Horizontal position welding method and system for austenitic stainless steel bottom-locking structure

An austenitic stainless steel, horizontal welding technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of difficult to guarantee the penetration depth of the workpiece, poor thermal conductivity, poor structure and performance of the workpiece, etc., and achieve the reduction of welding process requirements , reduce welding cost, improve the effect of forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

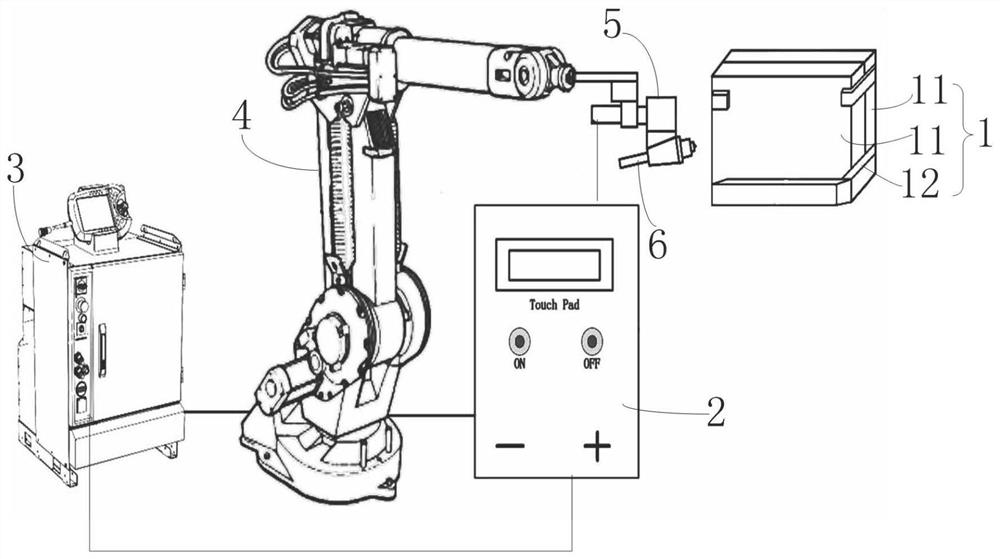

[0078] Embodiment 1, the two austenitic stainless steel layers 11 are both plate-shaped:

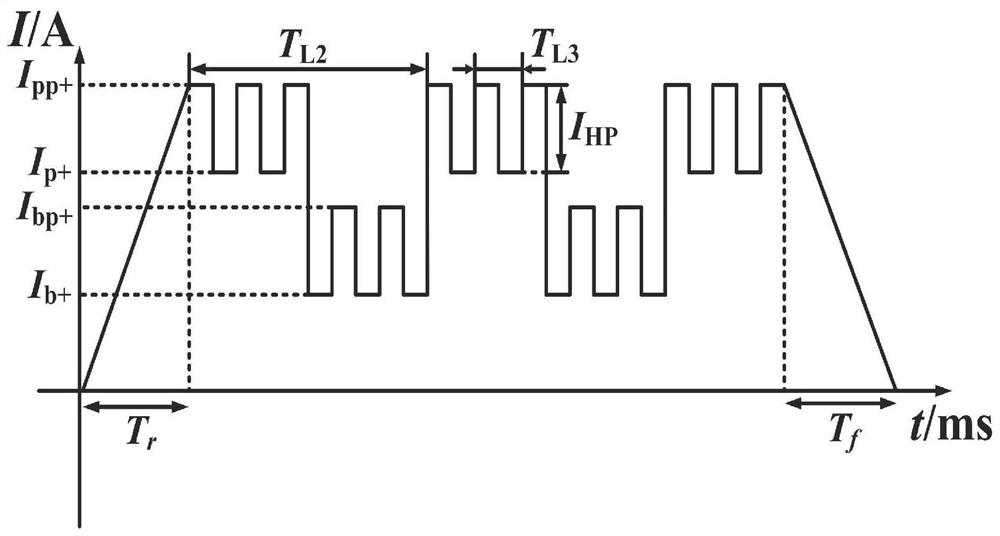

[0079] The working principle of the present invention is as follows:

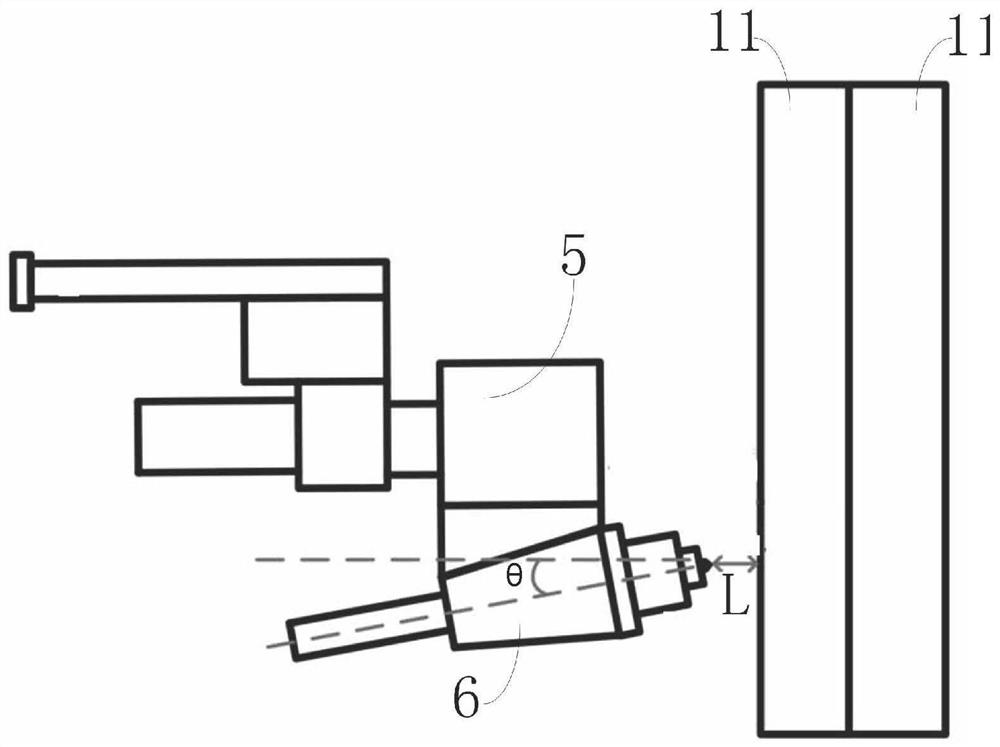

[0080] S1, prepare the austenitic stainless steel structure 1, the austenitic stainless steel structure 1 includes: two layers of austenitic stainless steel layers 11 and a fixing tool 12, the thickness of the single-layer austenitic stainless steel layer 11 is 2 to 5 mm, and the thickness of the two-layer austenitic stainless steel layer 11 is 2 to 5 mm. The total thickness of the solid stainless steel layers 11 being closely fitted together is 4 to 10 mm, the fixing tooling 12 fixes the two austenitic stainless steel layers 11 together, and the installation gap 103 between the two austenitic stainless steel layers 11 is less than 0.2 mm;

[0081]S2, pretreatment: the welding surface of the austenitic stainless steel structure 1 is ground by means of mechanical grinding, and then wiped with alcohol and acetone solut...

Embodiment 2

[0085] Embodiment 2: The two austenitic stainless steel layers 11 are both sleeve-shaped, and the two austenitic stainless steel layers 11 are sleeved and connected (then the austenitic stainless steel layer 11 located in the internal measurement is the inner cylinder, and the austenitic stainless steel layer 11 located on the outer side is When the tensite stainless steel layer 11 is an outer cylinder, the length of the outer cylinder can reach more than 4 meters, and the flat welding process cannot be used due to the limitation of the assembly process, and only the horizontal welding position welding process can be used), the working principle is different from that of Example 1: steps In S5, the industrial robot 4 is controlled to drive the argon arc welding torch 5 to continuously approach the outermost austenitic stainless steel layer 11 (outer cylinder) until the end of the tungsten rod 6 contacts the outermost austenitic stainless steel layer On the surface of 11 (outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com