Patents

Literature

185results about How to "Realize streamlined operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-layer white light LED (Light Emitting Diode) device with gradient refractive indexes and packaging method thereof

InactiveCN104037276AQuality improvementImprove performanceSemiconductor devicesRefractive indexLight-emitting diode

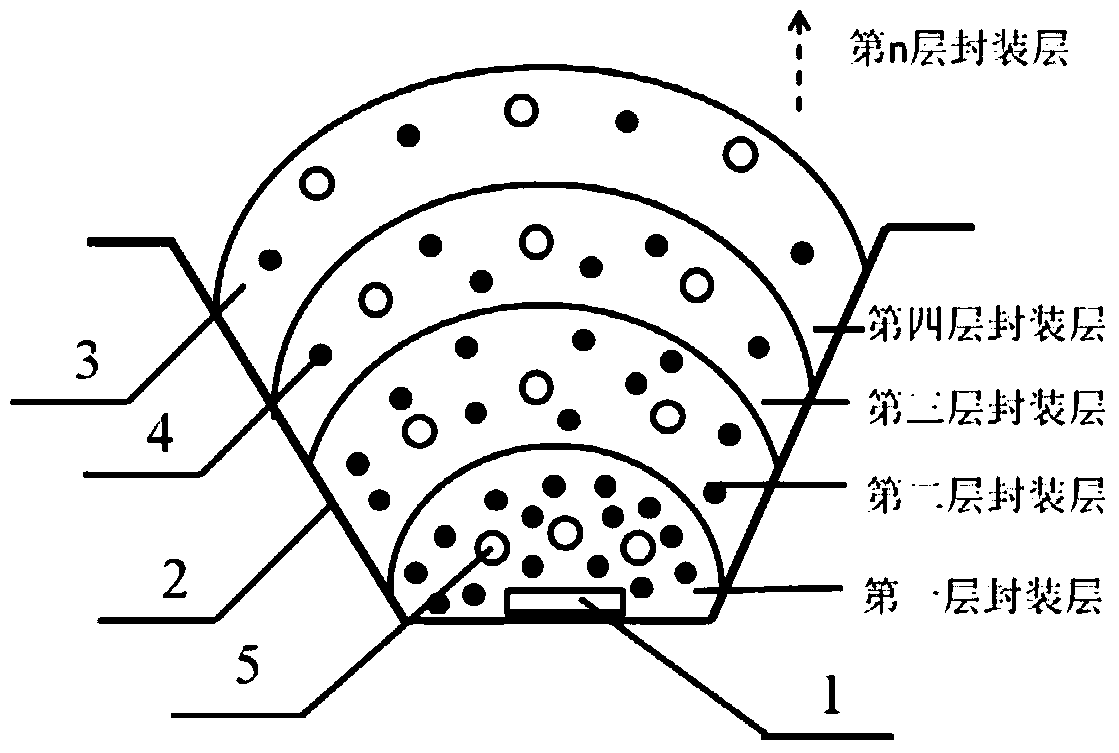

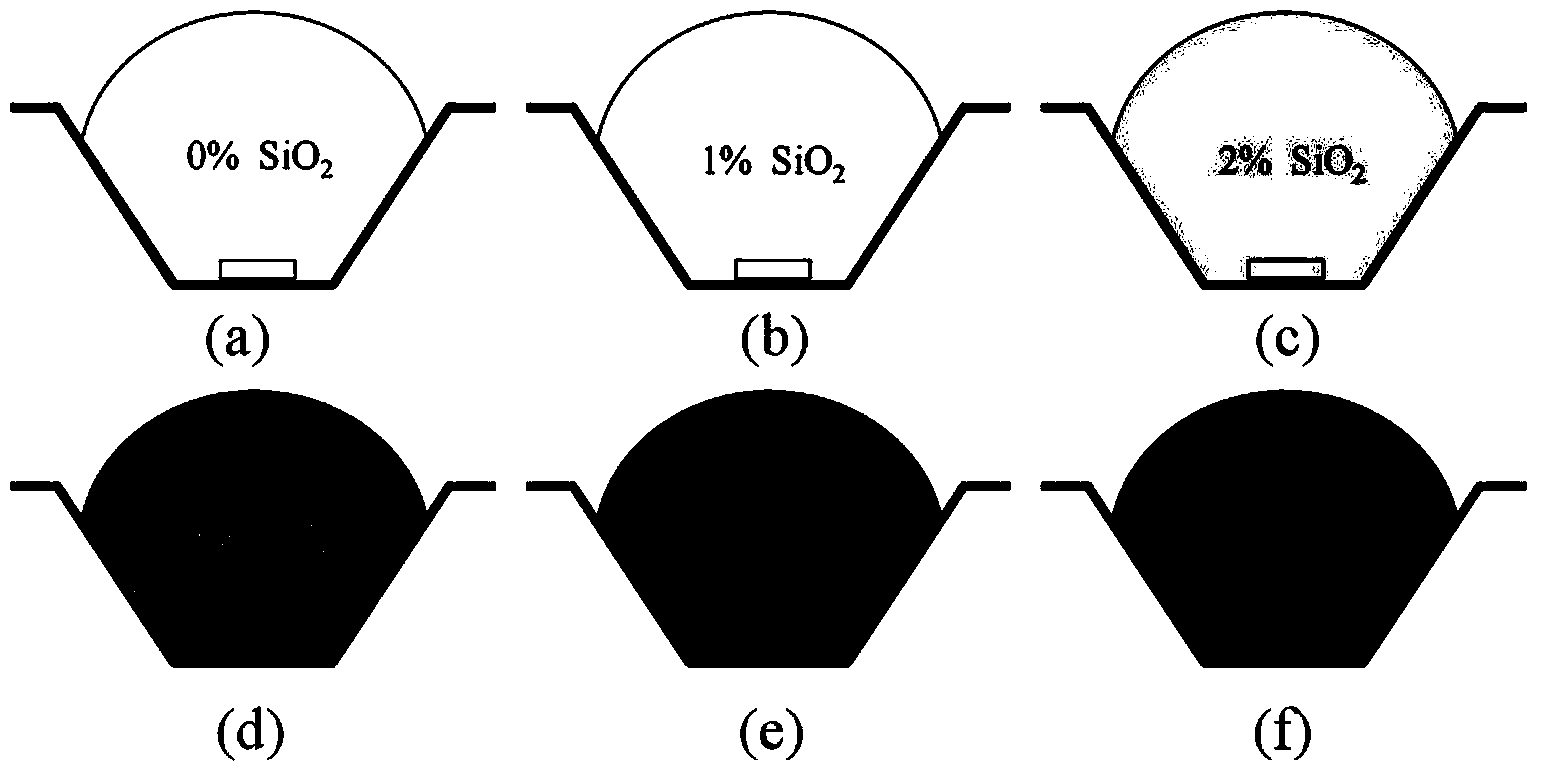

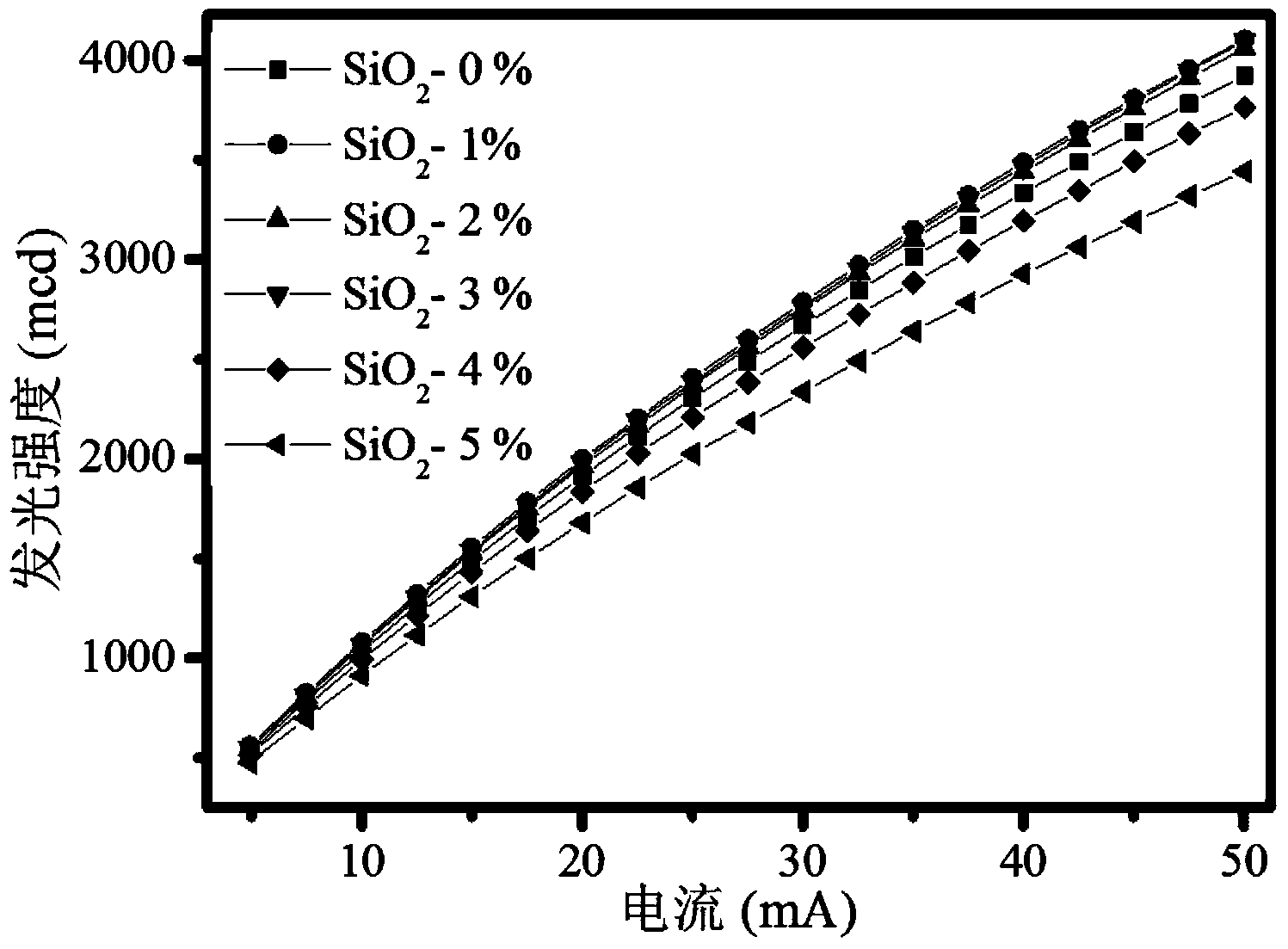

The invention discloses a multi-layer white light LED (Light Emitting Diode) device with gradient refractive indexes and a packaging method thereof. The LED device is characterized in that n packaging layers are gradually packed on the LED device layer by layer, wherein n is not less than 1; fluorescent powder and nano-scattering diluents are uniformly mixed in the packaging layer; the refractive index of the packaging layer is less than that of an LED chip, and the refractive indexes of the n packaging layers which face outwards from the LED chip are reduced layer by layer. According to the LED device, by building the multi-layer white light LED device with the gradient refractive indexes, the extracting capacity of the white light LED device on the multi-layer white light LED device can be remarkably improved; furthermore, the device is high in quality and stable and reliable in performance.

Owner:HEFEI UNIV OF TECH

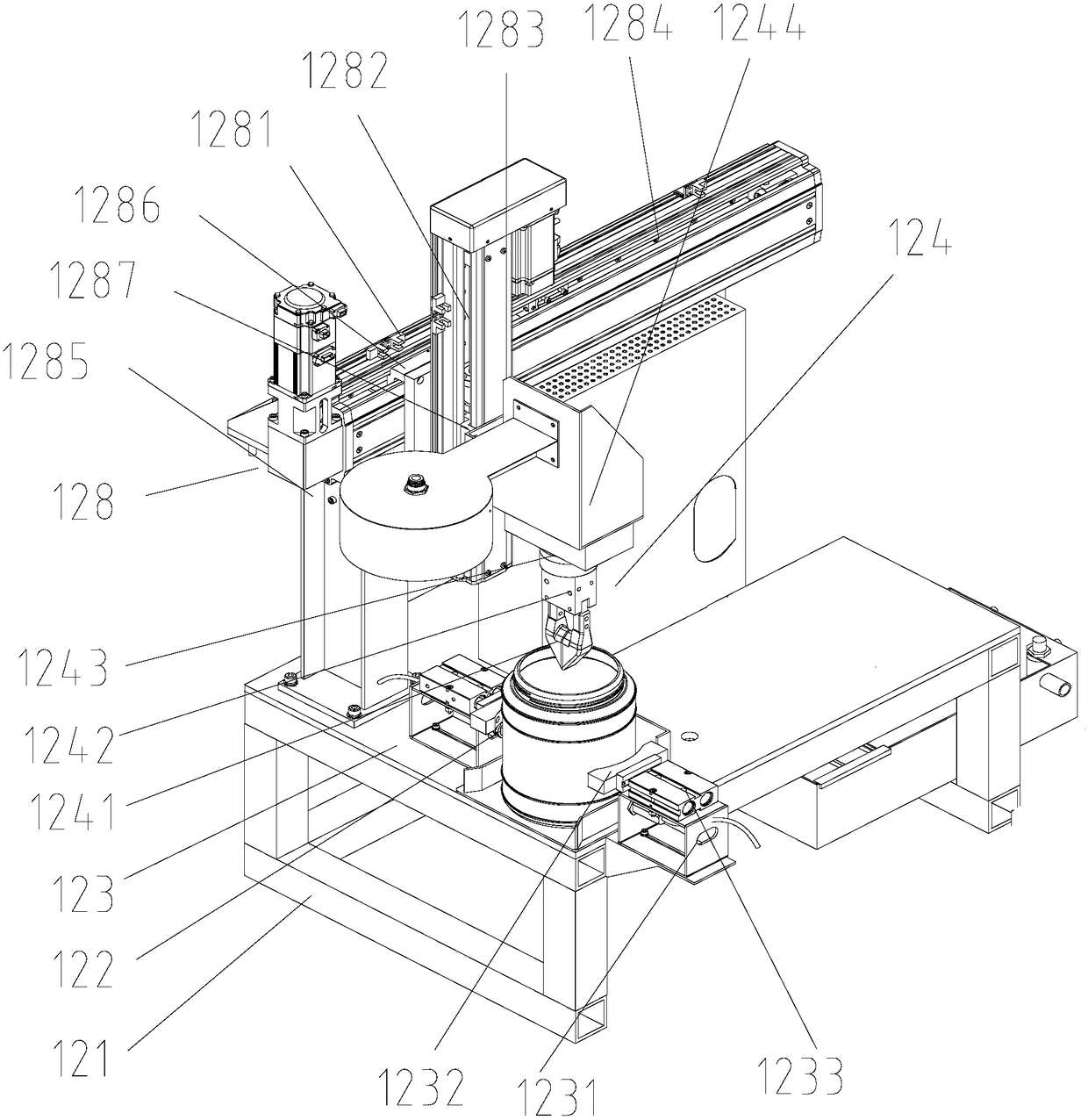

Integrated glue coating machine and operation method thereof

PendingCN106862009AReduce the difficulty of operationImprove operating precisionLiquid surface applicatorsCoatingsEngineeringCoating

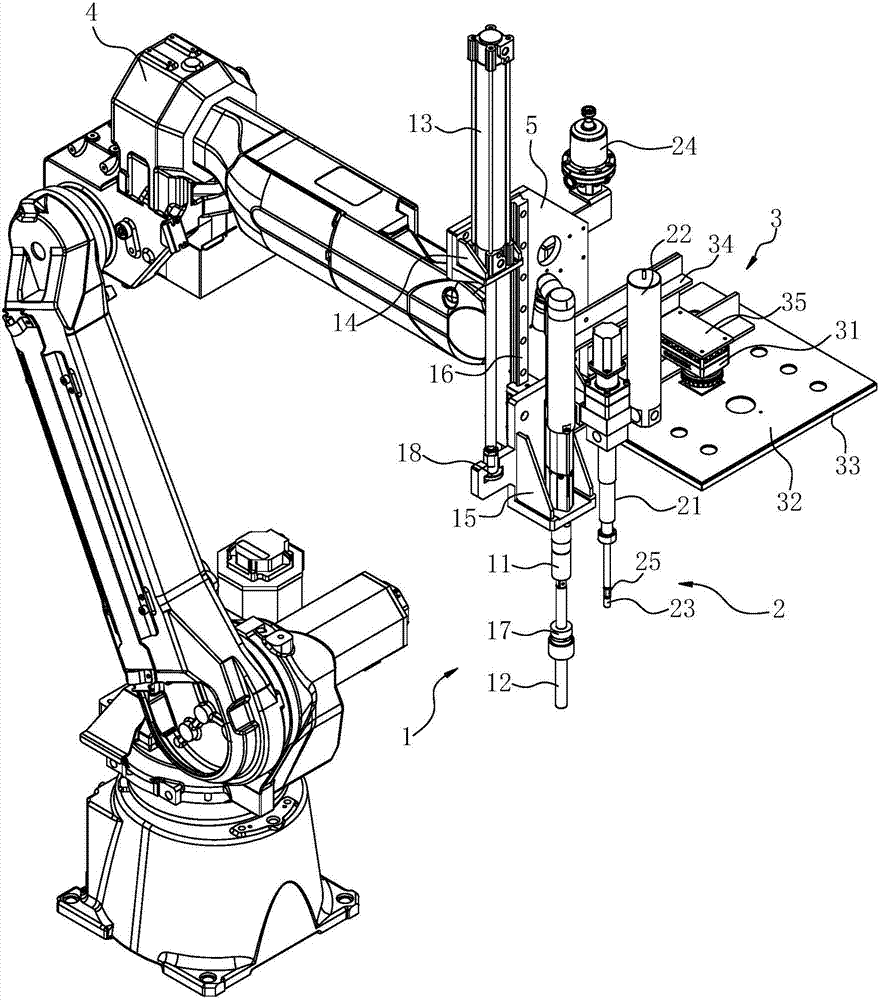

The invention discloses an integrated glue coating machine and an operation method thereof. The integrated glue coating machine comprises a screwing device, a glue coating device, a detection device and a robot, wherein the screwing device comprises a screwing shaft capable of moving in the vertical direction, and the end portion of the screwing shaft is detachably provided with a sleeve matched with a bolt; the glue coating device comprises a quantitative glue gun, the glue inlet end of the quantitative glue gun is connected with a glue storing tank, and the glue outlet end of the quantitative glue gun is connected with a glue needle; the detection device comprises a detection part used for workpiece positioning, machine type recognition and glue coating qualification degree detection; and the robot is provided with an operation end, and the screwing device, the glue coating device and the detection device are all connected with the operation end. The screwing device, the glue coating device and the detection device are all integrated on the robot, the function that one machine is multipurpose is achieved, the floor area of equipment is reduced, the production efficiency is improved, meanwhile, the integrated glue coating machine can be better compatible with different machine types, flexible production and equipment maintenance are facilitated, and the machine replaces the manual work to meet the real demands of clients for reducing the production cost and improving the production efficiency.

Owner:GUANGZHOU SEAHAWN IND ROBOTICS

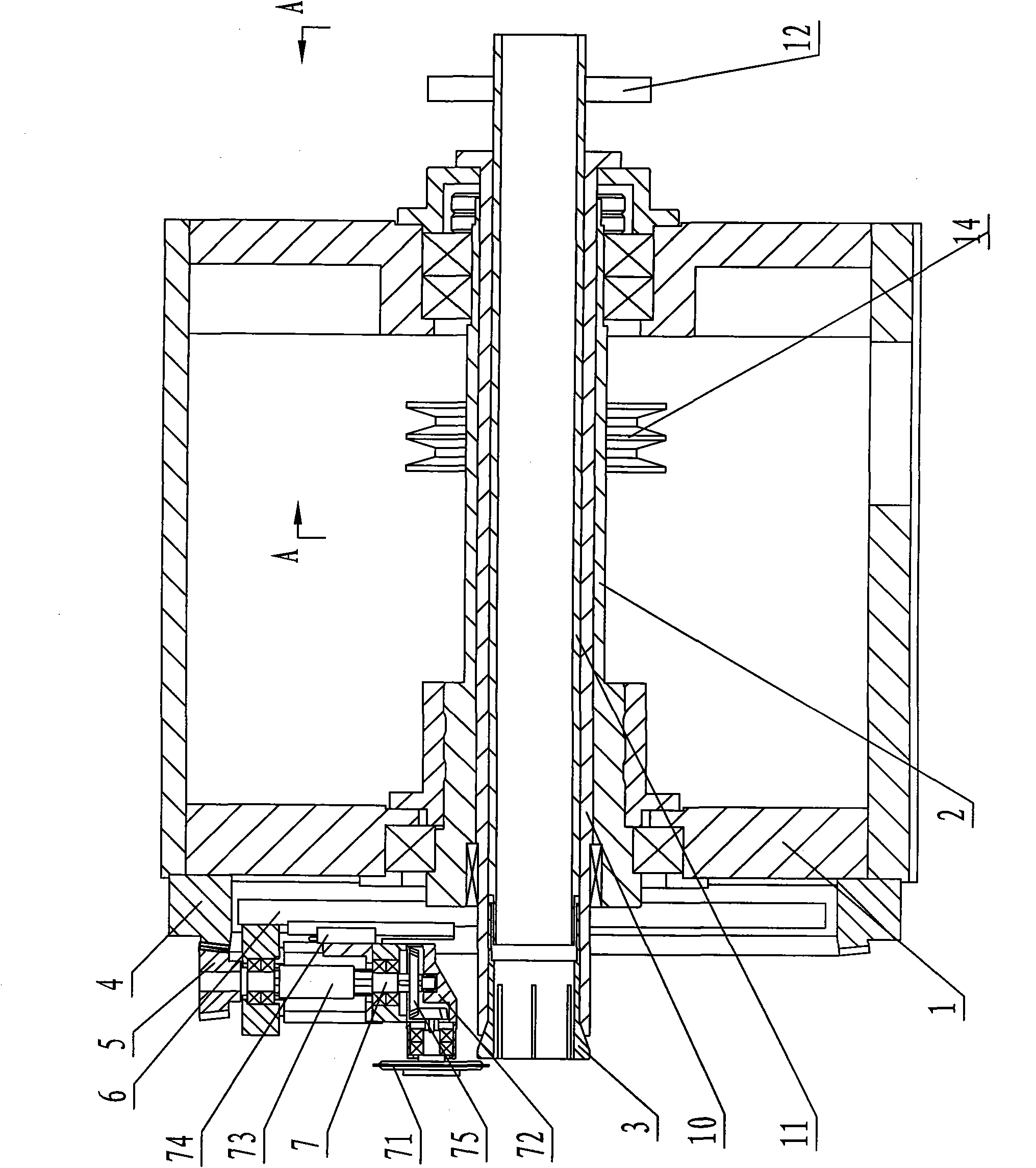

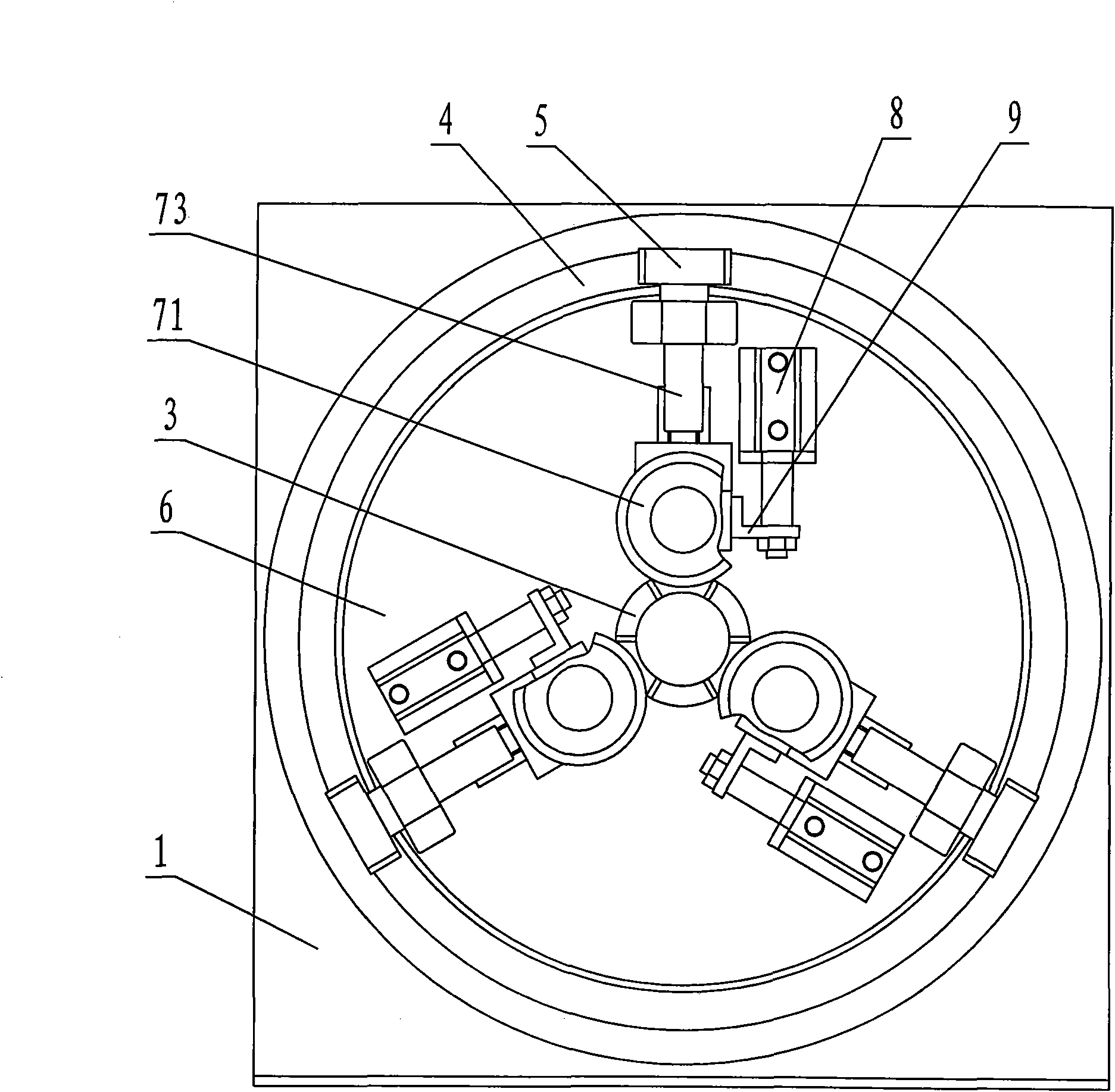

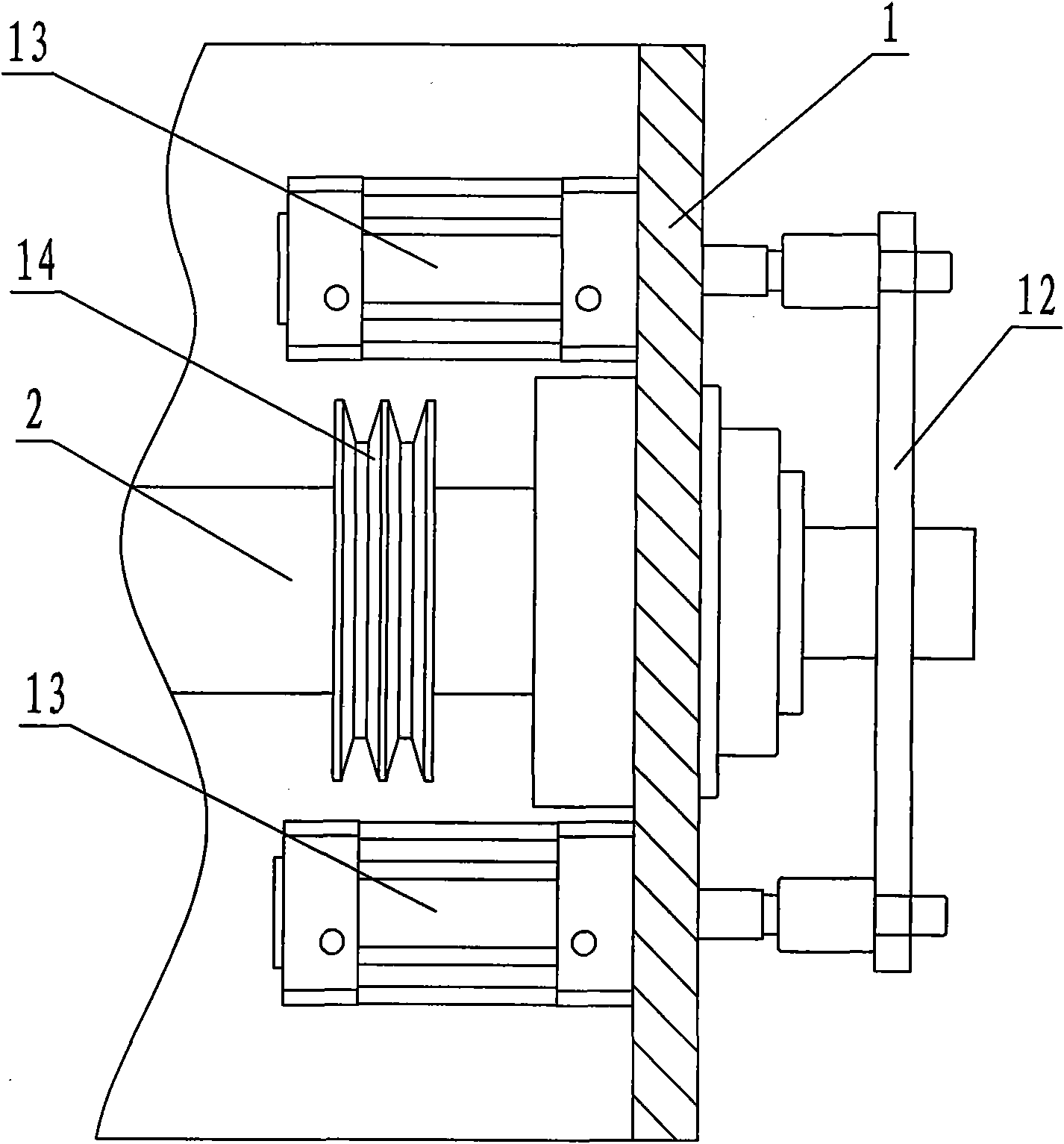

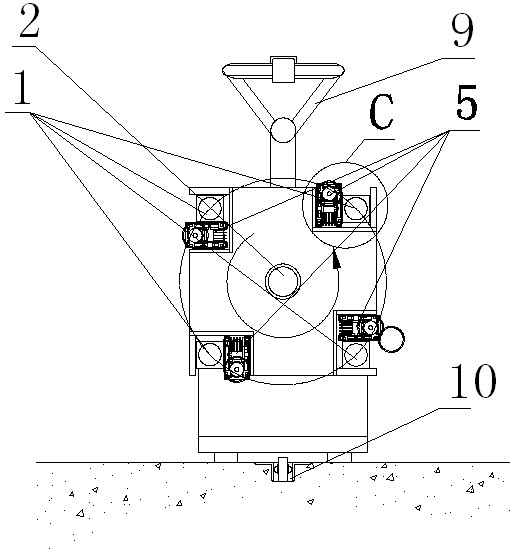

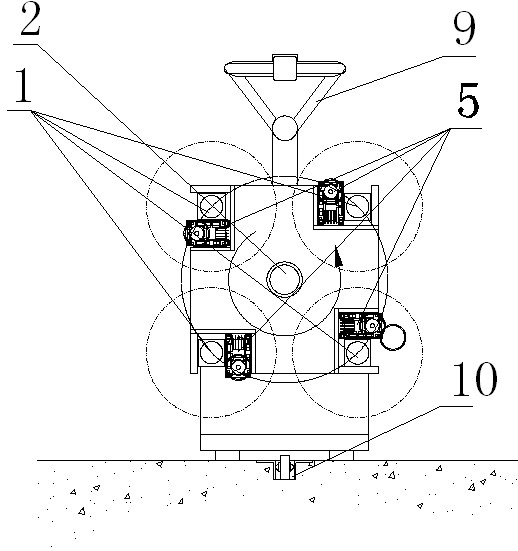

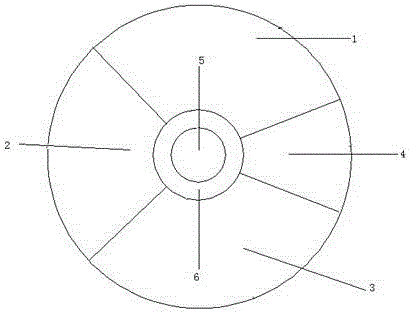

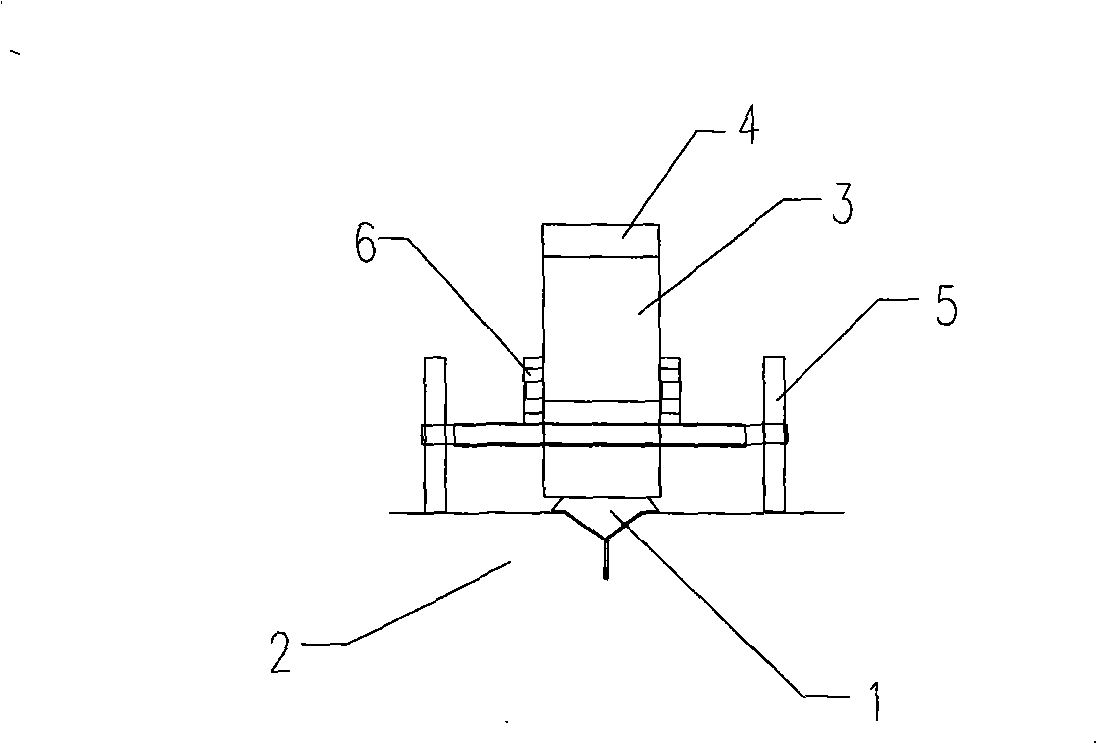

Full-automatic pipe cutting machine

InactiveCN101912994AExtended service lifeRealize streamlined operationTube shearing machinesKnife bladesEngineering

The invention discloses a full-automatic pipe cutting machine which comprises a frame, a rotary main shaft and a workpiece jacket, wherein, the workpiece jacket is positioned at the center of the front end of the main shaft and can telescopically clamp or loosen pipes; a large bevel gear is fixed on the front end surface of the frame, and the large bevel gear is meshed with a small bevel gear in a transmission manner; a turntable is fixed on the front end of the main shaft, and at least three cutting devices which can radially slide along the turntable are uniformly distributed on the circumference of the turntable; the small bevel gear is connected with the cutting devices in a transmission manner; the cutting devices comprise cutting blades; and when the main shaft drives the cutting devices to circumferentially rotate through the turntable, the small bevel gear is meshed with the large bevel gear in a transmission manner to drive the cutting blades to rotate. In the invention, by means of combination of high-speed autorotation and revolution of the cutting blades and radial movement along the pipes, the full-automatic pipe cutting machine cuts the pipes and makes an angled surface at cut positions to ensure bright, clear and tidy cross section of the pipes and improve machining precision; and a plurality of groups of the cutting blades can be employed simultaneously for machining the pipes, thus being beneficial to prolonging service life of the cutting blades and improving machining efficiency.

Owner:周志玉 +1

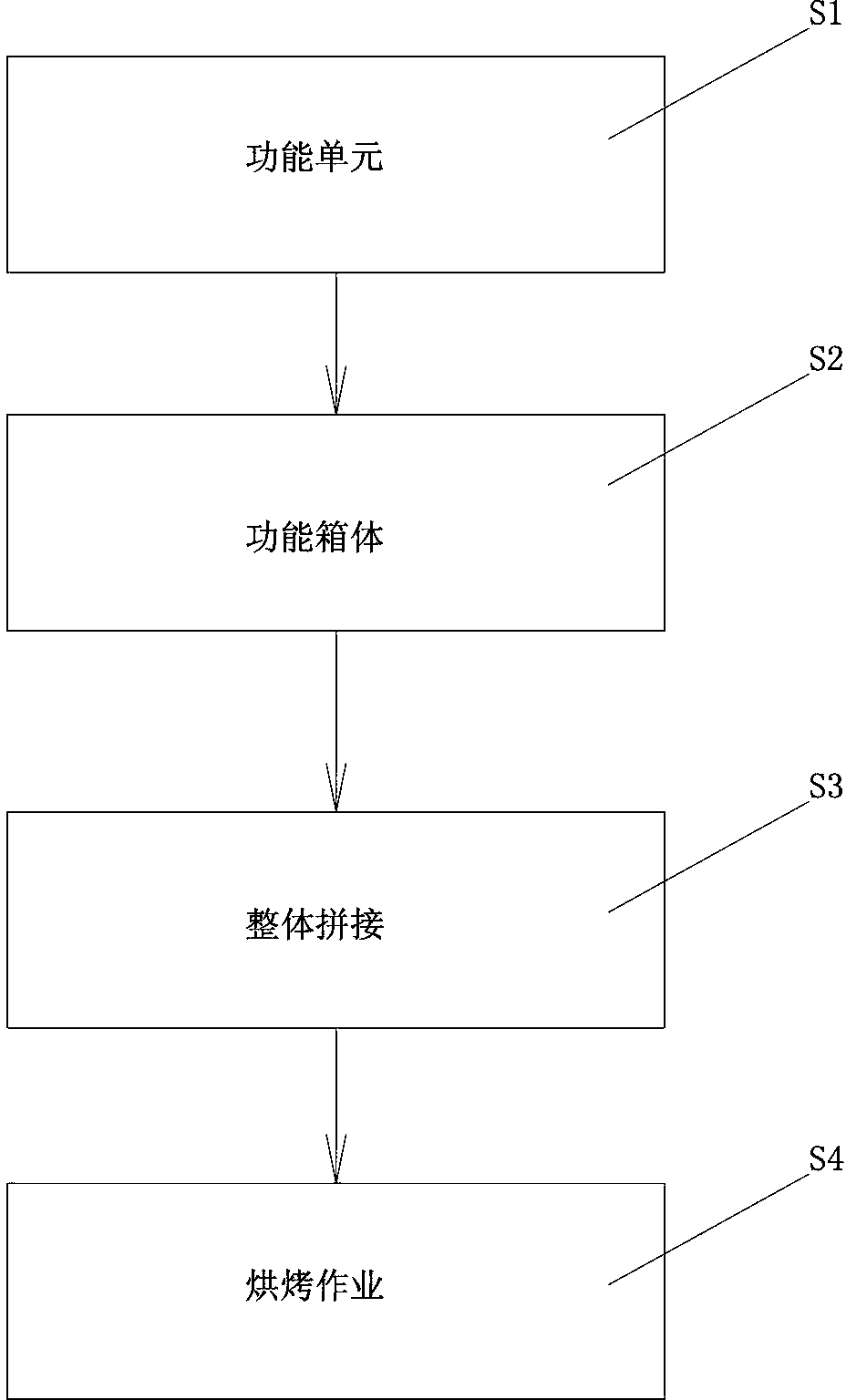

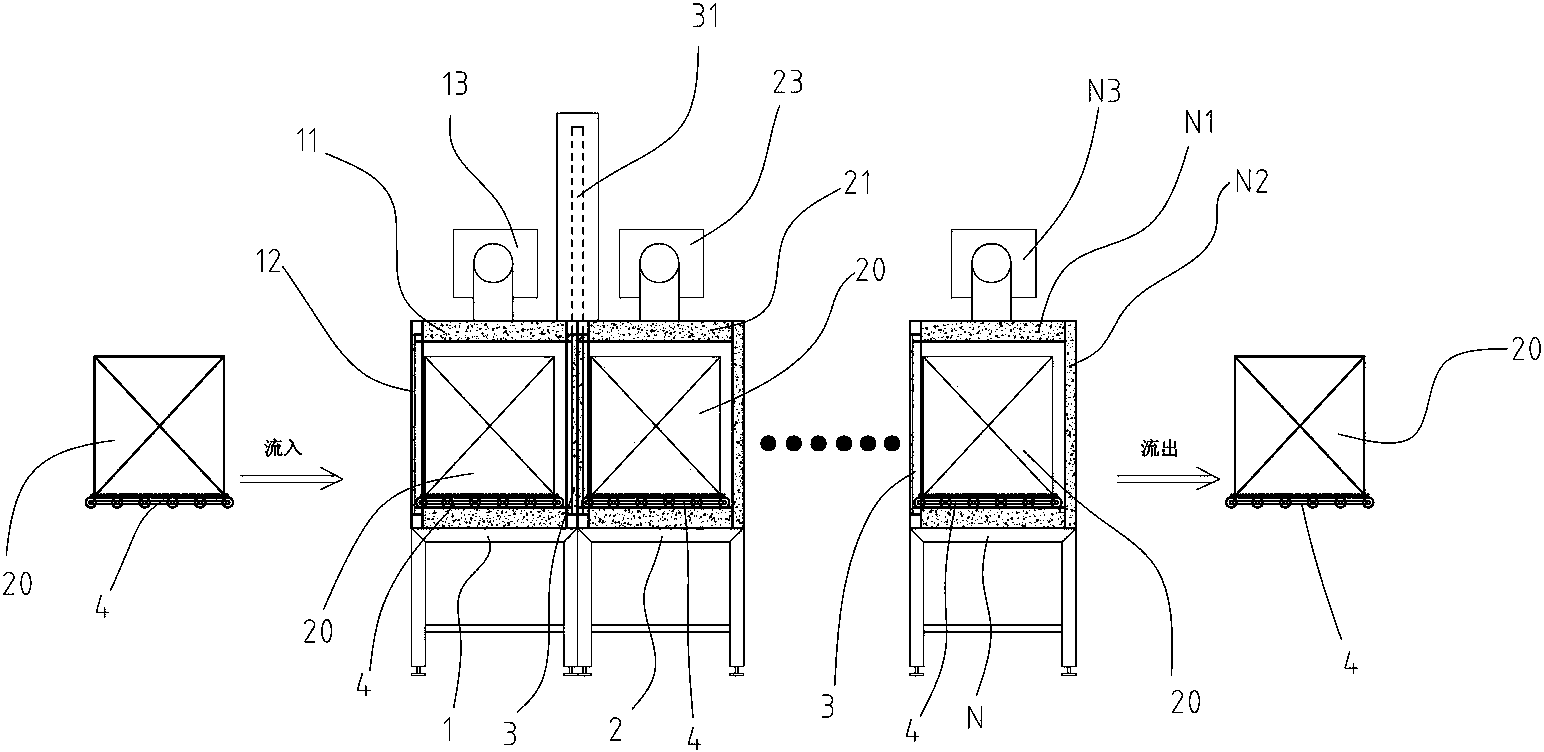

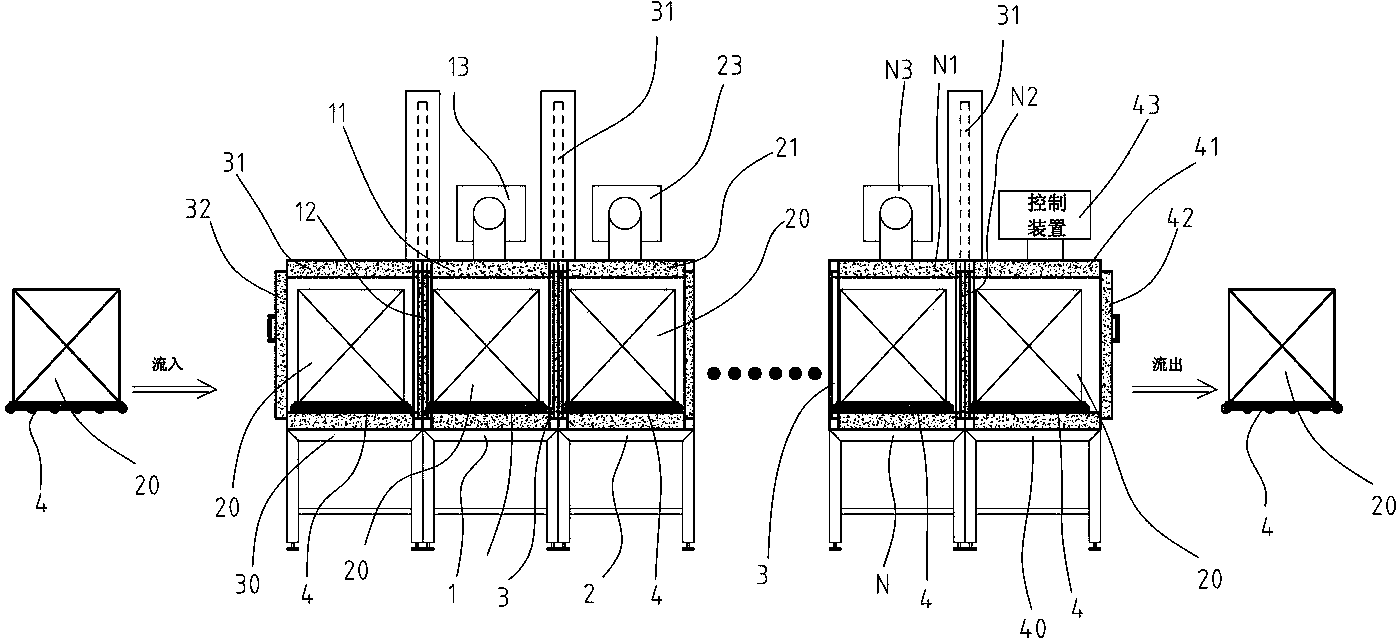

Full-automatic combining module new energy material vacuum baking method and vacuum baking line

ActiveCN103398558AReduce labor intensityShorten the timeCell electrodesDrying chambers/containersProduction lineThermodynamics

Owner:SHENZHEN XINYUREN TECH

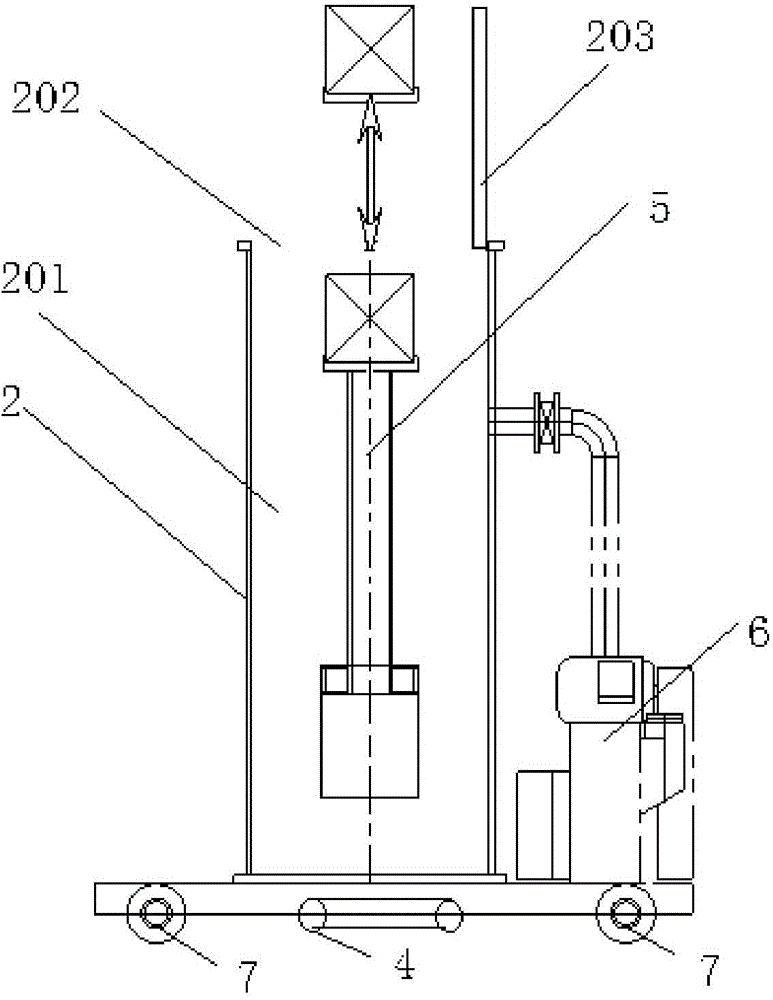

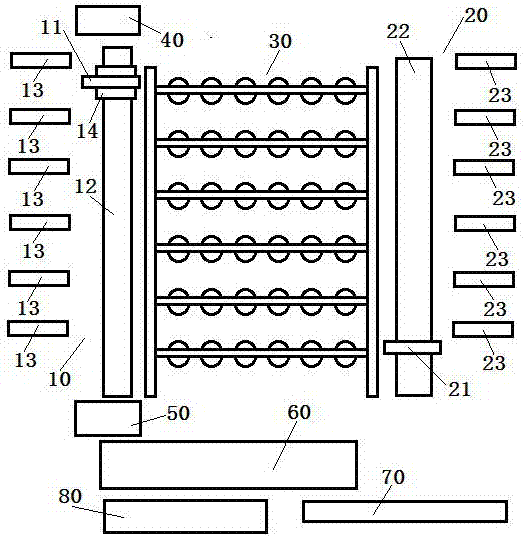

Bulk collecting and intensive placing spinning cake device for semiautomatic joint spinning machine

ActiveCN102424307AImprove coordinationRealize the function of unloadingFilament handlingUltimate tensile strengthMechanical engineering

The invention relates to a bulk collecting and intensive placing spinning cake device for a semiautomatic joint spinning machine. At present, equipment special for carrying and intensively placing spinning cakes scattered on every spinning machine. The bulk collecting and intensive placing spinning cake device comprises a forklift body, and is characterized by further comprising a driving piece, a spinning cake storage rod transposition device, a spinning cake storage rod lateral sway device, a plurality of spinning cake storage rods, spinning cake push heads and spinning cake storage rod reversing devices, wherein the spinning cake storage rod transposition device is provided with a filament taking working position; the spinning cake storage rod lateral sway device is arranged at the front end of the forklift body; the spinning cake storage rod transposition device is arranged on the spinning cake storage rod lateral sway device; on the spinning cake storage rod transposition device,every spinning cake storage rod is arranged on the spinning cake storage rod transposition device through a spinning cake storage rod reversing device; the spinning cake storage rods have horizontal structures; each spinning cake push head is arranged on a spinning cake storage rod respectively; and the driving piece is connected with the spinning cake push heads. The bulk collecting and intensive placing spinning cake device has a reasonable structural design, the labor frequency of workers can be lowered effectively, the labor intensity is lowered, and the labor resource is saved.

Owner:CHINA UNITED ENG

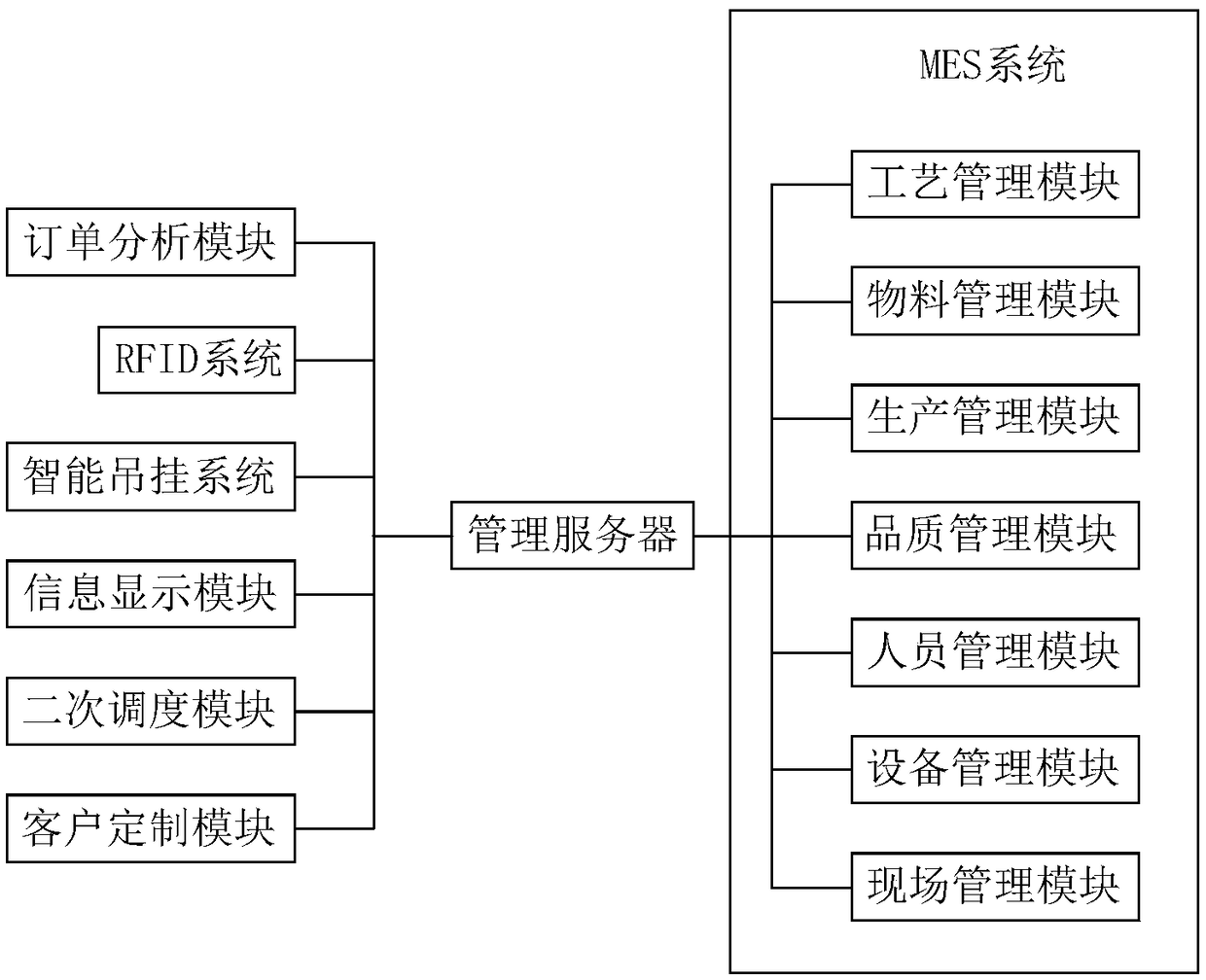

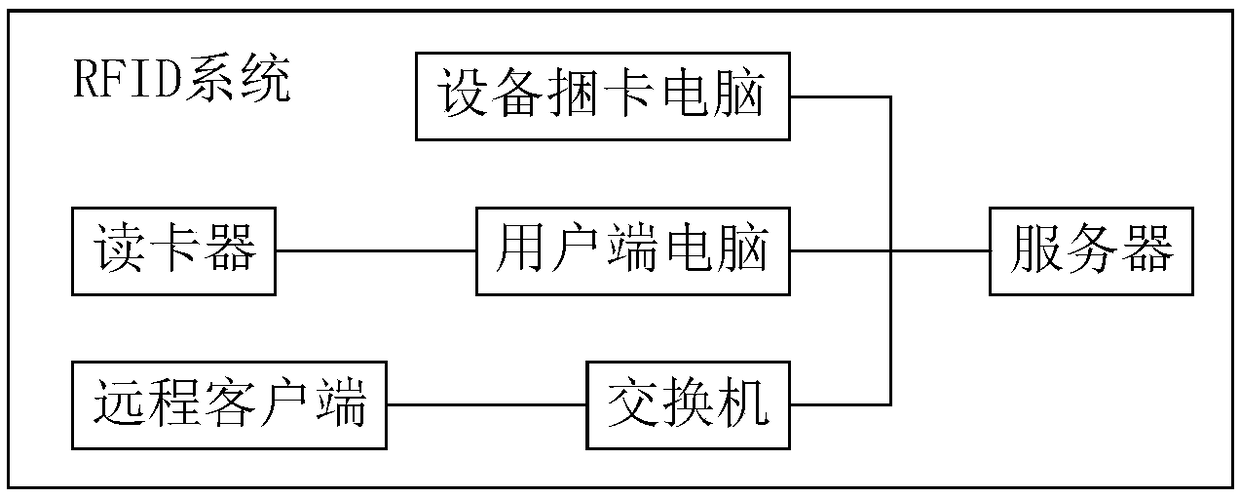

Intelligent screening and matching system for garment production

InactiveCN109034306AImprove management contentRealize streamlined operationData processing applicationsCo-operative working arrangementsManufacturing technologyMaterials management

The invention relates to the technical field of garment manufacturing, in particular to a garment production intelligent screening and matching system, comprises a management server, wherein the management server is connected with a MES system, an RFID system, an intelligent hanging system, an order analysis module, and the MES system comprises a process management module, a material management module, a production management module, a quality management module, a personnel management module, an equipment management module and a field management module. The MES system comprises a process management module, a material management module, a production management module, a quality management module, a personnel management module, an equipment management module and a field management module. AnMES system is adopted to manage that production, the management content is comprehensive, the streamlined operation can be realized, the efficiency is high, the RFID system is adopted to track the quality and the process, the product quality is improve, and the quality problem and the production change can be traced and flexibly adjusted. The MES system is characterized in that the MES system isadopted to manage the production, the management content is comprehensive, the flowing operation can be realized, and the efficiency is high.

Owner:WENZHOU JUDGER GARMENT CO LTD

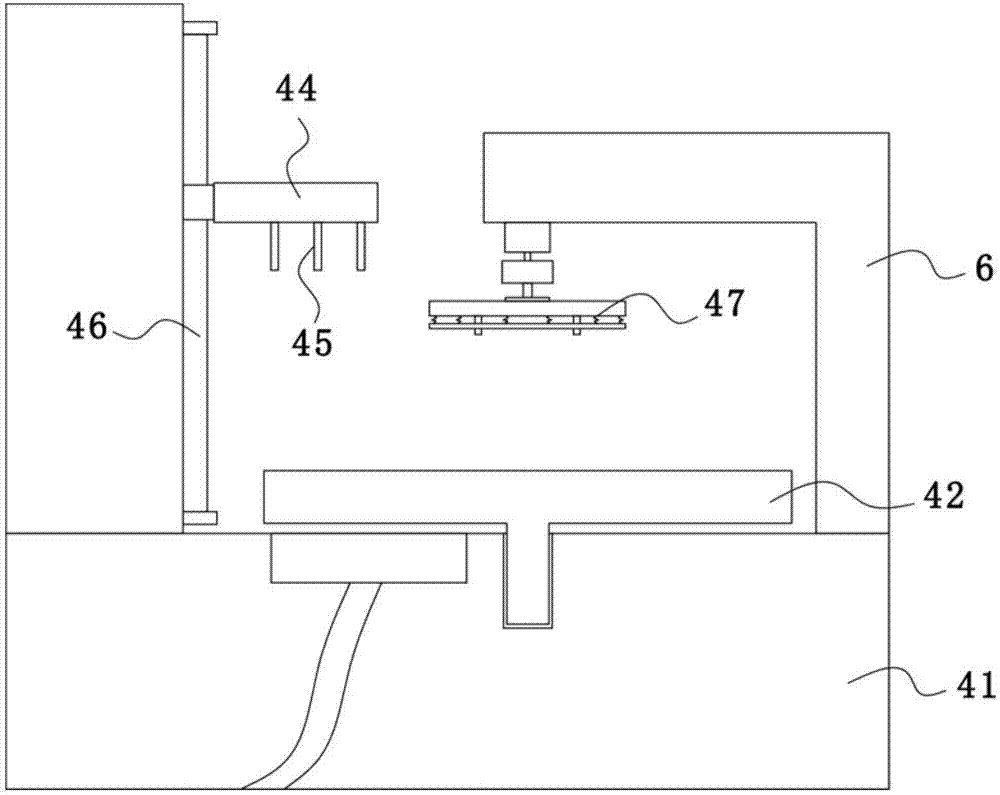

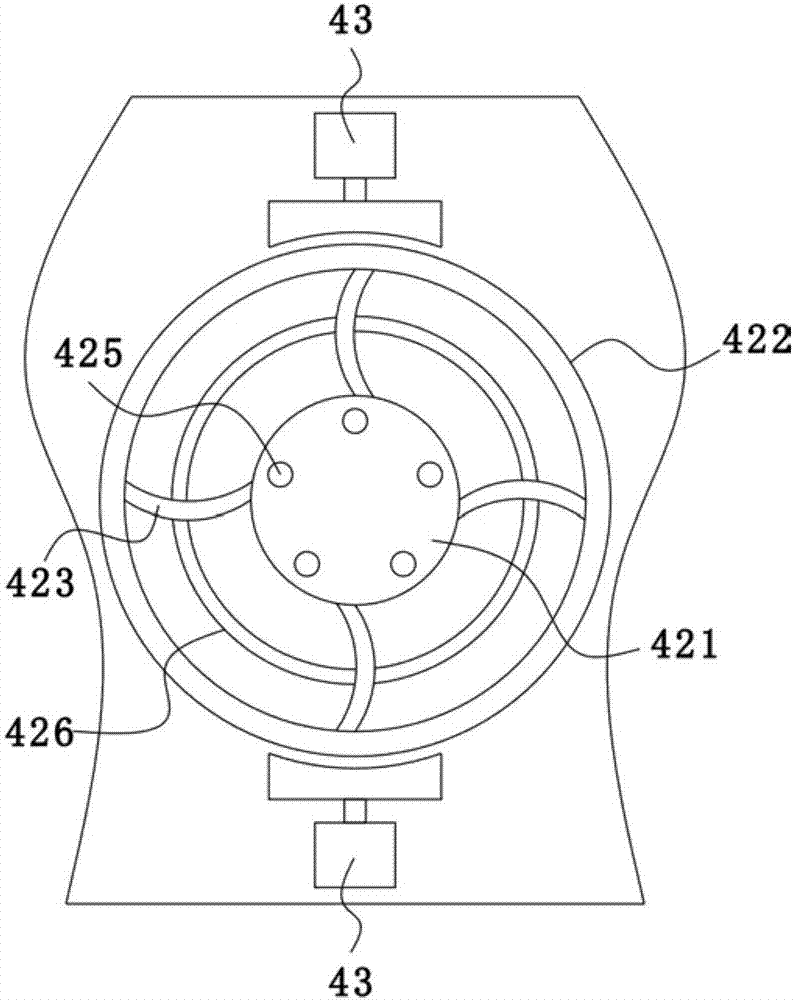

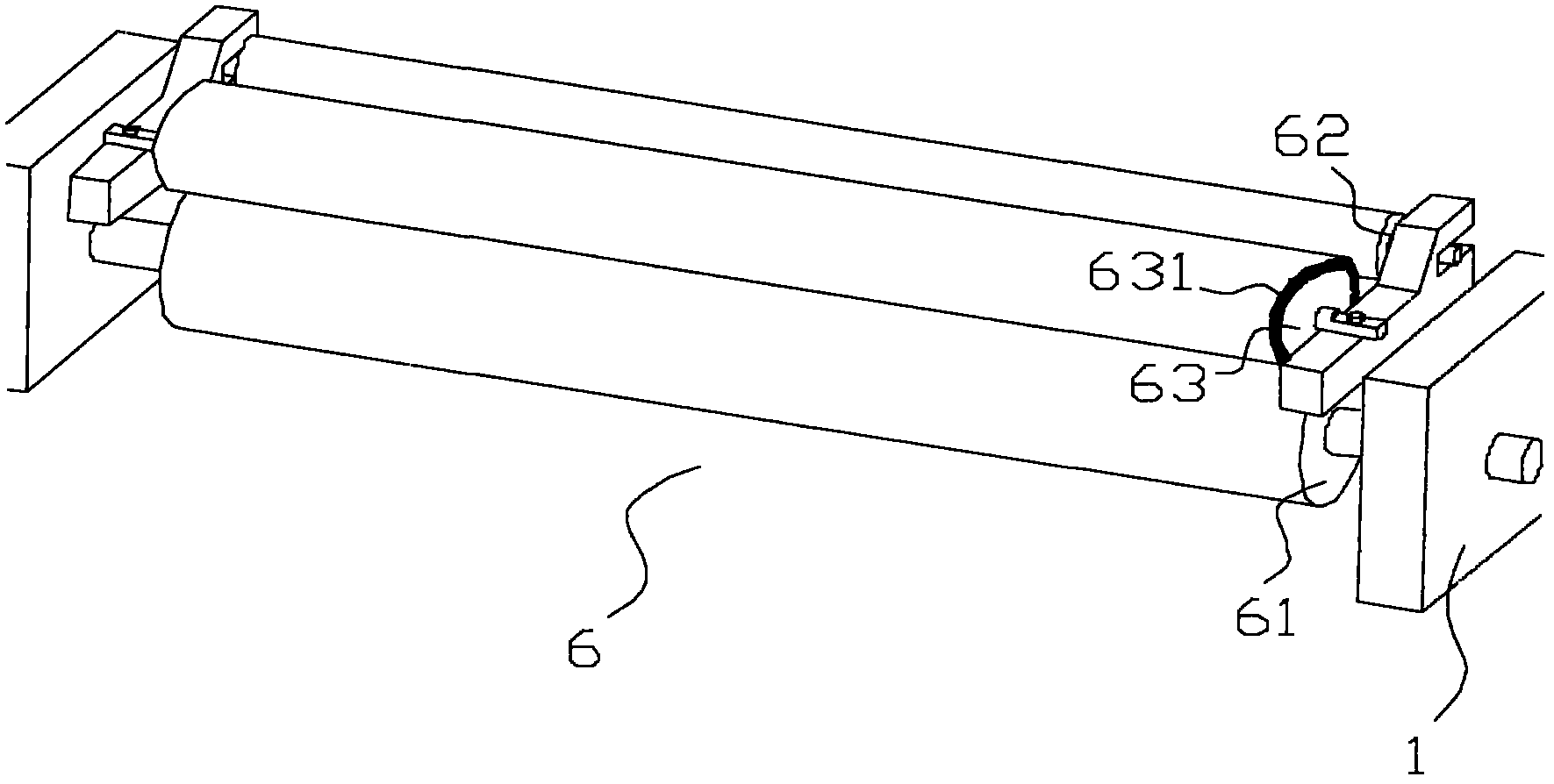

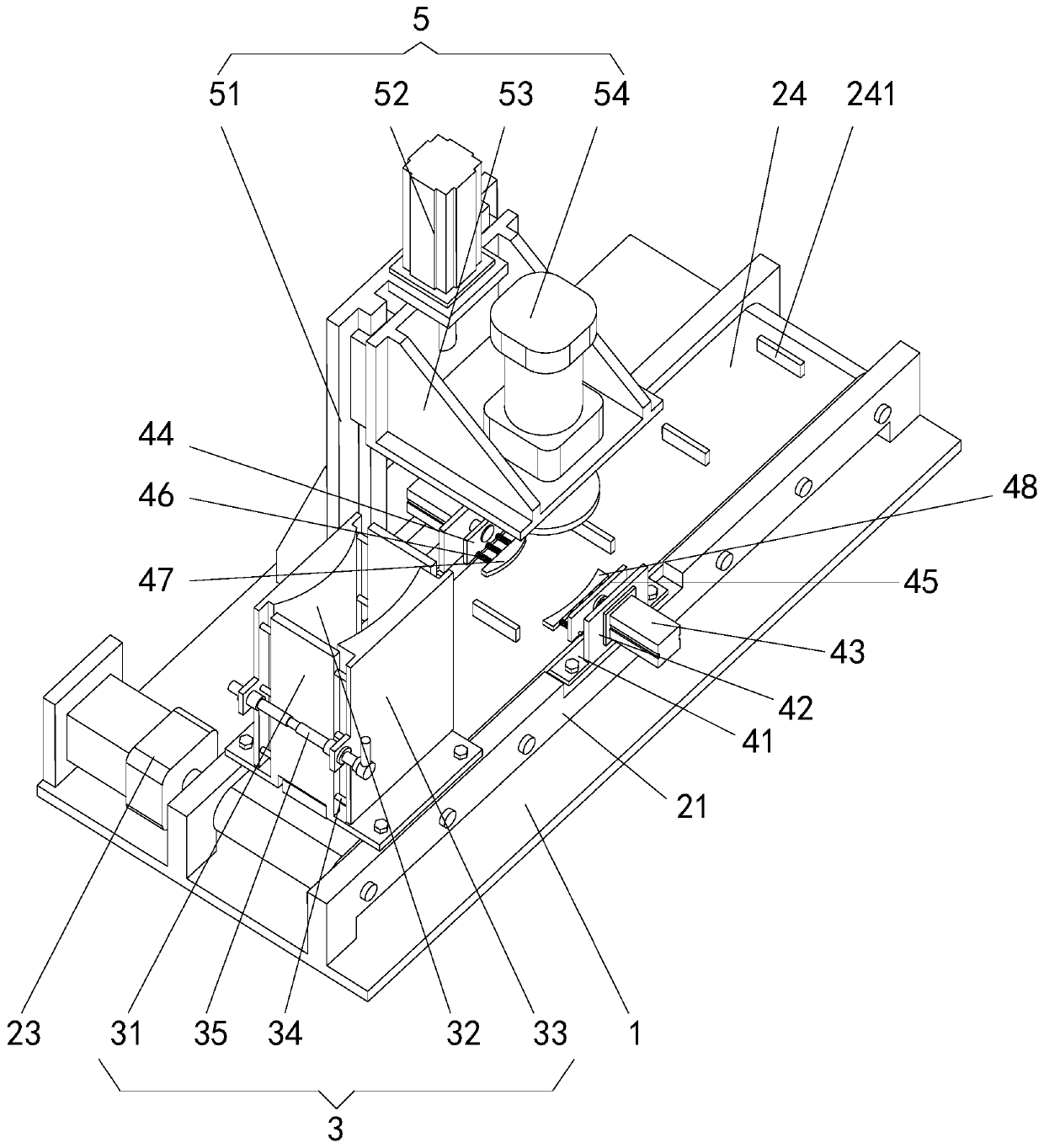

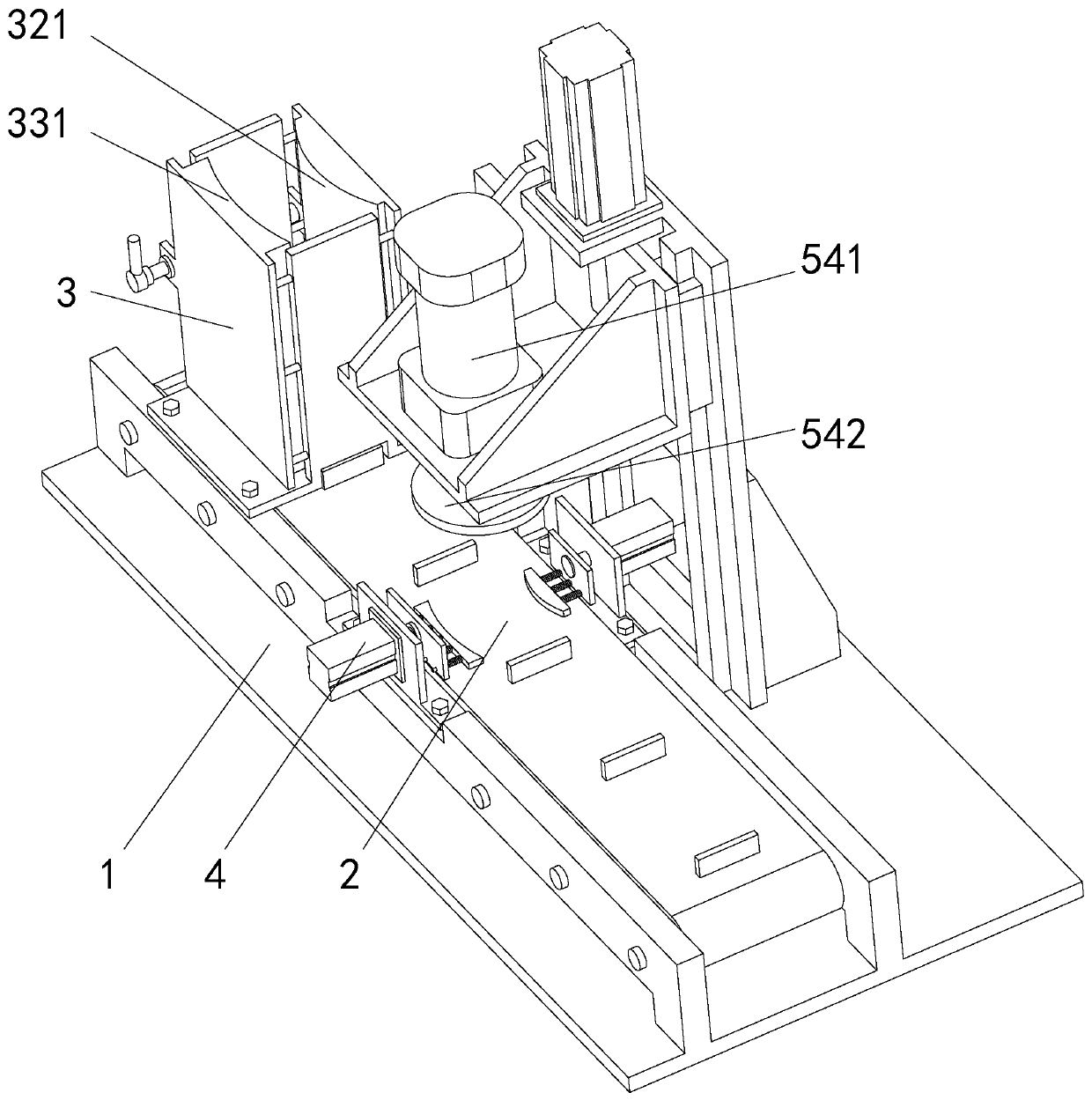

Capacitor core automatic welding device

ActiveCN103394784AAccurate transmissionEffective scrape offWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCapacitor

The invention provides a capacitor core automatic welding device which mainly solves the problems that due to the fact that the manual welding mode is adopted in the prior art, the welding quality is poor and the production efficiency is low. The capacitor core automatic welding device comprises a machining mechanism used for welding an element, an element conveying mechanism used for conveying the element to the machining mechanism for machining and an element automatic stacking mechanism used for automatically stacking the machined elements. According to the capacitor core automatic welding device, stations are connected through special core conveying mechanisms, so that flow operation is achieved, the production efficiency is improved to a great extent compared with that of manual operation or that of a single independent device, the product percent of pass is improved, and the capacitor core automatic welding device is simple and practical.

Owner:SHAANXI AEROSPACE ELECTROMECHANICAL ENVIRONMENTAL ENG DESIGNING INST CO LTD

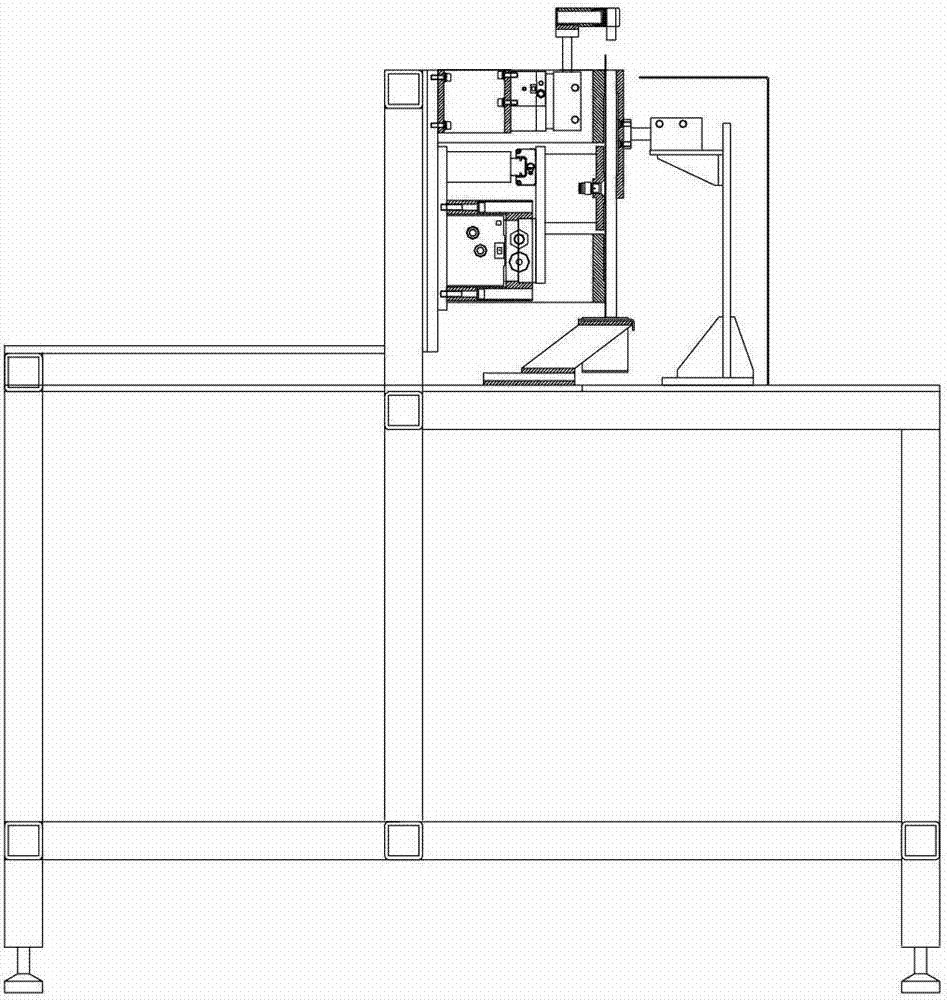

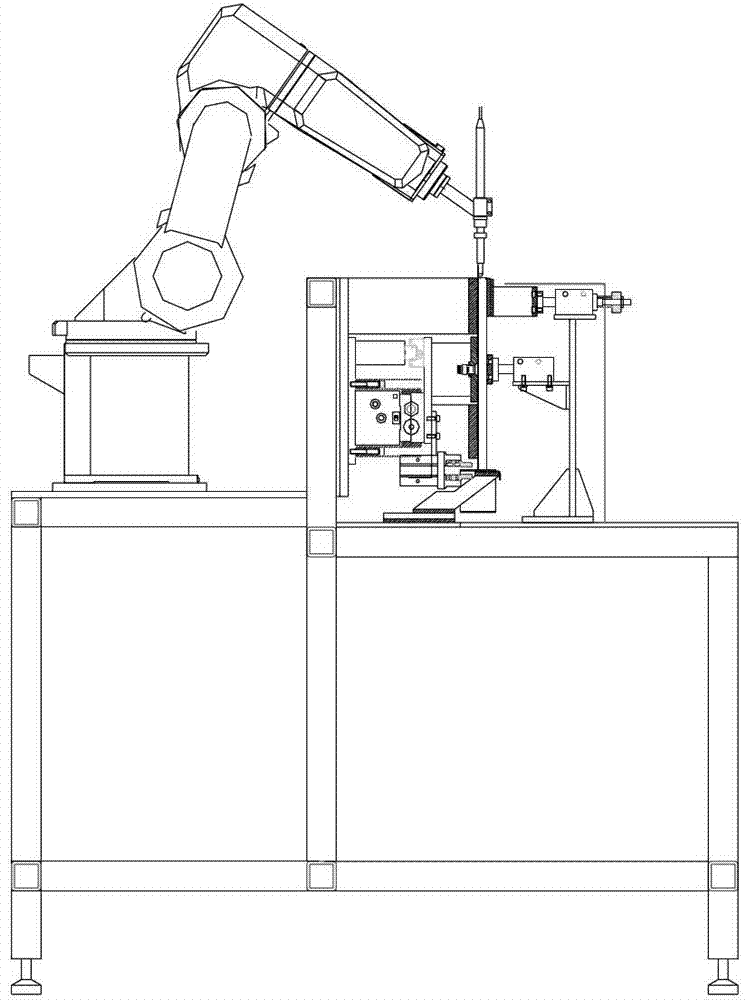

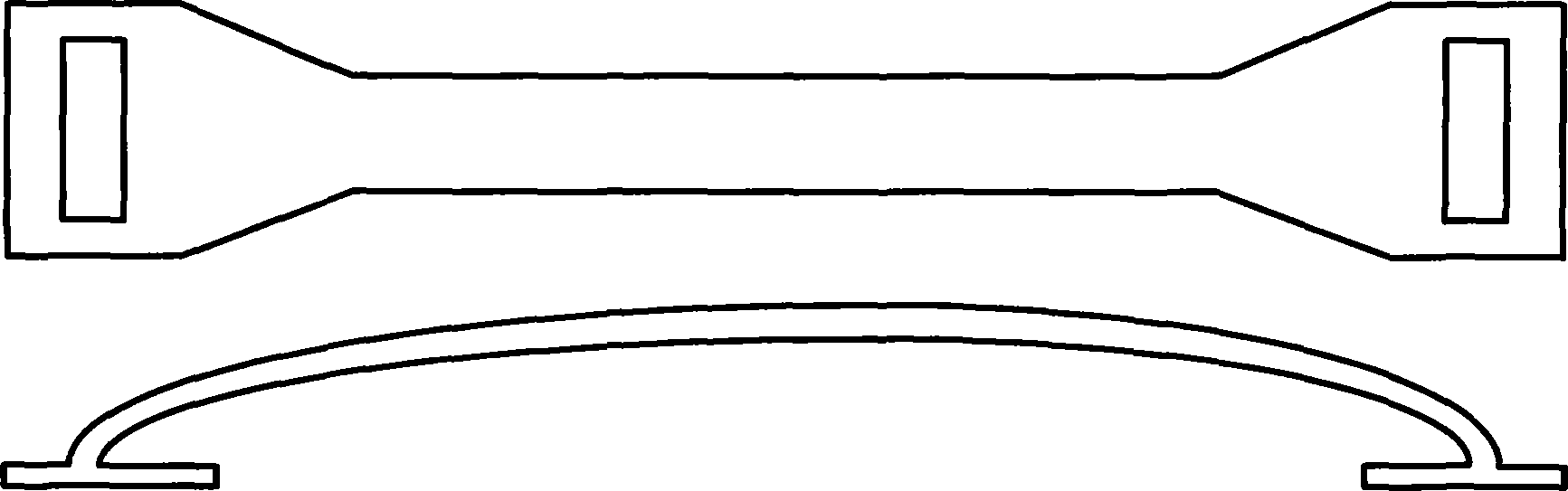

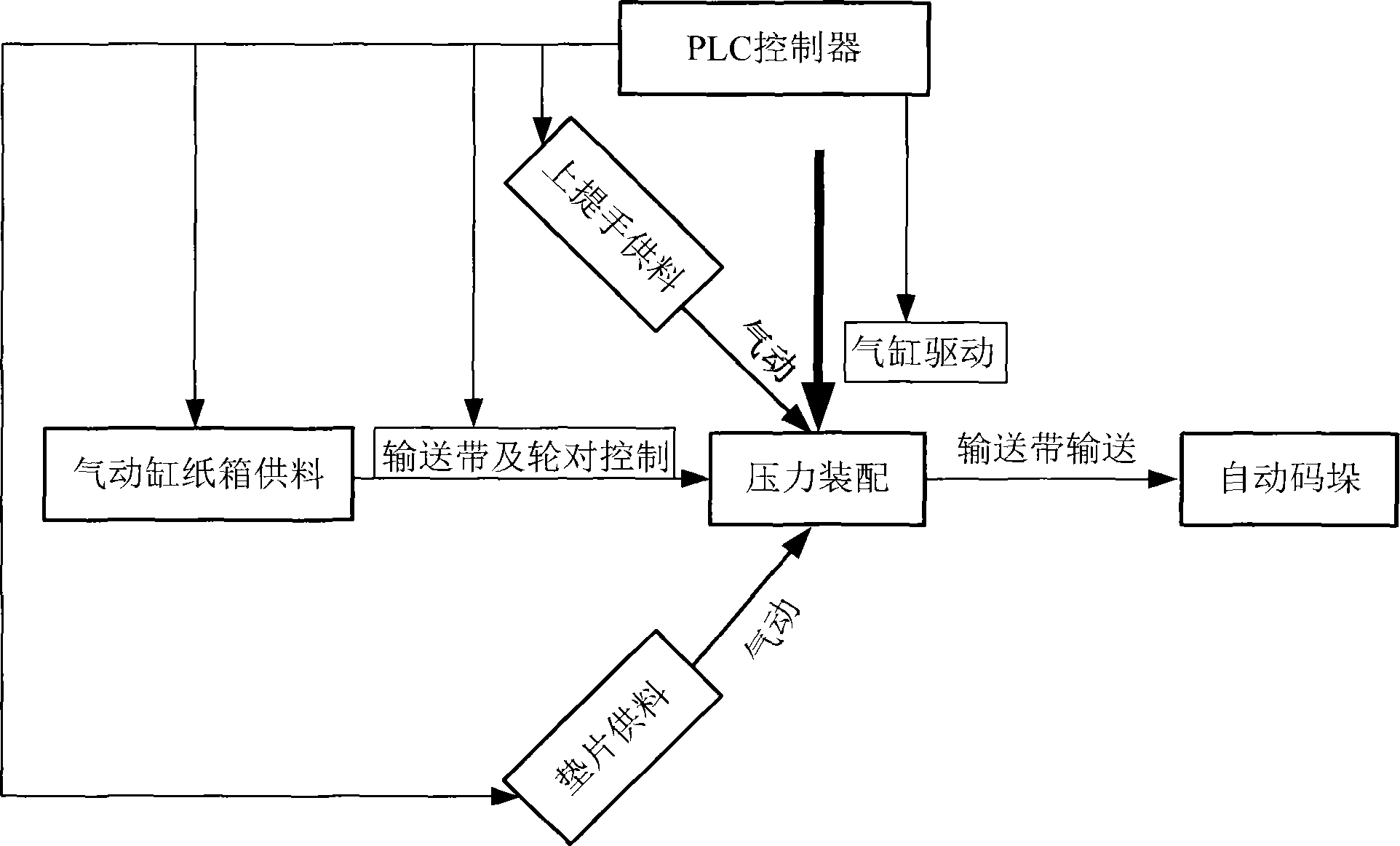

Packaging carton handle flexible automatic mounting production line

InactiveCN102632644AReduce auxiliary timeRealize streamlined operationPaper-makingBox making operationsProduction lineControl system

The invention discloses a packaging carton handle flexible automatic mounting production line which comprises a working platform, a carton loading part, a carton conveying and expanding part, an upper handle feeding part, a gasket mounting part and a control system, wherein the working platform is formed by welding an upright post and a beam; the carton loading part consists of a support cylinder, a rising guide rail and a carton box; the carton conveying and expanding part consists of a stepping motor, a conveying belt, a conveying belt wheel, a pinch roller, a support rod, a guide support track and an inductive limit stop; the upper handle feeding part consists of an upper handle bin, an upper handle feeding cylinder, an end push plate and an upper handle moving track; the gasket mounting part consists of a gasket bin, a gasket feeding cylinder and a gasket groove; and the gasket feeding cylinder pushes the gasket in the gasket bin into the gasket groove through the end push plate. The packaging carton handle flexible automatic mounting production line disclosed by the invention has the advantages of simple structure, compact movement and high action reliability, and can remarkably improve the mounting efficiency.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

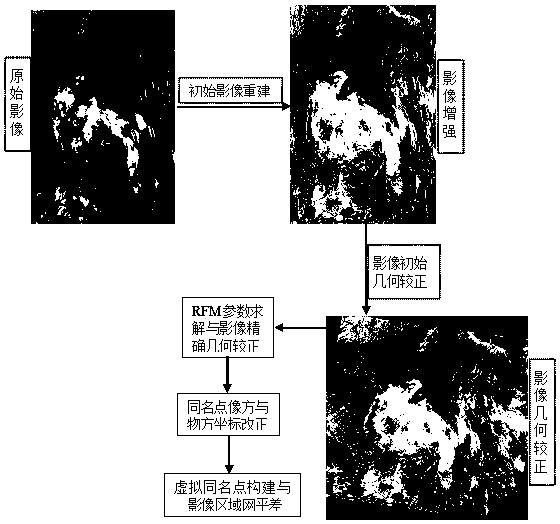

High-precision geometric positioning post-processing method using image-compensated remote sensing image/SAR image

ActiveCN109029368AHigh precisionRealize high-precision calculationPicture taking arrangementsSatellite radio beaconingObject basedObject point

The invention provides a post-processing method for geometric positioning of an object point using a remote sensing image / synthetic aperture radar (SAR) image. For the applied present situation that the accuracy of point position cannot meet requirements such as large and medium scale mapping, while using remote sensing image or SAR image to extract spatial location information of ground surfacesand ground objects; a linearized error equation is established according to a nonlinear mapping function of surface point image coordinate and object space coordinate, and a set of processing flow anda method for obtaining high-precision spatial position of ground surface and ground objects based on digital image is established by applying a model parameter estimation theory with errors-in-variables (EIV) contained in variables. The high-precision geometric positioning post-processing method is suitable for the block adjustment data processing of the space-borne optical remote sensing and thespace-borne SAR digital image, and can effectively solve the problem that the positioning accuracy is not high.

Owner:HUAIYIN TEACHERS COLLEGE

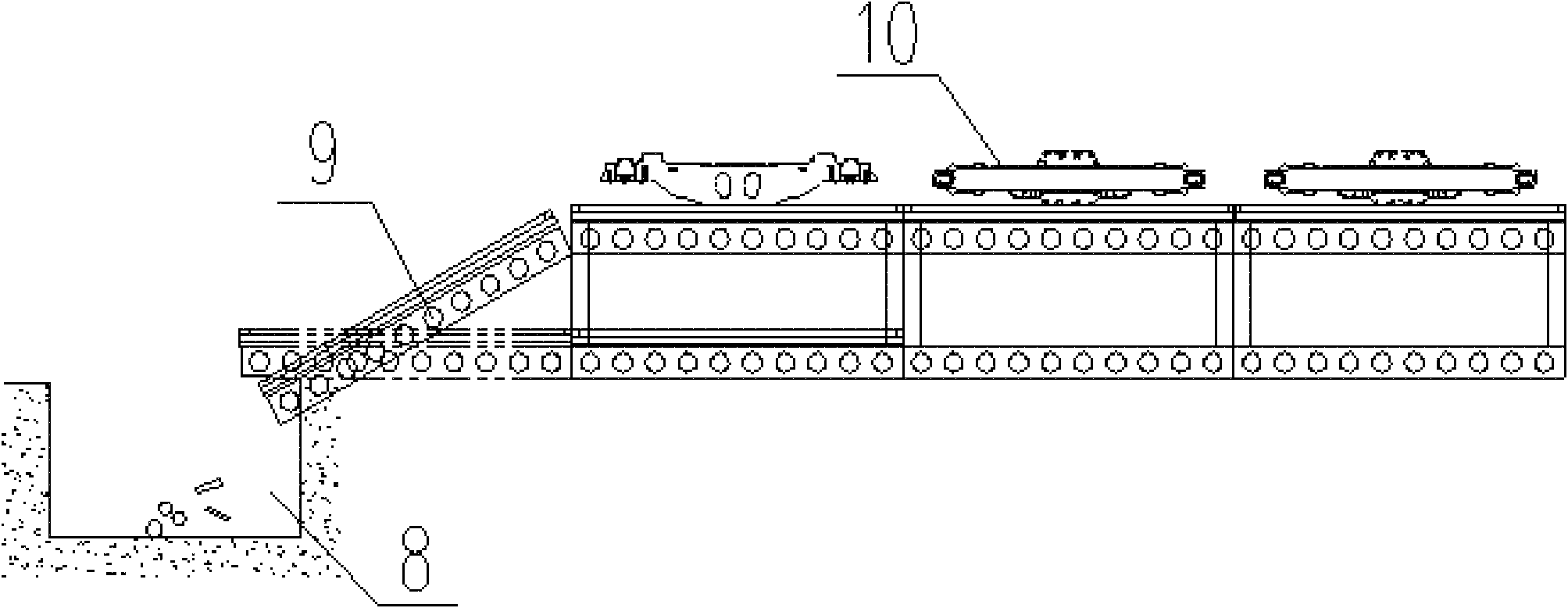

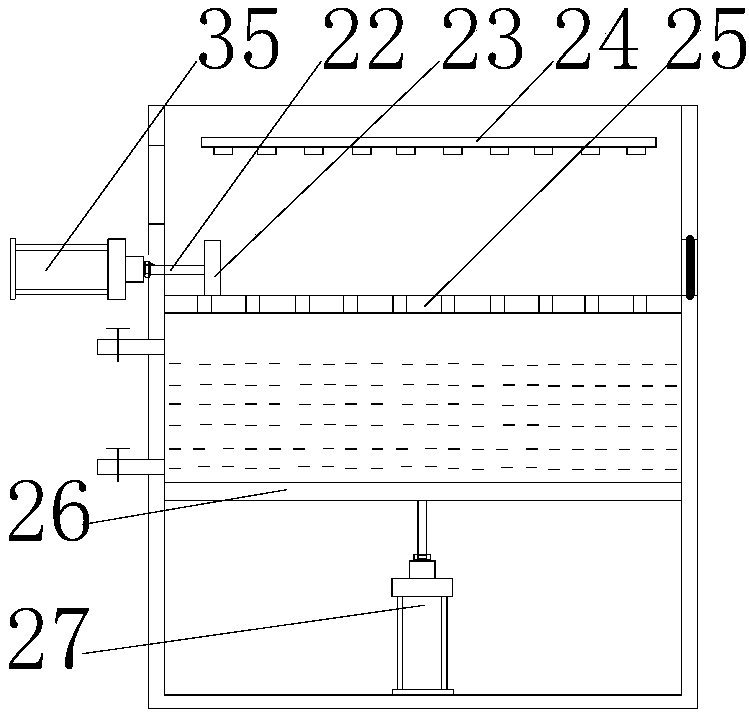

Casting continuous cleaning flow line and method thereof

InactiveCN102756115AThe Science of Continuous Cleaning MethodsThe continuous cleaning method is reasonableEngineeringSteel casting

The invention discloses a casting continuous cleaning flow line and a method thereof. The casting continuous cleaning flow line comprises a bottom plate, an upper flow line and a lower flow line, wherein the upper flow line comprises a bottom plate feeding station, a workpiece loading station, a primary cutting station, a primary gouging station, an overturning station, a secondary cutting position, a secondary gouging station, a workpiece unloading station, a bottom plate automatic cleaning and returning station which are arranged in sequence; the bottom plate moves along the stations; the lower flow line is connected with the upper flow line end to end to form a closed operation loop; and through the lower flow line, the bottom plate can be transmitted from the bottom plate automatic cleaning and returning station to the bottom plate feeding station. The casting continuous cleaning flow line and the method thereof have the advantages that the various defects of the existing manual cleaning flow line are overcome, the mechanization and the pipelining of cleaning works of large quantities of steel castings are realized, cutting scraps are effectively and quickly collected, the whole equipment is safe and reliable, is long in service life and is convenient and simple to operate and maintain, and the work site area is saved.

Owner:CRRC QIQIHAR ROLLING CO LTD

Suspension type oil cylinder cleaning device

ActiveCN105772451AFast cleaningImprove efficiencyHollow article cleaningDrying gas arrangementsEngineeringAssembly line

The invention provides a suspension type oil cylinder cleaning device. The cleaning device comprises an annular rack, a suspension device, a workpiece loading and unloading device, a cleaning device, a rinsing device and a drying device. The suspension device is fixedly connected with the annular rack, the workpiece loading and unloading device, the cleaning device, the rinsing device and the drying device are fixedly connected with the annular rack, and the workpiece loading and unloading device, the cleaning device, the rinsing device and the drying device are sequentially arranged in a spaced manner; the cleaning device comprises an inner wall cleaning brush, an outer wall cleaning brush, a high-pressure heating cleaning liquid spraying device and a vertical feeding device; the inner wall cleaning brush and the outer wall cleaning brush are located at the upper end of the vertical feeding device and are fixedly connected with the vertical feeding device; and the high-pressure heating cleaning liquid spraying device is fixedly connected with the outer wall cleaning brush. Circulation operation can be achieved, an oil cylinder is cleaned in an assembly-line manner, the cleaning efficiency is high, and the cleaning effect is good.

Owner:江苏昊阳传动科技有限公司

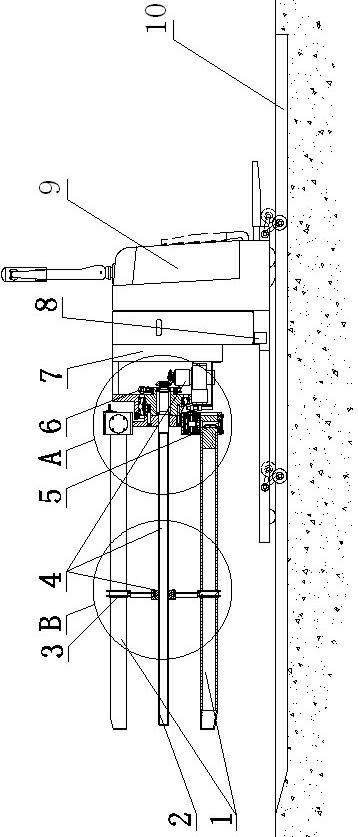

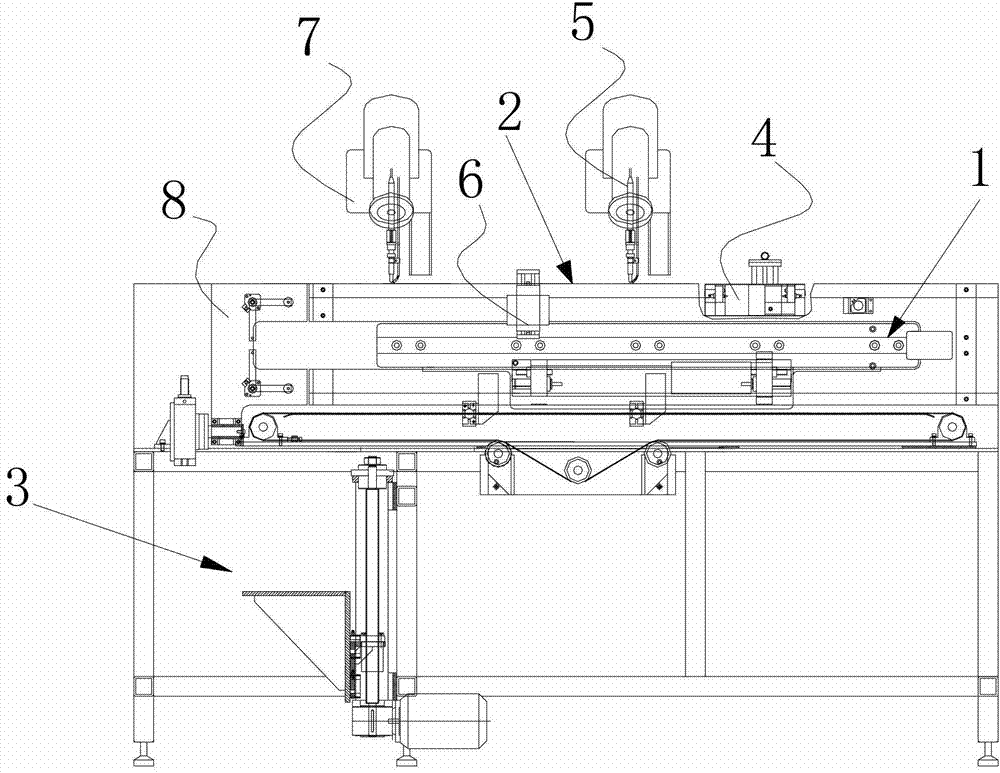

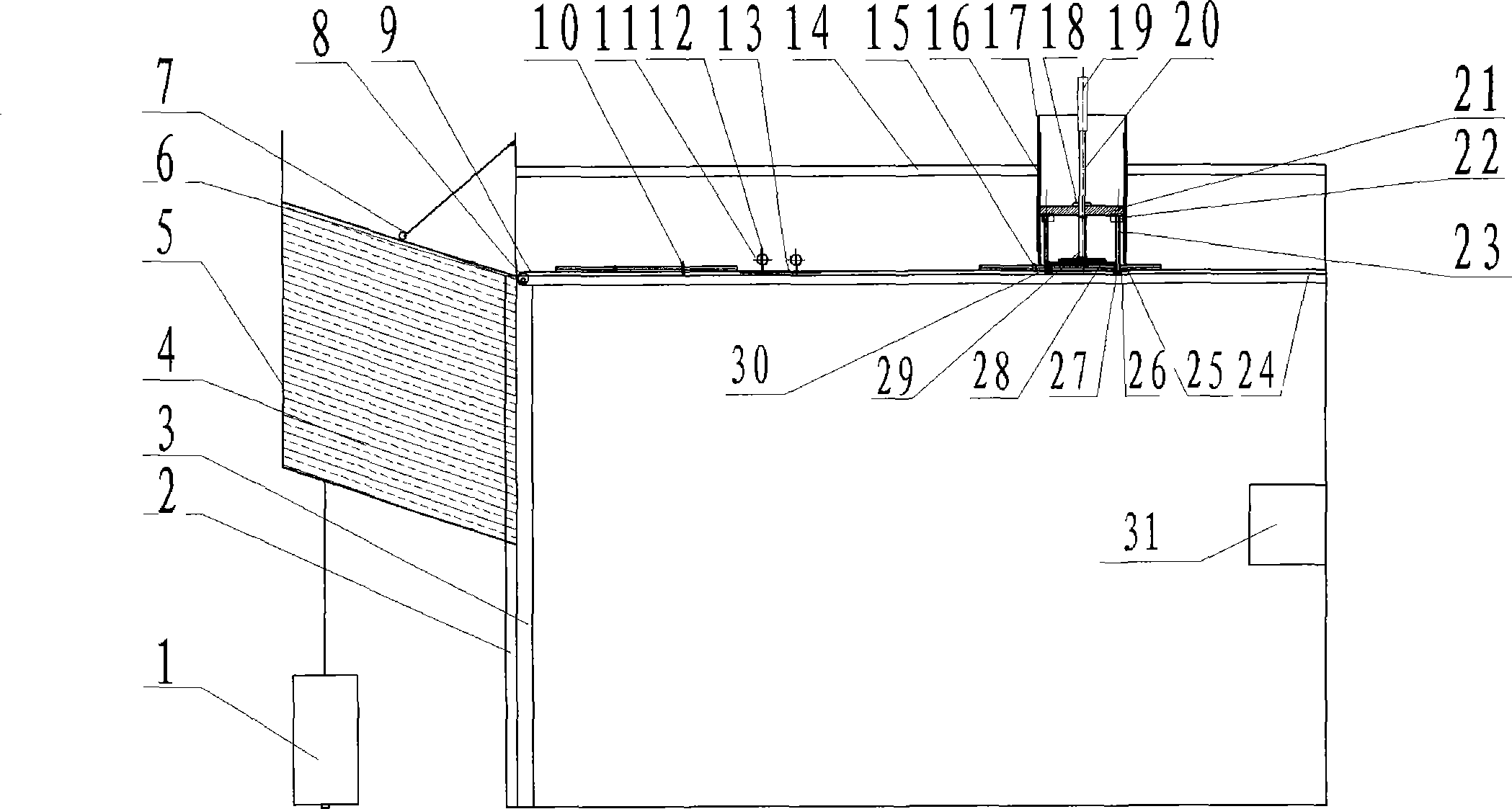

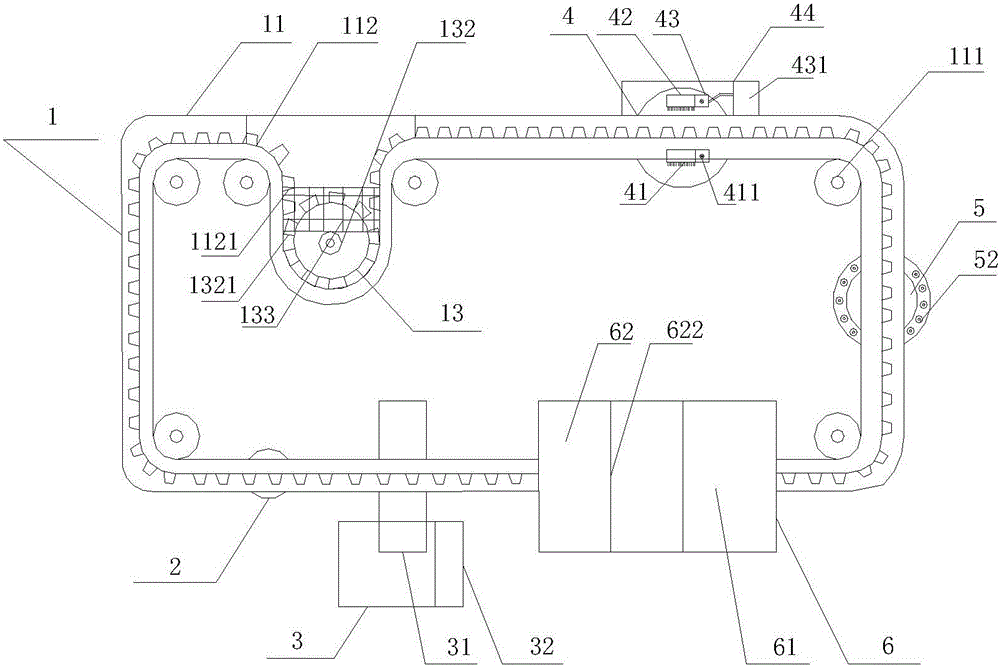

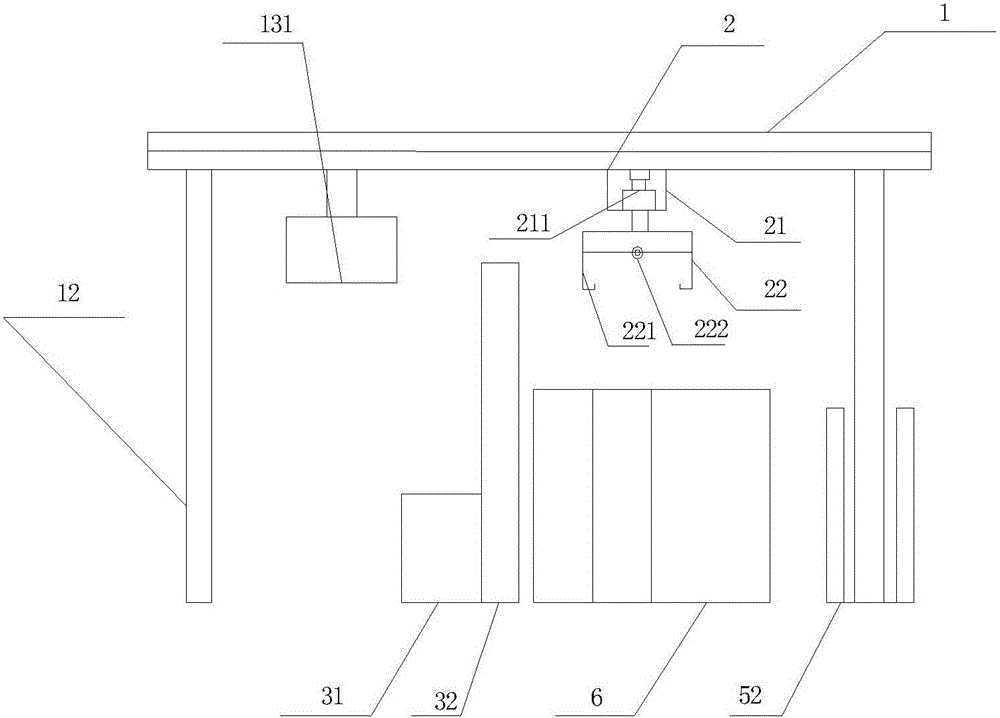

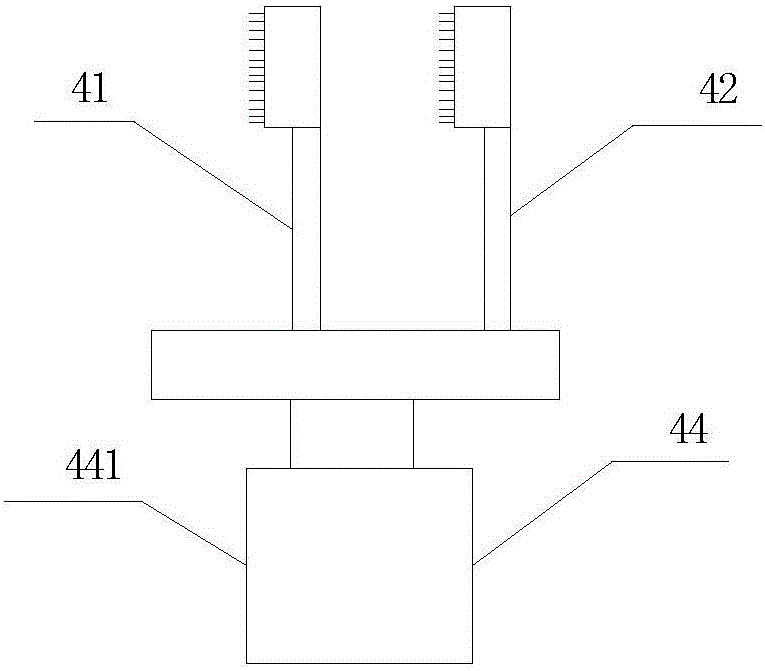

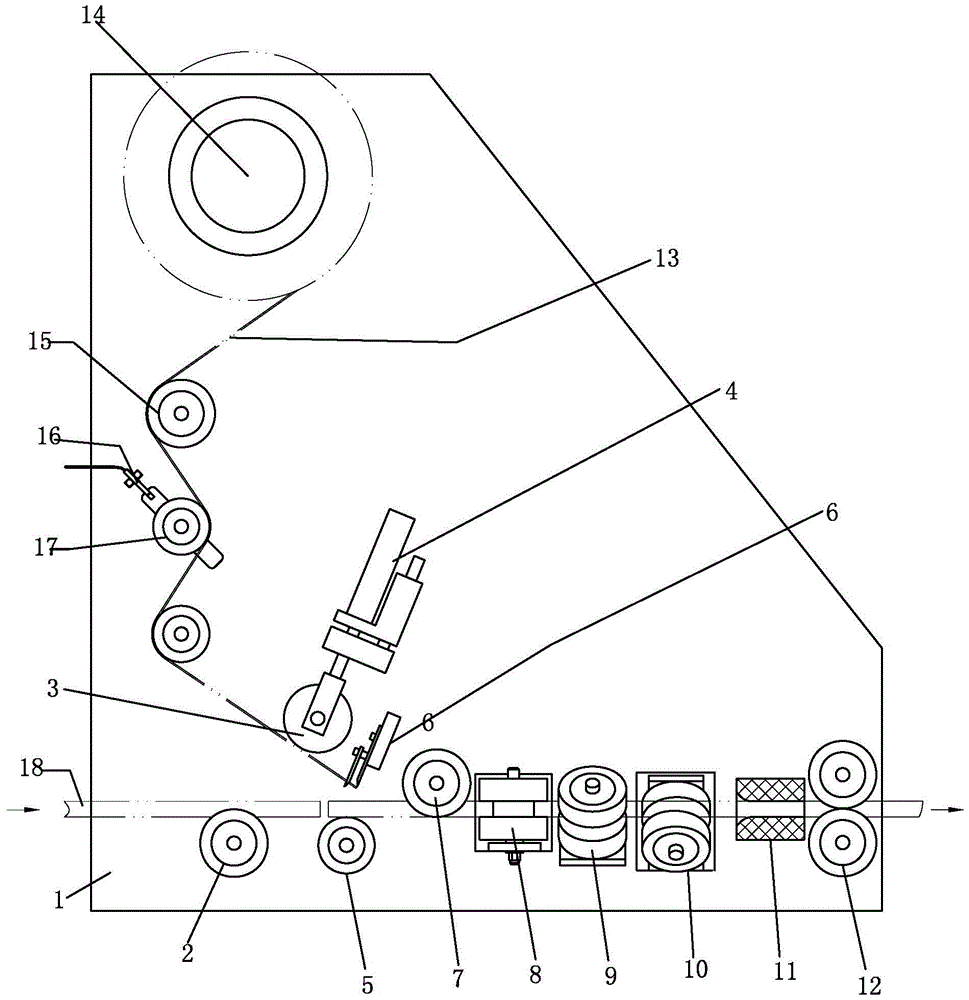

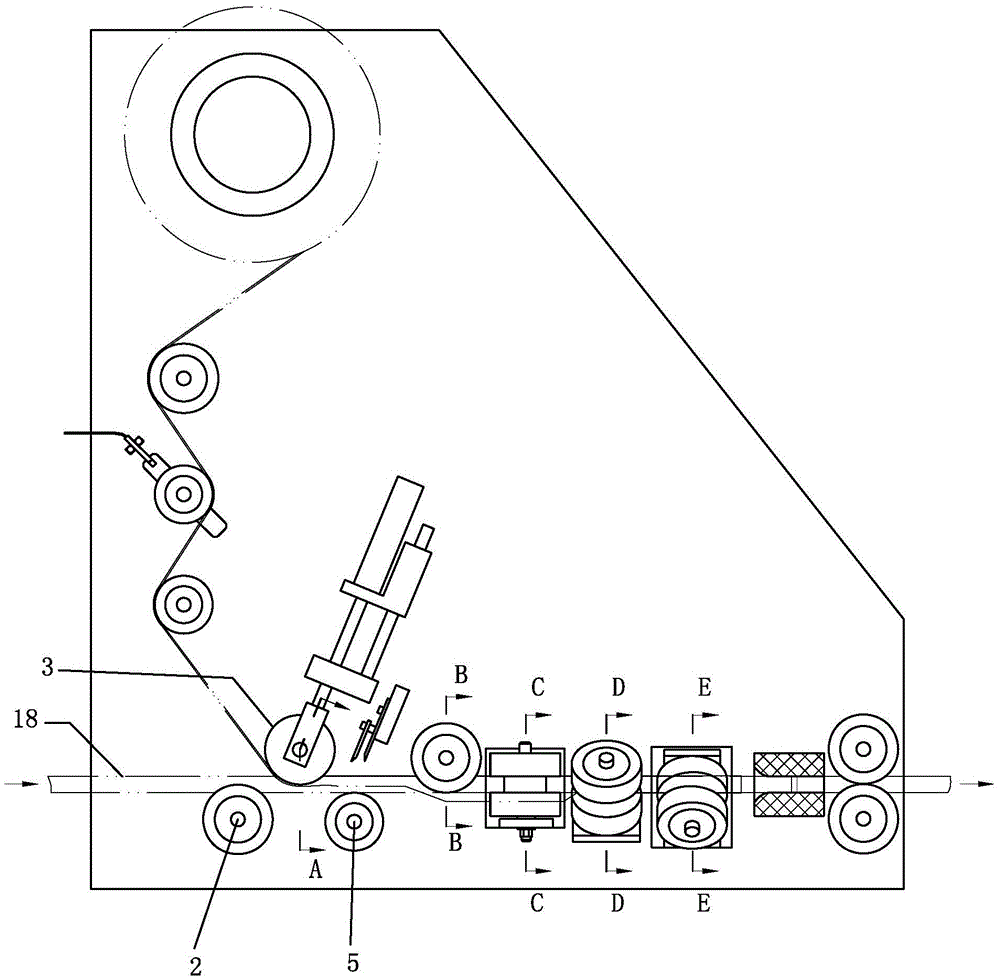

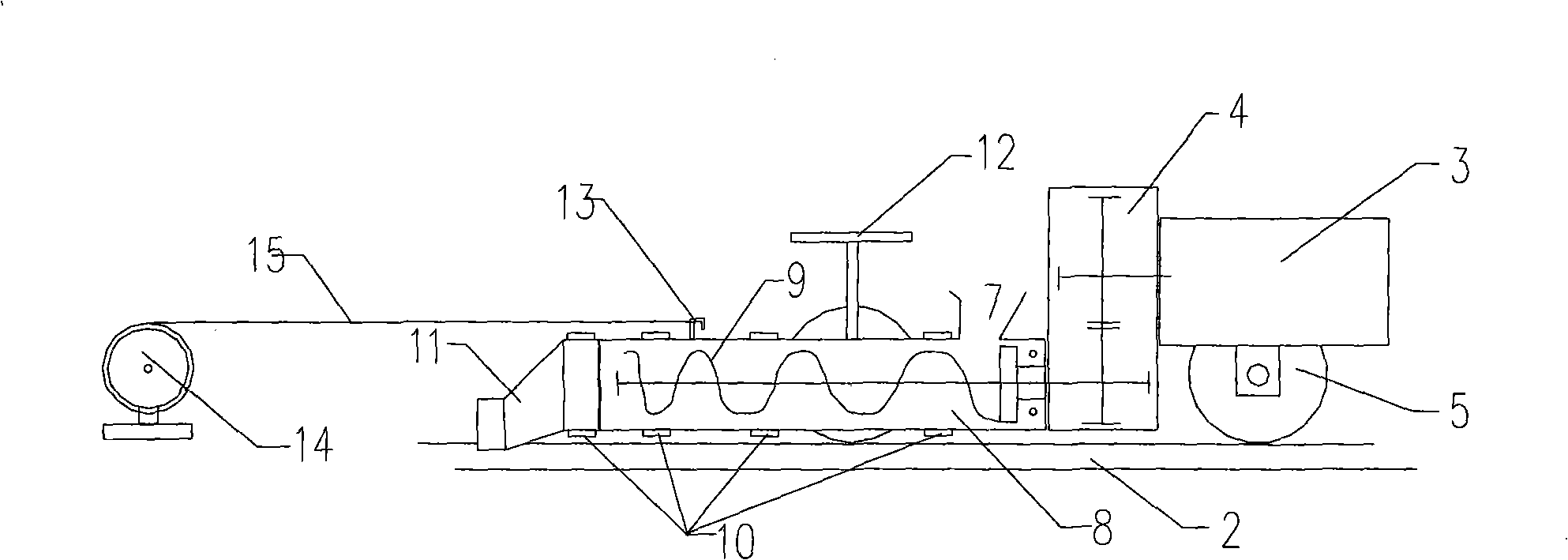

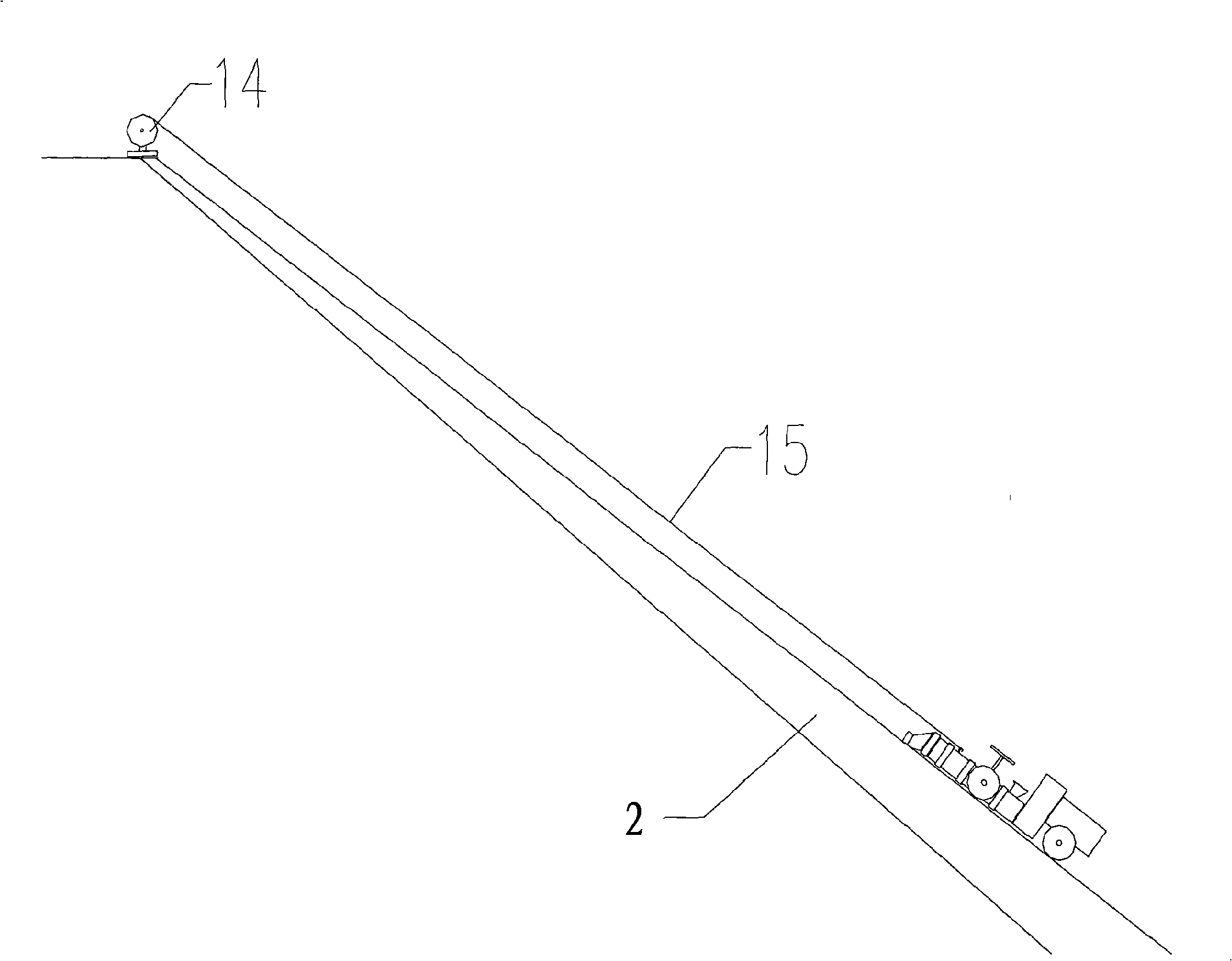

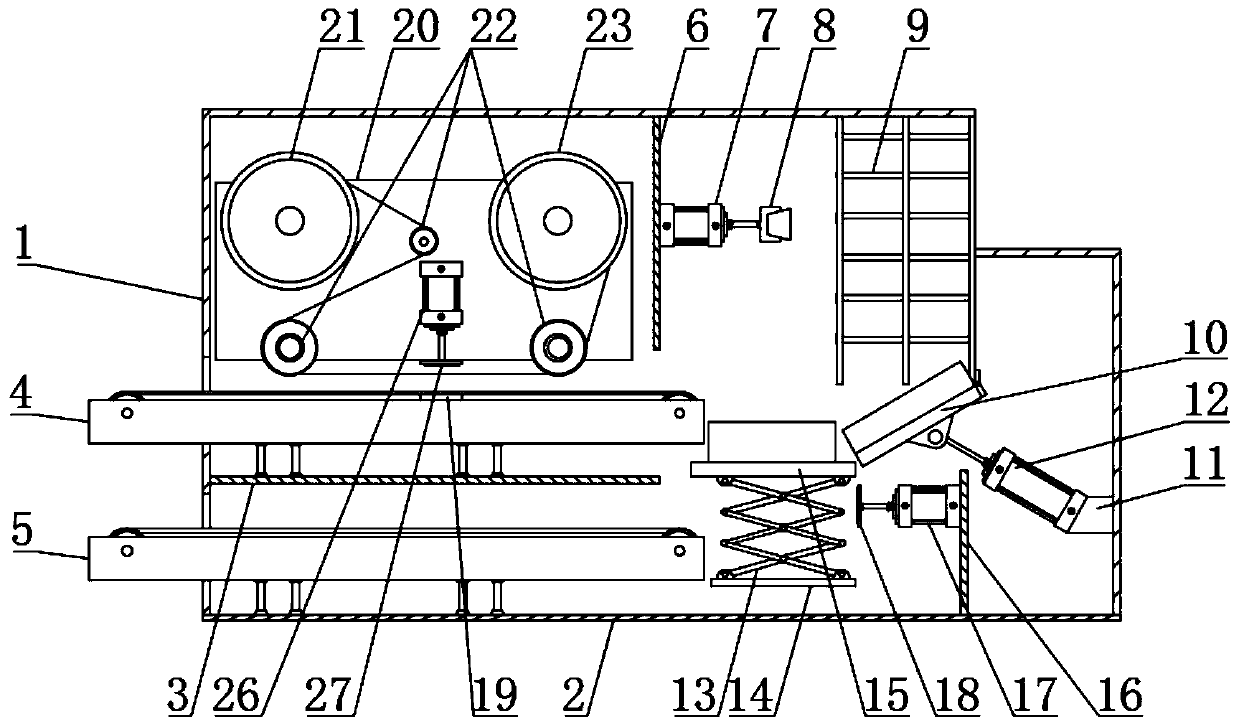

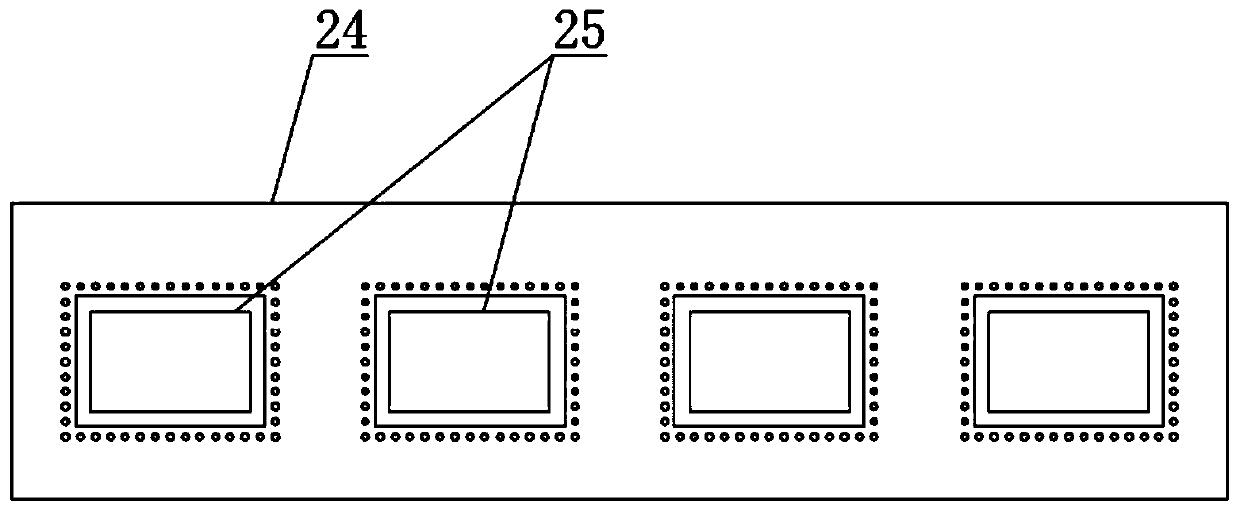

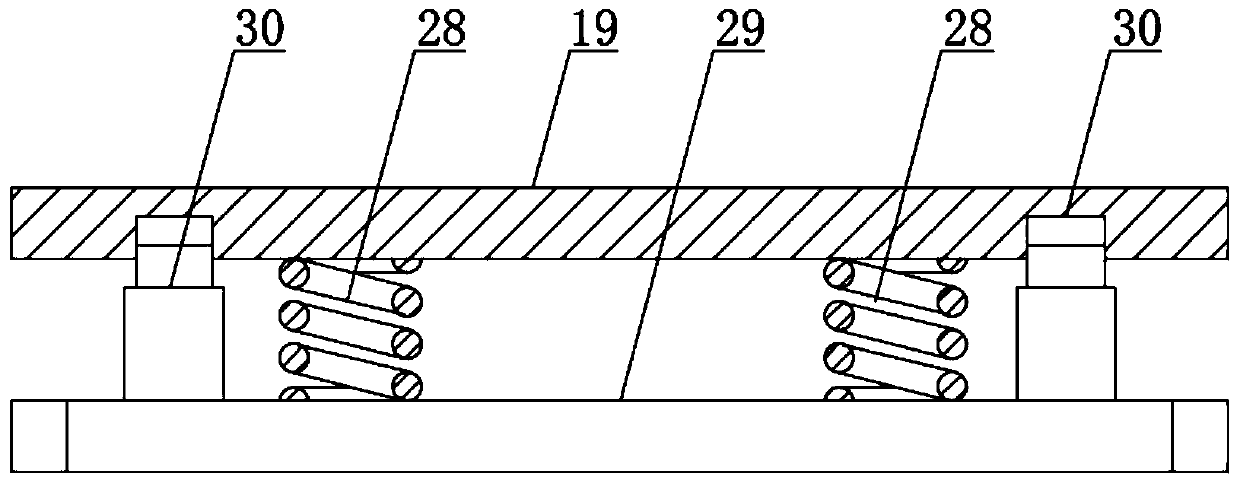

Automatic aluminum foil wrapping equipment for refrigerator air return pipe

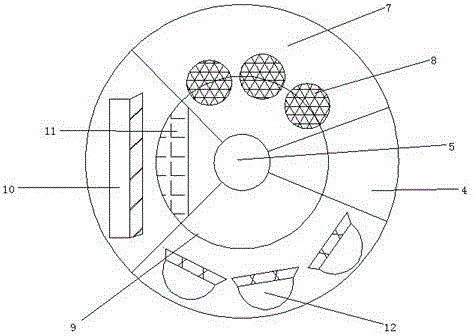

ActiveCN105564689ARealize streamlined operationIncrease productivityWrappingEngineeringAluminum foil

The invention discloses automatic aluminum foil wrapping equipment for a refrigerator air return pipe. The automatic aluminum foil wrapping equipment comprises a base plate (1), a front guiding wheel (2), a pressing wheel (3), an air cylinder (4), a supporting wheel (5), a blade (6), upper forming wheels (7), side forming wheels (8), outer oblique forming wheels (9), inner oblique forming wheels (10), a guiding connecting cylinder (11), rear guiding wheels (12), a material roller (14), a positioning roller (15), an inductor and a rotary vane roller (17). By the adoption of the automatic aluminum foil wrapping equipment, aluminum foil of the air return pipe is wrapped automatically, streamline operation of wrapping of the aluminum foil of the air return pipe can be achieved, the production efficiency and machining accuracy are greatly improved, and manpower can be saved.

Owner:GUANGDONG HOMA REFRIGERATOR CO LTD

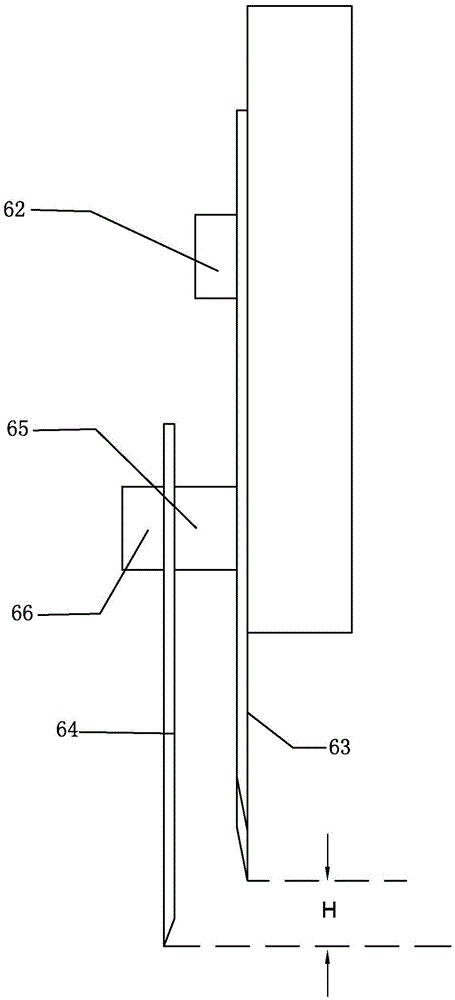

Device for detecting water absorbing characteristics of regenerated aggregate of building wastes and testing method

ActiveCN106840943AShorten the time intervalSave material resourcesWeighing by absorbing componentSteel tubeEngineering

The invention discloses a device for detecting water absorbing characteristics of regenerated aggregate of building wastes and a testing method. The testing device mainly comprises a water absorbing area, an air drying area, a weighing area and a material preparing area, wherein the water absorbing area is mainly provided with an arc-shaped water tank and a screen net; the air drying area is mainly provided with a fan and a water permeation net; the weighing area mainly comprises an electronic balance. The testing method comprises the following steps of soaking the screen net loaded with the aggregate into the water tank, and recording time; after 1min, lifting the screen net, quickly rotating an annular steel pipe, rotating the screen net to a fan opening, shaking the screen net, using the electronic balance to weigh after the aggregate is dried, and calculating the water absorbing percentage of the aggregate per 1min; according to the steps, circulating the test, accumulating the aggregate water soaking time until the maximum water absorbing rate of the aggregate is measured, drawing a water absorbing characteristic curve according to the test data, and analyzing, so as to obtain a conclusion. The device and the testing method have the advantages that the relationship curve of water absorbing percentage and water absorbing time of the regenerated aggregate of the building wastes can be simply and rapidly calculated, and the flow process operation of the testing process is realized.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER +1

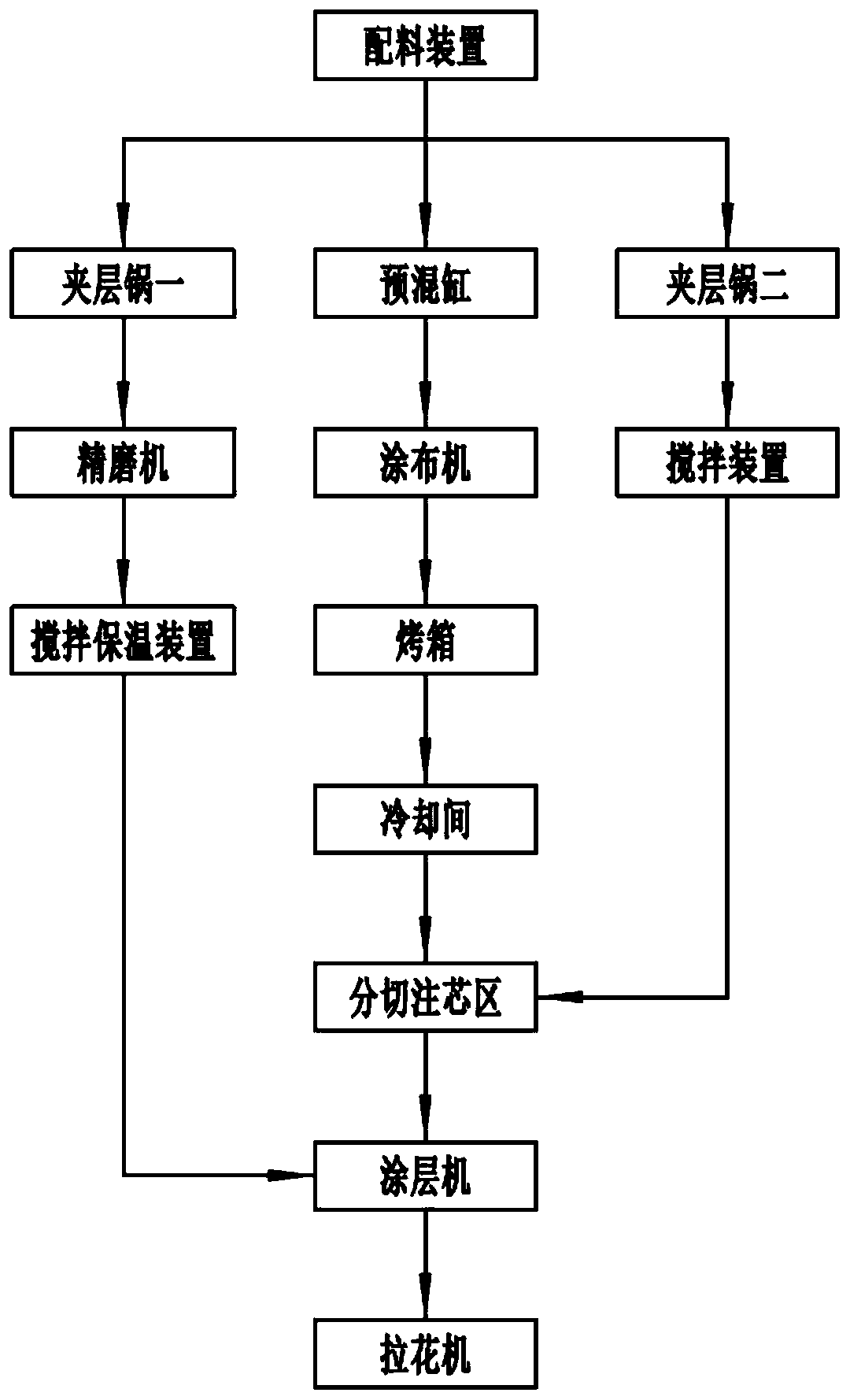

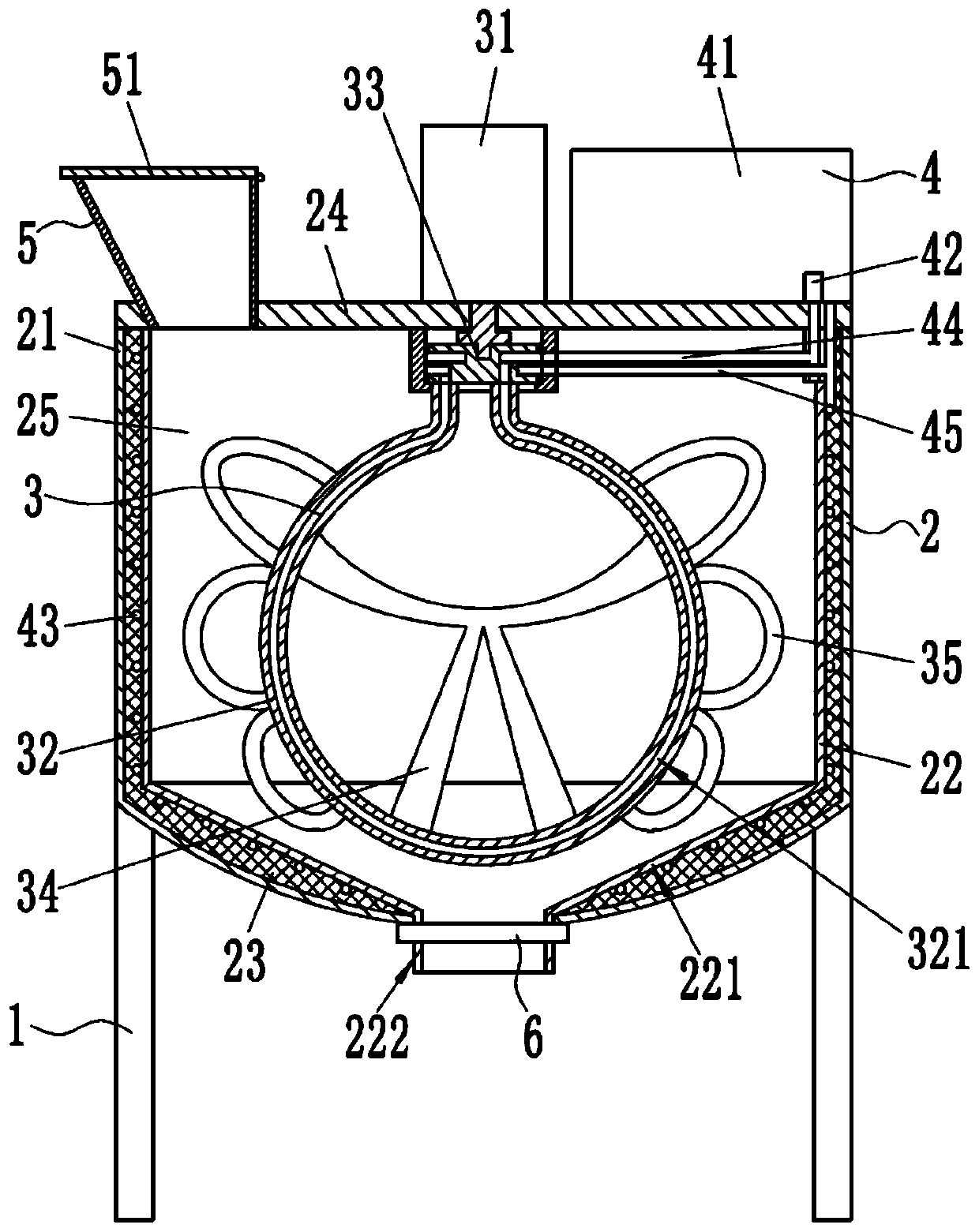

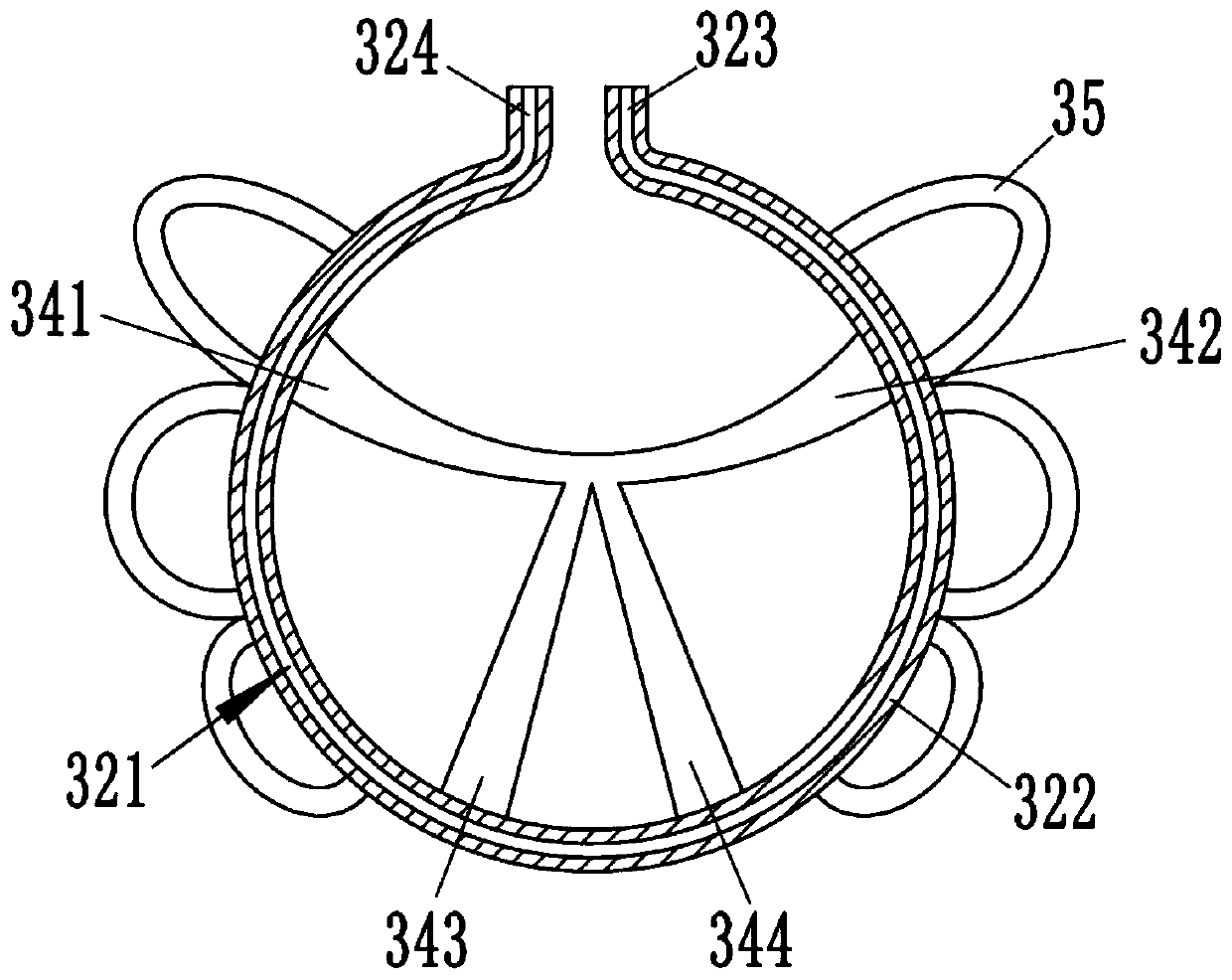

Coated sandwich cake and production process and production line thereof

InactiveCN111034769AGreat tasteNutrient maintenance and strengtheningDough treatmentRotary stirring mixersBiotechnologyEngineering

The invention discloses a coated sandwich cake and a preparation method thereof. The coated sandwich cake is a cold-processed cake processed by taking eggs, wheat flour, white sugar and the like as main raw materials, adding grease, milk powder, an emulsifier and other auxiliary materials, and carrying out procedures of flour beating, flour injecting, baking, demolding, cooling, slitting, core injecting, shaping, coating, drawing, cooling, packaging and the like. The coated cake produced by the invention has high environment adaptability. Through scientifically designed coating and filling slurry formulas, the good mouth melting property of the chocolate coating is ensured, and the coating and the filling are prevented from melting under the conventional logistics transportation and storage environment conditions.

Owner:FUJIAN CHANGTING PANPAN FOOD CO LTD

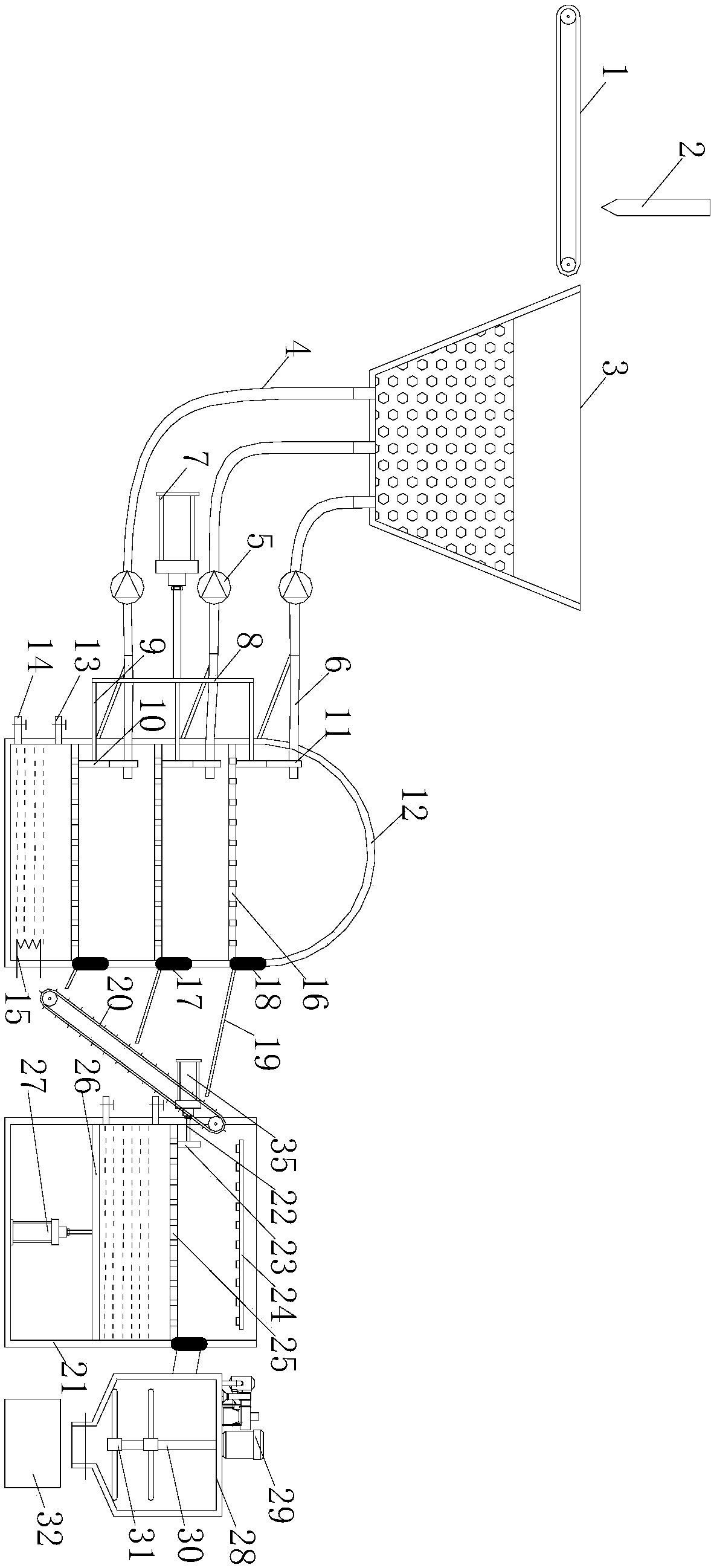

Dried kelp powder preparation apparatus and preparation method thereof

ActiveCN108497370ARealize streamlined operationReduce production efficiencyFruits/vegetable preservation by heatingGrain treatmentsAssembly lineEngineering

The invention relates to a dried kelp powder preparation apparatus. The dried kelp powder preparation apparatus comprises a first conveyor belt, a cutting unit, a softening unit, a washing unit, a drying unit, and a crushing unit; the cutting unit is used for cutting dried kelp on the first conveyor belt into pieces; the softening unit is used for softening the dried kelp; the washing unit is usedfor washing the softened kelp; the drying unit is used for drying the washed kelp; and the crushing unit is used for grinding the dried kelp into powder. The dried kelp powder preparation apparatus realizes assembly-line operation of dried kelp powder production, and is high in continuity and free of artificial participation during processing procedures; and thus, dried kelp powder production efficiency is greatly improved. And the produced dried kelp powder is clean and sanitary.

Owner:天津鼎拓恒远知识产权服务有限公司

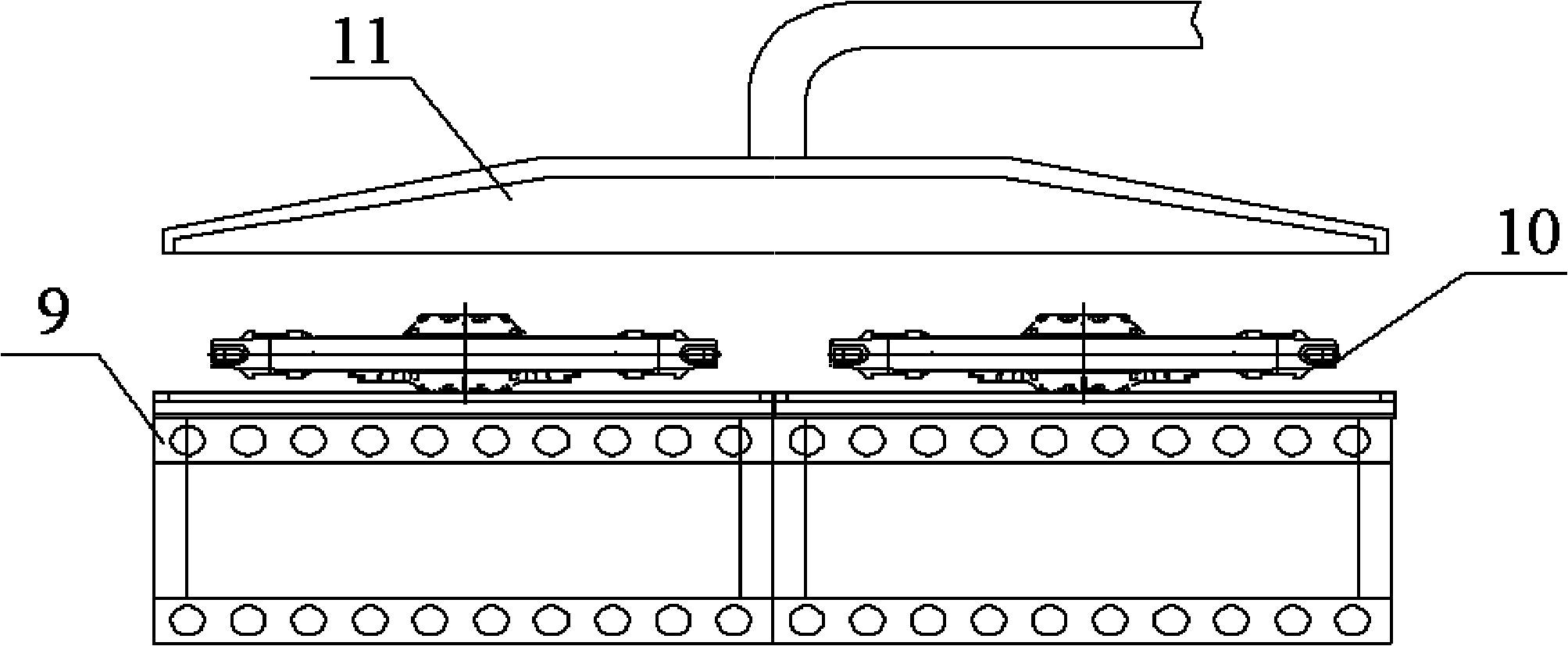

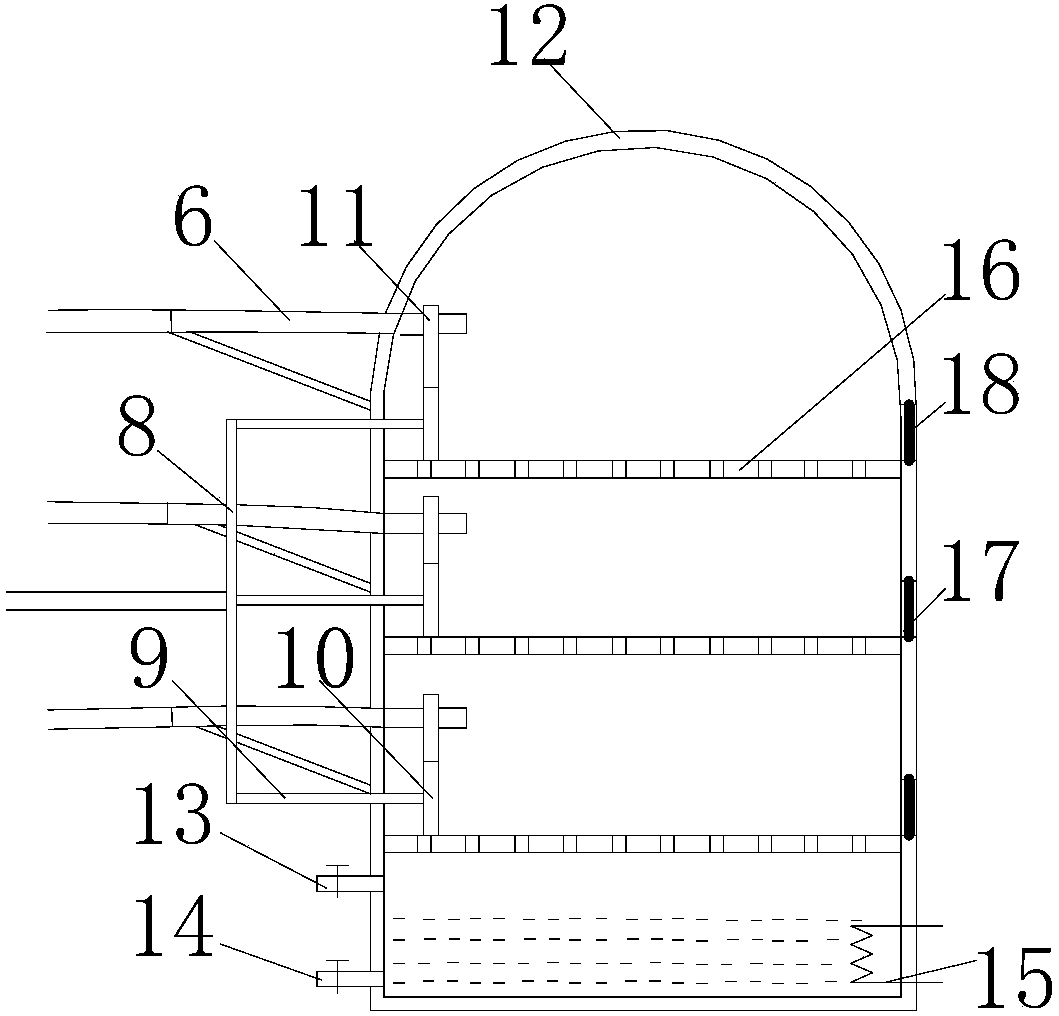

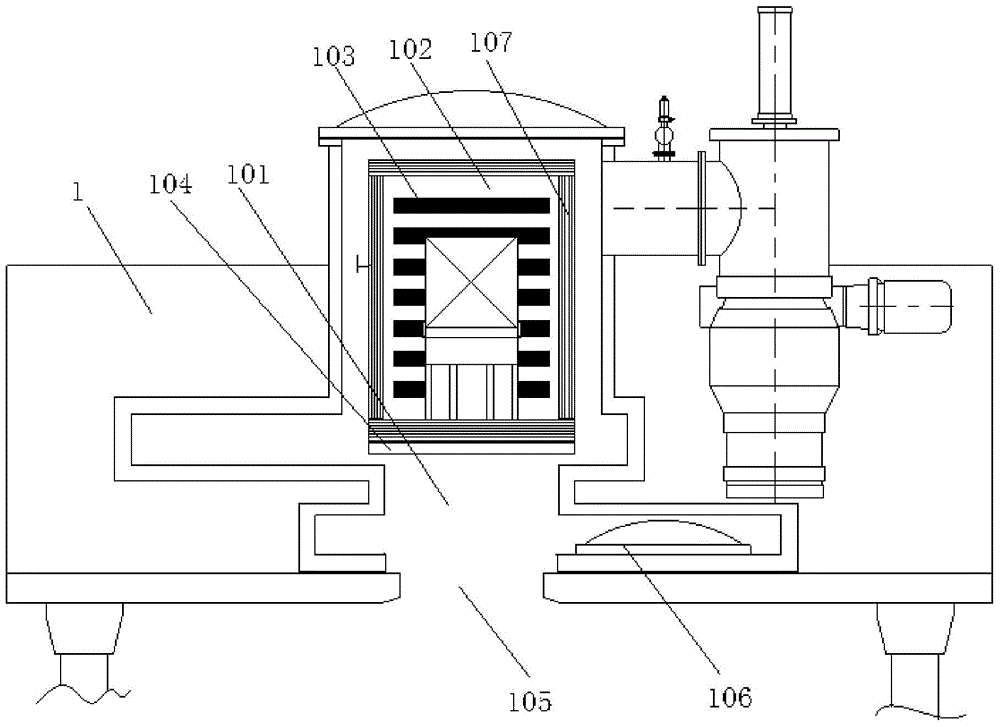

Vacuum quenching furnace

ActiveCN104451065ASatisfy mass quenchingRealize streamlined operationQuenching devicesThermal insulationQuenching

The invention discloses a vacuum quenching furnace. The vacuum quenching furnace comprises a heating chamber, a charging chamber and a quenching chamber, wherein a heating cavity is formed in the heating chamber, a heating box is fixed in the heating cavity, a heating plate is arranged in the heating box, a thermal insulation load bearing door is arranged at the bottom of the heating box, the bottom of the heating cavity is provided with a first material inlet and outlet provided with a first seal door, and the first seal door is arranged under the thermal insulation load bearing door; a charging cavity for containing materials is formed in the charging chamber, and the top of the charging cavity is provided with a second material inlet and outlet provided with a second seal door; a quenching cavity is formed in the quenching chamber, the quenching cavity is connected with a water tank and a water ring pump, the top of the quenching cavity is provided with a third material inlet and outlet provided with a third seal door, material lifting devices are arranged in the charging cavity and the quenching cavity respectively, and the heating chamber, the charging chamber and the quenching chamber are each connected with a vacuumization device. The vacuum quenching furnace can effectively shorten time delay and meet the requirement for quenching of a large batch of materials.

Owner:ADVANCED FOR MATERIALS & EQUIP

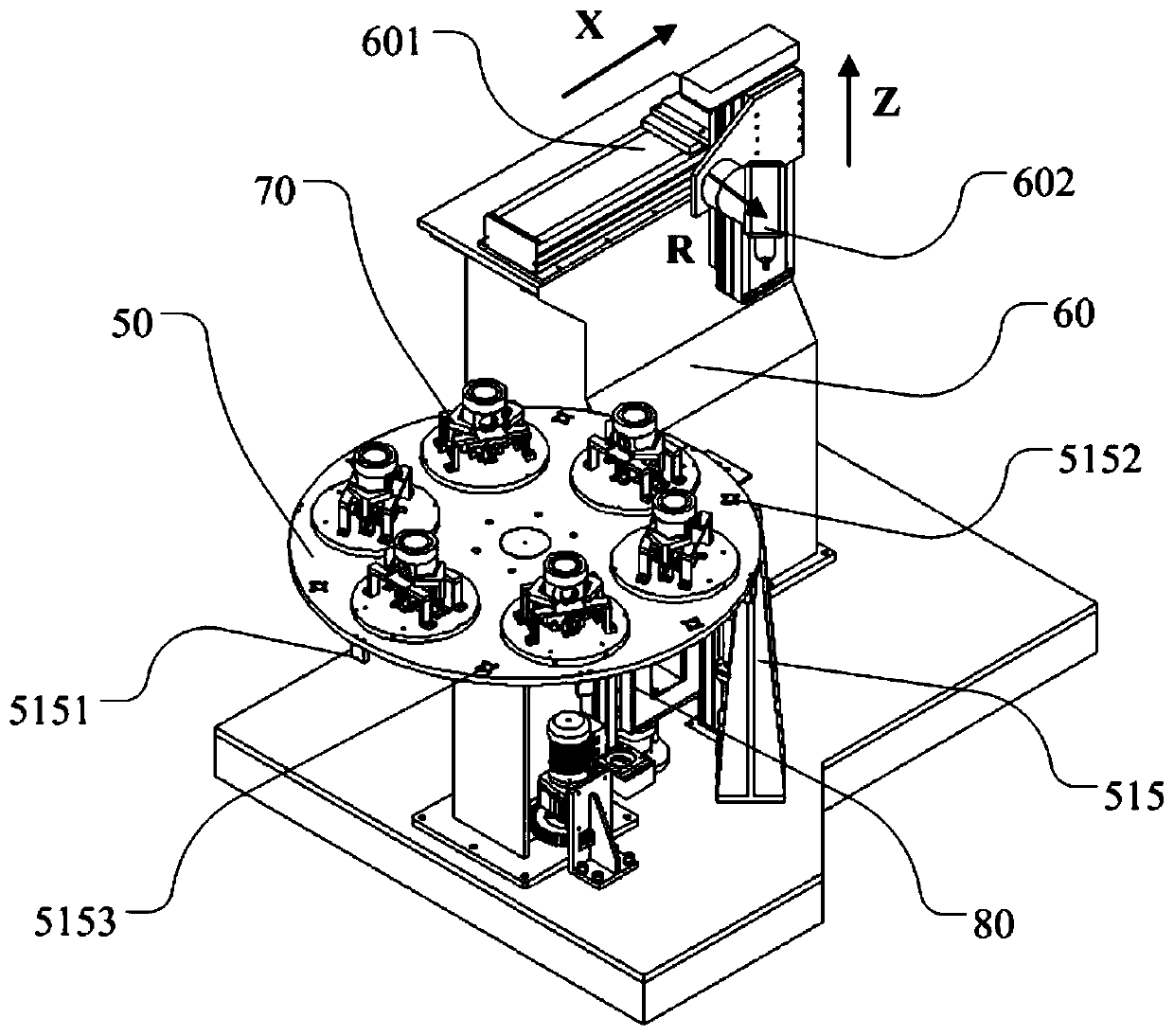

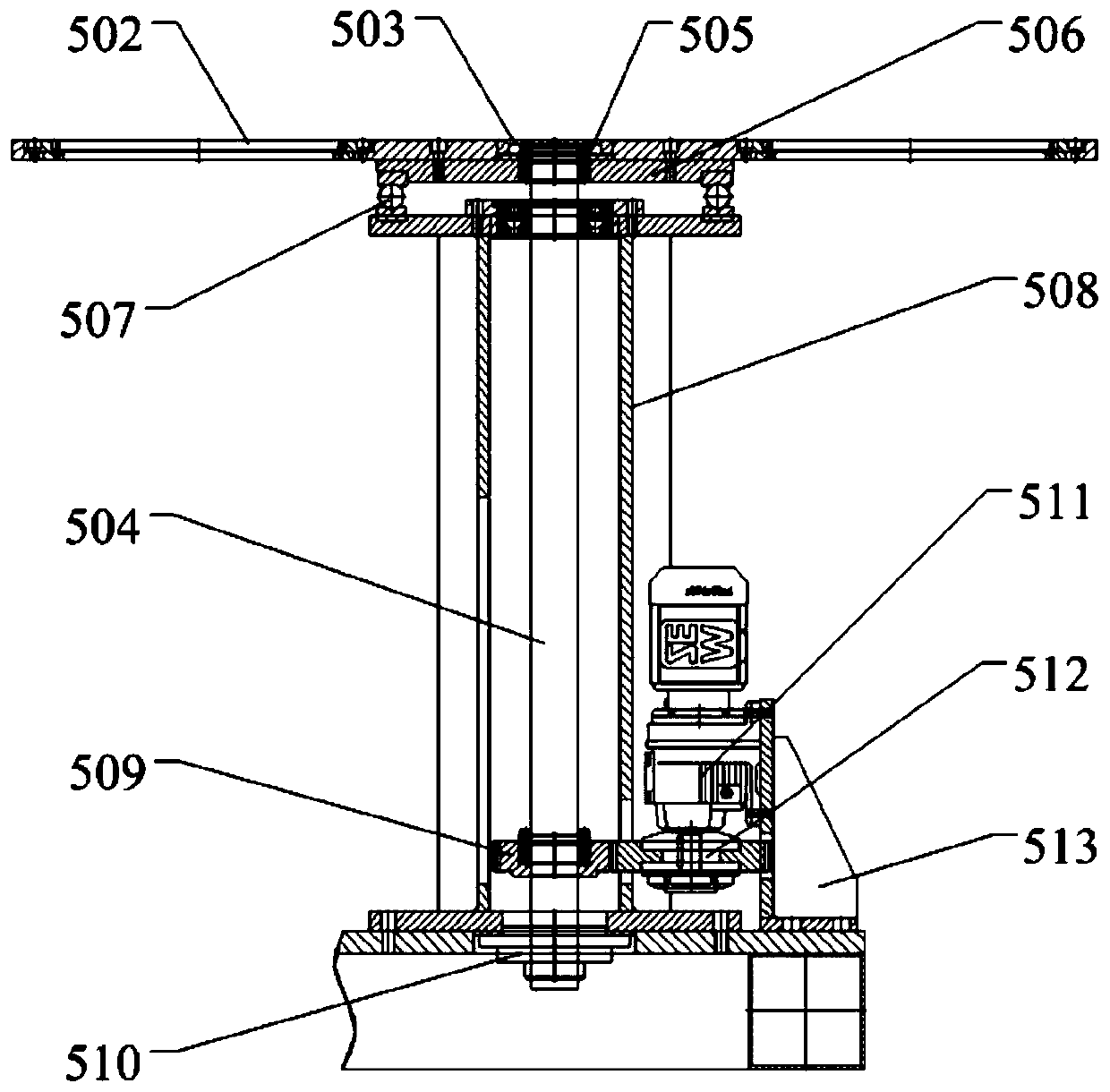

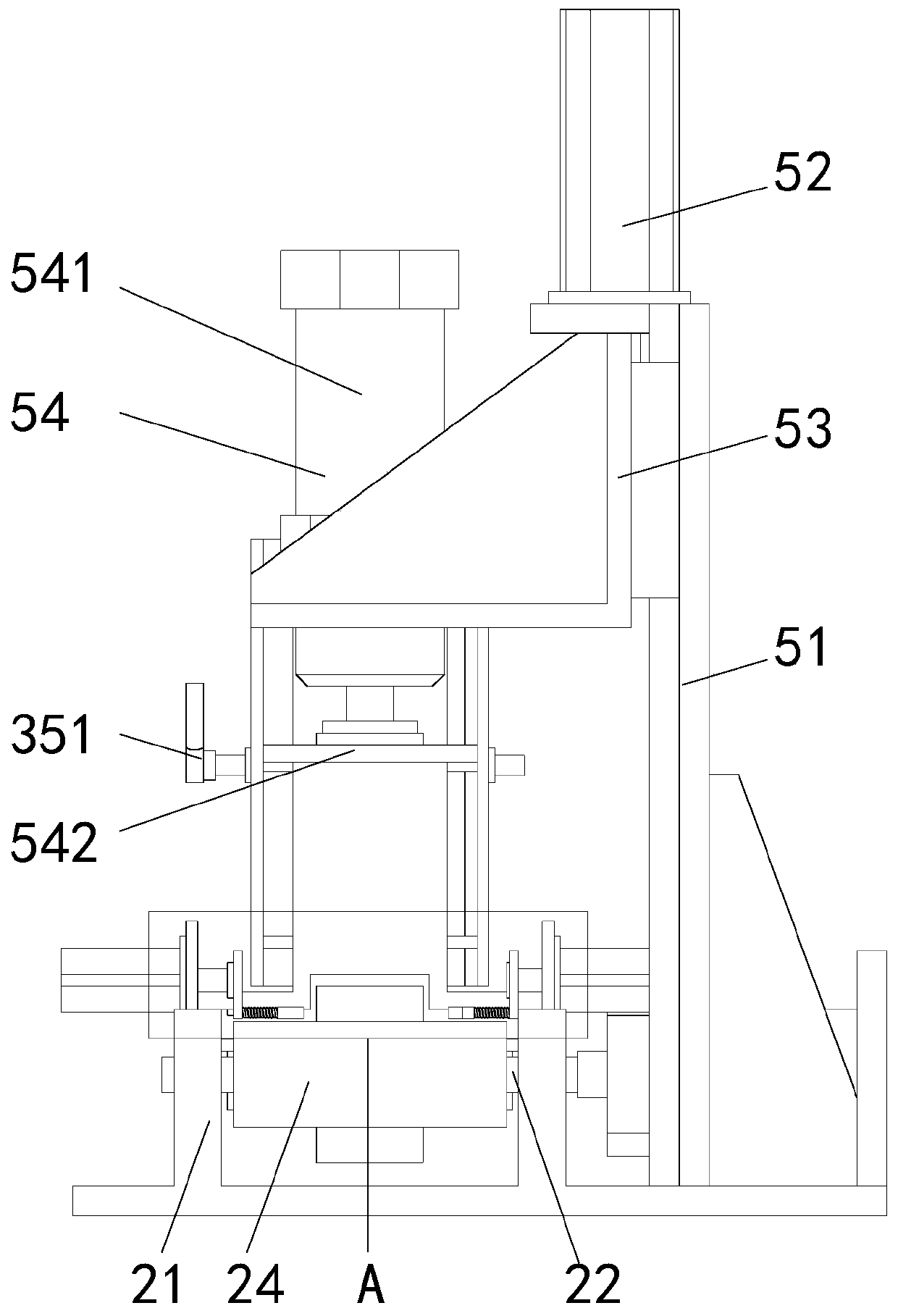

Welding system and method

PendingCN110421248APrecise positioningFlexible choiceWelding/cutting auxillary devicesAuxillary welding devicesLaserAutomation

The invention provides a welding system, a clamp and a welding method. The welding system comprises a rotary workbench, a jacking, clamping and rotating mechanism and a welding robot. The rotary workbench is provided with a feeding station and a welding station at least. The jacking, clamping and rotating mechanism is arranged below the rotary workbench and used for driving a workpiece to ascend,clamping the workpiece and driving the workpiece to rotate. The welding robot is used for carrying out laser welding on the circumference of the workpiece. The welding system further comprises the workpiece clamp. The workpiece clamp is separately arranged on the rotary workbench. The workpiece clamp can be separated from the rotary workbench under the upward jacking action of the jacking, clamping and rotating mechanism. According to the welding system, the clamp and the welding system, the workpiece clamp is precise in locating and flexible in selection, and can adapt to workpieces in different sizes; and the welding efficiency is high, operation is reliable, streamlined operation can be achieved, and the automation degree is high.

Owner:HUBEI HANTAI INTELLIGENT EQUIP

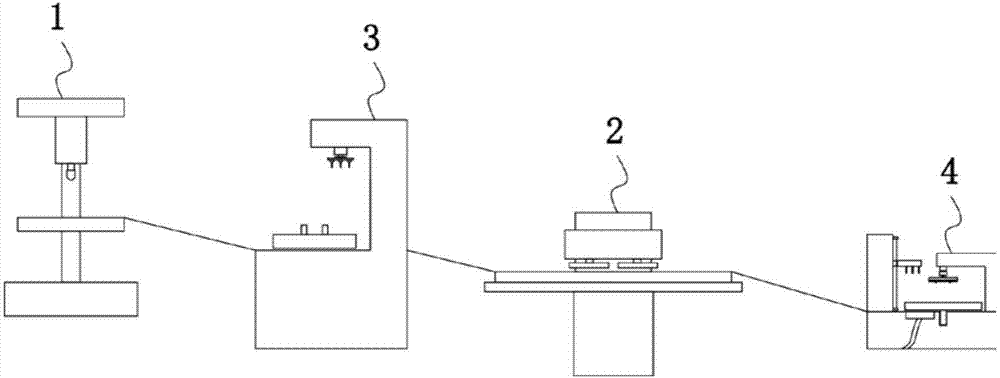

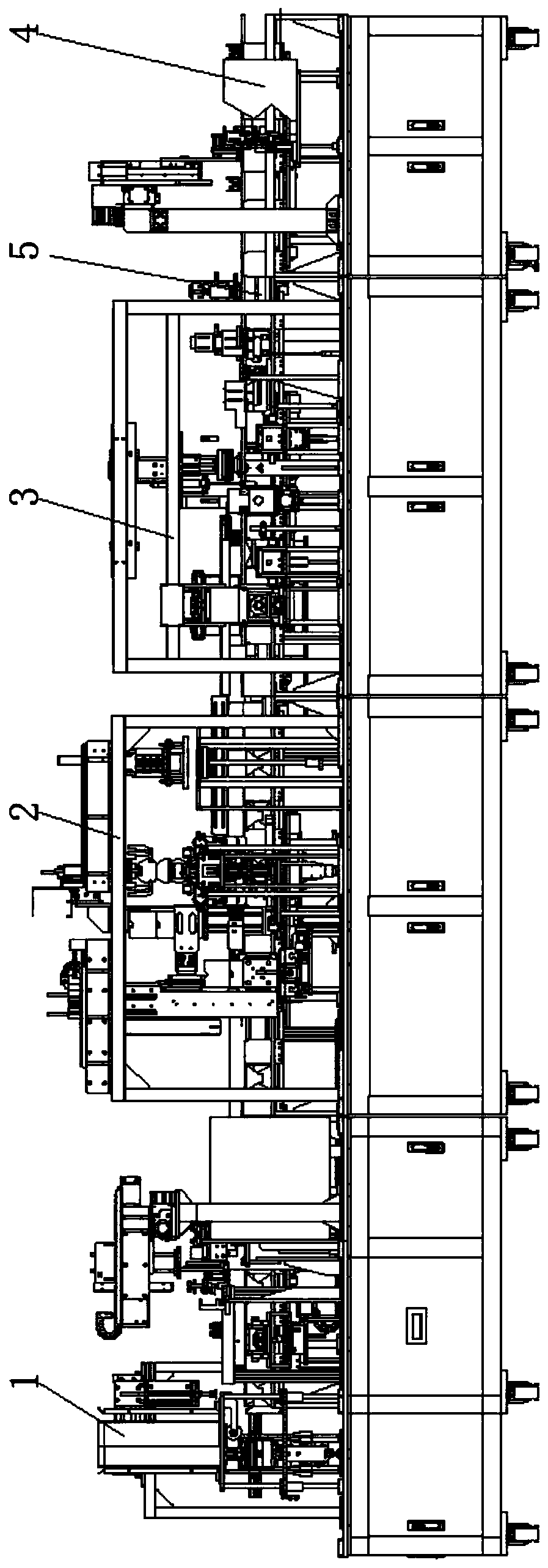

Automatic production line for brake disc

ActiveCN106891169ANo cloggingGuaranteed ventilation effectOther manufacturing equipments/toolsProduction lineEngineering

The invention discloses an automatic production line for a brake disc. The automatic production line comprises a feeding mechanism, a primary drilling mechanism used for fabricating connecting holes of a workpiece, a primary deburring fabricating mechanism and a discharging mechanism, wherein every two adjacent mechanisms are connected with each other through a conveyor belt. The automatic production line further comprises a secondary drilling mechanism used for fabricating ventilating holes of the workpiece. The secondary drilling mechanism is arranged between the primary drilling mechanism and the primary deburring fabricating mechanism. A secondary deburring fabricating mechanism is arranged between the primary deburring fabricating mechanism and the discharging mechanism and comprises a deburring operation platform and a workpiece connecting station rotatably arranged on the deburring operation platform. The automatic production line has the advantages that the secondary deburring fabricating mechanism is arranged, accordingly after the outer surface of the workpiece is cleaned by the primary deburring fabricating mechanism, burrs left in the ventilating holes can be cleaned by the secondary deburring fabricating mechanism, and the ventilating holes can be effectively prevented from being stuck with or blocked by the burrs.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

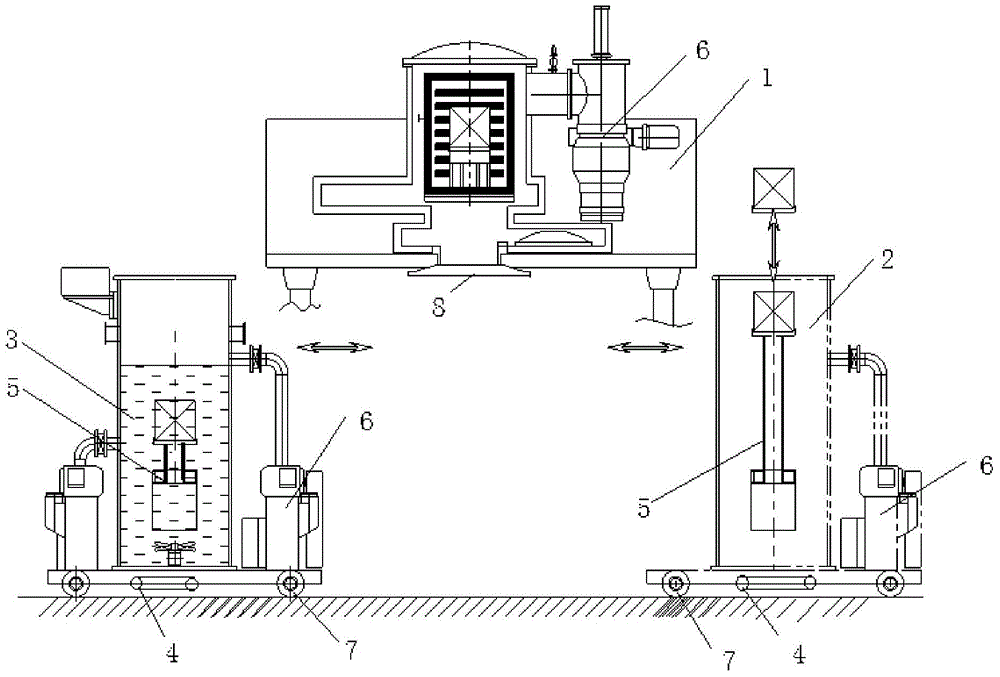

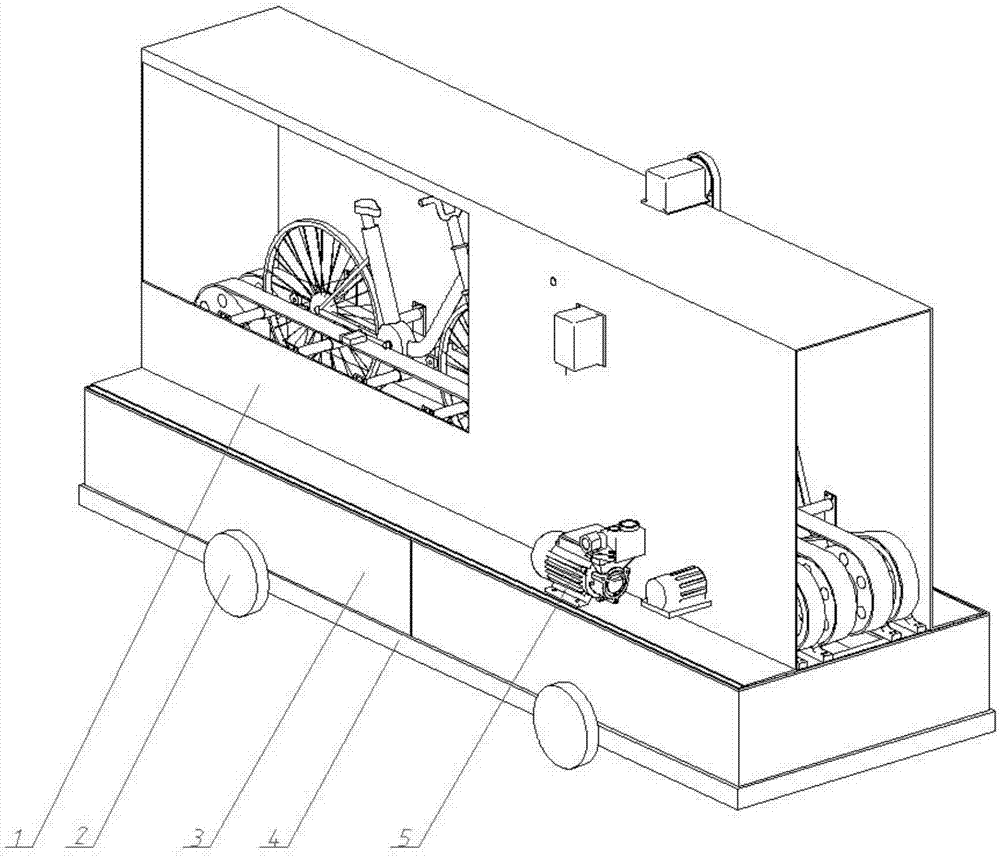

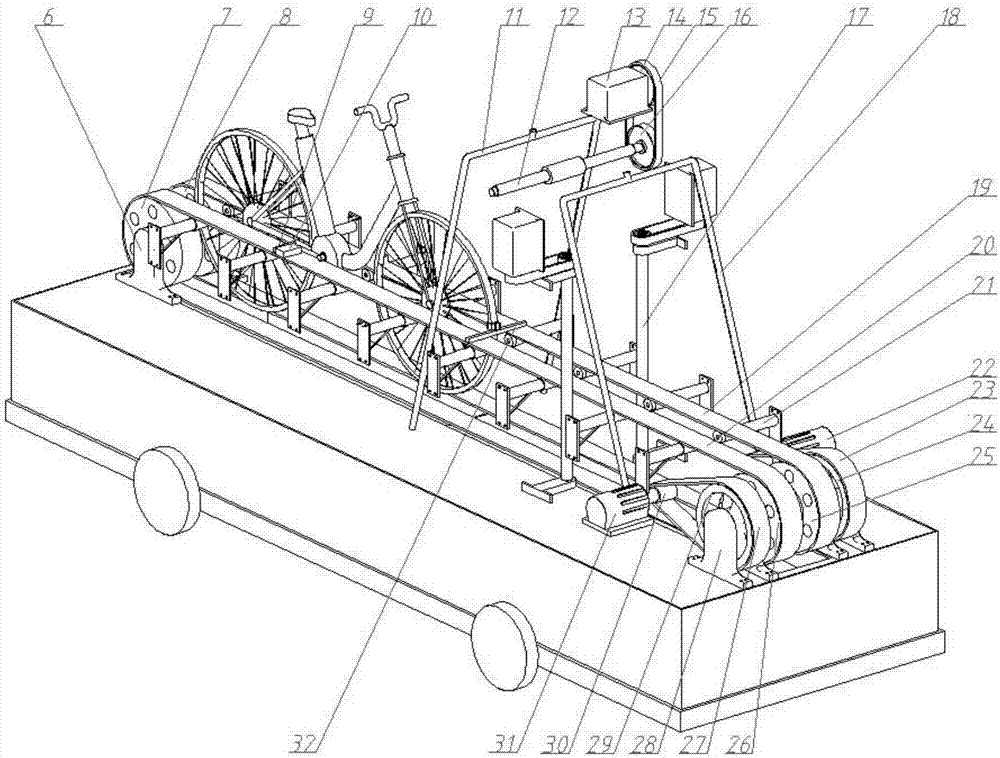

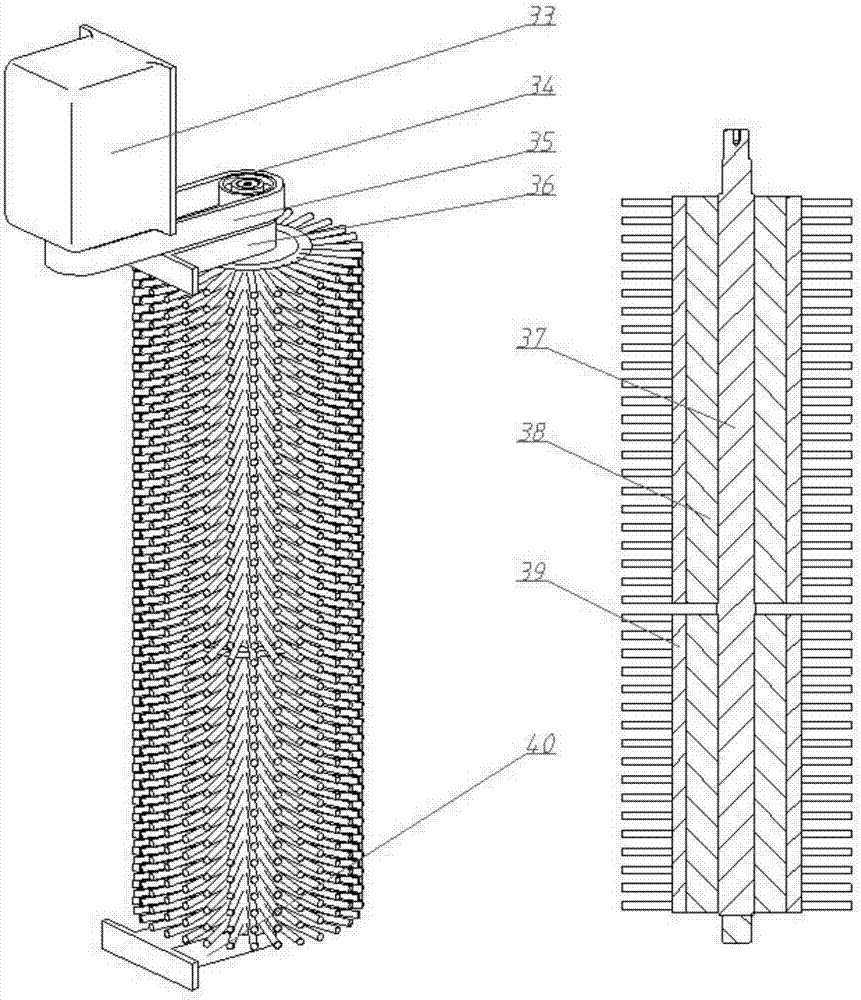

Automatic cleaning device of public bicycles on city road

PendingCN106915335AAchieve fixationPrevent rotationCleaning apparatus for vehicle exteriorsEngineeringElectrical and Electronics engineering

The invention discloses an automatic cleaning device of public bicycles on a city road. According to the automatic cleaning device of the public bicycles on the city road, the problems that in the prior art, bicycles are low in operation efficiency and poor in cleaning effect are solved, and the effects that cleaning efficiency is high, water for a machine is recycled, and manual labor is relieved are achieved. According to the scheme of the automatic cleaning device of the public bicycles on the city road, the automatic cleaning device of the public bicycles on the city road comprises a base and a side hairbrush; a spray mechanism is arranged on the base, one side of the spray mechanism is provided with a bicycle scrubbing mechanism which comprises a support, and the bicycle is arranged on one side of the support; and the top of the support is provided with a horizontally or obliquely arranged top hair brush which can rotate to clean the upper half portion of a bicycle body of the bicycle, and the side hairbrush is vertically arranged or obliquely arranged and can rotate to clean the lower half portion of the bicycle body of the bicycle.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Flexible material filling and pointing machine, and concrete deck joint method

InactiveCN101319493AGuaranteed freedom of movementHigh-precision seam travelCeramic shaping apparatusEarth-fill damsMouth pieceSurface layer

The invention relates to an engineering machine and an engineering method, in particular to a flexible filler inlaying machine for inlaying flexible filler into concrete panel seams of concrete face rockfill dams, as well as a concrete panel seaming method. The construction quality of flexible filler water-stopping layers of surface layers of the concrete face rockfill dams relates to dam safety and stability. Low efficiency and low quality of filler inlaying are always difficult problems perplexing engineers and technicians. The design of the invention seeks to be simple in equipment and concise in process, so as to achieve the effects of easy equipment maintenance and simple operation in practical construction, and to achieve high-speed high-quality construction. The inlaying machine is characterized in that: the inlaying machine has a machine body; a power machine is arranged inside the machine body; the power machine is connected with an extrusion screw of a filler chamber through a speed governor; the filler chamber is provided with a feed port; the machine body is provided with a traveling device; and an outlet of the filler chamber is provided with a die head and / or a mouth piece for controlling the shape of an filler extruding cross section. The concrete panel seaming method is characterized in that: filler in the filler chamber of the filler inlaying machine is heated through the extruding effect of the extrusion screw and / or through a heater; and the heated filler passes through the die head and / or the mouth piece which is arranged in the outlet of the filler chamber to control the shape of the filler extruding cross section, and then the extruded and shaped filler enters into concrete panel seams through inlaying.

Owner:张明军

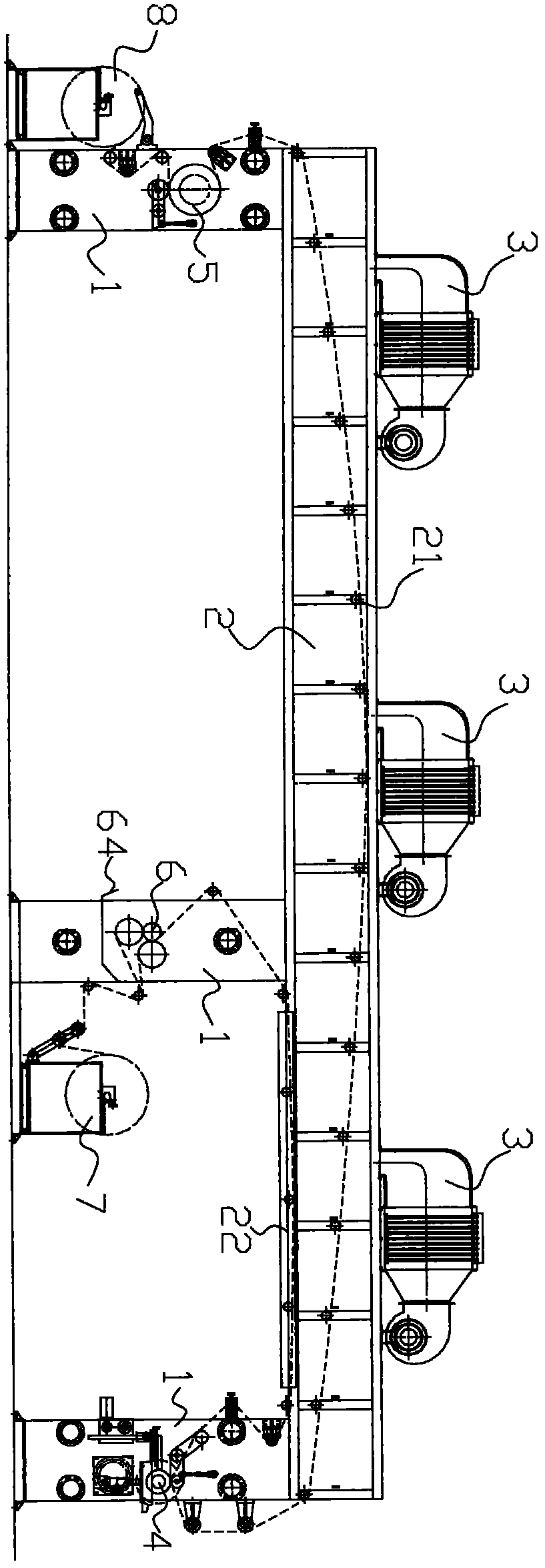

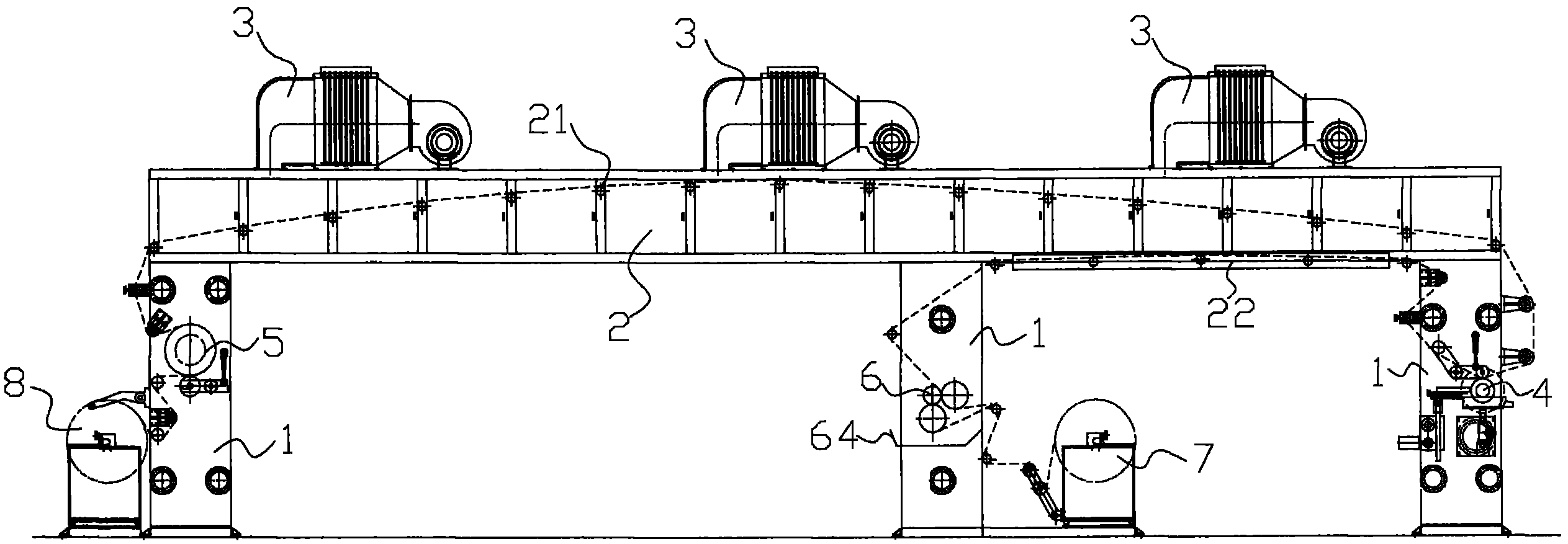

Anti-static low-temperature heat sealing coating machine

ActiveCN101972731AEasy to useSave time at workLiquid surface applicatorsCoatingsHigh rateWork period

The invention provides an anti-static low-temperature heat sealing coating machine which relates to a production device for coating film surfaces. A bottom is formed by multiple pairs of brackets; an internally sealed oven is arranged at the upper parts of the brackets; the oven is supported through the brackets; the oven is communicated with an air heater; the brackets are divided into three pairs, wherein two pairs of brackets are respectively arranged at four corners of the oven, and a pair of brackets are also arranged at two edges of the middle position of the oven; a device for uniformly coating films and a traction cooling device are arranged between the two pairs of brackets at the corners of the oven; a single-sided anti-static device is arranged between the other pair of brackets; an unrolling device is arranged at one side of the single-sided anti-static device; a rolling device is arranged at one side of the traction cooling device; film rolls to be treated are placed in the unrolling device; and the treated film rolls are placed in the rolling device. The invention has the advantages that the traditional devices used in multiple processes for treating films are integrated on one device, the machine of the invention can realize line production, can be used conveniently, can not occupy much space and shorten the working time, and the treated films have high rate of finished products and good product effect.

Owner:JIESHOU CITY TIANHONG PACKAGING MATERIAL

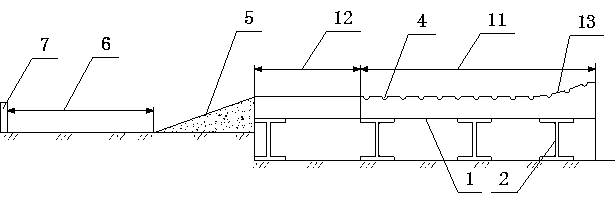

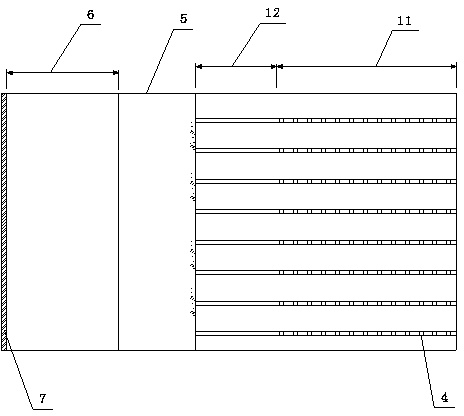

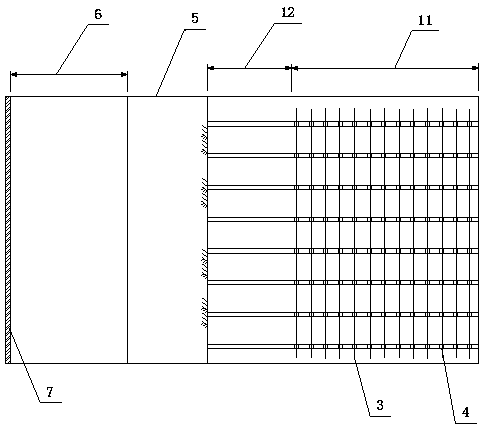

Serration-type steel reinforcement cage machining jig frame and construction method thereof

ActiveCN103586374AImprove processing qualityImprove processing progressMeshed-ring wire networkRebarMachining

The invention discloses a serration-type steel reinforcement cage machining jig frame, and belongs to the field of steel reinforcement cage machining. The jig frame is divided into a main rib welding and forming area and a spiral rib bonding area, wherein the tail portion of the main rib welding and forming area is an arc section, and the upper surface of the main rib welding and forming area is provided with a plurality of notches matched with intervals and diameters of main ribs at equal intervals. The construction method sequentially includes the following steps that the main ribs needing to be welded are placed in the notches of the main rib welding and forming area of each jig frame one by one, firstly, the main ribs on the arc section of each jig frame are welded and roll towards the spiral rib bonding area of the corresponding jig frame after welding, the main ribs sequentially roll, are sequentially welded and ultimately roll to the spiral rib bonding area, and spiral stirrups are bound. According to the jig frame and a construction method of the jig frame, all the main ribs of a machined steel reinforcement cage are evenly distributed, machining quality of the steel reinforcement cage is higher, function requirements can be met on the condition that the machining progress of the steel reinforcement cage is accelerated, construction operators and equipment investment are reduced, and machining cost of the steel reinforcement cage is reduced.

Owner:CCCC SHEC FOURTH ENG +1

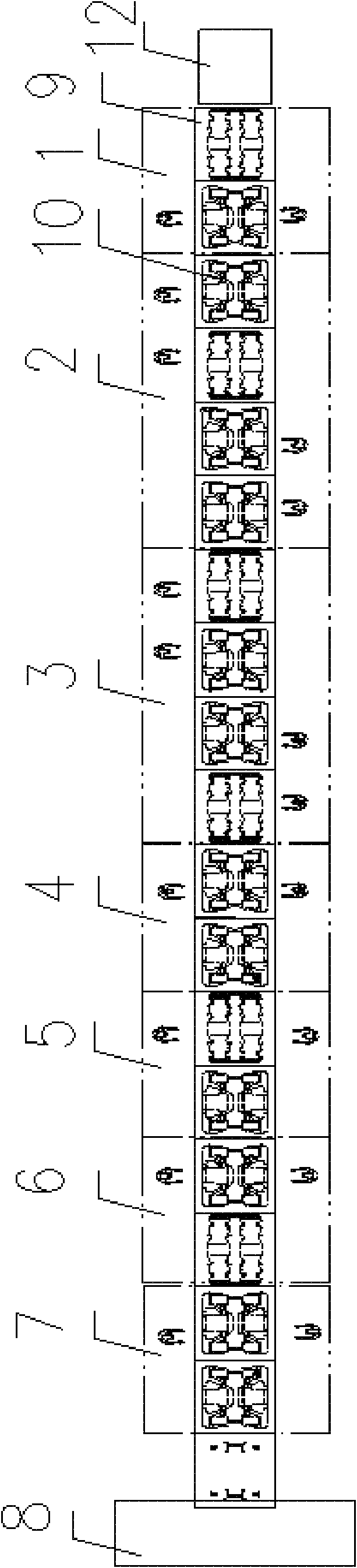

Fly maggot cultivation production line with adult maggot preprocessing device

The invention discloses a fly maggot cultivation production line with an adult maggot preprocessing device. The fly maggot cultivation production line comprises a cultivation disc for cultivating fly maggots, a cultivation disc carrying device for carrying the cultivation disc, a feeding device for feeding fly blow and feed to the cultivation disc carrying device, a first conveying belt for receiving adult maggots and residual feed output by the cultivation disc carrying device, a fly maggot separating device for separating the adult maggots and residual feed conveyed by the first conveying belt, a feed collecting device for receiving the residue feed output by the fly maggot separating device, a second conveying belt for receiving the adult maggots output by the fly maggot separating device and the adult maggot preprocessing device arranged at the output end of the second conveying belt. A stereoscopic framework with multiple layers of roller lines is adopted and matched with a first cross-layer transfer device and a second cross-layer transfer device to achieve stereoscopic circular carrying of the cultivation disc and then matched with the feeding device, the fly maggot separating device and the adult maggot preprocessing device to completely achieve streamlined operation of fly maggot cultivation.

Owner:苏州寰宇新博环保科技有限公司

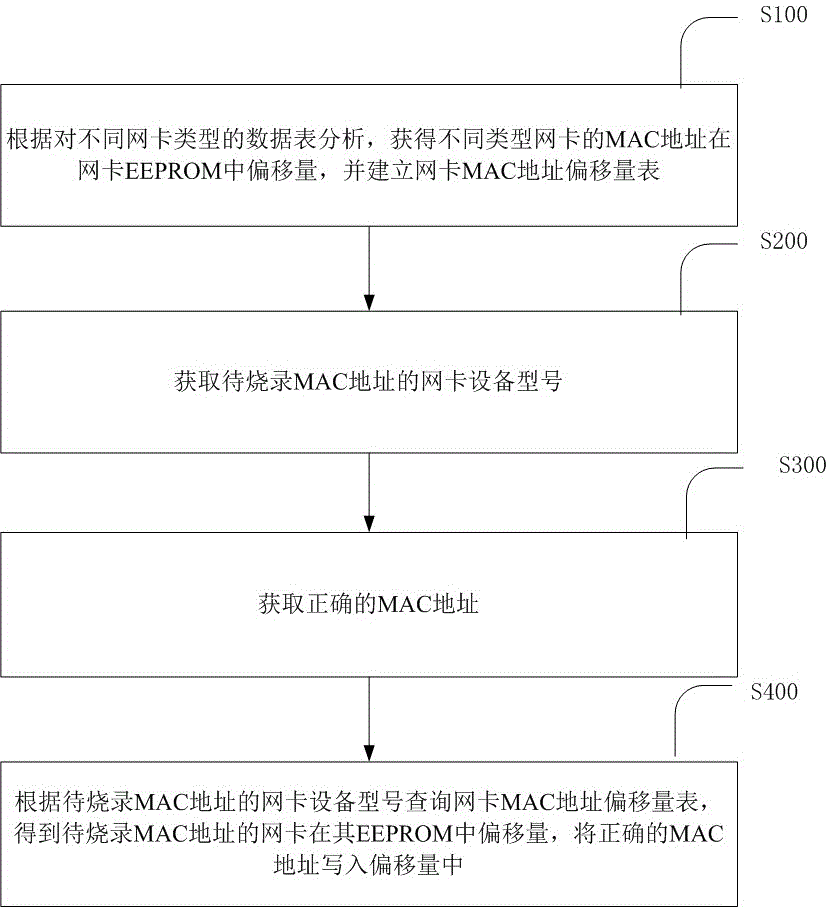

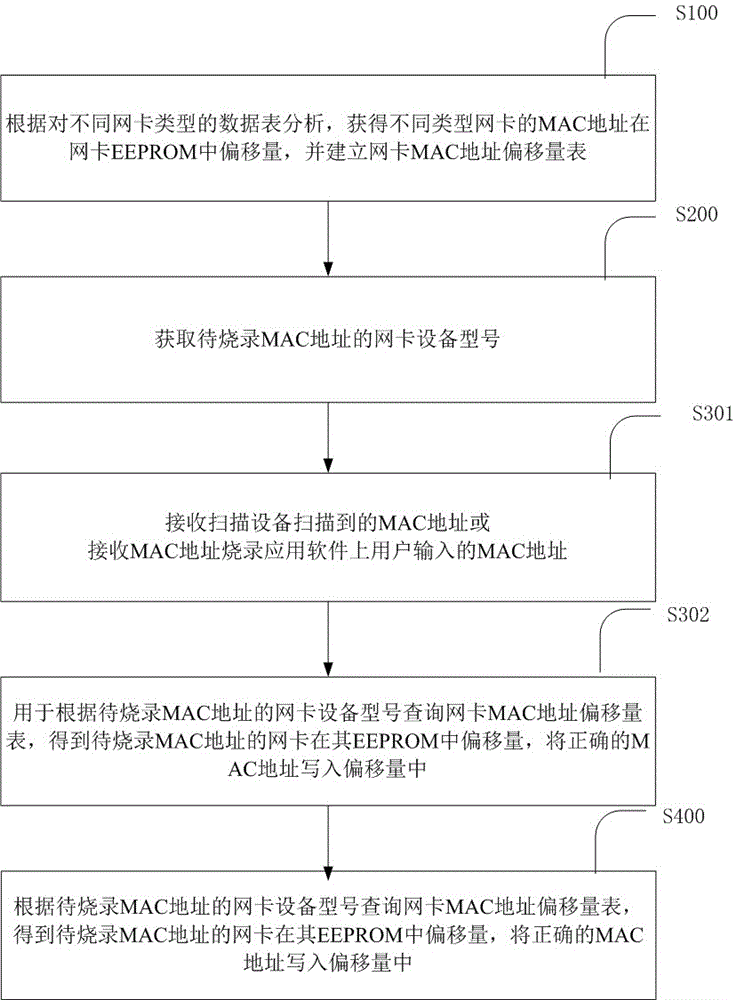

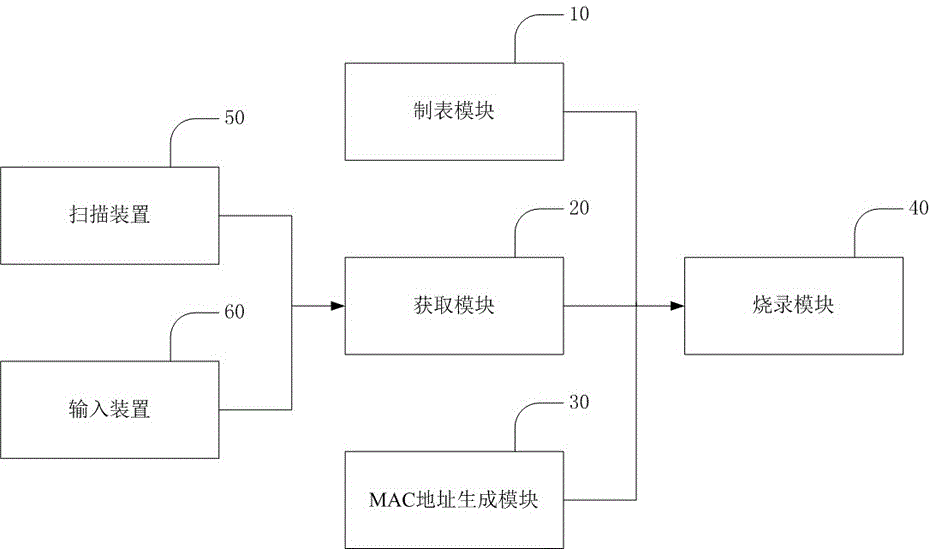

Network card MAC address burning method and apparatus based on Feiteng platform

The invention discloses a network card MAC address burning method and apparatus based on a Feiteng platform. The method comprises: step S100: according to the data sheet analysis of different types of network cards, the offsets of MAC addresses of different types of network cards in EEPROMs of the network cards are obtained and a network card MAC address offset table is established; Step S200: a model of a network card to be subjected to burning MAC address is obtained; Step S300: a correct MAC address is obtained; and Step S400: the network card MAC address offset table is inquired according to the model of the network card to be subjected to burning MAC address, the offset of the network card to be subjected to burning MAC address in an EEPROM thereof is obtained, and the correct MAC address is written in the offset. Through the reading of different types of network card data sheets, a unified burning method of MAC addresses of different models of network cards is obtained; only the specific location of conserving the MAC address in the EEPROM of the network card is operated; the network card MAC address is guaranteed to be correctly burned; the burning efficiency of the MAC address is improved; and streamline operation can be achieved.

Owner:湖南长城银河科技有限公司

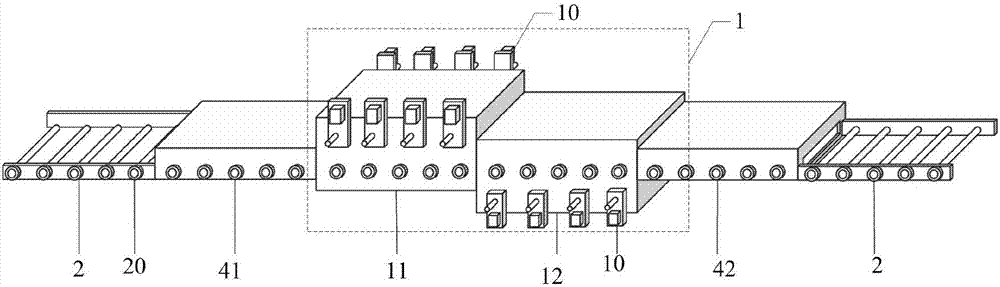

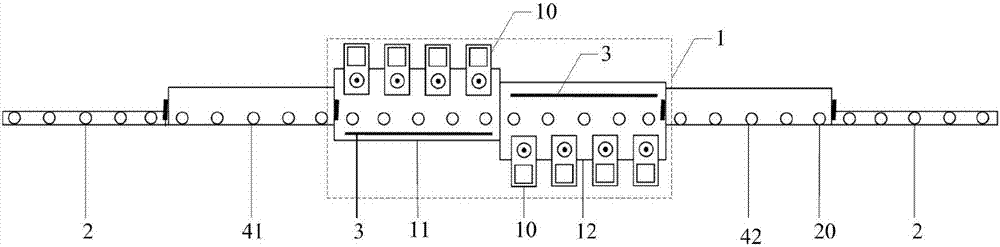

PCB plasma treatment device

ActiveCN107087349AHigh degree of processing automationImprove processing efficiencyCircuit board tools positioningInsulating layers/substrates workingEngineeringProcess engineering

Provided is a PCB plasma treatment device. The PCB plasma treatment device includes a process chamber and a transport rail, and the process chamber is used for providing a plasma processing site for printed circuit boards (PCB); a plasma source is arranged in the process chamber and used for conduct plasma processing on the printed circuit boards (PCB) in the process chamber; the transport rail penetrates through a process chamber body, is used for conveying the printed circuit boards (PCB) into the process chamber body through the inlet end of the process chamber body, and is used for conveying the printed circuit boards (PCB) in the process chamber body out of the process chamber body through the outlet end of the process chamber body. Compared with the prior art that the printed circuit boards (PCB) are manually placed in a centralized mode to be subjected to plasma treatment, by the adoption of the PCB plasma treatment device, streamlined operation can be achieved, and the efficiency of the plasma treatment is improved.

Owner:深圳优普莱等离子体技术有限公司

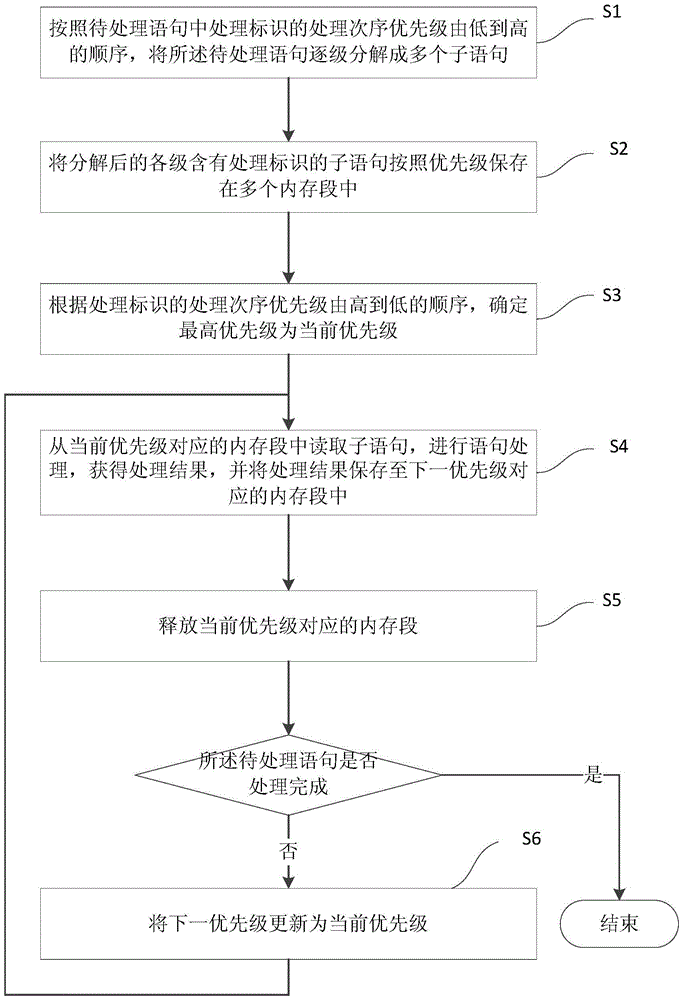

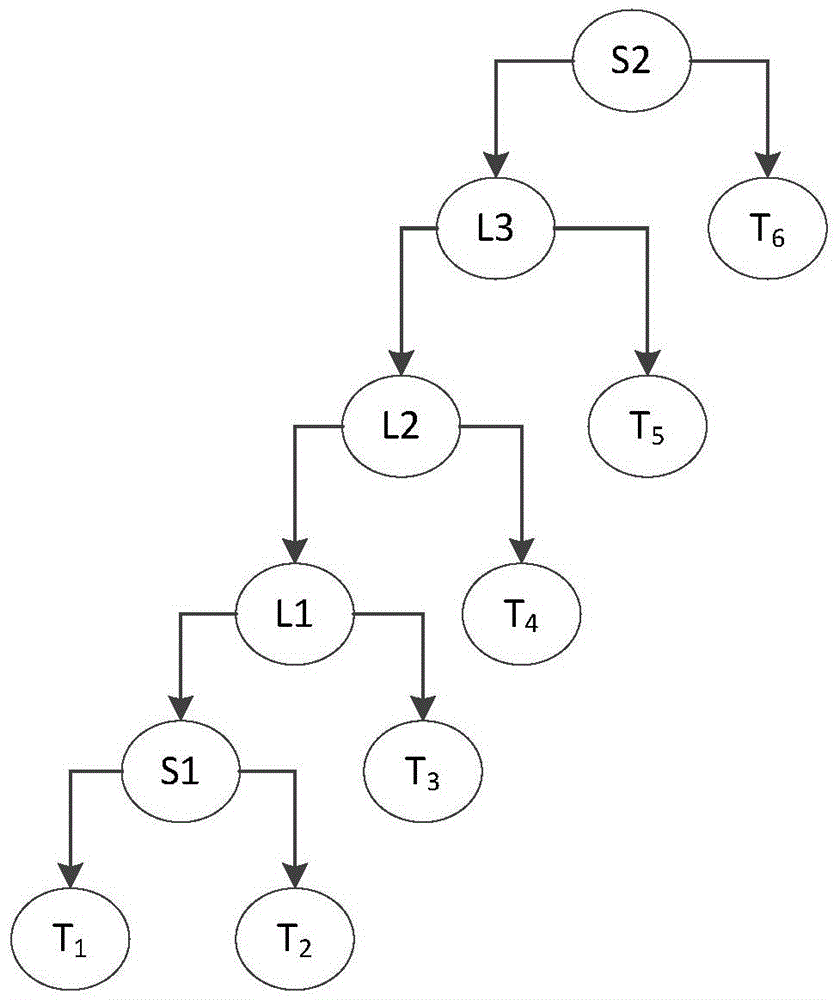

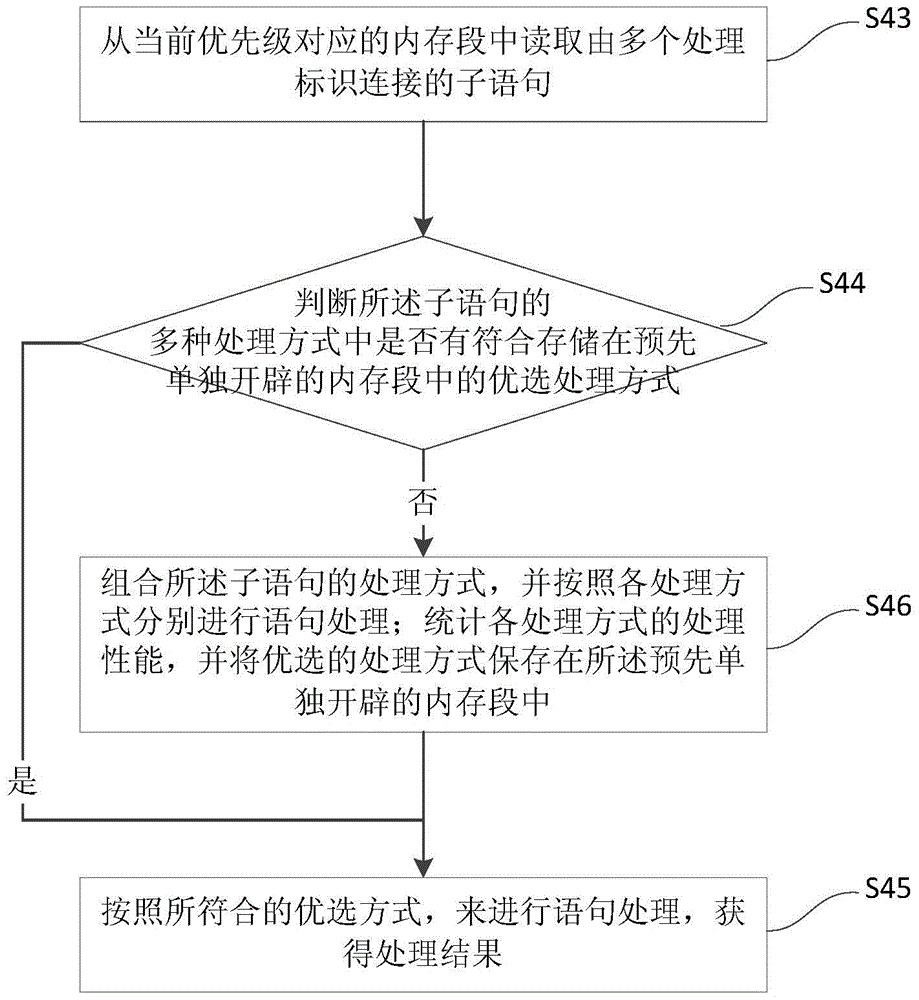

Memory management method and system

ActiveCN105786616AImprove efficiencyReduce the number of addressingResource allocationProcess identificationMemory management

The invention provides a memory management method and system. The method comprises the following steps: the system dividing a to-be-processed statement into a plurality of sub-statements step by step according to an order from high to low of processing order priorities of processing identifications in the to-be-processed statement, wherein the processing identification is used for identifying a logic processing relationship between the sub-statements in the same level; saving the each level of divided sub-statement containing the processing identification in a plurality of memory segments according to the priorities; determining the highest priority as the current priority according to the order from high to low of the processing order priorities of the processing identifications; reading the sub-statement from the memory segment corresponding to the current priority, processing the statement to obtain a processing result, and saving the processing result in the memory segment corresponding to the next priority; releasing the memory segment corresponding to the current priority, and updating the next priority as the current priority, and returning to an operation of reading or processing the sub-statement until the processing of the to-be-processed statement is finished. The method and system provided by the invention can improve the memory usage efficiency.

Owner:SHANGHAI DAMENG DATABASE

Friction material surface treatment device for brake pad production and manufacturing

ActiveCN110802462AUniform thicknessGuaranteed qualityEdge grinding machinesGrinding drivesAssembly lineBrake pad

The invention relates to a friction material surface treatment device for brake pad production and manufacturing. The friction material surface treatment device comprises a base plate and a smoothingdevice fixedly mounted on the base plate, and further comprises a conveying mechanism arranged on the base plate and used for conveying brake pads, an anti-return limiting discharge bin arranged on the conveying mechanism and used for collecting the brake pads and a clamping mechanism located below the smoothing device. The friction material surface treatment device for brake pad production and manufacturing can realize assembly line operation of surface smoothing on brake pad friction materials through division cooperation of all the mechanisms and is higher in efficiency. Moreover, the surface of the friction material of a machined brake pad is smooth in surface, the thicknesses of the brake pads are uniform, and the uniform quality of the brake pads is ensured.

Owner:瑞安市兆达机车部件有限公司

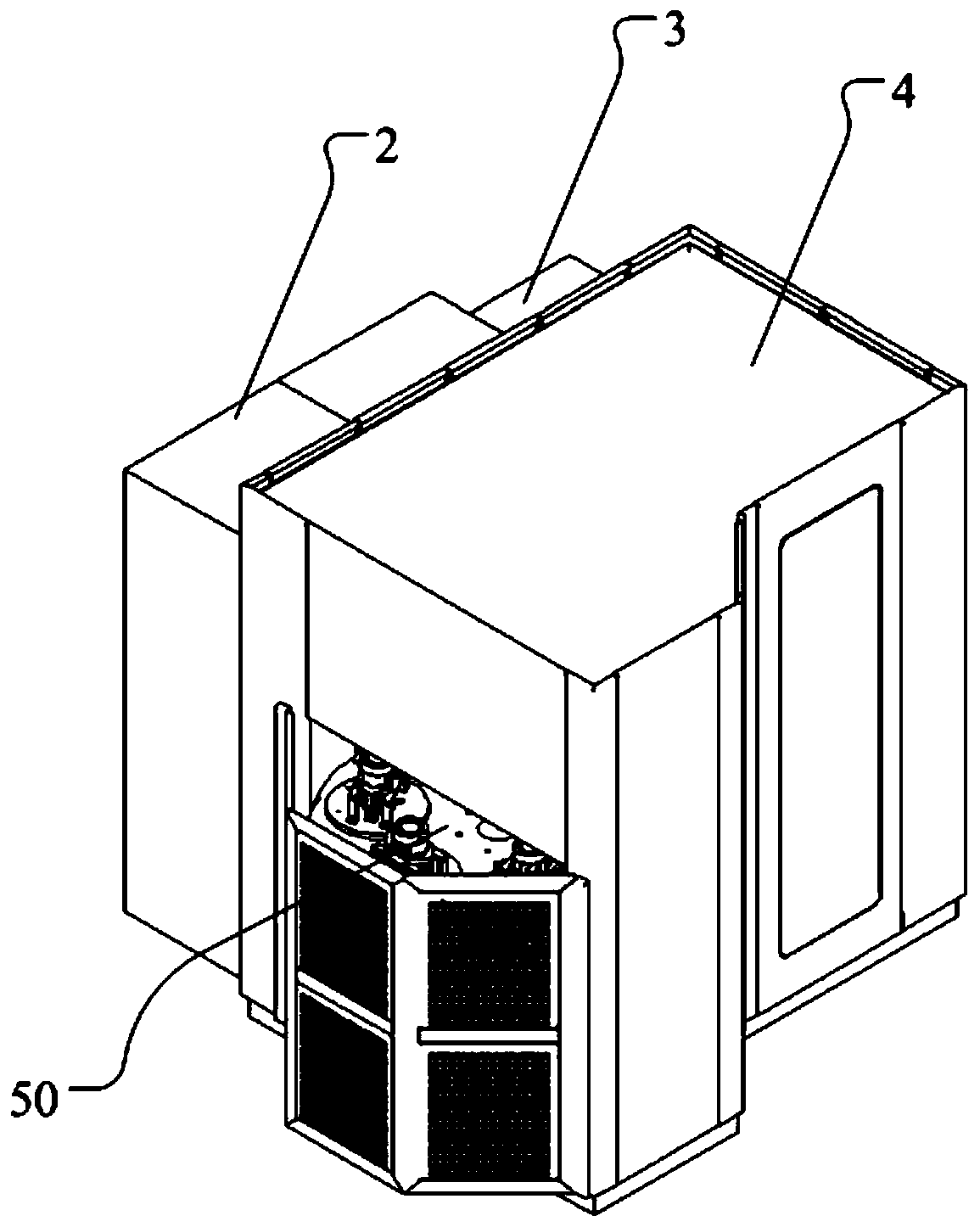

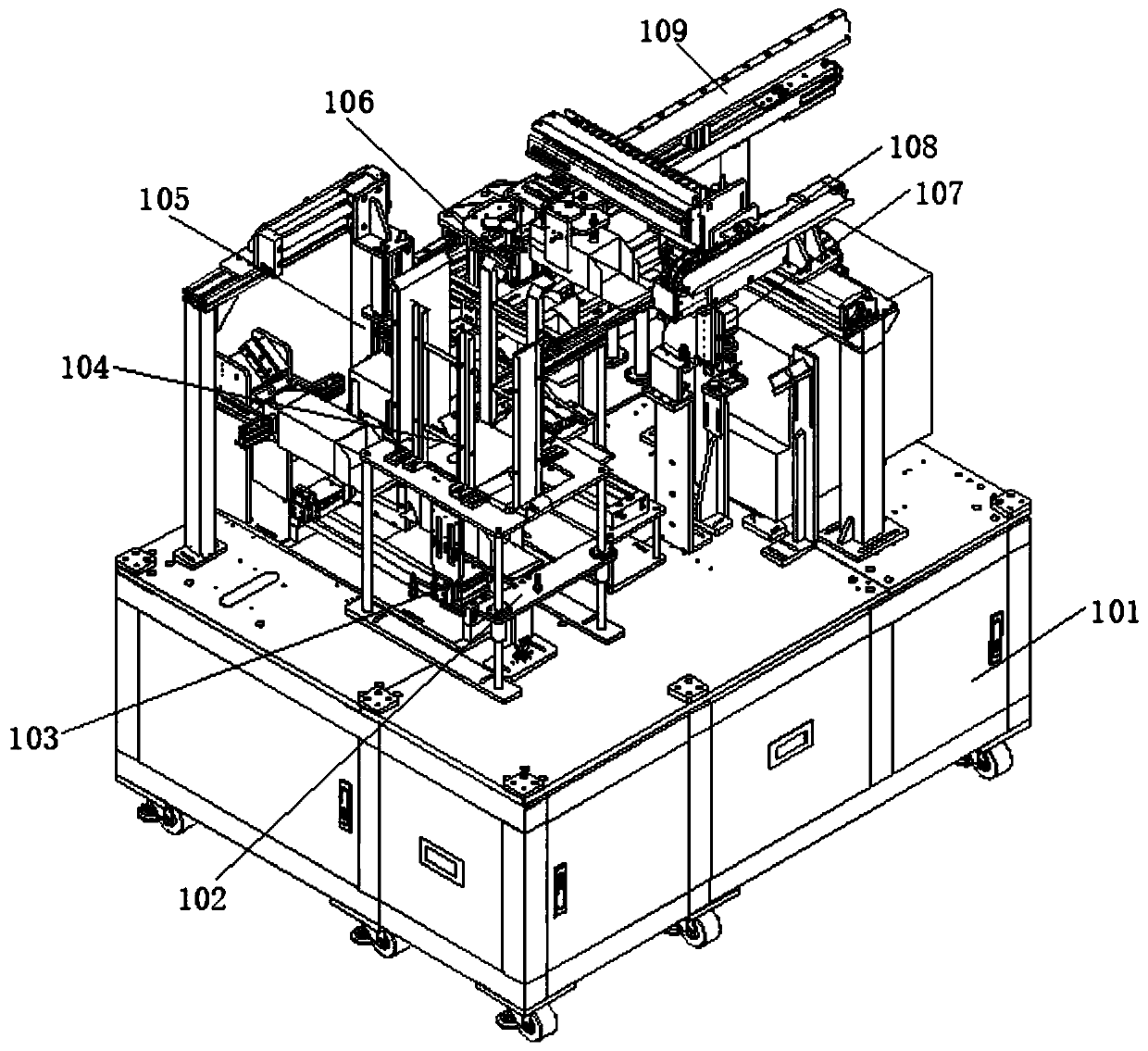

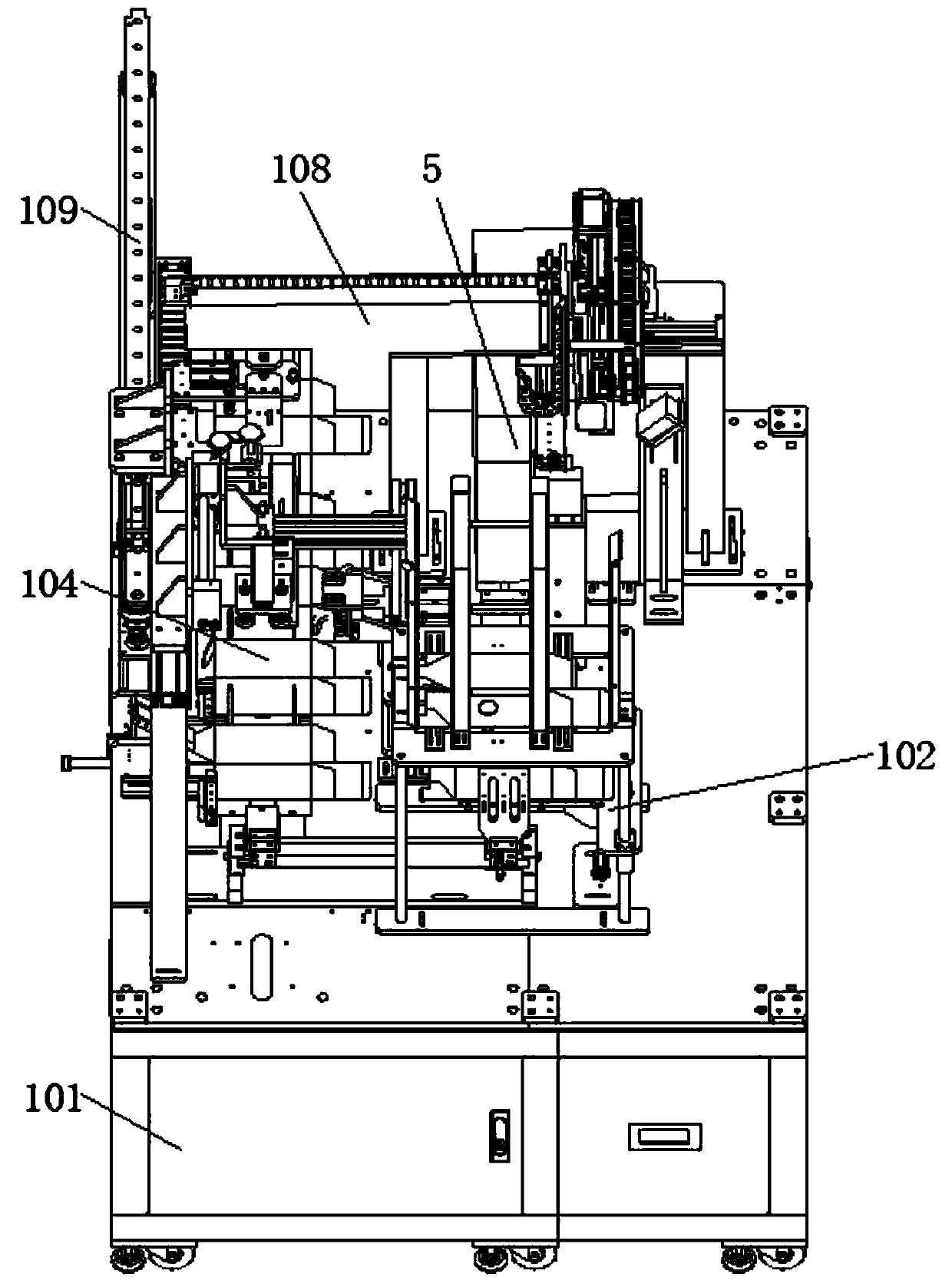

Automatic packaging production line for camera production

ActiveCN110481918AAutomate the packaging processSave packing timeLabelling flat rigid surfacesPackaging machinesProduction lineIndustrial engineering

The invention relates to the technical field of camera production, in particular to an automatic packaging production line for camera production. The automatic packaging production line comprises a first machine table device, a second machine table device, a third machine table device, a fourth machine table device and a conveying device, wherein the head end of the second machine table device isfixedly connected with the tail end of the first machine table device; the head end of the third machine table device is fixedly connected with the tail end of the second machine table device; and thehead end of the fourth machine table device is fixedly connected with the tail end of the third machine table device. According to the conveying device, a color box can be transplanted from left to right along with a line body, the forming labeling of the color box, the box entering of a product and an inner card, the box entering and packaging of accessories and the attaching of a sealing labelcan be completed in sequence, and the fully automated unmanned operation is achieved, so that the automatic packaging of a camera is achieved, the packaging time of the camera is greatly shortened, and the equipment utilization rate is improved; and the streamlined operation is achieved with a front-and-back working procedure, so that the labor intensity of operators is reduced.

Owner:广州功骏自动化科技有限公司

Full-automatic electronic product packaging device

The invention discloses a full-automatic electronic product packaging device. The full-automatic electronic product packaging device comprises a packaging bin, the packaging bin is provided with a first belt conveyor, a first code pasting device is arranged above the first belt conveyor, a packaging box storage cage is fixedly connected to the packaging bin, and a baffle is hinged to the lower part of the packaging box storage cage; the packaging bin is fixedly connected with a third supporting plate, the third supporting plate is fixedly connected with a rear end cover of a second cylinder, and a baffle is hinged to a piston rod of the second cylinder; the packaging bin is fixedly connected with a fourth supporting plate, the fourth supporting plate is provided with a lift, and a moving plate is placed on the lift; and a base is fixedly connected with a fifth supporting plate, the fifth supporting plate is fixedly connected with a rear end cover of a third cylinder, and a piston rod of the third cylinder is fixedly connected with a push rod. The full-automatic electronic product packaging device is simple in structure, small in occupied area and simple in operation, code pasting,code spraying and packaging streamlined operation can be realized, the packaging processing efficiency is high, and the packaging efficiency is high.

Owner:福建奥迈自动化科技有限公司

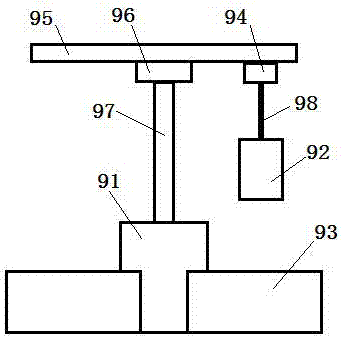

Stirring and grabbing device

PendingCN108931418AGuaranteed to workRealize streamlined operationWithdrawing sample devicesPreparing sample for investigationVertical planeEngineering

The invention relates to a stirring and grabbing device. The stirring and grabbing device comprises: a bottle clamping mechanism arranged at one end of a bracket and used for receiving and clamping asample bottle; a sampling head arranged above the bottle clamping mechanism, horizontally moving in a vertical plane along an up-and-down direction and a left-and-right direction and used for stirringsamples in the sample bottle and grabbing the samples; and a moving mechanism arranged at the side surface direction of the sampling head and driving the sampling head to move. The stirring and grabbing device of the invention can complete continuous stirring and grasping action, and the sampling head can carry out continuous operation, so line production is realized; and the stirring and grabbing device is compact in space and convenient to control.

Owner:JIANGXI GUANGMING INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com