Patents

Literature

4079results about How to "Start fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

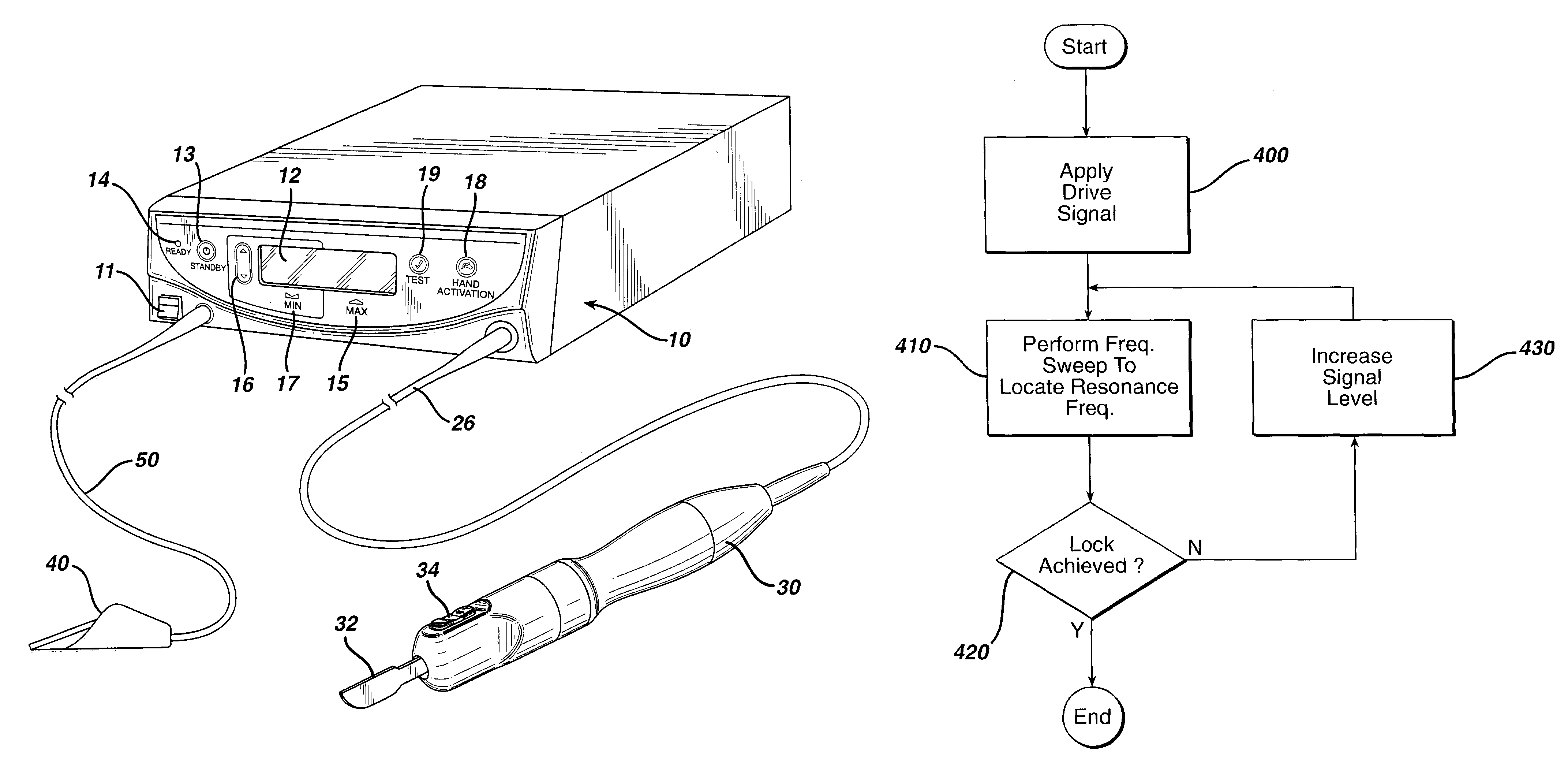

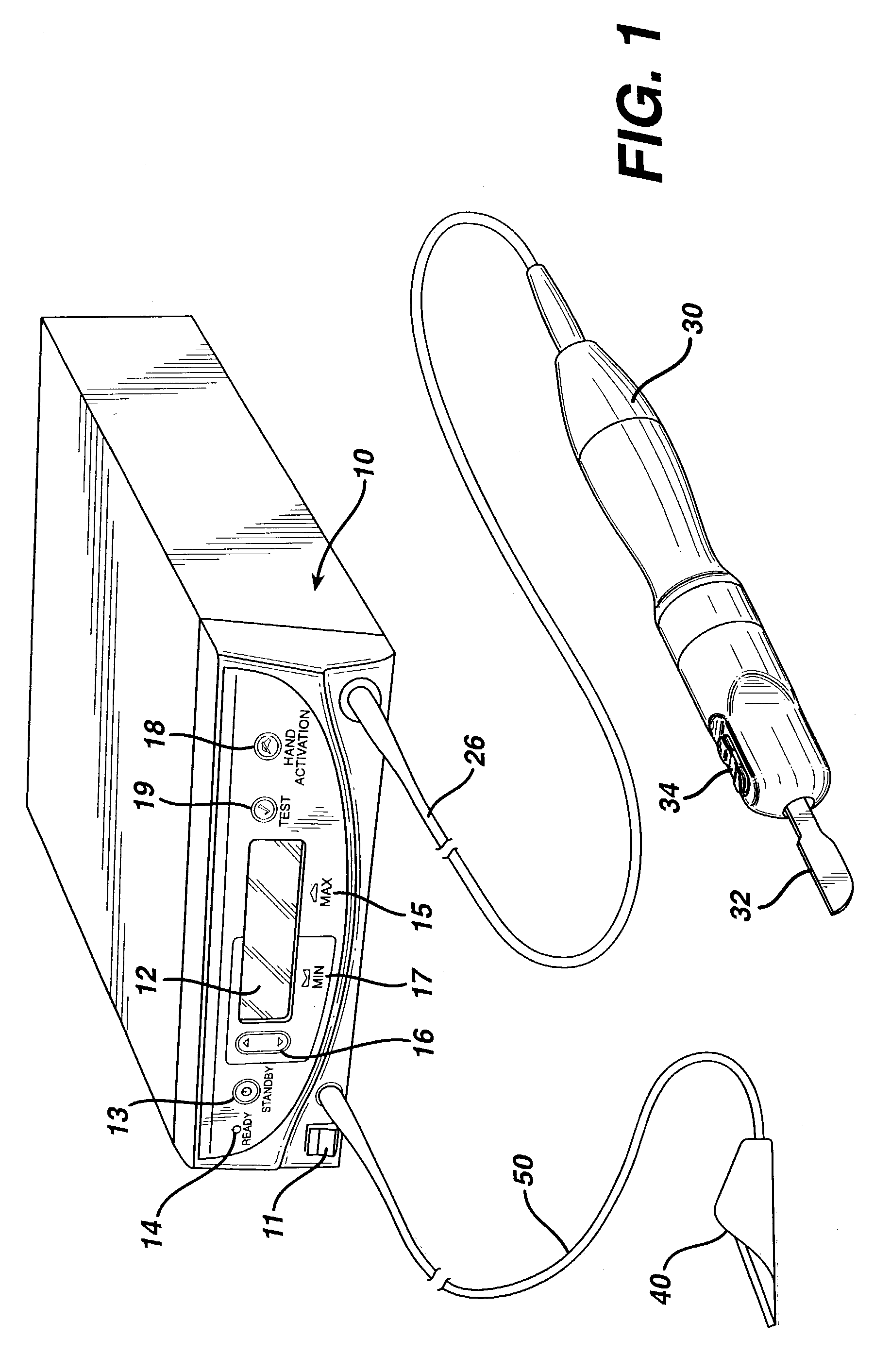

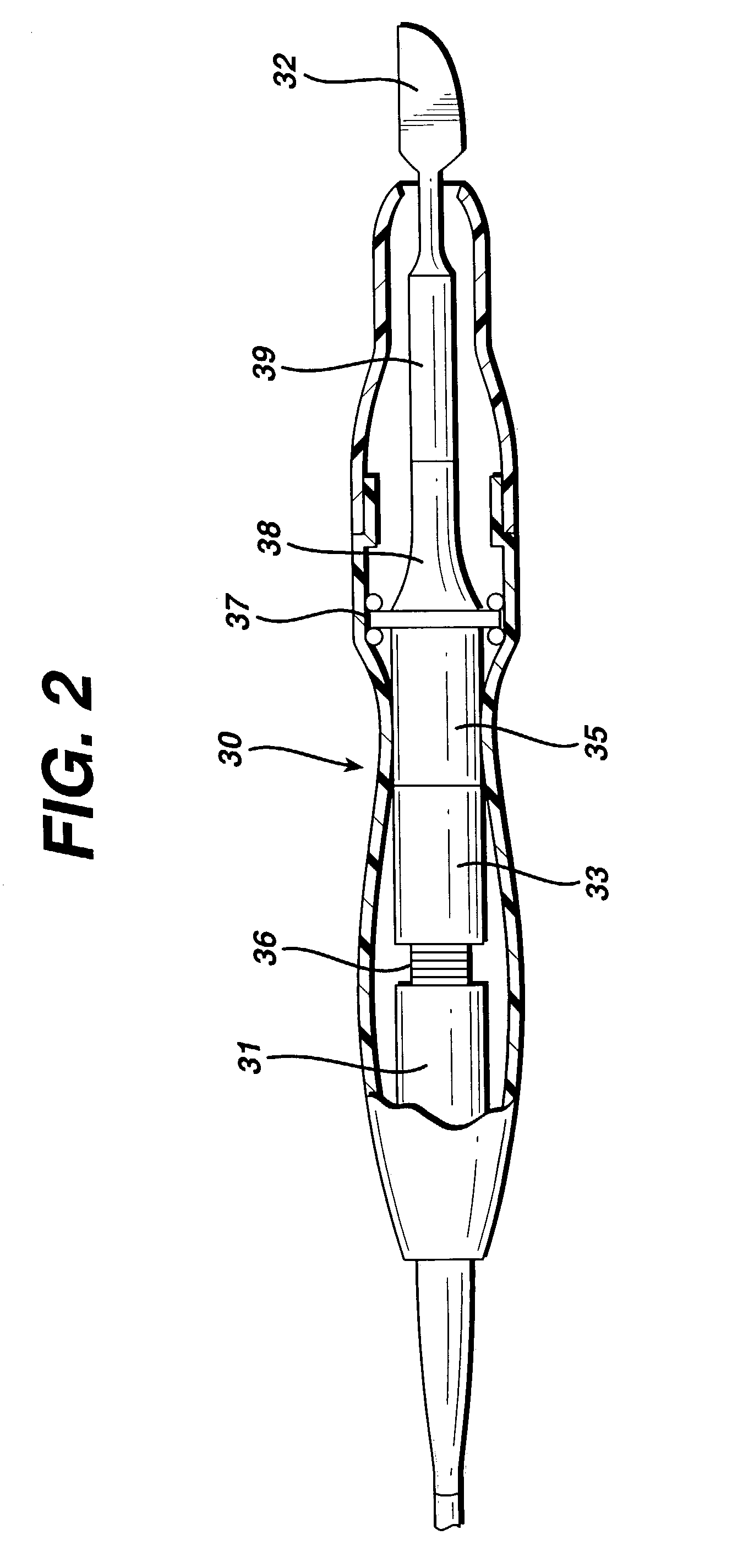

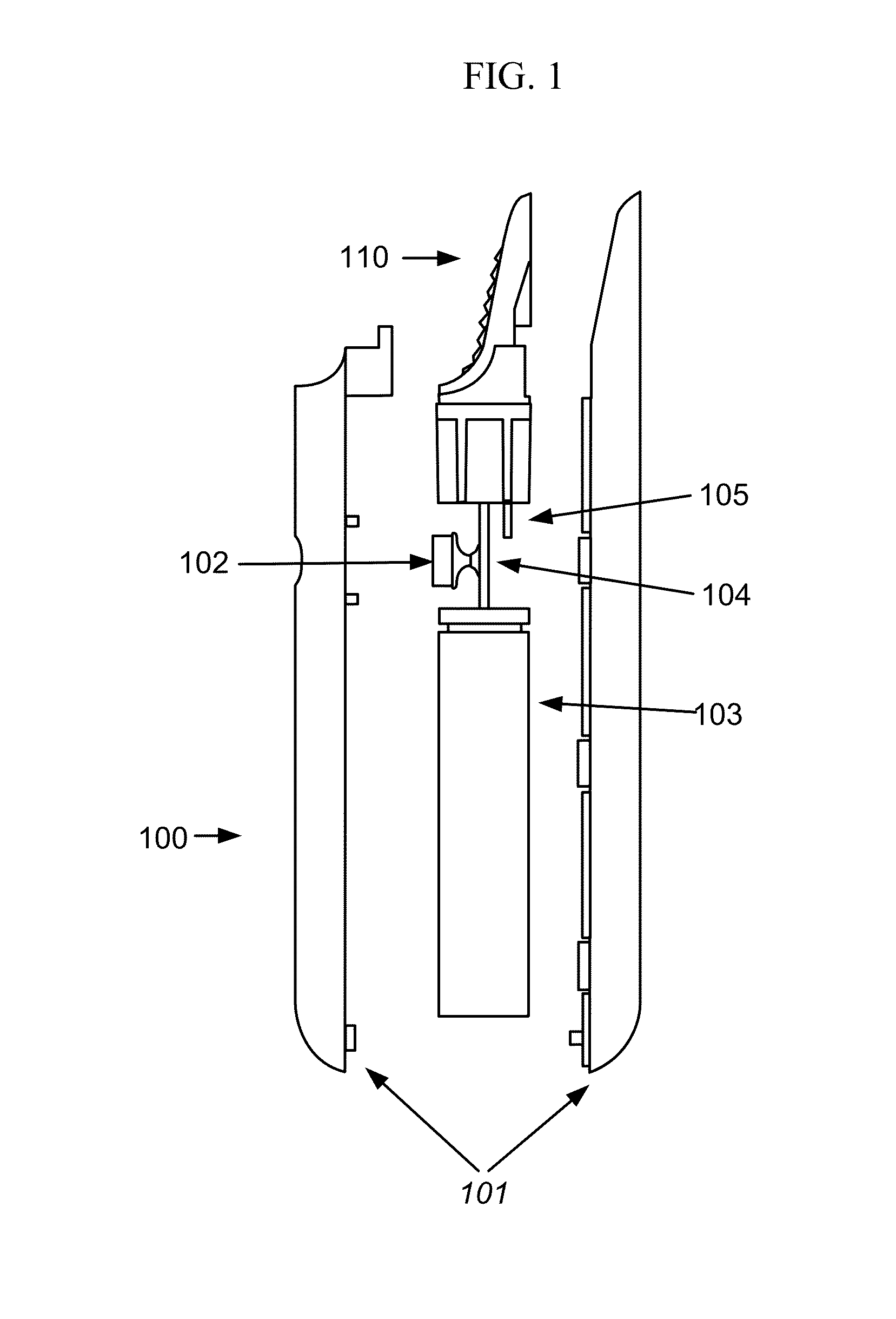

Method for driving an ultrasonic system to improve acquisition of blade resonance frequency at startup

InactiveUS7179271B2Increase load capacityImprove abilitiesSurgeryElectrical measurementsDriving currentResonance

The ability of an ultrasonic system to sweep and lock onto a resonance frequency of a blade subjected to a heavy load at startup is improved by applying a high drive voltage or a high drive current while systematically increasing the level of the applied signal. Increasing the drive signal to the hand piece results in an improved and more pronounced “impedance spectrum.” That is, under load, the increased drive signal causes the maximum phase margin to become higher and the minimum / maximum impedance magnitude to become more pronounced. Increasing the excitation drive signal to the hand piece / blade at startup significantly alleviates the limiting factors associated with ultrasonic generators, which results in an increase of the maximum load capability at startup.

Owner:ETHICON ENDO SURGERY INC

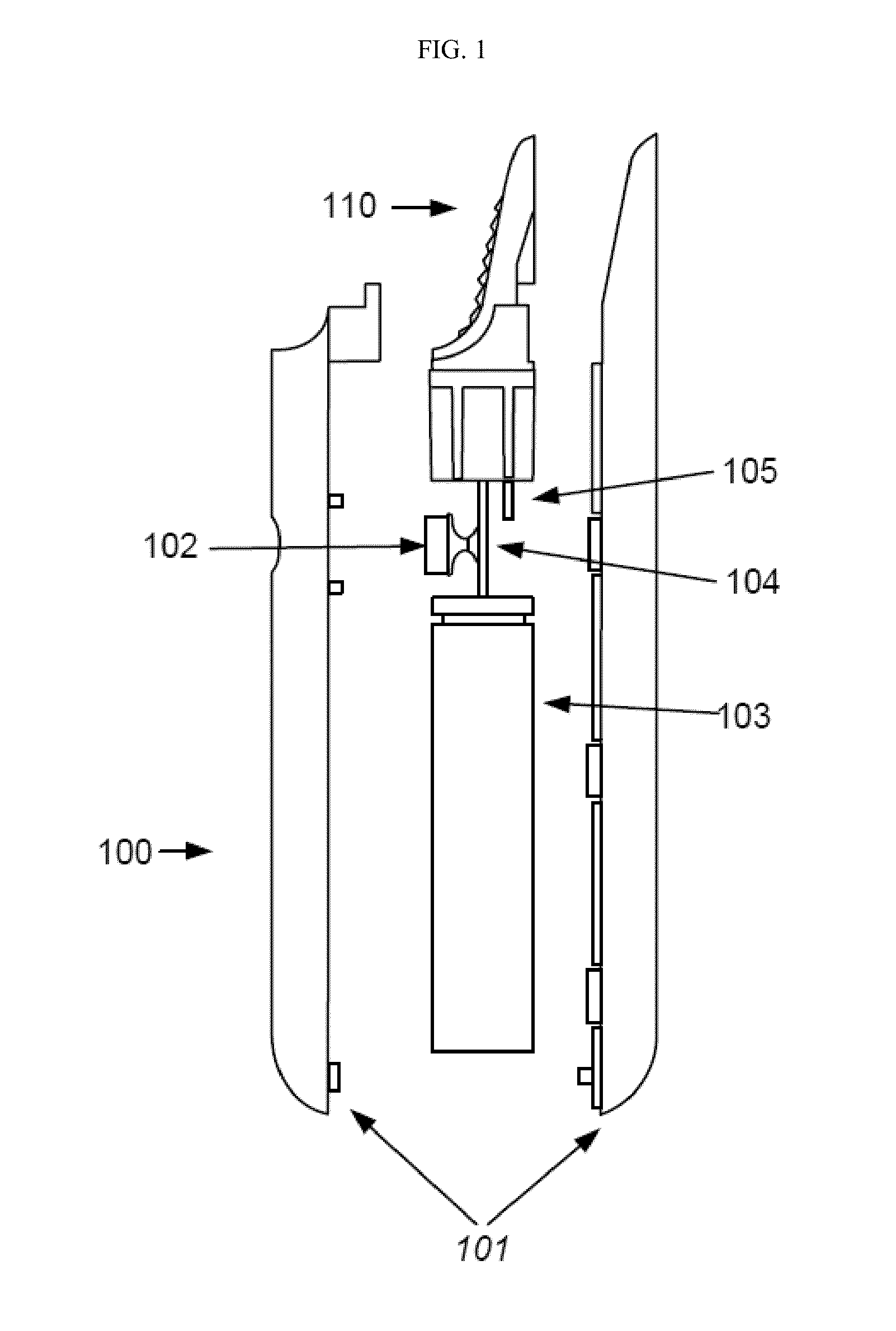

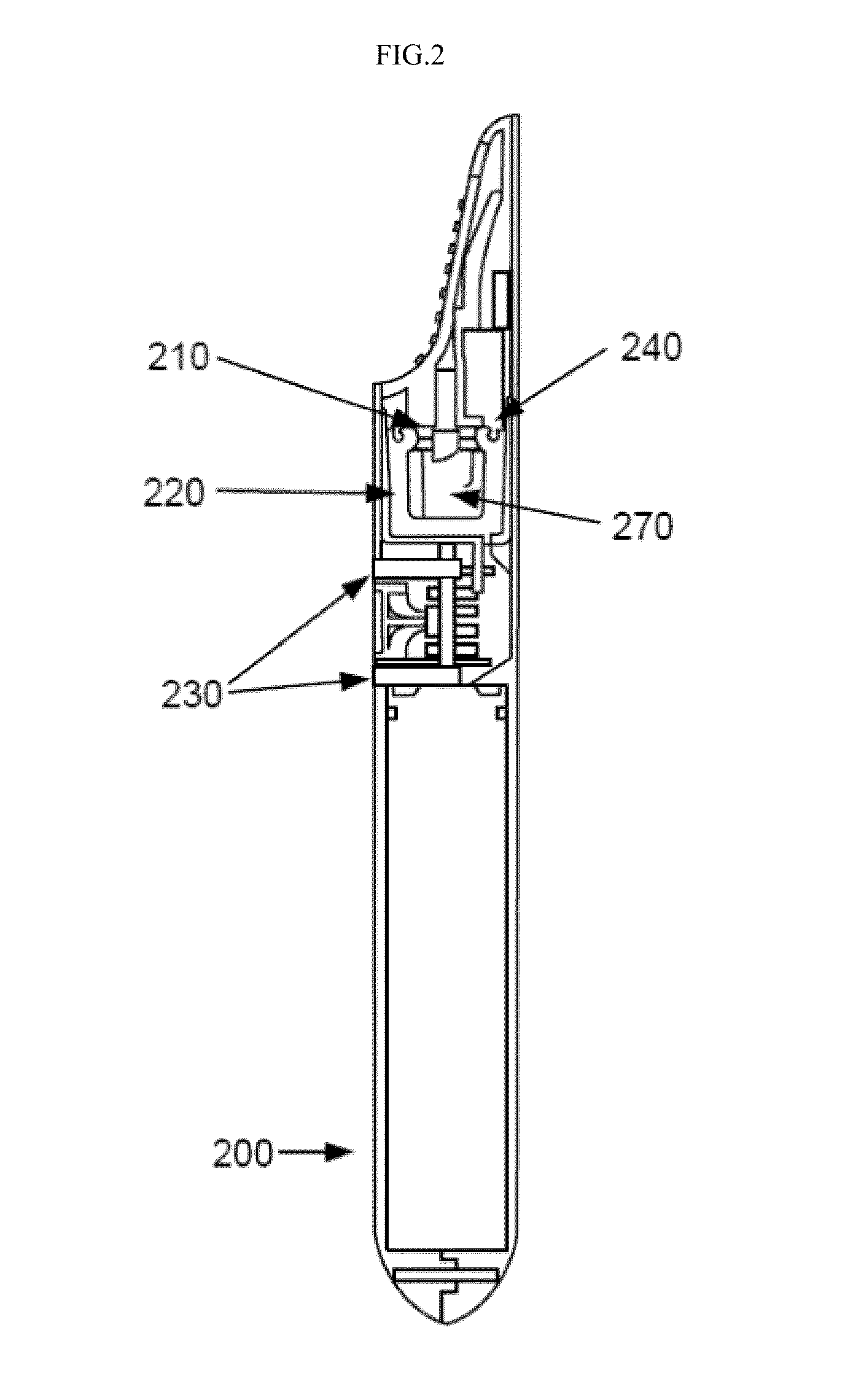

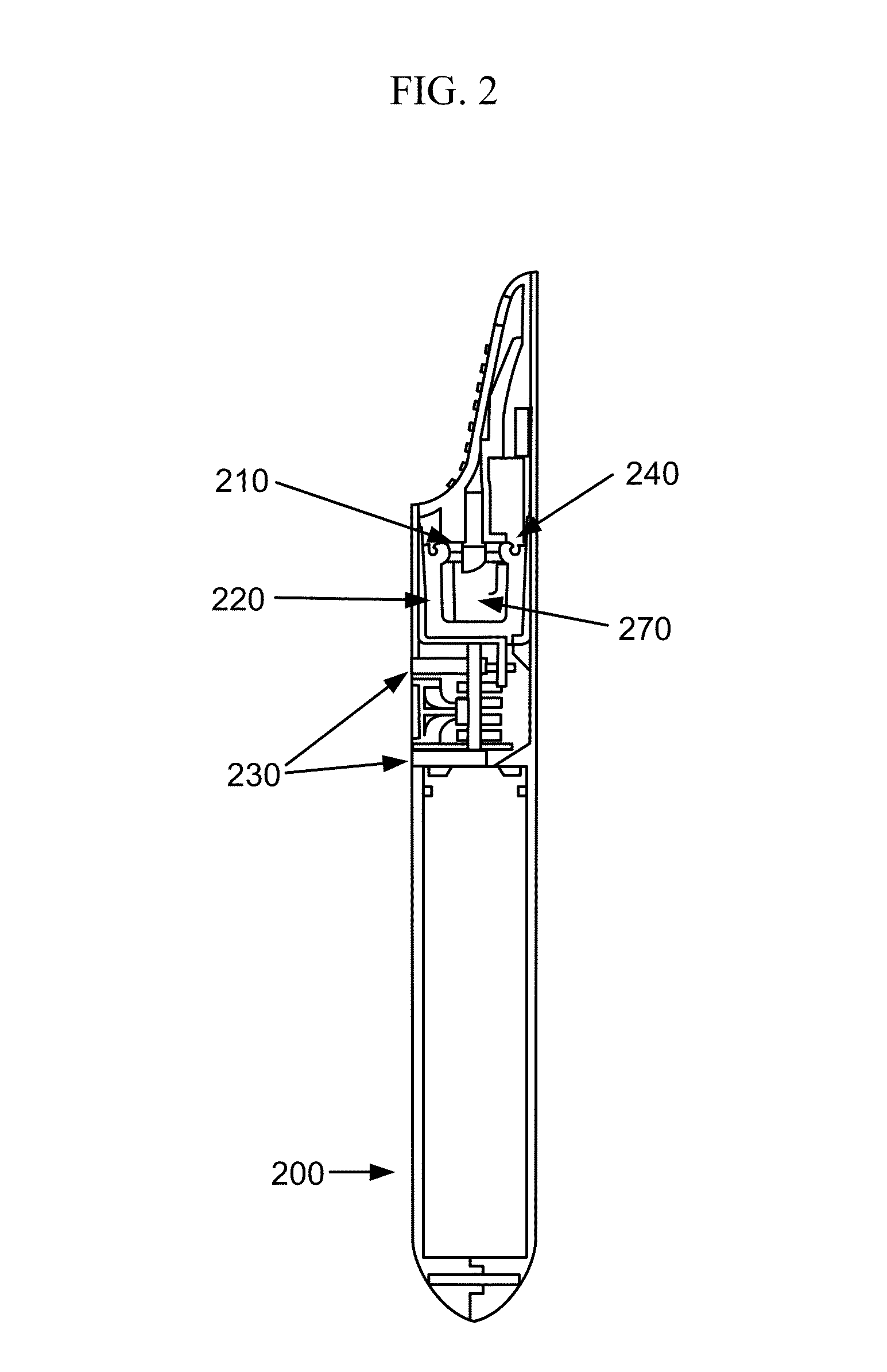

Low temperature electronic vaporization device and methods

ActiveUS20130042865A1Maintain efficiencyReduce the temperatureInput/output for user-computer interactionTobacco treatmentInhalationEnvironmental health

Low temperature electronic vaporization devices and method are described herein for emulating smoking wherein the devices generate an aerosol for inhalation by a subject by heating a viscous material that can have a tactile response in the mouth or respiratory tract.

Owner:JLI NAT SETTLEMENT TRUST

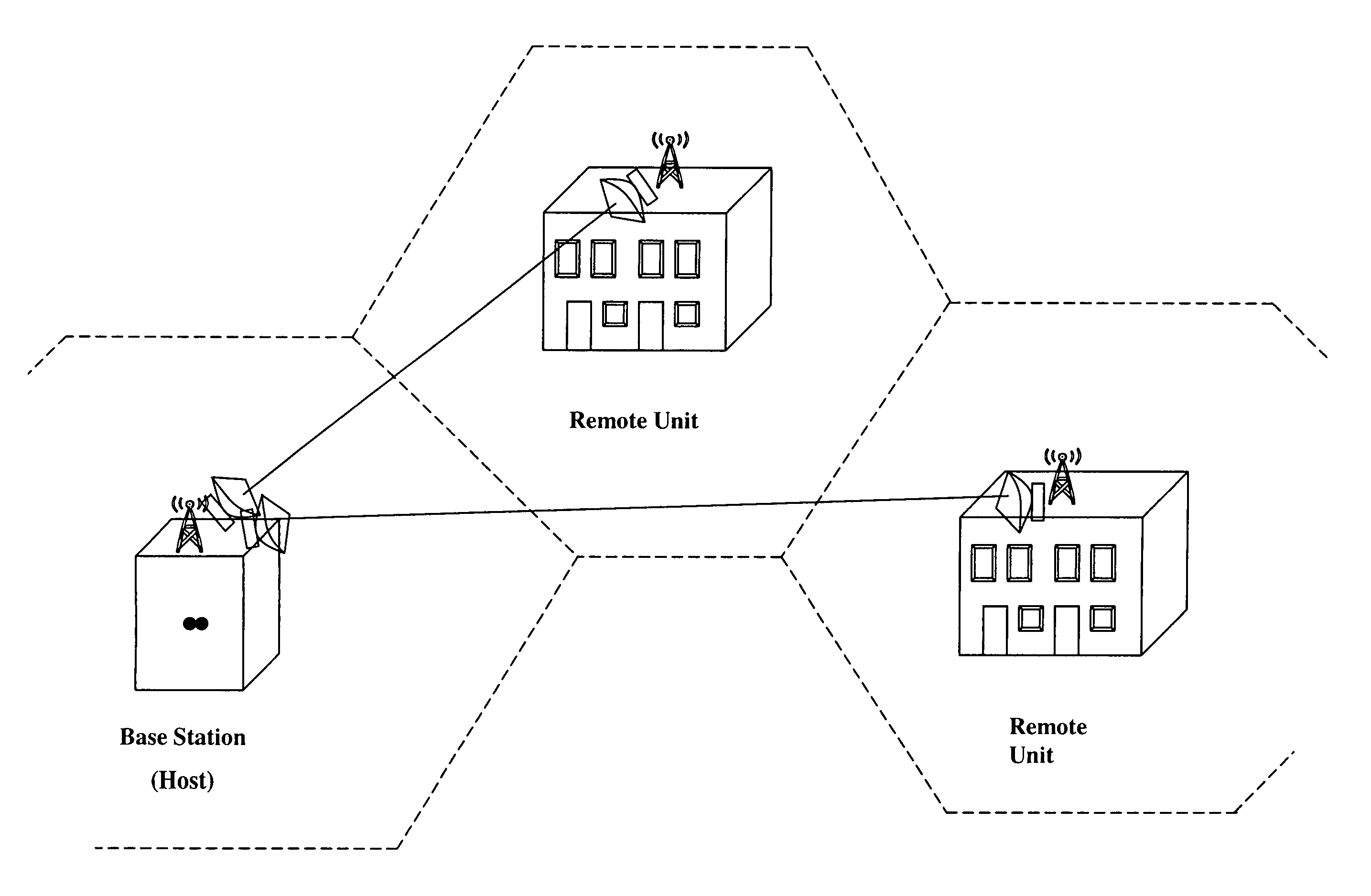

Cellular systems with distributed antennas

InactiveUS8090379B2Efficient use ofLow frequency wireless internet access bandwidth isInformation formatNetwork topologiesWireless transceiverTransceiver

A communication system providing wireless communication among wireless users through a number of cellular base stations, each including at least transport management equipment and broadband equipment, at least one of which supports at least remote cellular station including RF equipment for communication with users of cellular devices. The system includes at lease one wireless narrow beam communication link operating at millimeter wave frequencies in excess of 60 GHz connecting a remote cellular station with a cellular base station equipped with broad band conversion electronic equipment and transport management equipment. In preferred embodiment the communication system includes a large number of remote cellular stations with each remote cellular station serving a separate communication cell. Each remote cellular station is equipped with a low frequency wireless transceiver for communicating with the wireless users within the cell at a radio frequency lower than 6 GHz and a narrow beam millimeter wave wireless transceiver operating at a millimeter wave frequency higher than 60 GHz for communicating with another millimeter wave transceiver at another remote cellular station or a millimeter wave transceiver at a base station.

Owner:TREX ENTERPRISES CORP

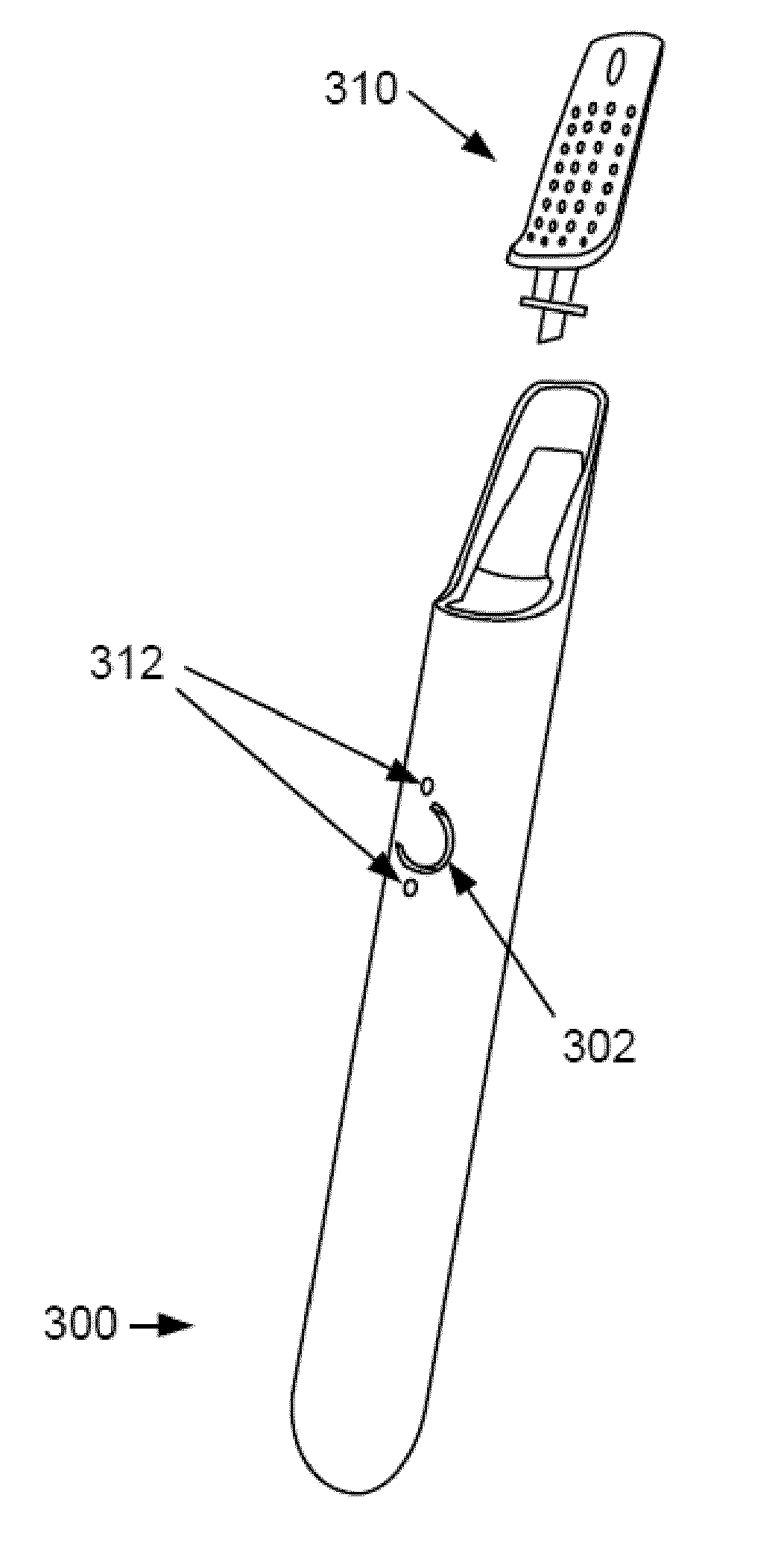

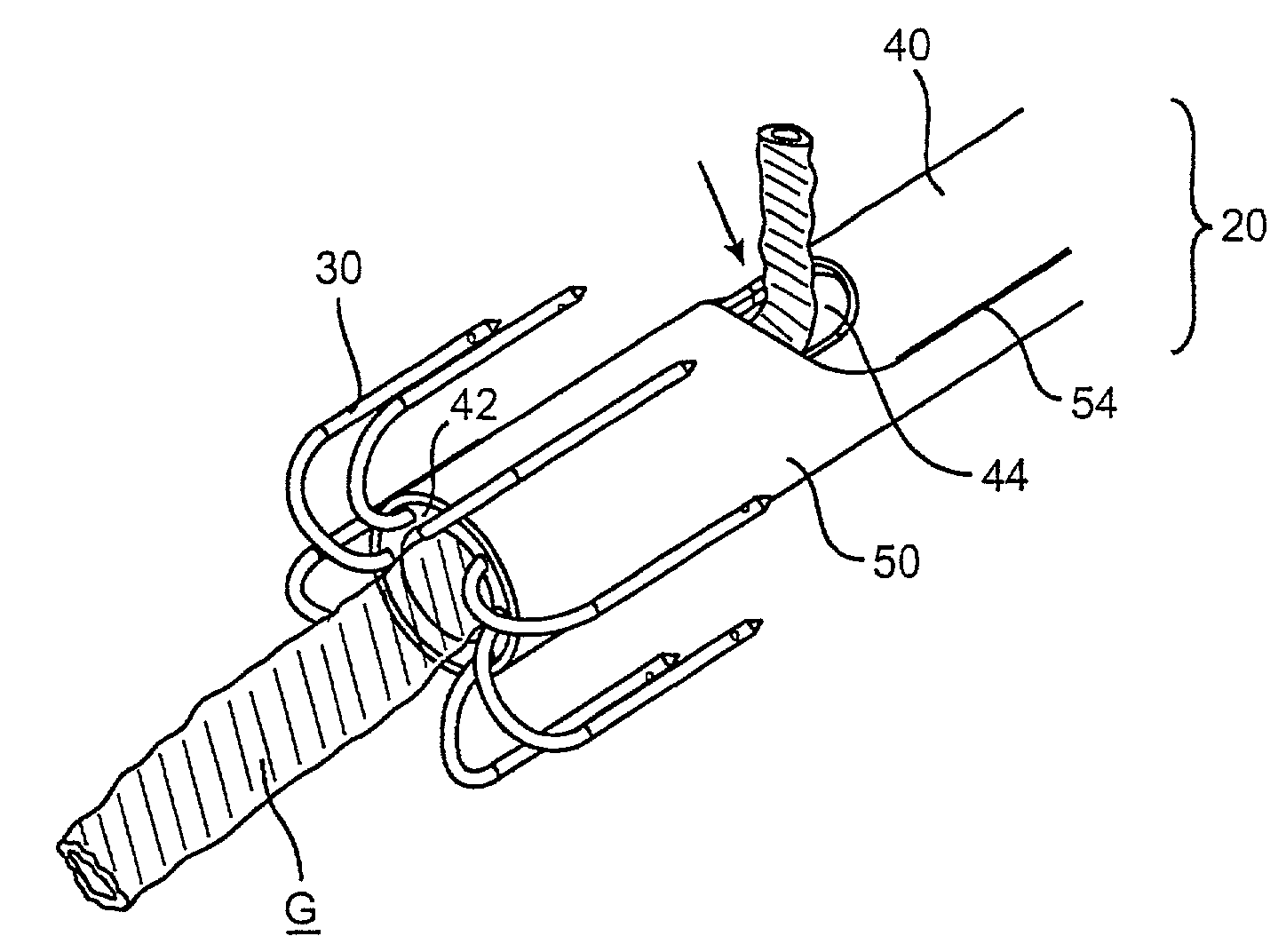

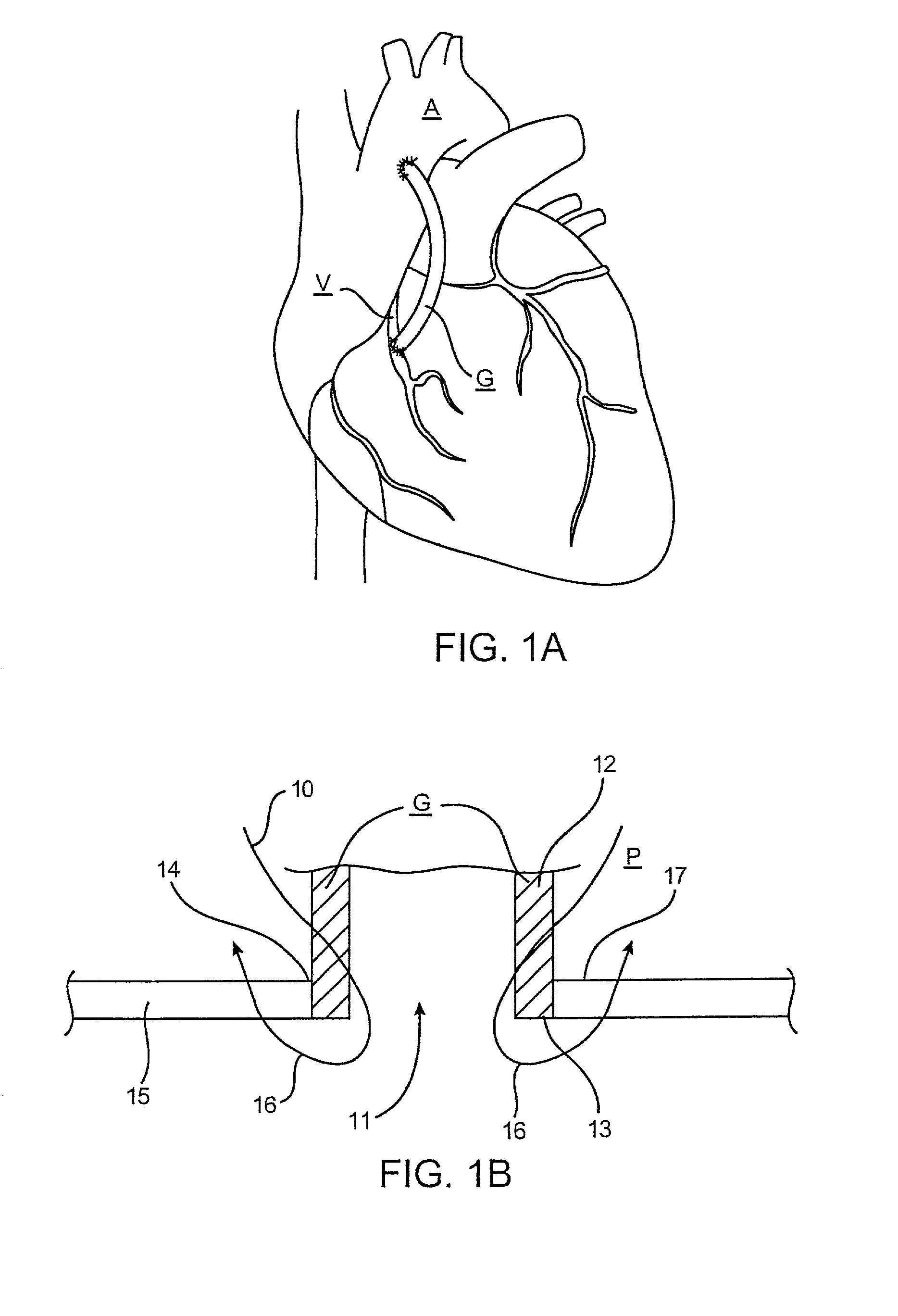

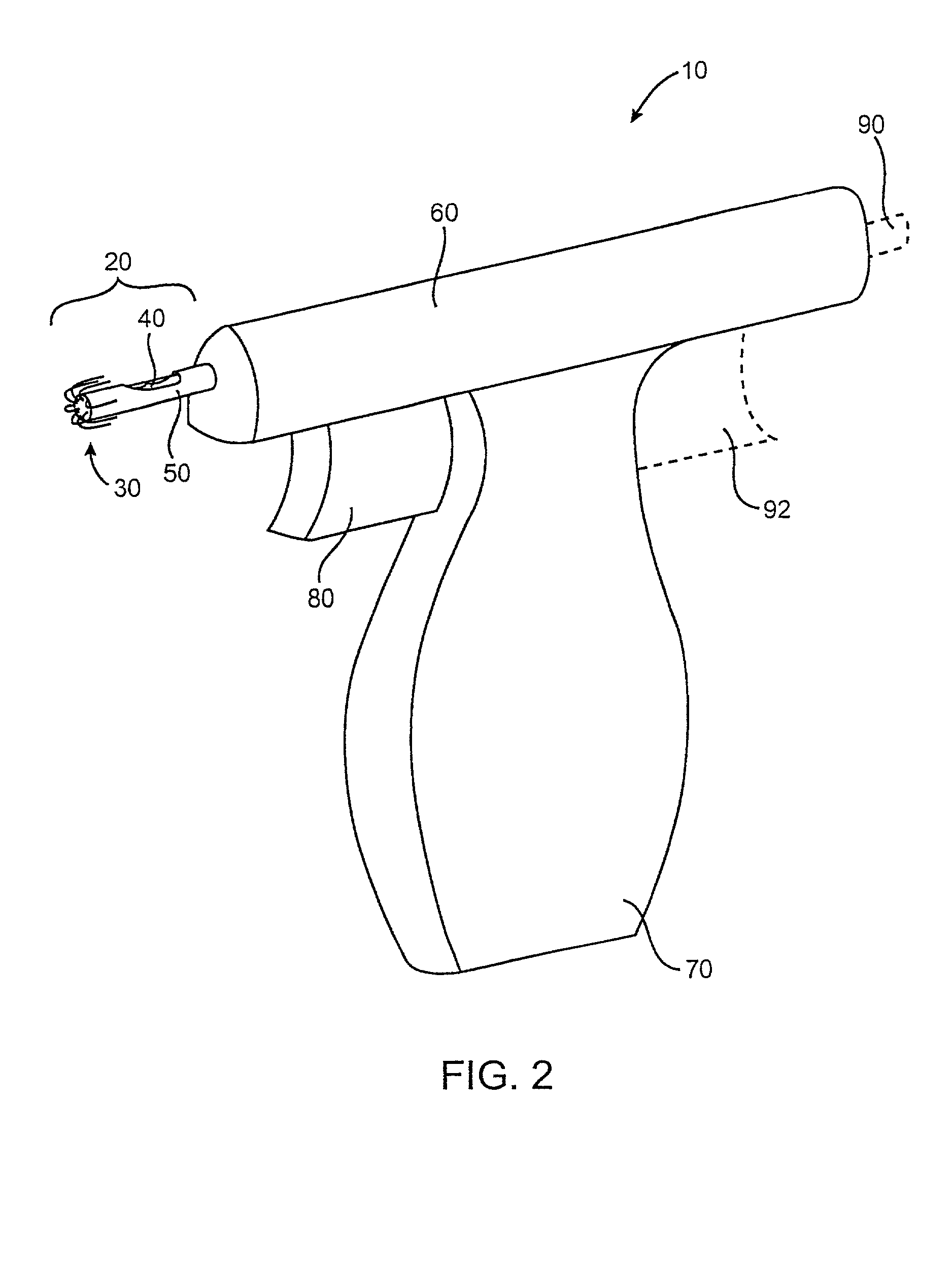

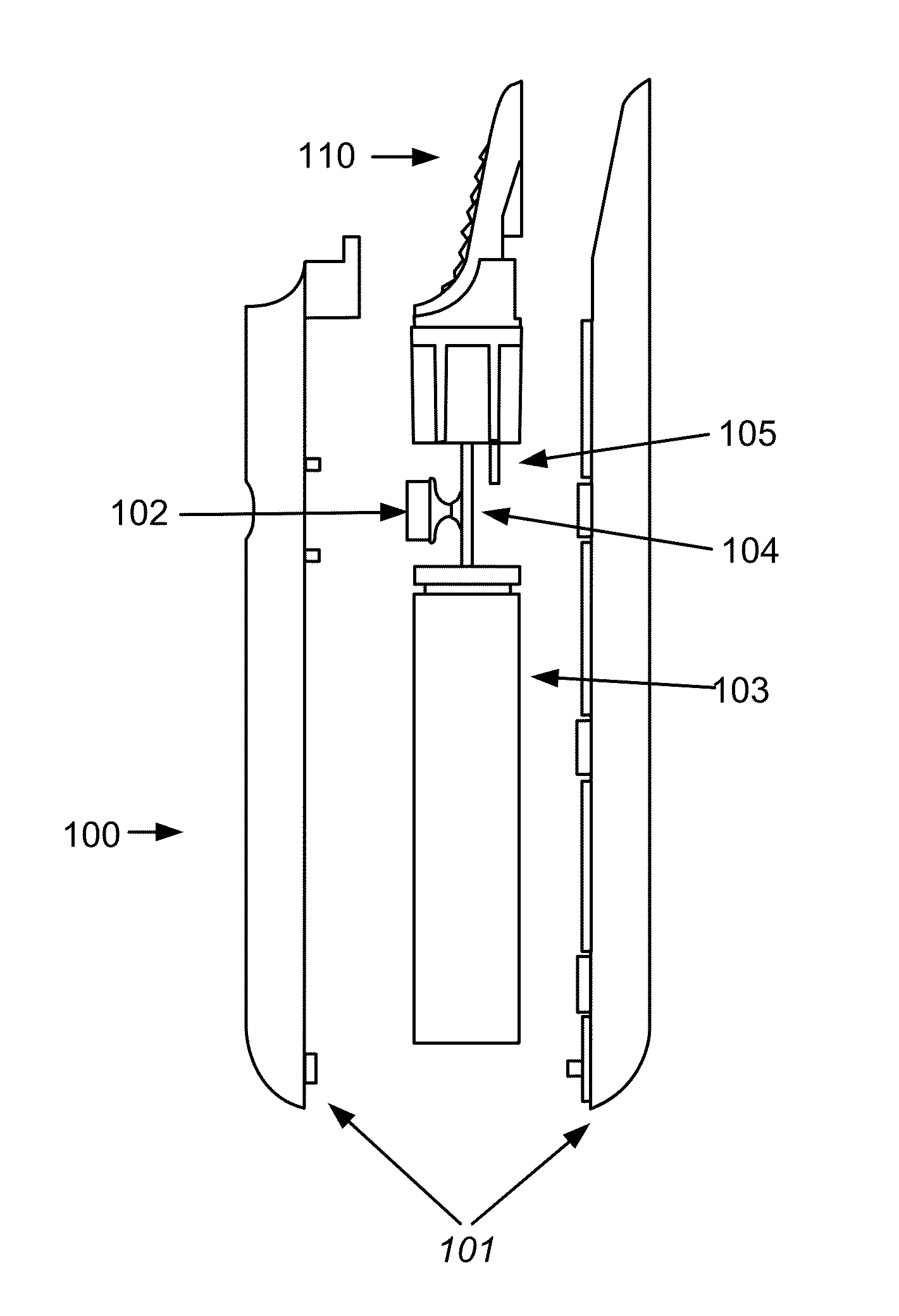

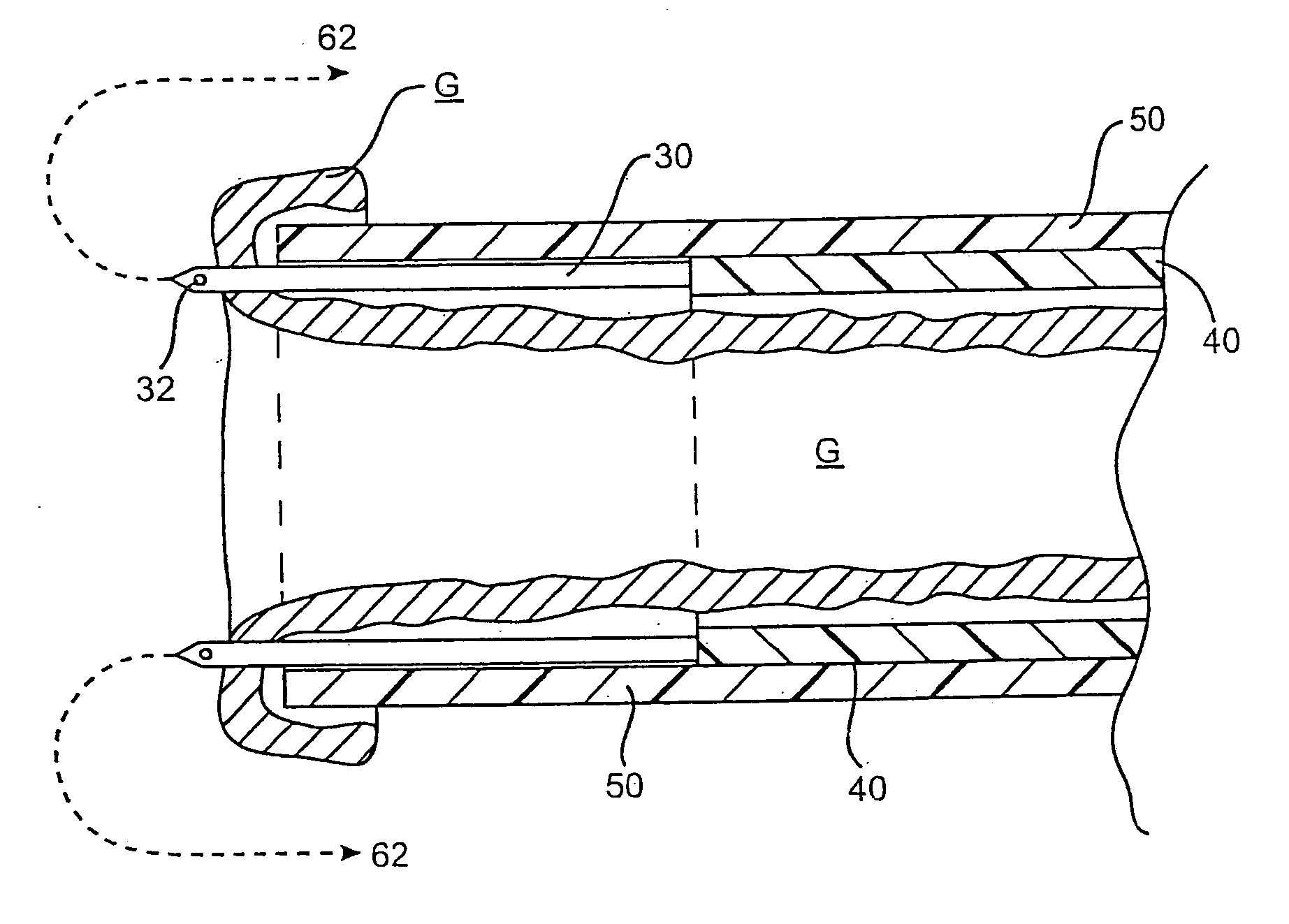

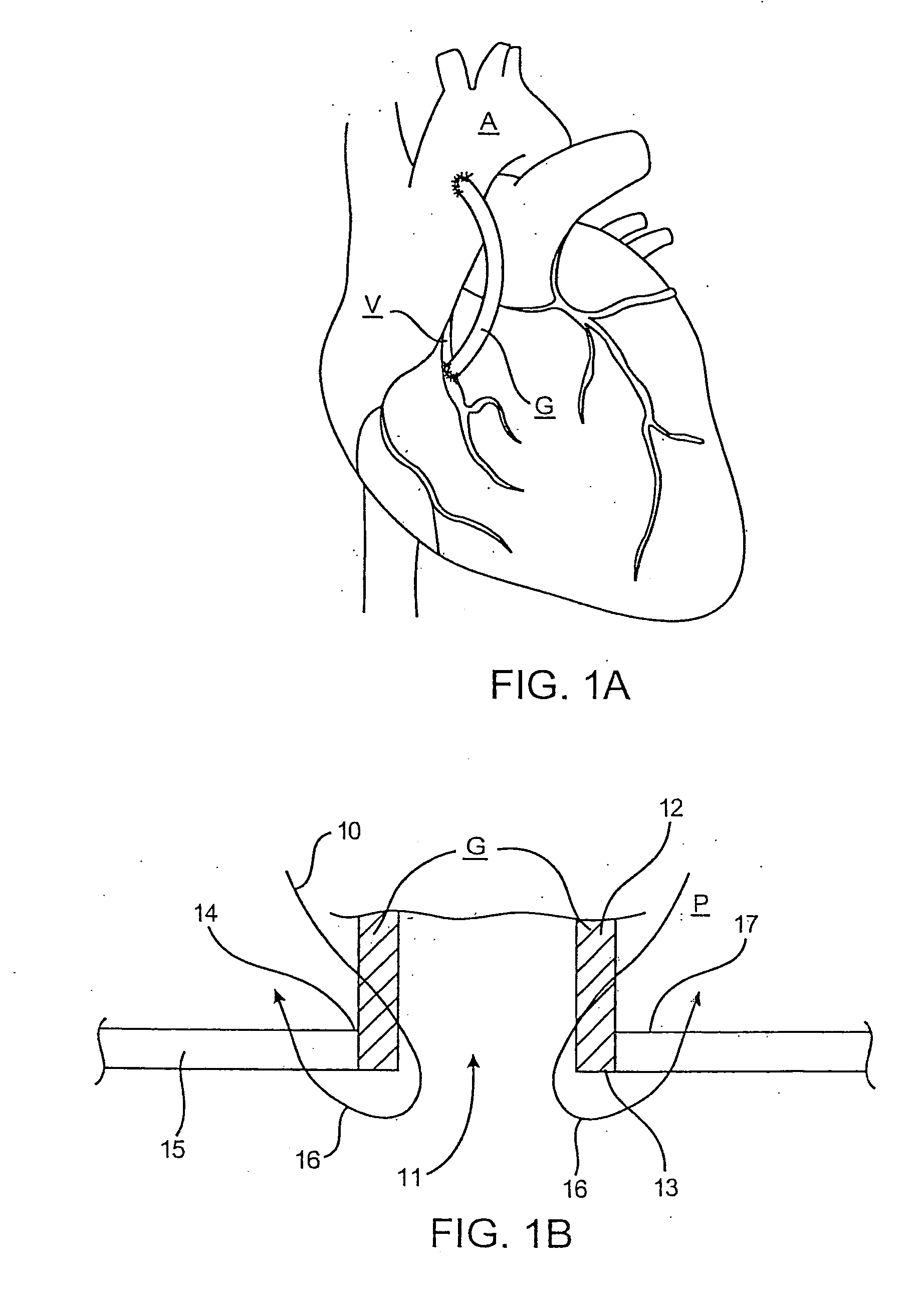

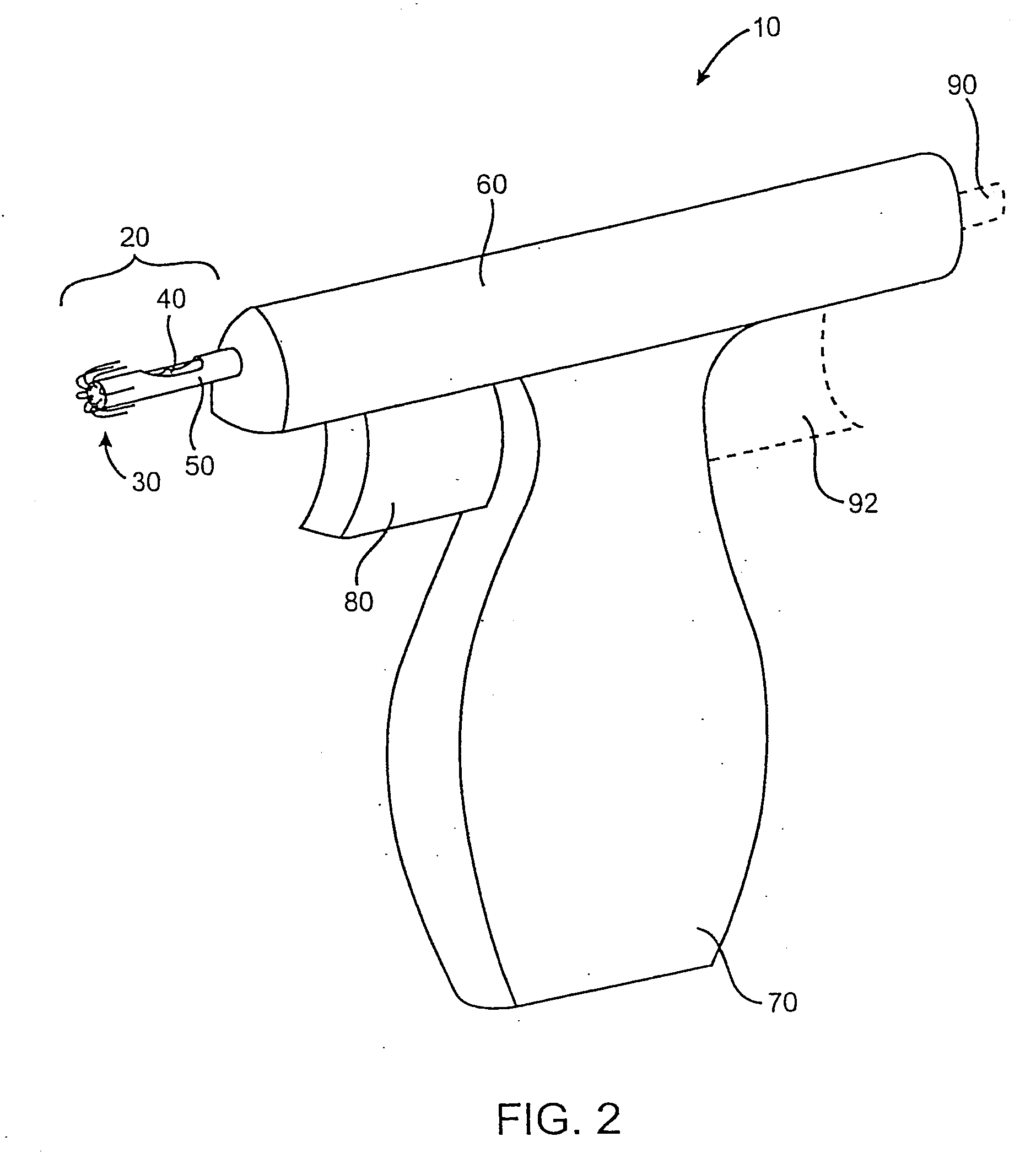

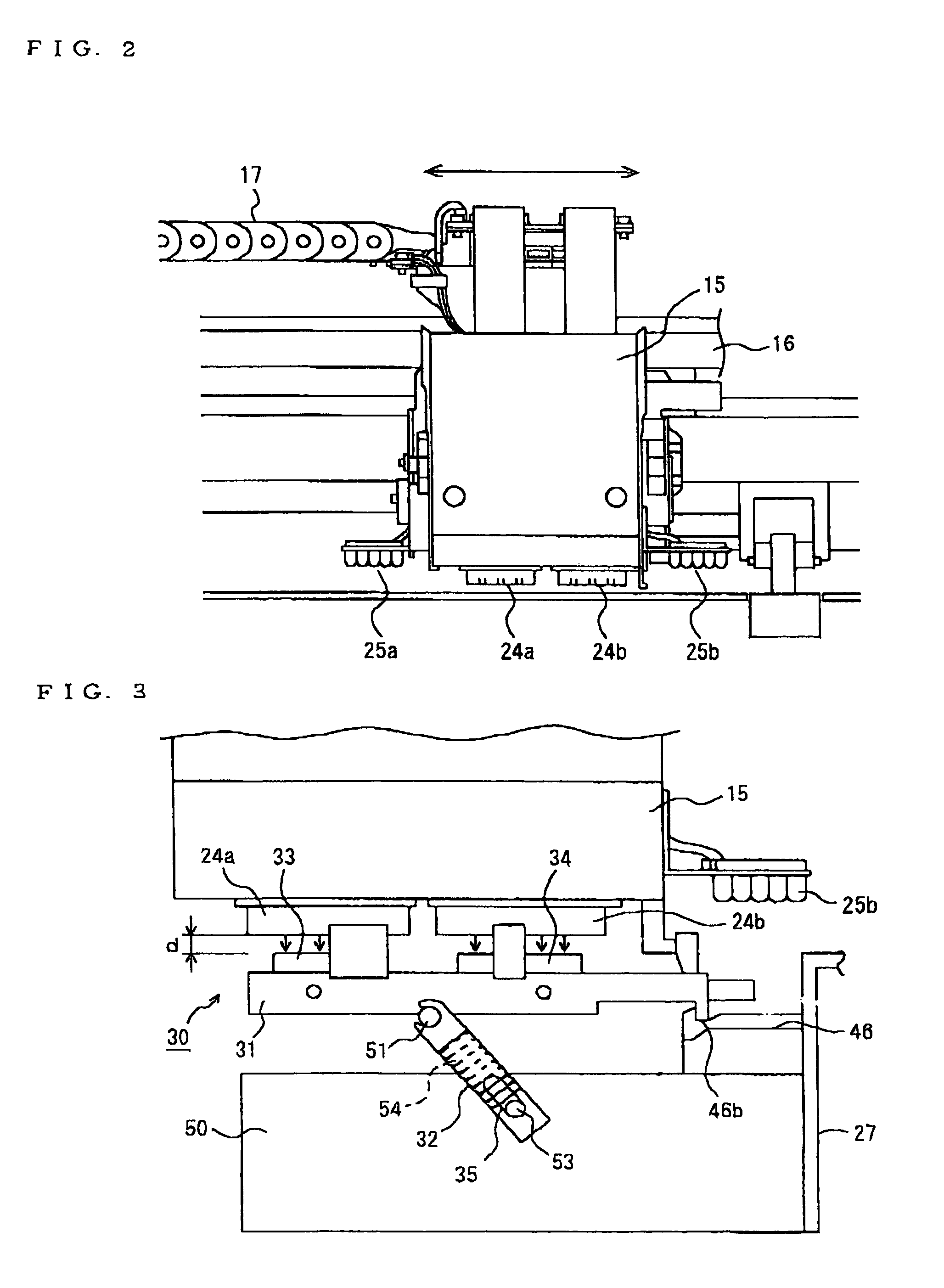

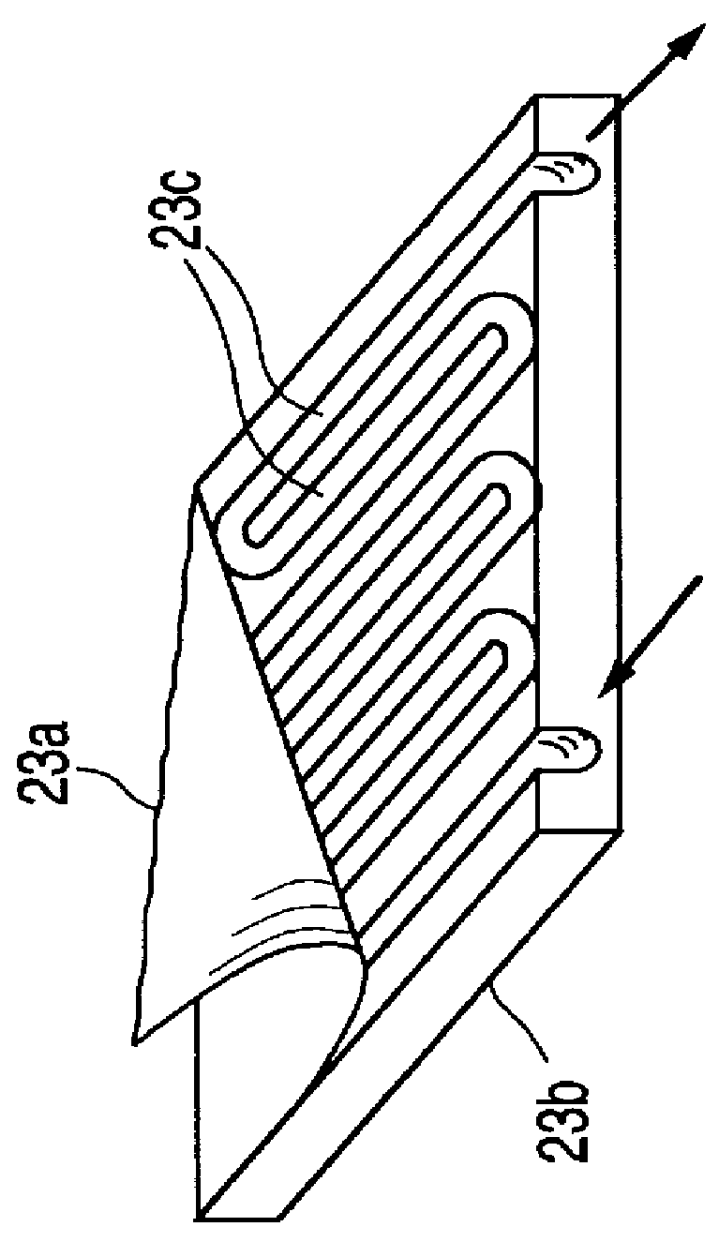

Device and method for performing end-to-side anastomosis

InactiveUS7048747B2Simplify deliveryReduce amount of timeSuture equipmentsSurgical needlesEnd to side anastomosisBiomedical engineering

Devices, methods, and kits are provided for suturing an end of a first body duct to a hole in the side of a second body duct. The present devices and methods are used to simplify the suturing procedure and thus reduce operating time. In one embodiment, the present device includes a structure for holding the end of the first body duct and positioning the end adjacent to the hole in the side of the second body duct. The structure of the device is typically a shaft having a surface adapted to receive the first body duct. A plurality of needles are arranged on the structure to be advanced along a plurality of paths. Each needle path first passes radially into and forwardly out of the end of the first body duct and into the hole of the second body duct. The path then everts so that the needles and associated sutures will pass outwardly through tissue peripheral to the hole when the end of the first body duct is on the structure adjacent to the hole in the second body duct. The needles preferably travel along such paths when they are advanced forward. In one embodiment, the device uses a J-shaped tube for guiding one of the needles along the desired path. In another embodiment, shape-memory needles having an arcuate profile are used to create the desired path.

Owner:ABBOTT LAB INC

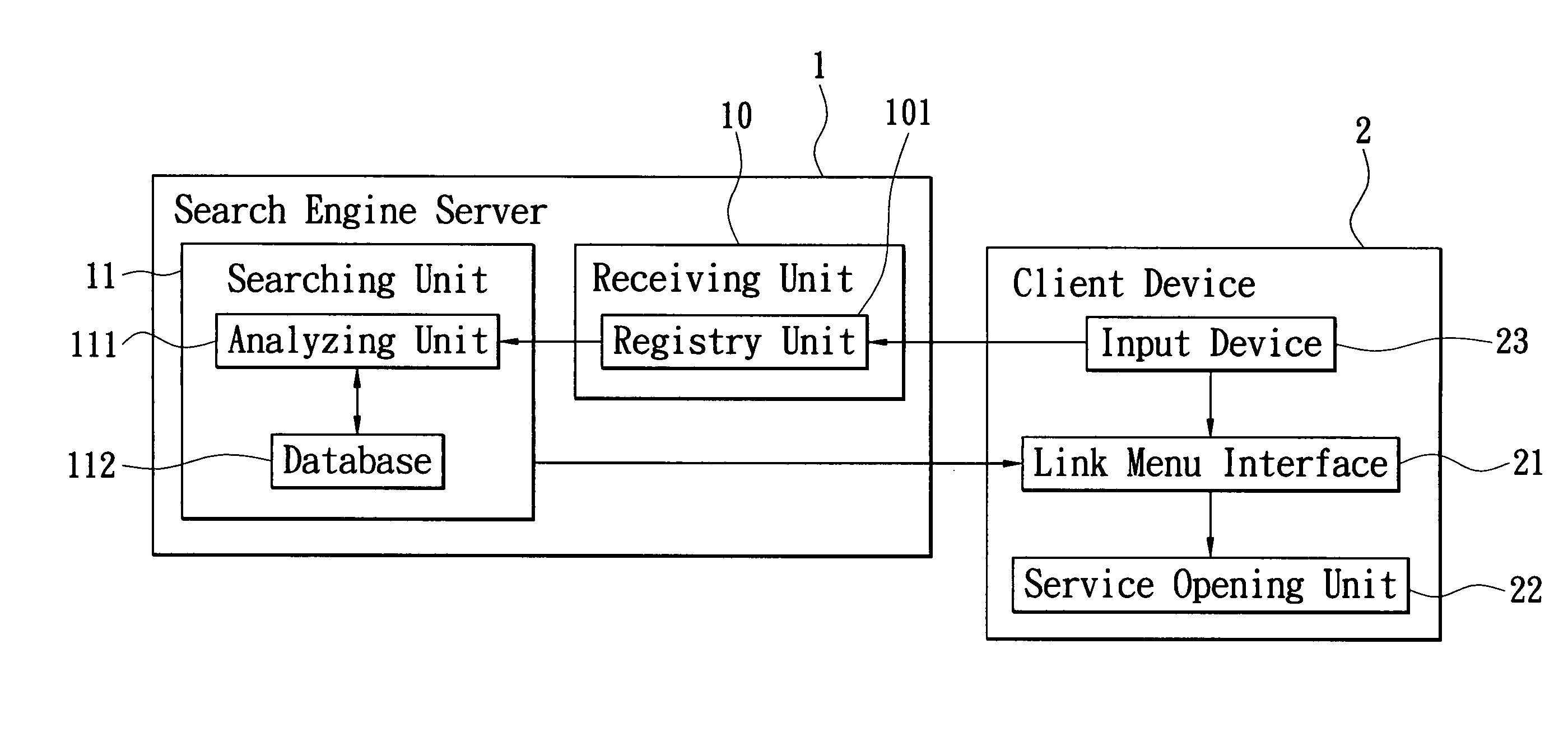

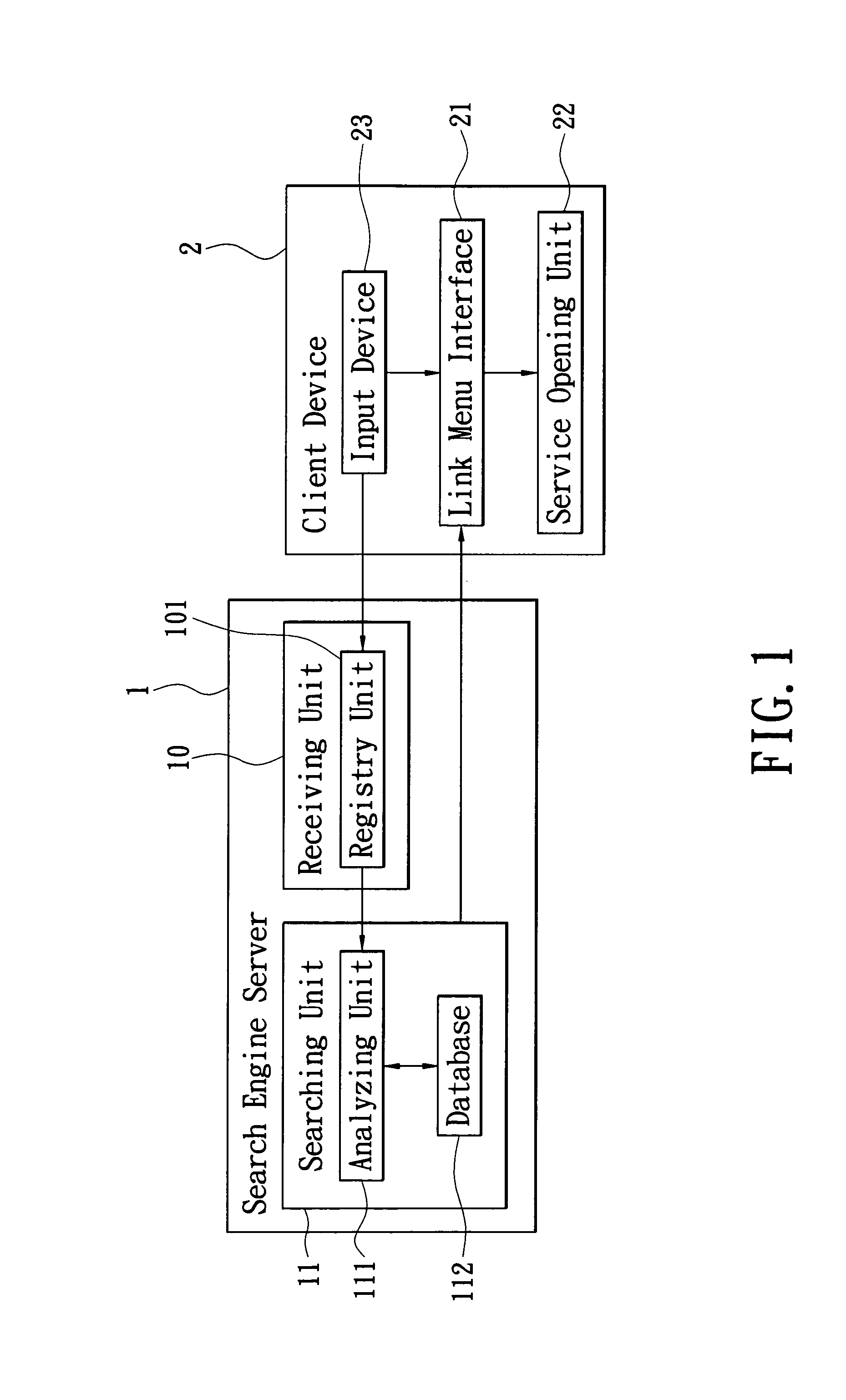

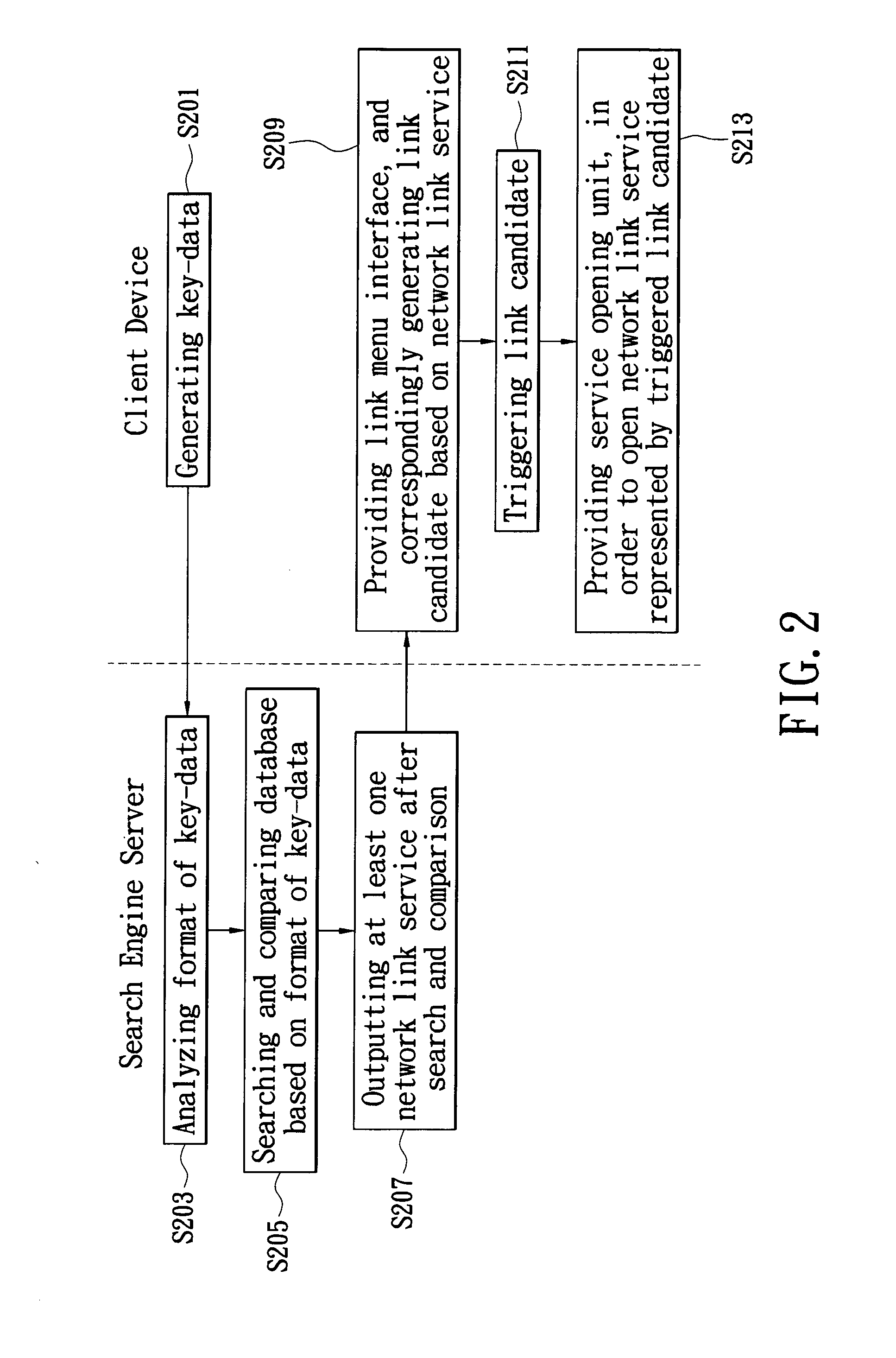

System of fast launching network link service and method thereof

InactiveUS20090043763A1Simplifying data search stepSimple and time-saving operationWeb data indexingDigital data processing detailsNetwork linkClient-side

A system of fast launching network link service comprising: a search engine server, and a client device. The search engine server, through a receiving unit, receives a key-data produced by the client device, and through an analysis unit of a search unit analyzes the form of key-data, and then searches a database to output at least one network link service. The client device, through a link menu interface, produces a link candidate corresponding to the network link service. Furthermore, the client device can open the network link service represented by the link candidate. Hence, the present invention can achieve the purpose of simplifying the steps of operating search engine.

Owner:PENG CHIEN CHIANG

Low temperature electronic vaporization device and methods

InactiveUS20130312742A1Maintain efficiencyReduce the temperatureInput/output for user-computer interactionTobacco treatmentInhalationEnvironmental health

Low temperature electronic vaporization devices and method are described herein for emulating smoking wherein the devices generate an aerosol for inhalation by a subject by heating a viscous material that can have a tactile response in the mouth or respiratory tract.

Owner:JUUL LABS INC

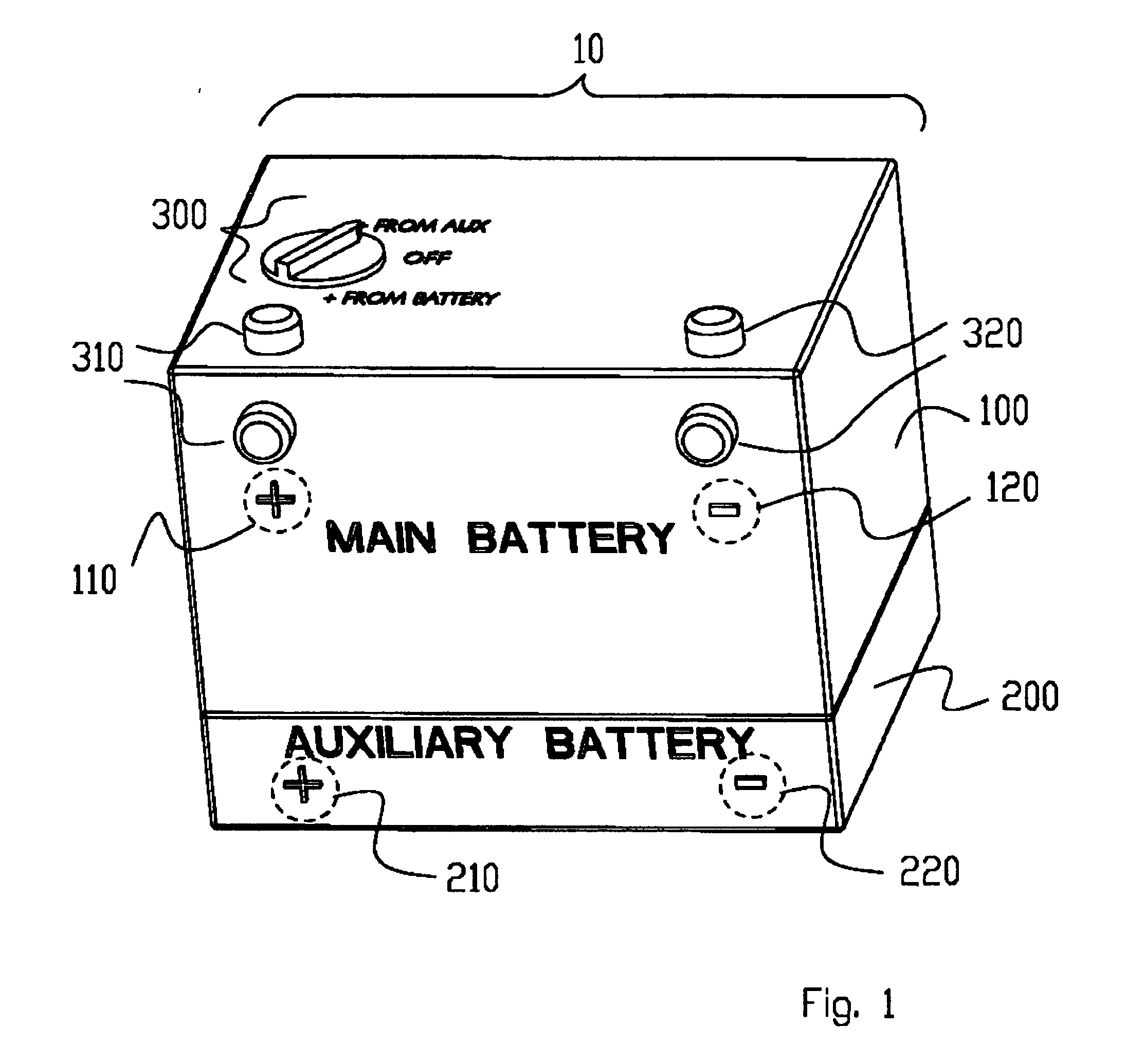

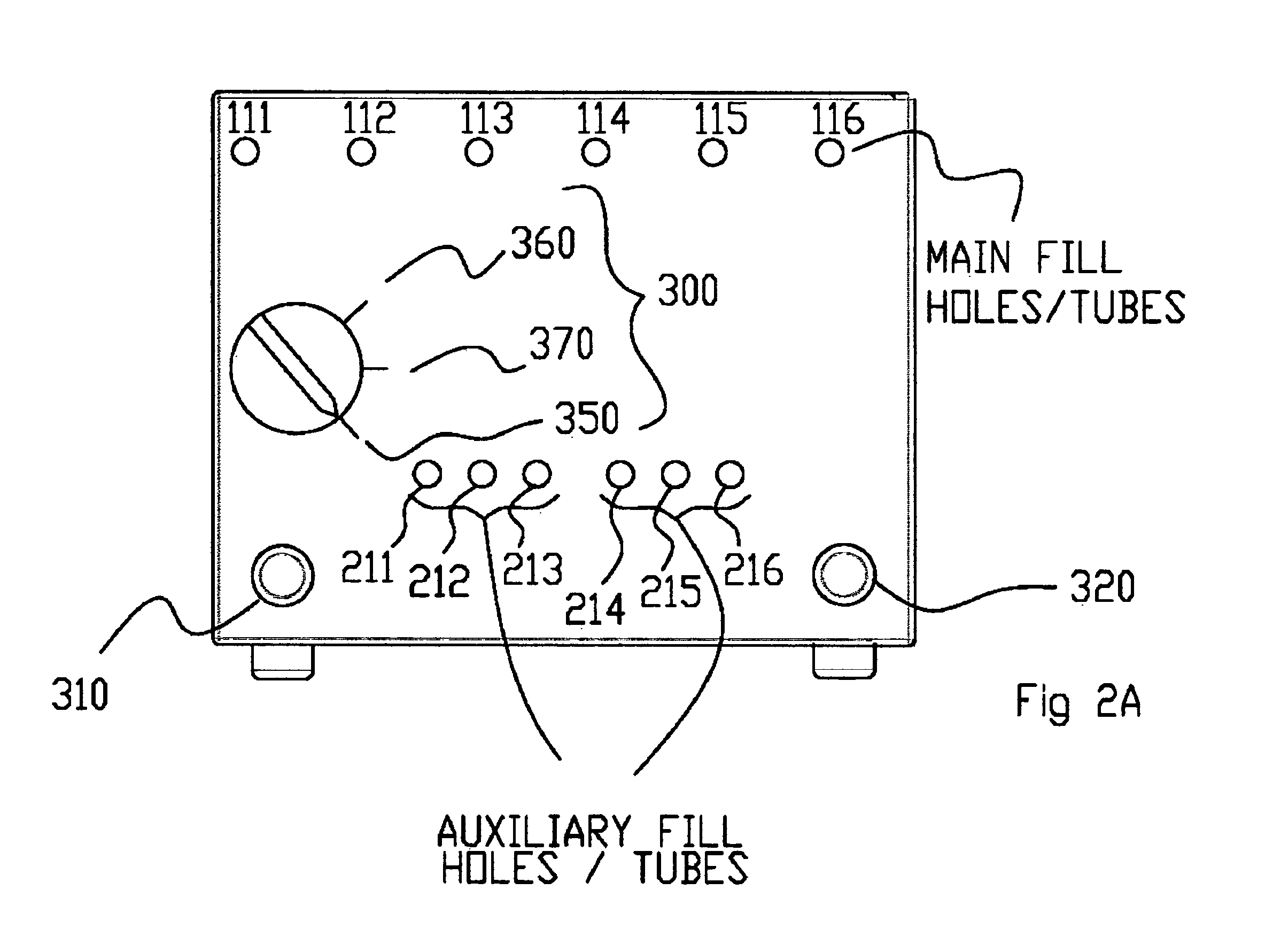

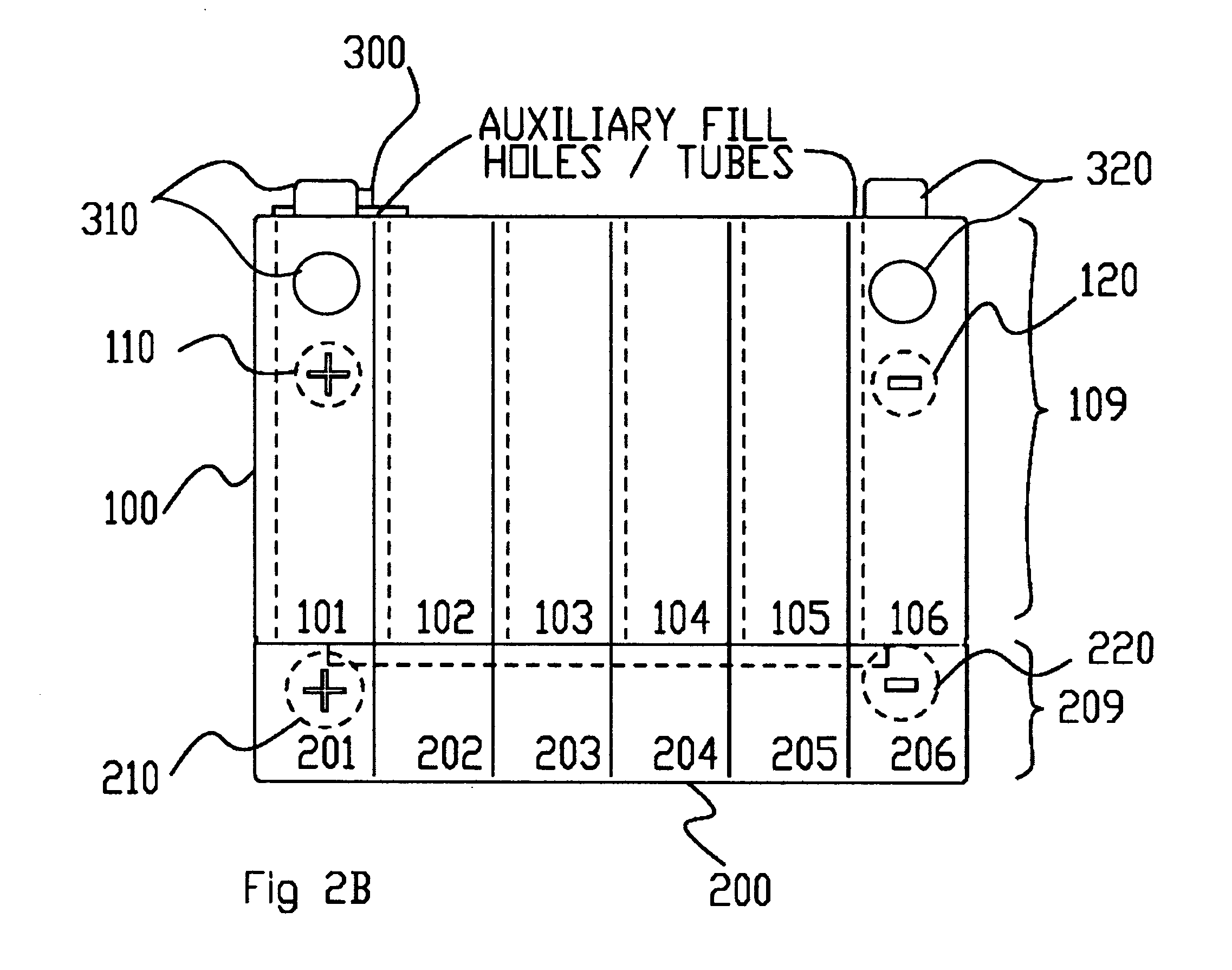

Multiple battery management system, auxiliary battery attachment system, and network controlled multiple battery system

InactiveUS20050035741A1Start fastIncrease costCharge equalisation circuitElectric devicesNetwork controlEngineering

The instant invention is directed to a multiple battery system and network controlled multiple battery system. A main battery having a main positive output and a main negative output is also provided, together with an at least one auxiliary battery having an at least one auxiliary positive output and an at least one auxiliary negative output. A main electrical circuit having an at least one switching device is provided with at least two operating positions. The two operating positions selectively couple the main and at least one auxiliary battery to the common positive terminal. In the first of the at least two operating positions electrical charge is provided to both the main battery and the at least one auxiliary battery. A controller is also provided and coupled to the main electrical circuit and switches the at least one switching device based on input from an at least one sensor.

Owner:RESERVE POWER CELL

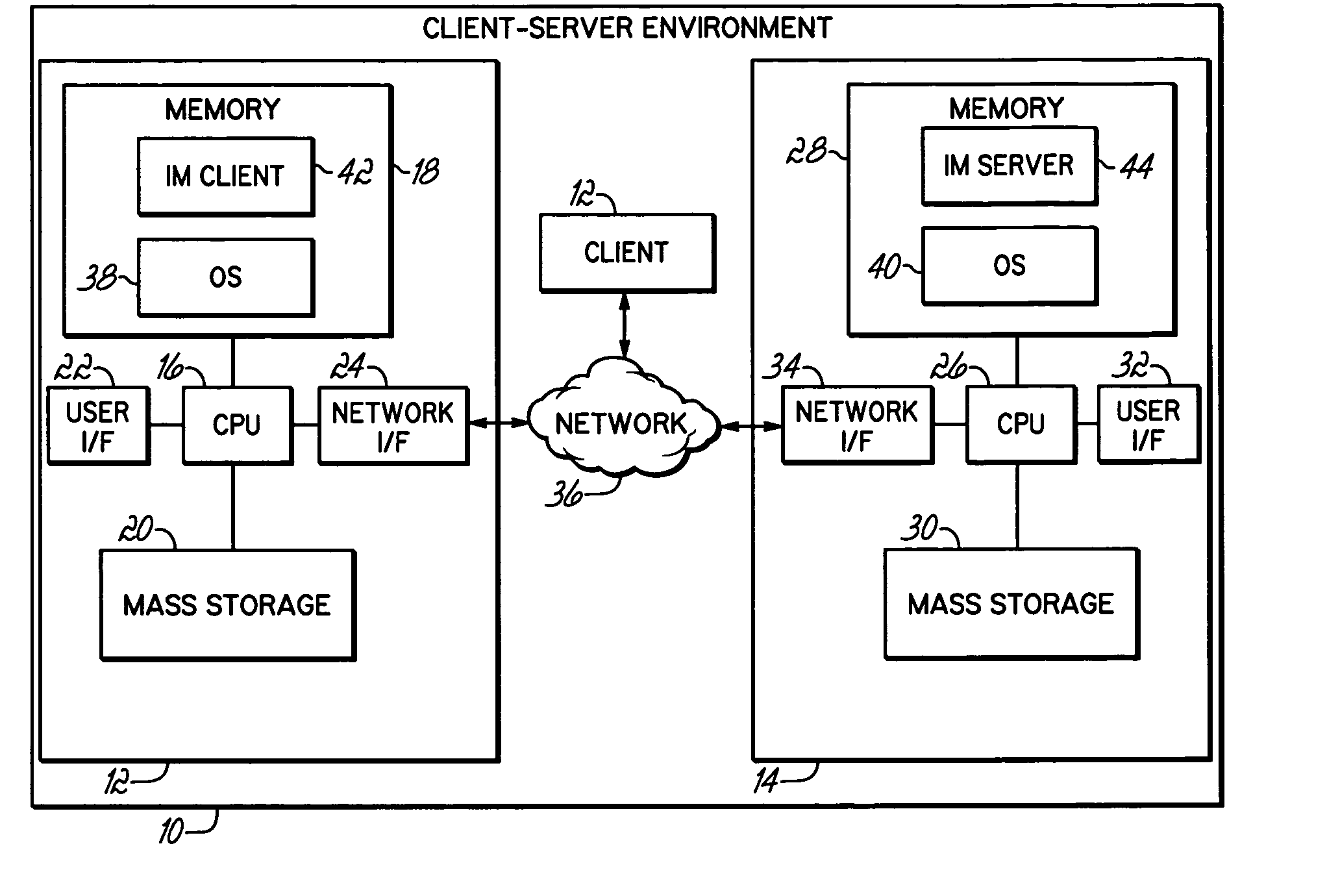

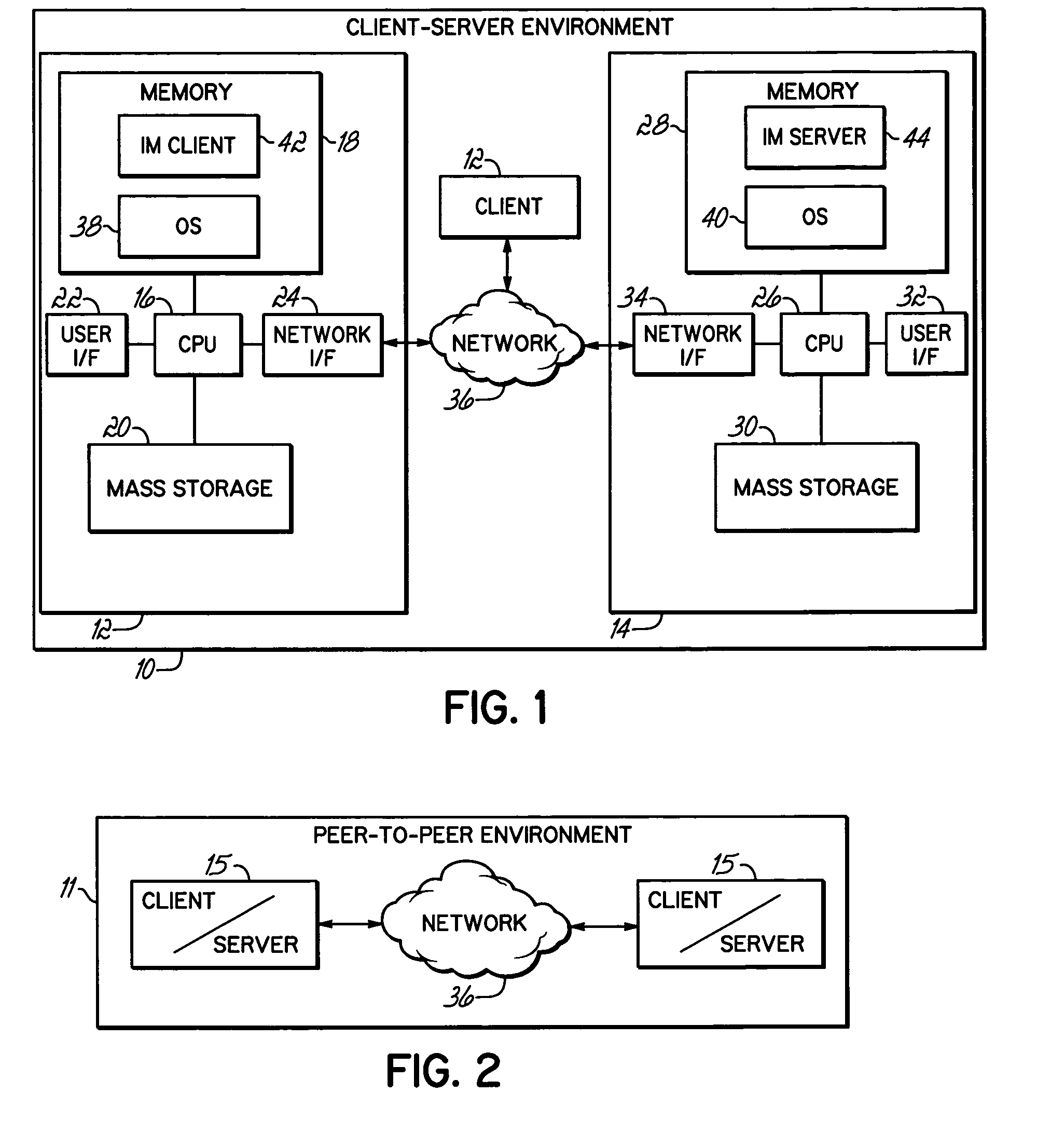

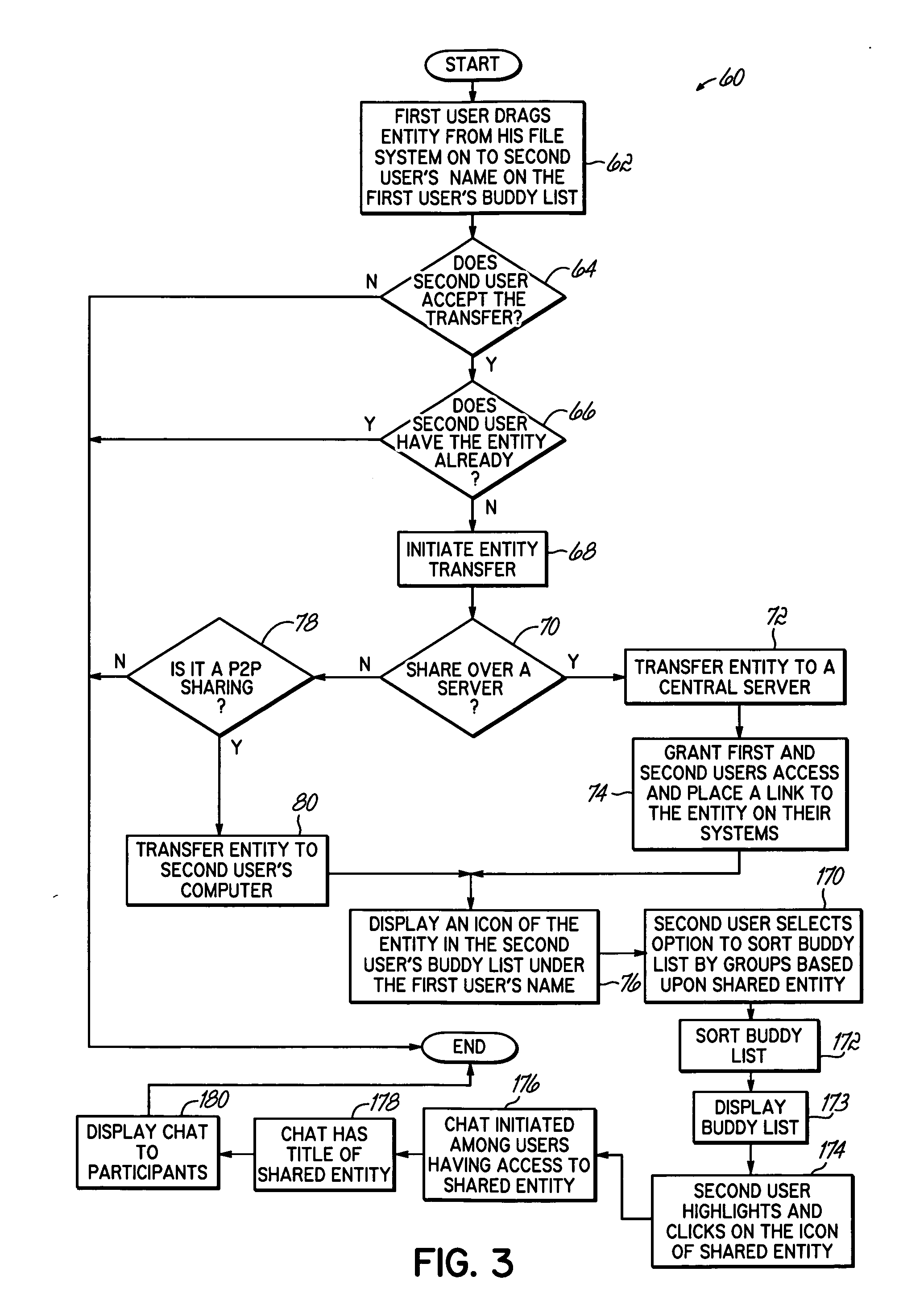

Identifying and displaying relevant shared entities in an instant messaging system

ActiveUS20070168448A1Quickly and reliably determiningQuickly and reliably accessingMultiple digital computer combinationsData switching networksElectronic mailInstant messaging

An apparatus, program product and / or method identify relevant shared entities and / or display shared entities in an instant messaging system. In particular, entities such as files, images, videos, e-mails, links, bookmarks, databases, transcripts of other instant messages, etc. that are shared between users participating in an instant message session may be identified and highlighted to indicate that the shared entities are related to the instant message session. Furthermore, a link to an entity may be sent to a user when the entity is referenced in an instant message of the instant message session. Additionally, a display representation of entities that are shared with a user may be displayed in the user's buddy list to indicate that the shared entity is accessible to the user and whom shared the entity with the user. Furthermore, a transcript may be associated with an entity.

Owner:IBM CORP

Device and method for performing end-to-side anastomosis

InactiveUS20060167477A1Simplifies suture deliveryAmount of timeSuture equipmentsSurgical needlesEnd to side anastomosisCatheter

Devices, methods, and kits are provided for suturing an end of a first body duct to a hole in the side of a second body duct. The present devices and methods are used to simplify the suturing procedure and thus reduce operating time. In one embodiment, the present device includes a structure for holding the end of the first body duct and positioning the end adjacent to the hole in the side of the second body duct. The structure of the device is typically a shaft having a surface adapted to receive the first body duct. A plurality of needles are arranged on the structure to be advanced along a plurality of paths. Each needle path first passes radially into and forwardly out of the end of the first body duct and into the hole of the second body duct. The path then everts so that the needles and associated sutures will pass outwardly through tissue peripheral to the hole when the end of the first body duct is on the structure adjacent to the hole in the second body duct. The needles preferably travel along such paths when they are advanced forward. In one embodiment, the device uses a J-shaped tube for guiding one of the needles along the desired path. In another embodiment, shape-memory needles having an arcuate profile are used to create the desired path.

Owner:ARCIA ROVIL P +2

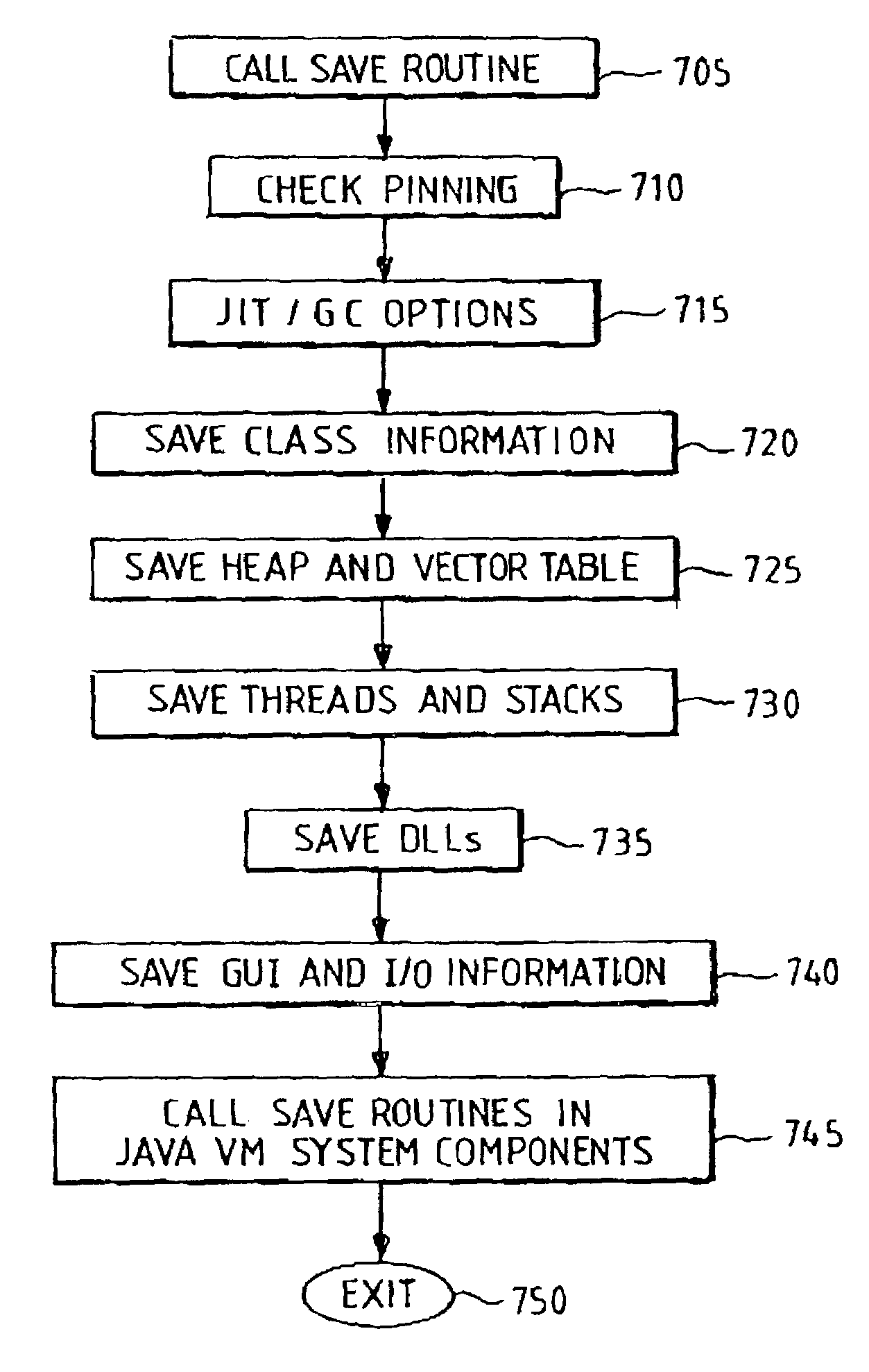

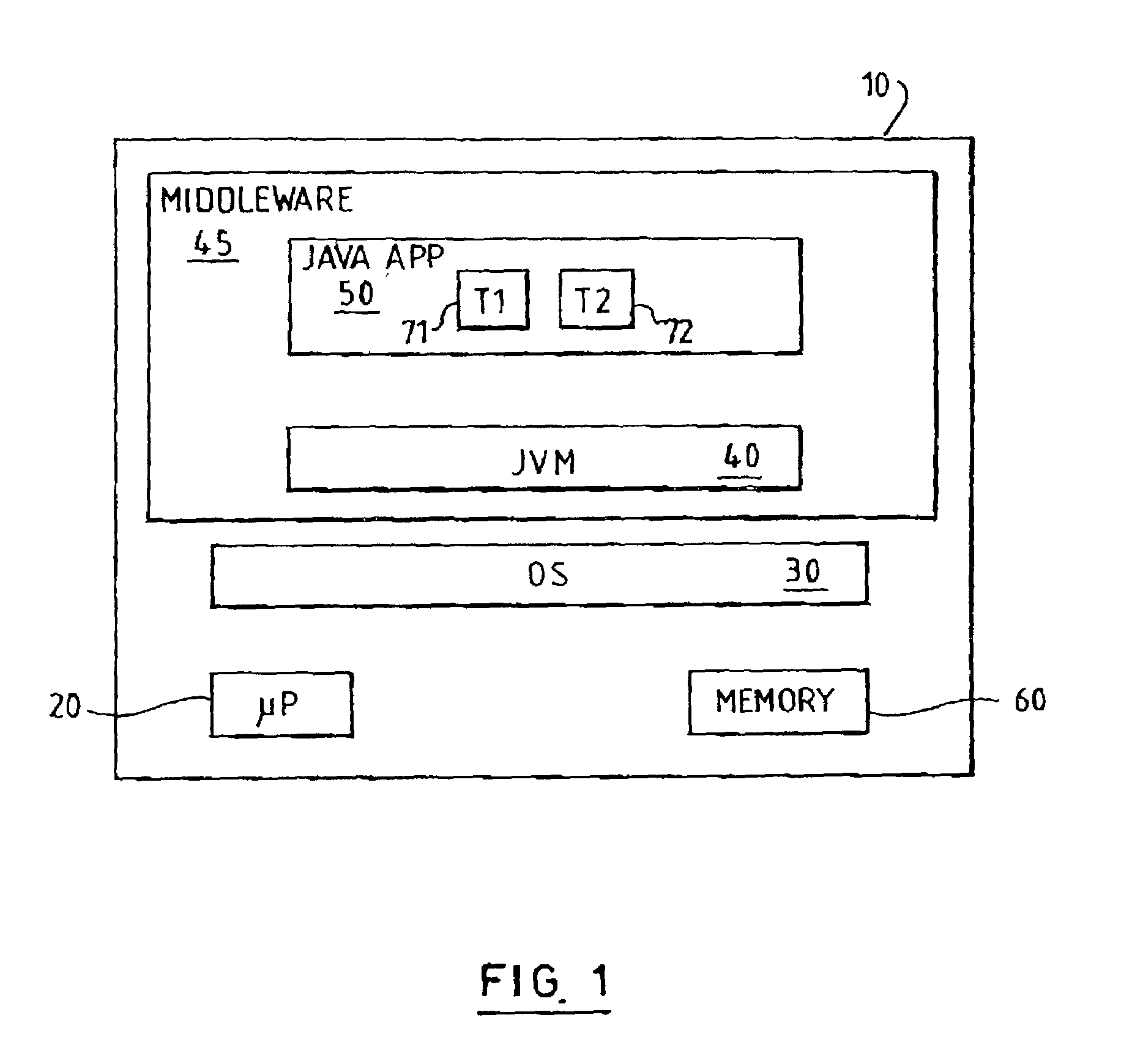

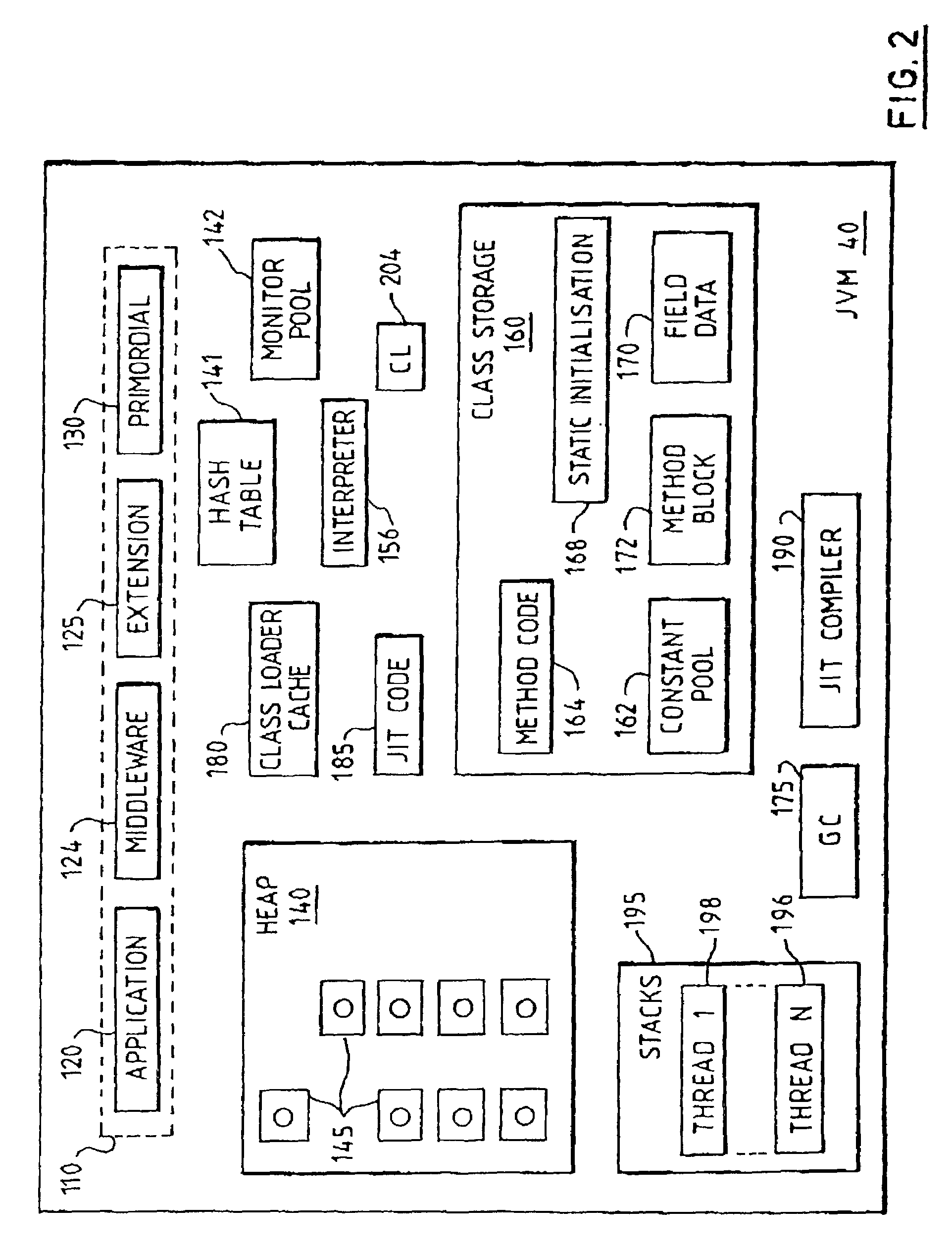

Method and apparatus for suspending a software virtual machine

InactiveUS7191441B2Flexible and convenientMinimise restore timeEnergy efficient ICTProgram initiation/switchingComputerized systemSerialization

A computer system includes a software virtual machine (such as Java) for running one or more applications. An object is provided that is responsive to a call from an application for placing the virtual machine and application into a state of suspension. This involves interrupting all current threads, and recording the state of the components of the virtual machine, including heap, threads, and stack, into a serialization data structure. Subsequently the serialization data structure can be invoked to resume the virtual machine and application from the state of suspension. Note that many virtual machines can be cloned from the single stored data structure. One benefit of this approach is that a new virtual machine can effectively be created in an already initialized state.

Owner:IBM CORP

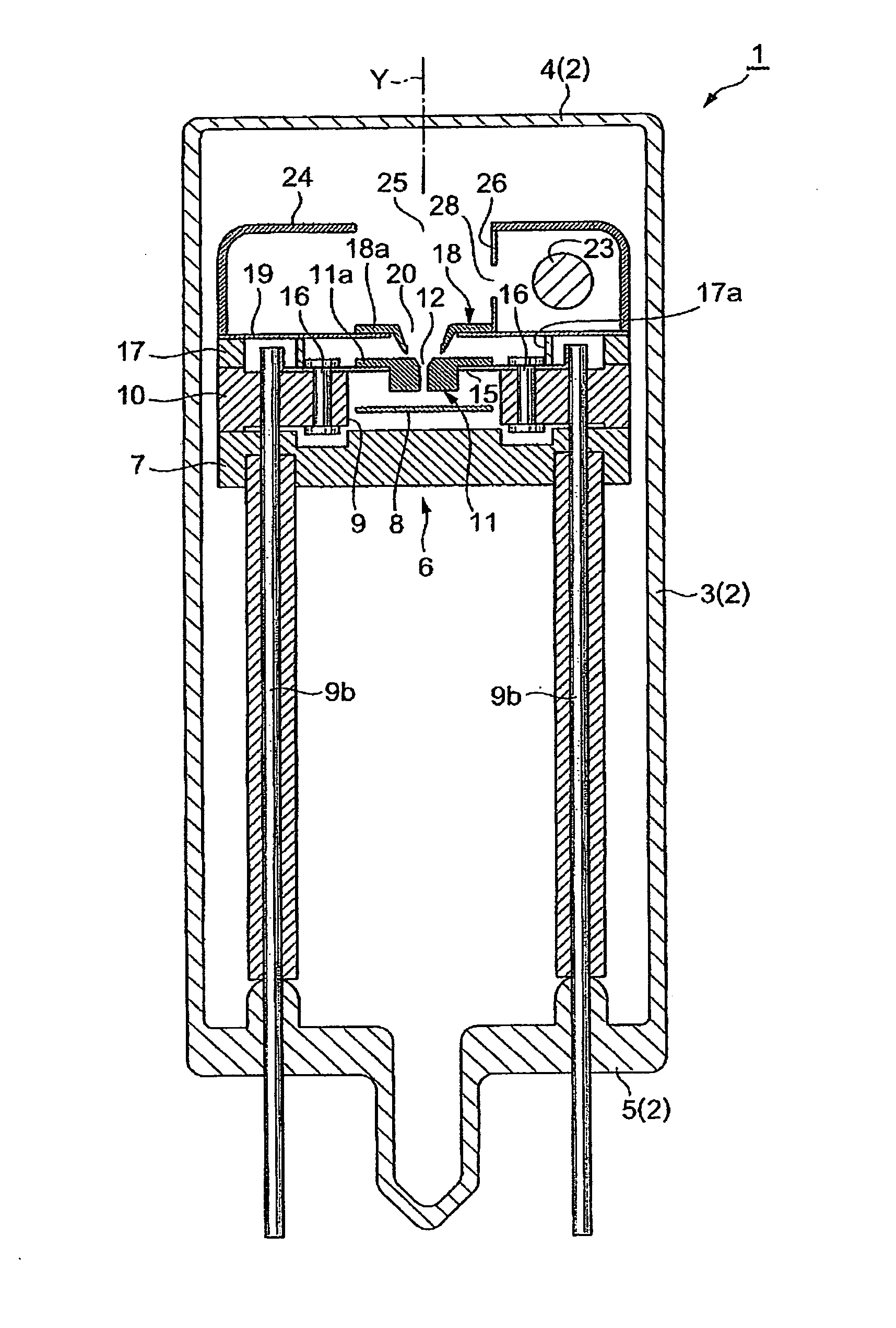

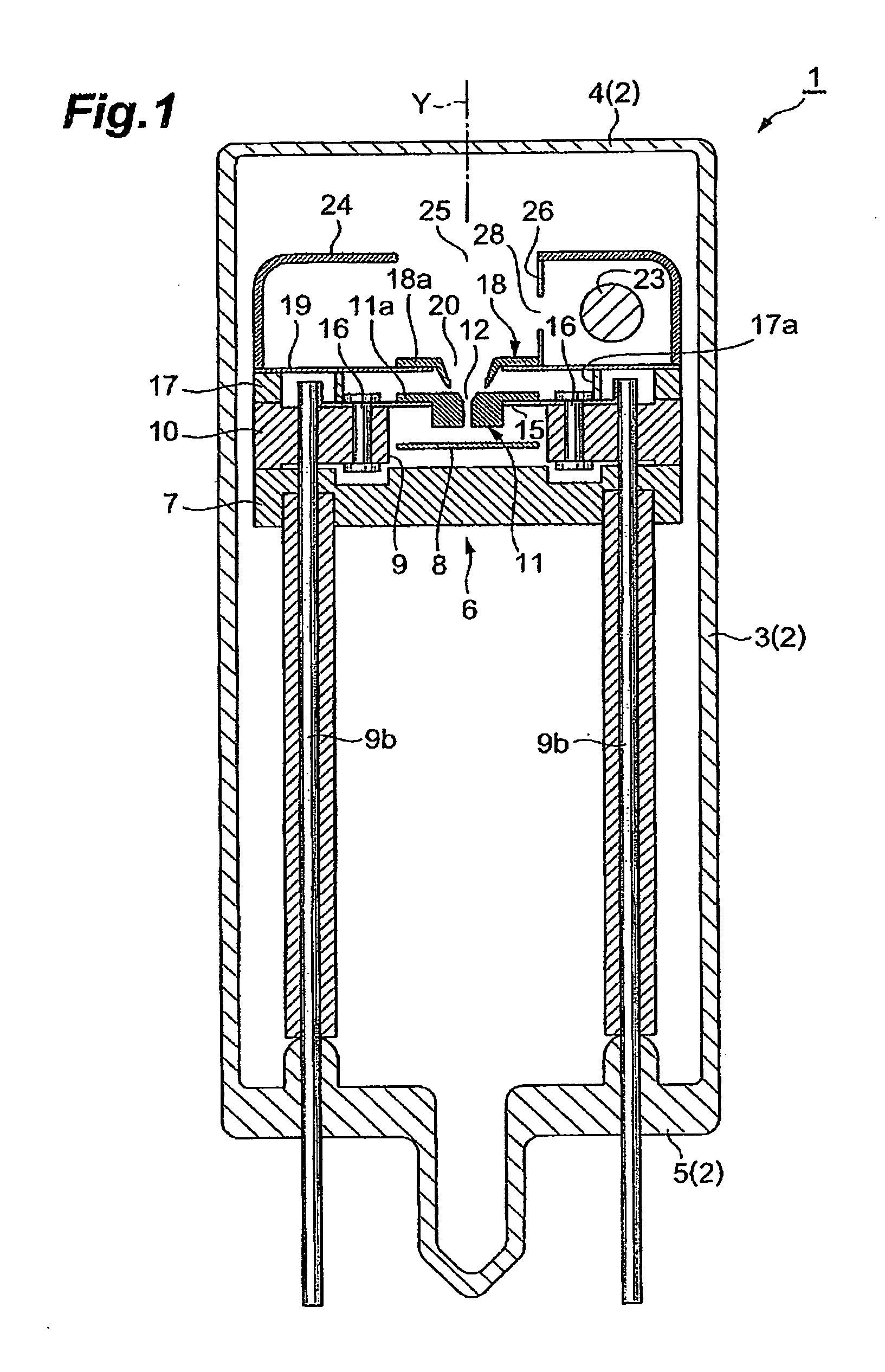

Gas discharge tube

ActiveUS20050231119A1Improvement of start propertyIncrease plasma densitySolid cathode detailsGas discharge lamp detailsStart timeHigh luminance

In the gas discharge tube according to the present invention, there is carried out narrowing of the discharge path with cooperation of the first opening 20 and the second opening 12 in order to obtain higher luminance of light. Further, in order to maintain excellent starting-properties of a lamp even if the discharge path is narrowed, a predetermined voltage is applied to a second discharge path limit portion 11 externally. Thereby, a positive or active starting discharge is produced in such a manner as to pass through the first opening 20. Further, the second opening 12 is comprised of not only a straight section 13 extending in a direction of an optical axis Y, but also a spread section 14 extending from an end portion of the straight section 13 toward the first opening 20. The spread section 14 has a function of improving the starting properties of the lamp and forms an arc ball, and the straight section has a function of improving a plasma density. Thereby, discharge at a starting time is made easy to pass through the second discharge path limit portion 11. As a result, a rapid start of discharge between a cathode 23 and an anode portion 8 is achieved in the second discharge path limit portion 11, and that contributes to proper generation of an arc ball after lighting.

Owner:HAMAMATSU PHOTONICS KK

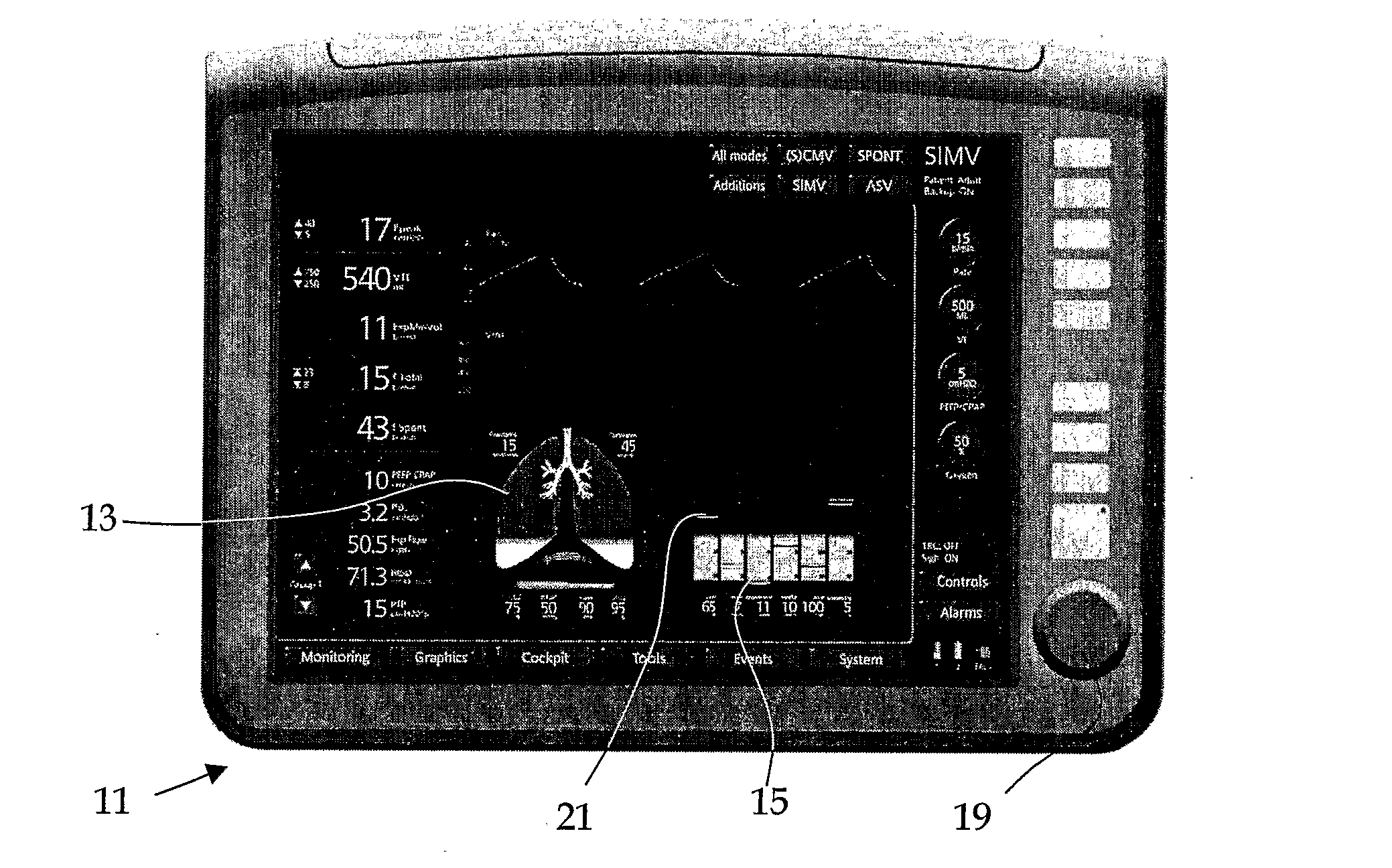

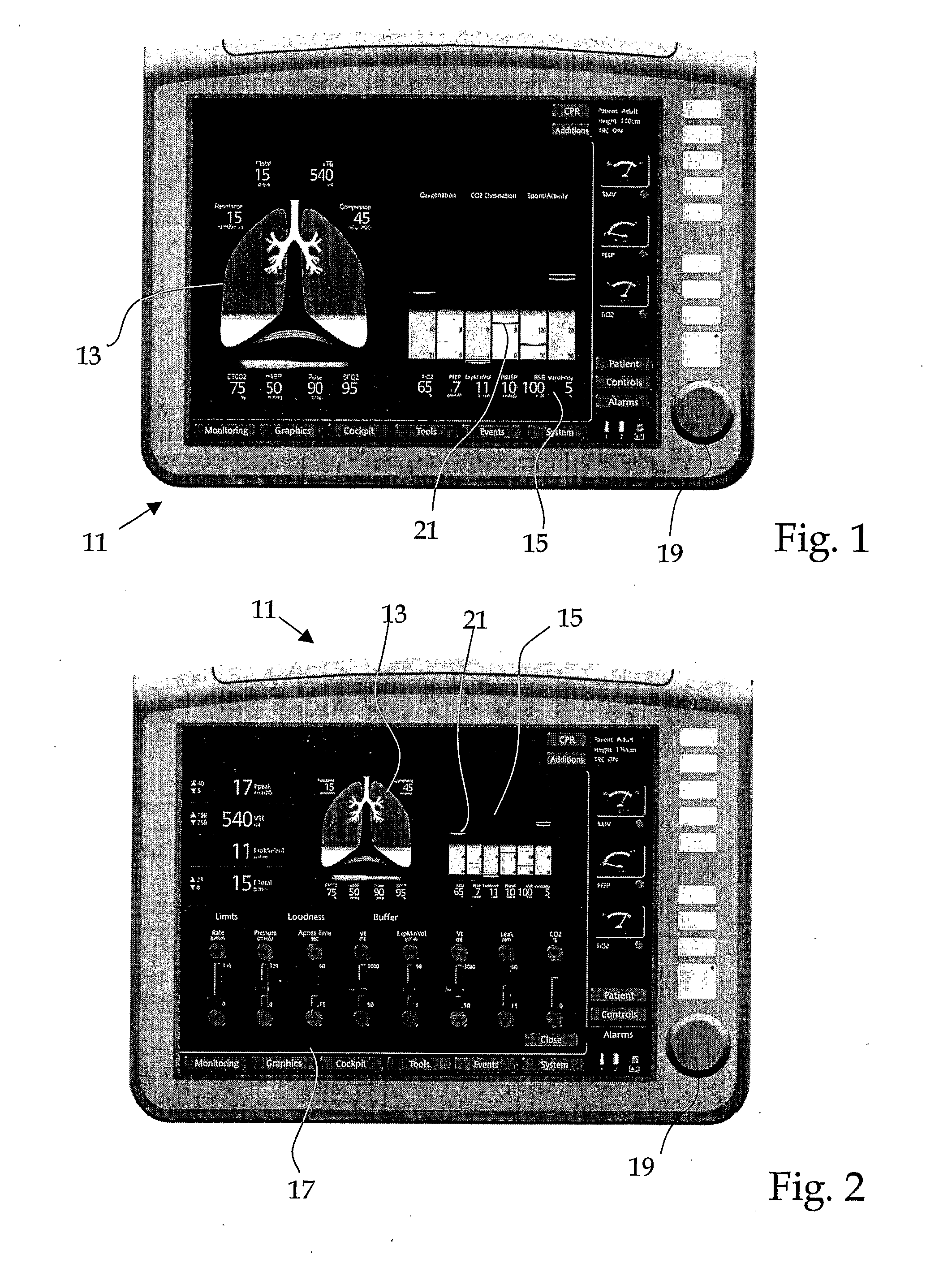

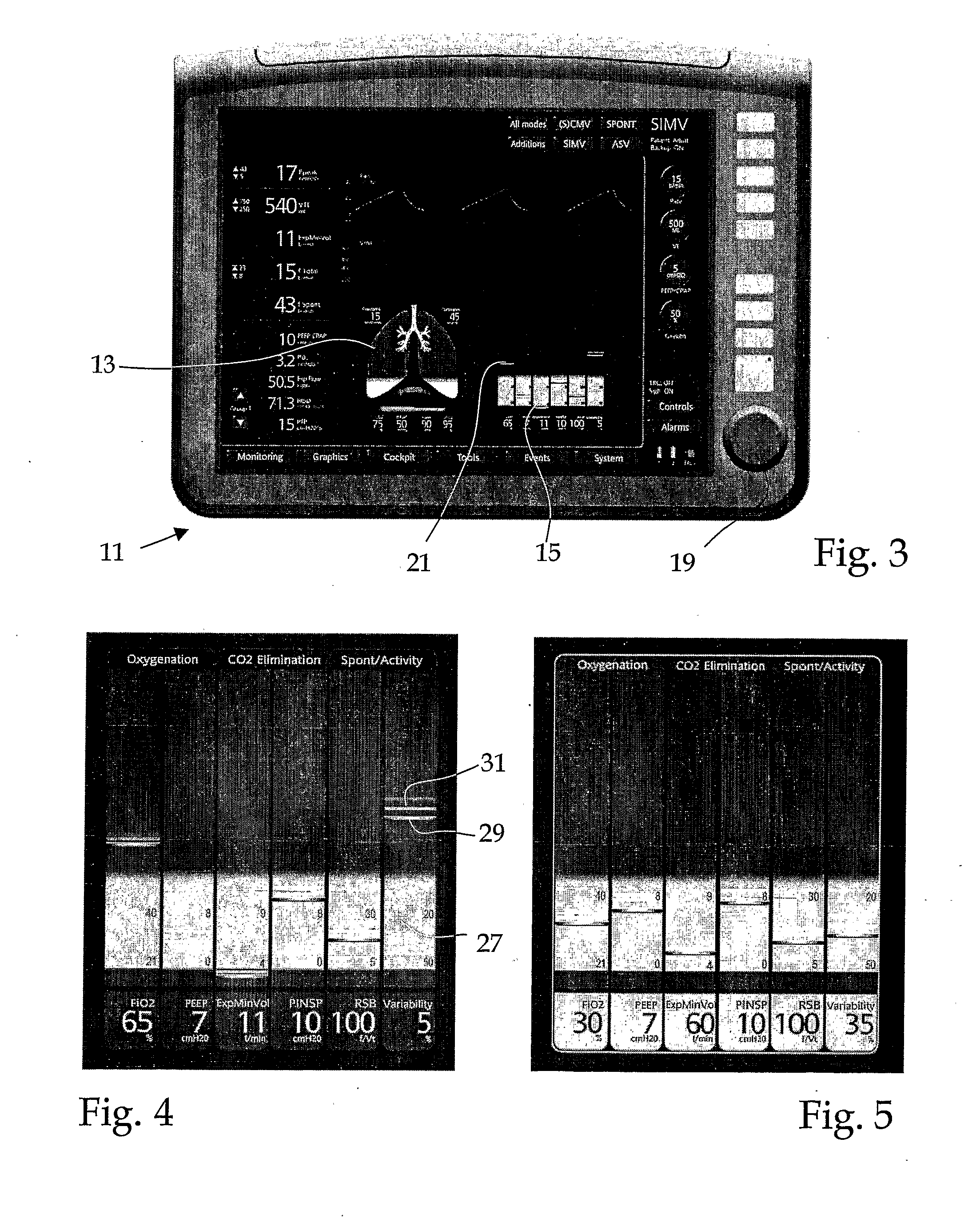

Method and a device for simplifying a diagnostic assessment of a mechanically ventilated patient

InactiveUS20090024008A1Increases intuitive readability of symbolImprove readabilityRespiratorsMedical devicesGraphicsAnimation

The invention relates to a method for acquiring several changing values and representing the acquired values on a monitoring screen, as well as to a device with a screen in order, on this, to represent changing values acquired during ventilation of the patient. The device comprises means for acquiring at least three changing values of different origin, and means for representing the values, which permit the acquired values to be qualitatively represented on the screen together in a single graphic element. This graphic element has a pictorial representation of a lung shape. The invention is characterised in that the means for representing the values are designed such that a volume change of the ventilated lung which is detected within each breath, is represented in an animated manner by way of size change of the lung shape corresponding to this corresponding volume change.

Owner:HAMILTON MEDICAL AG

Instrumentation

InactiveUS20050063055A1Optimize timingQuickly assimilatedCathode-ray tube indicatorsIndication of measured valuesComputer scienceInstrumentation

Owner:APTIV TECH LTD

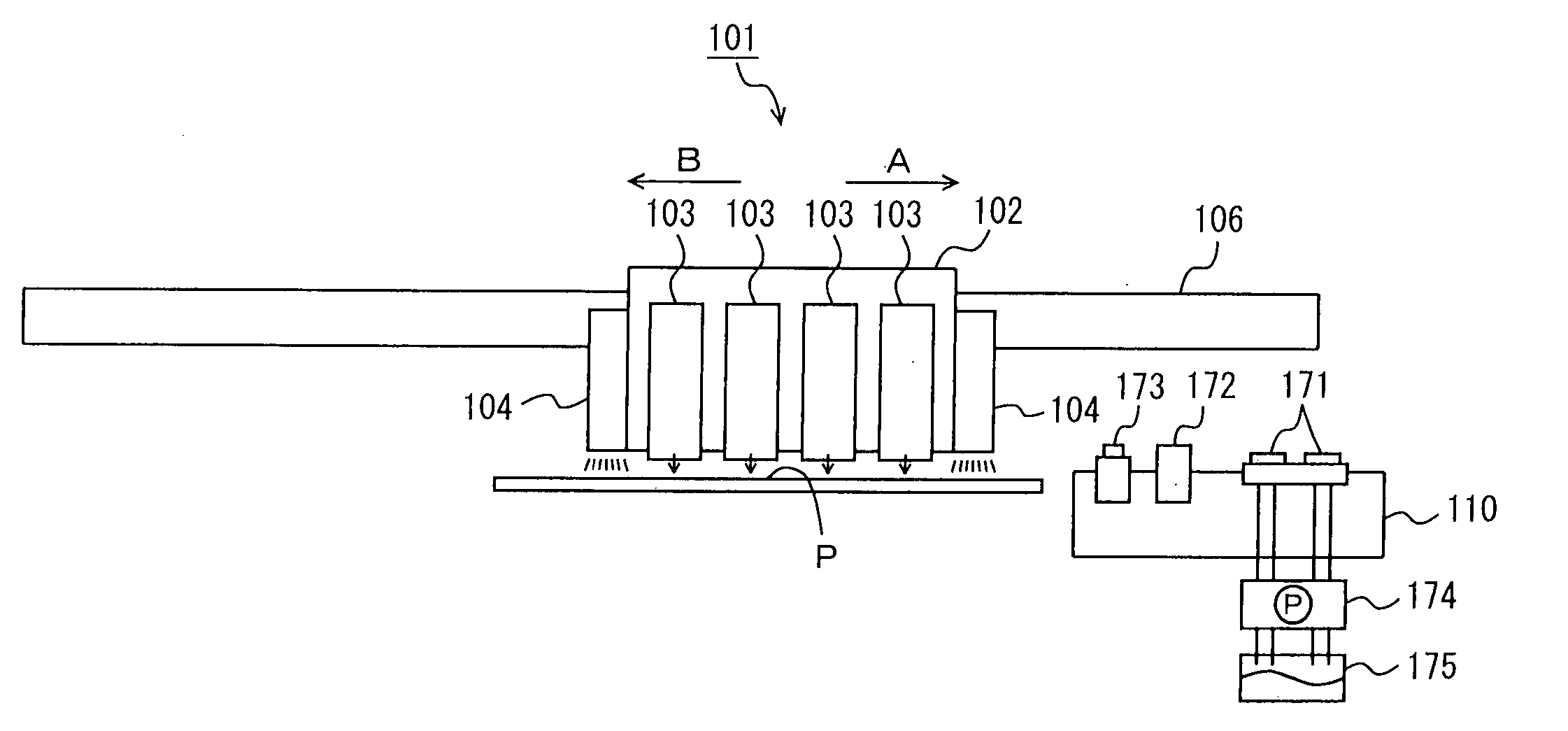

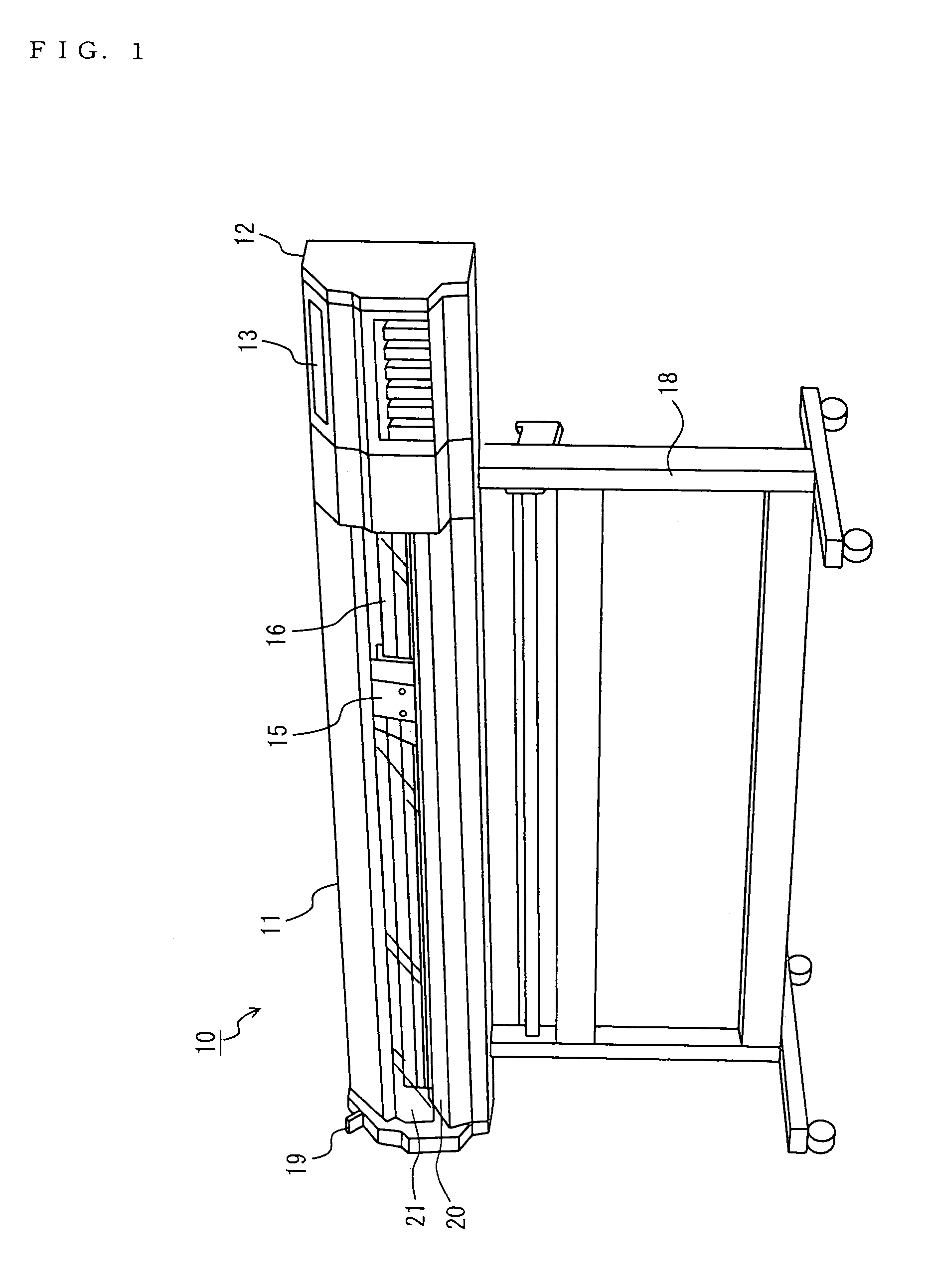

Ink jet printer

ActiveUS20050099478A1Start fastSolution to short lifeOther printing apparatusUltraviolet lightsInk printer

An ink jet head of an ink jet printer comprises an ink jet nozzle ejecting ultraviolet curing ink, a pair of ultraviolet LEDs provided on both sides of the ink jet nozzle in the moving direction for emitting ultraviolet light in order to cure the ultraviolet curing ink.

Owner:ROLAND DG CORP

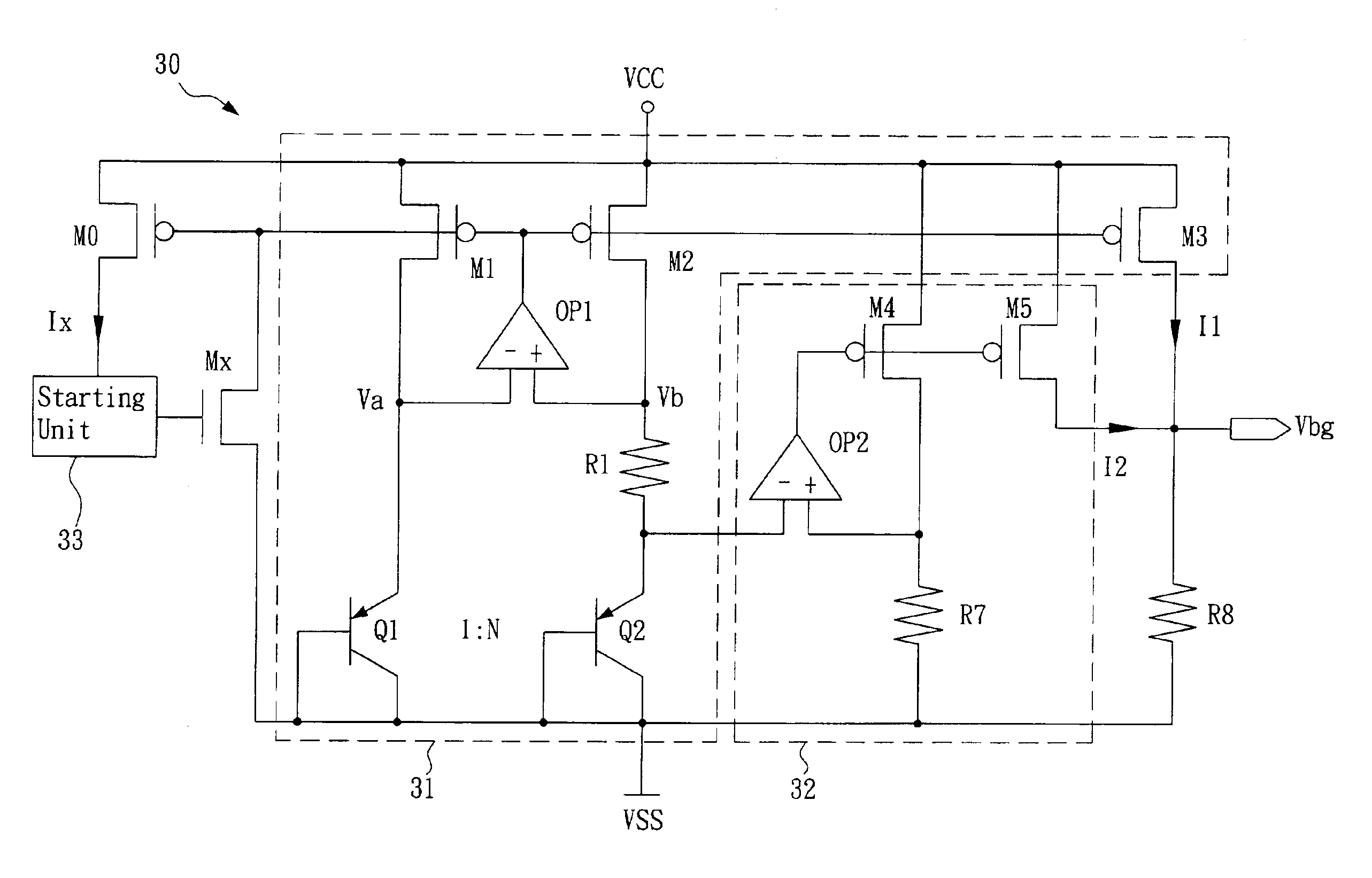

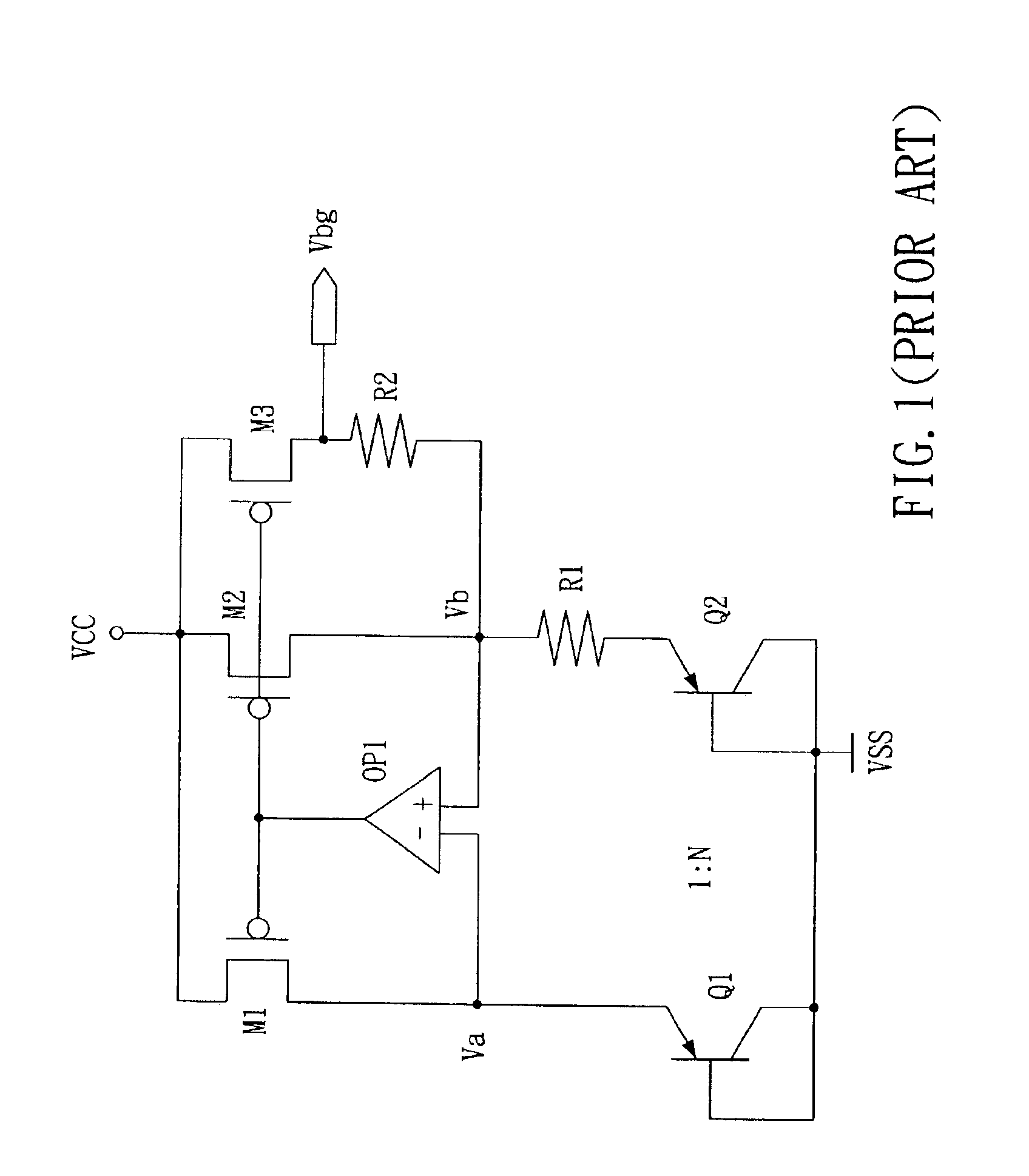

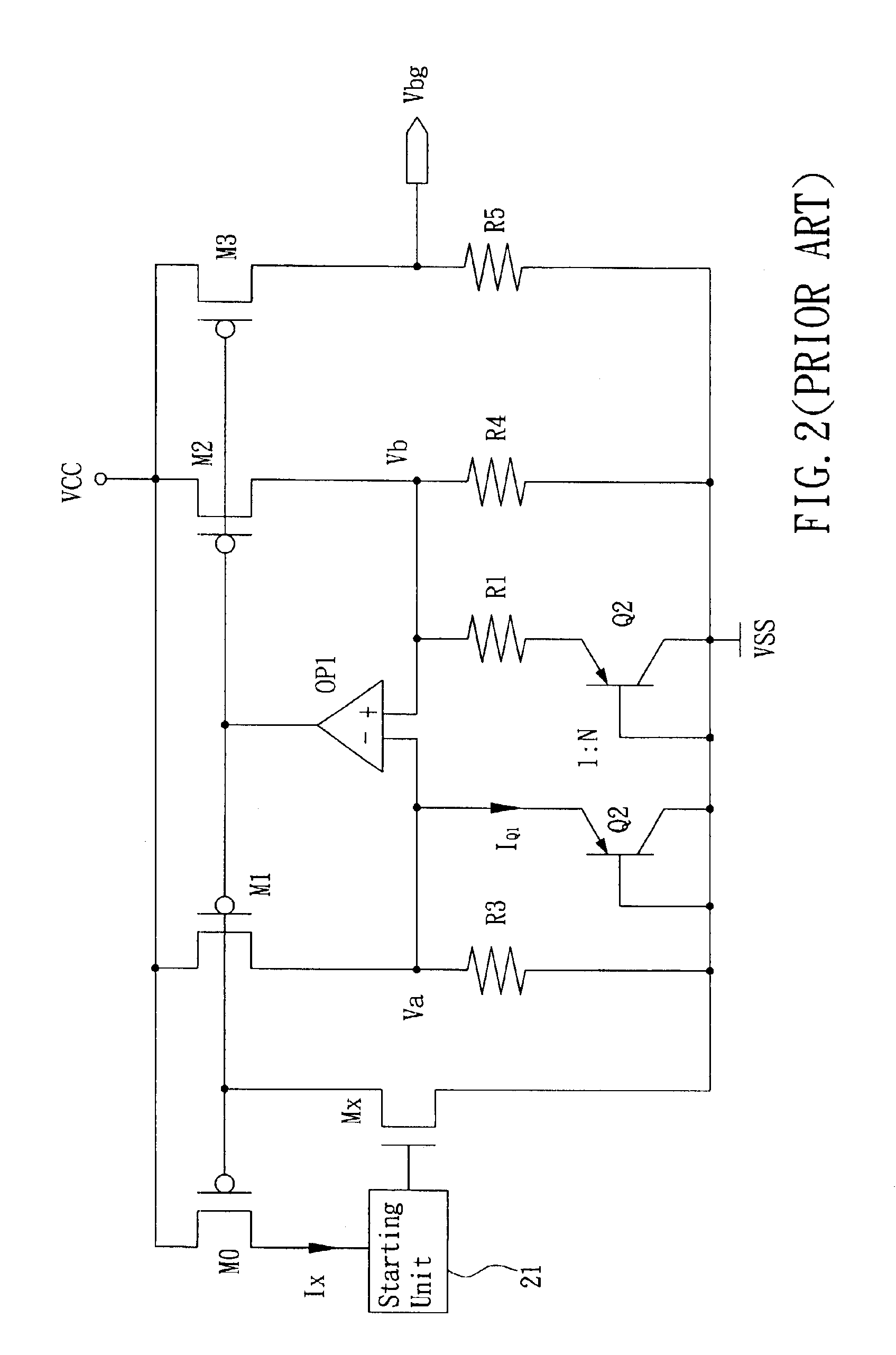

Fast start-up low-voltage bandgap voltage reference circuit

A fast start-up low-voltage bandgap voltage reference circuit is disclosed. The bandgap voltage reference circuit includes: a first current generator, which is implemented by a self-bias unit and a current mirror for generating a first reference current with positive temperature coefficient; a second current generator, which is connected to a point with negative temperature coefficient in the first current generator to generate a second reference current with negative temperature coefficient; and a resistor for converting the first reference current and the second reference current into a low-voltage bandgap voltage independent of temperature. Because the bandgap voltage reference circuit of the invention uses the resistor to convert the first reference current and the second reference current into voltage, the circuit can provide low-voltage bandgap voltage.

Owner:REALTEK SEMICON CORP

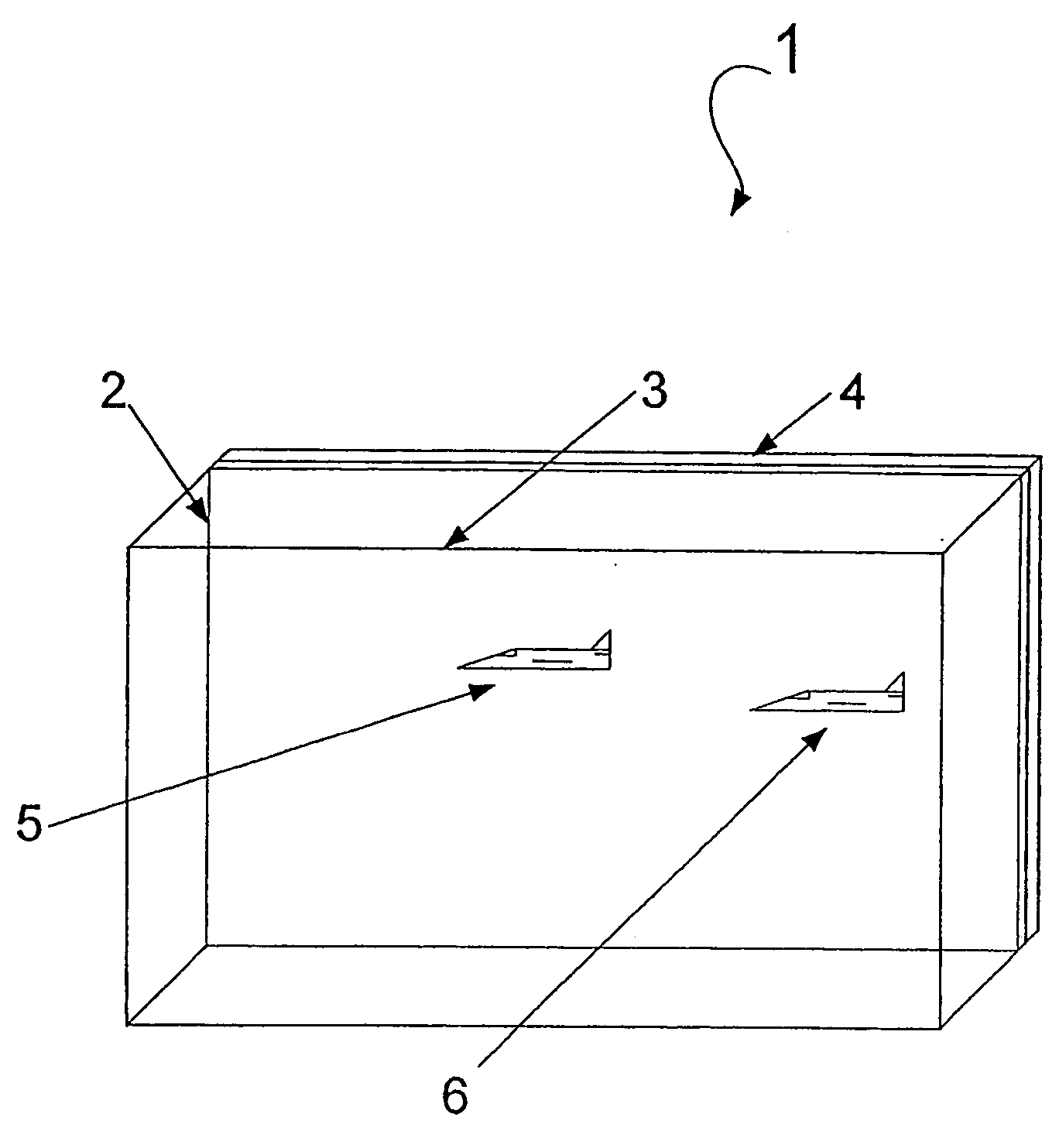

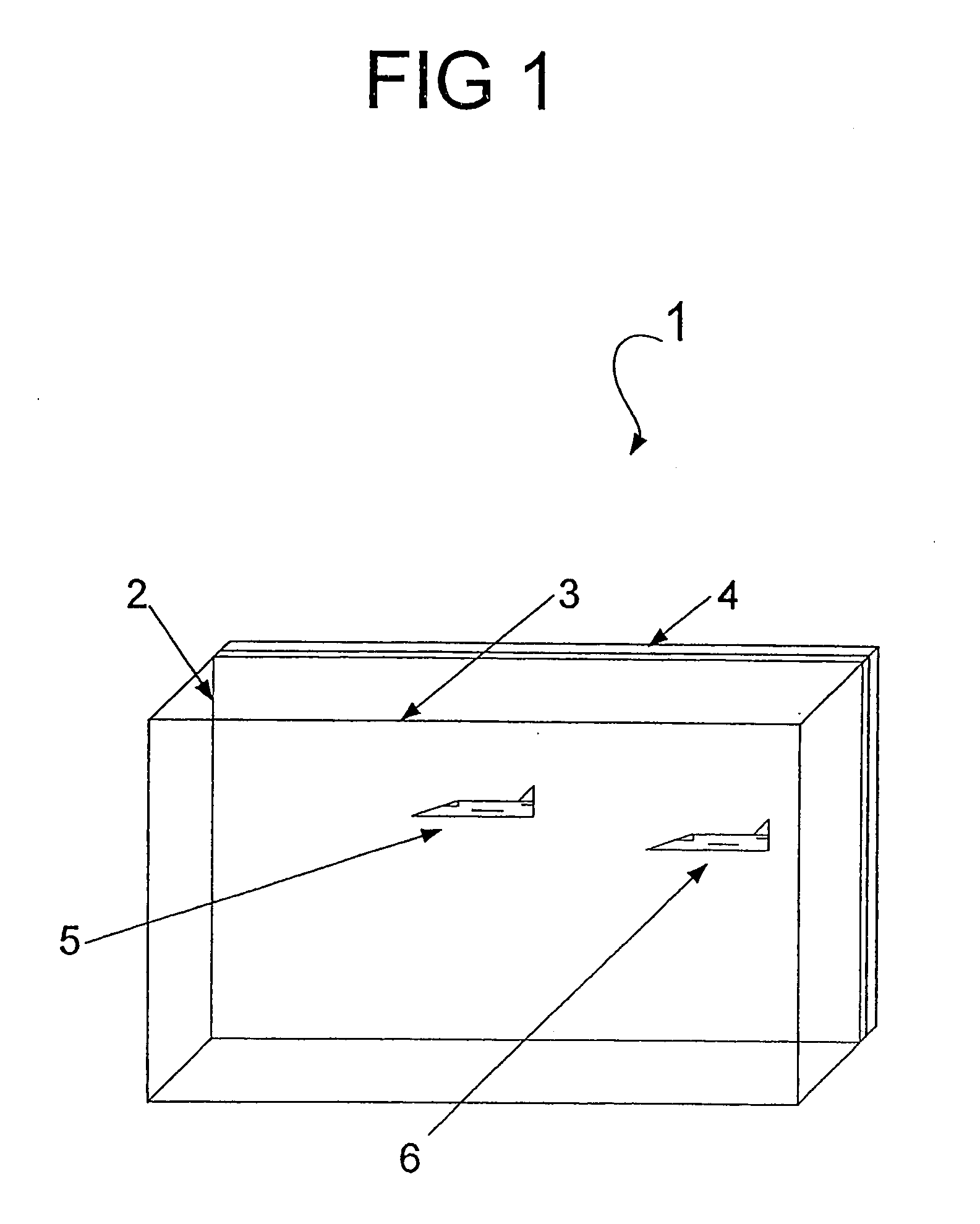

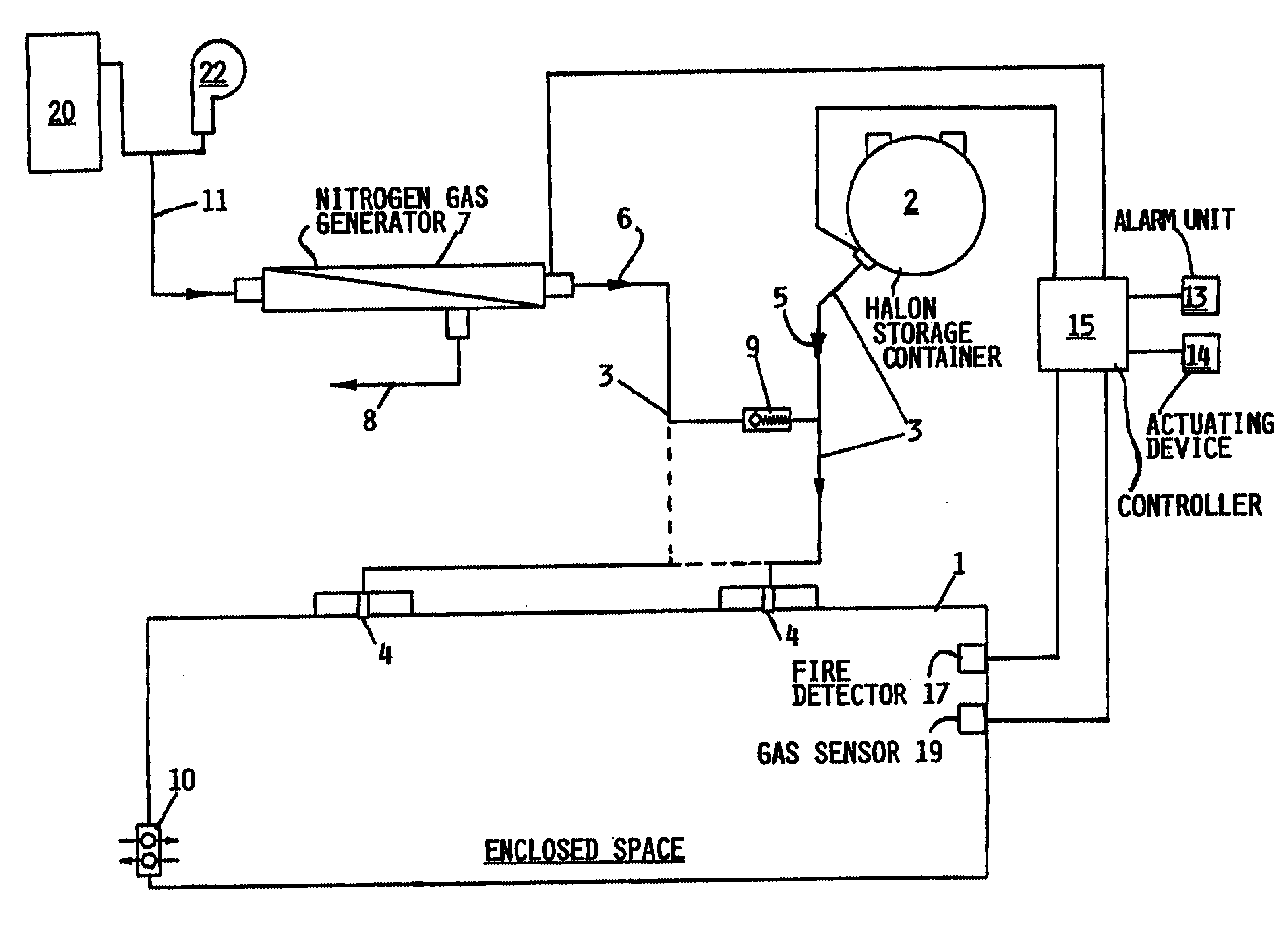

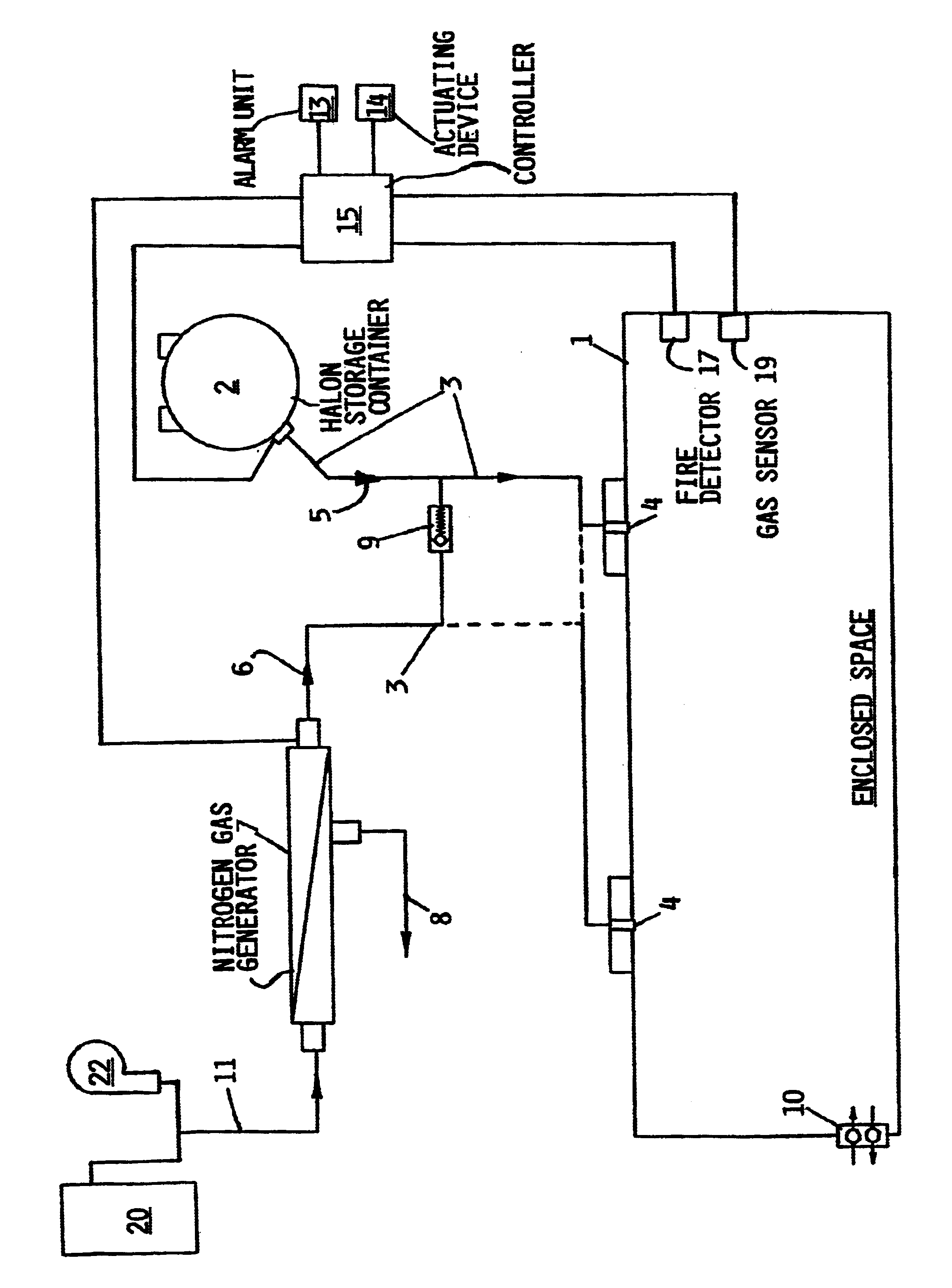

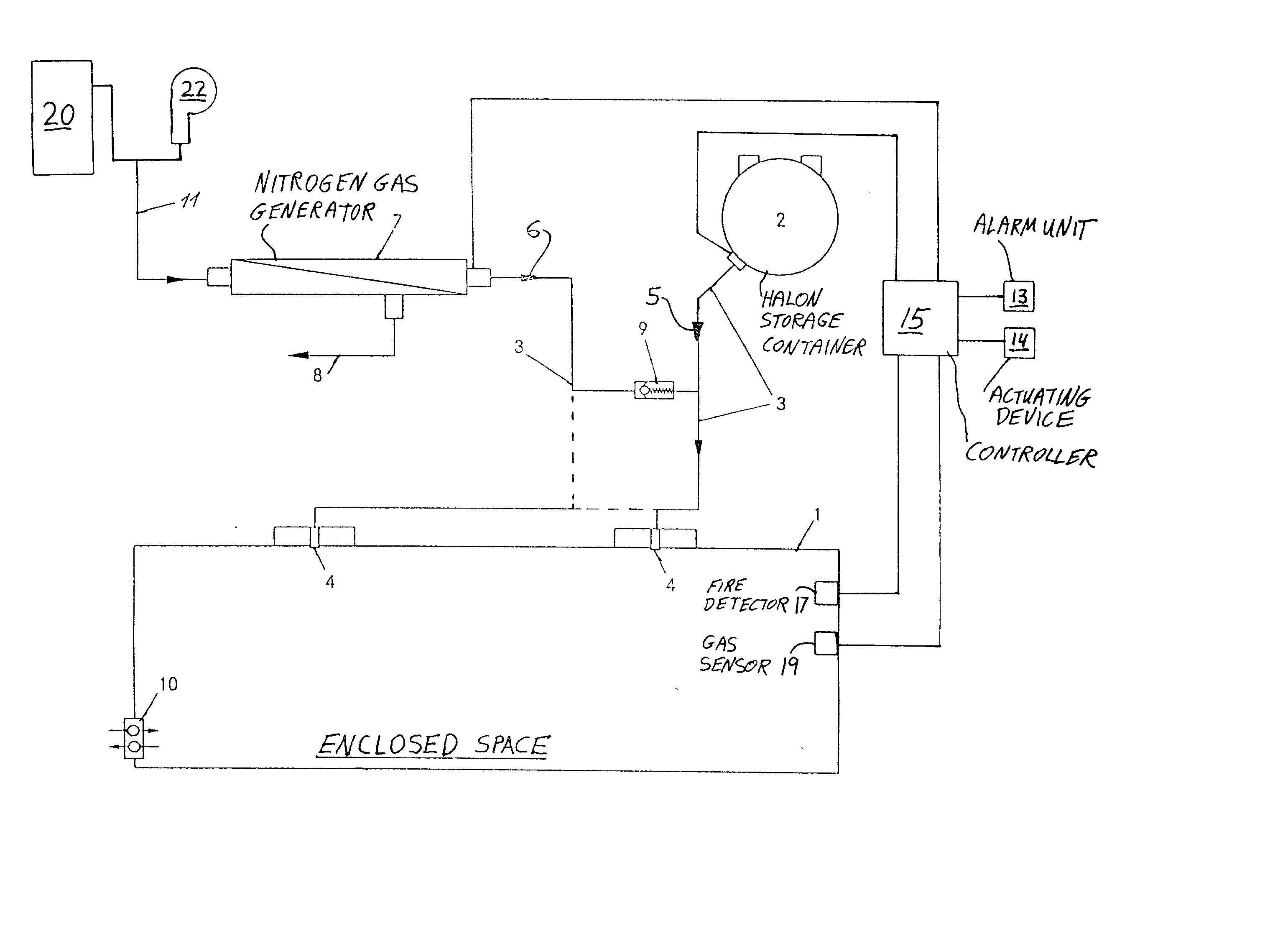

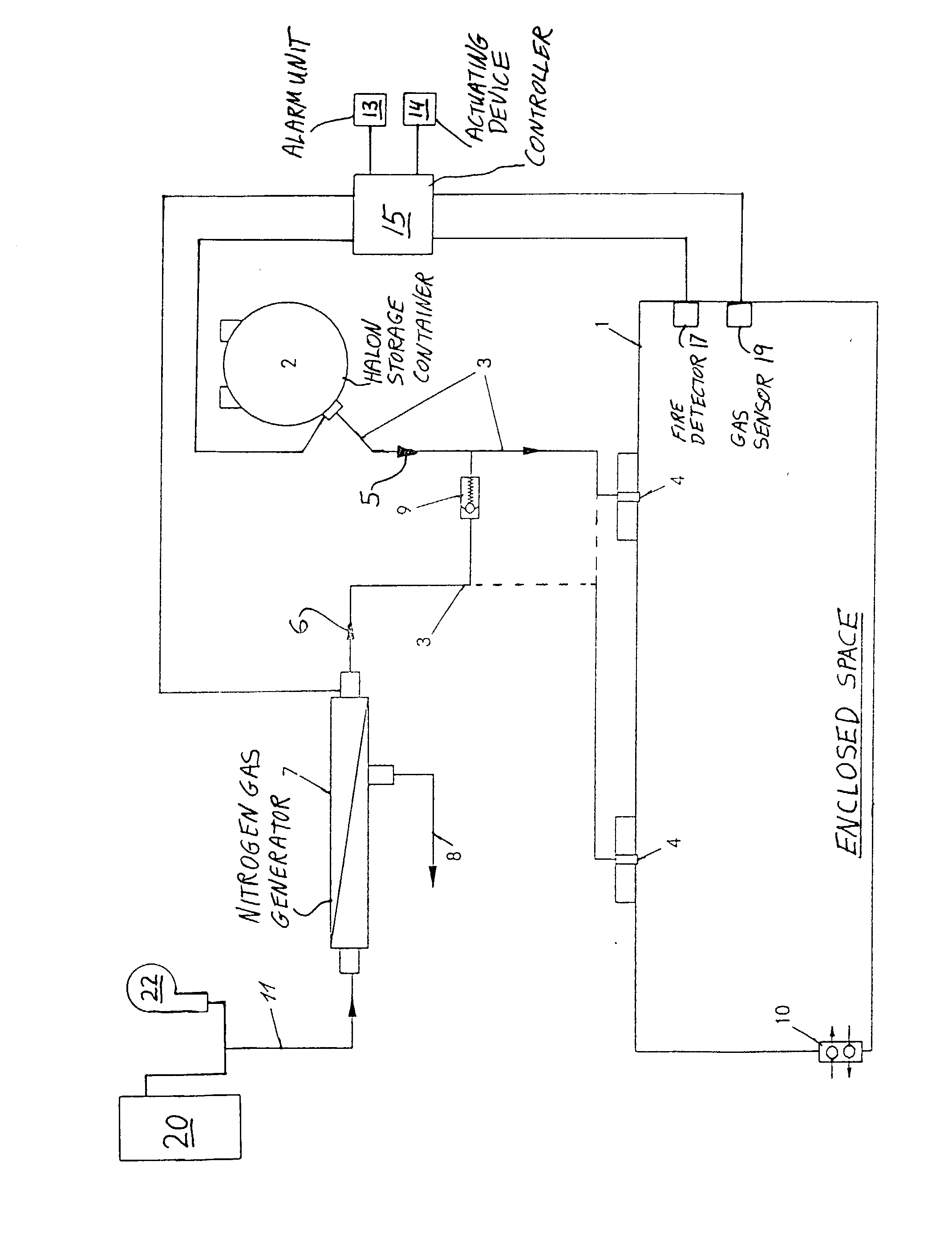

System for extinguishing and suppressing fire in an enclosed space in an aircraft

InactiveUS6676081B2Rapidly extinguishedInitial flame knockdown or extinguishing of the fire rather quicklyFire rescueEmergency apparatusMolecular sieveNitrogen generator

A system for extinguishing and suppressing a fire in an enclosed space includes a Halon storage container and a nitrogen generator that are both connected by a duct system to extinguishing nozzles arranged in the enclosed space. Halon is supplied as a first extinguishing agent from the container to achieve a rapid initial extinguishing of the fire. Nitrogen enriched air is supplied as a second extinguishing agent from the nitrogen generator to achieve a continuous long-term fire suppression, commencing simultaneously with or after the introduction of the Halon. The nitrogen generator may include a molecular sieve to continuously generate the nitrogen enriched air from an inlet flow of environmental air.

Owner:AIRBUS OPERATIONS GMBH

Ink jet printer

ActiveUS7232212B2Start fastSolution to short lifeOther printing apparatusUltraviolet lightsEngineering

An ink jet head of an ink jet printer comprises an ink jet nozzle ejecting ultraviolet curing ink, a pair of ultraviolet LEDs provided on both sides of the ink jet nozzle in the moving direction for emitting ultraviolet light in order to cure the ultraviolet curing ink.

Owner:ROLAND DG CORP

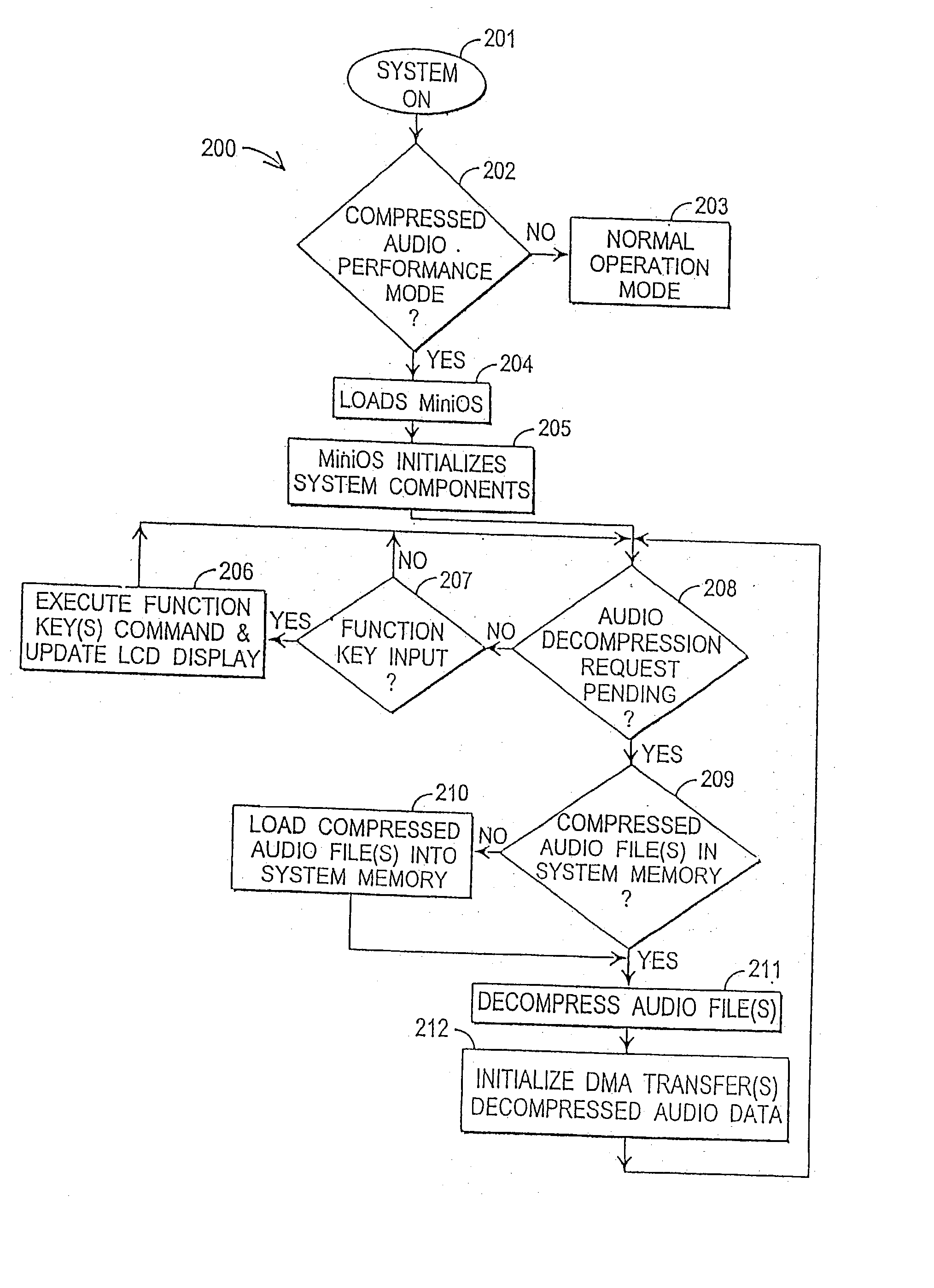

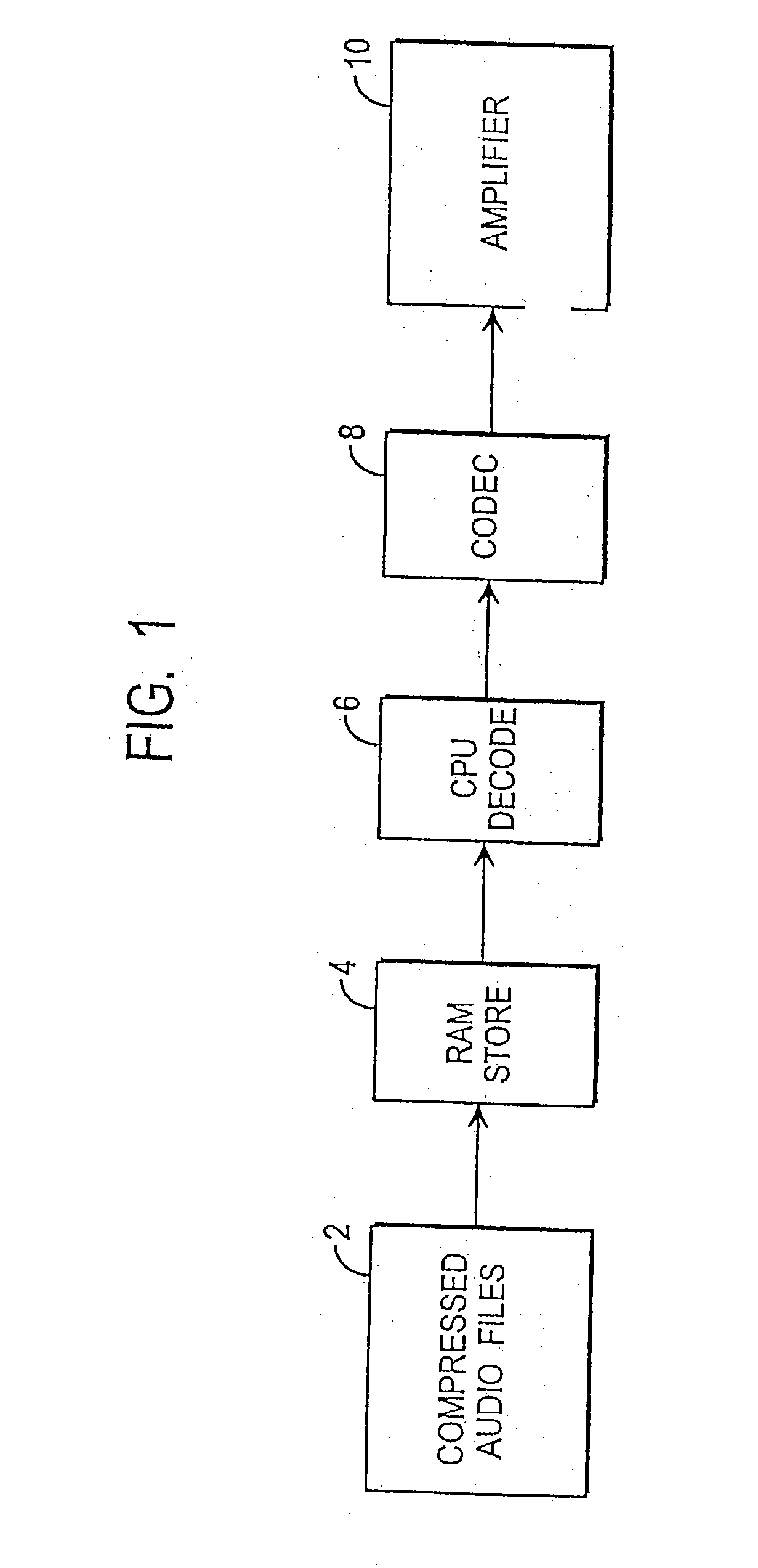

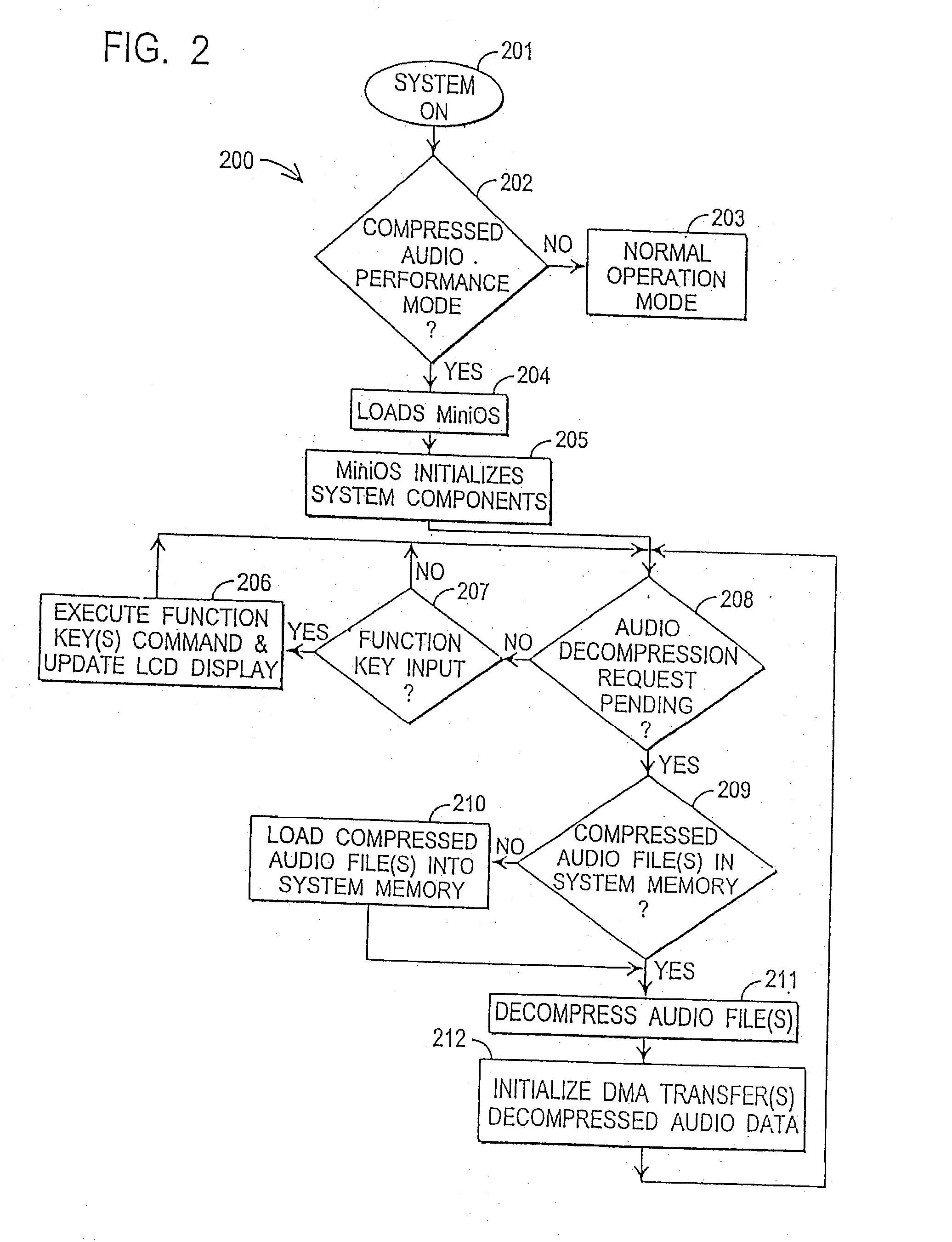

Low power digital audio decoding/playing system for computing devices

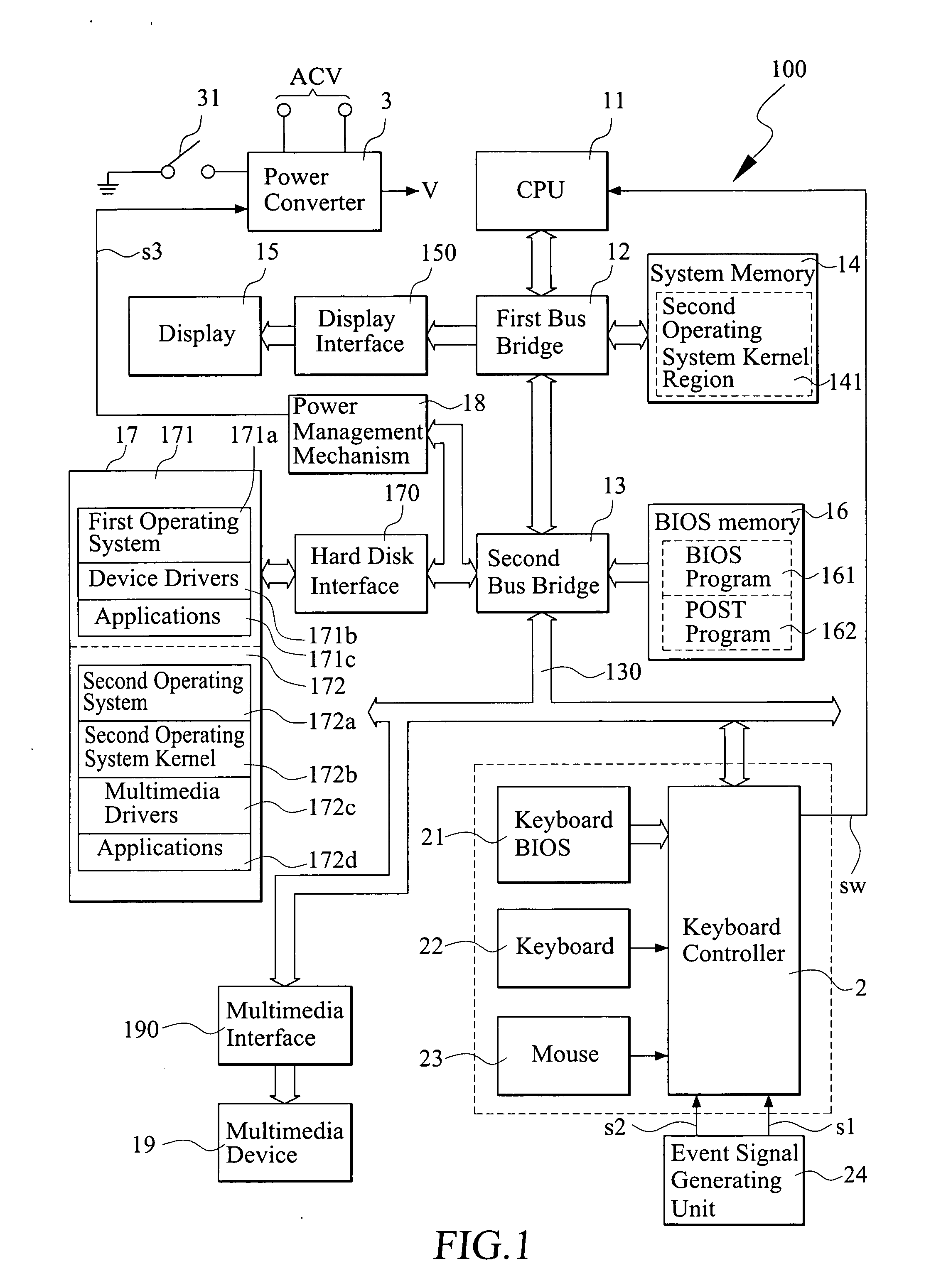

InactiveUS20040006690A1Start fastDigital computer detailsRecord information storageOperational systemControl signal

A computer system includes a system CPU responsive to a control signal to load a first operating system or a second operating system. The first operating system is run by the computer system in a first operation mode and the second operating system is run by the computer system in a second entertainment mode. A PC operating in an entertainment mode may operate a variety of entertainment software applications. A quick boot process is also provided. The quick boot process may include an accelerated BIOS boot process that defers and delays appropriate tasks. The quick boot process may also include: detecting a condition; performing a BIOS boot process; loading an image file associated with the condition; and executing the image file associated with the condition. The condition may be that associated hardware is unchanged from a previous boot. A parental control system is also disclosed.

Owner:MAISHI ELECTRONICS (SHANGHAI) LTD

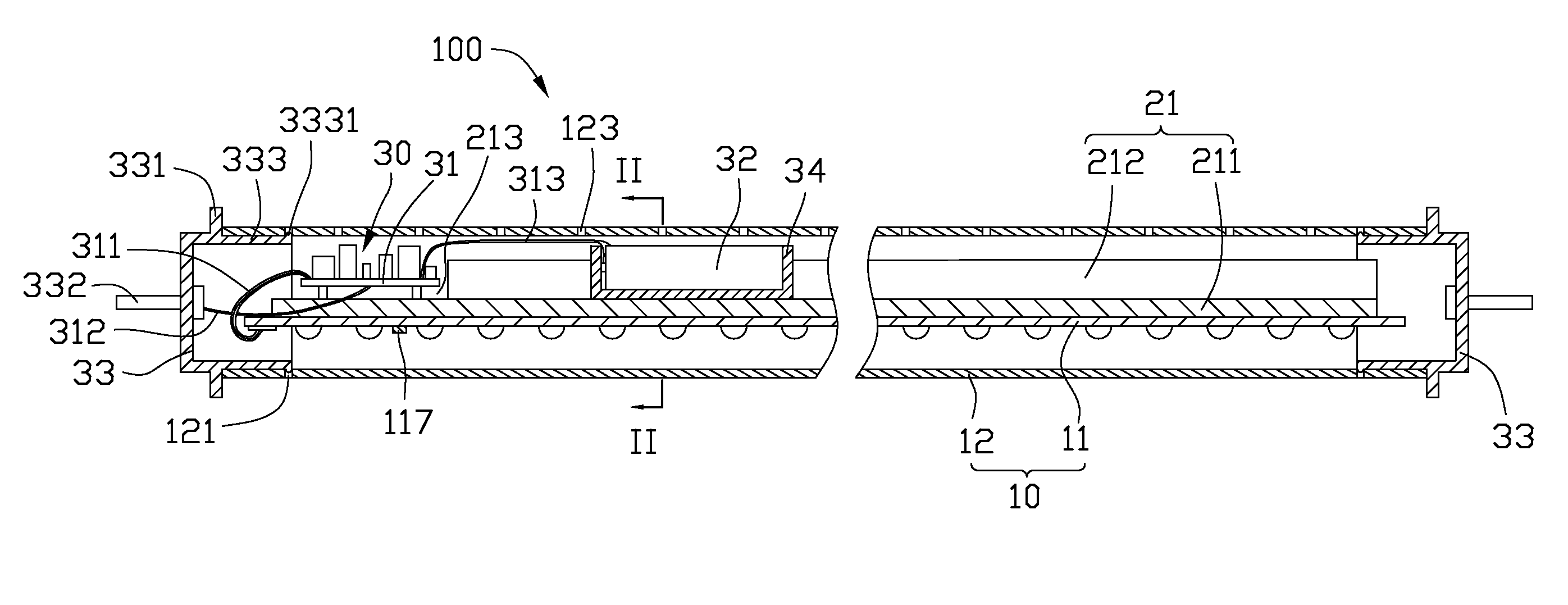

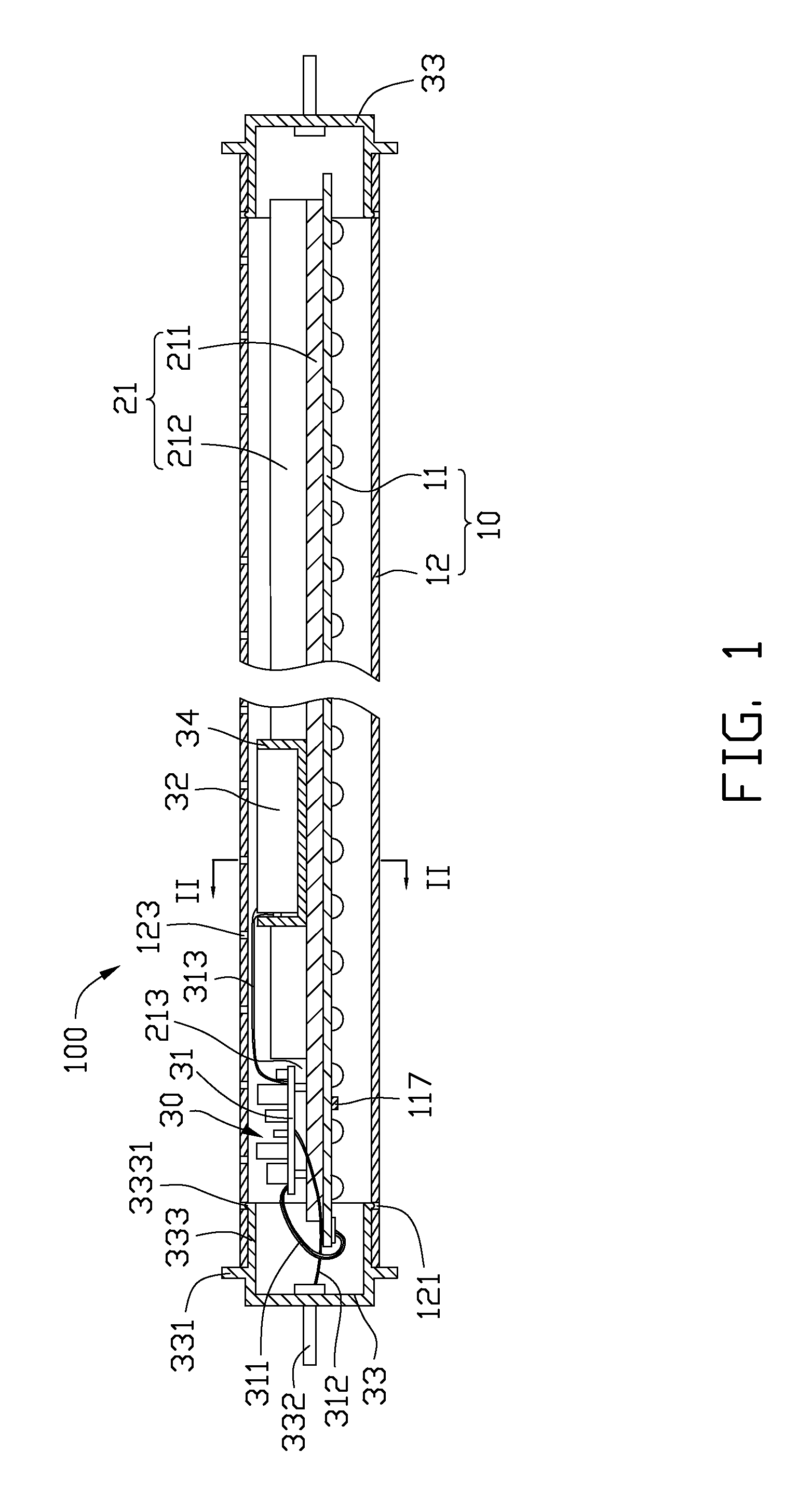

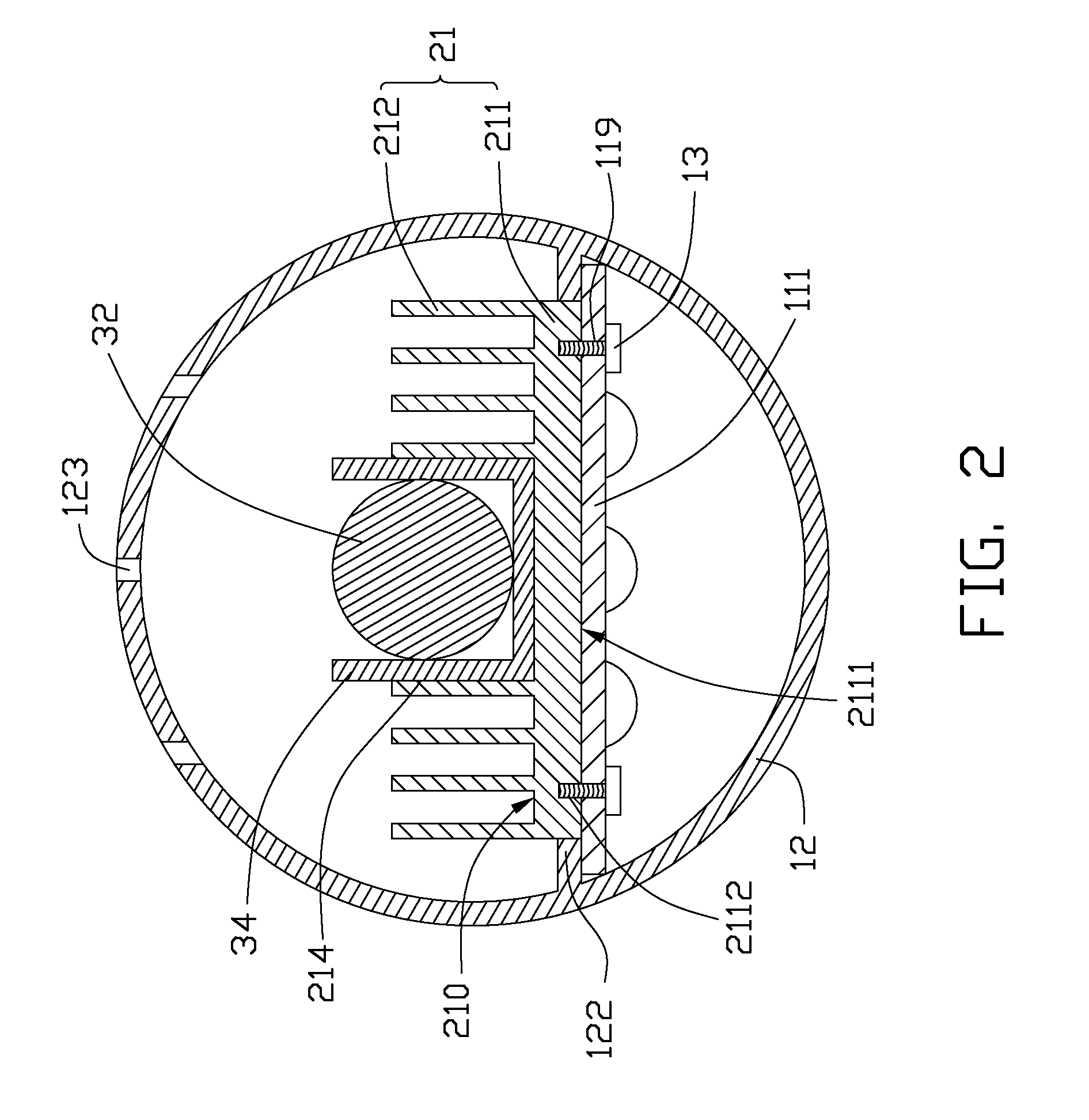

LED lamp

InactiveUS20110084554A1Reduce power consumptionIncrease brightnessPlanar light sourcesBatteries circuit arrangementsRechargeable cellEngineering

An LED lamp includes an optical part, a heat dissipation member and an electric part. The optical part includes a hollow light penetrable tube and an LED module received in the tube. The heat dissipation member is received in the tube to mount the LED module thereon. The electric part include a circuit board and a rechargeable battery arranged in the tube, and two end covers arranged at two opposite ends of the tube. The LED module is provided with at least one first LED and at least one second LED. The at least one first LED and the at least one second LED cooperatively function as a main light source to provide normal illumination when an external AC power source is supplied normally. The at least one second LED independently function as an auxiliary light source to provide emergency illumination when the external AC power source is interrupted.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

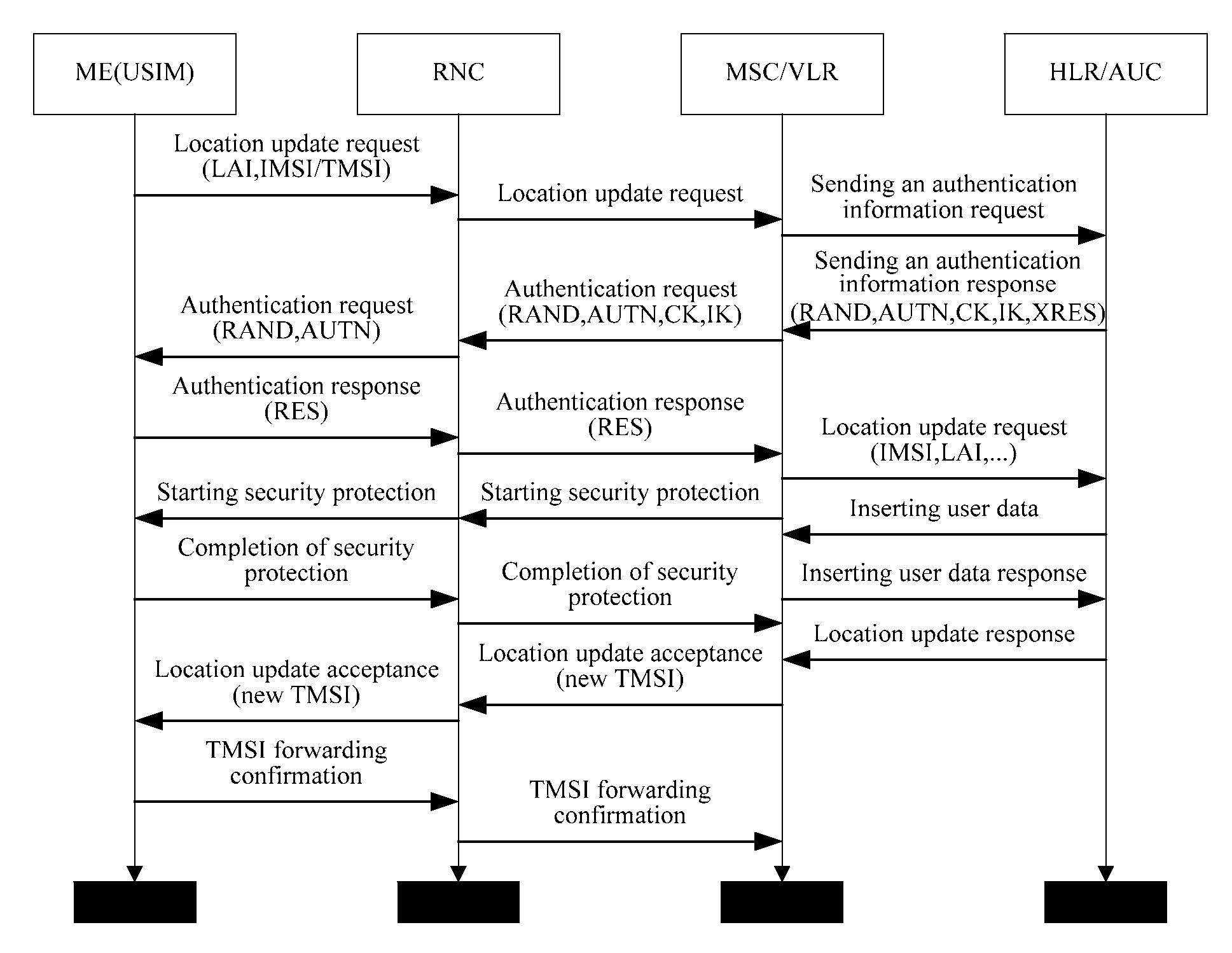

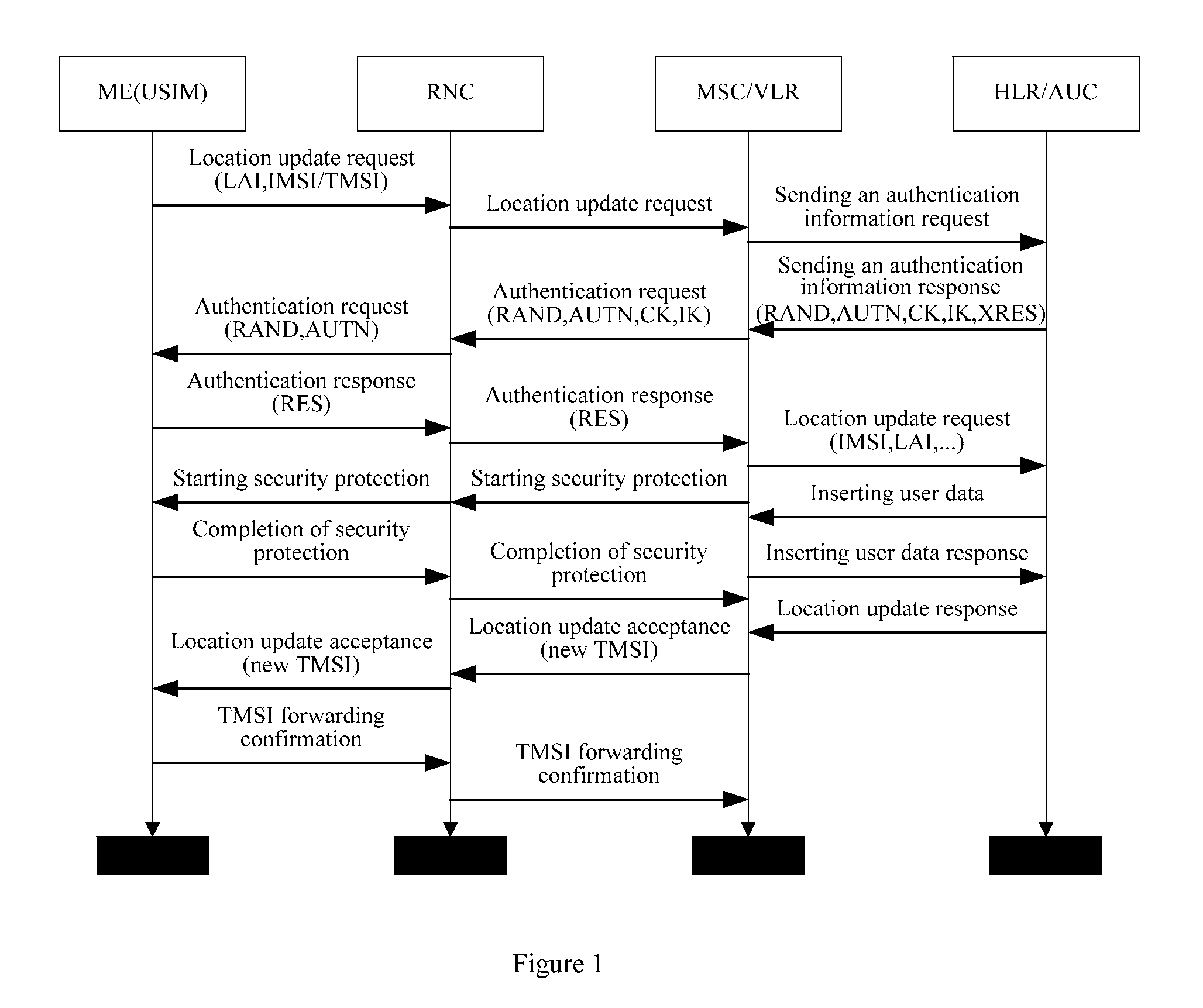

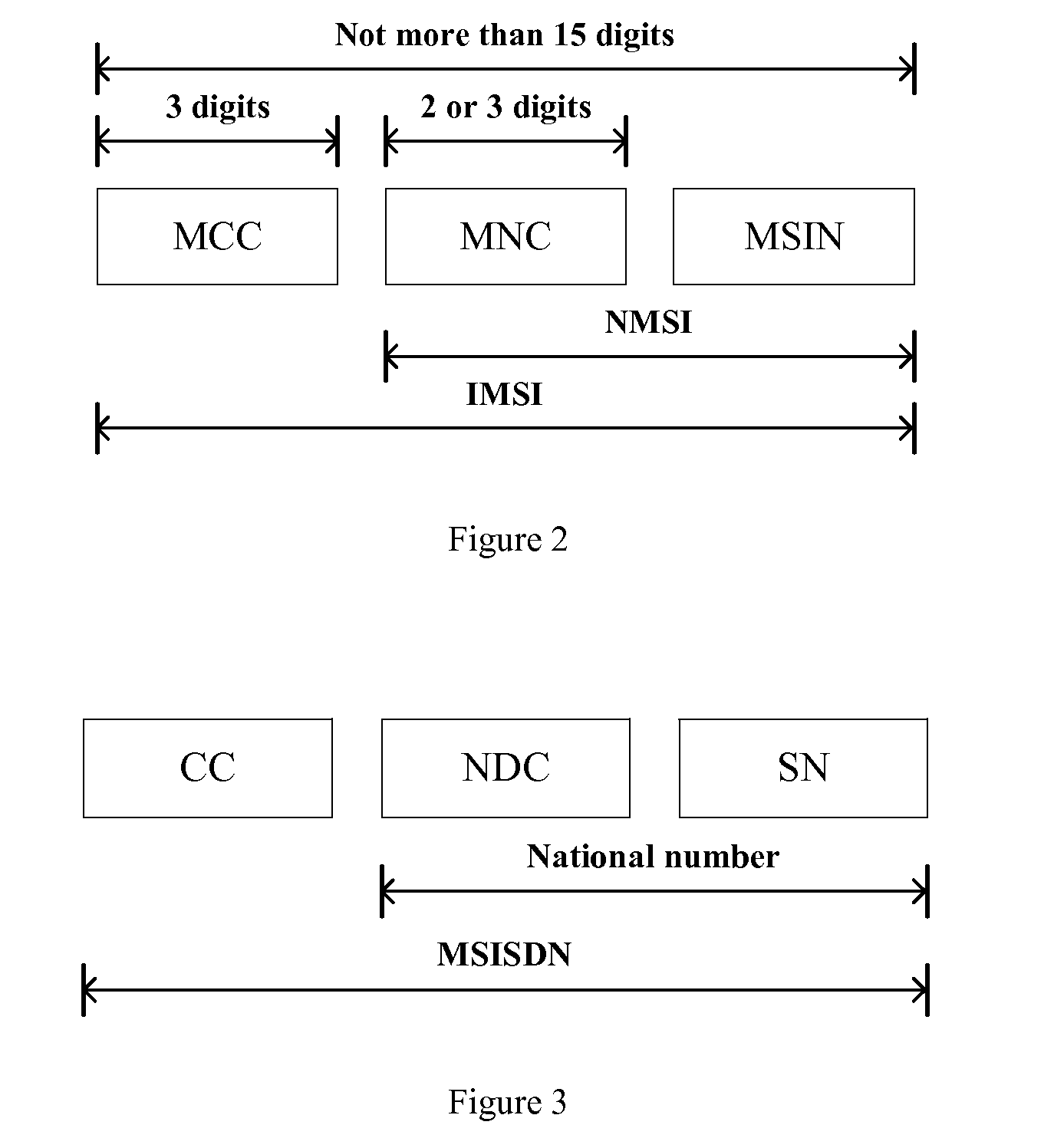

System and apparatus for mobile cs users to access IMS network and registration method for accessing

ActiveUS20090093249A1Reduce operating costsEasy networkingWireless network protocolsWireless commuication servicesAccess network

The present invention provides a system and apparatus for a mobile CS user to access an IMS network and a registration method for accessing. The network under the present invention comprises an IMS network for providing IMS services and a CS access network. The network contains a Register Proxy Function (RPF) entity, which comprises a first interface for communicating with the IMS network and a second interface for communicating with the CS access network. The RPF entity is adapted to map a CS registration event which is originated by the mobile CS user through the second interface to an IMS registration event, and initiate registration to the IMS network through the first interface on behalf of the mobile CS user. The technical solution under the present invention enables a mobile CS user to be registered to an IMS network practicably so that the CS user can enjoy rich IMS services.

Owner:HUAWEI TECH CO LTD

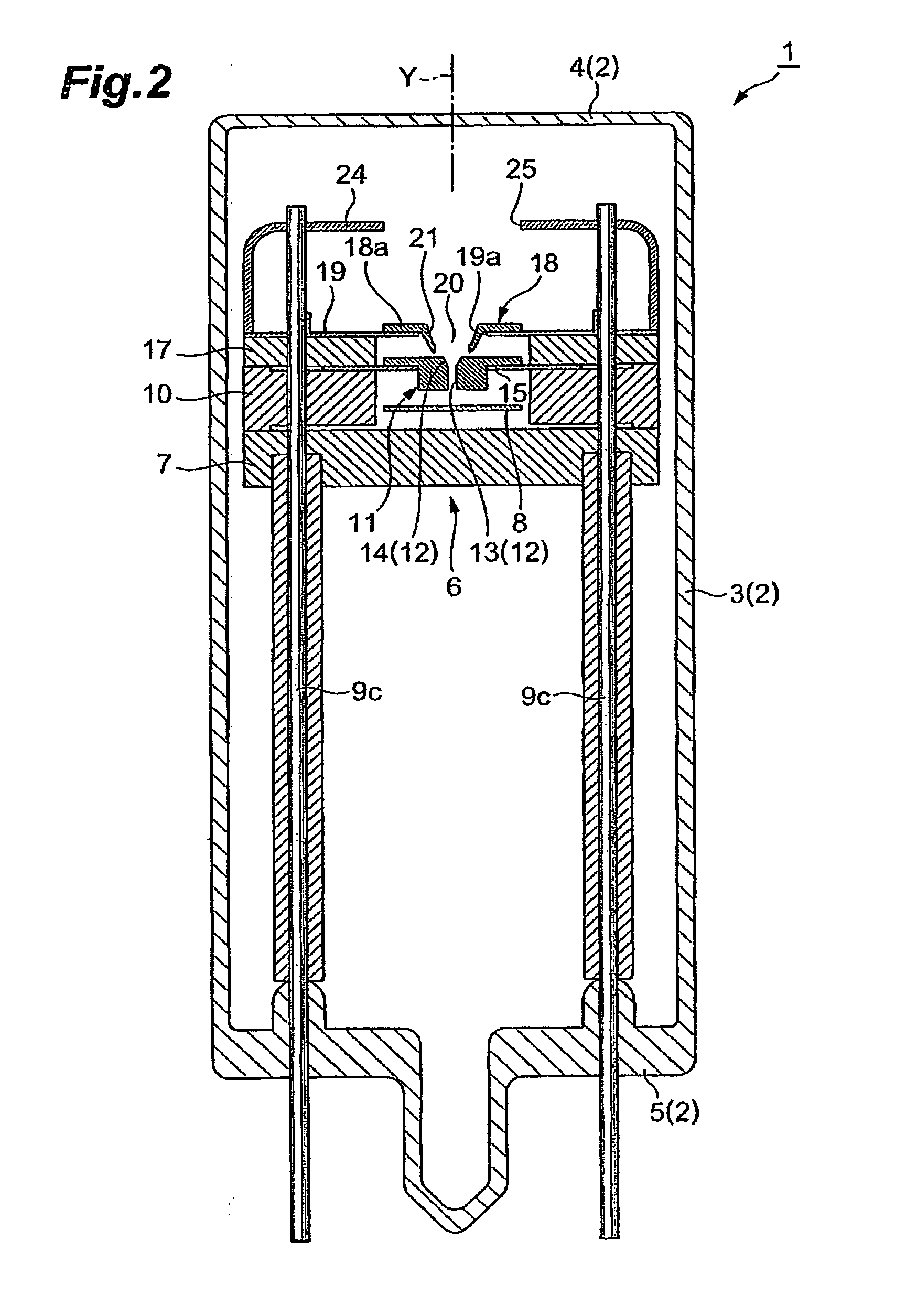

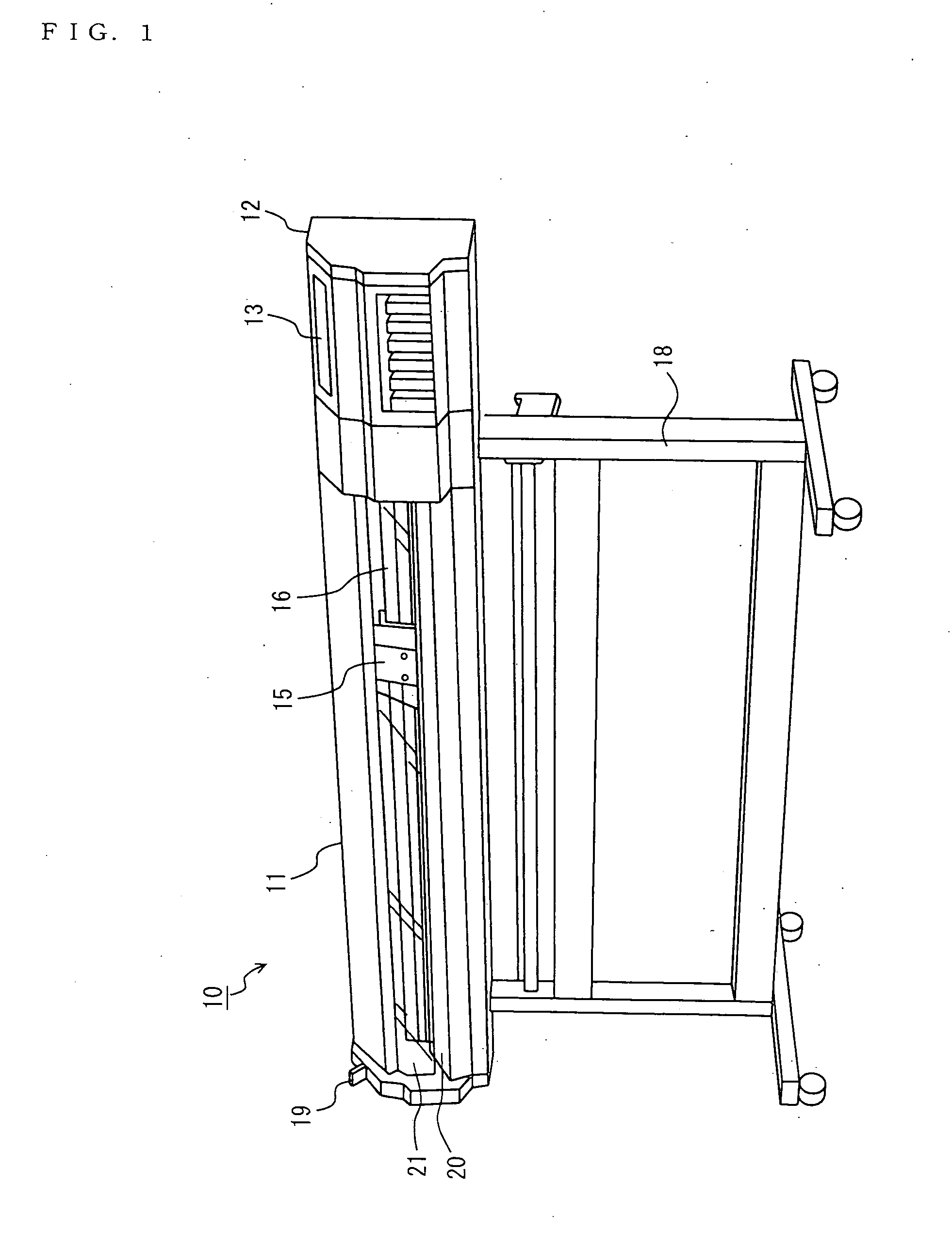

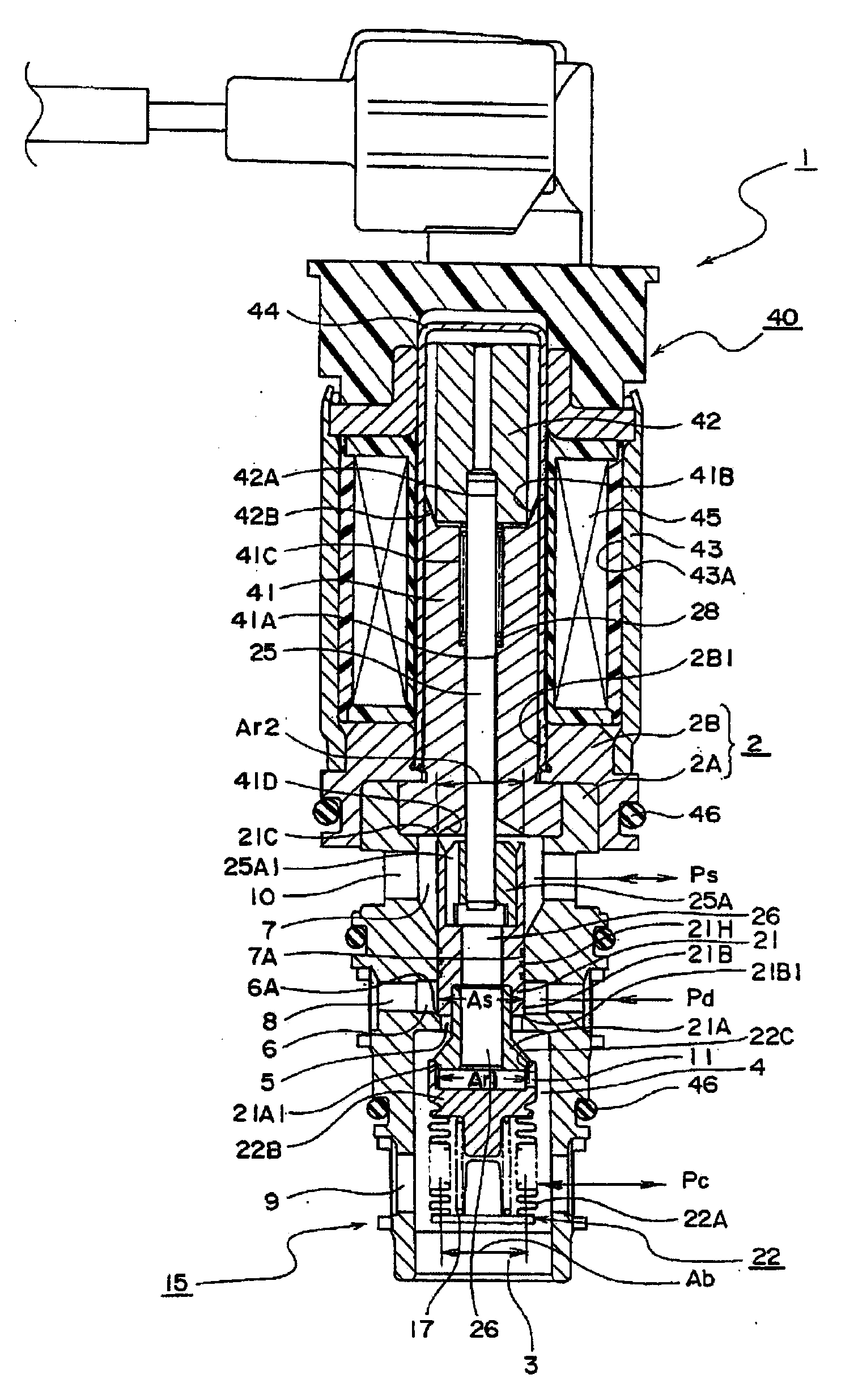

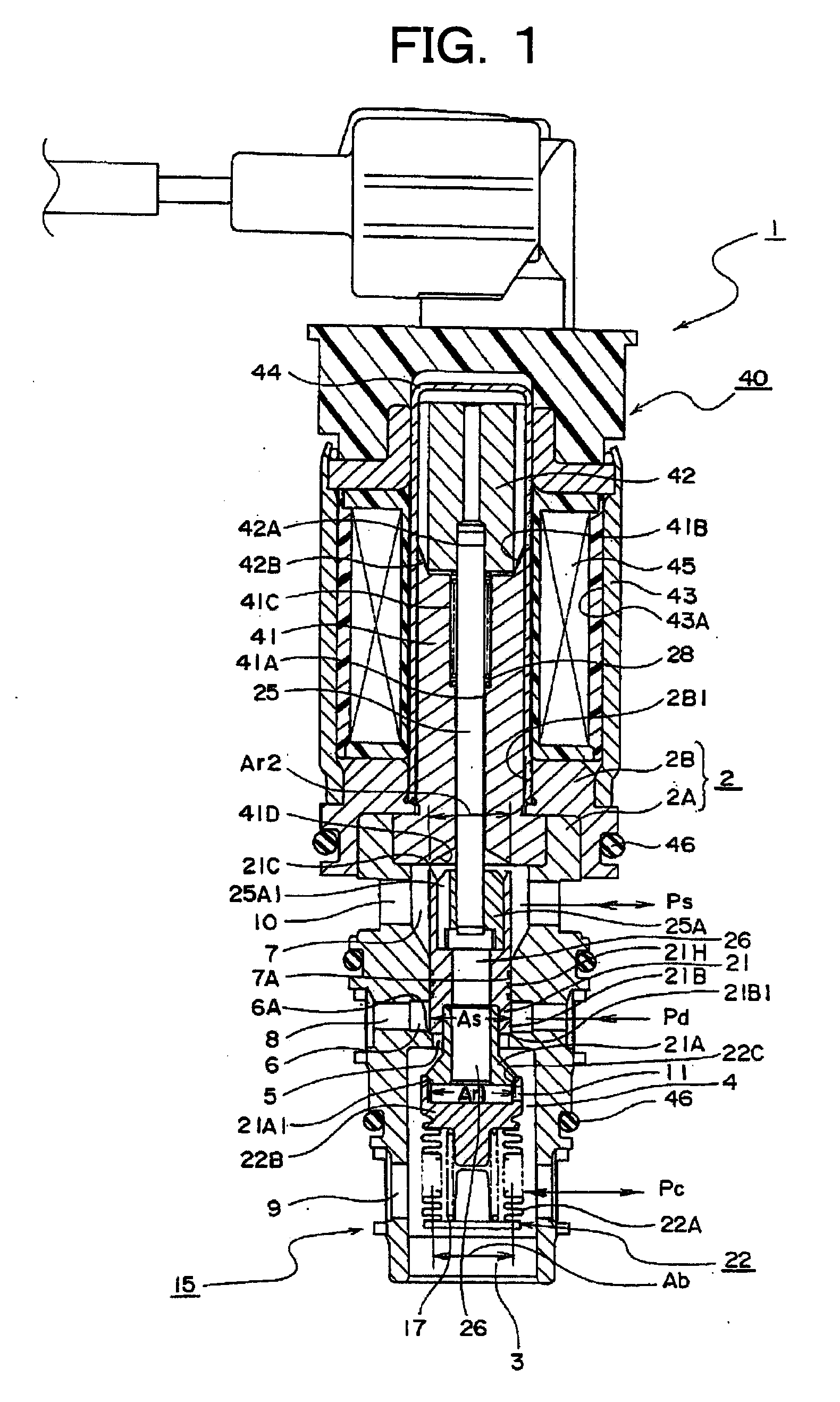

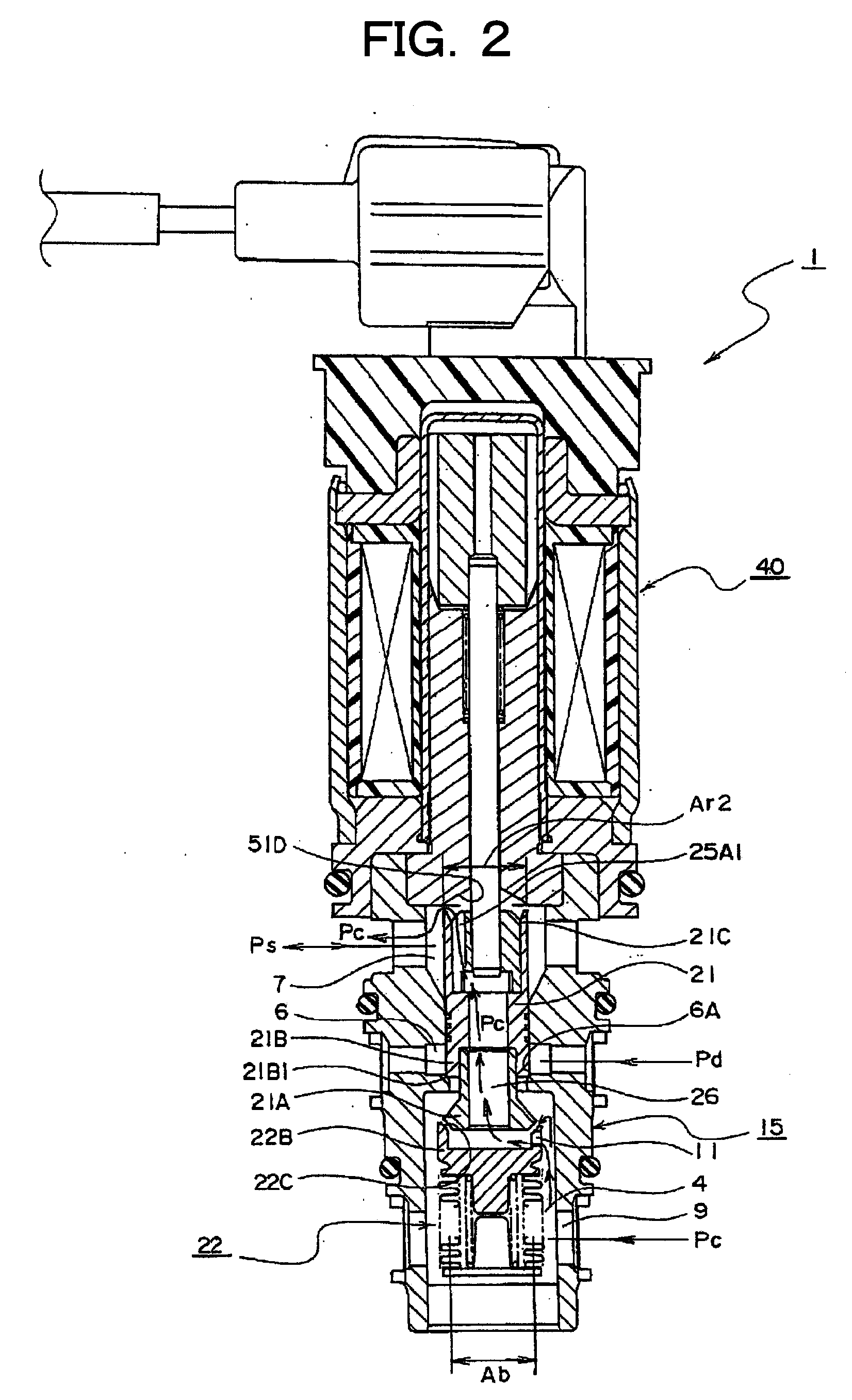

Displacement Control Valve

ActiveUS20090183786A1Reduce manufacturing costStart fastOperating means/releasing devices for valvesPipeline systemsPressure senseDisplacement control

The present invention comprising a valve main body having a first valve chamber, a second valve chamber and a third valve chamber, said first valve chamber communicating with a first communication passage, said second valve chamber having a second valve seat face for a valve hole and communicating with a second communication passage, said third valve chamber having a third valve seat face and communicating with a third communication passage; a valve body having a first valve member, a second valve member and a third valve member, said second valve member having a intermediate communication passage therein communicating with said first valve chamber and said third communication passage, said second valve member opening and closing a valve hole with respect to second valve seat face, thereby communicating with said first valve chamber and said second valve chamber, said third valve member performing a valve opening / closing action with respect to said third valve seat face in an reverse manner against said second valve member, thereby opening or closing the communication with said intermediate communication passage and said third communication passage, said first valve member performing a valve opening / closing action in the same direction to said second valve member; a pressure sensing member having a valve seat portion, said valve seat portion being disposed at a free end of said pressure sensing member, said valve seat portion performing a valve opening / closing action with respect to said first valve member, thereby opening or closing the communication with said first valve chamber and said intermediate communication passage; and a solenoid member driving said valve body in accordance with an electric current supplied thereto; and an auxiliary communication passage providing a communication between said first valve chamber and said intermediate communication passage.

Owner:MAHLE INT GMBH +1

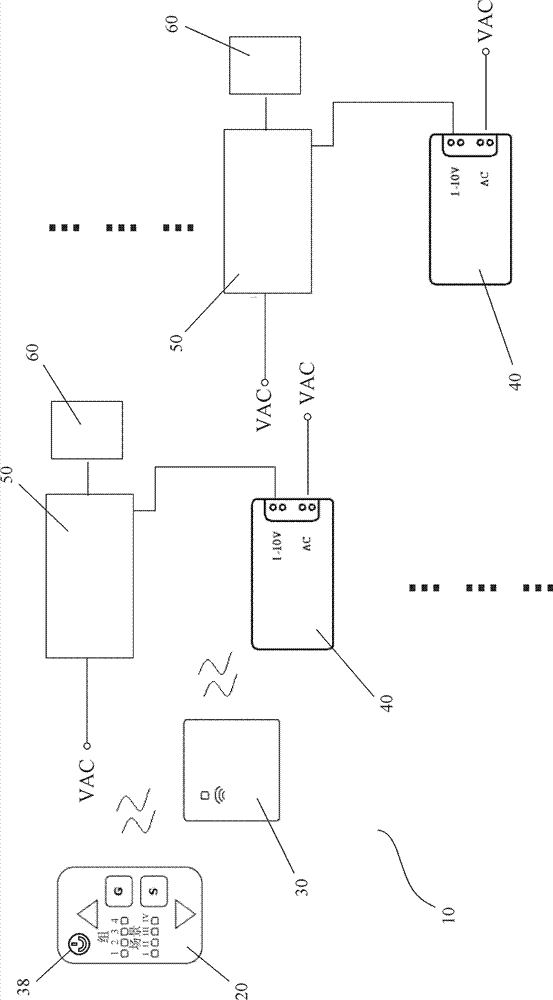

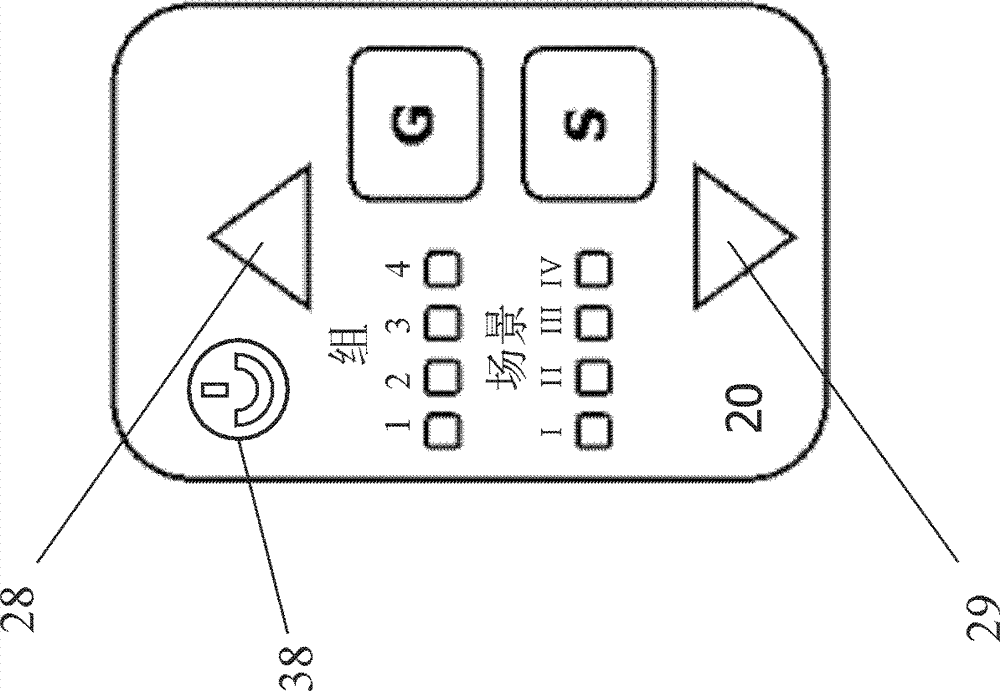

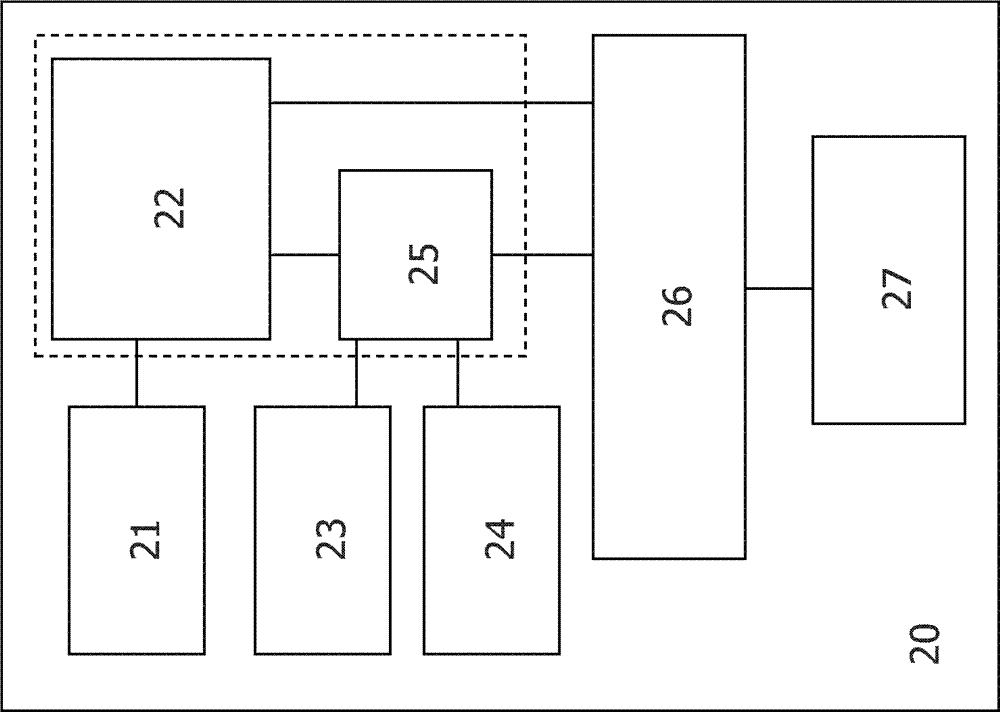

Wireless illumination control system and remote controller and system manager thereof

InactiveCN102791056AEasy to controlReduce energy consumptionTransmission systemsElectric light circuit arrangementControl signalSystems management

The invention discloses a wireless illumination control system which comprises a remote controller, a system manager, a plurality of dimmers, a plurality of drivers and a plurality of lamps, wherein the remote controller is in coupling connection with the system manager; the system manager is in coupling connection with each dimmer; commands are sent to the system manager by the remote controller; the system manager is used for converting the commands into control signals and sending the control signals to the corresponding dimmer; the dimmers are used for converting the control signals into dimming control signals and transmitting the dimming control signals onto the corresponding drivers; each driver is used for ensuring the corresponding lamp to emit light on the corresponding brightness level according to the corresponding dimming control signal; a plurality of lamps can be divided into a plurality of groups; a plurality of groups of lamps correspond to the setting of G keys on the remote controller; and the setting of one group of G keys can be named one scene S. According to the invention, 50 or more dimmers can be conveniently controlled, a range of 50 meters can be covered and the energy consumption of the remote controller is obviously reduced.

Owner:MASS TECH (HK) LTD

System for extinguishing and suppressing fire in an enclosed space in an aircraft

InactiveUS20030136879A1Rapidly extinguishedInitial flame knockdown or extinguishing of the fire rather quicklyFire rescueEmergency apparatusNitrogen generatorMolecular sieve

A system for extinguishing and suppressing a fire in an enclosed space includes a Halon storage container and a nitrogen generator that are both connected by a duct system to extinguishing nozzles arranged in the enclosed space. Halon is supplied as a first extinguishing agent from the container to achieve a rapid initial extinguishing of the fire. Nitrogen enriched air is supplied as a second extinguishing agent from the nitrogen generator to achieve a continuous long-term fire suppression, commencing simultaneously with or after the introduction of the Halon. The nitrogen generator may include a molecular sieve to continuously generate the nitrogen enriched air from an inlet flow of environmental air.

Owner:AIRBUS OPERATIONS GMBH

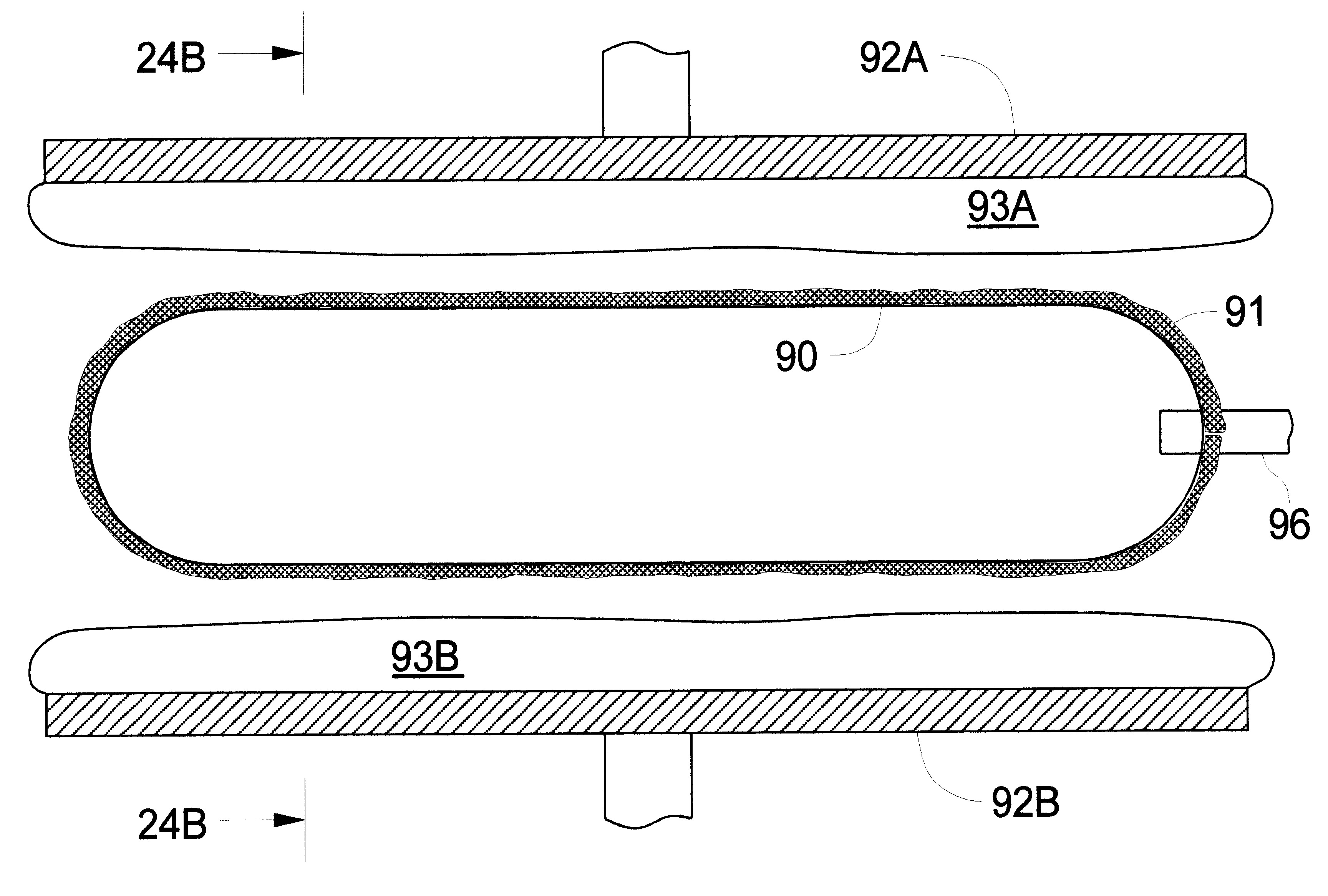

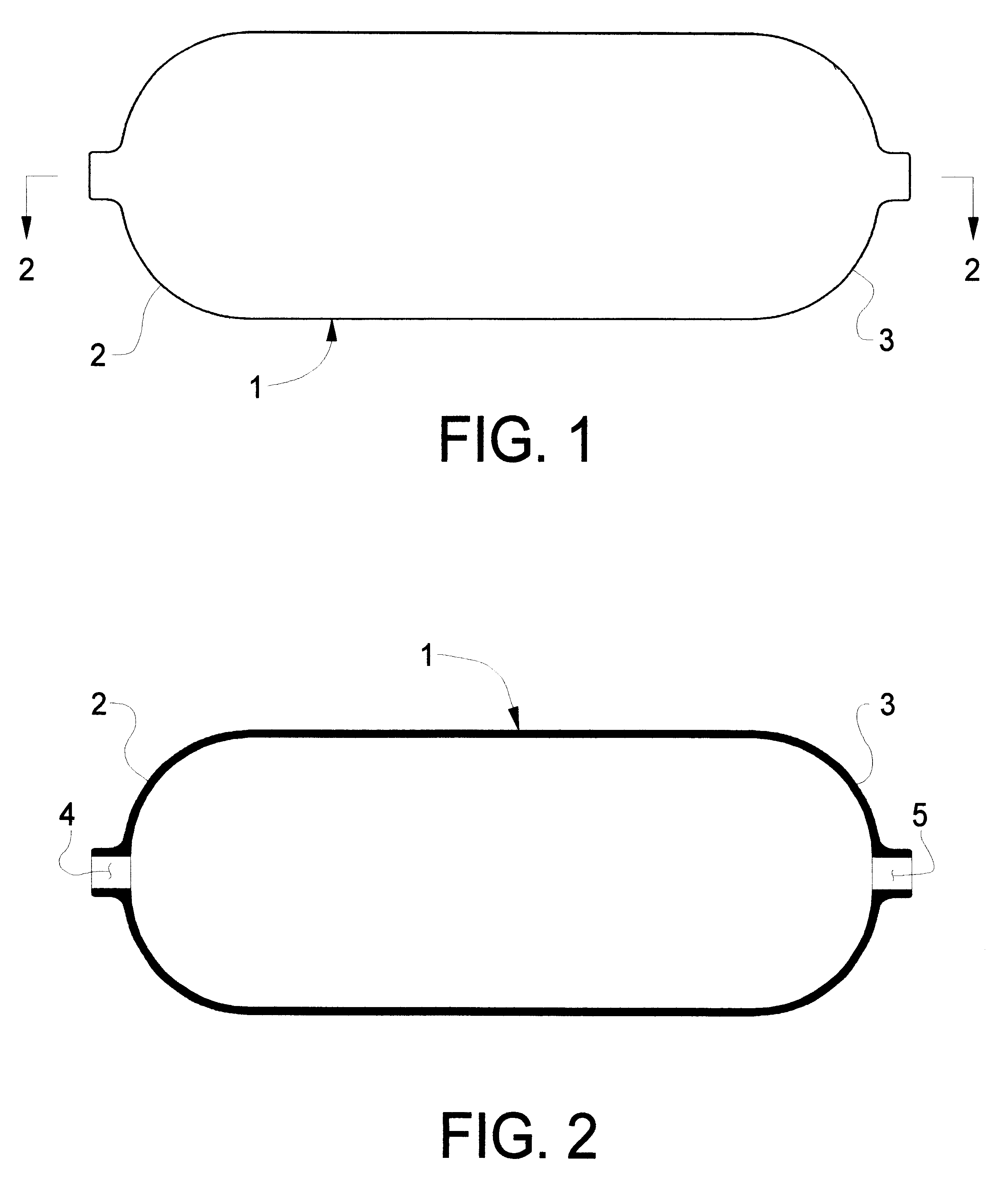

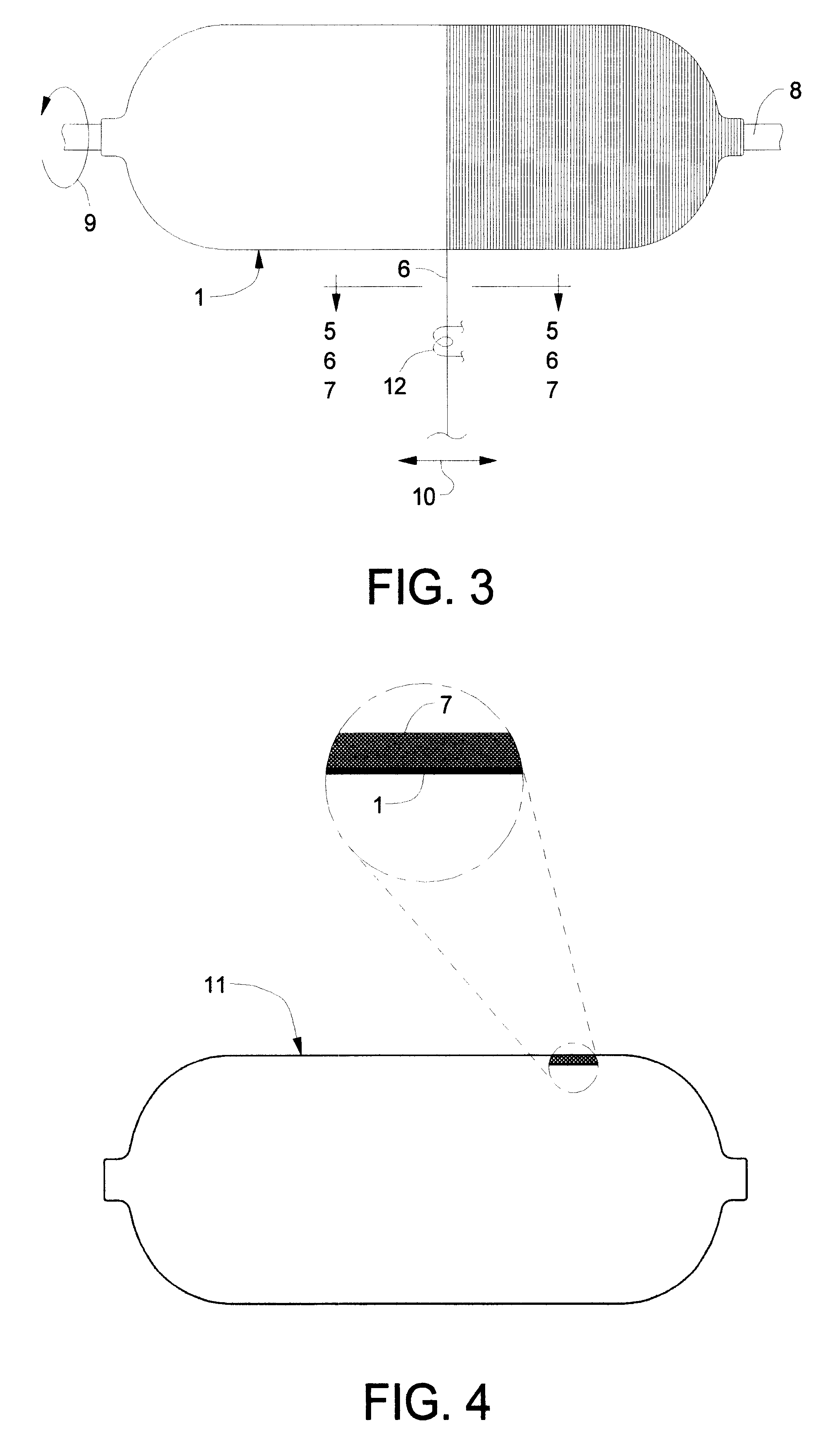

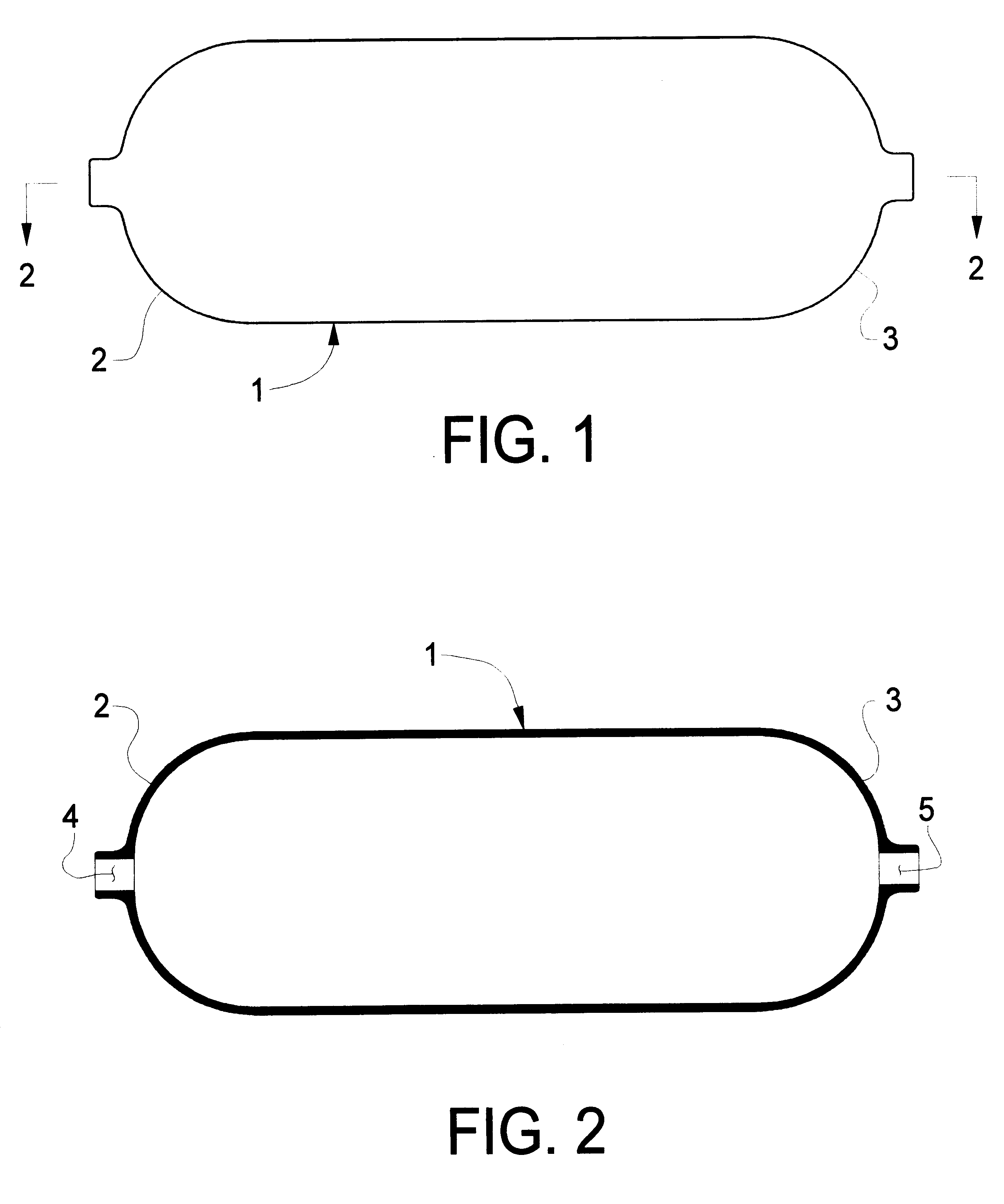

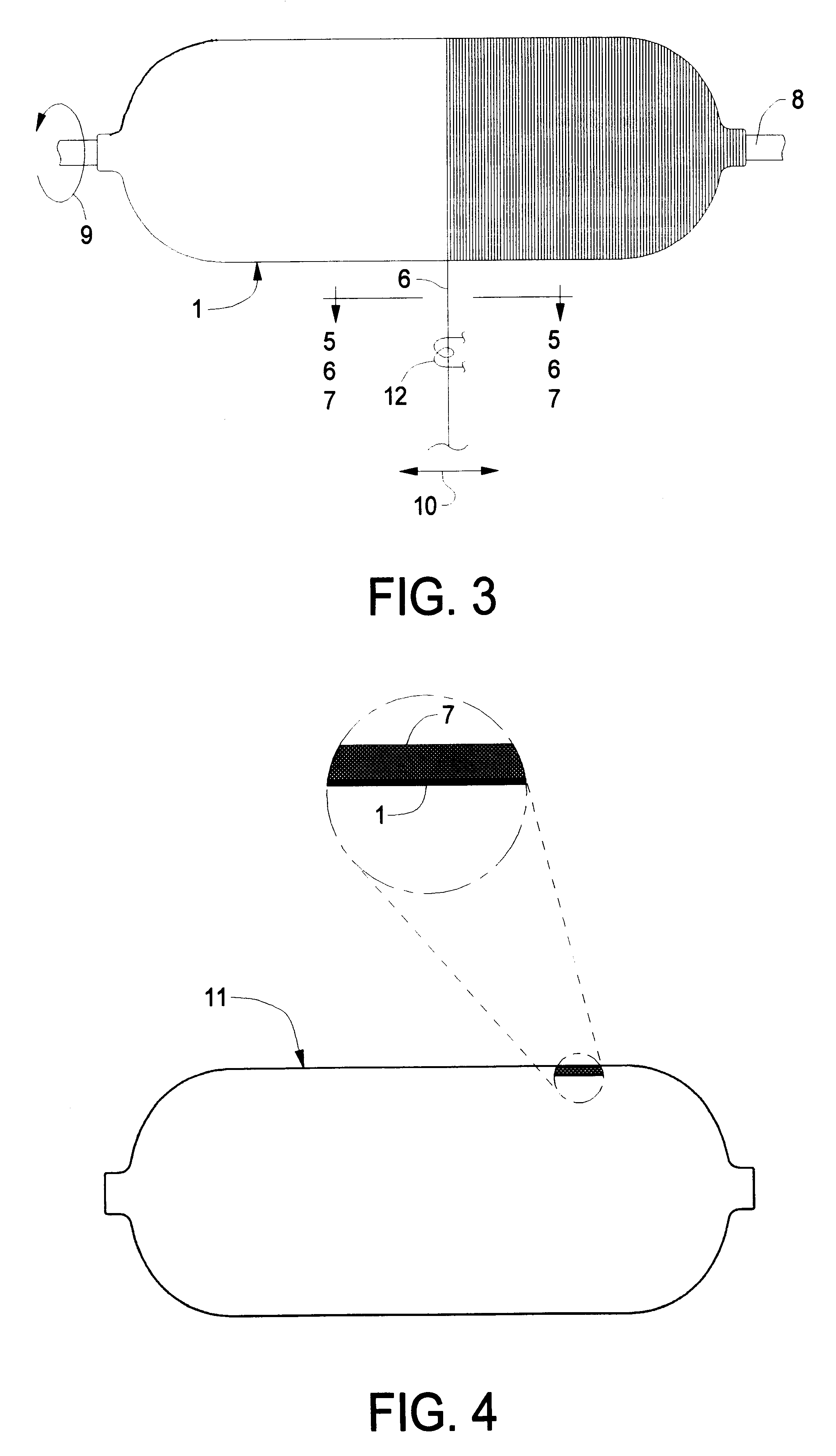

Method for fabricating composite pressure vessels and products fabricated by the method

InactiveUS6485668B1Speed up the processRatio is limitedLabelling non-rigid containersConfectioneryFiberSilicon rubber

A process, and the product thereof, for making a composite vessel having at least one closed end, the process including the steps of: fabricating a thermoplastic liner for the vessel; overlaying onto the liner a layer of commingled fiber and thermoplastic material to obtain a composite intermediate structure; pressing and heating the composite intermediate structure to effect at least partial consolidation in apparatus which includes upper and lower silicon rubber bags, the bags having dimensions such that, during operation, their facing peripheral regions abut to encompass the composite intermediate structure; then placing the composite intermediate structure in a mold; heating the composite intermediate structure in the mold while applying a force, such as internal gas pressure, tending to urge the composite intermediate structure against and into the shape of the interior walls of the mold until the thermoplastic liner and the overlaid layer fully consolidate; cooling the mold and composite vessel until the composite vessel is solidified; and removing the formed composite vessel from the mold. The commingled fiber and thermoplastic material may either be wound onto the liner or laid on the liner in the form of fabric woven from the fiber and threads of the thermoplastic material.

Owner:ESSEF CORP +1

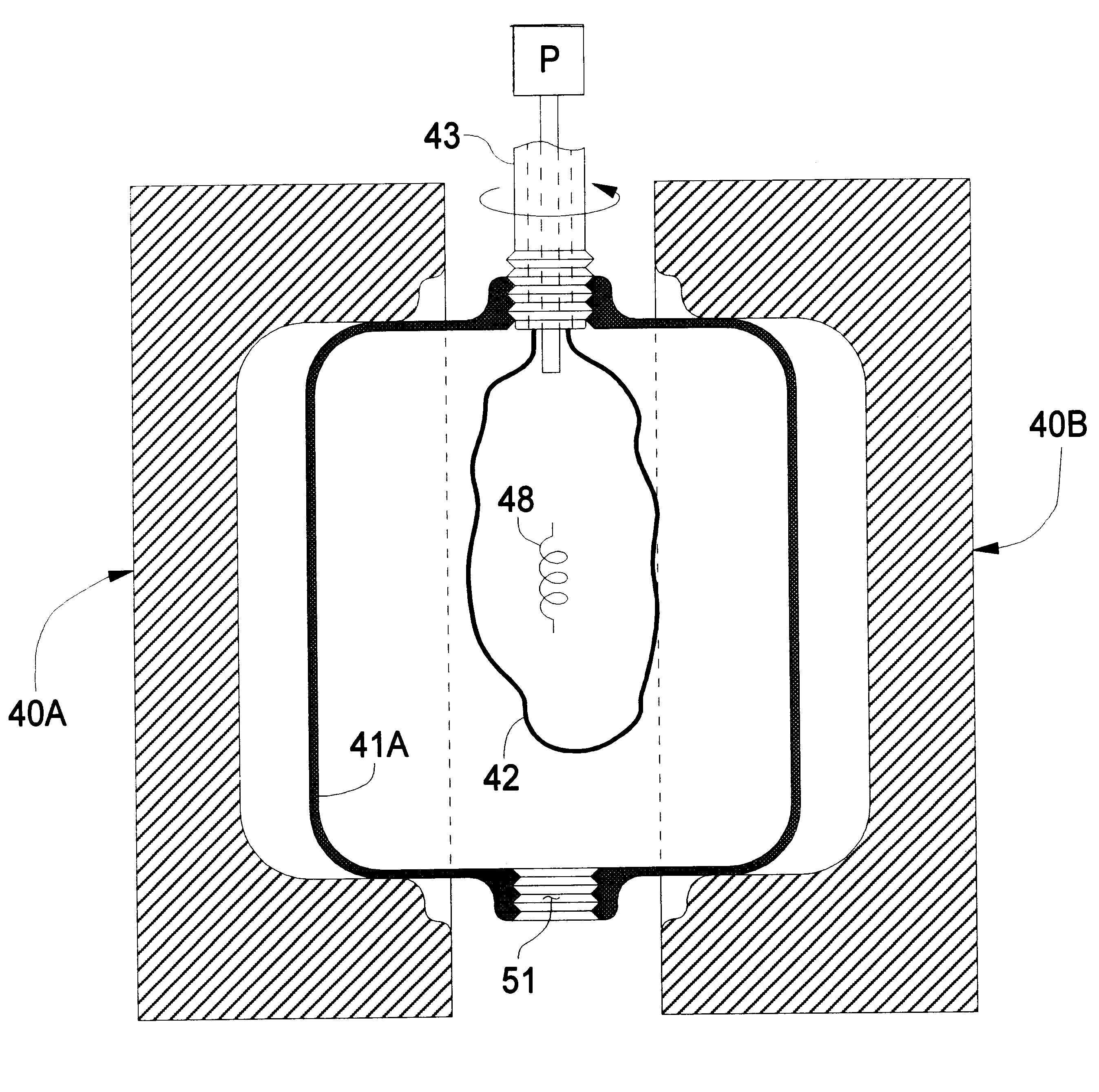

Method for making thermoplastic composite pressure vessels

InactiveUS6190598B1Speed up the processRatio is limitedLayered productsDomestic articlesGlass fiberEngineering

A process of making a composite vessel with superior mechanical and aesthetic characteristics includes the steps of: A) preforming a composite thermoplastic shell (e.g., by winding a commingled roving of fiberglass and a thermoplastic material onto a thermoplastic liner) having an opening for access to the interior; B) placing the shell (which may optionally be preheated) into a mold (which itself may optionally be preheated); C) introducing an inflatable bag containing a heater into the shell through the opening; D) heating the inflatable bag to a temperature which is sufficient to render the shell fluid while pressurizing the interior of the inflatable bag; E) continuing step D) until the shell forms against the interior walls of the mold; F) allowing the formed composite vessel to cool; G) removing the inflatable bag; and H) removing the formed composite vessel from the mold. Prior to step C), an insert having an opening may be juxtaposed in alignment with the opening in the shell such that, during step C), the inflatable bag is inserted through the opening in the insert. If desired for the intended purpose of the composite vessel, a portion of the exterior surface of the insert may be threaded such that threads are formed in the opening of the shell whereby the insert can be unscrewed leaving a threaded port into the vessel.

Owner:FLECK CONTROLS +1

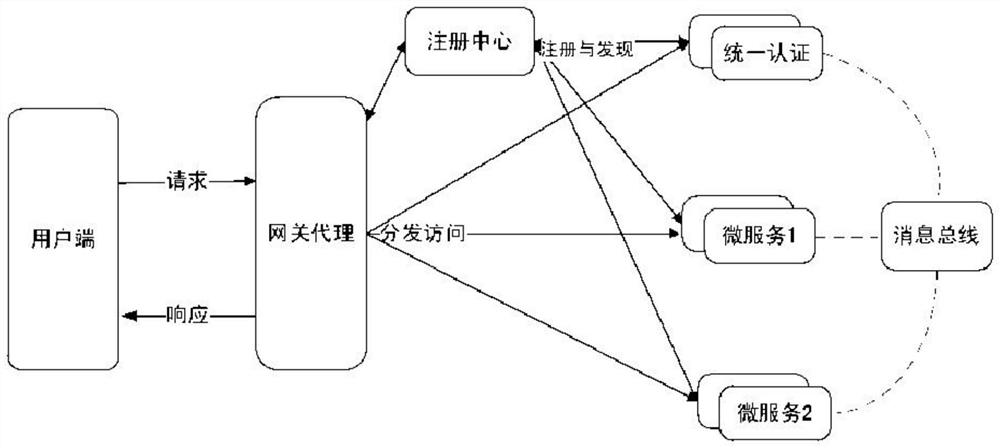

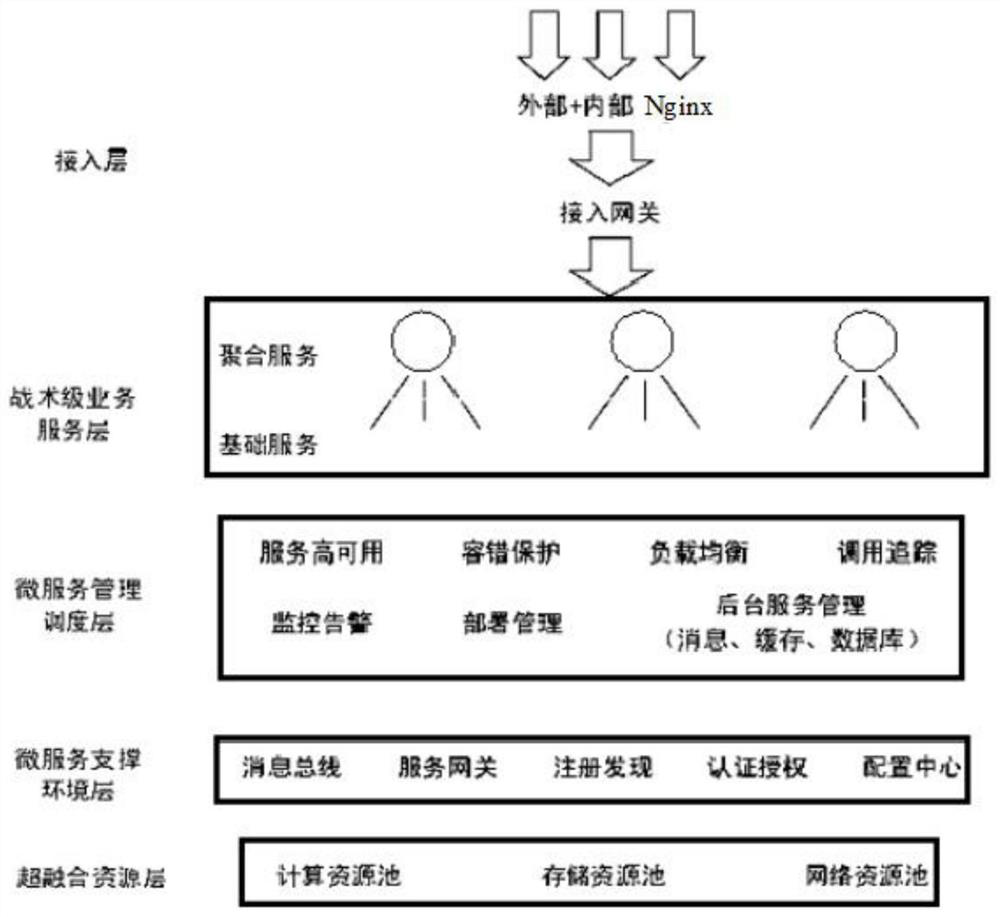

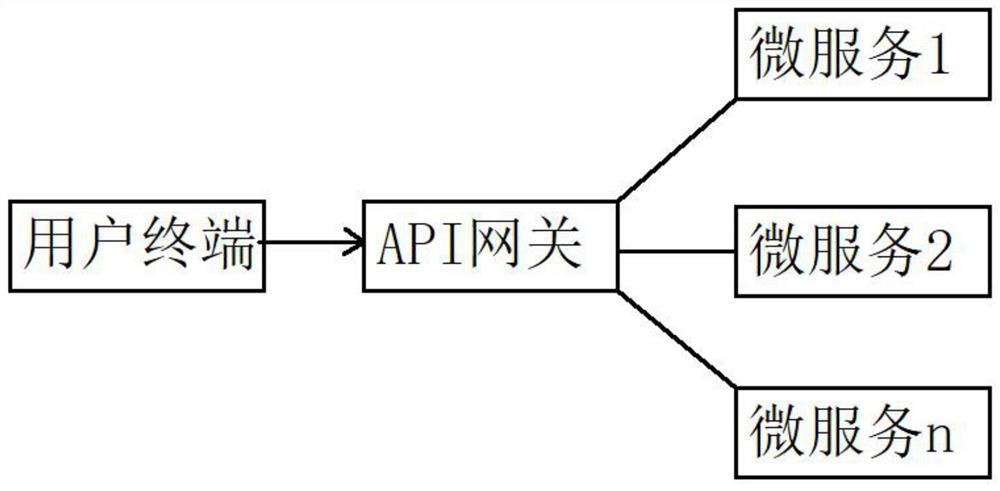

Application management method based on micro-service architecture

PendingCN112000448AGuaranteed operating efficiencyWith access cacheProgram initiation/switchingResource allocationService systemSystem deployment

The invention discloses an application management method based on a micro-service architecture. The method comprises the steps of tactical application-oriented micro-service technology architecture design, lightweight micro-service operation support environment construction, tactical environment-oriented micro-service reliable management technology and information service whole-process dynamic operation and maintenance. According to the invention, a leading-edge micro-service architecture is introduced for application management, a tactical-level service system is split into loosely-coupled and finer-grained service units; based on the application system deployment mode based on the micro-service framework, the method has the advantages of easiness in development and maintenance, quicker starting, easiness in local modification and deployment, telescopic deployment as required and the like; the application system support environment construction based on the micro-service is realized,the military application requirements for light weight and rapid deployment of the tactical environment are met, meanwhile, the project studies reliable management of the micro-service for the battlefield environment, and application operation and maintenance management with higher reliability is achieved through optimization technologies such as high-availability management, load balancing, service fault tolerance and call tracking.

Owner:BEIJING INST OF COMP TECH & APPL

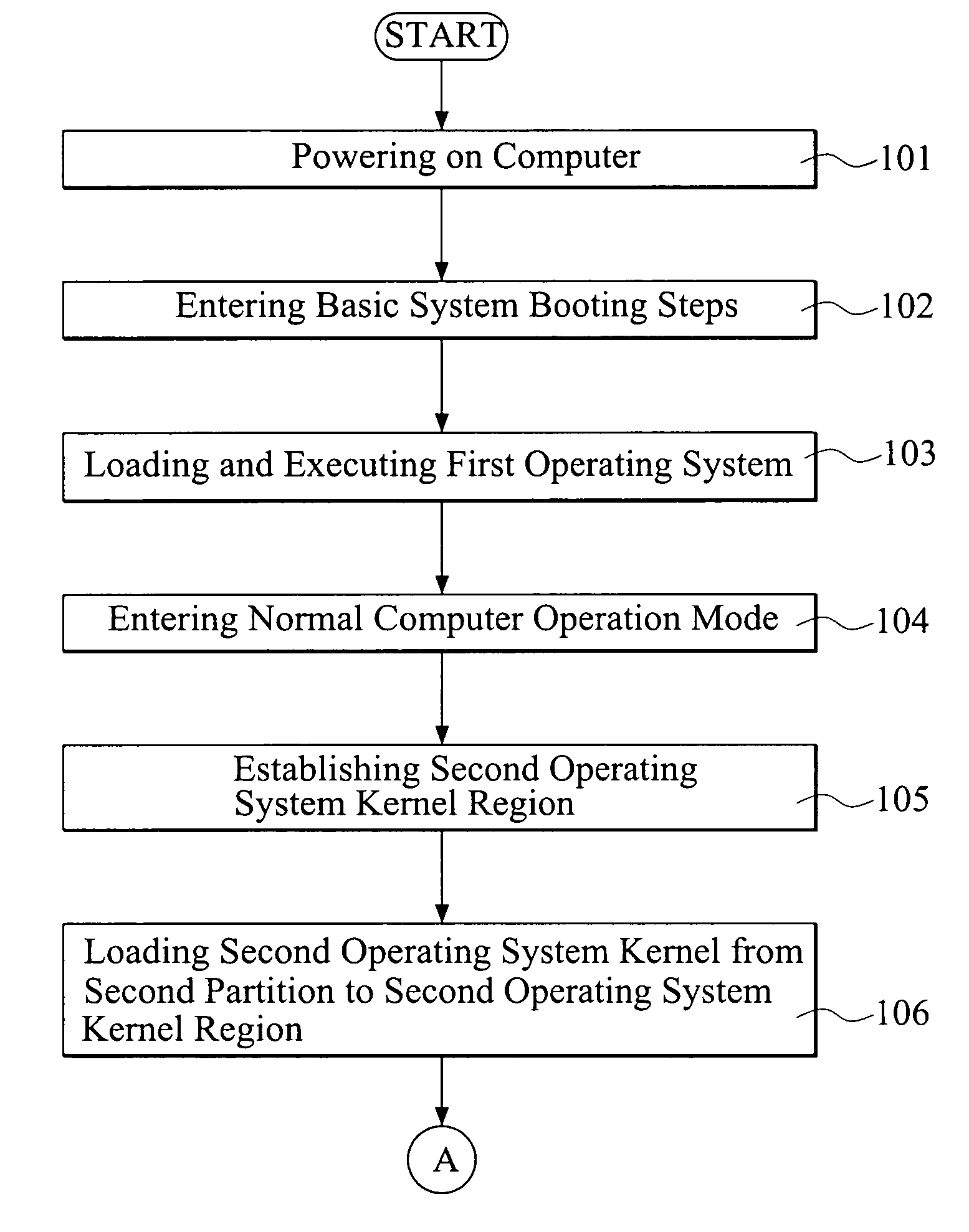

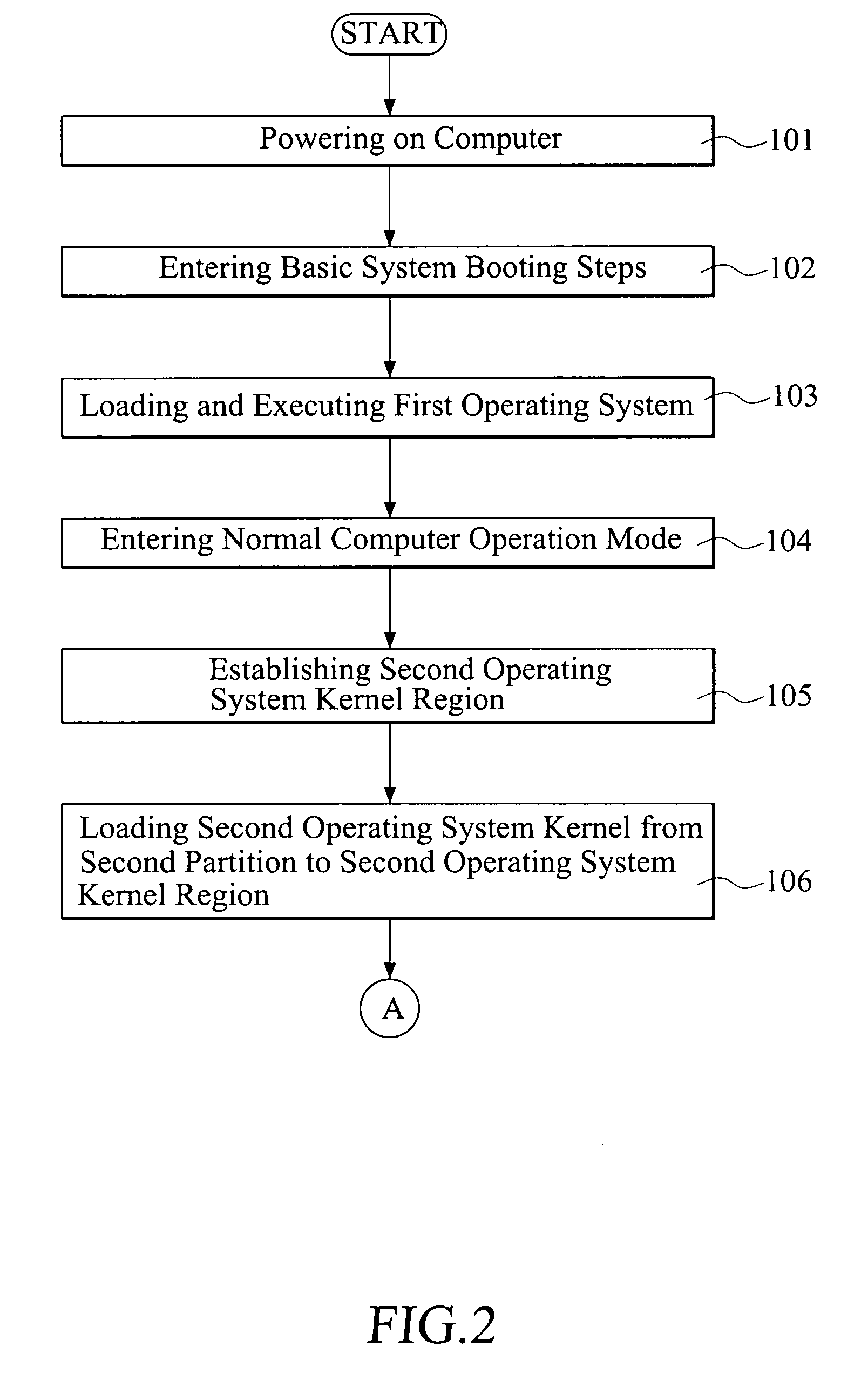

Method of fast booting for computer multimedia playing from standby mode

ActiveUS20070055860A1Easy to switchConsuming wasteful powerDigital data processing detailsDigital computer detailsOperational systemOperating system kernel

A method of fast booting for multimedia playing from a standby mode is provided, including installing at least a first operating system, a second operating system and the kernel of the second operating system in the hard disk of the computer. An event signal generating unit is connected to the computer. When the computer completes the booting process with the first operating system, a memory region for the kernel of the second operating system is established in the system memory, and the kernel of the second operating system kernel is loaded into the memory region. When the user shuts down the computer, the computer enters a standby mode. If the user operates the event signal generating unit when the computer is in the standby mode, the computer awakes and starts executing the second operating system kernel in the memory region and the computer enters the multimedia playing mode.

Owner:GETAC TECH CORP

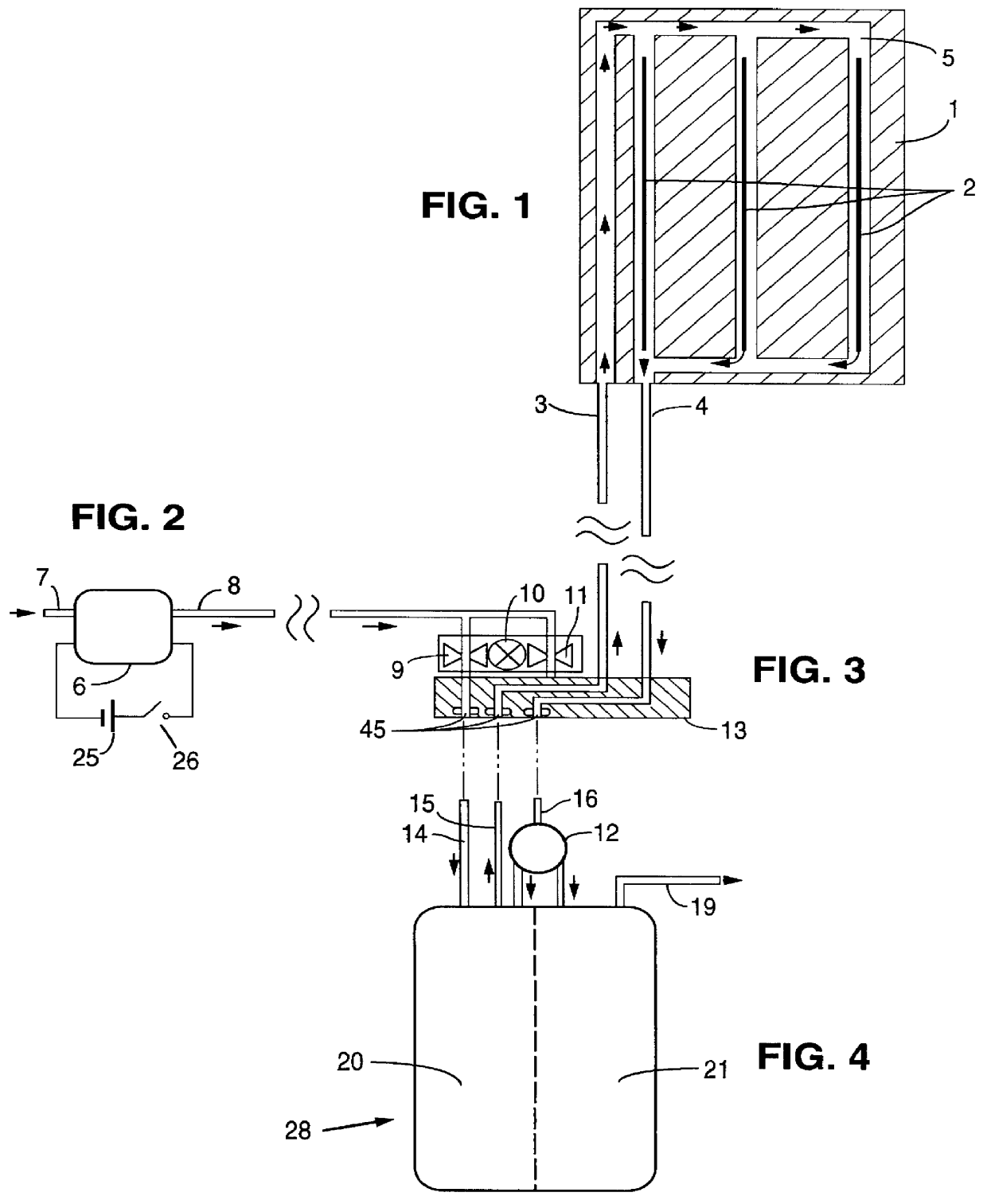

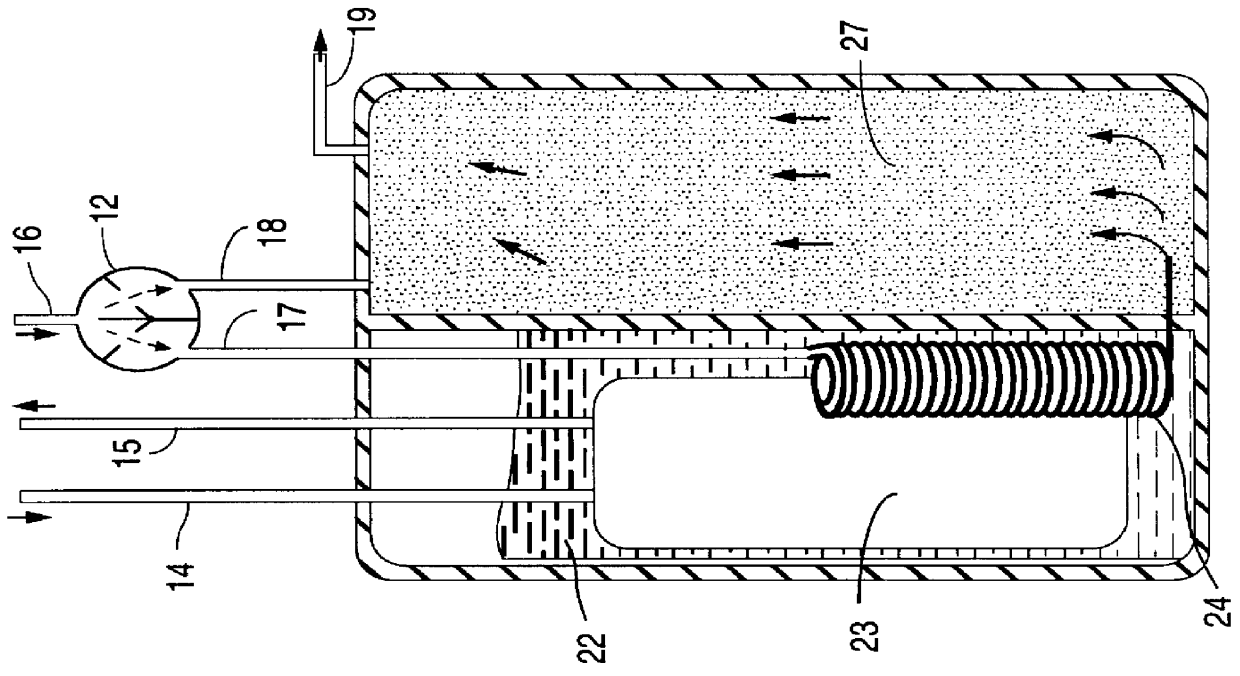

Portable heat generating device

InactiveUS6062210APromotes spontaneous flameless combustionReduce necessityExothermal chemical reaction heat productionOther heat production devicesElastomerThermal energy

A portable heat generating device in which fuel vapor and an oxygen supply (e.g. air) are directed through channels contained within a thin, flexible and compliant elastomeric sheet of material. Elongated catalytic heat elements, placed strategically within the channels, spontaneously interact with the fuel-air stream liberating heat energy. Means and methods are defined that permit flameless catalytic combustion to be uniformly extended over the length of each heat element, lowering power density but maintaining the overall power generated, permitting the use of many types of low temperature materials like plastics, polymers, and elastomers in the construction of the heater. The heat generation process is started by pumping an air stream into a reservoir containing a fuel source (e.g. methanol) thereby saturating the air stream with fuel vapor. The fuel vapor is mixed with a another stream of air to achieve a particular fuel / air ratio and directed into channels within the elastomeric sheet, reacting with the catalytic heat elements to produce flameless combustion. The warm exhaust gas is directed to a thermally controlled diverter valve. The valve senses the temperature of the liquid fuel supply and diverts some or all of the warm exhaust gas, as necessary, to heat the fuel and keep its temperature within a specified range. Exhaust by-products are passed into a miniature scrubber module adjacent to the fuel module. The scrubber absorbs any noxious components in the exhaust stream that may occur during start-up or rapid changes in operating condition.

Owner:CLIFFORD G WELLES

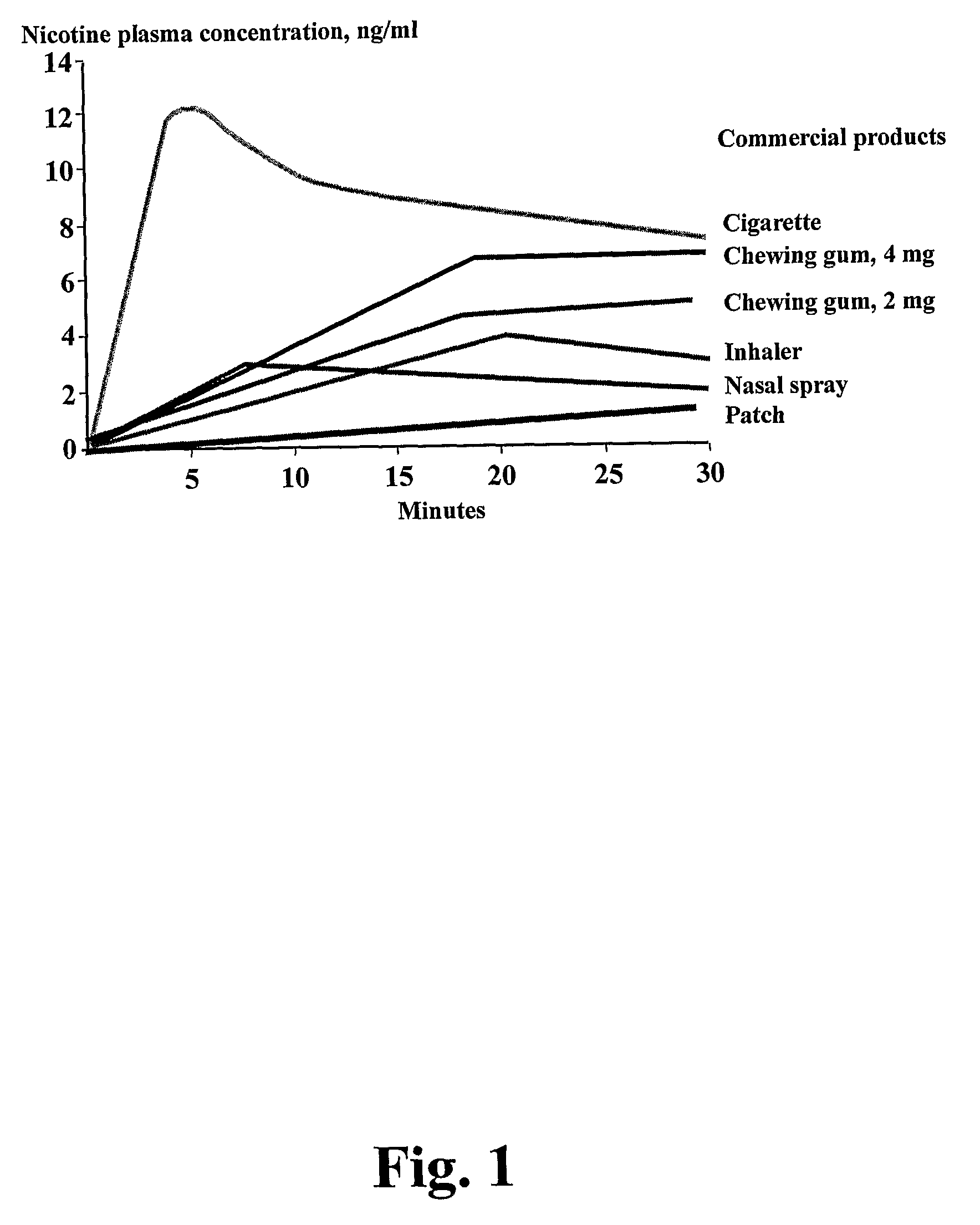

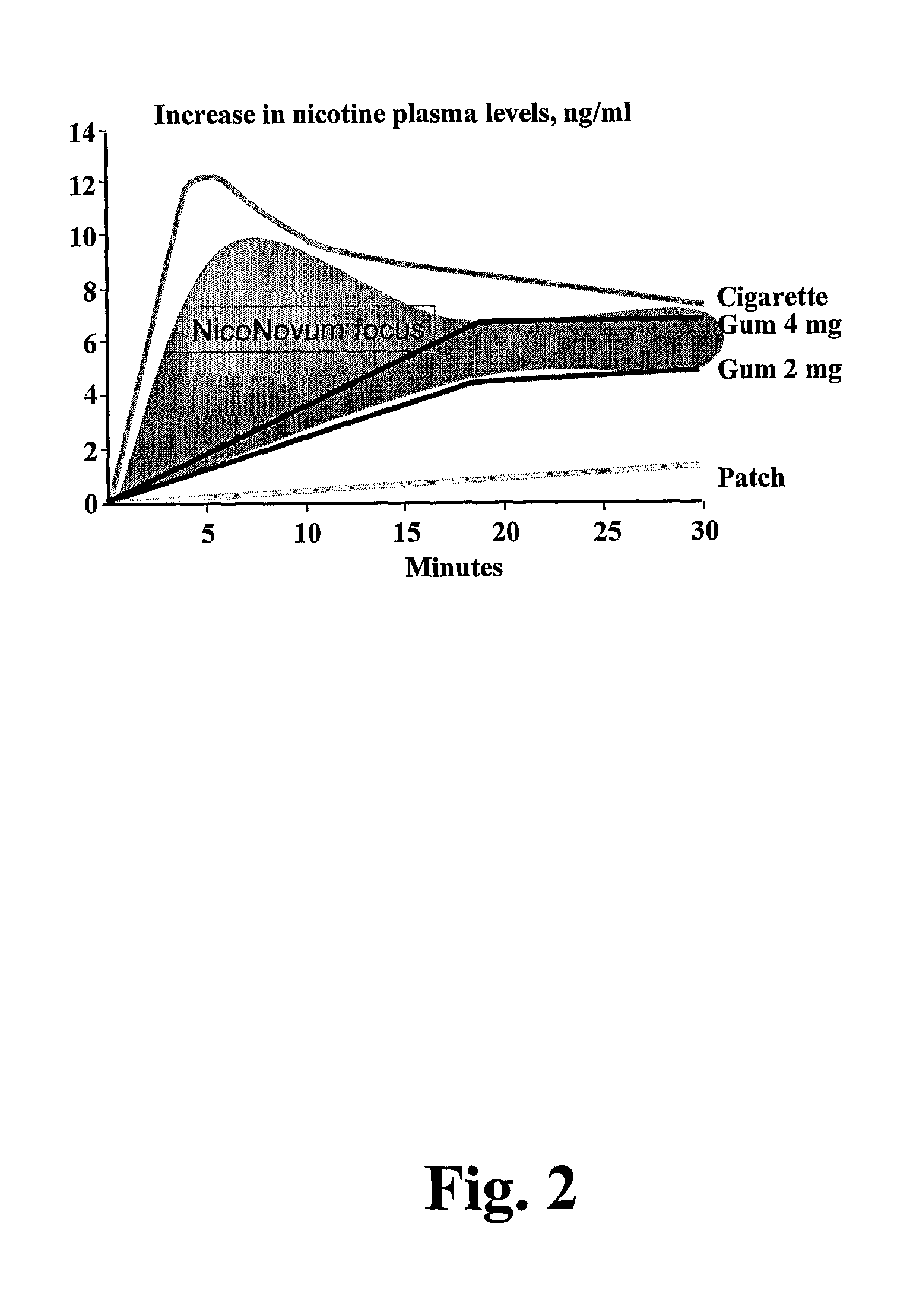

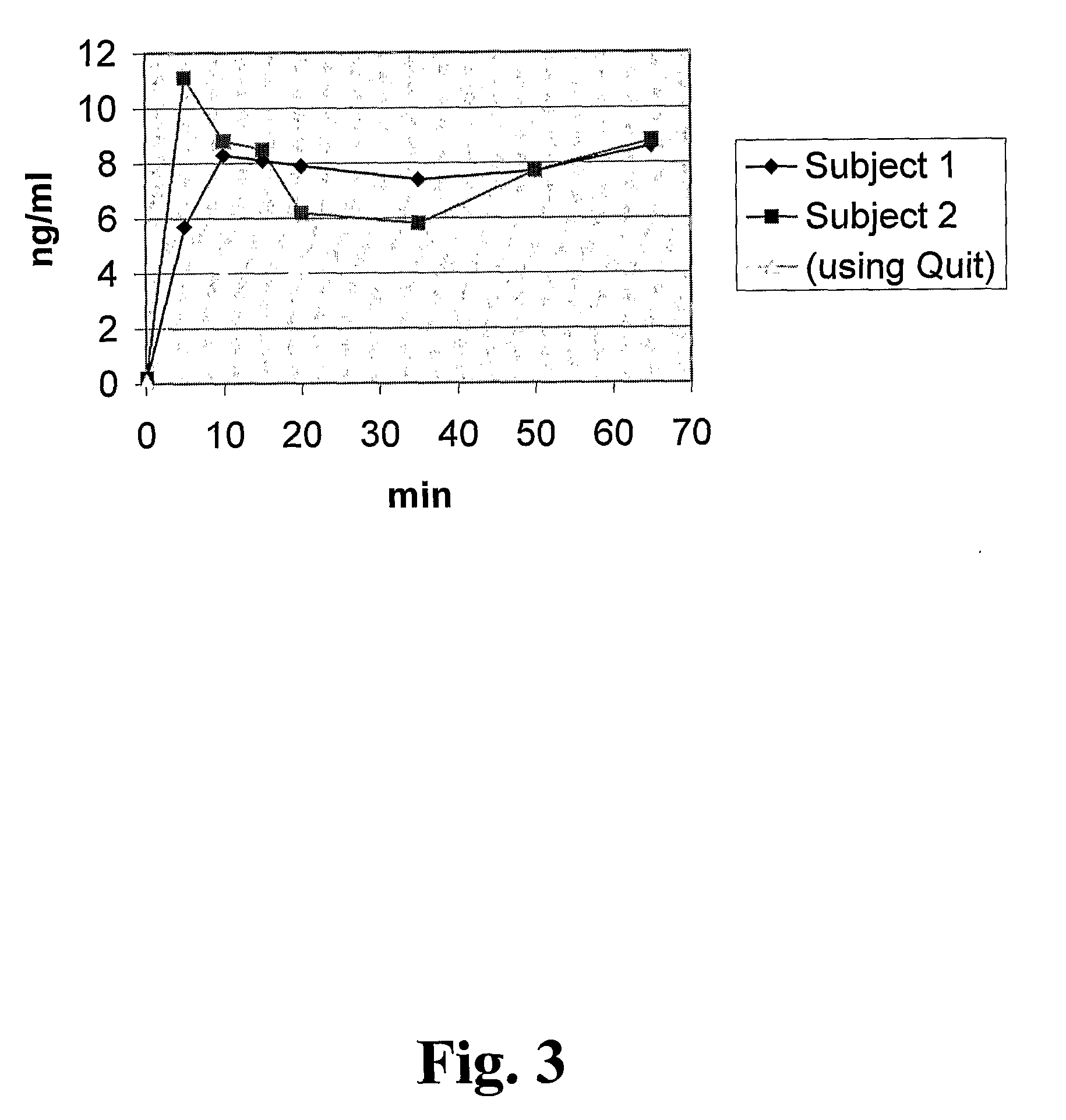

Use of an Artificial Sweetener to Enhance Absorption of Nicotine

The present invention relates to increased absorption of nicotine over the prior art. In particular the absorption of nicotine is enhanced after administration of a composition containing nicotine and a sweetener such as an artificial sweetener like saccharin to the oral mucosa in the form of a spray.

Owner:NICONOVUM AB

Low carbon alloy steel tube having ultra high strength and excellent toughness at low temperature and method of manufacturing the same

InactiveUS20060169368A1Increase burst pressureImprove toughnessFurnace typesHeat treatment furnacesWater basedNiobium

A low carbon alloy steel tube and a method of manufacturing the same, especially for a stored gas inflator pressure vessel, in which the steel tube consists essentially of, by weight: about 0.06% to about 0.18% carbon, about 0.3% to about 1.5% manganese, about 0.05% to about 0.5% silicon, up to about 0.015% sulfur, up to about 0.025% phosphorous, and at least one of the following elements: up to about 0.30% vanadium, upto t about 0.10% aluminum, up to about 0.06% niobium, up to about 1% chromium, up to about 0.70% nickel, up to about 0.70% molybdenum, up to about 0.35% copper, up to about 0.15% residual elements, and the balance iron and incidental impurities. After a high heating rate of about 100° C. per second; rapidly and fully quenching the steel tubing in a water-based quenching solution at a cooling rate of about 100° C. per second. The steel has a tensile strength of at least about 145 ksi and as high as 220 ksi and exhibits ductile behavior at temperatures as low as -100° C.

Owner:TENARIS CONNECTIONS LIECHTENSTEIN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com