Patents

Literature

155 results about "Chlorotoluene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chlorotoluene is a group of three isomeric chemical compounds. They (ortho-chlorotoluene, meta-chlorotoluene, and para-chlorotoluene) consist of a disubstituted benzene ring with one chlorine atom and one methyl group.

Preparation process of benzoyl chloride

ActiveCN103787874AReduce pollutionSave resourcesPreparation from carboxylic acid halideOrganic compound preparationBenzoic acidPtru catalyst

The invention discloses a preparation process of benzoyl chloride. The preparation process comprises the following steps of synthesis of benzotrichloride: carrying out temperature reaction on methylbenzene and chlorine under the catalytic action of a catalyst to synthetize a crude benzotrichloride product; synthesis of the benzoyl chloride: continuously stirring and heating the crude benzotrichloride product and benzoic acid to prepare a crude benzoyl chloride product after adding the catalyst; refining of the benzoyl chloride: carrying out reduced pressure distillation on the crude benzoyl chloride product to prepare a refined benzoyl chloride product; recovering benzoyl chloride raffinate, adding water to the benzoyl chloride raffinate which is subjected to the reduced pressure distillation, heating and stirring to transform the benzoyl chloride contained in the raffinate into the benzoic acid, cooling, then separating out benzoic acid. The preparation process disclosed by the invention is easy to safe to operate, effectively shortens the reaction time, achieves the purity of the prepared benzoyl chloride by 99.5%, reduces the environmental pollution by recycling residues, saves the resources, reduces the cost, meets the requirements of pharmaceutical chemicals and can carry out massive industrial production.

Owner:YIDU YOUYUAN IND CO LTD

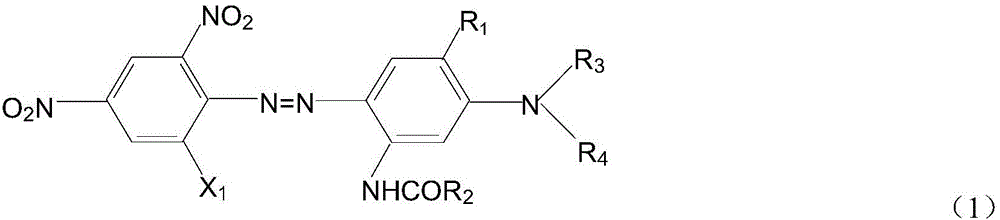

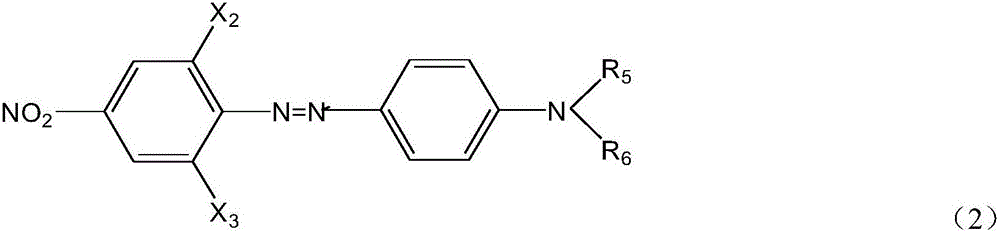

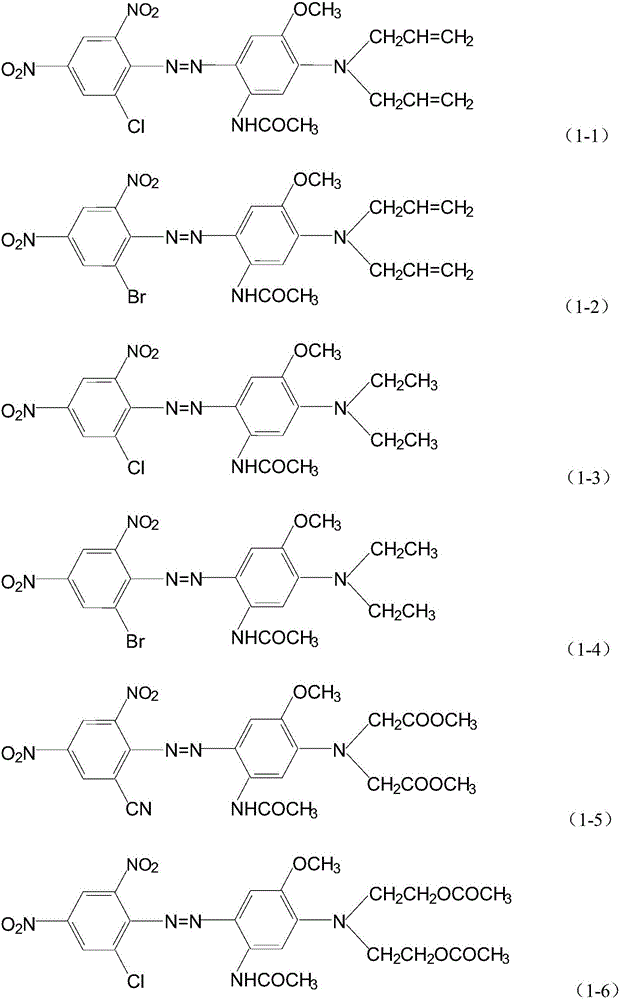

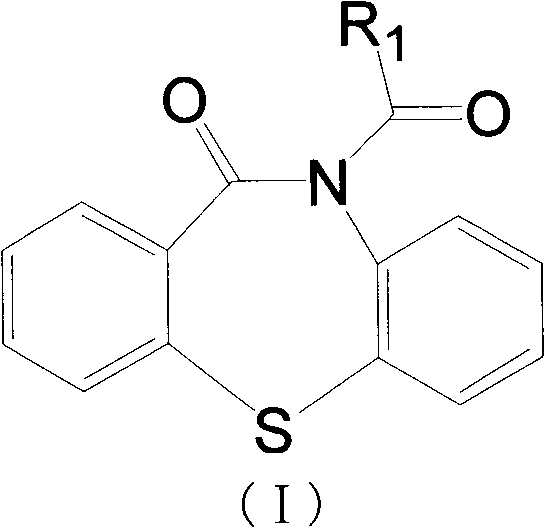

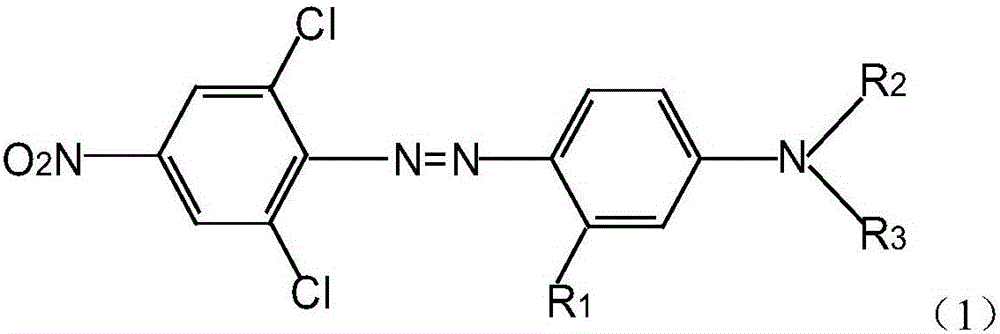

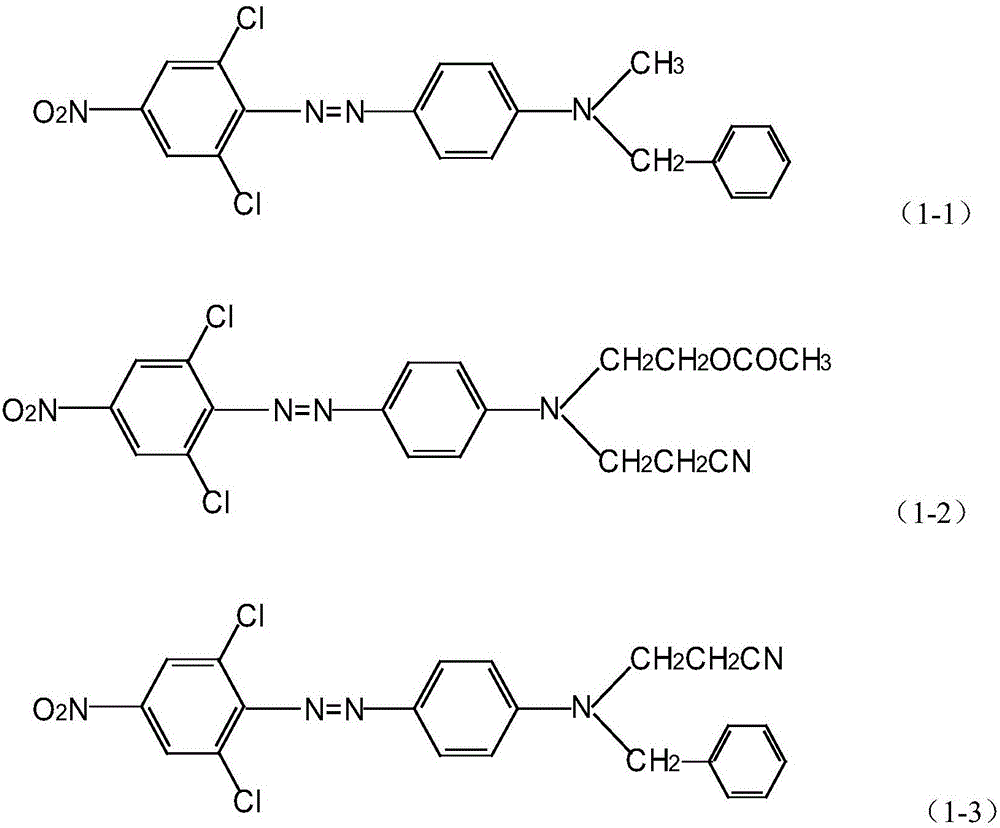

Disperse dye composition, and preparation method and application thereof

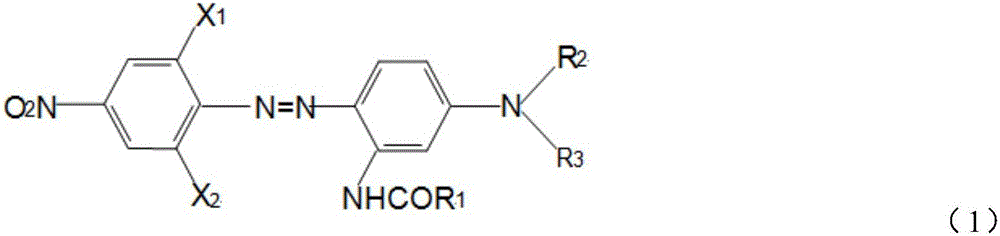

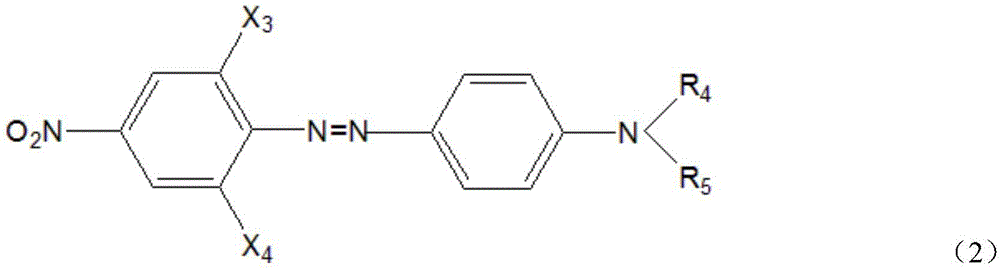

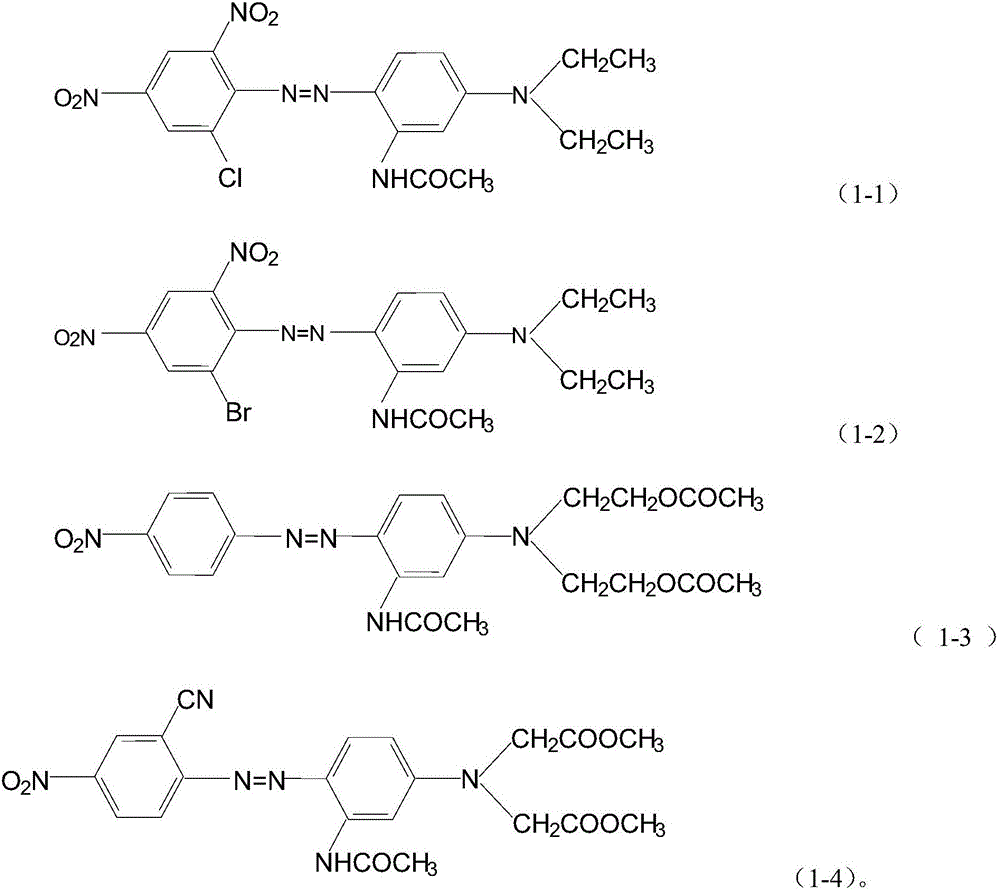

Disclosed are a disperse dye composition, and a preparation method and application thereof. The disperse dye composition comprises a component A composed of one or more of compounds shown as a formula (1) (please see the specifications for the formula), a component B composed of one or more of compounds shown as a formula (2) (please see the specifications for the formula), forbidden aromatic amine compounds, chlorinated phenols, chlorobenzene and chlorotoluene, optional auxiliaries, and other unavoidable impurities. The total content of the forbidden aromatic amine compounds is 10 ppm or below, the respective content of the various chlorinated phenols is 0.5 ppm or below, and the total content of the chlorobenzene and chlorotoluene is 1 ppm or below. The various environment protection indexes of the disperse dye composition meet the requirements of Oeko-Tex Standard 100(2016). In addition, after fabric is dyed through the disperse dye composition, the dyed fabric meets the baby level requirements of Oeko-Tex Standard 100(2016).

Owner:ZHEJIANG RUNTU INST +1

Method for preparing CLT acid (6-chloro-3-aminotoluene-4-sulfoacid) by utilizing o-chlorotoluene direct nitrification method

InactiveCN101906057AReduce pollutionLow equipment requirementsSulfonic acid preparationO-chlorotolueneRaw material

The invention relates to a method for preparing 6-chloro-3-aminotoluene-4-sulfoacid (hereinafter referred to as CLT acid) in a direct nitrification way by taking o-chlorotoluene as a raw material. The method comprises the following steps of: obtaining o-chlorotoluene nitrate by taking acidic Beta zeolite as a catalyst and acetyl nitrate as a nitrifying agent; reducing the o-chlorotoluene nitrate by utilizing iron powder; recrystallizing the reduced product and separating out 6-chloro-3-aminotoluene crystal and 6-chloro-4-aminotoluene containing little 6-chloro-3-aminotoluene by adopting an acid extraction method; adding dichlorobenzene and sulfuric acid in the 6-chloro-3-aminotoluene crystal, and carrying out sulfonation at 170-190 DEG C to obtain the CHLOROT acid; and carrying out sulfonation on the 6-chloro-4-aminotoluene containing little 6-chloro-3-aminotoluene to obtain 2B acid containing little CLT acid. The invention has the characteristics of low pollution, high yield, simple process, low device requirements, and the like.

Owner:YANBIAN UNIV

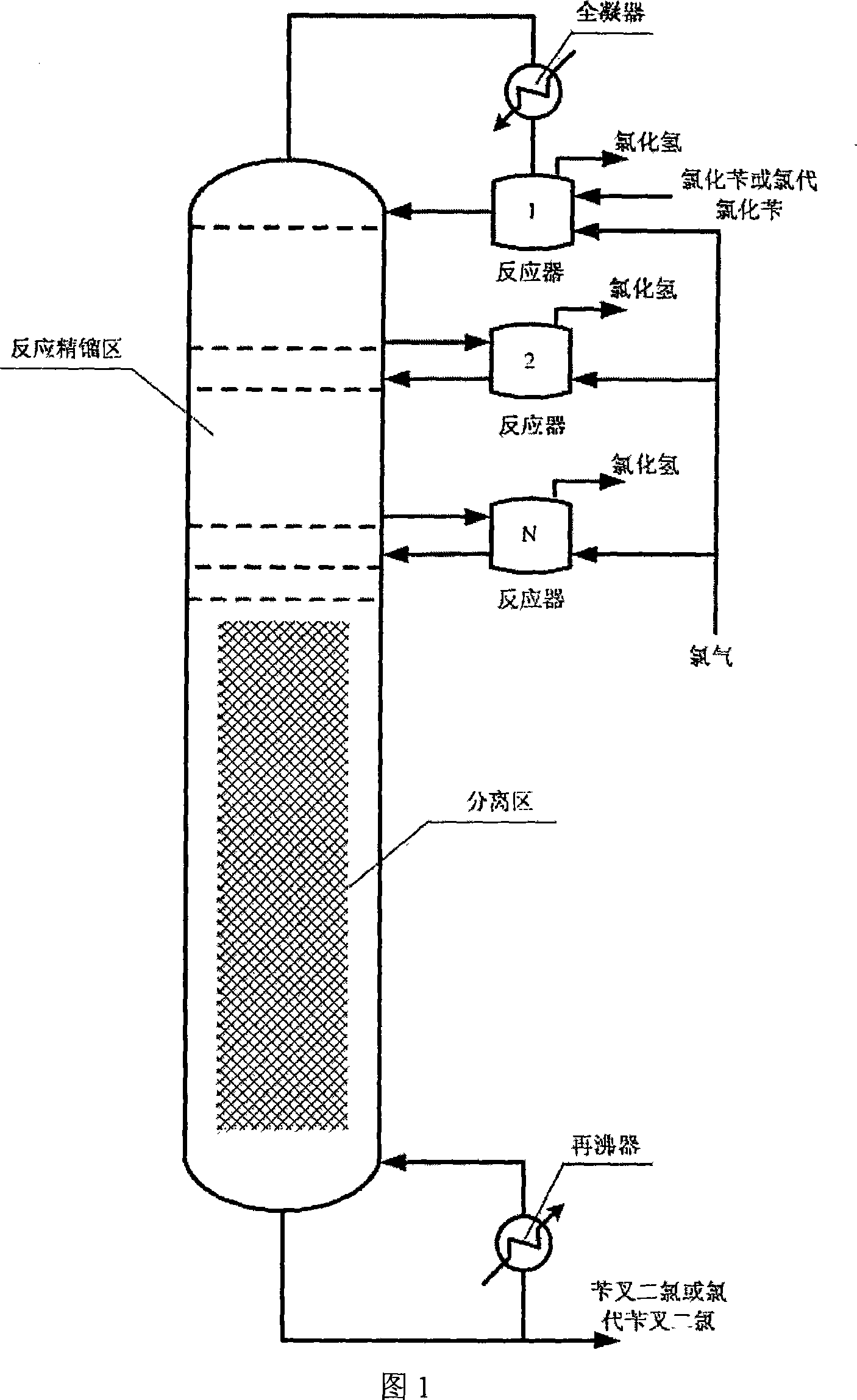

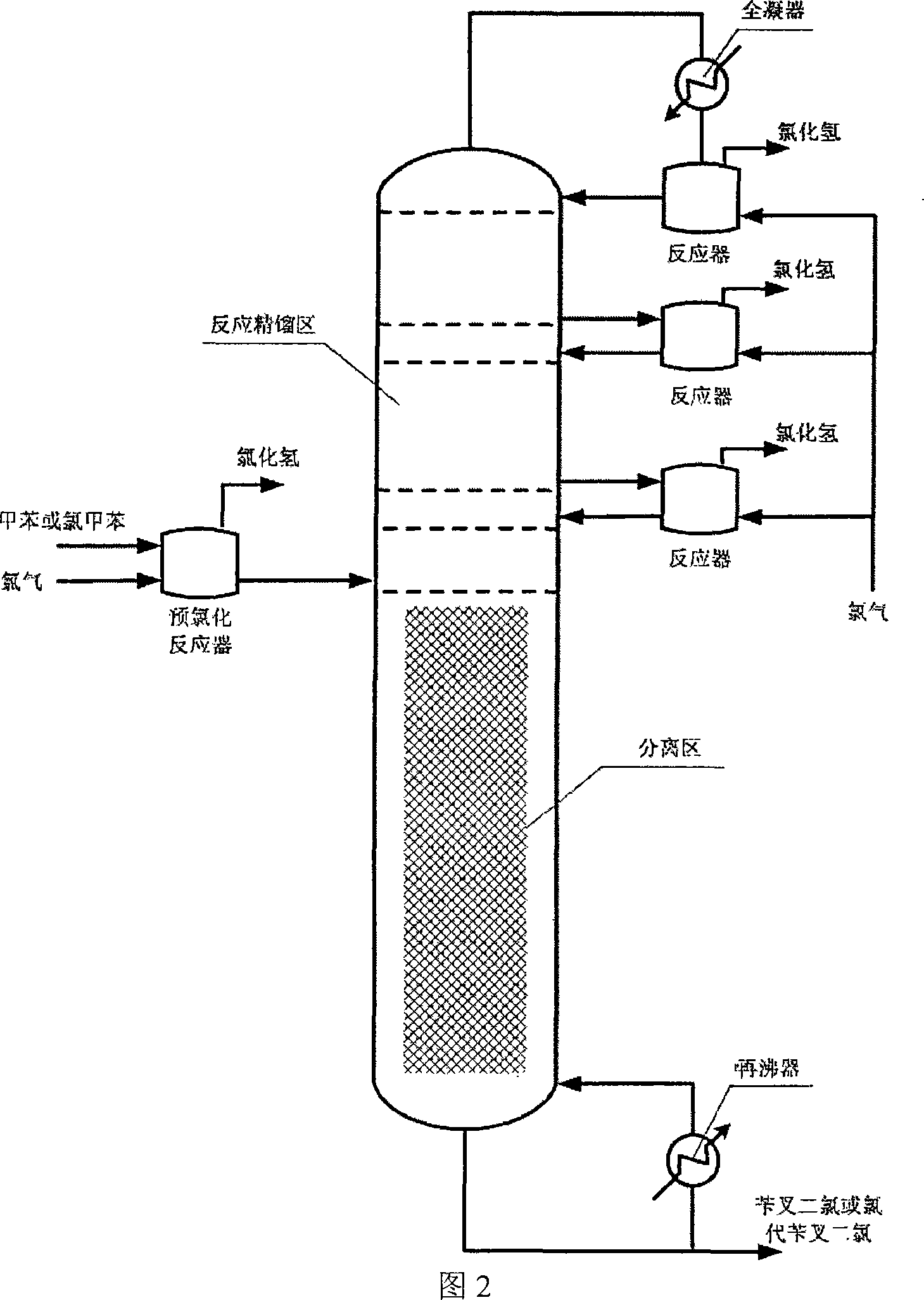

Process for producing benzal chloride or chloro benzal chloride

ActiveCN101070267AVolume can be adjusted freelyAdjust the volume arbitrarilyHalogenated hydrocarbon preparationNuclear chemistryBlue light

This invention relates to a preparation method of benzal dichloro or chlor-benzal dichloro. The invention process: inlet toluene or chlorotoluene, benzyl chloride or chlor- benzyl chloride and chlorine gas according to certain mol ratio to reactor that coupled with fractionating tower or prechlorination reactor, under series stable operation condition, control the operating pressure of fractionating tower at 0.002 to 0.05MPa. The chlorination is stimulated by sunlight or blue light, temperature of reactor is controlled at 80 to 120 deg.

Owner:NANTONG TIANSHI CHEM

Composite catalyst and application

InactiveCN101947468AQuality improvementHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsHalogenated hydrocarbon preparationAlcoholOrganic synthesis

The invention belongs to the field of organic synthesis, in particular to a composite catalyst and an application thereof in synthesizing benzo-trichloride. The method for preparing the composite catalyst comprises the following steps: adding 1 to 4 parts of initiators into 100 parts of chlorinated raw materials or chlorinated products so as to obtain a mixture A after the initiators are dissolved; adding alcohol-amine compounds into the mixture A, wherein the addition of the alcohol-amine compounds accounts for 0.02 to 0.05% of the mixture A; evenly mixing the alcohol-amine compounds and the mixture A, and standing so as to separate a water layer from an organic layer, then obtaining the organic layer, namely, the composite catalyst. The composite catalyst can be used for generating bis(trichloromethyl) benzene or 2-(trichloromethyl) benzene by catalyzing xylene or chlorotoluene, and solves the problems of long synthesis time, low yield, difficult reaction and a large amount of impurities for the bis(trichloromethyl) benzene in existing catalytic / chlorinated technology.

Owner:ZHEJIANG KANGFENG CHEM

Disperse dye composition as well as preparation method and application thereof

ActiveCN106800798AImprove washing fastnessEasy to useMonoazo dyesDyeing processDisperse dyeChlorobenzene

The invention discloses a disperse dye composition as well as a preparation method and an application thereof. The disperse dye composition comprises a component A consisting of one or more of compounds shown by formula (1), a component B consisting of one or more compounds shown by formula (2), forbidden aromatic amine compound, chlorinated phenol, chlorobenzene, chlorotoluene, optional accessory and other unavoidable impurities, wherein the total content of the forbidden aromatic amine compound is below 10ppm, the total content of chlorinated phenol of each kind is below 0.5ppm, and the total content of chlorobenzene and chlorotoluene is below 1ppm. The environmental protection indexes of the disperse dye composition meet the requirements of Oeko-Tex Standard 100 (2016); and the properties such as washing fastness after dyeing are excellent. Moreover, by adopting the disperse dyeing composition disclosed by the invention for dyeing, the dyed fabric meets the baby-level requirements of Oeko-Tex Standard 100 (2016).

Owner:ZHEJIANG RUNTU INST +1

Synthetic method of p-chlorobenzaldehyde

InactiveCN104447251AGood choiceHigh yieldCarbonyl compound preparation by hydrolysisHalogenated hydrocarbon preparationChlorobenzeneP-chlorobenzaldehyde

The invention discloses a synthetic method of p-chlorobenzaldehyde. The synthetic method comprises the following steps: performing illumination and chlorine reaction on p-chlorotoluene in the presence of a phosphorus trichloride initiator to generate p-chlorobenzal chloride, refining, and then performing catalytic hydrolysis for 6-12 hours to obtain p-chlorobenzaldehyde. The synthetic method of p-chlorobenzaldehyde, disclosed by the invention, is good in selectivity and high in yield.

Owner:CHANGSHU XINHUA CHEM

Anticorrosive self-cleaning paint

InactiveCN104479550ANo shrinkageNo exothermAntifouling/underwater paintsPaints with biocidesDisiloxanePtru catalyst

The invention relates to a self-cleaning paint, particularly an anticorrosive self-cleaning paint. The anticorrosive self-cleaning paint is prepared from the following raw materials in parts by weight: 20-30 parts of tetramethyldivinyl disiloxane, 25-40 parts of methylethoxy silicon oil, 10-15 parts of hydroxy hydrogenous silicon oil, 15-20 parts of chlorotoluene, 1-5 parts of ethanedioic acid, 0.1-0.5 part of cyclopentanol and 0.3-0.7 part of catalyst. The anticorrosive self-cleaning paint can not generate shrinkage or release heat, and has the advantages of moderate hardness, favorable thermal conductivity, favorable electric insulativity and high sealability.

Owner:JIANGSU NUOFEI NEW MATERIAL TECH

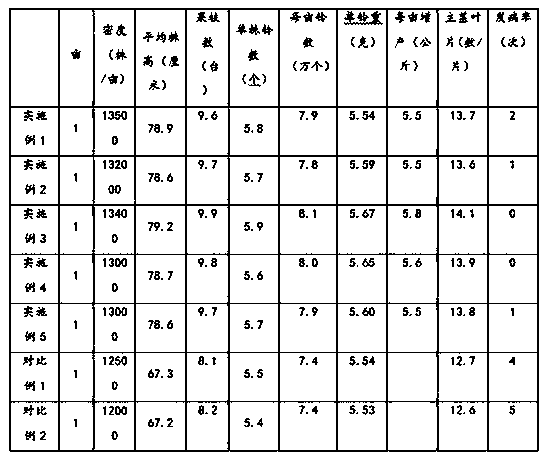

Cotton topping agent and preparation method thereof

InactiveCN110199997AEffectively control prosperityControl prosperityPlant growth regulatorsBiocidePaichongdingSulfonate

The present invention provides a cotton topping agent, which comprises, by weight, 0.8-2 parts of paichongding, 0.8-2 parts of hydroxypropylmethylcellulose, 3-6 parts of beta-methylnaphthalene, 5-10 parts of fosamine-ammonium, 10-15 parts of isonicotinic acid, 10-15 parts of iodophenoxyacetic acid, 15-20 parts of p-chlorotoluene, and 15-20 parts of sodium disec-octyl maleate sulfonate. According to the present invention, the cotton topping agent is organically dissolved, such that the cotton top can be killed, the cotton length can be effectively controlled, the ideal plant type can be shaped,the flower and the bud can be retained, the photosynthesis of cotton can be enhanced, the cotton boll can be increased, the diseases can be prevented and controlled, the boll opening early maturity can be achieved in advance by more than seven days, the micronaire value of cotton is not affected, and the purposes of high yield and stable production are achieved.

Owner:高俊毅

Method for preparing monochlorotoluene with toluene chloridizing method

The invention provides a method for preparing monochlorotoluene with a toluene chloridizing method. The method comprises the following specific steps of: adding iron powder or iron chloride serving as a catalyst into a toluene liquid, adding an aid, introducing chorine gas under a light-shading situation, controlling the temperature of an entire chloridizing process at 0-30 DEG C, and controlling the chlorine-introducing amount to keep the transformation rate of toluene between 96 percent and 99 percent; and cooling, and filtering an ion liquid out to obtain a toluene mono-chlorinated mixed solution. After the aid and iron or iron chloride serving as a catalyst used in the method are mixed and applied to toluene chloridizing, the selectivity of a product on toluene chloride is effectively increased, the highest selectivity on chlorotoluene / o-chlorotoluene is up to 2.1, the selectivity on m-chlorotoluene is less than 0.15 percent, and the selectivity on total dichlorotoluene is less than 1.0 percent.

Owner:常州新东化工发展有限公司

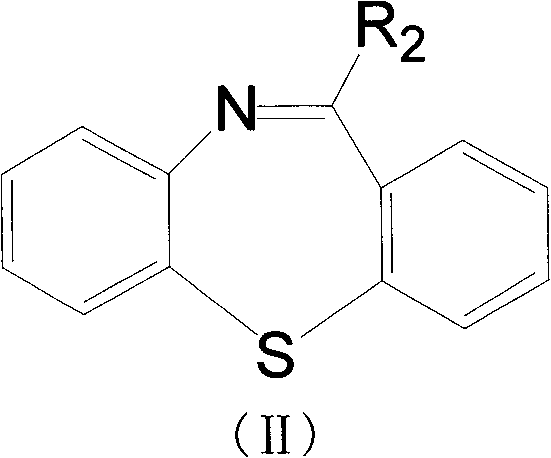

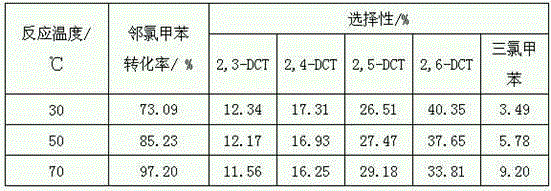

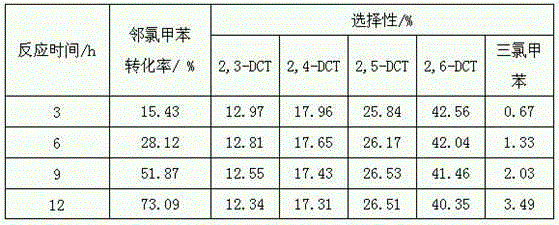

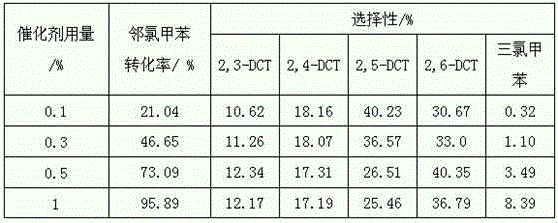

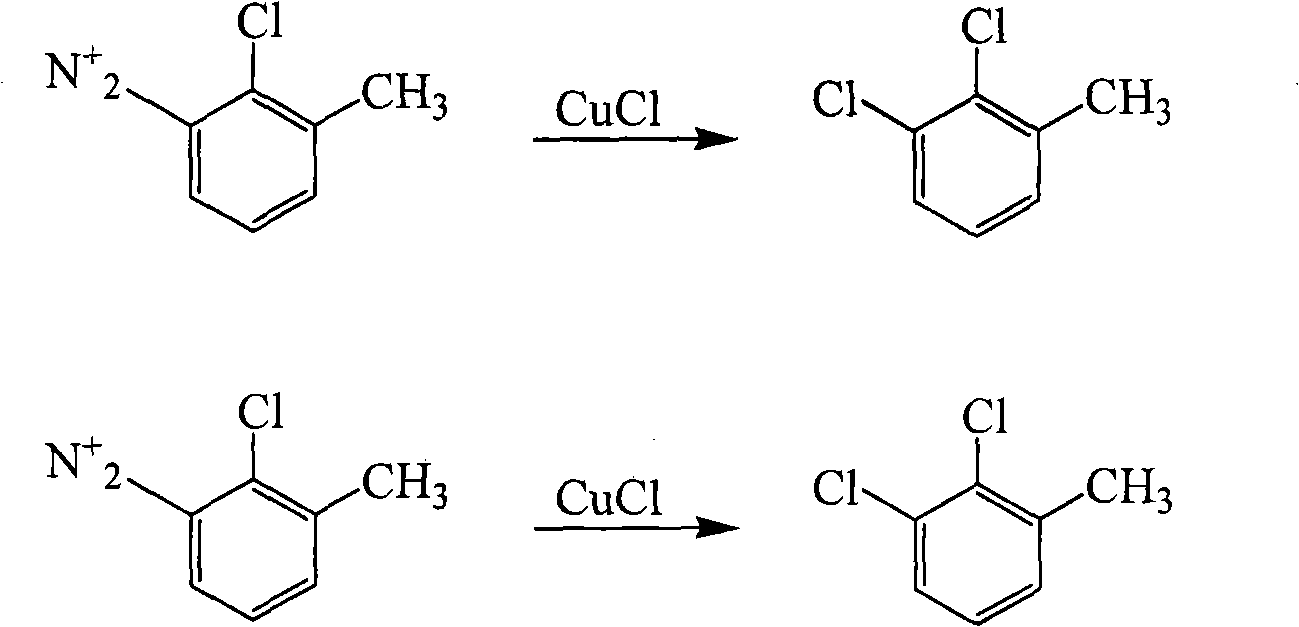

Method for preparing 2,6-dichlorotoluene by catalyzing o-chlorotoluene with ionic liquid

InactiveCN104803827AImprove conversion rateHigh catalytic activityHalogenated hydrocarbon preparationOrtho-chlorotoluenePtru catalyst

The invention discloses a method for preparing 2,6-dichlorotoluene by catalyzing o-chlorotoluene with an ionic liquid. According to the method for preparing 2,6-dichlorotoluene, Cl2 is taken as a chlorinating agent, under the action of a catalyst, namely, an aluminium chlorate ionic liquid, a raw material, namely, o-chlorotoluene, is directionally chlorinated, and the 2,6-dichlorotoluene is prepared; an intermediate of the aluminium chlorate ionic liquid is [BMIM]Cl, the molar ratio of AlCl3 to [BMIM]Cl is 1:3, and the usage amount of the aluminium chlorate ionic liquid accounts for 0.1%-1% of the mass of o-chlorotoluene; the method for preparing 2,6-dichlorotoluene by selectively chlorinating the o-chlorotoluene is simple in technology and mild in reaction condition, the used aluminium chlorate ionic liquid is good in catalytic activity and good in stability, can be separated from a product easily and can significantly improve the selectivity of 2,6-dichlorotoluene, and the method has the very high industrial application value.

Owner:NANJING ZHONGTENG CHEM +1

Production method of p-chlorotoluene

InactiveCN102603468AHalogenated hydrocarbon preparationMetal/metal-oxides/metal-hydroxide catalystsSilicon oxideO-chlorotoluene

The invention discloses a production method of p-chlorotoluene, comprising the steps of chloridizing toluene, removing toluene and rectifying mixed chlorotoluene. Toluene is chloridized by the steps of placing toluene in a chlorination kettle and adding a catalyst in the chlorination kettle, and feeding chlorine at 40-60 DEG C and carrying out a chlorination reaction. The catalyst used in the chlorination reaction is prepared by the steps of reacting alumina, silicon oxide and sodium oxide react at 120-150 DEG C for 6-8 hours and activating in a high-temperature activation furnace at 800 DEG C for 4-6 hours. The production method provided by the invention is simple and convenient and is easy to operate. In the total content of p-chlorotoluene and o-chlorotoluene in final products, the content of p-chlorotoluene is up to above 80%. After rectification, the content of p-chlorotoluene is up to above 99.5%.

Owner:江苏优普生物化学科技股份有限公司

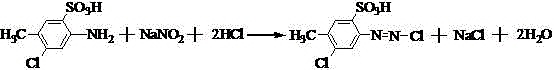

Industrial production method for red with small precipitation on machine surface and method for detecting precipitation on machine surface

ActiveCN104098923AGood application effectGood dispersionMonoazo dyesColor/spectral properties measurementsDispersitySodium nitrite

An industrial production method for a red with small precipitation on a machine surface and a method for detecting precipitation on a machine surface and belong to the technical field of pigment synthesis and detection. Amino chlorotoluene sulfonic acid sodium salt is subjected to acidification to obtain a turbid liquid; a sodium nitrite water solution is added to achieve diazotization so as to obtain a diazotized solution; the diazotized solution and 3-Hydroxy-2-naphthoic acid are subjected to coupled reaction with existence of a dispersant, and the obtained product is laked to obtain a red. Before laking, the dispersant is added to coat the pigment so as to obstruct growth of the pigment crystal form, the dispersity is improved, the applicability of the machine surface precipitation during application of the blue-ray red to plastics is remarkably improved, and the economic benefits are improved; the reaction conditions are mild, the requirements on equipment are low, and the reaction time is short; the dispersant is relatively common, the application difficulty of a modifier is relatively low, the performance of the obtained blue-ray red is good, the heat resistance can reach 220-230 DEG C, and the transference resistance is of 4 grade.

Owner:CROWN CHEMICAL CORP

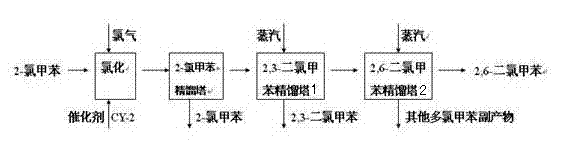

Method for producing 2,6-dichlorotoluene and 2,3-dichlorotoluene by utilizing 2-chlorotoluene to directionally chloridize

The invention relates to a method for producing 2,6-dichlorotoluene and 2,3-dichlorotoluene by utilizing 2-chlorotoluene to directionally chloridize, which comprises the following steps: 1) adding a directional chlorination catalyst; 2) reacting chlorine with 2-chlorotoluene; 3) stopping reaction; and 4) separating components. According to the method, under the action of the directional catalyst (CY-2), the 2-chlorotoluene reacts with the chlorine, and a rectifying column for different components is professionally designed and is used for separating unreacted raw materials and products from by-products, so that the required products, namely, the 2,6-dichlorotoluene and the 2,3-dichlorotoluene, are obtained. According to the method, the adverse factors of high cost and serious pollution of a technology for producing the 2,6-dichlorotoluene according to a traditional diazotization method are eliminated; the ideal reaction products can be obtained by controlling reaction temperature and reaction depth; and different components can be obtained from the reaction products through a rectifying technology according to a boiling point difference of the components.

Owner:江苏超跃化学有限公司

Method for preparing p-chlorobenzaldehyde

InactiveCN104557492ASimple processEase of industrial productionCarbonyl compound preparation by hydrolysisChlorobenzeneP-chlorobenzaldehyde

The invention discloses a method for preparing p-chlorobenzaldehyde, which comprises the following steps: reacting p-chlorotoluene with chlorine in the presence of an initiator under the irradiation of a mercury lamp at the chlorination temperature of 90-140 DEG C to obtain a p-chlorobenzyl chloride / p-trichlorotoluene mixture; and while controlling the average chlorination degree at 1.4-1.6, carrying out catalytic hydrolysis in a 3-6 wt% nitric acid solution for 6-12 hours to obtain the p-chlorobenzaldehyde. By using the method disclosed by the invention, the next hydrolysis step can be directly carried out without separating the intermediate; and thus, the method is simple in technique and can easily implement industrialized production.

Owner:CHANGSHU XINHUA CHEM

Method for selectively preparing o-chlorotoluene

InactiveCN103613482AHigh selectivityPhysical/chemical process catalystsHalogenated hydrocarbon preparationIron powderIodine

The invention provides a novel method for preparing o-chlorotoluene through chlorinating toluene. The technical scheme is as follows: the method comprises the steps of taking a mixture of elemental iodine and iron powder as a catalyst under dark conditions, adding the catalyst into a toluene solution, slowly introducing chlorine gas, controlling the temperature of a whole chlorination process to be 40-50 DEG C, and controlling an introduced chlorine gas volume so as to enable the toluene conversion ratio to be not lower than about 99%. According to the method, after the catalyst is applied to toluene chlorination, the percent content of o-chlorotoluene in a product is increased effectively, the content ratio of o-chlorotoluene to p-chlorotoluene reaches 2.0, the content of m-chlorotoluene is lower than 0.2%, and the total content of poly-chlorotoluene is lower than 5.0%.

Owner:SOUTHEAST UNIV

Disperse dye composition, and preparation method and application thereof

The invention relates to a disperse dye composition, and a preparation method and application thereof. The disperse dye composition comprises a component A formed by one or more of compounds shown in formula (1), a forbidden aromatic amine compound, chlorinated phenol, chlorobenzene, chlorotoluene, any auxiliary materials and other unavoidable impurities. According to the disperse dye composition, not only are various environment-protective indexes conform to the requirements of Oeko-Tex-Standard 100(2016), but also the total content of the forbidden aromatic amine compound in a dye composition chemical product for dyeing is 10ppm or lower, the total content of each chlorinated phenol is 0.5ppm or lower, and the total content of chlorobenzene and chlorotoluene (COCs) is 1ppm or lower. The sewage after the dyeing also can meet the environmental protection requirement; and meanwhile, the use is more convenient and secure. (Shown in description).

Owner:ZHEJIANG RUNTU INST +1

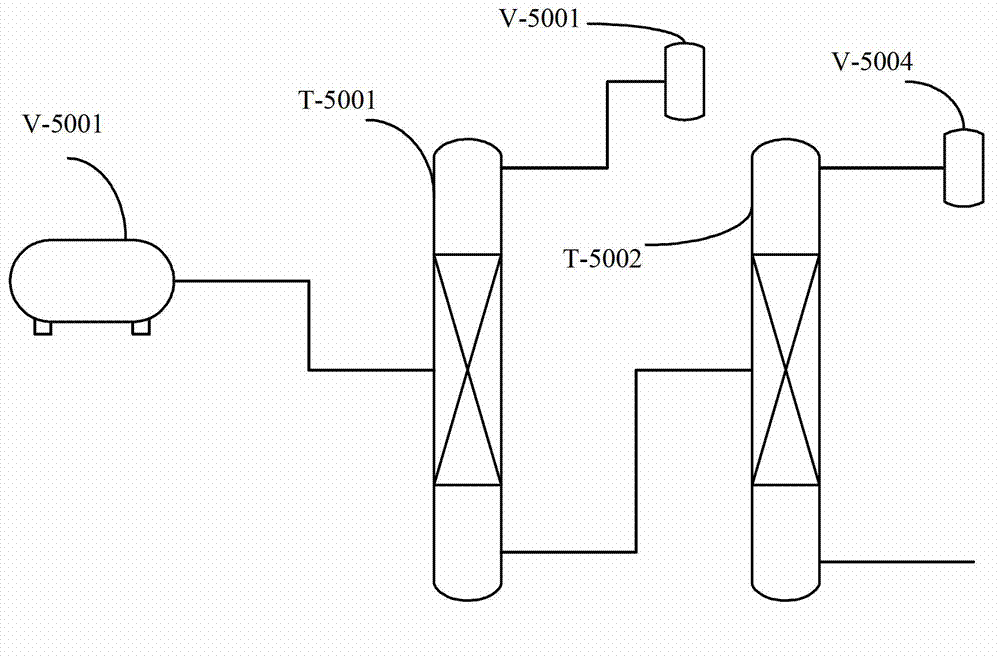

Method and device for producing chlorobenzyl chloride through continuous rectification

ActiveCN103172490AReduce labor intensityContinuous productionHalogenated hydrocarbon preparationSimple Organic CompoundsPulp and paper industry

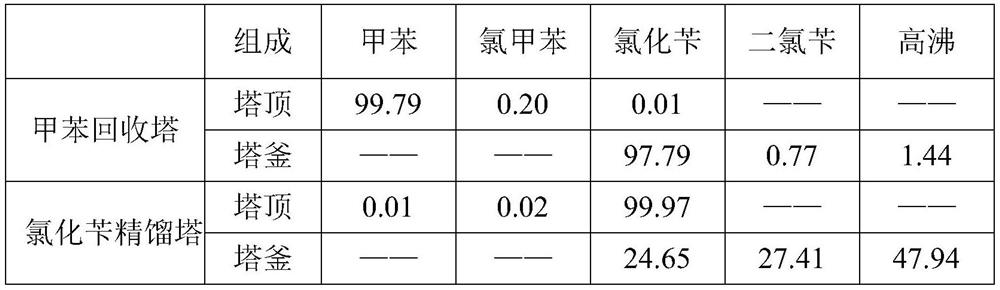

The invention provides a method and a device for preparing an organic compound, belonging to the technical field of rectification. The method comprises the following steps of: feeding a chlorinated product into a first rectifying tower through a middle section, distilling off chlorotoluene through the tower top, and feeding a product at the tower bottom into a second rectifying tower; and feeding the product into the second rectifying tower through the middle section, and obtaining a finished chlorobenzyl chloride product. The device for producing chlorobenzyl chloride through continuous rectification comprises the first rectifying tower and the second rectifying tower; a chlorinated product feeding hole is formed in the middle part of the first rectifying tower; and a discharging hole of a tower kettle is connected to a feeding hole in the middle part of the second rectifying tower. The continuous rectification production process of chlorobenzyl chloride provided by the invention has the advantages of being continuous for production, high in efficiency, steady in finished product quality, high in purity and low in labour intensity.

Owner:江苏长海化工有限公司

Method for preparing chlorotoluene

ActiveCN103102243AReduce dosageHigh activityHalogenated hydrocarbon preparationO-chlorotolueneEthyl Chloride

The invention relates to a method of toluene chlorination reaction and particularly relates to a method for preparing chlorotoluene through the toluene chlorination reaction. The method is characterized by adopting a made-to-order macroporous metal chelating resin as a catalyst; and the catalyst is chelated from an iron chloride water solution with the mass concentration of 10% and D418 styrene cation exchange resin with the particle size of 0.5-1.5 millimeters and the aperture of 0.6-1 nanometer at 60 DEG C under the conditions of stirring and ph of 3.5. Thus, electrophilic reaction during toluene chlorination is mainly carried out in a catalyst pore path; because chlorotoluene is smaller than o-chlorotoluene in molecular dimension and has higher diffusion velocity than o-chlorotoluene in a pore path with certain size, more para-position products are obtained; in addition, the method disclosed by the invention has low requirements on temperature and pressure; and the highest content ratio of chlorotoluene to o-chlorotoluene is 4.1:1 under the conditions of 10-80 DEG C and 0.05-0.1 MPa.

Owner:江苏超跃化学有限公司

Method of liquid phase catalyzing oxihalogenated foluene to halogenated benzaldehyde

ActiveCN1724500AOrganic compound preparationCarbonyl compound preparation by oxidationBromineChemistry

The invention relates to a process for synthesizing compounds of aldehydes and ketones, especially halogenated benzaldehyde, which comprises using mesoporous material as heterogeneous catalyst, transforming halogenated toluene into halogenated benzaldehyde through catalytic oxidation under low-temperature liquid phase. Experimental result shows that, the conversion rate of chloro- and bromo- toluene and selectivity of halogenated benzaldehyde are both high.

Owner:YUNNAN UNIV

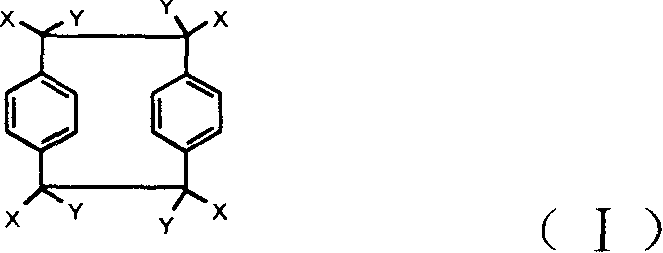

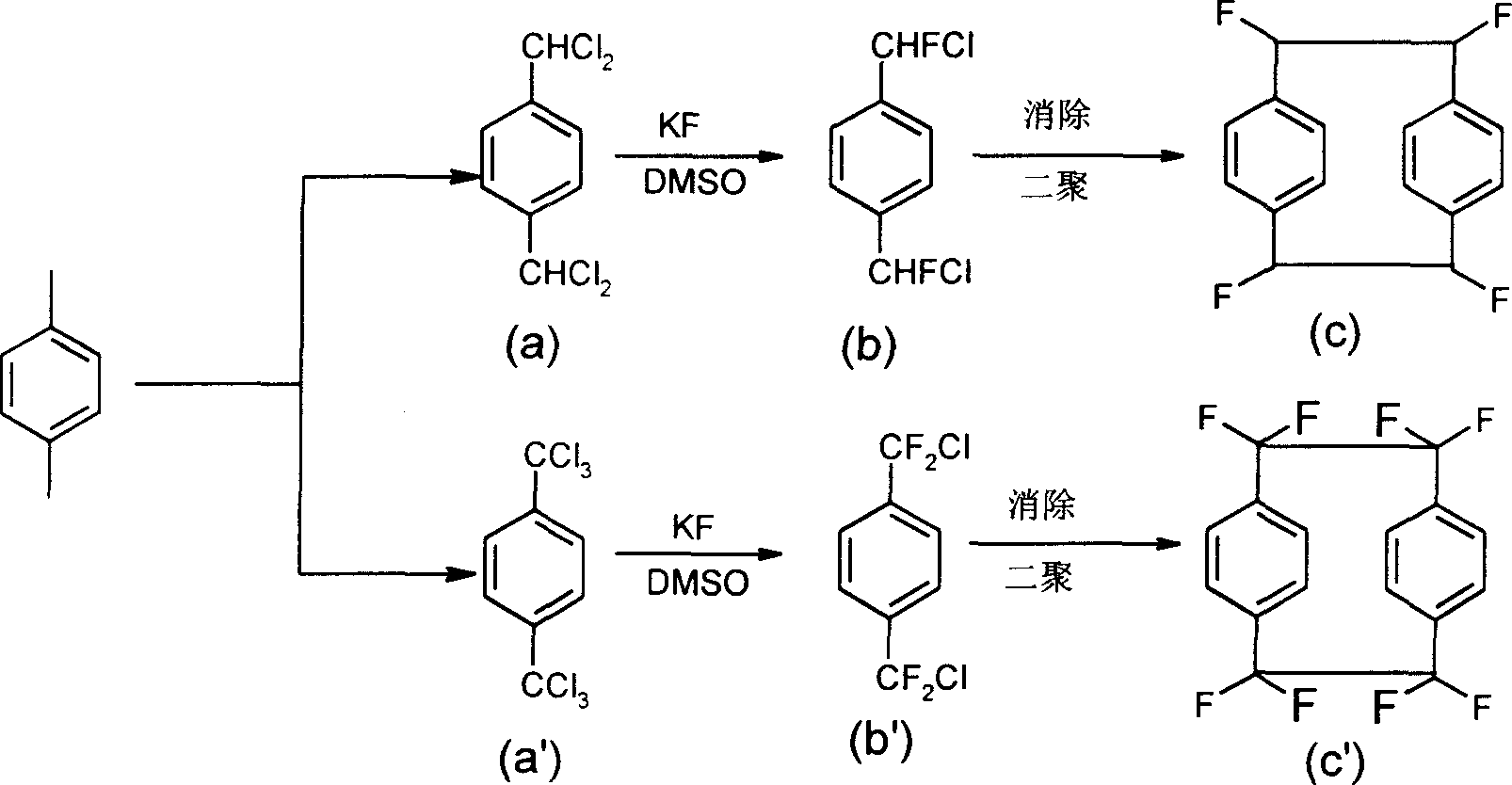

Method for synthesizing fluoro-polypxylene

InactiveCN1696088AHigh yieldStable outputHalogenated hydrocarbon preparationMetallole2-Chlorotoluene

A process for synthesizing the poly-p-fluoroxylene from P-xylene includes controlling the reaction point whiel chlorinating to obtain P-2,2-chlorotoluene or p-2,3-chlorotoluene, fluorinating to obtain p-2-Cl-fluorotoluene or p-2,2-fluoro-chlorotoluene, and catalytic cyclizing polymerization to obtain 1,2,9,10-tetrafluoro-poly-p-xylene or 1,1,2,2,9.9,10,10-octofluoro-poly-p-xylene.

Owner:SHANGHAI RECORD PHARM CO LTD +1

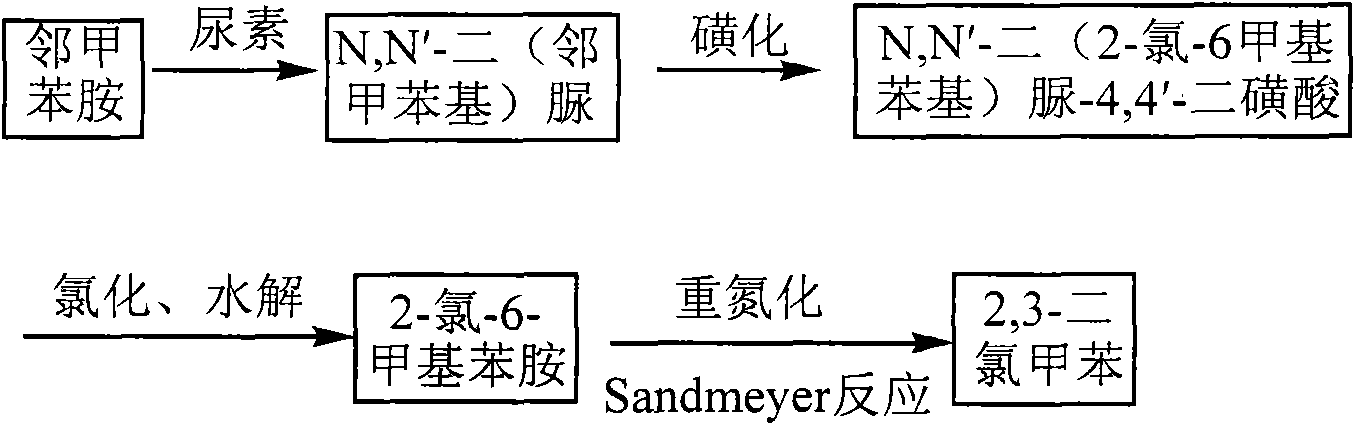

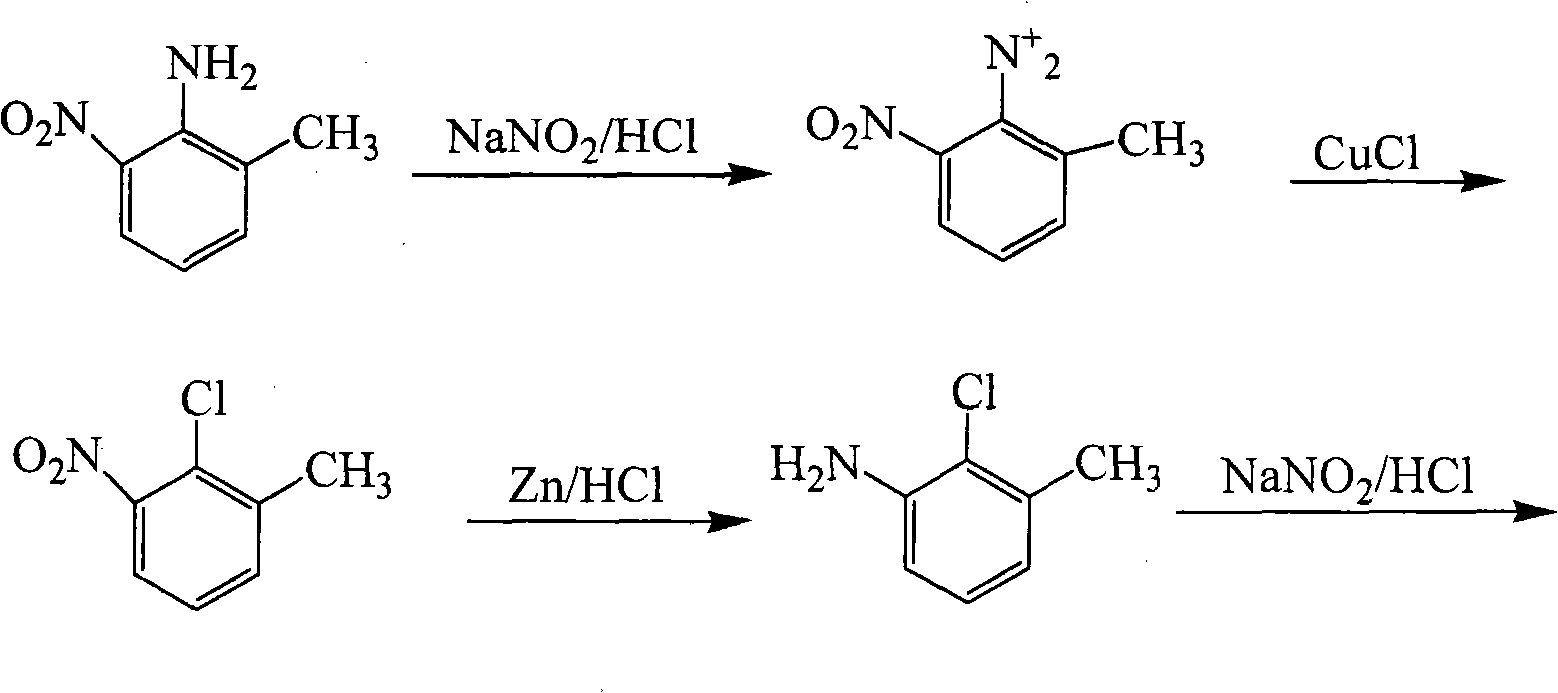

Method for preparing 2,3-dichlorotoluene

InactiveCN102079688ALow priceThe reaction operation is not cumbersomeChemical recyclingHalogenated hydrocarbon preparationSandmeyer reactionMethylaniline

The invention discloses a method for preparing 2,3-dichlorotoluene. The method comprises the following steps of: performing condensation on o-toluidine serving as an initiative raw material and urea to obtain N,N'-di(tolyl) urea; forming a sulfonic blocking group at an amino para-position through sulfonation; performing chlorination, removing carbonyl through hydrolysis and removing the blocking group through hydrolysis to obtain 2-chlorine-6-methylaniline; and performing diazotization and a Sandmeyer reaction to synthesize 2,3-dichlorotoluene to obtain the product. The method has the advantages of environmental friendliness, simple process, low cost and the like.

Owner:INNER MONGOLIA UNIV OF TECH

Method for synthesizing 7-bromo-6-chloro-4-quinazolinone

ActiveCN102351790ASave raw materialsThe reaction steps are simpleOrganic chemistrySodium bicarbonateNitrogen gas

The invention discloses a method for synthesizing 7-bromo-6-chloro-4-quinazolinone. The method comprises the following steps of: (1) dripping liquid bromine into suspension of m-chlorotoluene, n-butyl bromide and anhydrous ferric trichloride, washing with water and a saturated sodium bicarbonate solution, distilling, and recrystallizing; (2) mixing water, pyridine, tertiary butanol and the like, dissolving a product in the step (1) and potassium permanganate in a mixed solution, heating and refluxing, continuously adding potassium permanganate, filtering, washing with boiling water, regulating the pH value, cooling and filtering; (3) dissolving a product in the step (2) in a mixed solution of stronger ammonia water and ethyl acetate at room temperature under the protection of nitrogen, dripping into suspension of cuprous oxide and stronger ammonia water, adding ethylene diamine tetraacetic acid (EDTA), regulating the pH value, evaporating the ethyl acetate, cooling, and performing suction filtration; and (4) mixing a product in the step (3) and formamide, dissolving in dimethyl formamide (DMF), heating and refluxing, cooling, precipitating, filtering, washing with absolute ethanol, and recrystallizing by using ethylene glycol monomethyl ether. The method has the advantages of cheap raw materials, simplified steps and practicable process, avoids 6-bromoisatin, and is suitable for industrial production.

Owner:JIANGXI WANLI PHARMA CO LTD

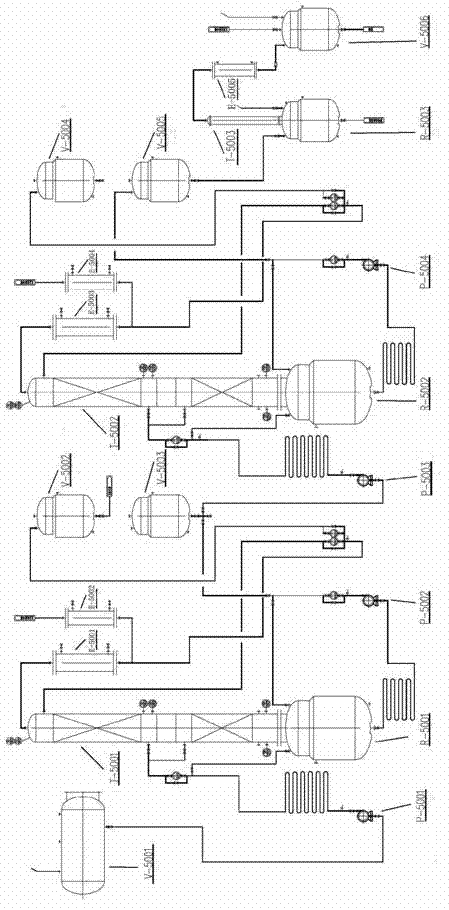

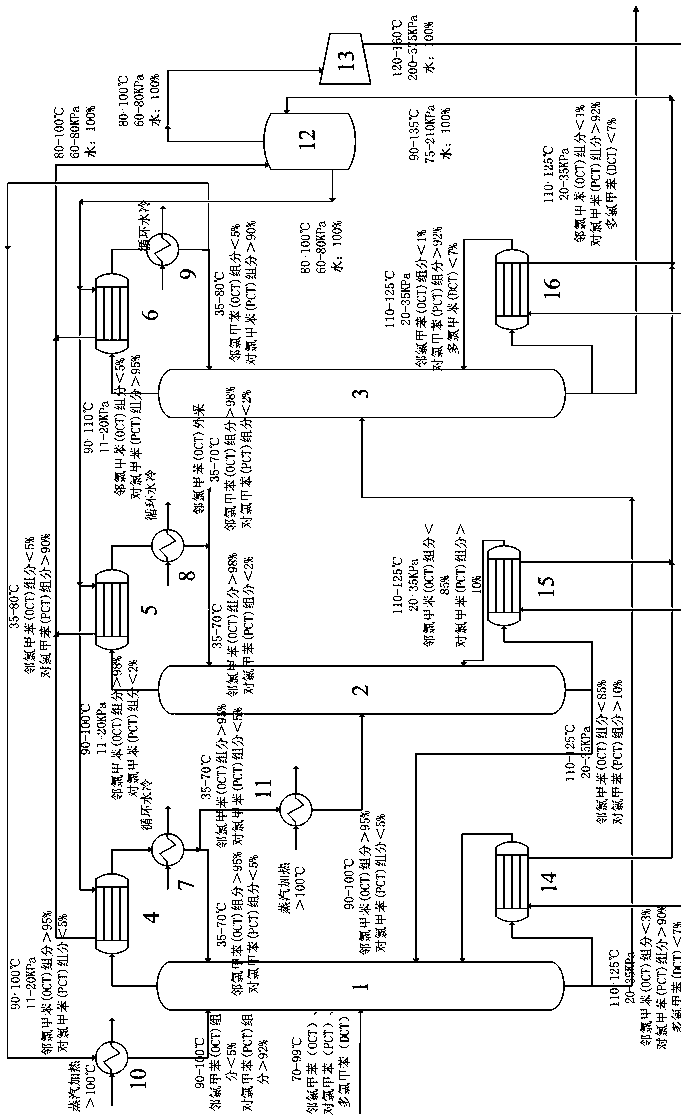

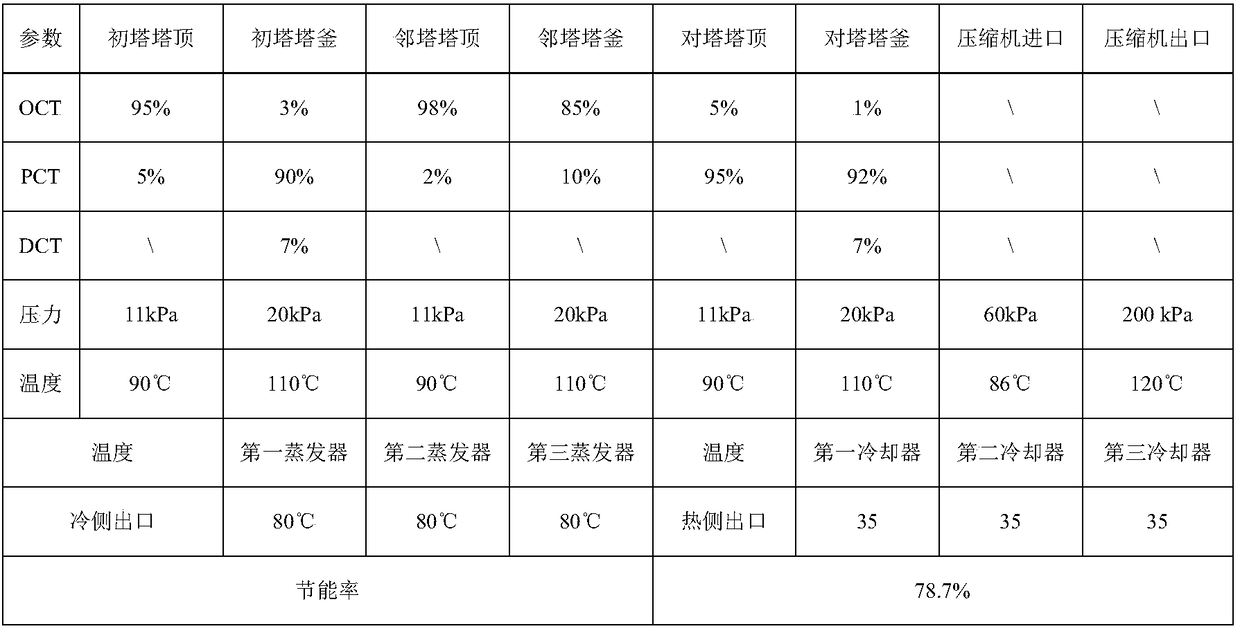

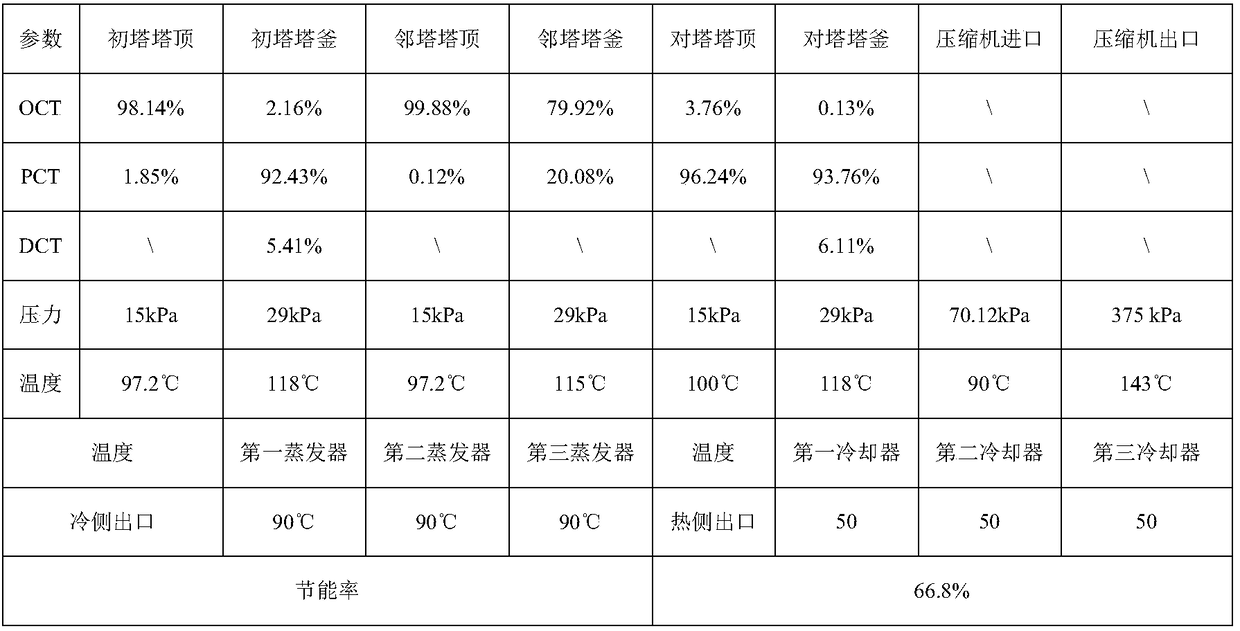

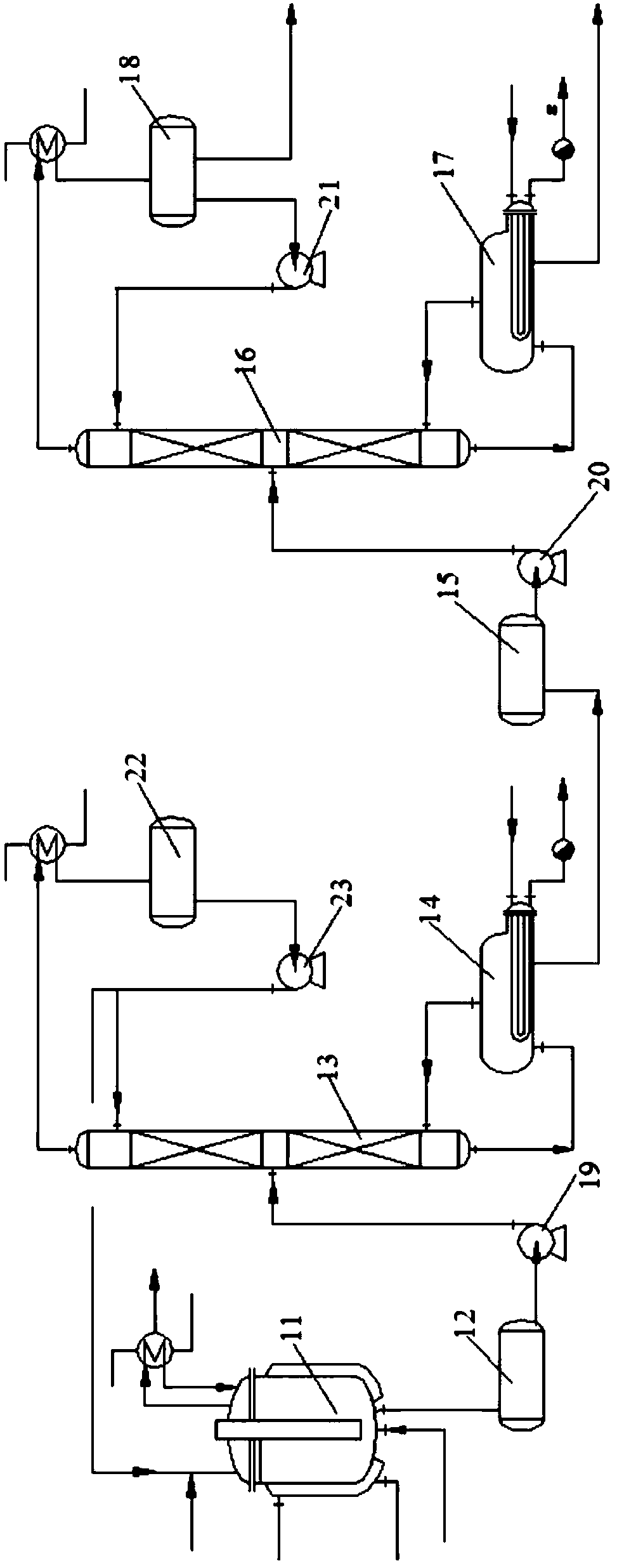

Mixed chlorotoluene MVR (mechanical vapor recompression) rectification system and method

PendingCN109134189AChemical industryHalogenated hydrocarbon separation/purificationChemical industryLiquid water

The invention belongs to the field of chemical industry and relates to a mixed chlorotoluene MVR (mechanical vapor recompression) rectification system and method. The system herein comprises a primarycolumn, an ortho-column, a para-column, evaporators, a cooler, a gas-liquid separation tank, a vapor compressor, reboilers and the like. The system is characterized in that continuous rectification via the primary column, ortho-column and para-column by means of rectification is carried out; mixed chlorotoluene mother liquor that is preheated is processed via the primary column to obtain crude o-chlorotoluene and p-chlorotoluene; the crude o-chlorotoluene and p-chlorotoluene are fed respectively into the ortho-column and the para-column for continued rectification; o-chlorotoluene with purityof higher than 98% is acquired from the top of the ortho-column; p-chlorotoluene with purity of higher than 92% is acquired from the bottom of the ortho-column; distillates from the three columns aresubjected to heat exchanging with liquid water in respective top evaporators; the liquid water absorbs heat and evaporates into water vapor; the water vapor is separated and purified by the gas-liquid separation tank before the resultant is heated and pressurized in the vapor compressor; the pressurized material enters the reboilers at the bottoms of the three columns to release latent heat to heat part of the bottom distillates. The system and method herein have the advantages of high separation efficiency, low energy consumption, low operation cost and the like.

Owner:JIANGSU LEKE ENERGY SAVING TECH CO LTD

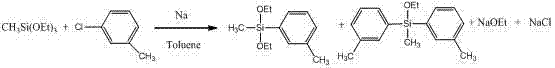

M-methylphenyldiethoxymethylsilane and preparation method thereof

ActiveCN102898454AMild reaction conditionsSimple processGroup 4/14 element organic compoundsSolventSilicon

Owner:HANGZHOU NORMAL UNIVERSITY

Method for preparing parachlorotoluene

InactiveCN105399600AHigh activityReduce dosageHalogenated hydrocarbon preparationMolecular sieveReaction rate

The invention provides a method for preparing parachlorotoluene. The method comprises the following steps of adding raw materials of methylbenzene and catalysts into a reaction kettle, and feeding chlorine into the reaction kettle to subject methylbenzene and chlorine to a liquid phase ring chlorination reaction; performing aeration after the reaction is completed, removing chlorine and hydrogen chloride remaining in reaction liquid, and rectifying the reaction liquid to separate out un-reacted methylbenzene and a small quantity of dichlorotoluene to obtain mixed chlorotoluene; separating mixed chlorotoluene through a melt crystallization method to obtain high-purity parachlorotoluene. According to the method, AlCl3 loaded L-shaped molecular sieve based catalysts are used for catalyzing methylbenzene for selective chlorination, the reaction rate is high, the catalytic activity is high, selectivity of parachlorotoluene is good, the requirement for process conditions is low, and the catalyst use amount is small; the catalyst is high in activity and capable of being recycled, and a good industrial prospect is achieved.

Owner:NANJING ZHONGTENG CHEM

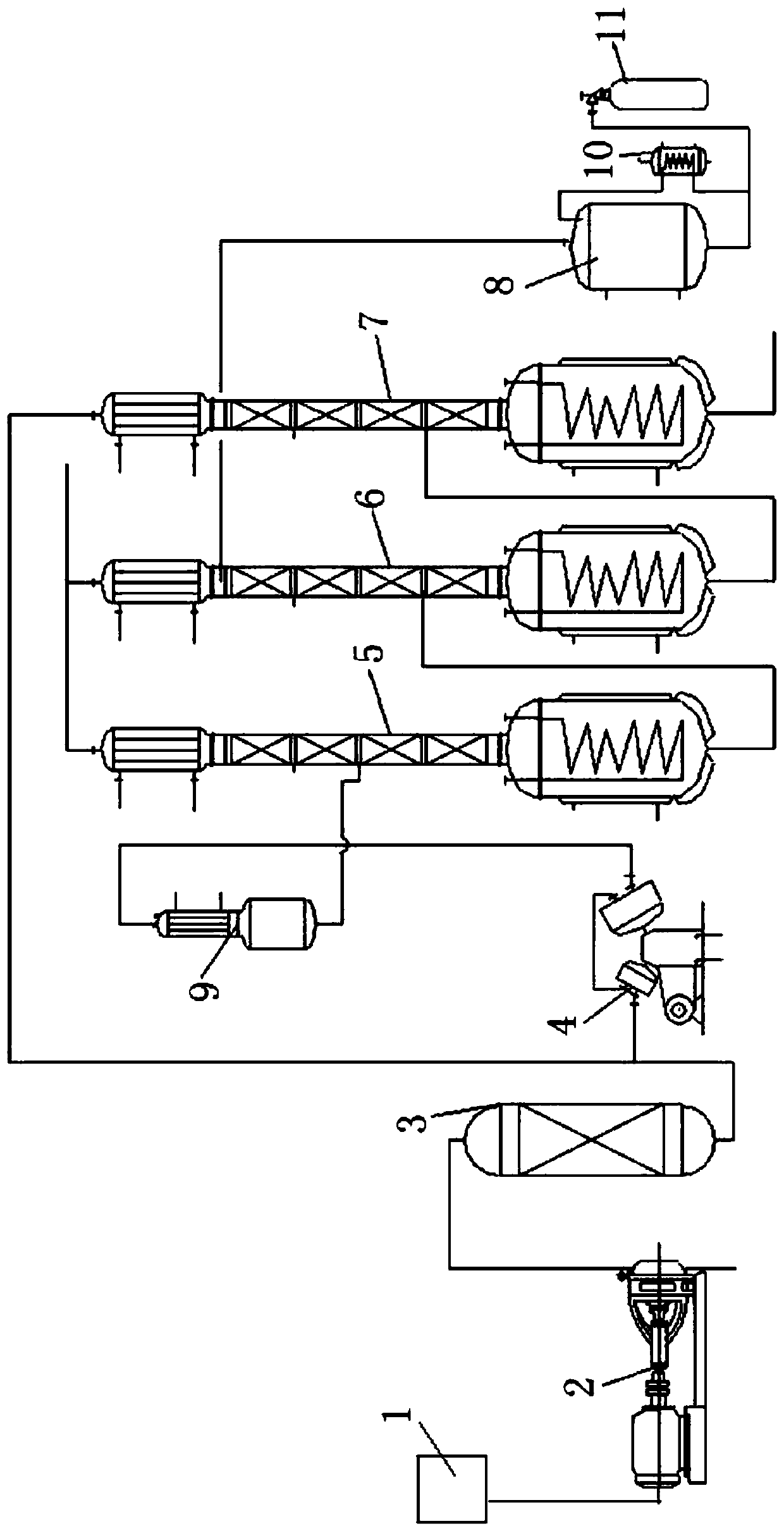

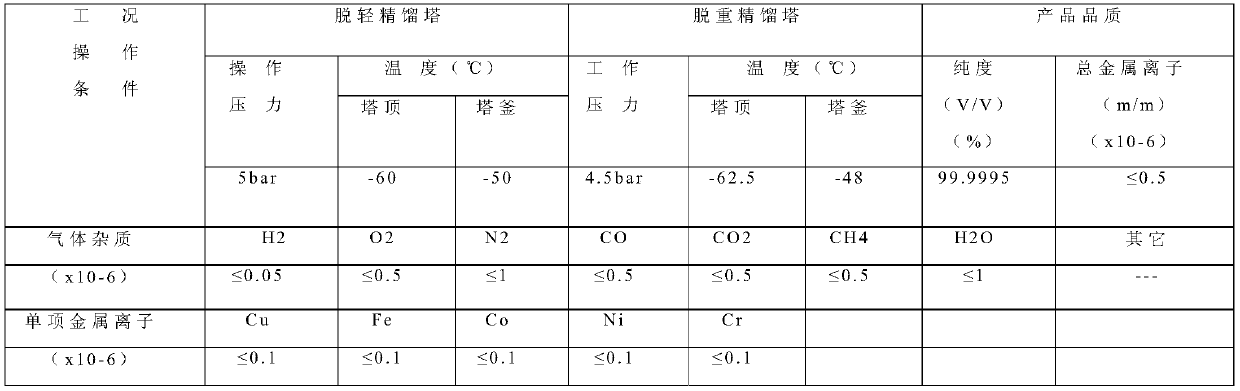

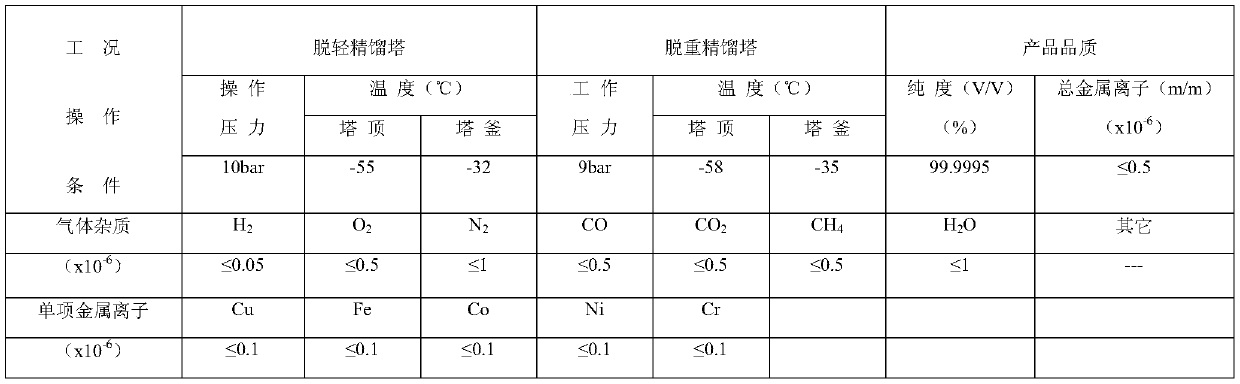

Preparation method of electronic-grade high-purity hydrogen chloride

PendingCN110255501AReduce pressure on environmental protectionImprove securitySolidificationLiquefactionHydrogen chloridePollution

The invention discloses a preparation method of electronic-grade high-purity hydrogen chloride. The preparation method includes subjecting toluene and chlorine to a chlorination reaction to produce chlorotoluene and a by-product, namely a hydrogen chloride gas, dewatering, liquefying and rectifying the by-product as a raw material to remove light components, and further performing rectification to remove heavy components to obtain the electronic-grade high-purity hydrogen chloride. The preparation method has the advantages that an original process for converting hydrogen chloride produced after toluene chlorination into hydrochloric acid is changed into a method for producing the electronic-grade high-purity hydrogen chloride, and the industrial hydrochloric acid is basically surplus waste liquid in actual chemical production and needs to be treated; by the preparation method, waste is turned into treasures, and new pollution is avoided.

Owner:SUZHOU JINHONG GAS CO LTD

Environmentally-friendly benzyl chloride production method and device

The embodiment of the invention discloses an environmentally-friendly benzyl chloride production method. The method comprises the following steps: feeding chlorine and methylbenzene into a chlorination reactor; performing optical chlorination; conveying the obtained chlorination liquid into a chlorination liquid storing tank for storing; conveying the chlorination liquid from the chlorination liquid storing tank into the middle part of a defluvium unguium rectifying tower; performing defluvium unguium rectifying; conveying the crude benzyl chloride product subjected to defluvium unguium rectifying into a crude product storing tank for temporary storing; conveying the crude benzyl chloride product from the crude product storing tank into the middle part of a finished product rectifying tower for rectifying the finished product; sampling and analyzing at every two hours; collecting the materials on the top of the tower when the benzyl chloride content is beyond 99.5wt%, the chlorotoluenecontent is less than 0.02wt%, and the 2, 4-dichlorotoluene content is less than 0.002wt%; and then feeding into a finished product packing system. With the adoption of the method, the benzyl chloridegoods containing chlorotoluene less than 300ppm and 2, 4-dichlorotoluene less than 20ppm can be continuously produced; and the demand of a dye company on environmentally-friendly benzyl chloride canbe met.

Owner:QIANJIANG XINYIHONG ORGANIC CHEM

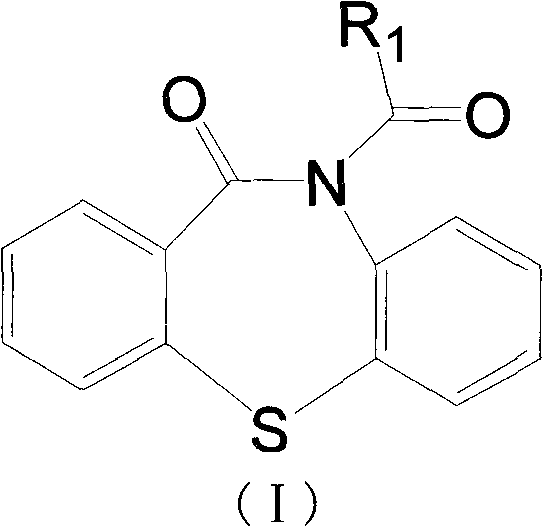

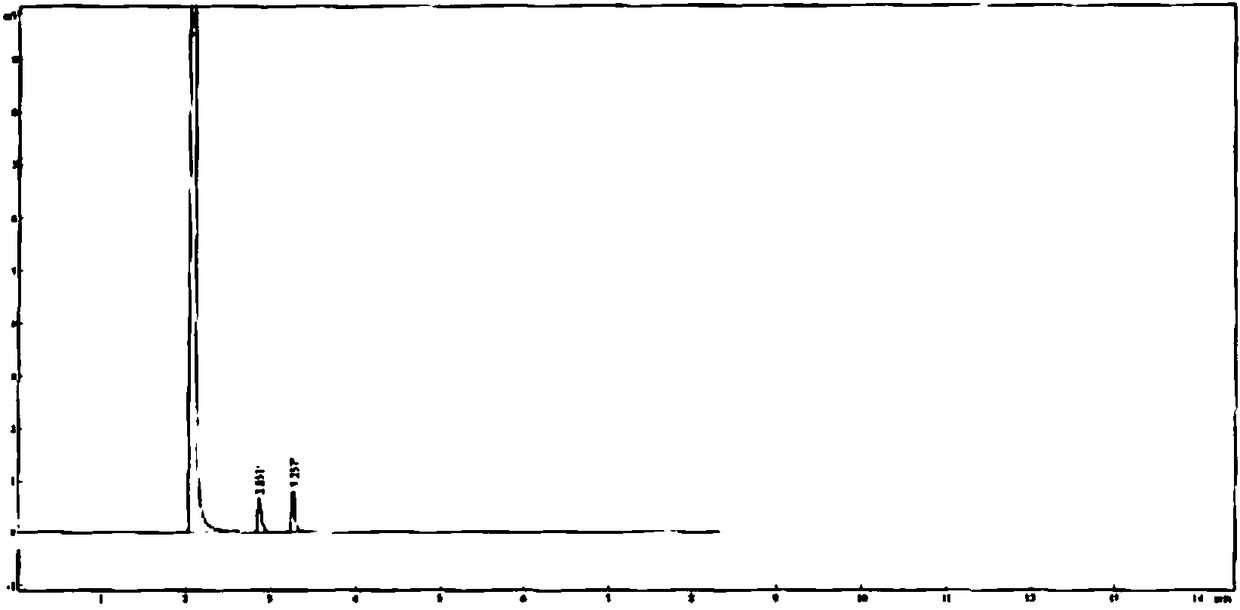

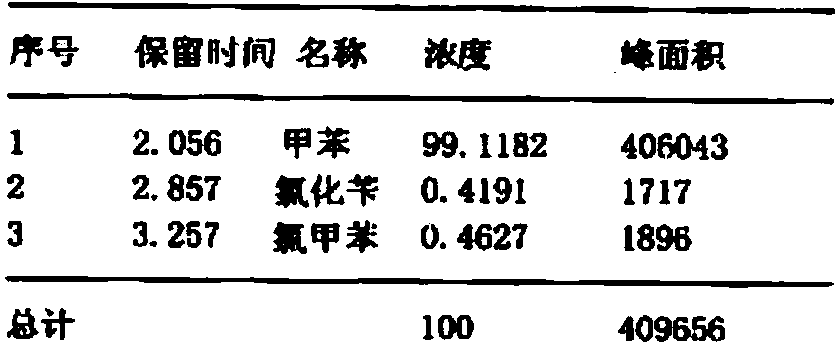

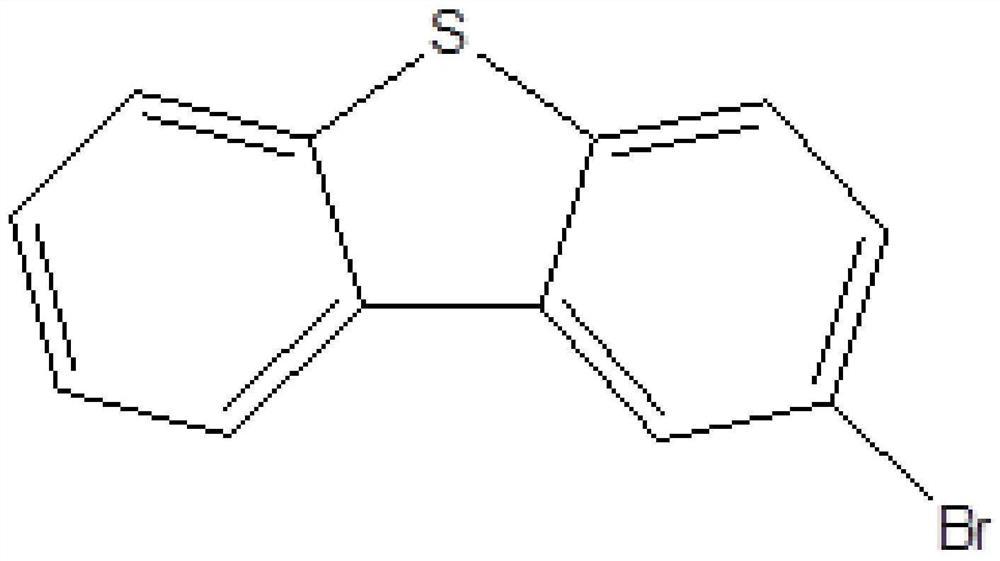

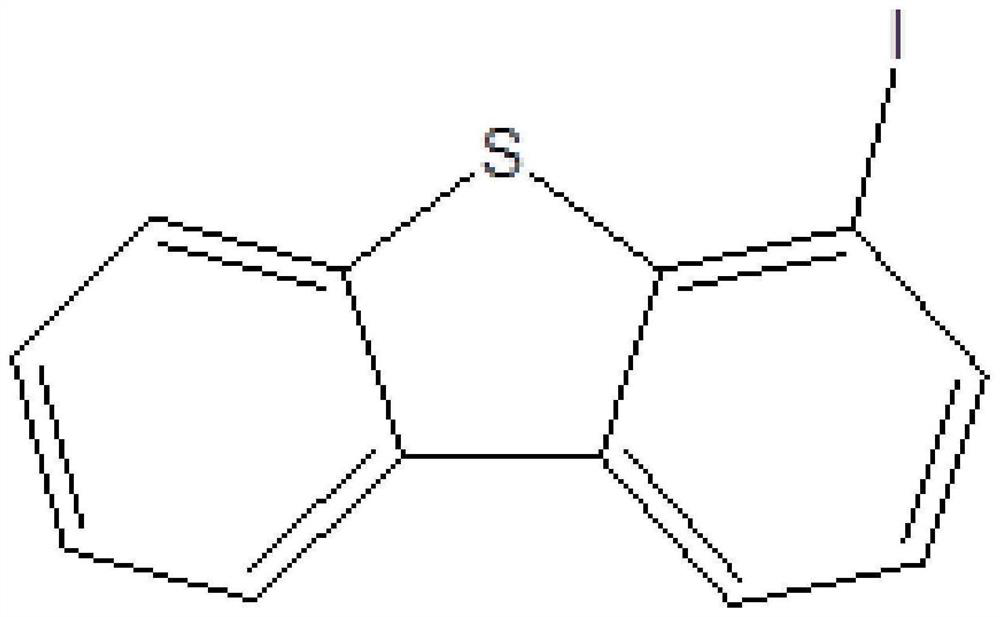

Method for selectively preparing o-chlorotoluene

ActiveCN113896612AHigh selectivityHalogenated hydrocarbon preparationOrtho-chlorotoluenePtru catalyst

The invention discloses a method for selectively preparing o-chlorotoluene, which is characterized in that a mixture of iron powder and a dibenzothiophene compound is used as a combined catalyst, and chlorine is introduced into toluene under a dark condition to obtain o-chlorotoluene. The temperature in the chlorination process is controlled to be 30-50 DEG C, and the conversion rate of toluene is 98-100% by controlling the chlorine introduction amount. The chlorination liquid obtained after the catalyst is applied to toluene chlorination takes o-chlorotoluene as a main product, the percentage content of o-chlorotoluene is effectively increased, the highest content of o-chlorotoluene reaches 68.50%, the content of m-chlorotoluene is smaller than 0.15%, the content of total dichlorotoluene is smaller than 2.21%, and the mass ratio of o-chlorotoluene to p-chlorotoluene reaches 2.28.

Owner:常州新东化工发展有限公司

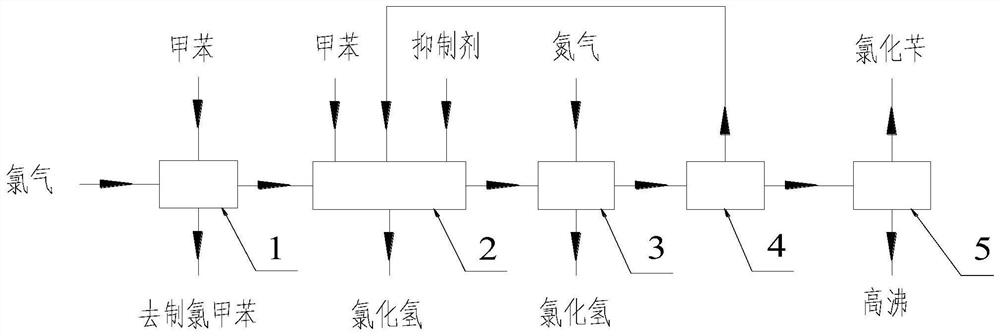

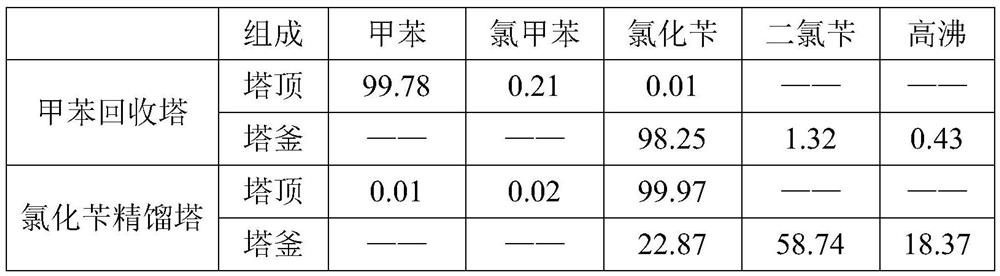

Method for reducing byproduct chlorotoluene in benzyl chloride production process

PendingCN112079685AReduce the content of metal ionsReduce generationHalogenated hydrocarbon preparationPhosphoric Acid EstersPhotocatalytic reaction

The invention discloses a method for reducing byproduct chlorotoluene in a benzyl chloride production process. The method comprises the following steps: by using dehydrated or deironed toluene and chlorine as raw materials and phosphate and other substances as side reaction inhibitors, carrying out heating and photocatalytic reaction in a photochlorination kettle to generate benzyl chloride, and adding the reaction solution into a toluene recovery tower to recover unreacted toluene, and adding the tower bottom material of the recovery tower into a benzyl chloride rectifying tower, and carryingout vacuum rectification and purification to obtain benzyl chloride with the purity of more than 99.9%. According to the method provided by the invention, the content of metal ions in the material can be reduced, and meanwhile, the inhibitors are added to promote partial inactivation of the metal ions, so that the generation of chlorotoluene is reduced, the purity of the benzyl chloride obtainedafter rectification is high, and the impurity content can reach the standard of environment-friendly benzyl chloride.

Owner:CHINA SALT CHANGZHOU CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com