Dried kelp powder preparation apparatus and preparation method thereof

A technology for dry kelp powder and a preparation device, which is applied in the directions of food preservation, metal processing, fresh-keeping of fruits and vegetables, etc., can solve the problems of limited kelp-shaped cooking pot capacity, unfavorable production of kelp powder, long production cycle, etc., so as to shorten the softening time, The effect of shortening cleaning time and reducing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

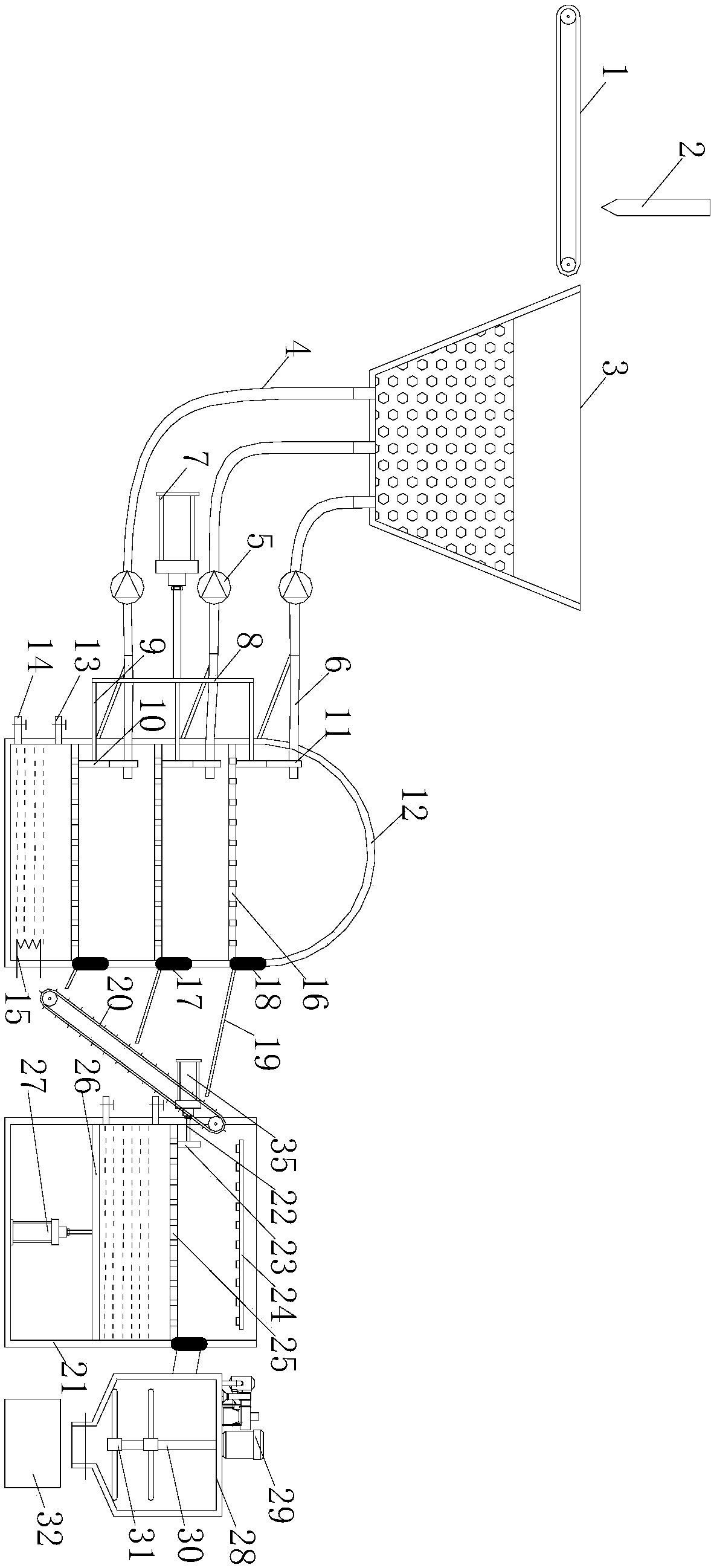

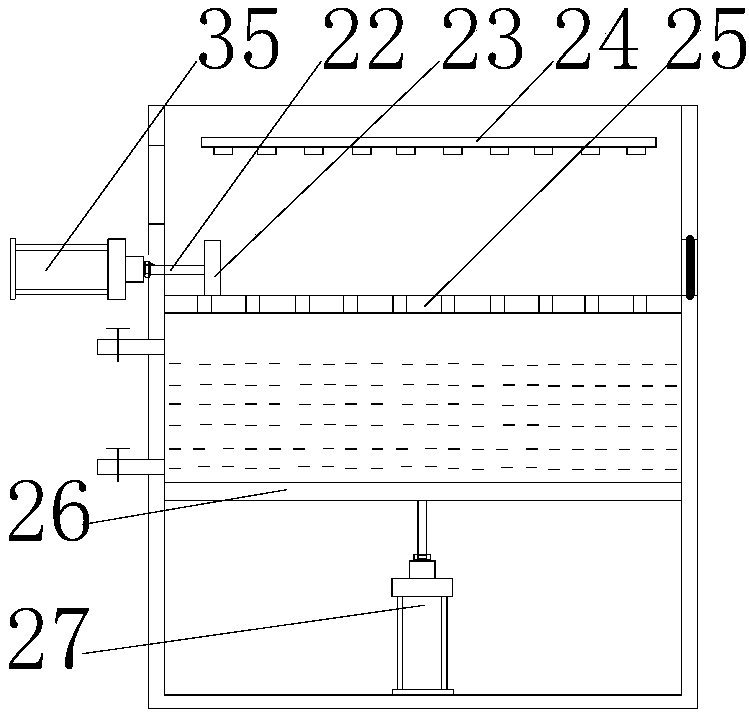

[0050] refer to figure 1 , a device for preparing dry kelp powder proposed by the present invention, the device includes: a first conveyor belt 1, a cutting unit 2, a softening unit, a cleaning unit, a drying unit and a crushing unit. The cutting unit 2 is used for cutting the dried kelp on the first conveyor belt 1 into pieces. The softening unit is used for softening the dried kelp. The cleaning unit is used for cleaning the softened kelp. The drying unit is used for drying the washed kelp. The crushing unit is used to grind the dried kelp into powder.

[0051] The cutting unit includes a cutting knife, which can reciprocate up and down relative to the first conveyor belt 1, so as to cut the kelp at a fixed distance during the movement of the kelp.

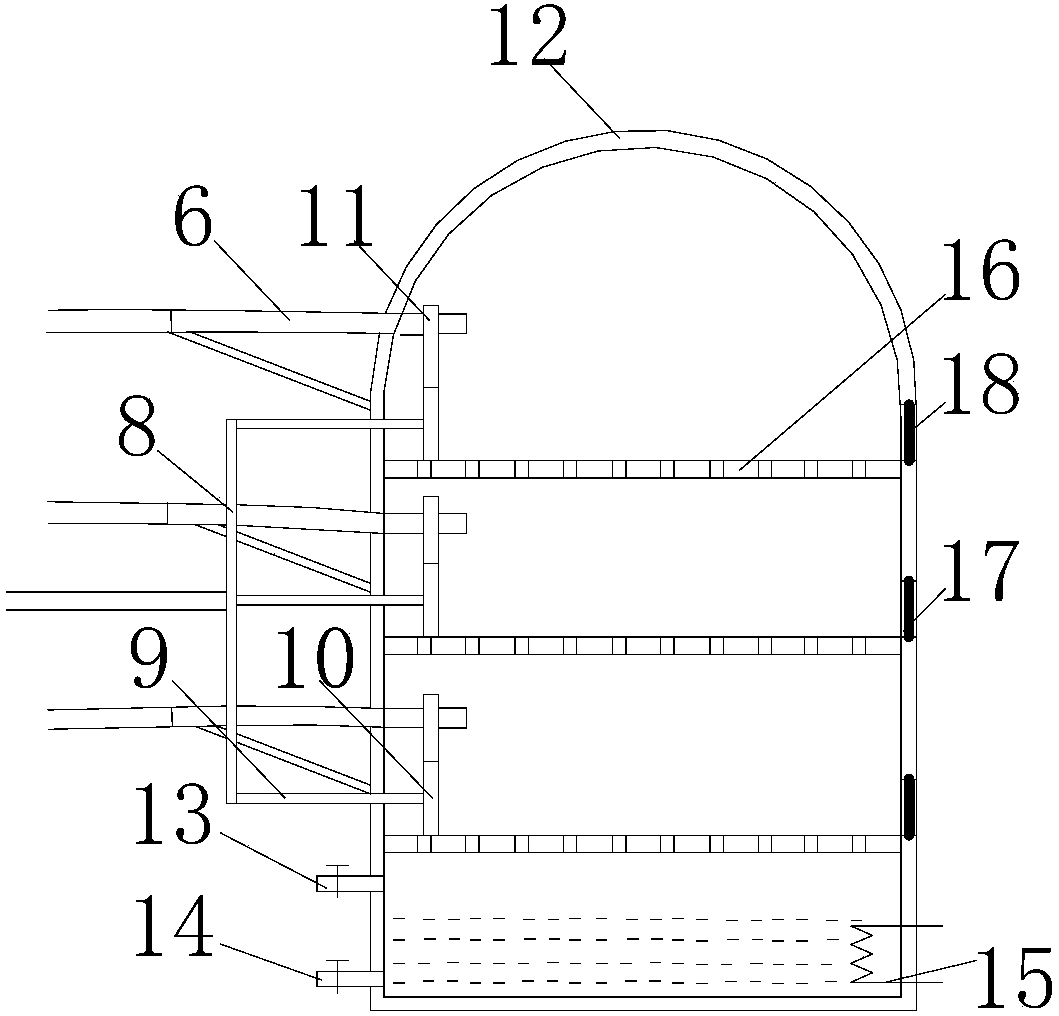

[0052] The softening unit includes an evaporator 12, and the evaporator 12 is horizontally provided with a plurality of partitions 16, and the partitions 16 are provided with through holes for steam circulation, and the part...

Embodiment 2

[0082] The present invention proposes a kind of preparation method of sea-tangle dry powder, comprises the following steps:

[0083] The selected dried kelp is placed on the first conveyor belt 1, the dried kelp is cut into blocks by the cutting unit 2, and the cut dry kelp is collected by the hopper 3;

[0084] Start the first cylinder 7, the first cylinder 7 drives the first push rod 9 to drive the first push plate 10 to the side of the evaporation kettle 12, open the feed valve 5, and the dry kelp in the hopper 3 enters the corrugated pipe through the feed pipe 4 Pipe 6. At the same time, the first cylinder 7 drives the first push rod 9 to drive the first pusher plate 10 to move in reverse. During the movement of the first pusher plate 10, the bellows 6 moves accordingly, and the dried kelp passes through the bellows. 6 is discharged from the discharge port, and evenly sprinkled on the partition 16, after the first pushing plate 10 moves to the other side of the evaporation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com