Pre-tensioning method prestressed concrete track board production line maintaining system and application thereof

A maintenance system and track slab technology, which is applied in the field of maintenance system of pretensioned prestressed concrete track slab production line, can solve the problems of sensor acquisition disorder, pipeline layout, increased workshop area, and low degree of automation, so as to improve maintenance work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the examples, but it should not be interpreted as a limitation of the present invention. The protection scope of the present invention is based on the content recorded in the claims, and any equivalent technical means made according to the specification is replaced without departing protection scope of the present invention.

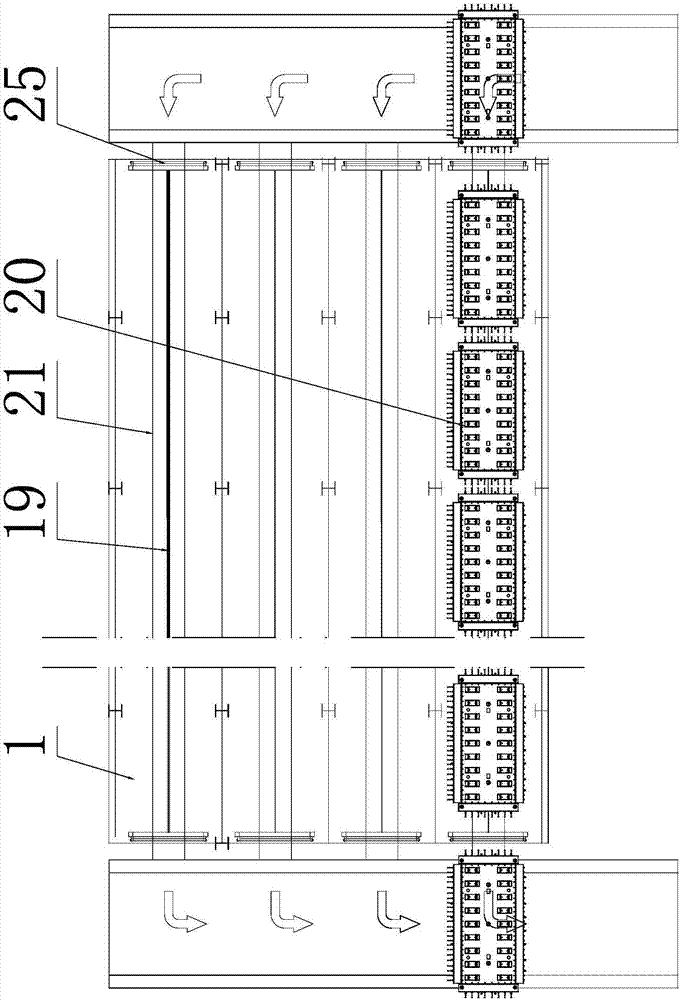

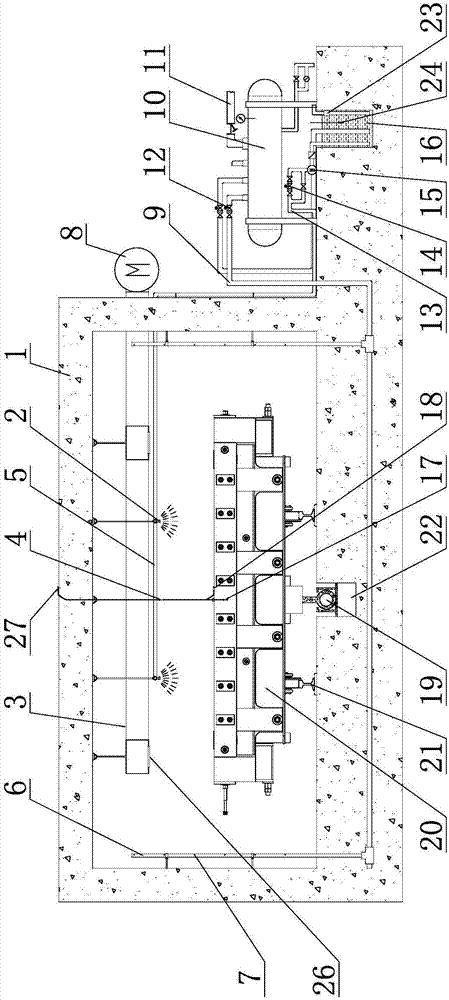

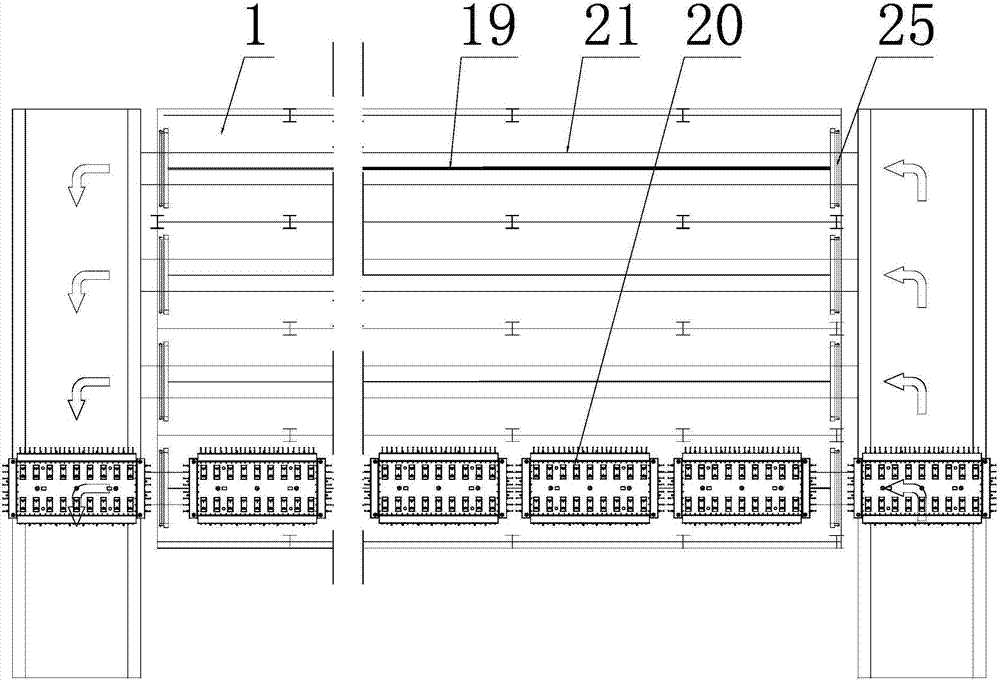

[0061] The overall concept of the curing system in this embodiment is as shown in the figure, including a steaming room 1 that can accommodate the mold 20. The steaming room 1 is provided with a nozzle and a nozzle connected to a steam control output device, a ventilation cooling device, and a constant temperature water supply device. , and the temperature and humidity detection device connected with the central control device, the mold self-propelled device and the temperature and humidity control device; the steaming room 1 is provided with a working track adapted to the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com