Monolithic sheet style quartz crystal frequency device and production thereof

A technology of frequency devices and quartz crystals, applied in monolithic chip quartz crystal frequency devices and its manufacturing field, can solve the problems of large product size, high manufacturing cost, poor air tightness, etc., achieve low cost and improve efficiency , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

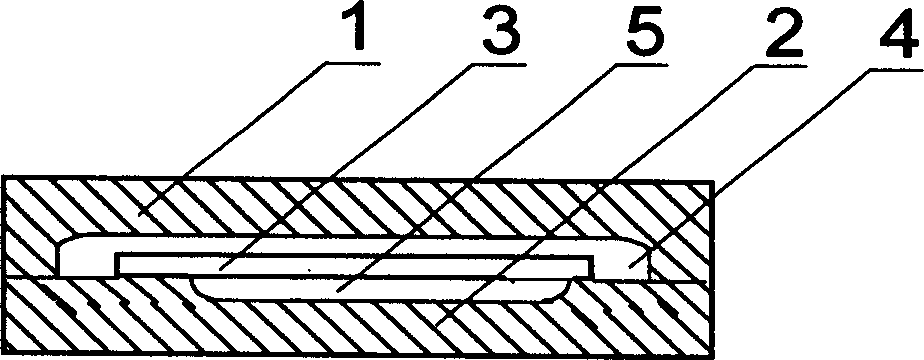

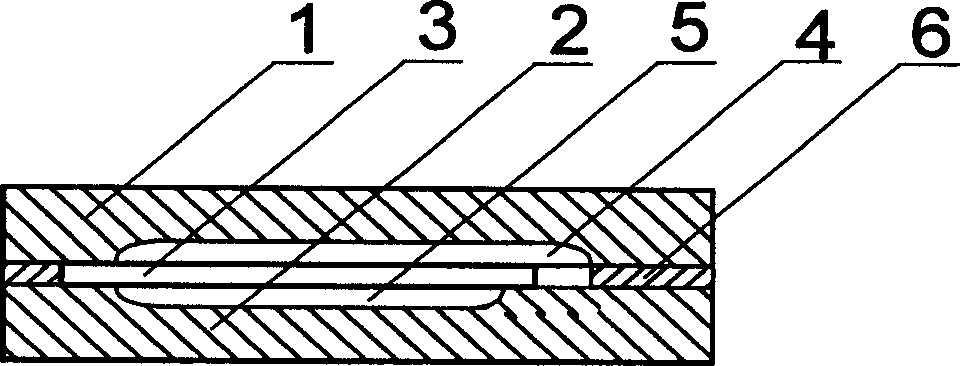

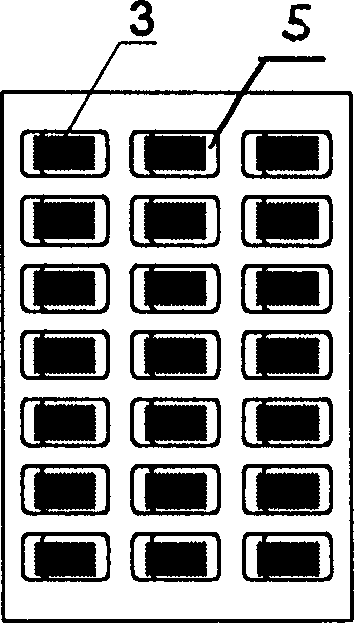

[0024] figure 1 , 2 Schematic diagrams of two different cross-sectional structures of the monolithic plate quartz crystal frequency device manufactured for the present invention. As can be seen from the figure, the quartz wafer 3 is hidden in a cavity (vibration cavity) composed of an upper cover pit 4 and a lower cover pit 5 . Firstly, according to the different size requirements of the pit 4 of the upper cover plate and the pit 5 of the lower cover plate, prefabricate two pieces of ceramics with an m×n array (wherein, m≥1, n≥1,) by a special method cover plate.

[0025] image 3 It is a schematic diagram of the lower cover plate with the wafer attached to the intermediate splint, Figure 4 It is a side view sectional view of the lower cover plate with the wafer attached to the intermediate splint, Figure 5 It is a schematic diagram of the lower cover plate with the wafer attached, Image 6 It is a side view sectional view of the lower cover plate with the wafer attach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com