Zinc-doped Ag-In-S quantum dot luminescent material and preparation method and application thereof

A quantum dot light-emitting, ag-in-s technology, applied in the direction of light-emitting materials, nanotechnology for materials and surface science, photosensitive equipment, etc., can solve the problem of hindering injection, restricting the development and application of quantum dot light-emitting materials, Zn doping The preparation steps of Ag-In-S quantum dots are cumbersome and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

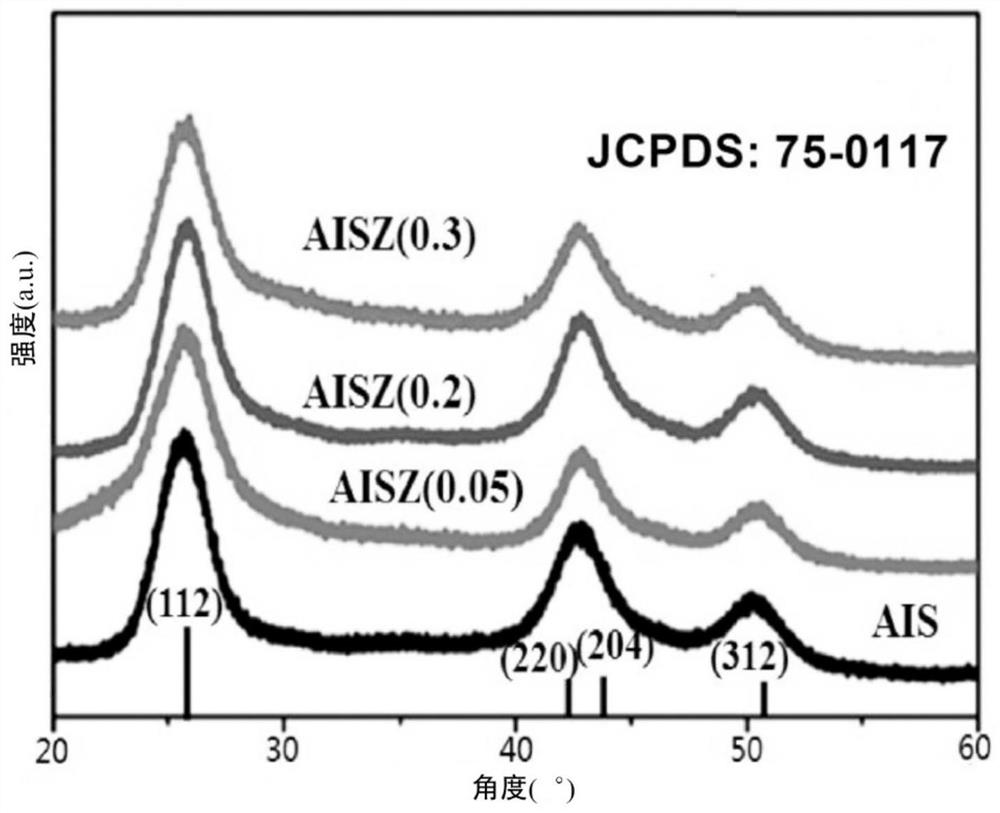

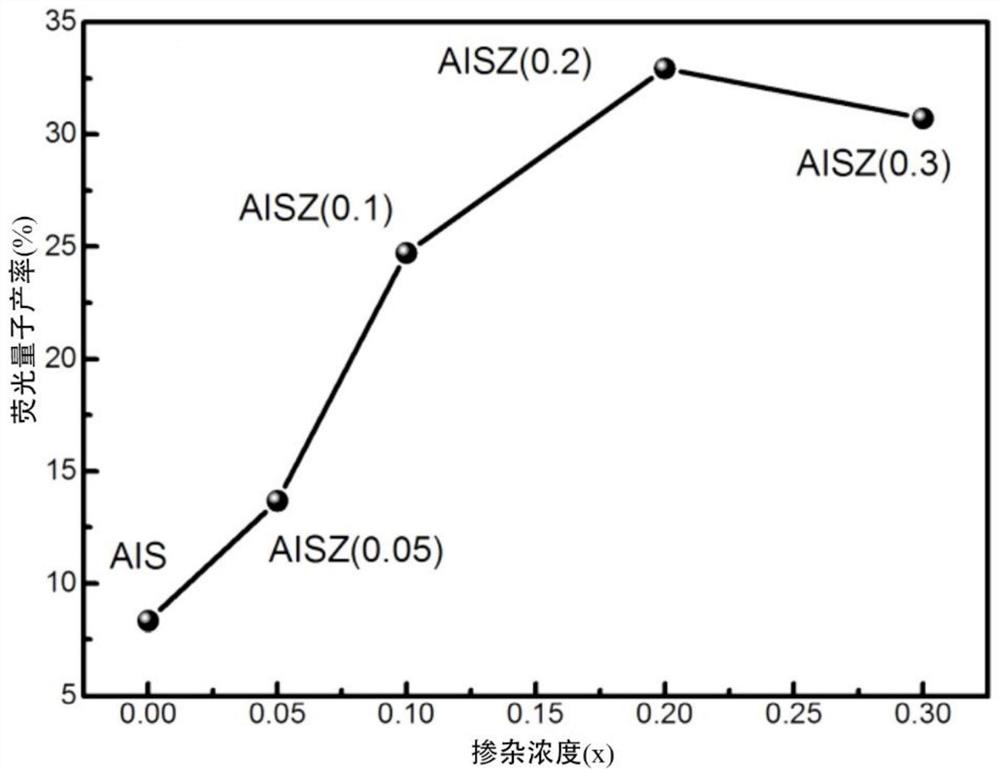

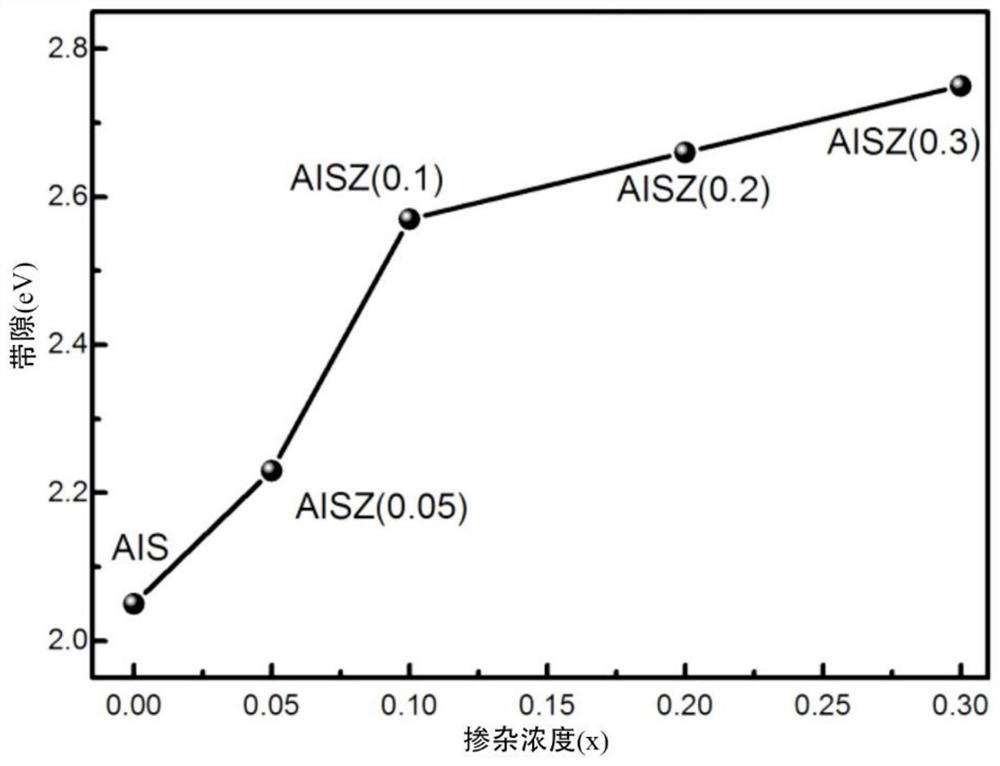

[0028] A kind of zinc-doped Ag-In-S quantum dot luminescent material AISZ (0.2), its Zn 2+ The doping amount Zn / (Ag+In)=20%. The preparation method of the quantum dot luminescent material comprises the following steps:

[0029] 1) Accurately weigh the following raw materials according to the stoichiometric ratio of Ag-In-S quantum dots Ag / In / S=1:3:4: 0.2mmol silver acetate, 0.6mmol indium acetate, and 0.8mmol sulfur powder. Dissolve the weighed sulfur powder in 1.2 mL oleylamine to obtain a sulfur precursor solution. In addition, according to the doping ratio of Zn / (Ag+In)=20%, 0.16 mmol of zinc acetate was accurately weighed.

[0030] 2) Add the weighed silver acetate, indium acetate and zinc acetate together with 16mL 1-octadecene and 8.0mL oleylamine into a 50mL three-neck flask, mix well and heat to 180°C under the protection of argon. Inject the sulfur precursor solution into the system and keep it warm for about 20 minutes. After the system was cooled to room tempera...

Embodiment 2

[0032] The preparation method of this embodiment and embodiment 1 is roughly the same, the difference is: Zn 2+ The doping amount Zn / (Ag+In)=5%, that is, the raw materials are adjusted to 0.2mmol silver acetate, 0.6mmol indium acetate, 0.8mmol sulfur powder, and 0.04mmol zinc acetate. The target sample thus prepared is AISZ(0.05) quantum dots.

Embodiment 3

[0034] The preparation method of this embodiment and embodiment 1 is roughly the same, the difference is: Zn2+ The doping amount Zn / (Ag+In)=10%, that is, the raw materials are adjusted to 0.2mmol silver acetate, 0.6mmol indium acetate, 0.8mmol sulfur powder, and 0.08mmol zinc acetate. The target sample thus prepared is AISZ(0.1) quantum dots.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandgap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com