Patents

Literature

1624 results about "Phosgene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosgene is the organic chemical compound with the formula COCl₂. It is a colorless gas; in low concentrations, its odor resembles freshly cut hay or grass. Phosgene is a valued industrial building block, especially for the production of urethanes and polycarbonate plastics. However, it is very poisonous and was used as a chemical weapon during World War I where it was responsible for 85,000 deaths. In addition to its industrial production, small amounts occur from the breakdown and the combustion of organochlorine compounds.

Polycarbonate preparation process

Disclosed is a polycarbonate composition and process from making same, wherein introduction of a chain terminator and an acyl halide other than phosgene is after at least 25 percent of the hydroxyl groups in the dihydric phenol have been converted to chloroformate groups.

Owner:TRINSEO EURO GMBH

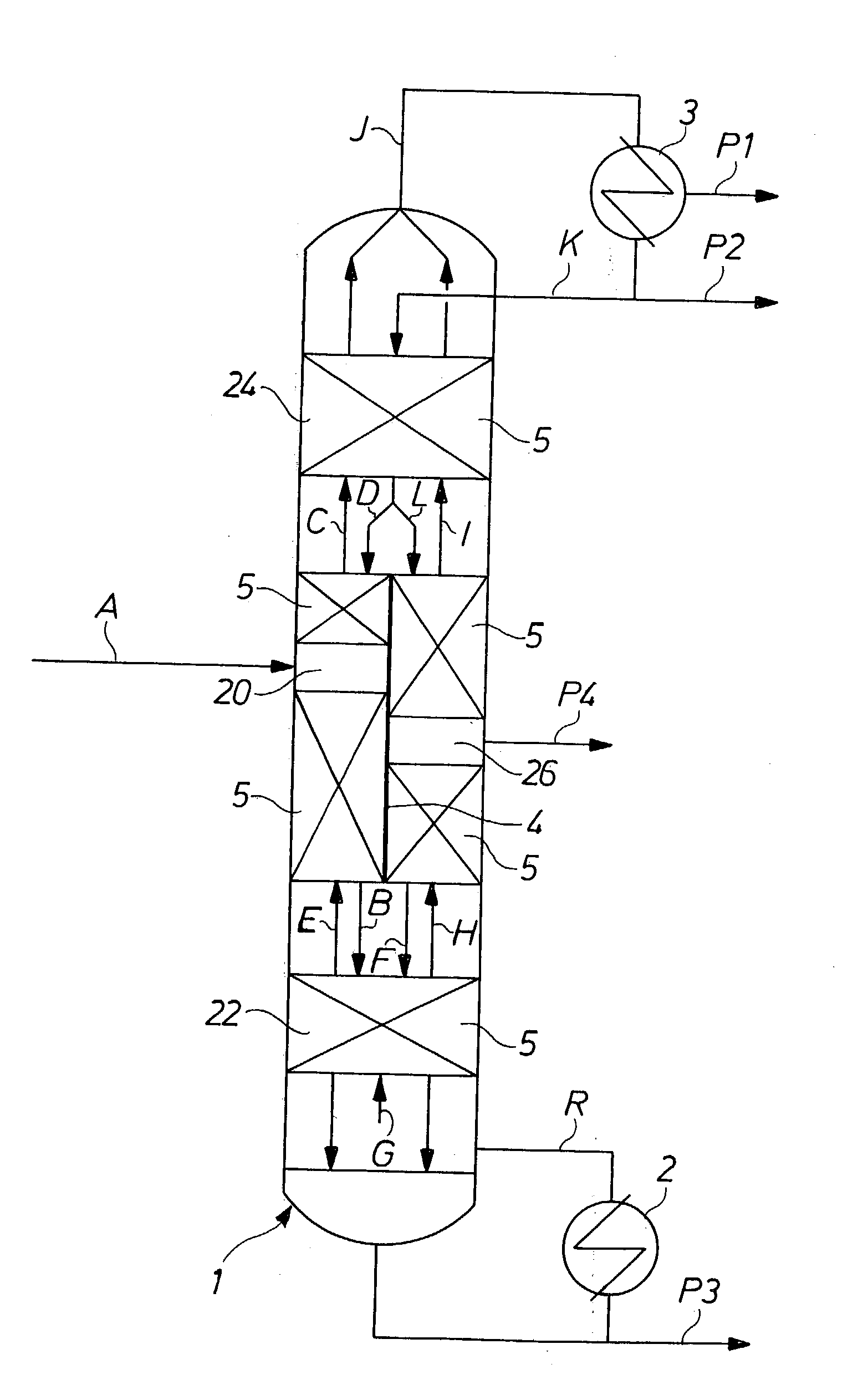

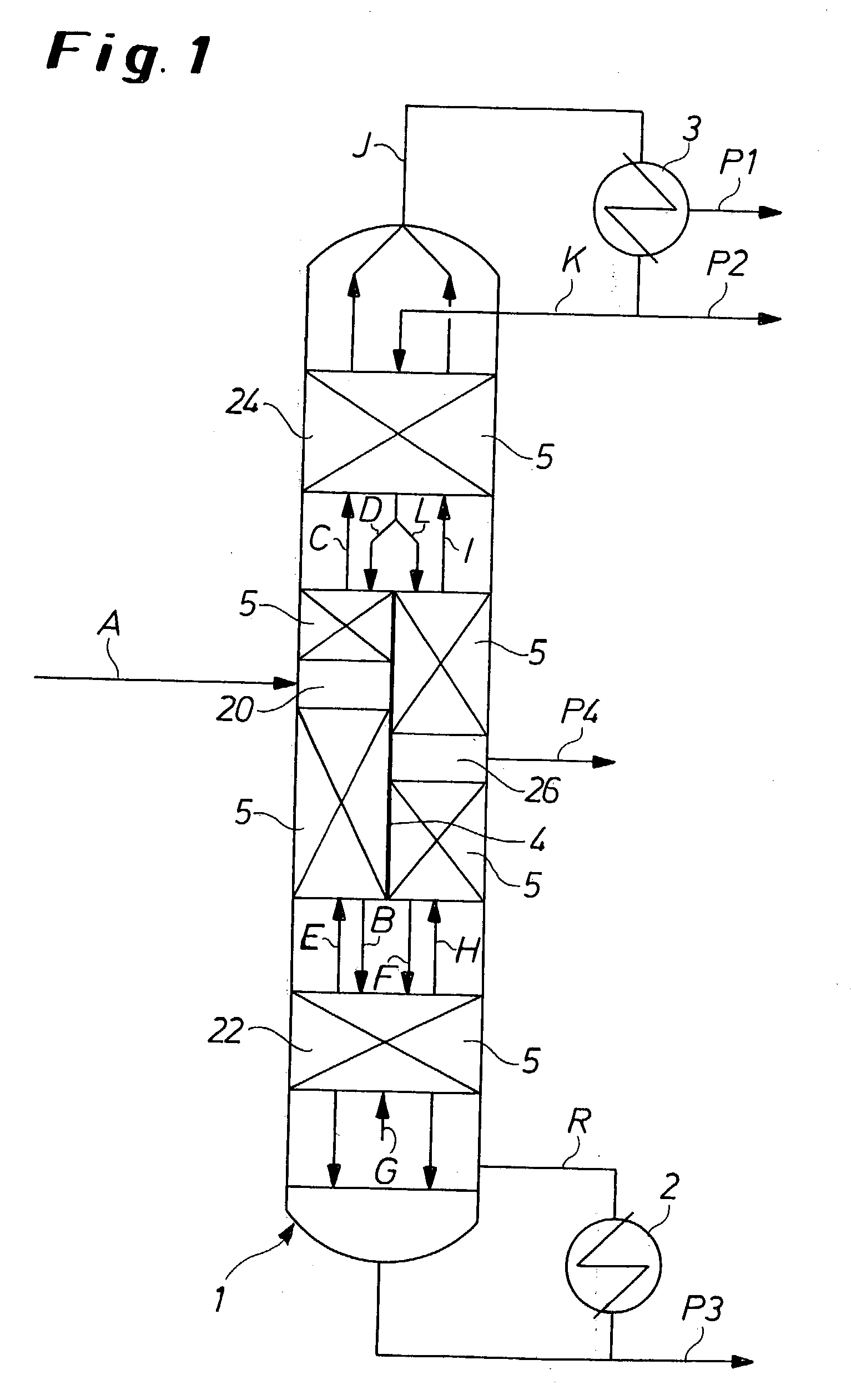

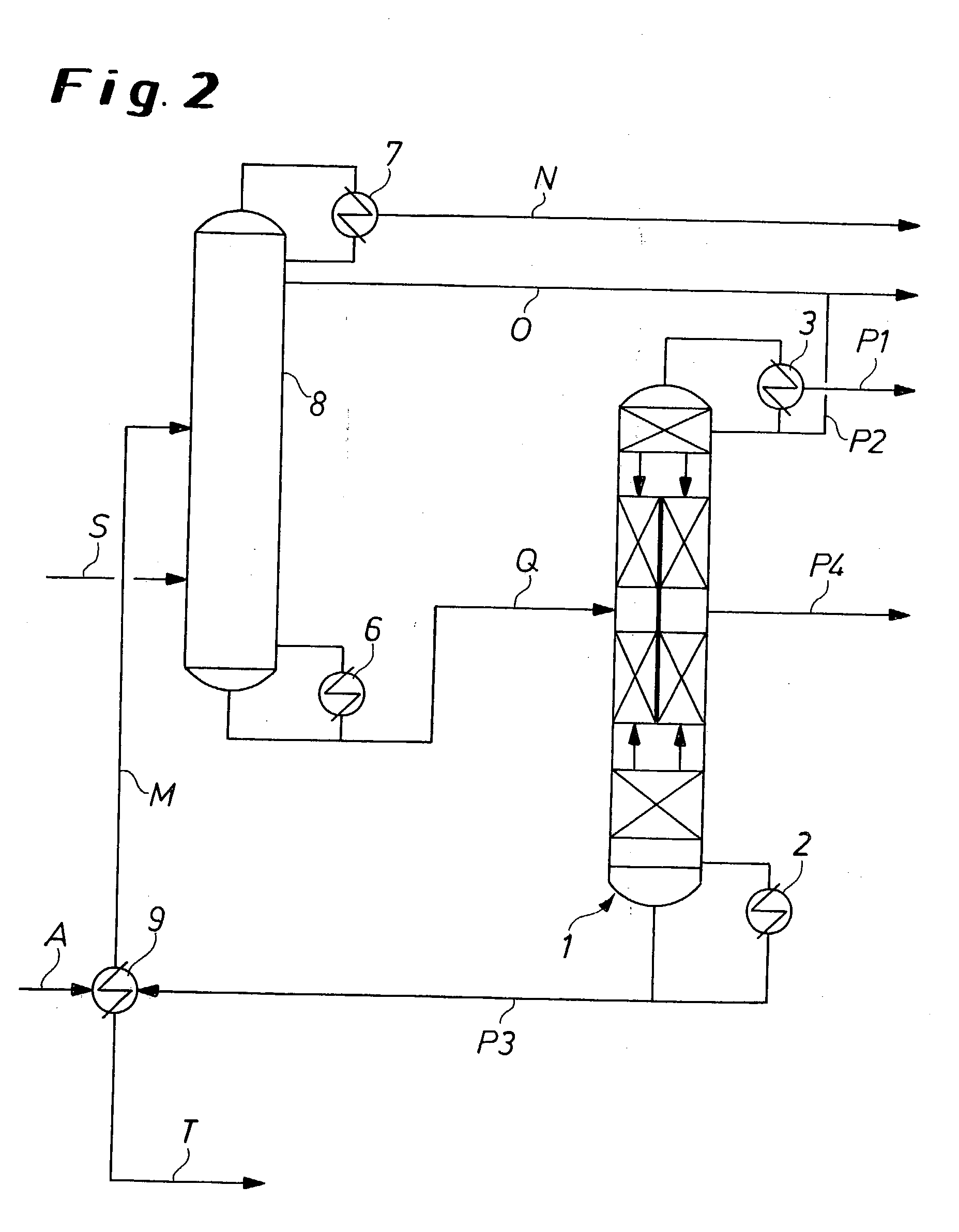

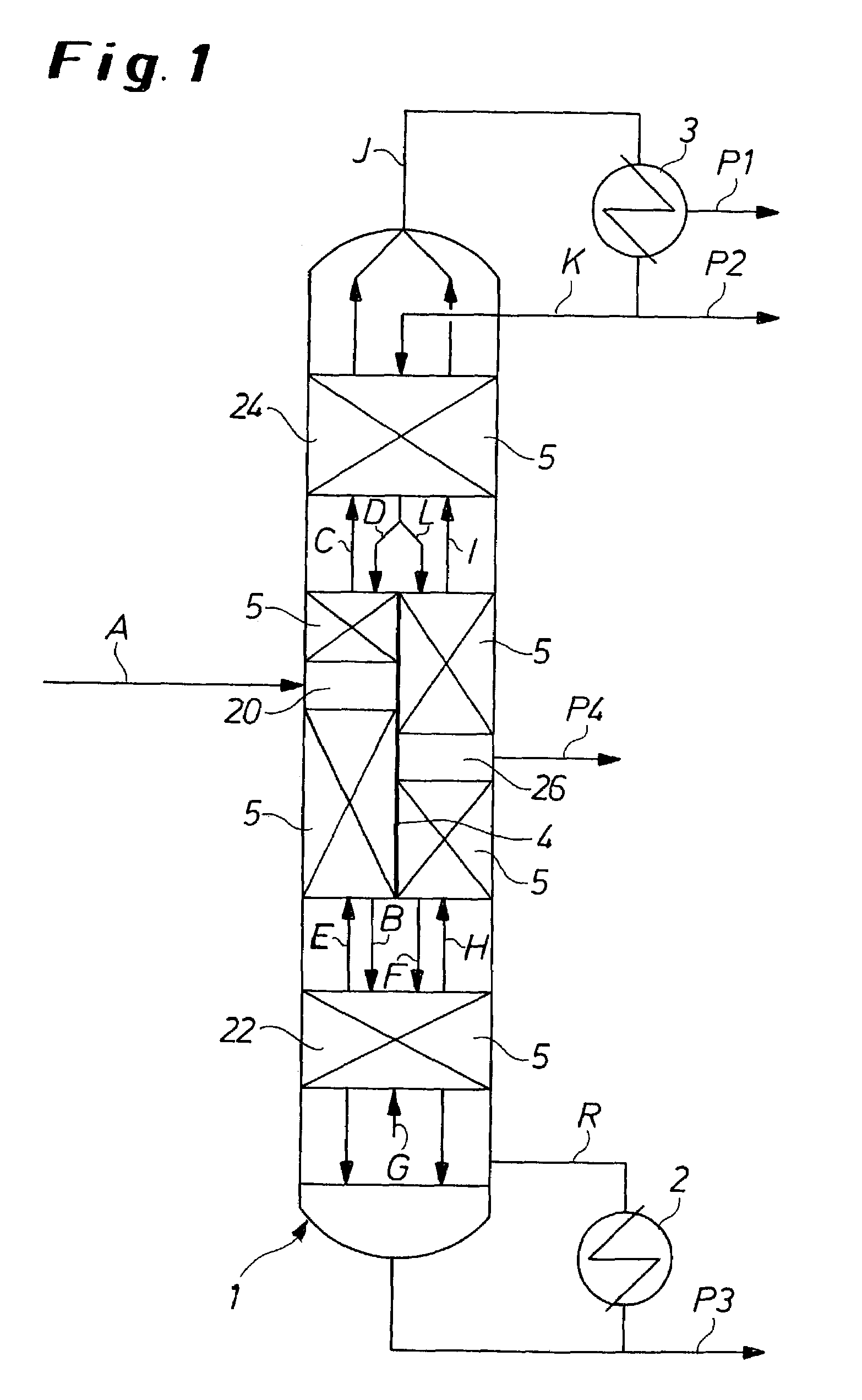

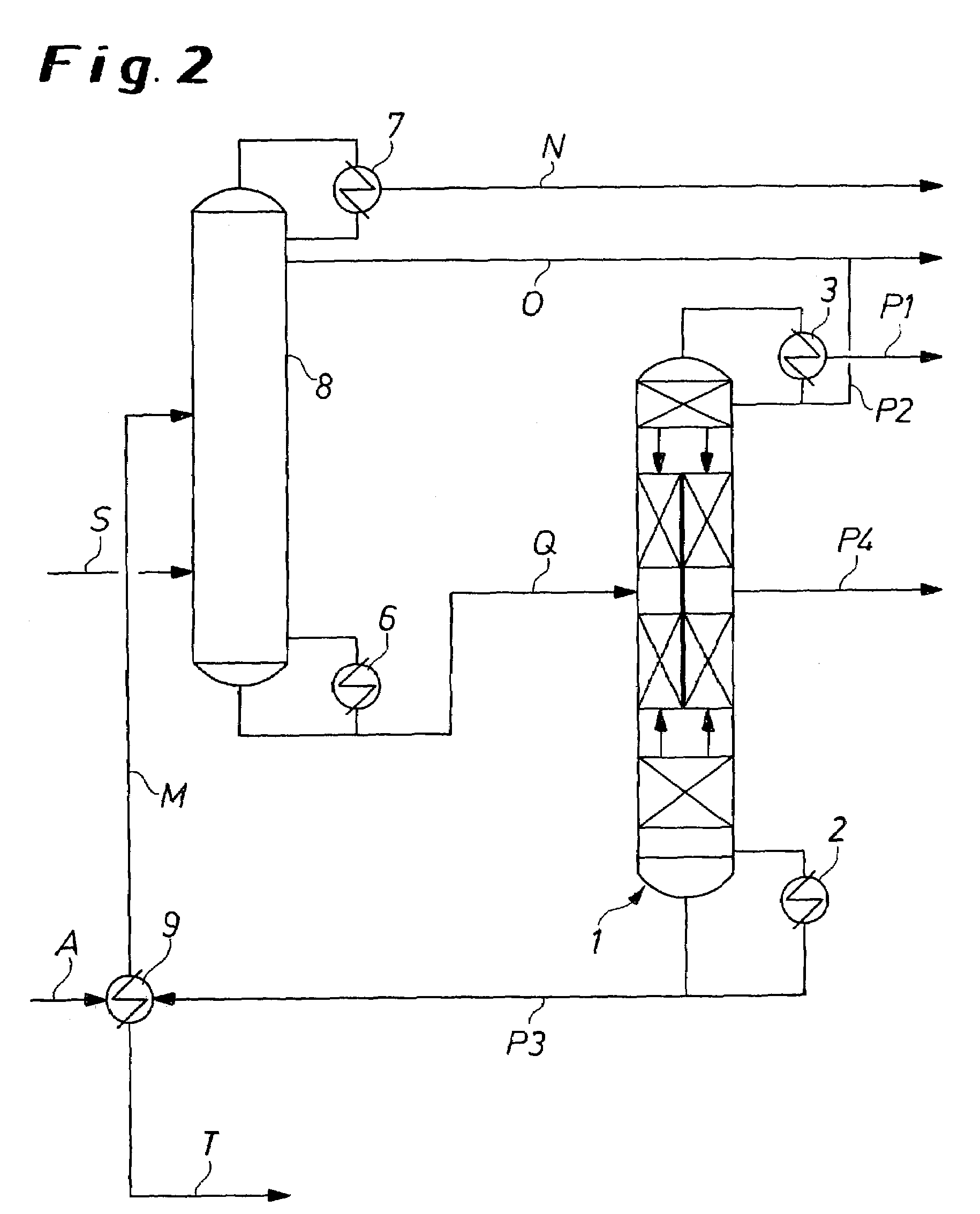

Process for the purification of mixtures of toluenediisocyanate incorporating a dividing-wall distillation column

InactiveUS20030230476A1Weaken energyLow investment costThermal non-catalytic crackingOrganic compound preparationPurification methodsOrganic solvent

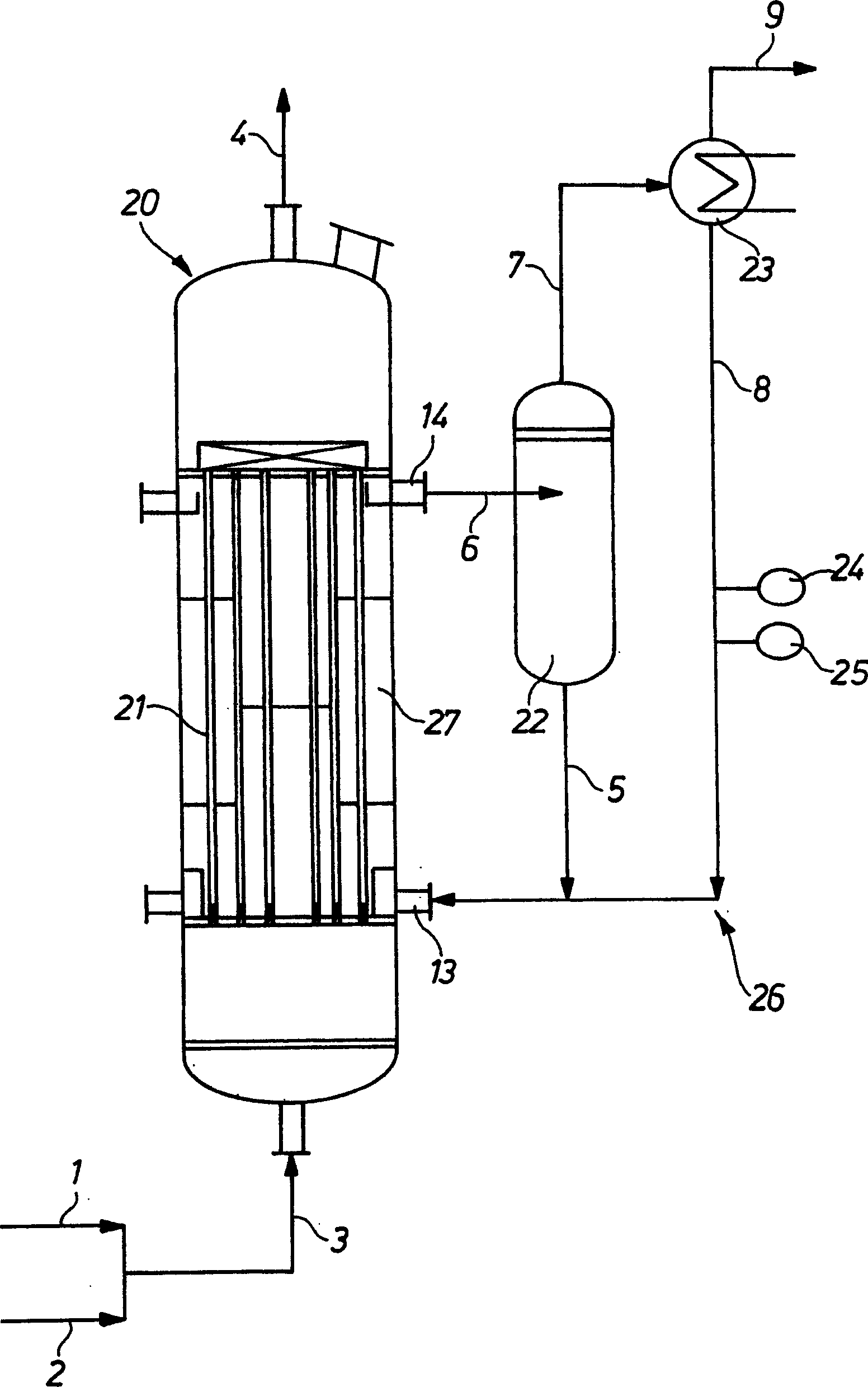

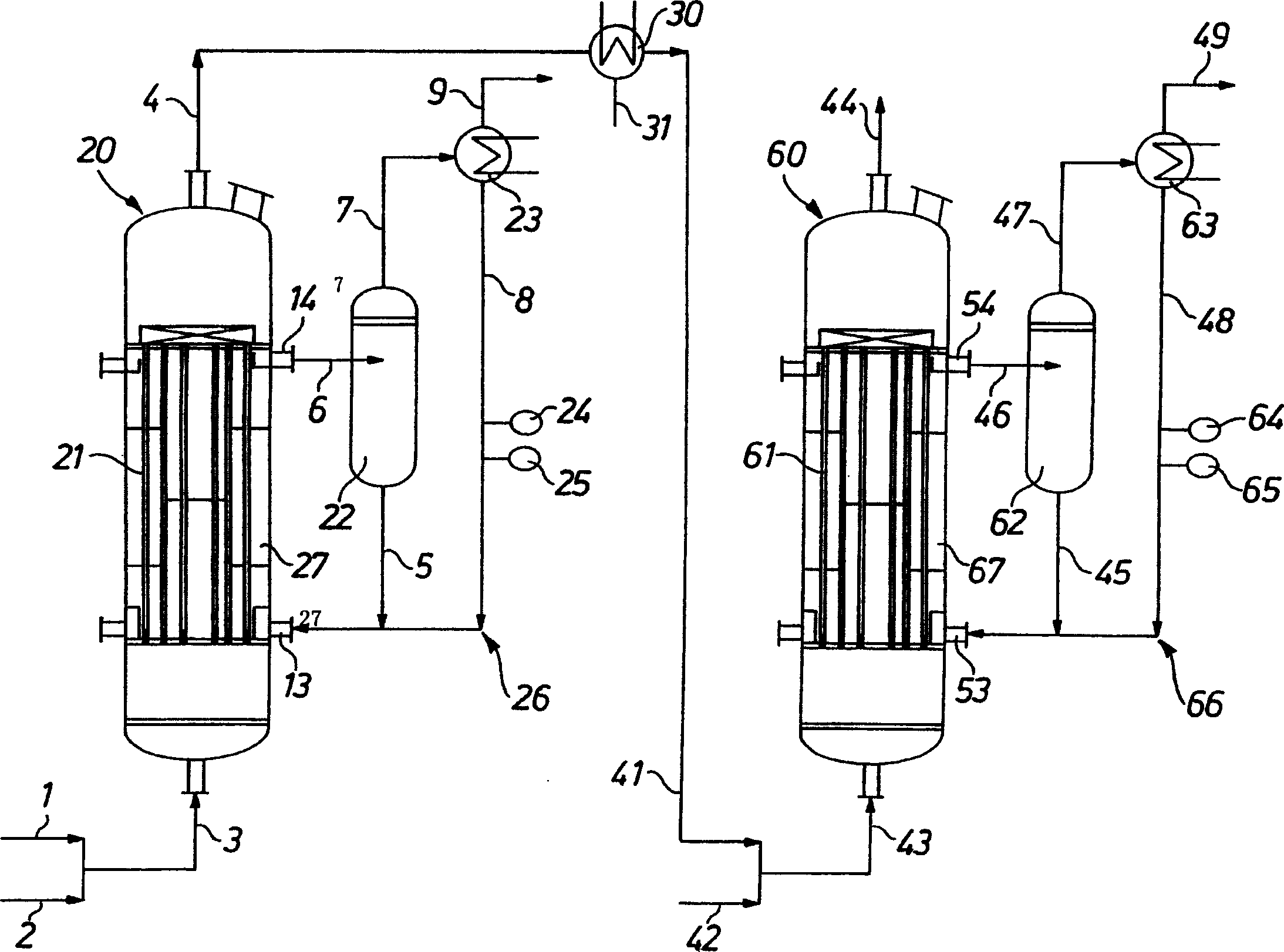

Process for the purification of toluenediisocyanate from a crude distillation feed comprising toluenediisocyanate, an organic solvent and less than 2% by weight phosgene by separating the crude distillation feed in a dividing-wall distillation column into at least four product fractions P1-P4. P1 is a phosgene enriched low-boiler product, P2 is a solvent-enriched product, P3 is a high boiler enriched bottoms and P4 is a toluenediisocyanate product stream.

Owner:COVESTRO DEUTSCHLAND AG

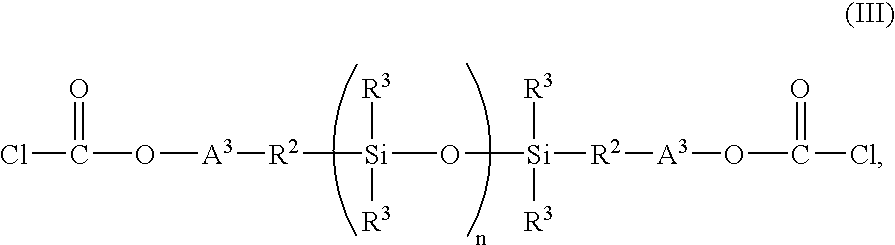

Method for preparation of copolyorganosiloxanecarbonates of high clarity

Owner:SHPP GLOBAL TECH BV

Sulfenylation process of pyrozole compound with trifluoromethanesulfonyl radical

InactiveCN1374298AEasy to manufactureHigh reactivityOrganic chemistryAcyl groupCombinatorial chemistry

The present invention relates to one sulfenylation process of pyrazole compound with CF3SO2K or the mixed salt of CF3SO2K and CF3SO2Na. CF3SO2K or the mixed salt of CF3SO2K and CF3SO2Na are made to react first with reagent A and then with pyrazole compound to obtain pyrazole compound with trifluoromethanesulfonyl radical, where the reagent A is selected from phosgene, TCF, POCl3, PC1 and SOC12. The present invention finds one new sulfenylation reagent, and is easy to prepare, high in reaction, activity, easy to use and high in yield.

Owner:JIANGSU PESTICIDE RES INST

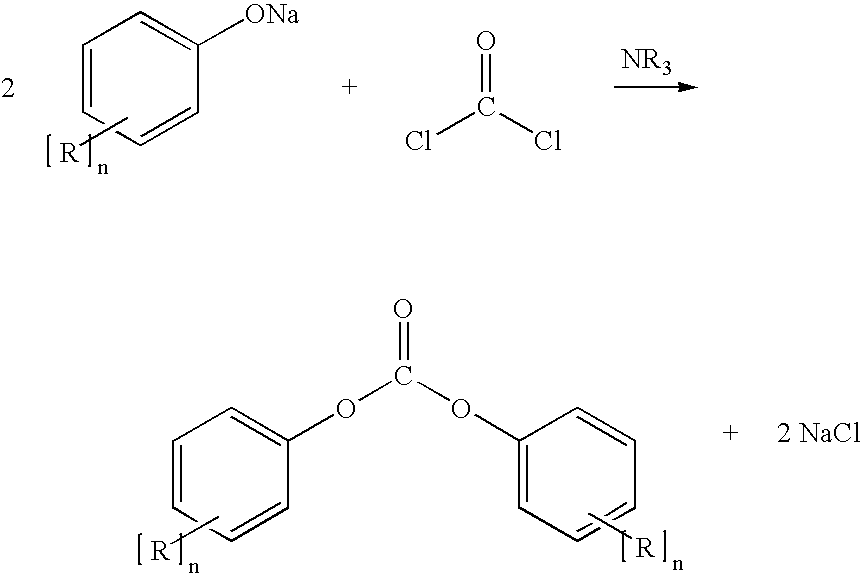

Process for the production of diaryl carbonates and treatment of alkalichloride solutions resulting therefrom

Processes comprising: (a) reacting phosgene and a monohydroxyl aryl compound in the presence of a suitable catalyst to form a diaryl carbonate and a solution comprising an alkali chloride; (b) separating the diaryl carbonate from the solution; (c) adjusting the pH of the solution to a value of less than or equal to 8 to form a pH-adjusted solution; (d) treating the pH-adjusted solution with an adsorbent to form a treated solution; (e) subjecting at least a portion of the treated solution to electrochemical oxidation to form chlorine and an alkali hydroxide solution; and (f) recycling at least a portion of one or both of the chlorine and the alkali hydroxide solution.

Owner:BAYER MATERIALSCIENCE AG

Method for preparing copolyestercarbonates

A method of preparing block copolyestercarbonates wherein at least one dihydroxy-substituted aromatic hydrocarbon moiety and at least one aromatic diacid chloride are reacted under interfacial conditions to give a hydroxy-terminated polyester intermediate. The dihydroxy-substituted aromatic compound is used in about 10 mole to about 125 mole percent excess relative to the diacid chloride. Enhanced control of hydroxy-terminated polyester intermediate molecular weight is achieved by limiting the amount of water present to provide a final salt level of greater than 30 percent. The final salt level is a theoretical value but is readily calculable. The hydroxy-terminated polyester intermediate is then converted to a block copolyestercarbonate by reaction with a carbonate precursor such as phosgene.

Owner:GENERAL ELECTRIC CO

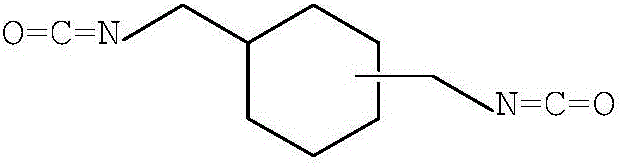

Preparation method of hydrogenated xylylene diisocynate

ActiveCN106674056AGood dispersionImprove liquidityOrganic compound preparationIsocyanic acid derivatives purification/separationXylyleneN dimethylformamide

The invention discloses a preparation method of hydrogenated xylylene diisocynate. The preparation method of the hydrogenated xylylene diisocynate comprises the following steps: (1) performing salt forming reaction on 1,3-cyclohexanol dimethylamine and concentrated hydrochloric acid in a two-phase reaction solvent to obtain amine salt, wherein the two-phase reaction solvent consists of water and an inert organic solvent insoluble in water ; (2) performing photochemical reaction on the ammonium salt obtained in the step (1) and phosgene in an inert solvent by taking N,N-dimethylformamide or N,N-dimethylacetamide as a catalyst to obtain reaction liquid, and performing aftertreatment on the reaction liquid to obtain the hydrogenated xylylene diisocynate. The preparation method of the hydrogenated xylylene diisocynate has the advantages of complete ammonium salt formation, small grain size of the ammonium salt, low viscosity of the ammonium salt, high space-time conversion rate of photochemical reaction, simple process, low cost and the like.

Owner:HUNAN HAILI CHEM IND

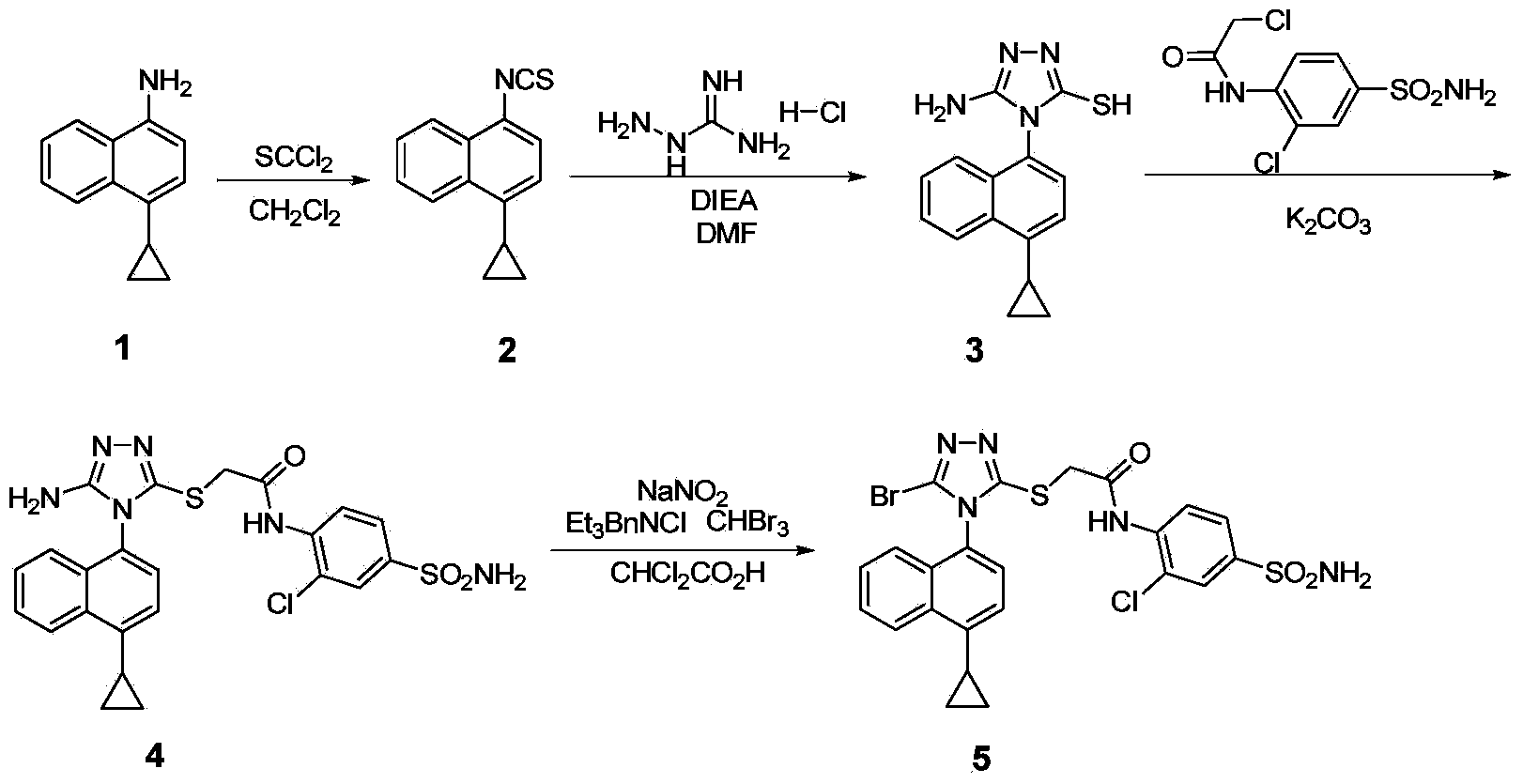

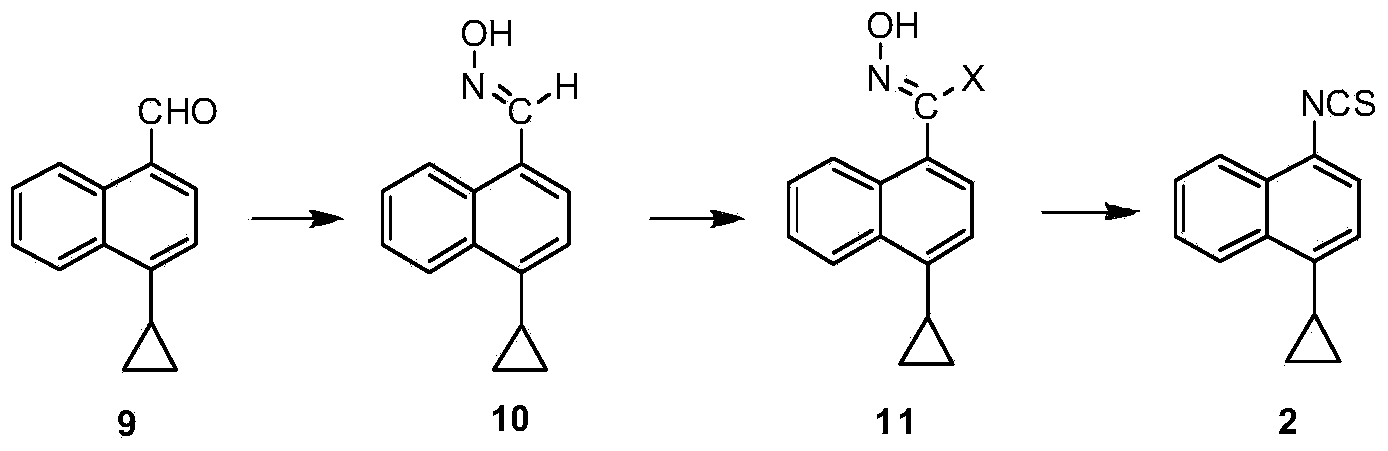

Preparation method of gout curative medicine Lesinurad and midbody of Lesinurad

The invention provides a novel Lesinurad midbody and provides a synthesis process of Lesinurad, which is economic, efficient, safe, environment-friendly and applicable to large-scale industrial production. The invention further provides a method for preparing the conventional Lesinurad midbody and Lesinurad by using the novel Lesinurad midbody. When synthesized from the novel Lesinurad midbody provided by the invention, the Lesinurad has advantages that the price of necessary raw materials is low, the raw materials are easy to obtain, heavy metal and solvents which are harmful to the environment are not used, the midbody and a product can be easily separated and purified, the operation is easy, application of thiophosgene which is high in toxicity and not easy to operate is avoided, and the total reaction yield is approximate to or higher than that in the prior art.

Owner:SUZHOU PENGXU PHARM TECH CO LTD

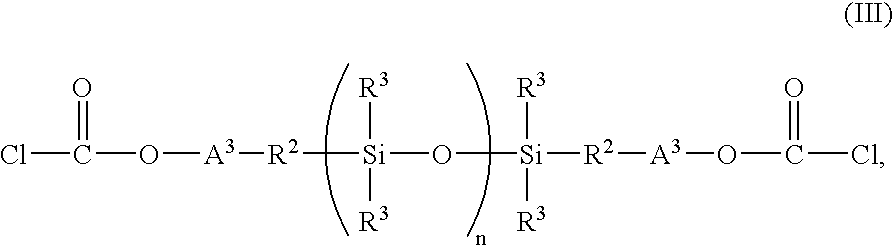

Method for preparation of copolyorganosiloxanecarbonates of high clarity

Copolyorganosiloxanecarbonates are prepared by first preparing an oligomeric aromatic polycarbonate, such as an oligomeric bisphenol A polycarbonate, in the presence of a tertiary amine as the only catalyst species; contacting the oligomeric polycarbonate mixture with a polyorganosiloxane bis(aryl)chloroformate, such as the bischloroformate of hydroxy-terminated eugenol polydimethylsiloxane; and introducing phosgene and / or chain termination agent either continuously or in stages. A feature of the process is the presence of dihydroxyaromatic compound in only one charge, at the beginning. The products have excellent physical properties, including transparency.

Owner:SHPP GLOBAL TECH BV

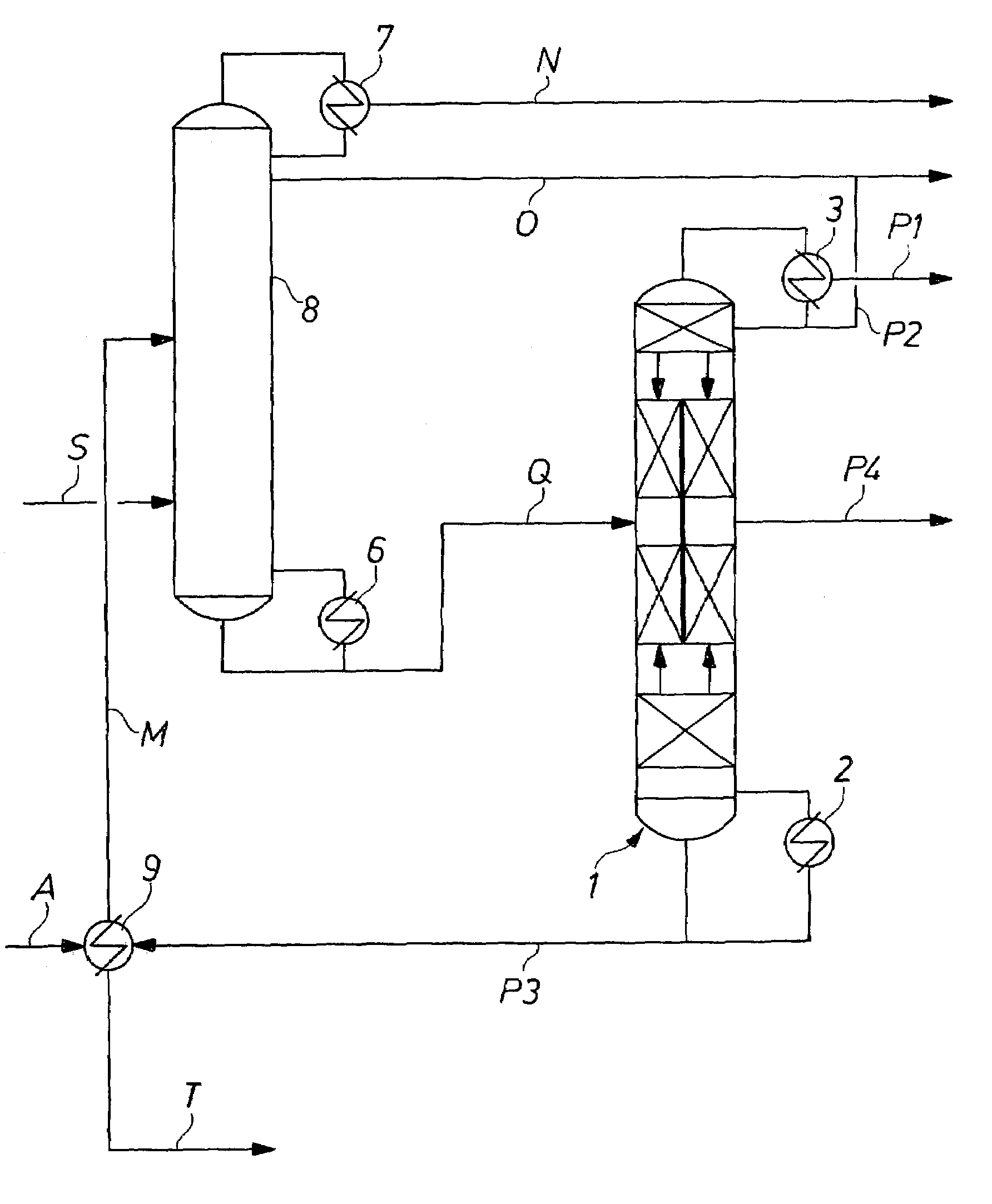

Process for the purification of mixtures of toluenediisocyanate incorporating a dividing-wall distillation column

InactiveUS7118653B2Lower energy requirementsLow investment costOrganic compound preparationIsocyanic acid derivatives purification/separationOrganic solventToluene diisocyanate

Owner:COVESTRO DEUTSCHLAND AG

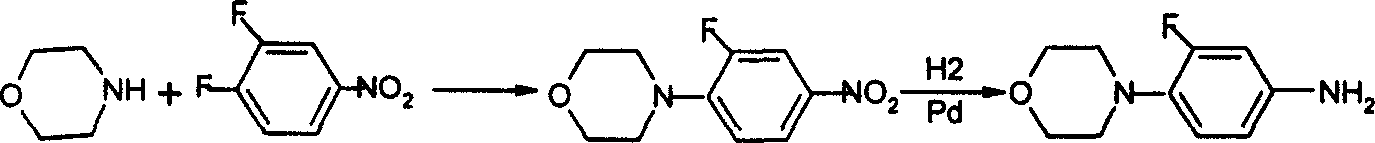

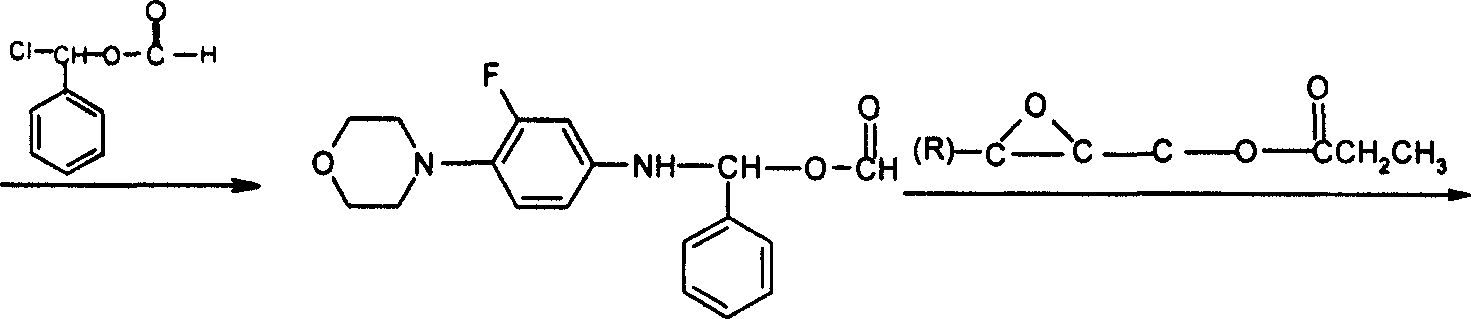

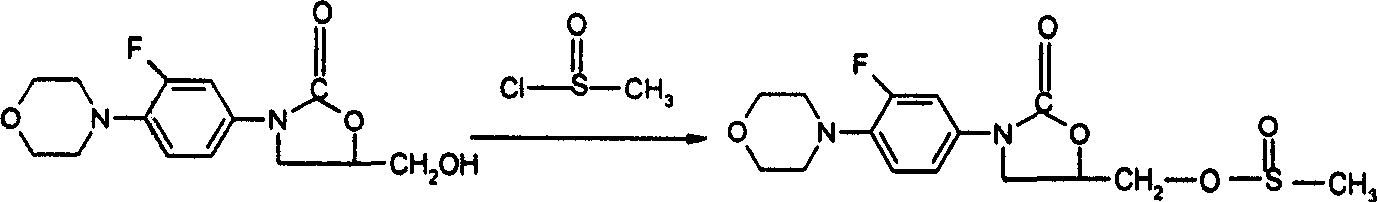

Prepn process of (R)-N-(3-fluoro-4-morpholinyl phenyl)-oxazolone-5-methyl alcohol

The present invention discloses the preparation process of Linezolid, and the preparation process includes the following steps: condensation of morpholine and 3, 4-difluoro nitrobenzene; reduction into 3-fluoro-4-morpholinyl aniline under the catalysis of Fe, and acylation with phosgene into 3-fluoro-4-morpholinylphenyl isocyanate; cyclization with (R)-butyl glycidate to produce (R)-N-(3-fluoro-4-morpholinylphenyl)-oxazolone-5-methyl alcohol; and further conventional synthesis steps. The present invention has simple technological process, mild reaction condition, cheap catalyst and low production cost, and is favorable to industrial production.

Owner:ZHENGZHOU UNIV

Preparation method of methylene diphenyl diisocyanate

ActiveCN106748887AImprove conversion rateInhibition of byproductsIsocyanic acid derivatives preparationOrganic compound preparationReaction rateOrganic phosphorus

The invention provides a preparation method of methylene diphenyl diisocyanate. The method comprises the following steps: performing a salt forming reaction on m-xylylenediamine and hydrogen chloride gas to obtain m-xylylenediamine hydrochloride; mixing the m-xylylenediamine hydrochloride, an organic phosphorus compound and solid phosgene for reaction to obtain methylene diphenyl diisocyanate. In a process of preparing methylene diphenyl diisocyanate, according to the application, an organic phosphorus compound additive is introduced, so that the reaction of m-xylylenediamine hydrochloride is promoted, therefore, the reaction rate and the effective conversion rate are improved.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

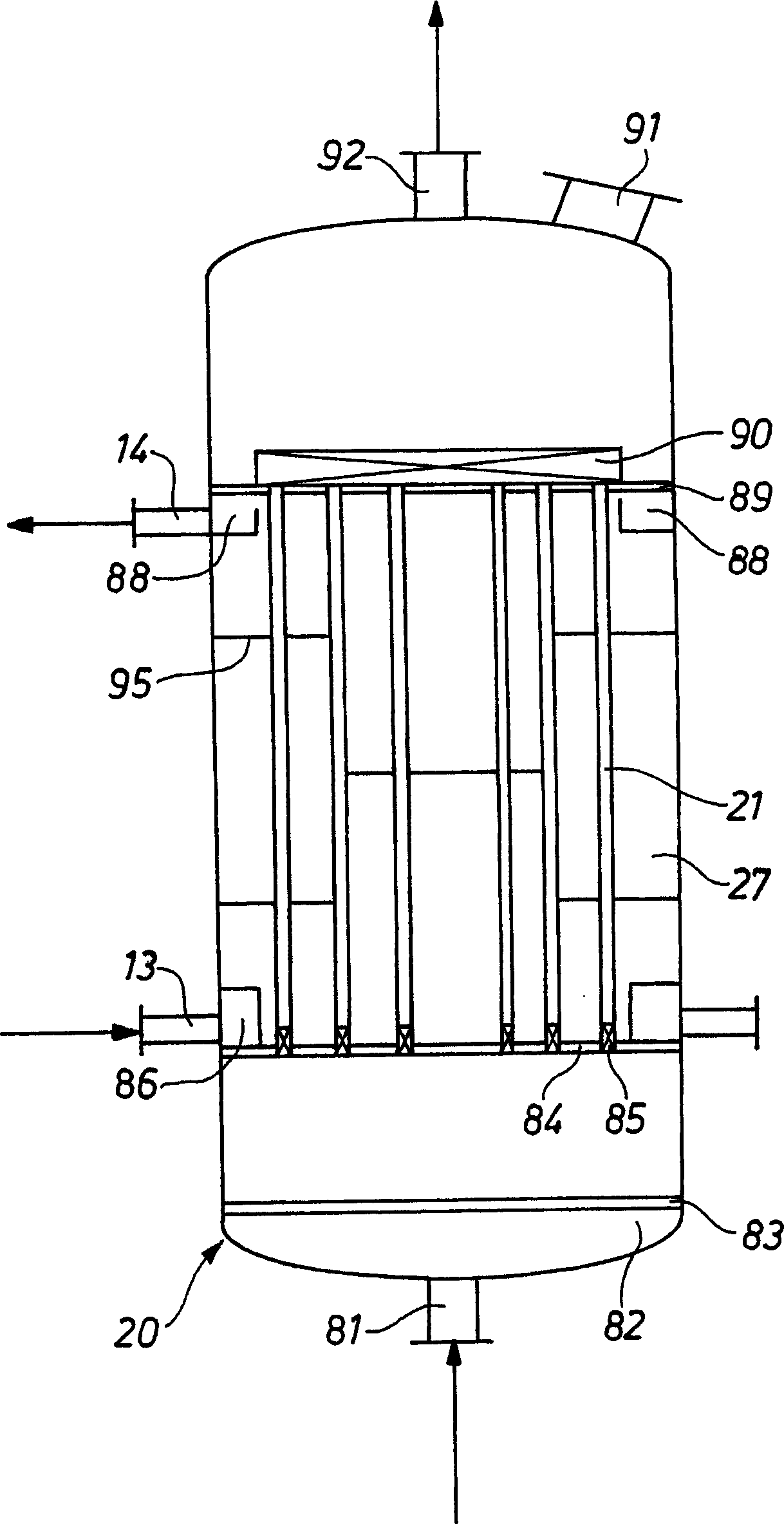

Process for the continuous preparation of organic monoisocyanates and polyisocyanates

InactiveUS20060041166A1Reduce equipment costsMinimize formationIsocyanic acid derivatives preparationOrganic compound preparationOrganic solventDecomposition

The invention relates to a process for the continuous preparation of organic isocyanates through the reaction of organic amines with phosgene in the presence of organic solvents under pressure whereby a concentrated phosgene-containing stream is mixed preferentially with an amine-containing stream in a jet mixer to create a combined jet of reacting amine-phosgene mixture, whereby the combined jet is discharged directly into a reactor vessel and the reactor vessel is operated at a temperature above the decomposition temperature of intermediate carbamoyl chloride products which can be formed upon mixing the aforementioned streams, wherein the combined jet is not pre-mixed with bulk reactor contents, wherein the jet mixer provides sufficiently rapid and thorough mixing and thereby enables an initial reaction temperature lower than the bulk reactor vessel temperature, and the combined jet entering the reactor has sufficient momentum to cause entrainment into it of a sufficient quantity of the bulk reactor contents to be rapidly dispersed and reach the bulk reactor temperature.

Owner:STUART JOSEPH Y

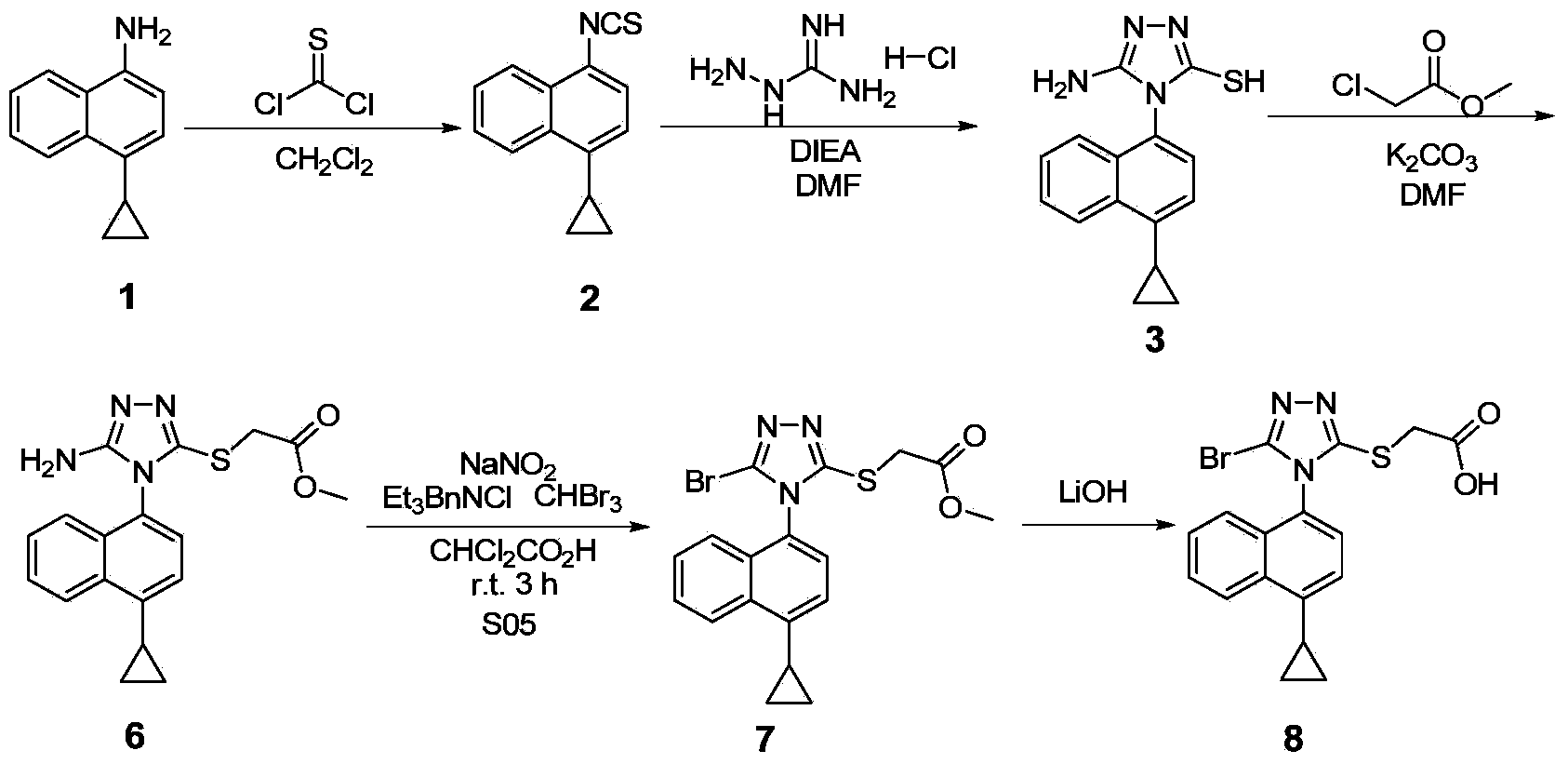

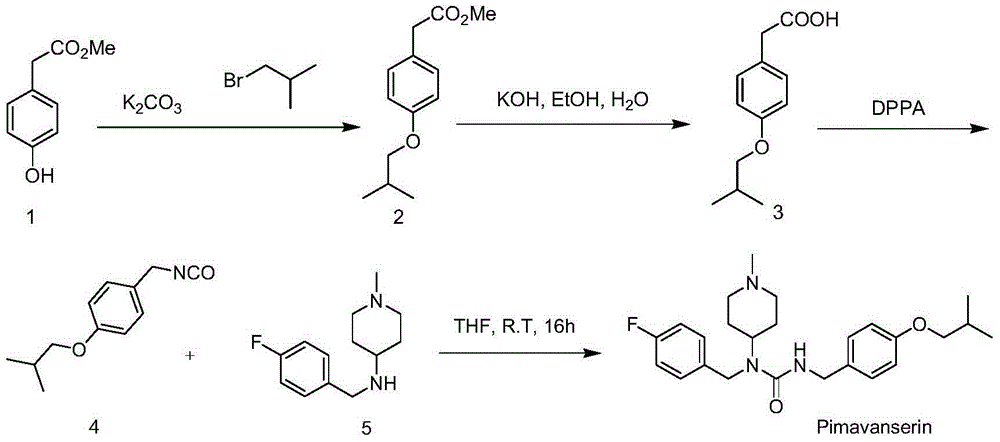

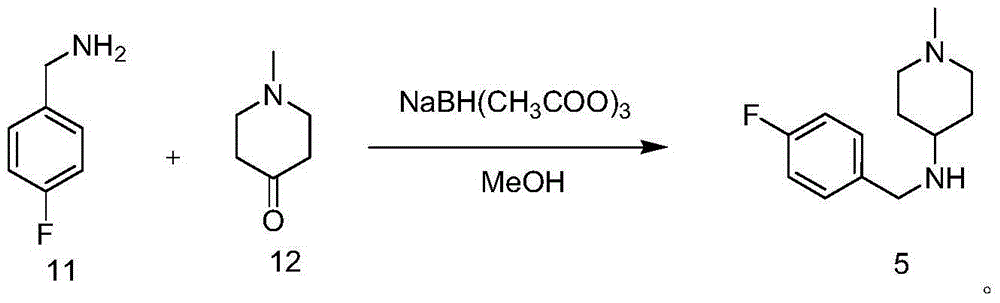

Intermediate of pimavanserin and similar compound thereof, and preparation method thereof, and method for preparing pimavanserin and similar compound thereof

ActiveCN105418460ALow priceEasy to separate and purifyCarbamic acid derivatives preparationOrganic compound preparationChemical compoundPhosgene

The present invention relates to an intermediate of pimavanserin and a similar compound thereof, and a preparation method thereof, and a method for preparing pimavanserin and a similar compound thereof. According to the present invention, the raw materials required by the intermediate have characteristics of low price, easy obtaining, easy separation purification and no requirement of post-treatment, the next step reaction can be directly performed through the one-pot method to prepare the pimavanserin and the similar compound thereof, the operation is simple, and the economical, efficient, safe and environmentally friendly synthesis process is provided for the preparation of the pimavanserin and the similar compound thereof; and with the application of the intermediate to prepare the pimavanserin, the high toxicity and the use of the difficultly-operated phosgene can be avoided, and the total yield of the reaction can achieves the level in the prior art even the higher level.

Owner:SUZHOU PENGXU PHARM TECH CO LTD

Process for preparing polyisocyanates by the adiabatic phosgenation of primary amines

ActiveUS20060025556A1Minimal costInhibition formationIsocyanic acid derivatives preparationOrganic compound preparationReaction temperaturePhosgene

A two-stage process for the preparation of organic isocyanates by reacting primary amines with phosgene in which a) in a first stage, amine and phosgene are reacted in an adiabatically managed reaction, in which the temperature of reaction is restricted to values between 100 and 220° C. by actively adjusting the absolute pressure in the reactor to values between 8 and 50 bar by decompression, and the temperature is held at values between 100 and 220° C. until the stoichiometric conversion of phosgene has reached at least 80%, and then b) in a second stage, the reaction mixture from a) is decompressed to an absolute pressure of 1 to 15 bar and the reaction mixture is reacted further at temperatures between 90 and 240° C., optionally with the introduction of heat.

Owner:COVESTRO DEUTSCHLAND AG

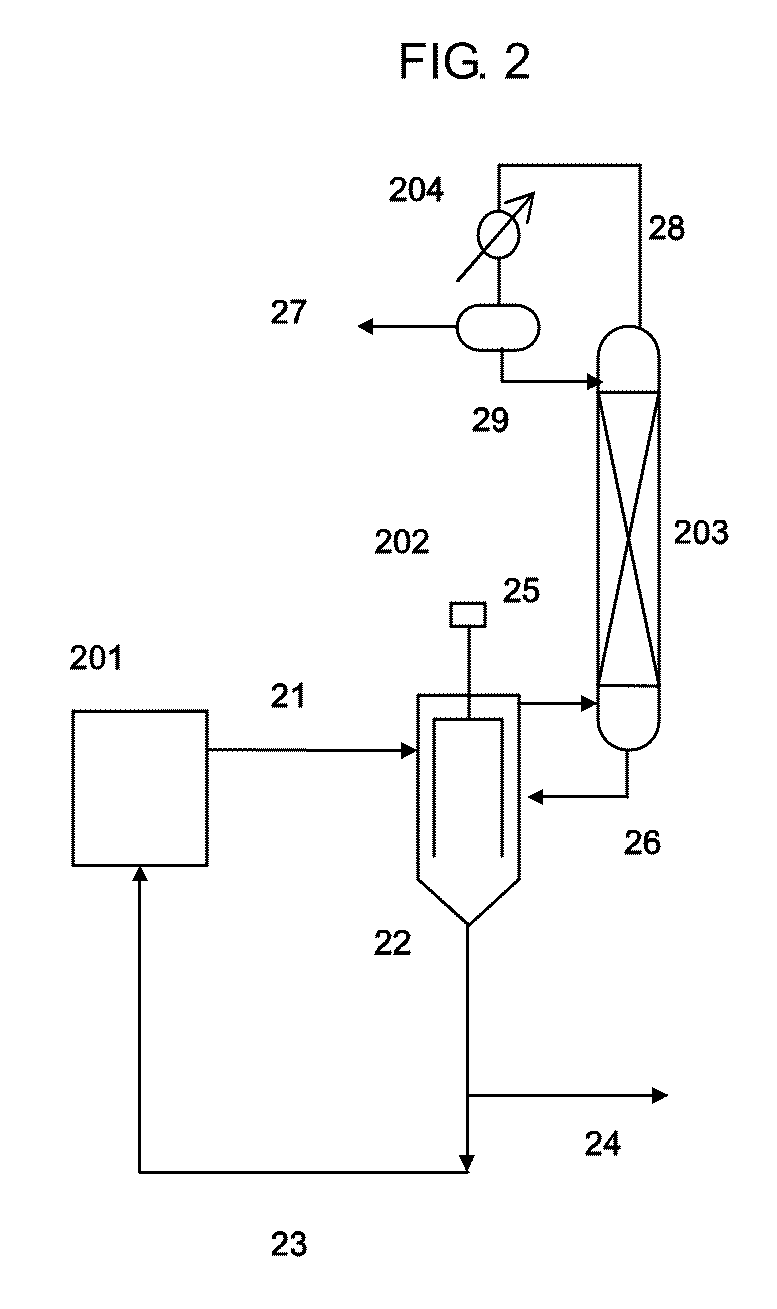

Process for the continuous preparation of isocyanates

ActiveUS20070299279A1High chemical yieldIncreased space-time yieldOrganic compound preparationIsocyanic acid derivatives purification/separationProcess engineeringPhosgene

Isocyanates are produced by reacting an organic amine with phosgene in process which includes at least three stages. The first stage is carried out in a dynamic mixer. The second stage is carried out in at least one reactor. The third stage is carried out in at least one material separating apparatus. The pressure in the reactor of the second stage must be greater than or equal to the pressure in the dynamic mixer. The pressure in the third stage material separating apparatus must be lower than the pressure in the second stage reactor.

Owner:COVESTRO DEUTSCHLAND AG

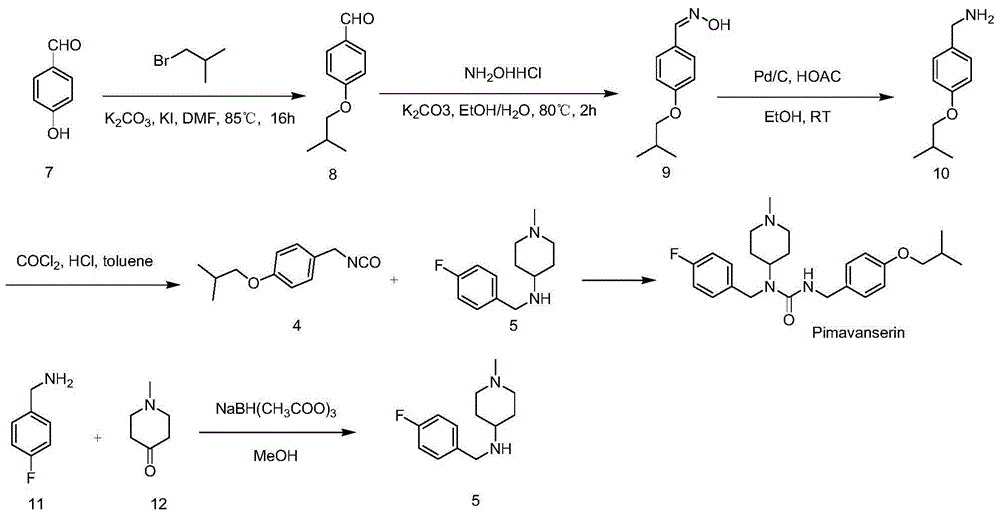

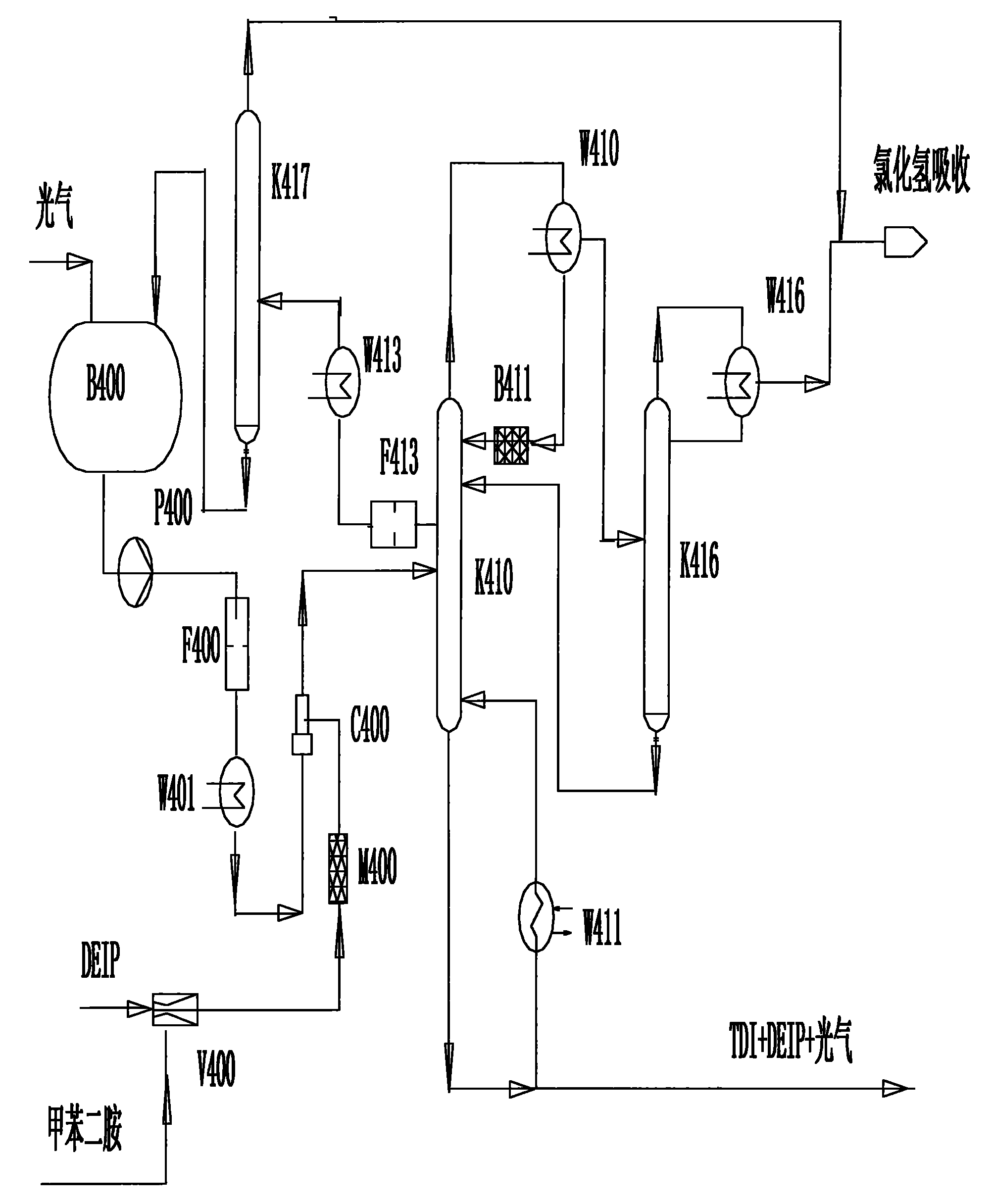

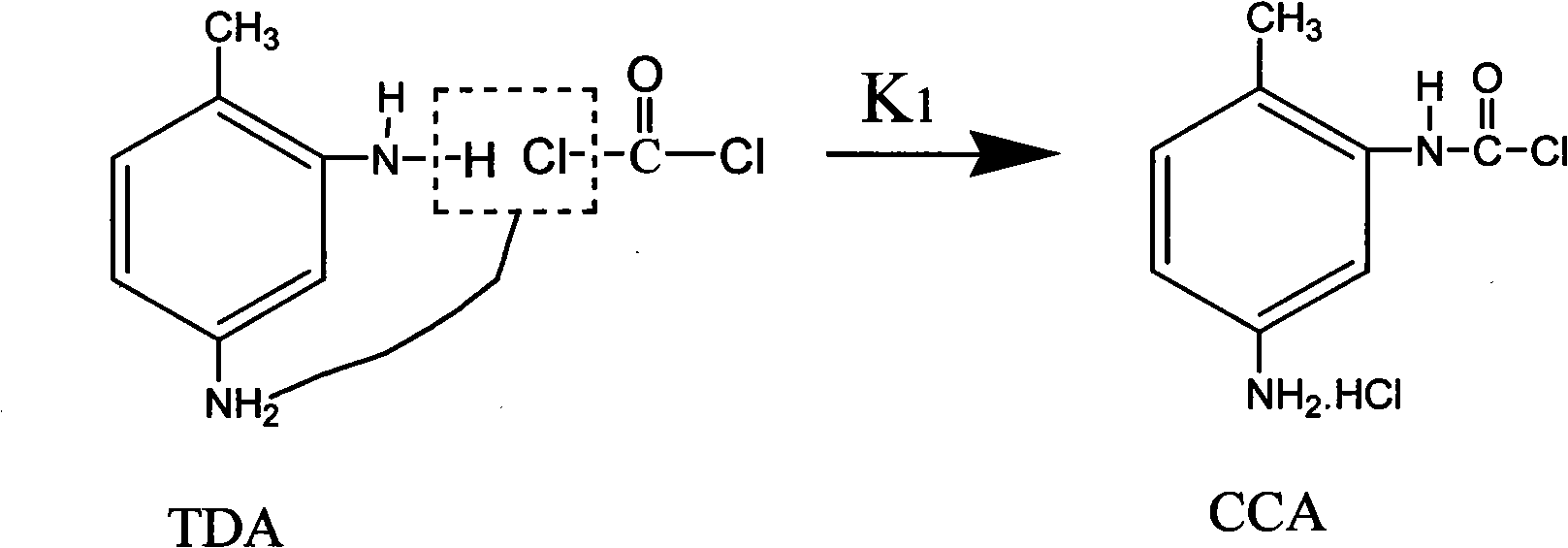

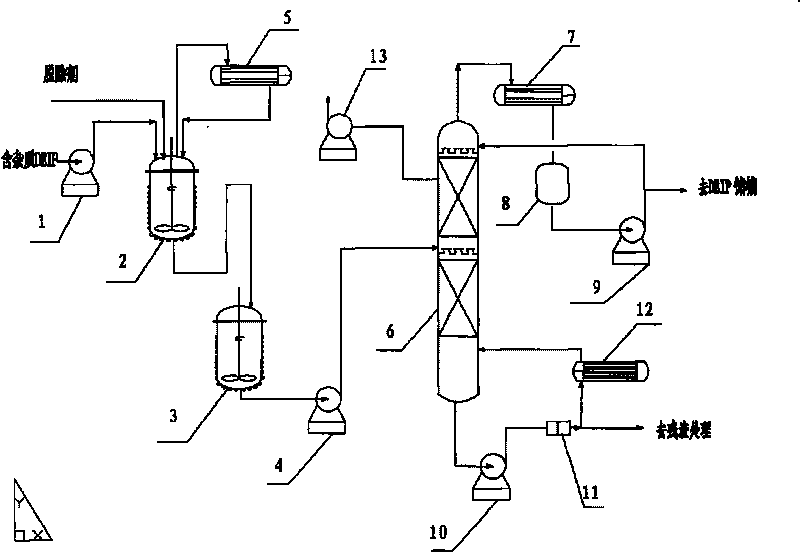

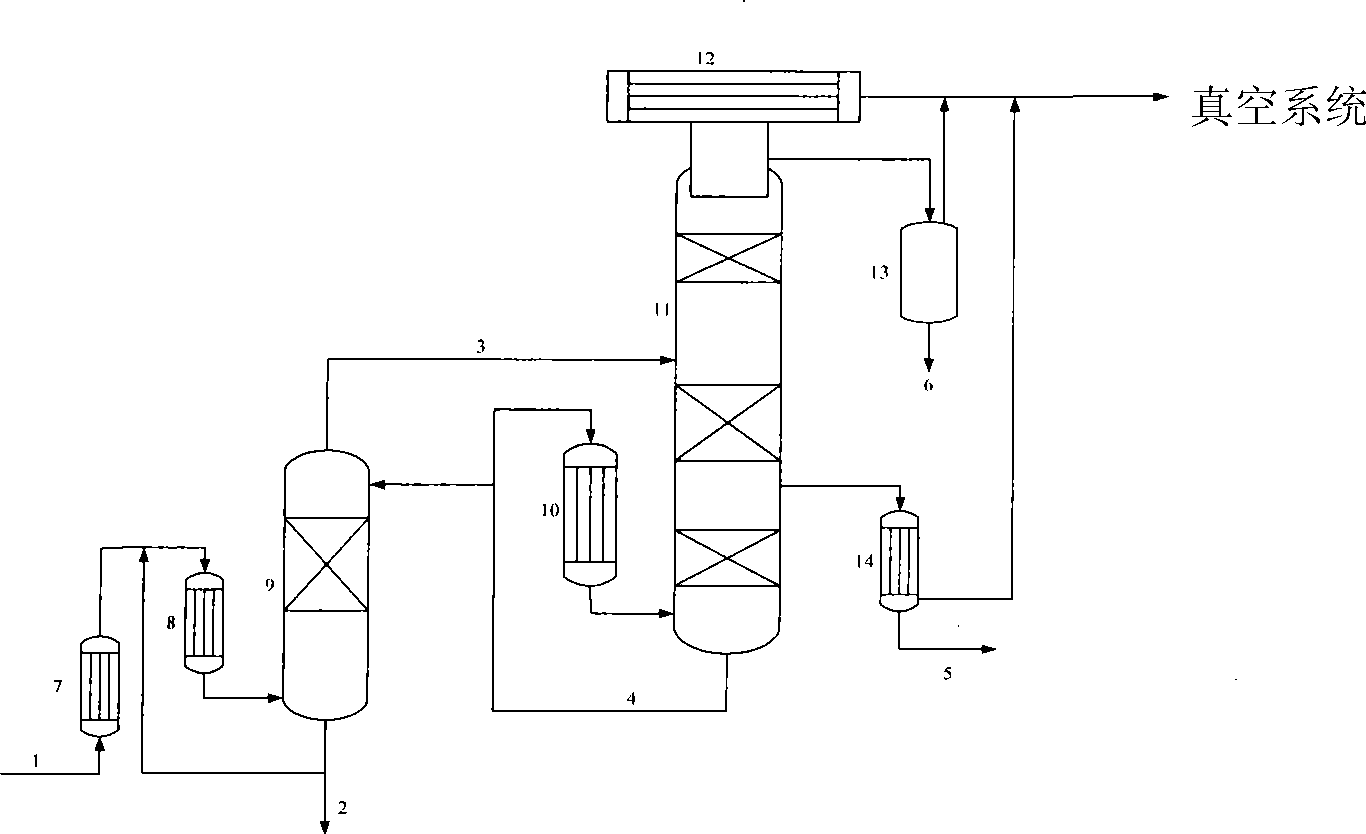

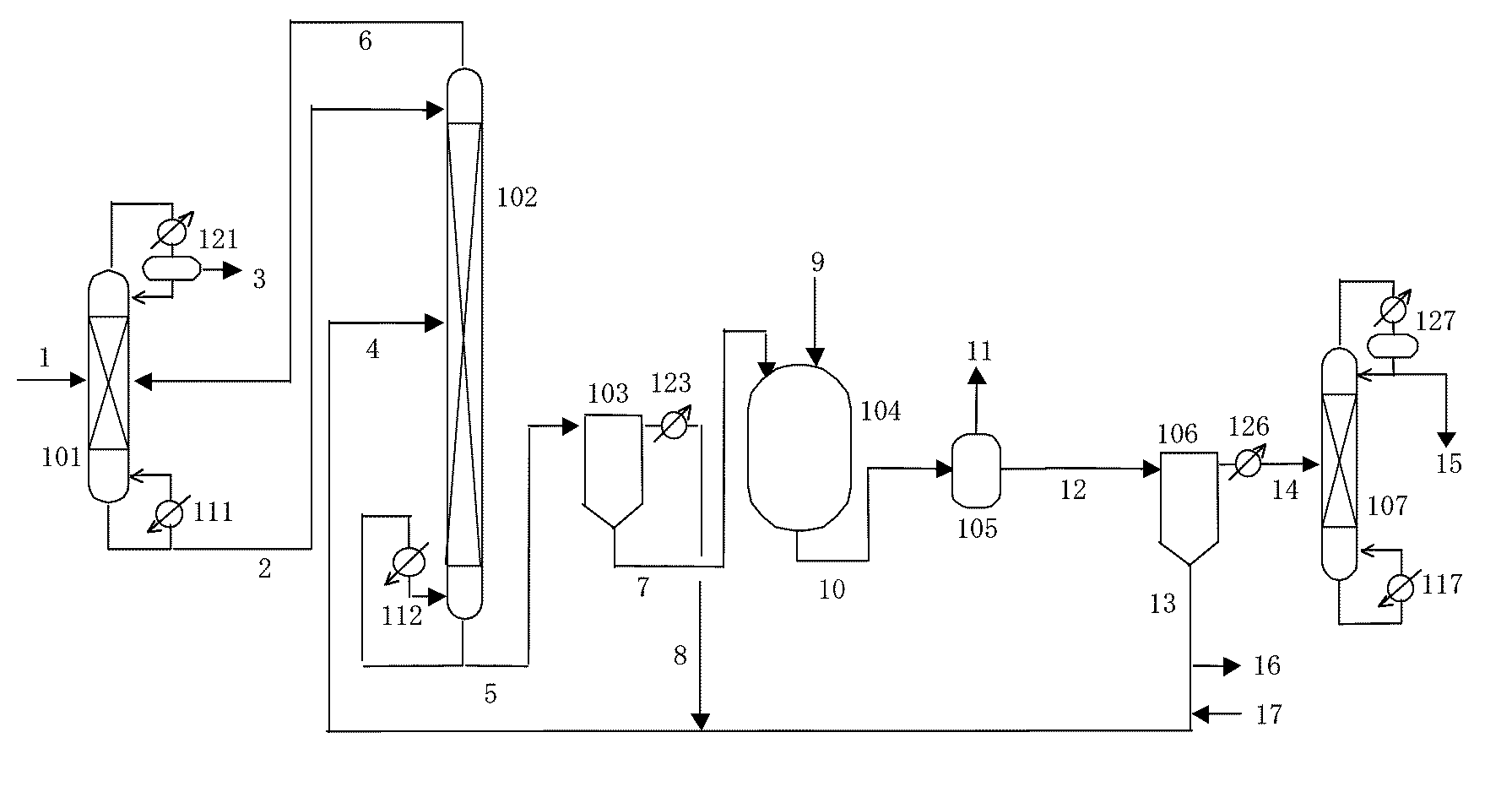

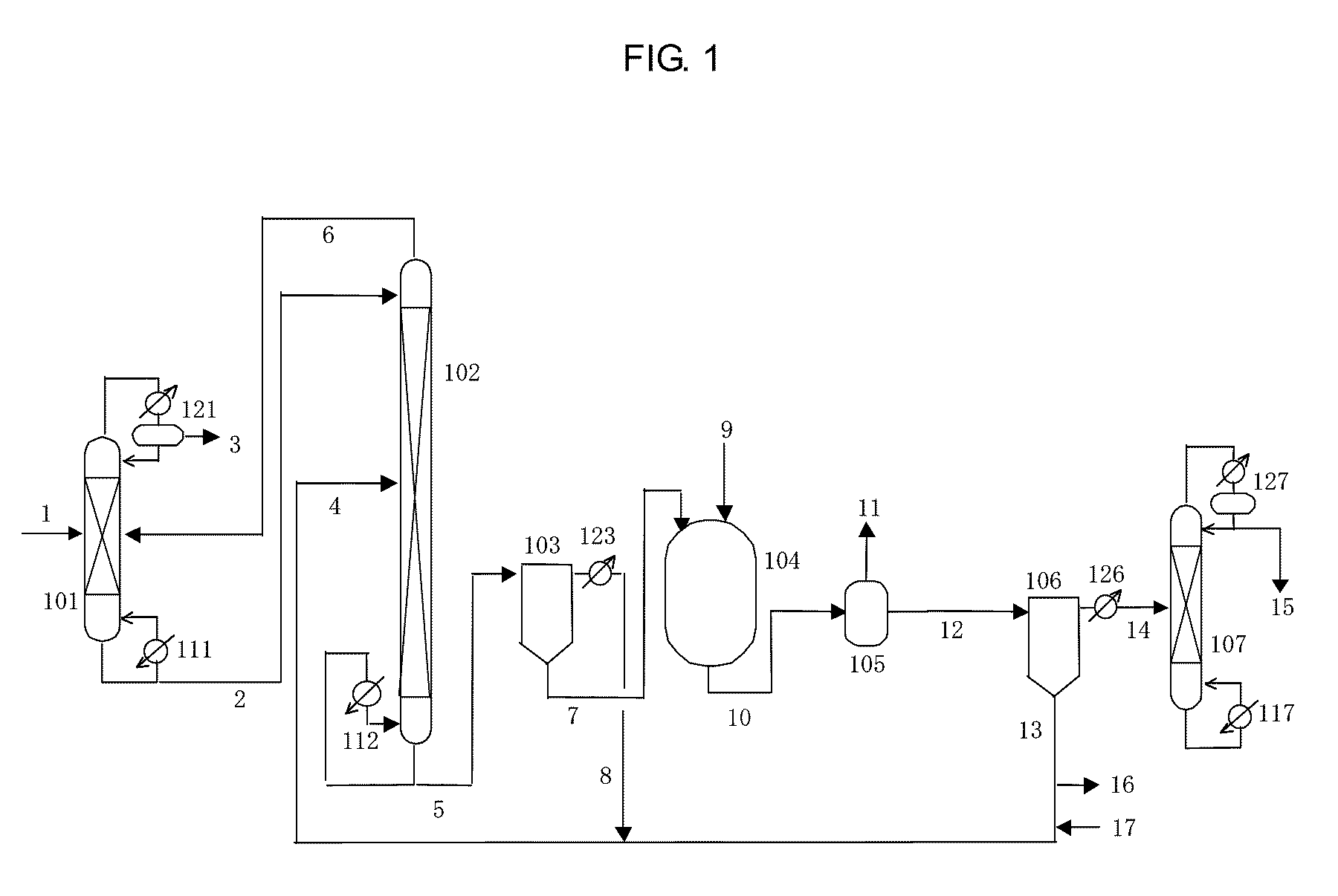

Method for continuously preparing toluene diisocynate

The invention relates to a method for continuously preparing toluene diisocynate, in particular to a method for preparing coarse toluene diisocynate by a phosgene method. The method comprises the following steps: mixing toluene diamine and DEIP solvent, performing low-temperature photochemical reaction on the mixture and excessive liquid phosgene in a jet reactor, heating and cracking a reaction product in a photochemical reaction tower to further decompose toluene dicarbamic chloride serving as an intermediate product to form the toluene diisocynate, recycling the reclaimed phosgene and the DEIP solvent, and delivering the hydrogen chloride gas serving as a side product to a hydrogen chloride absorption system.

Owner:甘肃银光聚银化工有限公司

Functional polyurethane prepolymer, method of preparing polyurethane by using the same, and application method thereof

A method of preparing polyurethane prepolymer does not require using a toxic isocyanate monomer (manufactured by harmful phosgene) as a raw material. Epoxy resin and carbon dioxide are used as major raw materials to form cyclic carbonates to be reacted with a functional group oligomer, and then amino groups in a hydrophilic (ether group) or hydrophobic (siloxane group) diamine polymer are used for performing a ring-opening polymerization, and the microwave irradiation is used in the ring-opening polymerization to efficiently synthesize the amino-terminated PU prepolymer, and then an acrylic group at an end is added to manufacture an UV cross-linking PU (UV-PU) oligomer which can be coated onto a fabric surface, and the fabric is dried by UV radiation for a surface treatment to form a washing-resisted long lasting hydrophilic or hydrophobic PU fabric.

Owner:TAMKANG UNIVERSITY

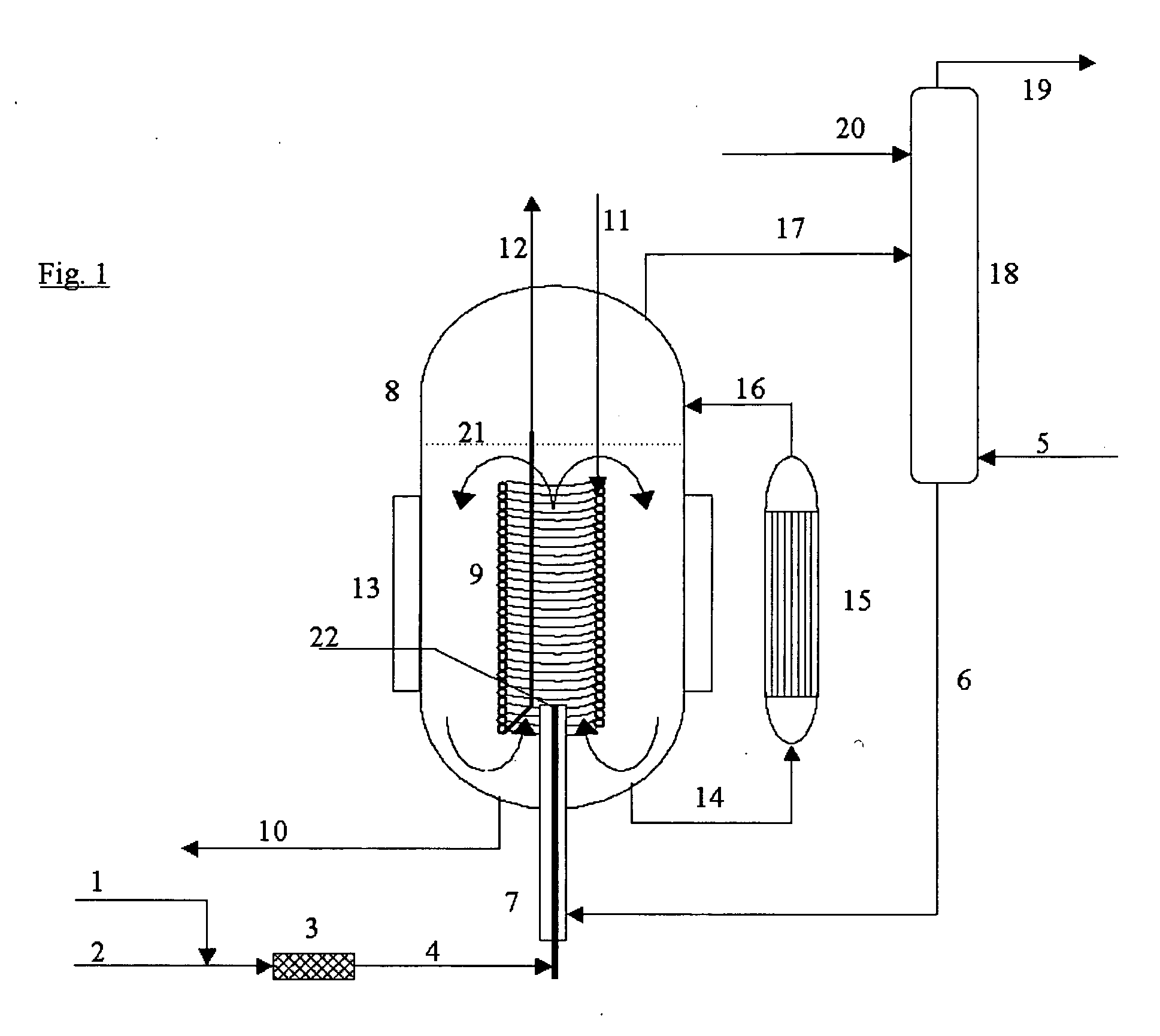

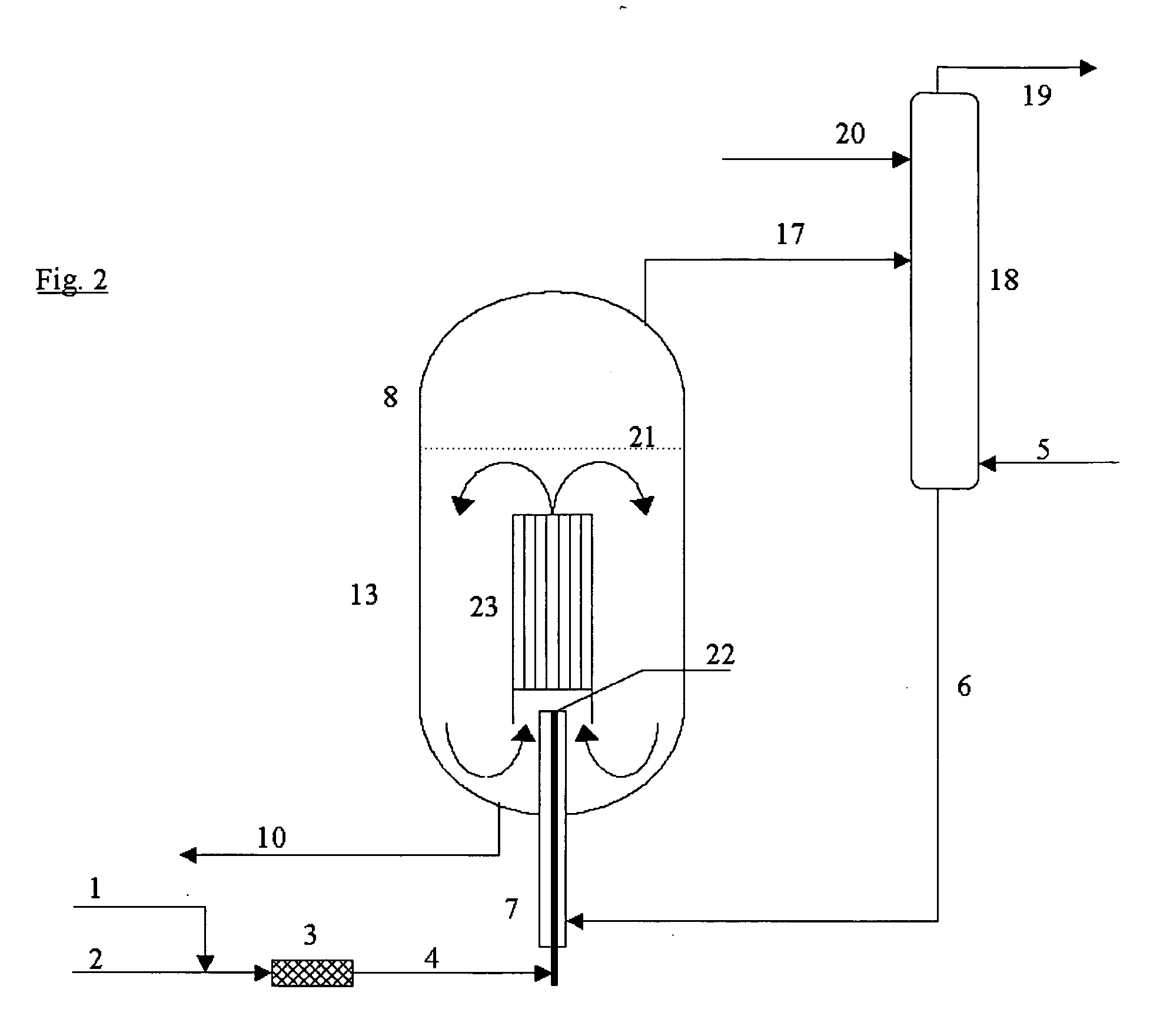

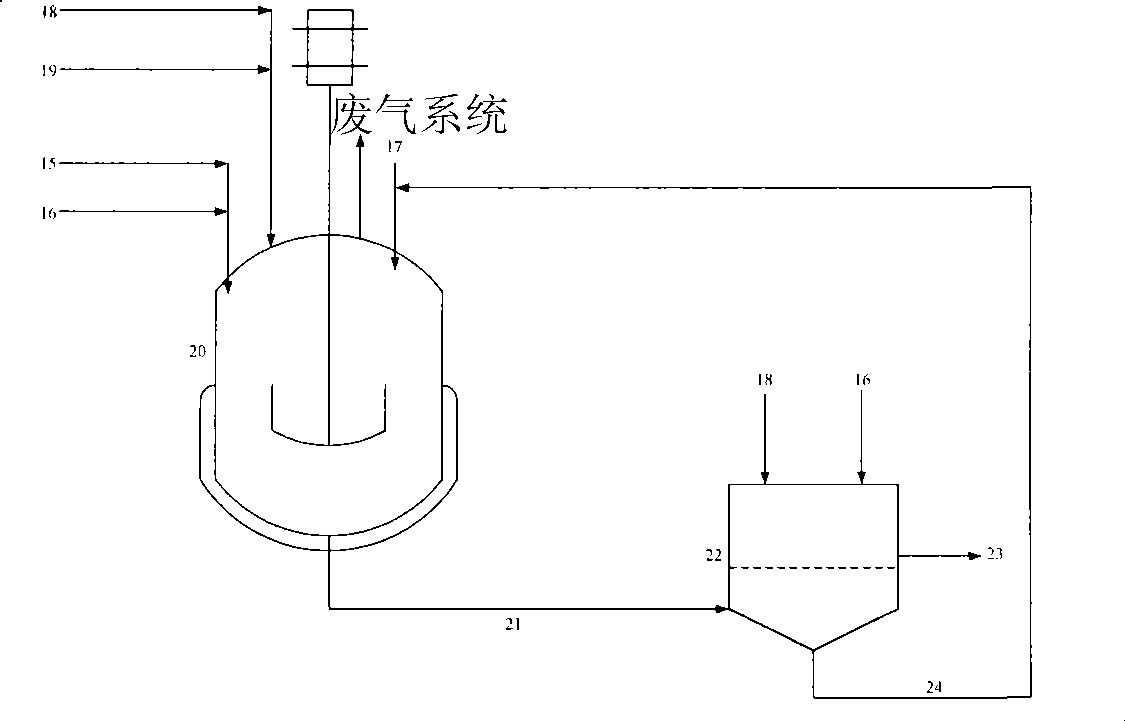

Method for continuously preparing phosgene

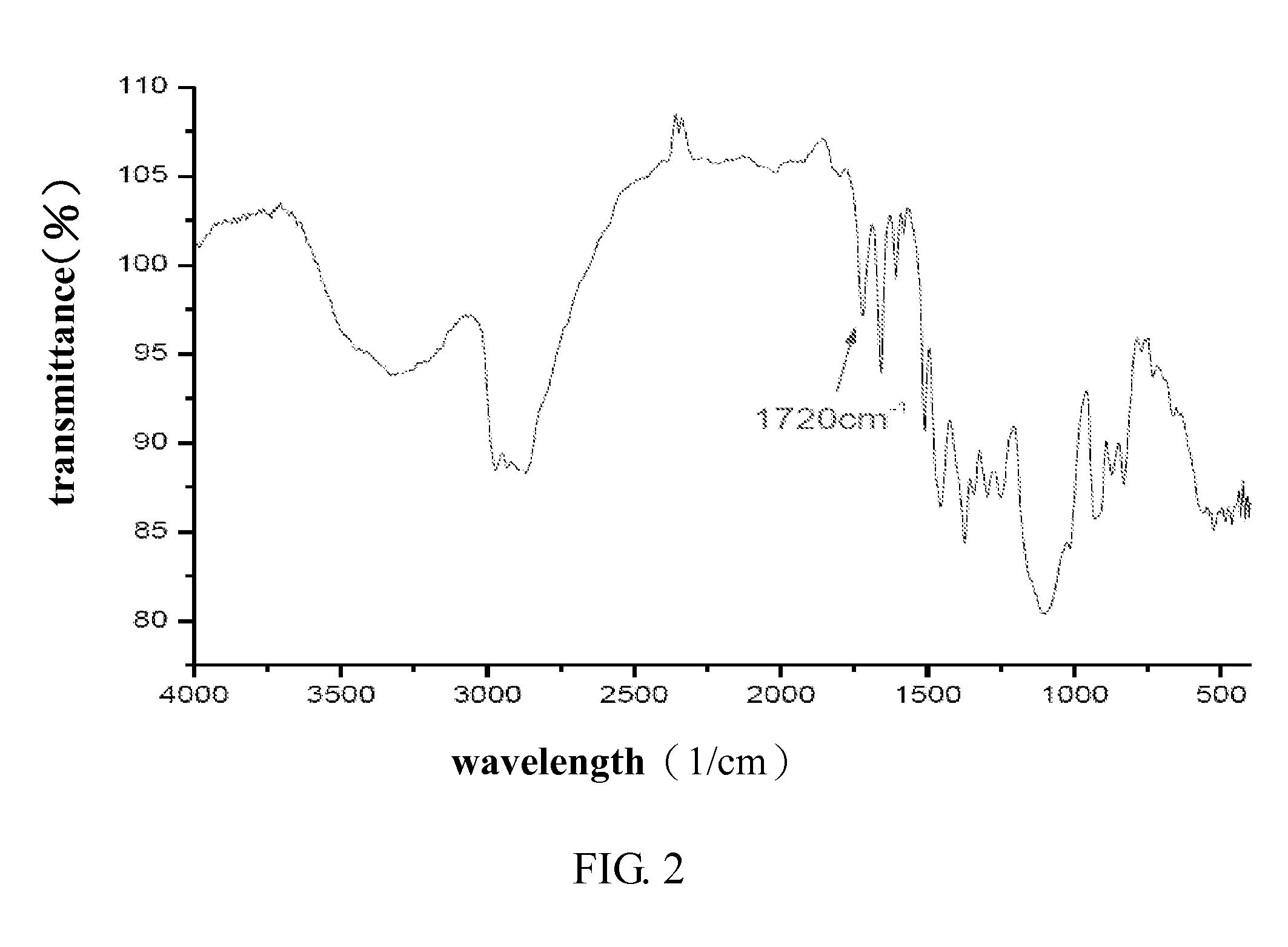

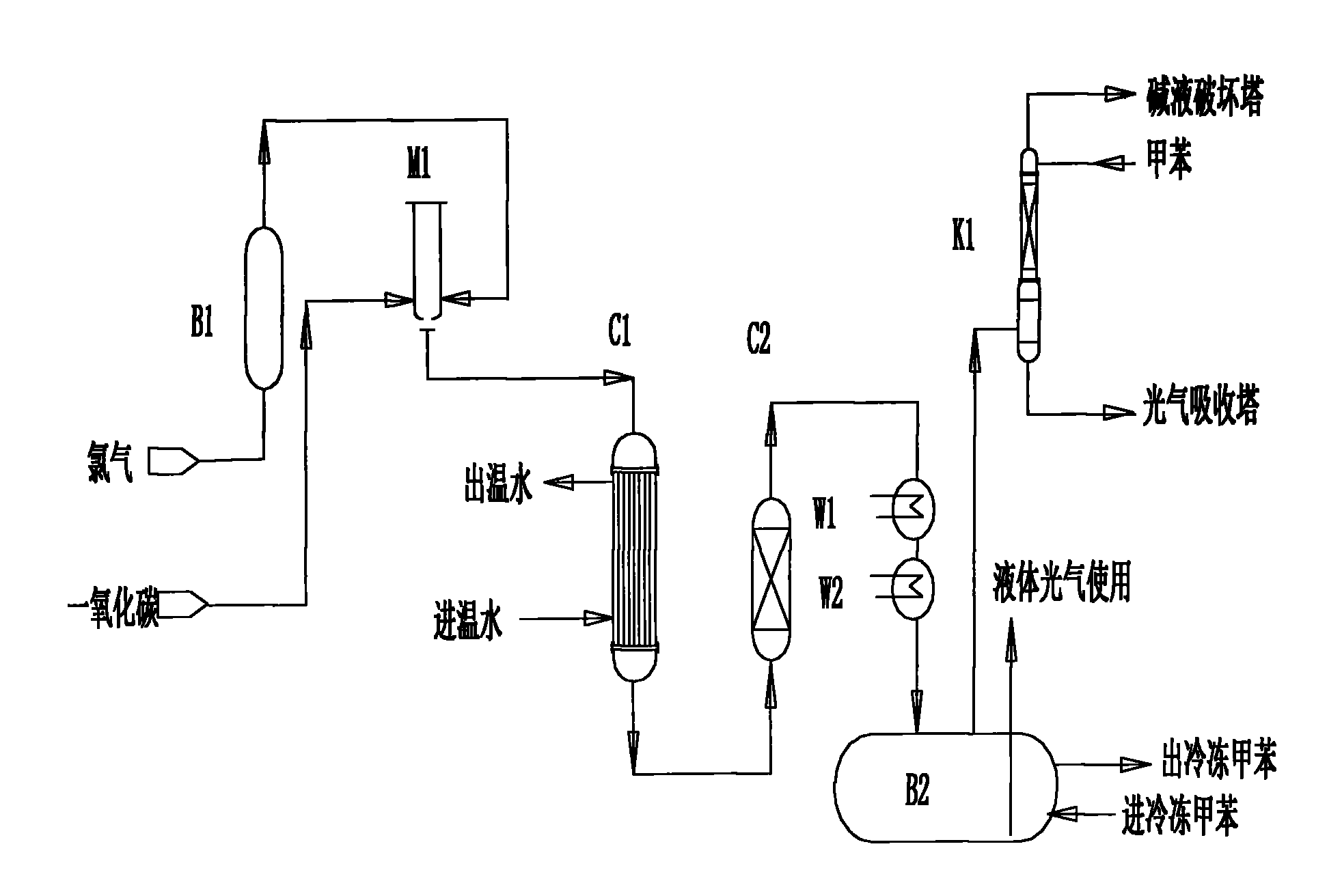

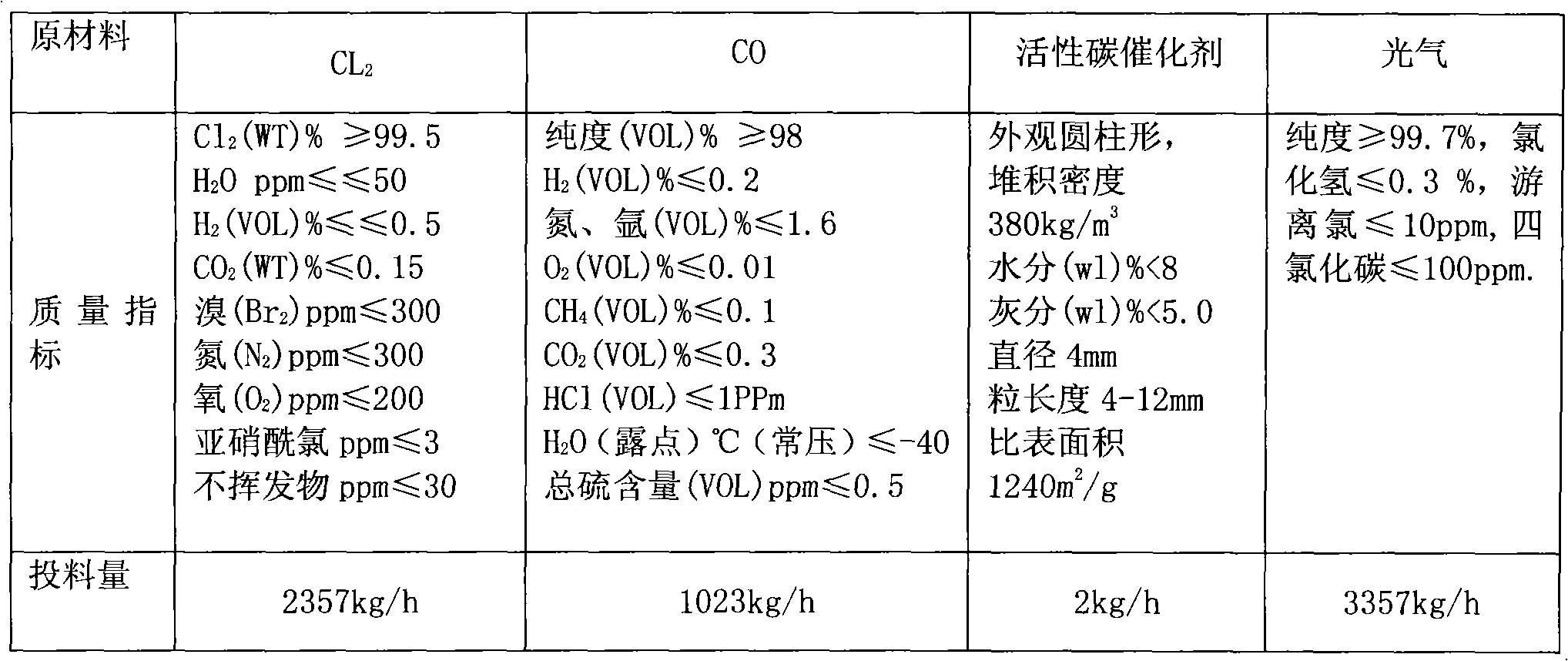

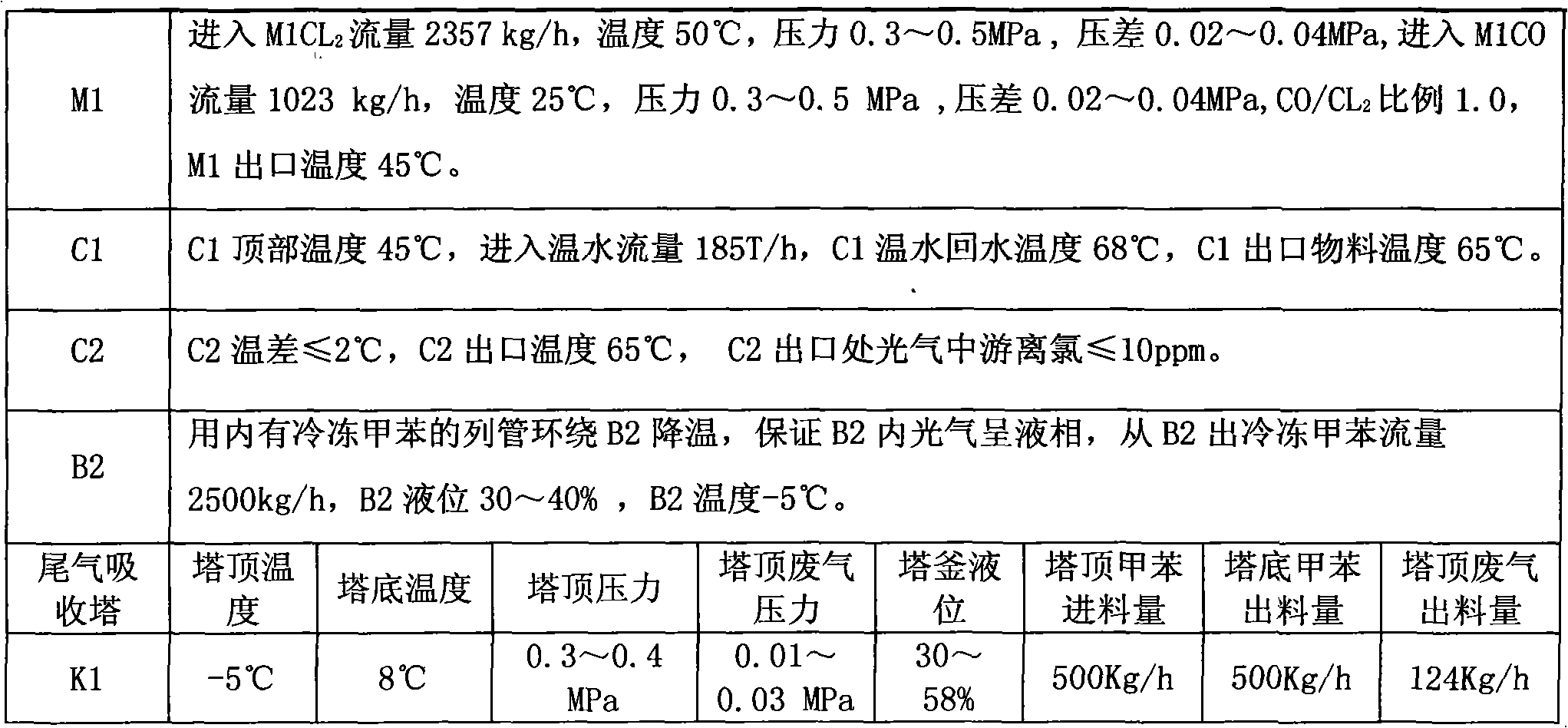

The invention relates to a method for producing phosgene through the reaction of chlorine and carbon monoxide, and in particular to a method that chlorine and carbon monoxide are used to perform an exothermic reaction in a tube reactor in the presence of an activated carbon catalyst and generate phosgene. In the method provided by the invention, after chlorine is mixed with excess carbon monoxidein a mixer M1, then the mixture enters a tubular reactor C1 to react under the action of the activated carbon catalyst and generate phosgene and then passes through a protection reactor C2 to ensure that chlorine reacts completely; and the heat generated by the reaction is led out by a 60 DEG C cooling water system in closed cycle, the generated gaseous phosgene is cooled through W1 condensation and W2 condensation and enters a phosgene gas-liquid separation tank B2, the un-condensed gas enters an exhaust gas absorber K1, and -5 DEG C toluene is used to absorb and recycle phosgene in tail gas.

Owner:甘肃银光聚银化工有限公司 +1

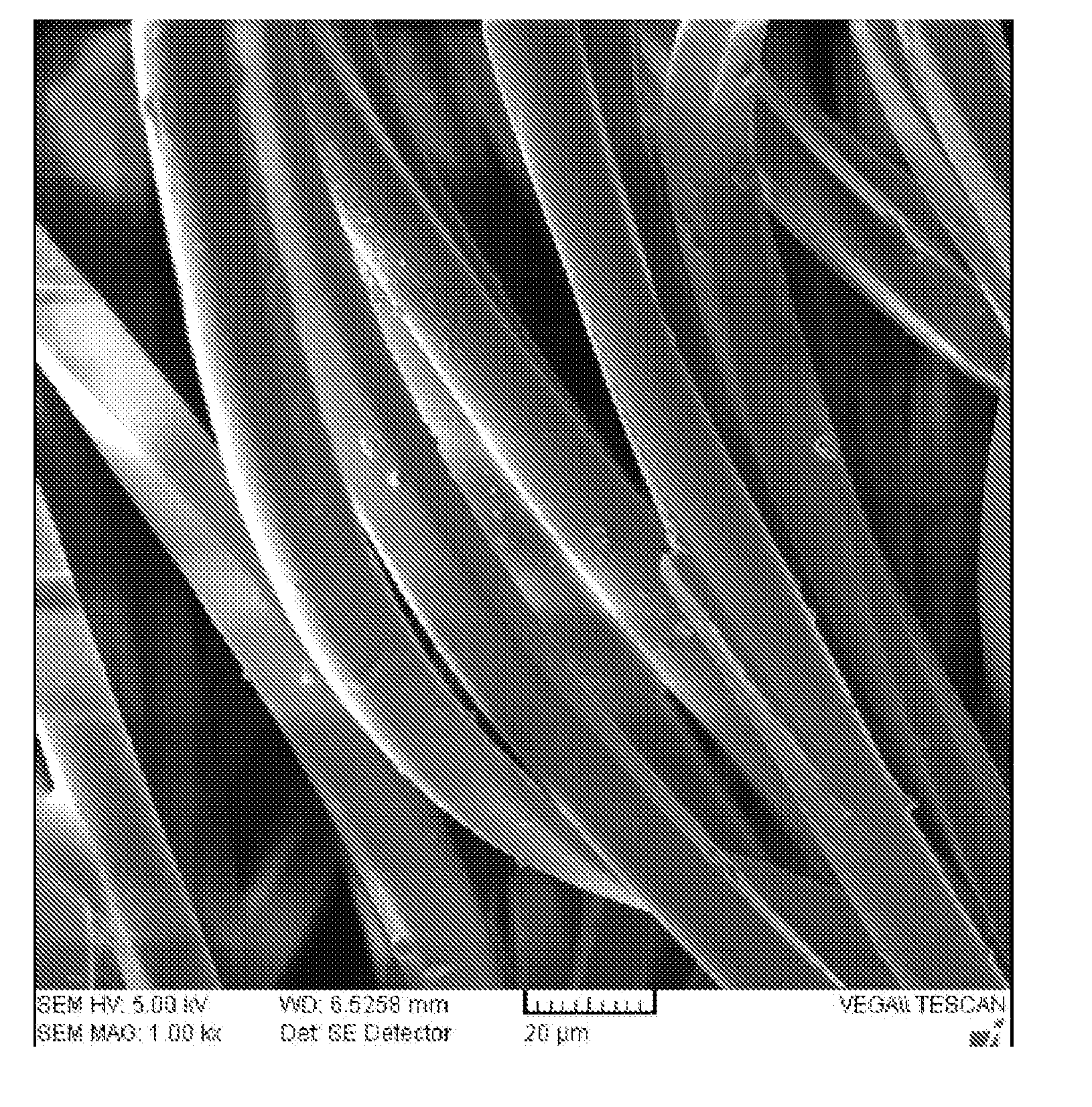

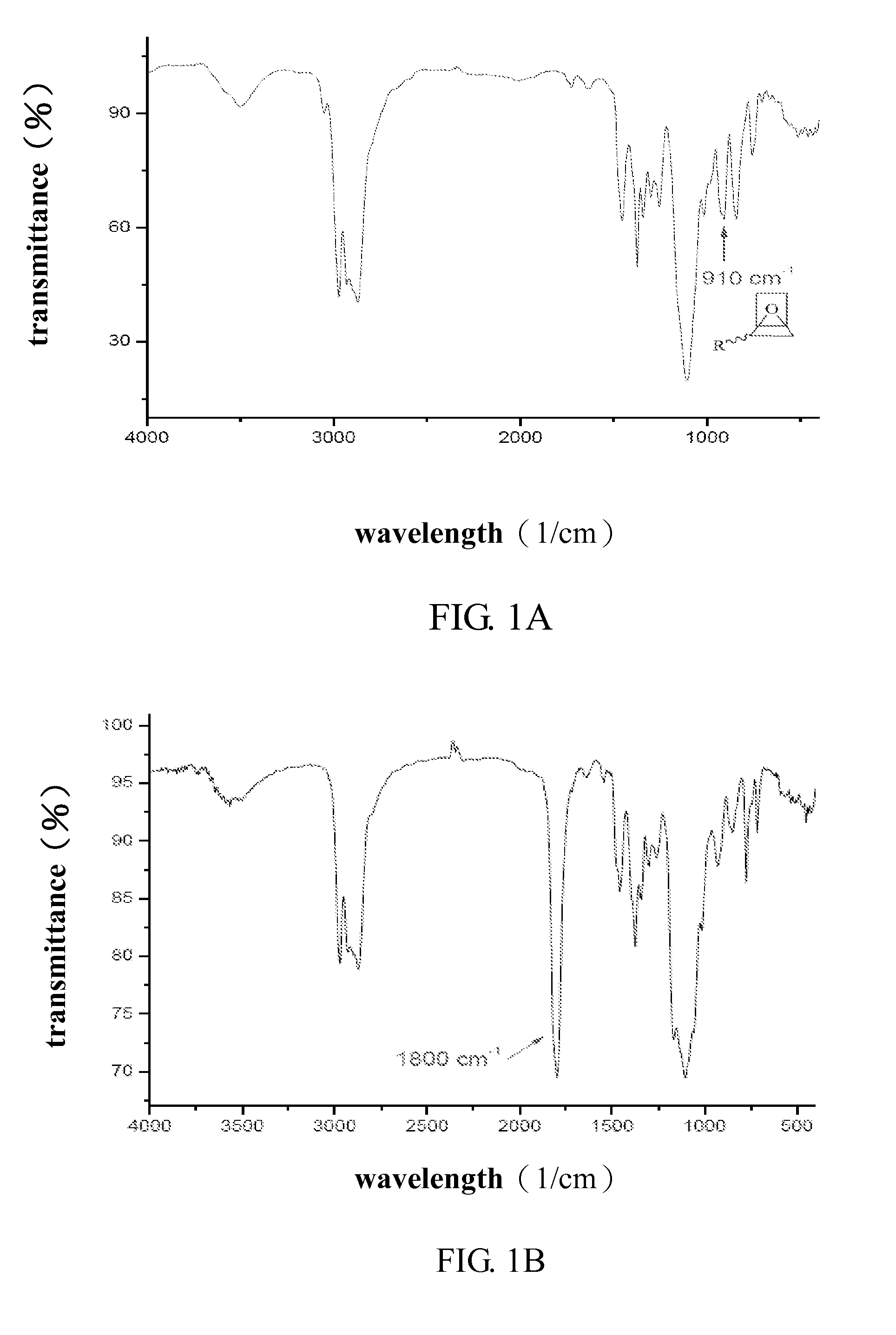

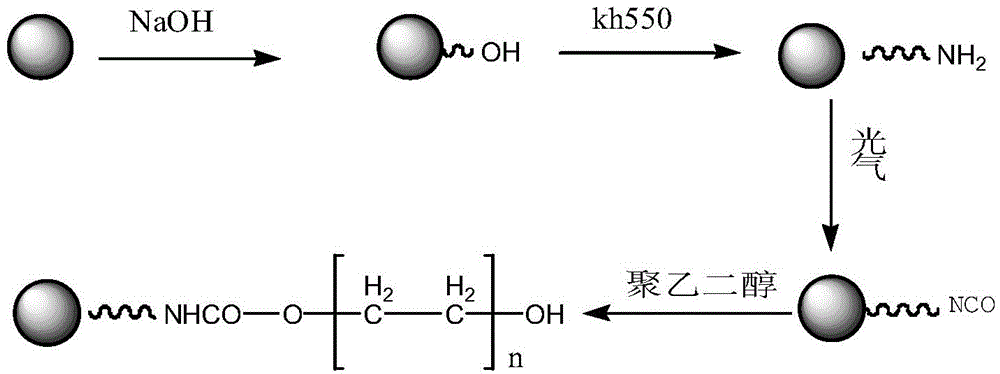

Hollow glass micro-spheres surface modification method

The invention discloses a hollow glass micro-spheres surface modification method. The specific steps of the method are: (1) acetone or ethanol are used for washing the surfaces of hollow glass micro-spheres, such that dirt is removed; and a sodium hydroxide solution is used for treating, such that the surfaces of the hollow glass micro-spheres are hydroxylated; (2) the surface-hydroxylated hollow glass micro-spheres obtained in the step (1) are treated by using an ethanol-water mixed solution containing kh550; with hydrolysis of a silane coupling agent and condensation of silanol, the material is grafted on the surface of the hollow glass micro-spheres; (3) the hollow glass micro-spheres obtained in the step (2) are subjected to phosgene treatment in dichlorobenzene, such that the surface amino groups of the hollow glass micro-spheres are subjected to isocyanate modification; and with the reaction of isocyanate and hydroxyl, polyethylene glycol is grafted on the surfaces of the hollow glass micro-spheres. The hollow glass micro-spheres provided by the invention can be better dispersed in epoxy resin. Bonding strength and acting force between epoxy resin and glass micro-spheres can be improved, and strength and toughness of an epoxy resin composite material can be further enhanced.

Owner:SHANGHAI MARITIME UNIVERSITY

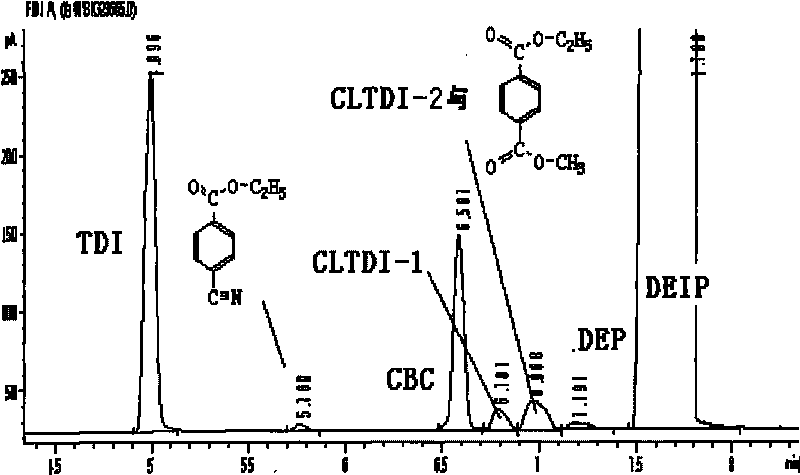

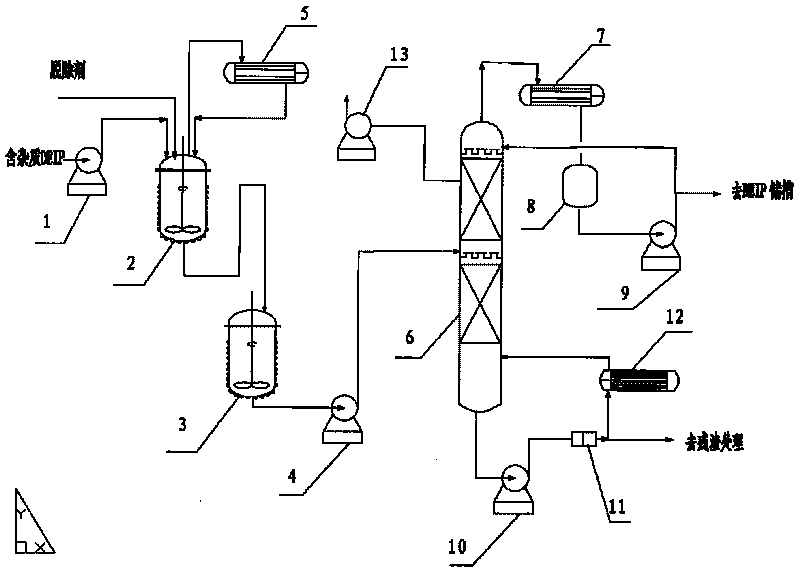

Method for purifying cyclic solvent in producing TDI

InactiveCN101698652AHigh removal rateLess removal rateIsocyanic acid derivatives preparationOrganic compound preparationPolyethylene glycolBenzoyl chloride

The invention relates to a method for purifying cyclic solvent in producing TDI, particularly relates to the case that if the abnormal condition that group impurities containing -NCO such as TDI, CI-TDI, m-CBC and the like are carried by the cyclic solvent DEIP occurs in producing toluene diisocynate (TDI) by a heavy solvent phosgene method, the -NCO group impurities react with TDA and phosgene in a photochemical process to lower TDI yield and generate urea and acid amides residual substances to lead to the problem that production is stopped to clean away obstruction due to the blocking of pipelines and device. The invention uses a processing method of reacting PEG or C2H5OH with -NCO group impurities, adopts rectification to separate the generated heavy components from DEIP to obtain pure DEIP at the tower top to return to a storing bank of the cyclic solvent, and the tower bottom obtains the reacted NCO components and original heavy component residual removal system, thus ensuring smooth operation of the device.

Owner:甘肃银光聚银化工有限公司 +1

Synthetic method of laurel acyl amino acid sodium

ActiveCN102875409AReasonable workmanshipHigh reaction yieldOrganic compound preparationCarboxylic acid amides preparationActive agentN acylaminoacid

The invention relates to a synthetic method of lauric acyl amino acid sodium, particularly to a synthetic method which uses lauric acid and phosgene as raw materials. The synthetic method comprises the following steps: ensuring that the reaction lasts for 1 to 20 hours at a temperature of 60 to 100 DEG C with the effect of organic amide catalyst; obtaining acyl chloride through vacuum distillation after the reaction is finished; dripping lauric acyl chloride obtained according to the phosgene method into amino acids alkaline solution for reaction; controlling and ensuring the pH value to be within the range of 8 to 10, the reaction temperature to be 15 to 20 DEG C, and the reaction time to be 4 to 5 hours; carrying out cooling after the reaction is finished; acidizing the reaction solution to pH 1 to 2 with hydrochloric acid solution; filtering, washing and drying white sediment to obtain lauric acyl amino acid; dissolving the prepared lauric acyl amino acid with alcohol; adding alcohol solution with sodium hydroxide of equal molar amount; and crystallizing, sucking, filtering and drying after cooling to obtain the lauric acyl amino acid sodium. According to the invention, the synthetic method is reasonable in process, high in reaction efficiency and good in product quality; the three wastes are seldom generated; and no residual phosphorus and sulfur are contained in the product. Therefore, the synthetic method can be widely used in the production of high-end surface active agents, and has significant utility value and social and economic benefits.

Owner:CHANGSHA PUJI BIOTECH

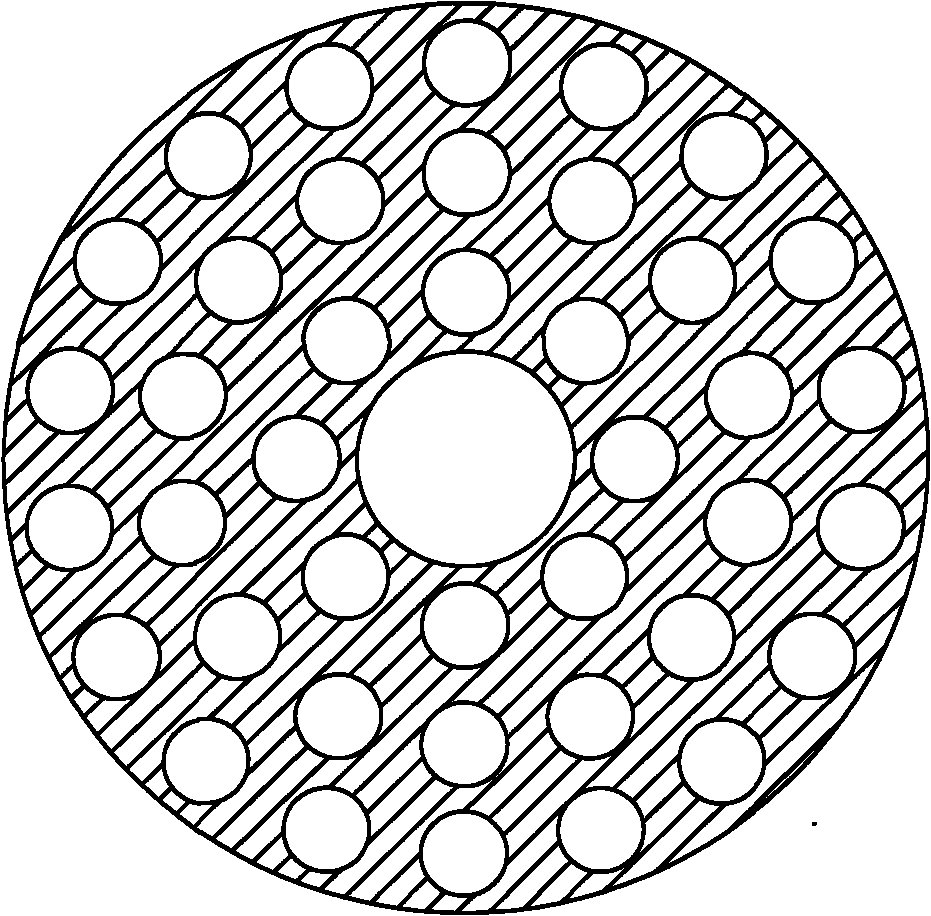

Phosgene producing method and equipment

ActiveCN1765740AEasy to manufactureImprove reliabilityProcess control/regulationChemical industryActivated carbonPtru catalyst

In the production of phosgene by reacting chlorine and carbon monoxide in the presence of an activated charcoal catalyst in a tube aggregate reactor with several reaction tubes surrounded by a coolant chamber, (a) the reaction tubes are cooled externally by evaporation cooling with water in the coolant chamber and (b) the reaction tubes operate at a pressure higher than that in the coolant chamber. An independent claim is also included for the plant used.

Owner:COVESTRO DEUTSCHLAND AG

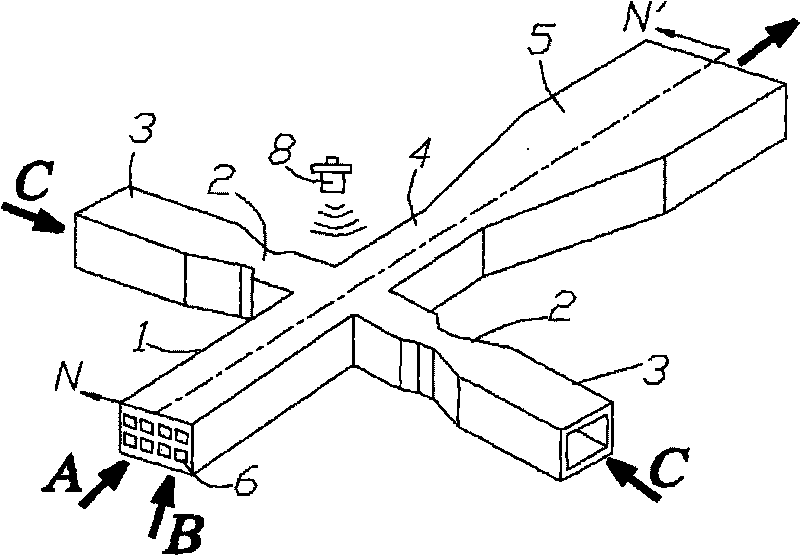

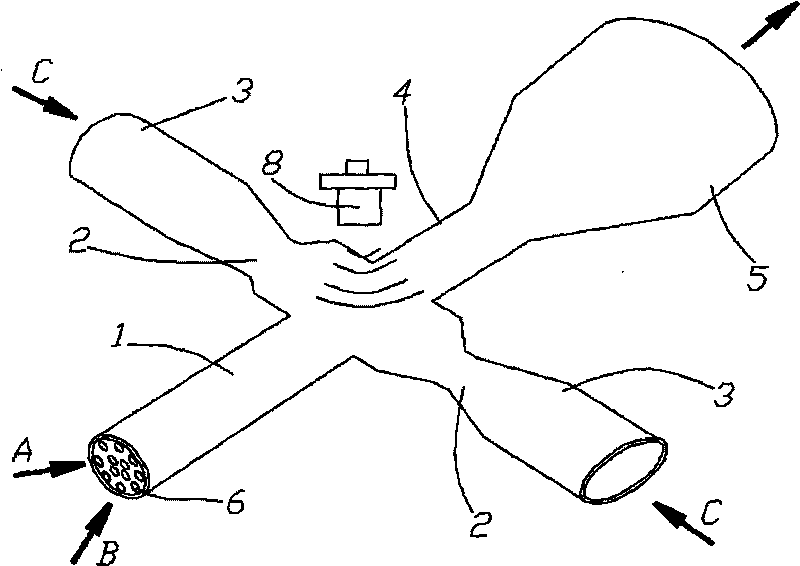

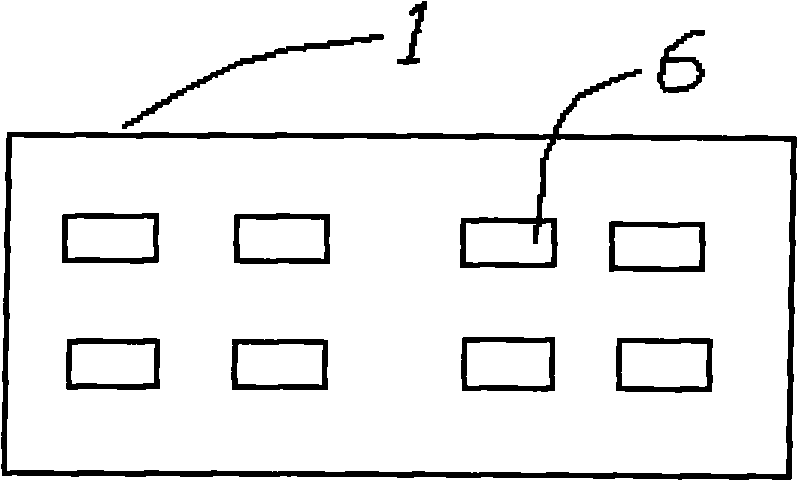

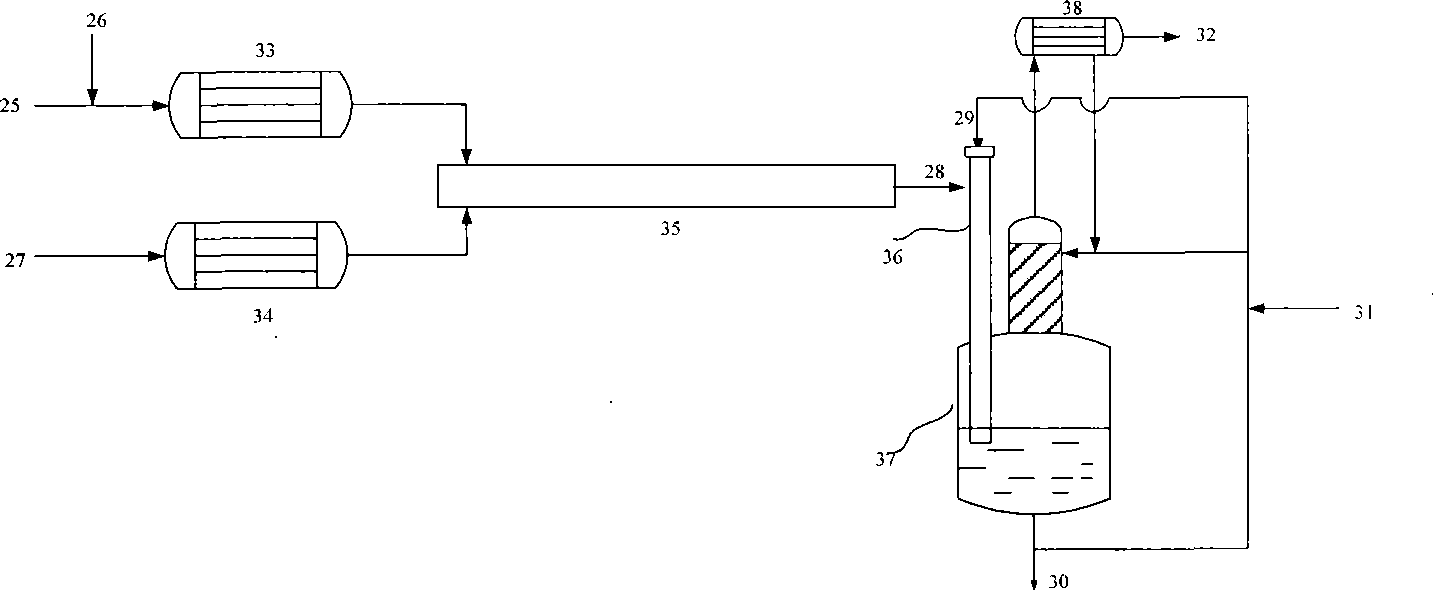

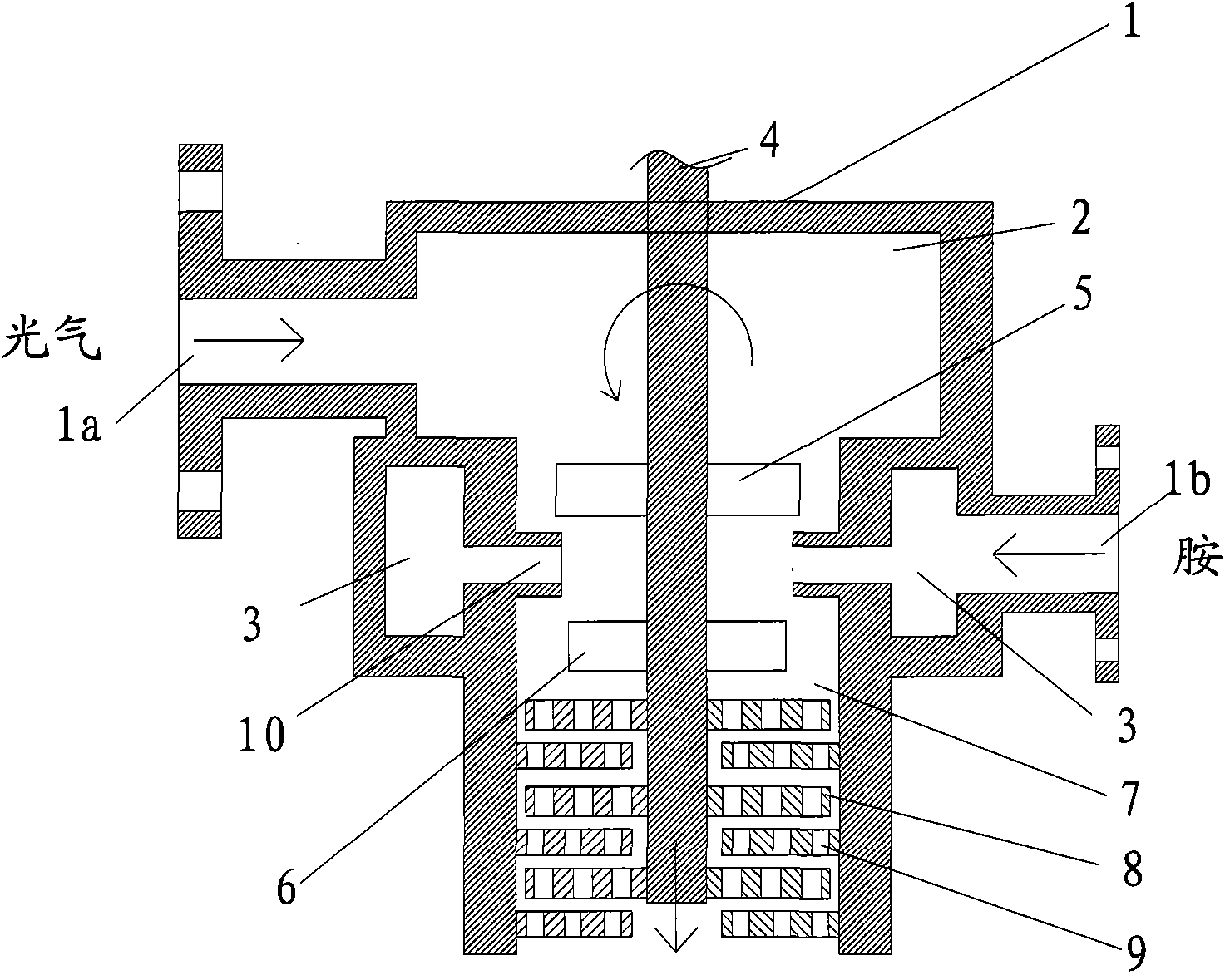

Mixer and method for preparing organic isocyanate

ActiveCN101708438ASimple structureGood microscopic mixing effectIsocyanic acid derivatives preparationFlow mixersOrganic solventEngineering

The invention discloses a mixer and a method for preparing organic isocyanate. The mixer comprises a main feed pipe, two side feed pipes and a discharge pipe, wherein the main feed pipe and the discharge pipe are arranged on the same axis, and the arrangement of the side feed pipes causes the axes of the side feed pipes and the axis of the main feed pipe are in 60-90 degrees; the point of intersection of the main feed pipe, the side feed pipes and the discharge pipe is provided with a mixed chamber, and an ultrasonic generator is arranged outside the mixed chamber; a microchannel is arranged in the main feed pipe; each side feed pipe is provided with a reduced section near the mixed chamber; and the discharge end of the discharge pipe is provided with an expansion pipe. The mixer of the invention has simple structure and favourable micromixing effect. When used for preparing organic isocyanate, the mixer of the invention can realize favourable micromixing of organic primary amine and phosgene, lowers the usage amount of inert organic solvent as well as the excessive degree of phosgene, reduces solid detention and lowers the danger of solid blockage.

Owner:TIANJIN UNIV +1

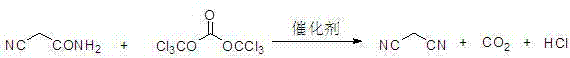

Synthetic method of malononitrile

InactiveCN103044286AHigh purityImprove stabilityPreparation by carboxylic acid amide dehydrationPtru catalystDistillation

The invention discloses a synthetic method of malononitrile. Cyanoacetamide reacts with triphosgene in the presence of a catalyst to synthesize malononitrile, wherein the catalyst is any one substance or a mixture of multiple substances selected from N,N-dimethyl formamide, sodium chloride, pyridine and triethylamine. The method provided by the invention employs the triphosgene as a dehydrating agent, and the triphosgene is low in cost, available and high in stability, and facilitates storage and transportation; the reaction products of the cyanoacetamide and the triphosgene only include carbon dioxide and hydrogen chloride gases except for the malononitrile, without solid waste, and therefore, after the reaction is completed, the steps of removing the solid waste by means of filtering, centrifuging and the like are not needed; the reaction mixture is directly subjected to reduced pressure distillation after the solvent is recovered so that the malononitrile having the purity of higher than 98% can be obtained; and the posttreatment is simple.

Owner:CHONGQING UNISPLENDOUR CHEM

Process for producing dicyclohexyl methyl hydride diisocyanate and its midbody

ActiveCN101429139AReduce poisonExtended service lifeIsocyanic acid derivatives preparationOrganic compound preparationOrganic solventHydrogen pressure

The invention discloses a method for preparing dicyclohexyl methane diisocyanate. The method comprises the following steps: a) a diamino diphenylmethane isomer mixture reacts in an organic solvent at a reaction temperature between 90 and 200 DEG C, under the hydrogen pressure between 3.0 and 12.0 MPa and under the action of a catalyst, so as to obtain a diamino dicyclohexyl methane isomer mixture; and b) the diamino dicyclohexyl methane isomer mixture obtained in the step a) and phosgene are heated to 330 to 400 DEG C so as to be gasify respectively and then are sent into a reactor with a mixing device to be mixed and react, have hydrogen chloride and phosgene removed, and are distilled, so as to obtain the dicyclohexyl methane diisocyanate. The method has the advantages of prolonging the life span of the catalyst and reducing cost. The invention also provides a complete technological process for preparing the dicyclohexyl methane diisocyanate.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD

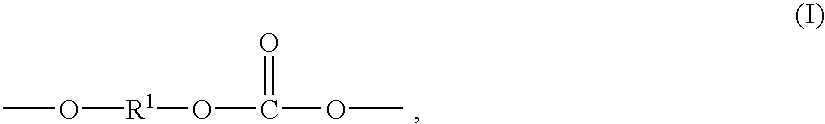

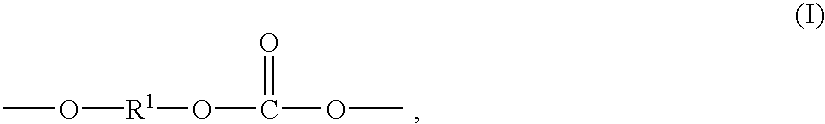

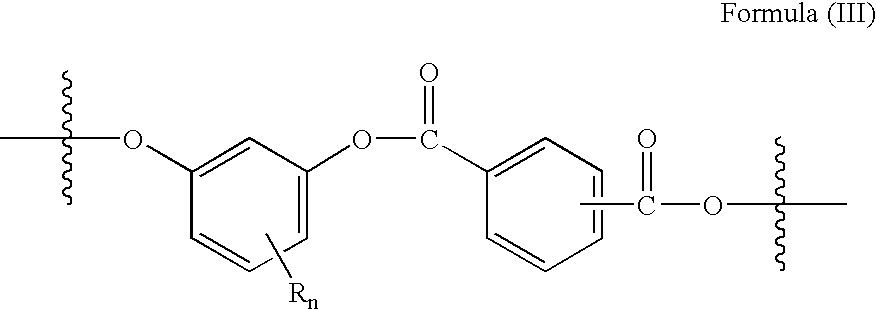

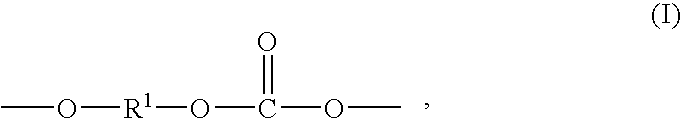

Process for producing isocyanates

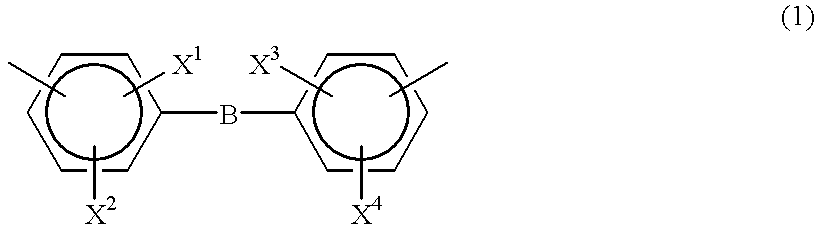

ActiveUS20100029981A1Efficient productionCarbamic acid derivatives preparationOrganic compound preparationCarbamateDecomposition

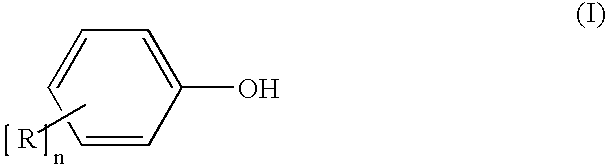

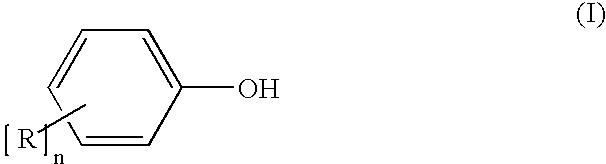

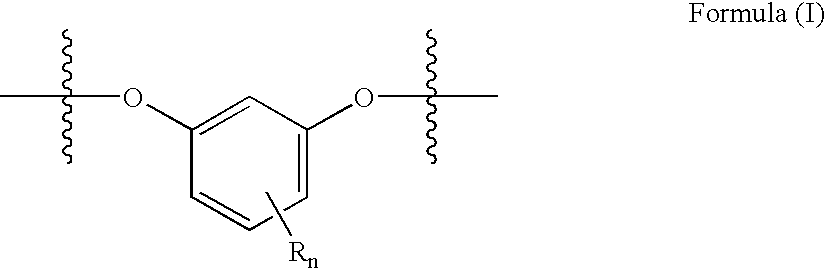

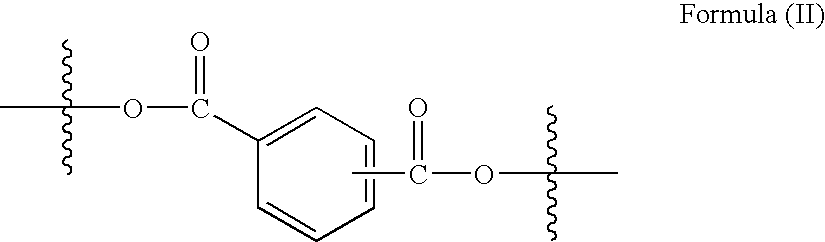

An object of the present invention is to provide a process that enables isocyanates to be stably produced over a long period of time at high yield without encountering various problems as found in the prior art when producing isocyanates without using phosgene. The present invention discloses a process for producing an isocyanate, comprising the steps of: reacting a carbamic acid ester and an aromatic hydroxy compound to obtain an aryl carbamate having a group derived from the aromatic hydroxy compound; and subjecting the aryl carbamate to a decomposition reaction, wherein the aromatic hydroxy compound is an aromatic hydroxy compound which is represented by the following formula (1) and which has a substituent R1 at least one ortho position of a hydroxyl group:(wherein ring A represents an aromatic hydrocarbon ring in a form of a single or multiple rings which may have a substitute and which have 6 to 20 carbon atoms;R1 represents a group other than a hydrogen atom in a form of an aliphatic alkyl group having 1 to 20 carbon atoms, an aliphatic alkoxy group having 1 to 20 carbon atoms, an aryl group having 6 to 20 carbon atoms, an aryloxy group having 6 to 20 carbon atoms, an aralkyl group having 7 to 20 carbon atoms or an aralkyloxy group having 7 to 20 carbon atoms, the group containing an atom selected from a carbon atom, an oxygen atom and a nitrogen atom; and R1 may bond with A to form a ring structure).

Owner:ASAHI KASEI CHEM CORP

Process for the preparation of isocyanates in the gas phase

ActiveUS20080146834A1Increase the number ofShorten the timeOrganic compound preparationIsocyanic acid derivatives purification/separationGas phaseContact time

An isocyanate is produced by reacting a primary amine with phosgene in the gas phase above the boiling point of the amine over an average contact time of 0.05 to 15 seconds under adiabatic conditions.

Owner:COVESTRO DEUTSCHLAND AG

Process for the production of 4,4'-diphenylmethane diisocyanate

InactiveUS20070117997A1Simple processOrganic compound preparationIsocyanic acid derivatives purification/separationDiphenylmethaneDistillation

The present invention relates to a process for the production of 4,4′-diphenylmethane diisocyanate (4,4′-MDI) by acid-catalyzed condensation of aniline with formaldehyde, reaction of the mixtures of di- and polyamines obtained with phosgene to form the corresponding mixture of MDI isomers and homologues (di- and polyisocyanates of the diphenylmethane series) and subsequent separation of the mixture by distillation to form 4,4′-MDI and polymeric MDI.

Owner:BAYER MATERIALSCIENCE AG

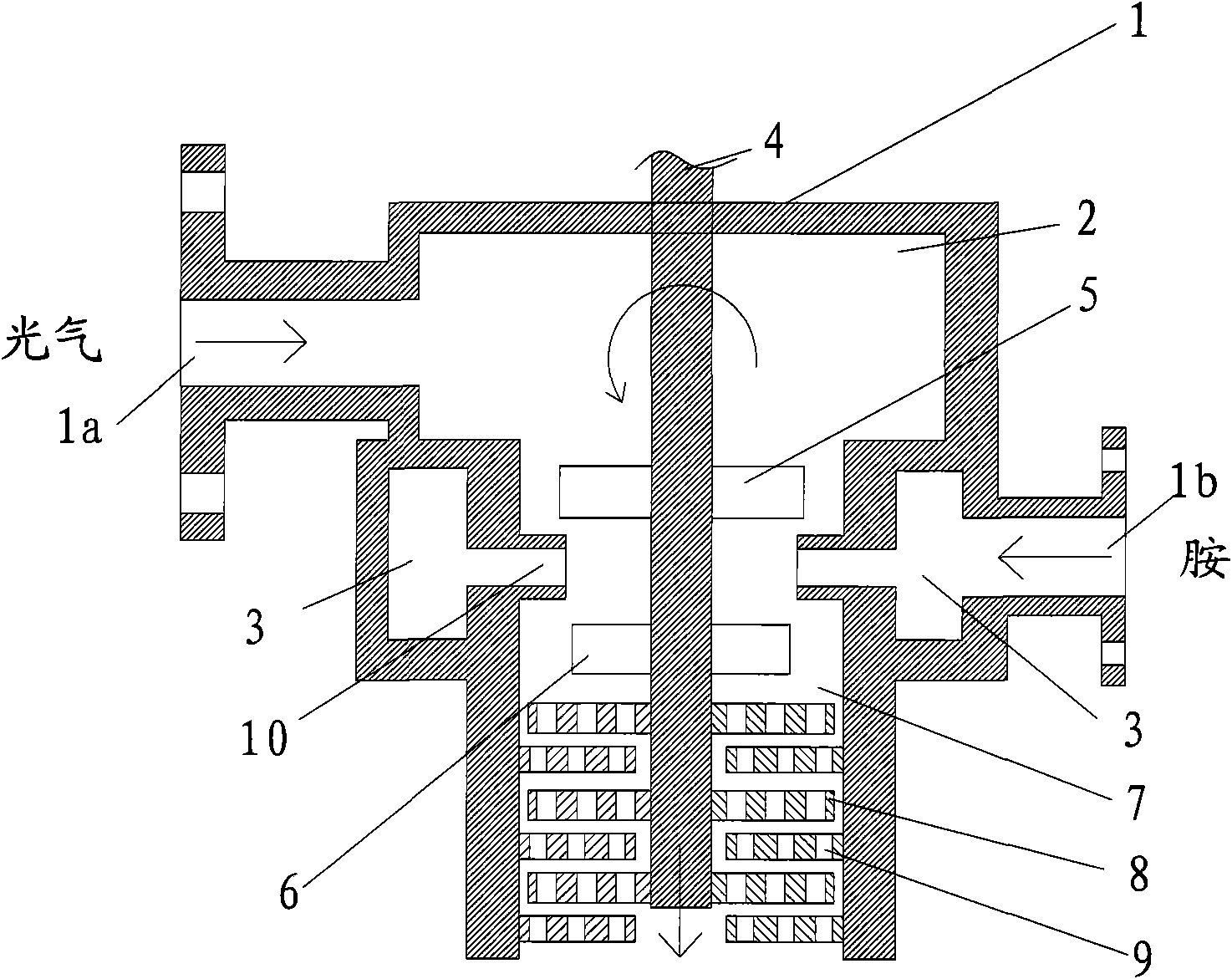

Stirring and grinding reactor and method for preparing isocyanate with same

ActiveCN101811017AIncreased initial mixingRapid responseIsocyanic acid derivatives preparationOrganic compound preparationSolid reactionEngineering

The invention relates to a stirring and grinding integrated reactor and a method for preparing isocyanate by using the reactor. The reactor comprises a reactor shell, a first reactant feeding hole, a first reactant distributing tray, a second reactant main feeding hole, an annular second reactant distributing tray, a stirring shaft, an axial stirring paddle, a radial stirring paddle, a dynamic grinding sheet, a static grinding sheet and at least one second reactant sub feeding hole, wherein the dynamic and static grinding sheets are provided with a plurality of passage holes. Quick mixing and quick reaction between the raw materials are realized by axial and radial strong stirring and a feeding method of a strongest mixing area, and the solid reaction product is further pulverized by hole passage type quick grinding combined through multilayer dynamic and static grinding trays so as to enhance the reaction effect, improve the yield and quality of the isocyanate, reduce the using amount of a solvent and the excess ratio of phosgene, improve the yield of the device, improve the quality of the product and reduce the energy consumption.

Owner:WANHUA CHEM GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com