Patents

Literature

777results about How to "Reduce welding costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

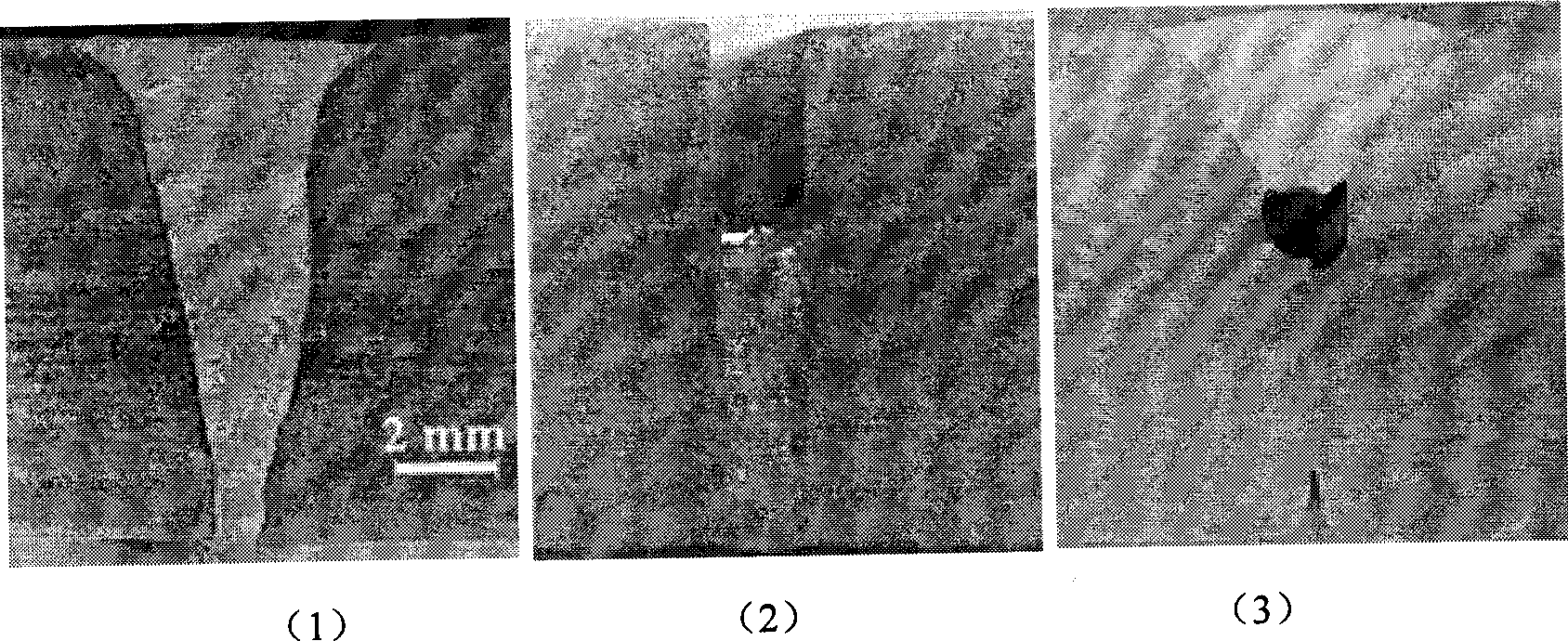

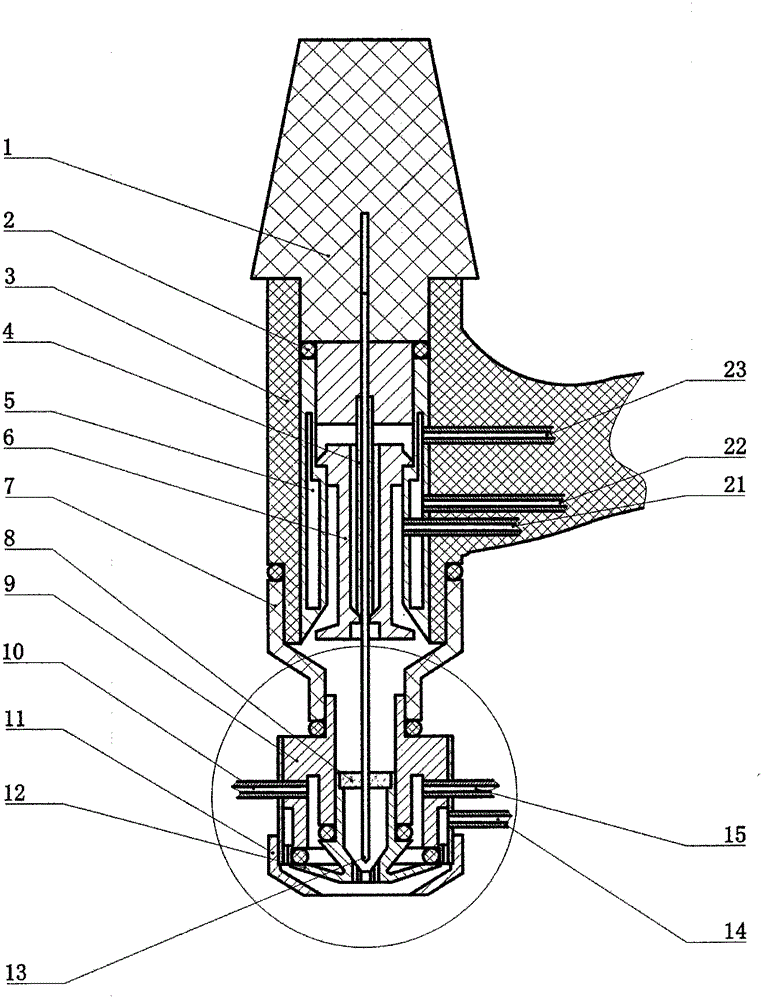

Integrated pin tool for friction stir welding and composite method of resistance-friction stir welding thereof

InactiveCN101537538AReduce wearExtended service lifeEngine sealsWelding/cutting media/materialsElectrical resistance and conductanceFriction welding

The invention discloses an integrated pin tool used for friction stir welding and a composite method of resistance-friction stir welding thereof. The pin tool comprises a pin tool body arranged on a friction welder and a tool pin arranged at the lower part of the tool pin body which is connected with the welder in a clamping and insulating manner; the pin tool also comprises a forced cooling system, a current carrying system, a gas shielding system, a temperature sensing and detecting system, a sealing and insulation system, an inner shaft shoulder and the tool pin, and is an integrated pin tool which has the functions of gas shielding, forced circulation cooling of internal liquid medium, automatic temperature sensing and detection, tool pin changing and composite non-keyhole resistance-friction stir welding. The invention overcomes the difficulty of friction stir welding of the high melting point metal and meets the harsh technical requirements of the friction stir welding of the low melting point metal, improves the quality of welding joints, prolongs the service life of the pin tool and realizes the friction stir welding of high melting point metal and low melting point light alloy, with low cost, high efficiency and excellent quality.

Owner:CHONGQING UNIV

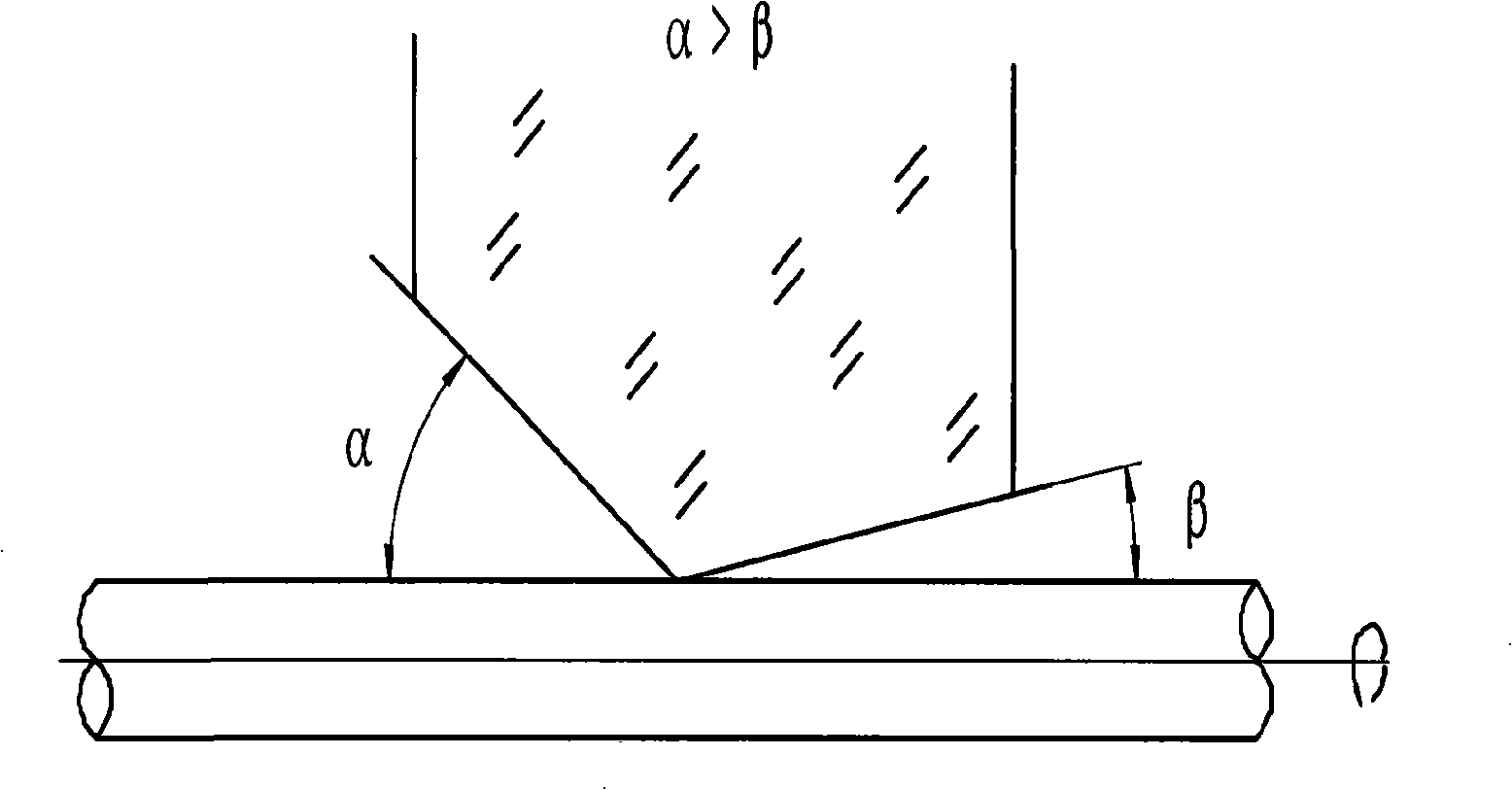

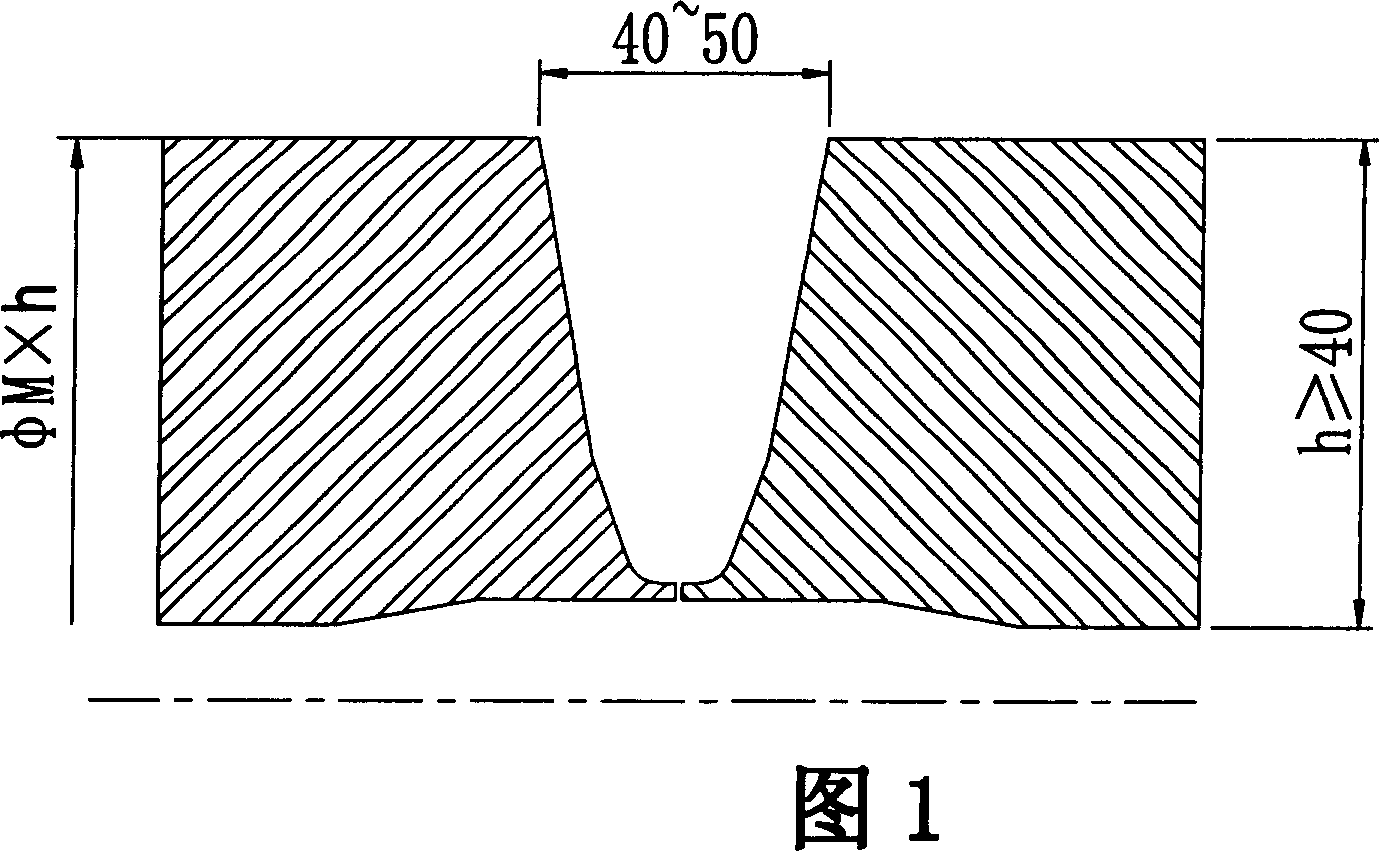

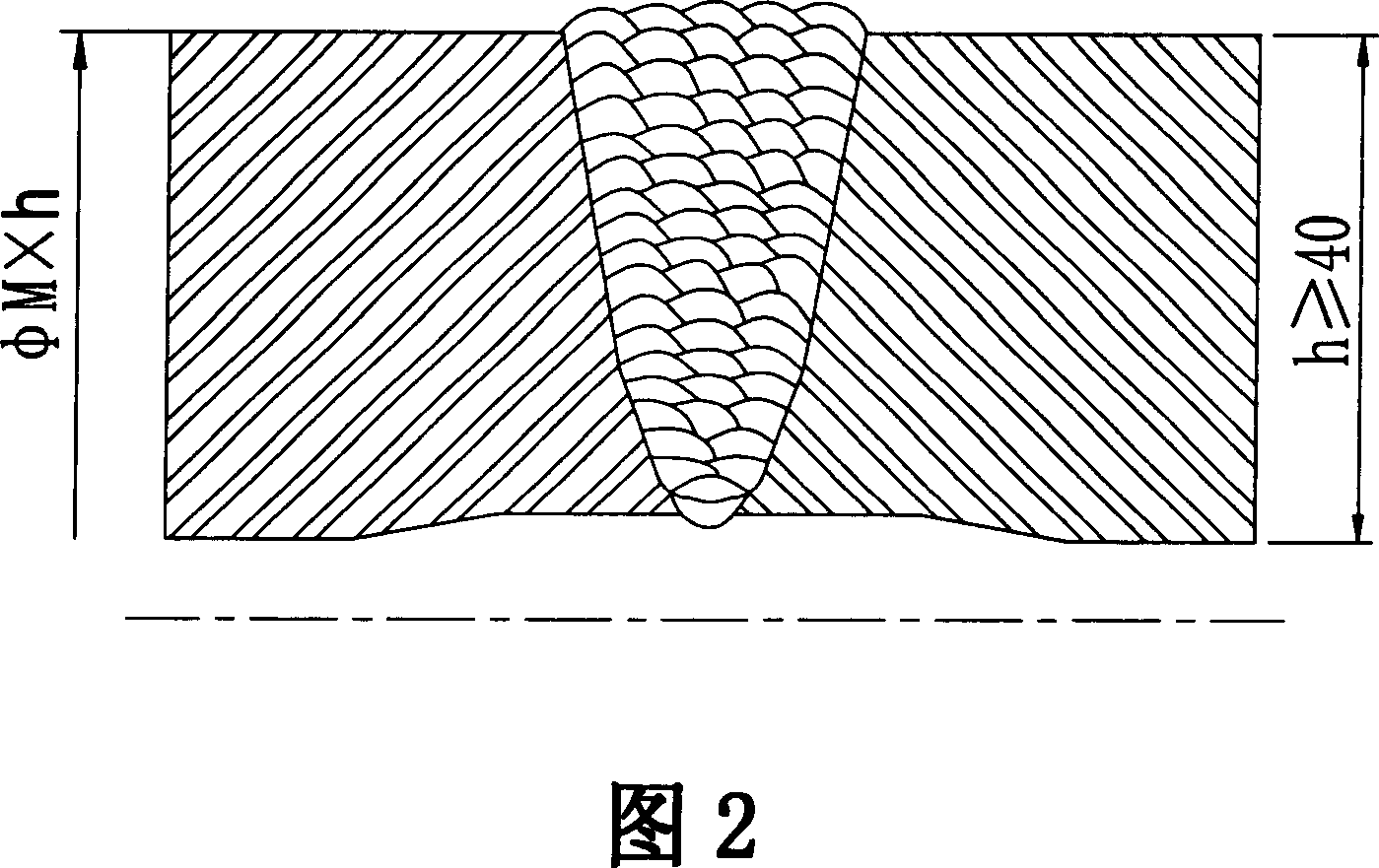

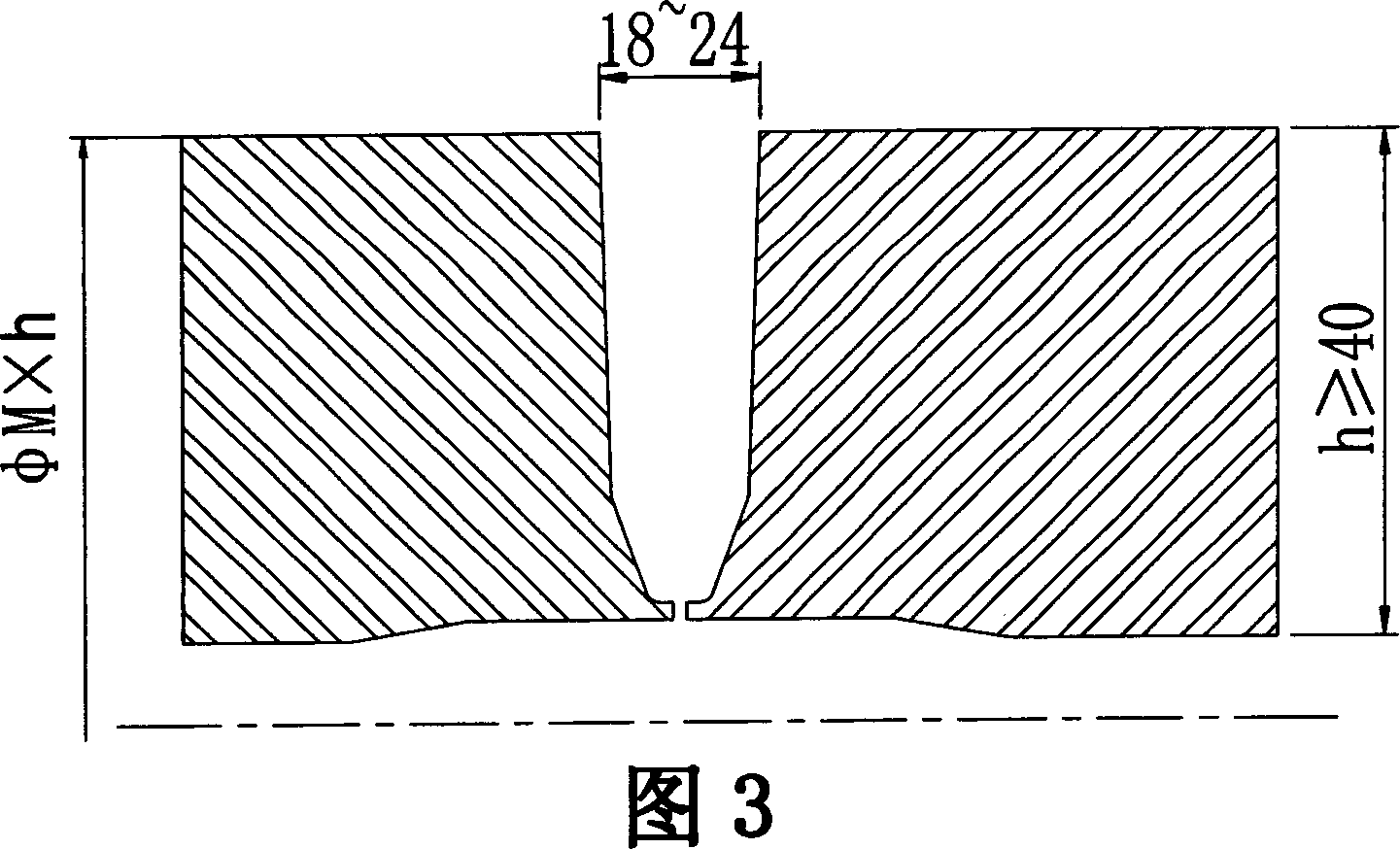

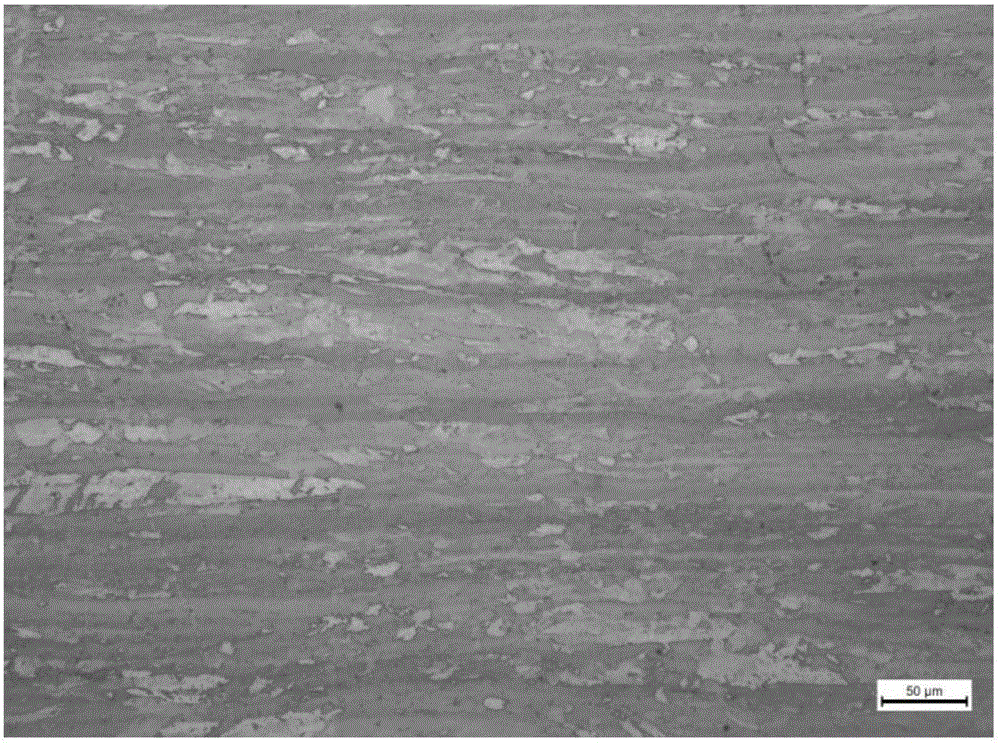

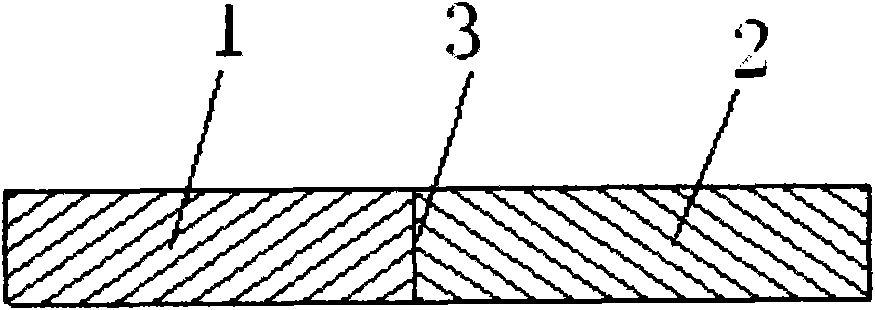

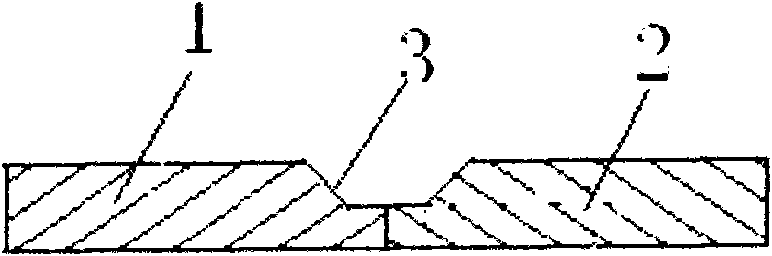

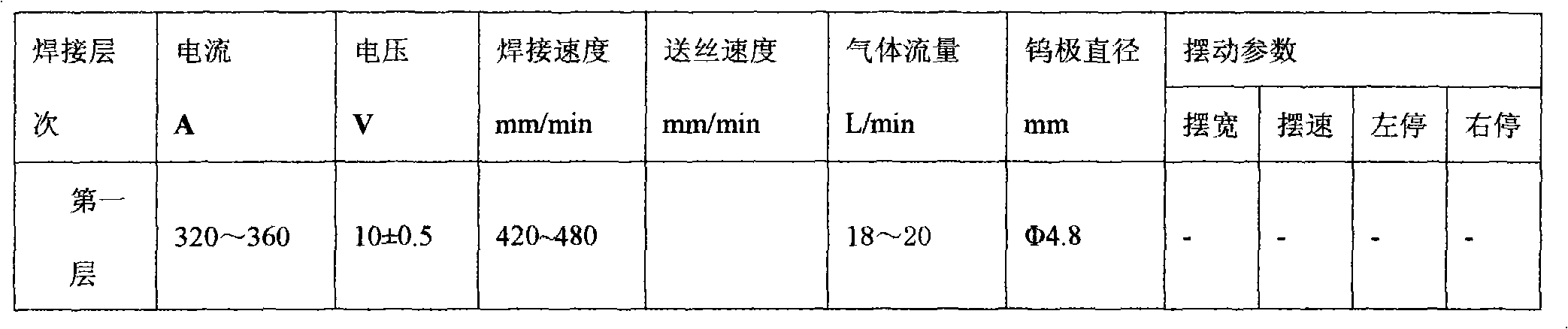

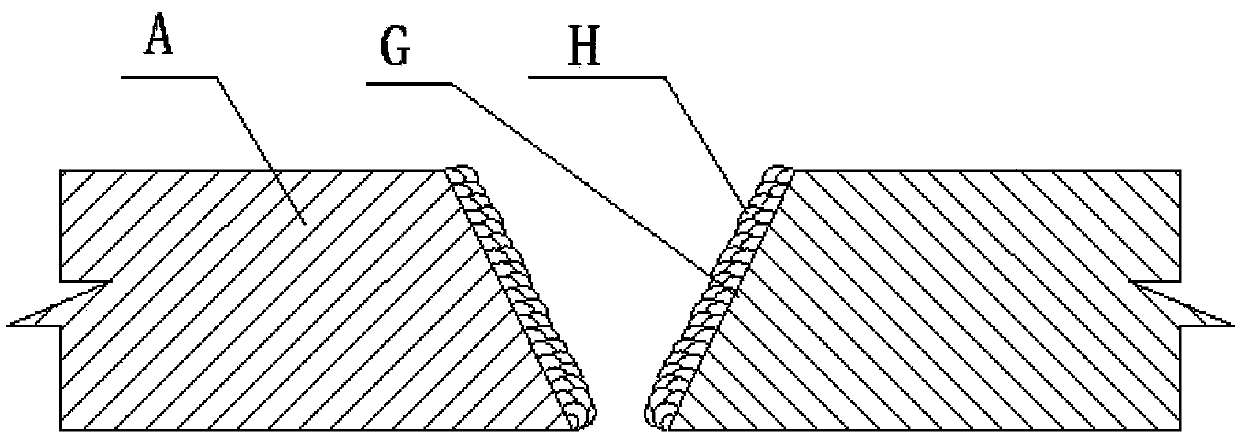

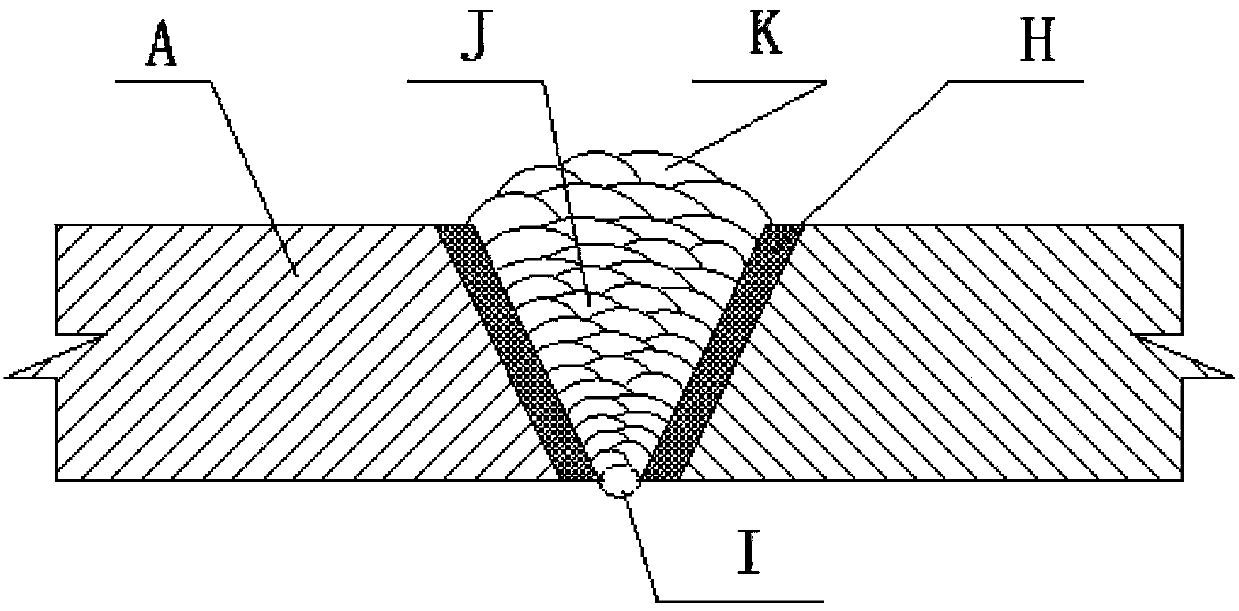

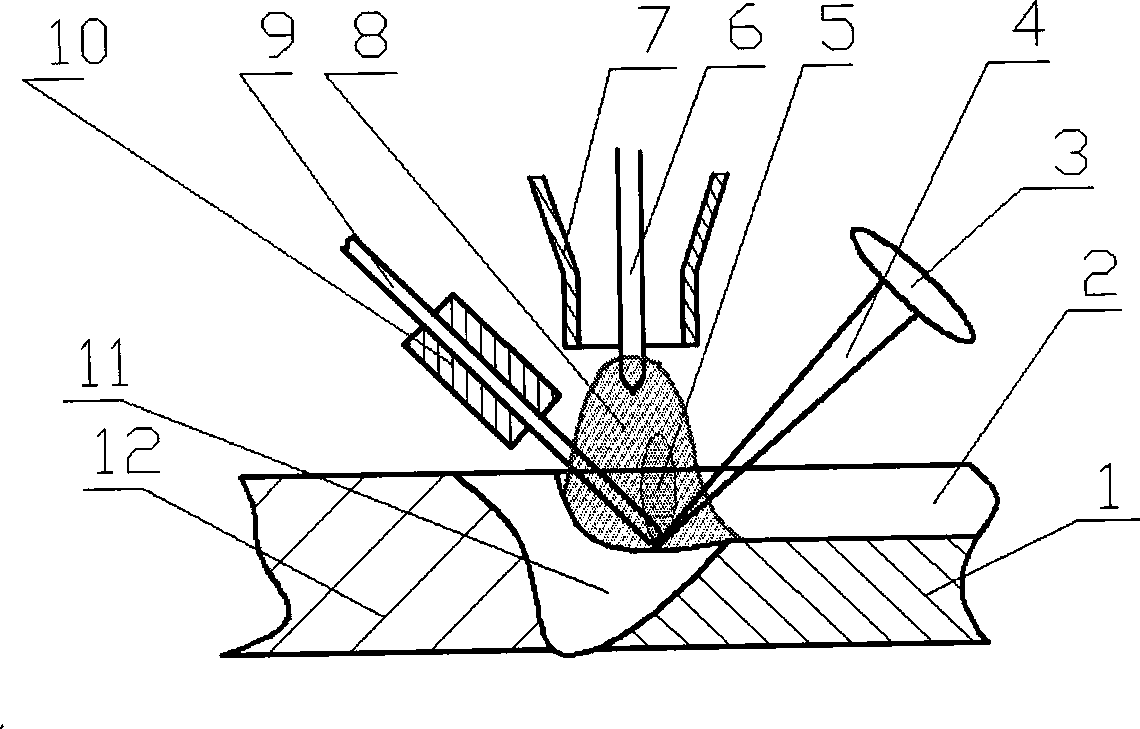

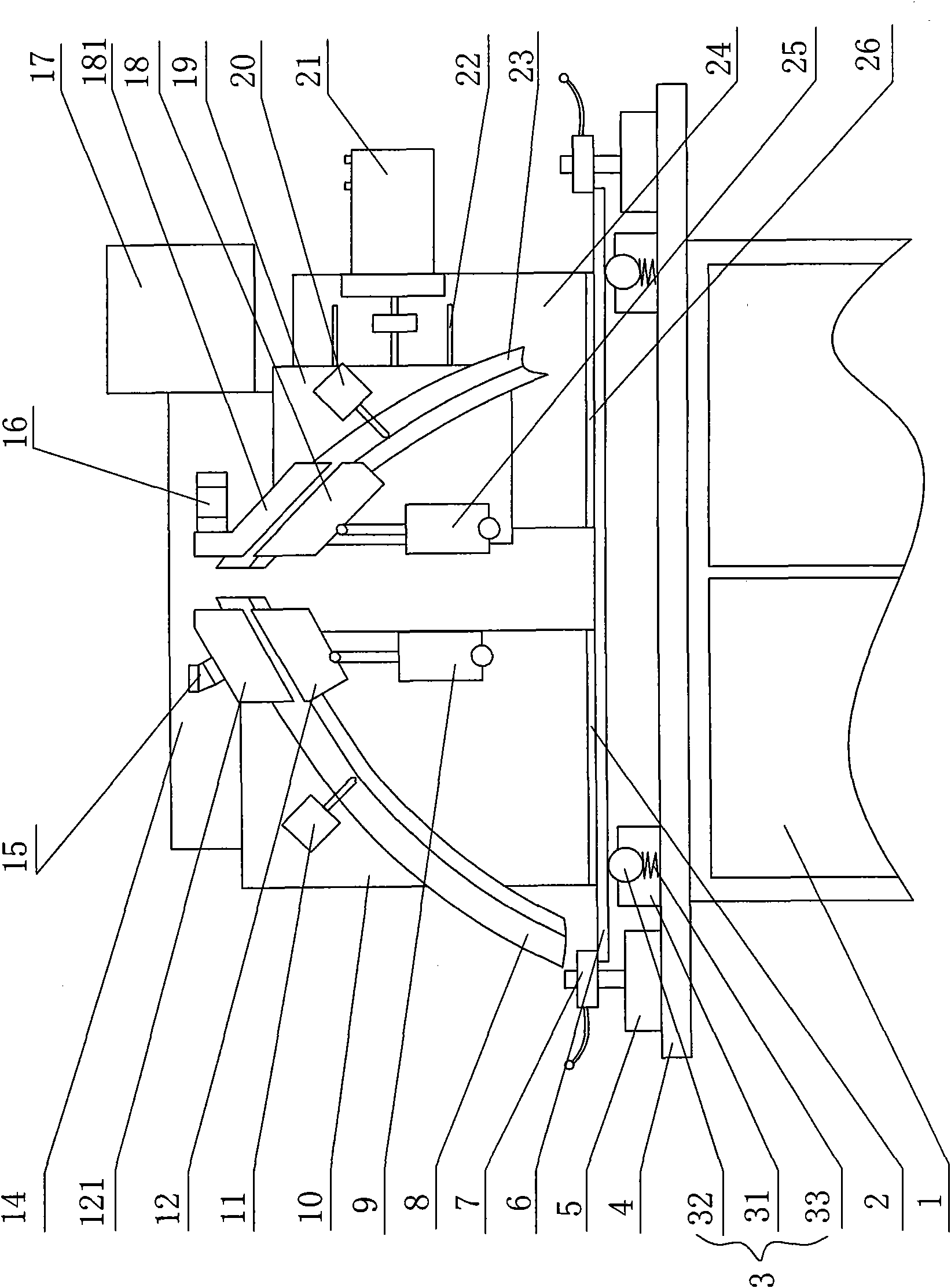

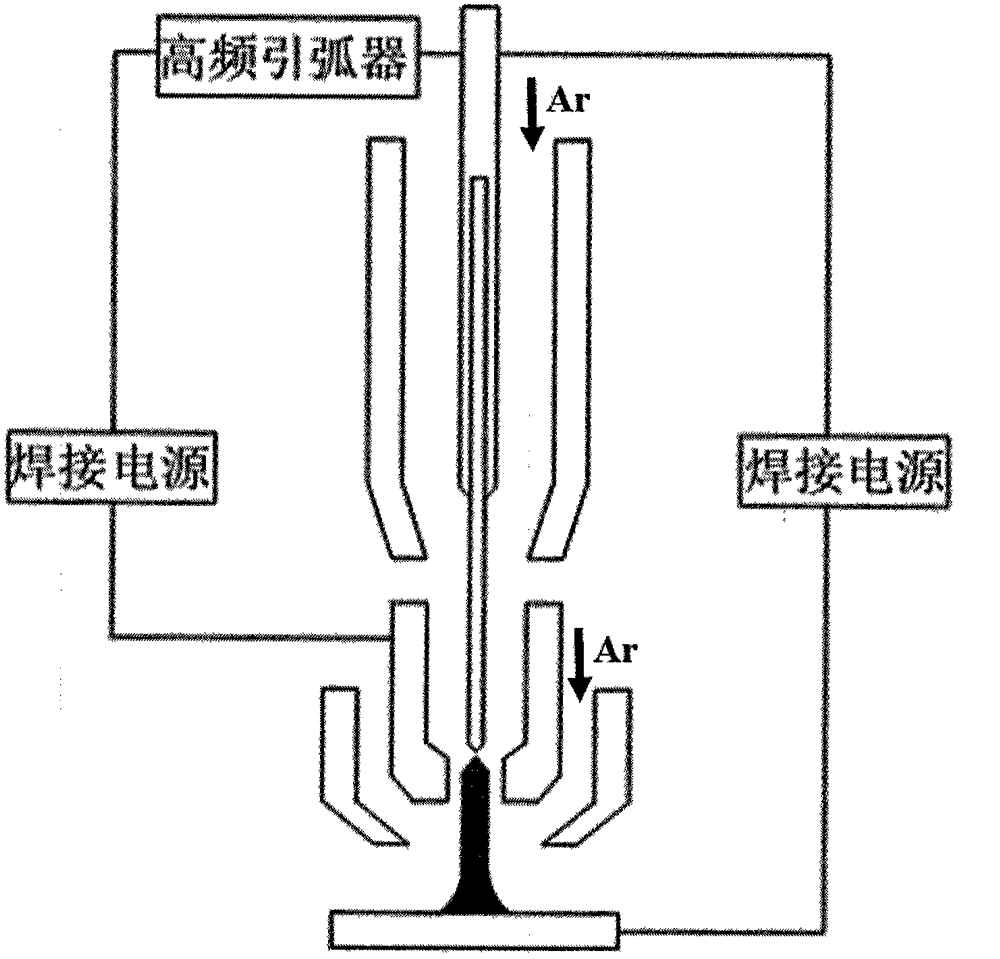

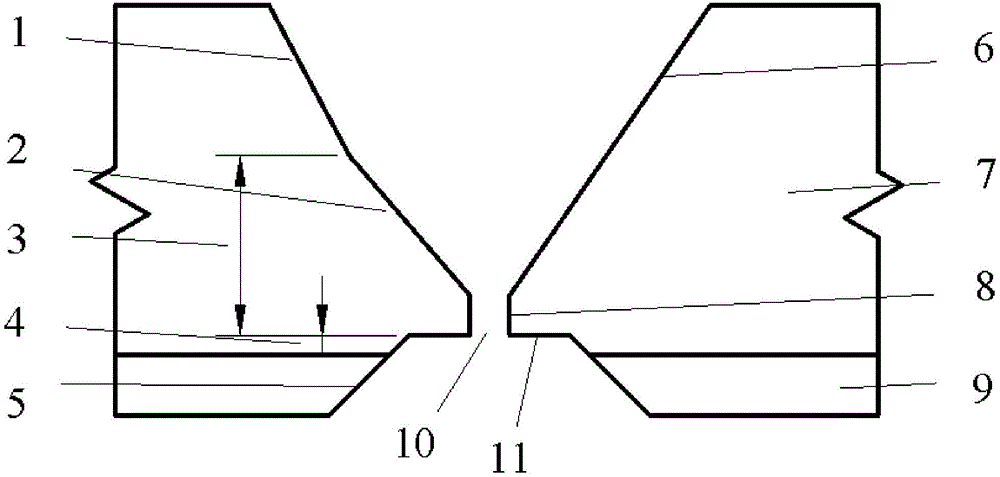

Large posted sides pipeline narrow gap tungsten electrode noble gas protecting all-position automatic soldering method

ActiveCN101077547AReduce fillingReduce welding costsArc welding apparatusWelding/cutting media/materialsNoble gasEngineering

The present invention relates to inert gas protected automatic narrow gap tungsten electrode welding process for large thick pipe with diameter over 325 mm and thickness over 40 mm. The automatic welding process includes forming combining chamfer in the opposite ends to be welded before welding, bottoming welding, single layer filling welding, and covering welding in linear or swinging weld pass. The process has less filled deposited metal, low welding cost, high welding efficiency and other advantages.

Owner:CHINA NUCLEAR IND 23 CONSTR

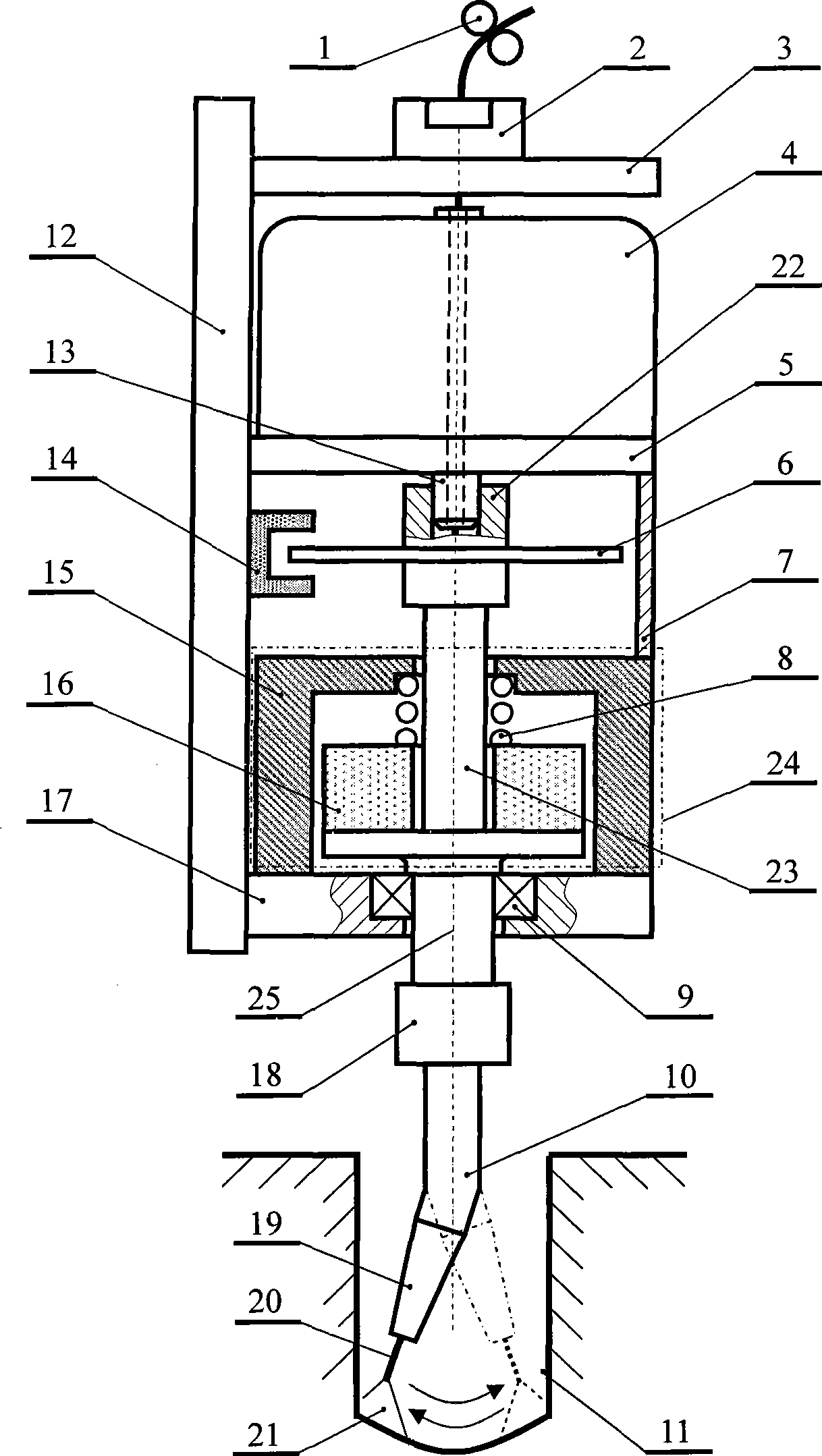

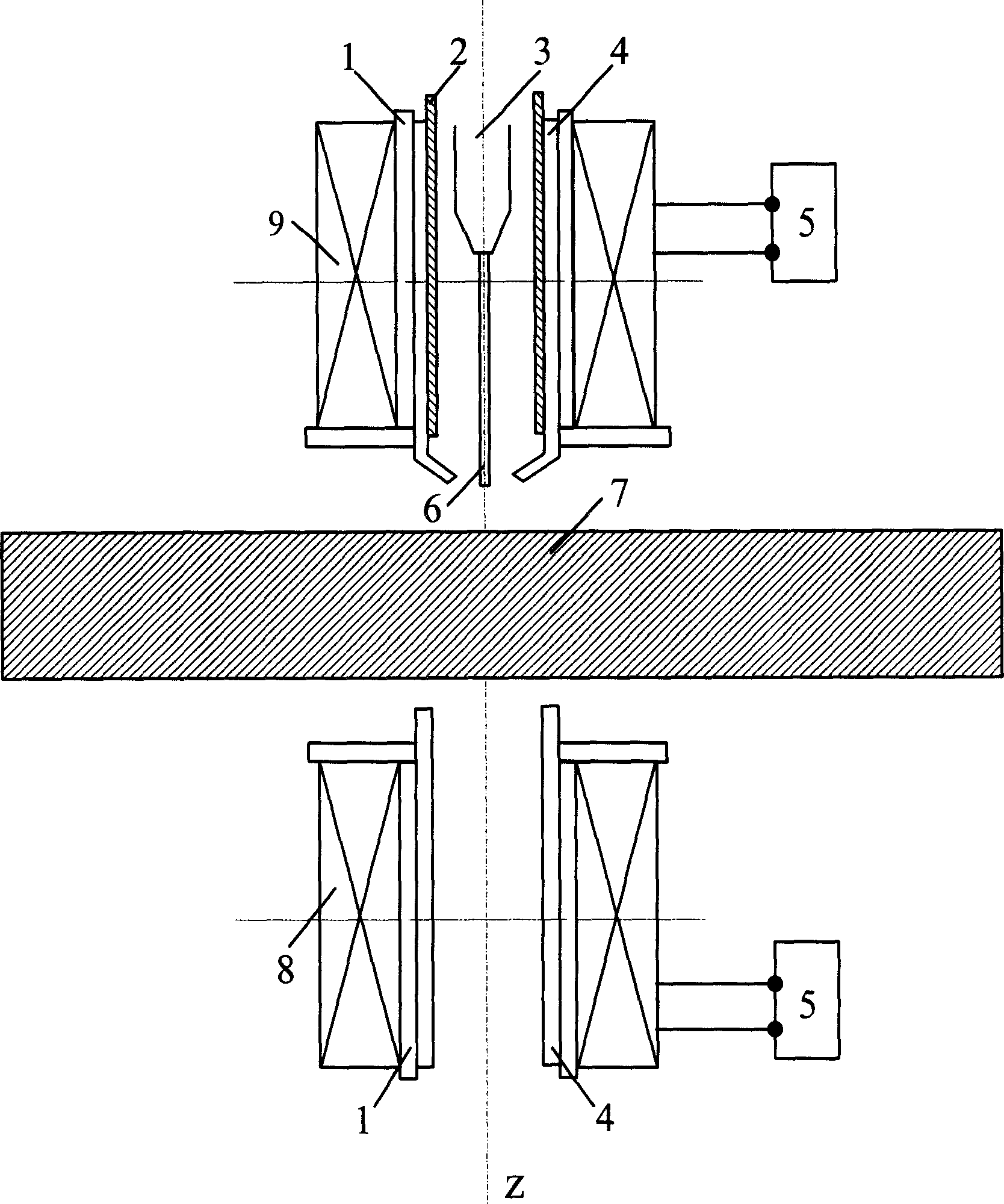

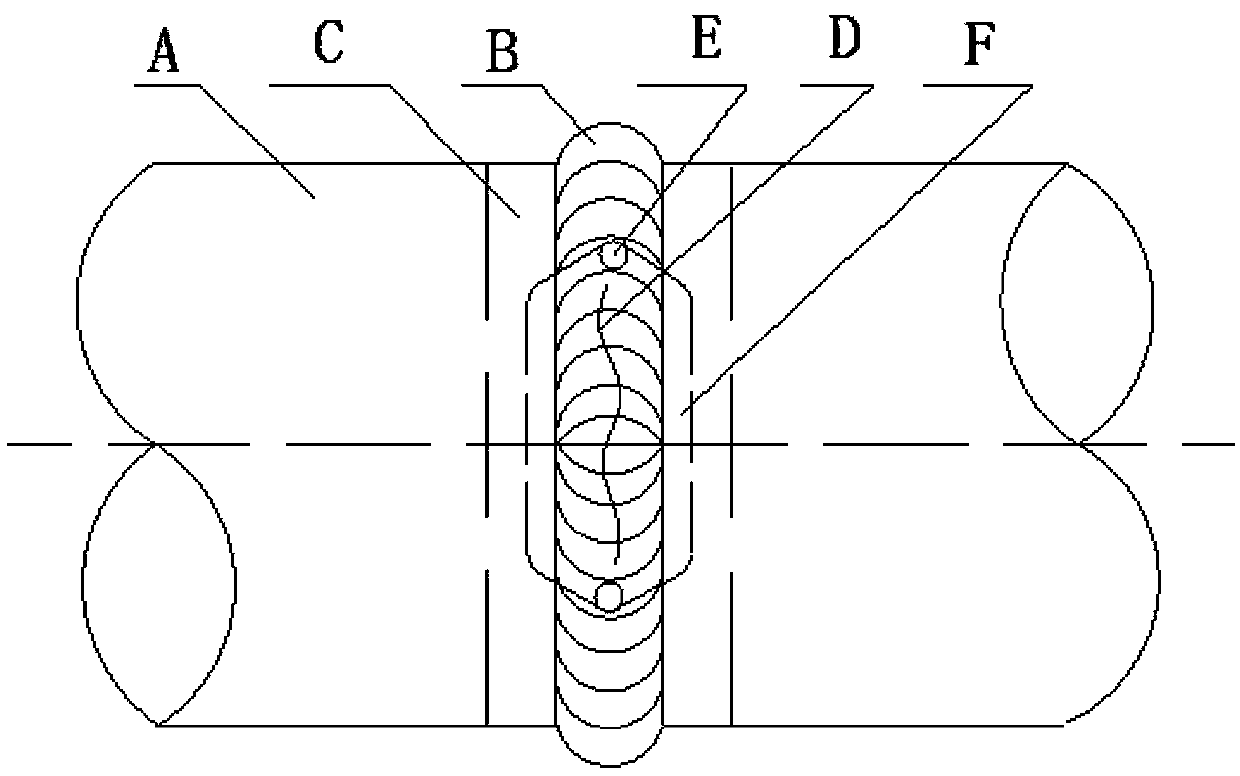

Method for welding rocking arc narrow clearance melting electrode with gas protection and welding torch

InactiveCN101412143AMeet the needs of different welding processes for weldsReduce drive powerElectrode supporting devicesCouplingEngineering

The invention discloses a rocking arc narrow gap consumable electrode gas shielded welding method and a welding torch. The method comprises the following steps: a connecting cable is fixed on an electric brush mechanism and a coupling head; a hollow shaft motor is connected with a straight conducting rod through a shaft joint; a welding wire passes through a center hole of a cable coupling head, and penetrates out a center hole of a current contact nozzle; the lower end of the straight conducting rod is fixed with a connecting piece; and one end of a minor bend conducting rod is connected with the straight conducting rod through the connecting piece, while the other end of the minor bend conducting rod is connected with the current contact nozzle. The hollow shaft motor directly drives the straight conducting rod and the minor bend conducting rod capable of extending into a divided edge of a workpiece to make reciprocating rotation around the central axial line of the welding torch, thereby driving electric arc of the end of the welding wire send from the center hole of the current contact nozzle to make arc rocking in the divided edge of the workpiece so as to realize rocking arc narrow gap welding. The welding torch has the advantages of simple and compact structure, low implementation cost, high reliability of operation, strong practicality, and can adapt requirement of welding process for mean position and spatial position with different welding seams. The welding wire has strong rocking regulation, good directivity of the electric arc, and high welding quality.

Owner:JIANGSU UNIV OF SCI & TECH

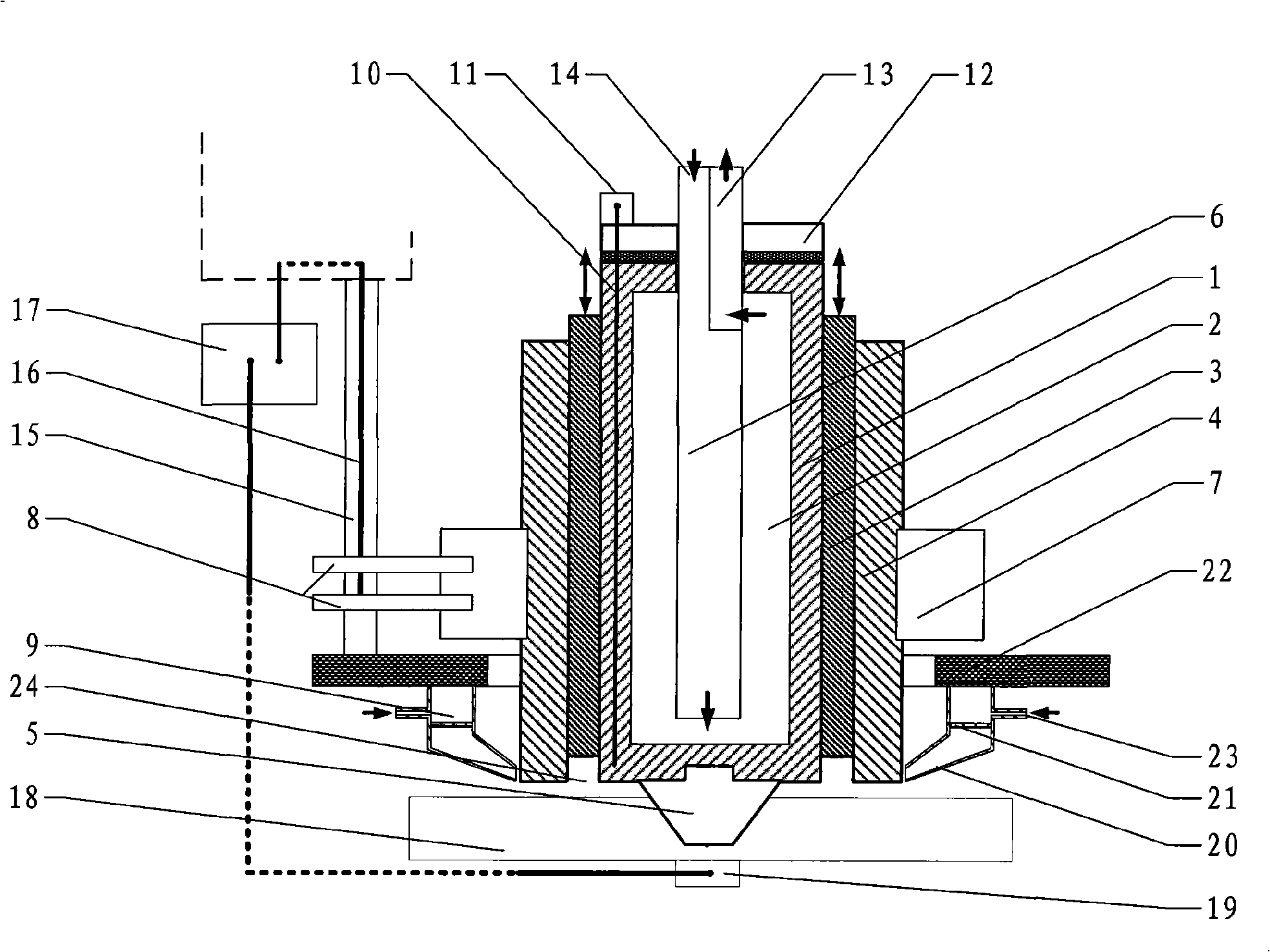

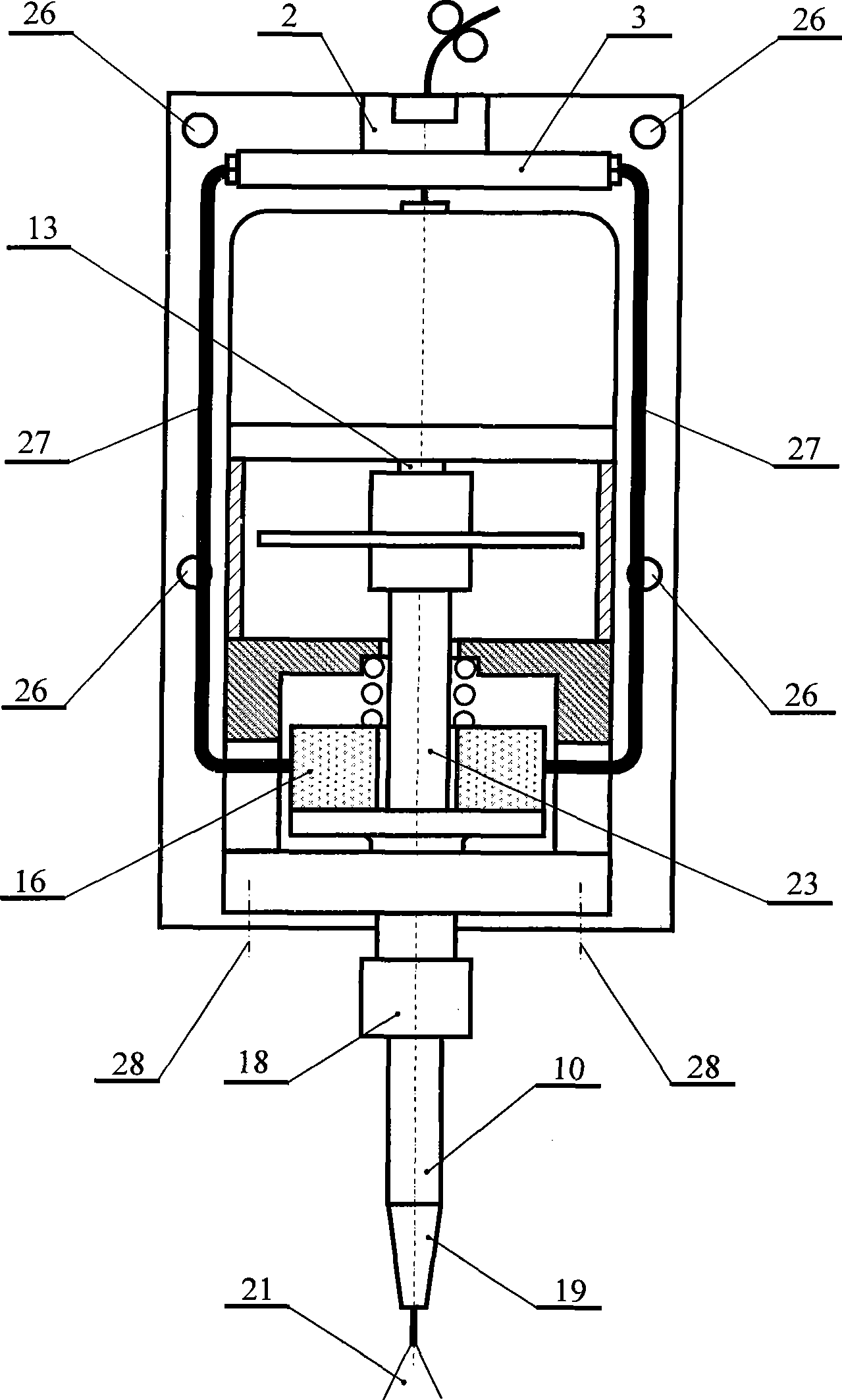

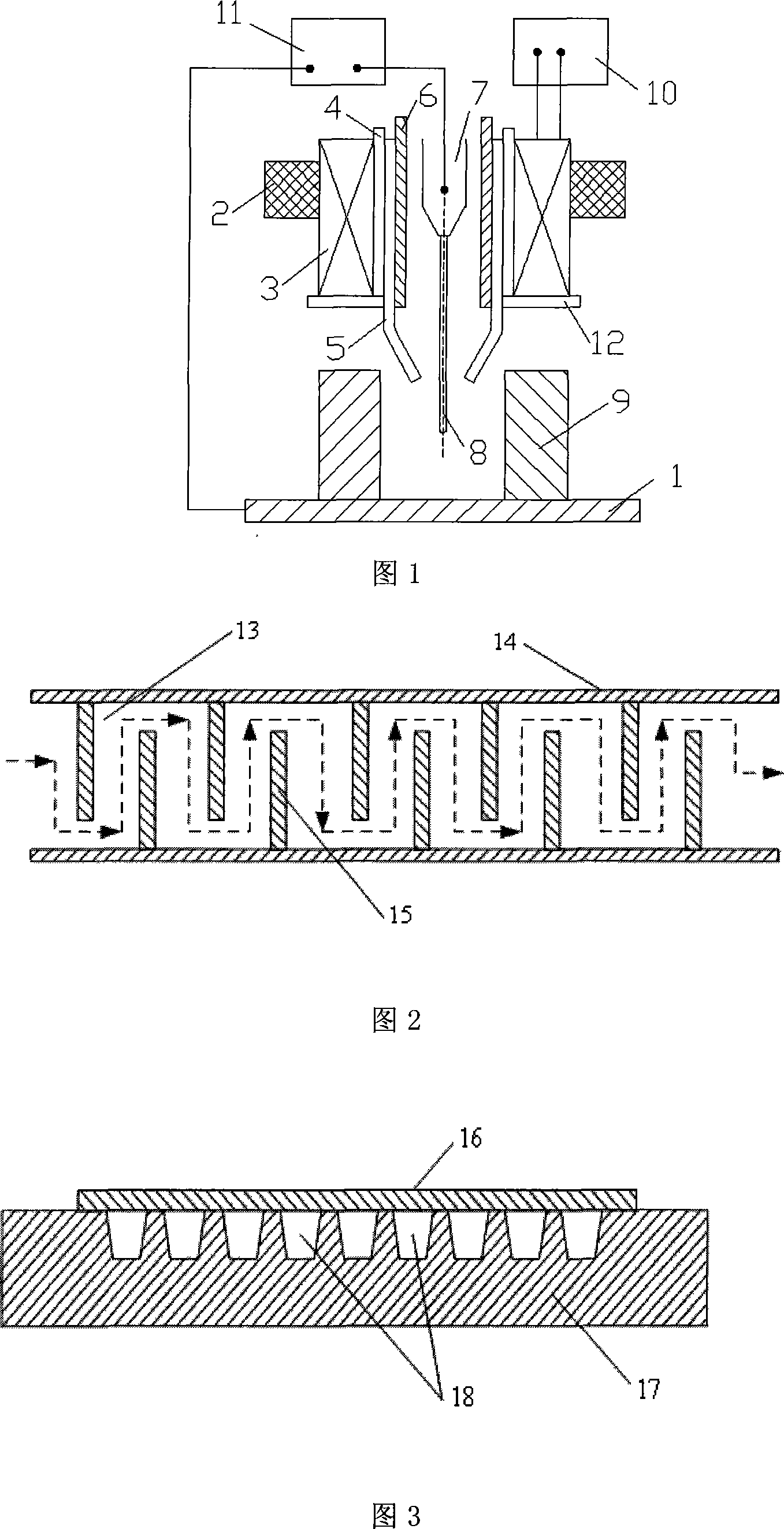

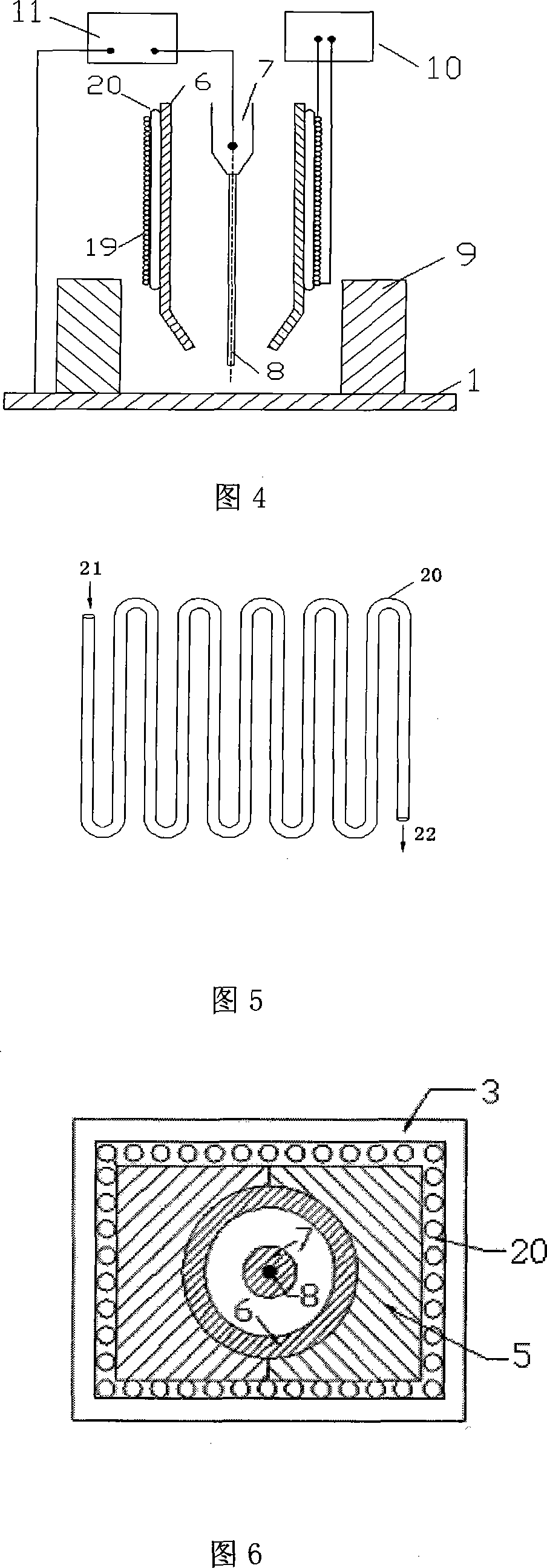

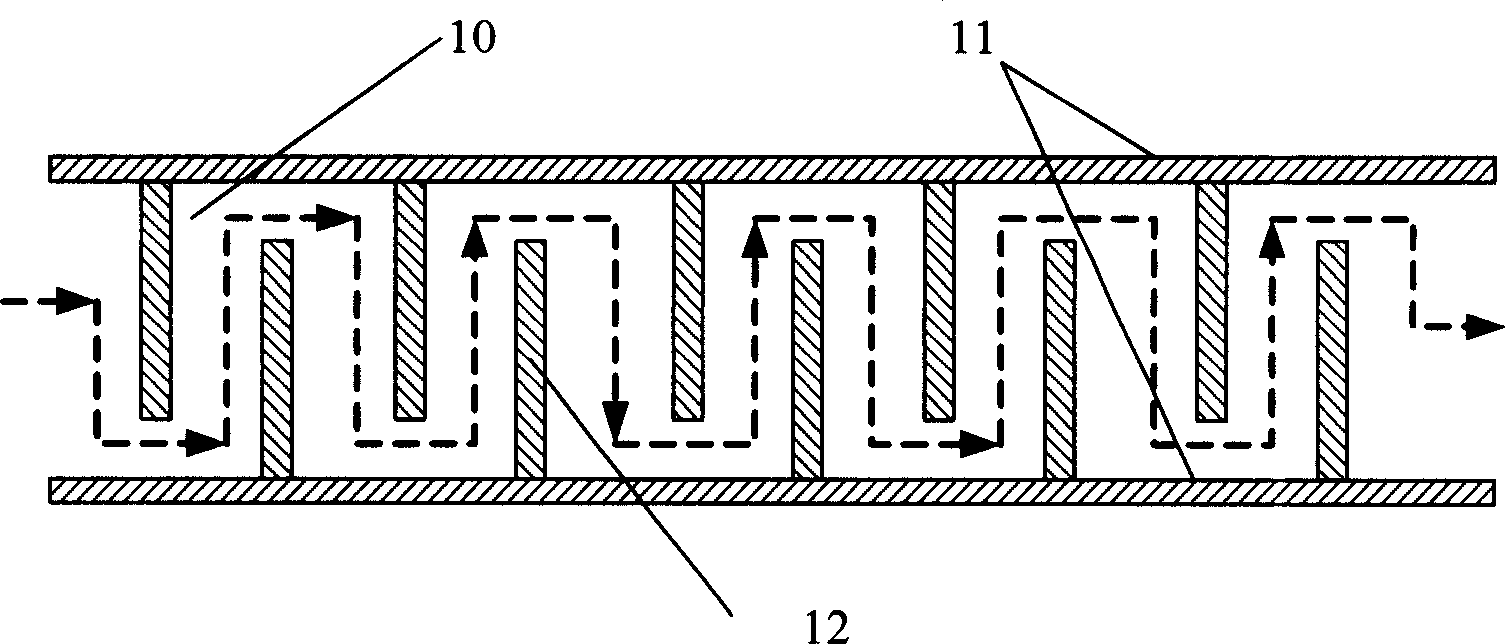

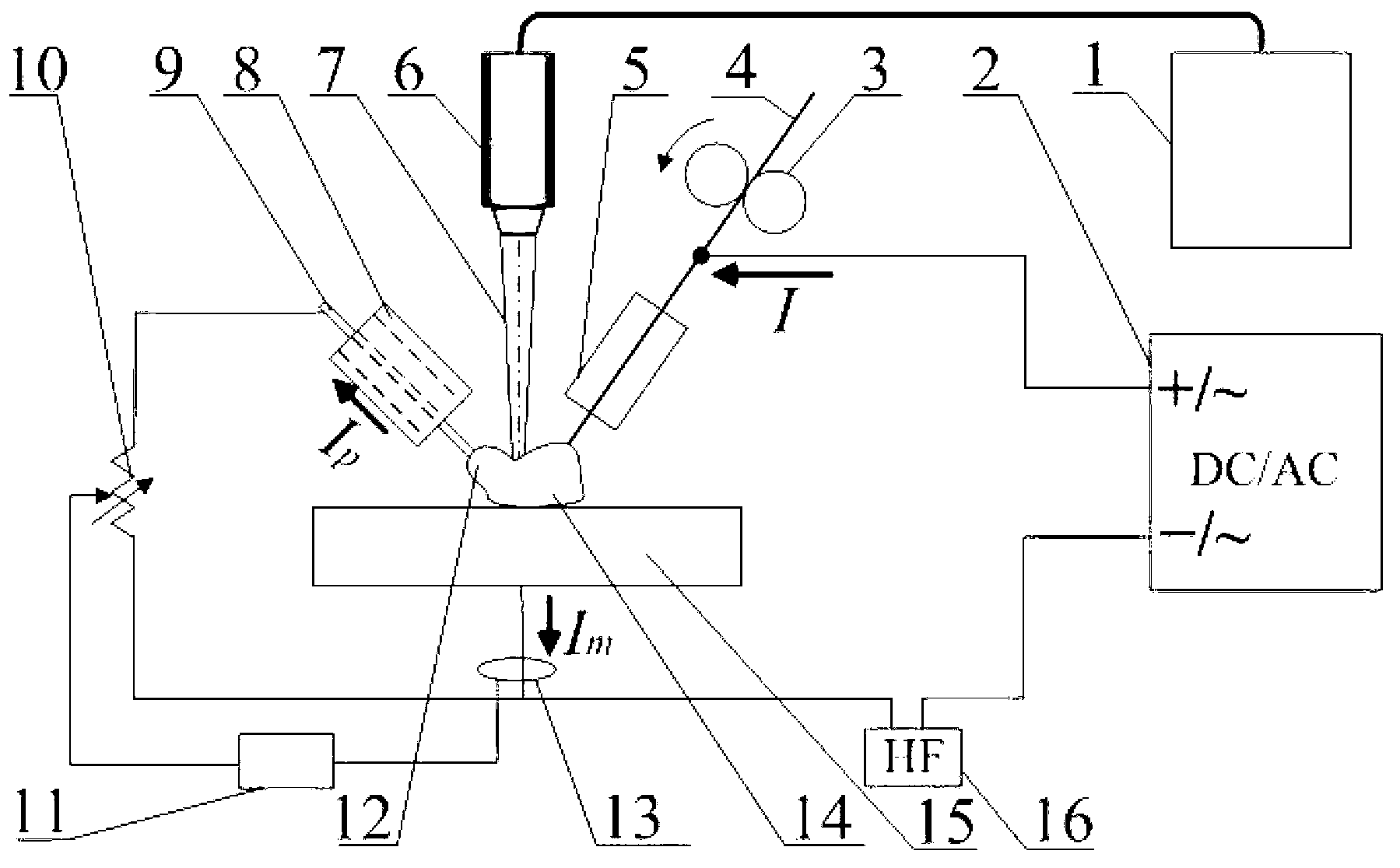

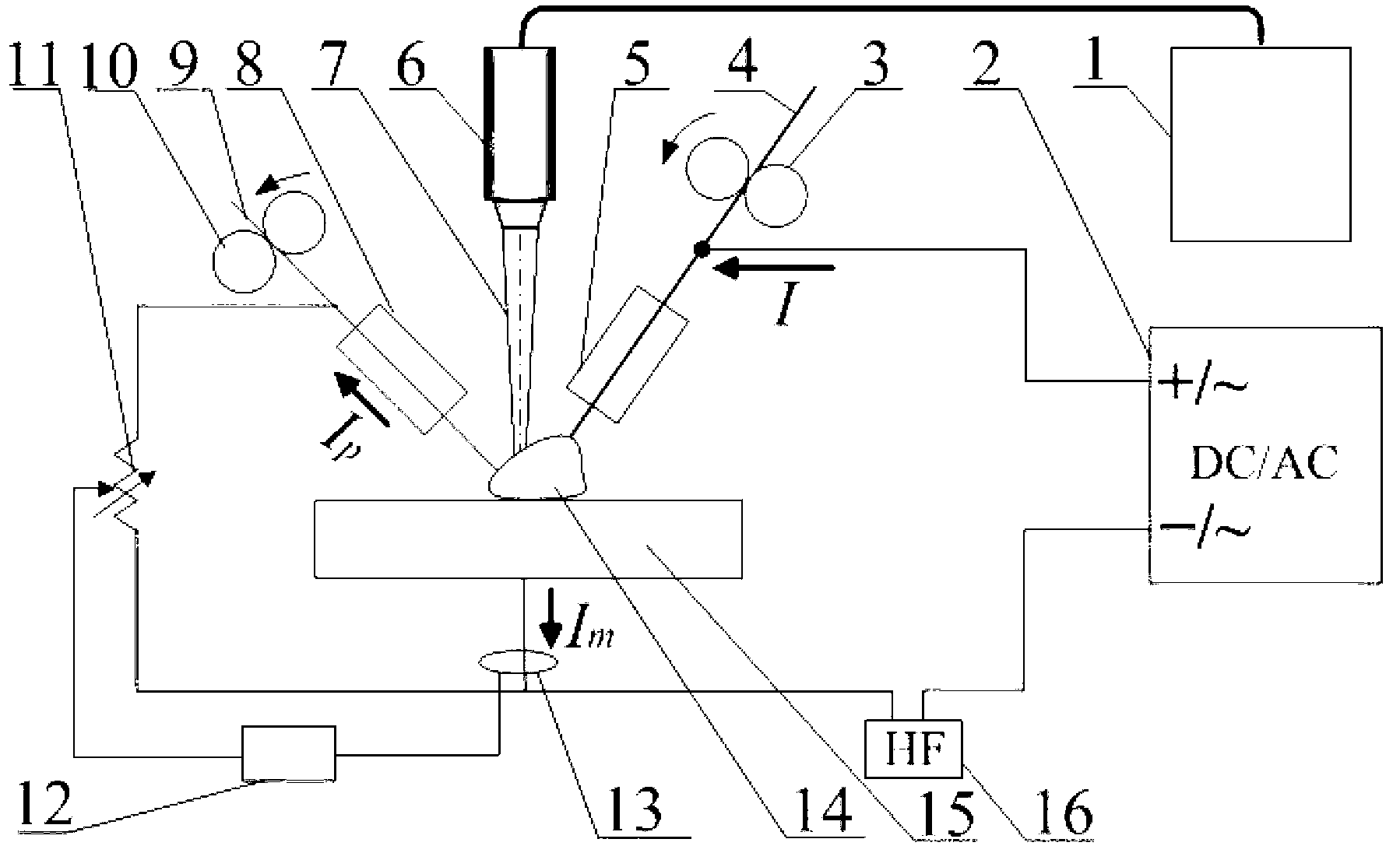

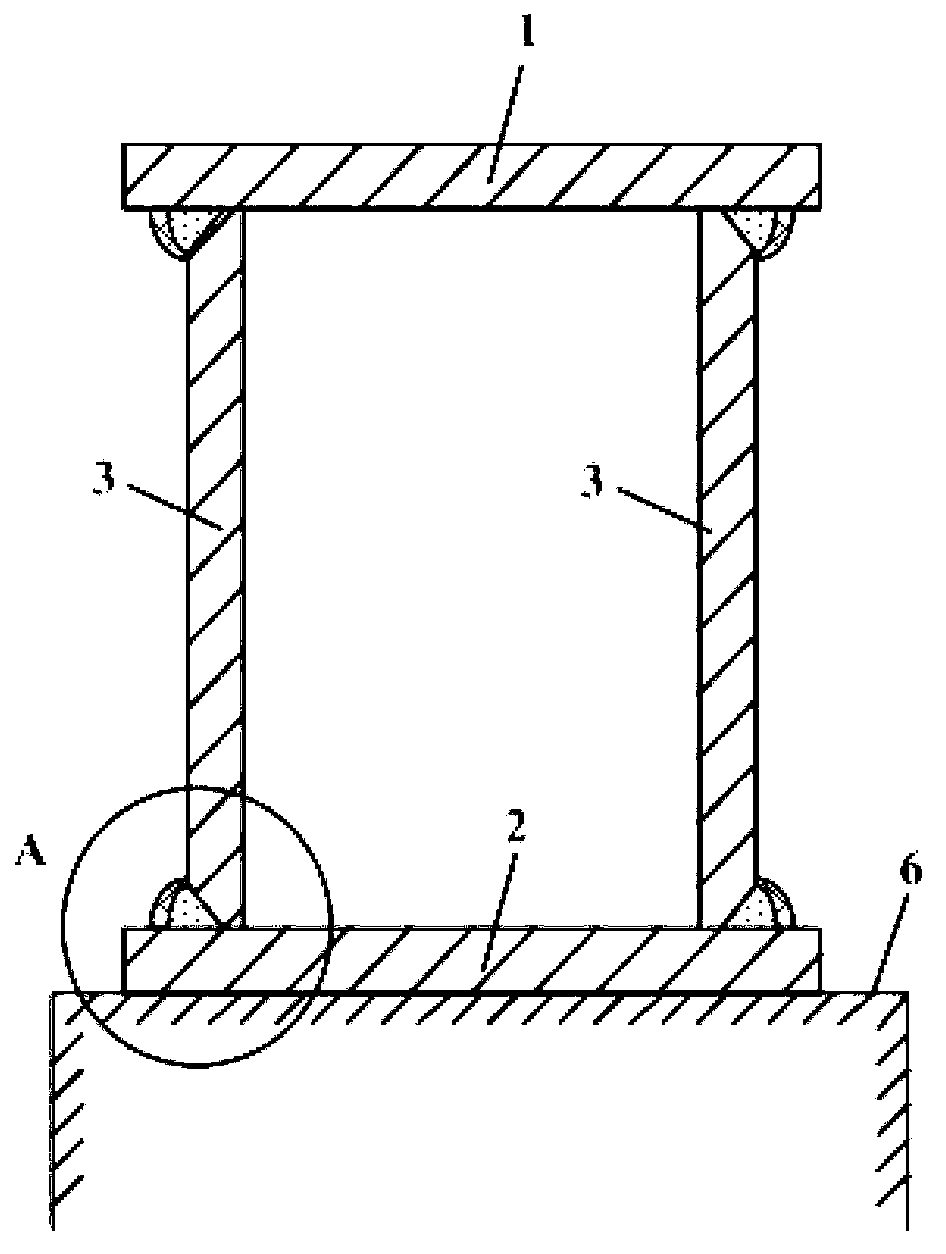

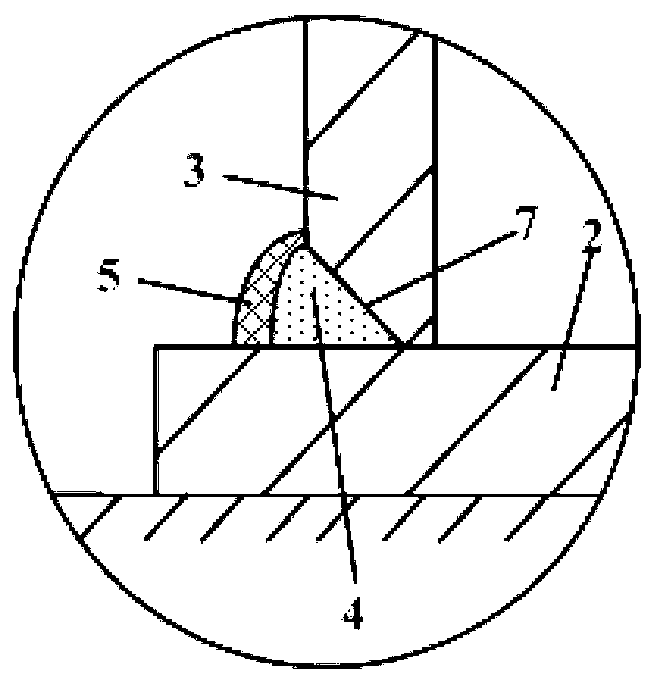

Moderate and high strength large-thickness component electromagnetic controlling narrow gap or ultra-narrow gap pulse efflux molten electrode gas-shield welding method and equipment

InactiveCN101143401AOvercoming arcingImprove crystallizationTransformers/inductances coolingWelding/cutting media/materialsElectric arcEngineering

The invention relates to a gas shielded welding method and device of a narrow gap or a super-narrow gap impulse jet current consumable electrode controlled by electromagnetic of the heavy section part with middle and high strength. The invention uses a magnetic coil (3) to provide excitation current processed by an excitation source, which can generate an extra magnetic field. Under the conditions of narrow gap or super-narrow gap, high feed rate, fused drop spray transfer and impulse welding current, the process of the gas shielded welding of the rotating jet current consumable electrode with high-melting frequency pulse that is controlled by the electromagnetic for the heavy section part with middle and high strength can be realized. The device of the invention comprises the excitation source, excitation equipment, auxiliary equipment and a water cooling system. The excitation equipment is the magnetic coil (3) with or without a conducting core (5). The excitation equipment is fixed on a welding burner (6), which is positioned above a work piece (9). The excitation current provided by the excitation source (10) produces stationary or time-varying electromagnetic mixing magnetic field that has the combination control over the processes of arc welding, wire burn-off, drop transfer, melting bath flow and welding line coagulation, which finally forms the welding line of good quality.

Owner:CHONGQING UNIV

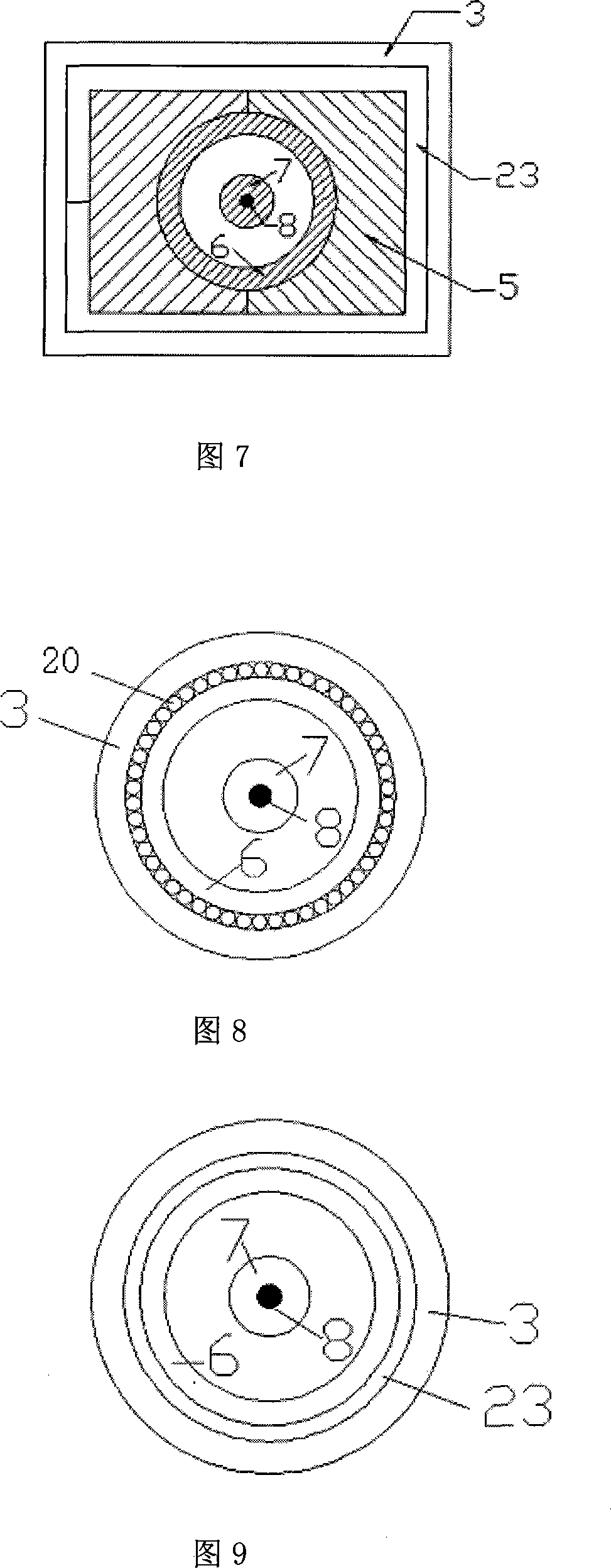

Magnetic control melting electrode welding method, and its developed application, and its universal equipment

A magnetically controlled welding method with consumable electrode features that a pair of exciting coils for upper and lower electrodes are arranged respectively above and under the workpiece to be welded, and an exciting power supply is used to provide the exciting current to said coils and generate an external vertical magnetic field for controlling and perform the welding to the workpiece protected by active gas or CO2. Its welding apparatus has exciting power supply, exciting unit and water cooling system.

Owner:WUHAN UNIV OF TECH

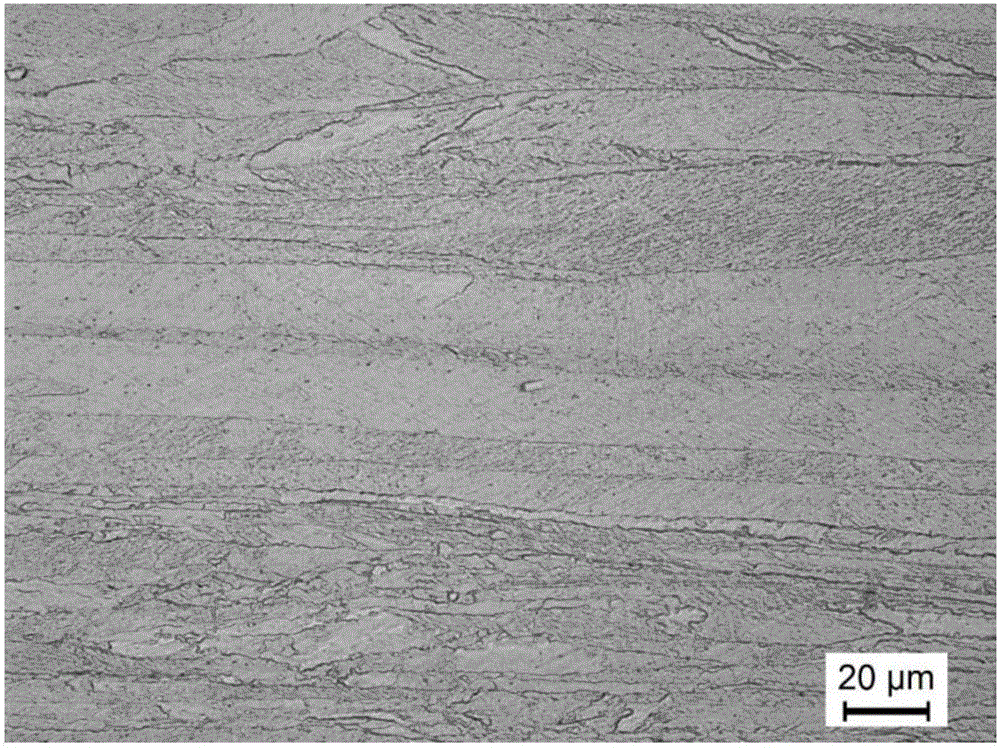

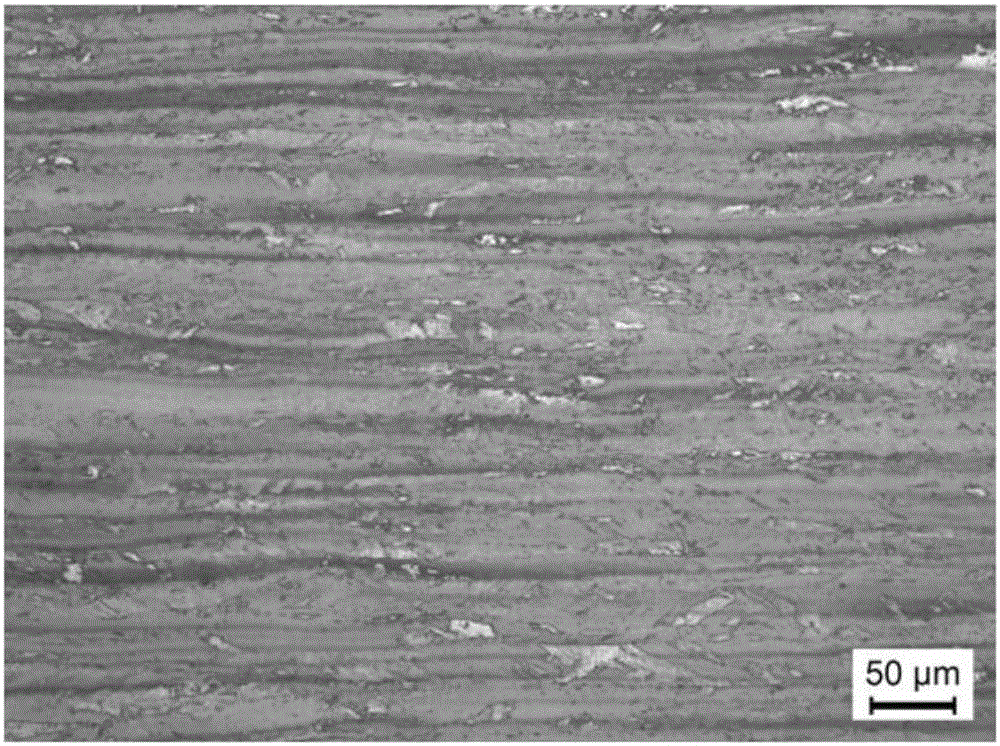

Superhigh strength thick steel plate capable of large-line energy welding and its manufacturing method

ActiveCN1676656AReduce manufacturing costGood welding performanceHigh intensityUltimate tensile strength

This is a super intensive thick steel board which can be welded with jug line power. It contains 0.01-0.06%C, 0.10-0.50%Si, 1.00 -1.40%Mn, 0.010-0.050%Nb, 0.040-0.090%V, 0.60-1.00%Cu, 0.20-0.50%Cr, 0.20-0.50%Mo, 0.50-0.80%Ni, 5ppm-30ppmB, 0.005-0.020%Ti, 0.040-0.070%Als, and remained Fe and inevitable impurity: 0.065<=(%Cu*%V)<=0.085. The producing method includes: casting technique, slab heating, hot rolling, which is asynchronous rolling in austenite non-crystallized area, strain relaxation and direct cooling by quenching. This invention associates well the steel board's high intensity, high ductility and good weldability. It decreases the quantity of alloying agent and reduces the cost for steel board's production. It can as well improve the low-temperature flexibil ity and welability of the steel board, as it realizes welding with jug line power. As a result, it needs no pre-heating to weld steel board above 0 degree Centigrade.

Owner:BAOSHAN IRON & STEEL CO LTD

900MPa high-strength steel preheating-free combined welding method

The invention discloses a 900MPa high-strength steel preheating-free combined welding method. 700-800 MPa low-hydrogen type high-tenacity shielded metal arc welding is adopted for backing welding, then a 900MPa high-tenacity solid wire is matched with Ar+CO2 mixed gas shielded welding for implementing filling welding, and a 800MPa flux-cored wire is matched with CO2 gas shielded welding for cosmetic welding. A crack-free welding joint can be obtained by welding 900MPa high-strength steel through adopting a preheating-free and postweld heat treatment free combined welding process, and a joint region is smooth and clean, and can meet operating requirements on a high-strength steel welding structure for higher bearing capacity because the room temperature tensile strength of weld metal is more than 860MPa and the damping power of a V-shaped notch of the weld metal with the test temperature of 0 DEG C is more than 90J; and meanwhile, the method has welding cost reduced by about 25 percent, simple and convenient operation and easy popularization.

Owner:SHANDONG UNIV

Cu-containing nanophase strengthened easy-to-weld steel and preparation method

The invention provides Cu-containing nanophase strengthened easy-to-weld steel and a preparation method. The Cu-containing nanophase strengthened easy-to-weld steel comprises the following components by weight percent: less than 0.05% of C, 0.1-0.3% of Si, 0.5-1.5% of Mn, less than 0.002% of S, less than 0.004% of P, 1.5-2.5% of Cu, 4-8% of Ni, 0.3-0.8% of Al, 0.2-1% of Mo, less than 1% of Cr, 001-0.04% of Nb, 0.01-0.05% of Ti, 0.01-0.08% of V, and the balance of Fe and inevitable impurity elements. The preparation method comprises the following steps: performing induction smelting and casting under argon protection; heating cast ingots at 1,100-1,200 DEG C for 1-3 h, directly performing hot rolling at the initial temperature of 1,050-1,150 DEG C and the final temperature of 950 DEG C, and performing super-speed high-pressure water cooling after final rolling, wherein the hot rolling deformation is 50-90%; and selectively conducting solution and aging heat treatment on a rolled steel plate to obtain high-strength high-toughness easy-to-weld steel. The alloy steel is high in strength, good in plasticity, excellent in low-temperature impact toughness and easy to weld. Besides, the machining process is high in controllability, the cost is low and the operation is simple.

Owner:HARBIN ENG UNIV

Automatic TIG gasket-free single-side welding and double-side molding process for aluminum alloy

InactiveCN102079003AReduce distortionImprove welding qualityArc welding apparatusWorkpiece edge portionsUltimate tensile strengthStainless steel wire

The invention discloses an automatic tungsten inert gas (TIG) gasket-free single-side welding and double-side molding process for aluminum alloy, which comprises the following steps of: selecting welding equipment and materials, performing assembly and clearing, performing tack welding, clearing grease dirt and oxide films in 50 millimeters of two sides of a groove by using acetone and a stainless steel wire wheel, placing a shell on a welding operation rack, regulating a welding gun to be aligned with the groove, preheating, welding a first layer without adding welding wires, clearing the oxide film on the surface of the seam by using the stainless steel wire wheel after the first layer is welded to expose metal luster, welding a second layer, adding the welding wires for covering the surface, and making the welding direction of the welding gun and a cylinder swing vertically to form a seam. The process has the advantages of high efficiency, low labor intensity, high welding quality, attractive appearance, no undercut or arc crater cracks, workpiece deformation resistance and high seam qualification rate.

Owner:陕西国德电气制造有限公司

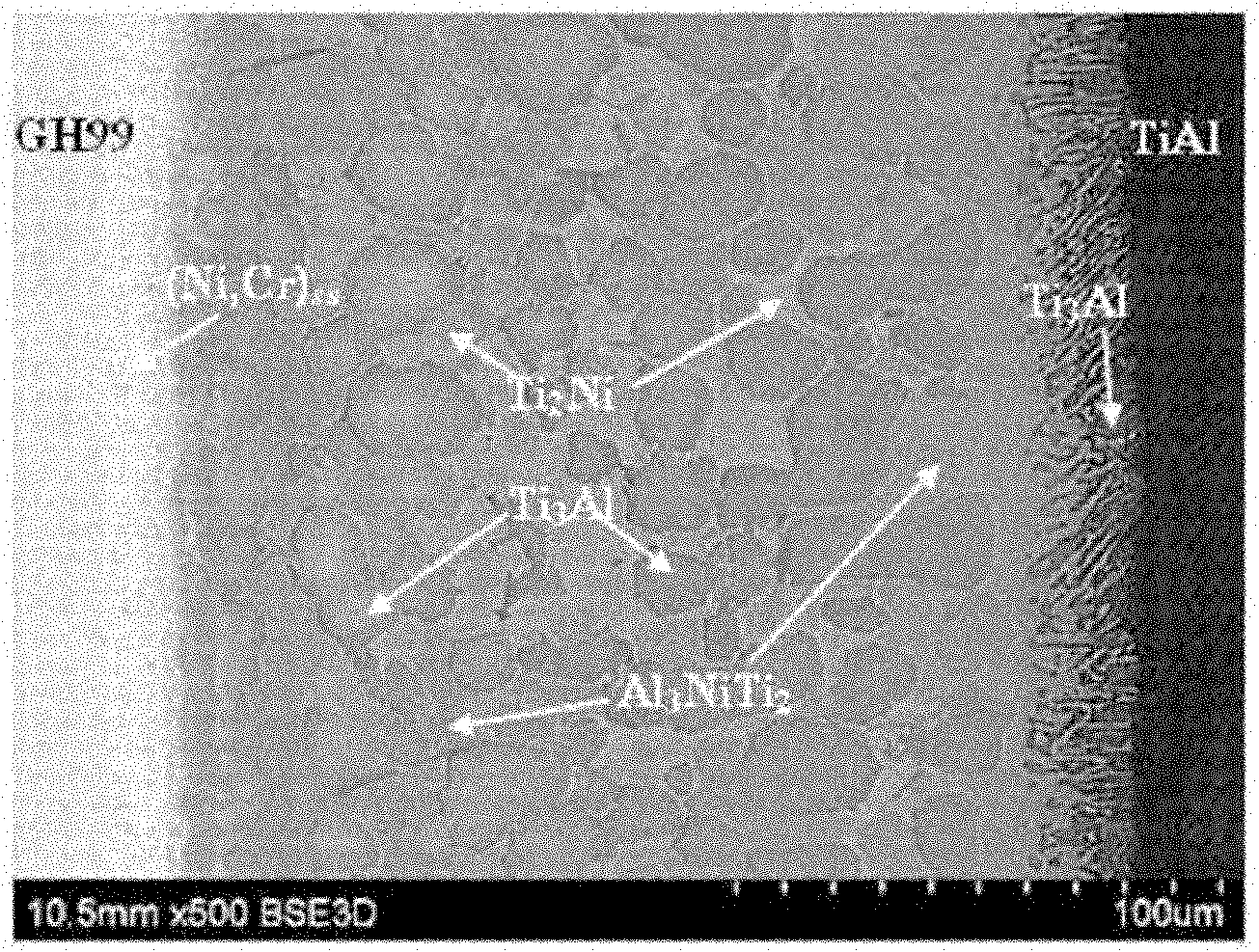

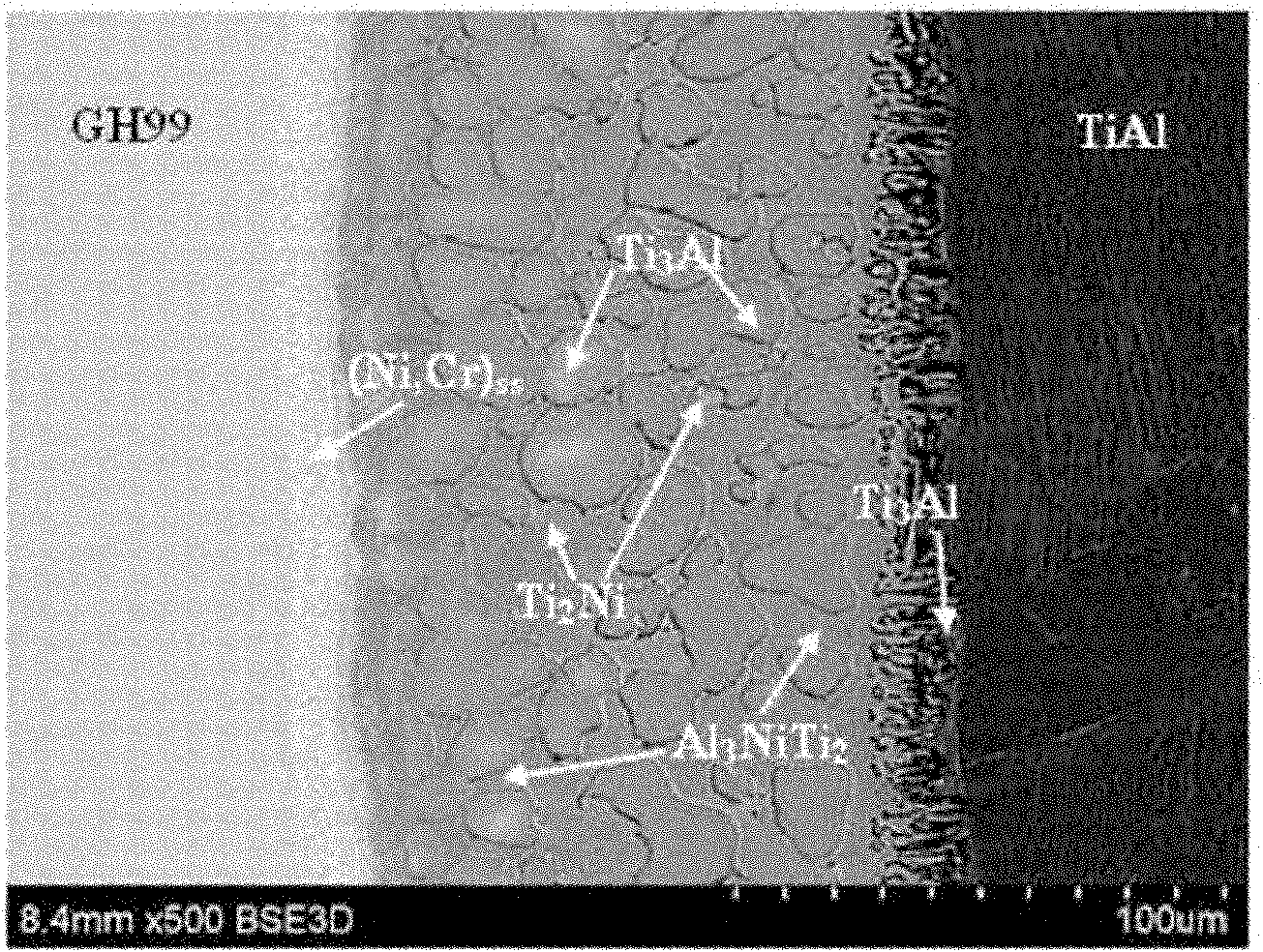

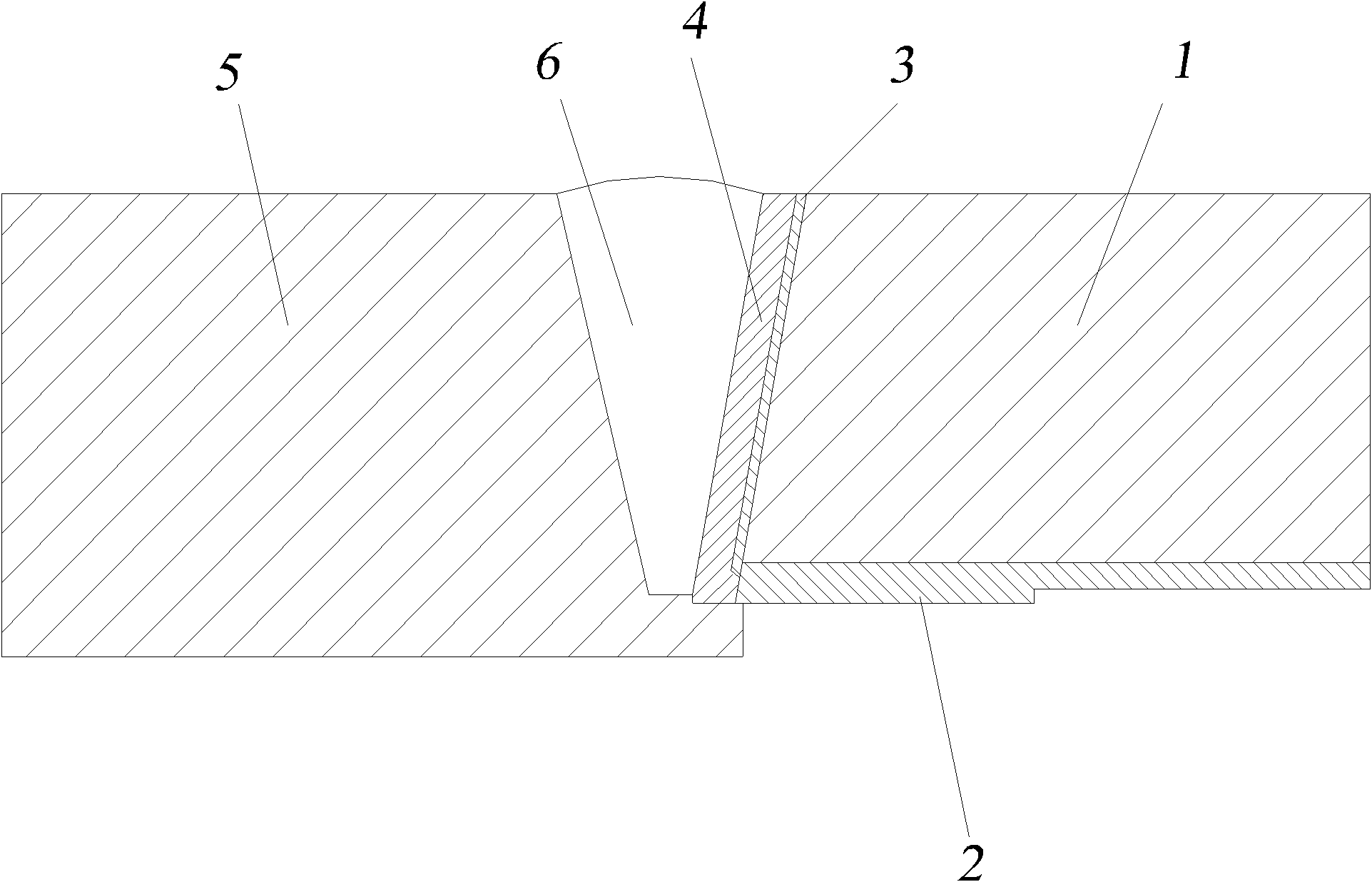

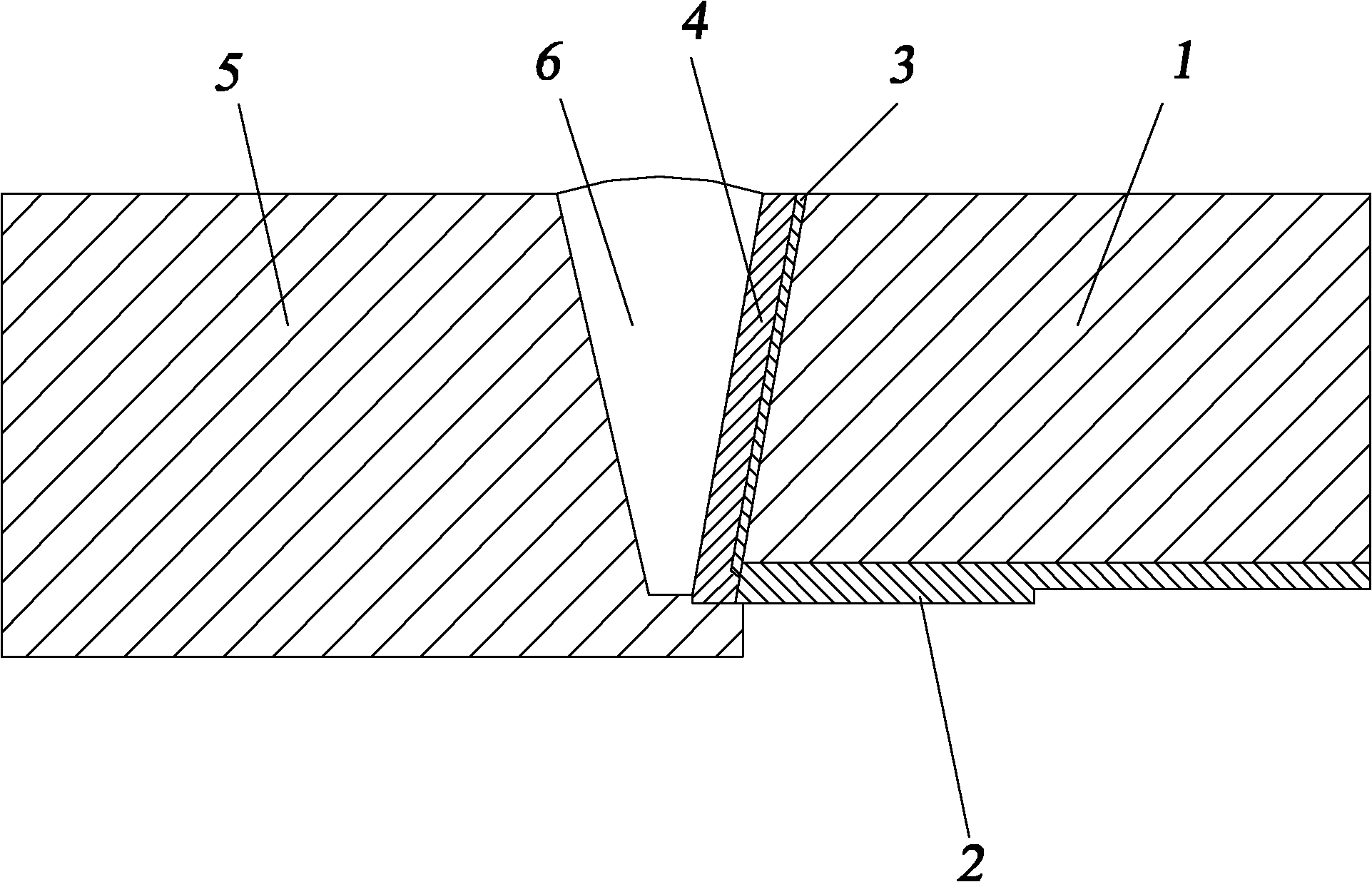

Contact reaction brazing connection method for TiAl based alloy and Ni based high-temperature alloy

ActiveCN101972877AAchieving a soldered connectionSimple processSoldering apparatusContact reactionsSuperalloy

The invention discloses a contact reaction brazing connection method for TiAl based alloy and Ni based high-temperature alloy, relating to a welding method for the TiAl based alloy and the Ni based high-temperature alloy and solving the problems of the traditional diffusion connection method for the TiAl based alloy and the Ni based high-temperature alloy that the process is complicated, the cost is high, the connection thermal cycle period is long, the efficiency is low, the requirement on the to-be-welded surface of a weldment is high, a silver brazing joint is not resistant to high temperature, and the brittle phase of high-temperature brazing is easy to aggregate and grow. The method comprises the steps of: treating the to-be- surface of a Ti foil, the TiAl based alloy and the Ni based high-temperature alloy, placing the Ti foil between the TiAl based alloy and the Ni based high-temperature alloy to form a weldment to be welded, and welding the weldment to be welded in a vacuum brazing furnace. The joint obtained in the invention has high shear strength up to 240-300MPa, and the shear strength is 180-210MPa at the high temperature of 800 DEG C, and the joint can be used as a hot end part for aerospace under high-temperature environment.

Owner:HARBIN INST OF TECH

Nuclear island primary device connection tube safe end dissimilar metal welding technology

ActiveCN101890562AMake sure the welding is successfulTake over reliableArc welding apparatusButt weldingSurface layer

The invention relates to a nuclear island primary device connection tube safe end dissimilar metal welding technology which comprises the following steps: selection of form of a welding groove: selecting a single groove form as the groove form of a primary device connection tube; overlay welding of stainless steel: overlay-welding a stainless steel anti-corrosion layer on the inner wall of the primary device connection tube; overlay welding of isolating layer: overlay-welding an isolating layer on the end face of the primary device connection tube by carrying out TIG overlay welding with hot wire to obtain a transition layer and carrying out submerged arc overlay welding to obtain a surface layer; butt welding: butting the safe end with the surface layer at the end face of the primary device connection tube in a submerged arc welding mode; and postweld heat treatment. The invention reduces the welding cost and the labor intensity of welders, and ensures the successful welding of the safe end structure, thereby laying foundation for reliable welding of the safe end and the primary device connection tube.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

CO2 gas protection welding process of 800 MPa high-strength steel

InactiveCN102179601AUniform strengthUniform hardnessArc welding apparatusWelding/cutting media/materialsThumb oppositionOperability

The invention discloses a CO2 gas protection welding process of 800 MPa high-strength steel. The CO2 protection welding process is characterized by comprising the following steps of: (1) machining a joint: machining an X-shaped groove on the joint; (2) using a solid welding wire with the diameter of 1.2 mm and the tensile strength of 800 MPa, wherein the solid welding wire comprises the following chemical components in percentage by weight: 0.04-0.10% of C, 0.30-0.80% of Si, 1.30-2.0% of Mn, 0.40-1.0% of Ni, 0.20-0.50% of Cr, 0.20-0.60% of Mo, 0.30-0.80% of Cu, 0.05-0.20% of Ti, 0.002-0.010% of B, less than and equal to 0.020% of P, less than and equal to 0.015% of S, less than and equal to 0.03% of Als, and the balance of Fe and inevitable impurities; (3) setting a welding mode: adopting CO2 gas protection welding and a DC power supply opposition method; and (4) welding: carrying out one-side welding with back formation on a first welding line, and then carrying out multilayer multipass welding, wherein interlayer temperature is less than and equal to 160 DEG C. The invention has the advantages of simple process, high operability and low welding energy consumption and welding cost and can be widely used for the technical fields of the gas protection welding of the high-strength steel.

Owner:武钢集团有限公司

Special connector crack repair process method

ActiveCN104209624AIncrease usageQuality improvementArc welding apparatusWelding/cutting media/materialsHeat-affected zoneEngineering

The invention provides a special connector crack repair process method, and belongs to the technical field of welding. Ray and coloring detection is conducted on a cracking welding joint. Performance restoring is conducted on the thermal processing area of the cracking welding joint. A cracking stopping hole is drilled close to an endpoint of the crack. The cutting range is widened, cracks are removed thoroughly at a time, and the crack cutting base material heat-affected zone is kept at a certain temperature. Grooves are machined, and coloring detection is conducted on the groove faces. Selected welding material can regulate alloy elements in the welding joint. Argon tungsten-arc welding is adopted, small-diameter welding wires are adopted, and the welding base material heat-affected zone is kept at a certain temperature. Multi-layer and multi-path build up welding is conducted on the groove faces. An arc pit is filled with normative collection arcs so that the arc pit can be prevented from cracks and other defects can be prevented, polishing and repairing are conducted on each connector so that the connectors can be well fused without causing defects, and connectors on all layers are staggered. A welding gun evenly swings so that it can be ensured that the groove openings in the two sides are well fused. The temperatures between the layers are controlled, and post thermal treatment is conducted on the repaired part according to the material after welding is conducted.

Owner:PETROCHINA CO LTD

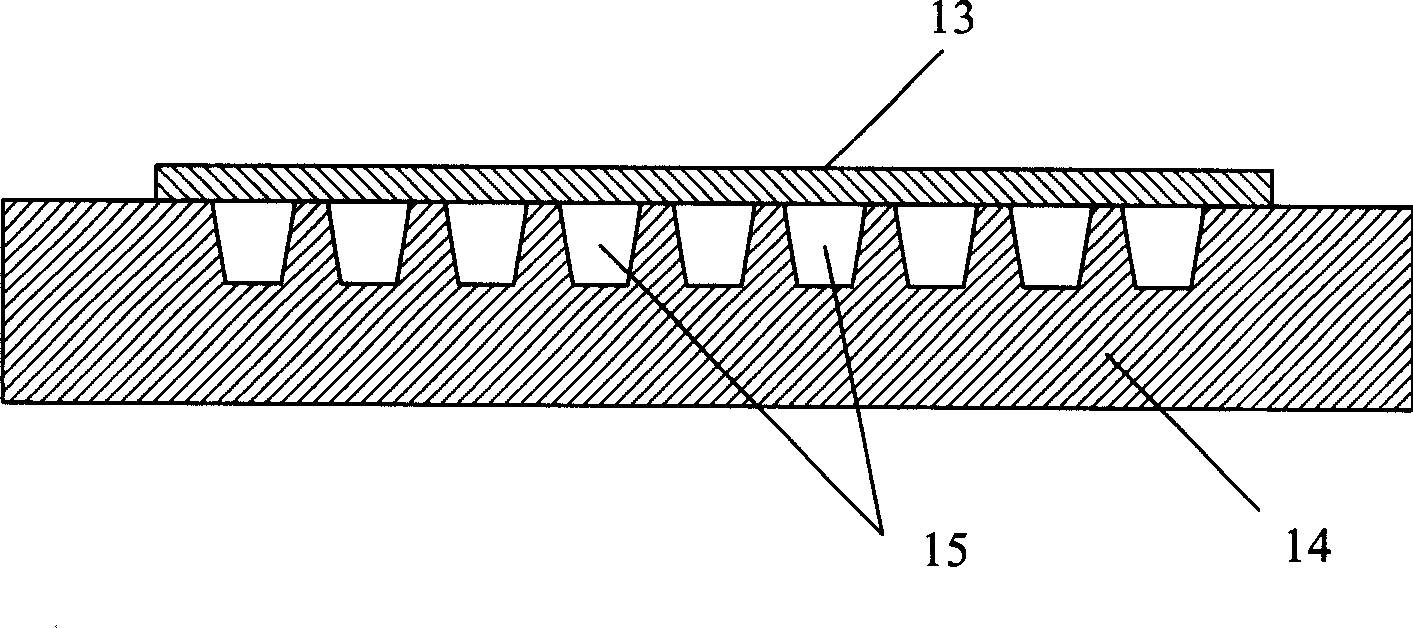

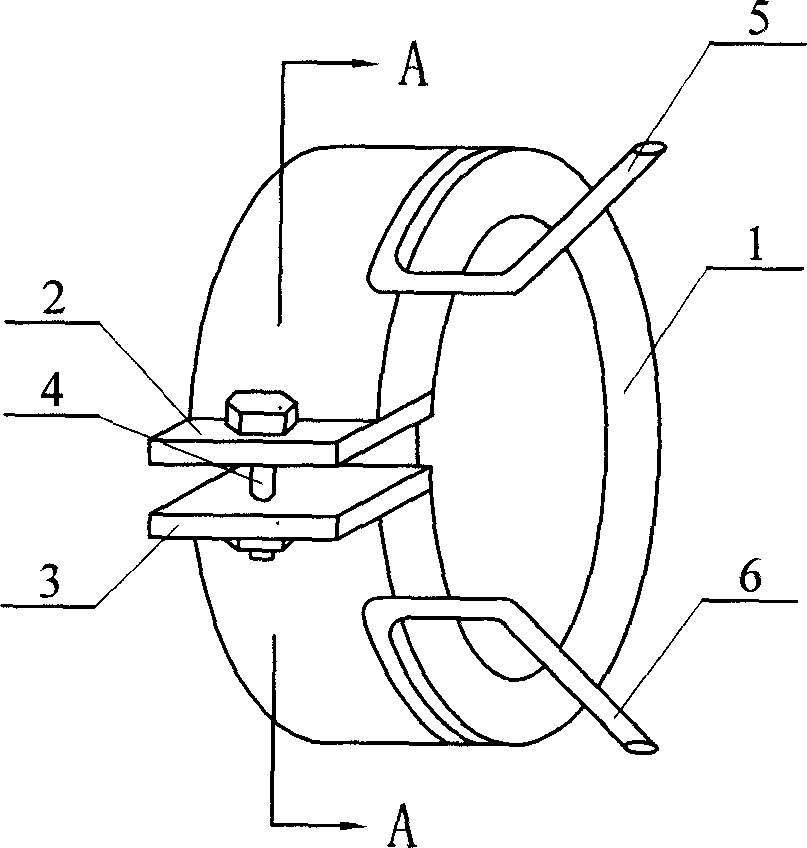

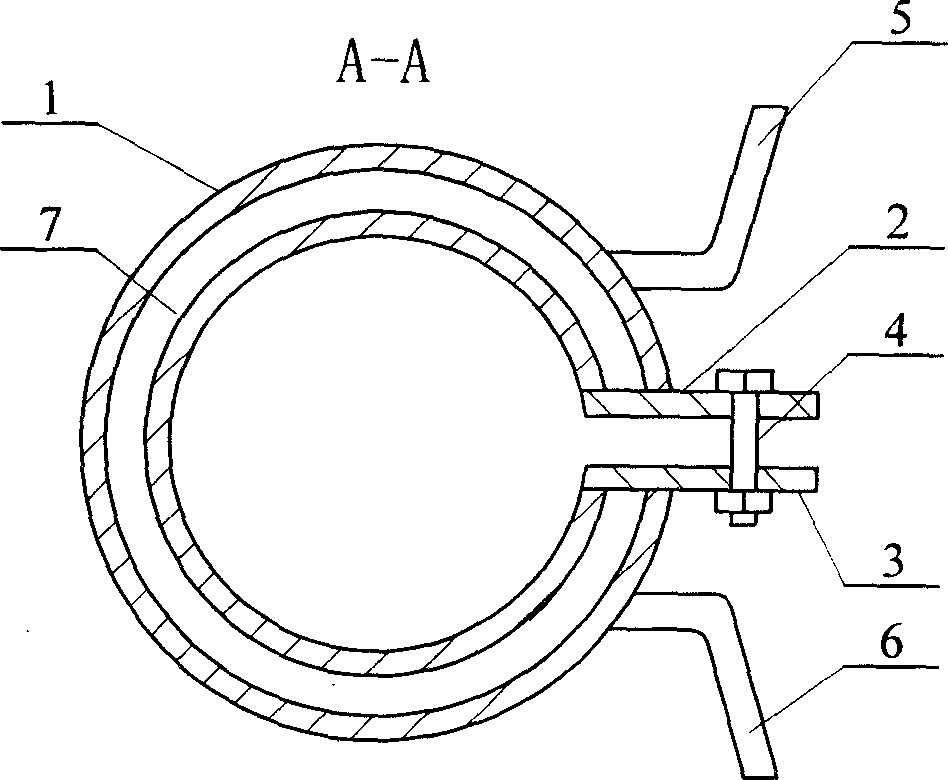

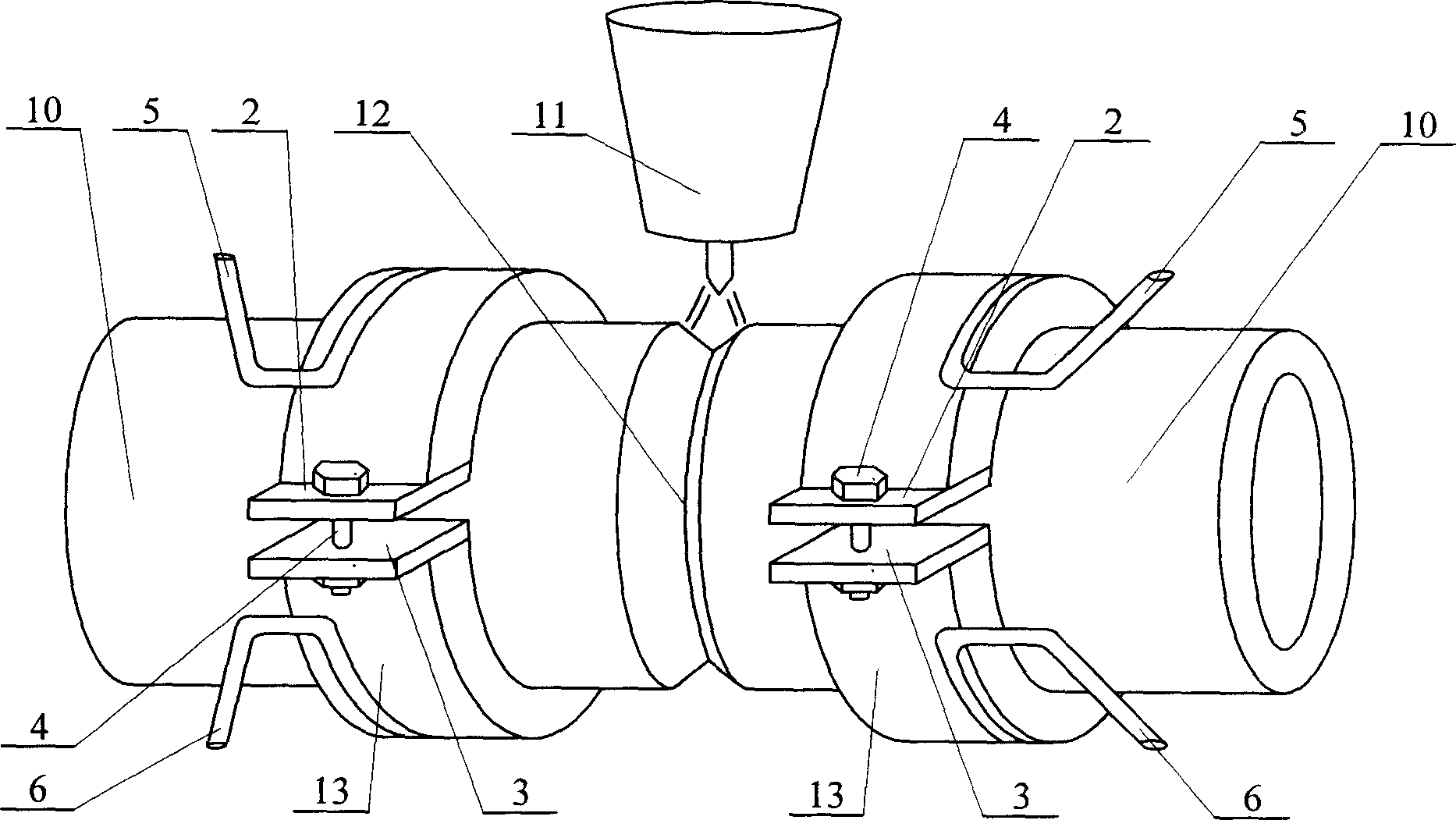

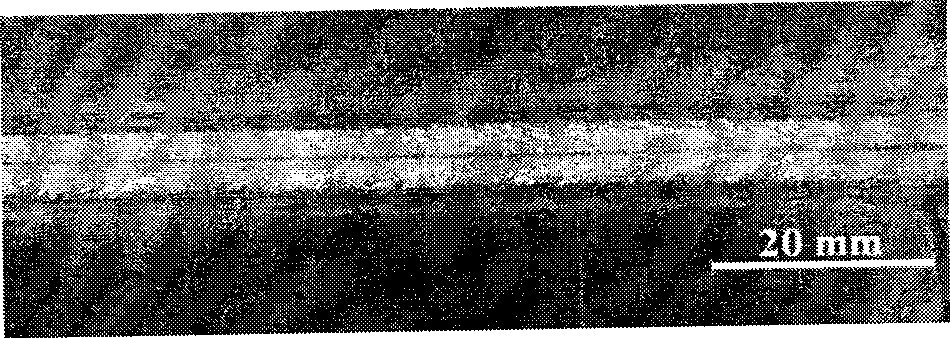

Water cooling jacket for titanium alloy tube ring seam by tungsten argon arc welding and seam following cooling welding method

The present invention relates to water cooling jacket for welding and corresponding welding method by means of using the water cooling jacket. The water cooling jacket has upper connecting plate with one side plane connected hermetically with the upper end of the C-shaped sleeve, and lower connecting plate with one side plane connected hermetically with its lower end. The welding method includes screwing the water cooling jacket tightly to the titanium alloy tube. The water cooling jacket of the present invention has simple structure and high cooling effect, and the welding and cooling method is simple, high in weld seam cooling speed, high welding quality, high welding efficiency, less argon consumption and low welding cost.

Owner:HARBIN INST OF TECH

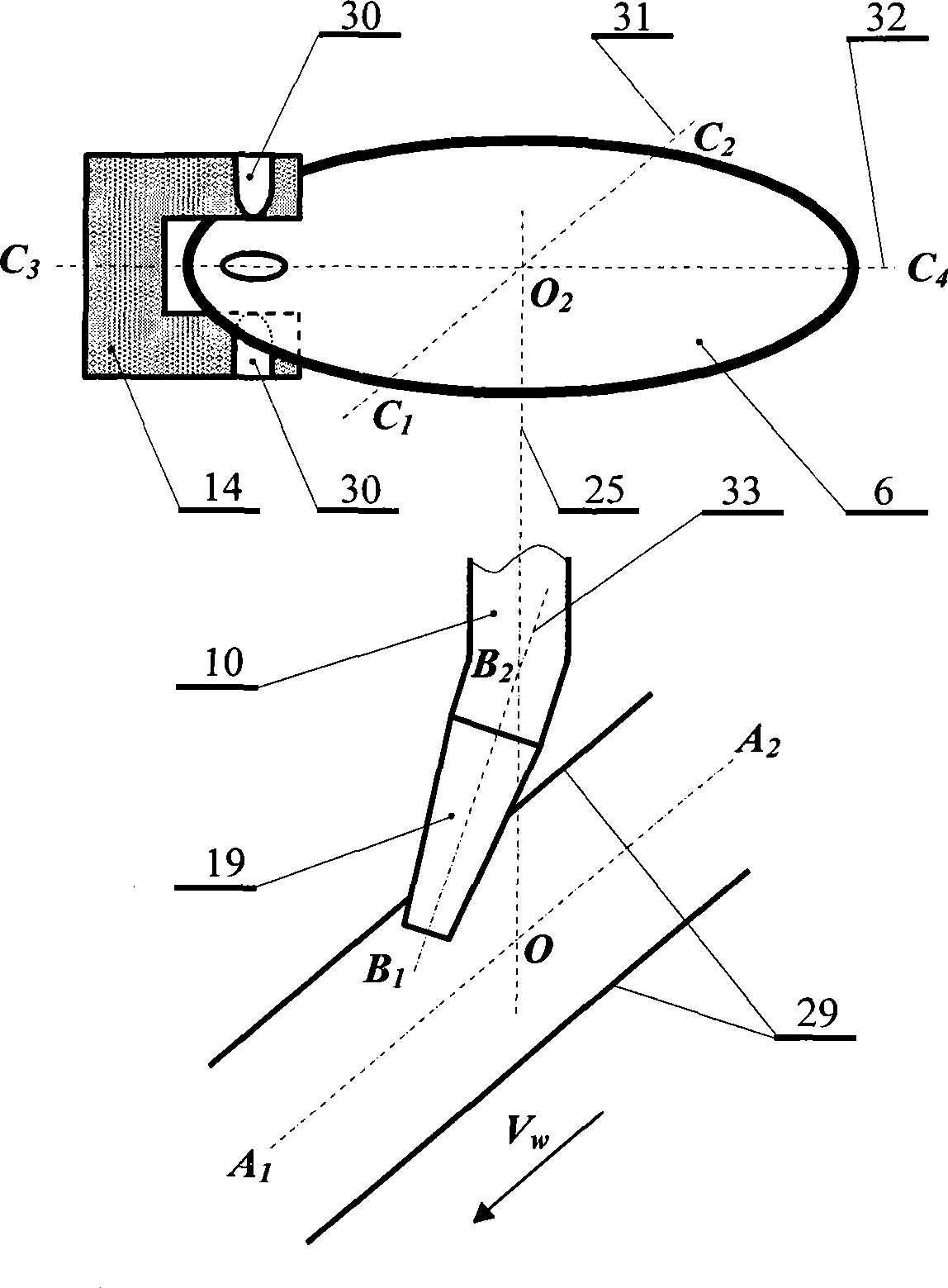

Narrow gap laser-arc hybrid welding method using filler wire

InactiveCN101474726AImprove welding efficiencySimple welding processLaser beam welding apparatusHigh power lasersEngineering

The invention relates to a narrow gap laser-arc composite welding method adopting a filler wire, belonging to the technical field of laser materials processing. The method adopts a high-power laser and an laser arc hybrid, and the arrangement mode thereof is that a laser bean and a welding wire are arranged in opposite directions corresponding to an electric arc, wherein the laser bean enters slantwise from the front part of the electric arc, and the welding wire is led into a divided edge gap from the rear of the electric arc, and after fusing the welding wire, a composite thermal source fills the gap, thereby realizing the single pass welding shaping of a work piece. The method fully utilizes the penetration fusion property of the laser and the high filling efficiency of the electric arc; and under the mutual actions of laser and arc, the stability of a welding process is improved, and the welding efficiency is increased.

Owner:BEIJING UNIV OF TECH

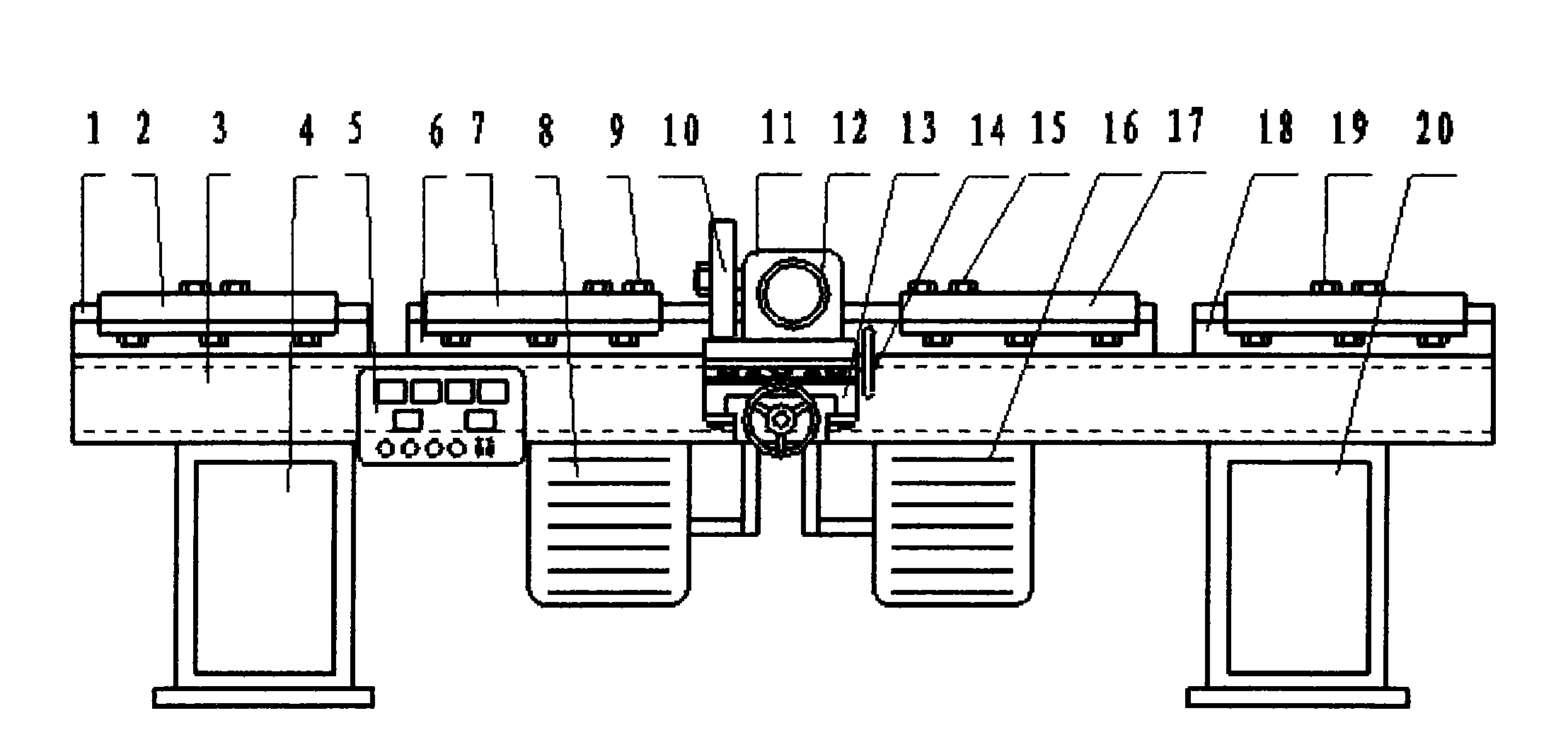

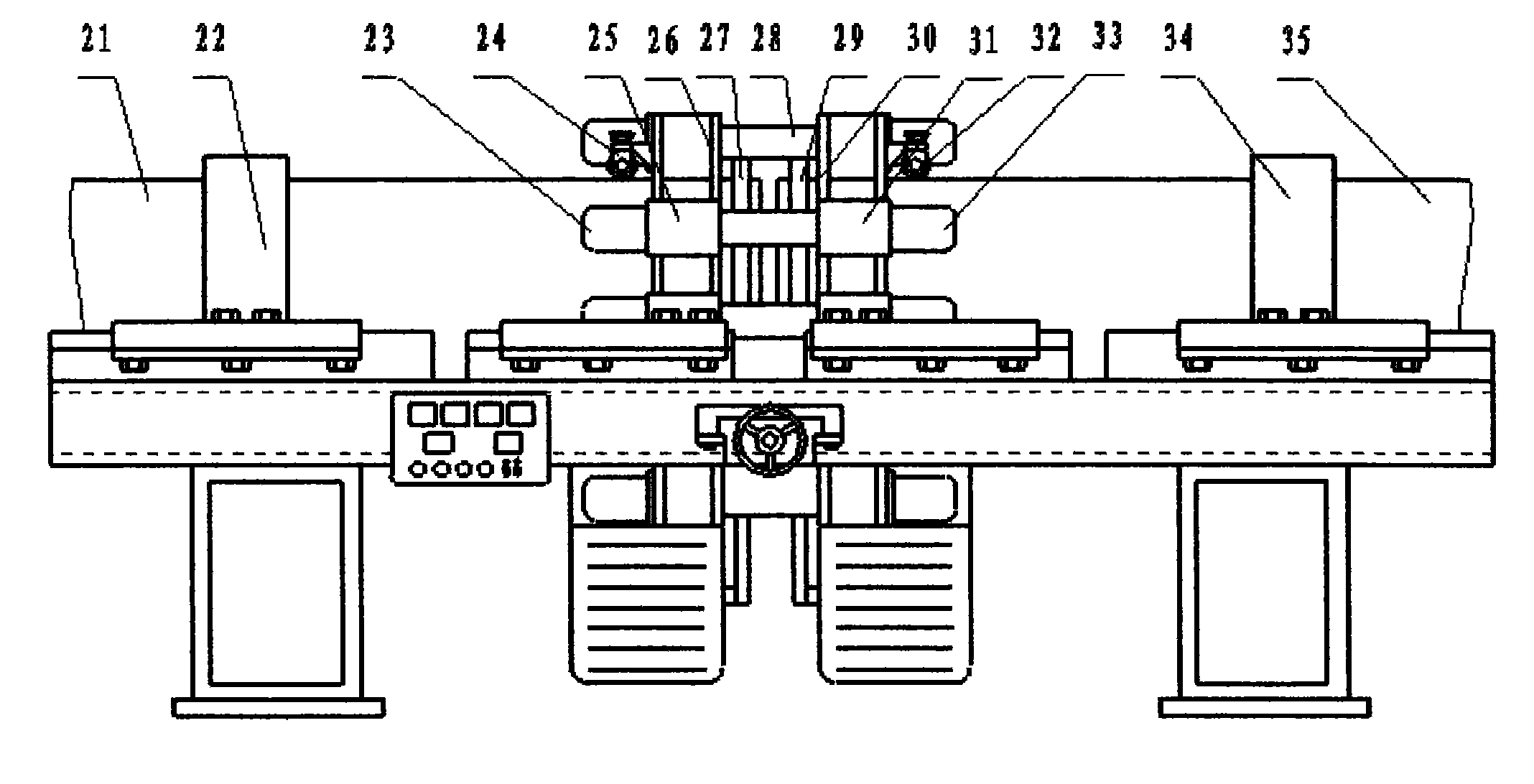

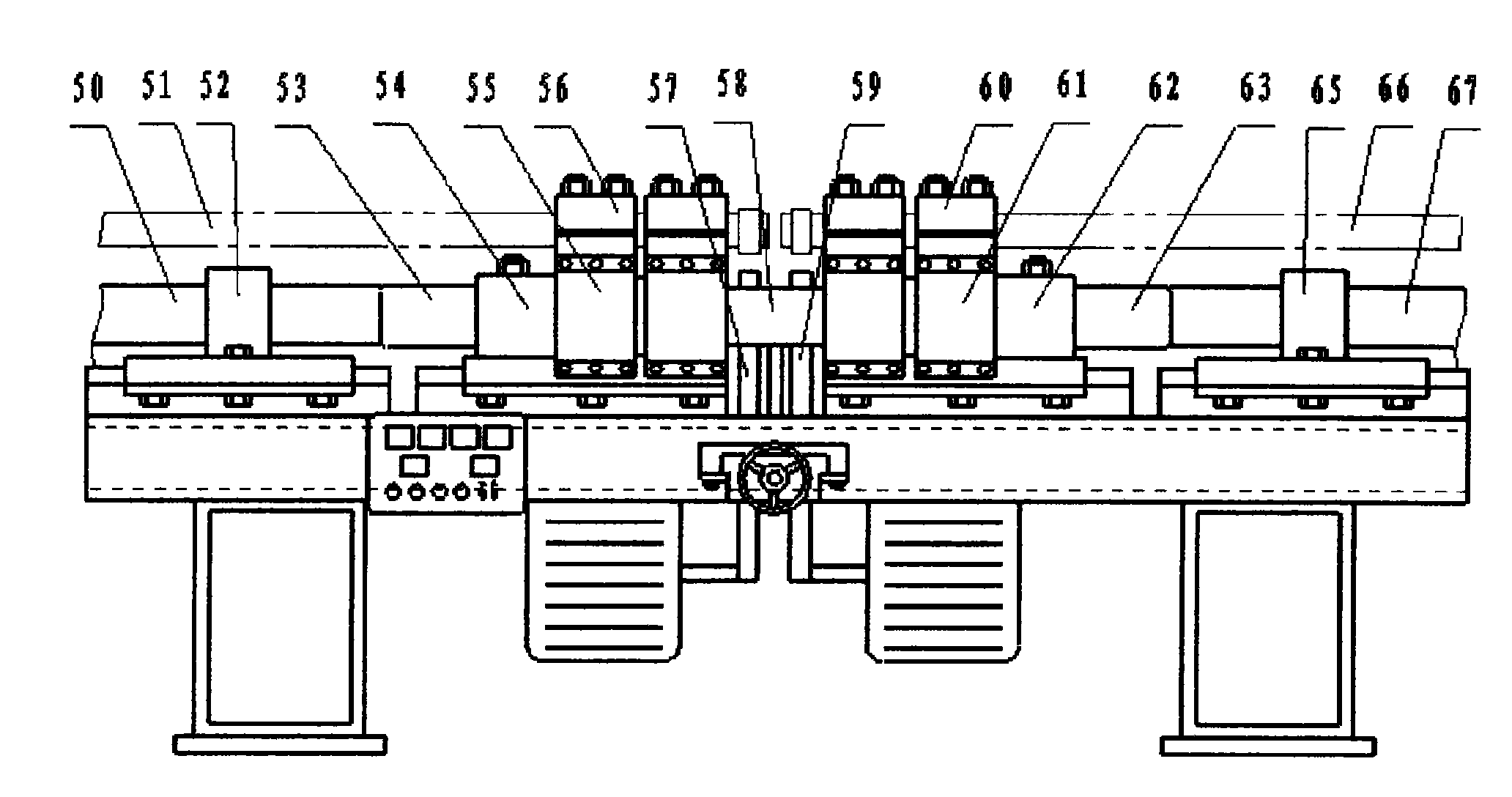

Steel induction heating solid phase welding method and butt welding machine tool

InactiveCN101623794ARealize welding automationLow priceWelding/cutting auxillary devicesAuxillary welding devicesButt weldingTransformer

The invention relates to a steel induction heating solid phase welding method and a butt welding machine tool. The butt welding machine consists of a machine body and a butt welding clamp, wherein the machine body mainly comprises a machine tool body, an electric cabinet, a welding controller, a left main guide rail, a left main slide rail, a left induction heating transformer, a tool holder, a right induction heating transformer, a right main guide rail, a right main slide rail and a hydraulic cabinet; and the hydraulic steel tube and steel rail butt welding clamp mainly comprise a left hydraulic cylinder, a left hydraulic cylinder fixing seat, a left steel rail fixing clamp, a left induction heating ring, a connecting rod of a piston rod, a right induction heating ring, a right steel rail fixing clamp, a right hydraulic cylinder fixing seat and a right hydraulic cylinder. The butt welding clamp is arranged on the end face to be welded of the steel product; and the induction heating rings are sleeved on the end face to be welded of the steel product respectively; an induction heating power supply is connected with the primary of the induction heating transformer by a cable, and the secondary of the induction heating transformer is connected with the induction heating rings respectively; and the induction heating rings can heat the end faces to be welded of two steel products to a thermoplastic state in a shot time, and the upsetting pull force is generated on the welding clamp, so that the two steel products are welded together.

Owner:陈炯

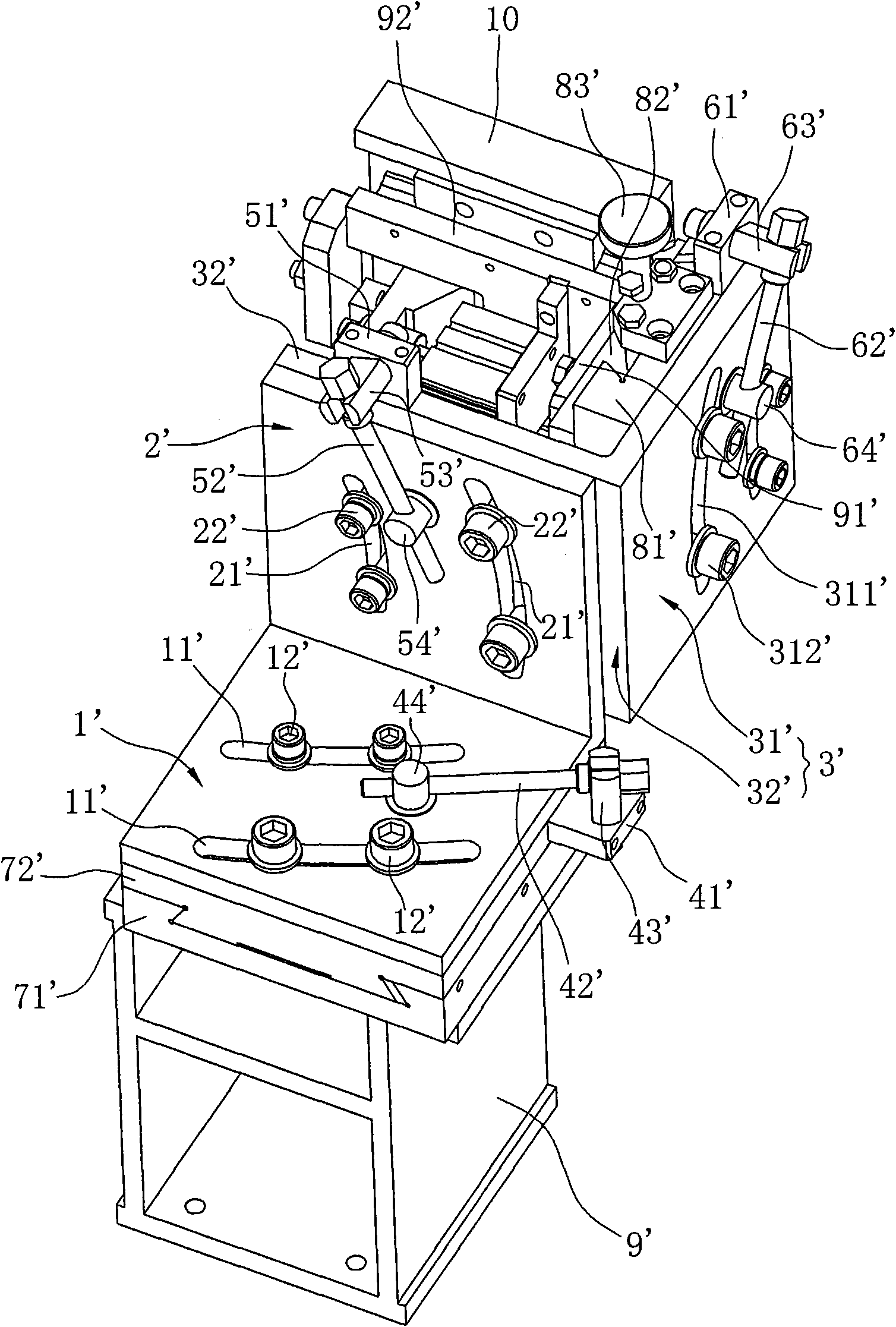

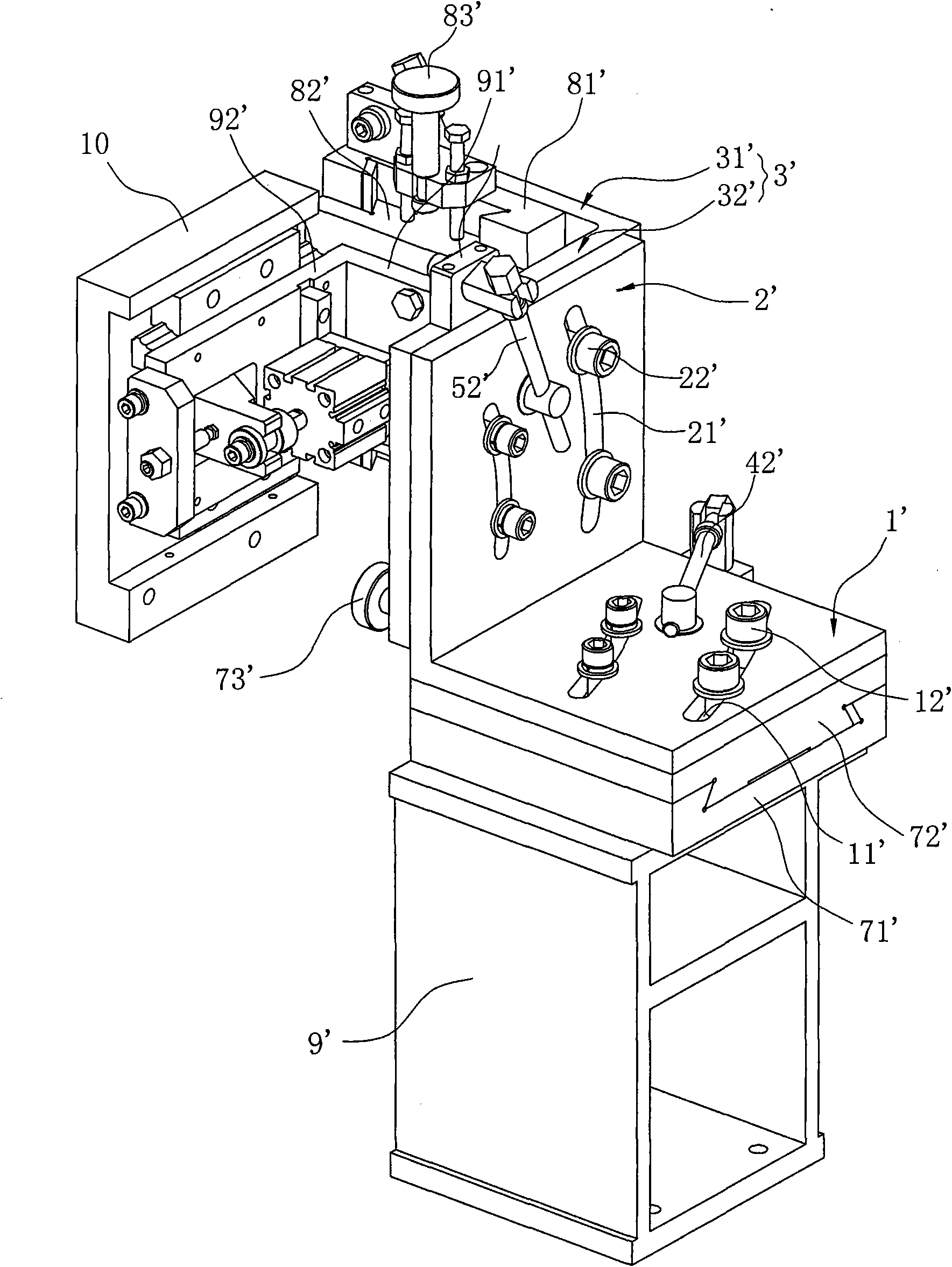

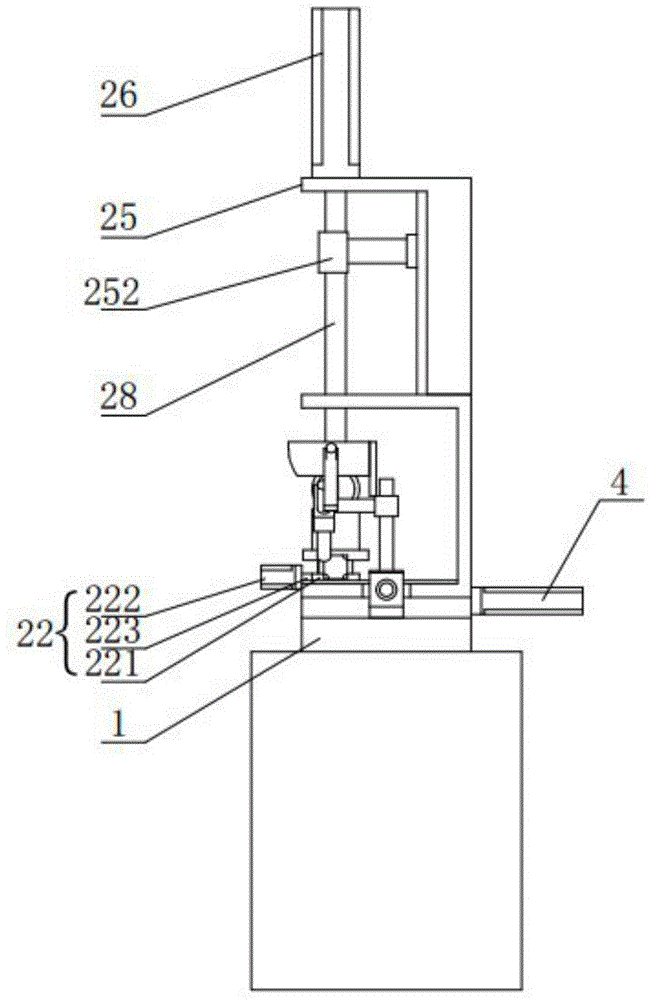

Flash butt welding machine for vehicle door corner welding

ActiveCN101979208AEffortless pushLabor-saving operationResistance welding apparatusButt weldingServo drive

The invention discloses a flash butt welding machine for vehicle door corner welding, which comprises a base, clamping devices, an upsetting mechanism and an electric controller, wherein the clamping devices comprise a first clamping device for clamping a right welding piece and a second clamping device for clamping a left welding piece. The flash butt welding machine is characterized by also comprising a clamp adjusting device and an adjusting bottom plate capable of moving freely in a space, wherein the second clamping device is fixedly arranged on the adjusting bottom plate; an upsetting device comprises a guide rail seat, a moving component slipping along the guide rail seat and a servo driving device for driving the moving component to move; the first clamping device is fixedly arranged on the moving component; and a first insulating plate is arranged between the bottom of the clamp adjusting device and the base, and a second insulating plate is arranged between the bottom of theguide rail seat and the base. Compared with the prior art, the flash butt welding machine can randomly adjust the space placing position of the welding piece to ensure the welding quality and the appearance and profile requirements of a welded product; and the clamp adjusting device is convenient and simple in operation, and improves the welding efficiency.

Owner:NINGBO XINTAI MACHINERY

Laser-arc composite welding device based on heat input control and welding method

ActiveCN103071935ALow heat inputReduce thermal deformationLaser beam welding apparatusHeat-affected zoneInput control

The invention provides a laser-arc composite welding device based on heat input control and a welding method. The laser-arc composite welding device based on the heat input control comprises a laser device, a laser head, an arc-welding power supply, a main consumable-electrode welding gun and a wire feeding mechanism and also comprises a bypass welding gun and a rheostat, wherein the laser head is connected with the laser device, the laser head is arranged above a workpiece, the main consumable-electrode welding gun and the bypass welding gun are symmetrically placed at both sides of a laser beam formed by the laser head, the main consumable-electrode welding gun is connected with the positive pole of the arc-welding power supply, the electrifying end of the workpiece is connected with the negative pole of the arc-welding power supply, and the bypass welding gun is connected with the negative pole of the arc-welding power supply by the rheostat. According to the laser-arc composite welding device based on the heat input control and the welding method, the welding heat input of a composite laser-arc heat source can be controlled, the heat affected zone and the welding deformation are reduced, and the metallurgical performance and the microstructure of a welding seam are improved. The laser-arc composite welding device based on the heat input control and the welding method not only are suitable for the fusion welding of homogeneous metal but also are suitable for the braze (fusion) welding of dissimilar metal, such as aluminum or steel and magnesium or steel.

Owner:哈尔滨哈船特装科技发展有限公司

Q690 and Q980 high-strength dissimilar steel non-preheating welding method

InactiveCN102513662AHigh plasticity reserveImprove applicabilityArc welding apparatusWelding/cutting media/materialsAbsorbed energyMixing ratio

The invention discloses a Q690 and Q980 high-strength dissimilar steel non-preheating welding method. A bottom layer of a to-be-welded workpiece adopts low-match 700-800MPa high-strength high-toughness welding wires, and adopts argon and carbon dioxide (Ar+CO2) mixed gas shield welding. A welding bead of a bottoming layer adopts 700MPa high-strength high-toughness solid wires, and a surface covering layer adopts 800MPa high-strength flux-cored wires. In a welding process, welding heat input is strictly controlled, and diffusible hydrogen content of welding lines is controlled at a super-low hydrogen level. The mixing ratio of argon and carbon dioxide of mixed gas shield welding is 75-95%Ar: 25-15CO2. By adopting the process without pre-heating or post-weld heat treatment to weld Q690 and Q980 high-strength dissimilar steel, welding joints which have no internal cracks can be obtained. An area of joints is flat and smooth, tensile strength at room temperature of weld metal is larger than 760MPa, and V-notch impact absorbing energy of weld metal at test temperature 0 DEG C is larger than 68J, thereby meeting the requirement of a high-strength dissimilar steel welding structure for high carrying capacity.

Owner:SHANDONG UNIV

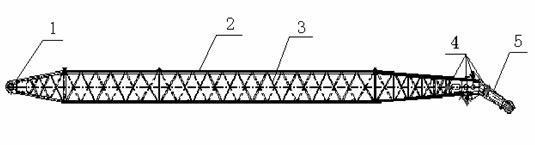

Welding method for high-strength steel truss-type cantilever crane

ActiveCN102489888AQuality assuranceLow costWelding/cutting auxillary devicesArc welding apparatusNumerical controlCantilever

The invention discloses a welding method for a high-strength steel truss-type cantilever crane. A main chord tube and a branch tube which are used as main parts of the high-strength steel truss-type cantilever crane are high-strength Q620E steel pipes. Feeding, open phase transversal and beveled edges of the steel pipes are cut and formed at one time by using a three-dimensional full-automatic numerical control steel pipe flame cutter. The main chord tube and the branch tube which are spliced are fixed by a tool plate. After local preheating, symmetrical welding and welding from the middle toboth sides and from bottom to top are adopted, flux-cored arc welding (FCAW) is adopted during welding and the arc is struck inside the beveled edge of a workpiece. The method provided by the invention not only ensures the welding quality of the high-strength steel truss-type cantilever crane with attractive appearance of welding lines, but also is simple and convenient to manufacture, is easy tocontrol welding deformation and has low welding cost.

Owner:WUHAN MARINE MACHINERY PLANT

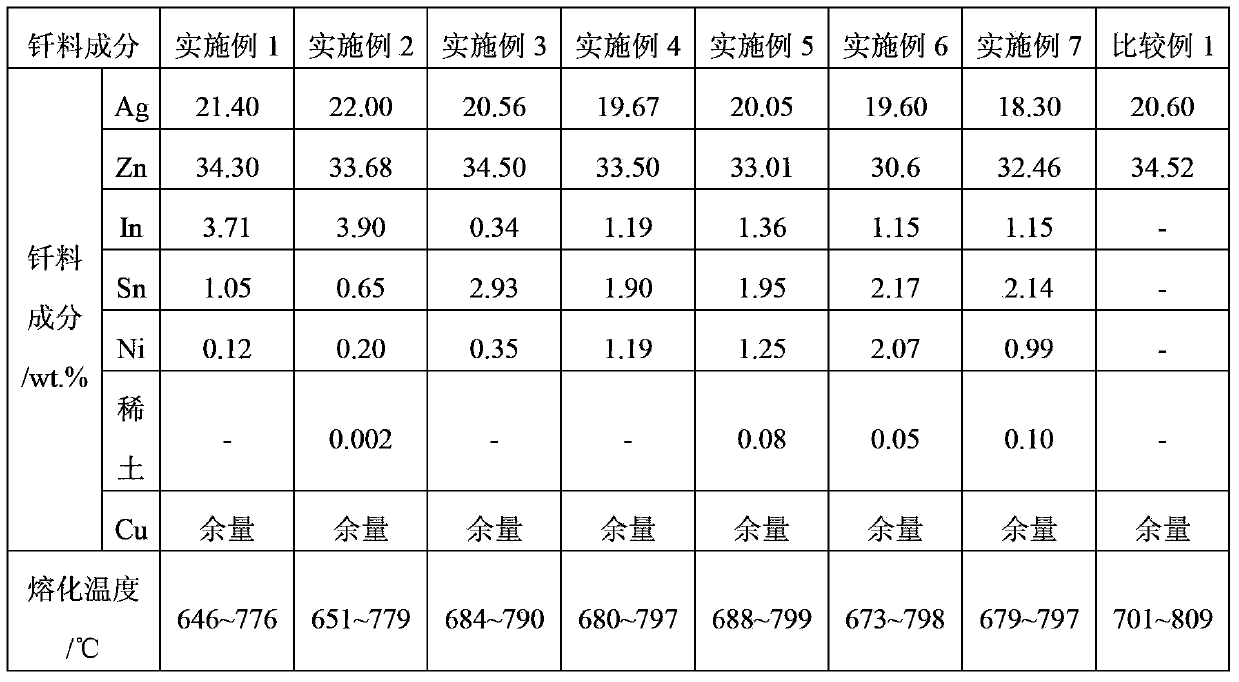

Silver solder for connecting brass and stainless steel

InactiveCN103418933ARight melting pointEasy to processWelding/cutting media/materialsSoldering mediaRare earthBrass

The invention relates to the technical field of welding materials, in particular to silver solder for connecting brass and stainless steel. The invention aims at overcoming the defects that existing solder for connecting the brass and the stainless steel is high in silver content and in welding cost, and providing the silver solder for connecting the brass and the stainless steel, wherein the silver solder is low in silver content and in welding cost, and non-cadmium silver solder containing more than 25wt.% of silver can be replaced by the silver solder for connecting the brass and the stainless steel. According to the technical scheme, the silver solder for connecting the brass and the stainless steel comprises components, by weight, 18-22 wt.% of Ag, 30-35wt.% of Zn, 0.3-4.5wt.% of In, 0.3-3.0wt.% of Sn, 0.1-2.5wt.% of Ni, 0.001-0.1wt.% of rare earth, and the balance Cu.

Owner:浙江信和科技股份有限公司

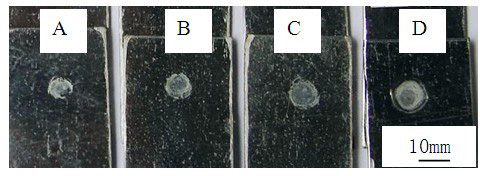

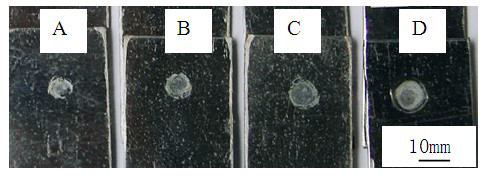

A resistance brazing method for galvanized steel sheets

InactiveCN102275046AFree from destructionExtended service lifeWelding apparatusMaterials scienceElectrical resistance and conductance

A resistance brazing method for galvanized steel sheets relates to the improvement of the resistance spot welding method for galvanized steel sheets. In the present invention, medium-temperature solder such as Zn-Al is placed on the two surfaces to be soldered. The solder can be sheet-like, foil-shaped, plated or sprayed on the surface to be soldered in advance, and the thickness of the solder is 0.05-0.5 mm. The electrode material can be an ordinary Cu-Cr-Zr electrode, and the electrode does not need special treatment. Set the resistance spot welding parameters, the welding current is 7000~14000A, the welding time is 10C~50C, the welding pressure is 0.7KN~5KN, start the resistance spot welding, and then let the weldment cool naturally. The invention can realize the connection without galvanized layer damage and copper pan under the premise that the galvanized steel sheet meets the strength, and improves the service life of the electrode.

Owner:CHONGQING UNIV OF TECH

Method for decreasing laser welding pores

InactiveCN107186339AStable working conditionGood effectLaser beam welding apparatusPorosityButt joint

The invention provides a method for decreasing laser welding pores, and relates to the technical field of laser welding. The method for decreasing the laser welding pores comprises the steps of (1) placing two metal to-be-welded parts in a horizontal butt joint manner to form a to-be-welded workpiece; (2) clamping and fixing the two ends of the metal to-be-welded workpiece; (3) preheating the metal to-be-welded workpiece through laser beams; and (4) starting a control switch, introducing a protective gas, igniting electric arcs for 1 s to 2 s, emitting laser, combining laser emitted by a laser A and a laser B into one laser beam, and moving a high pressure air rifle which injects acetone together with the laser A and the laser B. According to the method, a device utilized in the method comprises the two lasers, firstly, the material surface is subjected to preheating treatment, an oxide film generated on the surface is scrubbed through acetone, and then, the two lasers emit the two laser beams to melt the material for welding, so that metal weld joint porosity is obviously decreased, and porosity of 8% to 10% during laser welding is decreased to zero.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

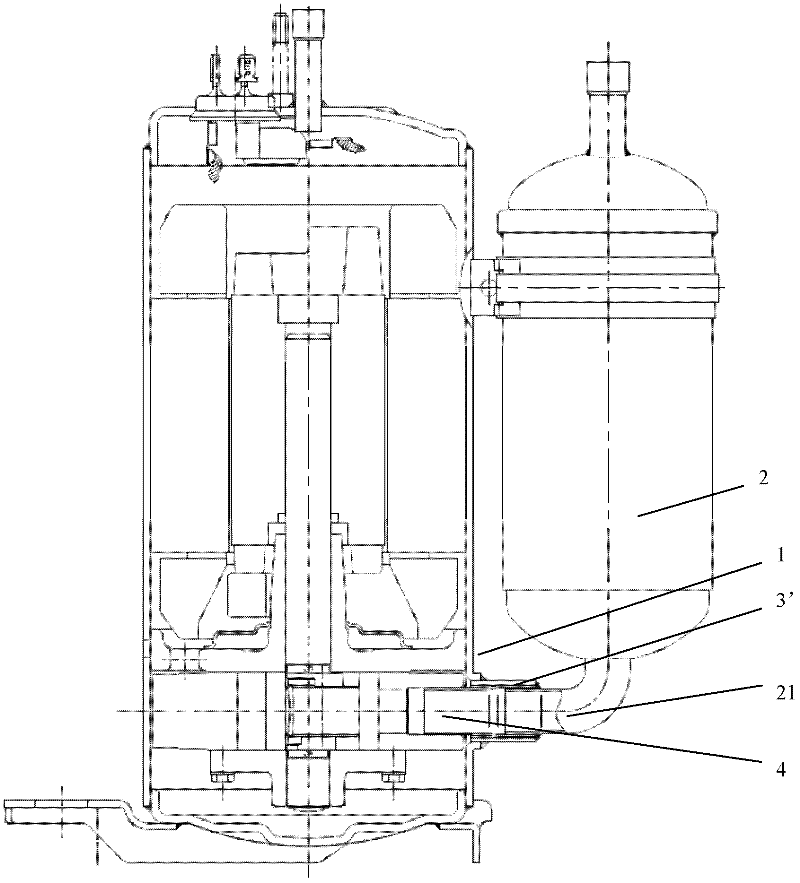

Resistance welding tube and manufacturing method and application thereof

InactiveCN102407410AEasy to makeReduce welding costsWelding/cutting media/materialsSoldering mediaElectrical resistance and conductanceLeakage rate

The invention discloses a resistance welding tube and a manufacturing method and an application thereof. The resistance welding tube disclosed by the invention adopts an iron basis material and is provided with an iron welding position and a copper welding position, wherein the copper welding position is covered with a copper layer; and the iron basis material is exposed on the iron welding position. The manufacturing method provided by the invention is simple; a welding tube formed by compounding copper and iron is obtained, wherein the part for being used to be welded with the iron (such as a compressor shell) is an iron material; the iron materials can be welded by resistance welding; compared with the existing technology that the iron material and the copper material are welded by silver solder and flame welding, the welding cost and the welding difficulty are lowered, the welding mechanical strength of the manufacturing method is improved by above 30%, the pressure resistance strength is improved by above 20% and the welding airtight leakage rate is reduced by above 70%; and the part for being used to be welded with the copper (such as a compressor copper tube) is a copper material, and the copper materials can be still welded by flame welding.

Owner:DONGGUAN JINRUI HARDWARE PROD

Welded assembly method of box girder

The invention relates to the technical field of welding technology, and discloses a welded assembly method of a box girder. The box girder comprises an upper cover plate, a lower cover plate and two web plates. The welded assembly method of the box girder comprises following steps in sequence: the upper cover plate, the lower cover plate and the two web plates are located and assembled to form a box-shaped structure, wherein each web plate is located and assembled between the upper cover plate and the lower plate, and the locating and assembling root portion of each web plate between the web plate and the upper cover plate and the lower cover plate is provided with a welding groove with an opening towards the outside of the box structure. Each web plate is welded and assembled with the upper cover plate and the lower cover plate, wherein each web plate is placed horizontally upward in sequence when each pair of locating and assembling connectors is carried out welding, and the welding groove corresponding to each web plate faces upward. The welded assembly method of the box girder can reduce the filling quantity of weld metal in the premix of guaranteeing the welding quality of the box girder, therefore reduces weld consumption, reduces welding cost of the box girder, and further improves welding and assembling efficiency.

Owner:ZOOMLION HEAVY IND CO LTD

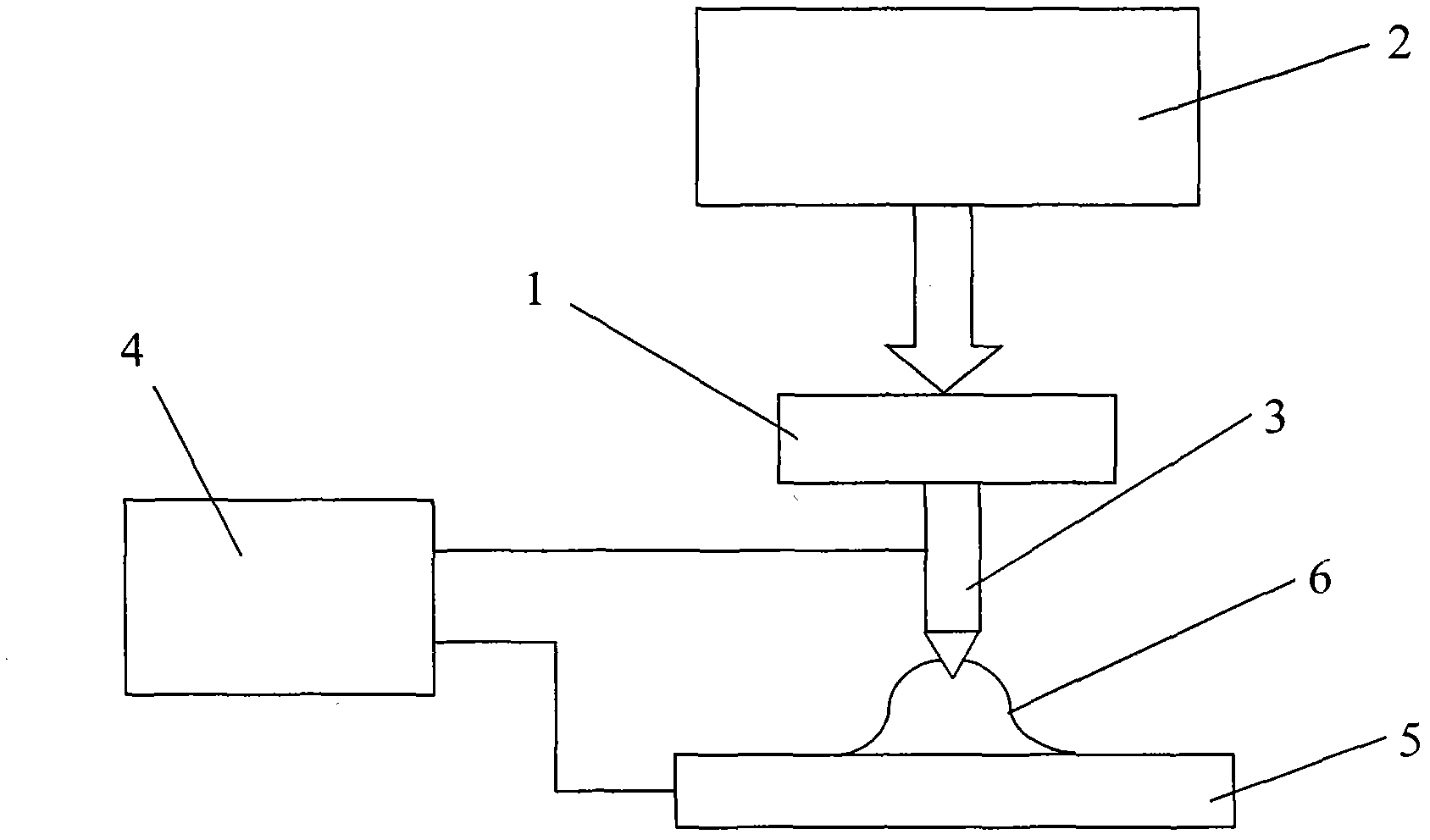

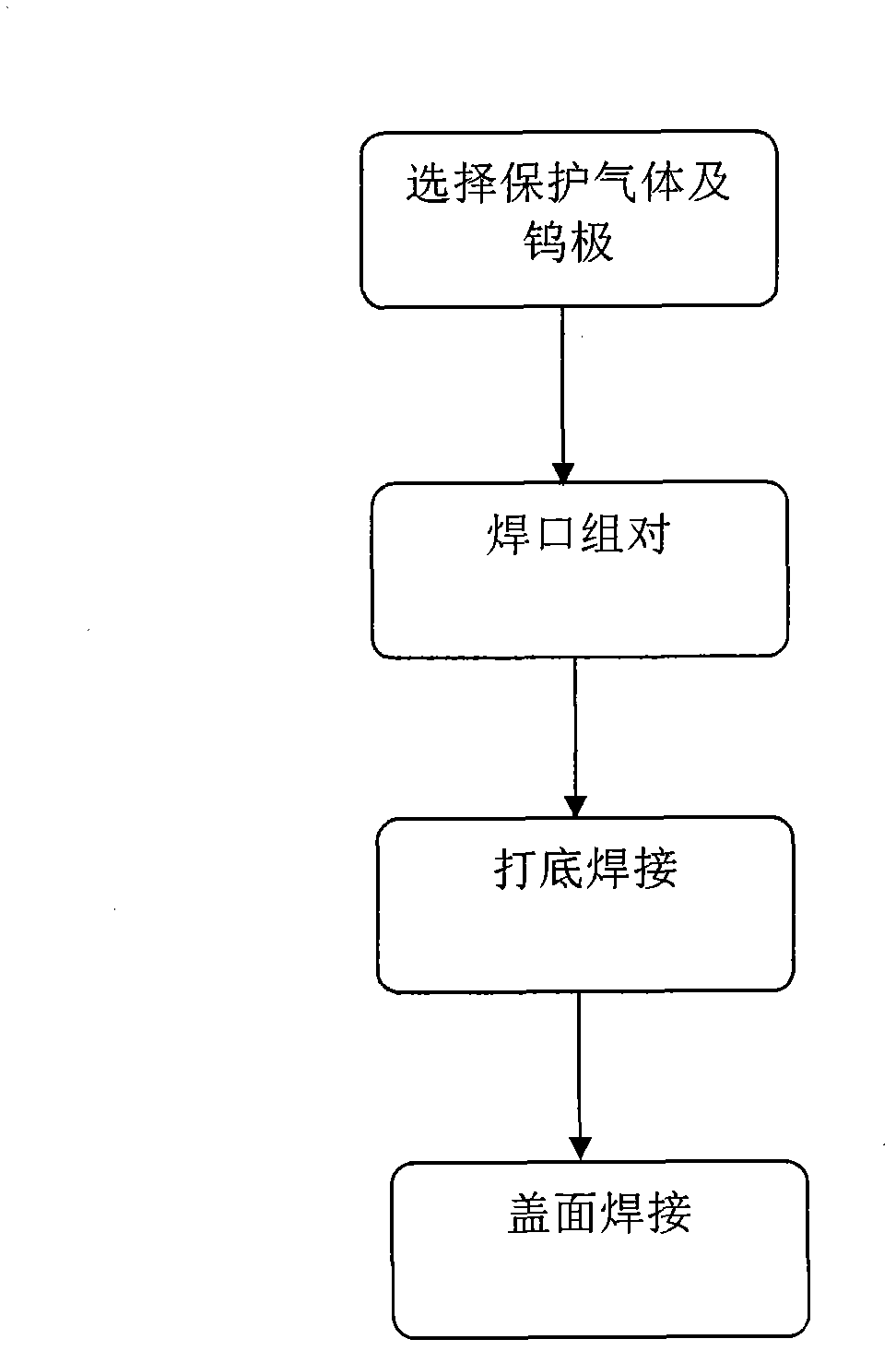

Method for welding cut surface butt joint formed by thin welding base materials

ActiveCN102699545AReduce process stepsReduce consumptionArc welding apparatusSignal onFilling materials

The invention relates to a method for a welding cut surface joint formed by assembling cut surface ports, in particular to a method for welding a cut surface butt joint formed by thin welding base materials in nuclear power engineering, and aims to solve the problems that the machining period of tubes and welding period are relatively long, the welding cost is high, and part of the materials are not completely welded in the prior art. According to the method, the thickness of each welding base material is less than or equal to 6.0mm. The method comprises the following steps of: selecting protective gas and a tungsten electrode; assembling craters; overlapping an ultrasonic electrical signal on pulse welding current to generate a stable ultrasonic- tungsten inert gas (TIG) combined weld electric arc by taking ultrasonic waves and TIG combined electric arc welding machine as a welding power supply of automatic welding equipment, and performing backing welding on the surface butt joints without feeding wires; performing cosmetic welding, and finishing welding. By the welding method, the processing step of forming a groove is eliminated, so that the welding workload, the consumption of welding filling materials and the welding cost are reduced, and the welding efficiency is improved.

Owner:CHINA NUCLEAR IND 23 CONSTR

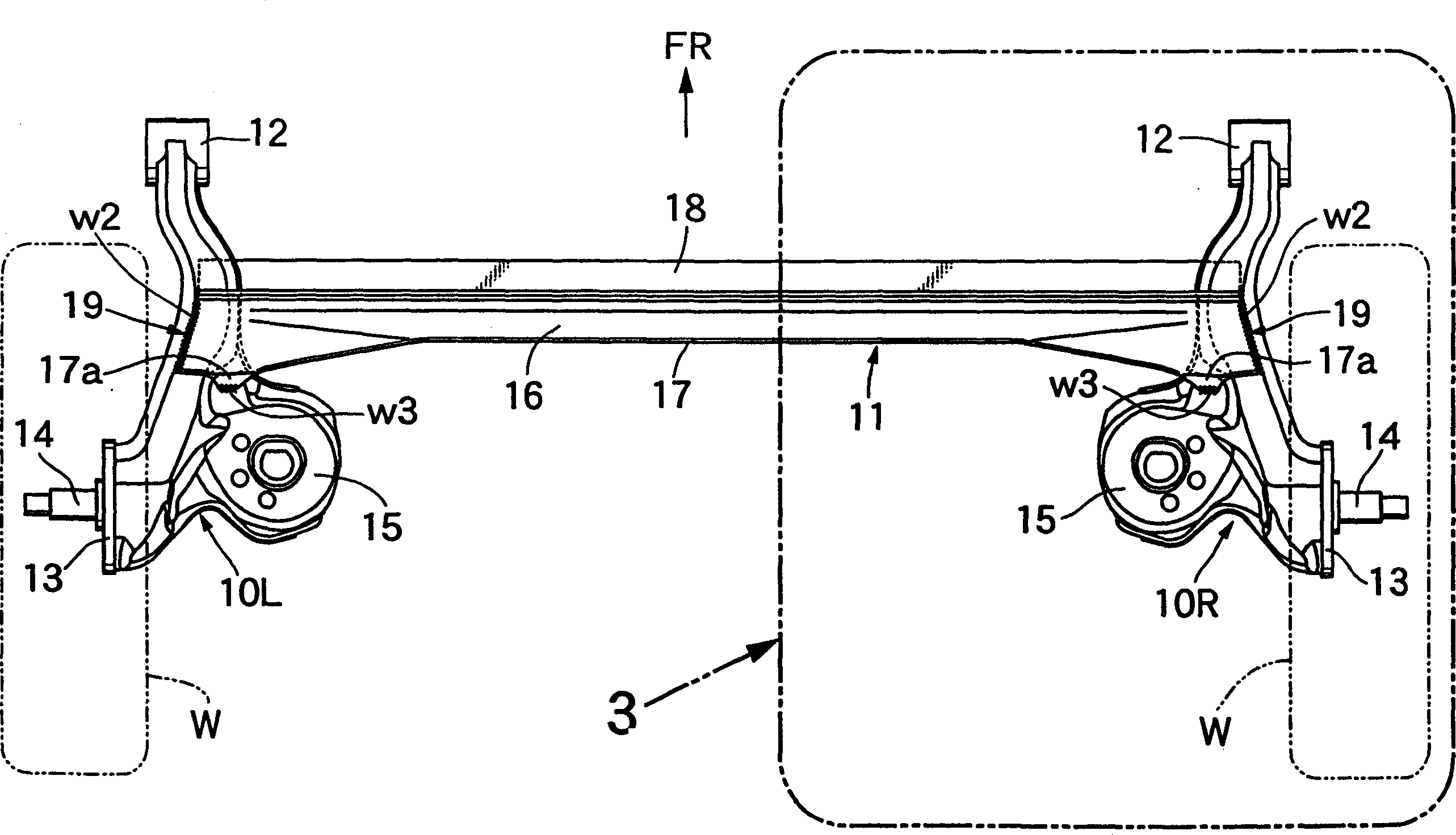

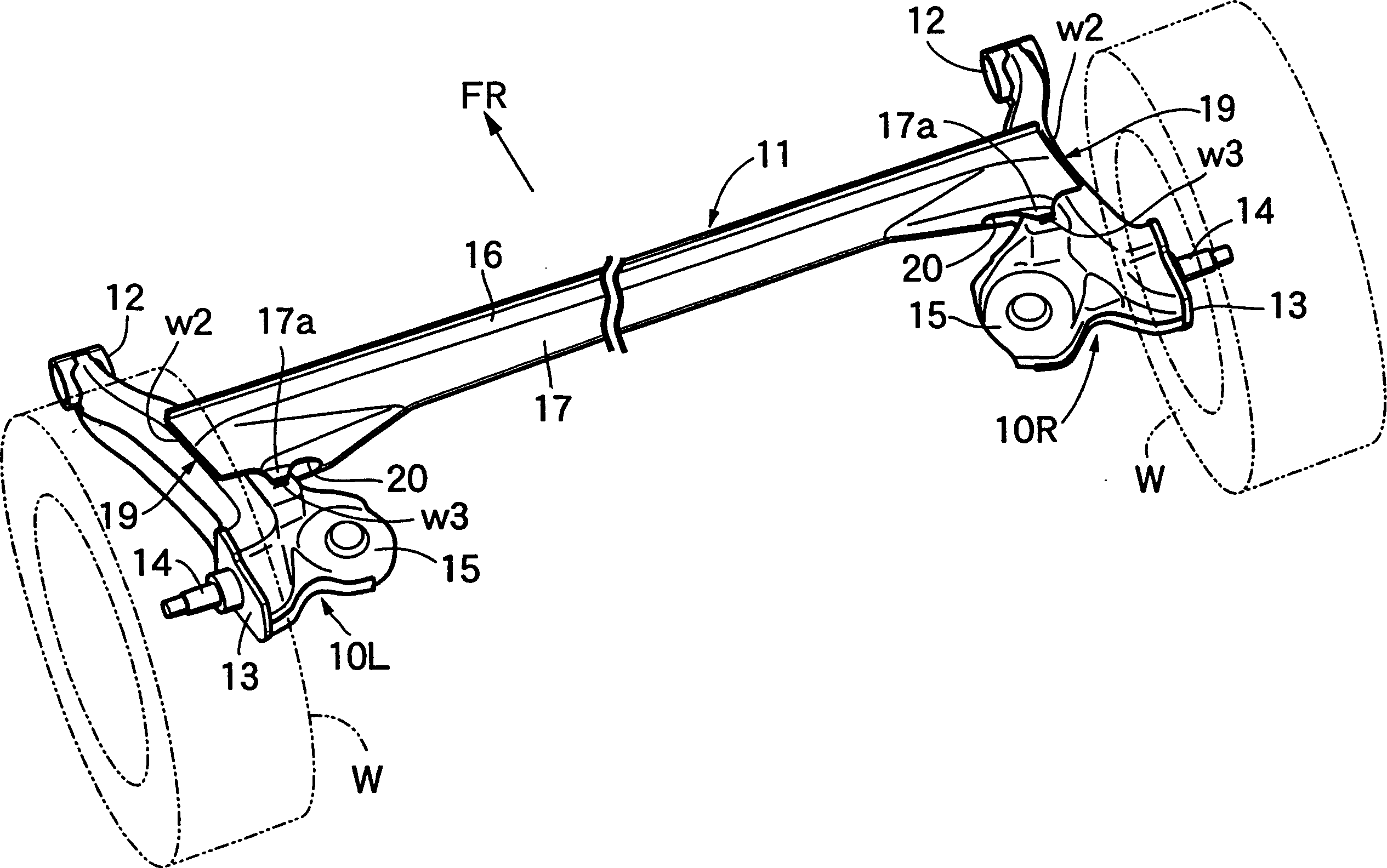

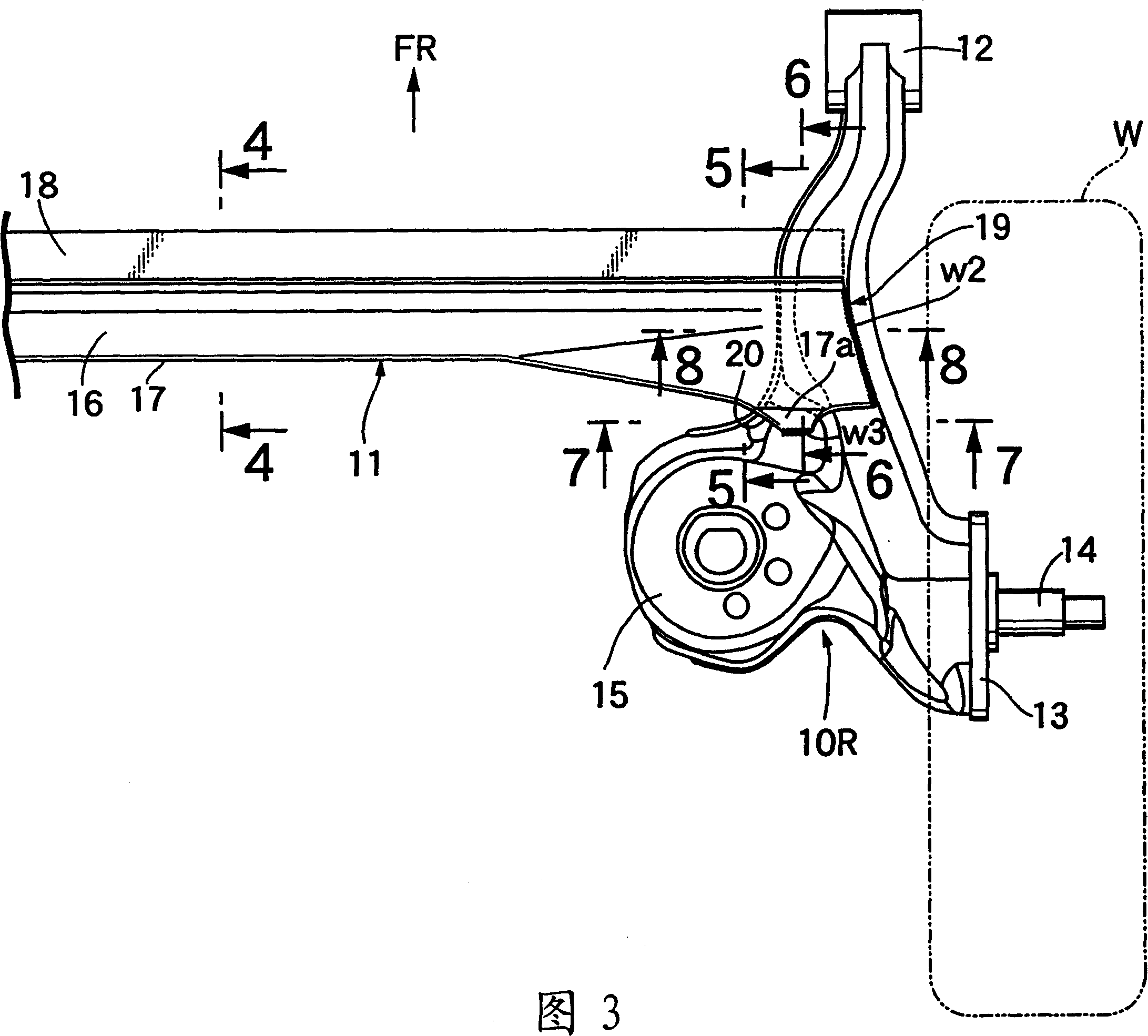

Torque beam suspension

InactiveCN1495054AIncrease toe-in rigidityImprove welding accuracyResilient suspensionsEffective lengthEngineering

To suppress increase in size of both end parts of a torsion beam to the minimum extent to reduce material cost and welding cost and increase effective length of the torsion beam capable of being twisted and deformed to ensure durability of a welded part. A torsion beam type suspension is constituted by connecting connection parts 19 at both ends of the torsion beam 11 having U-shaped cross section and extending in the right and left directions of a vehicle body with trailing arms 10L, 10R on the left and right sides extending in the forward and backward directions of the vehicle body and swinging vertically. The connection part 19 is provided with a slit 20 which is formed on a longitudinal wall 17 of the torsion beam 11 and extends in the left and right directions and whose one end is opened and upper and lower flanges 17a overhanging in the forward and backward directions from upper and lower fringe parts of the slit 20. While the slit 20 is fitted into the trailing arms 10L, 10R, outer end fringes of an upper wall 16 and a lower wall and the upper and lower flanges 17a are welded on the trailing arms 10L, 10R. (C)2004,JPO.

Owner:HONDA MOTOR CO LTD +1

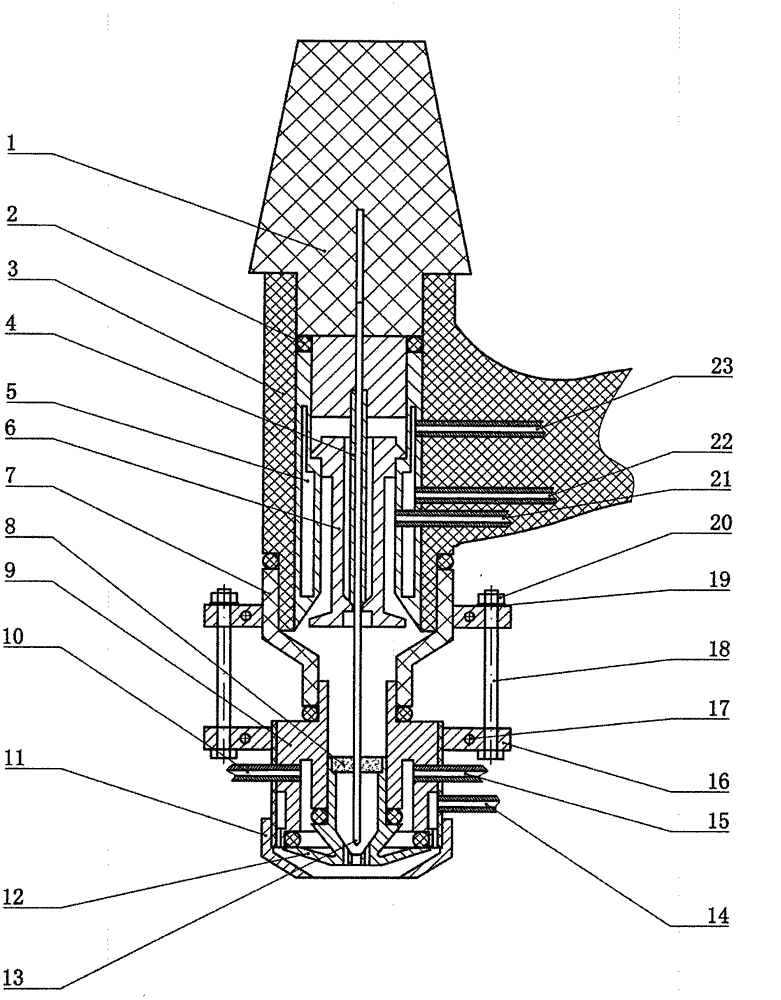

Plasma-arc welding device implemented by aid of TIG (tungsten inert gas) welding method

ActiveCN104668743AImprove welding efficiencyImprove welding qualityElectrode supporting devicesElectrode accessoriesSpray nozzleEngineering

The invention relates to a plasma-arc welding device implemented by the aid of a TIG (tungsten inert gas) welding method. The plasma-arc welding device comprises an upper gun and a lower gun. An upper spray nozzle is connected with the lower end of the upper gun and is mechanically coaxially connected with the lower gun. A water cooling groove is formed in the wall of the upper gun, an upper water inlet pipe, an upper water outlet pipe and an upper gas inlet pipe are arranged in the wall of the upper gun, a flow guide component, a tungsten electrode clamp and a tungsten electrode are coaxially arranged in the upper gun, and the tungsten electrode penetrates the tungsten electrode clamp and extends into the lower gun. A water cooling groove is formed in the wall of the lower gun, a lower water inlet pipe, a lower water outlet pipe and a lower gas inlet pipe are arranged in the wall of the lower gun, a lower spray nozzle is connected with the inner wall of the lower end of the lower gun, pore passages are arranged in the center of the lower spray nozzle, the tail end of the tungsten electrode is separated from each center pore passage of the lower spray nozzle by a certain distance, and a protective cover is connected to the outer wall of the lower end of the lower gun. The plasma-arc welding device has the advantages that plasma-arc welding can be implemented, the TIG welding efficiency and the quality of weld joints can be obviously improved, and the plasma-arc welding device is low in welding cost as compared with the traditional plasma-arc welding.

Owner:SHENYANG JINCHANG LANYU NEW MATERIAL CO LTD

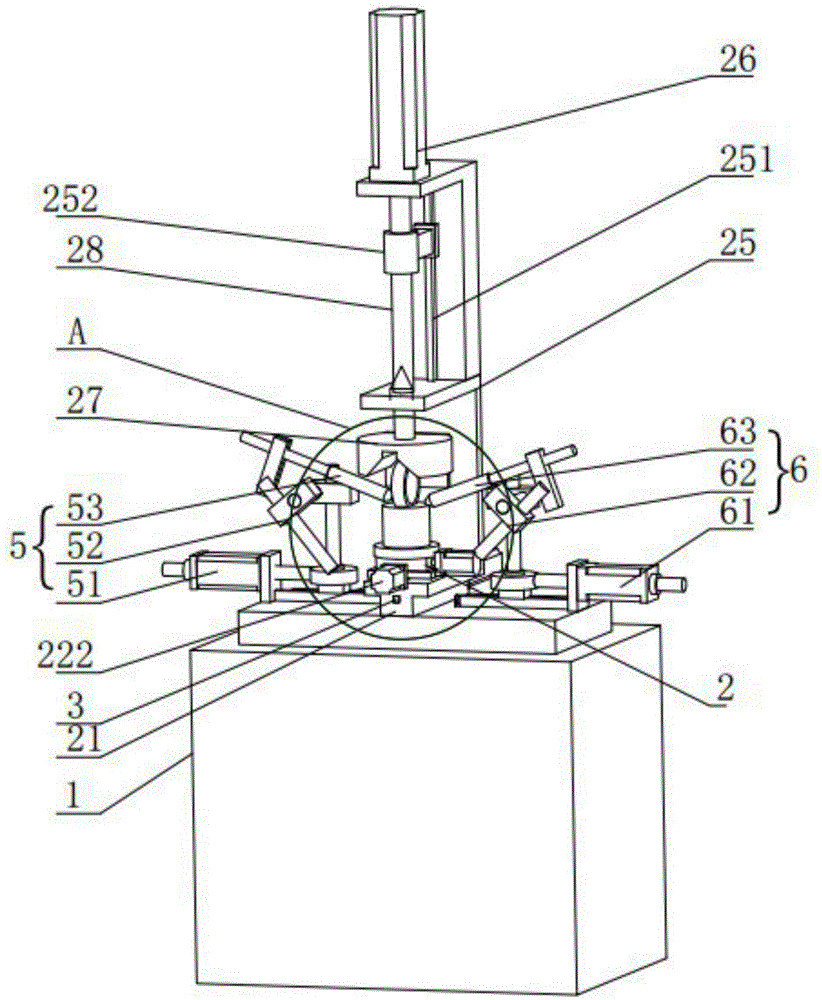

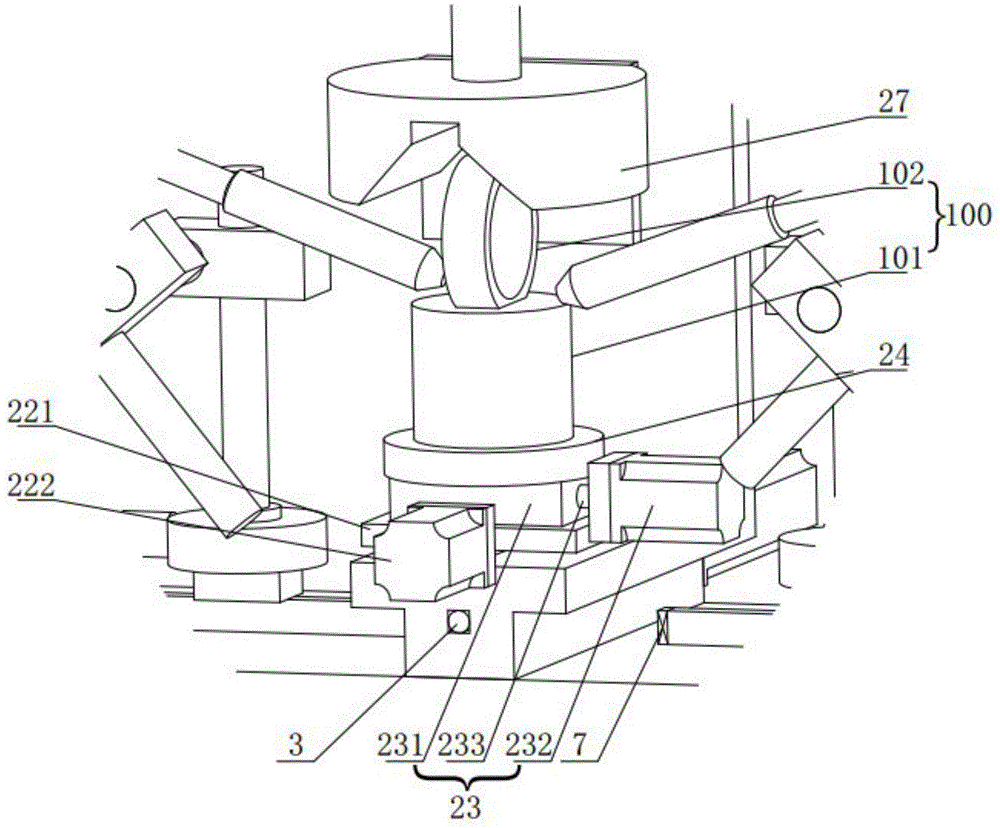

Automatic welding machine and automatic welding method thereof

ActiveCN104690464AImprove welding efficiencyReduce welding costsWelding/cutting auxillary devicesAuxillary welding devicesManipulatorEngineering

The invention relates to an automatic welding machine which comprises a base station, a clamp device, a first ball screw, a first servo motor, a first welding gun component and a second welding gun component. The clamp device is mounted on the base station, the first ball screw is penetratingly mounted in the clamp device and connected with the first servo motor which is fixedly mounted on the base station, the first servo motor drives the first ball screw to drive the clamp device to be in linear motion on the base station, the first welding gun component and the second welding gun component are positioned on two sides of the clamp device respectively, a first cylinder drives a first welding gun rack to adjust position of a first welding gun, and a second cylinder drives a second welding gun rack to adjust position of a second welding gun. The automatic welding machine has the advantages that welding needs on oil storage cylinders and dustproof covers of dampers diverse in structure can be met; the automatic welding machine can replace manual welding, so that welding efficiency is improved; the automatic welding machine can replace welding of a manipulator, so that welding quality is guaranteed while welding cost is lowered.

Owner:无锡乔尼威尔铁路设备科技有限公司

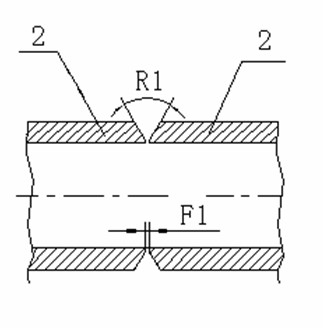

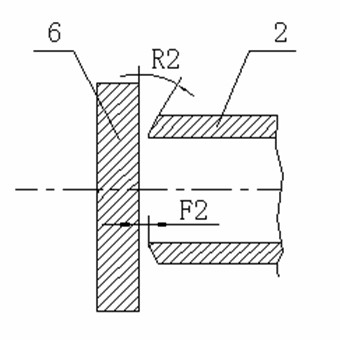

Bimetal composite pipe both-side welding process

ActiveCN104801826ASolve efficient welding problemsLow costArc welding apparatusWorkpiece edge portionsHeating furnaceHigh pressure

The invention provides a bimetal composite pipe both-side welding process. The process comprises (1) preparations before welding; (2) matrix bottom seal welding; (3) carbon steel matrix thermal weld bead welding; (4) carbon steel matrix filling and cover welding; (5) anti-corrosion lining slope grinding and cleaning; (6) anti-corrosion lining overlaying. The process has the advantages of being high in welding quality, small in labor intensity, low in construction cost and high in production efficiency and particularly applicable to welding of oceaneering composite vertical pipes, liquefied natural gas low-temperature high-pressure anti-corrosion pipes, oil and gas pipes, heating furnace pipes, chemical pipes and the like and applicable to deepwater composite pipe and pressure containing welding.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com