Method and equipment for induction heating and welding

A technology of induction heating welding and induction heater, applied in welding equipment, high-frequency current welding equipment, metal processing equipment, etc., can solve the difficulty of welding seam formation, increase welding workload and labor intensity of welders, shorten welding time, etc. problems, to achieve the effect of improving welding production efficiency, improving production labor conditions, and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

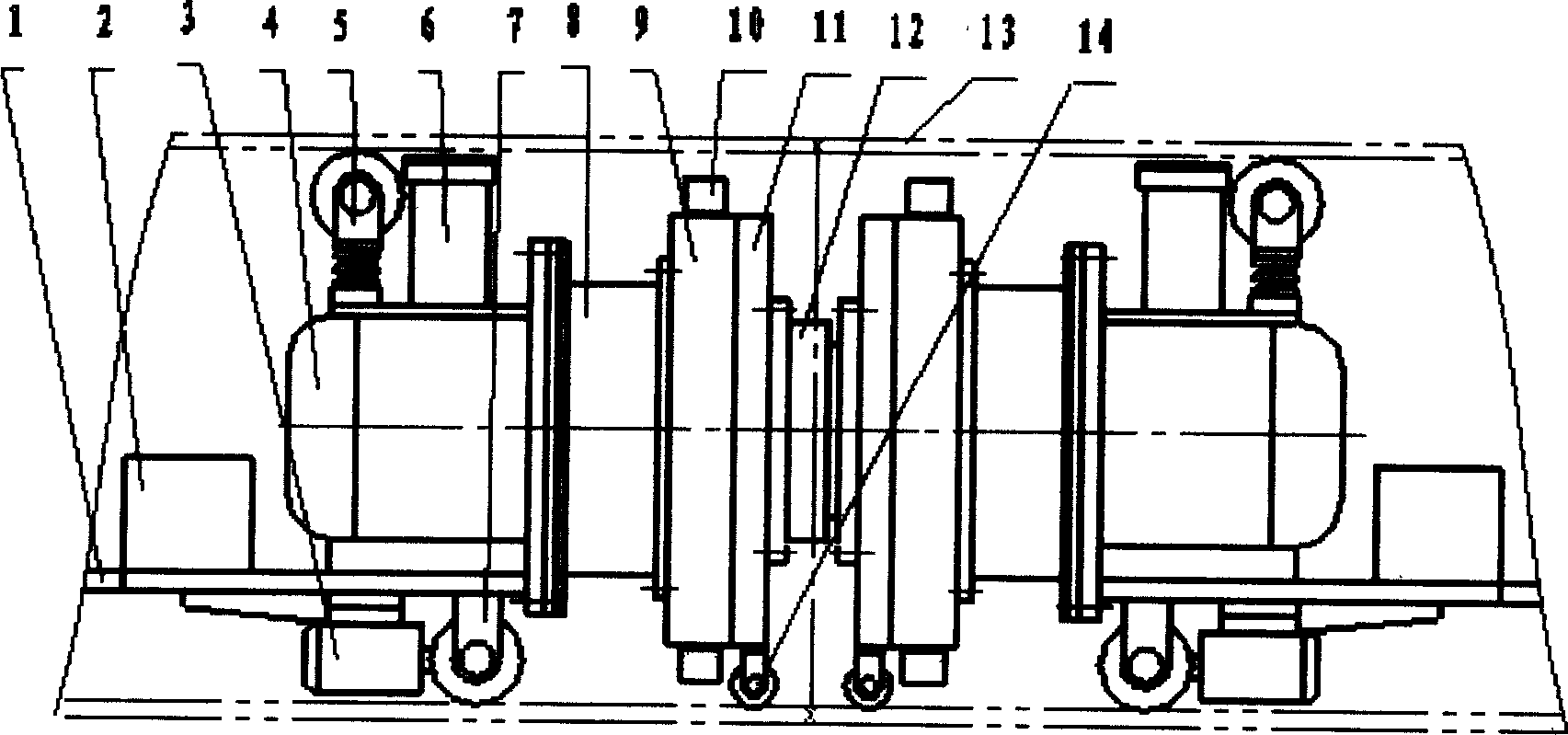

[0029] Such as figure 1 As shown, the trolley of the operation box is hinged to the mounting plate of the positioning motor, the box is installed on the trolley, and the control cables of the operation box are respectively connected to the traveling motor, positioning motor, electromagnet, and welding controller along the trolley.

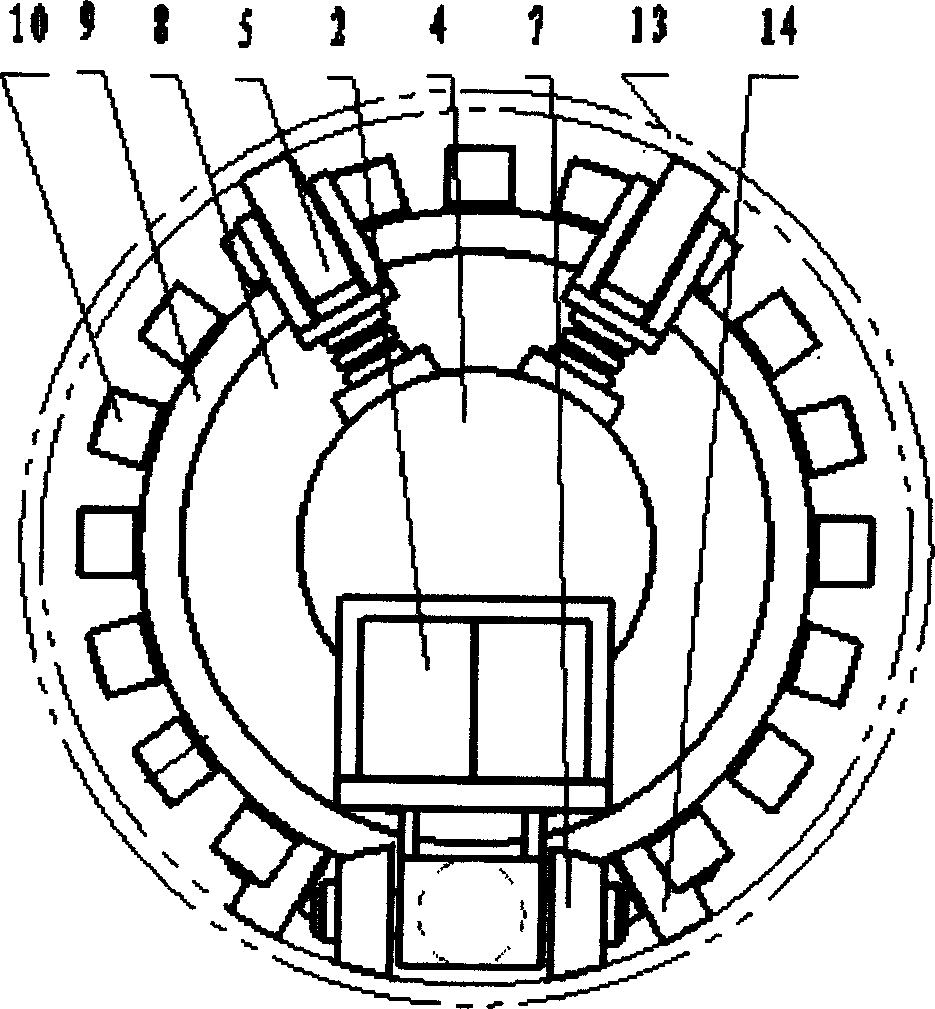

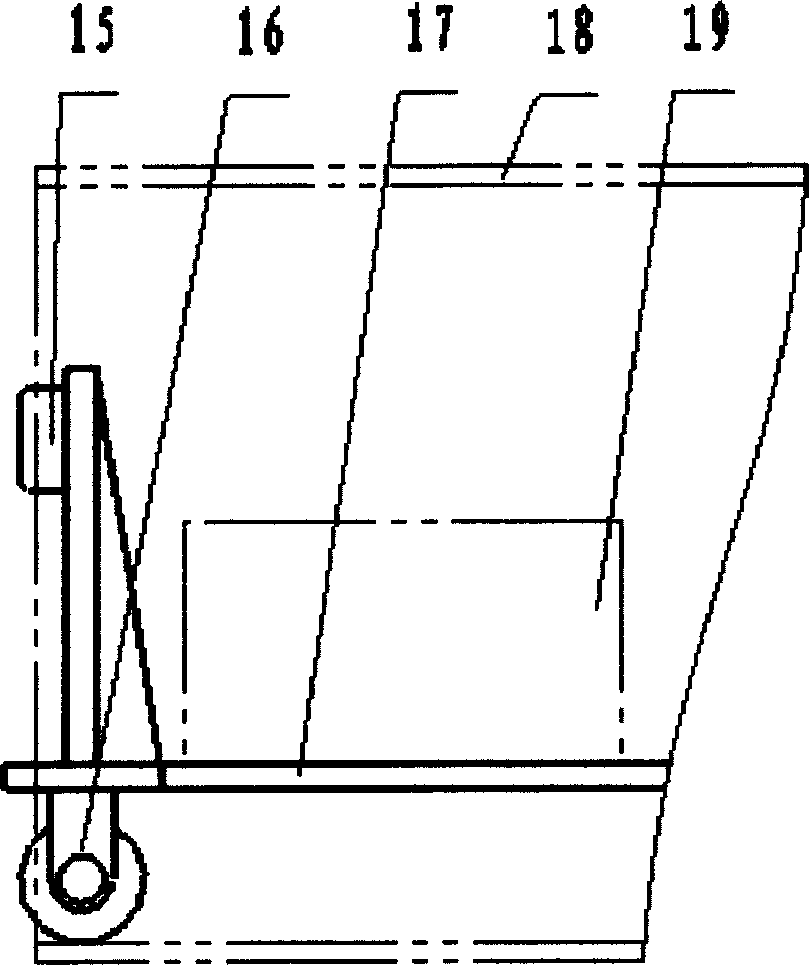

[0030] It can be seen from the figure that the steel pipe welding machine consists of a reduction gear set, a turntable, a gear mounting plate, an electromagnetic clutch, a positioning block, a connecting plate, a positioning block guide tube, a positioning plate, a tapered positioning plate, a spline shaft, a rolling bearing, a connecting short sleeve, and a positioning plate. Motor composition. The traveling mechanism is composed of a guide wheel, a pressing wheel, a traveling wheel, a traveling motor, a traveling reducer and an electromagnetic brake. The guide wheel is installed at the front end of the positioner, the pressing wheel is installe...

Embodiment 2

[0085] The basic structure of the steel pipe welding machine is exactly the same as that of the first embodiment, except that the positioning motor and the travel motor are replaced by the positioning hydraulic motor and the travel hydraulic motor, and the connection mode between the positioning hydraulic motor, the travel hydraulic motor and the reduction gear set remains unchanged: brake The electromagnet is replaced by the brake hydraulic cylinder, and the connection mode between the head end of the piston rod of the brake hydraulic cylinder and the brake shoe remains unchanged; the main contact of the contactor controlling the positioning motor, the travel motor, and the electromagnet is respectively connected to the three-position four-way electromagnetic On the electromagnet coil of the reversing valve, the positioning hydraulic motor, the traveling hydraulic motor and the brake hydraulic cylinder are controlled. The screw mechanism connecting two steel pipe welding machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com