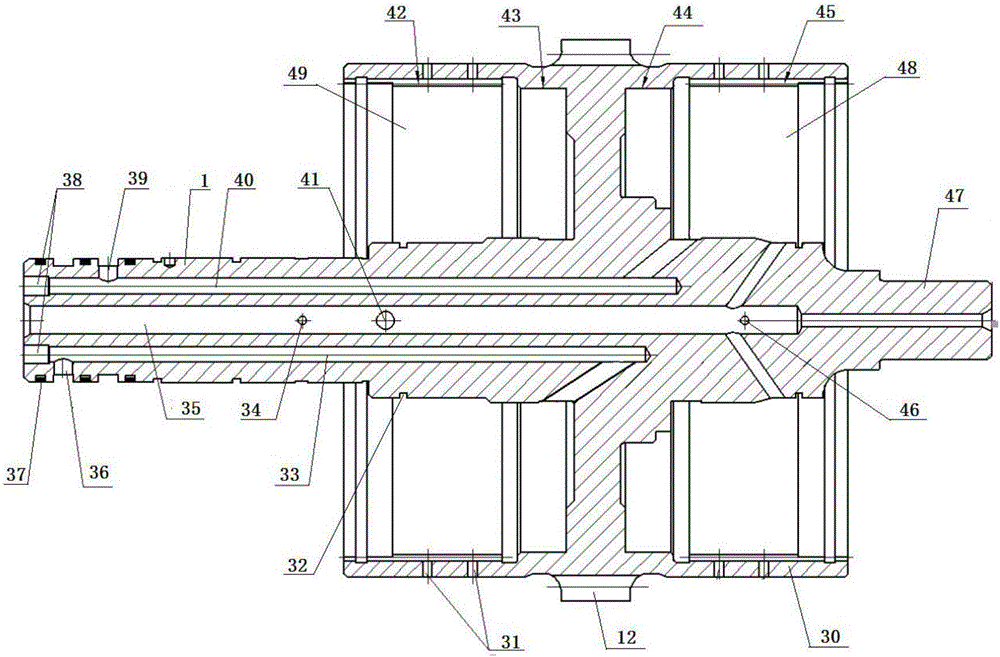

Integrated clutch axle hub transmission device

A technology of clutch shaft and transmission device, which is applied in the field of mechanical transmission, can solve the problems of slow response, large impact, and high labor intensity of operators, and achieve the effect of large bearing torque, multiple transmission paths, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

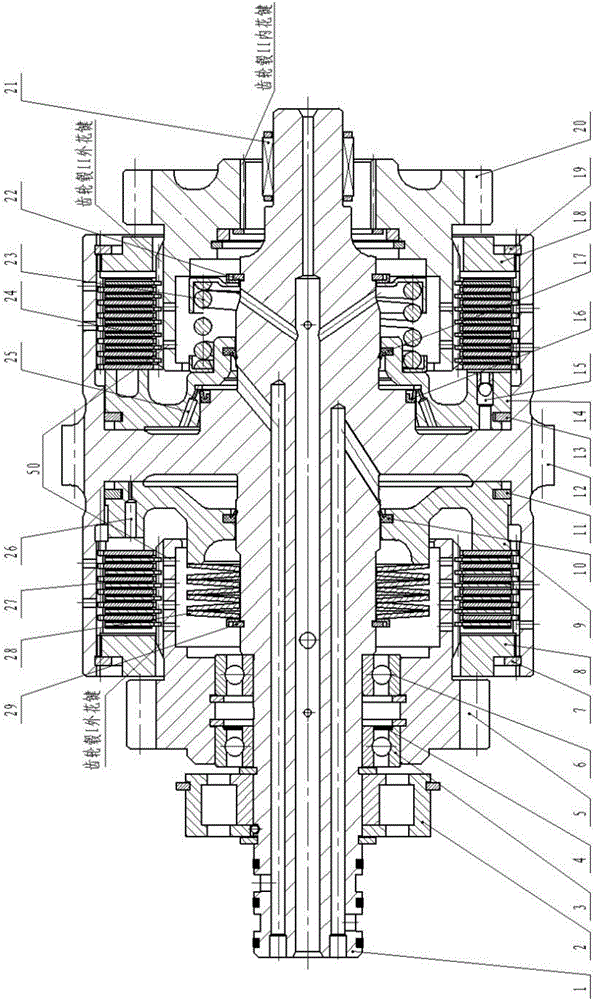

[0036] By engaging or disengaging the clutch A24 and the clutch B27, changing the transmission condition can make the integral clutch shaft-hub transmission device realize different power transmission:

[0037] When the clutch B27 is engaged and the clutch A24 is disconnected, the device can transmit power by the gear hub A5 and the external meshing gear 12;

[0038] When the clutch A24 is engaged and the clutch B27 is disconnected, the device can transmit power through the gear hub B20, the internal spline B45 and the external meshing gear 12;

[0039] When both the clutch A24 and the clutch B27 are engaged, the device can transmit power by the gear hub A5, the gear hub B20, the internal spline B45 and the external gear 12;

[0040] When both the clutch A24 and the clutch B27 are disconnected, the device can transmit power through the external meshing gear 12 .

[0041] The engagement and disengagement process of clutch B27 is as follows:

[0042] When there is no oil in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com