Patents

Literature

507results about How to "Beautiful weld shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

WC particle-reinforced Ni-based MIG hardfacing flux-cored wire

InactiveCN103406689AImprove toughnessGood "supportArc welding apparatusWelding/cutting media/materialsManganeseBoron carbide

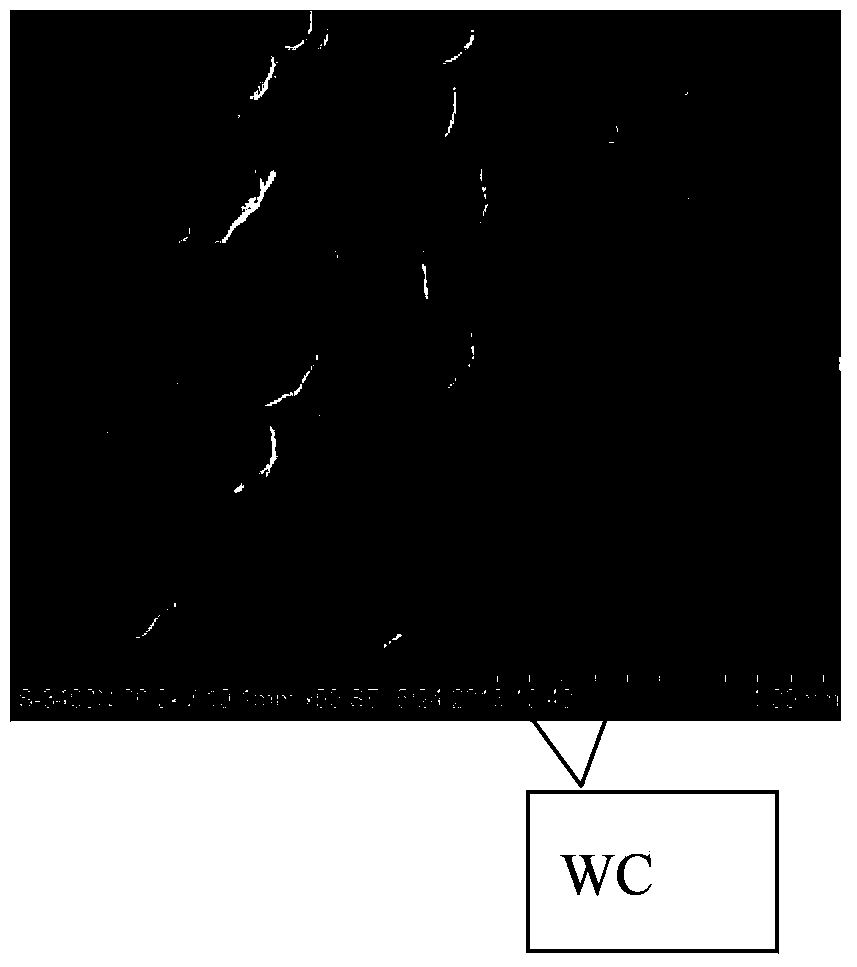

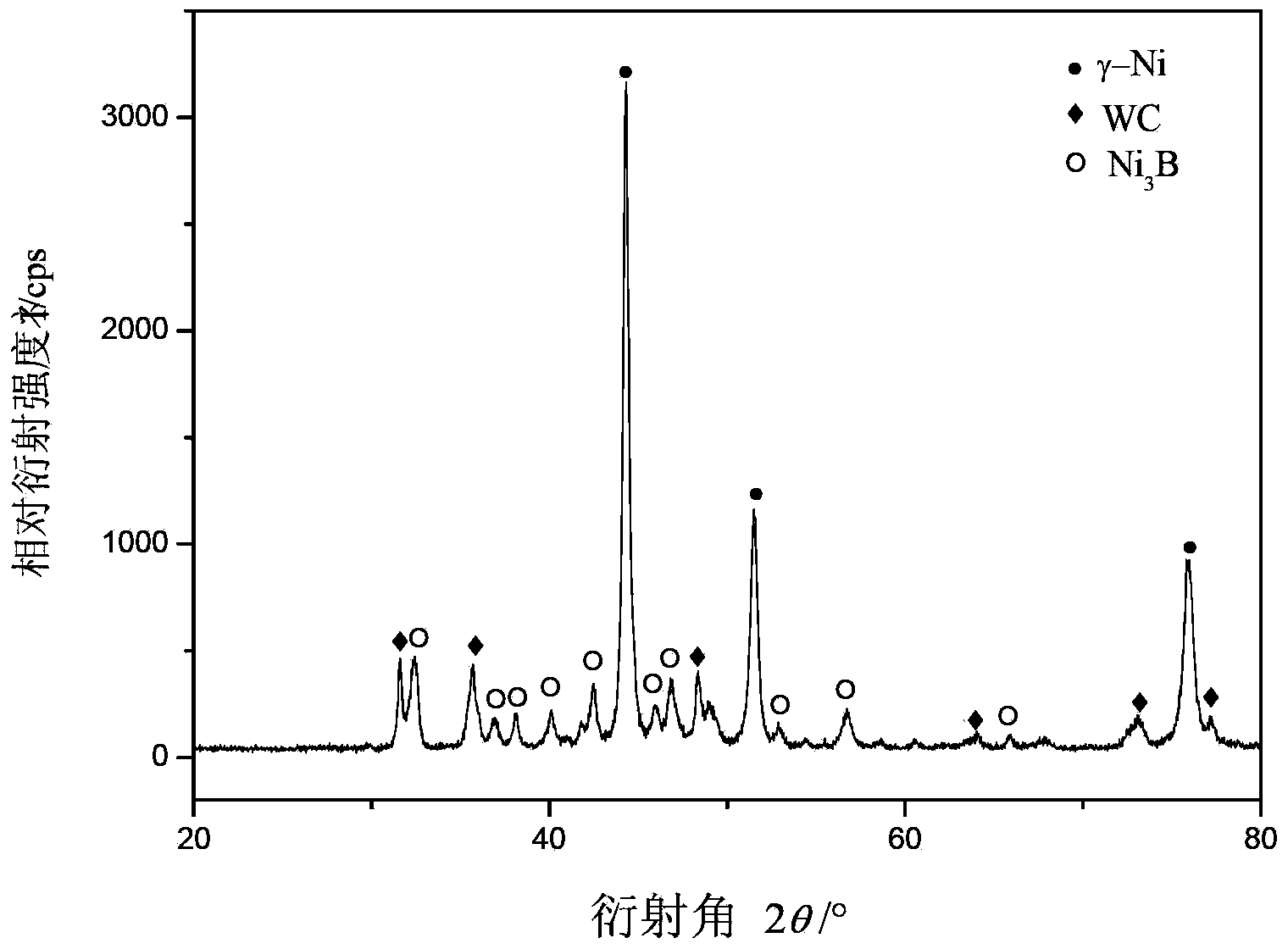

The invention discloses a WC particle-reinforced Ni-based MIG hardfacing flux-cored wire and belongs to surface-modified cored wires used in the technical field of engineering application. The flux-cored wire is composed of a nickel strap wrapper and core portion powder. Core ingredients comprise, by mass, 30%-75% of tungsten carbide, 4%-17% of silicon carbide, 3%-15% of boron carbide, 1%-5% of electrolytic manganese powder, 1%-12% of sodium fluoride and the balance of nickel powder. Ingredients of obtained deposited metal comprise 11.1%-30% of tungsten carbide, 1.3%-5.6% of silicon, 1%-5% of boron, 0.3%-1.48% of manganese and the balance of nickel. A surfacing layer prepared by flux-cored wires is high in hardness (>45HRC), and the hardness of WC hard phases in the surfacing layer reaches 1800HV0.3. According to the WC particle-reinforced Ni-based MIG hardfacing flux-cored wire, the 'shadow protection' effect is achieved mainly through matching of added WC particles and a Ni-based substrate, and therefore wear resistance can be achieved; besides, welding performance of surfacing alloy is improved by adding the deoxidizing agents including silicon and manganese, alterative Na / F and the like.

Owner:BEIJING UNIV OF TECH

Surfacing electrode for repairing hot forged mould

InactiveCN101898284AExcellent welding performanceImprove yieldWelding/cutting media/materialsSoldering mediaSolid componentSlag

The invention discloses a surfacing electrode for repairing a hot forged mould, which uses a low-carbon steel H08A core wire conforming to the GB / T3429 requirement. The solid component quality content of coating is as follows: 30-40% of marble, 12-20% of fluorite, 1.5-3% of zircon sand, 0-2% of soda ash, 2-5% of silicon epitaxy material, 1-3% of titanium white, 0-3% of flogopite, 1-2% of rare earth fluoride, 3-7% of manganese metal, 2-5% of ferrosilicon, 4-6% of ferrotitanium, 4-8% of chromium metal, 4-8% of ferromolybdenum, 6-12% of metallic nickel and 1-2% of aluminium magnesium alloy. The invention has favorable welding rod performance, smooth welding rod surface, high yield and stable eccentricity; electric arc is easy to ignite and is stable to burn; coating is even to melt, a welding line is attractive in shape, and slag is easy to clean; and a deposition metal weld metal buildup has moderate welding state hardness which reaches the requirements of the hot forged mould, thus improving the service life cycle of the hot forged mould.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

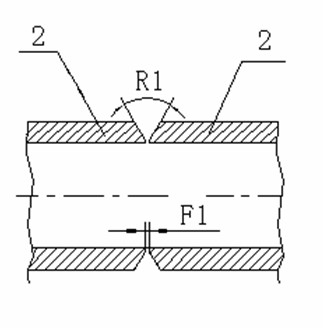

Automatic TIG gasket-free single-side welding and double-side molding process for aluminum alloy

InactiveCN102079003AReduce distortionImprove welding qualityArc welding apparatusWorkpiece edge portionsUltimate tensile strengthStainless steel wire

The invention discloses an automatic tungsten inert gas (TIG) gasket-free single-side welding and double-side molding process for aluminum alloy, which comprises the following steps of: selecting welding equipment and materials, performing assembly and clearing, performing tack welding, clearing grease dirt and oxide films in 50 millimeters of two sides of a groove by using acetone and a stainless steel wire wheel, placing a shell on a welding operation rack, regulating a welding gun to be aligned with the groove, preheating, welding a first layer without adding welding wires, clearing the oxide film on the surface of the seam by using the stainless steel wire wheel after the first layer is welded to expose metal luster, welding a second layer, adding the welding wires for covering the surface, and making the welding direction of the welding gun and a cylinder swing vertically to form a seam. The process has the advantages of high efficiency, low labor intensity, high welding quality, attractive appearance, no undercut or arc crater cracks, workpiece deformation resistance and high seam qualification rate.

Owner:陕西国德电气制造有限公司

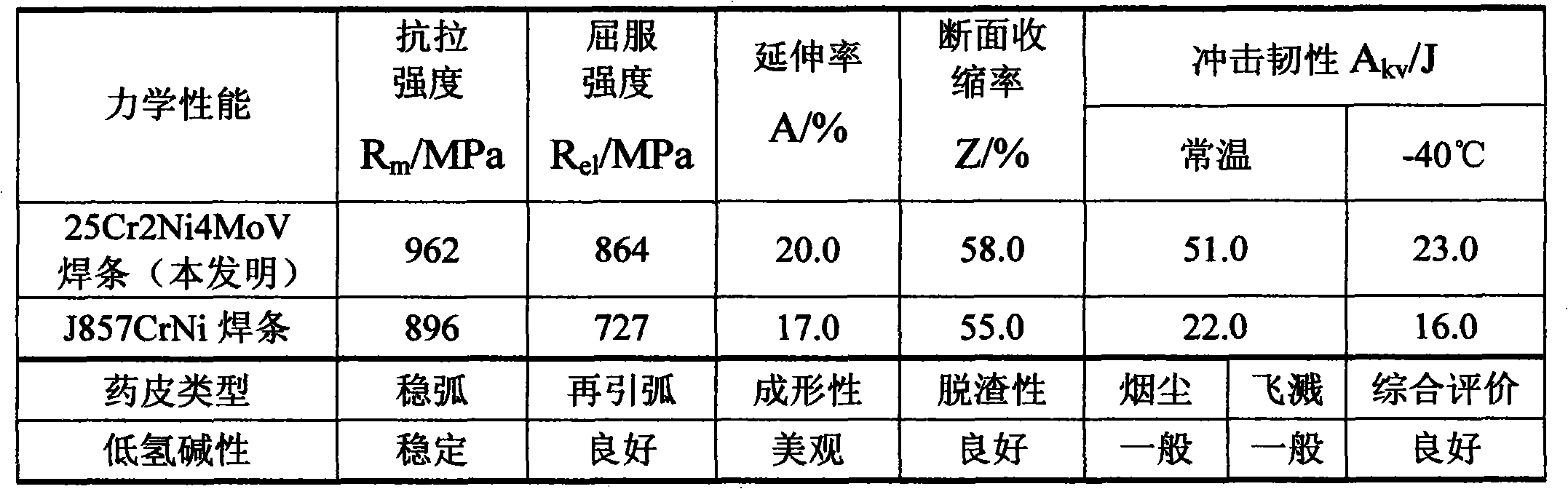

Low-hydrogen basic electrode for 25Cr2Ni4MoV alloy steel welding

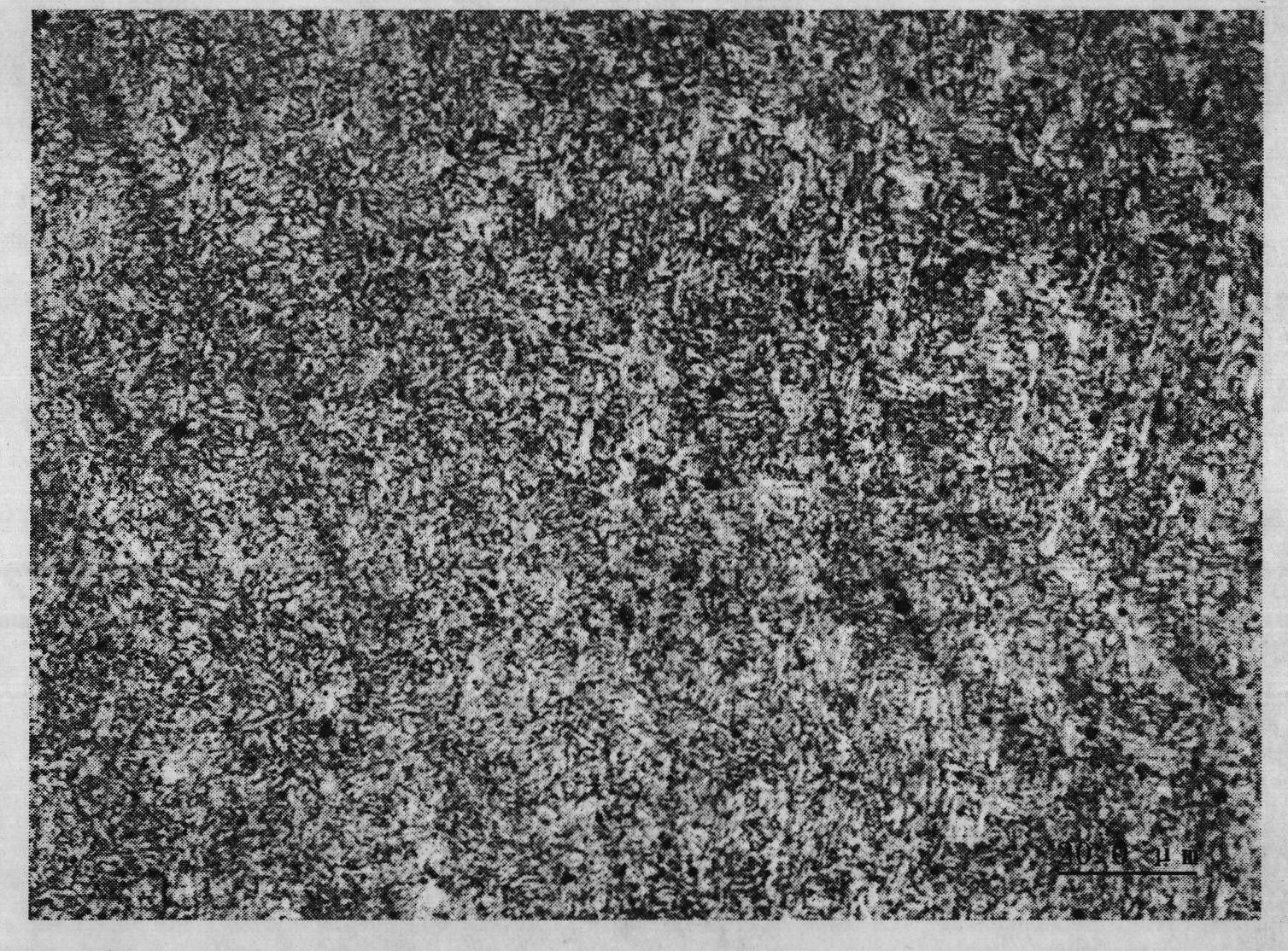

InactiveCN101890594AGood arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaFerrosiliconFerrotitanium

The invention discloses a low-hydrogen basic electrode for 25Cr2Ni4MoV alloy steel welding, which comprises a core wire and a coating, wherein the coating is prepared from the following materials in percentage by weight: 40-47% of marble, 16-24% of fluorite, 3-6% of quartz, 3-6% of zircon sand, 4-12% of rutile, 6-11% of ferrotitanium, 4-8% of low-carbon ferromanganese, 2-5% of ferrosilicon, 1-3% of rare earth ferrosilicon, 2.8-3.2% of synthetic mica and 0.5-1.5% of soda ash, and the sum of the weight percentage of all the components is 100%.The electrode prepared from the coating has the advantages of high arc stabilizing performance, good molten pool fluidity, fine splashing particles, easier deslagging after welding, uniform slag covering and delicate and attractive molded weld. Besides, the diffusible hydrogen content of the deposited metal of the prepared electrode is effectively limited.

Owner:XIAN UNIV OF TECH

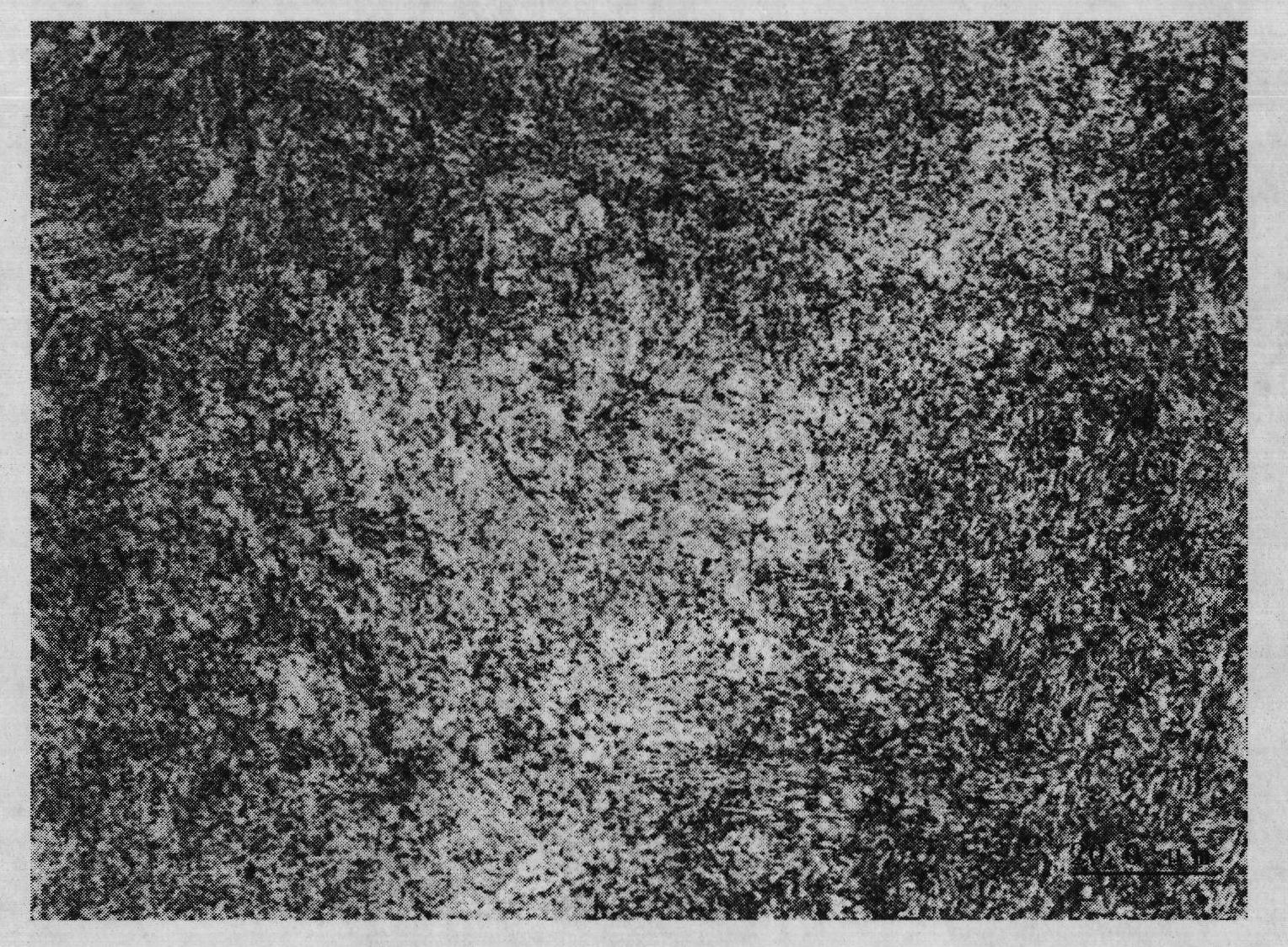

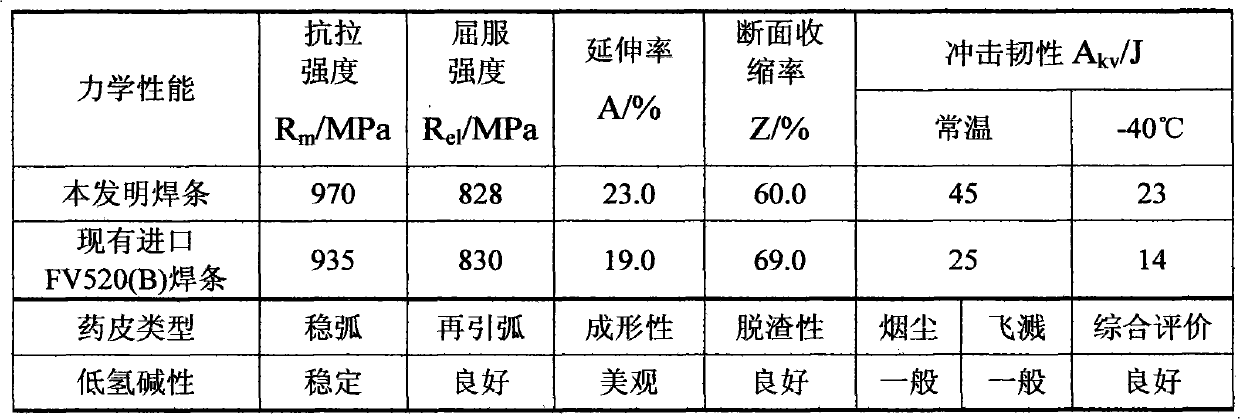

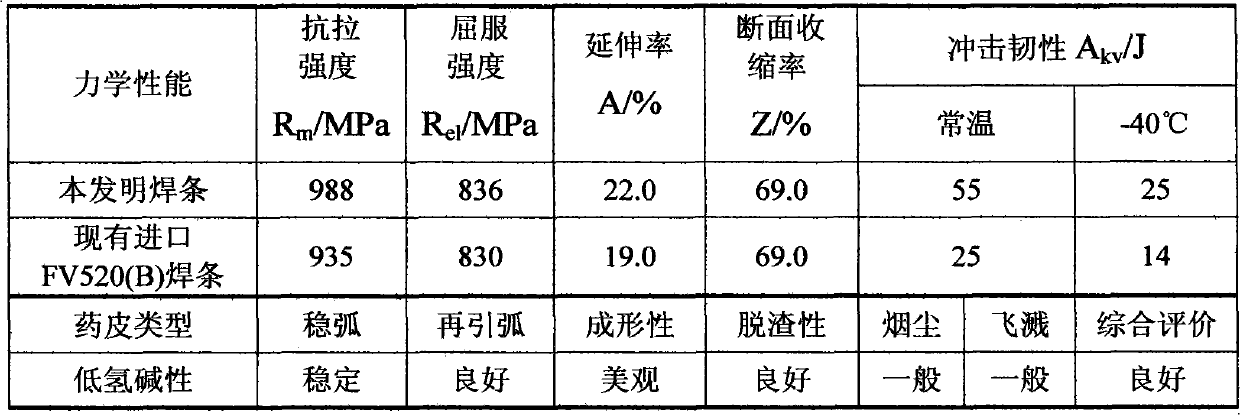

Low-hydrogen basic electrode for welding FV520 (B) stainless steel

ActiveCN101905395AImproved arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaSlagMolten bath

The invention discloses a low-hydrogen basic electrode for welding FV520 (B) stainless steel, comprising a core wire and an electrod covering, wherein the electrode covering comprises the following materials in weight percentage: 35%-45% of marble, 18%-26% of fluorite, 6%-9% of quartz, 3%-6% of zircon sand, 6%-12% of rutile, 1%-3% of ferrosilicon, 6%-10% of ferrotitanium, 5%-11% of low-carbon ferromanganese, 1%-3% of rare-earth ferrosilicon and 0.5%-1.5% of sodium carbonate, and the sum of the weight percentages of the components is 100%. Compared with the traditional special imported electrode for the FV520 (B) stainless steel, the electrode made of the electrode covering has the advantages of favorable arc stabilization performance, good fluidity of a molten bath, less splash and dust, easier slag removal after welding, uniform slag coverage, and delicate and attractive welding joint formation. The content of diffusible hydrogen generated by using the developed electrode for depositing metal is effectively controlled and meets the requirements of low-carbon contents.

Owner:SERVICE CENT OF COMMLIZATION OF RES FINDINGS HAIAN COUNTY

Submerged arc welding wire of high tensile pipeline steel

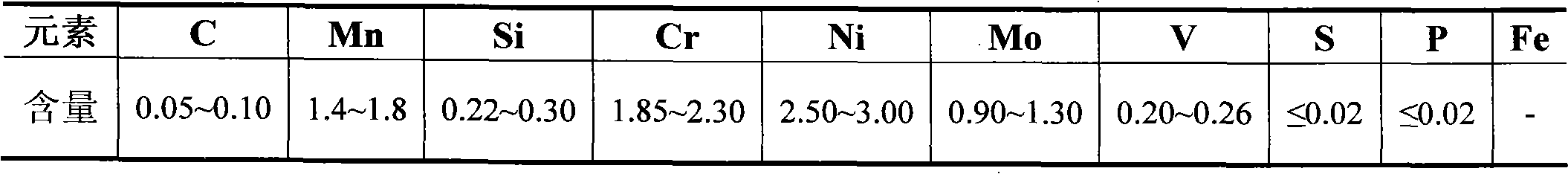

ActiveCN101905391AHigh yield strengthQuality improvementArc welding apparatusPipeline systemsCrack resistanceSheet steel

The invention discloses a submerged arc welding wire of a high tensile pipeline steel. The welding wire material comprises the following chemical components in percentage by weight: not more than 0.10 of C, not more than 0.6 of Si, 1.3-1.8 of Mn, 1.4-2.5 of Ni, 0.25-0.55 of Mo, not more than 0.12 of Ti, not more than 0.05 of V, not more than 0.35 of Cr, 0.0005-0.005 of B, not more than 0.015 of S, not more than 0.015 of P, and the balance of Fe and other inevitable impurities. The submerged arc welding wire of the high tensile pipeline steel provided by the invention has the yield strength of deposited metals of more than 690MPa and the tensile strength of more than 785Mpa, has attractive welding formation, high intensity, high flexibility and high crack resistance without defects of cracking, undercut and the like, and has favorable matching effect with X100 level pipeline steel plates, and meets the requirement on the welding of oil-gas transmission pipelines under the condition of higher pressure.

Owner:YICHANG MONKEY KING WELDING WIRE

Welding method of duplex stainless steels

InactiveCN102019485ALess welding spatterBeautiful weld shapeArc welding apparatusWelding/cutting media/materialsCarbon dioxideCorrosion

The invention belongs to a welding method of duplex stainless steels, comprising the following steps of backing welding, filling welding and cosmetic welding. 99.99% of argon inert gas shield is used for performing the backing welding of the manual tungsten electrode argon tungsten-arc welding, or gas shield formed by adding 80% of argon and 20% of carbon dioxide gas is used for performing semi-automatic filling and cosmetic welding. The welding method of the duplex stainless steels has the advantages that mechanical properties and corrosion resistance of welding joints can be fully ensured, welding spatters are reduced, and weld shaping is beautiful.

Owner:宋卫国

Low dust high crack-resistance flux-cored wire all position flux-cored wire and preparation thereof

InactiveCN101239429AImprove crack resistanceImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaBorideCrack resistance

A low-dust crack-resistant full-position flux-cored wire is characterized in that the medicinal powder used by the flux-cored wire is composed of chemical components according to following percentage by weight: 25% of TiO2, 2% of SiO2, 1% of ZrO2, 1% of fluoride, 0.5% of Si, 8% of Mn, 1% of Al, 3% of Mg, 0.3% of Ti, 0.1% of boride, 0.1% of Re, 0.1% of Na2O, 0.1% of K2O, residue percent is iron powder; the preparing method comprises following steps: steel band longitudinal shearing, edge preprocessing, rolling, wire drawing, and winding. The advantages of the invention are: the weld dust is reduced, and the crack resistant property of welding joint is increased; the welding wire is provided with stable welding arc, little splash, good all position welding performance, good-looking weld joint, excellent detachability and good mechanical performance.

Owner:TIANJIN SAINTEAGLE WELDING CO LTD

Weather-proof flux core wire used for coating-free bridge steel and preparing method of weather-proof flux core wire

ActiveCN106475706AImprove mechanical propertiesStable welding arcWelding/cutting media/materialsSoldering mediaSlagManganese

The invention discloses a weather-proof flux core wire used for coating-free bridge steel and a preparing method of the weather-proof flux core wire. The weather-proof flux core wire is composed of a steel skin and a powder core. The powder core comprises, by weight percent, 2%-8% of ferro-boron, 0.01%-2% of ferromolybdenum, 1%-6% of fluoride, 1.5%-8% of zircon sand, 2%-7% of magnesium powder, 2%-5% of quartz sand, 2%-8% of silicon iron, 5%-19% of electrolytic manganese, 1%-5% of ferromanganese, 1%-6% of nickel powder, 1%-8% of chromium metal, 1%-8% of copper powder, 2%-9% of ferrotitanium, 0.1%-5% of feldspar, 2%-8% of sodium titanate, 20%-40% of rutile and the balance iron powder. Compared with the prior art, the weather-proof flux core wire is stable in welding arc and little in splashing, slag removing is easy, a welding joint is formed attractively, the weather-proof flux core wire is suitable for all-position welding, the mechanical performance of the welding joint is good, the impact toughness at the temperature of minus 40 DEG C is larger than 80 J, and very high corrosion resistance is achieved.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

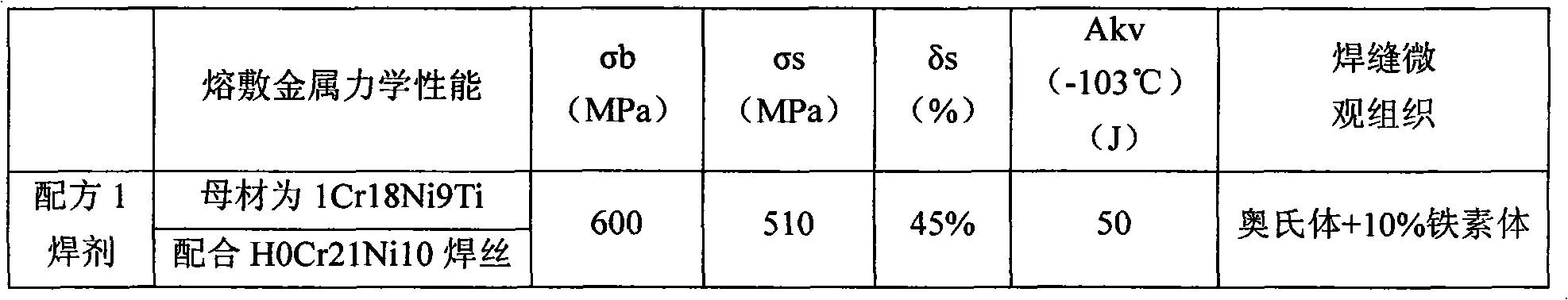

Sintered flux for stainless steel

InactiveCN101585123AEasy to remove slagArc stabilizationWelding/cutting media/materialsSoldering mediaSlagPotassium silicate

The present invention provides a sintered flux for stainless steel. The slag system of the flux is CaF2-Al2O3. The invention is characterized in that the oxidability and the sensibility of the gas hole are small. The stainless steel structure and the stainless steel overlaying welding can be welded when the sintered flux is matched with the corresponding welding stick. The invention is characterized in that the sintered flux comprises the following components: more than 40% by weight of calcium fluoride (CaF2), and furthermore the summation of the calcium fluoride and aluminum oxide (CaF2+Al2O3) is larger than or equal to 70% by weight; other components as follows: smaller than or equal to 5% by weight of CaCO3, 1-3% by weight of CrO3, smaller than 4% by weight of NaAlF6, 1-3% by weight of rare earth fluoride, 3-10% by weight of SiO2, 3-10% by weight of MnO, 1-3% by weight of TiO2, 5-10% by weight of MgO, and 1-3% of iron alloy; and bonding agent of sodium potassium silicate.

Owner:THE LINCOLN ELECTRIC HELI ZHENGZHOU WELDING MATERIALS

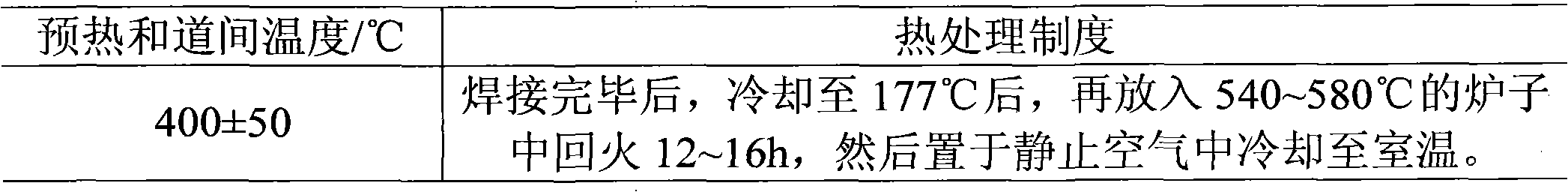

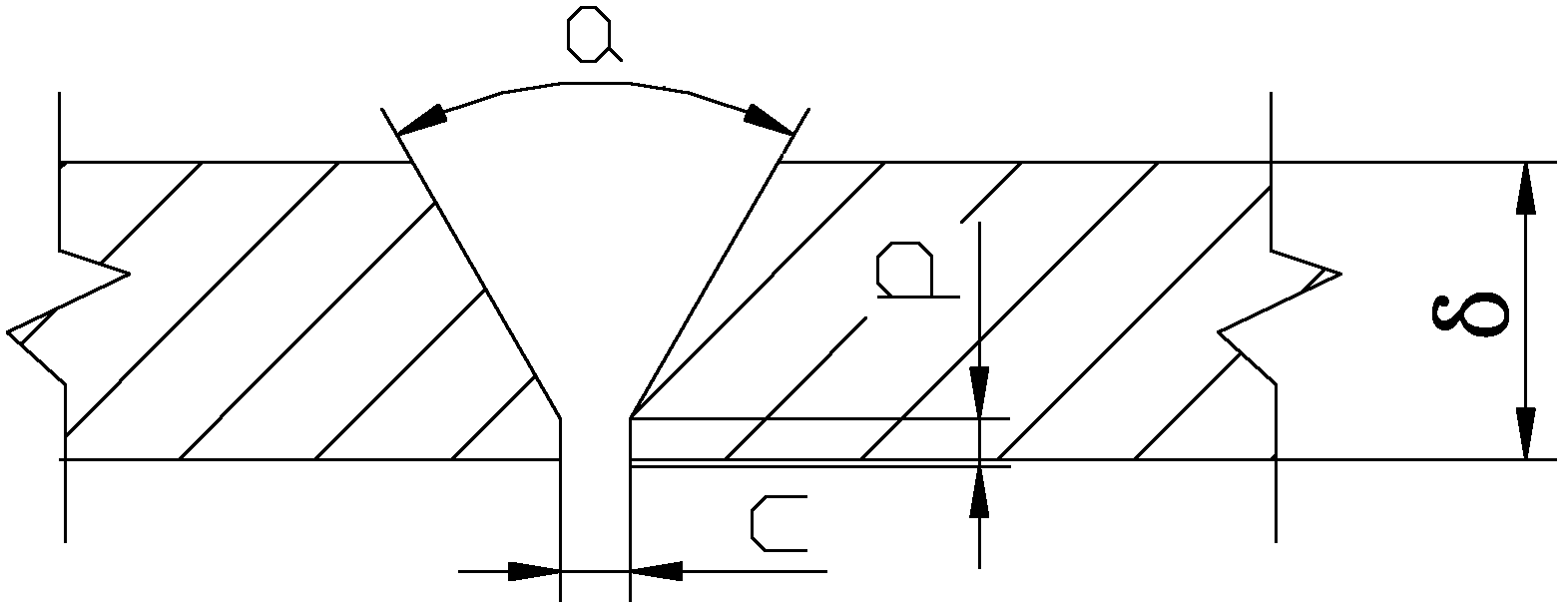

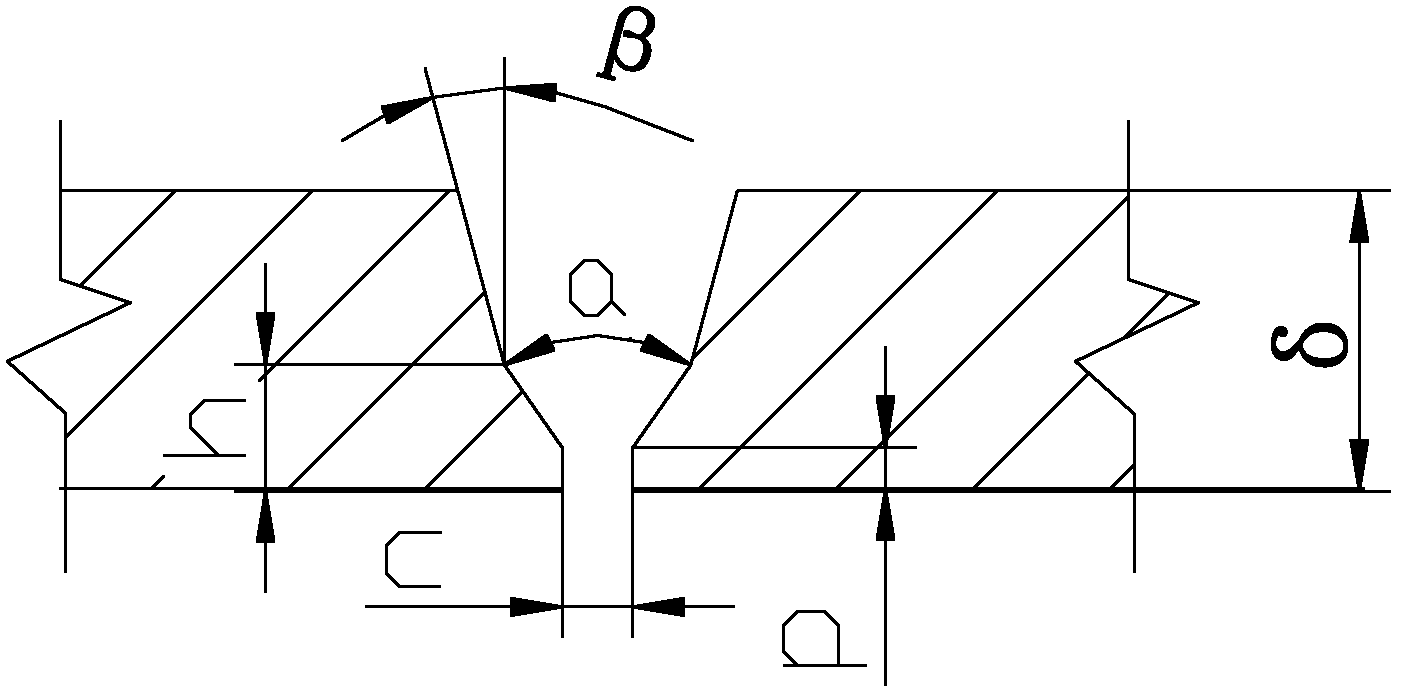

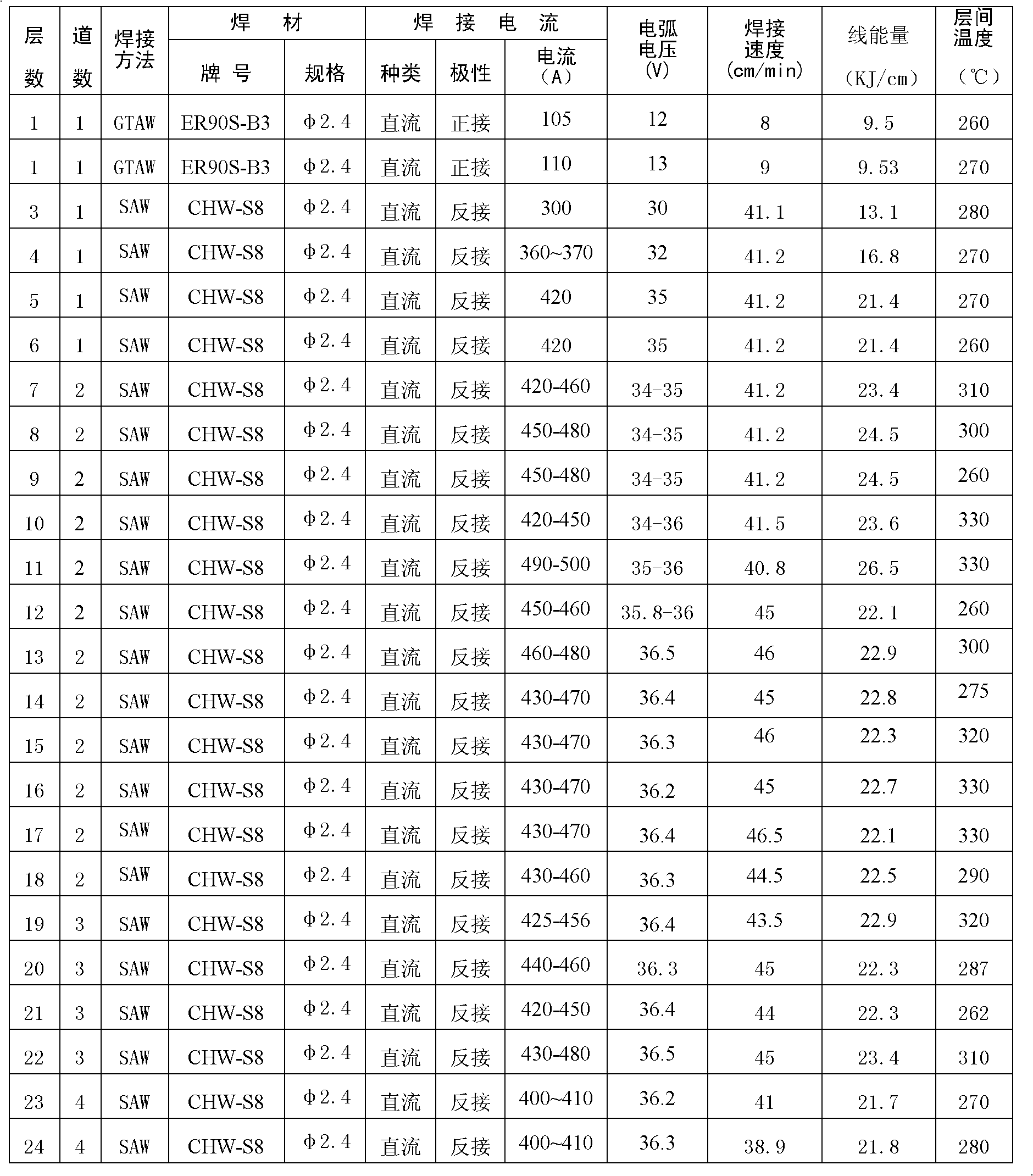

Thick-wall chromium-molybdenum steel pipeline submerged arc welding technology

InactiveCN102248267ABeautiful weld shapeImprove weld seam qualityArc welding apparatusPower flowEngineering

The invention discloses a thick-wall chromium-molybdenum steel pipeline submerged arc welding technology, which is characterized in that an automatic submerged arc welding is used for filling and welding a cover: a pipeline is placed on a rolling tire, an automatic submerged arc welder is used for welding the pipeline, the rolling tire is rotated to drive the pipeline to rotate during welding, and a welding gun is located at a flat welding position and always keeps still; welding parameters are as follows: the welding current is 240-500A, the voltage is 30-36.5V, the welding speed is 36-46.5 cm / min, the extension length of a welding wire is 8-12 mm, and a distance from a tail end of the welding wire to a weld surface is 5-6 mm. The average working efficiency by using the submerged arc welding technology to weld the thick-wall chromium-molybdenum steel pipeline is more than 4-6 times that of the manual welding, the thickness theta of a welding wall is more than the thick-wall pipeline of 30 mm, and the working efficiency is 8-12 times that of the manual welding.

Owner:SINOPEC THE FOURTH CONSTR

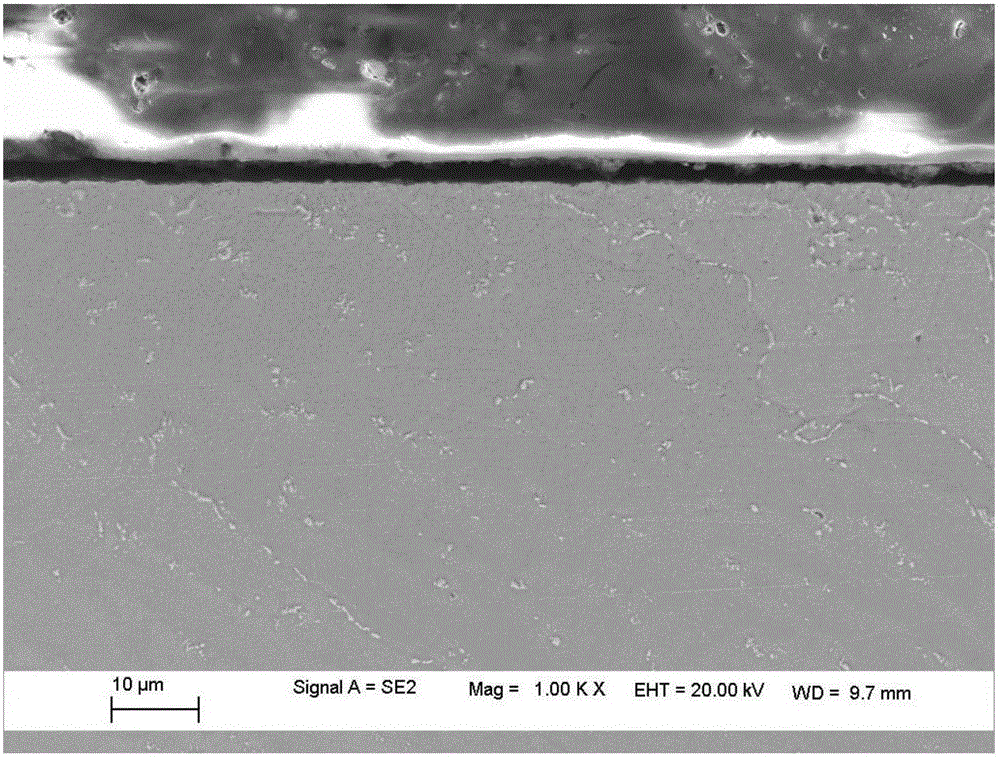

High-hardness self-protecting flux-cored welding wire for overlaying repair of continuous casting roller

InactiveCN104690451AHigh hardnessImprove wear resistanceArc welding apparatusWelding/cutting media/materialsArc stabilityHigh carbon

The invention discloses a high-hardness flux-cored welding wire for overlaying repair of a continuous casting roller, and belongs to the technical field of welding in material processing engineering. An H08A cold-rolled steel strip is adopted as an outer cover, a flux core comprises the following components in percentage by weight: 20-40% of TiO2, 5-15% of high-carbon ferrochrome, 12-30% of low-carbon ferrochrome, 0.5-5% of Mn-Si alloy, 0.5-5% of Al-Mg alloy, 5-15% of Ni, 0.5-2.5% of fluoride, 5-15% of Mo, 0.5-2.5% of V, 2-10% of Cr, 0.5-5% of Al2O3 and the balance of iron powder. The filling rate of the traditional Chinese medicine core of the flux-cored welding wire is 20-35%. The welding wire has the advantages that the flux-cored welding wire adopts a self-protecting overlaying manner, and shielding gas and welding flux are not needed in the overlaying repair process of the continuous casting roller, so that the repair cost can be greatly reduced, the manual labor intensity is lowered, and the production efficiency is improved; the welding wire has good arc stability, excellent abrasion-proof property and excellent thermal fatigue resistant property, and the service life of the continuous casting roller is effectively prolonged.

Owner:SHOUGANG CORPORATION

Sintered flux utilized in automatic submerged arc welding with multiple wires in high speed

InactiveCN1415454AGood composition uniformityImprove low temperature toughnessWelding/cutting media/materialsSoldering mediaWeld seamSoldering process

A sintering welding wire for the multi-wire high-speed autoamtic hidden arc welding contains MgO (19-28 mass%), CaF2 (12-18%), ZrO2 (8-15%), Al2O3 (18-24%), SiO2 (17-25%), CaO (7-13%), RE (0-7%), MnO (0-5%), TiO2 (0-5%), Na2O+K2O (2-5%), S (0-0.05%), and P (0-0.06%). Its advantages are stable arc, beautiful welded seam, and high welding speed (1.5-2 m / m).

Owner:YANSHAN UNIV

Manual argon-arc welding process of tungsten electrode

ActiveCN102528238AImprove welding qualityBeautiful weld shapeArc welding apparatusRetention timeControl theory

The invention discloses a manual argon-arc welding process of a tungsten electrode. According to the welding process, a porcelain mouth of an argon-arc welding torque is supported on a bevel for forming a fulcrum, and by adopting the steps of reasonably setting a gap and welding, a welder is easy to practice the amplitude, the frequency and the advance speed of a circular arc motion of the wrist till being skilled and can further uniformly control the retention time of an electric arc on the two sides of the bevel, uniformly control the length of the electric arc, uniformly control welding speed and effectively ensure linear energy input, so that the welding process has the advantages of aesthetic formed weld joint, uniform weld line, low heat input, compact tissue, stable quality of the weld joint and high quality of the weld joint on the inner pipe of a pipe.

Owner:江苏利柏特股份有限公司

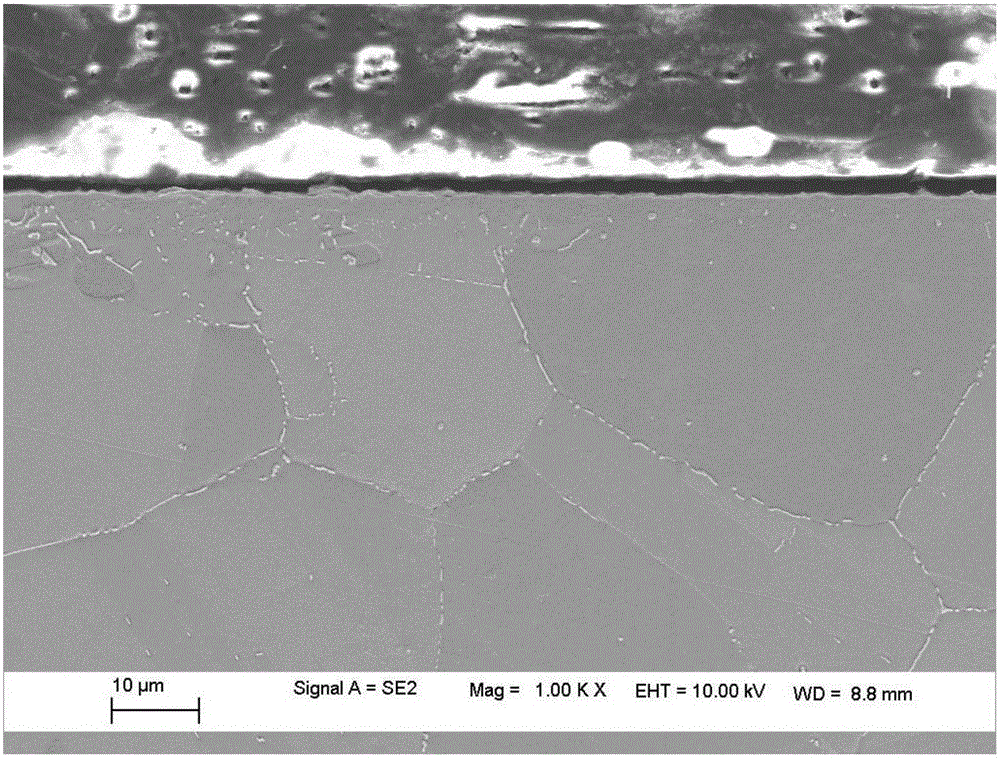

Surfacing flux-cored wire used for repairing hot-forging die

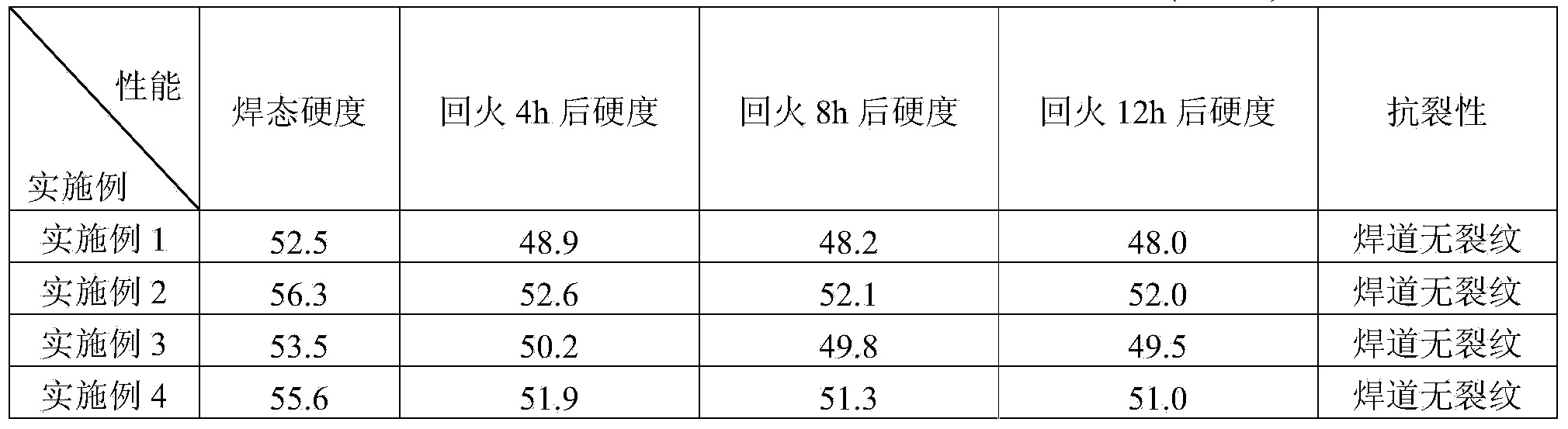

InactiveCN103862194AImprove crack resistanceNo crackArc welding apparatusWelding/cutting media/materialsCrack resistanceElectrolysis

The invention discloses a surfacing flux-cored wire used for repairing a hot-forging die and belongs to the technical field of welding materials. Flux-cored powder is wrapped by adopting a carbon steel belt, and comprises the following substances in mass percentage content: 2-6 percent of sodium fluoride, 5-8 percent of calcium fluoride, 3-5.5 percent of rutile, 1-5 percent of quartz, 4.3-13.2 percent of high-carbon ferrochrome, 24.8-38.3 percent of pure chromium powder, 6-11.3 percent of nickel powder, 1.5-3.5 percent of Fe-W powder, 2.5-5.1 percent of electrolytic manganese, 14.7-27.3 percent of Fe-Mo powder, 3.6-6.1 percent of ferrosilicon powder, 0.2-1.4 percent of ferrovanadium powder and the balance of reduced iron powder. The filling rate of the flux-cored wire is 20-35 percent. Compared with traditional materials, the surfacing flux-cored wire disclosed by the invention has the advantages that (1) the thermal stability and the thermal fatigue resistance are very good, and the hardness range is 48-52HRC; (2) surfacing metal is high in crack resistance, so that preheating before welding or immediate heat treatment after welding is not needed; (3) the surfacing manufacturability is good, and the appearance of a weld is attractive.

Owner:BEIJING UNIV OF TECH

Welding rod for welding of martensite heat-resistant steel

ActiveCN106346167AImprove mechanical propertiesHigh strengthWelding/cutting media/materialsSoldering mediaSlagManganese

The invention discloses a welding rod for welding of martensite heat-resistant steel and belongs to the technical field of welding materials. The welding rod consists of a core wire and a coating, wherein the core wire is prepared from components in percentage by weight as follows: 0.07%-0.10% of C, less than or equal to 0.3% of Si, 0.3%-0.7% of Mn, less than or equal to 0.004% of P, less than or equal to 0.002% of S, 8.5%-9.5% of Cr, 2.8%-3.3% of W, 2.8%-3.5% of Co, 0.04%-0.08% of Nb, 0.15%-0.25% of V, 0.8%-1.0% of Cu, 0.007%-0.011% of N, 0.011%-0.020% of B and the balance of Fe; the coating is prepared from components as follows: 30%-45% of marble, 18%-25% of fluorite, 5%-10% of rutile, 10%-16% of barium carbonate, 5%-10% of ferrotitanium, 1.5%-3% of electrolytic manganese, 5%-10% of iron powder, 0.4%-0.8% of sodium carbonate, 0.4%-0.8% of carboxymethyl cellulose and 0.8%-3% of chromium metal powder. The welding rod has the advantages that the arc is stable during welding, few splashes are caused, the all-position operability is good, the slag detachability is good, formed welds are attractive in appearance, and deposited metal after welding has high strength and high toughness close to that of a parent metal, higher endurance strength and excellent crack sensitivity.

Owner:CENT IRON & STEEL RES INST

Supercritical ferrite and heat-resistant steel matched electrode and production method thereof

ActiveCN103071946AReasonable tensile strengthReasonable shock valueWelding/cutting media/materialsSoldering mediaElectrolysisNiobium

The invention discloses a supercritical ferrite and heat-resistant steel matched electrode, which consists of a core wire and coating. The coating comprises the following components by mass percentage: 28-40 percent of marble, 18-28 percent of fluorite, 1.5-4 percent electrolytic manganese, 2-5 percent of ferrosilicon, 4-10 percent of silica powder, 20-26 percent of chromium metal, 1-1.8 percent of nickel powder, 4-5 percent of ferromolybdenum, 0.4-0.8 percent of ferrocolumbium, 0.2-0.6 percent of amorphous graphite, 3-8 percent of ferrotitanium, 0.4-0.8 percent of soda ash, 0.4-0.8 percent of CMC, 1-1.8 percent of ferrovanadium and 0.6-1.5 percent of ferrochrome nitride. The matched electrode provided by the invention is used for welding supercritical steam turbine ZG1Cr10MoVNbN steel with T91 / P91 pipe heat-resistant steel. Welds after welding have excellent performances such as higher strength, high toughness and better 100-thousand-hour endurance strength similar to the performance of bodies.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

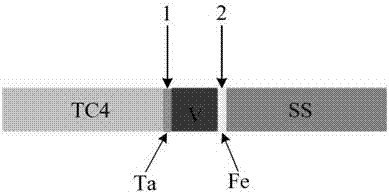

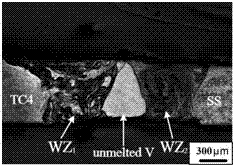

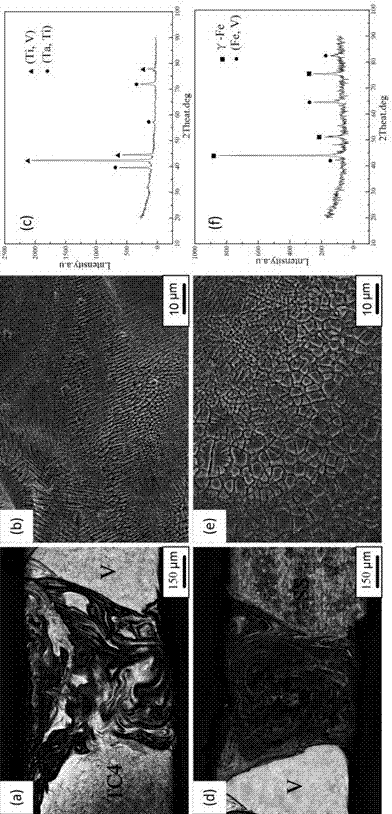

Laser welding method of titanium alloy-stainless steel dissimilar metal by adopting composite intermediate layer

ActiveCN107127454AEasy to shapeAvoid unfusedWelding/soldering/cutting articlesLaser beam welding apparatusOmegaTitanium alloy

The invention relates to a laser welding method of a titanium alloy-stainless steel dissimilar metal by adopting a composite intermediate layer, and belongs to the technical field of material welding (connection). According to the method, laser is adopted as a welding heat source, and a Ta / V / Fe composite layer is used as an intermediate layer material, so that formation of an omega brittle phase in a titanium alloy-vanadium welding line and an alpha brittle phase in a vanadium-stainless steel welding line can be controlled, the joint brittleness can be reduced, and the joint performance can be improved; by adopting the two welding, a high-quality high-efficiency welding joint which is made of a dissimilar metal material and contains a titanium alloy-vanadium welding line, an unmolten vanadium layer and a vanadium-stainless steel welding line can be obtained. The process comprises the steps of plate assembling and clamping, preload adjustment of a titanium alloy-intermediate layer-stainless steel contact face, and laser welding along the center line of a Ta intermediate layer and the center line of a Fe intermediate layer, so that connection of the titanium alloy-stainless steel dissimilar metal can be realized. The method has the advantages of stable welding process, attracted welding line formation, no welding defects including crack, pore, undercutting, uncomplete welding, incomplete fusion and the like, and good welding process performance.

Owner:JILIN UNIV

Metal powder type flux-cored wire used for welding high-impact-toughness steel

ActiveCN102489902AImprove impact toughnessImprove performanceWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention relates to a metal powder type gas shield flux-cored wire used for welding high-impact-toughness steel. The metal powder type gas shield flux-cored wire comprises 0.01-0.1wt% of C, 0.1-0.4wt% of Mn, 0.01-0.03wt% of Si, 0.005-0.015wt% of S, 0.005-0.015wt% of P and balance of ferric low carbon steel skin as well as flux accounting for 14-25% of the total weight of the metal powder type gas shield flux-cored wire, wherein the flux comprises the following components in percent by the total weight of the metal powder type gas shield flux-cored wire: 1.2-4.0% of middle-carbon ferromanganese, 0.20-2.0% of ferrosilicon powder, 0.05-0.5% of magnesium powder, 0.1-2.0% of molybdenum ferrous powder, 1-2% of nickel powder, 0.05-0.2% of fused magnesia, 0.01-0.3% of fluoride and 7-14% of ferrous powder; and all the components are blended and then are placed on a low-carbon steel thin steel strip to be rolled into strips and be drawn into wires. The metal powder type gas shield flux-cored wire provided by the invention has the characteristics that almost no slag is left on a deposited metal after welding, continuous multi-layer welding without removing slag can be carried out, welding speed is fast and efficiency is high, welding technological property is good, electric arc is stable, splashing is less and moulding is beautiful, welding low temperature toughness is high and vertical down welding can be realized by virtue of short circuit transition.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

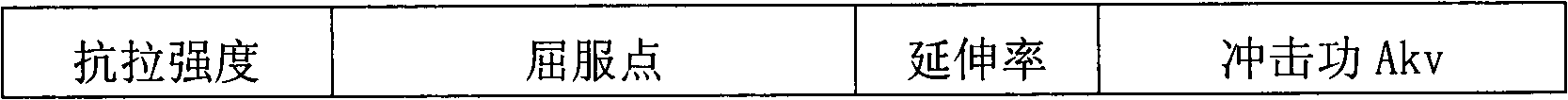

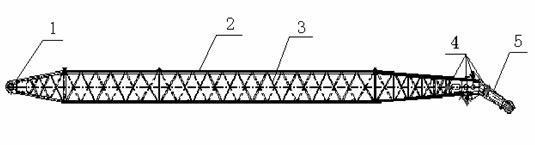

Welding method for high-strength steel truss-type cantilever crane

ActiveCN102489888AQuality assuranceLow costWelding/cutting auxillary devicesArc welding apparatusNumerical controlCantilever

The invention discloses a welding method for a high-strength steel truss-type cantilever crane. A main chord tube and a branch tube which are used as main parts of the high-strength steel truss-type cantilever crane are high-strength Q620E steel pipes. Feeding, open phase transversal and beveled edges of the steel pipes are cut and formed at one time by using a three-dimensional full-automatic numerical control steel pipe flame cutter. The main chord tube and the branch tube which are spliced are fixed by a tool plate. After local preheating, symmetrical welding and welding from the middle toboth sides and from bottom to top are adopted, flux-cored arc welding (FCAW) is adopted during welding and the arc is struck inside the beveled edge of a workpiece. The method provided by the invention not only ensures the welding quality of the high-strength steel truss-type cantilever crane with attractive appearance of welding lines, but also is simple and convenient to manufacture, is easy tocontrol welding deformation and has low welding cost.

Owner:WUHAN MARINE MACHINERY PLANT

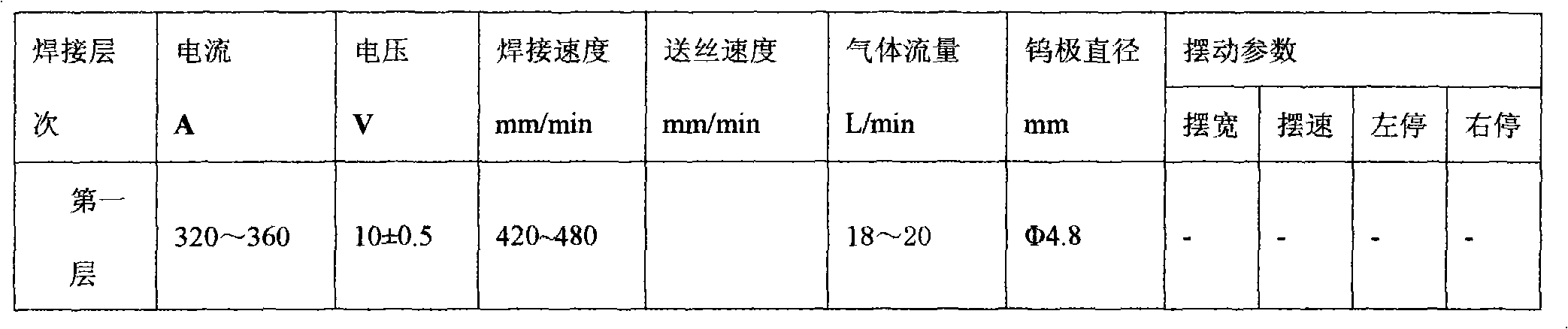

Welding wire for welding FV520B martensitic stainless steel and manufacturing method thereof

InactiveCN103990918AGood soldering requirementsImprove self-protection performanceWelding/cutting media/materialsWelding/soldering/cutting articlesSlagMartensitic stainless steel

A welding wire for welding FV520B martensitic stainless steel comprises a powder core and an outer skin. The powder core is composed of, by mass, 15 percent to 35 percent of rutile, five percent to 15 percent of zircon sand, two percent to five percent of quartz, four percent to 10 percent of feldspar, two percent to five percent of sodium carbonate, two percent to five percent of aluminum oxide, six percent to 12 percent of aluminum magnesium alloy, five percent to 10 percent of electrolytic manganese metal, 18 percent to 25 percent of chromium powder, six percent to 10 percent of nickel powder, two percent to six percent of ferroniobium and one percent to 10 percent of molybdenum powder, and the sum of the mass percent of all the components is 100 percent. The welding wire is good in arcing and arc stabilizing performance, good in molten pool fluidity, fine in splashed particle and even in postwelding slag coverage, and enables deslagging to be easy, welding joint forming is meticulous and attractive, the welding wire is suitable for large linear energy welding, the organization and performance obtained through the prewelding preheating and postwelding heat treatment process can meet actual production needs, and the welding requirement for FV520B martensitic stainless steel is met.

Owner:XIAN UNIV OF TECH

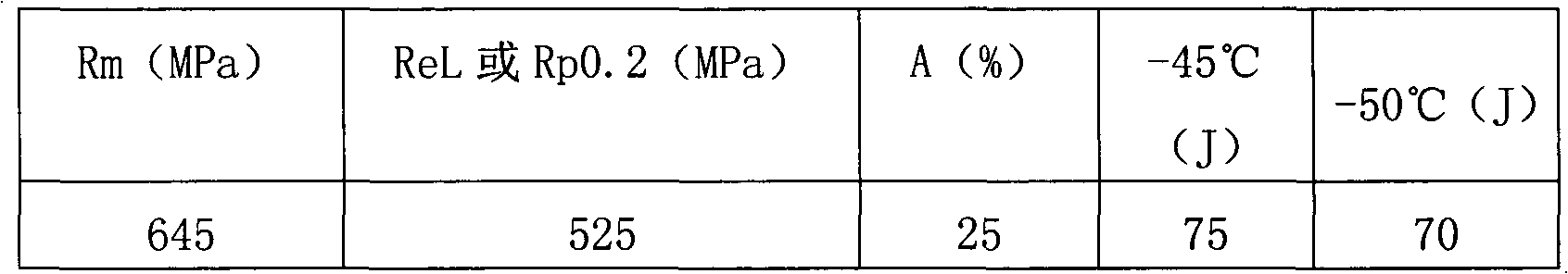

High-strength steel welding rod for hydroelectric engineering and preparation method for high-strength steel welding rod

ActiveCN107931888AIncrease temperatureImprove deformationWelding/cutting media/materialsSoldering mediaSlagManganese

The invention discloses a high-strength steel welding rod for hydroelectric engineering and a preparation method for the high-strength steel welding rod. The high-strength steel welding rod comprisesa welding core and a coating coated on the surface of the welding core, the coating comprises the following ingredients of, by weight, 9.5-10.5 parts of marble, 4.25-5 parts of fluorite, 1.5-2 parts of rutile, 1.5-2 parts of silica powder, 1-1.5 parts of manganese metal, 0.8-1.05 parts of silicon iron, 0.6-0.675 part of ferromolybdenum, 0.025-0.05 part of graphite, 0.05-0.50 part of chromium metal, 0.625-0.675 part of iron powder, 0.1-0.15 part of sodium carbonate, 0.1-0.15 part of sodium alga acid, 0.1-0.15 part of CMC, 0.05-0.075 part of ferroboron and 1.7-1.9 parts of nickel powder. By means of the high-strength steel welding rod for hydroelectric engineering and the preparation method for the high-strength steel welding rod, when welding is performed, an electric arc is stable, spatteris small, slag-removal is well performed, molding is good, whole position operation performance is good, vertical welding position strength in welding deposited metal reaches standard requirements, and the impact toughness of the deposited metal is larger than or equal to 47 J at the temperature of -40 DEG C.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

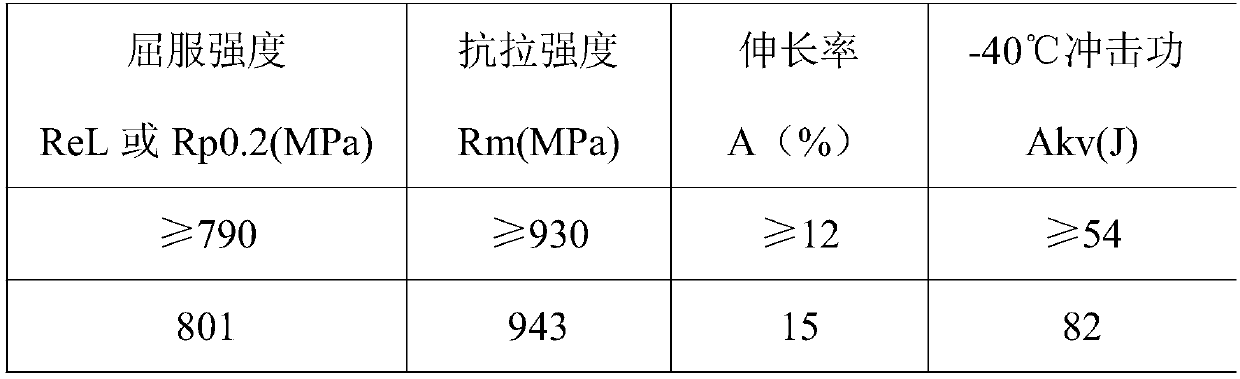

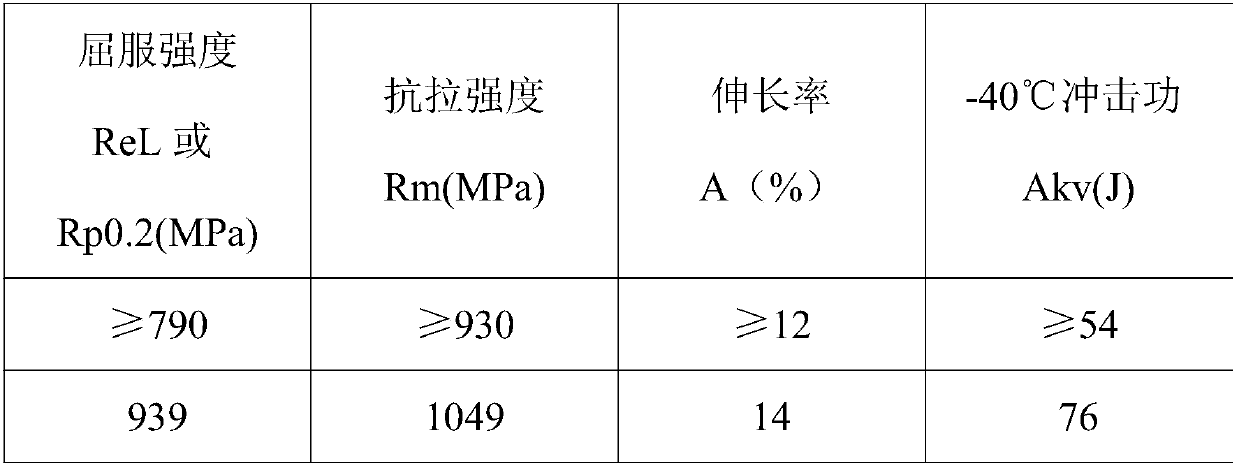

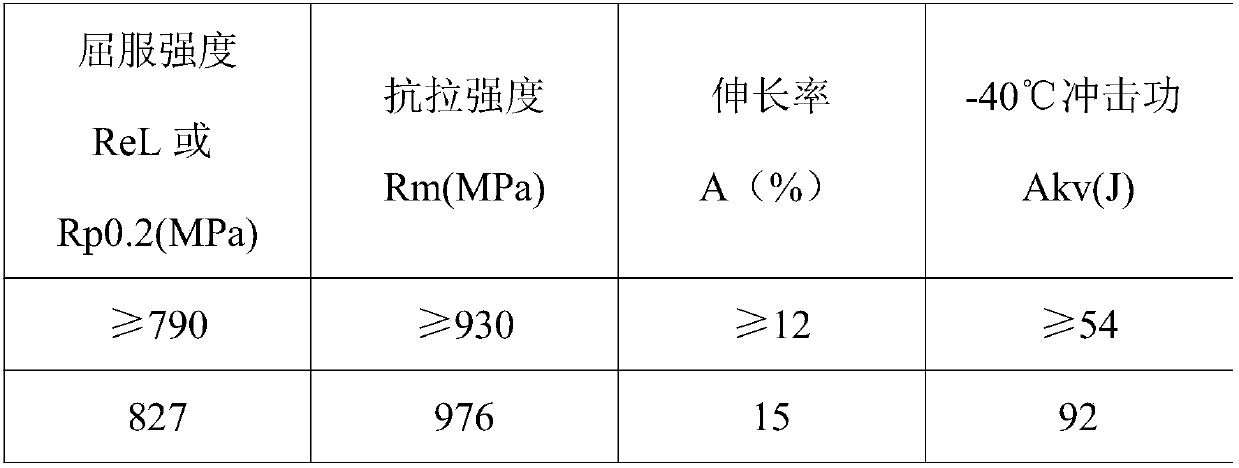

Gas protection solid welding wire for 1000 MPa high-strength steel welding and preparing and welding methods of gas protection solid welding wire

ActiveCN106312372AHigh strengthImprove impact toughnessArc welding apparatusWelding/cutting media/materialsSocial benefitsPower station

The invention discloses a gas protection solid welding wire for 1000 MPa high-strength steel welding and preparing and welding methods of the gas protection solid welding wire. Chemical ingredients of the welding wire include, by weight, 0.07-0.13 part of C, 0.3-0.5 part of Si, 1.8-2.3 parts of Mn, 2.7-3.2 parts of Ni, 0.3-1.2 parts of Cr, 0.4-0.85 part of Mo, 0.01-0.1 part of Ti, 0.01-0.03 part of Al, 0.008 part or below of P, 0.005-0.010 part of S, 0.3 part or below of Cu, 0.01-0.035 part of Nb and the balance Fe. The welding wire can replace an imported welding wire, the construction cost of high-strength steel for large hydropower stations, water pumping and energy storage power stations and the like can be remarkably reduced, and remarkable economic benefits and social benefits are achieved.

Owner:SICHUAN XIYE NEW MATERIAL

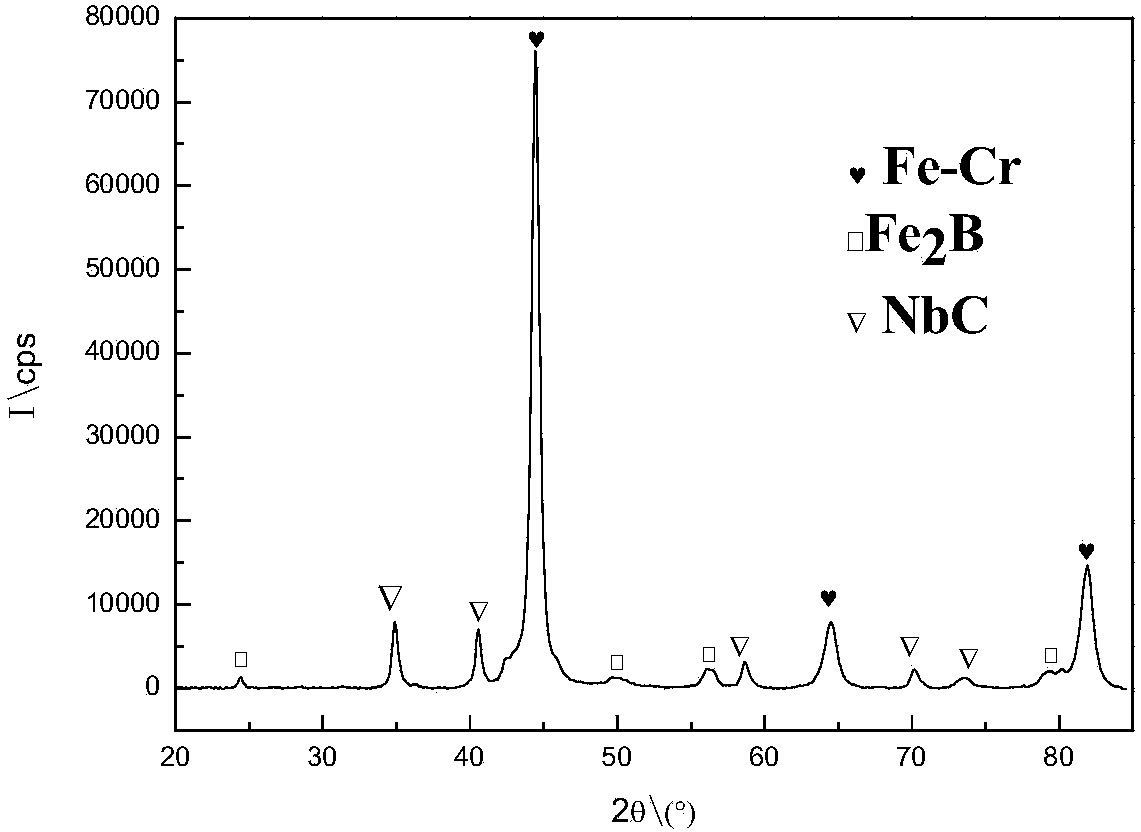

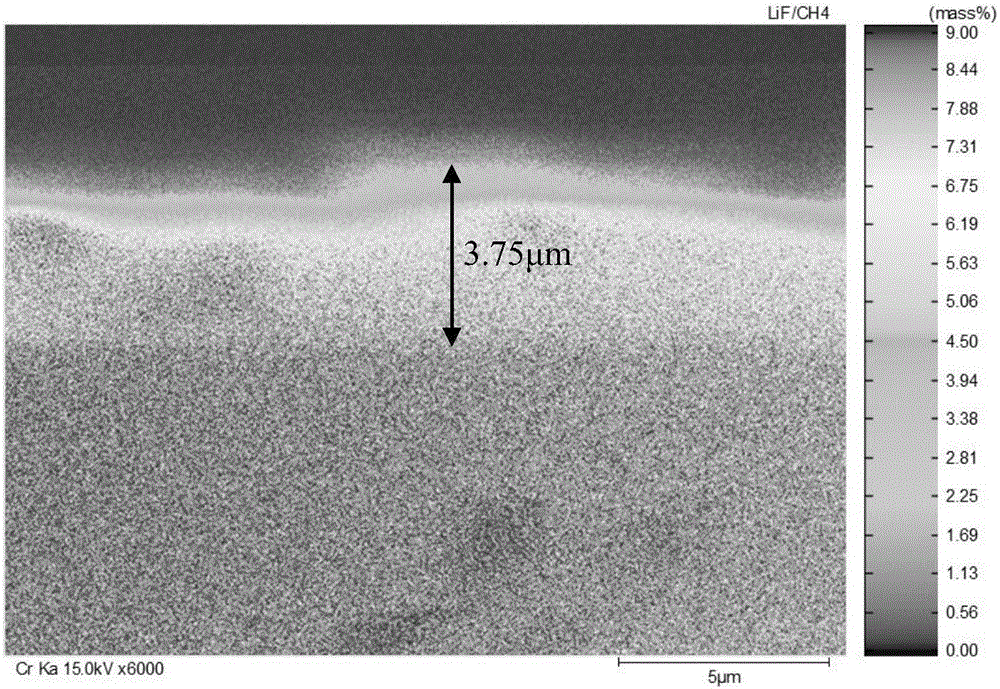

Fe-Nb-Mo-Cr-Mn-B iron-based surfacing flux-cored wire for wear-resistant strip of drill rod joint

InactiveCN103894756AImprove wear resistanceImprove crack resistanceArc welding apparatusWelding/cutting media/materialsBorideCrack resistance

The invention relates to an Fe-Nb-Mo-Cr-Mn-B iron-based surfacing flux-cored wire for a wear-resistant strip of a drill rod joint, and belongs to the technical field of welding materials. A carbon steel strip is adopted to coat flux core powder, filling rate of the flux-cored wire is 20-26%, and alloying elements of the flux-cored wire powder include, by mass, 0.6-1.2% C, 0.8-1.2% of B, 2-9% of Cr, 10-19% of Nb, 4-10% of Mo, 4-10% of Mn, 3-8% of Si, 1-4% of Ti and the balance Fe. Grain structures generated by a coating, carbide and boride after wire surfacing are closely arrayed into a hard metallographic phase to be dispersed in martensite, the size of an NbC hard phase is quite small and is about 1-2 micrometers. No crack exists after welding, average Rockwell hardness is more than 60HRC, and the flux-cored wire has reasonable wear resistance and crack resistance matching performance; surfacing manufacturability is good, weld joints are beautiful in formation, the wear-resistant strip is smooth, the flux-cored wire is few in splash, free of peeling, high in cohesiveness, reusable for surfacing and excellent in compatibility.

Owner:BEIJING UNIV OF TECH

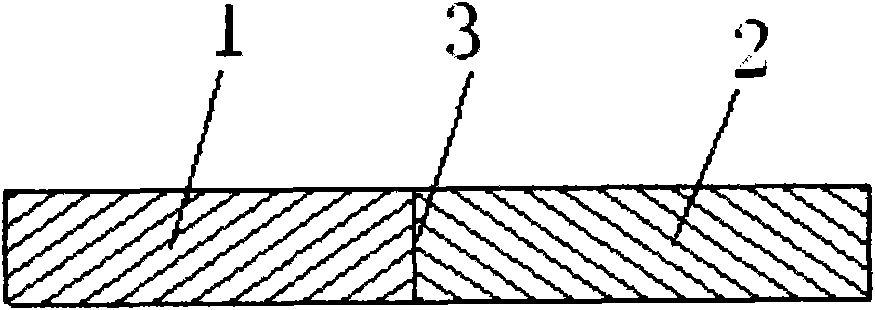

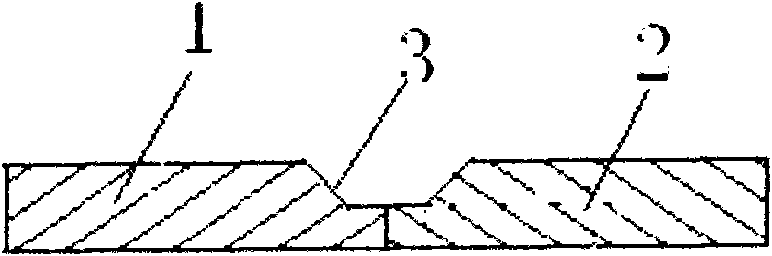

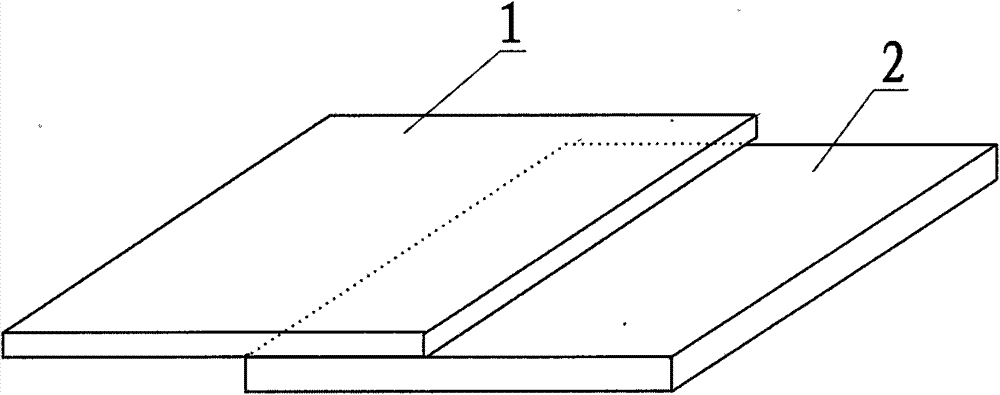

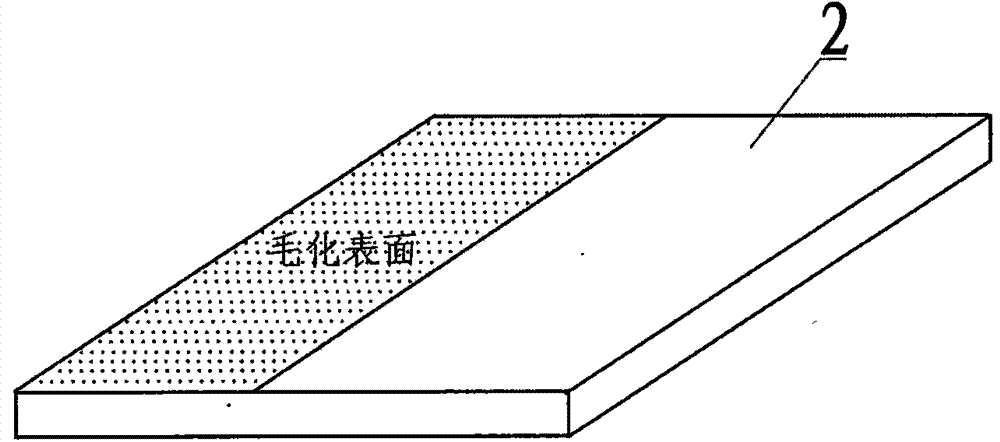

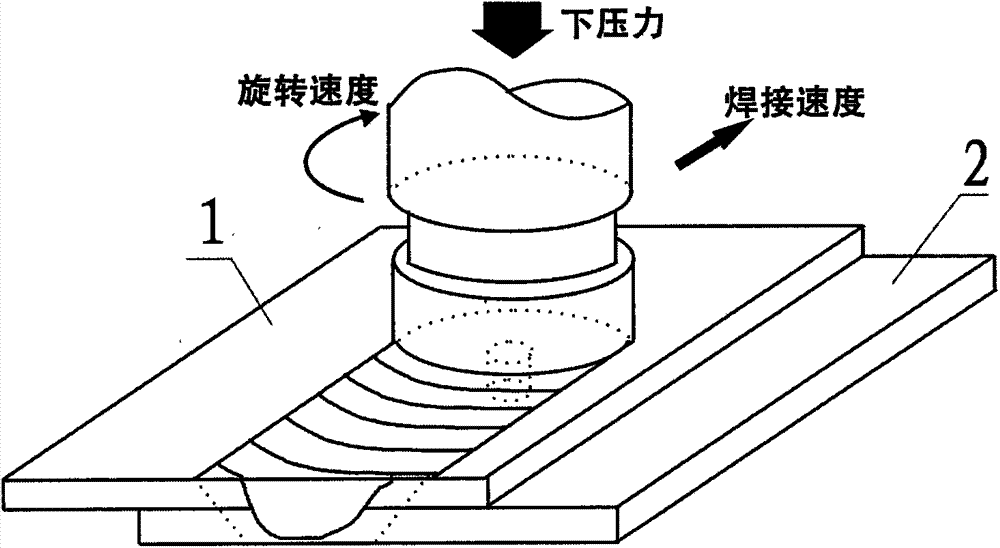

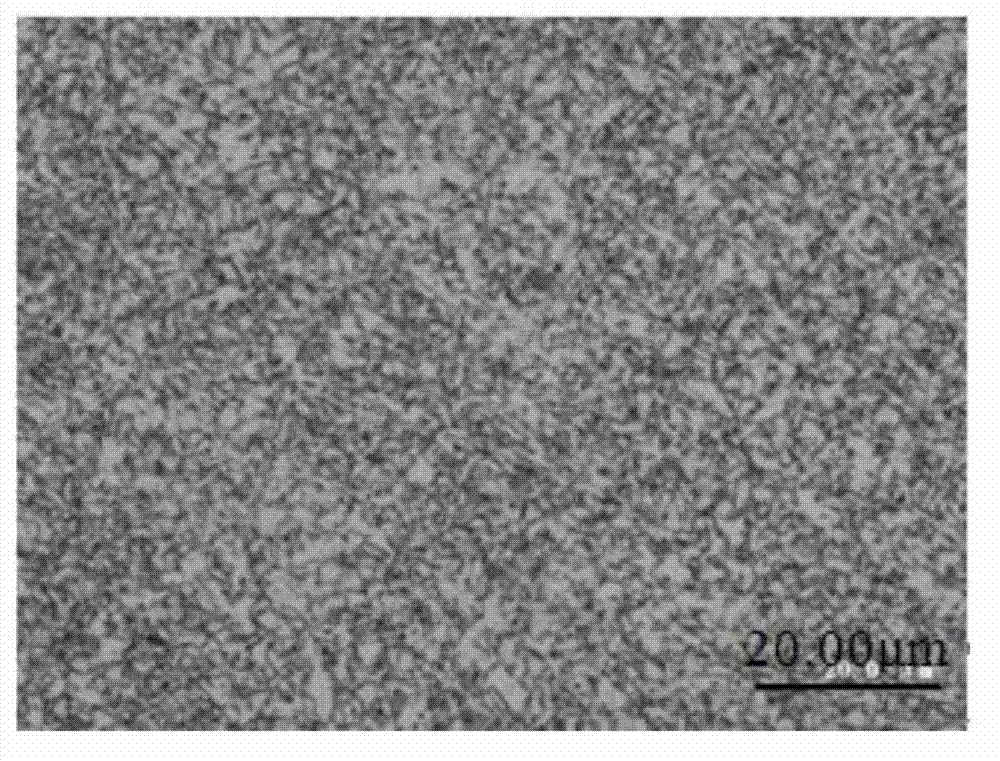

Steel surface roughing auxiliary stirring friction welding method for aluminum and steel dissimilar material lap connection

InactiveCN103894724AImprove mechanical propertiesReliable strengthWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingSheet steel

The invention relates to a steel surface roughing auxiliary stirring friction welding method for aluminum and steel dissimilar material lap connection. A fine convex-concave structure is obtained on the surface of a lap connection position of a steel plate through a roughing method, heat is generated through friction and plastic deformation of a stirring head and an aluminum plate, softened aluminum alloy is combined with the convex-concave structure of the surface of the roughed steel plate, the effective combination area is increased, a brittle intermetallic compound is suppressed from being formed between aluminum and steel, and effective and high-quality lap connection is formed between the steel plate and the aluminum plate. An aluminum steel dissimilar connector with beautiful formed welding joints, a good mechanical property and reliable strength is finally obtained, the welding operation process is simple, the welding cycle is effectively shortened, and automation is achieved easily.

Owner:HARBIN INST OF TECH

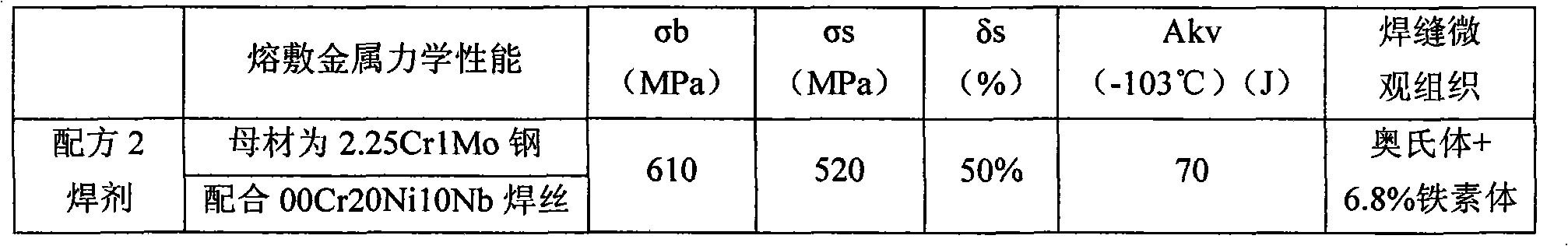

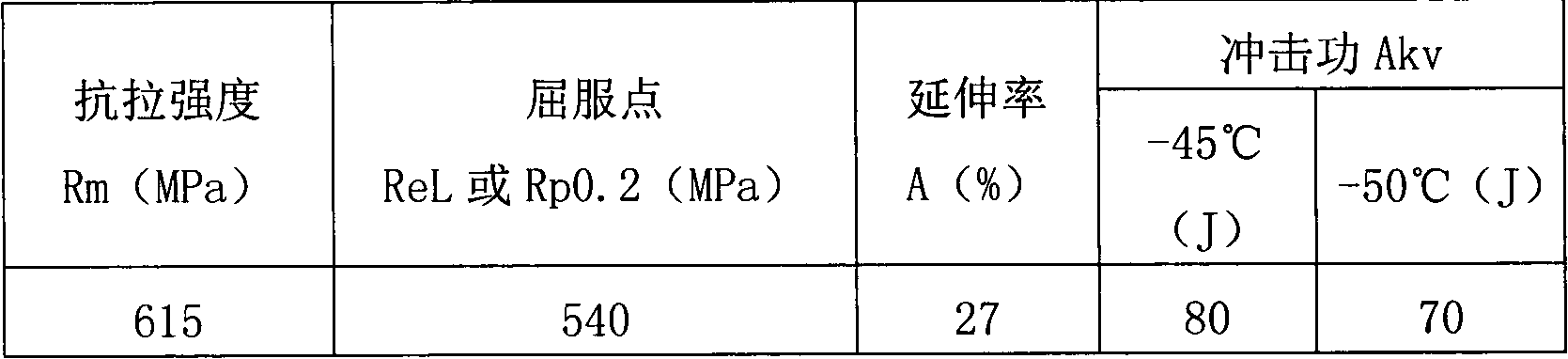

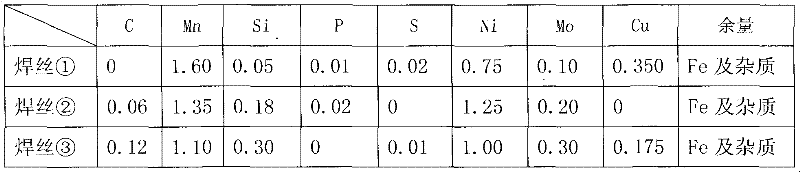

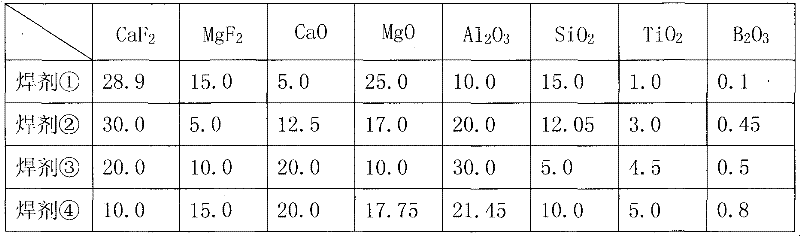

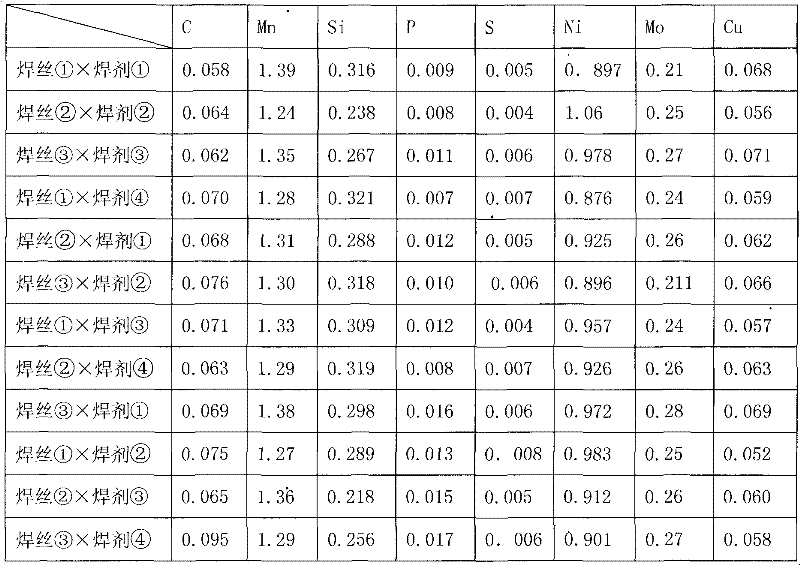

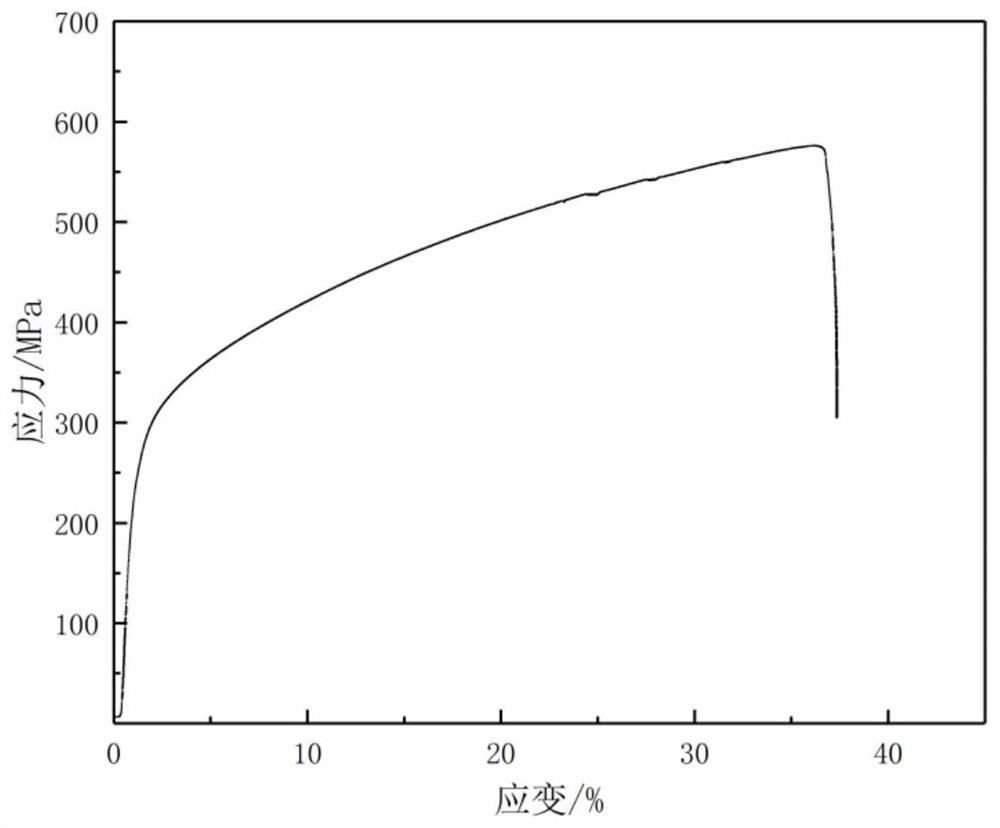

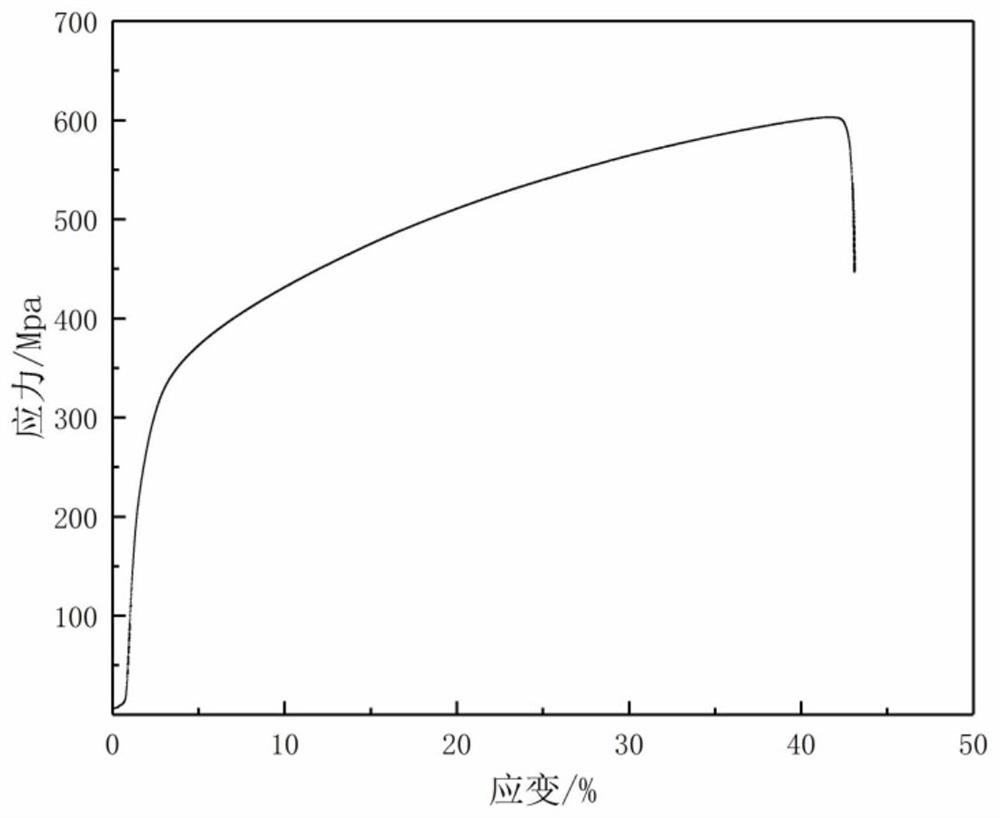

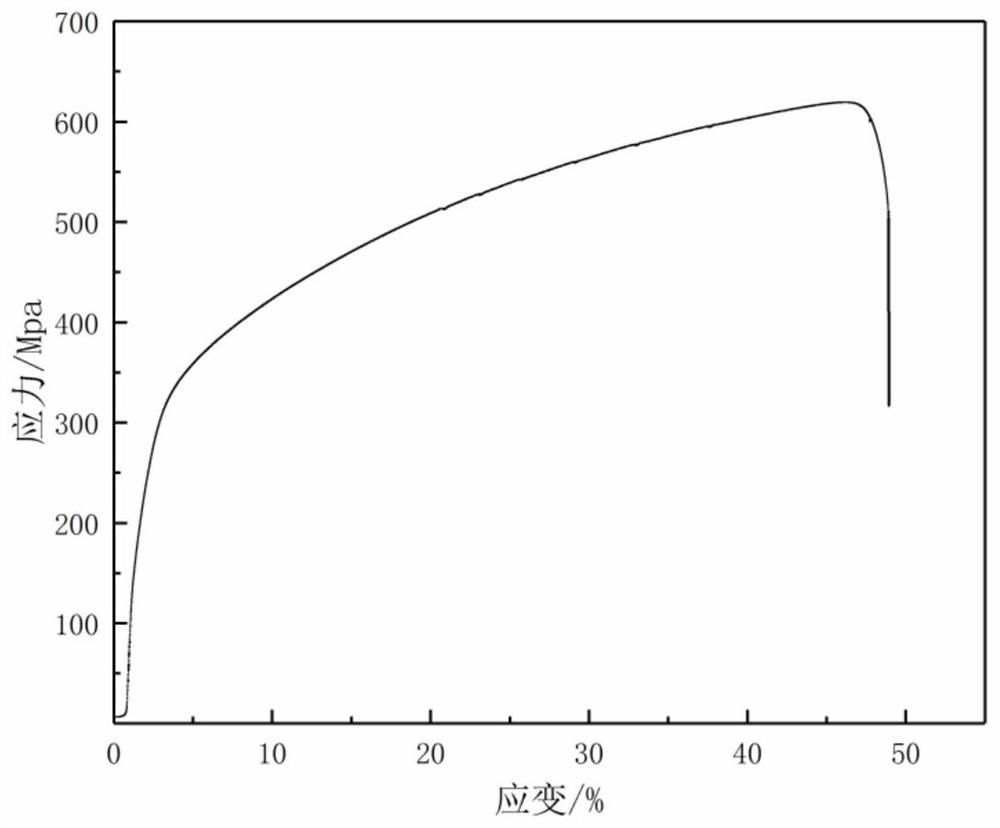

Submerged-arc welding wire and welding flux for high-intensity low-temperature steel

ActiveCN102233493AGood performance with welding operationArc stabilizationWelding/cutting media/materialsSoldering mediaCrack resistanceSlag

The invention discloses a submerged-arc welding wire and a submerged-arc welding flux for high-intensity low-temperature steel. After being matched with each other, the welding wire and the welding flux have extremely high welding operation performance that: an electric arc is stable, a welding seam is aesthetically molded, slag is easy to remove, and high crack resistance and high low-temperature impact properties are realized; and the welding seam (after being subjected to post-weld heat treatment at the temperature of 620 DEG C for 1 hour) has metal mechanical properties that: tensile strength is 480 to 660MPa, yield strength is 400 to 550MPa, elongation rate is 22 to 35 percent, and Charpy impact work is AKv(-51 DEG C) which is more than or equal to 160J.

Owner:KUSN GINTUNE WELDING

Welding flux for molten salt corrosion resistant nickel-base superalloy fusion welding

ActiveCN106077997AIncrease resistanceFacilitate preparation controlWelding/cutting media/materialsSoldering mediaRare-earth elementFusion welding

The invention discloses a welding flux formolten salt corrosion resistant nickel-base superalloy fusion welding and belongs to the technical field of welding materials. The welding flux comprises the following components in percentage by weight: 0.03%-0.06% of C, 0.04%-0.10% of Mn, 0.3%-0.5% of Si, not greater than 0.10% of Cu, not greater than 0.20% of Co, not greater than 0.015% of P, not greater than 0.015% of S, 0.01%-0.05% of rare earth element, 1.0%-5.0% of Fe, 6.0%-8.0% of Cr, 12.0%-18.0% of Mo, not greater than 0.3% of Al, not greater than 0.2% of Ti, 1.0%-2.0% of Nb and the balance of Ni, wherein Ti+Nb+Al is not greater than 2%. The invention also discloses a welding material for molten salt corrosion resistant nickel-base superalloy fusion welding, a connecting method of a molten salt corrosion resistant nickel-base superalloy and a structural member of the molten salt corrosion resistant nickel-base superalloy. According to the welding flux for molten salt corrosion resistant nickel-base superalloy fusion welding, the toughness and the oxidation resistance of a welded joint can be effectively improved, the excellent molten salt corrosion resistance and the excellent high temperature mechanical property can be guaranteed, the usage demands of molten salt and radiation environments with high usage temperature and performance requirements can be satisfied, and the welding flux is suitable for welding of a molten salt reactor structural material.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

High-tenacity low-hydrogen alkaline welding rod and preparation method thereof

InactiveCN103084757AImproved arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaFiberMisch metal

The invention discloses a high-tenacity low-hydrogen alkaline welding rod which comprises a coating and a welding core, wherein the coating comprises, by weight, 38%-44% of marble, 20%-25% of fluorite, 3%-5% of zircon sand, 1%-5% of ferrosilicon, 10%-15% of ferrotitanium, 5%-7% of mid-carbon ferromanganese, 2%-4% of titanium dioxide, 3%-6% of mica, 1.5%-2% of microcrystalline fiber, 1.2%-1.8% of nickel powder, and 1%-1.5% of misch metal, wherein sum of weight percentages of all components is 100%. The invention further discloses a preparation method of the high-tenacity low-hydrogen alkaline welding rod. The preparation method of the high-tenacity low-hydrogen alkaline welding rod includes the steps: enabling coating materials and K-Na mixing water glass to be mixed, crushing the mixture into a power ball with a cylindrical shape, putting the power ball into a pressing coating machine, coating the power ball with the cylindrical shape on a H08A welding core to form the welding rod, and then grinding the head and the tail and getting the high-tenacity low-hydrogen alkaline welding rod after drying. When the high-tenacity low-hydrogen alkaline welding rod is used for welding high-strength steel, no preheating is needed before welding, no heat treatment is needed after welding, content of diffusible hydrogen of deposited metal is controlled effectively, and the preparation method is simple.

Owner:XIAN UNIV OF TECH

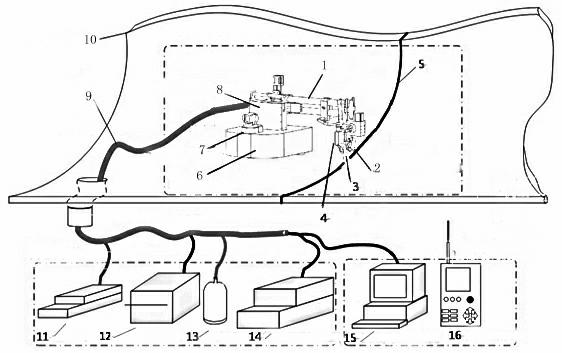

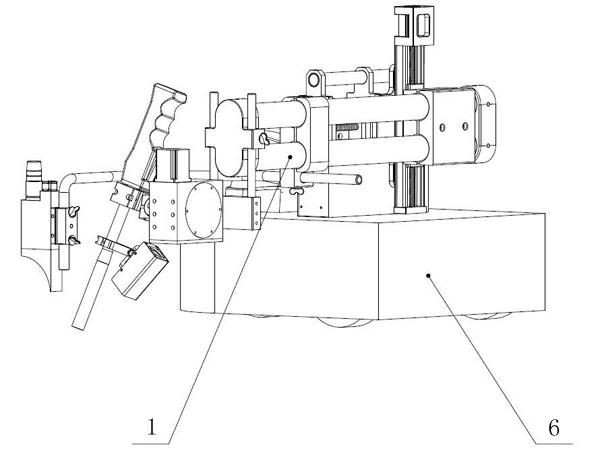

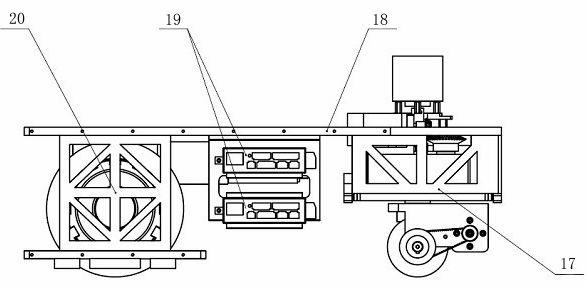

Autonomous mobile robot system for metal-inert-gas (MIG)/metal-active-gas (MAG) multilayer multipass welding of large thick plate

ActiveCN102689083AImprove performanceWith environmental monitoringElectrode supporting devicesDrive wheelShielding gas

The invention belongs to the technical field of welding of robots, and in particular relates to an autonomous mobile robot system for metal-inert-gas (MIG) / metal-active-gas (MAG) multilayer multipass welding of a large thick plate. The system comprises a robot body, a control system and an MIG / MAG welding system, wherein the robot body comprises a crawling mechanism and an operating mechanism; the control system comprises a sensing system, a robot body control box and a robot master control system; the MIG / MAG welding system comprises an MIG / MAG welding gun, an MIG / MAG welding power supply, a wire feeding machine, shielding gas and a weld cooling system; and the robot body, the control system and the MIG / MAG welding system are connected with one another through cables. The system has the advantages that a contact type magnet-wheel adsorption and non-contact type clearance adsorption composite mode and a three-wheel full-drive wheel type movement mode are used by the crawling mechanism, so that a robot can autonomously and flexibly move at all positions on the surface of an operating object, can be reliably adsorbed and can perform all-position welding operation, and the system is high in comprehensive performance.

Owner:DONGFANG ELECTRIC CORP LTD

Metal type flux-cored wire and method of manufacturing austenitic stainless steel structural part

ActiveCN111992923AShort preparation cycleIncrease productivityWelding/cutting media/materialsSoldering mediaManufacturing technologyFerrosilicon

The invention discloses a metal type flux-cored wire. The metal type flux-cored wire is adopted as a raw material, an austenitic stainless steel structural part is manufactured on the basis of an electric arc additive manufacturing technology, and the formed thin-wall structural part has excellent mechanical properties. Flux-cored alloy of the metal type flux-cored wire comprises, by mass percentage, 8% of silicon iron, 18%-22% of manganese powder, 27% of nickel powder, 26% of chromium powder, 4%-8% of molybdenum powder, 1%-3% of copper powder, 0.5% of titanium powder, 0.2% of aluminum powder,0.5% of lanthanum oxide, 1% of niobium carbide and the balance iron powder. The sum of the mass percentages of the components is 100%. The austenitic stainless steel thin-wall structural part obtained through additive manufacturing is attractive in appearance and has the excellent mechanical properties. The austenitic stainless steel metal type flux-cored wire for additive manufacturing can be used for additive manufacturing of complex parts in the fields of national defense, energy, petroleum, chemical engineering, aerospace and bioengineering.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com