Patents

Literature

1124results about How to "Solving Recycling Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst containing tungsten, vanadium and titanium

InactiveCN102936039AHigh purityHigh recovery rateTitanium dioxideVanadium compoundsHigh concentrationAmmonium paratungstate

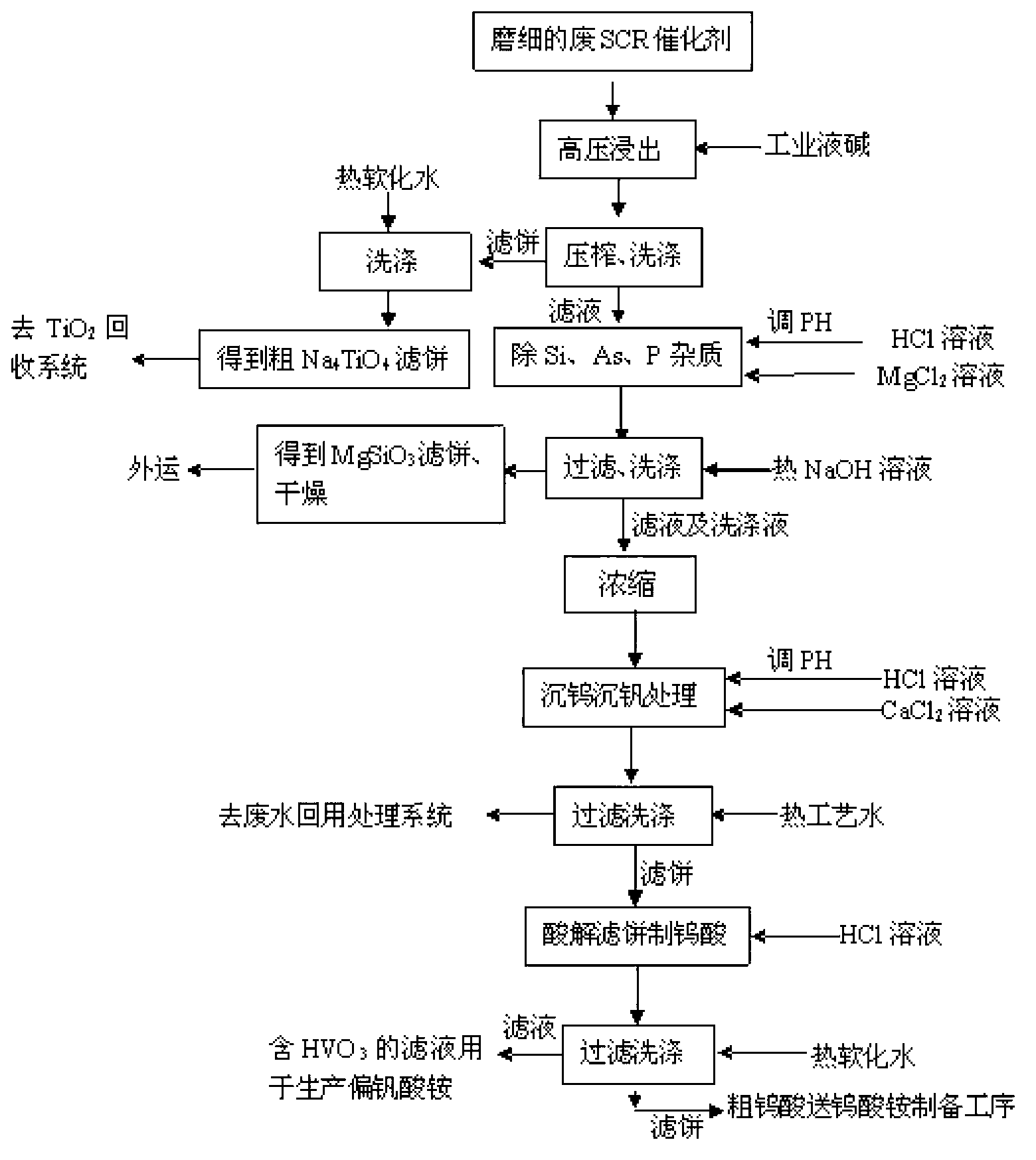

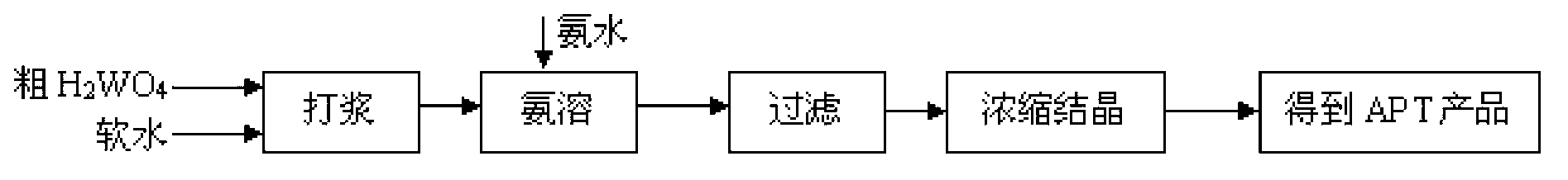

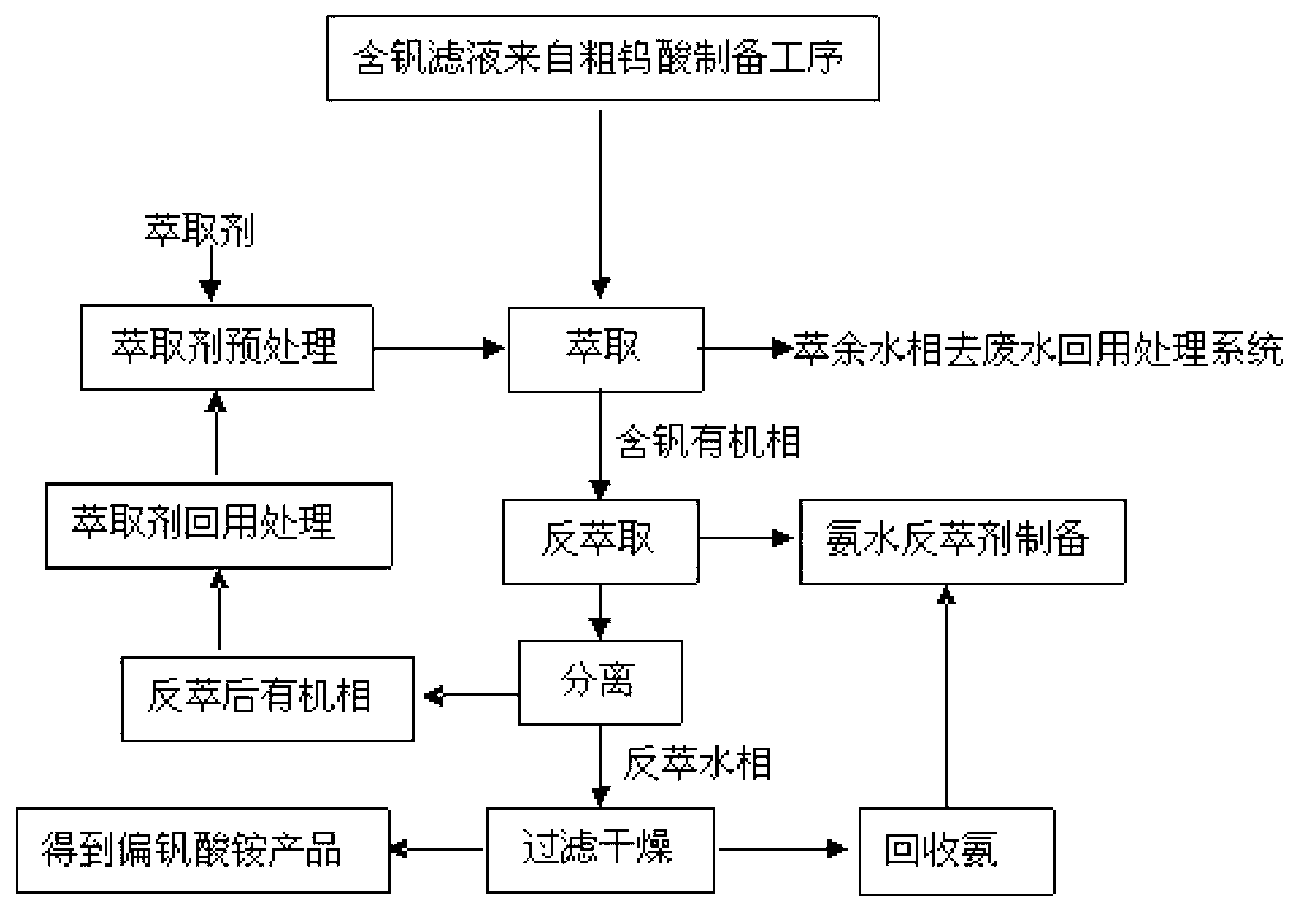

The invention discloses recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst. The process includes the following steps: a, preprocessing the SCR waste catalyst and leaching at the high temperature and under high pressure; b, adding hydrochloric acid into leaching liquid, adjusting pH, and removing impurities; c, adding hydrochloric acid into the leaching liquid, reacting, calcining and preparing rutile titanium dioxide; d, preparing ammonium paratungstate; e, preparing ammonium metavanadate; and f, recycling and treating waste water. Main products of ammonium paratungstate, ammonium metavanadate and rutile titanium dioxide obtained in the process are high in purity and recovery rate. By-products of silicon magnesium slags, salty mud, high-concentration sodium chloride liquid and barium sulfate dregs are high-purity harmless useful goods. The process is free of harmful secondary pollutant emission, environment-friendly and capable of circulating, has high economical and social benefit and is practicable.

Owner:曾瑞

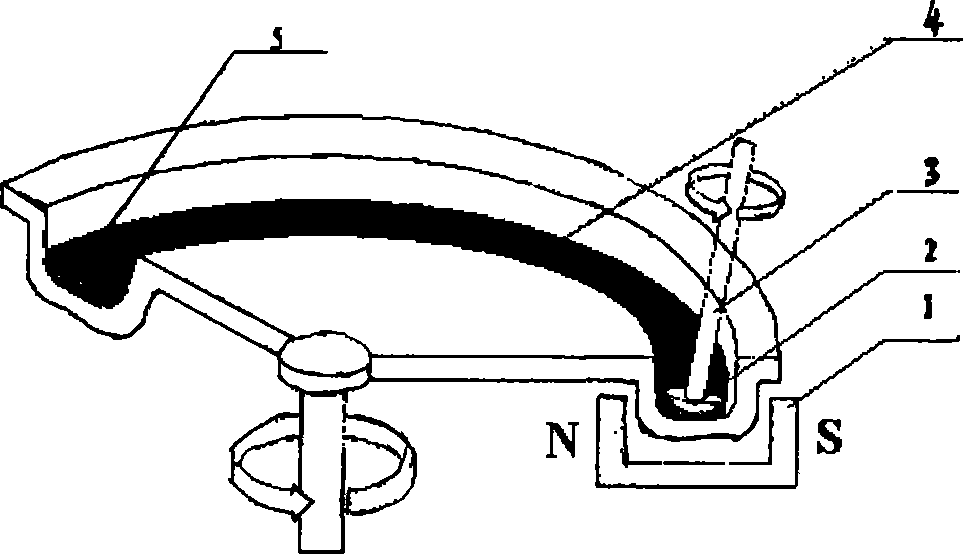

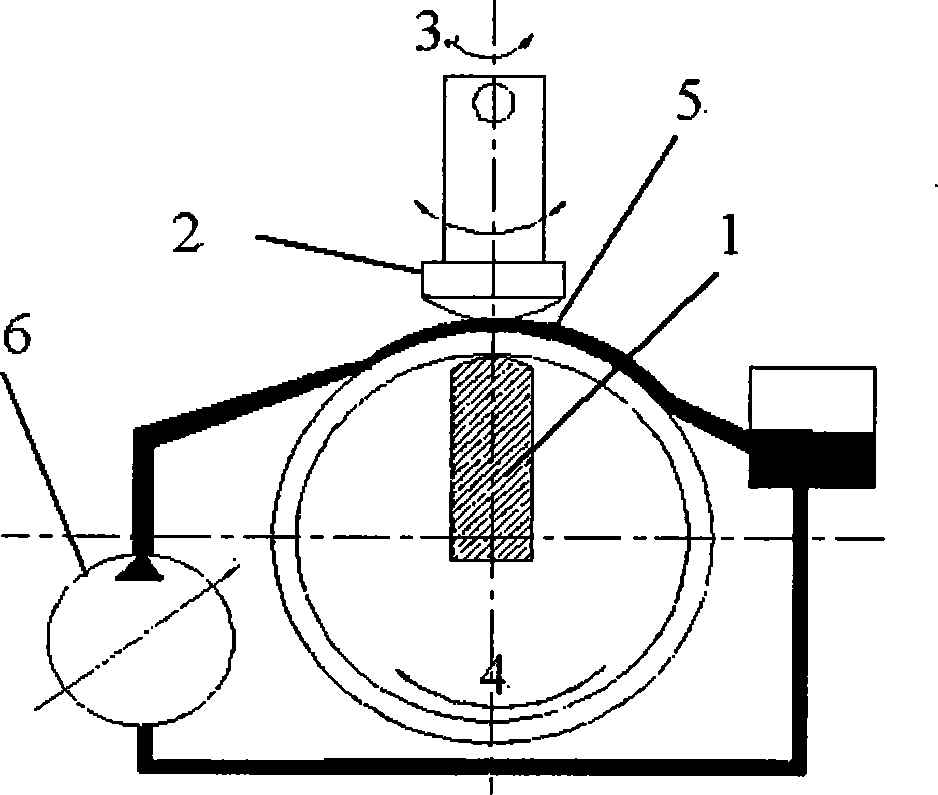

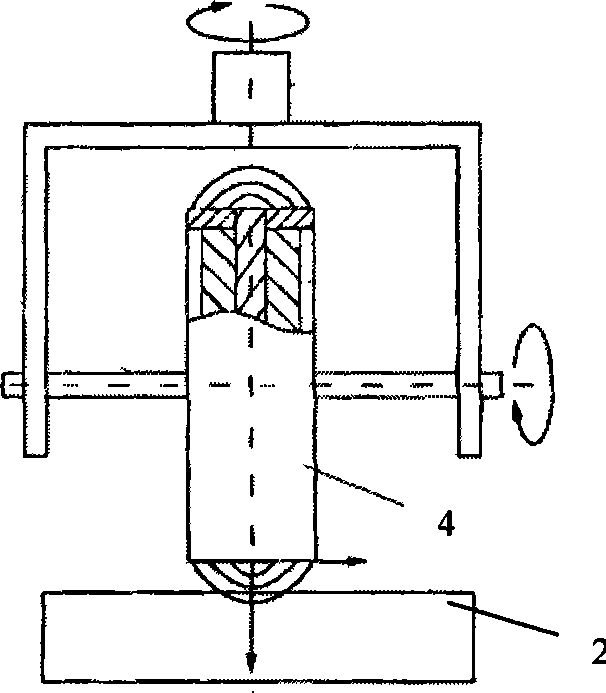

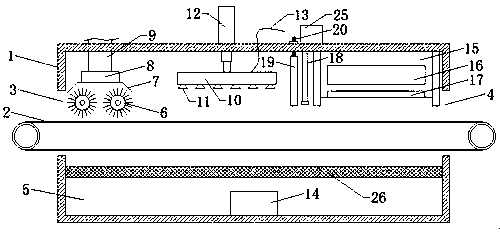

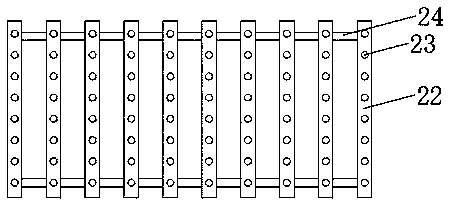

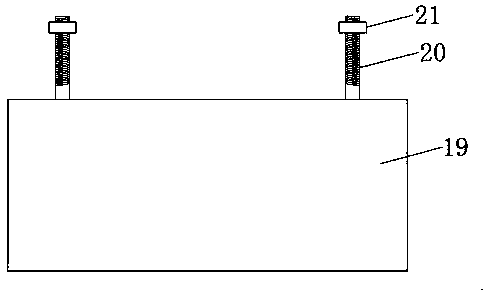

Magnetic current changing polishing device for large caliber aspheric surface optical part

InactiveCN101249626AWorkpiece clamping is simple and convenientMeet the processing capacityGrinding carriagesOptical surface grinding machinesMagnetic currentMachine tool

The invention discloses a magnetorheological finishing device for large-caliber aspheric optical parts. The magnetorheological finishing device comprises a machine tool, a finishing device, a magnetorheological finishing liquid circulating system for providing the finishing liquid with stable performance, and a control system connected with the components described above. The machine tool has four or more than four degrees of freedom. The finishing device is fixed on the machine tool and is positioned over the workpiece on the machine tool to be processed. The device has the advantages of simple and compact structure, low cost, simple control, wide range of application, and strong processing capacity, and is used for large-caliber aspheric optical parts.

Owner:NAT UNIV OF DEFENSE TECH

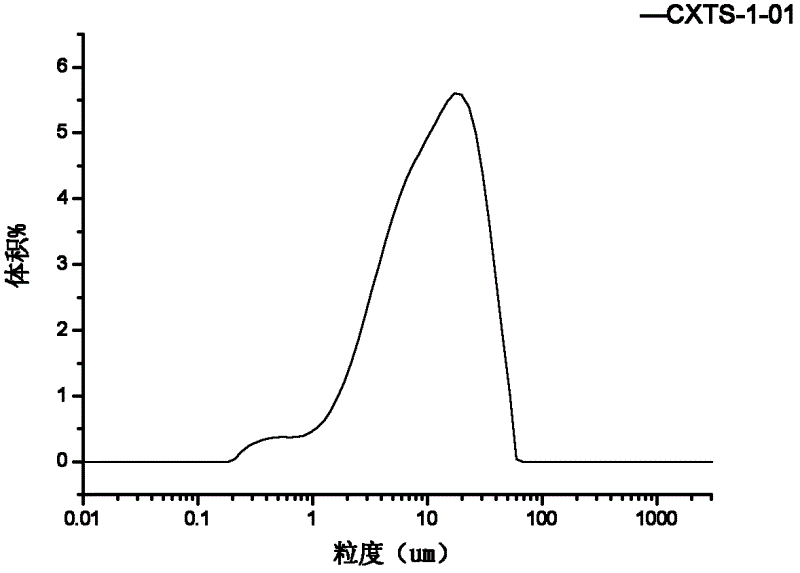

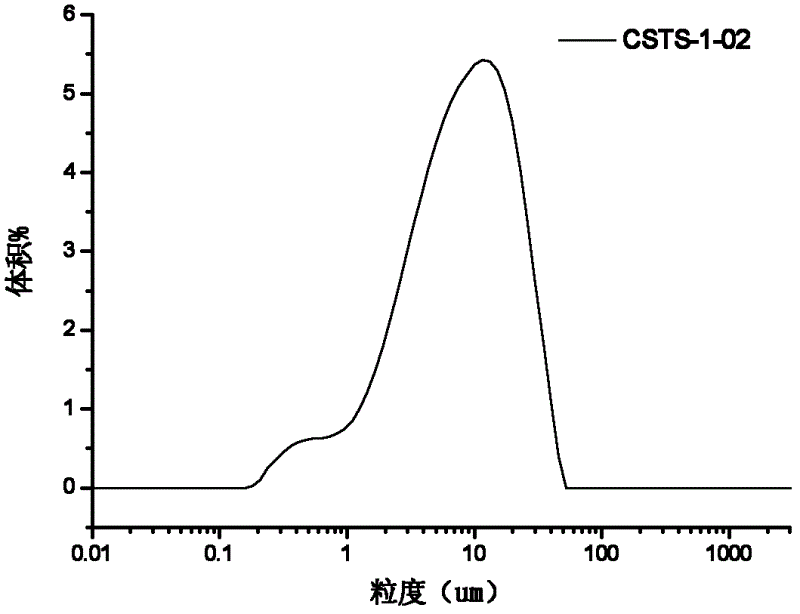

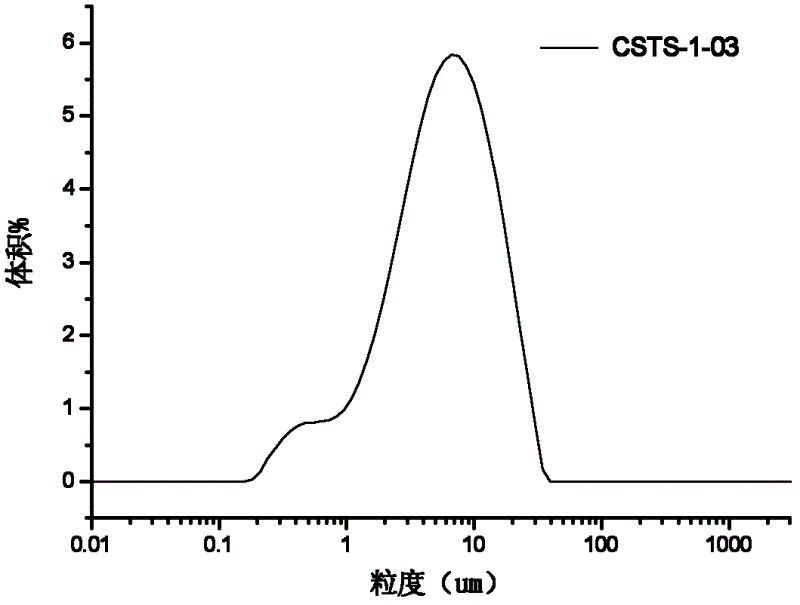

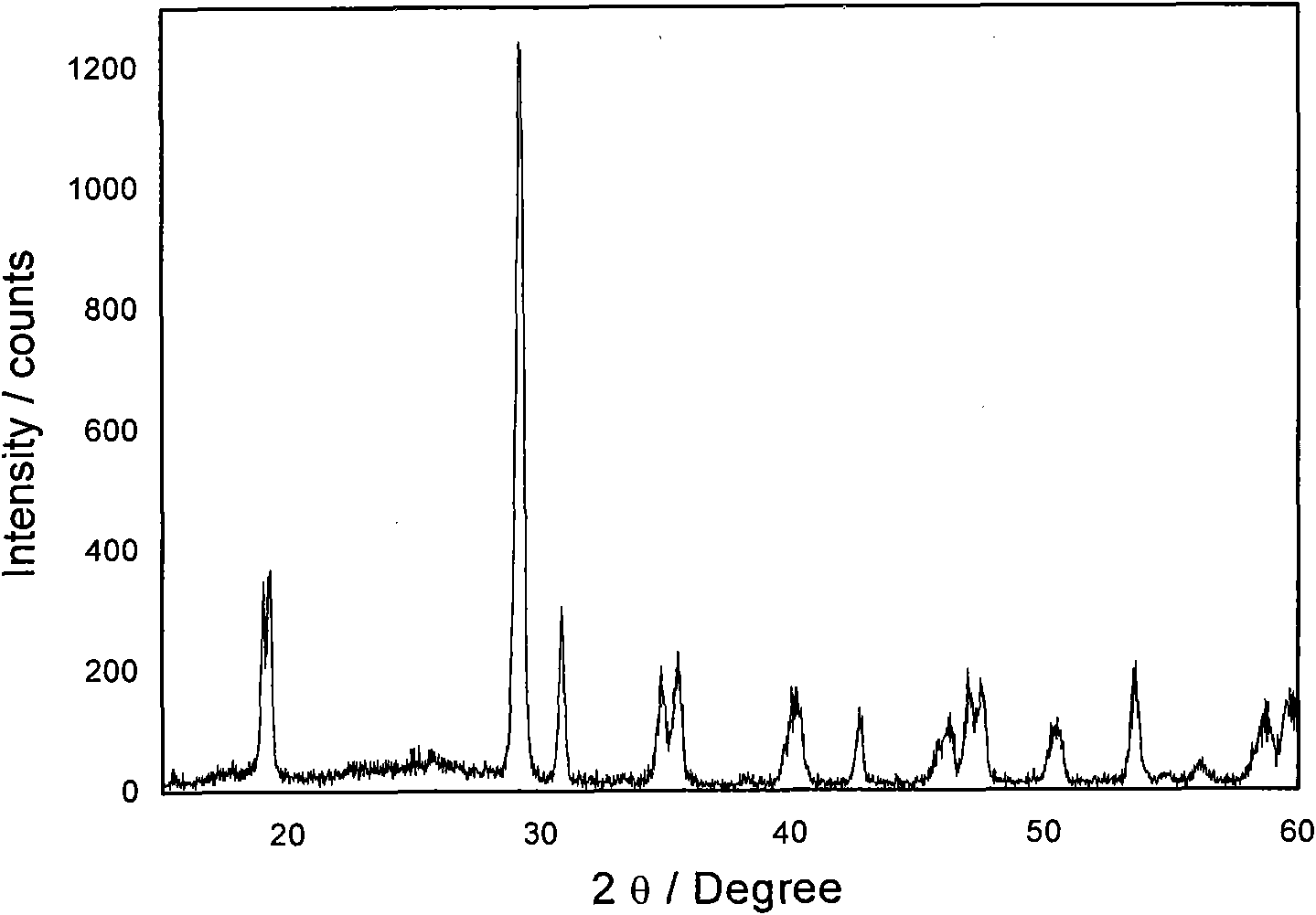

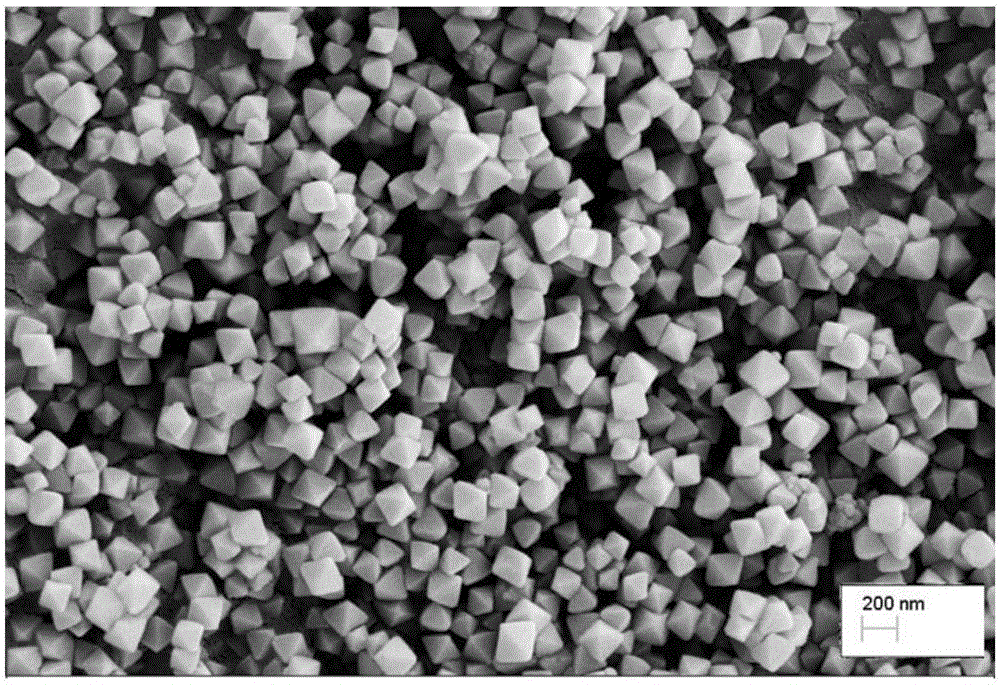

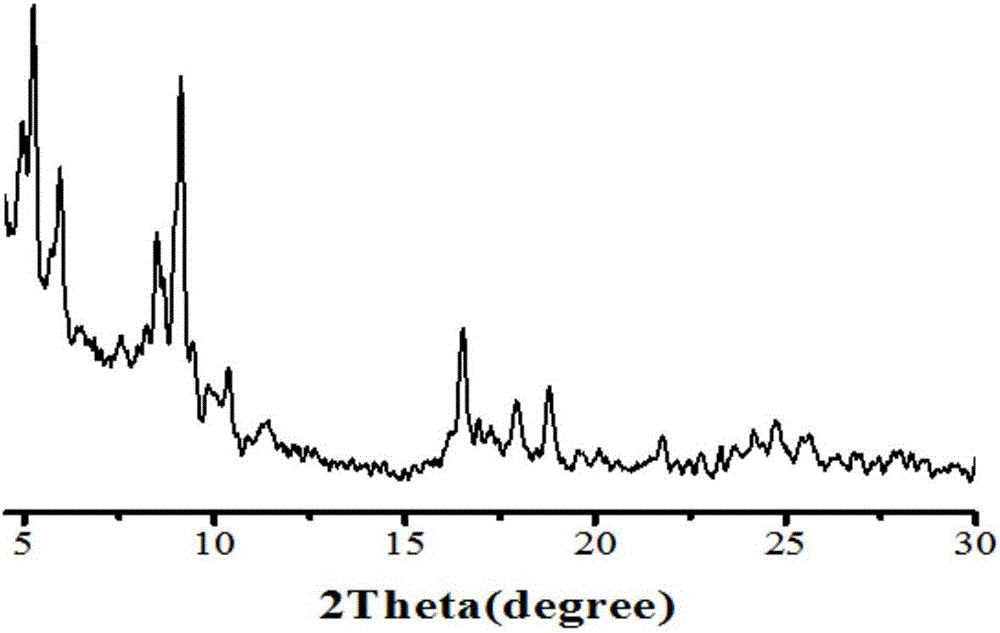

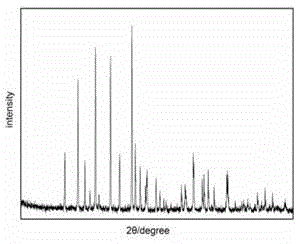

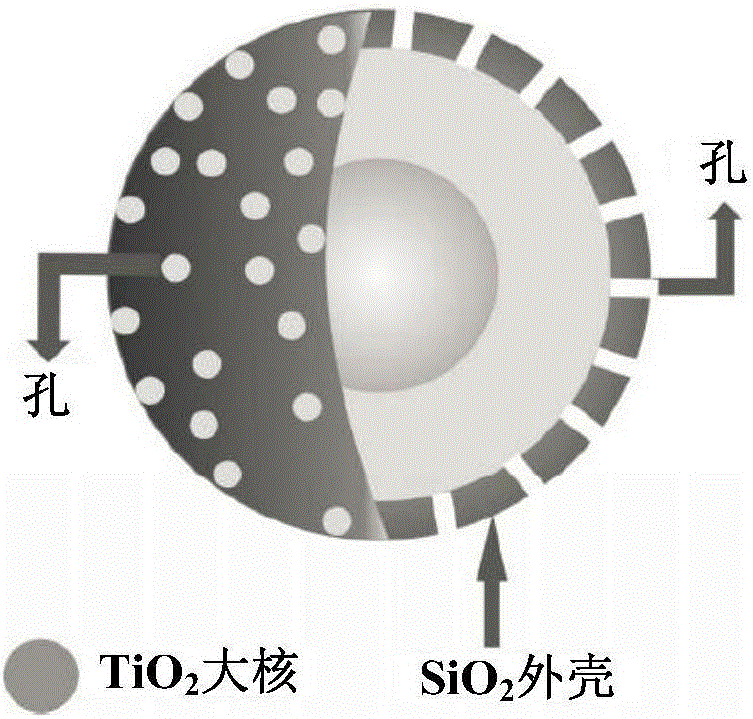

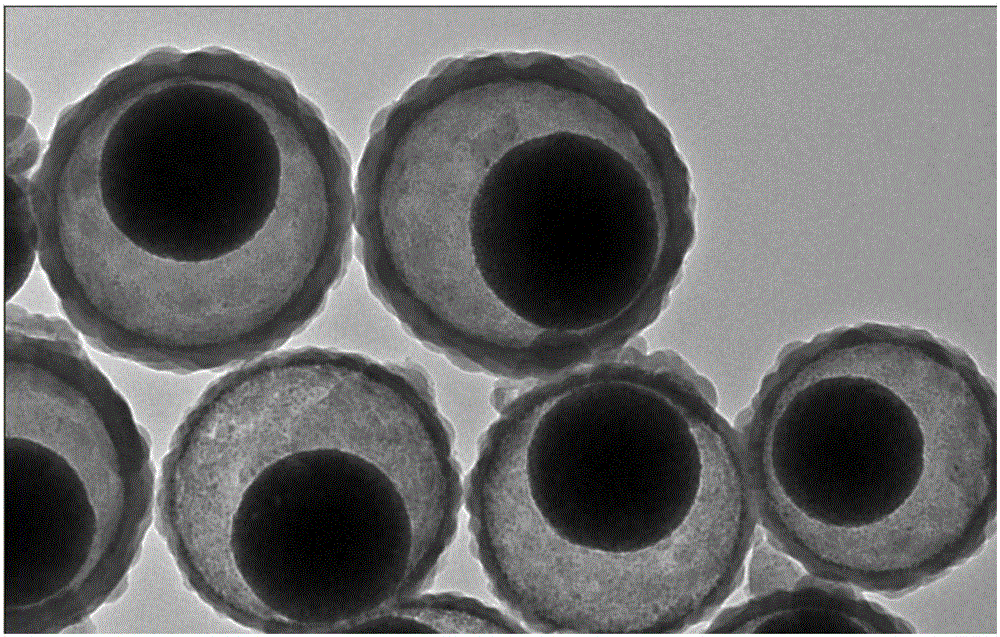

One-step molding method of titanium silicalite molecular sieve

ActiveCN102614911AImprove function and effectImprove adhesionMolecular sieve catalystsCatalyst activation/preparationMolecular sieveCyclohexanone

The invention relates to a one-step molding method of a titanium silicalite molecular sieve. The method comprises the following steps of crystallizing the titanium silicalite molecular sieve subjected to hydro-thermal synthesis; directly adding a matrix substance, a binder, a peptizing agent and a pore-enlarging agent without separating, washing and calcining; pulping; performing spray forming; and calcining the formed microspheres to remove a template agent to obtain large formed titanium silicalite molecular sieve particles which can be applied to ammoximation of cyclohexanone and epoxidation of olefin.

Owner:XIANGTAN UNIV

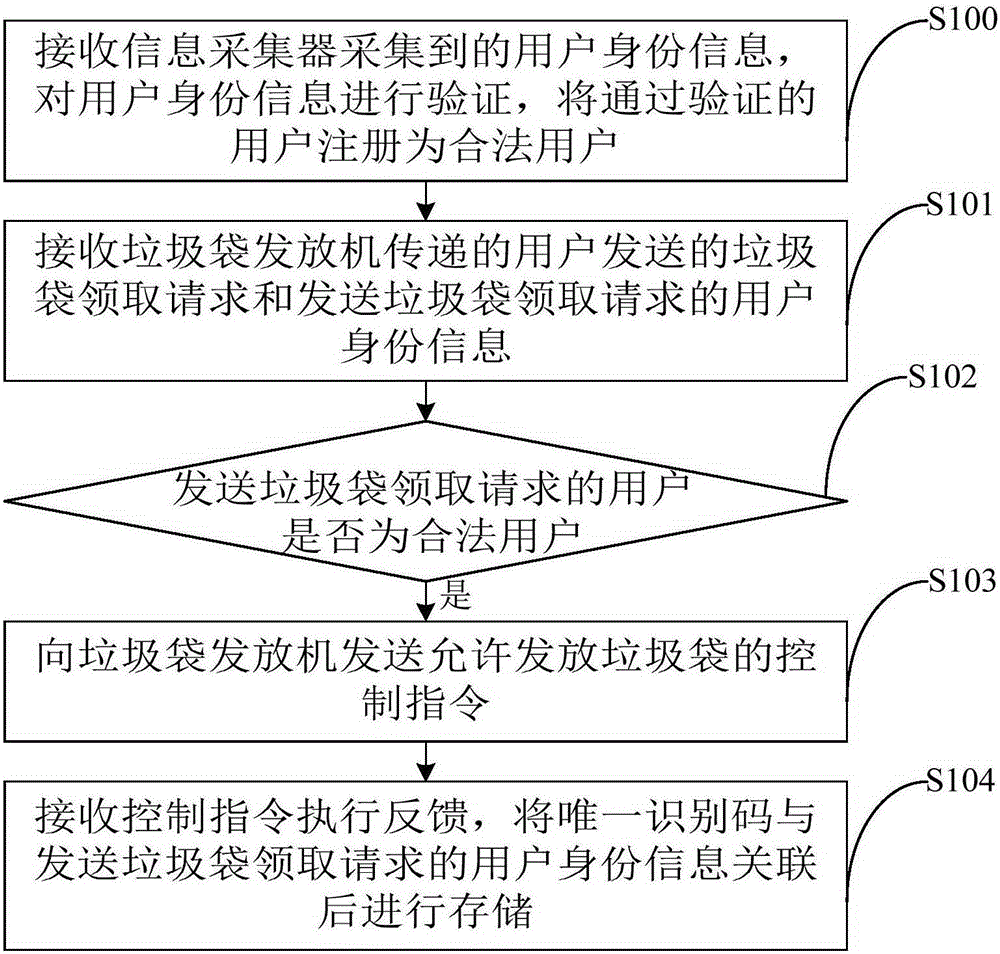

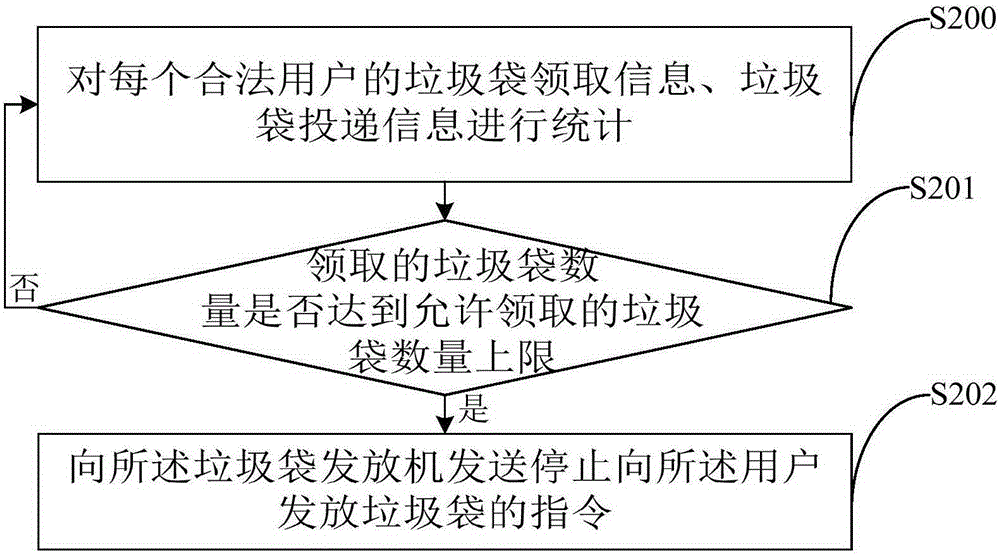

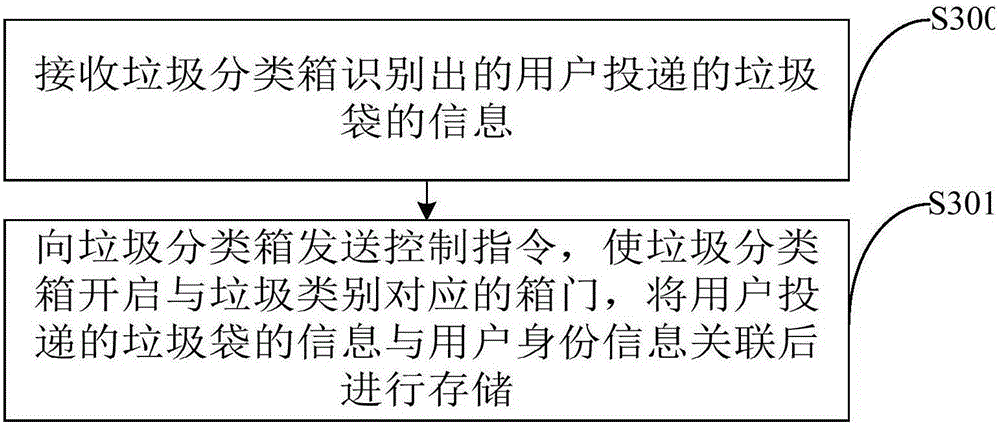

Garbage classification method, device and system

ActiveCN105173482AConvenient statisticsQuick StatisticsRefuse receptaclesClassification methodsOperating system

The embodiment of the invention provides a garbage classification method, device and system. The problem that the garbage classification effect needs to be improved in the prior art is solved. The garbage classification method includes the steps that identity information of a user is verified and the user passing the verification is registered as a legal user; a garbage bag acquisition request sent by the user and the identity information of the user sending the garbage bag acquisition request are received; whether the user sending the garbage bag acquisition request is a legal user or not is judged, if yes, a garbage bag issuing permission control instruction is sent to a garbage bag issuing machine, and the garbage bag issuing machine issues garbage bags with class labels to the legal user; and control instruction execution feedback sent by the garbage bag issuing machine is received and a unique identification code is correlated with the identity information of the user sending the garbage bag acquisition request and then stored. By the utilization of the garbage classification method, device and system, user garbage classification convenience can be remarkably improved, implementation is convenient, and application and popularization are easy.

Owner:蒋曙

Method for preparing composite fiber material for visible light photocatalytic degradation of organic pollutants

InactiveCN101884917ASolving Recycling ProblemsReduce chance of recombinationWater/sewage treatment by irradiationDispersed particle separationTextile fiberCompound (substance)

The invention provides a composite fiber material applied to visible light photocatalytic purification of sewage and air pollutants and a preparation method thereof. The composite fiber material is synthesized by loading a visible light response type bismuth-based photocatalytic material on a textile fiber material through a green chemical synthetic route. A powdered photocatalyst is solidly loaded by the unique net-like felt structure of the textile fiber material, so that the catalyst is prevented from losing and agglomerating during sewage treatment and air purification, and the separability and reusability are improved.

Owner:于建强 +2

Novel technique for extracting L-tryptophan from fermentation broth

ActiveCN101812009AThorough decontaminationShort filter timeOrganic chemistryAnimal feeding stuffIon exchangeUltrafiltration

The invention discloses a novel technique for extracting L-tryptophan from fermentation broth, which includes the following steps that: fermentation broth is pretreated, and the treated liquid is pumped into a ceramic microfiltration membrane filter, so that tryptophan microfiltrate without mycelium and mycoprotein are obtained; the tryptophan microfiltrate is pumped into an ultrafiltration membrane filter, so that tryptophan ultrafiltrate and concentrated liquid containing pigment and protein are obtained; the tryptophan ultrafiltrate is pumped into a nanofiltration membrane filter, so that concentrated tryptophan liquid and permeate containing salt are obtained; waste filtrate is comprehensively utilized to produce protein feed; industrial ethylic acid is used for promoting low-temperature crystallization, crystallization mother liquid is treated by the ion exchange method and used, and after crystals are centrifugally dehydrated and dried, the L-tryptophan product is obtained. The invention solves the problem on how to recover industrial ethylic acid, and greatly increases the extraction rate of L-tryptophan; and since the filtrate and the mycoprotein are comprehensively utilized, the product profit is maximized. The total extraction rate of L-tryptophan is 85.2 percent, and the refined product meets the standards of Chinese Pharmacopoeia edition 2005.

Owner:HENAN JULONG BIOLOGICAL ENG CO LTD

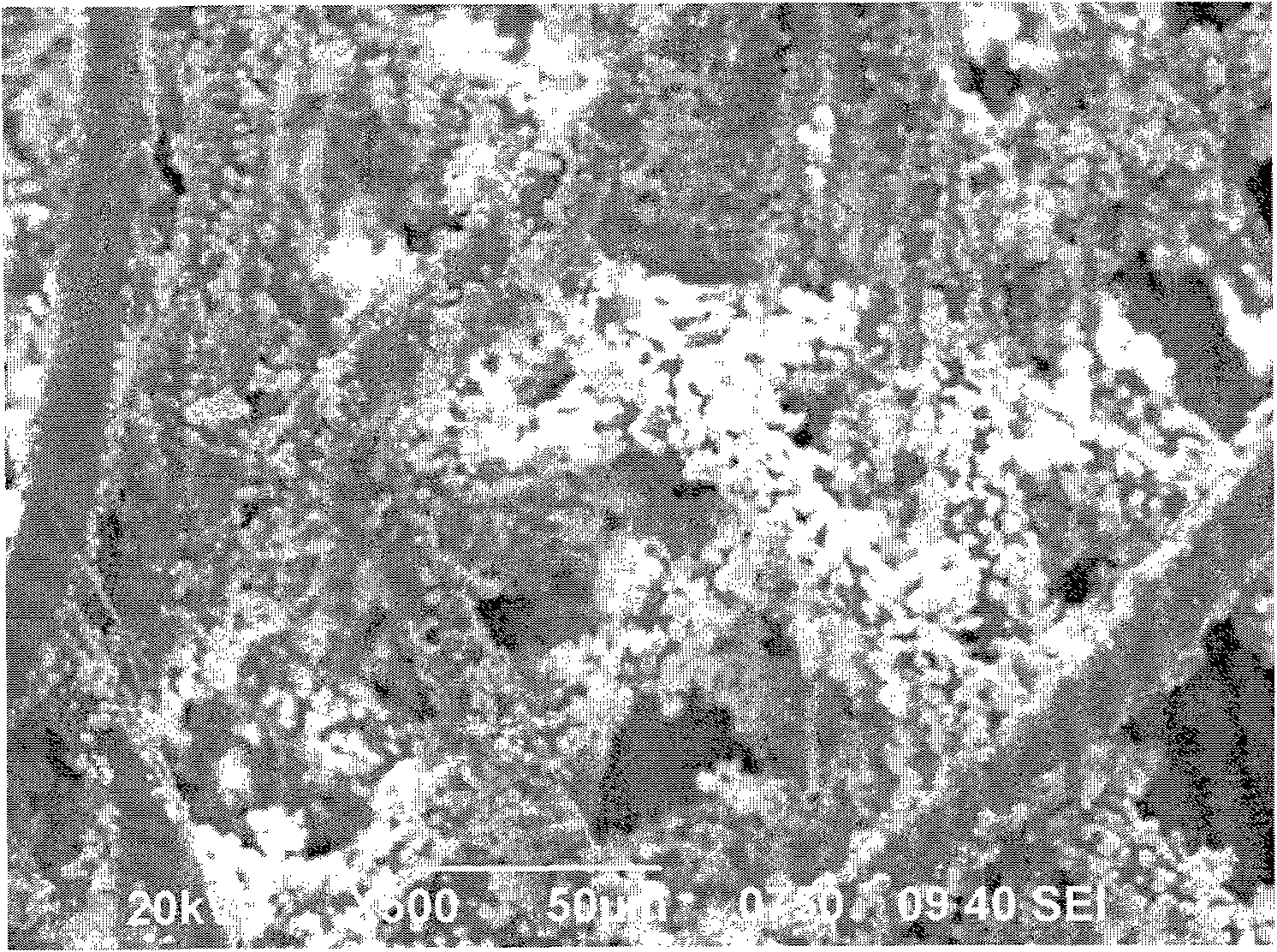

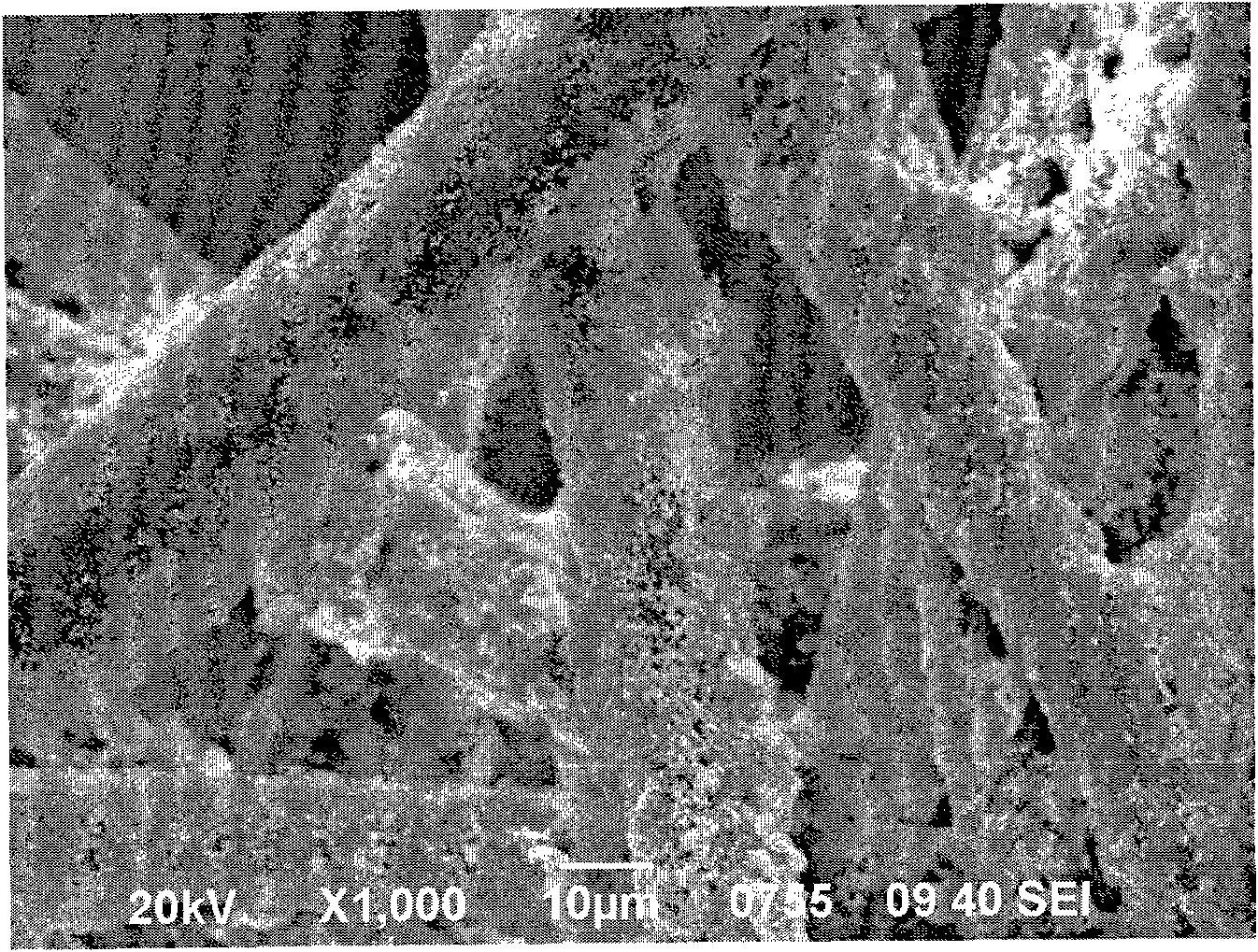

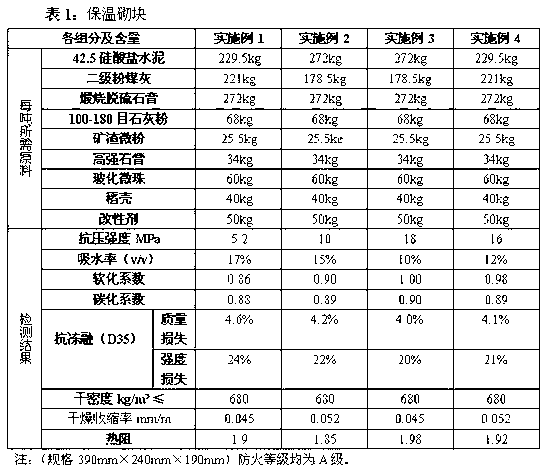

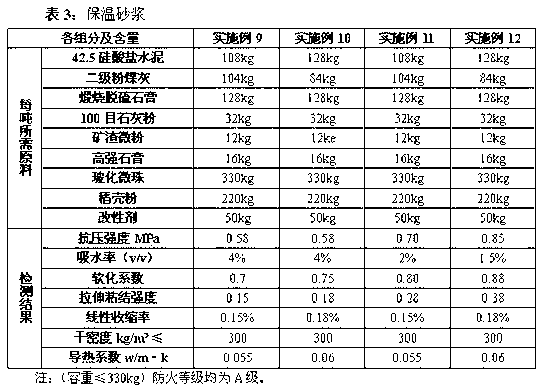

Building exterior wall thermal insulation material and preparation process thereof

The invention discloses a building exterior wall thermal insulation material. The building exterior wall thermal insulation material is formed by mixing a binding material, thermal insulation lightweight aggregate and a property-modifying additive according to the weight ratio of (40-85): (10-55):5. The building exterior wall thermal insulation material disclosed by the invention can be manufactured into wall thermal insulation mortar, thermal insulation blocks and thermal insulation boards, can be applied to different parts of a building, so as to ensure that the energy conservation index of the building meets the national mandatory standard, the fire rating can reach level A, and the drying shrinkage is low. A preparation process of the building exterior wall thermal insulation material is energy-saving, meanwhile, the recycling problem of industrial waste gypsum is solved, and the pollution of the industrial waste gypsum to the environment is avoided.

Owner:李奕

Method for preparing biodegradable polyester from consumed polyester

The invention discloses a method for preparing biodegradable polyester from consumed polyester. The method comprises the following steps of: reacting the consumed polyester and divalent alcohol under the action of a catalyst at the temperature of between 190 and 250 DEG C to decompose the polyester to a corresponding oligomer by the alcohol; adding aliphatic dibasic acid or esterification derivative of the aliphatic dibasic acid and acid or alcohol of multifunctional groups into the oligomer, and performing esterification reaction at the temperature of between 180 and 240 DEG C to obtain corresponding esterification products; and performing condensation polymerization reaction on the esterification products to obtain biodegradable aliphatic-aromatic copolyester. By the method, the consumed and reclaimed polyester material can be directly converted into a biodegradable polyester material, and a virtuous circle channel is provided for reclamation and utilization of non-degradable polyester white pollutants; and the biodegradable polyester material has excellent mechanical and processing properties.

Owner:KINGFA SCI & TECH CO LTD +2

Method for preparing high boiling silicone oil by using organic silicon high boiling substances

The invention relates to a method for preparing high boiling silicone oil by using organic silicon high boiling substances, comprising hydrolyzation of alcohol and neutralization, wherein the organic silicon high boiling substances are hydrolyzed in the mixed liquid of alcohol and water and refluxed for 1-4 hours; nitrogen purging is carried out on the reactant, and then the reactant is added with hydrogen chloride dissolved in urea, zinc oxide and ammonium bicarbonate and in the system thereof. The invention integrally uses the organic silicon high boiling substances and lowers the chlorine content in silicon oil products, ensures the molecular weight and viscosity to be controllable and mass to be more stable; the usage of the neutralizing agent and latent solvent is reduced greatly, thus reducing the production cost; the process is simple and the industrial production is easy.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

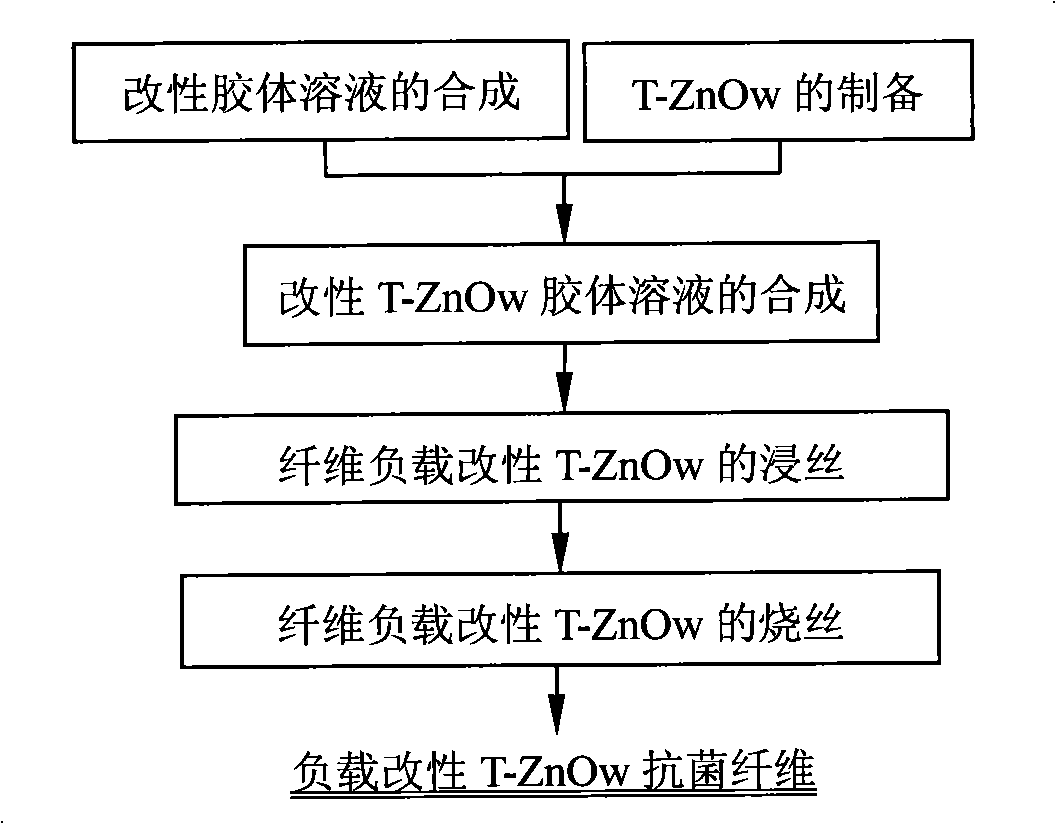

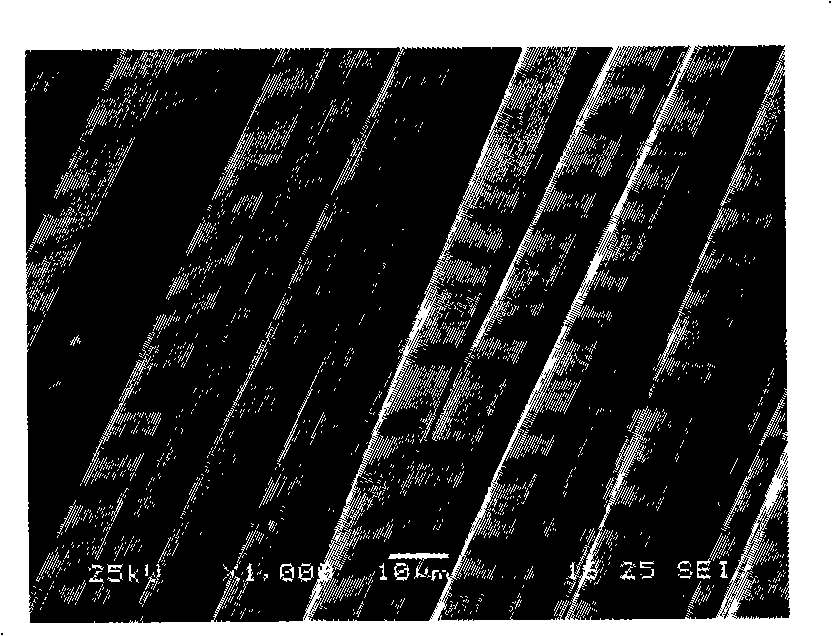

Inorganic coating anti-bacterial fiber and preparation thereof

InactiveCN101302710AHigh catalytic activityImprove photocatalytic activityBiocideCarbon fibresFiberSpatial structure

The invention discloses an inorganic antibacterial fiber of a coating layer and a preparation method thereof. The invention leads four-needle zinc oxide whisker that is blended with silver, ferric oxide, titanium dioxide or the mixture of the silver, the ferric oxide and the titanium dioxide to be modified, and expands the responsiveness of the four-needle zinc oxide whisker in the field of visible lights. The four-needle zinc oxide whisker or the modified four-needle zinc oxide whisker are loaded onto the fiber, and due to the special space structure, the four-needle zinc oxide whisker has strong holding power to the fiber and can be well loaded onto the fiber, thus well combining the high catalytic activity of the four-needle zinc oxide whisker and the high specific surface property of the fiber, greatly improving the catalytic efficiency of optical catalysts, and simultaneously solving the recycling problem of the optical catalysts.

Owner:CENT SOUTH UNIV

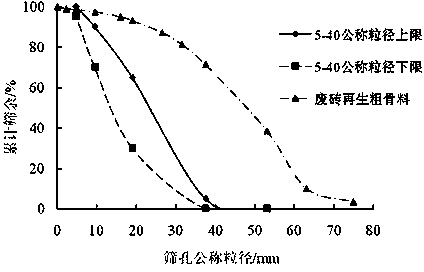

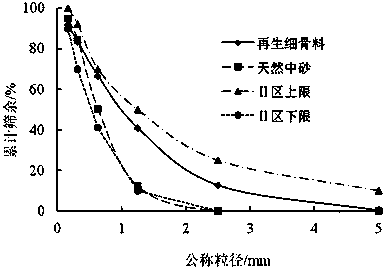

Recycled concrete produced from construction wastes and production method thereof

ActiveCN104072058ASolving Recycling ProblemsImprove recycling utilizationSolid waste managementBrickUltimate tensile strength

Owner:ZHENGZHOU UNIV

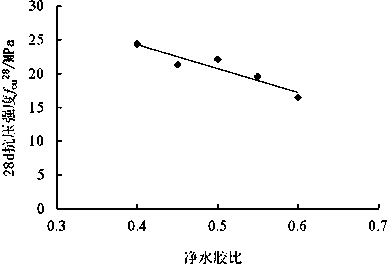

Resource recycling method for waste lithium batteries

InactiveCN105932351ARealize separation and recoveryReduce usageWaste accumulators reclaimingBattery recyclingEvaporationPollution

The invention discloses a resource recycling method for waste lithium batteries. The resource recycling method comprises the following steps: soaking in a solution for discharging, breaking shells and distilling an electrolyte under a vacuum condition or an inert atmosphere protection condition, mechanically smashing, separating current collectors and electrode materials by using difference of density, adding acid to dissolve filtered and separated carbon material, adding base to recycle transition metal elements in cathodes, adding salt to recycle lithium element, and carrying out evaporation-recrystallization to recycle byproducts. The manner that a dry method is combined with a wet chemical technology realizes separation recycling of battery materials, the method is low in invested cost and few in energy consumption, a recycling method for environmentally hazardous lithium hexafluorophate and inflammable carbonic ester is highlighted particularly, and secondary pollution cannot be caused in the recycling process; and moreover, no organic solvent is used in the process, zero emission of waste liquid is realized, and the method is suitable for large-scale recycling production.

Owner:上海赛特康新能源科技股份有限公司

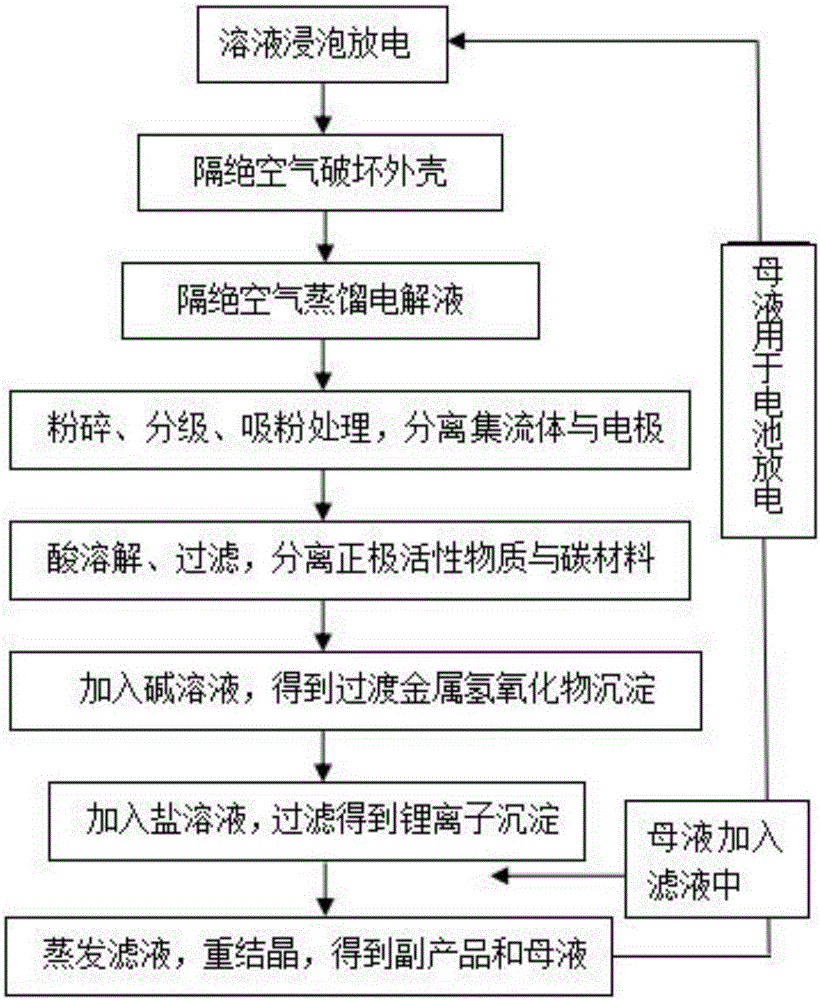

Paint-spraying device with desusting and drying integrated structure

InactiveCN109261416AGuaranteed long-term useSolving Recycling ProblemsPretreated surfacesLiquid spraying apparatusSprayerEngineering

The invention relates to the field of paint spraying, and particularly discloses a paint-spraying device with a desusting and drying integrated structure. The paint-spraying device comprises a shell,a conveying belt, a feeding inlet, a discharging outlet and a paint collection tank, wherein a dust suction hood, an installation support and a drying cavity are arranged / formed above the conveying belt from left to right in sequence; a plurality of brush rollers are arranged below the dust suction hood, the dust suction hood is communicated with a dust suction blower, and the installation supportis fixedly connected with an electrical telescoping rod which stretches and retracts in the vertical direction; a vertical hot air suction pipe is arranged on the outer portion on the left side of the drying cavity, and a wind deflector with adjustable height is arranged on the left side of the hot air suction pipe. By means of the drying cavity, the paint on the surface of wood can be quickly dried, meanwhile, hot air overflows outwards can be recycled, the hot air is prevented from flowing to the position of a paint sprayer, the paint is prevented from being dried in the sprayer, it is ensured that the paint sprayer is used for a long time, and the service life is prolonged.

Owner:湖南匡沐环保科技有限公司

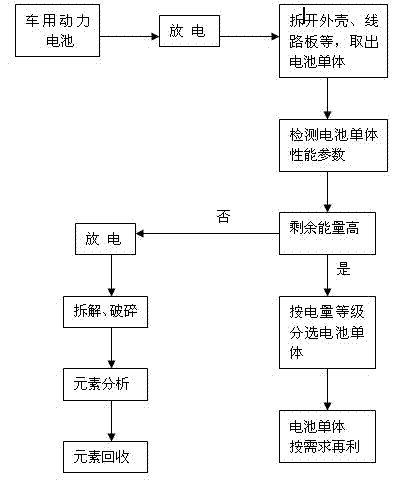

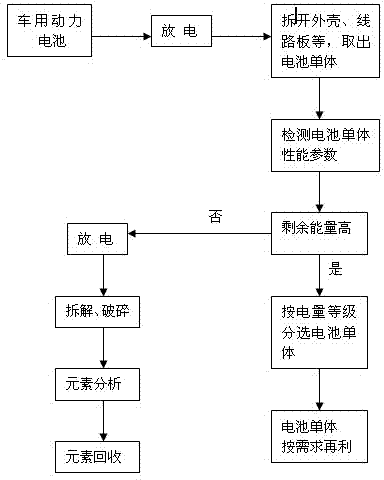

Method for recovering power cells for new energy vehicles

ActiveCN102347520ARealize cascade utilizationAvoid wastingWaste processingSolid waste disposalPower batteryElectrical battery

The invention discloses a method for recovering power cells for new energy vehicles. The method comprises the following steps of: (1) discharging the expired power cells for removing the remaining energy of the power cells to ensure that the subsequent processes can be performed safely; (2) initially partitioning; (3) detecting and classifying the performance parameters of single batteries; (4) disassembling the useless single batteries to take out the positive and negative pole pieces thereof; (5) performing elemental analysis on the obtained positive and negative pole pieces, based on the result of elemental analysis, determining the mixing amount of different batches of raw materials according to the contents of the elements and the proportion of each major element of a target product, and extracting the metal elements by hydrometallurgy to prepare the target product; and (6) sorting the employable single batteries by a battery sorter according to the residual capacitance of the single batteries, grading and classifying based on the capacitance, and then applying to products according to actual requirements.

Owner:GUANGDONG BRUNP RECYCLING TECH +3

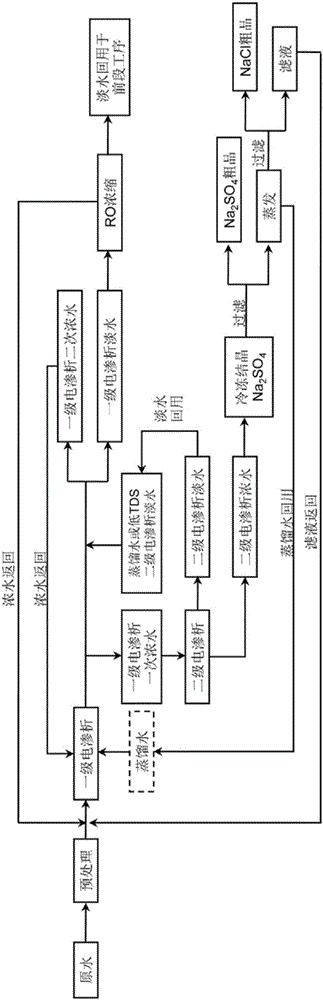

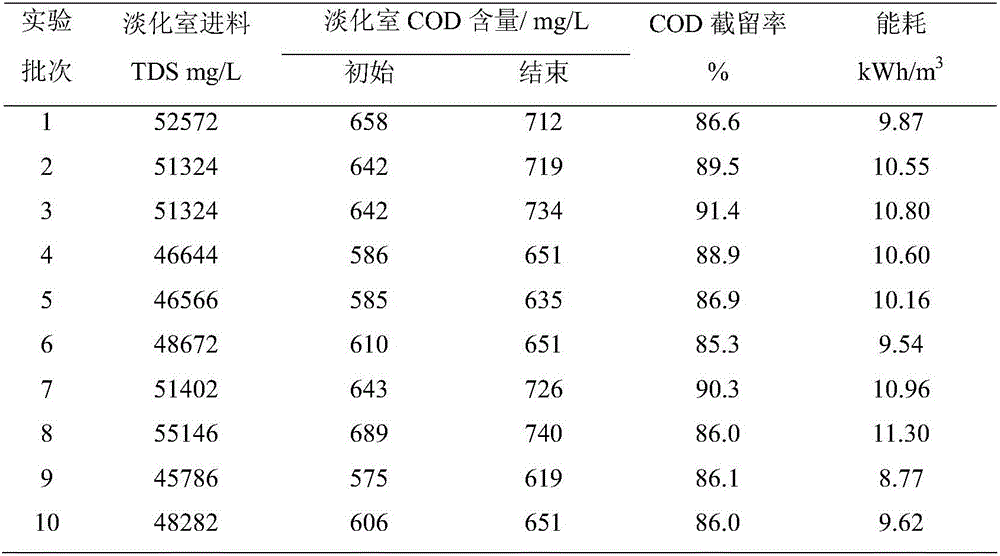

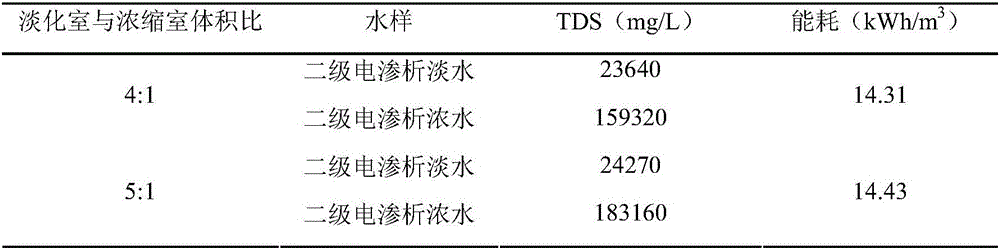

Method for separating salt from coal-chemical-industry wastewater through electroosmosis technique

ActiveCN105906111AImprove secondary use valueHigh purityGeneral water supply conservationScale removal and water softeningChemical oxygen demandSodium sulfate

The invention discloses a method for separating a salt from coal-chemical-industry wastewater through an electroosmosis technique. The method for separating the salt from the coal-chemical-industry wastewater through the electroosmosis technique is characterized by comprising the following steps of firstly, carrying out pretreatment on raw water of the coal-chemical-industry wastewater, then introducing the wastewater subjected to the pretreatment into primary electroosmosis, so as to realize the separation between the salt and a COD (Chemical Oxygen Demand), afterwards, introducing thick water subjected to the primary electroosmosis into secondary electroosmosis to carry out concentration, and separating out sodium sulfate and sodium chloride from an obtained concentrated solution through post-treatment, thereby completing treatment. According to the method provided by the invention, by applying the characteristic that the salt can be separated and concentrated through electroosmosis, the COD and the salt in the coal-chemical-industry wastewater which is subjected to the pretreatment are separated; afterwards, the separated salt is concentrated; the difficult problems of the separation and the recovery of the salt in the coal-chemical-industry wastewater are solved; the sufficient utilization of a solid salt resource is realized; further, a whole technical process is free from the emission of pollutants and is green and environmentally-friendly; the zero emission, in a real sense, of the coal-chemical-industry wastewater can be realized.

Owner:HEFEI CHEMJOY POLYMER MATERIALS CO LTD

Method for preparing silica aerogel composite material by adopting chloride-free and alcohol-free process

The invention discloses a method for preparing a silica aerogel composite material by adopting a chloride-free and alcohol-free process. The method comprises the following steps: S1, adopting a water-based silicon source as a raw material, regulating the pH value of sol with a chloridion-free acid, adding an additive after desalting, and uniformly stirring to obtain a first mixed solution; S2, immersing a fiber reinforced material into the first mixed solution, and completing gel curing; S3, standing the obtained composite gel material so as to obtain an aged composite gel material; S4, placing the aged composite gel material in a chloride-free and alcohol-free displacer to realize uniform solution infiltration; S5, performing surface methylsilane modification on the composite gel by usinga chloride-free surface modifier; S6, drying the modified composite gel, thereby obtaining the silica aerogel composite material. The invention provides a method for preparing the silica aerogel composite material without any chloride ion or alcohol substance in the formula.

Owner:SHENZHEN AEROGEL TECH CO LTD

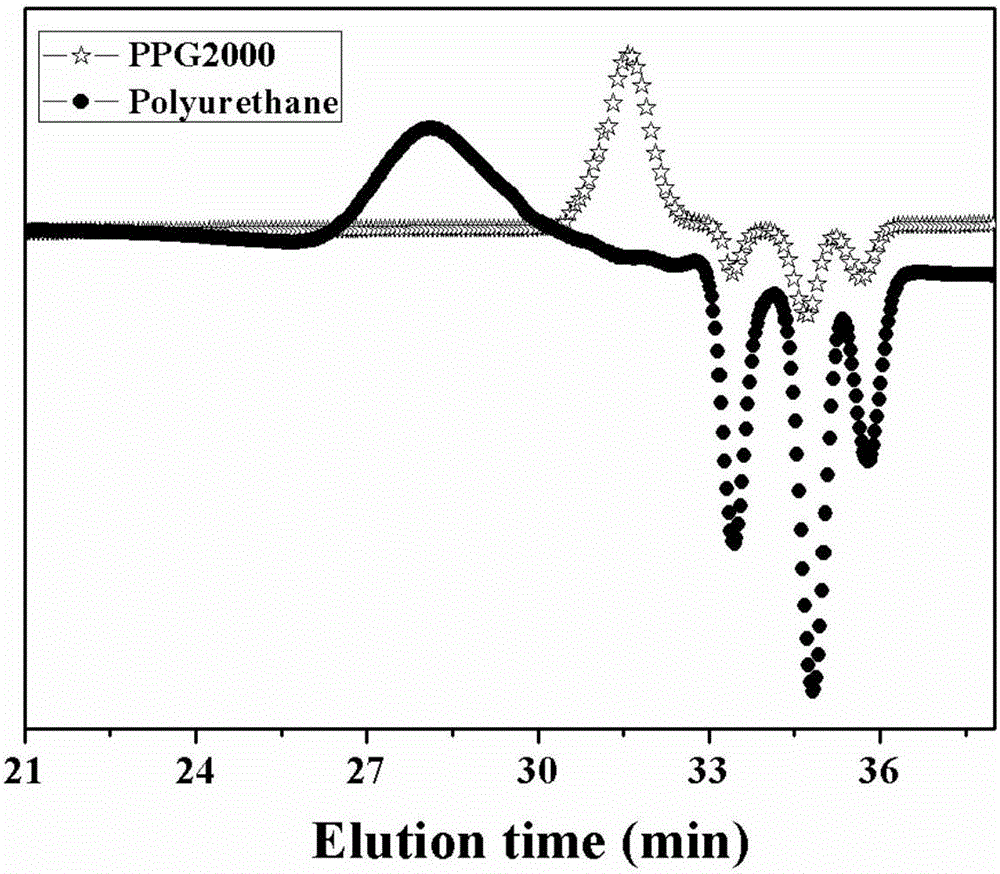

Metal-organic framework nanocrystal loaded polyurethane foam as well as preparation and application thereof

ActiveCN106366636AGood dispersionOvercoming the defects of difficult processingCarboxylic acid nitrile preparationOrganic compound preparationChemical industryMetal-organic framework

The invention discloses a metal-organic framework nanocrystal loaded polyurethane foam as well as a preparation and an application thereof. Polyurethane prepolymer and active amino on MOFs (Metal-Organic Frameworks) are taken to perform chemical doping, the great challenge that MOFs materials are difficult to process is overcome, MOFs nanoparticles are uniformly loaded in the polyurethane foam, a foam reactor is obtained by means of in-situ forming, a new process of building a complex mesoporous-microporous assembly based on microporous metal-organic skeleton nanoparticles as structural units is provided to observe catalysis of the MOFs nanoparticles on knoevenagel condensation; as water serves as a foaming agent and a green chemical method is adopted to prepare an integral flow-by foam reactor to catalyze an organic reaction, aftertreatment of a catalyst is simplified, loss of the catalyst is avoided, continuous flow-by cyclic catalyzation can also be performed, and a new method is provided for the treatment of environmental pollution and chemical industry.

Owner:SHANDONG NORMAL UNIV

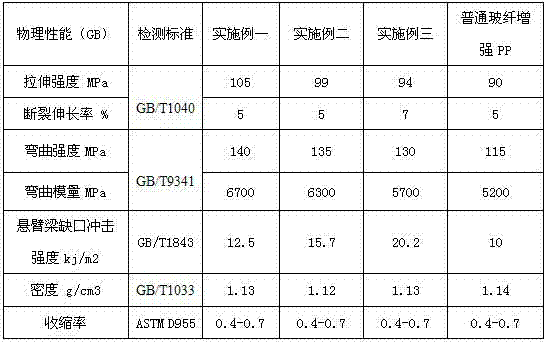

Reinforced polypropylene composite material and preparation method thereof

InactiveCN103589058ARaw materials are easy to getSolving Recycling ProblemsPolypropylene compositesGlass fiber

Owner:ORINKO NEW MATERIAL CO LTD

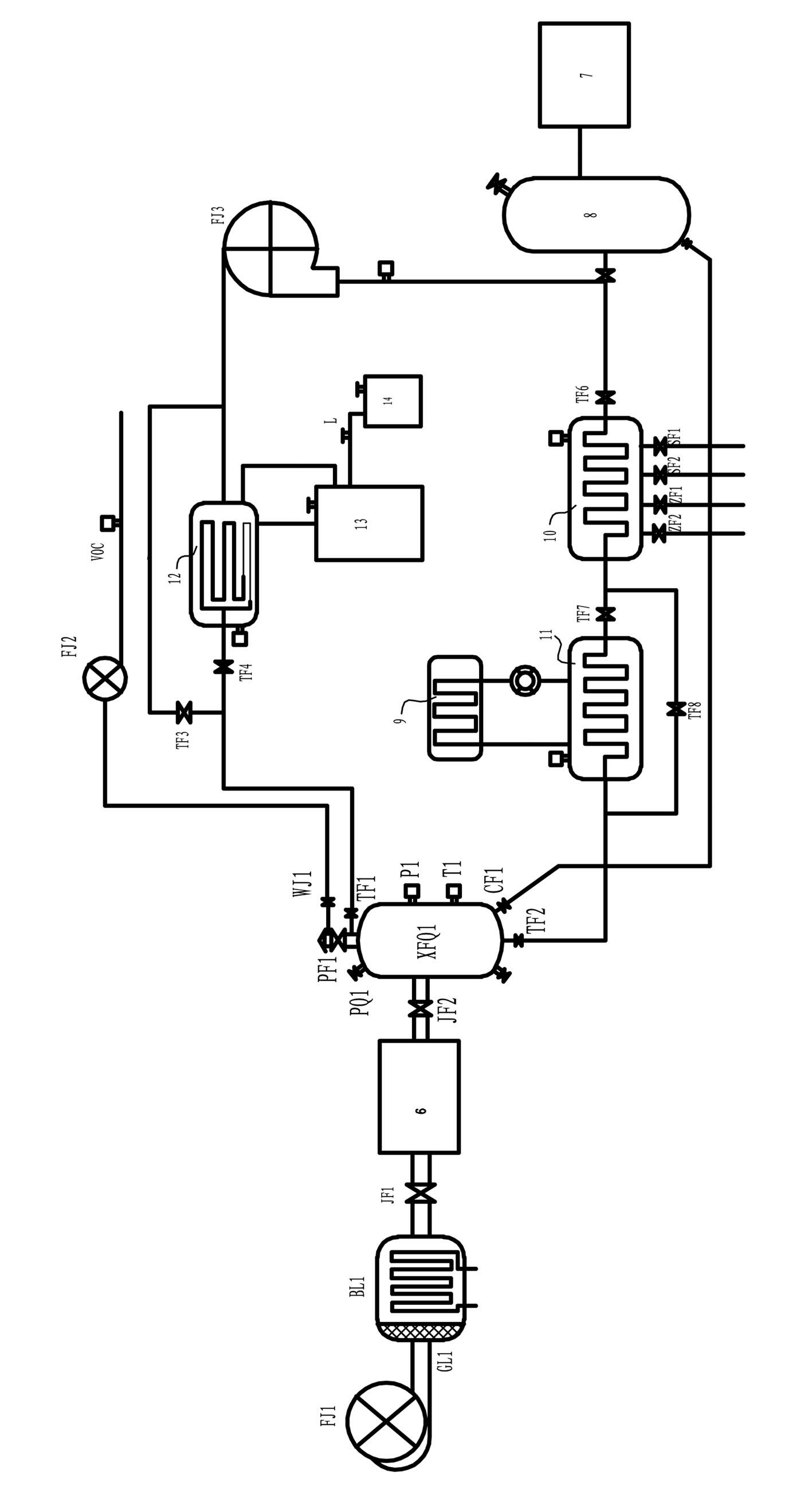

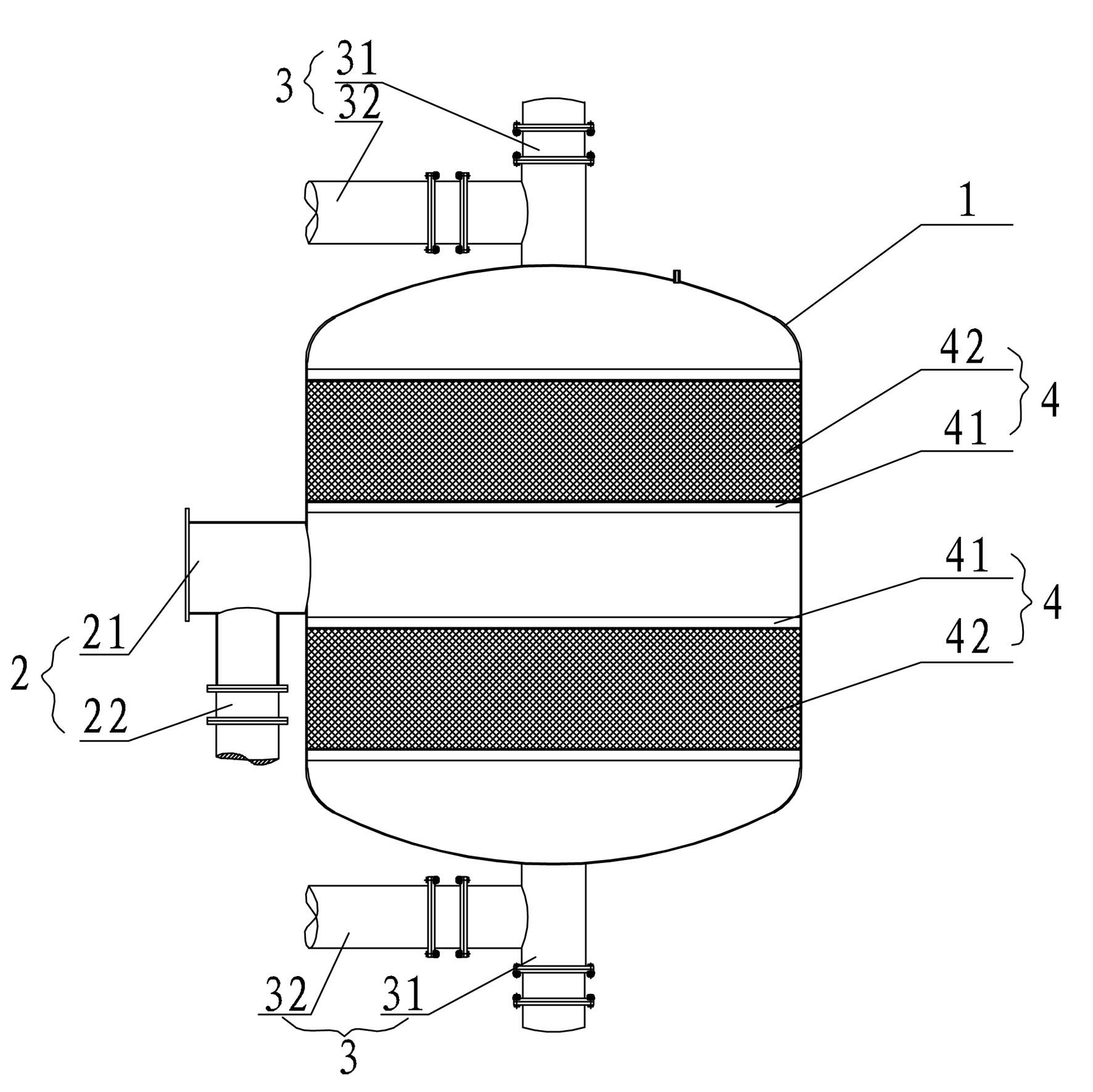

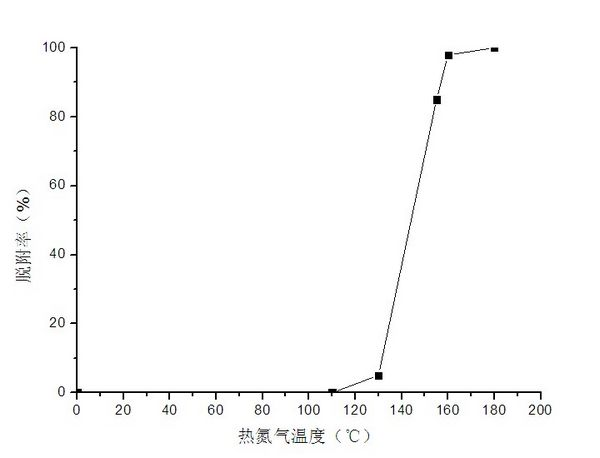

Organic waste gas desorption process

InactiveCN102614738AImprove adsorption and desorption efficiencySolving Acid Corrosion ProblemsDispersed particle separationCombustible gas purificationChemistryActivated carbon

The invention discloses an organic waste desorption process, which comprises the following steps of: (1) adsorbing: cooling and filtering organic waste gas, and collecting into an adsorber through a gas collecting system for adsorbing; (2) desorbing: desorbing the organic waste gas through thermal nitrogen gas to obtain desorbed mixed gas; and (3) recovering: recycling the desorbed gas, wherein during adsorption, the temperature of the thermal nitrogen gas is 110-160 DEG C; and the adsorber is a fixed bed adsorber which takes active carbon particles as an adsorbent. Due to the adoption of the process for desorbing, the desorption efficiency is increased, the thermal nitrogen gas desorption efficiency can be up to 98 percent, the problems of steam desorption acid corrosion is solved, and the service life of equipment is greatly prolonged; the water content of a mixed solution is low, so that treatment is not required, the mixed solution can be directly applied to production, and the economic benefit of the recovering system is increased; nitrogen gas desorption is adopted, so that the service life of an adsorption material in a reaction container is prolonged, the production cost is lowered, and manpower and materials are saved; and meanwhile, the problem that solvents which are miscible and slightly soluble in water such as alcohols, ketones, esters and the like cannot be directly recovered through steam desorption is solved. The organic waste gas desorption process is suitable for the industries of printing, light industry, coating, chemistry, electronics and the like.

Owner:河北沃夫智能科技有限公司

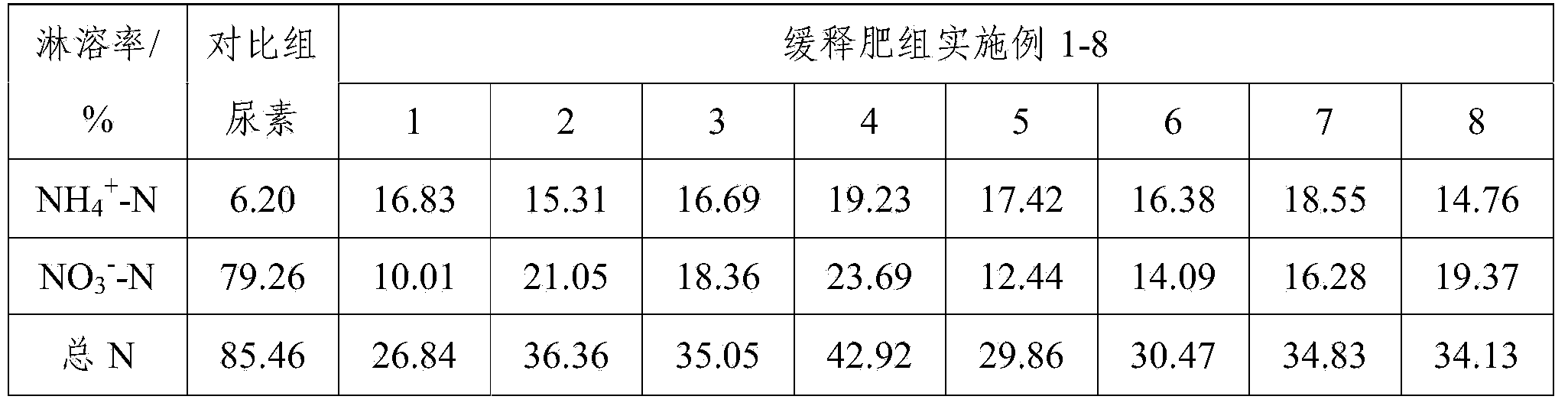

Charcoal-base polyaspartic acid slow-release urea as well as preparation method and application thereof

ActiveCN103804075ASolving Recycling ProblemsEmission reductionFertilizer mixturesField experimentDecomposition

The invention provides charcoal-base polyaspartic acid slow-release urea. The preparation method comprises the steps of 1) charring agricultural waste which is taken as a biomass raw material at 400-600 DEG C to obtain porous charcoal particles; 2) carrying out a reaction between urea and formaldehyde to obtain a modified urea solution; 3) adding polyaspartic acid and derivative thereof to the modified urea solution; 4) soaking the charcoal particles in the mixing solution obtained from the step 3) for 3-10 hours, and drying the soaked charcoal particles; 5) implementing a reaction between starch and a sodium hypochlorite solution to obtain an oxidized starch solution which serves as a binder; and 6) adding the dried charcoal particles to the binder, pelleting and drying to obtain the charcoal-base polyaspartic acid slow-release urea. The preparation method disclosed by the invention is low in cost, and can relieve conversion from NH4+-N to NO3--N, inhibit rapid decomposition and loss of the urea, prolong fertilizer efficiency, improve nitrogen use efficiency and relieve non-point source pollution; results of field experiments show that the slow-release urea product disclosed by the invention can effectively increase both production and income, and can achieve a yield-increasing effect under a circumstance of reducing application of fertilizer.

Owner:CNSG ANHUI HONG SIFANG FERTILIZER IND CO LTD

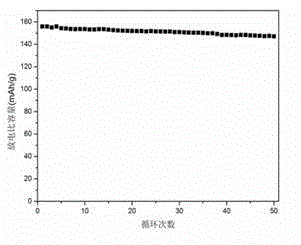

Method for recycling and preparing lithium iron manganese phosphate from positive electrode materials of waste lithium iron phosphate batteries

ActiveCN104609385ASolving Recycling ProblemsIncrease specific energySolid waste disposalWaste accumulators reclaimingPhosphoric acidLithium-ion battery

The invention discloses a method for recycling and preparing lithium iron manganese phosphate from positive electrode materials of waste lithium iron phosphate batteries. The method comprises the following steps: (1) discharging remnant electric quantities of the waste lithium iron phosphate batteries, disassembling the batteries, taking positive electrode sheets, washing, drying, roasting and separating lithium iron phosphate from aluminum foils; (2) by controlling the addition of acid, carrying out acid leaching on separated lithium iron phosphate, and filtering to separate insoluble iron phosphate and iron oxide to obtain a filtrate; (3) analyzing the filtrate, adjusting the molar ratio of the elements, namely, nLi to (nFe+Mn) to nP to 1: 1: 1 and adding a manganese source and a phosphorus source; and adjusting the pH to obtain a precipitate; drying the precipitate, adding a carbon source and mixing to obtain a pre-sintered material; and (4) carrying out solid sintering treatment on the pre-sintered material under non-oxidizing atmosphere to obtain the lithium iron manganese phosphate serving as the lithium ion battery positive electrode material. The method has the advantages of simplicity in process, environmental friendliness, good product properties and the like.

Owner:北京赛德美资源再利用研究院有限公司

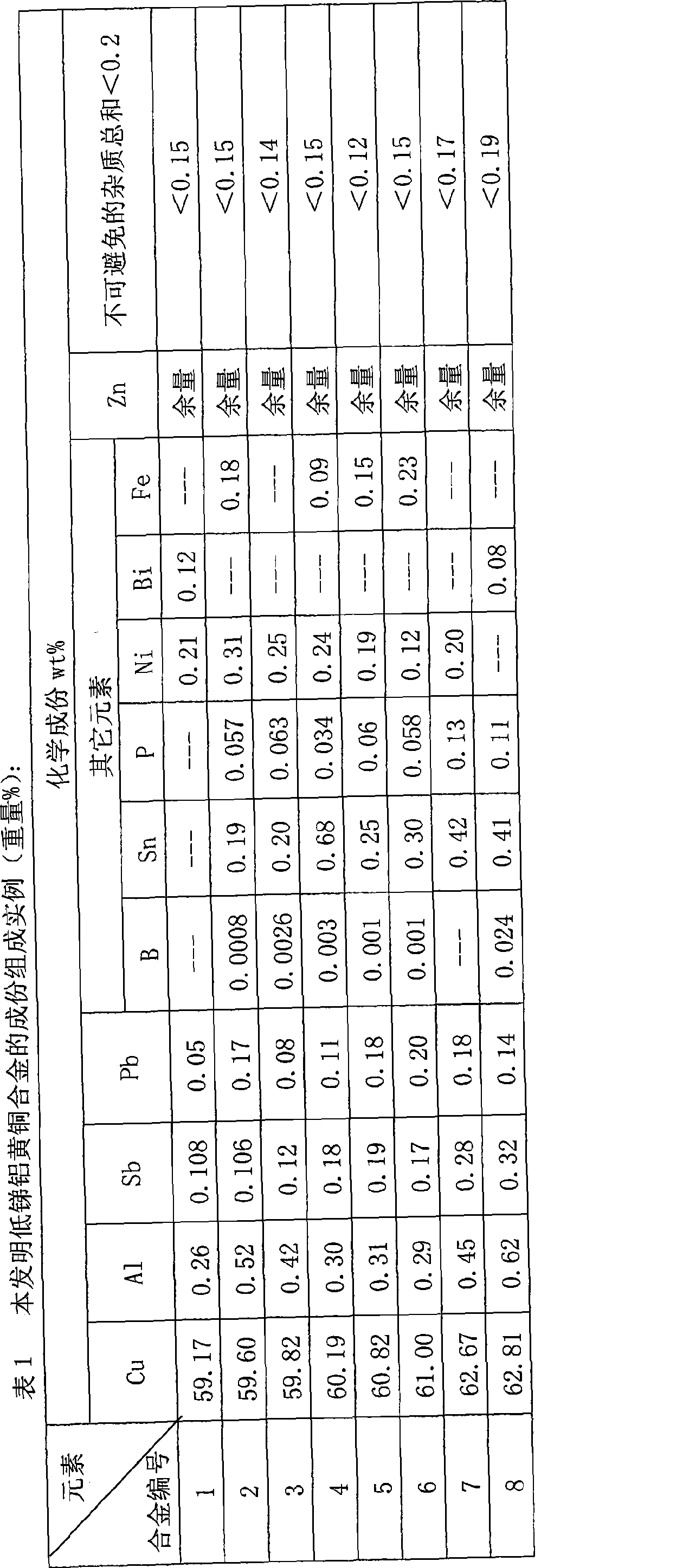

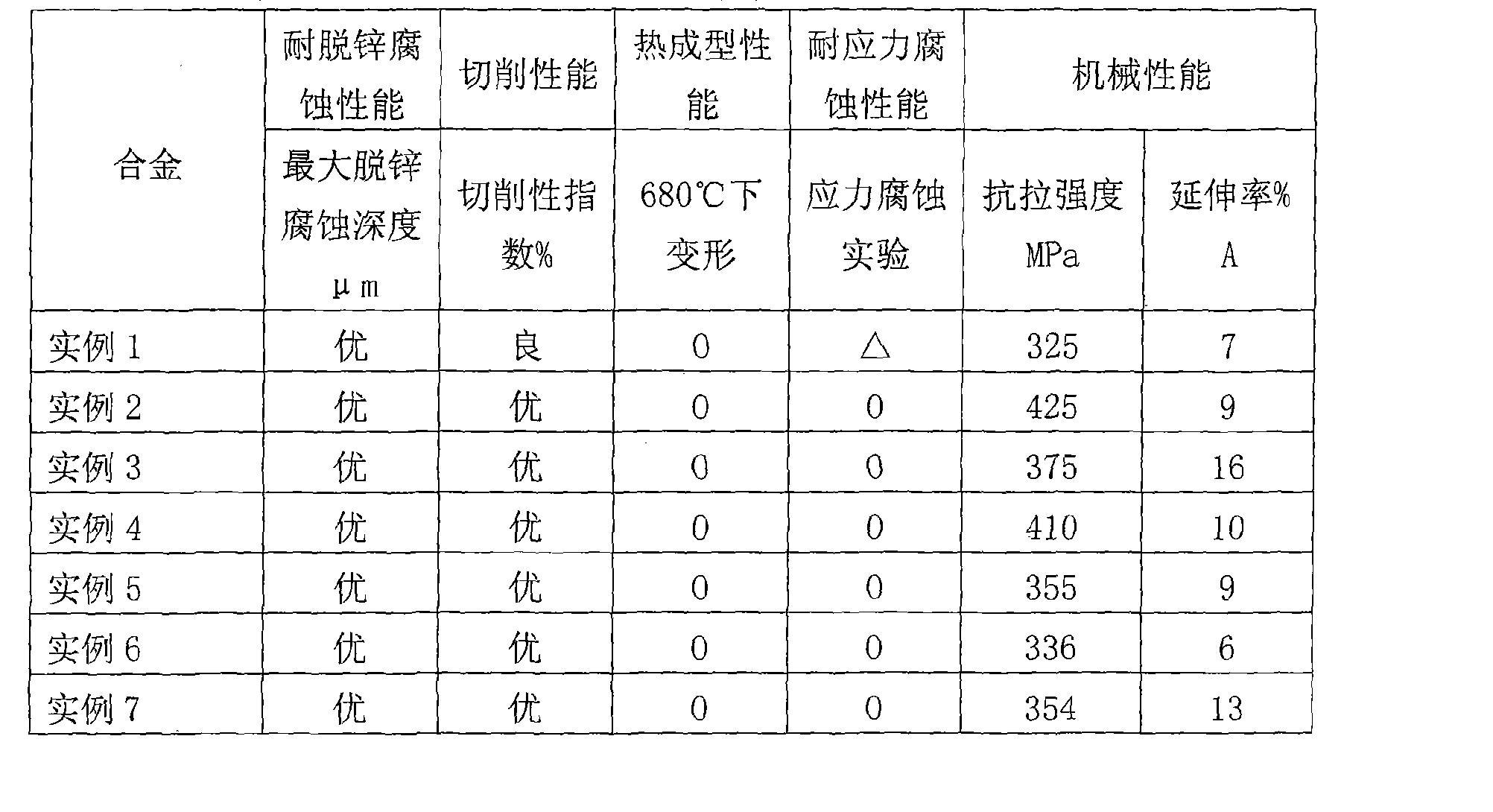

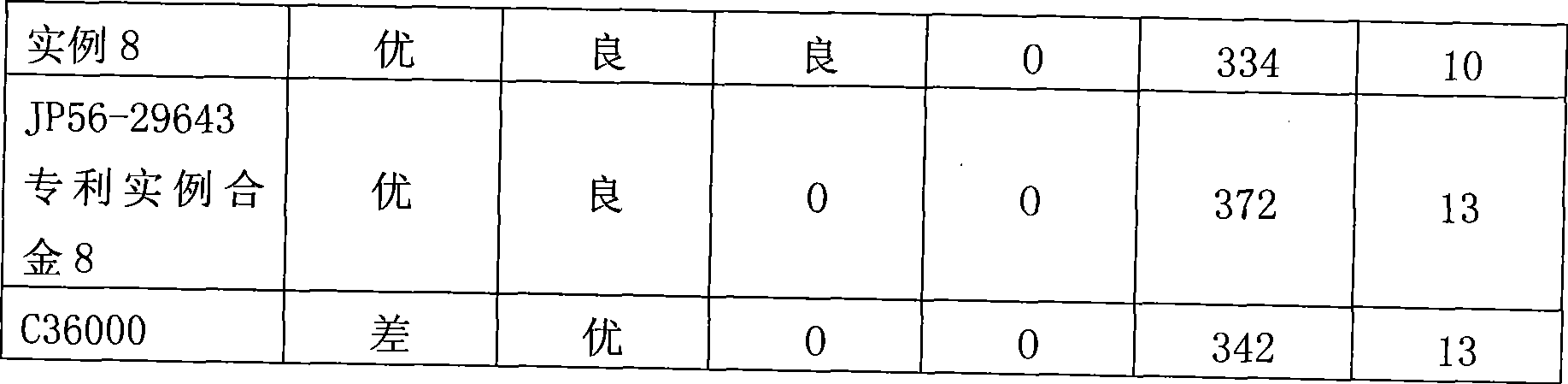

Dezincification corrosion resistant low-stibium aluminum yellow brass alloy and manufacturing method thereof

InactiveCN101440443AExcellent resistance to dezincificationImprove mechanical propertiesMechanical propertyImpurity

The invention discloses a low-stibium aluminum-brass alloy with dezincification corrosion resistance and a preparation method thereof. The alloy comprises the following chemical components: 58.8 to 63 weight percent of copper, 0.25 to 0.65 weight percent of aluminum, 0.105 to 0.35 weight percent of stibium, 0.03 to 0.25 weight percent of lead, 0.04 to 1.5 weight percent of other element, and the balance being zinc and inevitable impurities, wherein the weight percentage of the copper, the zinc, the aluminum, the stibium and the lead is more than 98.2 weight percent, and the other element is at least one element selected from boron, tin, phosphorus, nickel, bismuth and iron. The preparation method comprises: adopting methods of alloying treatment, covering, protecting, dreg removing, purifying and refining, casting the low-stibium aluminum-brass alloy by fusion, thermally processing the alloy at a temperature of between 680 and 740 DEG C; and then carrying out cold processing and intermediate thermal treatment on the alloy, and carrying out stress relieving annealing at a temperature of lower than 380 DEG C after a finished product is subjected to cold processing. The alloy product has the advantages of excellent dezincification corrosion resistance, thermal forming property, mechanical property and easy polishing and plating properties, good cutting property, remarkably excellent hygienic safety, simple manufacturing technique, low cost and easy recycling.

Owner:NINGBO POWERWAY ALLOY MATERIAL

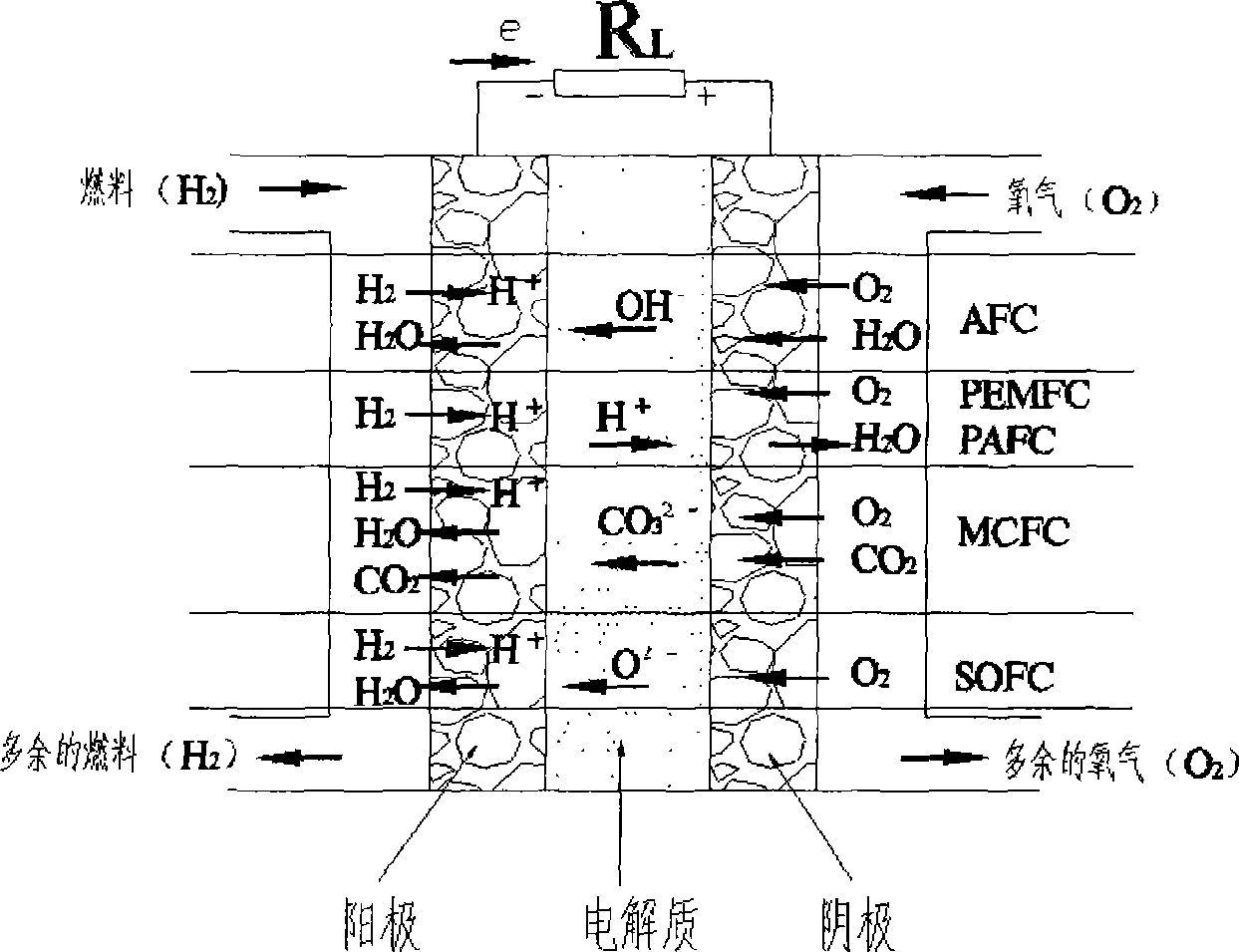

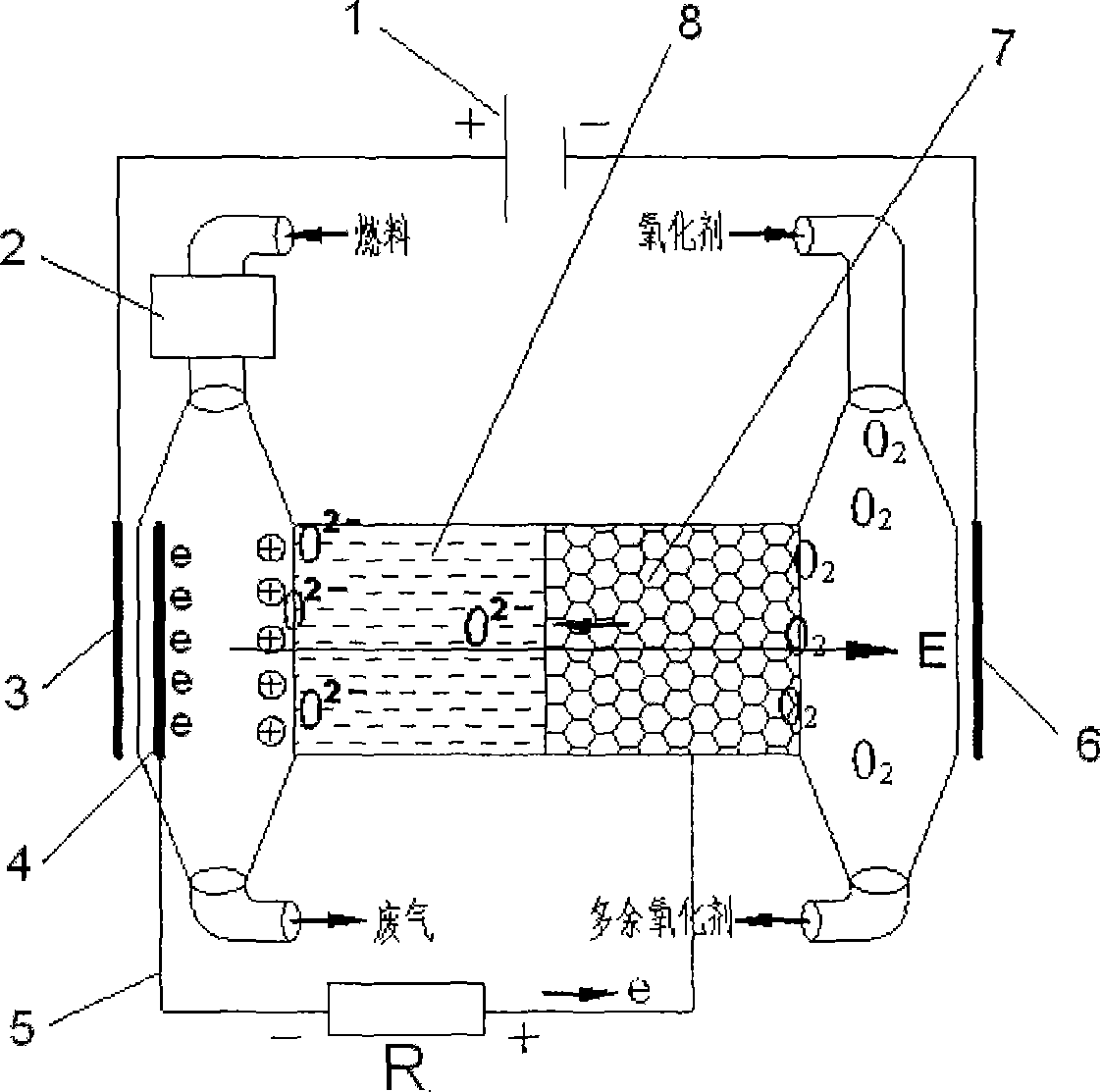

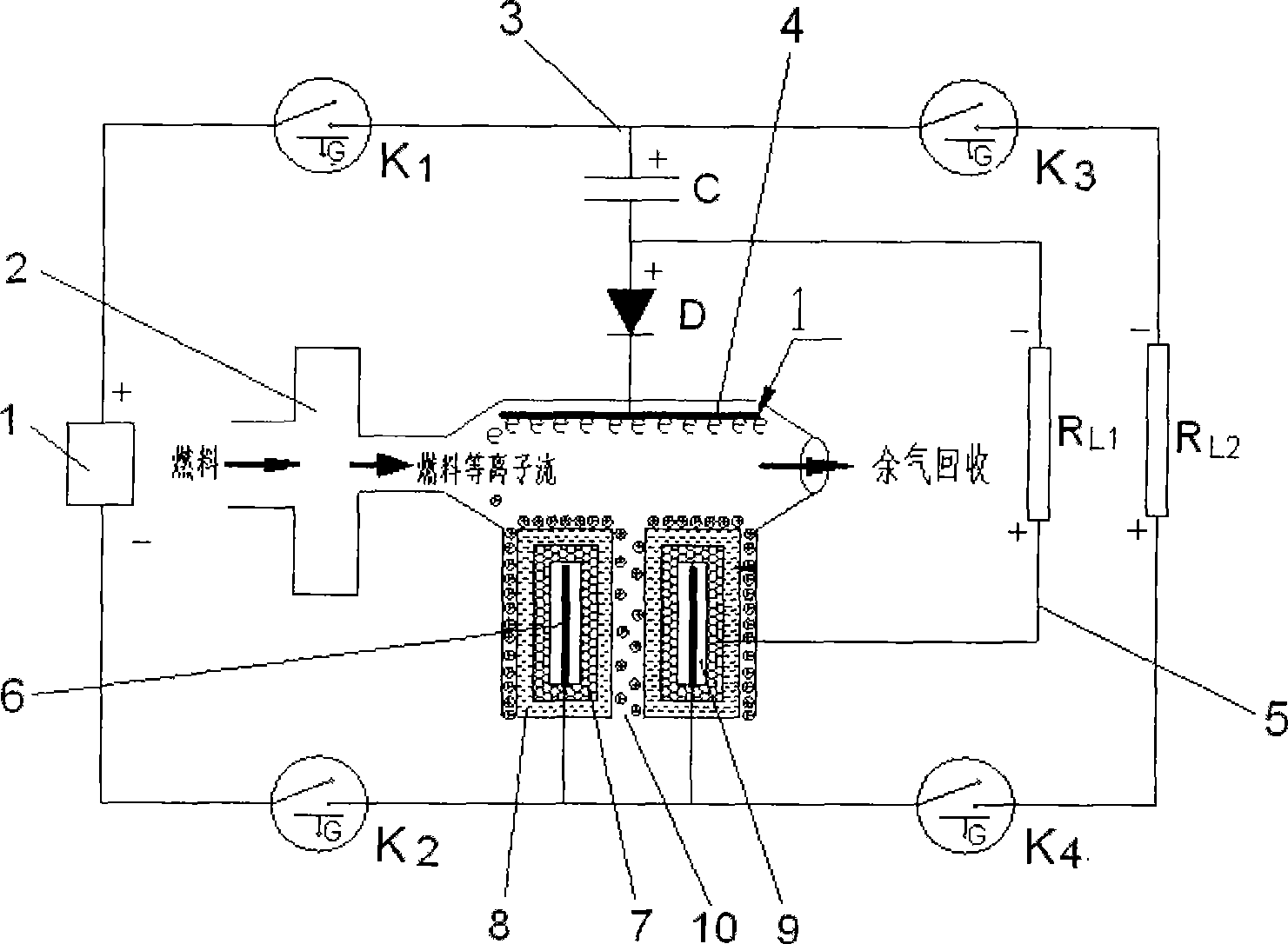

Plasma body fuel cell

InactiveCN101453028AStart fastIncrease powerFinal product manufactureFuel cell auxillariesPlasma jetElectrolysis

The invention provides a plasma fuel cell. An additional ion separation field with field direction which is vertical to running direction is arranged on a plasma flow operating path after a plasma jet generation unit; and corresponding collection structures are arranged on moving directions of separated cation and anion, wherein an electron collection structure is connected with an electric energy output circuit of an electron transfer circuit which is used for moving collected electrons out of the separation field; the electrons are transferred to a porous electrode structure which is on anion collecting side, is communicated with an oxygen introducing structure, and is isolated from the anions by a solid oxide electrolysis isolation structure; oxygen anions reduced by the electrons are combined with cations collected via isolation through the solid oxide electrolysis isolation structure to release converted electric energy to the outside. The cell can break electrostatic balance with feasibility, has a simple structure, can use various fuel gases and effectively recover fuel residual gas, does not need a noble metal catalyst or a biopolar plate so as to reduce the cost, and has the advantages of fast starting, large power and good loading adaptability.

Owner:肖远科 +1

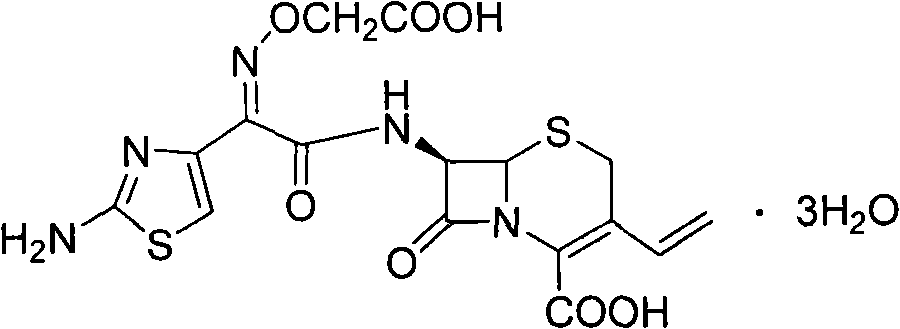

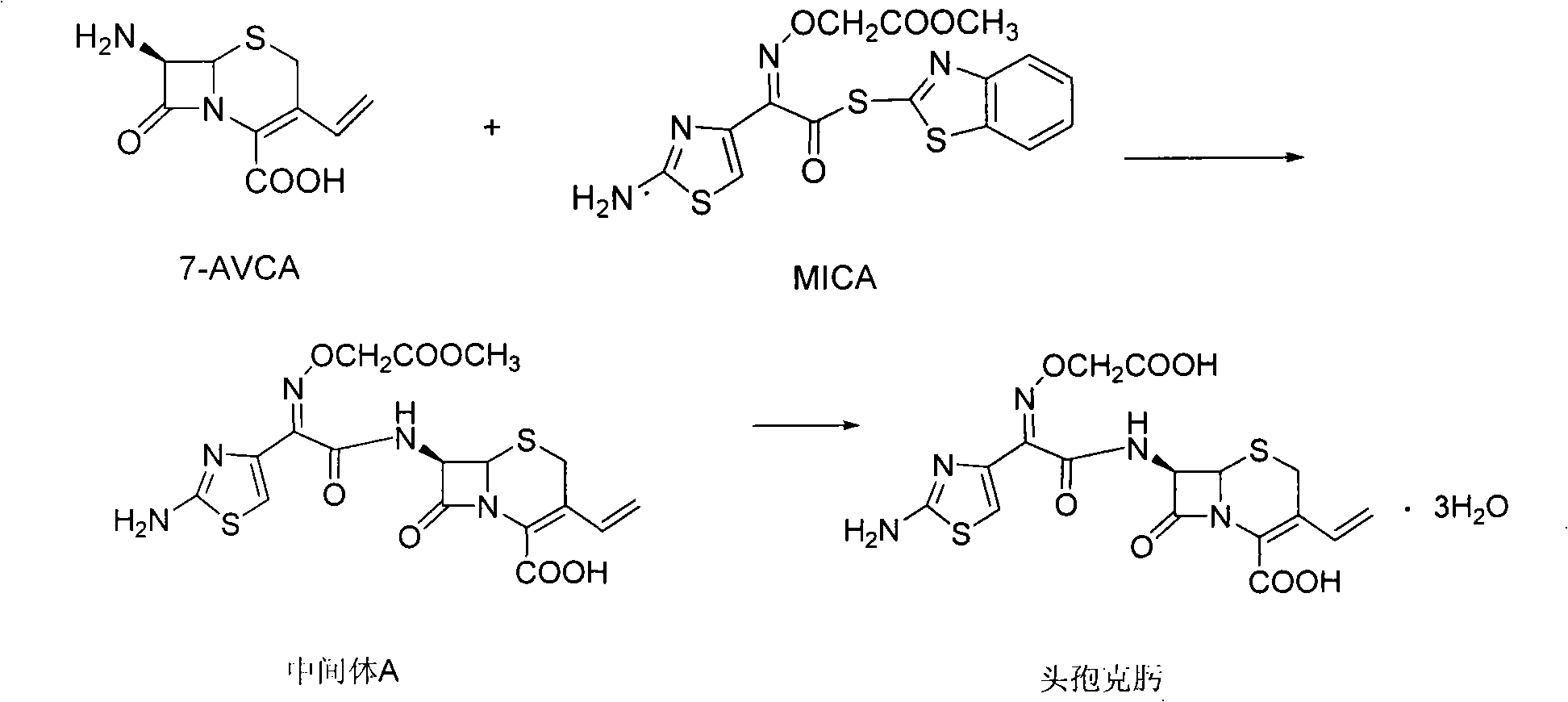

Synthetic method of antibiotic cefixime

InactiveCN101337969ASolve the recycling problemReduce waste water dischargeAntibacterial agentsOrganic chemistryTetrahydrofuranAcetone

The invention relates to a synthesis method of cefixime that is bacteriophage. 7-azyl-3-vinyl cephalosporanic acid (7-AVCA) is used as starting material to react with MICA active ester first, and an intermediate MECEF of cefixime is obtained through separation; the intermediate MECEF is directly hydrolyzed to generate a cefixime product without separation; the condensation and the hydrolyzation in a synthesis route of the cefixime product is combined into one. The synthesis method has the advantages that the technologcial conditions are simple, the operation is convenient, the product yield is high, the product quality is stable, and the method is suitable for the large-scale industrialized production; two-step reactions are combined into one, an intermediate A is not needed to be separated, the operation is simplified, and the production period is shortened; the yield can reach 200 to 212 percent; the purity quotient is more than 99 percent; the curative effect of the product is increased. Expensive tetrahydrofuran which is used in the reaction is replaced by low-cost acetone, the problem that tetrahydrofuran is mixed with the other reaction solvent and cannot be recycled and reused is solved, the wastewater discharge is reduced, the manufacture cost is lowered, and the competitive ability of the product is increased.

Owner:国药集团致君(苏州)制药有限公司

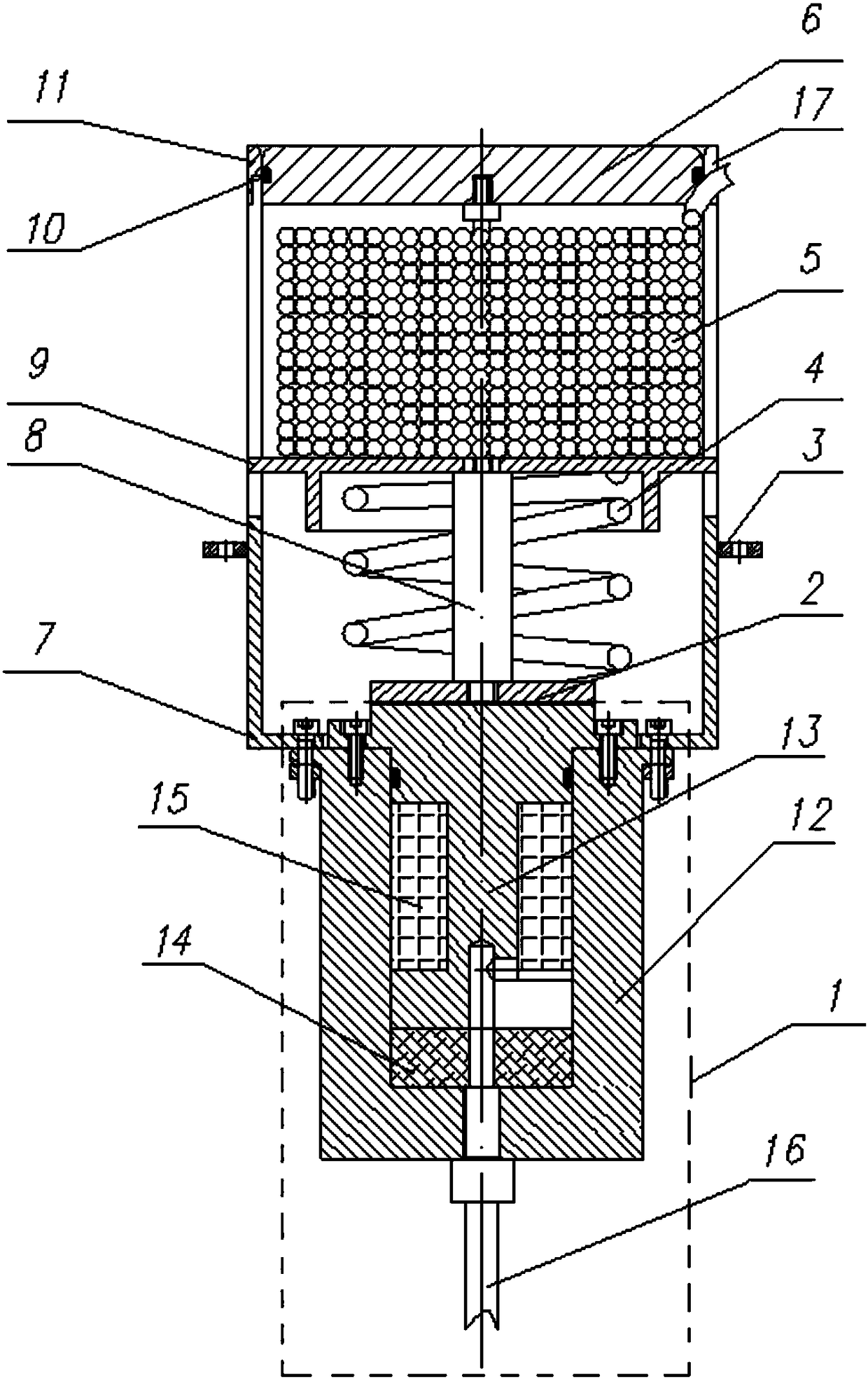

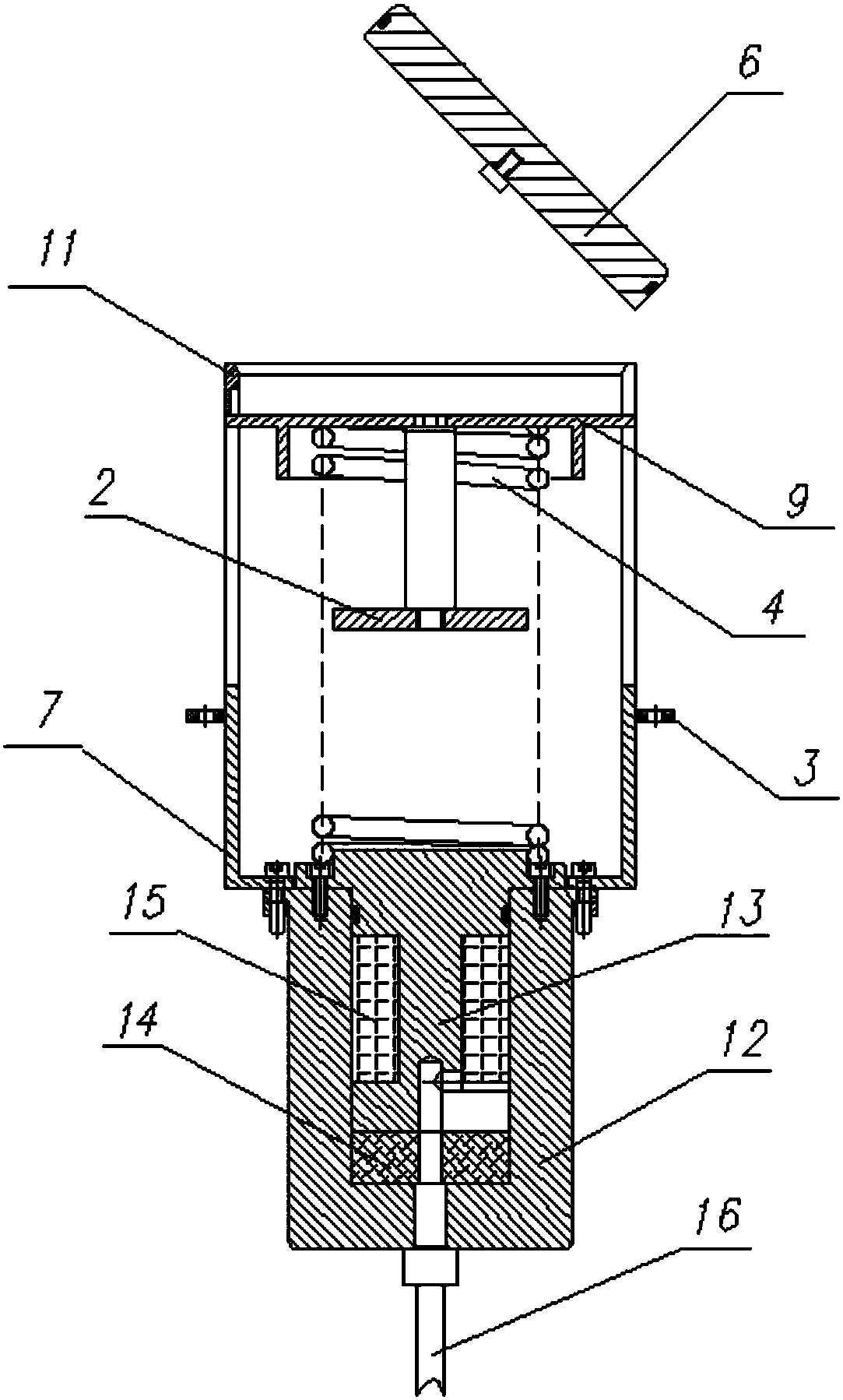

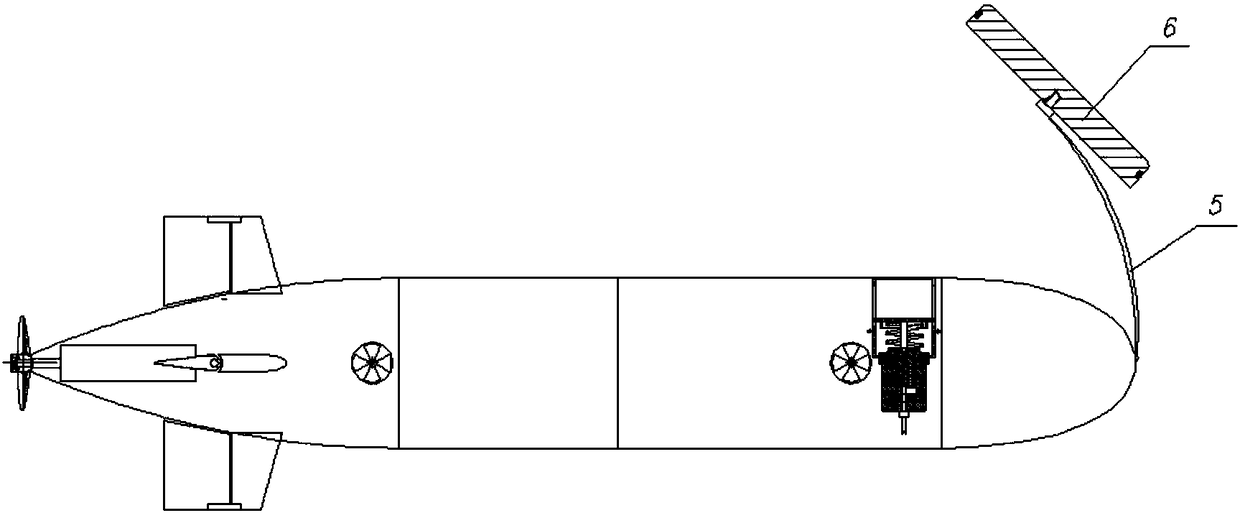

Underwater platform cable throwing device with buoy

InactiveCN108454783ASolving Recycling ProblemsFix security issuesBuoysUnderwater equipmentBuoyElectromagnet

The invention relates to an underwater platform cable throwing device with a buoy. When the cable throwing device is in a non-triggered state, a bottom plate is attracted by an electromagnet assembly,and a cable and a buoy assembly are located in a cable storage cavity; when the buoy assembly needs to be taken back on a platform or released at the indication position, the electromagnet assembly instantly loses the restraint on the bottom plate, at the moment, a spring pushes a top plate to move in the axial direction of the cable storage cavity under the effect of resilience, and the cable and the buoy assembly are thrown out of the cable storage cavity. The buoy assembly and the cable are gradually spread in air and fall and float on water after being thrown out of the cable storage cavity, and a GPS and a beacon module in the buoy assembly send a position indication signal to a mother ship. By means of the cable throwing device, the problems of taking back, safety guaranteeing and positioning of various underwater platforms can be solved.

Owner:CSIC NO 710 RES & DEV INST

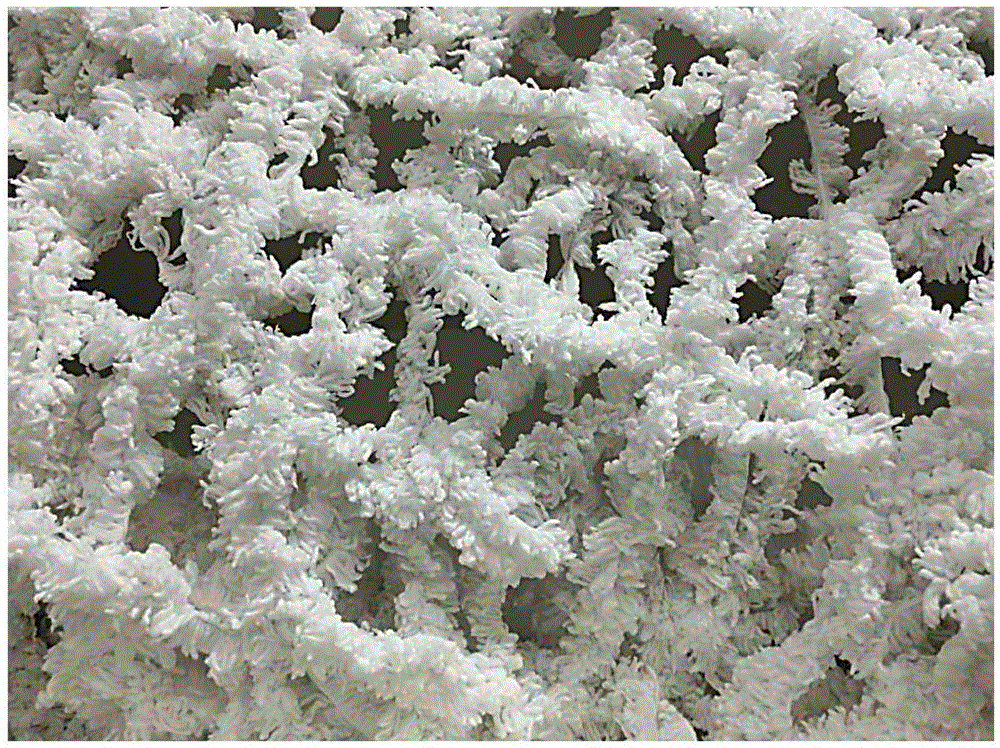

Functional nano-composite material, preparation method and application thereof

ActiveCN106694055APayloadAvoid low loadMicroorganismsOrganic-compounds/hydrides/coordination-complexes catalystsNanoparticleEngineering

The invention provides a functional nano-composite material, which comprises a flexible fiber carrier and a plurality of functional nanoparticles immobilized in the flexible fiber carrier. The flexible fiber carrier comprises at least one brush-like structure, and the plurality of functional nanoparticles are clamped and fixed in the at least one brush-like structure. The invention also provides a preparation method and application of the functional nano-composite material. In the invention, flexible fiber is adopted as the carrier to realize effective loading of the functional nanoparticles. The loading compounding mode can realize high capacity loading of the functional nanoparticles, and the loading rate is up to 10% of the weight of the flexible fiber carrier. At the same time, the functional nanoparticles can be extended to all scenes in which the flexible fiber carrier can be applied, can be applied to sewage purification, air purification, bacteria resistance, disinfection and other environmental protection fields, and the application range is very wide.

Owner:鲸果科技(杭州)有限公司

Phase-transfer catalyst for control of oxidizing reaction and oxidizing reaction procedure

InactiveCN1401425AMild reaction conditionsSolving Recycling ProblemsOrganic oxidationOrganic-compounds/hydrides/coordination-complexes catalystsChemistryPhase-transfer catalyst

A phase-transfer catalyst for controlled of oxidizing reaction has a chemical formula: QmHnXMpO4+3 or QmMO3(L). It is not soluble to reaction mediumd but can become the active substance soluble in reaction medium under the action of one reactant to further act on anothe reactant for selective reaction. When one of the reactants is consumed off, the catalyst can restore its initial structure and be educed out for cyclic use.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

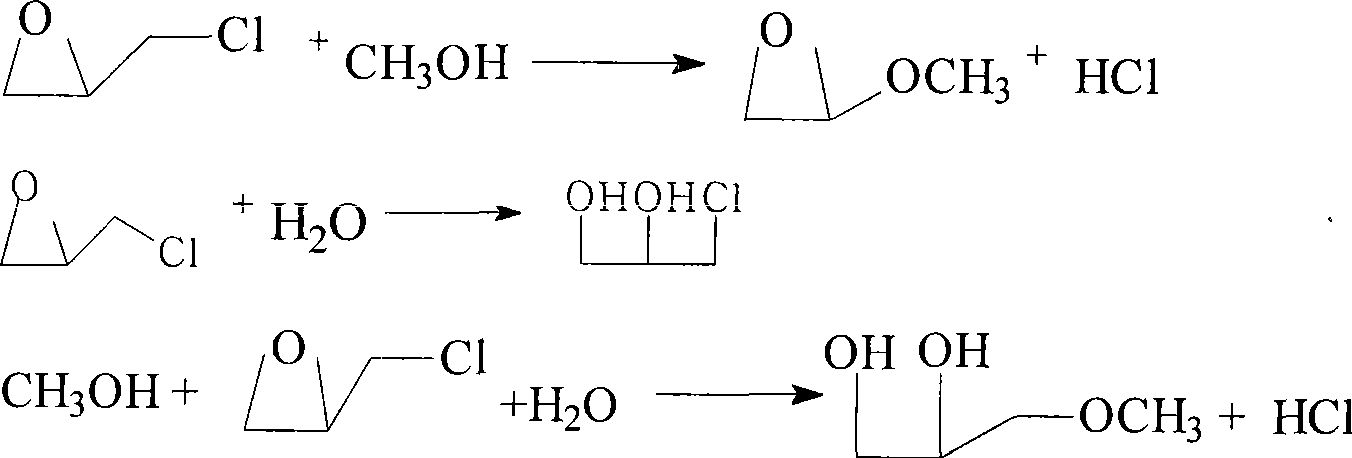

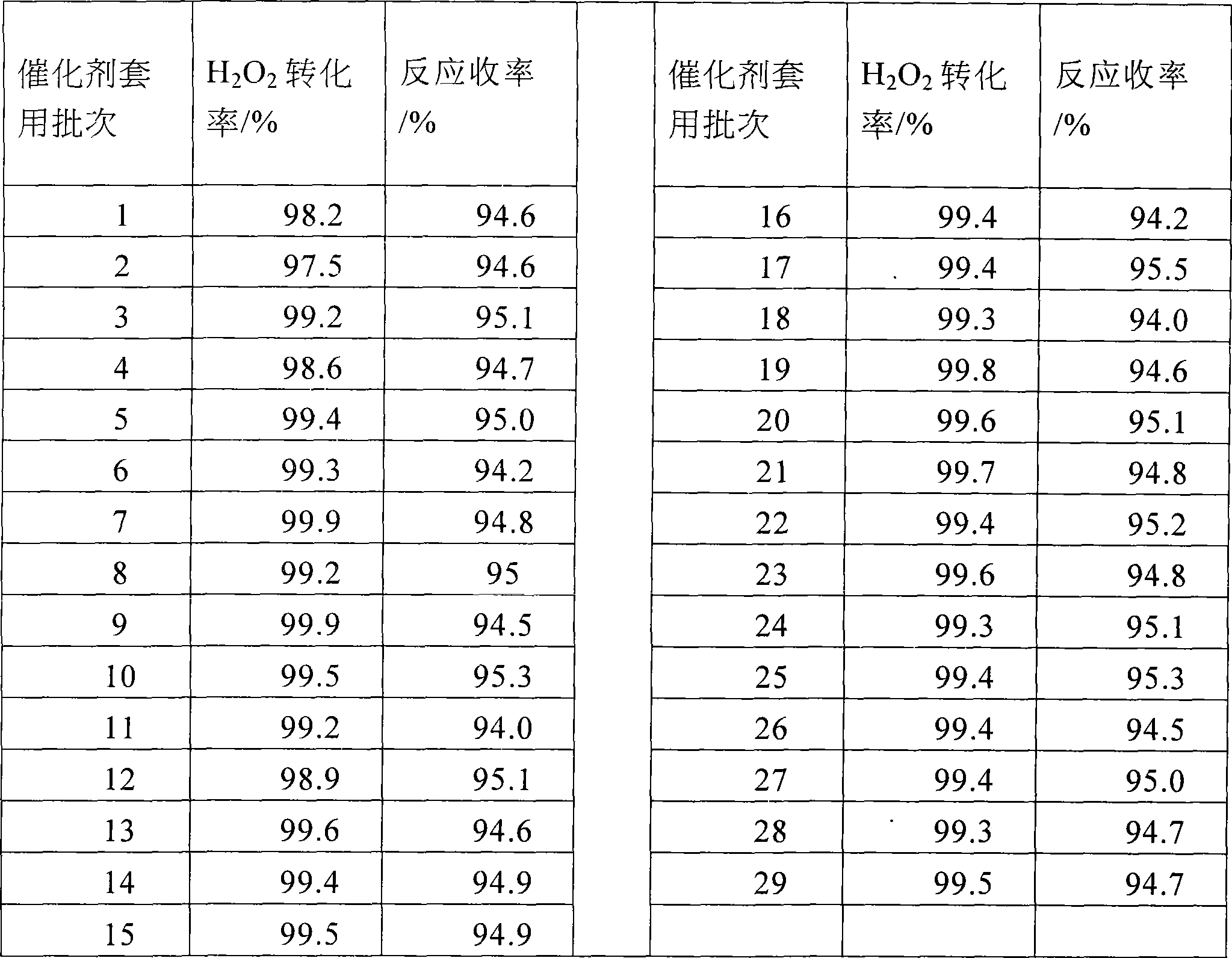

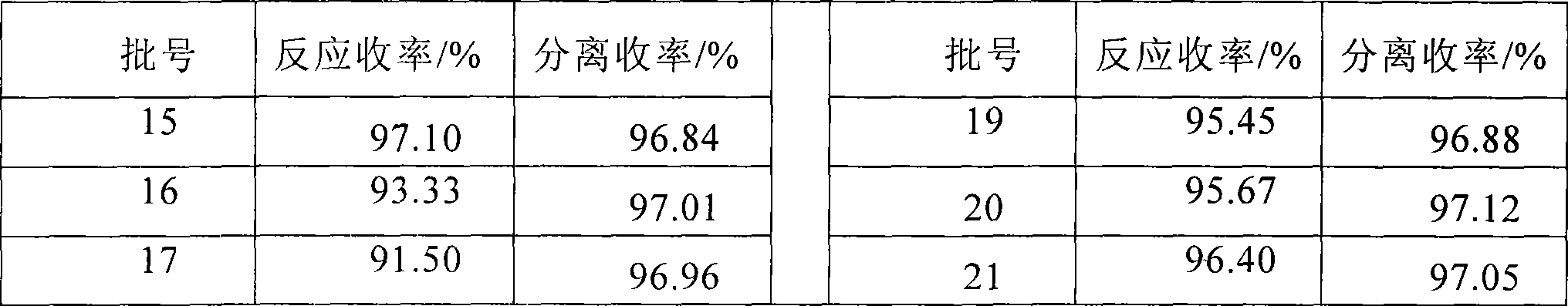

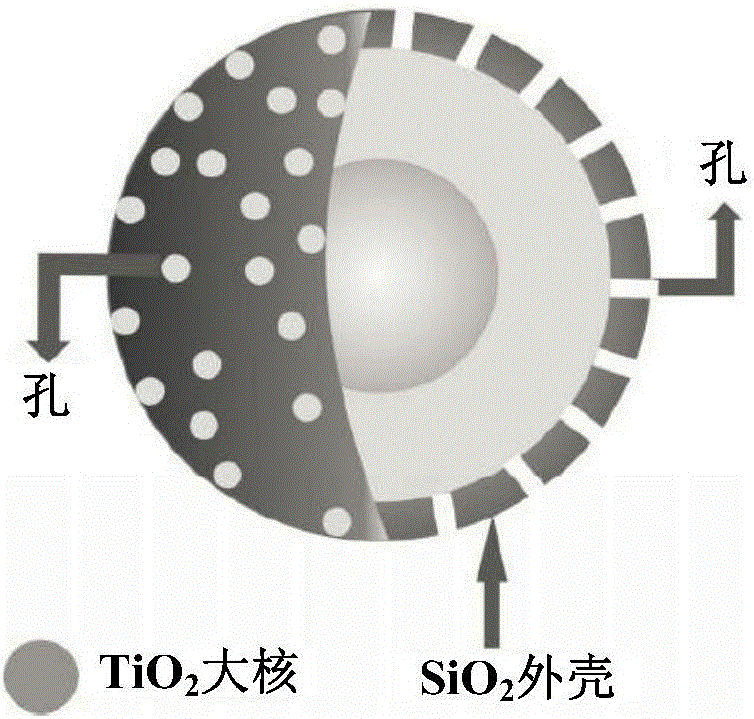

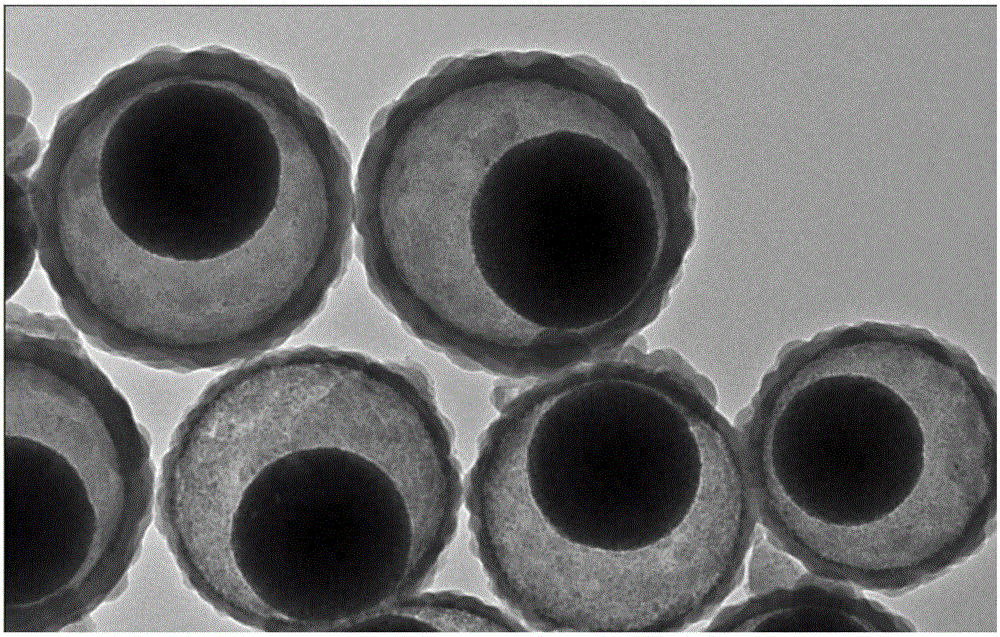

Production method of epoxy chloropropane by hydrogen peroxide method

The invention discloses a method for preparing epoxy chloropropane with the oxidation of chloropropene. The chloropropene, a solvent and fine particles of titanium silicate molecular sieve catalyst are put into a reaction pot and a hydrogen dioxide solution is added at 10 DEG C to 80 DEG C. The method is characterized in that a reaction is carried out under a subacidity condition and after the reaction, materials pass through an intermediate tank for oil-water dissociation to be divided into oil phase and water phase; the oil phase is sent into a rectifying tower for separating the chloropropene and ECH. After the water phase is filtered, a catalyst filter cake is washed by the solvent, regenerated or applied to an epoxidation reaction after being directly beat with the solvent. The ECH is extracted from an aqueous layer after filtration by the chloropropene. An extracted oil layer and an oil layer obtained from the separation of a reaction solution are combined and rectified, or the extracted oil layer is applied to the epoxidation reaction; water left from the extraction is rectified for recycling methanol and applied to the preparation of catalysts; and the method has simple procedures, small consumption amount of solvents, high separation yield of reaction products and easy realization of industrialization.

Owner:JIANGSU YANGNONG CHEM GROUP +2

Nano-composite fiber material and preparation method thereof

InactiveCN106592005APayloadAvoid low loadWater/sewage treatment by irradiationWater treatment compoundsFiberOrganic solvent

The invention provides a preparation method of a nano-composite fiber material. The preparation method includes the steps of (1), dispersing multiple functional nanoparticles into an organic solvent so as to form functional nanoparticle suspension; (2), providing a fusion-state organic polymer carrier material; (3), spraying the functional nanoparticle suspension on the fusion-state organic polymer carrier material so as to enable the functional nanoparticles to be attached to the surface of the fusion-state organic polymer carrier material; (4), curing a fusion-state organic polymer carrier material obtained from the step (3) so as to obtain the nano-composite fiber material. The invention further provides the nano-composite fiber material prepared by the preparation method. The nano-composite fiber material has the advantages that the functional nanoparticles can be effectively loaded on the organic polymer carrier material, so that high-capacity functional nanoparticle load can be achieved; the nano-composite fiber material can be applied to the environment-friendly fields of wastewater purification, air purification, bacterium resistance, disinfection and the like.

Owner:嘉兴迈之新材料科技有限公司

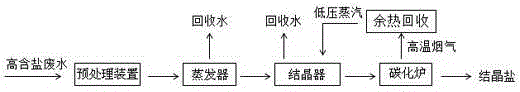

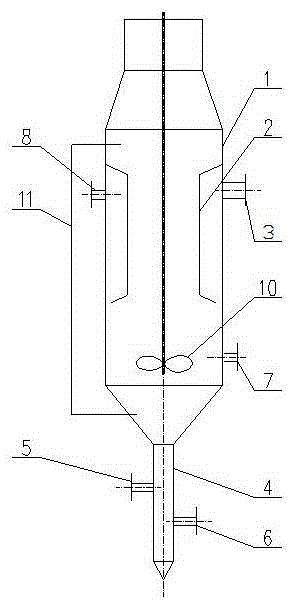

Salt crystallizing processing technology and device for zero discharge of high salt wastewater

ActiveCN105198148AAchieving zero emissionsSolve zero emissionsEnergy inputMultistage water/sewage treatmentEvaporationCarbonization

The invention discloses a salt crystallizing processing technology and device for zero discharge of high salt wastewater. The technology mainly comprises processes of preprocessing, evaporation, crystallization, carbonization and the like; a crystallizer mainly comprises a cylinder body, a double-horn shaped cylinder body, a washing tube, a cleaning port, a monitor, a mixing agitator and a heating device; firstly, the mixing agitator is subjected to relative preprocessing operations, then wastewater enters an evaporator, low-pressure steam provided by the outside is used for evaporating and crystallizing salt-containing wastewater in evaporator bundles, after the evaporation process is finished, the salt-containing wastewater is crystallized by the crystallizer, finally, organic matters and nitrate in the crystallized salt are removed in a carbonization stove, exhaust gas of the carbonization stove enters a combustion system, high temperature flue gas heat of the carbonization stove is subjected waste heat recovery, and low-pressure steam generated by a waste heat boiler is used as steam for external supply of the crystallizer. According to the salt crystallizing processing technology and device for zero discharge of the high salt wastewater, the high salt wastewater is further processed, the water recovery rate can reach 95% or above, at the same time, solid salt is crystallized, and zero discharge of high salt wastewater is realized.

Owner:JIANGSU SUNPOWER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com