Reinforced polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the polymer field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

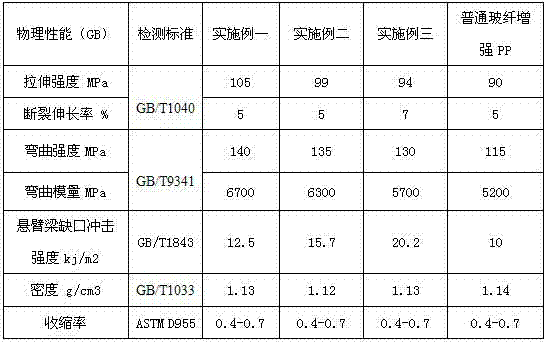

Examples

Embodiment 1

[0040] The reinforced polycarbonate composite material in the present embodiment is made up of following raw material by weight:

[0041] Isotactic homopolypropylene 64

[0042] Fiberglass 32

[0043] Propylene-alpha olefin copolymer 3

[0044] PP-g-MAH 5

[0045] Anti-floating agent 0.5

[0046] Lubricant calcium stearate 0.3

[0047] Lubricant polyethylene wax 0.2

[0048] Antioxidant 1010 1

[0049] Two (3,4 dimethyl dibenzylidene) sorbitol 0.1

[0050] Concrete preparation method comprises the following steps:

[0051] (1) Mix 64 parts of isotactic homopolypropylene, 3 parts of propylene-α-olefin copolymer, 5 parts of polypropylene grafted maleic anhydride (PP-g-MAH), 1 part of antioxidant 1010, and 0.2 parts of lubricant Add polyethylene wax, 0.3 part of lubricant calcium stearate, 0.5 part of anti-floating fiber agent, and 0.1 part of bis(3,4 dimethyl dibenzylidene) sorbitol into a mixer with nitrogen protection and mix at high speed for 10 minutes;

[0052](2) ...

Embodiment 2

[0055] The reinforced polycarbonate composite material in the present embodiment is made up of following raw material by weight:

[0056] Isotactic homopolypropylene 44

[0057] Random copolymer polypropylene 10

[0058] Fiberglass 30

[0059] Ethylene-octene copolymer 4

[0060] PP-g-MAH 4

[0061] Anti-floating agent 0.2

[0062] Lubricant calcium stearate 0.3

[0063] Lubricant ethylene bisstearamide 0.4

[0064] Antioxidant 1010 0.3

[0065] Antioxidant 168 0.2

[0066] Two (3,4 dimethyl dibenzylidene) sorbitol 0.1

[0067] Concrete preparation method comprises the following steps:

[0068] (1) 44 parts of isotactic homopolypropylene, 10 parts of random copolymerized polypropylene, 4 parts of ethylene-octene copolymer, 4 parts of polypropylene grafted maleic anhydride, 0.3 part of antioxidant 1010, 0.2 part of antioxidant Oxygen agent 168, 0.4 part of lubricant ethylene bis stearamide, 0.3 part of lubricant calcium stearate, 0.2 part of anti-floating fiber agent,...

Embodiment 3

[0072] The reinforced polycarbonate composite material in the present embodiment is made up of following raw material by weight:

[0073] Isotactic homopolypropylene 30

[0074] Random copolymer polypropylene 30

[0075] Fiberglass 29

[0076] EPDM rubber / propylene-alpha olefin copolymer 5

[0077] PP-g-MAH 6

[0078] Anti-floating agent 0.4

[0079] Lubricant calcium stearate 0.5

[0080] Lubricant polyethylene wax 0.5

[0081] Antioxidant 1010 0.1

[0082] Antioxidant 168 0.1

[0083] Two (3,4 dimethyl dibenzylidene) sorbitol 0.2

[0084] Concrete preparation method comprises the following steps:

[0085] (1) 30 parts of isotactic homopolypropylene, 30 parts of random copolymerized polypropylene, 5 parts of EPDM / propylene-α olefin copolymer, 6 parts of polypropylene grafted maleic anhydride, 0.1 part of antioxidant Agent 1010, 0.1 part of antioxidant 168, 0.5 part of lubricant polyethylene wax, 0.5 part of lubricant calcium stearate, 0.4 part of anti-floating fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com