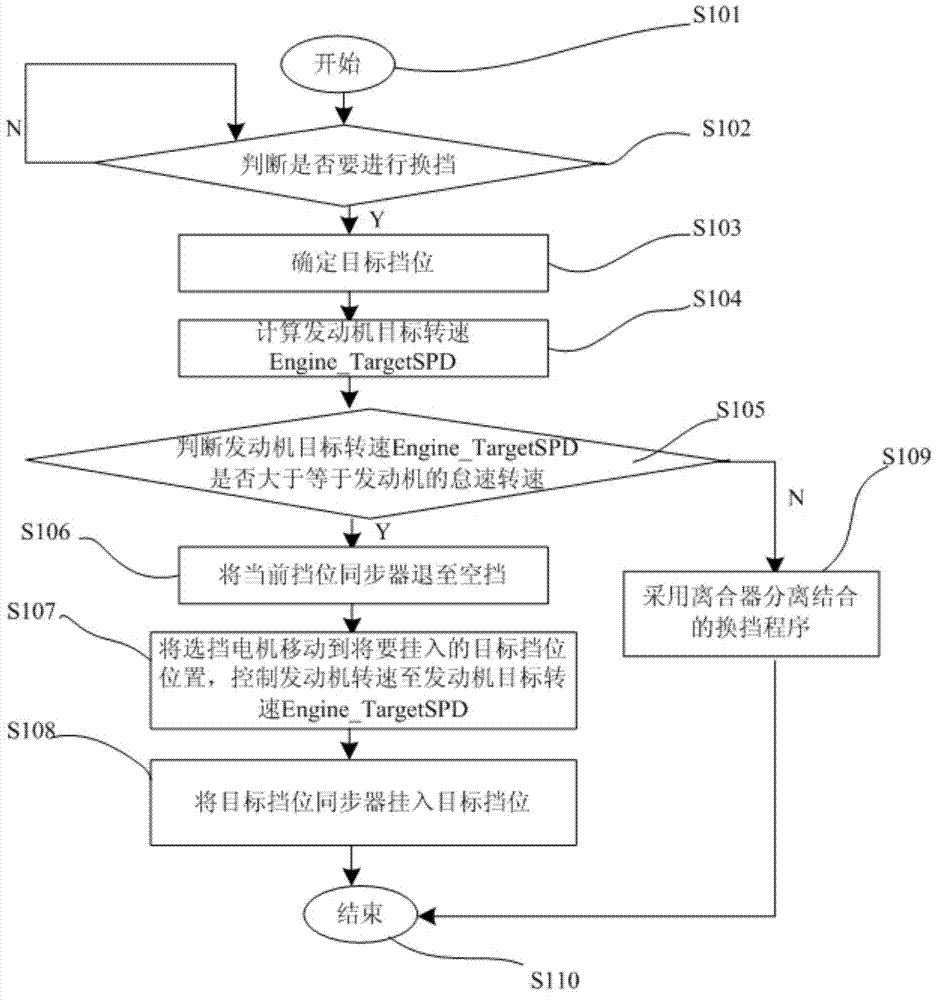

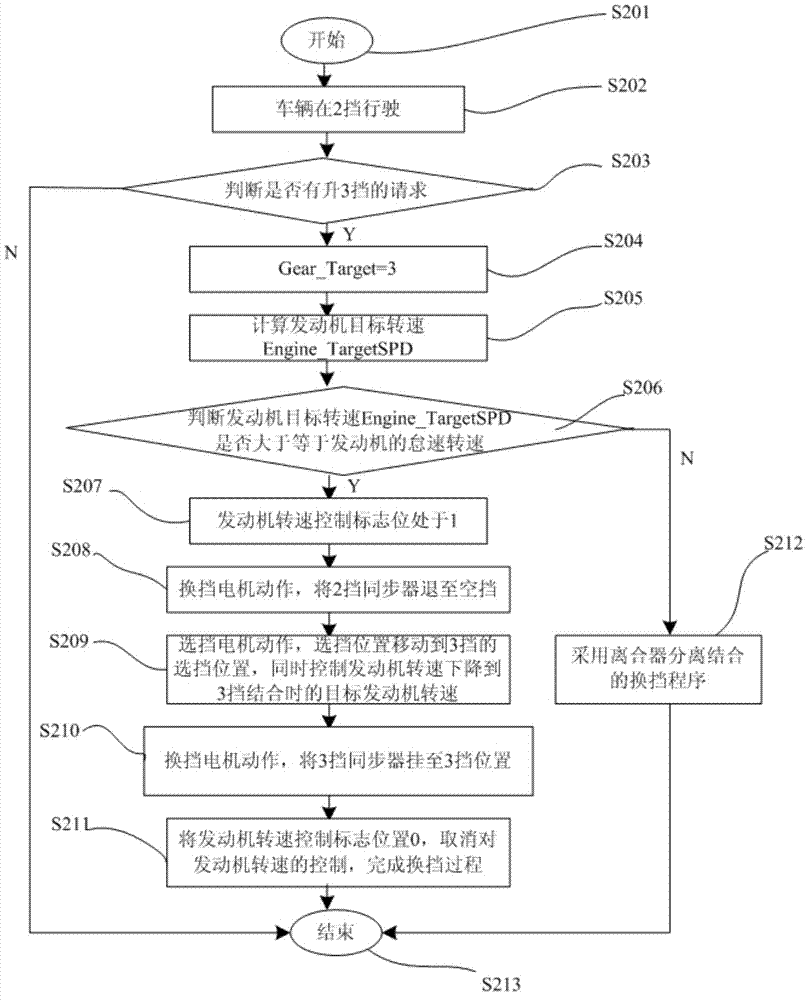

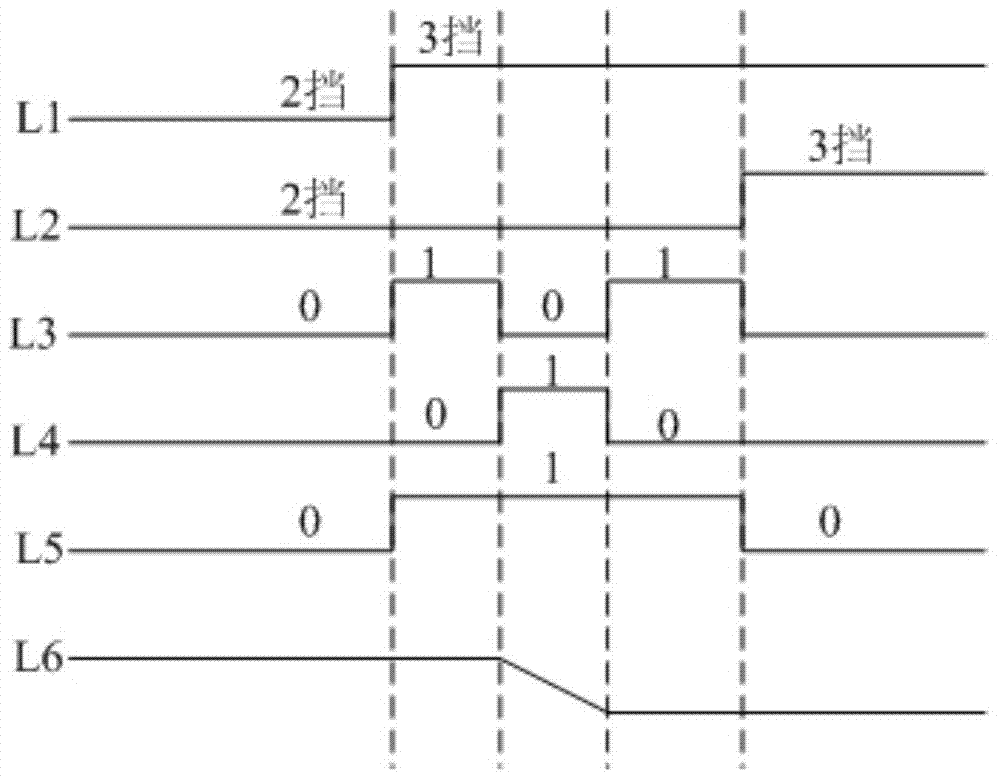

Shifting method for AMT (Automated Mechanical Transmission) automatic gearbox

ActiveCN103697154ASmall shift shockShorten shift timeGearing controlFluid gearingsMechanical transmissionElectric machine

The invention relates to a shifting method for an AMT (Automated Mechanical Transmission) automatic gearbox. The shifting method comprises the following steps A, during a driving process of a vehicle, judging whether shifting to other advancing gears or not according to a vehicle driving state parameter and an operation signal, if yes, executing step B, and if not, repeating step A; B, determining a target gear; C, calculating a target rotating speed of an engine according to a rate of the present vehicle speed to the gear speed of the target gear; D, judging whether the target rotating speed of the engine is greater than or equal to an idle speed or not, and if yes, executing steps E-G; E, maintaining the present rotating speed and using a shifting motor for retreating a present gear synchronizer to a neutral gear; F, controlling a gear selecting motor to act, and controlling the rotating speed of the engine to the target rotating speed of the engine when the gear selecting motor moves to the target gear position; G, controlling the gear selecting motor to act, shifting a target gear synchronizer to the target gear, cancelling the control on the rotating speed of the engine and finishing the gear shifting.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

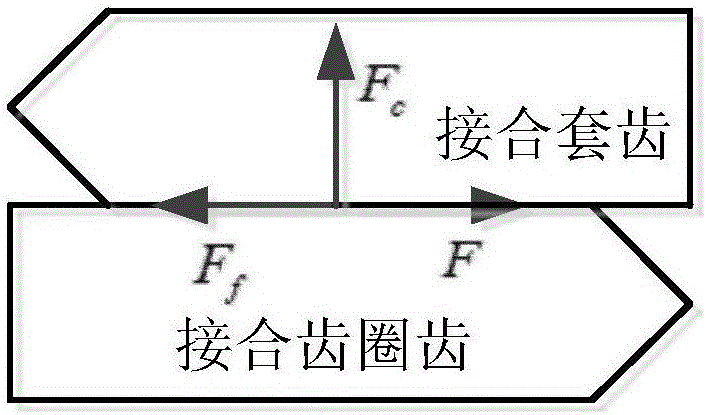

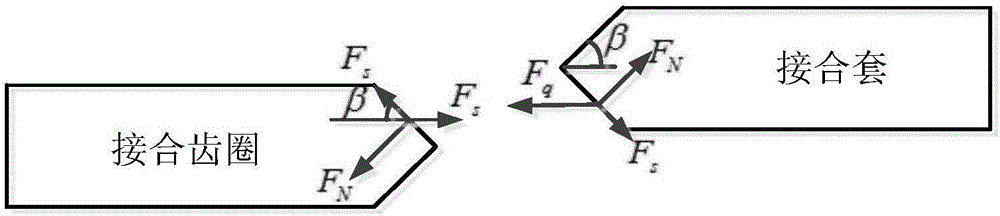

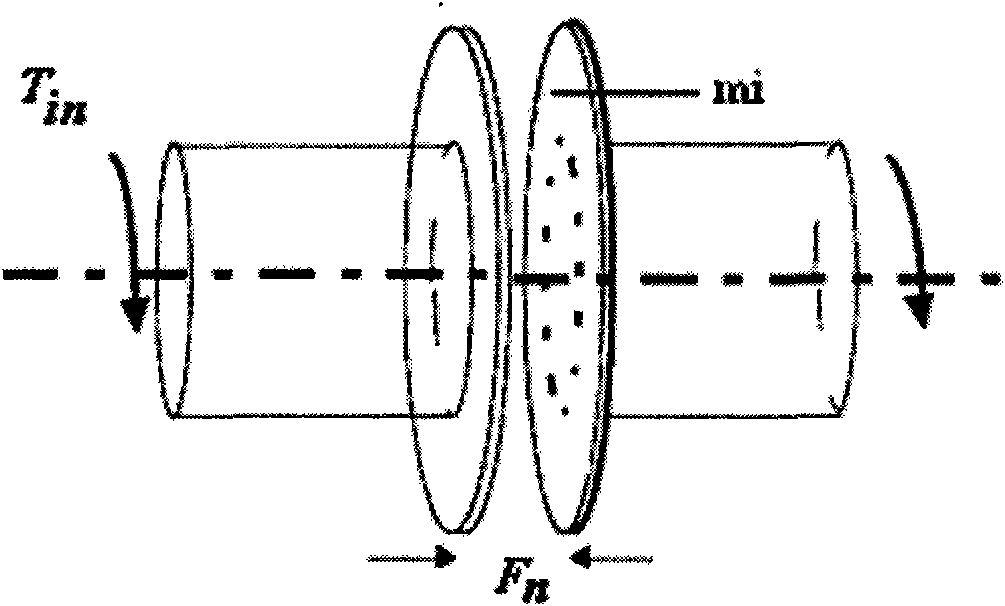

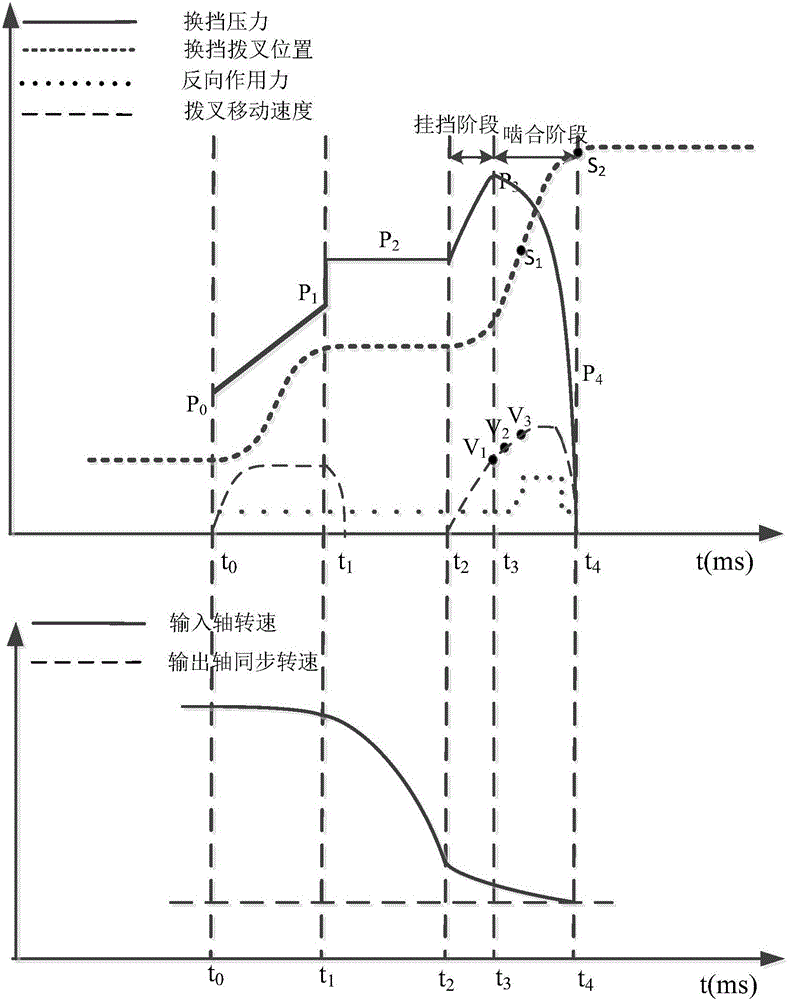

Gear engaging control method for dual-clutch automatic transmission with synchronizer

The invention provides a gear engaging control method for a dual-clutch automatic transmission with a synchronizer. According to the method, gear shifting is divided into two stages from synchronization to engagement, i.e., the gear engaging stage and the engaging stage. A closed-loop control mode is provided, smooth engaging of a gear sleeve and a connection gear is achieved by means of the control method that positive gear shifting force is controlled through a curve path mode and negative acting force is regulated in real time according to the position of a gear shifting fork and the moving speed of the gear shifting fork, and therefore gear shifting impact is reduced.

Owner:CHINA FIRST AUTOMOBILE

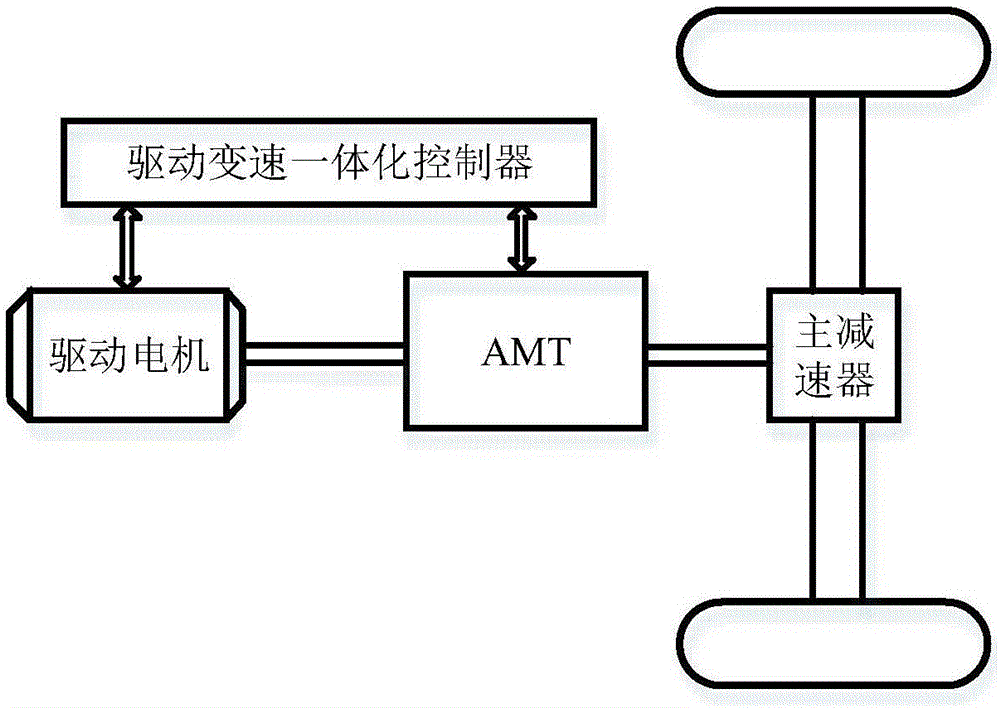

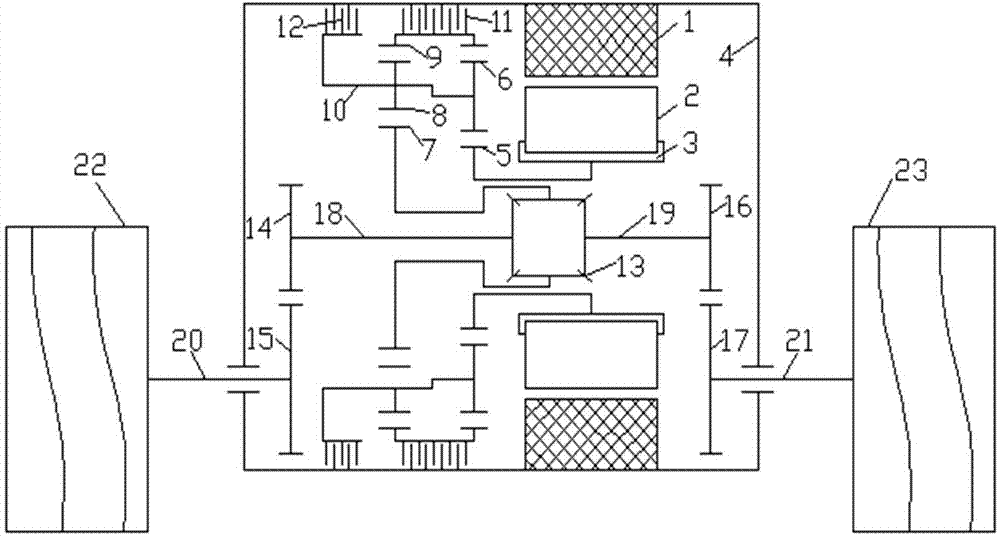

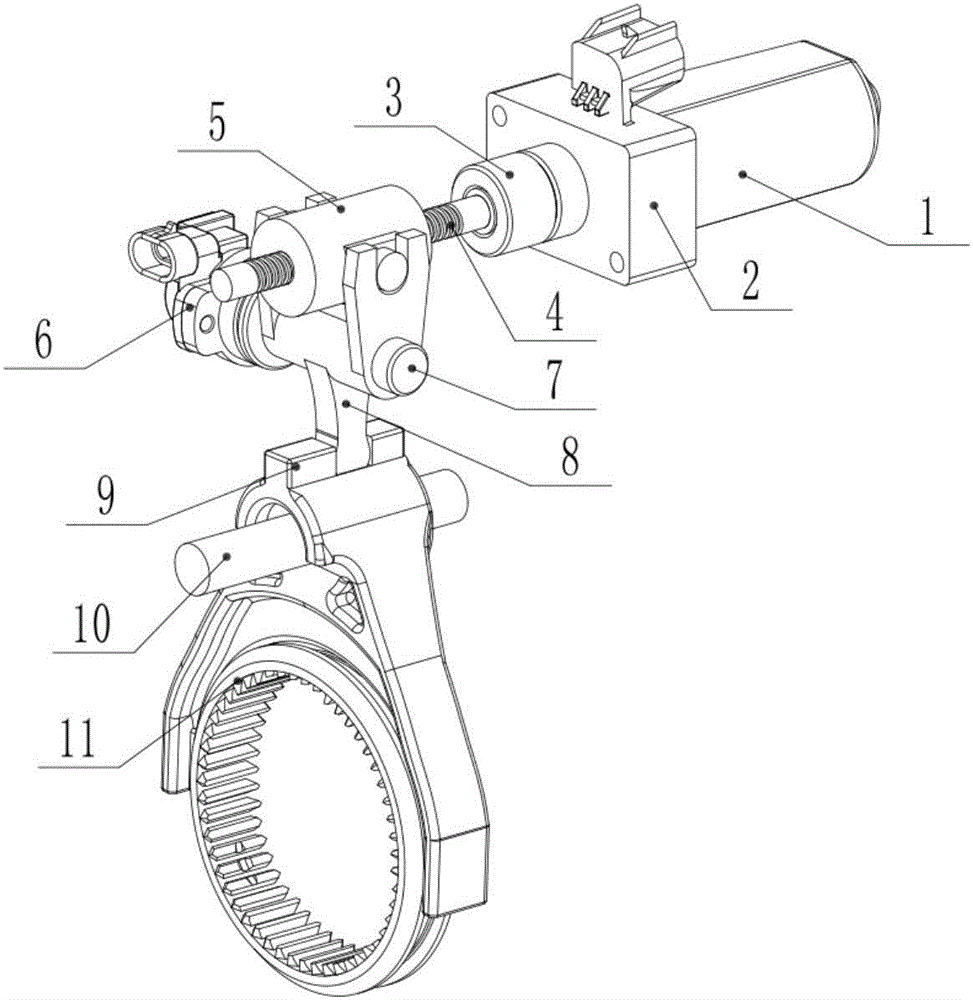

Motor and speed changer integrated power assembly for battery electric vehicles

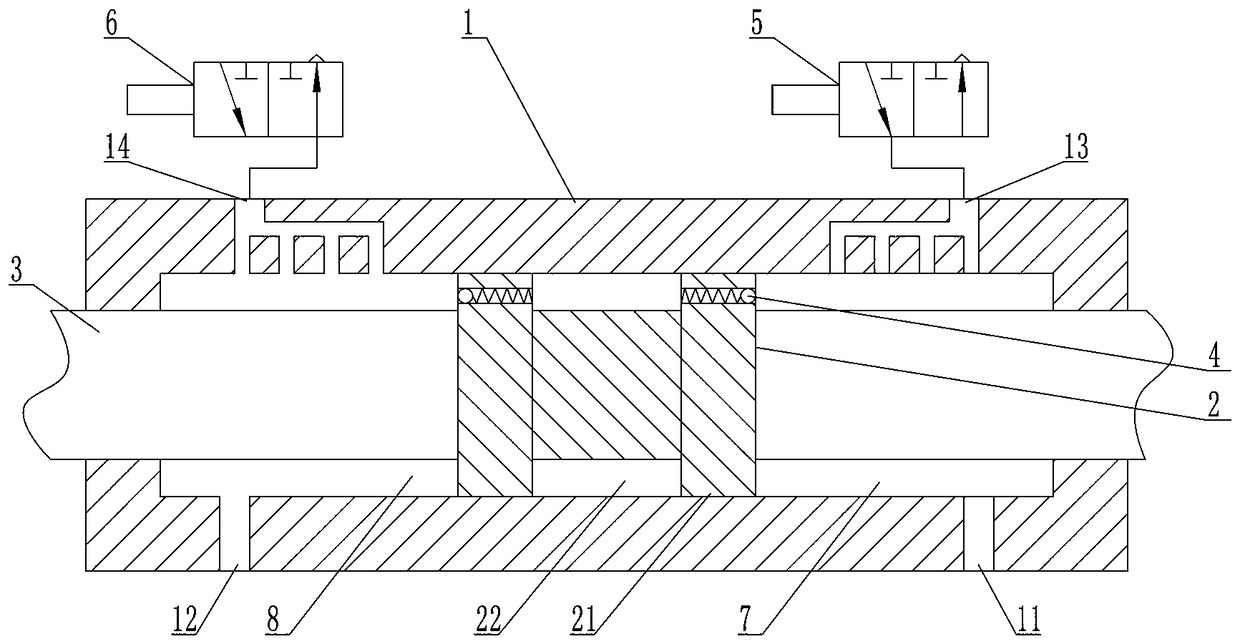

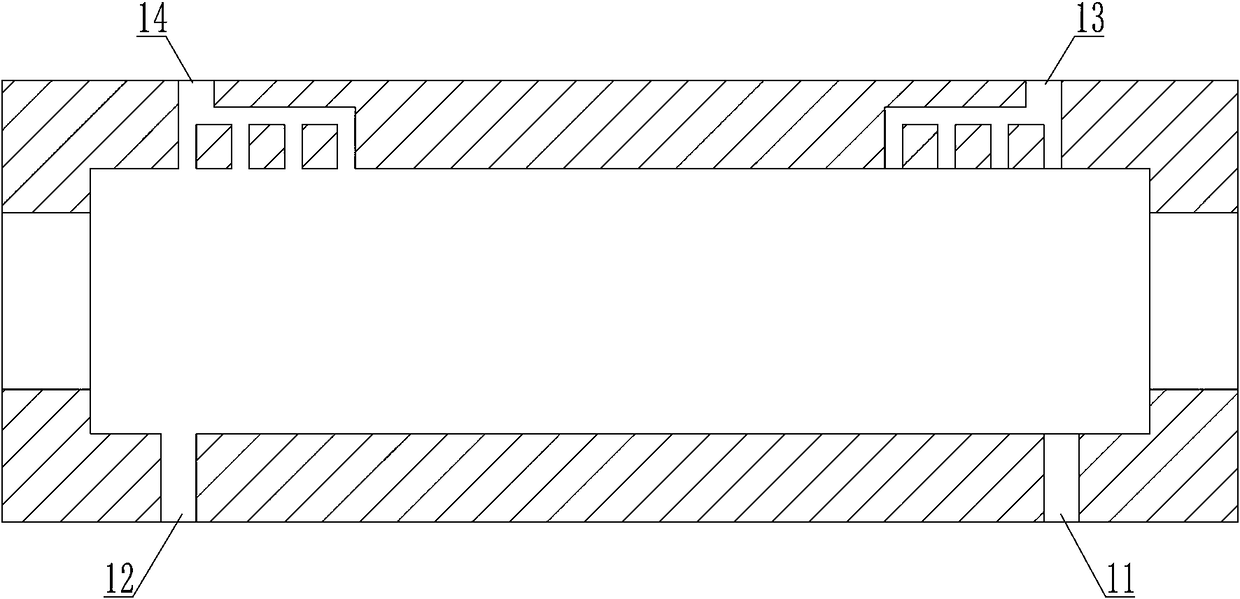

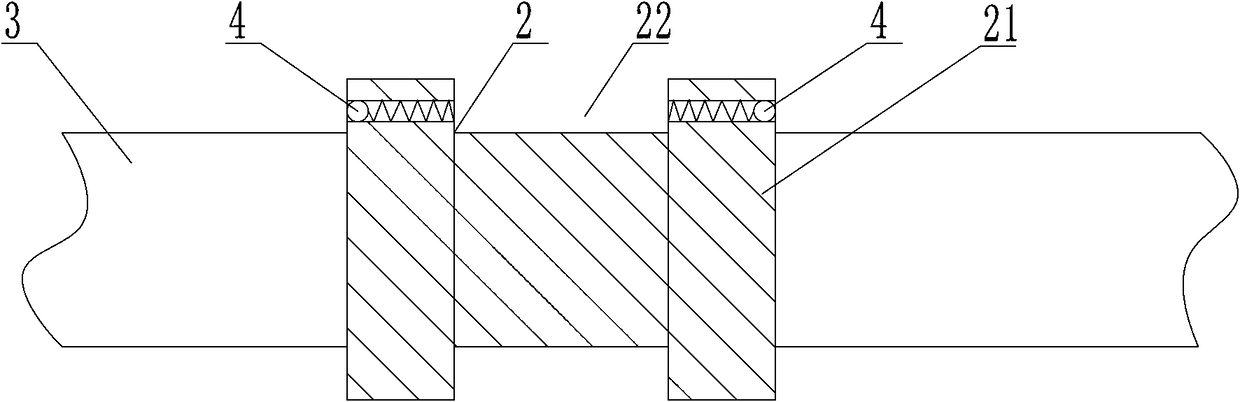

InactiveCN103895507ASmall shift shockReduce manufacturing costElectric propulsion mountingControl devicesVariatorPowertrain

The invention relates to a motor and speed changer integrated power assembly for battery electric vehicles. The motor and speed changer integrated power assembly comprises a motor, a speed changer and a differential mechanism; the motor comprises a stator, a rotor and a rotor base, and the stator is located on the inner wall of a motor shell; a first electromagnetic brake and a second electromagnetic brake are further arranged on the inner wall of the motor shell, a gear ring is arranged on the first electromagnetic brake in a matched mode, and a planet carrier is arranged on the second electromagnetic brake in a matched mode; the planet carrier is further respectively provided with three front-row planet wheels and three back-row planet wheels; front-row sun wheels are arranged at one axial end of the rotor base; back-row sun wheels are fixedly connected with flanges on a shell of the differential mechanism through screws; one end of the differential mechanism is located in the tubular rotor base, and the other end of the differential mechanism is located in the motor shell. By means of the motor and speed changer integrated power assembly, two-gear shifting can be achieved through different combinations of the two electromagnetic brakes; meanwhile, the motor and speed changer integrated power assembly is compact in structure, small in size and low in weight, and meets the automobile light-weight principle.

Owner:HEFEI UNIV OF TECH

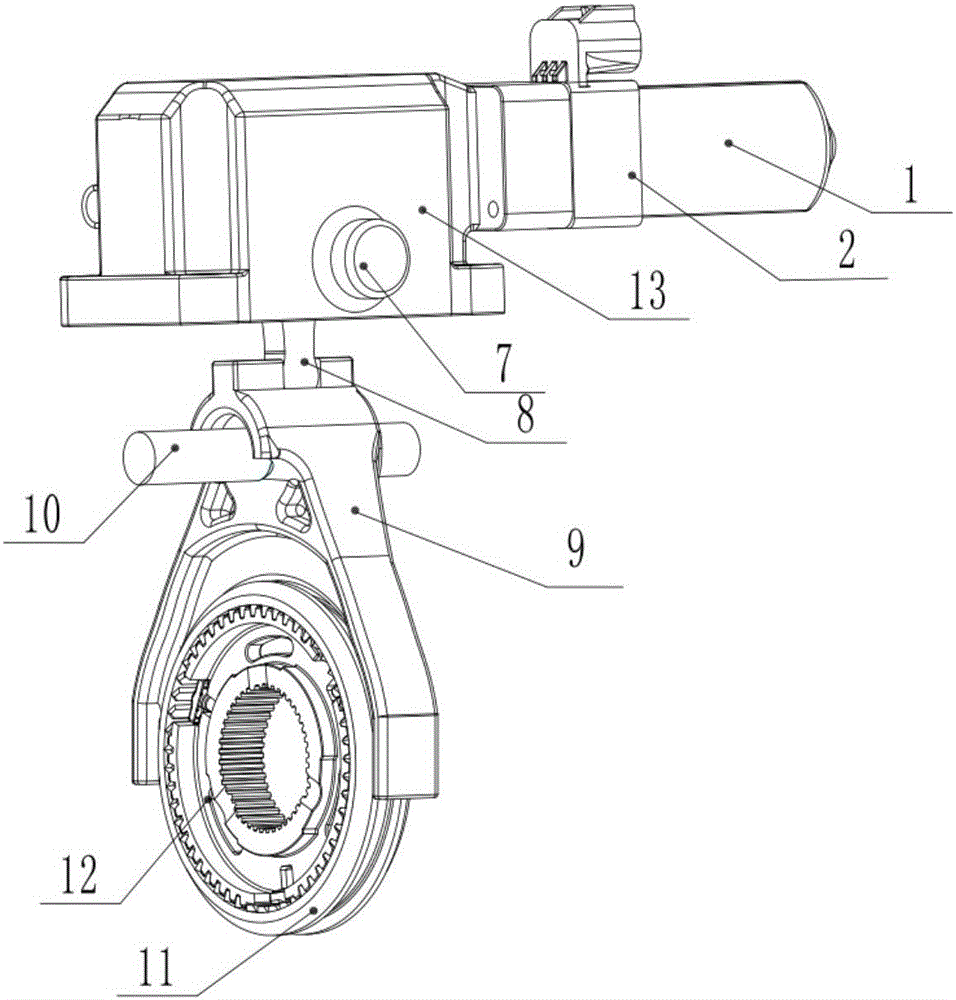

Automatic synchronous gear shifting system and electric automobile

InactiveCN106838300ASimple structureWith self-locking functionControlled membersGearing controlSelf lockingDowel

The invention discloses an automatic synchronous shifting system and an electric vehicle, belonging to the technical field of electric vehicles. The automatic shifting system provided by the present invention includes a power mechanism, a deceleration mechanism, a fork mechanism and a shifting mechanism. The deceleration mechanism of the present invention uses a lead screw and a nut sleeve to form a lead screw and nut pair. Compared with the self-locking pin or positioning pin that prevents off-gear in the existing automatic shifting system, the use of the lead screw and nut pair can not only achieve self-locking and The purpose of deceleration also simplifies the structure of the entire shifting system. The present invention also provides an electric vehicle using the above-mentioned automatic shifting system, the automatic synchronous shifting system for electric vehicles not only has a self-locking function, but also has low cost and reliable performance, and also saves the synchronous ring structure, thereby improving The shifting speed is reduced and the shifting shock is reduced.

Owner:HEBEI UNIV OF TECH

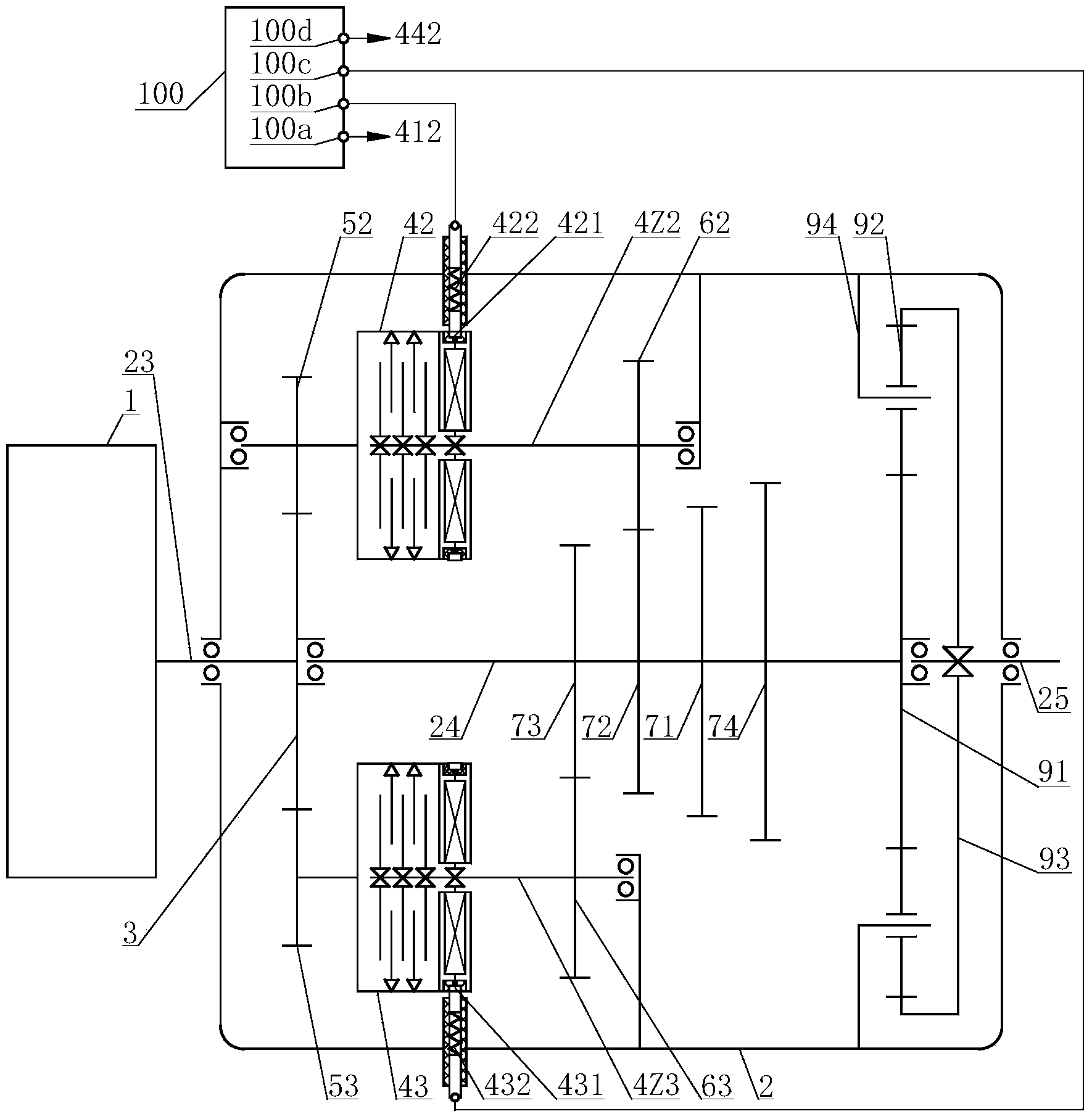

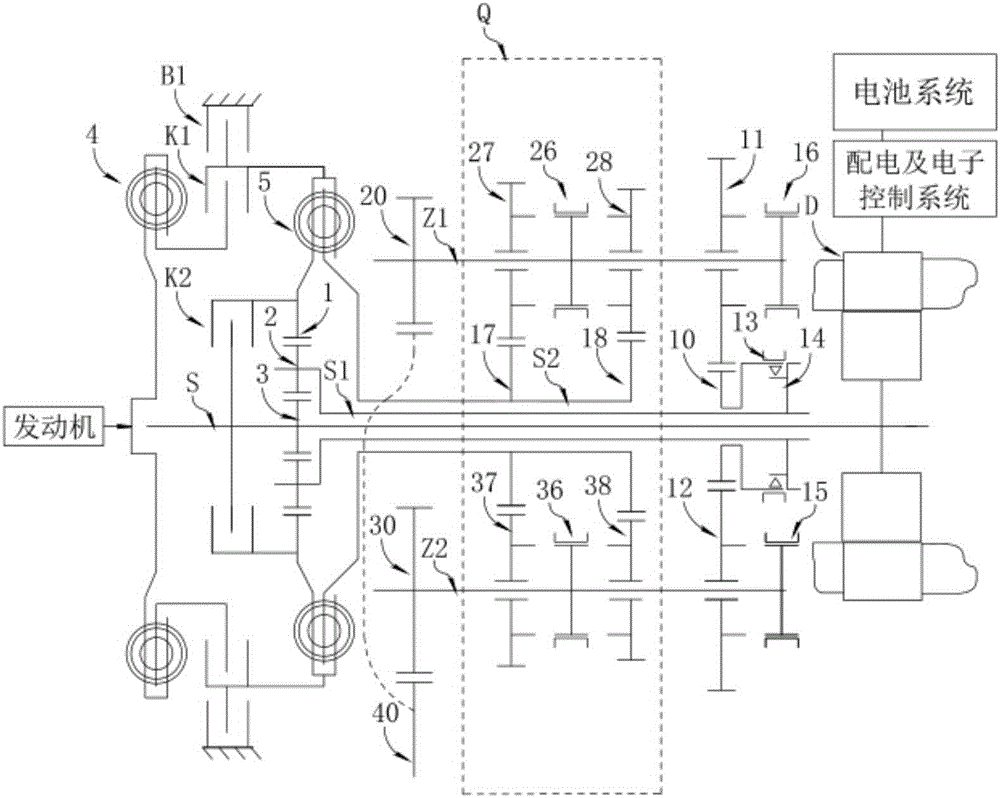

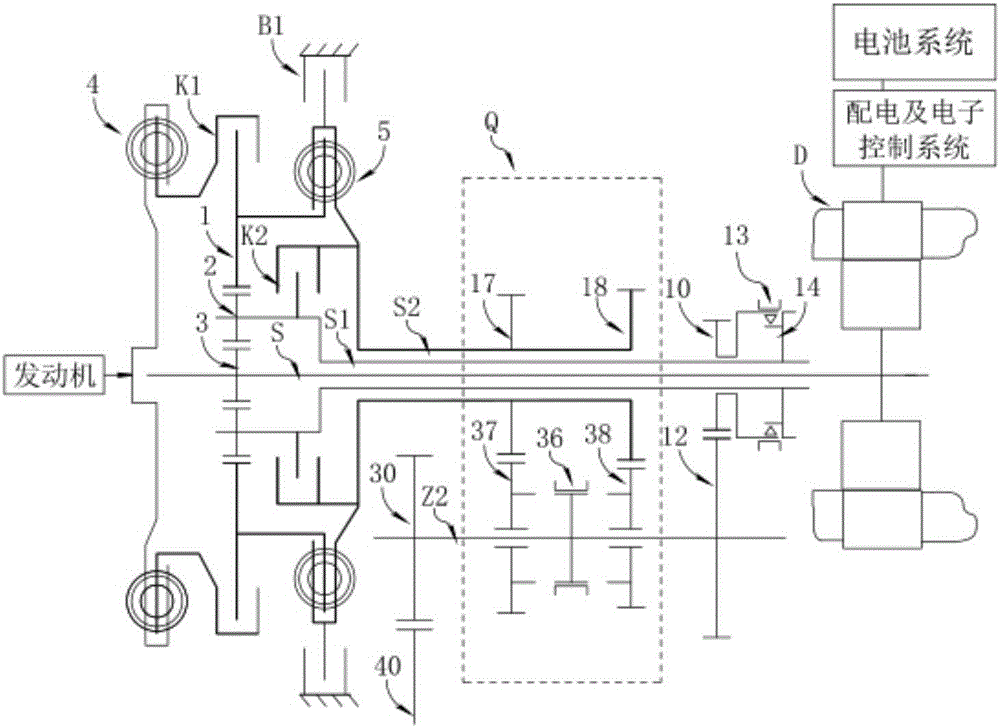

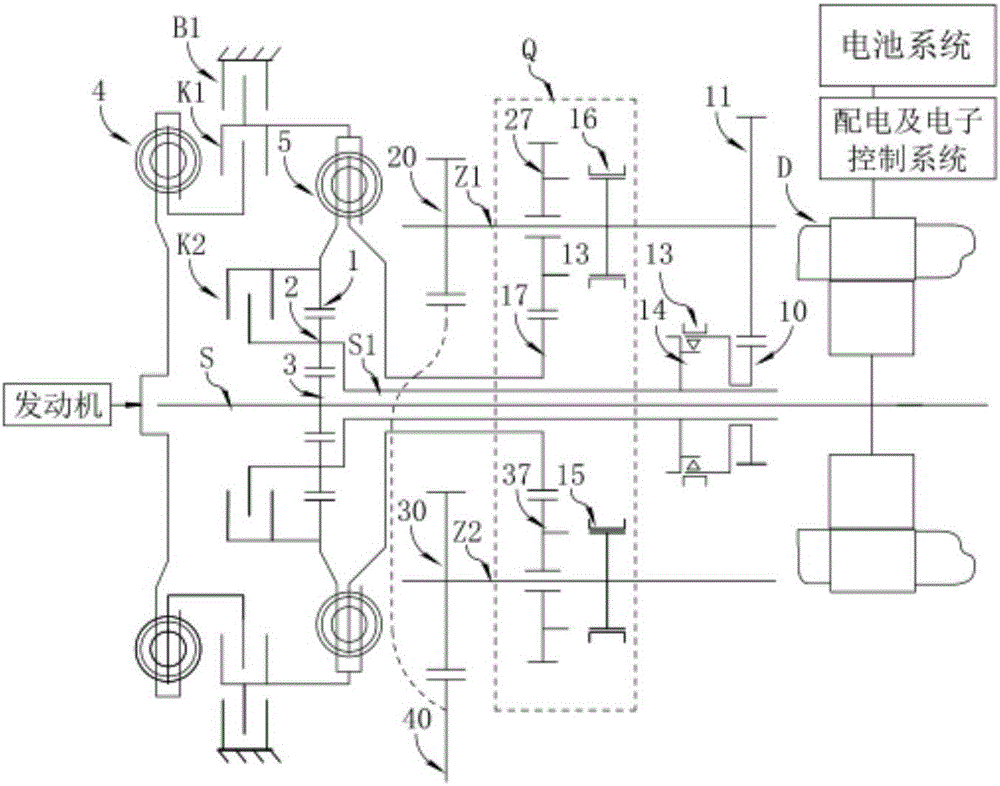

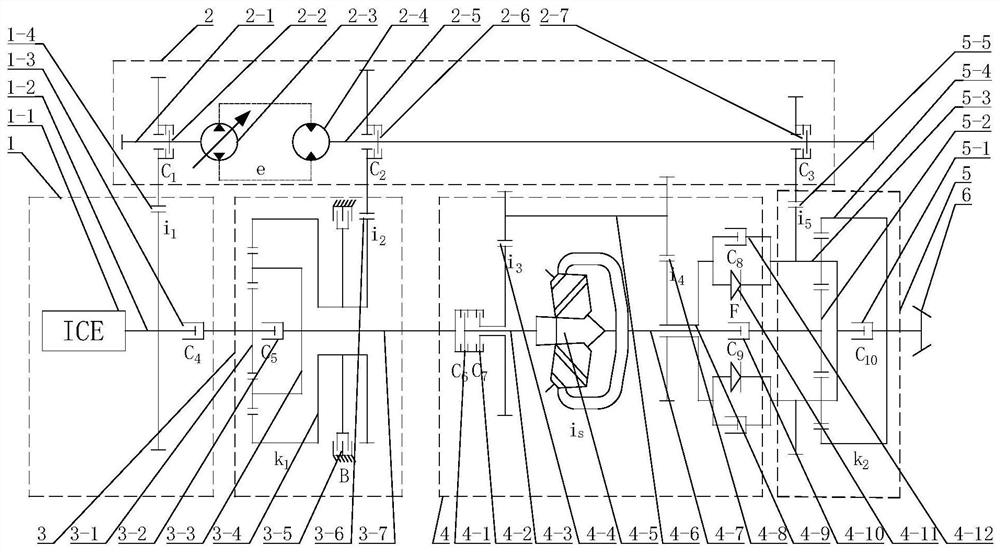

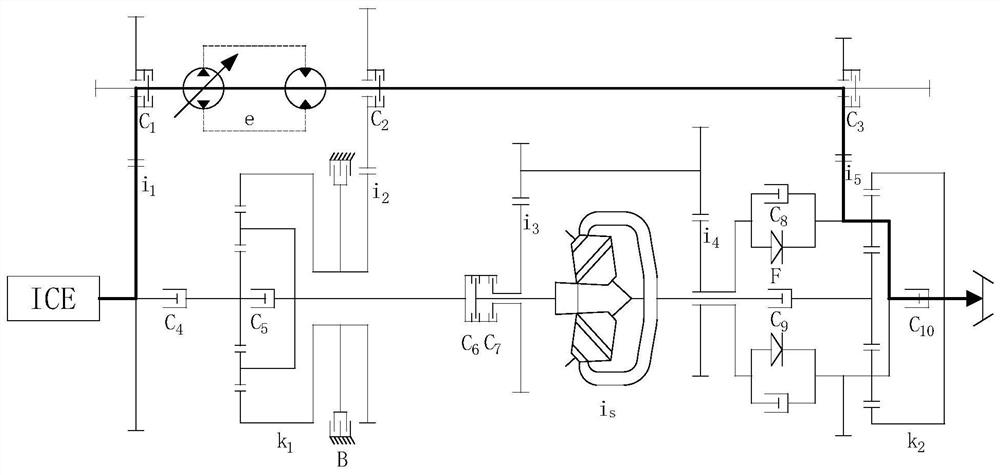

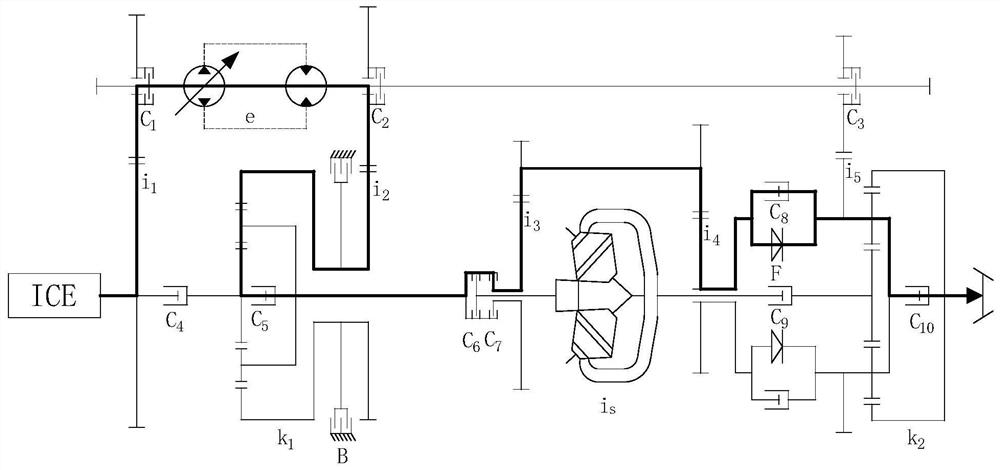

Plug-in multi-gears hybrid transmission

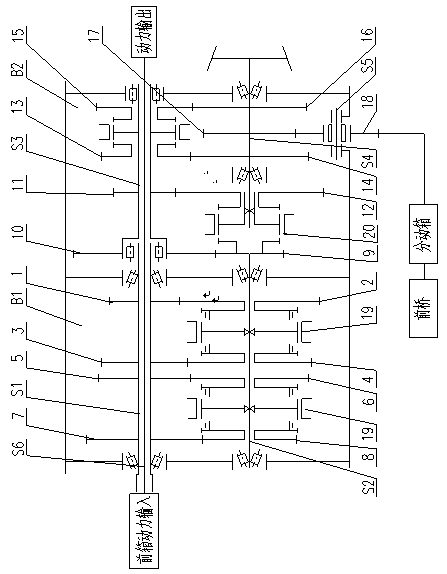

ActiveCN106609815ASmall shift shockHybrid vehiclesToothed gearingsLow speedElectronic control system

The invention discloses a plug-in multi-gears hybrid transmission comprising a planetary gear set for adjusting a power transfer path, a motor integrating functions such as startup, drive, power generation and the like, a first output system, a second output system, a battery system and a power distribution and electronic control system. The plug-in multi-gears hybrid transmission also includes a gear ring, a planet carrier and a sun gear arranged in the planetary gear set, a torsional damper arranged between an engine and the gear ring, a clutch K1 arranged between the engine and the gear ring and used for controlling connection or separation between the engine and a transmission, a brake B1 arranged between the gear ring and a transmission case, and a clutch K2 arranged between the gear ring and the sun gear in the planetary gear set and for controlling fixation or rotation between the gear ring and the sun gear. The plug-in multi-gears hybrid transmission has the characteristics that 1, the unique transmission structure is adopted, and the low-speed starting performance of the plug-in multi-gears hybrid transmission is much higher than that of ordinary transmissions, so that the plug-in multi-gears hybrid transmission has extremely high dynamic property; 2, multiple gears are arranged; and the engine and the motor are always in the best economic working state; 3, accelerating and gear-shifting are realized by the stepless speed regulation; the power is not interrupted; and extremely high shifting efficiency and gear-shifting ride comfort are realized.

Owner:雷世庆

Hybrid power vehicle driving system capable of governing speed by using motors during gear shifting

ActiveCN111976464ALower performance requirementsSimple structureHybrid vehiclesToothed gearingsDrive shaftGear wheel

The invention discloses a hybrid power vehicle driving system capable of governing speed by using motors during gear shifting. The hybrid power vehicle driving system comprises an engine, a planetarygear mechanism, a synchronizer and the first motor, the planetary gear mechanism comprises a sun gear fixedly connected with a transmission shaft of the engine, an outer gear ring connected with a brake, a planet carrier connected with the outer gear ring through a clutch, and a planetary gear arranged on the planet carrier and meshed with the sun gear and the outer gear ring respectively, and thesynchronizer is fixedly connected to an intermediate shaft. The two sides of the synchronizer can be connected with a first gear and a second gear which are separately arranged on the intermediate shaft in an idling and sleeving mode, the outer gear ring and the planet carrier are coaxially and fixedly connected with a third gear and a fourth gear respectively, and the third gear and the fourth gear are meshed with the second gear and the first gear respectively. The intermediate shaft, a transmission shaft of the engine and a transmission shaft of the first motor are fixedly connected with afifth gear, a sixth gear and a seventh gear respectively, and the fifth gear and the sixth gear are meshed with a differential gear which is fixedly connected to the differential and a seventh gear respectively. The system simplifies a transmission system, the motor is used for speed regulation during gear shifting, and the gear shifting impact is reduced.

Owner:DONGFENG MOTOR CORP HUBEI

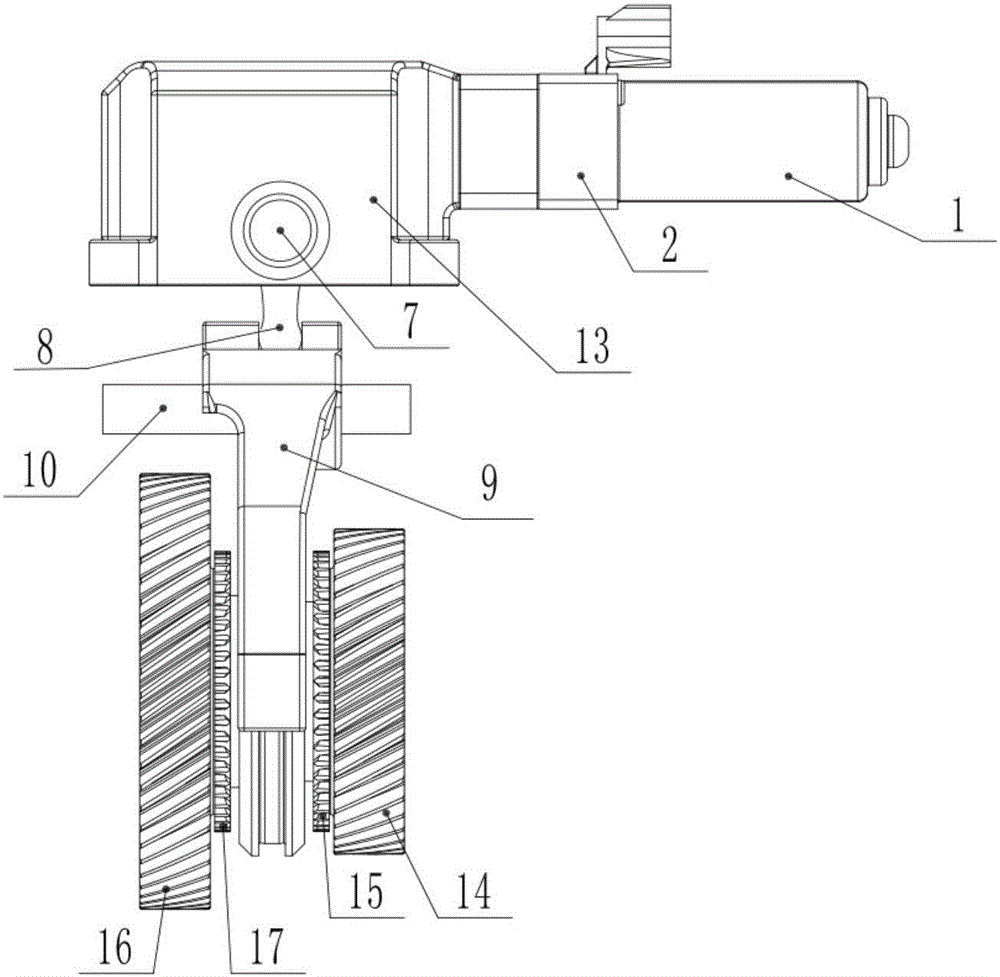

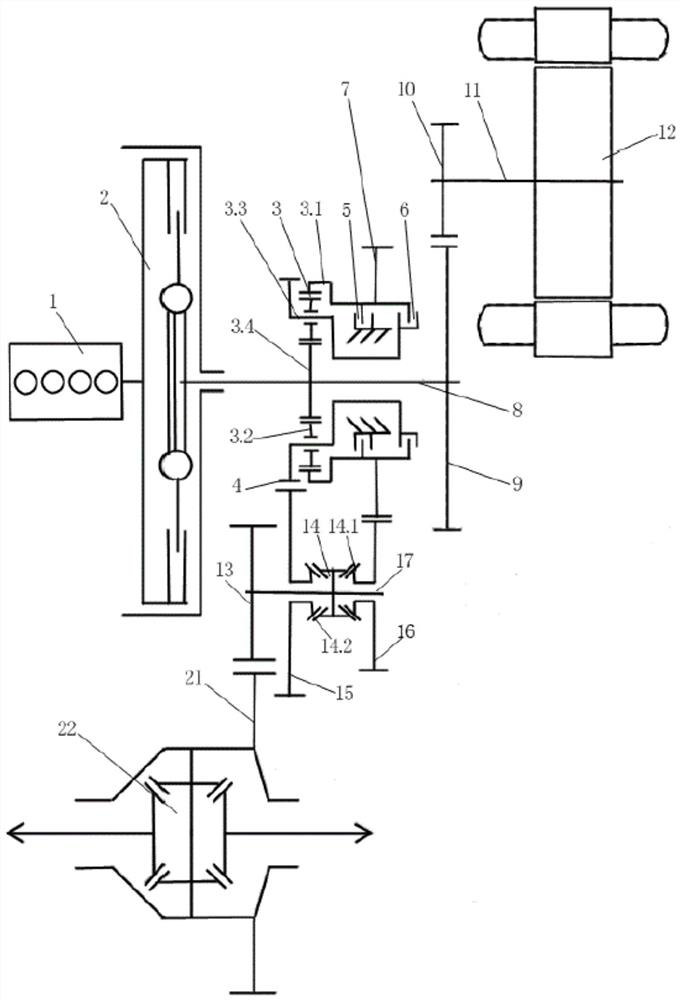

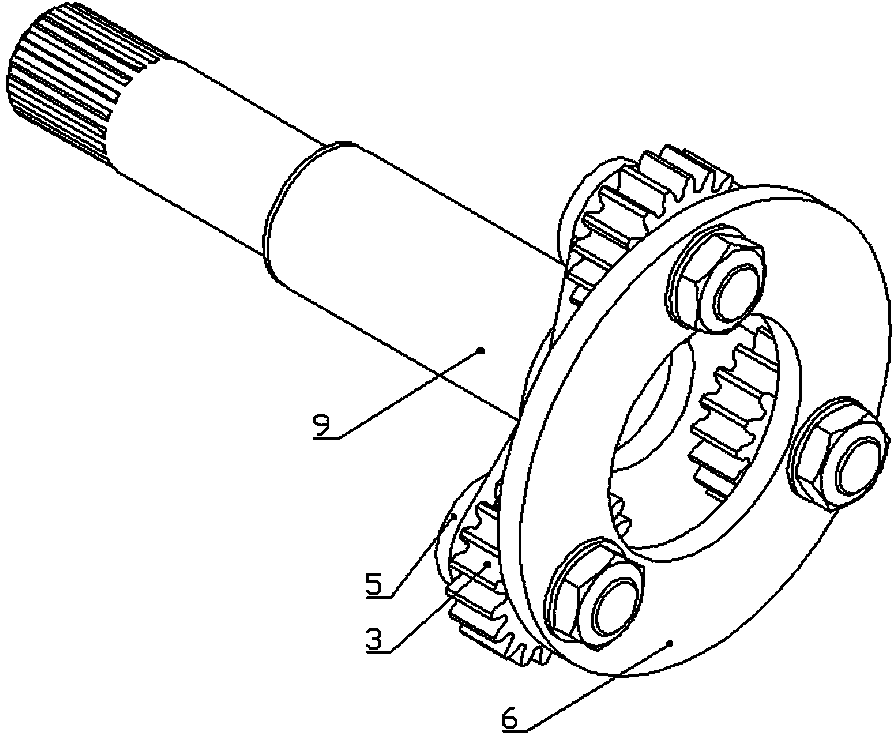

Motor-driven planetary gear train gear shifting mechanism

ActiveCN104329455ASimple internal structureSimple installation structureRoad transportGearing controlCircular discBall screw drive

The invention relates to a motor-driven planetary gear train gear shifting mechanism, which consists of a planetary gear train mechanism, a synchronizer and a gear shifting transmission fork mechanism, wherein the planetary gear train mechanism comprises a center wheel, an inner gear ring, a planetary carrier and three planetary gears; the planetary carrier is formed by the fact that a disk is coaxially connected with one spindle; the three planetary gears are evenly distributed on the disk and are respectively meshed with the center wheel and the inner gear ring; one side of the inner gear ring is connected with a tubular shaft sleeve; the shaft sleeve sheathes the spindle of the planetary carrier; one side of the synchronizer sheathes the shaft sleeve of the inner gear ring, and the other side of the synchronizer sheathes the spindle of the planetary carrier; the gear shifting transmission fork mechanism comprises a transmission fork, a ball screw and a servo motor. According to the motor-driven planetary gear train gear shifting mechanism, the ball screw driven by the servo motor is used for driving a gear shifting transmission fork to realize gear shifting, so that gear shifting impact is small, and gear shifting smoothness and service life are improved and prolonged. Since the servo motor is supplied with power by an automobile battery instead of directly consuming the kinetic energy of an engine, the efficiency of the engine is effectively improved.

Owner:HEFEI UNIV OF TECH

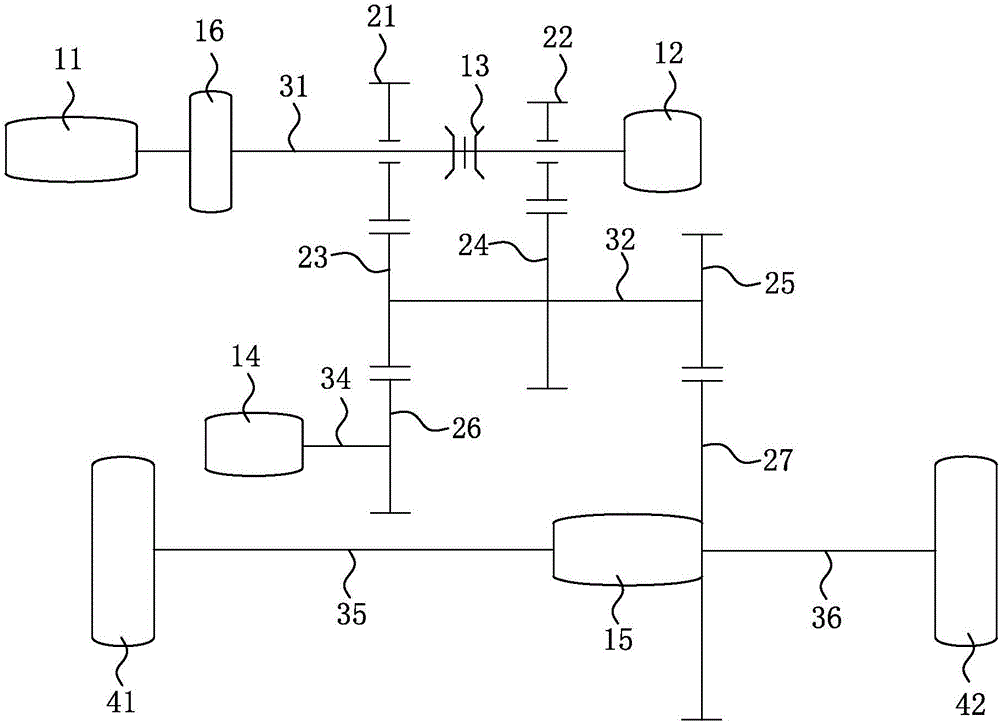

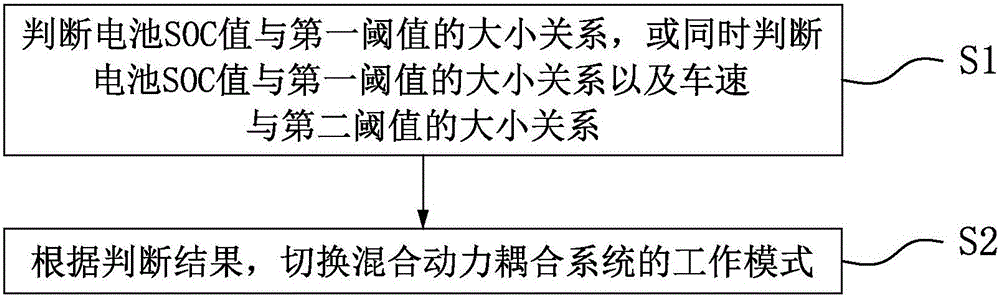

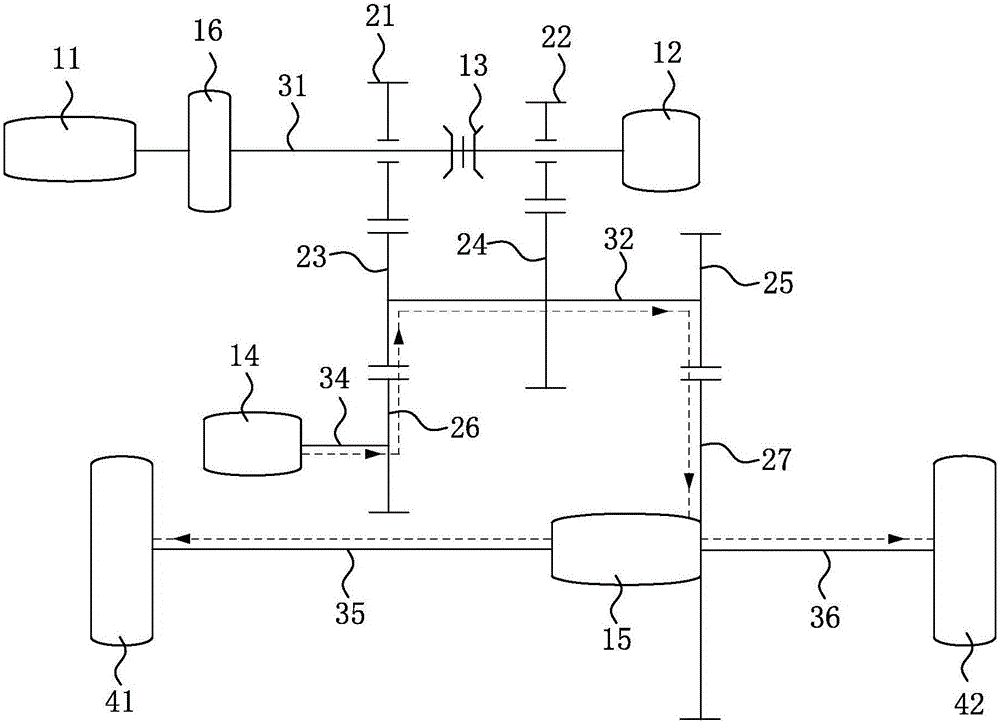

Hybrid coupled system and hybrid vehicle

ActiveCN106004406ASimple structureOptimize working rangeHybrid vehiclesGas pressure propulsion mountingGear wheelElectric machine

A hybrid coupled system is characterized in that an electric generator and an engine of the system are coaxially connected through a first shaft; a first gear and a second gear are arranged on the first shaft, a synchronizer is arranged between the first gear and the second gear and controls the first shaft to be connected with or separated from the first gear or the second gear, and a differential is connected with the engine and a driving motor through a gear shaft system. The hybrid coupled system does not need a clutch, is simple in structure, saves space and is convenient to arrange; when the engine participates in driving, two gears of the engine can be selected, so that the work range of the engine is optimized, and dynamic property and economic performance of the engine are improved; before and after gear shifting, through speed regulation of the electric generator and the driving motor, the gear shifting impact is reduced, and the service life of the synchronizer is prolonged; furthermore, the driving motor can output power while regulating the speed in a gear shifting process, and the condition of power failure is avoided. The invention further provides a hybrid vehicle.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

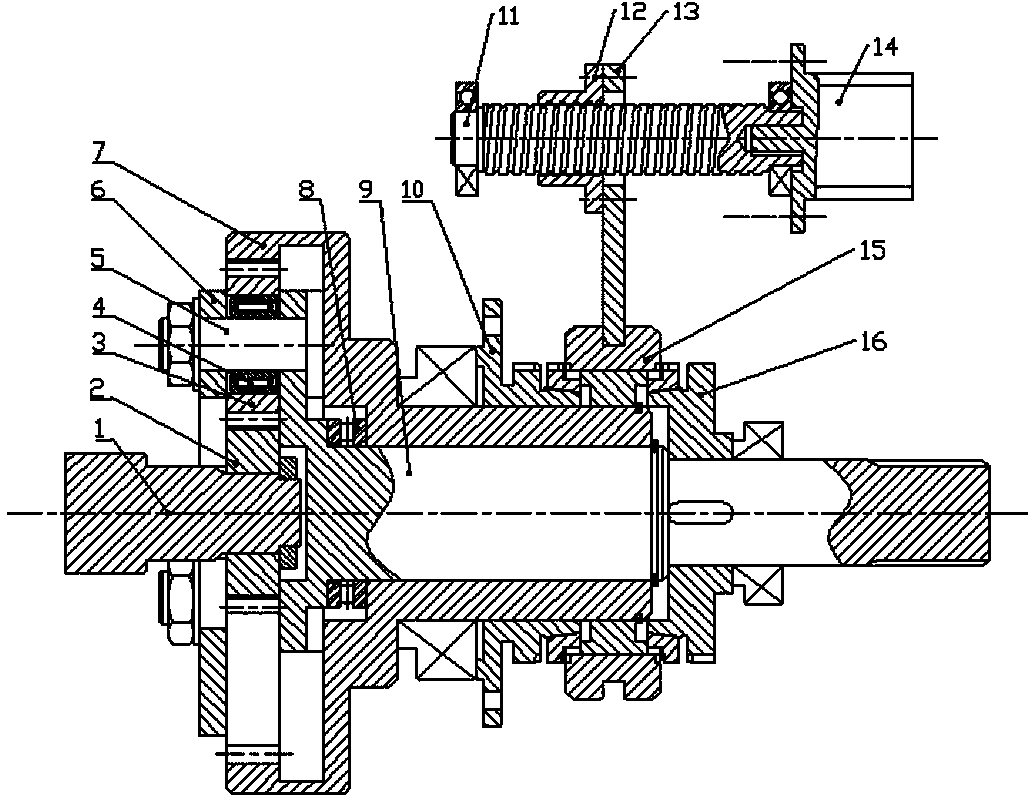

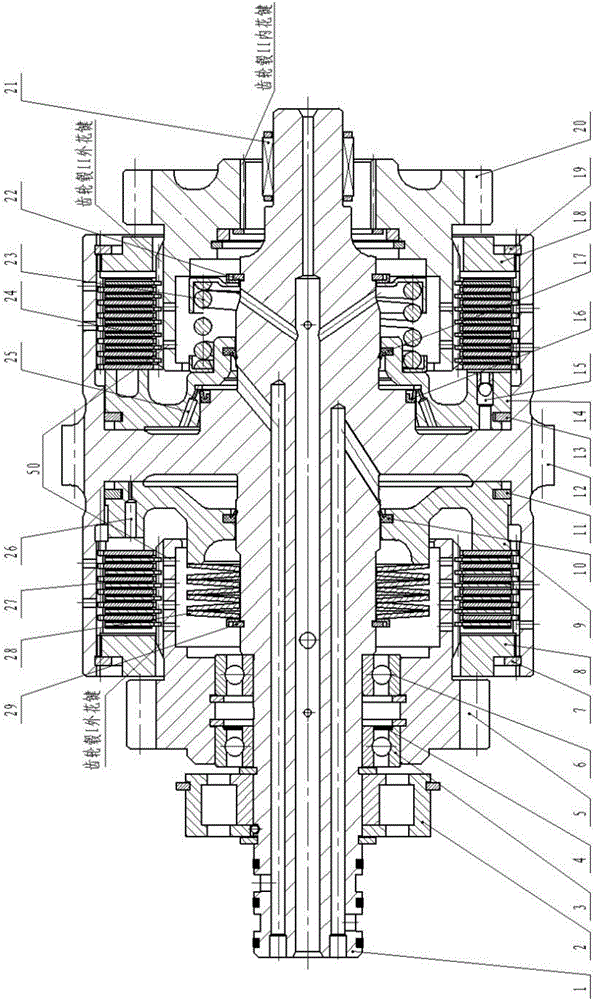

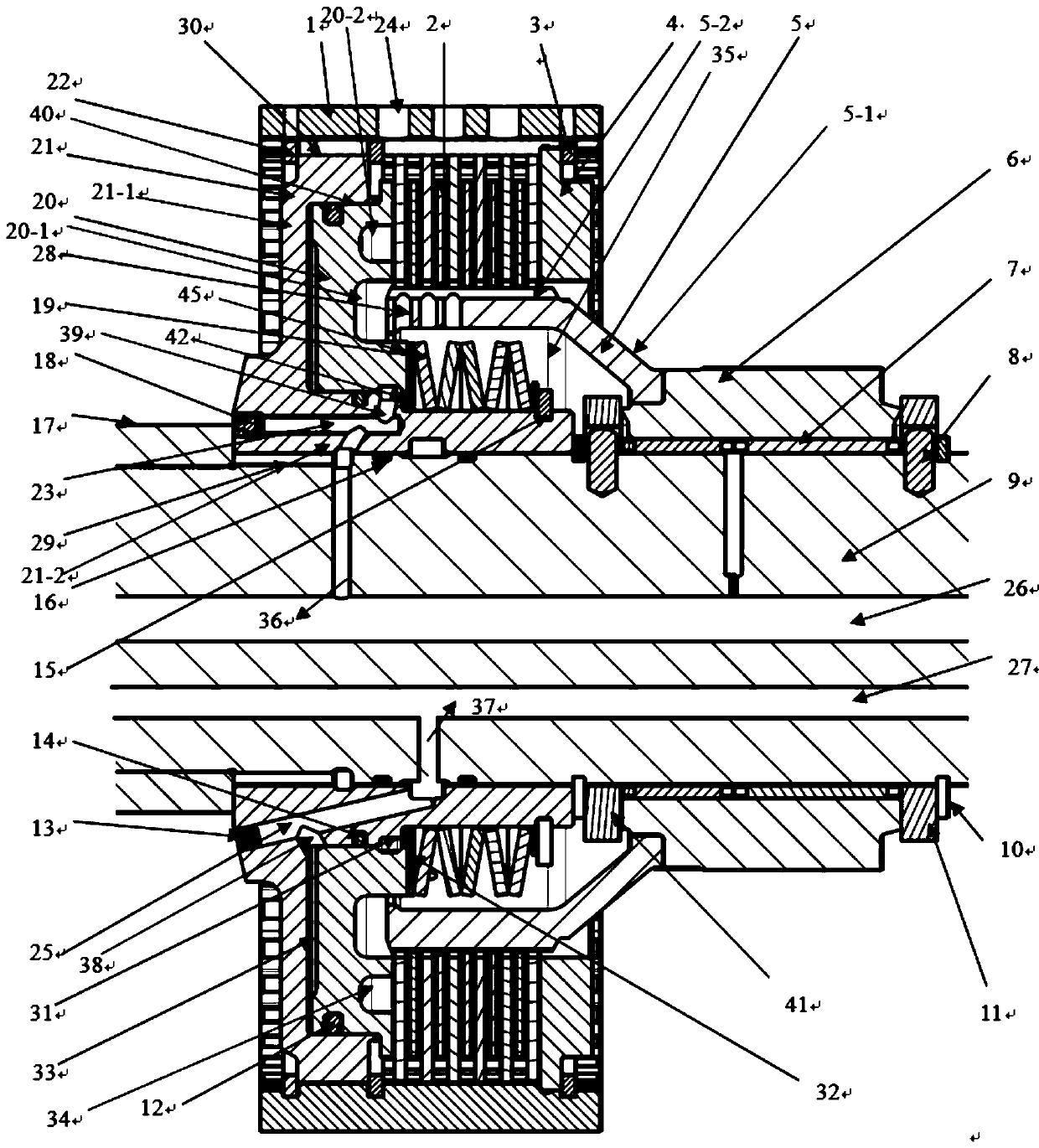

Integrated clutch axle hub transmission device

InactiveCN106763284AEasy to realize automatic controlSolve problems such as high labor intensityFluid actuated clutchesGear vibration/noise dampingInlet channelAutomatic control

The invention discloses an integrated clutch axle hub transmission device which comprises an external meshing gear, a spindle, a clutch, a bearing, a piston and a return spring. The power transmission path of a transmission axle hub can be changed by engagement and disengagement of the clutch according to the requirement of an electric control hydraulic system to implement different gears. The external meshing gear, a clutch hub and a transmission shaft are integrated by an integrated clutch axle hub to form integrated parts, deformation caused by welding and the like is avoided, transmission stability cannot be affected, the axle hub is provided with a clutch oil inlet channel, a friction pair and a bearing lubricating and cooling oil channel, and the clutch is disengaged by the piston and the return spring. The device has the advantages of compact structure, working stability, high bearing torque, easiness in implementing automatic control and the like.

Owner:贵州凯星液力传动机械有限公司

Control method for power system of automatic transmission automobile

ActiveCN106151493ALow efficiencyReduced Torque RequirementRoad transportGearing controlAutomatic transmissionCombustion

The invention provides a control method for a power system of an automatic transmission automobile. The engine revolution speed in the upshifting process is controlled by controlling output torque of an engine and pressure of a lock-up clutch of a hydraulic torque converter in the gear shifting process. By controlling the output torque of the engine and the pressure of the lock-up clutch of the hydraulic torque converter in the gear shifting process, the control method can enable the engine revolution speed to be kept in a constant range, and therefore a driver does not perceive the gear shifting process through the change of the engine revolution speed; and the influence of inertia torque on gear shifting can be effectively lowered, and meanwhile the negative effects that combustion is not sufficient, and the use efficiency of fuel oil is reduced are not caused.

Owner:SAIC GENERAL MOTORS +1

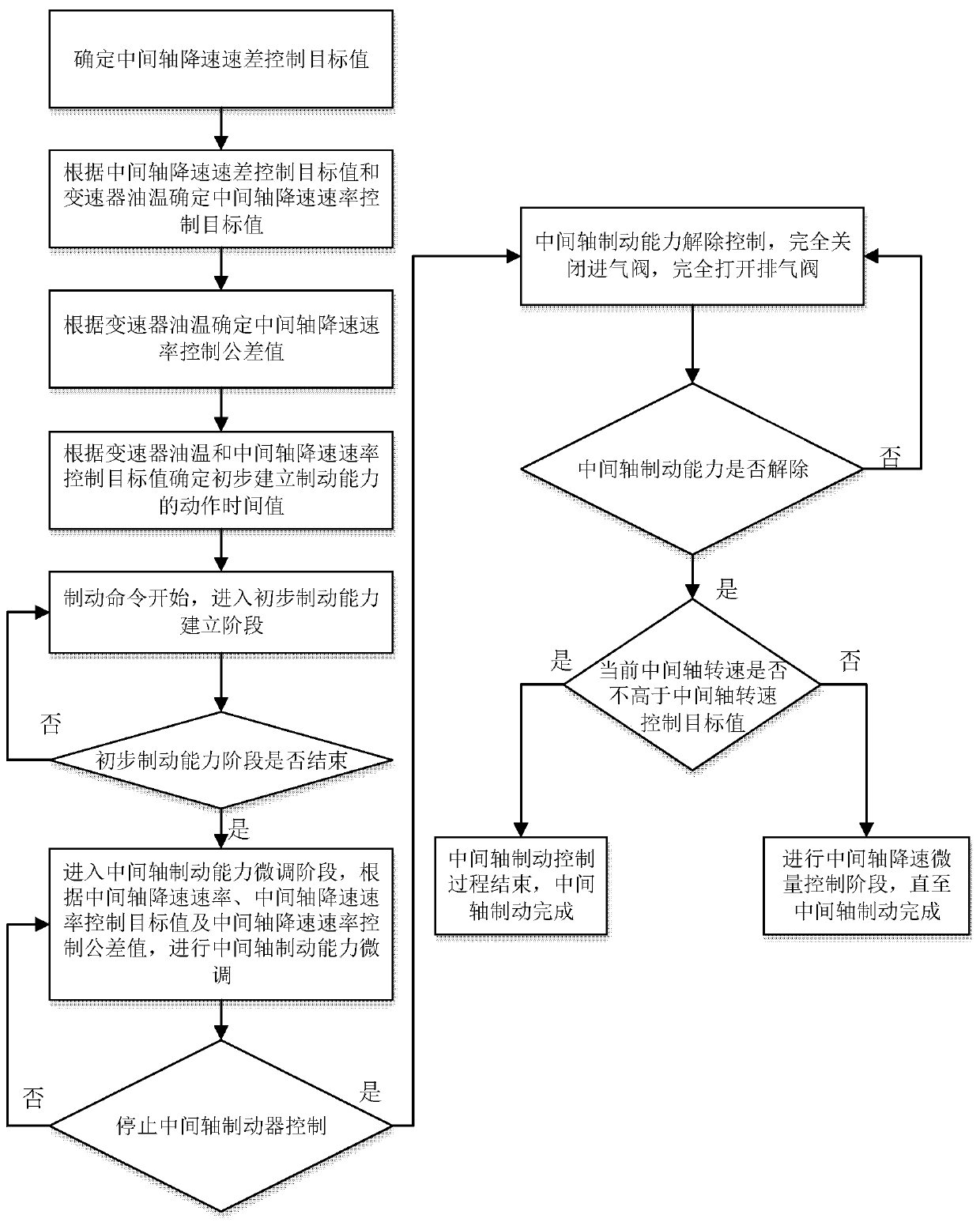

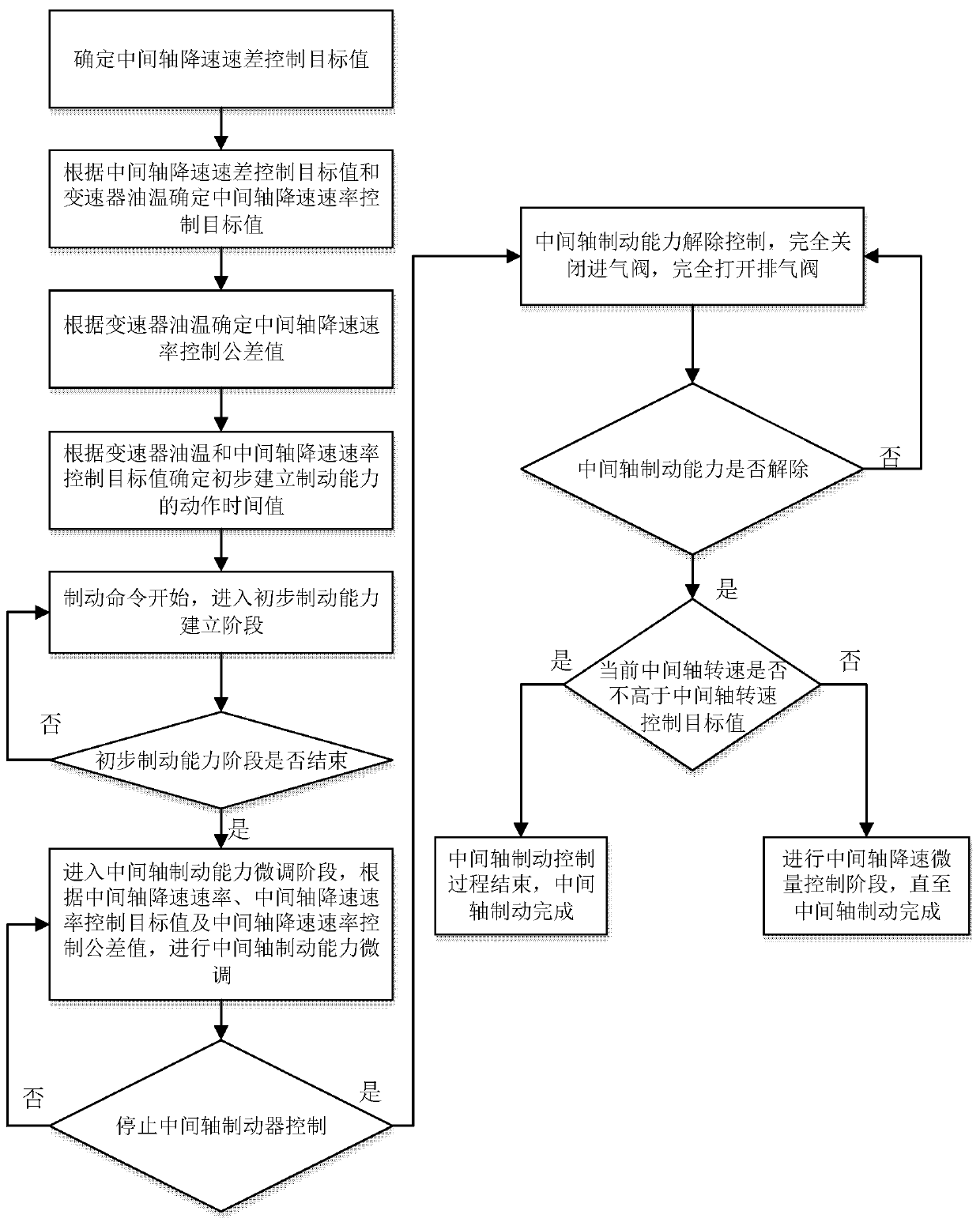

AMT intermediate shaft brake pneumatic control method based on dual PWM valve

ActiveCN111120642AGuaranteed deceleration ratePrevent overbraking problemsGearing controlControl objectiveControl theory

The invention relates to the field of transmission control, in particular to an AMT intermediate shaft brake pneumatic control method based on a dual PWM valve. The method comprises the following steps of determining intermediate shaft reduction speed difference control target value; determining intermediate shaft reduction speed rate control target value; determining intermediate shaft reductionspeed rate control tolerance value; determining action time value for preliminarily building brake capacity; starting a brake command, and executing a preliminary brake capacity building stage; executing an intermediate shaft brake capacity fine adjustment stage, and carrying out intermediate shaft brake capacity fine adjustment; decontrolling the intermediate shaft brake capacity; judging whetherthe current intermediate shaft rotating speed is not higher than the intermediate shaft rotating speed control target value or not, and if not, finishing the intermediate shaft brake control process,and finishing intermediate shaft brake; and if the current intermediate shaft rotating speed is higher than the intermediate shaft rotating speed control target value, executing the intermediate shaft reduction speed micro control stage until the intermediate shaft brake is finished. The problems of over brake and in-advance decontrolling in the prior art can be solved.

Owner:FAW JIEFANG AUTOMOTIVE CO

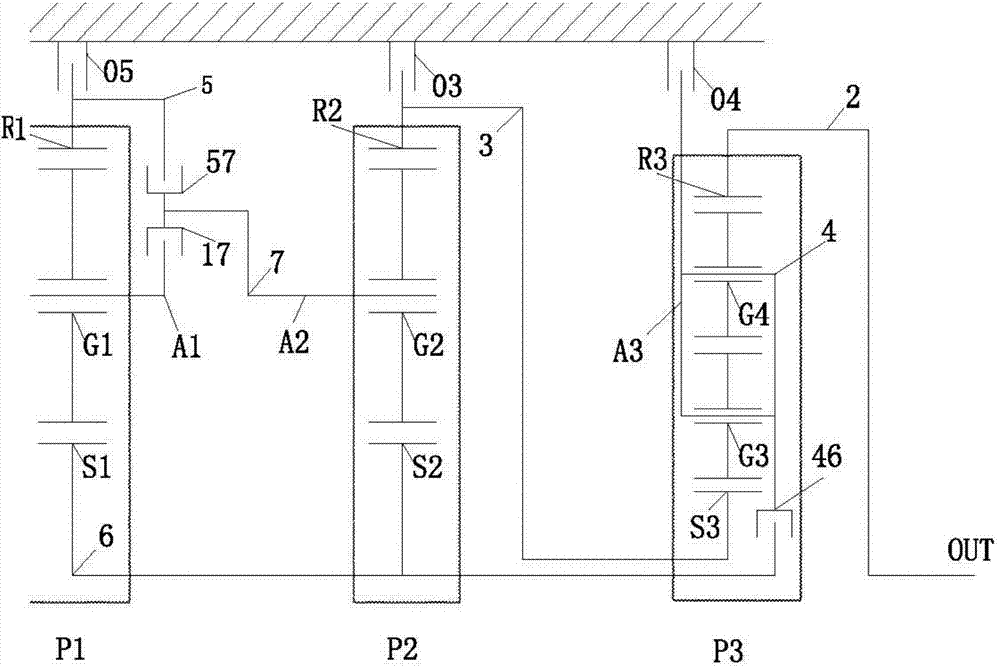

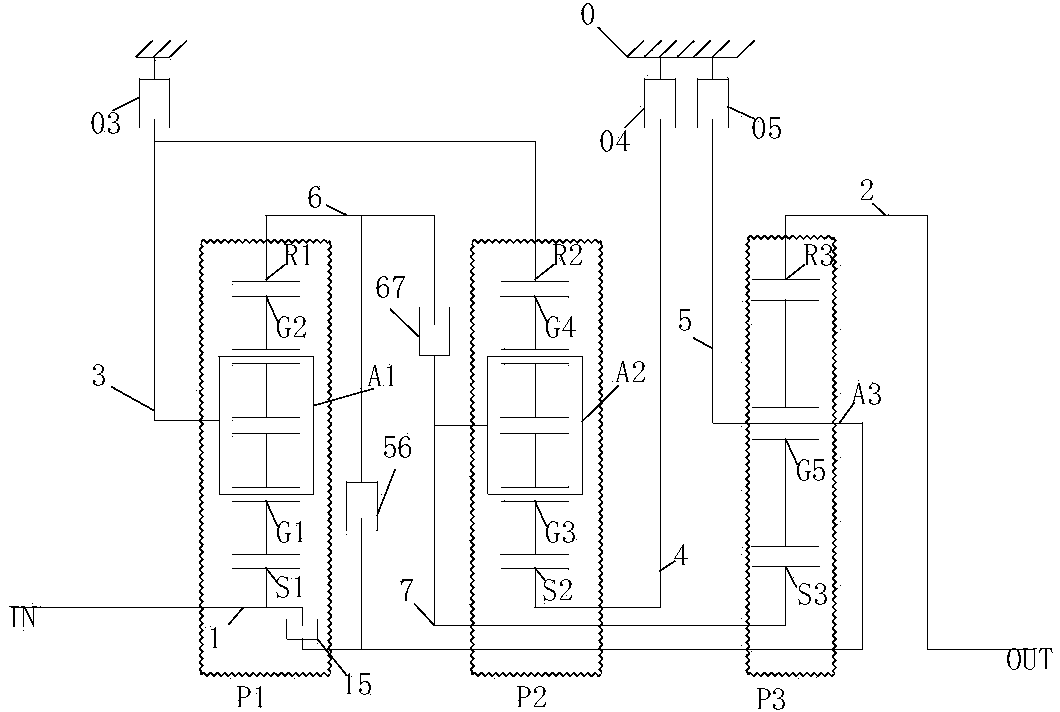

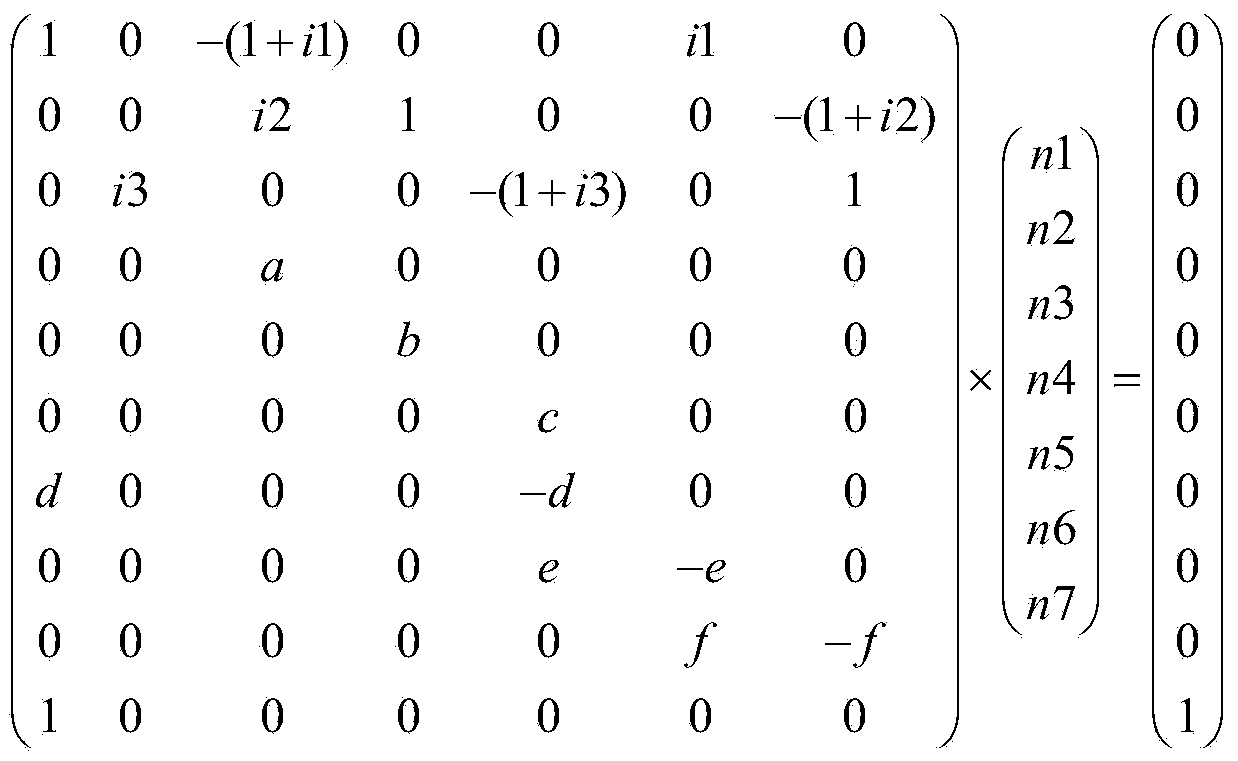

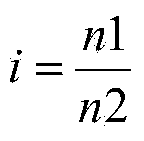

Multi-gear speed changer of planet gear structure

ActiveCN104295679ASmooth shiftingIncreased odds of working in the economyToothed gearingsTransmission elementsGear wheelCentre of rotation

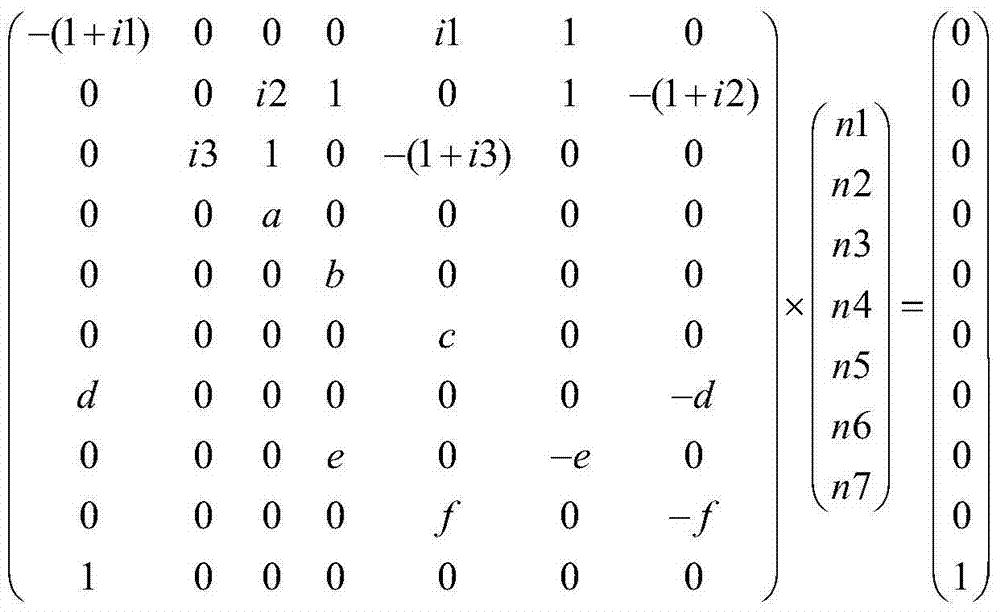

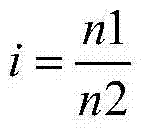

A multi-gear speed changer of a planet gear structure comprises a shell, an input component, an output component, a first planet gear set, a second planet gear set, a third planet gear set, a first interconnection component, a second interconnection component, a third interconnection component, a fourth interconnection component, a fifth interconnection component, a sixth interconnection component, a seventh interconnection component, a first torque transmission device, a second torque transmission device, a third torque transmission device, a fourth torque transmission device, a fifth torque transmission device and a sixth torque transmission device. The first planet gear set, the second planet gear set and the third planet gear set are sequentially arrayed from the input end to the output end. The six torque transmission devices comprise three brakes and three clutches, and the first torque transmission device is placed over the second planet gear set and is close to the shell. The second torque transmission device is placed between the second planet gear set and the third planet gear set and is close to the shell. The third torque transmission device is placed over the first planet gear set and is close to the shell. The fourth torque transmission device and the fifth torque transmission device are placed between the first planet gear set and the second planet gear set and are close to the shell. The sixth torque transmission device is placed on the right side of the third planet gear set and is close to a rotating center. All the above components are located inside the shell. The multi-gear speed changer is compact in structure.

Owner:BEIHANG UNIV

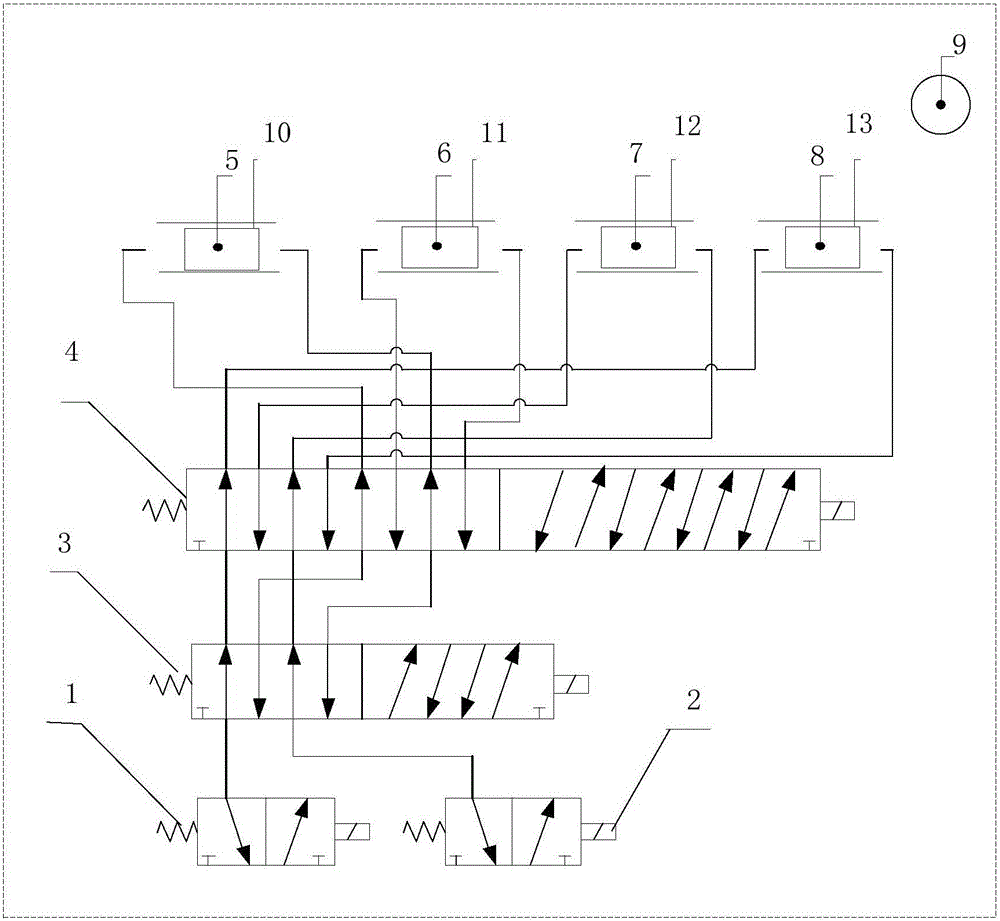

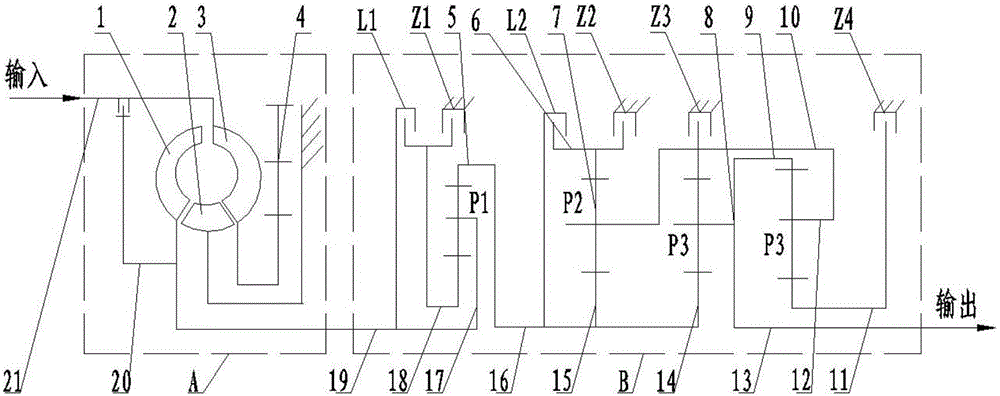

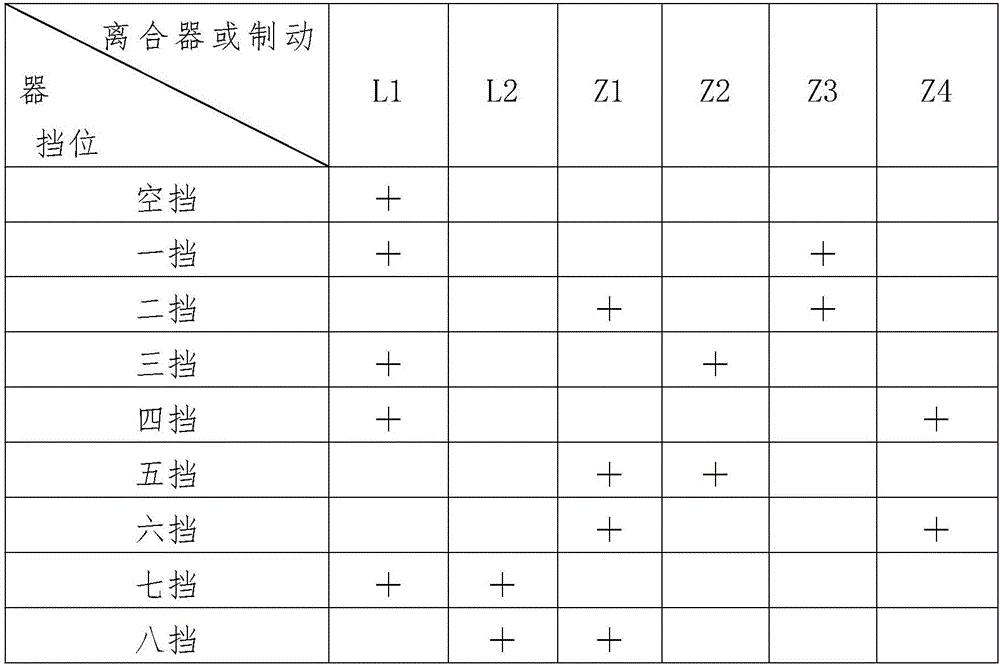

High-power hydraulic variable speed transmission device

ActiveCN105889450ASatisfy the load pressureMeet the needs of displacementGearing controlFluid gearingsFlywheelControl theory

The invention discloses a high-power hydraulic variable speed transmission device, which comprises an integral torque converter and a planetary speed changer, wherein an input flywheel, a locking clutch and a power taking device are also arranged in the torque converter; four planetary row assemblies, four brakes and two rotating clutches are arranged in the planetary speed changer; all parts are connected through splines or gears; the two rotating clutches and the four brakes are used for realizing different control; the gear requirements of eight forward gears and a neutral gear can be realized; the gear number can be reduced by decreasing the number of planetary rows and the brakes. The high-power hydraulic variable speed transmission device has the advantages that the application power is great; the structure is compact; the deformation is easy; the whole machine arrangement is favorably realized.

Owner:贵州凯星液力传动机械有限公司

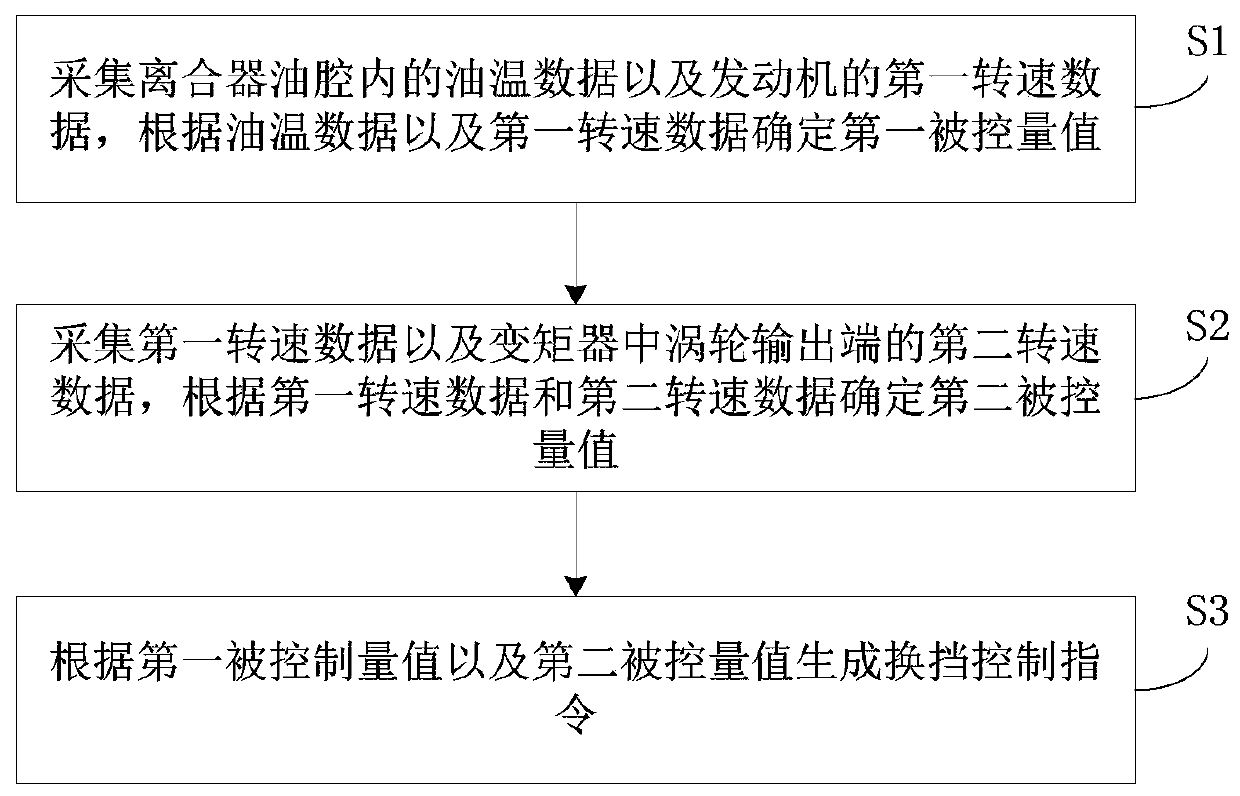

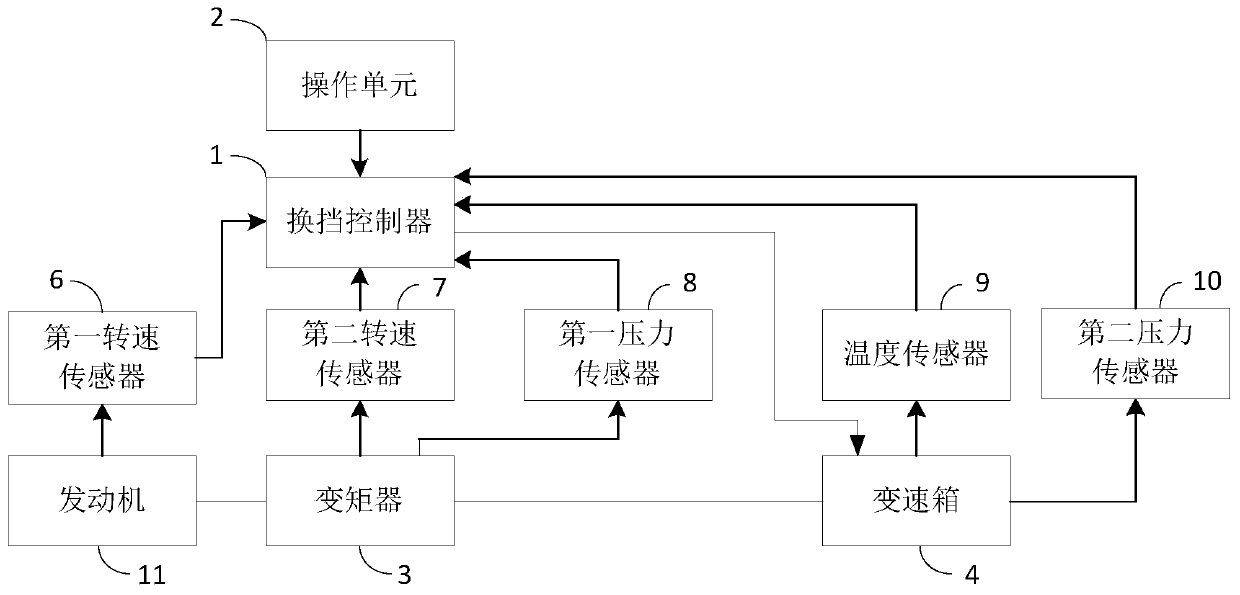

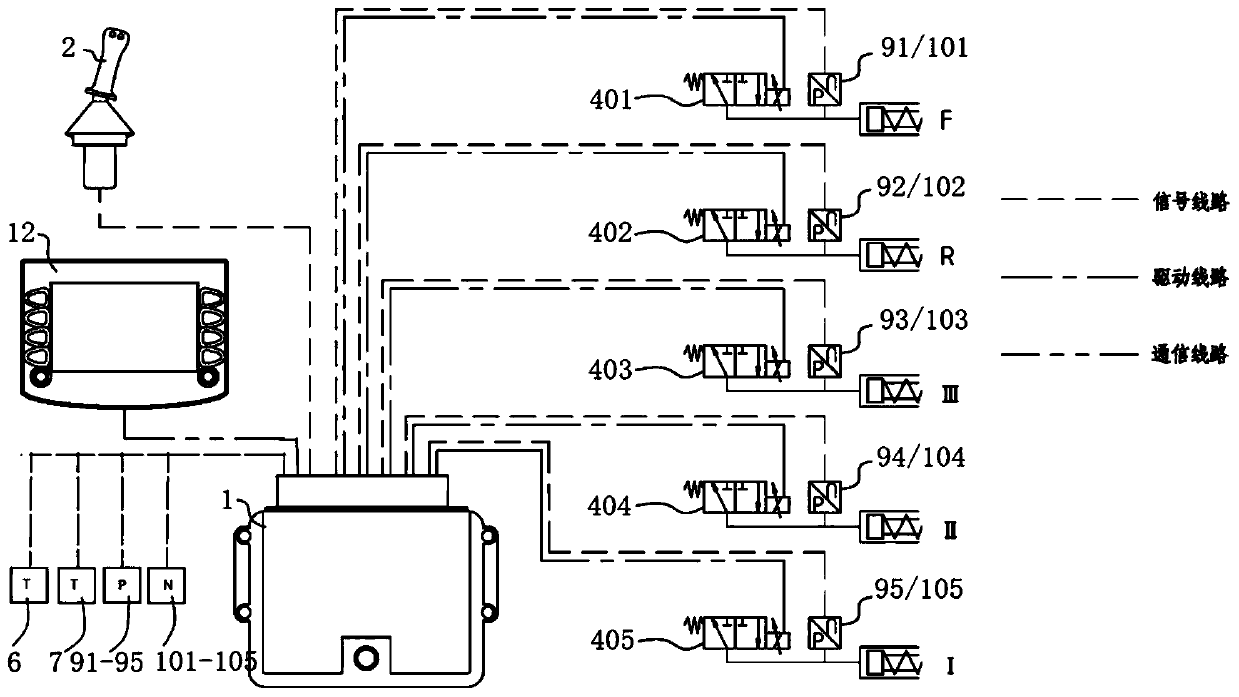

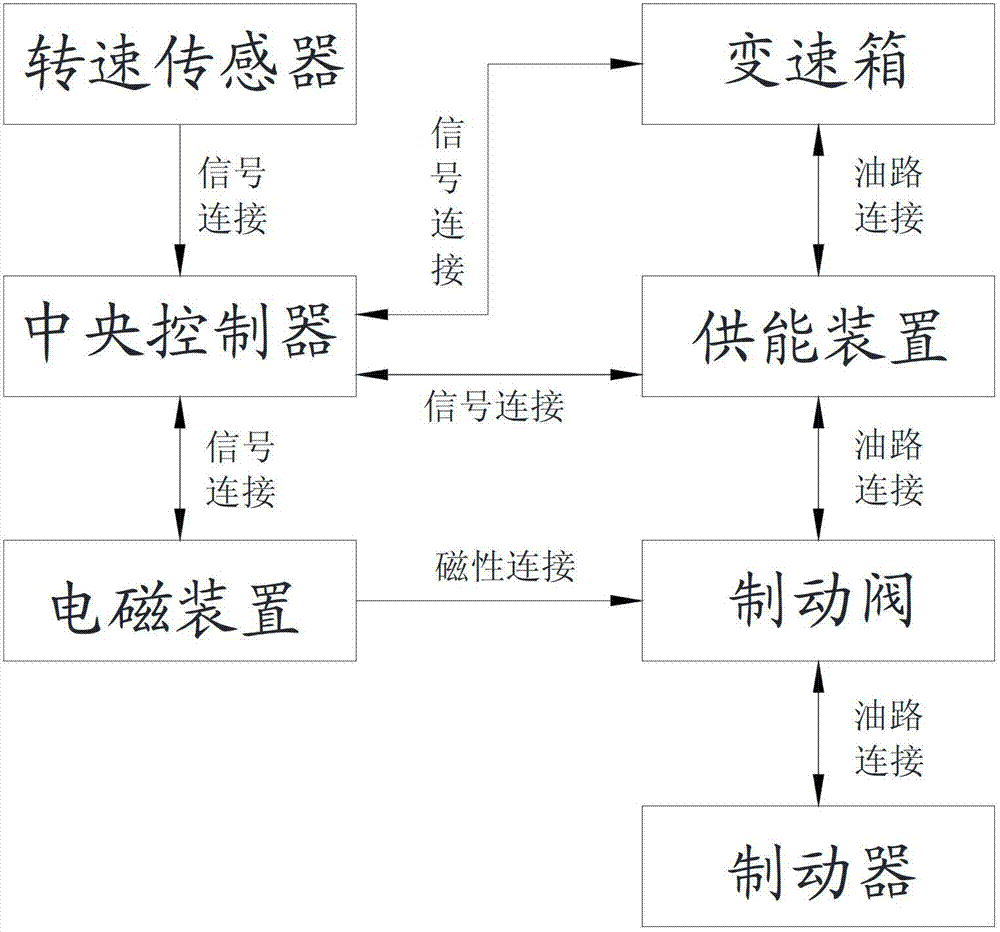

Bulldozer gear-shifting controller and system

ActiveCN111271443ASmall shift shockExtend your lifeClutchesGearing controlMagnetic valveControl theory

The invention discloses a bulldozer gear-shifting controller and a system. The gear-shifting controller is used for acquiring oil temperature data in a clutch oil cavity and first rotate speed data ofan engine so as to determine a first controlled volume value according to the oil temperature data and the first rotate speed data; acquiring first rotate speed data and second rotate speed data of aturbine output end in a torque converter so as to determine a second controlled volume value according to the first rotate speed data and the second rotate speed data; and generating a gear-shiftingcontrol command according to the first controlled volume value and the second controlled volume value. According to the gear-shifting controller, a target current value aiming at the control of a proportional electromagnetic value is determined by adopting the rotate speed of the engine and oil temperature data, a load of a bulldozer is determined based on the speed ratio of the rotate speed of the engine and the rotate speed of a torque converter turbine, and the engagement speed of a clutch is further determined, so that the bulldozer can carry out variable-speed adjustment under the full temperature range and the full rotate speed range, the gear-shifting impact of a gearbox can be effectively reduced, the service life of the gearbox is prolonged, and the comfort of drivers and passengers are improved.

Owner:SHANTUI CONSTR MASCH CO LTD

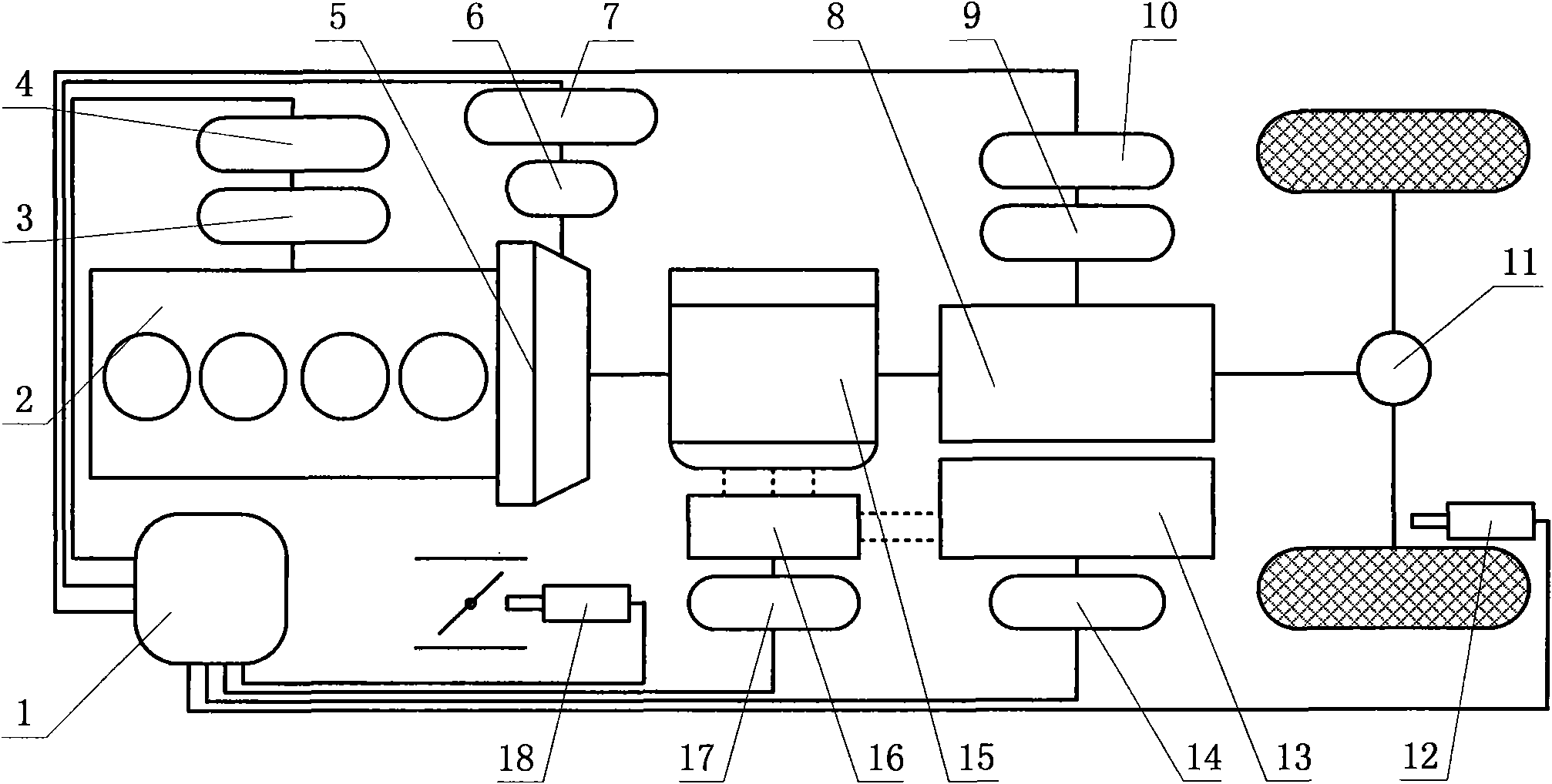

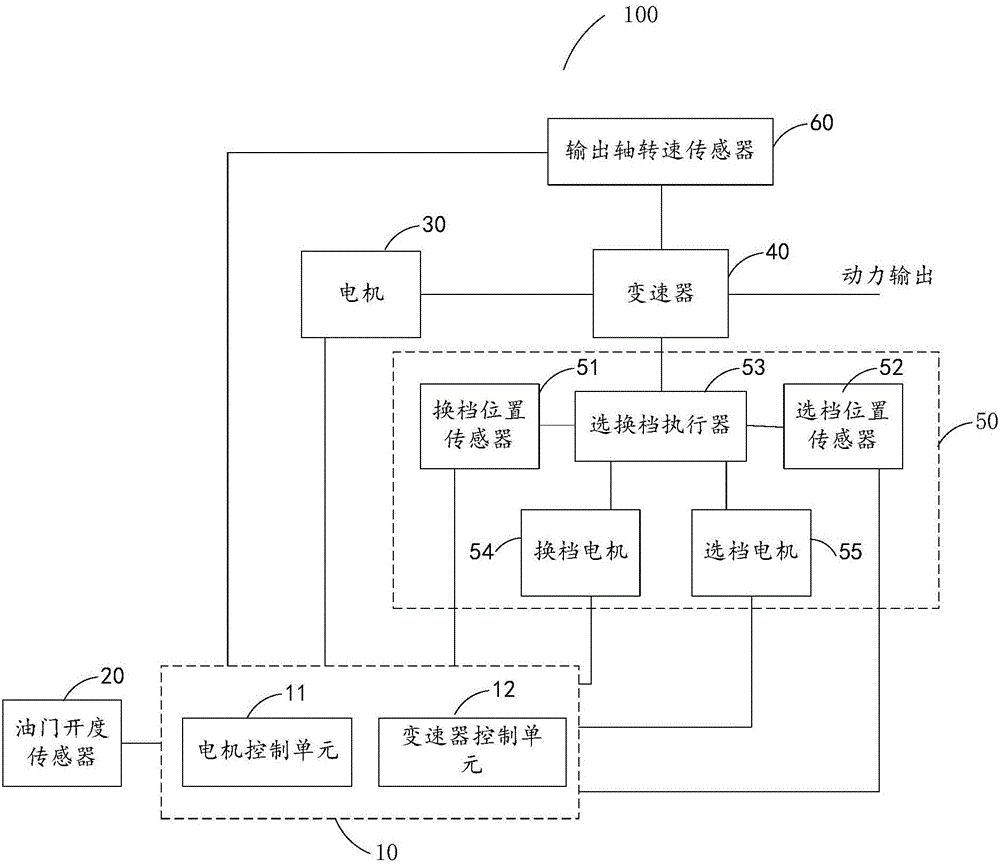

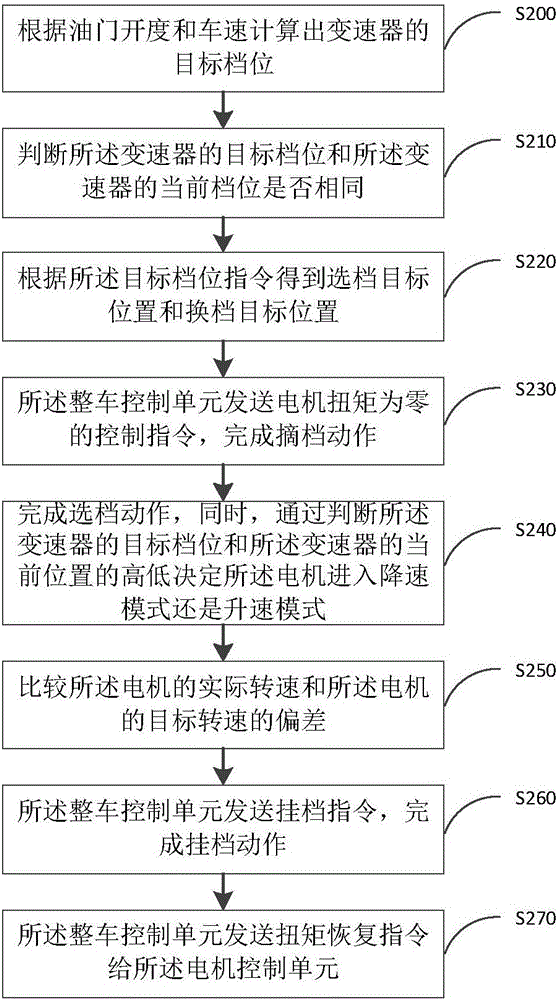

Power motor auxiliary gear-shifting control system and control method thereof

PendingCN106740856AExtended service lifeSmall shift shockDriver input parametersControl systemElectric machine

The invention discloses a power motor auxiliary gear-shifting control system and a control method thereof. The power motor auxiliary gear-shifting control system comprises a vehicle control unit, a throttle opening sensor, a motor, a transmission, a gear-selecting and gear-shifting execution device and an output shaft speed sensor, wherein the throttle opening sensor is connected with the vehicle control unit to transmit throttle opening information to the vehicle control unit, the motor is connected with the vehicle control unit and reaches a target speed according to the instruction action of the vehicle control unit after the vehicle control unit receives the throttle opening information, the gear-selecting and gear-shifting execution device is respectively connected with the vehicle control unit and the transmission and indicates gear-selecting and gear-shifting action of the transmission according to the instruction of the vehicle control unit, and the output shaft speed sensor is connected with the vehicle control unit to feed back acquired transmission output shaft speed information to the vehicle control unit. According to the power motor auxiliary gear-shifting control system and the control method thereof, gear-shifting quality can be improved, and the service life of the transmission is prolonged.

Owner:洁蓝德新能源科技有限公司

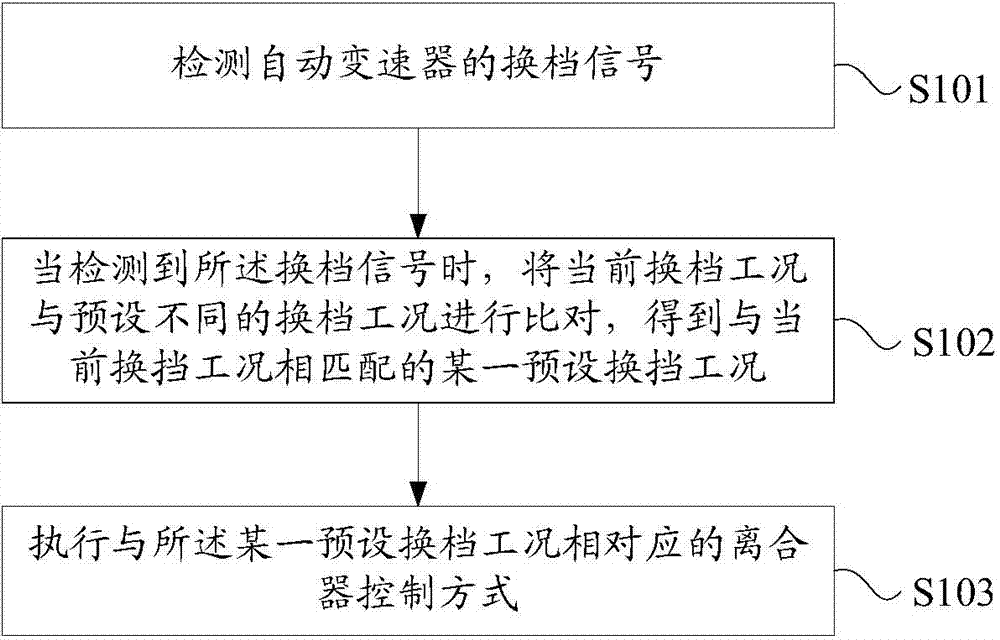

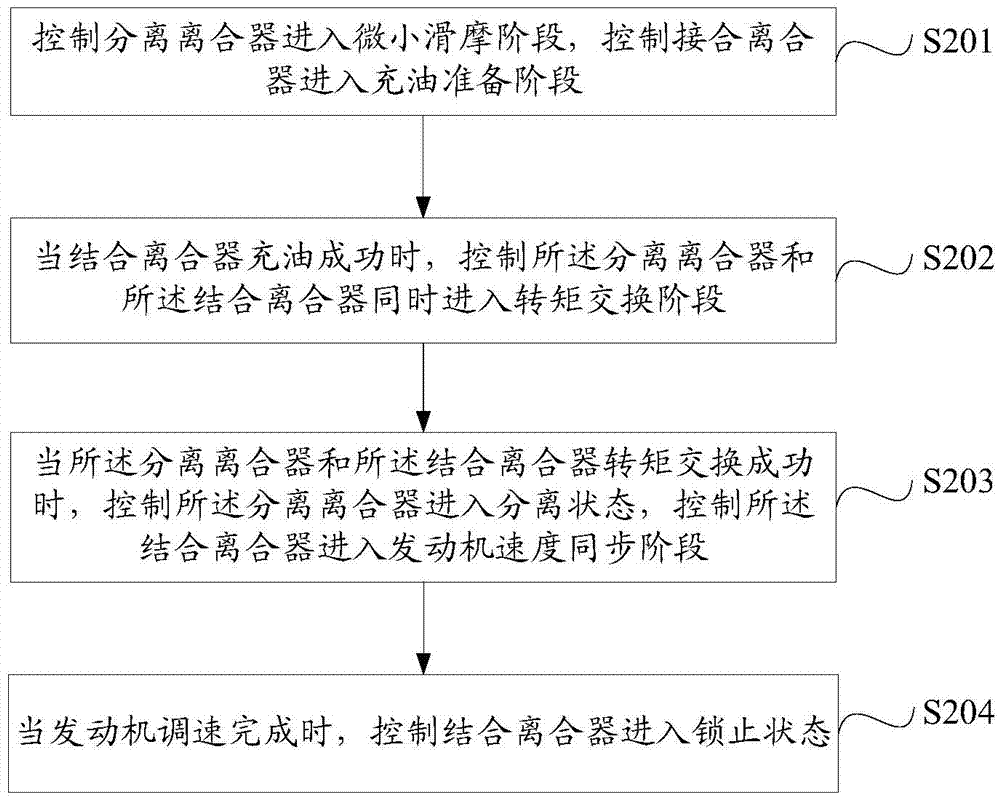

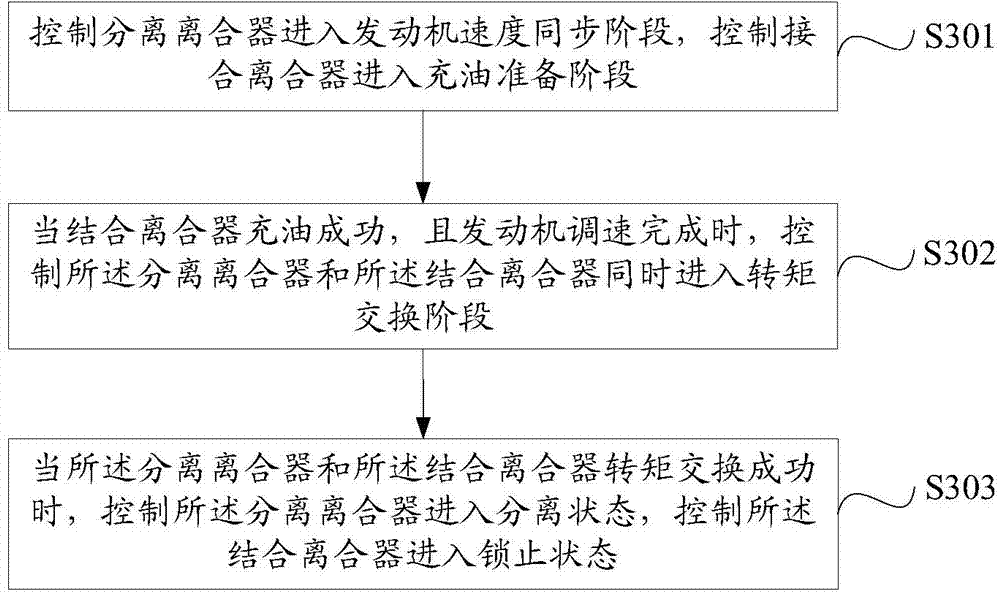

Hydraulic automatic gearbox gear-shifting control method and system

InactiveCN104121356ASmall shift shockImprove ride comfortGearing controlFluid gearingsVariatorControl mode

The invention discloses a hydraulic automatic gearbox gear-shifting control method and system. The method includes the steps of detecting a gear-shifting signal of an automatic gearbox; when the gear-shifting signal is detected, comparing a current gear-shifting working condition with different preset gear-shifting working conditions to obtain the certain preset gear-shifting working condition matched with the current gear-shifting working condition; executing a clutch control mode corresponding to the certain preset gear-shifting working condition. By means of the hydraulic automatic gearbox gear-shifting control method and system, the clutch control mode can be adjusted in time to adapt to the current gear-shifting working condition, so that gear-shifting impact can be reduced, and the gear-shifting smoothness can be improved.

Owner:SHENGRUI TRANSMISSION

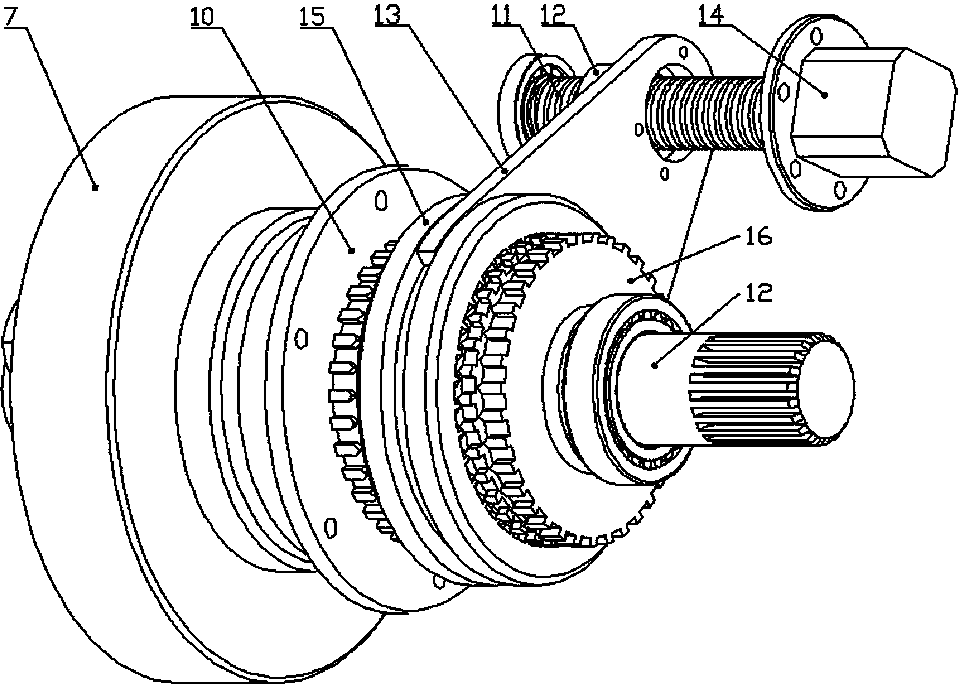

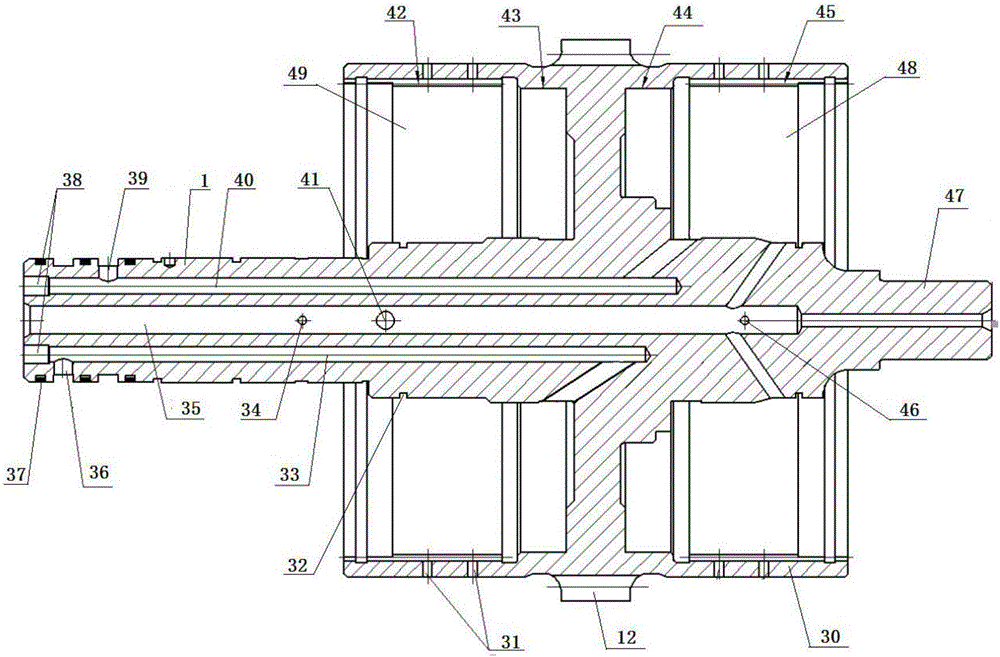

Single-clutch integrated structure

ActiveCN110701208AReduced drag lossGuaranteed normal switchingFluid actuated clutchesGear wheelEngineering

The invention discloses a single-clutch integrated structure. The single-clutch structure integrates an input shaft, a clutch support, a piston, a friction piece set, a dual piece set, a gear toothedwheel and other parts. When power is transmitted to the clutch support from the input shaft, a work oil path is full of high-pressure oil, the high-pressure oil arrives at a piston cavity, the pistonis pushed to compress a clutch, therefore, the power is transmitted to the gear toothed wheel, power transmission is carried out, the structure can ensure normal switching between different gears, andthe structure is compact. When the high-pressure oil pushes the piston to move, meanwhile, a lubricating oil path of the clutch is opened, the lubricating oil arrives at the clutch, the friction piece set is lubricated, the lubricating oil path is controlled by the work oil path, control is ensured through design of a mechanical structure, and a hydraulic system is simple in structure. Similarly,when the friction piece set does not need to transmit torque, the piston returns, meanwhile, the lubricating oil path is closed, dragging losses of the clutch are reduced, and efficiency is improved.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

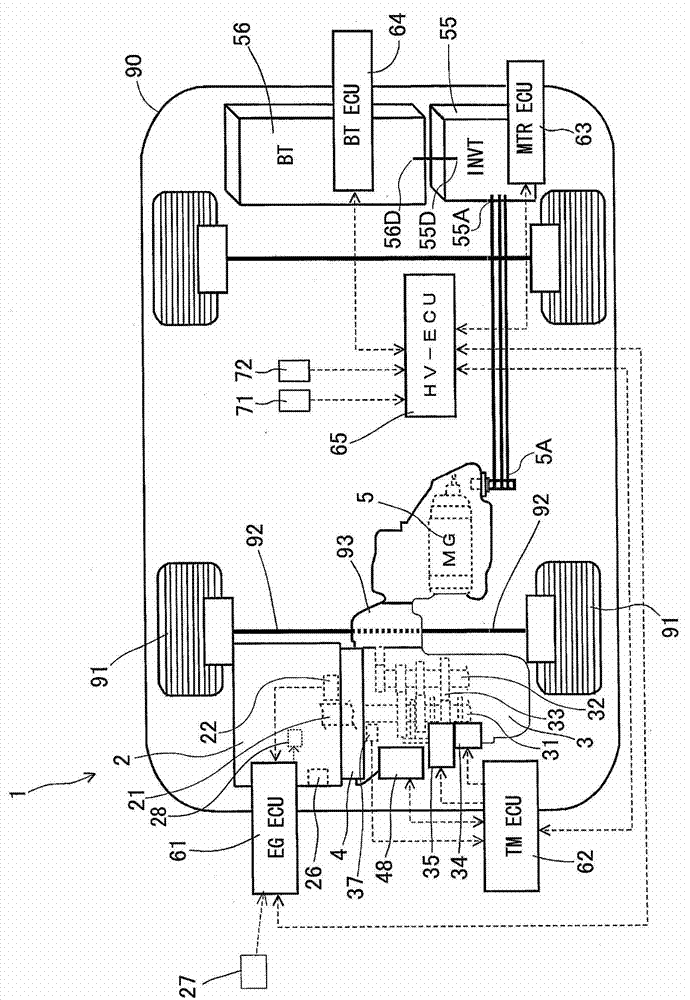

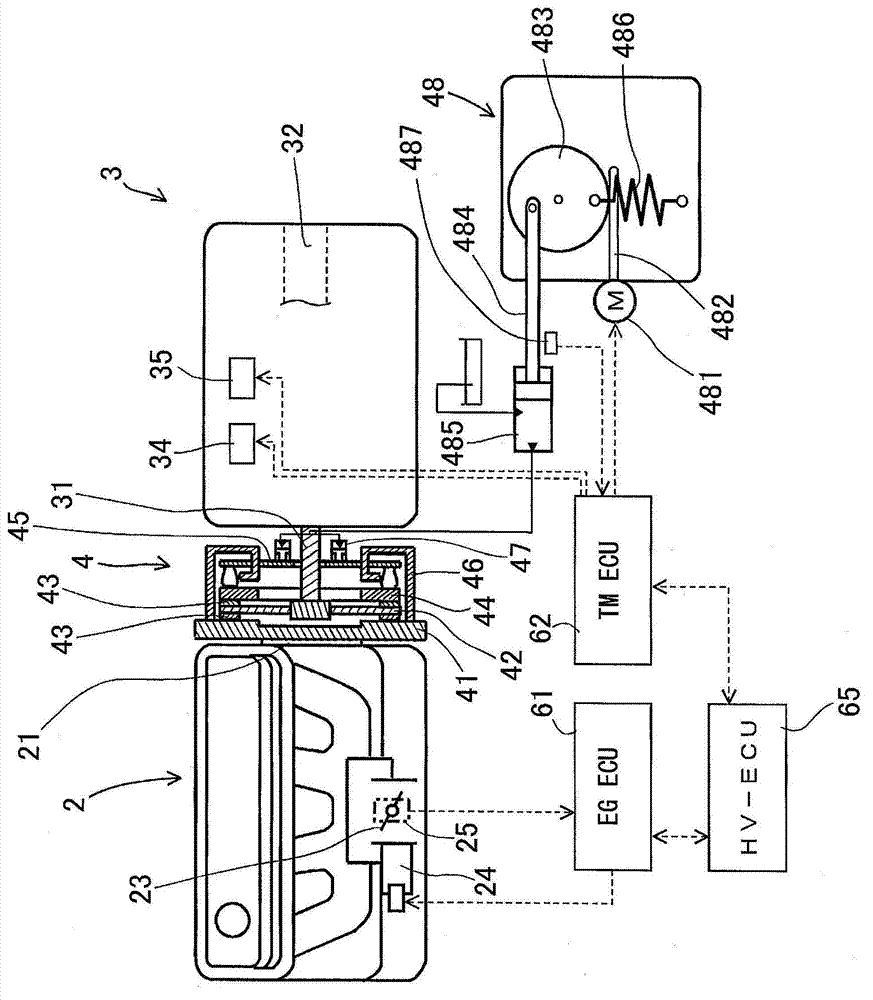

Gear shift control device for hybrid vehicle drive system

InactiveCN103072571ASmall torqueSuppress fluctuationsHybrid vehiclesPropulsion using engine-driven generatorsDrive wheelAutomatic transmission

A gear shift control device for controlling a hybrid vehicle drive system (1) including an engine (2), an automated transmission (3), a clutch (4), and a motor generator (5), includes a torque indication means for indicating a driver request torque (Tdrv) determined in accordance with an operation amount of an accelerator operated by a driver, a power generation interruption means changing a vehicle state to an engine driven state using all of the engine torque (Te) when a preliminary gear shift condition is satisfied in a state where the engine (2) drives a driving wheel (91) and the motor generator (5) is actuated to generate an electric power, a gear shift control means reducing the engine torque (Te) and generating an assist torque (Tast) by actuating the motor generator (5), disconnecting the clutch (4), and returning the clutch (4) to a connected state after changing gear sets of the gear train when a gear shift condition of the automated transmission (3) is satisfied.

Owner:AISIN SEIKI KK

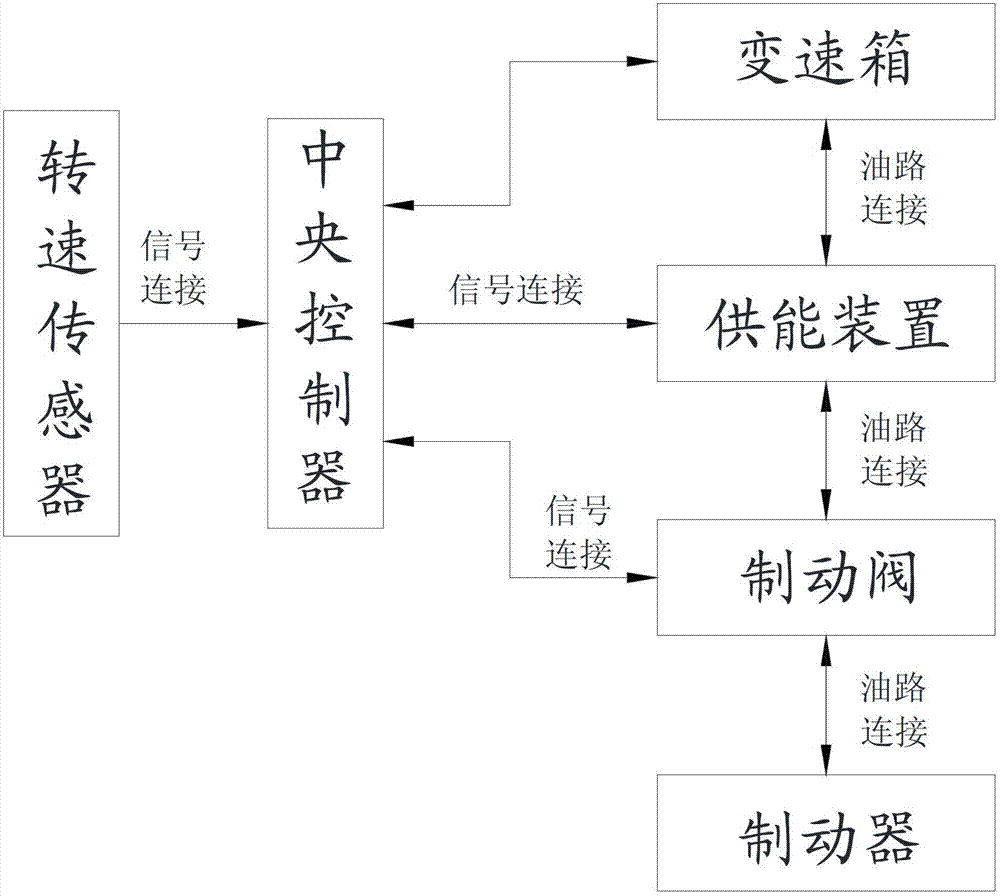

Electric control hydraulic reversing method, electric control hydraulic reversing system and engineering machinery

The invention provides an electric control hydraulic reversing method, an electric control hydraulic reversing system and engineering machinery. The electric control hydraulic reversing method comprises the following steps: a reversing command is received by a central controller; a gearbox is controlled to execute a neutral gear action; a brake valve is controlled to cause a brake to execute a brake action; a car speed is monitored in a real-time manner through a sensor; when the car speed is reduced to a shift condition, the brake valve is controlled to release the brake; and the gearbox is controlled to execute a reversing geared action. According to the electric control hydraulic reversing method and the electric control hydraulic reversing system provided by the invention, the brake valve and the gearbox are controlled by the central controller, so that a brake speed reduction action, a neutral position action and a shift reversing action after speed reduction, which are operated by an experienced worker, can be automatically completed, the reversing time and travel can be greatly reduced, and meanwhile, and a combination miss of firstly stepping on a brake pedal to reduce the speed and applying the reversing process can be avoided.

Owner:SANY HEAVY IND CO LTD (CN)

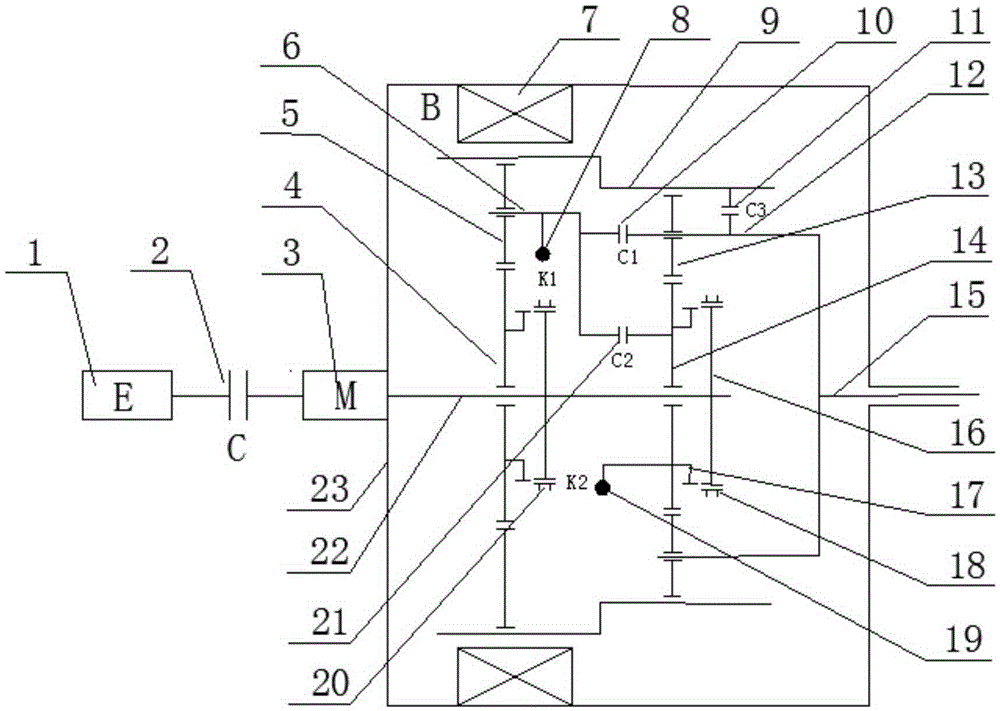

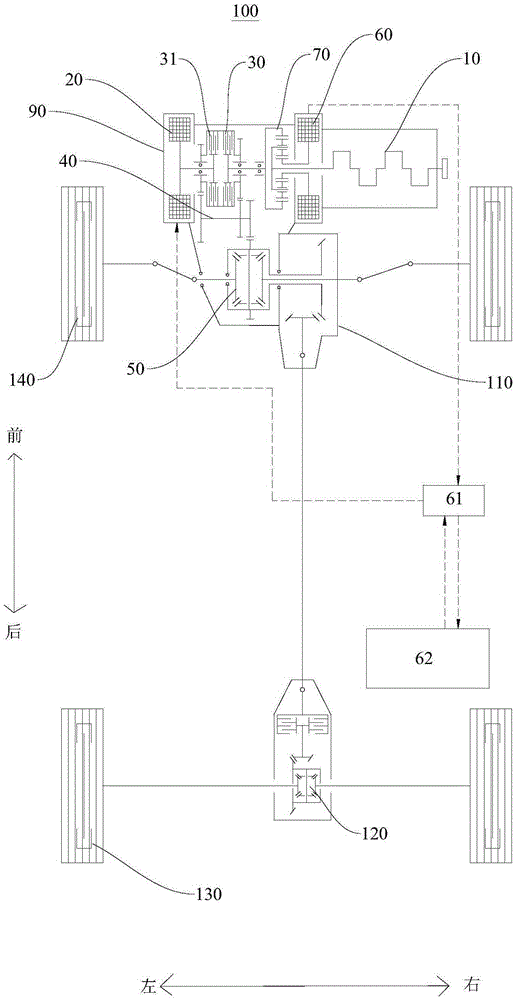

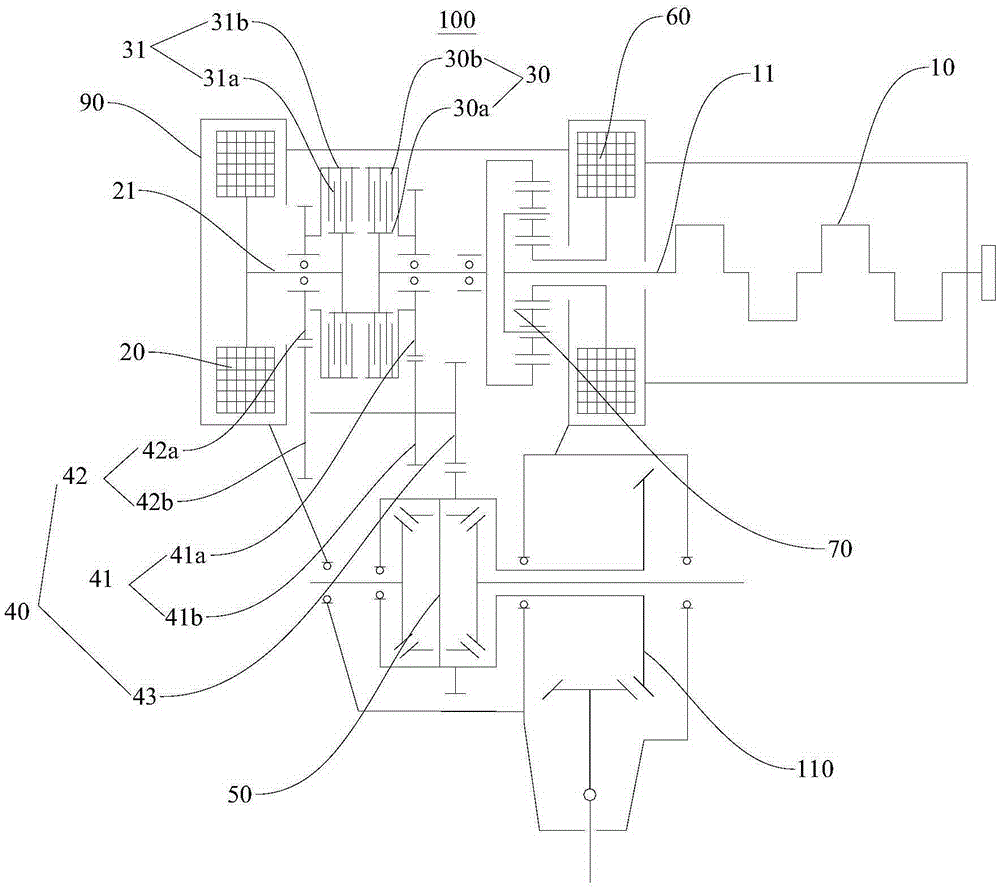

Multi-mode hybrid power special transmission

ActiveCN112224007ARealize dynamic decouplingAchieve direct driveHybrid vehiclesGas pressure propulsion mountingGear wheelEngineering

The invention discloses a multi-mode transmission special for hybrid power. The multi-mode transmission comprises an input shaft, a first planetary gear train, a second planetary gear train, an intermediate shaft, a differential mechanism, a first clutch, a second clutch, a first brake and a second brake. The input shaft is connected with an engine through a torque limiting shock absorber; the first planetary gear train comprises a sun gear A, a planet gear A, a planet carrier A and a gear ring A, the planet gear A is arranged between the sun gear A and the gear ring A and installed on the planet carrier A, and the planet gear A is meshed with the sun gear A and the gear ring A; the sun gear A is mounted on the input shaft; the second planetary gear train comprises a sun gear B, a planet gear B, a planet carrier B and a gear ring B. The invention has the beneficial effects that through the arrangement of the first clutch, the second clutch, the first brake and the second brake, the fixed connection mode of the first planetary gear train and the second planetary gear train is changed, static elements in the planetary gear trains are changed, and various transmission ratios are achieved under the condition that no extra gear pair is additionally arranged.

Owner:DONGFENG MOTOR CORP HUBEI

Gear-hydraulic pressure-pyramid integrated multi-mode composite transmission device

PendingCN113389869AMeet the requirements of multi-working conditionsImprove power utilizationGearing controlFluid gearingsGear wheelControl theory

The invention provides a gear-hydraulic pressure-pyramid integrated multi-mode composite transmission device. The gear-hydraulic pressure-pyramid integrated multi-mode composite transmission device comprises an input assembly, a hydraulic transmission mechanism, a front planetary gear mechanism, a pyramid type stepless variable transmission mechanism, a rear planetary gear mechanism, an output assembly, a clutch assembly and a brake assembly. The clutch assembly connects the output end of the input assembly with the input end of the hydraulic transmission mechanism and the input end of the front planetary gear mechanism. The output end of the hydraulic transmission mechanism is connected with the front planetary gear mechanism and the rear planetary gear mechanism through the clutch assembly. The clutch assembly connects the front planetary gear mechanism, the pyramid type stepless variable transmission mechanism, the rear planetary gear mechanism and the output assembly in sequence. The clutch assembly and brake assembly provide the continuous gear ratio between the input assembly and the output assembly. The multi-working-condition operation requirement of engineering machinery can be met, the engine power utilization rate is increased, and the fuel economy is improved.

Owner:JIANGSU UNIV

Hybrid dynamic system

ActiveCN106627094AImprove acceleration performanceLow costHybrid vehiclesGas pressure propulsion mountingClutchHybrid power

The invention provides a hybrid dynamic system, which includes an engine, a first motor, a first driving disc which drives with the engine, a first clutch of a first driven disc, a second driving disc which drives with the first motor, a second clutch of a second driven disc and deceleration assemblies which includes a high retaining gear pair, a low retaining gear pair and a deceleration output gear. The high retaining gear pair includes a high retaining driving gear and a high retaining driven gear which are mutually meshed. The high driving gear is connected with a first driven plate. The low retaining gear pair includes a lowretaining driving gear and a low retaining driven gear which are mutually meshed. The low retaining driving gear is connected with asecond driven plate. The deceleration output gear respectively and synchronously rotates with the high retaining driven gear and the low retaining driven gear.The hybrid dynamic system also includes a differential mechanism which drives with the deceleration output gear. Through setting the first clutch and the second clutch, the vehicle can meet torque and speed requirements.

Owner:GREAT WALL MOTOR CO LTD

Multi-gear speed changer for planetary gear structure

ActiveCN104214286ASmooth shiftingIncreased odds of working in the economyToothed gearingsTransmission elementsGear wheelControl theory

The invention relates to a multi-gear speed changer for a planetary gear structure. The multi-gear speed changer comprises a casing, an input component, an output component, first, second and third planetary gear groups, first, second, third, fourth, fifth, sixth and seventh interconnecting components and first, second, third, fourth, fifth and sixth torque transmission devices, wherein the first, second and third planetary gear groups are sequentially arranged from an input end to an output end, the six torque transmission devices comprise three brakes and three clutches, the first torque transmission device is positioned at the left side of the first planetary gear group and is arranged at the same side as the input component, the second and the third torque transmission devices are positioned between the second and third planetary gear groups in a parallel way and are near the casing, the fourth, fifth and sixth torque transmission devices are positioned between the first and second planetary gear groups, the fourth torque transmission device is near a rotating center, the fourth and sixth torque transmission devices are respectively positioned above the fourth torque transmission device, and all of the components are positioned in the casing. The multi-gear speed changer provided by the invention belongs to a multi-gear speed changer with a compact structure.

Owner:BEIHANG UNIV

Variable-speed drive device for tractor

PendingCN110307325ACompact structureSmall shift shockToothed gearingsGearing detailsTransfer caseVariator

The invention discloses a variable-speed drive device for a tractor. The device comprises a main variable-speed device, an auxiliary variable-speed device and a transfer case idle wheel. The main variable-speed device and the auxiliary variable-speed device are sequentially arranged front and back, one end of the main variable-speed device is connected with a tractor front transmission box, one end of the auxiliary variable-speed device is connected with a tractor rear axle, the transfer case idle wheel is connected with a tractor transfer case, through the above arranging manner, power is transmitted to the tractor rear axle, a tractor front axle and a power output shaft, through combination of the main variable-speed device and the auxiliary variable-speed device, 16 gears are achieved,the main variable-speed device adopts a synchronizer to achieve non-park gear shifting, gear shifting impact and gear shifting force are small, work efficiency is high, an auxiliary variable-speed driven shaft in the auxiliary variable-speed device and a small conical gear are whole, a low-gear driven gear and a high and low gear engaging sleeve cantilever are arranged on the front end of an auxiliary variable-speed driven shaft, the structure is compact, and the axial size of the variable-speed device is effectively reduced. A transfer case driving gear is engaged with the idle wheel on a transfer case idle wheel shaft, occupied space is small, and the speed ratio adjusting is convenient.

Owner:FIRST TRACTOR

Control device and control method for pneumatic automated mechanical transmission gear shifting force

The invention relates to a control device and control method for a pneumatic automated mechanical transmission gear shifting force. The control device for the pneumatic automated mechanical transmission gear shifting force comprises a structure characterized in that a control valve piston is connected with a push rod, and the control valve piston slides cooperatively in a hollow valve body so as to divide the valve body into a left cavity and a right cavity. A first air inlet and a first interface communicating with the left cavity, as well as a second air inlet and a second interface communicating with the right cavity are formed in the valve body; quick exhaust valves are arranged at two ends of the control valve piston; a first electromagnetic valve and a second electromagnetic valve communicate with the first interface and the second interface, and inflate a double-piston gear shifting air cylinder through a control valve; the push rod is pushed to move leftwards or rightwards so as to engage a gear and shift the gear, and drive the control valve piston sliding in the valve body to synchronously move at the same time; and the pressure in the double-piston air cylinder is adjusted cooperatively, so that an acting force after gear shift is reduced. The device provided by the invention solves the problems of excessive impact force, big gear shifting noise and easiness in damage of an original gear shifting actuator, and has the characteristics of simple structure, small gear shifting impact force, low noise, difficulty in damage, convenience in operation, no need of position detection, flexibility and reliability.

Owner:HUBEI YINGSUOER ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com