Patents

Literature

56results about How to "Shorten the softening time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

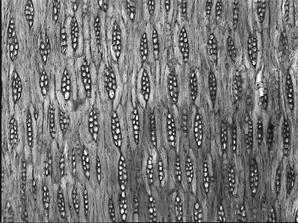

Wood softener, and preparation method and application thereof

ActiveCN102303332ALow elastic modulusShorten the timeWood treatment detailsWood impregnation detailsPolymer scienceAlcohol

The invention provides a wood softener, wherein components included in the wood softener and the weight percentage of each component are as follows: 10-80% glycerol, 0.2-3% anionic penetrating agent, and rest being water. The invention also provides a preparation method of the wood softener, wherein the following process is adopted: proportionally and evenly mixing glycerol with anionic penetrating agent and water, and stirring the mixture using a stirrer at 25-40 DEG C and at a speed ranging from 50-200 r / min for 1-3 min. The invention further provides a method for performing softening treatment on the wood, comprising the following steps of: adding the prepared softener to a container; putting small wood pieces in the softener; and heating to a range of 70-100 DEG C and keeping the temperature for 3-10 h. The invention additionally provides a method for processing wood slices, comprising the following steps of: adding the prepared softener to the container; heating to a range of 70-100 DEG C and keeping the temperature for 3-10 h; and then putting the softened wood pieces into mixed solution of absolute ethyl alcohol and anhydrous glycerol, and oscillating for 0.5-5 hours, thereby forming the wood pieces into wood slices. The wood slice is processed by the wood softener, which is used for identifying the type of wood.

Owner:山东省纤维检验局

Method for softening areca-nut using enzyme method and areca-nut

The invention discloses a method of softening betel nuts with enzyme and a betel nut thereof; the method comprises the following steps: (1), the preparation of raw material: washing and placing the betel nut in a container; (2), the enzyme solution preparation: respectively adding pectinase, cellulase and hemicellulase into water, adjusting the pH valve to 3-10 with acid or alkali, and evenly stirring the mixture to get the enzyme solution, wherein, based on mass ratio, water: pectinase: cellulose: hemicellulase is equal to 100: (0.03-2) : (0.03-1.2) : (0.01-0.8); (3) enzymatic softening: adding the enzyme solution obtained in step (2) into the container with the betel nut to enable the betel nut to be immersed in the enzyme solution, and carrying out enzyme treatment under the conditions that the vacuum degree in the container is kept for 4-35kPa and the temperature for 30-70 DEG C for 0.5-12 hours, so as to obtain the fiber-softened betel nut. The method can shorten the time for softening the betel nut, so the prepared betel nut tastes good and does not hurt the mouth cavity.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

In-situ warm-mixing regenerant for bituminous pavement, preparation method and construction method of in-situ warm-mixing regenerant

ActiveCN103013144ALow costLow heating temperatureRoads maintainenceBuilding insulationsRoad surfaceMaterials science

The invention relates to an in-situ warm-mixing regenerant for a bituminous pavement, and a preparation method and a construction method of the in-situ warm-mixing regenerant. The strength of a cold-regenerating mixture is longer in formation time; a finish coat in a certain thickness is required to be paved additionally; the property of the regenerated mixture is poorer; a lower level cold mixing technology is used generally; and cement is required to be added generally, so that the durability of the level is reduced. The in-situ warm-mixing regenerant for the bituminous pavement comprises the following raw materials in parts by mass: 10-30 parts of naphthenic hydrocarbon, 20-40 parts of furfural extract oil, 30-50 parts of deionized water, 10-20 parts of microwave absorption agent, 5-10 parts of surfactant, 5-10 parts of dispersing agent and 1-5 parts of antiaging agent. According to the in-situ warm-mixing regenerant, the preparation method and the construction method, the mixing cost can be lowered; the construction efficiency is improved; a use ratio of old materials is increased; compared with in-situ heat regeneration, the ageing of a bituminous mixture is reduced; the service life of the pavement is prolonged; a cooling rate is reduced; the discharge amount of harmful gas and dust is decreased; new aggregates and new bitumen are not required to be added; and the material cost is lowered.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

Method for ultrasonic combined extraction of long and uniform natural bamboo fiber

InactiveCN105586643AImprove surface roughnessKeep the lengthVegetable materialMechanical fibre separationCardingSurface roughness

The invention discloses a method for ultrasonic combined extraction of a long and uniform natural bamboo fiber. The method comprises the following steps: (1) raw bamboo treatment; (2) ultrasonic combined softening; (3) washing with water; (4) rolling and opening; (5) directed carding; (6) high-temperature boiling; (7) drying in the shade; (8) secondary carding; and (9) drying. By the ultrasonic combined softening technology at a room temperature, the amount pressure of the softener can be effectively reduced, the softening time is reduced, the softening efficiency is improved, the surface roughness of the bamboo fiber is increased, and subsequent utilization as a reinforcing material and interface bonding with the polymer are facilitated; bamboo fiber refining is carried out by physical methods of high-temperature boiling, drying in the shade and secondary carding; keeping of the length uniformity and mechanical strength of the bamboo fiber is facilitated; and the fineness uniformity of the bamboo fiber is improved.

Owner:JIANGXI ACAD OF FORESTRY +1

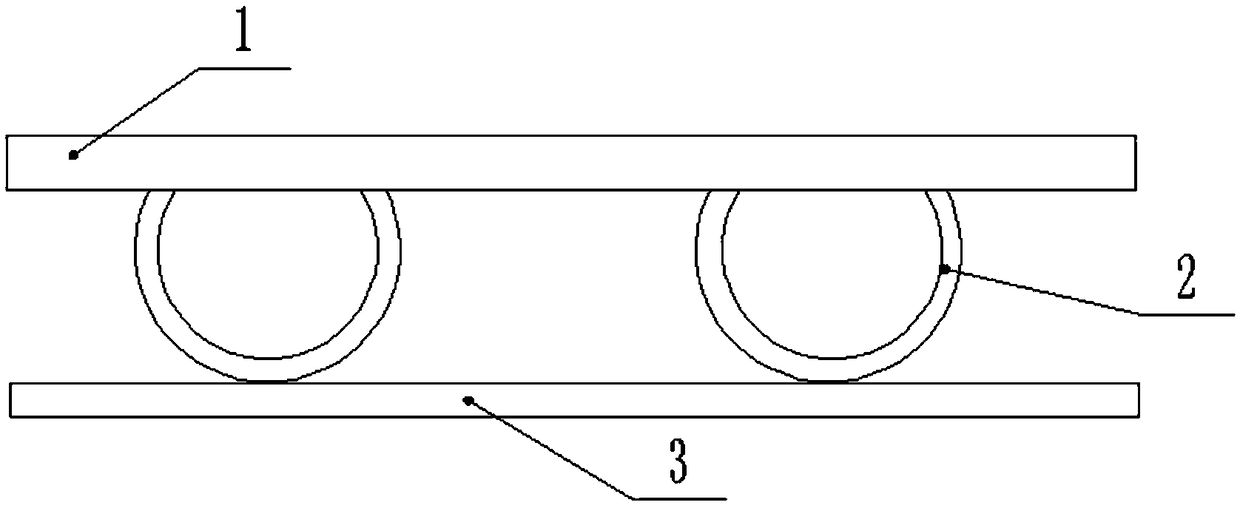

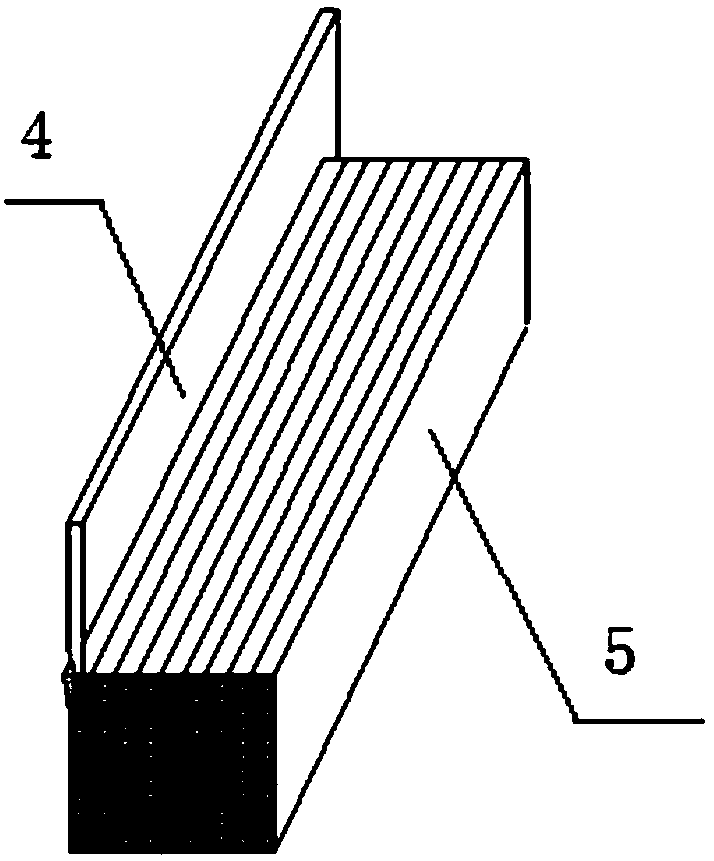

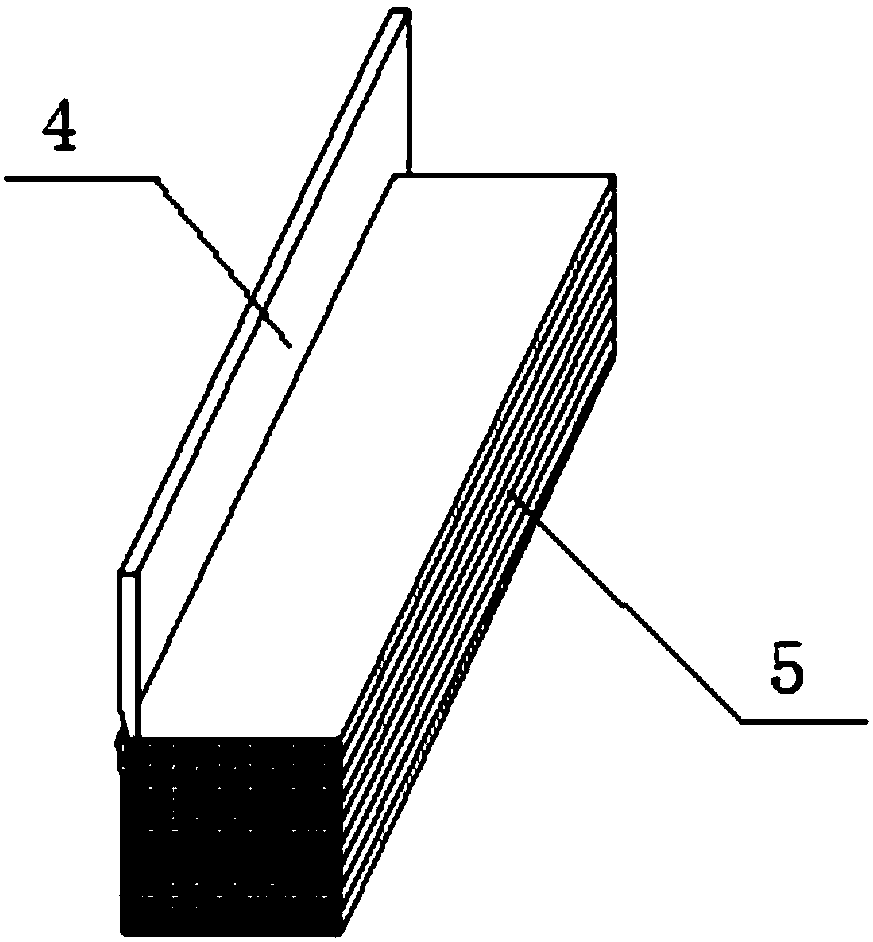

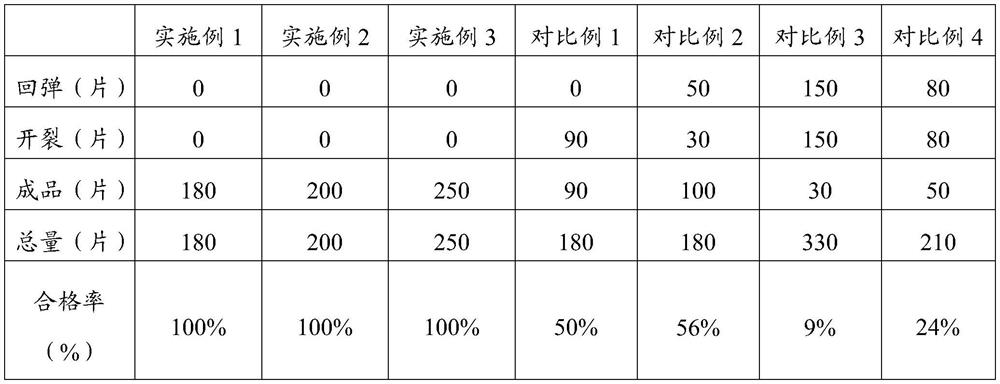

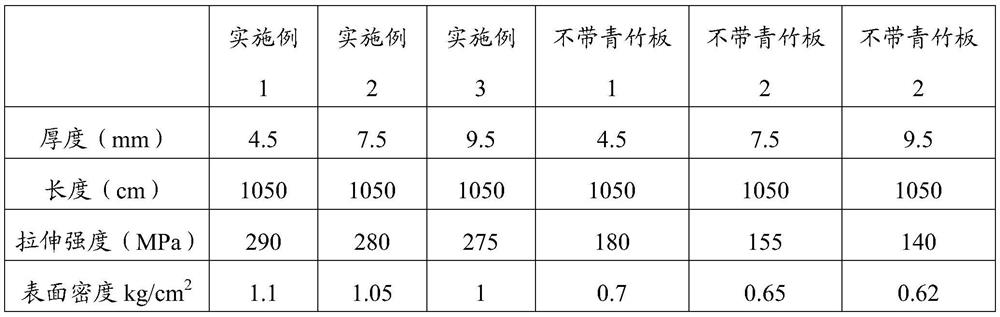

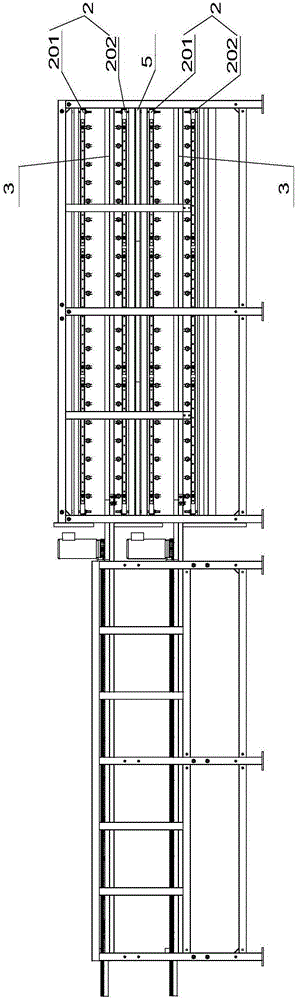

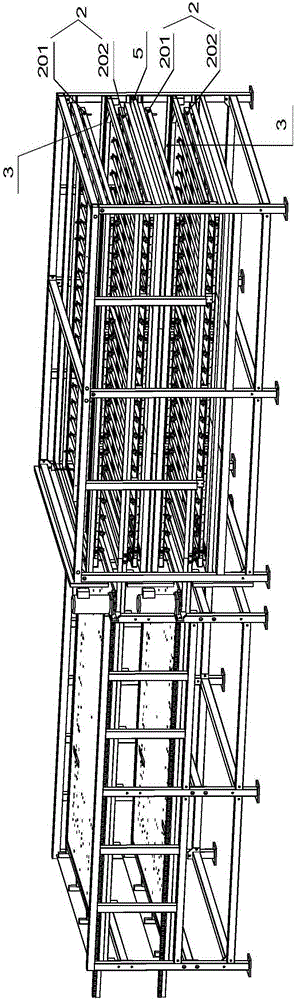

Production method for flattening and slicing bamboo veneer

InactiveCN109333703AShorten the softening timeSimplify the manufacturing processWood compressionWood treatment detailsAdhesiveEngineering

Owner:NANJING FORESTRY UNIV

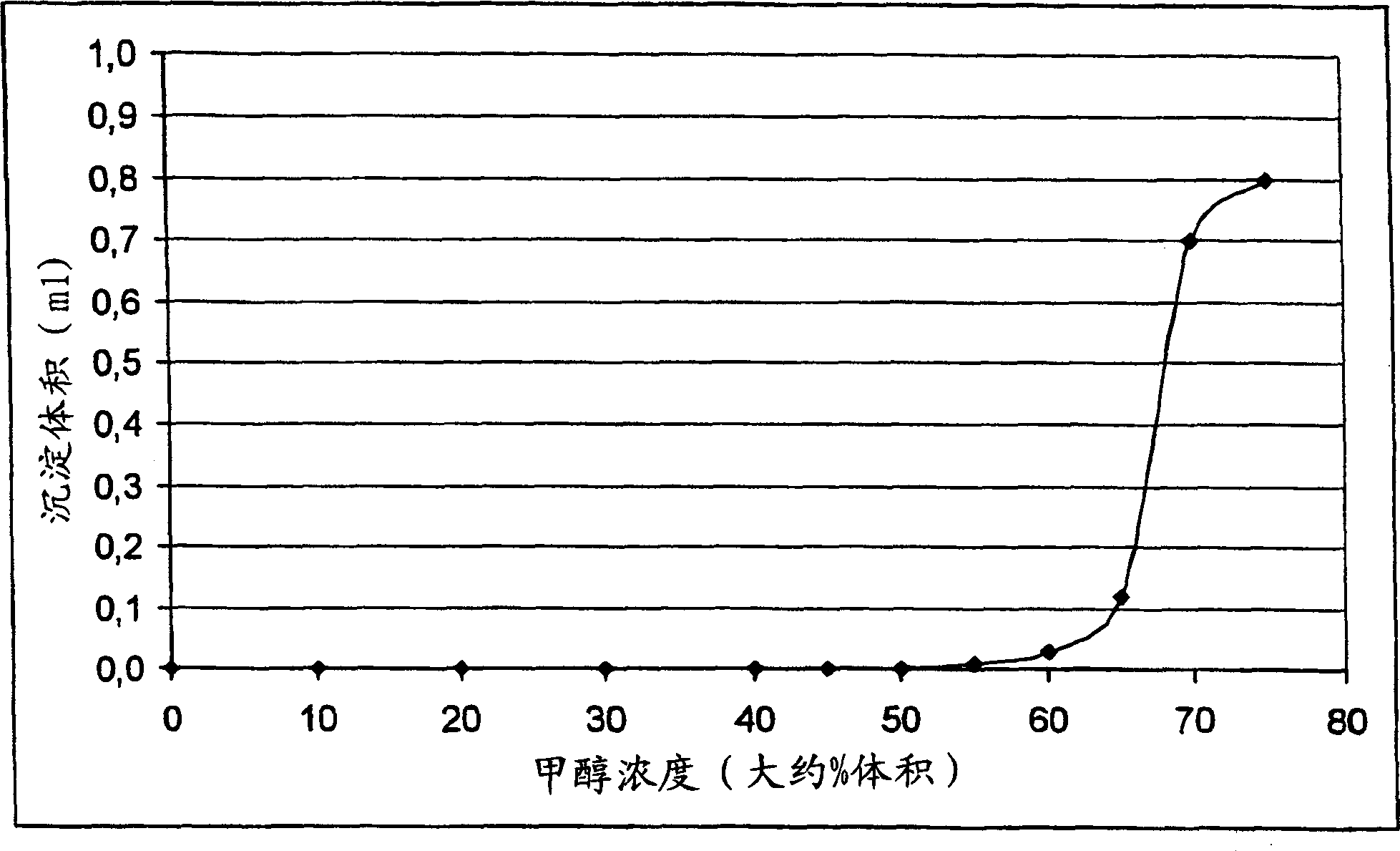

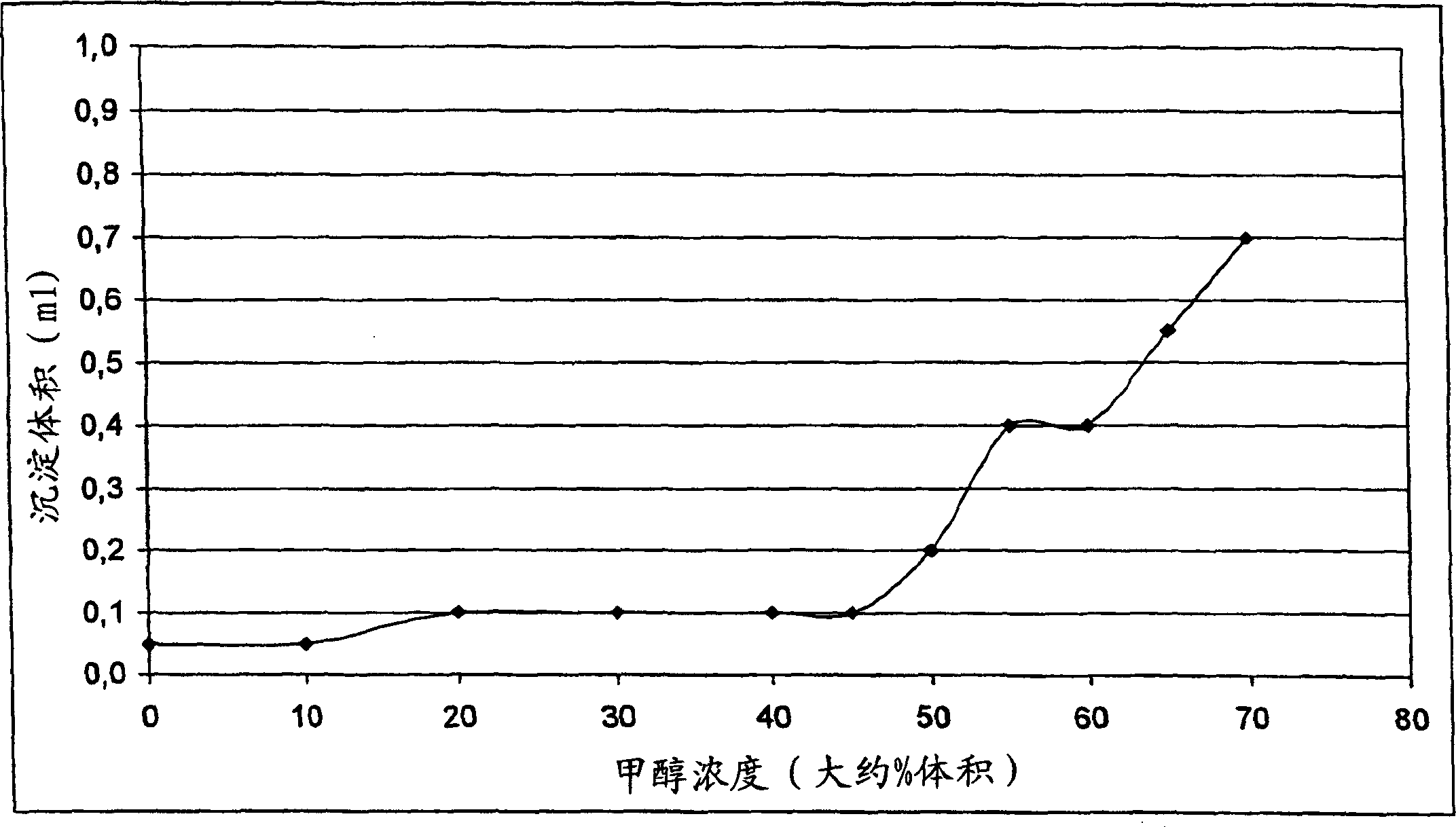

High-whiteness, non-heat-treated hydrophobic precipitated silica

InactiveCN1405085AGood electrical propertiesShorten the softening timeSilicaMaterial granulationHydrophobeHeat treated

To provide a hydrophobic precipitated silica which has a high whiteness and can be well blended in a compounded silicone rubber, and also to provide a method for production thereof and the use thereof.

Owner:DEGUSSA AG

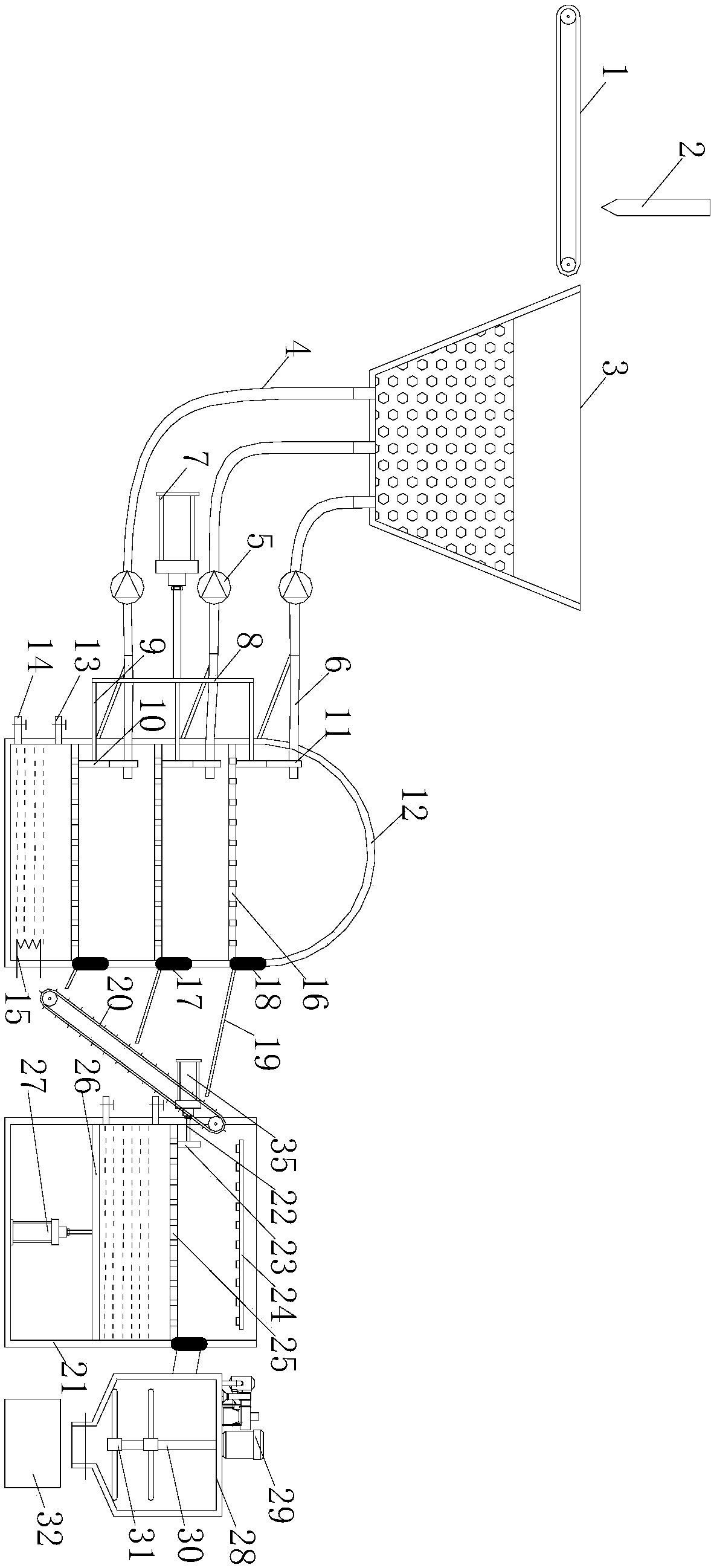

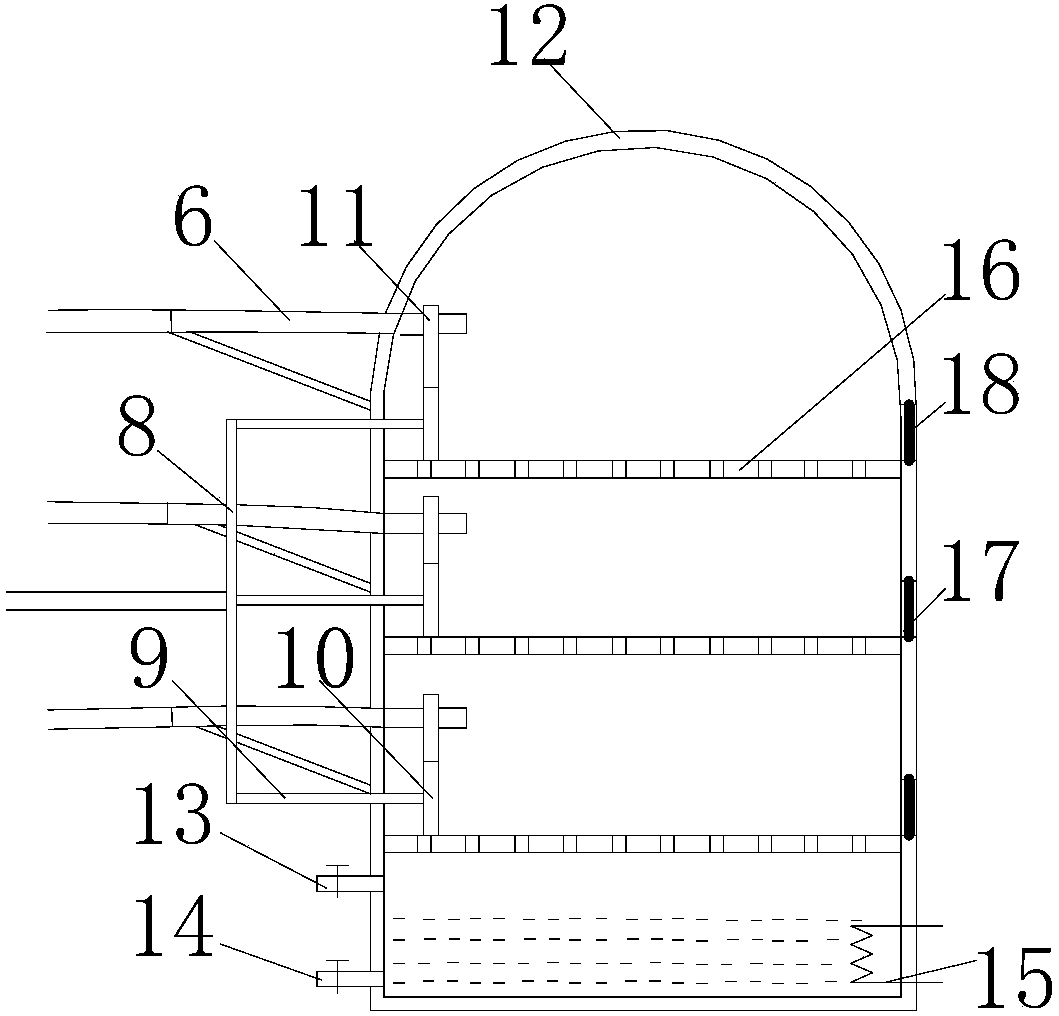

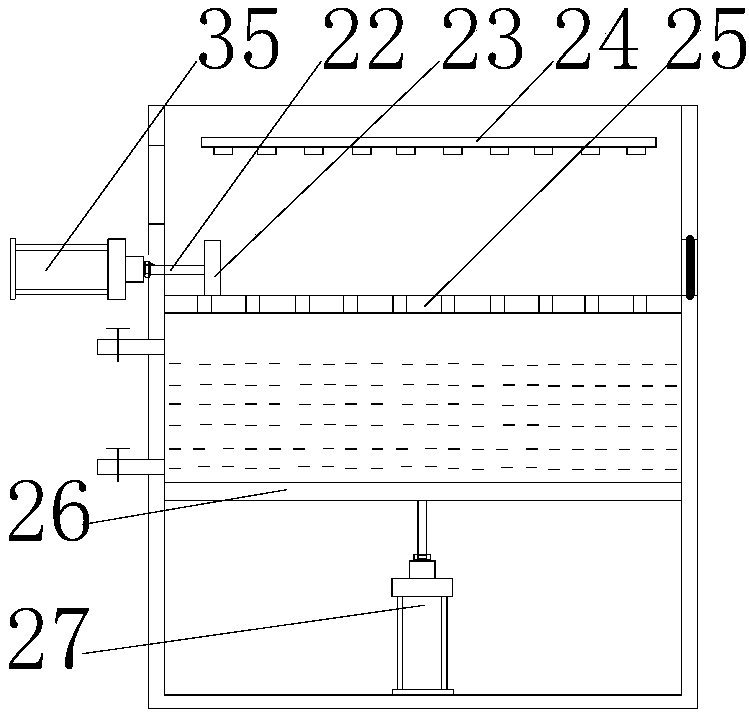

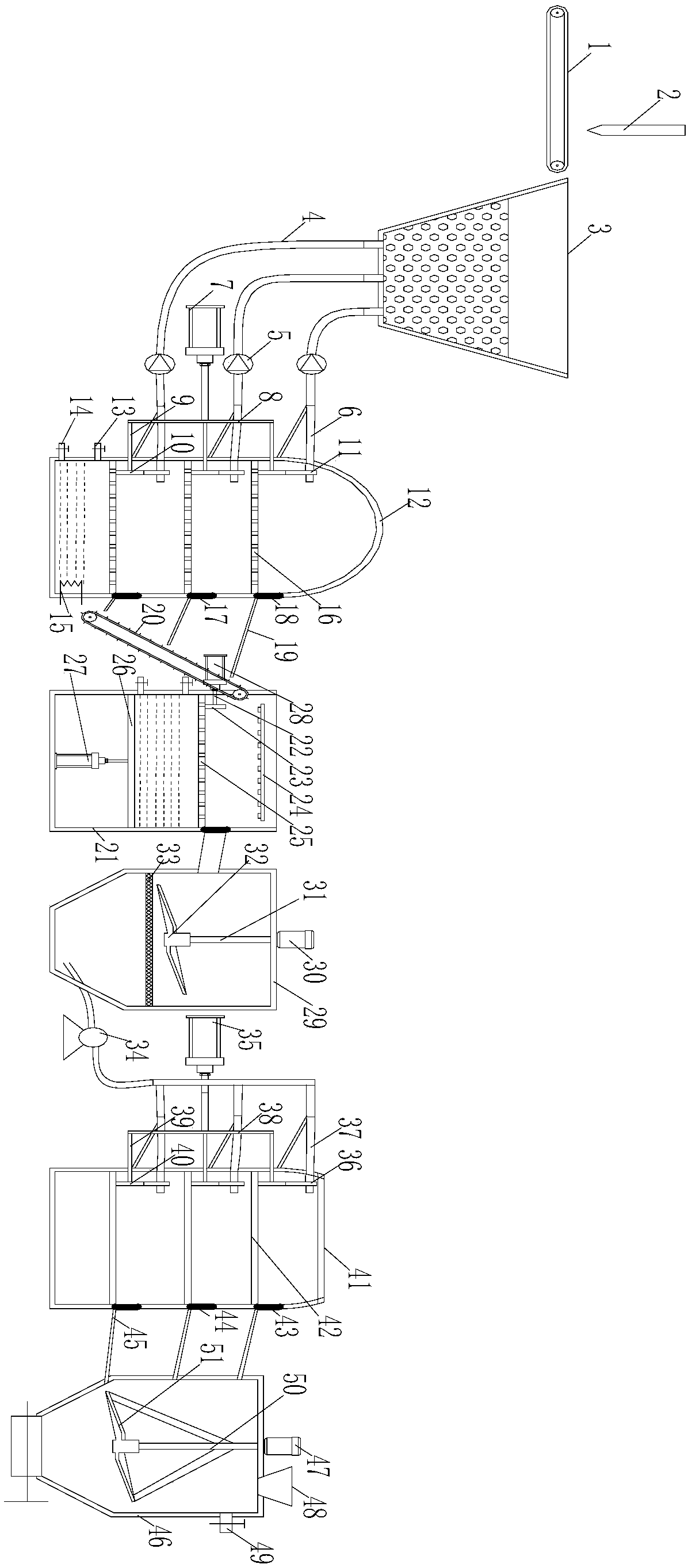

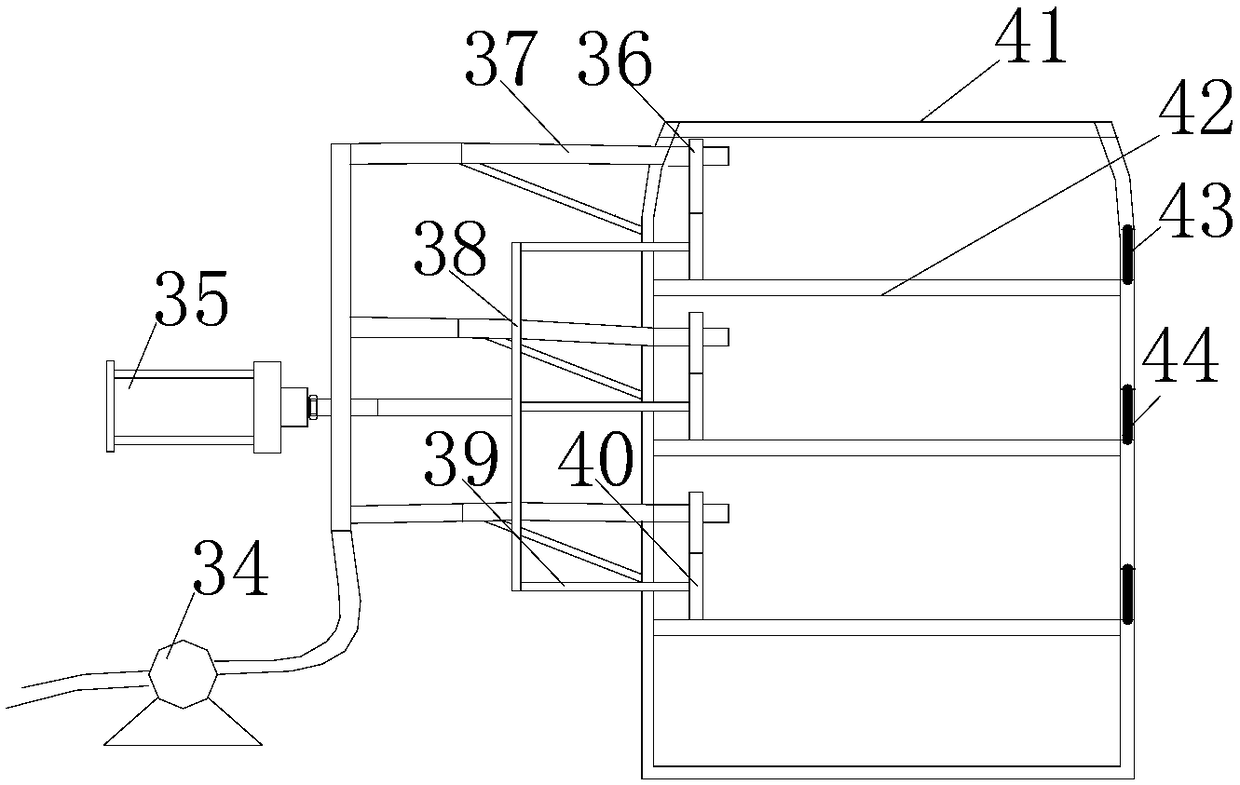

Dried kelp powder preparation apparatus and preparation method thereof

ActiveCN108497370ARealize streamlined operationReduce production efficiencyFruits/vegetable preservation by heatingGrain treatmentsAssembly lineEngineering

The invention relates to a dried kelp powder preparation apparatus. The dried kelp powder preparation apparatus comprises a first conveyor belt, a cutting unit, a softening unit, a washing unit, a drying unit, and a crushing unit; the cutting unit is used for cutting dried kelp on the first conveyor belt into pieces; the softening unit is used for softening the dried kelp; the washing unit is usedfor washing the softened kelp; the drying unit is used for drying the washed kelp; and the crushing unit is used for grinding the dried kelp into powder. The dried kelp powder preparation apparatus realizes assembly-line operation of dried kelp powder production, and is high in continuity and free of artificial participation during processing procedures; and thus, dried kelp powder production efficiency is greatly improved. And the produced dried kelp powder is clean and sanitary.

Owner:天津鼎拓恒远知识产权服务有限公司

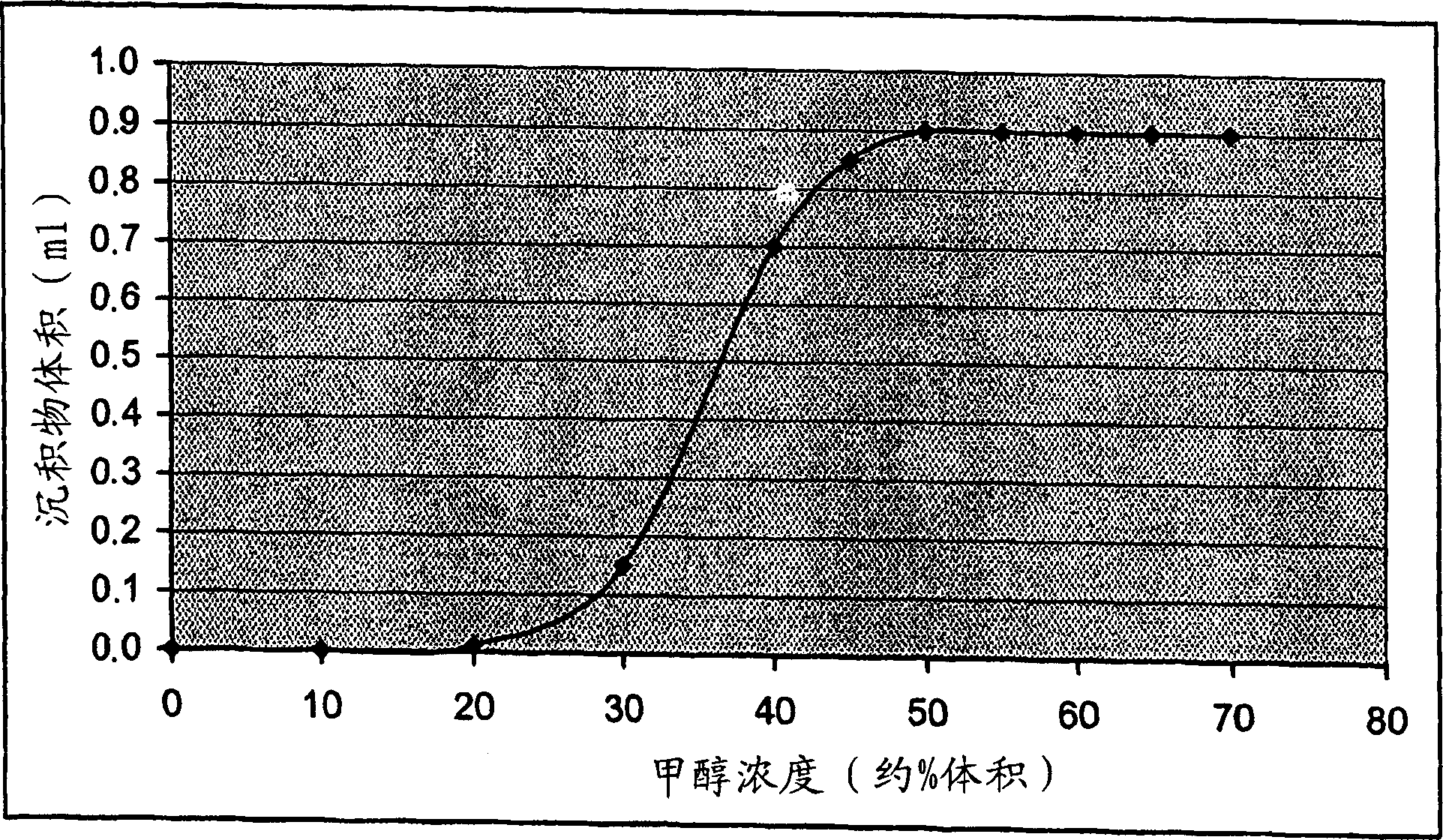

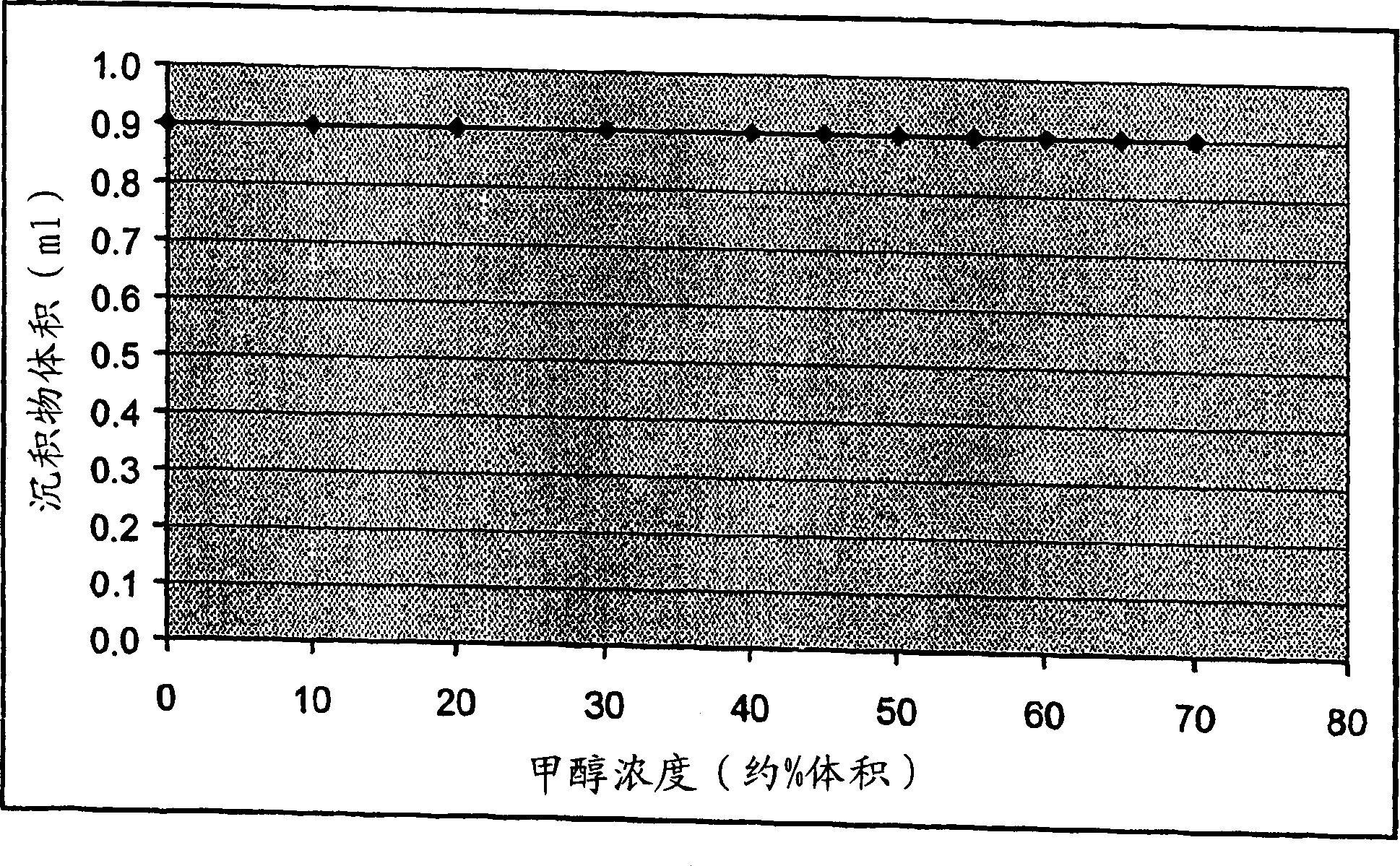

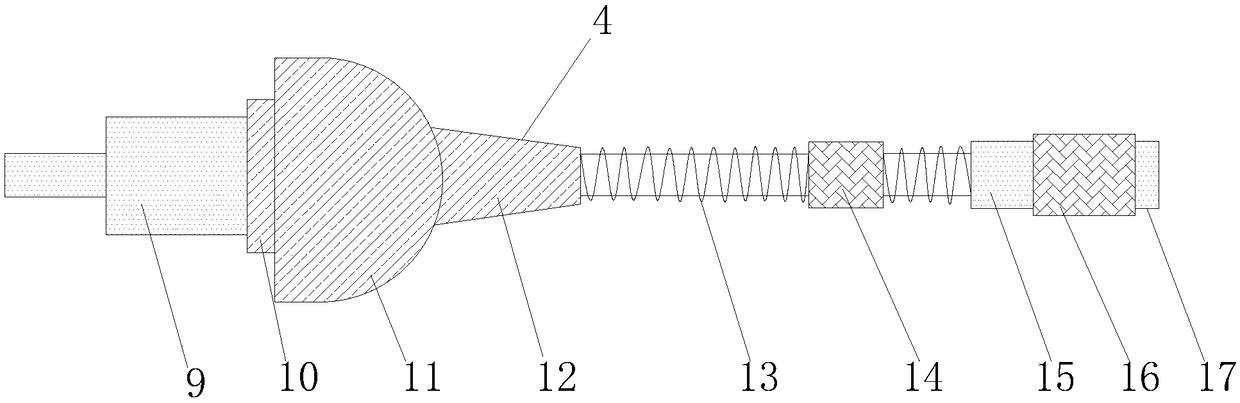

Wood softening agent and preparation method, wood softening method and wood slice manufacturing method

ActiveCN106584622AReduce stiffnessShorten the softening timeWood treatment detailsWood heatingAfter treatmentCellulose

The invention provides a wood softening agent and a preparation method thereof, a wood softening method using the wood softening agent, and a wood slice manufacturing method. The wood softening agent comprises lithium chloride and N, N-dimethyl acetamide and water, and the amount ratio of the three substances is 1:4:18. The wood slice manufacturing method includes the steps that wood is sawn into wood samples, the wood softening agent provided by the invention is added, the wood samples are placed in a constant temperature water bath, and after cooling, slicing is performed to form wood slices. According to the wood softening agent, a lithium chloride / N, N-dimethyl acetamide system is used for soaking, swelling and softening cellulose in the wood, and therefore the rigidity of the wood is lowered, the softening time is shortened, and energy consumption is reduced; and according to the softened wood obtained through the reagent and a treatment method, only the cellulose of the wood is softened, the structural characteristics of the wood are not changed, the softened wood keeps the state after treatment all the time, and restoration caused by environment condition changes is avoided.

Owner:SHANGHAI CONSTRUCTION GROUP

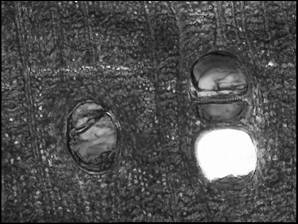

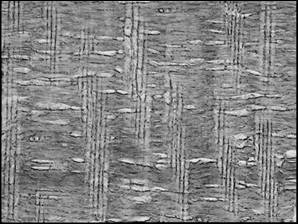

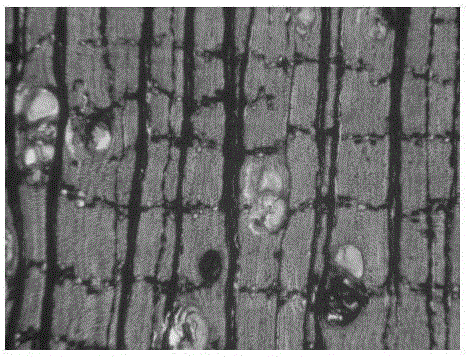

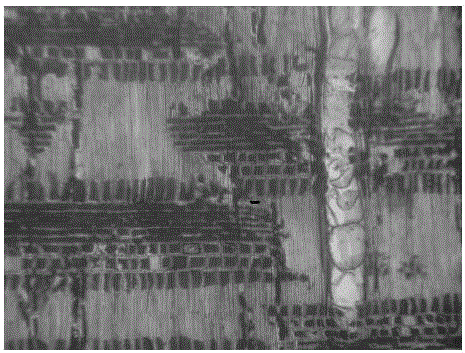

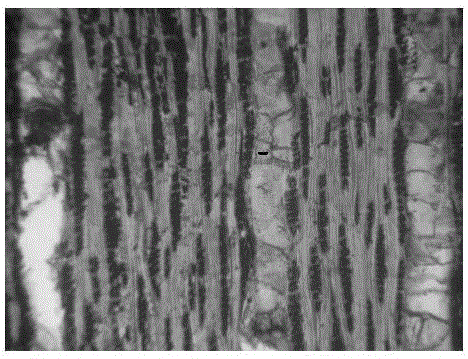

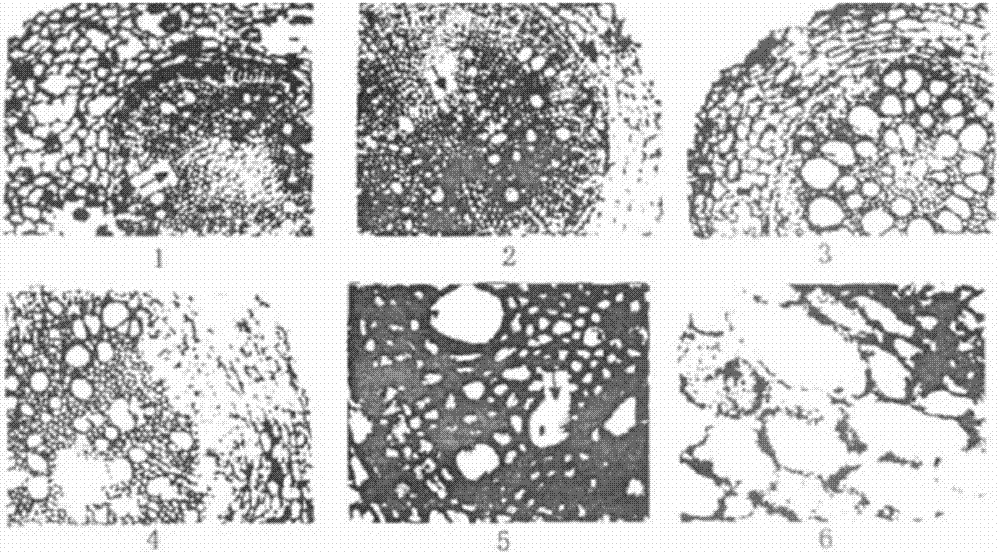

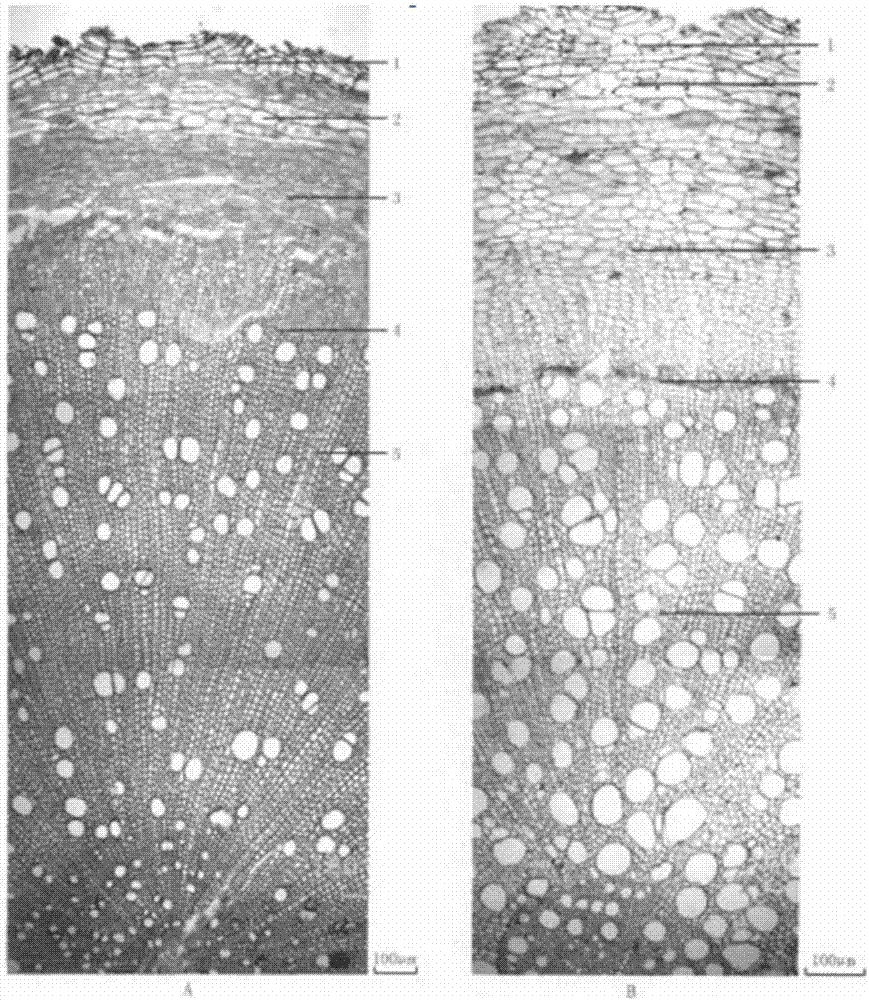

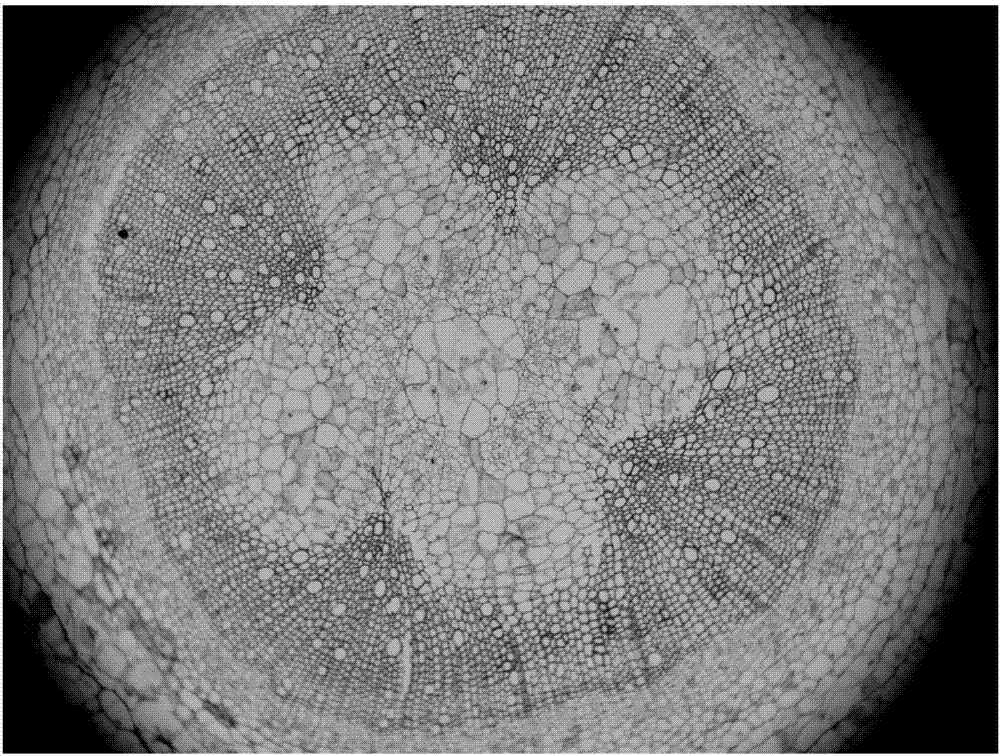

Preparation method of paraffin slices of eggplant root stalk part tissues

InactiveCN107167350AIntegrity guaranteedThe softening process is acceleratedPreparing sample for investigationWaxMicroscopic observation

The invention relates to a preparation method of paraffin slices of eggplant root stalk part tissues, and belongs to the technical field of biological histology. The method comprises the eleven steps of fixing, softening, dewatering, transparency treatment, wax soaking, coating and burying, wax trimming and slicing, slice unfolding and slice baking, wax removal, rehydration, dyeing, slice sealing and observation. The method belongs to a fast, convenient, safe and practical eggplant root stalk part tissue paraffin slice method. The result obtained by the method realizes high operability, high repeatability, high stability and high reliability. Through the microscopic observation, the slice quality is high; the effect is good; the tissue structure is clear. The method can be used for studying, observing and judging the form structure change of the eggplant root stalk part tissues, so that the physiological, pathological and morphological study can be performed on the eggplants. The method can also be widely applied to tissue slice experiments of eggplant fruits or even other plants; good scientific research application prospects are realized.

Owner:云南省农业科学院园艺作物研究所

Lily and tremella granule drink and preparation method thereof

The invention discloses a lily tremella granular beverage and a preparation method thereof. The lily tremella granular beverage is prepared from drinking purified water, a sweetener, concentrated pear juice, white fungus, lily, agar, citric acid and edible essence. The preparation process steps of the lily tremella granule beverage mainly include material preparation, pretreatment, softening, blending and posttreatment. The lily tremella granule beverage obtained in the present invention has the effects of nourishing yin and nourishing the lungs, moistening the intestines and laxative, and is especially suitable for drinking by people with yin deficiency and constipation; the preparation method of the lily tremella granule beverage provided by the present invention is simple to operate and requires less equipment , low cost and suitable for industrialized mass production.

Owner:SICHUAN JIUJIUAI FOOD

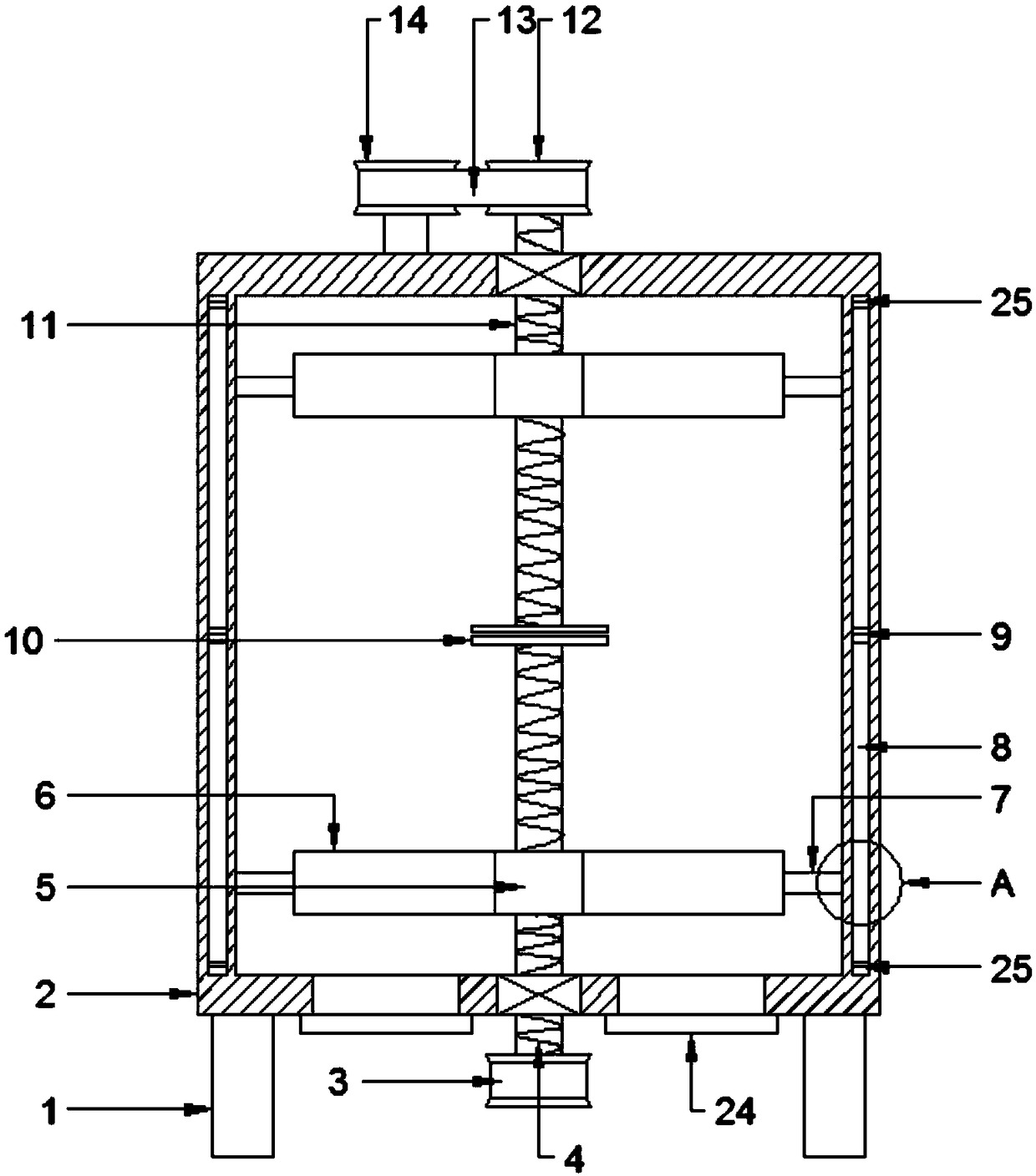

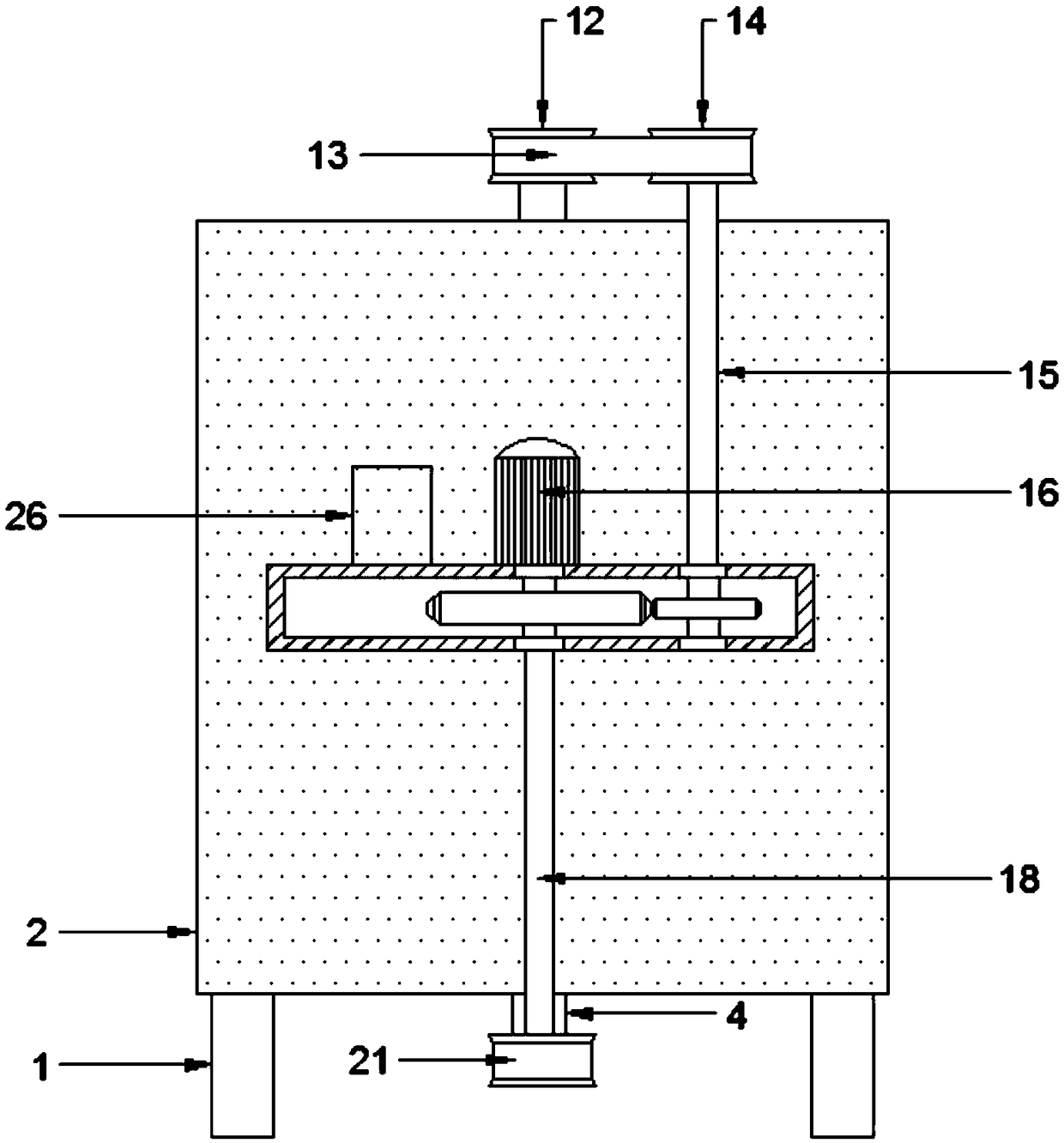

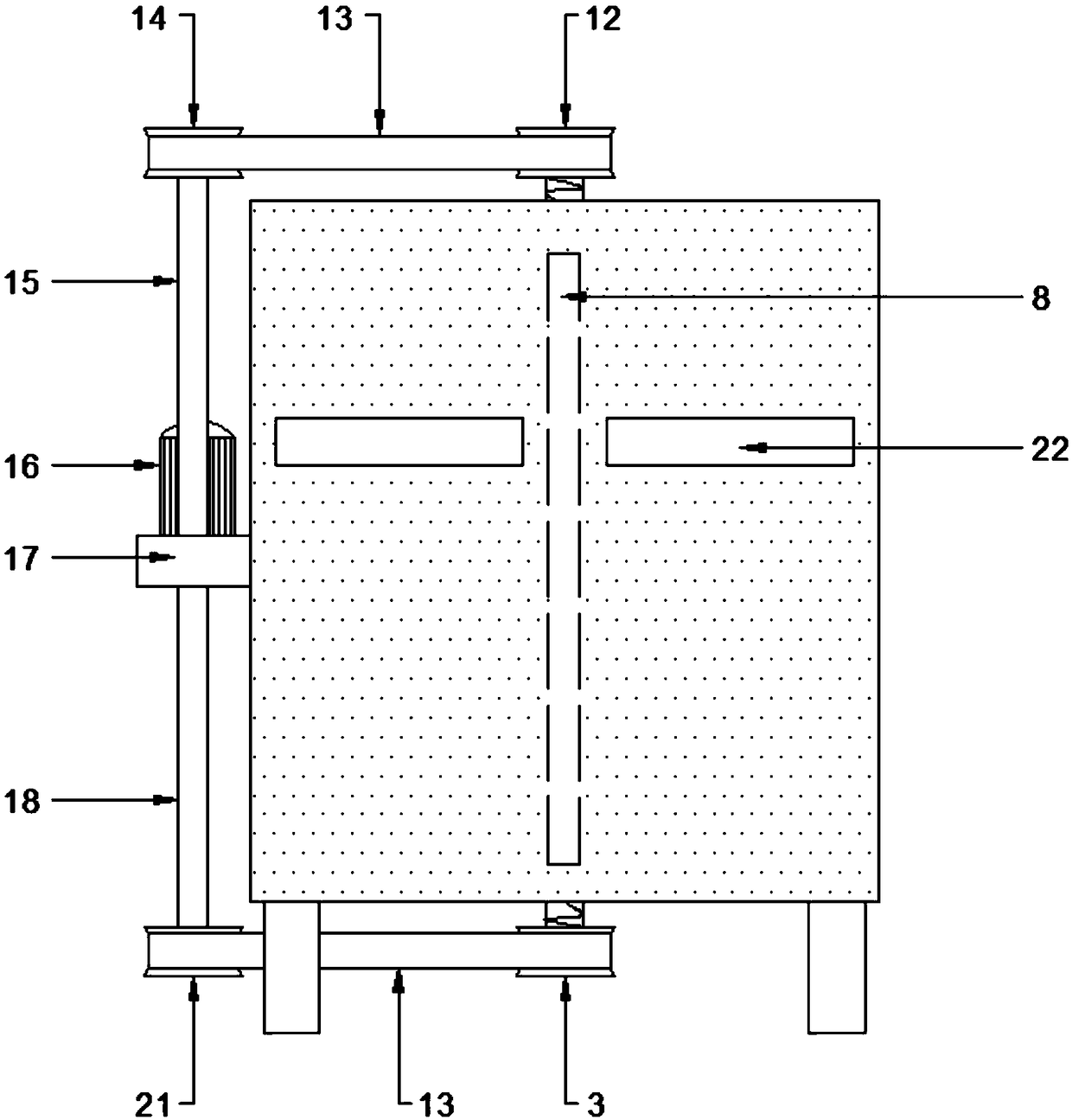

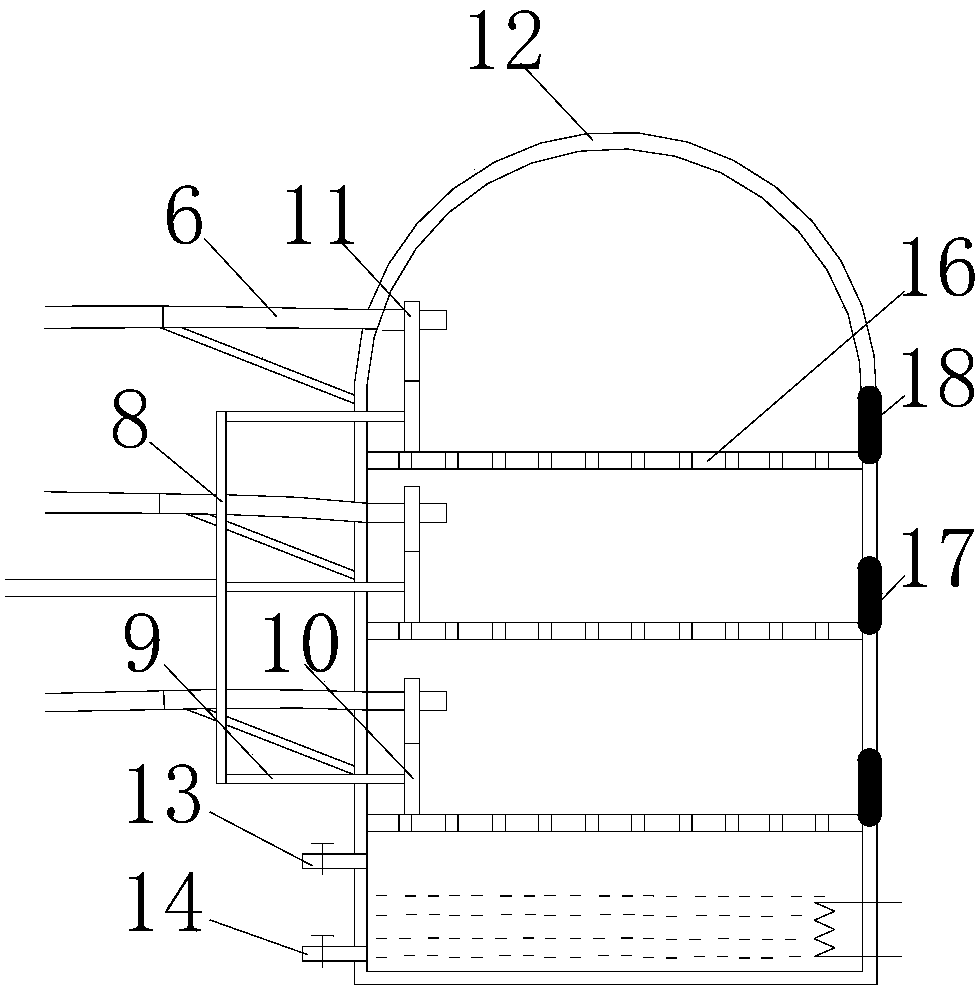

Bidirectional linkage grinding soaking device for waste paperboards

InactiveCN108797174ARealize reverse linkageIncreased immersion speedPaper recyclingRaw material divisionPaperboardElectric machinery

The invention discloses a bidirectional linkage grinding soaking device for waste paperboards. The bidirectional linkage grinding soaking device comprises a soaking box, the bottom face of the soakingbox is supported on the ground through supporting columns, feeding openings are formed in the two side walls of the soaking box, discharging openings are formed in the bottom face of the soaking box,a first threaded rod is rotationally fixed to the bottom face of the soaking box, a second threaded rod is rotationally fixed in the center of the top face of the soaking box, a pressing plate sleeves the rod walls of the first threaded rod and the second threaded rod in a threaded manner through a threaded hole, and is clamped in sliding grooves through limiting rods, forward touch switches andbackward touch switches are installed in the sliding grooves, a driving box is fixed on the back face plate of the soaking box, a driving motor is fixedly and reversely installed on the top face of the driving box, and a control box is arranged on the left side of the driving motor. According to the bidirectional linkage grinding soaking device for the waste paperboards, forward-backward automaticswitching of the driving motor can be achieved, the pressing plate grinds repeatedly up and down, the speed when the waste paperboards are soaked into water can be increased, mashing separating is carried out in the grinding process, and the soaking mashing efficiency of the waste paperboards is greatly improved.

Owner:湖南图强科技开发有限公司

Honey tremella tea

ActiveCN105212007AEnhance nourishing yin and moistening drynessGood laxative effectFood ingredient as thickening agentFood ingredient as taste affecting agentBiotechnologyIcing sugar

The invention discloses honey tremella tea. The honey tremella tea is prepared from, by weight, 2.5 parts to 4.0 parts of tremella, 5.0 parts to 6.0 parts of honey, 4.0 parts to 5.0 parts of fruit juice, 44 parts to 46 parts of powdered sugar and a proper amount of purified water. A preparing technology of the honey tremella tea includes the steps of tremella softening, mixing, filling, sterilizing and the like. The honey tremella tea is simple in production technology, low in production cost and easy to brew; the brewed product has the advantages of being sour, sweet, tasty, refreshing, high in physical feeling and obvious in yin nourishing effect, dryness moistening effect and bowel relaxing effect; the honey tremella tea is particularly suitable for fire-excess-from-yin-deficiency persons, intestinal-dryness-with-constipation persons and persons always staying up late.

Owner:CHENGDU SHIWEITIAN TECH CO LTD

Improved method for producing bamboo flattening board

The invention provides an improved method for producing a bamboo flattening board. According to the method, the following five measures are adopted: 1, processes are adjusted finely; 2, increasing the temperature and pressure of water vapor for softening bamboo sections; 3, gashing a bamboo flesh layer without damage; 4, determining thickness, removing tabasheer and planing; 5, improving a drying and stacking way. According to the invention, the process of enabling the thickness to be uniform and removing bamboo green, and the processes of removing inner and outer bamboo joints and planing the tabasheer layer roughly are performed simultaneously, so that the process can be reduced, the softening process is accelerated, energy conservation is achieved, and the work efficiency is improved; the structure of the roller surface is improved, and the bamboo flesh layer is gashed without damage, so that bamboos are saved and product quality is improved; the temperature and pressure in a softening tank are increased and the drying and stacking way is improved, so that the benefits of energy conservation and high work efficiency are achieved; the processes of determining thickness, removing tabasheer and planing are determined, and corollary equipment is manufactured, so that the quality and output of the bamboo flattening boards are improved greatly, and the slicing and removing ratio of bamboos is reduced obviously; the above measures are put forward, rapid determination of the optimizing process of the bamboo flattening board production method through the transverse feed of the bamboo sections is facilitated, and the process of industrialization is accelerated.

Owner:浙江德长竹木有限公司

Method for manufacturing bamboo-flattened slab

InactiveCN108582274AReduce thicknessImprove flatnessWood compressionWood treatment detailsPressure riseMicrocomputer

The invention discloses a method for manufacturing a bamboo-flattened slab. The method comprises the following steps that (1) the inner skin of bamboo is removed, and the inner skin layer of the wholebamboo section is planed by using a rotary-cut method; (2) the bamboo section is softened with water steam for temperature rise and pressure rise, the admission steam pressure is 1.35 MPa, the temperature is 180 DEG C, and the softening time is 5-7 minutes; (3) a bamboo fresh layer is free from damage gashes, and a conical pointed bulge of a pushing roller surface or a nicking tool is changed into an arc bulge with a curvature radius of n or a right trapezoid bulge with an upper bottom of n, a height of n and a lower bottom of 2n; (4) thickness defining, inner skin removing and planing are conducted, a blank plate is flattened and then subjected to thickness measuring by a thickness defining, inner skin removing and planing machine, and microcomputer programming is carried out for automatic planing; and (5) drying and carbonization are conducted, two inner skin surfaces are longitudinally and oppositely folded, and small square rods are clamped at two longitudinal ends of the top surface of one bamboo green separately to form a stacking unit to be put in a drying and disinfecting carbon dryer for drying and carbonization.

Owner:韩立根

Decanter for bottled wine

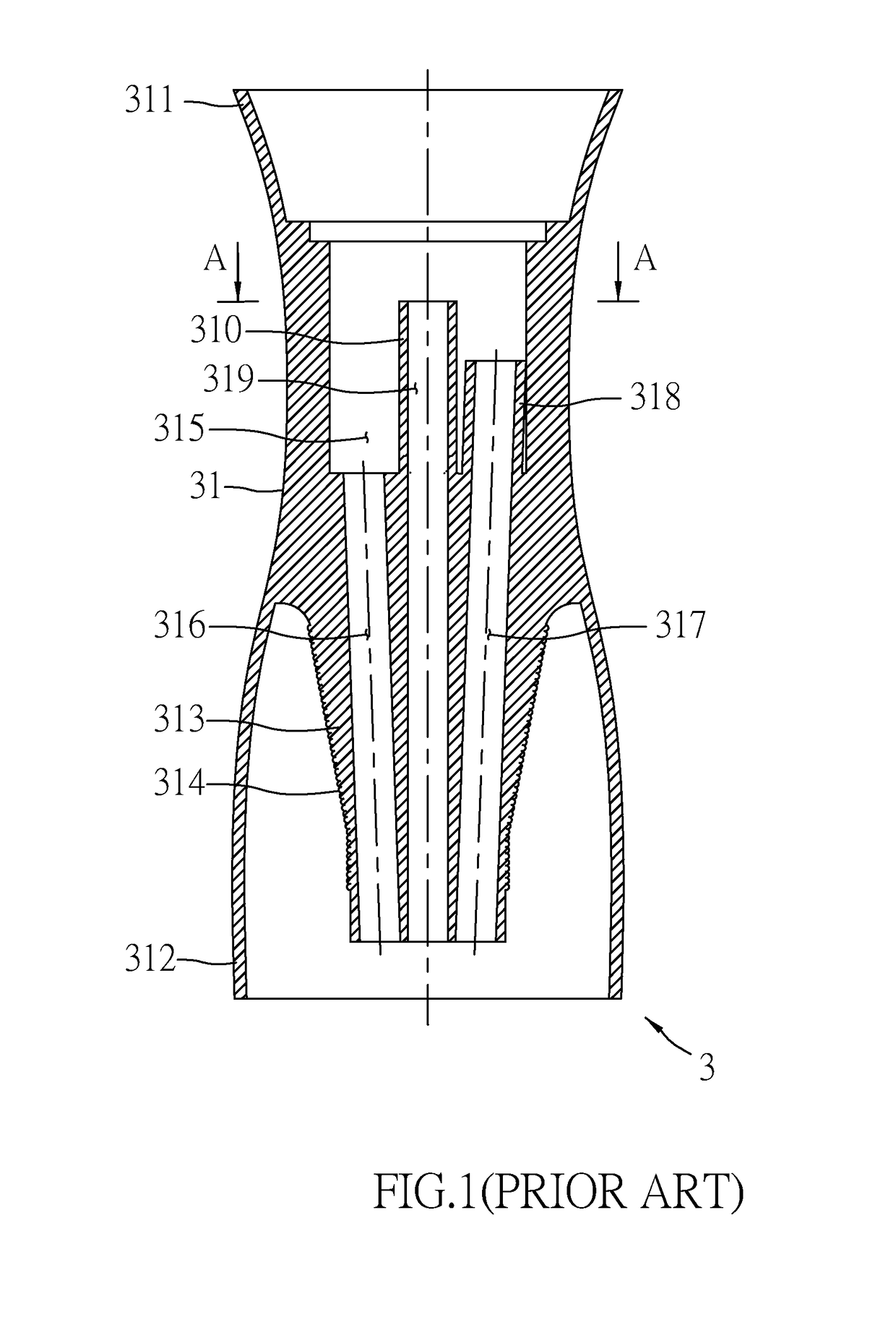

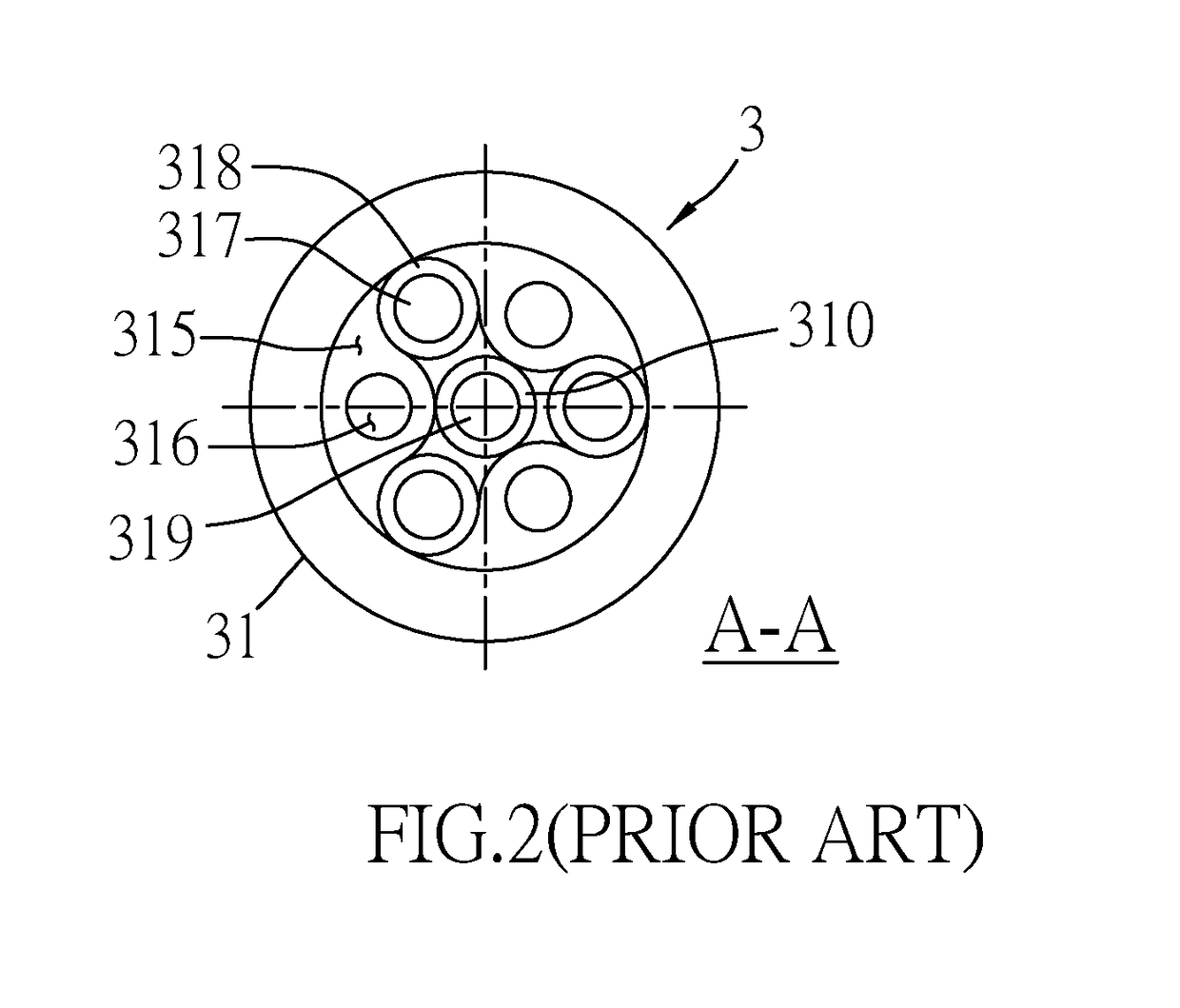

InactiveUS10220357B1Shorten the softening timePerfect aerationMixing methodsRotary stirring mixersEngineeringBottle

A decanter for bottled wine includes a main body having a first end, a second end, a bottle mouth insertion portion, an accommodating chamber and a wine guide portion, an outer cylinder covering the main body and a rotary shaft. At least one retaining ring is provided on an outer wall of the bottle mouth insertion portion. A bottom of the accommodating chamber has a plurality of equally spaced first through, protruding posts each having a second through hole, and an inner shaft seat. An inner end of the rotary shaft is pivotally connected to the inner shaft seat. The wine guide portion is disposed inside the second end of the main body and located at an outer end of the accommodating chamber. The wine guide portion includes an outer shaft seat for pivotally connecting an outer end of the rotary shaft and a plurality of wine guide holes.

Owner:HUANG LIANG PRECISION ENTERPRISE

Unfolding process of green bamboo strips

PendingCN113927685AHigh strengthUniform thicknessWood treatment detailsCane mechanical workingPulp and paper industryComposite material

The invention discloses an unfolding process for green bamboo strips, and belongs to the technical field of bamboo processing. The unfolding process comprises the following steps that bamboos are segmented and sectioned bamboo strips with cambered sections; the bamboo strips are expanded in an equal-arc and fixed-thickness mode after being pressurized, heated and softened; then, double-face protection gradual flattening is conducted under the heat preservation condition till the bamboo strips are completely flattened, and a bamboo board is obtained; and the bamboo board is continuously cooled, then subjected to ballasting, shaping and drying until the moisture content is 6-10%, and then subjected to fixed-width trimming to obtain a green bamboo board finished product. According to the unfolding process for the green bamboo strips, the green bamboo strips can be unfolded on the premise that oblique notching and green planing are not conducted, the problems of cracking and rebounding cannot occur in the unfolding process, the obtained green bamboo strips are smooth and flat, the obtained green bamboo strips have the characteristic of high strength, and the application range and field of the bamboo wood are further widened through the unfolding process.

Owner:FUJIAN LONTAI BAMBOO HOUSEHOLD CO LTD

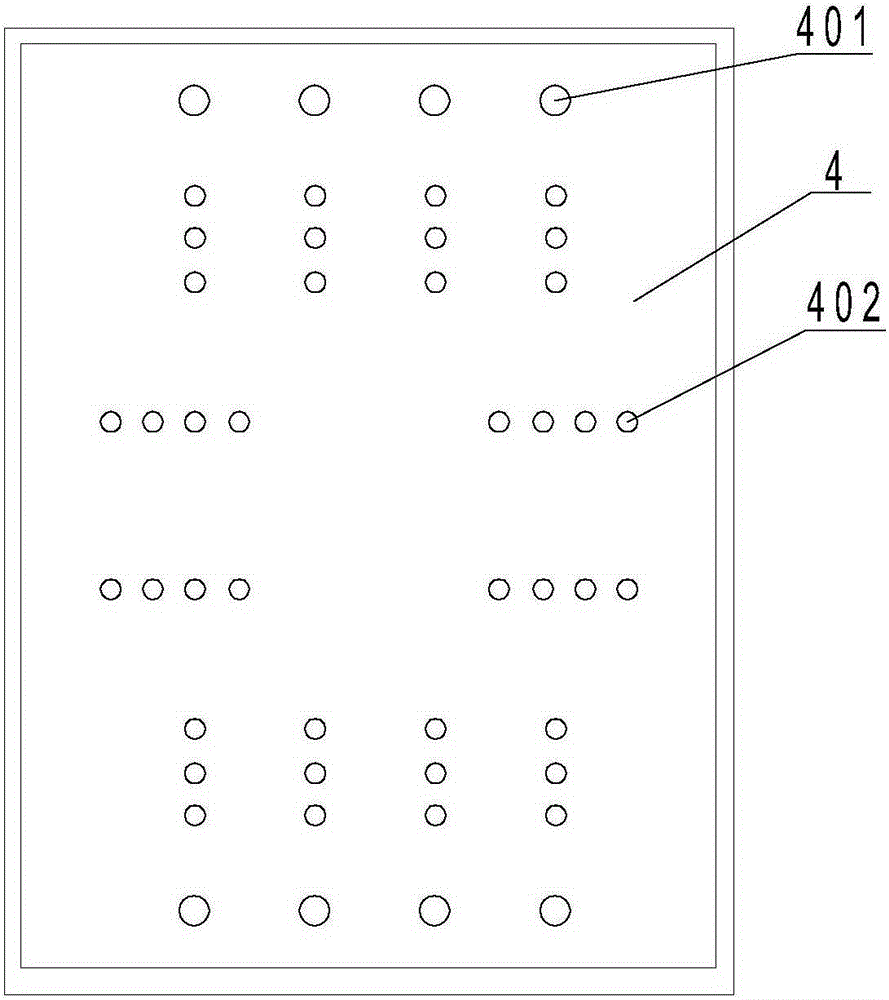

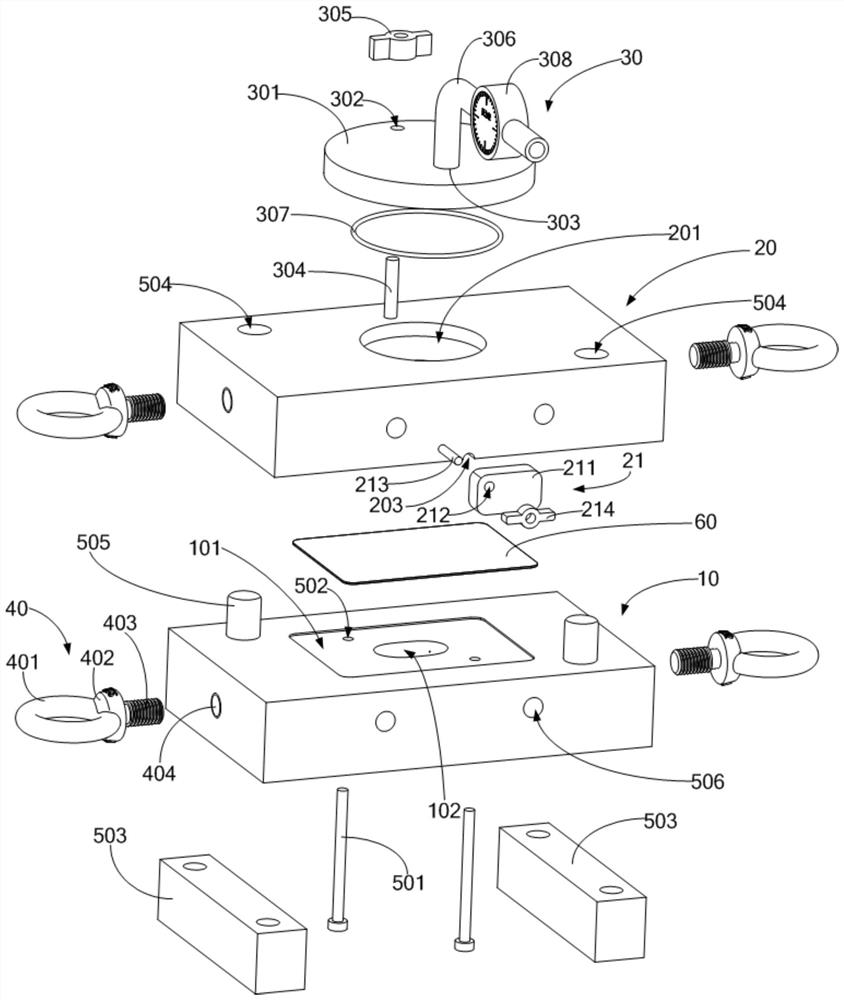

Die pressing automatic molding system for interior trim plate of car roof and process of die pressing automatic molding system

The invention relates to a die pressing automatic molding system and a process thereof, in particular to a die pressing automatic molding system for an interior trim plate of a car roof and a process of the die pressing automatic molding system. The system comprises a pressing die, a press, an automatic fabric clipping device, a robot and an oven. The oven comprises an oven rack, heating devices, rails located in the heating devices, and a grafter arranged on the rails and used for containing a base material. The grafter is provided with multiple positioning holes for positioning the base material and facilitating prick fetching and multiple vent holes. The robot is located between the automatic fabric clipping device and the oven. The process includes the steps of S1, fabric preparation; S2, base material preparation; S3, base material heating; S4, fabric fetching; S5, base material fetching; S6, pressing; S7, pressure maintaining; and S8, die opening and completing of the process. The accuracy of dynamic repeated positioning of the base material can be improved, and the purpose of accurate mobile positioning is achieved; and the system and the process have the beneficial effects of being high in machining efficiency, high in product quality, reasonable in process and convenient to operate, and are easy to use and popularize.

Owner:柳州裕信方盛汽车饰件有限公司

Preparation method for hydrophobic precipitated silicone dioxide with high whiteness and superlow hydroscopicity

InactiveCN1405239AGood electrical propertiesShorten the softening timeSilicaPigment treatment with organosilicon compoundsPolymer scienceFluidized bed

A hydrophobic precipitated silica is prepared by a process comprising: a) preparing a mixture of an organopolysiloxane derivative and a precipitated silica; b) conditioning the mixture obtained at a temperature ranging from 10 to 150 DEG C for a period ranging from 0.5 to 72 h, and c) conducting oxidative heat treatment under fluid conditions at a temperature more than 300 DEG C with an oxidizing gas. Said liquid condition is preferred set among the suspending bed, moving bed, fluidized bed and / or turbulent bed.

Owner:DEGUSSA AG

Device and method for making kelp paste

ActiveCN108433087AUnique flavorRealize streamlined operationFood shapingFood dryingFlavorTransmission belt

The invention relates to a device and method for making kelp paste. The device comprises a first transmission belt, a cutting unit, a softening unit, a washing unit, a slurrying unit, a drying unit and a material mixing unit, wherein the cutting unit is used for cutting dried kelps on the first transmission belt into blocks; the softening unit is used for softening the dried kelps; the washing unit is used for washing the softened kelps; the slurrying unit is used for crushing the kelps to form kelp pulp; the drying unit is used for drying the kelp pulp to form kelp blocks; and the material mixing unit is used for crushing the kelp blocks to form kelp powder, and mixing the kelp powder with auxiliary materials. Through the adoption of the device disclosed by the invention, deep-processingtreatment of kelps is realized; the kelp paste made by the device is clean, hygienic and unique in flavor; and in the processing course, streamline operation is realized, the continuity is high, manual participation is not needed, and the production efficiency is high.

Owner:天津鼎拓恒远知识产权服务有限公司

Method for processing gastrodia elata bl. original-shape slices

InactiveCN105560909ANo doubtEasily brokenFood mechanical treatmentFood dryingMechanical engineeringGeneral surgery

The invention discloses a method for processing gastrodia elata bl. original-shape slices, wherein the method comprises the following steps: washing gastrodia elata bl. cleanly, placing the gastrodia elata bl. in a normal pressure steamer, and carrying out water-insulation steaming at the temperature of 80-90 DEG C for 30-45 min until the gastrodia elata bl. is done for enzyme deactivation; placing the gastrodia elata bl. after enzyme deactivation in a drying oven, and carrying out first-stage drying; slicing the gastrodia elata bl. after drying by a dislocated opposite cutting method comprising the steps of dividing the gastrodia elata bl. after drying into an upper part and a lower part with the central axis as a boundary, slicing the upper part with the slice thickness of 2-3 mm, cutting until reaching the central axis, then slicing the lower part with the slice thickness still of 2-3 mm, cutting until reaching the central axis in the same way, but allowing the lower knife edge to be staggered with the upper knife edge, and thus obtaining the gastrodia elata bl. slices connected with each other; allowing the gastrodia elata bl. slices to stand, and carrying out first-stage back sweating; and after the first-stage back sweating is finished, respectively drying for 4 times, and carrying out back sweating for 3 times, to obtain the dried product. The method can ensures that the dried gastrodia elata bl. product is convenient to eat, the original shape of the gastrodia elata bl. can be kept, the hardness of the gastrodia elata bl. is reduced, standards are easy to control, and the method can be widely popularized.

Owner:贵州乌蒙腾菌业有限公司

All-bamboo unfolding process

ActiveCN113370332ANo deformationNo problem of crackingWood compressionWood treatment detailsProcess engineeringMachining process

The invention discloses an all-bamboo unfolding process, and belongs to the technical field of bamboo processing. The process comprises the following steps of: segmenting and sectioning all-bamboo into bamboo chips with radians; after being pressurized, heated and softened, unfolding the bamboo chips in a variable-arc and fixed-thickness mode, and planing off bamboo green and tabasheer; then, conducting double-face protection gradual flattening under the heat preservation condition till the bamboo chips are completely flattened, to obtain bamboo boards; and performing multi-layer ballasting shaping and compensation ballasting shaping drying on the cooled the bamboo board until the moisture content is 6-10% after being subjected to cooling treatment, and finally obtaining a bamboo board finished product after fixed-width trimming. According to the all-bamboo unfolding technology, unfolding treatment can be conducted on different sections of bamboo tubes, the effect that all-bamboo is unfolded through the same technology is achieved, it is not needed to configure multiple production technologies and corresponding production line in the unfolding process, the problem of cracking does not occur in the machining process, and the obtained bamboo board finished product is smooth and flat in surface and does not rebound.

Owner:FUJIAN LONTAI BAMBOO HOUSEHOLD CO LTD

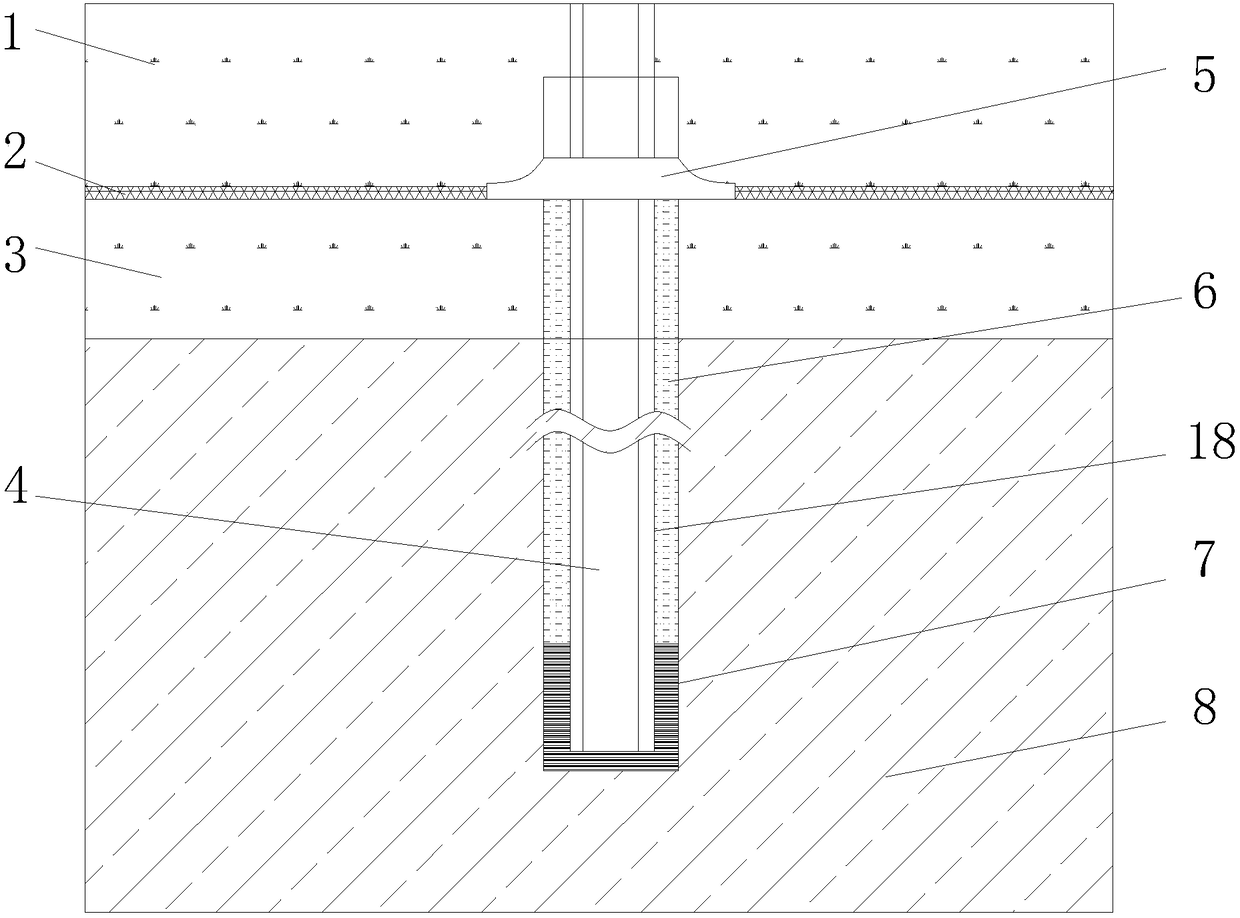

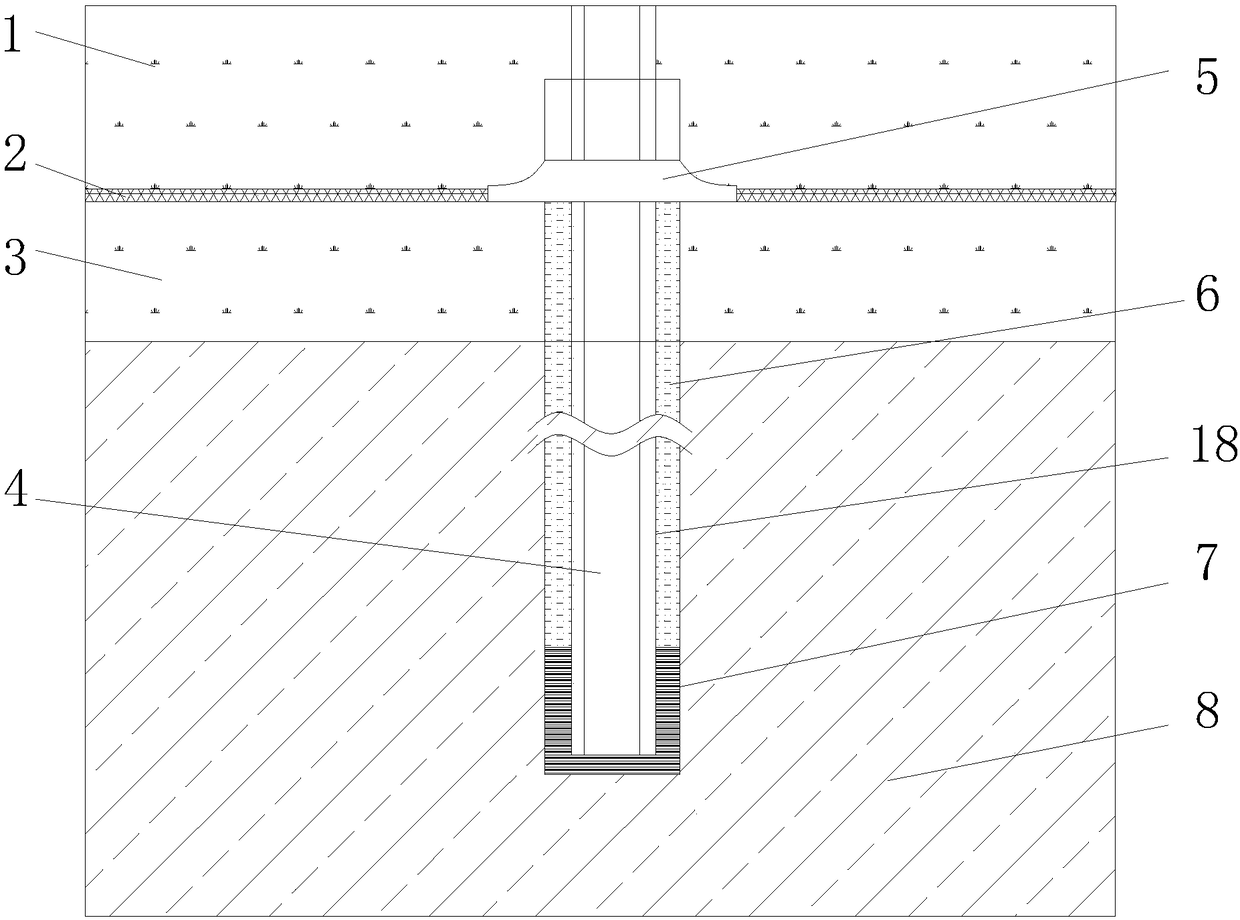

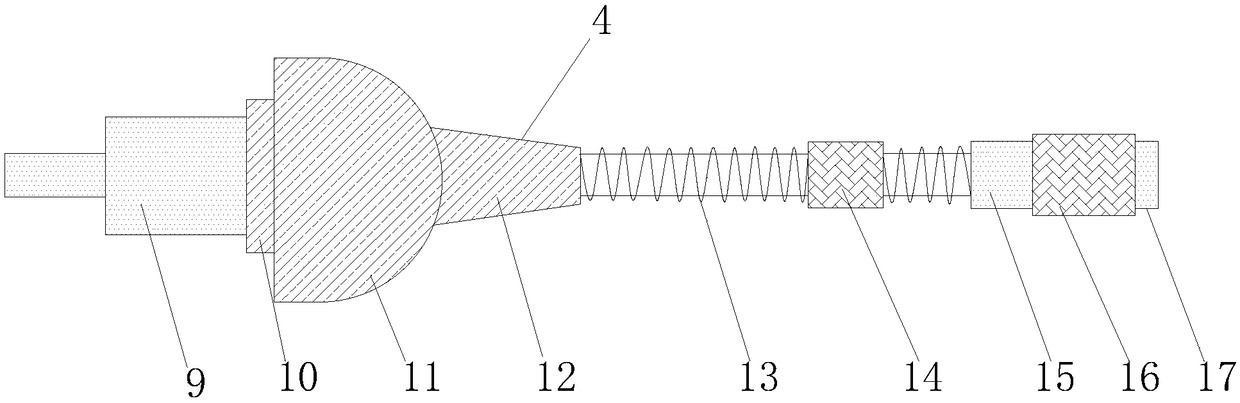

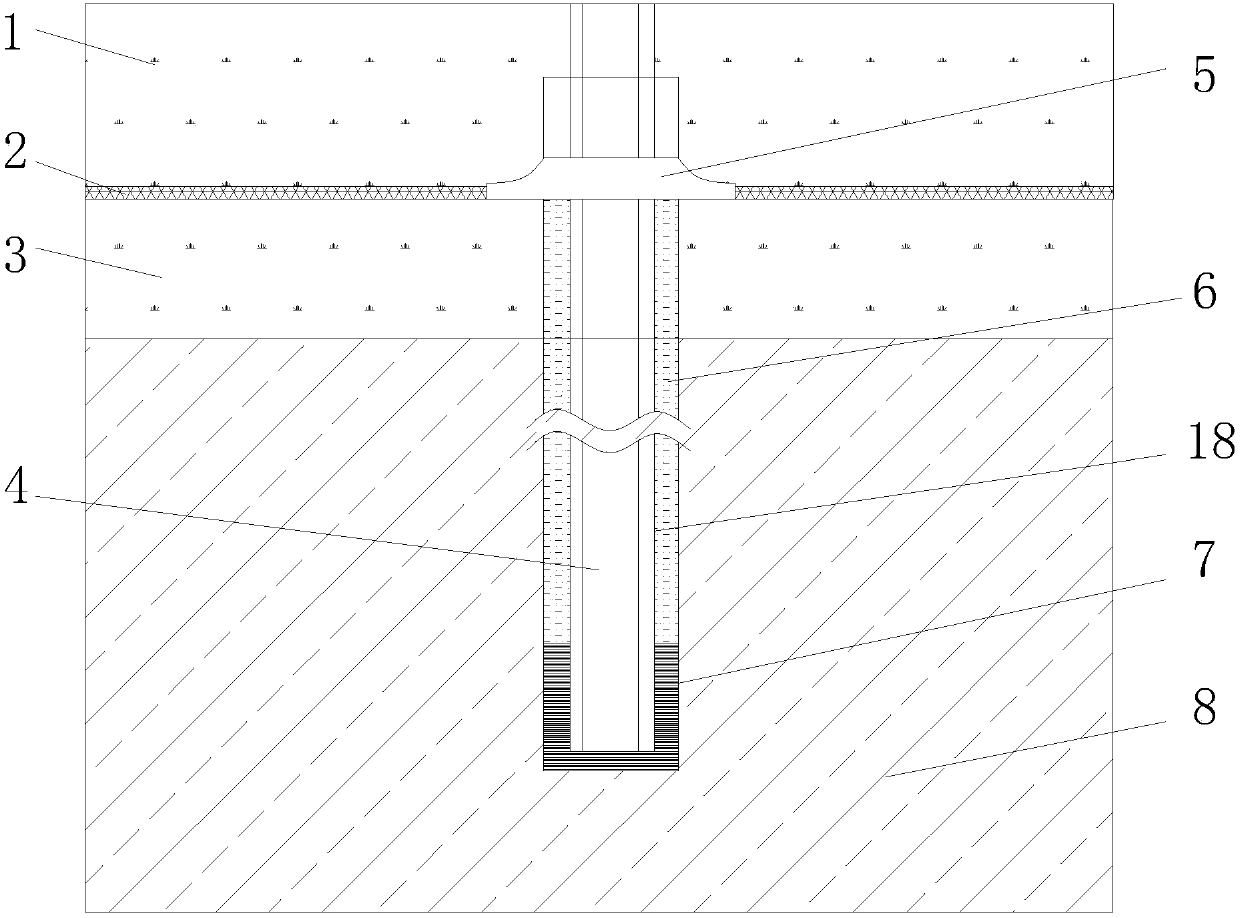

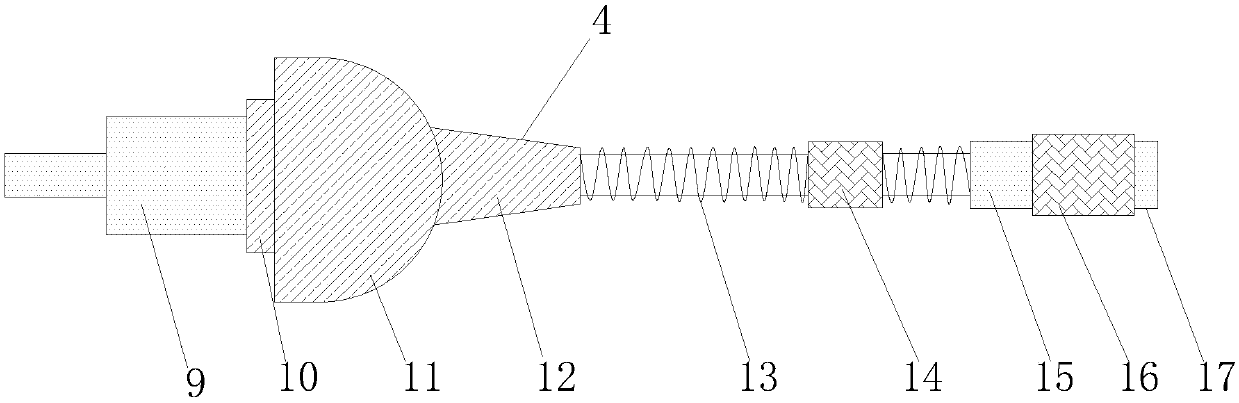

Soft rock roadway anchorage force device

InactiveCN108150207AIncreased bearing area and shear strengthAdd supportAnchoring boltsCement slurryGeomorphology

The invention discloses a soft rock roadway anchorage force device comprising an anchor rod, an anchor rod disc, cement slurry, mud rock and a bottom plate. The anchor rod is arranged inside the bottom plate and externally filled with re-jetting slurry; the lower portion of the re-jetting slurry is filled with inverted-arch initial-jetting slurry, and a mesh is arranged between the re-jetting slurry and the inverted-arch initial-jetting slurry; the mud rock is arranged on the lower portion of the inverted-arch initial-jetting slurry; the anchor rod disc is arranged on the surface of the anchorrod in a penetrating mode; and anchorage agents are arranged on the lower portion of the cement slurry and wrap the surface of the anchor rod. The anchorage agents and the cement slurry are adopted on the bottom plate and matched with a full-length anchorage method, so that the water insulation and anchorage effects are strengthened, and the defects that when water exists in the bottom plate, anchorage of the anchorage agents and the hole wall is affected by slime formed by contained water in an eye hole; only the requirement for pretention force can be met through a traditional method; and when a roadway is pressed, it cannot be ensured that the anchorage end meets the requirements for yield force and breaking force of the anchor rod, consequently, the anchor rod and the anchor agents are overall pulled out, and overall supporting loses efficacy are overcome.

Owner:朱胜伟

Wood softener and preparation method, wood softening method and method for making wood slices

ActiveCN106584622BReduce stiffnessReduce energy consumptionWood treatment detailsWood heatingWater bathsCellulose

The invention provides a wood softening agent and a preparation method thereof, a wood softening method using the wood softening agent, and a wood slice manufacturing method. The wood softening agent comprises lithium chloride and N, N-dimethyl acetamide and water, and the amount ratio of the three substances is 1:4:18. The wood slice manufacturing method includes the steps that wood is sawn into wood samples, the wood softening agent provided by the invention is added, the wood samples are placed in a constant temperature water bath, and after cooling, slicing is performed to form wood slices. According to the wood softening agent, a lithium chloride / N, N-dimethyl acetamide system is used for soaking, swelling and softening cellulose in the wood, and therefore the rigidity of the wood is lowered, the softening time is shortened, and energy consumption is reduced; and according to the softened wood obtained through the reagent and a treatment method, only the cellulose of the wood is softened, the structural characteristics of the wood are not changed, the softened wood keeps the state after treatment all the time, and restoration caused by environment condition changes is avoided.

Owner:SHANGHAI CONSTRUCTION GROUP

Tuna bone powder and preparation method thereof

The present invention discloses tuna bone powder and a preparation method thereof. High-quality tuna bones are repeatedly washed clean and drained for a standby application, then a subcritical water combined microwave treatment is used to enable fish bones to be fully softened, then after the fish bones are evenly mixed with a deodorant, putting still is conducted for 10-30 min, then the deodorantis washed clean with clean water, and finally the fish bones are dried, pulverized and sterilized to obtain the tuna bone powder. The subcritical water combined microwave treatment technology is usedfor processing the tuna bones, can effectively shorten softening time, enhances a softening effect, and reduces time cost loss. At the same time, the preparation method retains calcium, phosphorus and other nutritional components in the fish bones to the maximum extent, and avoids caused loss and waste of nutrients during the softening process. In addition, after the subcritical water combined microwave treatment, the preparation method lays foundation for late-stage deodorization, drying and pulverization, can effectively release minerals of hydroxyapatite, etc. in the fish bones, significantly increases protein content in the fish bones, and enables nutrients in the fine powder to be more liable to be digested and absorbed by human body.

Owner:荣成市广益水产食品有限公司

Method for preparing chlorophyll metallic sodium salt by taking silkworm feces as raw material

The invention belongs to the technical field of chlorophyll metallic sodium salt preparation, and particularly relates to a method for preparing a chlorophyll metallic sodium salt by taking silkworm feces as a raw material. The method comprises the following steps of (1) impurity removal of raw materials; (2) raw material softening; (3) immersing; (4) primary concentration; (5) separation; (6) secondary concentration; (7) paste dissolving and impurity removal; (8) saponification; (9) metallization; (10) acidification; (11) washing; (12) drying; and (13) salt forming. According to the method for preparing a chlorophyll metallic sodium salt by taking the silkworm feces as a raw material, which is disclosed by the invention, the purity and yield of products are increased, the yield can reach 1.5-2%, and the energy consumption is reduced.

Owner:WEIFANG HANXING CHLOROPHYLL

Wood softener, and preparation method and application thereof

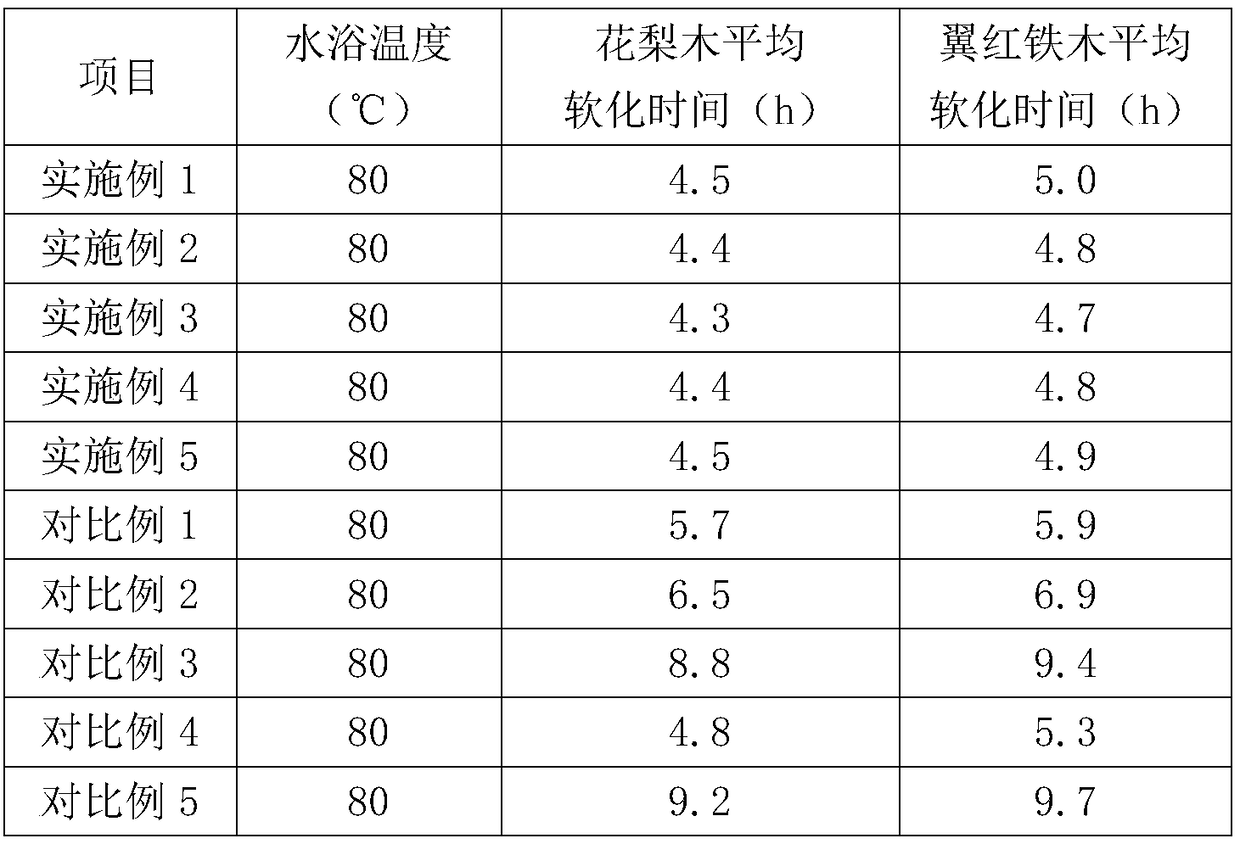

ActiveCN109366661ALow costLow softening temperatureWood treatment detailsWood impregnation detailsSulfonatePotassium

The invention discloses a wood softener, and a preparation method and application thereof. The wood softener is composed of the following materials, by weight: 14-18 parts of hydrogen peroxide, 5-7 parts of oleoyl cholamine, 4-6 parts of potassium trifluoromethane sulfonate, 2-4 parts of N,N-Dimethylacetamide, 1-5 parts of lithium acetate, and 0.8-1.2 parts of sodium tripolyphosphate, The wood sofener is prepared from hydrogen peroxide, oleoyl ethanolamine, trifluoromethane sulfonic acid potassium, N,N-Dimethyl acetamide, and lithium acetate and sodium tripolyphosphate according to the process; the prepared wood softener has low softening temperature and short softening time; under the same softening temperature, the softening time can be shortened by about 50%; softening efficiency is high, the cost of the wood softening can be reduced, and the softening effect is good; and the preparation method is simple, can easily achieve industrial production and is worth popularizing.

Owner:派韵家具江苏有限公司

Anchor rod anchoring force device for soft rock roadway

InactiveCN108167008AAdd supportSolve the problem of insufficient preloadAnchoring boltsEngineeringCement slurry

The invention discloses an anchor rod anchoring force device for a soft rock roadway. The anchor rod anchoring force device comprises an anchor rod, an anchor rod disc, cement slurry, mudstone and a bottom plate. The interior of the bottom plate is provided with the anchor rod. The exterior of the anchor rod is filled with re-jetting slurry. The lower portion of the re-jetting slurry is filled with inverted arch initial jetting slurry. Net pieces are arranged in the middles of the re-jetting slurry and the inverted arch initial jetting slurry. The lower portion of the inverted arch initial jetting slurry is the mudstone. The anchor rod disc is arranged on the surface of the anchor rod in a penetrating mode. The lower portion of the cement slurry is provided with an anchoring agent. The surface of the anchor rod is wrapped with the anchoring agent. According to the anchor rod anchoring force device, a method that the anchoring agent and the cement slurry are matched with full length anchoring is adopted, the water isolation and anchorage effects are improved, when the bottom plate contains water, slime formed due to eye holes with the water affects anchorage of the anchoring agent and the hole walls; and according to an adopted traditional method, pretightening force requirements can only be met, when the roadway is under pressure, it cannot be ensured that the anchorage end meets requirements of yield and breaking force of the anchor rod, so that the anchor rod and the anchoring agent are pulled out integrally, and whole support fails accordingly.

Owner:朱胜伟

Device for increasing inverted-arch anchor rod anchoring force for soft rock roadway

InactiveCN107842385AAdd supportSolve the problem of insufficient preloadAnchoring boltsShotcreteEngineering

The invention discloses a device for improving the anchoring force of an anti-bottom arch bolt in a soft rock roadway, which includes a bolt, a bolt plate, cement slurry, mudstone and a bottom plate. The inside of the bottom plate is provided with a bolt, and the outside of the bolt is filled with Re-spraying, the bottom of the re-spraying is filled with reverse bottom arch primary spraying, and a mesh is set in the middle of the re-spraying and reverse bottom arch primary spraying, the bottom of the reverse bottom arch primary spraying is mudstone, An anchor disc runs through the surface of the anchor rod, an anchoring agent is arranged under the cement slurry, and the anchoring agent is wrapped on the surface of the anchor rod. The present invention uses anchoring agent and cement slurry to cooperate with the full-length anchoring method through the bottom plate to enhance the water-proof and anchoring effect. When there is water in the bottom plate, the slime formed by water in the hole affects the anchoring agent and the hole wall. The traditional method only It can meet the pre-tightening force requirements, but when the roadway is pressed, the anchorage end cannot be guaranteed to meet the yield and breaking force requirements of the anchor rod, causing the anchor rod and anchoring agent to be pulled out as a whole, making the overall support invalid.

Owner:朱胜伟

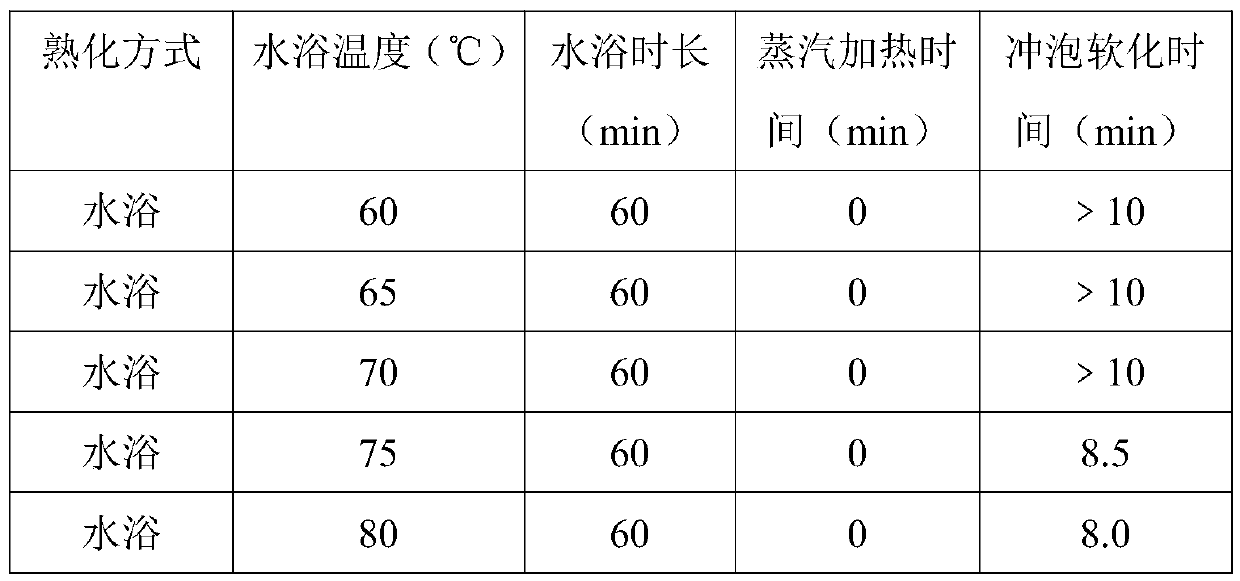

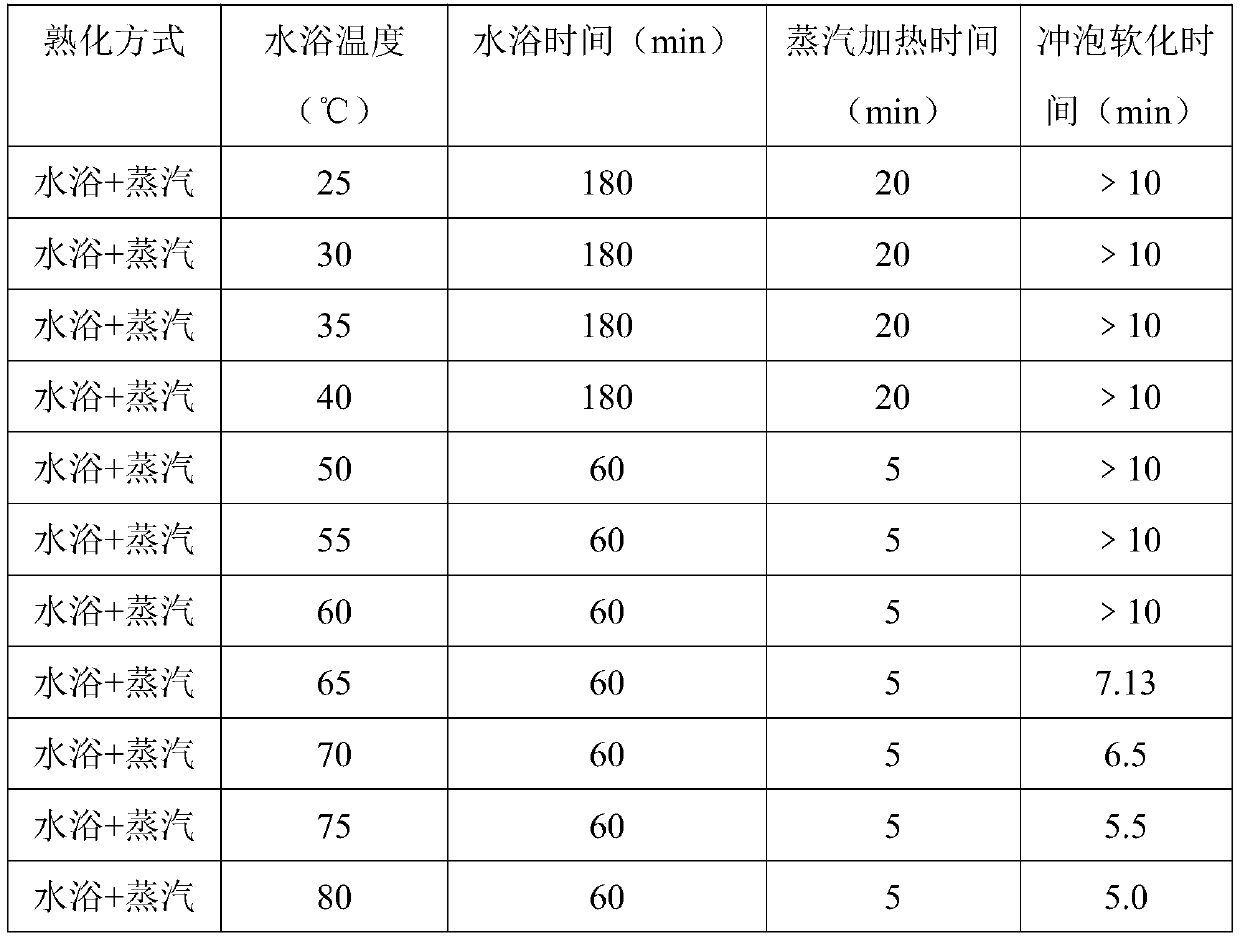

Making method of Chenopodium quinoa instant rice

InactiveCN110367458AAchieve full maturityGood rehydrationFood thermal treatmentFood dryingWater bathsRice dishes

The invention relates to a making method of Chenopodium quinoa instant rice. The making method includes the steps of firstly, performing water bath heating on Chenopodium quinoa; secondly, performingsteam heating on the Chenopodium quinoa; subjecting the Chenopodium quinoa to immersion cleaning with clean water; subjecting the Chenopodium quinoa to forced air drying, to be more specific, slowly transferring the cleaned Chenopodium quinoa into a support plate in a way that the thickness of the Chenopodium quinoa is 3-4cm, placing in a forced air drying oven, and continuously drying at 60-70 DEG C for 12-24 hours to obtain dried pre-cured Chenopodium quinoa. The making method has the advantages that starch and protein in the Chenopodium quinoa is thoroughly denatured, by using different heating manners, the pre-cured Chenopodium quinoa extremely high in reconstitution property is obtained after drying, the Chenopodium quinoa can be softened for eating after being reconstituted with boiling water for 5-7 minutes, and the fast-paced life requirements of people are satisfied.

Owner:TIANJIN AGRICULTURE COLLEGE

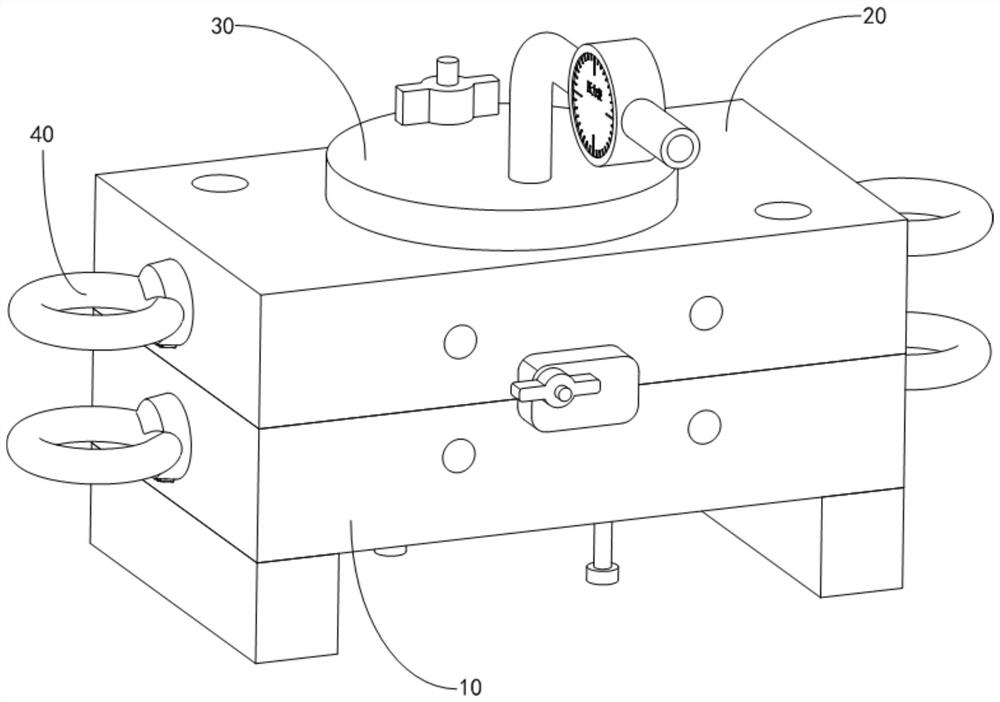

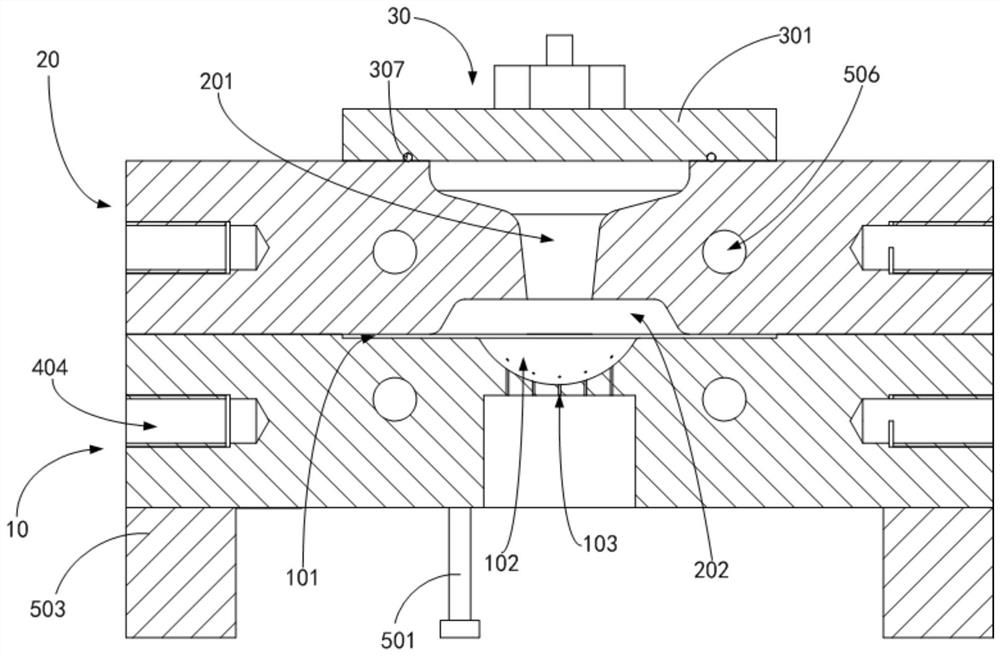

Glass forming device and glass forming method

PendingCN113943099ASoften evenlyShorten the softening timeGlass reforming apparatusGlass productionGlass formingMoulding device

The invention provides a glass forming device and a glass forming method. The device comprises: a lower mold provided with a glass accommodating groove, wherein the glass accommodating groove is internally provided with a mold core groove; an upper mold matched with the lower mold, wherein a through hole and a molten liquid groove are formed in the upper mold, the molten liquid groove is formed in the surface, facing the lower mold, of the upper mold, the molten liquid groove communicates with the through hole, and the molten liquid groove and the mold core groove are oppositely arranged; and an air pressure assembly connected to the through hole and used for applying air pressure into the glass accommodating groove through the through hole. According to the invention, to-be-processed-and-formed glass is placed in a glass accommodating groove, a heated molten liquid is poured into a through hole of a second mold, the heated molten liquid flows into a molten liquid groove and is evenly distributed on the surface, facing the molten liquid groove, of the glass so as to rapidly and evenly soften the glass and shorten the softening time, and the molten liquid groove is pressurized through the through hole to make the heated molten liquid indirectly pressurize the glass, so that the stress is uniform when the glass is attached to a mold core groove, the breakage is avoided, and the product yield is improved.

Owner:NEW AMERIOCEAN TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com