Patents

Literature

370results about How to "Guaranteed shock absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

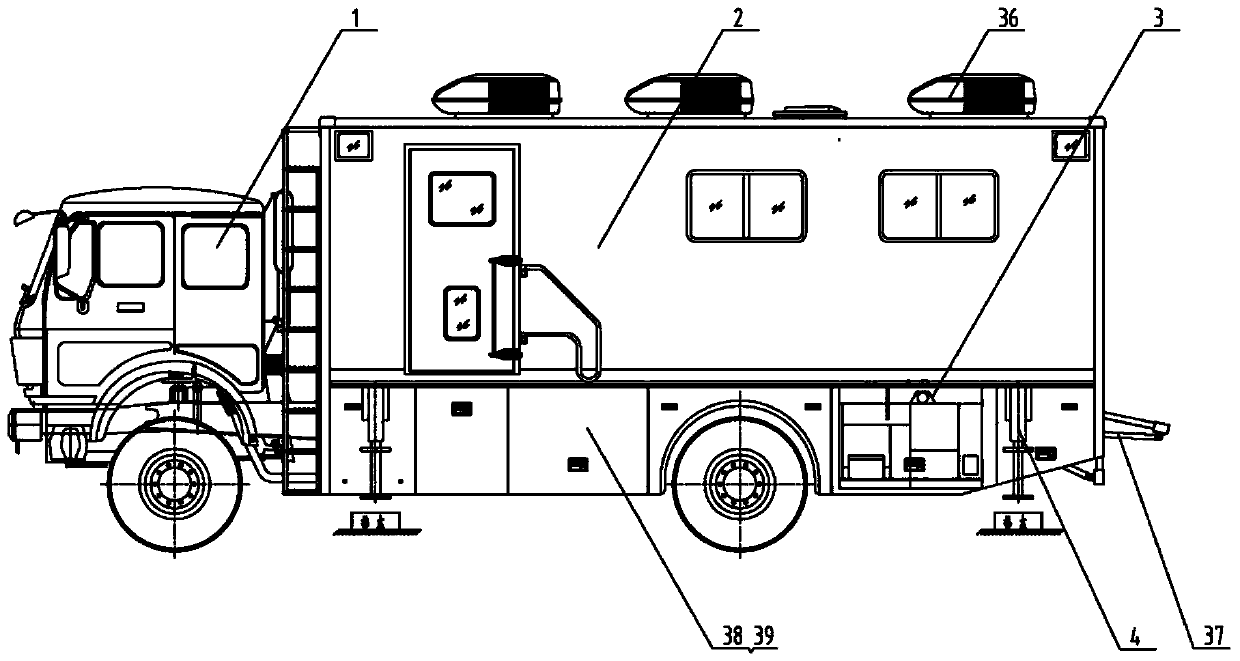

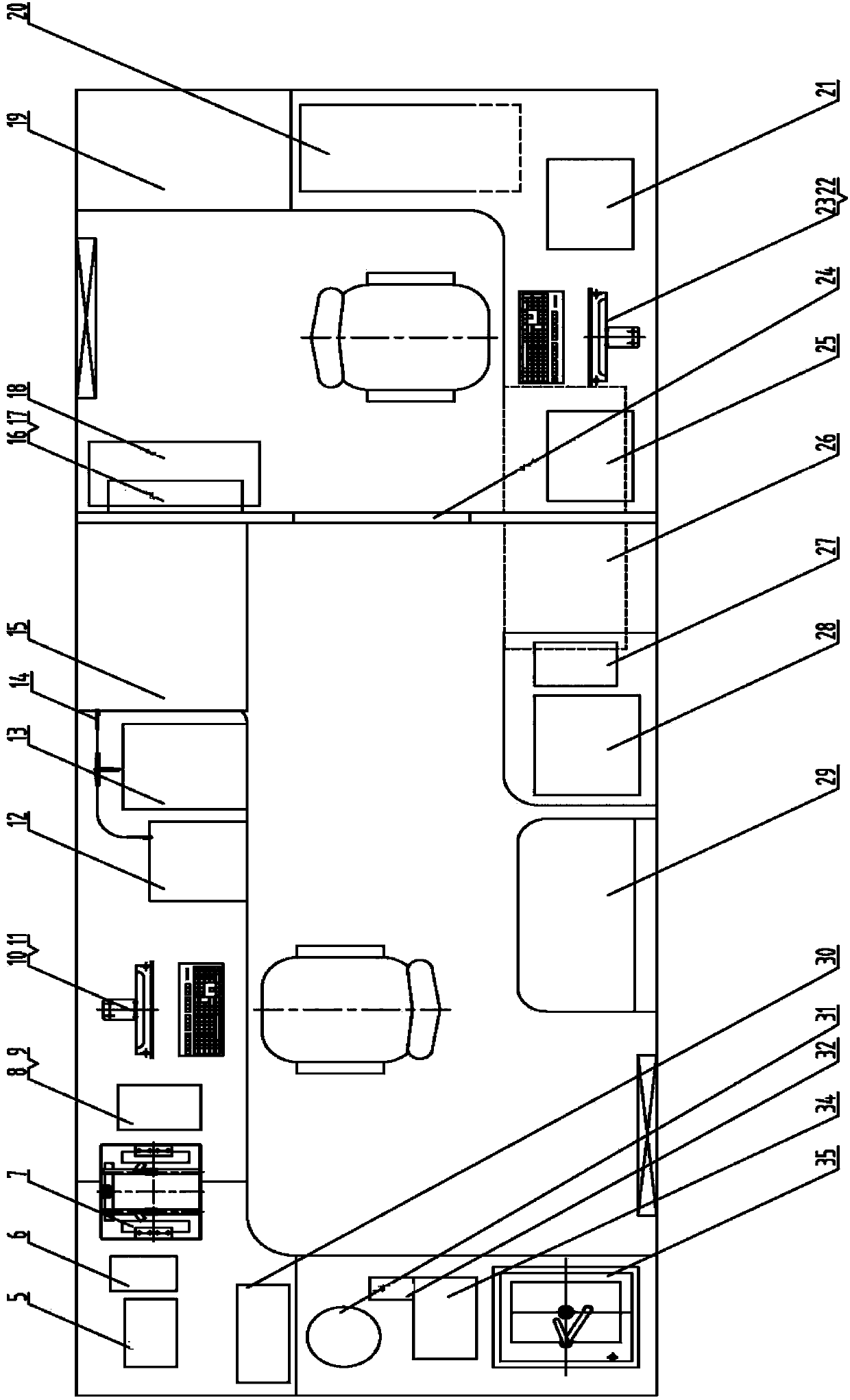

Online fracturing test vehicle

ActiveCN104369687AGuaranteed shock absorptionEasy to useFluid removalItem transportation vehiclesOnline testFracturing fluid

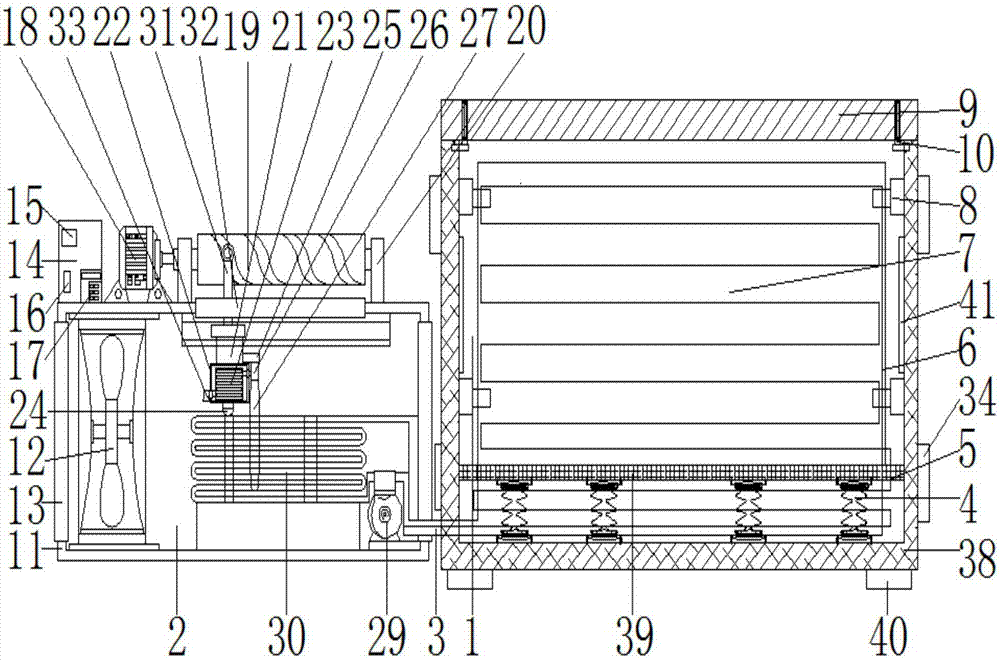

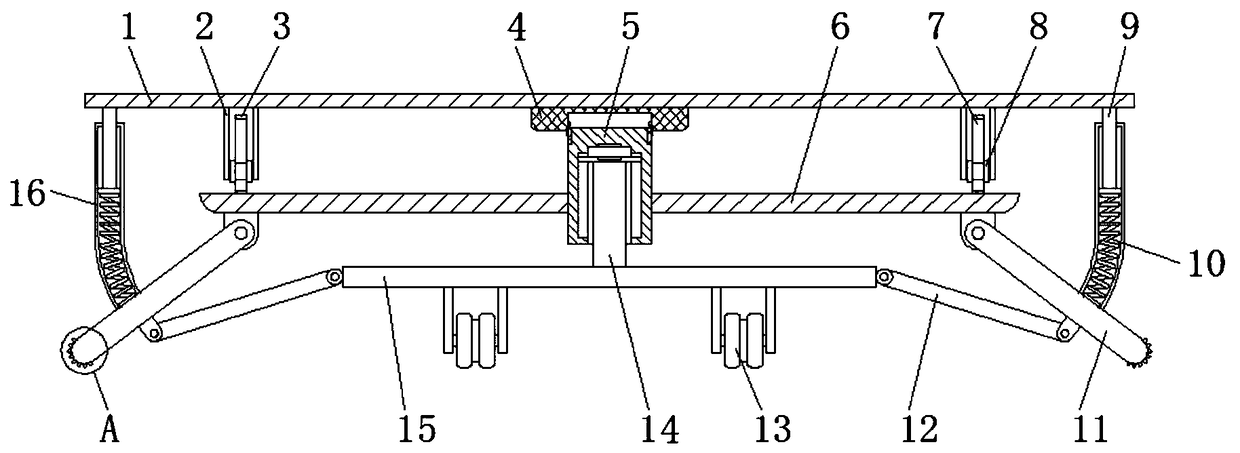

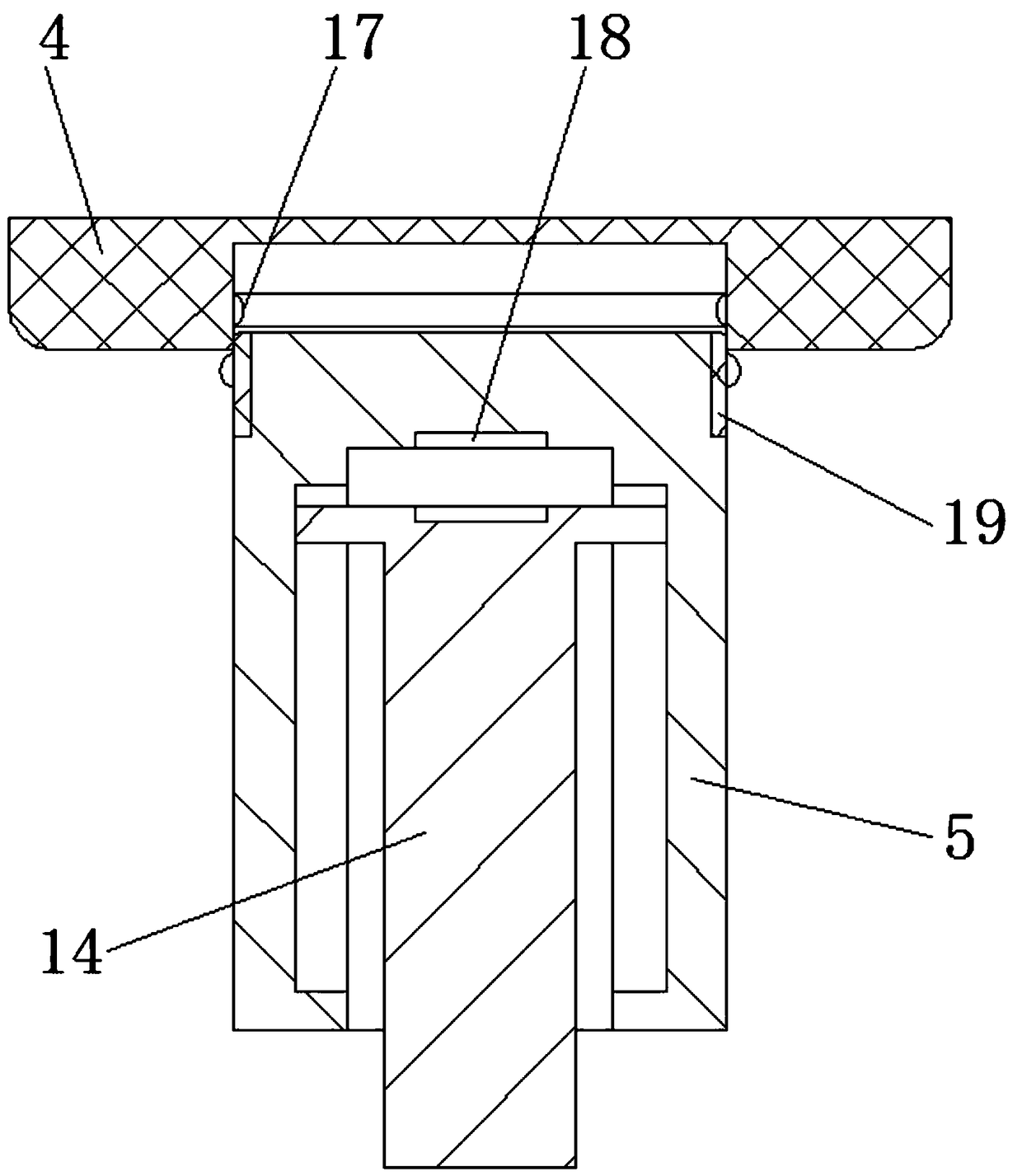

The invention relates to an online fracturing test vehicle. The online fracturing test vehicle comprises a chassis, a shelter, a back protection device, a skirt edge box, a heating system and an automatic leveling device, wherein the shelter is mounted at the upper part of the chassis; the back protection device is mounted at the back end of the chassis; the skirt edge box and a generator are mounted at the side of the chassis; the automatic leveling device is mounted at four corners of the bottom of the chassis; the heating system is mounted at the top of the chassis; the shelter is integrated with an experiment instrument for a fracturing fluid test and a support agent analysis evaluation test; and the experiment instrument for the fracturing fluid test and the support agent analysis evaluation test is mounted on the chassis provided with the shelter, so that the online test can be performed on spot, the detecting accuracy and preciseness can be improved, and the detecting efficiency is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

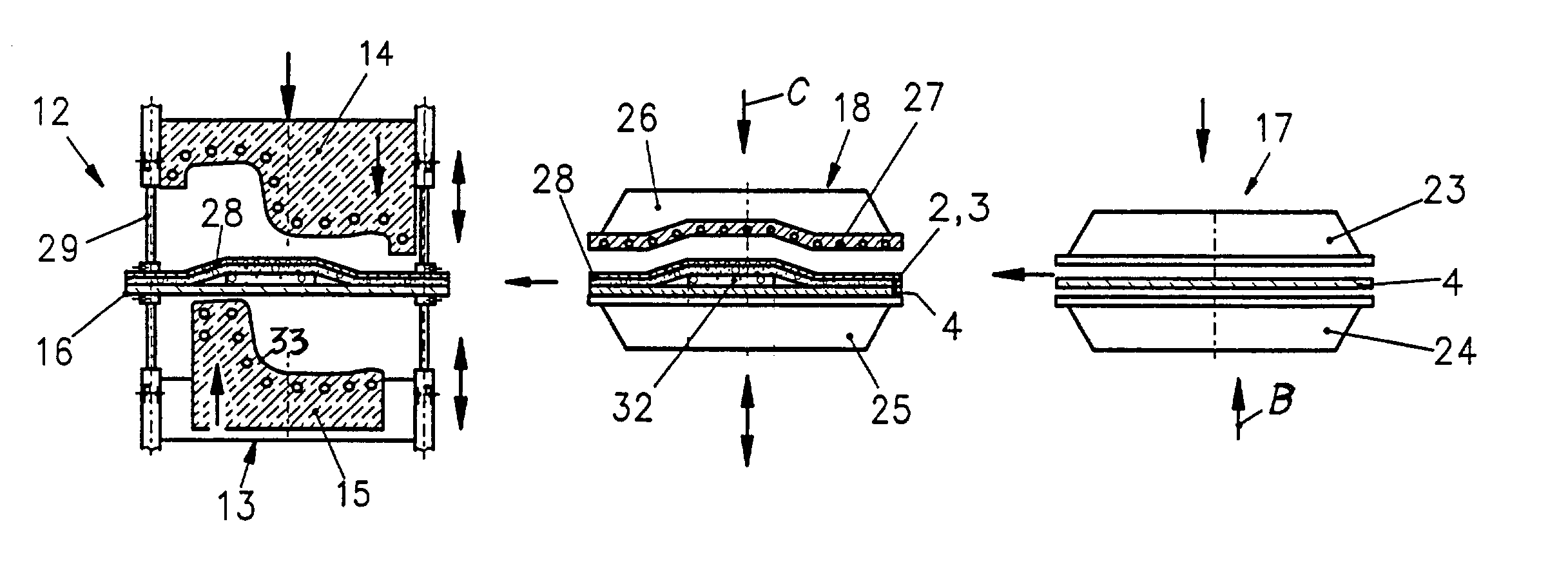

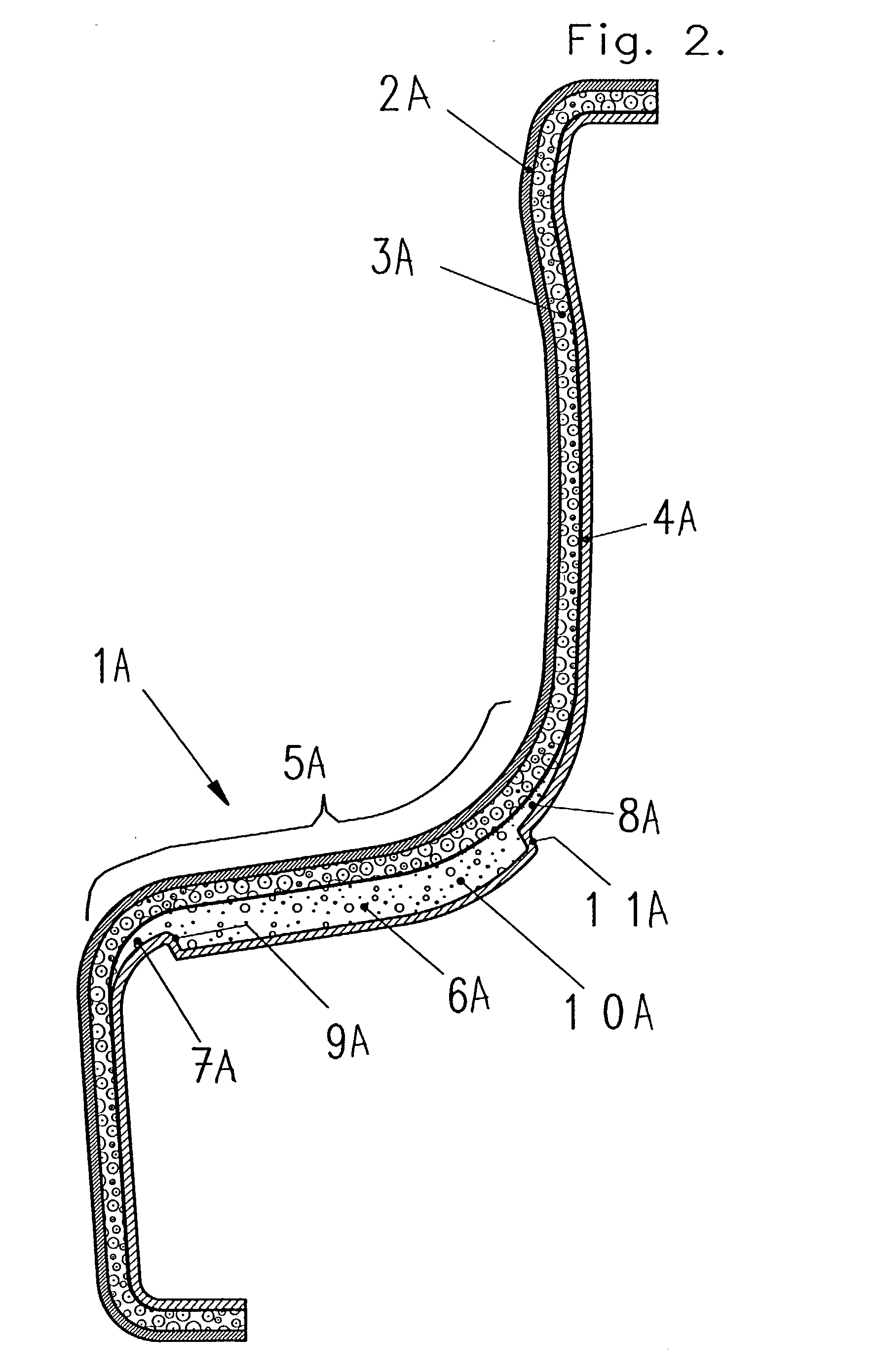

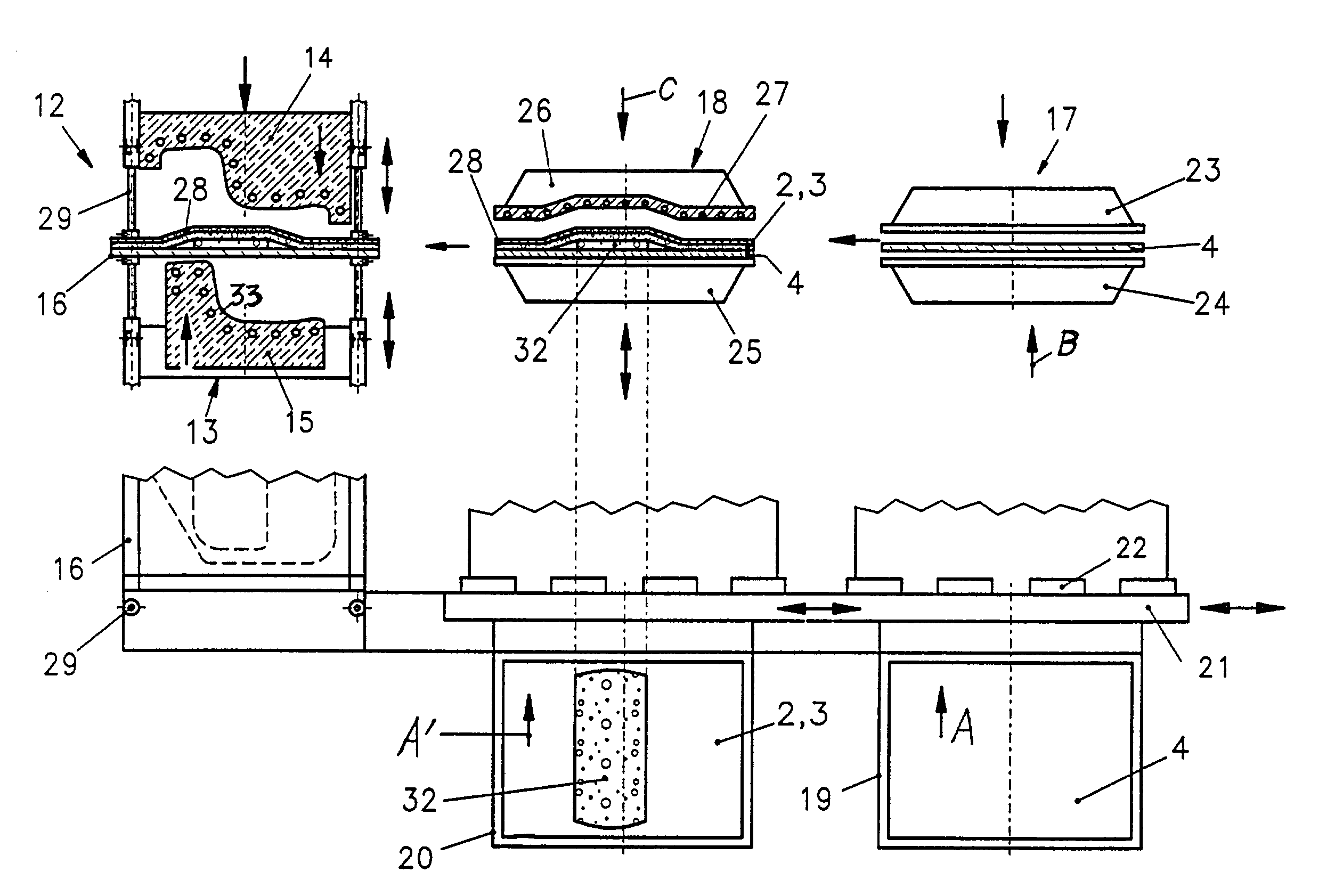

Method and apparatus for making a trim component with a foam core having a smoothly varying thickness

InactiveUS20030041955A1Guaranteed shock absorptionSoftness shockAdhesive processesEngine sealsThermoplasticPolymer science

A trim component includes a foam backing layer and a foam pad insert laminated between a cover material and a substrate. The foam pad insert provides an area of enhanced cushioning, and has smoothly tapered edges to ensure a smooth surface contour without a visible edge transition on the cover material. The foam pad insert has a lower melting temperature than the foam backing layer, both of which are thermoplastics. A foam pad insert is positioned and fixed on the back surface of the foam backing layer. A substrate material is heated and then laminated and molded with the foam and the cover material. The heat from the substrate partially softens and melts the foam backing layer and the foam pad insert. The partially melted foam pad insert is viscously deformed to form the tapered edges, as dictated by the smoothly varying mold gap spacing of the forming tools.

Owner:HERBERT OLBRICH

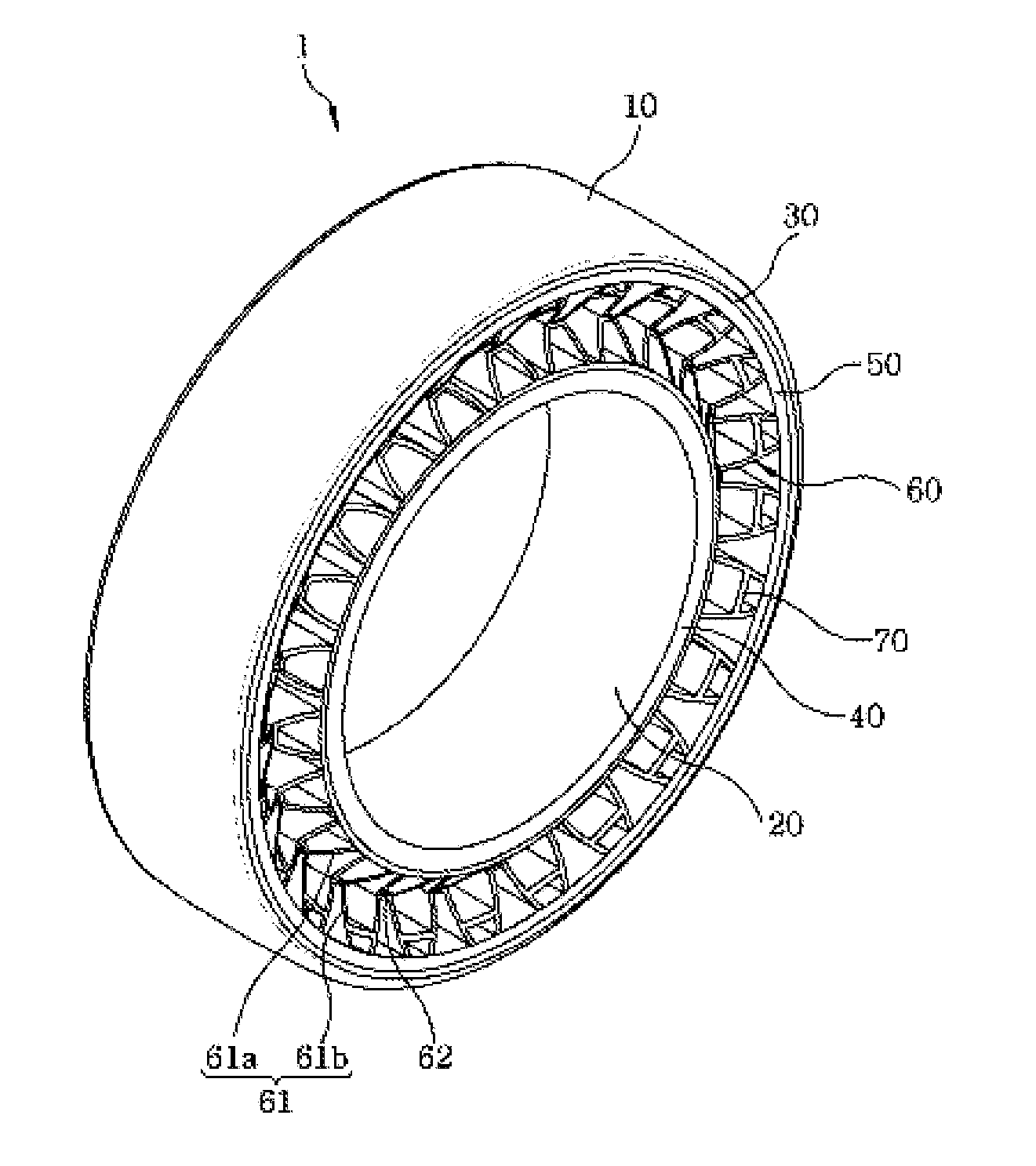

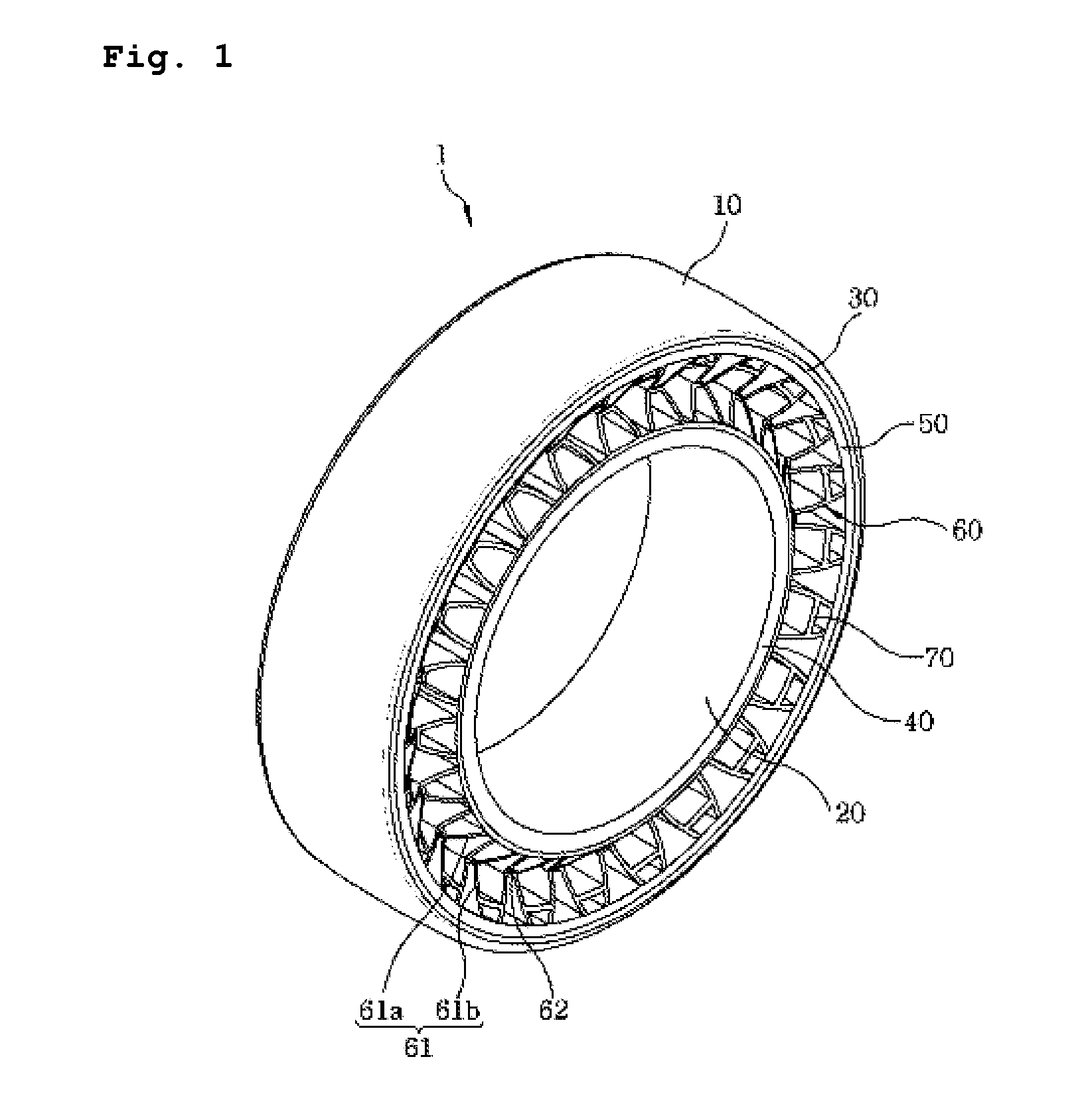

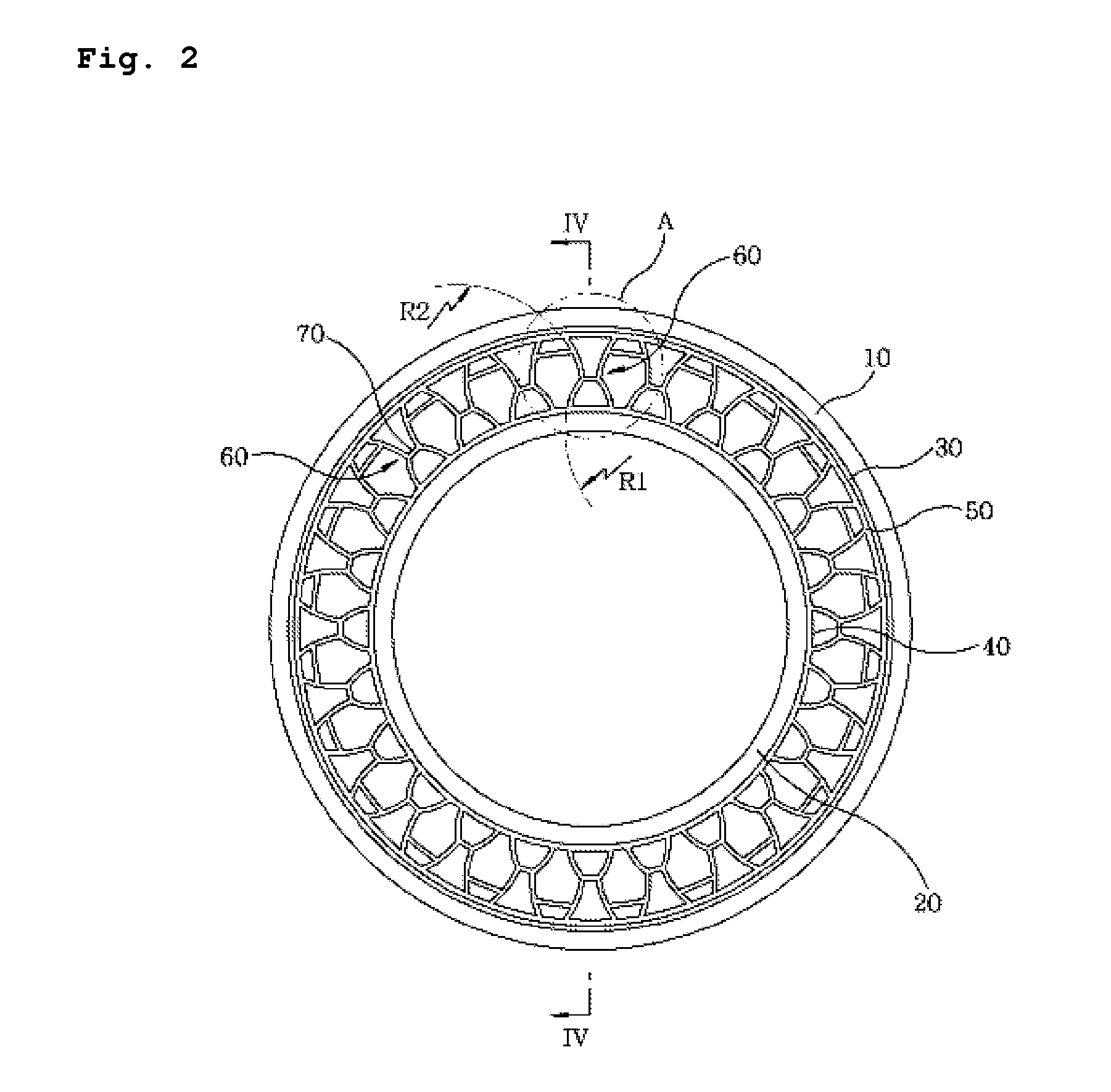

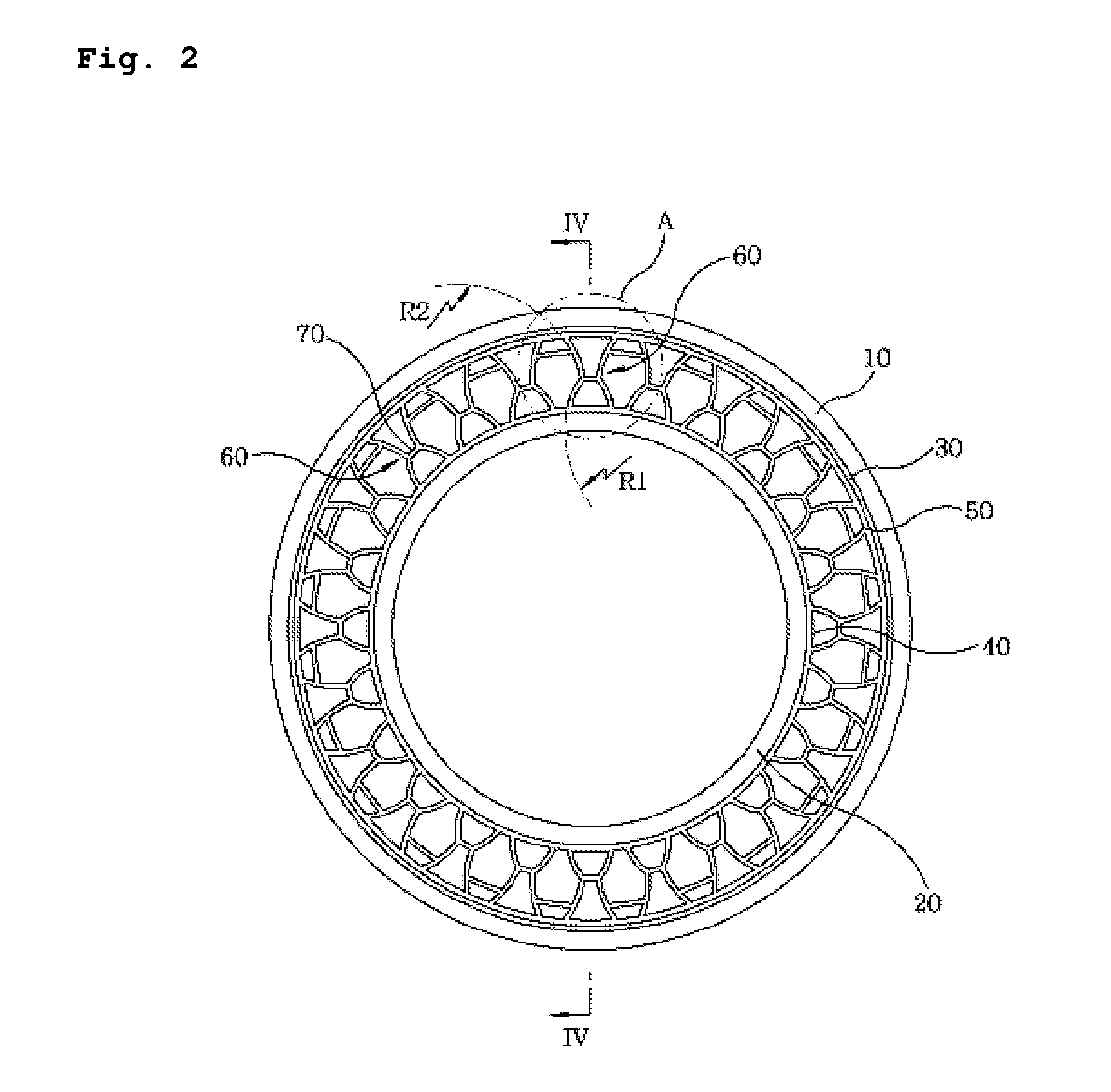

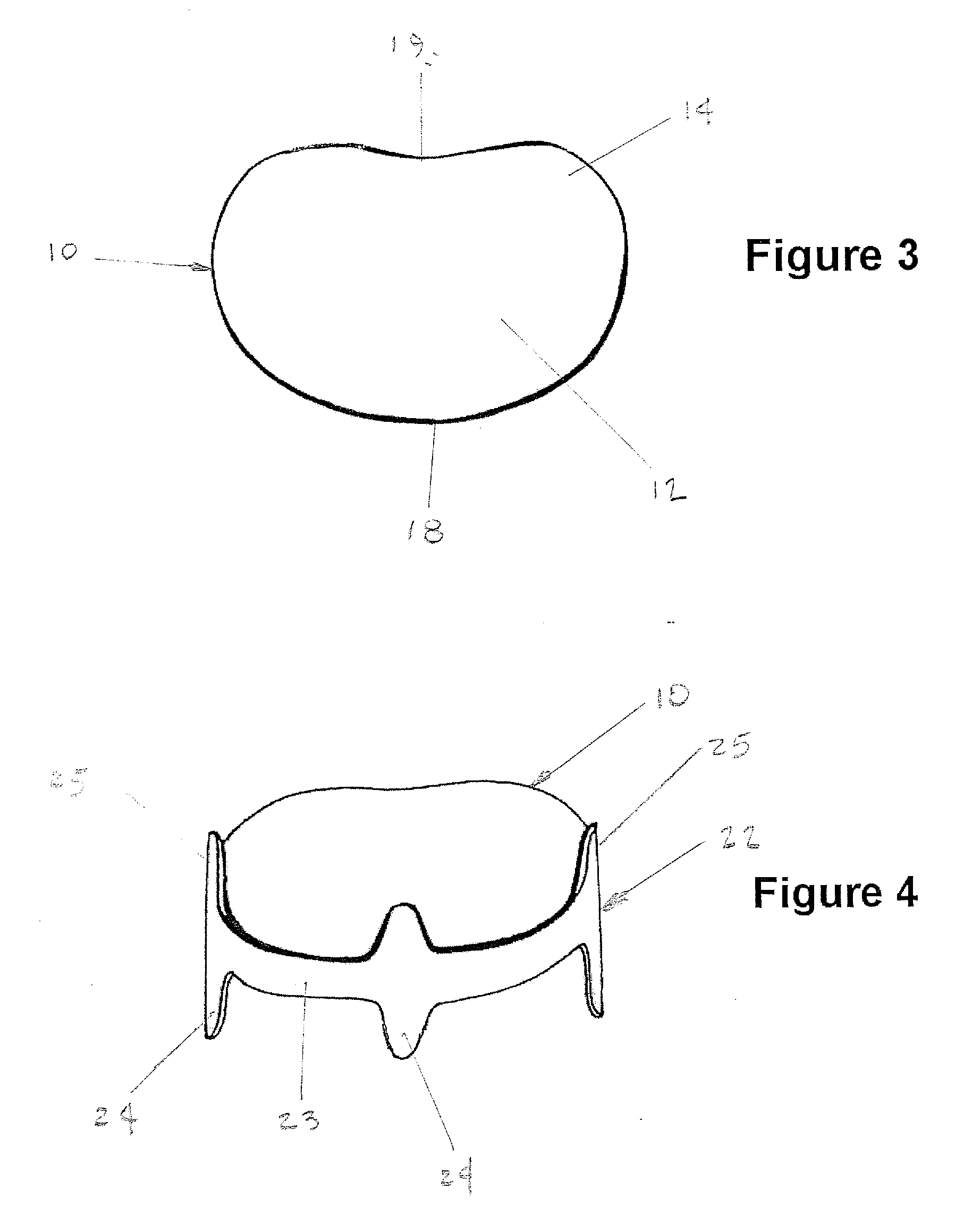

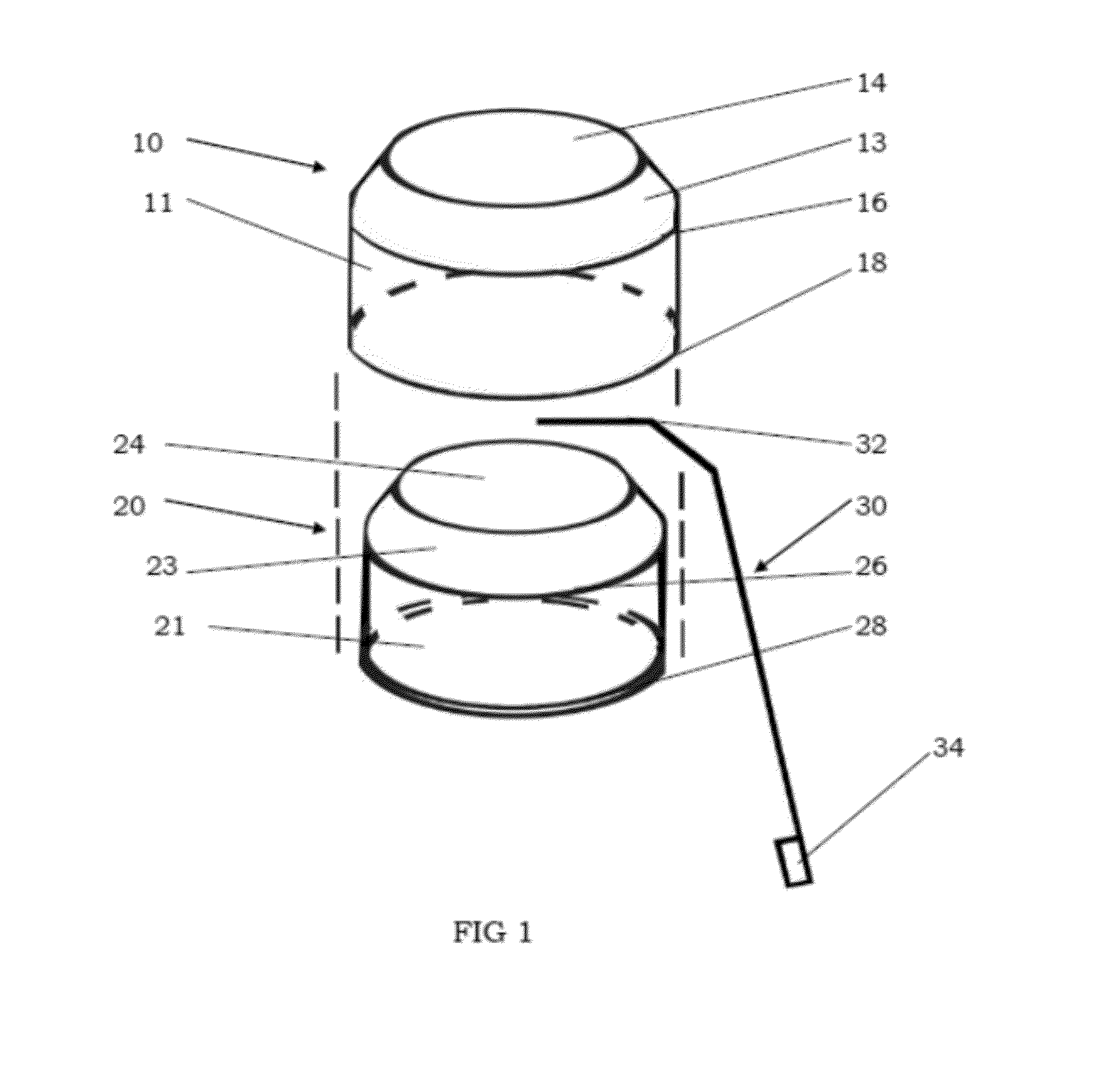

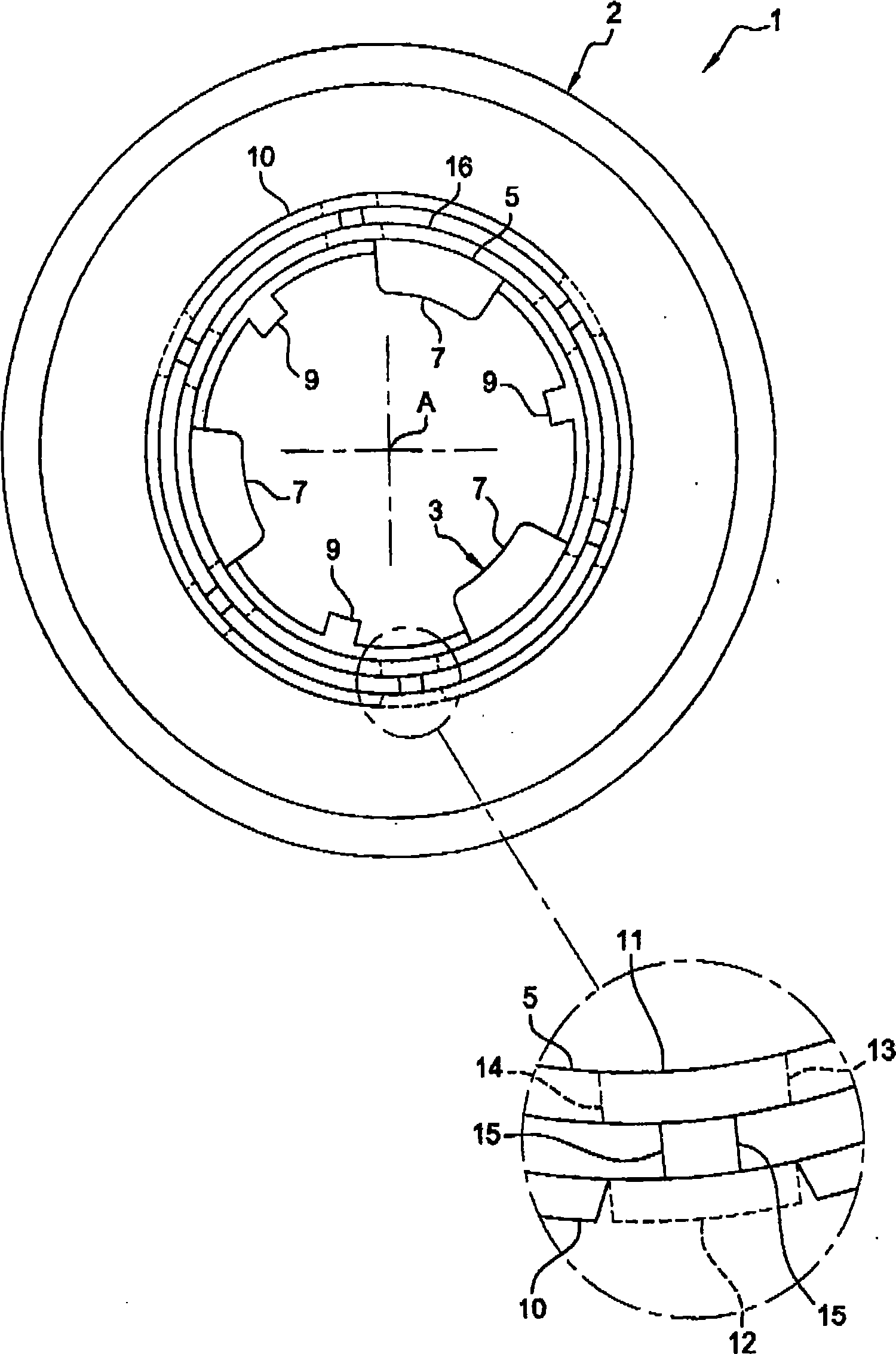

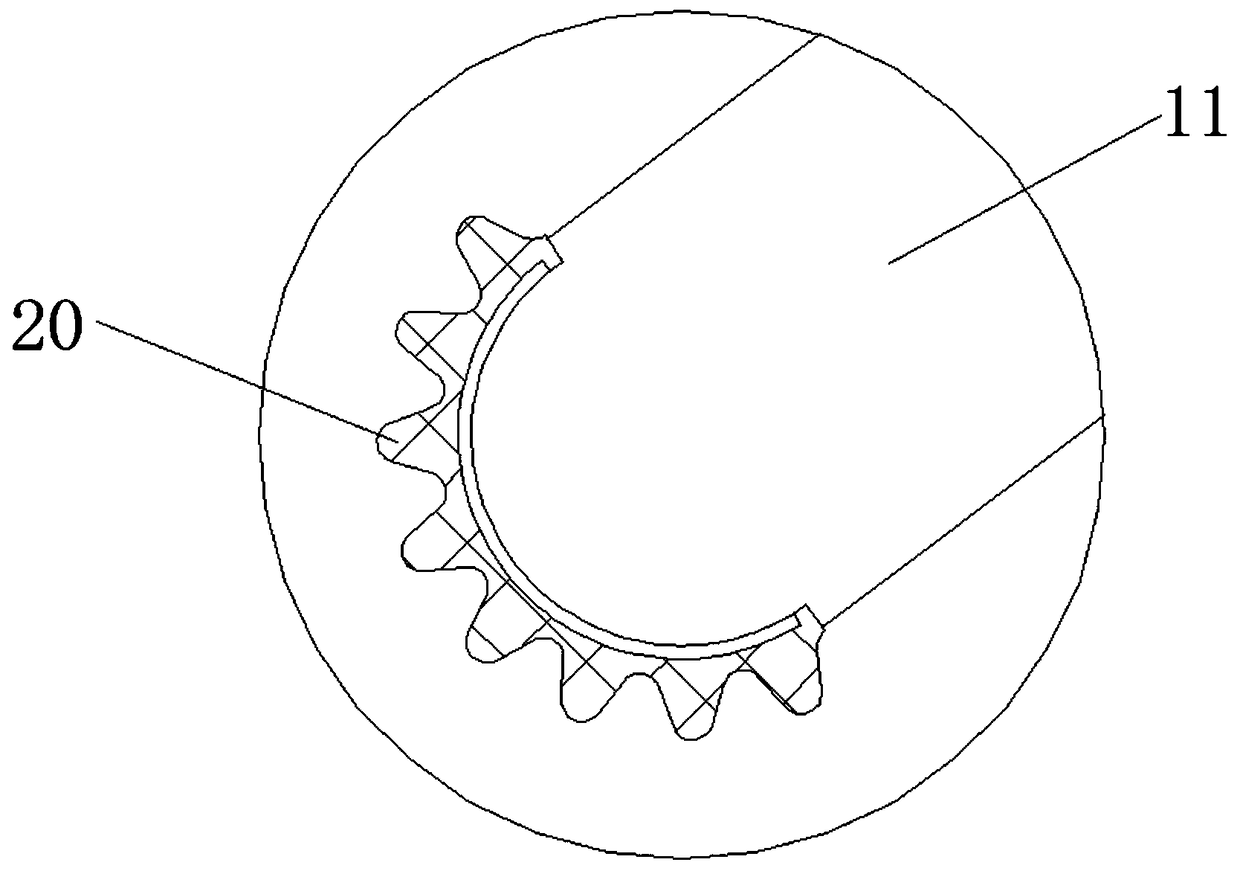

Airless tire

ActiveUS20140000777A1Guaranteed shock absorptionDurability of of shockNon-inflatable tyresSpoked wheelsElectrical and Electronics engineeringAirless tire

The present invention relates to an airless tire, and includes first and second bands that face each other with a distance interposed therebetween, a plurality of spokes that connect the first band to the second band and are provided at intervals, and first and second connecting members that connect the adjacent spokes. The spoke includes a first member of which one end is curved from the first band toward the second band, and a second member of which one end is curved from the second band toward the first band. The other ends of the first and second members are connected to each other, and the first and second members are curved in opposite directions.

Owner:HANKOOK TIRE WORLDWIDE

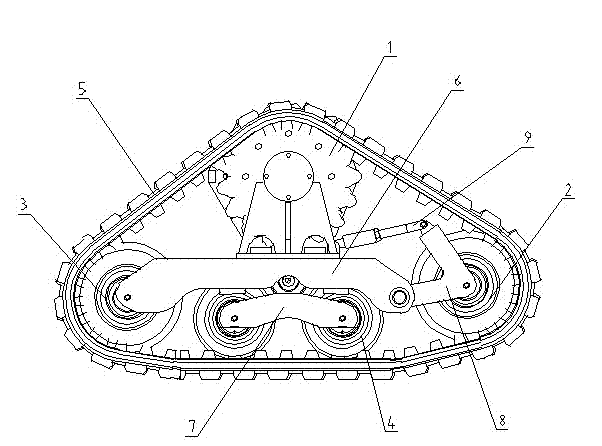

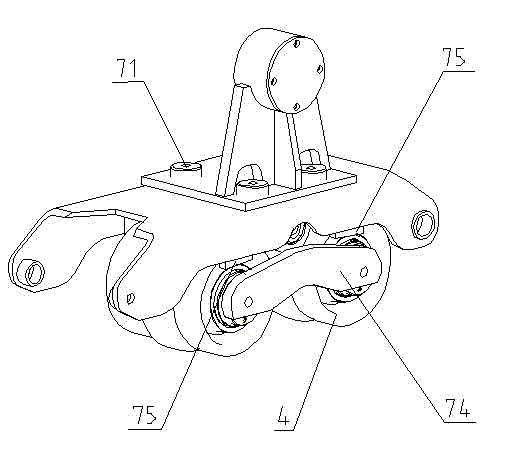

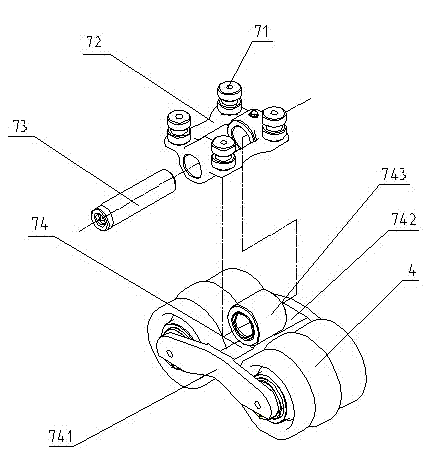

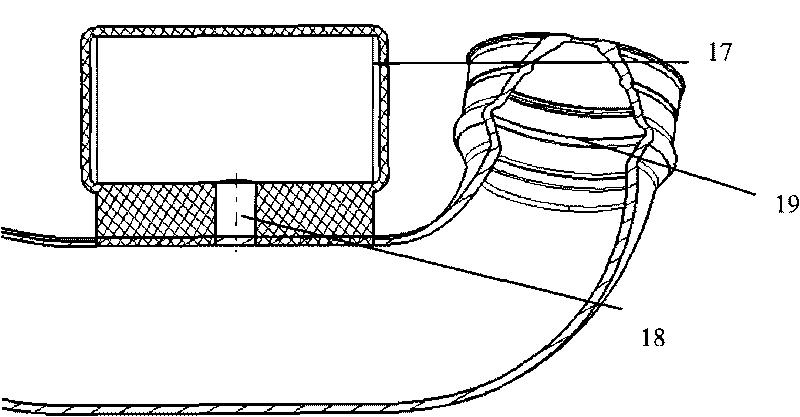

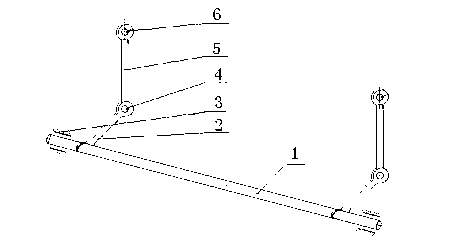

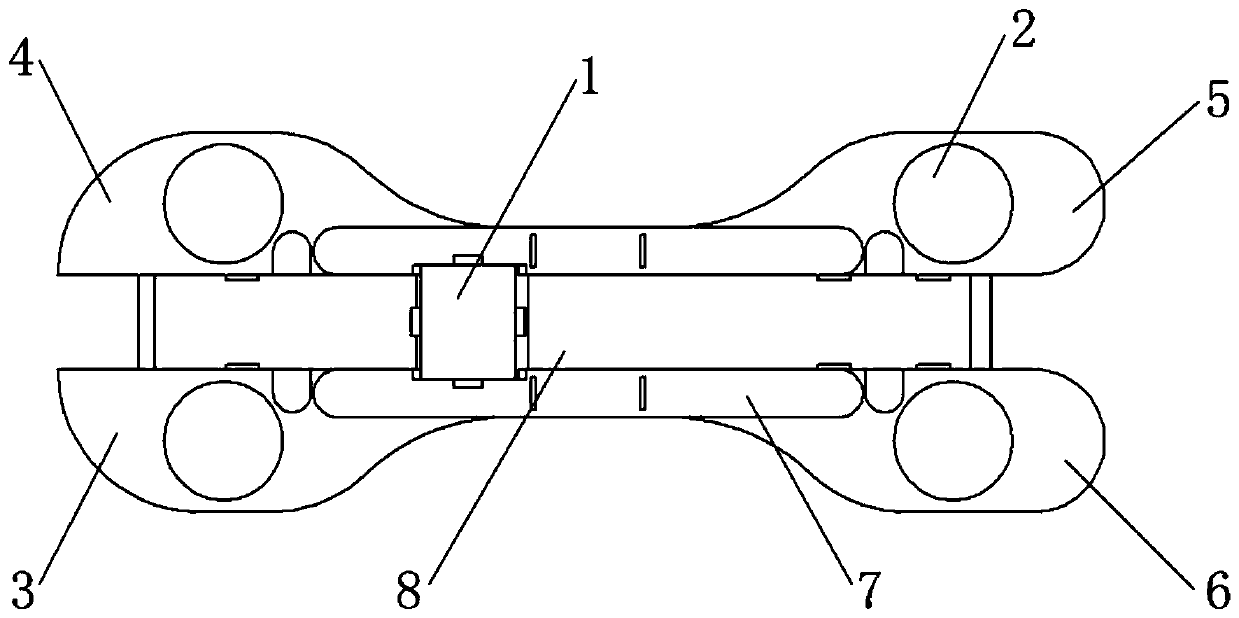

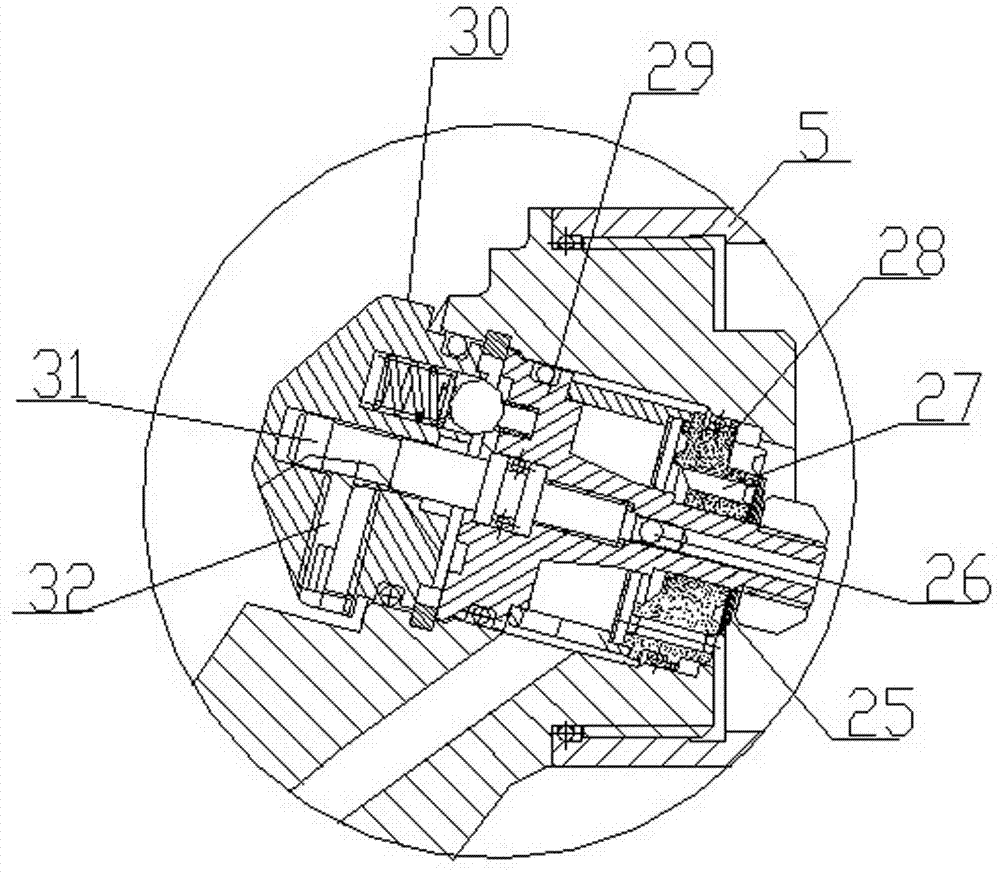

Triangular crawler walking system with suspended shock-absorbing device

InactiveCN102514641AImprove obstacle performanceExtended service lifeEndless track vehiclesDrive wheel

The invention relates to a triangular crawler walking system with a suspended shock-absorbing device. The triangular crawler walking system comprises a driving wheel, a tensioning wheel, a guide wheel, supporting wheels, a crawler and a support. The tensioning wheel and the guide wheel are respectively arranged at the two ends of the support. The driving wheel is arranged above the support. The supporting wheels are arranged between the tensioning wheel and the guide wheel and are connected with the support. The crawler surrounds the driving wheel, the tensioning wheel, the supporting wheels and the guide wheel to form a triangular structure. The supporting wheels are connected with the supporting through the suspended shock-absorbing device. The tensioning wheel is connected with the support through a V-shaped swinging rack. An adjusting rod which can adjust the tightness of the crawler is arranged between the swinging rack and the support. The support, the swinging rack and the adjusting rod form a linkage mechanism which can enable the tensioning wheel to swing. The triangular crawler walking system with the suspended shock-absorbing device has the beneficial effects that: 1) the rapid switching between a tire type and a crawler type of a skid loader can realized; and 2) by adopting the suspended shock-absorbing device, the obstacle detouring capacity of the entire loader is improved, the shock absorbing effect is guaranteed and the service life of the crawler walking system is improved.

Owner:JIANGSU LIUGONG MACHINERY

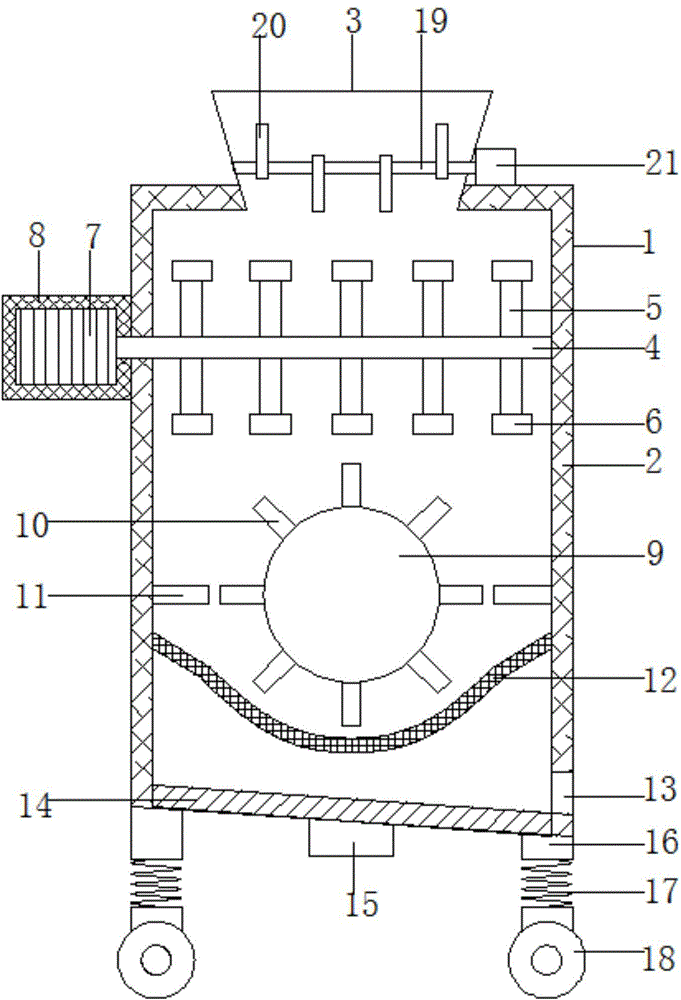

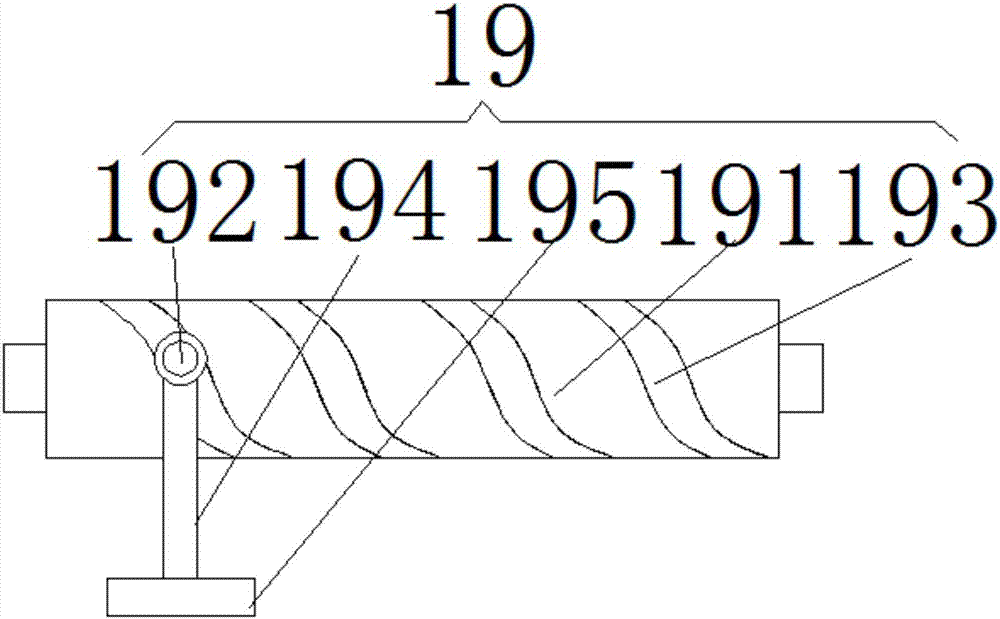

Movable anti-blocking pulverizer for ceramic production

InactiveCN104923344AAvoid cloggingImprove crushing effectGrain treatmentsElectric machineryDrive motor

The invention discloses a movable anti-blocking pulverizer for ceramic production. The movable anti-blocking pulverizer for ceramic production comprises a pulverizer body, a rotary shaft and eccentric wheels, wherein an electric heating layer evenly covers the outer wall of the pulverizer body, a feeding funnel is connected to the upper side of the pulverizer body, the rotary shaft is horizontally arranged in the feeding funnel, the eccentric wheels are evenly arranged on the rotary shaft, the centers of the eccentric wheels are evenly distributed around the rotary shaft, and the right end of the rotary shaft extends out of the feeding funnel to be connected with a driving motor. The movable anti-blocking pulverizer for ceramic production adopts two pulverizing mechanisms to pulverize a material, can fully pulverize the material, the working efficiency of the pulverizer is improved, the pulverizing effect is ensured, the material is heated and dried in the pulverizing process, material production efficiency is improved, vibration can be effectively reduced through the arranged eccentric wheels, material blockage in the feeding funnel can be prevented, and continuous feeding is ensured. In addition, noise of the pulverizer during working is small, the pulverizer can be freely and conveniently moved, and practicability and convenience are high.

Owner:顾广才

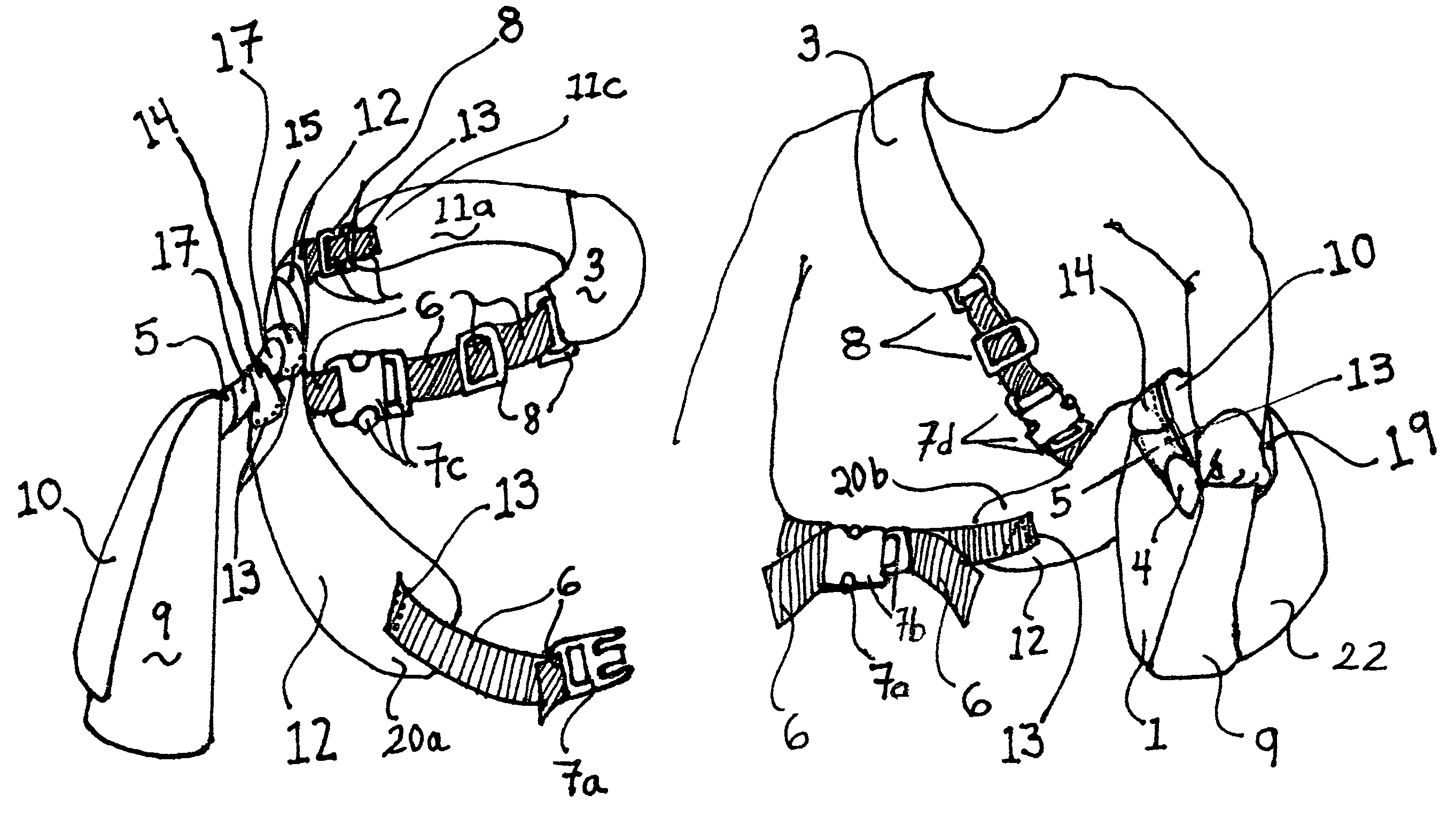

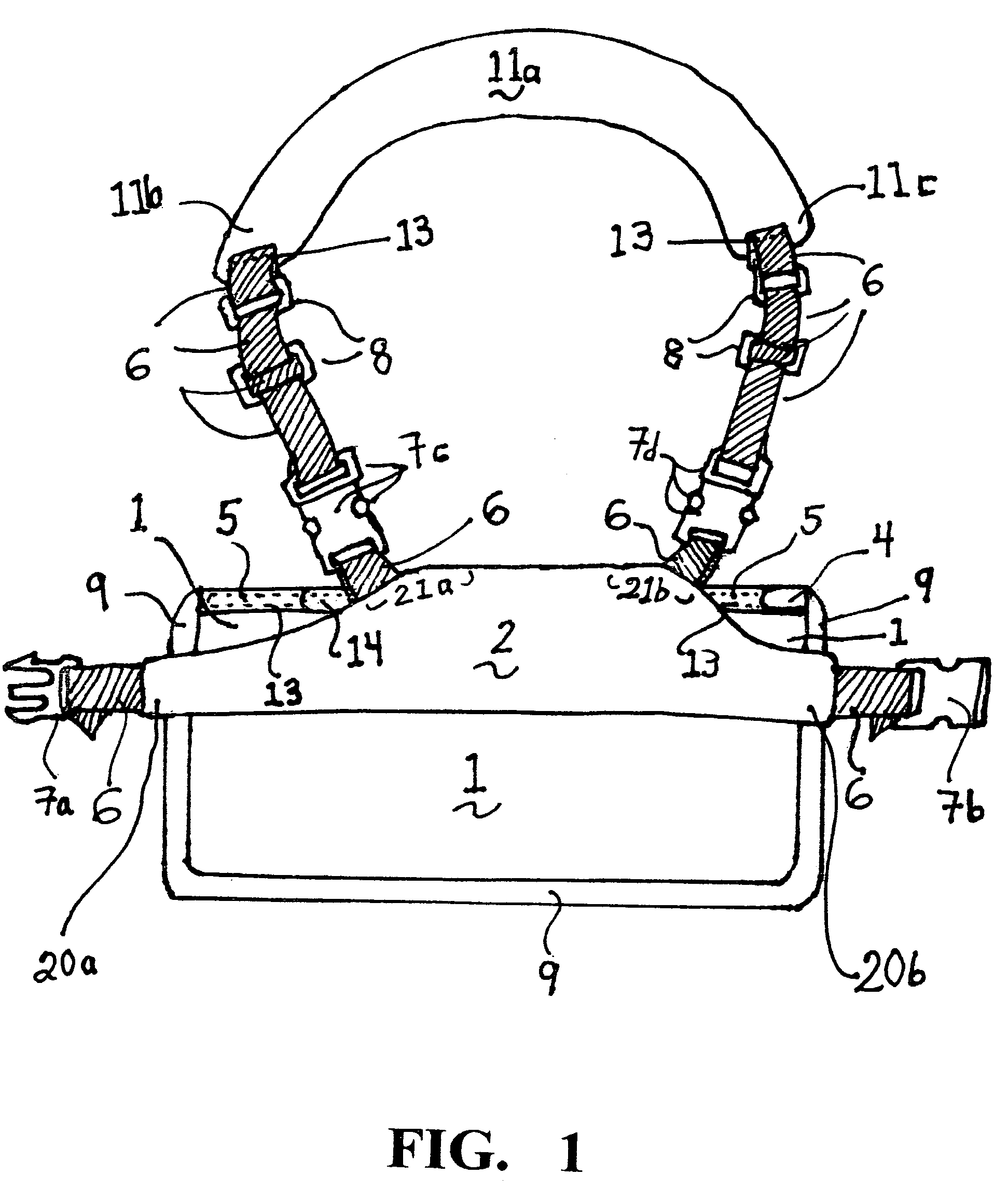

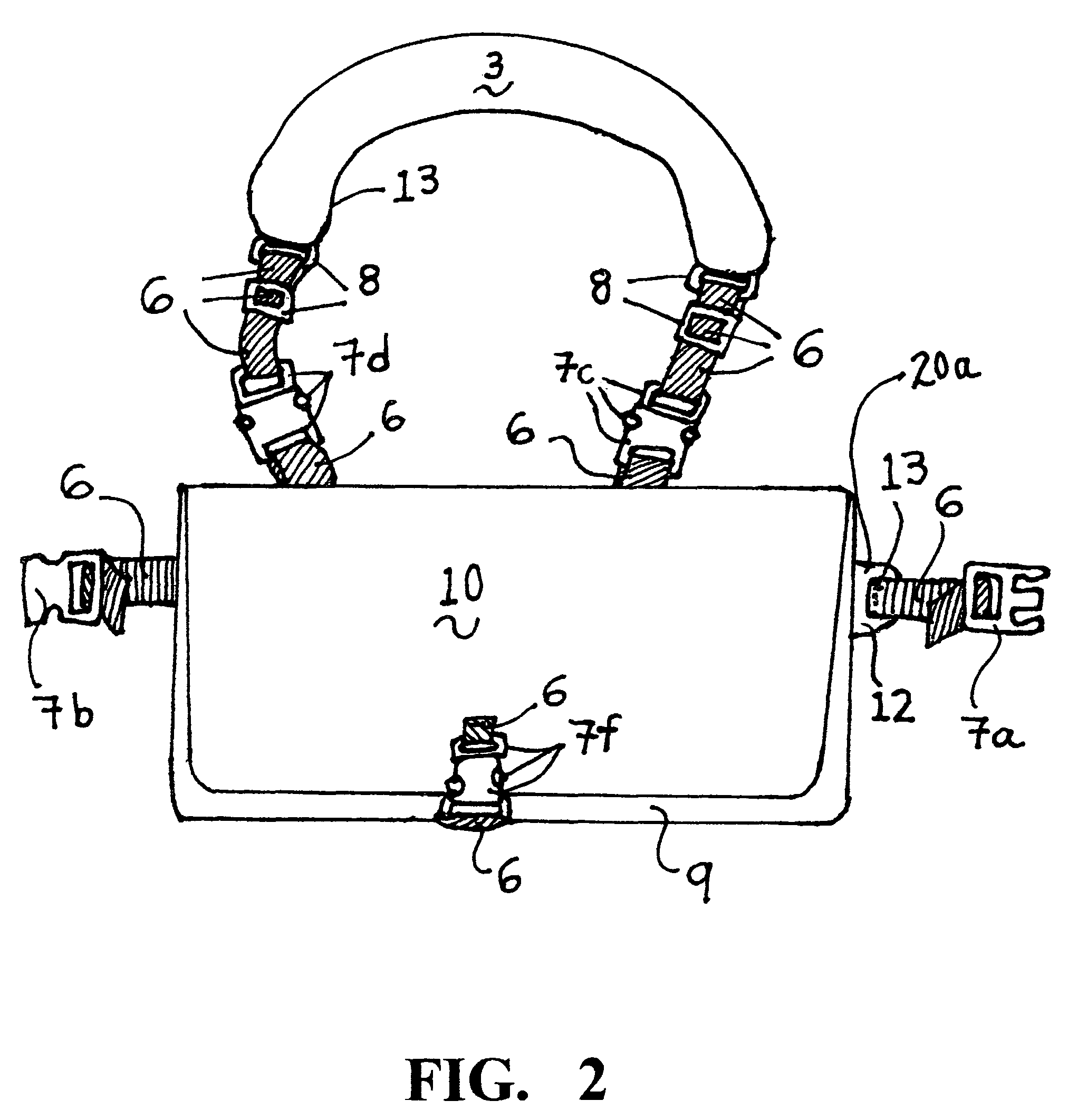

Shoulder strap and waist belt bag

InactiveUS7909214B2Without sagging or weight discomfortSolve the real problemTravelling sacksTravelling carriersYoung personEngineering

The present interlocking bag and waist belt invention assists the user that must carry weight comfortably while being able to access the contents. The embodiment of the present invention teaches a soft bag, a waist belt, an optional detachable shoulder strap, and a connecting system that includes a rigid member or semi-rigid member interlocking between the waist belt and the bag through placement in looped pieces which are fixed alternatively on bag and waist belt. This invention will be of importance to walking delivery people, but the utilization will be more expansive. People young and old who are attracted by the informality of messenger bags but who want more comfort, may use the present interconnecting bag and waist belt invention for school, work, and travel.

Owner:TOUGH TRAVELER

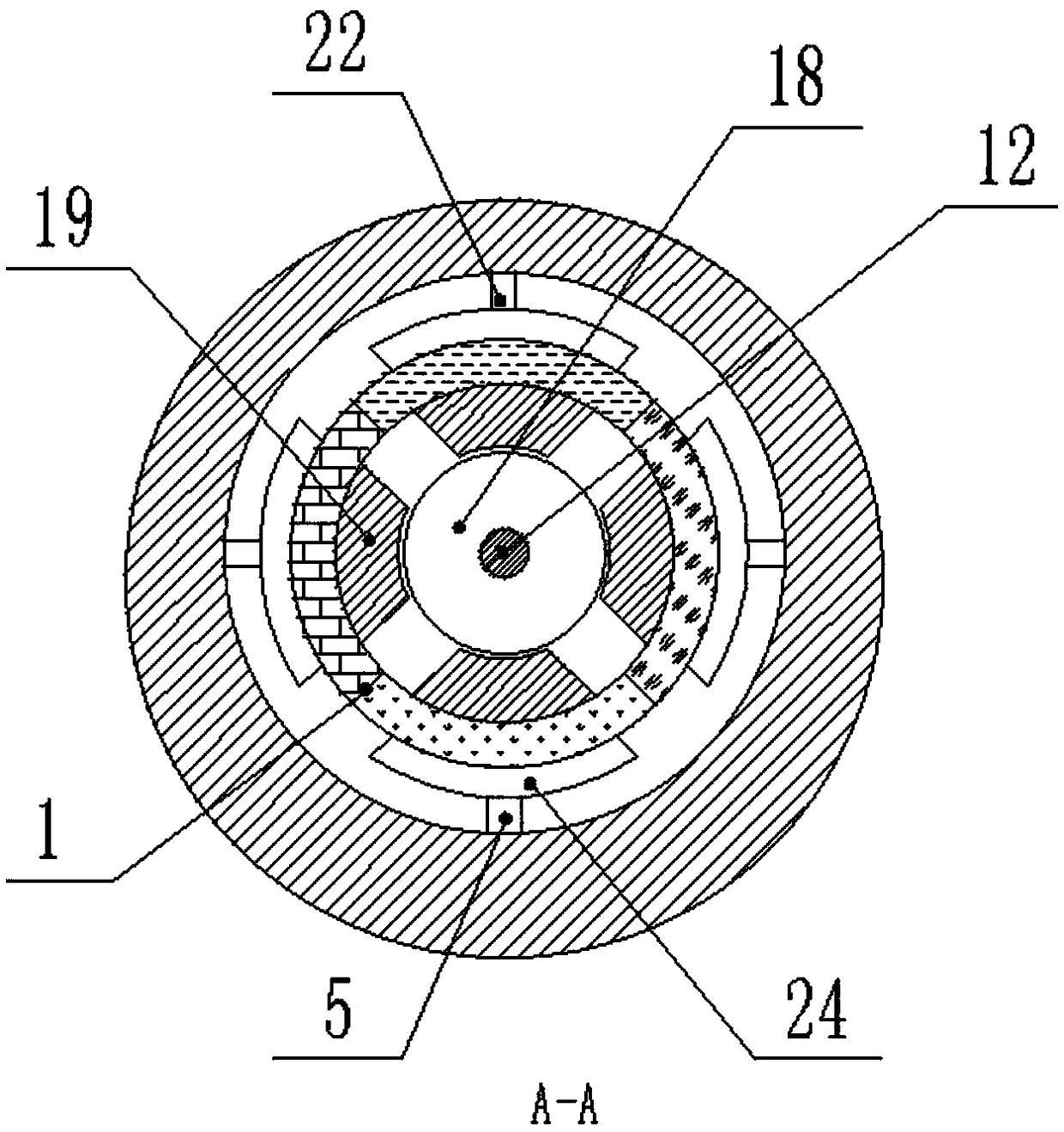

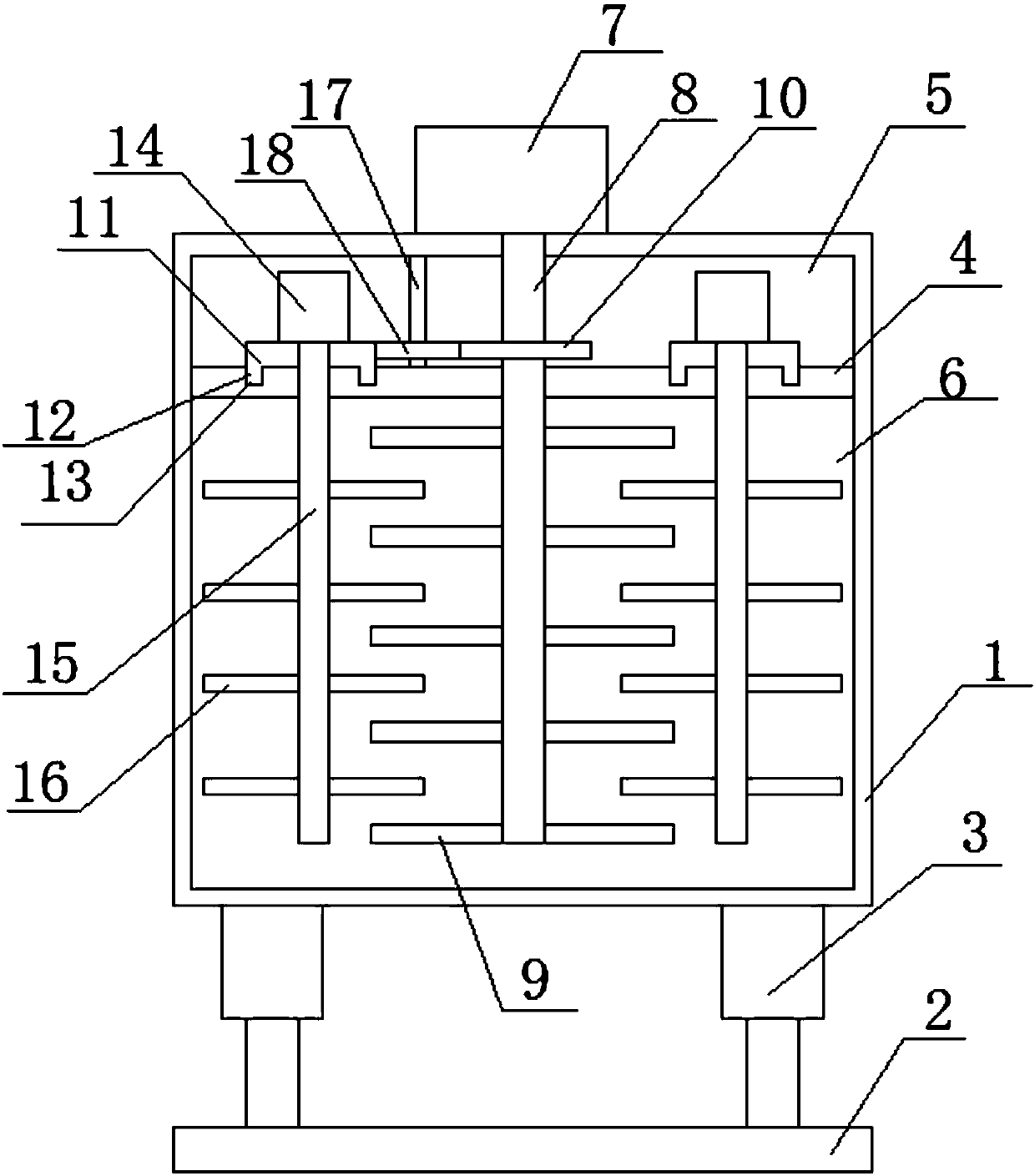

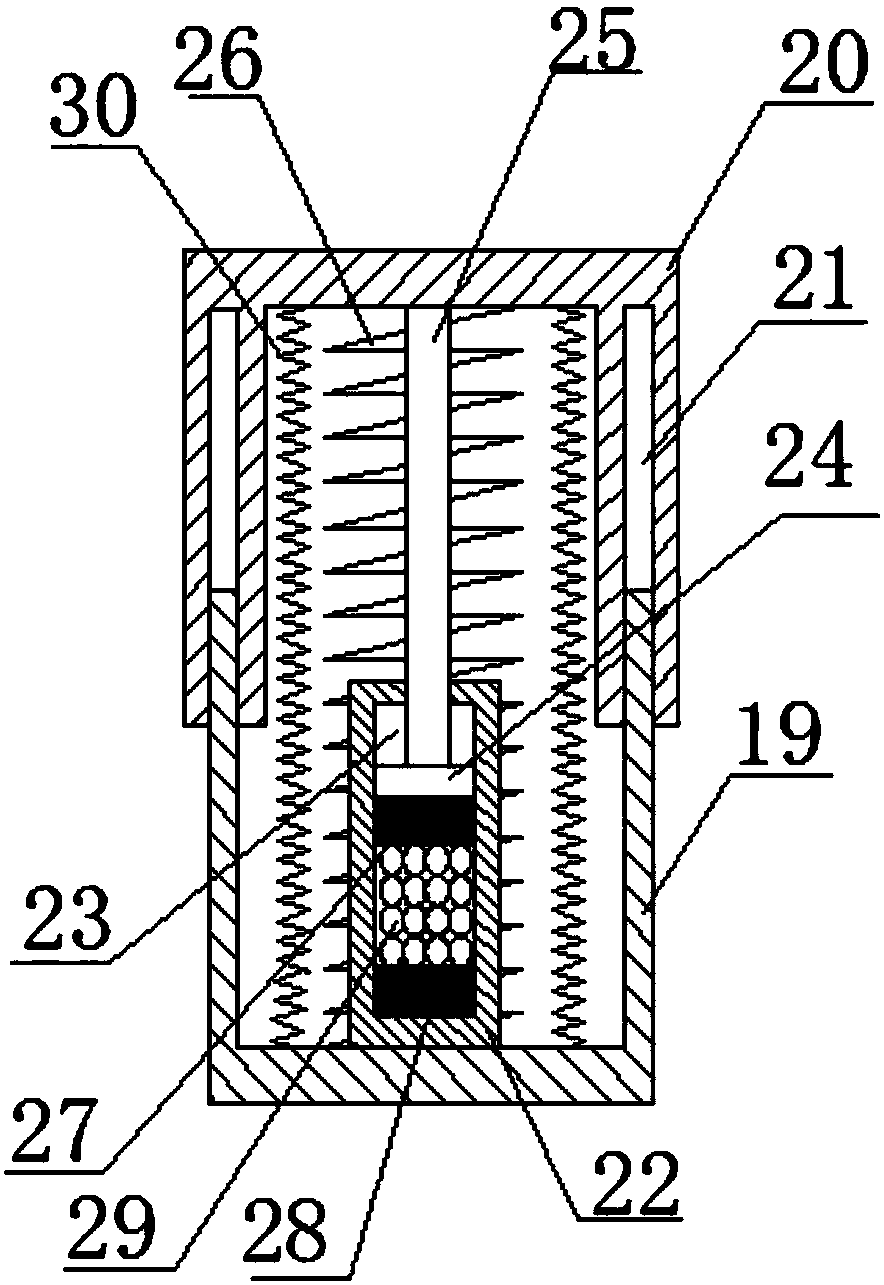

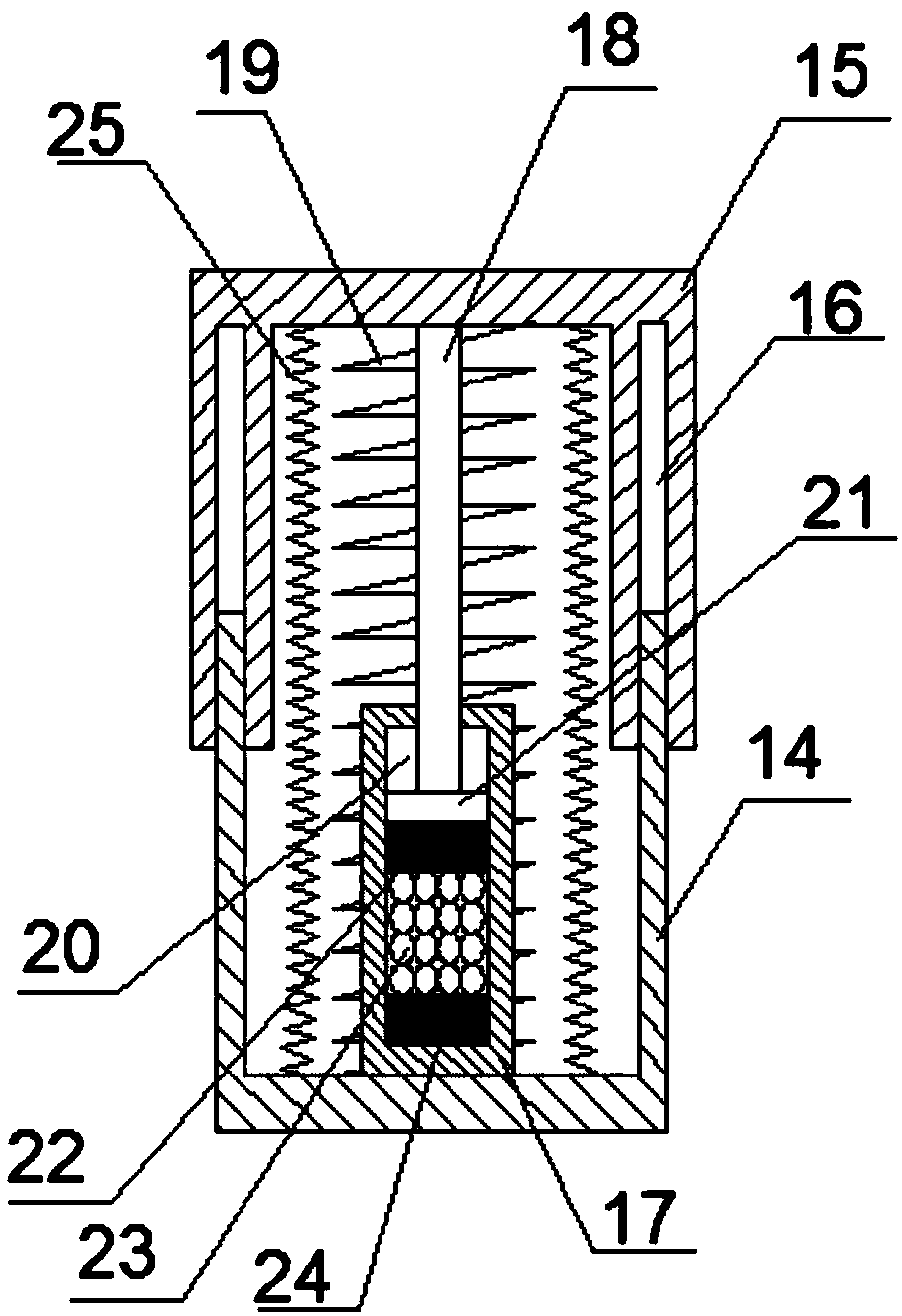

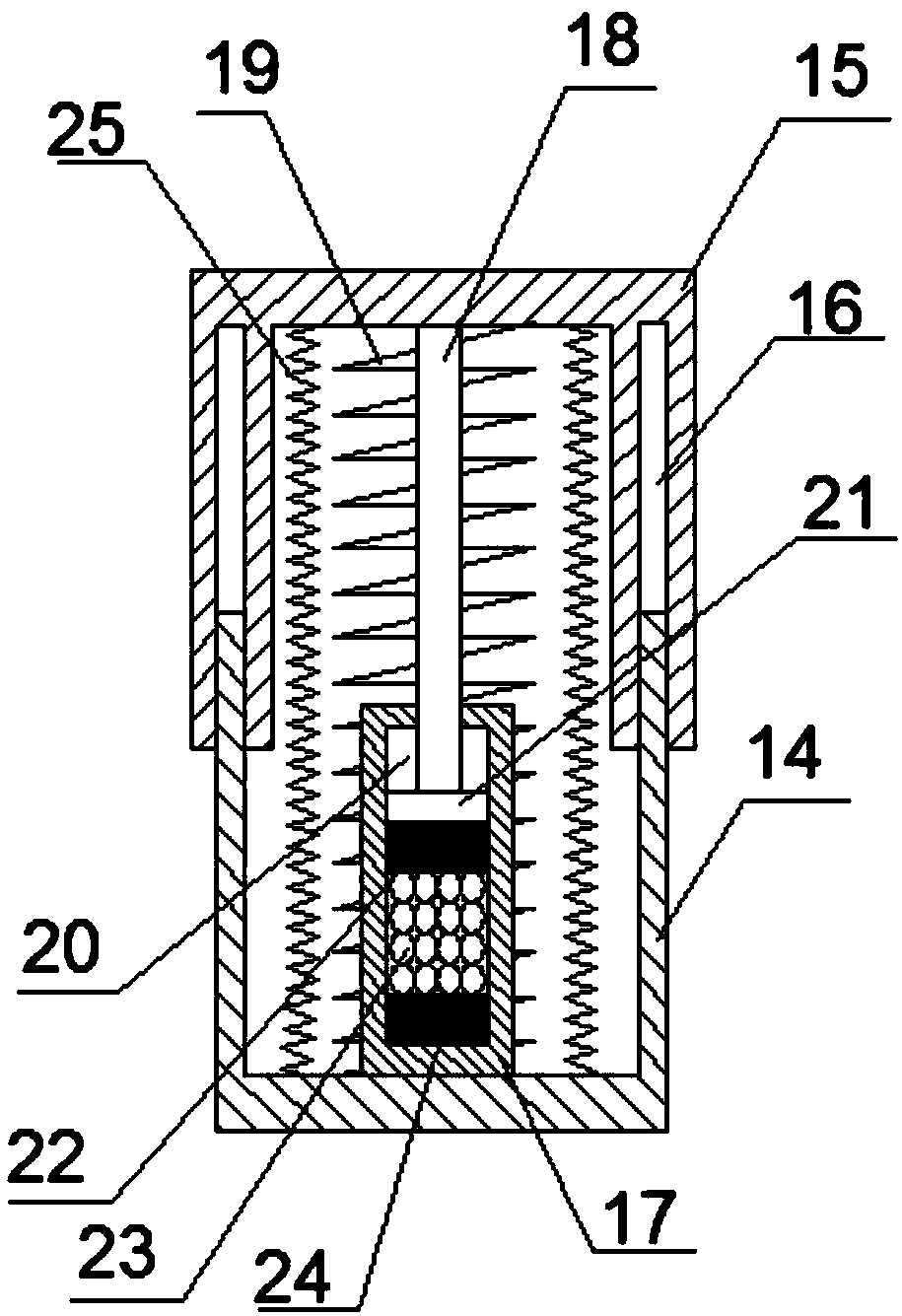

High-efficiency shock-absorbing permanent magnet motor

ActiveCN109494925AReduce vibrationExtended service lifeCooling/ventillation arrangementSupports/enclosures/casingsEngineeringPermanent magnet motor

The invention discloses a high-efficiency shock-absorbing permanent magnet motor, which comprises a motor base housing. The motor base housing is composed of four arc-shaped plates and two circular plates. The sidewalls of the four arc-shaped plates are successively attached and connected so as to form an annular shape. The high-efficiency shock-absorbing permanent magnet motor is simple in structure, can buffer the motor in multiple directions by means of a first spring, a second spring, a third spring and a fifth spring, reduces the vibration of the motor, thereby reducing the noise and prolonging the service life of the motor. A coolant liquid circulates in two annular tubes and a box so as to dissipate the heat inside. A fan rotates to dissipate the heat of internal components. A plurality of heat sinks are disposed outside a cylinder, ensures the high efficiency of heat dissipation and a long use time. The motor base housing can be taken out of the cylinder so as to facilitate thereplacement of the first spring and the third spring and the repair or replacement of the components inside the motor base housing, thereby ensuring the shock-absorbing function and the normal operation of the motor.

Owner:YANGZHOU FANGYUAN ELECTRICAL MFG

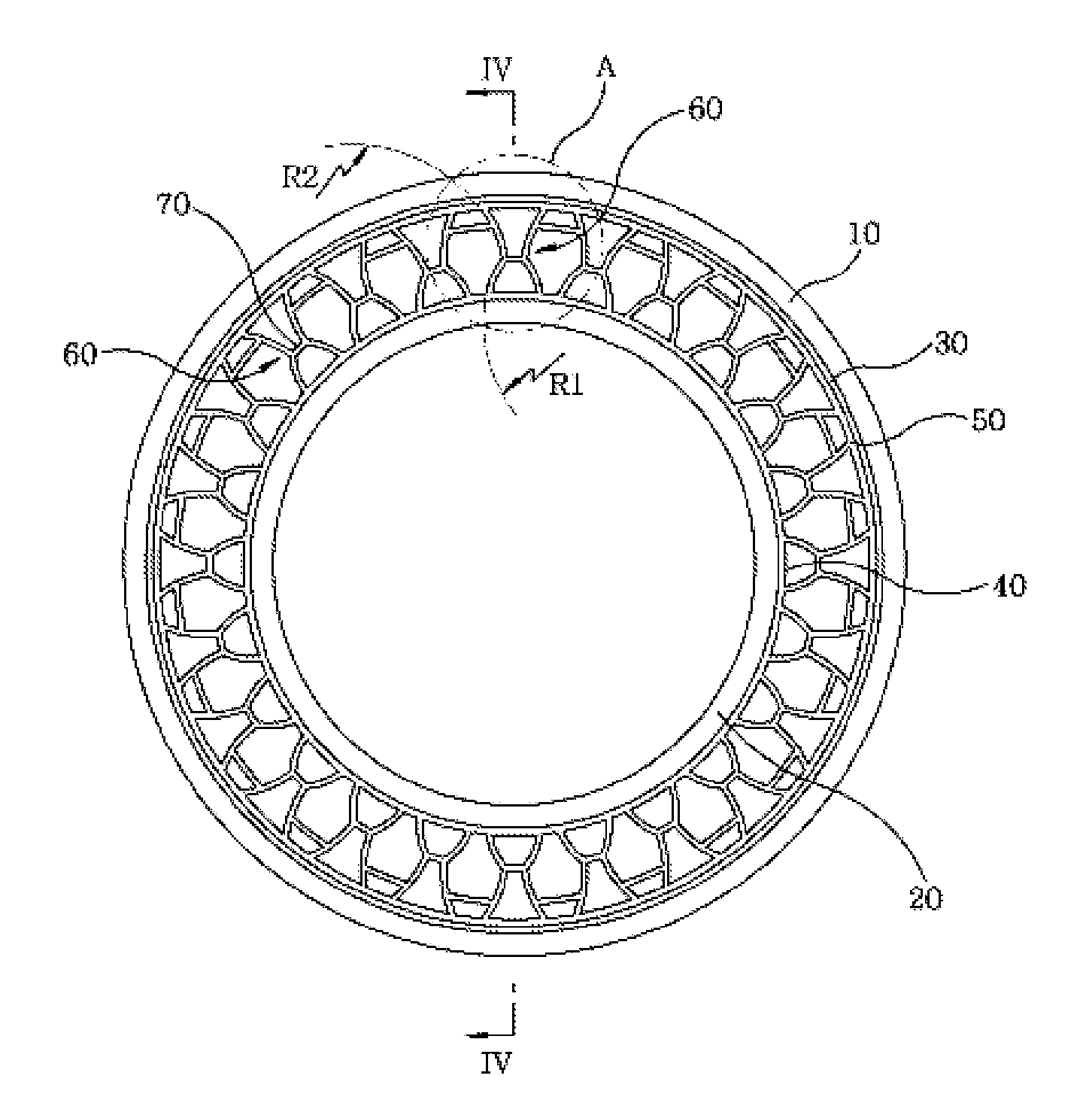

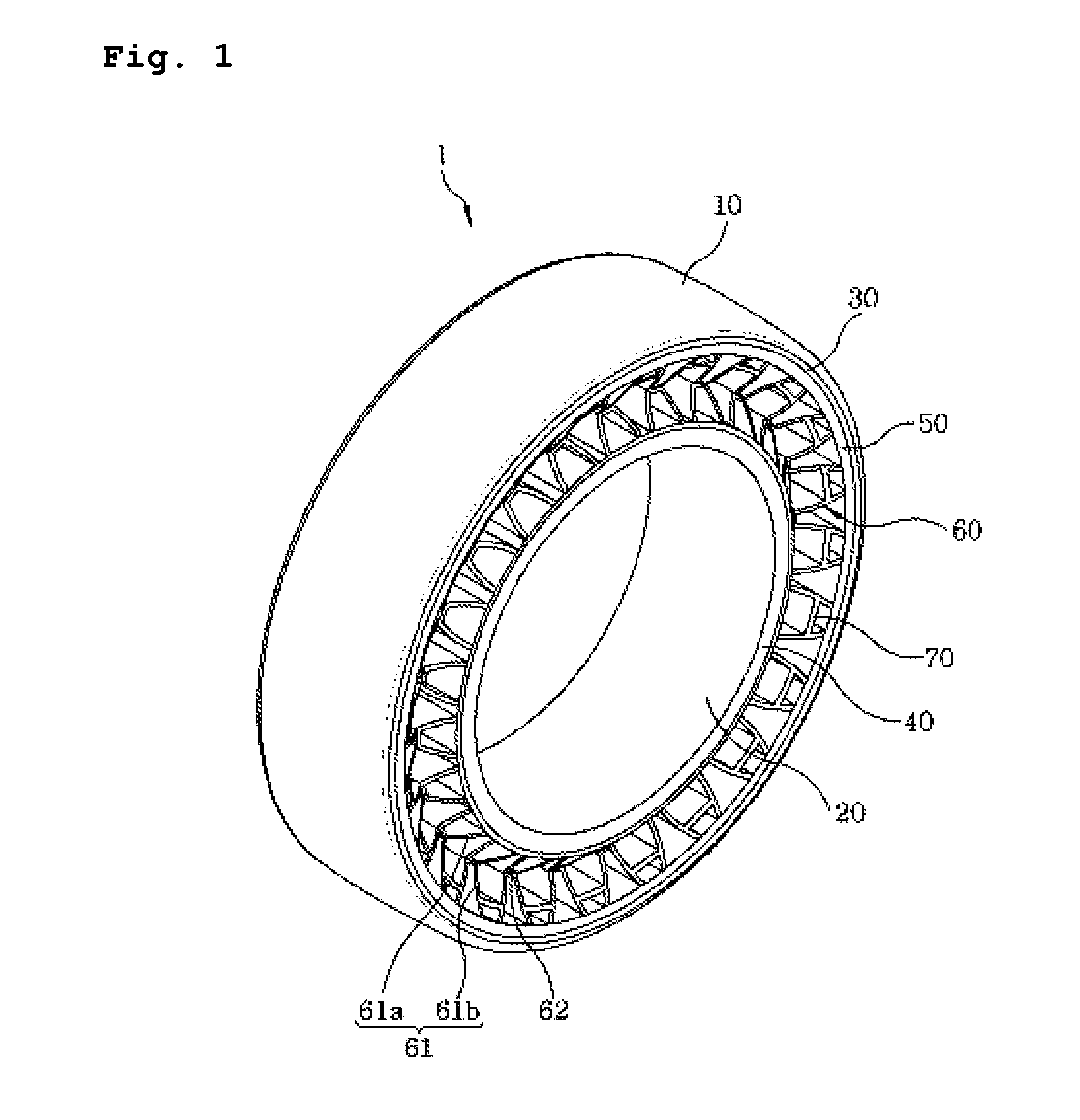

Airless tire

ActiveUS9387726B2Guaranteed shock absorptionDurability of of shockNon-inflatable tyresSpoked wheelsEngineeringElectrical and Electronics engineering

The present invention relates to an airless tire, and includes first and second bands that face each other with a distance interposed therebetween, a plurality of spokes that connect the first band to the second band and are provided at intervals, and first and second connecting members that connect the adjacent spokes. The spoke includes a first member of which one end is curved from the first band toward the second band, and a second member of which one end is curved from the second band toward the first band. The other ends of the first and second members are connected to each other, and the first and second members are curved in opposite directions.

Owner:HANKOOK TIRE WORLDWIDE

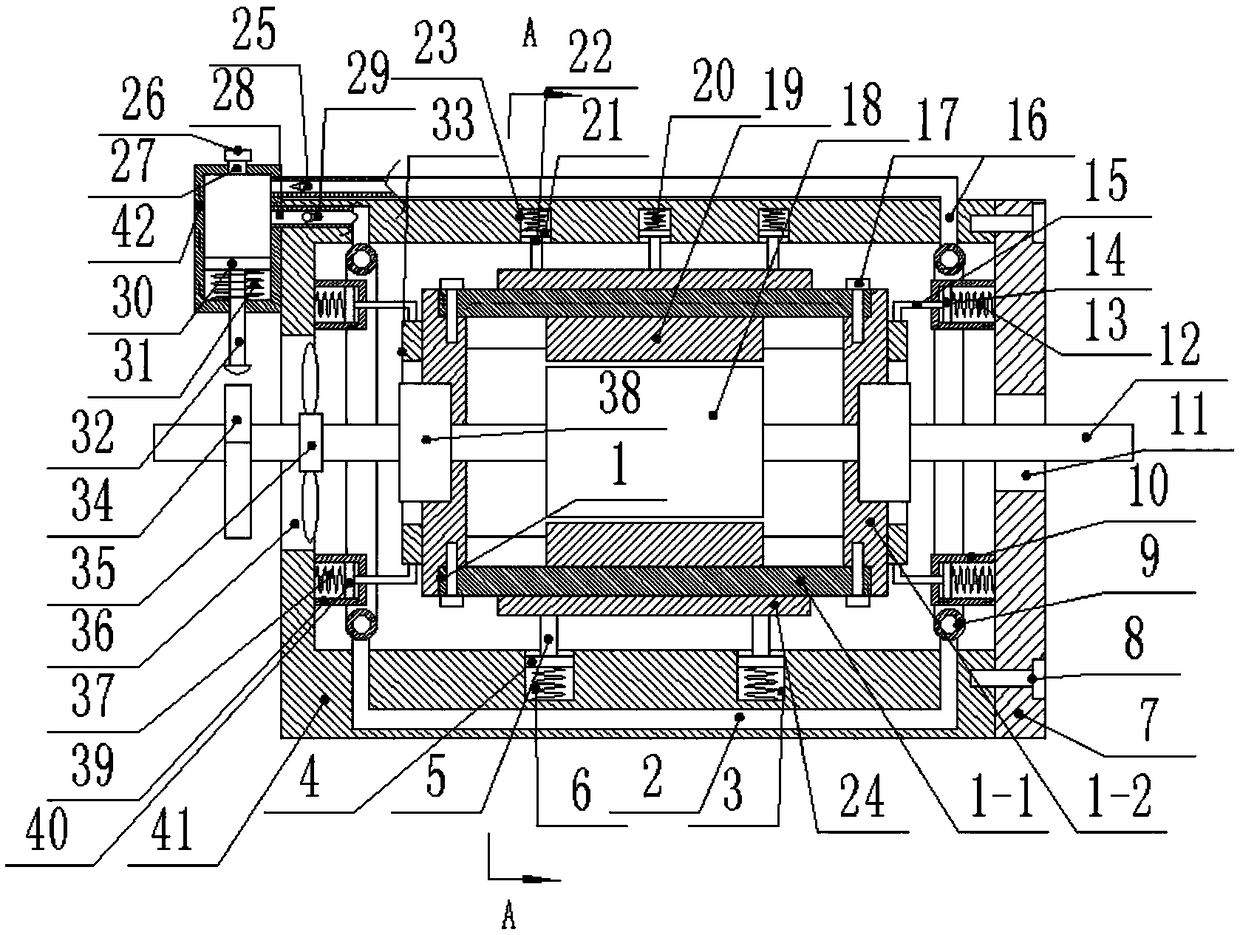

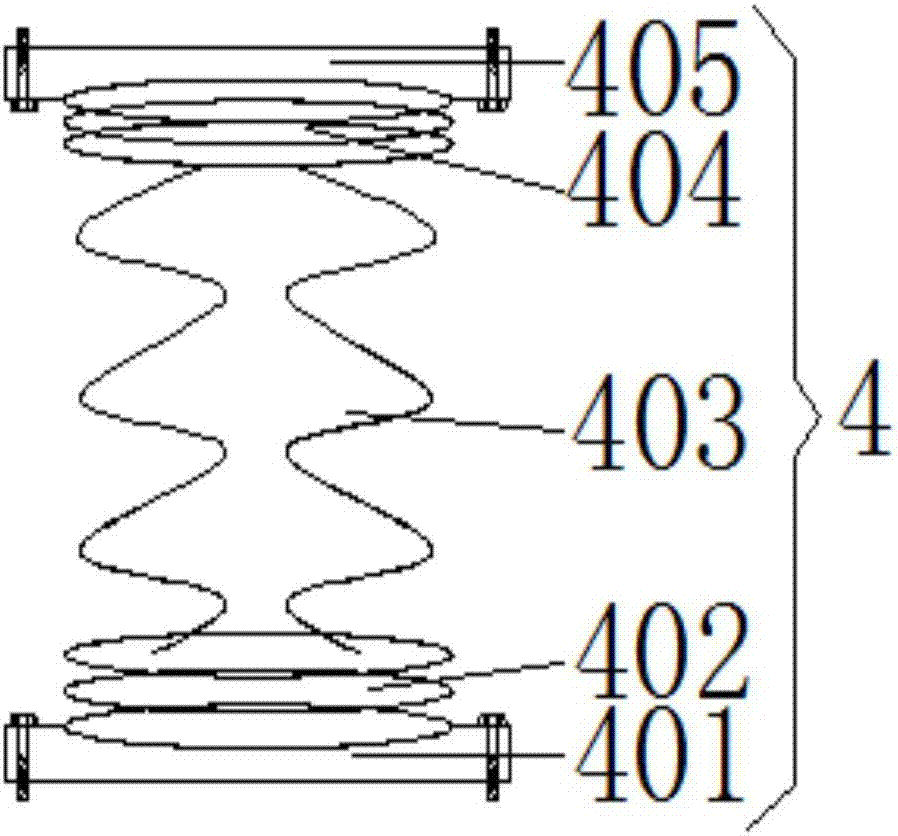

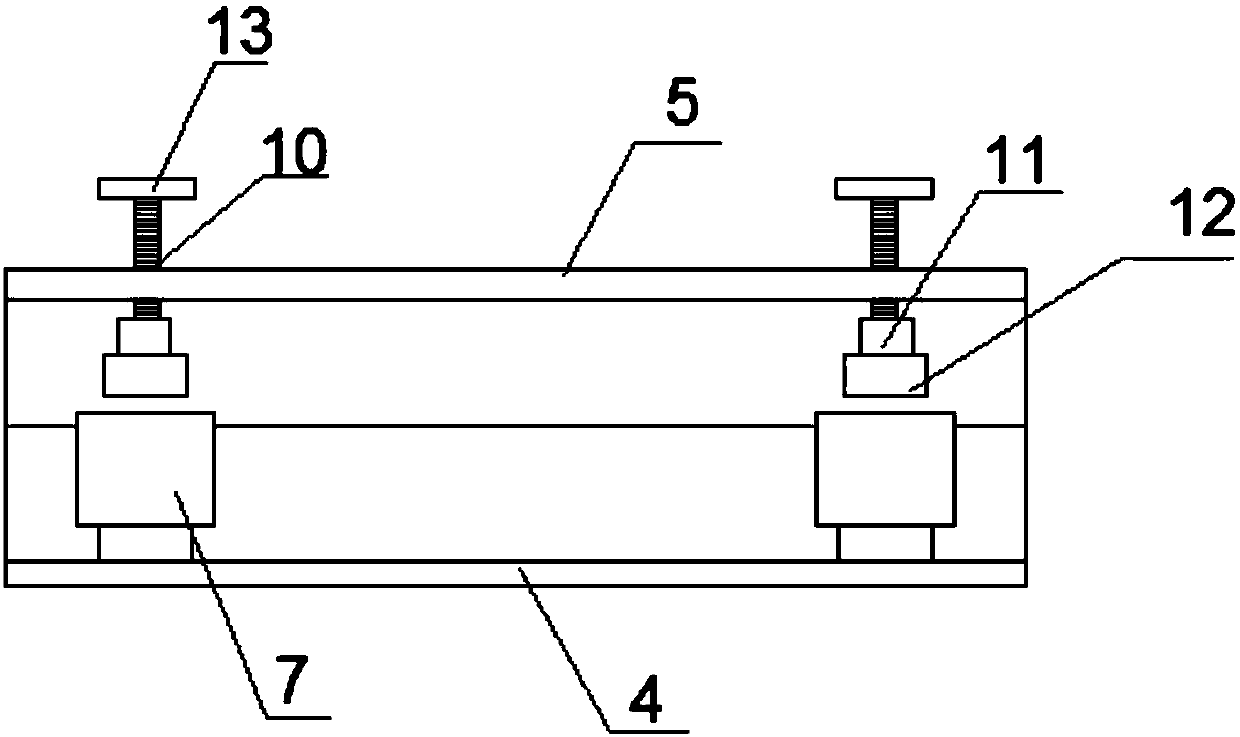

Damping device for computer mainframe box

InactiveCN104571385ARealize the first level of shock absorptionRealize the second level of shock absorptionDigital processing power distributionEngineeringGasket

The invention relates to a damping device for a computer mainframe box. The damping device comprises a U-shaped base and a mainframe body, wherein a supporting bottom plate is arranged inside the U-shaped base; a damping device part is arranged between a bottom surface of the U-shaped base and the supporting bottom plate; guide posts are arranged at the two sides of an upper end surface of the supporting bottom plate; the guide posts are connected with a slide sleeve on the mainframe body; supporting springs are arranged on positions, which are positioned on the guide posts, at upper and lower sides of the slide sleeve; locking gaskets and locking nuts are arranged at the upper ends of the guide posts. According to the damping device disclosed by the invention, during vibration, the supporting bottom plate moves up and down along the inner part of the U-shaped base under the action of the damping device part, so that first-stage damping of the mainframe body is realized; meanwhile, the slide sleeve on the mainframe body moves up and down along the guide posts under the action of the supporting springs, so that rigid impact of vibration to the mainframe body is avoided, second-stage damping of the mainframe body is realized, a damping effect of the mainframe is guaranteed, and electronic elements are protected.

Owner:HEFEI MENGLONG ELECTRONICS TECH

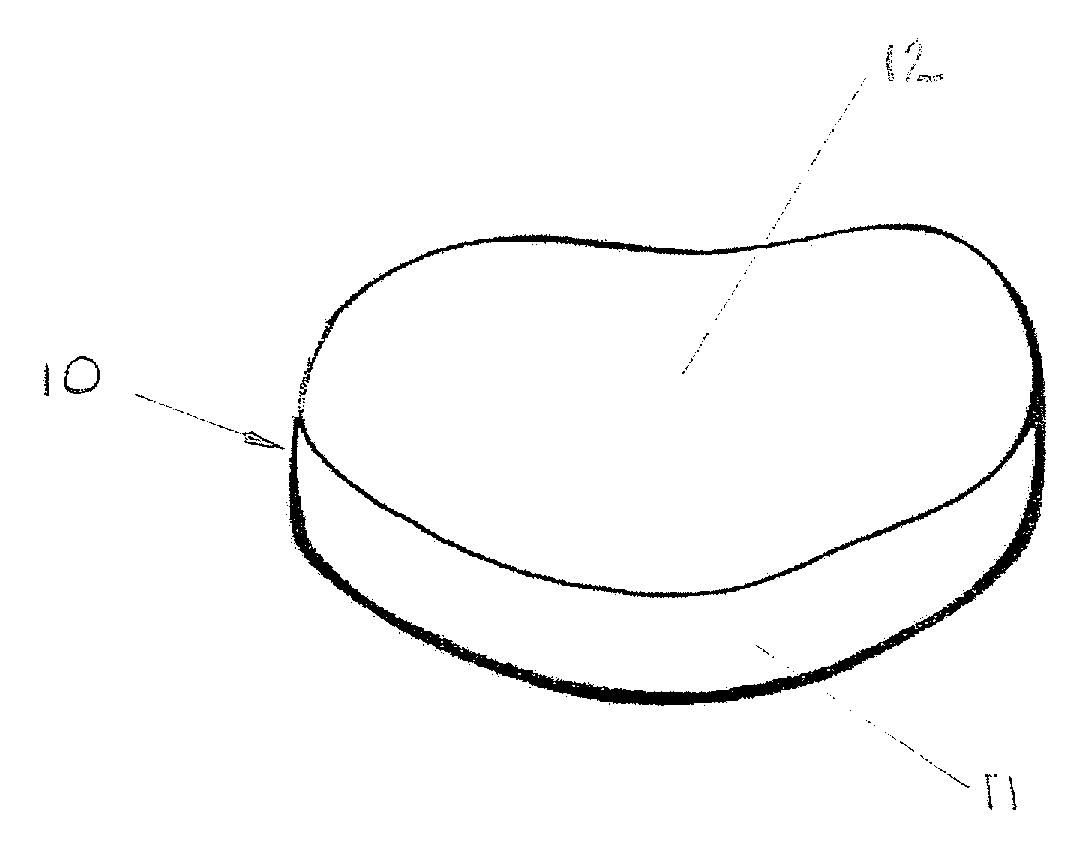

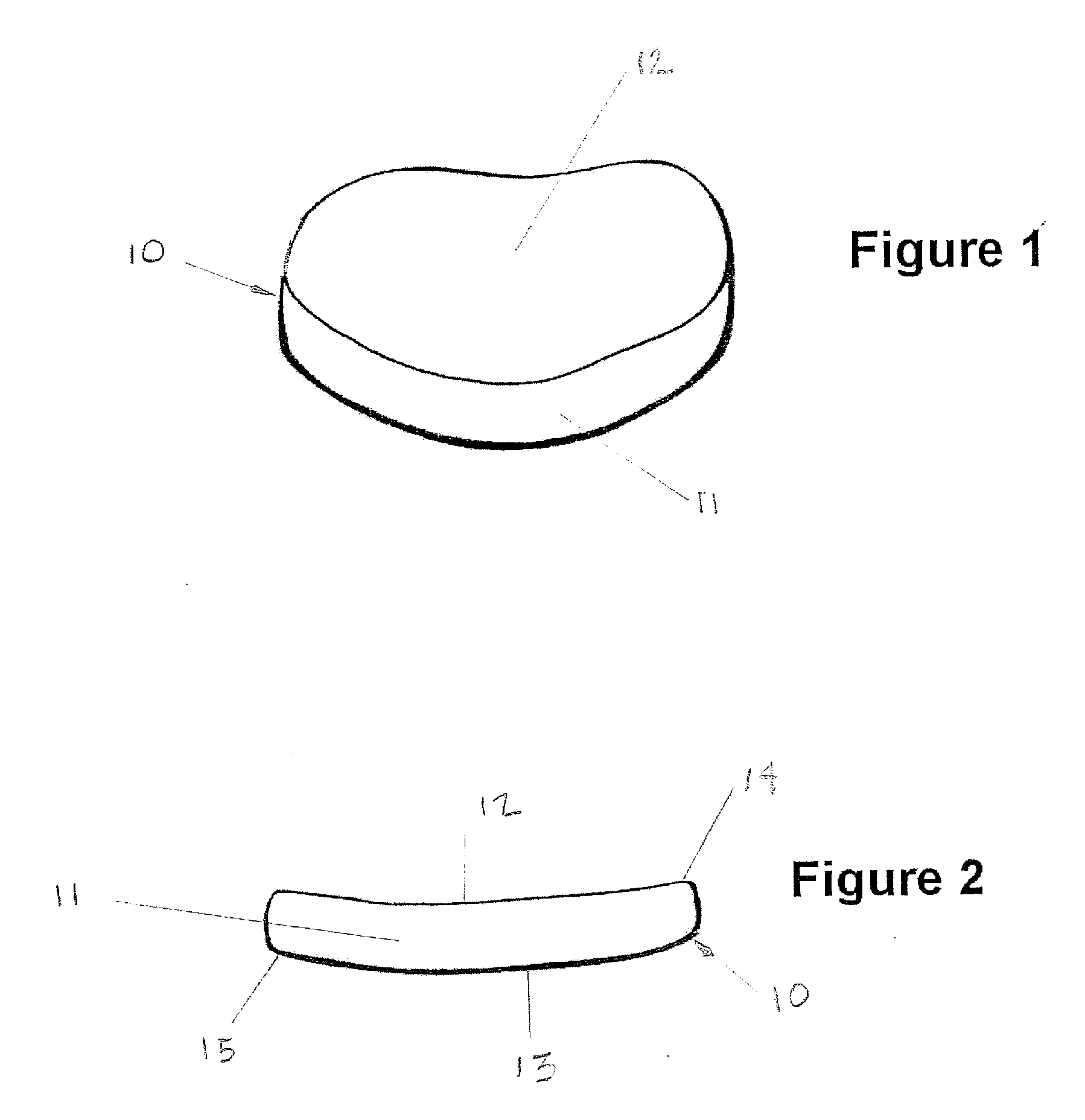

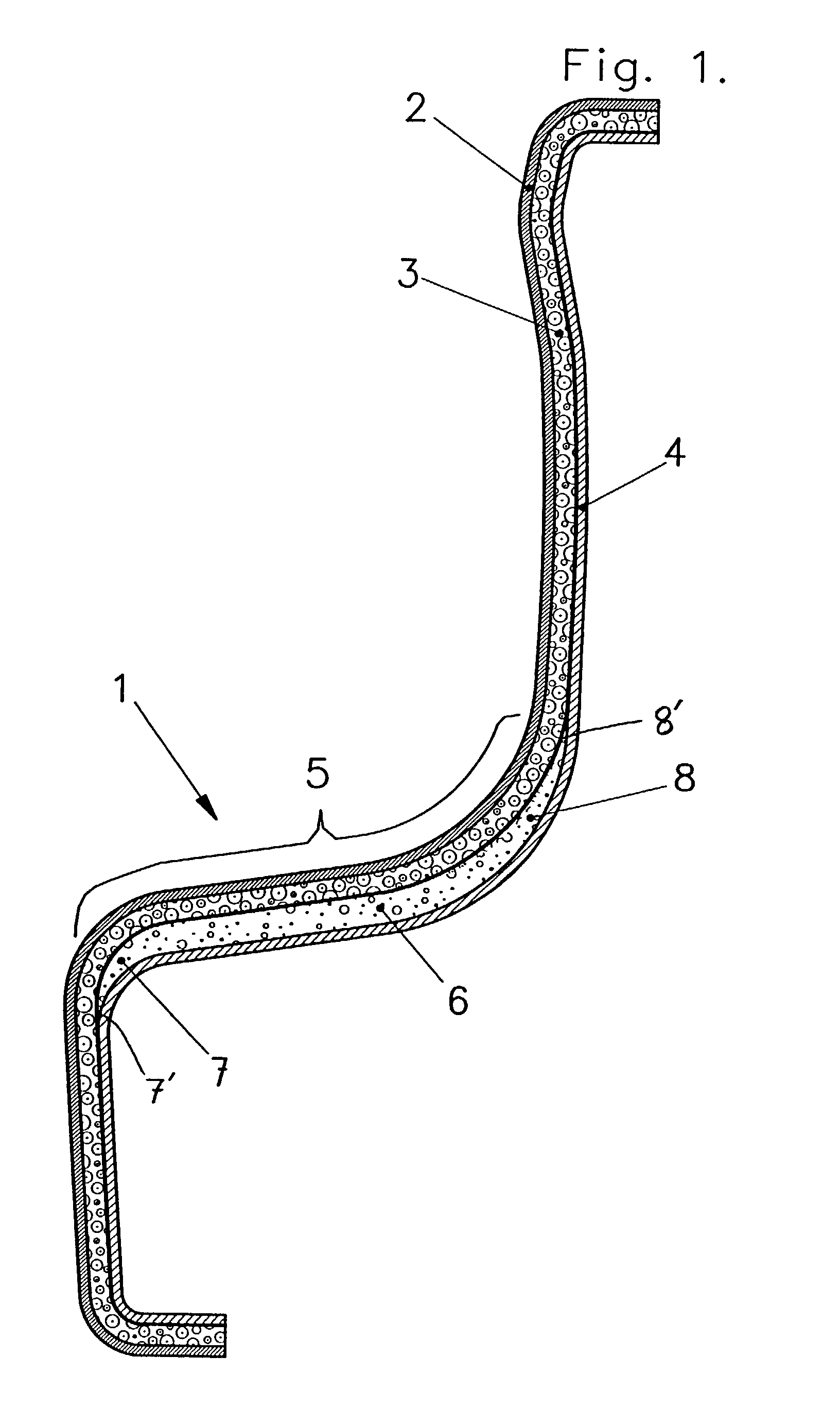

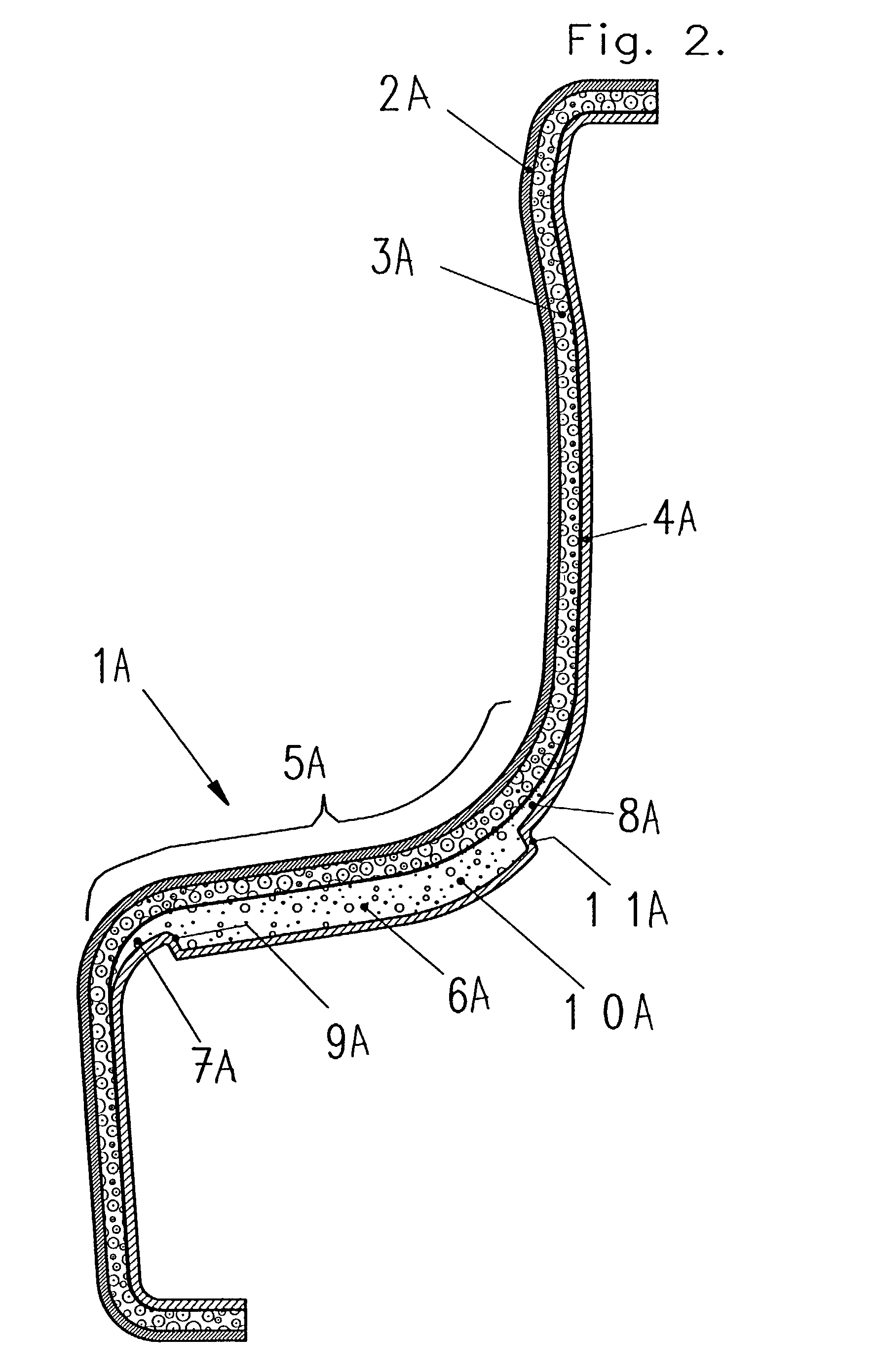

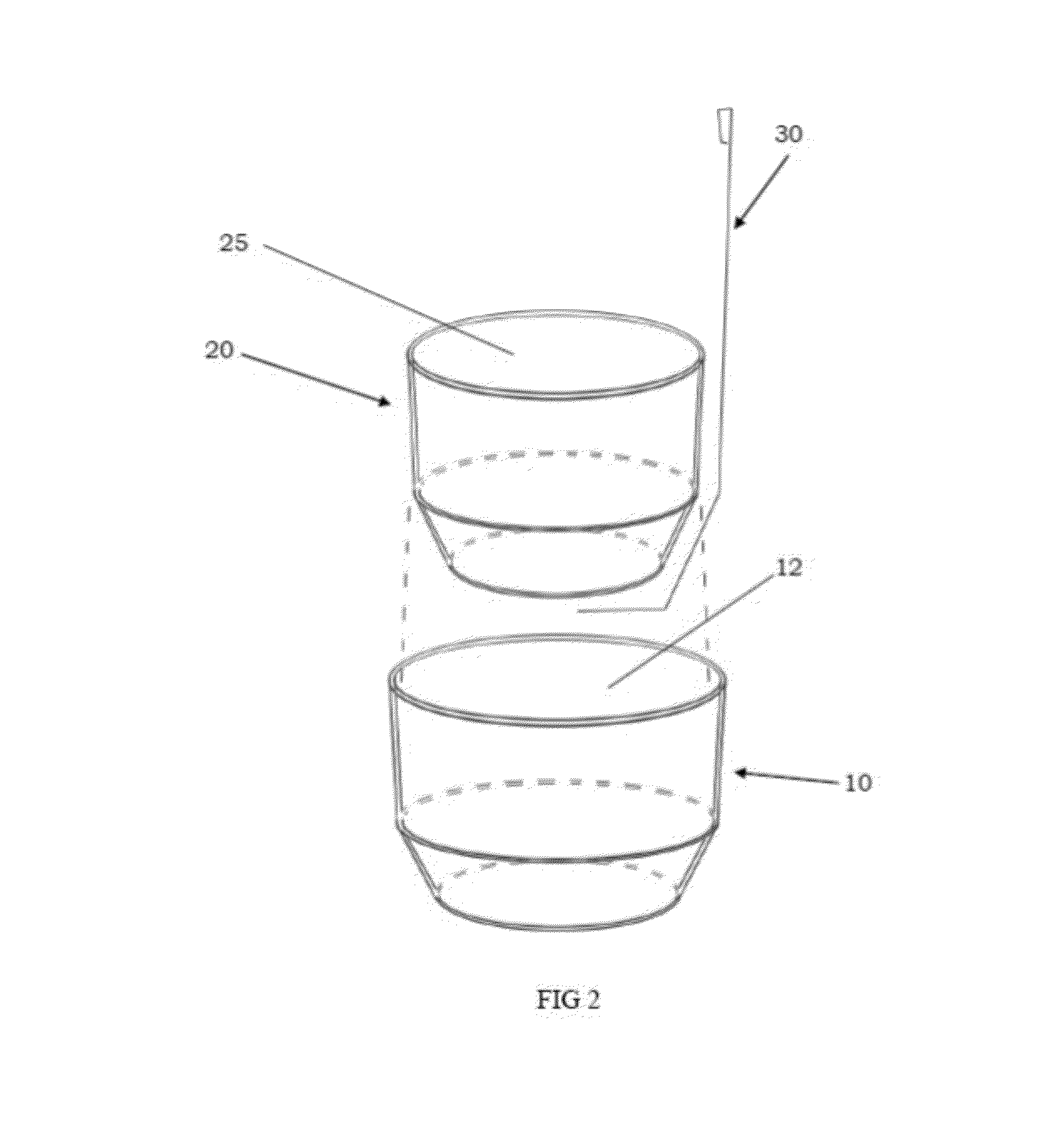

Flexible spinal disc

InactiveUS20070164464A1Allow flexibilityGuaranteed shock absorptionMovable spraying apparatusWood working apparatusMedicineIntervertebral space

Owner:SPINEMEDICA

Method and apparatus for making a trim component with a foam core having a smoothly varying thickness

InactiveUS6982021B2Varying thicknessIncreasing the thicknessAdhesive processesEngine sealsCushioningThermoplastic

A trim component includes a foam backing layer and a foam pad insert laminated between a cover material and a substrate. The foam pad insert provides an area of enhanced cushioning, and has smoothly tapered edges to ensure a smooth surface contour without a visible edge transition on the cover material. The foam pad insert has a lower melting temperature than the foam backing layer, both of which are thermoplastics. A foam pad insert is positioned and fixed on the back surface of the foam backing layer. A substrate material is heated and then laminated and molded with the foam and the cover material. The heat from the substrate partially softens and melts the foam backing layer and the foam pad insert. The partially melted foam pad insert is viscously deformed to form the tapered edges, as dictated by the smoothly varying mold gap spacing of the forming tools.

Owner:HERBERT OLBRICH

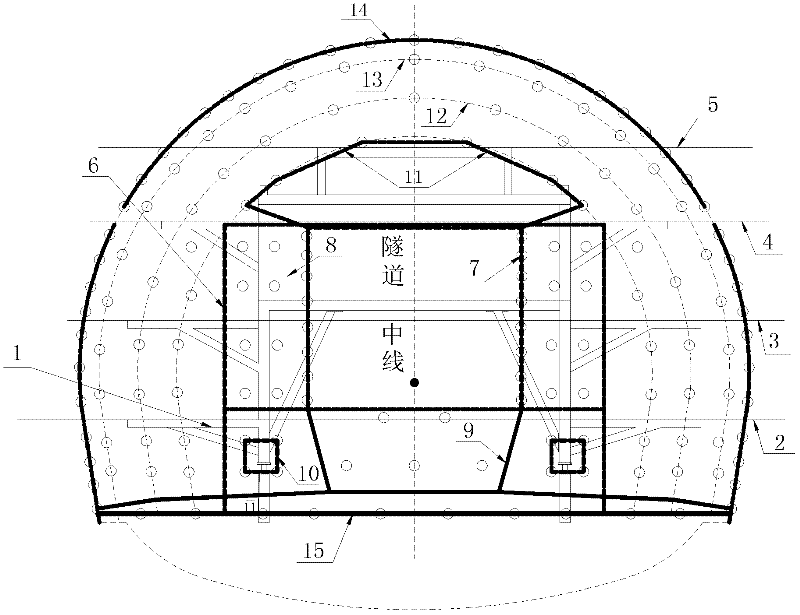

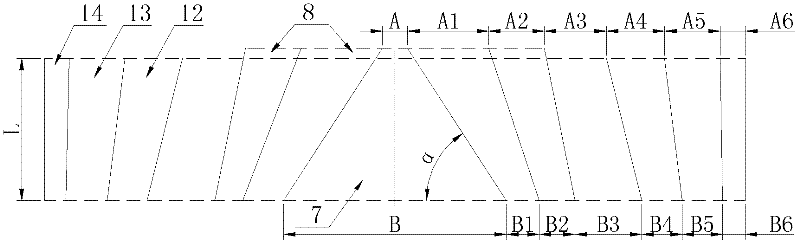

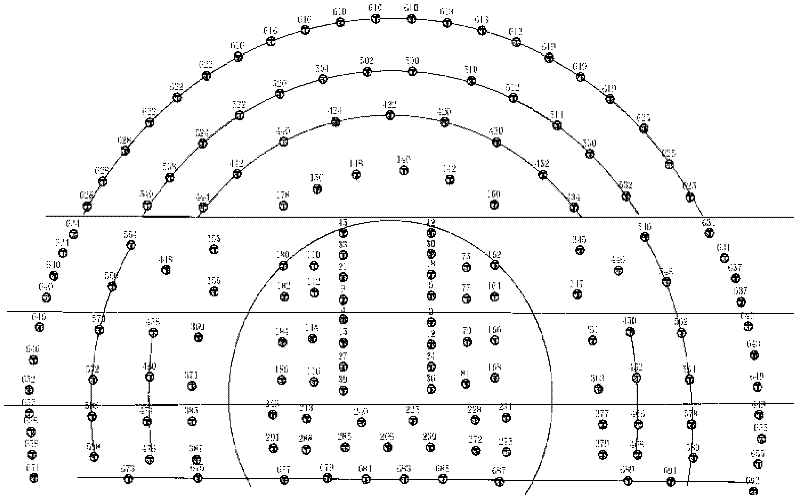

Full-face blasting vibration control construction method for tunnel electronic millisecond electric detonator

ActiveCN102506622AGuaranteed shock absorptionIncrease Single Cycle FootageBlastingDetonatorTime delays

The invention discloses a full-face blasting vibration control construction method for a tunnel electronic millisecond electric detonator, relating to the blasting vibration control technology. The method comprises the following step of: performing a full-face blasting damping control drilling-blasting design by combining blasting vibration requirements according to a tunnel engineering geological condition, an excavated section, an excavating method, a tunneling circulation footage, drilling machine tools and blasting equipment, wherein the drilling-blasting design is as follows: in order to realize the single blasting of cutting holes, auxiliary holes and base plate holes, peripheral holes which are blasted simultaneously are grouped, and the detonator time delay of each shot hole is set, so that the misphase blasting damping is realized; a use flow of the electronic millisecond electric detonator is designed, and the electronic millisecond electric detonator is used according to the flow; an analysis is carried out in the construction process according to the blasting effect and the vibration waveform obtained by blasting monitoring, information is fed back to guide the construction, and blasting parameters are adjusted continuously. The blasting construction method has the advantage of capability of obviously reducing the full-face blasting vibration.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Chemical material mixing device

InactiveCN107583532AExtended service lifeAvoid enteringRotary stirring mixersMixer accessoriesDrive wheelEngineering

Owner:TIANJIN KECHUANG FUXIN TECH CONSULTING CO LTD

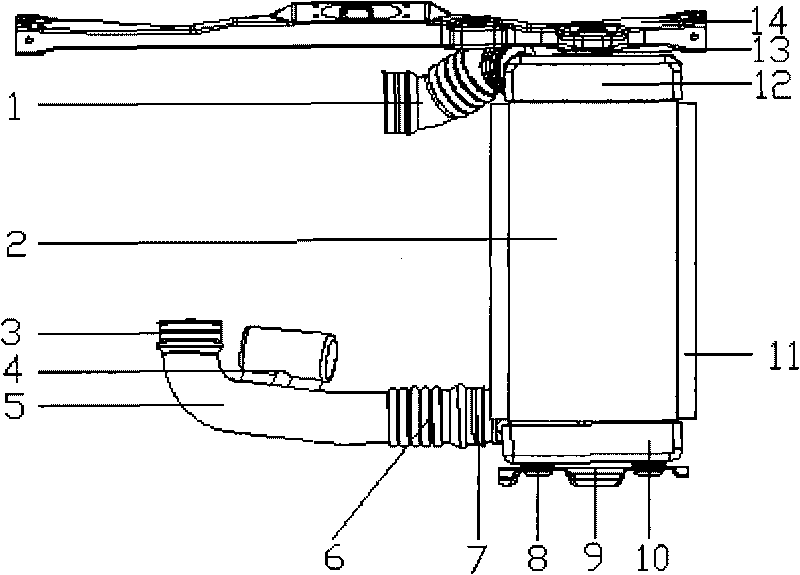

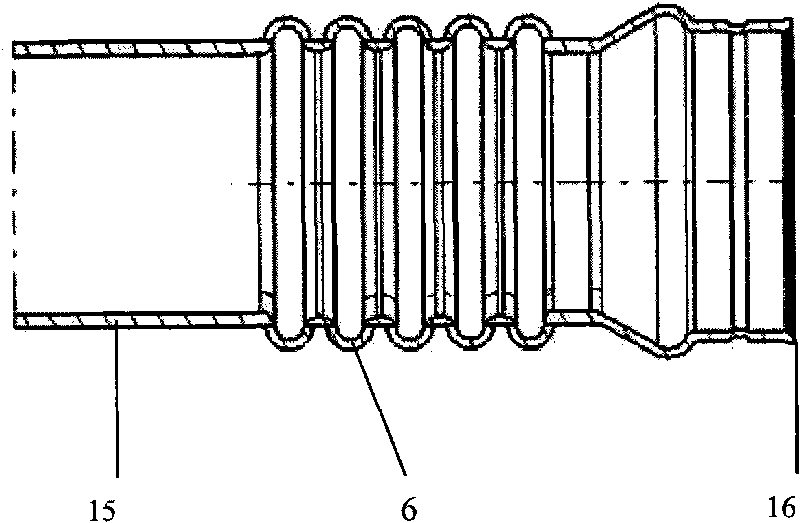

Intercooling system and constructing method thereof

ActiveCN101749101AGuaranteed cooling effectEliminate low frequency noiseInternal combustion piston enginesIntake silencers for fuelResonant cavityThermoplastic elastomer

The invention relates to an intercooling system and a constructing method thereof. The volume, the size of the outlet diameter, the length of an outlet pipe of a resonant cavity are calculated and determined by analyzing the noise of a specific frequency band generated by a supercharger in the operation process of the whole vehicle. The resonant cavity is designed in an intercooling gas outlet hosepipe according to the position of the whole vehicle and the space arrangement condition so as to eliminate the noise of the low-frequency part of the mechanical supercharger and improve the NVH performance of the whole vehicle. The intercooling system pipeline guarantees the hosepipe joint has excellent sealing property and also guarantees the requirements of the pipeline for flexibility and pressure resistance by adopting a thermoplasticity elastic material and a unique structure.

Owner:CHERY AUTOMOBILE CO LTD

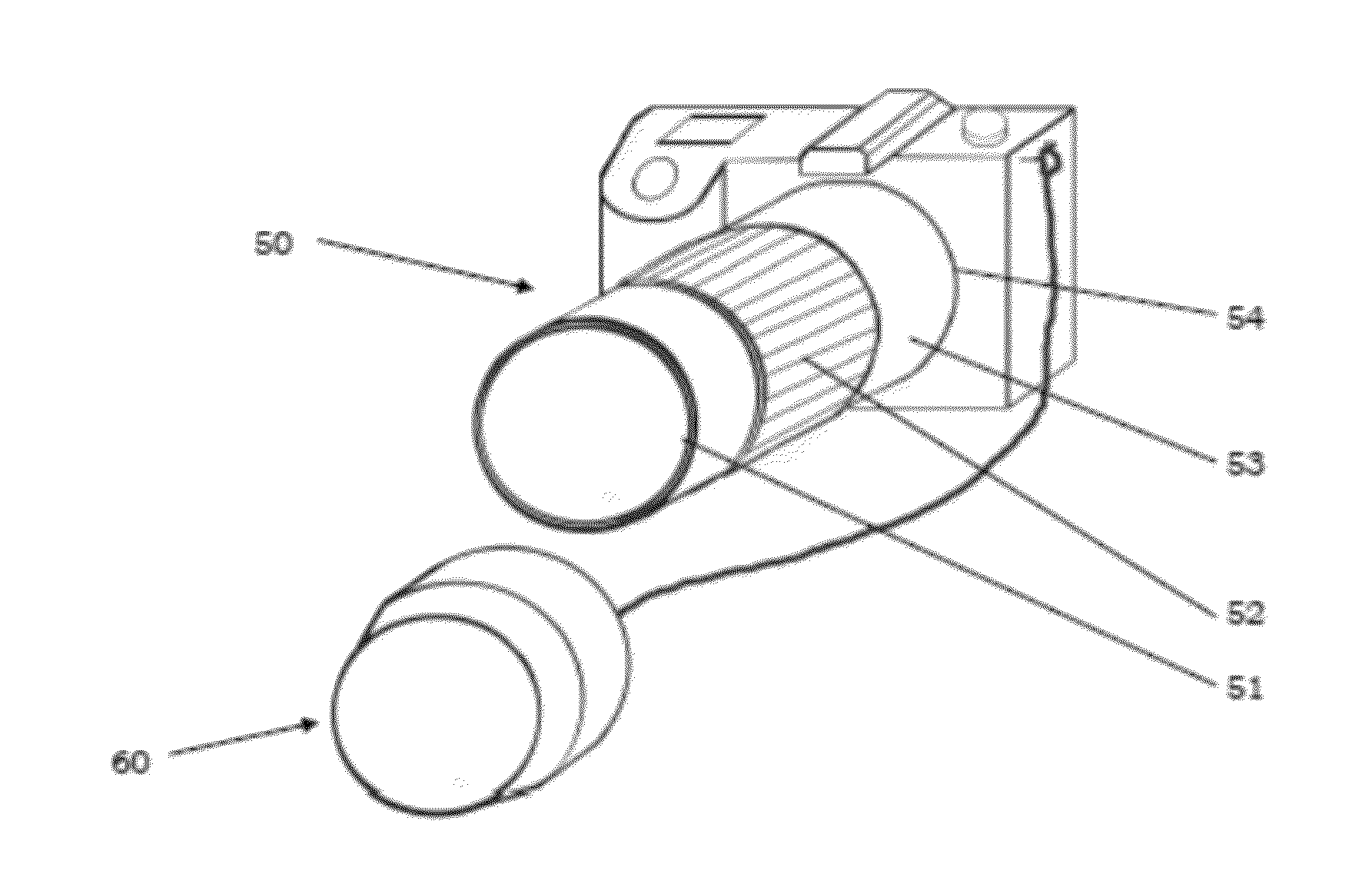

Protective cup lens cover

InactiveUS8292523B2Without potentially damaging the delicate components of the camera lens or the finish of the lens barrelImprove protectionTelescopesCamera filtersCamera lensProtective cup

A padded protective cup shaped covering sized to slip over a camera lens is disclosed. The covering is designed to fit on either the front portion of the lens or the lens mount. The protective covering has beveled side walls which allow it to fit easily on a variety of different lenses. The protective covering is made from two separate layers of material, an outer cup made from a firm yet flexible material, and the inner liner made from a soft pliable material. The soft inner liner allows the covering to easily adhere to the camera lens, and also provides impact protection. The outer cup provides additional impact protection. The outer cup also includes a domed top portion which provides a crumple zone or impact bumper. In one embodiment the outer cup has a clear optical grade lens or filer lens inserted or incorporated therein, which allows the camera user to take a photograph without removing the protective lens.

Owner:DELUXGEAR

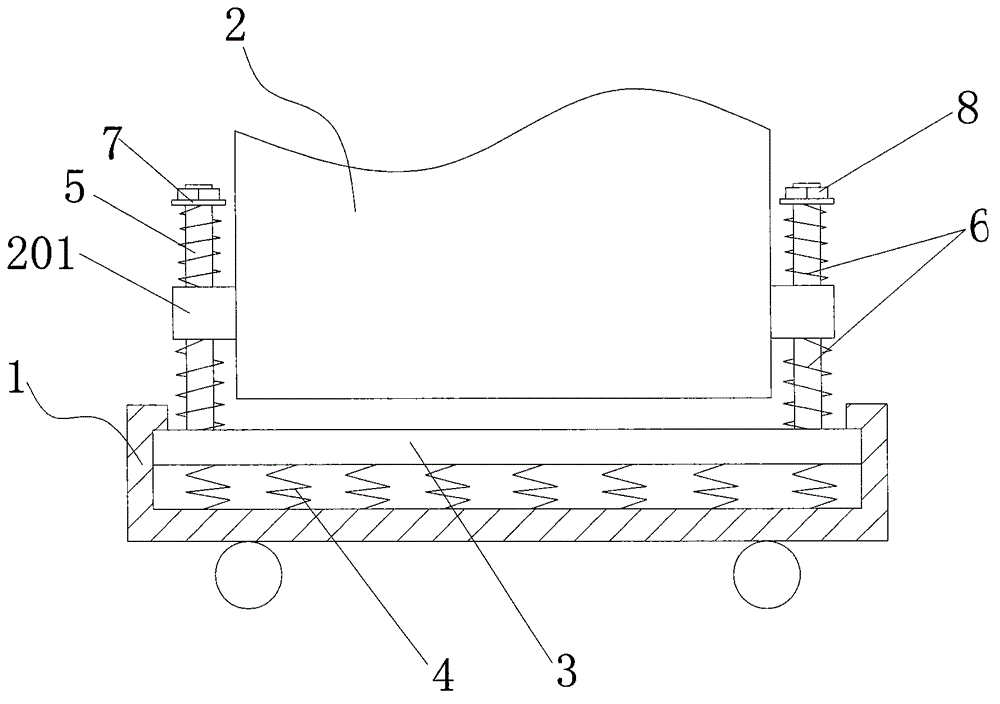

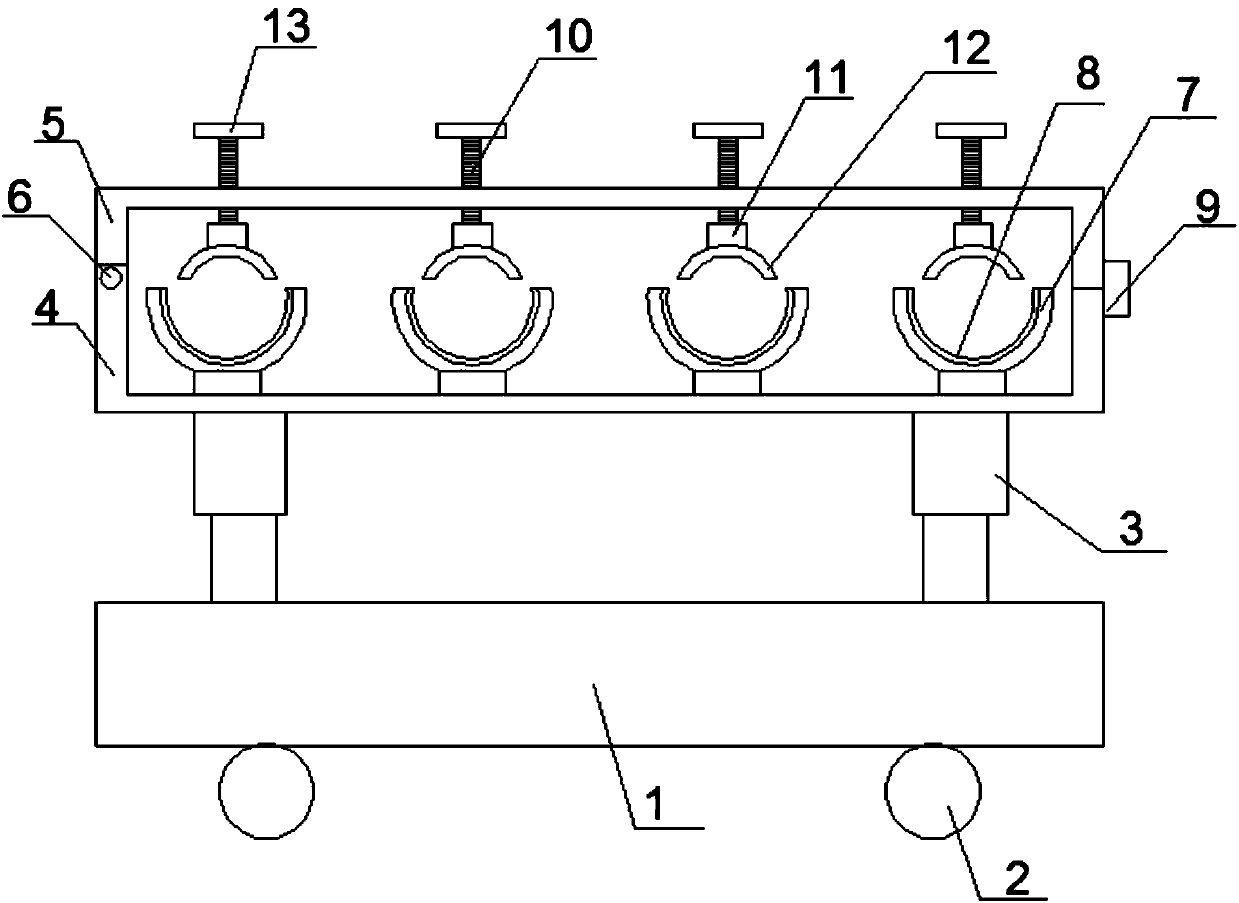

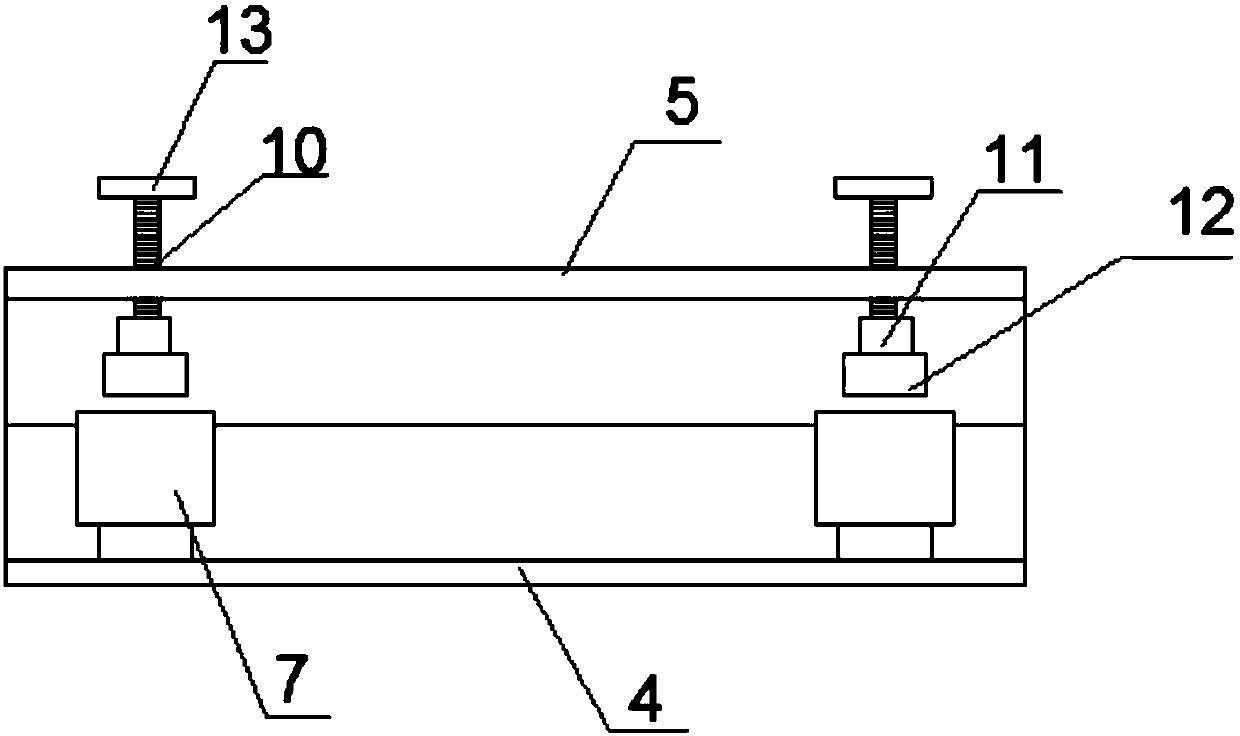

Transport vehicle with good shock absorption effect and for pipeline machining

InactiveCN108045419AAvoid damageAvoid enteringNon-rotating vibration suppressionSupporting partsFixed frameEngineering

The invention discloses a transport vehicle with a good shock absorption effect and for pipeline machining. The transport vehicle comprises a base. Universal wheels are arranged at the four corners ofthe lower side of the base. Shock absorption devices are bilaterally symmetrically arranged on the upper side of the base. Each shock absorption device comprises a supporting barrel and a telescopicbarrel. Sliding cavities are formed in the barrel walls of the telescopic barrels. The upper ends of the supporting barrels are arranged in the sliding cavities. Struts are arranged at the lower endsin the supporting barrels. Telescopic rods are arranged at the upper ends of the struts. Damping springs are arranged on the outer sides of the struts and the telescopic rods. Dust covers are arrangedon the outer sides of the damping springs. A support is arranged at the upper ends of the shock absorption devices. Multiple sets of fixed seats symmetrically arranged front and back are arranged inthe support from left to right. A fixing frame is arranged at the upper end of the support and provided with multiple threaded rods matched with the fixed seats. The lower ends of the threaded rods are rotationally connected with connecting seats. Arc-shaped press boards are arranged at the lower ends of the connecting seats. The transport vehicle is simple in structure, convenient to use, good inshock absorption effect, wide in application range and long in service life.

Owner:ZHENGZHOU GUOZHI NETWORK TECH CO LTD

Seal cooling device for battery of electric car

InactiveCN107471991AAchieving tightnessAvoid damageElectric propulsion mountingSecondary cellsAutomotive batteryElectric cars

The invention relates to the field of electric car fittings, in particular to a seal cooling device for a battery of an electric car. The seal cooling device for the battery of the electric car comprises a battery seal box and a heat dissipation box. The sides, close to each other, of the battery seal box and the heat dissipation box communicate through a pipeline, and the bottom of the inner wall of the battery seal box is fixedly connected with a battery supporting plate through a damping device; the top of the battery supporting plate is fixedly connected with a battery box, and the positions, right opposite to the battery box, of the two sides of the inner wall of the battery seal box are provided with damping fixing buckles; a seal cover is arranged at the top of the battery seal box, and one side of the bottom of the inner wall of an outer frame is fixedly connected with a heat dissipation fan; and a through slot matched with the heat dissipation fan is formed in one side of the outer frame, and the bottom end of a cross rod is fixedly connected with a through pipe. The seal effect on the battery is achieved, damping is ensured in the car moving process, the damage to the battery due to moving is reduced, the temperature of the battery is reduced through cooling of cooling liquid so that the battery can be used continuously, and the failure factors are reduced.

Owner:安吉天剑电器科技有限公司

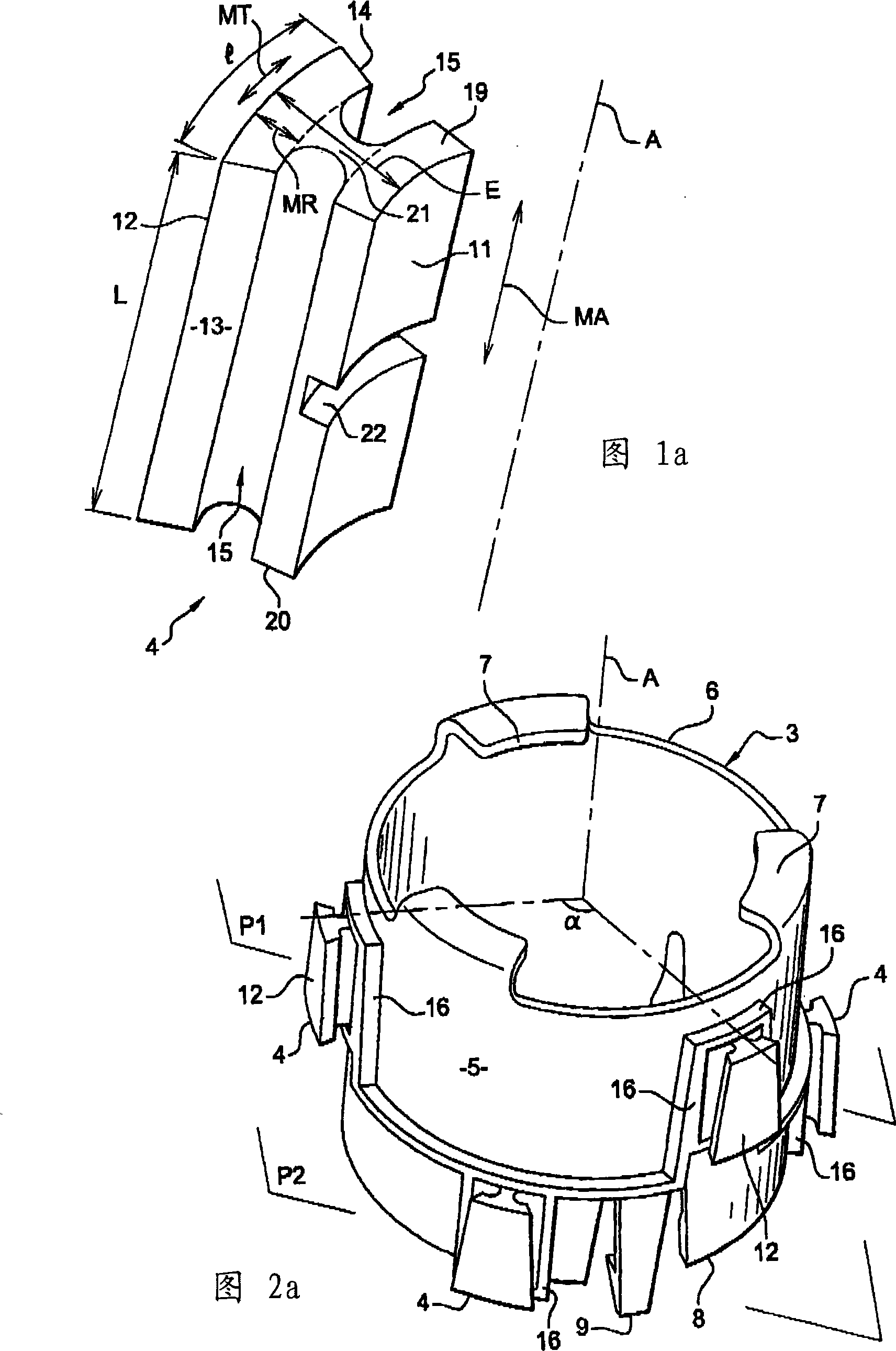

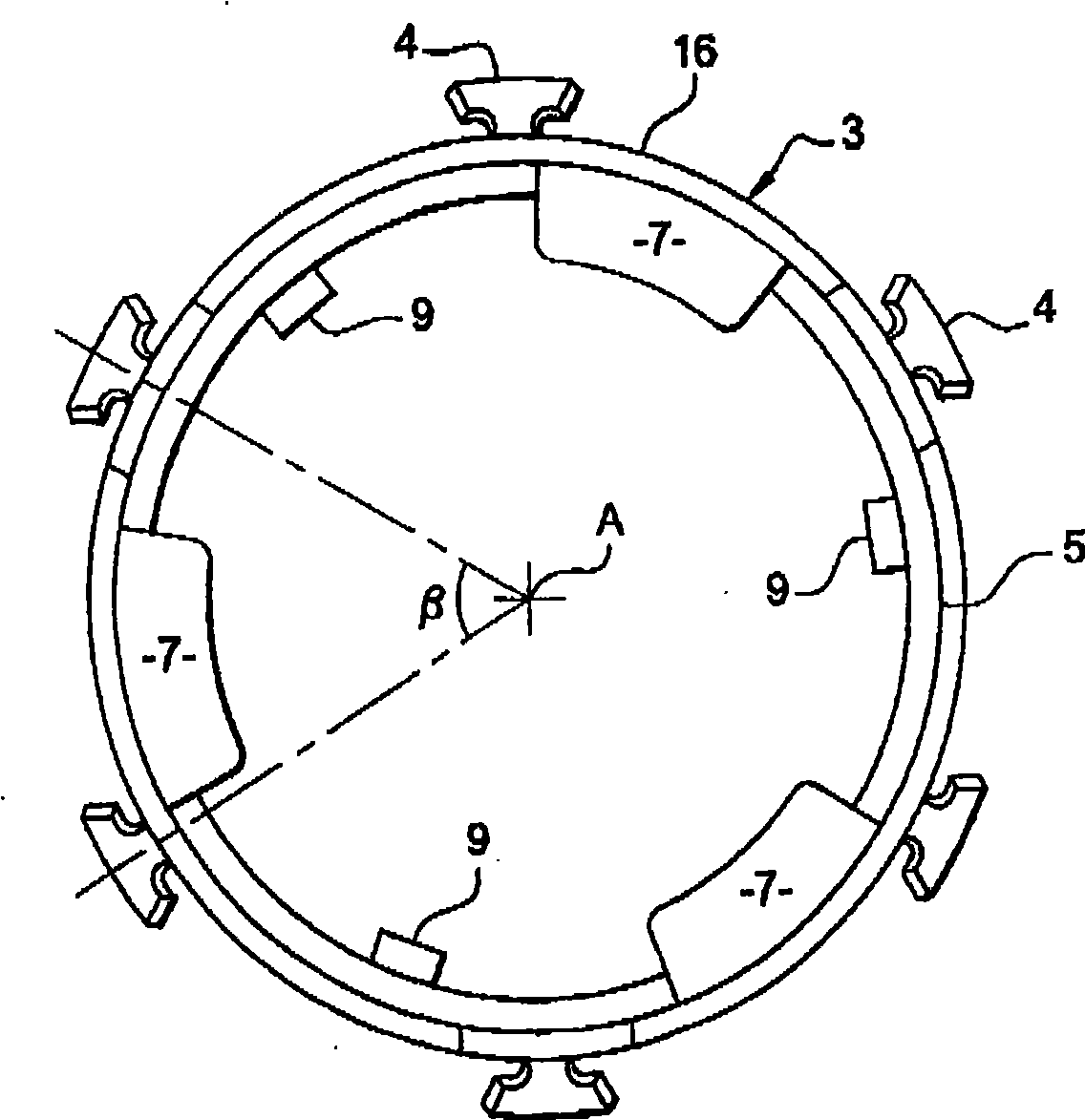

Support device for the motor of a heating and/or air-conditioning ventilation system

ActiveCN101488683AGuaranteed shock absorptionImprove comfortPump componentsNon-rotating vibration suppressionEngineeringMechanical engineering

The invention relates to a support device for the motor of a heating, ventilation and / or an air-conditioning ventilation system comprising a base, a ring which extends according to an axis and which is able to house the motor, and at least a decoupling means which connects the base and the ring, wherein the ring comprises a first face extending according to the axis A and the base comprises a second face extending according to the axis A. The decoupling means is interposed between the first and the second faces.

Owner:VALEO SYST THERMIQUES

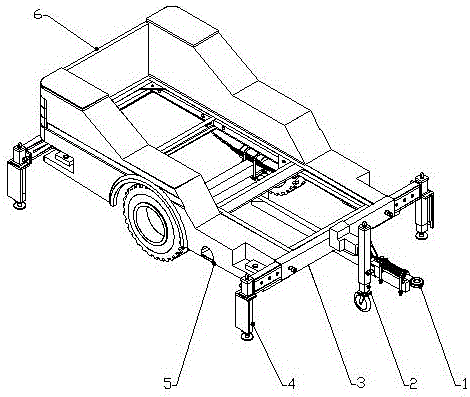

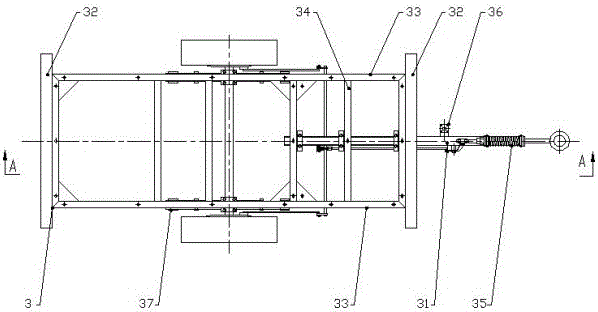

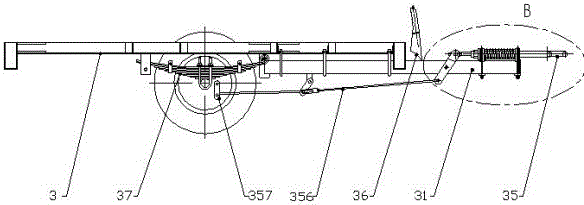

Trailer provided with support devices

InactiveCN105835845ASmall and flexibleEnsure driving safety performanceVehicle fittings for liftingAutomatic initiationsTruckVehicle frame

The invention relates to special vehicles, in particular to a trailer provided with support devices. The trailer comprises a chassis truck provided with a frame and side wall assemblies, wherein the frame is provided with the support devices, each support device comprises an inner sleeve and a landing leg, and a fixing block is arranged on the landing leg; a T-shaped block is mounted on an end surface of each inner sleeve, a hole in the T-shaped block is nested in a hole in the fixing block; first limiting pins and second limiting pins are mounted on the frame; a third limiting pin is mounted on each fixing block; a round hole which allows the first limiting pin to be nested is formed in one side of each inner sleeve, and a long-strip-shaped hole allowing the second limiting pin to be nested is formed in the other side of each inner sleeve. Compared with the prior art, the trailer is maneuverable, small and flexible, the obstacle passing capability and the bearing capability of the trailer are met, the stability and the shock absorption of equipment on the trailer during running can be guaranteed, the tires can be protected from deformation by external force during long-time parking of the trailer, and the service life of the tires is prolonged.

Owner:LONGYAN HAIDEXIN AUTOMOBILE

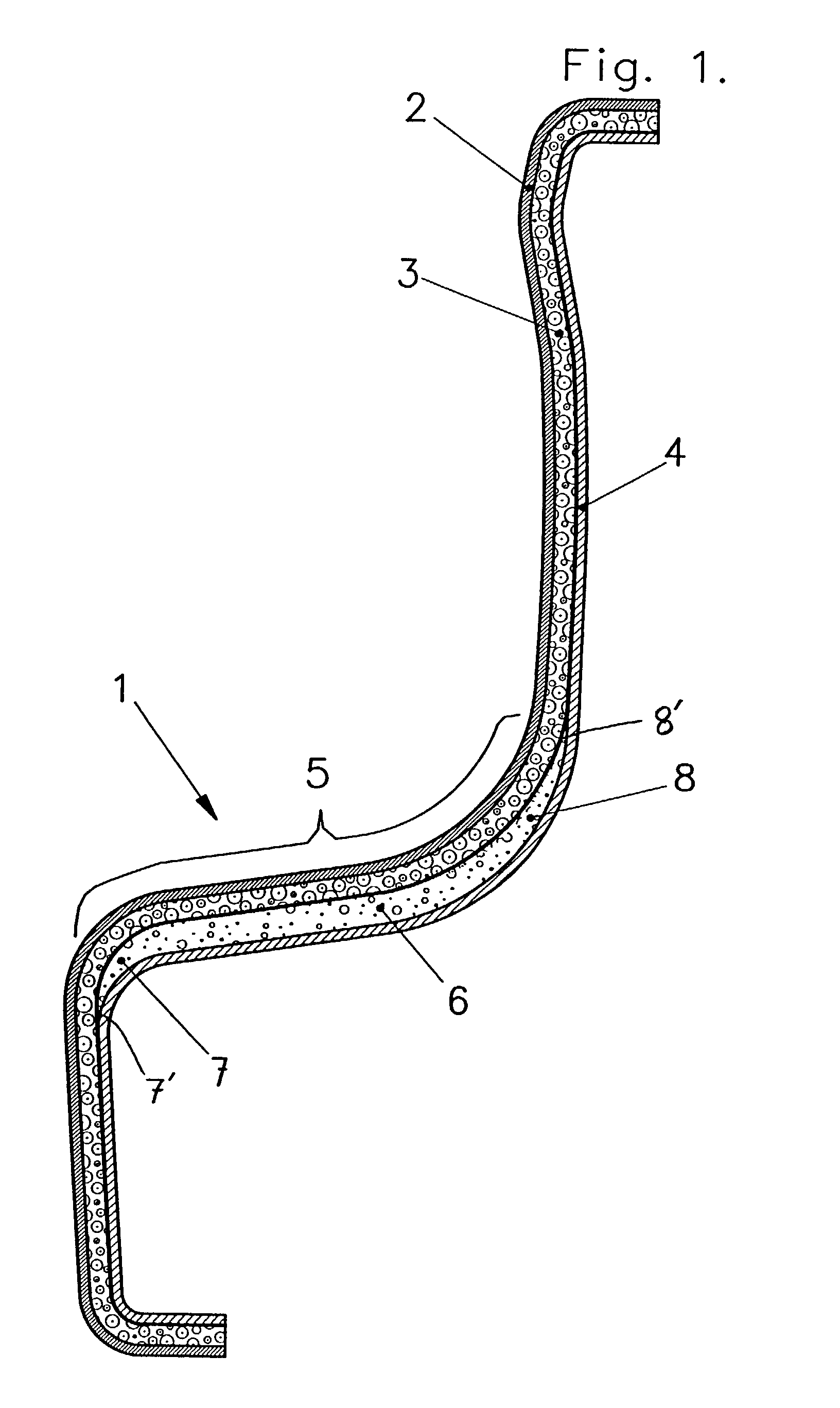

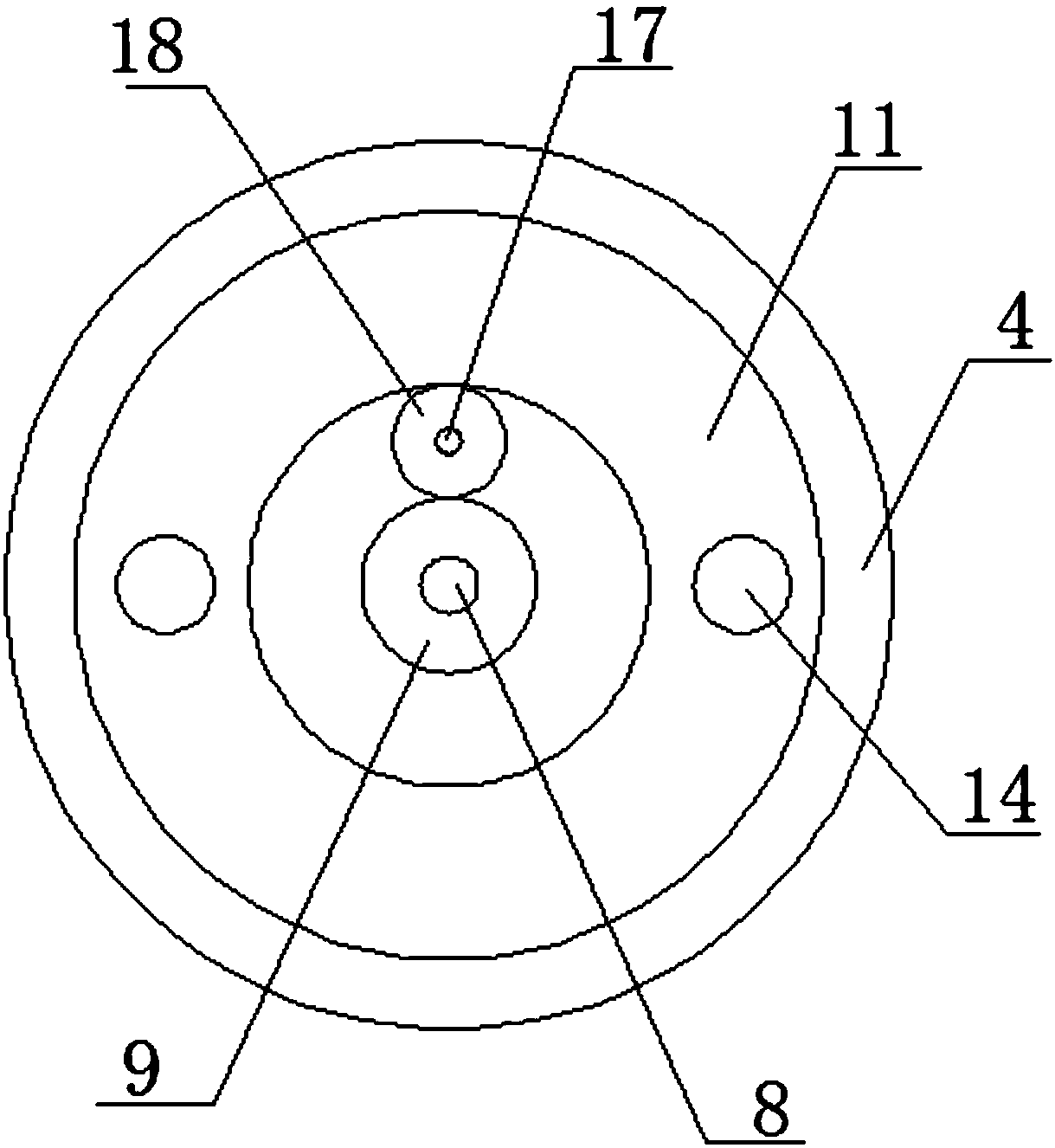

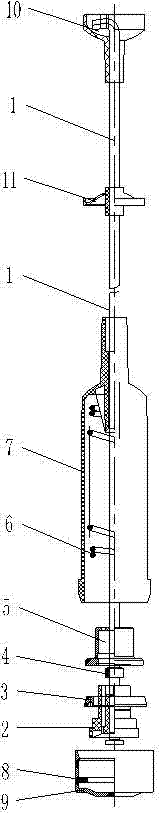

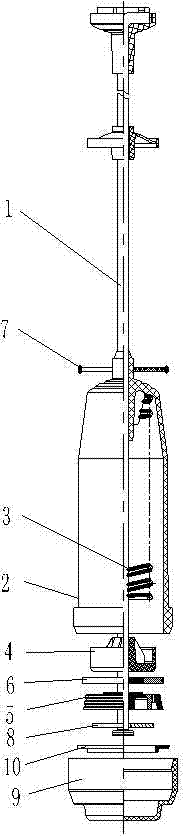

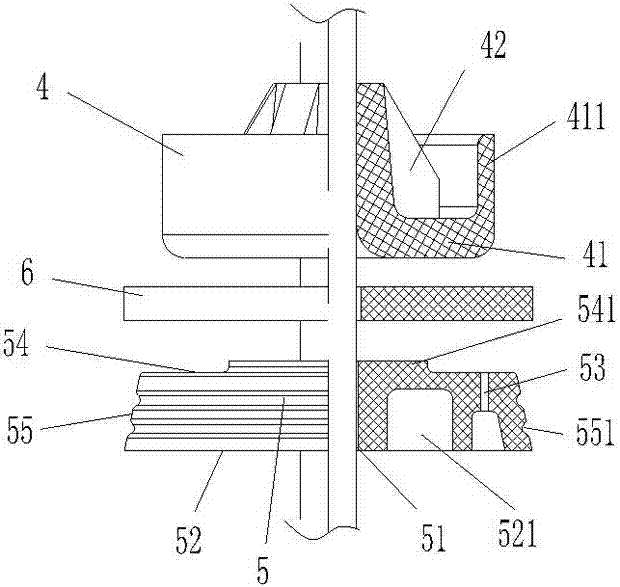

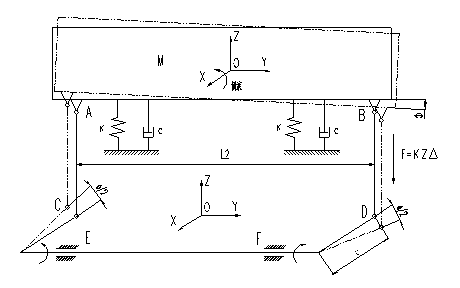

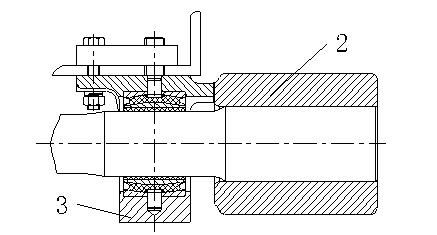

Washing machine suspension device and washing machine

ActiveCN104762790AReduce noiseReduce vibrationOther washing machinesWashing machine with receptaclesSliding contactAbsorption effect

A suspension apparatus of a washing machine, and the washing machine. The suspension system comprises a suspender (1), a sleeve (2), a spring (3), a spring retainer (4), and a sliding leather cup (5). The sleeve (2) is movably disposed on the suspender (1). The spring (3), the spring retainer (4) and the sliding leather cup (5) are all located inside the sleeve (2) from top to bottom. The sliding leather cup is in sealing and sliding contact with the inner wall of the sleeve (2). A flexible oil-containing layer is disposed between the spring retainer (4) and the sliding leather cup (5). The flexible oil-containing layer is disposed between the spring retainer (4) and the sliding leather cup (5), when the flexible oil-containing layer is extruded by the sliding leather cup (5) and the spring retainer (4), grease in the flexible oil-containing layer is extruded out, and the grease can relieve abrasion between the sleeve (2) and the side end surface of the sliding leather cup (5), so that the service life of the sliding leather cup (5) is extended, and the shock absorption effect of the suspension system is ensured when the washing machine works. In addition, when the sleeve (2) is stressed and vertically moves, the flexible oil-containing layer can block rapid circulation of air, vibration is effectively relieved, and the shock absorption effect of the suspension system is further improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Novel transverse elasticity positioning method of side-rolling resistant torsion bar for railway vehicle and device of method

ActiveCN103241257AGuaranteed anti-roll actionGuaranteed shock and noise reductionBogiesTorsional deformationEngineering

The invention provides a novel transverse elasticity positioning method of a side-rolling resistant torsion bar for a railway vehicle. A groove is formed at each of assembling ends of a supporting seat and a torsion arm; an elastic thrust pad is arranged between the supporting seat and the torsion arm for transverse elasticity positioning; and the two ends of the elastic thrust pad are fixed on the supporting seat and the torsion arm by bolts or pins respectively for achieving circumferential positioning, and ensuring no circumferential movement during torsion or shearing. The method achieves no transverse impact or transverse motion in a using process of the side-rolling resistant torsion bar for the railway vehicle, and the elastic thrust pad and a torsion bar component are subjected to torsional deformation simultaneously, and bear a vertical load and an impact load, so that a side-rolling resistant function, a shock absorption function and a noise reduction function of the side-rolling resistant torsion bar for the railway vehicle are ensured.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

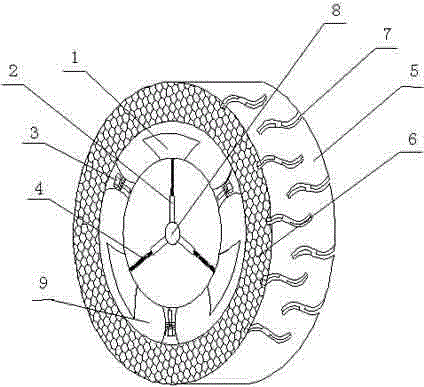

High-strength buffering tire

InactiveCN105270082AImprove carrying capacitySimple structureHigh resiliency wheelsHoneycombHigh intensity

The invention discloses a high-strength buffering tire. The high-strength buffering tire comprises a tire body and a tire tread (5), and is characterized in that the tire body comprises an inner steel ring (9) and an outer steel ring (6) which are coaxial; the inner side of the inner steel ring (9) is fixed through a shock absorber with an axle hole (8) as the center; axe-shaped buffering rings (1) which are evenly distributed at equal intervals are arranged on the outer side of the inner steel ring (9); fixing devices (3) are arranged at the gap between the axe-shaped buffering rings (1); the outer steel ring (6) is of a steel structure internally filled with a honeycomb-shaped part; and S-shaped concave threads (7) are formed in the outer portion of the tire tread (5). The bearing performance of the tire can be improved while the shock absorption and buffering performance is achieved, the service life of the tire is prolonged, and the application prospects are wide.

Owner:QINGDAO BOYANDA IND TECH RES INST GENERAL PARTNERSHIP

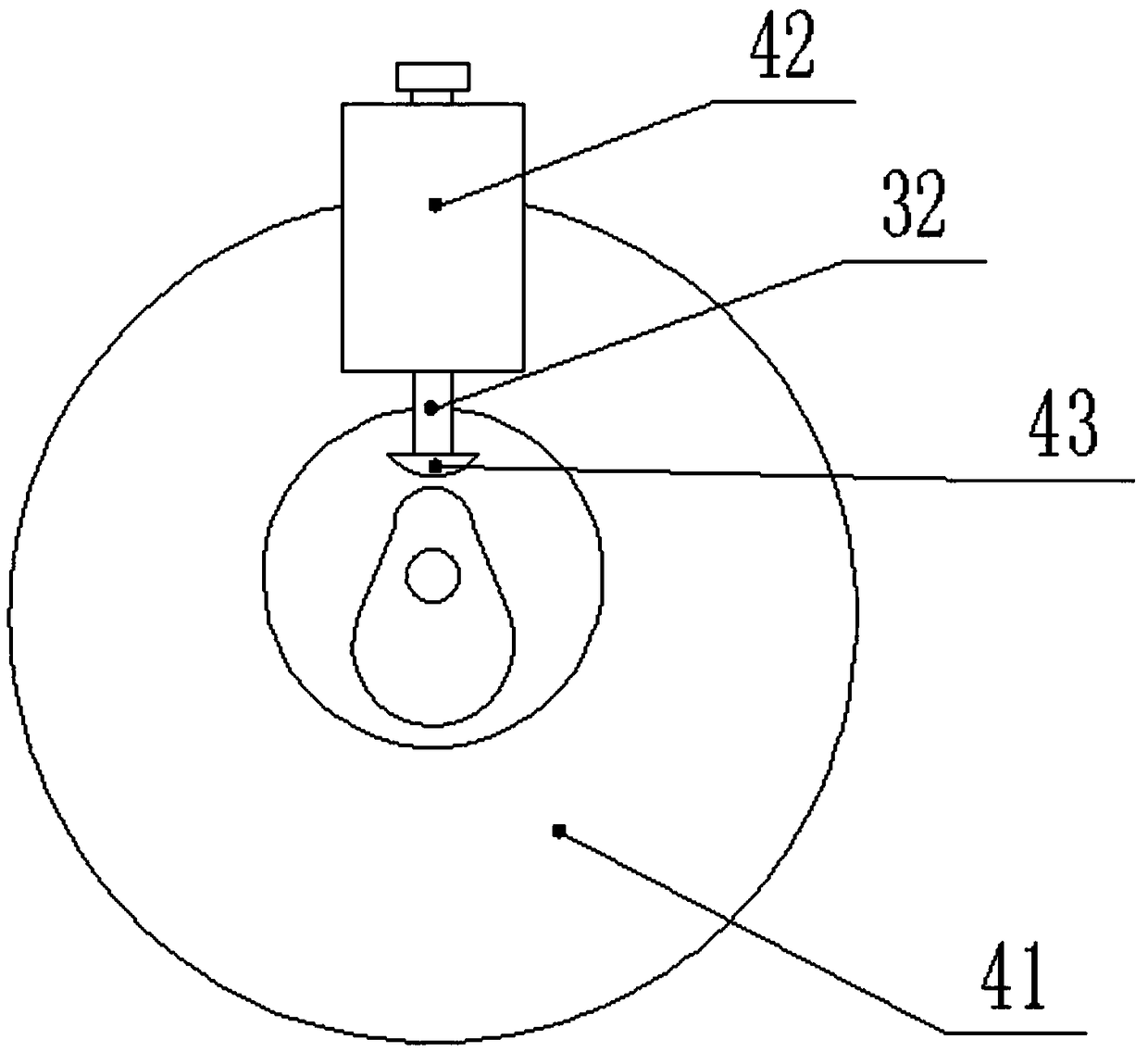

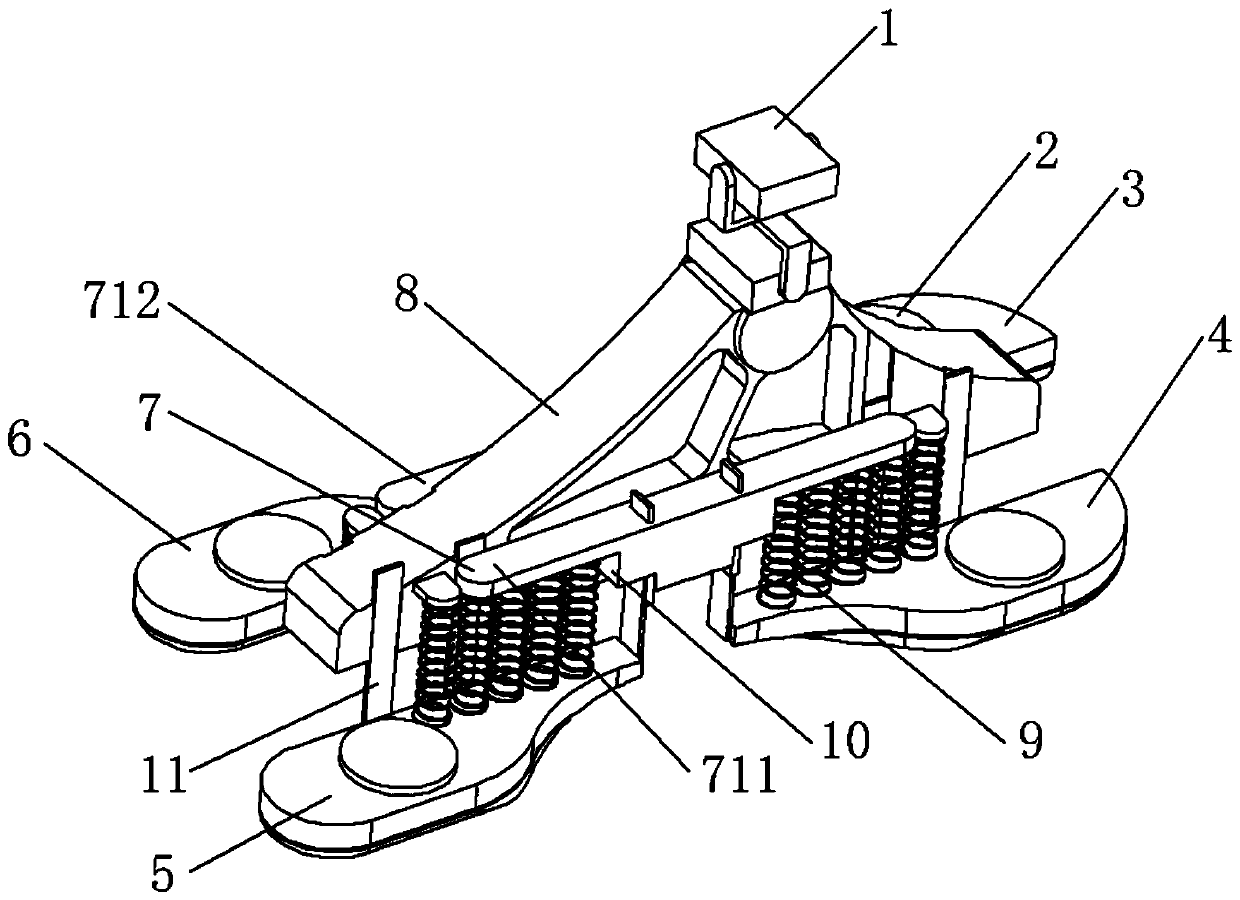

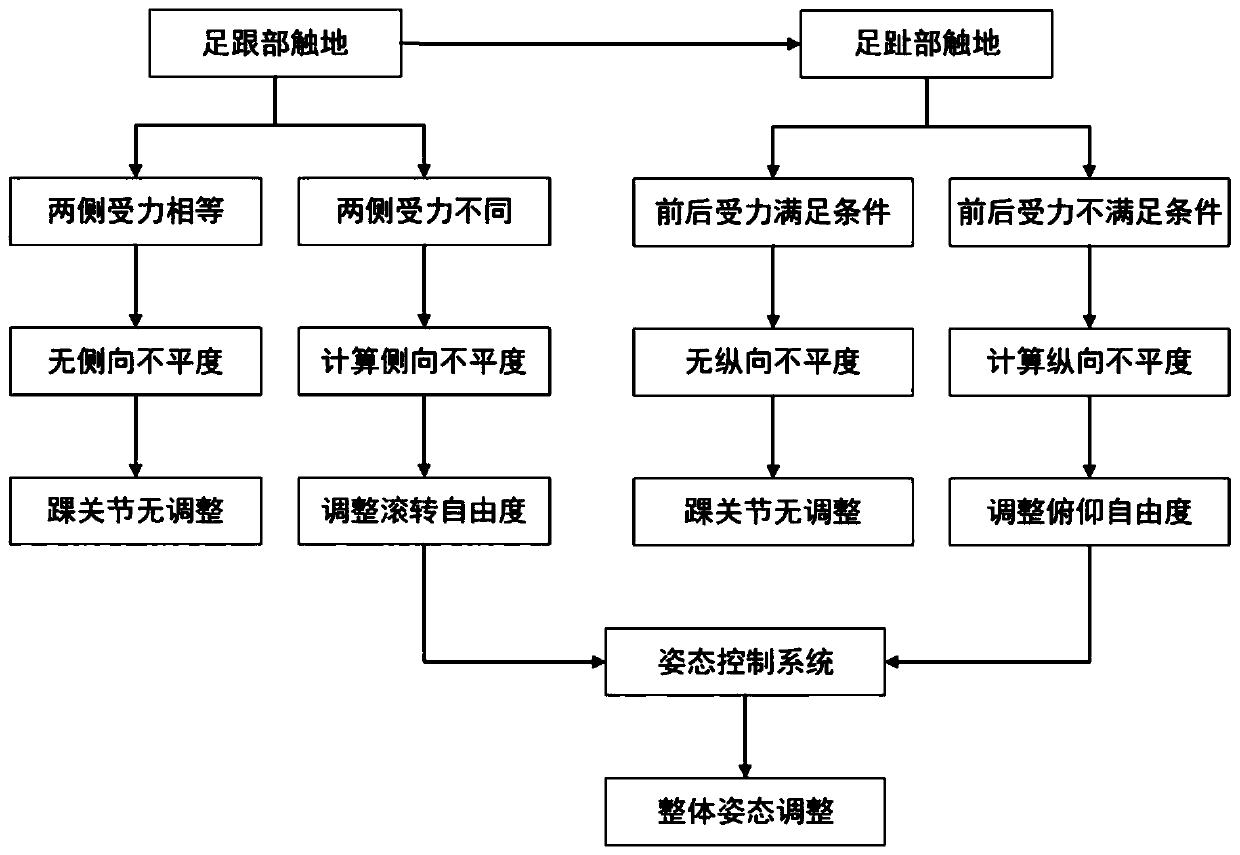

Foot structure of biped robot and all-terrain pavement adaptation method thereof

ActiveCN111267993AGuaranteed shock absorptionGuaranteed forceVehiclesGround contactPhysical medicine and rehabilitation

The invention relates to a foot structure of a biped robot and an all-terrain pavement adaptation method thereof. When the biped robot adopting the foot structure walks on a non-flat road surface, active adaptation can be conducted according to the actual terrain of the road surface, the corresponding posture is adjusted in time, the standing and walking stability of the biped robot is rapidly andeffectively improved, and the problems, for example, that when the biped robot walks on the uneven road surface, the foot ground contact area is small, and overall balance is difficult to maintain are solved. According to the all-terrain road surface adaptive foot structure, the foot bottom is divided into four areas, and the four areas are independently stressed and deformed, so the foot of therobot is kept in good contact with the ground on the uneven road surface; and meanwhile, the situation that the foot touches the ground is obtained through the force measuring sensors distributed in the four areas of the foot, the actual topographic distribution of the foot is speculated according to the situation, related joints of the robot are driven to be adjusted, and active adaptation of thefoot and the overall posture of the robot to the uneven road surface is completed.

Owner:ZHEJIANG LAB

High performance anti-ultraviolet TPE plastic

The present invention discloses a high performance anti-ultraviolet TPE plastic, and the plastic comprises the raw materials in parts by weight: 30-60 parts of TPE, 20-25 parts of polypropylene, 10-18 parts of polyether type polyurethane elastomer, 5-15 parts of MBS, 13-18 parts of epoxy resin, 5-10 parts of carbon nanotubes, 5-15 parts of wollastonite, 5-15 parts of kaolin, 5-10 parts of glass microspheres, 6-12 parts of titanium dioxide, 0.5-2.5 parts of polyethylene waxes, 1-2 parts of dicumylperoxide, 10-20 parts of composite mineral materials, 0.5-1.5 parts of [gamma]-glycidyl ether oxypropyl trimethoxysilane, 1-3 parts of maleic anhydride grafted ABS, 0.3-0.6 parts of rare earth metal compounds, 0.5-1.5 parts of maleic anhydride, 1-2 parts of a dispersant, 1-2 parts of a light stabilizer, and 0.5-2.5 parts of an ultraviolet absorbent. The high performance anti-ultraviolet TPE plastic of the present invention is outstanding in anti-ultraviolet property, good in sealing property and water resistance, high in hardness, and favorable in shock absorption property.

Owner:NINGGUO HUASHENG PLASTIC PROD

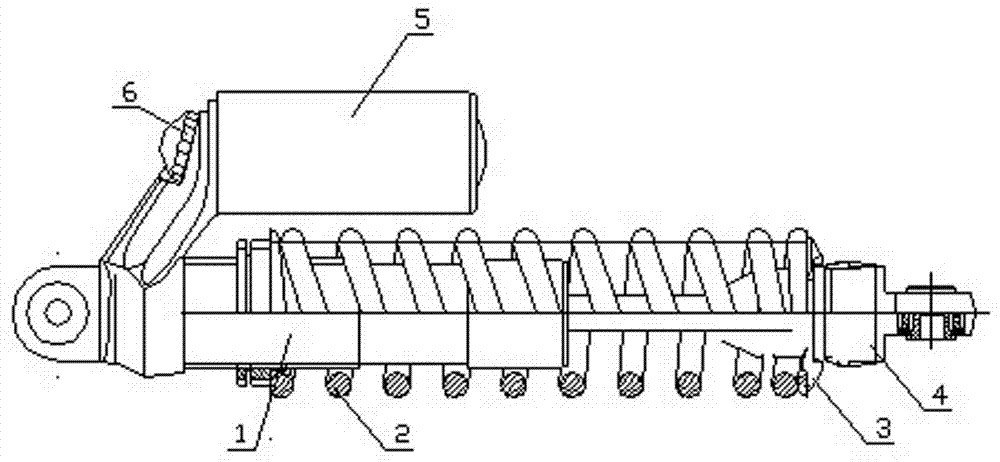

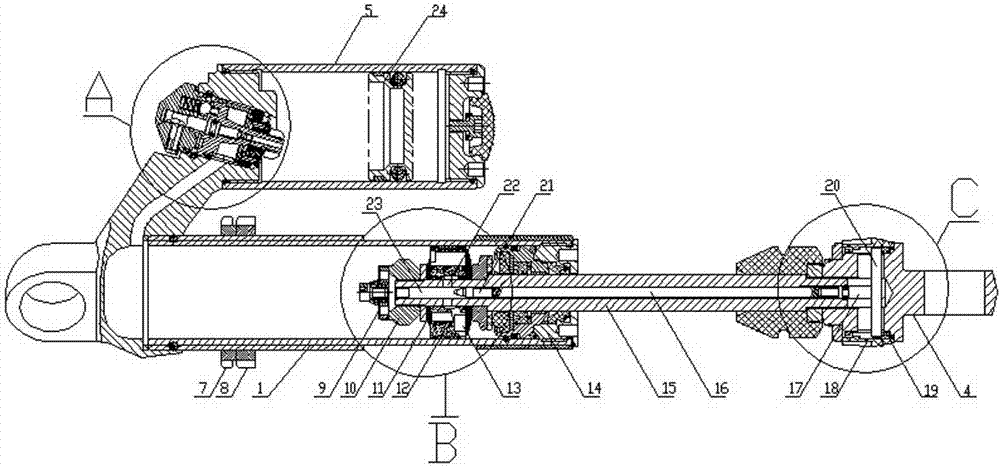

Motorcycle shock absorber with damping force adjustable

InactiveCN103527698AImprove shock absorptionImprove adsorption capacitySpringsLiquid based dampersEngineeringShock absorber

The invention discloses a motorcycle shock absorber with damping force adjustable. The problems that an existing shock absorber is poor in adjusting capacity of damping force, and the damping force cannot be adjusted and restored are solved. The motorcycle shock absorber comprises a piston cylinder, a piston and a piston rod, the piston is provided with a rebound valve, and the rebound valve is communicated with a channel. A radial through hole is formed in the piston rod, and is communicated to the channel, and an ejector pin used for adjusting the flow of the radial through hole is arranged inside the piston rod. The flow of the radial passing of the piston rod is adjusted through the ejector pin, then the flow of the channel of the rebound valve is adjusted, and therefore the damping force is adjusted and restored, the riding feedings of different riders are met, and the shock absorption performance of the shock absorber is improved. The motorcycle shock absorber is suitable for the shock absorption of motorcycles, and especially suitable for the shock absorption of racing motorcycles.

Owner:广东川南减震器有限公司

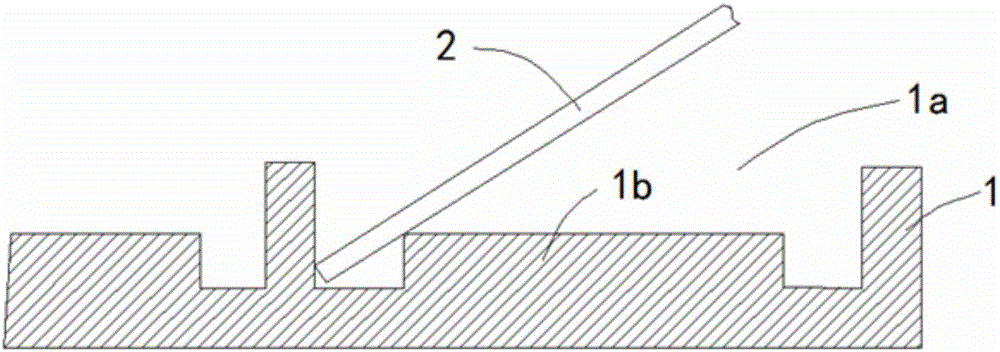

Low friction cylinder of shock absorber and manufacturing method thereof

ActiveCN104455168AMeet the use requirementsGuaranteed shock absorptionSpringsCylindersButt weldingEngineering

The invention discloses a low friction cylinder of a shock absorber and a manufacturing method of the low friction cylinder of the shock absorber. The manufacturing method of the low friction cylinder of the shock absorber comprises the following steps: A. raw material pretreatment; B. longitudinal shearing; C. pipe welding. Pipe welding comprises the following steps: uncoiling, shearing and butt welding of the end of the pipe, material storing, rough molding of the welded pipe, welded seam extruding, welding, deburring inside and outside of the welded seam, cooling, refined molding of the welded pipe, eddy current detection, straightening, sizing and cutting off, and finished welded pipe inspecting, wherein the mixture of rust-preventative oil and water is adopted to cool when welding, and an inside and outside arc cutting tool is adopted to deburr, the width of the welded seam is 2 times the wall thickness of the steel pipe; D. cleaning and drying; E. bright annealing; F. dipping in reactive drawing oil; G. the first cold-drawing; H. dipping in reactive drawing oil again; I. the second cold-drawing; J. straightening; K. cutting off; L. chamfering; M. cleaning, welding an upper end-plate, drilling a hole at the lower portion of the steel pipe, immersion in rust-preventative oil, and packing. With the manufacturing method of the low friction cylinder of the shock absorber, the welded seam pipe used for the cylinder can be manufactured, and the friction of the welded seam pipe can meet requirements of the shock absorber for friction.

Owner:ZHANGJIAGANG BONDED ZONE YAXIN PRECISION PIPE MAKING

An unmanned aerial vehicle undercarriage with good shock absorbing effect

InactiveCN109204790AImprove shock absorptionImprove protectionAlighting gearEngineeringFrictional resistance

The invention discloses an unmanned aerial vehicle undercarriage with good shock absorbing effect, including a fixing plate, wherein the top outer wall of the fixing plate is provided with a fixing sleeve mounting groove, a fixing sleeve is welded on the inner wall of the fixing sleeve mounting groove, one side inner wall of the fixing sleeve is slidably connected with a sliding bar, and a connecting plate is welded on the bottom outer wall of the sliding bar, two sides of the bottom outer wall of the fixing plate are connected with supporting legs through hinges, one side outer wall of the two supporting legs and two sides outer walls of the connecting plate are connected with connecting rods through hinges, and two sides of the top outer wall of the fixing plate are welded with a limit plate. The undercarriage is helpful to ensure that the shock absorbing effect can be achieved no matter whether the unmanned aerial vehicle falls vertically or inclined. The undercarriage is helpful toimprove the protection effect of UAV and the stability of UAV. The undercarriage can further increase the frictional resistance of the supporting foot, and it is helpful to enhance the stability of the supporting foot and the stability of the supporting plate.

Owner:易蕾

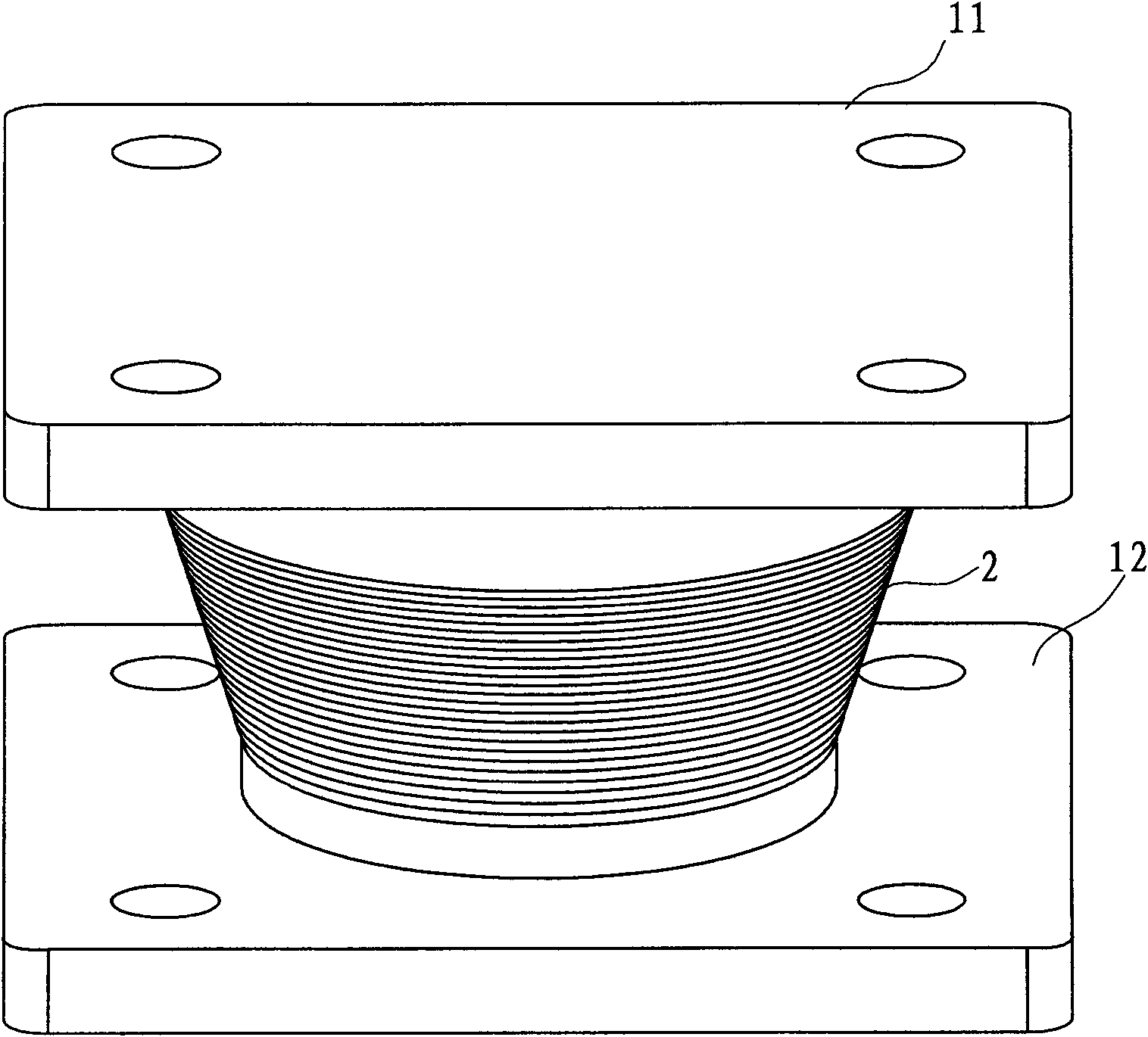

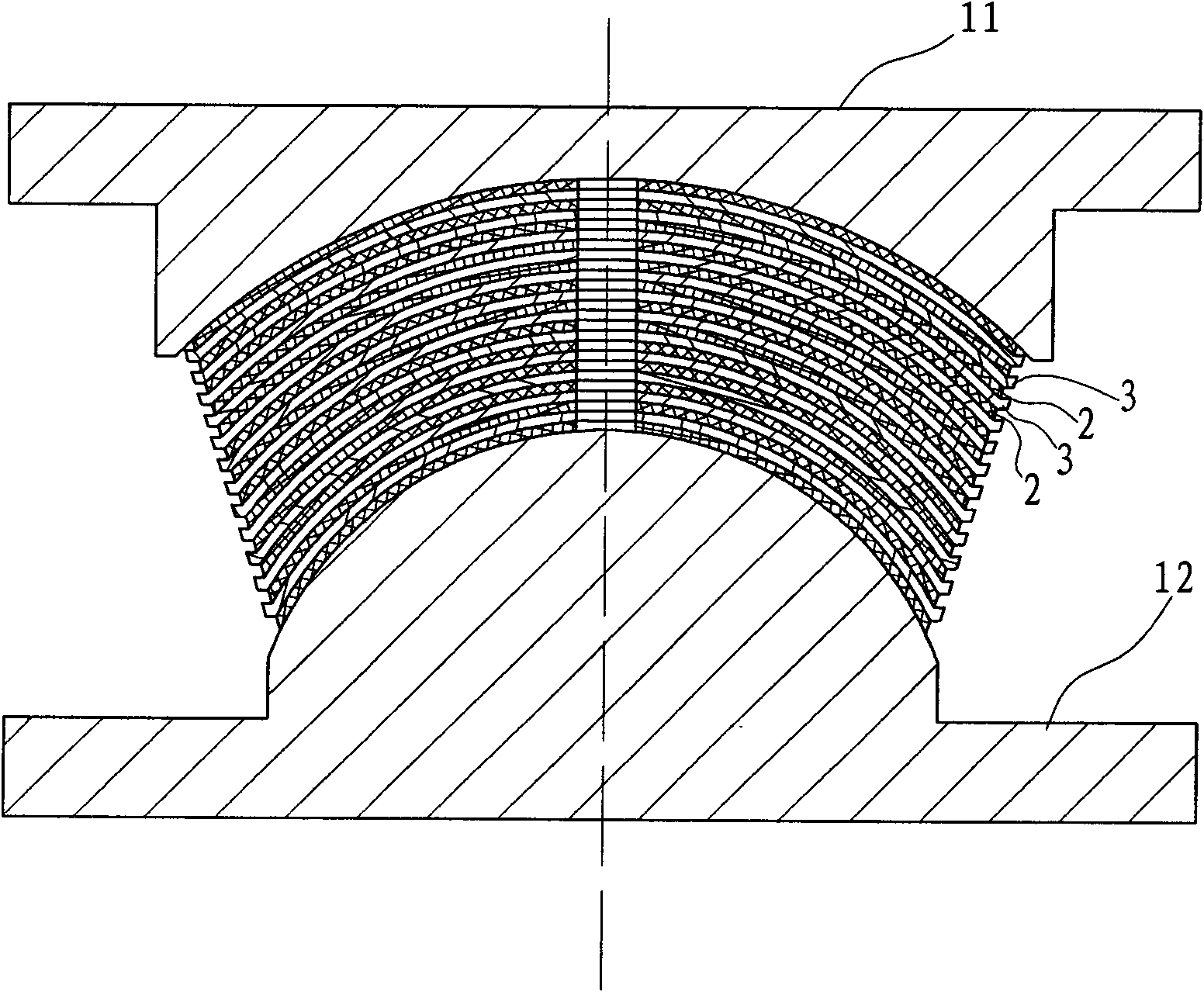

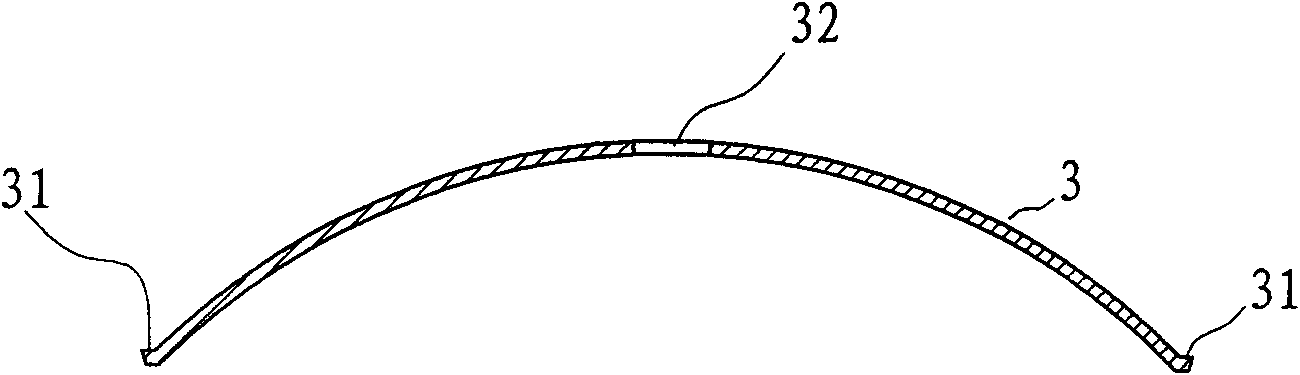

Elastic bearing and manufacturing method thereof

ActiveCN101666359AWith sound absorption and noise reduction effectGuaranteed shock absorptionYielding couplingState of artCarrying capacity

The invention discloses an elastic bearing comprising a first connecting piece and a second connecting piece which are arranged on two ends thereof. The elastic bearing is characterized in that multiple layers of rubber sheets with the functions of buffering and shock absorption are cohered between the first connecting piece and the second connecting piece, and thus metal gland bushes are coheredat interval between the rubber sheets. The invention also discloses a manufacturing method of the elastic bearing. Compared with the prior art, the invention has the following advantages that the rubber sheet has elasticity and the metal gland bush can also ensure connection strength and carrying capacity by combining the rubber sheet with the metal gland bush for connection; the structure has buffering and shock absorption functions for strong impact force and has adsorbing and denoising function for instantaneously produced noise.

Owner:ZHEJIANG SHITAI IND CO LTD

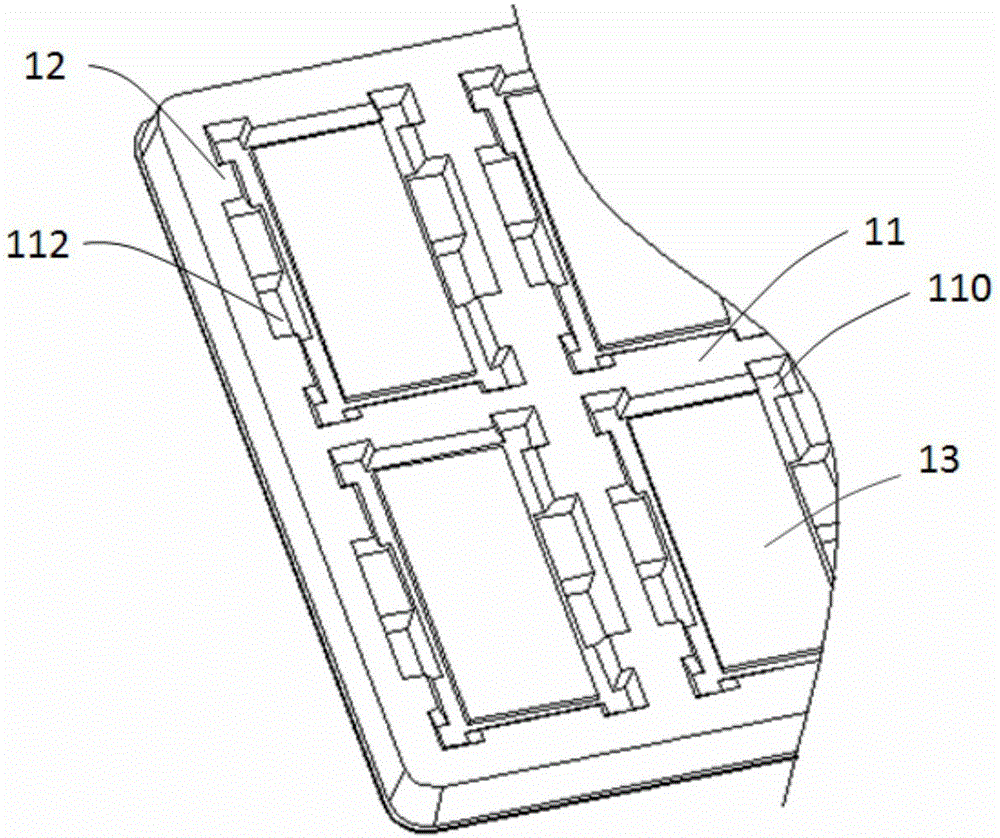

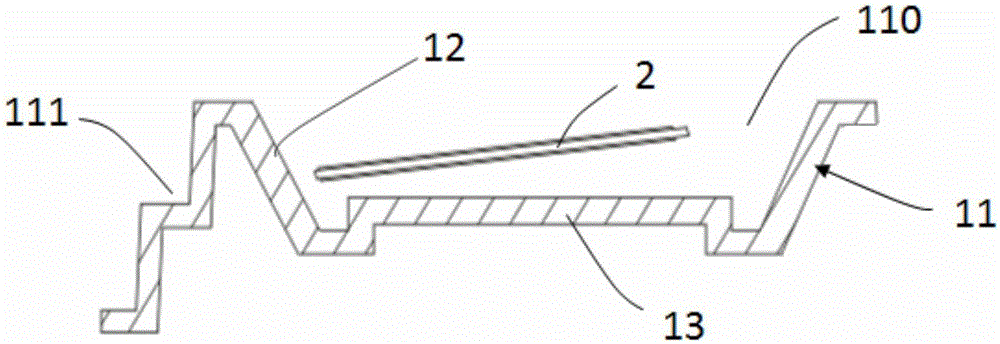

Liquid crystal display panel tray

ActiveCN106219010ANot easy to get stuckGuaranteed shock absorptionTray containersContainers to prevent mechanical damageLiquid-crystal displayEngineering

The invention discloses a liquid crystal display panel tray. The liquid crystal display panel tray comprises a main shell body and a plurality of grooves formed in the main shell body at intervals. The bottom surfaces of the grooves are higher than the bottom surface of the main shell body. A first boss is formed by being inwards concaved from the lateral surface of each groove toward the inside of the groove. A second boss is formed by being inwards concaved from the bottom surface of each groove toward the inside of the groove. The boss surfaces of each first boss incline towards the four sides. The bosses are arranged at the bottom of the lateral wall of each groove of the liquid crystal display panel tray, and the boss surfaces on each lateral wall incline towards the four sides, so that a liquid crystal display panel is not prone to interfere with the lateral walls or the boss surfaces on the lateral walls, thereby not being clamped when taken and put, the phenomenon of partial damage to the liquid crystal display panel is avoided, and meanwhile the shock absorption performance of the tray is guaranteed.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

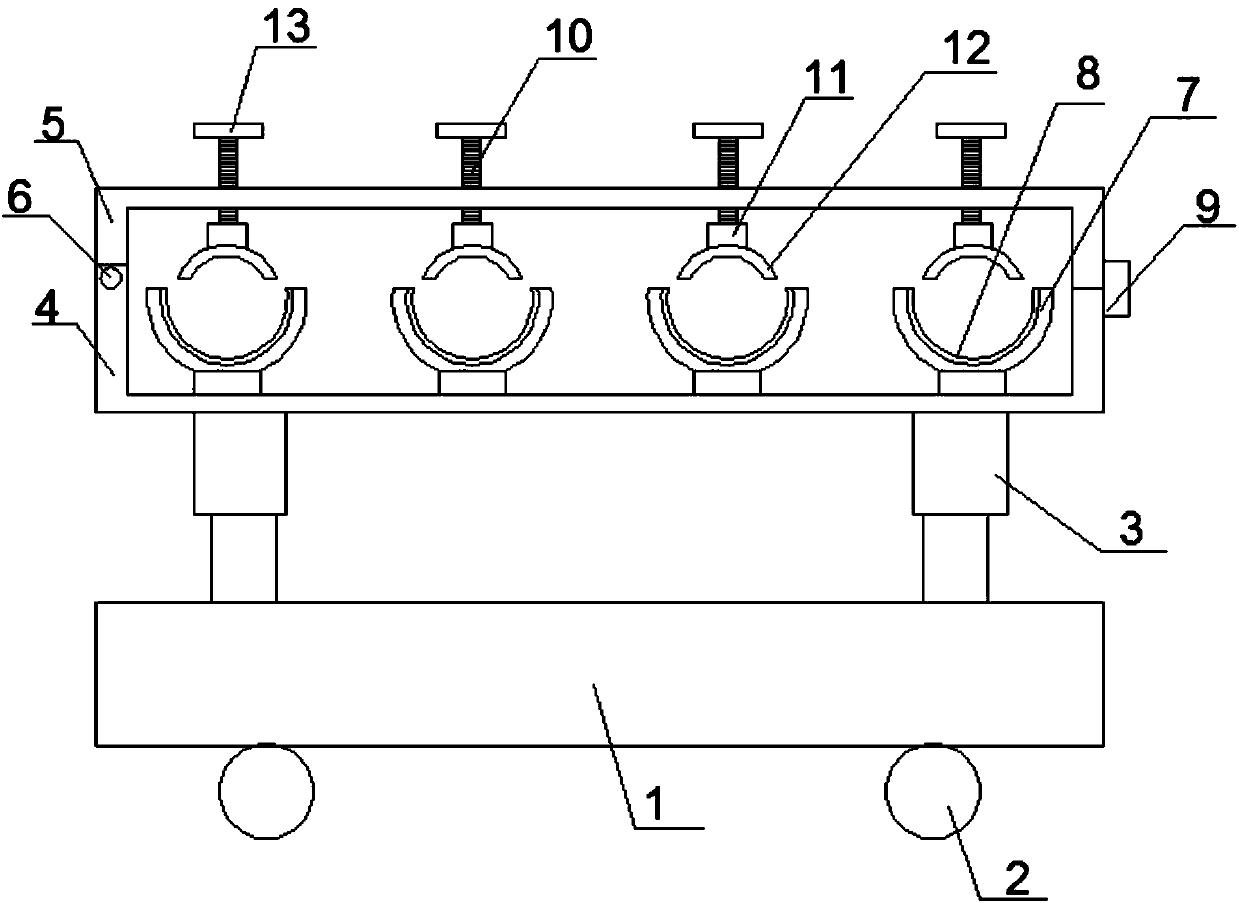

Transport cart for pipeline processing with good shock absorption effect

InactiveCN108099977APrevent slippingAvoid sizeHand carts with multiple axesHand cart accessoriesFixed frameEngineering

The invention discloses a transport cart for pipeline processing with a good shock absorption effect. The transport cart comprises a base, universal wheels are arranged at four corners of the lower side of the base, damping devices are symmetrically and bilaterally arranged on the upper side of the base, the damping devices comprise supporting cylinders and telescopic cylinders, sliding chambers are formed in the cylinder walls of the telescopic cylinders, the upper ends of the supporting cylinders are arranged inside the sliding chambers, supporting columns are arranged at inner lower ends ofthe supporting cylinders, telescopic rods are arranged at the upper ends of the supporting columns, shock-absorbing springs are arranged outside the supporting columns and the telescopic rods, dust covers are arranged outside the shock-absorbing springs, supporting frames are arranged at the upper ends of the damping devices, a plurality of groups of front and rear symmetric fixing bases are arranged inside the supporting frames from left to right, fixing frames are arranged at the upper ends of the supporting frames, a plurality of threaded rods which are matched with the fixing bases are arranged on the fixing frames, connecting bases are rotatably connected to the lower ends of the threaded rods, and arc-shaped press plates are arranged at the lower ends of the connecting bases. The transport cart is simple in structure, convenient to use, good in shock absorption effect, wide in application range and long in service life.

Owner:刘翠玲

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com