Ferrite-based low frequency electromagnetic wave-absorbing material and preparation method thereof

A technology of electromagnetic wave absorption and ferrite, which is applied in chemical instruments and methods, electrical components, iron compounds, etc., can solve problems such as system automatic control failure, interruption of electric wave transmission, and information transmission error, and achieve good electromagnetic wave absorption effect, Effect of increasing diffuse reflection and expanding absorption bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

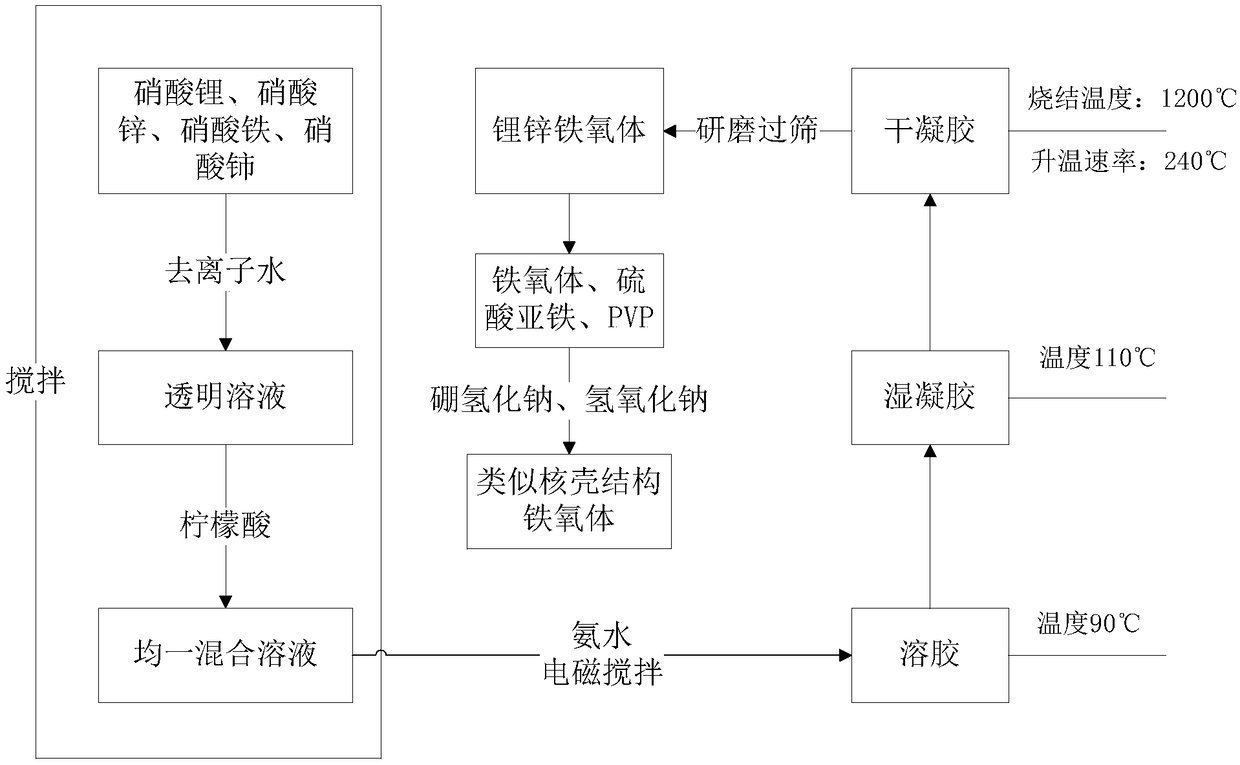

[0040] The preparation method comprises the following steps:

[0041] S1: Dissolving sodium borohydride and sodium hydroxide powder in deionized water and forming a transparent sodium borohydride aqueous solution under the action of magnetic stirring;

[0042] S2: Add appropriate amount of lithium zinc ferrite particles, ferrous sulfate, and PVP into deionized water and mechanically stir for 30 minutes;

[0043] S3: dropping the mixed solution of sodium borohydride aqueous solution and lithium-zinc ferrite into the electroless plating reaction tank to fully react;

[0044] S4: Collect the reaction product with a magnet, wash and dry, and grind to obtain the final product: lithium zinc ferrite powder with nano-iron sheets on the surface.

[0045] Lithium zinc ferrite is prepared from metal salt solution, sodium citrate and ammonia water.

[0046] The lithium zinc ferrite includes: lithium element, zinc element, iron element, cerium element and oxygen element;

[0047] The st...

Embodiment 1

[0055] Embodiment 1, preparation of electromagnetic wave absorbing agent based on ferrite;

[0056] The lithium zinc ferrite particle of this embodiment, the stoichiometric ratio of each component is as follows:

[0057] The stoichiometric ratio of each element in the metal salt solution lithium: zinc: iron: cerium: oxygen=0.4:0.2:2.35:0.3:4;

[0058] Described metal salt solution comprises lithium nitrate, zinc nitrate, ferric nitrate, cerium nitrate solution;

[0059] The molar ratio of the total molar number of metal ions in the metal salt solution to the citric acid molecule is 1.

[0060] The present invention also provides the preparation of the lithium zinc ferrite, comprising the following steps:

[0061] a. Weigh quantitative lithium nitrate, zinc nitrate, iron nitrate, cerium nitrate and other metal compounds according to the specific stoichiometric ratio of lithium zinc ferrite, and dissolve them in deionized water together, and electromagnetically stir until unif...

Embodiment 2

[0074] Embodiment 2, preparation of electromagnetic wave absorbing agent based on ferrite;

[0075] The lithium zinc ferrite particle of this embodiment, the stoichiometric ratio of each component is as follows:

[0076] The stoichiometric ratio of each element in the metal salt solution lithium: zinc: iron: cerium: oxygen=0.25:0.5:2.3:0.2:4;

[0077] Described metal salt solution comprises lithium nitrate, zinc nitrate, ferric nitrate, cerium nitrate solution;

[0078] The molar ratio of the total molar number of metal ions in the metal salt solution to the citric acid molecule is 1.

[0079] The present invention also provides the preparation of the lithium zinc ferrite, comprising the following steps:

[0080] a. Weigh quantitative lithium nitrate, zinc nitrate, iron nitrate, cerium nitrate and other metal compounds according to the specific stoichiometric ratio of lithium zinc ferrite, and dissolve them in deionized water together, and electromagnetically stir until unif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com