Device and method for extracting pure carbon monoxide and oxygen-rich gas by aid of cryogenic technology

A carbon monoxide and hydrogen-rich technology, used in refrigeration and liquefaction, liquefaction, cold treatment separation, etc., can solve the problems of unsatisfactory heat exchanger effect, many machines and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

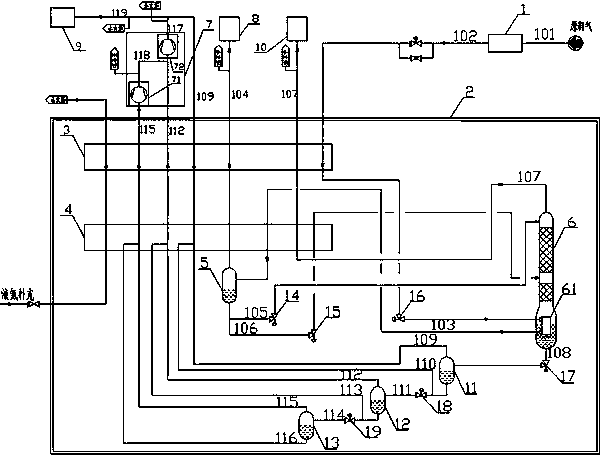

[0029] A device for producing pure carbon monoxide and hydrogen-rich gas by cryogenic method, such as figure 1 As shown, the device includes a front-end pretreatment unit 1 and a cryogenic separation and purification unit 2, and the cryogenic separation and purification unit 2 includes a first main heat exchanger 3, a second main heat exchanger 4, a first gas-liquid separation 5, the second gas-liquid separator 11, the 3rd gas-liquid separator 12, the 4th gas-liquid separator 13 and rectifying tower 6, and described rectifying tower 6 comprises the evaporator 61 of tower body itself and tower body bottom . The separated and purified feed gas is N-containing 2 , Ar, CH 4 and trace H 2 S, CO 2 CO and H 2 Mixed gas, the front-end pretreatment unit 1 is connected to a first pipeline 101 for inputting raw gas, the gas outlet of the front-end pretreatment unit 1 is connected to a second pipeline 102, and the second pipeline 102 passes through the first The main heat exchanger...

Embodiment 2

[0037] A method for producing pure carbon monoxide and hydrogen-rich gas by cryogenic method, wherein the device for producing pure carbon monoxide and rich hydrogen gas by cryogenic method used in the method is the device described in the first embodiment, and will not be repeated here. Methods include:

[0038] 1) Raw synthesis gas (CO+H 2 content ≥ 90% (mol%)) enters the front-end pretreatment unit 1 through the first pipeline 101, and removes the trace amount of methanol and carbon dioxide contained in the raw material synthesis gas through the molecular sieve adsorption in the front-end pretreatment unit 1, and removes impurities. The purified syngas enters the first main heat exchanger 3 through the second pipeline 102 and is cooled to a certain temperature (about 140K, the setting is different according to different working conditions), and then enters the distillation tower 6 through the second pipeline 102 for evaporation The heat exchanger 61 is cooled as a heat sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com