Ceramic-TiAl micro-laminated composite material board and preparation method thereof

A composite material plate and composite material technology, which is applied in the field of micro-laminated composite material plate and its preparation, can solve the problems of insufficient fracture toughness and insufficient strength of TiAl composite material plate, and achieve good high-temperature plasticity, low cost, and improved performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

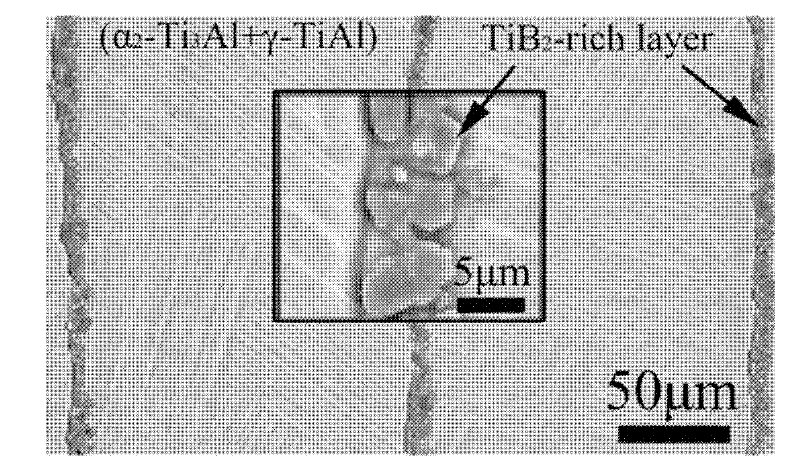

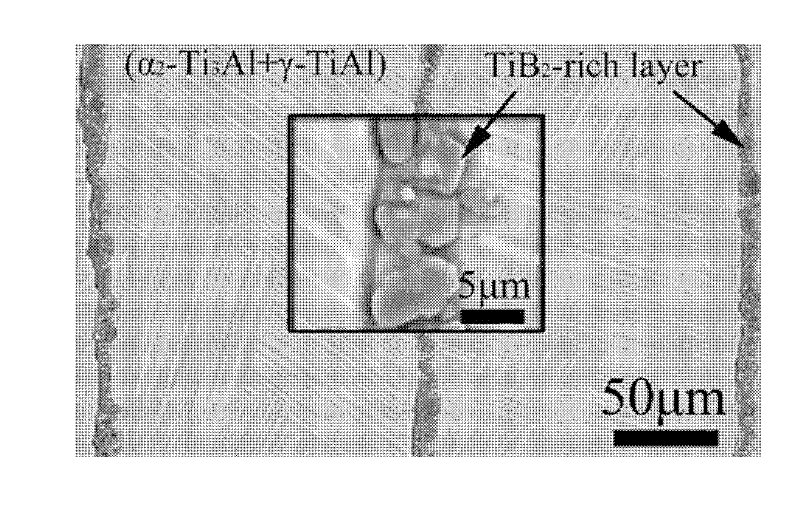

[0019] Specific embodiment 1: The ceramic-TiAl micro-laminated composite material plate of this embodiment is made by alternately stacking, rolling and heat treatment of pure Ti foil and ceramic-reinforced Al-based composite foil. Ceramic-reinforced Al-based composite foil The material is made of ceramic reinforcement and pure Al powder by hot pressing, sintering and rolling; the ceramic layer and the TiAl layer in the ceramic-TiAl micro-laminated composite material plate are alternately overlapped, and the stacking interval is 20-200μm.

[0020] The ceramic reinforcement selected in this embodiment does not react with titanium and aluminum.

[0021] The ceramic-reinforced Al composite foil of this embodiment is a multilayer composite material in which ceramic layers and TiAl layers alternately overlap. It can not only fully play the role of toughening and strengthening the micro-laminated structure, but also exert the high-temperature performance of the ceramic phase. Solve the pr...

specific Embodiment approach 2

[0022] Embodiment 2: The difference between this embodiment and embodiment 1 is that the thickness of a single layer of pure Ti foil is 100-500 μm, and the ratio of single layer thickness of pure Ti foil to ceramic-reinforced Al-based composite foil is 1: 0.88~0.98. Others are the same as the first embodiment.

[0023] The thickness of a single layer of pure Ti foil in this embodiment is preferably 200-250 μm.

[0024] The single-layer thickness ratio of the pure Ti foil and the ceramic-reinforced Al composite foil in this embodiment is preferably 1:0.91 to 0.97.

specific Embodiment approach 3

[0025] Specific embodiment three: The difference between this embodiment and specific embodiment one or two is: the volume fraction of pure Al powder in the ceramic reinforced Al-based composite foil is 90% to 99.9%, and the ceramic reinforced Al-based composite The volume fraction of the ceramic reinforcement in the foil is 0.1%-10%. Others are the same as the first or second embodiment.

[0026] In this embodiment, the respective volumes can be calculated based on the density and mass of the pure Al powder and the ceramic reinforcement.

[0027] In this embodiment, the volume fraction of pure Al powder in the ceramic reinforced Al composite foil is preferably 92% to 98%, and the volume fraction of ceramic reinforcement in the ceramic reinforced Al composite foil is preferably 2% to 8%.

[0028] In this embodiment, the volume fraction of pure Al powder in the ceramic reinforced Al composite foil is more preferably 94% to 96%, and the volume fraction of ceramic reinforcement in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com