Patents

Literature

310results about How to "Small tissue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-boron low-alloy high-speed steel roll and preparation method thereof

ActiveCN101831590AReduce the amount addedReduce manufacturing costRollsElectric furnaceHardnessHigh-speed steel

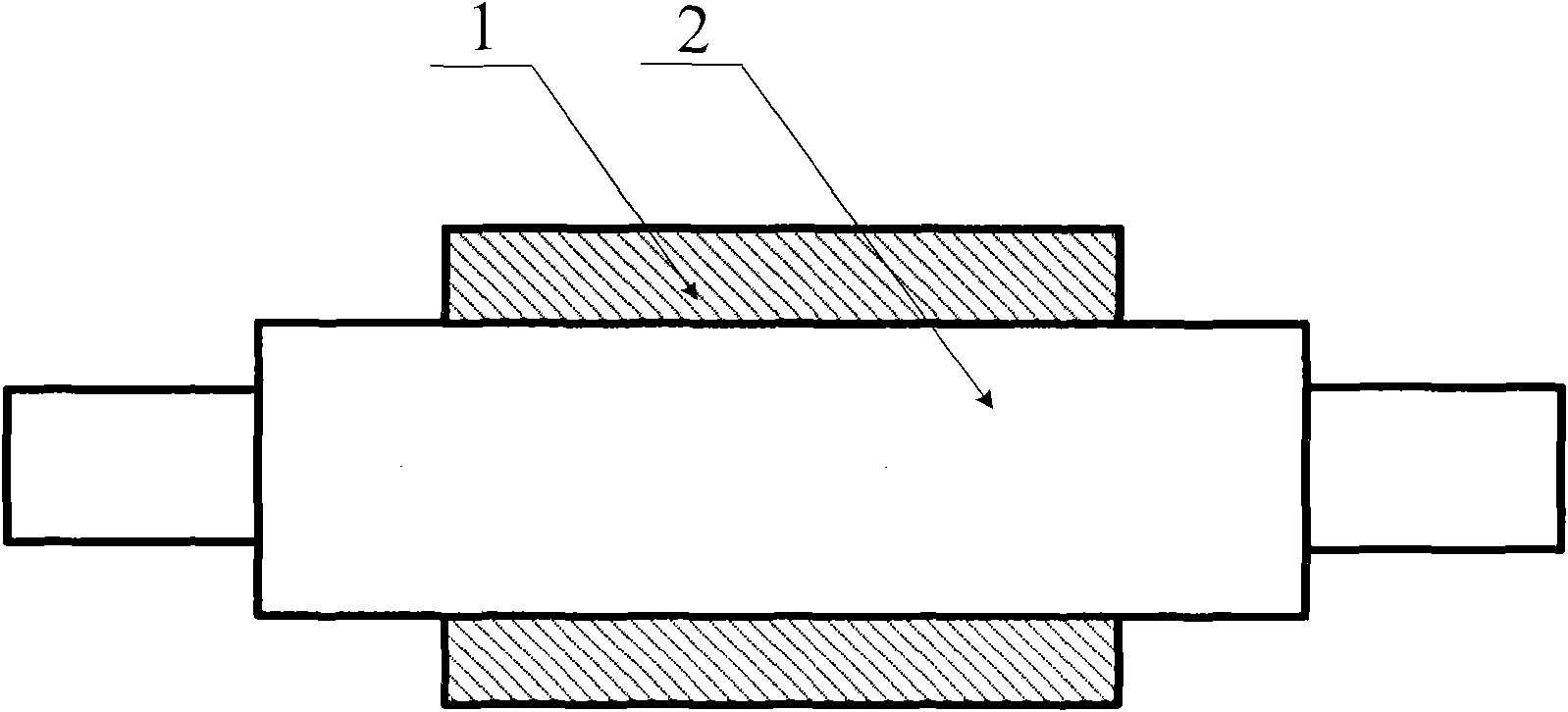

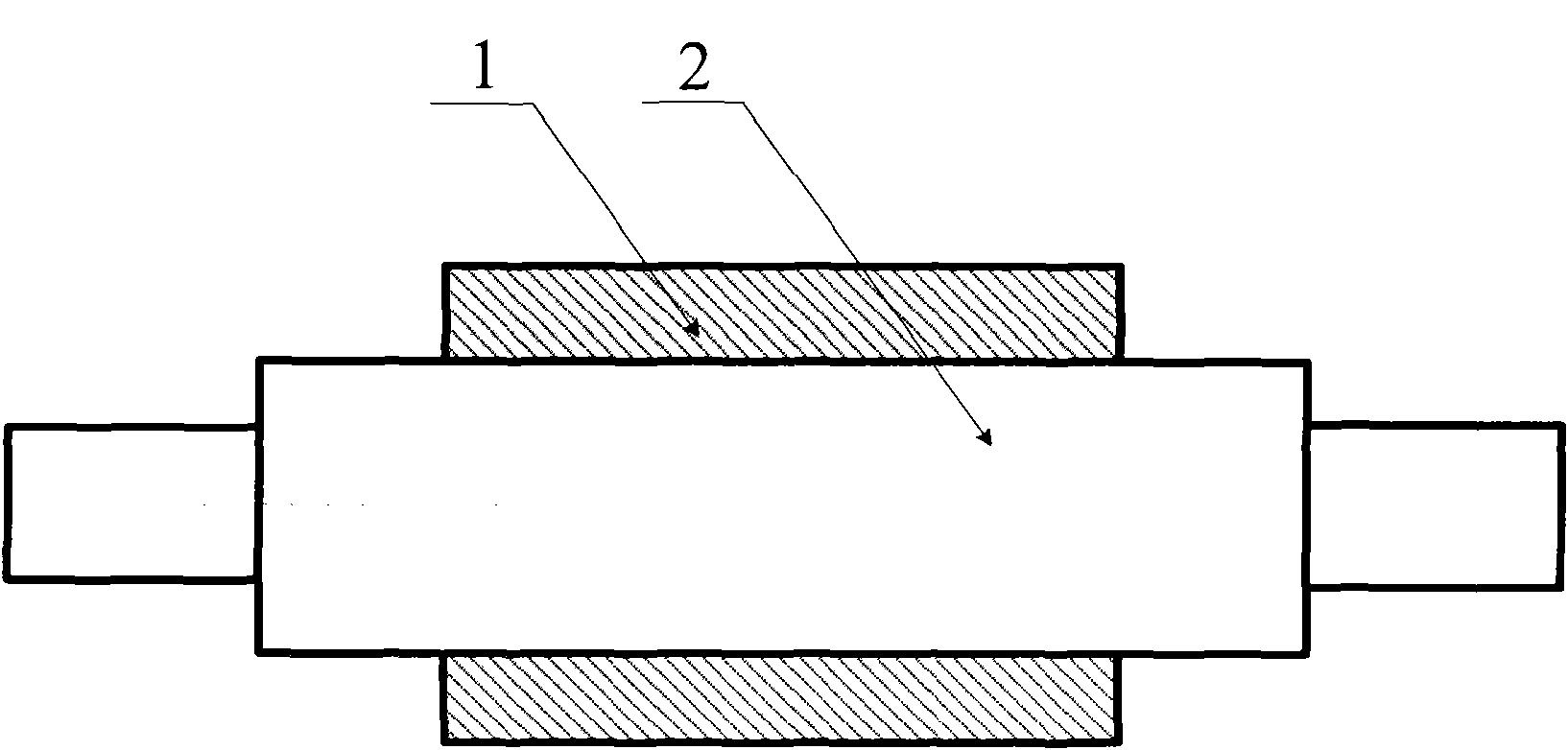

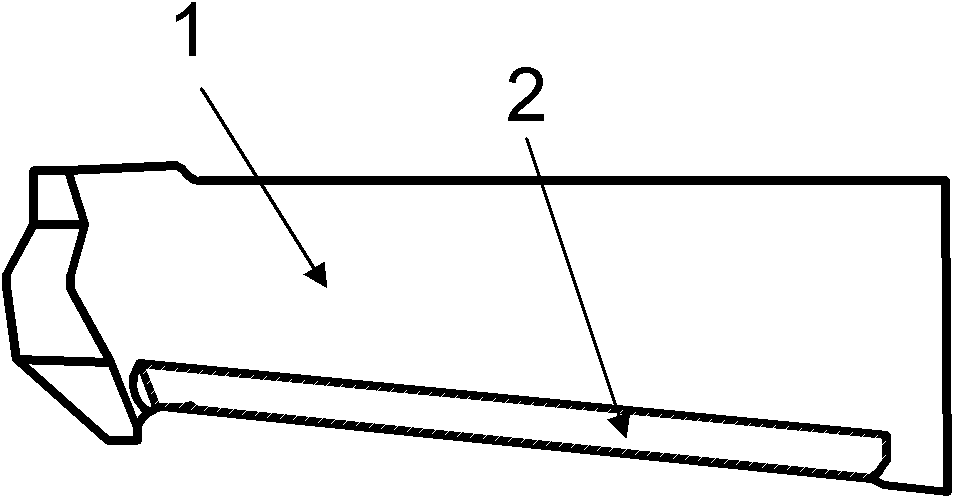

The invention relates to high-boron low-alloy high-speed steel roll and a preparation method thereof. The roll comprises two parts, namely a roll barrel (1) and a roll core (2), wherein the roll barrel comprises the following chemical components by weight percent: 0.32-0.55% of C, 1.42-2.13% of B, 5.2-6.5% of Cr, 2.5-4.5% of W, 1.6-1.8% of V, 0.5-1.0% of Nb, 0.3-1.0% of Si, 0.3-1.0% of Mn, 0.10-0.20% of Ti, 0.05-0.12% of N, 0.04-0.12% of Y, 0.08-0.15% of Mg, less than 0.04% of P, less than 0.04% of S and the balance Fe. The roll prepared by the method of the invention is characterized by high hardness, deep quenched depth and good wear resistance and thermal fatigue resistance, and has good use effect in the production of hot rolled steel.

Owner:JIANGSU DONGYE ROLL

High-speed steel roll ring and its production

A high-speed steel roller ring for rolling wire or rod material contains C, W, Mo, V, Cr, Al, Ni, Co, Nb, Ti, Ce, Na, Mg, Si, Mn, S, P and Fe proportionally. It is prepared through smelting in electric furnace, centrifugal casting, and annealing, high-temp quenching and tempering twice. Its advantages are high hardness, tension strength and toughness for breaking, smooth surface and high size stability.

Owner:XI AN JIAOTONG UNIV

Aluminum alloy powder capable of being used for 3D printing and preparing method and application of aluminum alloy powder

ActiveCN109487126AReduce H

<sub>2</sub>

O contentReduce generationAdditive manufacturing apparatusIncreasing energy efficiencyMechanical propertyCorrosion

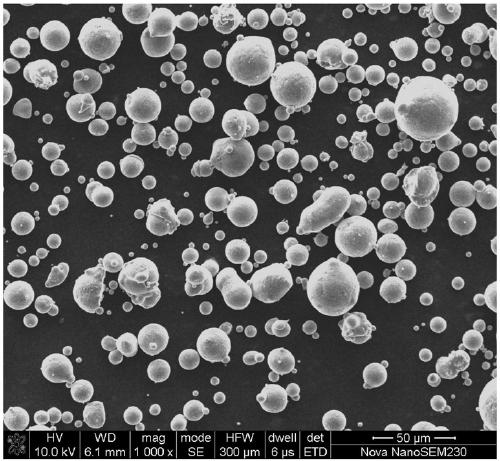

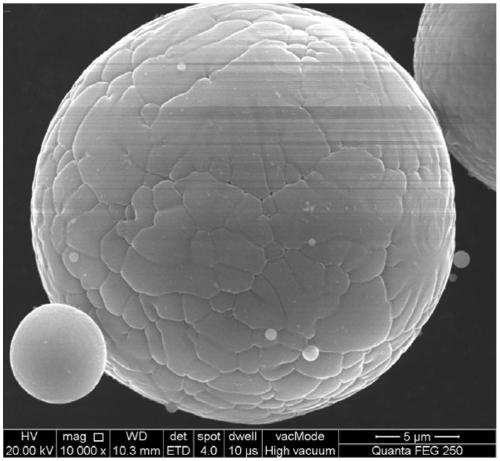

The invention provides an aluminum alloy powder capable of being used for 3D printing and a preparing method and application of the aluminum alloy powder. The aluminum alloy powder comprises the following components including, by weight, 1.00%-10.00% of Mg, 0.10%-1.80% of Sc, 0.1%-1.60% of Zr, 0.05%-3.50% of Mn, 0.01%-0.90% of Fe, 0.01%-3.00% of Cu, 0.01%-3.00% of Si, 0.01%-3.50% of Zn, 0.01%-0.08% of Cr, 0.01%-0.08% of Ni and the balance Al. A 3D printing workpiece prepared through the aluminum alloy powder has the beneficial effect of being fine in tissue, good in mechanical property, high in stress corrosion resistance and the like.

Owner:CRRC IND INST CO LTD +1

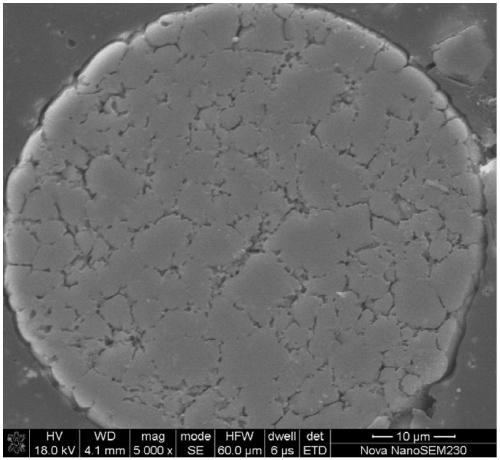

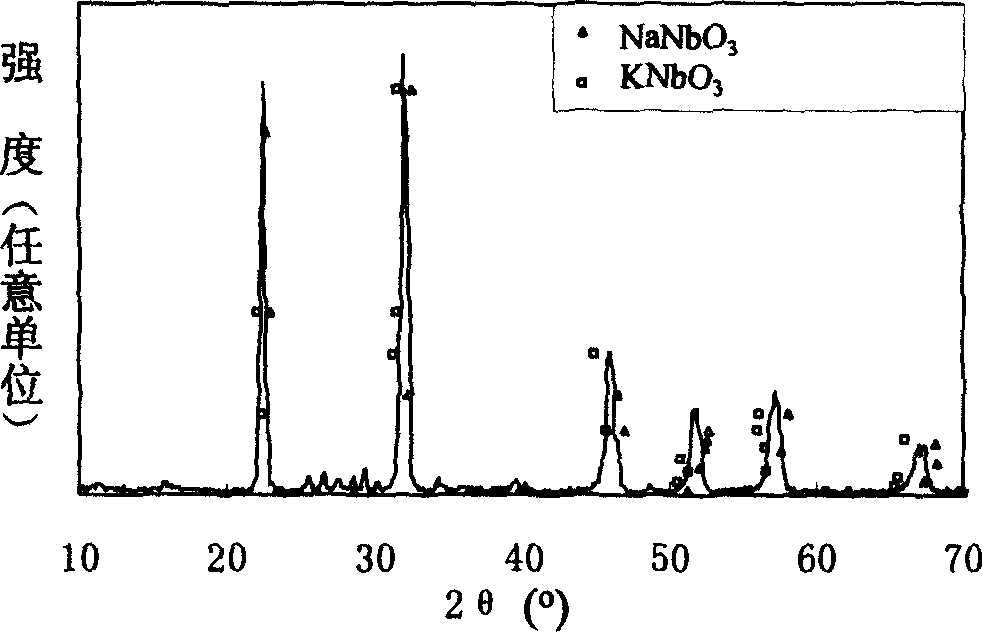

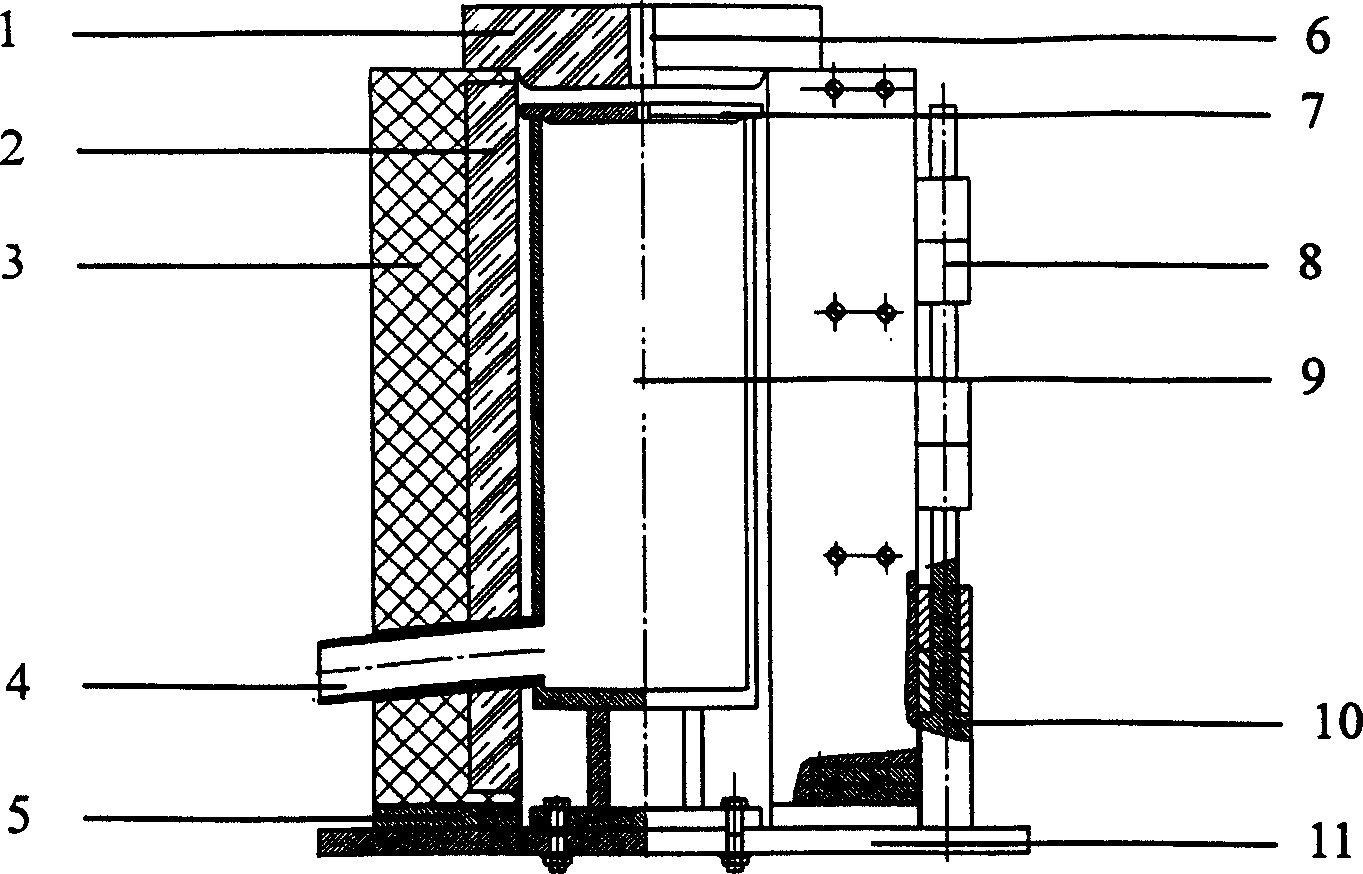

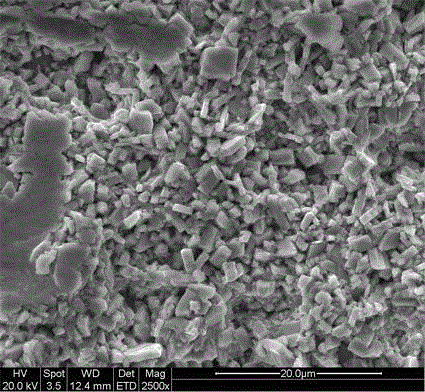

Lead free piezoelectric ceramics of potassium sodium niobate and preparation thereof

ActiveCN1644562ALower sintering temperatureShort sintering timePiezoelectric/electrostrictive/magnetostrictive devicesElectric fieldNatural state

A niobic acid potassium sodium system lead-free piezoelectric ceramic and its production are disclosed. The components of the niobic acid potassium sodium system lead-free piezoelectric ceramic are (1-n)KxNa1-xNbO3.nMH, it is prepared by SPS process. The production is carried out by grinding mixing raw materials, calcining synthesizing niobate, using SPS process for the obtained powdery material, annealing treating under oxygen atmosphere, and obtaining piezoelectric / ferroelectric ceramic materials. Its advantages include lead-free composition, good piezoelectric performance, low calcining temperature, short calcining time and fine tissue.

Owner:TSINGHUA UNIV +2

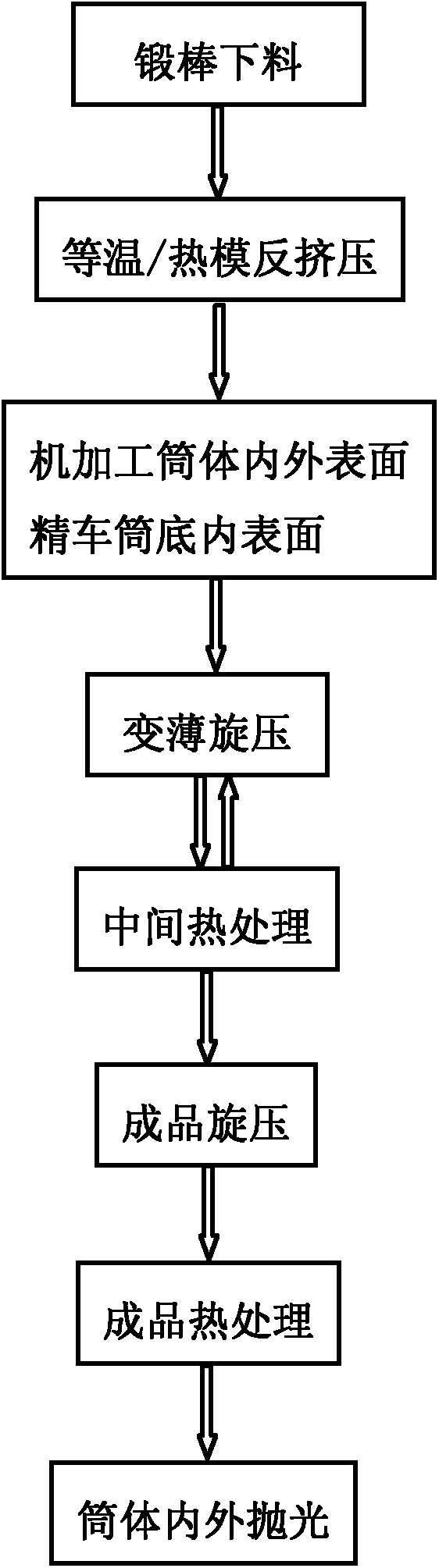

Machining method of high-quality large-diameter thin-wall metal barrel body

The invention relates to a machining method of a high-quality large-diameter thin-wall barrel body. The machining method comprises the following steps. Firstly, isothermy or hot die anti-extrusion technology is utilized, and anti-extrusion is performed on an alloy forging rod. Secondly, machining is performed on the inner and outer surfaces of a spinning barrel billet, and finish turning is performed on the inner surface of the barrel bottom of the barrel billet. Thirdly, multi-pass brute force thinning spinning is performed on the machined spinning barrel billet, and the spinning is hot spinning or cold spinning. Fourthly, intermediate heat treatment is performed on a spinning semi-finished product, and the intermediate heat treatment is annealing or solution treatment. Fifthly, the third step and the fourth step are performed repeatedly and alternatively so that finished product spinning is performed. Sixthly, scouring and cleaning are performed on the barrel body, and finished product heat treatment is performed. Seventhly, polishing of the inner and outer surfaces of the barrel body after heat treatment in the sixth step is performed, and a finished product barrel body is obtained. By adoption of the machining method of the high-quality large-diameter thin-wall barrel body to machine a large-diameter thin-wall metal barrel body without welding lines, organization is even and fine, comprehensive performance is high, the process is short, product additional values are high, and good application and popularizing prospects and certain economic and social benefits are achieved.

Owner:有研金属复材技术有限公司

High strength heat resistant aluminium alloy

The present invention is one kind of high strength heat resistant aluminum alloy capable of being used at 300-400 deg.c for long period. The high strength heat resistant aluminum alloy consists of Si 6.5-17.5 wt%, Cu 2.0-5.0 wt%, Ni 1.0-3.0 wt%, Mn 0.4-1.0 wt%, Mg 0.4-1.2 wt%, Ti 0.1-1.0 wt%, B 0.02-0.2 wt%, Zr 0.1-1.0 wt%, Cd 0.1- 0.6 wt%, P 0.005-0.05 wt%, and Al for the rest, and has Si / Mg ratio of 10-20 and Cu / Mg ratio of 4-13. The alloy includes Al3X grains with homogeneously distributed L12 crystal structures and TiB2 grains with homogeneously distributed hcp crystal structures possessing high heat stability, and grain fining and high temperature strengthening effects. The high strength heat resistant aluminum alloy may be made into part through cheap casting or used as the base material for composite material.

Owner:XIAN TECHNOLOGICAL UNIV

Laser cladding technological method and alloy material for laser cladding

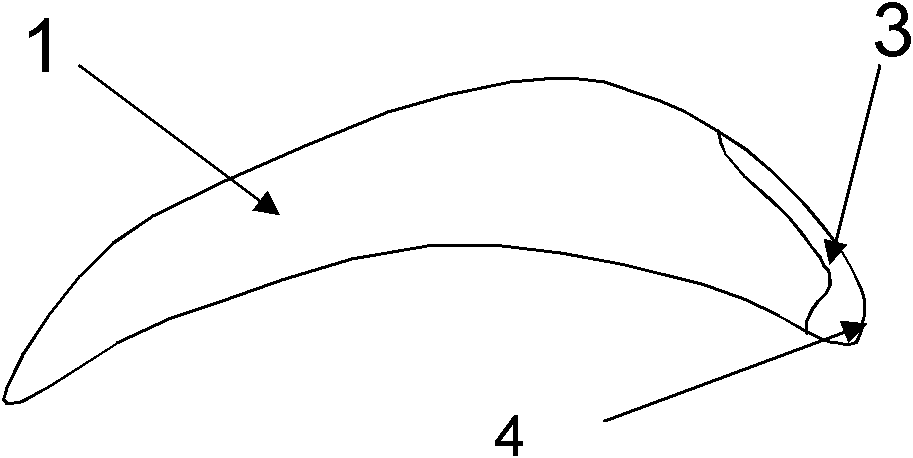

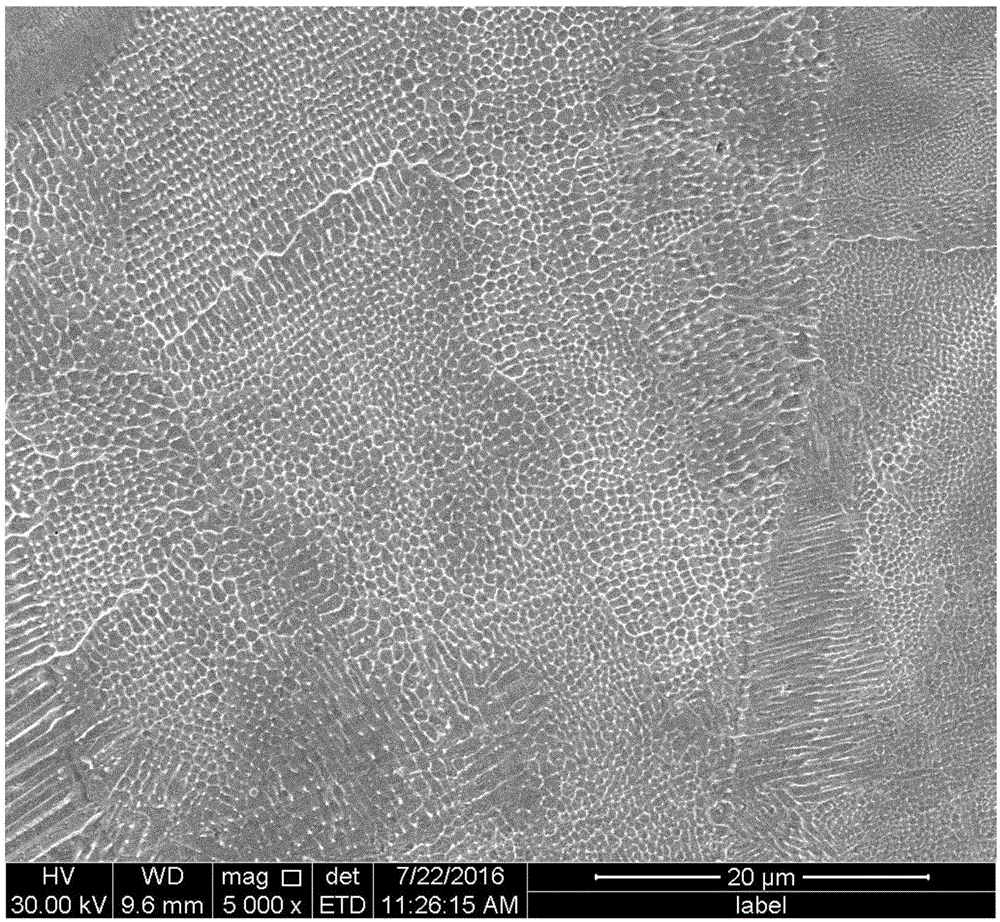

ActiveCN102168210AUniform tissueSmall tissueMetallic material coating processesLaser beam welding apparatusCavitationSlag

The invention discloses an alloy material for laser cladding. The alloy material is alloy powder and contains the following components in percent by weight: C: 0.85-0.98%, Cr: 35-45%, Fe: 3-5%, Si: 0.5-1.0%, W: 3.5-5.5%, Mo: 1 .0-1.5%, Ni: 6-8%, V: 1.5-2.0%, Ti: 1.0-2.0%, B: 0.5-1.5%, Nb: 0.10-0.50%, Re: 0.5-1.5%, and Co: the balance. The invention also discloses a laser cladding technological method adopting the alloy material. In the technical scheme, under the combined action of the added alloy elements, cladding layer tissue is uniform and tiny and has no pore, no inclusion and no included slag; and preheating is not needed when a blade is cladded and crack does not emerge. The alloy material has high rigidity and excellent cavitation resistance; without follow-up heating treatment, a cladded part can be directly fine machined to use; and the laser treatment technology has good adaptivity and is simple and feasible in operation.

Owner:HANGZHOU BOHUA LASER TECH

Wear-resisting white cast iron and preparation method thereof

The invention provides a wear-resisting white cast iron and a preparation method thereof, and belongs to the technical field of wear-resisting materials. The liquid wear-resisting white cast iron is smelted in an electric furnace at first, and the liquid iron is composed of 2.9-3.3% of C, 4.5-5.5% of Mn, 6.0-7.2% of Cr, 0.45-0.70% of B, 0.50% of Si<, 0.05% of S<, 0.05% of P< and the balance of Fe by mass fraction. Modification treatment is performed on the wear-resisting white cast iron by adding a compound modificator to a casting ladle, wherein the addition amount of the compound modificator accounts for 1.8-3.0% of the mass fraction of the liquid iron in the casting ladle; besides, the wear-resisting white cast iron has excellent properties after being quenched by air cooling at a temperature ranging from 950 to 1000 DEG C and tempered at a temperature ranging from 280 to 320 DEG C.

Owner:BEIJING UNIV OF TECH

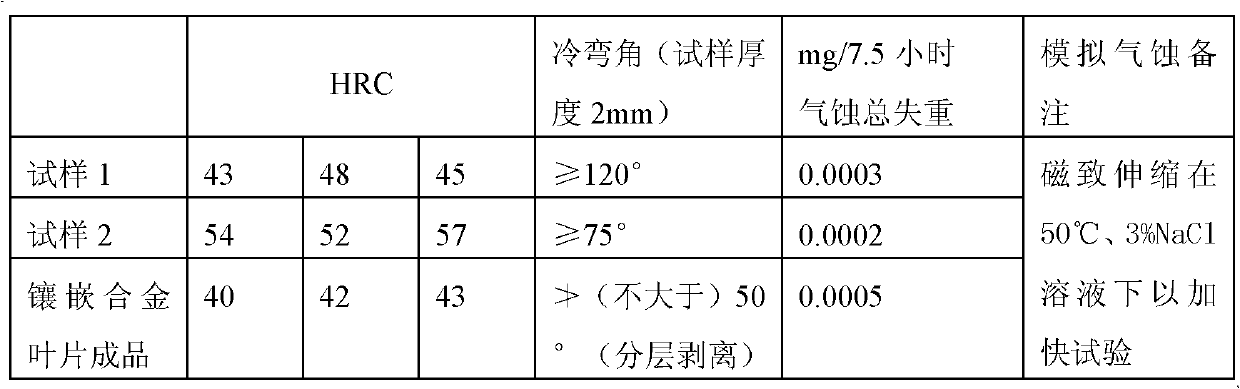

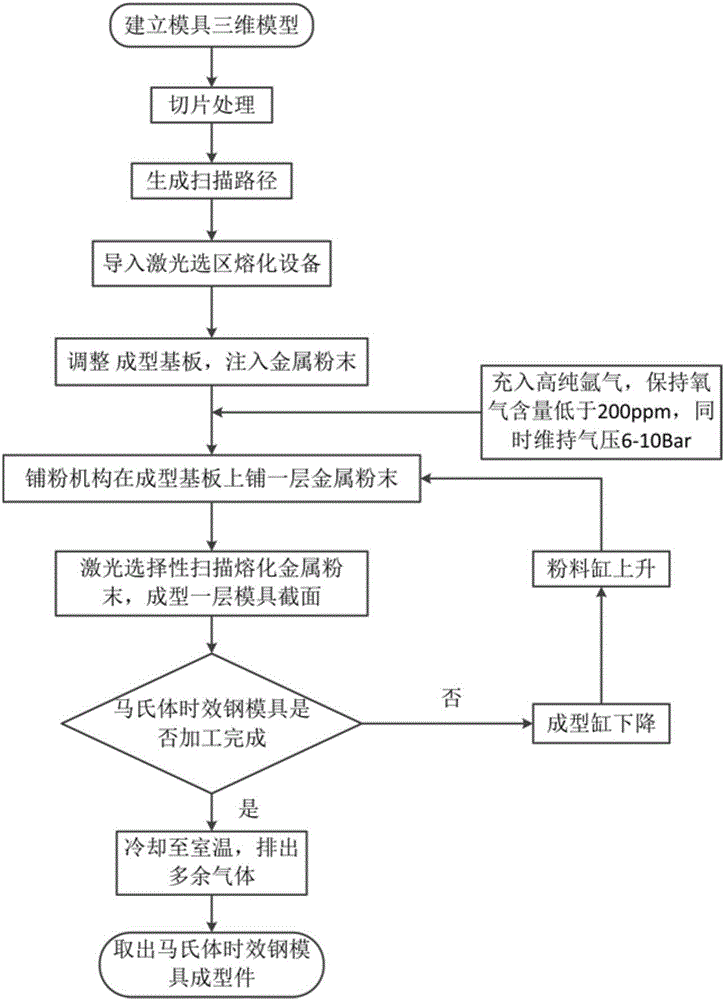

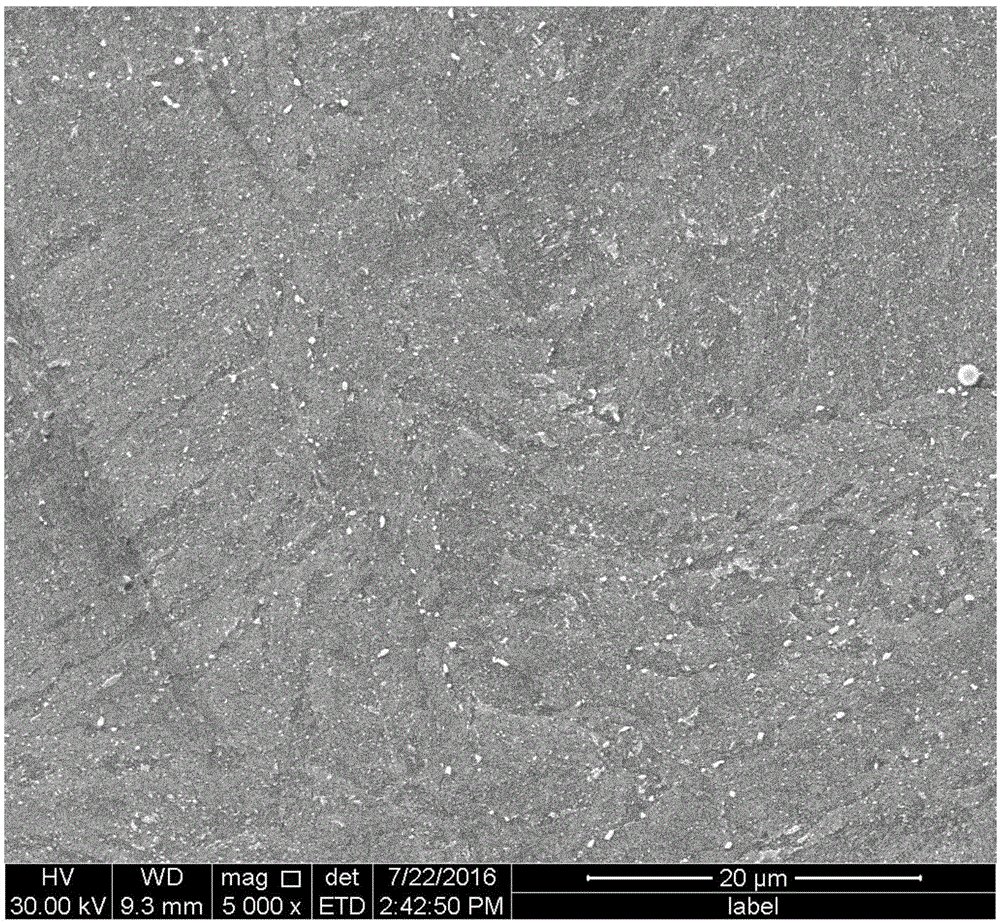

Forming method of maraging steel mold adopting selective laser melting

InactiveCN106825566AEasy to manufactureReduce pollutionAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingManufacturing cost reduction

The invention discloses a forming method of a maraging steel mold adopting selective laser melting. A three-dimensional structure of the mold is designed firstly by using three-dimensional design software such as Solidworks, ProE and Ug; and then the three-dimensional mold is subjected to slicing layering and route planning treatment, data are guided into a selective laser melting device, reasonable technical parameters are set, and the mold with a complex cooling channel is formed at a time. The mold formed by the method has the advantages of being high in compactness, few in internal defect, high in forming efficiency and high in free degree on the follow-up forming cooling channel. According to the forming method of the maraging steel mold adopting selective laser melting, the production period of the mold is effectively shortened, forming efficiency is high, external disturbance is small, the compressive property and production efficiency of the mold are remarkably improved, and meanwhile manufacturing cost is greatly reduced. After the directly-formed mold is subjected to solution and aging treatment, hardness and strength of the mold are remarkably improved, and the using requirements of the mold are met.

Owner:SOUTH CHINA UNIV OF TECH

Large-thickness steel plate for oceaneering and production method thereof

The invention belongs to the technical field of steel and iron, and in particular discloses a large-thickness steel plate for oceaneering and a production method thereof. The large-thickness steel plate for oceaneering comprises the following components in percentage by weight: 0.07-0.09 percent of C, 0.15-0.40 percent of Si, 1.40-1.50 percent of Mn, not more than 0.012 percent of C, not more than 0.005 percent of S, 0.60-0.70 percent of Ni, 0.030-0.040 percent of Nb, 0.020-0.045 percent of Al, 0.13-0.17 percent of Mo, 0.04-0.05 percent of V, 0.012-0.020 percent of Ti and the balance of Fe and inevitable impurities. The large-thickness steel plate for oceaneering has the advantages of pure steel quality, good low-temperature impact toughness, high thickness (Z direction) tensile cross section contractibility rate, large thickness, high strength, good low-temperature aging impact toughness and low product cost. The large-thickness steel plate for oceaneering, provided by the invention,is suitable for use of large-thickness structures for oceaneering.

Owner:WUYANG IRON & STEEL +1

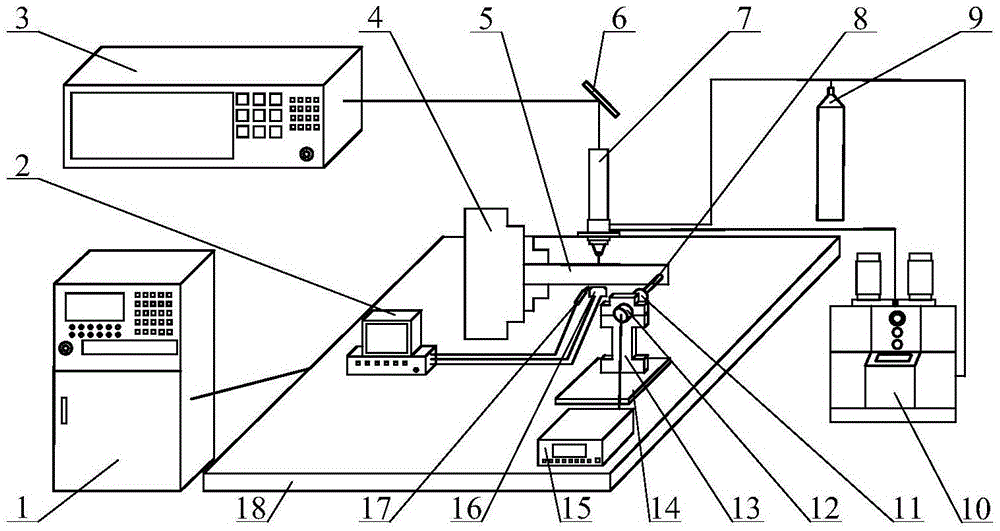

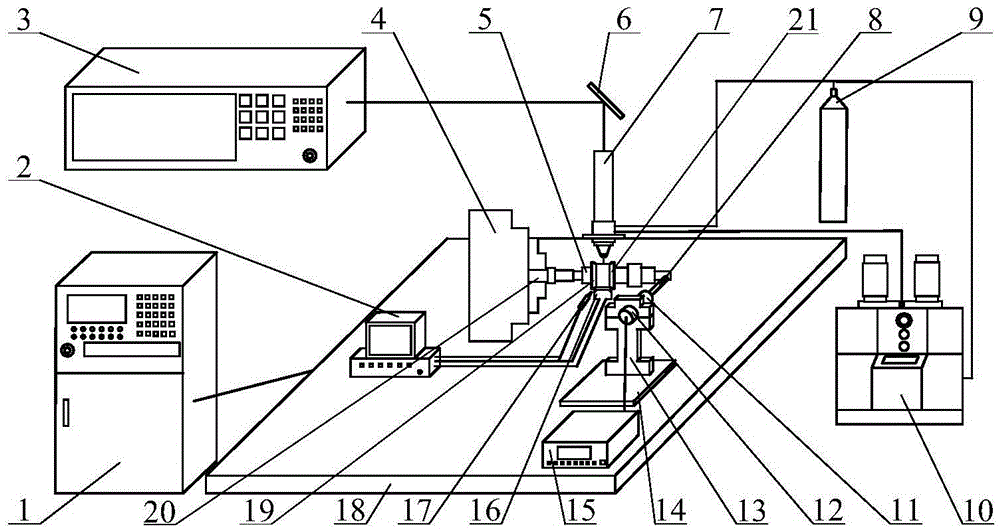

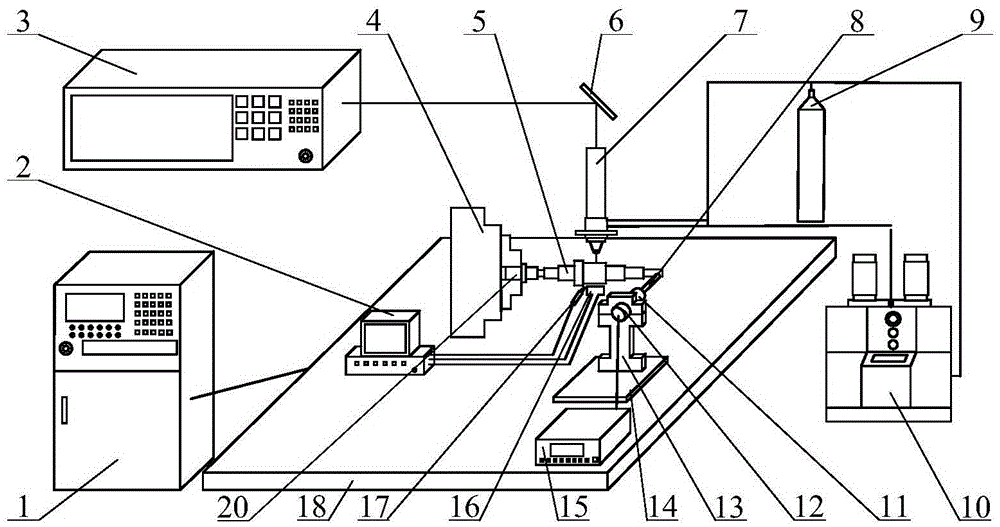

Gradient wear-resistant coating and method for preparing same

ActiveCN105543839AImprove wear resistanceHigh temperature resistantSuperimposed coating processWear resistantUltrasonic oscillation

Provided are a gradient wear-resistant coating and a method for preparing the same. Co50+0.15% CeO2 powder, Co50+0.25% CeO2+6% Ni / Wc powder and Co50+0.4% CeO2+12% Ni / WC powder are used for preparing the gradient wear-resistant coating with the structure of a bottom layer, a transition layer and a wear-resistant layer on the surface of a workpiece in a coaxial powder supply manner and a laser cladding manner, and the wear resisting performance of the work surface of a part is improved. An ultrasonic vibration device and a contour tracing electromagnetic induction heating device are adopted in the cladding process. Ultrasonic oscillation of a certain degree is applied to the area close to a cladded area of the workpiece, the grain size of a cladding layer can be remarkably refined, residual stress can be remarkably eliminated, and therefore generated cracks are reduced, and a cladding layer structure with good performance is obtained. The contour tracing electromagnetic induction heating device can be utilized for effectively reducing thermal stress brought by the temperature gradient of the cladding layer and relieving the cracking tendency. According to the technological parameters of the ultrasonic vibration device, the work frequency ranges from 10 kHz to 20 kHz, the maximum output power is 1,000 W, and the pneumatic pressure ranges from 0.3 MPa to 0.6 MPa. According to the technological parameters of the contour tracing electromagnetic induction heating device, the voltage is 380 V, the frequency is 60 Hz, and the heating temperature ranges from 150 DEG C to 1,000 DEG C.

Owner:CHANGCHUN UNIV OF SCI & TECH

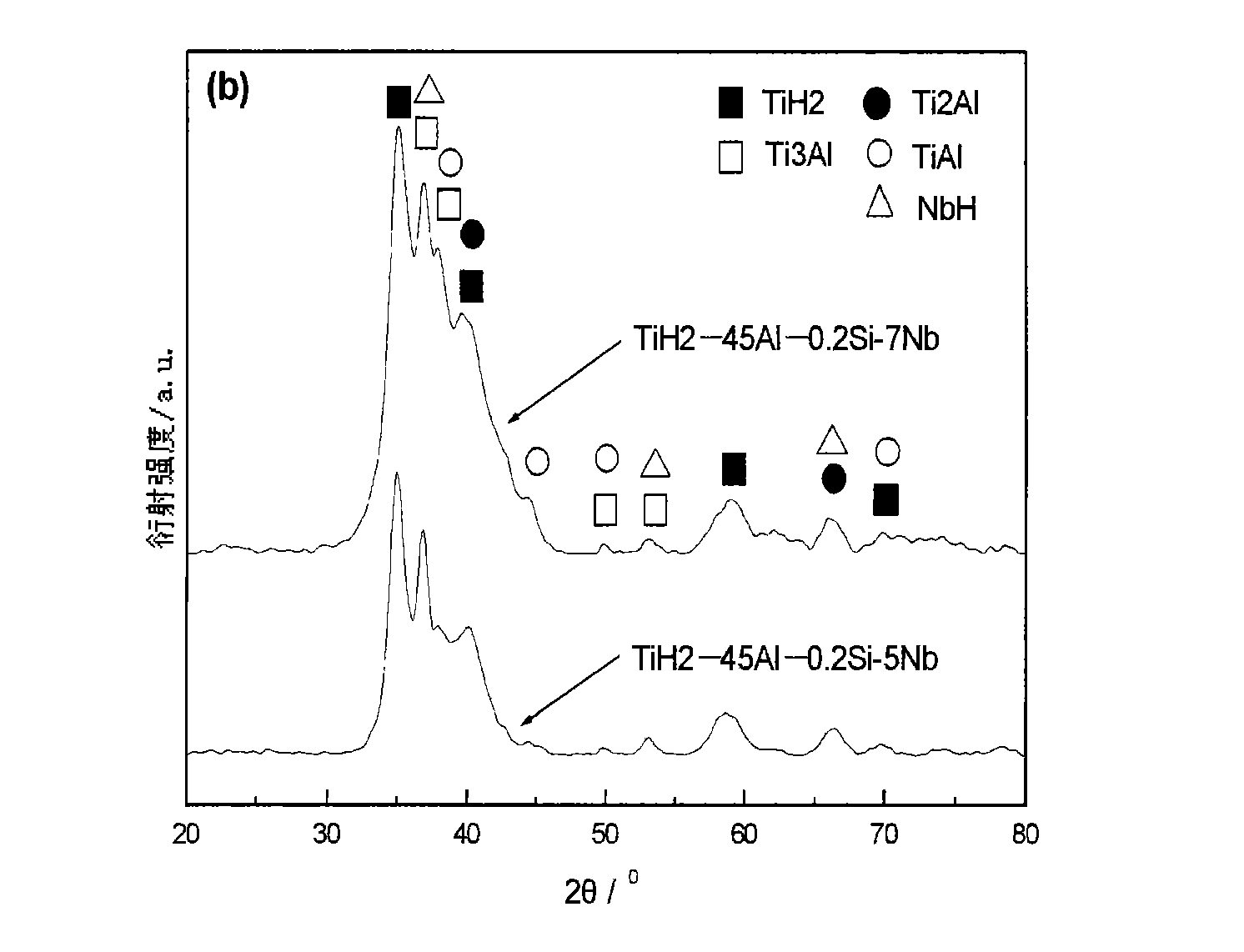

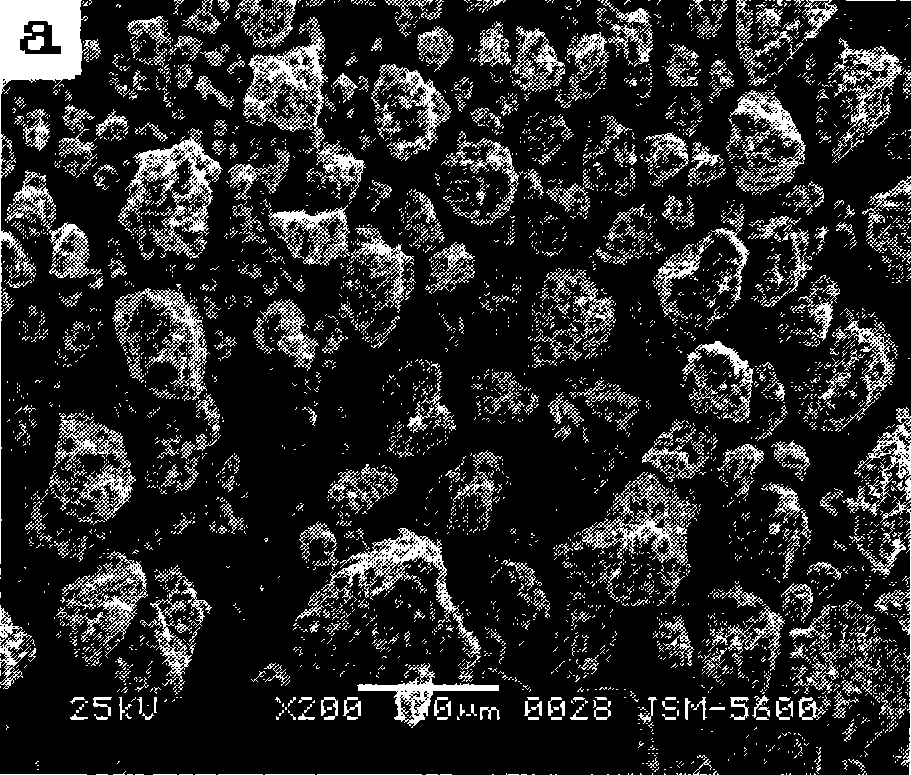

Gamma-group Ti-Al alloy material with high-temperature resistance oxidation and manufacture method thereof

The invention relates to a Gamma-based titanium-aluminum alloy material with high temperature oxidation resistance and a manufacturing method thereof, which aims at overcoming shortages of Gamma titanium-aluminum alloy produced by the conventional technique such as casting, forging and vacuum sintering, etc. The components of the Gamma-based titanium-aluminum alloy material are: 39.8-49.8 percent of Ti (at), 45-48 percent of Al (at), 0.2-0.3 percent of Si (at) and 5-12 percent of Nb (at). To produce the Gamma-based titanium-aluminum alloy material with high temperature oxidation resistance, the mechanical alloying is adopted, namely, mixed powder comprising nano-crystals, amorphous materials and part of TiAl intermetallic compound are fist obtained by high energy ball milling, and then spark plasma sintering is done to the ball-milled mixed powder so as to obtain the Gamma-based titanium-aluminum alloy with high performance in a short sintering time. The Gamma-based titanium-aluminum alloy material prepared by the invention has the advantages of fine TiAl based alloy structure, uniform compositions, high density and excellent high temperature oxidation resistance.

Owner:CHANGCHUN UNIV OF TECH

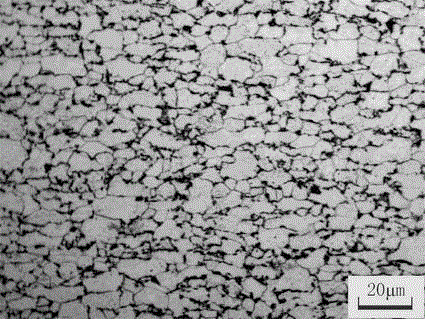

Semi-solid die-casting aluminum alloy material and die-casting molding method using same

A semi-solid die-casting aluminum alloy material comprises 6%-9% of Si, 0-0.3% of Cu, 0.25%-0.55% of Mn, 0.2%-0.5% of Mg, 0.6%-1.2% of Fe, 0-0.15% of Ni, 0-0.15% of Zn, 0-0.15% of Pb, 0-0.05% of Sn, 0-0.2% of Ti, 0-0.15% of impurities, and the balance Al. The content of Si is controlled to be 6%-9% and the content of Fe is controlled to be 0.6%-1.2%, so that the good die-casting molding performance, corrosion resistance and demoulding effect are ensured; meanwhile, 0.25%-0.55% of Mn is added to form a MnAl6 compound, so that the harmful effect of iron is effectively weakened; also, Mn can hinder the recrystallization process of aluminum alloy, the recrystallization temperature is increased, and favorable conditions are provided for the semi-solid pulping process of alloy slurry; in addition, 0.2%-0.5% of Mg is contained properly so as to improve the tensile strength.

Owner:FUJIAN KINRUI HIGH TECH CO LTD

Large-diameter seamless steel tube for high-pressure gas cylinders and manufacturing method thereof

The invention belongs to the technical field of metallurgy, and provides a large-diameter seamless steel tube for high-pressure gas cylinders and a manufacturing method thereof. The large-diameter seamless steel tube for high-pressure gas cylinders comprises the following chemical components in percentage by mass: 0.30-0.60% of C, 0.20-0.50% of Si, 0.20-0.60% of Mn, at most 0.010% of P, at most 0.010% of S, 0.90-1.70% of Cr, 2.50-3.50% of Ni, 0.25-0.55% of Mo, 0.05-0.25% of V and the balance of Fe. The manufacturing method adopts spongy iron and scrap steel as raw materials for steelmaking. The large-diameter seamless steel tube has the advantages of high heat stability, high strength, impact toughness, stable enduring plasticity, high heat resistance, excellent corrosion resistance and excellent fatigue resistance, and the yield strength is not lower than 1000 MPa.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Magnesium alloy electromagnetic low-temperature semicontinuous casting method

The magnesium alloy electromagnetic low-temp. semicontinuous casting method includes the steps of melting magnesium, adding compound fire-resisting elements, adding alloy elements, heat-insulating, standing still and semicontinuous casting under the electromagnetic field. It utilizes the addition of compound fire-resisting elements to implement smelting of magnesium alloy free from coverage or protection so as to shorten technological process and raise melt quality, and utilizes the application of electromagnetic field and optimization of crystallizer structure to implement the low-temp. and high-speed semicontinuous casting of magnesium alloy.

Owner:NORTHEASTERN UNIV

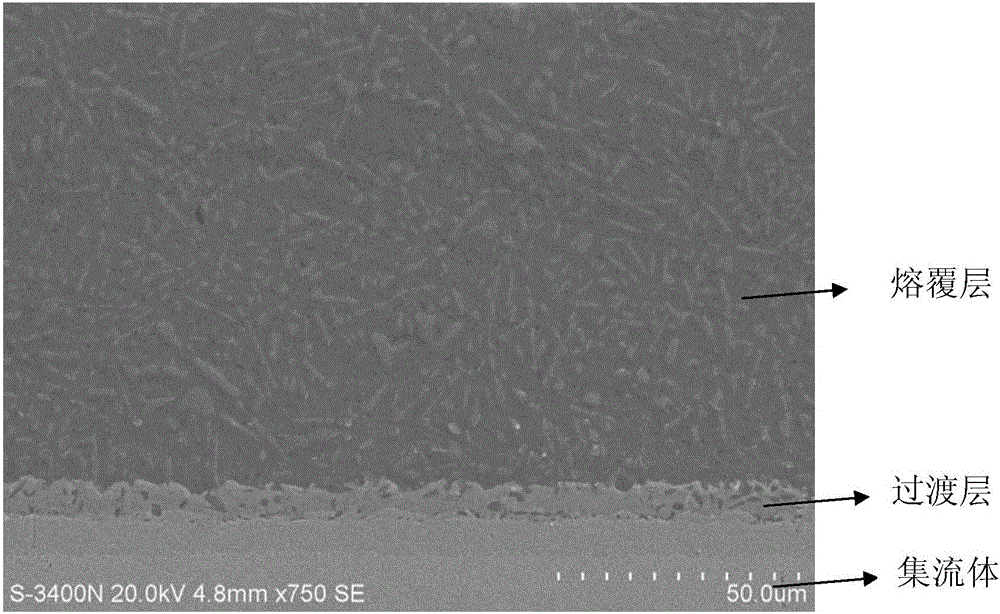

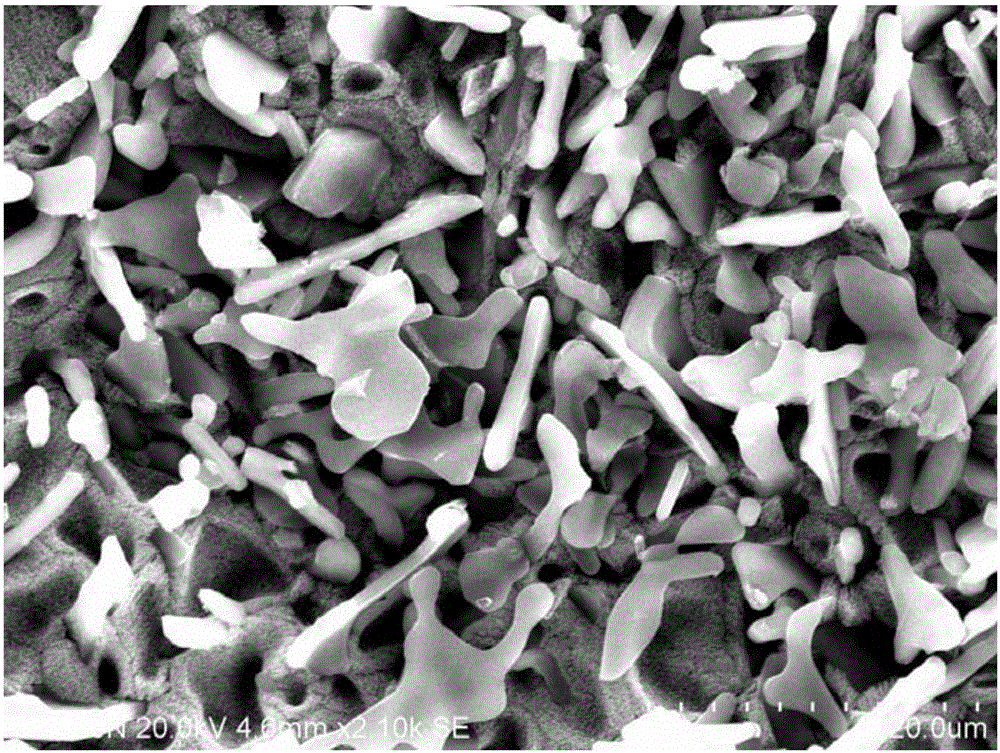

Method for producing lithium ion battery silicon cathode through combination of laser cladding, diffusion welding and dealloying

The invention discloses a method for producing a lithium ion battery silicon cathode through combination of laser cladding, diffusion welding and dealloying. The method is characterized by including preparing an aluminum-silicon alloy precursor according to the laser cladding technology, welding the aluminum-silicon alloy precursor to a current collector through diffusion welding, and removing element aluminum in the precursor by a corrosive agent to finally obtain the silicon cathode subjected to current collector metallurgical bonding. The method has the advantages that shedding of silicon materials and the current collector of the produced silicon cathode can be avoided effectively during charging and discharging, operation is simple and efficiency is high.

Owner:BEIJING UNIV OF TECH

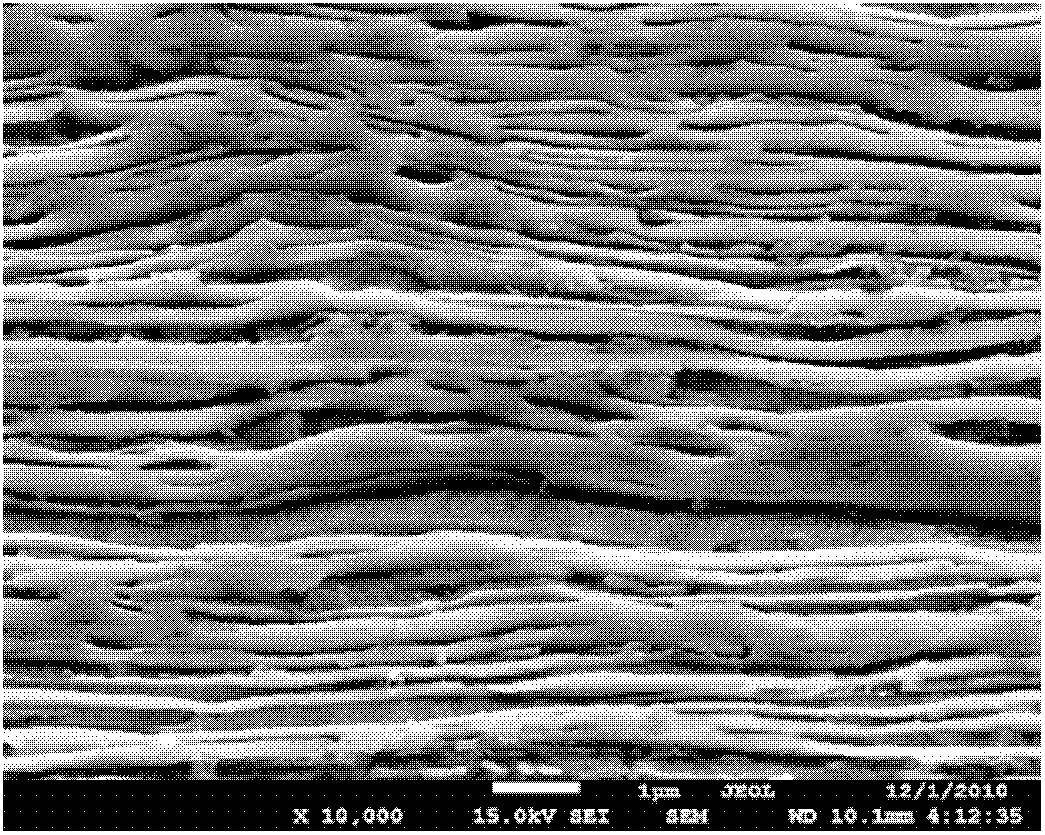

Molybdenum copper alloy foil sheet and preparation method thereof

The invention provides a molybdenum copper alloy foil sheet and a preparation method thereof. The thickness of the molybdenum copper alloy foil sheet is 0.1-1.0mm. Molybdenum phases and copper phases are uniformly distributed in a short-fiber mode. The copper phases are in lap joint with each other. The molybdenum copper alloy foil sheet comprises 20wt%-50wt% of copper with the balance being molybdenum. The preparation method includes the steps of carrying out compression moulding, presintering and infiltration sintering on mixed powder after the mixed powder is subjected to high-energy ball-milling treatment, obtaining a molybdenum copper alloy plate, and carrying out hot rolling, heat treatment and cold rolling on the molybdenum copper alloy plate to obtain the molybdenum copper alloy foil sheet. Through adoption of the high-energy ball-milling treatment, the infiltration sintering and appropriate rolling process, the molybdenum copper alloy foil sheet and the preparation method thereof solve the problems that existing molybdenum copper alloy is poor in deformation processing performance and low in density. The molybdenum copper alloy foil sheet prepared through the method is smooth and clean in surfaces and excellent in thermal conductance performance, has more than 99% of high density, and is applicable for the field of preparation and application of electronic packaging materials and heat sink materials.

Owner:GRIMAT ENG INST CO LTD

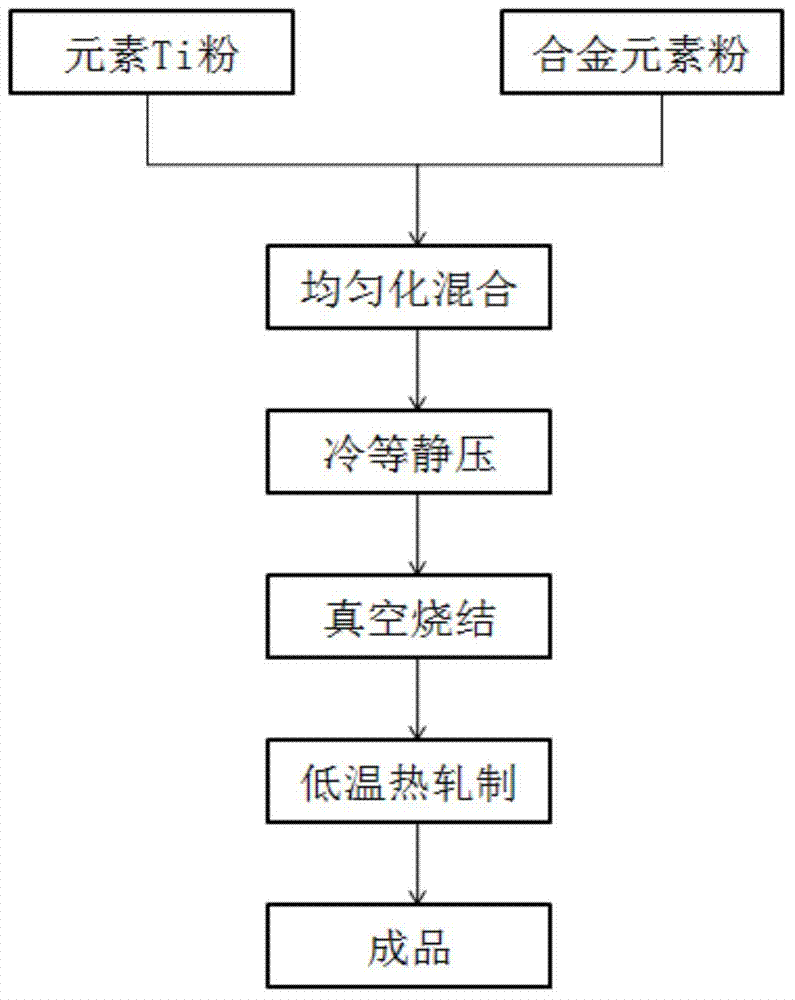

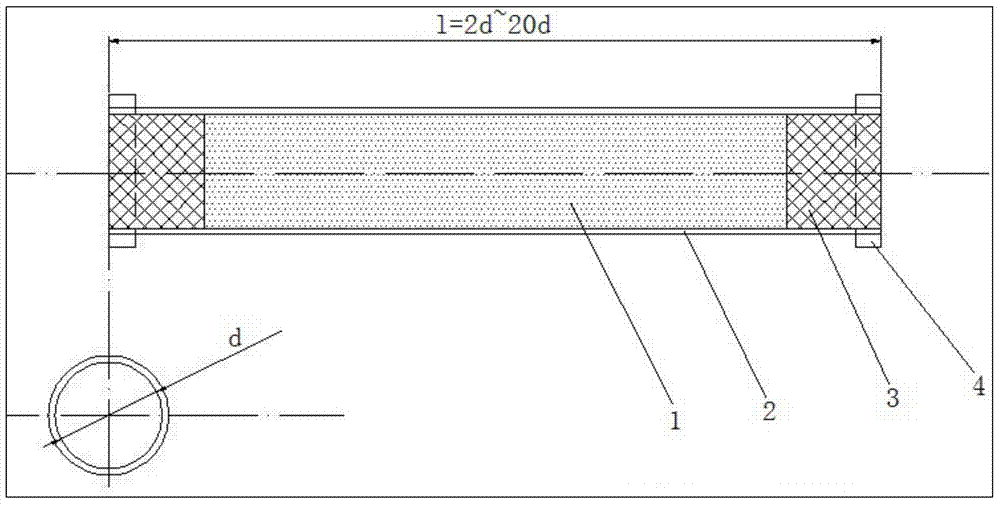

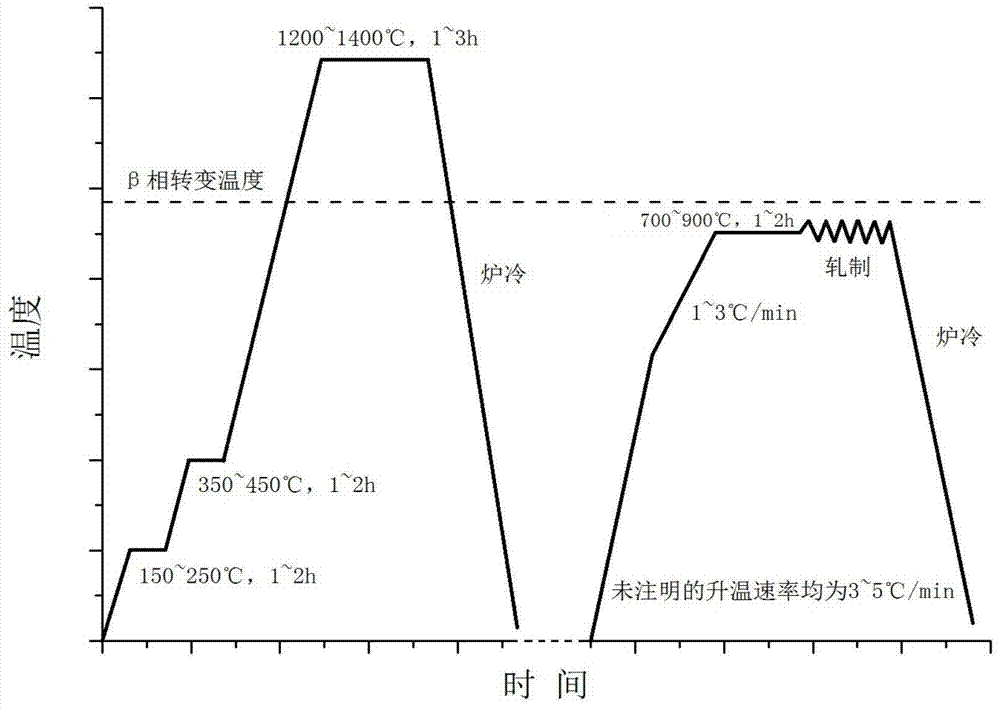

Method for preparing powder metallurgy titanium alloy bar

ActiveCN104263981AThe process steps are simpleShorten the production cycleDiameter ratioTitanium alloy

The invention discloses a method for preparing a powder metallurgy titanium alloy bar. The method comprises the following steps: by taking Ti powder and alloy element powder as raw materials, sufficiently and uniformly mixing the Ti powder and the alloy element powder, and putting the mixed powder into an isostatic cool pressing sleeve for isostatic cool pressing treatment, thereby preparing a crude bar blank; performing vacuum sintering on the prepared crude bar blank, and performing furnace cooling, thereby preparing a sintered bar blank; and performing low-temperature thermoplastic deformation treatment on the prepared sintered bar blank, thereby obtaining the powder metallurgy titanium alloy bar with a large height-diameter ratio, wherein the alloy element powder comprises one or more of Al, V, Mo, Fe, Mn, Zr and intermediate alloy powder of the above elements, and the mass ratio of the alloy element powder is controlled to be within 15%. The method disclosed by the invention is low in cost, small in investment and good in product property, and the powder metallurgy titanium alloy bar can be used for manufacturing high-performance fasteners.

Owner:FUJIAN LONGXI BEARING (GROUP) CO LTD +1

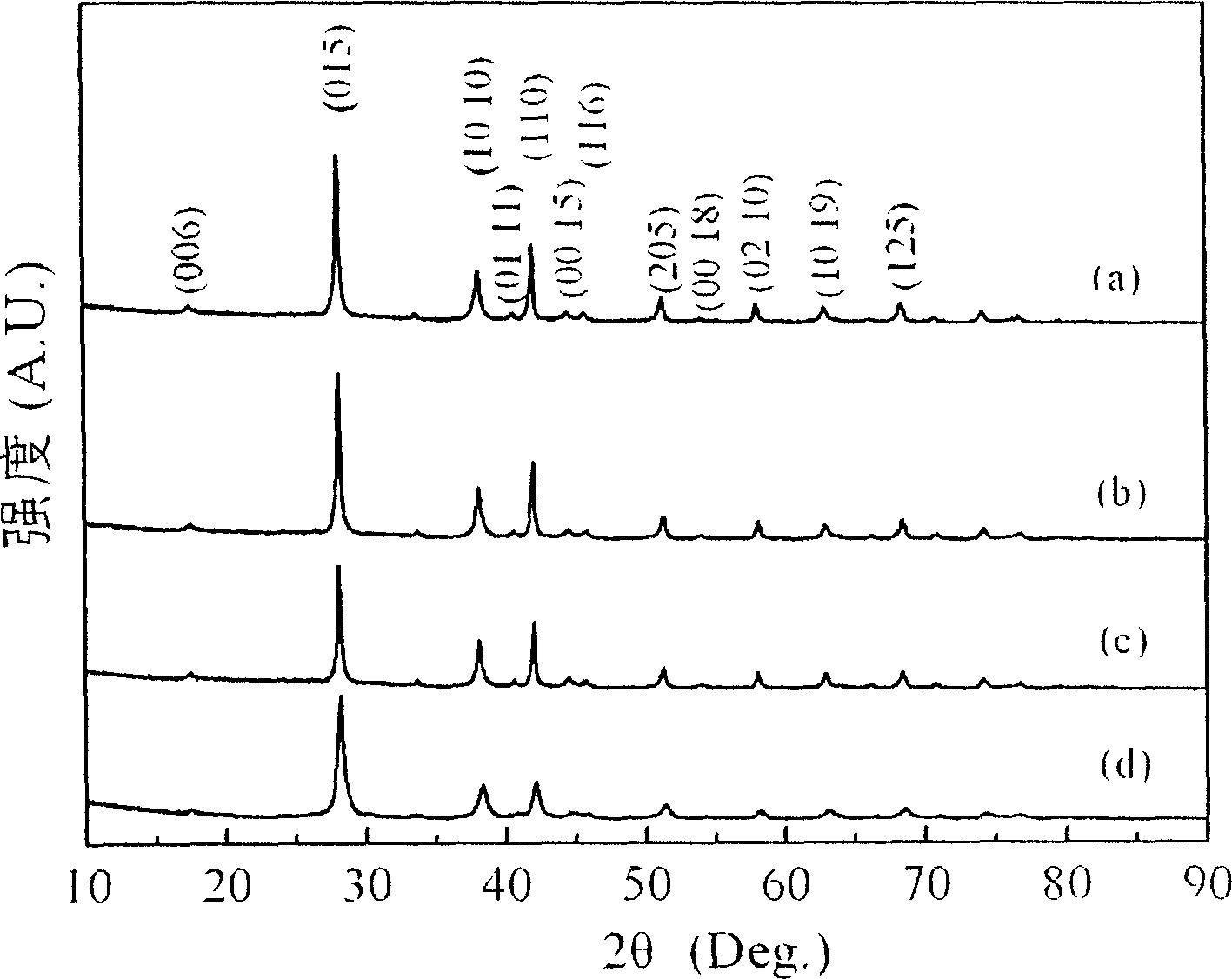

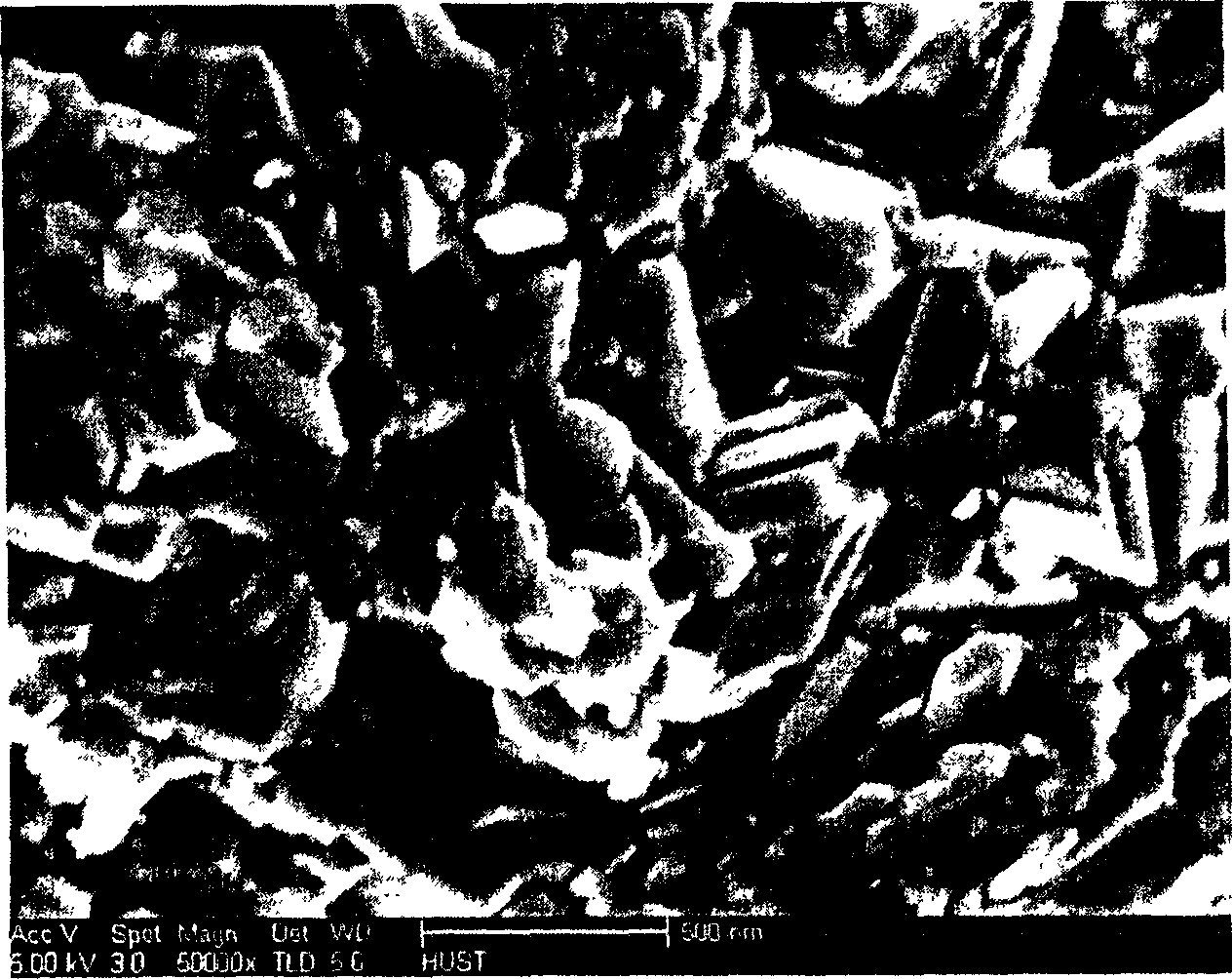

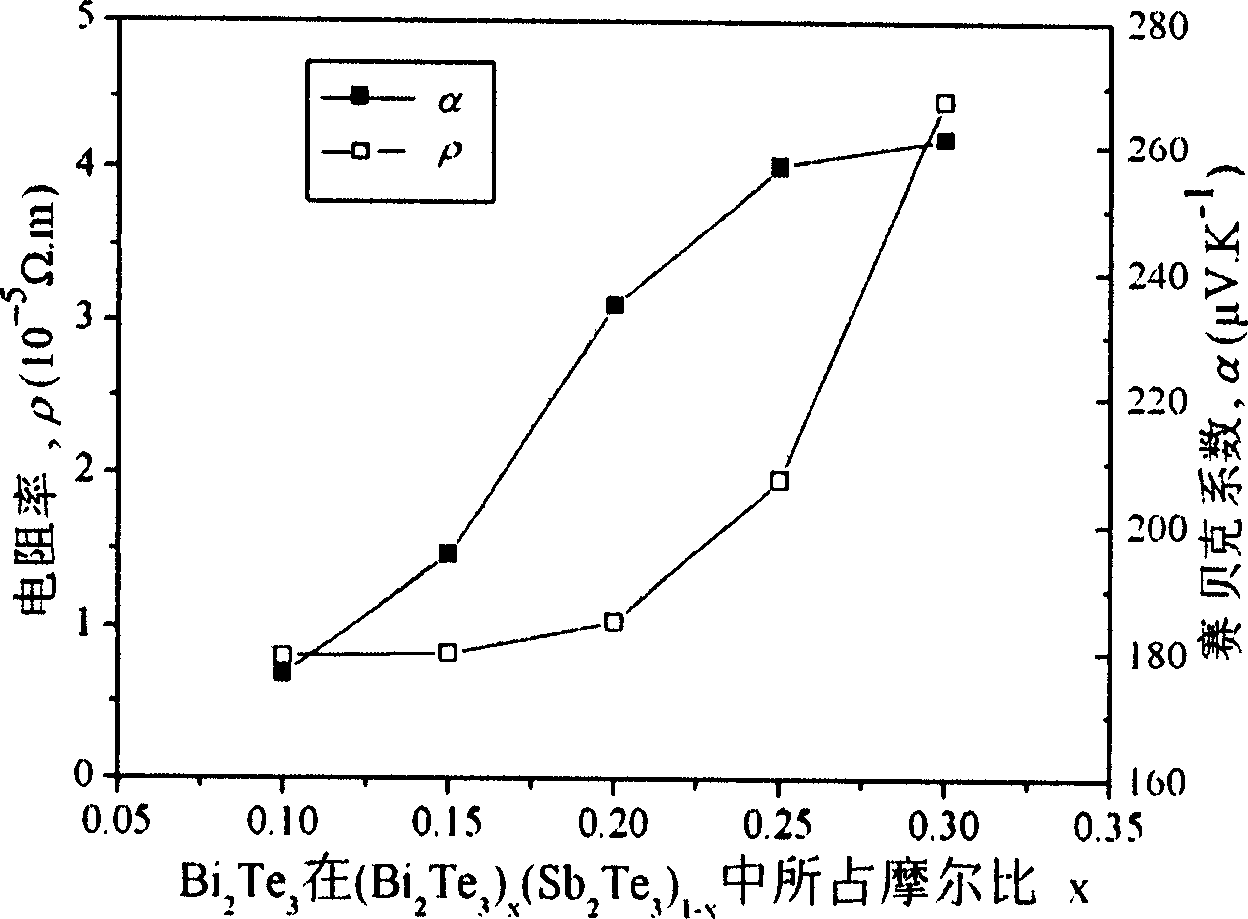

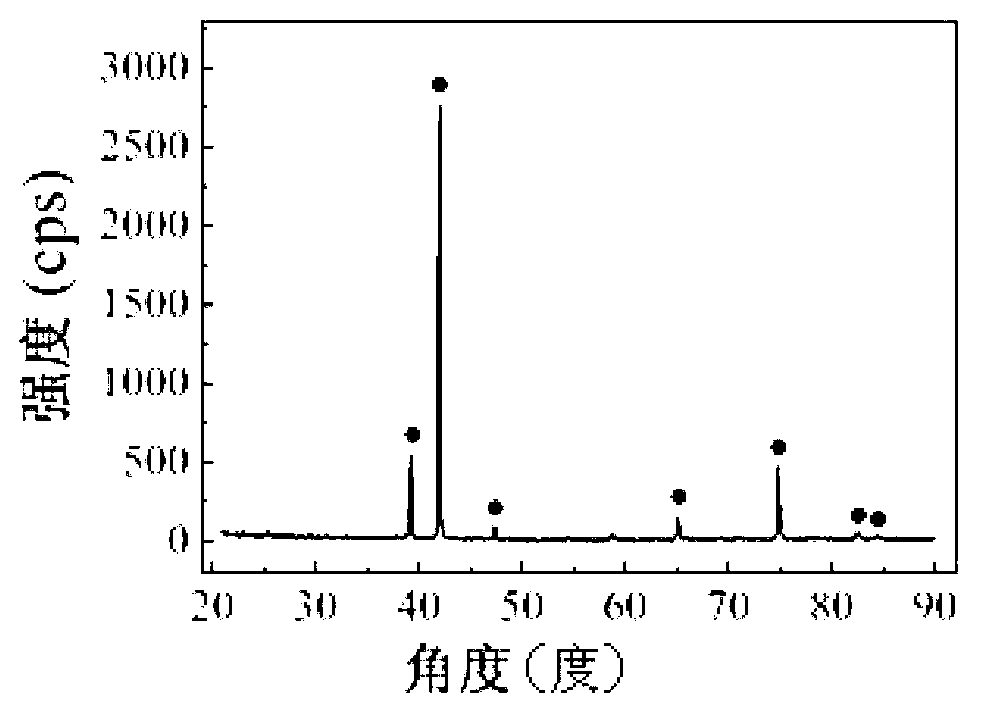

Method for preparing Bi-Sb-Te series thermoelectric material

InactiveCN1843667AUniform compositionSmall tissueThermoelectric device manufacture/treatmentThermoelectric materialsHigh energy

The invention provides a method for preparing thermoelectrical material in Bi-Sb-Te system, which comprises: preparing raw material powders in atom rate that Bi:Sb:Te=2x:2-2x:3, while 0.1<=x<=0.3; mixing and ball grinding it with high-energy to attain alloy powder, while the ball material mass percentage is 10:1-20:1, the rotational speed of ball grinding is 300-400r / min, the time of ball grinding is 8-12hours, and ball grinding uses inertia gas protection; activating said alloy powder with plasma to be sintered, while the temperature increase speed is 30-100Deg. C / min, the sintering temperature is 300-500Deg. C, the pressure when temperature increases is 15-25MPa, the pressure at constant temperature is 40-60MPa, and the time for constant temperature is 10-30mins; and the whole sintering process is process under the inertia gas protection or vacuum condition; the thermolelectrical valve at room temperature can reach 5.26*10-3 / K.

Owner:HUAZHONG UNIV OF SCI & TECH

A kind of manufacturing method of thin-walled, ultra-long nickel-copper alloy pipe

The invention discloses a method for manufacturing thin-wall and ultra-long nickel-copper alloy pipes. The method comprises the following steps of: 1, smelting nickel and copper serving as raw materials in a vacuum induction furnace to prepare nickel-copper alloy ingots; 2, drawing and forging the nickel-copper alloy ingots into bar billets, and machining the bar billets into light bars; 3, rolling the light bars into pipe billets by adopting a cone mill, and removing scales on the surfaces of the pipe billets; 4, performing cold rolling machining; 5, sequentially cogging the cold rolled pipebillets, and performing crystallization and annealing treatment and boring treatment to obtain pipes; 6, continuously rolling the pipes, and performing annealing treatment and acid washing to obtain finished pipes; and 7, straightening the finished pipes, and thus obtaining the thin-wall and ultra-long nickel-copper alloy pipes with diameter-thickness ratio of 50 to 70 and length of over 15,000 millimeters. The finished nickel-copper alloy pipes machined with high deformation and cold-rolled by a continuous rolling production process have high tensile strength and yield strength and meet the plasticity requirement.

Owner:WESTERN TITANIUM TECH

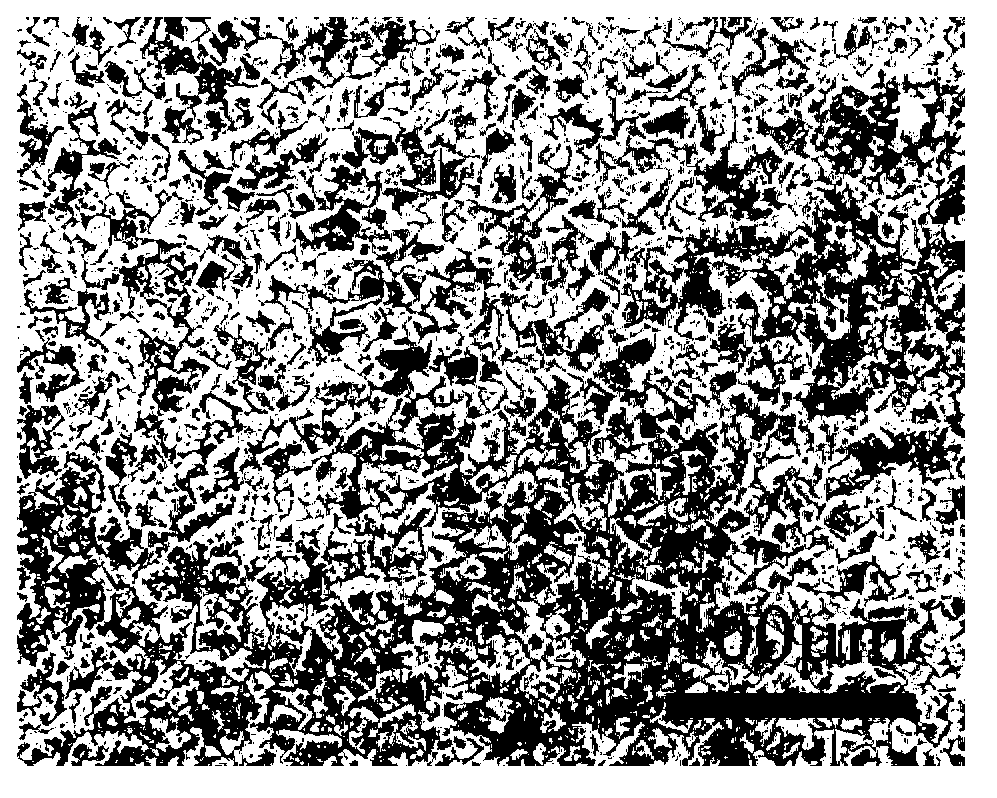

Hot working method for improving structure property of Ti5553 titanium alloy

The invention discloses a hot working method for improving structure property of Ti5553 titanium alloy, which comprises the steps of: firstly, performing two-phase region re-forging (alpha equiaxial+ beta transformation) on a titanium alloy blank; and then, performing beta forging on the re-forged blank (the beta forging is a forging method of heating above phase transformation point); and finally, performing beta thermal treatment to primarily form a fine and dense net basket structure after the re-forging operation; and a fine flaky alpha phase inversion in beta crystal grain and a fine, disperse and discontinuous alpha phase inversion at the crystal boundary are generated during the final beta thermal treatment process to improve the comprehensive structure property of the beta titanium alloy. By means of the heating re-forging in two-phase region (alpha equiaxial+ beta transformation) and the beta forging, nucleation energy and broken crystal structures formed by relatively large deformation quantity lay a good foundation for improving the flaky alpha phase inversion and the granular beta phase inversion in the successive beta thermal treatment, so as to obtain a member with uniform, fine and dense structure and good comprehensive performance indexes.

Owner:SHAANXI HONGYUAN AVIATION FORGING

Low-melting-point and high-intensity aluminum alloy powder brazing filler metal and preparing method of low-melting-point and high-intensity aluminum alloy powder brazing filler metal

ActiveCN104227263APrevent corrosionImprove performanceWelding/cutting media/materialsSoldering mediaSiluminSolidus

The invention discloses a high-intensity aluminum alloy powder brazing filler metal with the melting point being lower than 490 DEG C and a preparing method of the high-intensity aluminum alloy powder brazing filler metal with the melting point being lower than 490 DEG C, and belongs to the technical field of aluminum alloy brazing. The brazing filler metal comprises the following ingredients in parts by weight: 8.6 to 9.5 percent of Si, 16.5 to 17.5 percent of Cu, 8.5 to 9.5 percent of Ge, 4.5 to 5.0 percent of Ni, 4.0 to 5.0 percent of Zn, 0.70 to 0.75 percent of Sr, 0.35 to 0.40 percent of Bi, 0.40 to 0.45 percent of La, 0.40 to 0.55 percent of Ce, 0.10 to 0.20 percent of Yb and the balance Al. The brazing filler metal is prepared by adopting a flux rapid cooling-ball milling technology, the melting point is lower than 490 DEG C, the brazing temperature is 500 to 520 DEG C, and the brazing filler metal is applicable to aluminum alloy brazing with the solid phase line temperature higher than 500 DEG C, such as in-furnace brazing, vacuum brazing, induction brazing and flame brazing. The brazing filler metal is matched with QJ201 for brazing 3003 aluminum alloy, and the shearing intensity of a brazing joint is greater than 74MPa.

Owner:ZHEJIANG UNIV

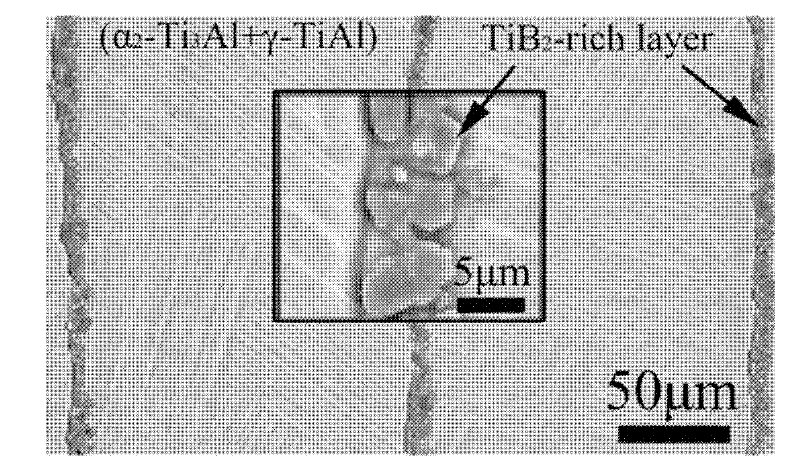

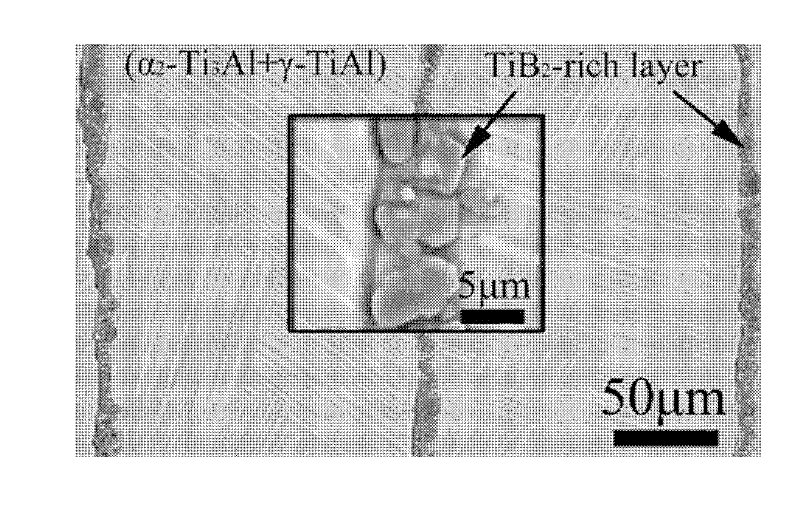

Ceramic-TiAl micro-laminated composite material board and preparation method thereof

InactiveCN102501457ALow equipment requirementsLow costLaminationLamination apparatusUltimate tensile strengthIntermetallic

The invention relates to a ceramic-TiAl micro-laminated composite material board and a preparation method thereof, relates to a micro-laminated composite material board and a preparation method thereof, and is mainly used for solving the problems that the single TiAl intermetallic compound board has poor high-temperature strength so as not to satisfy the use requirements of aerospace high-temperature components working at 800-1000 DEG C and the TiAl composite material board, which is prepared by powder metallurgy, casting and other traditional methods and has the characteristic that a ceramic granule reinforcing body is uniformly distributed in a TiAl substrate, has poor fracture toughness. The ceramic-TiAl micro-laminated composite material board is prepared by alternately laminating and rolling pure Ti foils and ceramic-reinforced Al-based composite material foil materials, and carrying out heat treatment. The preparation method comprises the steps of: (1) preparing ceramic-reinforced Al-based composite material foil materials; (2) alternately laminating and rolling pure Ti foils and ceramic-reinforced Al-based composite material foil materials; (3) reacting and annealing; (4) carrying out compact treatment; and (5) carrying out high-temperature heat treatment, homogenizing and annealing. The ceramic-TiAl micro-laminated composite material board is used for aerospace machine manufacturing field.

Owner:HARBIN INST OF TECH

Titanium aluminum-ceramic layered material and preparation method thereof

InactiveCN103264542ASmall tissueHigh temperature strengthLaminationLamination apparatusTitaniumThermal treatment

The invention discloses a titanium aluminum-ceramic layered material and a preparation method thereof, which relate to a layered material and a preparation method thereof, and mainly solve the problem that aluminum fusion loss causes uncontrollable constituents when an element foil reaction annealing method is used for preparing a TiAl base plate material. The titanium aluminum-ceramic layered material is made by an in-situ synthesis technology and prepared from pure Ti foils and an Al base composite foils through alternating lamination, hot-pressing and reaction annealing. The method comprises the following steps of: firstly, preparing an Al base composite material; secondly, carrying out hot extrusion and rolling on the Al base composite material; thirdly, carrying out surface preparation on the rolled Al base composite material foils and the pure Ti foils; fourthly, carrying out alternating lamination and hot-pressing on the foils; fifthly, performing low temperature thermal treatment; sixthly, performing thermal treatment for densifying; and seventhly, performing heat preservation, thus obtaining the titanium aluminum-ceramic layered material. The preparation method provided by the invention is used for preparing the titanium aluminum-ceramic layered material.

Owner:HARBIN INST OF TECH

High-strength steel plate for ocean engineering and production method thereof

InactiveCN105586537APlay a role in diffusion strengtheningImprove low temperature toughnessQuenchingMechanical property

The invention discloses a high-strength steel plate for ocean engineering and a production method thereof. The production method comprises the working procedures of smelting, continuous casting, heating, rolling, heat stacking and heat treatment, wherein the molten steel obtained in the smelting procedure comprises the following chemical ingredients with contents in percentage by mass: 0.05-0.09% of C, 0.10-0.30% of Si, 1.1-1.35% of Mn, not greater than 0.010% of P, not greater than 0.003% of S, 0.15-0.4% of Ni, 0.15-0.35% of Cr, 0.10-0.30% of Mo, 0.020-0.050% of Nb, 0.03-0.05% of V, 0.020-0.050% of TAl, and balance Fe and inevitable impurities; a quenching and tempering process is adopted in the heat treatment procedure; during the quenching process, a heating temperature is 880-910 DEG C, and a total heating time is PLC +(20-40) minutes; and during the tempering process, a heating temperature is 580-620 DEG C, a total heating time is 1.5-2 minutes per millimetre, and air cooling is carried out after discharge. According to the method disclosed by the invention, through adjustment and optimization for the proportion of alloy elements in the steel plate, and quenching and low-temperature short-time tempering, good mechanical properties of the steel plate can be guaranteed under a low-carbon-equivalent condition, and the steel plate is enabled to have good structure, comprehensive property and welding property.

Owner:WUYANG IRON & STEEL

Low-cost continuous casting billet produced large-thickness steel plate for low-temperature pressure vessel and production method thereof

The invention discloses a low-cost continuous casting billet produced large-thickness steel plate for low-temperature pressure vessel and a production method thereof. The steel plate comprises the following chemical components in percentage by mass: 0.05-0.10% of C, 0.20-0.50% of Si, 1.30-1.60% of Mn, less than or equal to 0.012% of P, less than or equal to 0.005% of S, 0.020-0.050% of Alt, less than or equal to 0.70% of Ni, less than or equal to 0.040% of Nb, and the balance of Fe and inevitable impurities. The production method specifically comprises the procedures of smelting, casting, heating, rolling, and heat treatment. According to the present invention, with reasonable composition design and the production process of controlled rolling and controlled cooling, and heat treatment, and by completely using continuous casting billets for production, the maximum thickness of the steel plate reaches up to 120 mm; the produced steel plate has favorable comprehensive mechanical properties and welding properties, and is low in production cost and high in market competitiveness, thus meeting the increasing market demand.

Owner:WUYANG IRON & STEEL

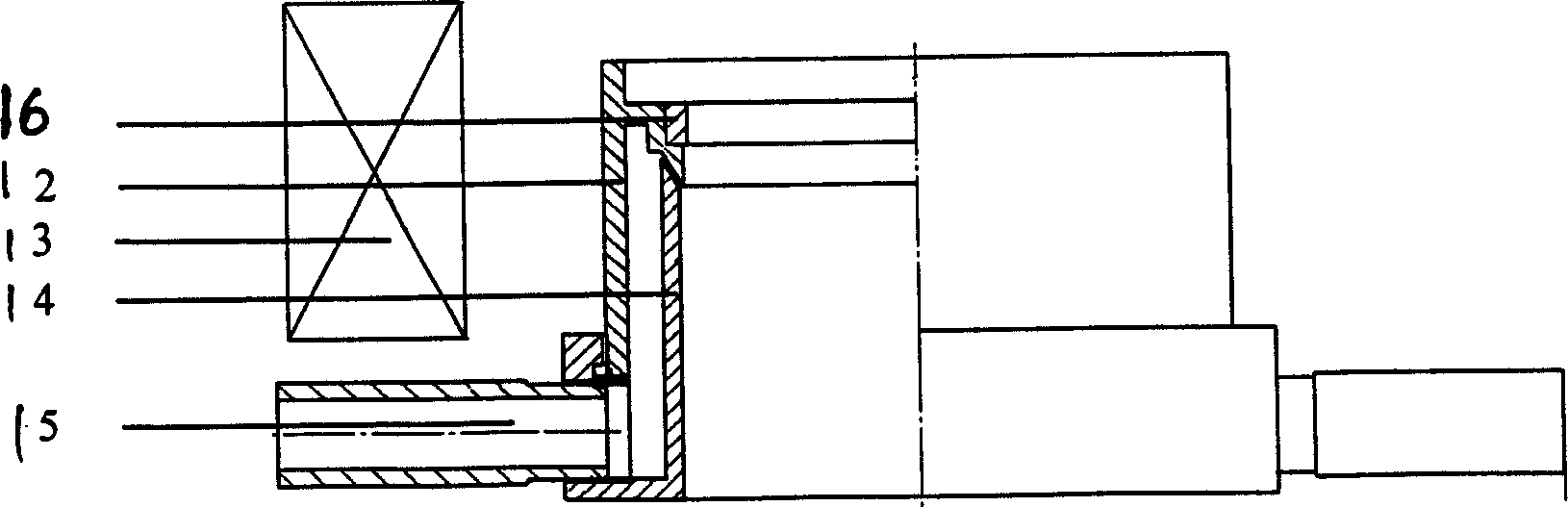

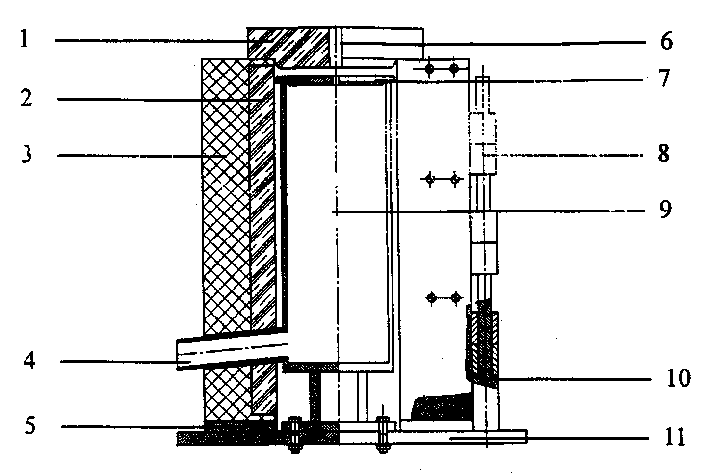

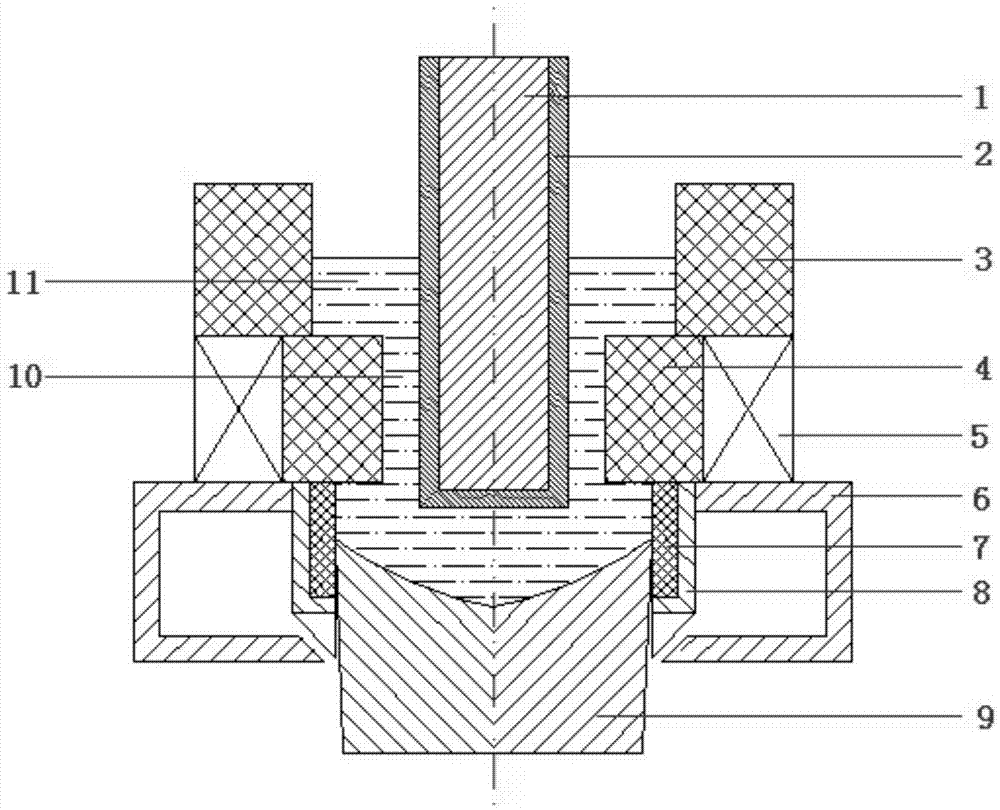

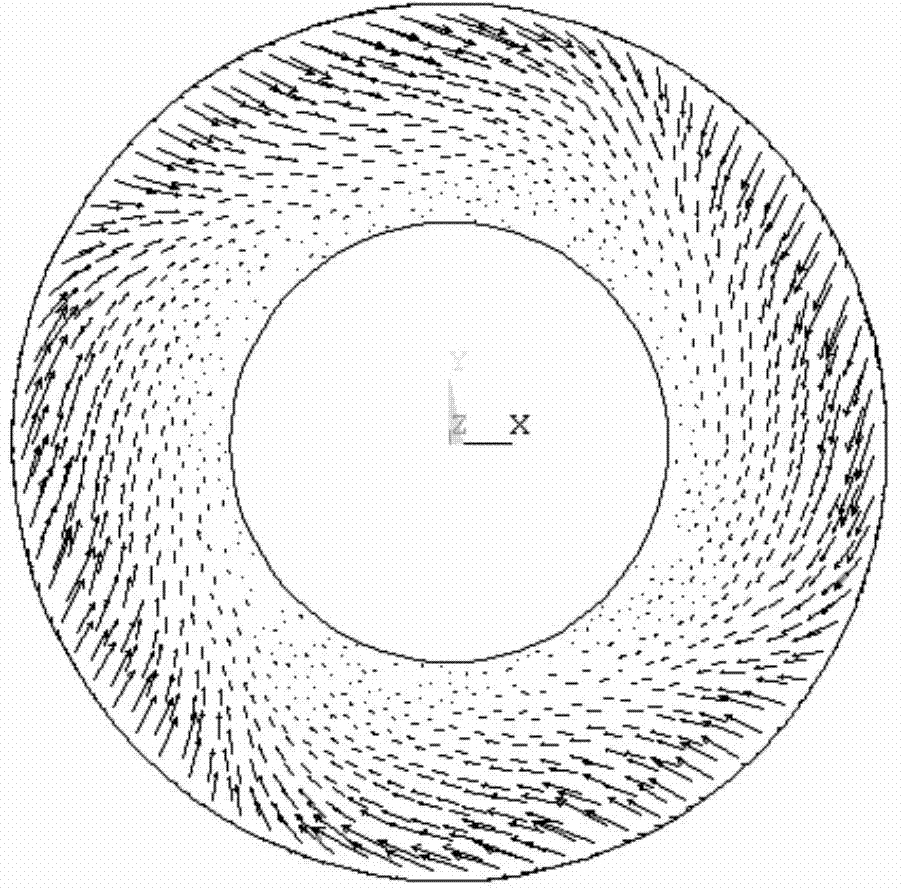

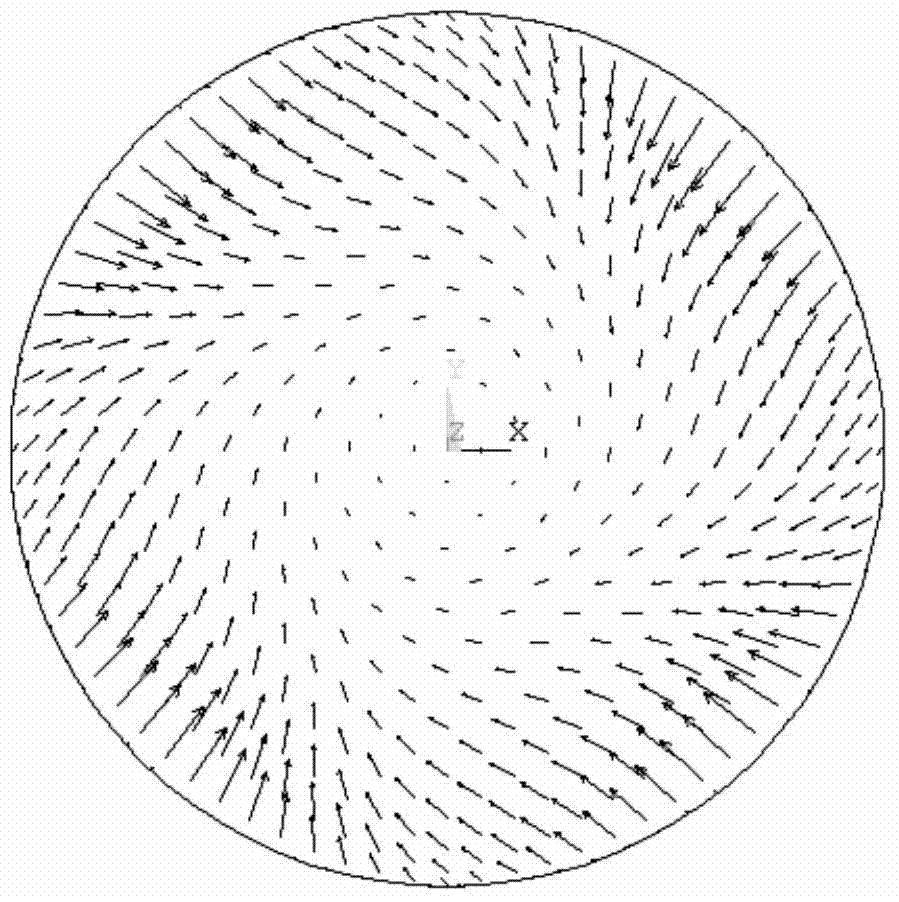

Device and method for continuous preparation of large-size high-quality aluminum alloy cast ingots

The invention relates to a device and a method for continuous preparation of large-size high-quality aluminum alloy cast ingots. The device comprises a magnetism conducting mandrel, a hot ejector, a flow guide pipe, an electromagnetic stirrer, a cooling water jacket, a graphite annulus and a crystallizer. The graphite annulus is inlaid in the crystallizer, the cooling water jacket is arranged outside the crystallizer, the electromagnetic stirrer is arranged outside the flow guide pipe which is arranged on the upper portion of the crystallizer, the hot ejector is arranged on the upper portion of the flow guide pipe, the magnetism conducting mandrel is arranged in the center of the flow guide pipe, and a gap passage is formed between the magnetism conducting mandrel and the inner wall of the flow guide pipe. A magnetic field generated by the electromagnetic stirrer forms an unimpeded magnetic circuit with the magnetism conducting mandrel along aluminum alloy melts in the gap passage, the magnetic field in the gap passage is distributed uniformly, the aluminum alloy melts in the gap passage are stirred uniformly, a temperature field and a component field are uniform, and accordingly adverse effects of electromagnetic stirring skin effect are avoided, and acquisition of high-quality aluminum alloy cast ingots with thinner textures and uniform components is benefited.

Owner:有研金属复材技术有限公司

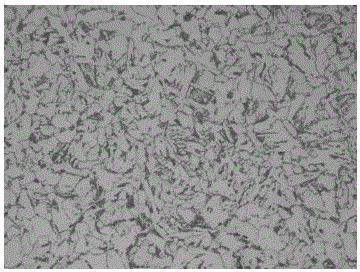

Automotive alloying hot-dip galvanized steel with tensile strength of 440 MPa and production method

InactiveCN104975226ASmall tissueUniform tissueHot-dipping/immersion processesContinuous annealingPre treatment

Automotive alloying hot-dip galvanized steel with tensile strength of 440 MPa comprises, by weight, 0.08%-0.11% of C, smaller than or equal to 0.03% of Si, 1.10%-1.40% of Mn, 0.015 wt%-0.030% of P, smaller than or equal to 0.010% of S and 0.020%-0.070 of Als. A production method comprises the production steps of hot metal pretreatment, converter refining and RH furnace treatment, continuous casting, casting blank heating, hot rolling, the first time of rapid cooling, reeling, acid pickling, cold rolling, continuous annealing, hot galvanizing, the second time of rapid cooling, alloying, the third time of rapid cooling and finishing. The yield strength of the automotive alloying hot-dip galvanized steel is 330-360 MPa, the tensile strength of the automotive alloying hot-dip galvanized steel is not lower than 440 MPa, the ductility of the automotive alloying hot-dip galvanized steel is larger than or equal to 32%, the roughness of the alloying hot-dip galvanized steel is 0.6-1.5 [u]m, and the PC value of the automotive alloying hot-dip galvanized steel is not smaller than 90 / cm; a galvannealed coating of the automotive alloying hot-dip galvanized steel is small, even and compact in tissue, the pulverization degree is not larger than 2, and the pulverization resisting capability is excellent. Meanwhile, ingredients and technology of the automotive alloying hot-dip galvanized steel are simple, cost is low, and production efficiency is high.

Owner:武汉钢铁有限公司

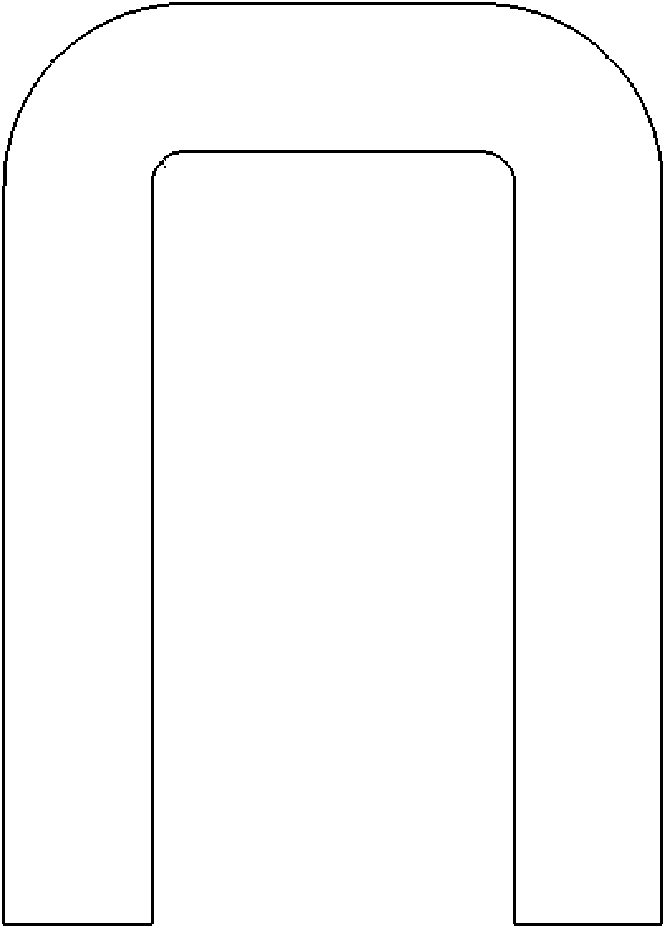

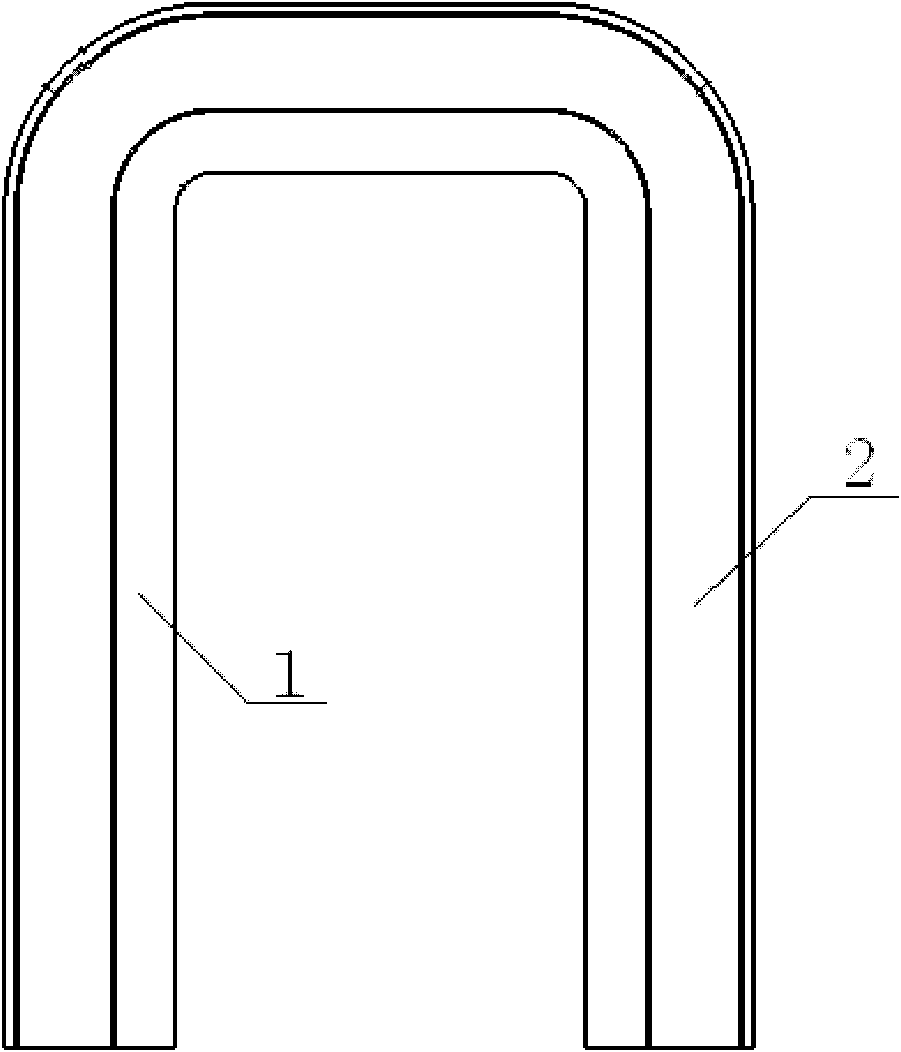

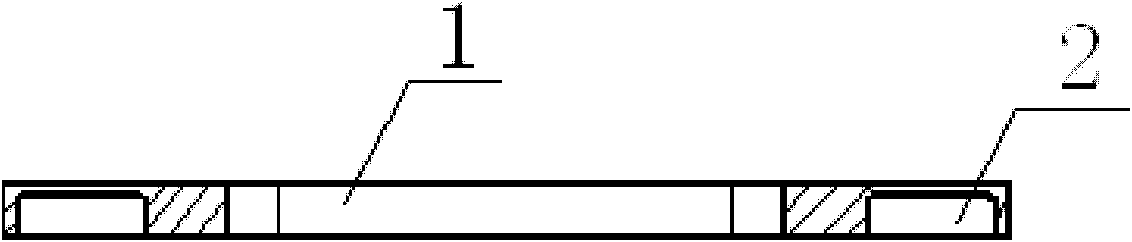

Technology for processing test blanket module (TBM) first wall U-shaped flow-containing cooling pipeline set

The invention discloses a technology for processing a test blanket module (TBM) first wall U-shaped flow-containing cooling pipeline set. The technology comprises the following steps of:1, processing U-shaped frame components by using reduced activation ferritic / martensitic spherical powder; 2, processing a U-shaped groove on each U-shaped frame component in a U-shaped frame direction; 3, performing butt point processing on two U-shaped frame components on which the U-shaped grooves are processed to form a U-shaped cooling pipeline; and 4, vertically and sequentially stacking the U-shaped cooling pipelines, and performing butt joint on the U-shaped cooling pipelines to realize the integration of the first wall U-shaped cooling pipeline set. The technology can greatly improve material utilization rate, quality safety performance, and avoid the problems of high price, large difficulty in a technology and the like in a hot isostatic pressing technology.

Owner:SOUTHWESTERN INST OF PHYSICS

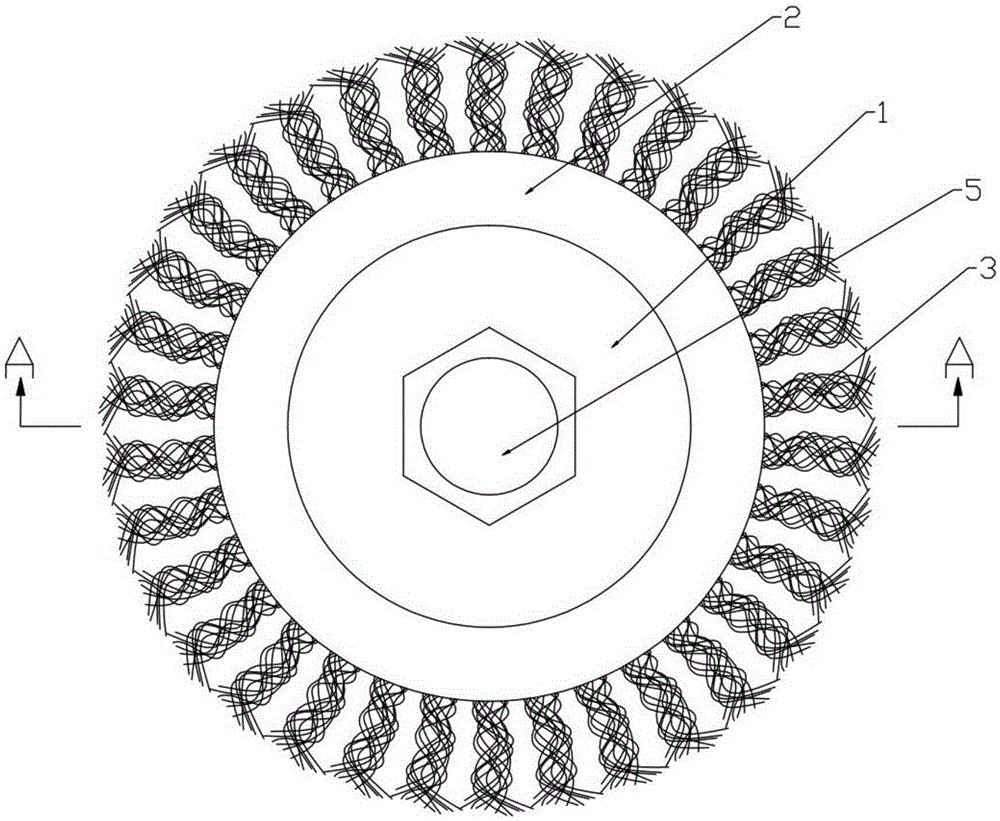

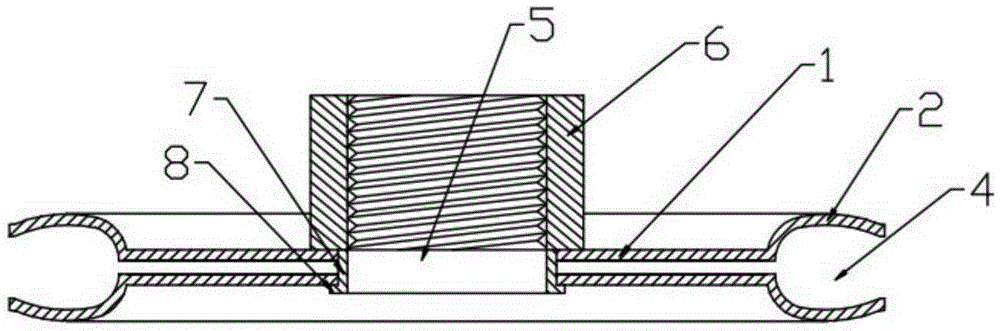

Metal wire polishing wheel

InactiveCN105415212ALight in massReduce quality problemsFlexible-parts wheelsMetallic material coating processesAlloy substrateEngineering

The invention provides a metal wire polishing wheel. The metal wire polishing wheel comprises an upper clamping plate and a lower clamping plate. A plurality of metal wire beams are installed between the edge parts of the upper clamping plate and the lower clamping plate in a central symmetrical mode. A fastener is installed between through holes of the upper clamping plate and the lower clamping plate. A longitudinal installation hole is formed in the middle of the fastener and internally provided with an internal thread. Both the upper clamping plate and the lower clamping plate are divided into the annular sunk parts in the middles and the annular protruding parts at the edges. The annular protruding part of the upper clamping plate and the annular protruding part of the lower clamping plate are symmetrical and form an annular installation groove of the metal wire beams. The metal wire beams are formed by twisting a plurality of metal wires made from an aluminum alloy composite material. The aluminum alloy composite material comprises an aluminum alloy substrate and a ceramic layer arranged on the surface of the aluminum alloy substrate through laser cladding. The metal wire polishing wheel is compact and firm in structure, convenient to install and use and good in thermal conductivity, heat dispersion, mechanical property and usability.

Owner:NINGBO DAHUA GRINDING WHEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com