Ultraviolet-proof invisible car cover film with self-repairing function and preparation method of ultraviolet-proof invisible car cover film

An anti-ultraviolet and self-healing technology, applied in the field of automobile clothing, can solve the problems of easy scratching of the polyurethane film substrate layer, affecting the service life of the invisible automobile clothing film, etc., to achieve the effect of prolonging the life, avoiding damage, and excellent anti-graffiti.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

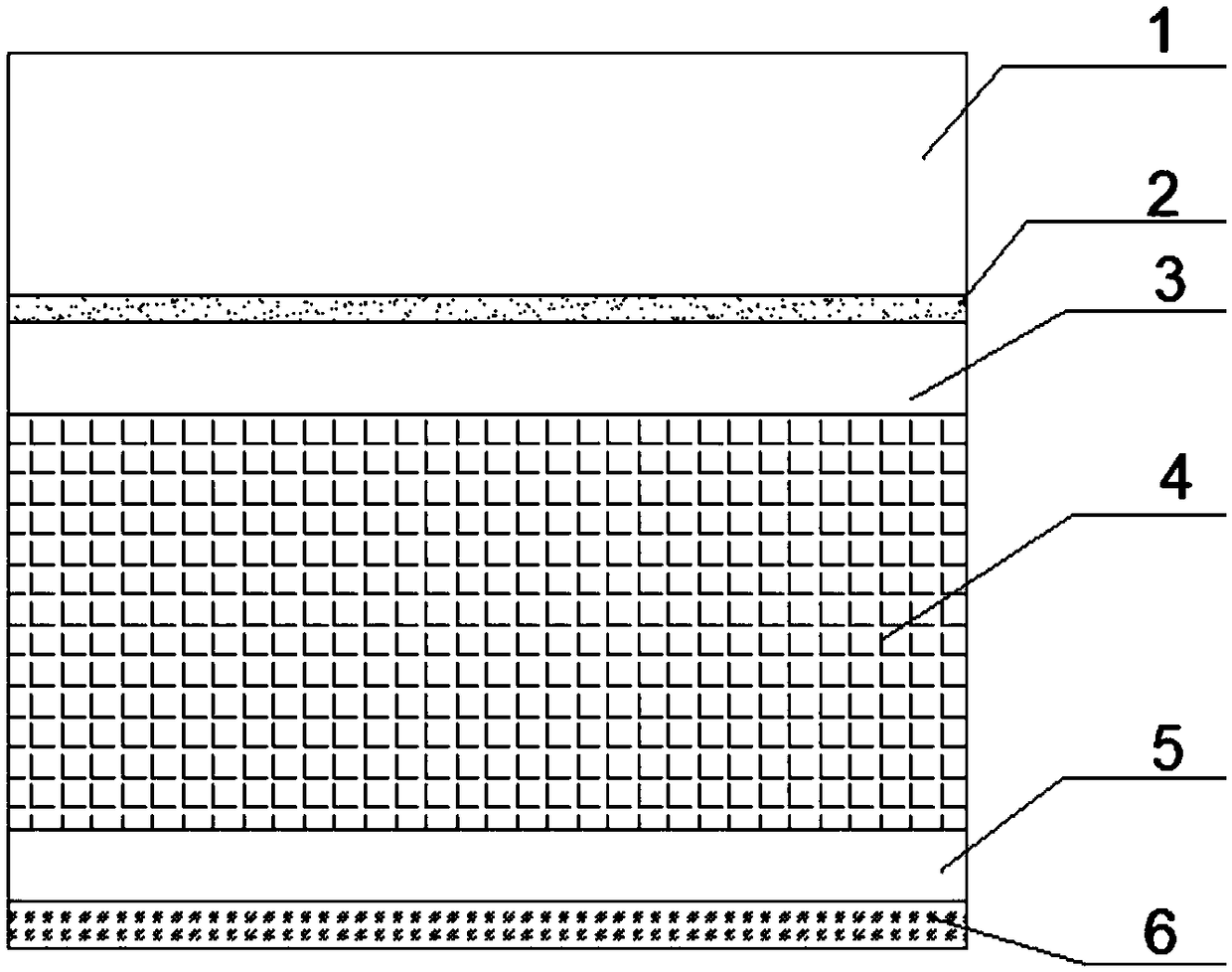

[0031] The anti-ultraviolet invisible car coating film with self-repairing function includes a TPU base material layer 4, and also includes a self-repairing layer 3, a protective silica gel layer 2, and a PET layer 1 arranged on the upper surface of the TPU base material layer 4 from bottom to top. And the pressure-sensitive adhesive layer 5 and release layer 6 arranged on the lower surface of the TPU base material layer 4 sequentially from top to bottom, the upper surface of the TPU base material layer 4 is provided with a self-healing layer 3 by coating, and the protection The silica gel layer 2 is arranged on the lower surface of the PET layer 1 by coating, the self-healing layer 3 is bonded to the protective silica gel layer 2 arranged on the lower surface of the PET layer 1 by a pressure roller, and the TPU substrate layer 4 The lower surface is coated with a pressure-sensitive adhesive layer 5, and the pressure-sensitive adhesive layer 5 is pasted with a release layer 6 b...

Embodiment 2

[0043] The anti-ultraviolet invisible car coating film with self-repairing function includes a TPU base material layer 4, and also includes a self-repairing layer 3, a protective silica gel layer 2, and a PET layer 1 arranged on the upper surface of the TPU base material layer 4 from bottom to top. And the pressure-sensitive adhesive layer 5 and release layer 6 arranged on the lower surface of the TPU base material layer 4 sequentially from top to bottom, the upper surface of the TPU base material layer 4 is provided with a self-healing layer 3 by coating, and the protection The silica gel layer 2 is arranged on the lower surface of the PET layer 1 by coating, the self-healing layer 3 is bonded to the protective silica gel layer 2 arranged on the lower surface of the PET layer 1 by a pressure roller, and the TPU substrate layer 4 The lower surface is coated with a pressure-sensitive adhesive layer 5, and the pressure-sensitive adhesive layer 5 is pasted with a release layer 6 b...

Embodiment 3

[0055] The anti-ultraviolet invisible car coating film with self-repairing function includes a TPU base material layer 4, and also includes a self-repairing layer 3, a protective silica gel layer 2, and a PET layer 1 arranged on the upper surface of the TPU base material layer 4 from bottom to top. And the pressure-sensitive adhesive layer 5 and release layer 6 arranged on the lower surface of the TPU base material layer 4 sequentially from top to bottom, the upper surface of the TPU base material layer 4 is provided with a self-healing layer 3 by coating, and the protection The silica gel layer 2 is arranged on the lower surface of the PET layer 1 by coating, the self-healing layer 3 is bonded to the protective silica gel layer 2 arranged on the lower surface of the PET layer 1 by a pressure roller, and the TPU substrate layer 4 The lower surface of the coating is provided with a pressure-sensitive adhesive layer 5, and the pressure-sensitive adhesive layer 5 is pasted with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com