Functional nano-composite material, preparation method and application thereof

A composite material and functional nanotechnology, which is applied in the field of nanocomposite materials and their preparation, can solve problems such as easy agglomeration, difficulty in recycling, and reduced activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a nanomotor polyester composite fiber web, which includes a polyester fiber web and a plurality of nanomotors fixed in the polyester fiber web, the plurality of nanomotors are clamped and fixed in the polyester fiber web, And the loading of the nanomotor is 0.1%-10% of the mass of the polyester fiber web.

[0051] The polyester fiber net is assembled into bundles by 2-10 polyester fiber brushes, and then woven by the brush bundles into a network structure, wherein the polyester fiber brushes are first made of polyester fiber brushes with a density of about 400 tex After the coarse yarn is broken up and napped, it is woven into a one-dimensional continuous loop structure with a diameter of 1-3 cm, and then the loop structure is cut in half to form a brush-like structure with multiple fiber burrs. The plurality of functional nanoparticles are naturally sandwiched between the plurality of fiber burrs. Through thermal expansion and contraction of m...

Embodiment 2

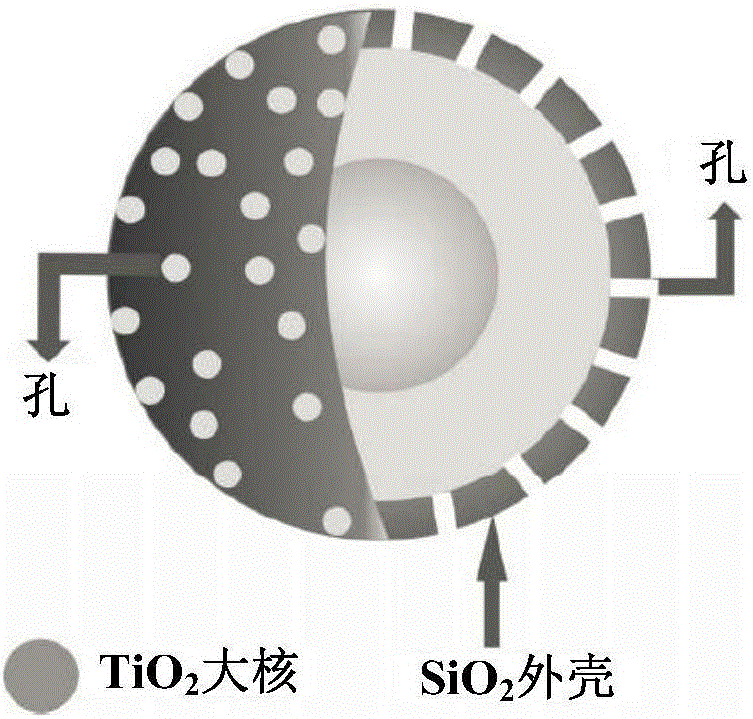

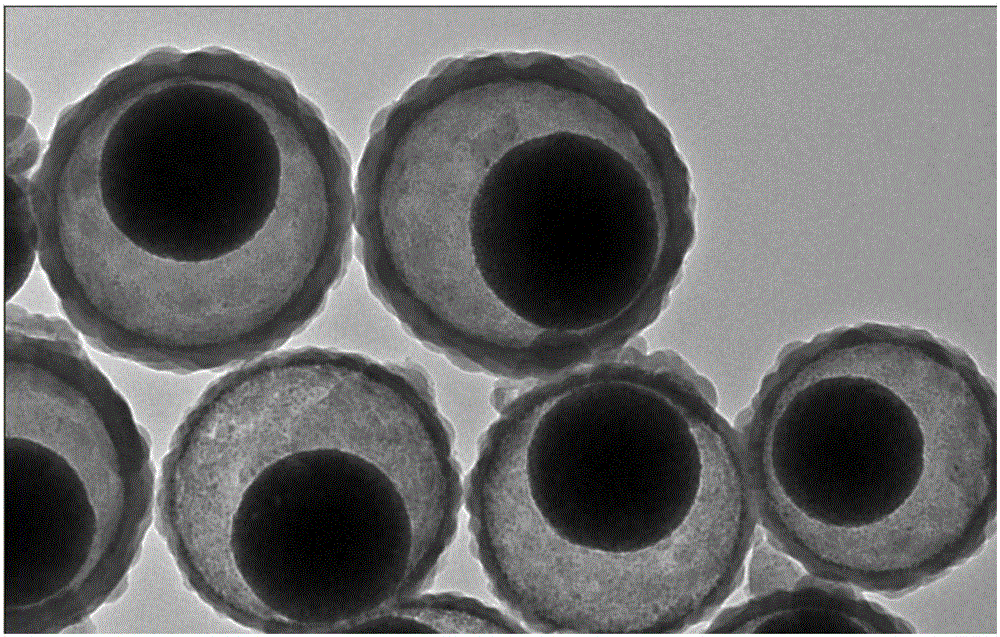

[0058] This embodiment provides a multi-core nano-motor aramid composite fiber brush, the structure of which is basically the same as that of the nano-motor polyester composite fiber web provided in Example 1. The steps are: in this embodiment, the flexible fiber used The carrier is an aramid fiber brush, and the preparation method of the aramid fiber brush is basically the same as that of the polyester fiber brush provided in Example 1; Figure 4 The shown multi-core nanomotor is used as a functional nanoparticle, and the loading capacity of the multi-core nanomotor is XX of the mass of the aramid fiber brush. The multi-core nanomotor comprises a plurality of dispersed titanium dioxide cores and a mesoporous silicon dioxide shell wrapping the multiple titanium dioxide cores, and the mesoporous silicon dioxide shell is spaced apart from the multiple titanium dioxide cores to form a cavity.

[0059] The preparation method of the multi-core nanomotor used in this example is basi...

Embodiment 3

[0062] This embodiment provides a nano-motor polyester composite fiber web, the structure of which is basically the same as that of the nano-motor polyester composite fiber web provided in Example 1. The steps are: in this embodiment, adopt such Figure 5 and Image 6 The shown nanomotor is used as a functional nanoparticle, and the loading of the nanomotor is 0.1%-10% of the quality of the polyester fiber web; the nanomotor includes a titanium dioxide core, and a mesoporous silica shell wrapping the titanium dioxide core , and a plurality of platinum metal nano-branches, the mesoporous silica shell and the titanium dioxide core are spaced apart to form a cavity, and the plurality of platinum metal nano-branches are dispersed in the cavity.

[0063] The preparation method of the multi-core nanomotor used in this embodiment is basically the same as that of the multi-core nanomotor in Example 2, the difference is that it further includes the following steps: (1) mixing chloropla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com