Method for purifying cyclic solvent in producing TDI

A technology of circulating solvent and purification tower, applied in chemical instruments and methods, organic chemistry, preparation of isocyanic acid derivatives, etc., can solve the problems of expensive, difficult to avoid, and burden on the slag removal system, and achieve remarkable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

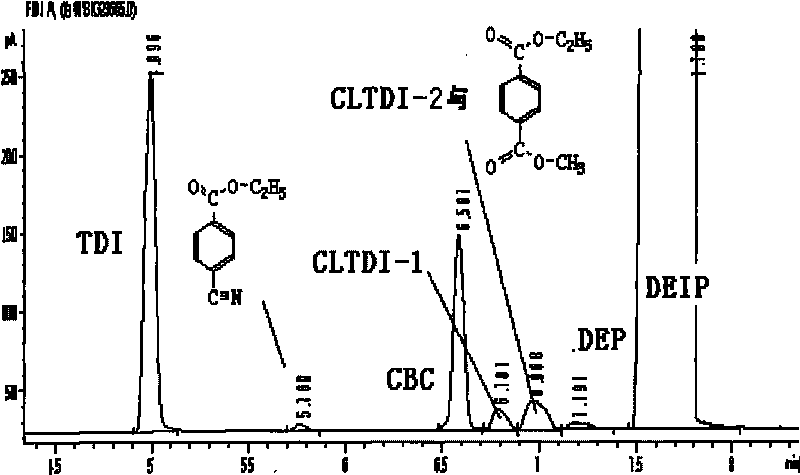

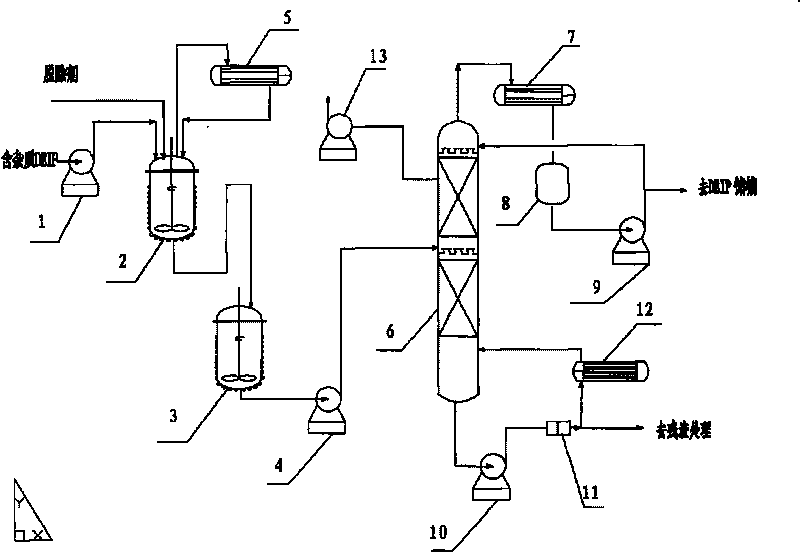

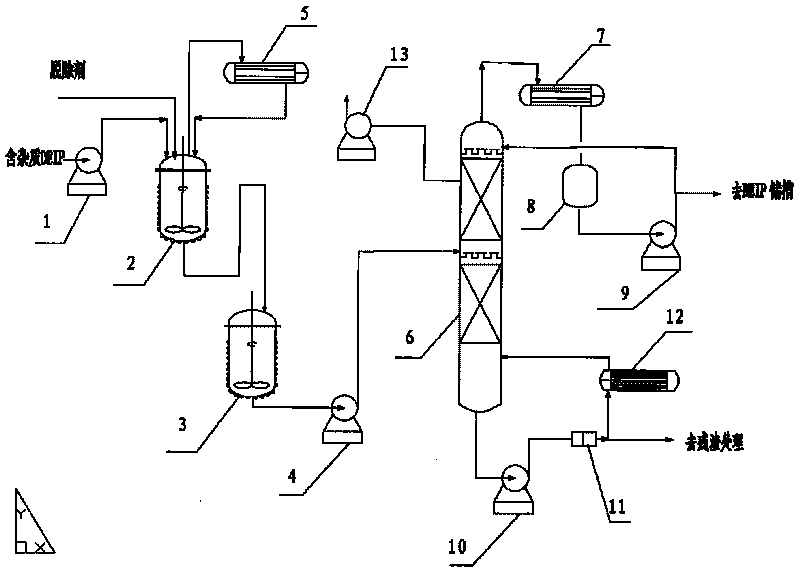

Method used

Image

Examples

Embodiment 1

[0055] Example 1: The continuous production process condition control is as follows:

[0056]

Embodiment 2

[0057] Example 2: The control of batch production process conditions is as follows:

[0058]

Embodiment 3

[0059] Example 3: The process conditions of batch production with ethanol as the remover are controlled as follows:

[0060] In this experiment, the raw material is also a solvent with low NCO concentration. The concentration measured by the chemical method is 2092PPM. The additional reactant is changed to ethanol. Because ethanol has a relatively low boiling point and is easier to volatilize, the ratio is increased, and the molar ratio of NCO: ethanol is 1:10, react.

[0061]

[0062]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com