Wood softener, and preparation method and application thereof

A softener and wood technology, applied in the field of wood anatomy, can solve the problems of long softening treatment time, high equipment requirements, and high toxicity to the human body, and achieve the effects of ensuring health, low equipment requirements, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

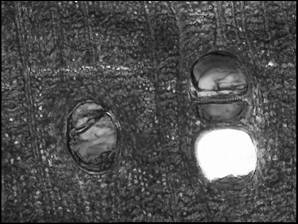

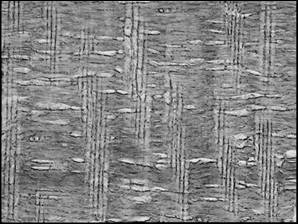

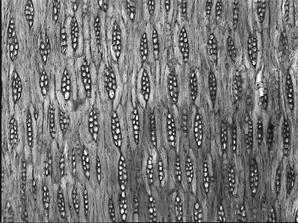

Image

Examples

Embodiment 1

[0057] The sample is red rosewood ( Delbergia. spp. , Dalbergia), its 12% air-dry density is greater than 0.85 g / cm 3 , the method for processing wood slices comprises the following processes:

[0058] 1. Select the three characteristic cross-sections of rosewood, diameter and string, and saw the wood into small pieces of wood with a size of 1cm×1cm×1cm;

[0059] 2. Weigh glycerol, anionic penetrant and water in the following percentage by weight

[0060] Glycerol 50%

[0061] Anionic penetrant 0.2%

[0062] Water surplus, the anionic penetrating agent is Mersolat H95, which is a derivative of secondary alkylsulfonic acid compound, the average carbon chain length is C15, the average molecular weight is 330, and the active substance content is 95%;

[0063] 3. Mix the weighed glycerol, anionic penetrant and water evenly, and stir with a stirrer at a speed of 220 rpm for 2.5 minutes at 35°C to prepare a wood softener;

[0064] 4. Put the small pieces of sawn rosewood into ...

Embodiment 2

[0068] The sample is rosewood ( Pterocarpus spp. , Pterostilbene), its 12% air-dried density is greater than 0.76 g / cm 3 , the method for processing wood slices comprises the following processes:

[0069] 1. Select the three characteristic cross-sections of rosewood, diameter and chord, and saw the wood into small wooden blocks with a size of 1cm×1cm×1cm;

[0070] 2. Weigh glycerol, anionic penetrant and water in the following percentage by weight

[0071] Glycerol 20%

[0072] Anionic penetrant 1%

[0073] The balance of water, the anionic penetrating agent is fatty alcohol polyoxyethylene ether sodium sulfate;

[0074] 3. Mix the weighed glycerol, anionic penetrant and water evenly, and stir with a stirrer at a speed of 160 rpm for 2 minutes at 30°C to prepare a wood softener;

[0075] 4. Put the small pieces of rosewood sawn into the prepared wood softener, heat to 100°C, and keep the heat for 5 hours;

[0076] 5. Put the softened rosewood pieces into a mixed solutio...

Embodiment 3

[0079] The sample is striped ebony ( Diospyros spp. , Persimmon genus), its 12% air-dry density is greater than 0.90 g / cm 3 , the method for processing wood slices comprises the following processes:

[0080] 1. Select the three characteristic cross-sections of the striped ebony: transverse, diameter, and chord, and saw the striped ebony into small pieces of wood with a size of 1cm×1cm×1cm;

[0081] 2. Weigh glycerol, anionic penetrant and water in the following percentage by weight

[0082] Glycerol 60%

[0083] Anionic penetrant 1.5%

[0084] Water surplus, the anionic penetrating agent is an alkyl carboxylate;

[0085] 3. Mix the weighed glycerol, anionic penetrant and water evenly, and stir with a stirrer at a speed of 260 rpm for 2.5 minutes at 40°C to prepare a wood softener;

[0086] 4. Put the sawn striped ebony block into the prepared wood softener, heat it to 80°C, and keep it for 7 hours;

[0087] 5. Put the softened striped ebony blocks into a mixed solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com