Patents

Literature

685results about "Labelling flat rigid surfaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

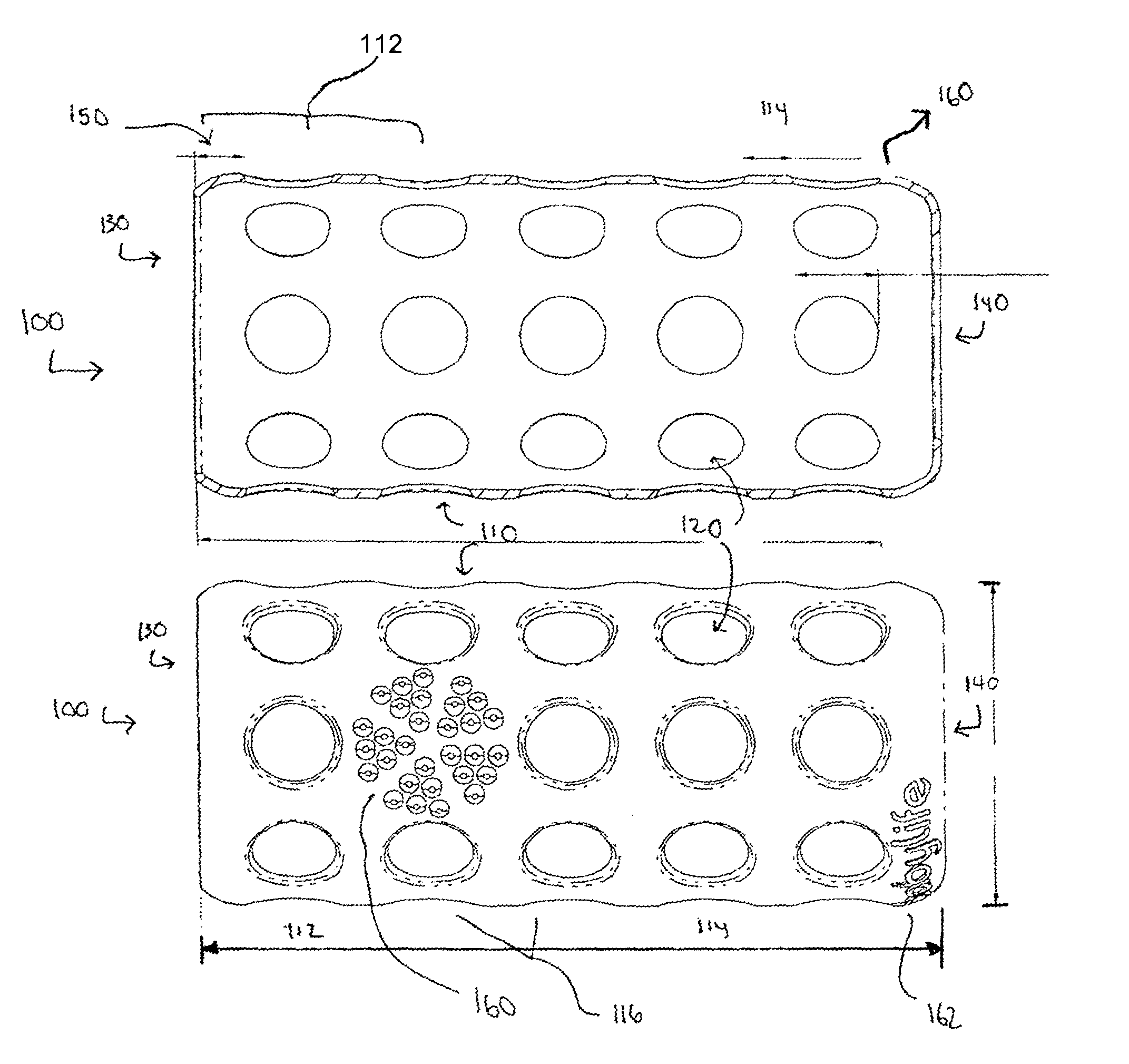

Seam sealing apparatus and process therefor

InactiveUS20030010439A1Easy to cleanWell mixedAdhesive processesManual label dispensersAdhesiveSurgical Gowns

Apparatus and a method for sealing of protective barrier fabric seams in otherwise impermeable articles such as garments, footwear, surgical gowns and the like, are provided, the sealed seams maintaining the imperviousness of the article, including seamed joints, to water, body fluids, pathogens and chemicals. In one pass through the apparatus, a sealed seam in a protective barrier fabric joint, using a curable adhesive sealant, is provided along a predetermined and specified length of the joint. The preferred adhesive is a silicone, most preferably a two-part, thermosetting silicone elastomeric adhesive. Also provided are mixing dies for use, inter alia, in the process which are especially suited for applying the two-part adhesive sealant. In addition, variable-residence-time curing apparatus, which effects variable, controlled, desired cures of the adhesive, all in a one-pass operation, is provided, together with precise metering pumps, especially suited for supplying the seam sealing adhesives in the process of the invention.

Owner:WL GORE & ASSOC INC

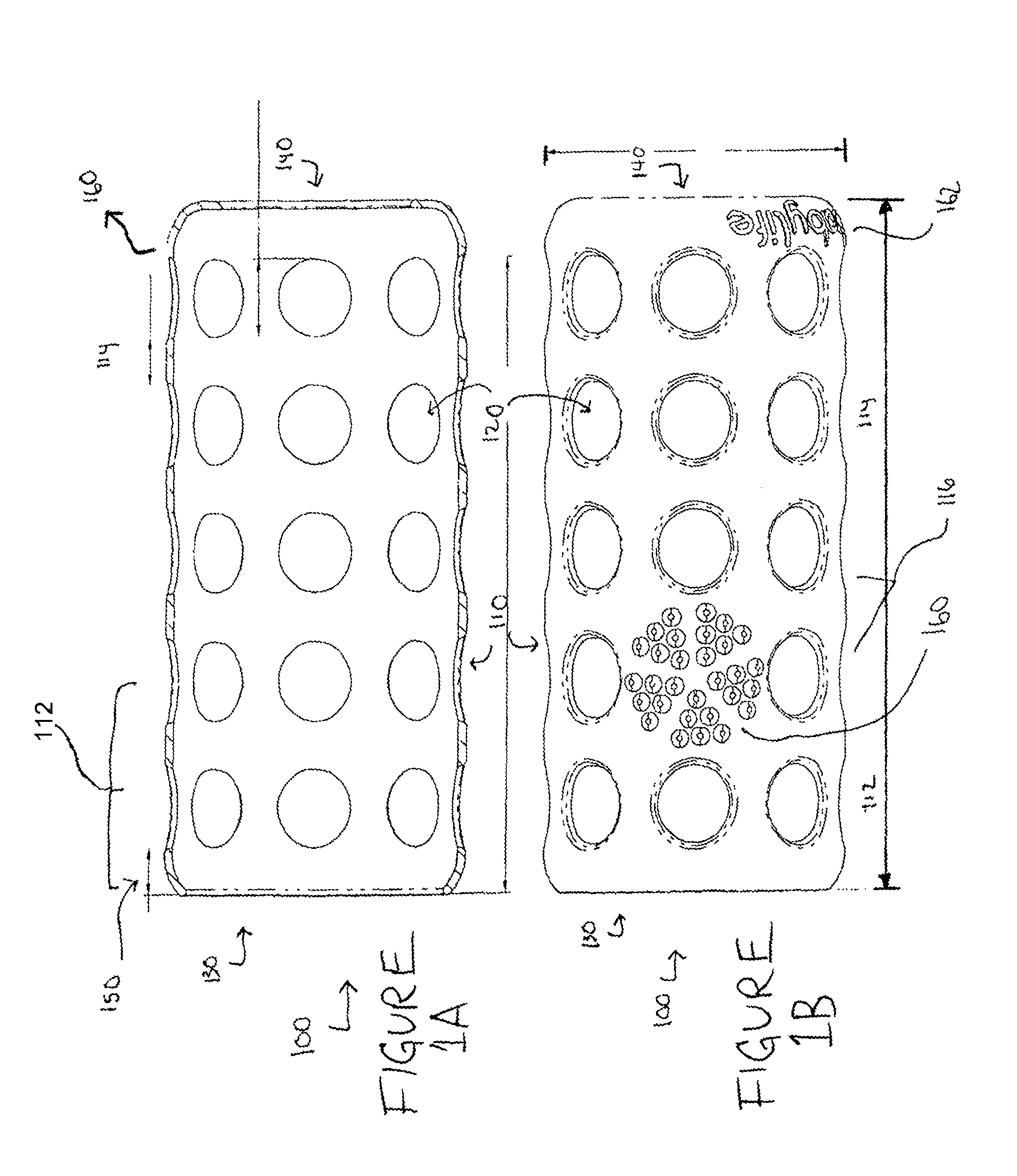

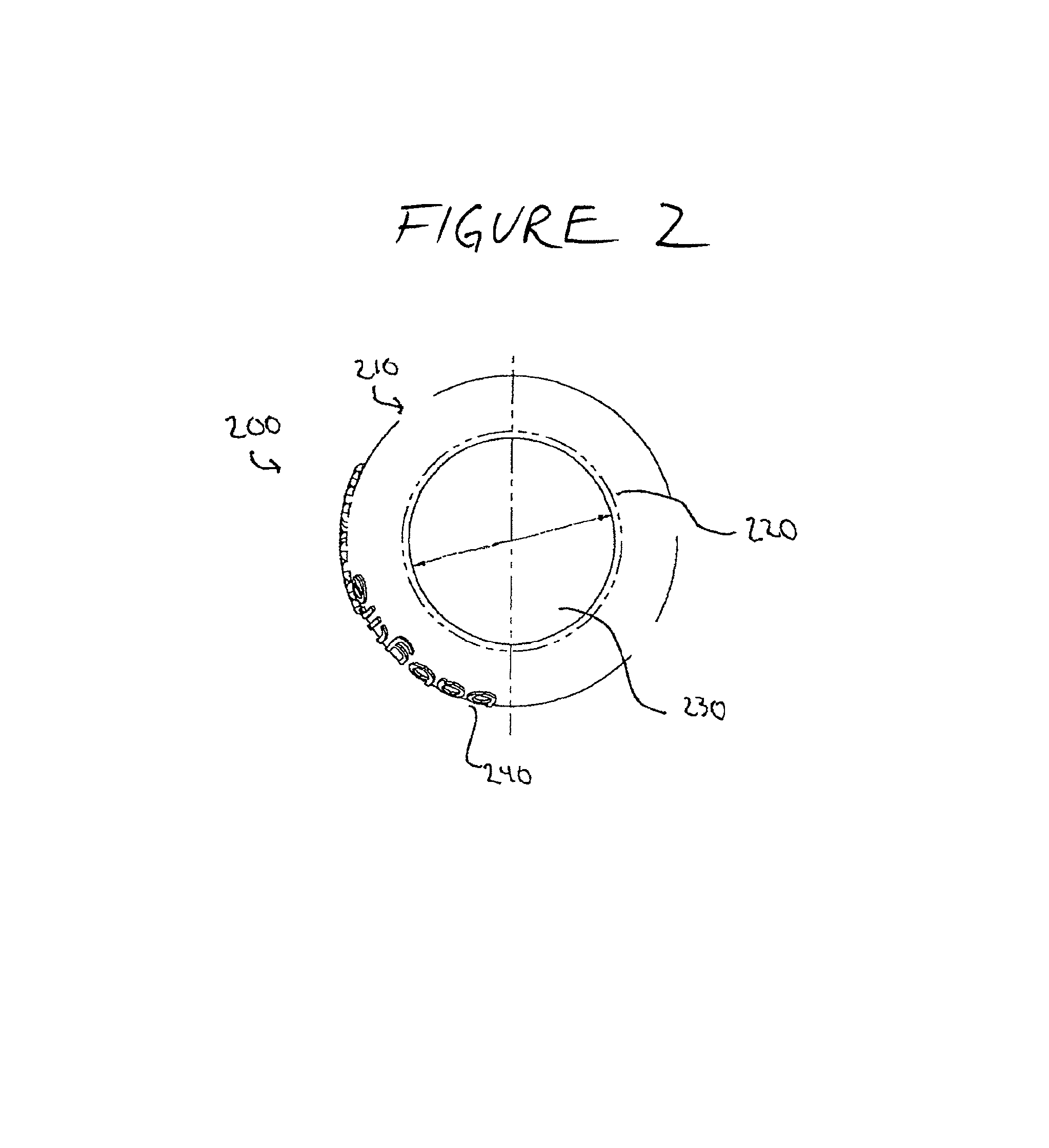

Protective sleeves for containers

Aspects of the invention include a sleeve or wrap for protecting a container. In certain embodiments, the sleeve or wrap is a protective encasement for protecting a container, such as a bottle. In certain embodiments, the sleeve or wrap includes a body with a lumen, wherein the body is configured for holding and / or containing the container. For instance, in one embodiment, the protective sleeve includes a tubular body and at least a first opening in the protective body that is adapted for receiving the container. In certain embodiments, the body of the sleeve includes silicone. Accordingly, in certain embodiments, the sleeve is a protective silicone sleeve that is adapted to hold and / or contain a container, thereby protecting the container from damage (e.g., breaking). Also provided is a system for protecting a container that includes a protective sleeve, as described above, and a container that is configured for being associated, e.g., fit within, the protective sleeve.

Owner:MARCUS JOY LLC DBA BABYLIFE

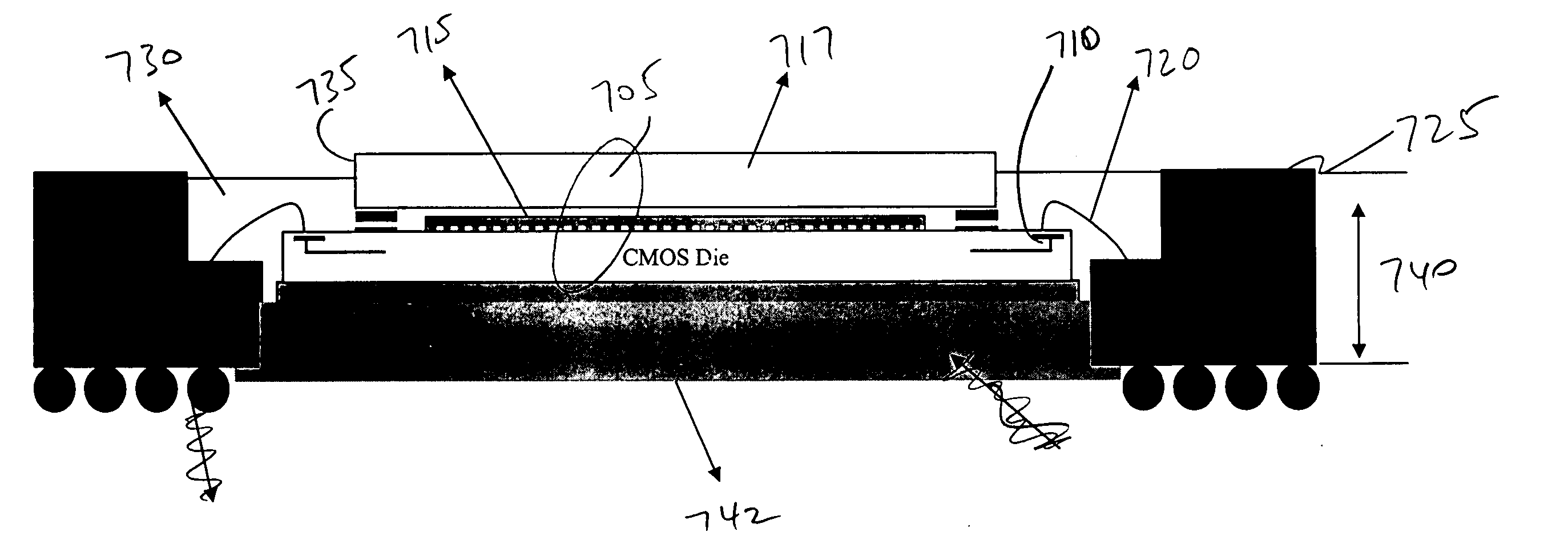

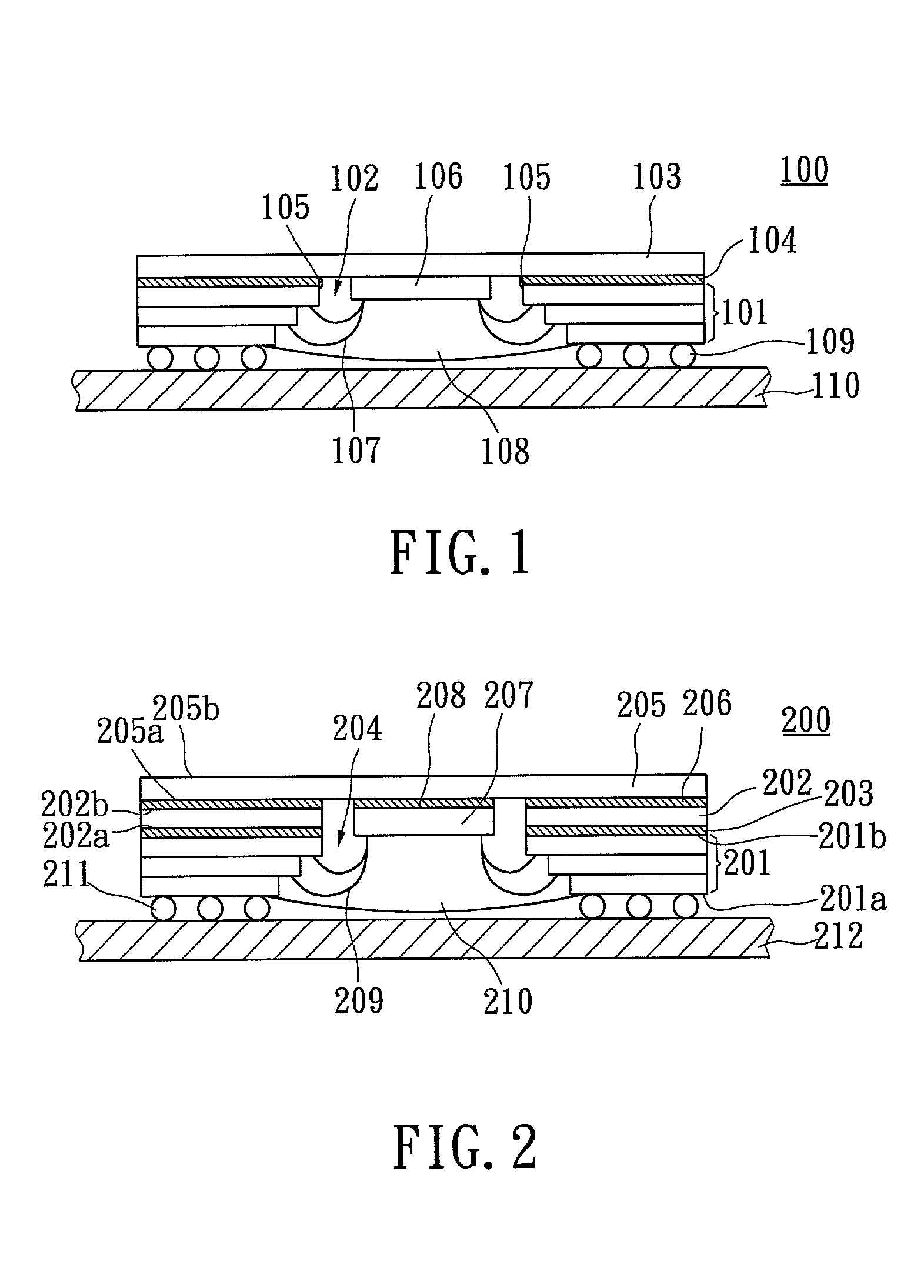

Method and system for hermetically sealing packages for optics

ActiveUS20050101059A1Covering/liningsSemiconductor/solid-state device detailsHermetic sealBonding process

A method for hermetically sealing devices. The method includes providing a substrate which includes a plurality of individual chips. Each of the chips includes a plurality of devices and each of the chips are arranged in a spatial manner as a first array. The method also provides a transparent member of a predetermined thickness which includes a plurality of recessed regions arranged in a spatial manner as a second array and a standoff region. The method also includes aligning the transparent member in a manner to couple each of the plurality of recessed regions to a respective one of said plurality of chips. The method further includes hermetically sealing each of the chips within one of the respective recessed regions by using at least a bonding process to isolate each of the chips within one of the recessed regions.

Owner:MIRADIA INC

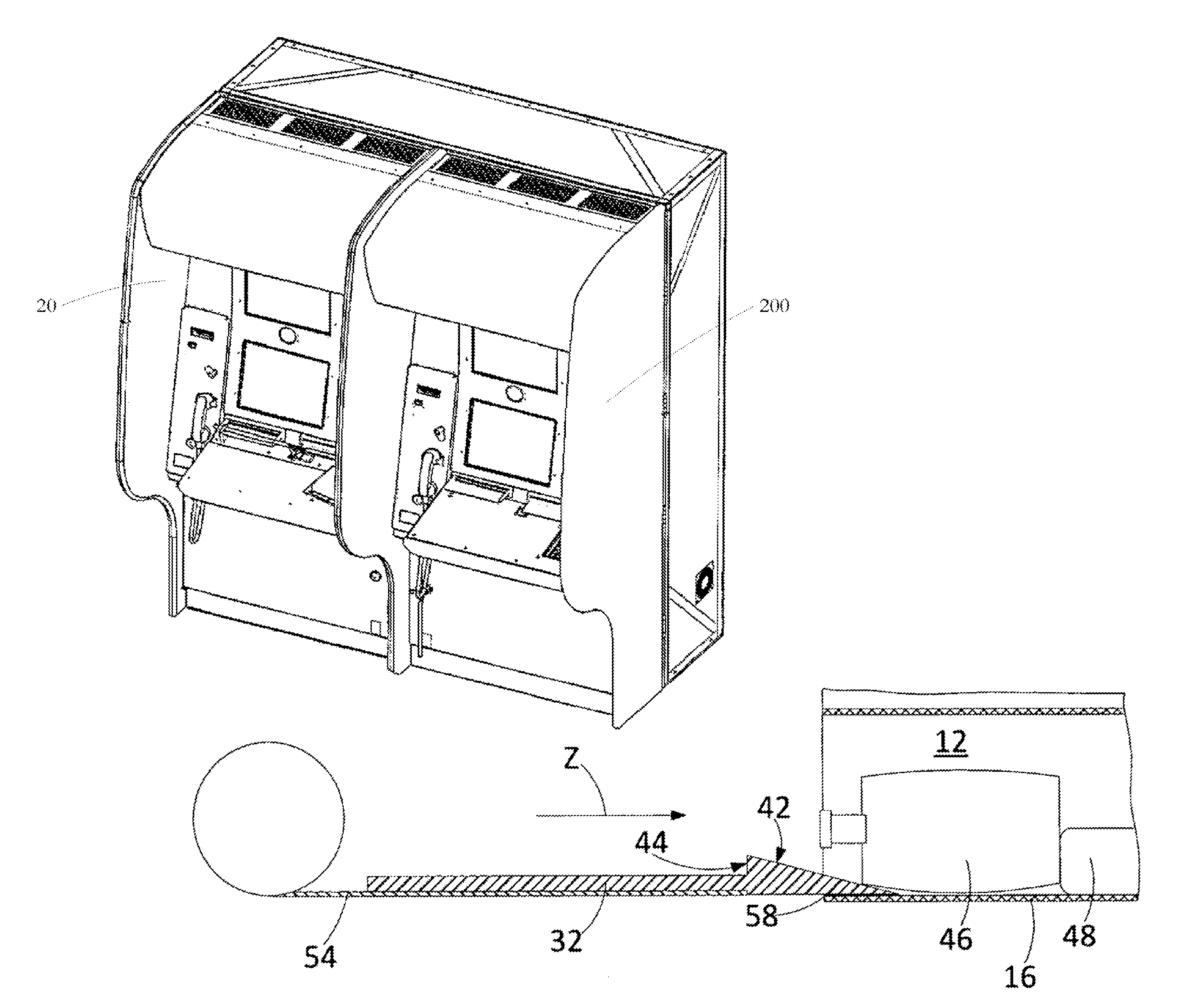

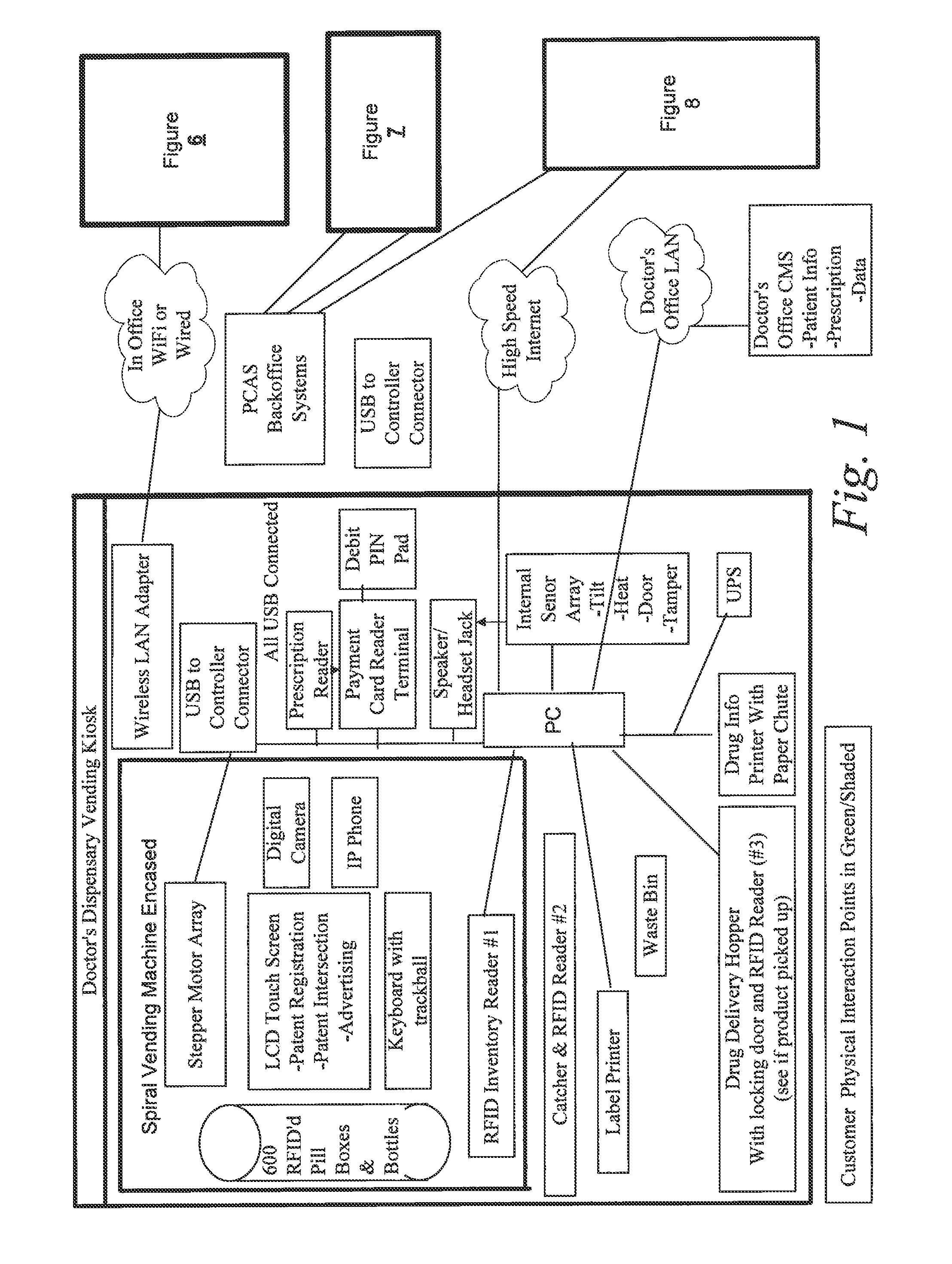

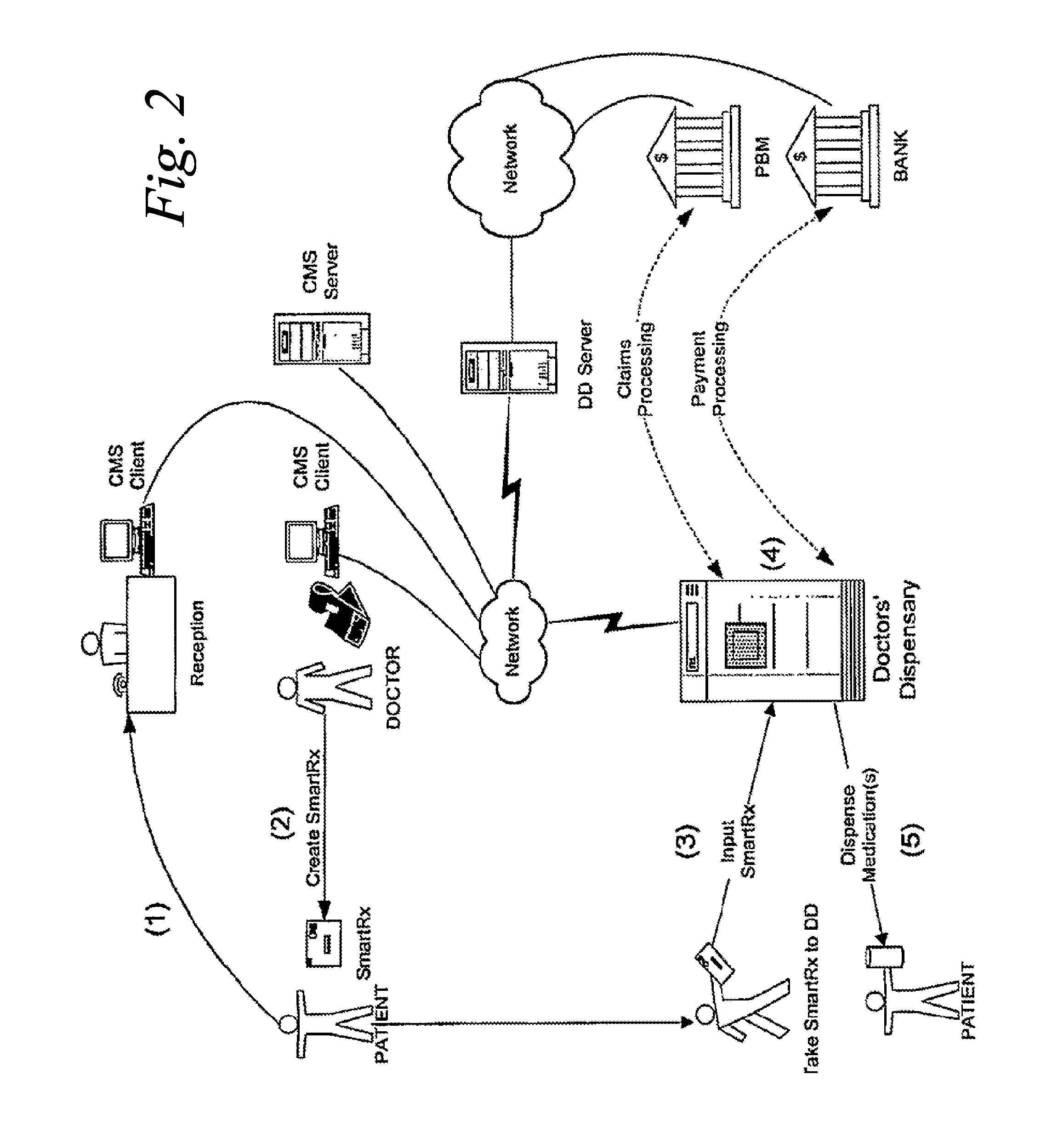

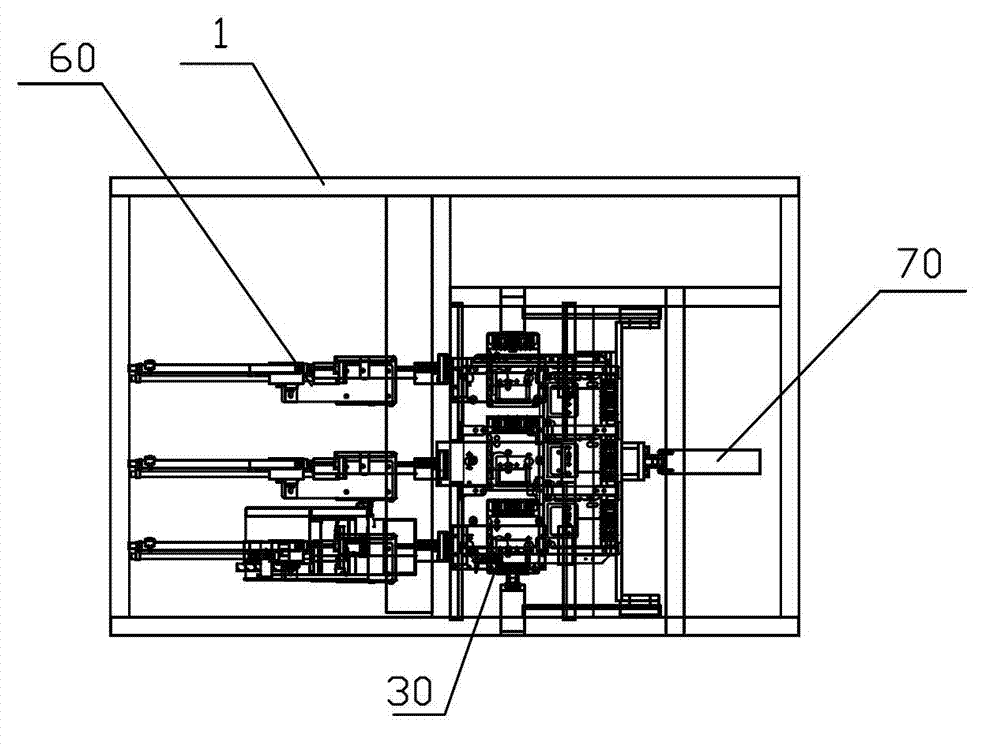

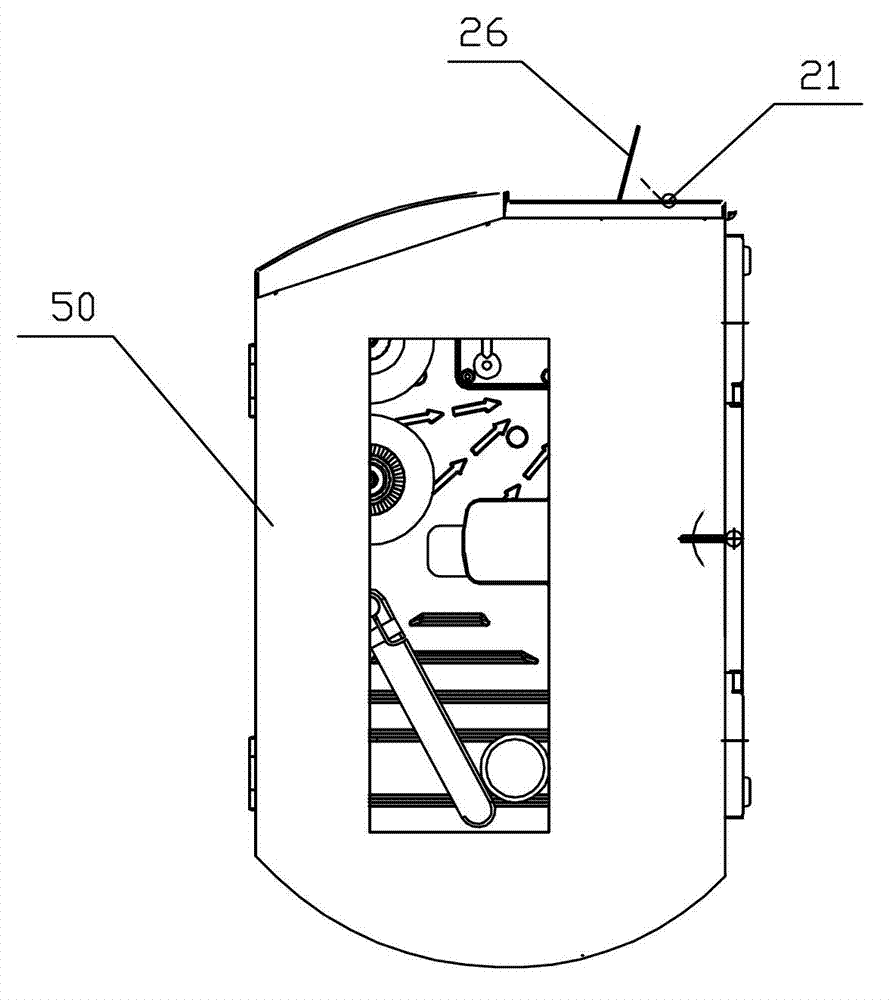

Vending machine for storage, labeling and dispensing of a container

ActiveUS8738177B2Low costPrevent heat-induced deterioration thereofLiquid surface applicatorsDrug and medicationsControl systemEngineering

A vending machine, in communication with a remote station, delivers a labeled container to a user from storage holding containers of different sizes and shapes and containing different products such as medicaments. A control system is operable to select a specific unlabeled container from among the other containers in storage, and to move the selected unlabeled container to a labeling module where a label is applied after the position of the label and / or the selected unlabeled container are / is adjusted so as to result in the label being applied at a desired position and angular orientation with respect to the selected unlabeled container. The control system is further operable to move the labeled container to a delivery zone accessible to the user.

Owner:MEDAVAIL

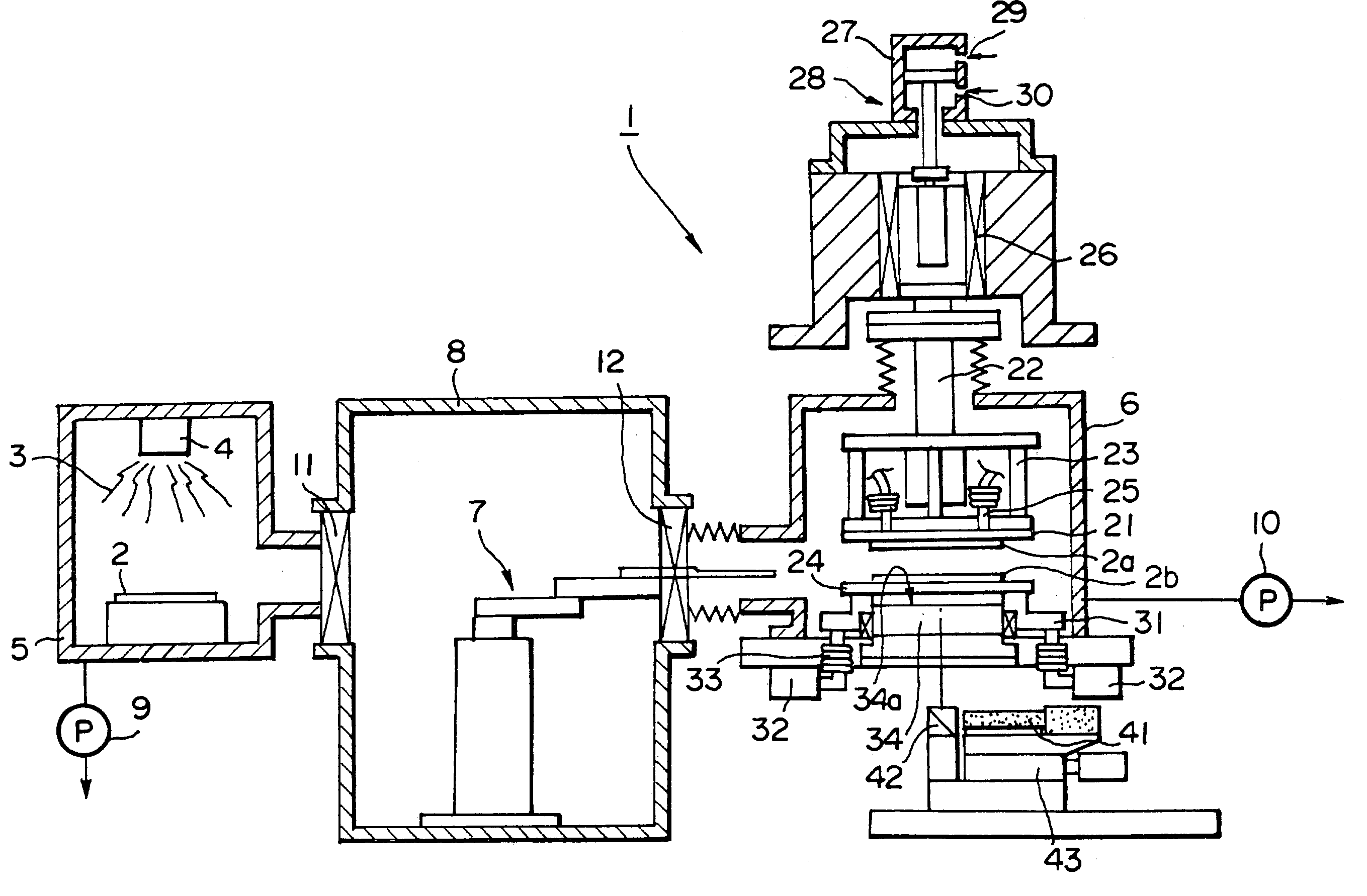

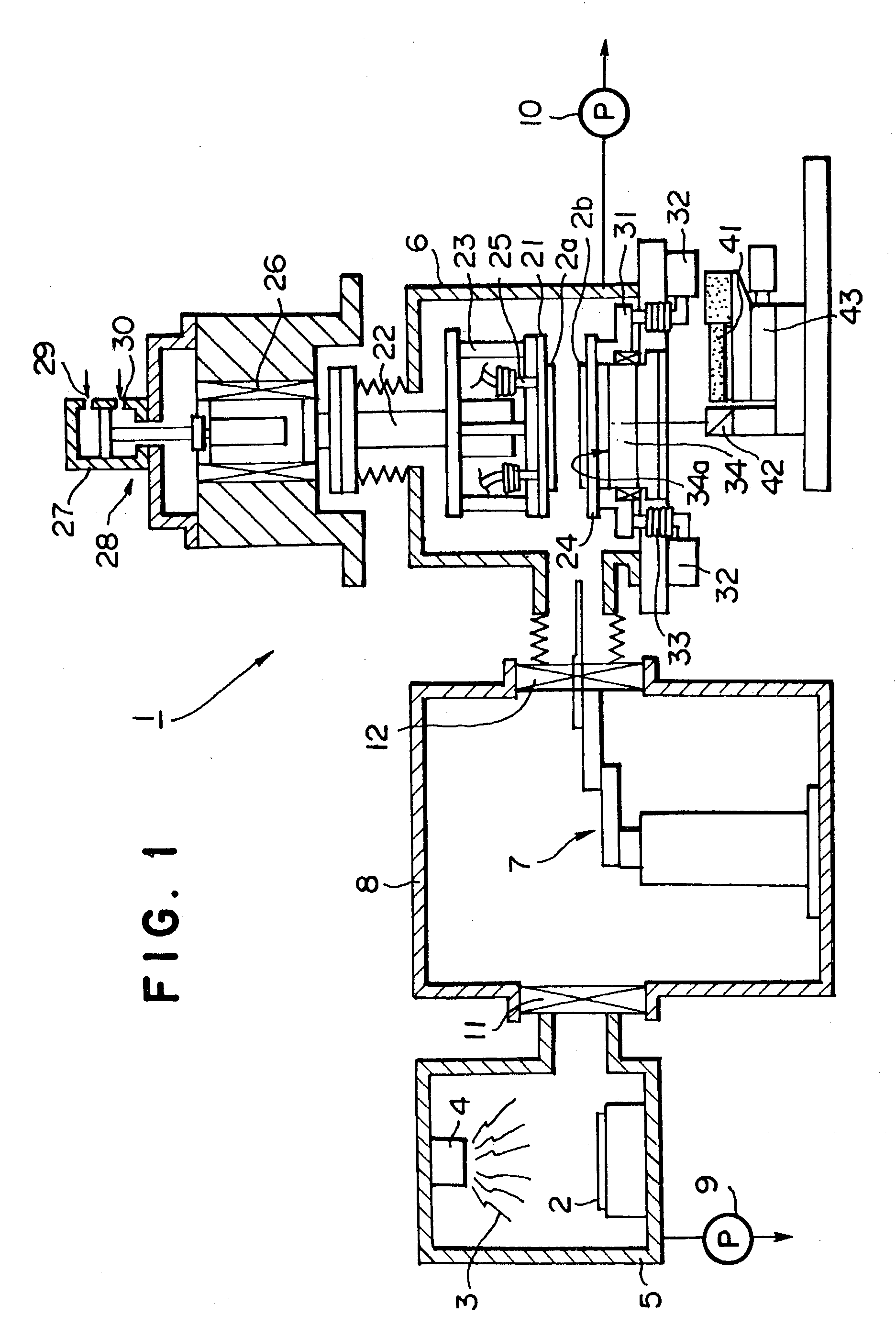

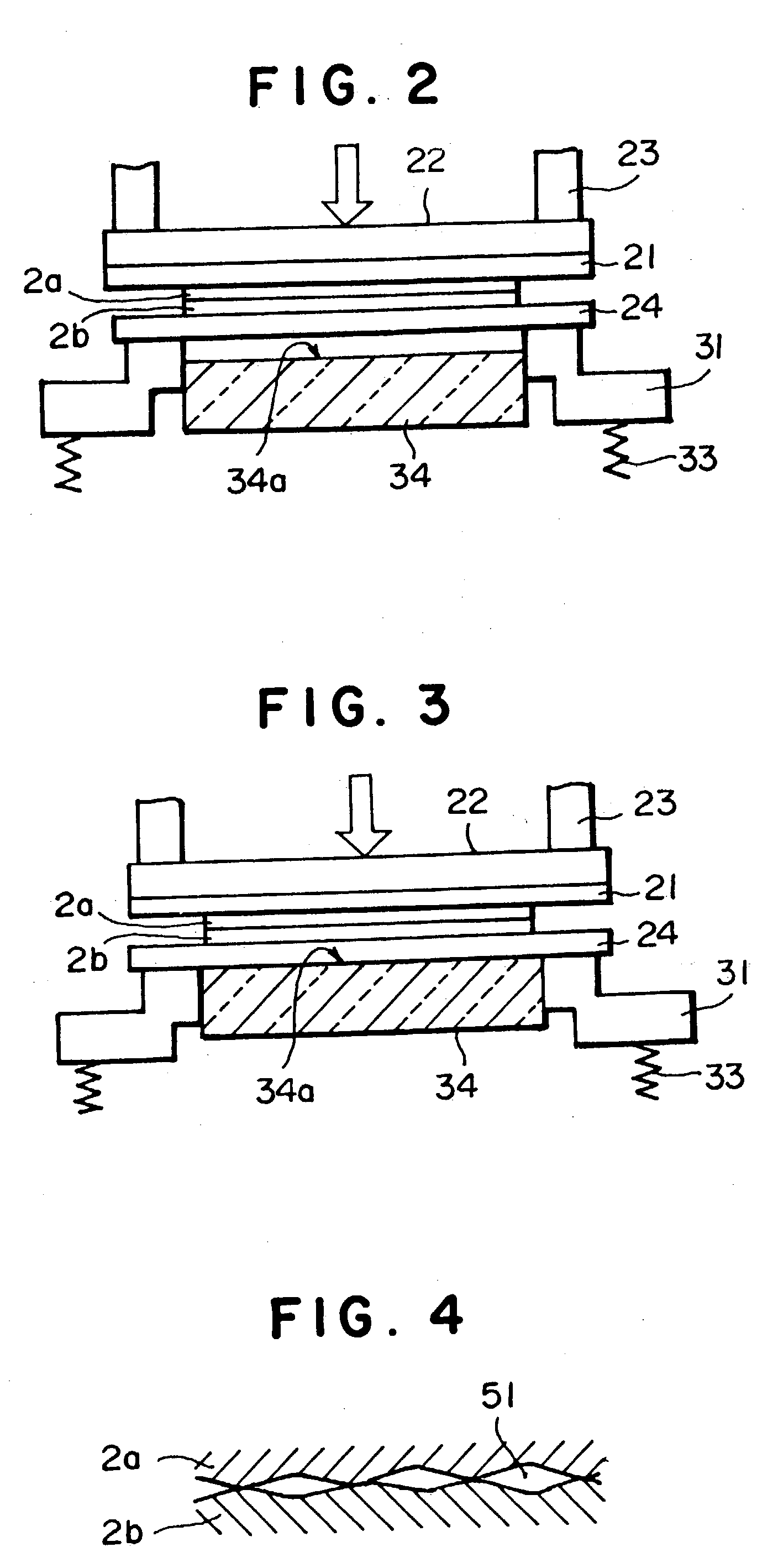

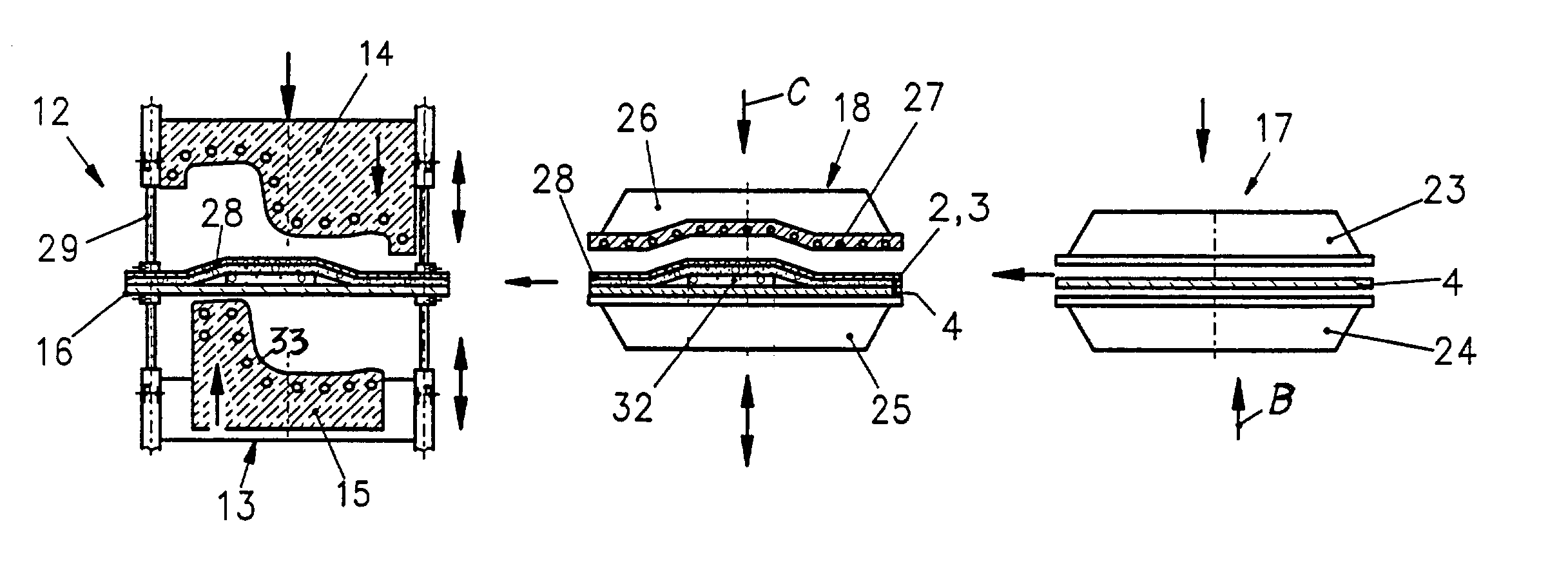

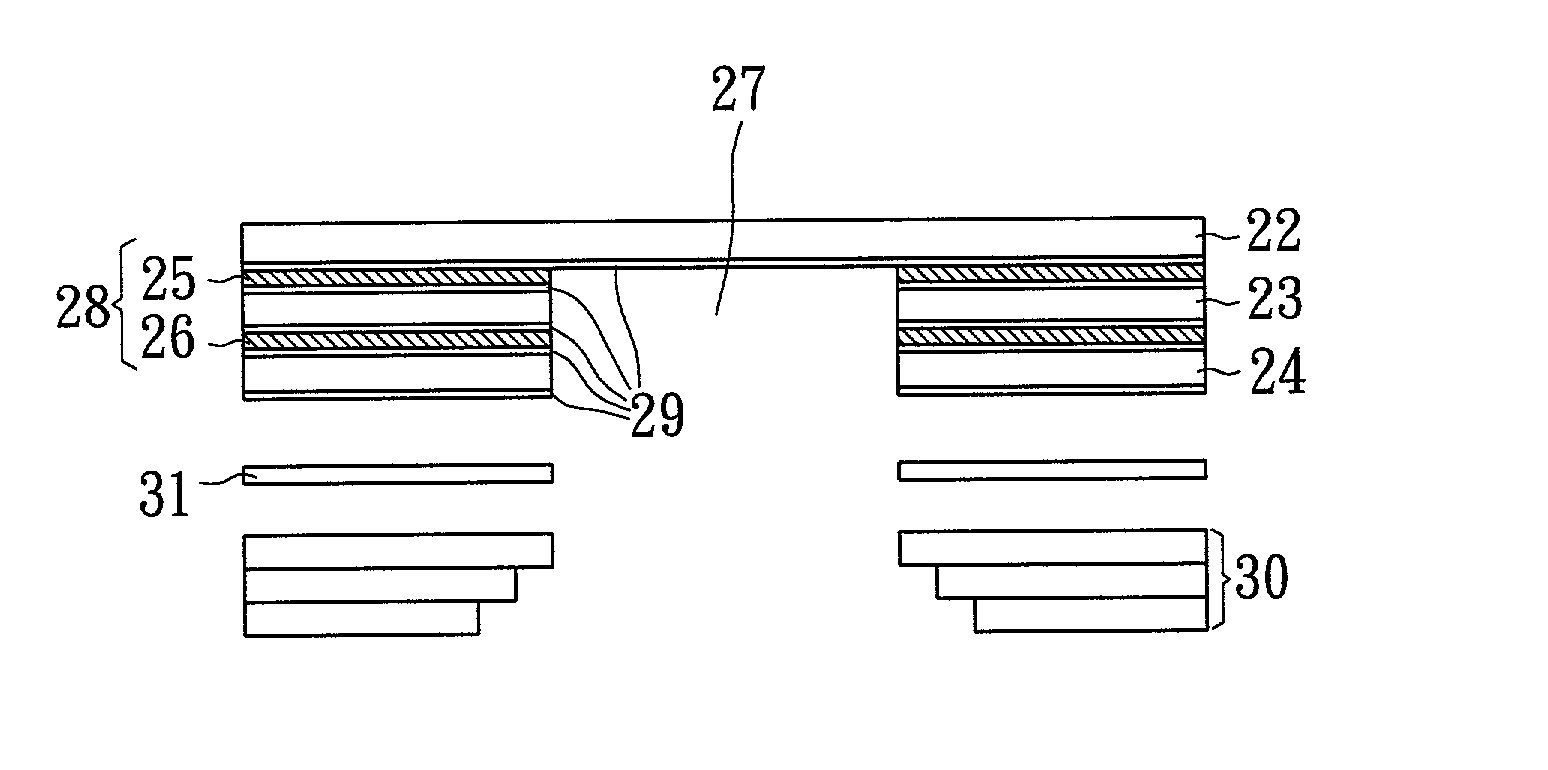

Method and apparatus for mounting

A method and an apparatus for mounting: the method for bonding a plurality of objects to each other, comprising the steps of disposing, apart from each other, a first object, a second object and a holding means therefor, and a backup member having a reference positioning surface in this order, adjusting the parallelism of the second object or the holding means therefor relative to the reference positioning surface, adjusting the parallelism of the first object or the holding means therefor relative to the second object or the holding means therefor, bringing the first object into contact with the second object to temporarily bond both objects to each other, bringing the holding means for the second object into contact with the reference positioning surface of the backup member, and pressing both objects against each other for final bonding, whereby, finally, a highly reliable and accurate bonding state can be achieved.

Owner:TORAY ENG CO LTD +1

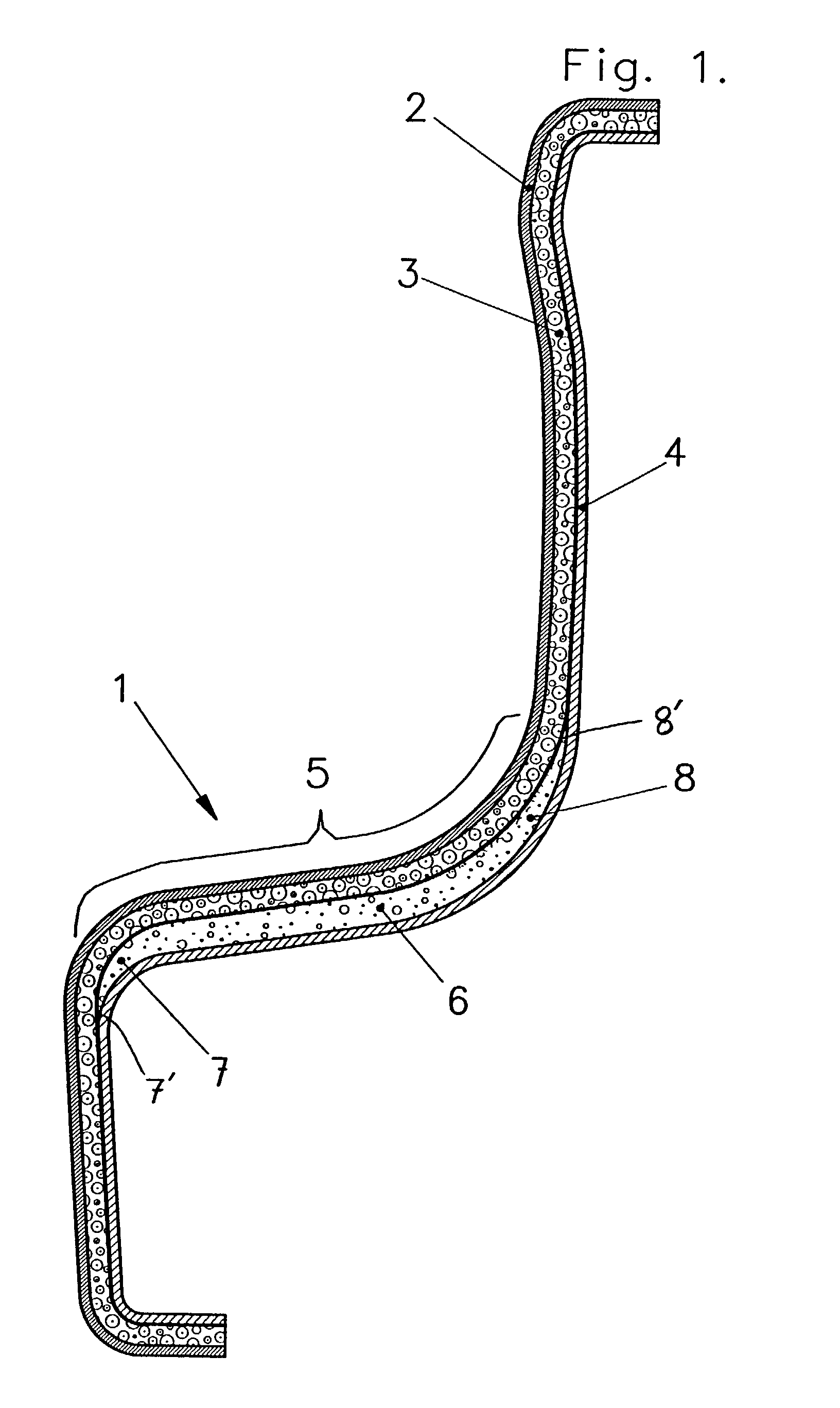

Method and apparatus for making a trim component with a foam core having a smoothly varying thickness

InactiveUS20030041955A1Guaranteed shock absorptionSoftness shockAdhesive processesEngine sealsThermoplasticPolymer science

A trim component includes a foam backing layer and a foam pad insert laminated between a cover material and a substrate. The foam pad insert provides an area of enhanced cushioning, and has smoothly tapered edges to ensure a smooth surface contour without a visible edge transition on the cover material. The foam pad insert has a lower melting temperature than the foam backing layer, both of which are thermoplastics. A foam pad insert is positioned and fixed on the back surface of the foam backing layer. A substrate material is heated and then laminated and molded with the foam and the cover material. The heat from the substrate partially softens and melts the foam backing layer and the foam pad insert. The partially melted foam pad insert is viscously deformed to form the tapered edges, as dictated by the smoothly varying mold gap spacing of the forming tools.

Owner:HERBERT OLBRICH

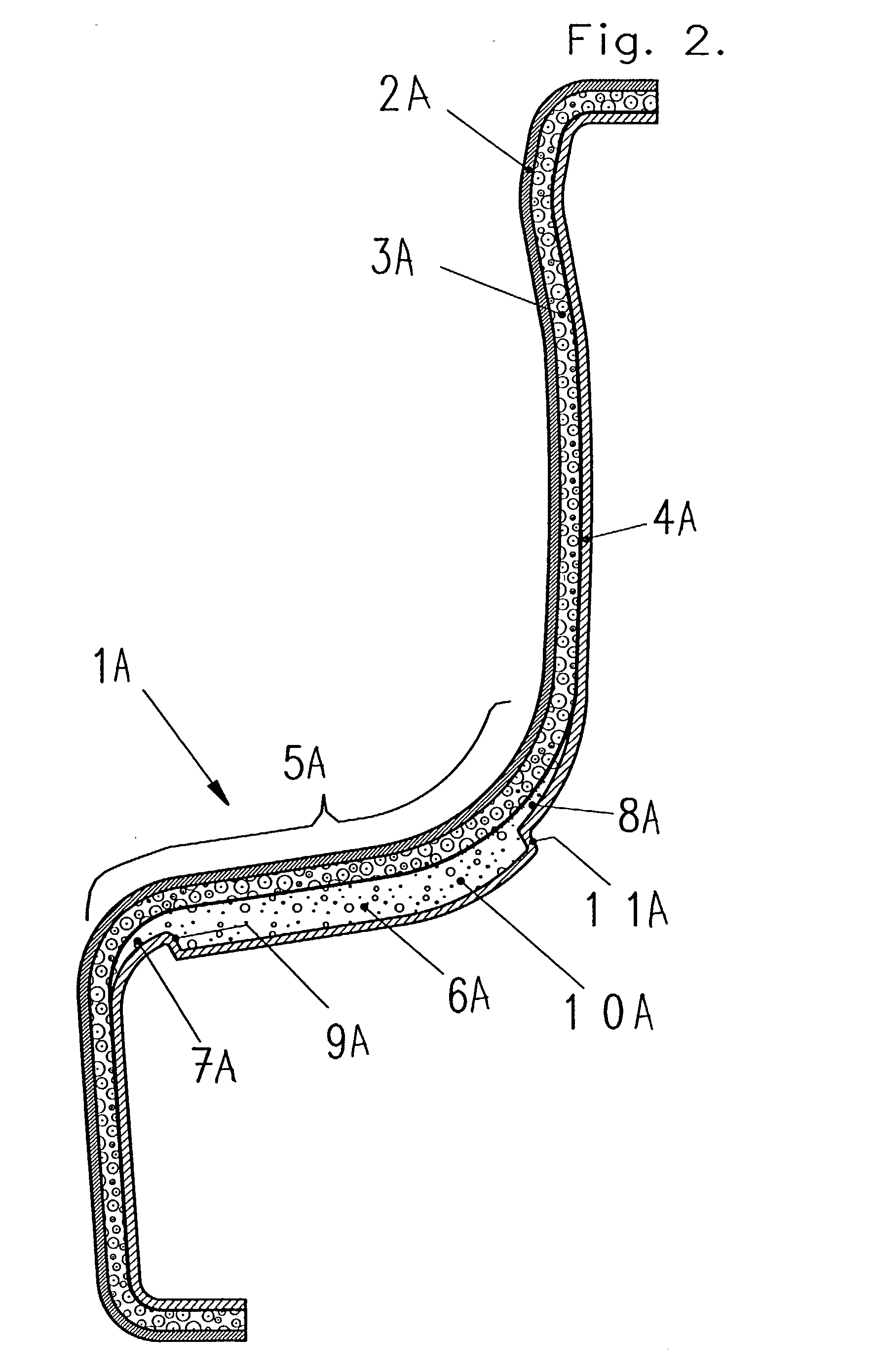

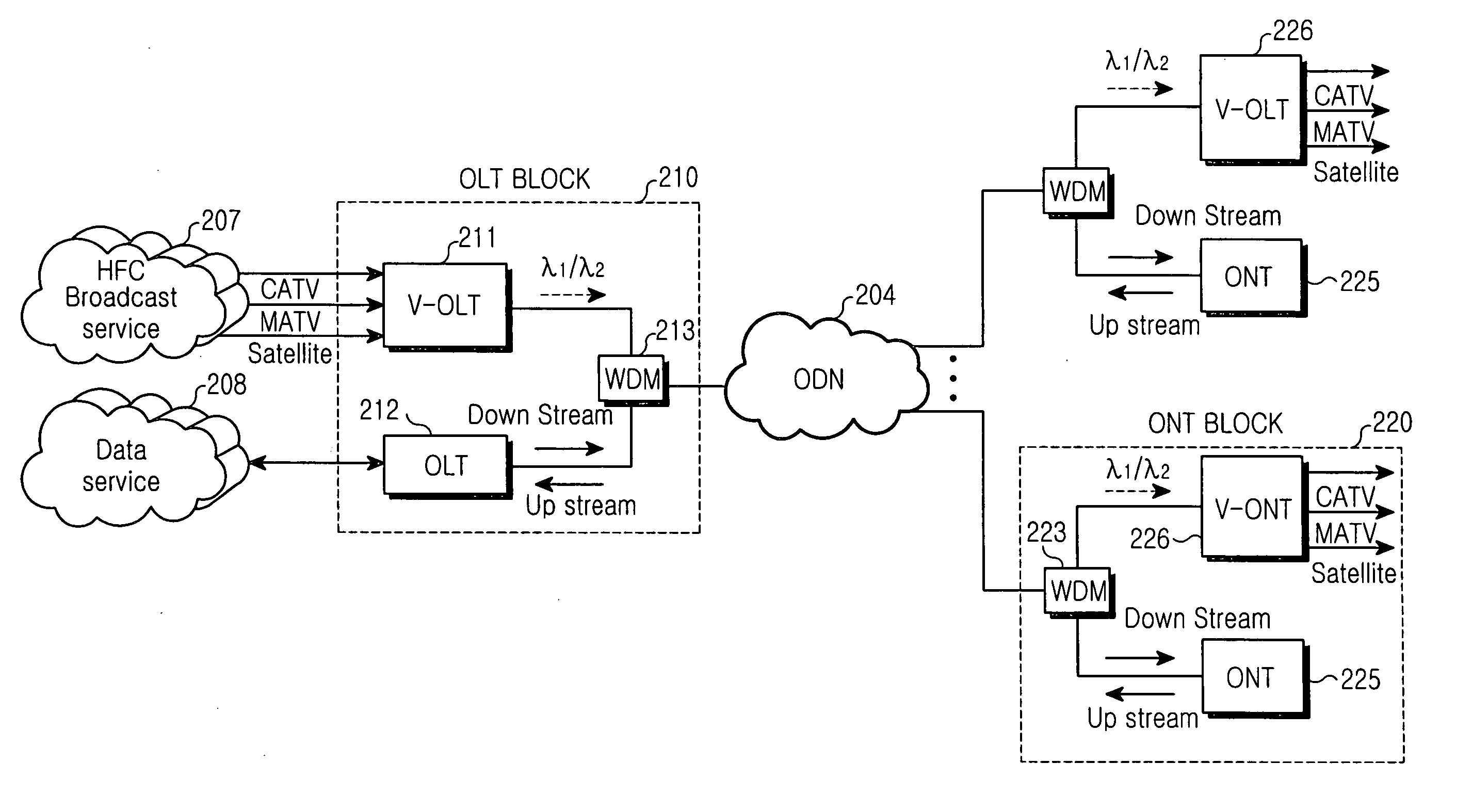

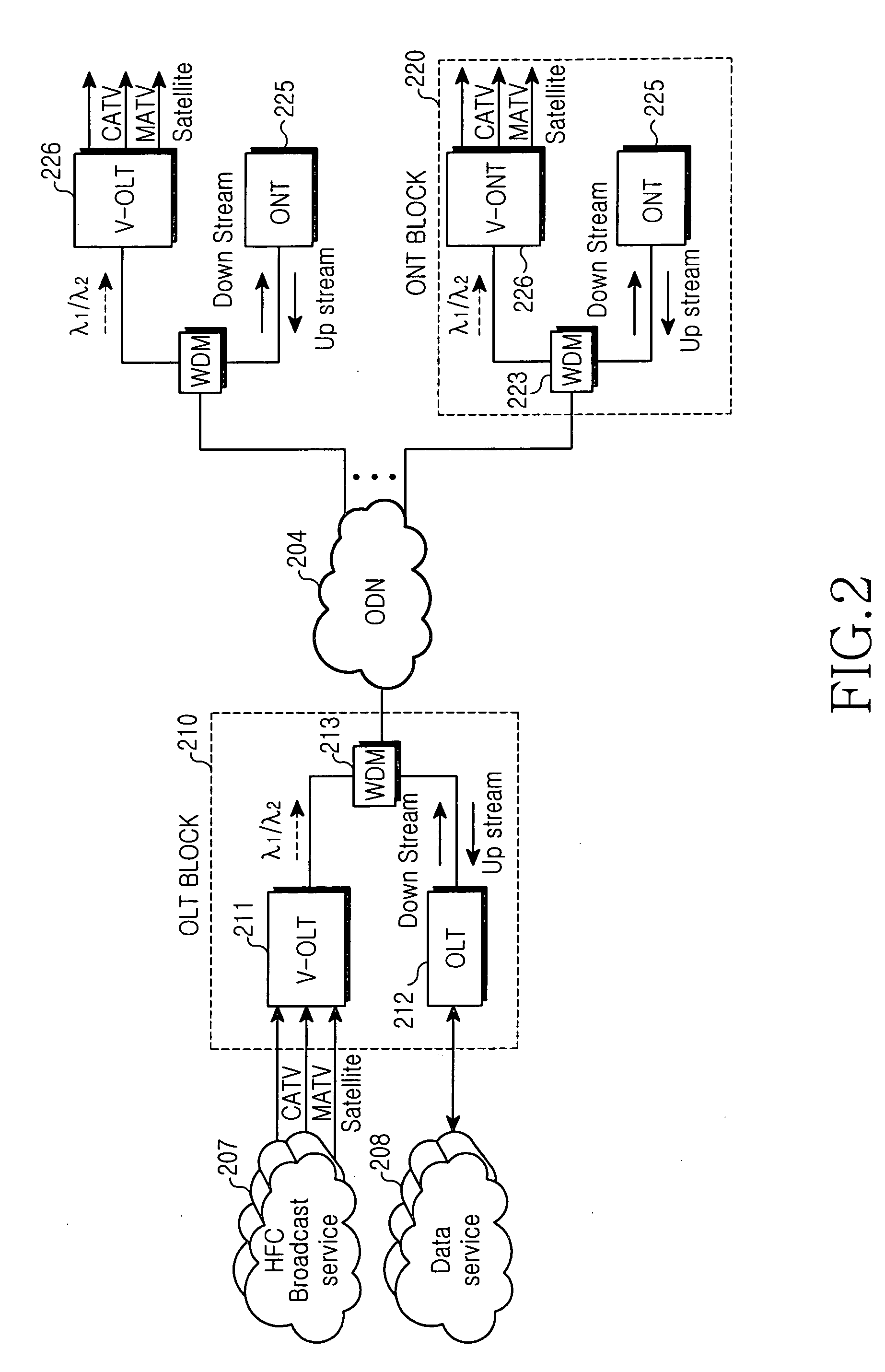

FTTH system based on passive optical network for broadcasting service

InactiveUS20050172328A1Low costWavelength-division multiplex systemsOptical transmission adaptationsNetwork terminationFiber

A fiber to the home (FTTH) system based on a passive optical network (PON) includes an optical line terminal (OLT) block, an optical network terminal (ONT) block, and an optical distribution network (ODN). The ONT block includes a video-optical line terminal (V-OLT) and an optical line terminal (OLT) in order to output optical signals of the video-optical line terminal (V-OLT) and the optical line terminal (OLT) by multiplexing the optical signals. The VOLT receives cable TV, master antenna TV, and satellite broadcasting optical signals inputted from a broadcasting service network so as to output received signals as a first optical signal having a predetermined wavelength band. The OLT includes a first downstream data optical transmitter and a first upstream data optical receiver and outputs a data communication signal inputted from a data service network as a second optical signal having different wavelength from the video-optical line terminal. The ONT block includes a video-optical network terminal (V-ONT) and an optical network terminal (ONT) in order to split multiplexed data communication signals, and cable TV broadcasting, master antenna TV broadcasting, and satellite broadcasting optical signals. The V-ONT processes the split cable TV broadcasting, master antenna TV and satellite broadcasting optical signals so as to provide subscribers with the split cable TV broadcasting, master antenna TV and satellite broadcasting optical signals. The optical network terminal (ONT) has an upstream data optical transmitter and a downstream data optical receiver so as to process split data communication signals. The optical distribution network (ODN) connects the optical line terminal block to the optical network terminal as an optical transmission medium.

Owner:SAMSUNG ELECTRONICS CO LTD

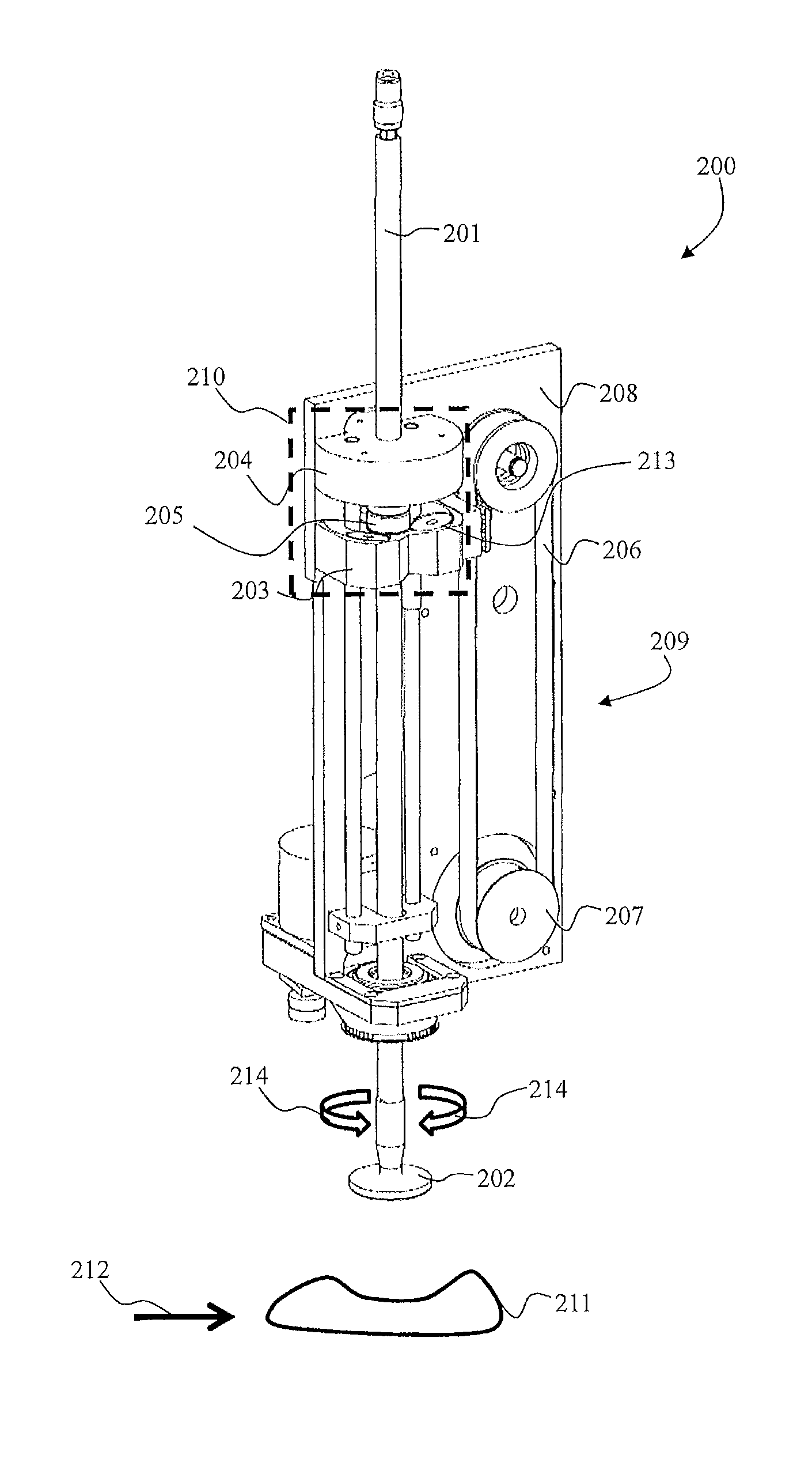

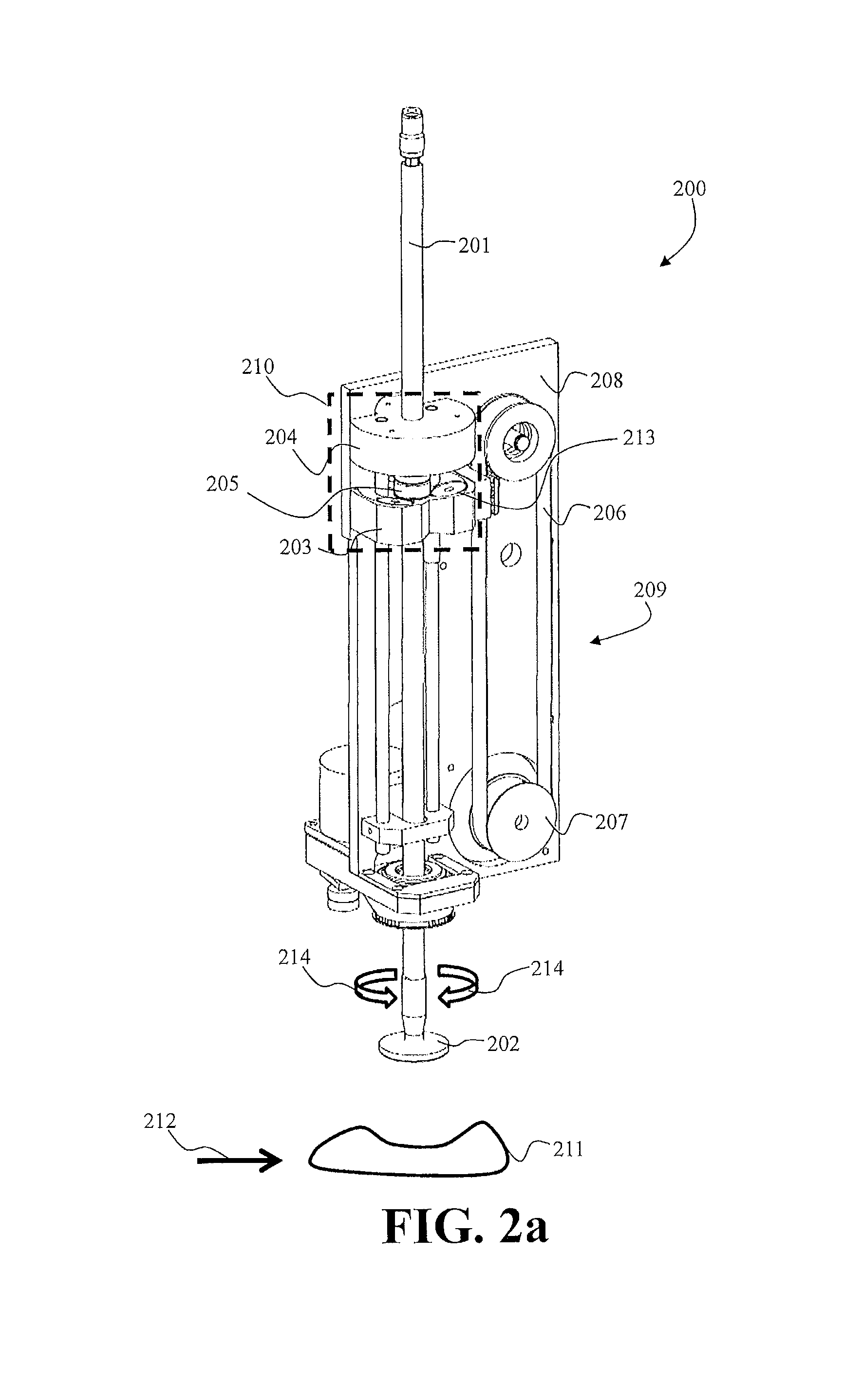

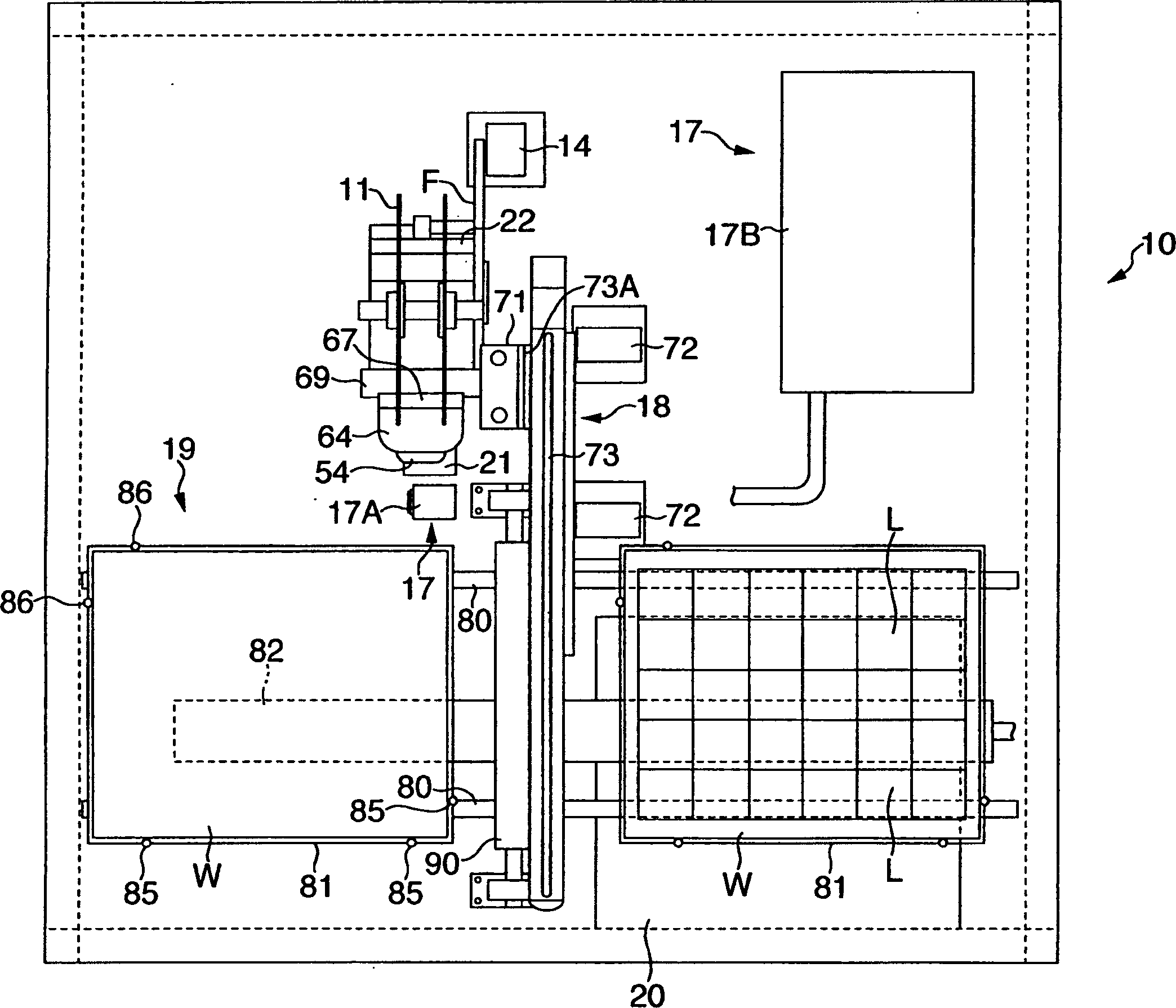

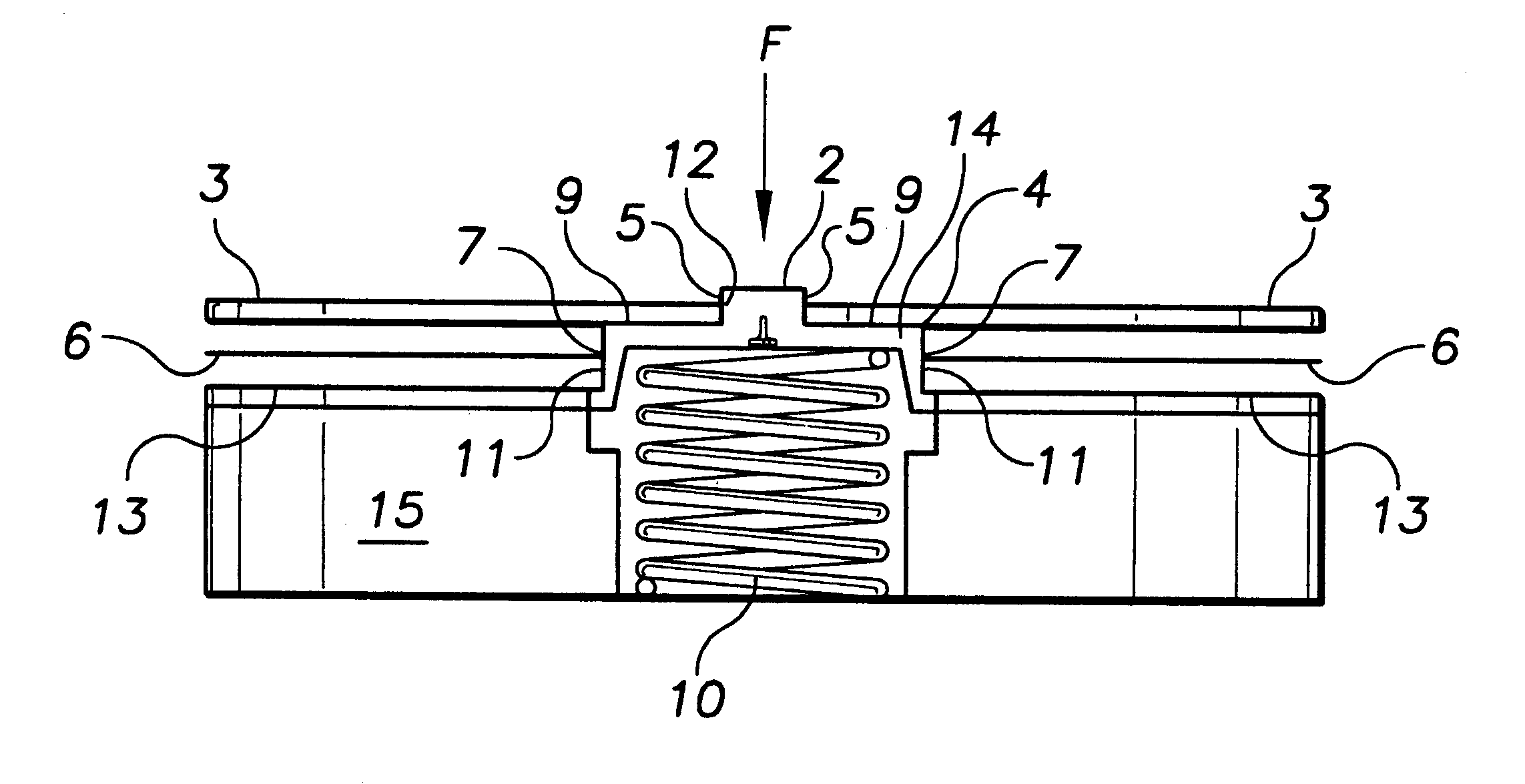

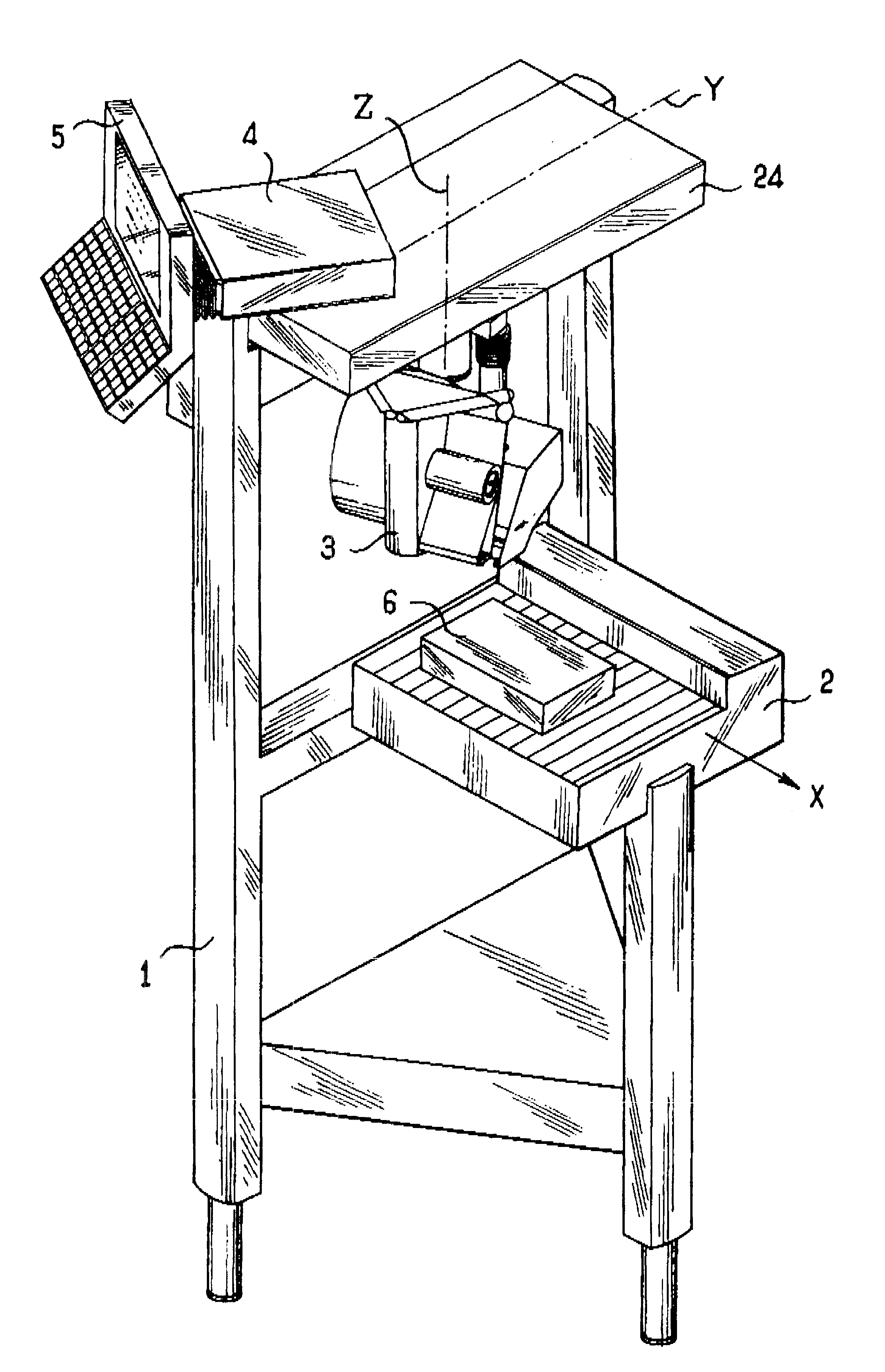

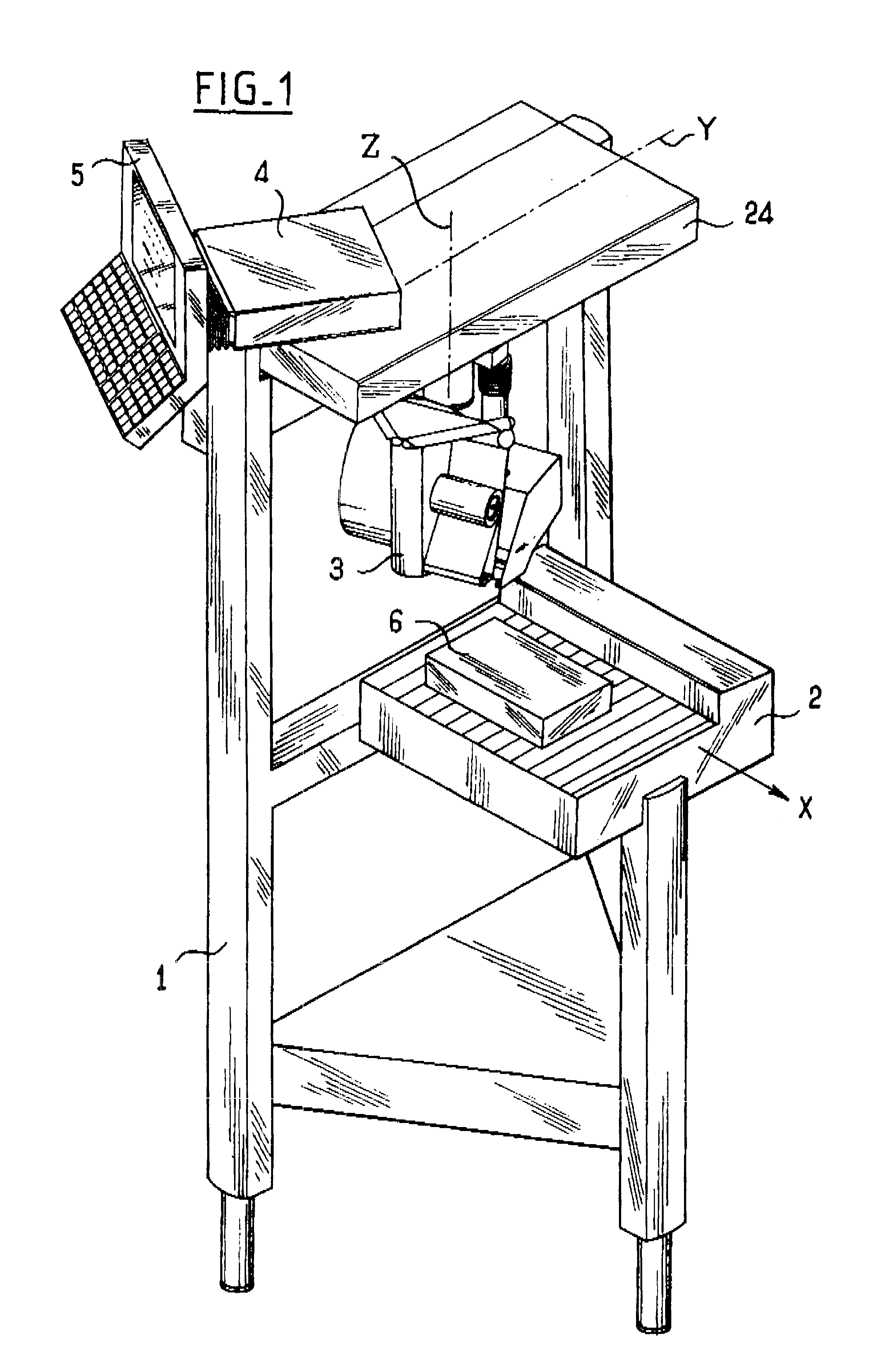

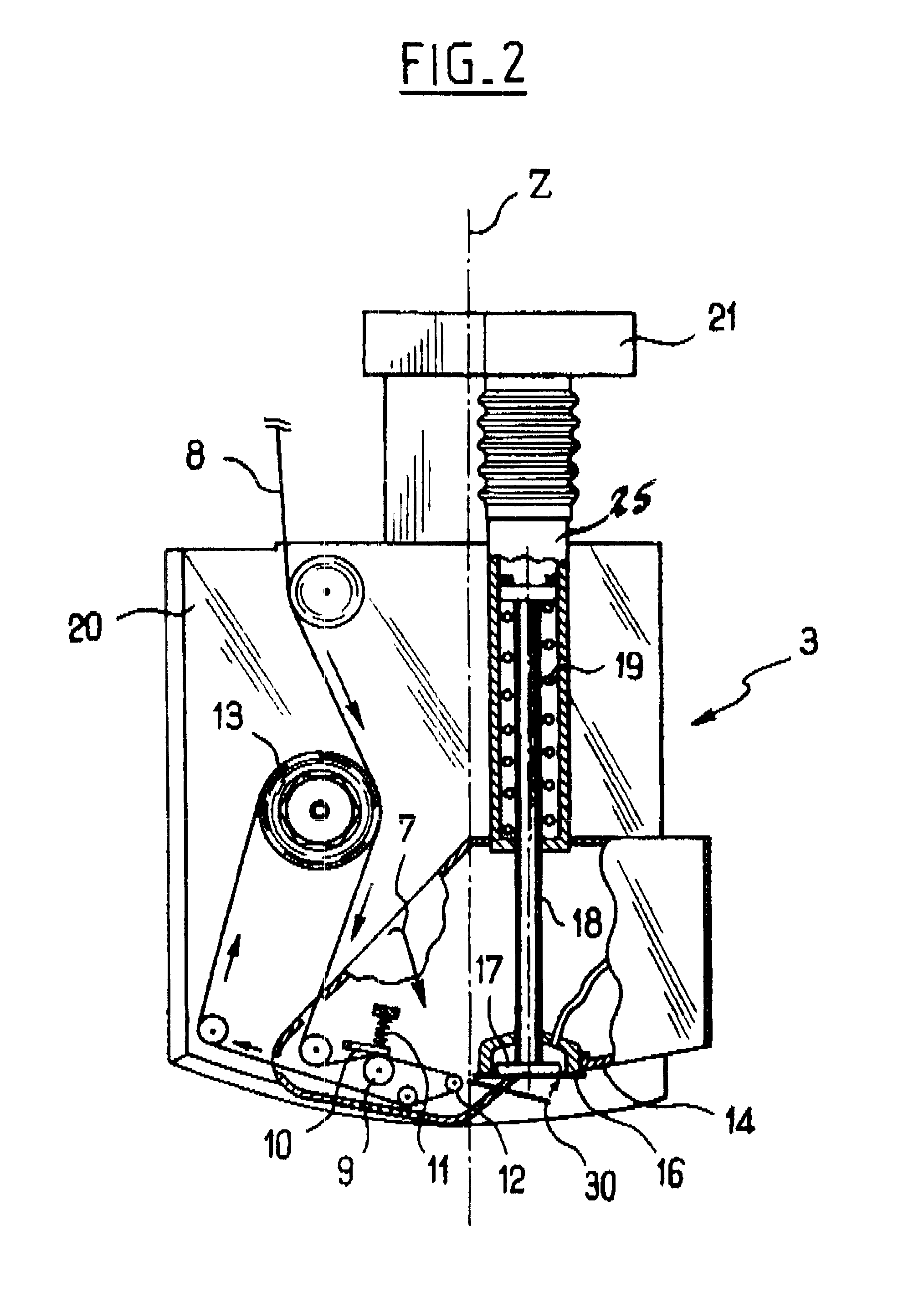

Labeling device for labeling objects, in particular moving objects

ActiveUS20140041806A1Reduce riskEfficiently returnedControlling laminationLaminationRest positionEngineering

A labelling device includes a linearly displaceable piston operably connectable to a moving mechanism for moving the piston from a resting position to a labelling position. A label carrying mechanism is arranged at the distal end of the piston for carrying an adhesive label and affixing the adhesive label to an object via physical contact at the labelling position of the piston. A force-switching-state system is provided to maintain the piston in relation to the moving mechanism in an attracting force state and the piston moves with the moving mechanism. The physical contact creates an opposite repelling force from the object onto the label carrying mechanism causing separation of the displaceable piston from the moving mechanism. This separation causes a change of the force state of the displaceable piston from an attracting to a repelling force state, causing the linearly displaceable piston to move back to the resting position.

Owner:MAREL HF

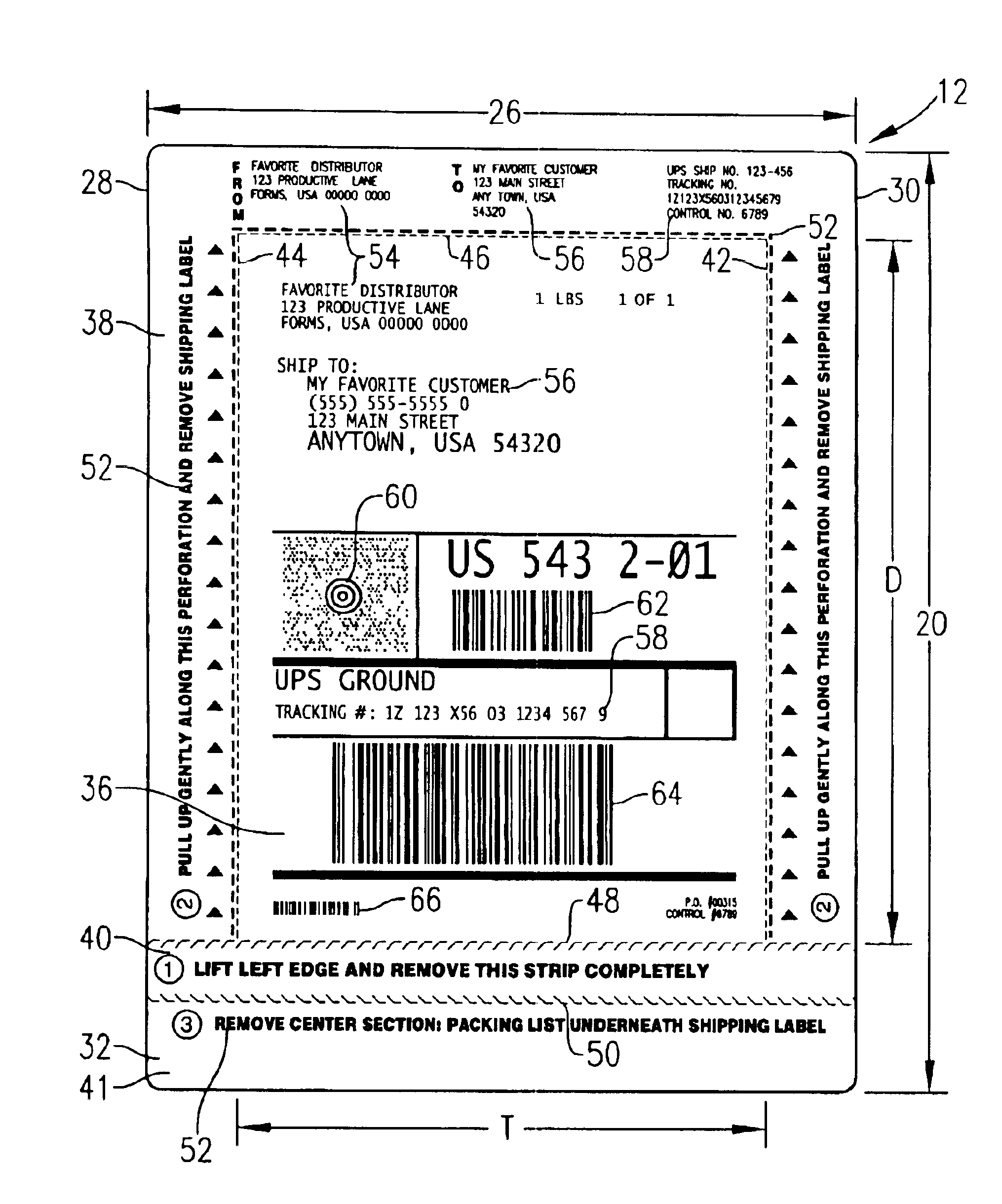

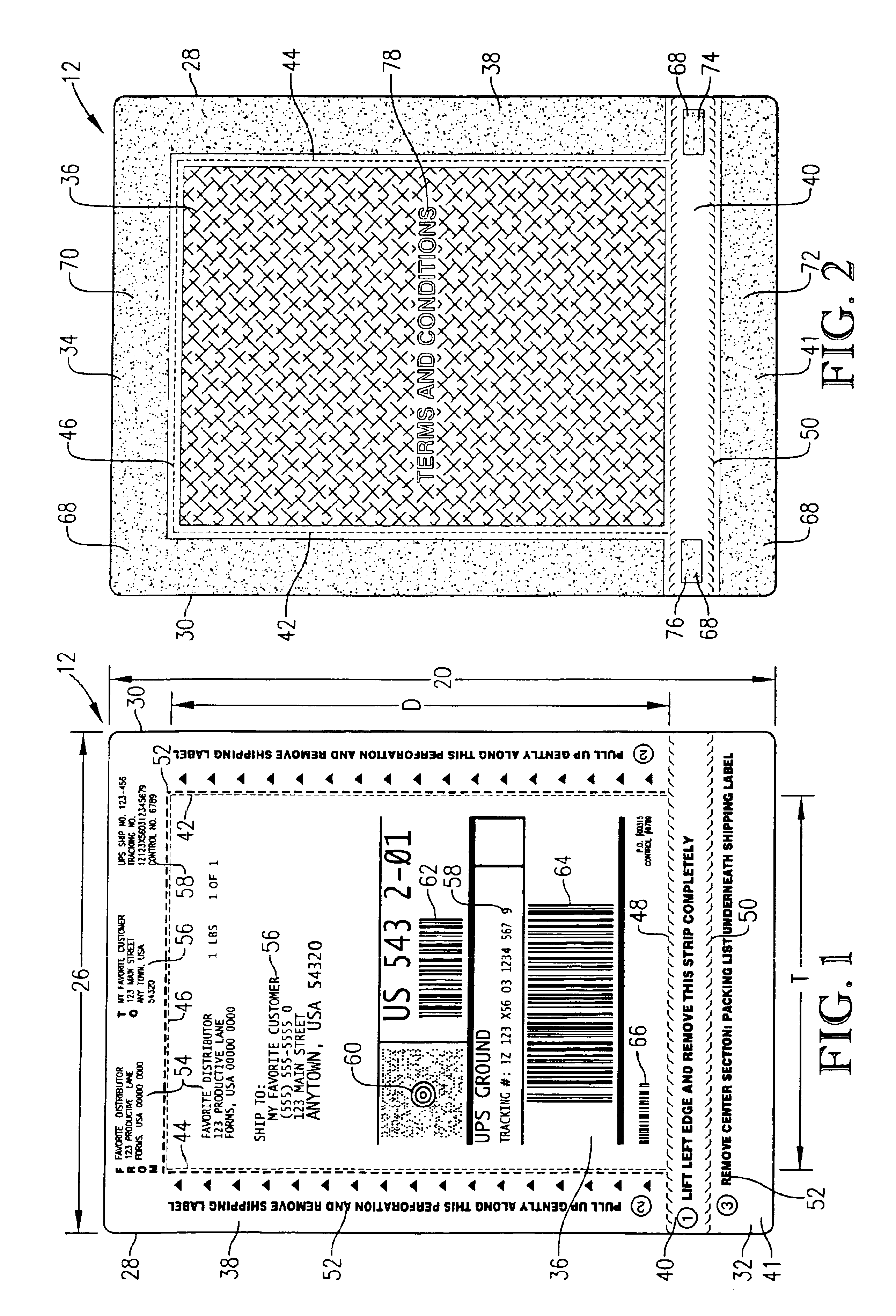

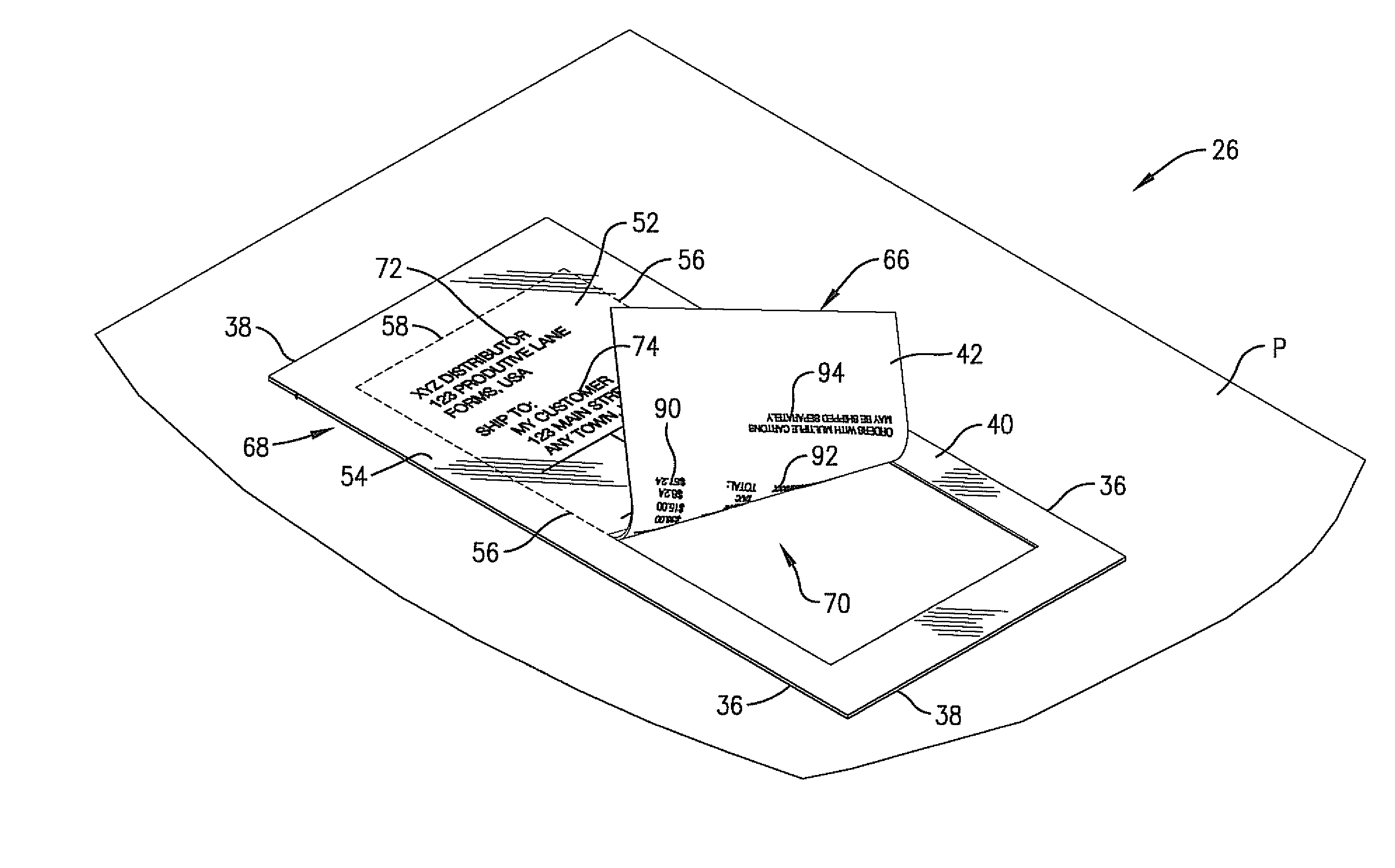

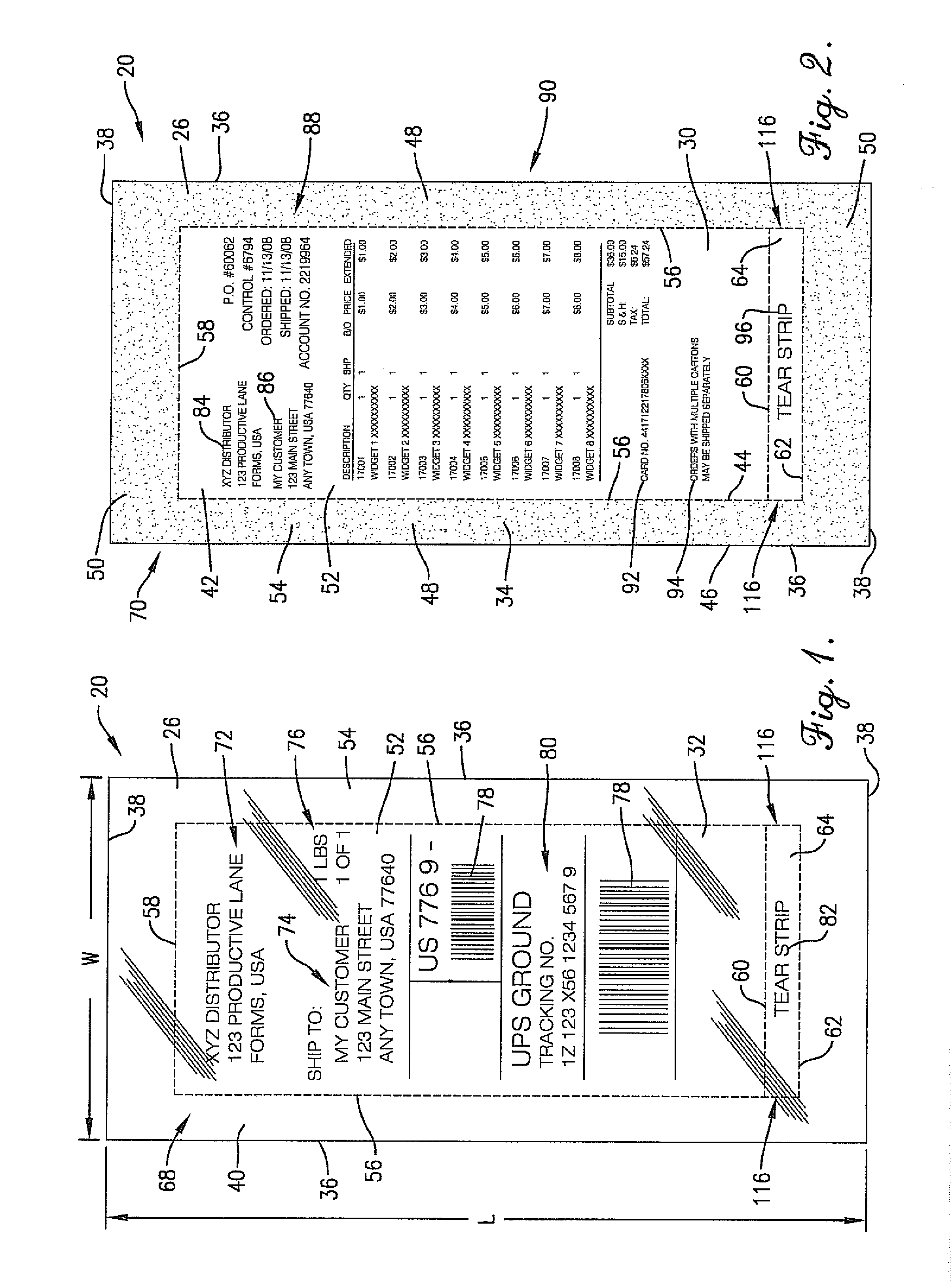

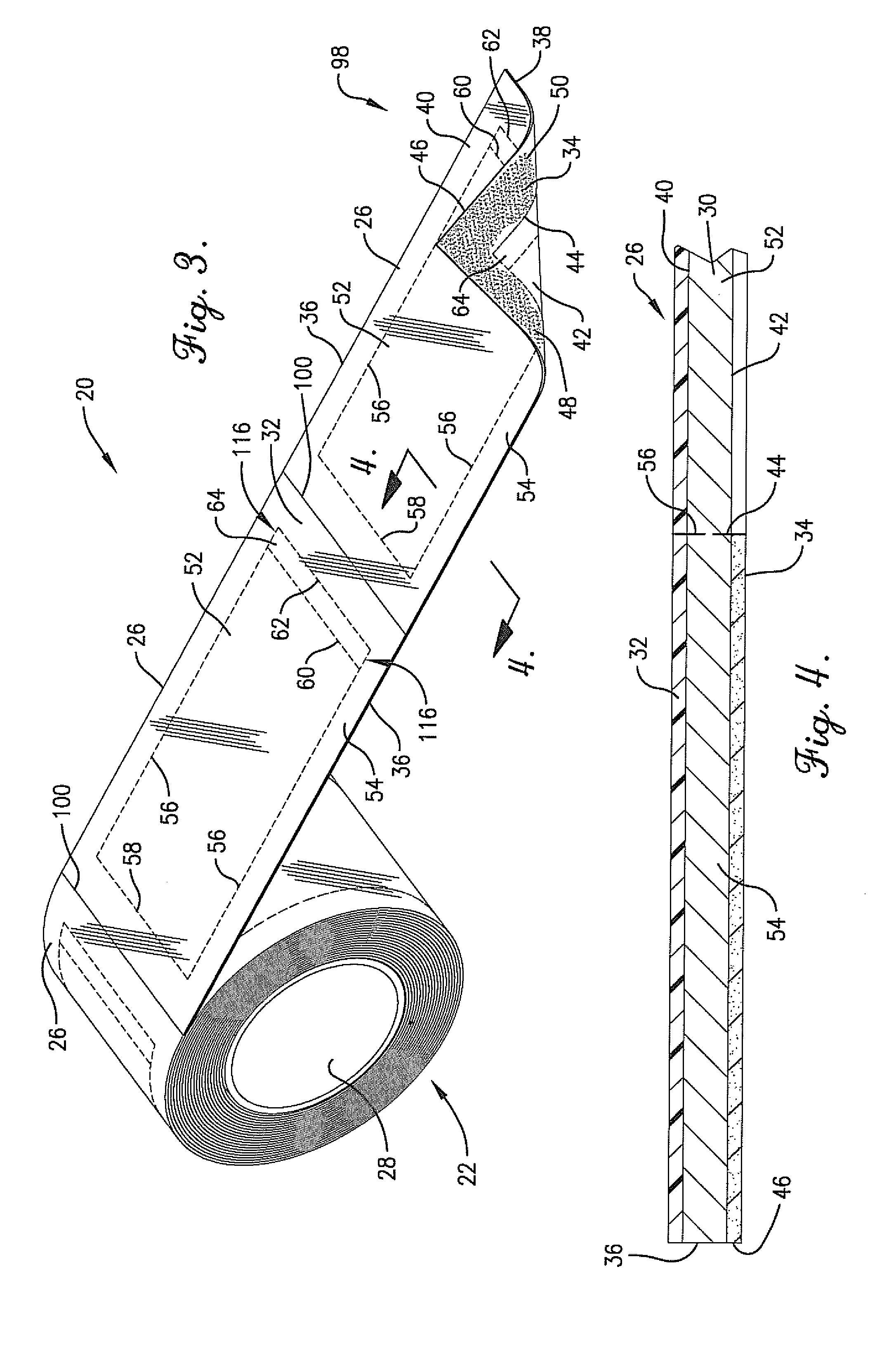

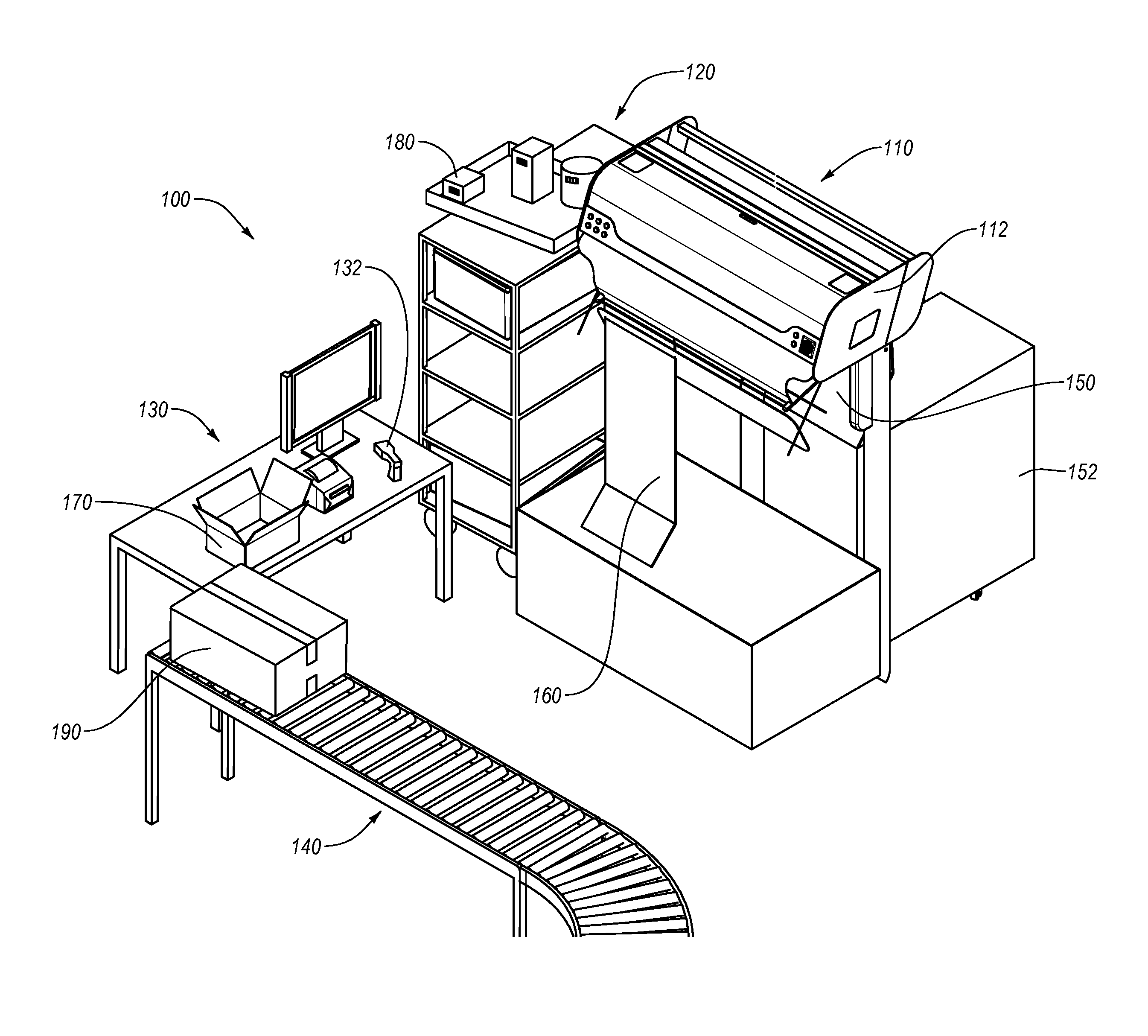

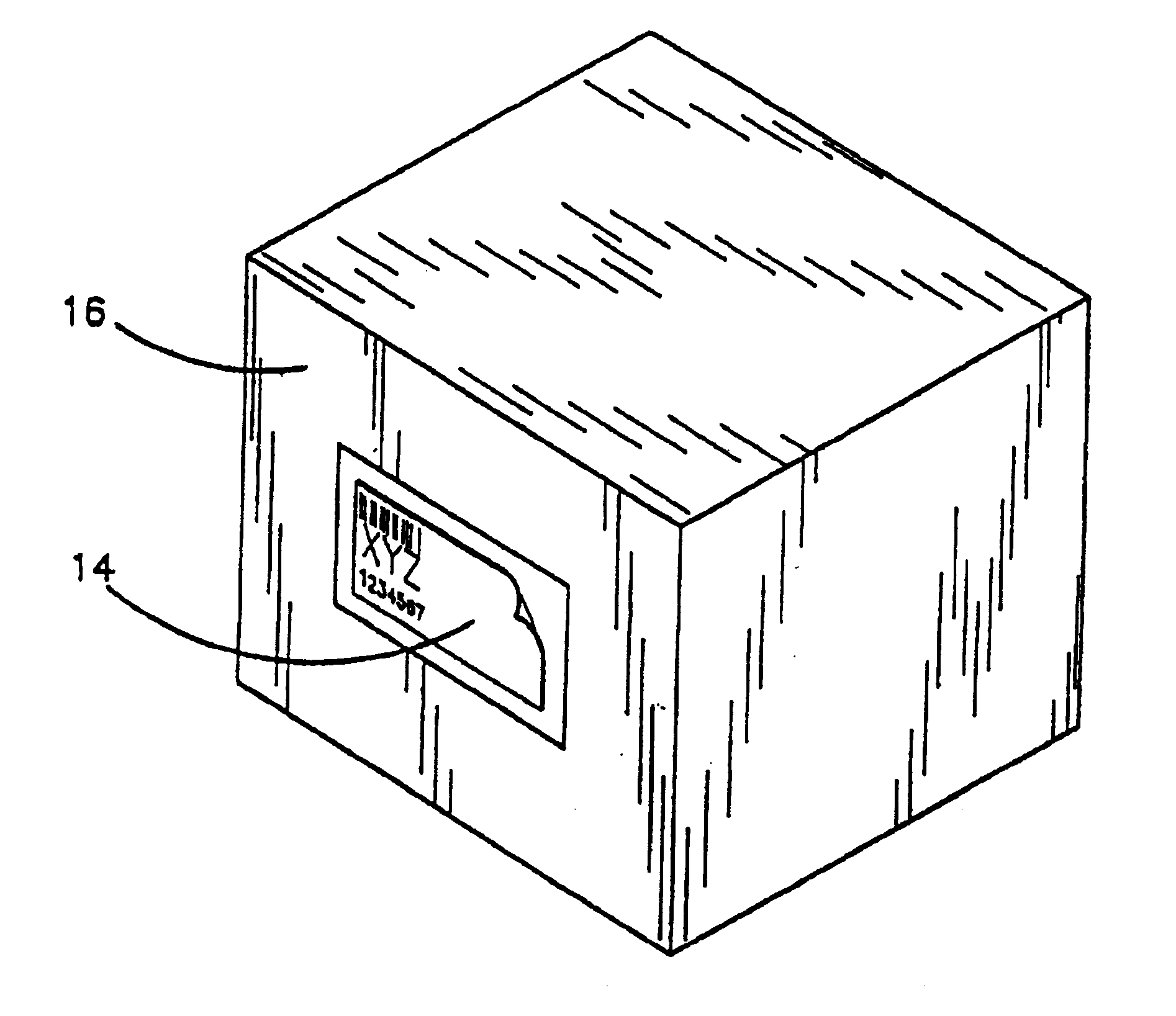

Sequentially placed shipping and packing label system

A system for providing a shipping label and a packing list on a container is provided which enables rapid and automated sequential application of a packing list and a shipping label to the container. The shipping label is configured complemental to the packing list whereby the packing list may first be adhered directly to the container and then the shipping label may be placed thereover. The shipping label may be applied over the packing list while the container moves continuously down a conveyor. The invention further includes an apparatus for sequentially applying the packing list and then the shipping label, and a method for applying the packing list and shipping label in registry.

Owner:PREMIER PRINT & SERVICES GROUP

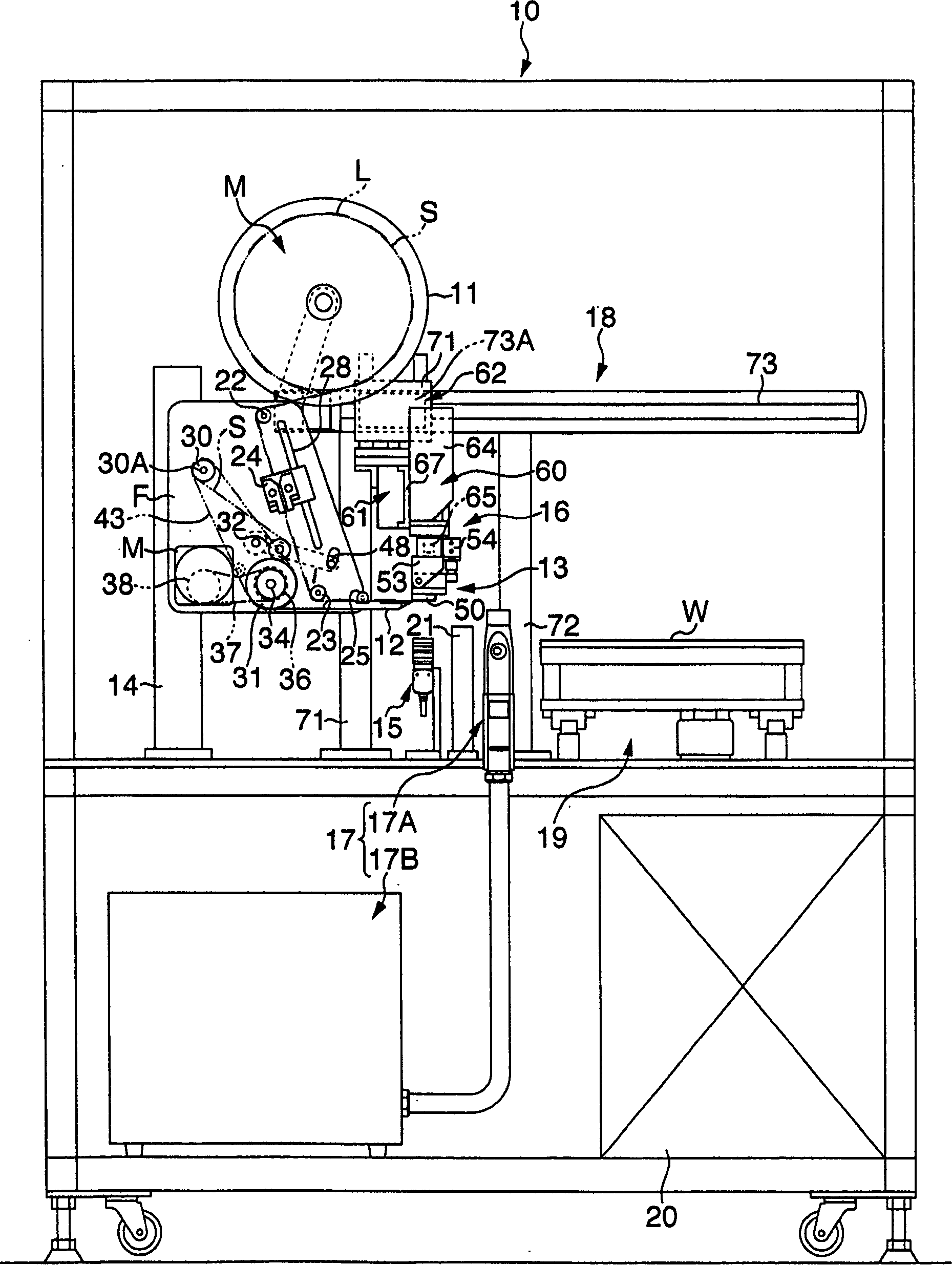

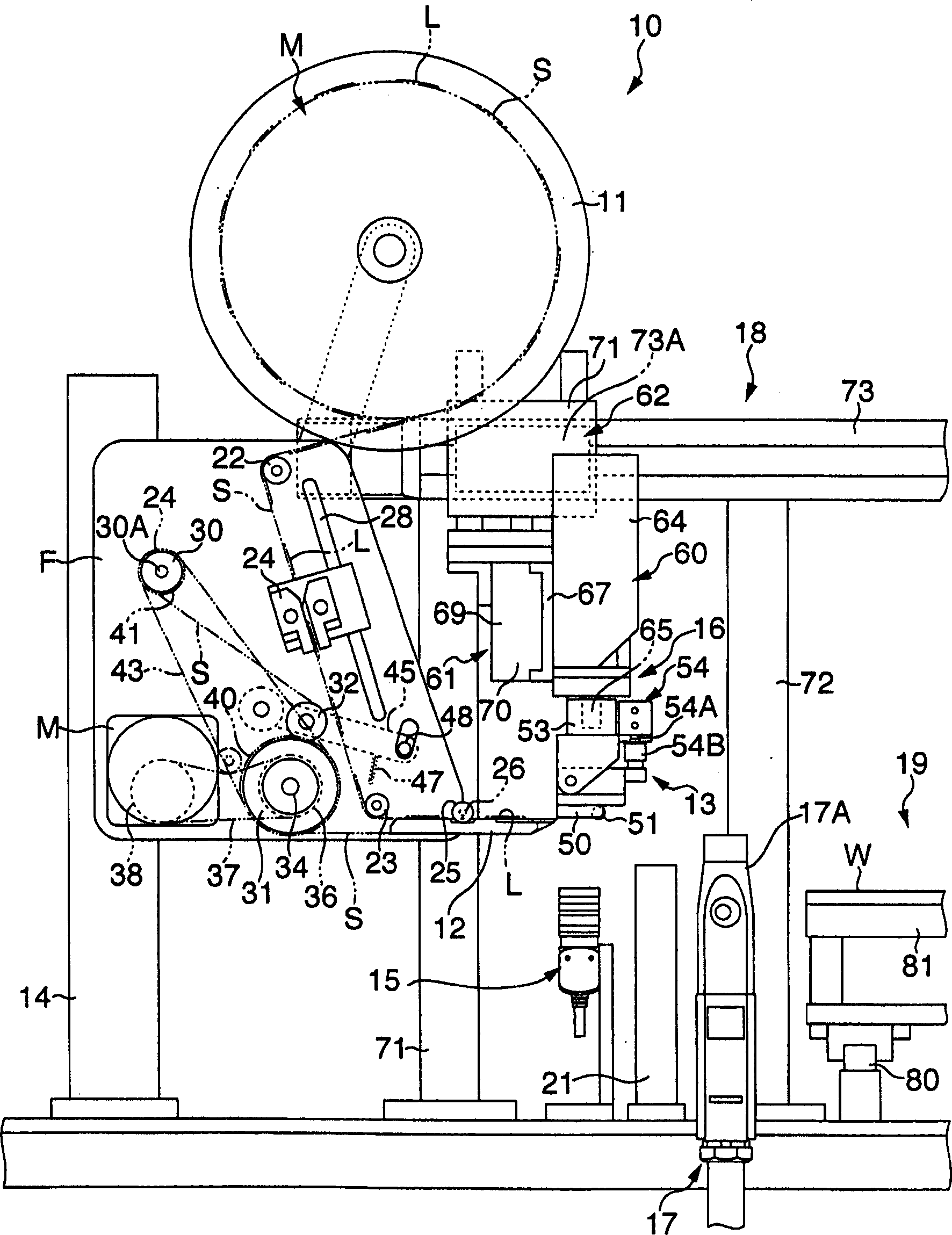

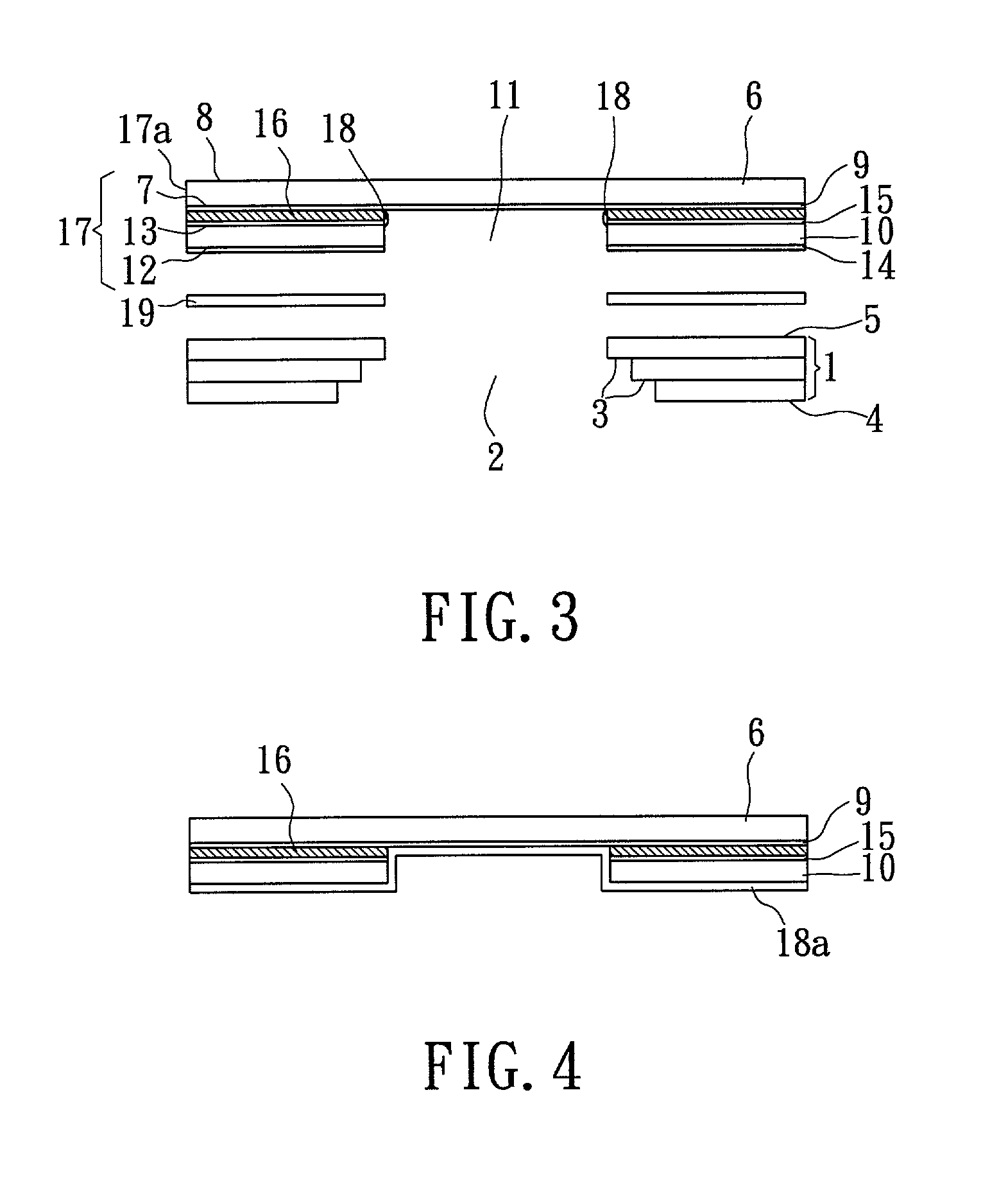

Label sticking device and label sticking method

InactiveCN1733556ANo loss of information continuityManual label dispensersLabelling flat rigid surfacesEngineeringRelease liner

A label sticking device is provided with a suction head 50 which holds a label L peeled off from a release liner S in the process of paying out a raw sheet M, a camera 15 which inspects a position of the sucked label, a label-positioning device 16 which adjusts a positional deviation of the label when the deviation is detected, a printing device 17 which prints on an adhesive layer of the label, a shifter 18 which shifts the label printed toward an object to be stuck with the label, and a controller 20 which controls these devices.

Owner:LINTEC CORP

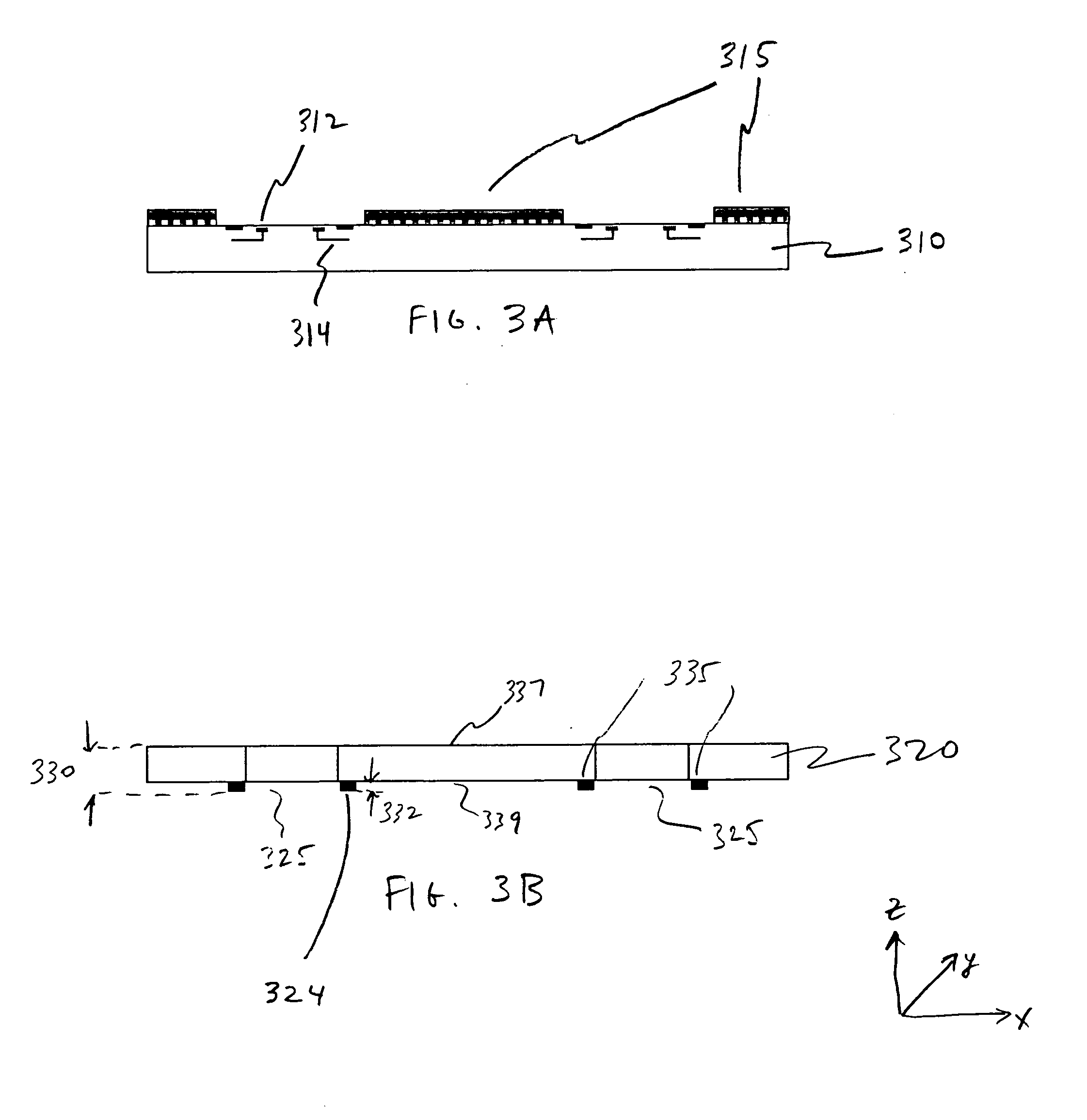

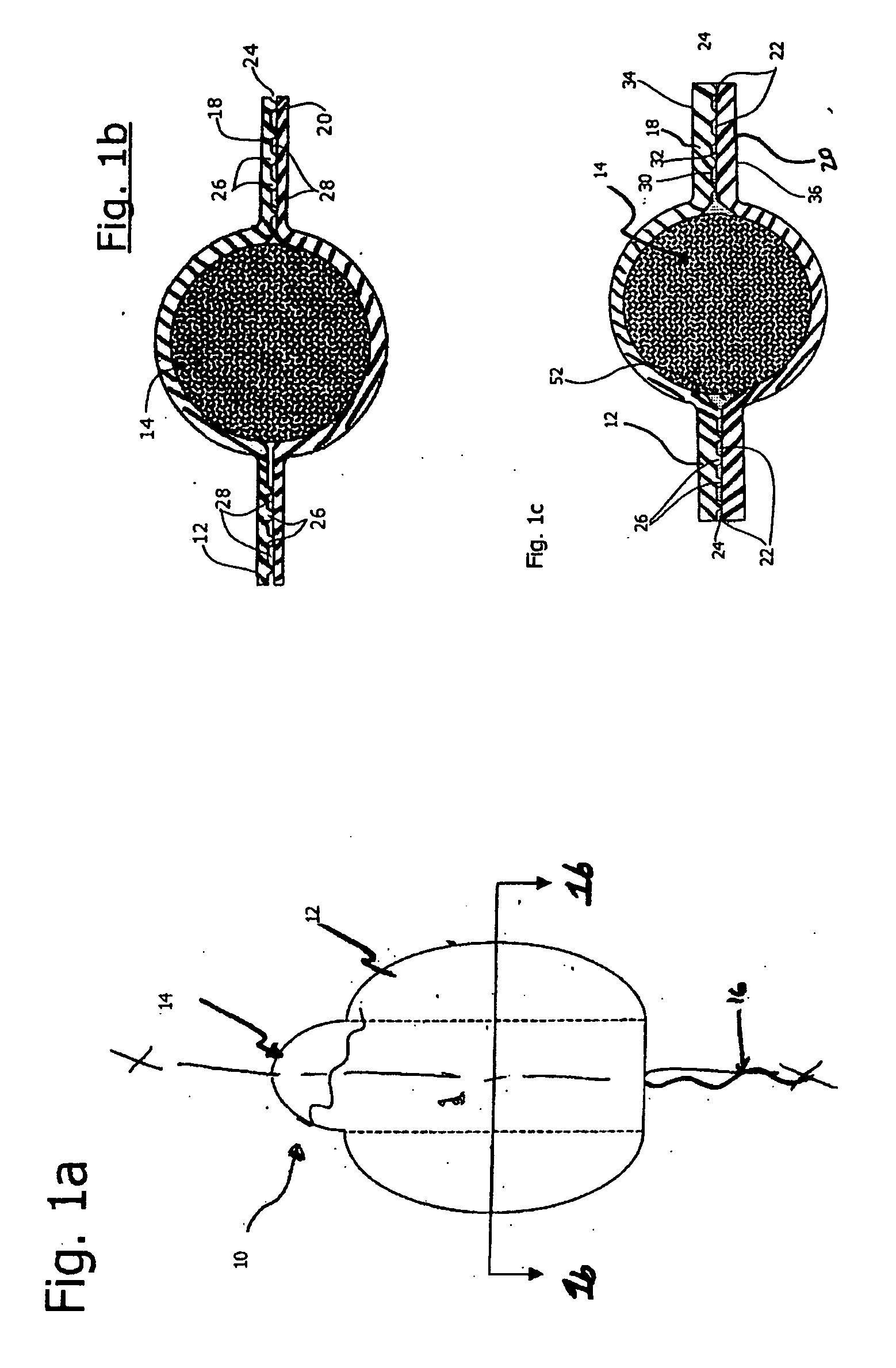

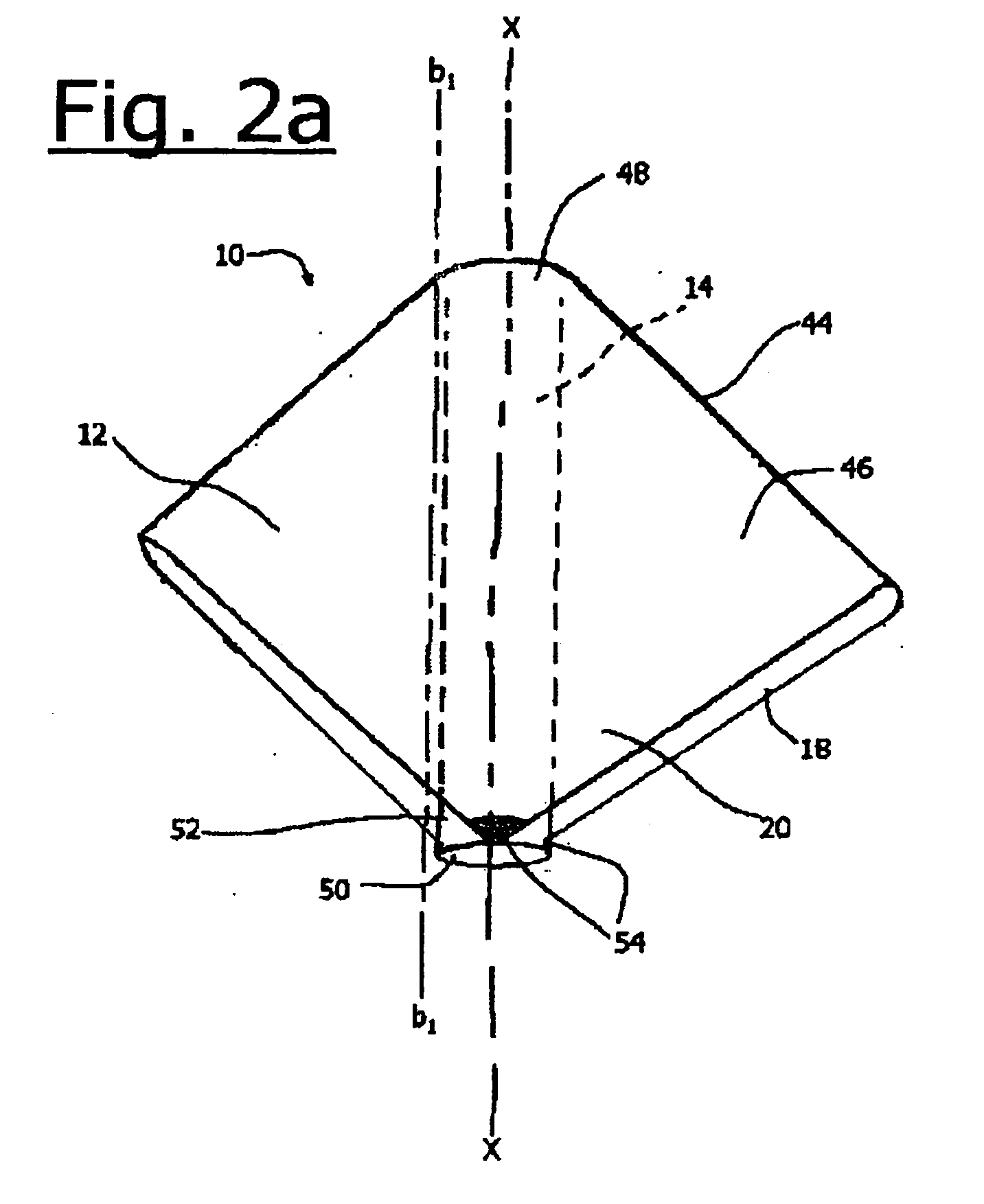

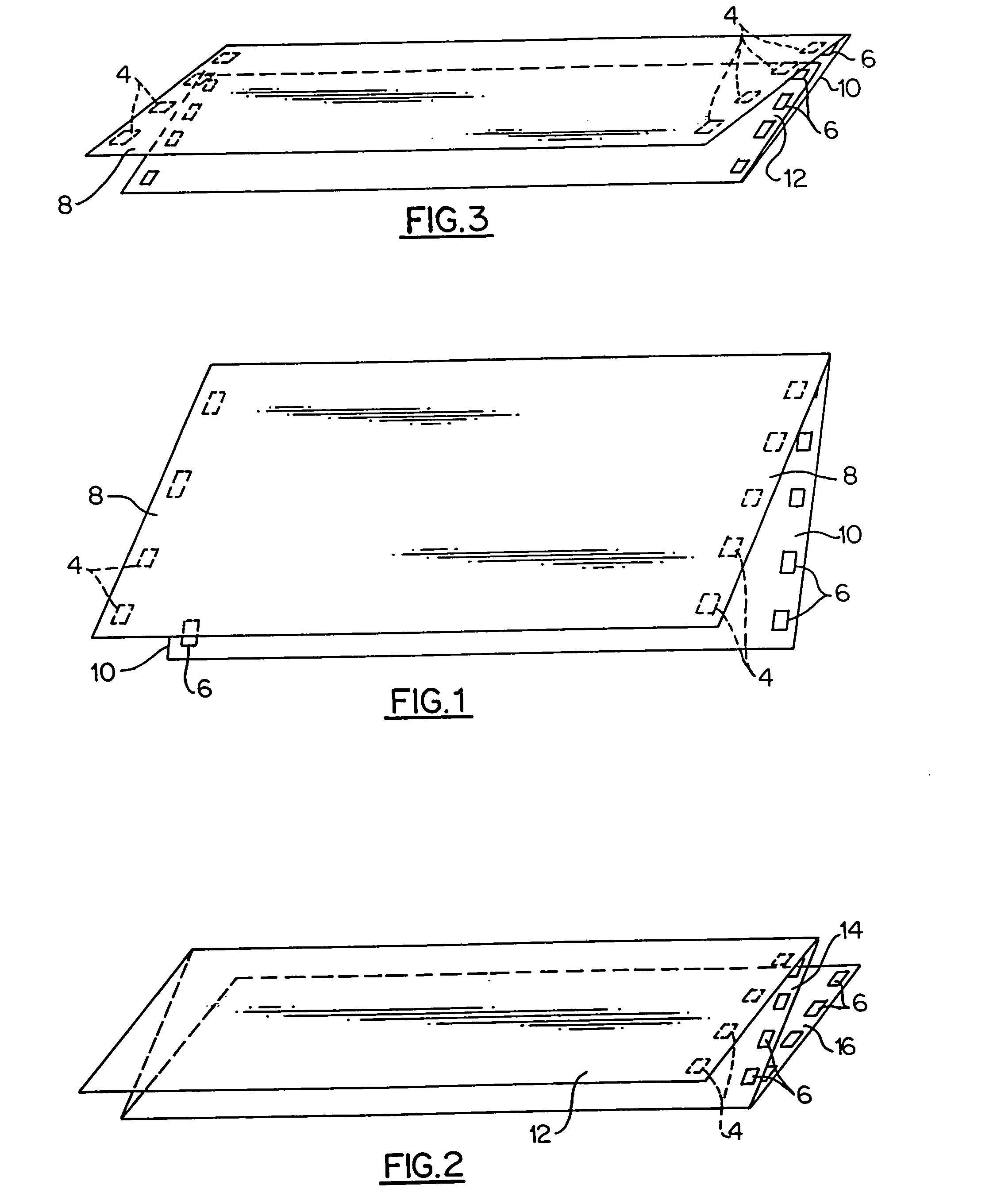

Intravaginal device with fluid transport plates

ActiveUS20070049893A1Increase contact areaReduce by-pass leakageBaby linensNon-woven fabricsFluid transportEngineering

An intravaginal device has a fluid storage element and at least one fluid transport element in fluid communication with the fluid storage element. The at least one fluid transport element has a first plate and a second plate coupled to the first plate. The second plate is capable of separating from the first plate sufficiently to provide inter-plate capillary action. The at least one fluid transport element is bendable about an axis substantially parallel to the longitudinal axis of the fluid storage element. The invention also includes methods and apparatus useful in the production of an intravaginal device.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

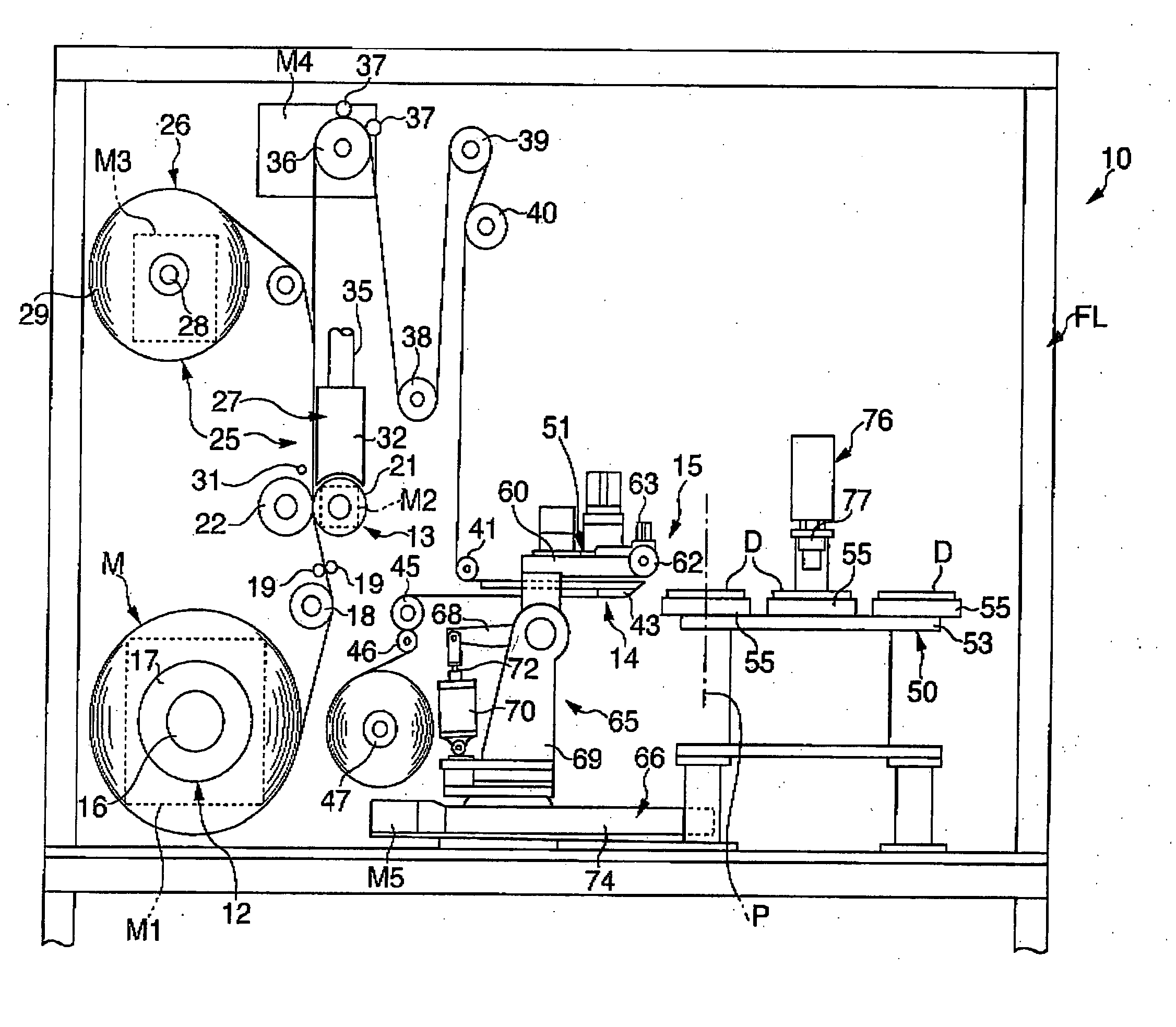

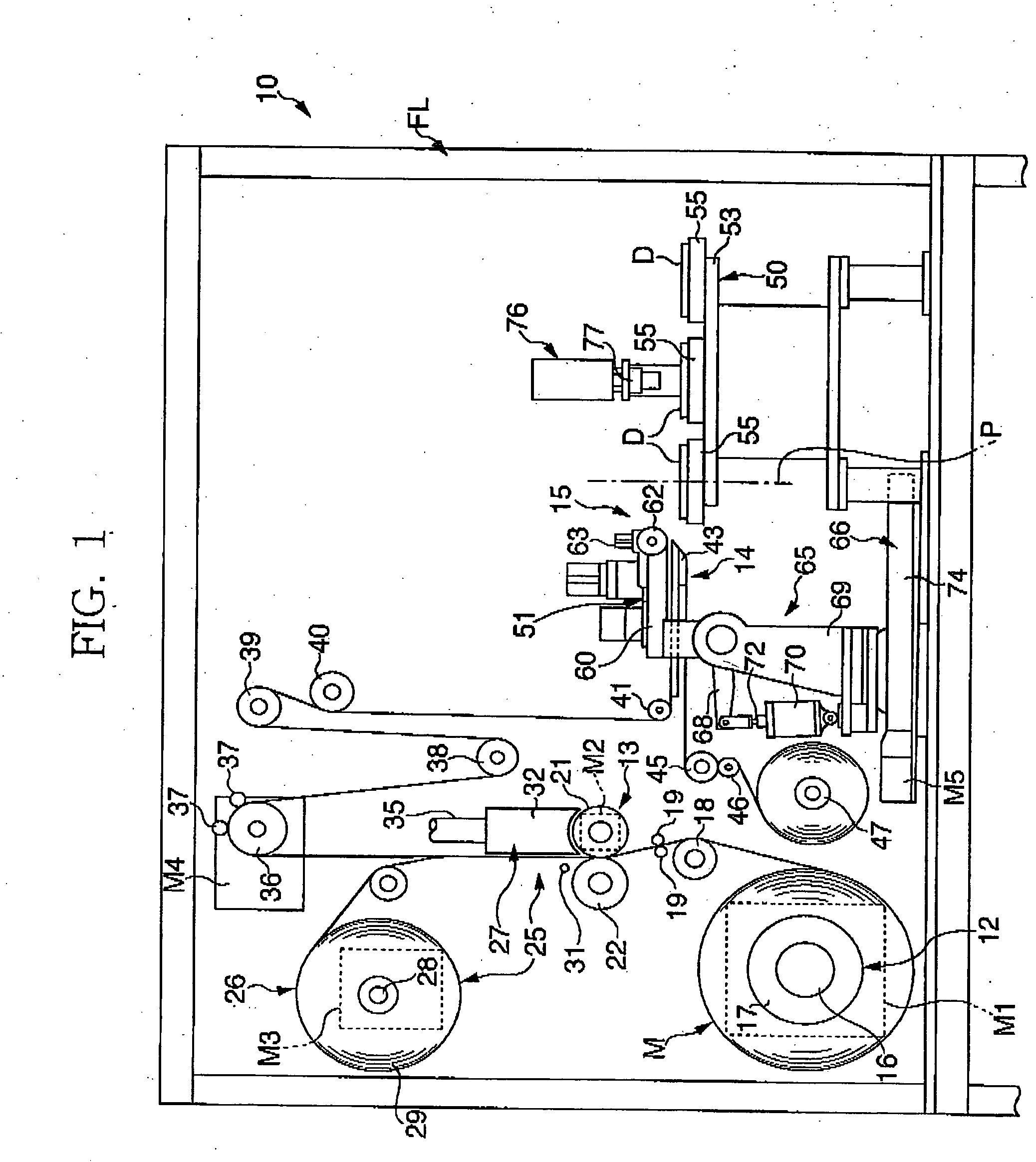

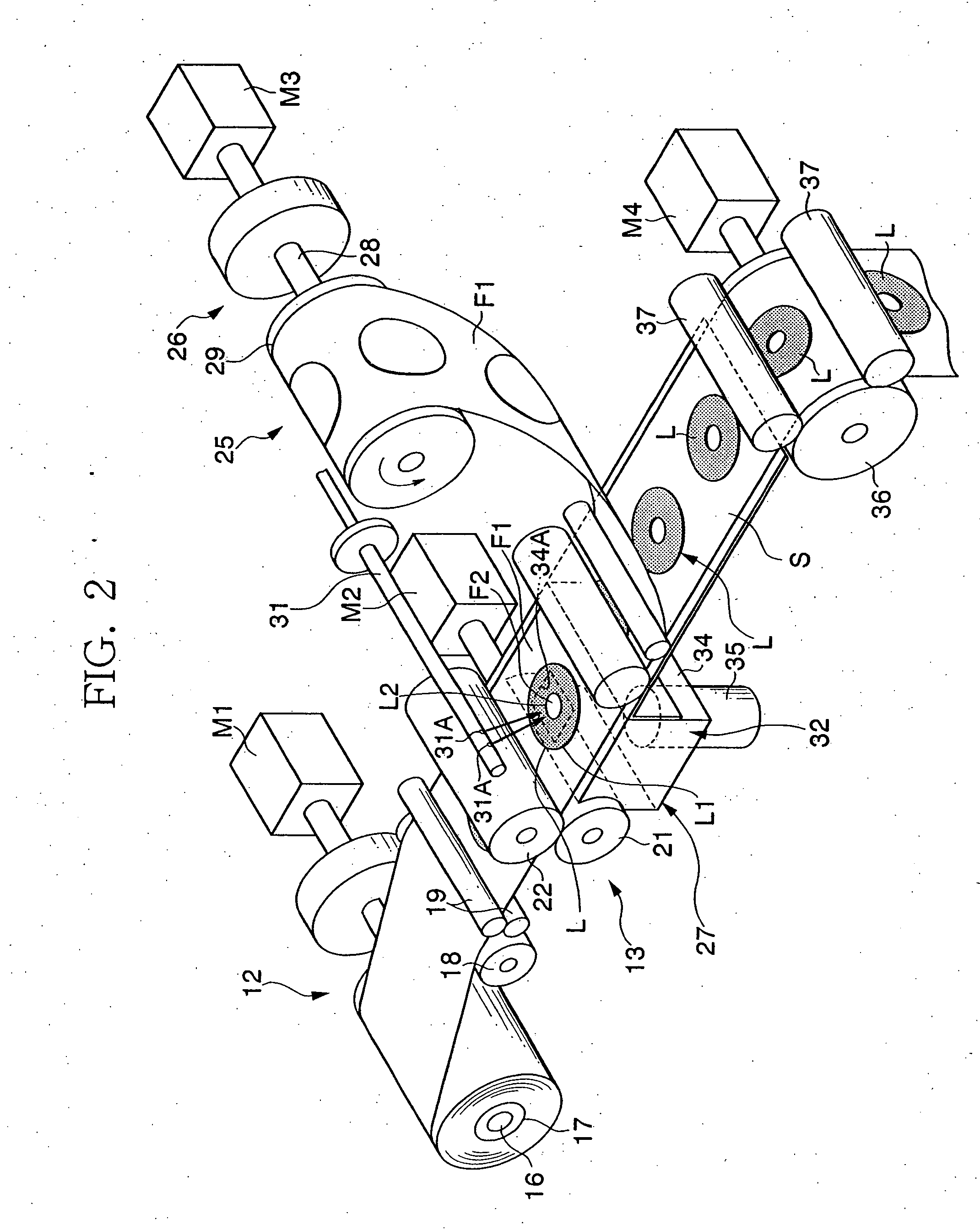

Laminating apparatus

InactiveUS20060185796A1Improve accuracyAvoid effectively conventional lamination failureMechanical working/deformationRecord carriersEngineeringMotor controller

Using a strip material carrying a film for forming a label to a base sheet, cuts are formed in the film at a by a cutting means while feeding the strip material, and film areas excluding labels are collected. The labels are left on the base sheet and, after being peeled off at a peeling means, the label is sucked and held by the label holding member. The label is subsequently transferred to a recording substrate at a laminating position and is laminated onto a recording substrate while being pressed by a press roller. The strip material is motivated by a motor. A dancer roller disposed between the cutting means and the peeling means removes slack in the strip material, and a motor controller controls the speed of the motor based on the sensed position of the dancer roller.

Owner:LINTEC CORP

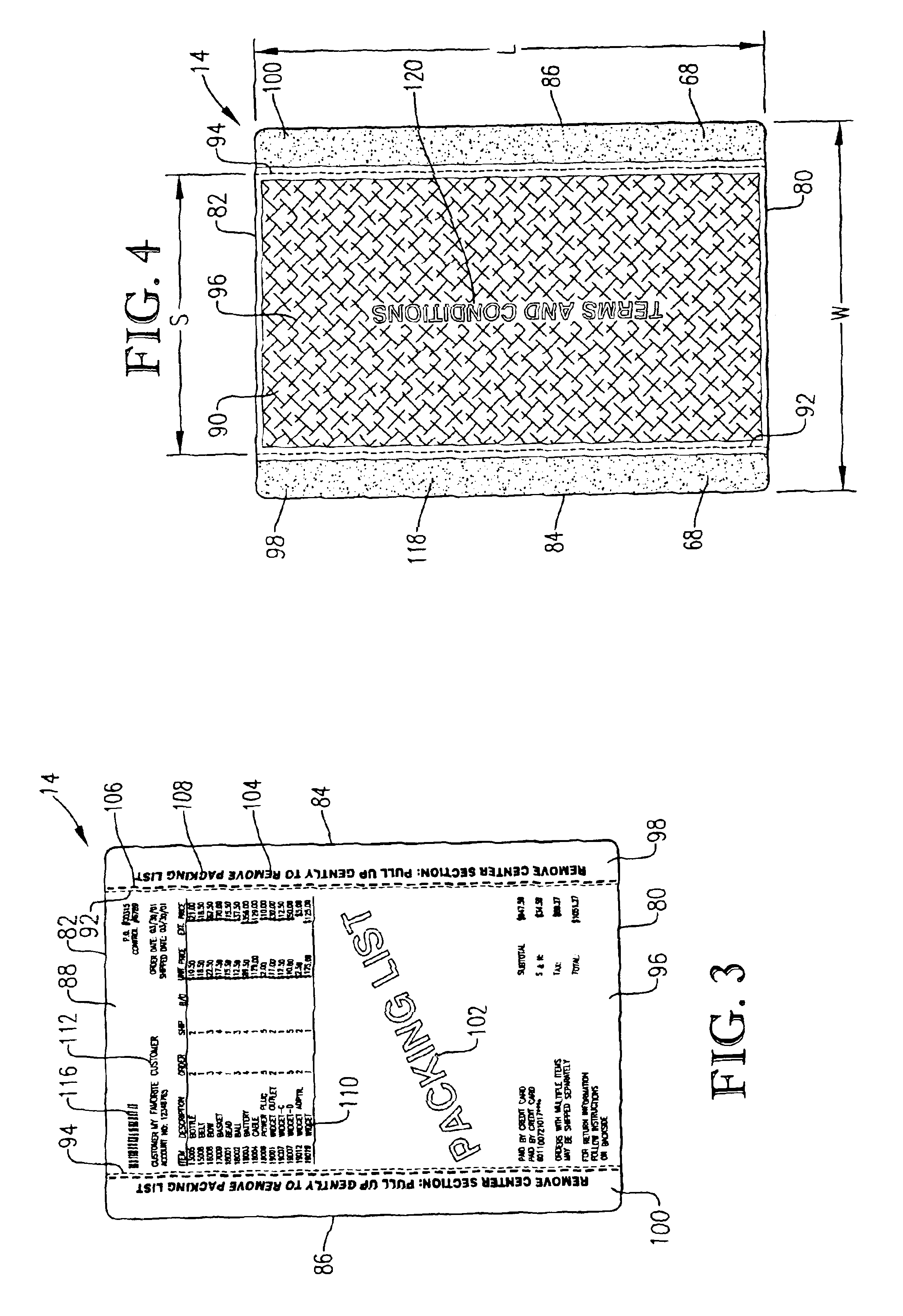

Linerless packing and shipping label system

A linerless duplex label system is operable to print and apply a linerless duplex label to a substrate. A plurality of linerless duplex labels are provided and each label includes a single-ply stock with top and bottom faces. The label also includes an endless adhesive border applied to the bottom face. The label is configured so that multiple labels can be removably adhered to each other by the adhesive border, with at least one linerless duplex label being removably overlaid onto at least one other duplex label.

Owner:PREMIER PRINT & SERVICES GROUP

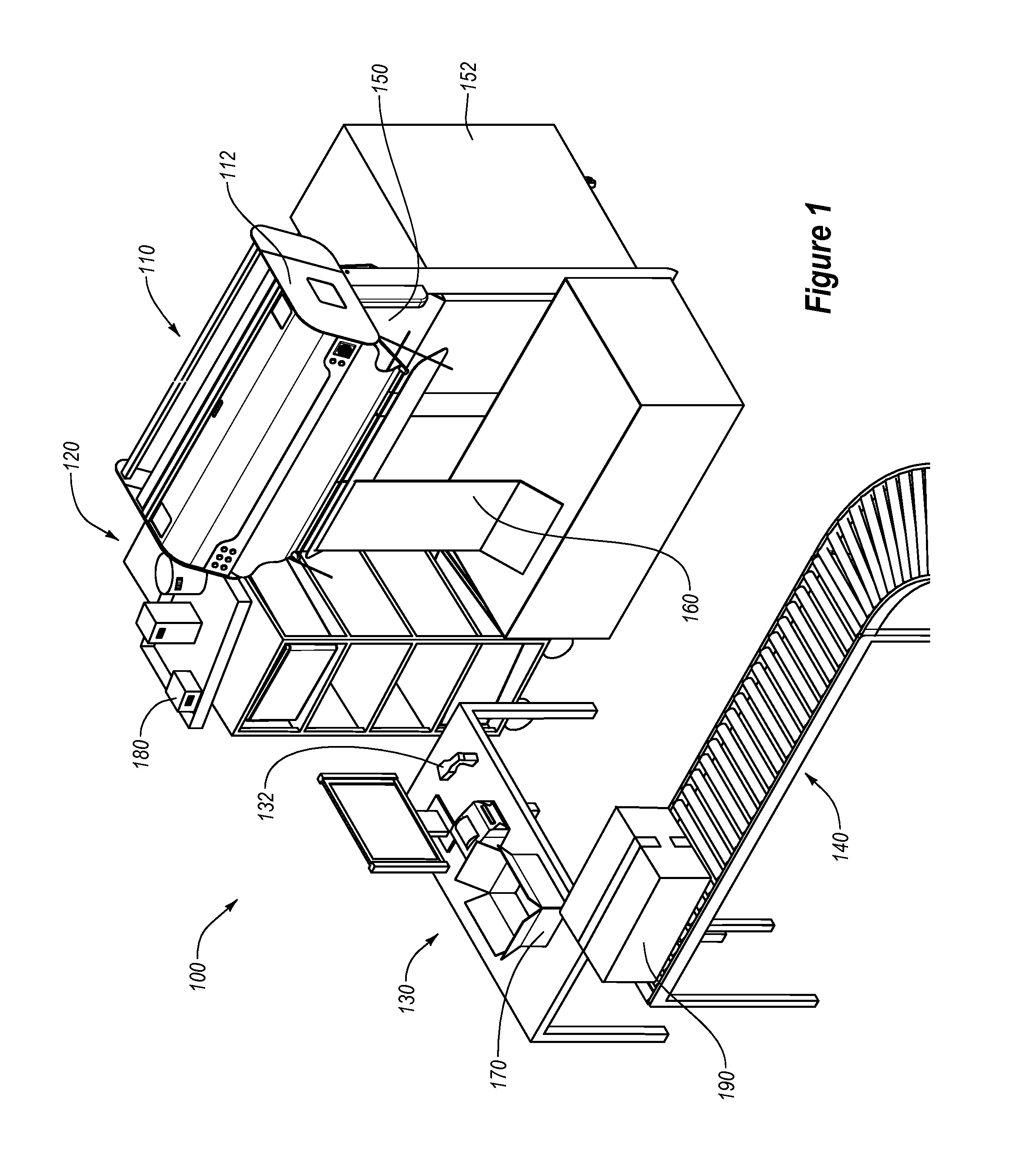

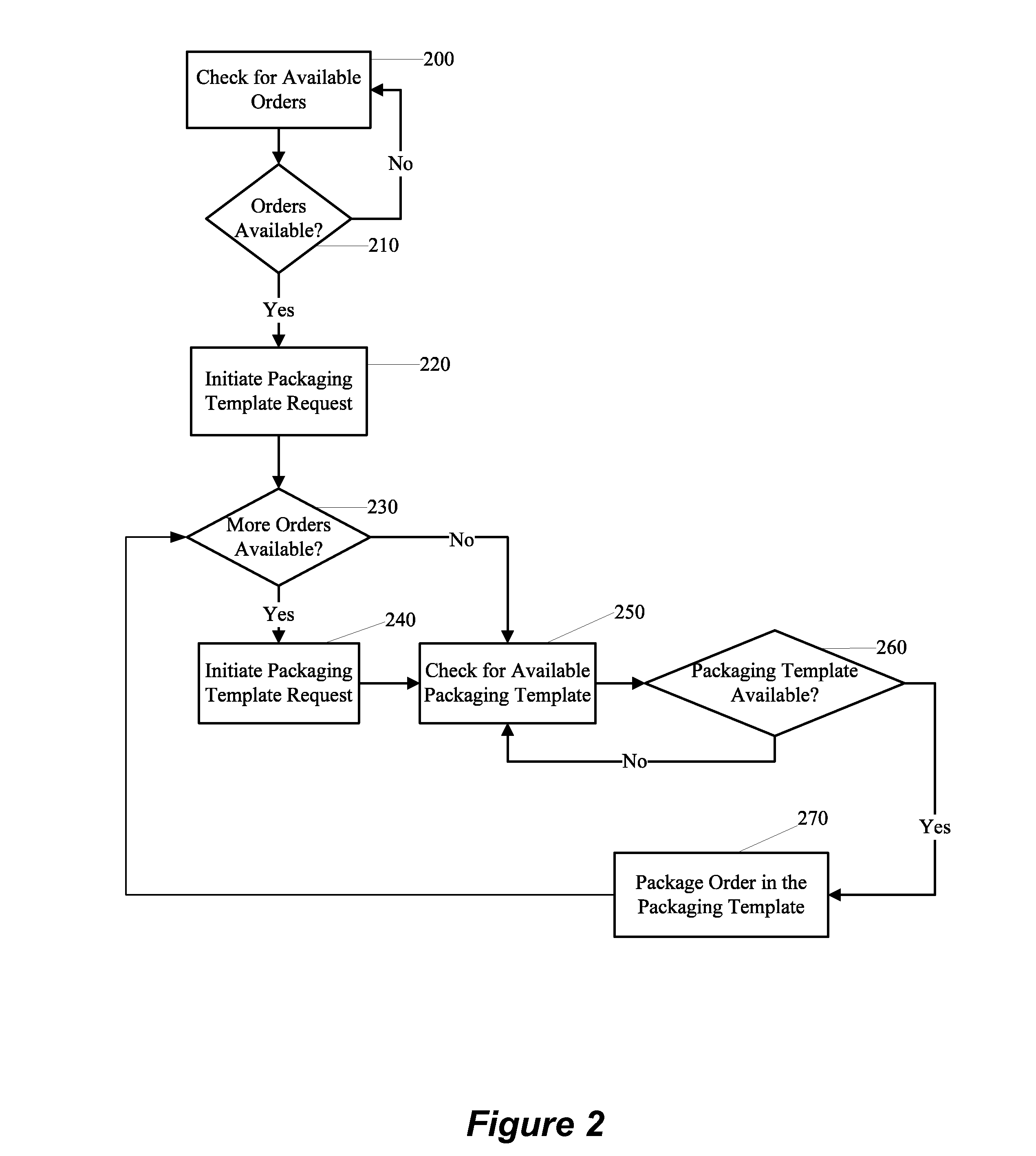

Box-last packaging system

ActiveUS20150019387A1Computer controlBuying/selling/leasing transactionsComputer scienceSoftware engineering

Implementations of the present invention relate to systems and methods for receiving an order that has been gathered and is ready for packaging. After the order is received, a tracking code can be scanned. The tracking code may be associated with packaging information relating to the order's packaging attributes. A request can then be send to a packaging system to generate a packaging template. The packaging system can then generate the requested packaging template.

Owner:PACKSIZE

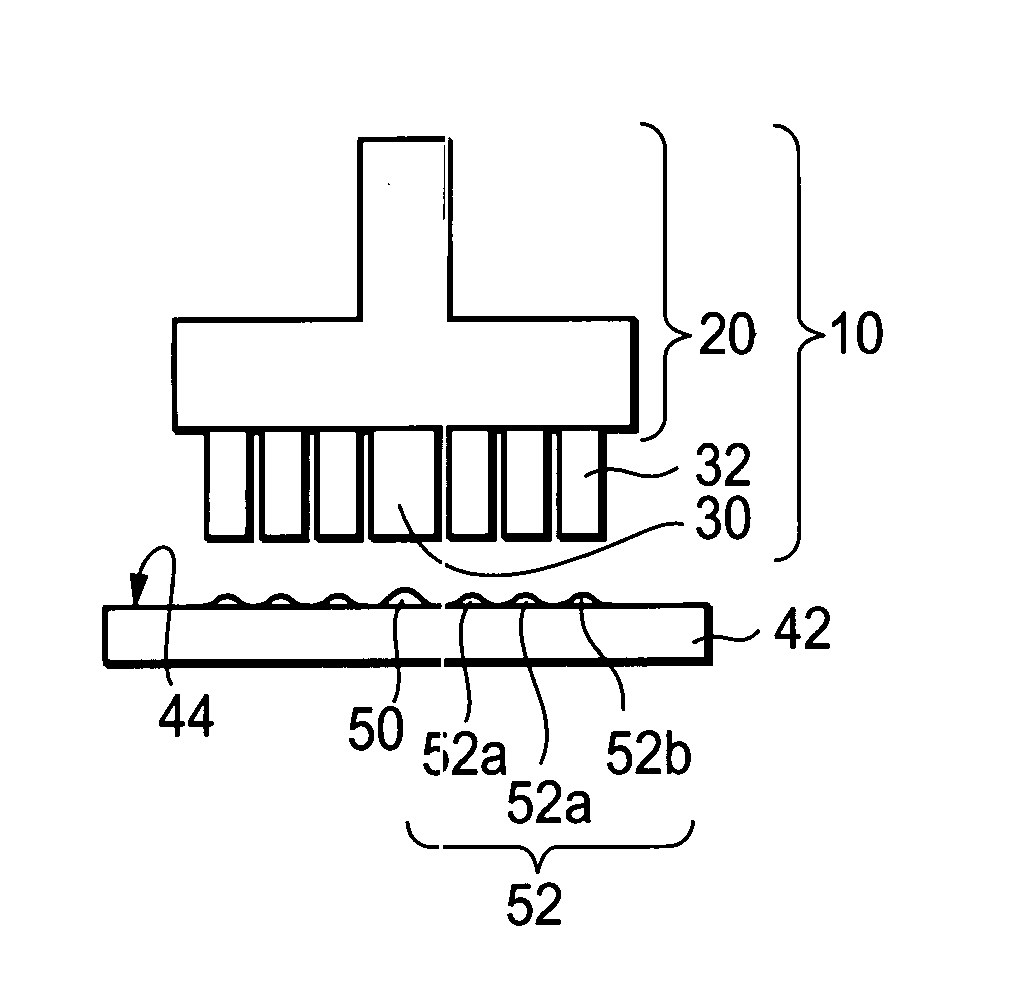

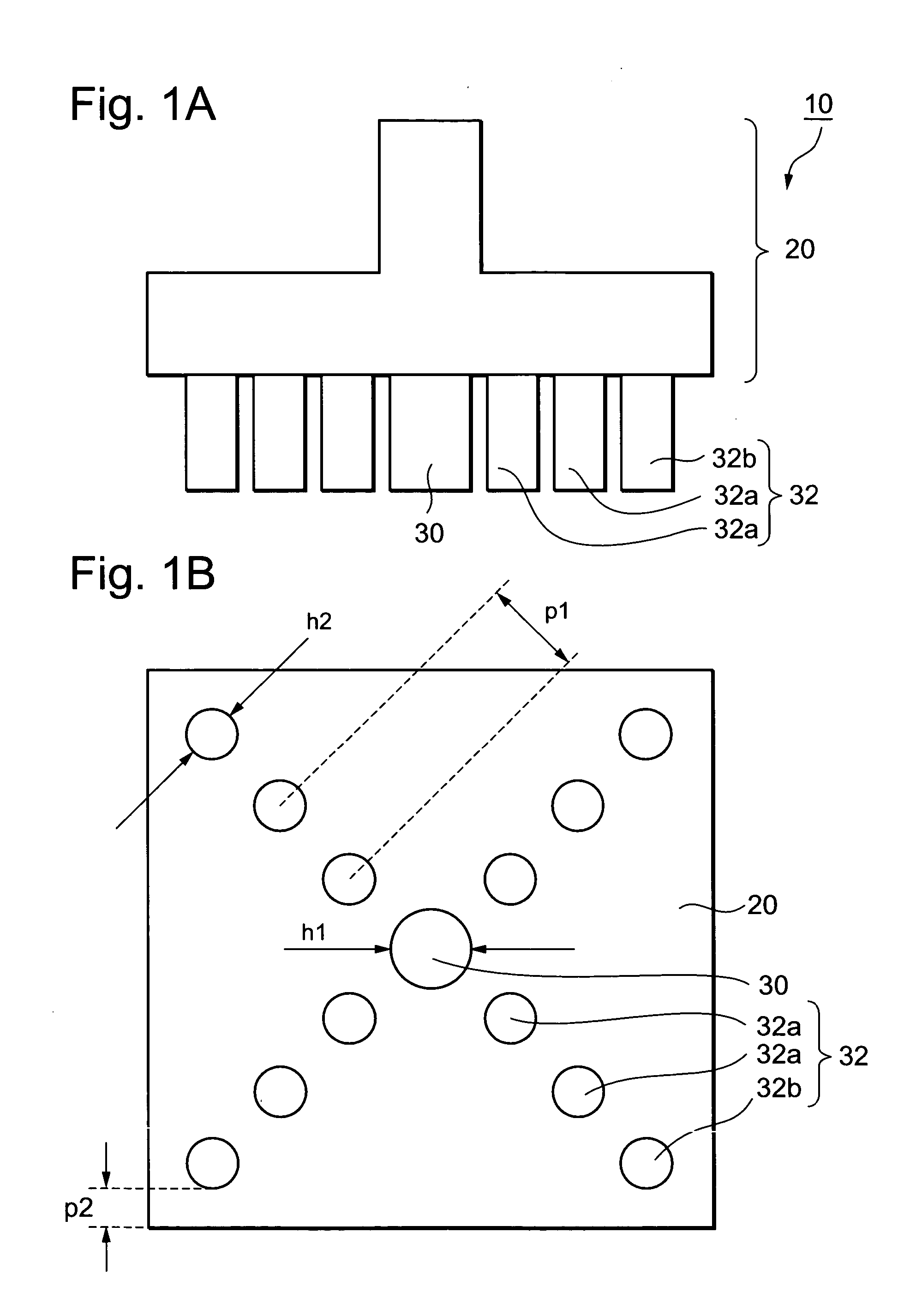

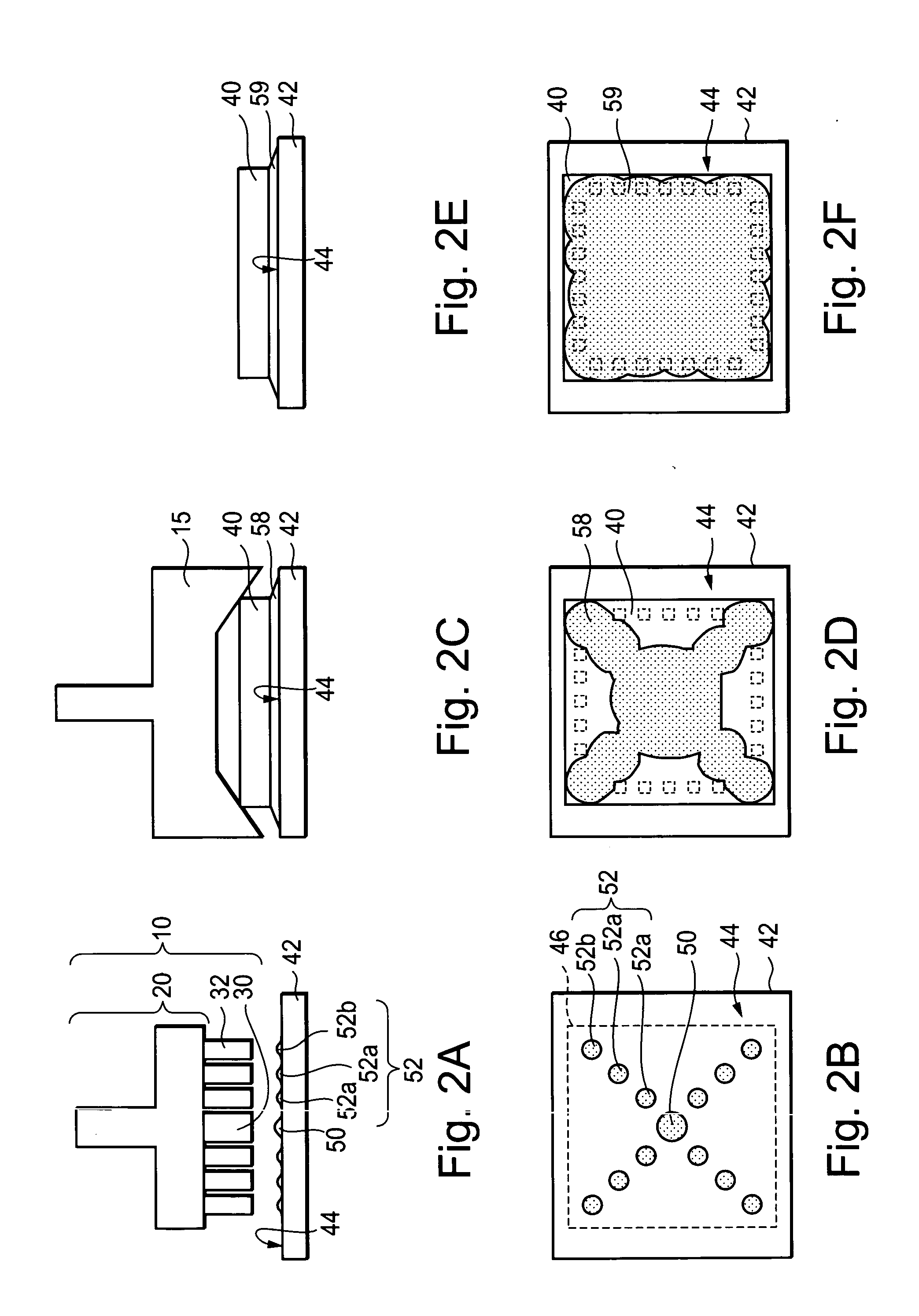

Dies bonding apparatus and dies bonding method

InactiveUS20050172891A1Effect can be causedGood effectLiquid surface applicatorsSolid-state devicesEngineeringDie bonding

A dies bonding apparatus is provided with a nozzle unit for supplying an adhesive agent to a rectangular bonding area of a chip mounting surface. The nozzle unit includes a central nozzle for discharging an adhesive agent to the center of the bonding area, and a plurality of peripheral nozzles provided around the central nozzle and whose amount of discharge of the adhesive agent is smaller than the amount of discharge of the adhesive agent from the central nozzle.

Owner:OKI ELECTRIC IND CO LTD

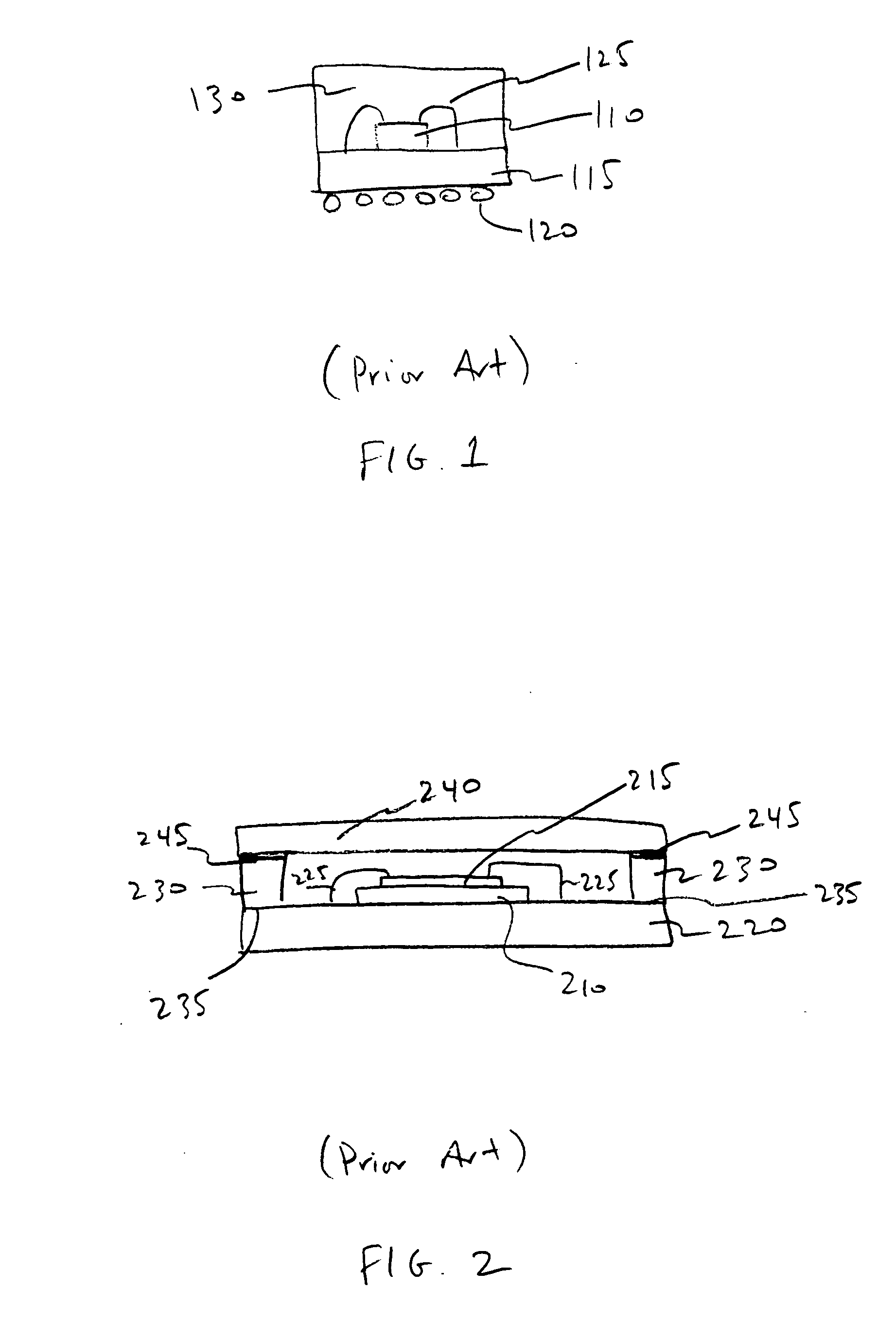

Attachment of a stiff heat spreader for fabricating a cavity down plastic chip carrier

InactiveUS20020144775A1Good heat dissipationReduce weightSemiconductor/solid-state device detailsAdhesive processes with surface pretreatmentElectronic chipAdhesive materials

A stiff heat spreader element for making a cavity down plastic chip carrier having benefits of excellent heat dissipation property, low weight, small thickness, low warpage and low twist is disclosed. The stiff heat spreader element is formed by bonding a heat spreader and a thermally conductive sheet with using a first bonding sheet. The first bonding sheet is a prepreg or prepregs made of fiber-reinforced resin. A second bonding sheet is used to bond a circuit substrate and the stiff heat spreader element. The second bonding sheet is made of a single adhesive layer or a stack of adhesive layers. The adhesive layer is made of an adhesive material, or a flake-filled adhesive material, or short fiber-filled adhesive material, or a particle-filled adhesive material. The second bonding sheet is not a prepreg or prepregs. The circuit substrate has an opening to receive an electronic chip.

Owner:PHOENIX PRECISION TECH CORP

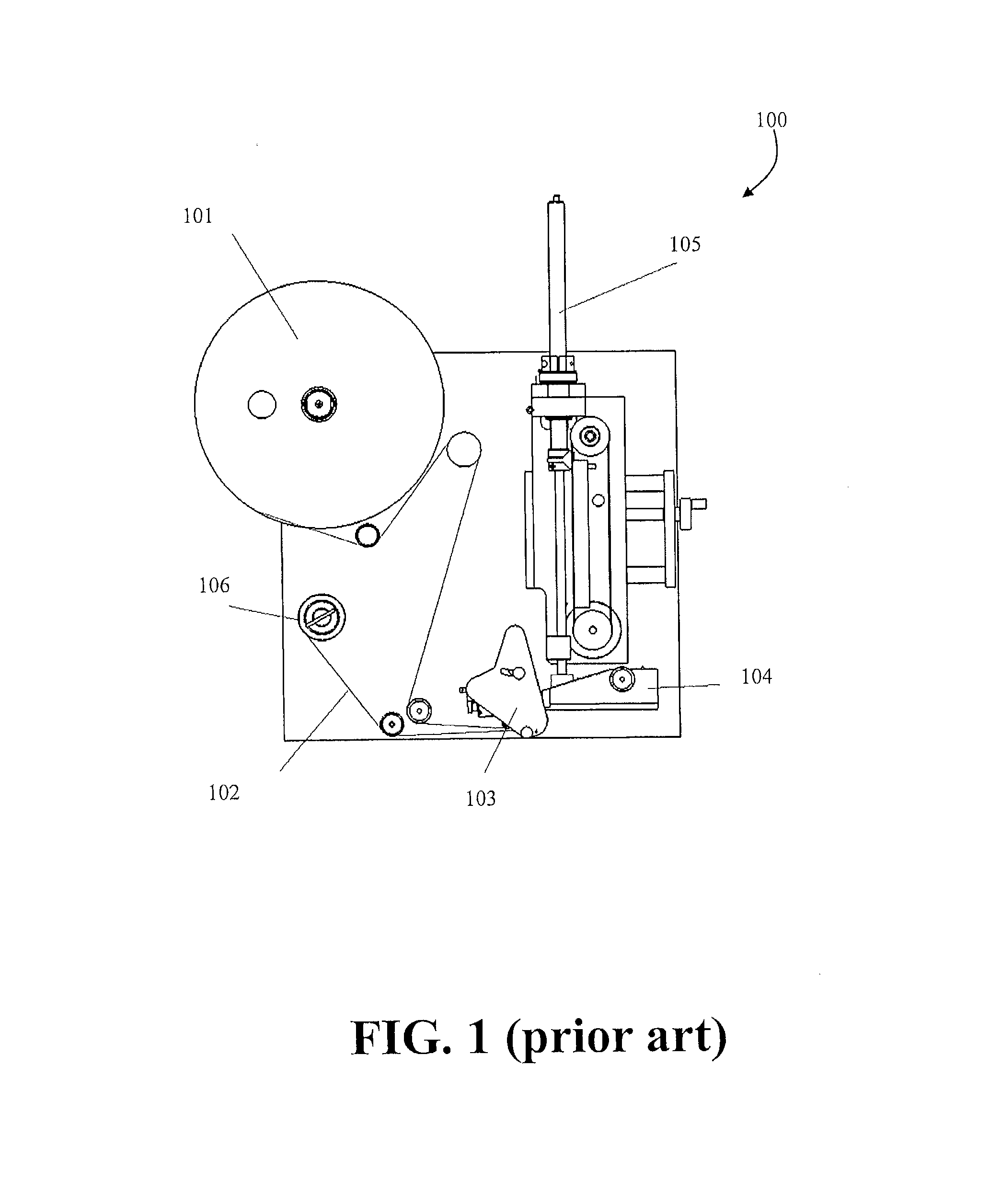

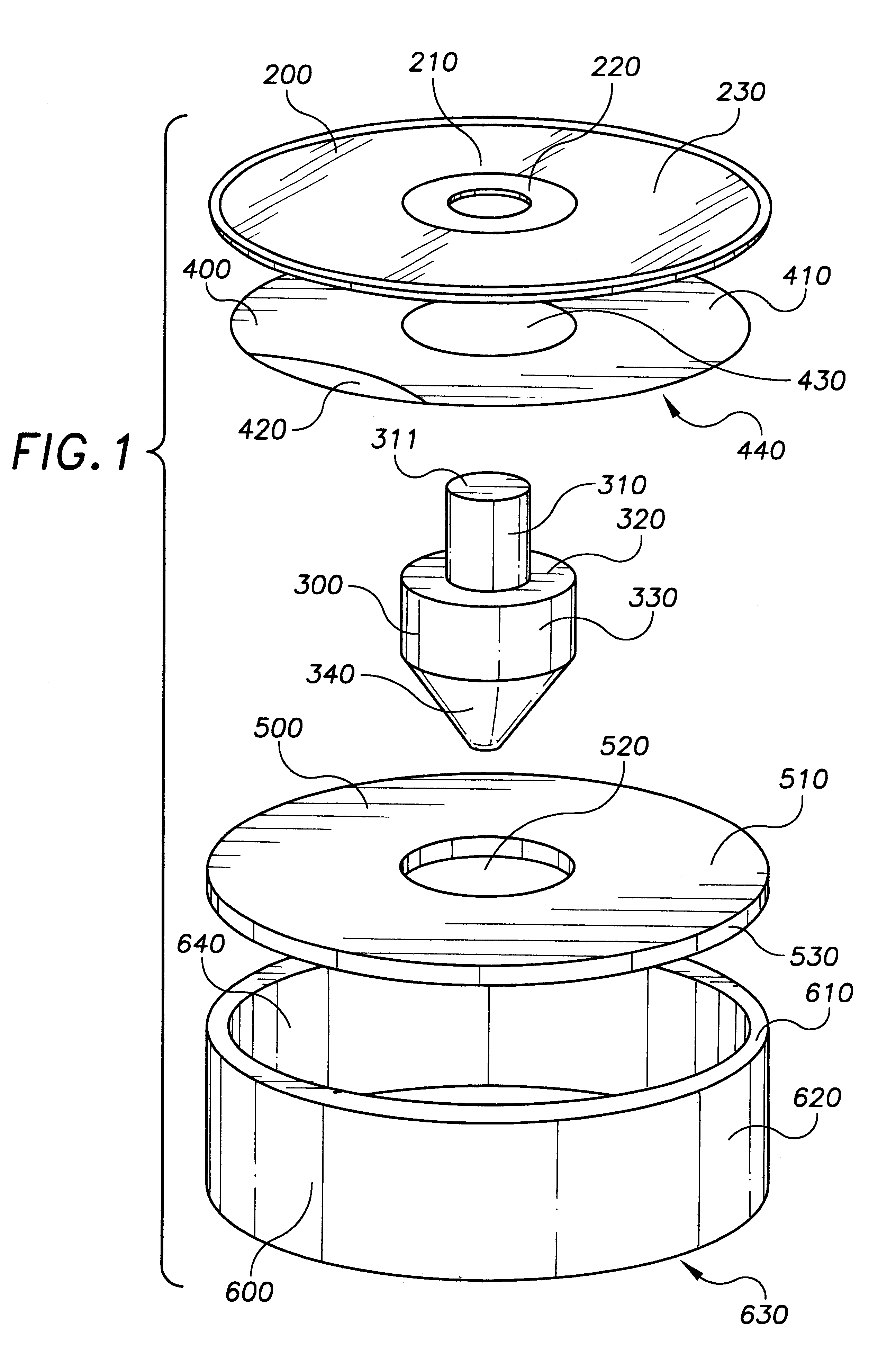

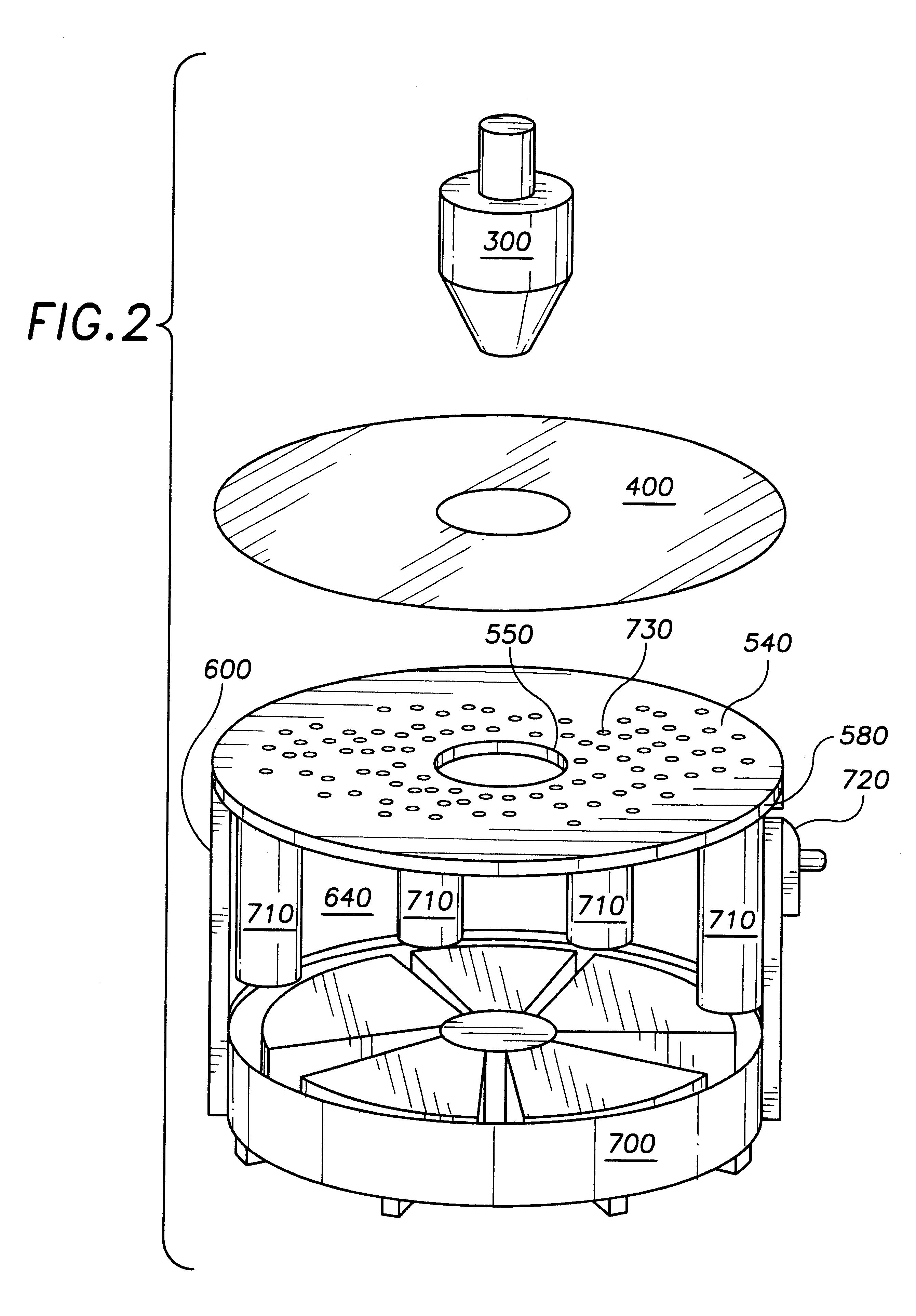

Disk labeling devices

InactiveUS6321814B1Reduce needEfficient labeling deviceStampsMechanical working/deformationEngineeringMechanical engineering

A labeler for the placement of a label, having a central aperture and a peripheral edge, onto a surface of a disk, having central hole and an outer edge, comprising a disk positioning member having points of contact with the spindle hole and / or the outer edge of the disk, for positioning the disk; a label positioning member having points of contact with the central aperture and / or peripheral edge of the label, for positioning the label; and a joining member interconnected with said disk positioning member and said label positioning member, having a first position in which the label and the disk are spaced and a second position in which the disk and the label are contacted. The label positioning member is preferably a tapered cylinder which is adapted to be inserted in the central aperture. The disk positioning member is preferably a cylindrical rod. The tapered cylinder and cylindrical rod may be an integral structure.

Owner:FELLOWES INC +1

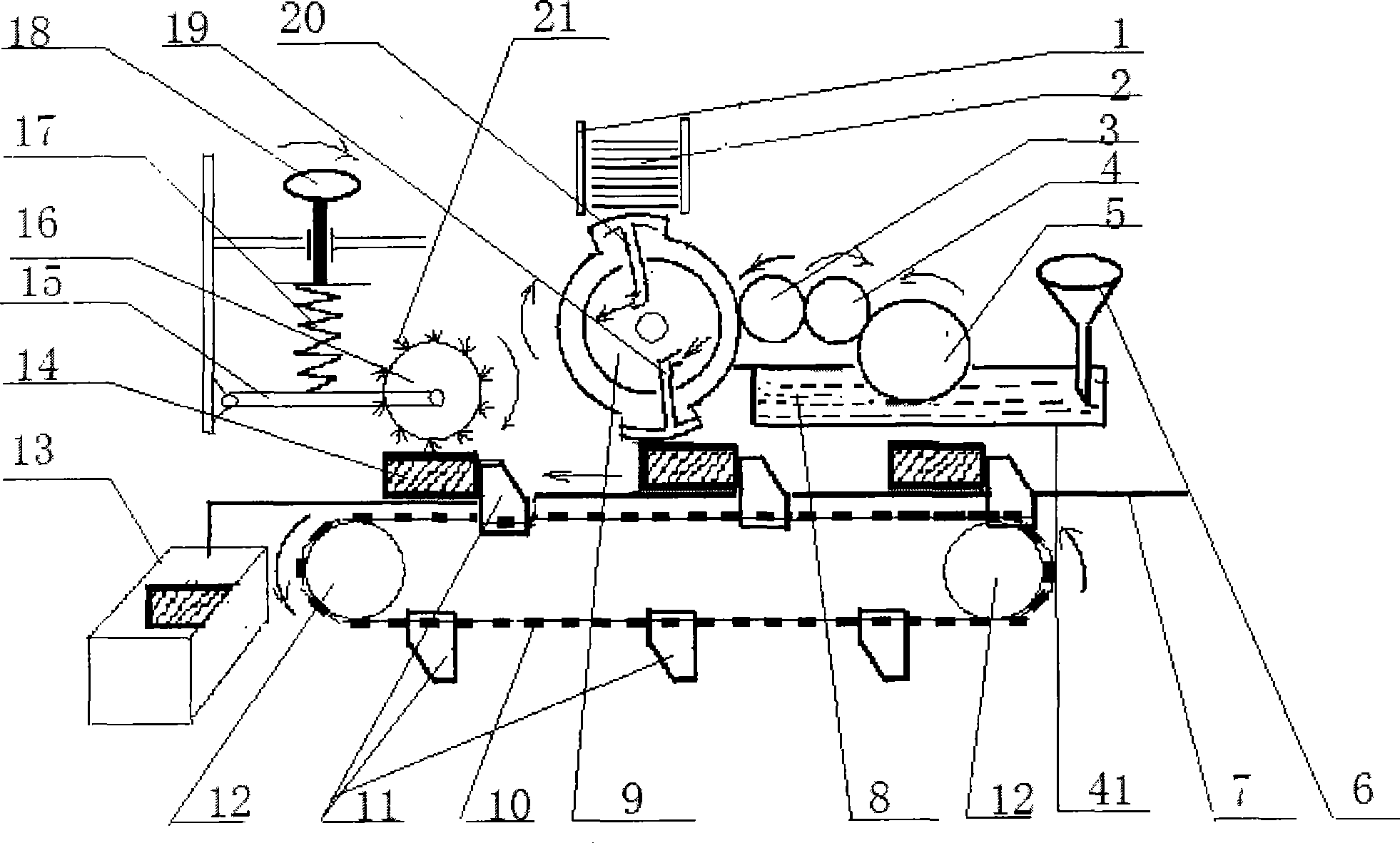

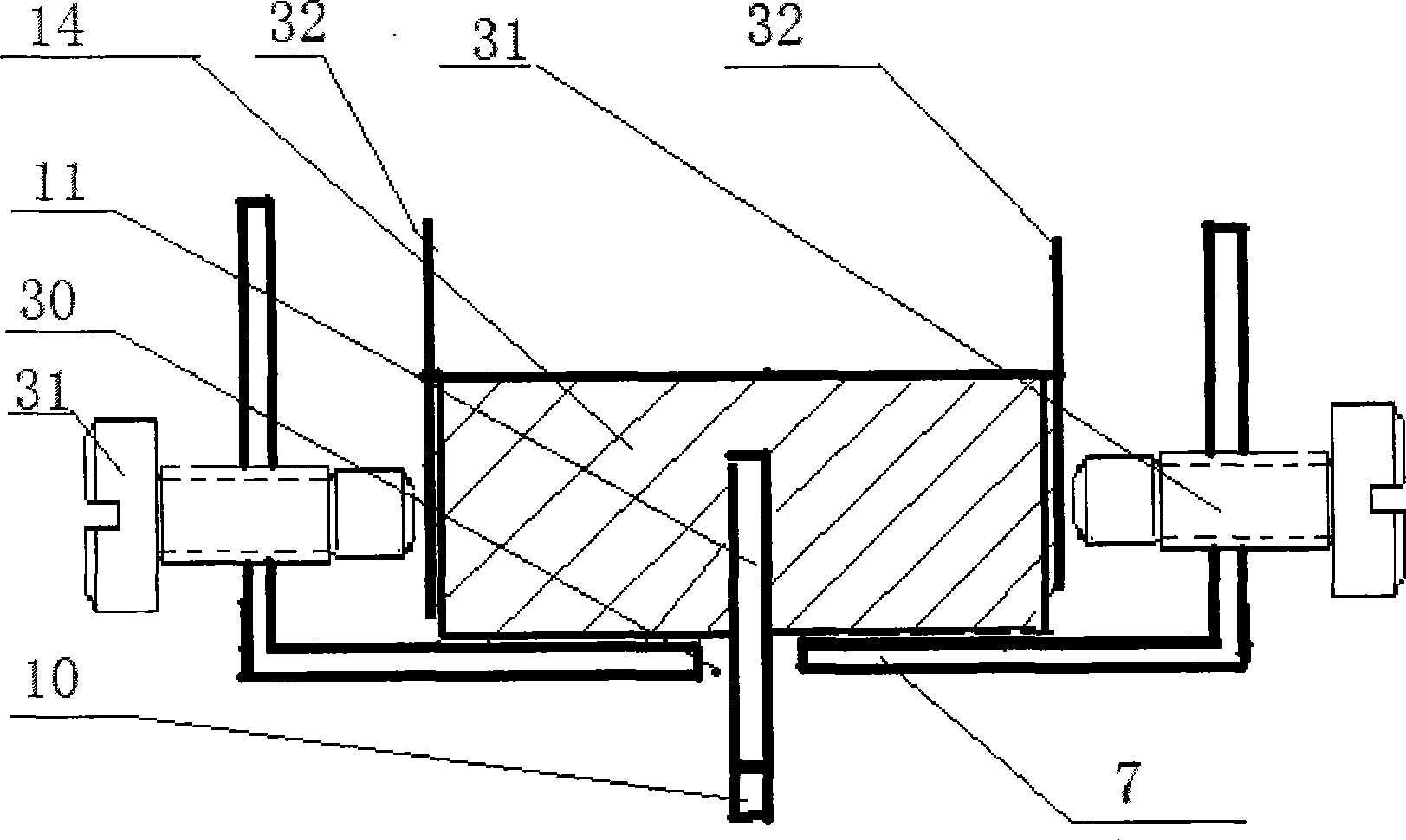

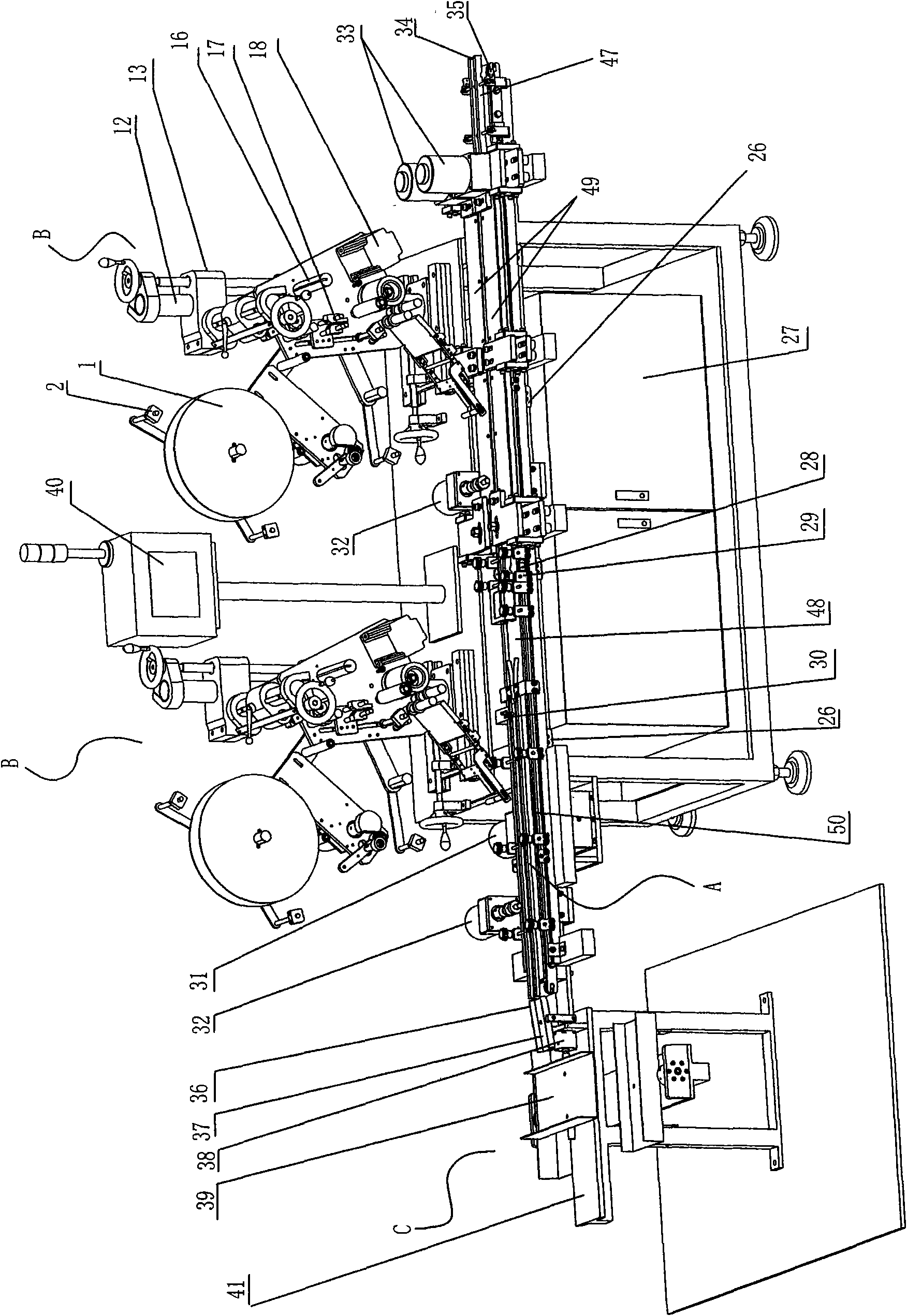

Electromechanical device for continuously, rapidly and pneumatically labelling

InactiveCN101486392AStable and reliable labelingBad labelingLabelling flat rigid surfacesLabelling machinesEngineeringAir compressor

The invention particularly relates to an electromechanical device capable of continuously, rapidly and pneumatically labelling, which consists essentially of a pneumatic suction mechanism, a pneumatic paper pasting mechanism, a glue spreading mechanism and a pressure-brushing and flat-pasting mechanism. A main rotating disc of the pneumatic suction mechanism is provided with an air suction port connected with an air compressor, an intermediate soft rubber roller is placed between a soft rubber roller coated with glue and a soft rubber roller adhered with glue, and the pressure-brushing and flat-pasting mechanism comprises a pinch roller shaft, a pinch roller, pressure-brush of kernel and a spring. A box to be printed is arranged on a middle passage of a printing box, and a toggle plate is driven by a square adjustable tooth-shaped chain. The electromechanical device is characterized by stable and reliable labeling, no malposition or bubbling of labeling, high efficiency and strong commonality; besides, the design of the pneumatic mechanisms has less pressure loss and easy overload protection, and the pneumatic mechanisms take air as medium which is easy to obtain and discharge and does not pollute the environment.

Owner:南通健美体育用品有限公司

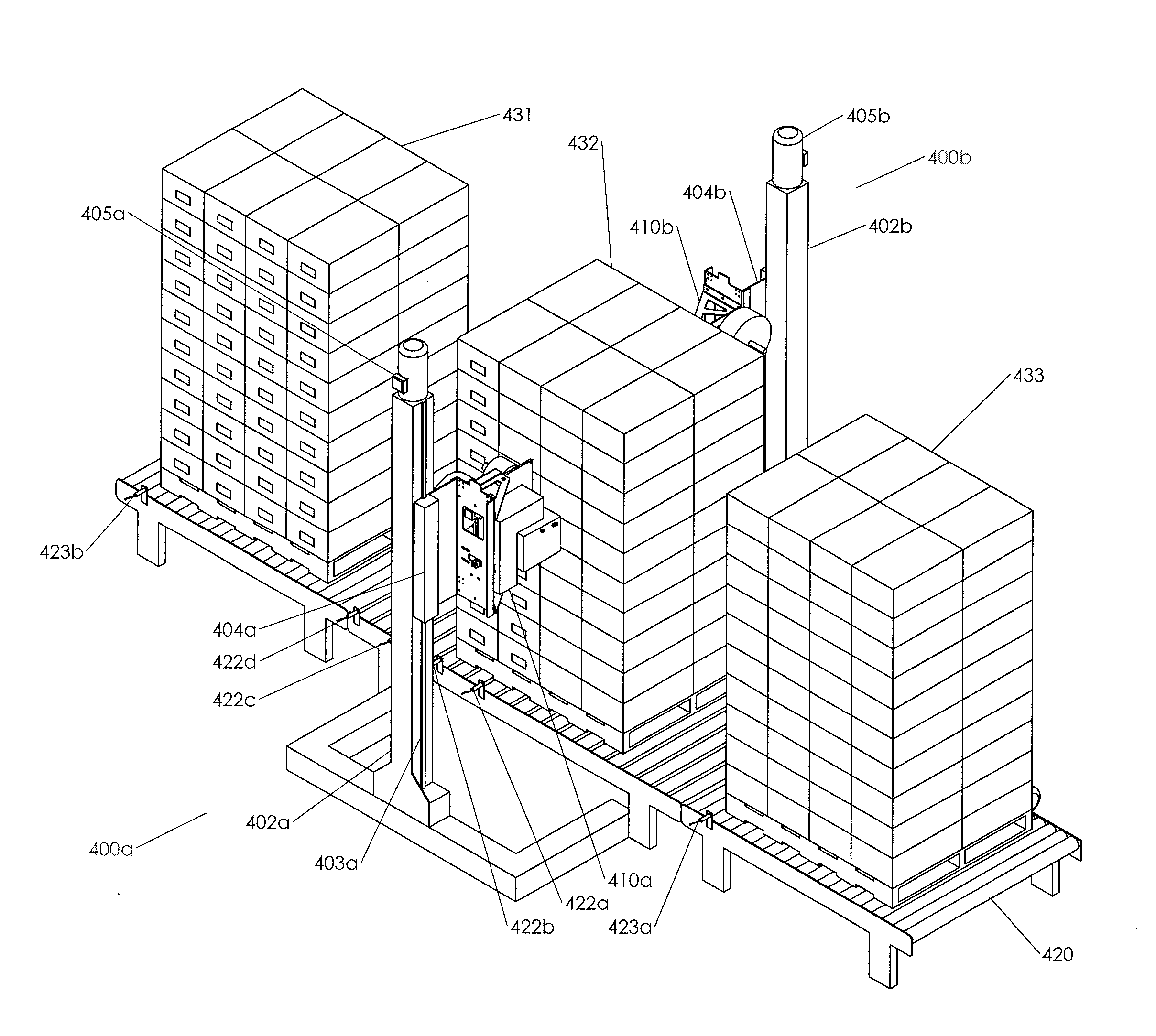

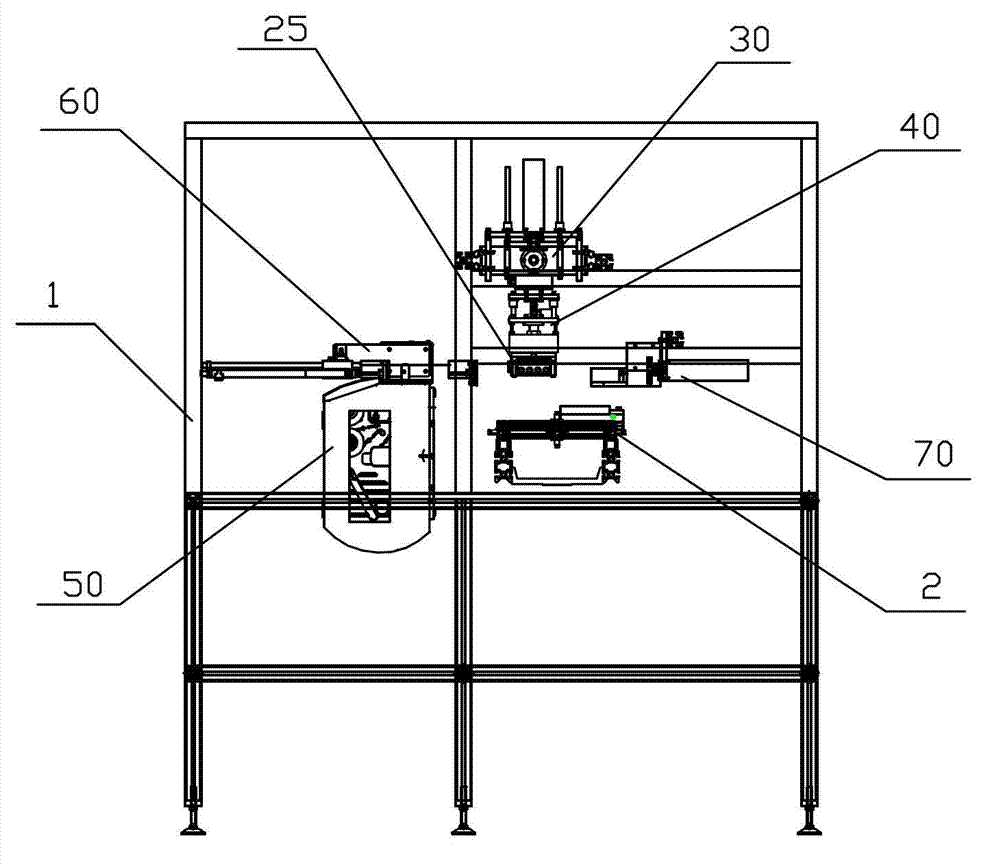

Container Labeling Systems and Methods of Use

ActiveUS20150225104A1Quickly and efficiently labeledLaborious and time-consumingMechanical working/deformationTypewritersEngineeringPallet

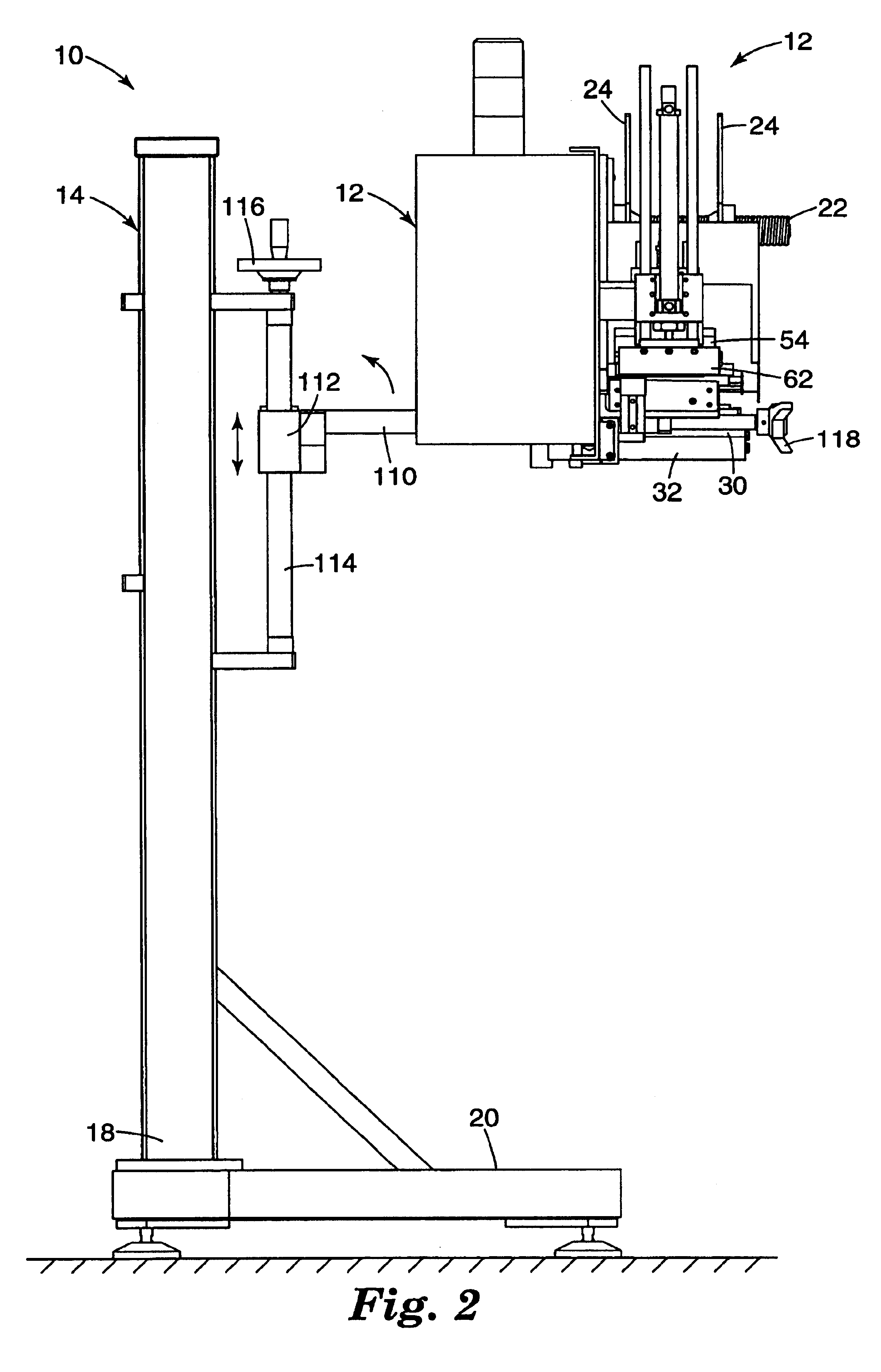

The invention relates to labeling and / or printing devices, methods and systems for applying coding and / or labeling to containers that are stacked or otherwise organized in a group (e.g., containers stacked on a pallet). In embodiments of the invention, labeling and / or printing devices are mounted on carriages that are capable of moving in a vertical direction to apply labels as they move. Horizontal movement is imparted either by moving such carriages in a horizontal direction adjacent to the containers, or by moving the containers themselves (or the pallet holding them) in a horizontal direction adjacent to such carriages. Multiple carriages with labeling devices may be provided to provide simultaneous labeling to more than one side of a group of stacked containers. Embodiments of the invention are capable of providing labeling of containers that are uniformly or non-uniformly grouped or stacked.

Owner:REED LORIN

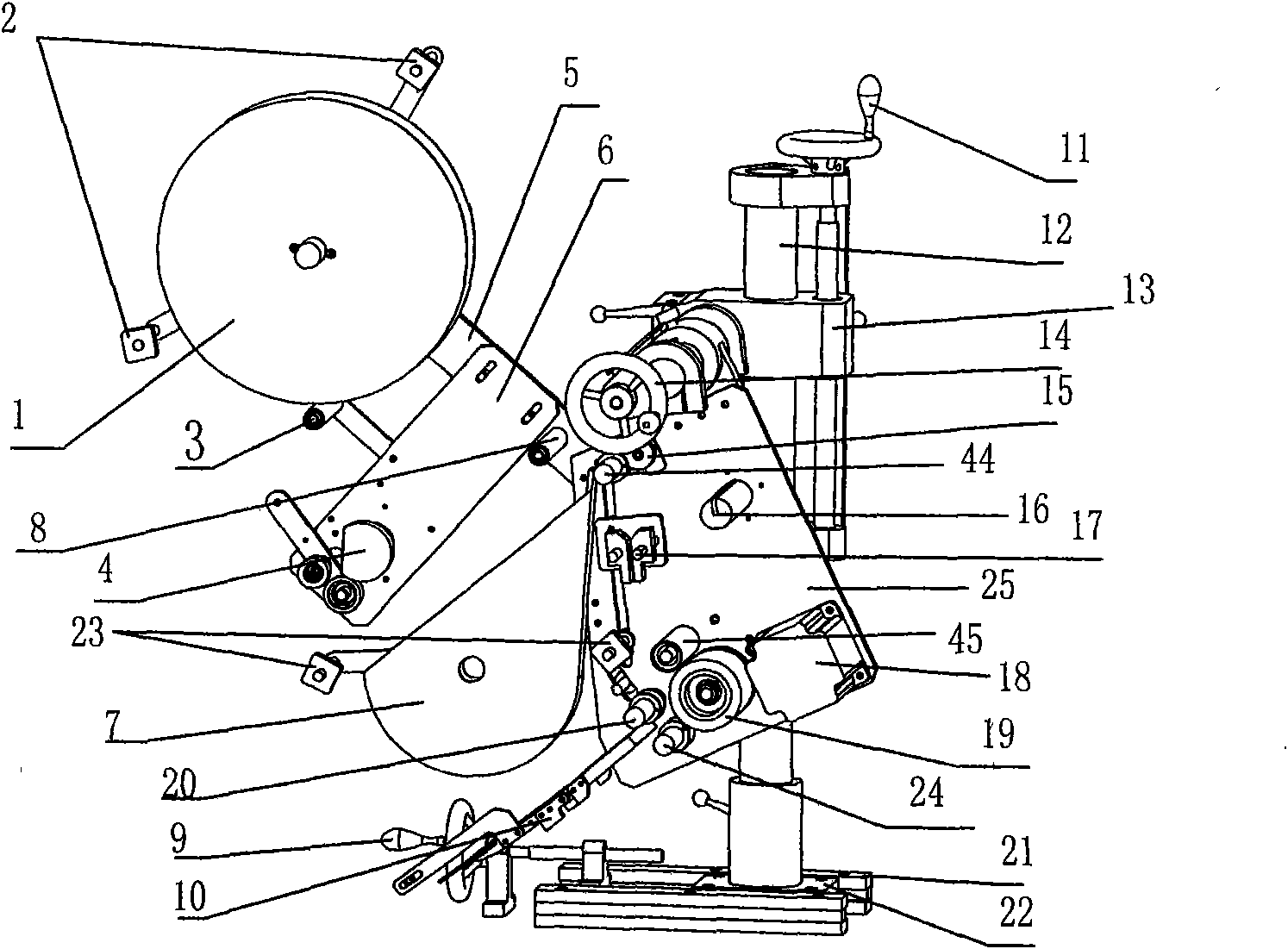

Labeler of lighter

ActiveCN101643120ARealize online monitoringGuaranteed unityLabelling flat rigid surfacesLabelling machinesCombustible gasElectric machinery

The invention relates to a labeler of a lighter. The existing labelers have no special clamps or conveying devices for clamping the shell of the lighters, and the gas storage tanks of the lighters areinternally provided with combustible gas or combustible liquid, which is dangerous. The invention comprises a labeler frame, on which a horizontally-placed conveying device and a vertically-placed labeling mechanism are arranged. The invention is characterized in that the conveying device comprises a bottom conveying component and a lateral conveying component; the bottom conveying component comprises a bottom conveying belt driven by a bottom conveying motor, and the bottom conveying belt is horizontally placed on the labeler frame; the lateral conveying component comprises lateral conveyingbelts driven by a lateral conveying motor, and the two lateral conveying belts are arranged at two sides of the bottom conveying belt to form a clamping channel; and the labeling mechanism is positioned above the clamping channel. The invention has a clamping channel for clamping the shell of the lighter, thus ensuring security during labeling process, simultaneously improving labeling efficiency, ensuring uniform labeling position and reducing production cost.

Owner:XINHAI TECH GRP CO LTD

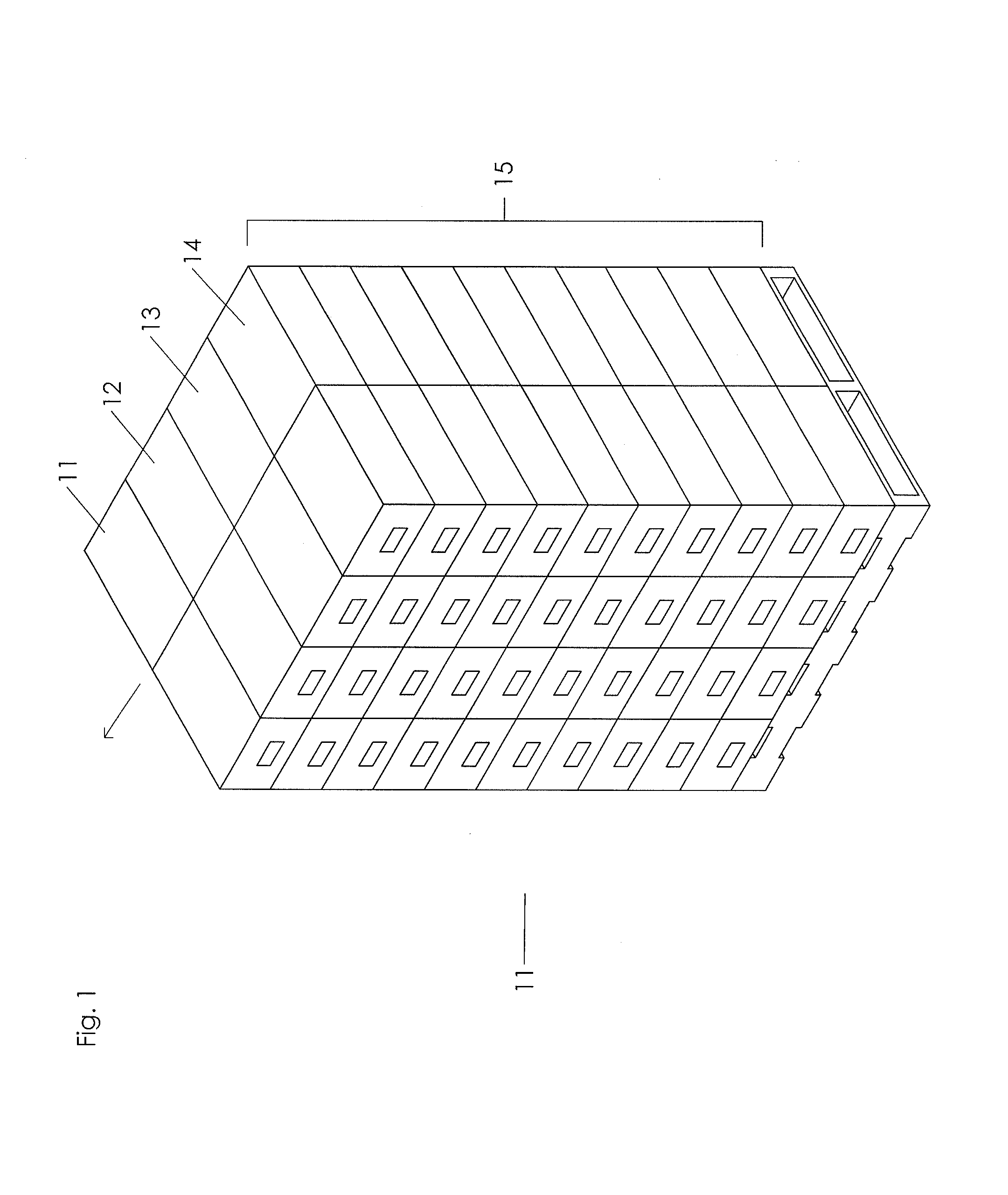

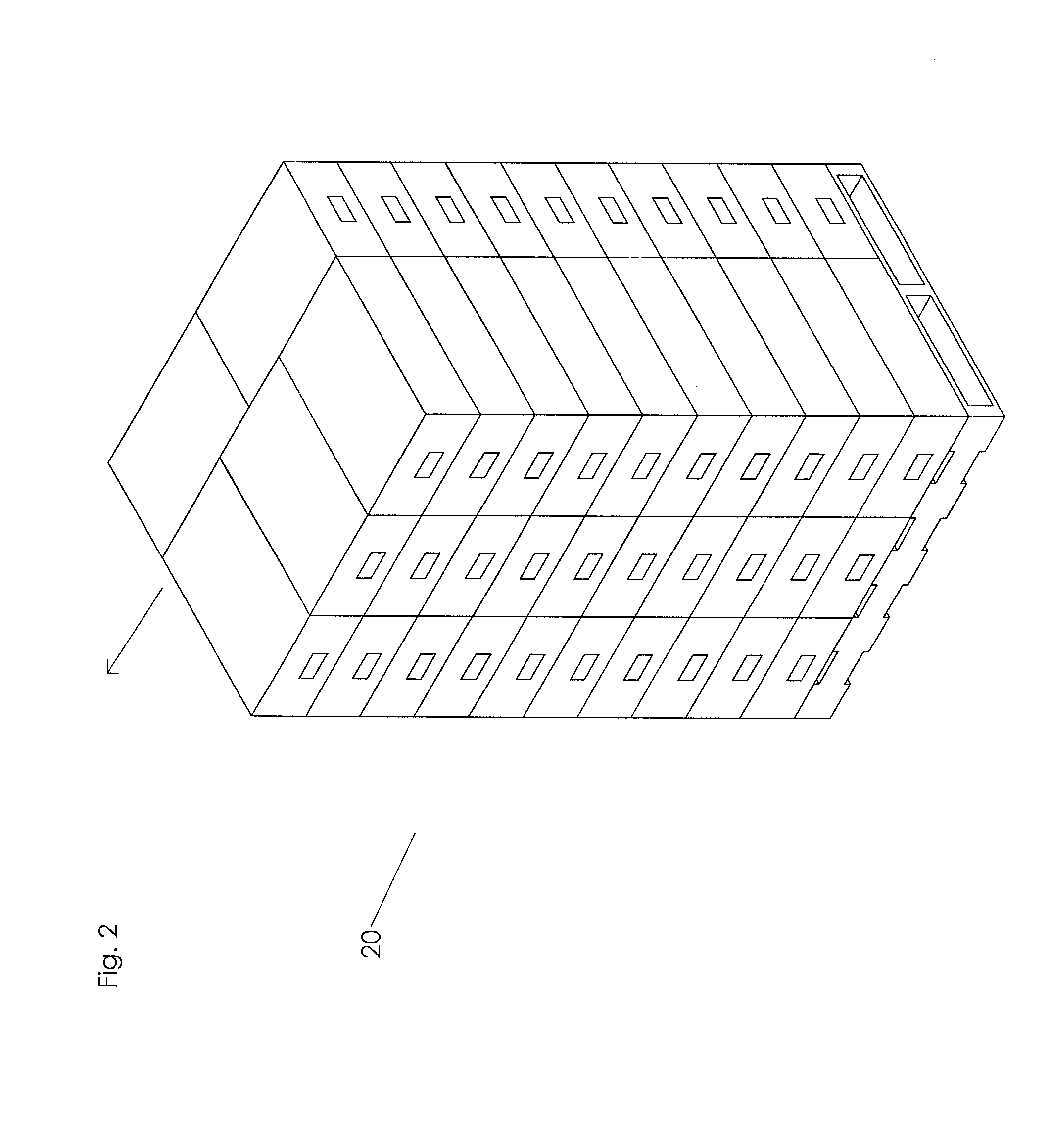

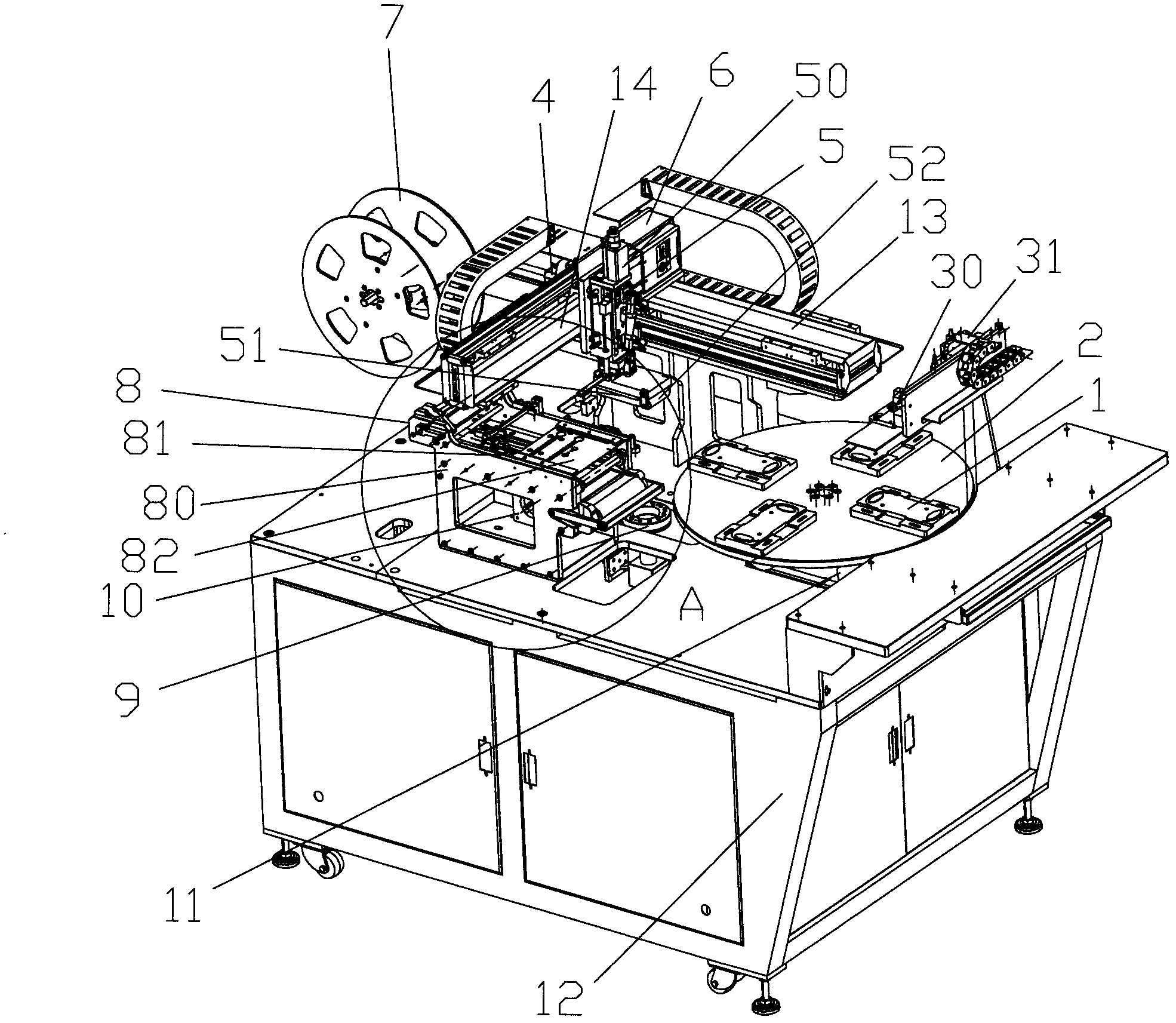

Labeling machine

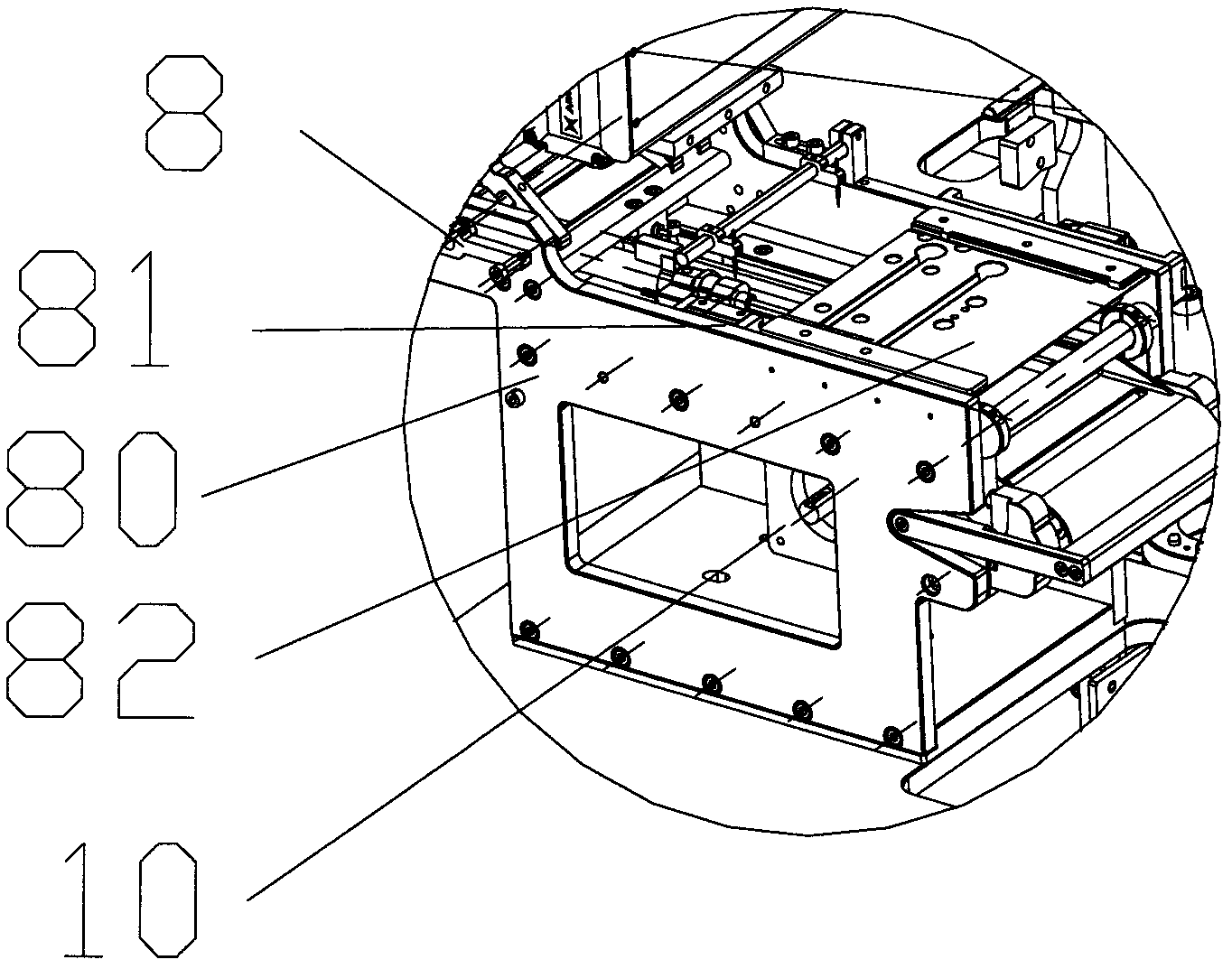

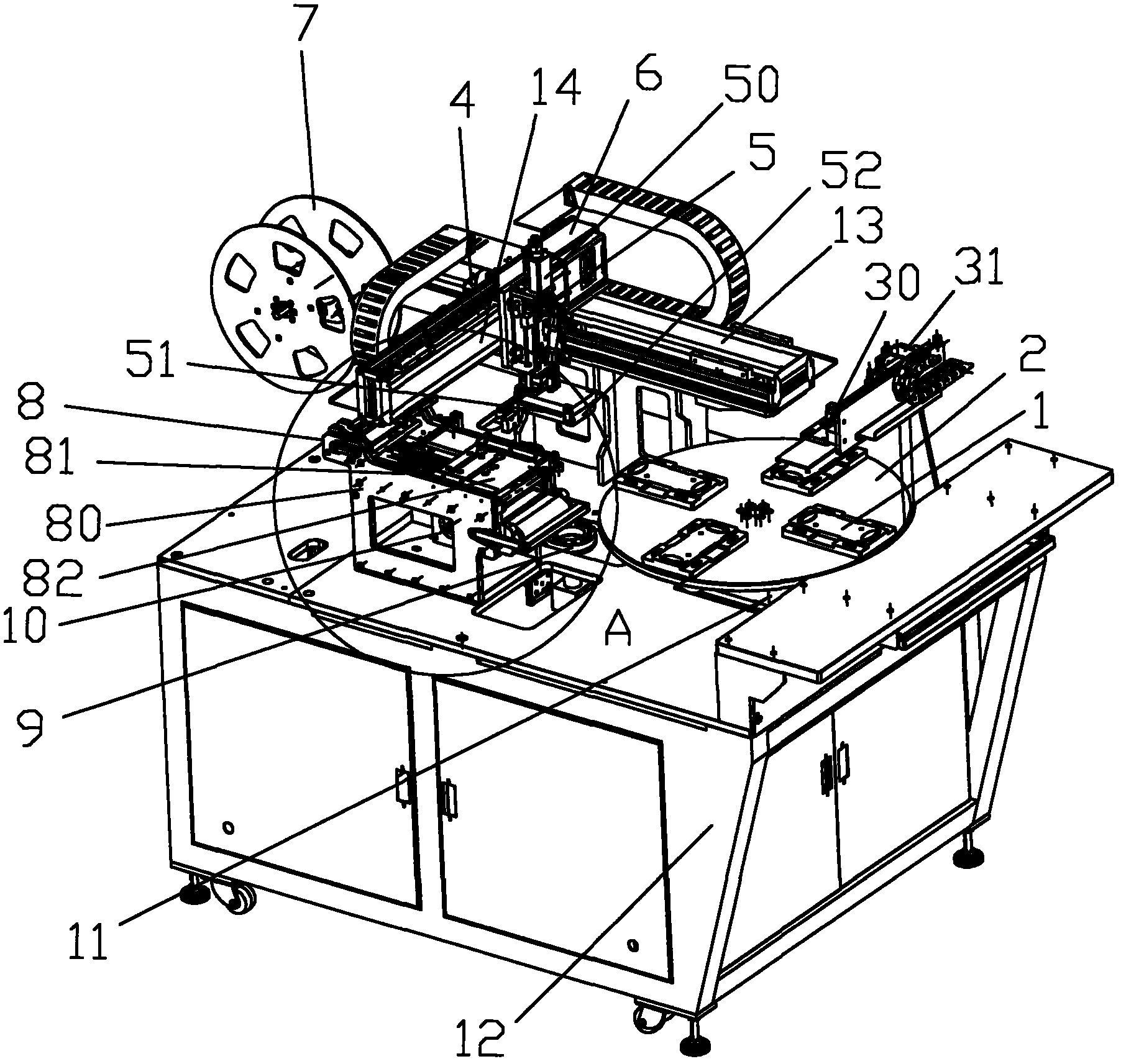

InactiveCN102530336AReduce manual interventionSave human resourcesLabelling flat rigid surfacesLabelling machinesAxis cylinderEngineering

The invention provides a labelling machine which comprises a machine frame, a rotating bedplate, a material belt wheel disc, a material conveying device. a material pressing device and a material taking device, wherein the rotating bedplate is arranged at one end of the machine frame; the material belt wheel disc is arranged at the other end of the machine frame; the material conveying device and the material pressing device are arranged between the rotating bedplate and the material belt wheel disc; the material taking device is arranged on one side of the material belt wheel disc; a positioning jig for positioning a mobile phone screen is arranged on the rotating bedplate; the material conveying device comprises a sliding platform, a motor arranged below the sliding platform, and a sensor arranged between the sliding platform and the material belt wheel disc; and the material pressing device comprises a Y-axis slide track arranged on the machine frame, an X-axis slide track arranged on the Y-axis slide track, a Y-axis cylinder used for driving the X-axis slide track, a sliding suck head arranged on the X-axis slide track, and an X-axis cylinder used for driving the sliding suck head. The manual intervention is less in the manufacturing process, the human resources are saved, the working efficiency and the rate of good products are improved greatly, and the labor cost is saved.

Owner:杨传军

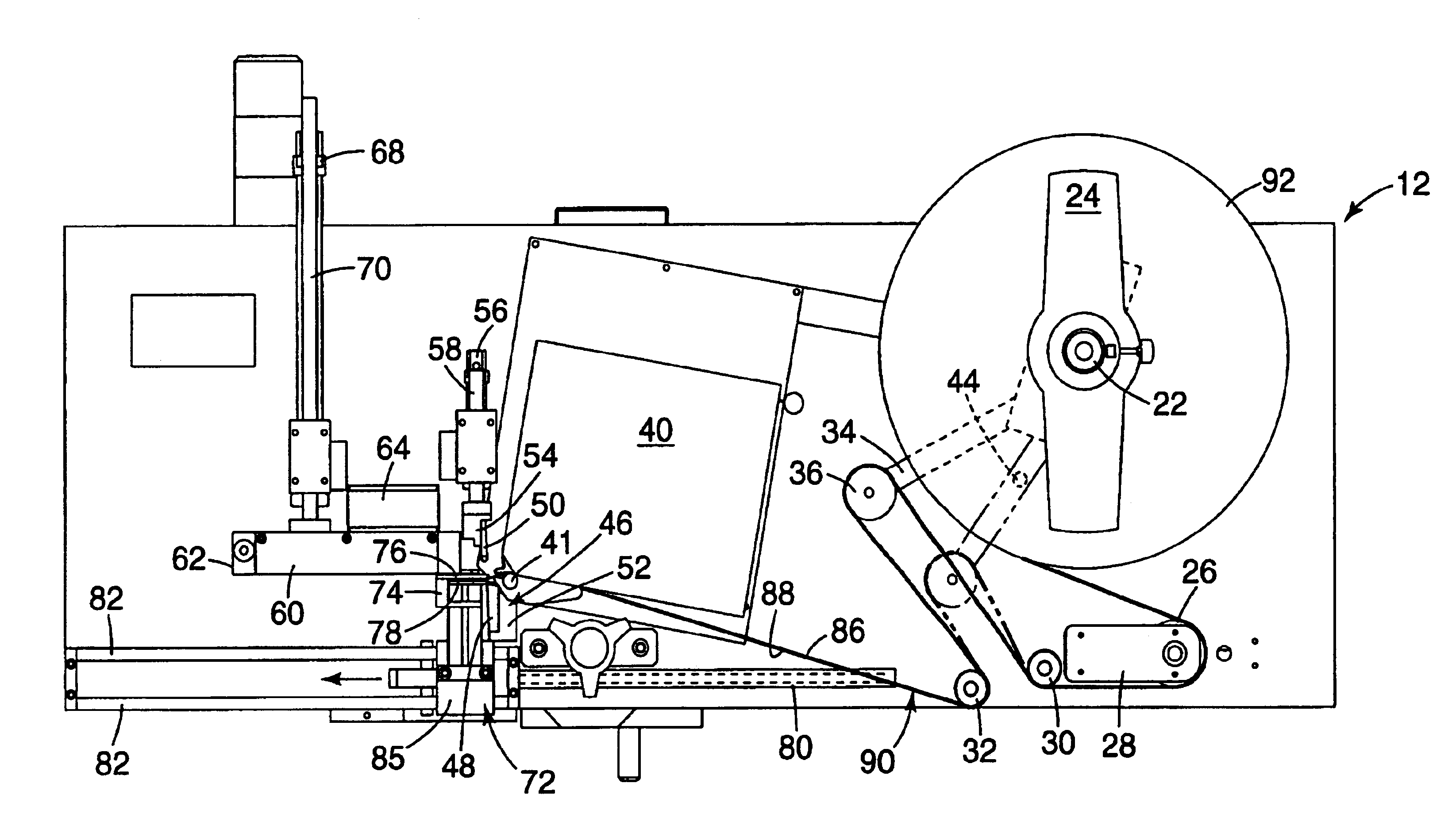

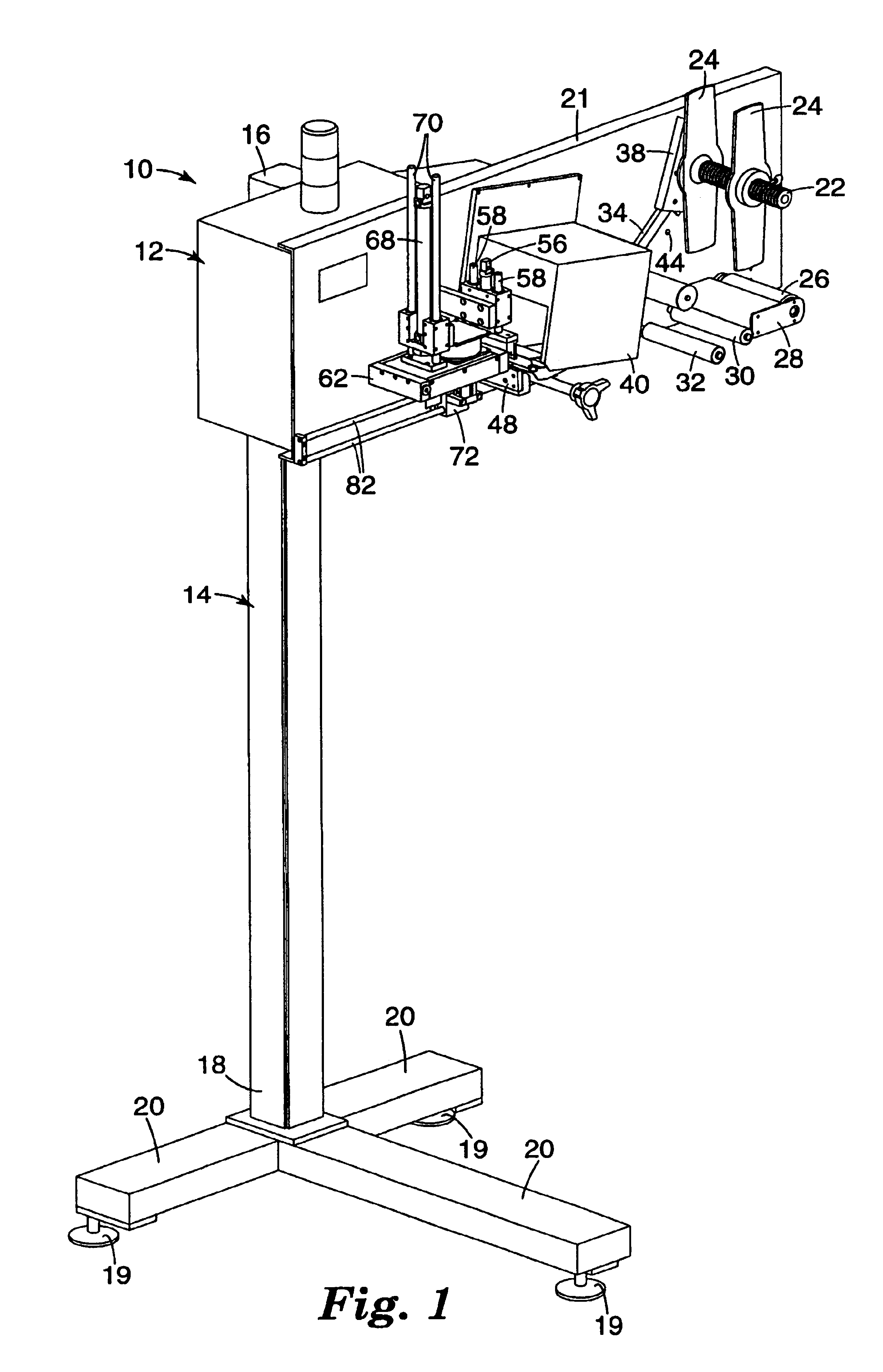

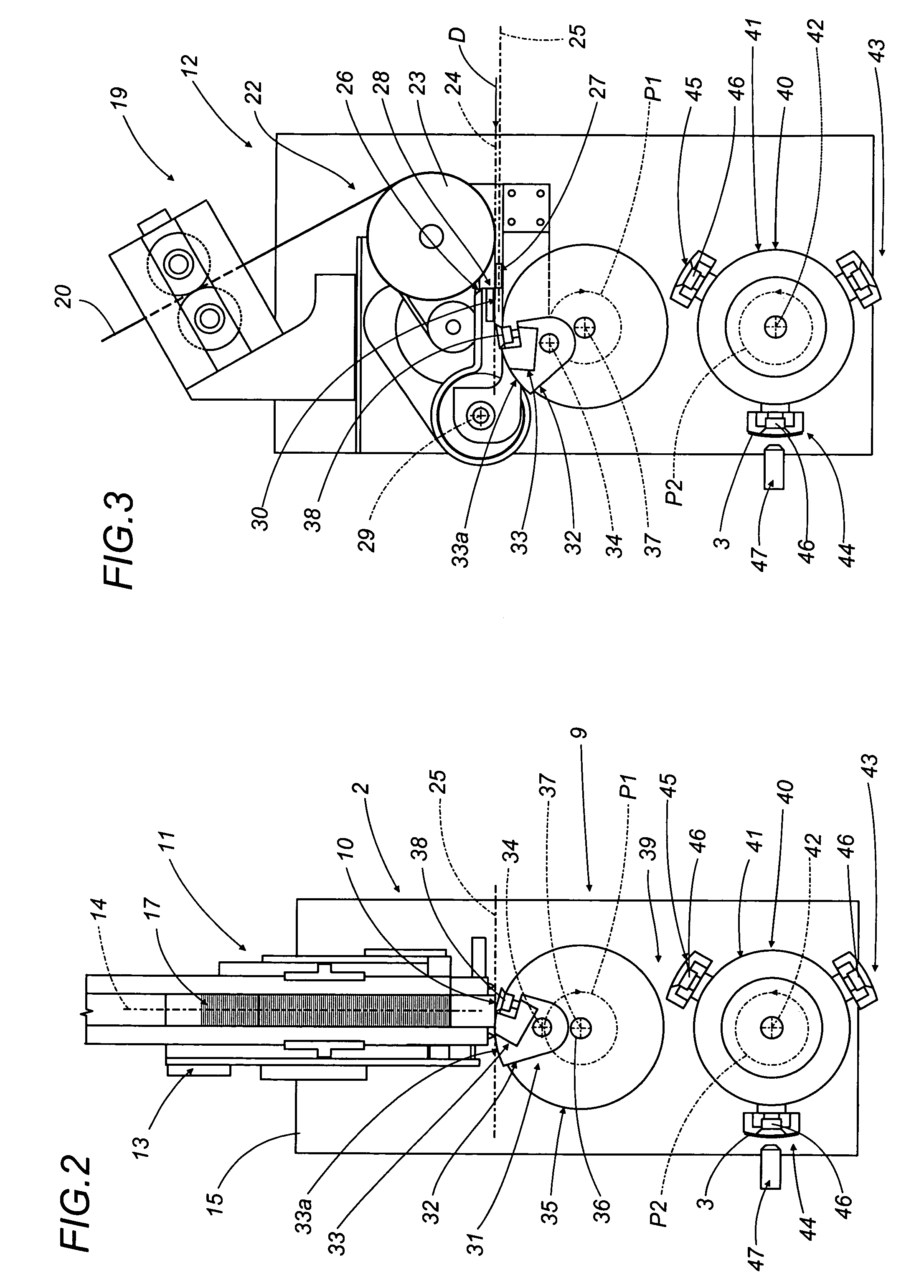

Apparatus for printing and applying tape and methods of printing and applying tape

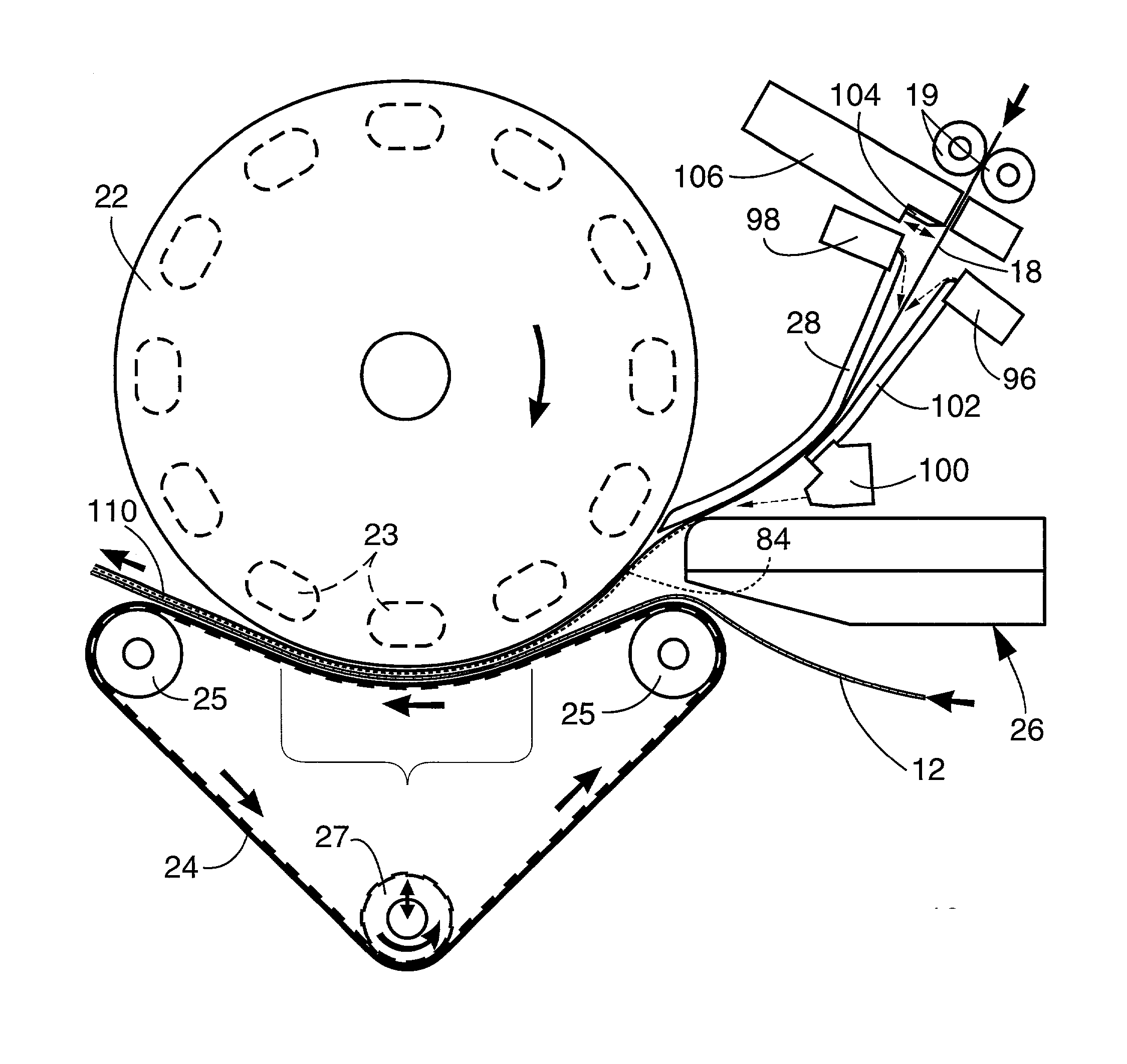

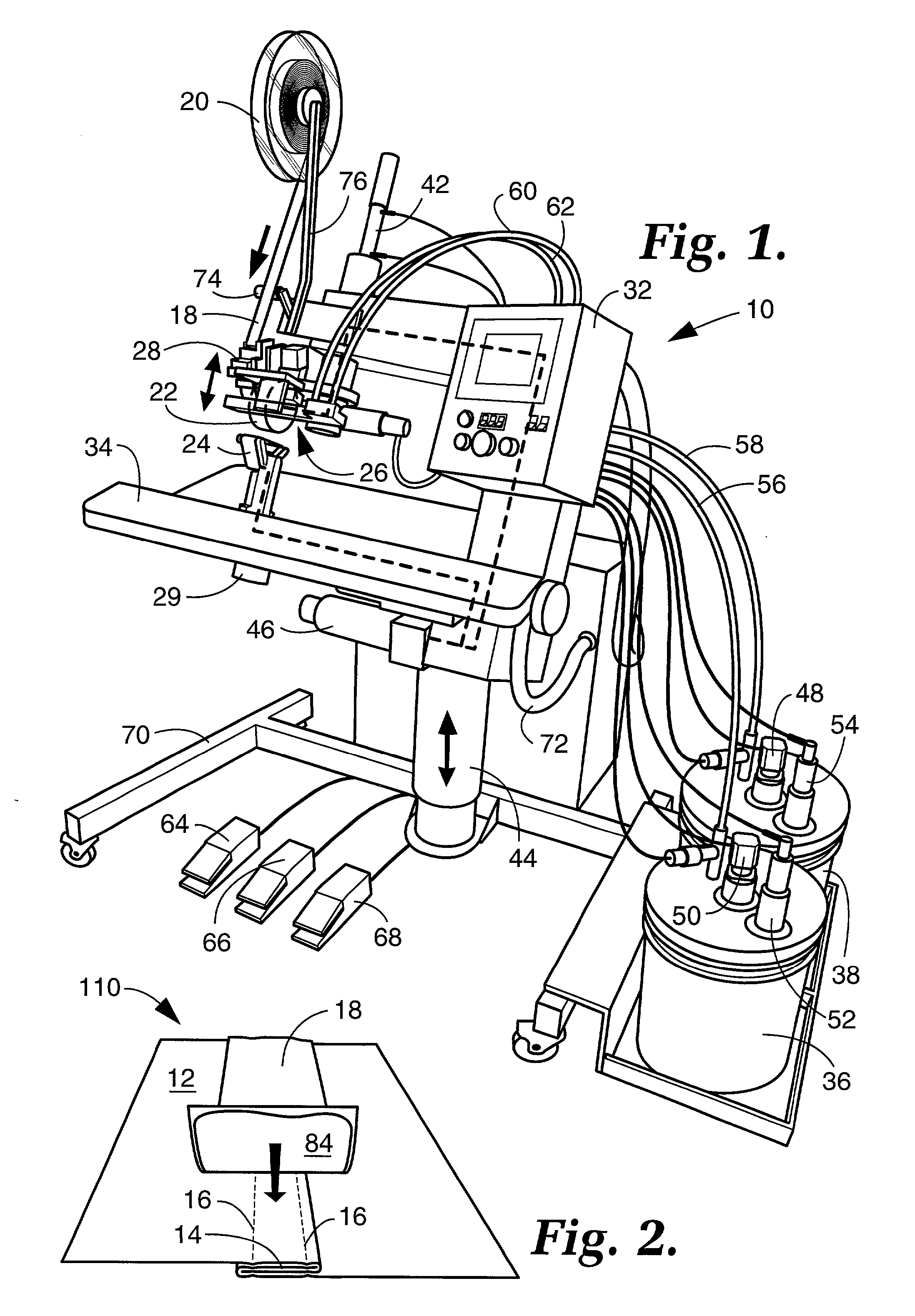

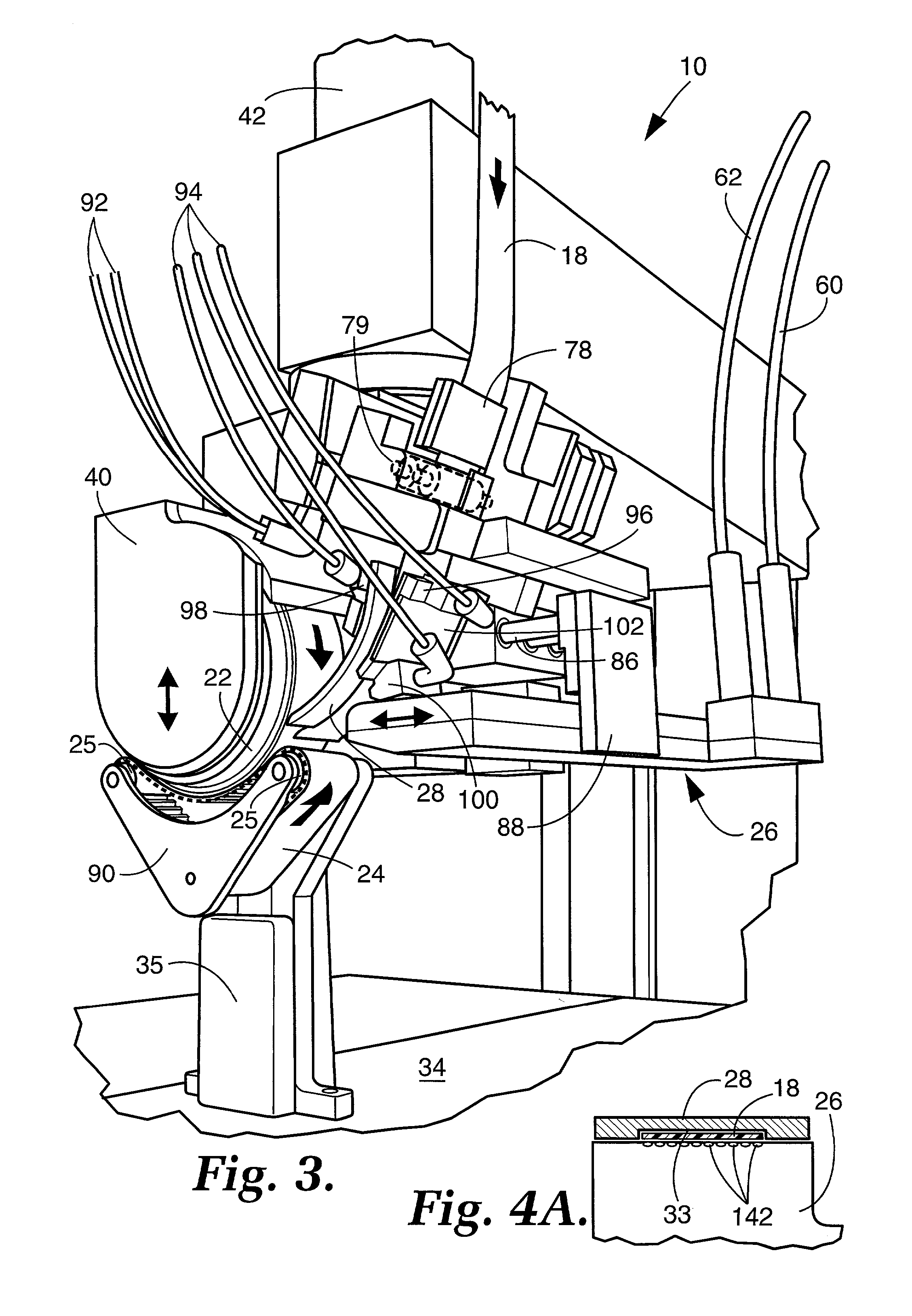

InactiveUS6884312B2Improve performanceMinimizing eliminating concernLamination ancillary operationsManual label dispensersEngineeringElectrical and Electronics engineering

An apparatus for printing and applying tape. A preferred embodiment of the invention provides an apparatus that includes a printer for printing on tape, a tape puller that pulls the printed tape out from the printer, and an applicator that applies the printed tape to an object. The present invention also generally relates to methods of printing and applying tape to objects.

Owner:3M INNOVATIVE PROPERTIES CO

Label system for reusable containers and the like

A method of labeling reusable containers is disclosed. A placard having a release coating on one side is adhesively secured to the container. The placard is transparent with instructional printing applied to one surface. Pressure-sensitive labels are placed on the exposed surface of the placard. The labels contain indicia relating to the status of the container. When the status of the container changes, the label is removed and a new label is substituted on the placard.

Owner:PETROU ROBERT J

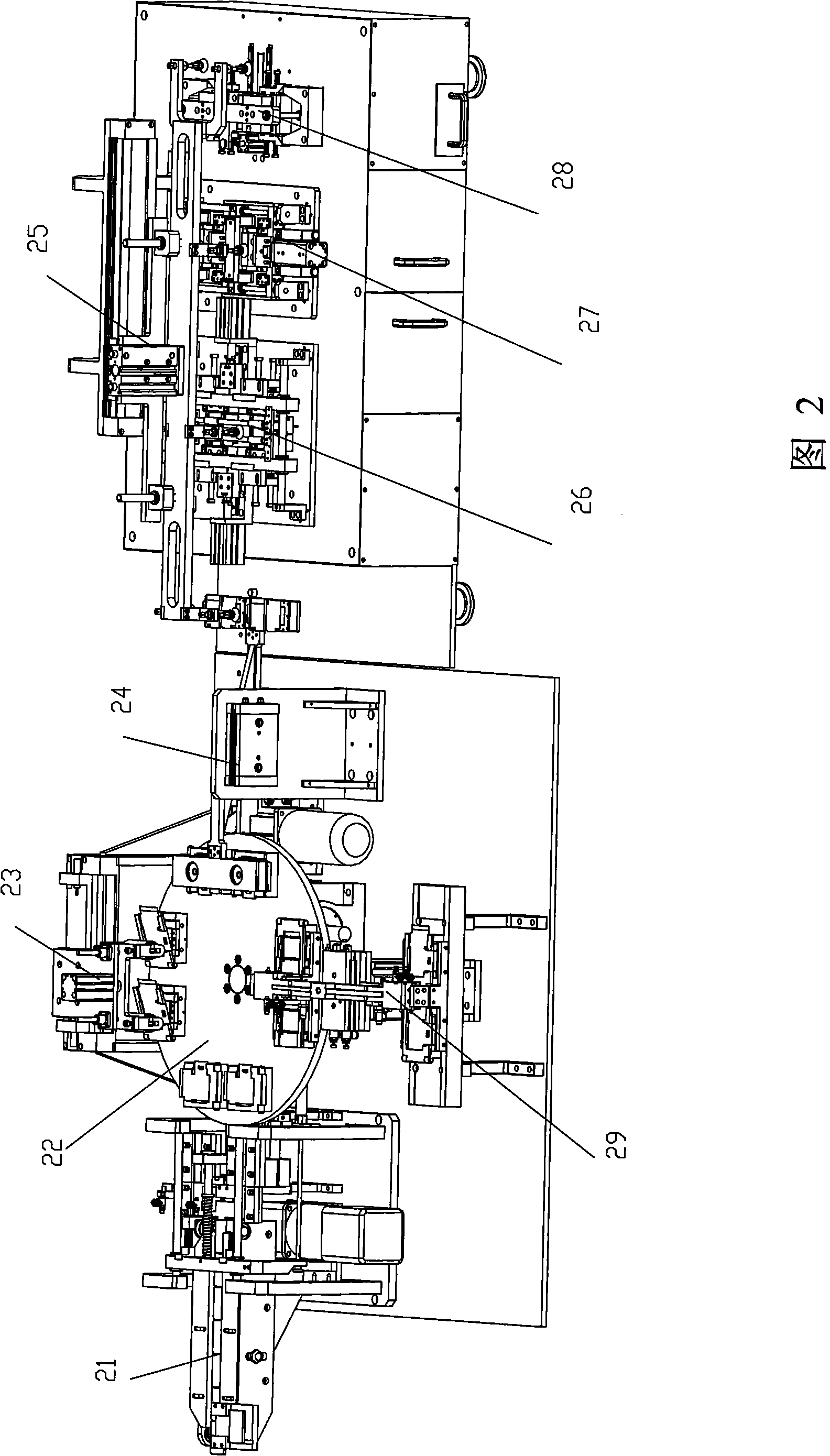

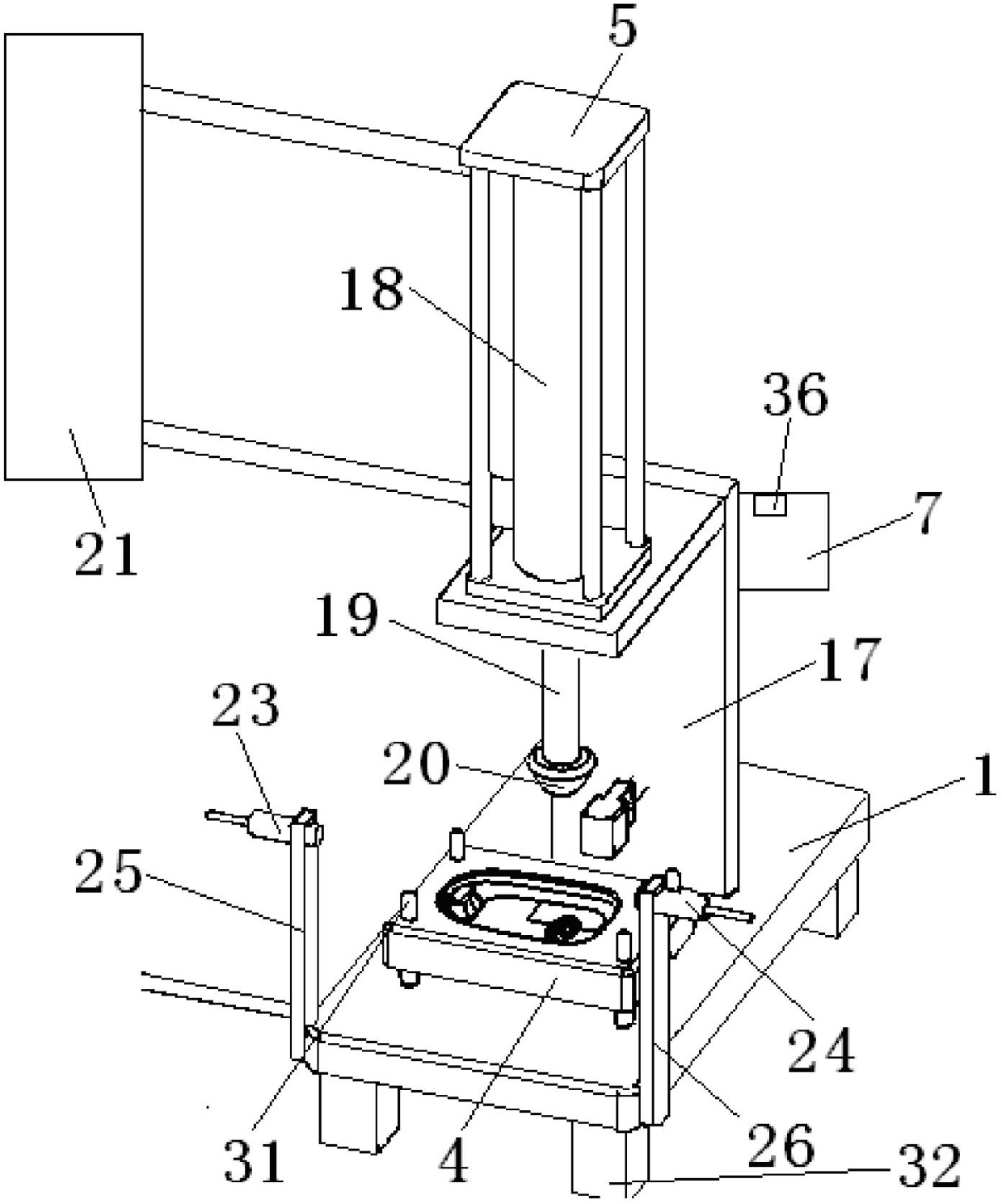

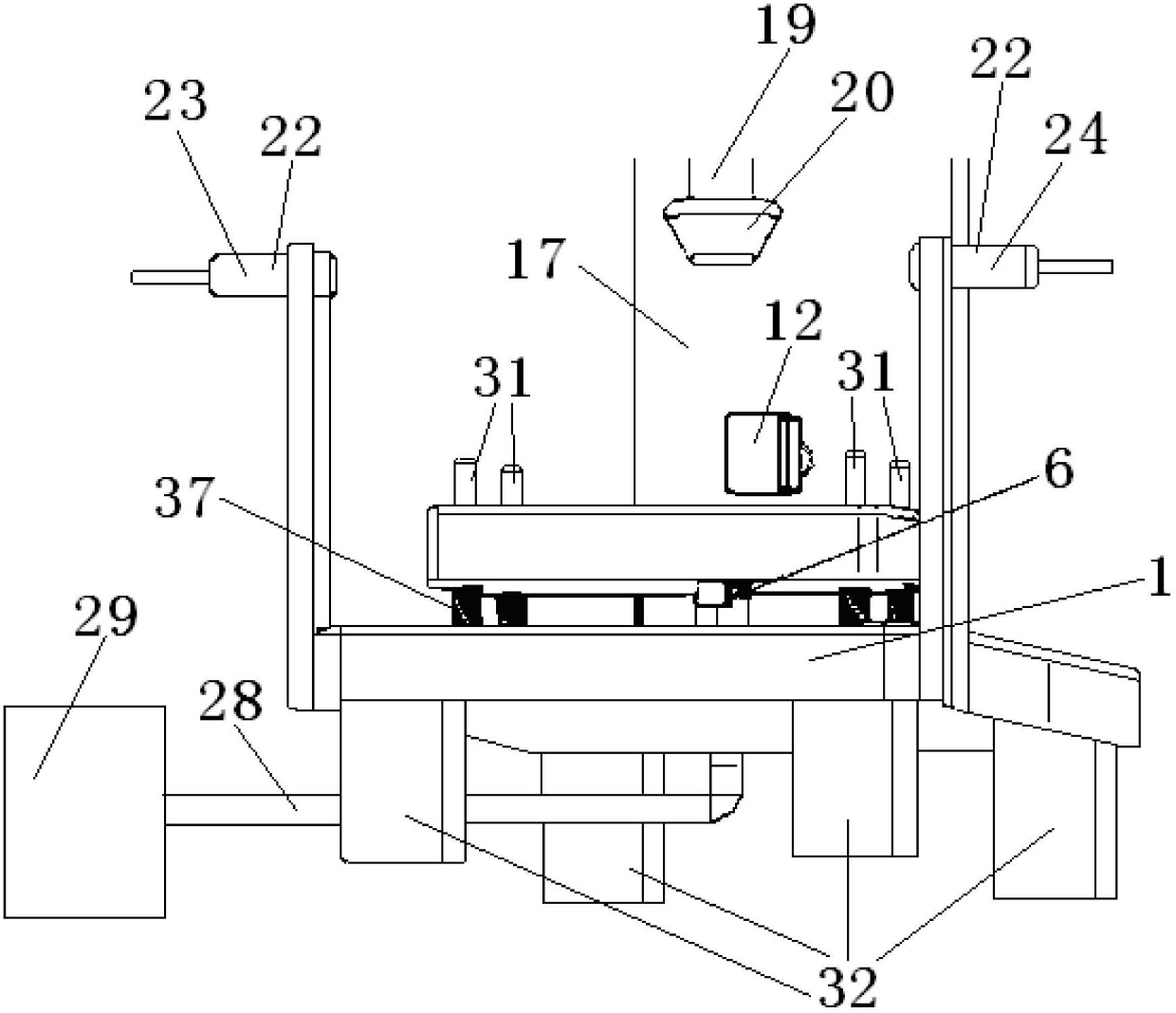

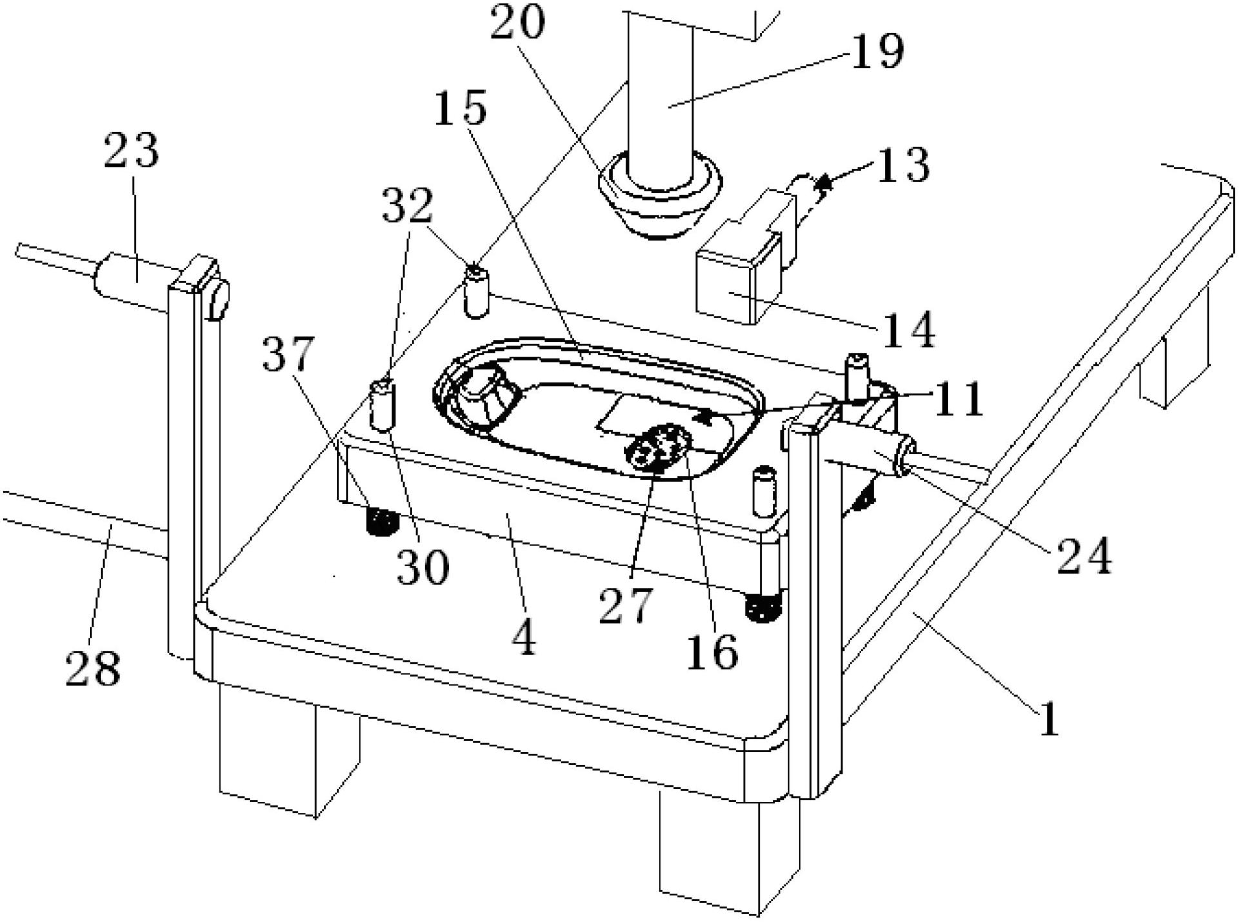

Labeling device of single-phase watt-hour meter and labeling method therefor

ActiveCN103072728AImprove quality and efficiencyIncrease productivityLabelling flat rigid surfacesLabelling machinesElectricityControl system

The invention relates to a labeling device of a single-phase watt-hour meter and a labeling method therefor. The labeling device of a single-phase watt-hour meter comprises a support, a conveying track and a control system, wherein the conveying track and the control system are connected to the support. The conveying track is provided with a photoelectric sensor and a positioning device, wherein the photoelectric sensor and the positioning device are electrically connected to the control system. The support is provided with a lifting positioning mechanism, a watt-hour meter sucker mechanism, a label printing mechanism and a labeling mechanism, wherein the lifting positioning mechanism, the watt-hour meter sucker mechanism, the label printing mechanism and the labeling mechanism are electrically connected to the control system. The watt-hour meter sucker mechanism is located below the lifting positioning mechanism and is corresponding to the positioning device. The labeling mechanism is arranged at a side of the watt-hour meter sucker mechanism. The label printing mechanism is arranged below the labeling mechanism. The labeling method comprises the following steps that the lifting positioning mechanism enables the watt-hour meter sucker mechanism to fall; a watt-hour meter from the conveying track is sucked by the watt-hour meter sucker mechanism; the watt-hour meter sucker mechanism with the watt-hour meter is lifted and rotated; and a label printed by the label printing mechanism is sucked by the labeling mechanism and then is pasted on a side of the watt-hour meter. The labeling device and the labeling method provided by the invention realize automatic labeling, save time and labor force, realize accurate labeling positioning and improve watt-hour meter quality and production efficiency.

Owner:HANGZHOU DECHUANG ELECTRONICS

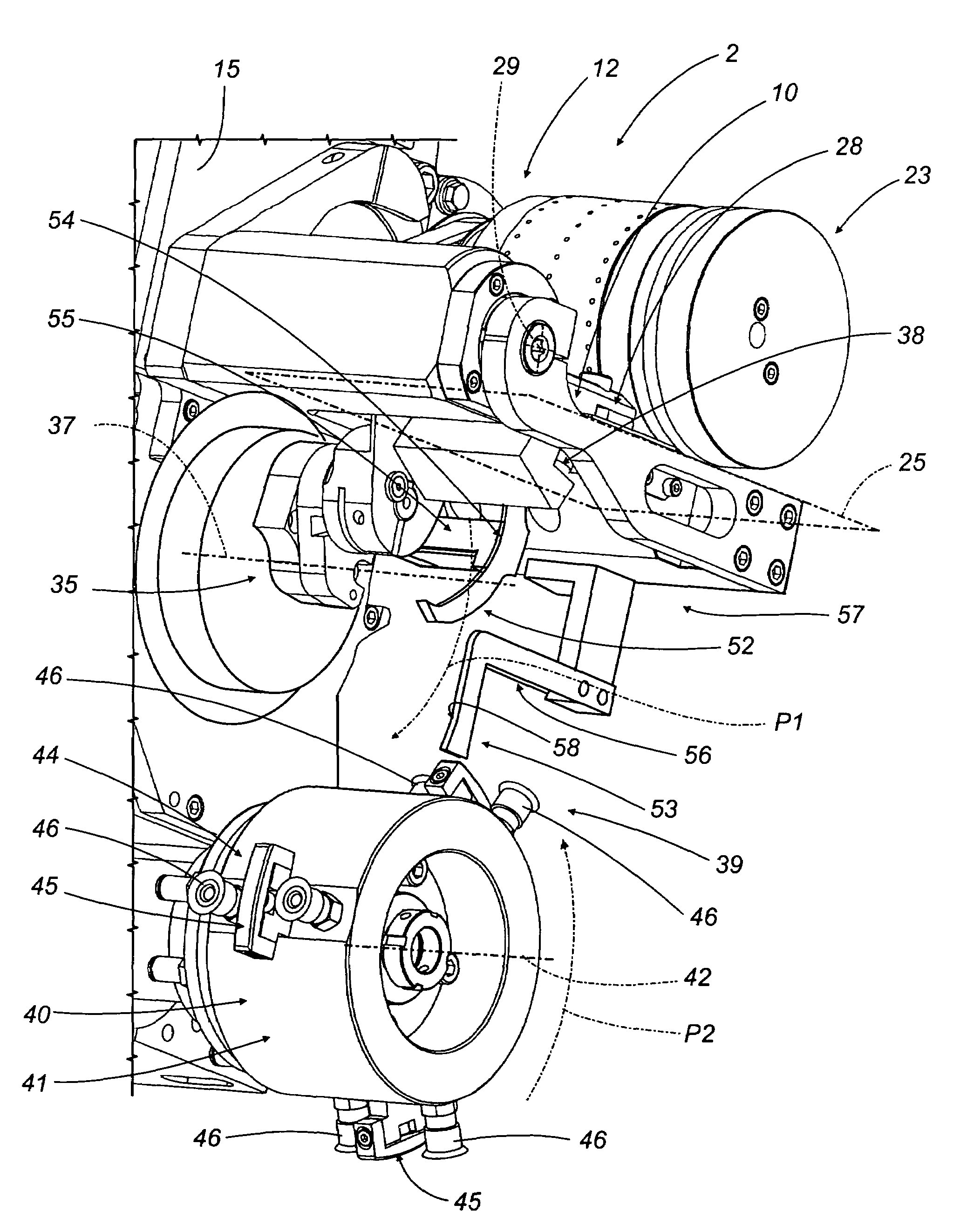

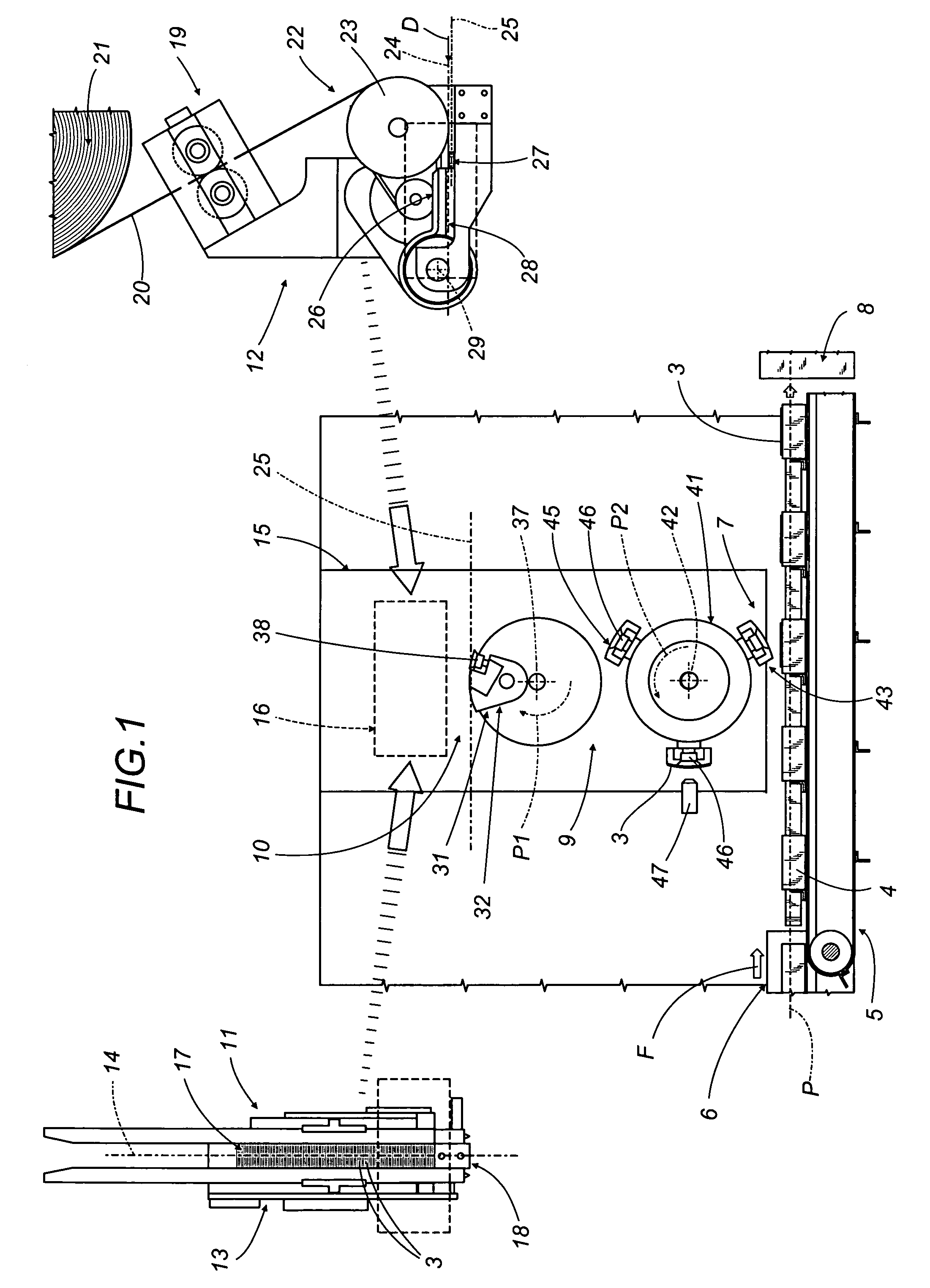

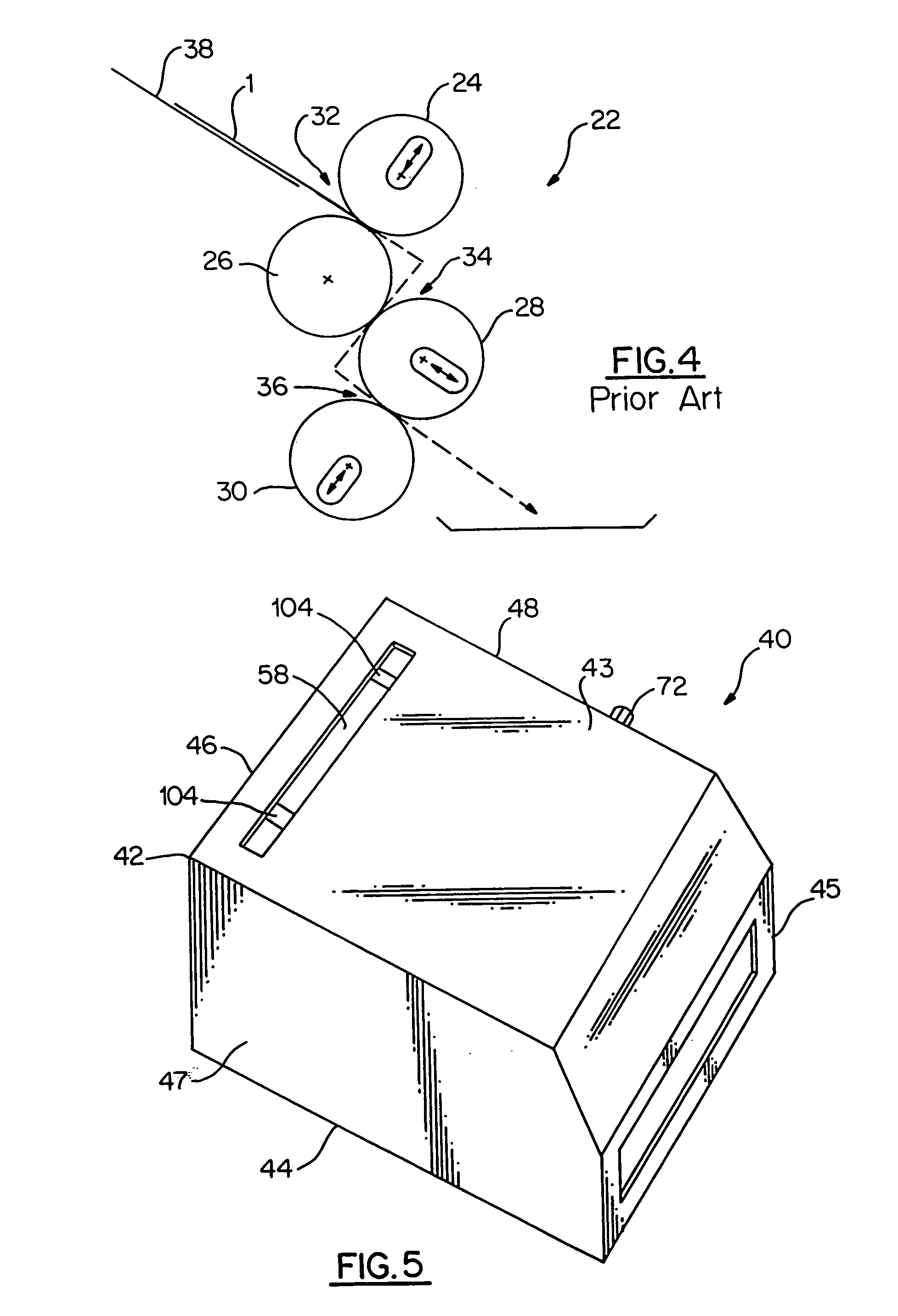

Unit for applying printed slips to packets in packaging machines

InactiveUS7252131B2Mechanical working/deformationLaminationSingle itemElectrical and Electronics engineering

Printed slips are applied to packets in a cigarette packer by a unit comprising a first device designed to feed slips procured as single items and ordered in a stack, or a second device designed to feed slips obtainable as cuts generated from a continuous strip; the two feed devices are conceived as mutually interchangeable accessory components that can be mounted in identical manner to a universal pickup and application device that is installed permanently in the machine and able to take up the slips with equal facility from either the first or the second feed device at a pickup station.

Owner:GD SPA

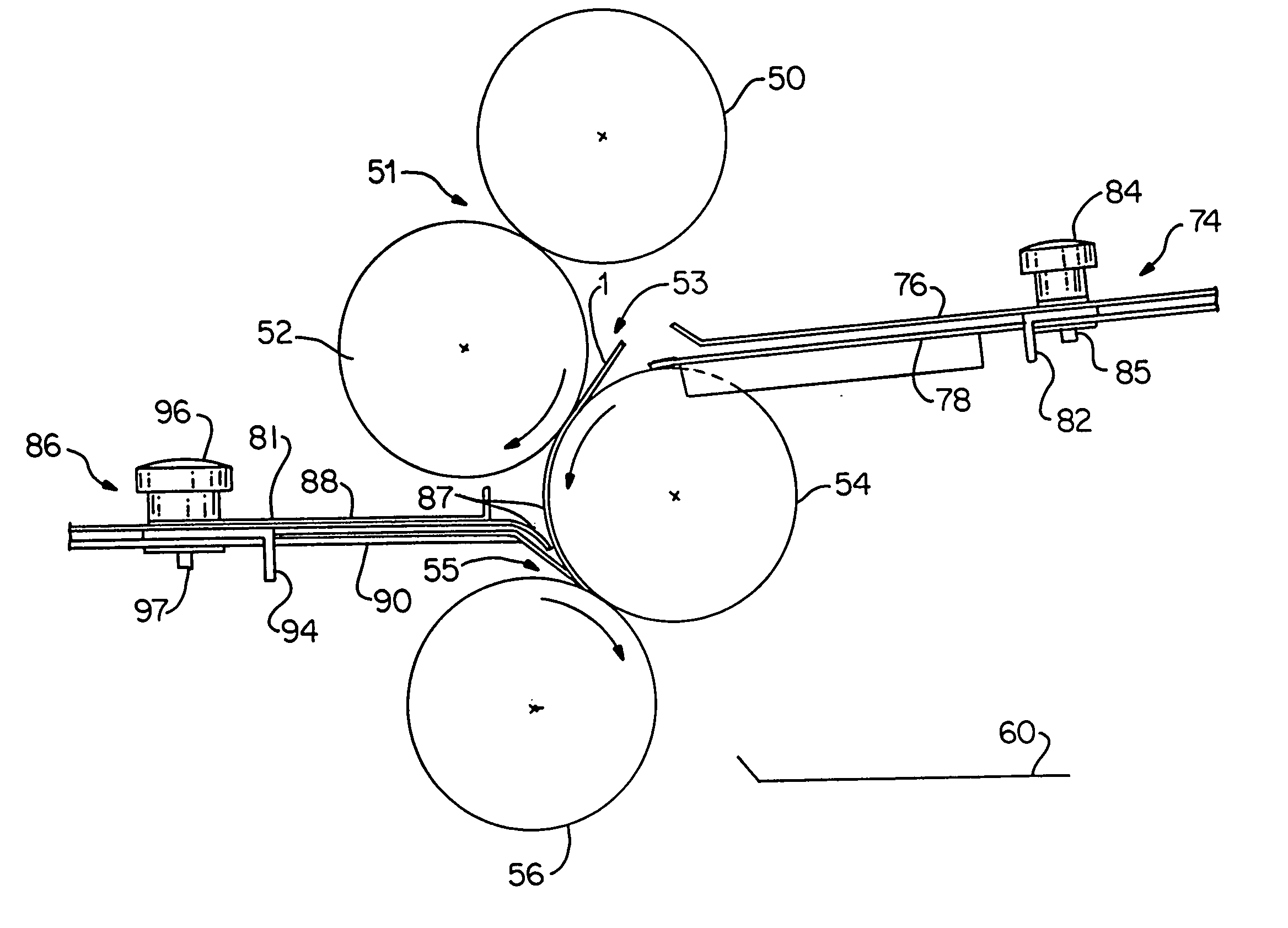

Automated fold and seal apparatus

InactiveUS20050092440A1Improve sealingSufficient sealing pressureMechanical working/deformationShaft and bearingsMotor driveFolded form

A folding and sealing apparatus supporting a feed platform for feeding a supply of pre-glued forms to the folding and sealing apparatus. The housing accommodating a first roller, a second roller, a third roller and a fourth roller, and the first and second rollers forming a first nip, the second and third roller forming a second nip and the third and fourth roller forming a third nip. A motor drives at least one of the rollers via a drive mechanism. At least one of the rollers having a resilient portion to accommodate an object mounted on a form, passing through the nips while maintaining appropriate folding and sealing pressure on the supporting form to provide a sufficient sealing pressure to the folded form, as the folded form passes through the nips to facilitate both folding and sealing of the folded form. A cleaning arm is provided adjacent one of the rollers to remove debris therefrom, and a collection bin is provided adjacent the third nip for collecting the folded and sealed forms upon exiting from the folding and sealing apparatus.

Owner:LINDSAY WAYNE R +1

Labeling machine

InactiveUS6634400B2Avoids incessant go-and-return tripSimple designMechanical working/deformationManual label dispensersEngineeringLabelling machine

The invention provides a labeling machine comprising a structure, a labeling head capable of pivoting relative to the structure about a pivot axis, the labeling head being fitted with gripper means for gripping a label holding it in a plane that is substantially normal to the pivot axis of the labeling head, and placing means carried by the labeling head and adapted to take the label held by the gripper means and place it on an article to be labeled that is present on the labeling machine. According to the invention, the gripper means hold a label in such a manner that a corner thereof coincides substantially with the point of intersection of the pivot axis and the plane of the label.

Owner:NS TESTUT

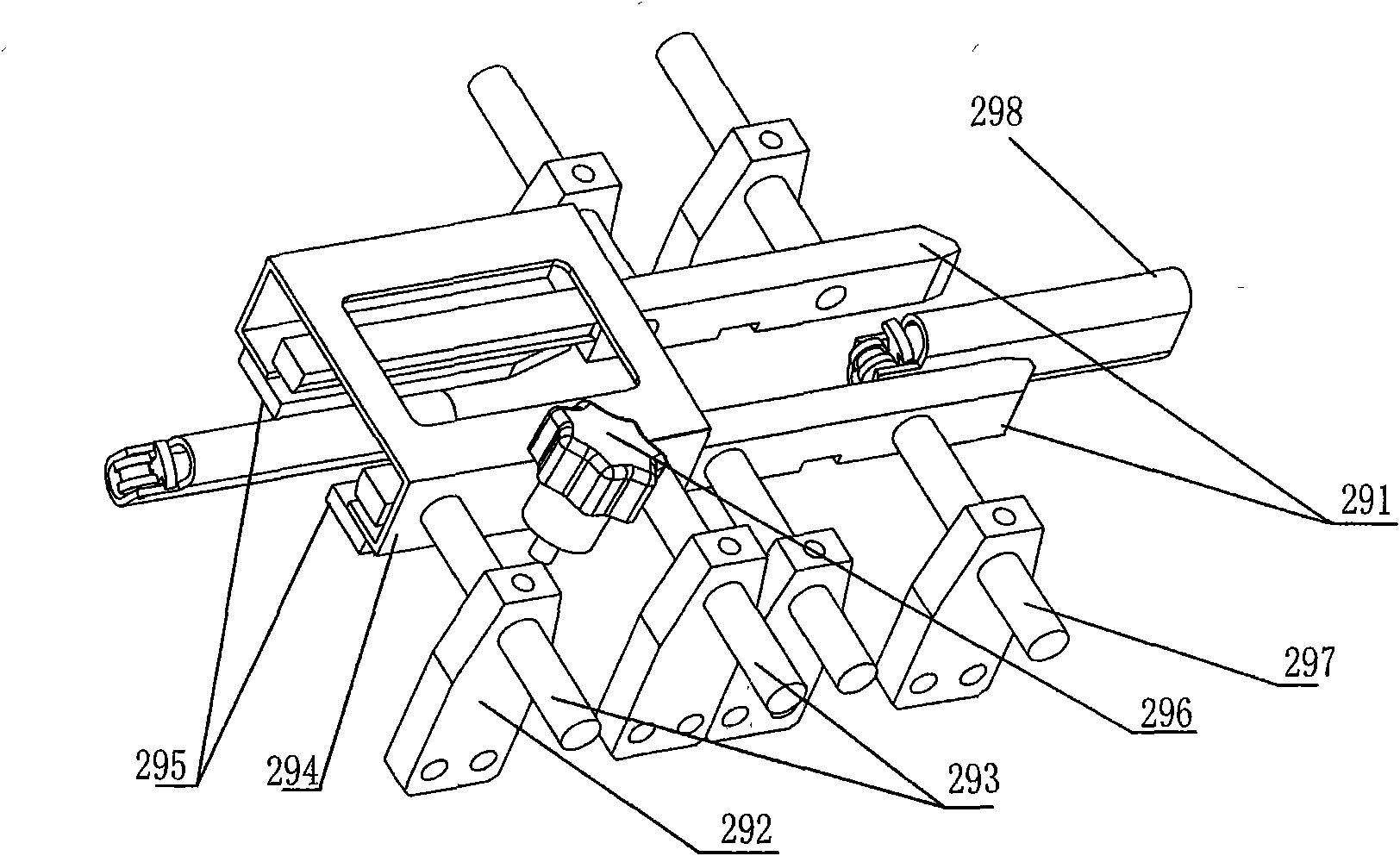

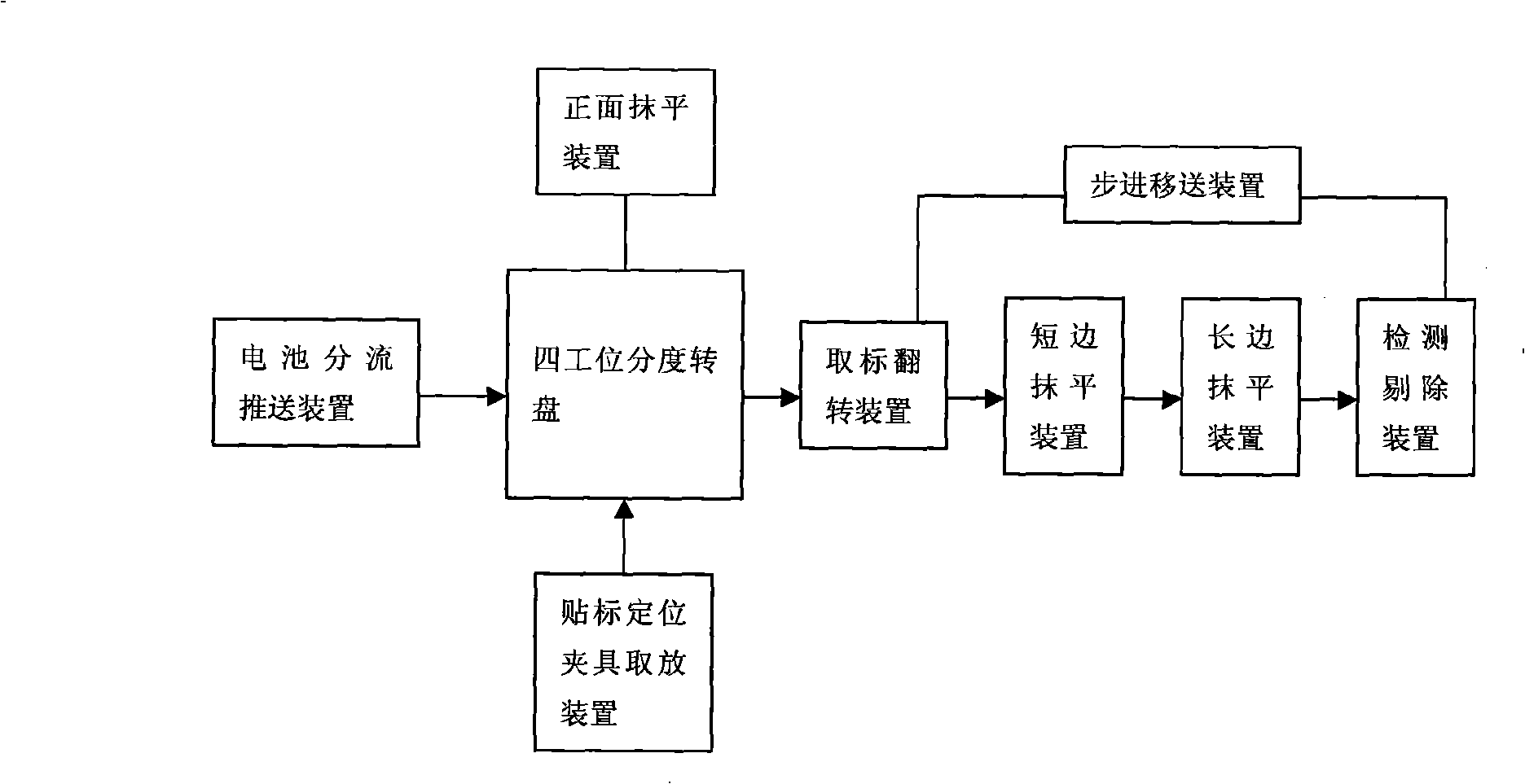

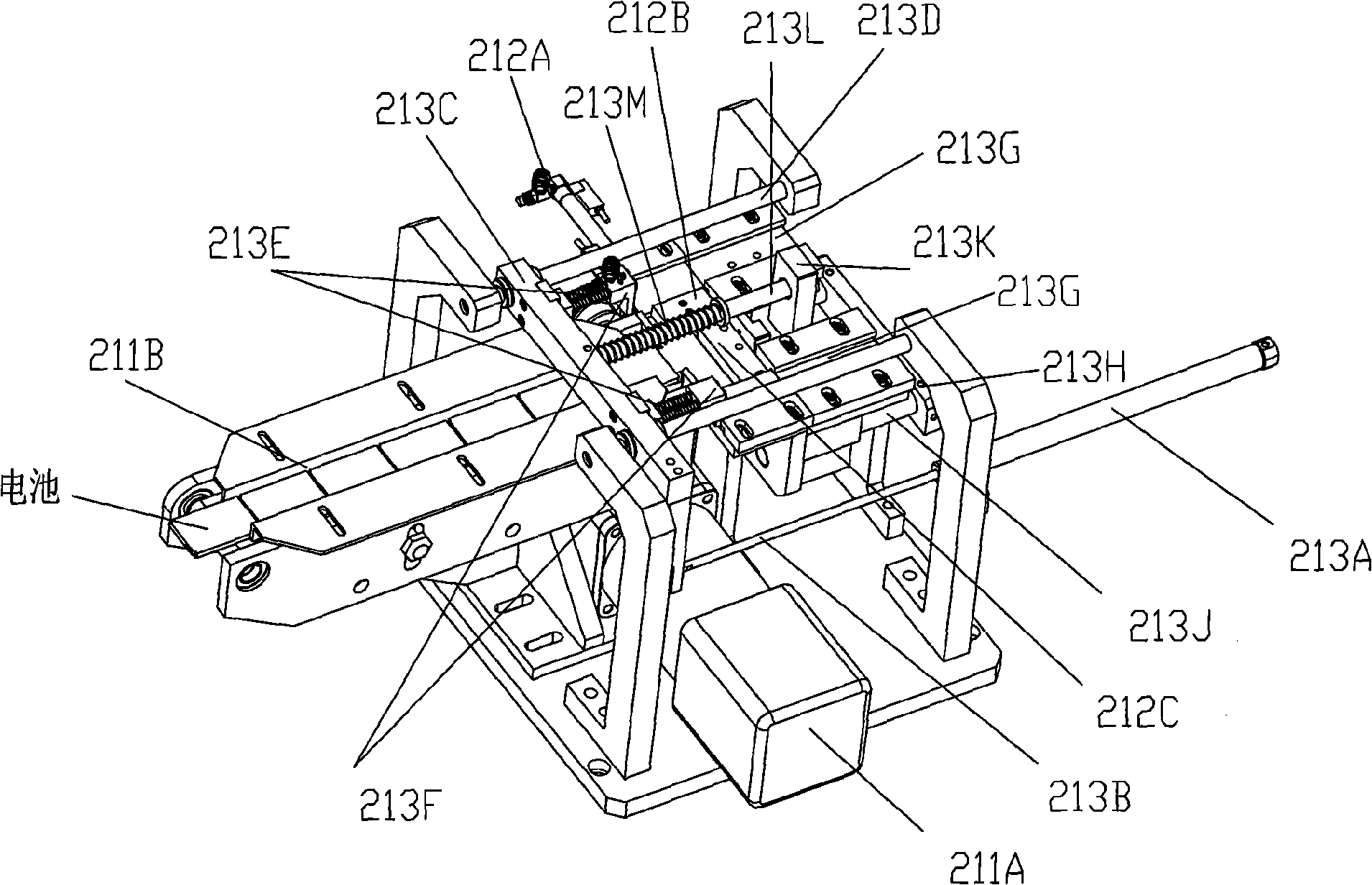

Label holder and mobile phone cell automatic labeler therewith

InactiveCN101279653AIncrease productivityImprove qualified product rateLabelling flat rigid surfacesLabelling machinesMobile phoneBiomedical engineering

The invention discloses a label clamp, comprising a clamp base and a clamp frame cover; the clamp frame cover is rotationally matched with the clamp base; the clamp frame cover is provided with a hollow part used for fixing the label; the clamp base is provided with a battery jar used for containing the battery; the clamp frame cover and the clamp base are mutually attracted magnetically. The invention also discloses a mobile phone battery automatic labeling machine using the label clamp.

Owner:GRAND TECH SHENZHEN

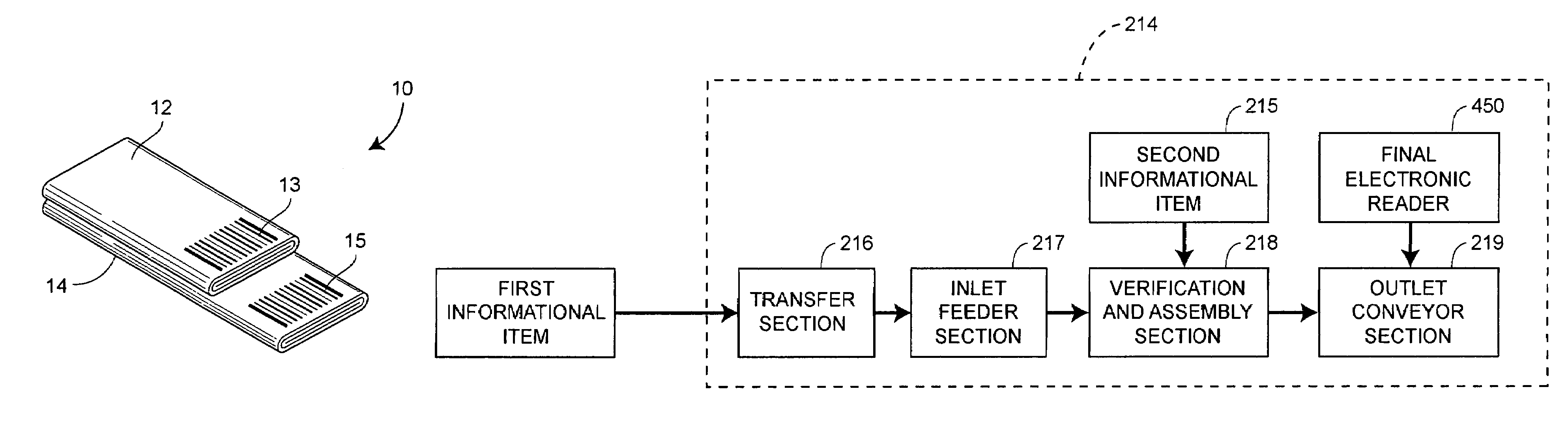

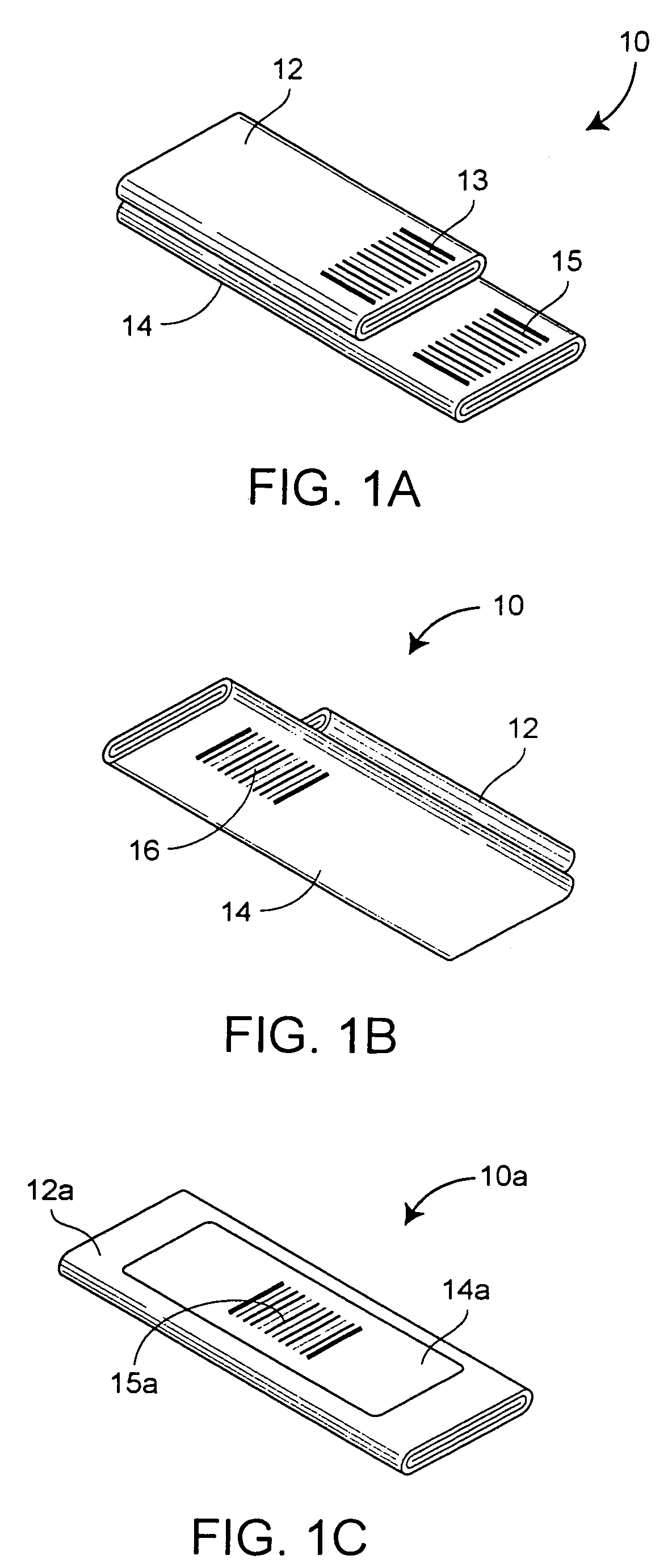

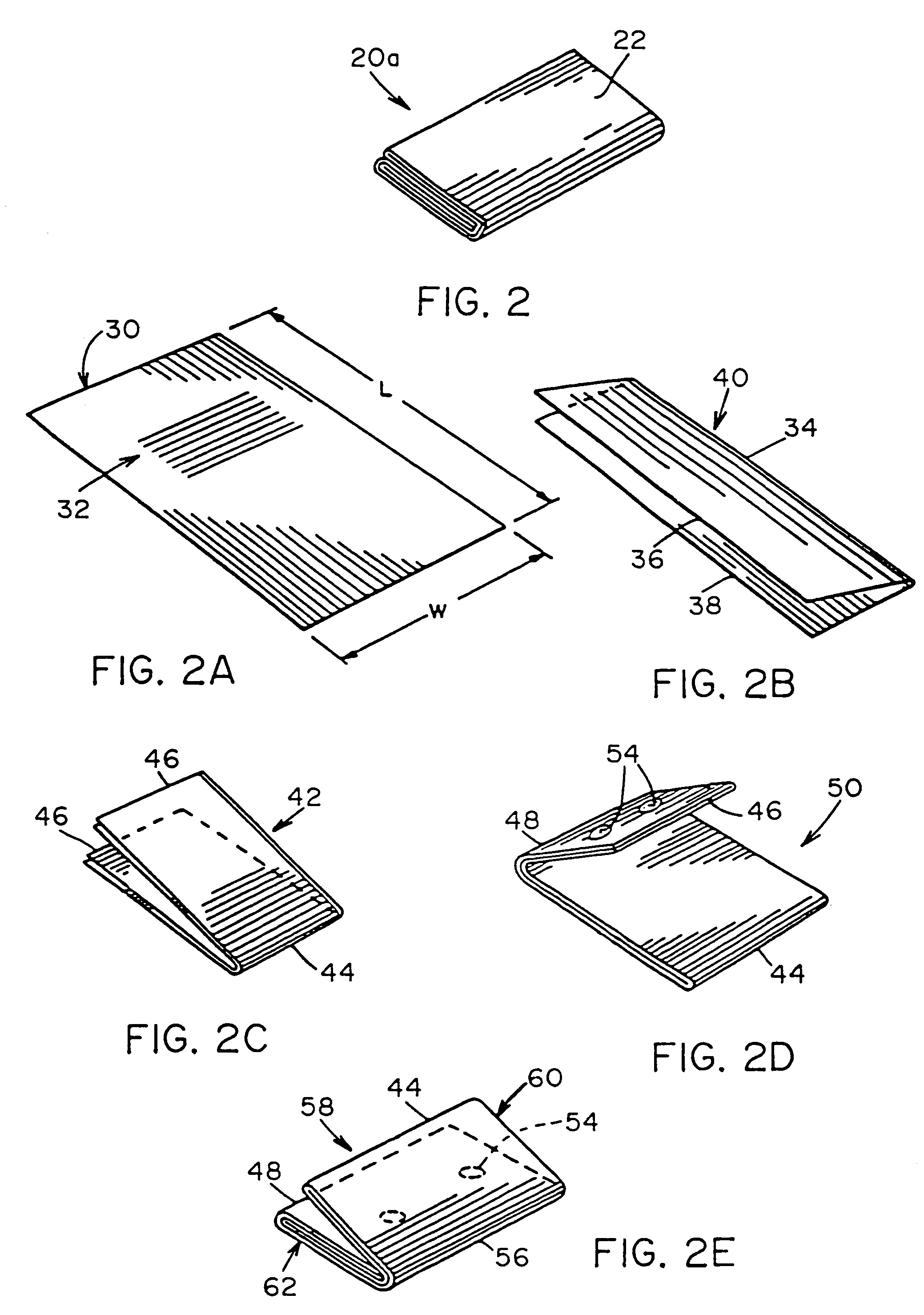

Method of forming composite informational item

InactiveUS7247130B2Mechanical working/deformationPaper/cardboard articlesAdhesiveMechanical engineering

A method of forming a composite informational item having information regarding a pharmaceutical product printed thereon from a first informational item, such as a bidirectionally folded outsert or a booklet, and a second informational item, such as a bidirectionally folded outsert or a booklet, may comprise (a) forming the first informational item; (b) automatically conveying the first informational item from a location in a first feed apparatus to a bonding location; (c) providing a plurality of the second informational items in a second feed apparatus different than the first feed apparatus; (d) automatically depositing a releasable adhesive on a face of one of the informational items; (e) automatically conveying one of the second informational items from a location in the second feed apparatus to the bonding location; and (f) causing a face of the first informational item to make contact with a face of the second informational item so that the first informational item and the one second informational item are releasably bonded together via the releasable adhesive applied to the face of one of the informational items.

Owner:G&K VIJUK INTERN CORP

Sign pasting device and sign pasting method using same

InactiveCN102673853AGuarantee paste qualityError-proofLabelling flat rigid surfacesLabelling machinesEngineeringElectric control

The invention provides a sign pasting device applied to the technical field of sign pasting, and further relates to a sign pasting method using the sign pasting device. The pasting device comprises bases (4) for placing a plastic part (3) to be pasted with a sign, wherein the bases (4) are arranged on a supporting platform (1); a press-fit component (5) is arranged above each base (4) and has a liftable structure; a photo sensor (6) is further arranged on the base (4) and is connected with an alarm component (36); and both the photo sensor (6) and the press-fit component (5) are connected with an electric control component (7). The sign pasting device has stable pressure during sign pasting, and has an error-proofing function so as to solve the problem of omissions and errors caused by visual fatigue of an operator; and furthermore, the sign pasting device is strongly universal and can adapt to the pasting of signs of different shapes on the plastic part.

Owner:震宇(芜湖)实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com