Infrared light perfect absorber and preparation method thereof

An infrared light and absorber technology, applied in optics, instruments, filters, etc., can solve the problem of large area, low-cost preparation, inability to effectively expand electronic control or optoelectronic functional device platforms, and inability to achieve infrared broadband or infrared ultra-high Broadband light absorption and other issues, to achieve the effect of reducing cost requirements, easy large-area preparation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

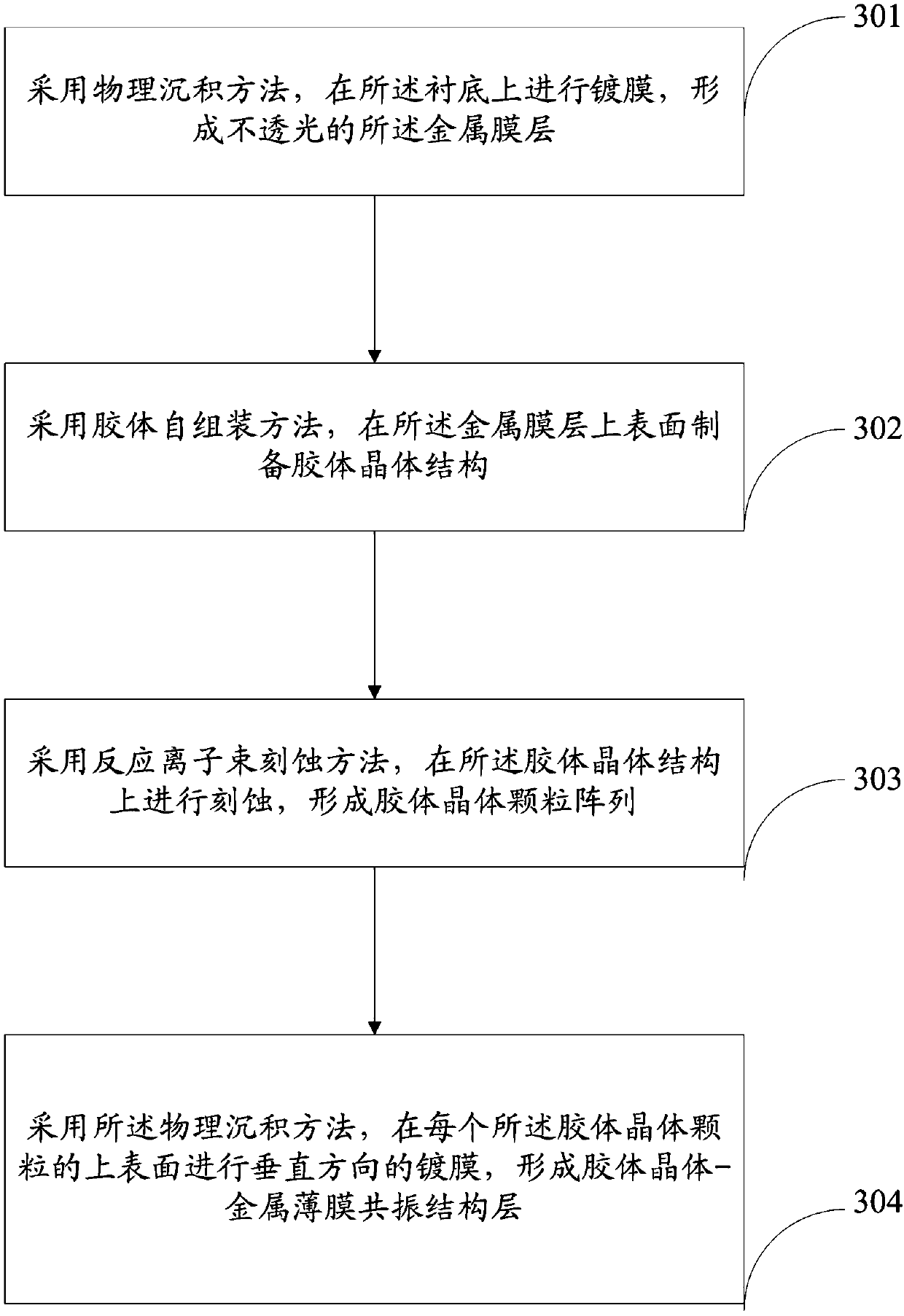

Method used

Image

Examples

Embodiment 1

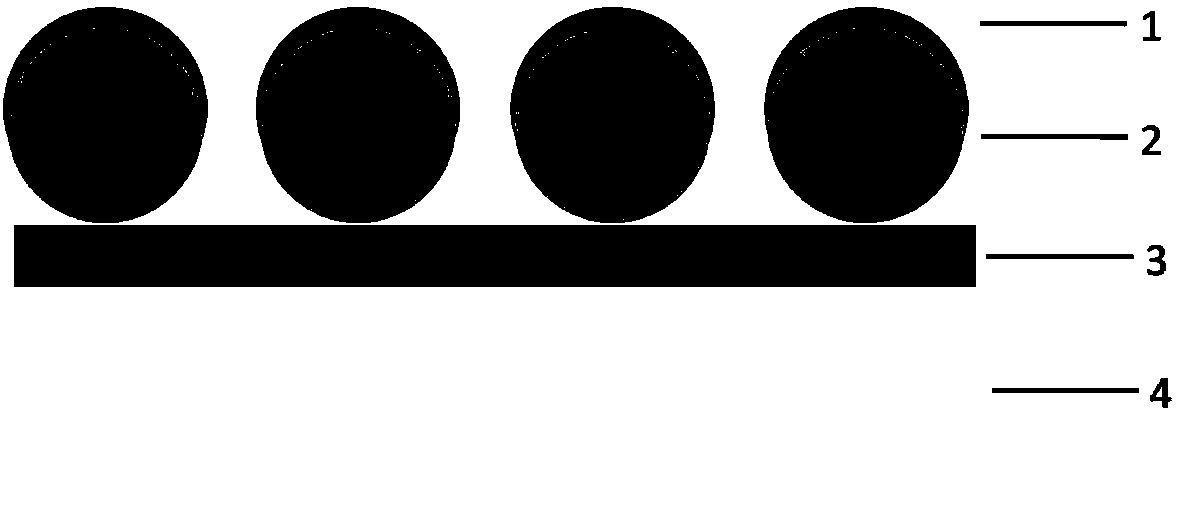

[0034] figure 1 It is a schematic side view of an infrared light perfect absorber structure according to an embodiment of the present invention, figure 2 It is a schematic top view of the structure of an infrared light perfect absorber according to the embodiment of the present invention. Such as figure 1 and figure 2 As shown, the infrared light perfect absorber provided by the present invention includes a substrate 4, an opaque metal film layer 3 arranged on the substrate 4, and a colloidal crystal-metal thin film resonant film layer arranged on the metal film layer 3 structural layer. Wherein, the colloidal crystal-metal film resonance structure layer is composed of a plurality of identical colloidal crystal particles 2 and a metal film 1 deposited on the upper surface of each colloidal crystal particle 2 . The colloidal crystal particles 2 are evenly arranged on the metal film layer 3 , that is, the colloidal crystal-metal film resonance structure is a non-close-pack...

Embodiment 2

[0053] The substrate 4 of the infrared light perfect absorber provided by Embodiment 2 of the present invention is a silicon wafer, the metal material is gold, the thickness of the metal film layer 3 is 100 nm, the material of the colloidal crystal particles 2 is polystyrene, and the colloidal crystal particles 2 are engraved The diameters before and after etching are 1000 nm and 700 nm respectively, that is, the gap g between adjacent colloidal crystal particles 2 after etching is 300 nm. The metal thin film 1 in the colloidal crystal-metal thin film resonance structure layer is a gold film, and the thickness of the metal thin film 1 is 15nm.

[0054] Figure 4 It is the light absorption figure of the infrared light perfect absorber provided by the second embodiment of the present invention, such as Figure 4 As shown, it can be found from the spectrogram of the experimental test that the maximum absorption rate reaches 98% in the 1.541 micron band, and the absorption rate i...

Embodiment 3

[0056] The substrate 4 of the infrared light perfect absorber provided by Embodiment 3 of the present invention is glass, the metal material is gold, the thickness of the metal film layer 3 is 100nm, the material of the colloidal crystal particles 2 is polystyrene, and the colloidal crystal particles 2 are etched The front and rear diameters are 1000 nm and 600 nm respectively, that is, the gap g between adjacent colloidal crystal particles 2 after etching is 400 nm. The metal thin film 1 in the colloidal crystal-metal thin film resonance structure layer is a gold film, and the thickness of the metal thin film 1 is 15nm.

[0057] Figure 5 It is the light absorption figure of the infrared light perfect absorber provided by Embodiment 3 of the present invention, as Figure 5 As shown, it can be found from the spectrogram that the maximum absorption rate reaches 99% in the 1.258 micron band, and 99.9% in the 1.266 micron band. In addition, the absorbance in the spectral range ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com