Patents

Literature

2376 results about "Pipe welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

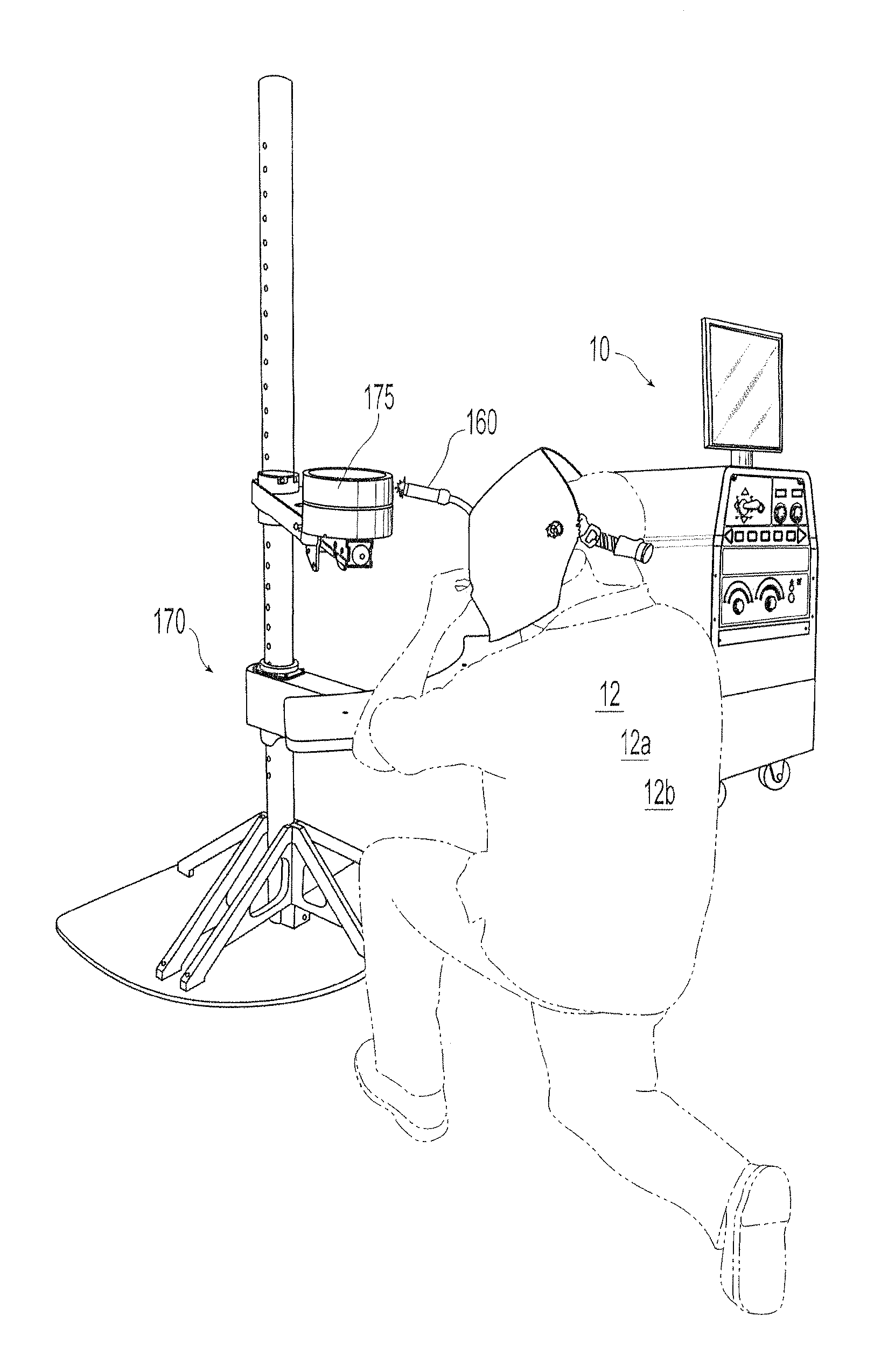

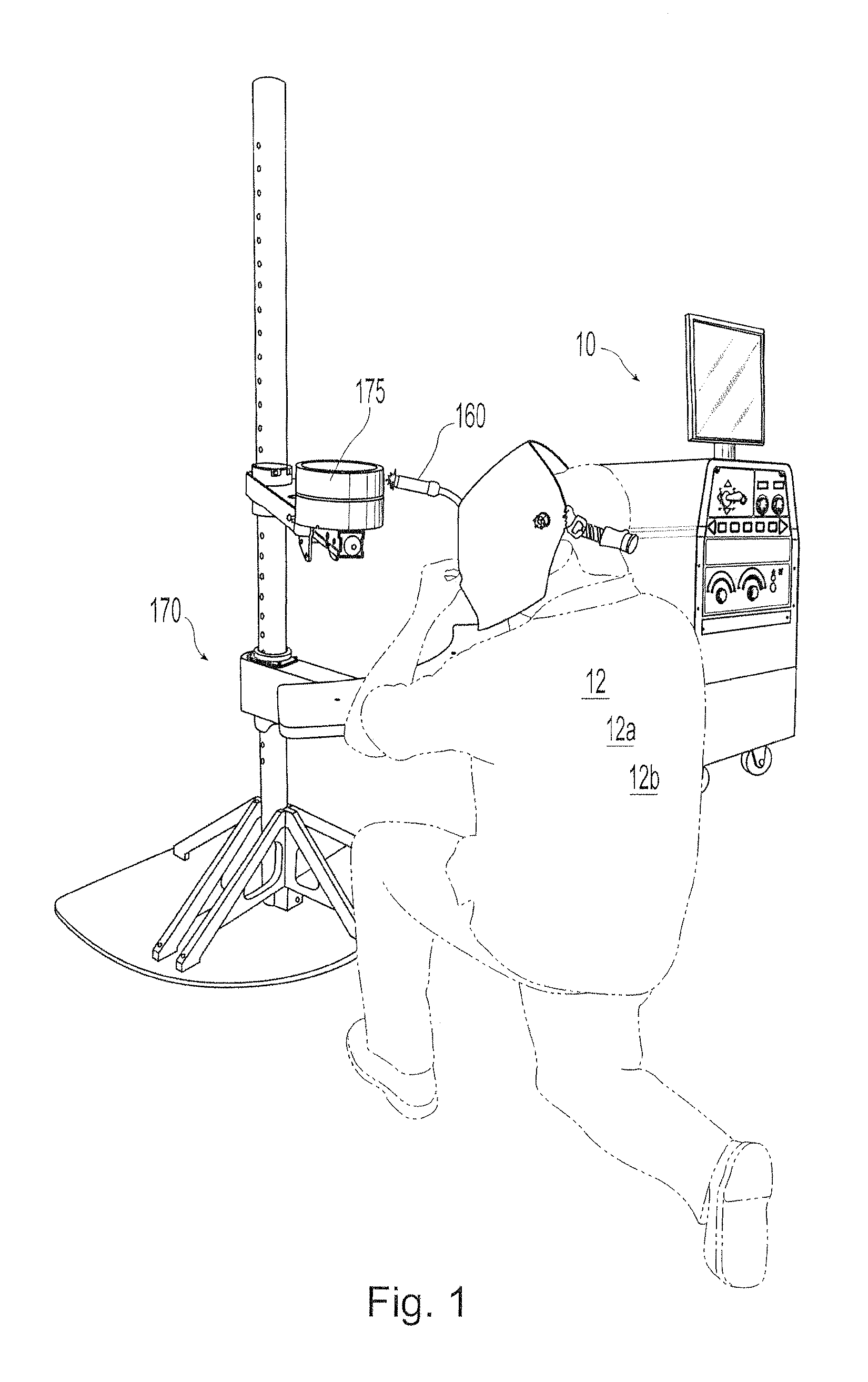

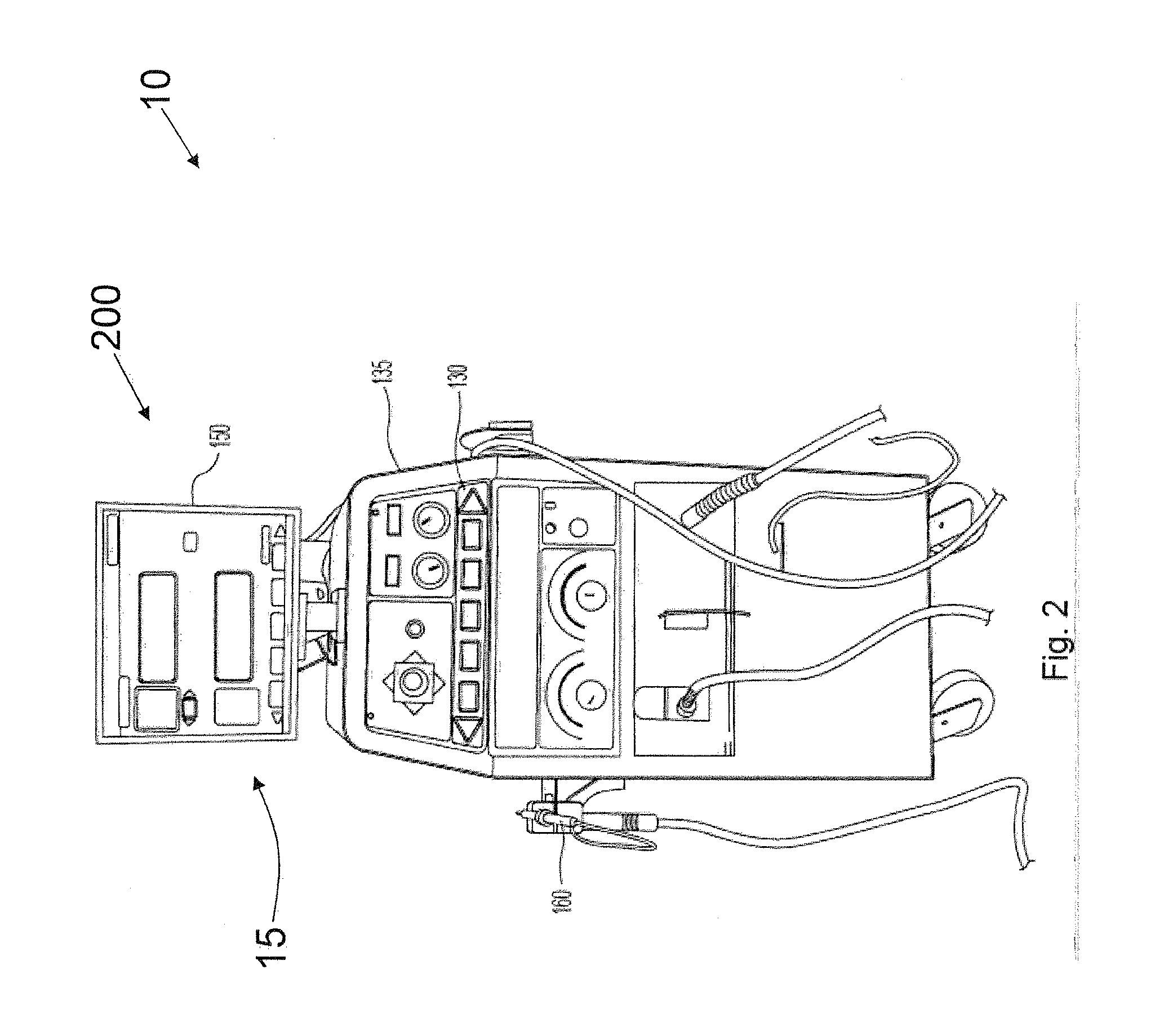

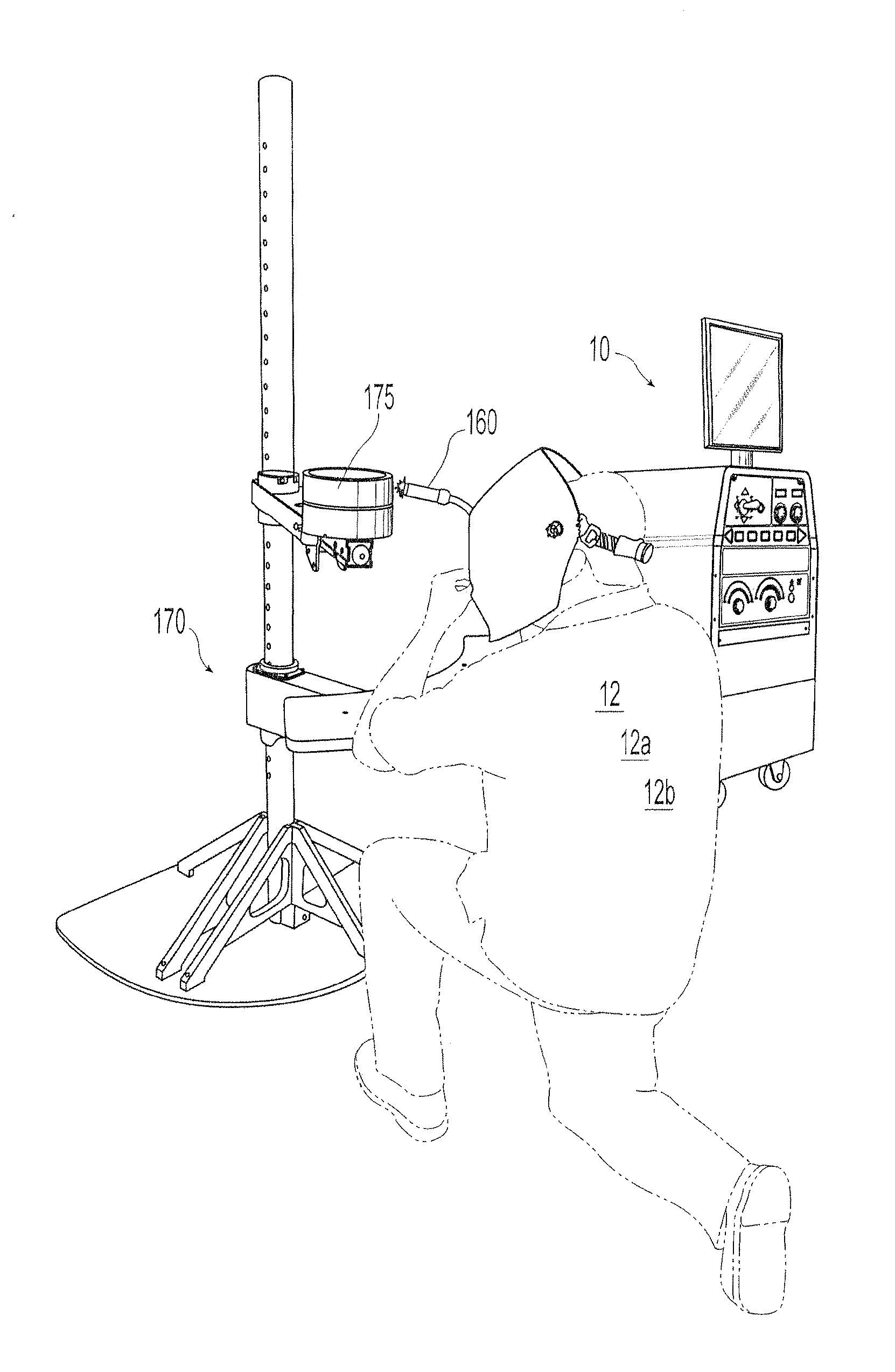

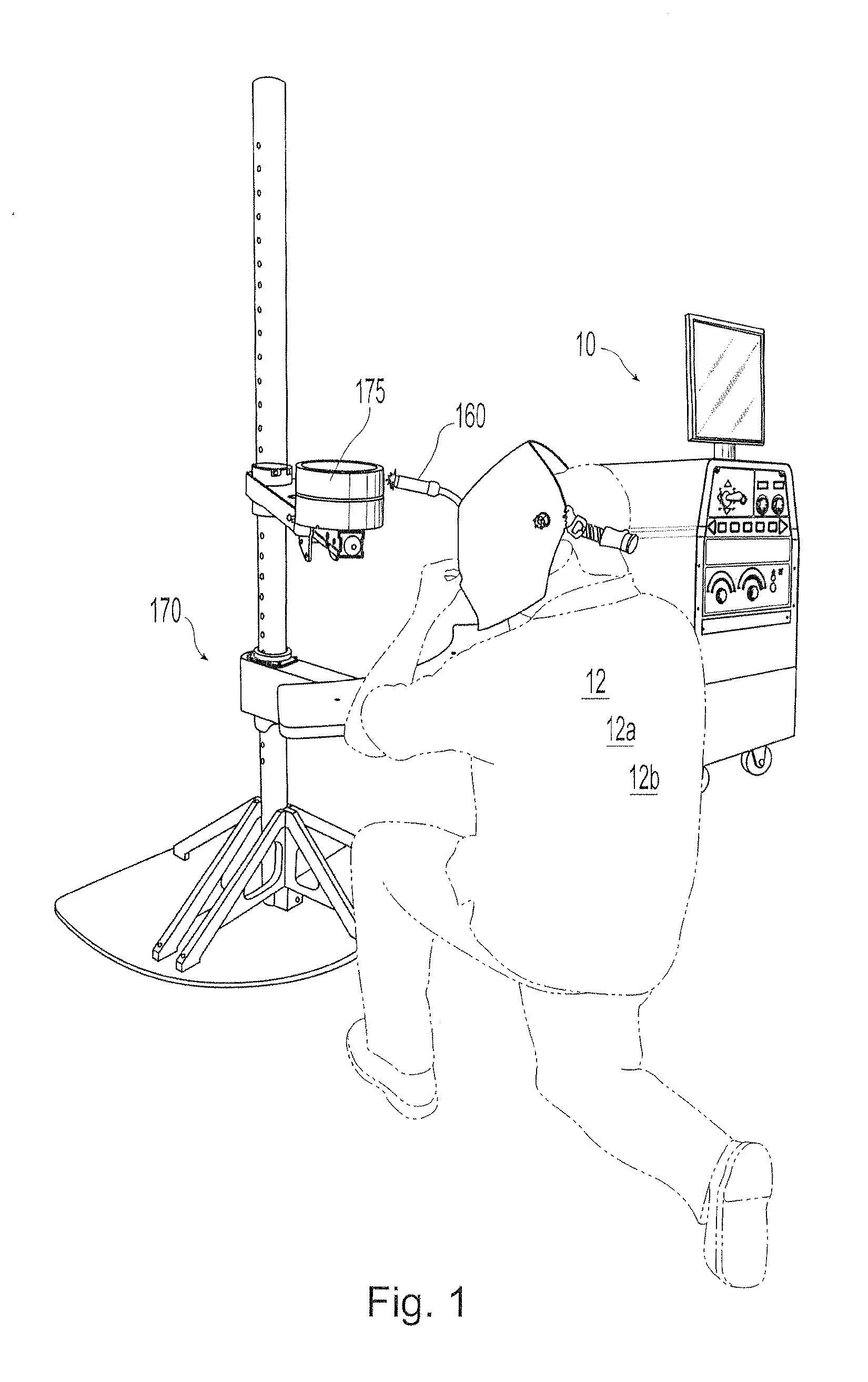

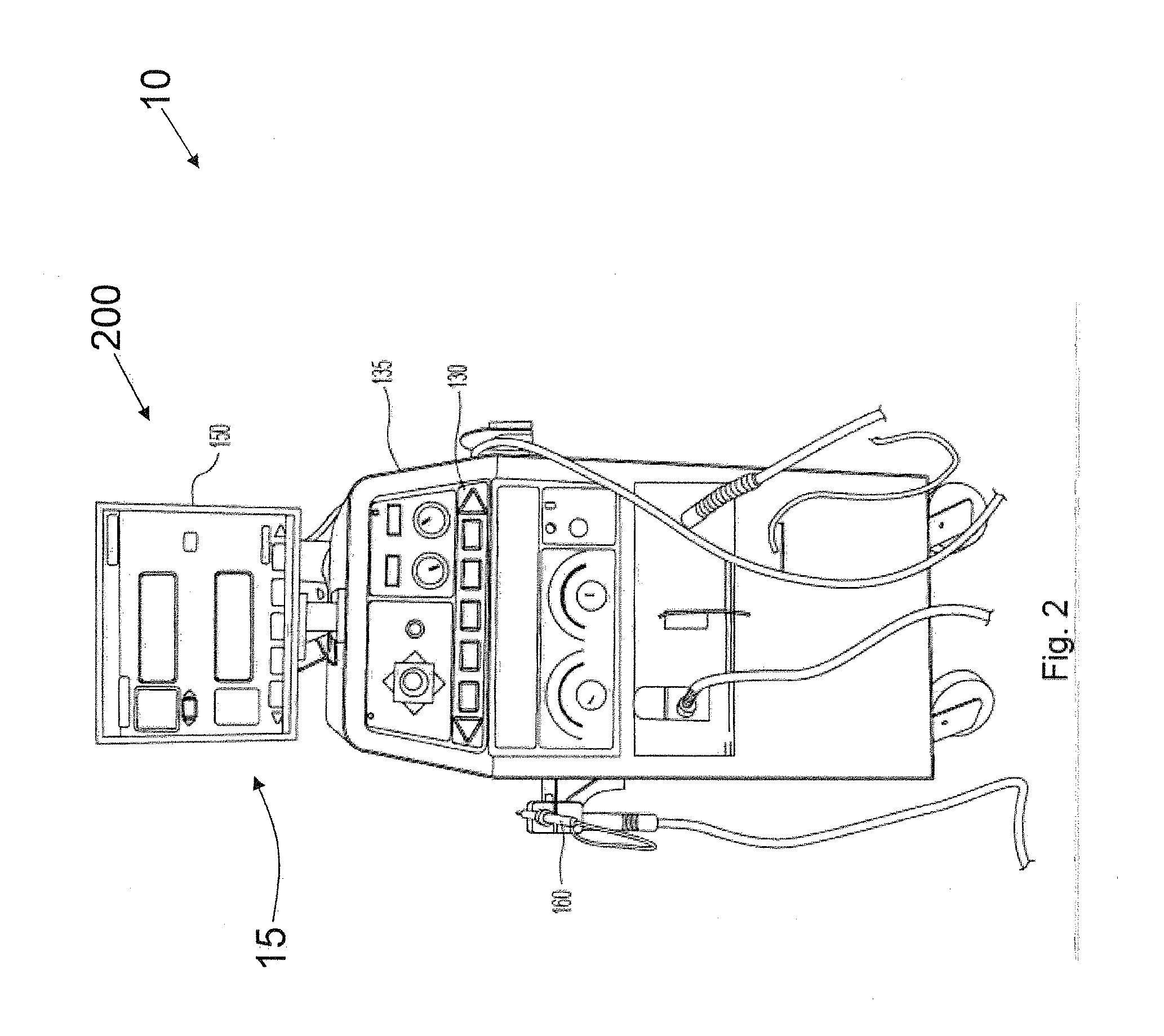

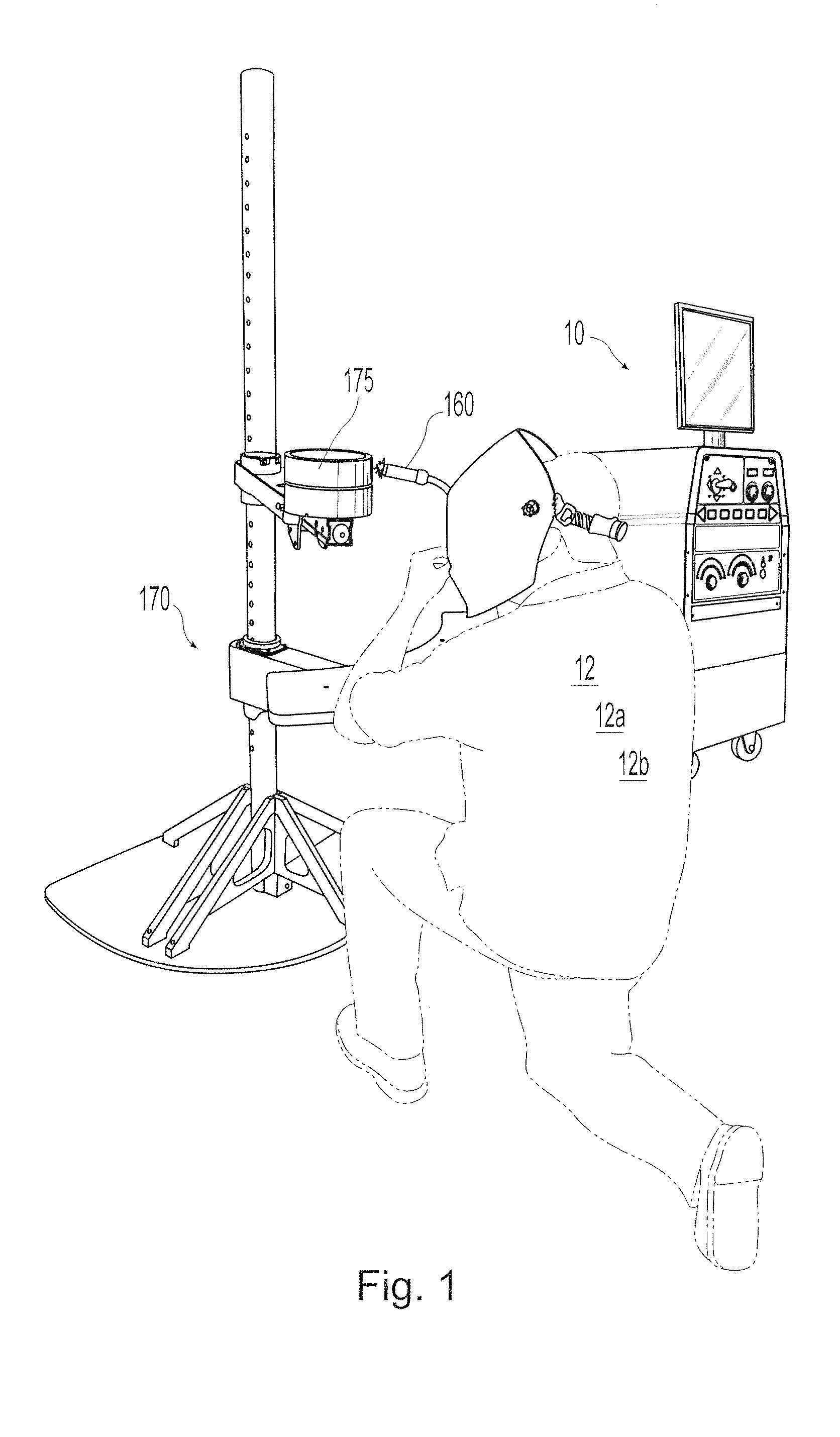

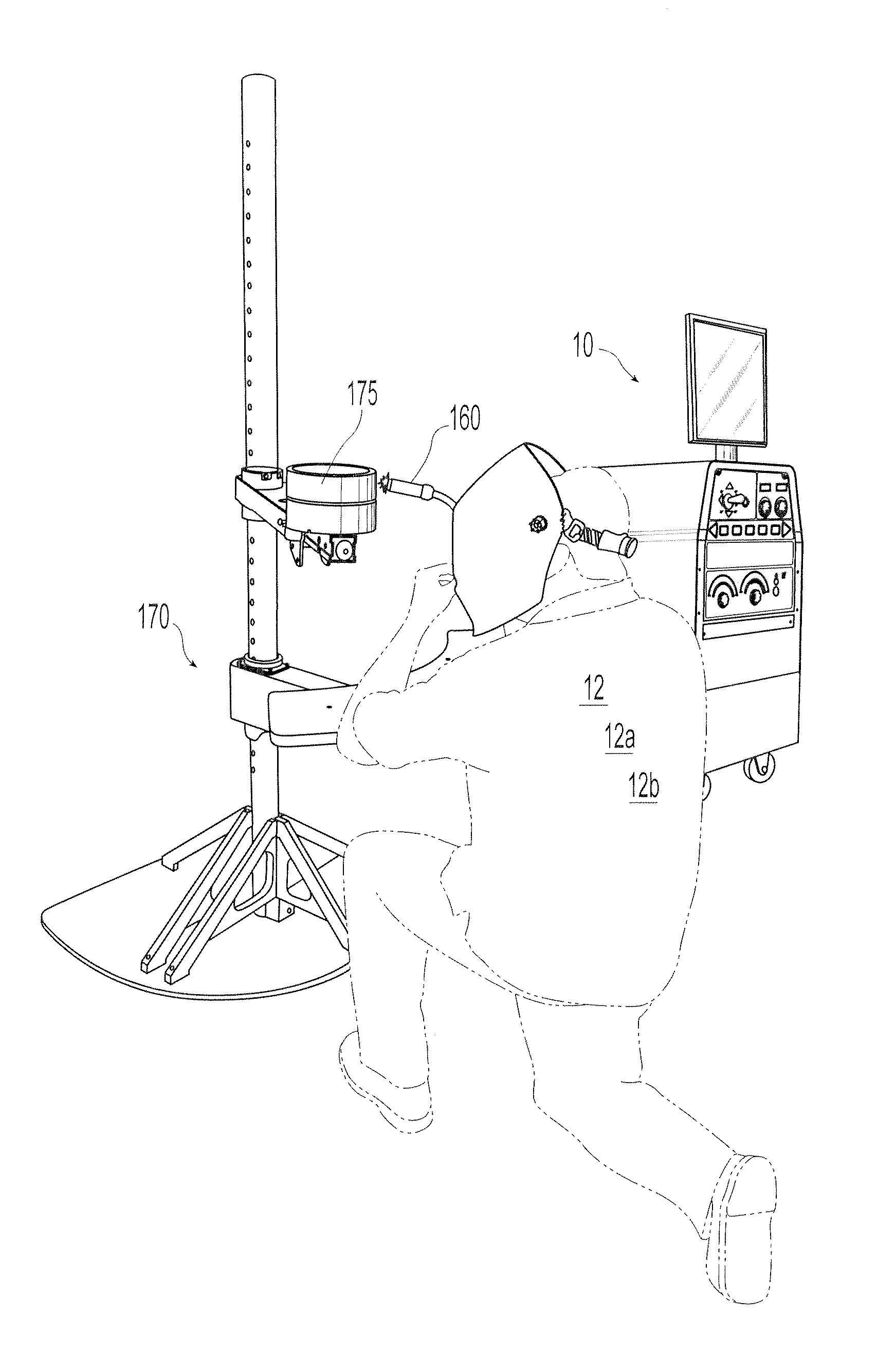

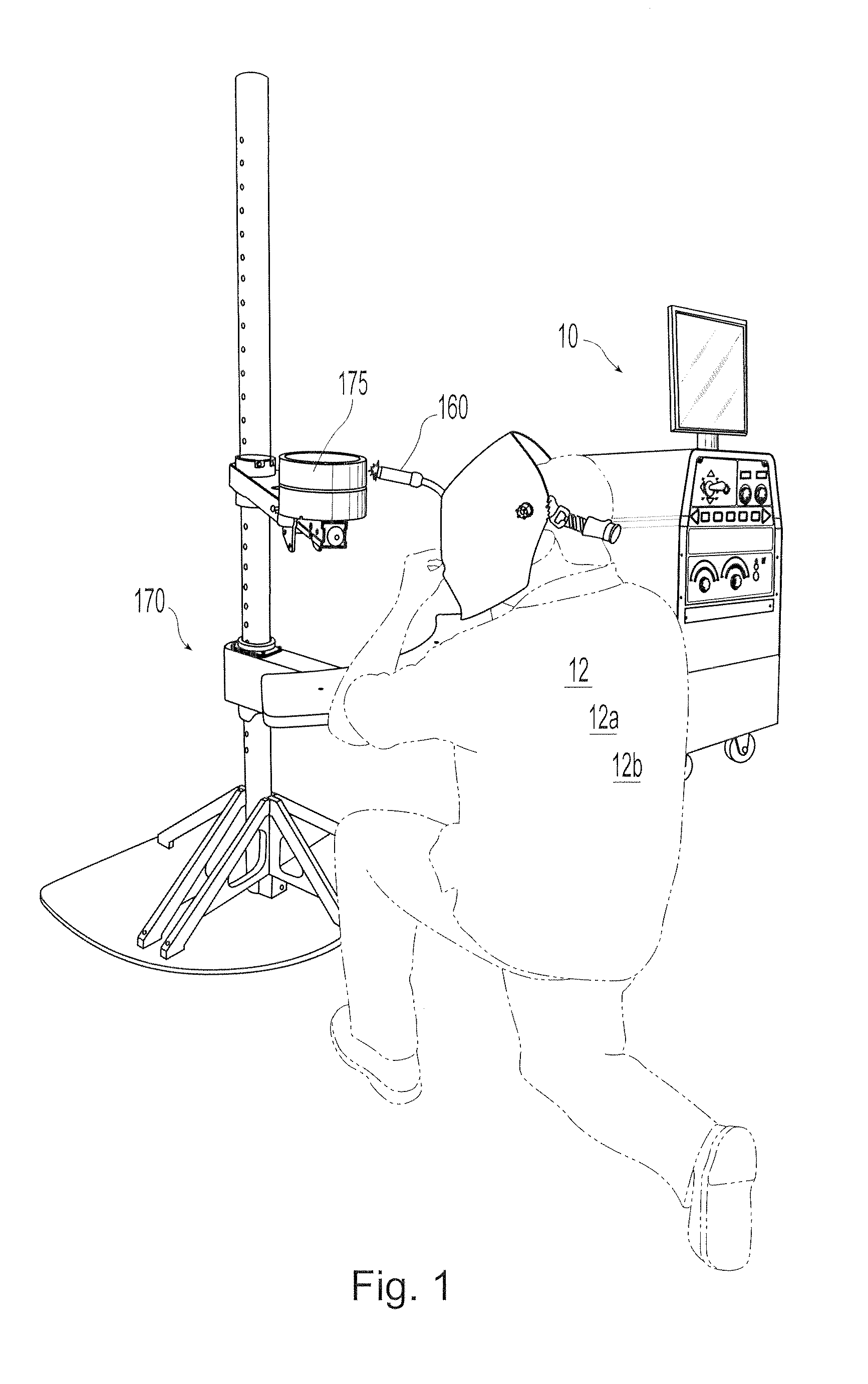

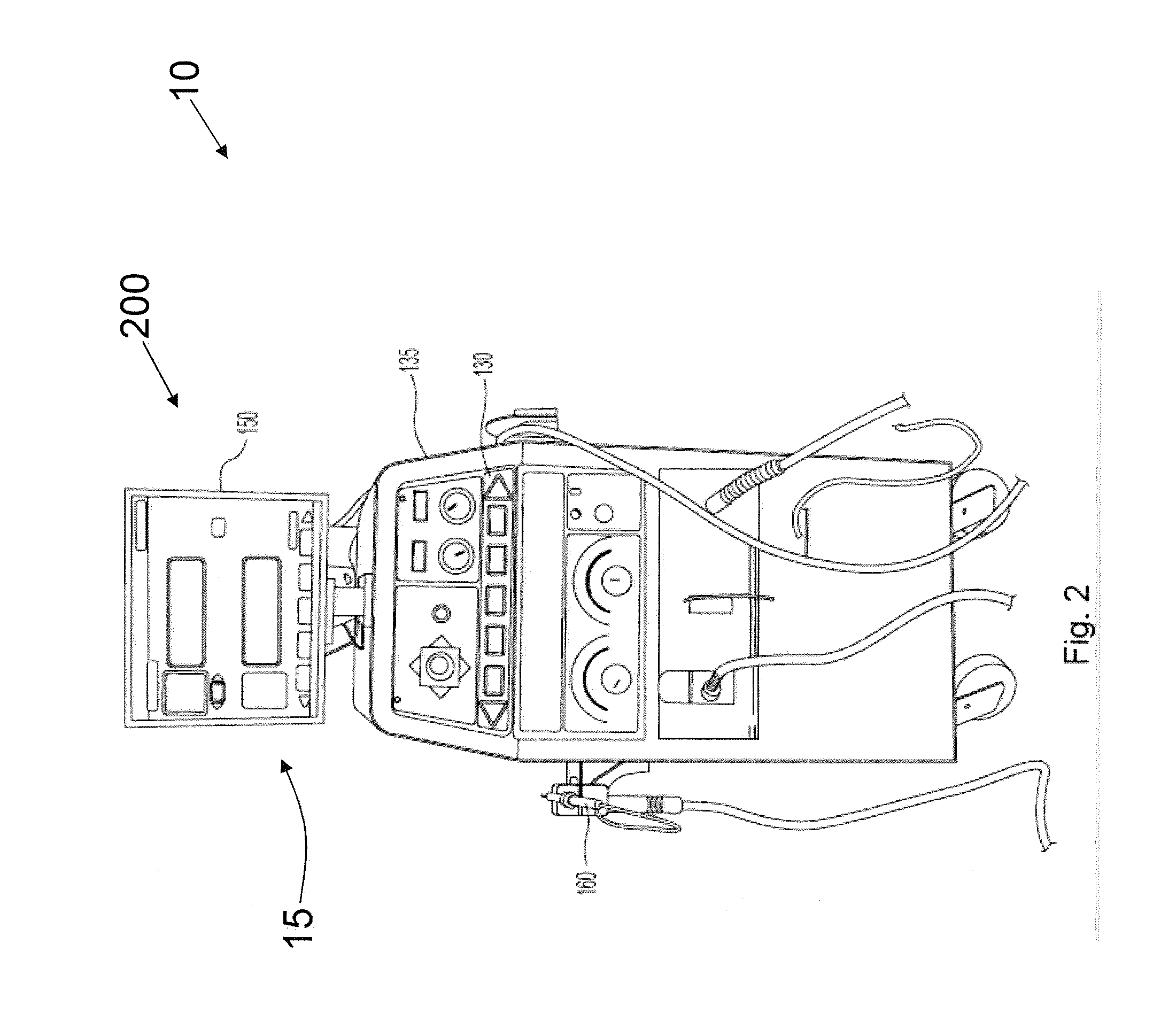

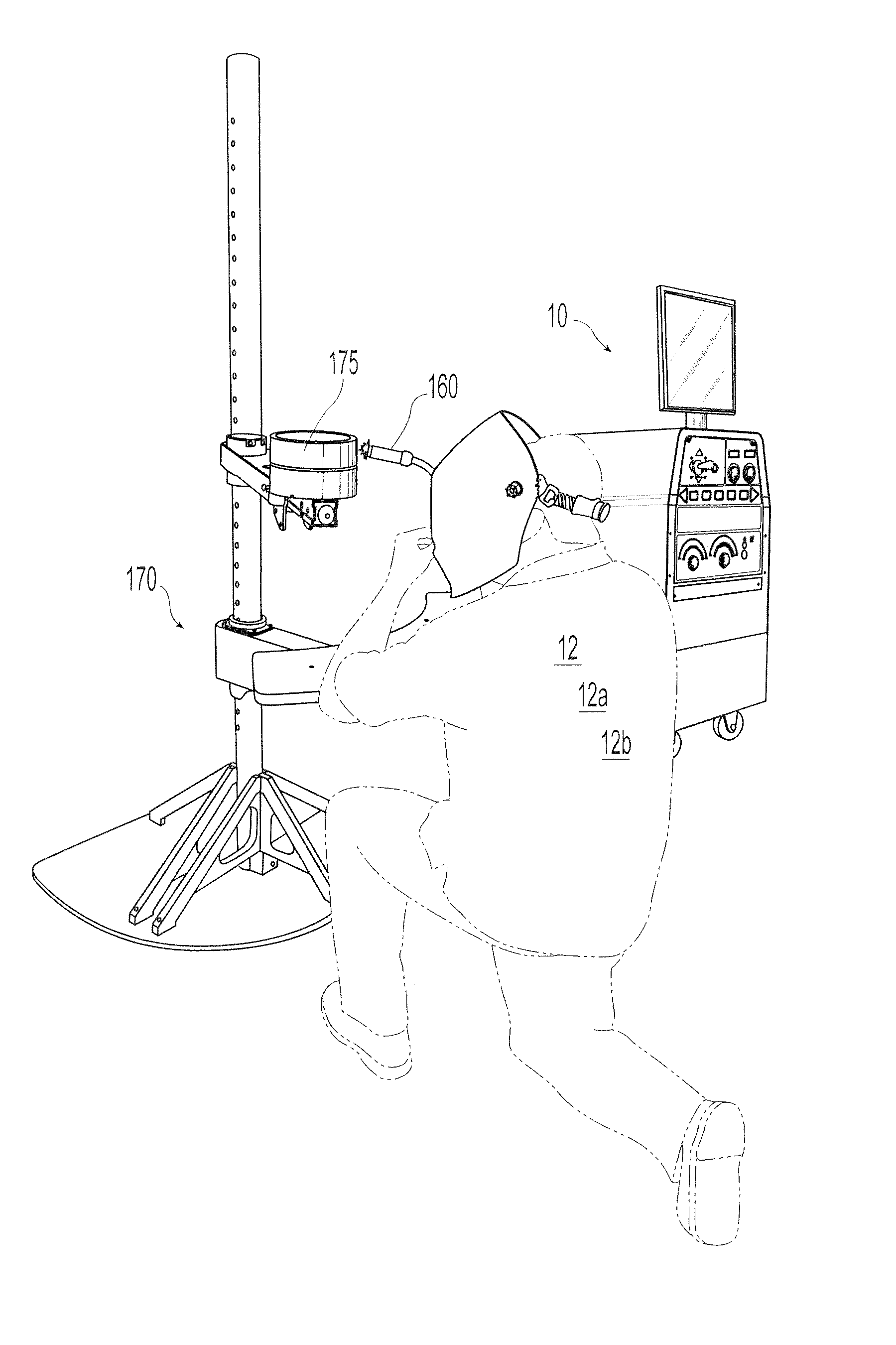

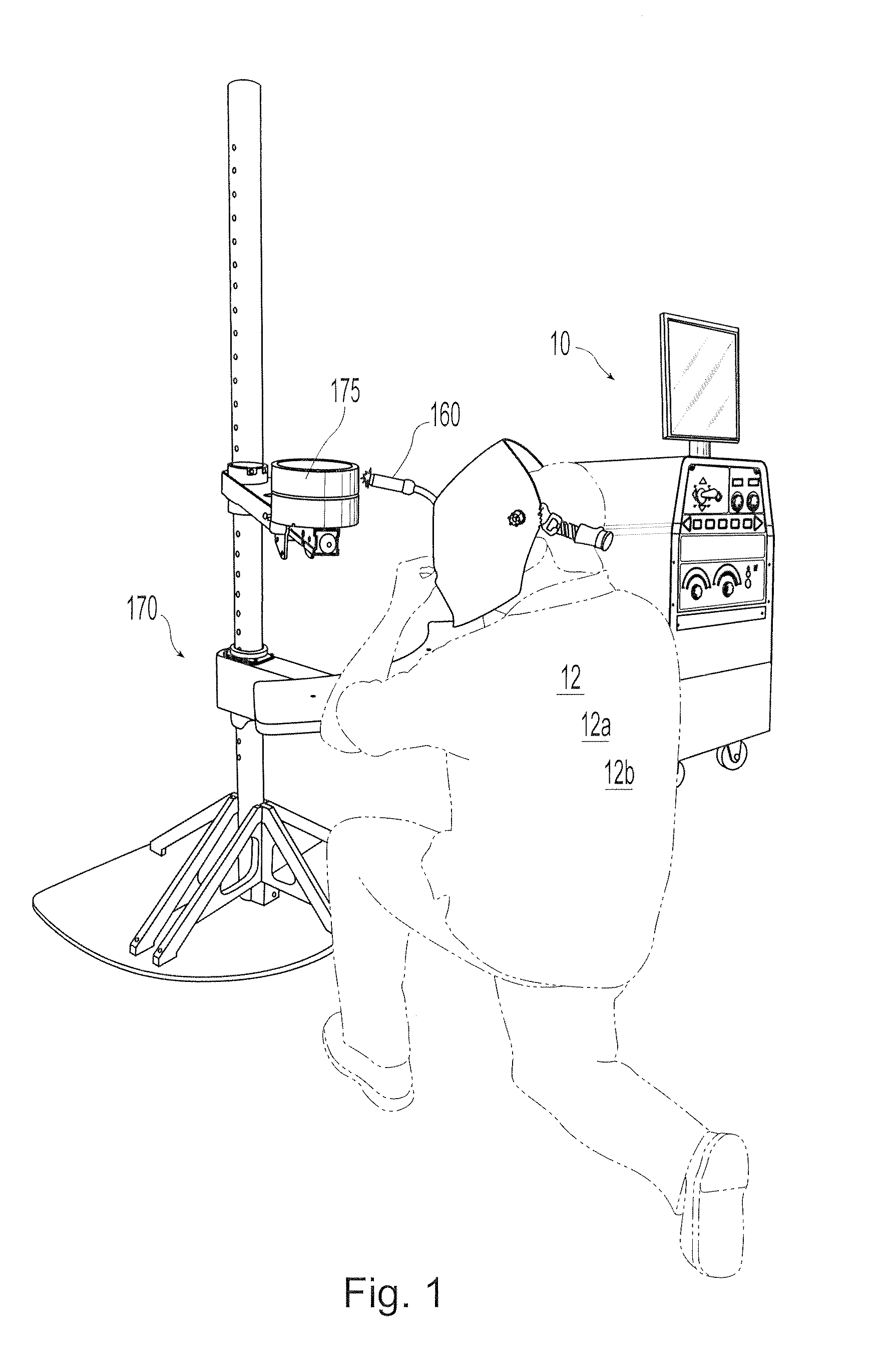

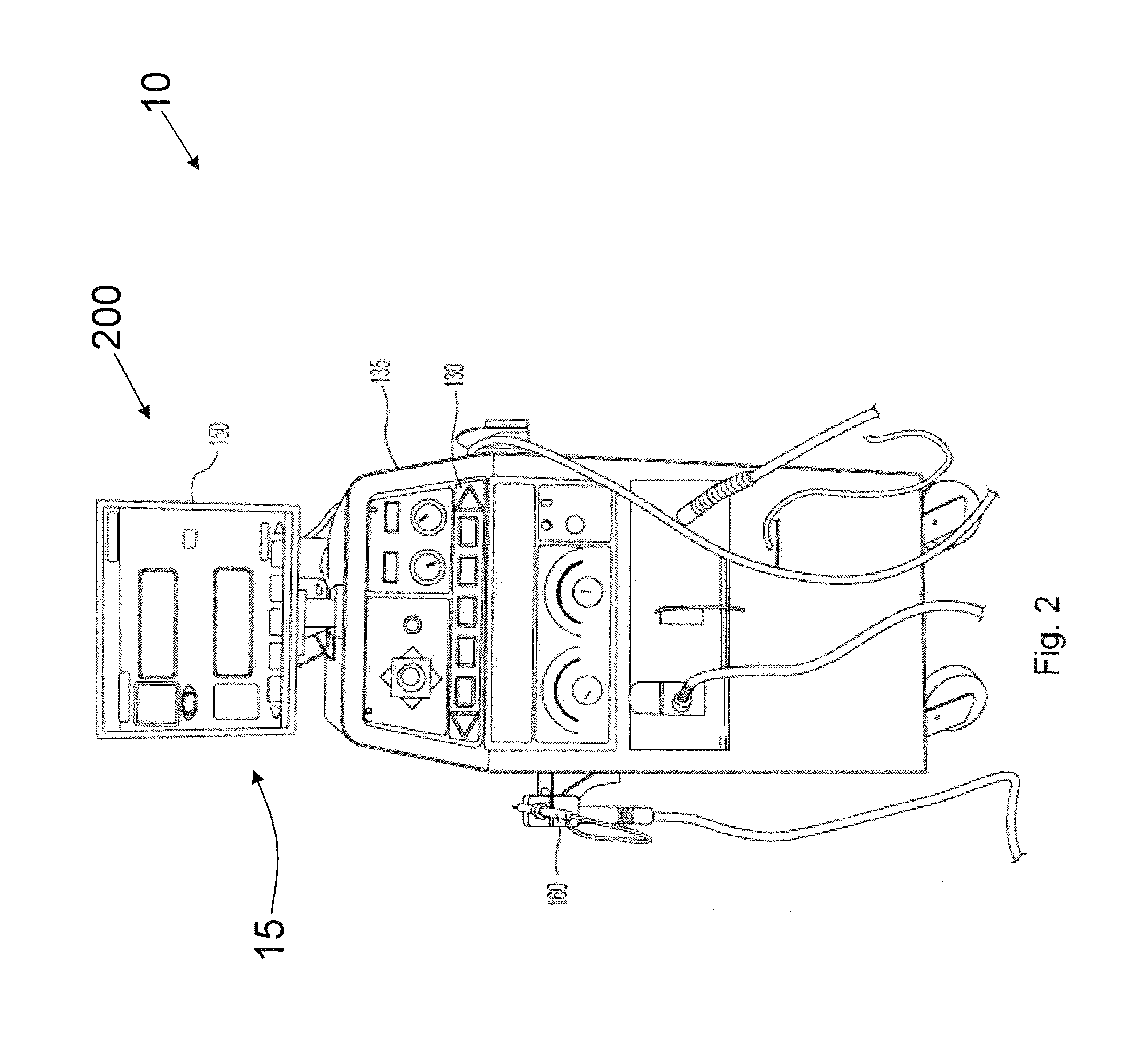

Virtual reality GTAW and pipe welding simulator and setup

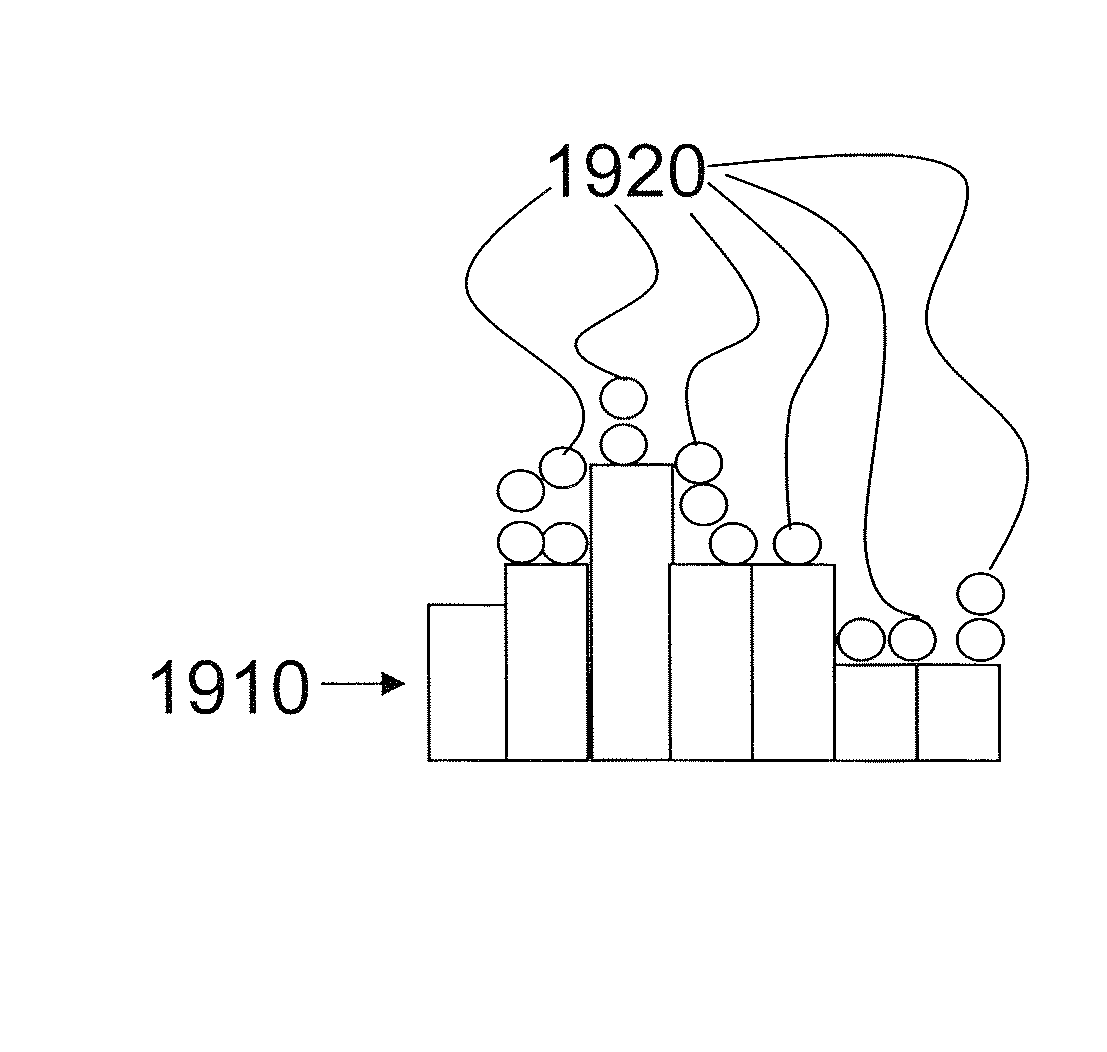

A simulator facilitating virtual welding activity. The simulator may include a logic processor based subsystem operable to generate an interactive welding environment in virtual reality space that emulates welding activity by simulating a virtual weld puddle having dynamic, real time molten metal fluidity and heat dissipation characteristics, responsive to performing a simulated welding activity in real time. The simulator may include a foot pedal device in operative communication with the logic processor based subsystem and configured to affect a characteristic of the virtual weld puddle in real time, responsive to user control of the foot pedal device. The simulator may be configured to track the movements of a mock welding tool and a mock filler wire and determine interaction between the virtual weld puddle, a corresponding virtual welding tool, and a corresponding filler wire in virtual reality space that would result in the welding tool becoming contaminated.

Owner:LINCOLN GLOBAL INC

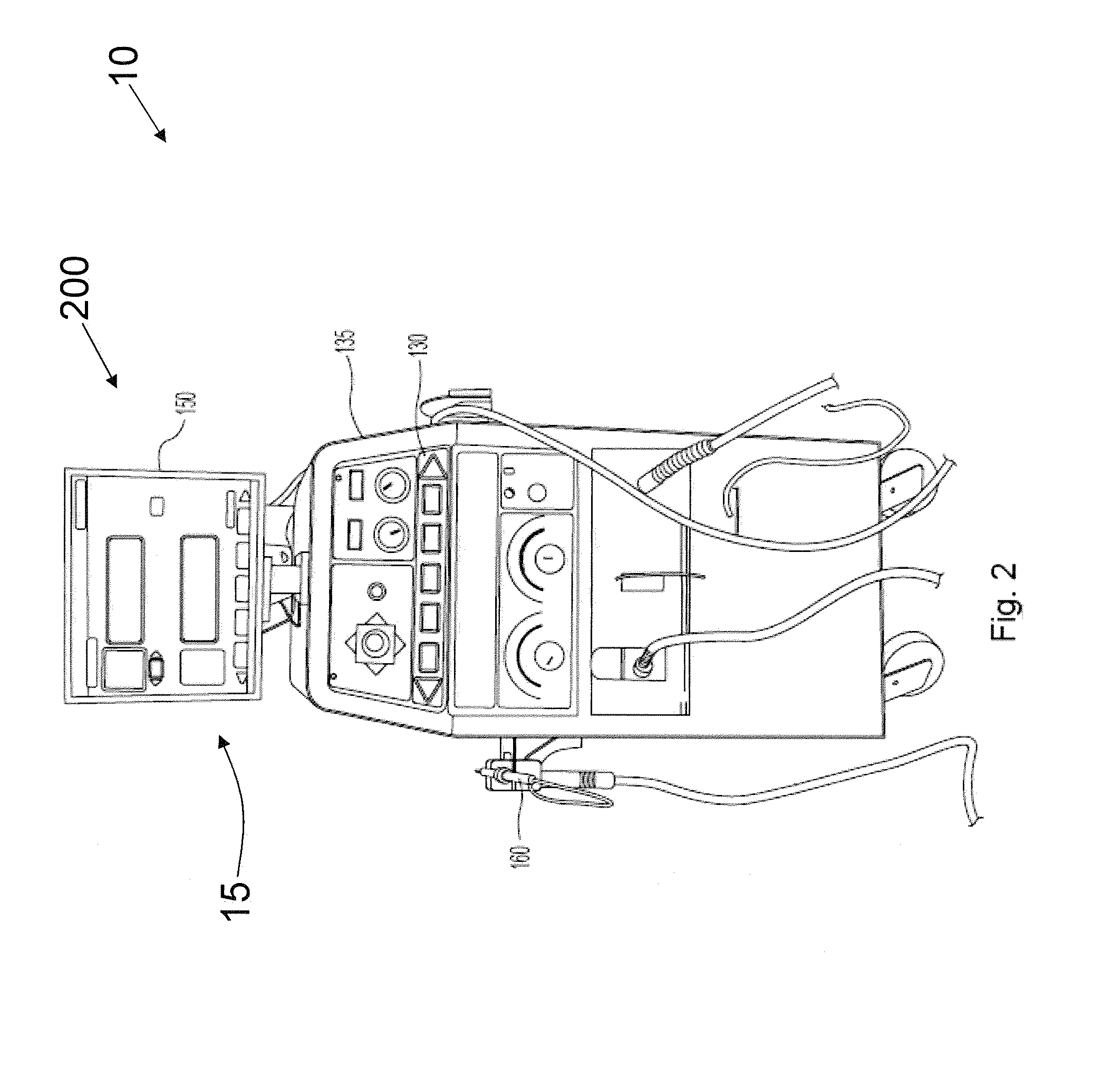

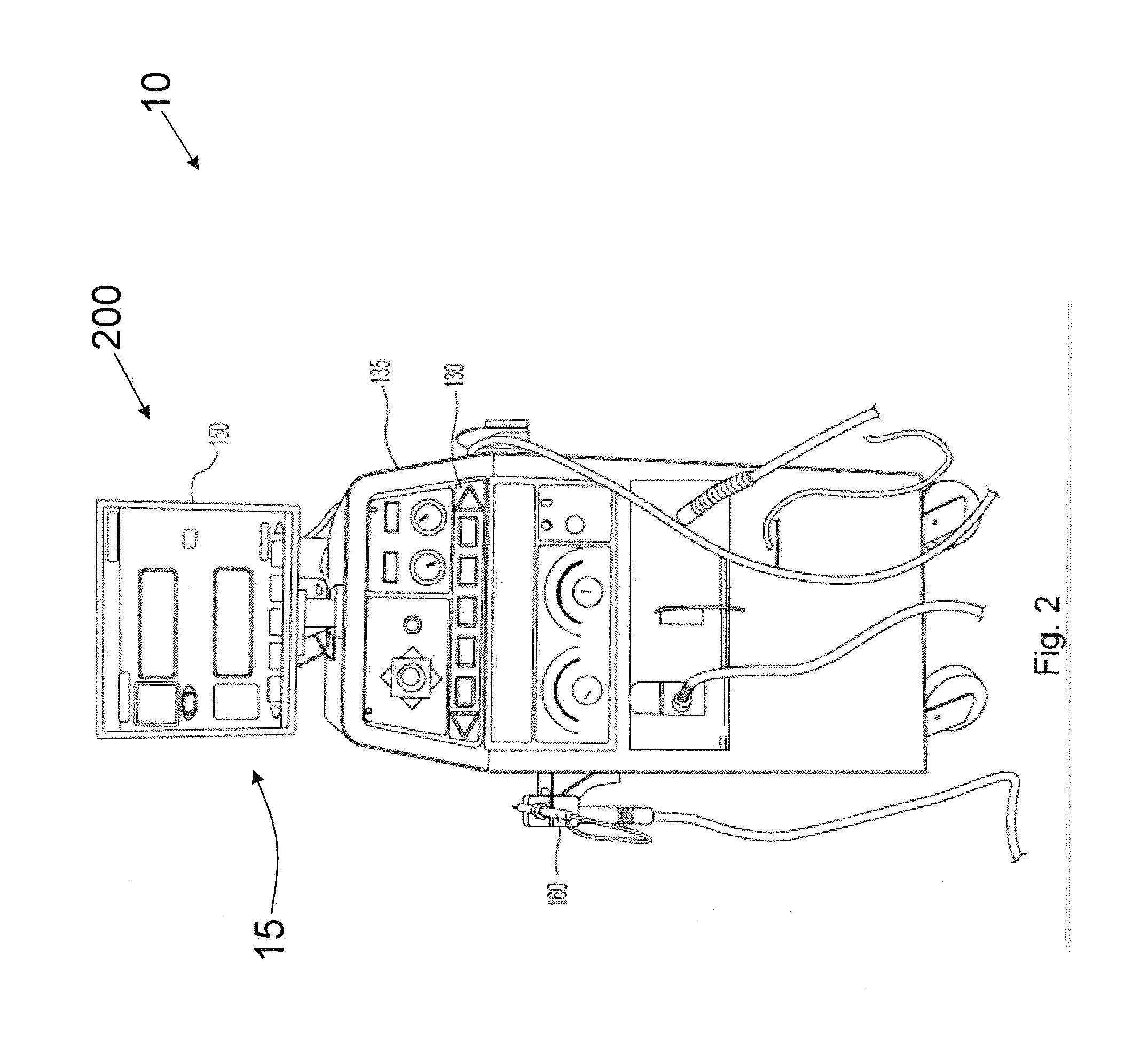

Virtual reality gtaw and pipe welding simulator and setup

ActiveUS20130189657A1Affect characteristicArc welding apparatusEducational modelsSimulationClassical mechanics

Owner:LINCOLN GLOBAL INC

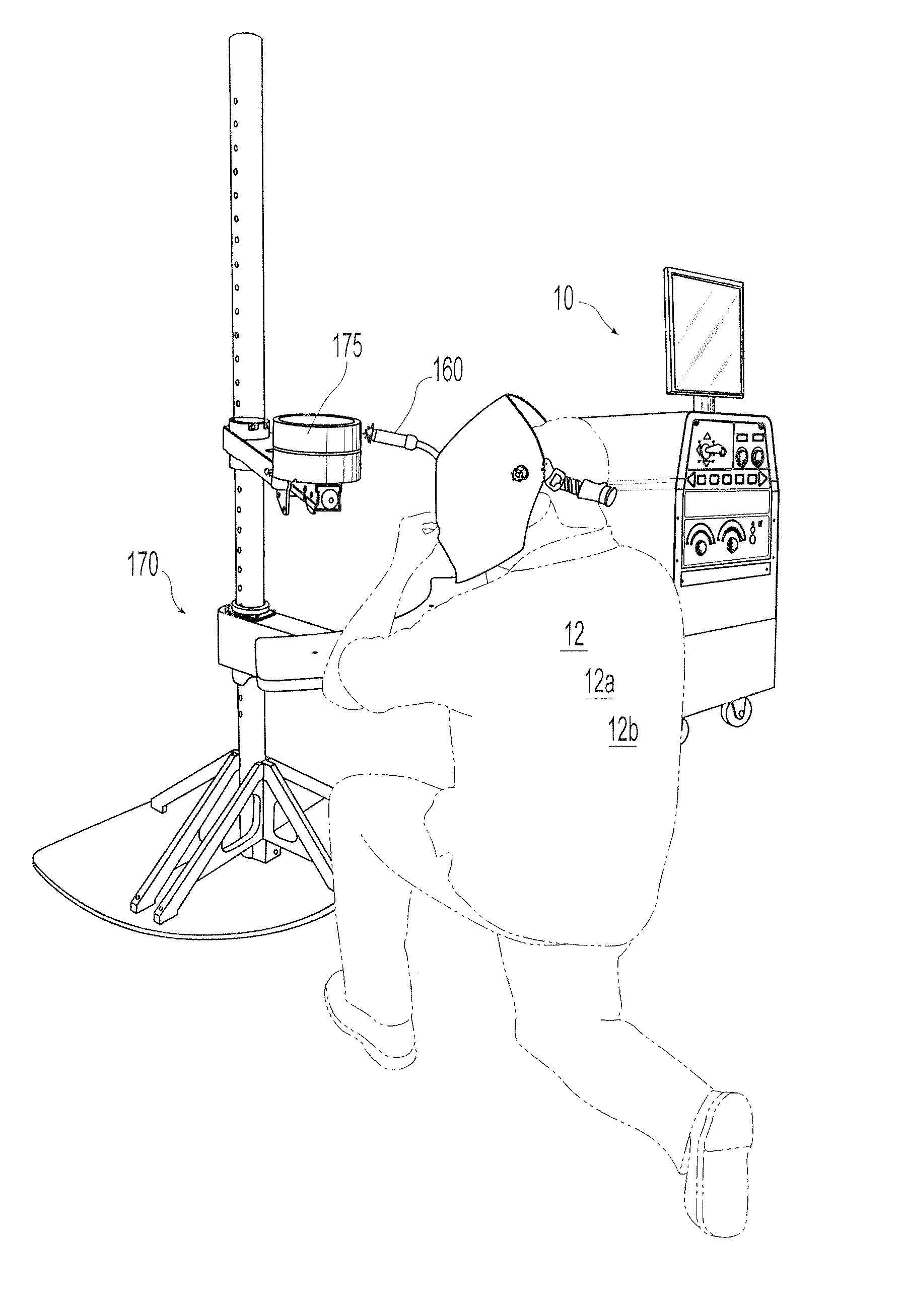

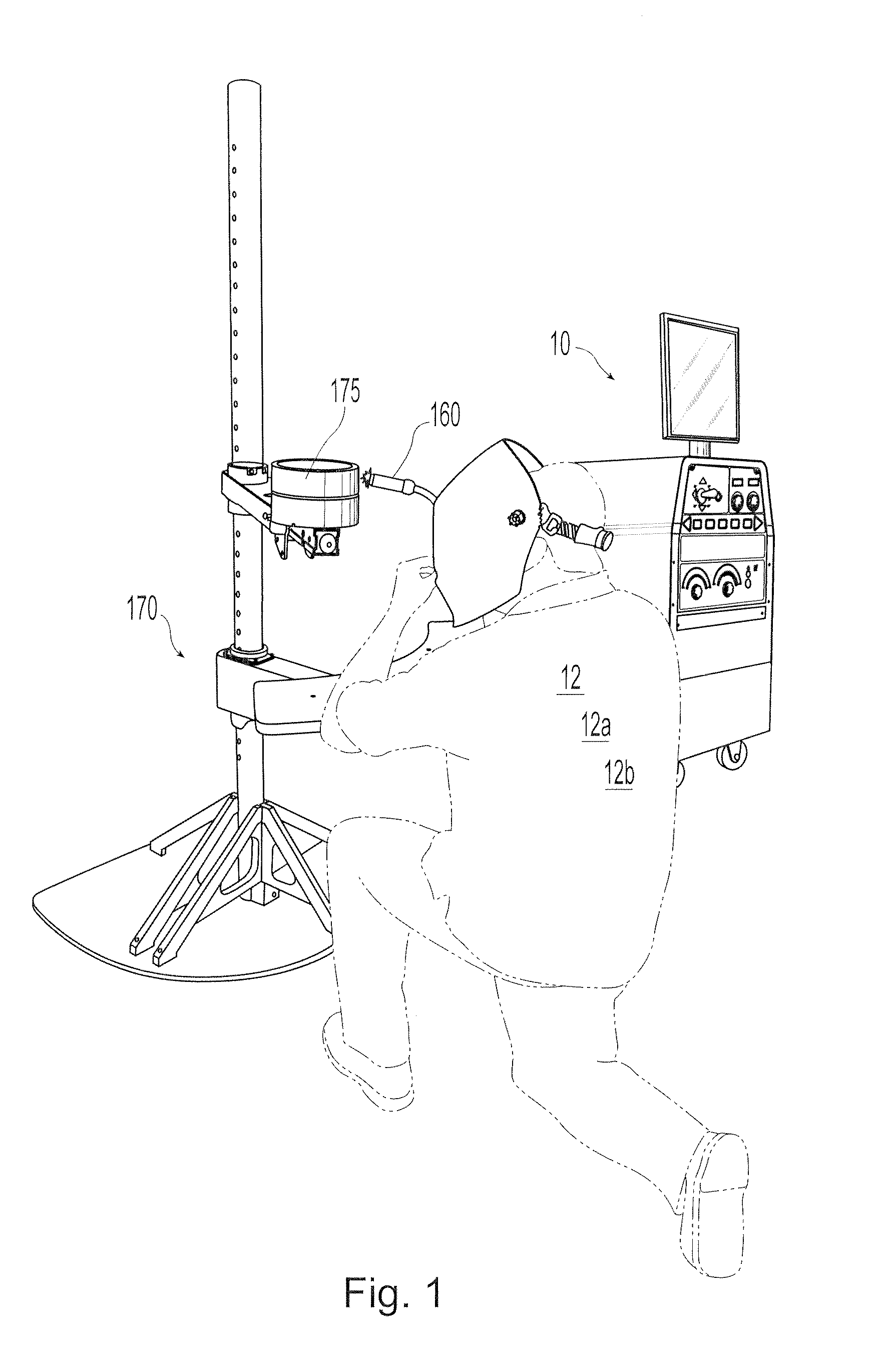

Virtual reality pipe welding simulator

A simulator facilitates virtual welding activity of pipe and open root weld joints. The simulator may include a logic processor based system operable to execute coded instructions for generating an interactive welding environment that emulates welding activity on a section of virtual pipe having at least one virtual weld joint. It also includes a display connected to the logic processor based system for visually depicting the interactive welding environment, wherein the display depicts the section of virtual pipe. A mock welding tool is provided for performing virtual welding activity on the at least one weld joint in real time where one or more sensors are adapted to track movement of the input device in real time for communicating data about the movement of the input device to the logic processor based system.

Owner:LINCOLN GLOBAL INC

Virtual reality pipe welding simulator and setup

ActiveUS20130209976A1Enhance learning objectiveAccurate settingEducational modelsTeaching apparatusSimulationDisplay device

A simulator facilitates virtual welding activity of orbital weld joints. The simulator may include a logic processor based system operable to execute coded instructions for generating an interactive welding environment that emulates welding activity on a section of virtual pipe having at least one virtual weld joint. It also includes a display connected to the logic processor based system for visually depicting the interactive welding environment, wherein the display depicts the section of virtual pipe. A pendant is provided for performing welding equipment setup and virtual welding activity on the at least one weld joint in real time where one or more sensors are adapted to track movement of the input device in real time for communicating data about the movement of the input device to the logic processor based system.

Owner:LINCOLN GLOBAL INC

Virtual reality pipe welding simulator and setup

InactiveUS20140017642A1Enhance learning objectiveAccurate settingCosmonautic condition simulationsEducational modelsSimulationDisplay device

A simulator facilitates virtual welding activity of orbital weld joints. The simulator may include a logic processor based system operable to execute coded instructions for generating an interactive welding environment that emulates welding activity on a section of virtual pipe having at least one virtual weld joint. It also includes a display connected to the logic processor based system for visually depicting the interactive welding environment, wherein the display depicts the section of virtual pipe. A pendant is provided for performing welding equipment setup and virtual welding activity on the at least one weld joint in real time where one or more sensors are adapted to track movement of the input device in real time for communicating data about the movement of the input device to the logic processor based system.

Owner:LINCOLN GLOBAL INC

Virtual reality pipe welding simulator and setup

Owner:LINCOLN GLOBAL INC

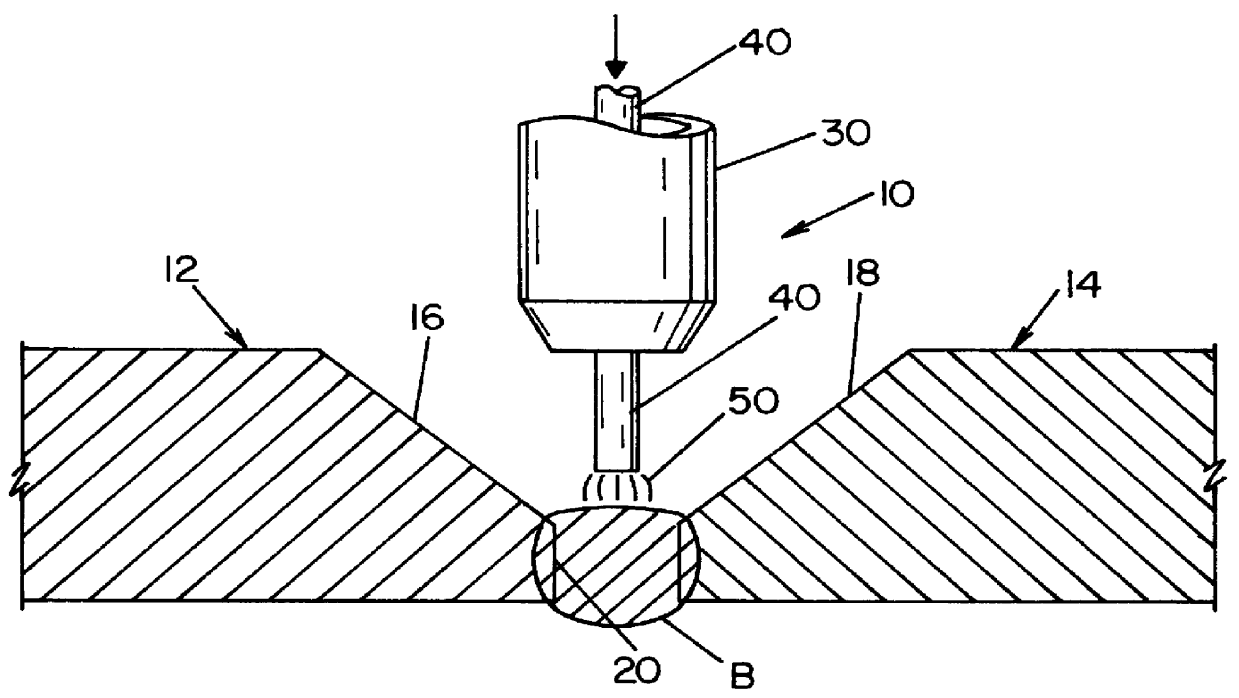

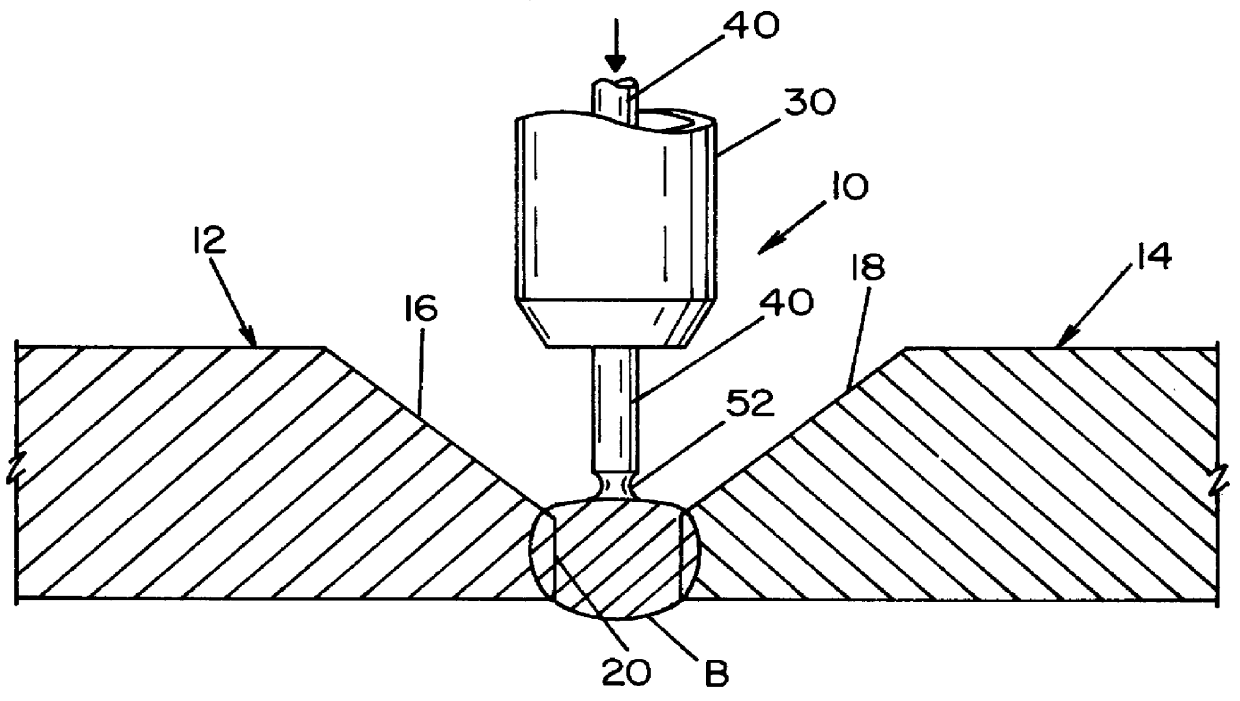

Method of pipe welding

InactiveUS6093906AGood lookingIncrease driving speedArc welding apparatusWelding/cutting media/materialsSulfurManganese

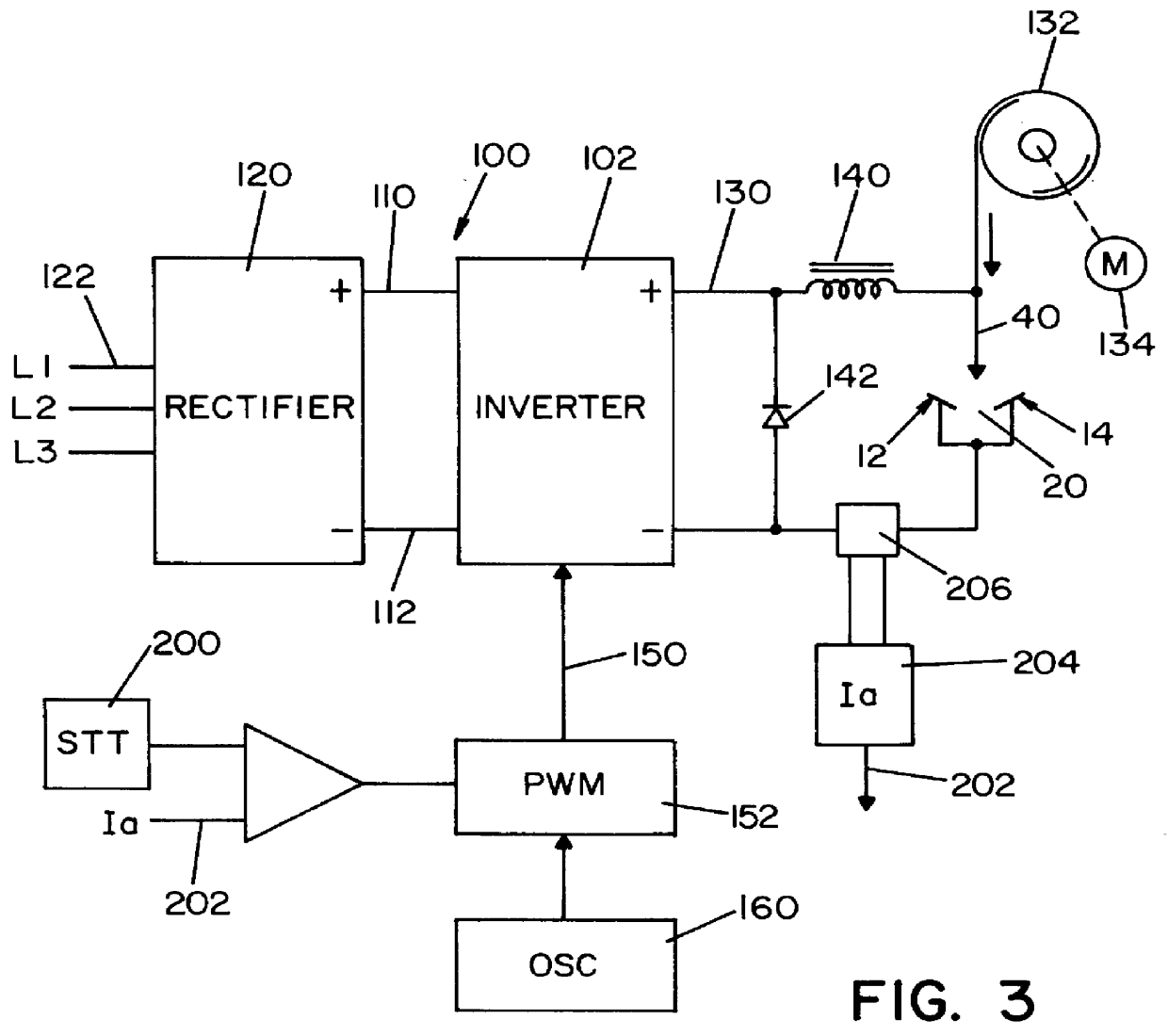

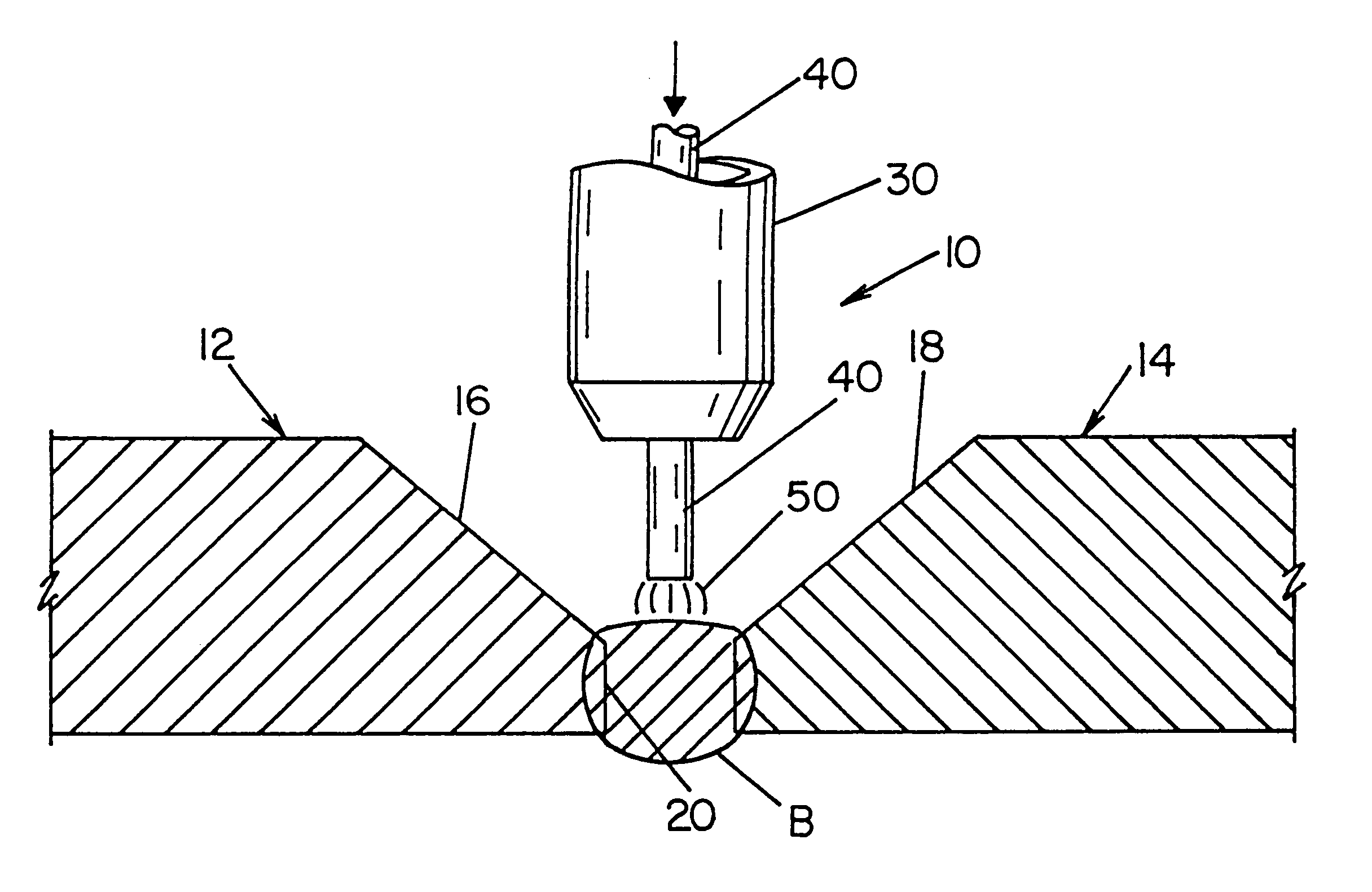

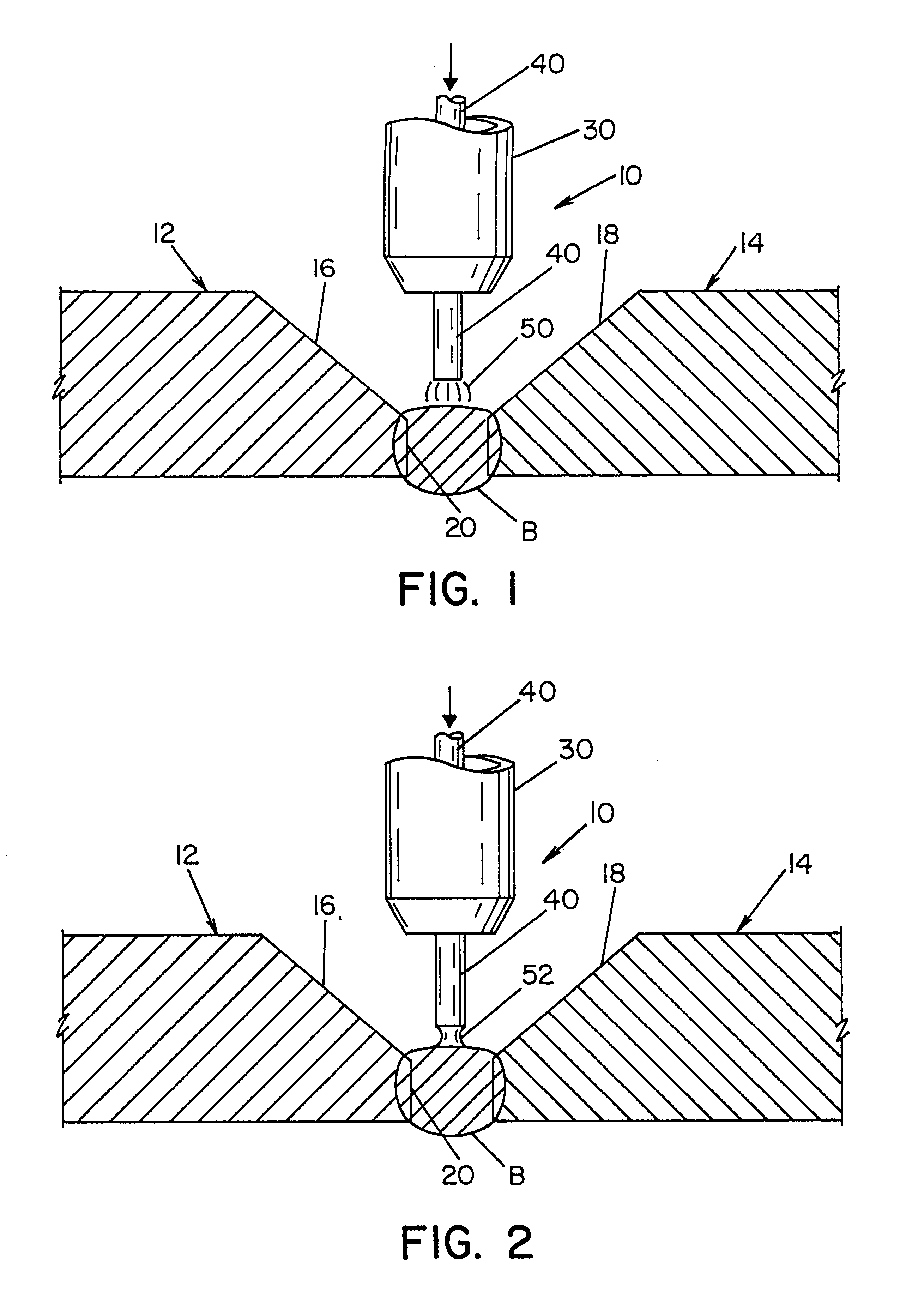

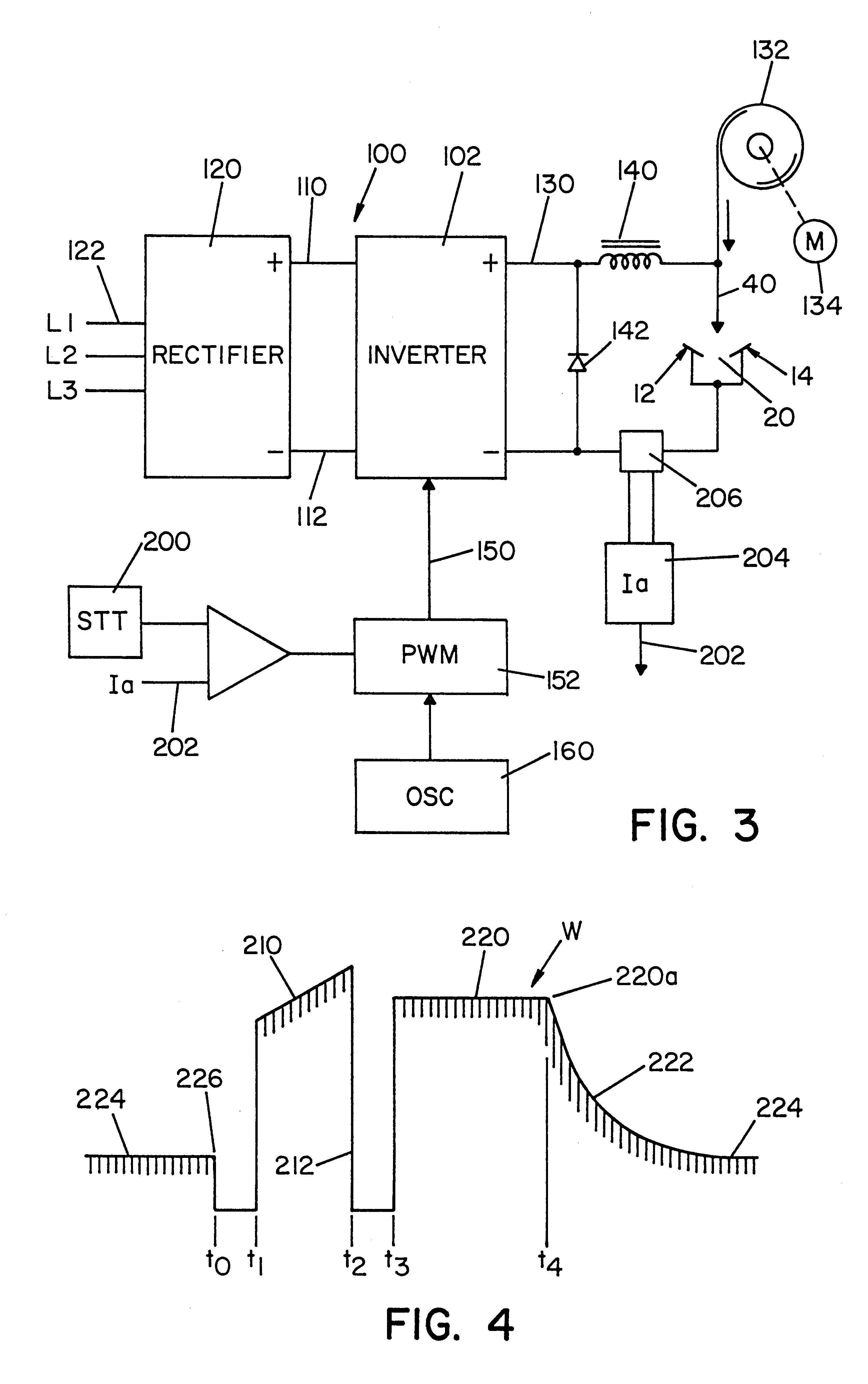

A method of welding the ends of two pipes at the open root between the spaced ends by an STT electric arc welder, which comprises: selecting a welding wire having 0.06-0.15% by weight carbon, 0.90-1.40% by weight manganese, and 0.45-0.75% by weight silicon, as well as phosphorous, copper, stainless steel alloys and sulfur; maintaining the sulfur at a given percentage level of the selected wire in the specific range of 0.015 to 0.035% by weight; and maintaining said phosphorous at a given percentage level of said selected wire in the specific range of less than about 0.015%.

Owner:LINCOLN GLOBAL INC

Method of pipe welding

InactiveUS6204478B1Good lookingIncrease driving speedMeasurement of fluid loss/gain rateArc welding apparatusSulfurManganese

A method of welding the ends of two pipes at the open root between the spaced ends by an STT electric arc welder, which comprises: selecting a welding wire having 0.06-0.15% by weight carbon, 0.90-1.40% by weight manganese, and 0.45-0.75% by weight silicon, as well as phosphorous, copper, stainless steel alloys and sulfur; maintaining the sulfur at a given percentage level of the selected wire in the specific range of 0.015 to 0.035% by weight; and maintaining said phosphorous at a given percentage level of said selected wire in the specific range of less than about 0.015%.

Owner:LINCOLN GLOBAL INC

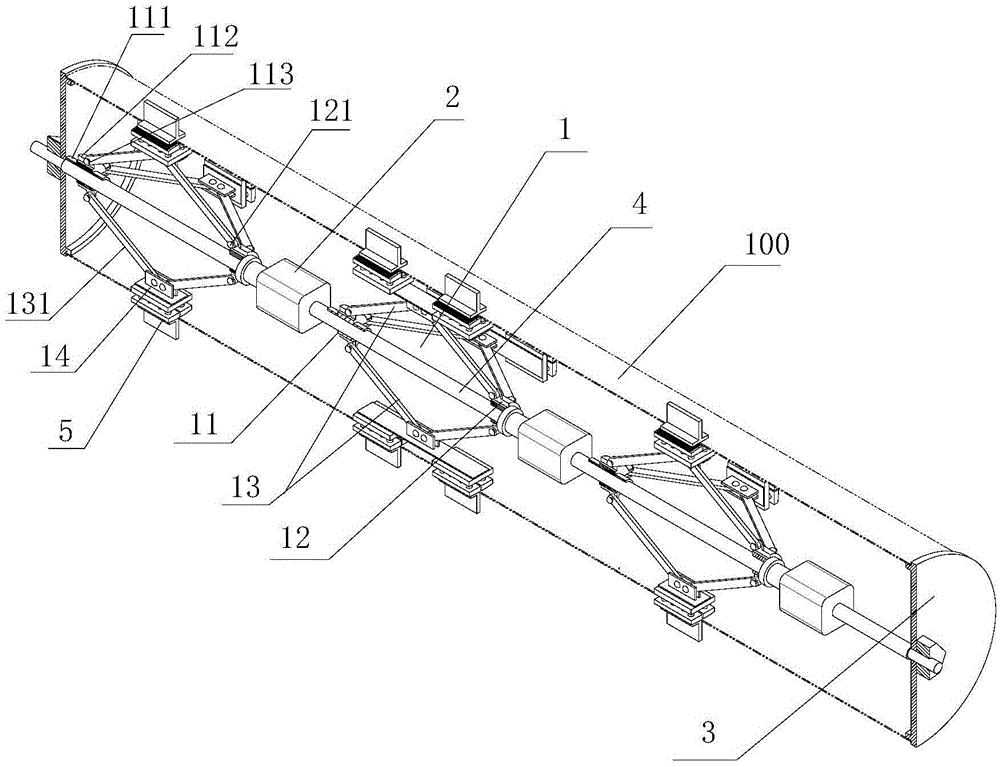

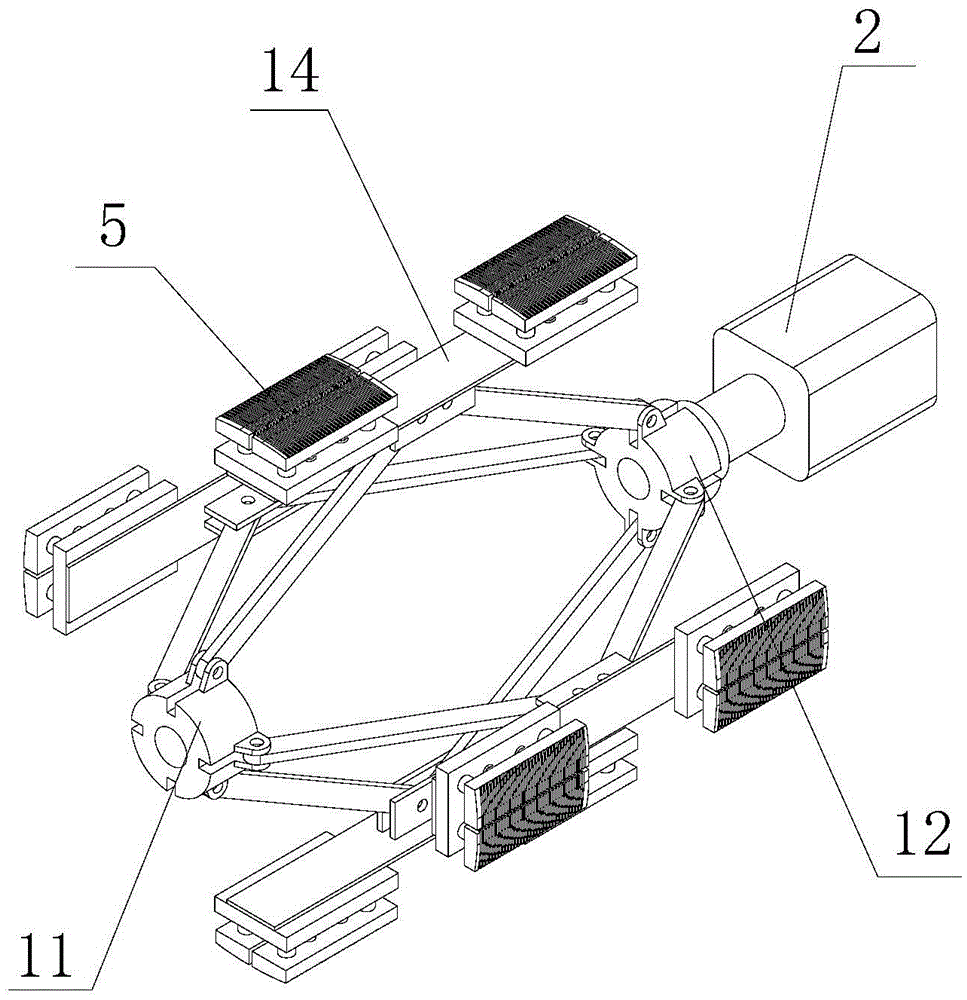

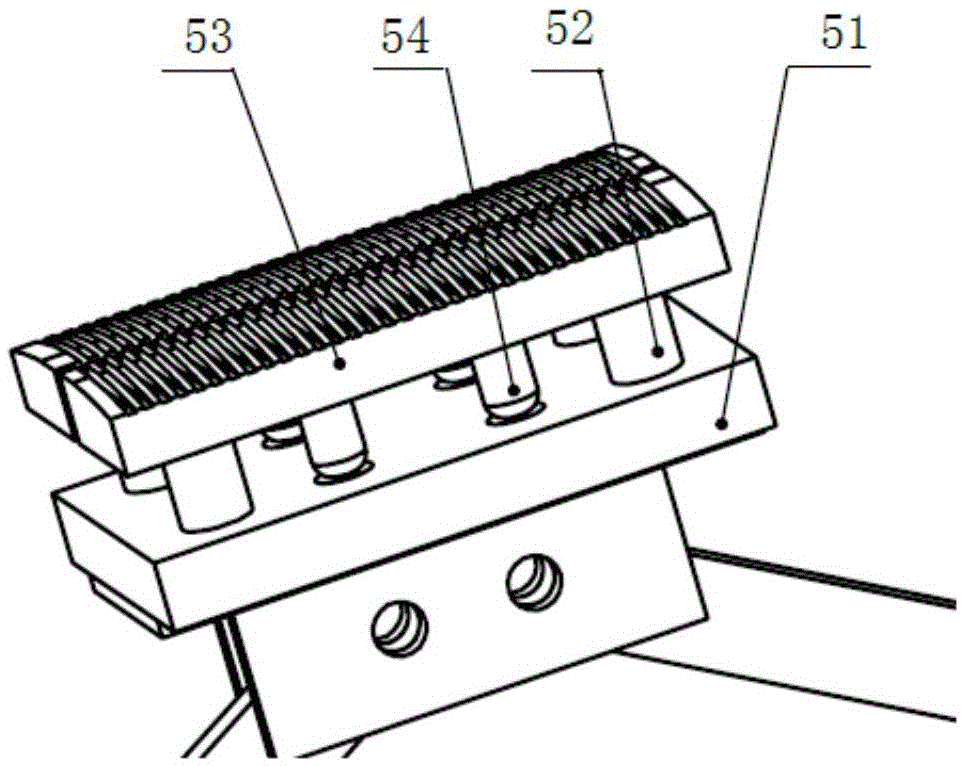

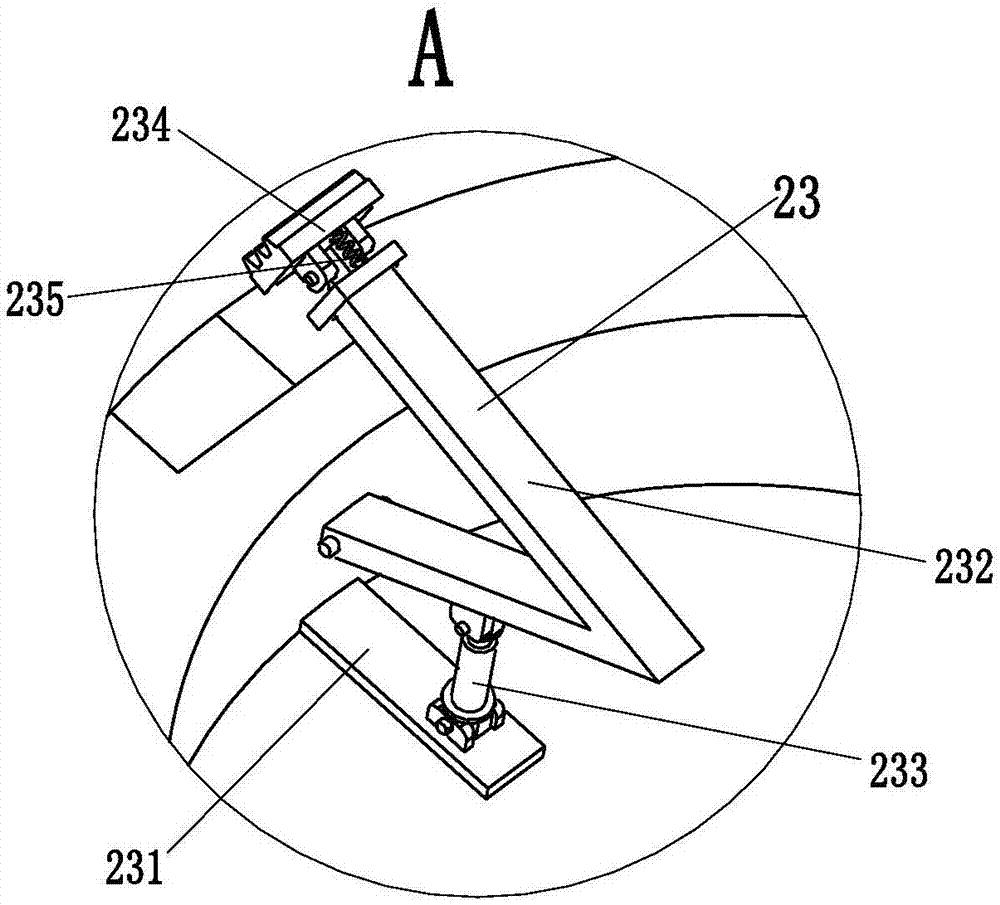

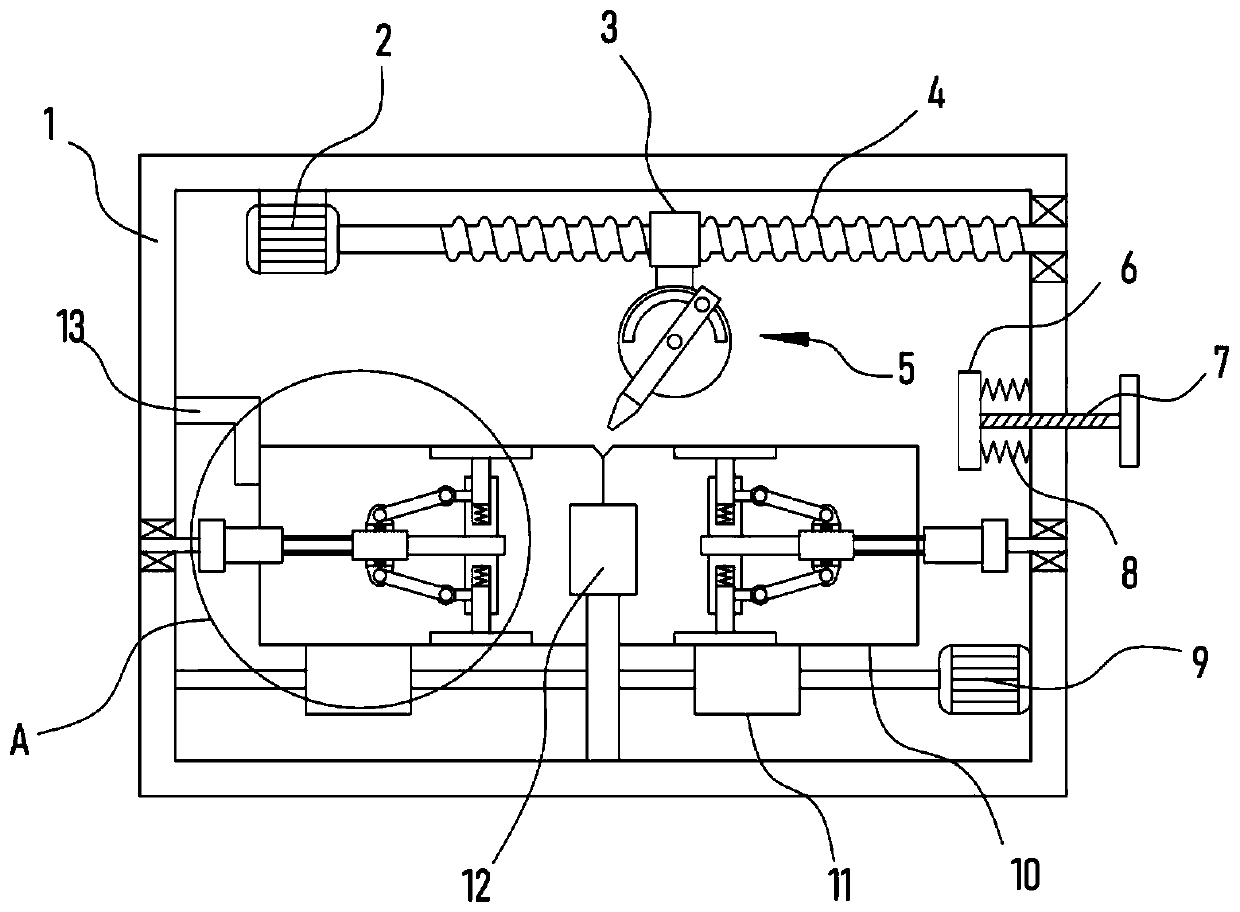

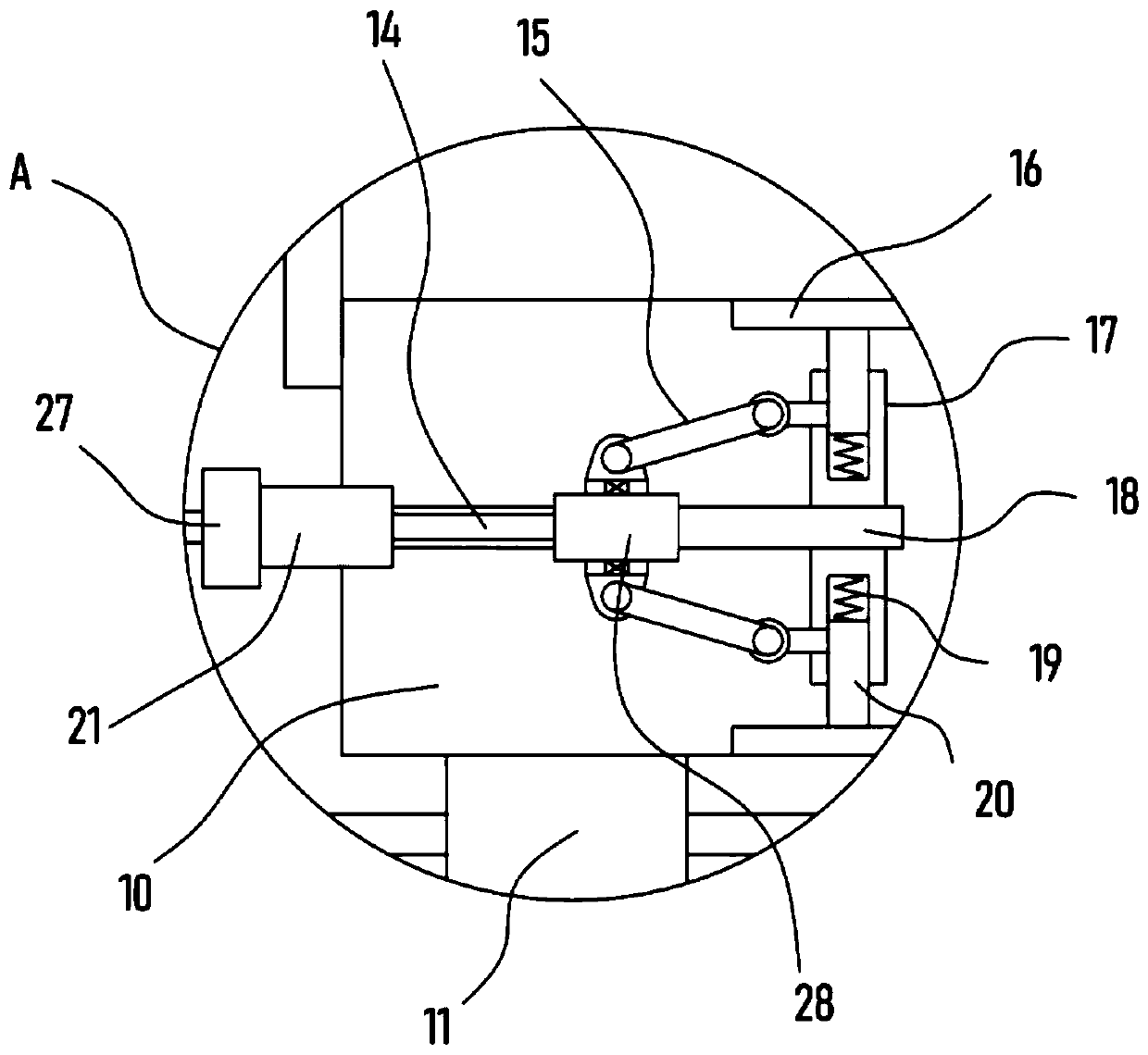

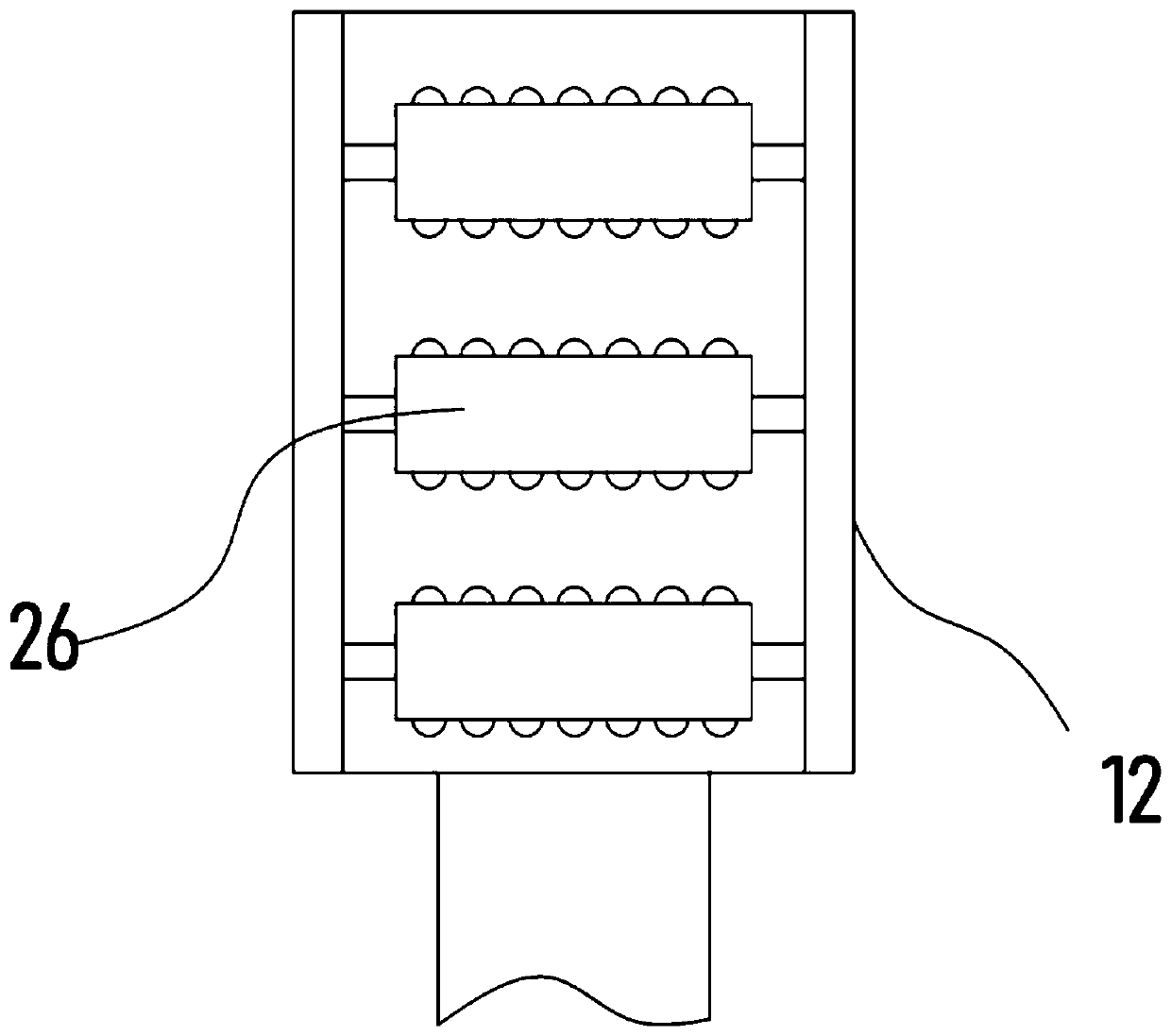

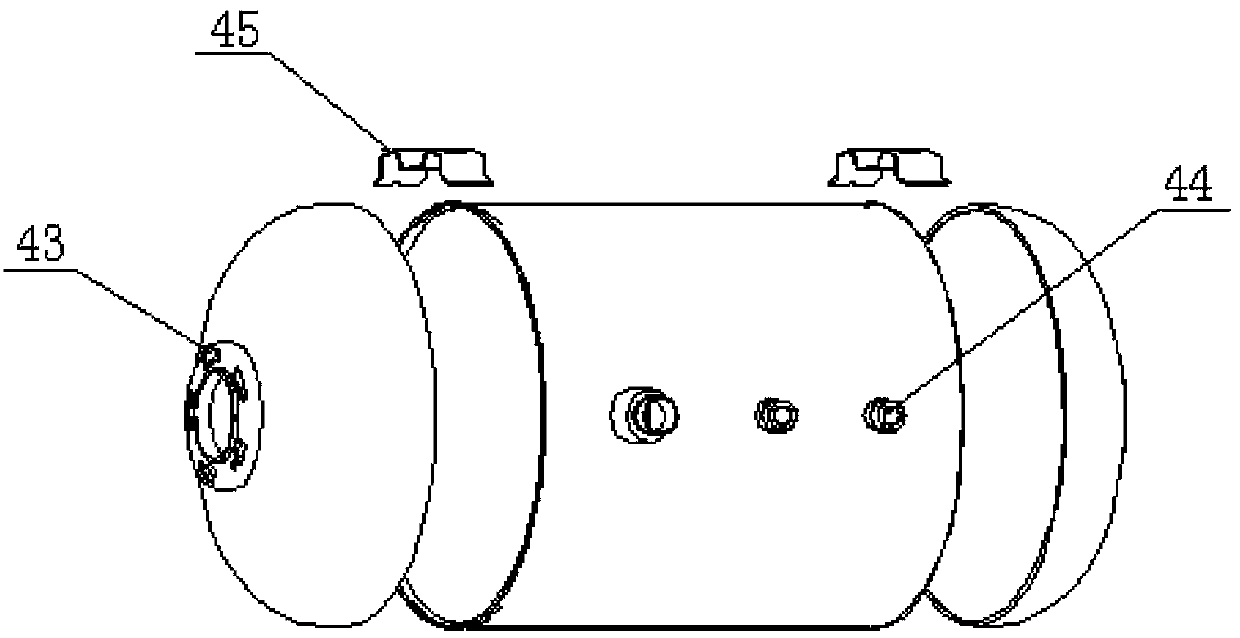

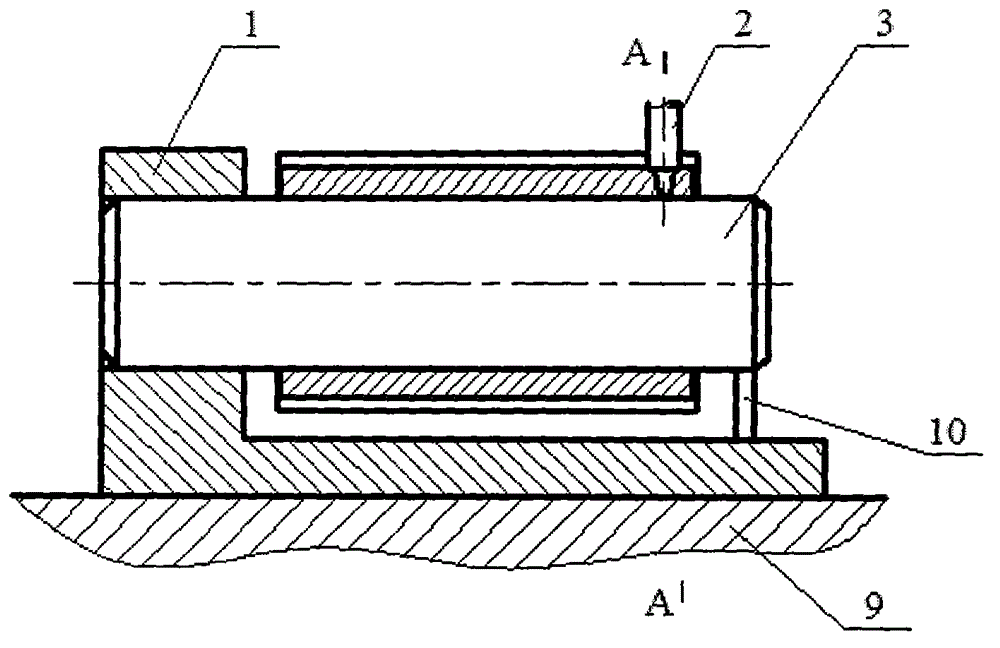

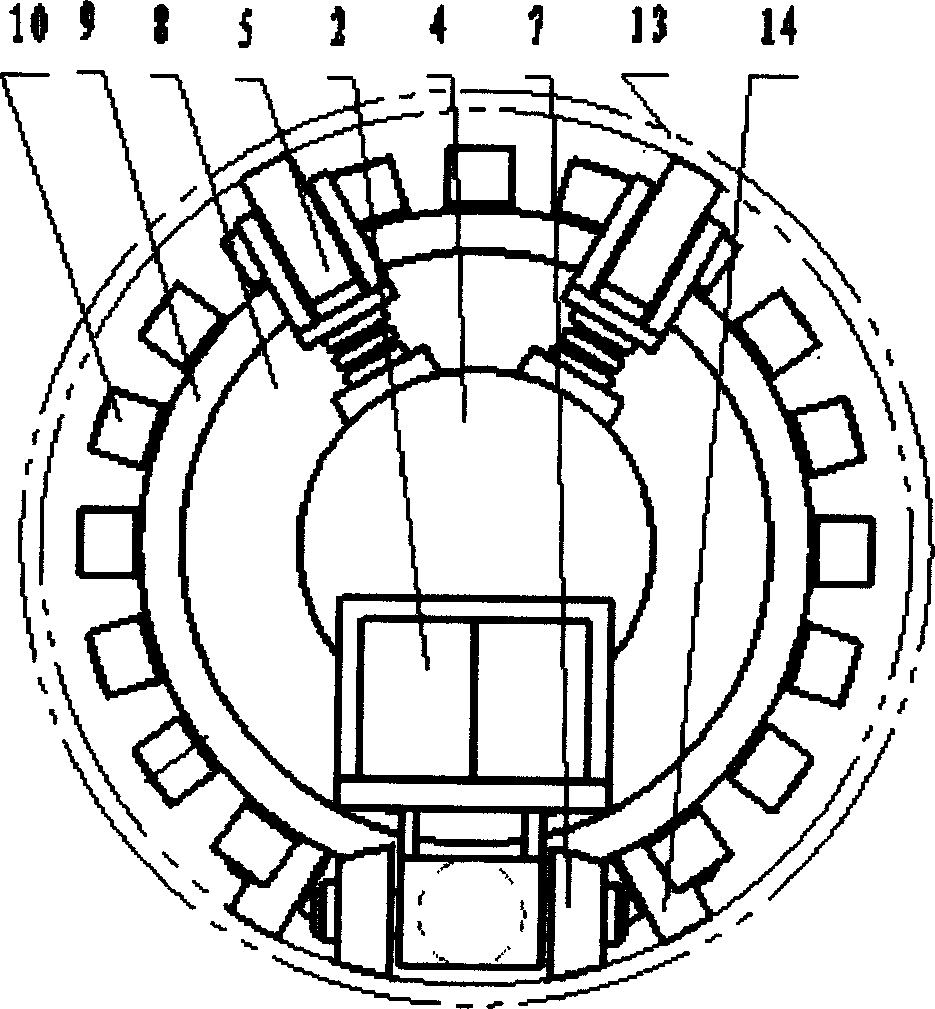

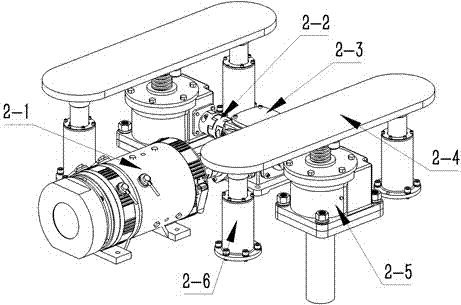

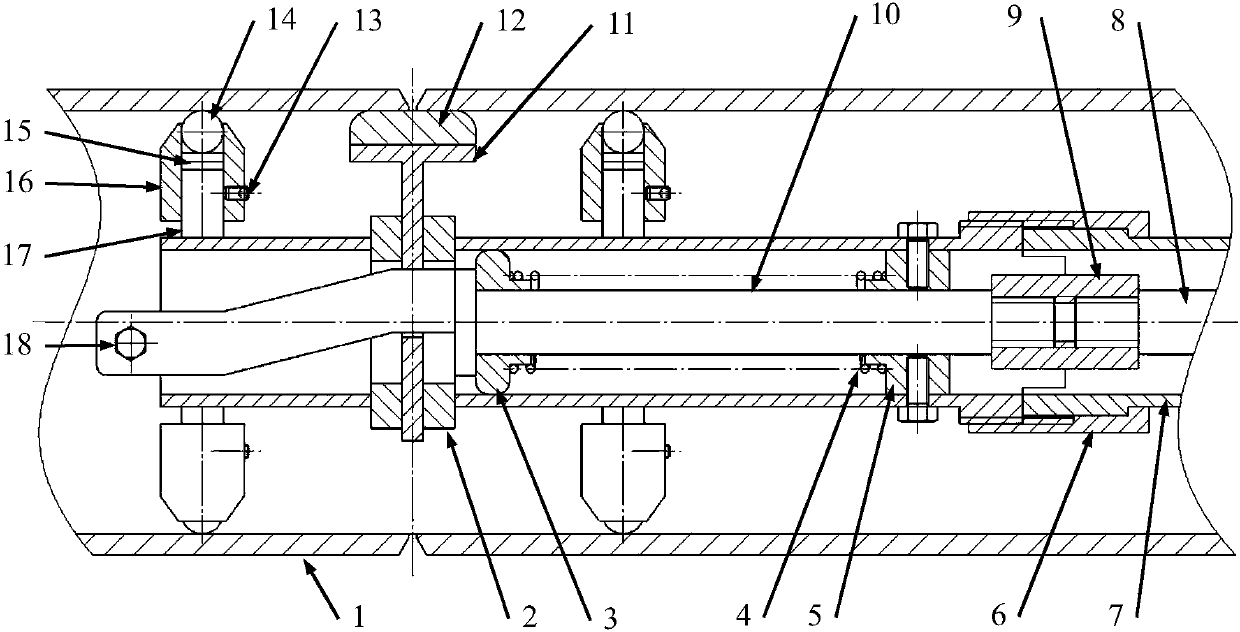

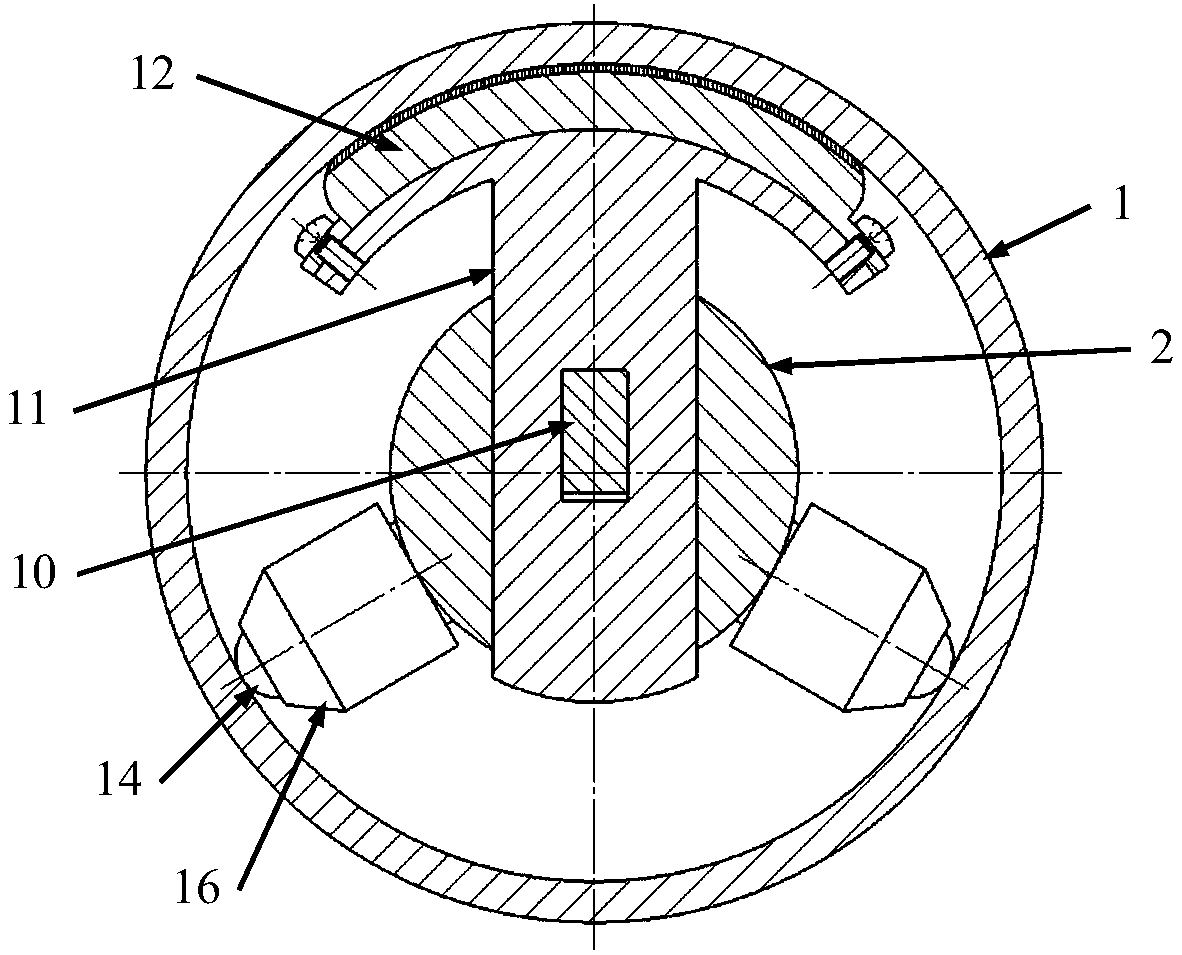

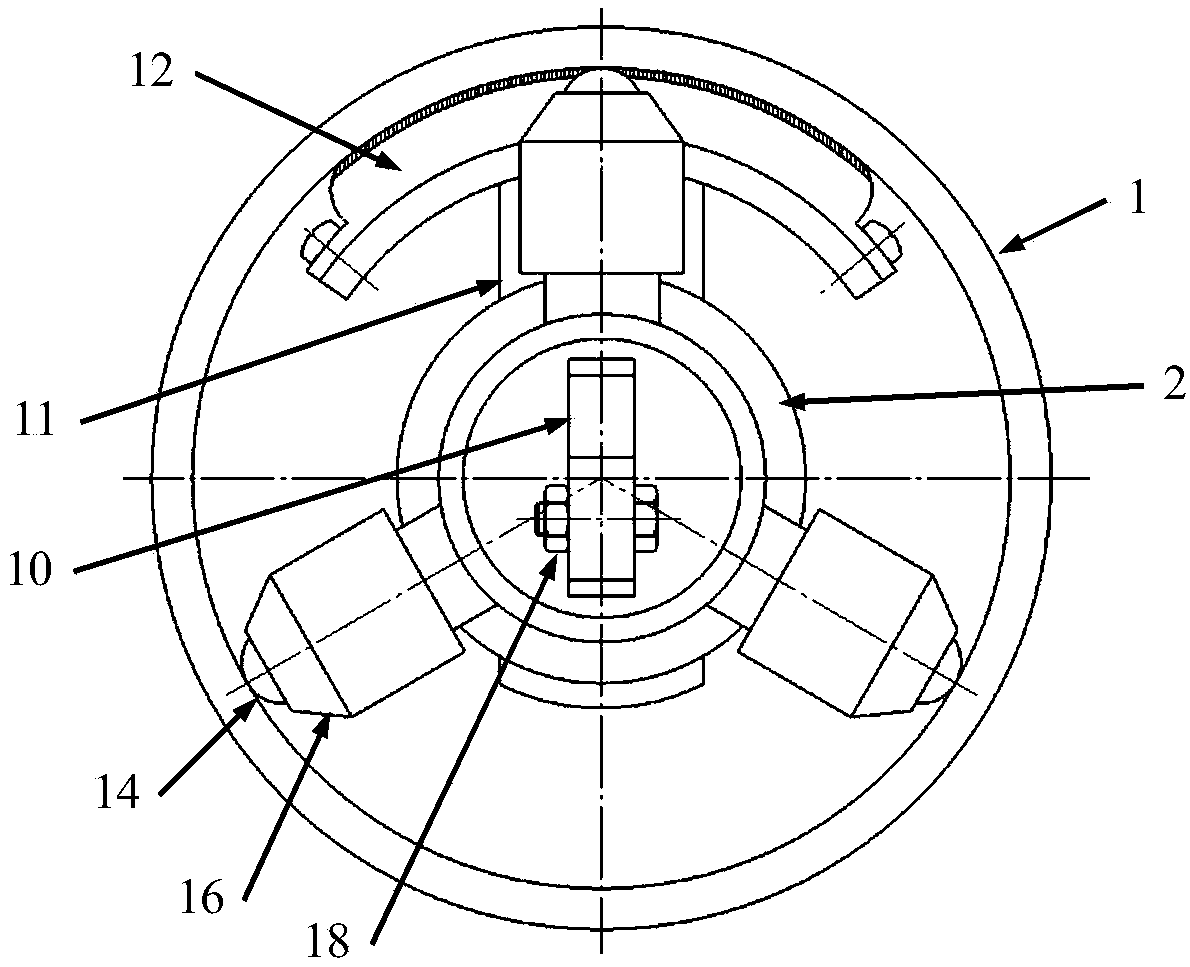

Rhombic internal support clamp for round pipe welding

ActiveCN105598631ASolve protection problemsImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesDiagonalThermal deformation

The invention discloses a rhombic internal support clamp for round pipe welding. The rhombic internal support clamp comprises at least one rhombic internal support unit, push cylinders corresponding to the rhombic internal support units one to one, two end covers, a main shaft and a plurality of pressing back-blowing modules, wherein the main shaft is arranged at the center of a round pipe, and both ends of the main shaft are respectively fixed in the centers of the two end covers; each push cylinder is fixedly arranged on the main shaft; each rhombic internal support unit comprises a positioning ring, a movable ring and at least one rhombic supporting frame; the positioning rings fixedly sleeve the main shaft; the movable rings sleeve the main shaft and can move back and forth along the main shaft along with the pushing of the corresponding push cylinders; one pair of diagonals of each rhombic supporting frame is respectively hinged to the corresponding positioning ring and the corresponding movable ring, and the other pair of diagonals of each rhombic supporting frame is respectively hinged to two supporting platforms; at least one pressing back-blowing module is fixed on each supporting platform. According to the rhombic internal support clamp, the internal protection problem for pipe welding is solved, the quality of welds is improved, and thermal deformation is relieved.

Owner:SHANGHAI PURUIMA INTELLIGENT TECH CO LTD

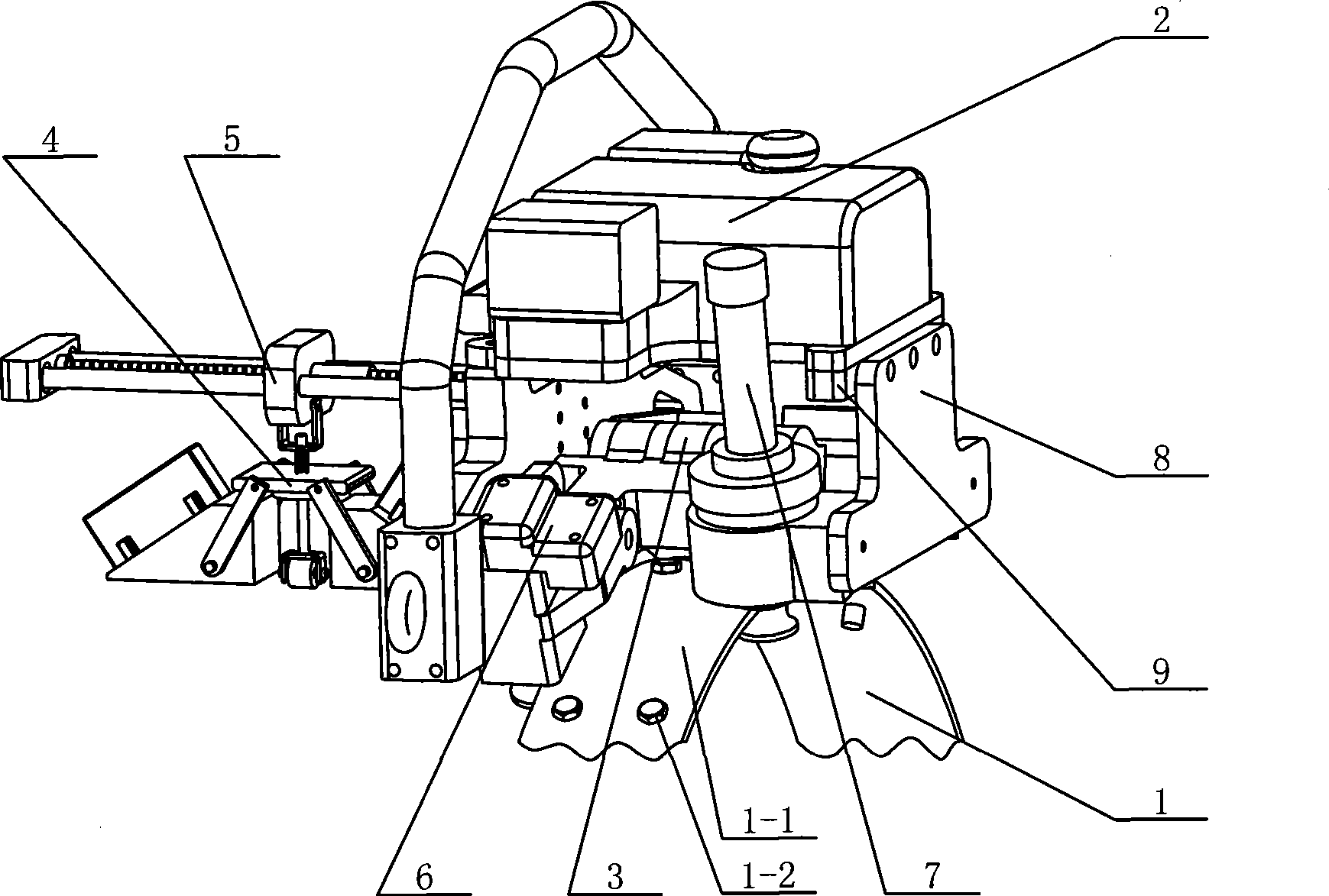

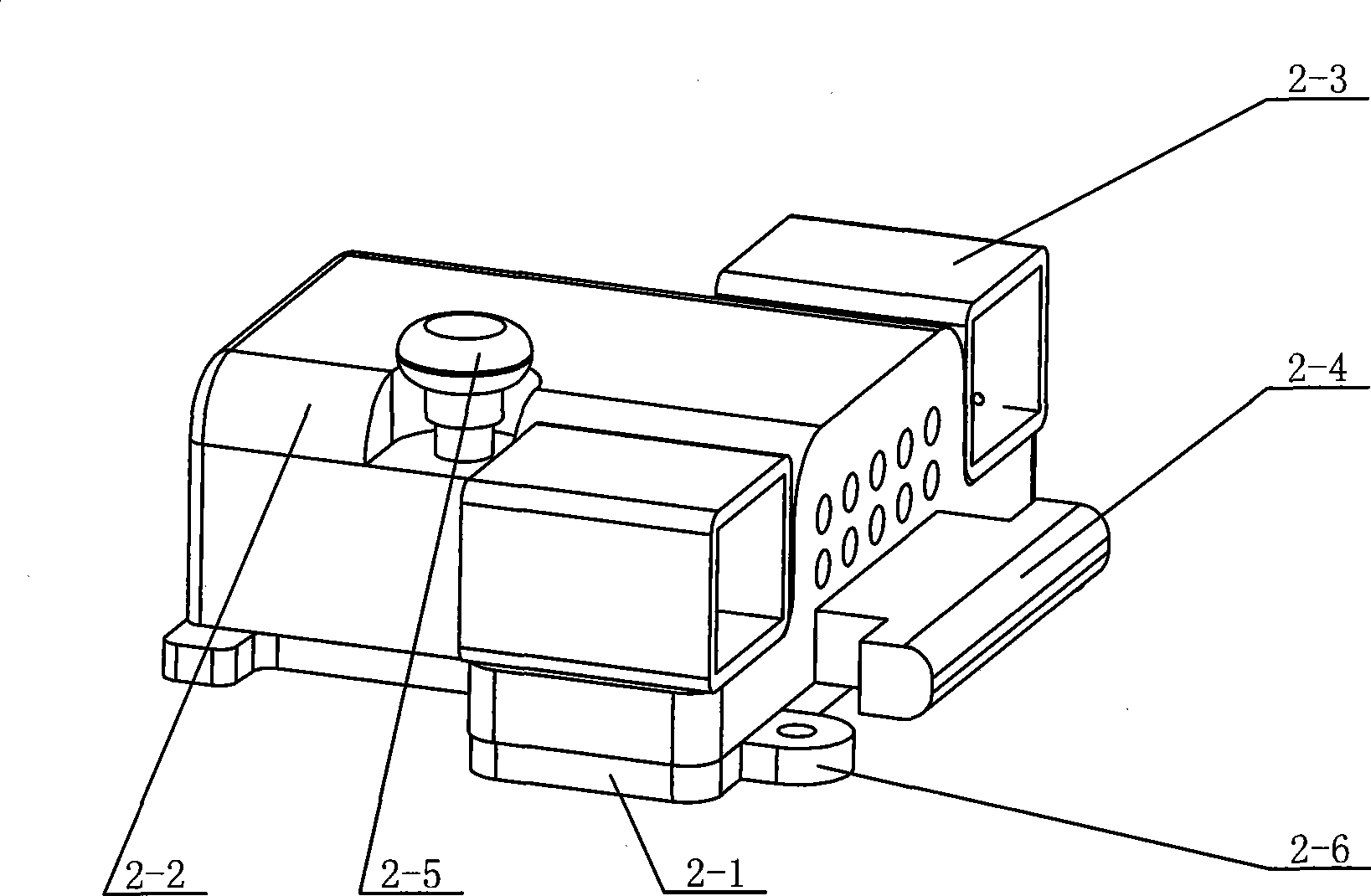

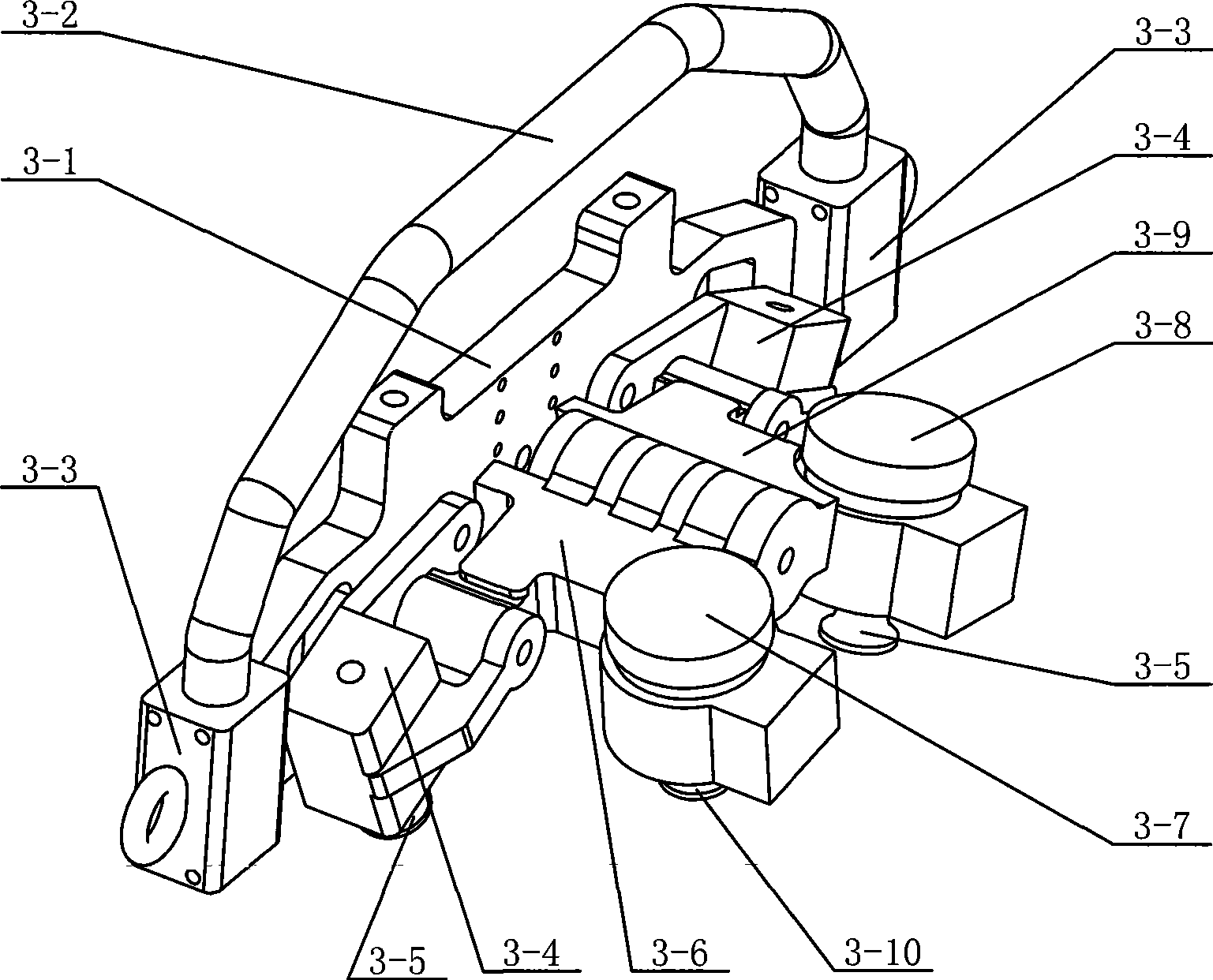

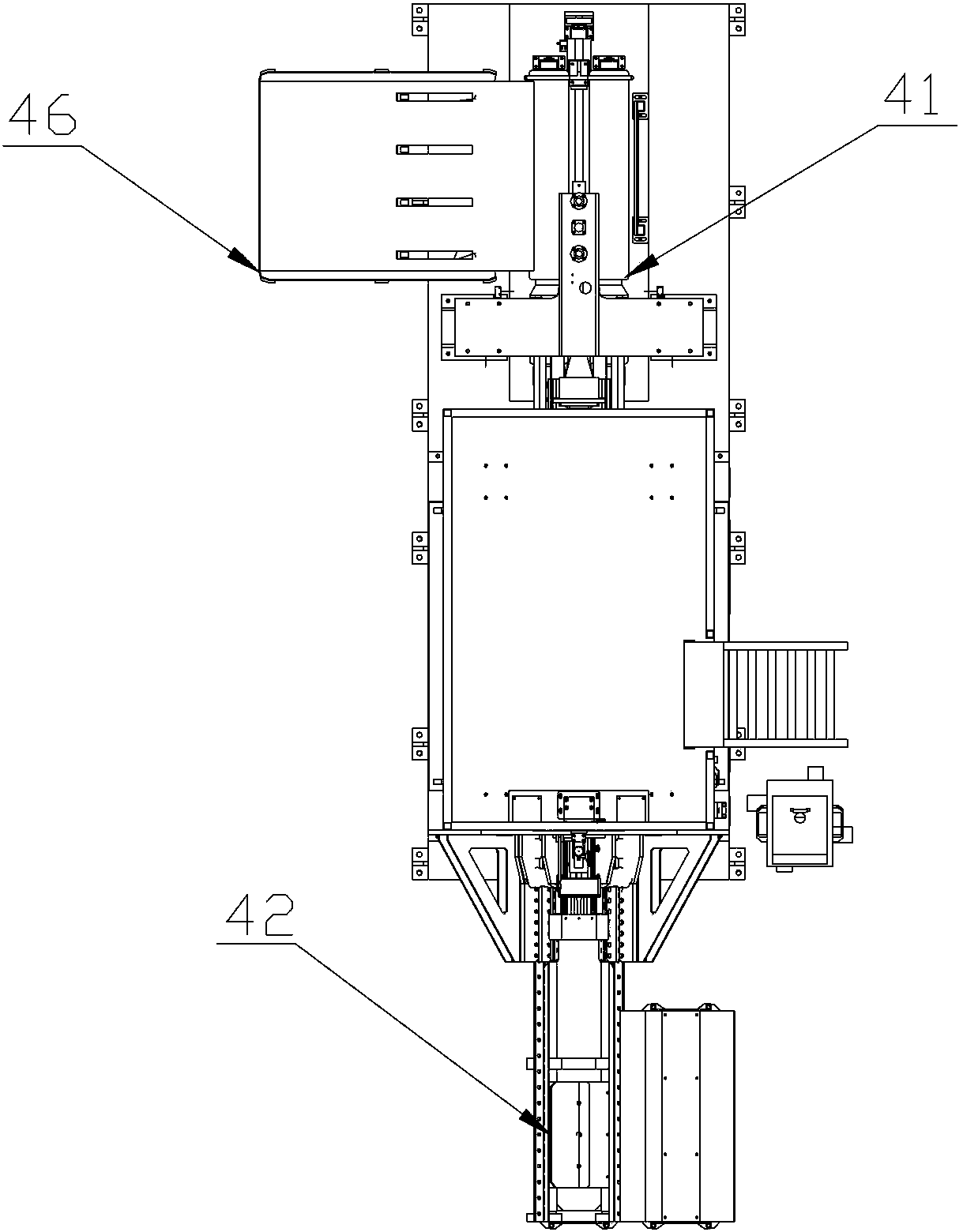

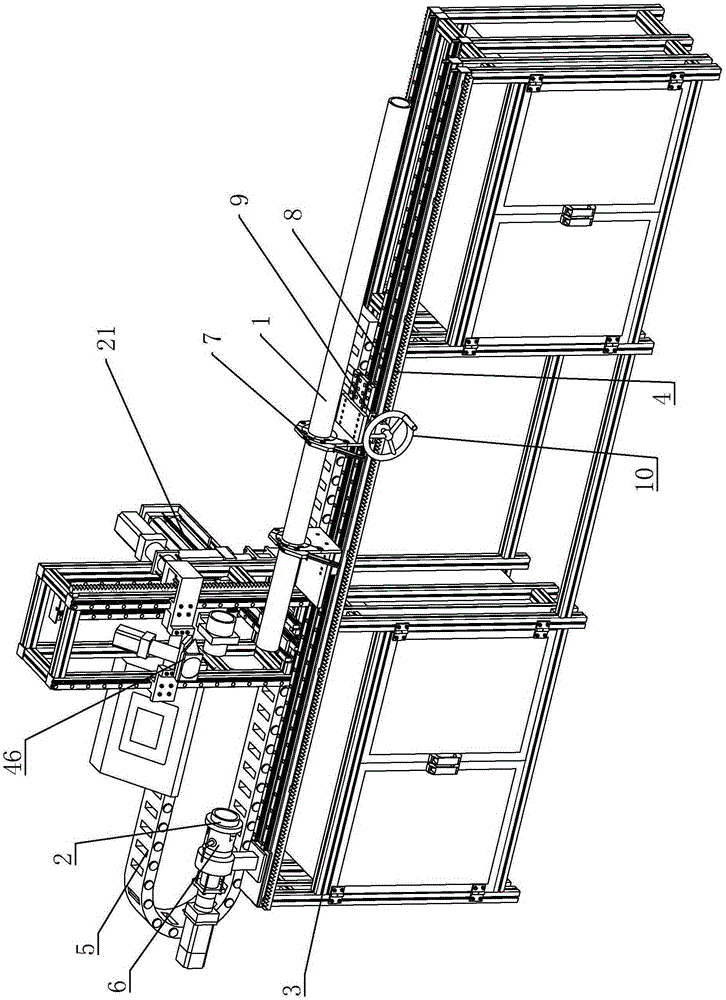

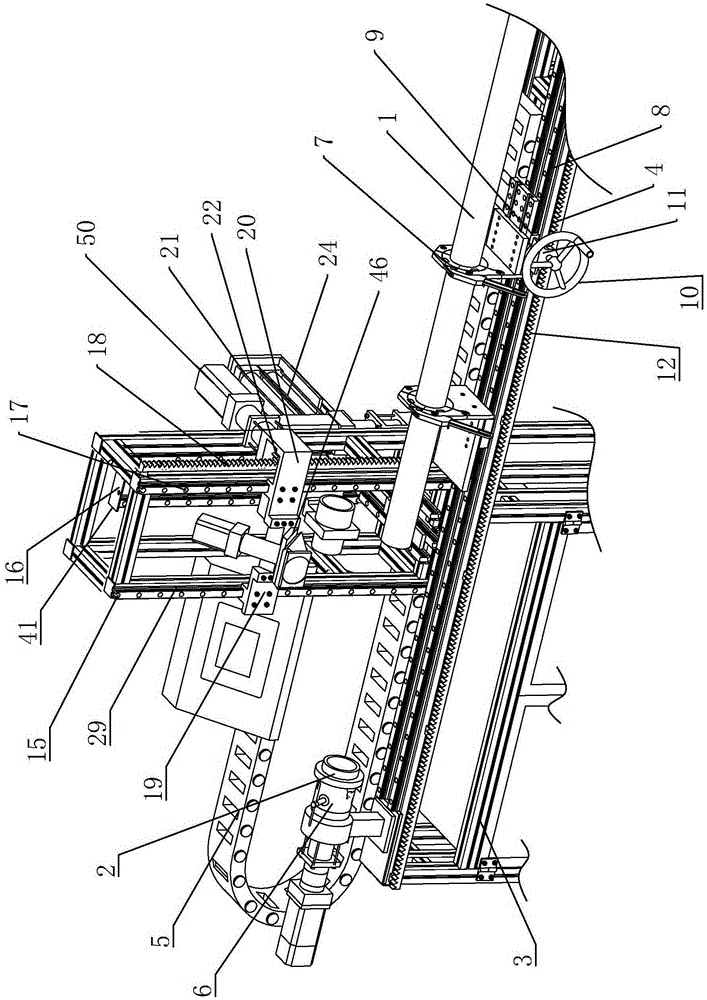

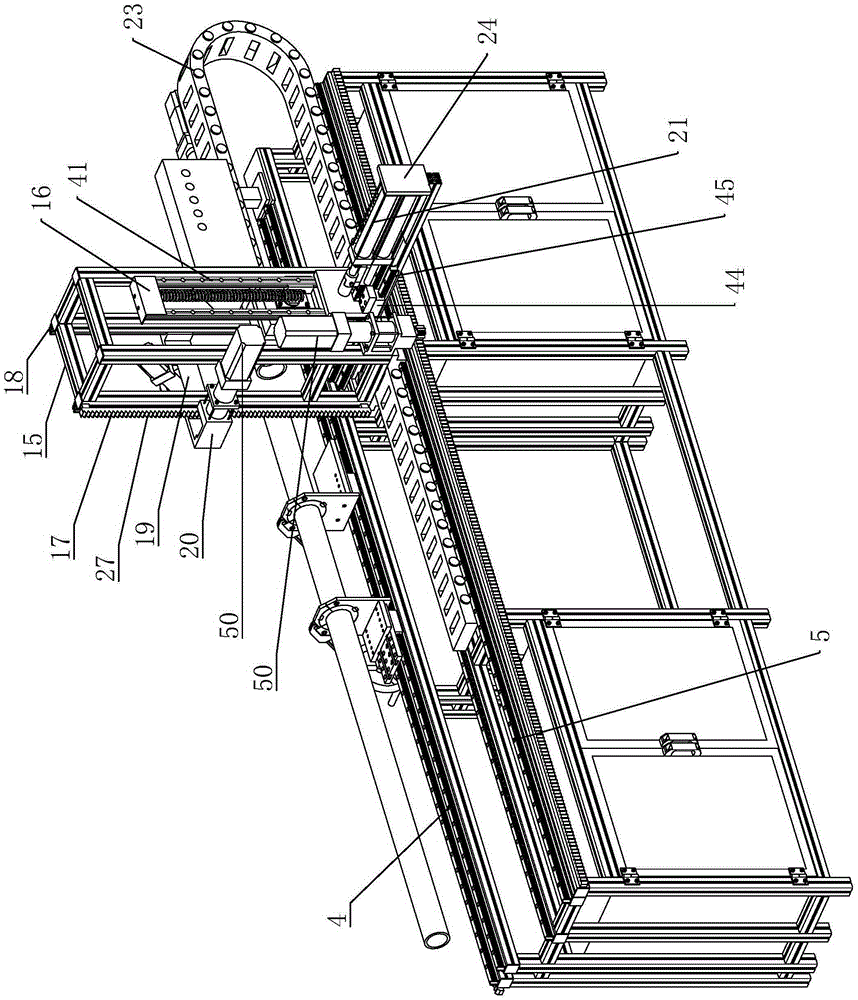

Full-automatic detection apparatus suitable for multi-diameter pipe welding seam

InactiveCN101368932AReduce radiation pollutionReduce misjudgmentMaterial analysis using sonic/ultrasonic/infrasonic wavesNon destructiveWeld seam

The invention provides an automatic detection device suitable for multi-diameter pipeline welding lines. A carrier dolly module (3) of the invention is arranged on a flexible track module (1); a scanner module (2) is fixed on the upper part of the carrier dolly module (3) through a vertical plate (8) and a horizontal plate (9); a probe combination module (4) is fixed on the lateral side of the carrier dolly module (3) through a tracking module (5); an encoder (6) is fixedly arranged on an angle adjusting block (3-4) of the carrier dolly module (3); and a motor (7) is fixedly arranged on a reduction gearbox (3-7) of the carrier dolly module (3). The invention can be applied to the diameter welding line detection of a series of pipelines; the efficiency of the detection technique of the invention in the pipeline girth welding line non-destructive detection is much higher than that of manual ultrasonic detection; and the invention is obviously superior in detection speed, environmental radiation pollution reduction and labor intensity decrease.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Automatic welding treatment integrated machine for flange plates of pipeline installing and connecting joints

InactiveCN107877075AImprove grinding effectEasy to fixWelding/cutting auxillary devicesAuxillary welding devicesAfter treatmentEngineering

The invention relates to an automatic welding treatment integrated machine for flange plates of pipeline installing and connecting joints. The automatic welding treatment integrated machine comprisesa supporting base plate, a fixing device, a polishing device, a welding device, a rotating device and a post-weld treatment device, wherein the fixing device is arranged in the middle of the supporting base plate, the polishing device is located above the fixing device and is arranged on the supporting base plate, the rotating device is located on the outer side of the fixing device and is connected to the supporting base plate, the welding device and the post-weld treatment device are arranged on the rotating device, and the welding device is located on the front side of the post-weld treatment device. The automatic welding treatment integrated machine has the advantage that the existing problems that when flanges are welded to steel tubes, multiple fixation cannot be carried out on the flanges, the flanges are not fixed firmly and need to be polished manually before welding, the polishing effect on the flanges before welding is not good, the welding operation cannot be performed automatically, the flanges and the steel tubes need to be subjected to post-weld treatment manually, and the manual post-weld treatment is not thorough can be solved.

Owner:范满香

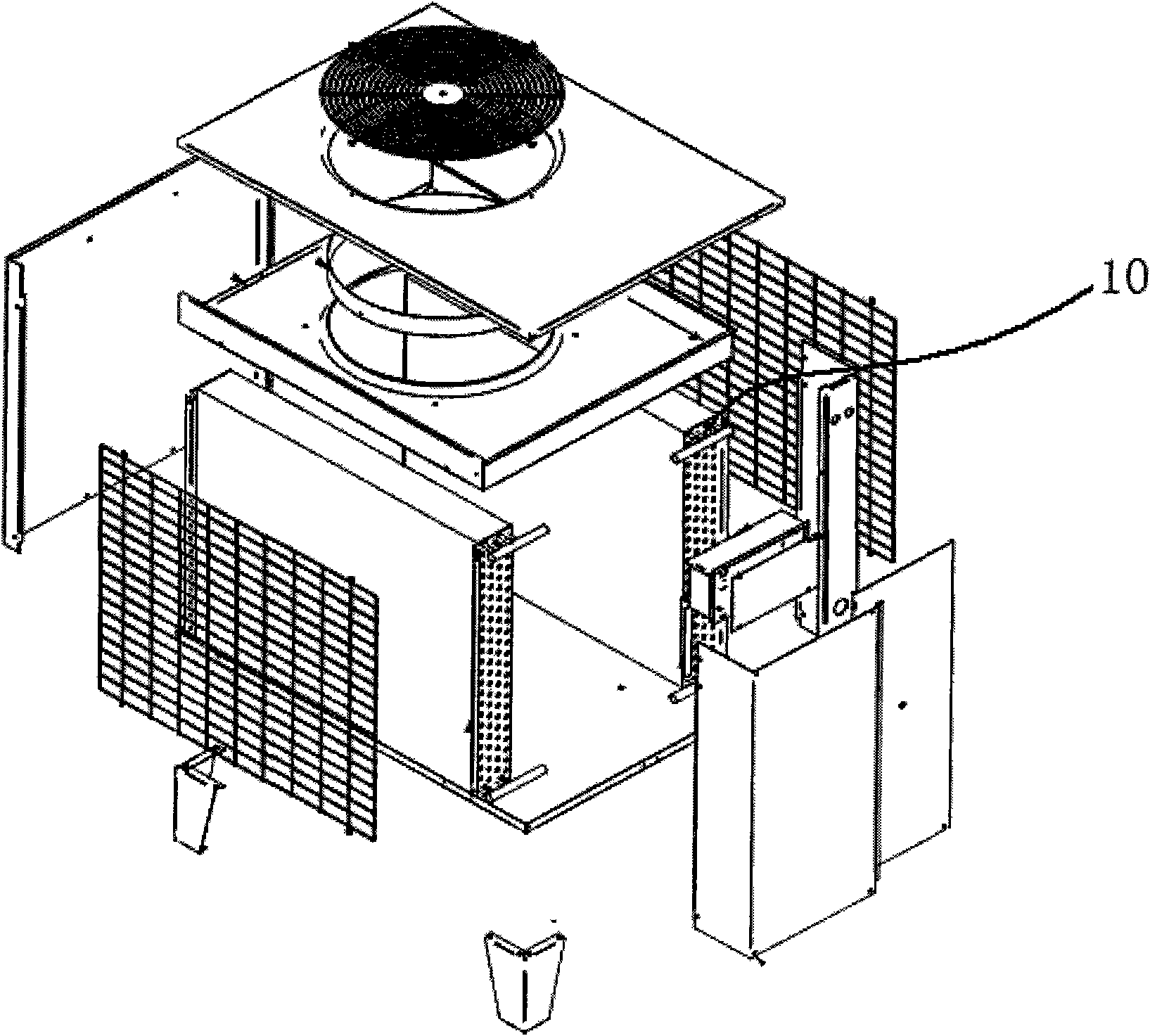

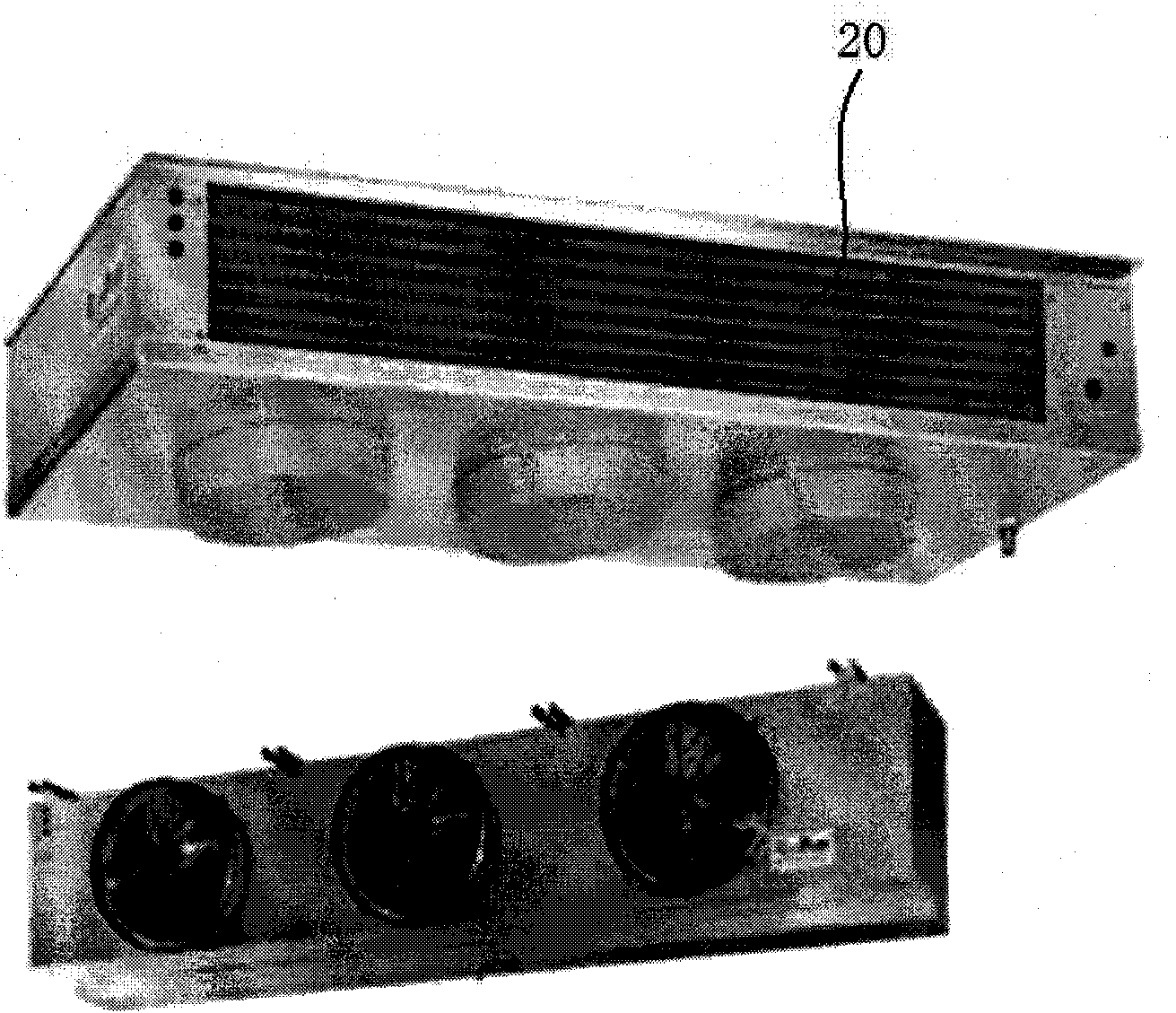

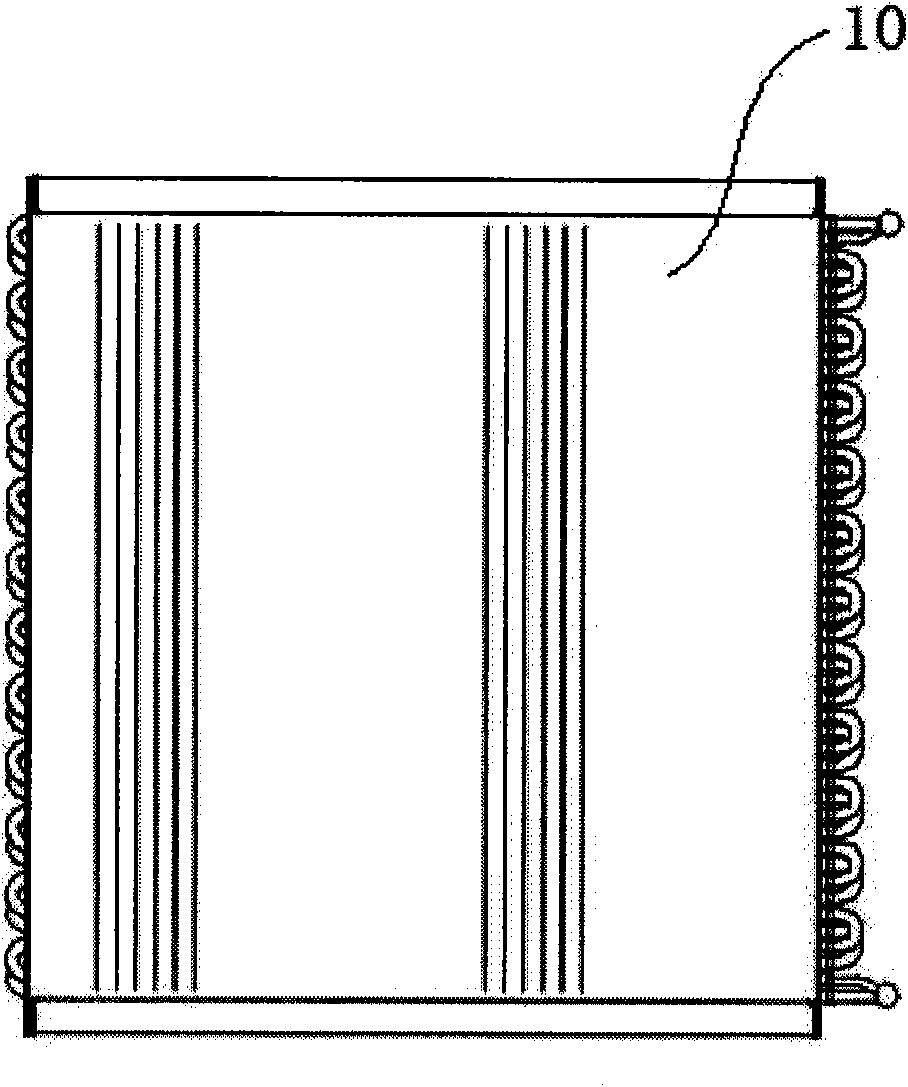

Heat exchanger with micro-channel, parallel-flow and all-aluminum flat pipe welding structure and application

InactiveCN101936670ASmall flow resistanceImprove heat transfer efficiencyEvaporators/condensersStationary conduit assembliesPotential differenceEngineering

The invention discloses a heat exchanger with a micro-channel, parallel-flow and all-aluminum flat pipe welding structure. The heat exchange part of the heat exchanger is formed by arranging flat pipes consisting of aluminum extruded thin-walled sections in parallel. Compared with the prior art, the heat exchanger with the micro-channel, parallel-flow and all-aluminum flat pipe welding structure has the advantages that: 1, the heat exchange efficiency of a refrigerant and the inner walls of the flat pipes is improved by 40 percent, and the flow resistance of the refrigerant in collecting pipes of the heat exchanger is reduced by 40 percent; 2, the heat exchange efficiency of fins on an air side is improved by 40 percent, and the wind resistance of the heat exchanger on the air side is reduced by 40 percent; 3, the heat exchange performance of the whole heat exchanger is improved by 40 percent; 4, compared with the prior art, the heat exchanger consumes 40 percent less refrigerant; and5, compared with the conventional copper-aluminum structure, the all-aluminum structure endows the heat exchanger with longer service life because of no copper-aluminum potential differences. The heat exchanger adopting the flat pipes has the characteristics of capability of bearing the conventional limitation of high-pressure resistance value of the refrigerant, compact product structure, light unit weight, short process flow, high manufacturing reliability and relatively lower cost. The invention also discloses the application of the heat exchanger.

Owner:王磊

Metal pipeline welding device for water conservancy construction

InactiveCN110216477AGuaranteed smoothImprove welding efficiencyWelding/cutting auxillary devicesOther manufacturing equipments/toolsEngineeringWeld seam

The invention discloses a metal pipeline welding device for water conservancy construction, and relates to the technical field of water conservancy construction machinery. The metal pipeline welding device comprises a supporting frame, wherein a servo motor is fixedly mounted on the top in the supporting frame; two supporting limiting mechanisms for supporting a pipeline are arranged in the supporting frame; a welding assembly which is in drive connection through a translation mechanism is arranged above the pipeline; and the welding assembly comprises a connecting disc, and a welding gun which is connected on the connecting disc through a steering mechanism. According to the metal pipeline welding device disclosed by the invention, the supporting limiting mechanisms are arranged to clampand fix from the inner part of the pipeline, so that the pipeline does not deviate while driven by a rotary roller to rotate, and the pipeline rotates for enabling welding efficiency of the welding gun to be higher; the arranged welding gun can regulate a welding inclination angle through the steering mechanism, and can meet welding operation of different process requirements; and a grinding roller can be arranged to grind a welding seam after the pipeline is welded, so that flatness of the welding seam is guaranteed after the pipeline is welded.

Owner:赵玉研

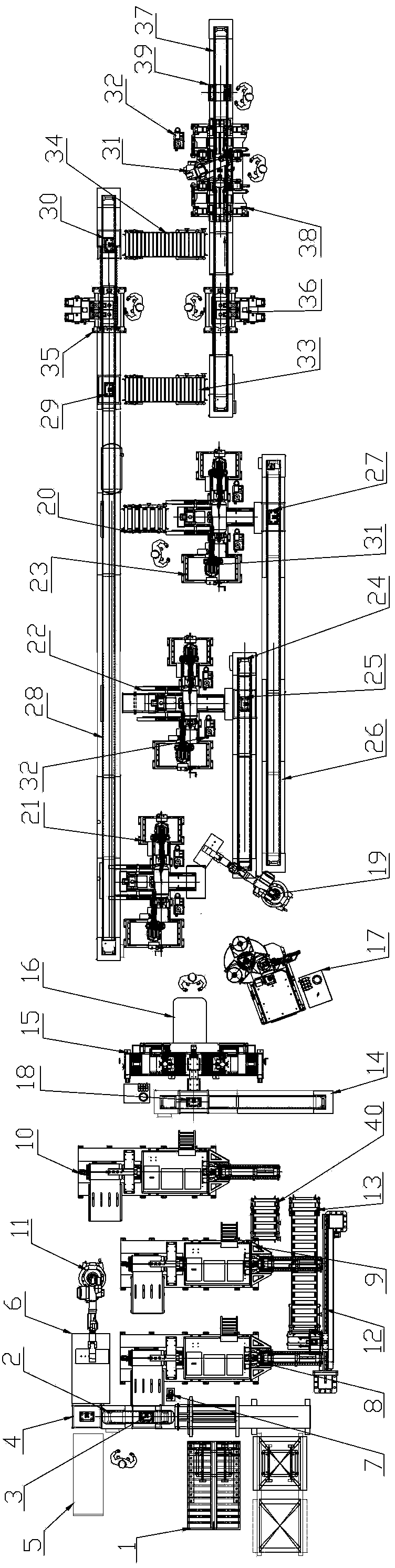

Semi-automatic liner welding production line

ActiveCN103962843AReasonable layoutStable deliveryOther manufacturing equipments/toolsWelding apparatusProduction lineSemi automatic

The invention provides a semi-automatic liner welding production line. The semi-automatic liner welding production line comprises a sheet metal edge-coiling mechanism, a straight seam welding plant, an end cover girth welding device, a water inlet / outlet pipe welding device, and a technologic rack welding device, wherein the devices are connected by conveyor chains; the sheet metal edge-coiling mechanism is an edge coiling machine; the straight seam welding plant is a working station for finishing straight seam welding of the edge rolling liner, and comprises three ion tunnel straight seam welders; the girth welding device comprises three-station assembly machine and three horizontal type girth robot workstations; the water inlet / outlet pipe welding device is a magnesium rod water pipe welder; the technologic rack welding device is a robot rack welder. The semi-automatic liner welding production line disclosed by the invention, compared to the prior art, is reasonable in layout, can reduce the occupied area of the production equipment by 60%, the labor by 260%, and improve the production efficiency by nearly 3 times.

Owner:HUNAN JINGYI AUTOMATION

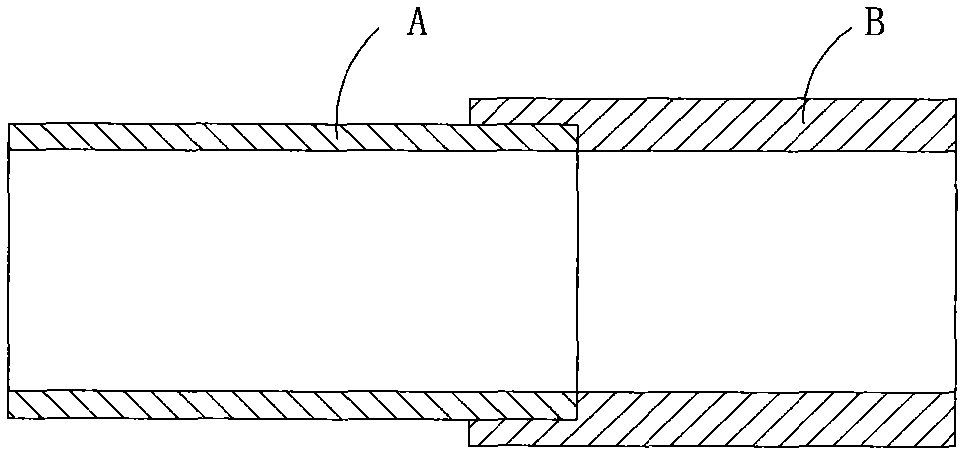

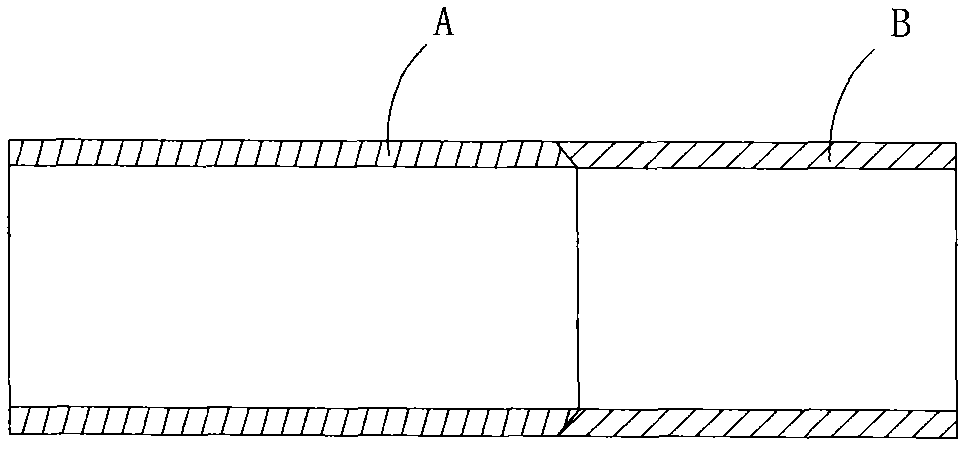

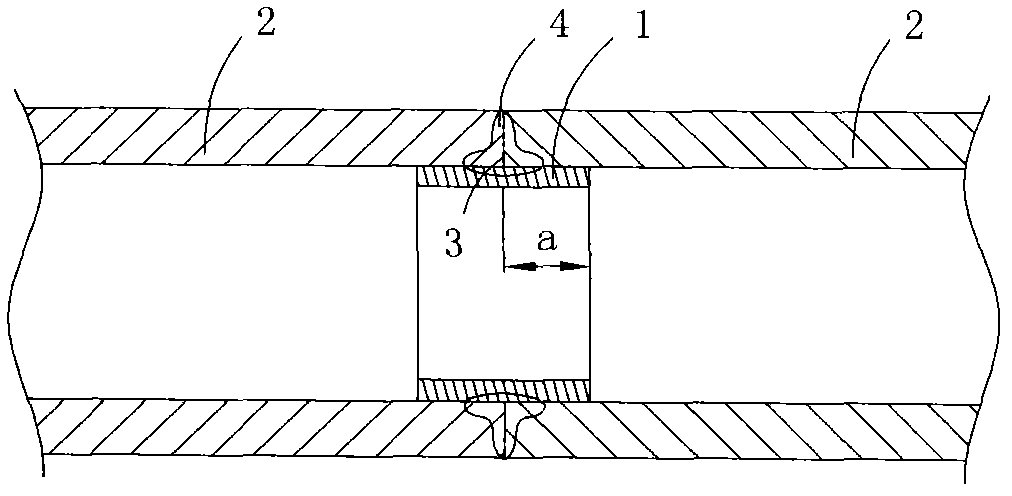

Metal pipe welding method and metal pipe welding assembly

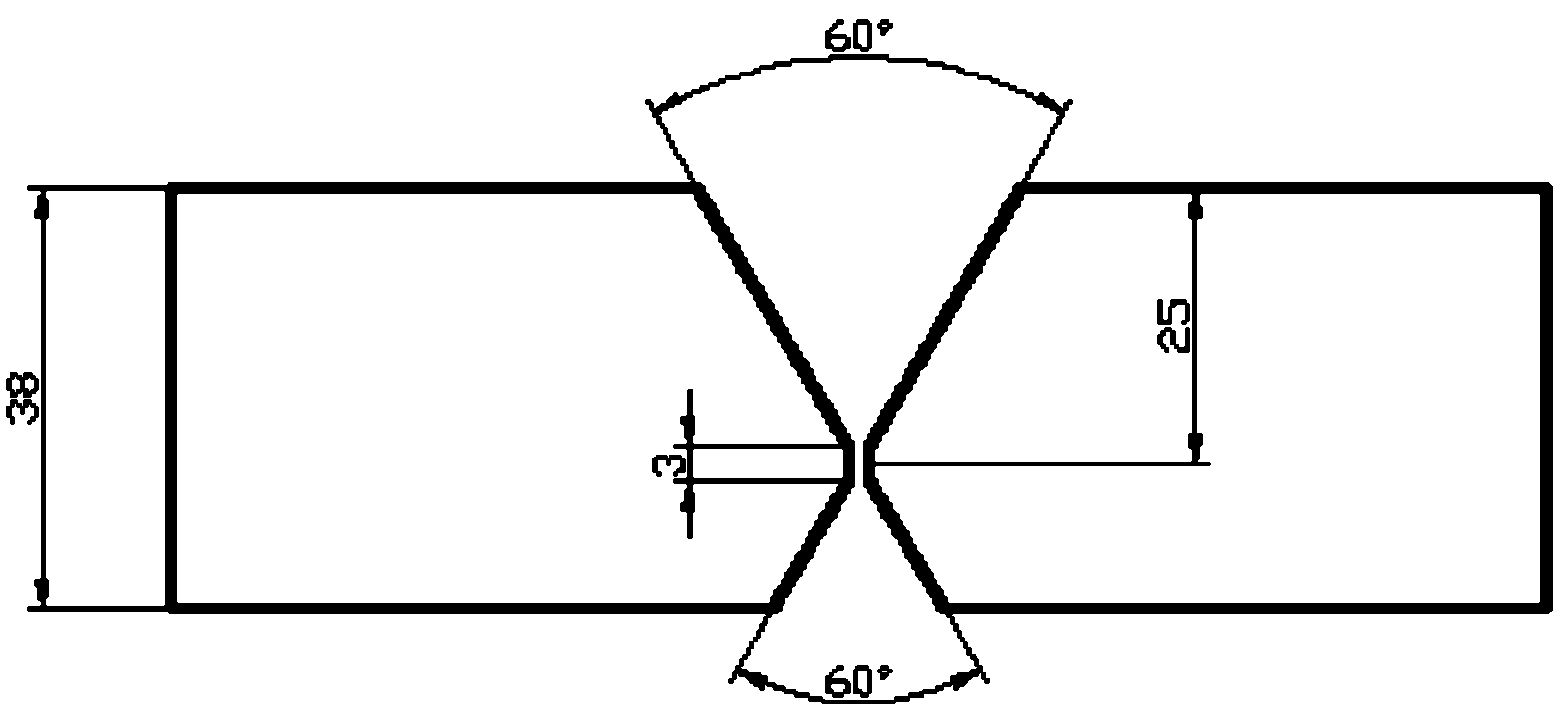

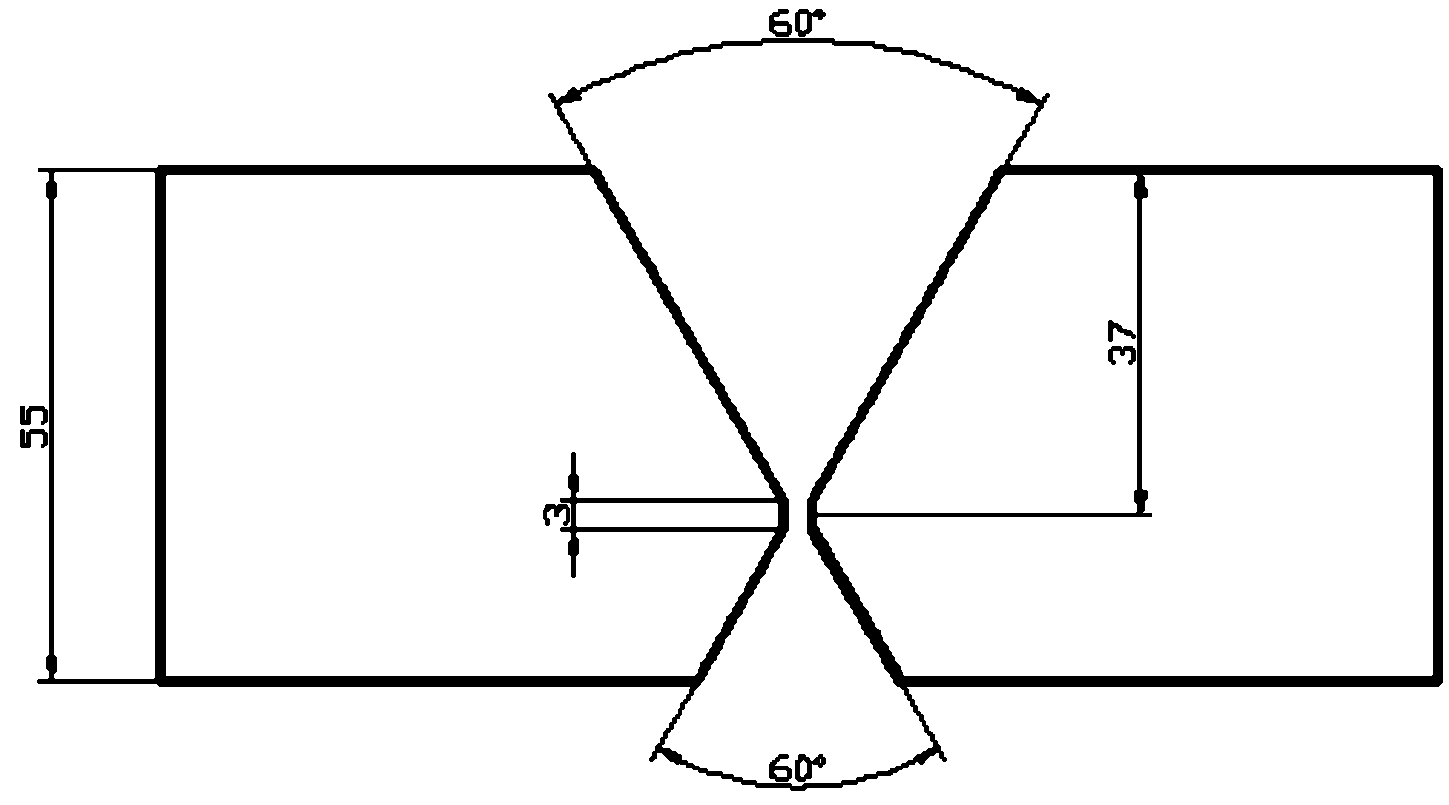

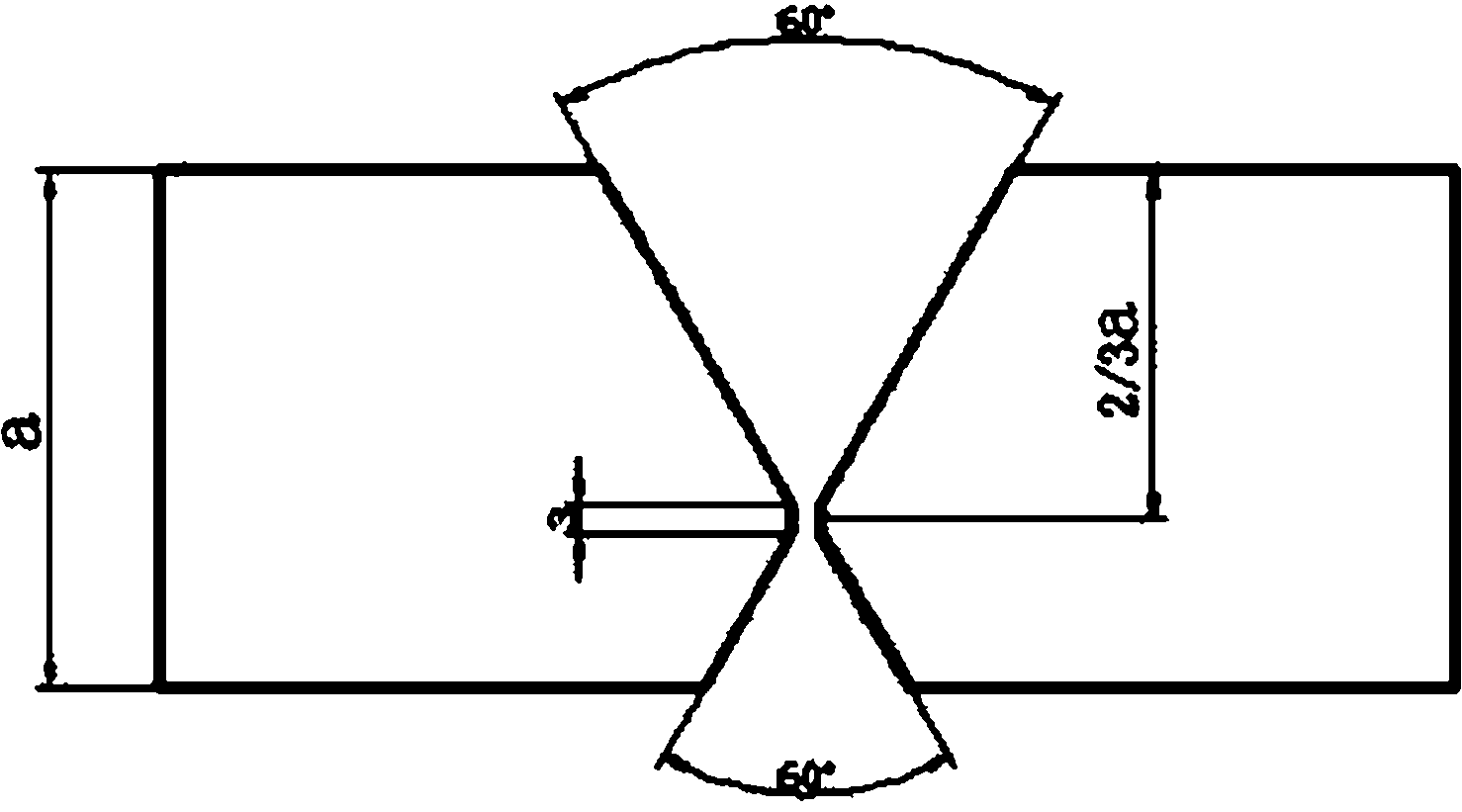

InactiveCN102554484ANot easy to burn throughImprove welding strengthNon-disconnectible pipe-jointsWorkpiece edge portionsShielding gasUltimate tensile strength

The invention discloses a metal pipe welding method and a metal pipe welding assembly. The method comprises the steps of: (1) inserting one end of a liner tube into the pipe cavity at the welded end of a pipe to be welded in such a manner that the other end of the liner tube protrudes out of the welded end of the pipe to be welded; (2) inserting the portion of the liner tube protruding out of the welded end of the pipe to be welded into the pipe cavity of the welded end of another pipe to be welded, and butt-connecting the welded ends of the two pipes to be welded to form a seam to be welded; and (3) welding the pipes at the seam to be welded to form a fusion region so as to connect the welded ends of the two pipes to be welded. The metal pipe welding assembly comprises two pipes to be welded and a liner tube, wherein both ends of the liner tube are respectively inserted in the pipe cavity of one pipe to be welded; and a fusion region is formed by welding at the joint of the welded ends of the two pipes to be welded. During conducting gas shielded welding, the metal pipe welding method can ensure the final welding seam strength equal to the strength of the two pipes at both ends without filling the inner side of the welding seam with a protective gas, and can effectively prevent occurrence of hanging accretions.

Owner:浙江天力久田管业有限公司

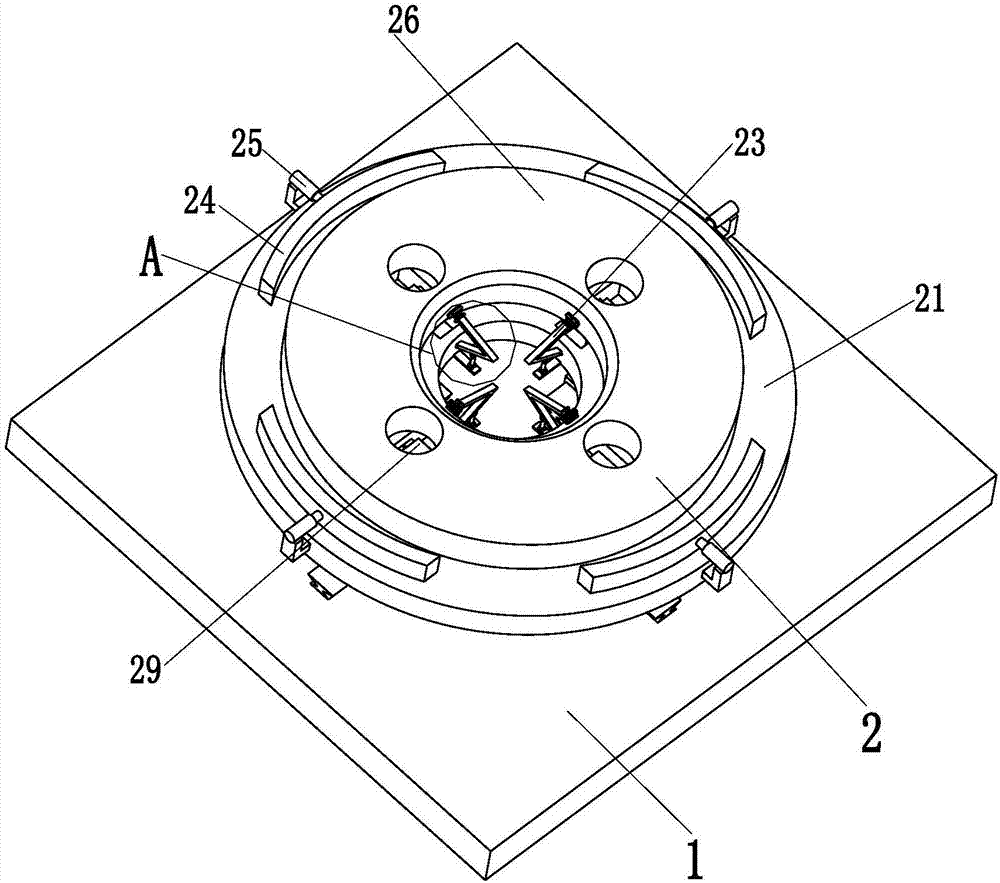

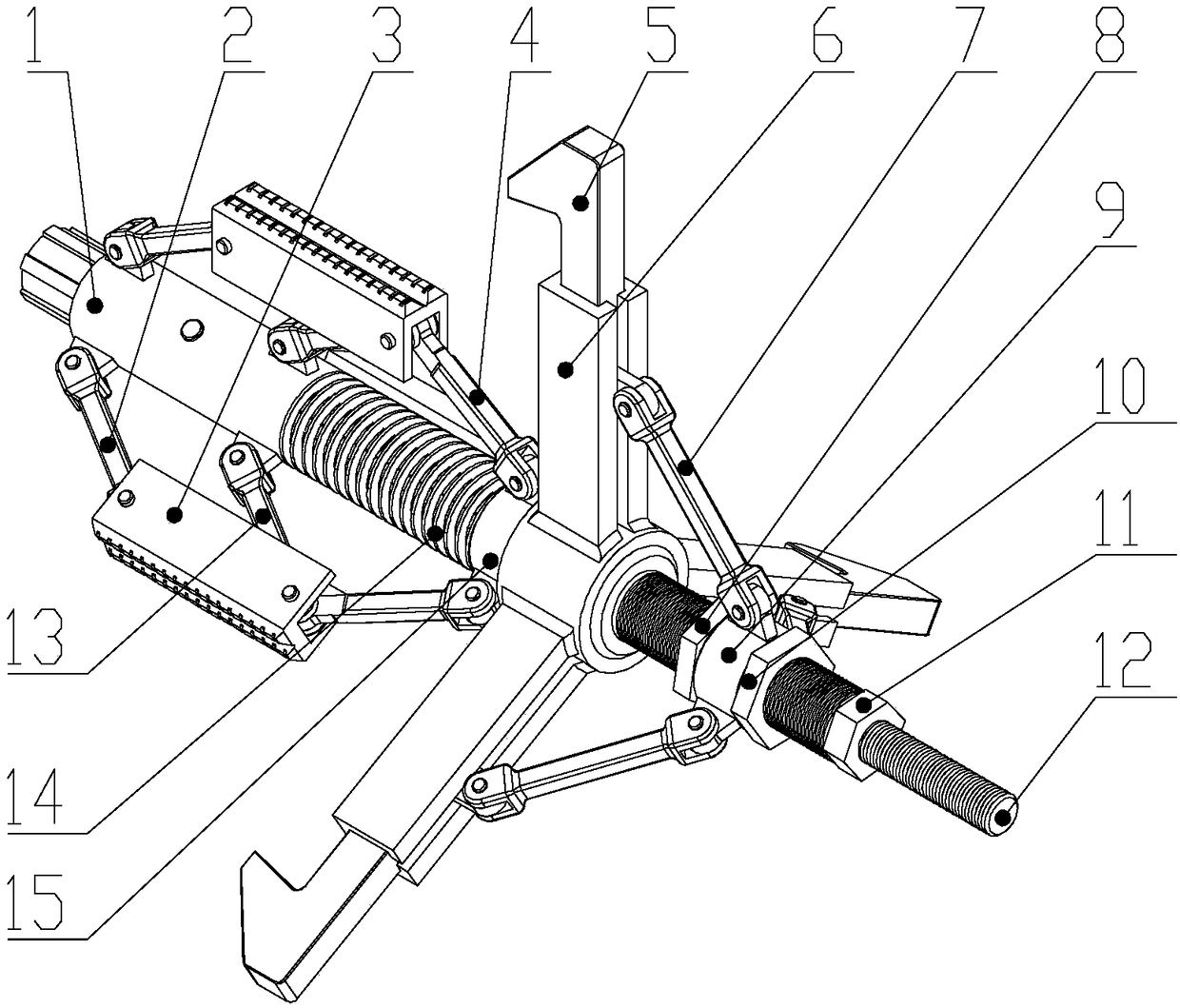

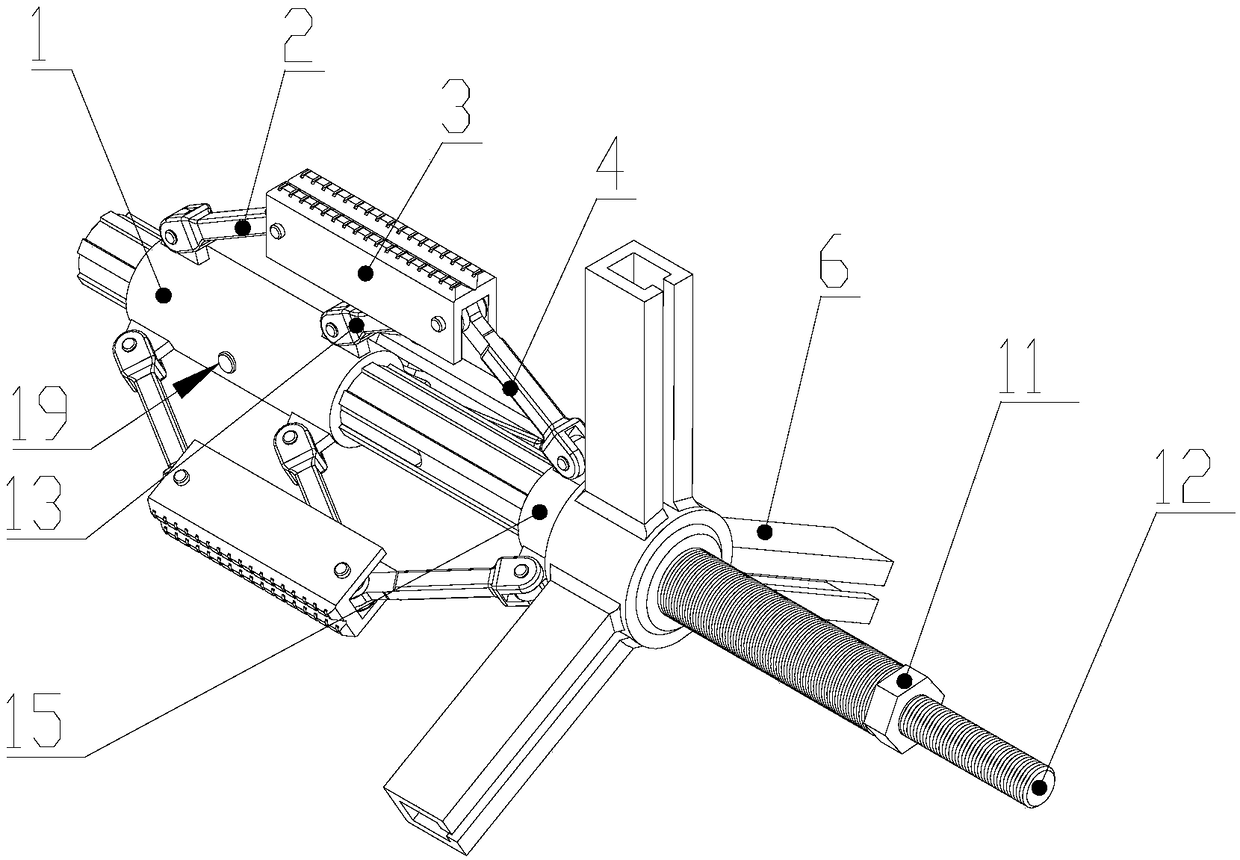

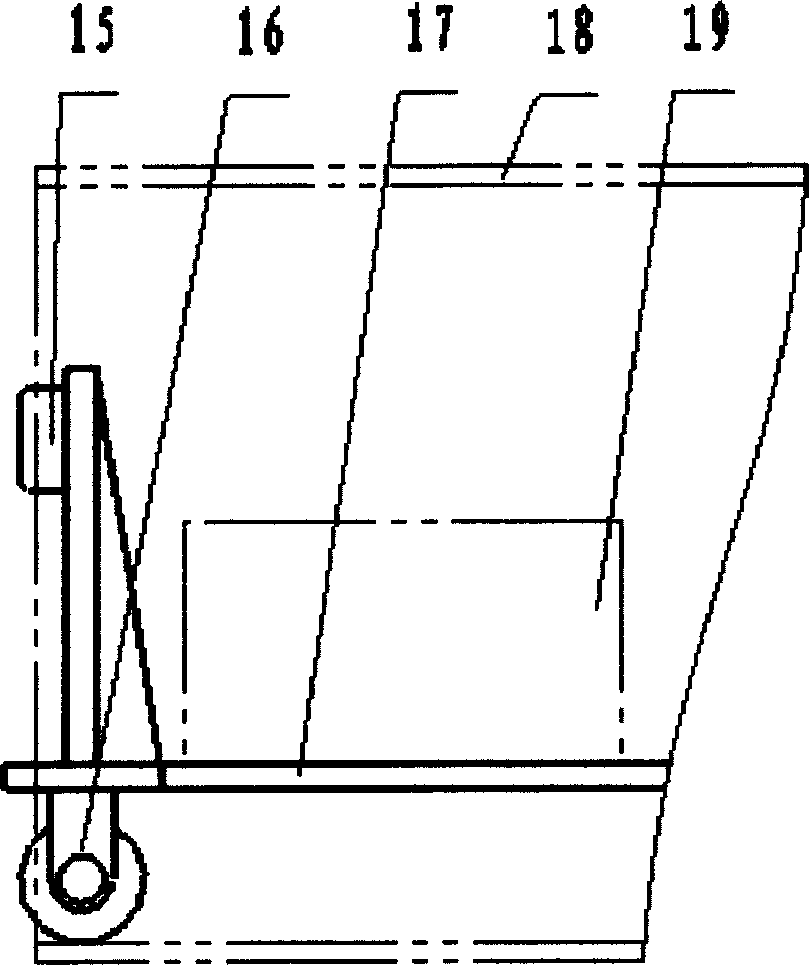

Automatic centering fixture for flange welding

ActiveCN108637584AInhibit sheddingIncrease frictionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPipe welding

The invention aims at providing an automatic centering fixture for flange welding, for achieving the purpose of pipe orifice centering in a welding process for a flange and a pipeline. The automatic centering fixture for flange welding is simple in structure, low in machining cost, and suitable for engineering application. The following technical scheme is adopted in the invention: an automatic centering fixture for flange welding is characterized in that a main body is divided into two parts, that is, a flange clamping mechanism and a pipeline clamping mechanism; the flange clamping mechanismis composed of a lock hook 5, a rack 6, a long connection rod 7, a large nut I 8, a triangular support I 9 and a large nut II 10; and the pipeline clamping mechanism is composed of a slide support 1,a connection rod I 2, a supporter 3, a connection rod III 4, a rack 6, a small nut 11, a pull rod 12, a connection rod II 13, a spring 14 and a triangular support II 15.

Owner:湖南鼎睿机械有限公司

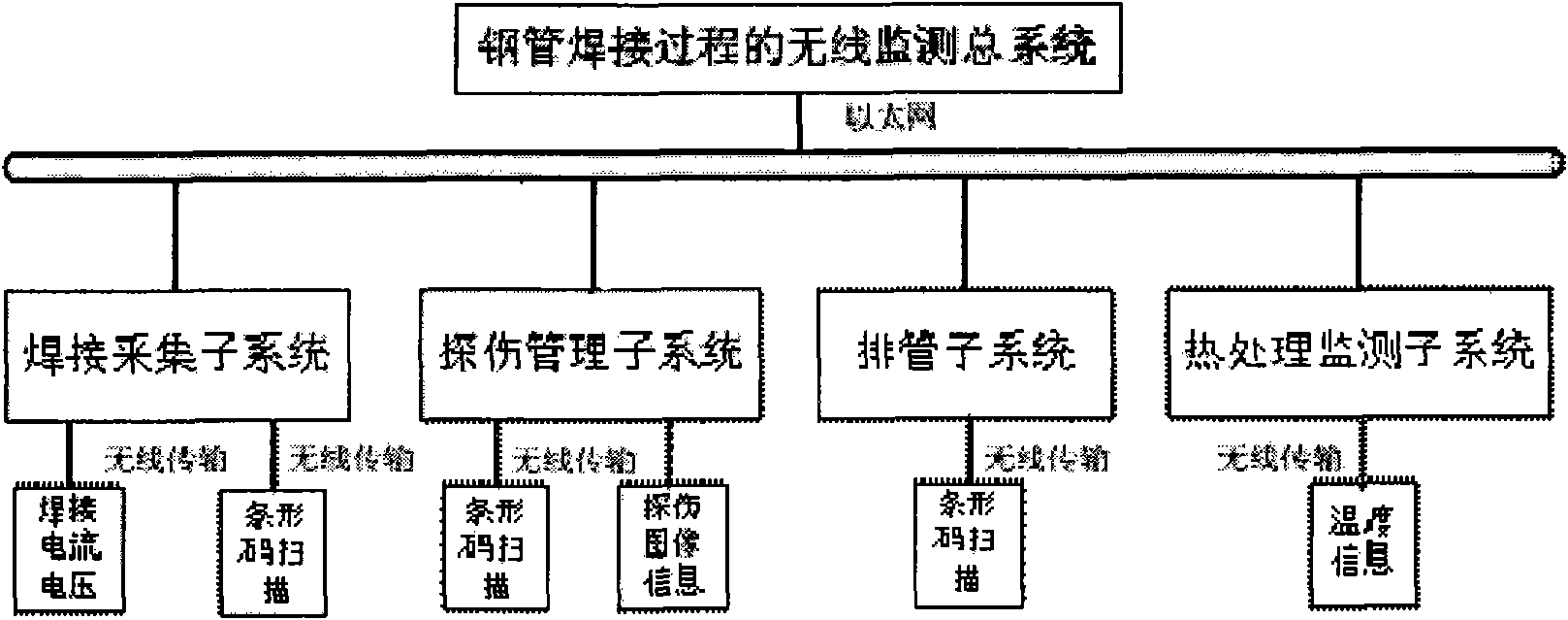

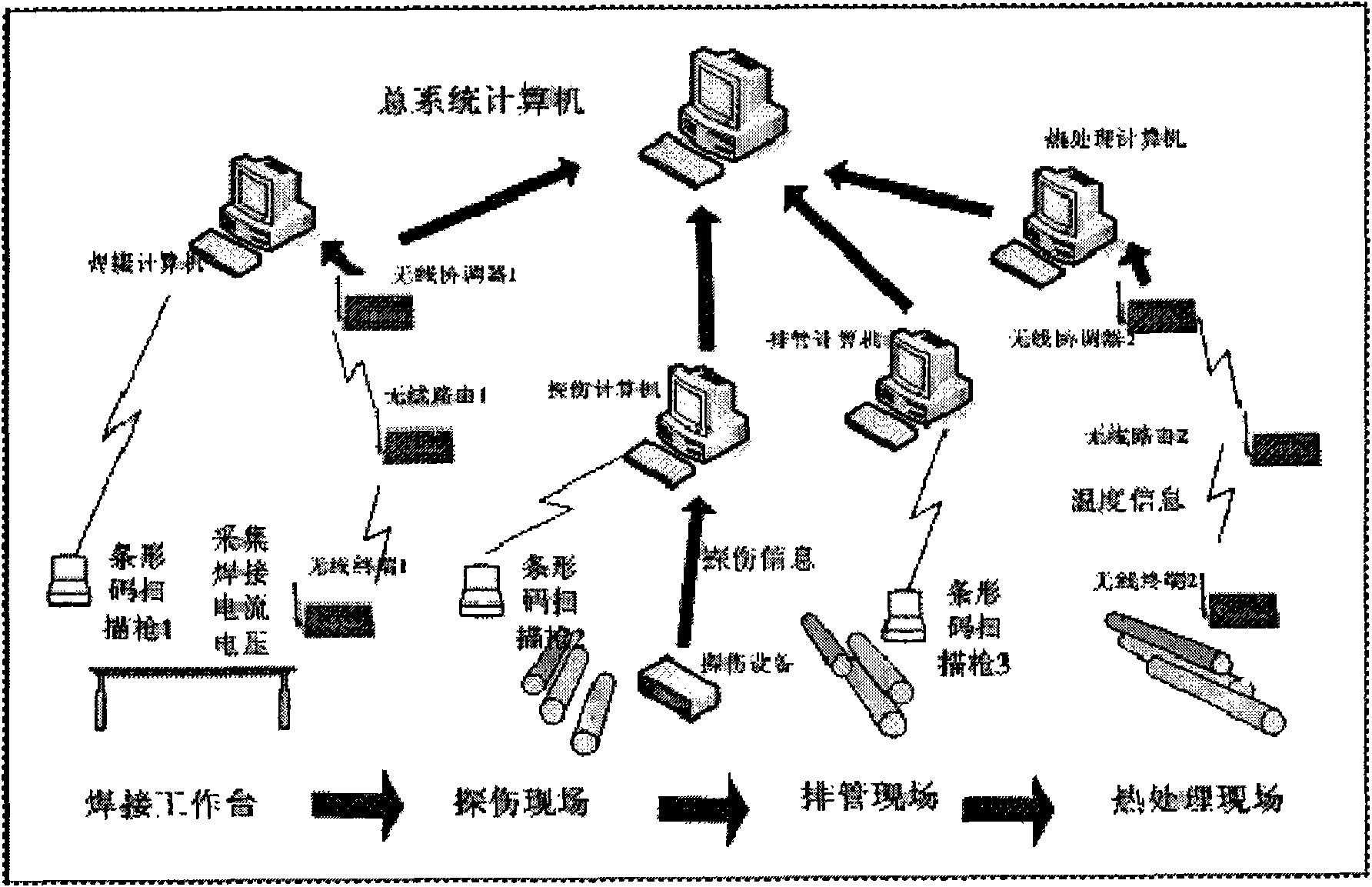

Steel pipe welding data collecting and processing system based on wireless sensor network

ActiveCN101801115ARealize data collectionRemove uncertaintyThermometer detailsNetwork topologiesData acquisitionHandling system

The invention relates to a steel pipe welding data collecting and processing system based on a wireless sensor network, comprising a welding information collecting subsystem, a flaw detection management subsystem, an exhaust pipe subsystem and a thermal treatment information collecting subsystem based on the wireless sensor network. The whole system tracks and identifies the steel pipe to be welded by adopting a radio frequency identification (RFID) technique. By overall quality monitoring as well as data collecting and processing in the welding process of the steel pipe, the invention eliminates uncertainty of quality detection of the steel pipe welding line, integrates the processing information integrally and finally realizes real-time and overall management of the welding quality of the steel pipe.

Owner:SHANGHAI INST OF PROCESS AUTOMATION & INSTR

Submerged arc welding wire of high tensile pipeline steel

ActiveCN101905391AHigh yield strengthQuality improvementArc welding apparatusPipeline systemsCrack resistanceSheet steel

The invention discloses a submerged arc welding wire of a high tensile pipeline steel. The welding wire material comprises the following chemical components in percentage by weight: not more than 0.10 of C, not more than 0.6 of Si, 1.3-1.8 of Mn, 1.4-2.5 of Ni, 0.25-0.55 of Mo, not more than 0.12 of Ti, not more than 0.05 of V, not more than 0.35 of Cr, 0.0005-0.005 of B, not more than 0.015 of S, not more than 0.015 of P, and the balance of Fe and other inevitable impurities. The submerged arc welding wire of the high tensile pipeline steel provided by the invention has the yield strength of deposited metals of more than 690MPa and the tensile strength of more than 785Mpa, has attractive welding formation, high intensity, high flexibility and high crack resistance without defects of cracking, undercut and the like, and has favorable matching effect with X100 level pipeline steel plates, and meets the requirement on the welding of oil-gas transmission pipelines under the condition of higher pressure.

Owner:YICHANG MONKEY KING WELDING WIRE

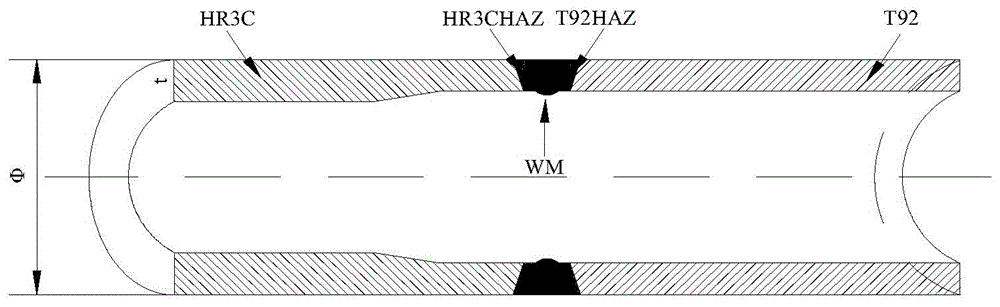

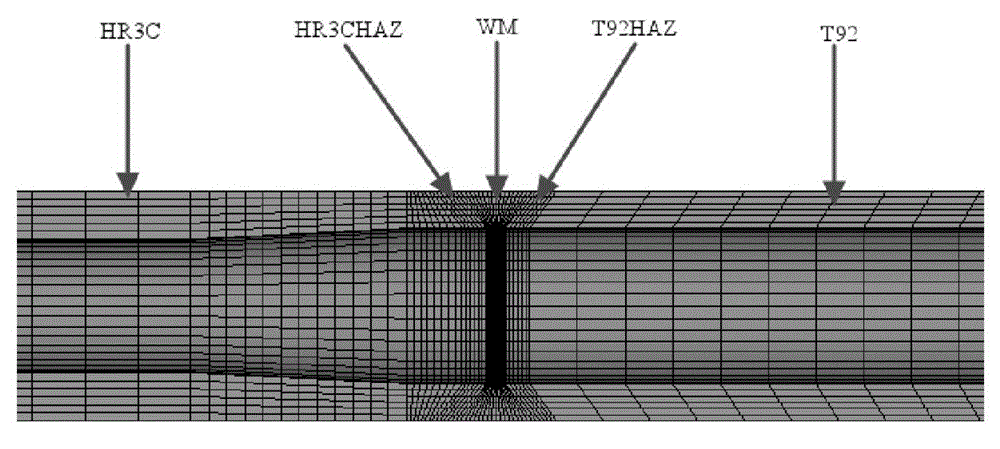

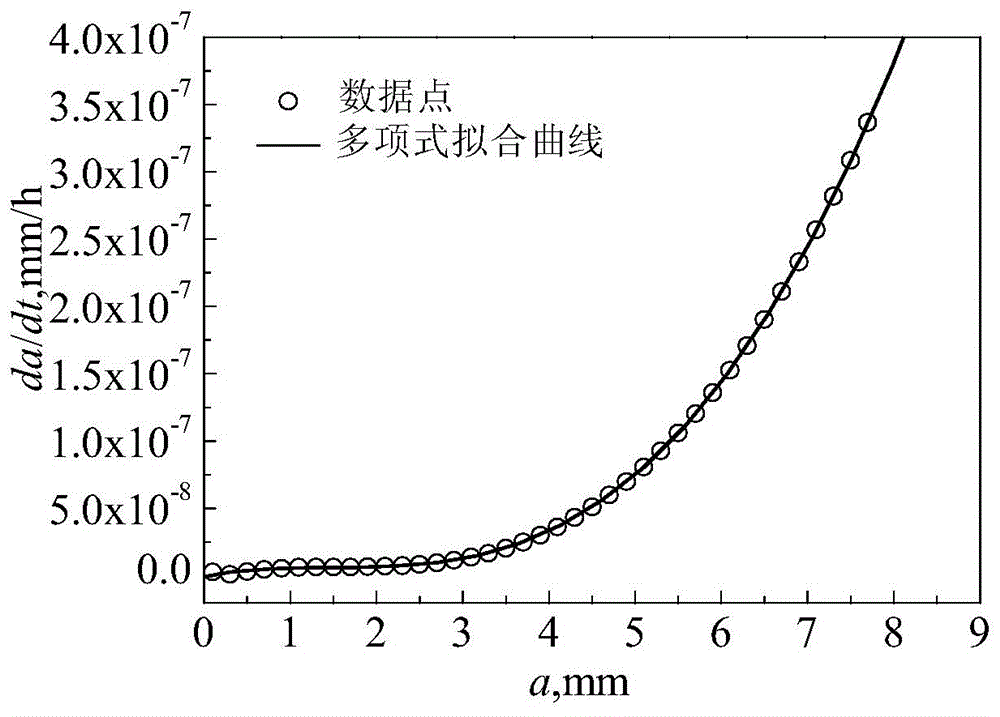

Service life evaluation method of ultra-supercritical boiler special steel pipe welding connector

InactiveCN104156577AAvoid the problem of too much errorSpecial data processing applicationsSupercritical steam generatorEngineering

The invention relates to a service life evaluation method of an ultra-supercritical boiler special steel pipe welding connector. The method includes the steps of firstly: using an NSW-MOD theoretical model to determine mathematic relation between a creep damage accumulation process and crack growth rate on the basis of a crack tip creep damage accumulation process; secondly, using a polynomial to fit a da / dt-a curve to obtain a maximum curvature point, namely the turning point a of creep crack growth; thirdly, calculating to obtain the ratio a / (S-a0), namely the creep crack growth service life loss a / (S-a0) of the special steel pipe welding connector under high temperature and high pressure, of special steel pipe welding connector pipeline wall thickness S to the difference (S-a0) of S and initial crack length a0; acquiring the creep crack growth residual service life of the special steel pipe welding connector under high temperature and high pressure by numerical integration between the crack length a at the turning point and the pipe wall thickness S. The method has strict physical and theoretical basis, and service life predication is highly matched with actual service life.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

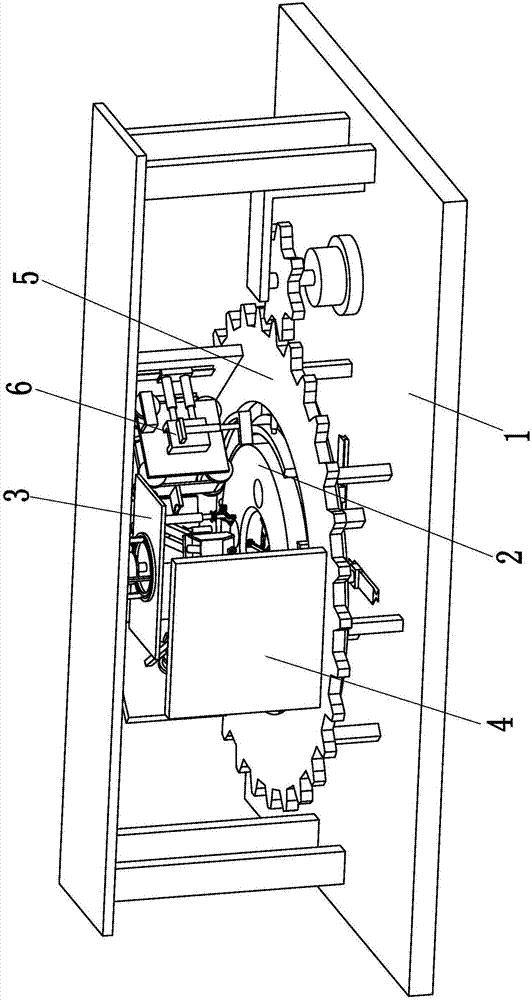

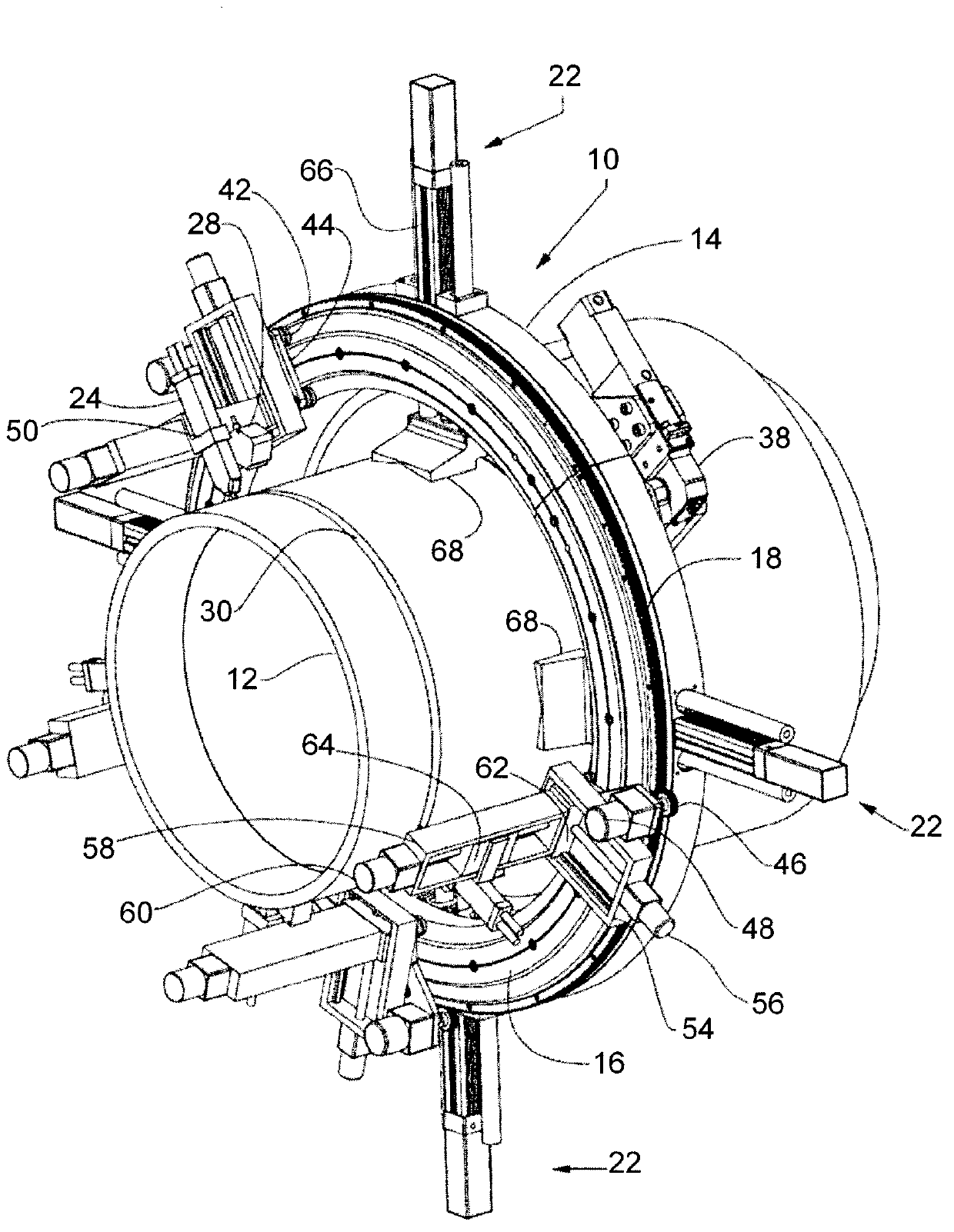

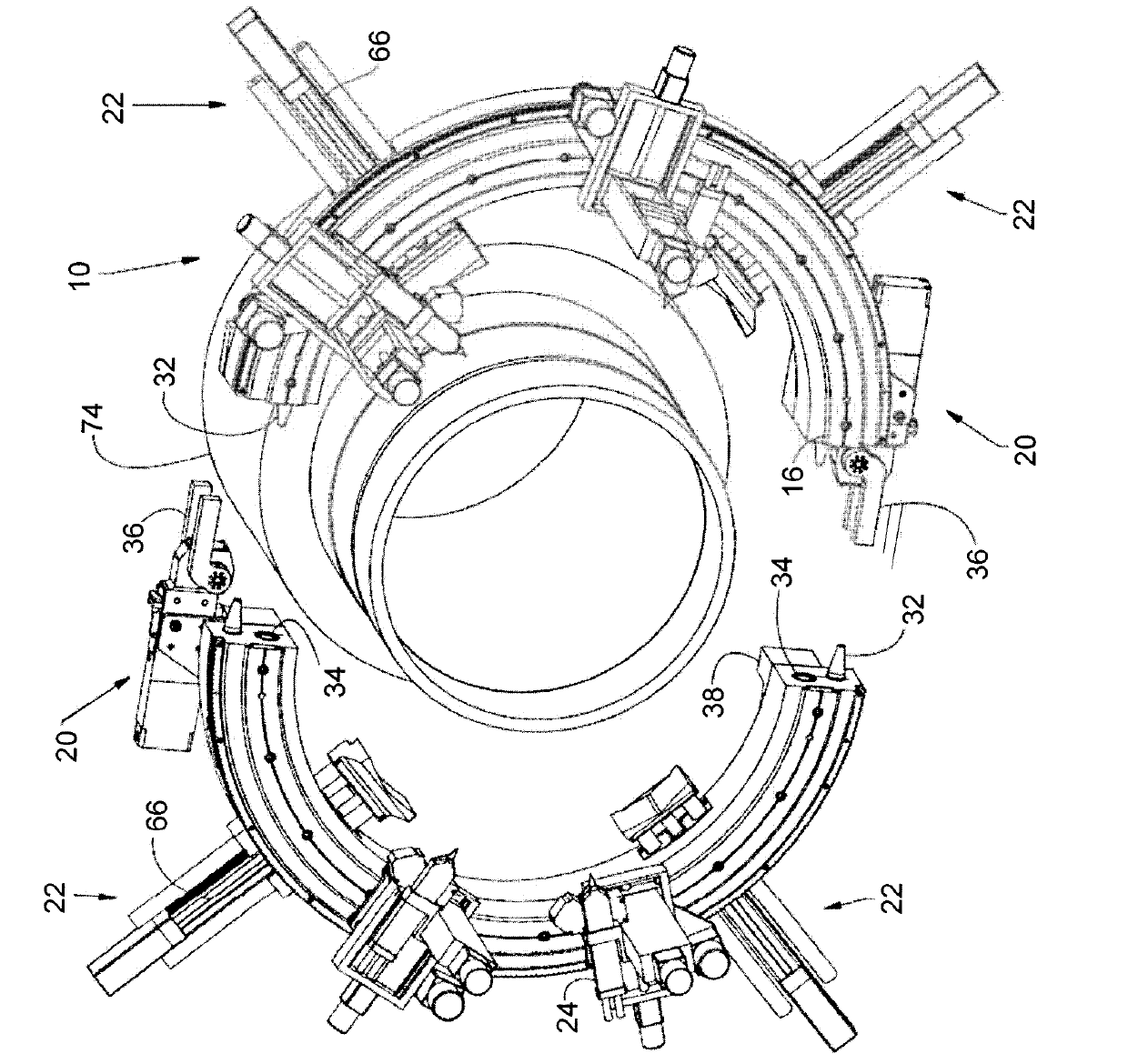

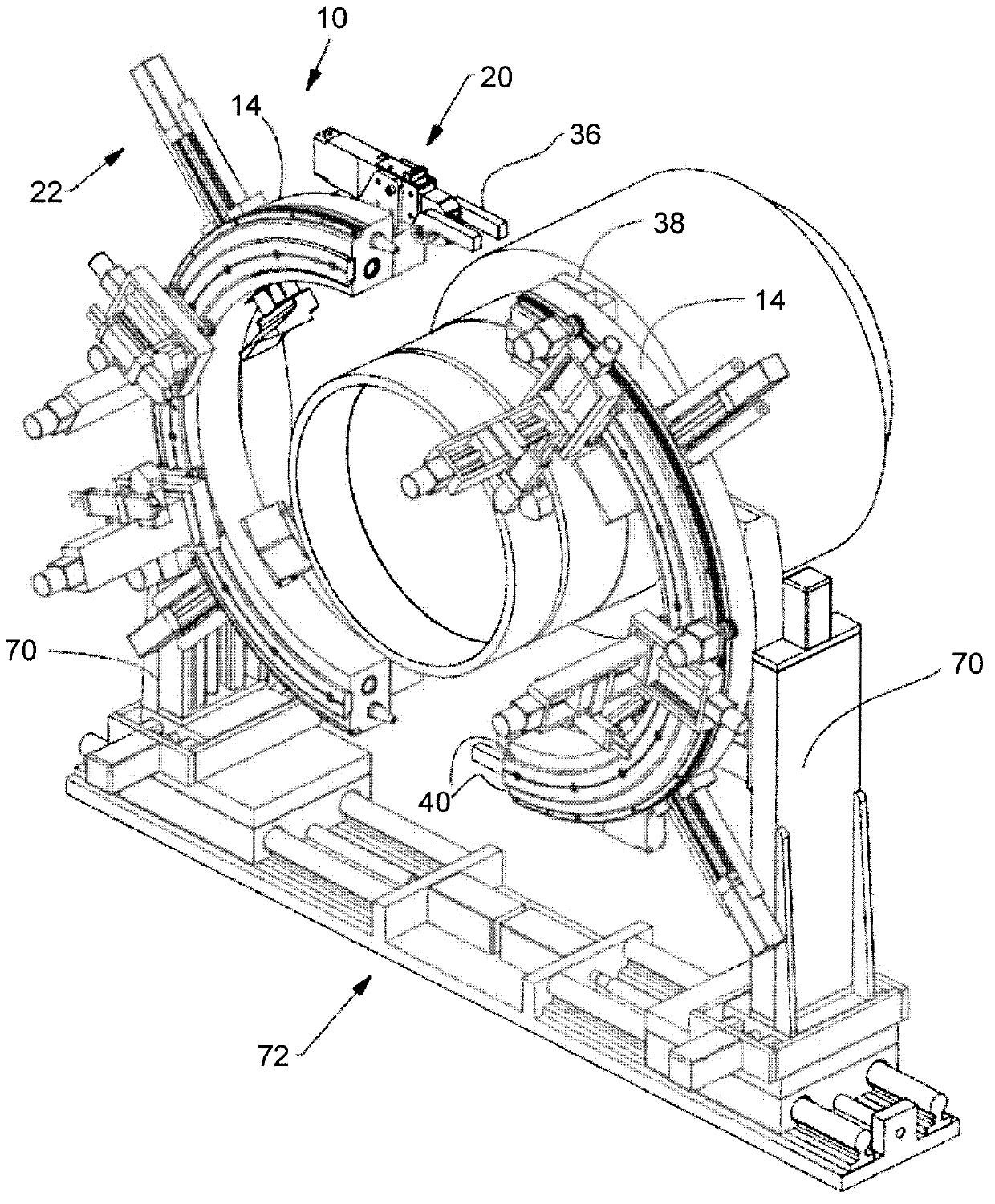

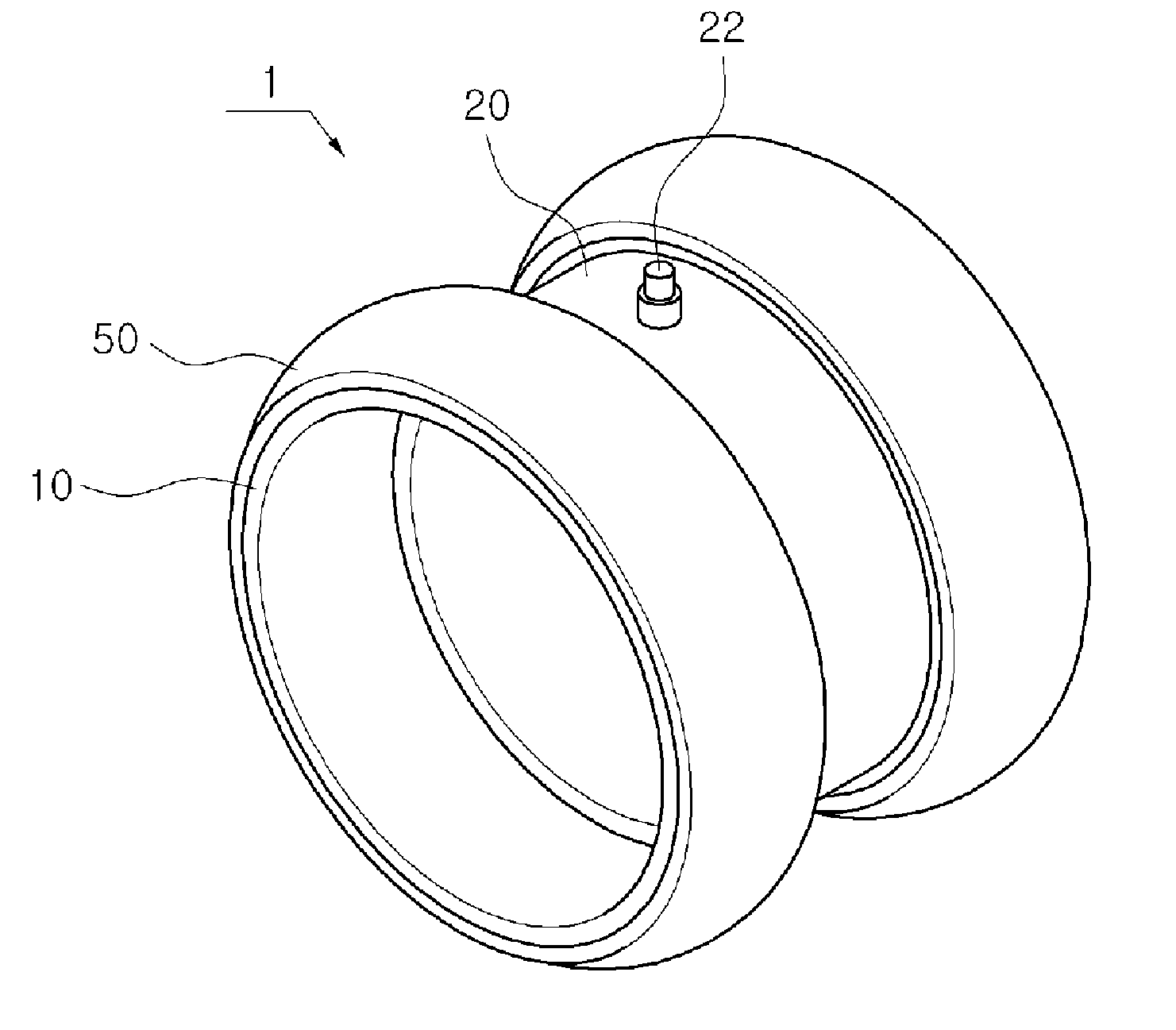

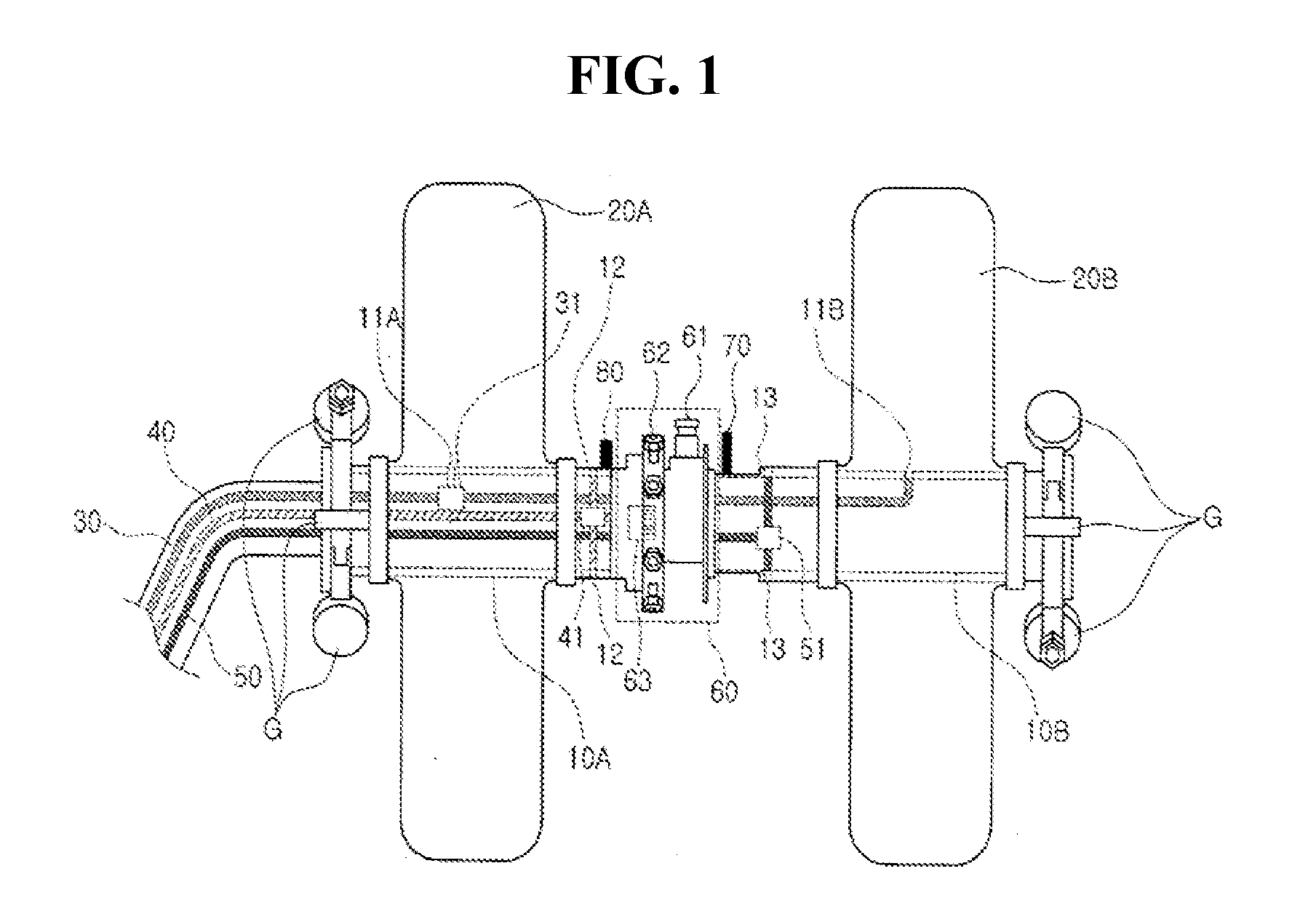

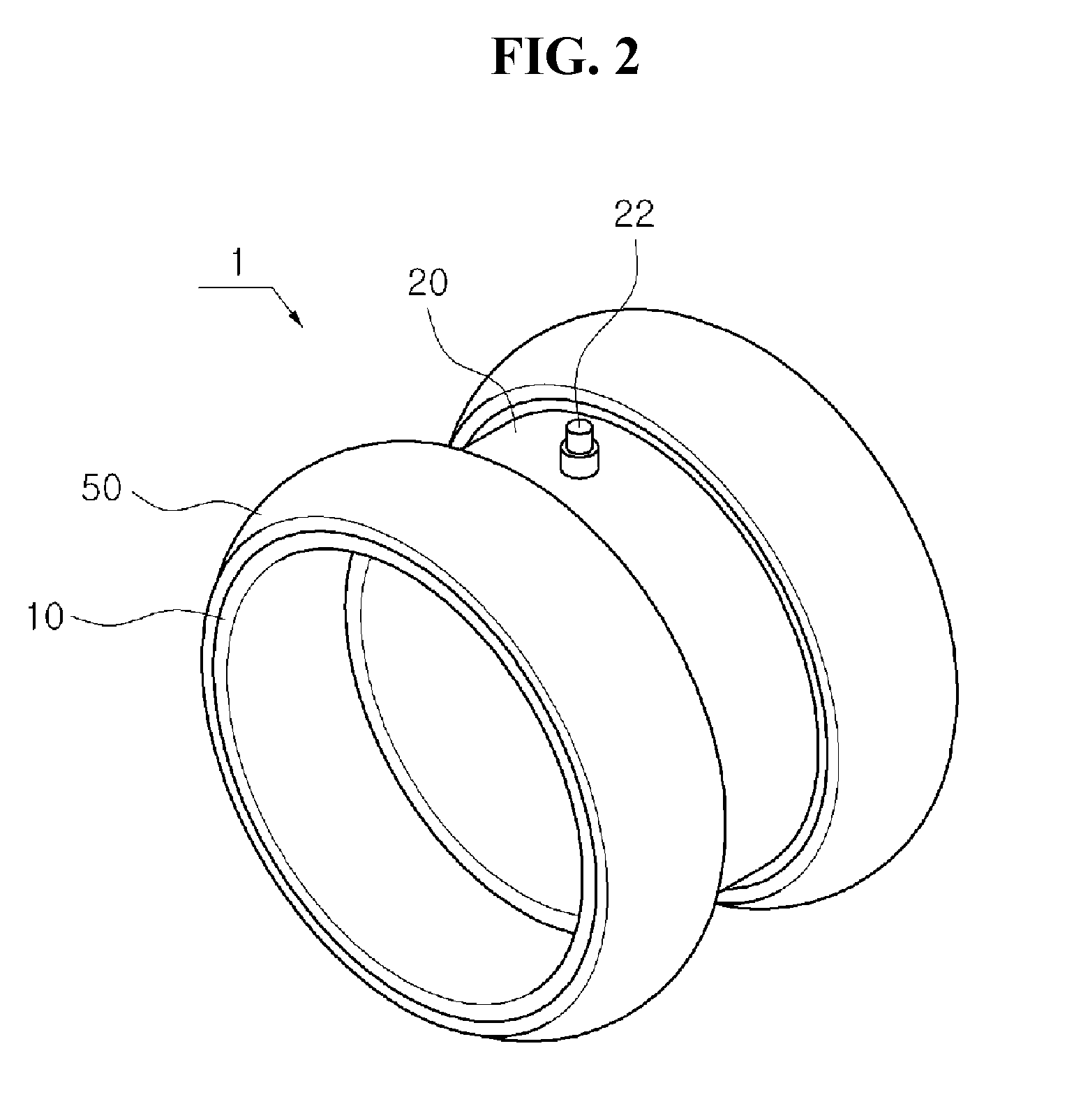

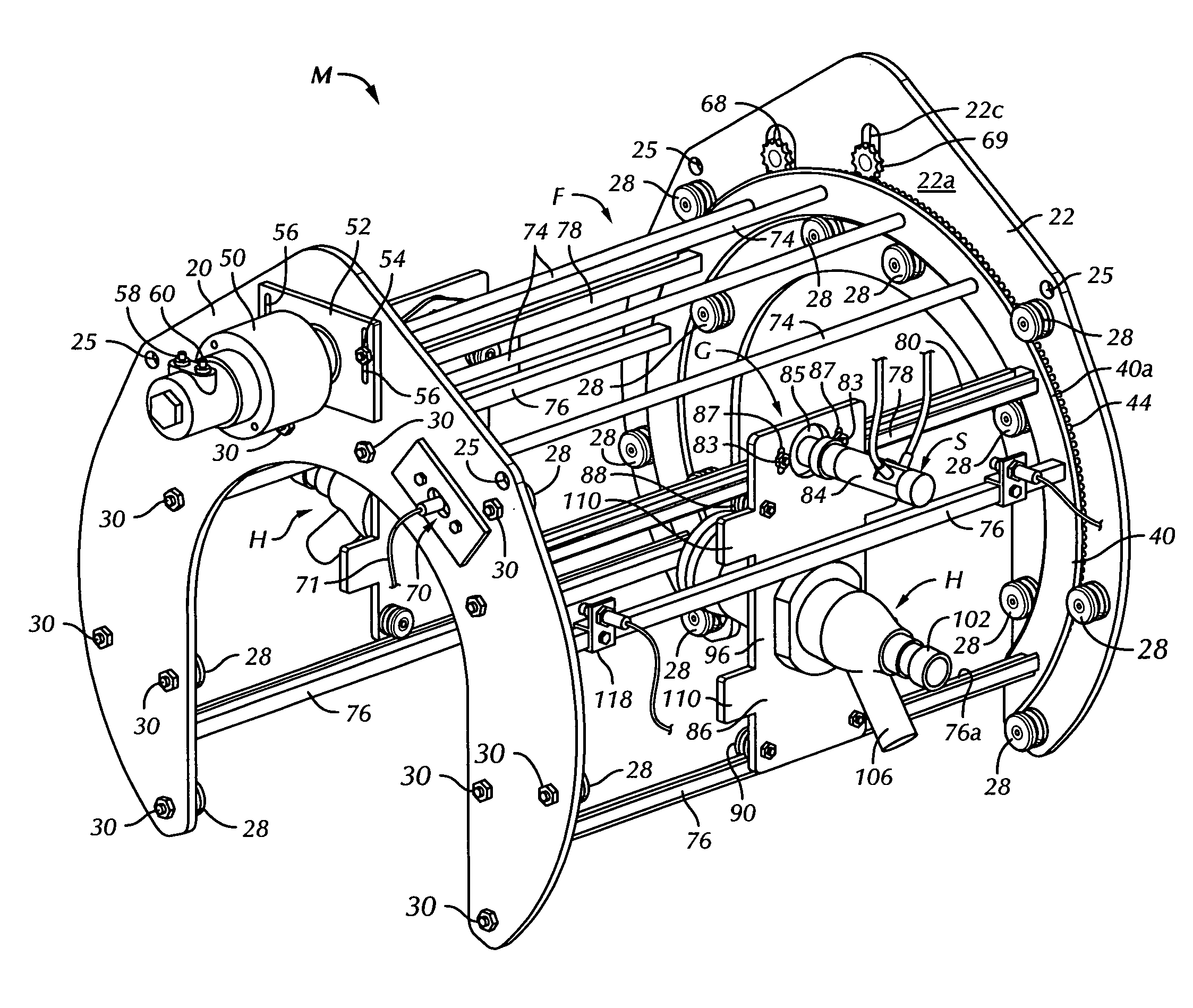

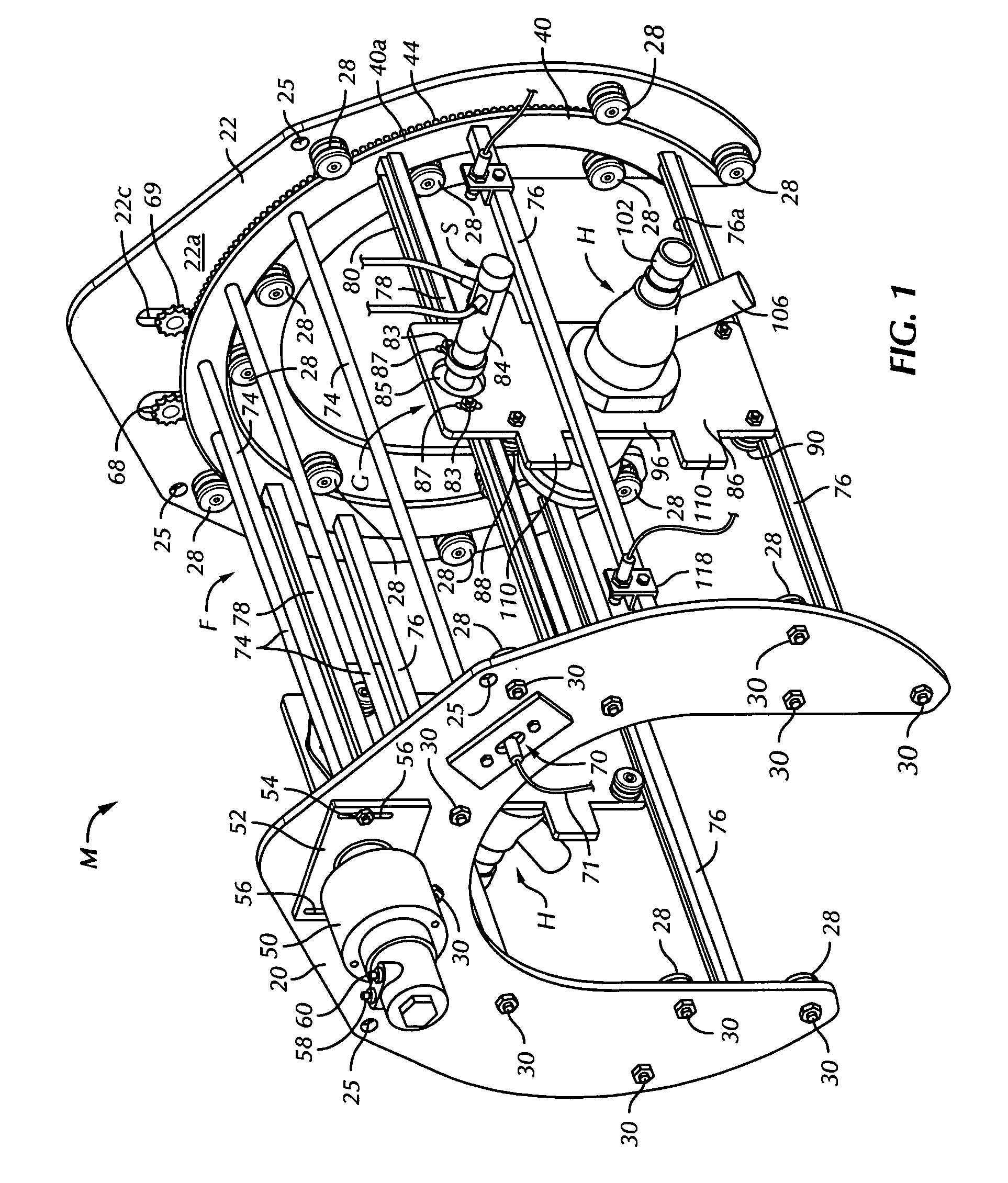

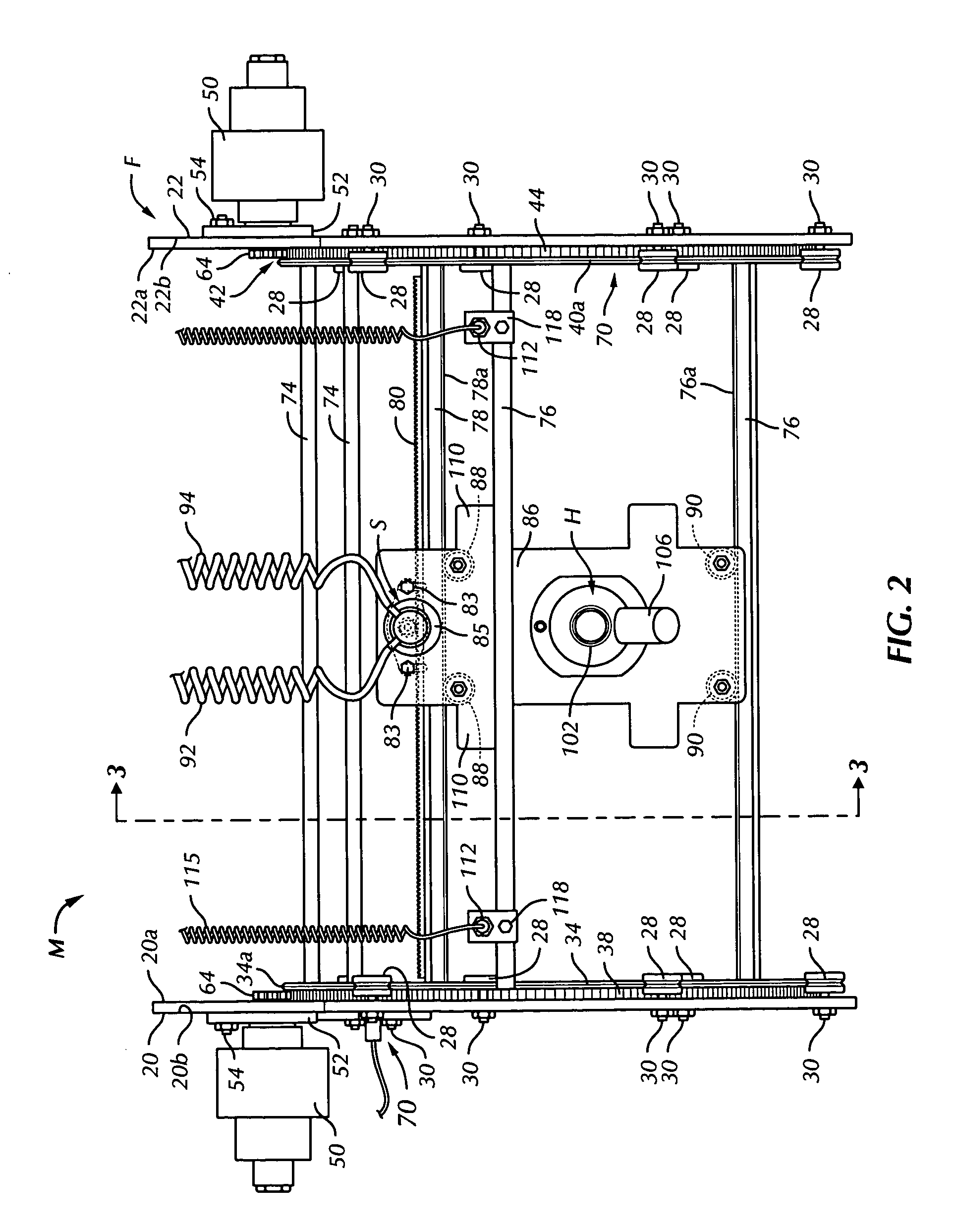

Orbital welding apparatus

A pipe welding arrangement that allows for real-time independent control of all carriages, torches, and ancillary components by design is provided. The approach uses a split-ring race that is mounted on a backing ring of similar design. Numerous welding heads are mounted on carriages that are distributed at set intervals along the circumference of the race. The left and right side race and backing ring assemblies are split at the twelve o'clock and six o'clock positions. They can be decoupled and spread apart horizontally to facilitate installation and for clearing obstacles. Alignment tools (tapered pins) acilitate assembly. Locking devices located near each split interface, coupled with the alignment pins, assure that the race acts as a continuous unit during the welding operation. Linear actuators mounted on the backing rings maintain concentricity between the race and the welded tube and act as a positive clamping system.

Owner:J RAY MCCDERMOTT SA

Welding device for plastic pipe

The invention discloses a welding device for a plastic pipe. The technical scheme is characterized in that the welding device comprises a rack, a pipe clamp jig used for clamping a main pipe, a first clamp used for clamping a pipe welding head and a second clamp used for clamping branch pipes, which are arranged on the rack, a hot-melting heating device, a linear motion system for realizing the relative axial motion of the pipe clamp jig and the first clamp, and a three-axis motion system used for enabling the second clamp to move towards the sidewall of the main pipe and realizing the entrance of the hot-melting heating device to the axial directions of the branch pipes or the separation of the hot-melting heating device from the axial directions of the branch pipes, wherein the hot-melting heating device has two working state, the first one is that the hot-melting heating device is used for heating the sidewall of the main pipe and the end heads of the branch pipes respectively, and the second one is the hot-melting heating device is used for heating the sidewall of the main pipe and the sidewall of the pipe welding head respectively. Hot-melting heating among the same pipelines can be realized on one device, hot-melting heating for the pipe welding head and the main pipe can be realized, and hot-melting heating for the plurality of branch pipes arranged on the main pipe can be realized; and the hot-melting welding device is automatic in welding, high in efficiency, high in welding quality, and easy for working personnel to operate.

Owner:盛忆镐科技(江苏)有限公司

Production method of ultra-large-diameter thin-walled pressure-resistant aluminum alloy pipe

InactiveCN104668306AGood weld strengthGood weld consistencyNon-electric welding apparatusWeld seamConductor Coil

The invention discloses a production method of an ultra-large-diameter thin-walled pressure-resistant aluminum alloy pipe. The production method comprises the steps: (1) feeding, (2) winding or rolling of a reel, (3) performing stirring friction welding, (4) performing solid solution quenching, (5) reshaping, (6) performing aging treatment, and (7) performing pressure resistance test. The aluminum alloy pipe produced by using the method is high in welding seam strength, high in welding seam consistency, high in pipeline roundness and high in internal pipe pressure resistance. According to each series of typical alloys subjected to the method and the process, the minimum yield strength of a pipe welding seam and the allowable internal pipe pressure resistance (applicable to gas and liquid) are as follows: (1) if the alloy is 2XXX, sigma <0.2> is greater than or equal to 290 Mpa, and P (internal pressure) is greater than or equal to 15 Mpa; (2) if the alloy is 6XXX, sigma<0.2> is greater than or equal to 200 Mpa, and P (internal pressure) is greater than or equal to 10 Mpa; (3) if the alloy is 7XXX, sigma<0.2> is greater than or equal to 395 Mpa, and P (internal pressure) is greater than or equal to 20 Mpa.

Owner:郑英

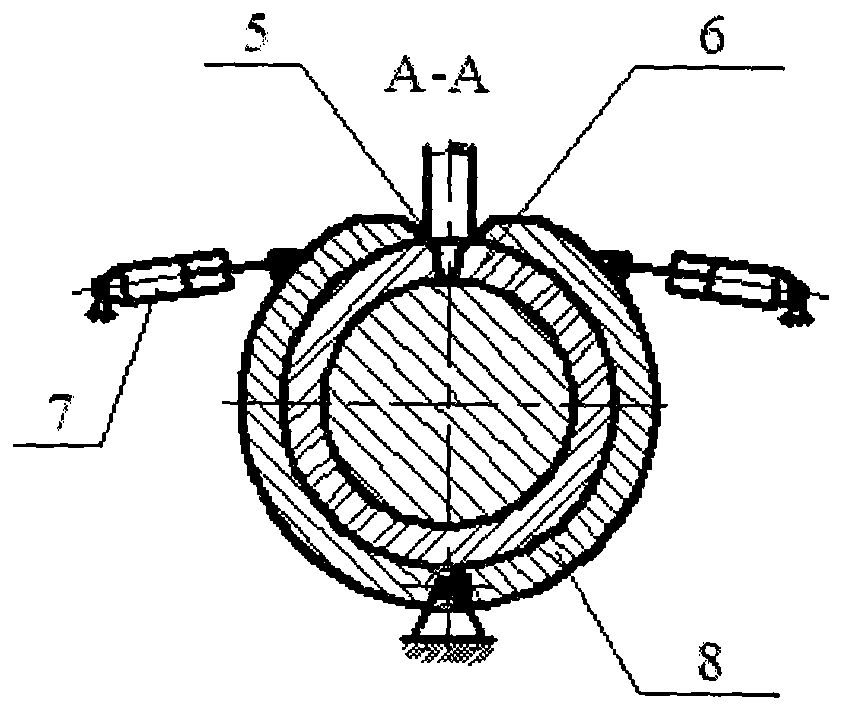

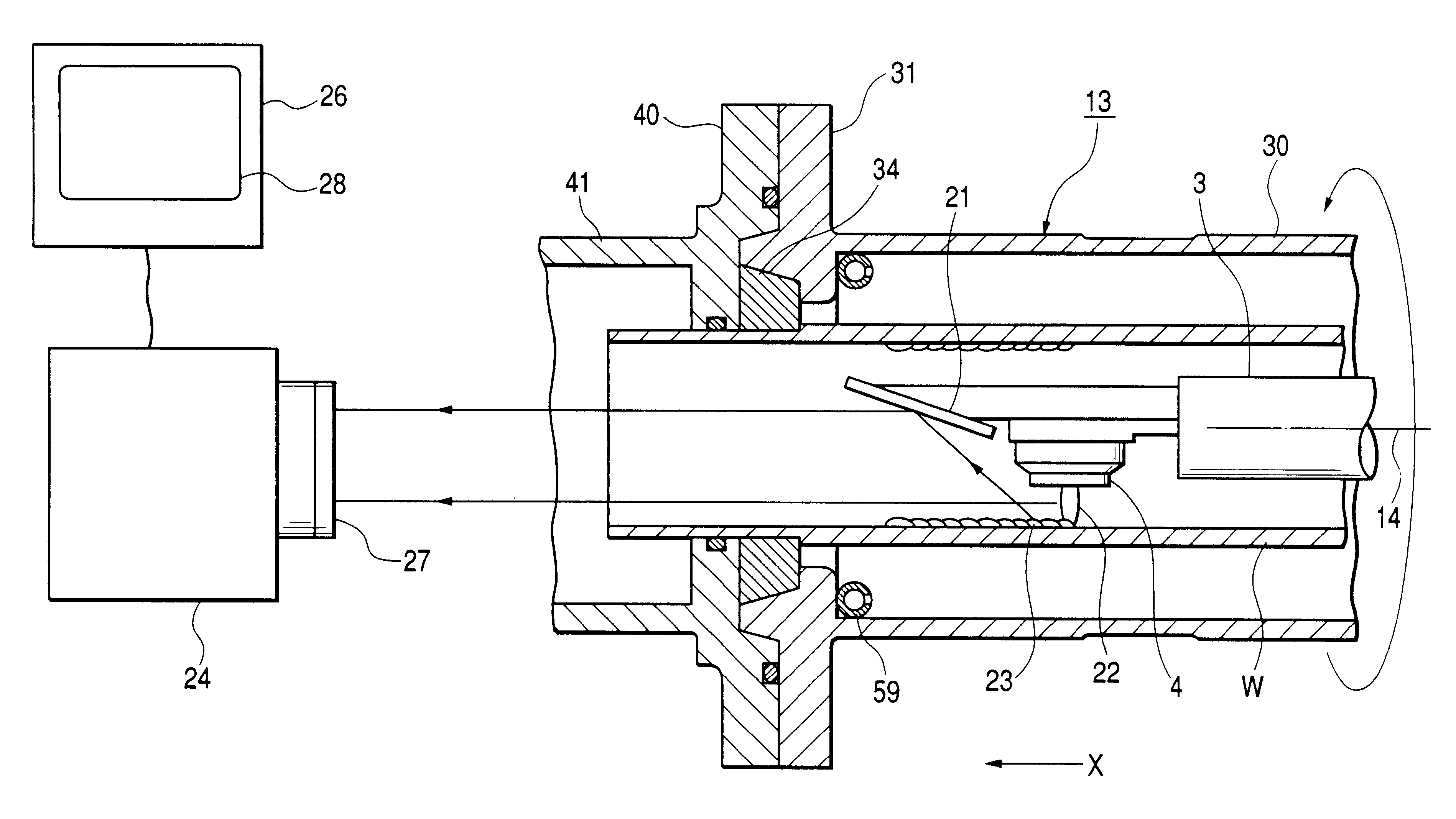

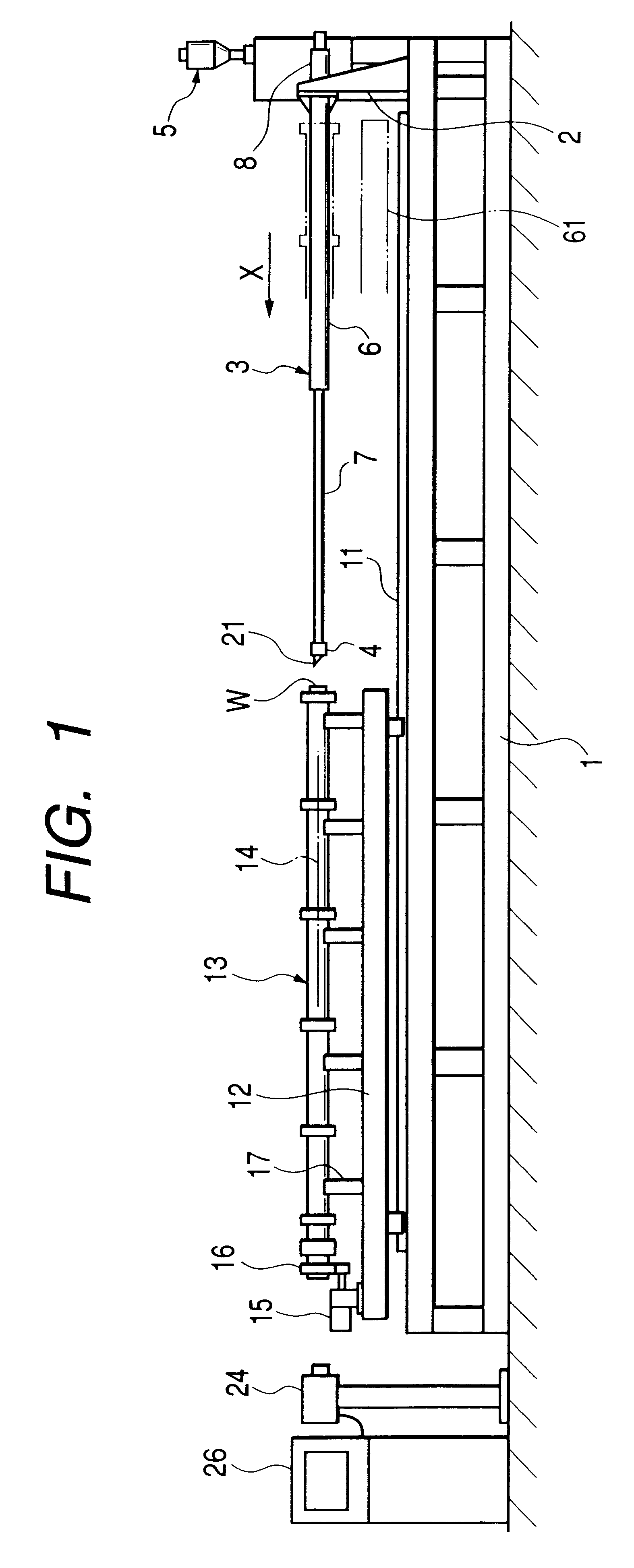

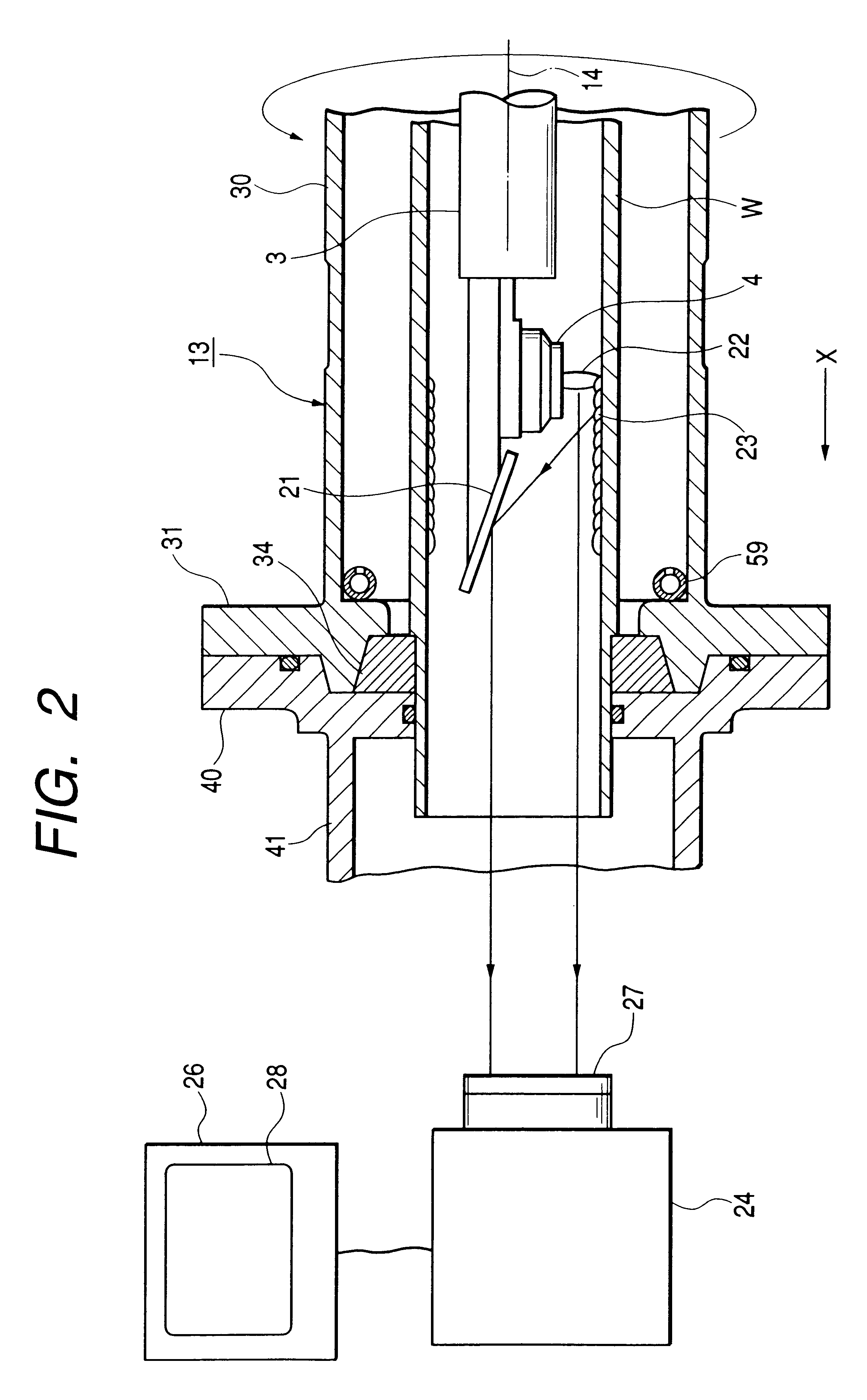

Internal metal pipe welding apparatus and monitoring system

InactiveUS6417488B1Quantity of bending of the metal pipeWelding/cutting auxillary devicesArc welding apparatusDevice MonitorMonitoring system

A metal pipe inner surface weld-mounting apparatus having a monitoring device is constituted by an arm, a horizontal torch, a mirror, a camera and a monitoring device. The arm has a supported base end portion, which is horizontally extended. The horizontal torch is attached to a leading end portion of the arm. The weld-mounting is performed on an inner surface portion of a metal pipe supported rotatably around a horizontally extending axis while at least one of the metal pipe and the horizontal torch is moved in a direction of the axis. The mirror is attached to the leading end portion of the arm. The camera is disposed in a position separated from the mirror for picking up an image of weld-mounting beads in a neighborhood of arc light of the horizontal torch through the mirror. The monitoring device monitors a condition of the weld-mounting.

Owner:DAIDO STEEL CO LTD

Purging device for pipe welding

InactiveUS20150083785A1Avoid damageEasy to replaceShielding gas supply/evacuation devicesWelding/cutting auxillary devicesPipe weldingBlocking layer

Disclosed is a purging device for pipe welding, comprising: a pair of sealing tools that are disposed inside a pipe, expand by supplied air and are in contact with an inner wall of the pipe; and a connection pipe that is disposed between the pair of sealing tools, is a cylindrical body, wherein the sealing tools are respectively fixed to either side end of the connection pipe and the connection pipe is provided with a gas nozzle for discharging inert gas supplied from the outside, wherein each of the sealing tools further comprises a blocking layer that is flame retardant and is coupled in such a manner as to surround an outer circumferential surface of each of the sealing tools.

Owner:PARK JIN WOO

Pipe weld cleaning machine

Owner:SUS SERVICES INT

Method and equipment for induction heating and welding

InactiveCN1730221ALight structureCompact structureHigh frequency current welding apparatusChemical industryPetrochemical

The invention relates to an induction soldering method and its welding equipment in welding equipment welding. Welding equipment consists of pipe-welding machine and induction heater. The equipment can automatically weld pipe transforming liquid, raw petroleum, natural gas and medium in chemical industry, and has high use value in water resources and electric power department and petrochemical industry.

Owner:陈炯

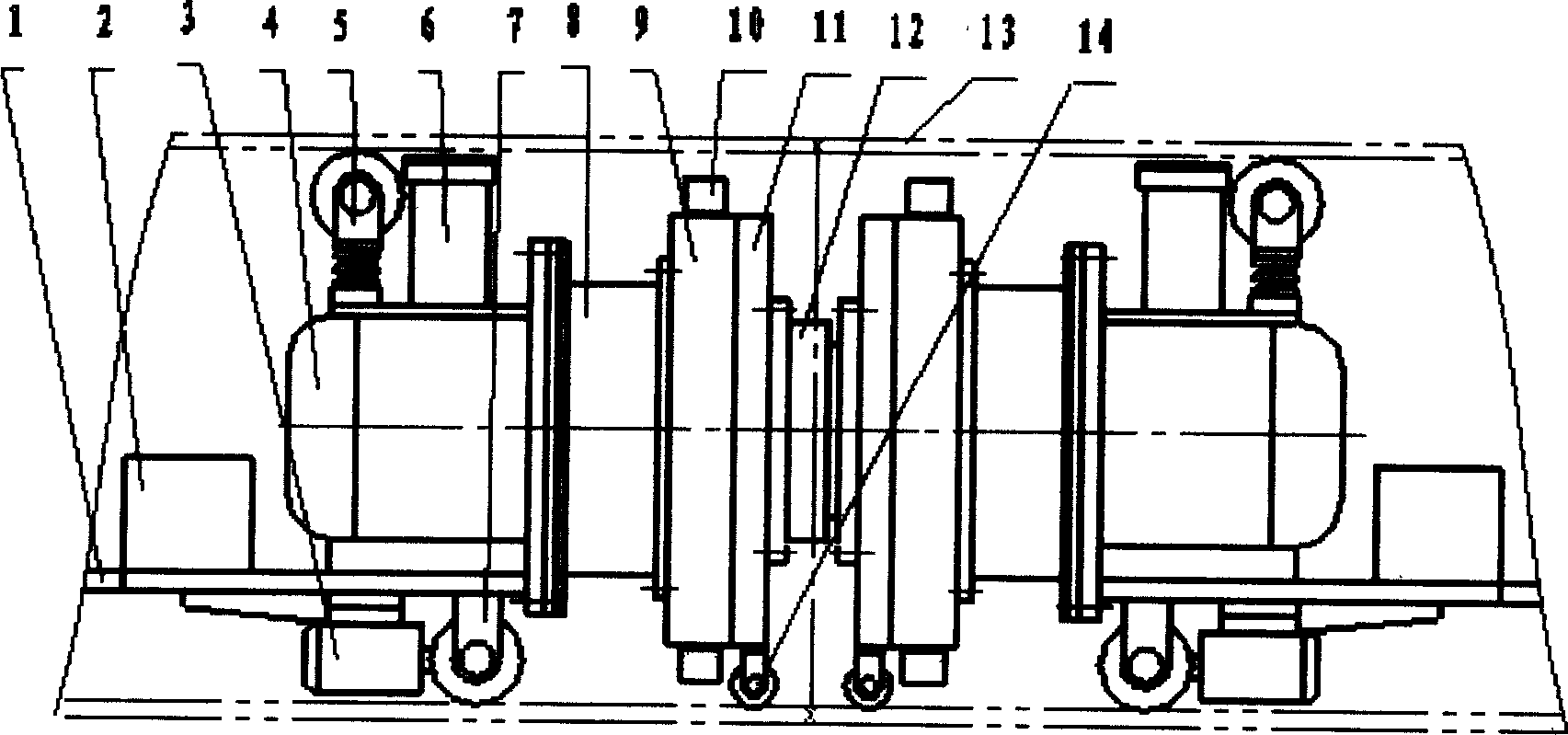

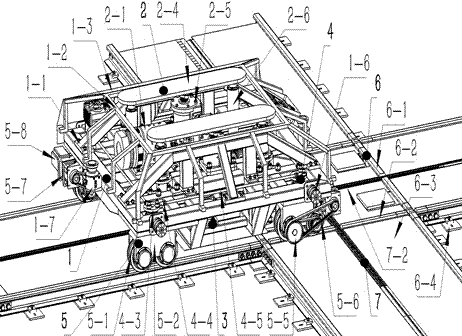

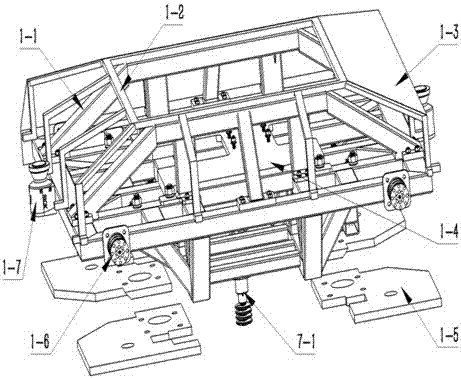

Four-wheel synchronous rail change welding material transfer trolley

InactiveCN107140395AOptimize layoutGuaranteed uptimeMechanical conveyorsEngineeringMaterial transfer

The invention discloses a four-wheel synchronous rail change welding material transfer trolley. The trolley mainly comprises a trolley body, a workpiece lifting mechanism, a trolley body lifting mechanism, reversing mechanisms, advancing mechanisms, rails and a sliding electrifier; the workpiece lifting mechanism is mounted at the upper part of the trolley body; the trolley body lifting mechanism is mounted in a frame of a square steel pipe welding structure of the trolley body; the advancing mechanisms are mounted at four corners of the trolley body, and are connected with the reversing mechanisms; rails comprise longitudinal and transverse rails vertically intersected; the workpiece lifting mechanism can meet the requirements of lifting workpieces in different stations; when the transfer trolley is steered, the trolley body lifting mechanism lifts up the transfer trolley body, and the reversing mechanisms drive the advancing mechanisms to turn by 90 degrees; then, the trolley body lifting mechanism downwards move; and after the transfer trolley is descended, wheels are contacted with the rails to realize conversion of longitudinal and transverse directions of the transfer trolley. Compared with the prior art, the trolley is simple in overall structure, firm and fast in rail change mode, totally lifted, high in loading tonnage and stable in operation, and can greatly improve the production efficiency.

Owner:CHANGCHUN UNIV OF SCI & TECH

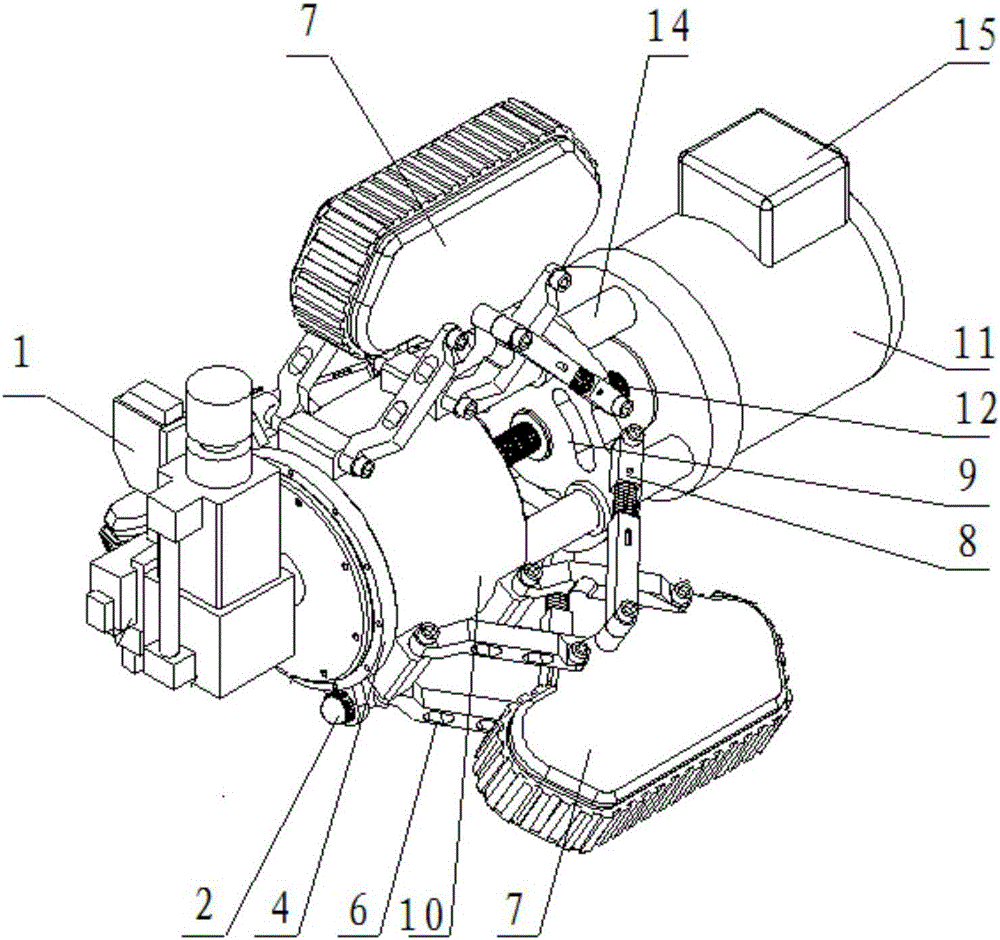

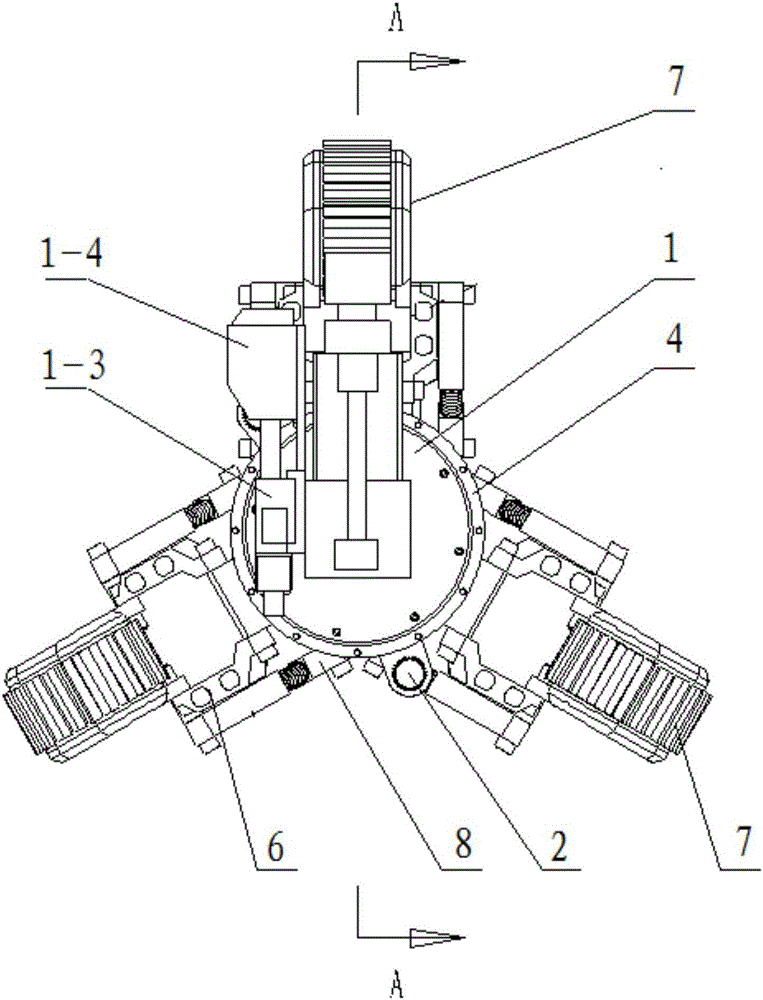

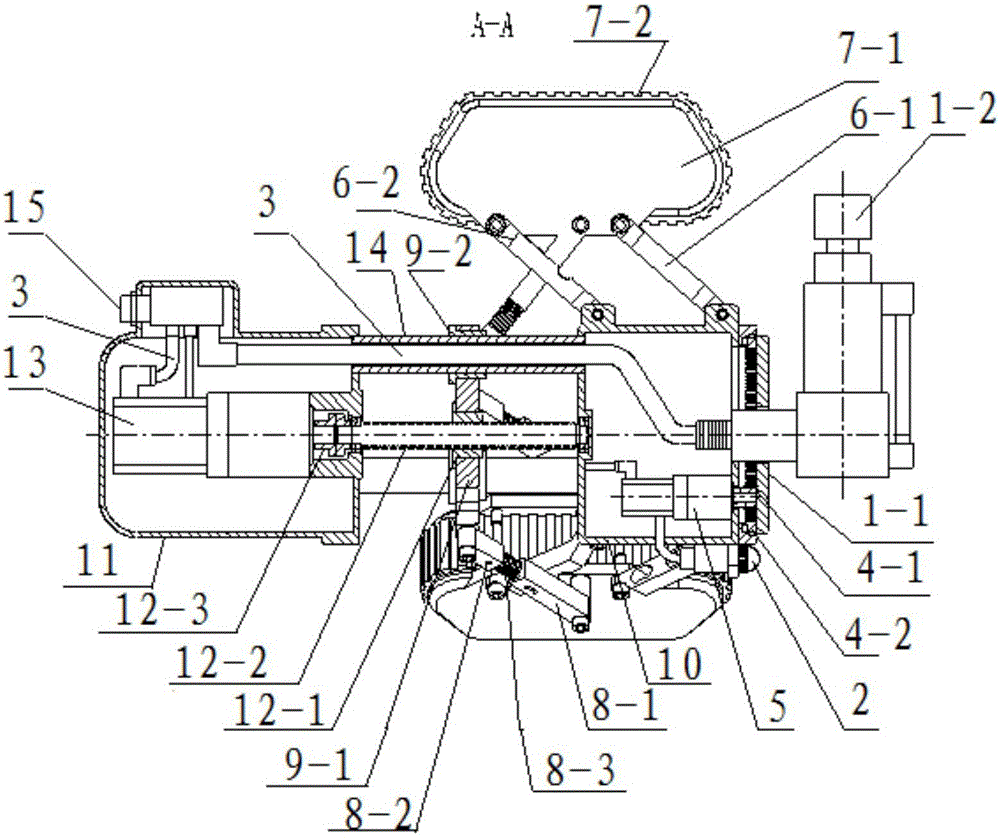

Laser root welding robot inside pipeline

ActiveCN105834586AAccurate guidanceQuality assurancePipeline systemsEndless track vehiclesEngineeringPipe welding

The invention discloses a laser root welding robot inside a pipeline and belongs to the technical field of pipeline welding. The laser root welding robot inside the pipeline comprises a weld joint welding device. A first transmission device is connected with the weld joint welding device. A front end machine base is connected with the first transmission device. A first gear motor is arranged in the front end machine base. One end of a connecting device is movably connected with the front end machine base. A crawler type traveling device is movably connected with the other end of the connecting device. One end of a pushing device is movably connected with the crawler type traveling device. A driving device is movably connected with the other end of the pushing device. A second transmission device is connected with the driving device. One end of the second transmission device is movably connected with the front end machine base. According to the laser root welding robot inside the pipeline, the welding fusion depth is large, the welding speed is high, accurate welding track guidance is provided for a laser welding head, and the quality of laser root welding is guaranteed.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Welding method of high-strength steel for pressure steel pipe of 610MPa hydropower station

InactiveCN102101210AReduce the tendency to produceImprove toughnessArc welding apparatusAluminum silicateStress relief

The invention relates to a welding method of high-strength steel for a pressure steel pipe of a 610MPa hydropower station, belonging to the technical field of steel pipe welding. In the method, a constant-strength low-hydrogen electric welding rod is used for priming, and a constant-strength matched welding rod is adopted to continuously weld and fill a weld pass by adopting a submerged-arc welding method, wherein the welding line energy is strictly controlled to be about 30-40kJ / cm, and the interpass temperature is controlled to be 100-150 DEG C; and after welding, an aluminum silicate plate is used for covering a welding joint for slow cooling so as to realize the welding of a steel plate for a steel pipe for a 610MPa hydropower station without preheating before welding and heat treatment after welding. The method solves the problems that the traditional steel for the pressure steel pipes of the 610MPa hydropower station needs to be preheated before welding and subjected to stress relief heat treatment after welding, and the welding efficiency is low.

Owner:SHOUGANG CORPORATION

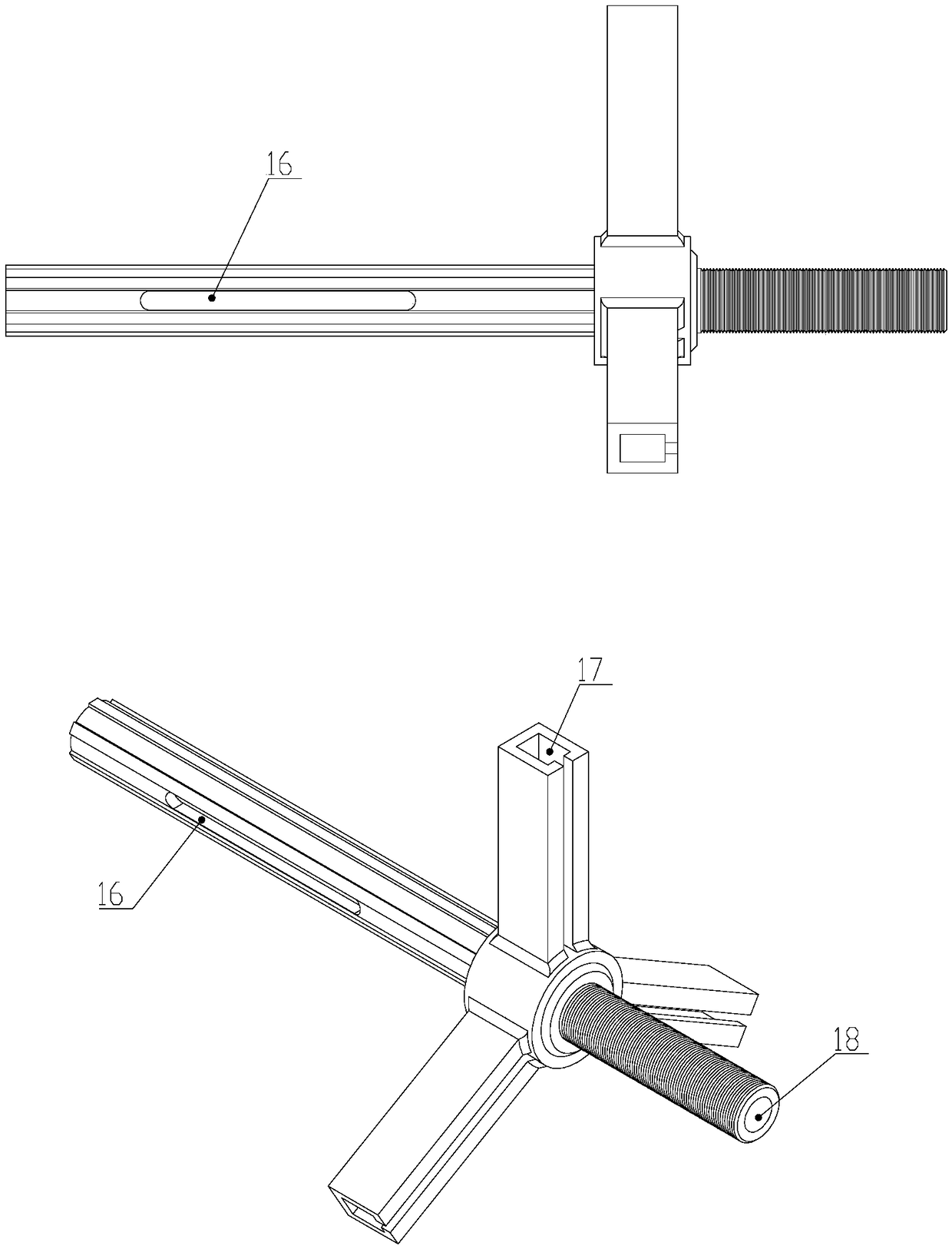

Pipe welding arc-shaped liner device

ActiveCN107825059ACompact structureEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesPush and pullCoupling

The invention relates to a pipe welding arc-shaped liner device. According to the aim, a liner device which can be used for improving the welding quality during pipe construction is provided. The pipewelding arc-shaped liner device is characterized by comprising six sets of head support opening alignment components, a head liner guide and push component, a middle barrel rod connecting component and a tail push and pull positioning component; each set of head support opening alignment components comprises a fixed jackscrew, a wearable steel ball, a plurality of distance adjusting gasket, a steel ball barrel and a steel ball base; the head liner guide and push component comprises a support barrel, a sliding ring, a compression spring, a fixing ring, a guide rail rod, a sliding support, an arc-shaped liner, a limiting bolt and a nut; the middle barrel rod connecting component comprises a connecting barrel, a barrel coupling, a connecting rod and a rod coupling, and the middle barrel rodconnecting component is used for connecting the head and the tail of the device and transmitting rotation or push-and-pull motion of the tail; and the tail push and pull positioning component comprises a push-and-pull handle and a clamping reed.

Owner:东营市东凯园区运营管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com