Synthetic method of malononitrile

A synthesis method and a technology of malononitrile are applied in the chemical industry, and can solve the problems of volatility, complicated post-processing operations, and high viscosity of phosphorus-containing solid waste, and achieve simple post-processing, convenient storage and transportation, low cost and easy availability. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

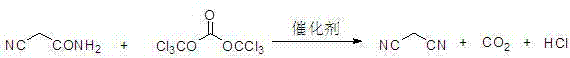

Method used

Image

Examples

Embodiment 1

[0022] Add 16.8g (0.2mol) of cyanoacetamide, 3mL (0.039mol) of N,N-dimethylformamide and 100mL of acetonitrile into a four-neck flask equipped with mechanical stirring, a thermometer and a constant pressure dropping funnel, and heat up to 80 ℃; Dissolve 24g (0.08mol) triphosgene in 40mL toluene to form a homogeneous solution, then add the solution dropwise to the aforementioned four-neck flask at a constant speed, and the dropwise addition is completed in 3 to 4 hours; then, reflux for 8 hours, and the reaction Tail gas carbon dioxide and hydrogen chloride that produce are absorbed with sodium hydroxide solution, HPLC analysis cyanoacetamide content is 0.3%, finish reaction, be down to room temperature, use residual hydrogen chloride gas and phosgene in the reaction solution of nitrogen purging, distillation recovery solvent, again in Under reduced pressure distillation at a vacuum of -0.095MPa, the fraction with a boiling point of 105-115°C was collected to obtain 10.10 g of m...

Embodiment 2

[0024] Add 16.8g (0.2mol) cyanoacetamide, 4g (0.04mol) triethylamine and 100mL toluene to the four-neck flask as described in Example 1, and raise the temperature to 80°C; dissolve 24g (0.08mol) triphosphine Form a homogeneous solution in 40mL of toluene, then add the solution dropwise to the aforementioned four-neck flask at a constant speed, and the dropwise addition is completed in 3-4 hours; then, reflux for 8 hours, and the tail gas carbon dioxide and hydrogen chloride produced by the reaction are washed with sodium hydroxide The solution was absorbed, and the content of cyanoacetamide was 0.5% according to HPLC analysis. After the reaction was completed, the temperature was lowered to room temperature, and the residual hydrogen chloride gas and phosgene in the reaction solution were purged with nitrogen, and the solvent was recovered by distillation, and then depressurized under the condition of vacuum degree of -0.095MPa After distillation, the fraction with a boiling po...

Embodiment 3

[0026] Add 16.8g (0.2mol) cyanoacetamide, 0.5g (0.0085mol) sodium chloride and 100mL acetonitrile to the four-neck flask as described in Example 1, and heat up to 80°C; 24g (0.08mol) triphosgene Dissolve in 40mL of toluene to form a homogeneous solution, then add the solution dropwise to the aforementioned four-necked bottle at a constant speed, and the dropwise addition is completed in 3-4 hours; then, reflux for 10 hours, and the tail gas carbon dioxide and hydrogen chloride produced by the reaction are oxidized with hydrogen Sodium solution suction, HPLC analysis cyanoacetamide content is 0.46%, finishes the reaction, cools down to room temperature, purging residual hydrogen chloride gas and phosgene in the reaction solution with nitrogen, distills and recovers the solvent, then decomposes under the vacuum degree of -0.095MPa. Distilled under high pressure to collect fractions with a boiling point of 105-115°C to obtain 7.51 g of malononitrile. The purity by GC analysis was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com