Low friction cylinder of shock absorber and manufacturing method thereof

A low-friction, shock absorber technology, used in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problem of low cost, the friction force cannot hit the shock absorber, and the high cost of seamless steel pipes problems, to achieve the effect of extending the service life, ensuring the shock absorption effect, and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below through specific examples.

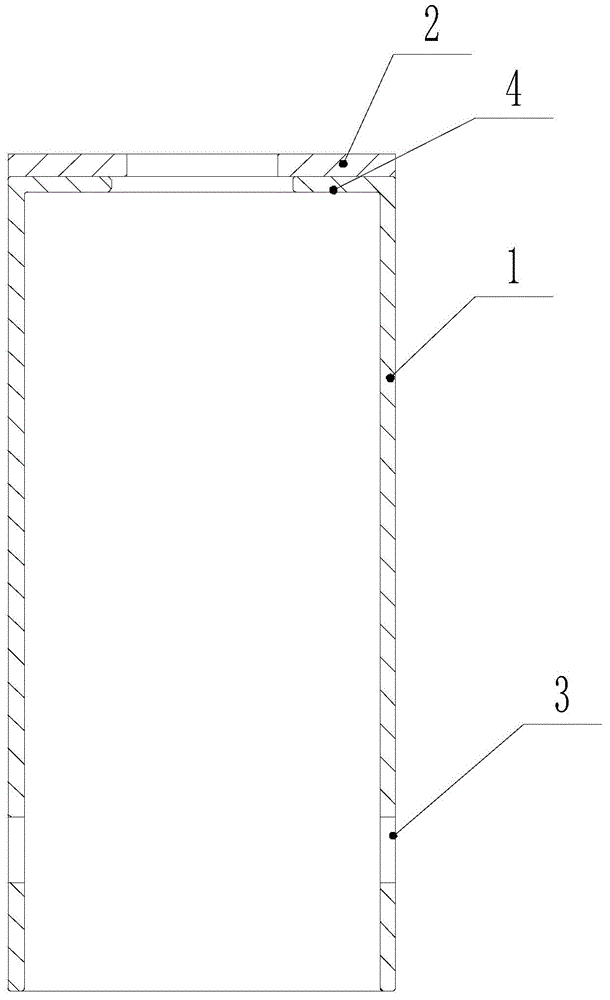

[0032] Such as figure 1 As shown, a method for manufacturing a low-friction cylinder of a shock absorber, comprising the following steps:

[0033] A. Raw material pretreatment: cold-roll the formed steel plate, so that the thickness of the steel plate after cold rolling is one third of the thickness of the steel plate before cold rolling; after cold rolling, the thickness of the steel plate is reduced by two thirds After that, the metallographic structure will be tighter and the surface defects will be less, so the friction force of the inner wall of the welded pipe will be reduced.

[0034] B. Slitting: Slitting the pretreated steel plate into strips and winding;

[0035] C. Process the coiled steel plate into welded pipe, which includes the following steps: uncoiling → end shear butt welding → material storage → rough forming of welded pipe → weld seam extrusion → welding → ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com