Patents

Literature

162results about How to "Improve bonded state" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

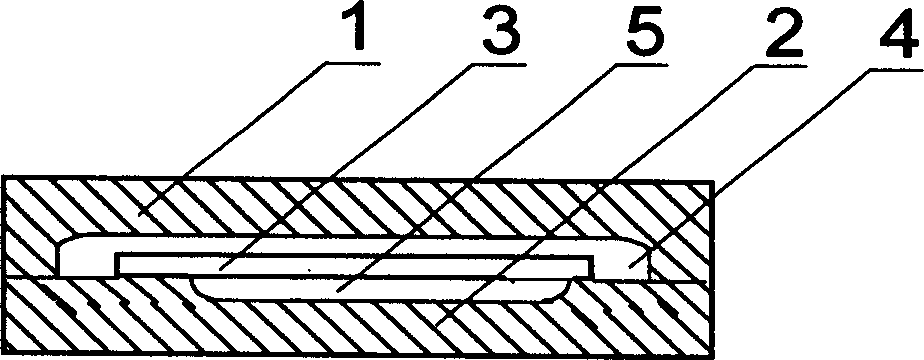

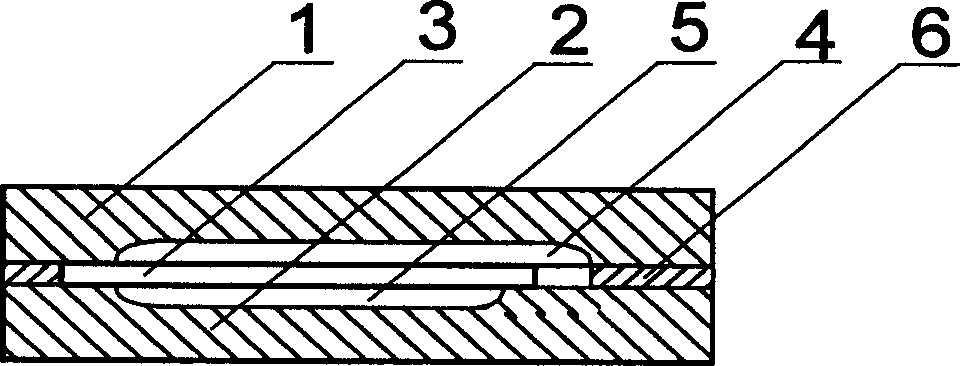

Multilayer wiring board, method for producing the same, and method for producing fiber reinforced resin board

InactiveUS20050218503A1Reduction factorImprove bonded stateSemiconductor/solid-state device detailsSolid-state devicesGlass fiberFiber

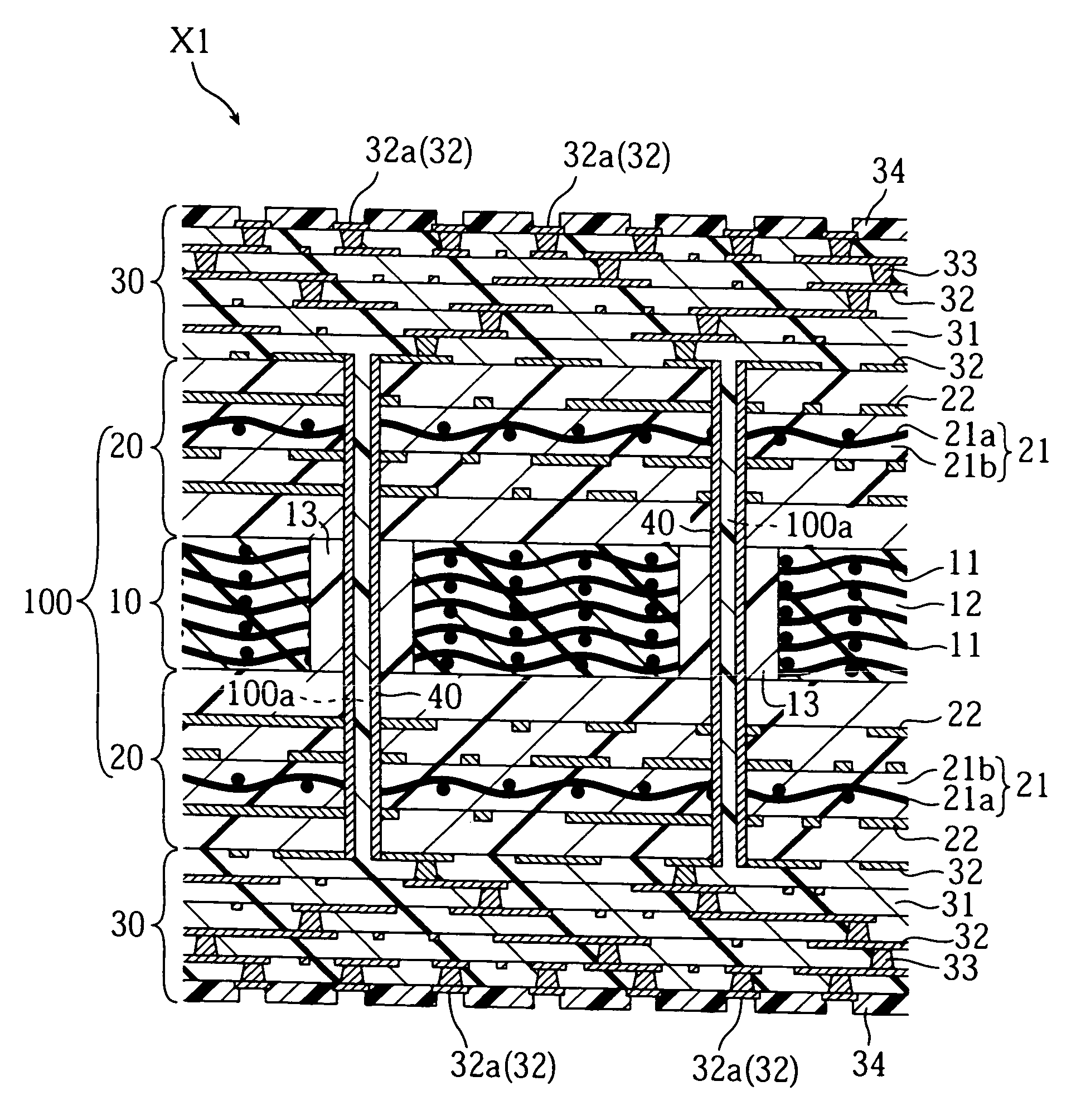

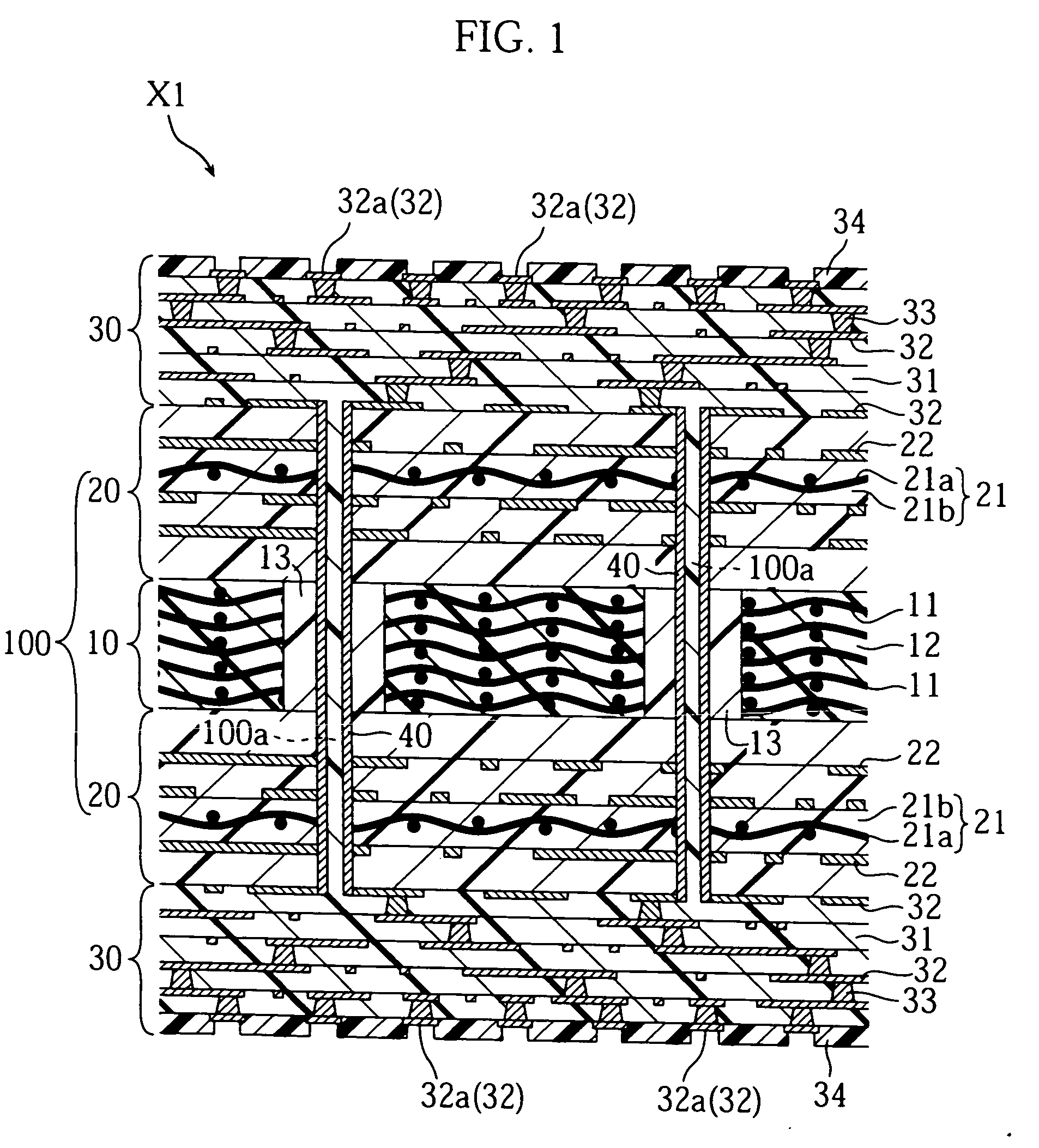

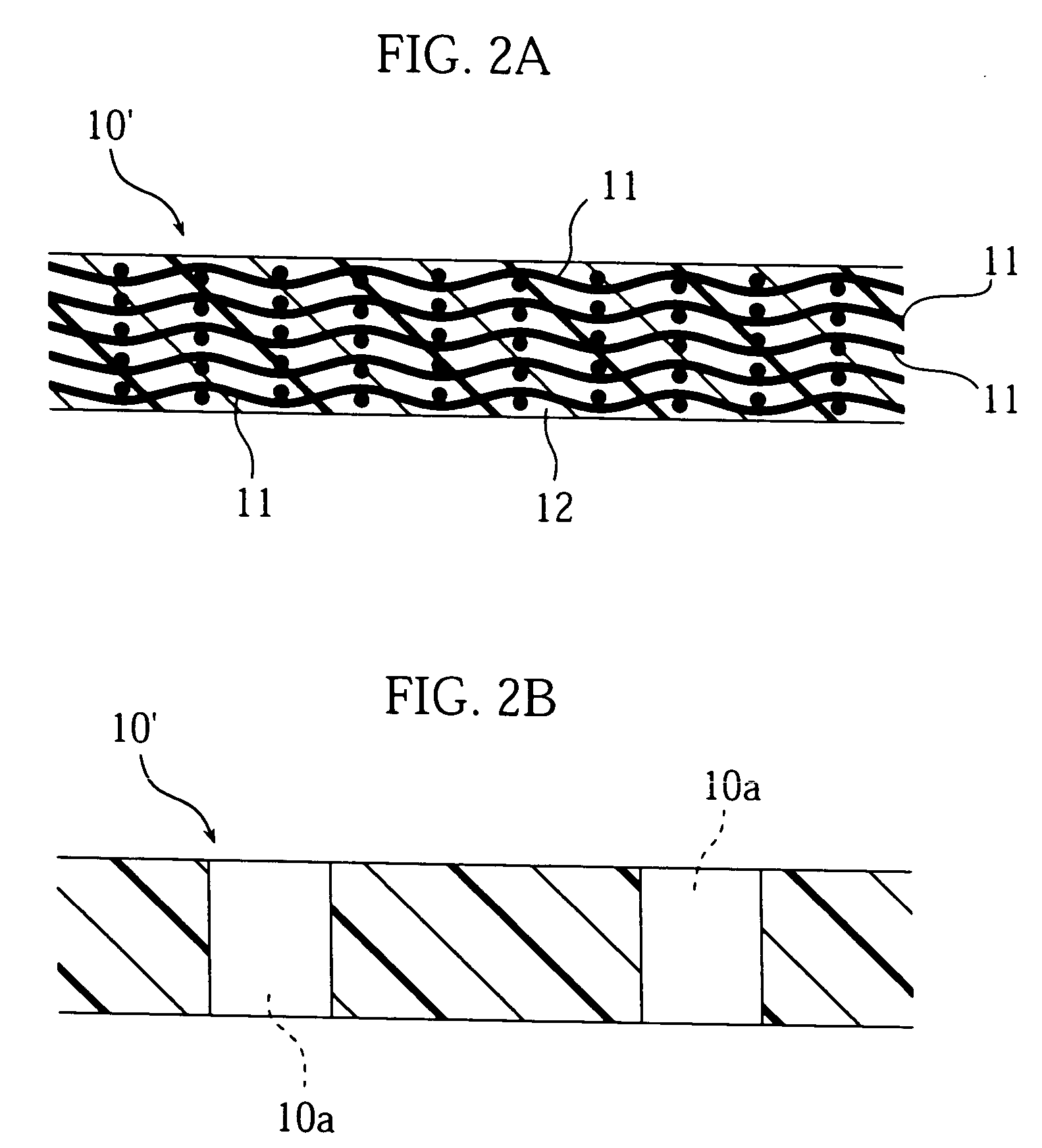

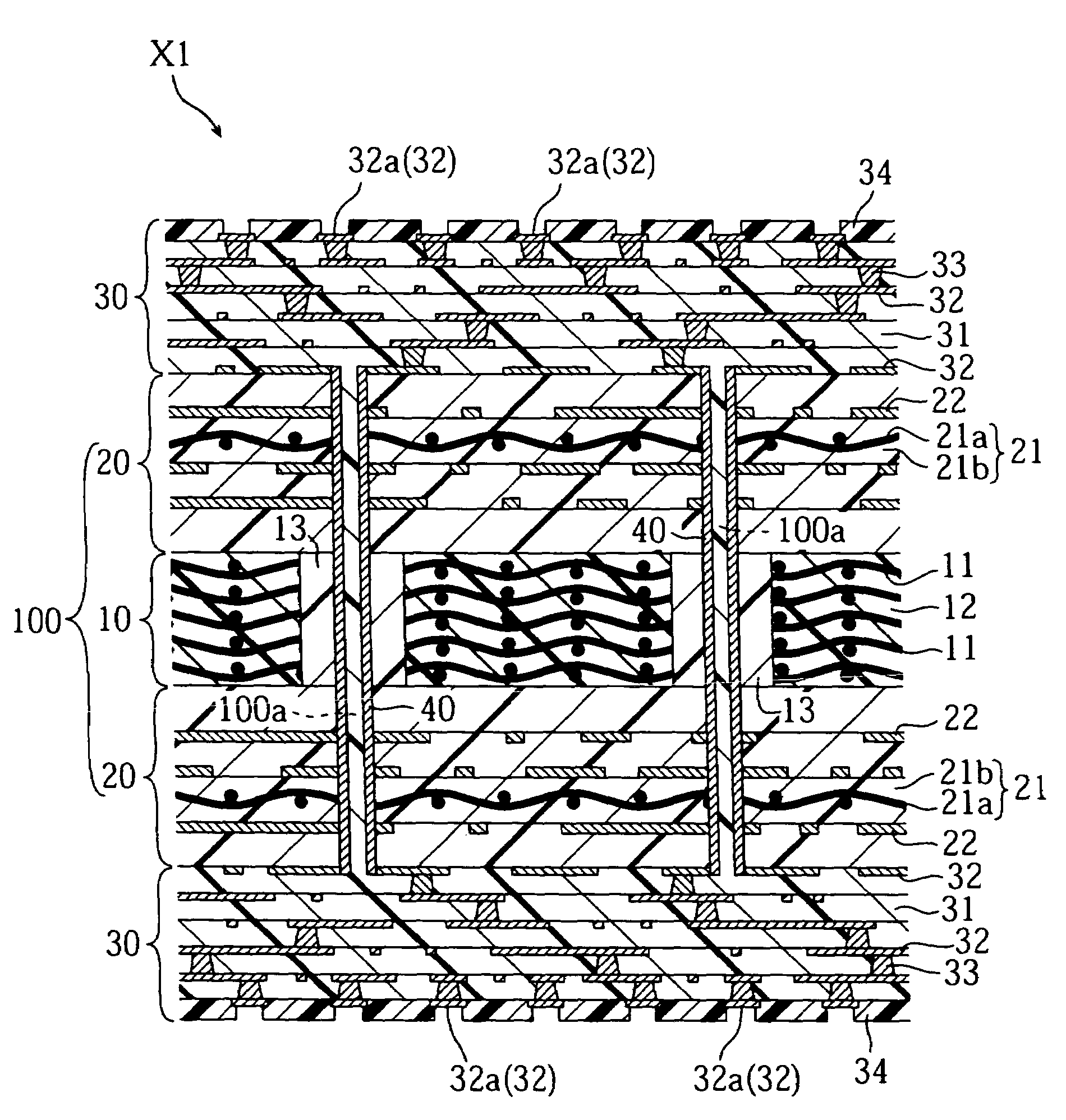

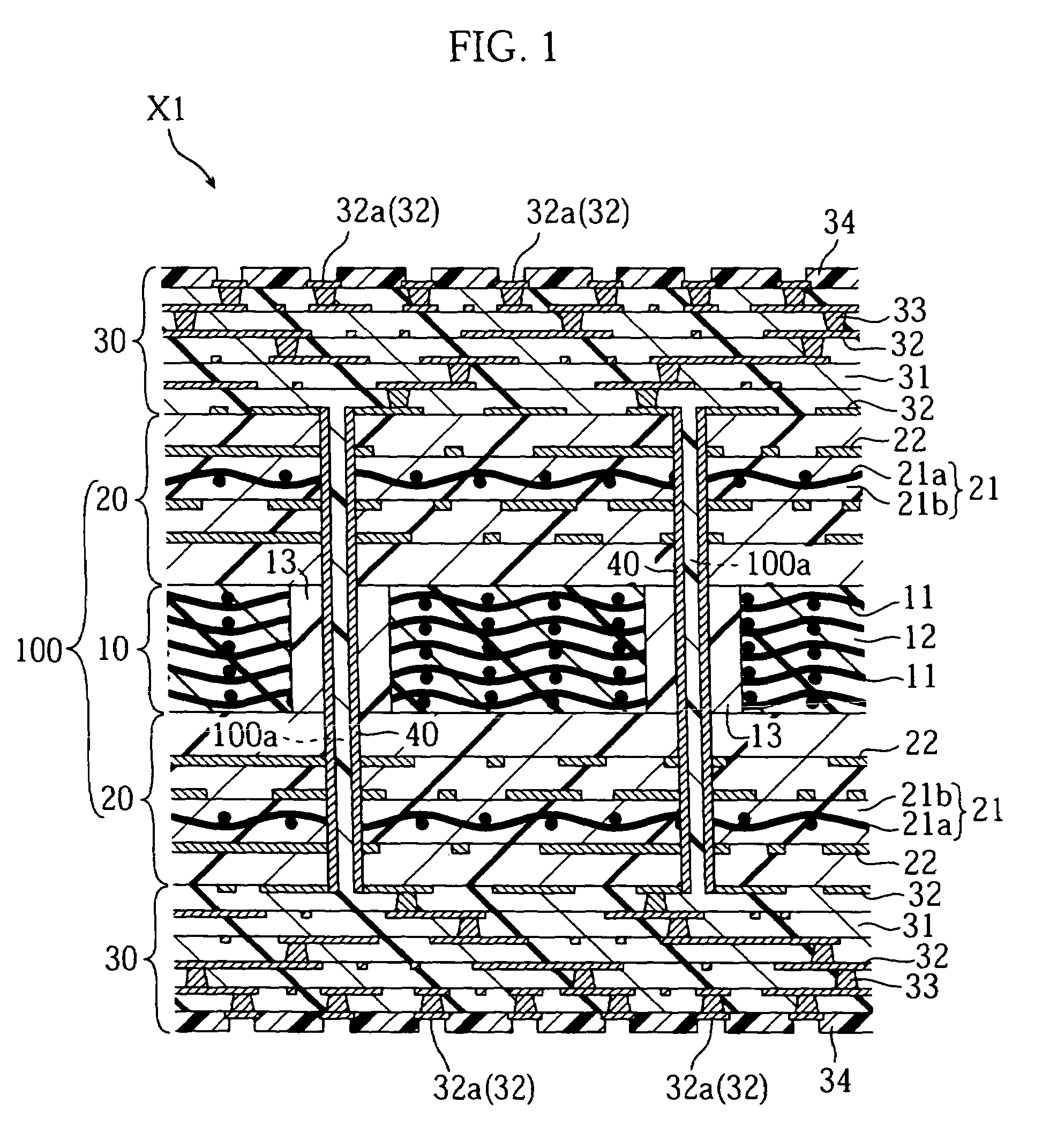

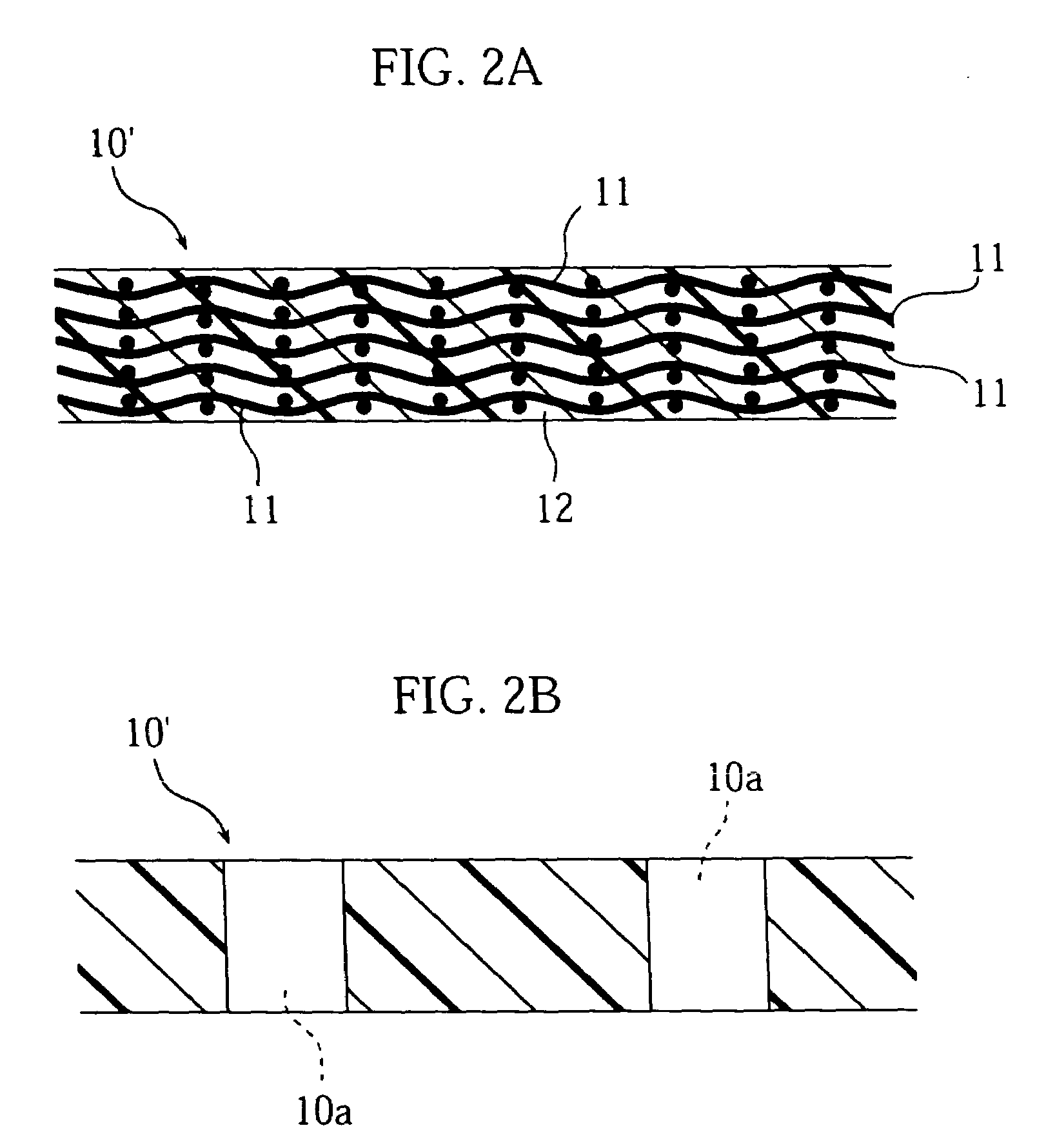

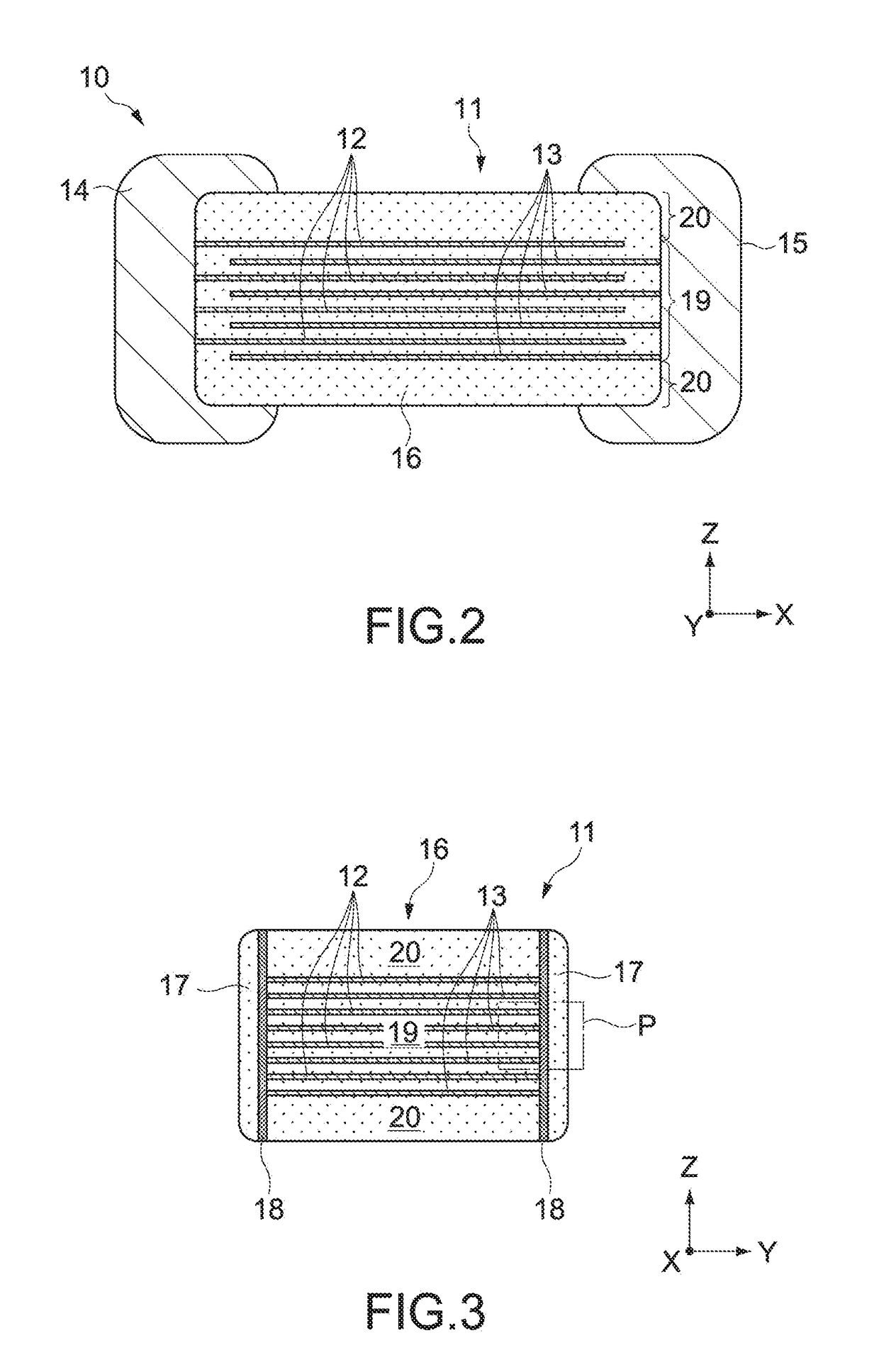

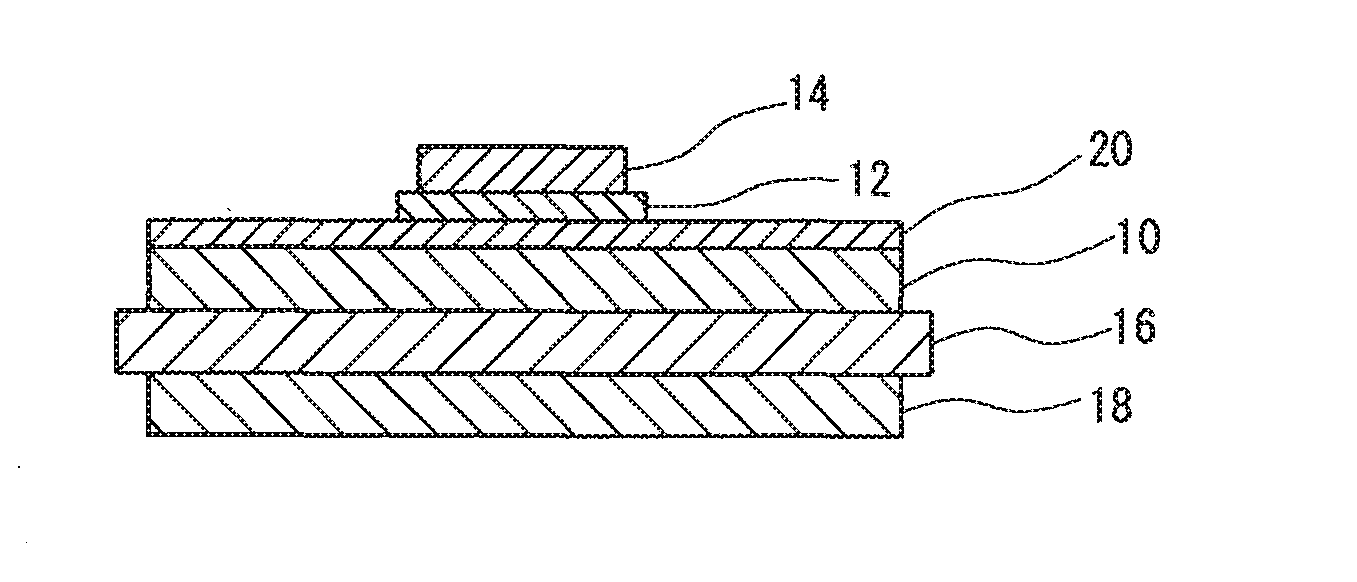

A multilayer wiring board (X1) comprises a core portion (100) and out-core wiring portion (30). The core portion (100) comprises a carbon fiber reinforced portion (10) composed of a carbon fiber material (11) and resin composition (12), and an in-core wiring portion (20) which has a laminated structure of at least one insulating layer (21) containing a glass fiber material (21a) and a wiring pattern (22) composed of a conductor having an elastic modulus of 10 to 40 GPa and which is bonded to the carbon fiber reinforced portion (10). The out-core wiring portion (30) has a laminated structure of at least one insulating layer (31) and a wiring pattern (32) and is bonded to the core portion (100) at the in-core wiring portion (20).

Owner:FUJITSU LTD

Multilayer wiring board incorporating carbon fibers and glass fibers

InactiveUS7224046B2Reduction factorImprove bonded stateSemiconductor/solid-state device detailsSolid-state devicesGlass fiberFiber

A multilayer wiring board (X1) comprises a core portion (100) and out-core wiring portion (30). The core portion (100) comprises a carbon fiber reinforced portion (10) composed of a carbon fiber material (11) and resin composition (12), and an in-core wiring portion (20) which has a laminated structure of at least one insulating layer (21) containing a glass fiber material (21a) and a wiring pattern (22) composed of a conductor having an elastic modulus of 10 to 40 GPa and which is bonded to the carbon fiber reinforced portion (10). The out-core wiring portion (30) has a laminated structure of at least one insulating layer (31) and a wiring pattern (32) and is bonded to the core portion (100) at the in-core wiring portion (20).

Owner:FUJITSU LTD

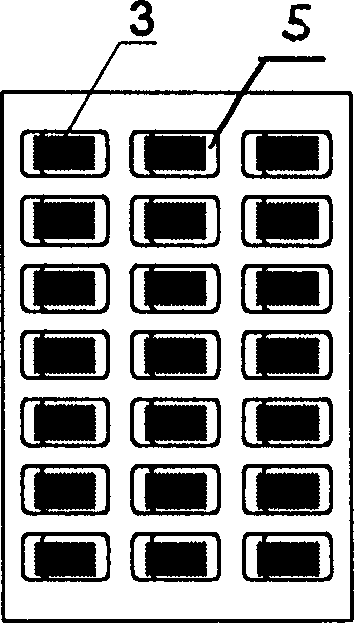

Multi-Layer Ceramic Capacitor and Method of Producing the Same

ActiveUS20170243697A1Avoid crackingAvoid delaminationFixed capacitor dielectricStacked capacitorsCeramic capacitorCeramic

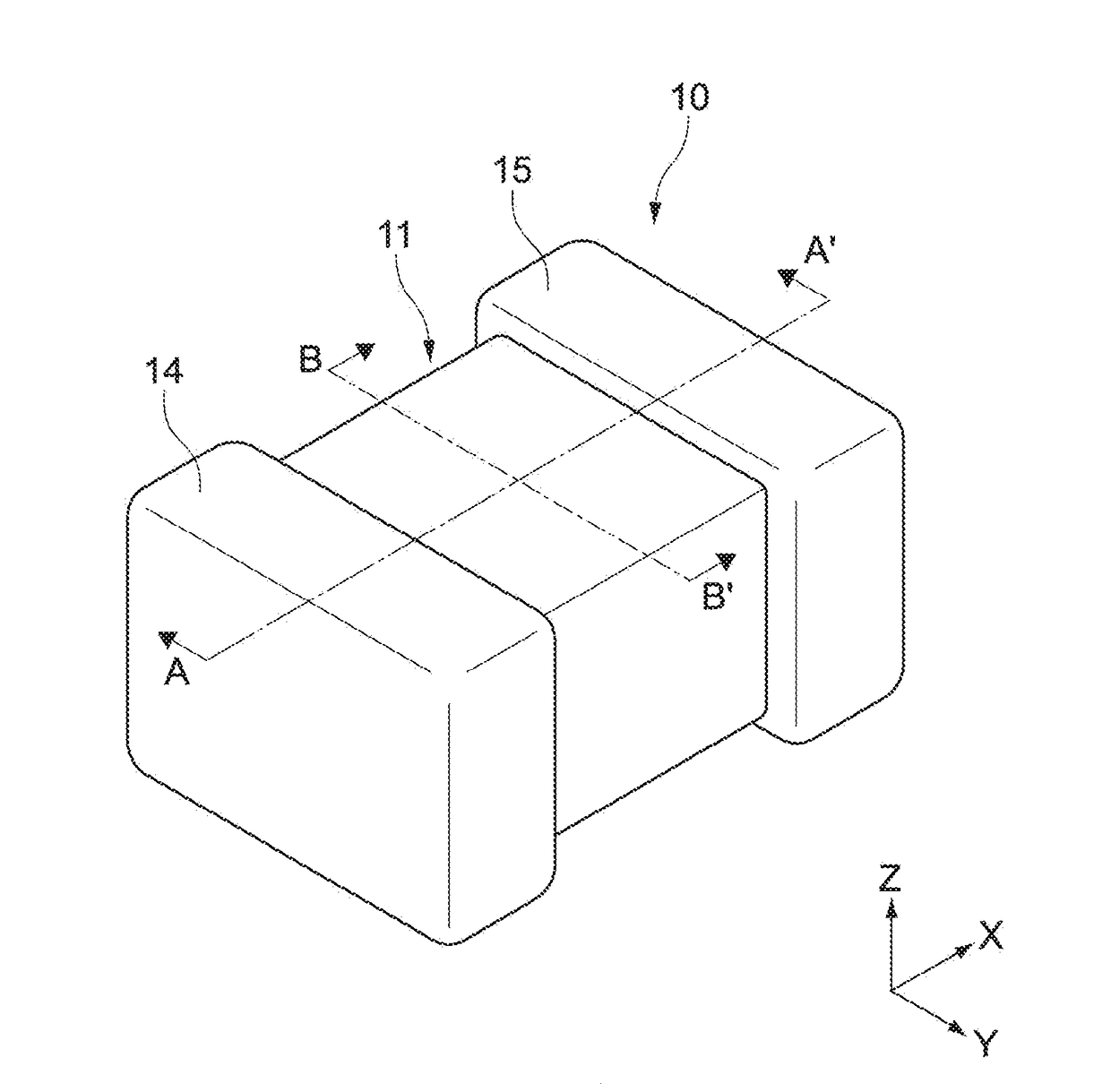

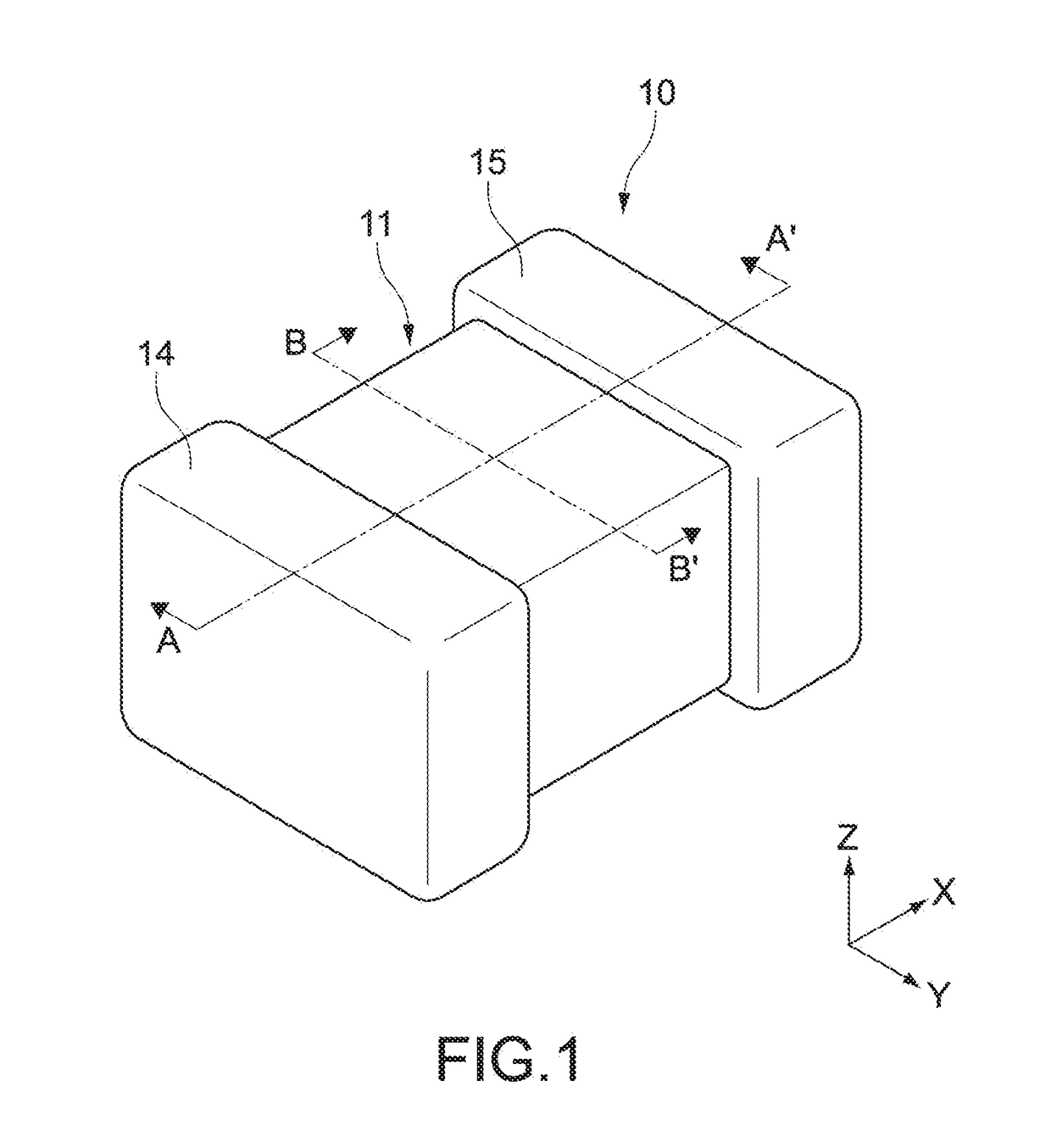

A multi-layer ceramic capacitor includes a multi-layer unit, a side margin, and a bonding unit. The multi-layer unit includes ceramic layers and internal electrodes. The ceramic layers are made of first ceramics and laminated in a first direction, the first ceramics having a first average crystal grain diameter. The internal electrodes are disposed between the ceramic layers. The side margin is made of second ceramics and covers the multi-layer unit from a second direction orthogonal to the first direction, the second ceramics having a second average crystal grain diameter. The bonding unit is made of third ceramics and disposed between the multi-layer unit and the side margin, the third ceramics having a third average crystal grain diameter that is larger than the first average crystal grain diameter and the second average crystal grain diameter.

Owner:TAIYO YUDEN KK

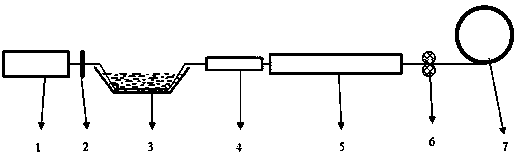

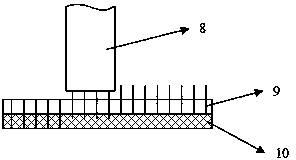

Ultrasonic-assisted laser material additive manufacturing device and realization method thereof

ActiveCN106363173AImprove bonded stateGood mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyNumerical controlCavitation

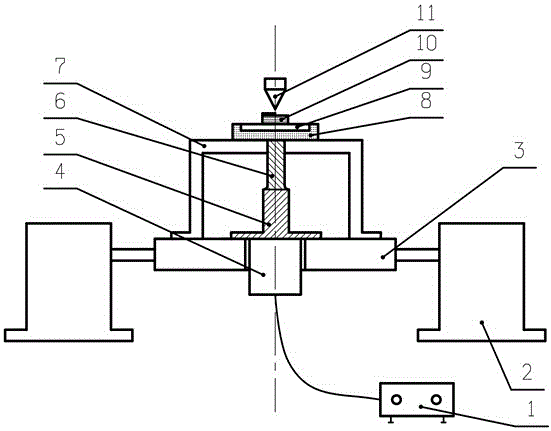

The invention discloses an ultrasonic-assisted laser material additive manufacturing device, which comprises a precise double-shaft numerical control rotating table, a support fastening base, a mold, an ultrasonic device, a base plate and a powder supply spray nozzle, wherein the precise double-shaft numerical control rotating table mainly consists of a double-support rotating table and a processing table; the support fastening base is arranged on the processing table; the mold is arranged on the support fastening base and is provided with a groove; the ultrasonic device is arranged in a way of passing through the processing table and the support fastening base and is connected with the bottom of the mold; the base plate is arranged in the groove formed in the mold; the powder supply spray nozzle is positioned above the base plate. The invention also provides a realization method of the ultrasonic-assisted laser material additive manufacturing device. The ultrasonic vibration is transmitted to the base plate, so that the base plate generates resonance; ultrasonic vibration stirring is performed in a molten pool formed under the laser effect in the laser material additive manufacturing process; a cavitation effect and a mechanical effect are generated; the combination state between layers can be improved; the formation probability of microsegregation and air holes inside forming elements can be reduced; meanwhile, crystal grains are refined; the residue stress is reduced; the forming elements with the good mechanical property are obtained.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

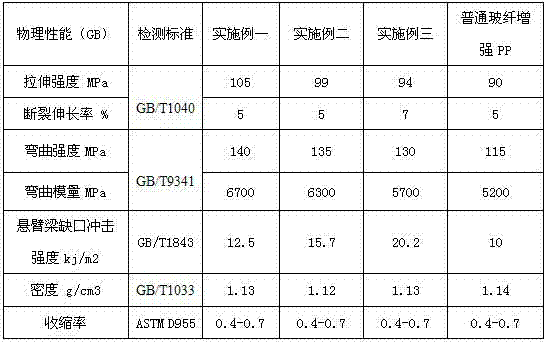

Reinforced polypropylene composite material and preparation method thereof

InactiveCN103589058ARaw materials are easy to getSolving Recycling ProblemsPolypropylene compositesGlass fiber

Owner:ORINKO NEW MATERIAL CO LTD

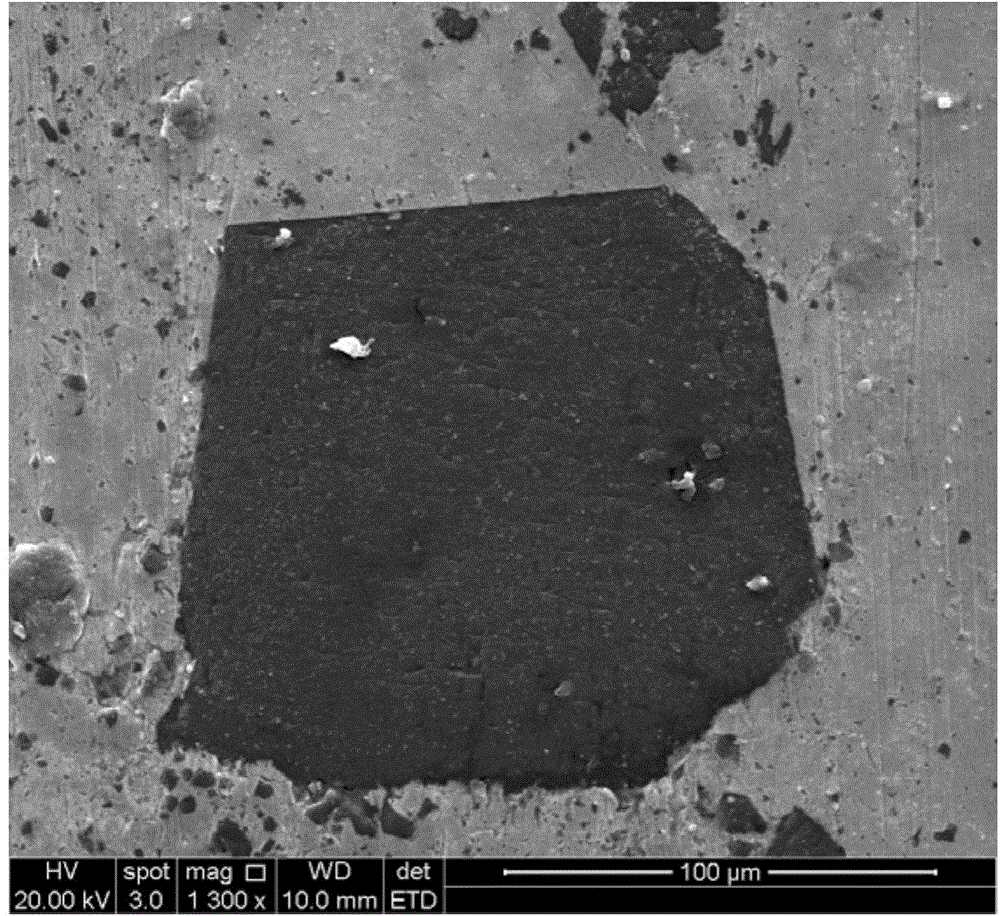

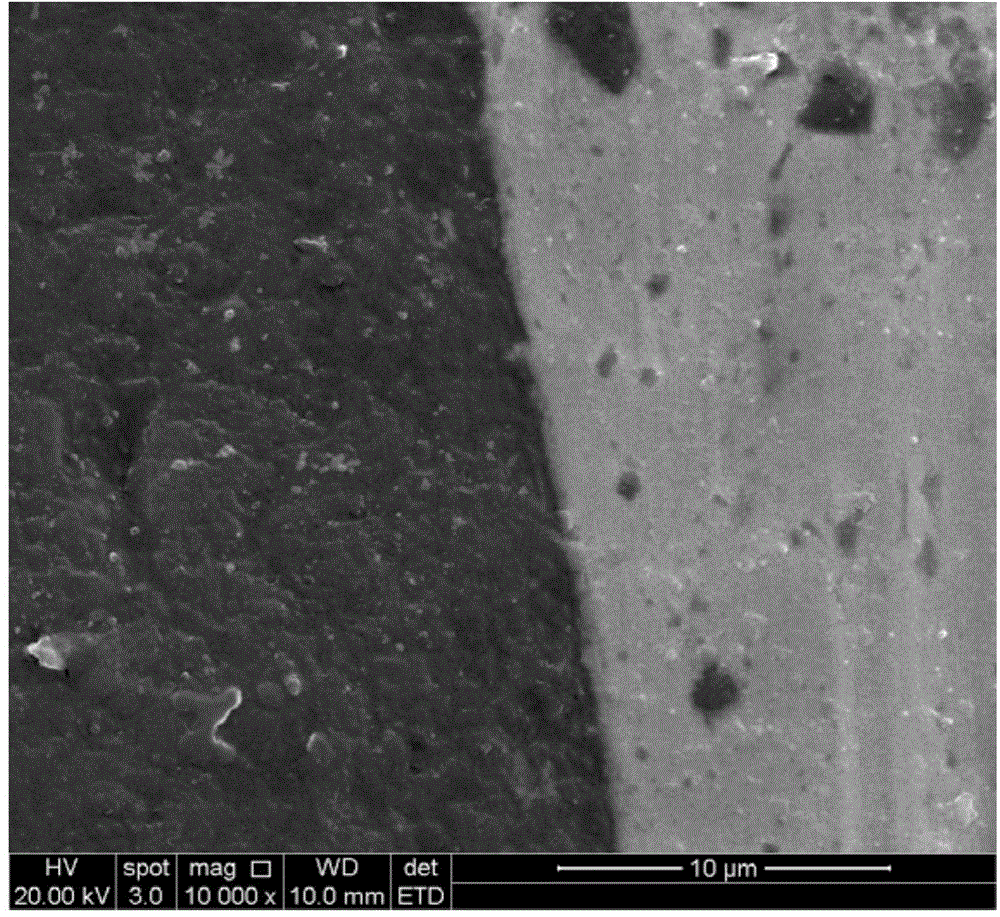

Preparation method of high heat-conducting diamond/copper-based composite material

InactiveCN103981382AHigh thermal conductivityImprove interfaceSuperimposed coating processNon wettingChemical plating

The invention relates to a preparation method of a high heat-conducting diamond / copper-based composite material which consists of matrix copper, diamond powder and a molybdenum coating, wherein the volume fraction of molybdenum is 1-2%, the balance of diamond particles and copper. In diamond and copper, the volume fraction of the diamond powder is 15-50%. The preparation method provided by the invention can solve the problem that in methods of infiltration, powder metallurgy and the like, diamond powder and copper are non-wetting to lead to sintering densification. The preparation method comprises the following steps: I, plating molybdenum on the surfaces of the diamond particles by adopting a magnetron sputtering method to prepare molybdenum-coated diamond powder; II, plating copper on the surface of the molybdenum-coated diamond powder by a chemical plating method to prepare copper and molybdenum-coated diamond powder; III, mixing the composite powder obtained in step II and pure copper powder in a certain proportion by a mechanical mixing manner; and IV, hot pressing and sintering the mixed powder prepared in step III in vacuum to obtain the diamond / copper-based composite material. The material has a good interface bonding condition, high density and heat conductivity.

Owner:WUHAN UNIV OF TECH

Production method for drug balloon

The invention discloses a production method for a drug balloon. The production method comprises the following steps: 1) preparing a medicinal solution; 2) spraying the medicinal solution on the surface of a balloon with layer by layer through a multi-time spraying technology. The production method has the beneficial effects that an oversaturated paclitaxel medicinal solution is prepared, and is directly applied to ultrasonic spraying to obtain a completely-crystallized medicinal coating. The multi-time spraying technology is used, and the medicinal coating is subjected to solvent steam treatment to obtain a medicinal coating with a small crystal size and a good binding effect between the crystal and a substrate. The drug balloon produced by the production method has the advantages that medicinal loss can be lowered greatly in passing and expanding processes, and the drug utilization rate is increased.

Owner:SHANGHAI SHENQI MEDICAL TECH CO LTD

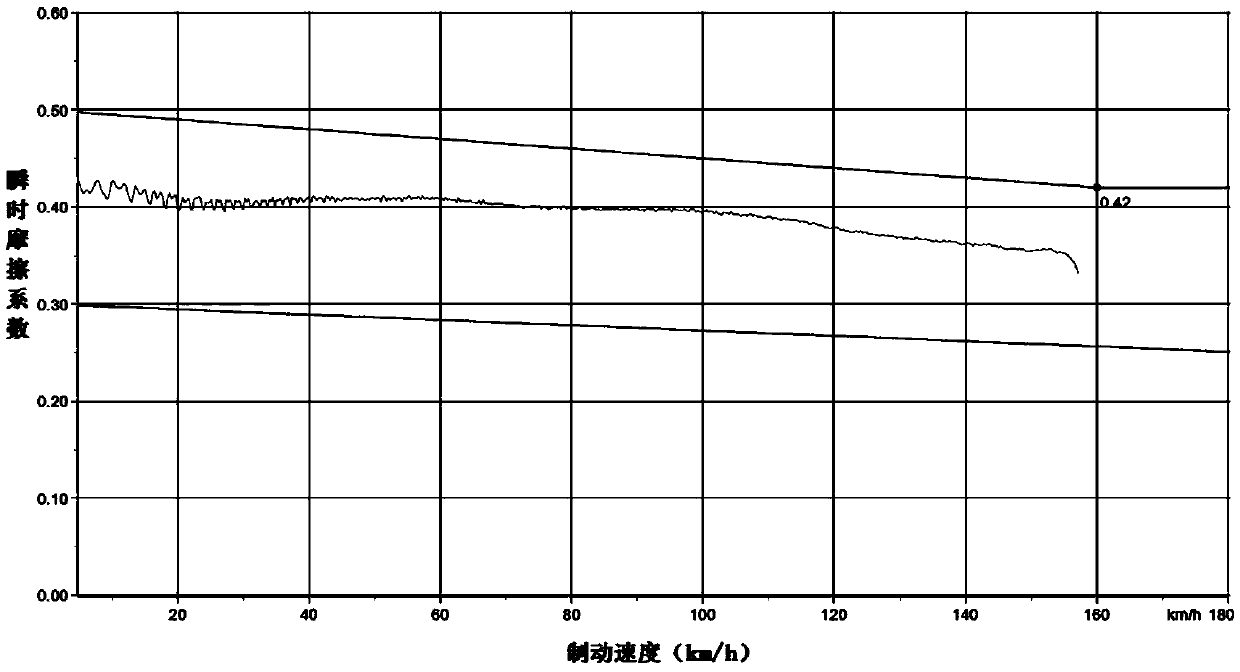

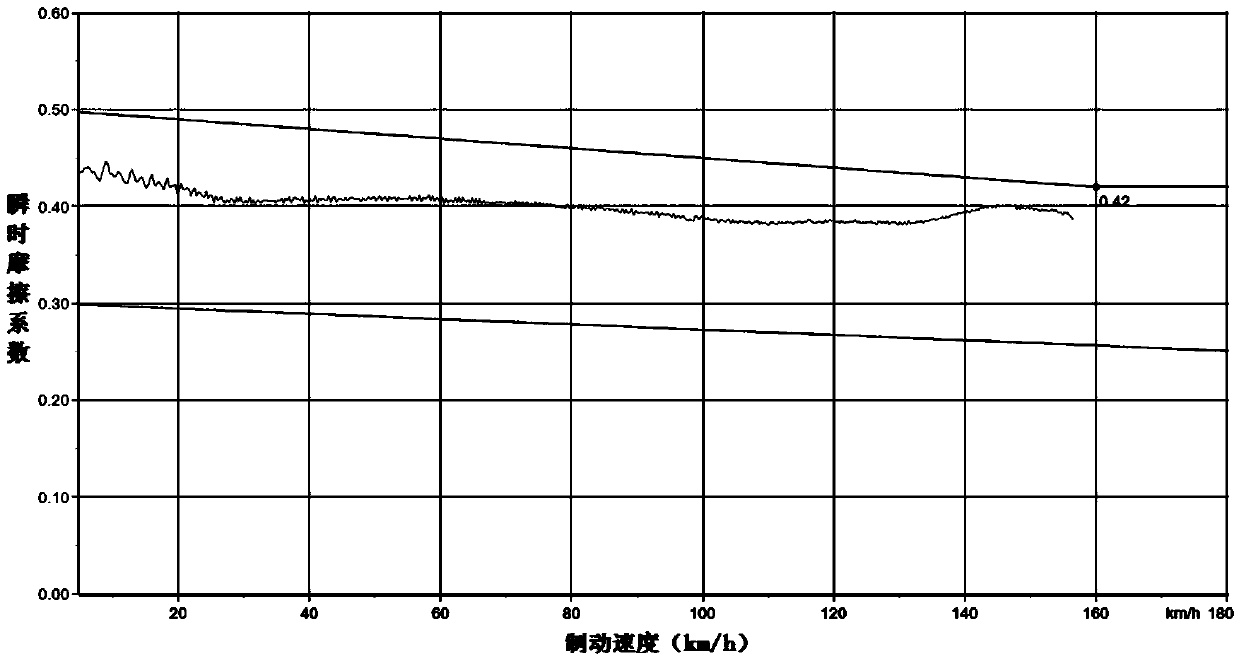

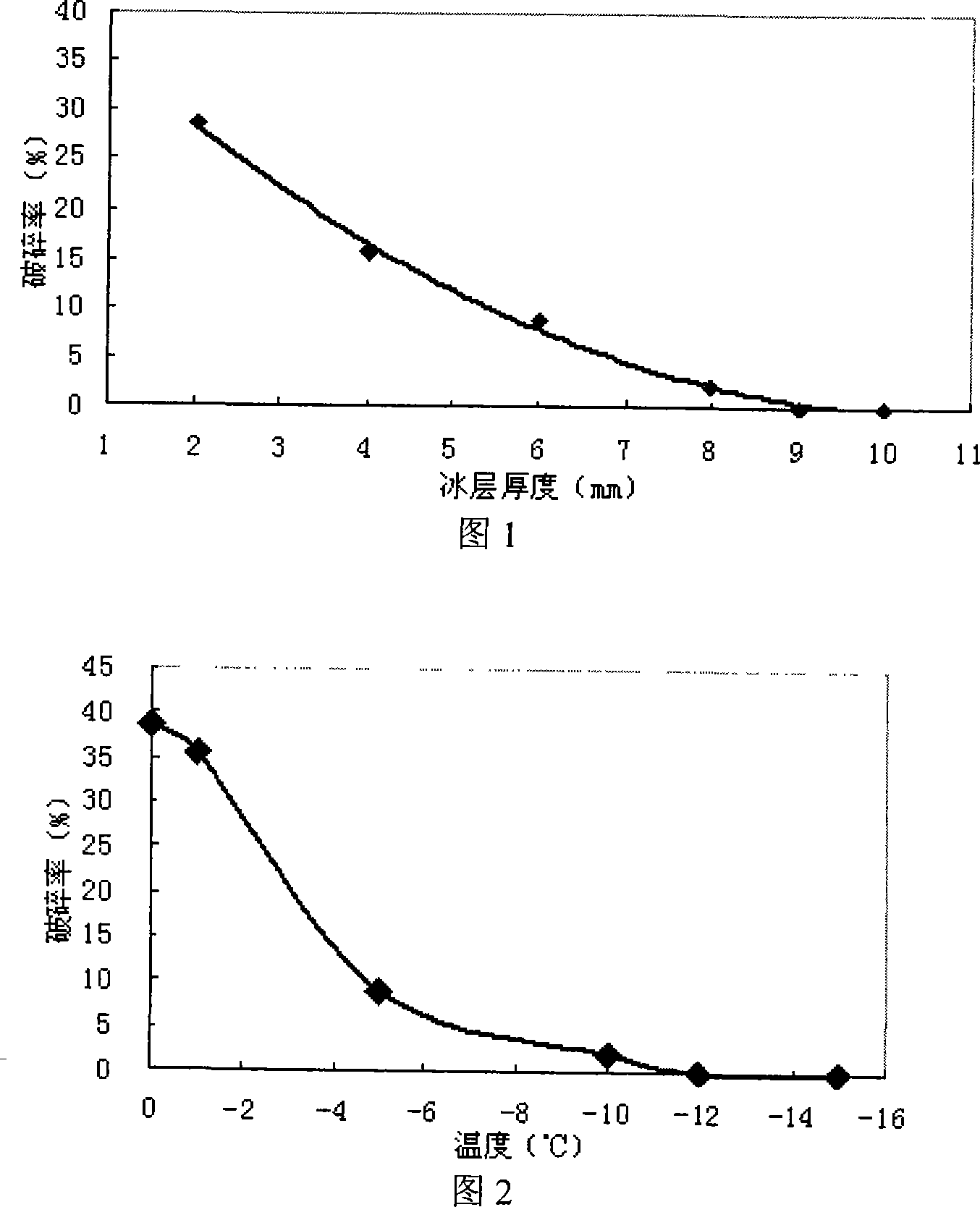

Construction method for rubber grain asphalt concrete pavement

InactiveCN101153478AImprove deformation abilityGood flexibilityIn situ pavingsSnowpackWear resistant

A method for constructing rubber particles asphalt concrete road surfaces relates to a method for constructing asphalt concrete road surfaces, aiming to resolve the problems that: the asphalt concrete road surfaces have weak wear-resistant, and the attachment coefficient and the adhesive force are reduced and vehicles have the problem of braking stability when the road surfaces are covered by snow and ice. The construction method comprises the following steps that: compositions by weigh percentage of the following materials are adopted: 76.5 to 91.5 percent of mineral aggregate, 2.5 to 7.5 percent of asphalt, 4 to 10 percent of mineral powder and 2 to 6 percent of rubber particles; the mineral aggregate is heated up to 190 to 200 DEG C, the rubber particles are added into the mineral aggregate with mixing about 20 to 25 seconds, the asphalt heated up in advance and the mineral powder are added into the rubber particles and the mineral aggregate with mixing lasting for 70 to 80 seconds, and then the road surfaces are subject to the pavement, the first stage initial pressure, the first and the second stage re-pressure and the second stage final pressure. The invention can increase the deformation capabilities of the road surfaces effectively, improve the bond state between the road surfaces and snow, and the invention can improve the attachment coefficient, increase the adhesive force, and improve the braking and turning operation stability of vehicles when the road surfaces are cover by snow and ice.

Owner:HARBIN INST OF TECH

Powder metallurgy brake pad friction material and preparation method thereof

The invention relates to a powder metallurgy brake pad friction material and a preparation method thereof. The preparation method comprises the following specific steps: (A) raw materials are weighed, and include the following components in percentage by mass: 46-56% of copper, 25-35% of ferrochrome, 8-18% of graphite and 4-7% of silicon carbide; (B) the raw materials are fully mixed; (C) the raw materials are molded by pressing; and the pressing pressure is 15-20 MPa; and (D) the pressurization and the sintering are performed; the sintering temperature is 950-1050 DEG C; the sintering time is 7-15 h; and the sintering pressure is 0.5-3 MPa. The prepared powder metallurgy brake pad friction material is high in purity, excellent in friction performance and lower in cost.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

Method and device of adhering polarizer onto substrate

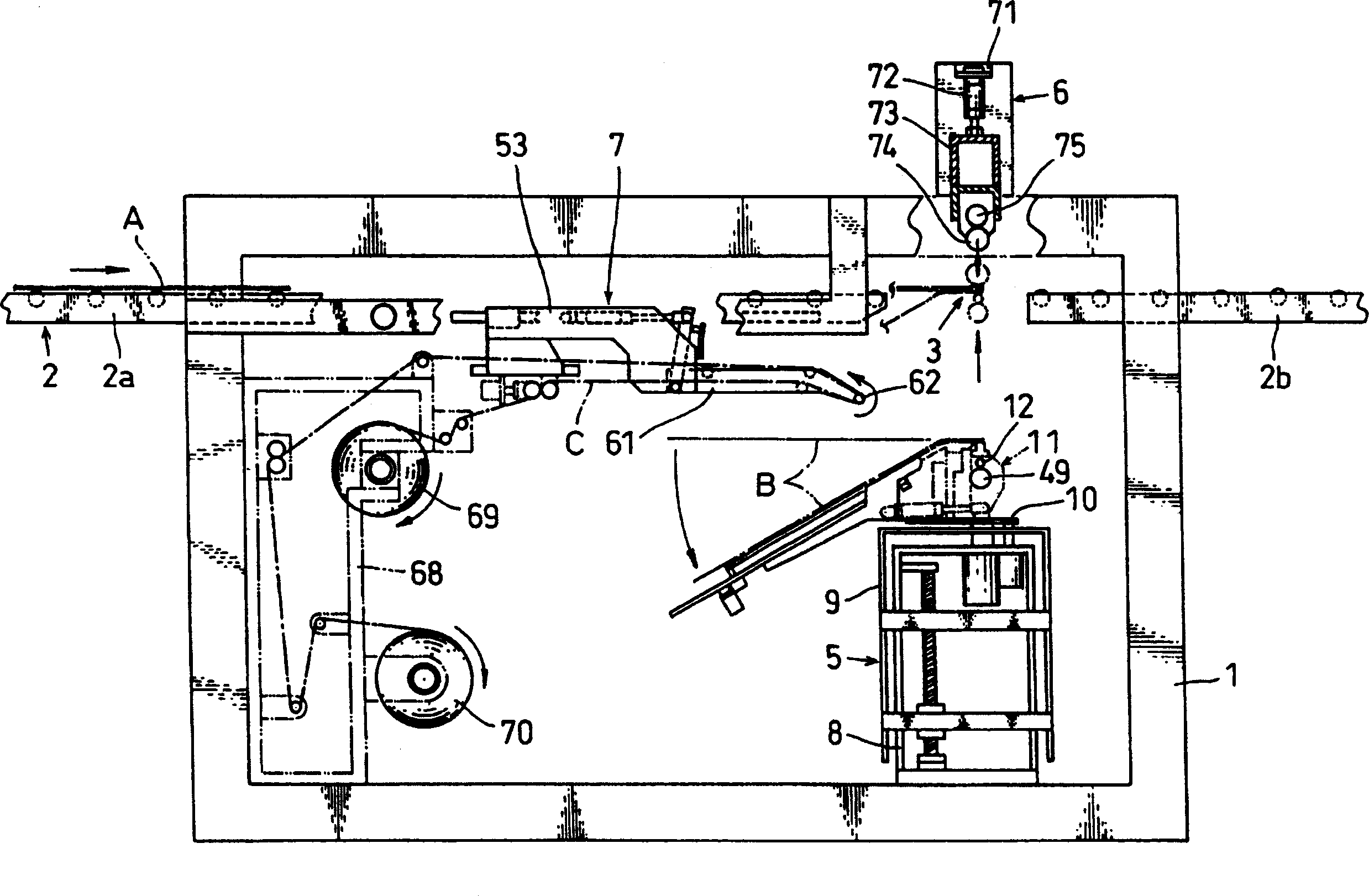

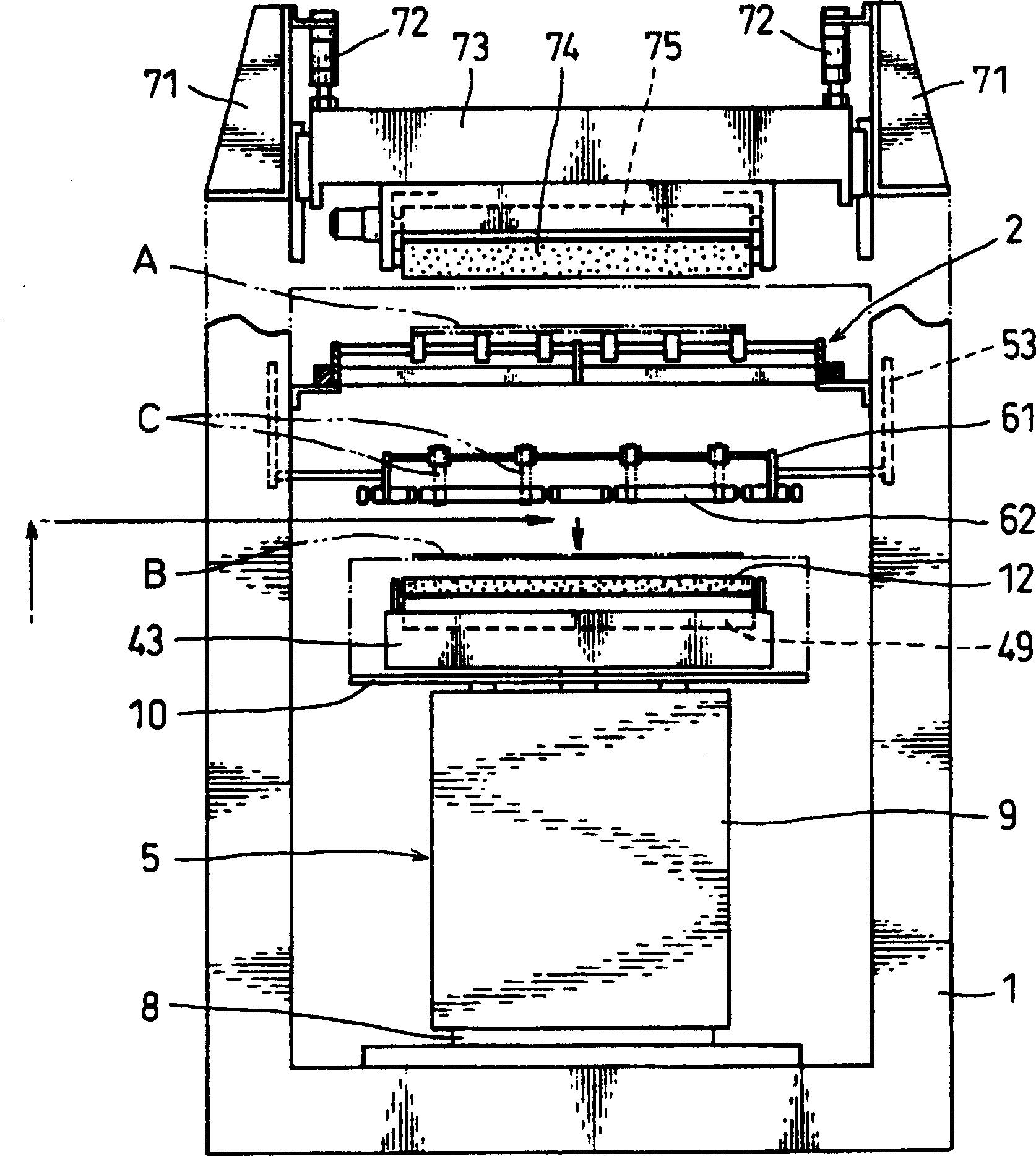

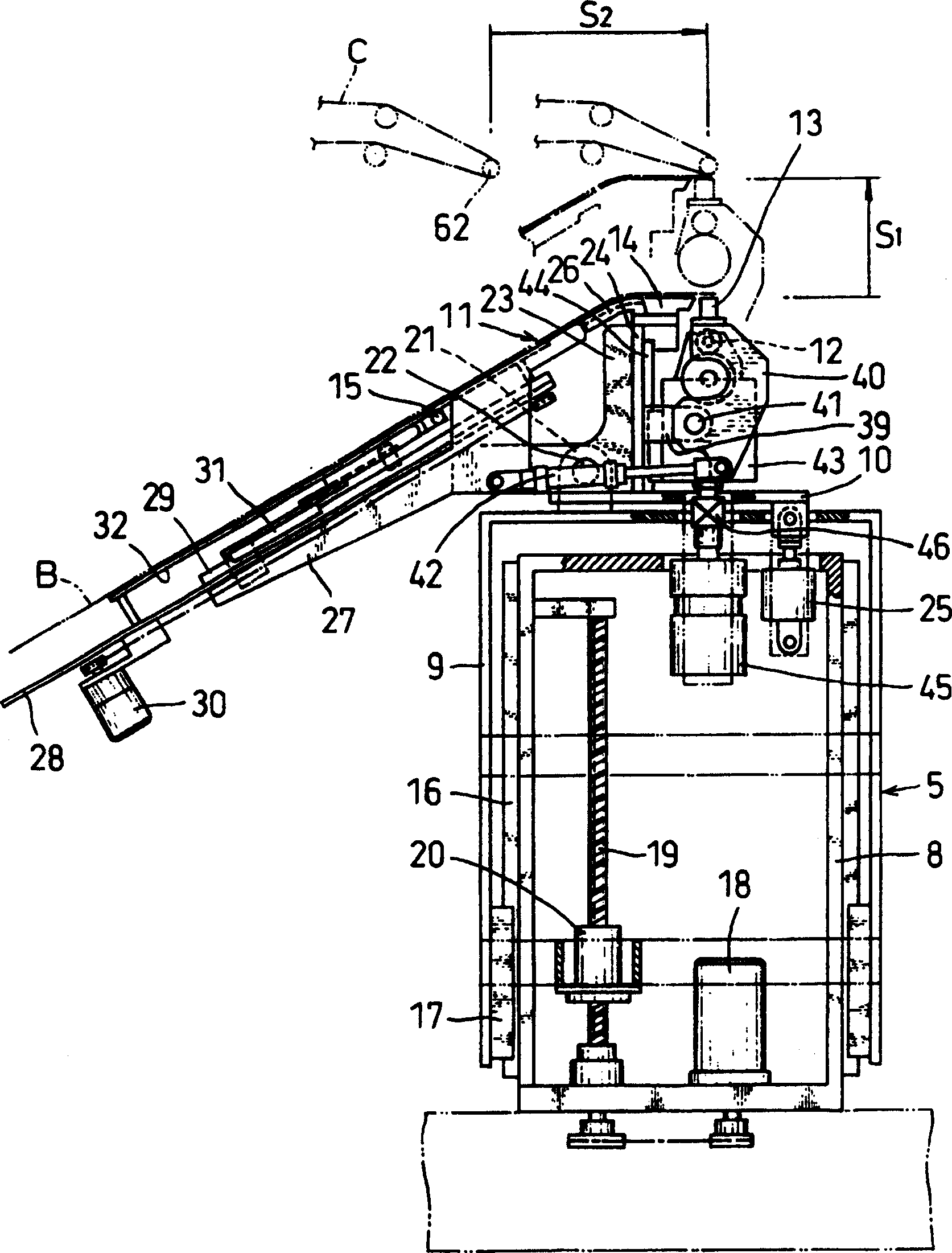

Provided is a method for sticking a polarizing plate to a liquid crystal panel particularly suitable for sticking the polarizing plate to the large size liquid crystal panel by mounting a polarizing plate sticking unit on a conveyance line of the liquid crystal panel, thus adopting a structure with no stage and saving space and making the structure compact as far as possible. A device for sticking the polarizing plate is constructed in such a way that a release sheet E of the polarizing plate B is released so as to expose an adhesive layer and subsequently the polarizing plate B is stuck to a substrate A while transferring the substrate A such as the liquid crystal panel along the conveyance line 2 in one direction from the carry-in side to the carry-out side.

Owner:SHARP KK

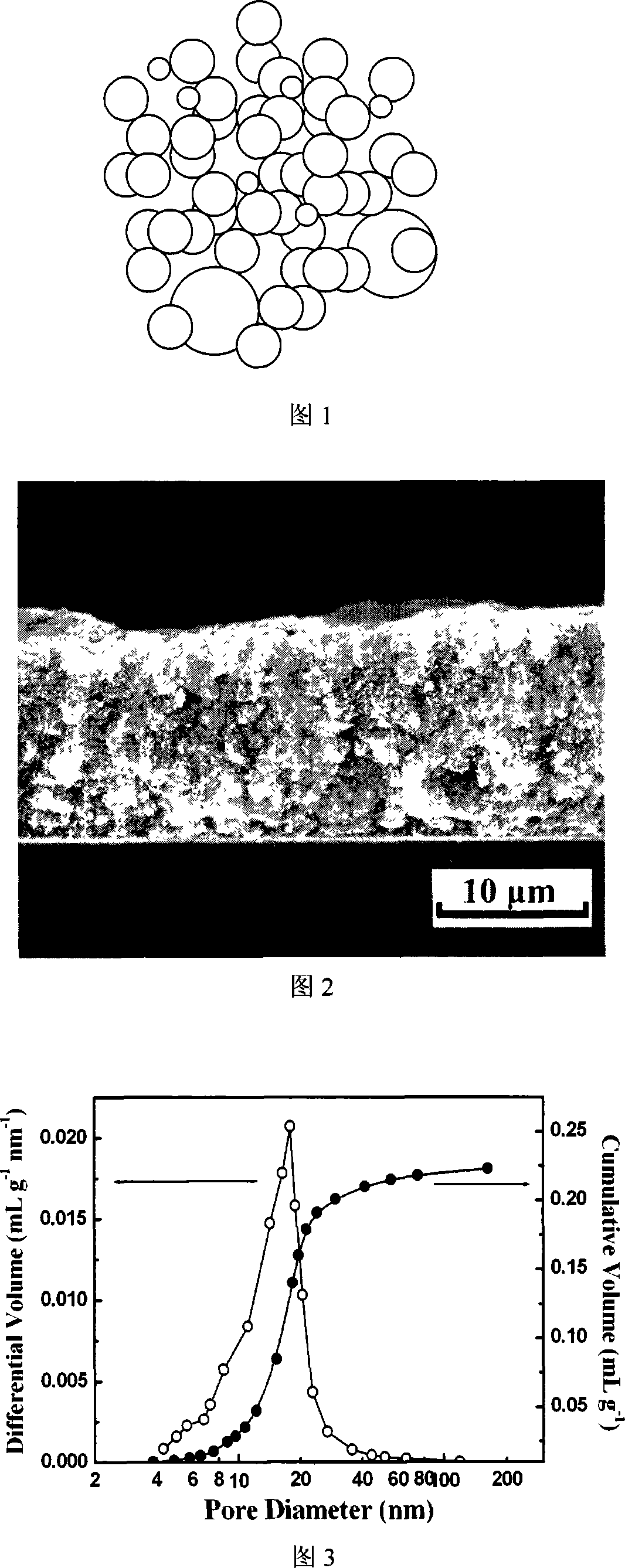

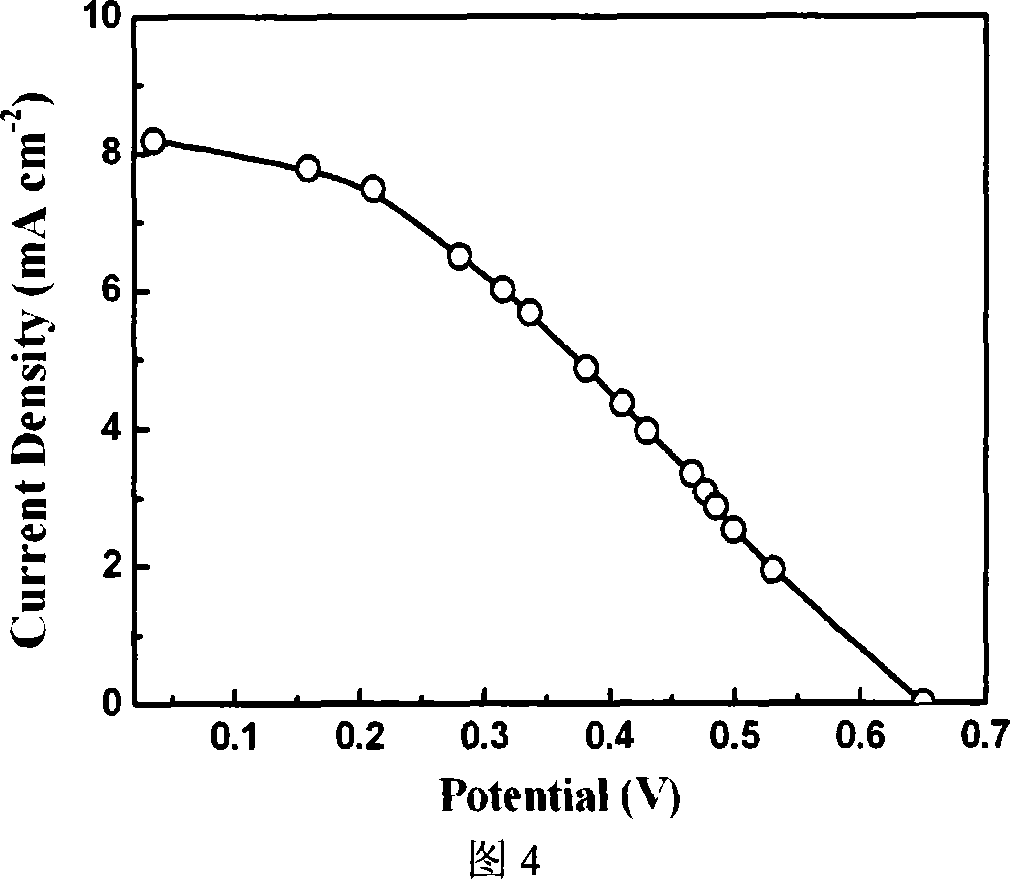

Making method for flexible dye sensitized solar battery nano crystal thin film

InactiveCN101127374AImprove battery efficiencyLow industrialization characteristicsLight-sensitive devicesElectrode manufacturing processesNanometreAirflow

The utility model belongs to field of solar battery, and relates to a manufacturing approach of flexible nanometer-crystalline film of dye sensitizing solar battery, which adopts nanostructured porous TiO2 powder as the material and forms the porous TiO2 film by depositing on a conducting substrate by vacuum deposition. The utility model is characterized in that a porous TiO2 film is made by vacuum cold coating, wherein the nanostructured porous TiO2 powder is accelerated by airflow and impacts on the substrate or the TiO2 coat at a high speed to speed up the combinations of the powder under the pressure of high speed impact at instantaneous high temperature rise; therefore the coat is combined well with the substrate and so are the grains in the coat. The film made by the above approach dose not need to go through high temperature process during manufacturing and after manufacturing, therefore is suitable for manufacture of flexible nanometer-crystalline film of dye sensitizing solar battery.

Owner:XI AN JIAOTONG UNIV

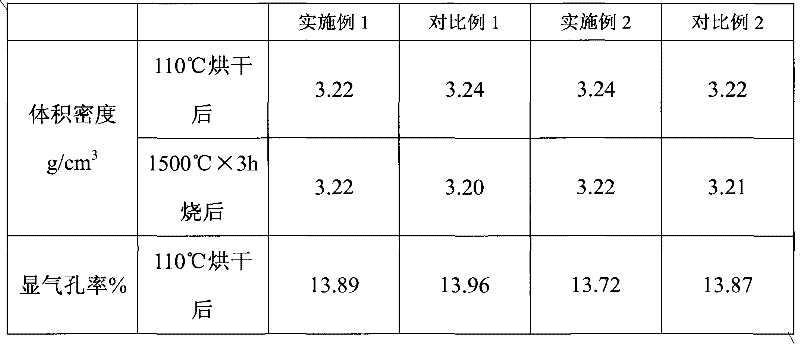

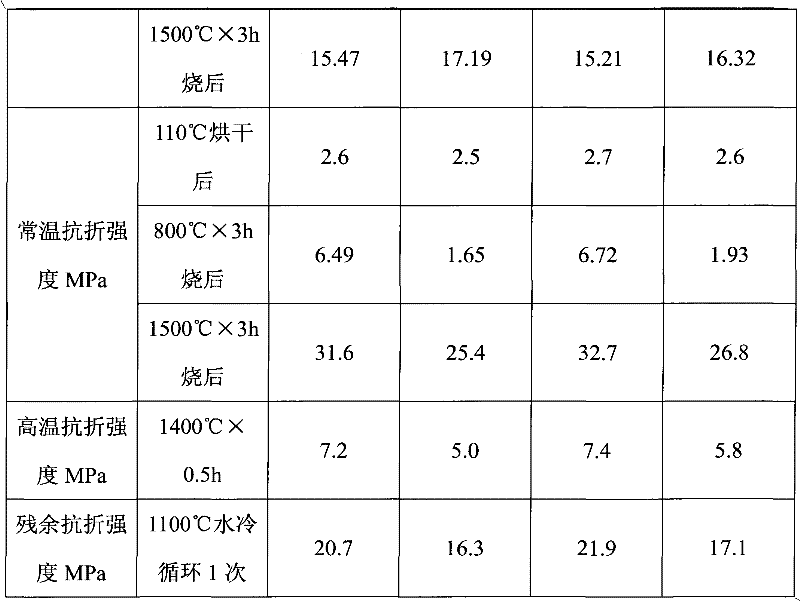

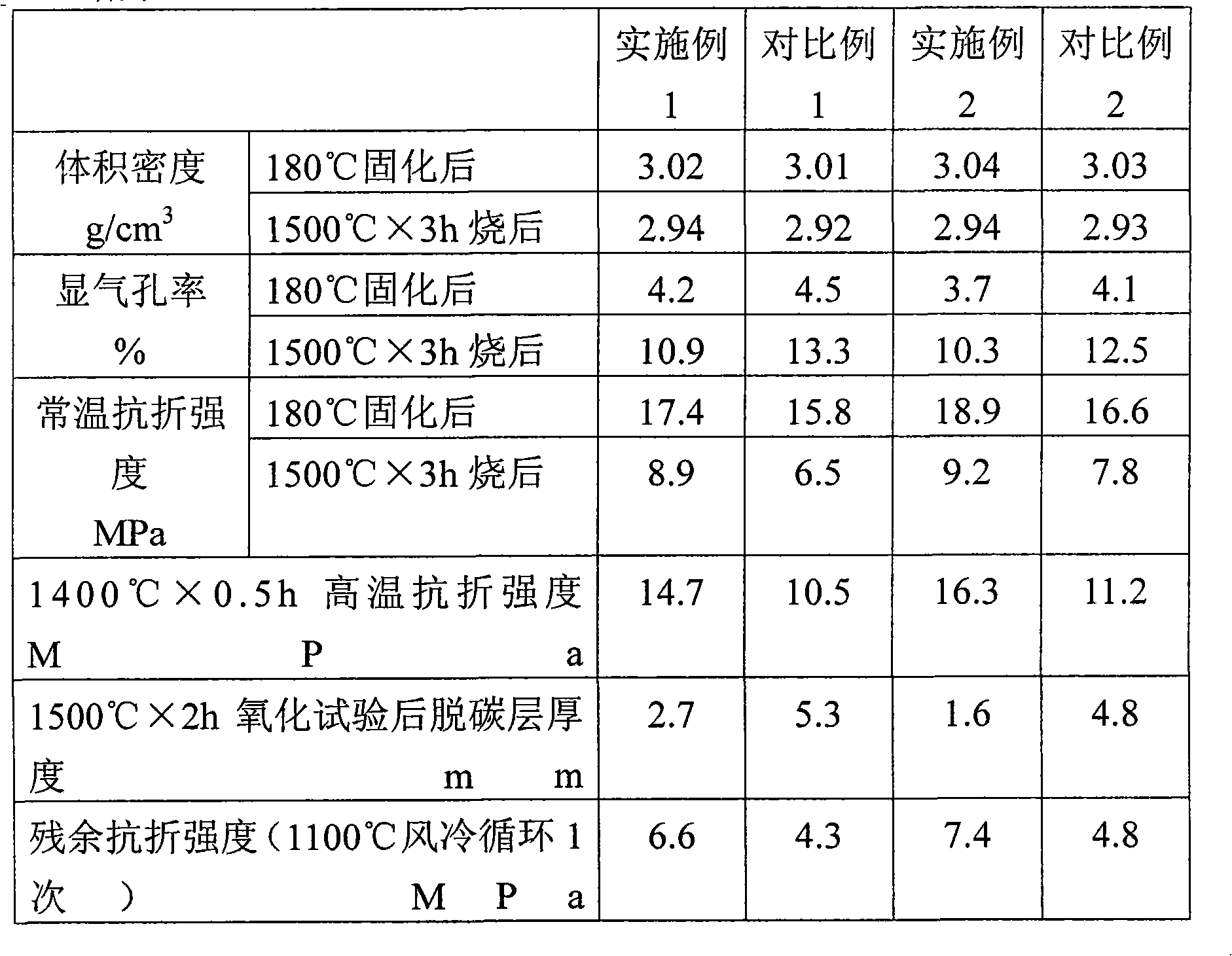

A kind of corundum refractory castable

The invention discloses a corundum refractory castable. The raw materials used include a main material and an added organic dispersant. The main material is composed of corundum particles and fine powder, nano zinc oxide, aluminum oxide powder, and a binder. The weight percent of the raw materials is: 80-95wt% of corundum particles and fine powder, 3-15wt% of alumina micropowder, 1-5wt% of binder, 0.2-5wt% of nano-zinc oxide, and the added organic dispersant is the weight of the main material. 0.05-0.3 wt%. The present invention utilizes the characteristics of fine particle size of nano-zinc oxide powder, high activity at high temperature, moderate price and the like to improve the structure of the corundum castable, increase the medium-temperature strength, and prepare a corundum castable with excellent comprehensive performance and moderate price.

Owner:浙江亿维高温材料有限公司

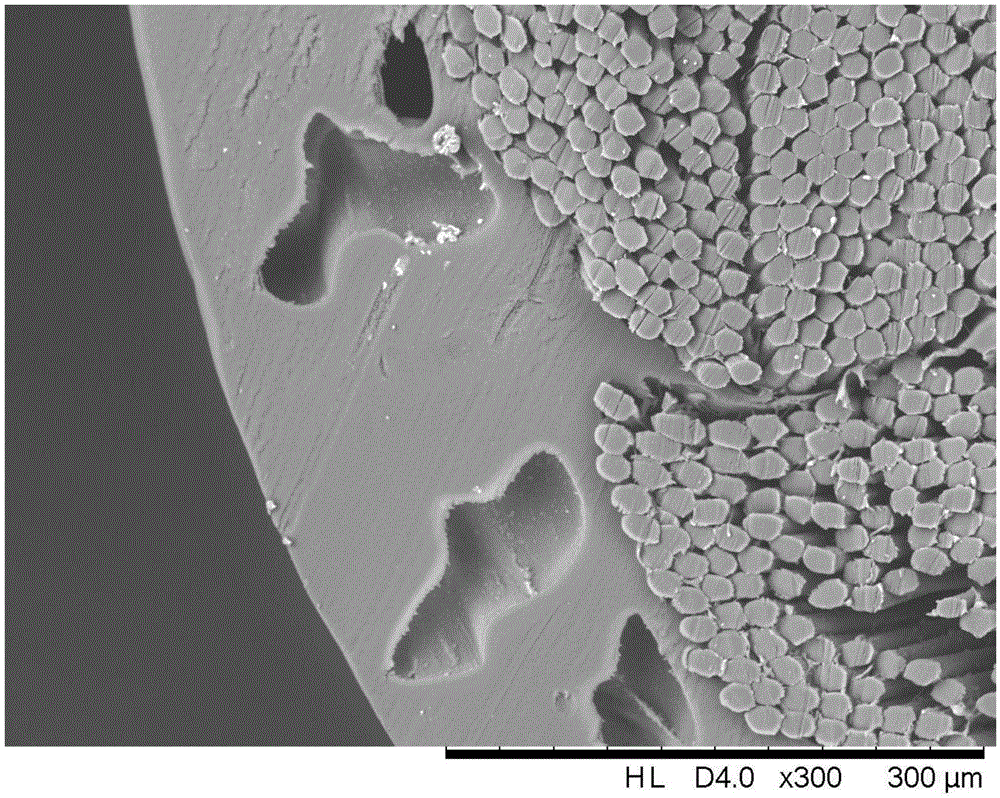

Centrifugal ceramic composite vertical mill roller sleeve and manufacturing method thereof

The invention discloses a centrifugal ceramic composite vertical mill roller sleeve and a manufacturing method thereof. The centrifugal ceramic composite vertical mill roller sleeve comprises an inner layer and an outer layer. The outer layer is high-chromium cast iron, and ceramic particles are embedded in the outer layer. The high-chromium cast iron is prepared from, by weight, 2.3-3.3% of C, 0.3-1.0% of Si, 0.6-1.2% of Mn, 18-22% of Cr, 0.7-1.7% of Ni, 1.5-3.0% of Mo, 0-0.03% of P, 0-0.03% of S and the balance Fe and inevitable impurities. According to the vertical mill roller sleeve, the material proportion of the inner layer and the outer layer is optimized; high-alloy elements are adopted by the outer layer, the matrix can be effectively reinforced by increasing the content of alloy such as C, Cr, Mo and V, the total amount of carbide is increased, and therefore the smoothness of a friction surface can be effectively improved; the outer layer of the roller sleeve is made to be high in abrasion resistance, high in strength and enough in toughness, and the service life of the roller sleeve is effectively prolonged. According to the manufacturing method, a heat treatment technique of annealing, quenching and tempering is adopted, the purposes of improving the carbide form, promoting structural transformation and refining structures are achieved, so that the abrasion resistance and fracture toughness of the roller sleeve are improved.

Owner:河北津西钢铁集团重工科技有限公司

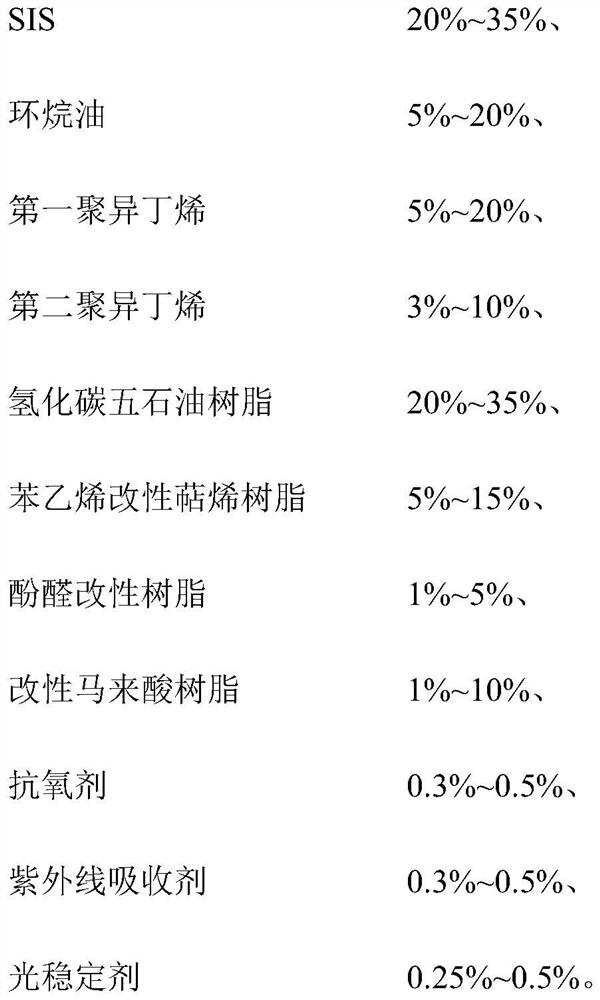

Non-asphalt-based pre-paved waterproof coiled material with high water soaking resistance and preparation method of non-asphalt-based pre-paved waterproof coiled material

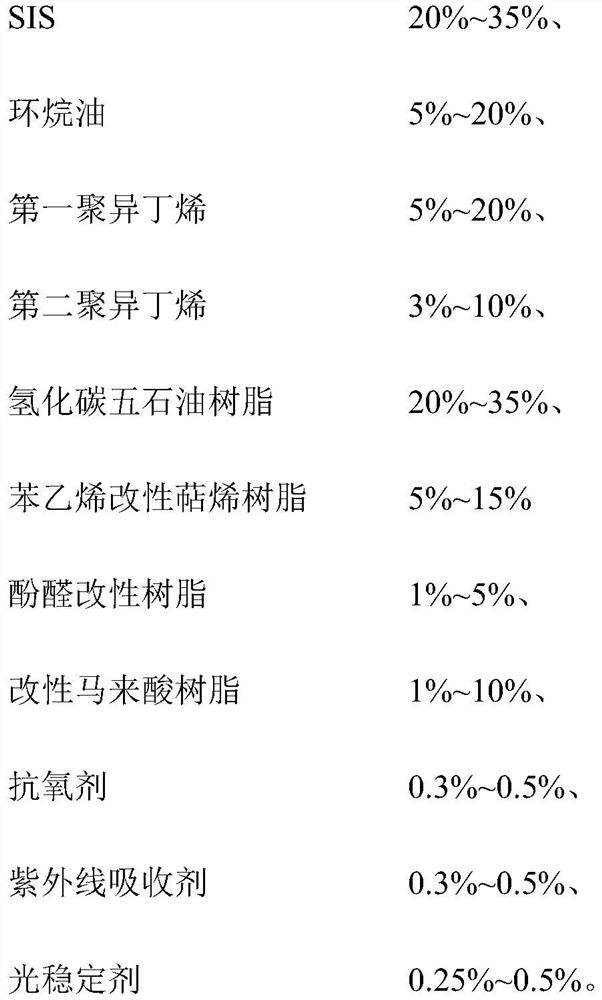

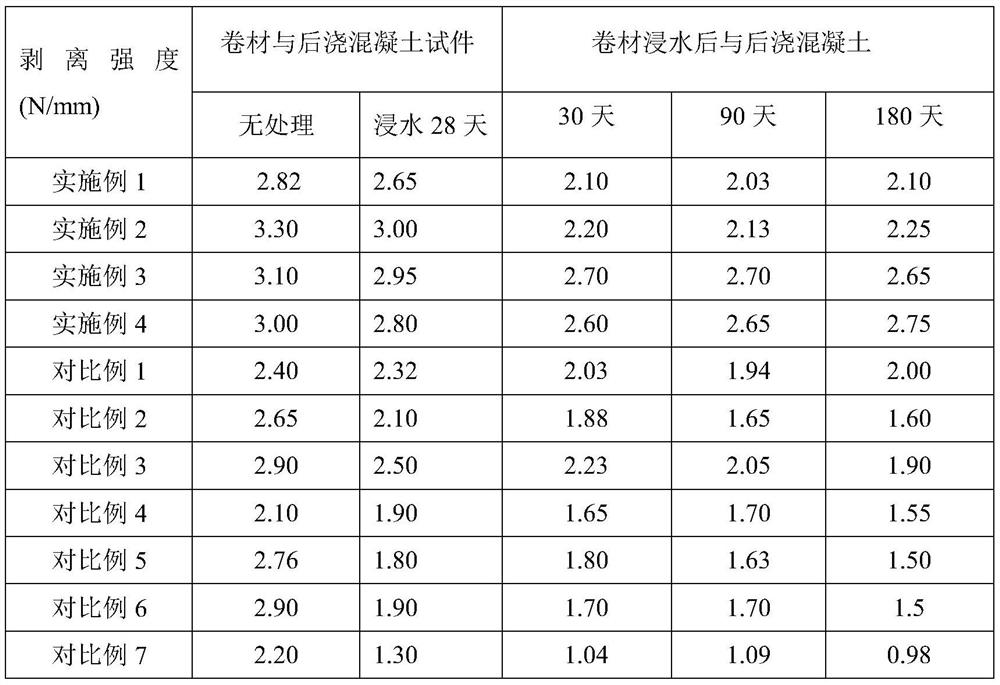

ActiveCN112852359ALow water absorptionIncrease wetting angleMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer scienceHydrolysate

The invention provides a non-asphalt-based pre-paved waterproof coiled material with high water soaking resistance and a preparation method thereof. The non-asphalt-based pre-paved waterproof coiled material comprises a polymer sheet layer, a polar hot-melt pressure-sensitive adhesive layer and a strong-hydrophobicity isolation sand layer, and the polar hot-melt pressure-sensitive adhesive comprises the following raw materials: SIS, naphthenic oil, first polyisobutene, second polyisobutene, hydrogenated C5 petroleum resin, styrene modified terpene resin, phenolic modified resin, modified maleic resin, an antioxidant, an ultraviolet light absorber and a light stabilizer. The high-hydrophobicity isolation sand is inorganic mineral particles treated by coupling agent hydrolysate. The prepared non-asphalt-based pre-paved waterproof coiled material has the characteristic of excellent water soaking resistance, after being soaked in water for 180 days, the isolation sand covered on the coiled material is still not easy to fall off, and the bonding surface at the lap joint can still keep a good bonding state, so that the good construction application performance of the coiled material is ensured.

Owner:江苏雨中情防水材料有限责任公司

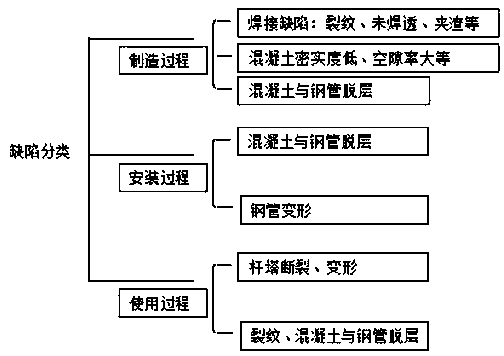

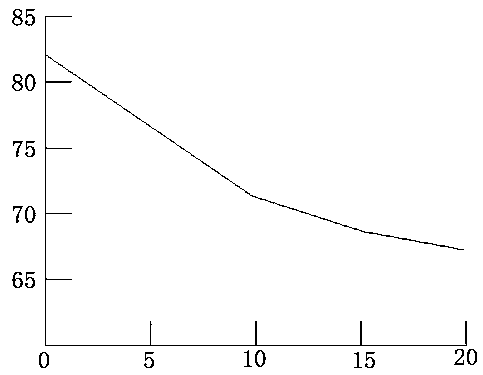

Qualitative and quantitative defect detection method for thin-walled centrifugal concrete steel tube tower

ActiveCN110879278AEasy constructionEconomically reasonableAnalysing solids using sonic/ultrasonic/infrasonic wavesTesting manufactured objectsTowerUltimate tensile strength

The invention provides a qualitative and quantitative defect detection method for a thin-walled centrifugal concrete steel tube tower. The method comprises the following steps: S1, introducing an advanced phased array defect imaging detection technology into steel tube pole weld joint detection, accurately judging the property, size and severity of defects, and achieving nondestructive evaluationof standard exceeding defects of a steel tube pole; S2, studying the influence of the welding temperature on the performance of the thin-walled centrifugal concrete steel tube tower; S3, testing the bonding condition of a concrete-filled steel tube by means of nondestructive testing; S4, determining a safety evaluation method for the allowable defect size of a defect-containing thin-walled centrifugal concrete steel tube tower; and S5, researching reinforcement schemes for the defect-containing thin-walled centrifugal concrete steel tube tower; and checking the strength of the defect-containing thin-walled centrifugal concrete steel tube tower under different reinforcement schemes, and comparing and analyzing the feasibility and economy of the different reinforcing schemes.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +1

Electronic part mounting substrate and method for producing same

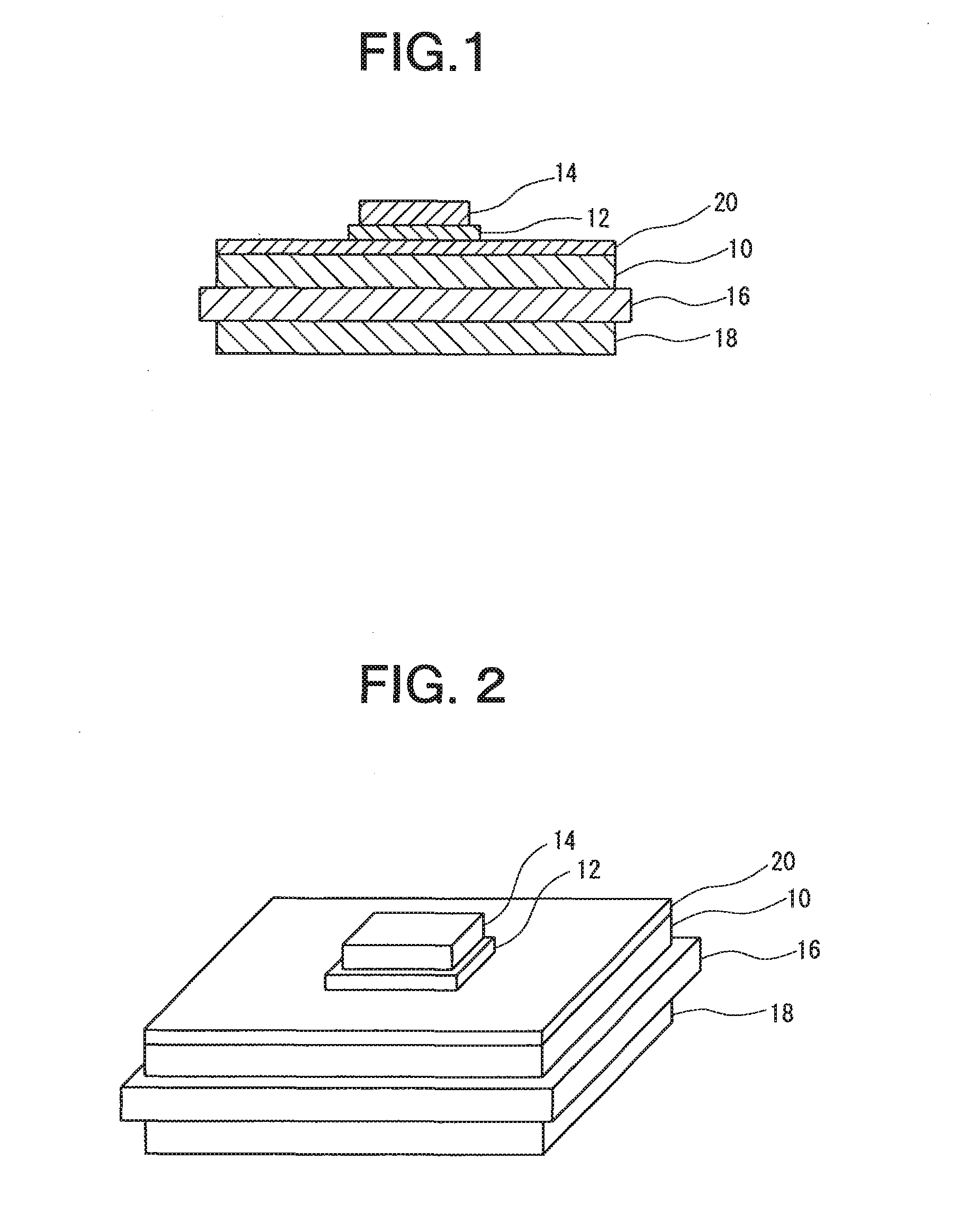

ActiveUS20160211195A1Improve thermal shock resistanceImprove bonded stateFinal product manufactureSemiconductor/solid-state device detailsSilver pasteMachined surface

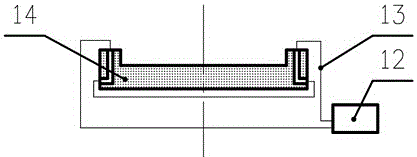

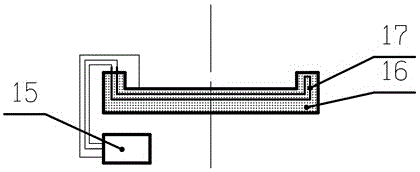

In a method for producing an electronic part mounting substrate wherein an electronic part 14 is mounted on one major surface (a surface to which the electronic part 14 is to be bonded) of the metal plate 10 of copper, or aluminum or the aluminum alloy (when a plating film 20 of copper is formed on the surface), the one major surface of the metal plate 10 (or the surface of the plating film 20 of copper) is surface-machined to be coarsened so as to have a surface roughness of not less than 0.4 μm, and then, a silver paste is applied on the surface-machined major surface (or the surface-machined surface of the plating film 20 of copper) to arrange the electronic part 14 thereon to sinter silver in the silver paste to form a silver bonding layer 12 to bond the electronic part 14 to the one major surface of the metal plate 10 (or the surface of the plating film 20 of copper) with the silver bonding layer 12.

Owner:DOWA METALTECH CO LTD

Method for preparing phenolic resin system Z-pin by using twisted carbon fibers

The invention discloses a method for preparing phenolic resin system Z-pin by using twisted carbon fibers, wherein reinforcing materials for extruding and forming the Z-pin are the twisted carbon fibers with twist degree of 80-100 t / m. The method uses the twisted fibers to generate pressure on a resin matrix to restrain the growth of bubbles in phenolic resin, and modifies the defect of generation of air holes in the Z-pin products due to volatilization of phenolic resin curing products. The obtained Z-pin products can be used for reinforcing ablation-resisting and heat-preventing composite materials of a carbon fiber / phenolic resin system, and prominently modify the stripping resistance and the scouring resistance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

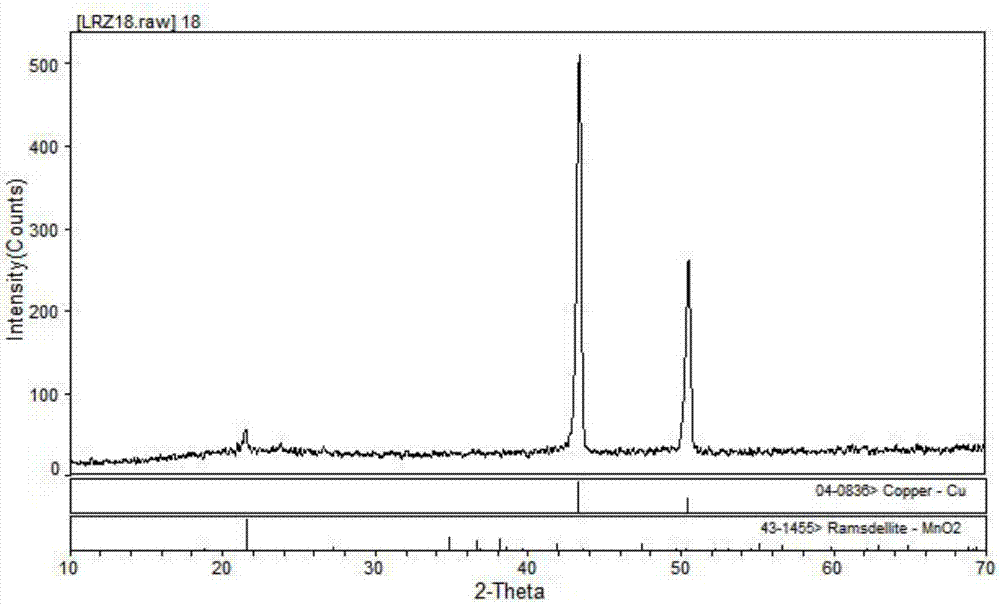

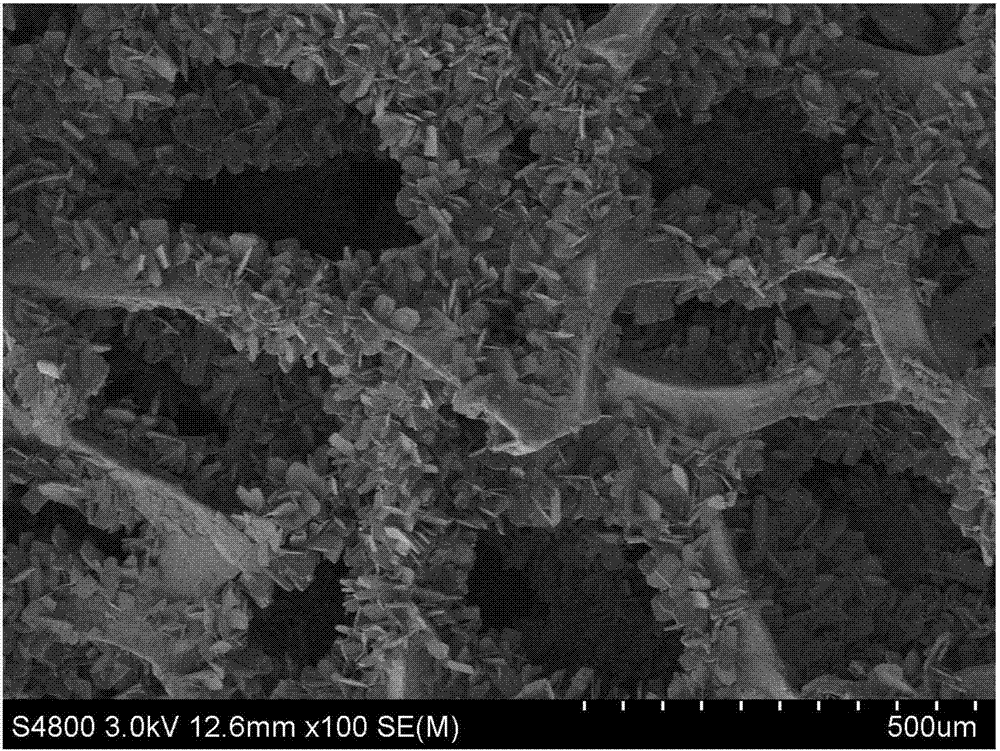

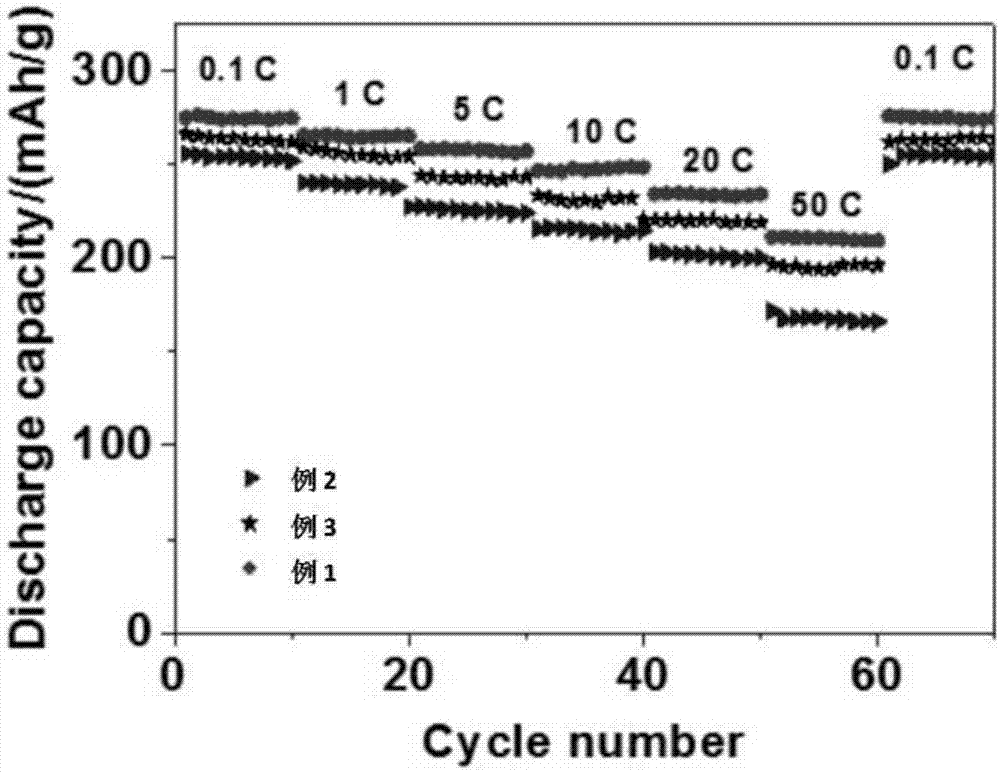

Manganese dioxide/copper foam sodium ion battery self-supporting negative pole preparation method

ActiveCN107093703ACapacity does not affectExcellent rate performanceElectrode carriers/collectorsSecondary cellsAlcoholSulfate

The invention discloses a manganese dioxide / copper foam sodium ion battery self-supporting negative pole preparation method. The method comprises the steps that flake copper foam is treated with absolute ethyl alcohol, washed to be clean and dried, and an electrode substrate is obtained; a manganese sulfate solution of a certain concentration is prepared; the obtained solution and a copper foam sheet are put into a hydrothermal reaction kettle, heating and heat preservation are conducted for a certain time through hydrothermal induction heating equipment, and then the manganese dioxide / copper foam sodium ion battery self-supporting negative pole with a three-dimensional porous communicating frame-shaped structure is obtained.

Owner:SHAANXI UNIV OF SCI & TECH

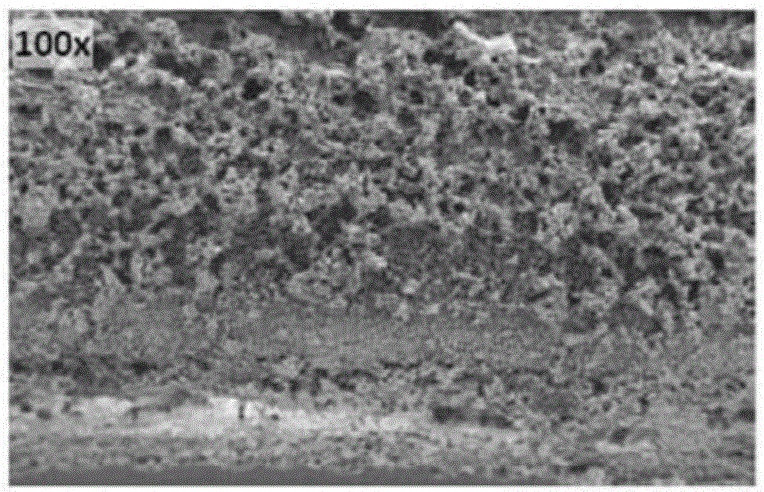

Preparation method of enhanced polyisophthaloyl metaphenylene diamine hollow fiber membrane

ActiveCN105597569AImprove solubilityBreaking hydrogen bondsSemi-permeable membranesFiberHollow fibre membrane

The invention discloses a preparation method of an enhanced polyisophthaloyl metaphenylene diamine hollow fiber membrane. The preparation method includes the following processing steps of (1) preparation of a hollow braided hose: adopting a well-known two-dimensional braiding technique to braid fibers into the hollow braided hose, and taking the hollow braided hose as an enhancing body of the enhanced hollow fiber membrane; (2) preparation of PMIA membrane casting dissolving fully dried PMIA resin, additives and a pore-forming agent in an organic solvent at the temperature of 60-70 DEG C, stirring for 4-6h to obtain homogeneous solution, and performing vacuum defoaming to obtain the PMIA membrane casting (3) preparation of the enhanced PMIA hollow fiber membrane: adopting a coextrusion composite spinning process to subject the hollow braided hose obtained in the step (1) and PMIA membrane casting solution obtained in the step (2) to coextrusion through an annular spinning jet, uniformly coating the surface of the hollow braided hose with the membrane casting solution, and fully curing to obtain the enhanced PMIA hollow fiber membrane.

Owner:TIANJIN POLYTECHNIC UNIV

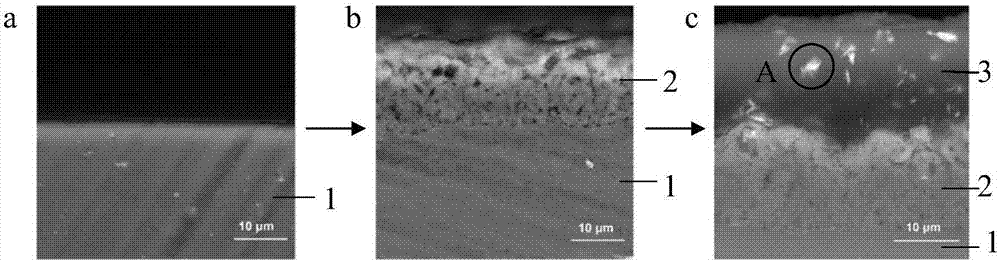

Preparation process of self-lubricating ceramic base composite material

ActiveCN106884192AHigh bonding strengthExtended service lifeAnodisationElectrophoretic coatingsMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a preparation process of a self-lubricating ceramic base composite material. The preparation process comprises a microarc oxidation ceramic layer process and an electrophoretic deposition coating process; microarc oxidation electrolyte comprises the following components and concentrations: Na2SiO3 is 4 g / l; Na2WO3 is 4 g / l; KOH is 2 g / l; and EDTA-2Na is 2 g / l; the microarc oxidation comprises the following electric parameters: the forward voltage is 420 v; the negative voltage is 120 v; the power supply frequency is 1500 Hz; and the forward duty ratio is 60%; electrophoretic deposition electrolyte comprises the components of: acrylic acid anode electrophoretic paint with 10% of solid parts, MoS2 nanoparticles with a particle size of 40 nm, and polyethylene glycol; the concentration of the MoS2 nanoparticles is 10 g / l; and the electrophoretic deposition comprises the following electric parameters: the forward voltage is 360 v; the negative voltage is 0 v; the power supply frequency is 20 Hz; and the forward duty ratio is 5%. The preparation process adopts the microarc oxidation ceramic layer process and the electrophoretic deposition coating process in succession, guarantees excellent bonding state of the ceramic base composite material, and prepares the ceramic base composite material with anti-attrition and self-lubricating performances.

Owner:DALIAN MARITIME UNIVERSITY

Rubber particle sheet pavement material and method for paving rubber particle sheet pavement

InactiveCN101219870AImprove elastic deformation abilityImprove deformation abilityIn situ pavingsSolid waste managementSnowpackSnow removal

The invention relates to a rubber particle asphalt pavement material and a method for paving the rubble particle asphalt road surface, in particular to an asphalt pavement material and a method for paving the asphalt road surface. The invention solves the problems that the prior asphalt road surface does not possess the capability of inhibiting condensation of ice and snow on the road surface or removing ice and snow; adopting other methods for removing snow on the road causes the problems of environmental pollution, low utilization rate of equipments, influence on traffic capacity of working road, high energy consumption, high cost, complex process and difficult maintenance. The rubber particle asphalt pavement material is prepared with 76.5 to 91.5 portions of ore aggregate, 2.5 to 7.5 portions of asphalt, 4 to 10 portions of mineral powder, and 2 to 6 portions of rubber articles by weight portions. The method for paving the road surface comprises that I. the ore aggregate, the asphalt, the mineral powder and the rubber particles are weighed; II. the mixture of the rubber particles and the asphalt is prepared; and III. the mixture of the rubber particles and the asphalt are stirred, paved and rolled. The road surface of the invention can effectively inhibit the condensation of ice and snow on the road surface, and facilitate the following mechanical snow removal as well as road surface management and maintenance. The invention has low cost in road pavement and improvement effects in service performance of the road.

Owner:HARBIN INST OF TECH

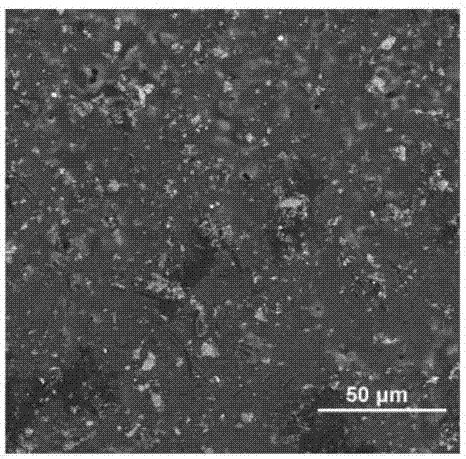

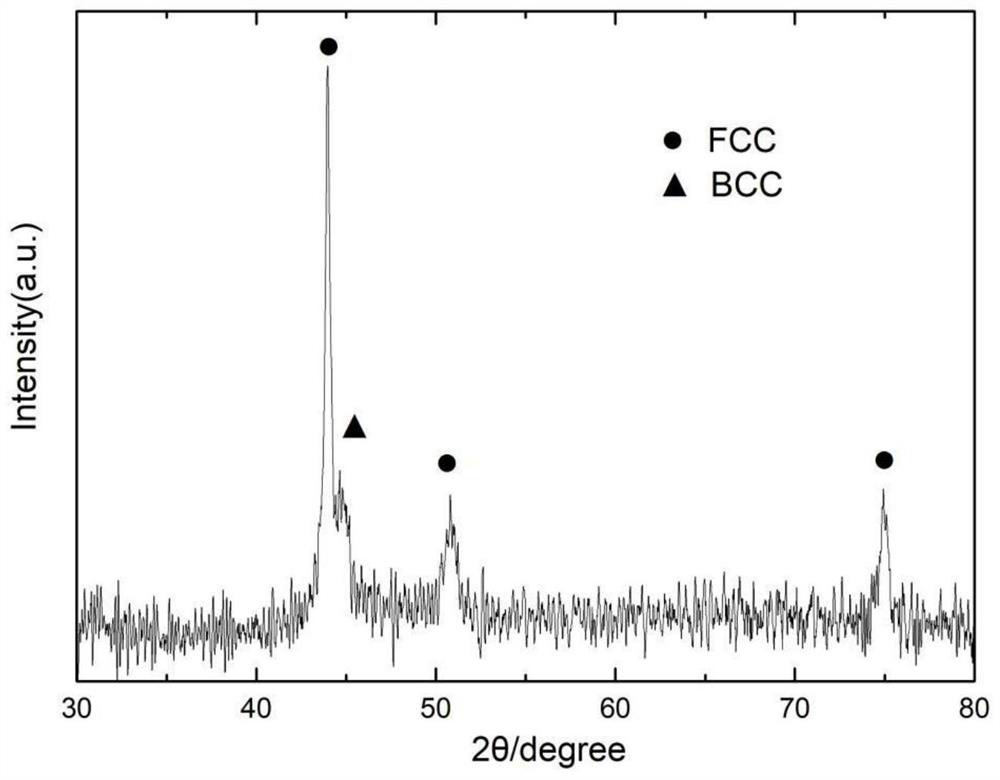

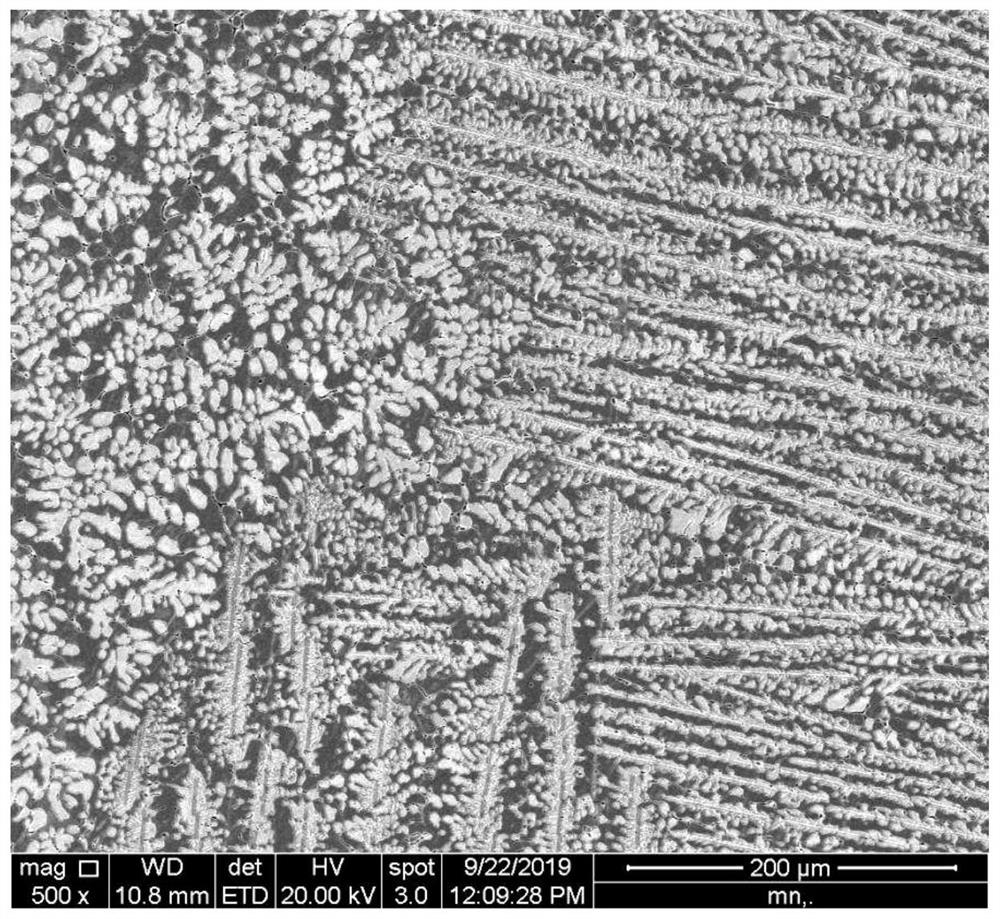

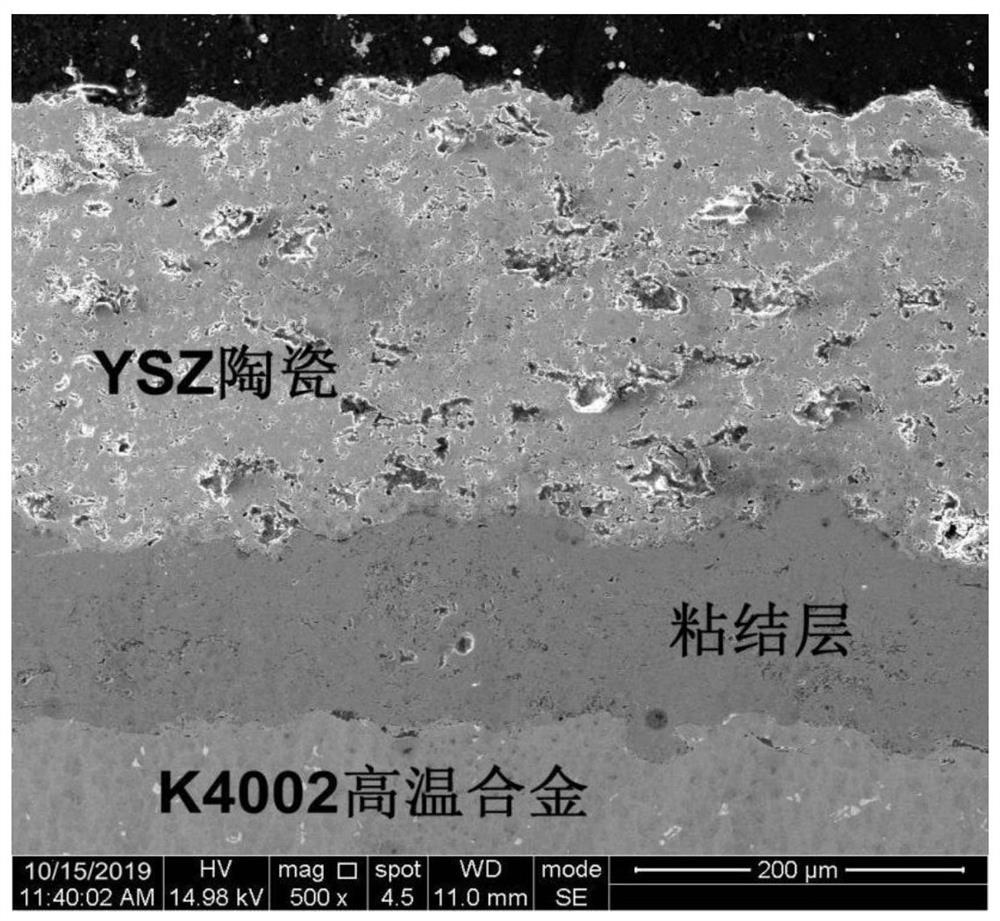

High-entropy alloy resistant to high-temperature oxidation, thermal barrier coating and preparation method thereof

ActiveCN111809094AUniform mechanical propertiesIncreased content of antioxidant elementsMolten spray coatingHigh entropy alloysAlloy substrate

The invention provides a high-entropy alloy resistant to high-temperature oxidation, a thermal barrier coating and a preparation method thereof. The AlCoCrFeNiTaHfY high-entropy alloy is prepared by adding alloy elements Fe, Ta and Hf into NiCoCrAlY. The designed high-entropy alloy contains Fe and Hf and has high Ta content, the configurational entropy of the high-entropy alloy is higher than 1.5R, and the high-entropy alloy has the general characteristics of high-entropy alloy. The alloy is simple in phase structure and is of a BCC and FCC double-phase structure without complicated intermetallic compound precipitated phases. Compared with the NiCoCrAlY, the thermal barrier coating provided with the high-entropy alloy as a bonding layer exhibits a lower heat generation oxide increase rateunder a 1,150 DEG C cyclic oxidation condition; an oxide layer of the high-entropy alloy is uniform and dense and is well combined with an alloy substrate; and the high-entropy alloy has the potentialof serving as a bonding layer material.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

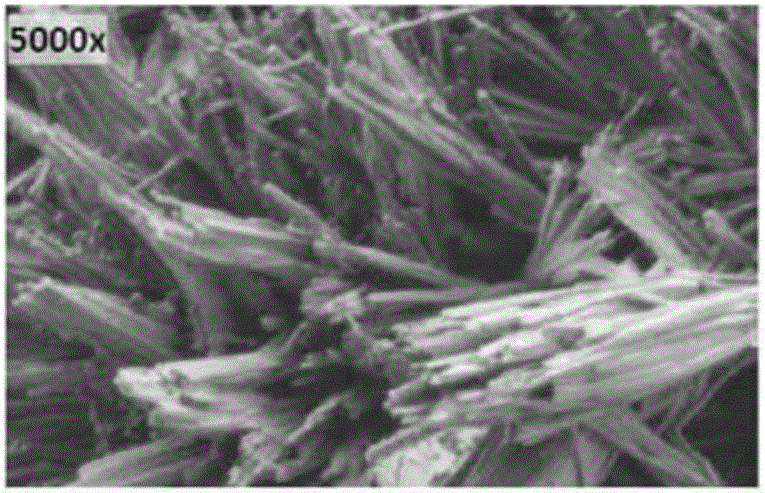

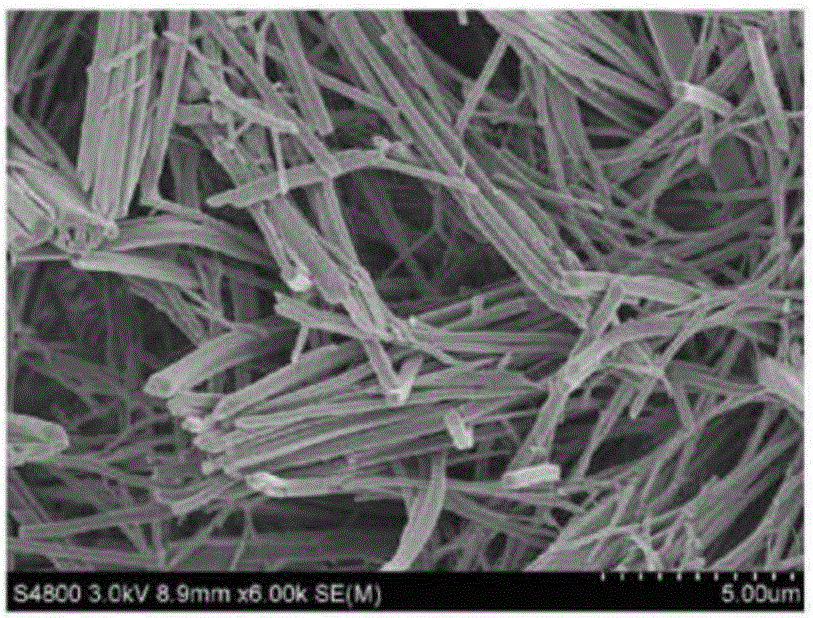

Glass fiber reinforced PA6 composition and preparation method thereof

The invention provides a glass fiber reinforced PA6 composition and a preparation method thereof. The glass fiber reinforced PA6 composition is prepared from 30-60 parts of PA6, 1-10 parts of PA66, 25-45 parts of glass fibers, 0-5 parts of a flexibilizer, 5-10 parts of a nucleating agent and 5-10 parts of a surface improver through mixing and extrusion granulation. By utilizing short-cut glass fibers with a rectangular cross section, a fiber floating phenomenon can be reduced; and besides, the short-cut glass fibers are mutually matched with nylon 66 and the surface improver to ameliorate the surface fiber floating caused after the injection molding of a glass fiber reinforced PA6 material and improve the mechanical property and compressive property of the glass fiber reinforced PA6 composition.

Owner:HEFEI GENIUS NEW MATERIALS

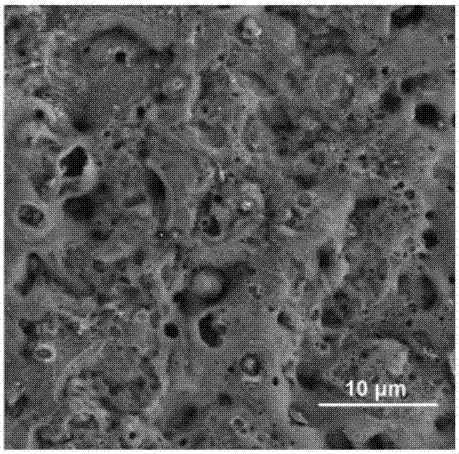

Sintered aluminum electrolytic capacitor ultrahigh-voltage anode foil and preparation method thereof

ActiveCN110993348AAvoid it happening againHigh specific capacityElectrolytic capacitorsMetallurgyAdhesive

The invention discloses a sintered aluminum electrolytic capacitor ultrahigh-voltage anode foil and a preparation method thereof. The preparation method comprises the following steps: 1) mixing spherical aluminum powder with a solvent and an adhesive to prepare aluminum powder slurry; 2) selecting an aluminum foil base material, and coating the surface of an anode foil with the aluminum powder slurry, and carrying out vacuum drying treatment after coating; 3) sintering the coated and dried aluminum foil; and 4) performing low-voltage to ultrahigh-voltage anodic oxidation treatment after the sintering process, and obtaining the sintered aluminum electrolytic capacitor anode foil after the final anodic oxidation process. The aluminum powder slurry is prepare from high-purity aluminum powder,the solvent and the adhesive, and the surface of the aluminum foil substrate is uniformly coated with the slurry for sintering under certain conditions, so that the aluminum powder and the aluminum powder and the aluminum powder and the aluminum foil substrate are sintered together to form the three-dimensional porous aluminum foil. The method is simple in process and environmentally friendly, raw materials are saved, and generation of a large amount of acid and alkali waste liquid containing metal ions generated by a traditional corrosion process is avoided.

Owner:XI AN JIAOTONG UNIV

Low-carbon magnesia carbon brick containing nanometer zinc oxide

A low-carbon magnesia carbon brick containing a nanometer zinc oxide is characterized in that the low-carbon magnesia carbon brick comprises the four following raw materials by weight percentage: 80-94wt% of electric melting magnesia particles, 1-5wt% of crystalline flake graphite, 1-3wt% of metal Al and 1-5wt% of nanometer zinc oxide, and 2-4wt% of a phenol formaldehyde resin with the quantity of the weight percentage sum of the four raw materials. The low-carbon magnesia carbon brick utilizes the characteristics of the nanometer zinc oxide powders such as fine granularity, high activity at high temperature, moderate price, and the like to improve the microstructure of the low-carbon magnesia carbon brick, prompts the used metal Al antioxidant to sufficiently play the role and prepares the low-carbon magnesia carbon brick with excellent comprehensive performance and moderate price. The prepared low-carbon magnesia carbon brick can be used for the steel-making furnace, the refining furnace and the lining of the steel ladle in the steel metallurgical industry, reduces the carbon added in the molten steel, reduces the temperature reduction of the molten steel and is beneficial for improving the quality of the steel and saving the energy resource.

Owner:ZHENGZHOU UNIV

Monolithic sheet style quartz crystal frequency device and production thereof

InactiveCN1780141AImprove bonded stateImprove air tightnessImpedence networksEngineeringAir tightness

A frequency generator with monolithic quartz crystal chips is composed of upper and lower cover plates, crystal chips, pits on said cover plates, and internal and external electrodes. Its preparing process includes such steps as preparing two cover plates with m*n pit array, sticking the crystal chips onto lower cover plate by electrically conductive adhesive, sticking it with upper cover plate, cutting to become product units, and evaporating to form electrodes.

Owner:上海晶赛电子有限公司

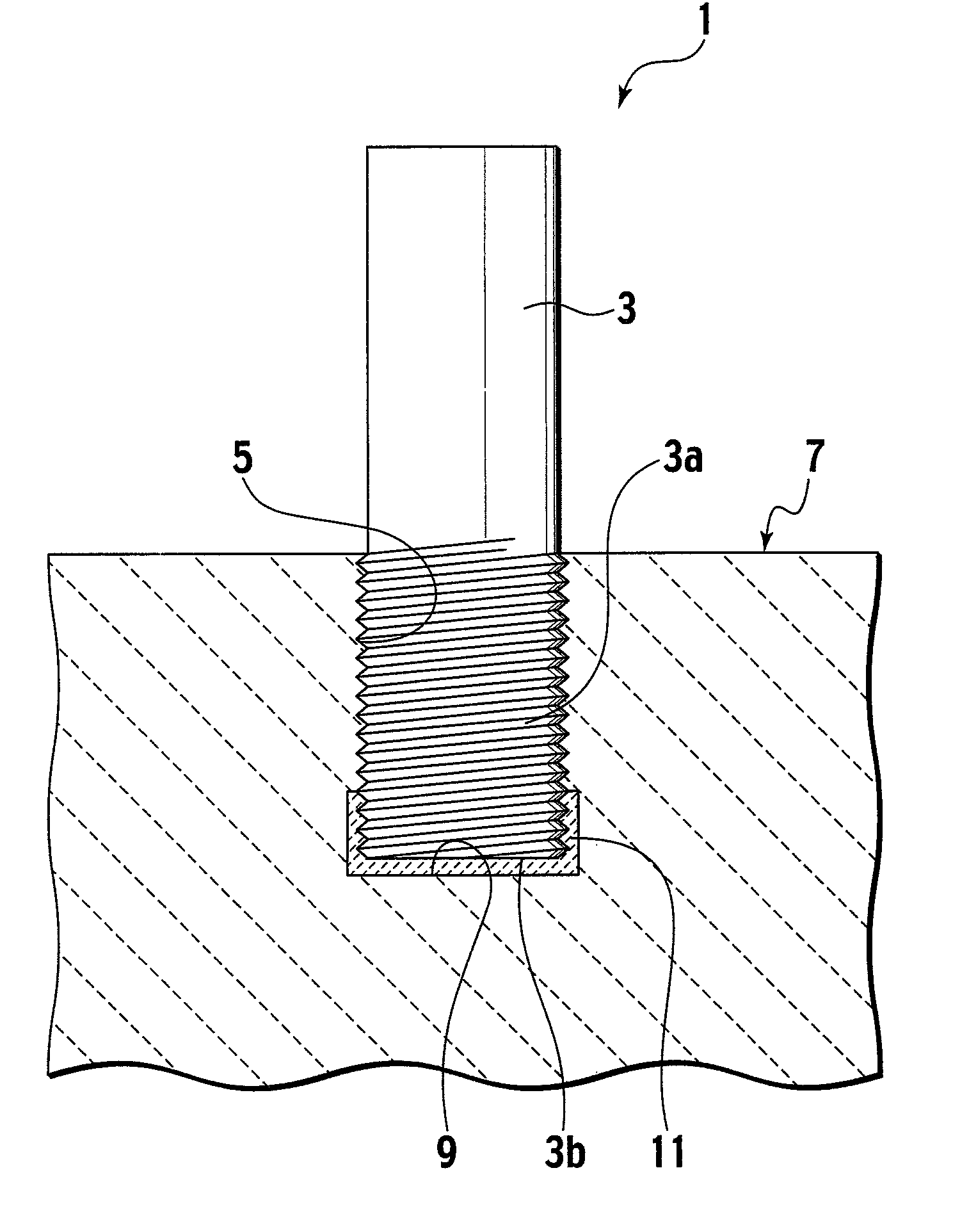

Aluminum nitride bonded body, and manufacturing method of the same

InactiveUS20070144667A1Simplifies bonding processReduces thermal deformationLaminationLamination apparatusExtremity PartAluminium nitride

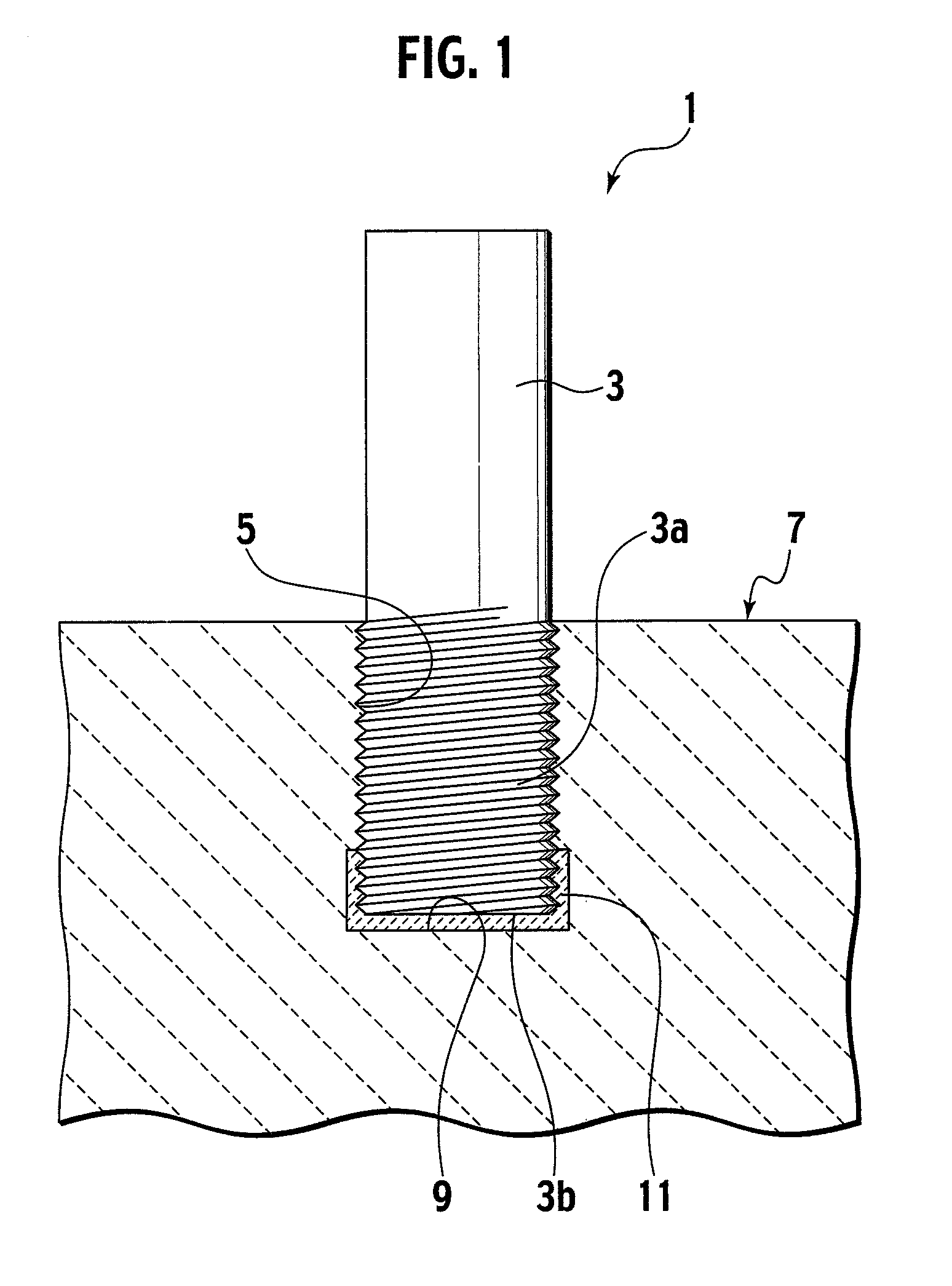

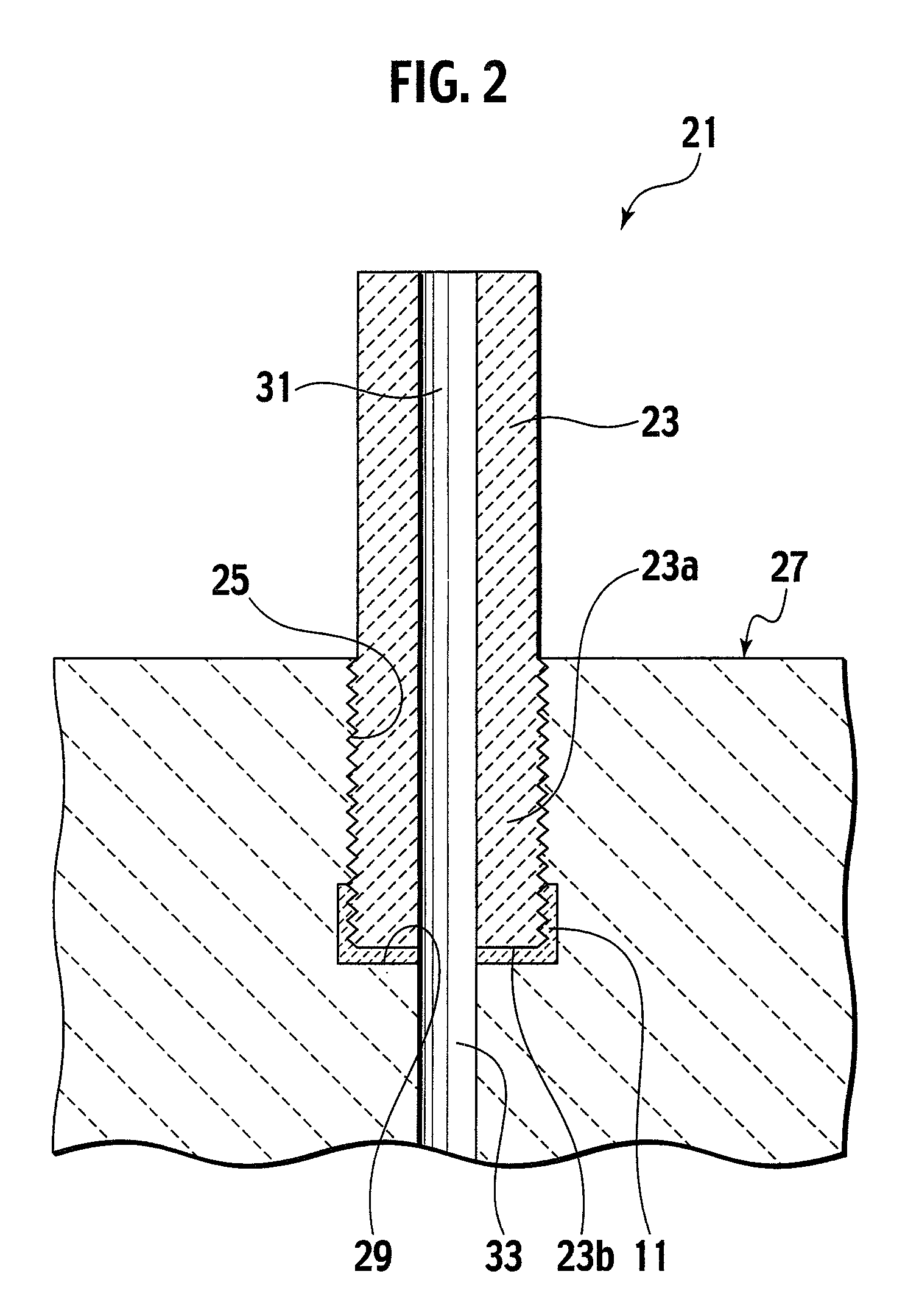

An aluminum nitride bonded body includes: a stick-like attaching body containing aluminum nitride; an attached body containing aluminum nitride, in which a tip end portion of the attaching body is screwed to a support hole; and a bonding layer for bonding the attaching body and the attached body to each other.

Owner:NGK INSULATORS LTD

Preparing method of ultra-wide aluminum alloy thin plate based on rapid set powder metallurgy high-silicon aluminum alloy

InactiveCN107088657AHigh densitySmall tissueTurbinesOther manufacturing equipments/toolsSolution treatmentPunching

The invention provides a preparing method of an ultra-wide aluminum alloy thin plate based on a rapid set powder metallurgy high-silicon aluminum alloy. The preparing method includes the following steps that high-silicon aluminum alloy powder is contained into a sheath to be subjected to vacuum degassing, heating, heat preservation and vacuumization are carried out, then the sheath is sealed, is heated and is subjected to heat preservation, decrustation hot extrusion is carried out after heating is complete and even, and a high-silicon aluminum alloy rod is obtained; the high-silicon aluminum alloy rod is machined to remove the peripheral aluminum sheath, solution treatment is carried out, heating and aging treatment are treatment, and the high-silicon aluminum alloy is obtained; after the high-silicon aluminum alloy is heated, punching, chambering, swaging, annular rolling and multi-pass hot powerful thinning spinning molding are carried out, intermediate annealing treatment is carried out, multi-pass cold powerful thinning spinning molding is carried out, and a tube blank is obtained; and finally, polishing, solution treatment and aging treatment are carried out, and cutting and unfolding are carried out to form the ultra-wide aluminum alloy thin plate based on the rapid set powder metallurgy high-silicon aluminum alloy. The high-silicon aluminum alloy prepared through the method is fine in material texture and even, ultra-wide, simple in preparing method and low in cost.

Owner:郭和谦

Modified glass-fiber-reinforced PA6 (polyamide 6) composition and preparation method thereof

The invention provides a modified glass-fiber-reinforced PA6 (polyamide 6) composition and a preparation method thereof. The composition is prepared by mixing and carrying out extrusion granulation on the following components: 30-60 parts of PA6, 1-10 PA66, 25-45 parts of glass fiber, 5-15 parts of hollow glass microsphere, 0-5 parts of toughener, 5-10 parts of nucleator and 5-10 parts of surface modifier. The hollow glass microspheres and surface modifier are matched to improve the bonding state between the glass fibers and nylon resin and reduce the separation between the glass fibers and nylon resin, so that the glass fibers are well coated in the nylon resin; and the glass fibers and resin synchronously flow in the working process, and can not be easily torn away, thereby greatly reducing the exposure of the glass fibers. The mechanical properties and compression resistance of the modified glass-fiber-reinforced PA6 composition are enhanced.

Owner:HEFEI GENIUS NEW MATERIALS

Waste paper pulping and papermaking advanced waste water treatment technique

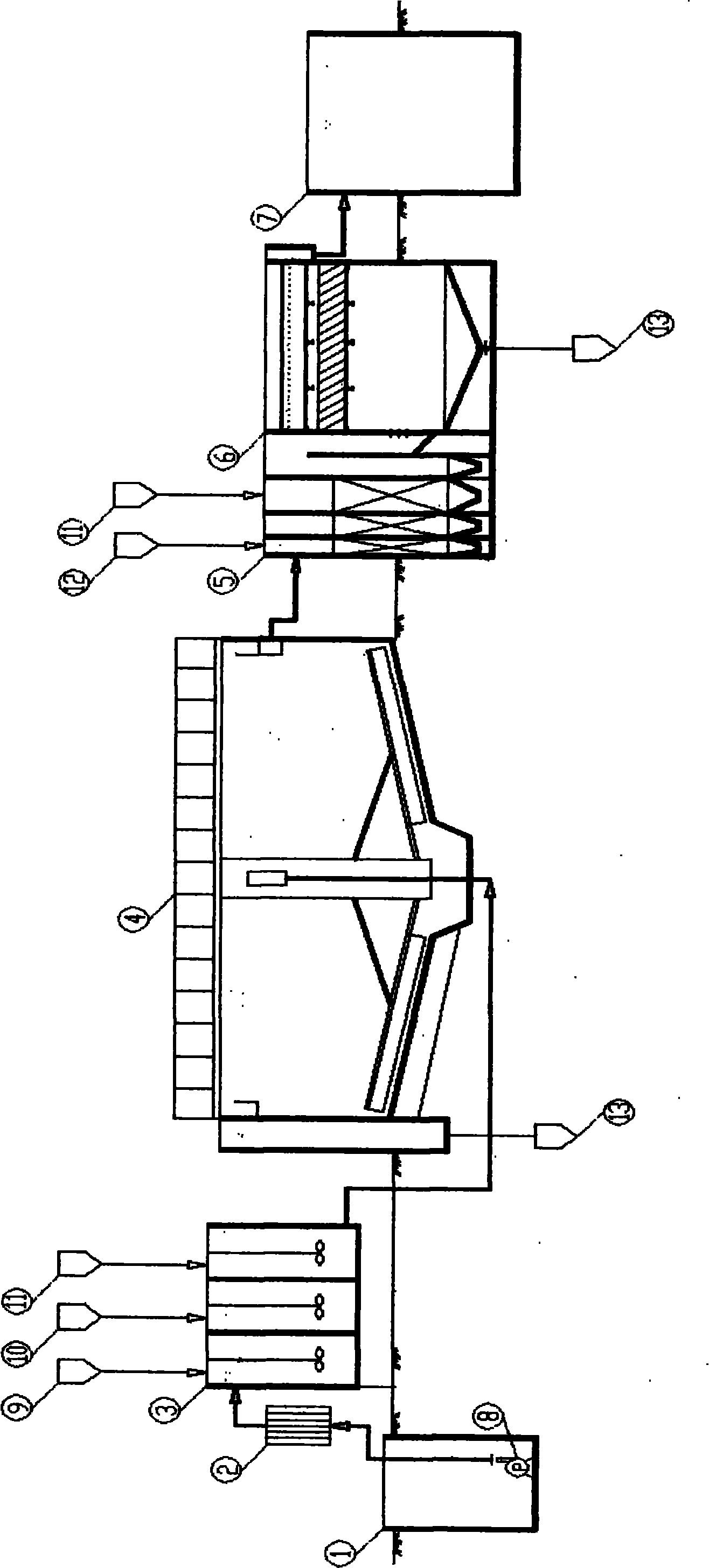

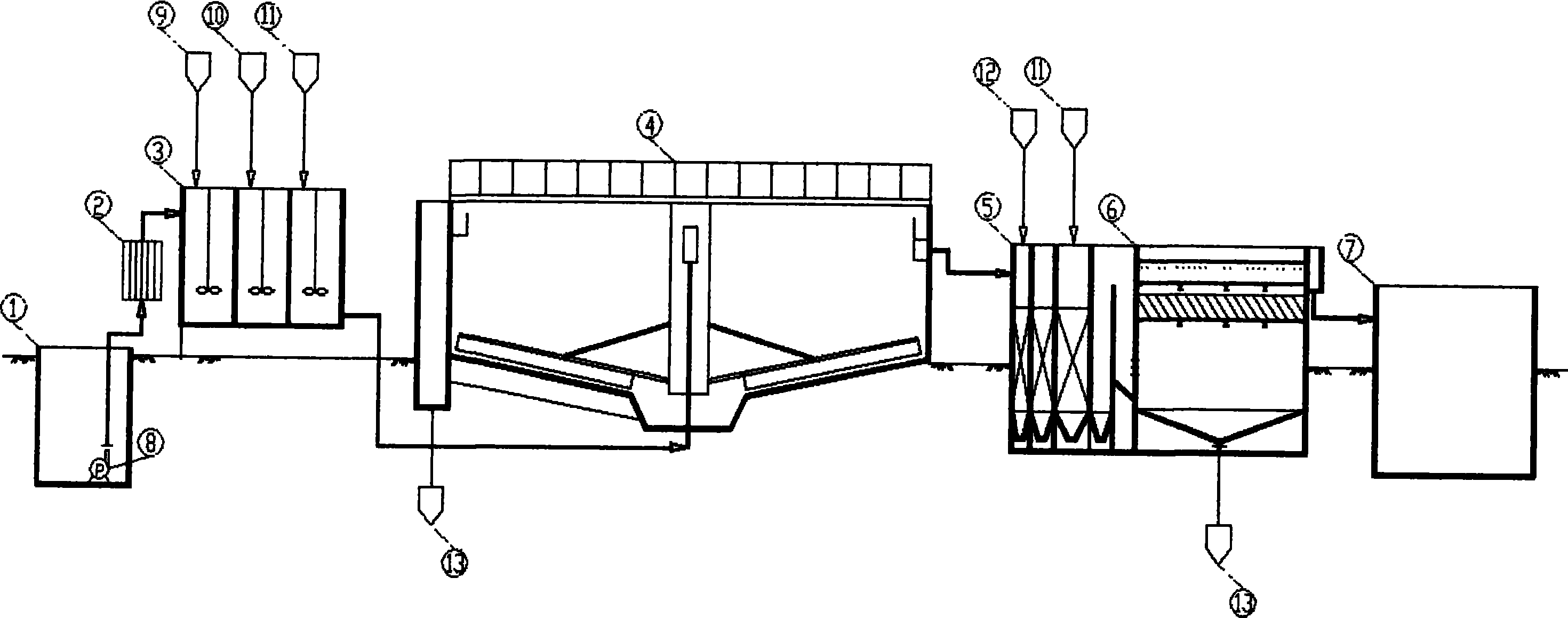

InactiveCN101786758AImprove reaction speedIncrease responsivenessWater/sewage treatment by magnetic/electric fieldsMultistage water/sewage treatmentMagnetizationWastewater

The invention discloses a waste paper pulping and papermaking advanced waste water treatment technique, comprising the following steps of: waste water collection, magnetization, first-stage dosing reaction, first-stage precipitation, second-stage dosing reaction, second-stage precipitation and temporary storage of clear water. The technique has the advantages that (1) the technique is based on physicochemical technology, and the design is scientific and reasonable, so that good effect of advanced waste water treatment can be ensured; (2) the technique not only removes organic pollutant and chroma in the waste water with high efficiency, but also greatly reduces the hardness of the waster water and lays foundation for recycling the waste water; and (3) the technique has wide technical applicability and strong shock resistance capability.

Owner:SHANDONG ACAD OF ENVIRONMENTAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com