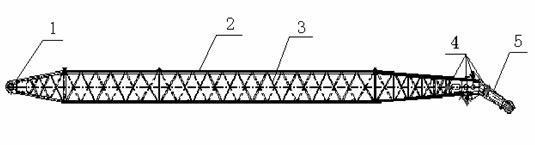

Welding method for high-strength steel truss-type cantilever crane

A welding method and truss-type technology are applied in the field of high-strength steel Q620E steel pipe to make high-strength steel truss-type booms, which can solve the problems of high welding cost, low strength and low welding efficiency, and achieve high welding efficiency, saving processing costs, and ensuring The effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

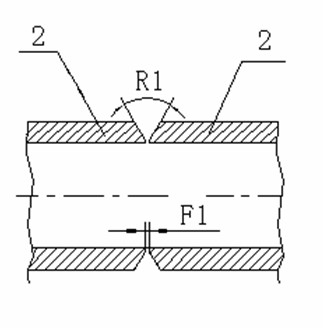

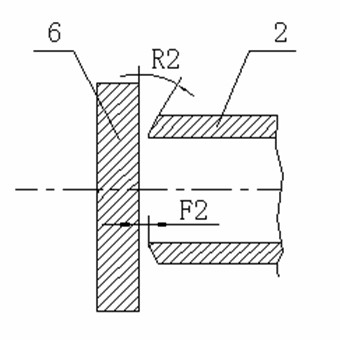

[0027] A welding method for a high-strength steel truss-type jib. The main components of the jib, the main chord 2 and the branch pipe 3, are made of high-strength steel pipes. The specific process steps are as follows:

[0028] ① Cutting, opening intersecting lines and grooves of main chord 2 and branch pipe 3. Both the main chord 2 and the branch pipe 3 are made of high-strength Q620E steel pipe, which is low-alloy high-strength steel with a thickness of 12mm. All intersecting lines and grooves are cut by a three-dimensional automatic CNC steel pipe flame cutting machine. The cutting nozzle for flame cutting adopts 1# fast cutting nozzle (diffusion type), the distance from the cutting nozzle to the workpiece is 10mm; the throat diameter of the cutting oxygen hole is 0.2mm; the preheating flame power is 6L / min; the propane pressure is 35kPa; The pressure is 200kPa; the cutting speed is 40cm / min. The cutting speed is adjusted according to the thickness of the cutting material...

Embodiment 2

[0040] A welding method for a high-strength steel truss-type jib. The main components of the jib, the main chord 2 and the branch pipe 3, are made of high-strength steel pipes. The specific process steps are as follows:

[0041] ⑦ Cutting, opening intersecting lines and grooves of main chord 2 and branch pipe 3. Both the main chord 2 and the branch pipe 3 are made of high-strength Q620E steel pipe, which is a low-alloy high-strength steel with a thickness of 16mm. All intersecting lines and grooves are cut by a three-dimensional automatic CNC steel pipe flame cutting machine. The cutting nozzle for flame cutting adopts 1# fast cutting nozzle (diffusion type), the distance from the cutting nozzle to the workpiece is 12mm; the throat diameter of the cutting oxygen hole is 0.25mm; the preheating flame power is 7.5L / min; the propane pressure is 40kPa; The oxygen pressure is 220kPa; the cutting speed is 42cm / min. The cutting speed is adjusted according to the thickness of the cuttin...

Embodiment 3

[0053] A welding method for a high-strength steel truss-type jib. The main components of the jib, the main chord 2 and the branch pipe 3, are made of high-strength steel pipes. The specific process steps are as follows:

[0054] The blanking, intersecting lines and grooves of the main chord 2 and branch 3. Both the main chord 2 and the branch pipe 3 are made of high-strength Q620E steel pipe, which is low-alloy high-strength steel with a thickness of 20mm. All intersecting lines and grooves are cut by a three-dimensional automatic CNC steel pipe flame cutting machine. The cutting nozzle for flame cutting adopts 1# fast cutting nozzle (diffusion type), the distance from the cutting nozzle to the workpiece is 15mm; the throat diameter of the cutting oxygen hole is 0.3mm; the preheating flame power is 8.3L / min; the propane pressure is 45kPa; The oxygen pressure is 250kPa; the cutting speed is 45cm / min. The cutting speed is adjusted according to the thickness of the cutting ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com