Patents

Literature

378 results about "Nitrogen generator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitrogen generators and stations are stationary or mobile air-to-nitrogen production complexes.

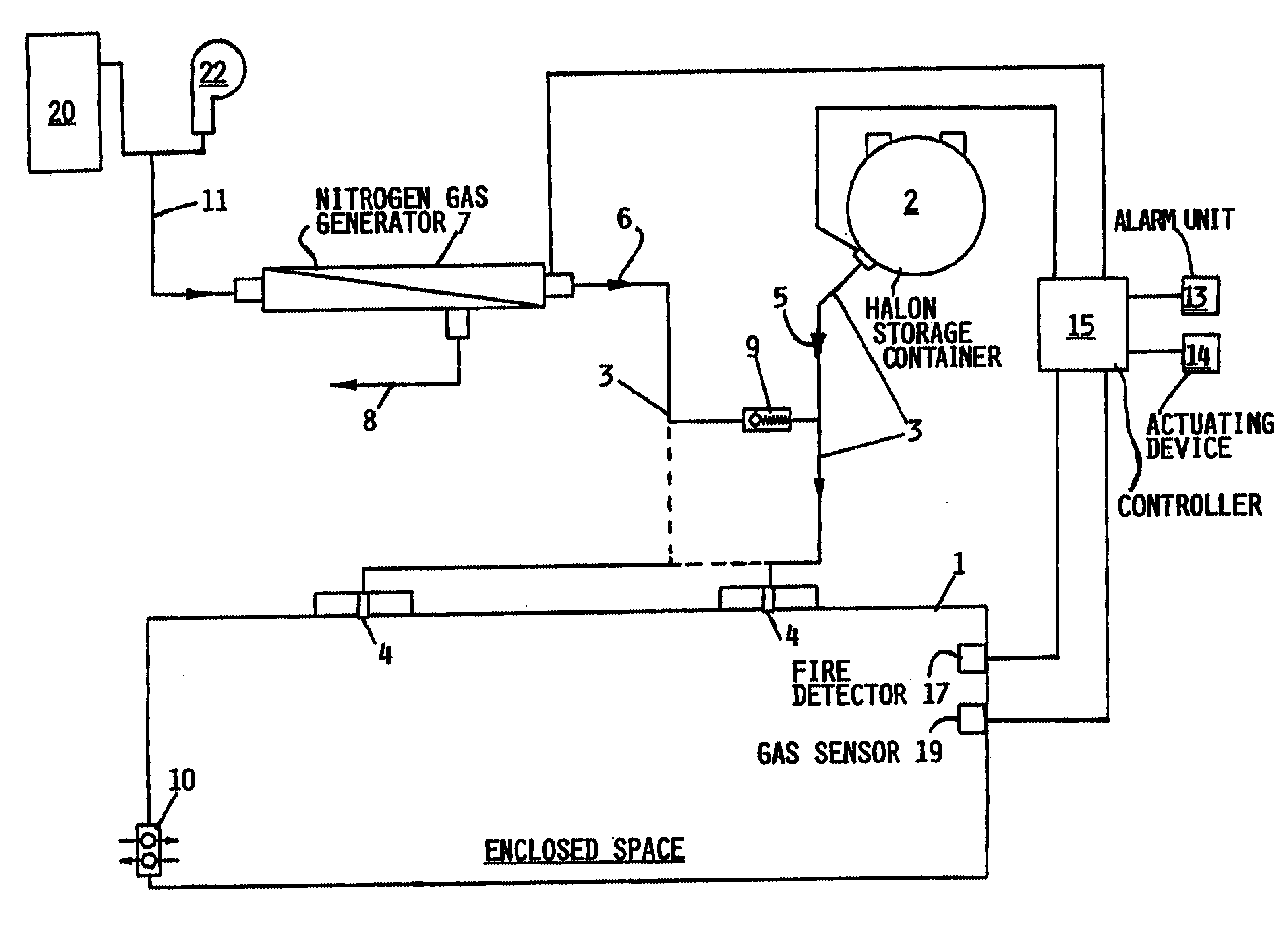

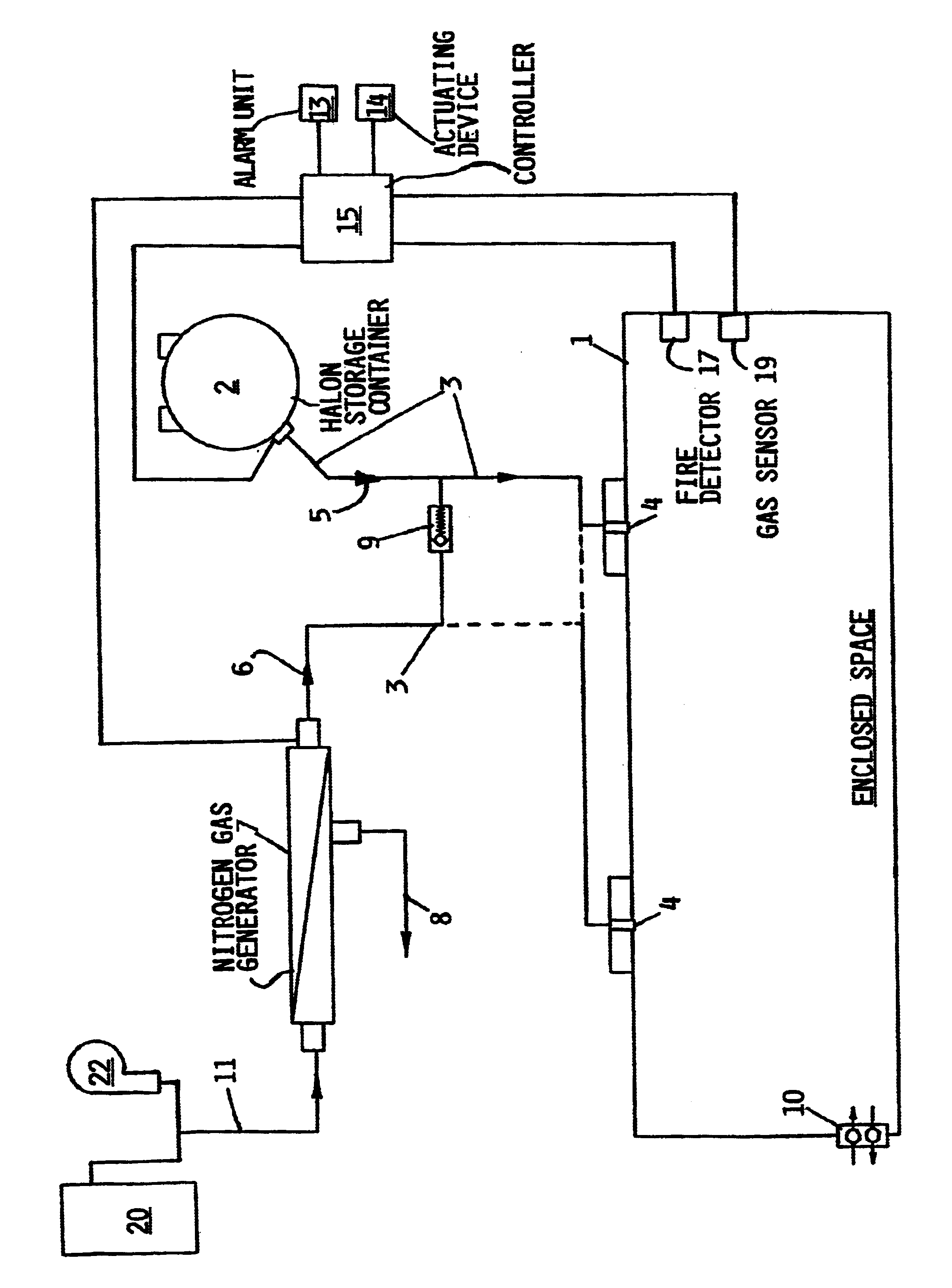

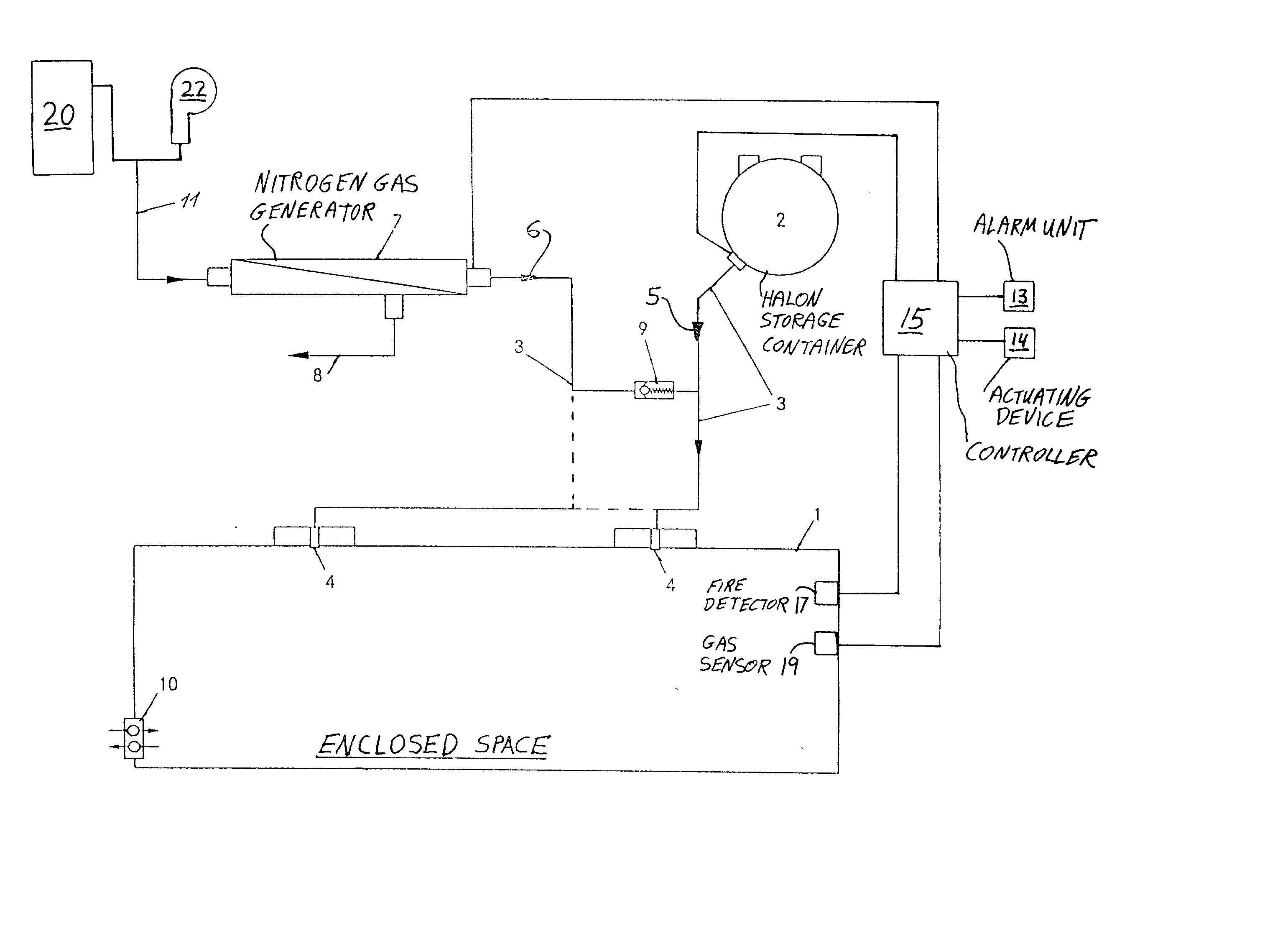

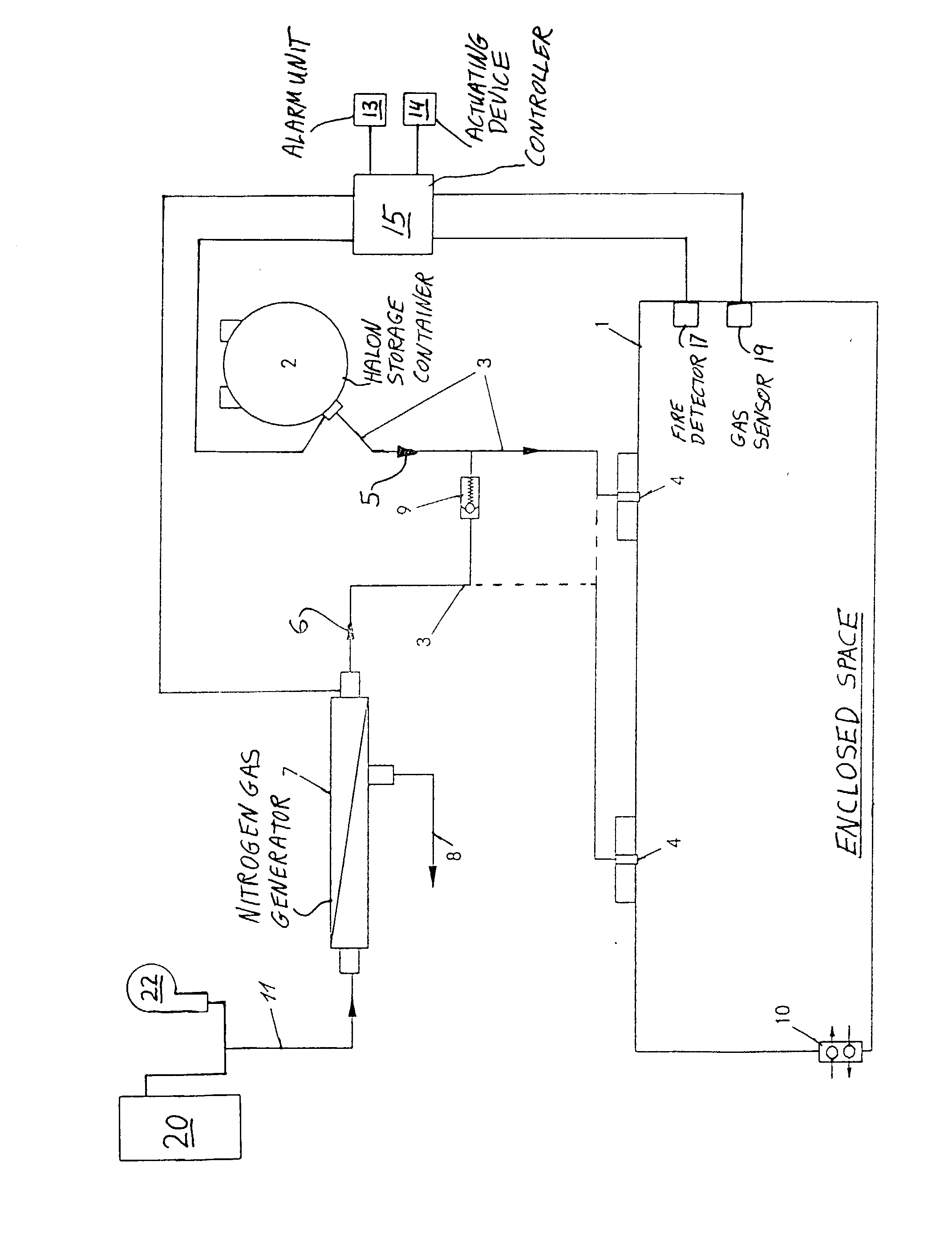

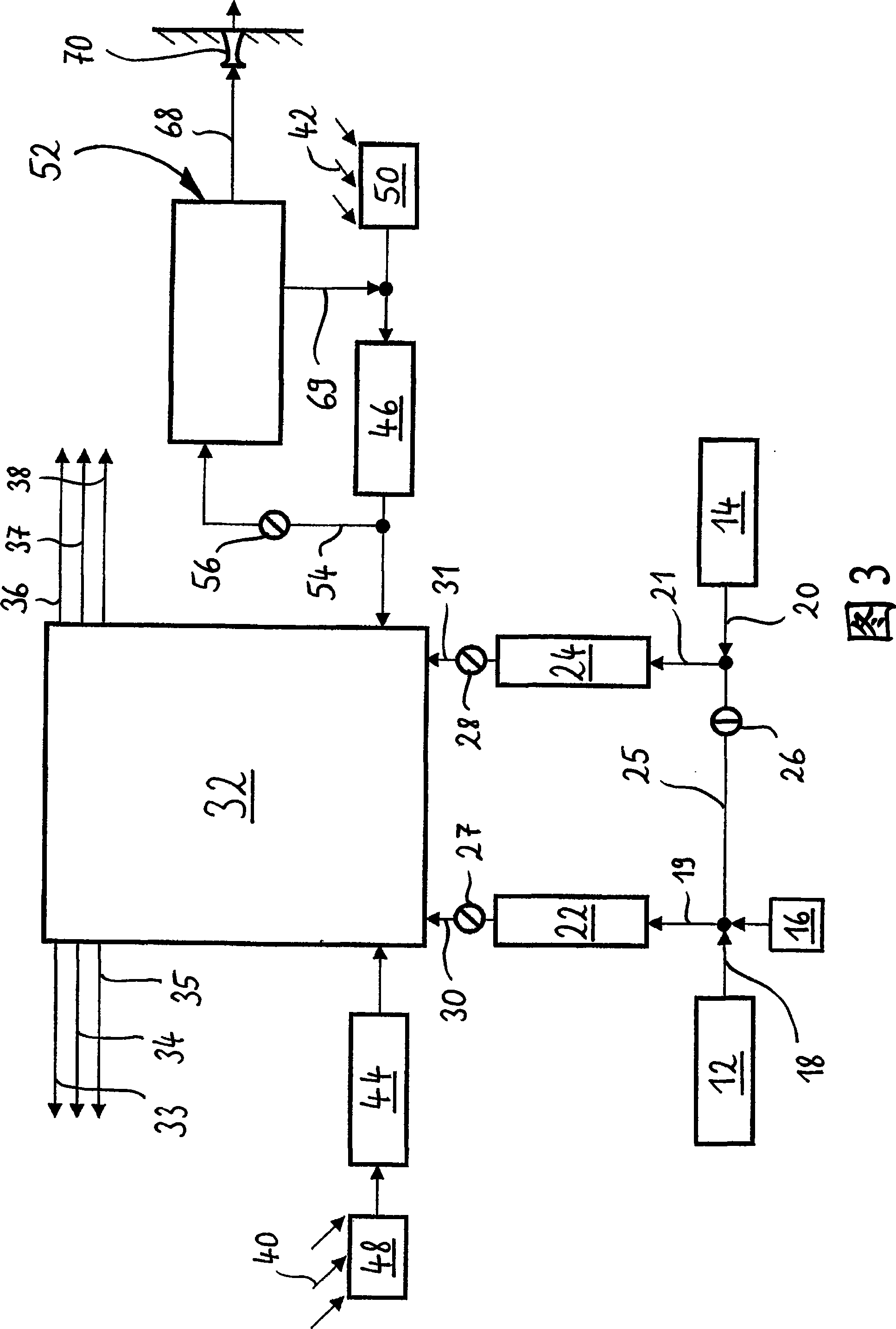

System for extinguishing and suppressing fire in an enclosed space in an aircraft

InactiveUS6676081B2Rapidly extinguishedInitial flame knockdown or extinguishing of the fire rather quicklyFire rescueEmergency apparatusMolecular sieveNitrogen generator

A system for extinguishing and suppressing a fire in an enclosed space includes a Halon storage container and a nitrogen generator that are both connected by a duct system to extinguishing nozzles arranged in the enclosed space. Halon is supplied as a first extinguishing agent from the container to achieve a rapid initial extinguishing of the fire. Nitrogen enriched air is supplied as a second extinguishing agent from the nitrogen generator to achieve a continuous long-term fire suppression, commencing simultaneously with or after the introduction of the Halon. The nitrogen generator may include a molecular sieve to continuously generate the nitrogen enriched air from an inlet flow of environmental air.

Owner:AIRBUS OPERATIONS GMBH

System for extinguishing and suppressing fire in an enclosed space in an aircraft

InactiveUS20030136879A1Rapidly extinguishedInitial flame knockdown or extinguishing of the fire rather quicklyFire rescueEmergency apparatusNitrogen generatorMolecular sieve

A system for extinguishing and suppressing a fire in an enclosed space includes a Halon storage container and a nitrogen generator that are both connected by a duct system to extinguishing nozzles arranged in the enclosed space. Halon is supplied as a first extinguishing agent from the container to achieve a rapid initial extinguishing of the fire. Nitrogen enriched air is supplied as a second extinguishing agent from the nitrogen generator to achieve a continuous long-term fire suppression, commencing simultaneously with or after the introduction of the Halon. The nitrogen generator may include a molecular sieve to continuously generate the nitrogen enriched air from an inlet flow of environmental air.

Owner:AIRBUS OPERATIONS GMBH

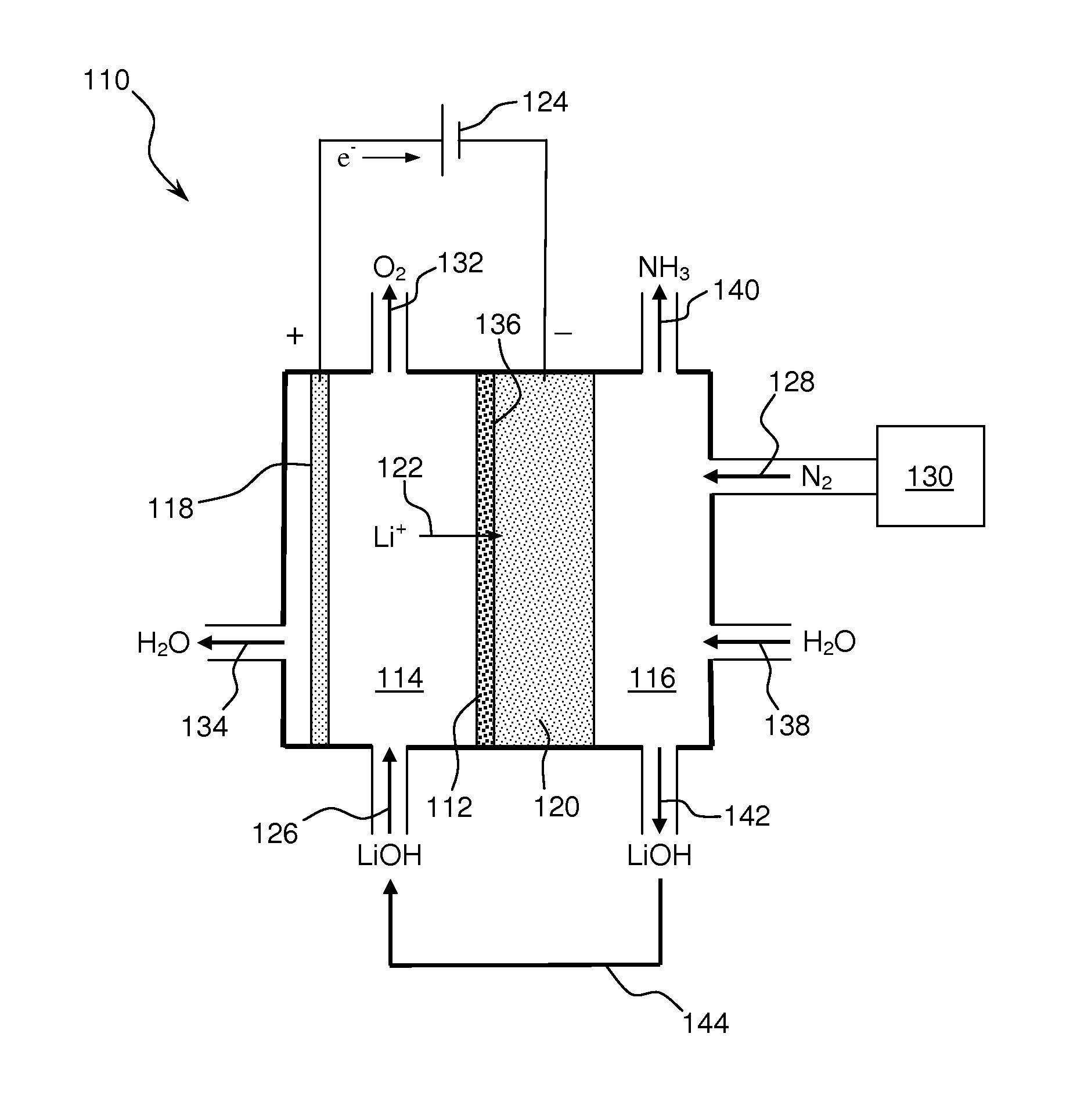

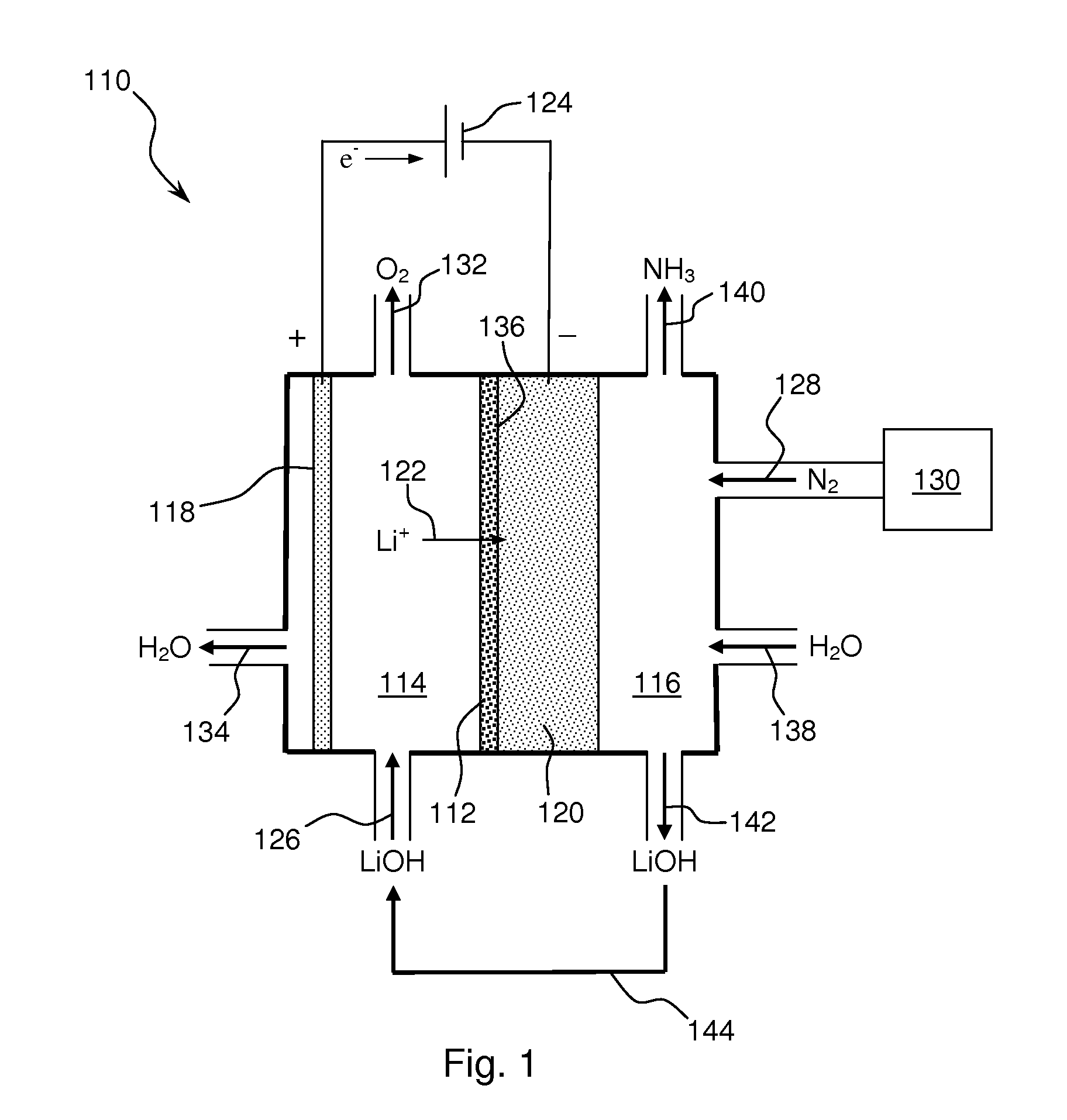

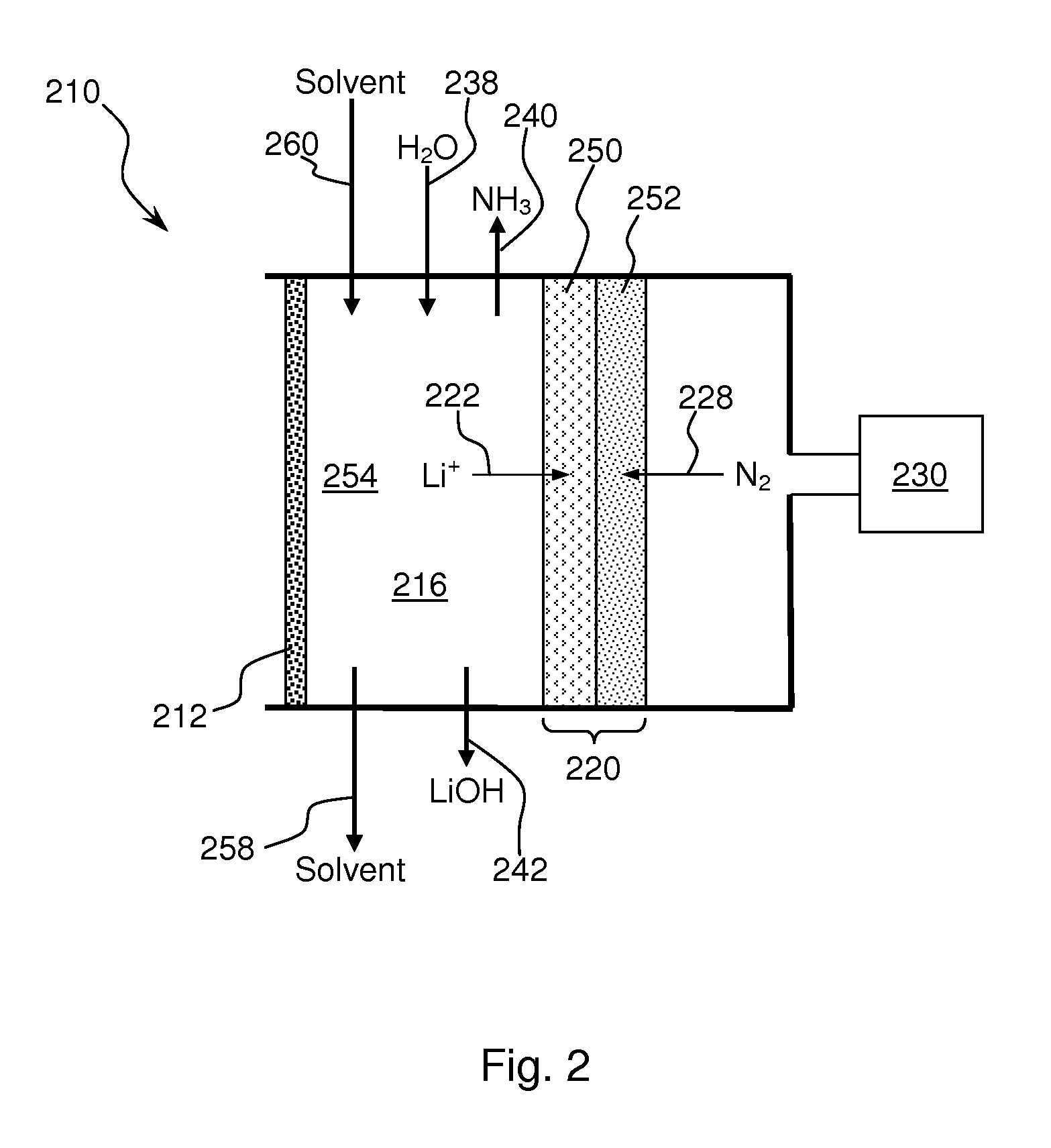

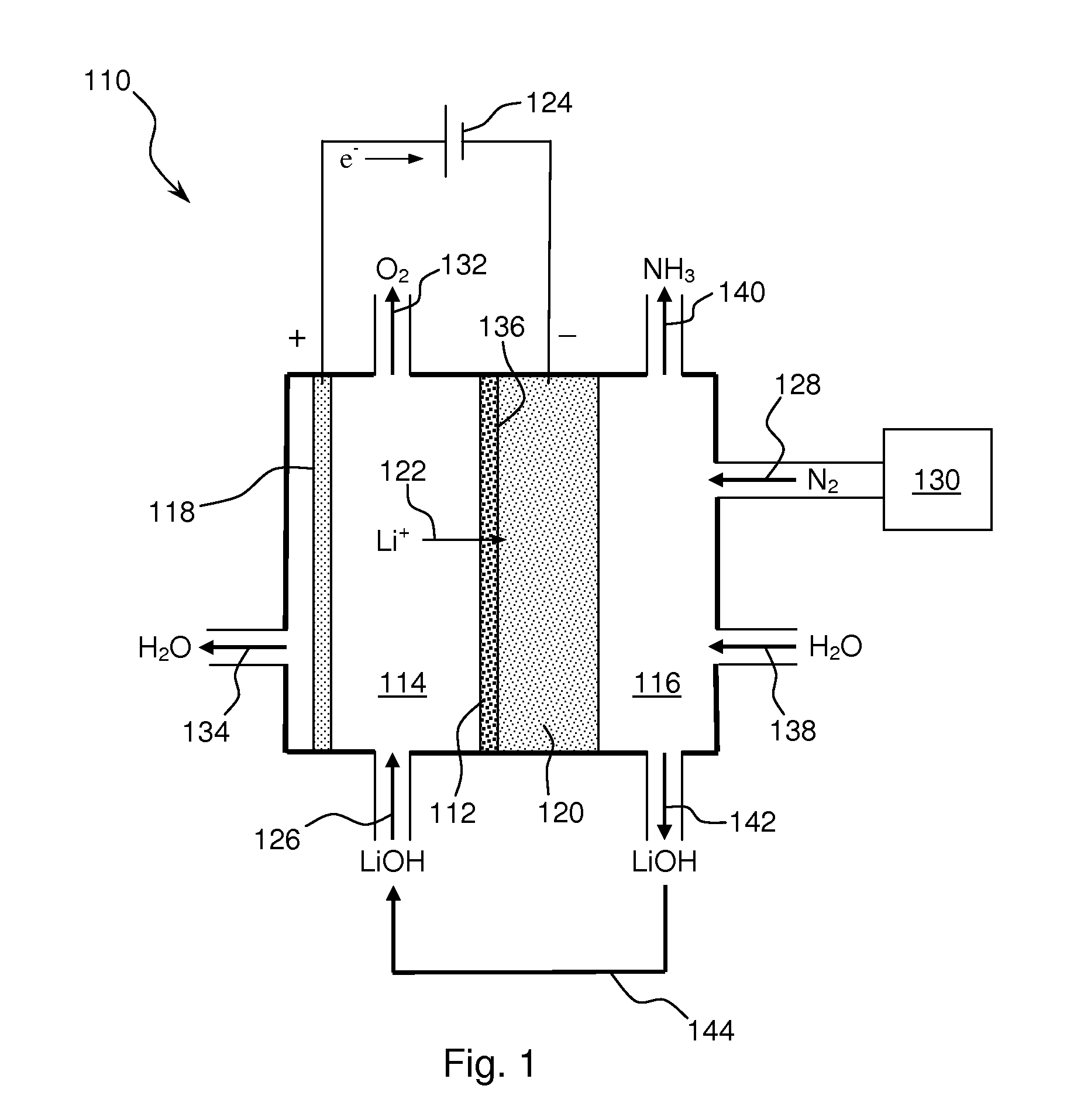

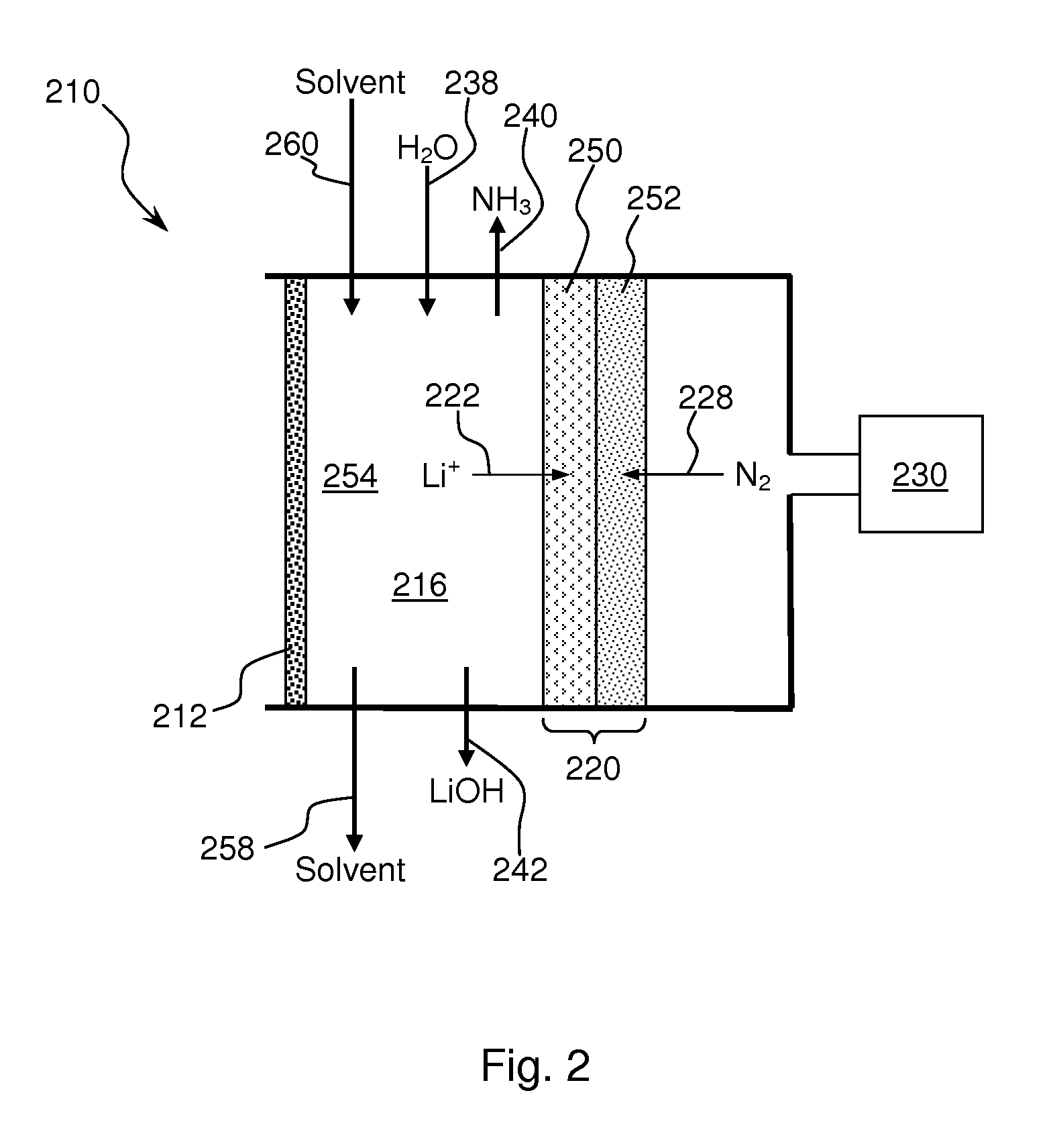

Ammonia synthesis using lithium ion conductive membrane

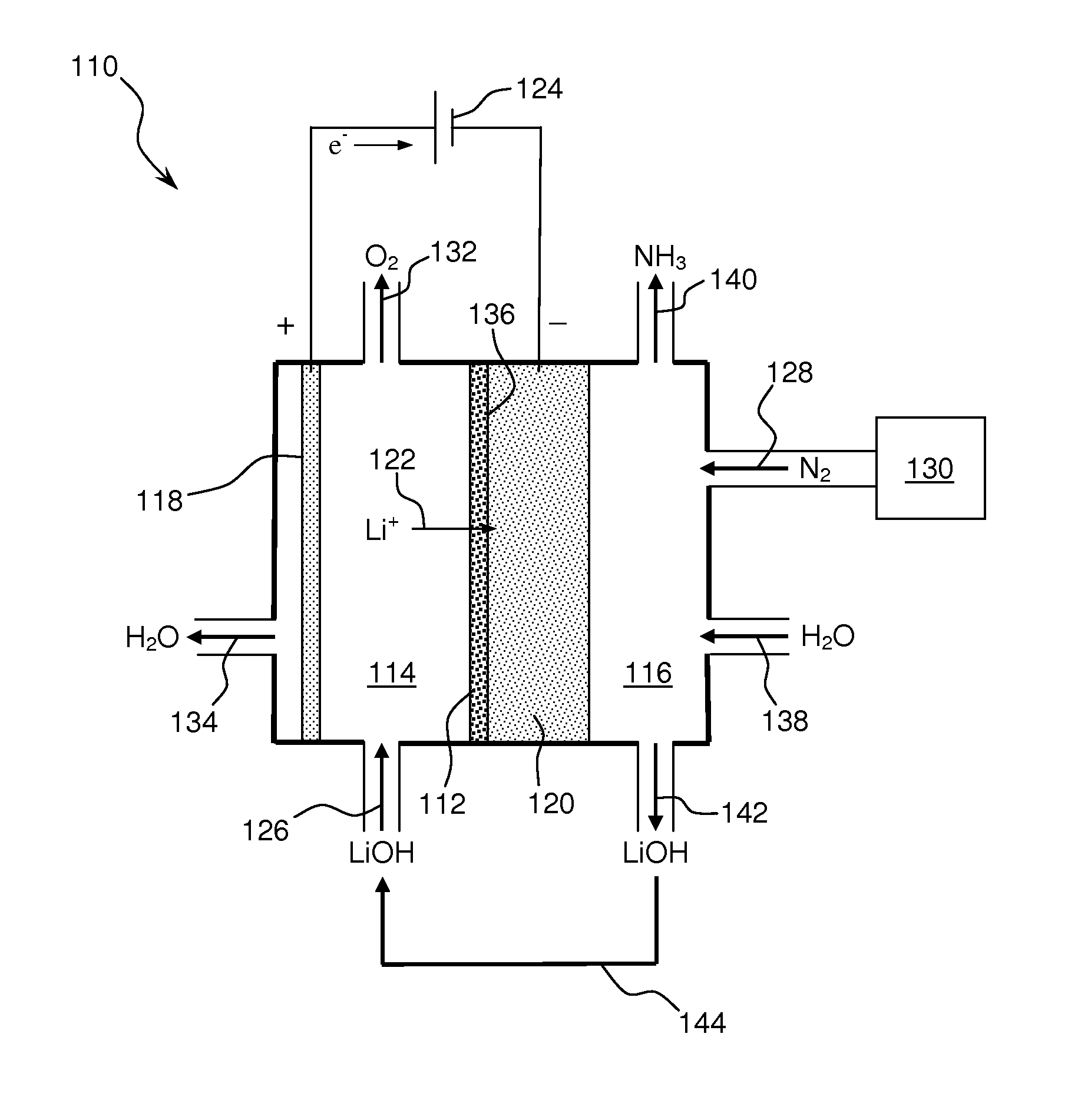

Ammonia is synthesized using electrochemical and non-electrochemical reactions. The electrochemical reactions occur in an electrolytic cell having a lithium ion conductive membrane that divides the electrochemical cell into an anolyte compartment and a catholyte compartment. The catholyte compartment includes a porous cathode closely associated with the lithium ion conductive membrane. The overall electrochemical reaction is: 6LiOH+N2→Li3N (s)+3H2O+3 / 2O2. The nitrogen may be produced by a nitrogen generator. The non-electrochemical reaction involves reacting lithium nitride with water and / or steam as follows: Li3N (s)+3H2O→3LiOH+NH3 (g). The ammonia is vented and collected. The lithium hydroxide is preferably recycled and introduced into the anolyte compartment. The electrolytic cell is shut down prior to reacting the lithium nitride with water. The cathode is preferably dried prior to start up of the electrolytic cell and electrolyzing Li+ and N2 at the cathode.

Owner:ENLIGHTEN INNOVATIONS INC

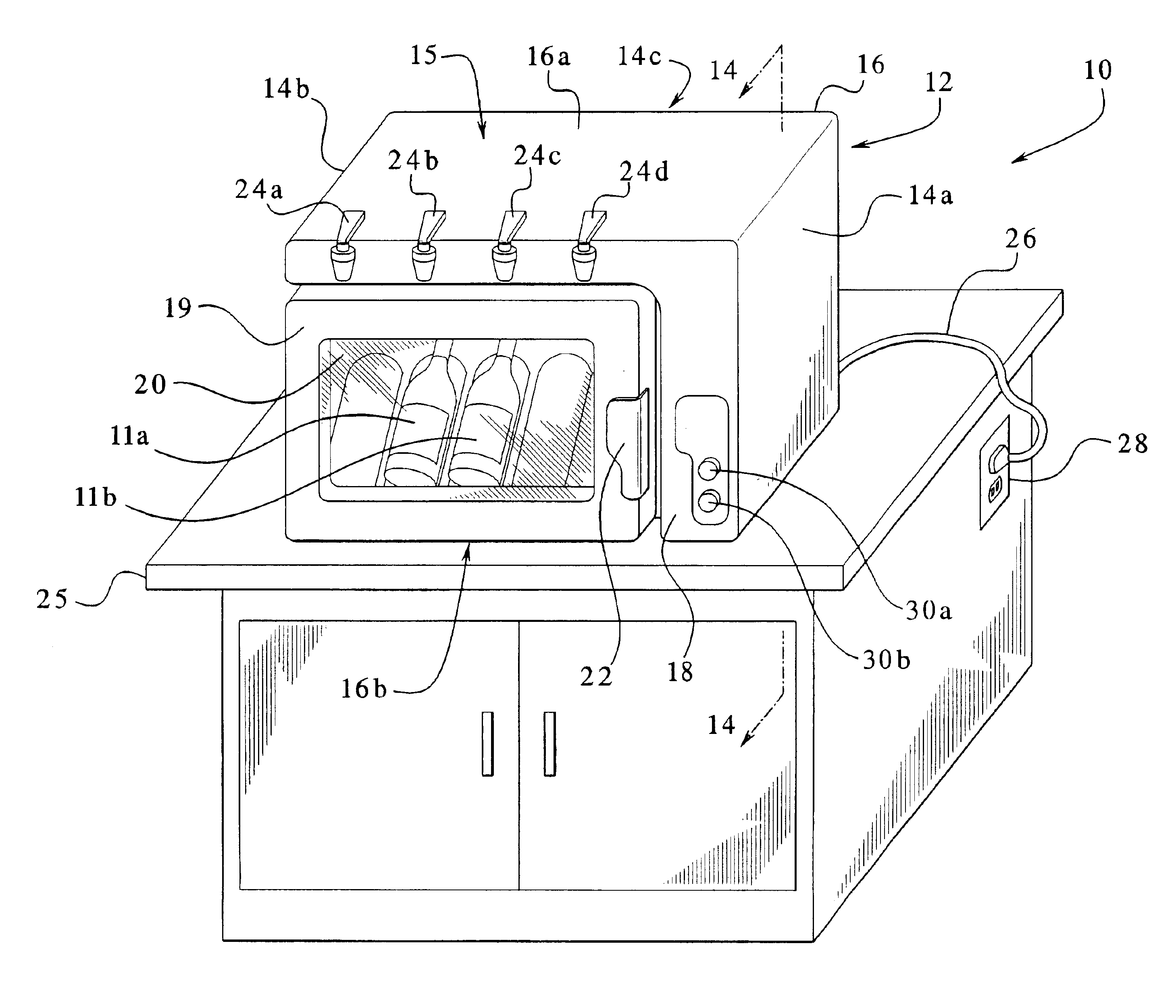

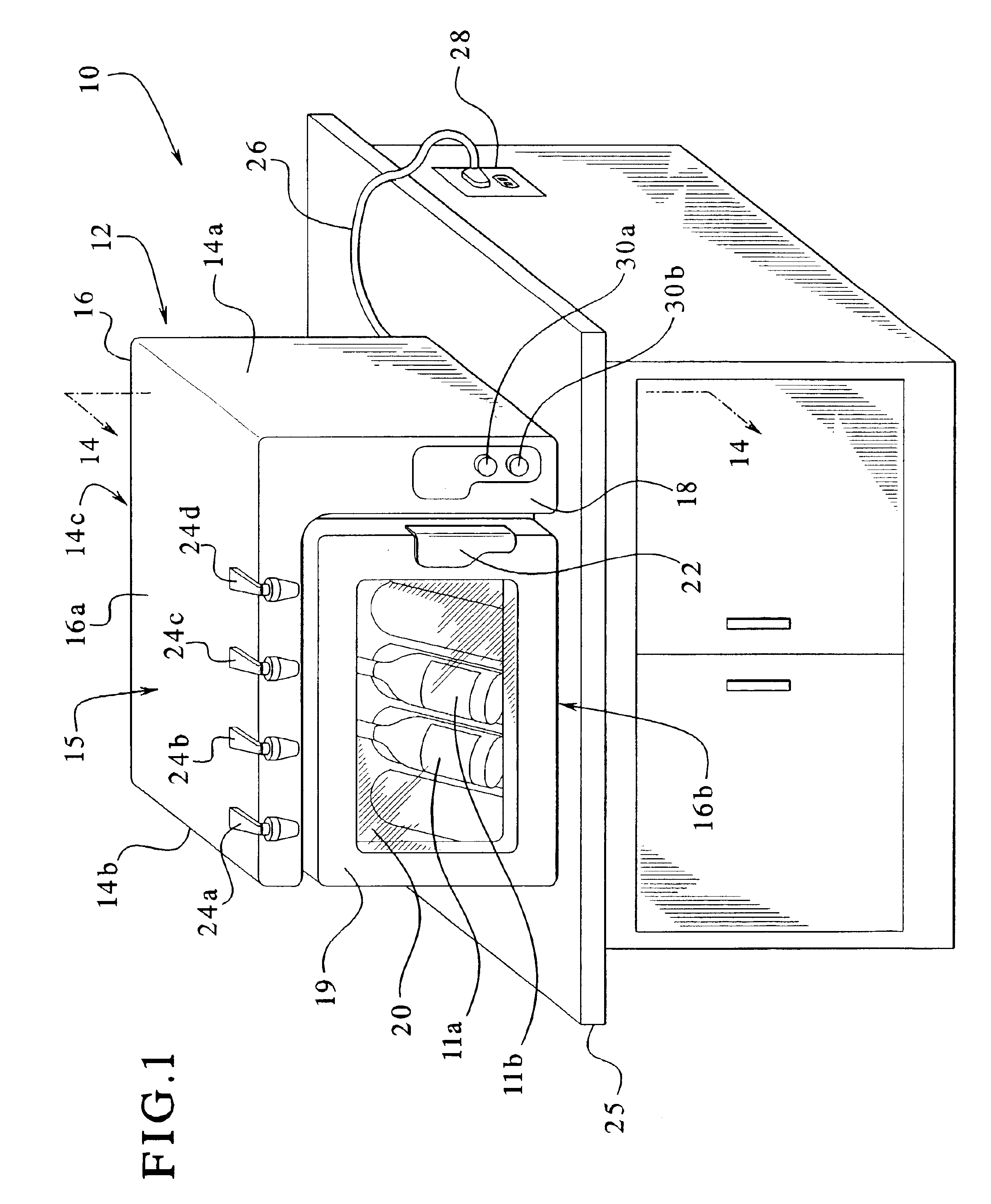

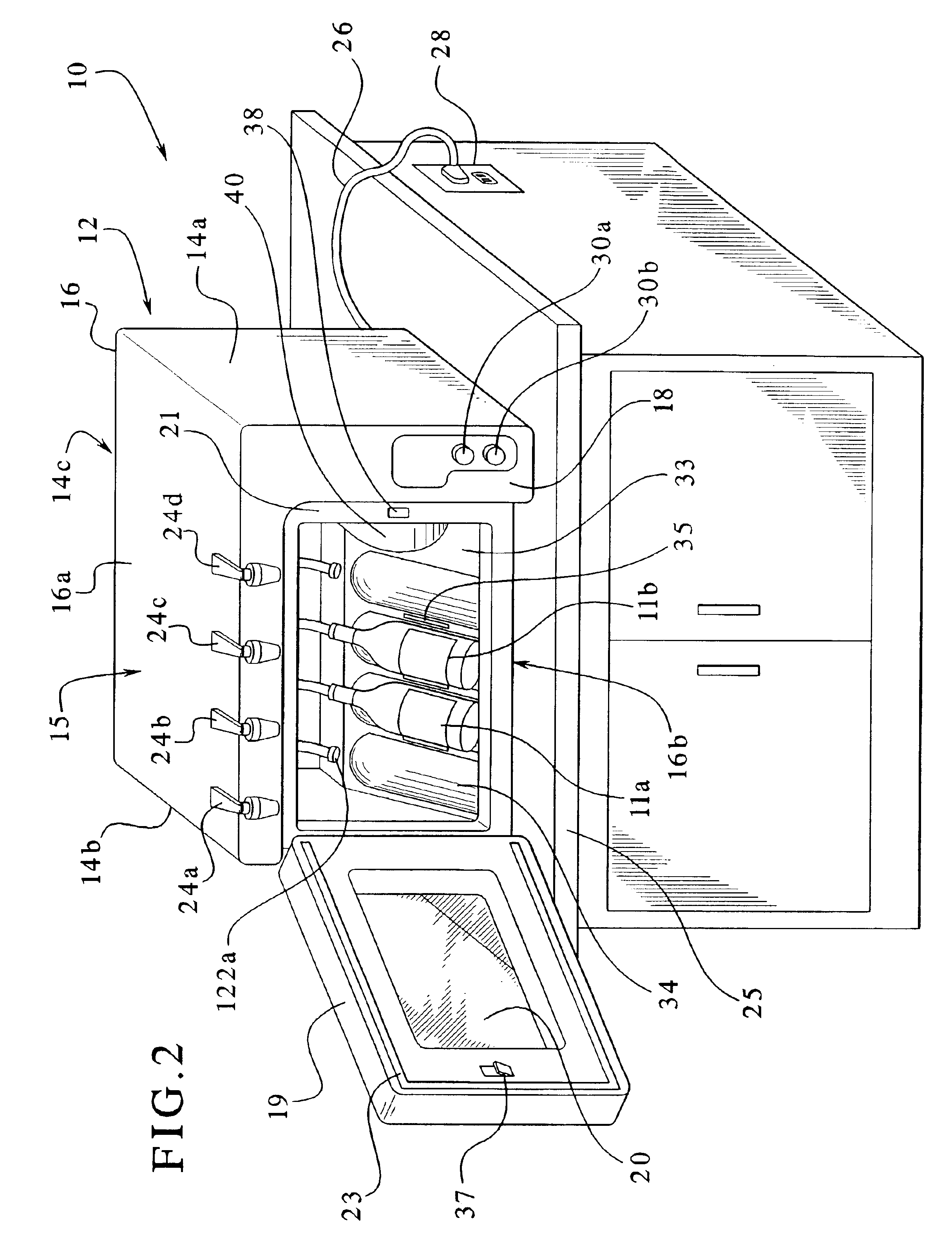

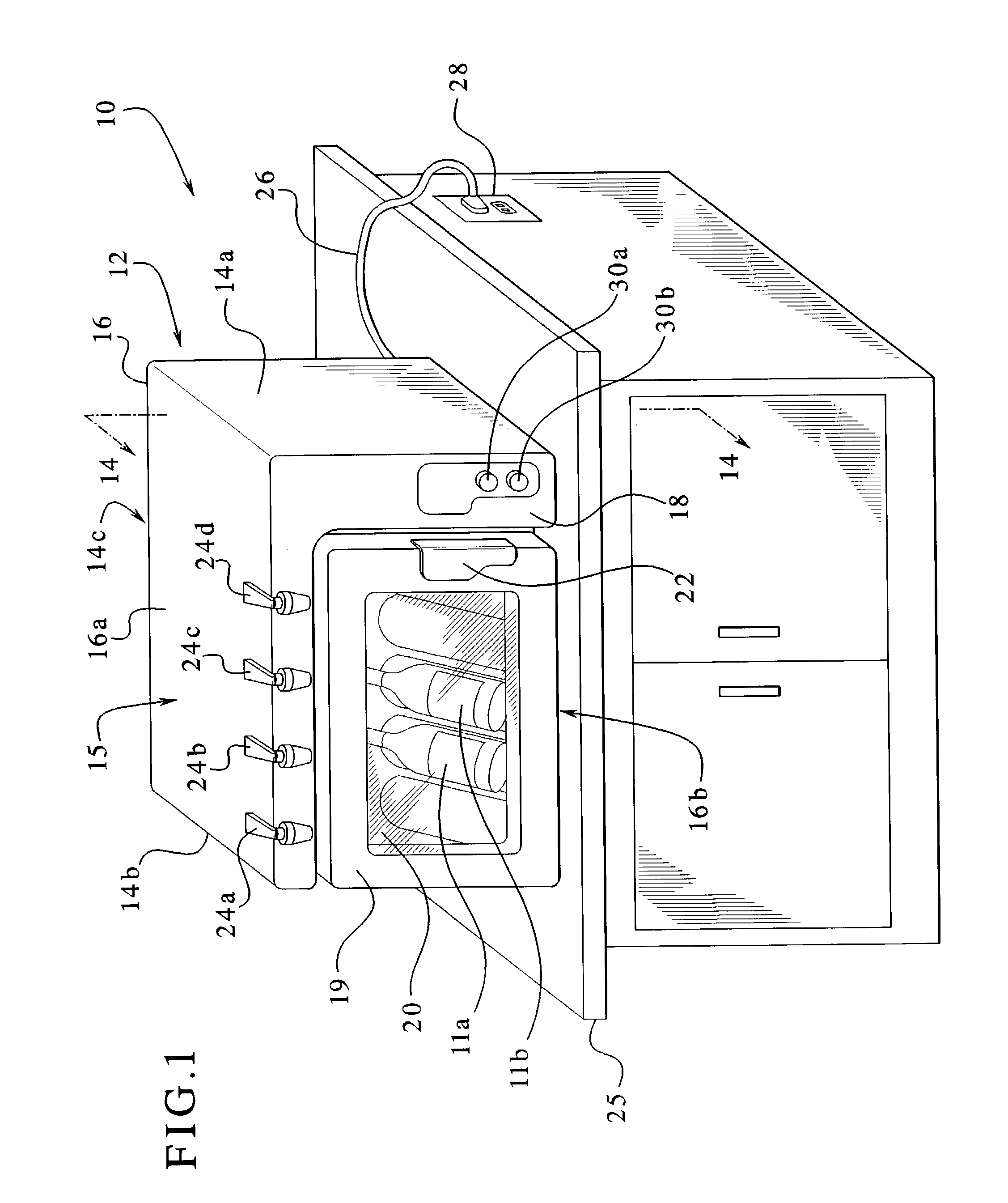

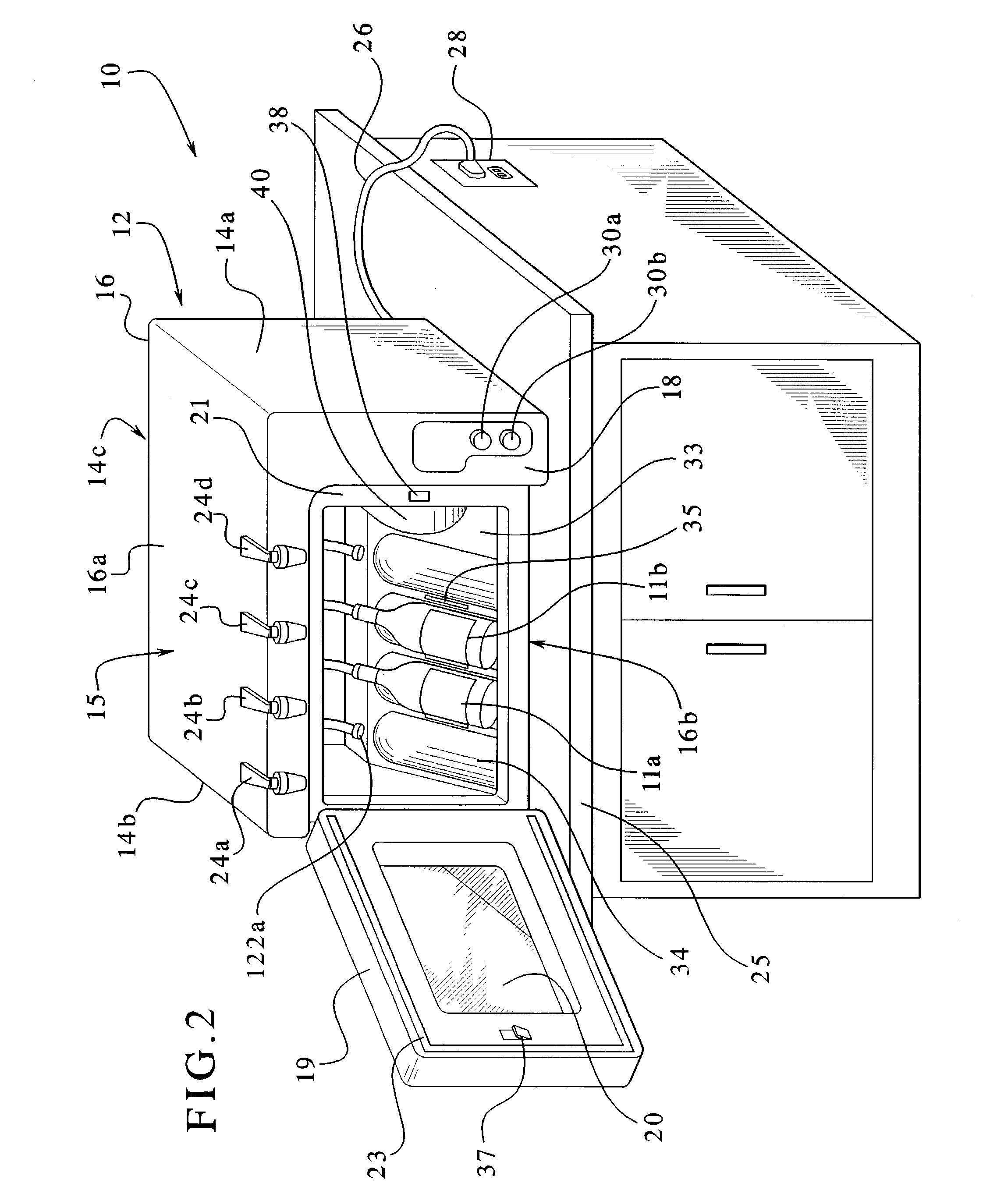

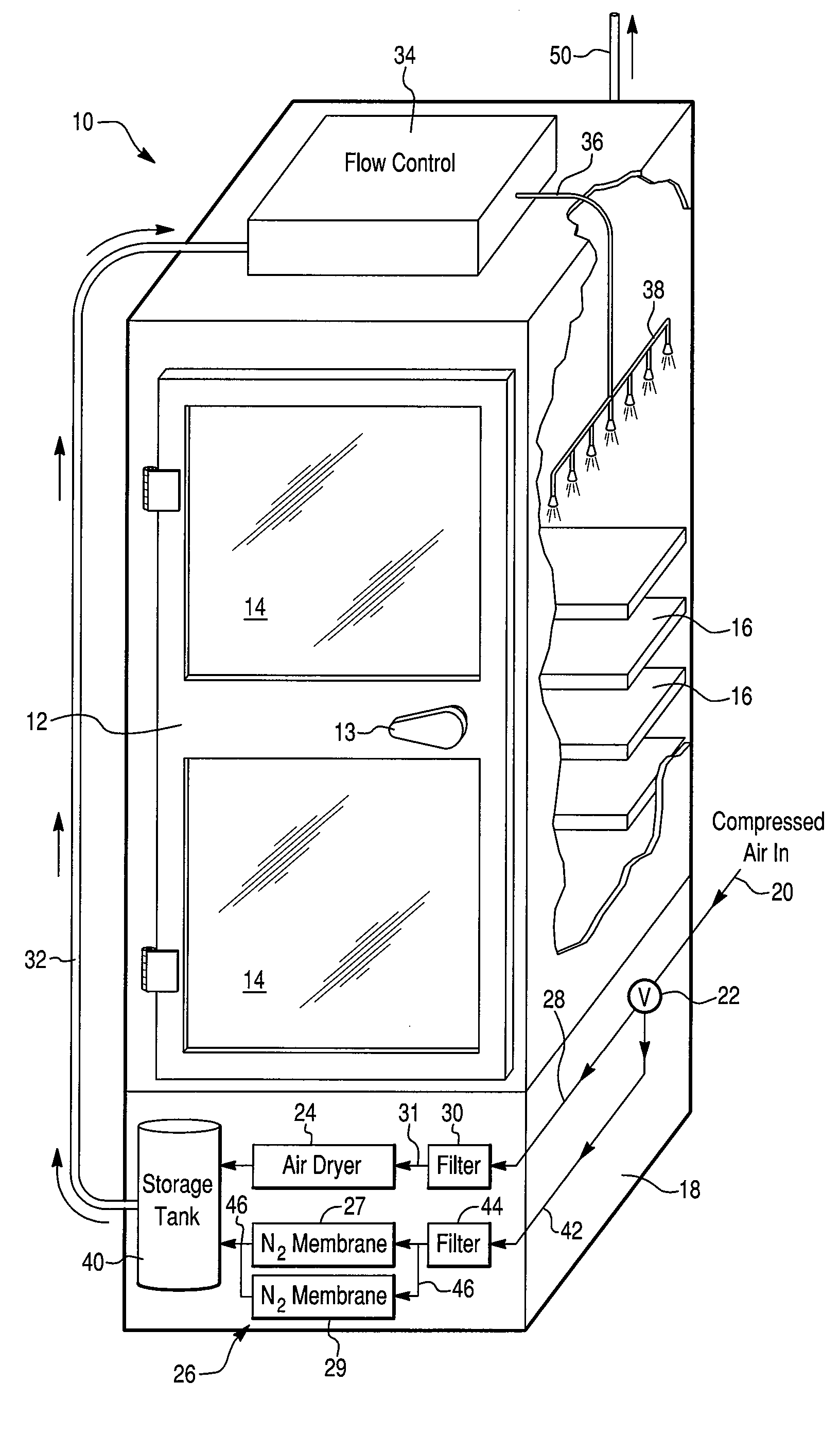

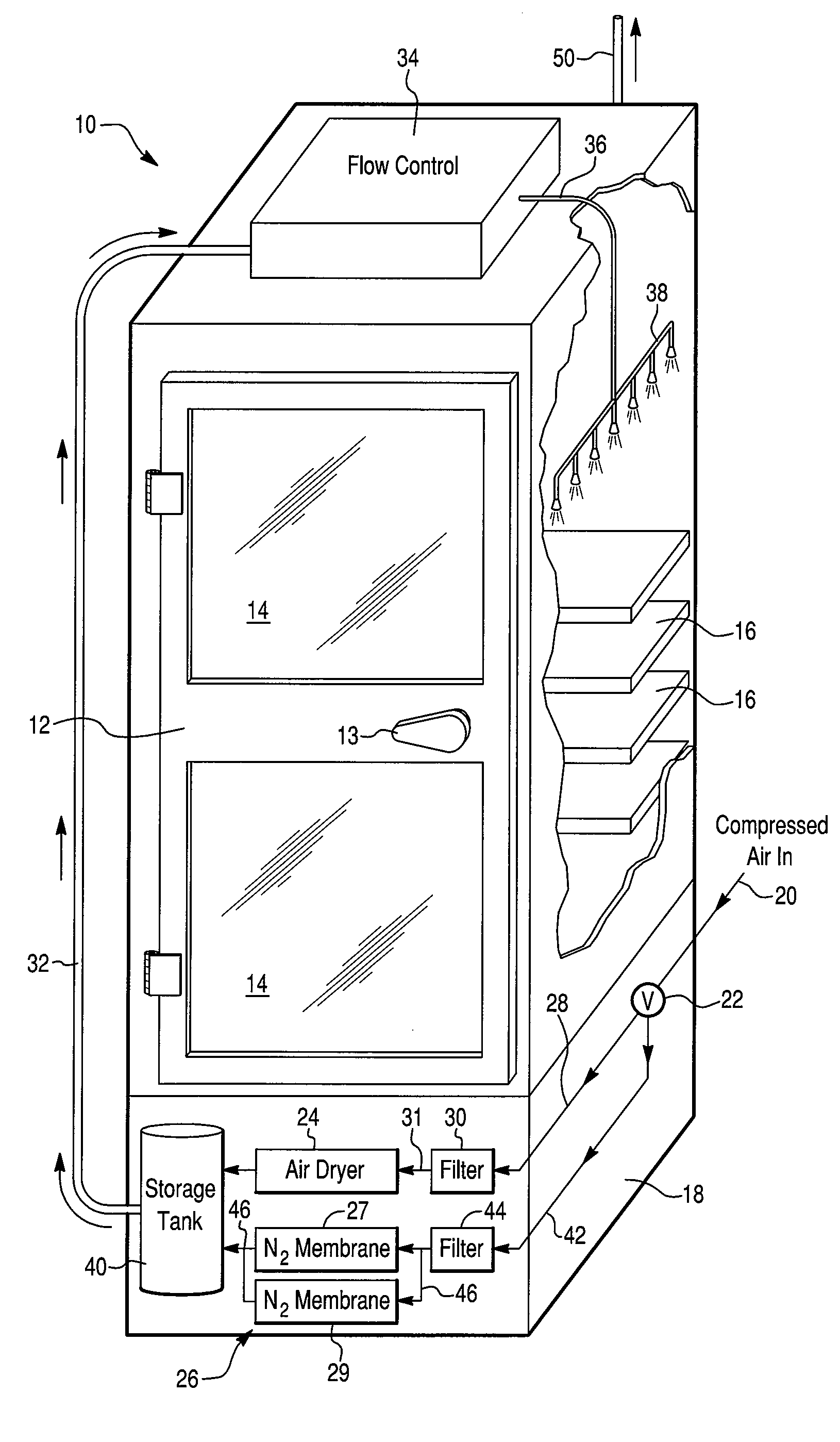

Wine or champagne preservation and dispensing apparatus

An apparatus for preserving and dispensing wine or champagne. The apparatus provides a housing having a container support for holding wine or champagne bottles, a plurality of removable stoppers for insertion in the bottles, a nitrogen generator for generating a nitrogen rich gas from air, a nitrogen storage tank for storing the generated nitrogen rich gas, a cooling system for cooling certain bottles and dispensers for providing wine or champagne from the bottles to a user. The nitrogen generator draws in ambient air, adsorbs the oxygen from the air and stores nitrogen rich gas in the nitrogen storage tank. The nitrogen storage tank supplies the nitrogen rich gas to the bottles for preserving the wine or champagne. The stoppers include a nitrogen line and a supply line. The nitrogen line communicates nitrogen rich gas into the bottles and the supply line communicates wine or champagne from the bottles to the dispensers.

Owner:VIN VALET

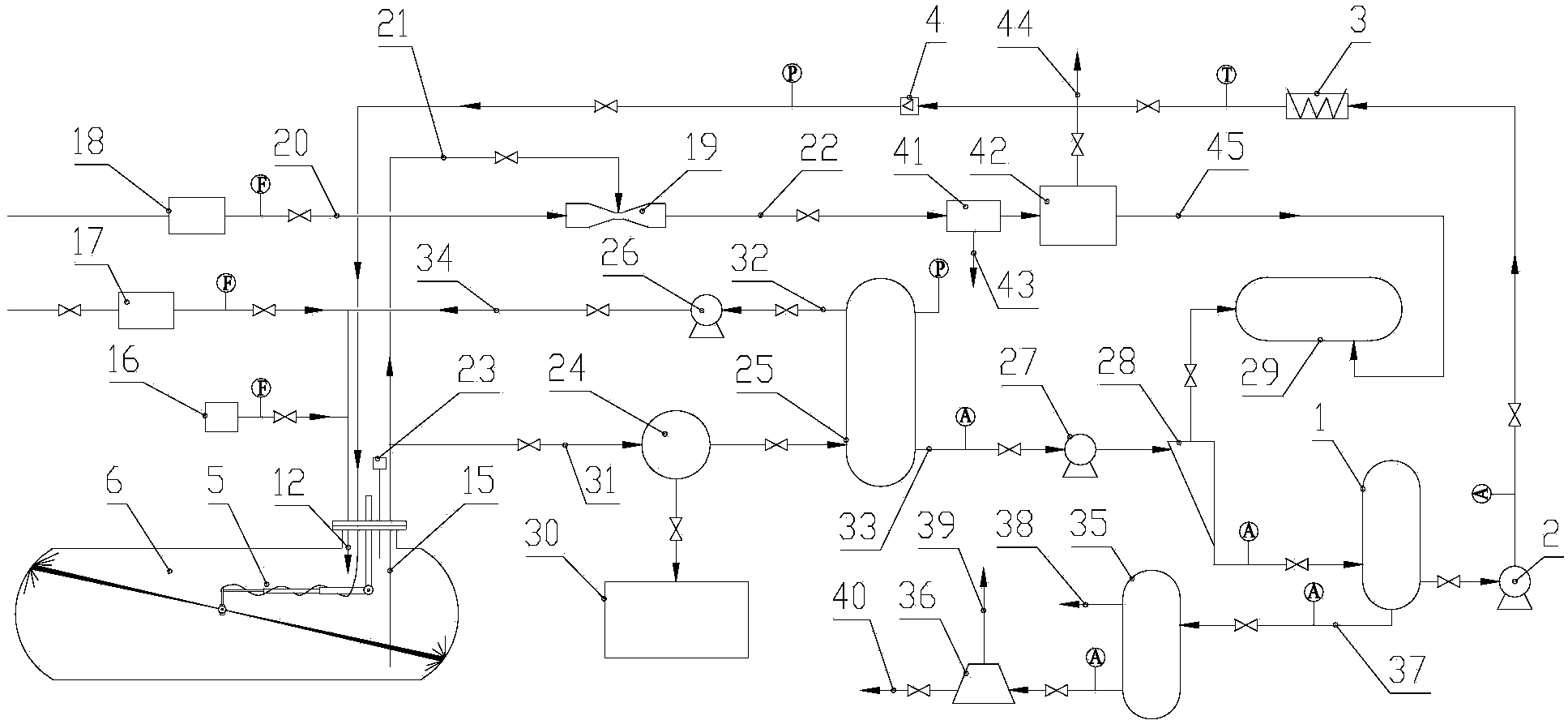

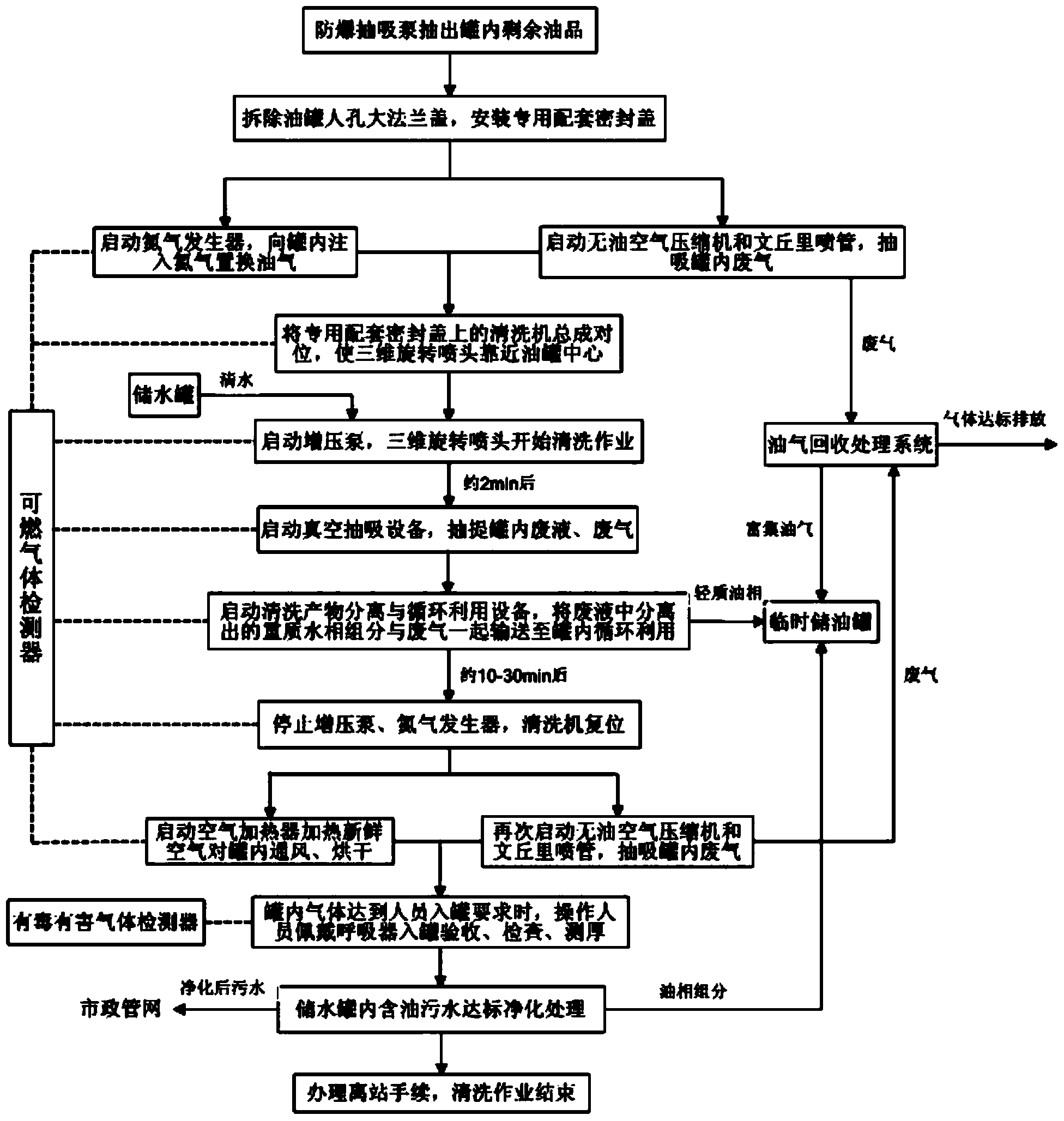

Mechanical cleaning system for underground storage tank of filling station

ActiveCN104001702ACompact structureWater/sewage treatment by centrifugal separationHollow article cleaningNitrogen generatorWater storage tank

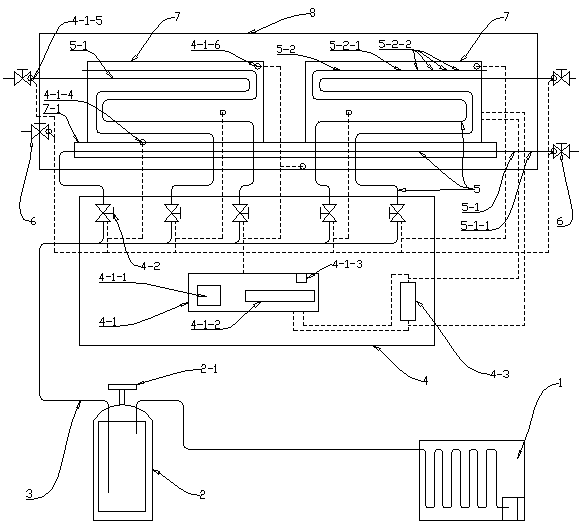

The invention discloses a mechanical cleaning system for an underground storage tank of a filling station. The mechanical cleaning system comprises a low-pressure jet cleaning device, an air replacement device, a gas atmosphere monitoring device, a cleaned-away dirt separation and recycling device, an oily sewage discharge standardization treatment device and an oil and gas recovery treatment device. The low-pressure jet cleaning device comprises a water storage tank, a booster pump, a heater, a turbine flowmeter and a cleaning machine, wherein the water storage tank, the booster pump, the heater, the turbine flowmeter and the cleaning machine are connected in sequence through pipelines. The air replacement device comprises a nitrogen generator, an air heater and an oilless air compressor. The oil and gas recovery treatment device comprises a precooler and an activated carbon adsorption tank, wherein the precooler and the activated carbon adsorption tank are connected with each other. The cleaned-away dirt separation and recycling device comprises a filter, a vacuum suction tank, a suction pump and an axial inlet hydrocyclone. The oily sewage discharge standardization treatment device comprises a compact vertical swirling air-floatation separation tank and a disk centrifuge. The mechanical cleaning system is intrinsically safe, efficient, environmentally friendly, compact in structure and capable of meeting related discharge requirements.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

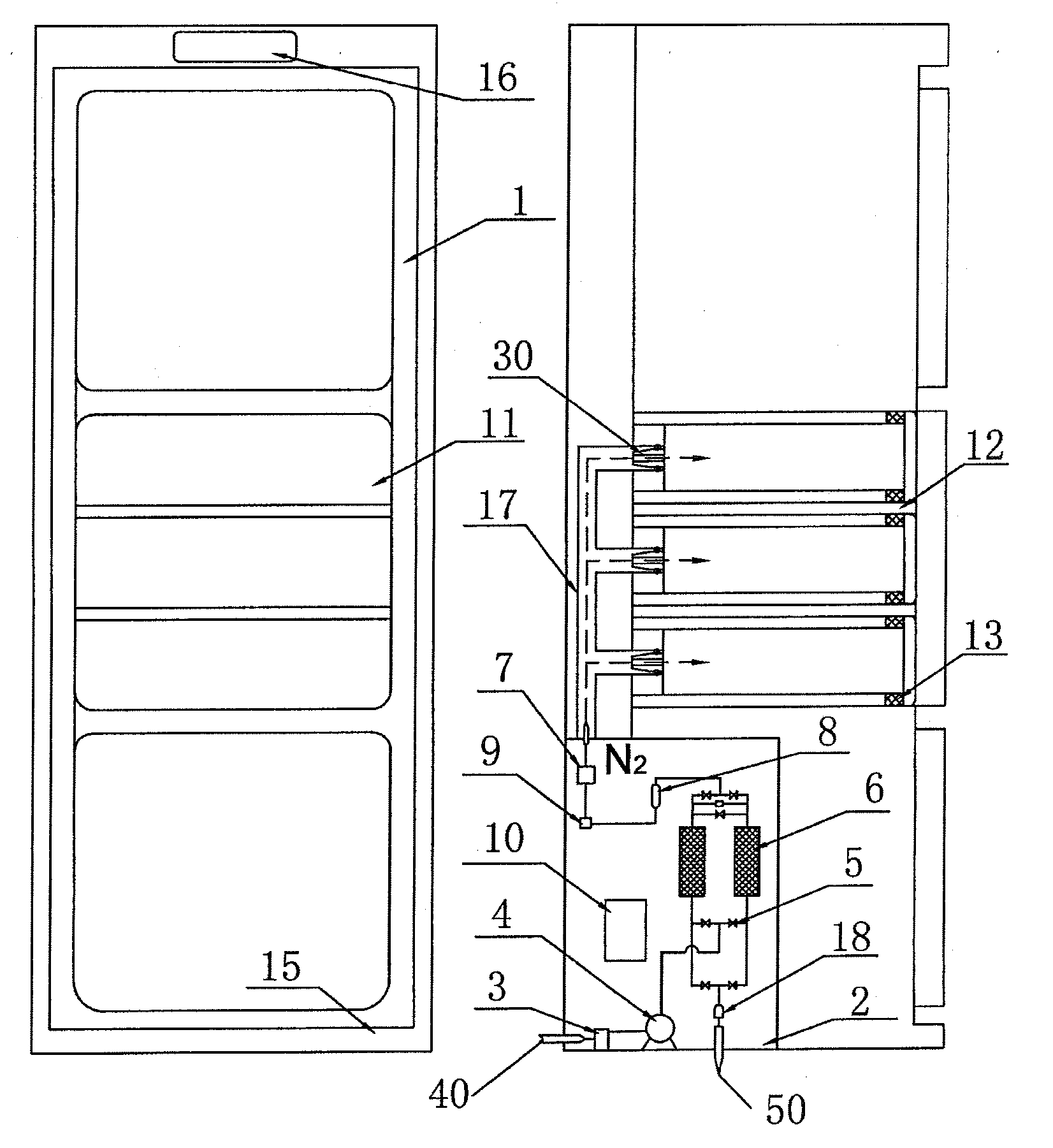

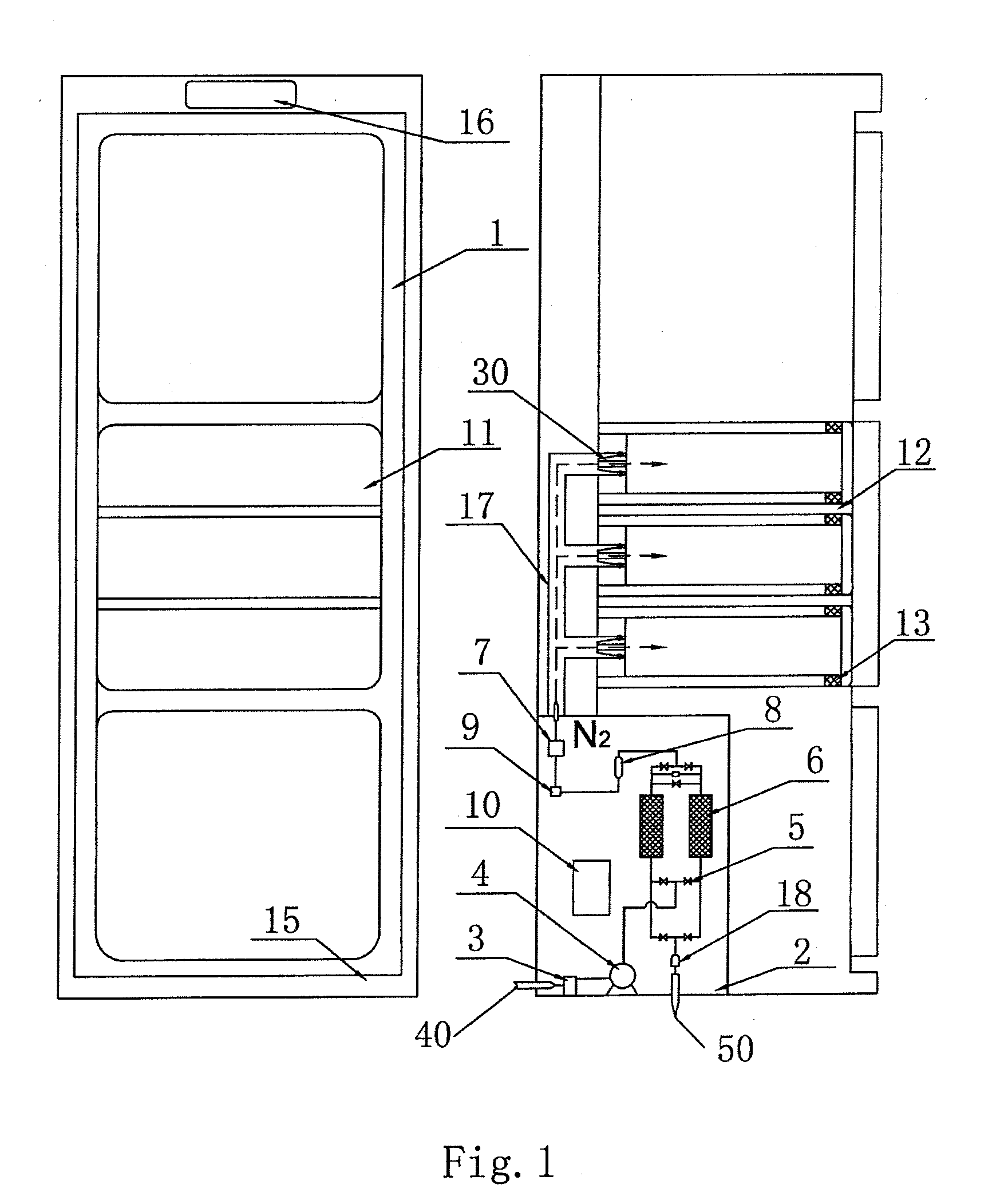

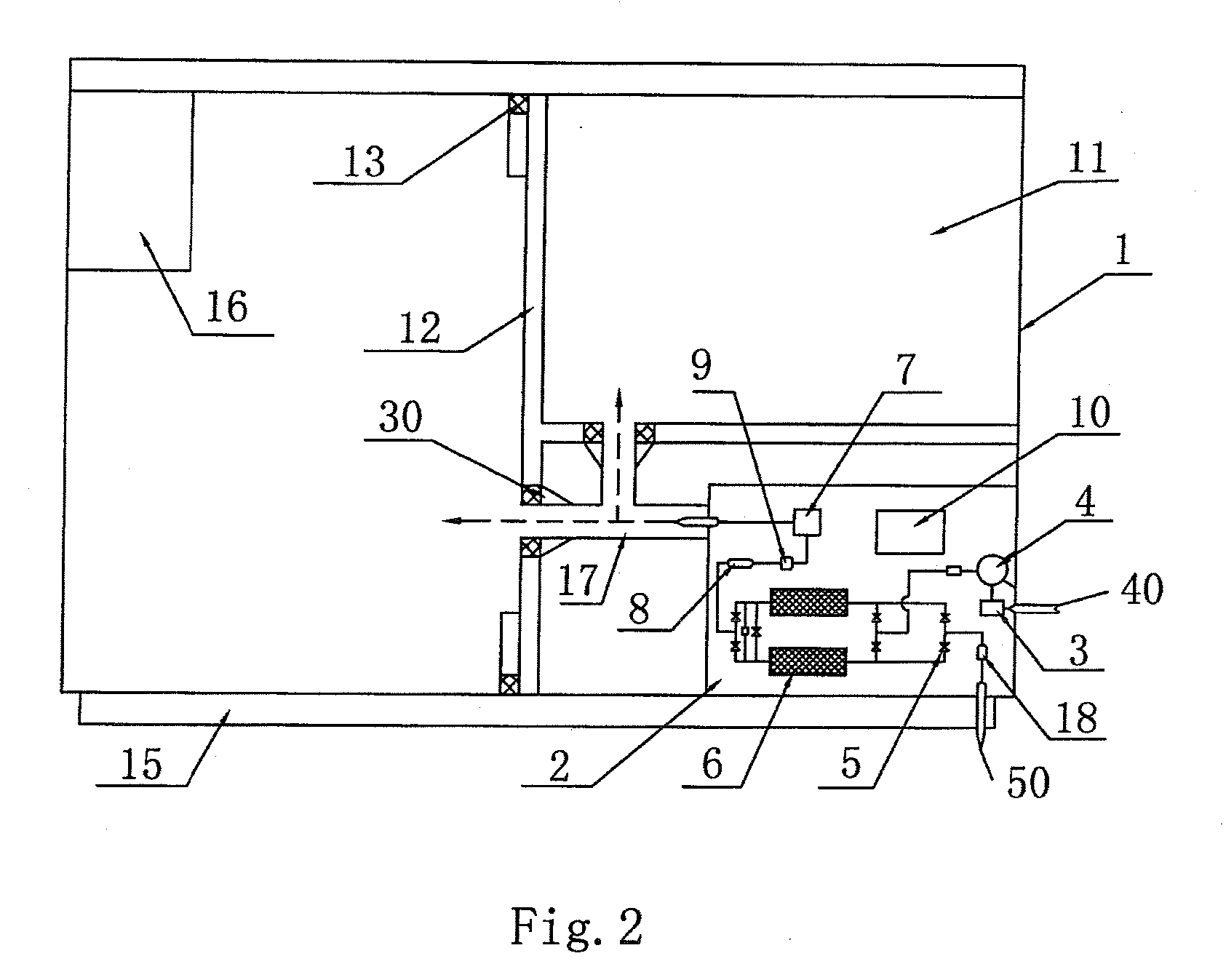

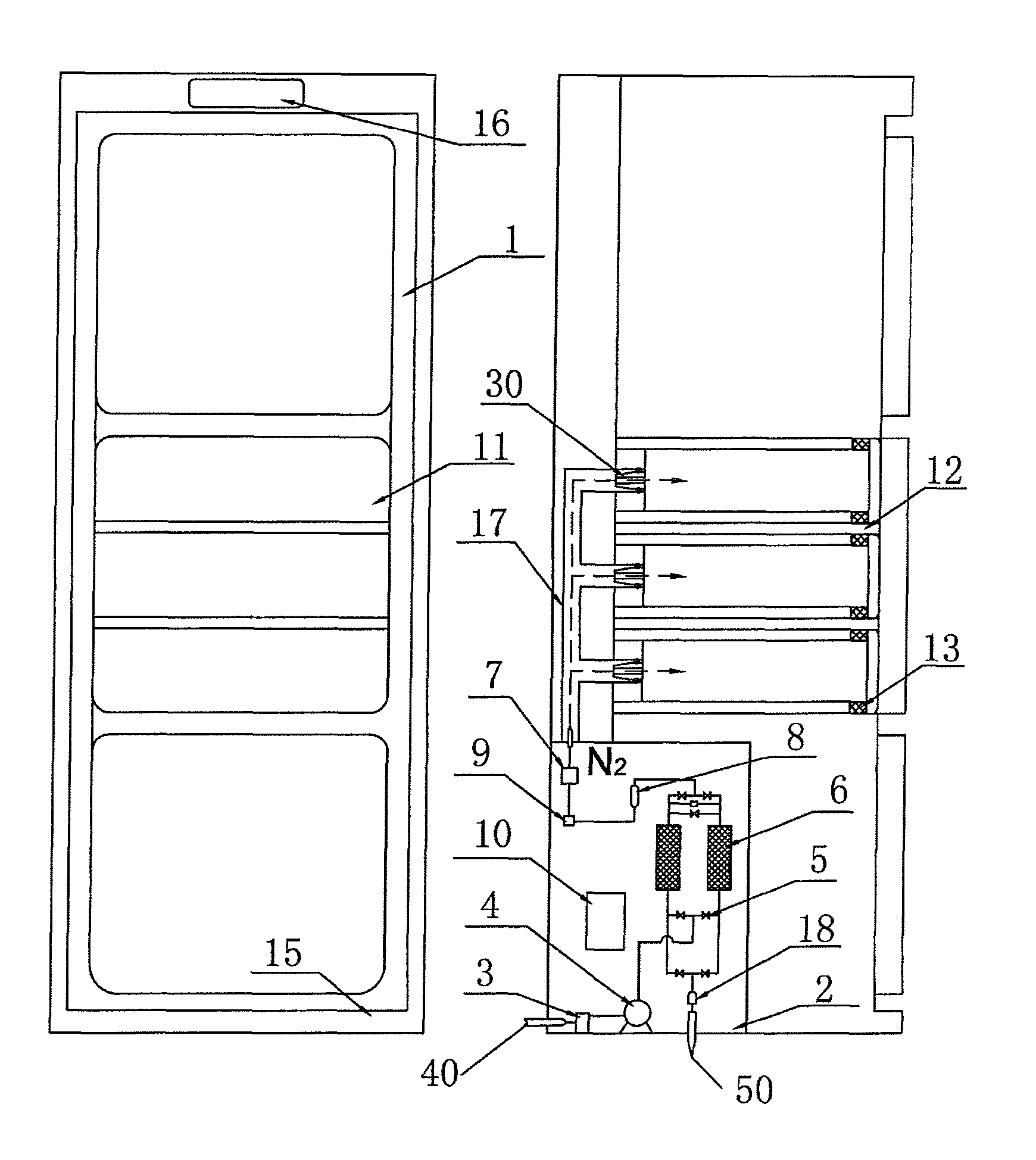

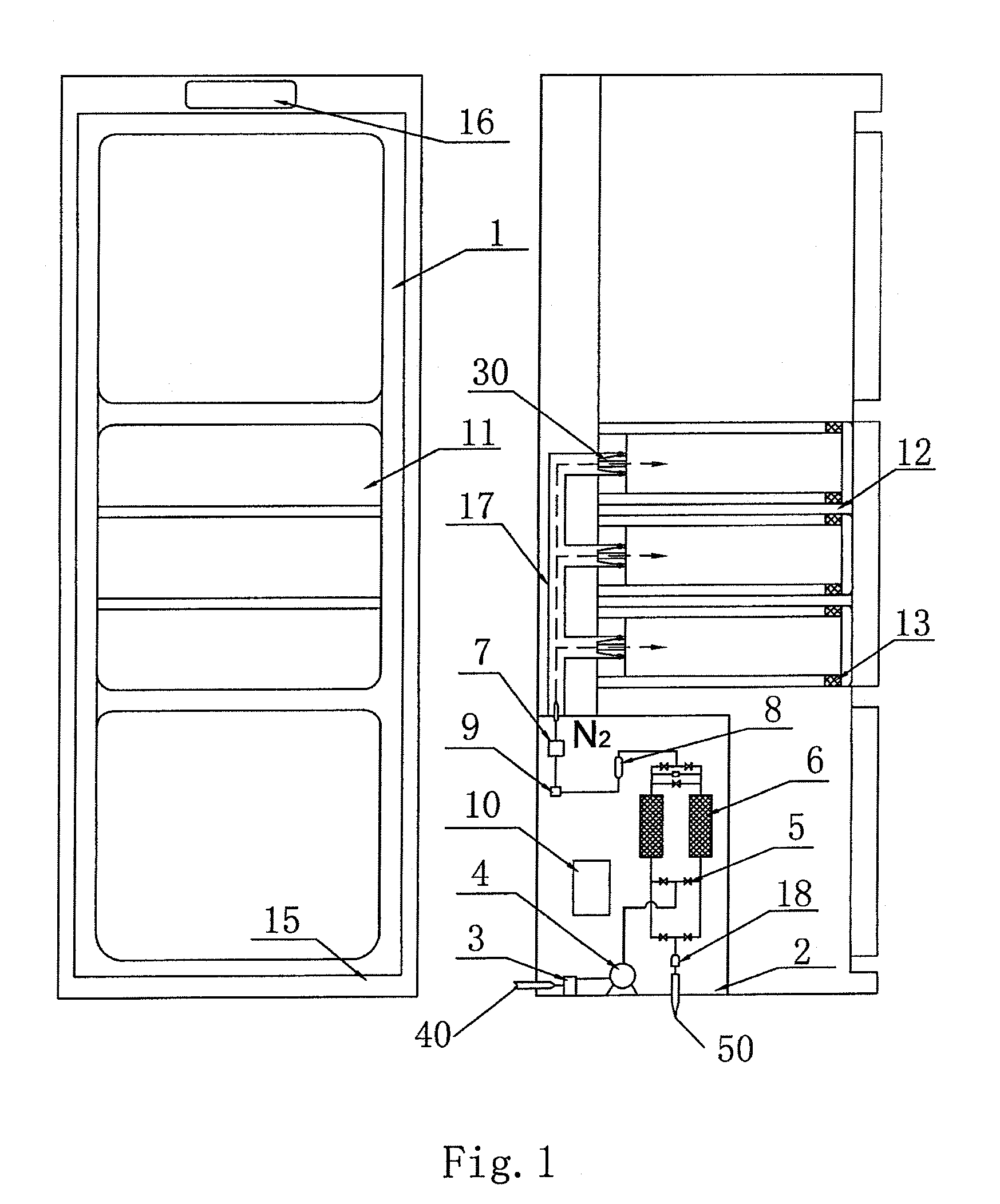

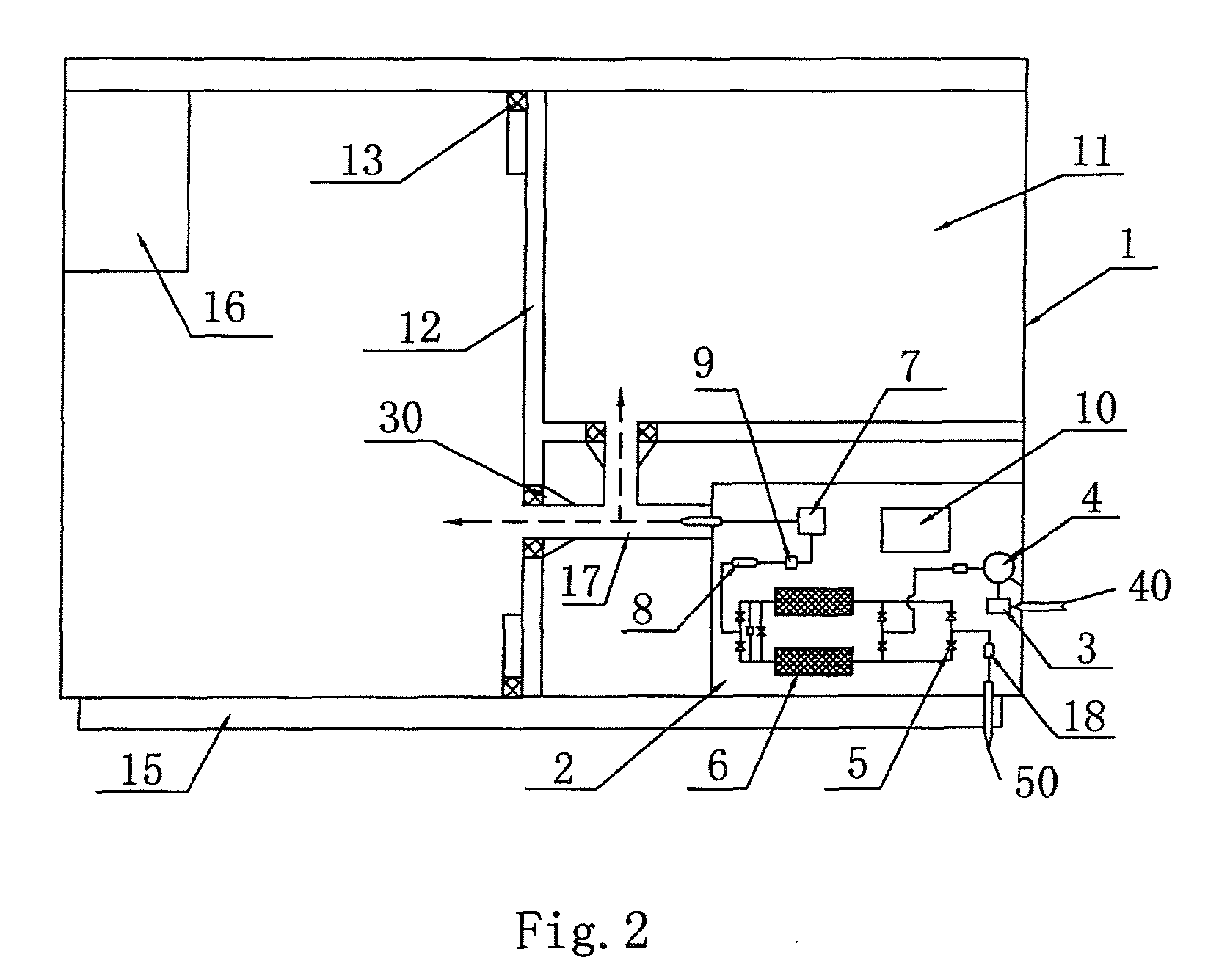

Refrigeration and freezing device with fresh-keeping function by supplying nitrogen

InactiveUS20100269525A1Compact structureDouble functionFruit and vegetables preservationLighting and heating apparatusNitrogen generatorMolecular sieve

A refrigeration and freezing device with fresh-keeping function by supplying nitrogen comprises a box body, a refrigerating and freezing chamber disposed inside the box body, a door to the refrigerating and freezing chamber, a control device and a nitrogen generator; wherein said nitrogen generator is disposed either inside or outside the box body of the refrigeration and freezing device, said nitrogen generator comprises an air inlet, an oxygen outlet, a nitrogen outlet, an air filter connected with the air inlet, a compressor, a pipe device for transmitting gas, at least one carbon molecular sieve absorber, at least one control valve to control different absorbers to work alternately, a nitrogen storage container, a nitrogen purifier, a pressure reducing valve for adjusting the pressure of the produced nitrogen, a ventilating muffler disposed on a pipe to the oxygen outlet and a control circuit.

Owner:WANG DONG LEI

Consecutive reaction apparatus for moisture sludge through anhydration and pyrolysis under microwave irradiation as well as method thereof

ActiveCN104163555AGood heating selectivityRapid pyrolysisSludge treatment by pyrolysisByproduct vaporizationRadiation lossNitrogen generator

The invention discloses a consecutive reaction apparatus for moisture sludge through anhydration and pyrolysis under microwave irradiation as well as a method thereof. The condensation comprises a sludge warehouse, a stirrer, a hopper feeder, a sludge-shaped controller, a belt sender, a power control microwave irradiation device, a microwave pyrolysis reaction chamber, a pressure sensing controller, a blower fan, a condensation heat exchanger, a scraper plate separator, an oil-water separating device, a liquid dredging groove, a coke storage tank, a product oil tank, a product gas tank, a nitrogen generator, a coke crusher, a sludge water pot and a gas shunting plate. According to the invention, microwave material internal heating characteristic can be fully used for reducing heat radiation loss, moisture sludge is directly performed with anhydration and pyrolysis to obtain the cracking oil, combustible gas and solid coke; heat recovery of the product gas and auxiliary microwave heating characteristic of the products residue are fully used for reducing the operation cost, and sludge pyrolysis efficiency and products quality can be increased. The apparatus has the advantages of simple structure, small volume, reasonable design and convenient market popularization, and is suitable for industrial application of microwave sludge continuous pyrolysis.

Owner:ZHEJIANG UNIV

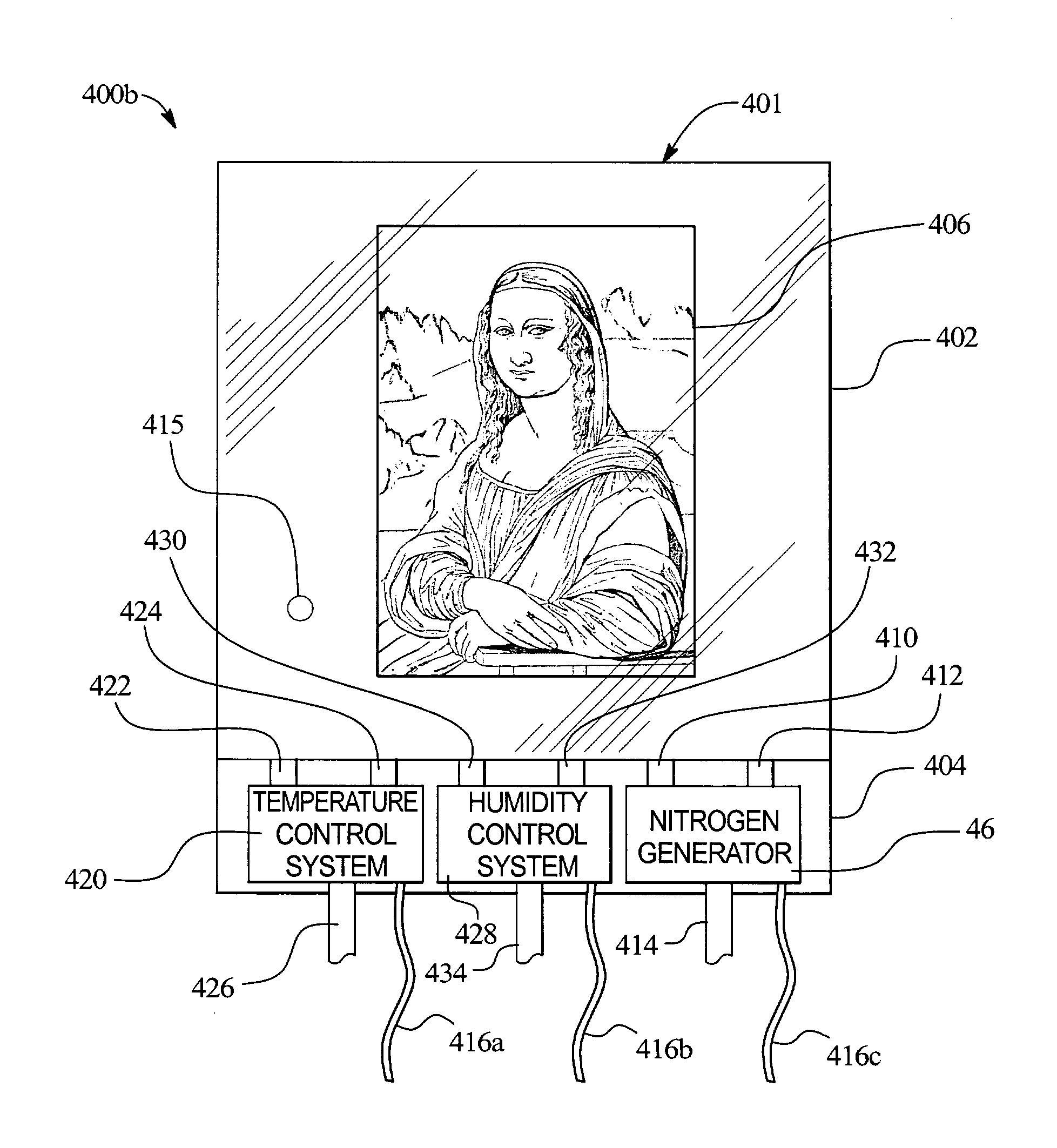

Apparatus and method for preserving collectible items

The present invention relates to an apparatus and method for preserving one or more collectible items. The apparatus includes a housing and a nitrogen generator. A nitrogen generator generates a nitrogen rich gas and supplies the nitrogen gas to the housing, which displaces the oxygen inside the housing to preserve the collectible item or items enclosed by the housing. The nitrogen rich gas significantly reduces the degradation of the collectible item due to the exposure of the item to oxygen in the air. In another embodiment, the apparatus further includes a temperature control system and a humidity control system to control the temperature and humidity inside the housing. This further aids in preserving a collectible item for relatively long periods of time by reducing the effects of the environment on the item.

Owner:VIN VALET

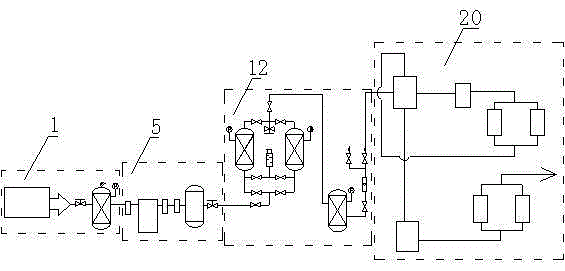

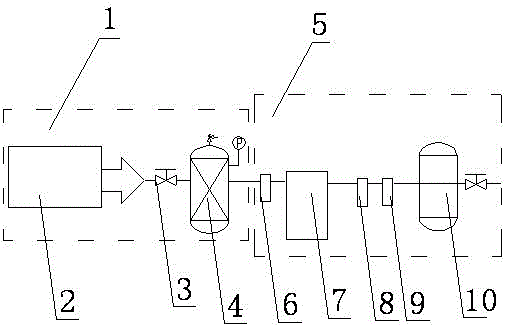

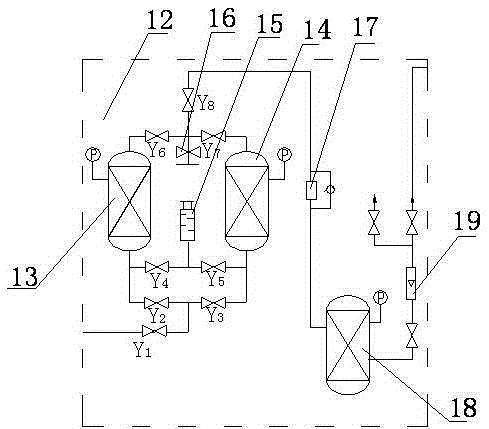

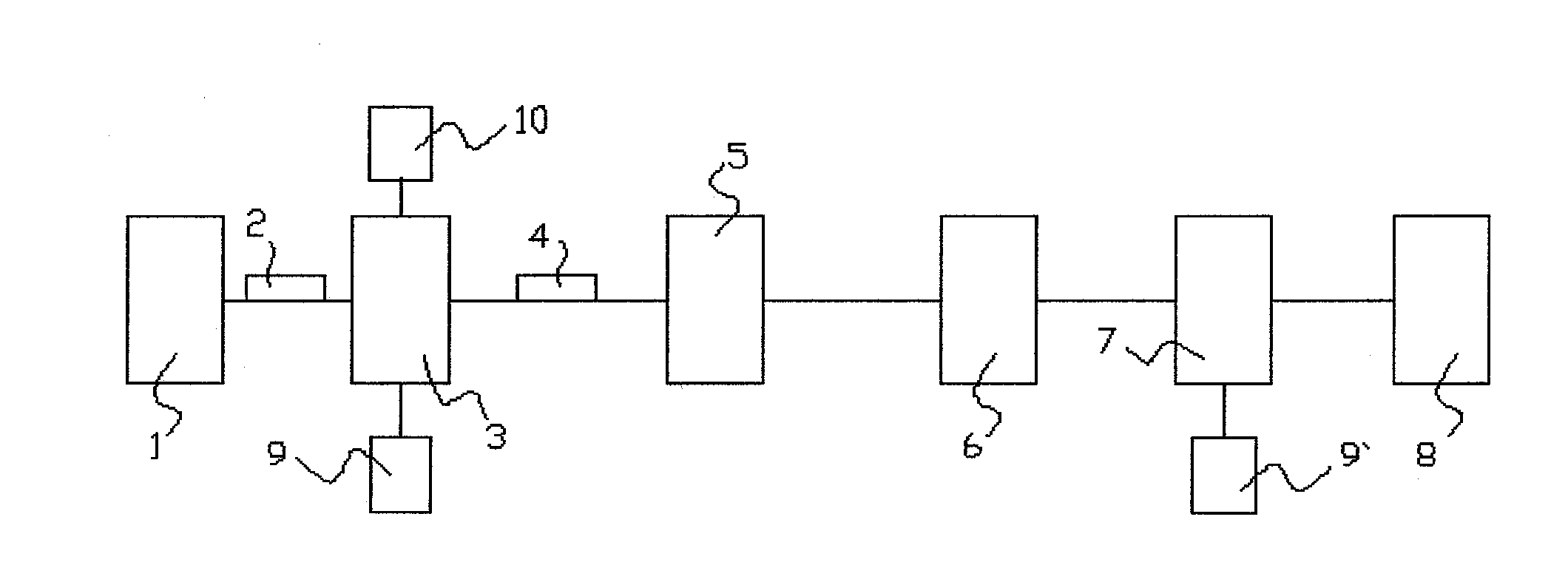

High purity nitrogen producing machine and nitrogen producing technology thereof

ActiveCN105384152AHigh purityMeeting high-purity demandsNitrogen purification/separationNitrogen gasExhaust pipe

The invention relates to a high purity nitrogen producing machine, which is characterized by comprising an air compressing system (1), an air purification system (5), a pressure swing adsorption nitrogen producing system (12), and a deoxidization system (20), wherein the air compressing system (1), air purification system (5), pressure swing adsorption nitrogen producing system (12), and deoxidization system (20) are arranged in sequence from the front to the back. The machine can be used in fields such as food preservation, electronic assembly, metallurgy, chemical pharmacy, petroleum and natural gas, and the like. The purity of nitrogen gas produced by the machine is high and can reach 99.9995%, and thus the high purity requirement can be met. Two adsorption towers can be rapidly and automatically switched during the production process, and thus the efficiency of nitrogen production is high. Moreover, the exhaust pipes of the adsorption towers are provided with a muffler, and generated noise is reduced therefore. At the same time, the holes of carbon molecular sieve in adsorption towers are adjusted so as to improve the adsorption effect of the carbon molecular sieve.

Owner:JIANGYIN TONGYUE MACHINERY EQUIP

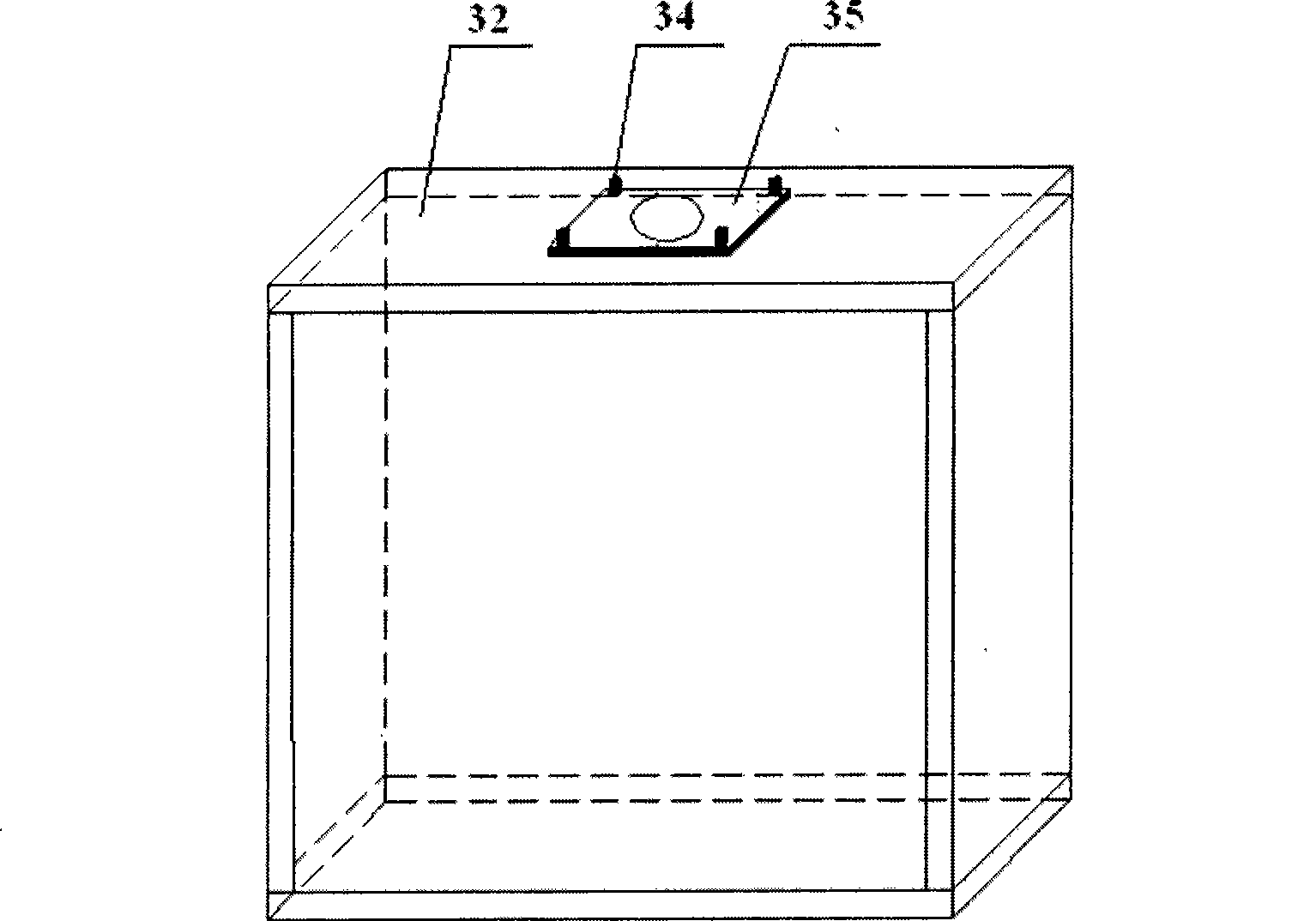

Multifunctional micro controlled atmosphere storage fresh-keeping box

InactiveCN101508372ALess investmentEasy to manageFruit and vegetables preservationEdible seed preservationNitrogen generatorAir pump

The invention discloses a multifunctional small-sized air conditioned storage fresh-keeping box in the technical field of storage and fresh-keeping engineering of farm products. An air conditioned insulation box body of the storage fresh-keeping box is assembled by air-tight insulation structural plates formed by combining and pressing colorful plastic-clad steel plates and urethane foam; and air condition on the storage of fruits and vegetables in the box body is finished through regulation control for air conditioning devices, namely an air conditioning distributor, an air control transmitter, a nitrogen generator, a carbon dioxide generator, an air removing device, an air pump, an air-tight insulation box body, a signal controller and a microcomputer processor. The storage fresh-keeping box solves the problems of difficult master on air conditioned storage indexes and process in the operation modes of the prior large and medium sized air conditioned cold stores, difficult control for physiological diseases after extraction, difficult centralized treatment, various operations, various tests, large investment, inaccurate results, and the like.

Owner:CHINA AGRI UNIV

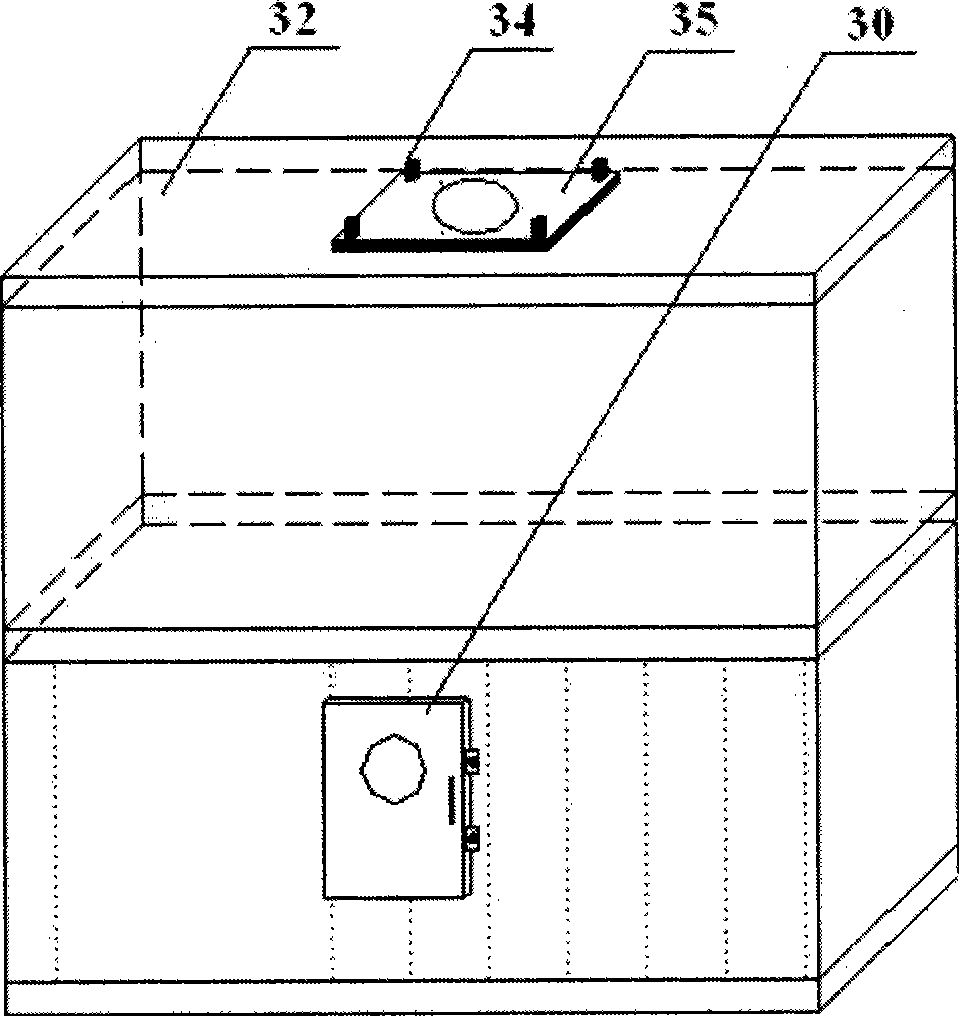

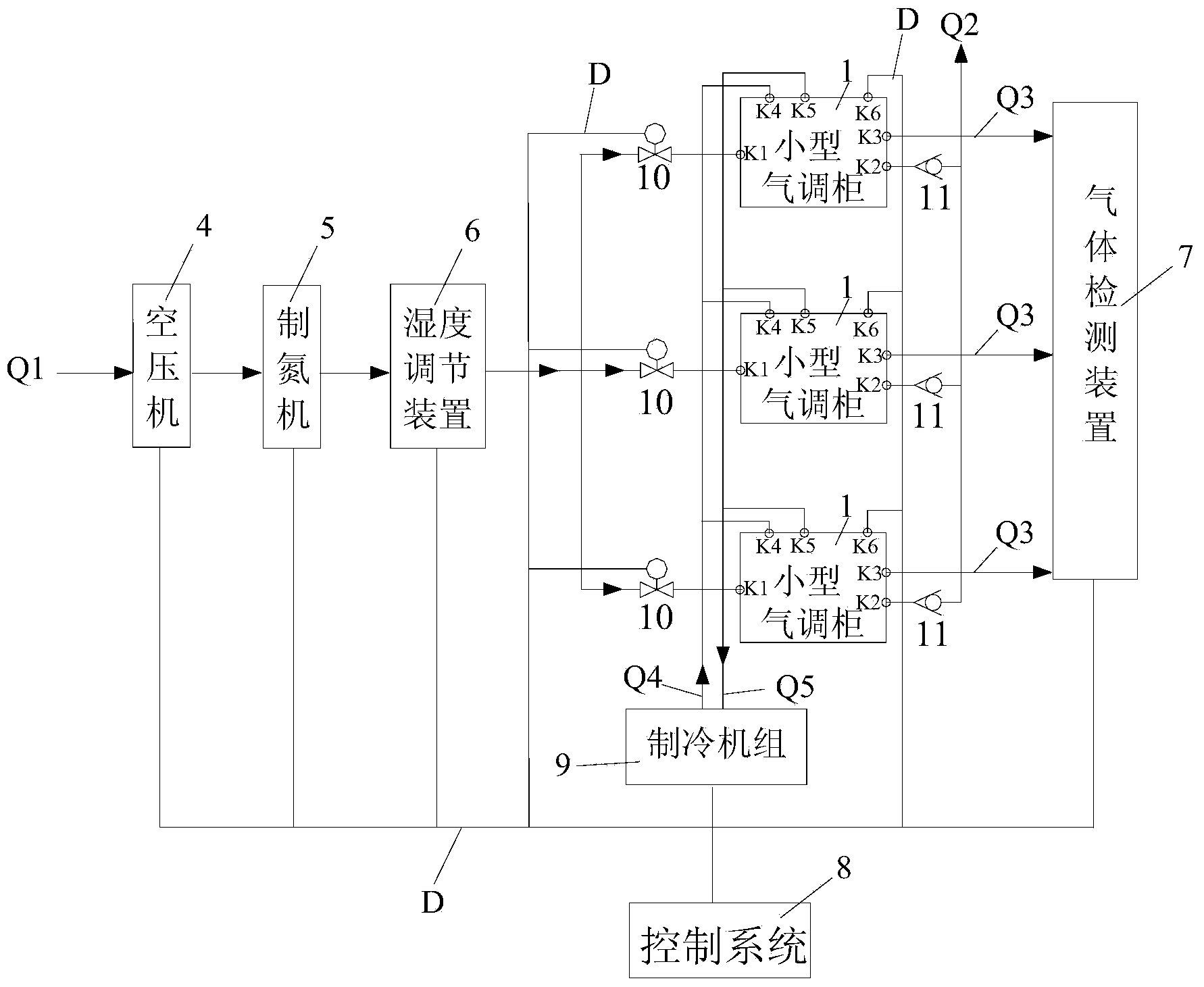

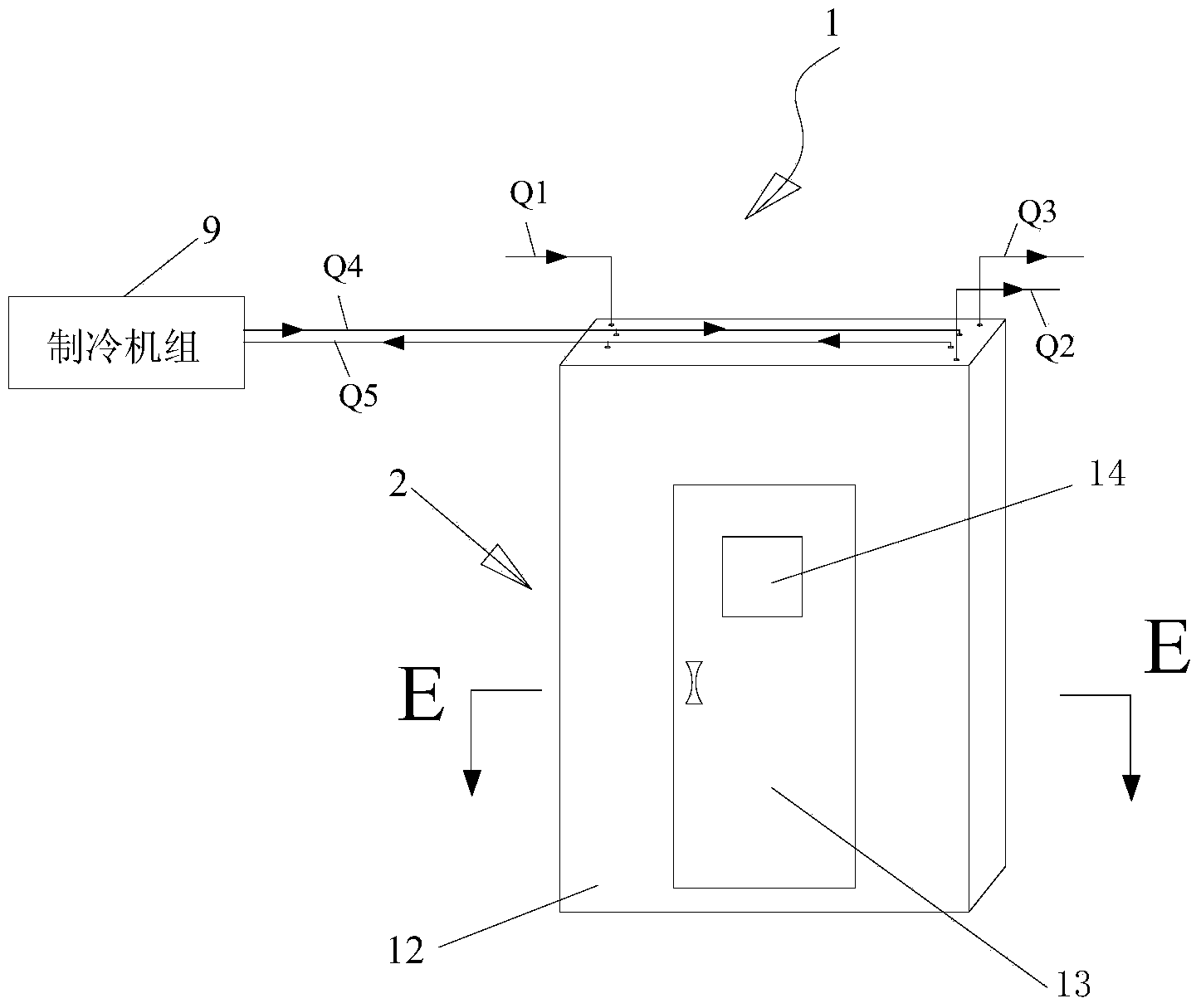

Multi-variety and small-batch fruit and vegetable modified atmosphere packaging device and multi-variety and small-batch fruit and vegetable modified atmosphere packaging technology

ActiveCN103548990AImprove storage effectStrong anti-swingFruit and vegetables preservationNitrogen generatorControl system

The invention discloses a multi-variety and small-batch fruit and vegetable modified atmosphere packaging device and a multi-variety and small-batch fruit and vegetable modified atmosphere packaging technology. The modified atmosphere packaging device comprises an air compressor, a nitrogen making machine and a humidity control device which are connected in series, wherein the humidity control device is connected with a plurality of small air conditioning cabinets which are arranged in parallel; gas production detection holes, refrigerant inlets and refrigerant outlets of the plurality of small air conditioning cabinets are respectively connected with a gas detection device and a refrigerating unit; cable output holes of a temperature and humidity sensor are respectively connected with the input end of a control system; the control system is connected with the gas detection device, the air compressor, the nitrogen making machine and the humidity control device. The modified atmosphere packaging technology comprises the steps of confirming the air conditioning parameters of the small air conditioning cabinets; controlling the fresh-keeping temperature; controlling the nitrogen and the humidity of the air conditioning cabinets as well as the gas detection; detecting the gas content and the humidity in the air conditioning cabinets regularly. The device and the technology have the beneficial effects that the plurality of small air conditioning cabinets can be respectively used for carrying out preservation on the different fruits and vegetables in a classifying way, and the control system is used for respectively controlling the air conditioning parameters of the small air conditioning cabinets to be within the best range all the time, so that the aim of keeping the fruits and vegetables to be fresh for a long time can be achieved.

Owner:TIANJIN CNRO SCI TECH

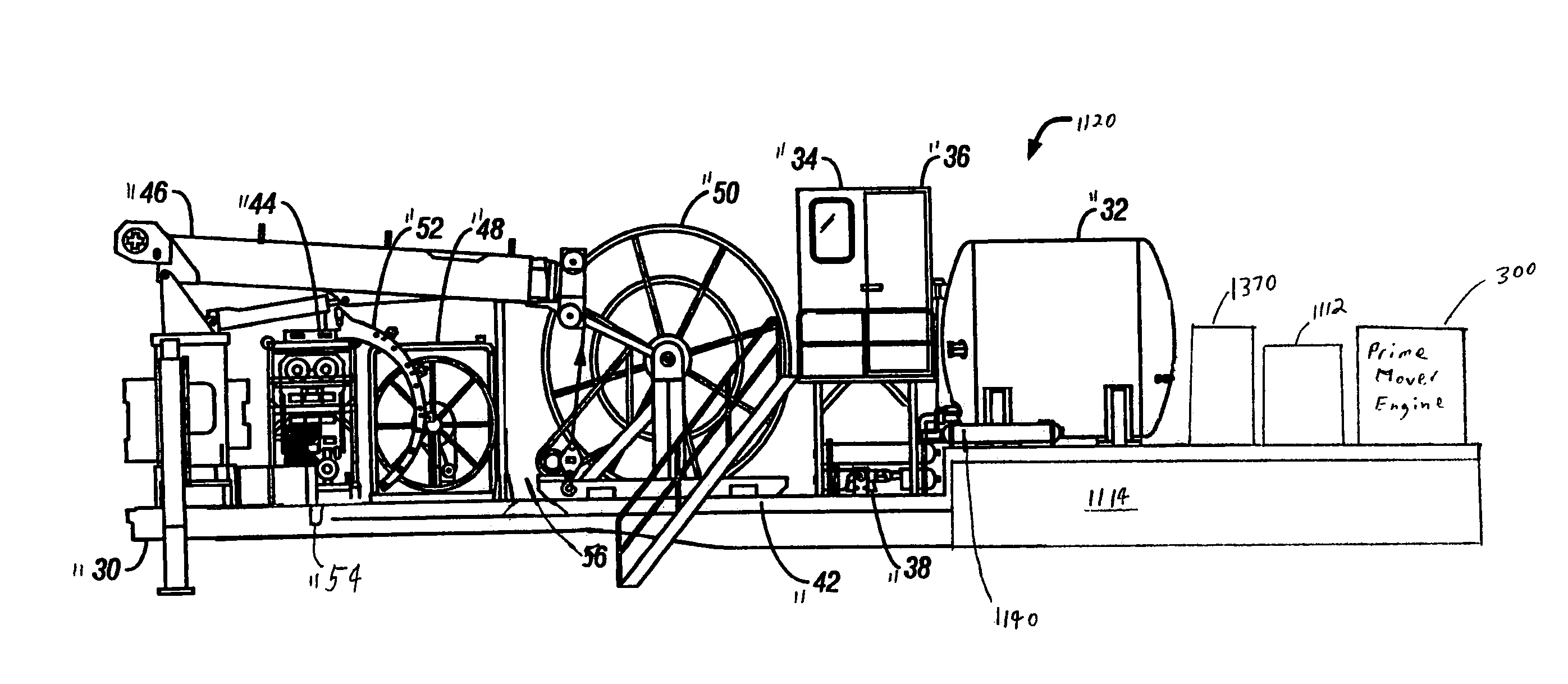

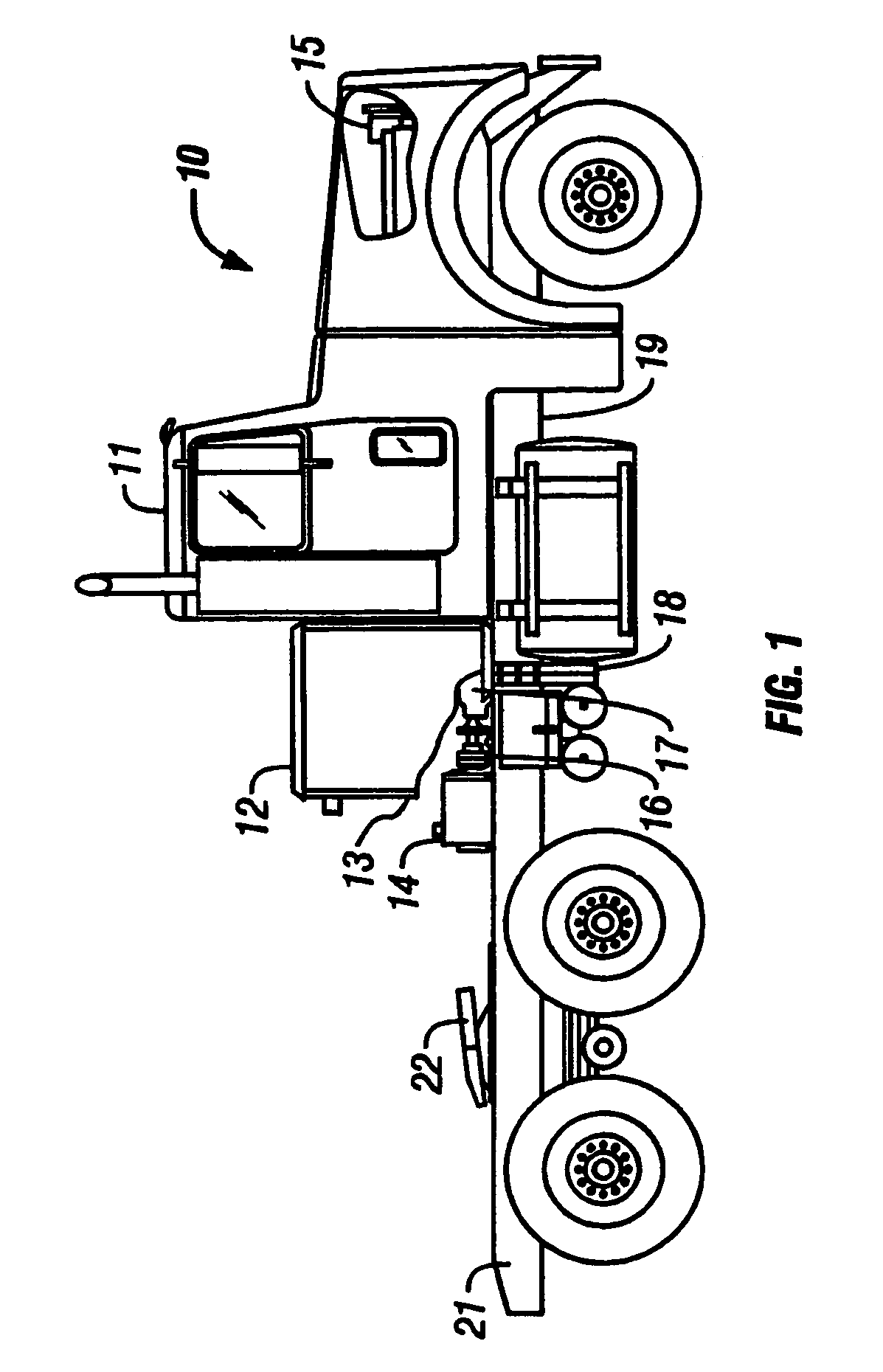

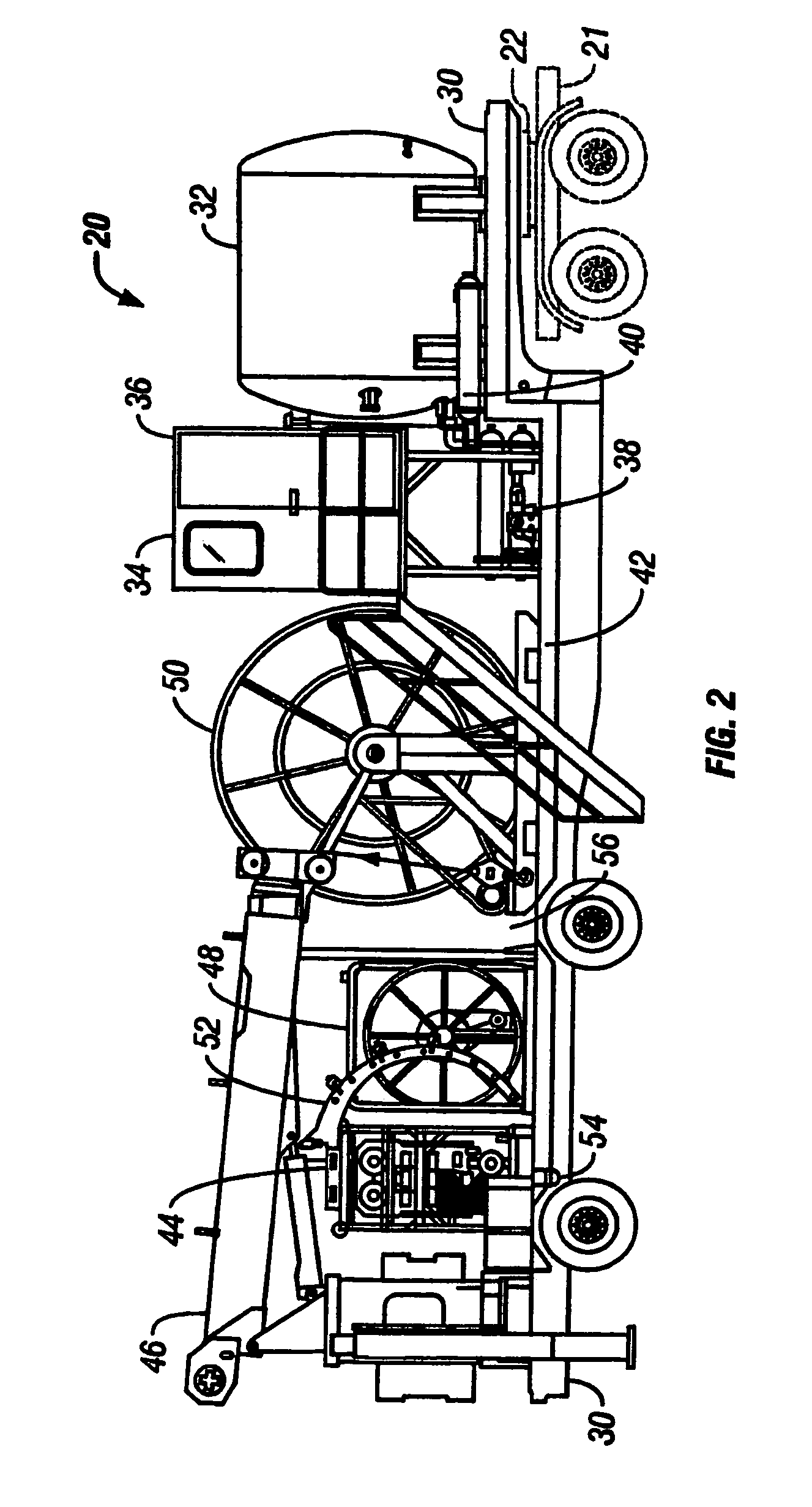

Three in one combined power unit for nitrogen system, fluid system, and coiled tubing system

A single tractor unit is provided for pulling a trailer, in which the tractor itself drives a plurality of hydraulic motors which control a crane unit, a coiled tubing injection unit, and the pumps and motors associated with a liquid nitrogen system which is used for injecting gaseous hydrogen into a workover well with coiled tubing. In an alternative mode, the liquid nitrogen system is replaced with nitrogen generators or tanks of compressed nitrogen gas. In another alternative embodiment, a separate engine, preferably mounted with the other equipment on a trailer, skid, or barge, replaces the single tractor engine for driving the plurality of hydraulic motors. In yet another embodiment, a single engine drives a plurality of well treating systems on an off-shore installation.

Owner:P E T INT

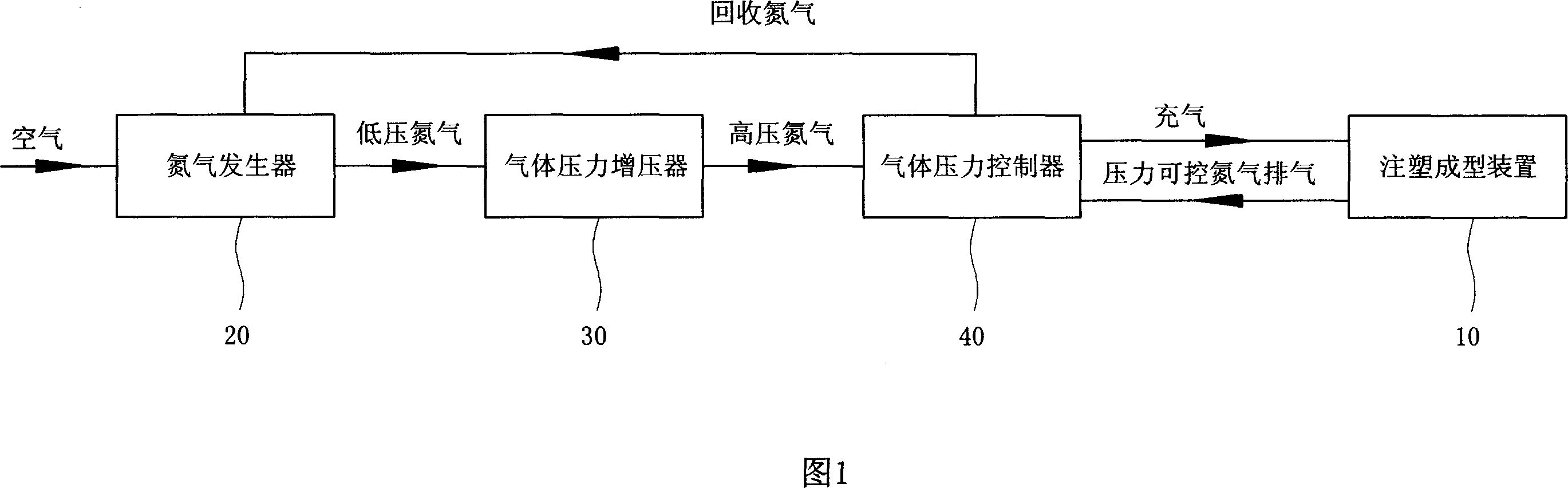

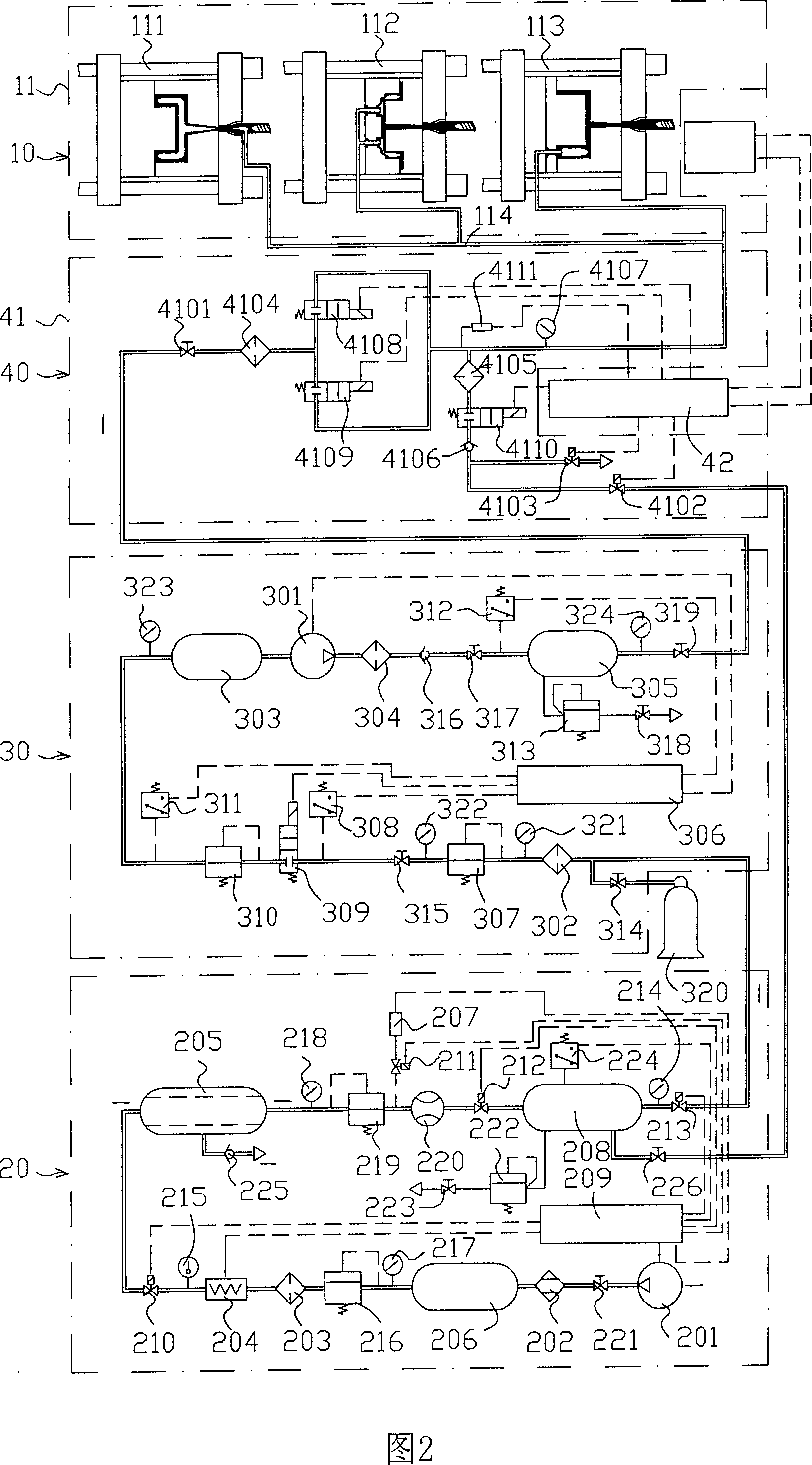

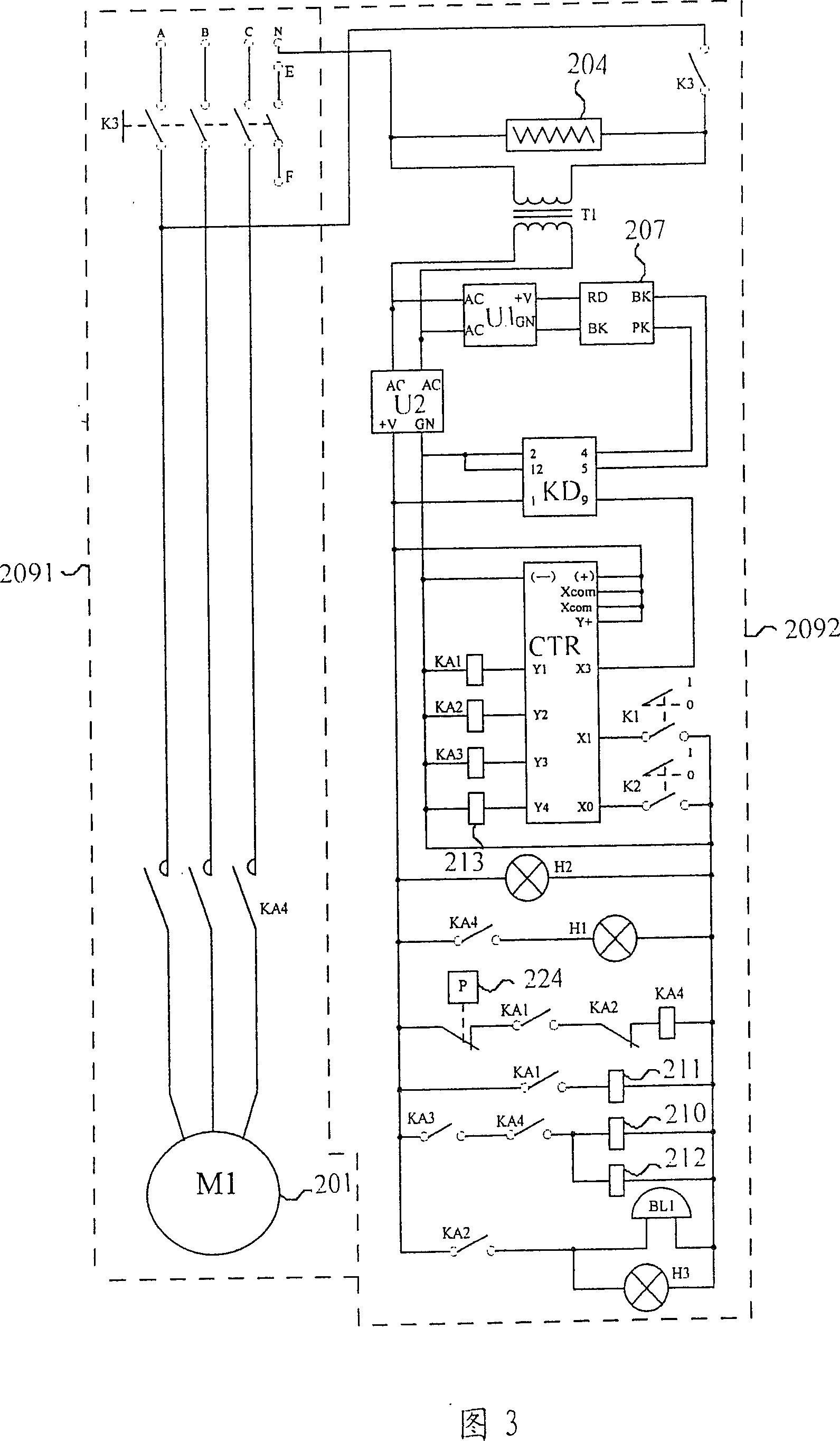

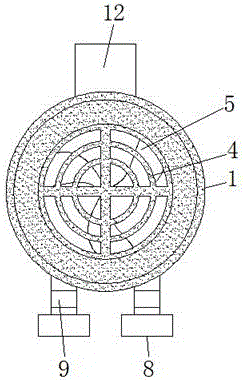

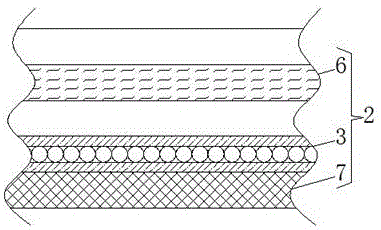

Pressure-sustaining gas assistant injection molding system

InactiveCN1990212AQuality improvementSmooth gas injectionNitrogen purification/separationNitrogen generatorAutomatic control

The invention discloses an auxiliary injection molding system of constant pressure gas, which comprises the following parts: injection molding device (10), nitrogen generator (20), gas pressure booster (30) and gas pressure controller (40), wherein the gas pressure controller (40) connects injection molding device (10) and gas pressure booster (30); the gas pressure booster connects nitrogen generator (20).

Owner:韩国海 +1

Dry Cabinets for Use in Moisture Sensitive Device Management in Electronics Manufacturing

InactiveUS20070068035A1Prevent moisture-induced failureLow costDrying gas arrangementsDrying machines with progressive movementsNitrogen generatorEngineering

A dry cabinet for storing surface mount devices in a low humidity environment containing an integrated dry gas forming means in the form of a desiccator or a nitrogen generator which can receive a source of compressed air and form a dry air stream or a concentrated dry nitrogen stream which can be directed into the interior space of the cabinet to maintain the environment within the cabinet a low relative humidity. The cabinet with it self contained dry gas forming source is more economical than prior art dry cabinets which require a centralized nitrogen source.

Owner:THERIAULT MARTIN

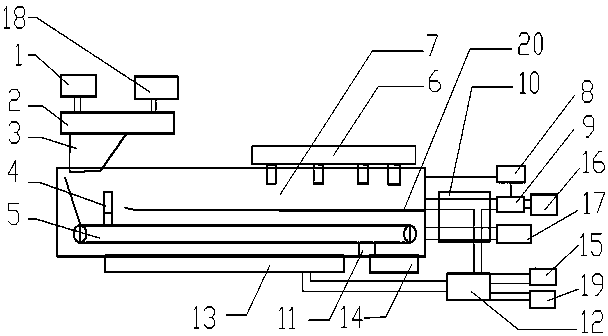

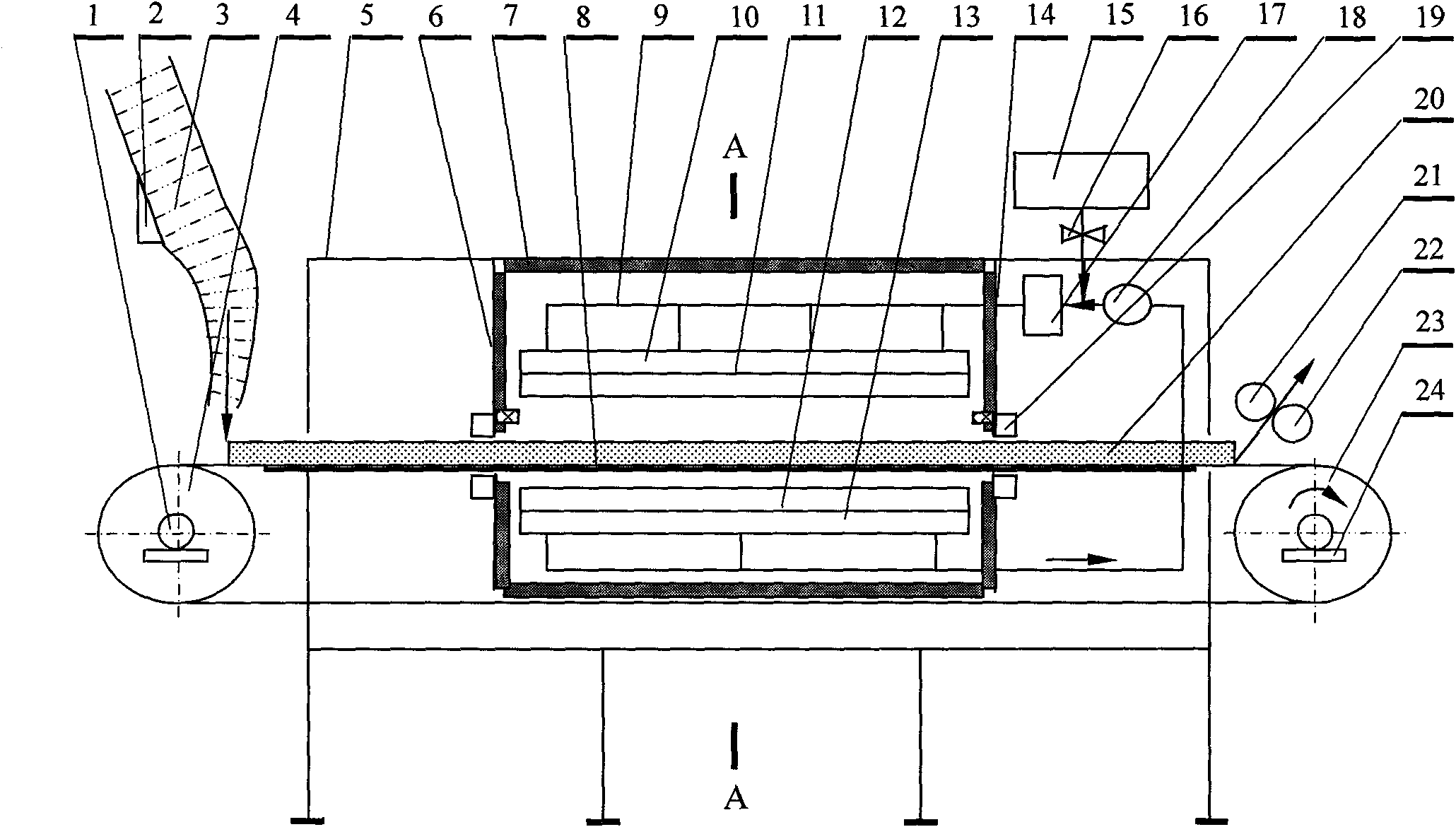

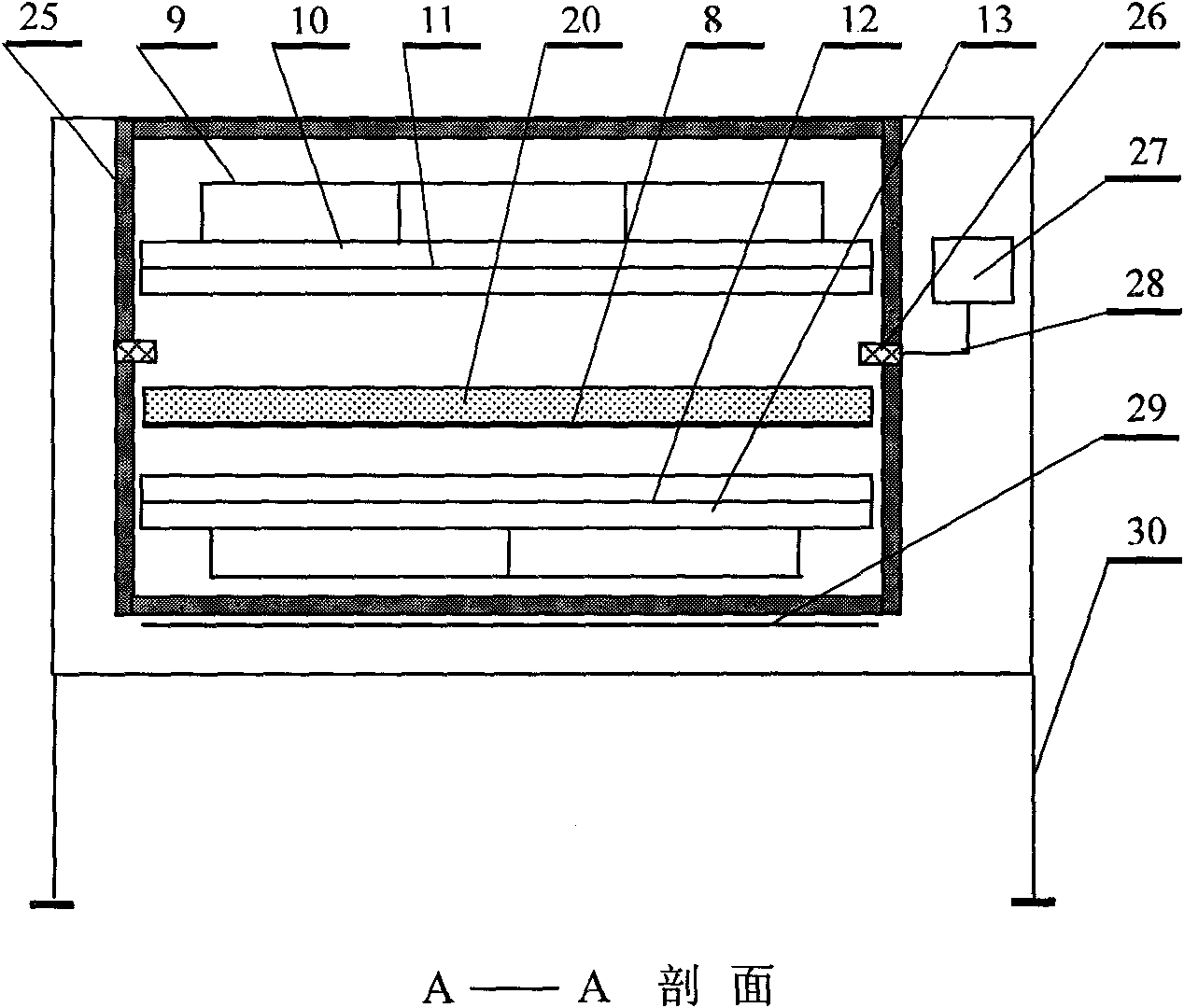

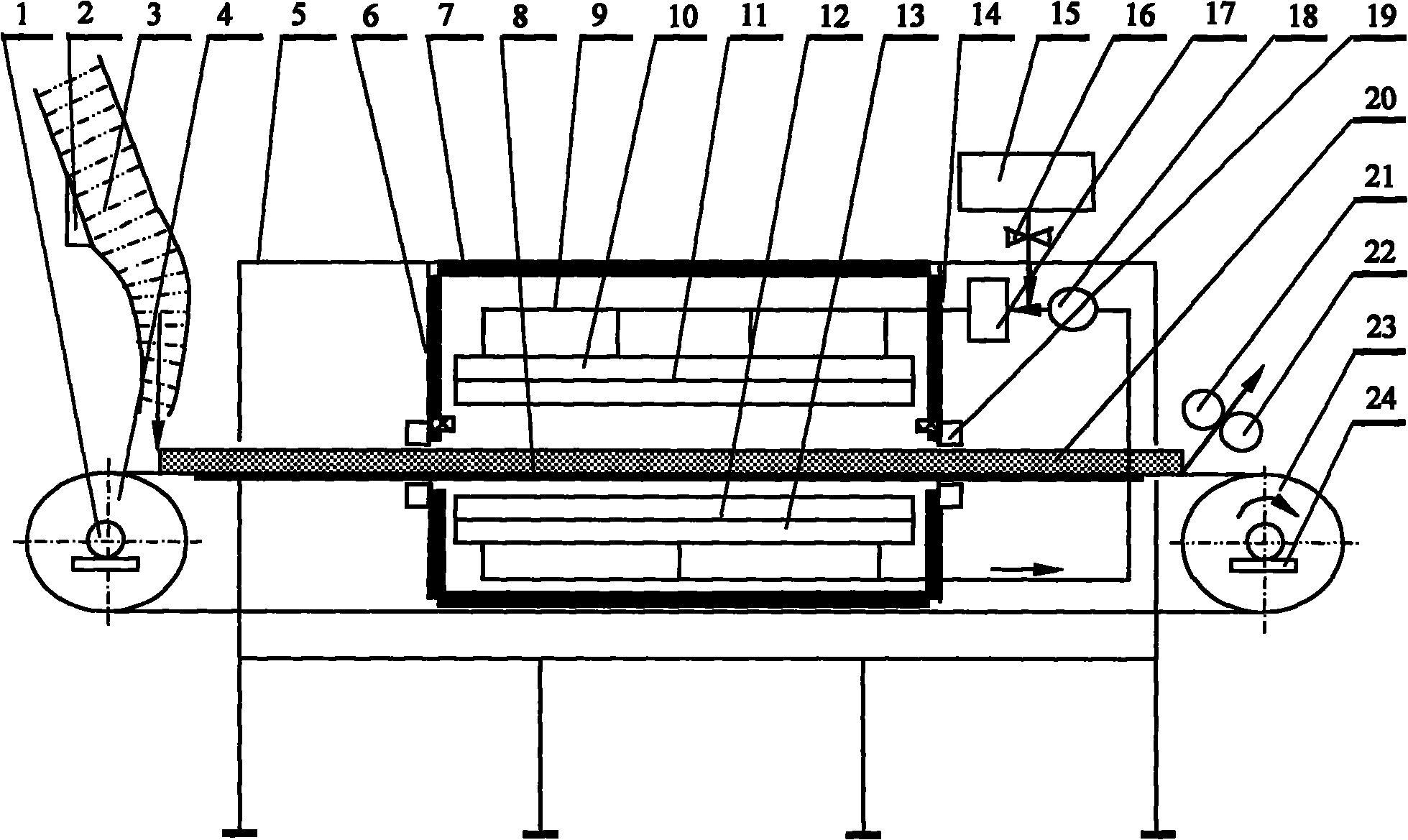

Aramid fiber high-temperature forming machine

InactiveCN102051697ASave powerPrevent oxidationArtificial filament heat treatmentNitrogen generatorTemperature control

The invention discloses an aramid fiber high-temperature forming machine. The machine comprises a screen conveying mechanism, a fiber guide mechanism, a heating mechanism, a temperature controlling and retaining system, a nitrogen circulation and control mechanism, a stander and the like, wherein an electric screen roller drives a screen conveying belt and a screen driven wheel; the screen conveying belt moves on a horizontally arranged bracket; an inlet end and an outlet end are provided with a fiber guide plate and a fiber outlet roller; an outlet end of a fan is connected with a heater and is connected with a temperature equalizer above the screen conveying belt through a pipeline; a temperature buffer below the conveying belt is connected with an inlet end of the fan through a pipeline; a heat-insulating plate is arranged on the inner side of an inner box body; the two ends of the inner box body are provided with air curtains; a plurality of temperature sensors are arranged in the box body and connected with a temperature controller; a nitrogen generator is connected with the outlet end of the fan through a control valve; and the inner box body is embedded in a box body shell and is supported by a plurality of adjustable machine legs. The machine can meet the technical requirements on high-temperature thermal forming in a strand loose state during production of aramid fiber and saves energy.

Owner:陈如巧

Emergency refrigerating device for battery energy storage system

InactiveCN105449307ASolve the problem of inconvenient replenishmentAvoid damageBatteries circuit arrangementsSecondary cells servicing/maintenanceProcess mechanismLiquid nitrogen container

The invention relates to the field of battery energy storage system security, in particular to the field of power battery security. An emergency refrigerating device for a battery energy storage system adopts liquid nitrogen phase-change refrigeration, and comprises a nitrogen generator, a liquid nitrogen container, a cooling pipe, a cooling valve, refrigerating passages and a pressure release valve. The nitrogen generator is used for nitrogen generation and cooling storage during battery charging. A rechargeable micro battery supplies power for the cooling valve, and the controller is provided with an independent signal collecting and logic processing mechanism without depending on a battery management system (BMS); and the controller comprises a vibration sensor which can sense the accidents such as collision and explosion. A closed refrigerating passage is generally mounted on a heat-dissipation module of the battery, and the heat of the battery is dissipated through the heat-dissipation module. An open refrigerating passage is mounted on the battery, and a plurality of small holes formed in the part, close to the battery, of the pipeline are used for uniformly spraying liquid nitrogen onto the battery. The emergency refrigerating device has the beneficial effects that the liquid nitrogen is used for emergency refrigeration, and can reach the effect of quick cooling, so that thermal runaway of a battery pack is prevented, and a thermal runaway chain reaction is avoided to the maximum extent.

Owner:周哲明

Systems and methods for producing ammonia fertilizer

InactiveUS20130039833A1Bioreactor/fermenter combinationsBiological substance pretreatmentsNitrogen generatorHydrocotyle bowlesioides

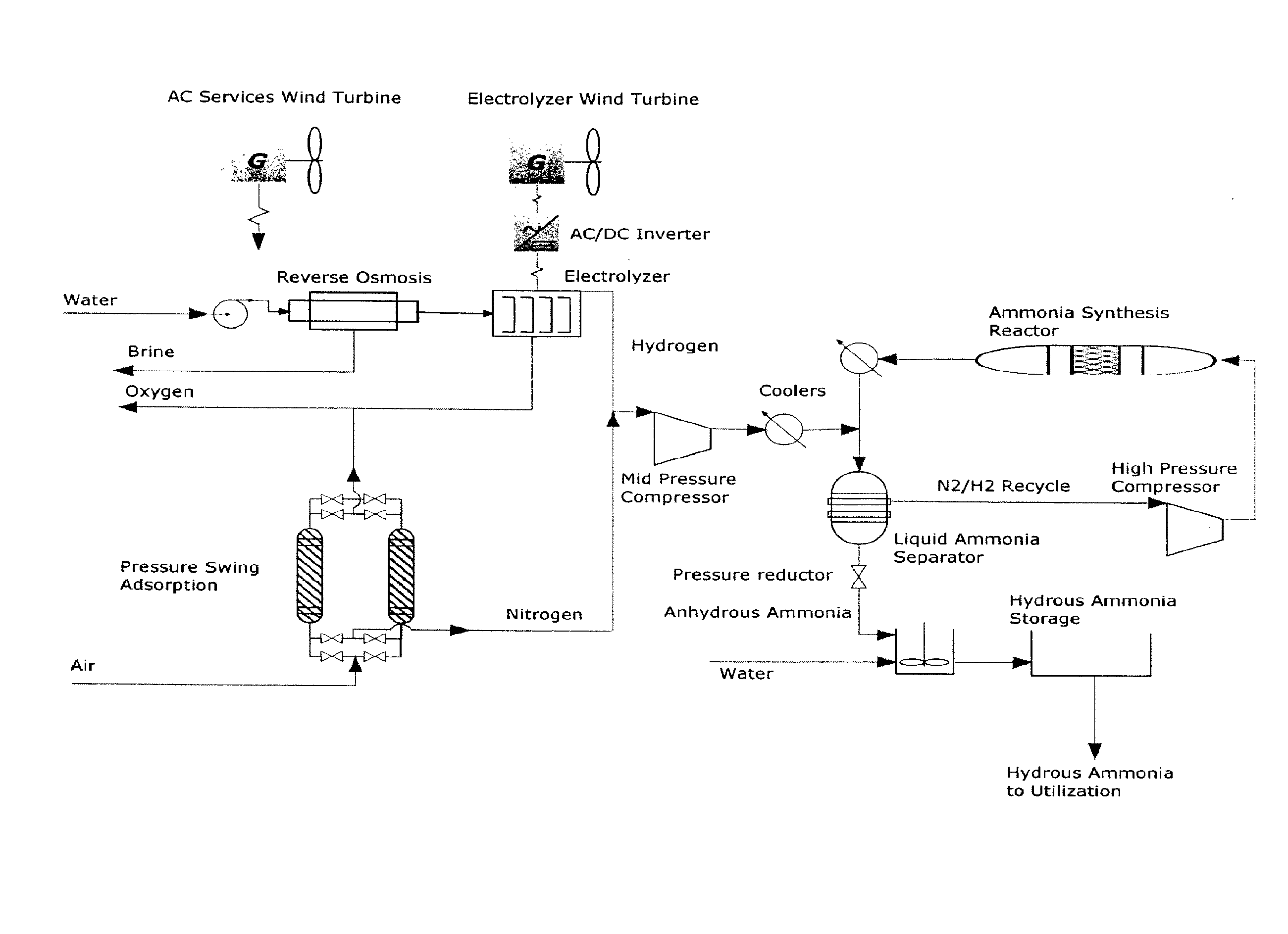

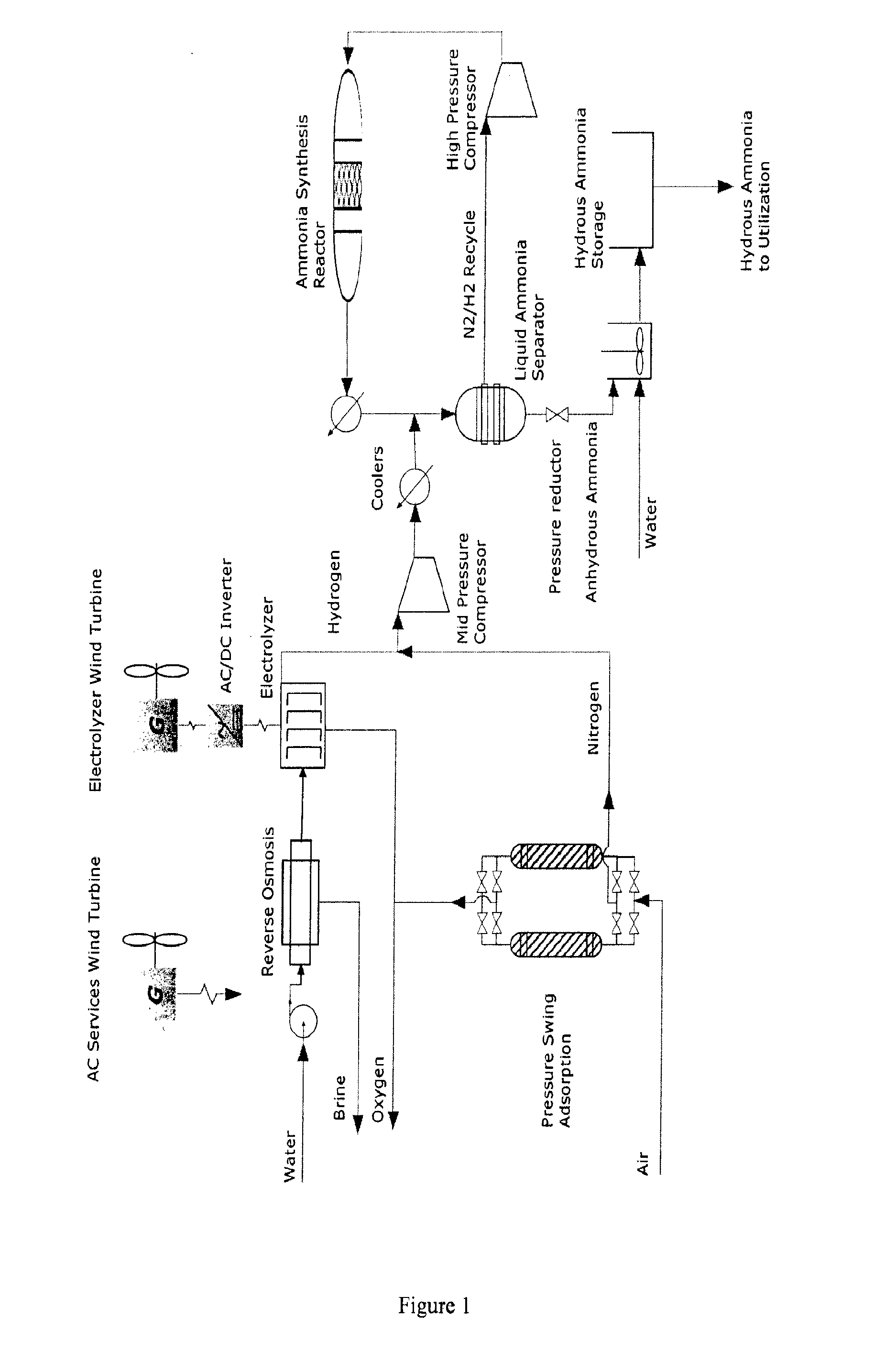

Provided herein are systems and methods for producing ammonia fertilizer for culturing algae and aquaculture. The integrated systems provided herein can be installed on a hydrocarbon production platform and encompasses equipment and processes for generating electricity, preparation of an aqueous electrolyte, hydrogen generation by electrolysis, catalysis of ammonia formation, collection of ammonia, and optionally a nitrogen generator, and a plurality of subsystems for algae culture, and aquaculture.

Owner:LIVEFUELS

Ammonia synthesis using lithium ion conductive membrane

Ammonia is synthesized using electrochemical and non-electrochemical reactions. The electrochemical reactions occur in an electrolytic cell having a lithium ion conductive membrane that divides the electrochemical cell into an anolyte compartment and a catholyte compartment. The catholyte compartment includes a porous cathode closely associated with the lithium ion conductive membrane. The overall electrochemical reaction is: 6LiOH+N2→Li3N (s)+3H2O+3 / 2O2. The nitrogen may be produced by a nitrogen generator. The non-electrochemical reaction involves reacting lithium nitride with water and / or steam as follows: Li3N (s)+3H2O→3LiOH+NH3 (g). The ammonia is vented and collected. The lithium hydroxide is preferably recycled and introduced into the anolyte compartment. The electrolytic cell is shut down prior to reacting the lithium nitride with water. The cathode is preferably dried prior to start up of the electrolytic cell and electrolyzing Li+ and N2 at the cathode.

Owner:ENLIGHTEN INNOVATIONS INC

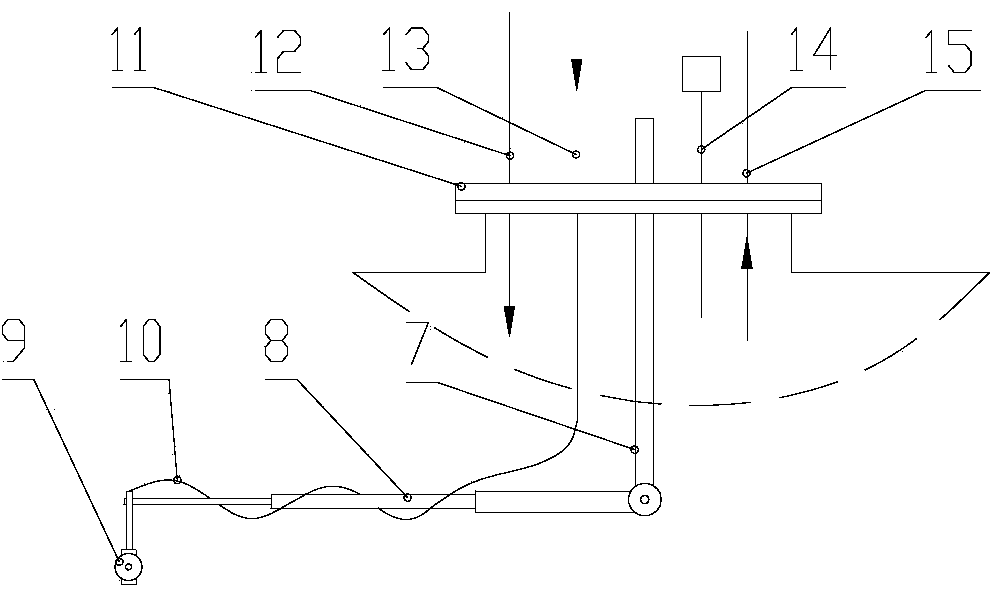

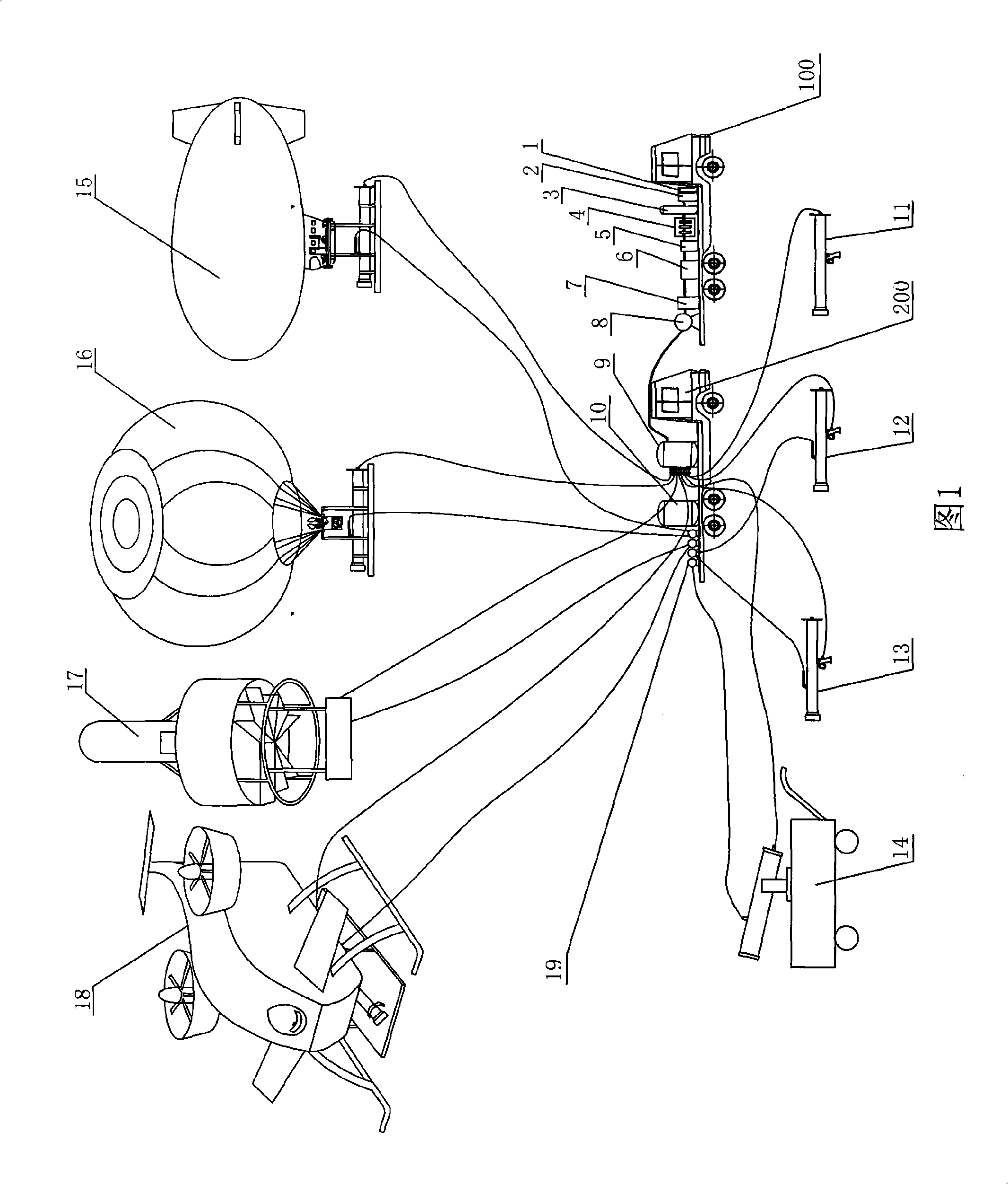

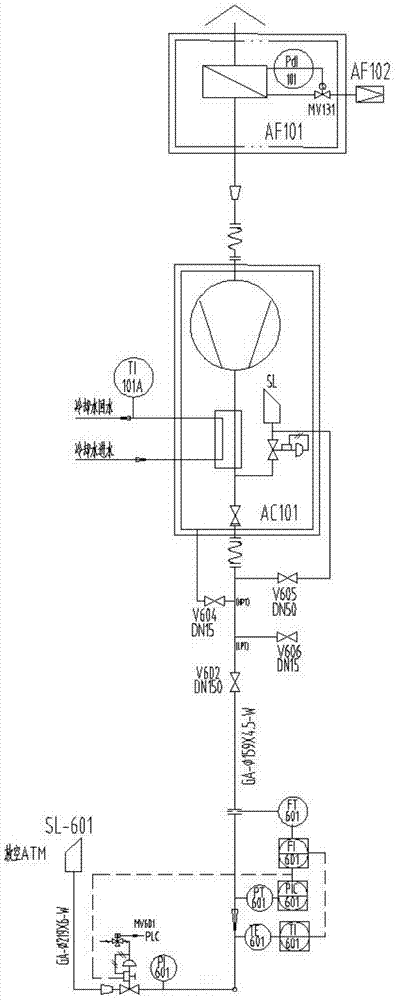

Extinguishment method of fire-fighting truck with movable nitrogen making machine group and equipment thereof

InactiveCN101301515AStable pressureEasy to useNitrogen preparationFire rescueNitrogen generatorExtinction

The invention relates to a fire-extinguishing method and a fire-extinguishing device for a mobile nitrogen generator fire engine, wherein, nitrogen is prepared by a fixedly arranged or connected device on a mobile nitrogen generator nitrogen preparation vehicle and then inputted to a nitrogen storage tank of a multifunctional fire-fighting vehicle; the nitrogen storage tank and a water storage tank are arranged on multifunctional fire-fighting vehicle; the nitrogen storage tank is connected with various branched air pipes; the water storage tank is connected with a pump unit which is connected with the various branched water pipes; and the water pipes and the air pipes are respectively connected to a pulse air-blast spray nozzle, a two-phase flow water fog fire-fighting gun, a pulse water cannon, a fire-fighting airship, a fire-fighting fire balloon, an unmanned fire-fighting rotary wing aircraft and a fire helicopter. The fire-extinguishing method and the fire-extinguishing device take nitrogen as extinguishing agent and the nitrogen preparation device fixed on the fire engine as nitrogen source to perform nitrogen fire extinction on the fire scene, which can not pollute the surrounding environment and can not generate secondary disasters. The fire-extinguishing method and the fire-extinguishing device are capable of realizing multifunctional large-range solid fire-fighting and are suitable for large-range fire scenes.

Owner:BEIJING SMHW MAGNETIZATION TECH CO LTD

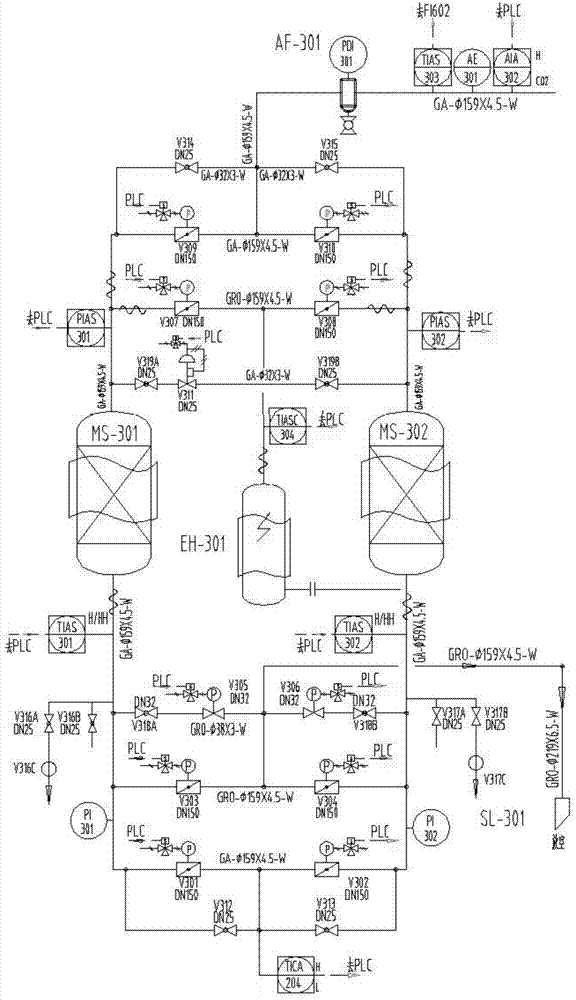

Double-tower double-condensation backflow expansion nitrogen making machine and nitrogen making method thereof

PendingCN107345737AAvoid enteringReduce exhaust pressureSolidificationLiquefactionNitrogen generatorAir filter

The invention discloses a double-tower double-condensation backflow expansion nitrogen making machine comprising an intake pretreatment device and a nitrogen making device which are connected through a pipeline. The intake pretreatment device comprises an air filter, an air compressor, a pre-cooling unit and a purifier. The nitrogen making device comprises a main heat exchanger used for heat exchange, a subcooler used for cooling, rectifying towers, a main condensation evaporator, an auxiliary condensation evaporator and an expansion machine. The rectifying towers comprise an upper tower and a lower tower. The lower tower is provided with an air inlet. The air inlet communicates with the purifier through the main heat exchanger by means of a pipeline. The invention further provides a nitrogen making method of the double-tower double-condensation backflow expansion nitrogen making machine. Oxygen-enriched liquid air is used for step-by-step evaporation in the main condensation evaporator and an auxiliary condensation evaporator, and under the condition of obtaining high-purity gas nitrogen products at the equal pressure, it is achieved that compared with a conventional double-tower single-condensation backflow expansion high-purity nitrogen making machine, the double-tower double-condensation backflow expansion nitrogen making machine can lower the discharge pressure of the air compressor, reduce the electricity consumption and reduce the processing air quantity, thereby reducing the comprehensive energy consumption.

Owner:苏州制氧机股份有限公司

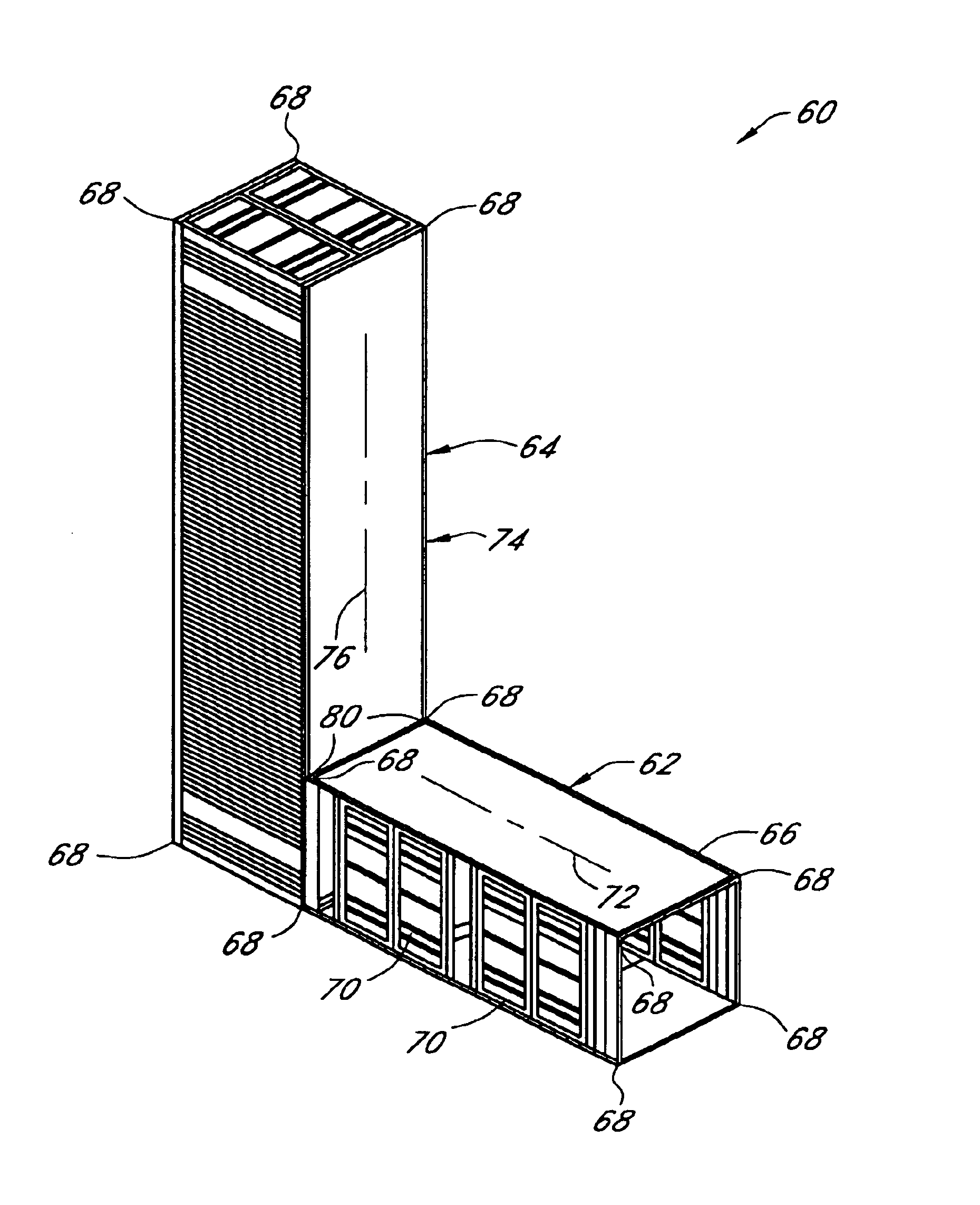

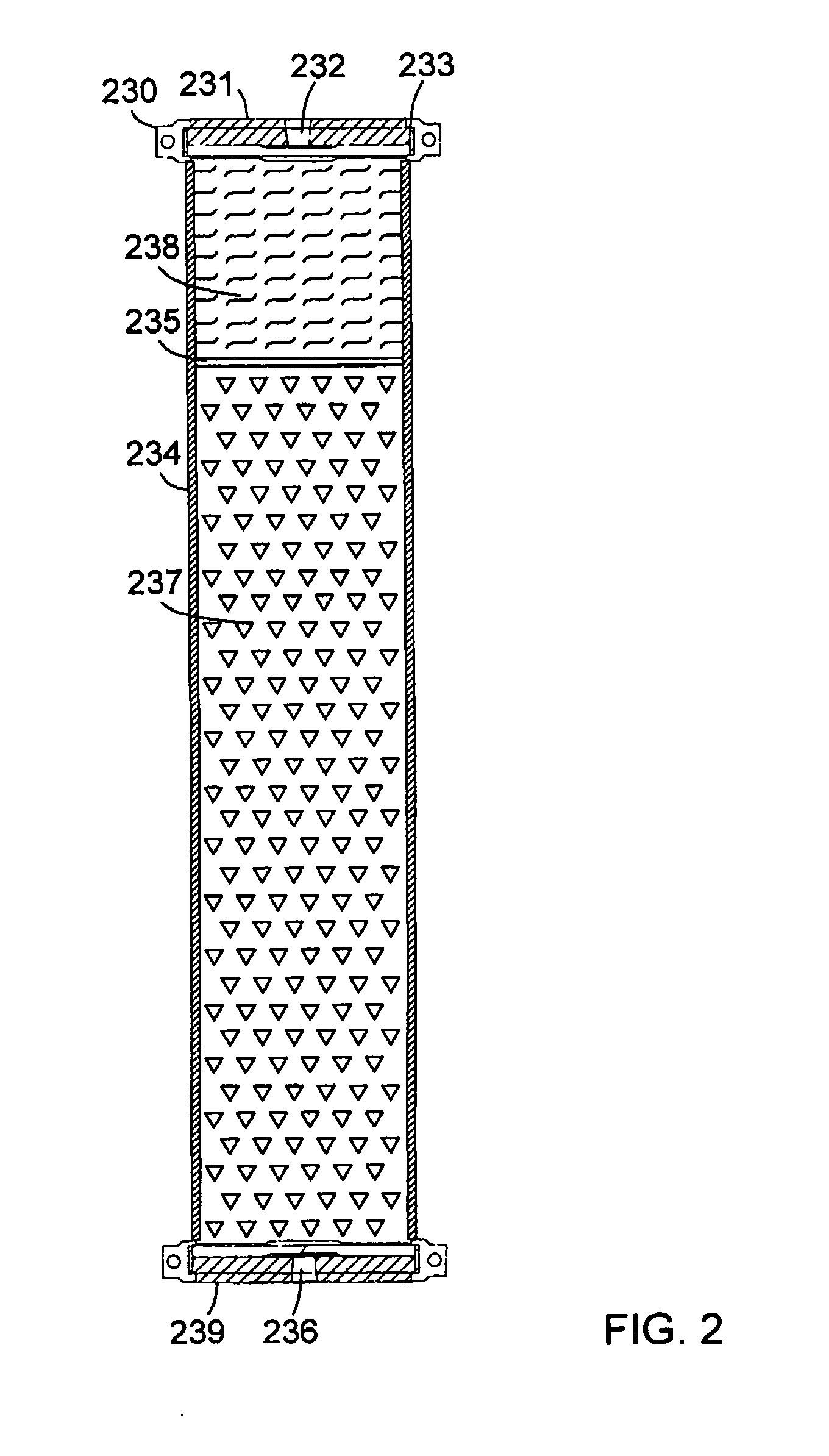

Nitrogen generator

InactiveUS6910350B2Efficient and quick assemblyProvide stabilitySolidificationLiquefactionNitrogen generatorFractionating column

A portable cryogenic nitrogen generator consists of an air preparation unit and a cryogenic distillation unit mounted inside separate standard-sized ISO containers that can be easily shipped to a drilling site and efficiently and quickly assembled into an operative state. The containers can be connected together at anchor points on the housings of both containers, making the nitrogen generator assembly more stable. The air preparation unit includes an absorption device and optionally includes one or a plurality of air compressor units. The cryogenic distillation unit includes a distillation column and associated heat exchangers. The air preparation and cryogenic distillation units connect through apertures in their respective containers and operate while being mounted in the containers.

Owner:PACIFIC CONSOL INDS

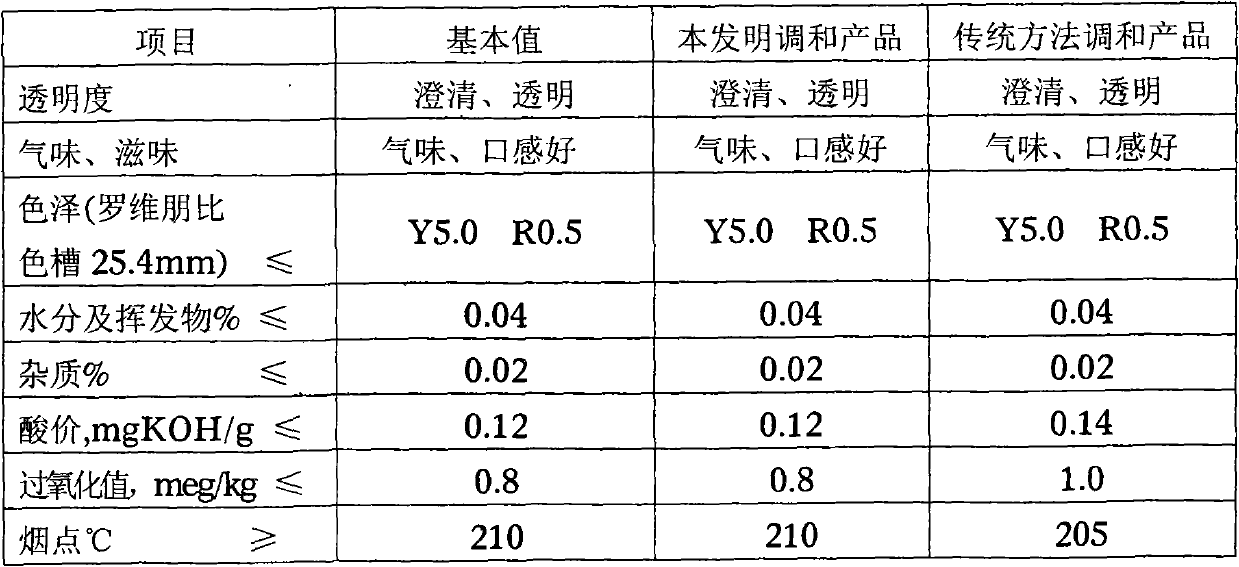

Circulating pressurized nitrogenization stirring method for blending edible blend oil

InactiveCN101999476AWell mixedHomogeneous deploymentFinished edible oils/fats preservationEdible oils/fats production/working-upOil and greaseNitrogen generator

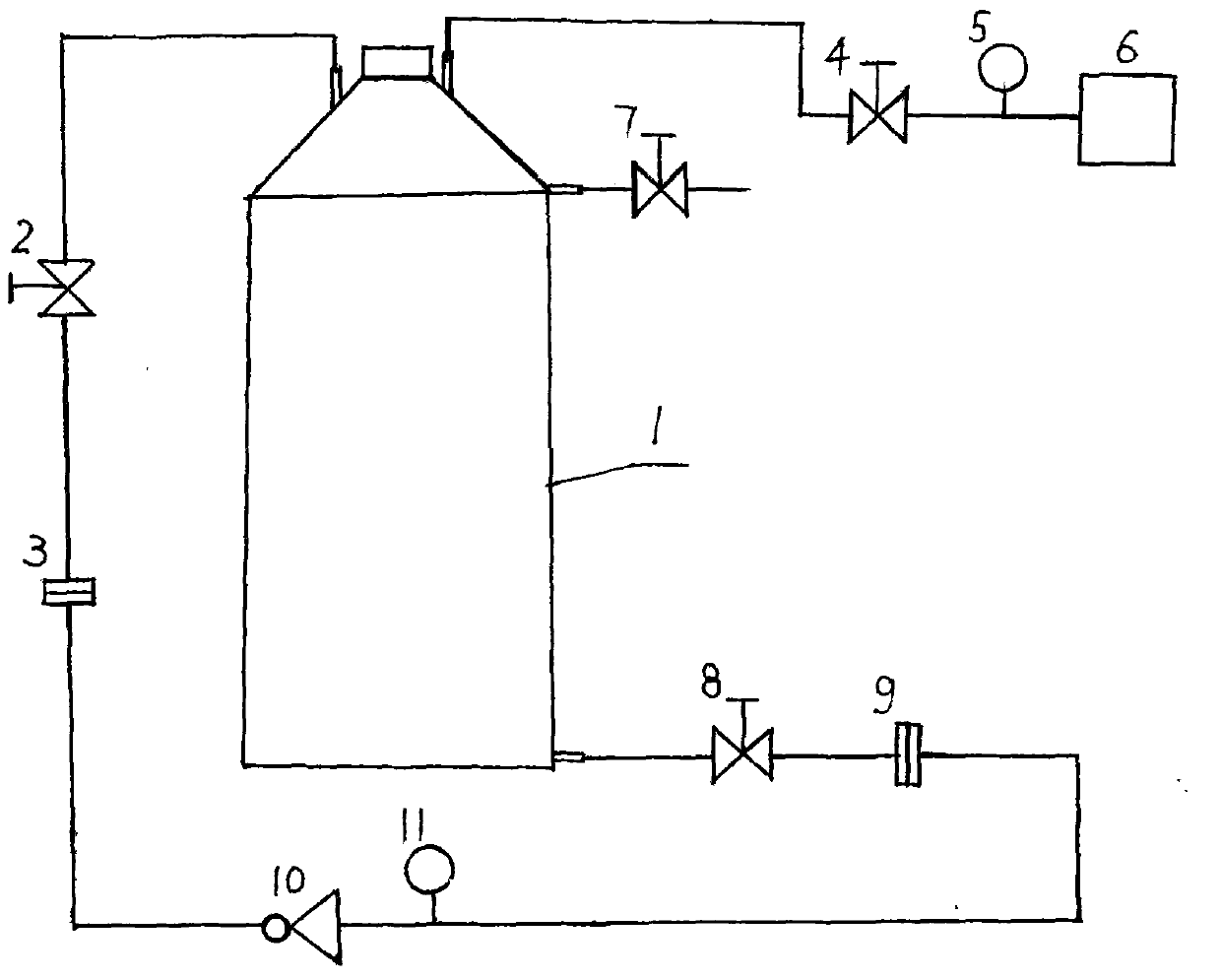

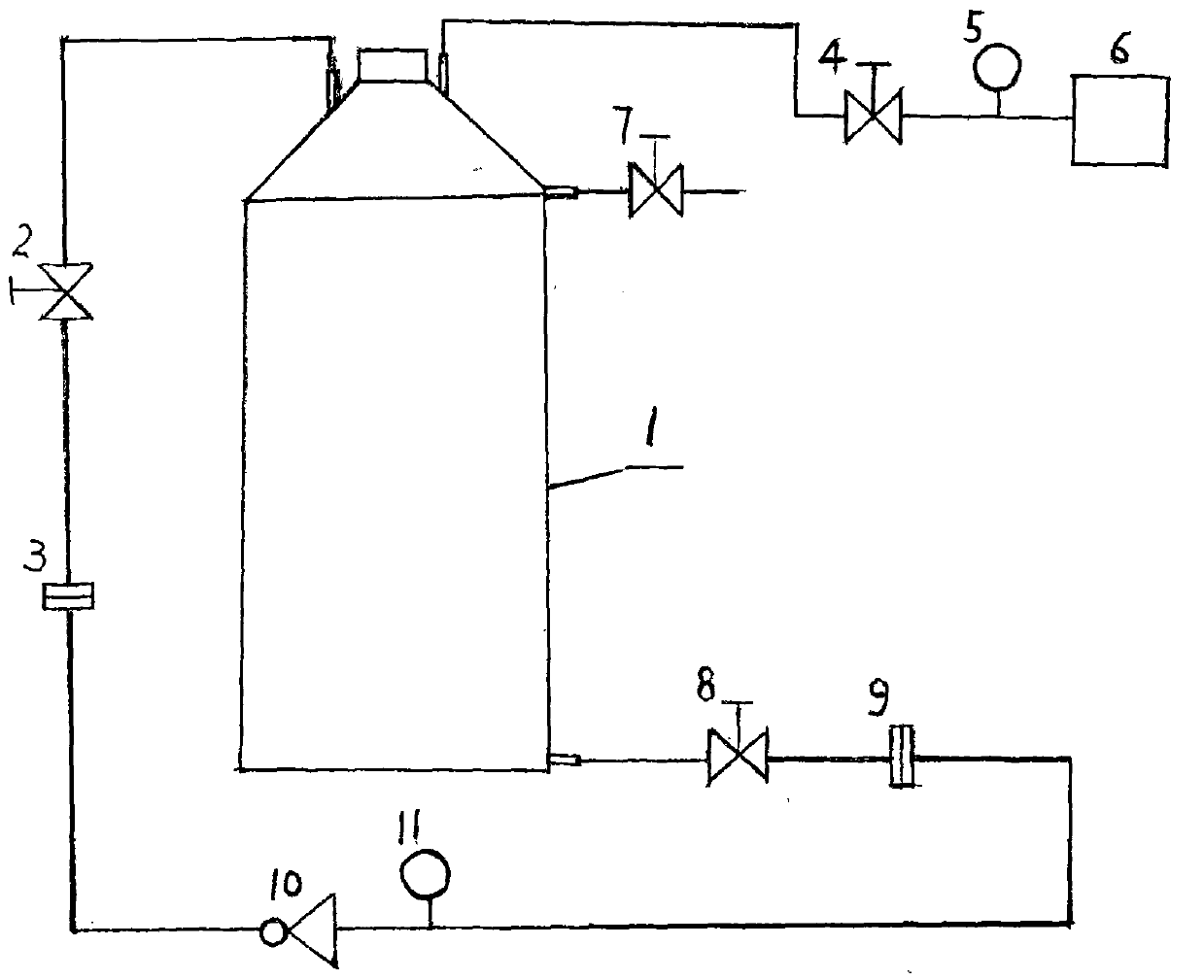

The invention provides a circulating pressurized nitrogenization stirring method for blending edible blend oil. The method is characterized in that a sealed blend oil tank is used; the upper of a tank top is provided with an oil inlet and an inlet regulating valve, wherein an air inlet is connected with an air inlet regulating valve and a nitrogen generator; an exhaust port and an exhaust valve are arranged at the lower part of the tank top; and an oil outlet and an outlet regulating valve are arranged at the lower part of a tank body. The technology adopted by the method of the invention comprises the following steps: the first step: feeding oil ingredients; the second step: communicating the inlet air pipe of a wheel gear pressure pump with an oil inlet regulating valve, and communicating an outlet air pipe with an oil outlet regulating valve; the third step: starting the nitrogen generator, and using nitrogen to replace air in the cavity of the tank; and the fourth step: starting the wheel gear pressure pump, when the exhaust air pressure reaches 0.1-0.6 MPa, the nitrogen is fed into the blend oil tank from the oil outlet, and the nitrogen with higher pressure is used for stirring the mixed oil in the tank, so that the mixed oil can be blended evenly. In the method of the invention, oxygen which is easy to result in oxidative rancidity of the oil is completely isolated in the stirring process, thereby realizing sufficient mixing and homogeneous blending, and ensuring production of high-quality blend oil.

Owner:HUNAN JINDIAN GREASE

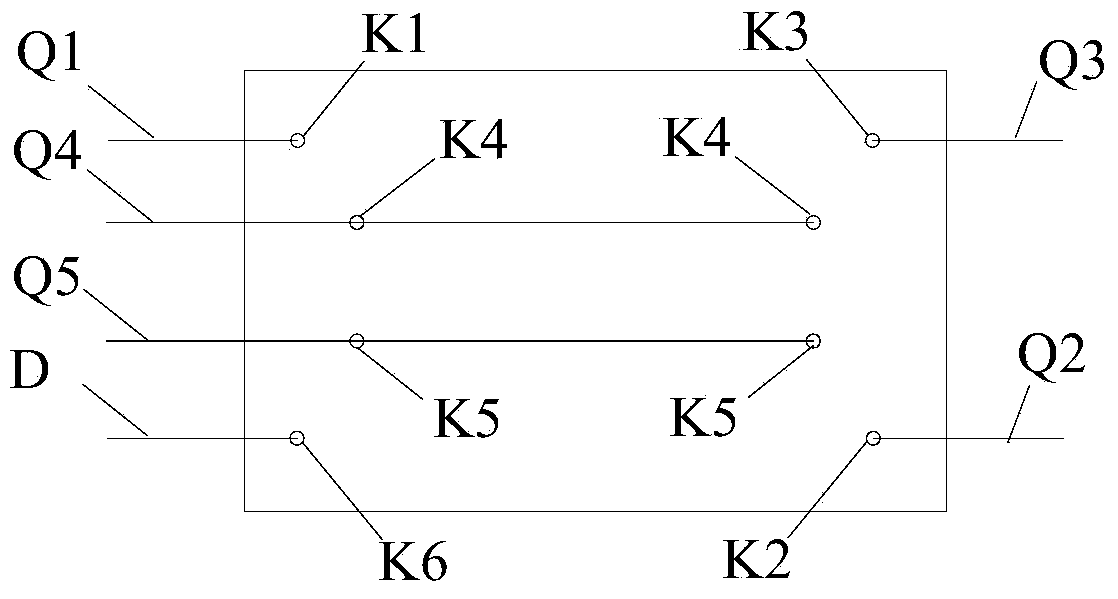

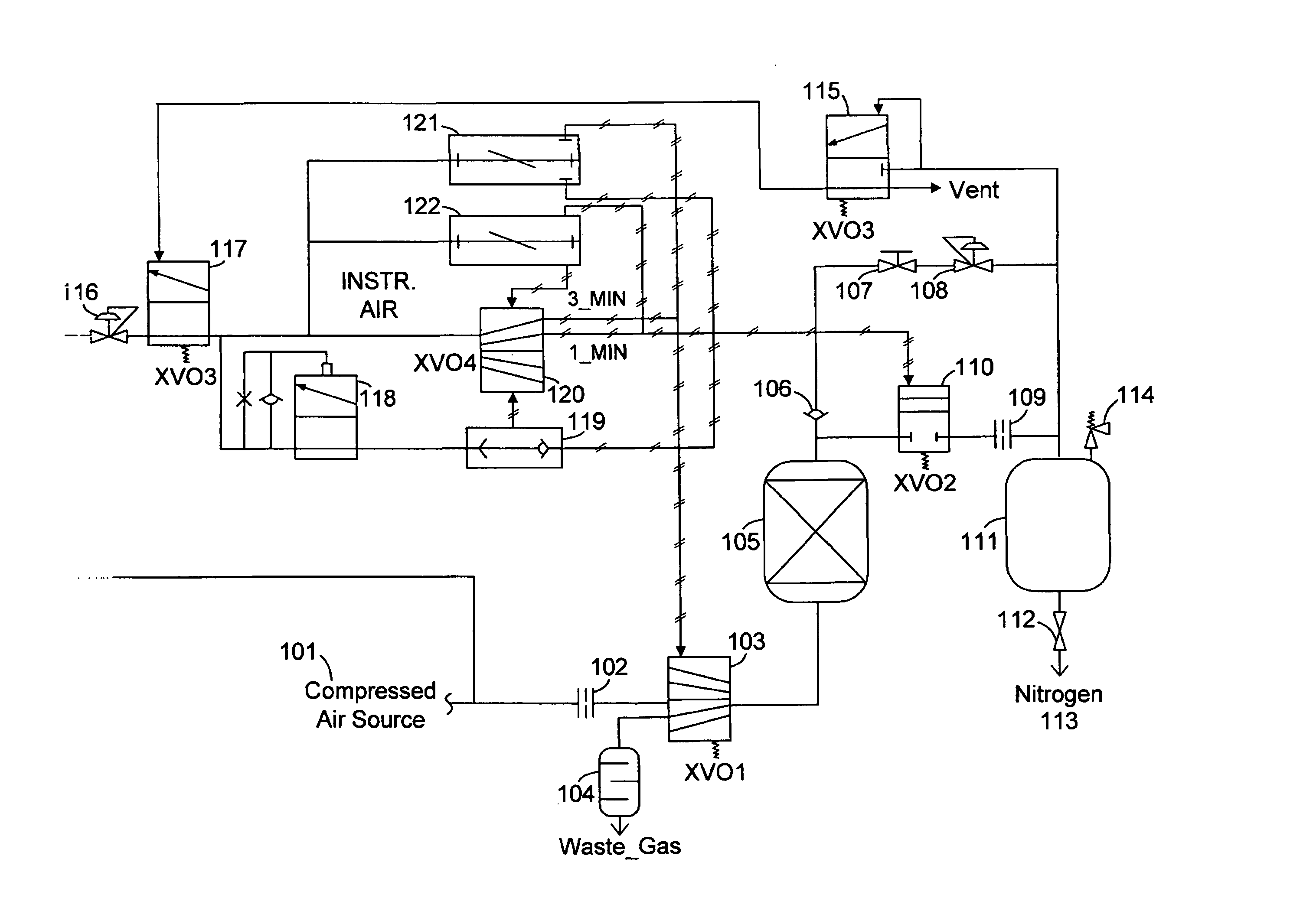

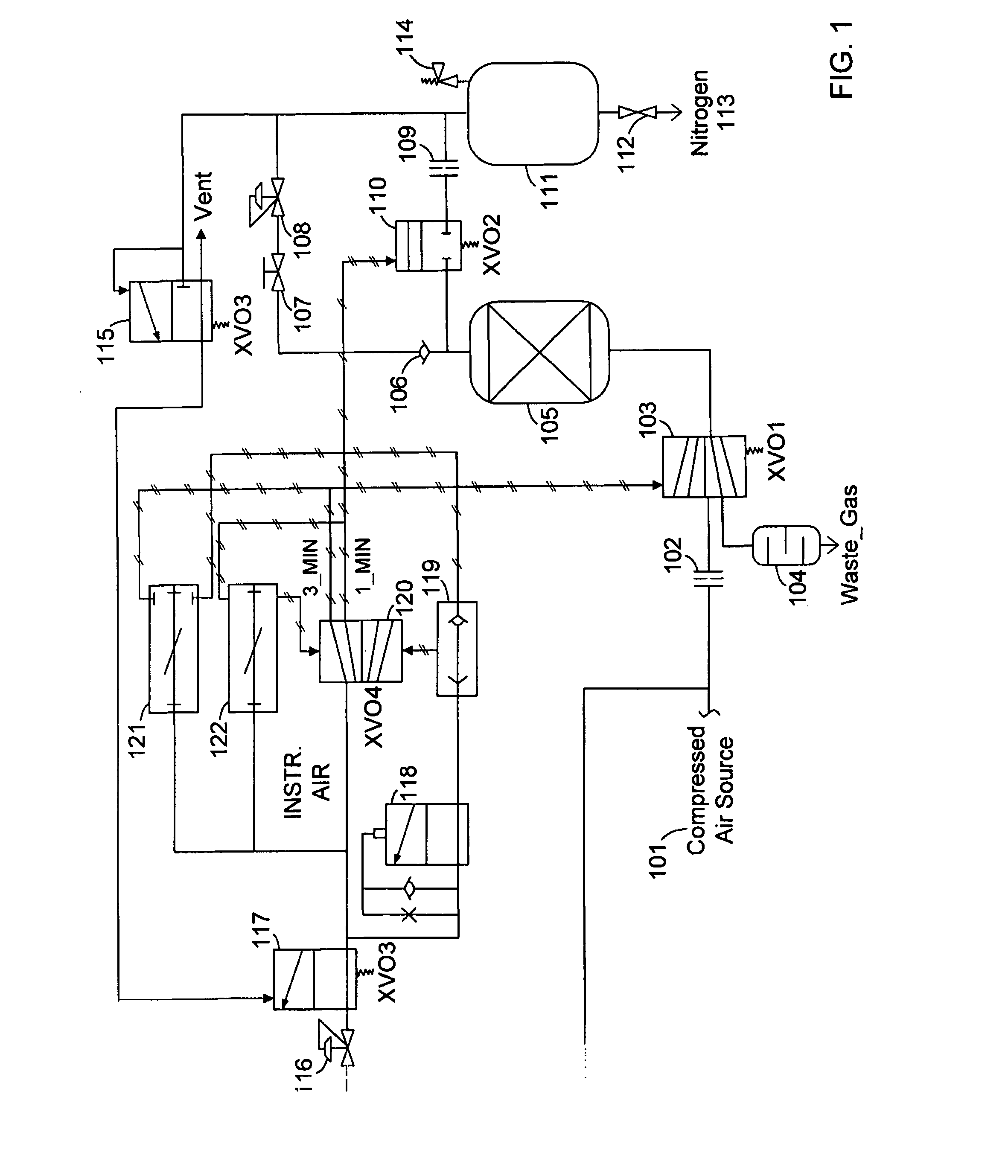

Methods and systems for generation of gases

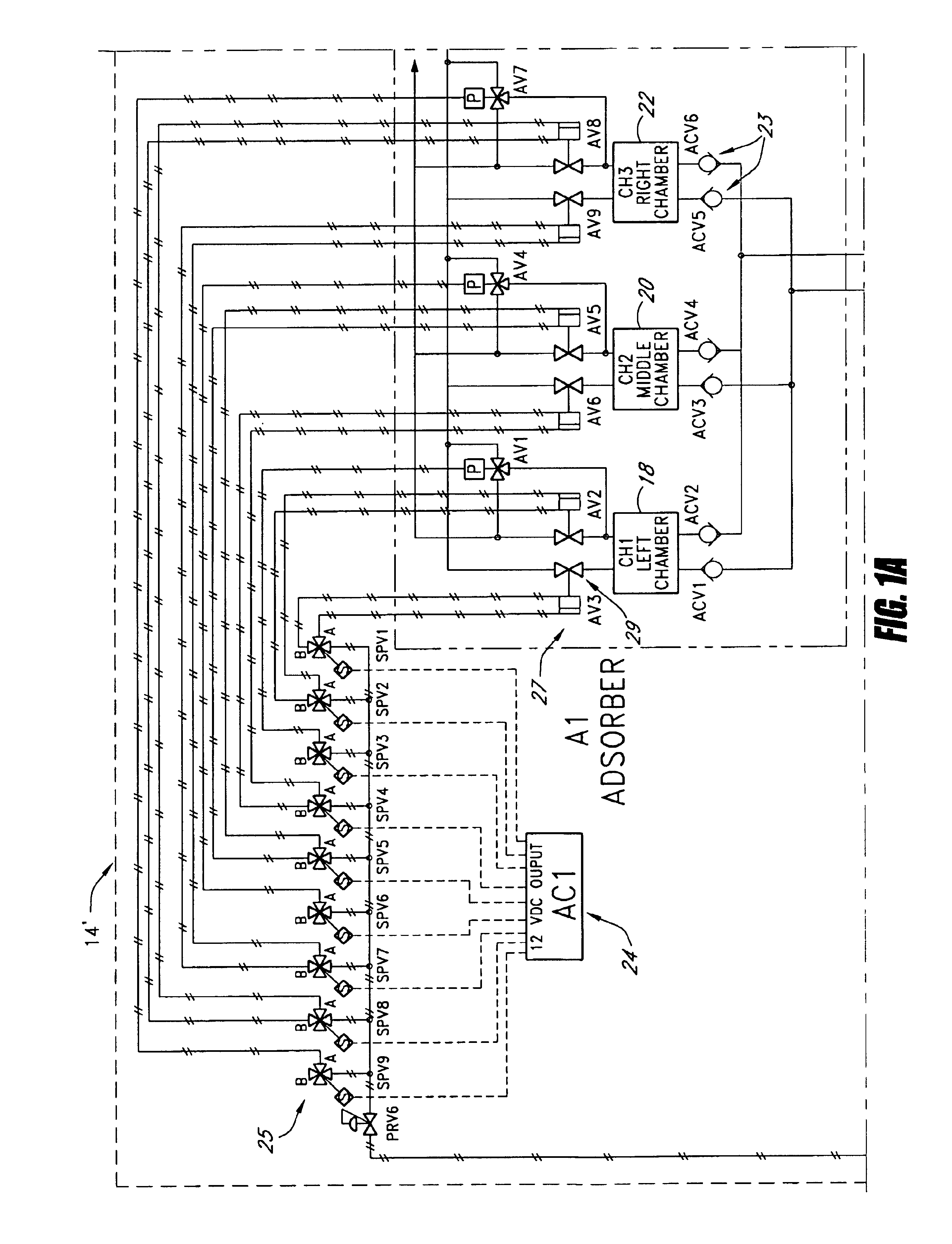

A method of operating a nitrogen generator is provided, wherein the method includes providing a source of compressed air and operating a plurality of pneumatic valves with the compressed air. The method also includes operating at least one pneumatic timer to toggle the nitrogen generator between a production mode where compressed air is channeled to a nitrogen adsorber to produce nitrogen, and a regeneration mode where substantially oxygen-rich air in the nitrogen adsorber is exhausted into the atmosphere.

Owner:INNOVENTOR ENG

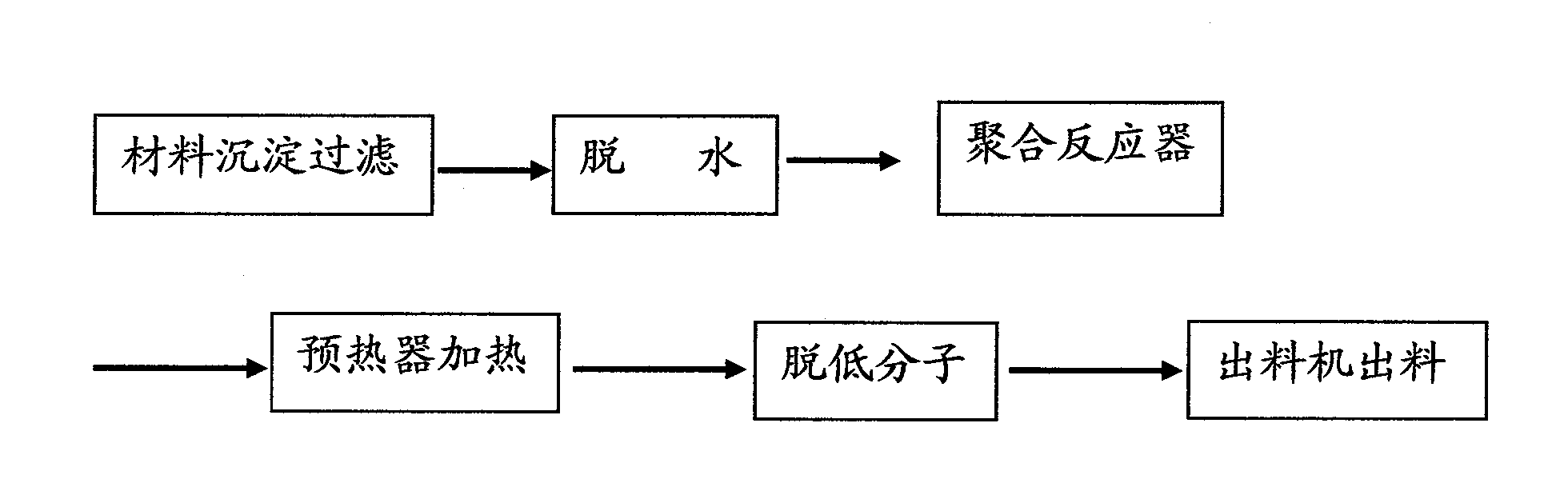

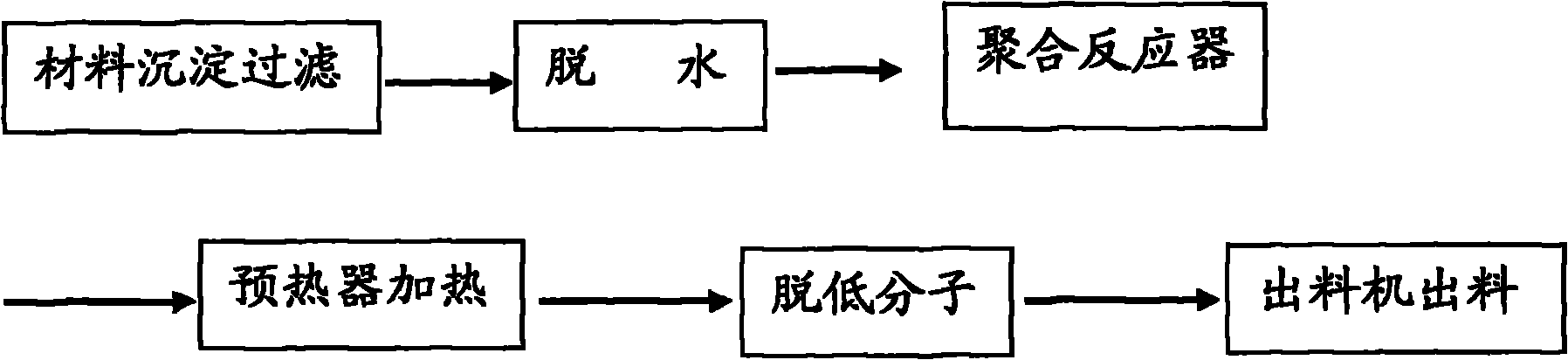

Production process and equipment of methyl vinyl silicone rubber

The invention discloses a production process and production equipment of methyl vinyl silicone rubber, which relate to a raw rubber polymerization process. The invention is characterized in that the production equipment of the methyl vinyl silicone rubber consists of a filter, a metering tank, a dehydrating kettle, a metering pump, a preheater, a polymerization cylinder, a low molecule removing device, a nitrogen generator, a vacuum pump, a discharging machine and the like. The filter is connected with the dehydrating kettle through the metering tank, the dehydrating kettle is connected with the preheater through the metering pump; the preheater is connected with the polymerization cylinder by a pipe; the polymerization cylinder is connected with the low molecule removing device, and the low molecule removing device is connected with the discharging machine by a pipe. The production process of the methyl vinyl silicone rubber comprises: metering dimethyl carbonate (DMC) by the filter; and filling the DMC into the dehydrating kettle, adding alkaline cement, end-capping agent and the like in mixing amount, delivering the mixture to the polymerization kettle through a preheater and a feeding pump, performing polymerization at a certain temperature, filling the reaction solution in the low molecule removing device to remove low molecules under vacuum and filling into the discharging machine to generate raw robber.

Owner:刘宏领

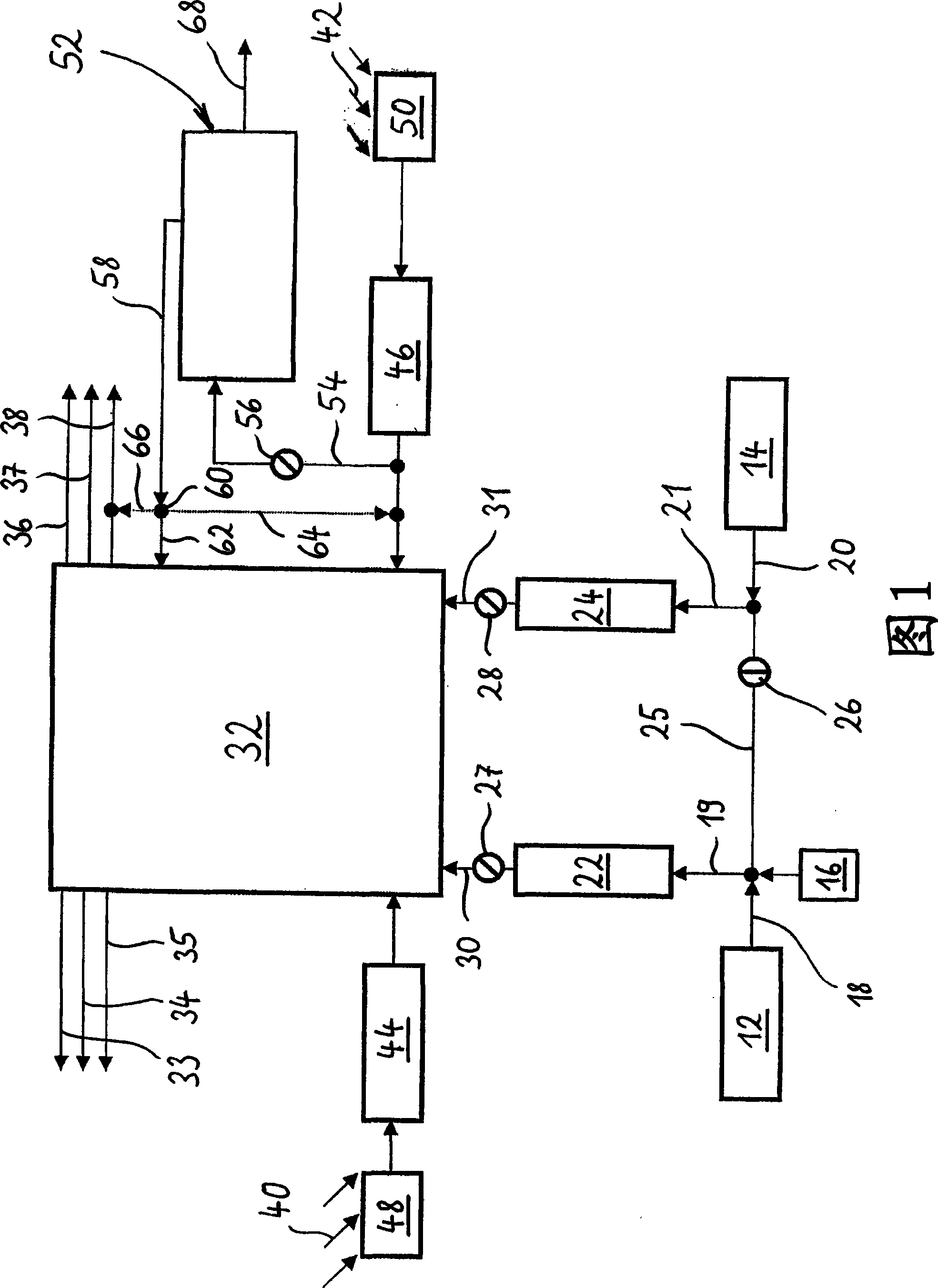

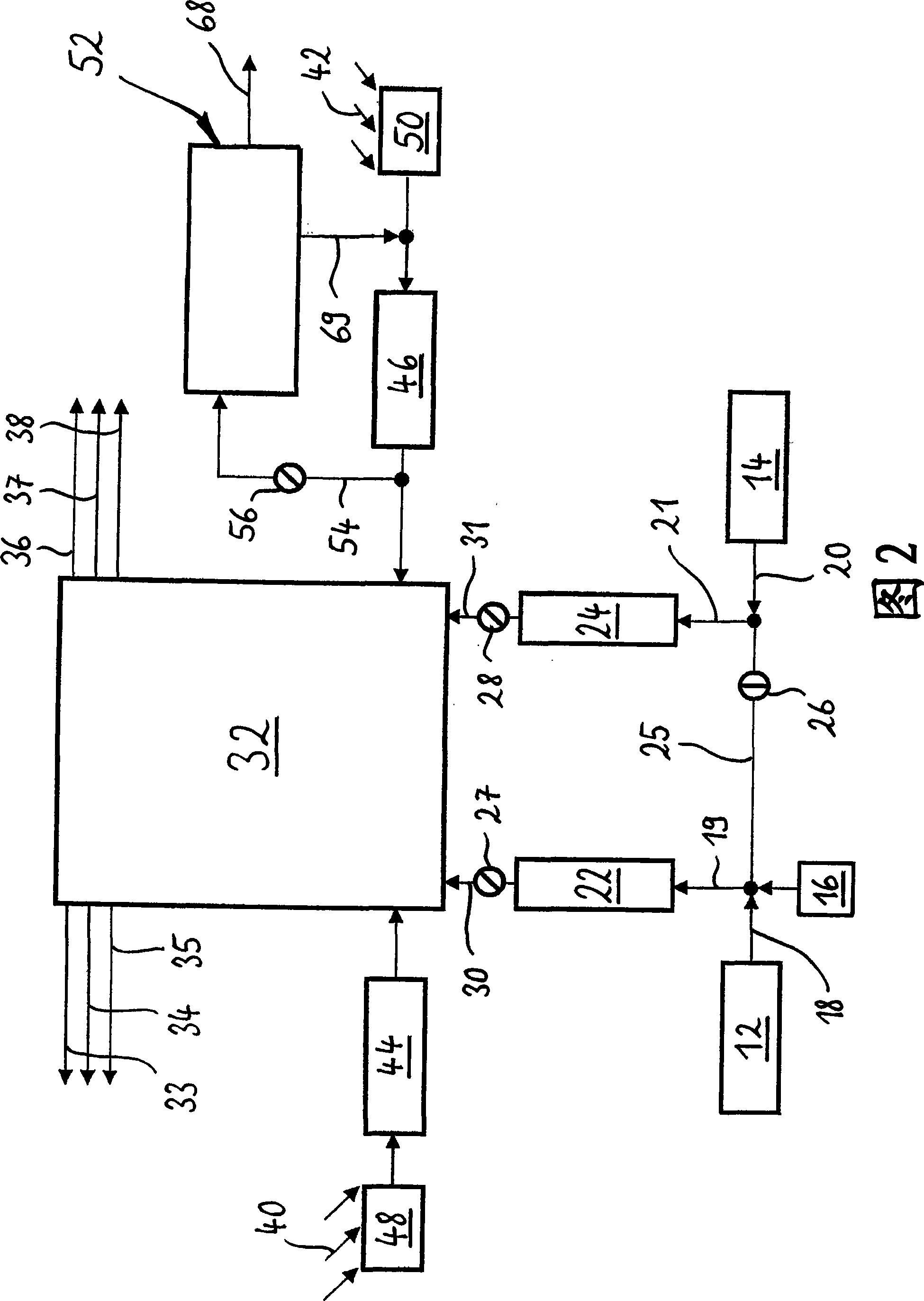

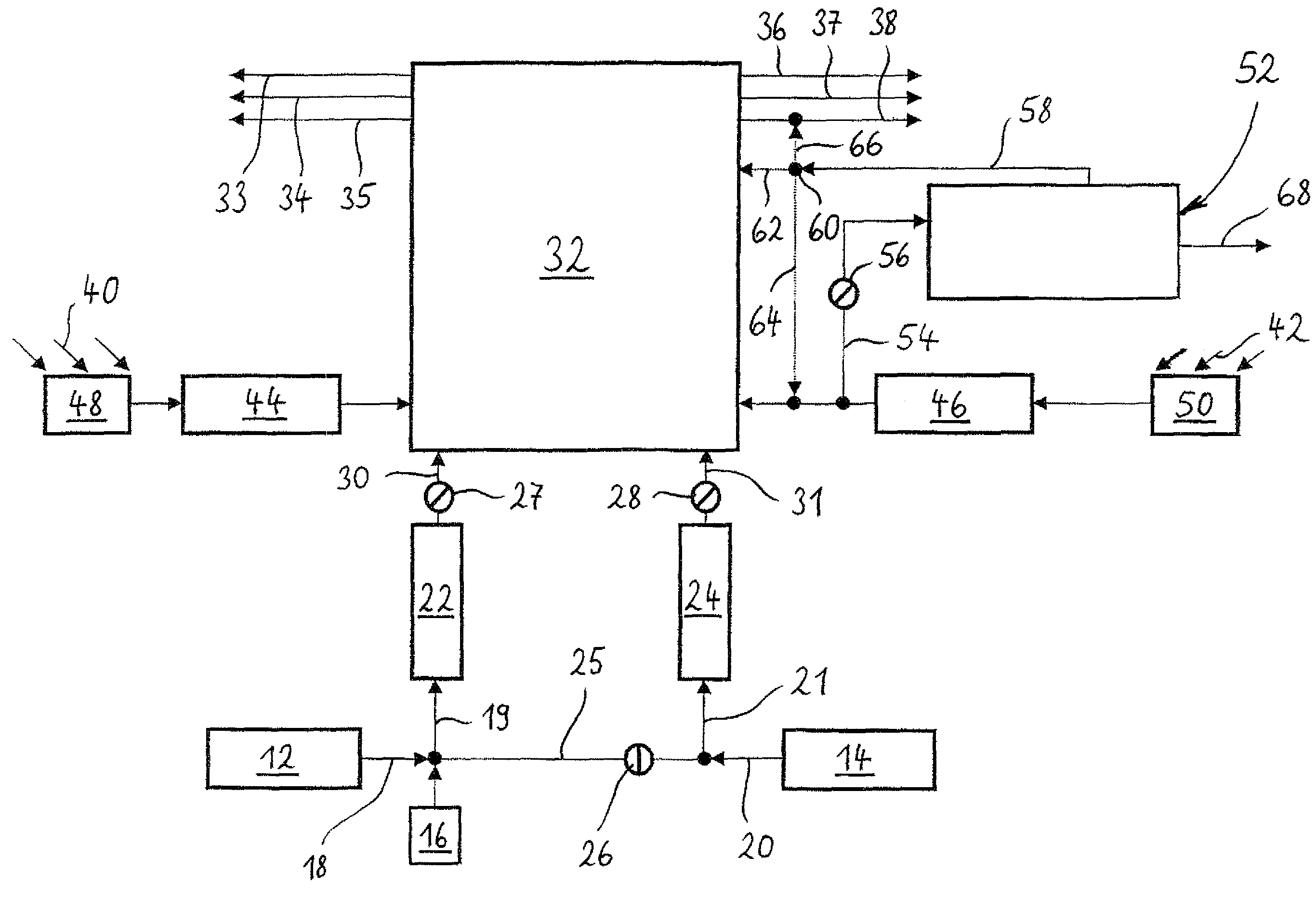

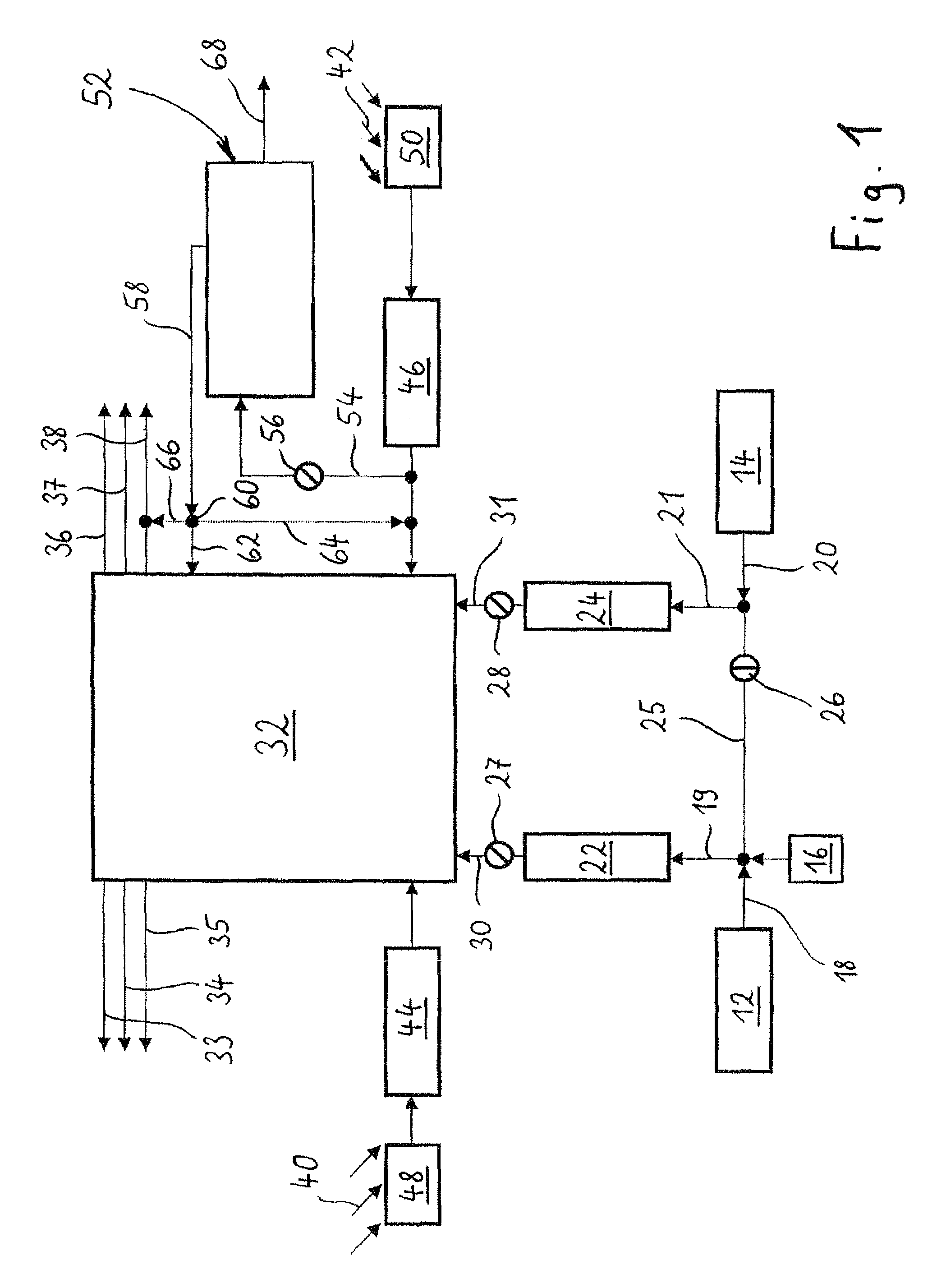

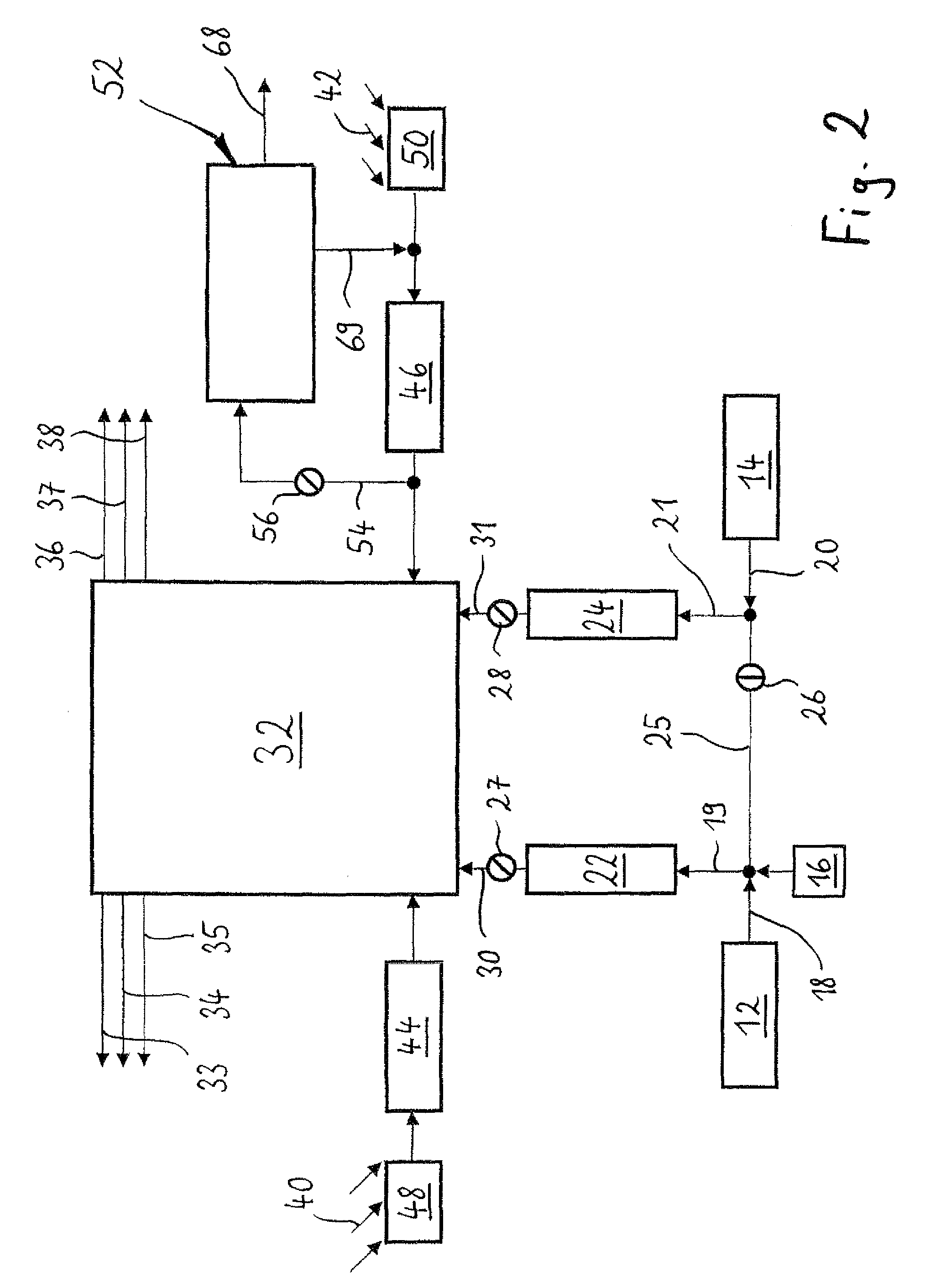

System for improving air quality in an aircraft pressure cabin

ActiveCN101384484ASmall sizeLow costAir-treatment apparatus arrangementsEnergy efficient board measuresNitrogen generatorFlight vehicle

A system for improving the air quality in a pressure cabin of an aircraft comprises a recirculation air circuit by means of which a portion of the cabin air, referred to as recirculation air, is withdrawn from the pressure cabin, filtered and then recirculated into the pressure cabin. To increase the oxygen partial pressure of the air fed back into the pressure cabin, the quantity of recirculation air is passed wholly or partially through a nitrogen generator (52) which generates nitrogen and an oxygen-containing waste gas from the recirculation air supplied. The oxygen-containing waste gas of the nitrogen generator (52), together with any remaining quantity of recirculation air untreated by the nitrogen generator (52), is recirculated into the pressure cabin. The nitrogen generator (52), to which only recirculation air is supplied, utilises a pressure gradient existing in flight between the pressure cabin and the outside of the aircraft for nitrogen generation.

Owner:AIRBUS OPERATIONS GMBH

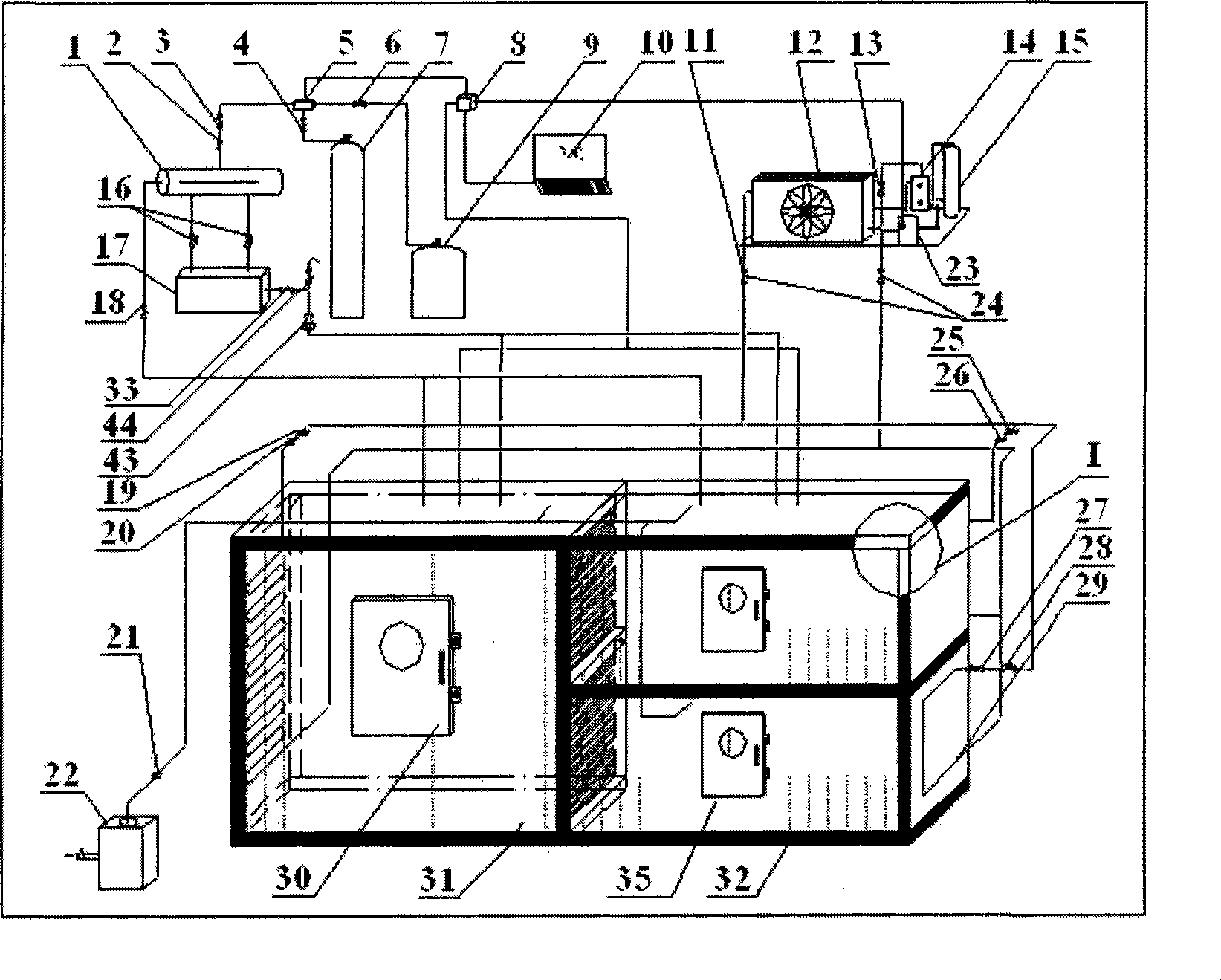

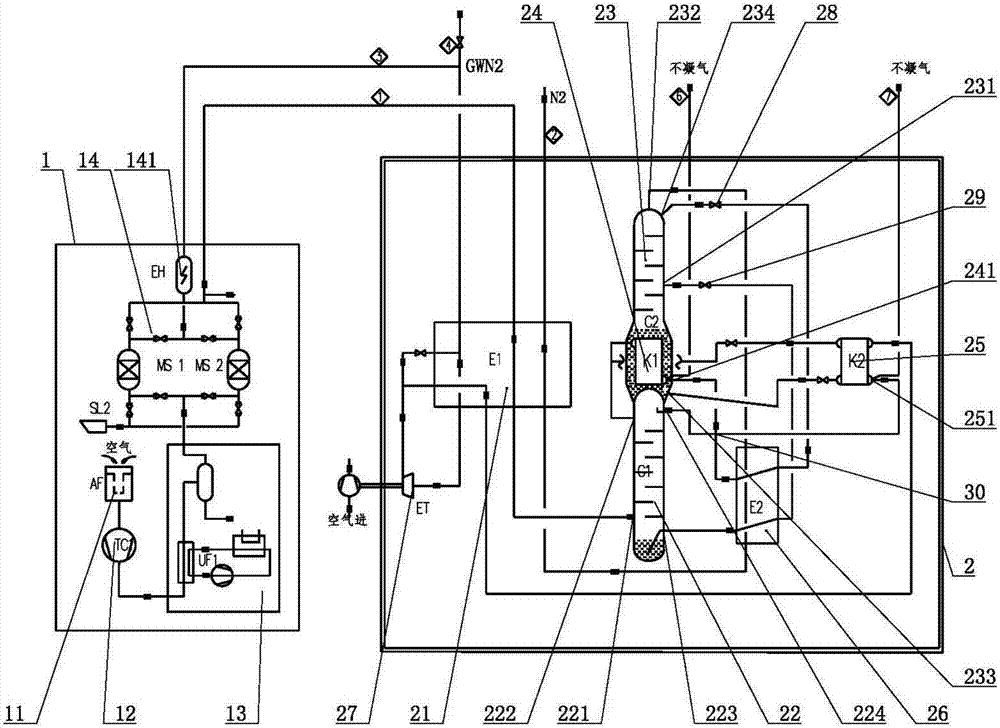

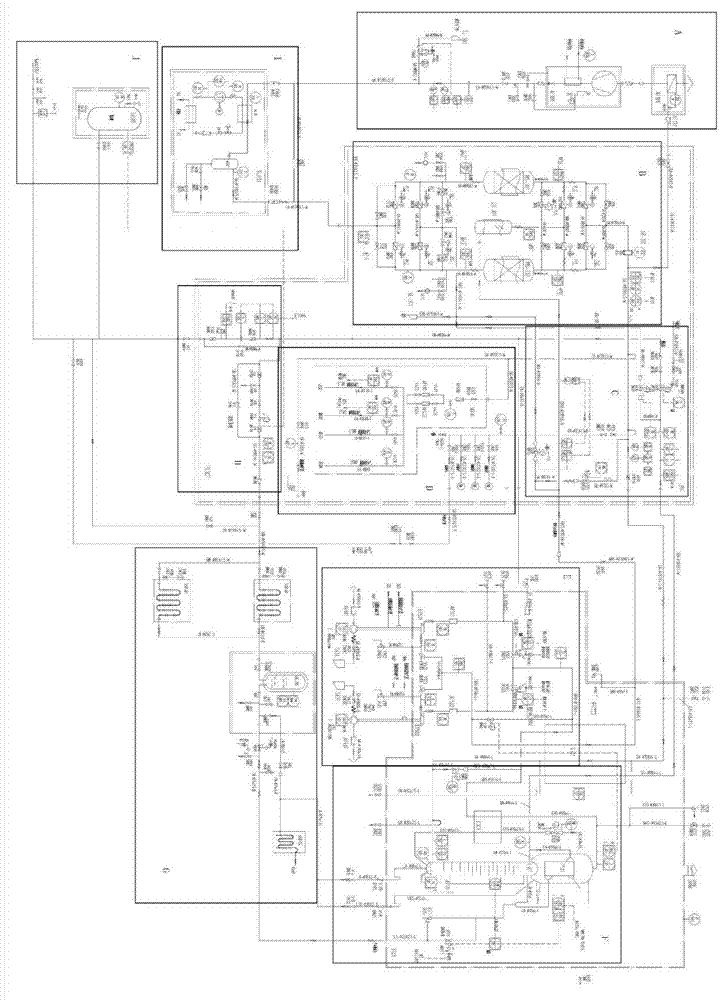

Remote monitoring and non-manual control device and method for nitrogen making machine

ActiveCN103760850ASafe and smooth startUninterrupted air supplySolidificationLiquefactionAutomatic controlNetwork connection

The invention relates to the technical field of nitrogen making devices, in particular to a remote monitoring and non-manual control device and method for a nitrogen making machine. The device comprises a network connection computer and a computer programming tool PLC system or a DCS programming tool, and is characterized in that one end of a filter on an air compression system A is connected with a main air pipeline on the rear portion of a dust filter in an air preprocessing system B through a pipeline and a valve, clean air is introduced to serve as a back flushing air source of the filter, the other end of the air compression system A is connected with one end of a butterfly valve on a water separation system I through a pipeline, each electric device is provided with a local start device and a remote start device, and continuous air supply of the devices is guaranteed by means of a PLC or DCS programming control system and a safety protection system. Compared with the prior art, the remote monitoring and non-manual control device and method have the advantages that full-automatic control is achieved, a nitrogen making device is monitored remotely and in real time through a network, safe and stable start, operation and stop of the device are guaranteed, a liquid nitrogen standby system is automatically started in abnormal situations, and continuous air supply is guaranteed.

Owner:上海加力气体有限公司

System for improving air quality in an aircraft pressure cabin

ActiveUS8074927B2Flexible operationLow costRespiratorsAir-treatment apparatus arrangementsNitrogen generatorEngineering

A system for improving the air quality in a pressure cabin of an aircraft includes a recirculation air circuit in which a portion of the cabin air, referred to as recirculation air, is withdrawn from the pressure cabin, filtered and then recirculated into the pressure cabin. To increase the oxygen partial pressure of the air fed back into the pressure cabin, the quantity of recirculation air is passed wholly or partially through a nitrogen generator which generates nitrogen and an oxygen-containing waste gas from the recirculation air supplied. The oxygen-containing waste gas of the nitrogen generator, together with any remaining quantity of recirculation air untreated by the nitrogen generator, is recirculated into the pressure cabin. The nitrogen generator, to which only recirculation air is supplied, utilizes a pressure gradient existing in flight between the pressure cabin and the outside of the aircraft for nitrogen generation.

Owner:AIRBUS OPERATIONS GMBH

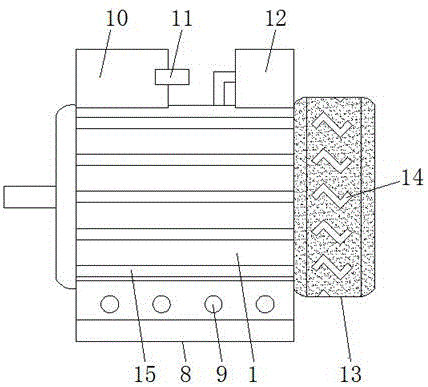

Electric motor with anti-explosion function

InactiveCN106253550AWith explosion-proof functionReduce the chance of explosionCooling/ventillation arrangementSupports/enclosures/casingsNitrogen generatorInternal pressure

The invention discloses an electric motor with an anti-explosion function. The electric motor comprises an anti-explosion shell, wherein the anti-explosion shell comprises a shell wall; the shell wall comprises an inner layer and an outer layer; a hollow cavity is formed between the inner layer and the outer layer; a solid body anti-explosion layer is arranged on one side, far from the outer layer, of the inner layer; a ceramic insulating layer is arranged on one side, far from the inner layer, of the solid body anti-explosion layer; uniformly-arranged heat dissipation sheets are arranged on the outer side face of the anti-explosion shell; a pressure relief cavity and a nitrogen generator are arranged on the top of the anti-explosion shell; an air delivery pipe is arranged on one side, close to the pressure relief cavity, of the nitrogen generator; and a safety relief valve is arranged on one side, close to the nitrogen generator, of the pressure relief cavity. By adoption of the electric motor with the anti-explosion function, the internal pressure of the anti-explosion shell is effectively reduced, so that the explosion probability of the electric motor is lowered, the safety coefficient of the electric motor in use is improved, and the internal temperature of the electric motor is effectively lowered; and even if the electric motor runs for a long time, the internal temperature of the electric motor is not too high, thereby providing effective guarantee to personnel security and property security.

Owner:陈节庆

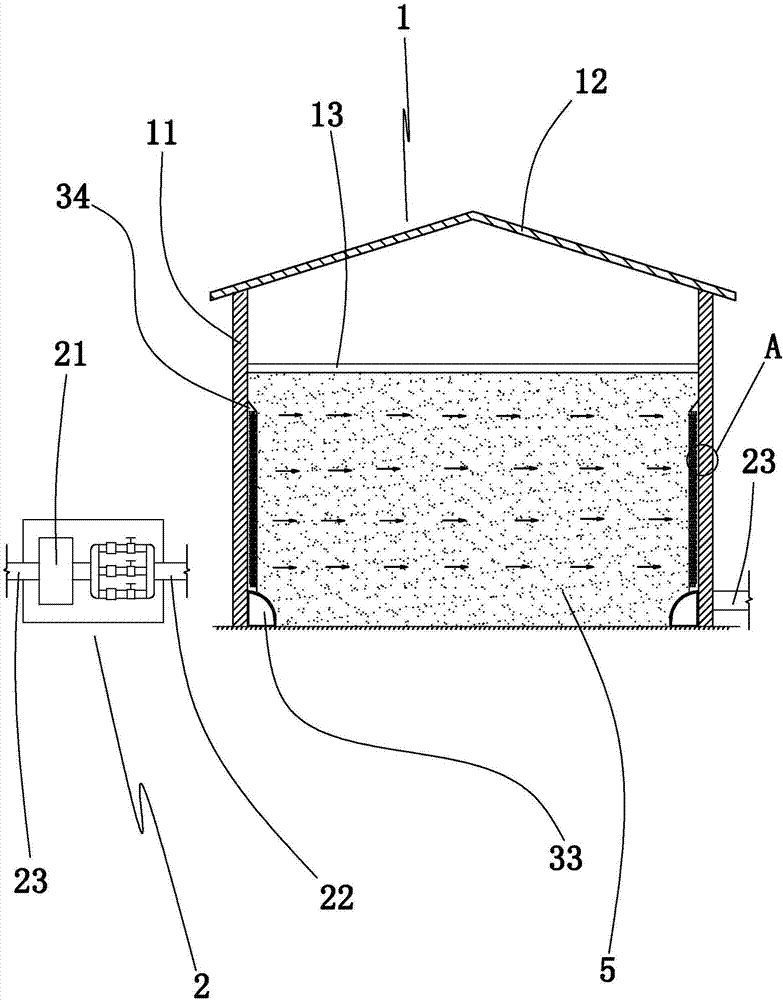

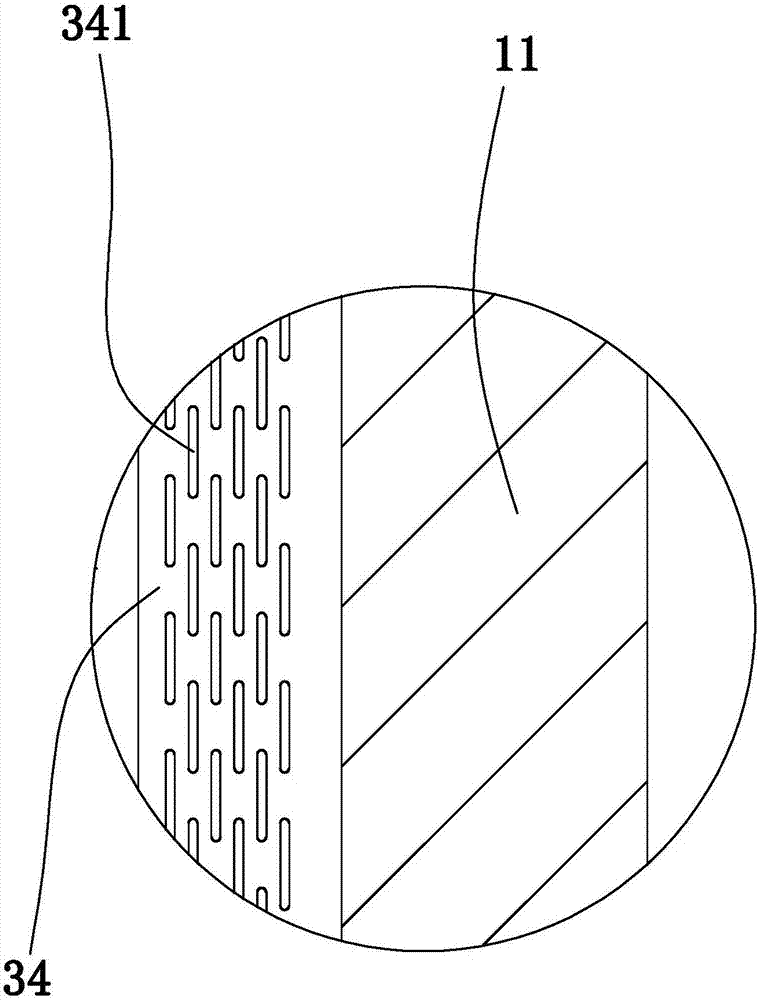

Grain bin transverse nitrogen-charging adjustment system and storage method

ActiveCN107258247AEffective Nitrogen FillingEffective insecticideNitrogen purification/separationAgriculture tools and machinesNitrogen generatorButt joint

The invention discloses a grain bin transverse nitrogen-charging adjustment system. The system comprises a grain storage bin and a membrane separation nitrogen generator, and further comprises two air-adjusted air duct structures; the air-adjusted air duct structures comprise wall air ducts, open-close doors, main air ducts and a plurality of vertical support air pipes, a plurality of air holes are formed in the vertical support air pipes, and nitrogen supplying air holes are connected to one end of the nitrogen supplying pipe in a butt joint mode; connectors which are connected with the wall air duct of one air-adjusted air duct structure in a butt joint mode are arranged at the other end of the nitrogen supplying pipe, air inlets of a nitrogen preparation main engine are connected to one end of an air return pipe in a butt joint mode, and the connectors which are connected with the wall air duct of another air-adjusted air duct structure in a butt joint mode are arranged at the other end of the air return pipe; a nitrogen supplying on-off valve is arranged on the nitrogen supplying pipe, and a nitrogen concentration detection instrument and a pressure determinator are all arranged on the air return pipe. The grain bin transverse nitrogen charge air-adjusted system has the advantages that a grain bin can be effectively filled with nitrogen, accordingly, grain piles in the grain bin can be effectively subjected to disinfestation, mould inhibition and preservation, and the system is good in gas distribution uniformity, high in nitrogen efficiency and less in nitrogen waste.

Owner:浙江省粮食局直属粮油储备库

Refrigeration and freezing device with fresh-keeping function by supplying nitrogen

InactiveUS8065885B2Compact structureDouble functionFruit and vegetables preservationLighting and heating apparatusNitrogen generatorMolecular sieve

A refrigeration and freezing device with fresh-keeping function by supplying nitrogen comprises a box body, a refrigerating and freezing chamber disposed inside the box body, a door to the refrigerating and freezing chamber, a control device and a nitrogen generator; wherein said nitrogen generator is disposed either inside or outside the box body of the refrigeration and freezing device, said nitrogen generator comprises an air inlet, an oxygen outlet, a nitrogen outlet, an air filter connected with the air inlet, a compressor, a pipe device for transmitting gas, at least one carbon molecular sieve absorber, at least one control valve to control different absorbers to work alternately, a nitrogen storage container, a nitrogen purifier, a pressure reducing valve for adjusting the pressure of the produced nitrogen, a ventilating muffler disposed on a pipe to the oxygen outlet and a control circuit.

Owner:WANG DONG LEI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com