Double-tower double-condensation backflow expansion nitrogen making machine and nitrogen making method thereof

A nitrogen generator and double condensation technology, which is applied in the field of mechanical equipment, can solve the problems of increased processing air volume and comprehensive energy consumption, and achieve the effects of reducing the processing air volume, reducing comprehensive energy consumption, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to better understand the technical content of the present invention, specific embodiments are given together with the accompanying drawings for description as follows.

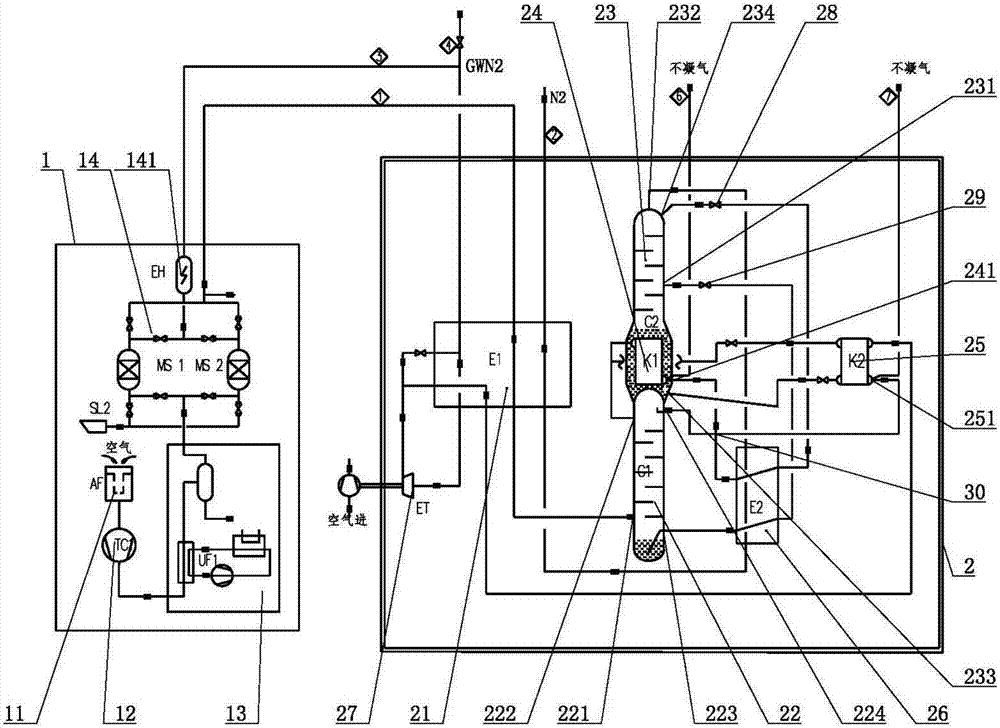

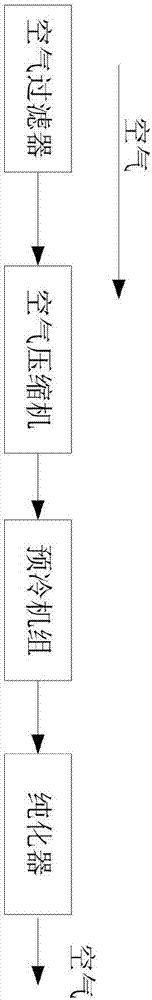

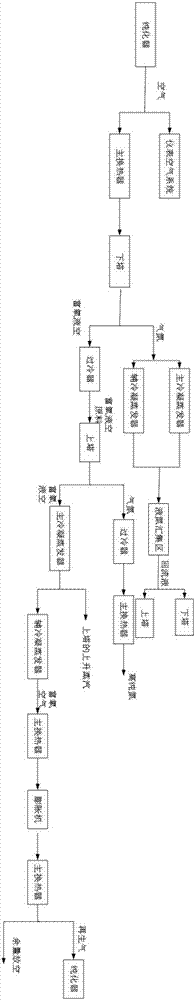

[0048] Such as figure 1 combine Figure 2A , Figure 2B As shown, the double-tower double-condensation reflux expander nitrogen generator includes an intake air pretreatment device 1 and a nitrogen generator 2 connected to each other through pipelines.

[0049]The air intake pretreatment device 1 includes an air filter 11 that removes dust and mechanical impurities, an air compressor 12 that compresses external air, and a pre-cooling unit 13 that cools the air output by the air compressor 12 through pipelines in sequence. And a purifier 14 for purifying the output air of the pre-cooling unit 13 . In this way, it is possible to reduce the harmful impurities of the raw materials from entering the main condensing evaporator 24 and the auxiliary condensing evaporator 25 .

[0050] In this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com