Method for single-side welding double-side forming of HG785D steel plate by robot

A single-sided welding double-sided, robot technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problem of lack of research on high-strength steel plates, and achieve improved weld forming quality, high product qualification rate, and improved welding. The effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A kind of HG785D steel plate robot single-sided welding double-sided forming method of the present invention, operates according to the following steps,

[0028] The first step: choose welding equipment;

[0029] Choose a robot, welding power source and positioner with matching power;

[0030] Step 2: Select the size of the groove form;

[0031] Select a butt joint with thickness M;

[0032] The third step: analyze and determine the welding process parameters;

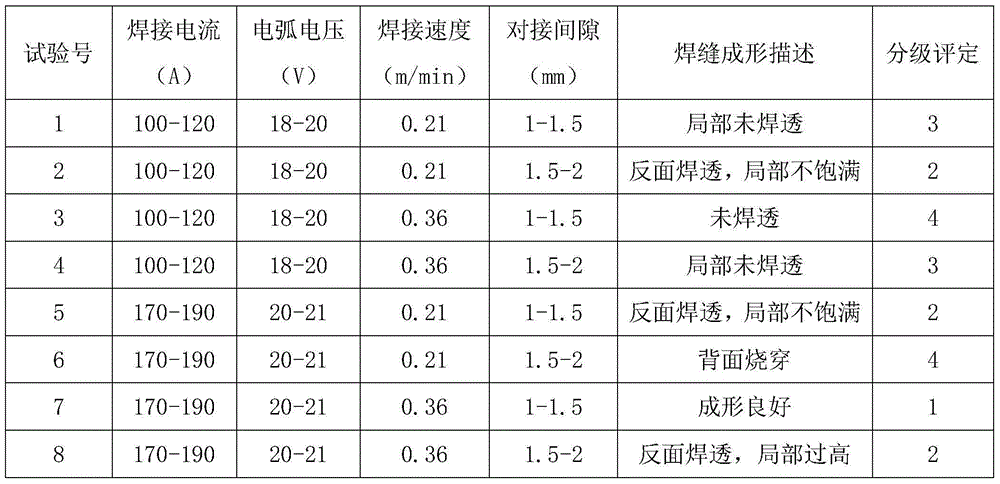

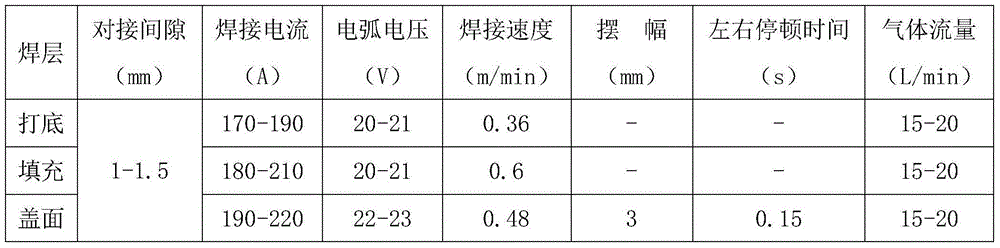

[0033] Pulse welding with small welding deformation is used for welding. According to the forming condition of the back of the weld, the corresponding welding process parameters that cannot be welded on one side and formed on both sides are eliminated, and the three factors of welding current, welding speed and butt joint gap are selected, and the orthogonal test is passed. Design and determine the best parameter combination of the three;

[0034] Step 4: Check the docking gap;

[0035] Check whether the bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com