Patents

Literature

101 results about "Cryogenic technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cryogenic Technology Cryogenic air separation technology is used by many industries that rely on an uninterrupted supply of atmospheric gases. ... Cryogenic air separation is the preferred technology for producing very high purity oxygen and nitrogen. It is the most cost effective technology for high production rate plants.

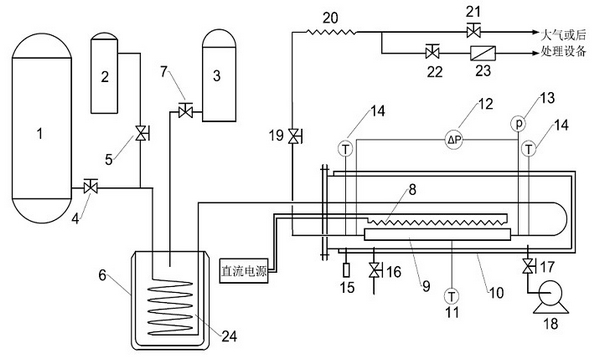

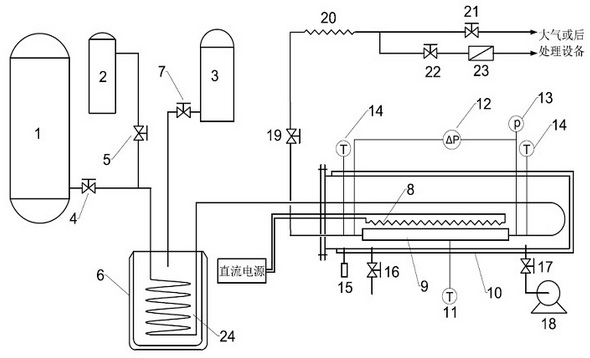

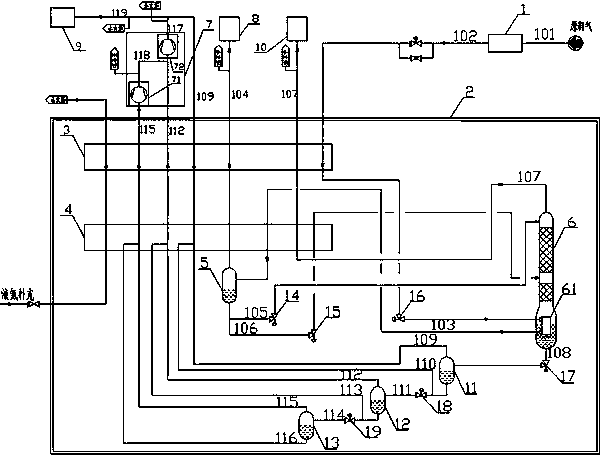

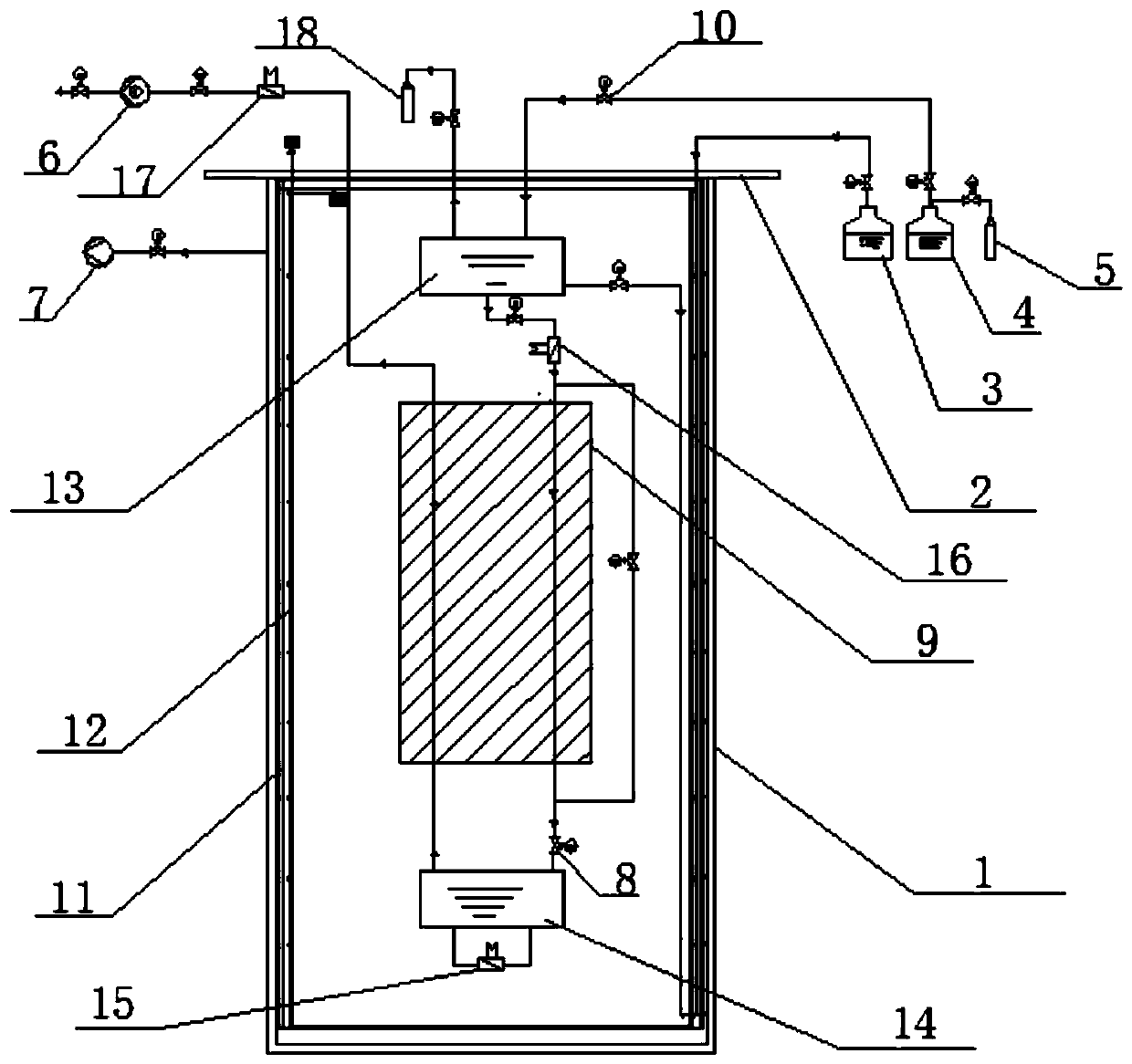

Testing system for researching flow boiling heat transfer character and pressure drop character of cryogenic fluid

InactiveCN102435632AImprove utilization efficiencyImprove securityMaterial heat developmentFlow boiling heat transferCooling coil

The present invention provides a testing system for researching flow boiling heat transfer character and pressure drop character of cryogenic fluid, which belong to the technical field of cryogenic engineering and cryogenic technique. The testing system comprises a cryogenic self-pressurized storage tank, a nitrogen steel cylinder, a liquid nitrogen steel cylinder, a wide-mouth dewar, a cooling coil, an electric heating device, heat exchange equipment to be tested, a test vacuum dewar, a temperature transducer, a pressure transducer, a differential pressure transducer, a vaporizer and a gas flowmeter. The cryogenic self-pressurized storage tank is used as a pressurization device in the testing system and cryogenic fluid is outputted under a certain pressure, which can simplify the testingsystem. The heat exchange equipment to be tested is arranged in the test vacuum dewar for reducing heat loss in the testing. A vacuum valve is arranged in the test vacuum dewar and can be connected to outer high pressure nitrogen for blowing the inner part of the test vacuum dewar when necessary, which can improve the system safety. The testing system has the advantages of less land occupation, small investment, simple control, easy operation, safe, reliable and applicability to various cryogenic fluids including flammable and explosive cryogenic fluids.

Owner:SHANGHAI JIAO TONG UNIV

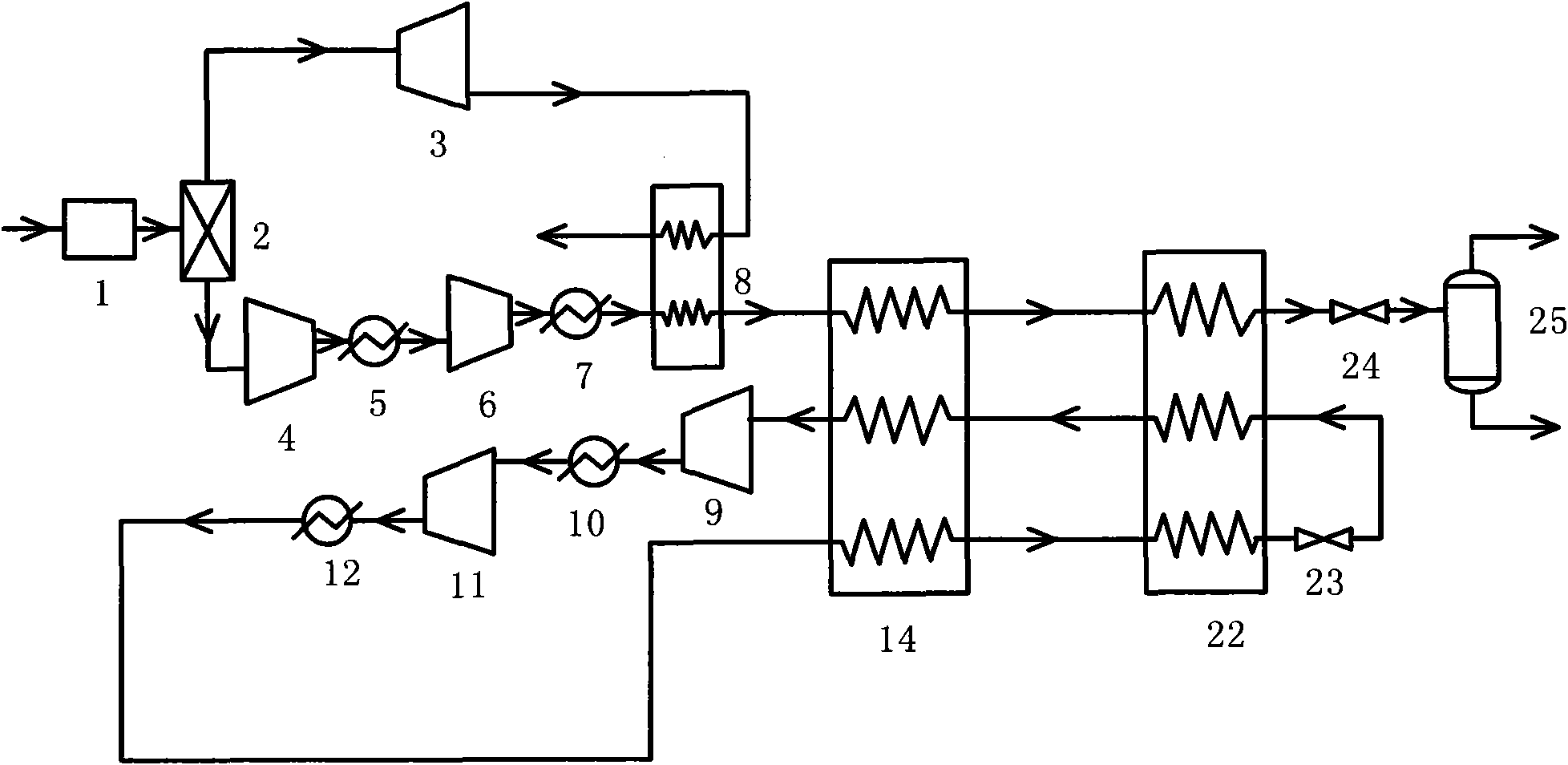

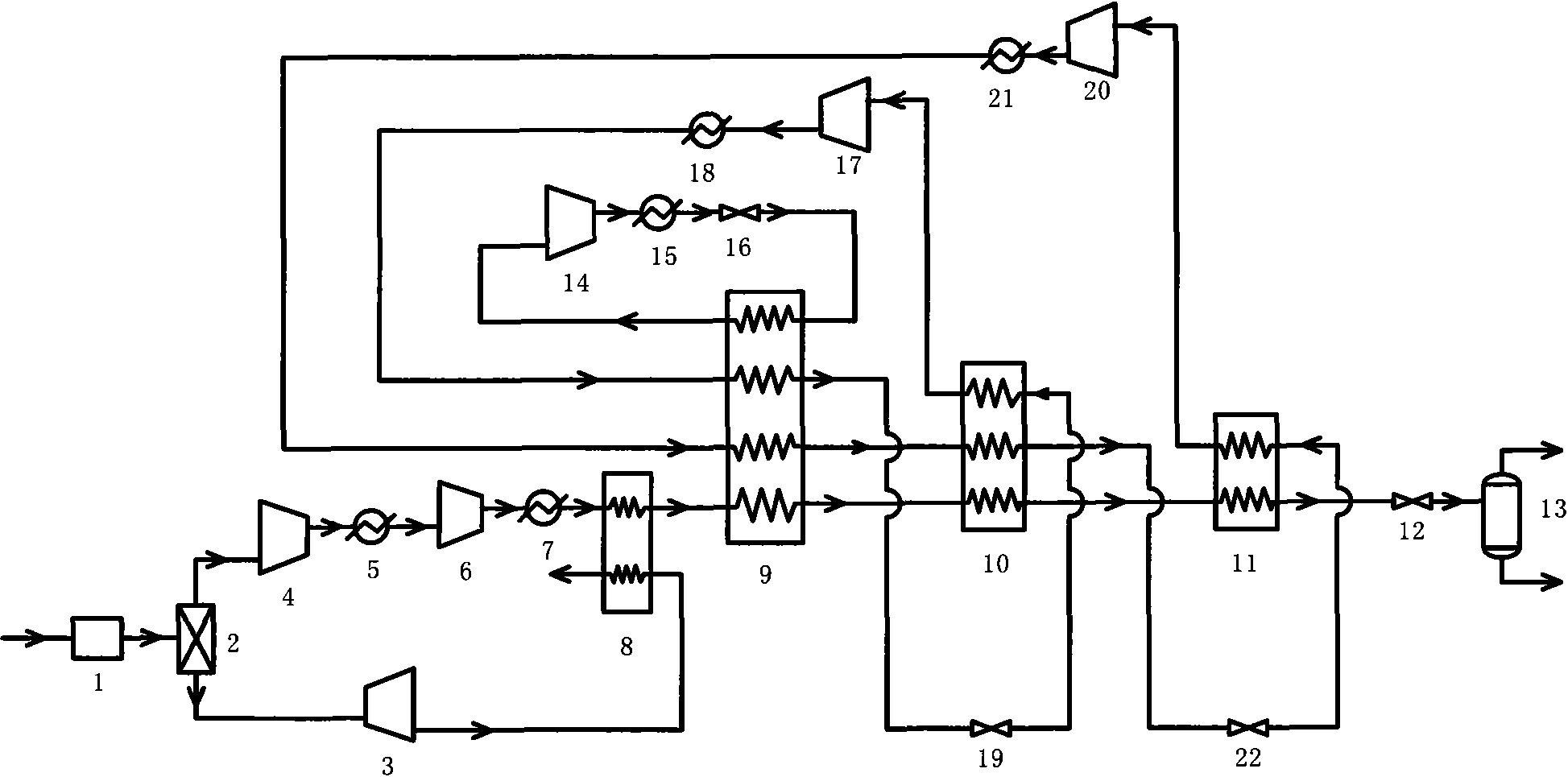

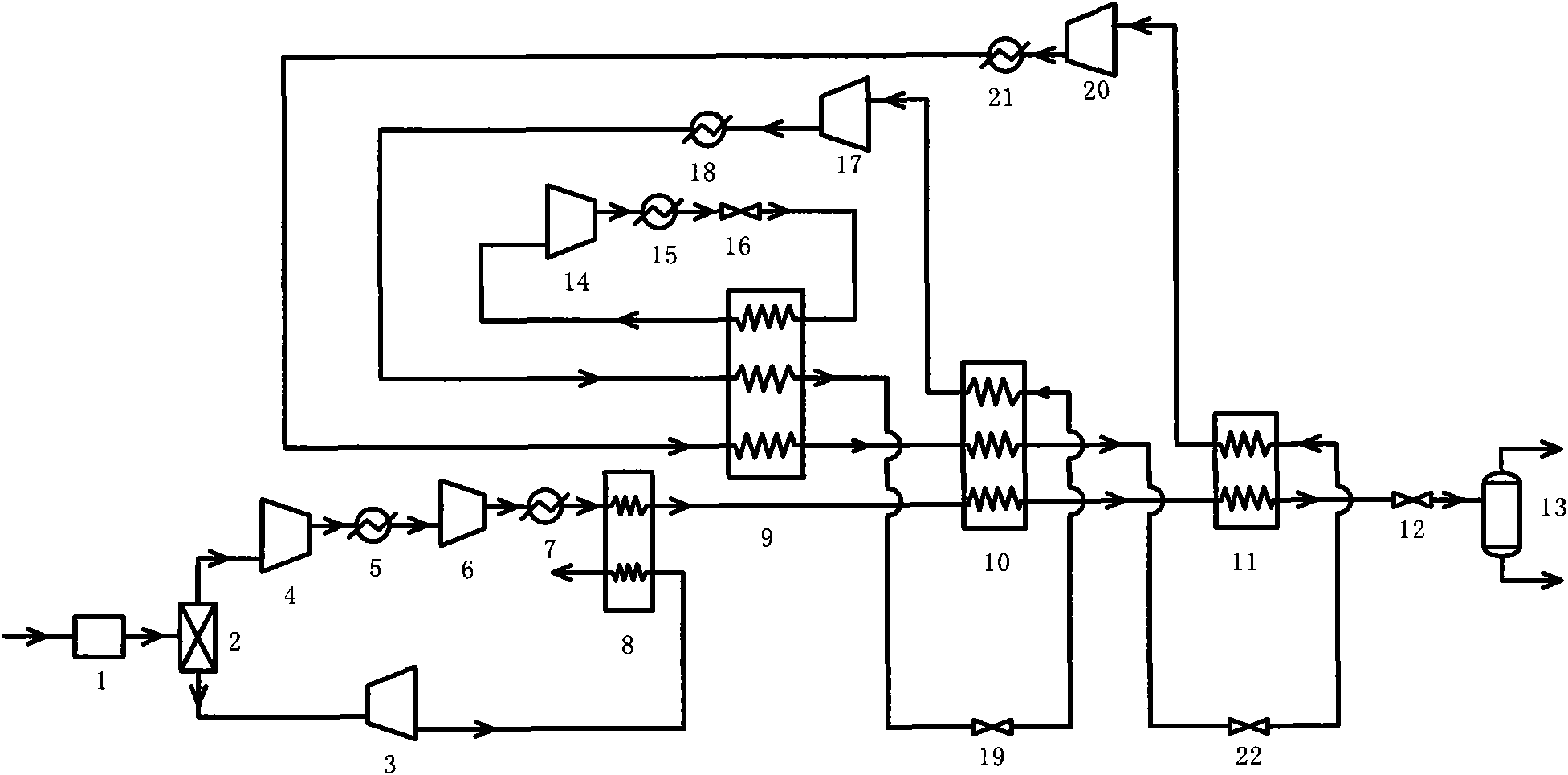

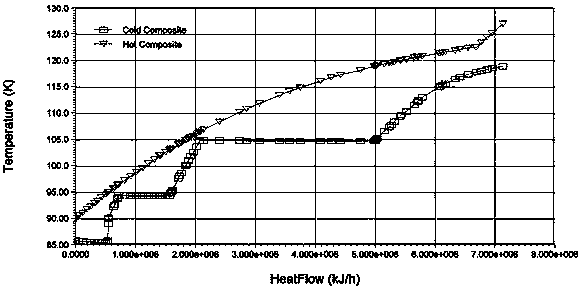

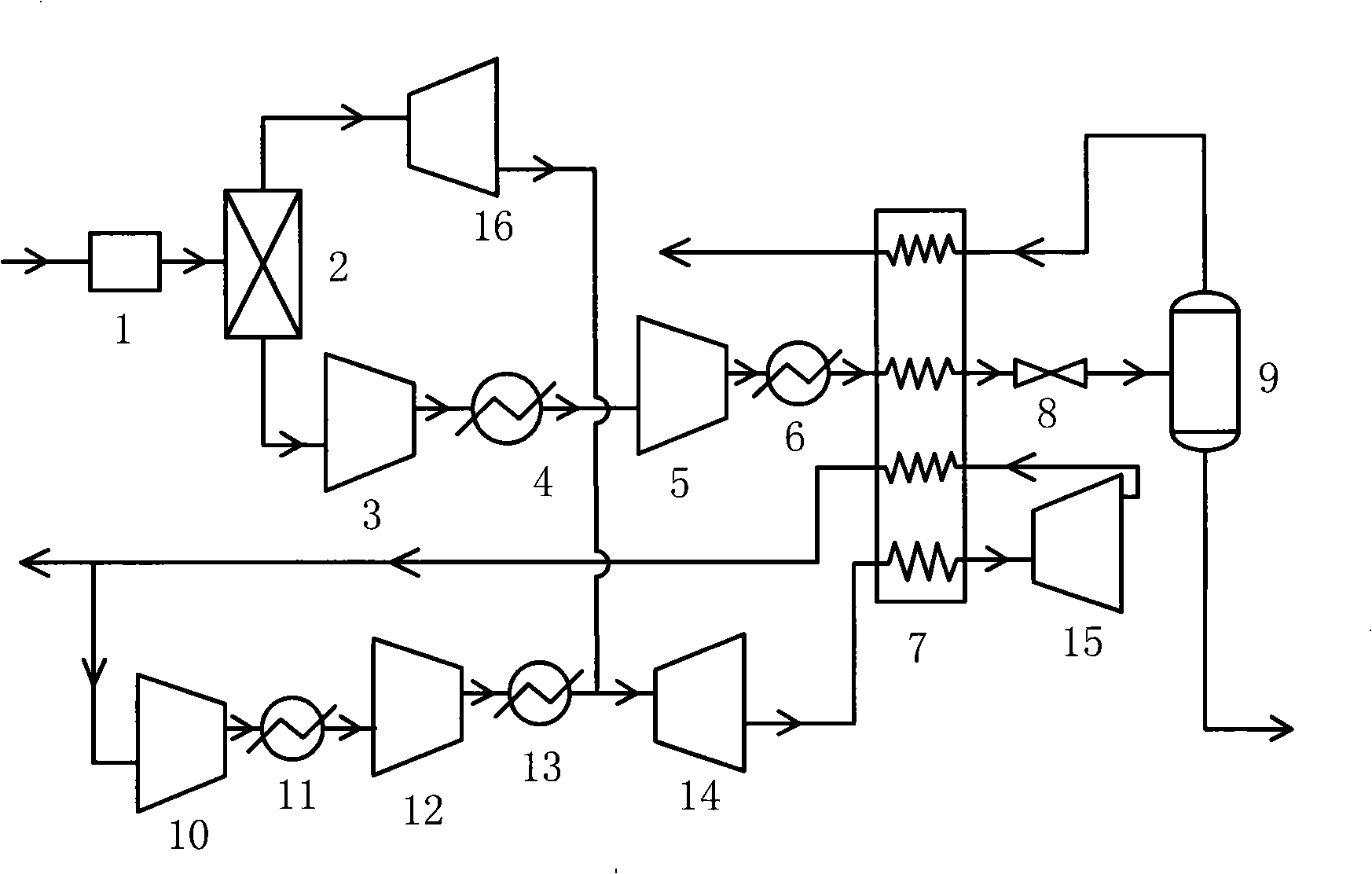

Mixed refrigerant re-circulated liquefaction process for precooling coalbed methane (CBM) by residual pressure of pressure swing adsorption (PSA)

InactiveCN101625190AReduce liquefaction power consumptionReduce power consumptionSolidificationLiquefactionChemical industryCryogenic technology

A mixed refrigerant re-circulated liquefaction process for precooling coalbed methane (CBM) by residual pressure of pressure swing adsorption (PSA) belongs to the technical field of chemical industry and low temperature. The invention provides an integrated process of adsorption and liquefaction of CBM with high nitrogen content. The process comprises the following steps: before liquefaction, firstly desorbing most nitrogen in the CBM by the PSA process, adopting the residual pressure of adsorption in the above nitrogen to precool the CBM after expanding the residual pressure and liquefying the CBM by the mixed refrigerant re-circulated liquefaction process which is widely applied in the natural gas liquefaction industry. The precooling process of the nitrogen with residual pressure saves the mixed refrigerant flow used for providing cooling capacity, thus reducing the overall power consumption of the system. With the increase of the nitrogen content of the CBM and the residual pressure of adsorption in the nitrogen, the temperature of the precooled CBM gradually decreases, the number of cooling stages of mixed refrigerant cycle can be correspondingly lessened and more power consumption is saved.

Owner:SHANGHAI JIAO TONG UNIV

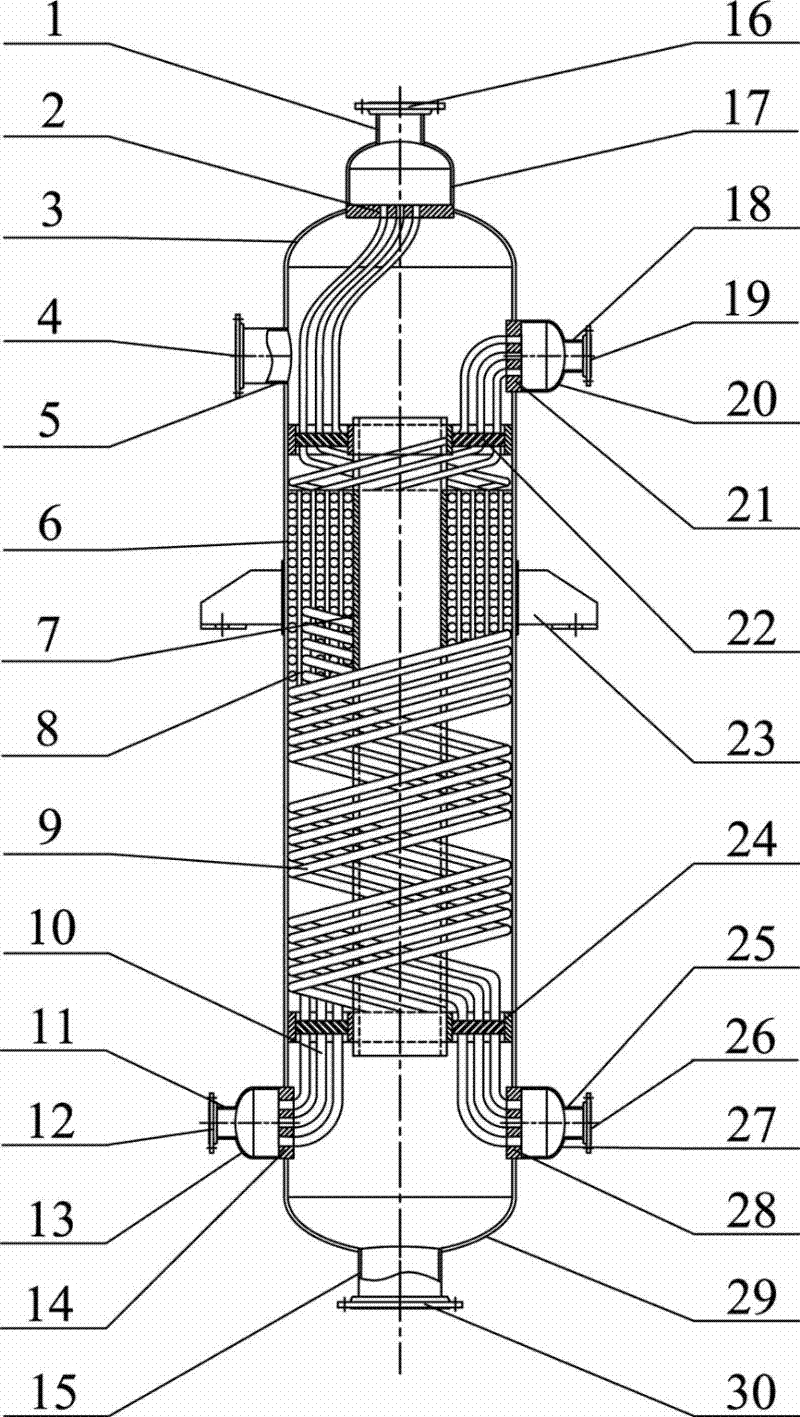

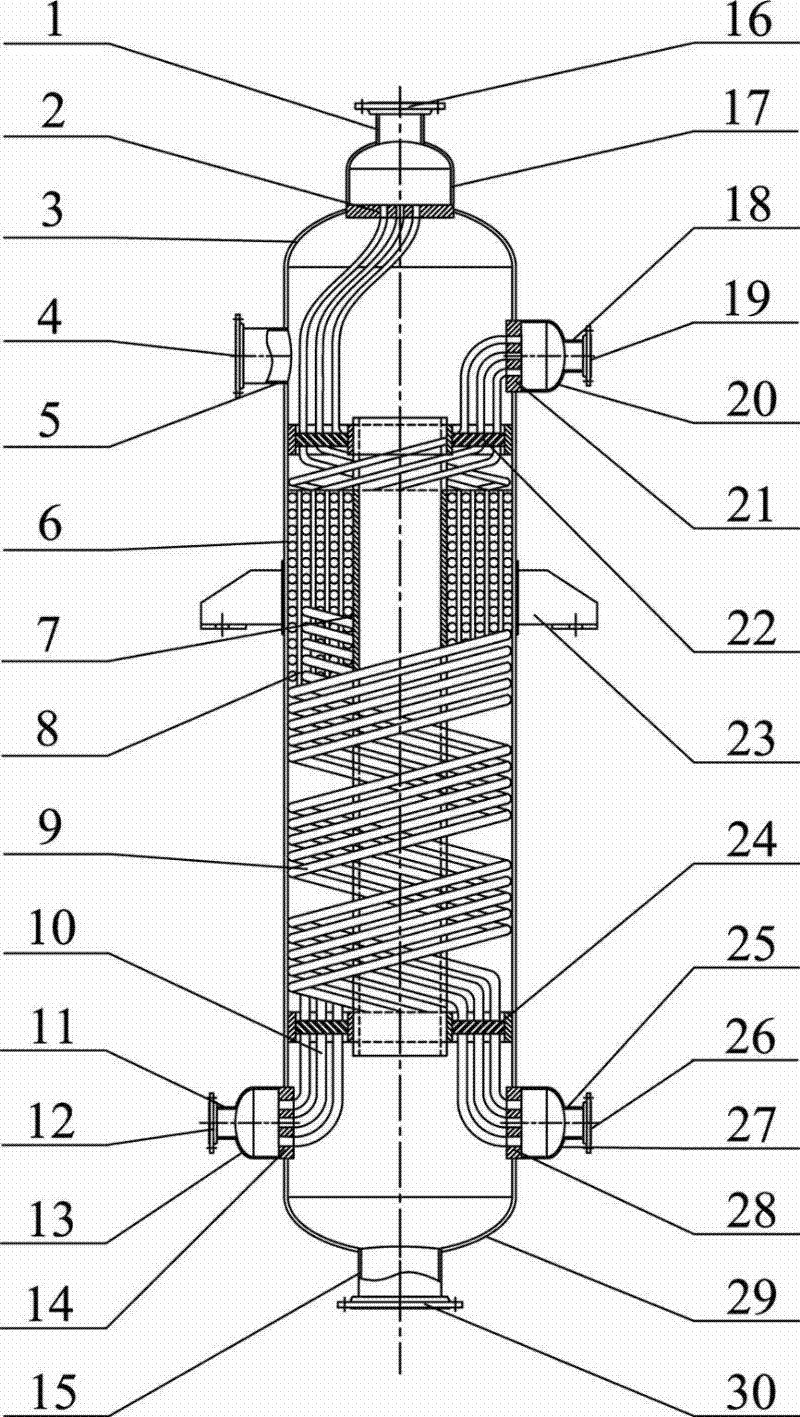

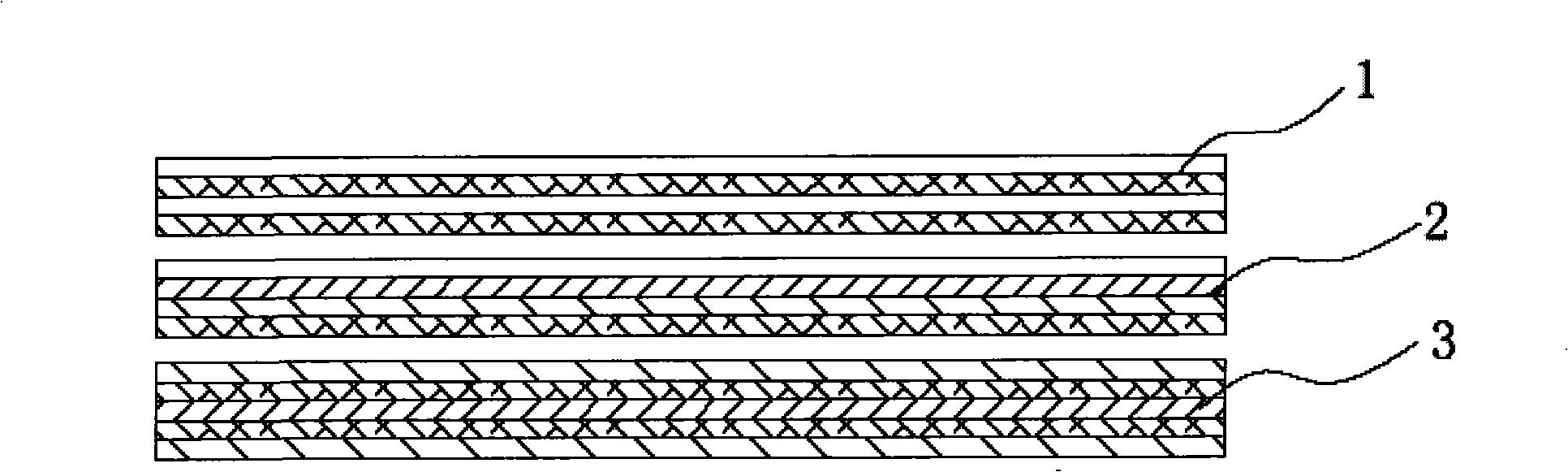

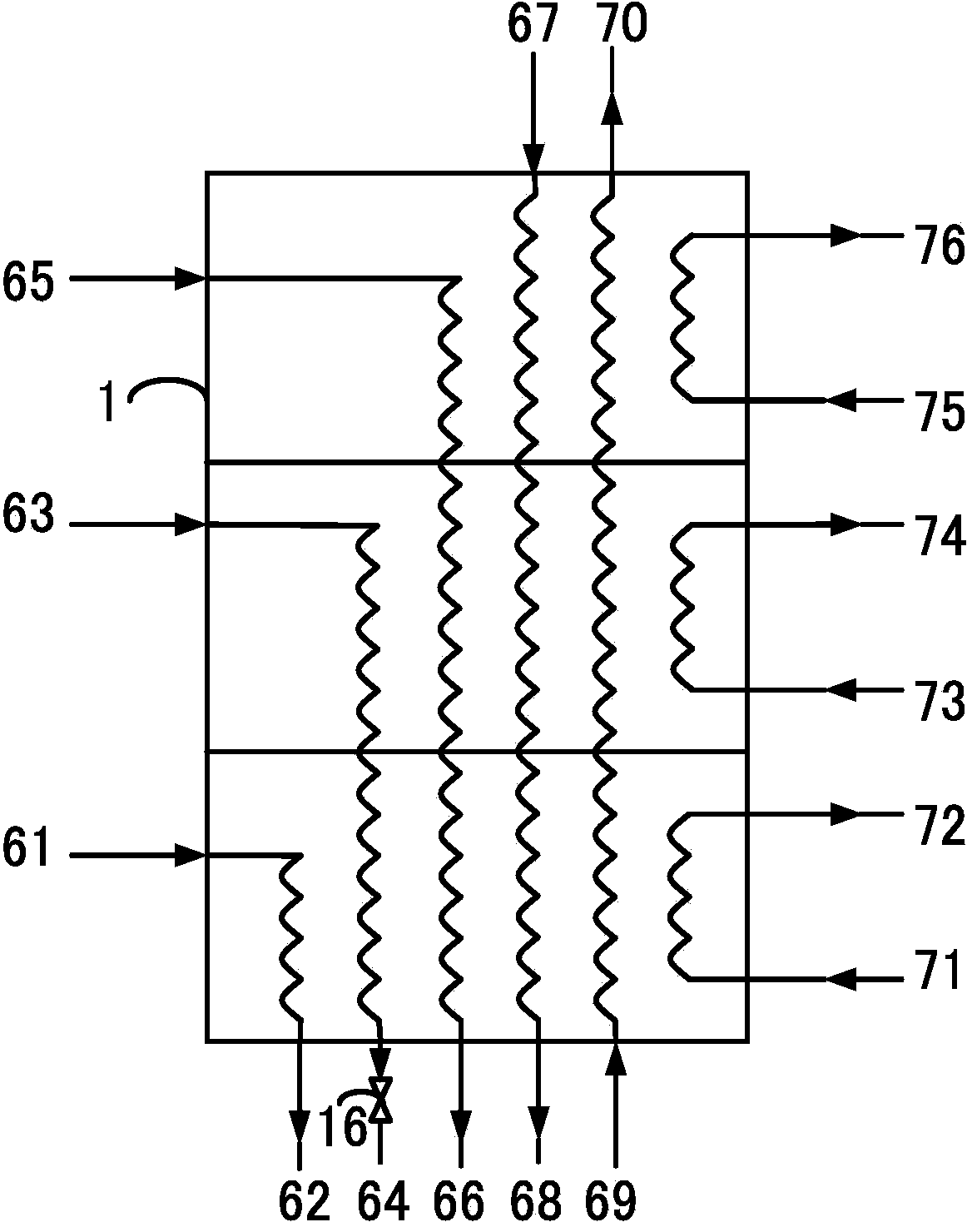

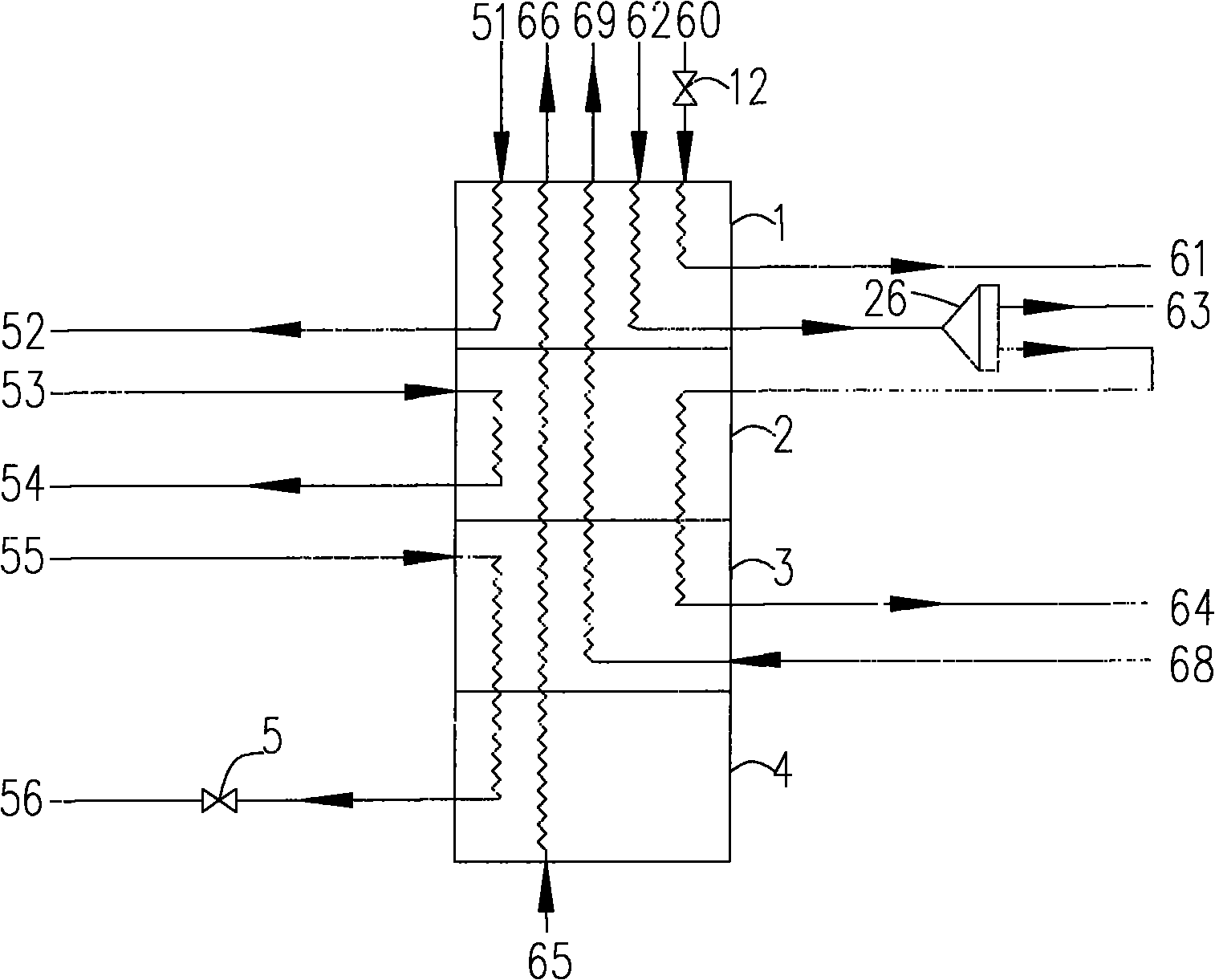

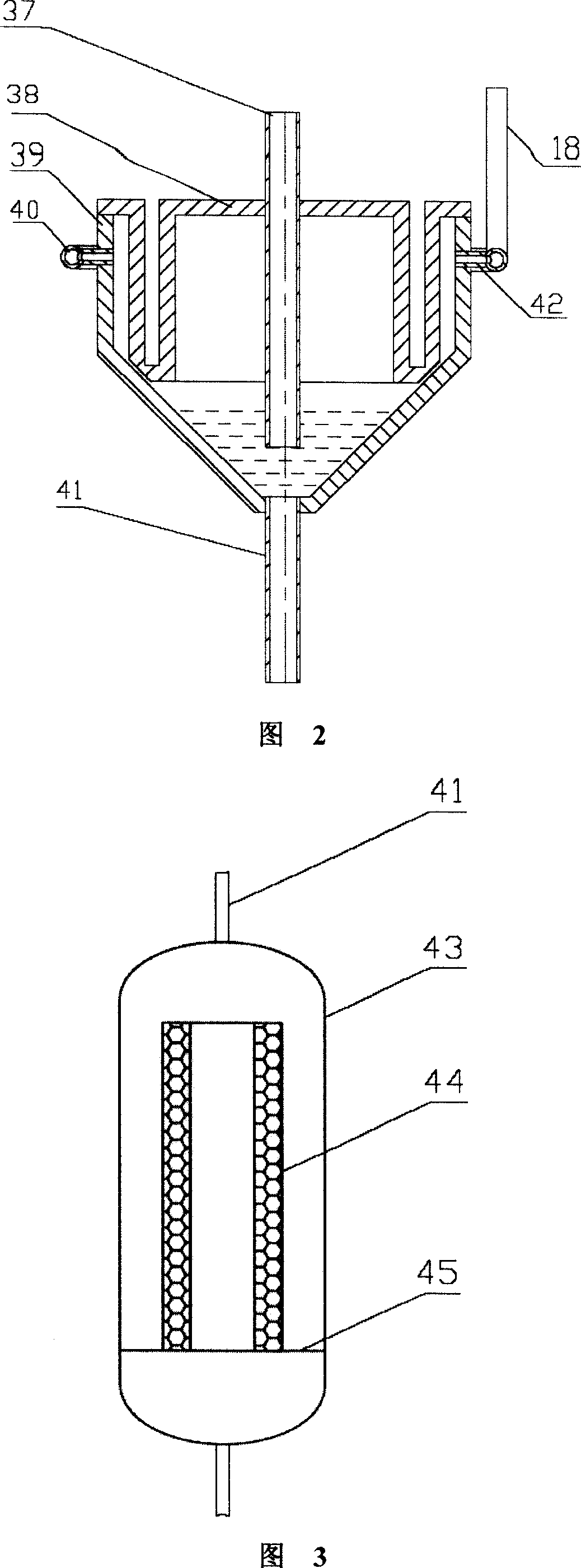

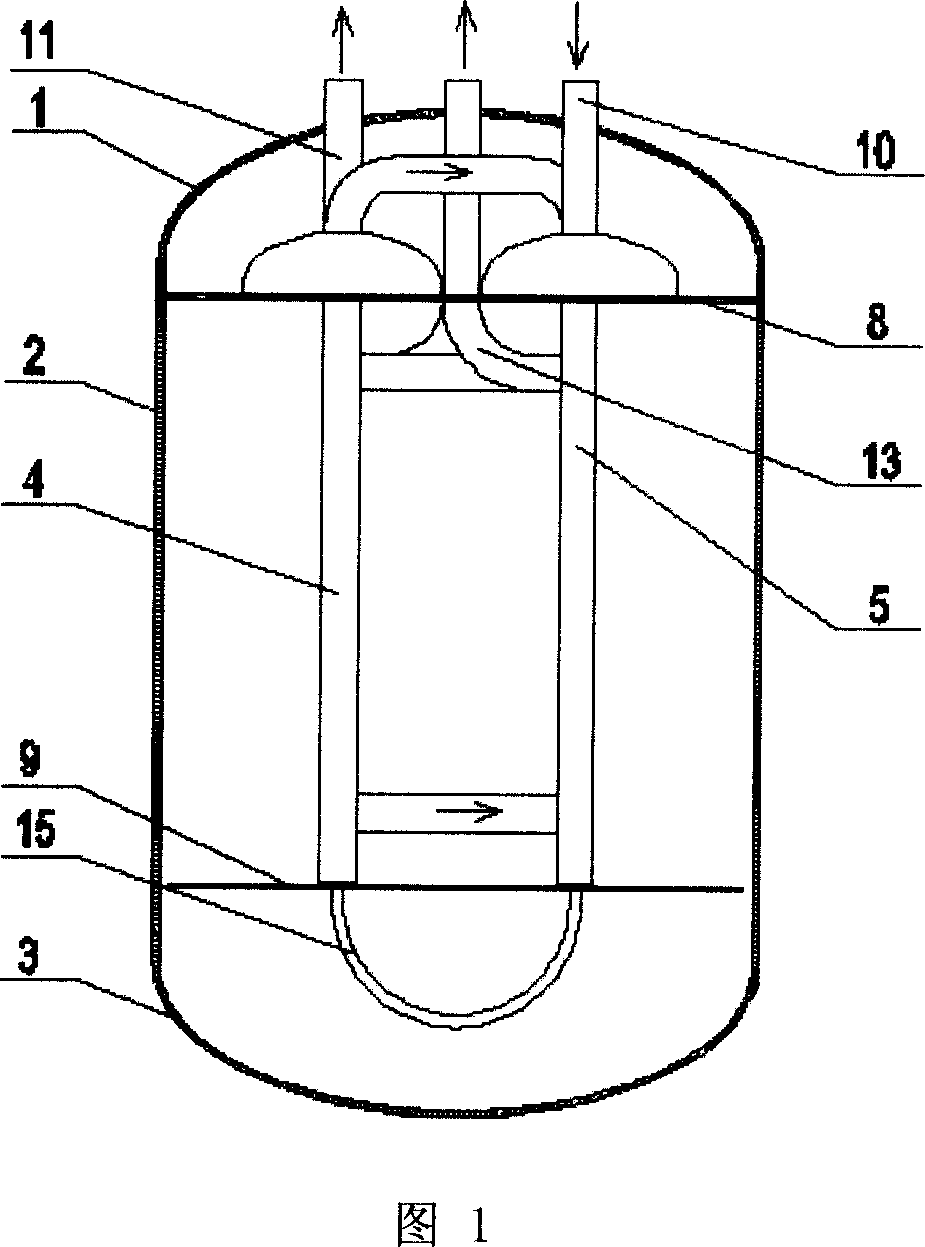

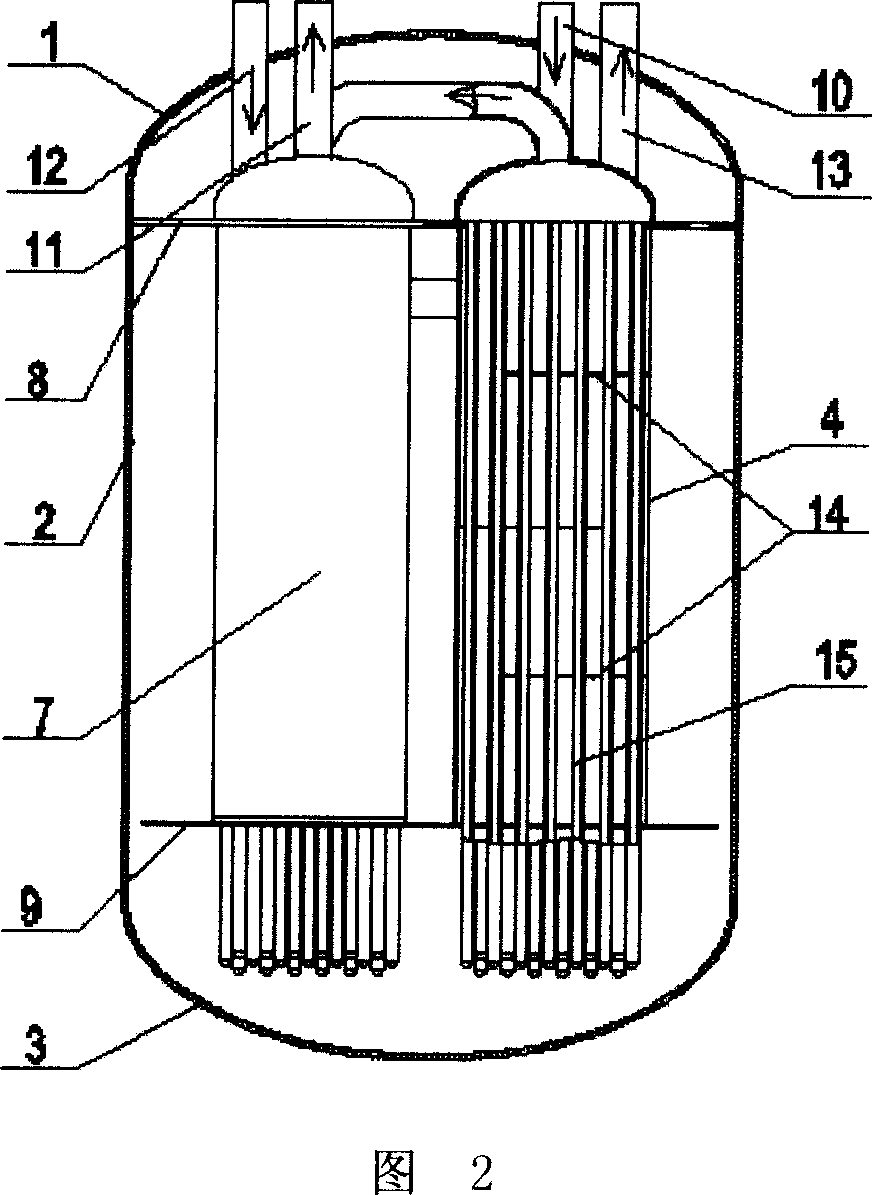

Liquefied natural gas (LNG) low temperature liquefied three-level refrigeration spiral wound tube type heat exchanger

InactiveCN102538387AWith self-tightening adjustment functionReduce volumeSolidificationLiquefactionThree levelSpiral wound

The invention belongs to the field of natural gas low temperature liquefied technology, and relates to a liquefied natural gas (LNG) three-level low temperature liquefied process device and a mixed refrigerant refrigeration technology, which cools 6.0MPa, -120DEG C natural gas into -164DEG C to be liquefied in two-steam spiral wound tube type heat exchanger by applying a certain proportion of non-azeotropic N2-CH4 mixed refrigerant, thereby being convenient for LNG to be stored in a surpercooling mode and being convenient to transport. The non-azeotropic N2-CH4 mixed refrigerant is firstly precooled and liquefied by a three-level refrigerant spiral wound tube type heat exchanger, and is throttled to a shell pass after being liquefied to cool a LNG tube bundle and a N2-CH4 mixed refrigerant precooling tube bundle from a secondary outlet in -120DEG C, thereby leading natural gas and precoolded refrigerant in the tube pass to be liquefied, and achieving the purpose of precooling mixed refrigerant before throttling and liquefying nature gas at low temperature. The LNG three-level low temperature liquefied process device is compact in structure and high in heat exchange efficiency, can be used to exchange heat for mixed gas with low-temperature phase transition, solves the difficult problem of LNG three-level low temperature technology, and increases low temperature heat exchange efficiency of a LNG system.

Owner:张周卫

Preparation method for hibiscus esculentus flower tea

The invention discloses a preparation method for hibiscus esculentus flower tea, and belongs to the technical field of flower tea deep-processing. The preparation method comprises the steps as follows: (1) collecting, namely collecting fresh hibiscus esculentus flowers which bloom and just close on a sunny day, immediately placing into a low-temperature insulation box of about 0 DEG C, and controlling the storage and transportation time to be not more than 2 h; (2) freezing, namely freezing for 12-24 h at the temperature of subzero 18-subzero 25 DEG C; (3) freezing and drying, namely placing into a freezer dryer for freezing and drying for 16-24 h at the temperature of 40-50 DEG C below zero; and (4) sealing and packaging. The preparation method is simple and convenient. Compared with the conventional drying method, the preparation method has the following advantages: (1) the collected fresh hibiscus esculentus flowers are timely stored, transported and prepared by adopting the cryogenic technology; and (2) the prepared hibiscus esculentus flower tea can keep active ingredients such as flavones, polysaccharides and the like to the hilt, and the active ingredients are prevented from being destroyed by high temperature.

Owner:JIANGSU UNIV

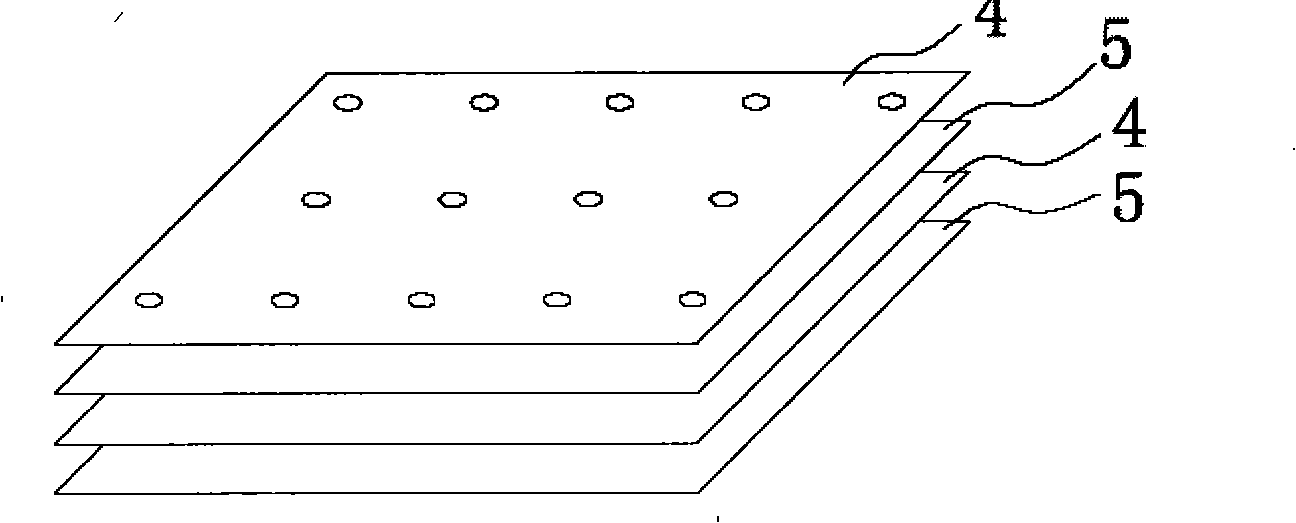

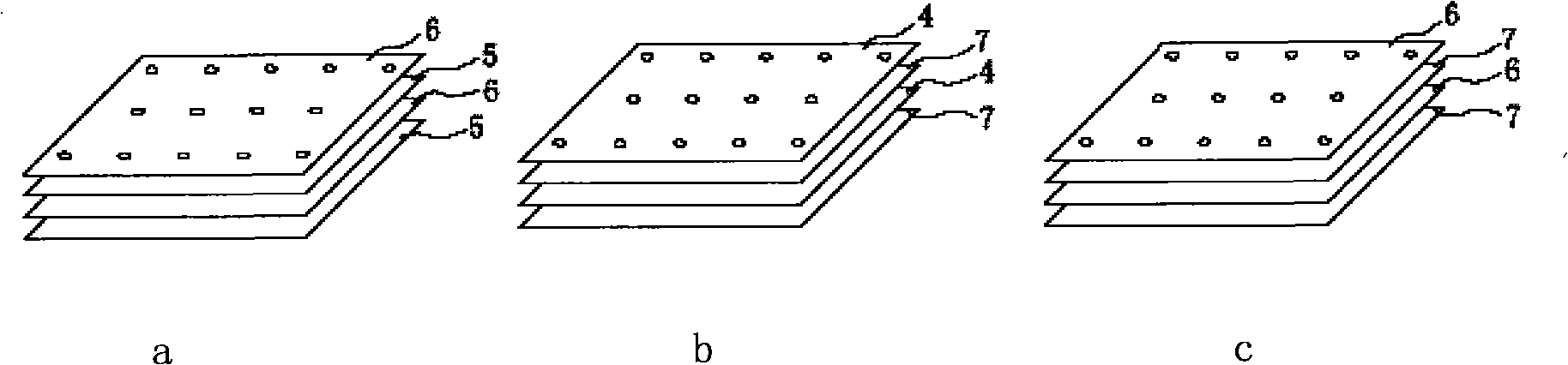

Various material composite fire retardant -type high vacuum multiple layer heat insulation structure

InactiveCN101307857AGuaranteed flame retardant performanceGuaranteed CompatibilityThermal insulationPipe protection by thermal insulationFiberGlass fiber

The invention relates to an inflaming retarding type high vacuum multilayer heat insulation structure combined with multiple materials, which belongs to the cryogenic engineering and cryogenic technical field. The invention comprises a high temperature side combination, a transition combination and a low temperature side combination, wherein the high temperature side combination adopts an alternating combination of the aluminum foil and the glass fiber paper; the transition combination adopts an alternating combination of the double-sided aluminum coated sheet and the glass fiber paper or the aluminum foil and the chemical fiber paper or the double-sided aluminum coated sheet and the chemical fiber paper; and the low temperature side combination adopts a mixed combination of the aluminum foil, the glass fiber paper and the chemical fiber paper. The insulation structure of the invention is characterized in that the whole structure can retard inflaming without exterior inflaming and the low temperature heat-insulating performance is superior to that of the traditional inflaming retarding type heat insulation structure, thereby decreasing the use of the heat insulating materials, lowering the cost of the heat insulating materials, shortening the intervals of the vacuum interlayers, increasing the inner effective volume of the low temperature vessel when the outside dimensions are the same, and contributing to the light weight and the volume maximization of the mobile low temperature accumulating conveyers.The inflaming retarding type high vacuum multilayer heat insulation structure combined with multiple materials has more obvious economic benefit and social benefit in the cryogenic engineering.

Owner:SHANGHAI JIAO TONG UNIV

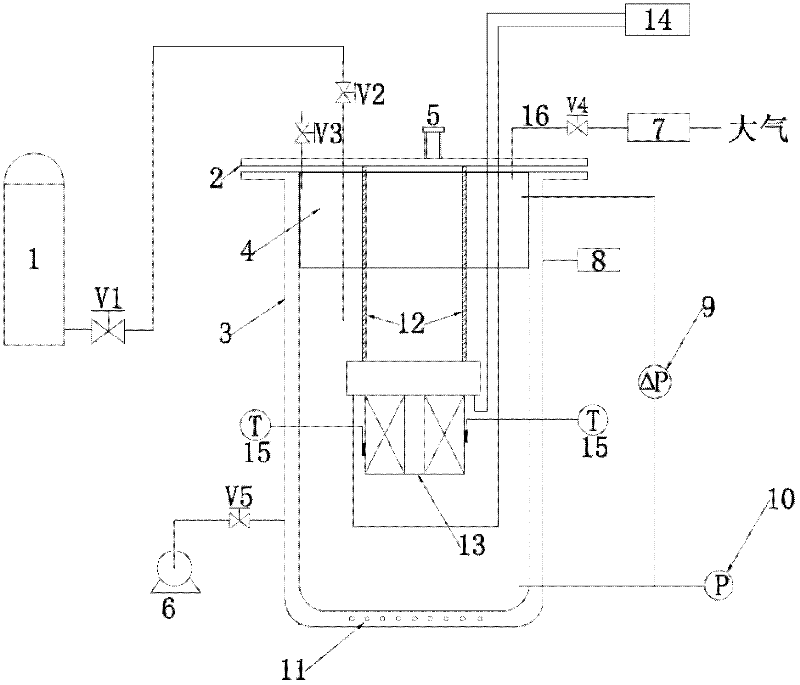

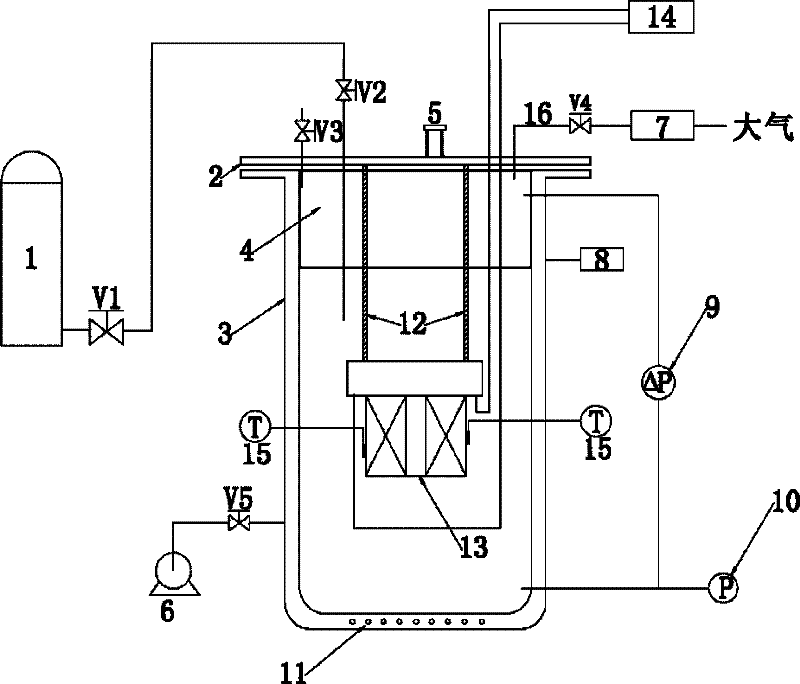

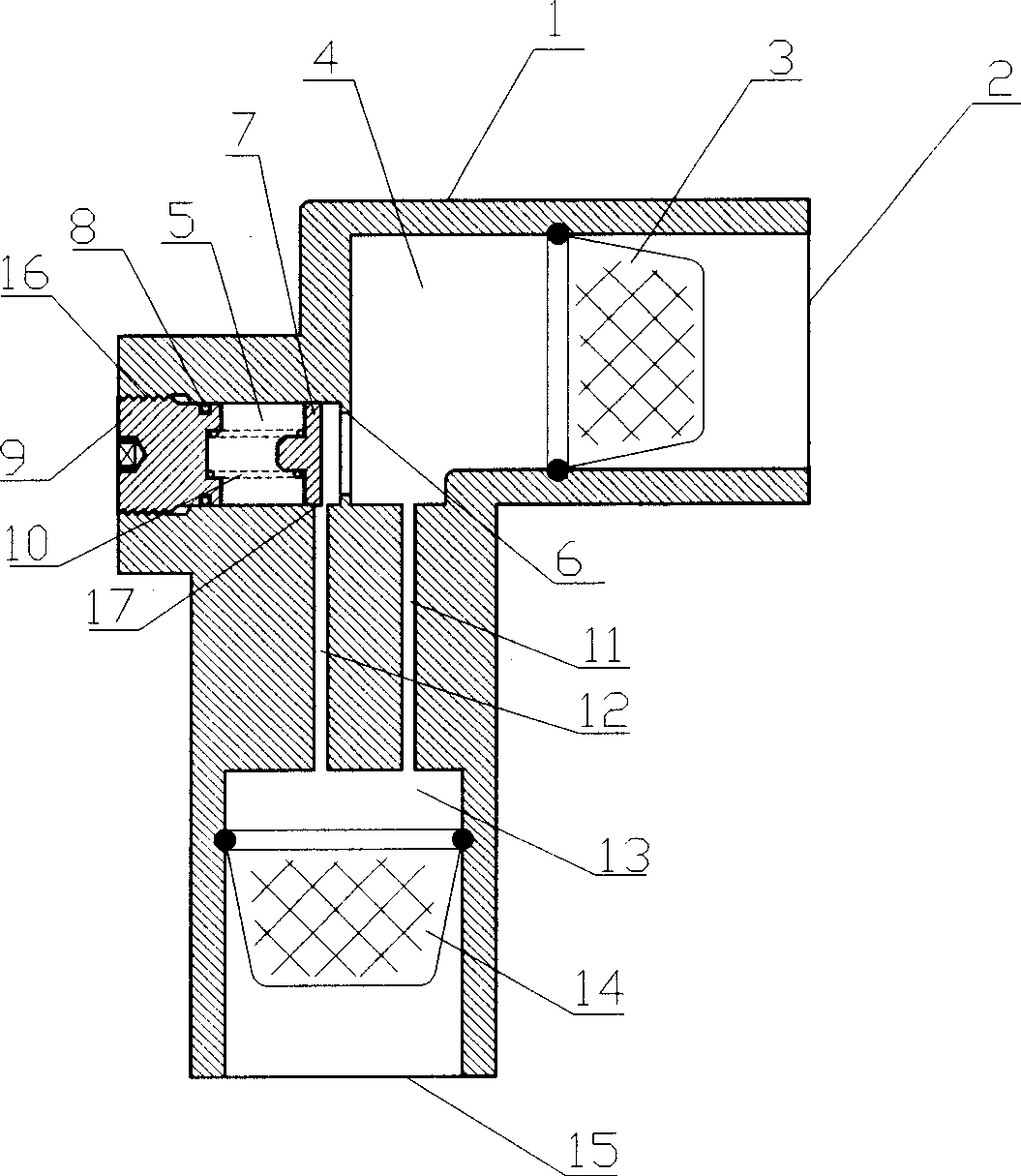

Liquid nitrogen low-temperature system for superconducting current limiter

InactiveCN102496679ALow costEasy to replaceSuperconductor detailsNormal-superconductive switchable devicesLiquid nitrogen containerThermal insulation

A liquid nitrogen low-temperature system for a superconducting current limiter belongs to the field of low-temperature engineering and technique. The liquid nitrogen low-temperature system comprises a liquid nitrogen container, a liquid nitrogen valve, a liquid nitrogen refuel valve, a safety valve, a valve cap, a test Dewar, a thermal insulation layer, a rupture disk, a deflation valve, a flow meter, a vacuum measurement gauge, a pressure difference sensor, a pressure sensor, a support part, a pumping valve, a vacuum pump, a superconducting current limiter, a control circuit, a temperature sensor and a discharging air pipe. In the invention, the system adopts the liquid nitrogen as the cooling working medium; the superconducting current limiter for the test is placed in the test Dewar; switching between the superconducting state and superconducting loss state of the superconducting current limiter can be realized through the control circuit; and the pressure, pressure difference and temperature measured by the pressure sensor, the pressure difference sensor and the temperature sensor, and the quality flow of the gasified nitrogen in the superconducting loss state measured by the flow meter are inputted into a computer, so as to evaluate the refrigeration wastage of the low-temperature system of the superconducting current limiter, and study the influence of the bubbles exerted on the low-temperature system pressure intensity when superconducting current limiter is abnormal. The low-temperature system has the advantages of simple structure, good economical efficiency, and favorable safety.

Owner:SHANGHAI JIAO TONG UNIV

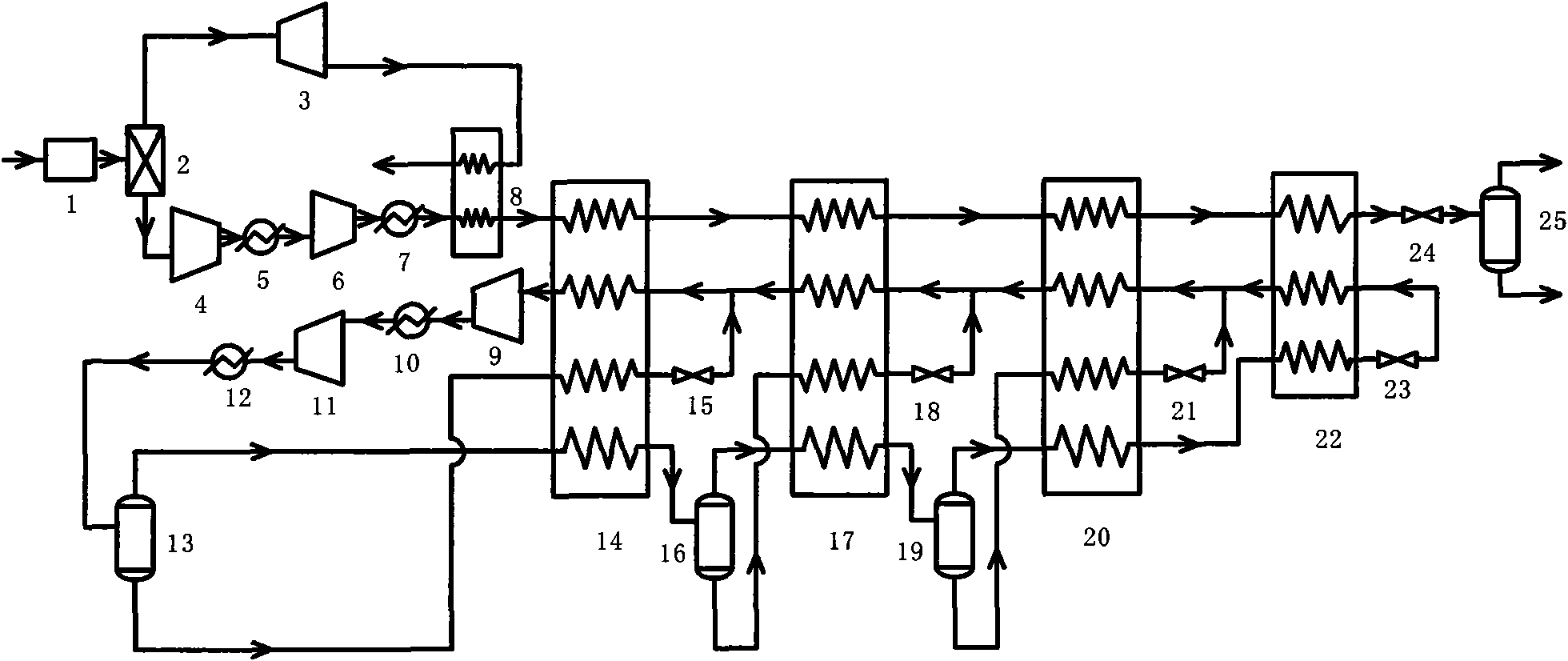

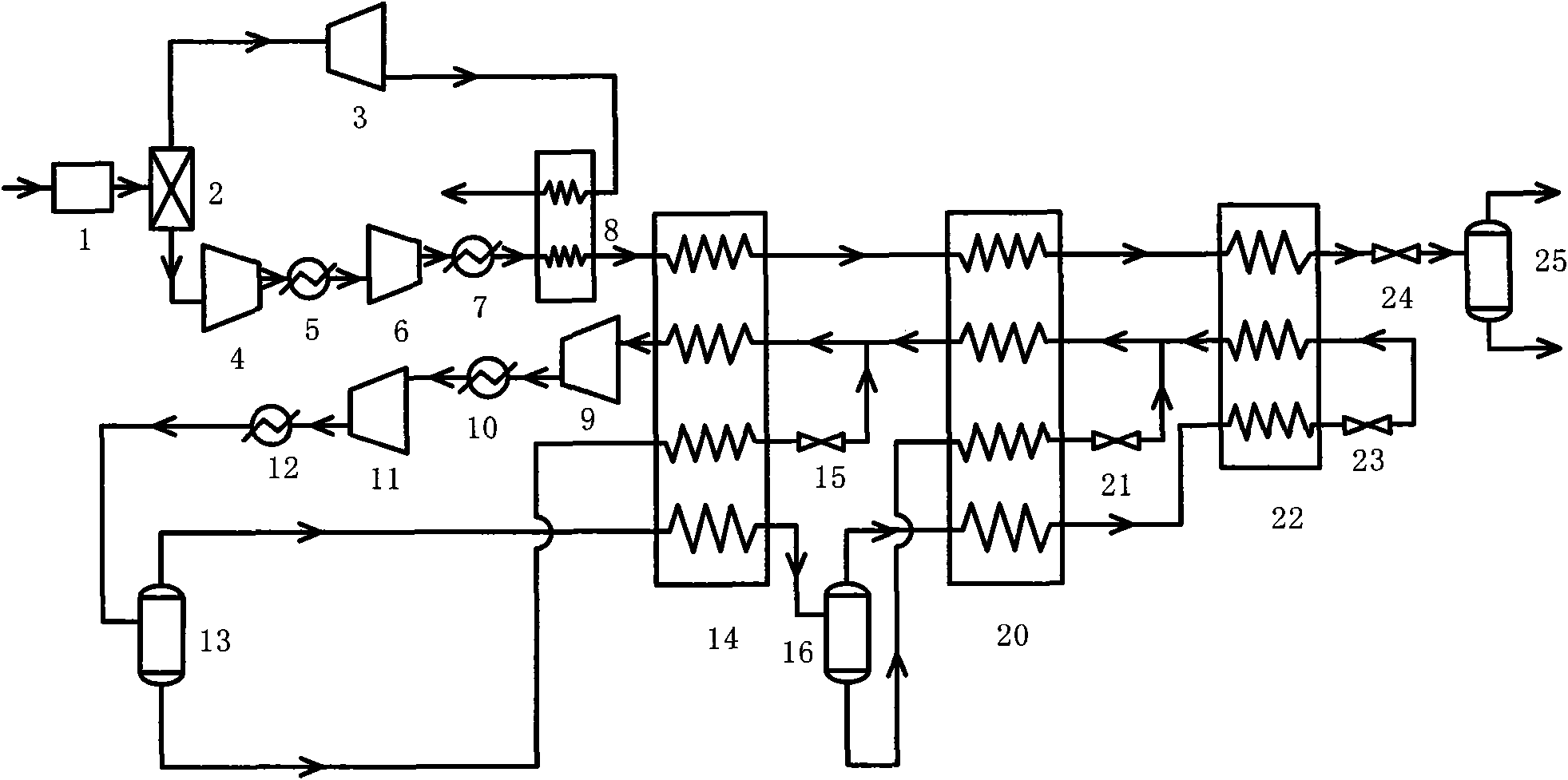

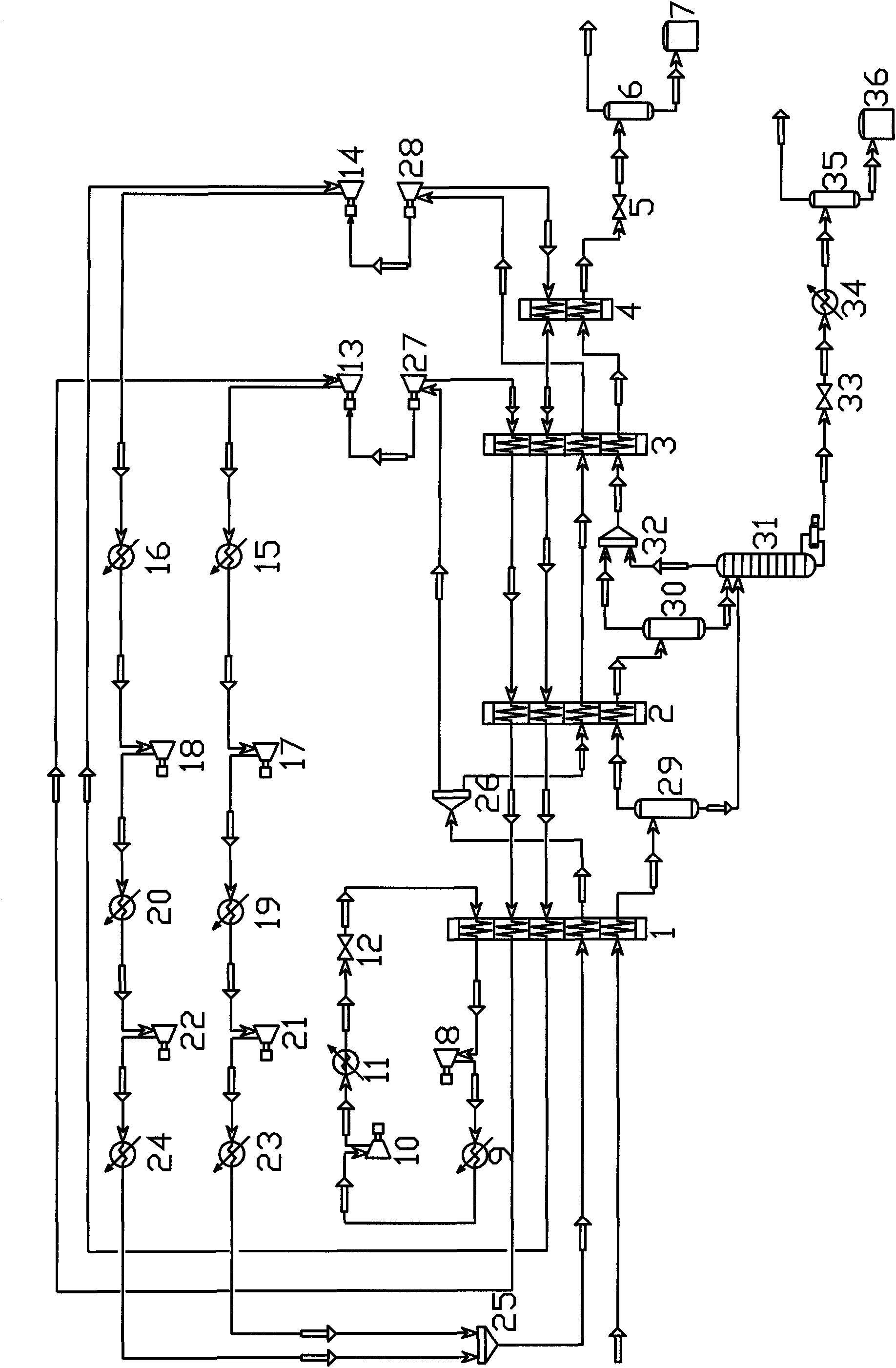

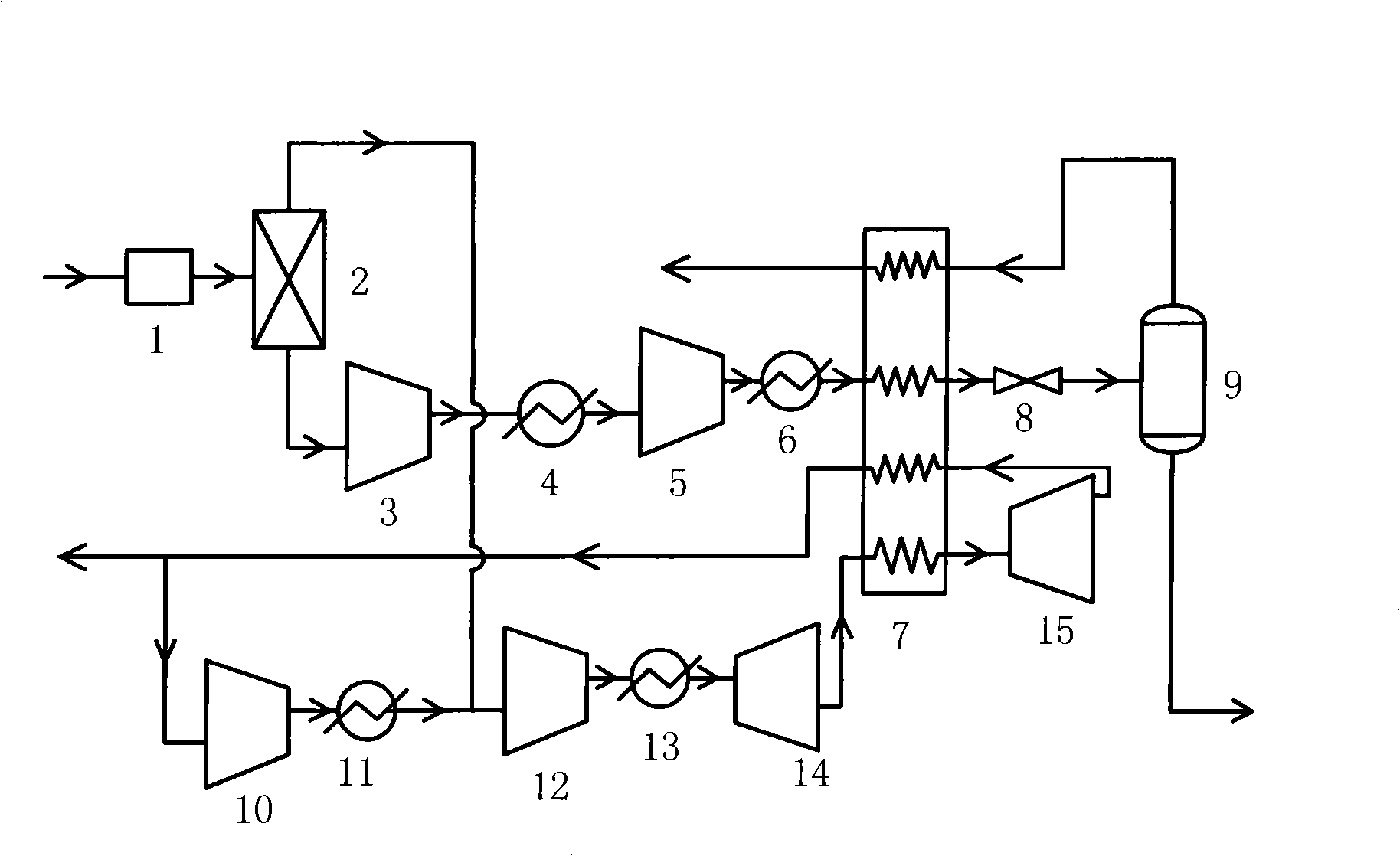

Cascade type liquefaction process for precooling coalbed methane (CBM) by residual pressure of pressure swing adsorption (PSA)

InactiveCN101625189AReduce liquefaction power consumptionReduce power consumptionSolidificationLiquefactionChemical industryCryogenic technology

A cascade type liquefaction process for precooling coalbed methane (CBM) by residual pressure of pressure swing adsorption (PSA) belongs to the technical field of chemical industry and low temperature. The invention provides an integrated process of adsorption and liquefaction of CBM with high nitrogen content. The process comprises the following steps: before liquefaction, firstly desorbing most nitrogen in the CBM by the PSA process, adopting the residual pressure of adsorption in the above nitrogen to precool the CBM after expanding the residual pressure and liquefying the CBM by the cascade type liquefaction process formed by propane, ethane and methane three-stage refrigeration cycle. The precooling process of the nitrogen with residual pressure saves the propane flow used in first-stage cooling, thus reducing the overall power consumption of the system. With the increase of the nitrogen content of the CBM and the residual pressure of adsorption in the nitrogen, the temperature of the precooled CBM can be lower than that of the precooled original propane, therefore, the precooled CBM can be directly led into heat exchangers to which the ethane provides cooling capacity, and the ethane consumption can be saved, thus further reducing the power consumption.

Owner:SHANGHAI JIAO TONG UNIV

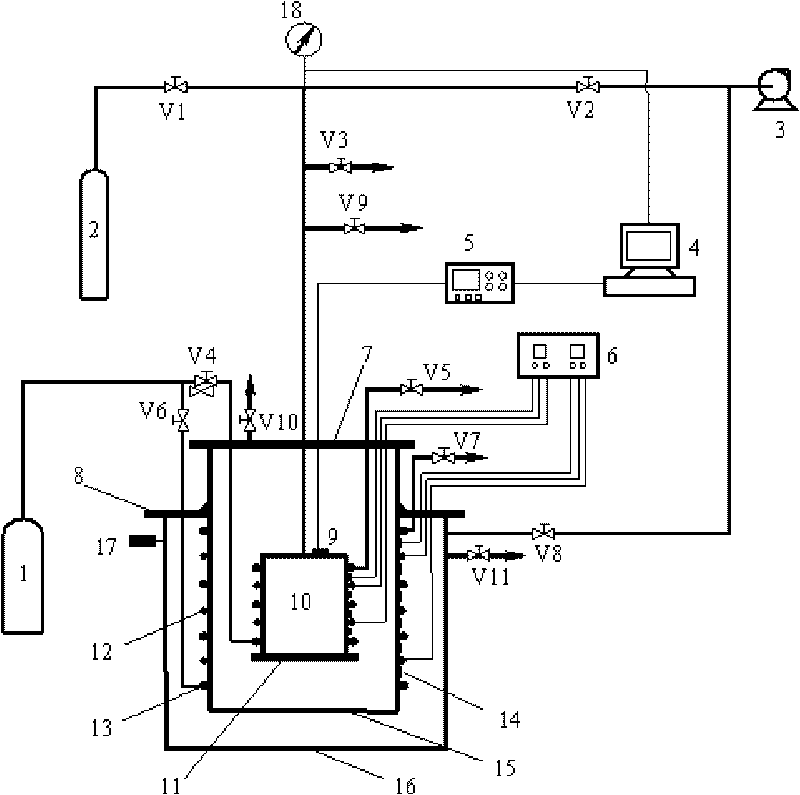

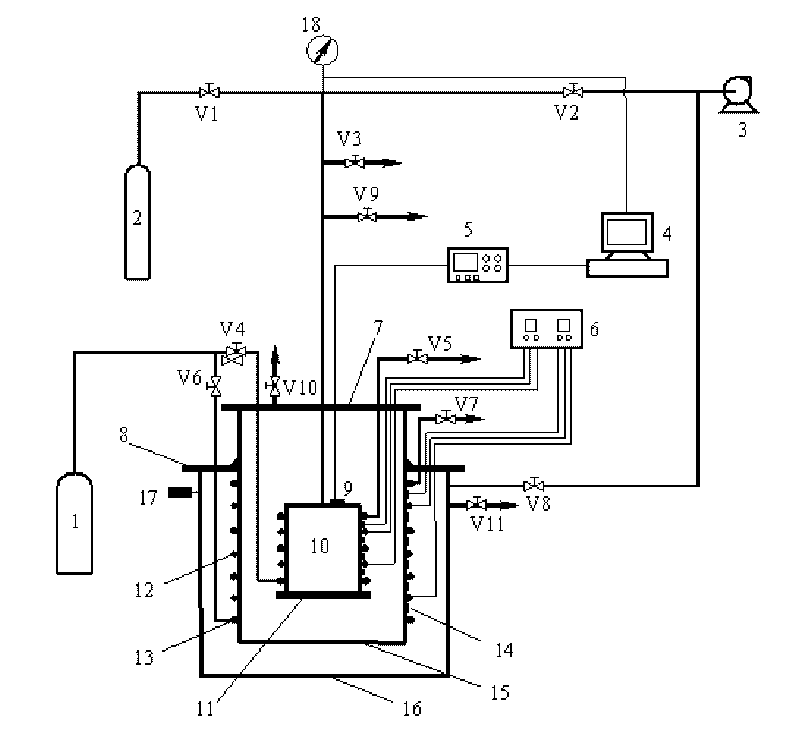

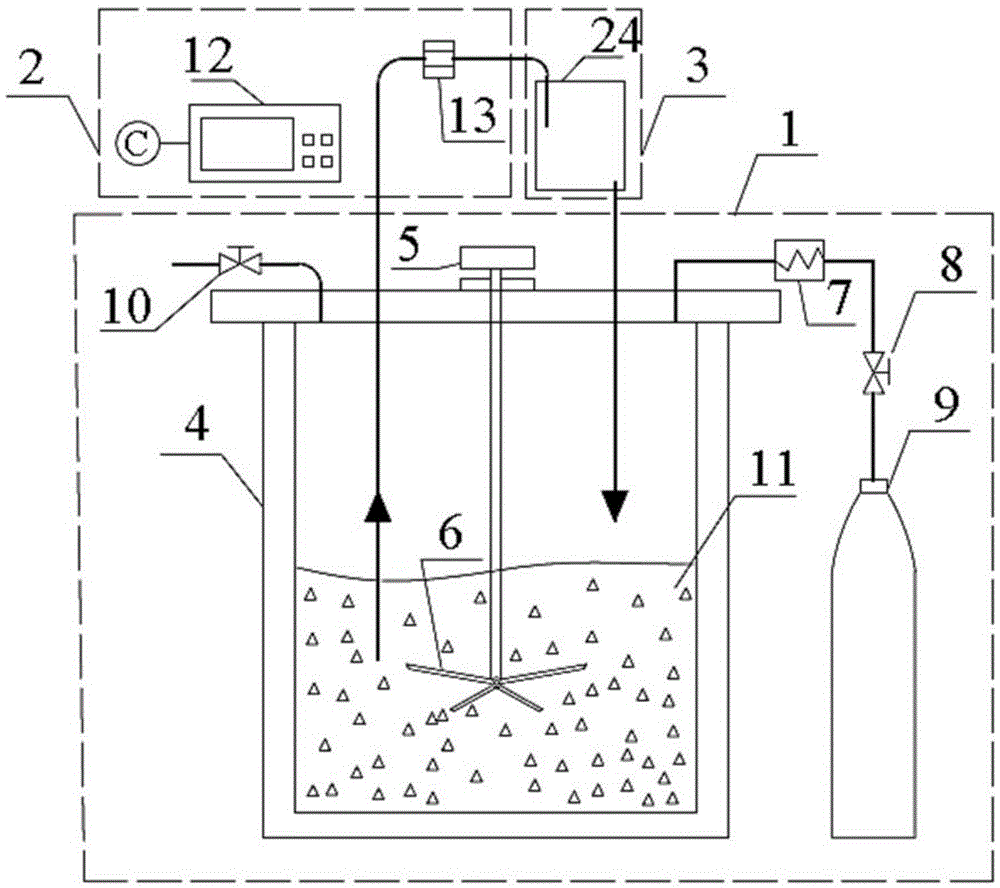

Wide temperature zone hydrogen storage material low temperature hydrogen storage performance testing device

InactiveCN101762435AGuaranteed replacementShorten test timeMaterial analysisGas cylinderData acquisition

The invention relates to wide temperature zone hydrogen storage material low temperature hydrogen storage performance testing device, belonging to the low temperature engineering and low temperature technical field and being applicable to measuring low temperature hydrogen storage performance of multiple hydrogen storage materials in wide temperature zone. The testing device comprises a liquid nitrogen Dewar, a high pressure hydrogen gas cylinder, a vacuum set, a data acquisition computer, a temperature acquiring device, a PID temperature controller, a flange, a platinum resistor, a sample room, a heating wire, a cooling coil, a thermocouple, a Dewar, a vacuum gauge, a pressure sensor and a valve. The testing device takes circulating liquid nitrogen as cooling working medium and combines electrical heating to realize temperature regulation in wide temperature zone. The PID temperature controller regulates heating amount of the heating wire by the temperature signal acquired by the thermocouple. The pressure sensor and temperature acquiring device transmit the acquired data to the data acquisition system. The flange of sample room is arranged at the bottom of the sample room, inner Dewar and outer Dewar flanges are welded into a whole, thus ensuring replacement of sample. The testing device is simple in structure, is easy to manufacture and has better economy.

Owner:SHANGHAI LNG NEW ENERGY TECH

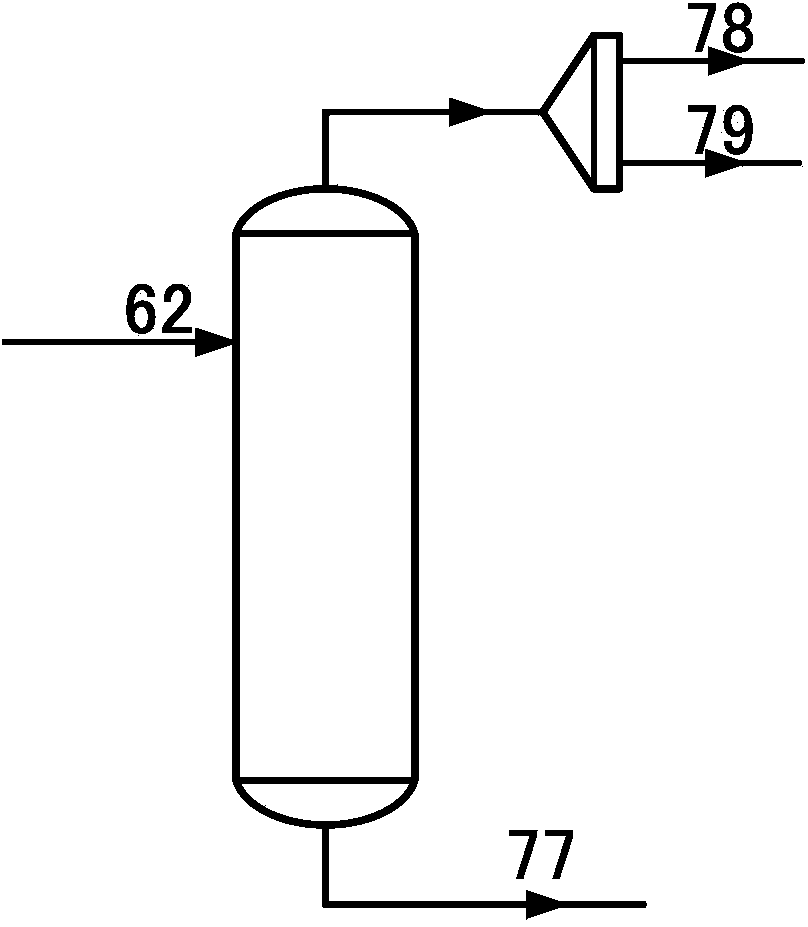

Device and method for extracting pure carbon monoxide and oxygen-rich gas by aid of cryogenic technology

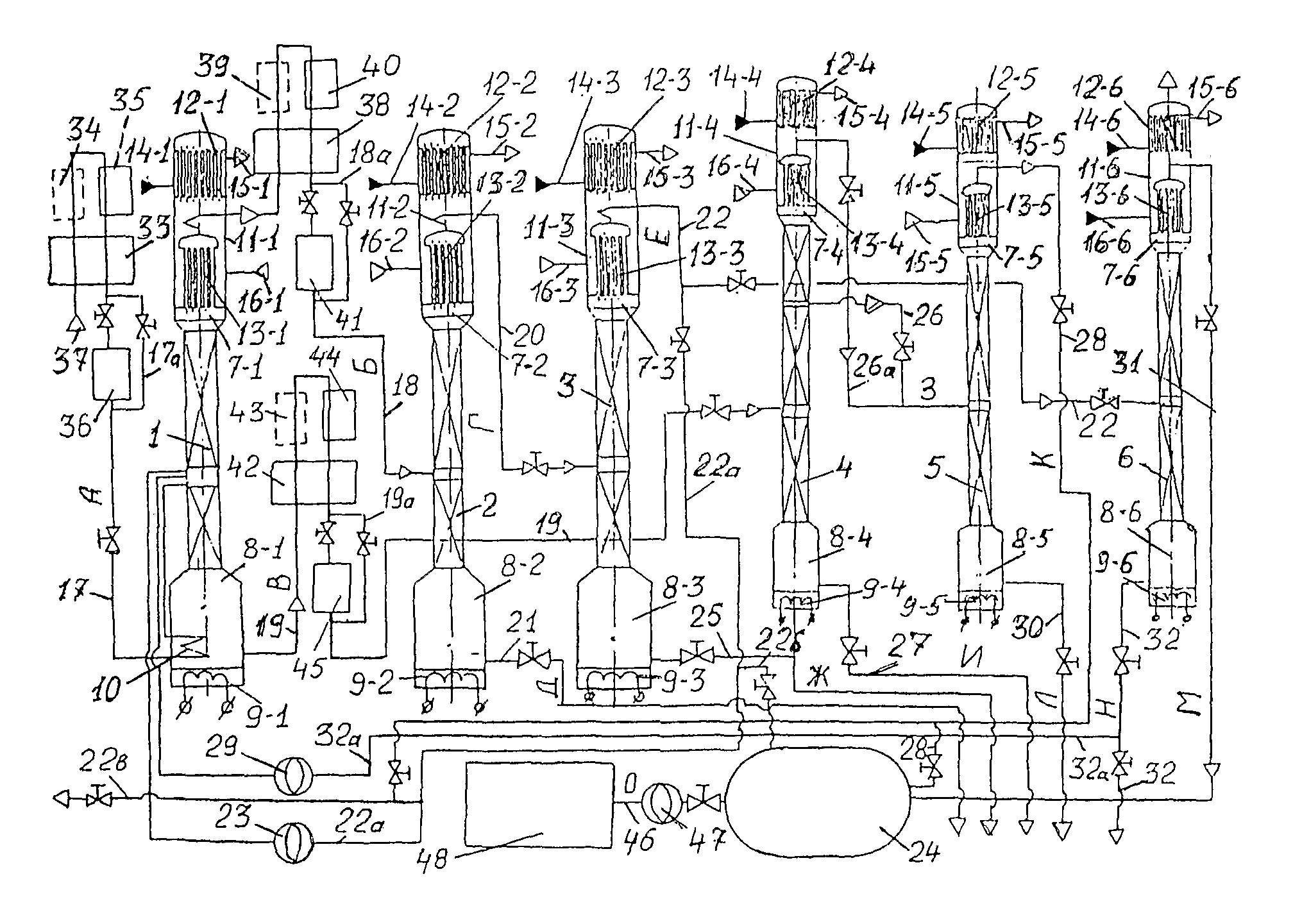

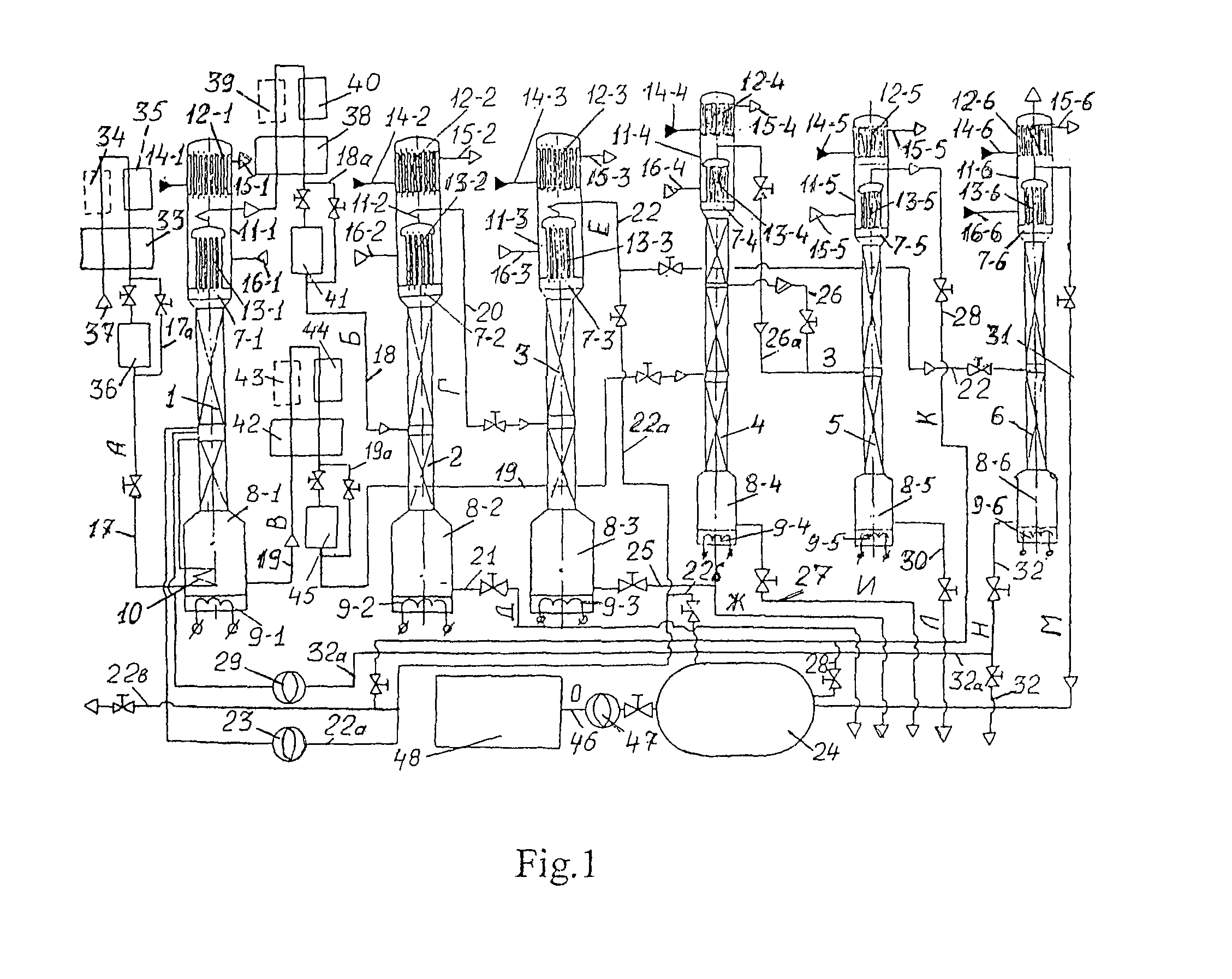

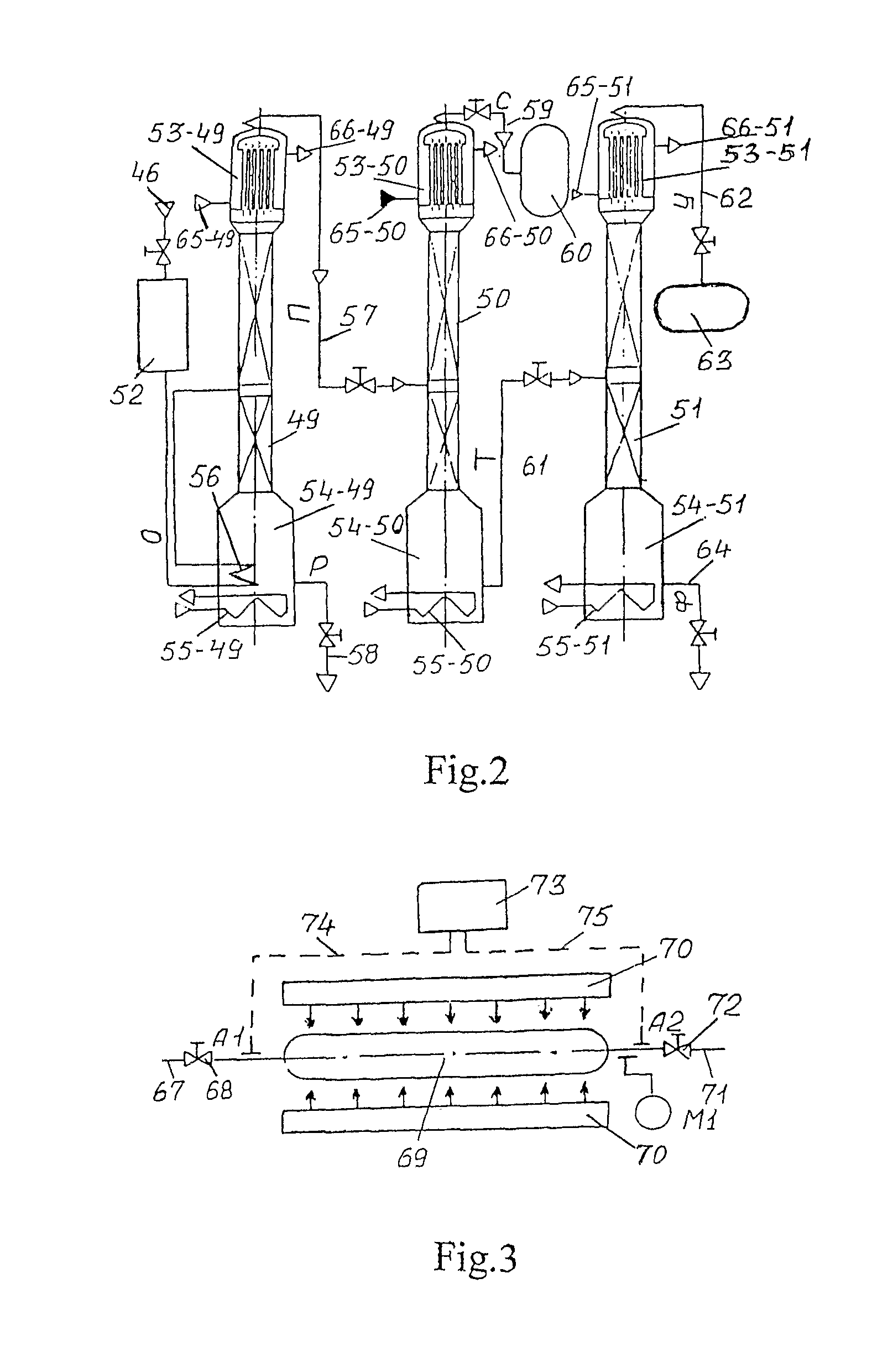

InactiveCN104236253AImprove heat transfer effectReduce energy consumptionSolidificationLiquefactionVapor–liquid separatorNitrogen

The invention relates to a device and a method for extracting pure carbon monoxide and oxygen-rich gas by the aid of a cryogenic technology. The device comprises a front-end pretreatment unit and a cryogenic separation and purification unit. The cryogenic separation and purification unit comprises a first main heat exchanger, a second main heat exchanger and a rectifying tower, the rectifying tower comprises a tower body and an evaporator at the bottom of the tower body, and the cryogenic separation and purification unit comprises a first gas and liquid separator, a second gas and liquid separator, a third gas and liquid separator and a fourth gas and liquid separator. The device and the method for extracting the pure carbon monoxide and oxygen-rich gas by the aid of the cryogenic technology have the advantages that cold flow can be provided for the integral device by the aid of a Joule-Thomson effect, accordingly, energy consumption is low, good heat exchange effects can be realized, and a technological process is simple; the perfect heat exchange effects can be realized by the aid of the device and the method, nitrogen circulation refrigeration and a large quantity of supplemented liquid nitrogen can be omitted, equipment can be reduced, and the energy consumption can be lowered.

Owner:KAIFENG AIR SEPARATION GROUP

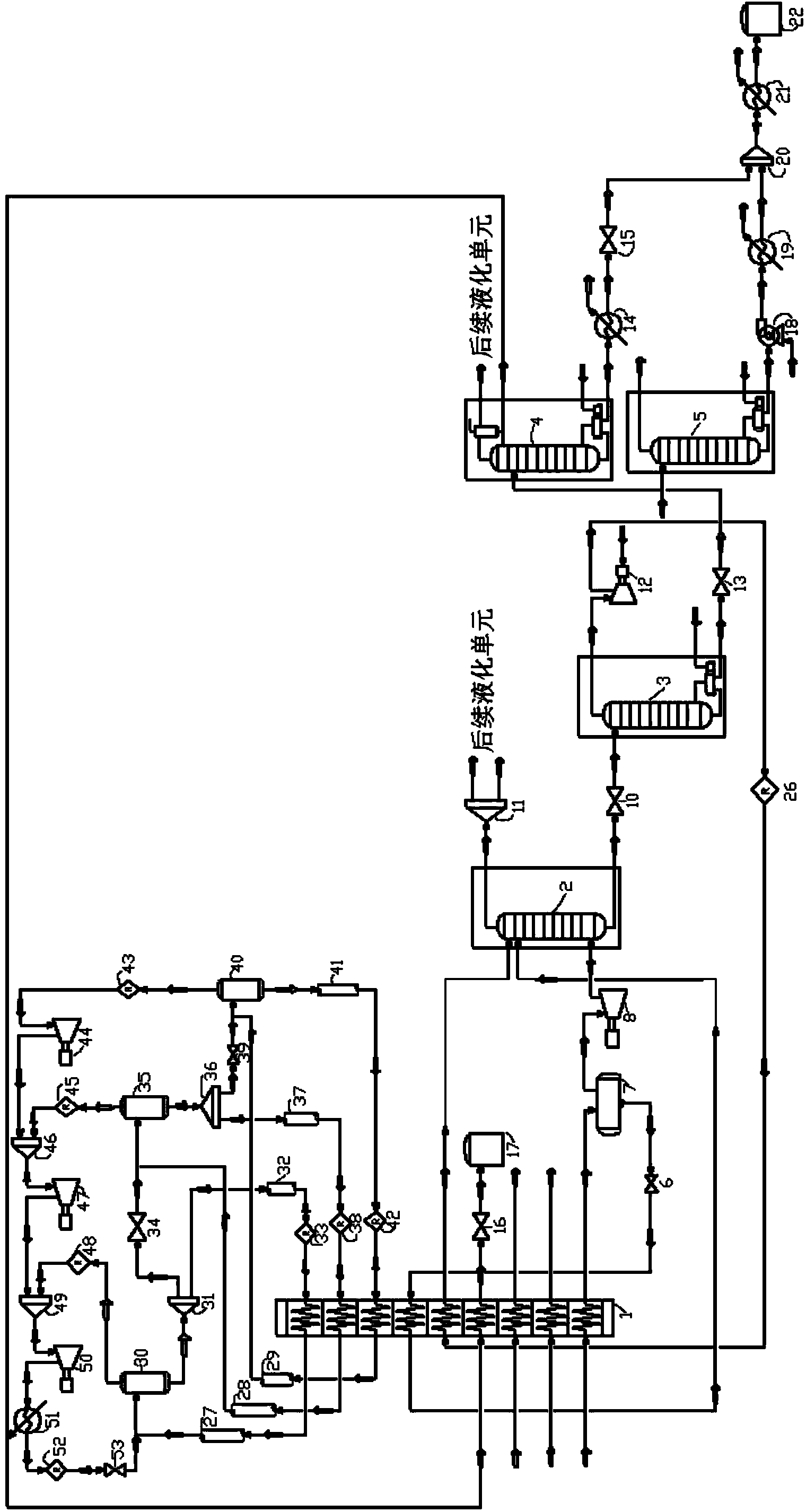

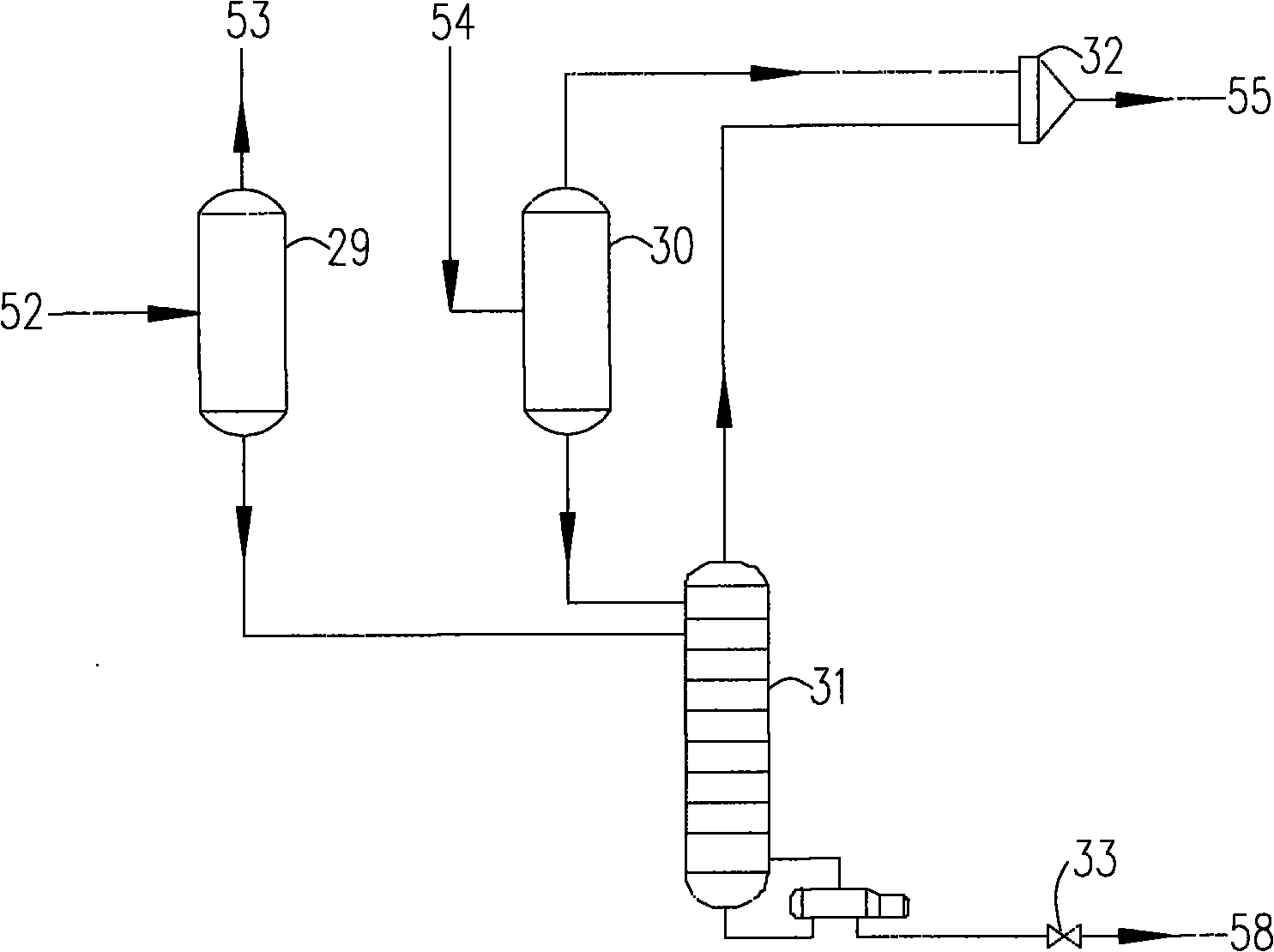

Heavy hydrocarbon recovery method of propane precooling and deethanizer top reflux

InactiveCN103865601AHigh recovery rateReduce startup timeSolidificationLiquefactionRecovery methodCryogenic technology

The invention provides a heavy hydrocarbon recovery method of propane precooling and deethanizer top reflux and belongs to the technical field of chemical engineering and low temperatures. The heavy hydrocarbon recovery method is designed modularly, and a liquefaction process is composed of propane precooling circulation, deethanizer top product reflux gas-liquid separation, gas-liquid separation of natural gas and natural gas heavy hydrocarbon removal, wherein the propane circulation is used for precooling a natural gas, the LPG (Liquefied Petroleum Gas), a nitrogen gas refrigerant and a deethanizer top product reflux material flow, the deethanizer top product is returned to a precooling cold box and further cooled and recycled, and the deethanizer top product does not go through gas-liquid separation after being cooled. A liquid phase obtained by virtue of the gas-liquid separation of the natural gas is returned to the precooling cold box to intensify the cooling capacity, and the process is added with a reflux part. The heavy hydrocarbon recovery method is applicable to heavy hydrocarbon recovery of the offshore liquefied petroleum gas, and the yield of the heavy hydrocarbon and the yield of the LPG both are high.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Process for compact natural gas liquefying and floating production

The invention provides a process for compact natural gas liquefying and floating production and belongs to the field of chemical and cryogenic techniques. In the process, a modular design is adopted, and a liquefaction process consists of propane precooling circulation, double nitrogen expansion cooling circulation, natural gas heavy hydrocarbon removal and liquefaction pipe, wherein propane circulation is used for precooling natural gas and providing a nitrogen coolant; the double nitrogen expansion cooling circulation is used for deeply cooling and liquefying the natural gas; and the heavy hydrocarbon separation is realized by the cold energy generated in liquefaction. The process is suitable for producing liquid natural gas offshore and can prevent the influences of the shaking of a ship on a liquefying process.

Owner:CHINA NAT OFFSHORE OIL CORP +1

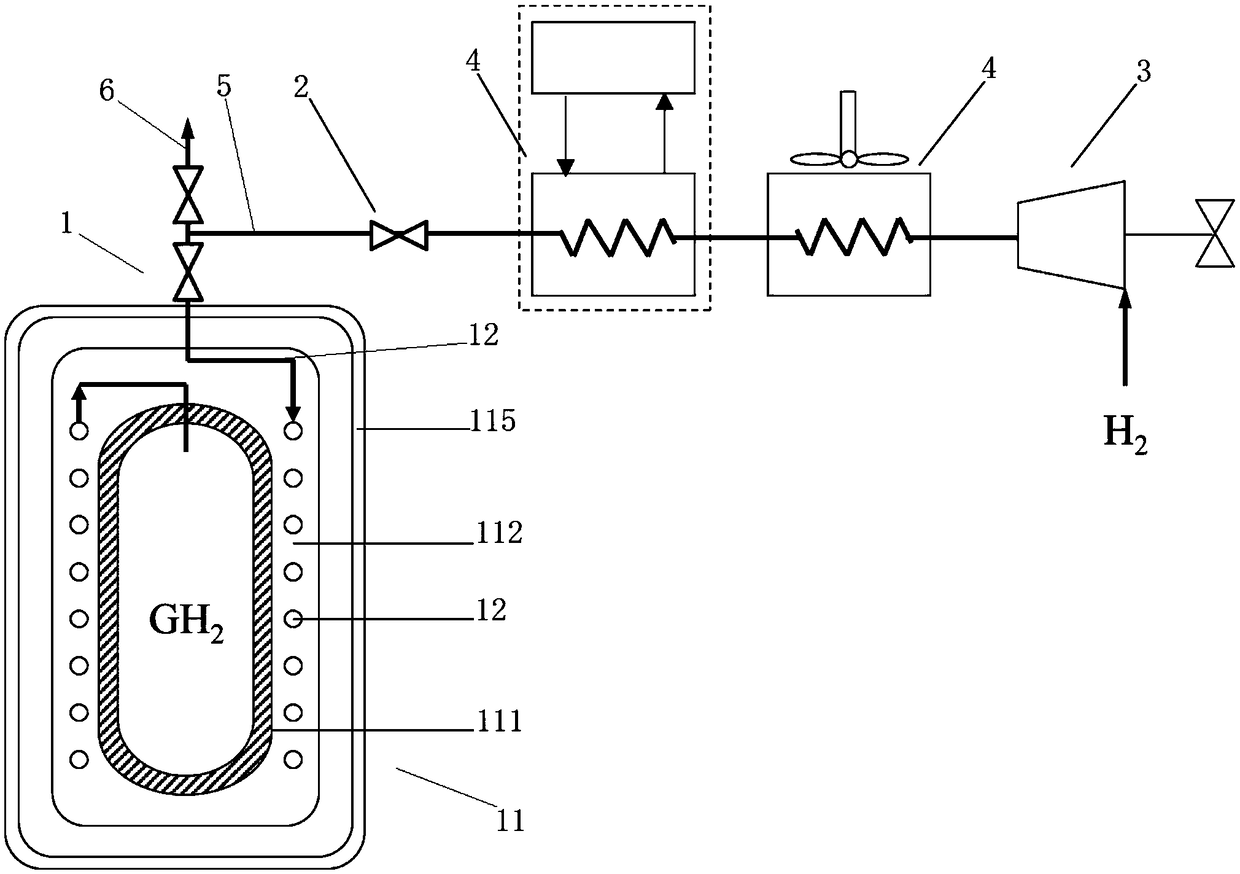

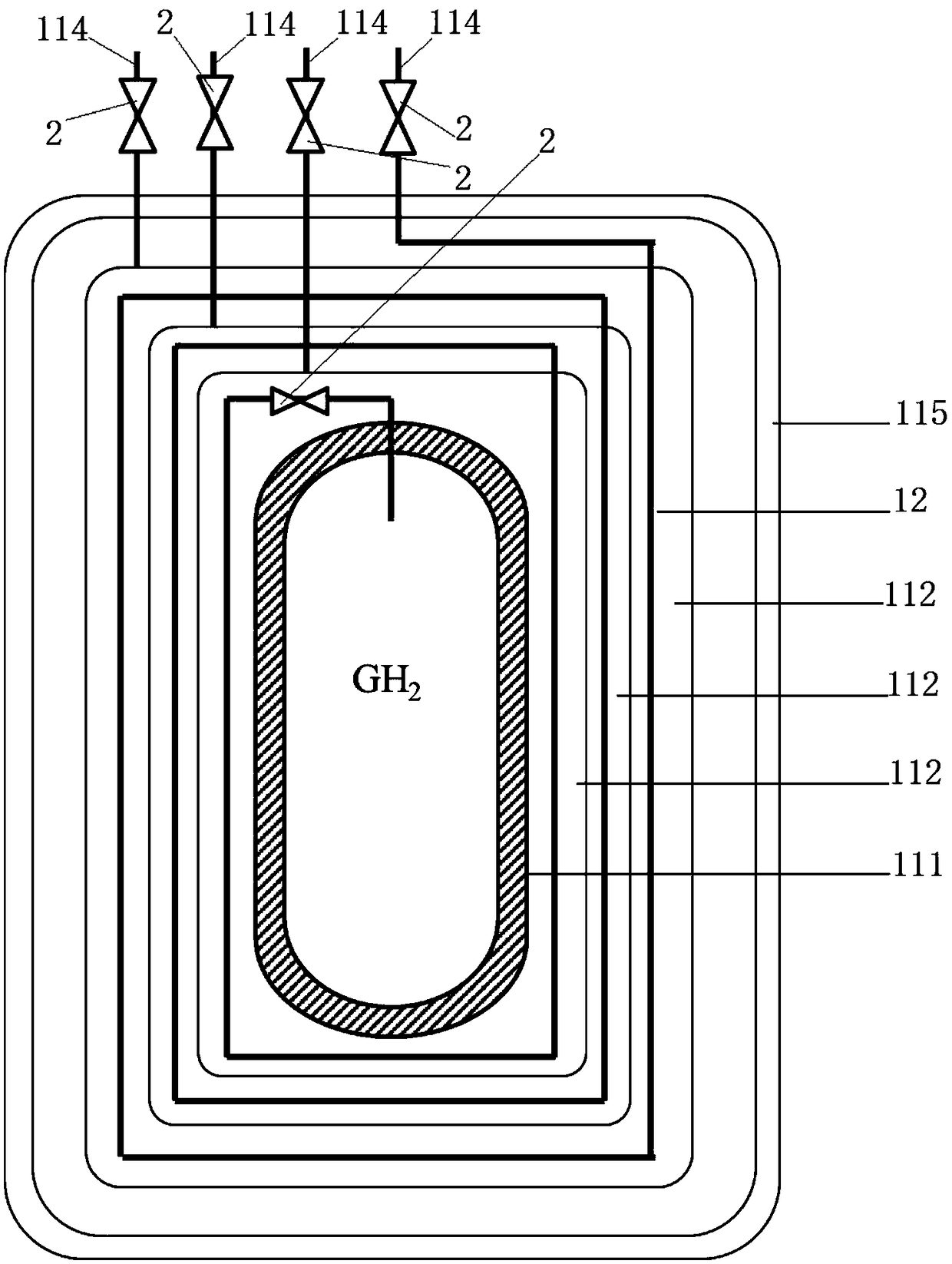

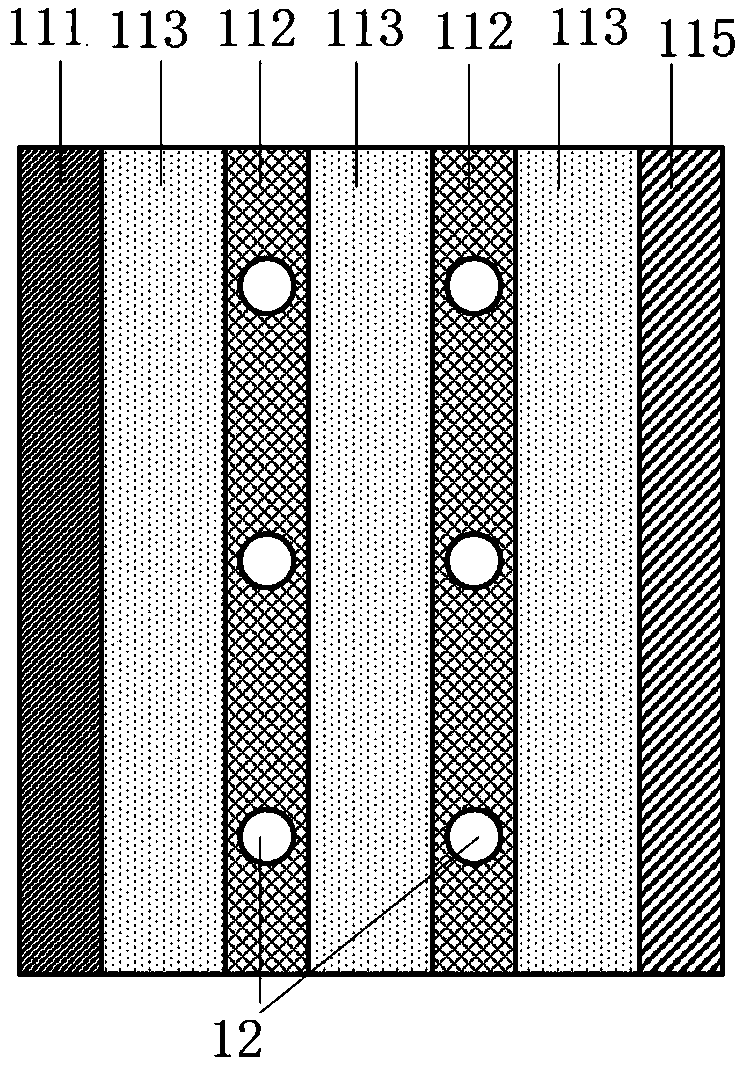

Low-temperature Dewar container and low-temperature high-pressure hydrogen storage system

ActiveCN108644604AWith cooling functionSolution to short lifeFluid handledPressure vesselsGas phaseHigh pressure hydrogen

The invention relates to a refrigeration and low-temperature technology, and provides a low-temperature Dewar container. The low-temperature Dewar container comprises a low-temperature Dewar module; the low-temperature Dewar module comprises a hydrogen storage pressure bearing layer and a cold storage sandwich layer; a hydrogen accessing coil is arranged in the cold storage sandwich layer, is bentto extend in the cold storage sandwich layer, and is provided with a high-pressure hydrogen inlet and a high-pressure hydrogen outlet; and the high-pressure hydrogen outlet communicates with the hydrogen storage pressure bearing layer. The invention further provides a low-temperature high-pressure hydrogen storage system, which comprises the low-temperature Dewar container. As supercharging module and a cooling module cooperate for supercharging and cooling, the hydrogen density can be increased in a state of maintaining hydrogen phase to achieve the purpose of improving the hydrogen storagequality in the hydrogen storage pressure bearing layer; and compared with a traditional hydrogen storage technology, the hydrogen storage and release process can be realized under the conditions of lower pressure and higher temperature, and the cold storage sandwich layer can use the cooling capacity in the hydrogen storage and release process.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

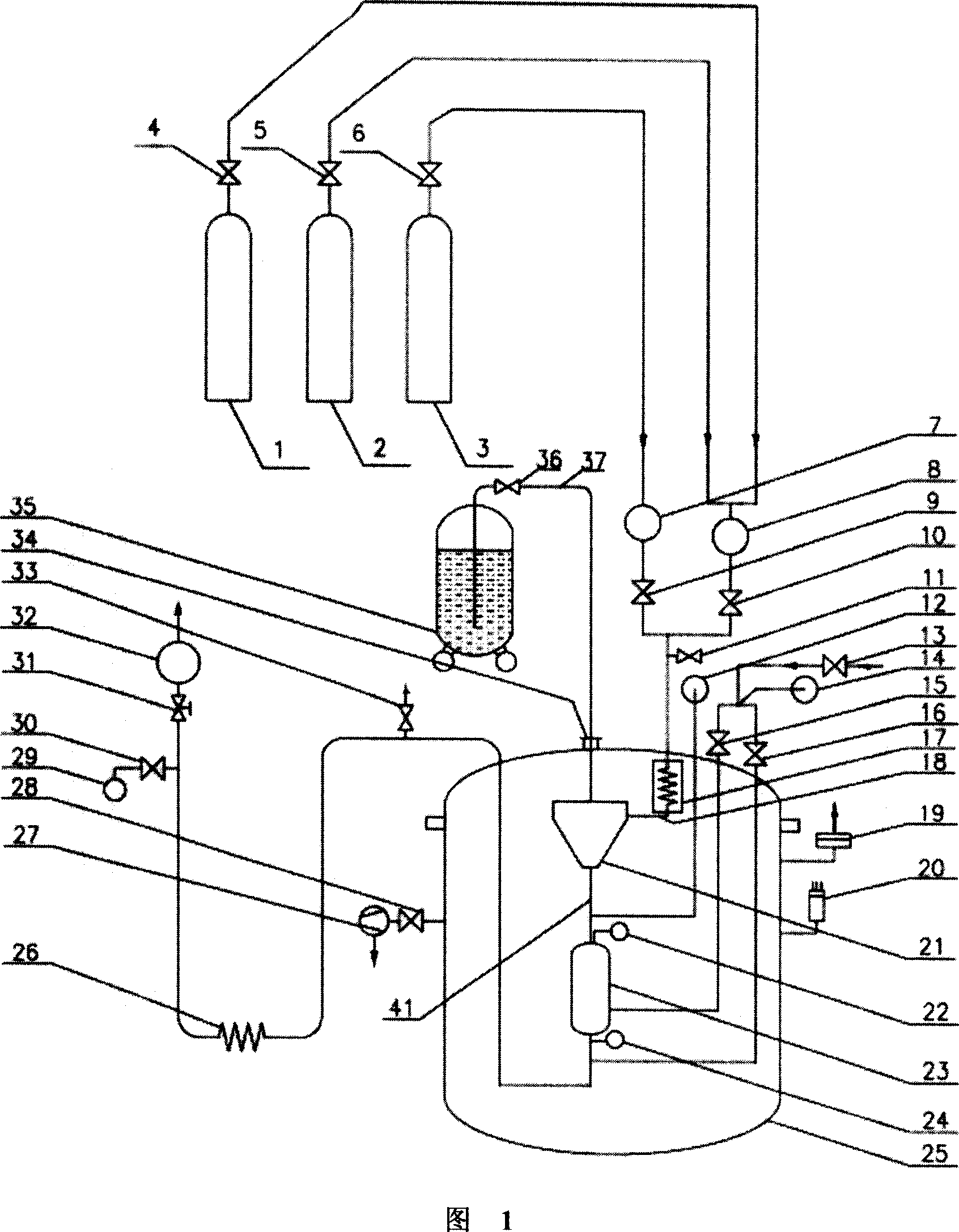

Experimental equipment for testing characteristic of liquid helium filter

InactiveCN101008595AReduce consumptionReduce lossComponent separationPreparing sample for investigationGas liquid chromatographicGas phase

This invention relates to one helium filter property test device in low temperature engineer and technique field, which comprises oxygen steel bottle, nitrogen gas steel bottle, helium steel bottle, mixture gas pre-cooling device, gas and liquid mixture, liquid helium filter, vacuum box, heat conversion device, gas phase color spectrum, sampling valve, liquid helium Dewar, helium flow meter, nitrogen gas and oxygen flow meter. This invention adopts metal filter structure and adopts nitrogen gas and oxygen as mixture gas to lower the mixture gas pre-cooling gas temperature form roommate one to liquid nitrogen temperature.

Owner:SHANGHAI JIAO TONG UNIV

Semi-opening type coal bed gas nitrogen dilated and liquefied process taking advantage of variable pressure for adsorbing residual pressure

InactiveCN101285638AReduce work of liquefactionReduce power consumptionSolidificationLiquefactionSemi openCryogenic technology

The invention provides a semi-open type coalbed methane nitrogen expansion liquefaction technique by adopting swing pressure to absorb the excess pressure, belonging to the chemical and low temperature technical field. The invention provides an adsorption-liquefaction integrated flow of the high nitrogen content coalbed methane. Before the liquefaction process, most part of the nitrogen in the coalbed methane is removed in the pressure-swing adsorption process; afterwards, the coalbed methane is liquefied by the nitrogen expansion and liquefaction process, wherein, the nitrogen with excess pressure separated by the adsorption process is mixed with certain amount of circulating nitrogen to form the semi-open type nitrogen expansion circulation, different mixing processes are designed according to different ranges of the absorbed excess pressure to provide refrigerating amount for the coalbed methane liquefaction, thereby saving the nitrogen compression work and lowering the liquefaction work of the unit product of the system. Moreover, the higher the nitrogen content in the raw material gas of the coalbed methane, the higher the adsorbed excess pressure and more power dissipation is saved.

Owner:SHANGHAI JIAO TONG UNIV

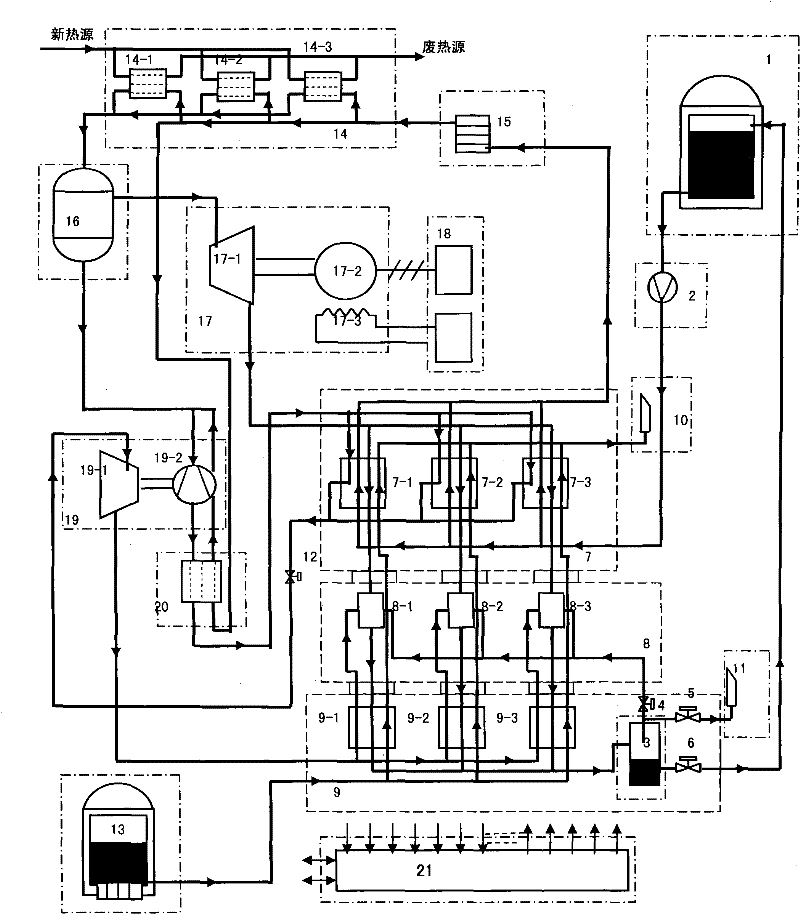

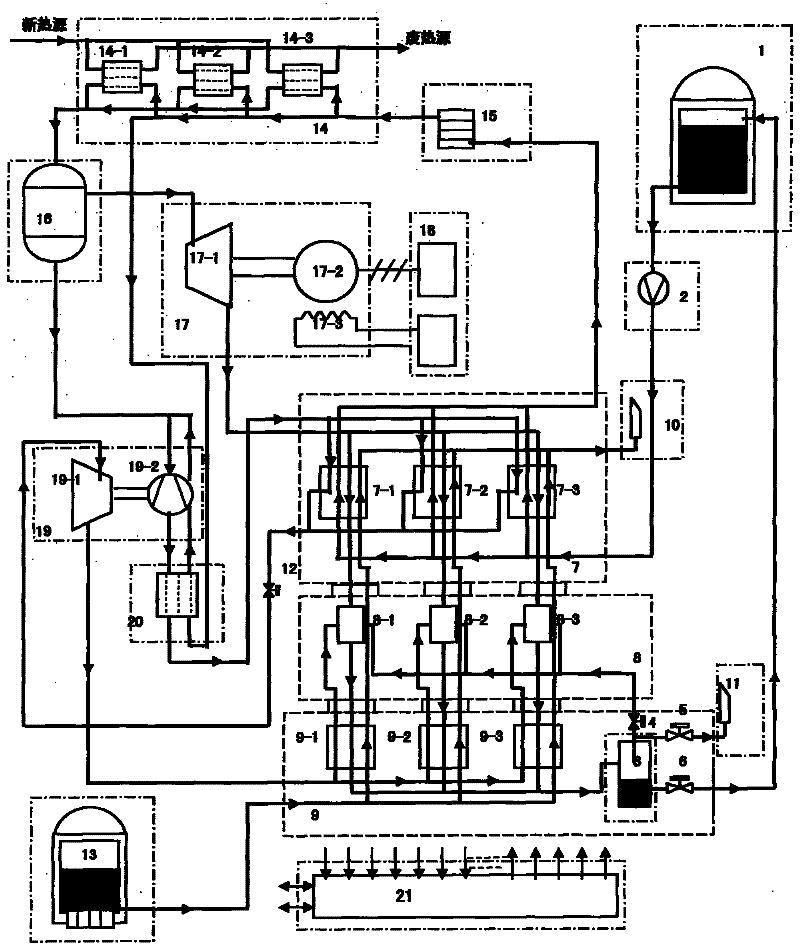

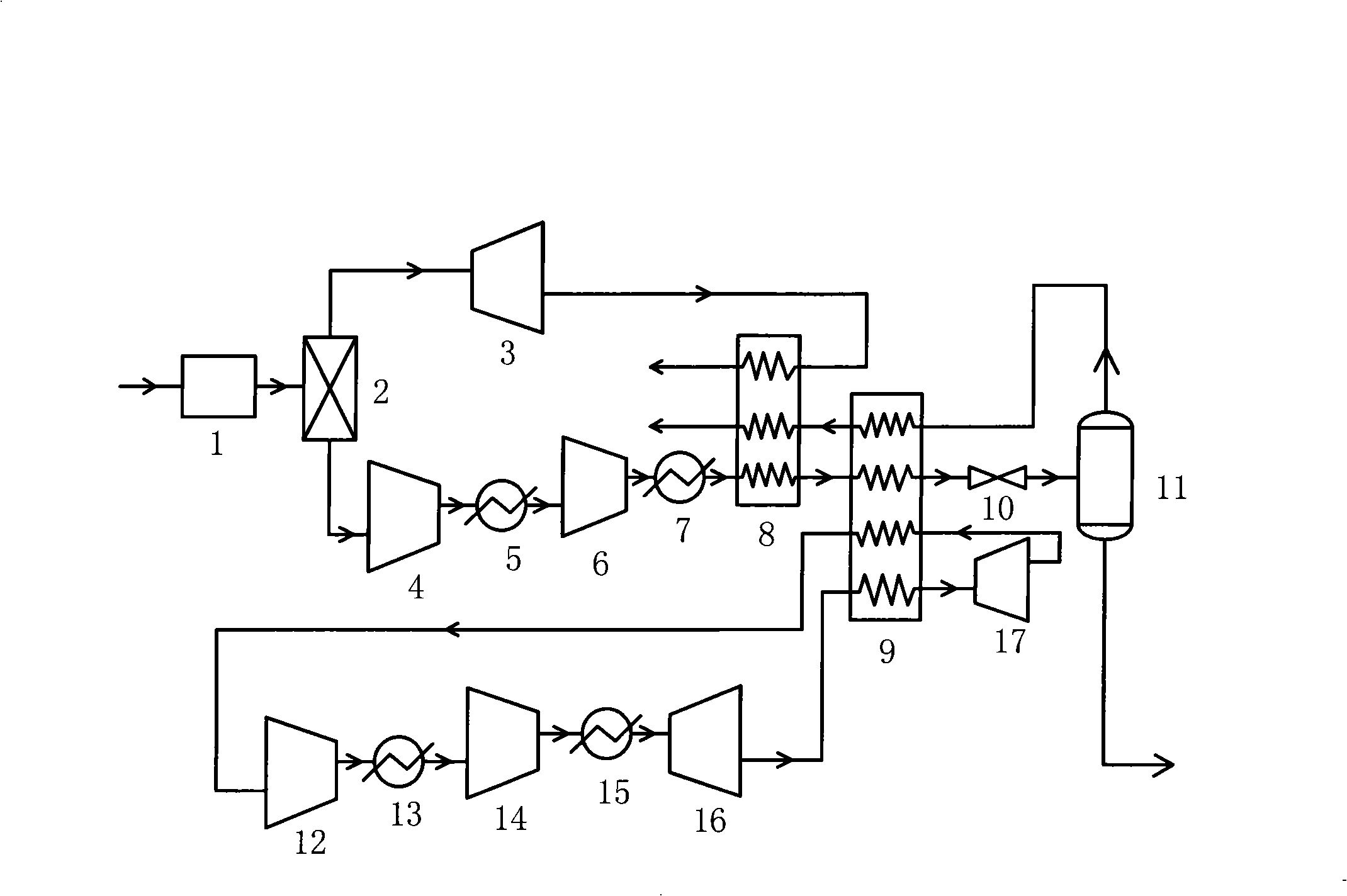

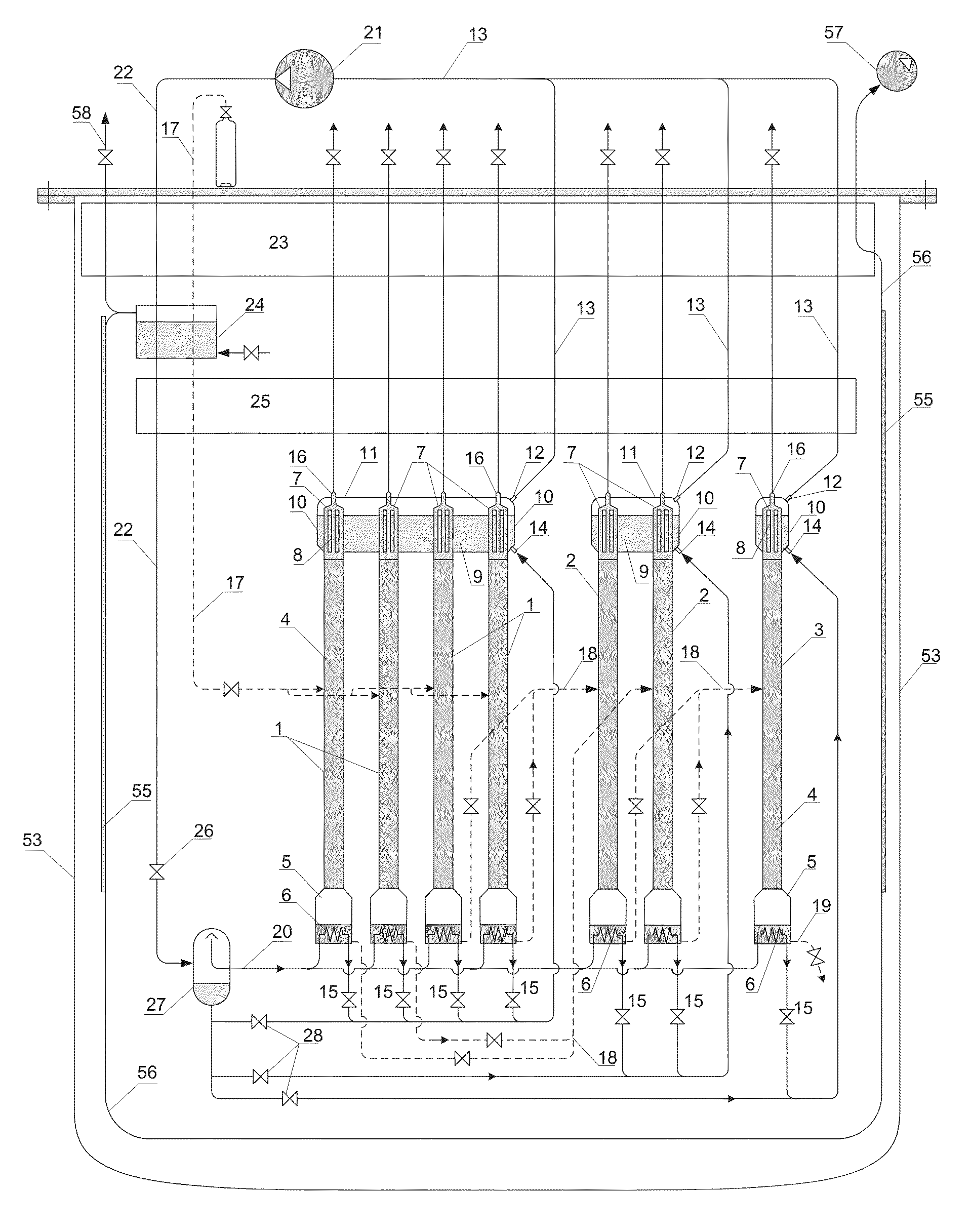

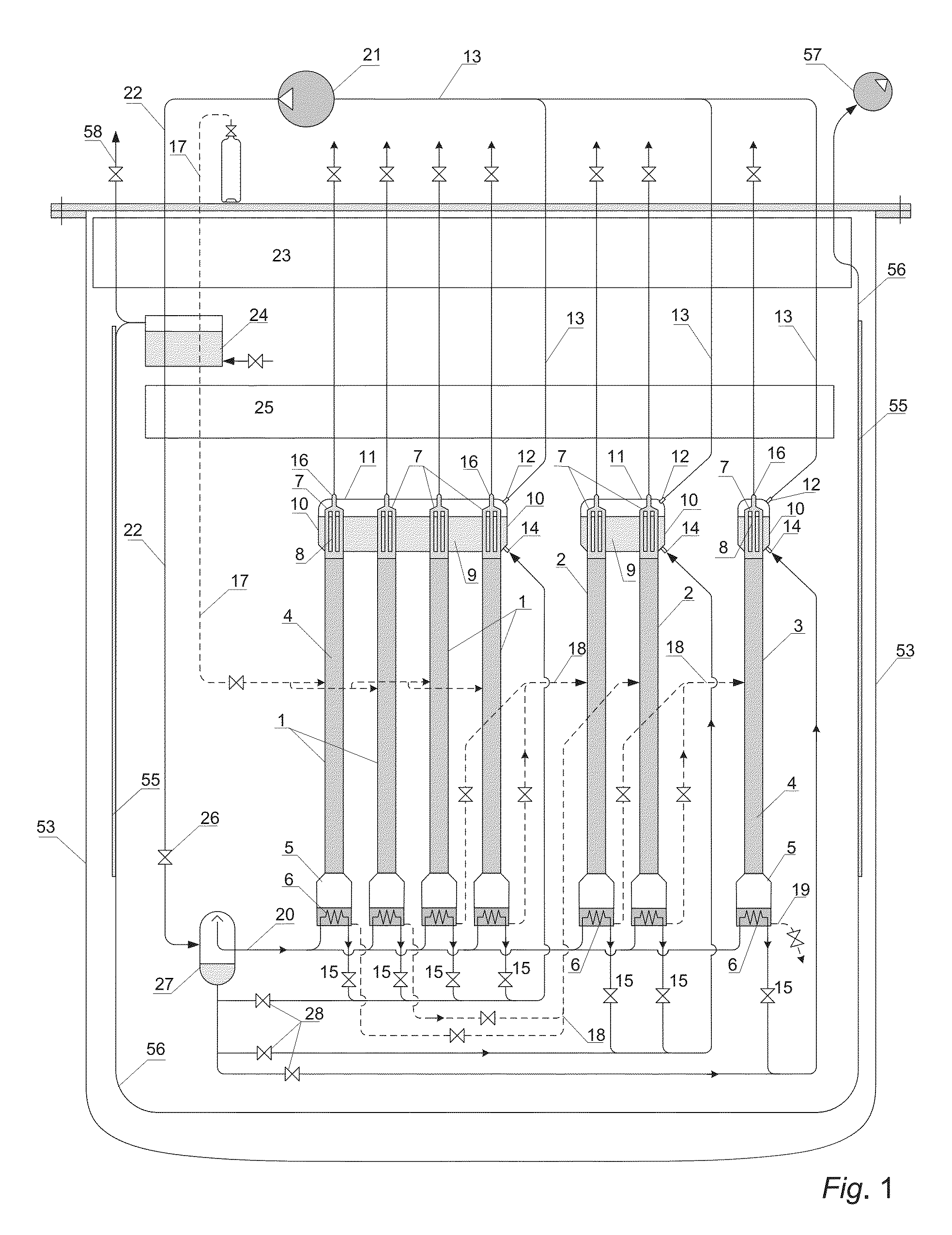

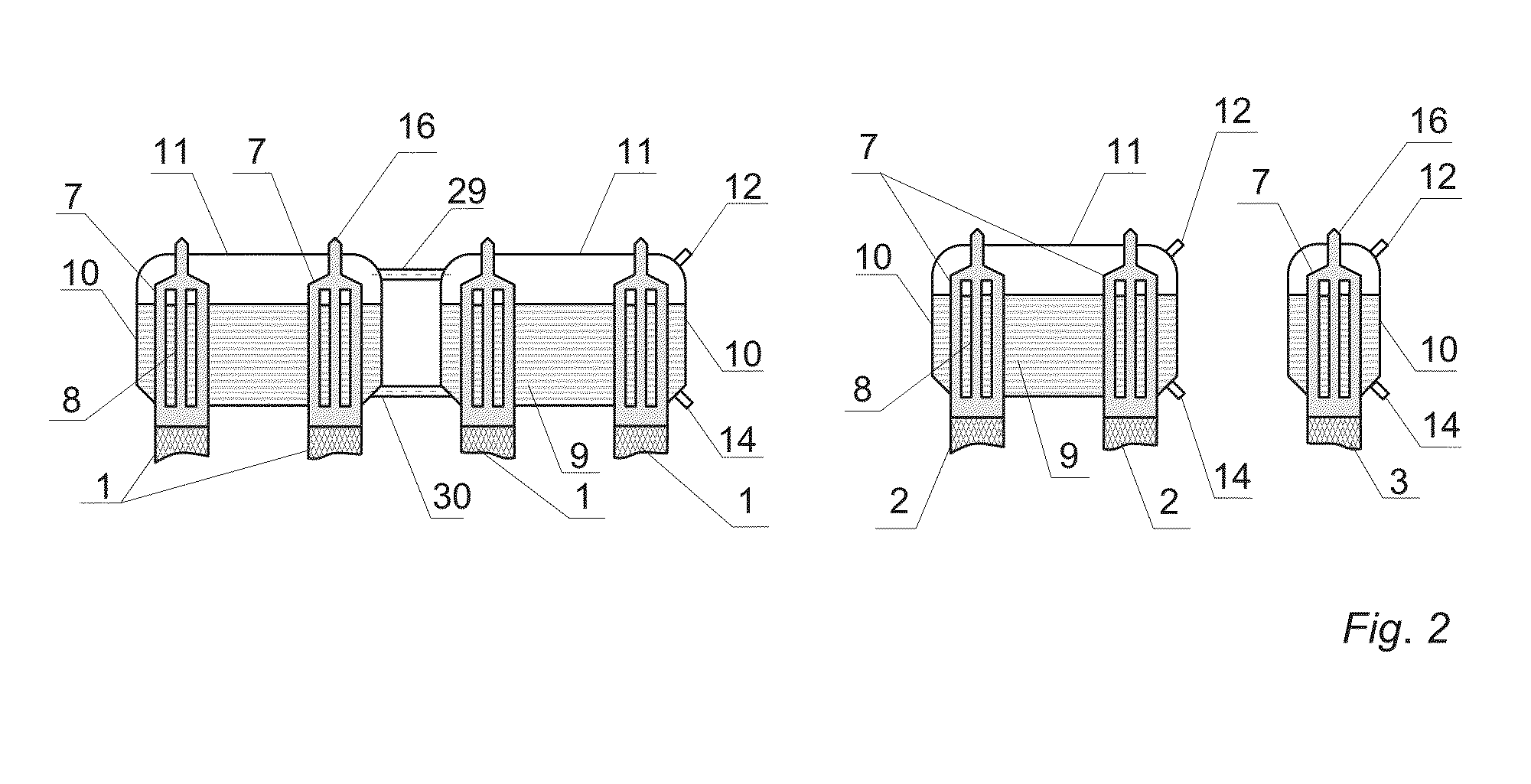

Method and equipment for realizing low-temperature thermal power generation by cryogenic technology

Low-temperature thermal power generation is realized in a new circulating mode. Natural substances such as liquid air, liquid nitrogen, liquid argon (1) and the like which exist in the atmosphere are taken as refrigeration working substances; the liquid nitrogen and the liquid argon are taken as assistant cold sources (13); the working substances are conveyed by a low-temperature liquid pump (2) in a pressure boosting mode; the working substances are cooled and cold is recovered by a low-temperature heat exchanging device (7); an intermediately-cold working substance performs heat exchange (15 and 14) with a low-grade heat source to generate intermediate-and-high pressure gas; one part of gas working substance of which the enthalpy value is increased is inflated to do work to generate electricity (17); and electric energy is merged into a local power grid (18). The other part of working substance is inflated in the pressure boosting mode (19) to generate the cold; the working substance is cooled, condensed, mixed and recovered by a low-temperature heat exchanging device (9) and an ejector (8); the working substance is supercooled in a liquefying mode (5) and recycled; and parameter detection, control and the like are realized by a computer control system (21).

Owner:墙新奇

Pre-cooled type coal bed gas nitrogen dilated and liquefied process taking advantage of variable pressure for adsorbing residual pressure

InactiveCN101285639AReduce liquefaction power consumptionReduce power consumptionSolidificationLiquefactionCryogenic technologyNitrogen gas

The invention provides a coalbed methane nitrogen expansion liquefaction technique by adopting swing pressure to absorb and pre-cool the excess pressure, belonging to the chemical and low temperature technical field. The invention provides an adsorption-liquefaction integrated flow of the high nitrogen content coalbed methane. Before the liquefaction process, most part of the nitrogen in the coalbed methane is removed in the pressure-swing adsorption process; the coalbed is pre-cooled after the nitrogen is expanded by adopting the adsorption excess pressure of the nitrogen; afterwards, the coalbed methane is liquefied by the nitrogen expansion and liquefaction process. The pre-cooling process of the nitrogen with excess pressure saves the refrigerating amount provided for the nitrogen expansion circulation, thereby reducing the compression work of the nitrogen and lowering the liquefaction work of the unit product of the system. Moreover, the higher the nitrogen content in the raw material gas of the coalbed methane, the higher the adsorbed excess pressure and more power dissipation is saved.

Owner:SHANGHAI JIAO TONG UNIV

Gas low temperature heat exchanger capable of self eliminating stress and pollution proof

InactiveCN1948884AReduce air permeabilitySmooth inner surfaceIndirect heat exchangersSocial benefitsProduct gas

The invention relates to gas low temperature heat exchanger with apontaneous subsiding stress energy pollution prevention. It includes low temperature heat exchanger tunnel body, below end plate, up end plate, A, B, C, and D four tube and shell heat exchangers, tube plate, shoe plate, tube pass inlet pipe and outlet pipe, shell pass inlet pipe and outlet pipe. The shell body of the four tube and shell heat exchangers adopted U shape heat exchanger is narrow rectangle. And the four is set in the low temperature heat exchanger tunnel body and connected each other in series. The low temperature heat exchanger adopts 0Cr18Ni9 / 304 which has little gas permeability, smooth and wear-proof inner surface, strong corrosion resistance, stable performance, and can prevent the air from polluting. In addition, it can remove the stress by itself caused by flatulence due to heat and cold to improve its selling performance. The invention has great economic and social benefits.

Owner:SHANGHAI JIAO TONG UNIV

Critical-cross carbon dioxide refrigerating system restriction sleeve

InactiveCN1737472ALow costSimple structureMechanical apparatusCompression machinesAuto regulationLow voltage

This invention relates to a critical carbon dioxide refrigerating system restriction sleeve, which belongs to cryogenic technology field. The invention comprises valve body, high-voltage air intake, intake filter, high-voltage cavity, cylinder, piston top center, piston, sealing ring, adjusting bolt, spring, main restriction sleeve, auxiliary restriction sleeve, low-voltage cavity, outlet filter and low-voltage liquor outlet, wherein one end of the high-voltage cavity is connected with the high-voltage air intake, and behind the high-voltage inlet it sets the intake filter, the cylinder is connected with the other end of the high-voltage cavity; in the cylinder it sets piston, spring, adjusting bolt and sealing ring sequentially, and the piston top center is set in the top of the cylinder; the parallel main restriction sleeve and auxiliary restriction sleeve are set in the valve body vertically, and the intake of the main restriction sleeve is connected directly with the high-voltage cavity. The invention applies the restriction sleeve as the restrictive element, by which the flow can be adjusted automatically according to the intake high-voltage changing of the restriction sleeve.

Owner:SHANGHAI JIAO TONG UNIV

Preparing method of strong-flavor Maofeng-jasmine instant tea

The invention discloses a preparing method of strong-flavor Maofeng-jasmine instant tea. According to the technical scheme, a method of gradually rising the temperature from an ultralow temperature is mainly adopted so that tea fragrance can be firstly maintained through the low temperature and then gradually released, then the fragrance of jasmine flowers and wintersweet flowers is gradually released and absorbed by Maofeng tea leaves, a cryogenic technology is adopted in both smashing and extraction treatment, thus partial fragrance is maintained to be not entirely released, and when a finished tea product is made in high-temperature water, a large amount of fragrance is still sent forth; meanwhile, a low-temperature extraction technology is adopted so that it can be guaranteed that health-care components like phenols, alcohol, lipid, saccharides contained in the jasmine flowers, wintersweet flowers and the Maofeng tea leaves are not damaged.

Owner:长兴众化生物科技有限公司

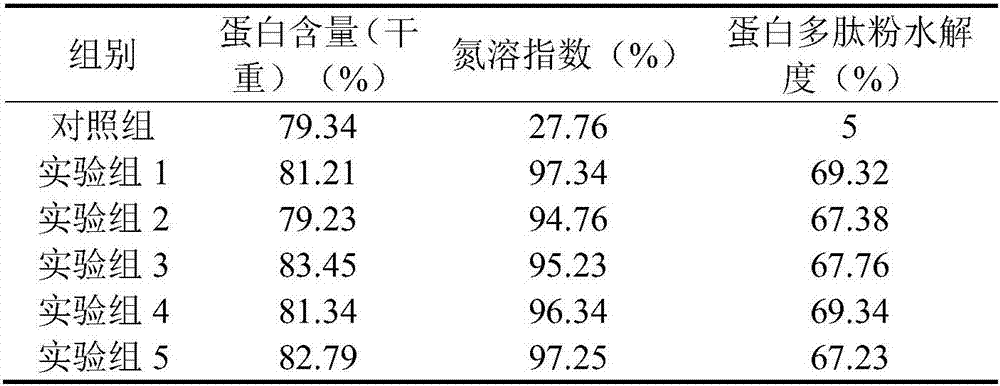

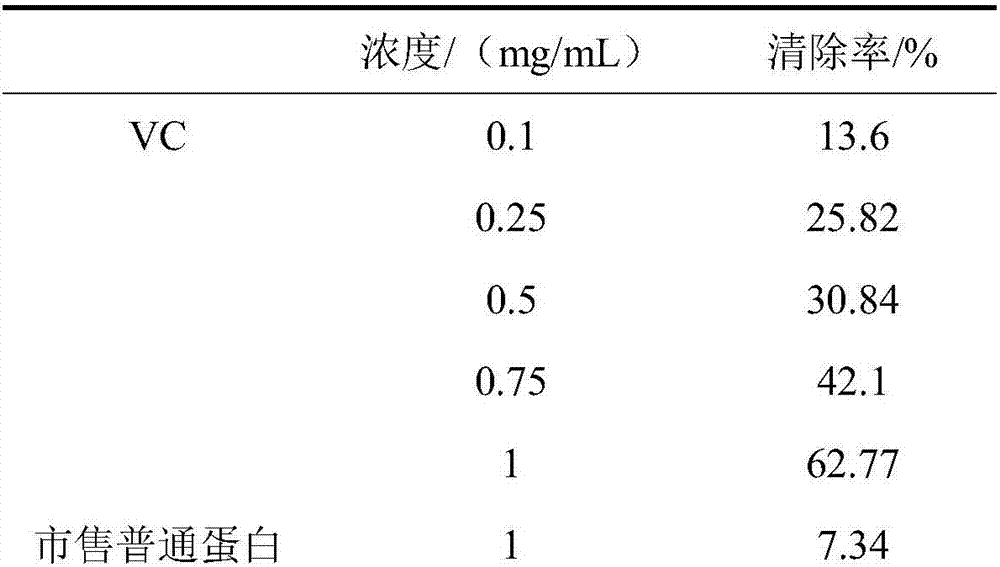

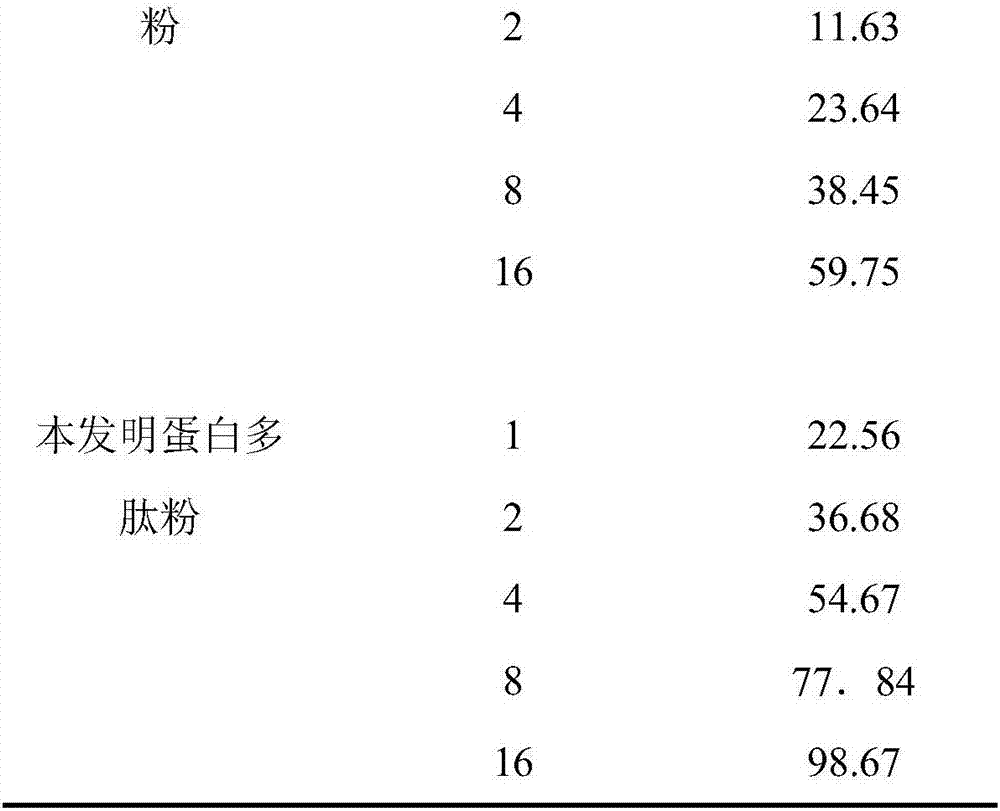

Protein polypeptide powder, preparation and application thereof

InactiveCN107019226AImprove digestion and absorption ratePromote digestion and absorptionFood ingredient as antioxidantFood ingredient as taste affecting agentSolubilityCholesterol

Belonging to the food field, the invention in particular relates to a protein polypeptide powder, preparation and application thereof. The invention specifically adopts soybean, walnut, broccoli and broccoli seed buds as the raw materials, employs cryogenic technology to prepare protein powder, and makes full use of yeast and lactic acid bacteria for fermentation, thereby greatly improving the solubility of protein polypeptide powder, and effectively promoting digestion and absorption of the body to protein polypeptide. The obtained protein polypeptide powder not only is nutritious, good in health care effect, and easy for digestion and absorption, but also has the functions of protecting stomach, resisting body oxidation, improving intestinal flora, and reducing cholesterol, etc., is good in sense and flavor, also can guarantee the food safety of protein polypeptide powder within shelf life without adding any preservative, overcomes the defects of single function, unsatisfactory nutrition and health care effects, human body indigestion caused by excessive intake of protein and the like in ordinary commercially available protein powder.

Owner:PHARMA CO LTD TIANJIN HEZHIYOUDE

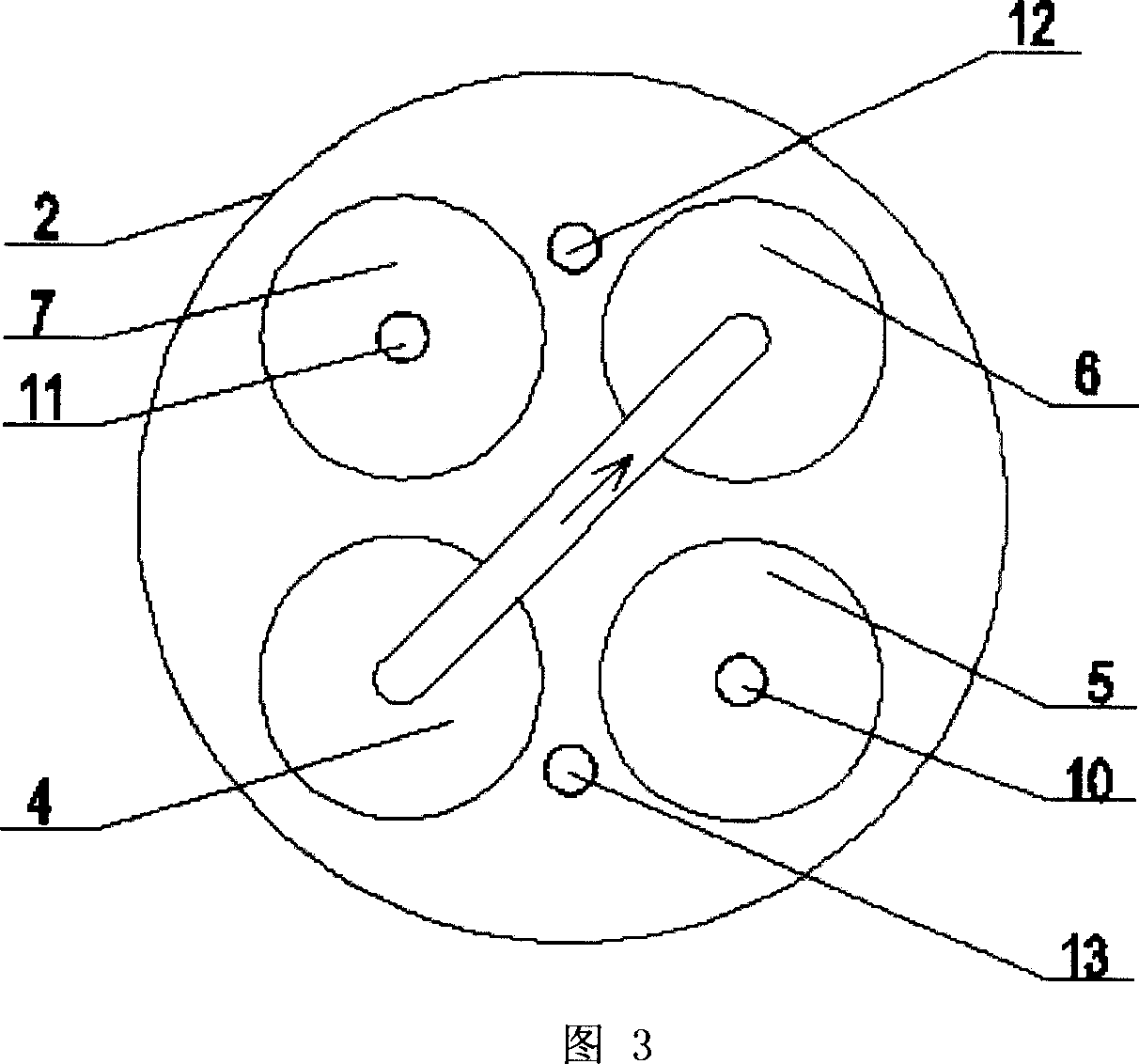

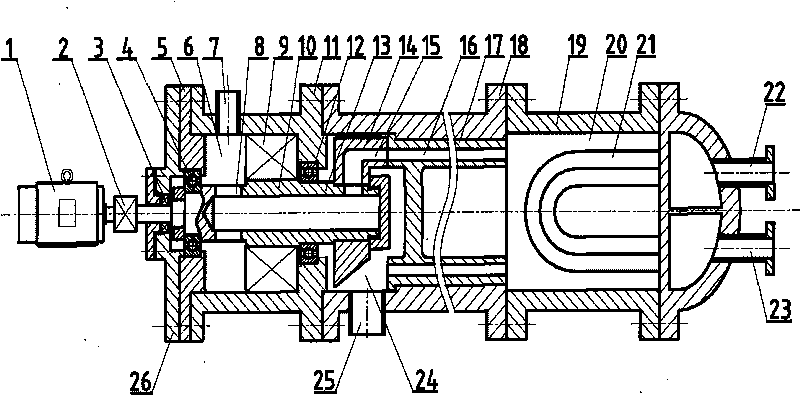

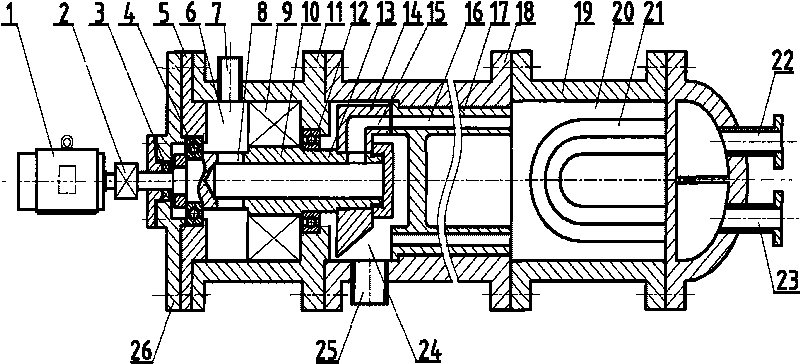

Mixed containing cavity heat dissipation gas wave refrigerating machine

ActiveCN101762110AShorten the receiving tube lengthDissipativeCompression machinesShock waveKinematic wave

The invention relates to a mixed containing cavity heat dissipation gas wave refrigerating machine, belonging to the field of gas expansion refrigeration low temperature technology, a pressure gas is jetted to a receiving pipe to generate kinematic waves to dissipate energy, thereby realizing refrigeration, the rotating speed is low and the operation is simple. The mixed containing cavity heat dissipation gas wave refrigerating machine is mainly composed of a machine body, a rotating jet flow distributor, a short receiving pipe, a receiving pipe cylinder, a mixed containing cavity and a heat exchanging unit and is characterized in that the end of the short receiving pipe is opened and is communicated with the mixed containing cavity, the heat exchanging unit is arranged in the mixed containing cavity, and the energy of a compression wave or a shock wave, which is transmitted to the mixed containing cavity from the short receiving pipe, is adsorbed by the heat exchanging unit. The heat dissipation and buffer structure that the mixed containing cavity is spliced by the short receiving pipe is adopted in the invention, therefore, the complete machine volume is small, the pipe can not be broken by vibration, the refrigeration efficiency is high, the changing fluctuation is little, the exhaust of refrigeration gas condensate is very convenient, and the transformed energy is easy to be recycled. The mixed containing cavity heat dissipation gas wave refrigerating machine can be widely used in the field of condensation separation of mixed gas, light dydrocarbon recycle in petroleum gas, low temperature dehydration of natural gas, low-temperature gas source supply and the like.

Owner:DALIAN UNIV OF TECH

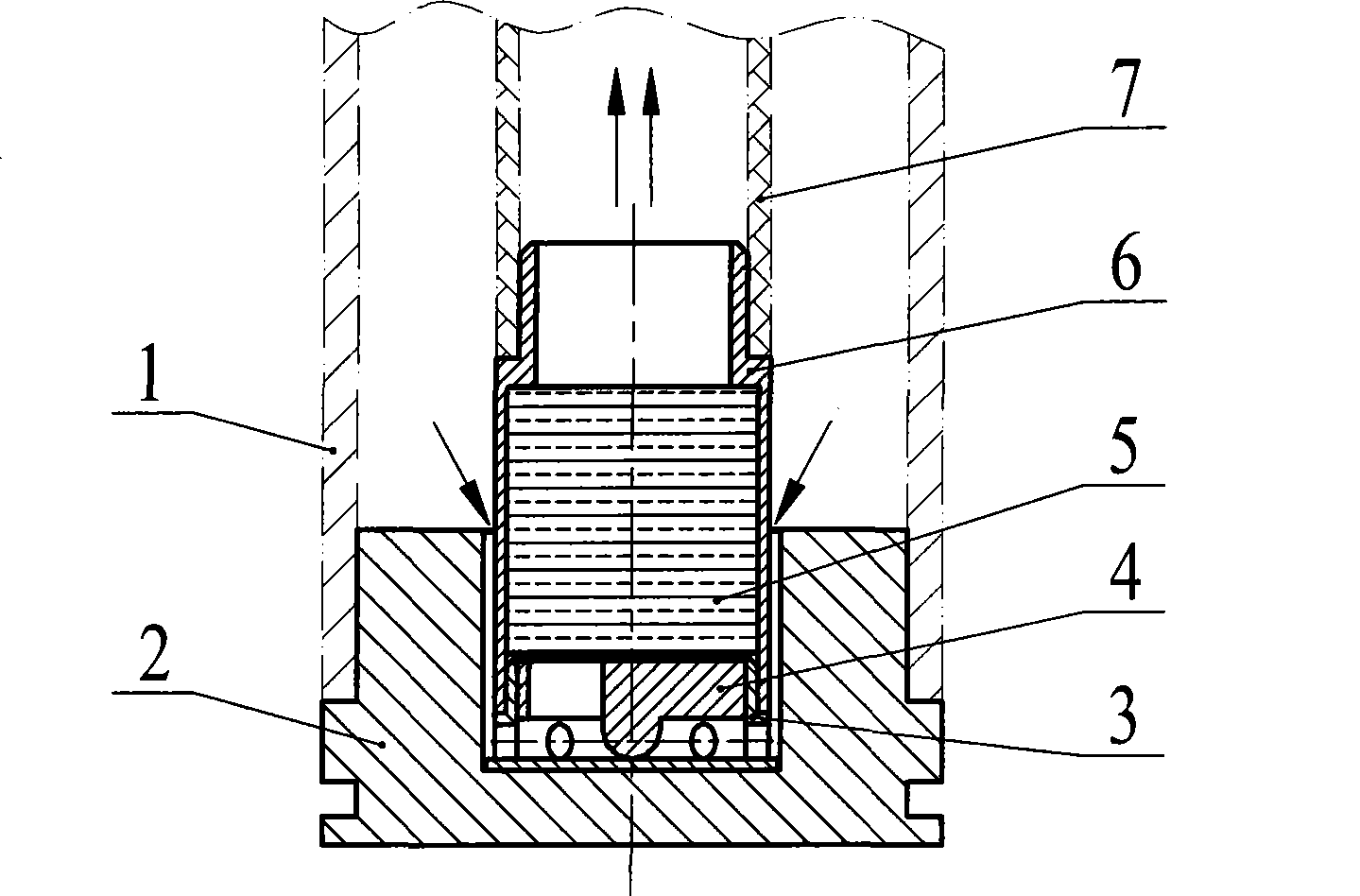

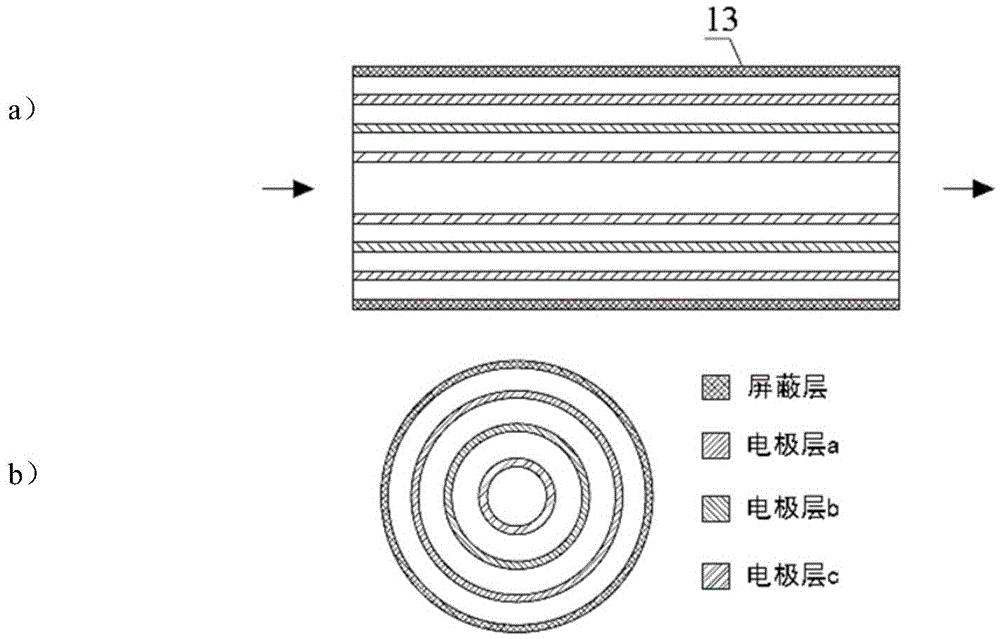

Cool end heat exchanger of pulse tube refrigerator

InactiveCN101469919AImprove heat transfer efficiencyIncrease the heat exchange areaCompression machinesEvaporators/condensersPulse tube refrigeratorEngineering

The invention discloses a coaxial pulse-tube refrigerator combined type cold end heat exchanger, belonging to the gas heat exchanging cryogenic technical field. The invention is composed of a cold junction, a cold cap, a cold cap flow guider, a silk net stuffing and a heat exchanger. The cold cap flow guider is of umbrella-shaped structure and is arranged in a cold cap cavity to form an airflow stabilizing cavity. The silk net stuffing stuffed in the heat exchanger is supported tightly by the cold cap and the cold cap flow guider, and the cold cap and the cold cap flow guider are matched with the heat exchanger closely. The bottom surface of the cold cap is attached to the cold junction inner cavity bottom surface closely, the outer wall surfaces of the cold cap and the heat exchanger and the cold junction inner cavity surface form an annular clearance channel. The invention has simple structure, convenient assembling, improves heat exchanging area and heat exchanging coefficient, stabilizes the flow state of the airflow, can be used for multiple types of coaxial pulse-tube refrigerators and other refrigerating and heat exchanging apparatuses.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

Double-thermal-shield negative-pressure low-temperature heat exchanger test device

InactiveCN110793797AHigh precisionExpand the scope of the experimentStructural/machines measurementRadiation leakageCryogenic technology

The invention relates to a double-thermal-shield negative-pressure low-temperature heat exchanger test device, and belongs to the technical field of ultra-low temperature. The device includes a low-temperature cold-box and external equipment. The low-temperature cold box is composed of a box body, liquid nitrogen and liquid helium thermal-shields, a 4.5K liquid helium slot, a 1.8K super-flow helium slot, a tested heat exchanger, a heater and a pneumatic regulating valve. The external equipment is composed of liquid nitrogen and liquid helium Dewars, a helium steel cylinder, a gas cabinet, a manual regulating valve, a heater, a room-temperature decompression pump and a vacuum pump. A vacuum is made by the vacuum pump to reduce heat transfer of gas in the cold box, the double cold screens are arranged to reduce radiation leakage heat, the helium steel cylinder provides liquid supply power for the liquid helium Dewar and can adjust pressure entering the 4.5K liquid helium slot, the gas cabinet can recover helium from evaporation of the 4.5K liquid helium slot, a bypass valve is arranged at an inlet of the tested heat exchanger, high-pressure path flow can be reduced, and working statedeviation running of experiment is realized. The device can carry out experiment in a multi-working-state manner, and has the advantages of a simple structure, reliable operation, controllable variable parameters and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

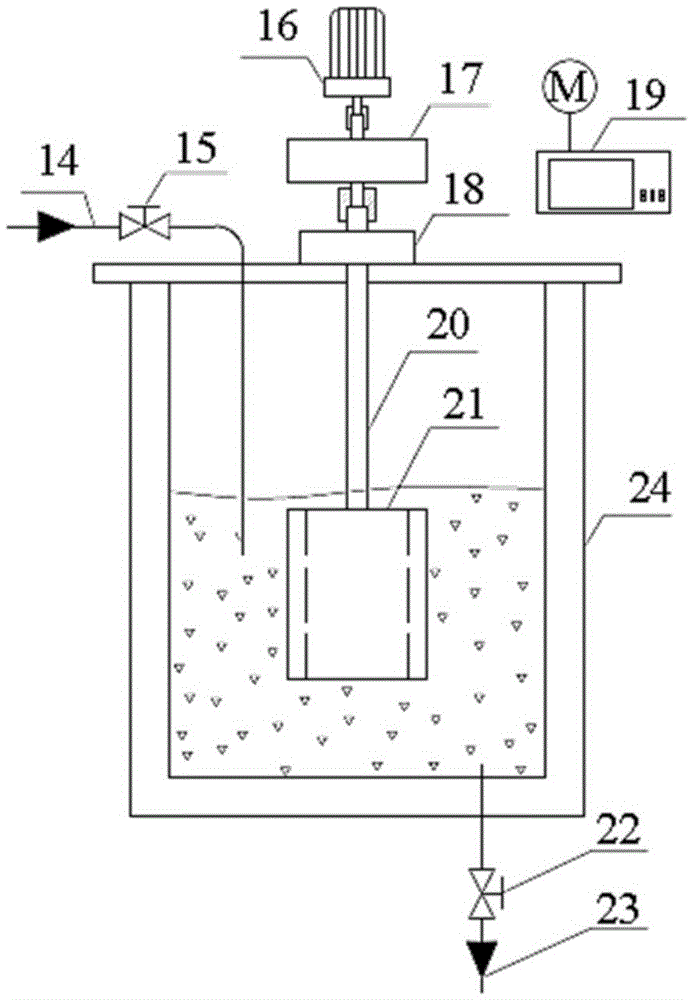

Measuring apparatus and method for obtaining apparent viscosity physical property of low-temperature thick liquid through combination with density measurement

ActiveCN105547910ALow costSimple preparation processFlow propertiesSpecific gravity measurementMeasurement deviceLiquid viscosity

The invention discloses a measuring apparatus and method for obtaining apparent viscosity physical property of a low-temperature thick liquid through combination with density measurement. The apparatus comprises a low-temperature-thick-liquid feeding unit, a low-temperature-thick-liquid-density measuring unit, and a low-temperature-thick-liquid-viscosity measuring unit. The low-temperature-thick-liquid feeding unit is connected to the low-temperature-thick-liquid-density measuring unit and the low-temperature-thick-liquid-viscosity measuring unit in sequence through pipelines in order to enable the low-temperature thick liquid to pass through the two units. The low-temperature-thick-liquid-density measuring unit is internally provided with a density measuring electrode and an LCR measuring instrument and can measures density of the low-temperature thick liquid. The viscosity measuring unit calculates density of a stirred objective fluid through torque, of a rotating cylinder, measured by a torque transducer. The low-temperature measuring apparatus adapts to measurement of density and viscosity of a solid-liquid thick liquid or a single-phase fluid at a low temperature and is simple in process. Density measured values and viscosity measured values measured by the measuring apparatus are corresponding one to one, so that the measured results are entire. The apparatus and method can be widely applied to fields, such as air separation, spaceflight, and superconductors, with respect to deep cryogenic technology.

Owner:ZHEJIANG UNIV

Method and apparatus for purifying and separating a heavy component concentrate along with obtaining light gas isotopes

Owner:SAVINOV MIKHAIL JURIEVICH +1

High-activity and high-content superoxide dismutase (SOD) roxburgh rose composite tablet preparation method

The invention provides a preparation method for a high-activity and high-content superoxide dismutase (SOD) roxburgh rose composite tablet preparation method. Wild roxburgh roses are used as a raw material, and superoxide dismutase (SOD) is extracted by a whole-course low-temperature technology; after making is executed, a thin film coating technology is adopted to avoid air contact, so that the content and the activity of the SOD are retained to the maximum extent; the activity preservation period of the SOD can be prolonged during tablet making. The method comprises the steps of material selection, pulping, enzymolysis, rough filtration, ultrafiltration, granulation and tabletting. The preparation method has the characteristics of simplicity, quickness, high activity, short response time, high content and good effect; the problems of difficulty in storage of the SOD and loss of effective components of a finished product are solved.

Owner:李良奎

Cryogenic heat treatment technology for improving performances of countershaft gear

InactiveCN105400944ASmall quenching deformationHigh surface hardnessSolid state diffusion coatingFurnace typesHardnessCryogenic technology

The invention discloses a cryogenic heat treatment technology for improving performances of a countershaft gear. According to the technology, a salt bath quenching technology and a cryogenic technology are combined, so that the defects that the countershaft gear is liable to quenching deformation and is low in surface hardness are improved, and the service life of a countershaft is prolonged. The cryogenic heat treatment technology for improving performances of the countershaft gear is characterized by comprising the specific steps of cleaning, preheating, carburization, salt bath quenching, cryogenic treatment and secondary tempering. Compared with the prior art, the technology has the advantages that in the quenching stage, salt bath quenching is combined with a novel technology of cryogenic treatment, so that the deformation degree of the countershaft gear after carburization and quenching is enabled to be small, and the surface hardness is greatly improved.

Owner:张贺佳

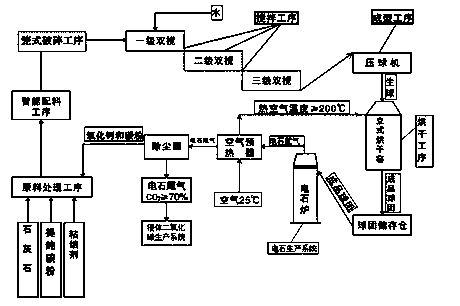

Method for producing calcium carbide by virtue of waste gas

ActiveCN104355312AGreat economyHuge environmental benefitsEnergy inputCalcium carbideThermal energySeparation technology

The invention relates to a process technology for producing calcium carbide by virtue of waste gas, dust and waste heat, and belongs to the technical field of industrial production of calcium carbide. Dust in the waste gas produced in calcium carbide production is recovered as a part of raw materials for calcium carbide production according to a chemical principle of calcium carbide production, a new powdery raw material is supplemented, a high-performance Xuguang calcium carbide binder is added to prepare pellets, a great amount of heat produced by combusting carbon monoxide in the calcium carbide waste gas and the sensible heat of furnace gas are taken as heat sources for drying the calcium carbide pellets, tail gas containing more than or equal to 70 percent of carbon dioxide is produced by the combustion of carbon monoxide, carbon dioxide is separated by a pressure swing absorption gas separation technology or a membrane separation technology, and according to market demands, liquid carbon dioxide with high added value is prepared by a cryogenic technology, or dry ice is further prepared. According to the process technology, the calcium carbide waste gas, dust and waste heat are effectively utilized, energy is saved, consumption is reduced, and the economic benefits of a calcium carbide enterprise are comprehensively improved.

Owner:云南云博天环境科技有限公司

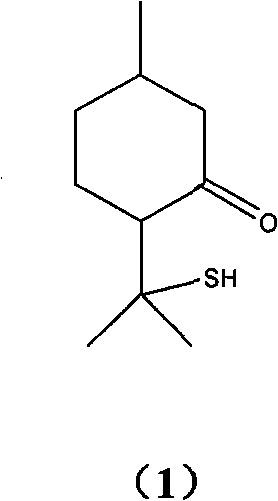

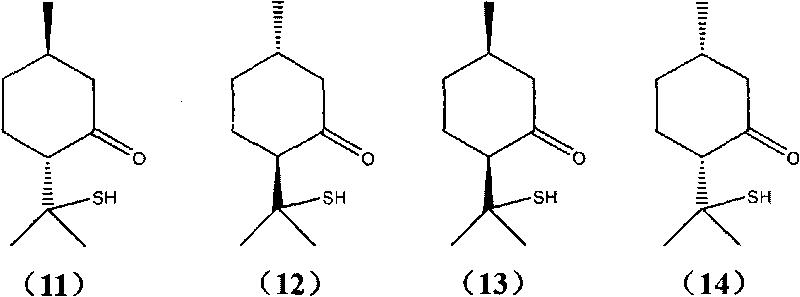

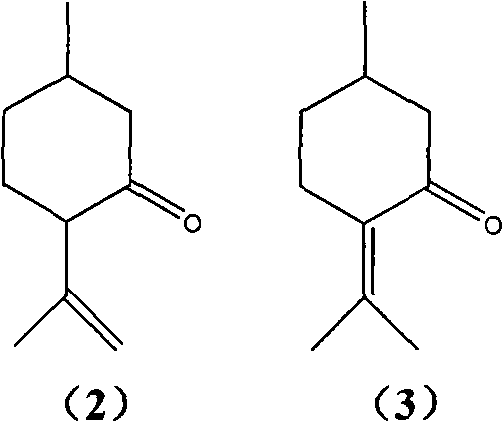

Synthesis method of thio-menthone perfume

InactiveCN101735120AEase of industrial implementationLess investmentThiol preparationMenthoneState of art

The invention relates to a synthesis method of thio-menthone perfume, which comprises the steps of: preparation of chloro-menthone, preparation of sodium hydrosulfide, preparation of crude thio-menthone, rectification of the crude thio-menthone and the like. Compared with the prior art, the method is convenient for industrial implementation, less in equipment investment and easy in operation; the technique has highest yield in the preparation of the thio-menthone under the technical condition of normal pressure and normal temperature; meanwhile, the method solves the problems of high equipment investment, strong equipment corrosion, high power consumption, hard operation and the like caused by the technology for preparing the thio-menthone at high pressure and low temperature.

Owner:HUABAO FLAVOURS & FRAGRANCES CO LTD

Assembly for separating gas mixtures in fractionating columns

Owner:BONDARENKO VITAL LEONIDOVICH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com