M-methylphenyldiethoxymethylsilane and preparation method thereof

A technology of m-methylphenyldiethoxymethylsilane and methylphenyldiethoxymethylsilane, which is applied to compounds containing silicon element m-methylphenyldiethoxymethylsilane and its In the field of synthesis, it can solve the problems of solvent recycling and environmental pollution, and achieve the effects of saving operating costs, simple separation and purification, and improving the utilization rate of reaction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

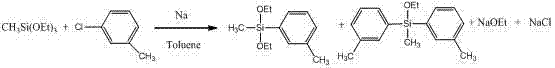

Method used

Image

Examples

Embodiment 1

[0023] In a dry 250mL four-neck flask equipped with a reflux condenser, a mechanical stirrer and a Pt-100 platinum resistance, add 100g (0.561 moles) of methyltriethoxysilane, and add 18g (0.783 moles) of freshly cut Sodium flakes, heat up to 102°C, beat the sodium flakes into sodium sand; within 4 hours, add 47g (0.371 moles) m-chlorotoluene into the reaction system dropwise through a constant pressure dropping funnel, and control the reaction temperature between 108~110 ℃, continue to react for 2 h after the dropwise addition, after cooling to 25°C, slowly add 1.5g (0.0326 moles) of absolute ethanol within 0.5h to neutralize the excess metal sodium, and then cool at 25°C Keep it for 1h; then add 10mL (0.083 moles) of dimethyldichlorosilane dropwise to the mixture within 1h to neutralize the generated sodium alkoxide; after the dropwise addition, continue the reaction at this temperature for 3h. Then the reaction mixture was suction-filtered under reduced pressure to obtain a...

Embodiment 2

[0026] In a dry 1000mL four-neck flask equipped with a reflux condenser, a mechanical stirrer and a Pt-100 platinum resistance, add 450g (2.524 moles) of methyltriethoxysilane, and add 58.2g (2.530 moles) of freshly chopped The sodium flakes were heated up to 105°C, and the sodium flakes were beaten into sodium sand; within 2 hours, 160g (1.264 moles) of m-chlorotoluene was added dropwise to the reaction system through a constant pressure dropping funnel, and the reaction temperature was controlled between 102~ 105°C, continue to react for 4 hours after the dropwise addition, after cooling to 30°C, slowly add 5.1g (0.111 moles) of absolute ethanol within 1.0h to neutralize the excess metallic sodium, and then cool at 30°C Then, 30mL (0.257 moles) of methyltrichlorosilane was added dropwise to the mixture within 2h to neutralize the generated sodium alkoxide; after the dropwise addition was completed, the reaction was continued at this temperature for 4h. Then the reaction mixt...

Embodiment 3

[0029]In a dry 500mL four-neck flask equipped with a reflux condenser, a mechanical stirrer and a Pt-100 platinum resistance, add 253g (1.419 moles) of methyltriethoxysilane, and add 21.8g (0.948 moles) of freshly chopped The sodium flakes were heated up to 104 ° C, and the sodium flakes were beaten into sodium sand; within 6 hours, 60 g (0.474 moles) of m-chlorotoluene was added dropwise to the reaction system through a constant pressure dropping funnel, and the reaction temperature was controlled between 105~ 108°C, continue to react for 5 hours after the dropwise addition, after cooling to 20°C, slowly add 2.0g (0.043 moles) of absolute ethanol within 1.0h to neutralize the excess metal sodium, and then cool at 20°C Then, 13mL (0.108 moles) of dimethyldichlorosilane was added dropwise to the mixture within 1.5h to neutralize the generated sodium alkoxide; after the dropwise addition, the reaction was continued at this temperature for 2h. Then the reaction mixture was suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com