Houghite photocatalyst based on visible light response and preparation method thereof

A technology of talc light and visible light, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low activity, poor light corrosion resistance, and limited visible light catalytic materials Application and development issues, to achieve the effect of excellent performance, low cost, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

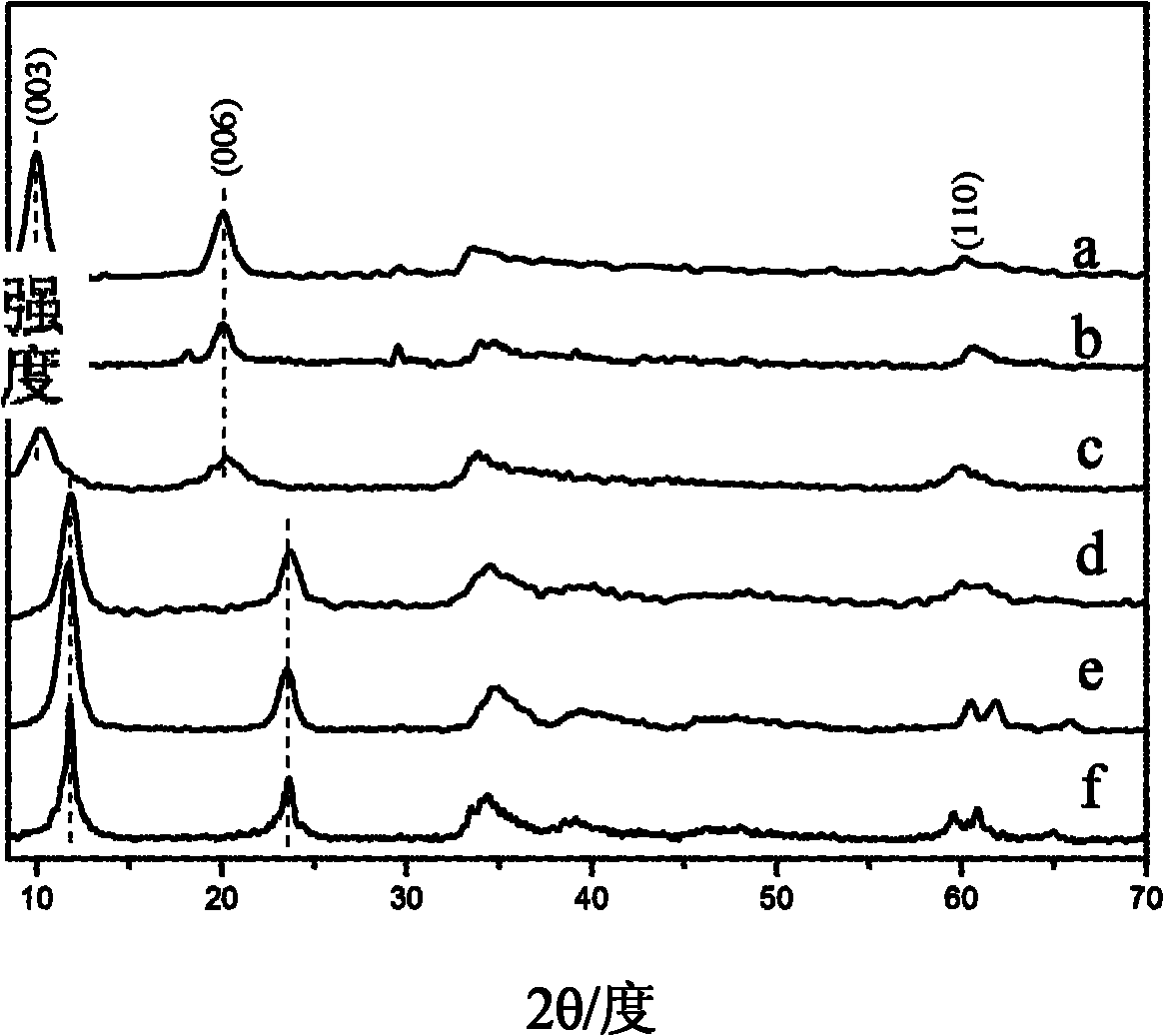

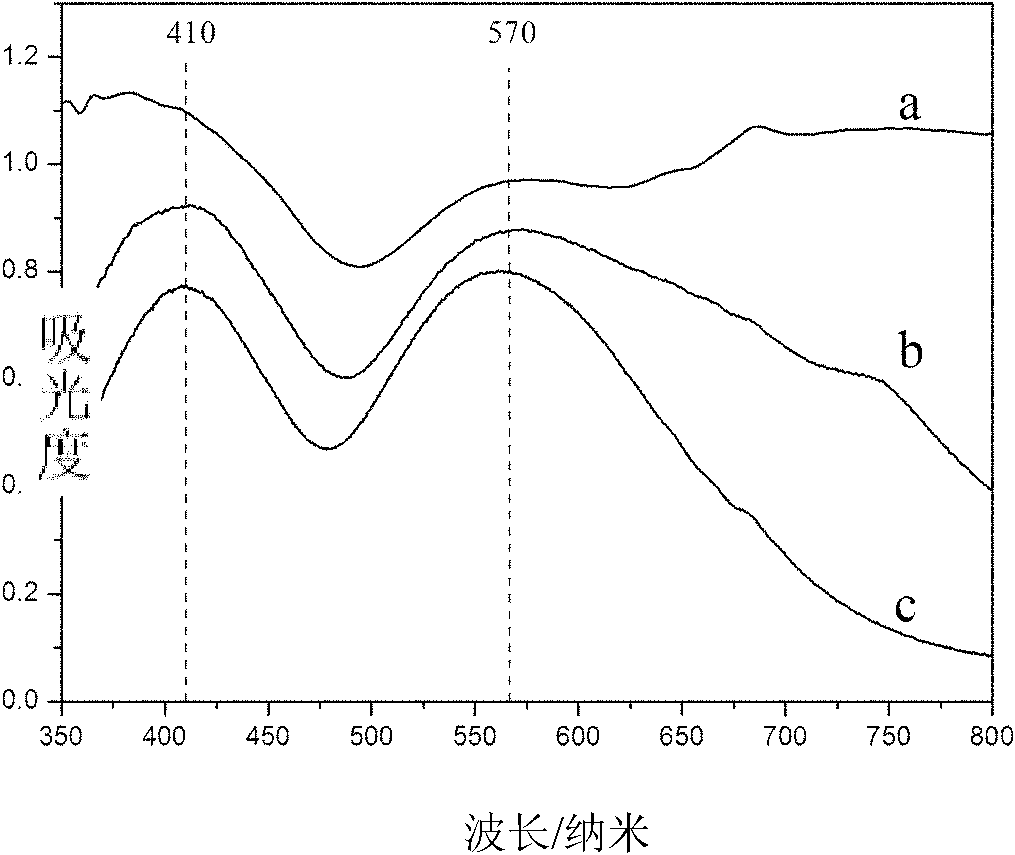

Embodiment 1

[0020] 1. Preparation of interlayer anion as NO by nucleation crystallization isolation method 3 - The hydrotalcite colloid:

[0021] a. 0.045mol solid Cu(NO 3 ) 2 ·3H 2 O and 0.0225mol of solid Cr(NO 3 ) 3 9H 2 O dissolved in 45mL to remove CO 2 of deionized water;

[0022] b. Dissolve 0.135mol of NaOH in 45mL to remove CO 2 of deionized water;

[0023] c. Add the above two mixed solutions prepared by step a and step b into the rotary liquid film reactor at the same time, adjust the slit width between the reactor rotor and the stator to be 2mm, the operating voltage is 85V, the rotor speed is 5000rpm, and the rotation time 2min;

[0024] 2. Add the obtained hydrotalcite colloid into the reaction kettle, crystallize at 120°C for 24 hours, take it out, cool it to room temperature, wash it thoroughly with deionized water until the pH of the supernatant is 7, and store it at 60°C After drying for 12 hours and grinding, a hydrotalcite photocatalyst based on visible lig...

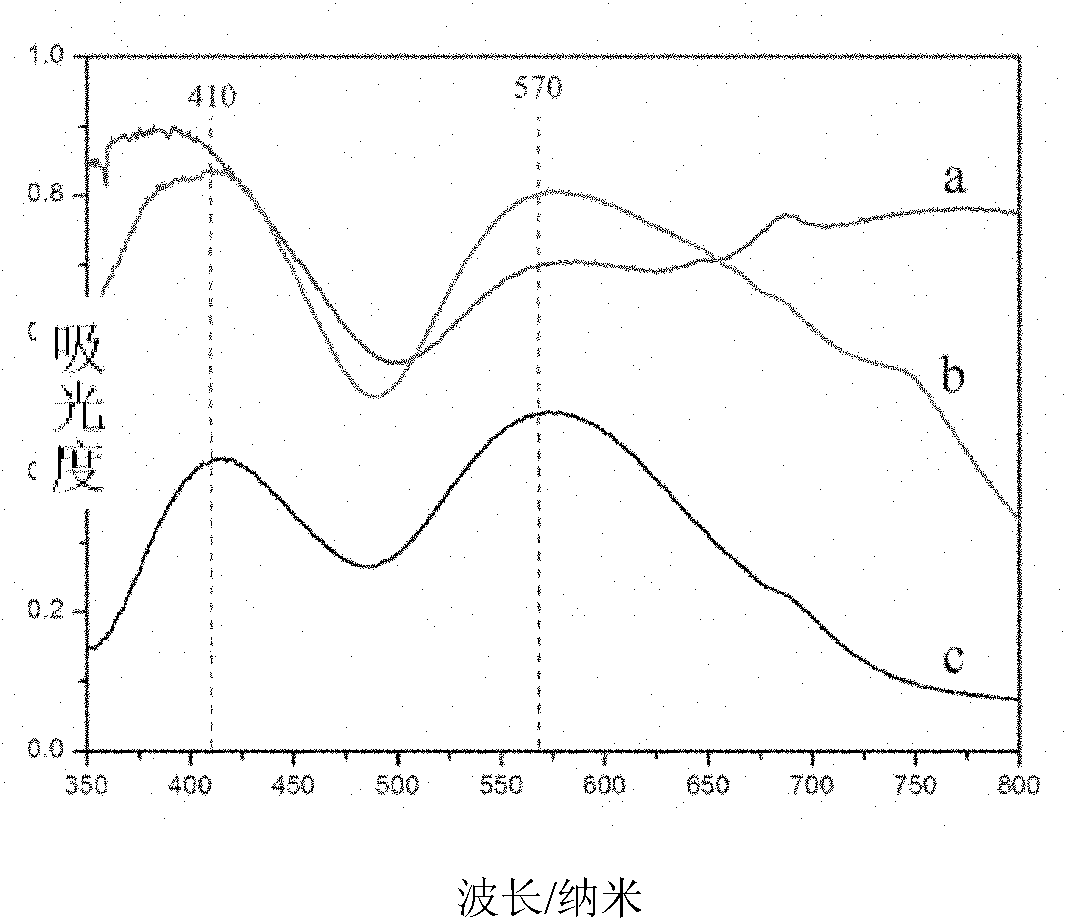

Embodiment 2

[0028] 1. Preparation of interlayer anion as NO by nucleation crystallization isolation method 3 - The hydrotalcite colloid:

[0029] a. 0.05mol solid Ni (NO 3 ) 2 ·6H 2 O and 0.025mol of solid Cr(NO 3 ) 3 9H 2 O dissolved in 120mL to remove CO 2 of deionized water;

[0030] b. Dissolve 0.35mol NaOH in 100mL to remove CO 2 of deionized water;

[0031] c. Add the above two mixed solutions prepared by step a and step b into the rotary liquid film reactor at the same time, adjust the slit width between the reactor rotor and the stator to be 2mm, the operating voltage is 85V, the rotor speed is 5000rpm, and the rotation time 2min;

[0032]2. Add the obtained hydrotalcite colloid into the reaction kettle, crystallize at 120°C for 24 hours, take it out, cool it to room temperature, wash it thoroughly with deionized water until the pH of the supernatant is 7, and store it at 60°C After drying for 12 hours and grinding, a hydrotalcite photocatalyst based on visible light r...

Embodiment 3

[0036] 1. Preparation of interlayer anion as NO by nucleation crystallization isolation method 3 - The hydrotalcite colloid:

[0037] a. 0.072mol solid Zn(NO 3 ) 2 ·6H 2 O and 0.036mol of solid Cr(NO 3 ) 3 9H 2 O dissolved in 60mL to remove CO 2 of deionized water;

[0038] b. Dissolve 0.24mol NaOH in 80mL to remove CO 2 of deionized water;

[0039] c. Add the above two mixed solutions prepared by step a and step b into the rotary liquid film reactor at the same time, adjust the slit width between the reactor rotor and the stator to be 2mm, the operating voltage is 85V, the rotor speed is 5000rpm, and the stirring time 2min;

[0040] 2. Add the obtained hydrotalcite colloid into the reaction kettle, crystallize at 120°C for 24 hours, take it out, cool it to room temperature, wash it thoroughly with deionized water until the pH of the supernatant is 7, and store it at 60°C After drying for 12 hours and grinding, a hydrotalcite photocatalyst based on visible light re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com