Patents

Literature

49results about How to "Improve weld seam quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flux-cored wire for austenitic stainless steel welding

ActiveCN102451961AReduce carbon contentImprove oxidation capacityArc welding apparatusWelding/cutting media/materialsManganeseRutile

The invention discloses a flux-cored wire for austenitic stainless steel welding. The flux-cored wire consists of a flux core and an external steel belt; the external steel belt is an austenitic stainless steel belt of which the carbon content is less than 0.025 percent; the carbon content of the flux core is not greater than 0.04 percent and carbon accounts for 18.0 to 24.0 percent based on the total weight of the flux-cored wire; the flux core comprises the following components in percentage by weight: 18.5 to 25.0 percent of metal chromium powder, 8.0 to 10.0 percent of metal nickel powder, 2.0 to 5.0 percent of electrolytic manganese metal, 1.0 to 3.0 percent of aluminum magnesium alloy, 28.0 to 35.0 percent of rutile, 3.0 to 5.0 percent of quartz, 2.0 to 5.0 percent of zircon sand, 2.0 to 5.0 percent of feldspar, 1.0 to 2.0 percent of cryolite, 2.0 to 5.0 percent of arc stabilizer and the balance of iron powder; and the arc stabilizer consists of K2O, Na2O and TiO2 in a weight ratio of (6.0-8.0):(8.0-10.0):(68.0-70.0), and the water content is not greater than 400 ppm.

Owner:CHINA JINGYE ENG TECH CO LTD +1

Flux-cored wire for austenitic stainless steel all-position welding

ActiveCN102229029AGood workmanshipGood slag removalWelding/cutting media/materialsSoldering mediaElectrolysisPotassium

The invention relates to a flux-cored wire for austenitic stainless steel all-position welding, and the flux-cored wire is composed of a flux core and an external stainless steel belt, wherein, the flux core accounts for 22-24wt% of the flux-cored wire, and the flux core comprises the following components in percentage by weight: 20-23% of metal chromium powder, 7-8.5% of metal nickel powder, 2-4% of electrolytic manganese metal, 3-4% of aluminium powder, 0.5-1% of ferrotitanium, 32-34% of rutile, 1-2% of quartz, 2-4% of zircon sand, 4-6% of albite, 2-4% of potassium feldspar, 1-1.5% of cryolite, 1-1.5% of lithium carbonate, 0.1-0.5% of bismuth oxide and the balance of iron powder. The ratio of the albite to the potassium feldspar in the flux core is 1.2-2, the sum of the albite and the potassium feldspar is not more than 10wt% of the flux core, the external stainless steel belt is the austenitic stainless steel 304L, the carbon content is less than 0.025wt%, the diameter of the flux-cored wire is 0.9-1.2mm, and the flux-cored wire can be used for realizing the austenitic stainless steel all-position welding.

Owner:北京远达国际工程管理咨询有限公司 +1

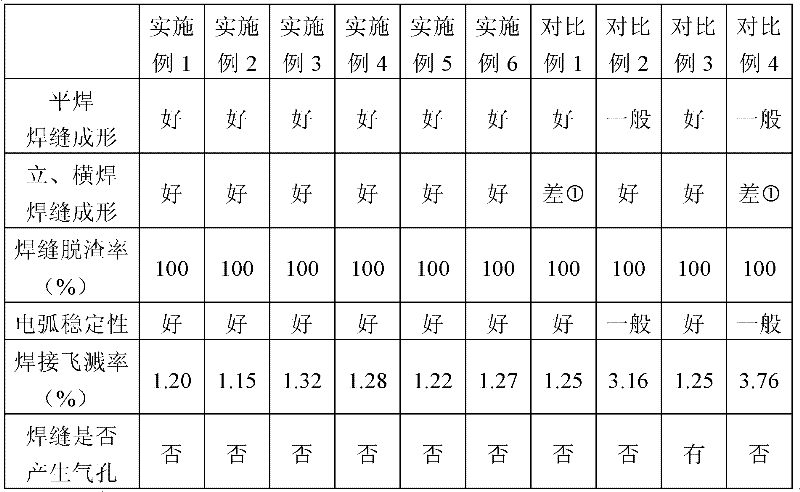

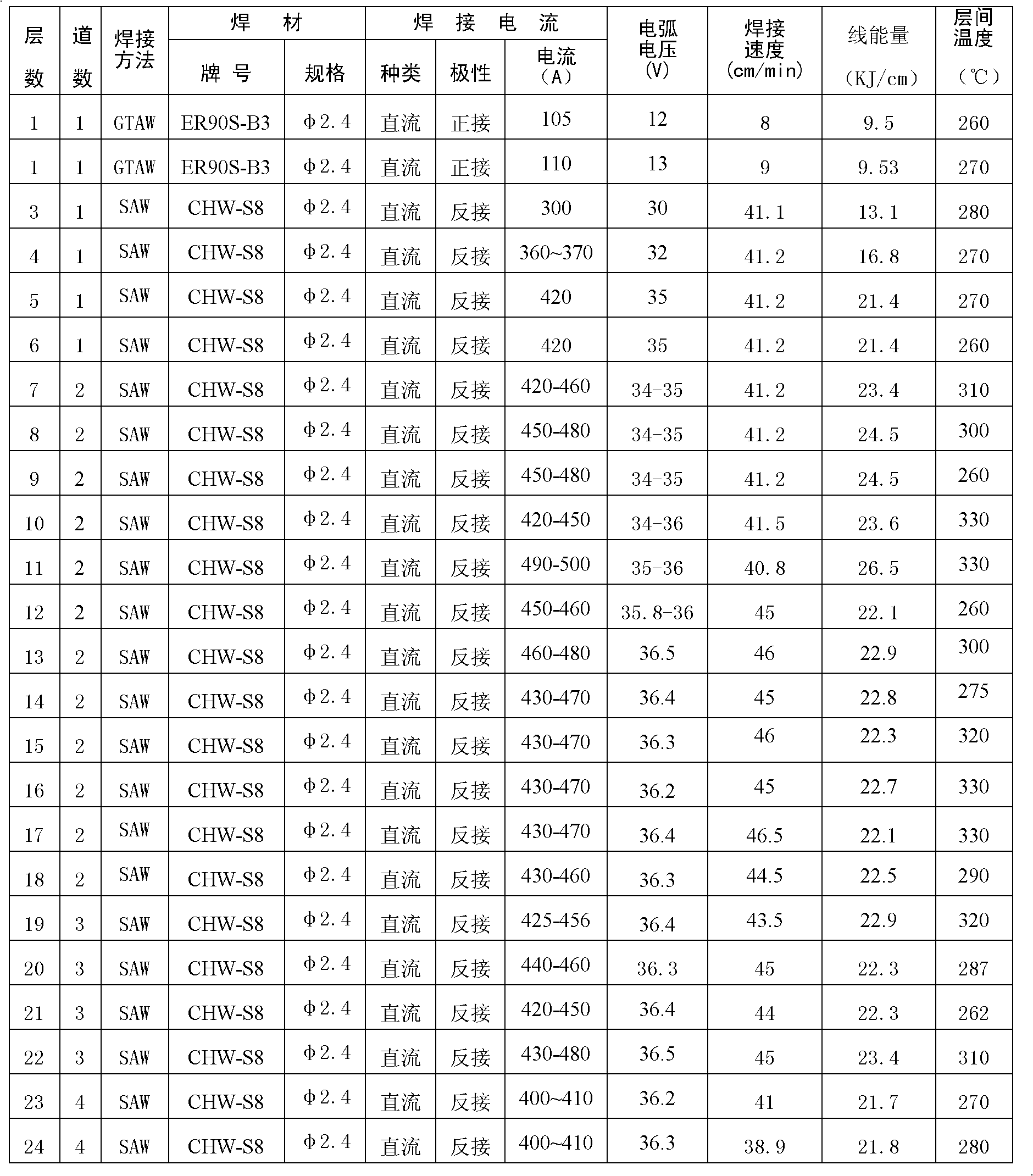

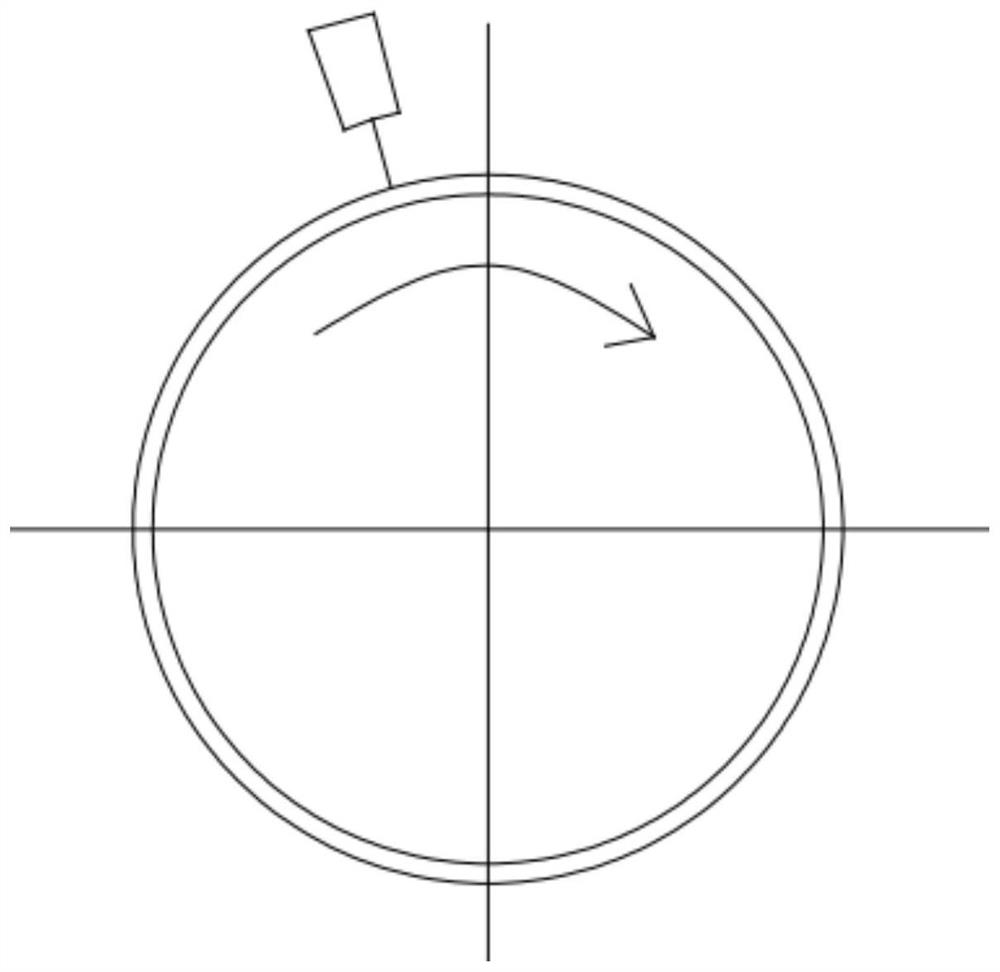

Thick-wall chromium-molybdenum steel pipeline submerged arc welding technology

InactiveCN102248267ABeautiful weld shapeImprove weld seam qualityArc welding apparatusPower flowEngineering

The invention discloses a thick-wall chromium-molybdenum steel pipeline submerged arc welding technology, which is characterized in that an automatic submerged arc welding is used for filling and welding a cover: a pipeline is placed on a rolling tire, an automatic submerged arc welder is used for welding the pipeline, the rolling tire is rotated to drive the pipeline to rotate during welding, and a welding gun is located at a flat welding position and always keeps still; welding parameters are as follows: the welding current is 240-500A, the voltage is 30-36.5V, the welding speed is 36-46.5 cm / min, the extension length of a welding wire is 8-12 mm, and a distance from a tail end of the welding wire to a weld surface is 5-6 mm. The average working efficiency by using the submerged arc welding technology to weld the thick-wall chromium-molybdenum steel pipeline is more than 4-6 times that of the manual welding, the thickness theta of a welding wall is more than the thick-wall pipeline of 30 mm, and the working efficiency is 8-12 times that of the manual welding.

Owner:SINOPEC THE FOURTH CONSTR

Flux-cored wire for gas-shielded welding of high-chromium-nickel all-austenitic stainless steel

InactiveCN102699579AGuaranteed processing effectIncrease widthWelding/cutting media/materialsSoldering mediaChromium nickelManganese

The invention provides a flux-cored wire for the all-position welding of an austenitic stainless steel, comprising flux powder and a stainless steel band for external use, wherein the weight of a flux core accounts for 28.0-30.0 percent of the total weight of the flux-cored wire, the flux core contains the following components accounting for the flux core in percentage by weight: 25.0%-28.0% of metallic chromium powder, 29.0%-32.0% of metallic nickel powder, 4.0%-5.0% of electrolytic metallic manganese, 2.0%-4.0% of high carbon ferro-chrome, 18.0%-20.0% of rutiles, 1.0%-2.0% of quartz, 1.0%-2.0% of zircon sands, 1.0%-3.0% of feldspars, 0.5%-1.0% of fluorspars, 0.5%-1.5% of calcium carbonate, 0.5%-1.5% of barium carbonate, and the balance of ferrous powder. The flux-cored wire has good welding process property and is suitable for the all-position gas-shielded welding of a high-chromium-nickel all-austenitic stainless steel.

Owner:CHINA JINGYE ENG +1

Surface preprocessing method for laser welding of aluminum alloy

ActiveCN108436270AReduce reflectivityImprove cleanlinessWelding/soldering/cutting articlesMetal working apparatusSurface cleaningSurface roughness

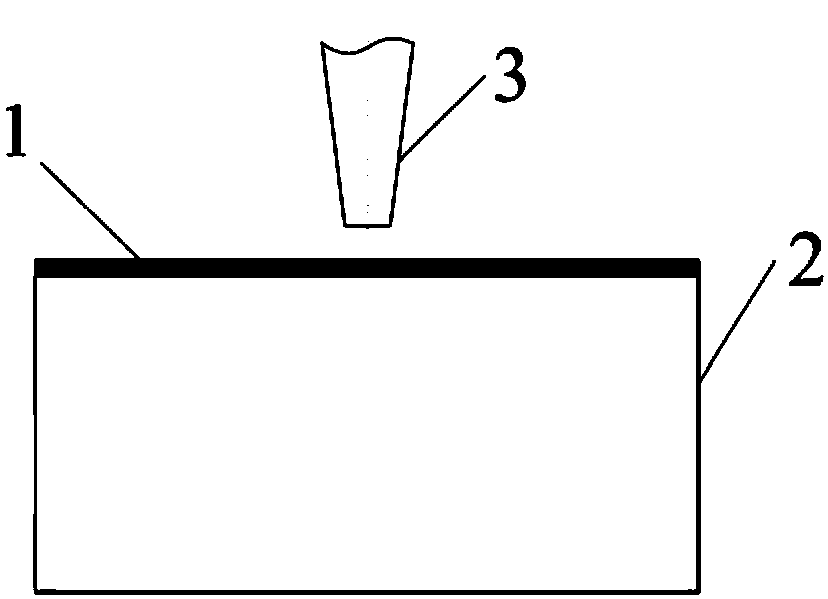

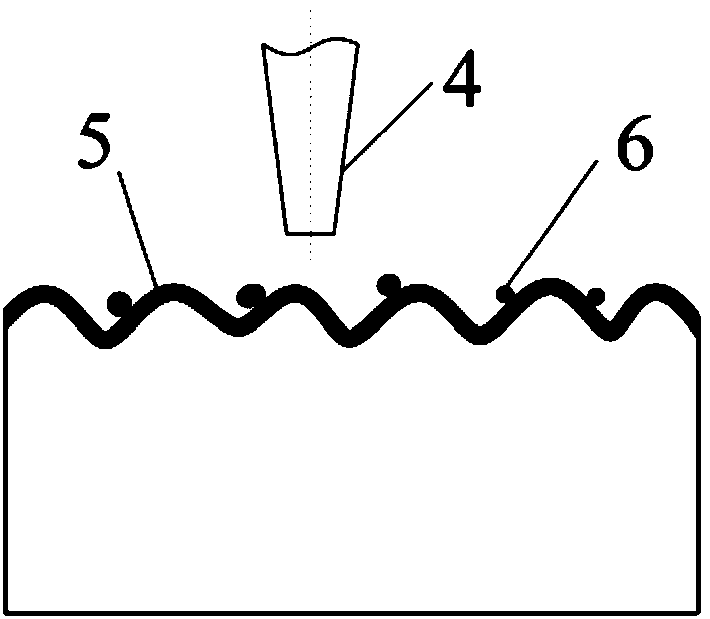

The invention provides a surface preprocessing method for laser welding of an aluminum alloy. The method is characterized by comprising the steps of 1) performing surface texturing treatment on an area, to be welded, of the aluminum alloy through short-pulse laser with energy density of I1, thus forming a regular ripple microstructure; and increasing the surface roughness of the area, to be welded, of the aluminum alloy, wherein the I1 is more than the burning loss threshold Ia of the aluminum alloy; 2) cleaning the surface of the area, to be welded, of the aluminum alloy through the short-pulse laser with the energy density of I2; removing polluting matters on the surface of the microstructure of the area, to be welded, of the aluminum alloy through the short-pulse laser with energy density of I2 so as to remove pollutants on the surface of the microstructure of the area, to be welded, of the aluminum alloy; and increasing the surface cleanness of the area, to be welded, of the aluminum alloy, wherein the I2 is more than the washing threshold Ic of the aluminum alloy and is less than the burning loss threshold Ia of the aluminum alloy; and 3) starting to weld the aluminum alloy within 30min. With the adoption of the method, two major problems that the reflectivity of the aluminum alloy surface to to laser is high, and a surface oxide film is hard to remove, can be synchronously solved; and the forming quality of a weld joint of the aluminum alloy is obviously improved.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

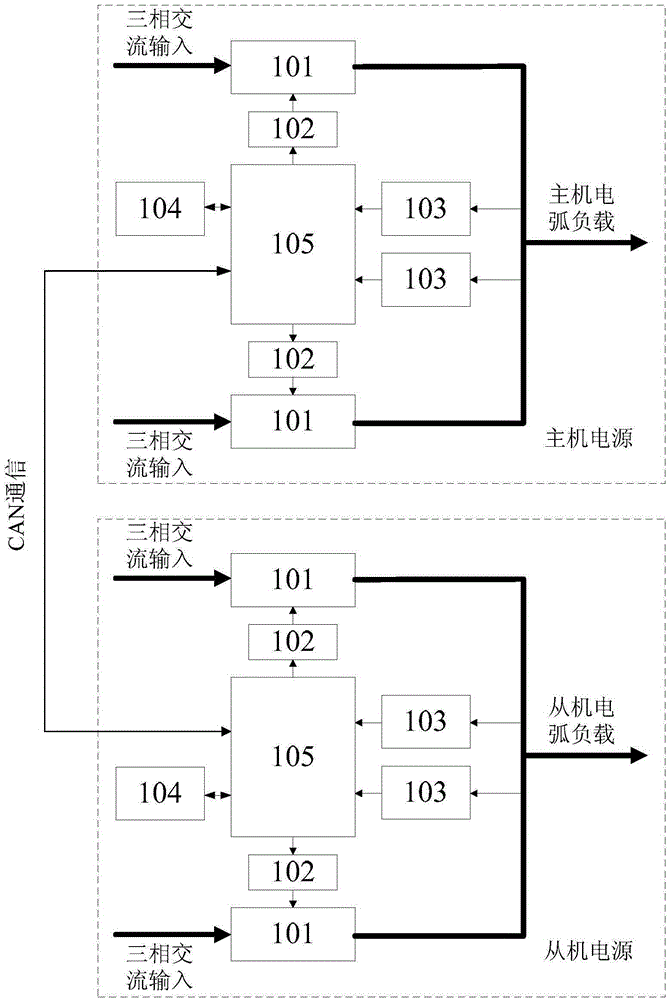

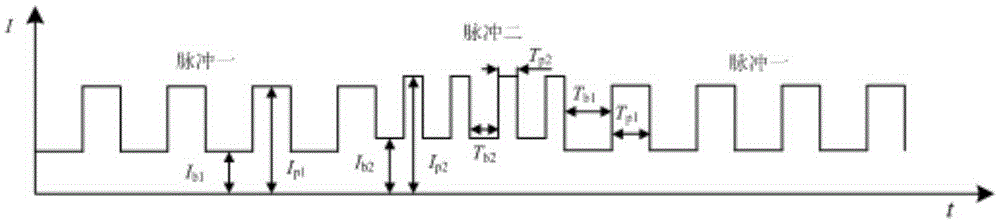

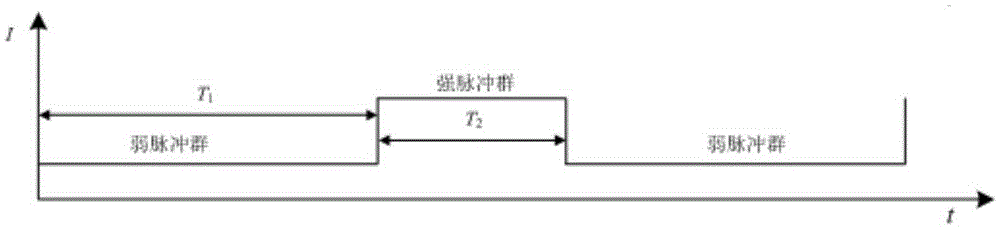

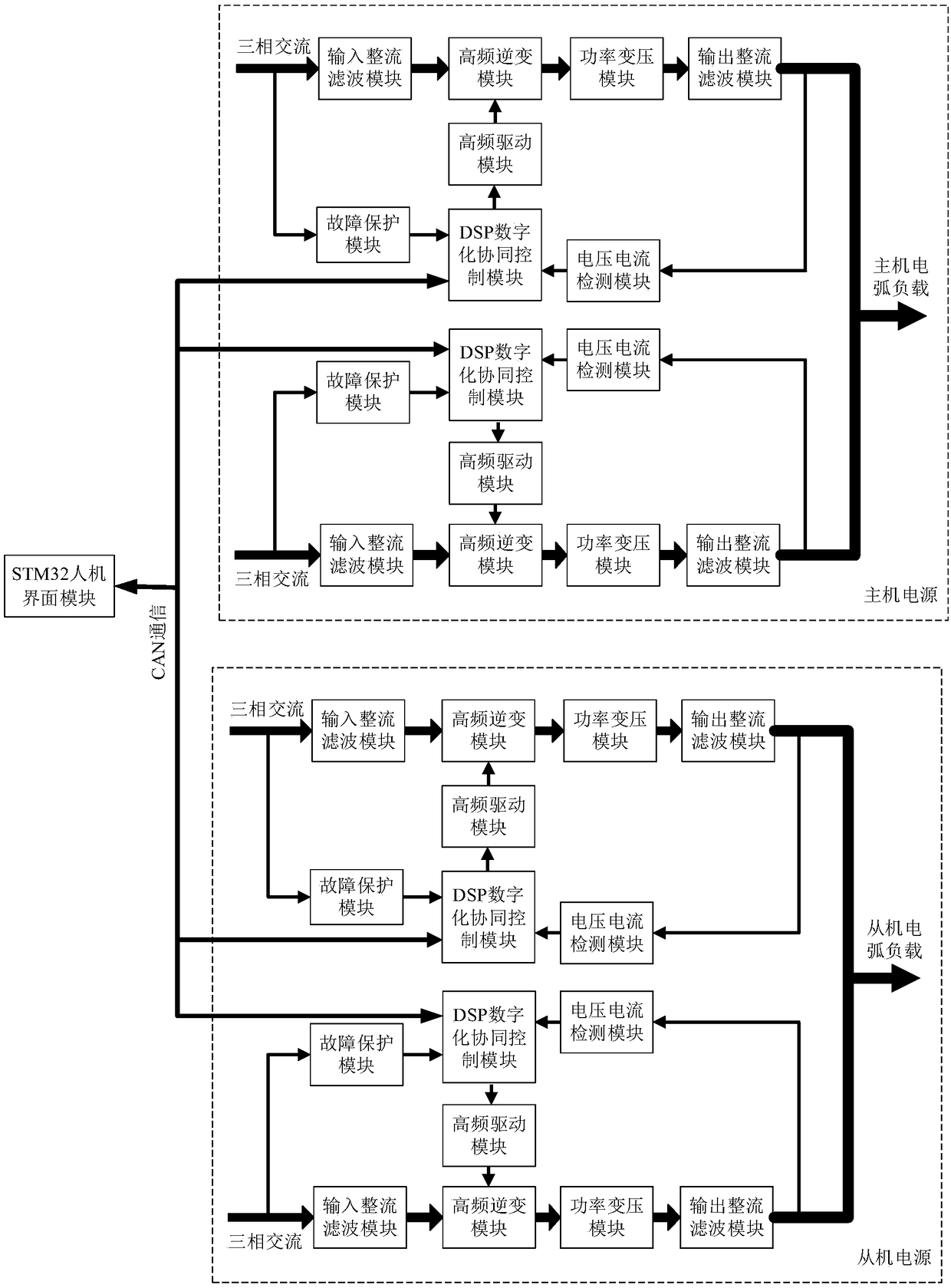

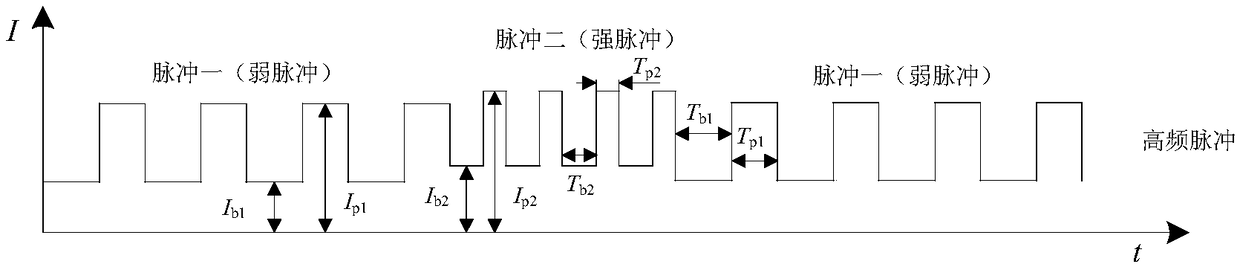

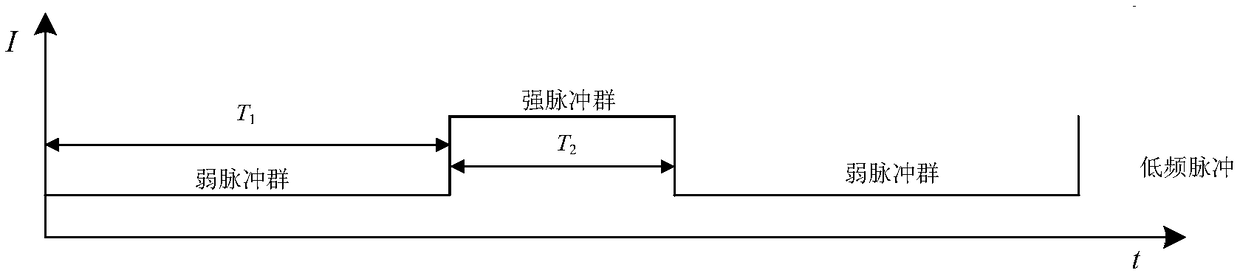

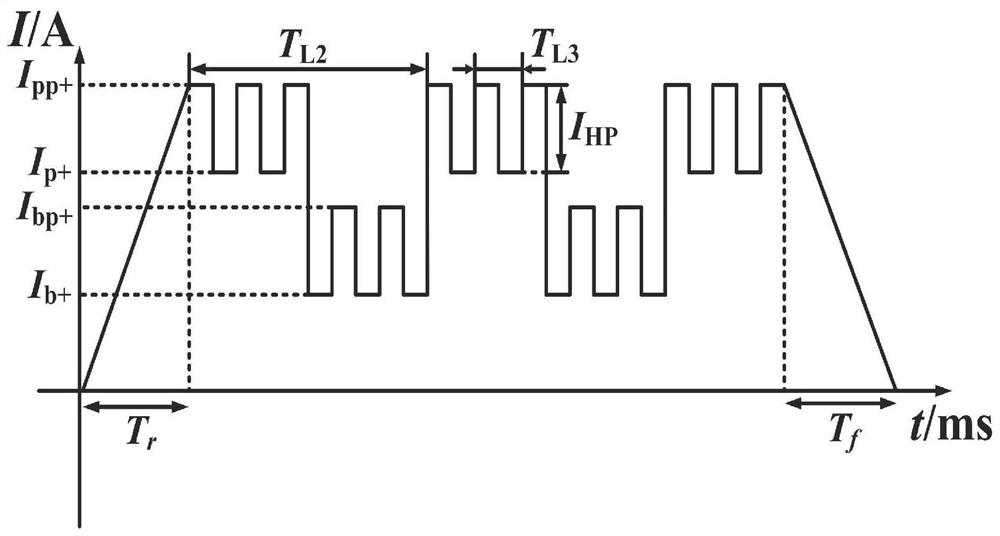

High-power double-wire pulse MIG welding low-frequency modulation type double-pulse control system

InactiveCN105269117AImprove welding efficiencyEasy to achieve one-time forming weldingWelding accessoriesHuman–machine interfaceAlternating current

The invention discloses a high-power double-wire pulse MIG welding low-frequency modulation type double-pulse control system. The system comprises a main engine power supply for supplying current to a front wire and cooperatively controlling the whole system, and a slave engine power supply for supplying current to a back wire, wherein a main engine and the slave engine power supply are connected through a CAN bus; the main engine power supply and the slave engine power supply respectively comprise two main circuits and control circuits; one ends of the two main circuits are connected with three-phase alternating current, and the other ends are connected with an electric arc load after parallel connection; the main circuits comprise power conversion modules; and the control circuits comprise human-computer interface modules, DSP digital cooperation control modules, high-frequency driving modules and voltage current detecting modules. The system can realize synchronous, alternating and random three types of low-frequency modulation type double pulses, and uses two ways of low-frequency modulation type double pulses of main and slave engines for acting on high-power double arcs and double-wire molten drops and causing the molten pool resonance to improve the welding process stability, to optimize the welding line structure and to improve the welding line forming quality.

Owner:SOUTH CHINA UNIV OF TECH

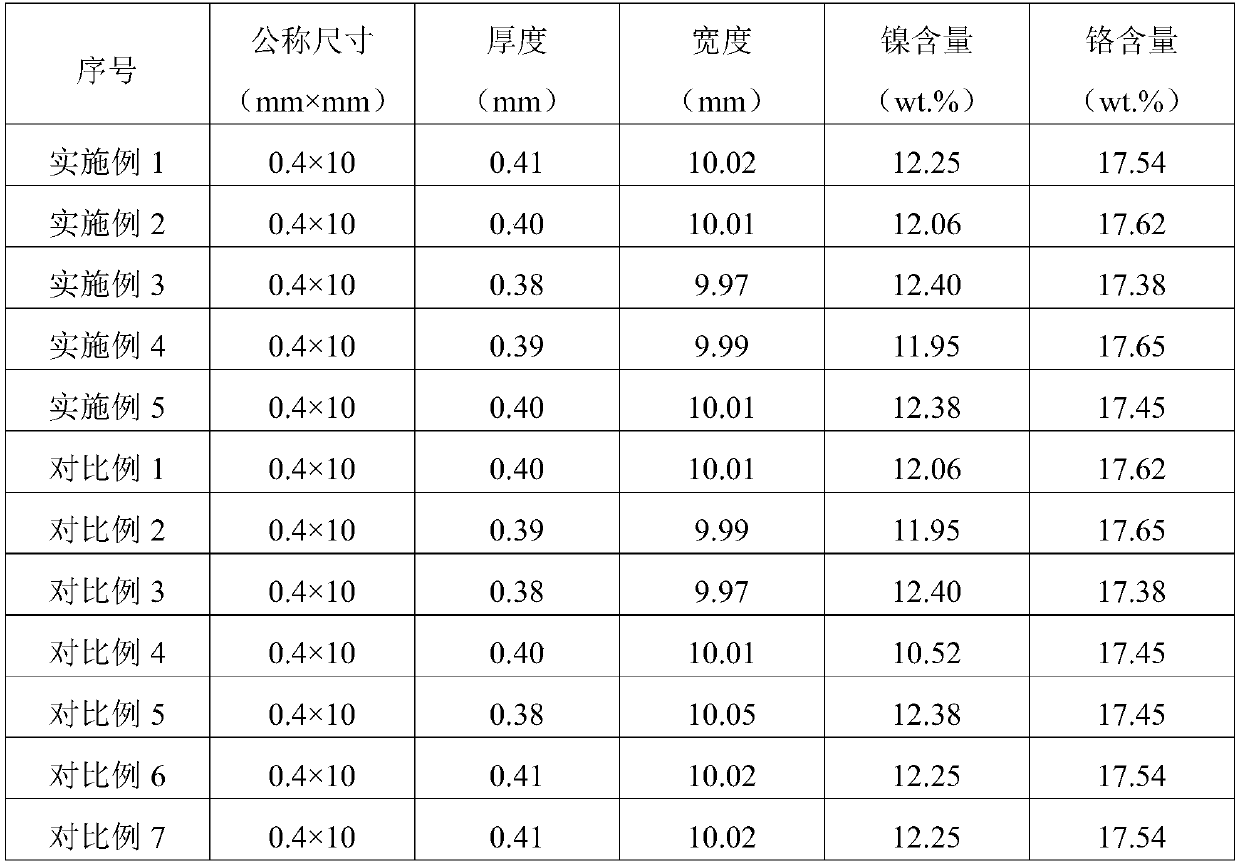

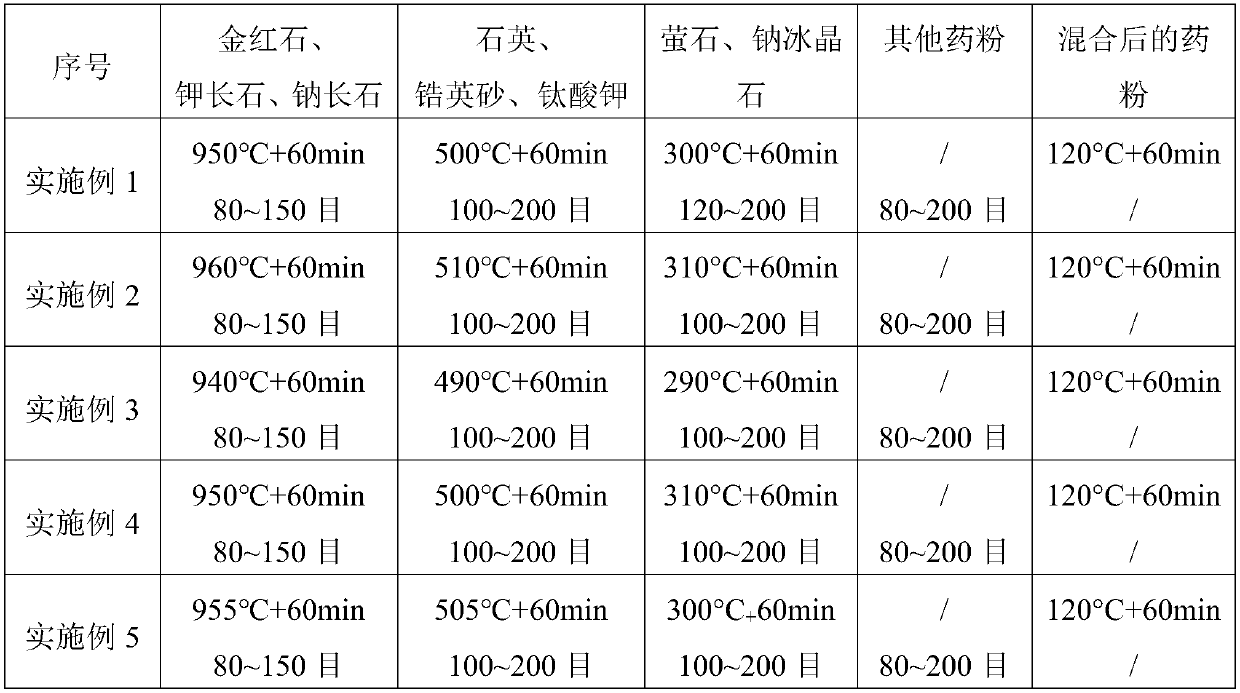

Flux-cored wire used for super duplex stainless steel gas shielded welding and preparation method thereof

ActiveCN110142529ASimple welding processReduce acidityWelding/cutting media/materialsSoldering mediaAusteniteZircon

The invention discloses a flux-cored wire used for super duplex stainless steel gas shielded welding and a preparation method thereof. The flux-cored wire is composed of an external use steel belt andflux powder, wherein the external use steel belt is made of an austenitic stainless steel belt with 17.0%-18.0% of chromium and 11.0%-12.5% of nickel; and the flux powder comprises the following components of, in percentage by weight, 36.0%-38.0% of chromium powder, 9.0%-13.0% of high-nitrogen chromium iron, 2.5%-3.0% of electrolytic manganese metal, 4.0%-5.0% of molybdenum powder, 0.5%-1.0% of ferrosilicon, 1.0%-1.5% of ferrotitanium, 0.5%-1.0% of aluminum-magnesium alloy, 18.0%-20.0% of rutile, 1.0%-2.0% of quartz, 5.0%-6.0% of zircon sand, 1.0%-1.5% of potassium feldspar, 3.0%-3.5% of albite, 1.0%-1.5% of fluorite, 0.5%-1.0% of sodium cryolite, 1.0%-1.5% of potassium titanate, 0.1%-0.3% of bismuth oxide and the balance iron powder. According to the flux-cored wire used for super duplexstainless steel gas shielded welding and the preparation method thereof, the components and the two-phase proportion of deposited metal can be balanced, thus obtaining a duplex stainless steel welding joint which is good in forming quality and excellent in corrosion resistance.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

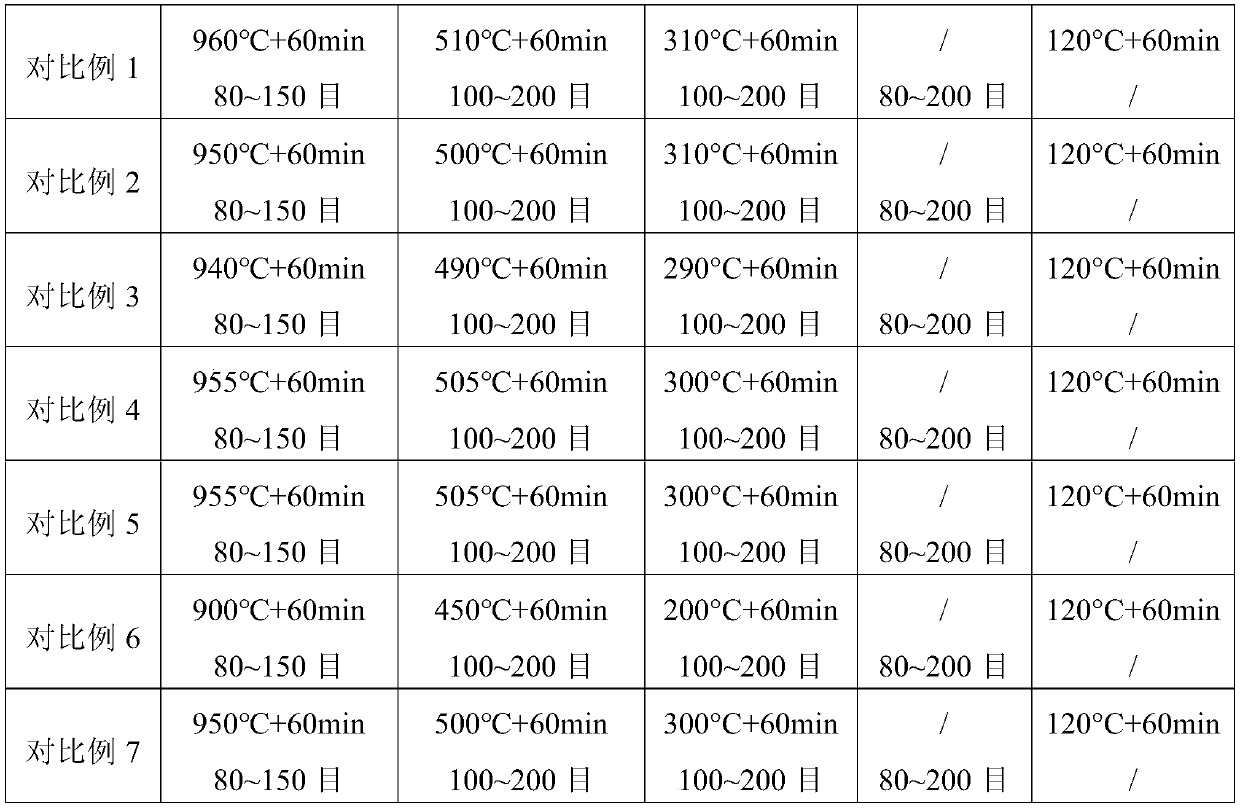

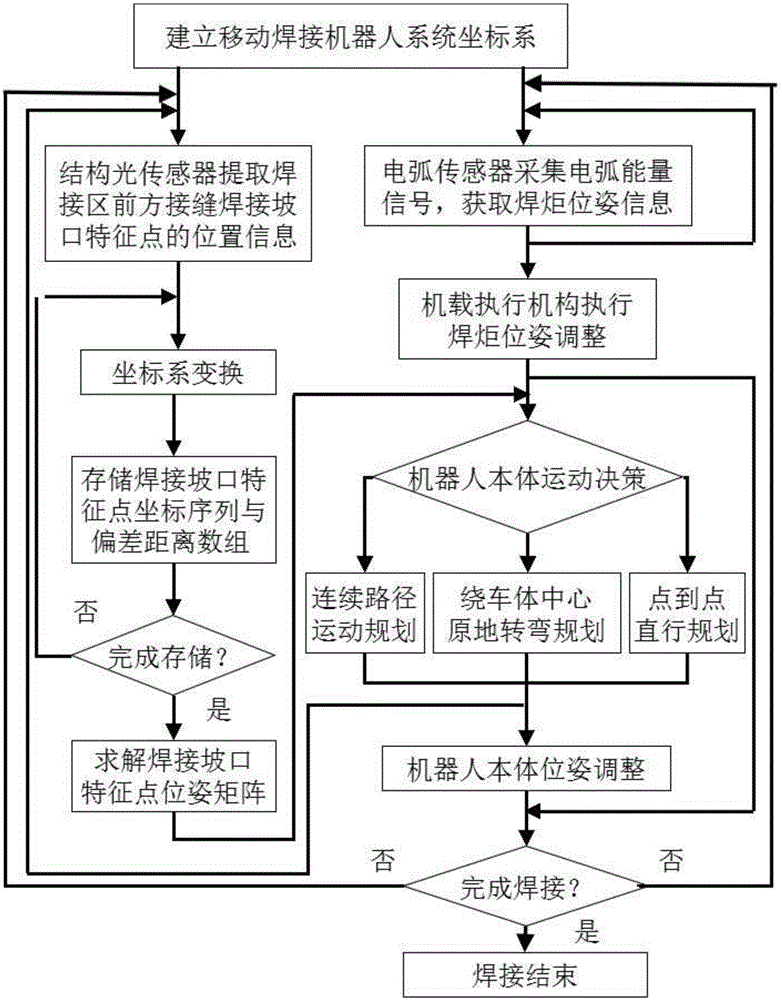

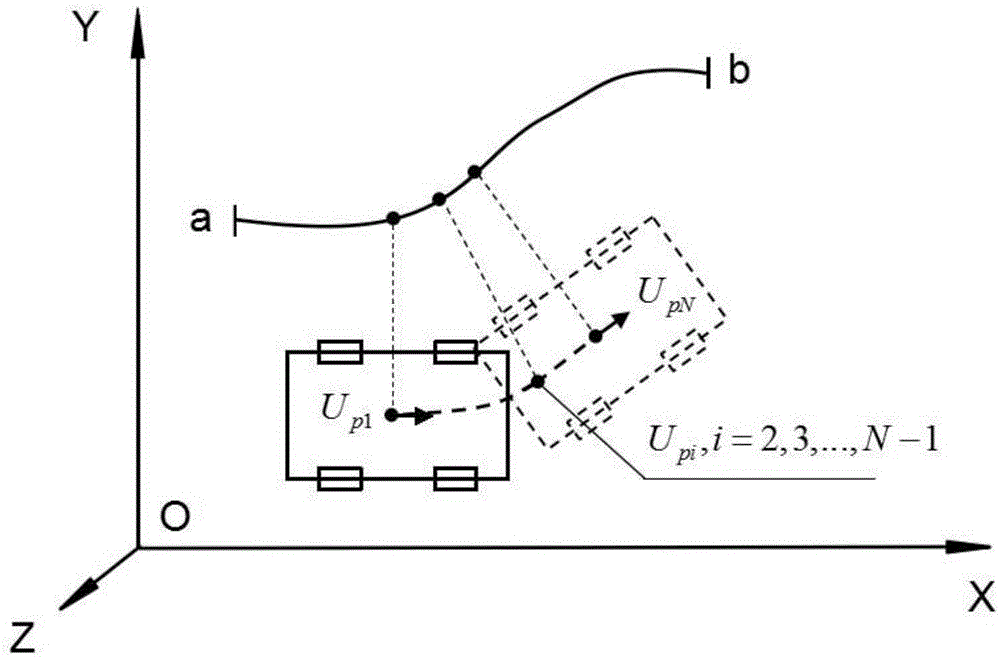

Cooperative control method for track online dynamic programming and weld pass tracking in welding process

ActiveCN105081524AImprove stabilityImprove weld seam qualityArc welding apparatusVision sensorControl theory

The invention provides a cooperative control method for track online dynamic programming and weld pass tracking in a welding process and belongs to the technical field of movable welding robots. According to the method, the advantages that the joint welding groove detection in front of a welding area is achieved by a structured light visual sensor detecting area ahead of an electric arc, and welding torch poses are obtained by an electric arc sensor in real time are combined sufficiently; based on the weld pass isometric approximation theory, the cooperative decoupling control over the track online dynamic programming and weld pass tracking of a robot body is achieved. By means of the method, the welding speed stability and weld pass tracking accuracy of a movable welding robot in the large structure complex tracking welding joint welding process can be improved, and the local large curvature of the joint track and the welding joint forming quality in a bevel area are improved; the method can be applied to the movable robot welding process in equipment manufacturing of ships, energy sources, rail transit and the like and is especially applicable to the welding occasions of curved welding joints of large bevel or large curvature.

Owner:TSINGHUA UNIV

High-power twin-wire double-pulse MIG welding power supply system with adjustable high-and-low-frequency pulse phases and control method thereof

ActiveCN108746944AImprove welding efficiencyEasy to achieve one-time forming weldingArc welding apparatusDouble phaseWelding power supply

The invention discloses a high-power twin-wire double-pulse MIG welding power supply system with adjustable high-and-low-frequency pulse phases and a control method thereof. The power supply system comprises an STM32 human-computer interface module, a host power supply and a slave power supply, wherein the STM32 human-computer interface module is connected to DSP digital synchronic control modulesin the host power supply and the slave power supply; the host power supply provides current for a previous wire; the slave power supply provides current for a latter wire; and the host power supply,as well as the slave power supply, consists of two parallel main circuits and a control circuit. The power supply system can realize seven high-and-low-frequency pulse phase modes; two host and slavelow-frequency modulation double phases act on a high-power twin arc for double-wire melt dripping to arouse resonance of a molten pot; the temperature gradient of a temperature field of the molten potis optimized; double-arc interference is reduced; and the welding stability is improved, the weld microstructure is optimized, and the weld forming quality is improved.

Owner:SOUTH CHINA UNIV OF TECH

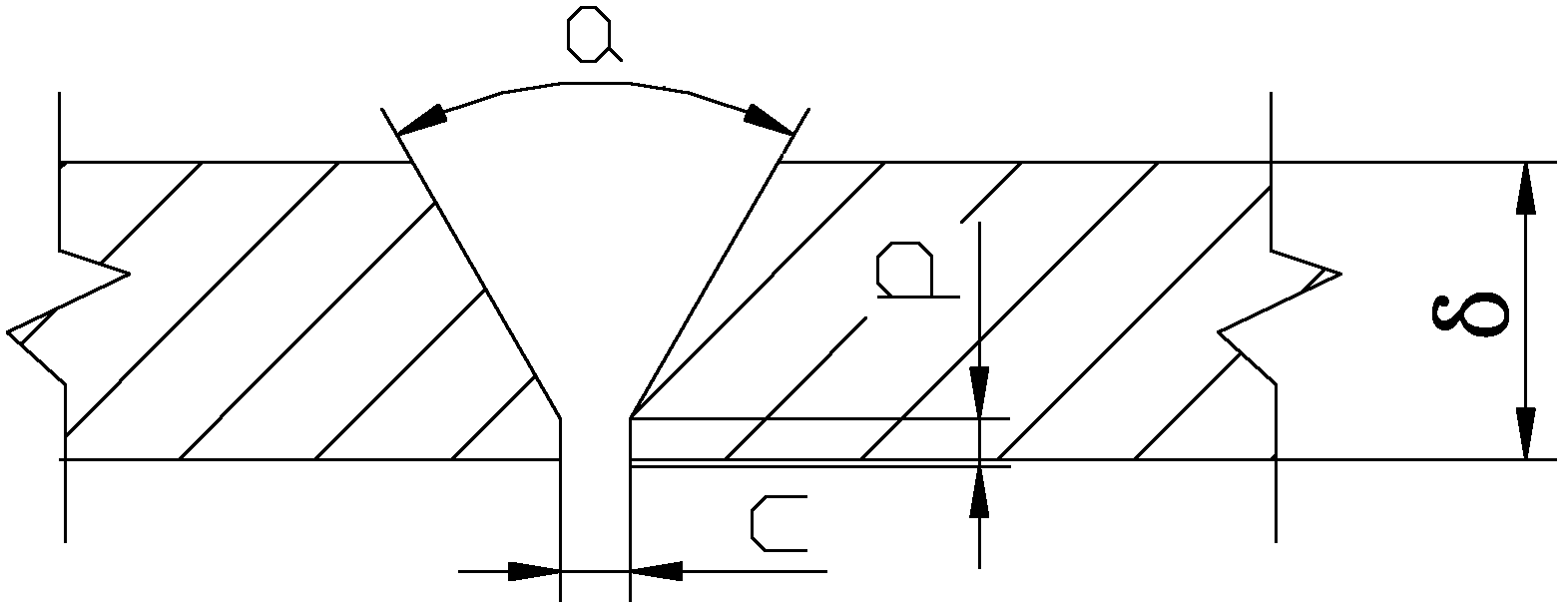

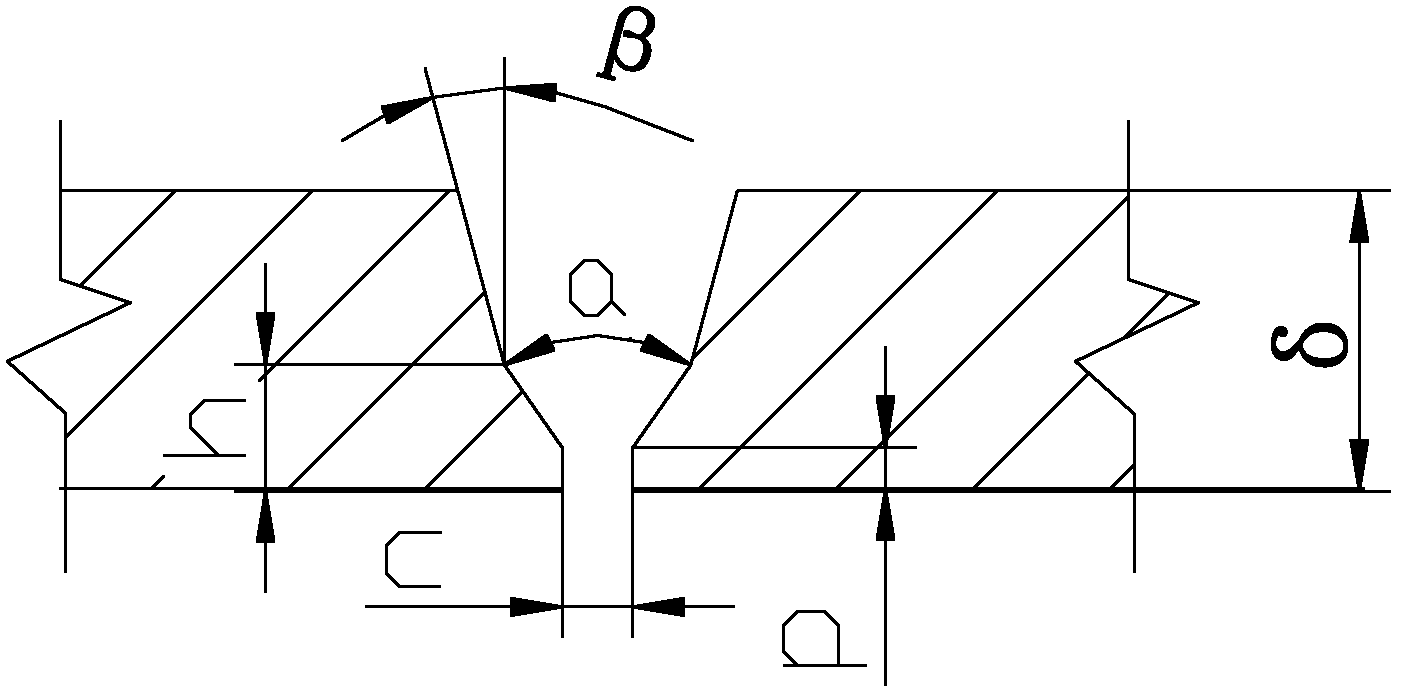

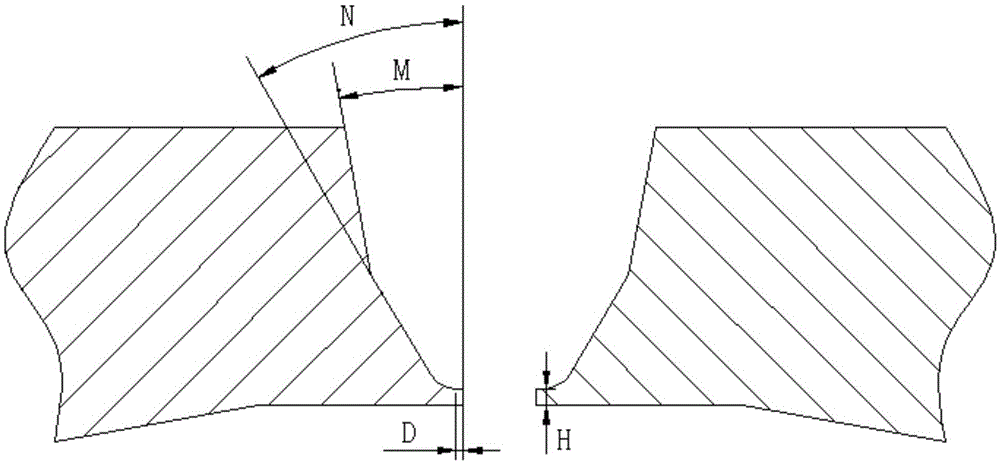

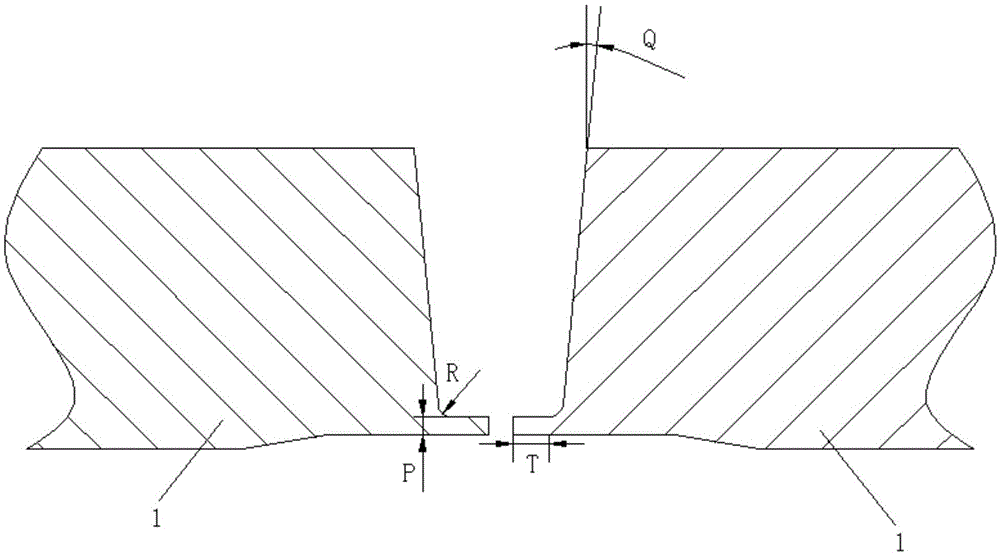

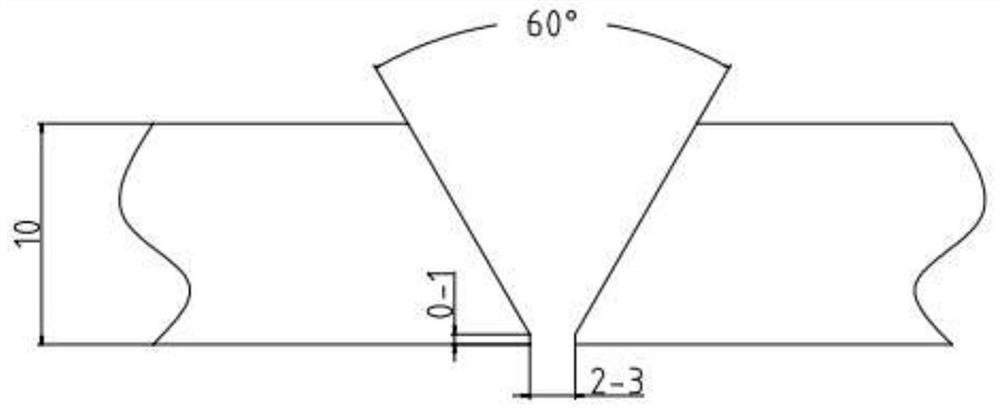

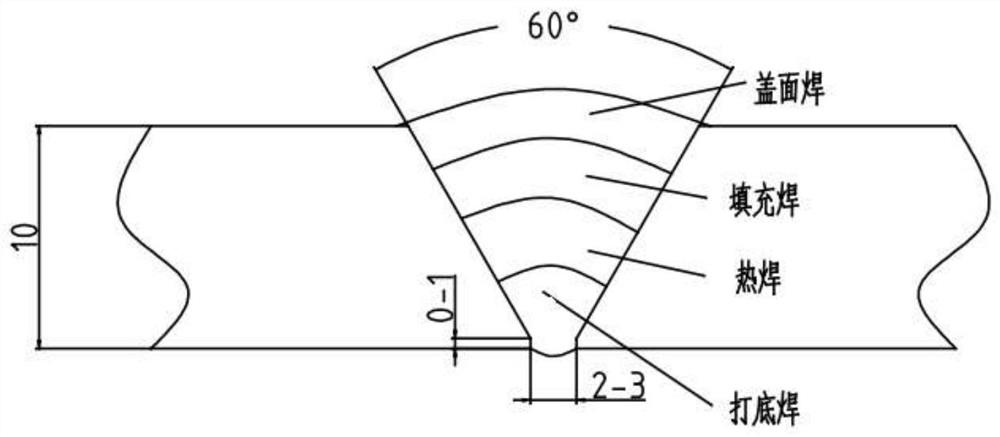

Method for welding main steam or main water supply pipeline of nuclear island in nuclear power plant

ActiveCN105458476AImprove efficiencyShorten the welding periodWelding accessoriesNuclear powerNuclear engineering

The invention belongs to the technical field of welding, and provides a method for welding a main steam or main water supply pipeline of a nuclear island in a nuclear power plant in order to solve the problems that an existing method for the main steam or main water supply pipeline of the nuclear island is low in efficiency and large in labor intensity, and a welder is likely to be wounded. The method comprises the steps that 1, groove machining is carried out on the main steam or main water supply pipeline of the nuclear island, a machined groove is a U-shaped groove, the groove angle of the groove ranges from 5 degrees to 8 degrees, the length of the truncated edge of the groove ranges from 1.8 mm to 3 mm, the thickness of the truncated edge ranges from 1.8 mm to 3 mm, and the radius of a chamfer ranges from 1.8 mm to 3 mm; 2, pipeline assembly is carried out; 3, tack bar spot welding fixing is carried out through manual argon tungsten-arc welding; 4, pipeline preheating is carried out; 5, bottoming, filling and cover face welding are completed through automatic argon tungsten-arc welding; and 6, post thermal treatment and stress relief thermal treatment are carried out. According to the method for welding the main steam or main water supply pipeline, the working efficiency of welding the main steam or main water supply pipeline of the nuclear island is improved, welding material consumption is reduced, the working environment of the welder is improved, and the labor intensity of the welder is lowered.

Owner:CHINA NUCLEAR IND 23 CONSTR +1

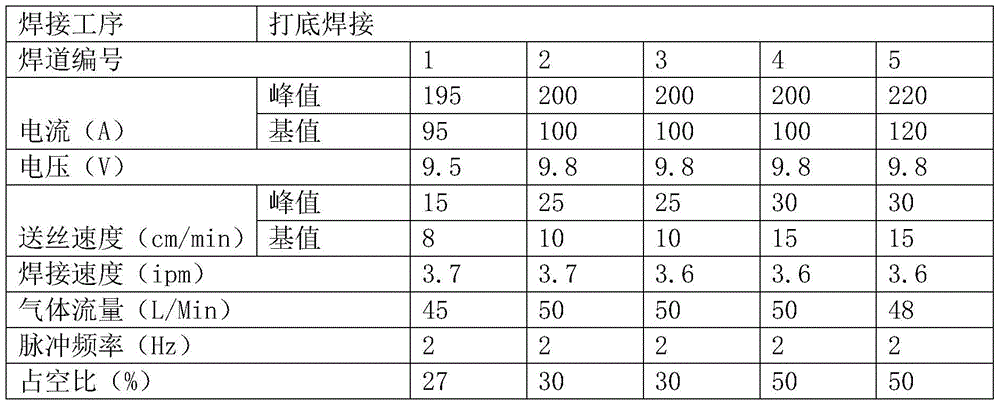

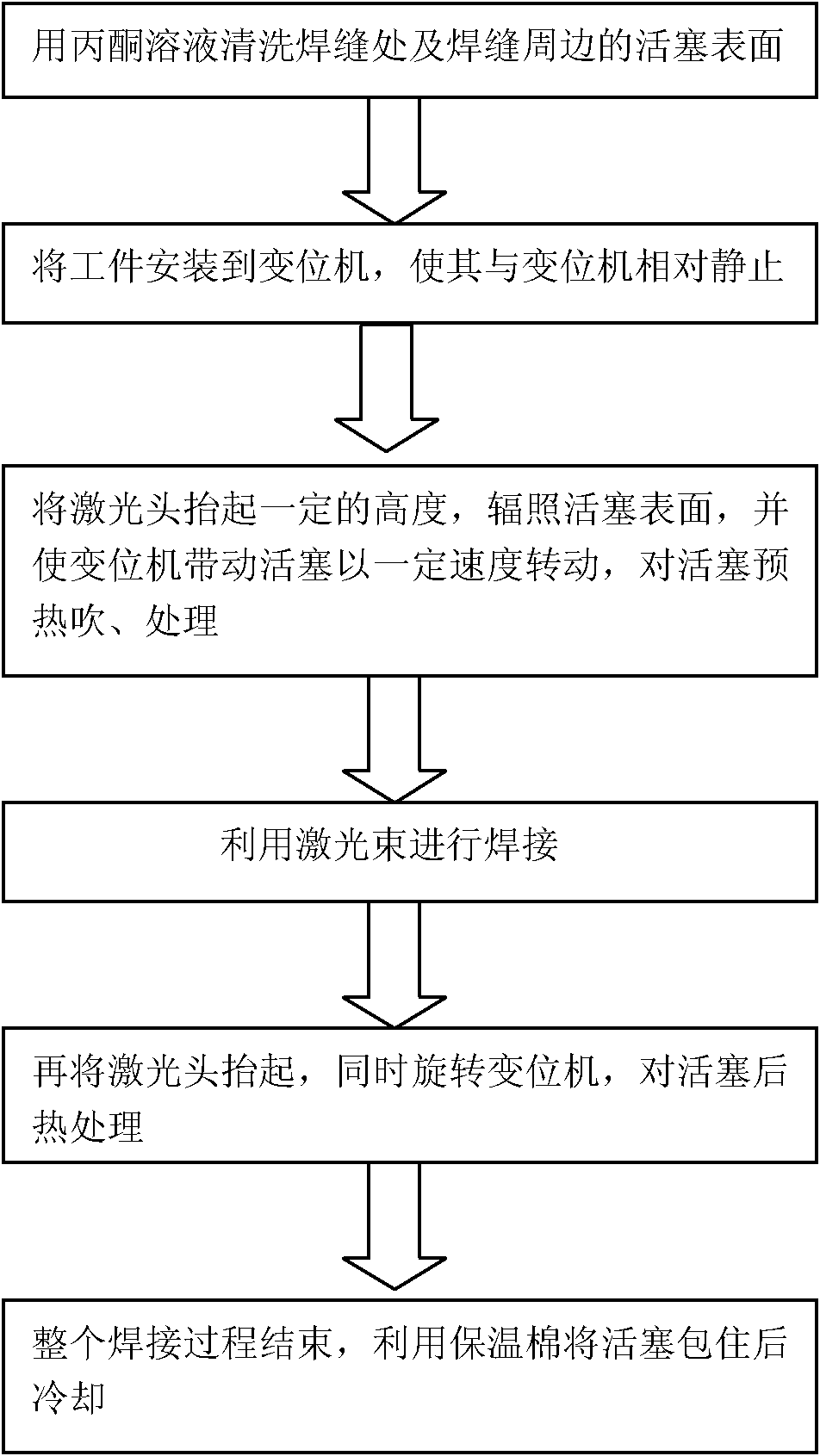

Method for welding piston by laser with laser heat treatment

InactiveCN102463414AImprove weld seam qualitySimple processLaser beam welding apparatusNumerical controlInterference fit

Owner:SIASUN ROBOT & AUTOMATION LIMITED BY SHARE

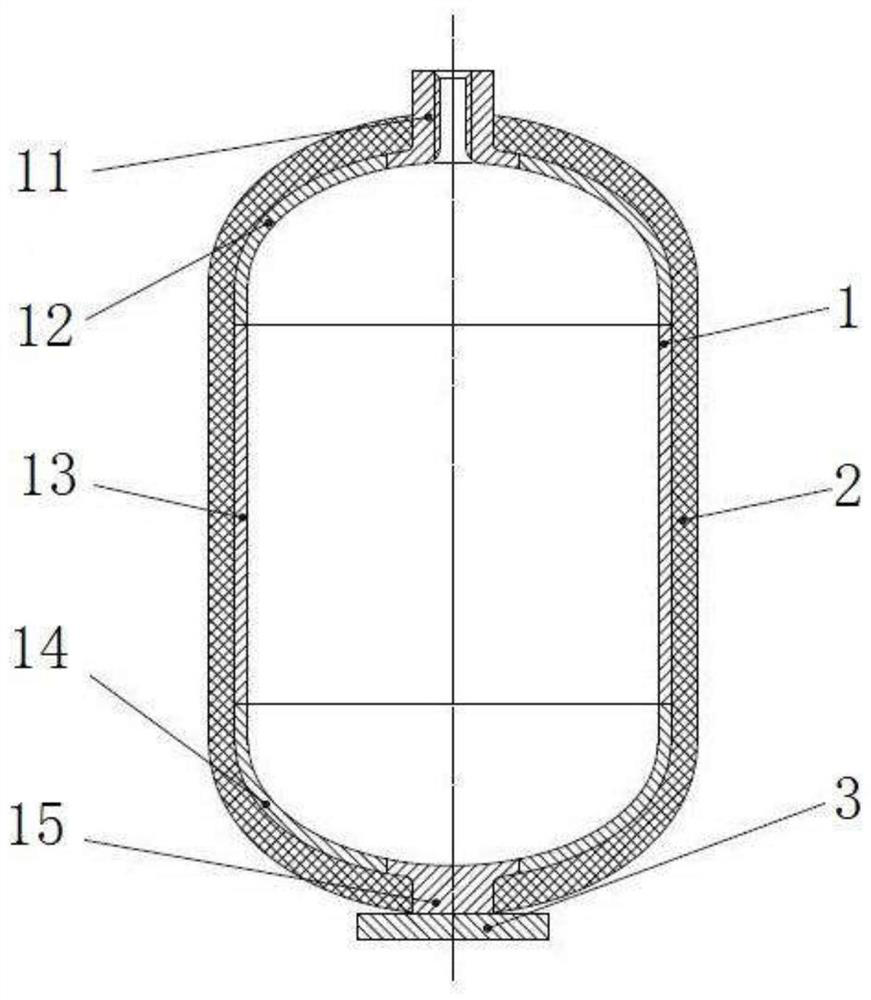

Metal lining carbon fiber winding composite material gas cylinder and manufacturing method thereof

PendingCN112963722AHigh winding precisionImprove stress-strain coordinationVessel mounting detailsVessel manufacturingEpoxyFiber

The invention relates to the technical field of composite material gas cylinders, in particular to a metal lining carbon fiber winding composite material gas cylinder and a manufacturing method thereof. The metal lining carbon fiber winding composite material gas cylinder comprises a nickel-base alloy lining, a carbon fiber / epoxy resin composite layer and a metal flange. The nickel-based alloy lining is formed by welding an air port joint, an air port end sealing head, a cylinder body, a sealing end sealing head and a sealing end joint. The carbon fiber / epoxy resin composite layer is wound on the outer surface of the nickel-based alloy lining. The metal flange is connected with the bottom of the sealing end sealing head. The metal lining carbon fiber winding composite material gas cylinder is simple in structure, high in reliability, high in safety, high in pressure bearing capacity, small in body mass, wide in medium storage range and high in high and low temperature environment resistance, the performance requirements for high performance factors and long fatigue life can be met at the same time, and the requirements for light high-strength composite gas cylinders in the fields of spaceflight, aviation, ships and the like are met.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

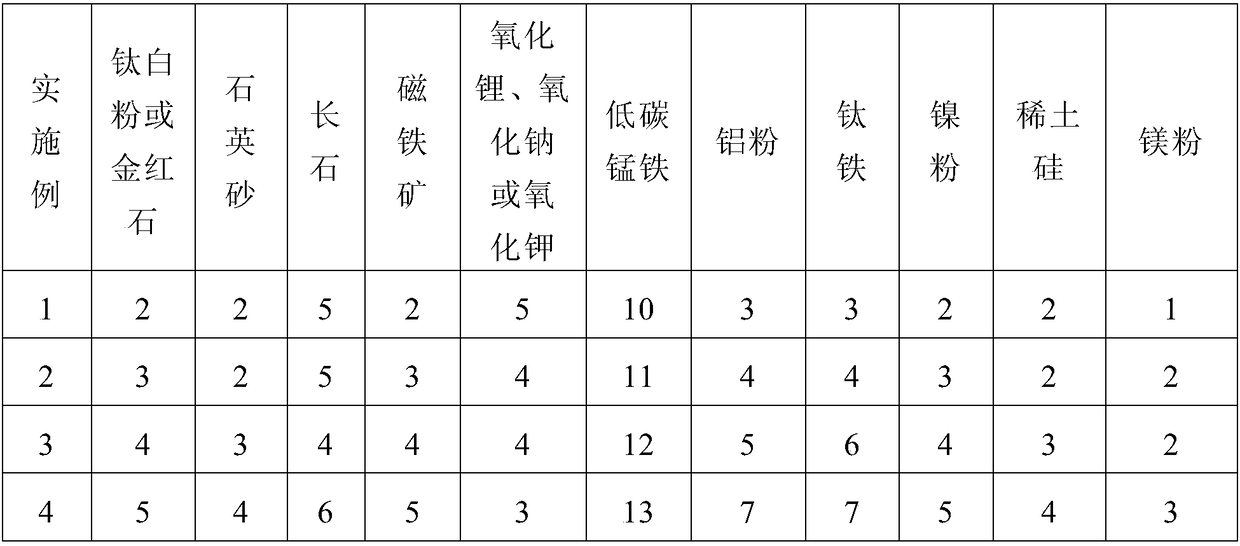

Large-heat input gas-electric vertical welding gas shielded flux-cored wire based on grain refinement mechanism

ActiveCN109128573AImprove mechanical propertiesImprove low temperature impact toughnessWelding/cutting media/materialsSoldering mediaLithium oxidePotassium

The invention provides a large-heat input gas-electric vertical welding gas shielded flux-cored wire based on a grain refinement mechanism. The large-heat input gas-electric vertical welding gas shielded flux-cored wire comprises a flux-cored wire outer skin and inner powder, wherein a low-carbon steel cold-rolled steel strip is adopted by the flux-cored wire outer skin, and the flux-cored wire comprises, by mass, less than 0.06% of C, less than 0.3% of Si, less than 0.8% of Mn, less than 0.02% of P, less than 0.01% of S, and the balance Fe and inevitable impurities; the powder comprises, by mass, 1-5% of one or two of titanium dioxide or rutile, 2-6% of quartz sand, 3-8% of feldspar, 1-5% of magnetite, 2-5% of one or more of lithium oxide, sodium oxide or potassium oxide, 10-15% of low-carbon ferromanganese, 3-8% of aluminum powder, 3-8% of ferrotitanium, 2-6% of nickel powder, 2-6% of rare earth silicon, 1-3% of magnesium powder, and the balance reduced iron powder; and the powder accounts for 15-20% of the total mass of the flux-cored wire. The flux-cored wire can be used for 100kj / cm-300kj / cm large-heat input gas-electric vertical welding of a thick steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD

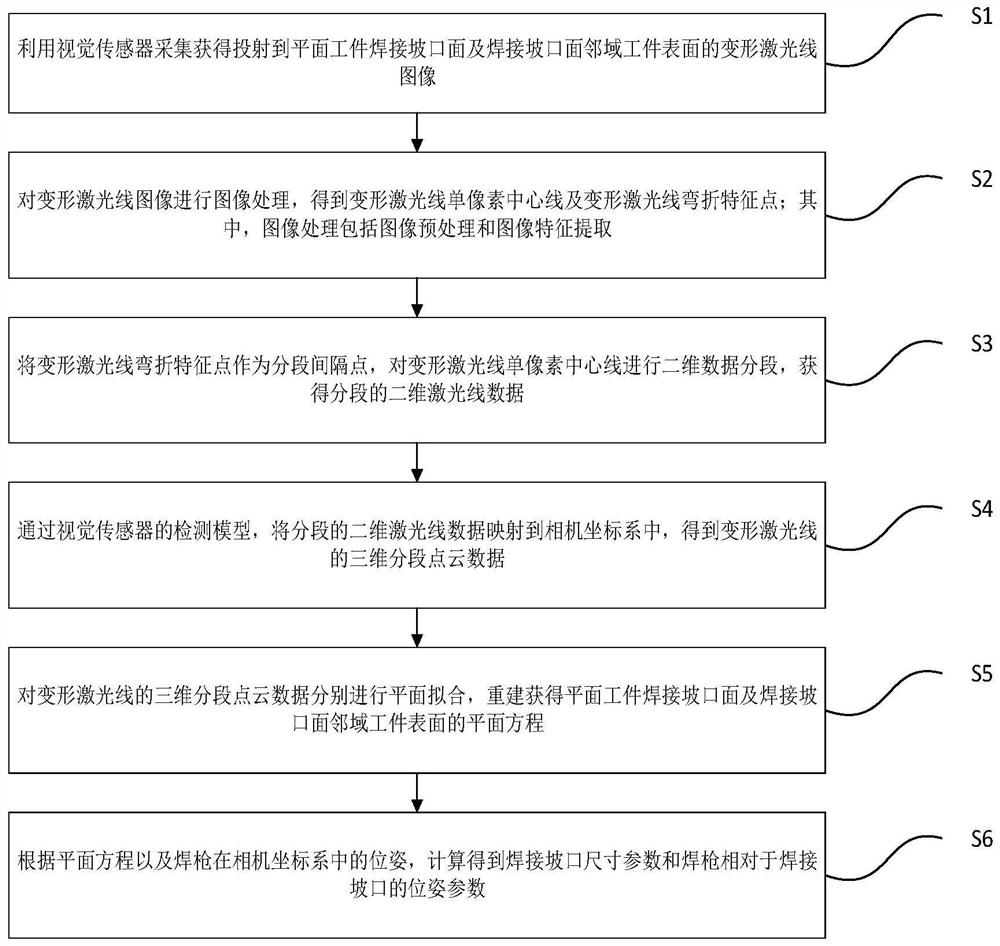

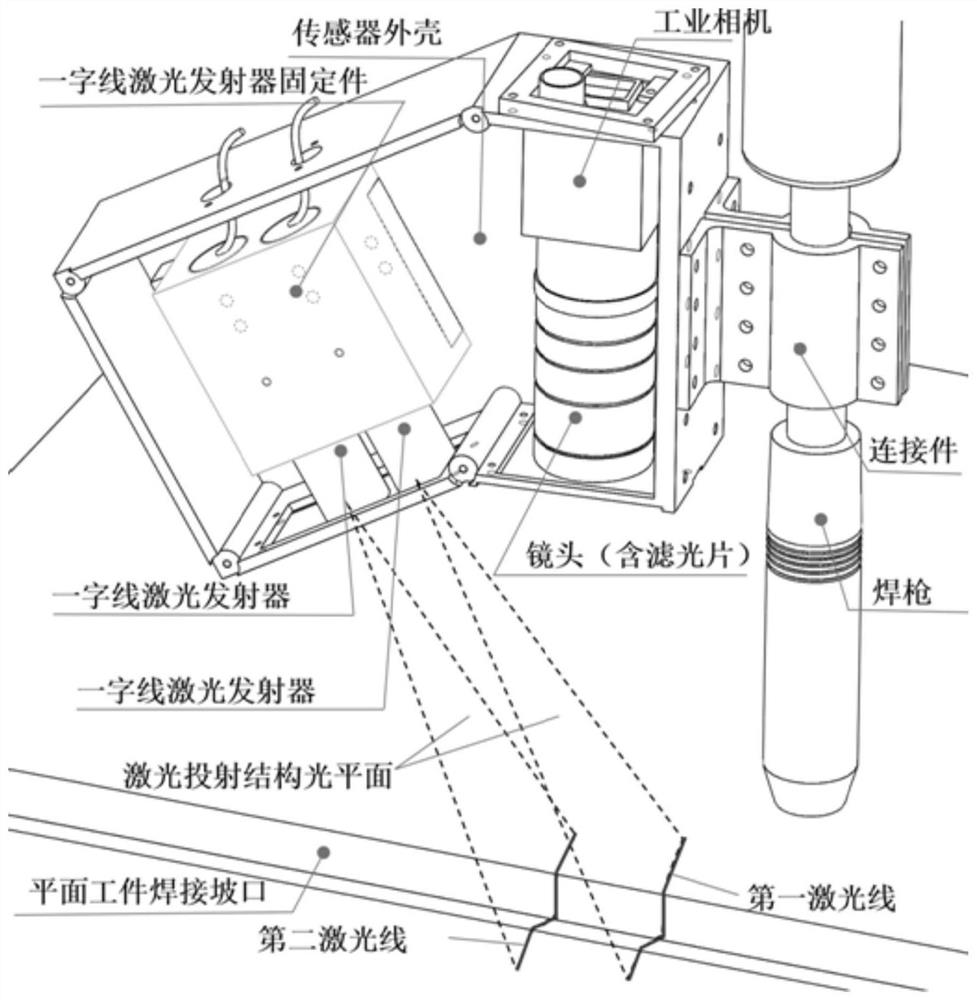

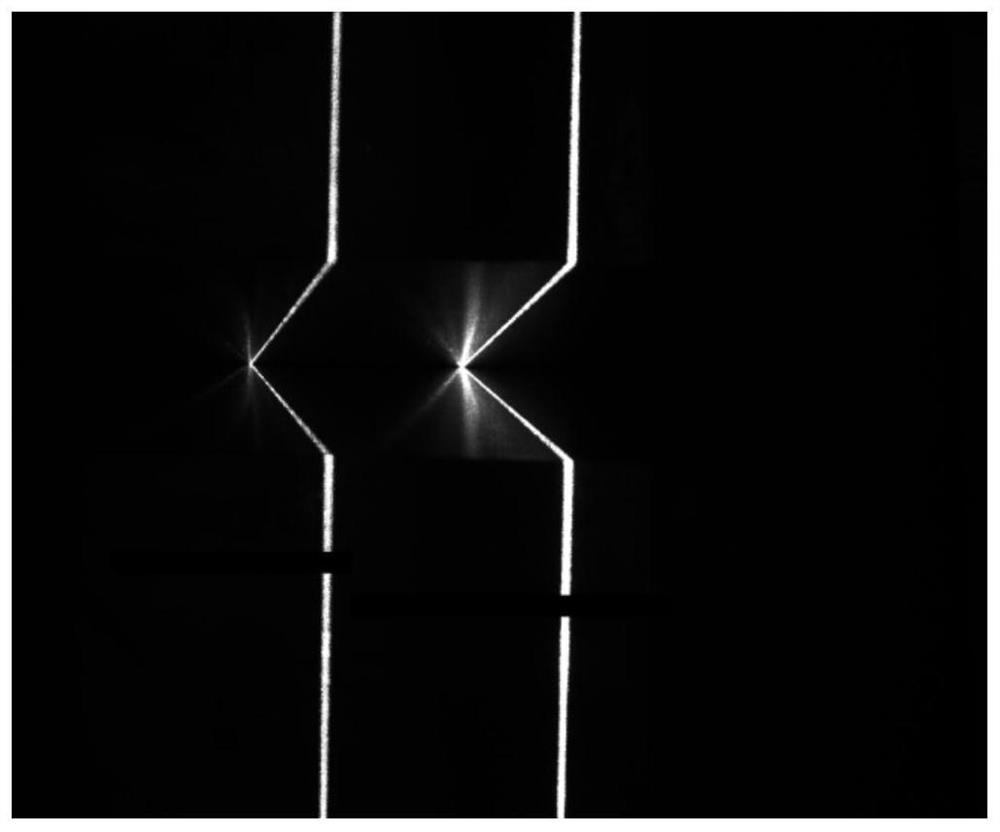

Welding groove size and welding gun relative pose high-precision detection method and device

PendingCN114792337AImprove adaptabilityImprove robustnessImage enhancementImage analysisPoint cloudVision sensor

The invention discloses a high-precision detection method and device for the size of a welding groove and the relative pose of a welding gun, and the method comprises the steps: collecting a single deformation laser line image through a visual sensor; processing the deformed laser line image to obtain two-dimensional laser line data points; carrying out two-dimensional data segmentation on the deformed laser line image; obtaining three-dimensional segmented point cloud data of the deformed laser rays through a visual sensor detection model; plane fitting is carried out on the segmented three-dimensional point cloud data, and plane equations of a plane workpiece welding groove surface and a welding groove surface neighborhood workpiece surface are obtained through reconstruction; and according to the plane equation obtained through reconstruction, the size of the welding groove and pose parameters of a welding gun relative to the welding groove are solved. According to the invention, the integrated detection of the welding groove size parameter and the welding gun relative pose parameter of the visual sensor relative to any pose of the welding groove is realized, the detection precision and adaptability are high, and the detection robustness and integration of the visual sensor are improved at the same time.

Owner:TSINGHUA UNIV

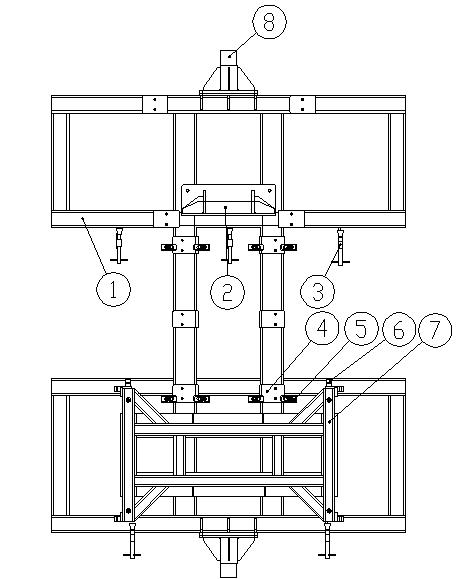

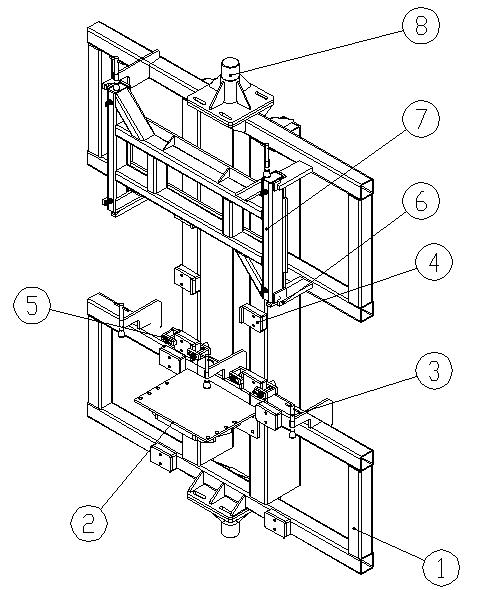

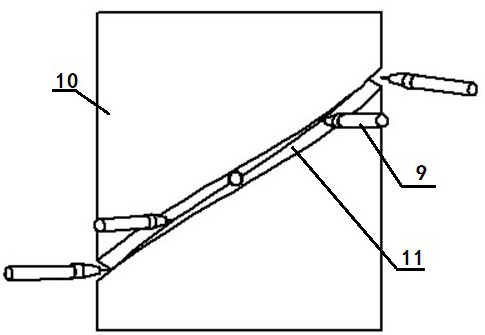

Bolster and buffer welding tool

ActiveCN102152049AReduce welding difficultyImprove weld seam qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding deformation

The invention relates to a bolster and buffer welding tool which is characterized by comprising a tool steel structure (1), a corbel clamping tool (7), a corbel positioning block (6), a pressing plate device (5), a position changing unit, a coupler plate mounting base (2), a steel aluminum cushion block (4) and a compacting device (3), wherein two ends of the tool steel structure (1) are providedwith connecting bases (8) mounted on the position changing unit; one end of the tool steel structure (1) is fixedly welded with the coupler plate mounting base (2), and the corbel positioning block (6) and the steel aluminum cushion block (4) are positioned based on the coupler plate mounting base (2), the corbel clamping tool (7) is positioned by the other end of the tool steel structure (1) viathe corbel positioning block (6); and the pressing plate device (5) and the compacting device (3) are fixedly welded on the tool steel structure (1). The bolster and buffer welding tool adopts the position changing unit to adjust the tool angle to realize 360-degree rotation of the tool, and turns vertical welding and overhead welding into flat welding, thereby reducing overlap stack and lack of penetration, and meanwhile, a pair of F-shaped pliers is adopted for being matched with the compacting device to fix welding members, thus welding deformation is prevented and good welding quality, accurate positioning and convenience in loading and unloading are guaranteed.

Owner:南京雷尔伟新技术股份有限公司

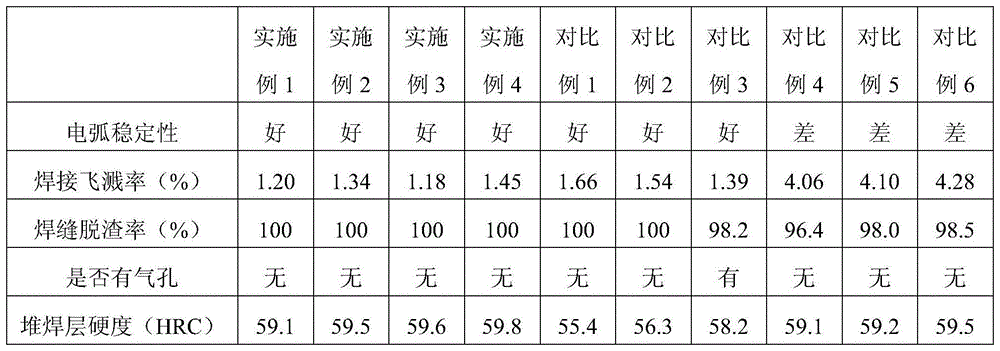

Chromium-titanium-strengthened high-carbon high-alloy-steel wear-resistant surfacing flux-cored wire and preparing method thereof

ActiveCN106271197AReduce hardening tendencyReduces tendency to flakeWelding/cutting media/materialsSoldering mediaWear resistantManganese

The invention discloses a chromium-titanium-strengthened high-carbon high-alloy-steel wear-resistant surfacing flux-cored wire. The chromium-titanium-strengthened high-carbon high-alloy-steel wear-resistant surfacing flux-cored wire is prepared from an external carbon steel belt and chemical powder wrapped by the external carbon steel belt; the weight of the chemical powder accounts for 38.0% to 42.0% of the total weight of the welding wire, and the chemical powder is prepared from 20.0%-25.0% of high carbon chromium iron, 38.0%-45.0% of ferrotitanium, 1.2%-1.6% of metal manganese powder, 2.0%-2.2% of metal molybdenum powder, 3.5%-4.0% of graphite, 2.5%-5.0% of silicon calcium alloy, 2.0%-3.0% of zirconium quartz sand, 8.0%-10.0% of fluorite, 0.1%-0.2 % of boron carbide and the balance iron powder. A preparing method includes the steps that the U-shaped external carbon steel belt is made, the chemical powder is added into the U-shaped groove, five-pass continuous drawing reducing is carried out after an opening is sealed, and the flux-cored wire is obtained. The chromium-titanium-strengthened high-carbon high-alloy-steel wear-resistant surfacing flux-cored wire is suitable for surfacing composite manufacturing and on-line repairing of a grinding roller and a grinding disc, and the service life of the grinding roller and the service life of the grinding disc can be remarkably prolonged.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

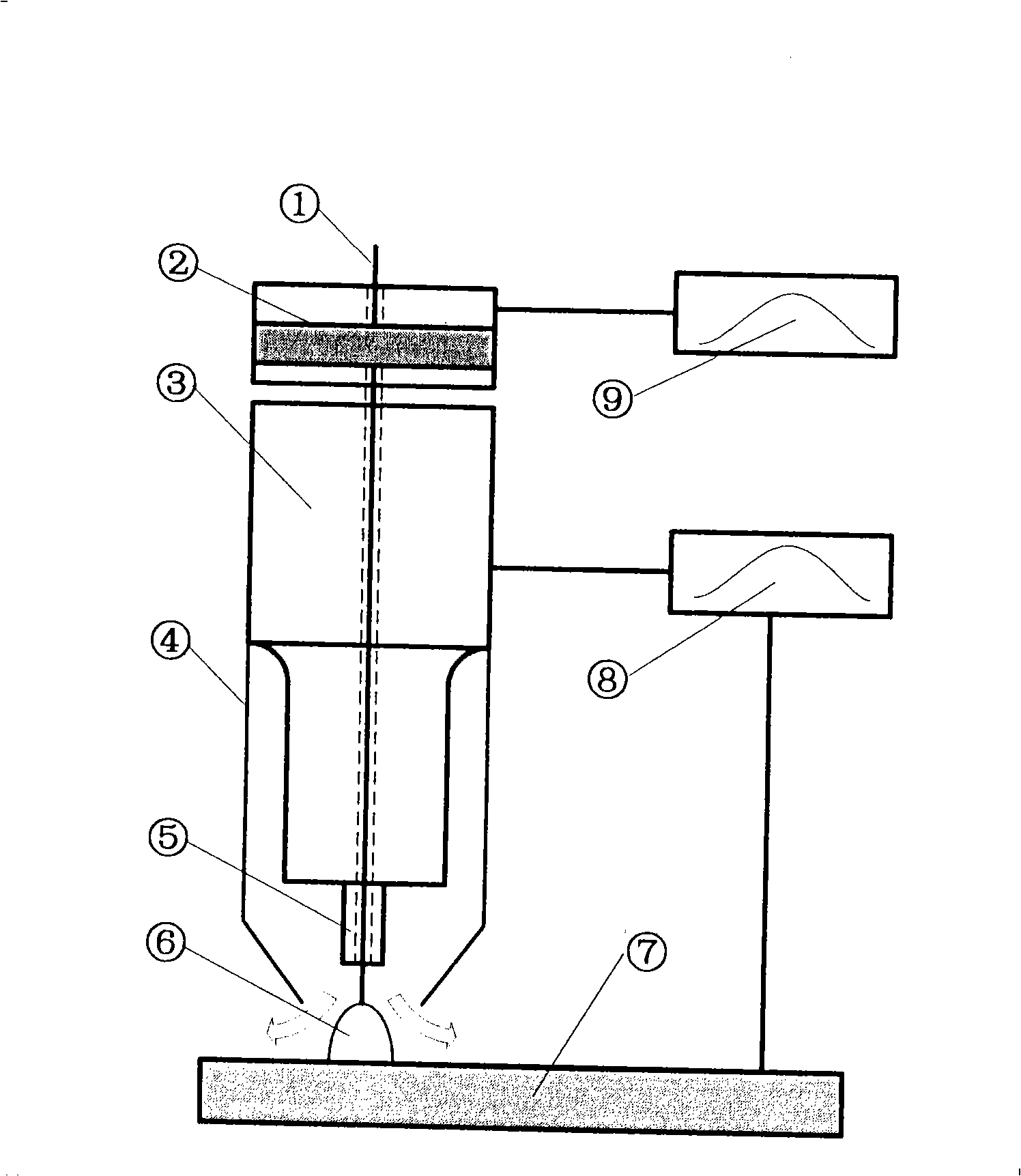

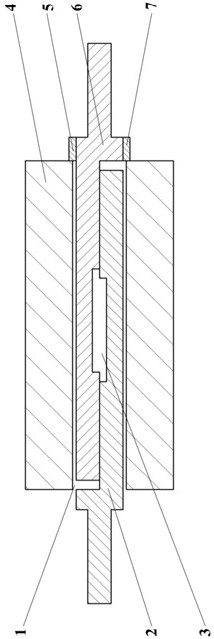

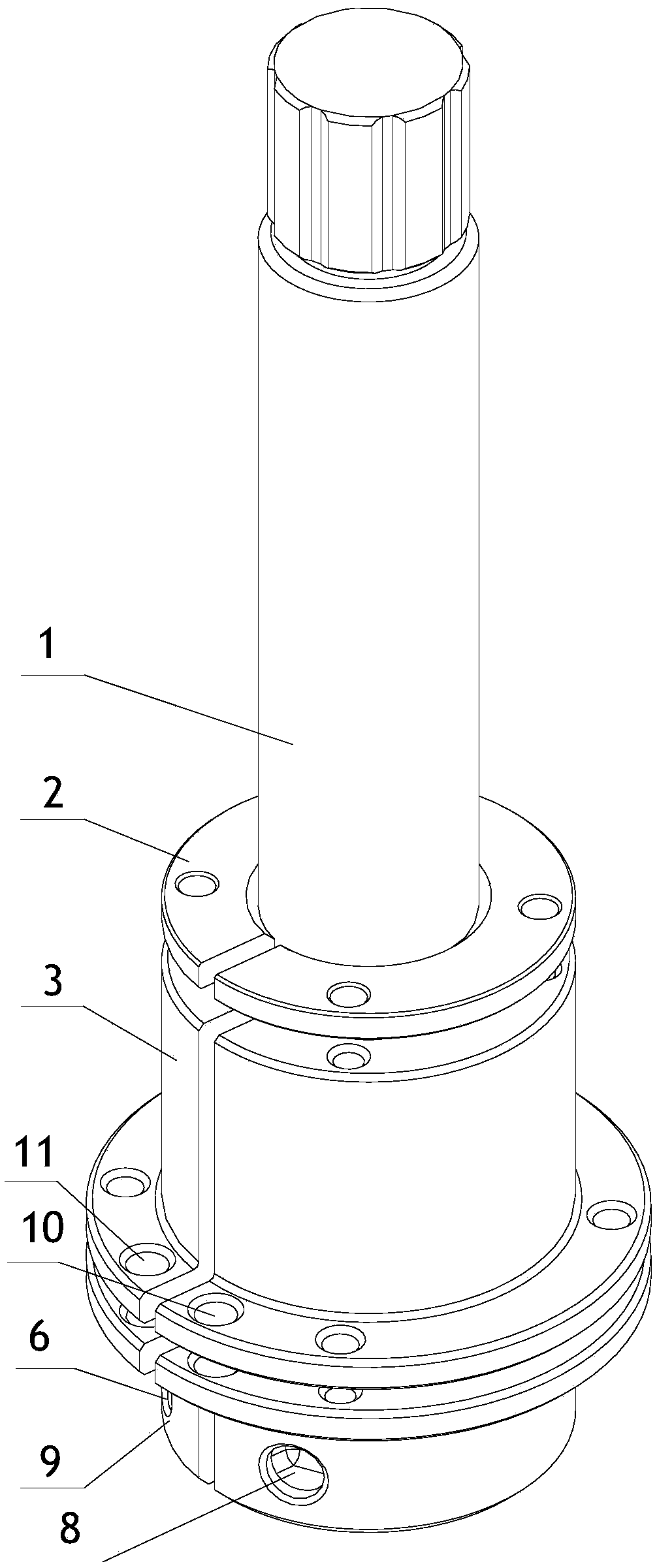

Electric arc welding method and device using additional acoustic pressure mode

InactiveCN101269437AWeld firmlyIncrease weld penetrationWelding accessoriesAcoustic energyEngineering

The invention relates to an arc welding method adopting an external sound pressure mode and a device, and the arc welding method aims to provide a gas shielded welding device of a complex method which can realize stable process, high welding formation quality and greatly improved welding efficiency. The device consists of an acoustic energy transducer (2), an acoustic amplitude-change rod (3), a protective gas injecting nozzle (4), a welding electrode clamp (5), an acoustic generation source (9) and a welding source (8). Under the non-melt electrode mode, the arc welding method has the advantages of stable welding process, improved weld penetration of a single-pass weld and high welding formation quality, as well as realization of high effective welding under the common non-melt electrode welding environment. When being used under the melt electrode mode, the arc welding method has the advantages of greatly improved welding efficiency, effective control of welding heat input quantity, changed weld penetration due to the changed acoustic frequency, the protective gas injecting nozzle, the welding height and other parameters, and effective control of solidification and crystalline state of the molten metal.

Owner:HARBIN INST OF TECH

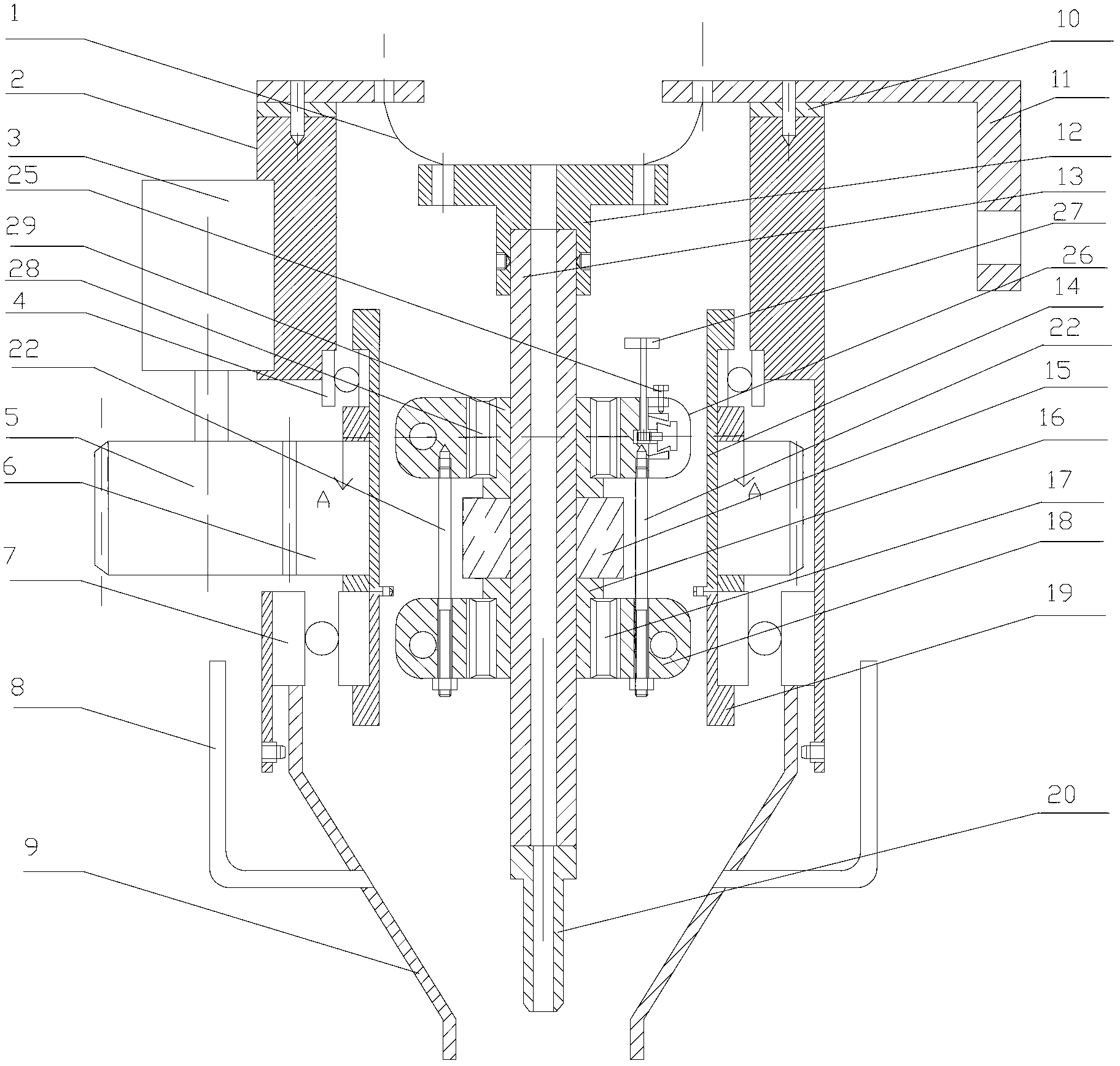

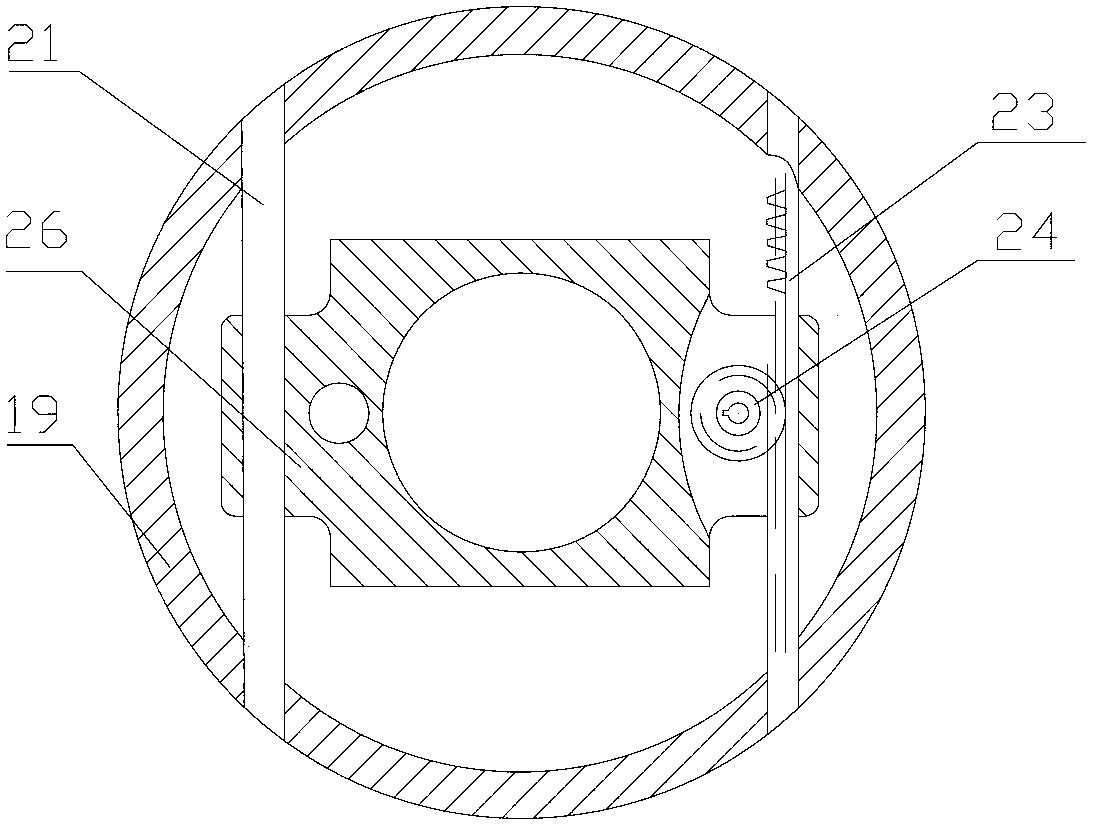

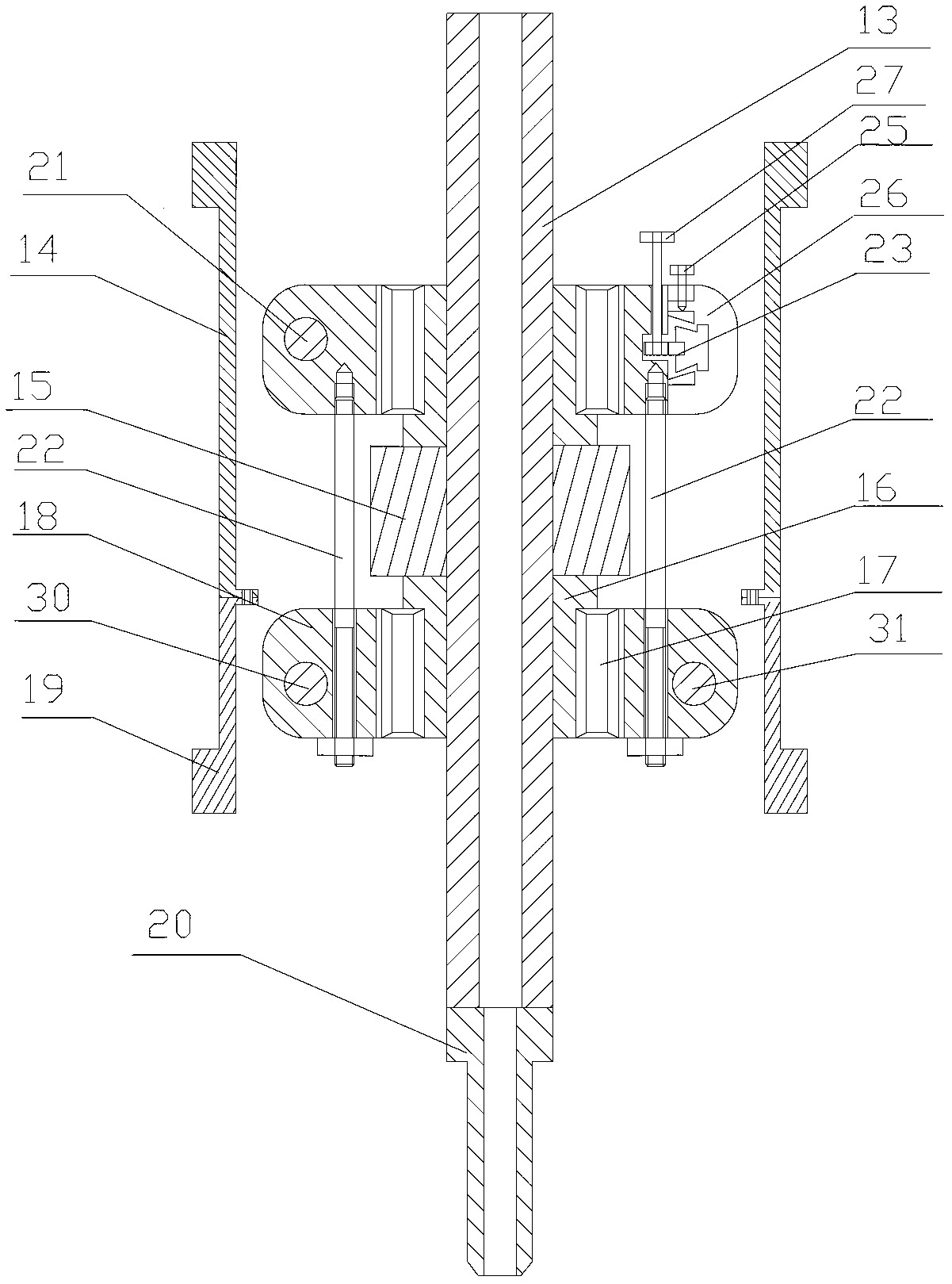

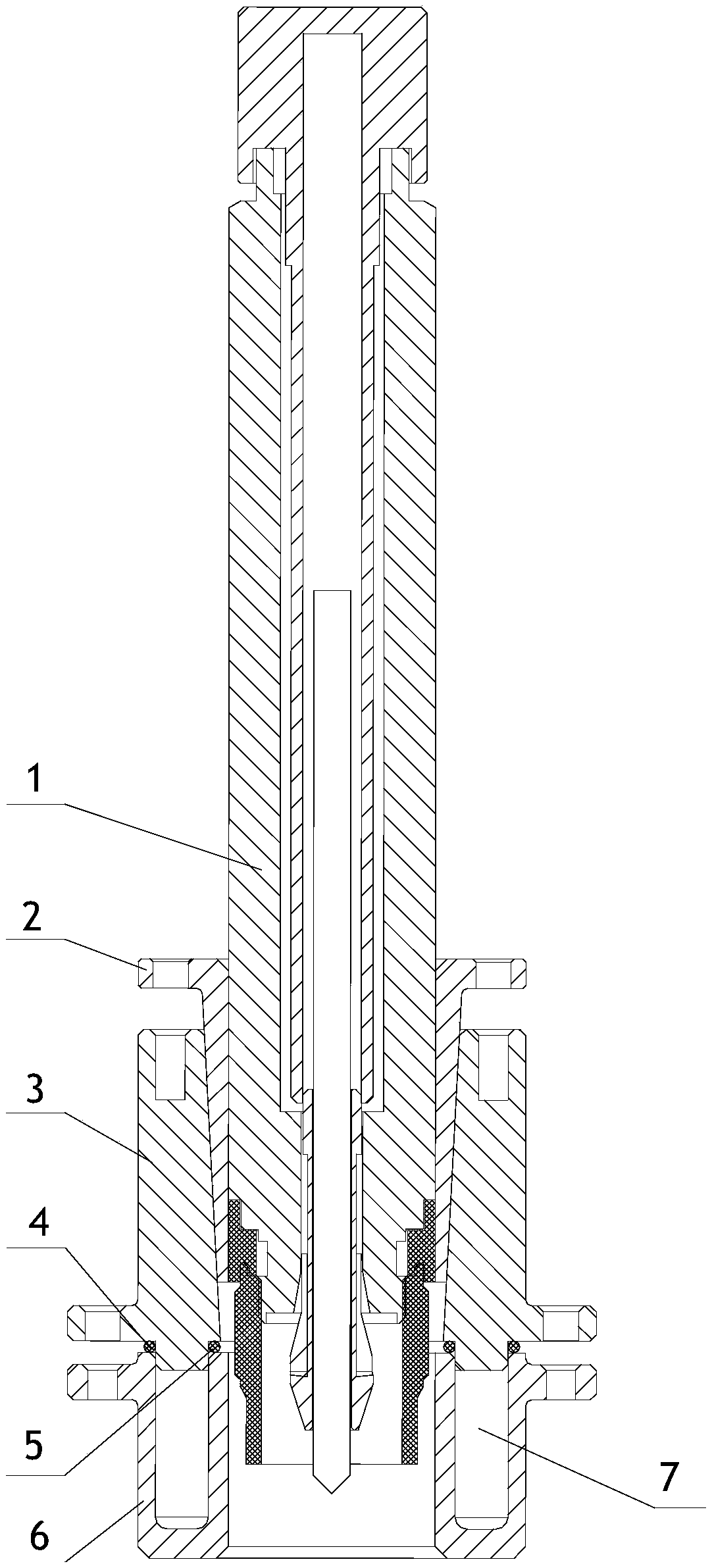

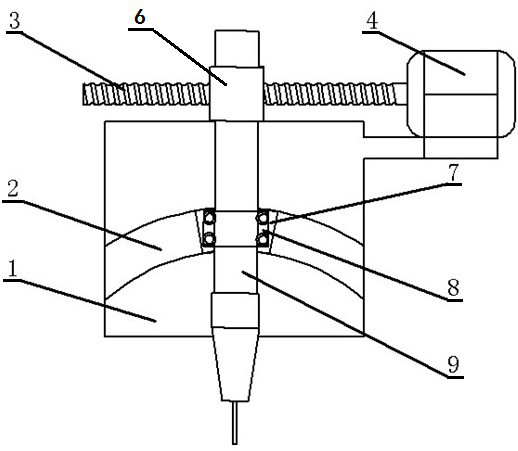

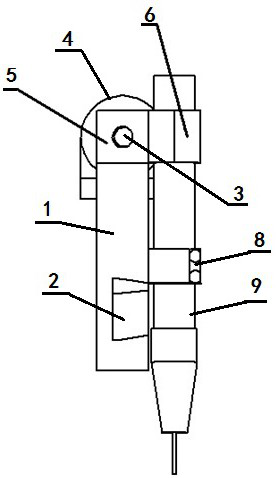

Welding gun for rotating arc gas metal arc welding

ActiveCN103182595AExtend your lifeLow maintenanceElectrode supporting devicesElectrode accessoriesElectricityGas metal arc welding

The invention discloses a welding gun for rotating arc gas metal arc welding. The welding gun comprises a welding gun outer barrel, wherein the welding gun outer barrel is internally provided with an eccentric assembly, the eccentric assembly comprises an upper inner barrel, a lower inner barrel and an eccentric slide block adjustment mechanism, the welding gun also comprises a hollow rotation shaft arranged on the eccentric assembly, when the upper inner barrel and the lower inner barrel rotate, the hollow rotation shaft does eccentric revolution surrounding the axle line of the upper inner barrel and the lower inner barrel, and does reversed rotation surrounding the self axle line at the same time, the front end of the hollow rotation shaft is connected with an electric conduction nozzle, the rear end of the hollow rotation shaft is connected with an electric conduction disc, during the welding, the electric current flows into the electric conduction disc through a flexible cable from an end cover, then reaches the electric conduction nozzle through the hollow rotation shaft, and is conducted onto a welding wire, a rotating arc generated along with the rotation of the hollow shaft and the electric conduction nozzle. The flexible cable can stably conducting electricity in a fixing manner, and the problem of stable electric conduction between a rotating part (the hollow rotation shaft) and a fixing part (welding cable) is solved. The welding gun disclosed by the invention can be used for a variety of positions welding such as flat position welding, over-head position welding, vertical position welding and horizontal position welding, and the appearance of a welded joint is good and in a clear fish-scale pattern shape.

Owner:SOUTH CHINA UNIV OF TECH

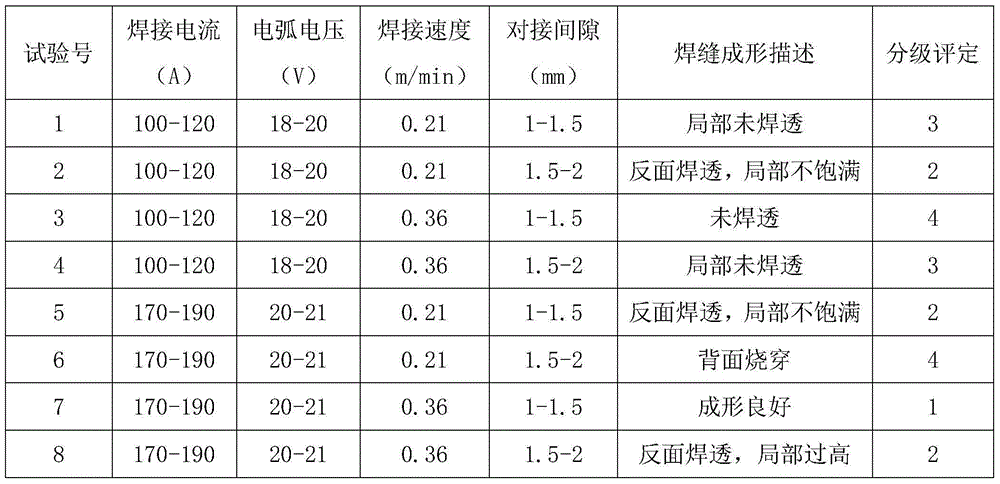

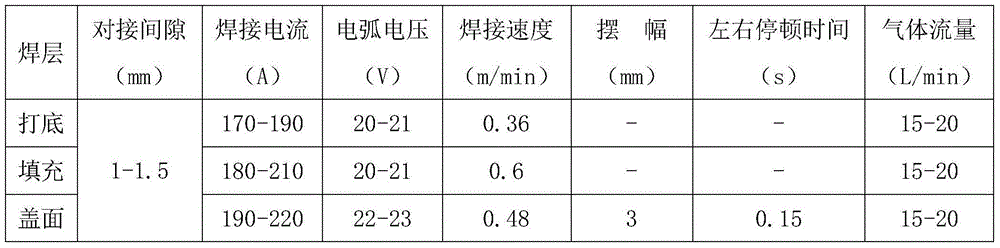

Method for single-side welding double-side forming of HG785D steel plate by robot

InactiveCN103949755AImprove pass rateImprove weld seam qualityArc welding apparatusButt jointEngineering

The invention discloses a method for single-side welding double-side forming of an HG785D steel plate robot, belongs to the technical field of welding a load-carrying truck chassis, a crane lifting arm and multiple sorts of high-strength spandrel girders. The invention solves the technical problem by providing the method for single-side welding double-side forming of the HG785D steel plate robot, which aims to improve the welding seam forming quality of a product, therefore the welding percent of pass is increased, the worker labor intensity is reduced, and the advanced manufacturing level of an enterprise is improved. The invention adopts the technical scheme that the keys for realizing single-side welding double-side forming and the actual operation are firstly taken into consideration, the influences of welding current, welding speed and butt joint gap on welding quality are analyzed, and the problem that the welding percent of pass of single-side welding double-side forming is low is solved by adopting methods of determining the welding current, the welding speed and the joining gap, and the like. The method for single-side welding double-side forming of the HG785D steel plate robot provided by the invention can be widely applied to the field of single-side welding double-side forming.

Owner:CHANGZHI QINGHUA MACHINERY FACTORY +1

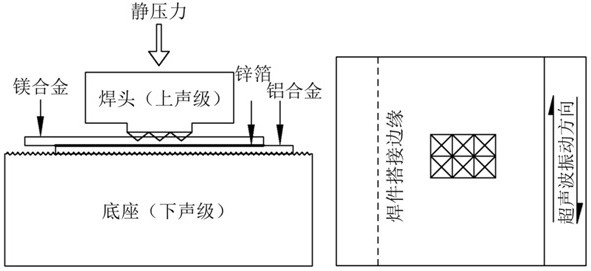

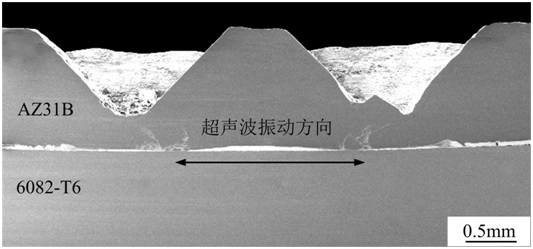

Ultrasonic-assisted eutectic reaction brazing method for dissimilar metal

The invention relates to an ultrasonic-assisted eutectic reaction brazing method for dissimilar metal, and belongs to the technical field of dissimilar material welding. The ultrasonic welding of a magnesium alloy and an aluminum alloy is carried out by adding a zinc intermediate layer, so that the generation of Mg-Al intermetallic compounds is successfully avoided, the welding quality and strength of a joint are improved, proper welding process parameters are adjusted to weld a workpiece, and the influence of different process parameters on the shear strength of a joint is researched, and the adjusted process parameters are as follows that the welding energy is 0-9999 J, the welding amplitude is 60%-100%, and the welding static pressure is 0-0.65 MPa. By means of parameter adjustment, a 0.1 millimeter magnesium alloy sheet and a 0.1 millimeter aluminum alloy sheet can be connected through dissimilar materials, and it is guaranteed that the welding joint is small in deformation, good in forming and free of welding defects such as cracks and air holes, when the welding energy is 1700 J, the welding amplitude is 95%, the welding static pressure is 0.4 MPa, the joint shear strength reaches the maximum and is 57.62 MPa, and compared with the Mg / Al ultrasonic welding process without a middle layer, the joint strength is improved by 89.66%.

Owner:JILIN UNIV

Magnetically-controlled plasma welding method and welding device

InactiveCN109590590AIncrease the electric field strengthImprove welding effectPlasma welding apparatusMetallic materialsEngineering

The invention discloses a magnetically-controlled plasma welding method and a welding device. According to the magnetically-controlled plasma welding method, adding of a longitudinal magnetic field along the direction of a welding gun between the welding gun and a workpiece welded is adopted. Under restraint of a longitudinal magnetic field, the drastic contracting effect is produced by electric arcs. The electric field intensity of the electric arcs is strengthened conspicuously, and thus the electric arcs have strong longitudinal penetrating power. Therefore, by adding the longitudinal magnetic field between the welding gun and the workpiece welded, a high-thickness plate or other special metal materials which are difficult to weld can be welded easily; and moreover, under the action ofelectrified coil current, the workpiece welded also has function of preheating before welding and heat treatment after welding, and the welding joint molding quality is improved obviously.

Owner:邢台子中电子科技有限公司

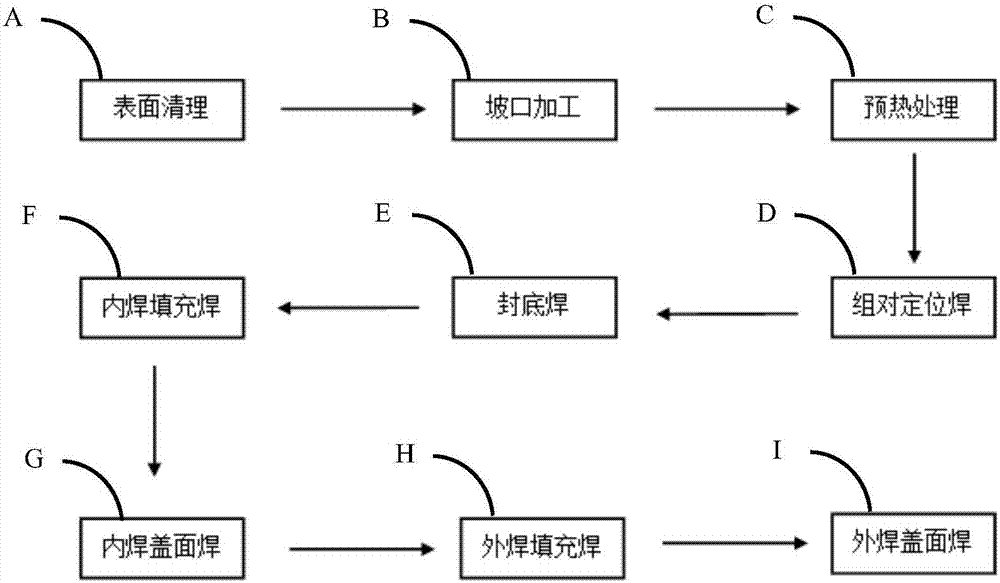

Welding process for straight seam welded pipe

ActiveCN107538142APrevent splashBeautiful weld shapeArc welding apparatusTubular articlesSeam weldingMaterials science

The invention provides a welding process for a straight seam welded pipe, and relates to the technical field of pipeline welding. The straight seam welded pipe with five welding layers is made by welding a steel plate in a winded mode, and the welding process comprises the following steps that edge preparation is conducted on a steel plate to obtain a curled steel plate; group alignment positionedwelding is conducted on the curled steel plate and a base body of the straight seam welded pipe is formed; and the straight seam welded pipe with the five welding layers can be obtained by sequentially conducting back run welding, inner welding filling welding, inner welding cosmetic welding, outer welding filling welding and outer welding cosmetic welding on the base body of the straight seam welding pipe.

Owner:JIANGSU TONGYU STEEL PIPE GRP

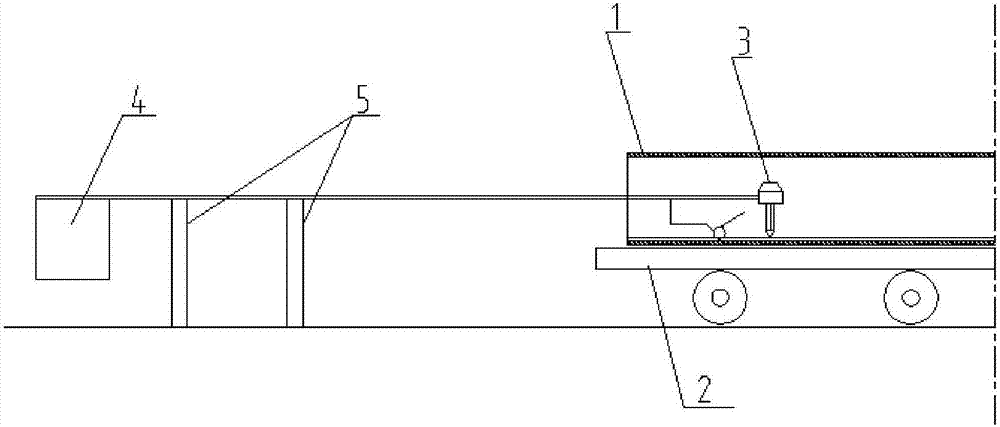

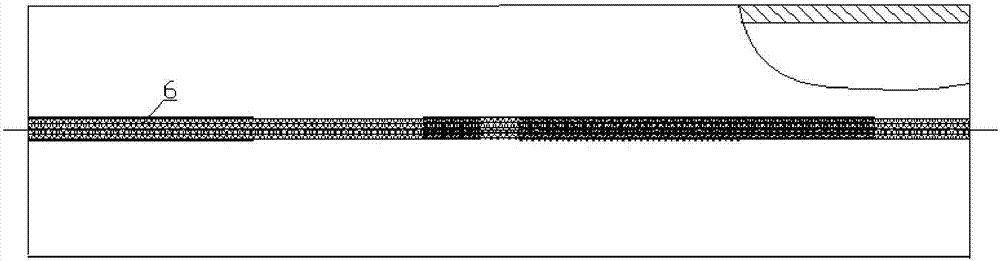

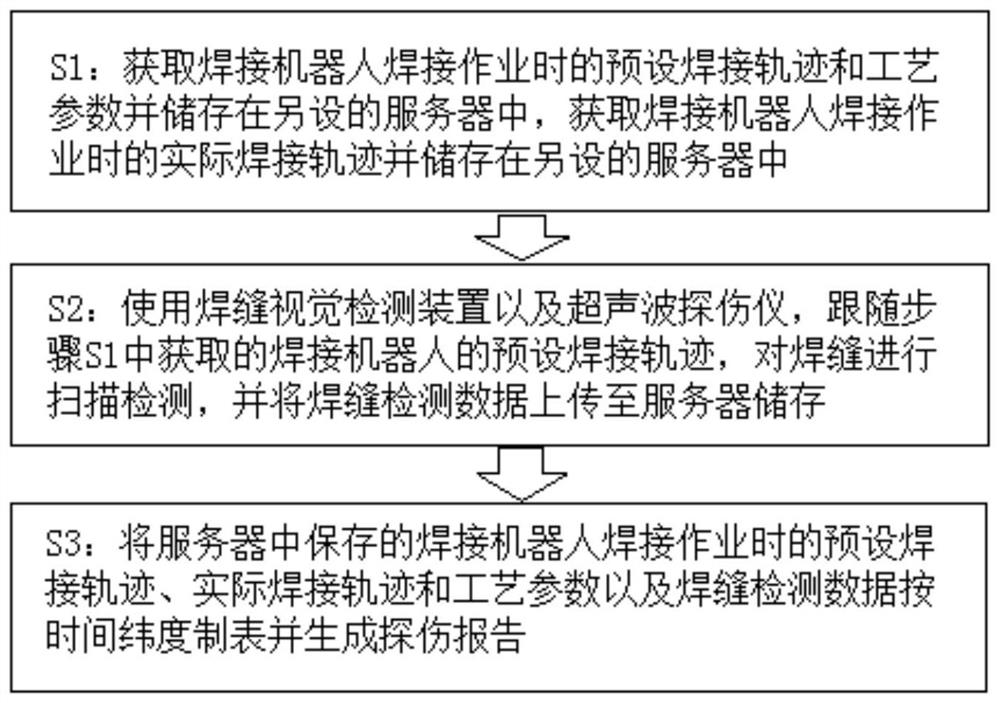

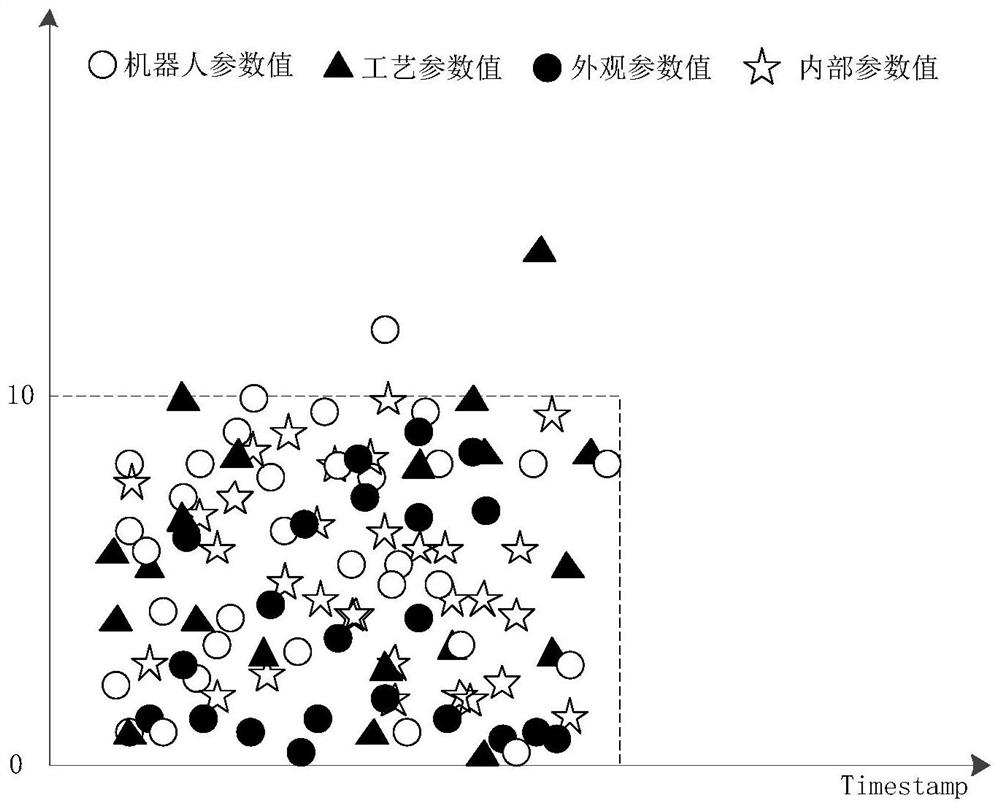

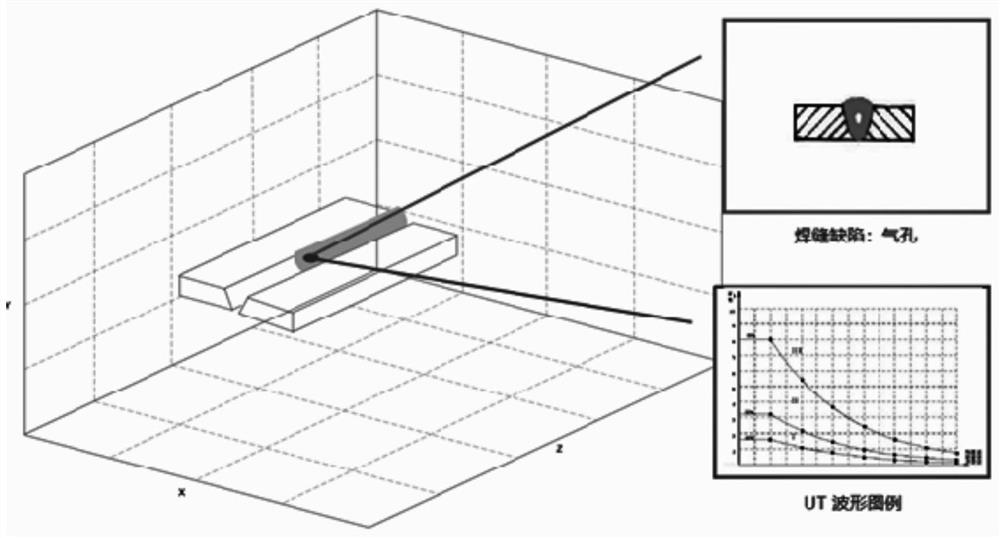

Weld defect automatic detection method and device

PendingCN114487113AEasy to retrospective analysisImprove weld seam qualityAnalysing solids using sonic/ultrasonic/infrasonic wavesOptically investigating flaws/contaminationEngineeringWeld seam

The invention discloses a welding seam defect automatic detection method which comprises the following steps: S1, acquiring a preset welding track and process parameters during welding operation of a welding robot and storing the preset welding track and process parameters in an additionally arranged server, and acquiring an actual welding track during welding operation of the welding robot and storing the actual welding track in the additionally arranged server; s2, a welding seam visual detection device and an ultrasonic flaw detector are used for scanning and detecting the welding seam along with the preset welding track, obtained in the step S1, of the welding robot, welding seam detection data are uploaded to a server to be stored, the welding seam visual detection device detects appearance parameters of the welding seam, and the ultrasonic flaw detector detects internal parameters of the welding seam; and S3, tabulating the preset welding track, the actual welding track, the process parameters and the welding seam detection data stored in the server during the welding operation of the welding robot according to the time latitude, and generating a flaw detection report. The invention further discloses an automatic weld defect detection device.

Owner:卡尔克鲁斯机器人科技(中国)有限公司

Flux-cored wire for titanium- or niobium-contained austenitic stainless steel welding

InactiveCN103418940BImprove slag removal rateImprove forming qualityWelding/cutting media/materialsSoldering mediaAusteniteZircon

A flux-cored wire for titanium- or niobium-contained austenitic stainless steel welding comprises welding flux powder and an external-use stainless steel band. A flux core accounts for 21.0-25.0% of the total weight of the flux-cored wire. The flux core comprises, by weight percentage, 15.0-18.0% of chromium powder, 9.5-11.0% of nickel powder, 4.0-5.0% of ferroniobium, 4.0-6.0% of electrolytic manganese, 1.0-3.0% of silicon-calcium alloy powder, 10.0-15.0% of rutile, 3.5-5.0% of quartz, 15.0-20.0% of zircon sand, 6.0-11.0% of feldspar, 1.5-2.5% of cryolite, 0.5-1.0% of lithium carbonate, 0.5-0.8% of bismuth oxide, and the balance of iron powder. In the flux core, the proportion of the content sum of titanium dioxide and zirconium dioxide to the content of silicon dioxide is 1.5-2.0; the proportion of the content of manganese powder to that of silicon-calcium alloy powder is 2.0-3.0. The external-use stainless steel band is austenitic stainless steel band 304L with carbon content lower than 0.02wt%. The diameter of the flux-cored wire is 0.9-1.2mm. By the flux-cored wire with good welding process property, all-position welding of titanium- or niobium-contained austenitic stainless steel can be achieved.

Owner:CHINA JINGYE ENG TECH CO LTD +1

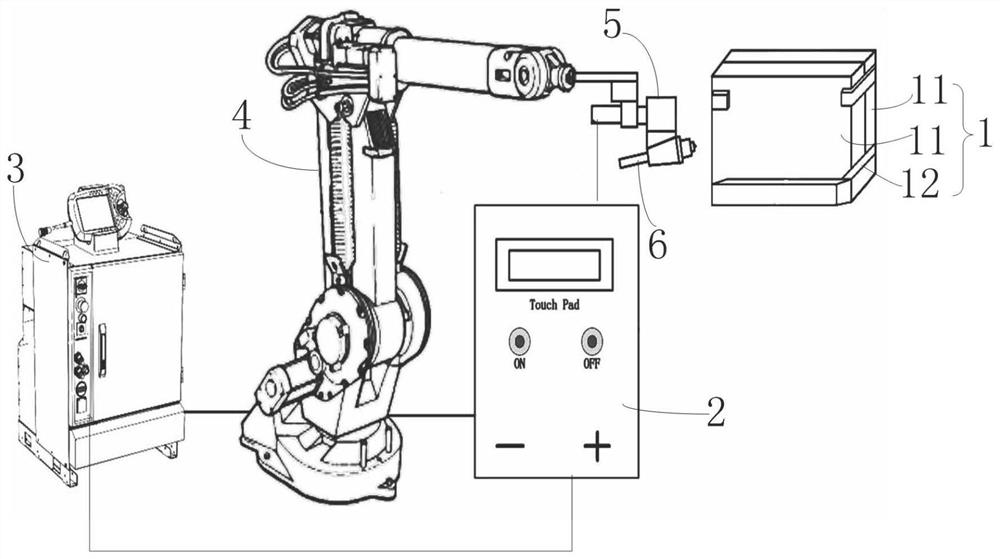

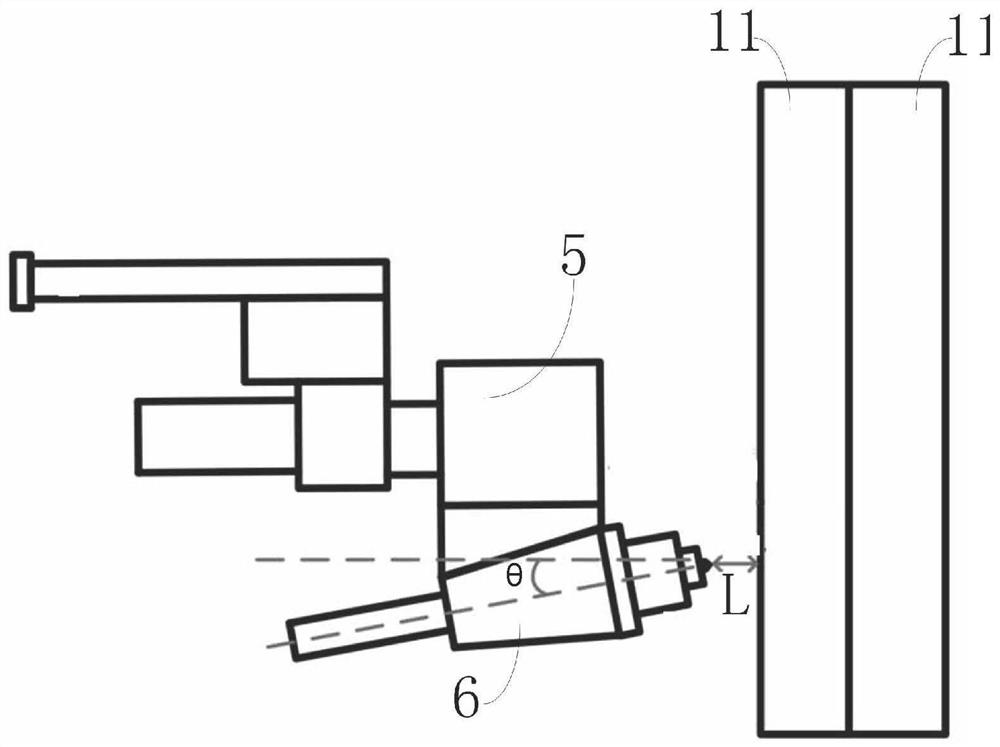

Horizontal position welding method and system for austenitic stainless steel bottom-locking structure

ActiveCN113427107ALow cost requirementsLow welding process requirementsWelding accessoriesWelding power supplyIndustrial robotics

The invention discloses a horizontal position welding method for an austenitic stainless steel bottom-locking structure. The horizontal position welding method sequentially comprises the following steps of, preparing a austenitic stainless steel structure; carrying out pretreatment; installing a horizontal position welding system; adjusting the welding position, specifically, adjusting the included angle theta between the axis of a tungsten electrode bar and a horizontal line to be 10-15 degrees, and adjusting the distance L between the end of the tungsten electrode bar and the surface of the austenitic stainless steel structure to be 3-5 mm; and staring welding. The invention further discloses a horizontal position welding system for the austenitic stainless steel bottom-locking structure. A high-frequency pulse welding power source is electrically connected with a control cabinet, an industrial robot and an argon arc welding torch, the control cabinet is electrically connected with the industrial robot, the argon arc welding torch is fixed to the industrial robot, a tungsten electrode bar is fixed to the argon arc welding torch, the angle theta between the axis of the tungsten electrode bar and the horizontal line ranges from 10 degrees to 15 degrees, and the distance L between the end part of the tungsten electrode bar and the surface close to the austenitic stainless steel structure is 3-5mm. According to the horizontal position welding method and system for the austenitic stainless steel bottom-locking structure, the welding cost is reduced, the welding process requirement is lowered, and the forming quality of a welding seam is improved.

Owner:BEIHANG UNIV

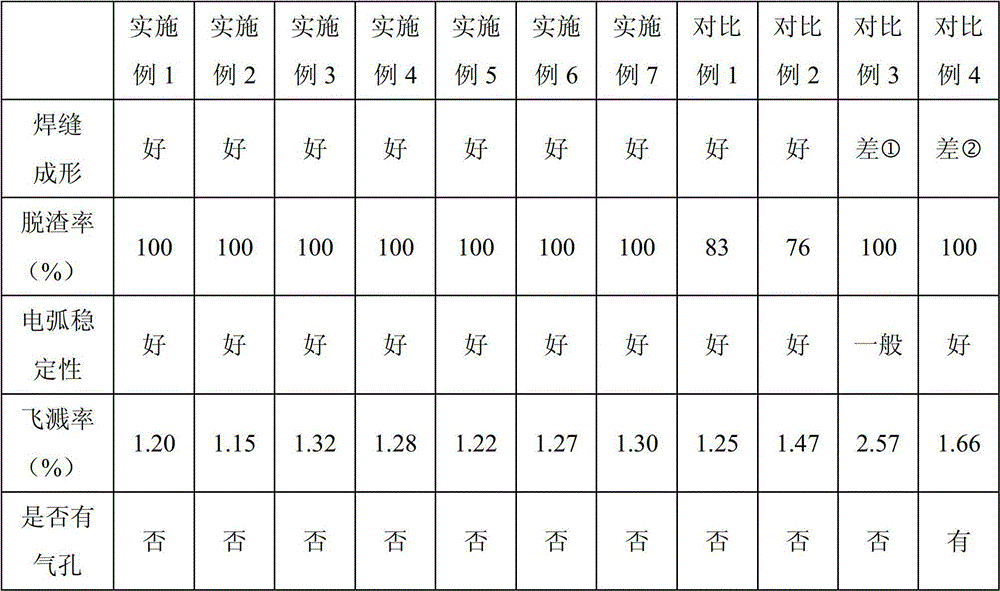

Flux-cored wire for austenitic stainless steel all-position welding

ActiveCN102229029BGood workmanshipEasy to remove slagWelding/cutting media/materialsSoldering mediaElectrolysisPotassium

The invention relates to a flux-cored wire for austenitic stainless steel all-position welding, and the flux-cored wire is composed of a flux core and an external stainless steel belt, wherein, the flux core accounts for 22-24wt% of the flux-cored wire, and the flux core comprises the following components in percentage by weight: 20-23% of metal chromium powder, 7-8.5% of metal nickel powder, 2-4% of electrolytic manganese metal, 3-4% of aluminium powder, 0.5-1% of ferrotitanium, 32-34% of rutile, 1-2% of quartz, 2-4% of zircon sand, 4-6% of albite, 2-4% of potassium feldspar, 1-1.5% of cryolite, 1-1.5% of lithium carbonate, 0.1-0.5% of bismuth oxide and the balance of iron powder. The ratio of the albite to the potassium feldspar in the flux core is 1.2-2, the sum of the albite and the potassium feldspar is not more than 10wt% of the flux core, the external stainless steel belt is the austenitic stainless steel 304L, the carbon content is less than 0.025wt%, the diameter of the flux-cored wire is 0.9-1.2mm, and the flux-cored wire can be used for realizing the austenitic stainless steel all-position welding.

Owner:北京远达国际工程管理咨询有限公司 +1

Welding gun angle real-time automatic adjusting device

InactiveCN113478137ARealize stepless adjustmentTroubleshoot auto-tuning issuesWelding/cutting auxillary devicesAuxillary welding devicesBall screwControl system

The invention discloses a welding gun angle real-time automatic adjusting device which comprises a mounting plate, wherein an arc-shaped groove is formed in the mounting plate; an arc-shaped guide rail is mounted in the arc-shaped groove; a sliding table is mounted in the arc-shaped guide rail and fixedly connected with the middle of a welding gun through a locking device; a servo motor is fixedly mounted on one side of the upper portion of the mounting plate; a rotating shaft of the servo motor is connected with a ball screw; a screw nut is mounted on the ball screw; the outer side edge of the lead screw nut is fixedly connected with a sliding sleeve; and the upper portion of the welding gun is sleeved with the sliding sleeve. The device can achieve automatic adjustment of the posture of the welding gun in the current automatic welding process, is simple in structure and wide in application range, an automatic welding control system does not need to consider posture adjustment of the welding gun and only needs to design a mechanism and a control system according to a welding path, the welding gun can synchronously achieve angle rotation in the moving process, the welding seam forming quality is good, the welding efficiency is high, an executing mechanism and the control system of automatic welding equipment are greatly simplified, cost is reduced, and popularization is facilitated.

Owner:江西华赣环保装备有限公司

Pipeline steel two-in-one butt weld pipeline deep penetration high-speed welding process method

InactiveCN113070549ABeautiful weld shapeAvoid Weld CrackingArc welding apparatusPipeline systemsButt weldingLine tubing

The invention discloses a pipeline steel two-in-one butt weld pipeline deep penetration high-speed welding process method, and relates to the technical field. The method is applied to a filling weld bead and a cosmetic weld bead, adopts downhill welding, and comprises the following steps that S1, a pipe fitting to be welded is cut off and bevelled by adopting a machining method, and rust and oil dirt near a groove of the pipe fitting are removed according to standard regulations; S2, a welding material matched with a base material and a dry, oil-free and rust-free welding wire special for pipeline steel are used, and pre-welding inspection is carried out on the used welding wire before welding; and S3, a 1G process method that a pipe rotates and the position of a welding machine head is not changed is adopted, welding is carried out without backing protection on the back face, and it is guaranteed that back face penetration is free of defects. Welding quality is guaranteed, procedures are simplified, deposition efficiency is high, and welding efficiency is improved.

Owner:南京奥特自动化有限公司

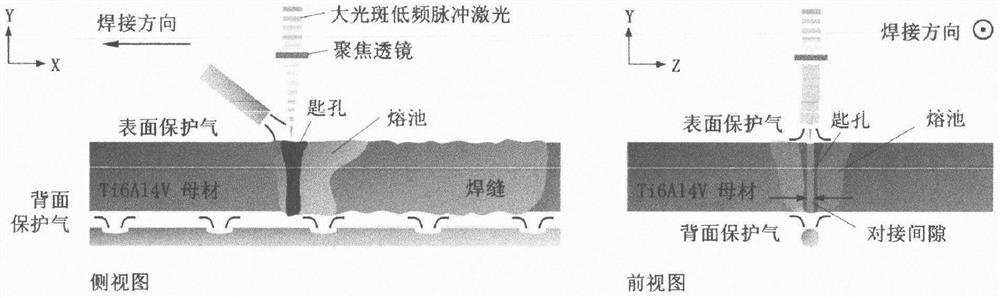

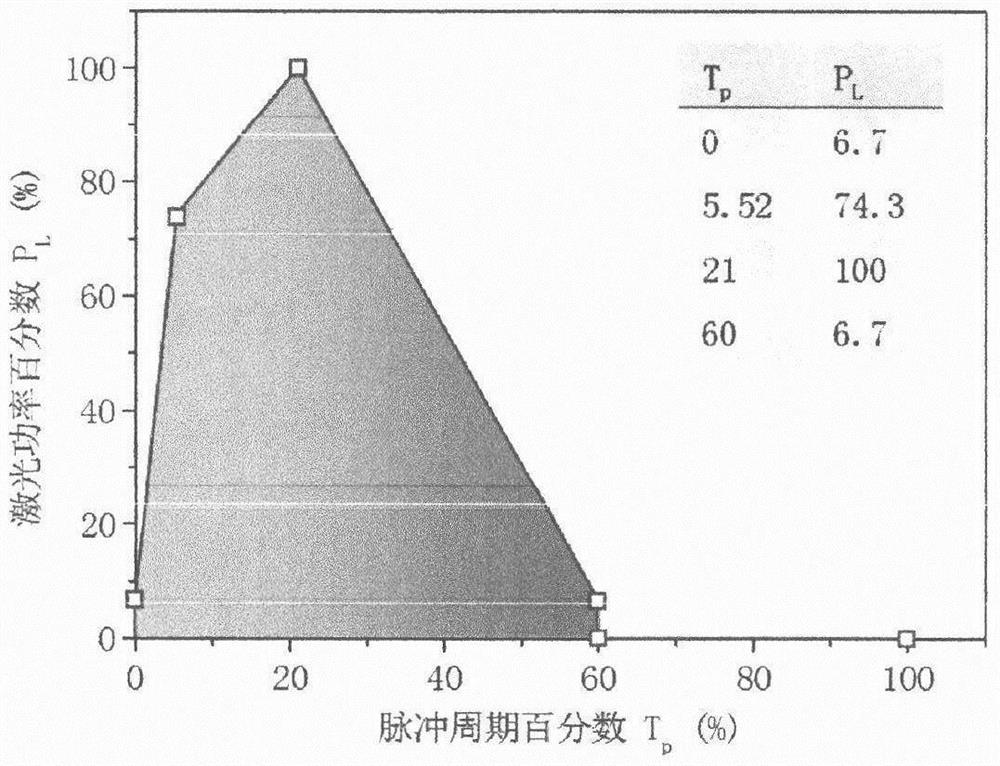

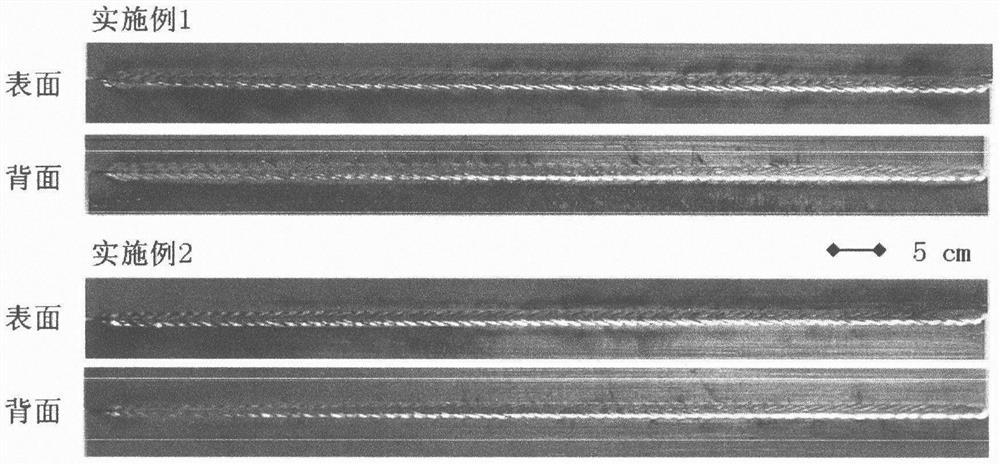

A Laser Welding Process for Improving the Fitting Margin of Thin Plate Titanium Alloy Tailored Welding

ActiveCN113245703BIncrease cooling rateReduce sensitivityWelding/soldering/cutting articlesLaser beam welding apparatusThin slabThermal deformation

The invention discloses a laser welding process for improving the assembly margin of thin-plate titanium alloy tailor welding, which belongs to the technical field of high-energy beam welding. This process aims at the instability of the groove gap caused by factors such as machining burrs, assembly errors, and thermal deformation in the laser tailor welding process of thin plates, resulting in problems such as welding deviation and missing welding. The spot size of the focal spot increases the cooling rate of the welding spot while obtaining sufficient amount of interstitial metal, and realizes the non-filling laser welding of 1.2mm thick titanium alloy under the condition of 0.2‑0.3mm tailor welding assembly gap, and the weld seam The continuity and uniformity are good, there is no obvious welding defect, and the effective assembly gap reaches 25% of the plate thickness. This process can significantly reduce the gap sensitivity of laser welding of sheet metal and improve the quality of weld seam formation. The invention has great significance for promoting the application and development of the laser welding technology in the thin plate tailor welding field.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

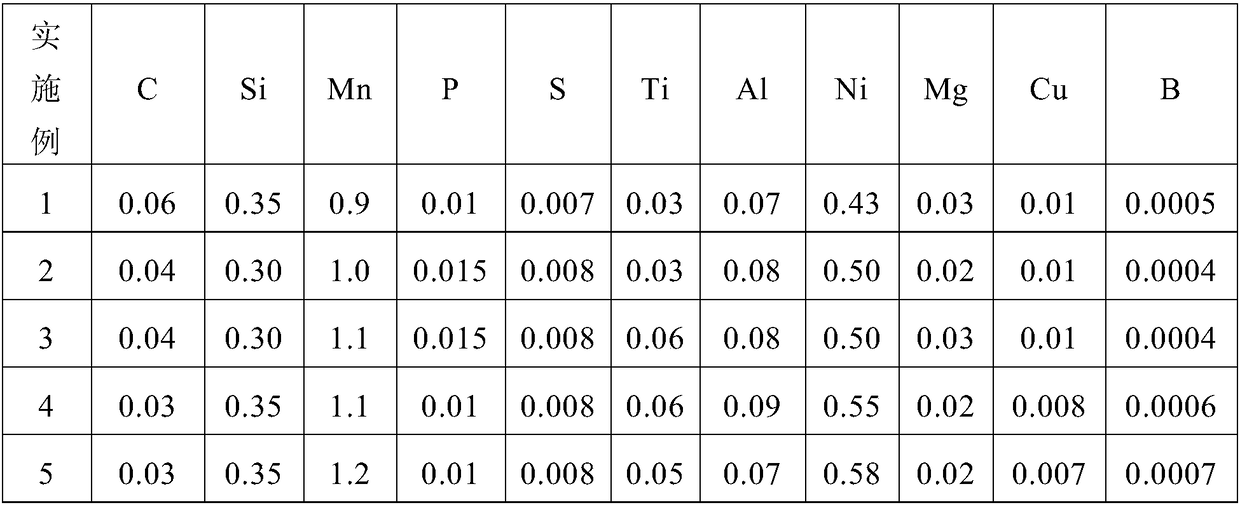

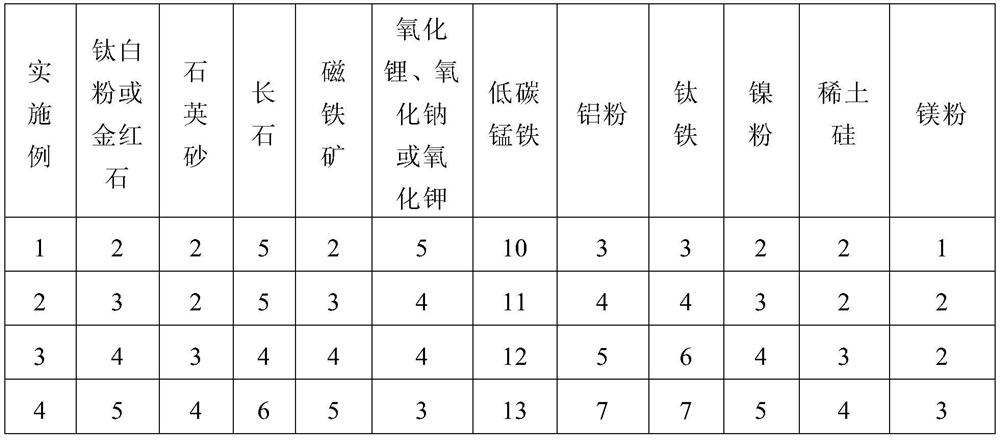

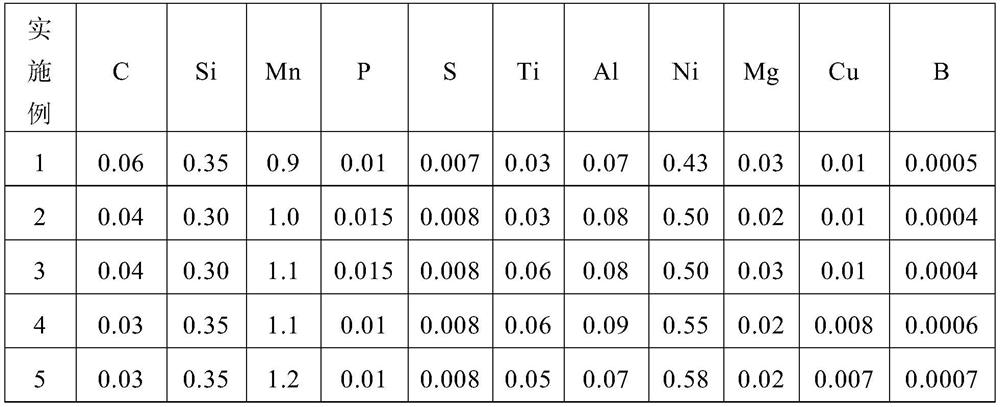

A high heat input gas-electric vertical welding gas-shielded flux-cored wire based on grain refinement mechanism

ActiveCN109128573BPromote high melting point interstitial phaseNucleation refinementWelding/cutting media/materialsSoldering mediaLithium oxideMagnetite

A high heat input gas-electric vertical welding gas-shielded flux-cored wire based on a grain refinement mechanism, including a flux-cored wire sheath and its inner drug powder, wherein the flux-cored wire sheath is made of low-carbon steel cold-rolled steel strip, which The mass percentage of the composition is: C<0.06%, Si<0.3%, Mn<0.8%, P<0.02%, S<0.01%, and the balance is Fe and unavoidable impurities; the mass percentage of the composition of the powder is: titanium dioxide Or one or both of rutile: 1-5%, quartz sand: 2-6%, feldspar: 3-8%, magnetite: 1-5%, lithium oxide, sodium oxide or potassium oxide One or more: 2-5%, low-carbon ferromanganese: 10-15%, aluminum powder: 3-8%, titanium iron: 3-8%, nickel powder: 2-6%, rare earth silicon: 2- 6%, magnesium powder: 1-3%, and the rest is reduced iron powder; and the powder accounts for 15-20% of the total mass of the flux-cored wire. The welding wire of the invention can be used for gas-electric vertical welding of thick steel plate with large heat input of 100kJ / cm-300kJ / cm.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com