Patents

Literature

3269 results about "Metal thin film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

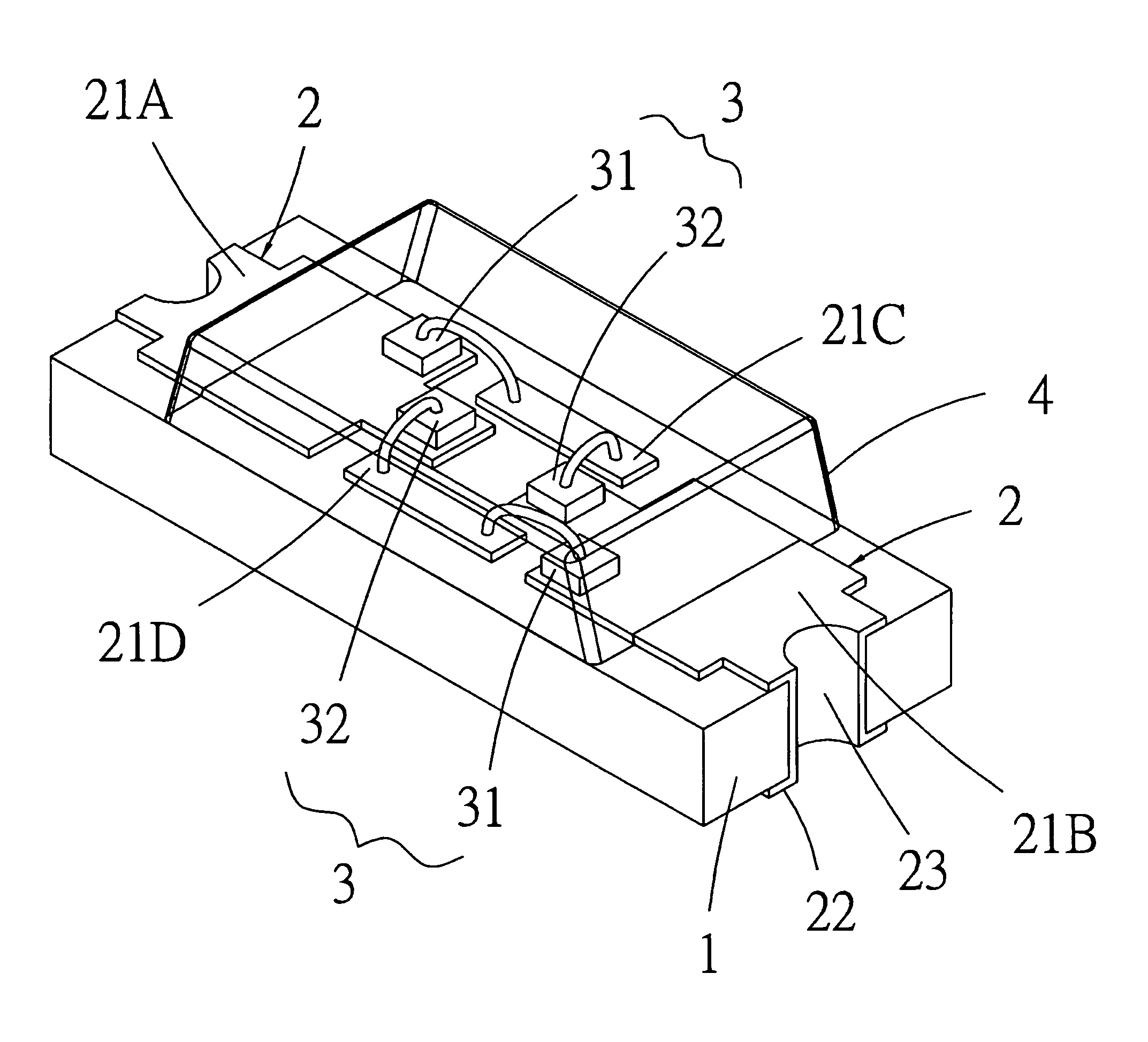

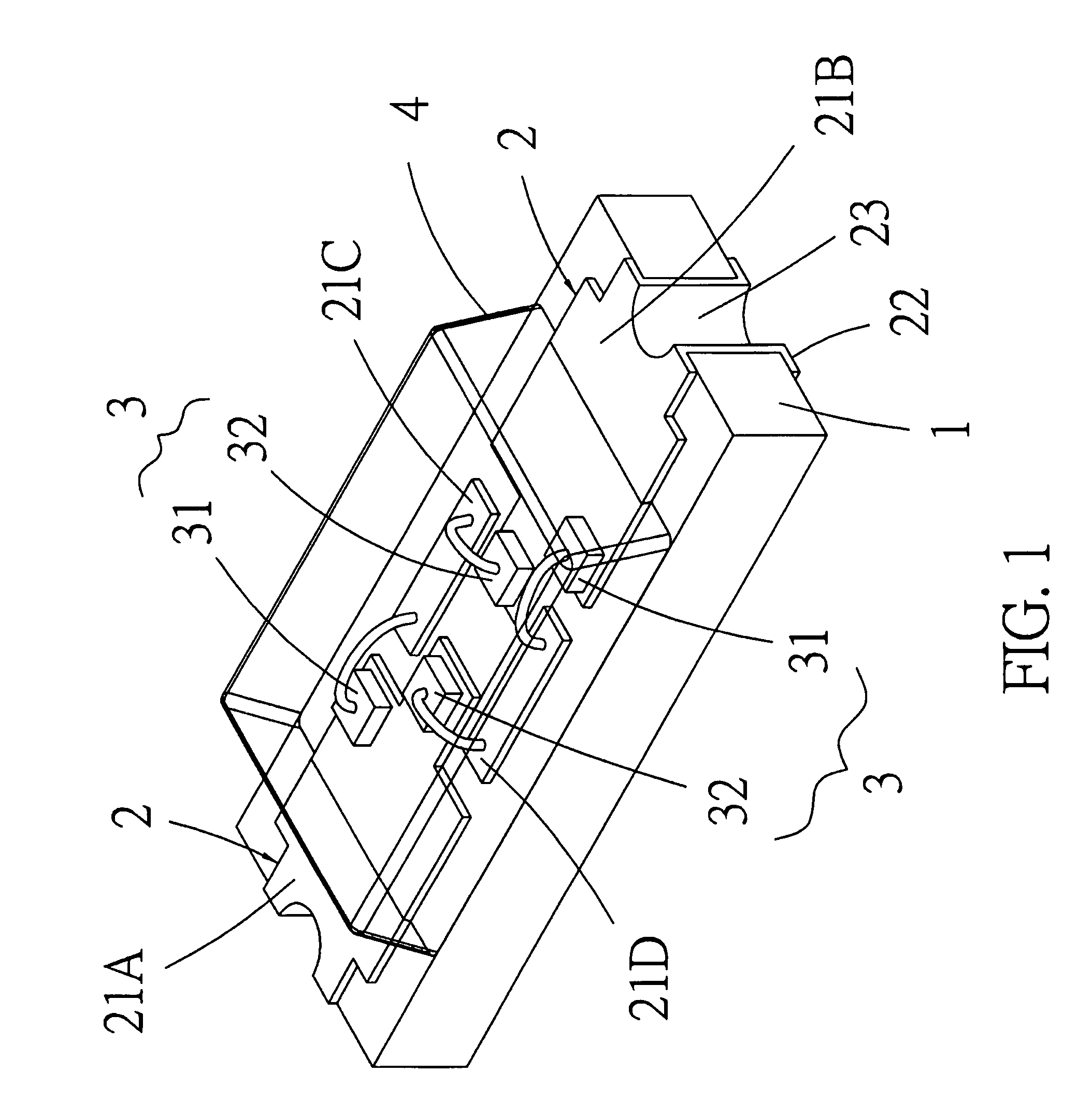

Polarless surface mounting light emitting diode

A polarless surface mounting light emitting diode comprises a substrate; an upper surface of the substrate being etched with four independent metal thin film blocks; a lower surface of the substrate being formed with two independent metal thin film blocks; two ends of the substrate being formed with electroplated through holes; a plurality of metal thin films adhered upon the upper and lower surfaces of the substrate; two light emitting assemblies, each light emitting assembly being formed by a chip resistor and a chip light emitting diode; and a package layer. The connection of the polarless surface mounting light emitting diode of the present invention is not limited by the polarity. Any end of the polarless surface mounting light emitting diode can be connected to positive electrode or negative electrode.

Owner:LIN PETER P W

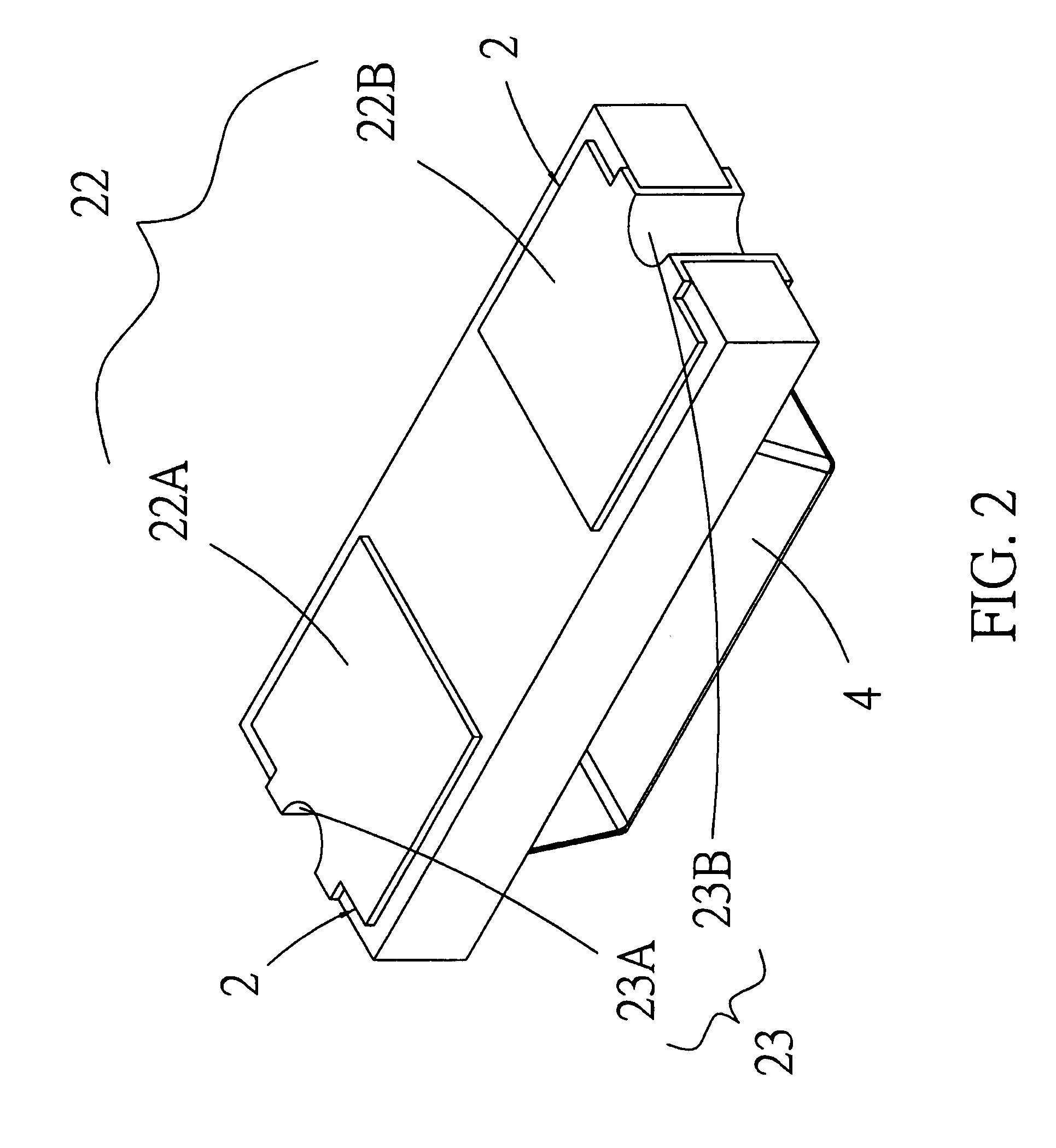

Enhanced thin film deposition

ActiveUS20070148350A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesNitrogen

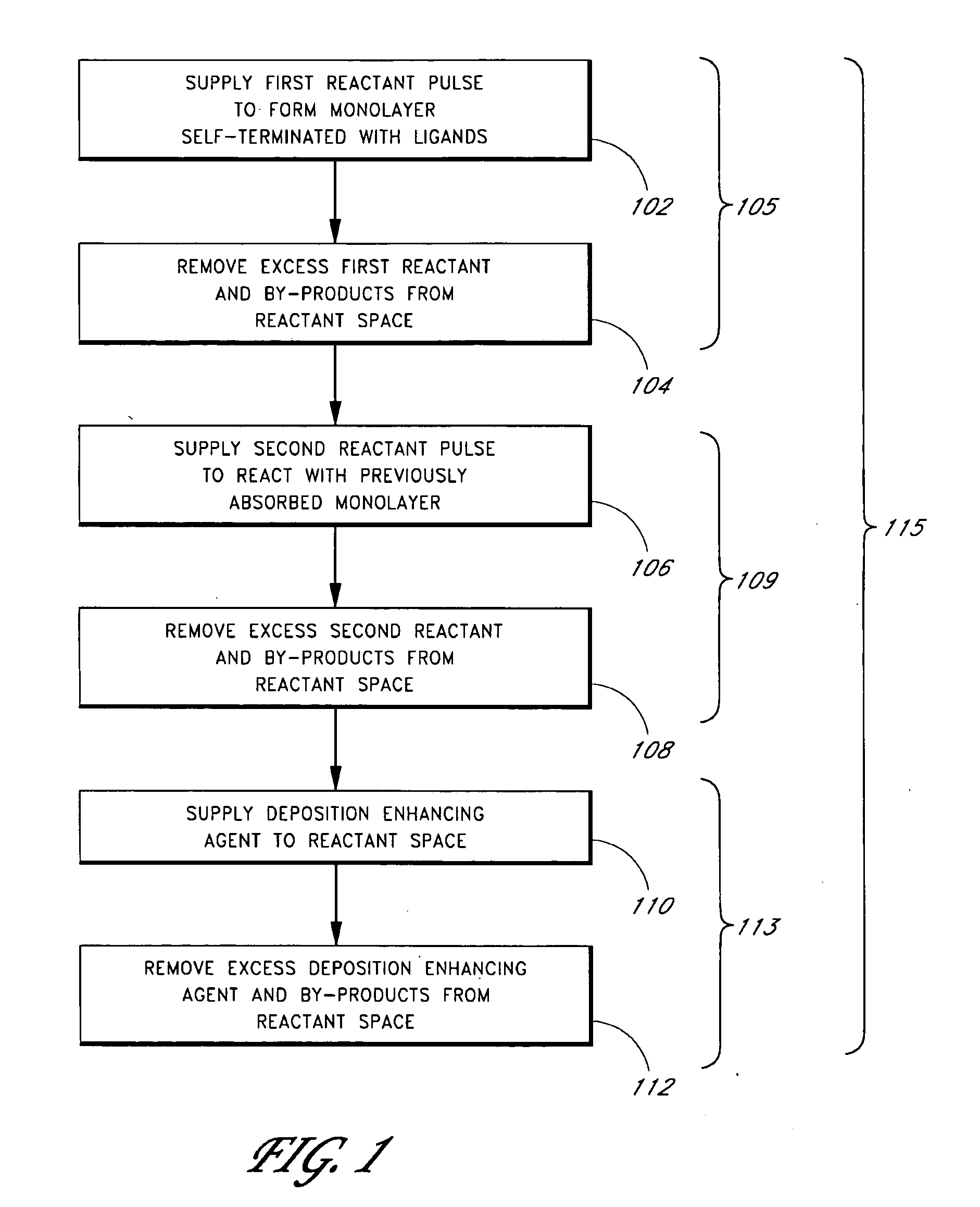

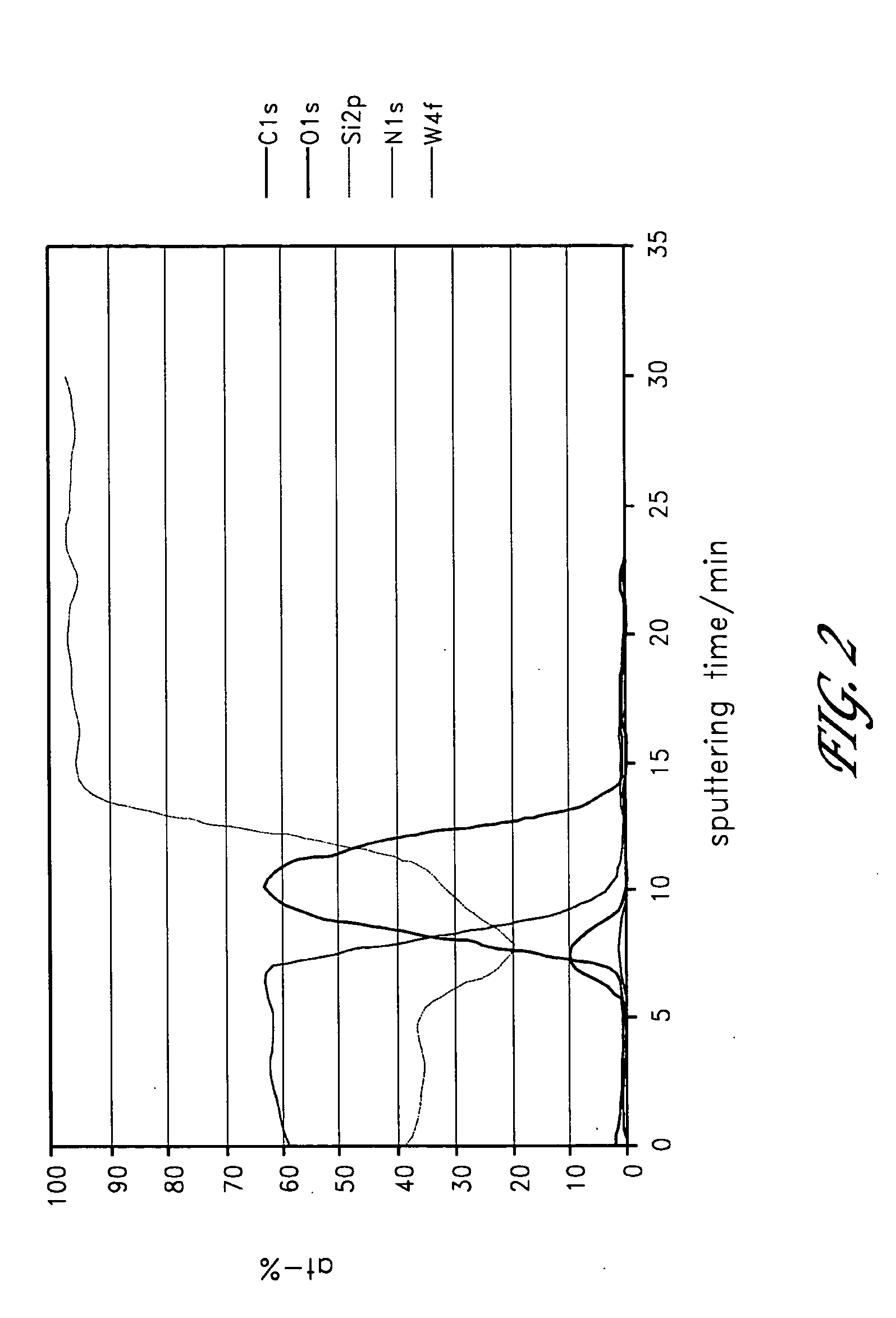

Methods of producing metal-containing thin films with low impurity contents on a substrate by atomic layer deposition (ALD) are provided. The methods preferably comprise contacting a substrate with alternating and sequential pulses of a metal source chemical, a second source chemical and a deposition enhancing agent. The deposition enhancing agent is preferably selected from the group consisting of hydrocarbons, hydrogen, hydrogen plasma, hydrogen radicals, silanes, germanium compounds, nitrogen compounds, and boron compounds. In some embodiments, the deposition-enhancing agent reacts with halide contaminants in the growing thin film, improving film properties.

Owner:ASM INTERNATIONAL

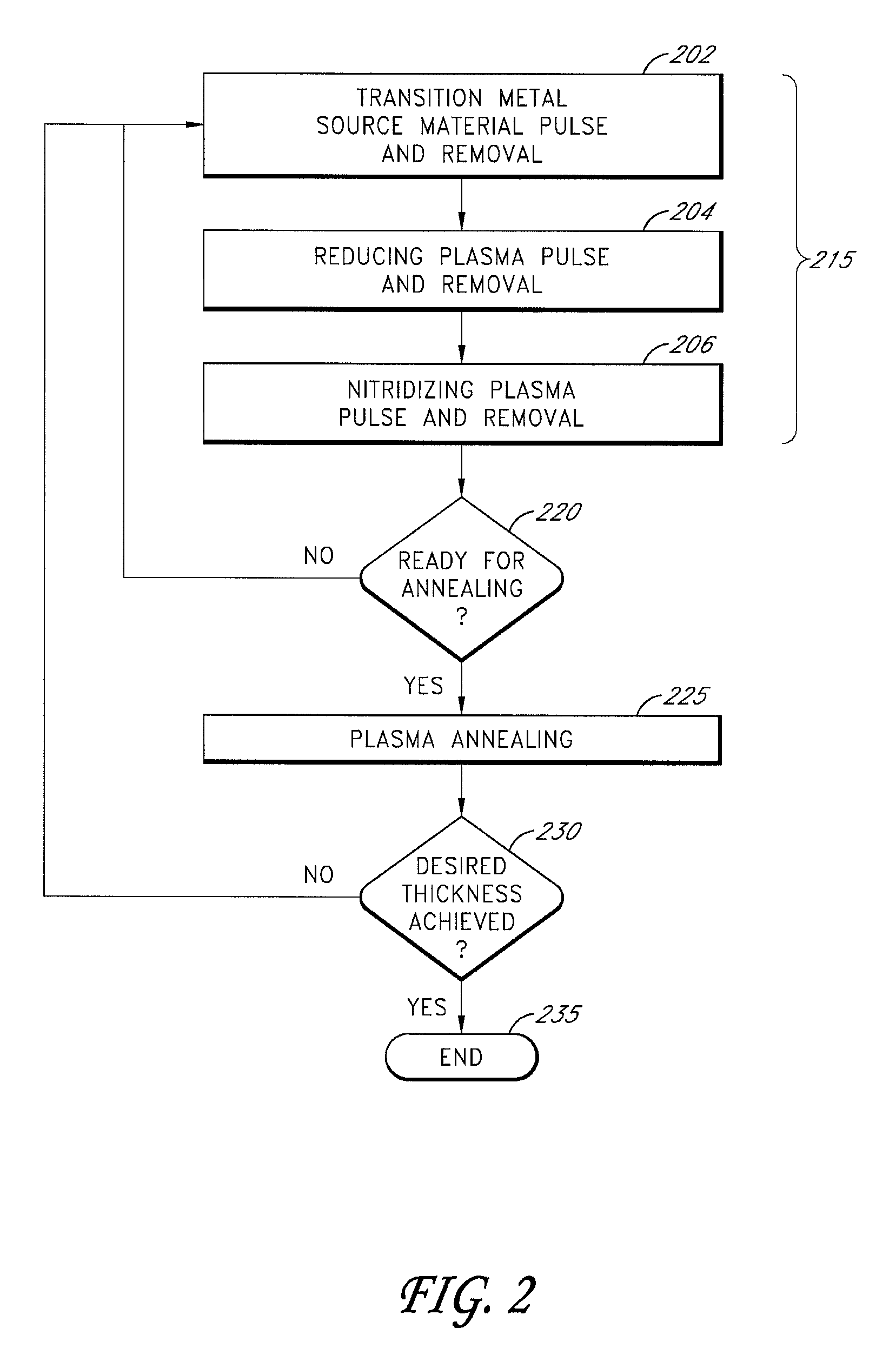

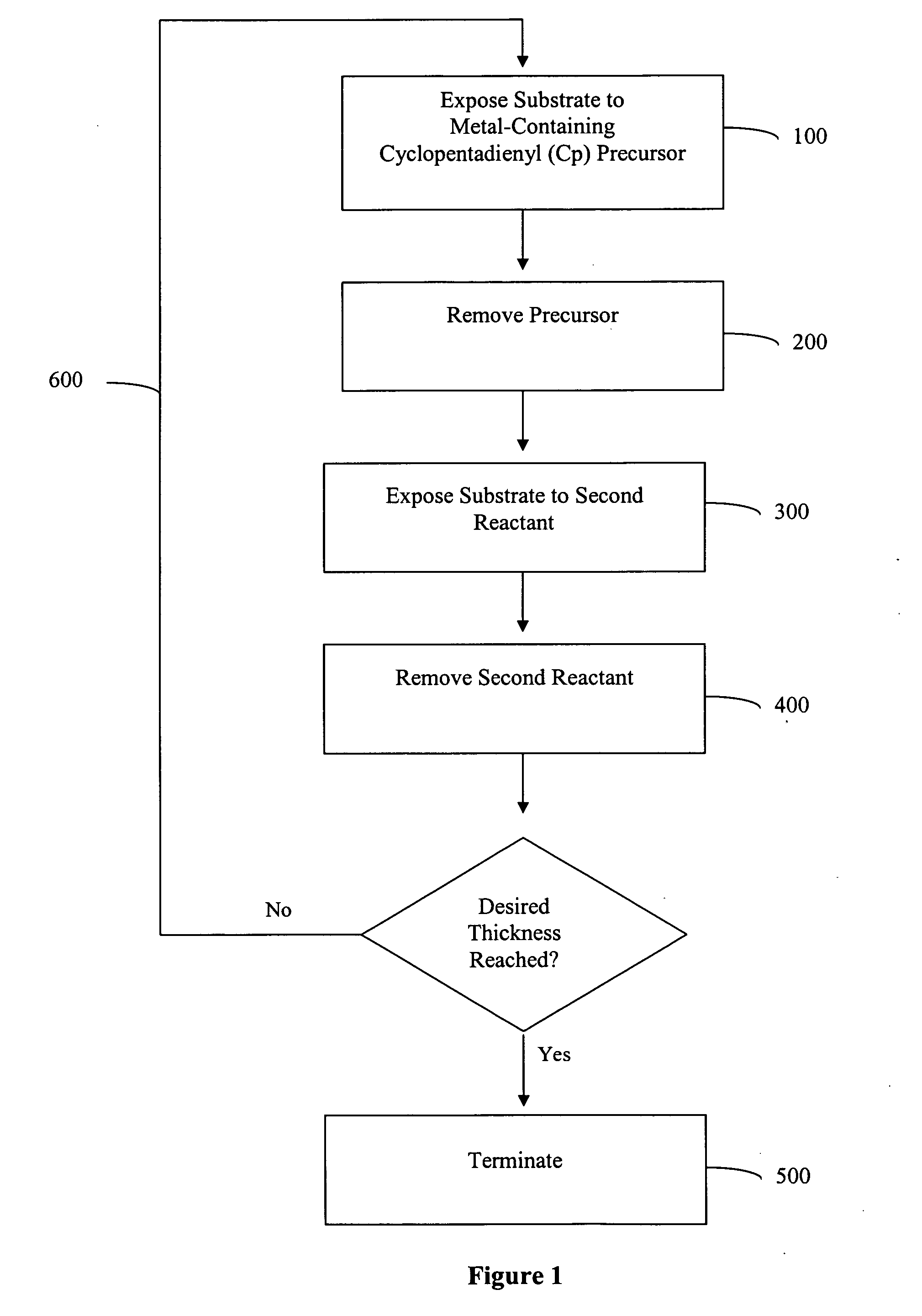

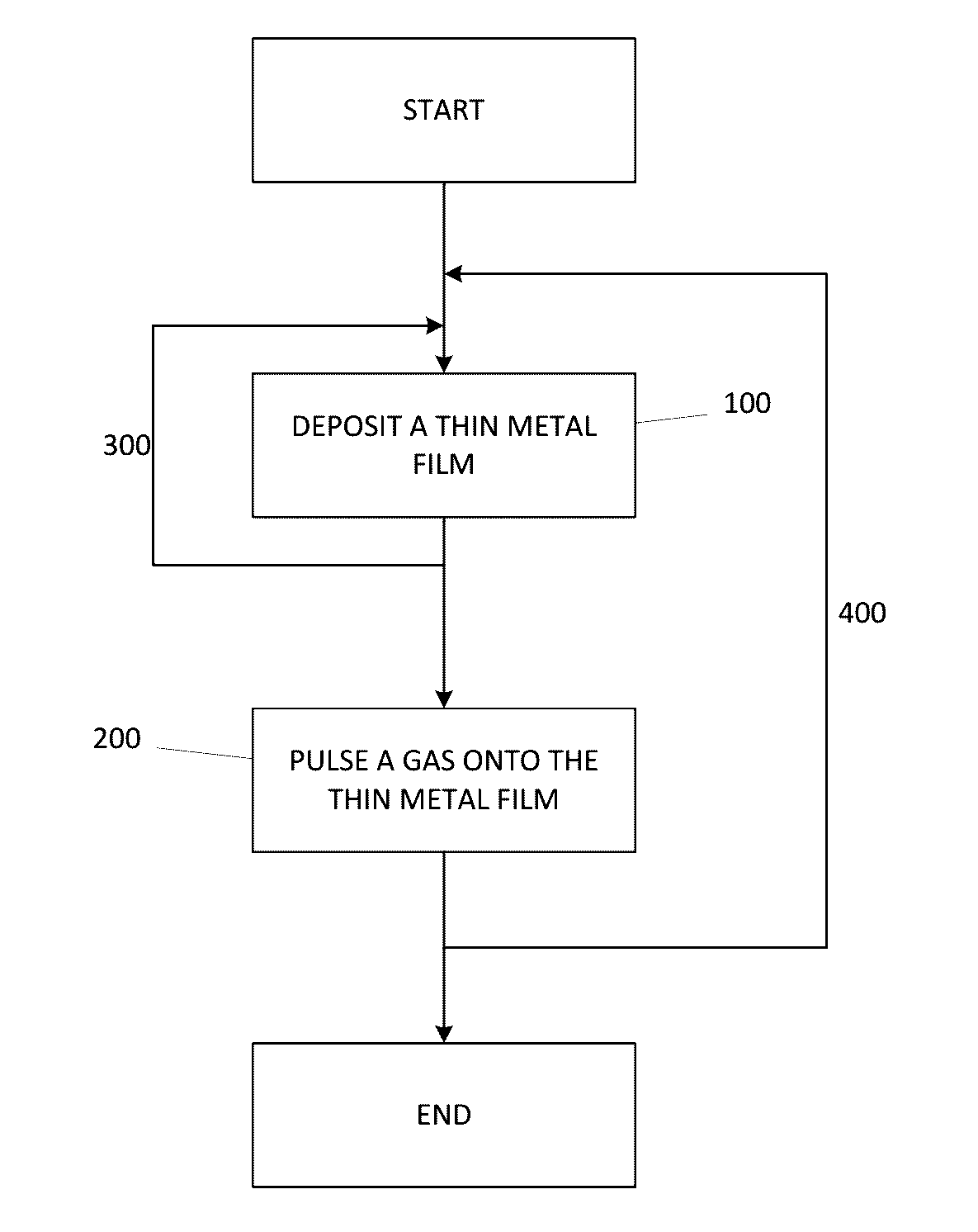

Periodic plasma annealing in an ALD-type process

ActiveUS7713874B2Increase probabilityReduce susceptibility to oxidationPolycrystalline material growthSemiconductor/solid-state device manufacturingGas phaseVapor phase

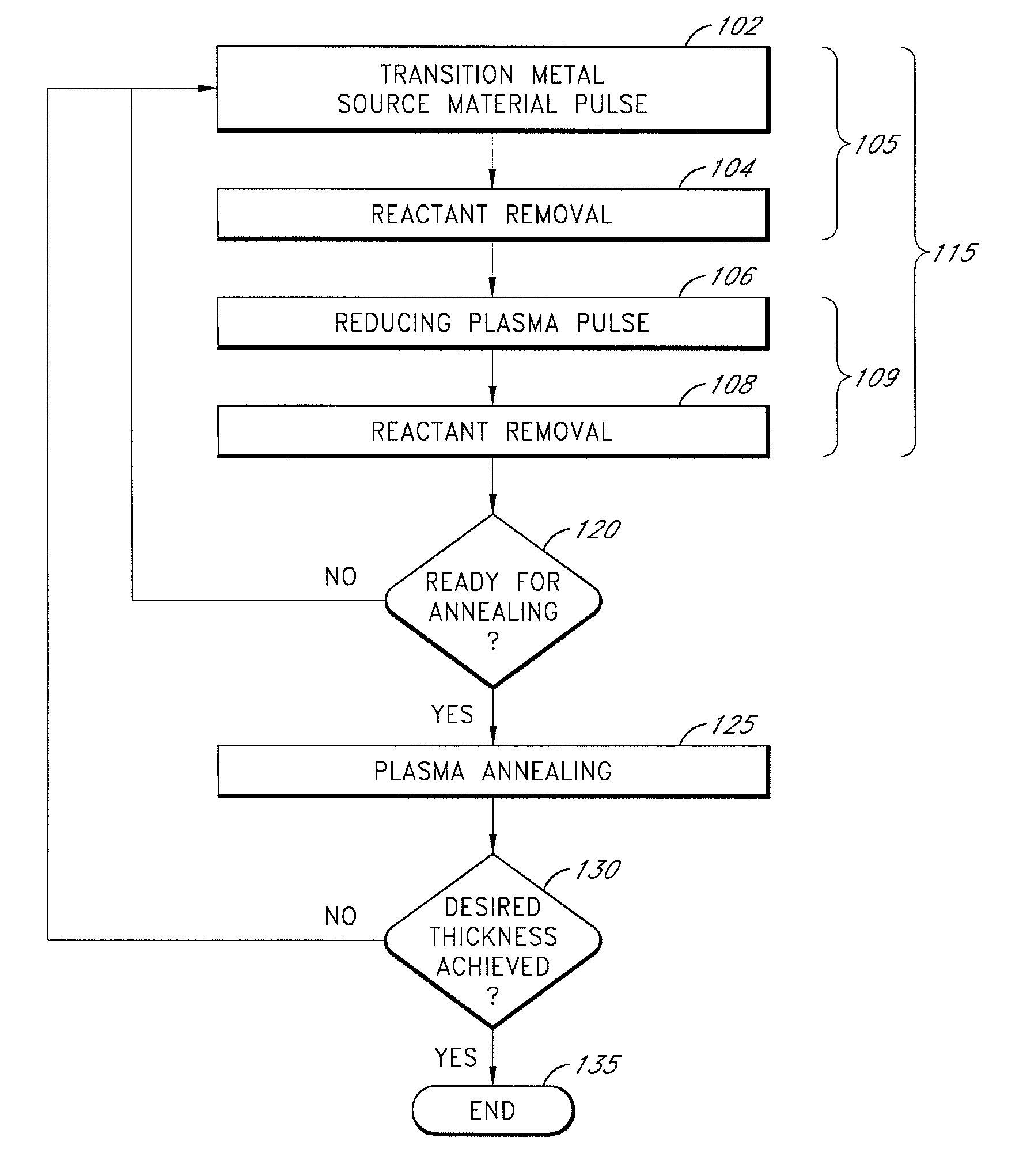

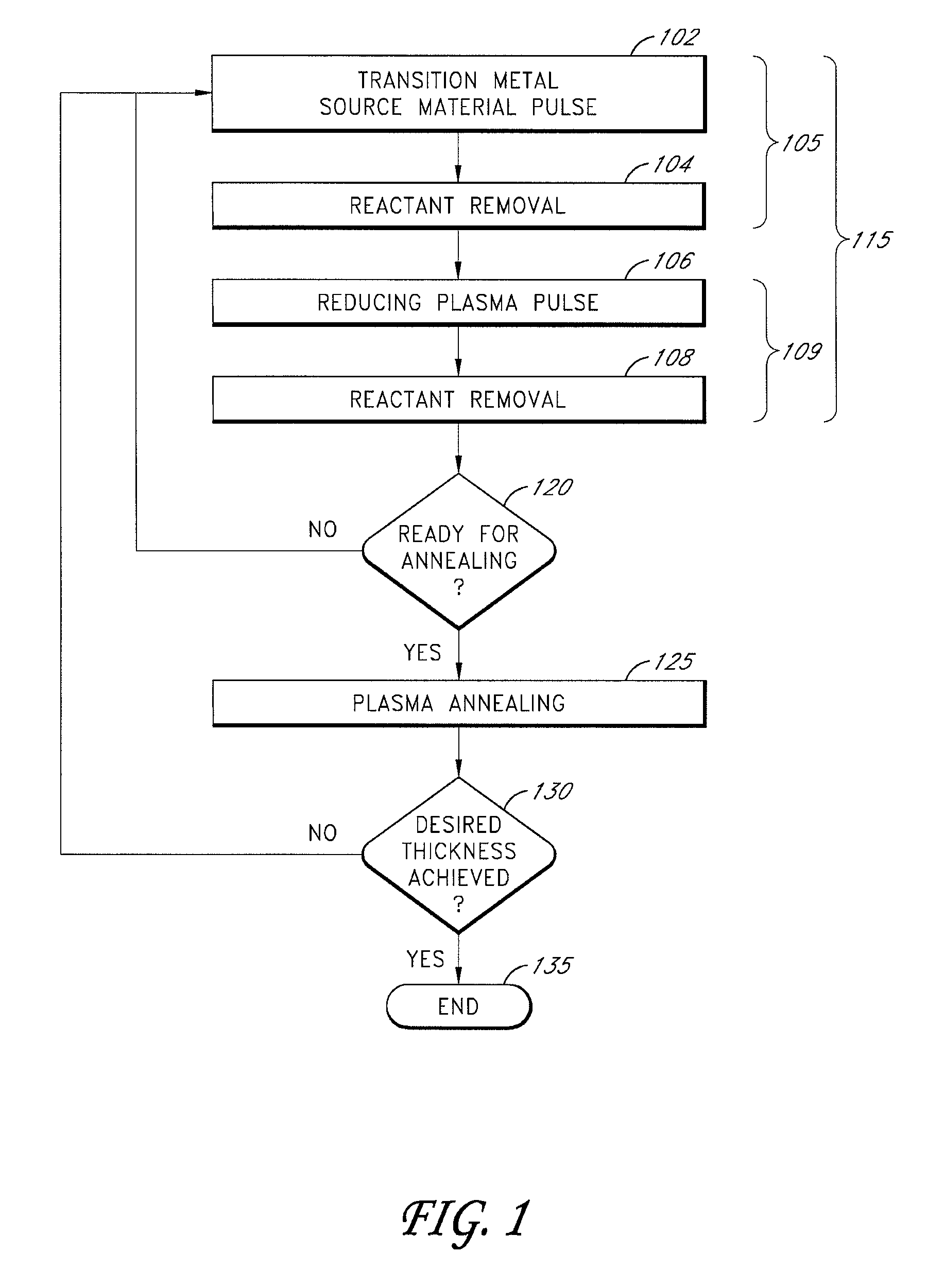

Methods for performing periodic plasma annealing during atomic layer deposition are provided along with structures produced by such methods. The methods include contacting a substrate with a vapor-phase pulse of a metal source chemical and one or more plasma-excited reducing species for a period of time. Periodically, the substrate is contacted with a vapor phase pulse of one or more plasma-excited reducing species for a longer period of time. The steps are repeated until a metal thin film of a desired thickness is formed over the substrate.

Owner:ASM IP HLDG BV

Metal nitride carbide deposition by ALD

InactiveUS7410666B2Material nanotechnologySemiconductor/solid-state device detailsHydrogen halideCorrosive chemical

Owner:ASM INTERNATIONAL

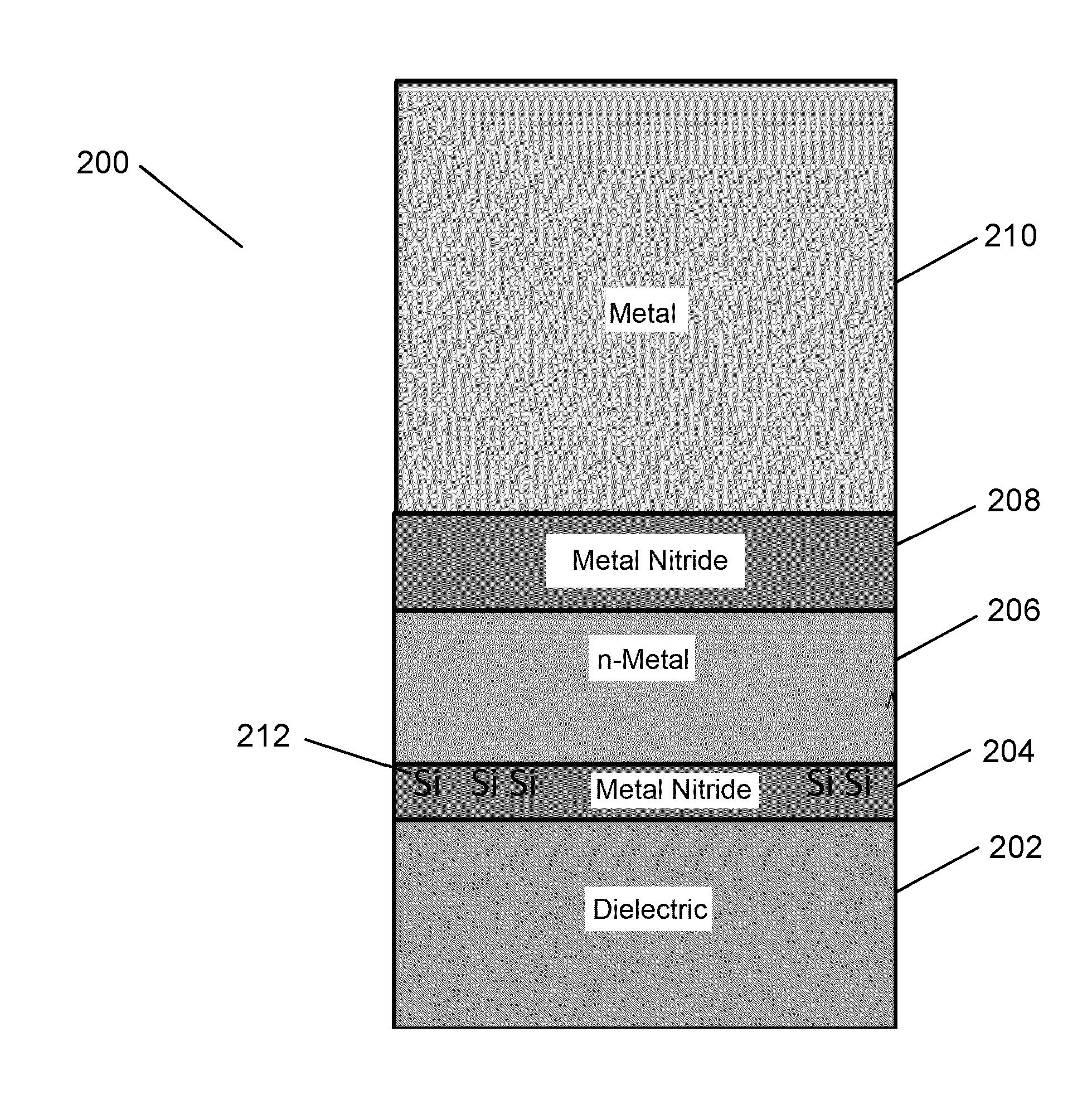

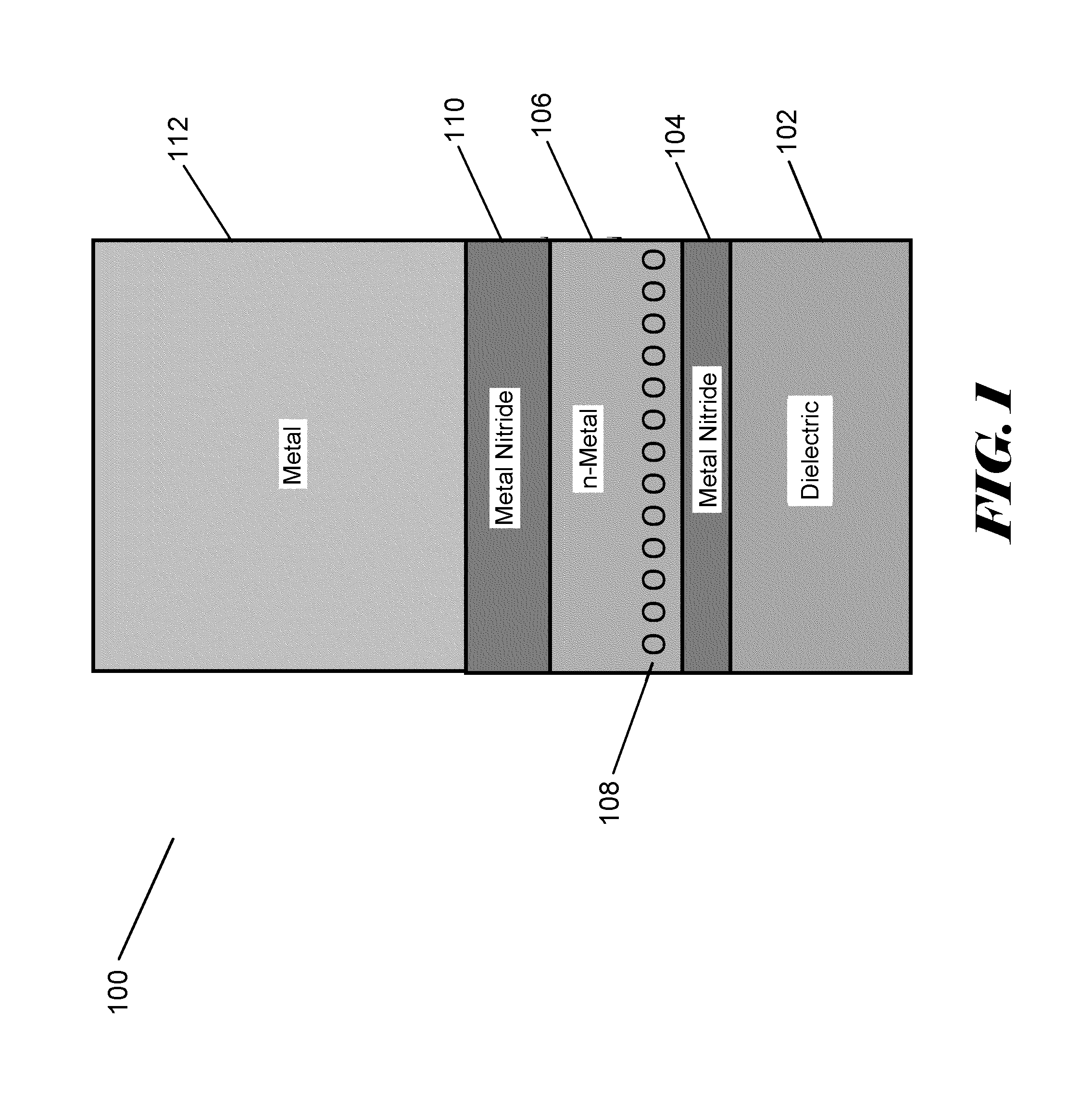

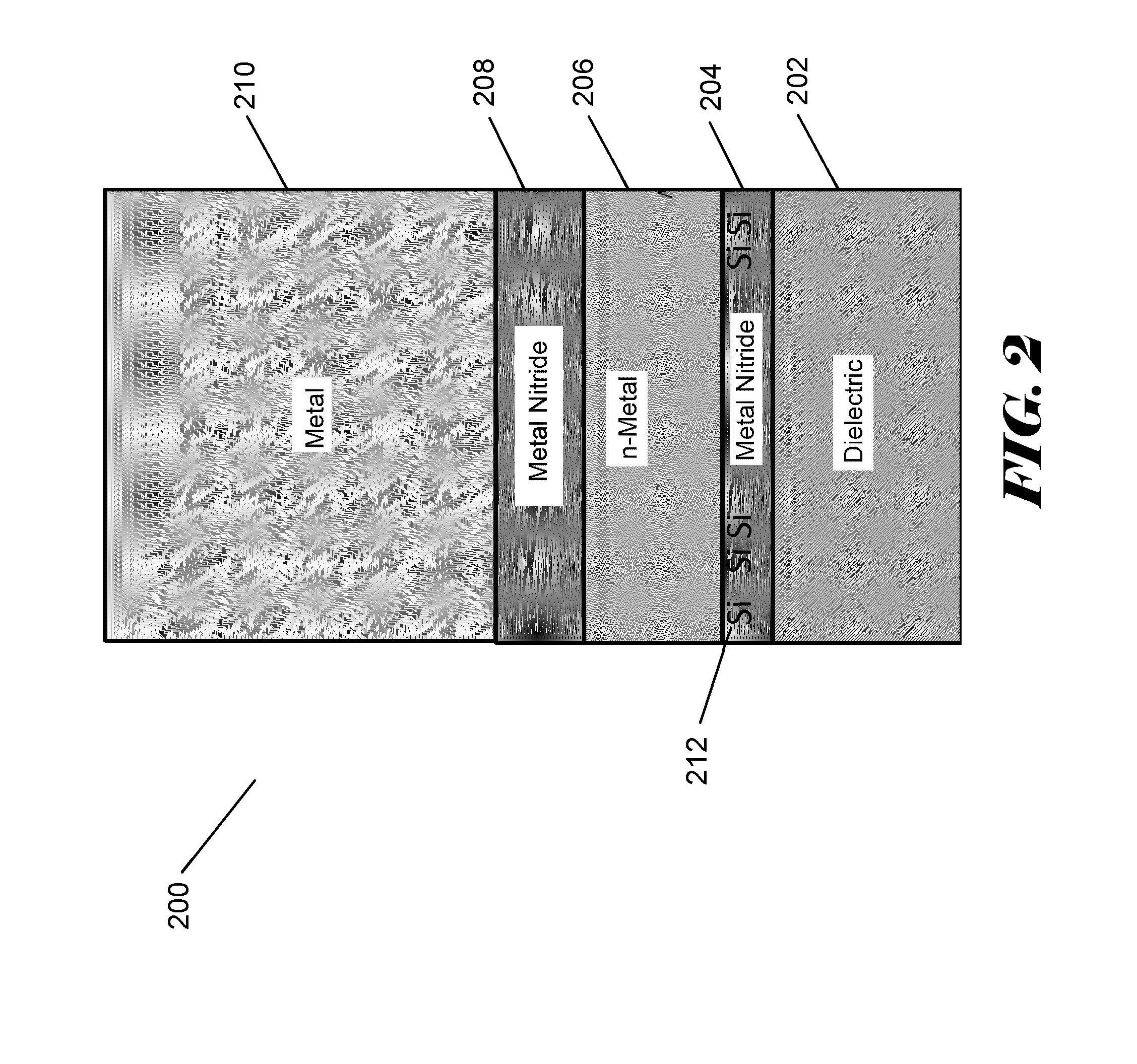

Silane or borane treatment of metal thin films

ActiveUS20140273428A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesGate stack

The negative effect of oxygen on some metal films can be reduced or prevented by contacting the films with a treatment agent comprising silane or borane. In some embodiments, one or more films in an NMOS gate stack are contacted with a treatment agent comprising silane or borane during or after deposition.

Owner:ASM IP HLDG BV

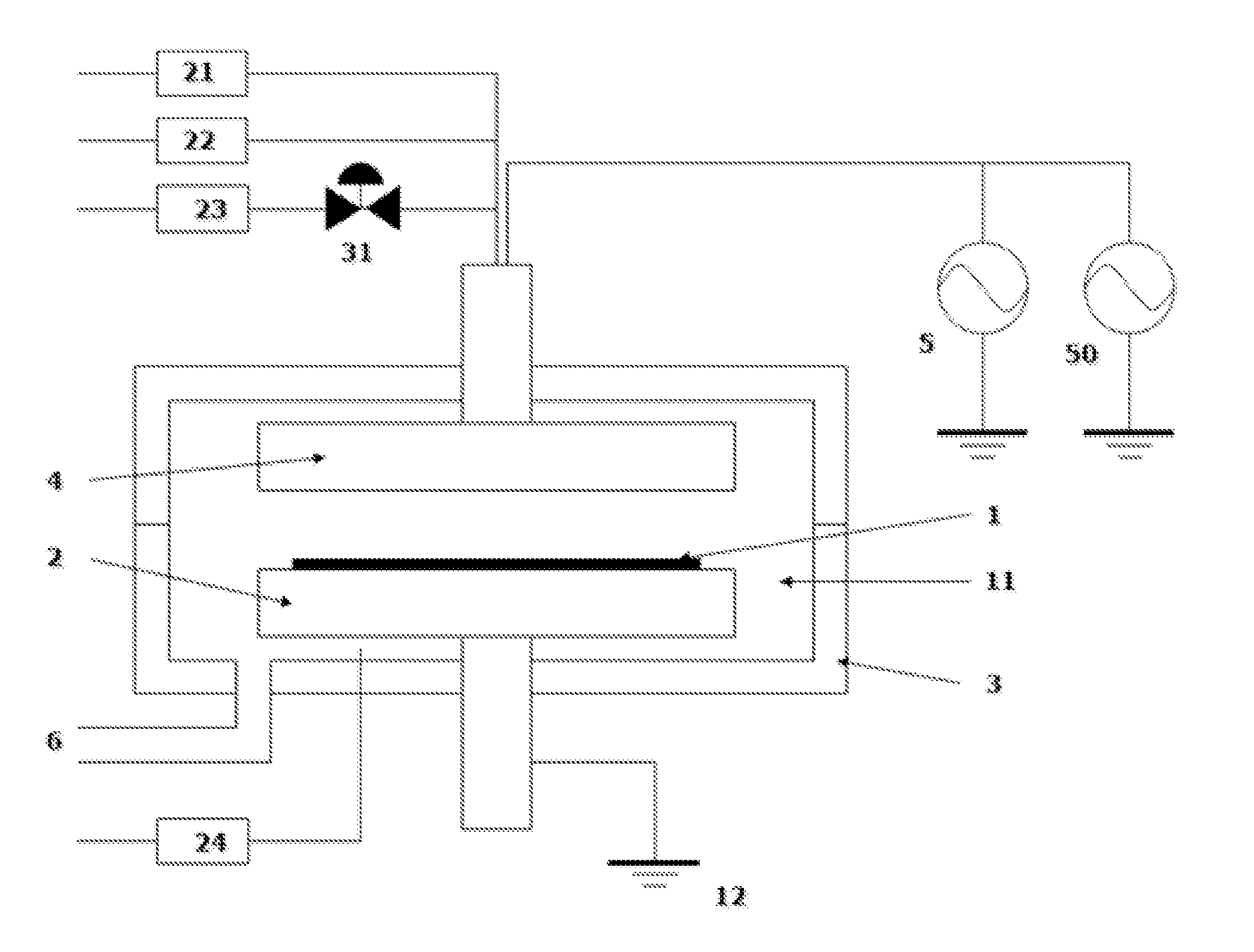

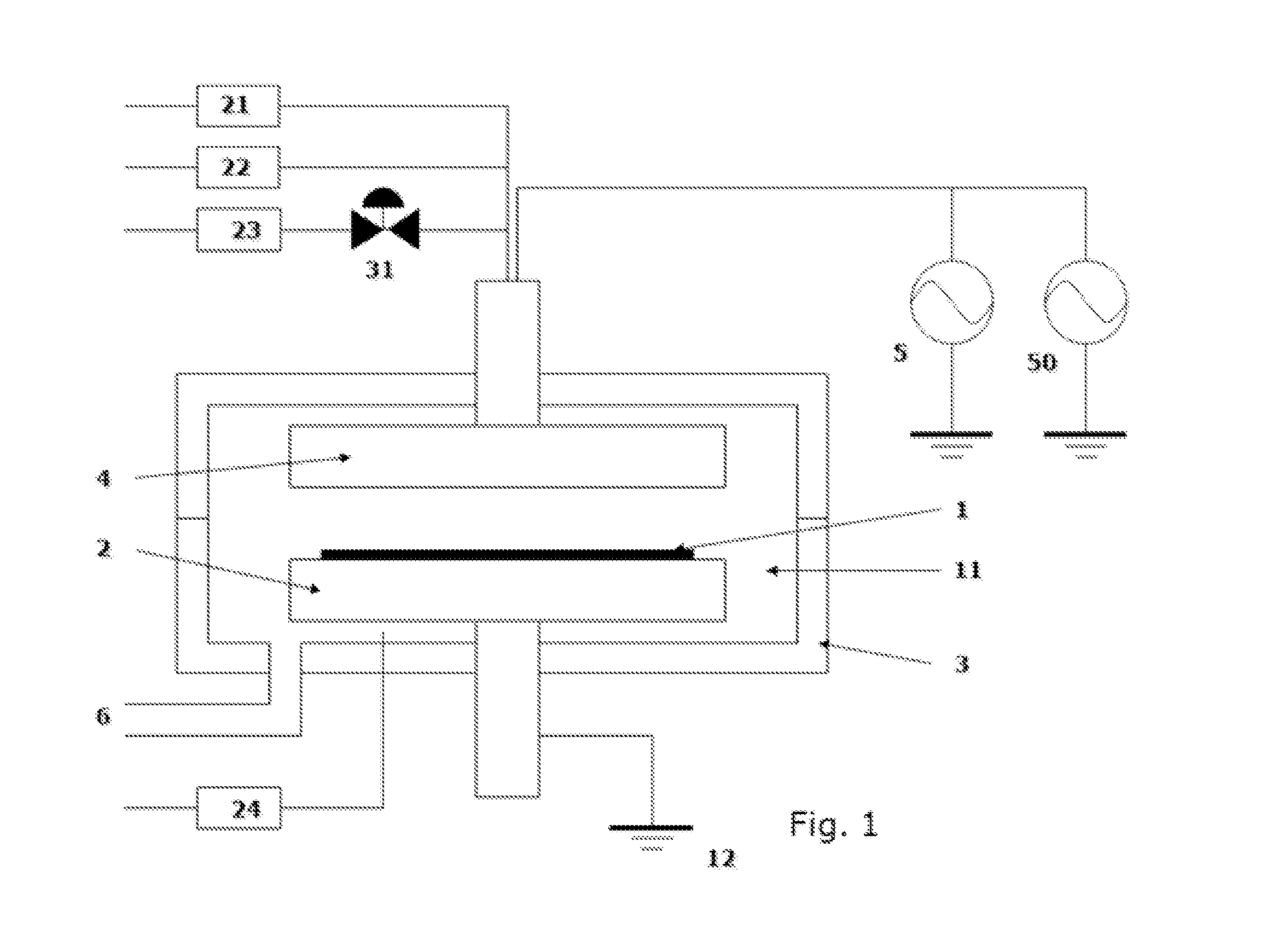

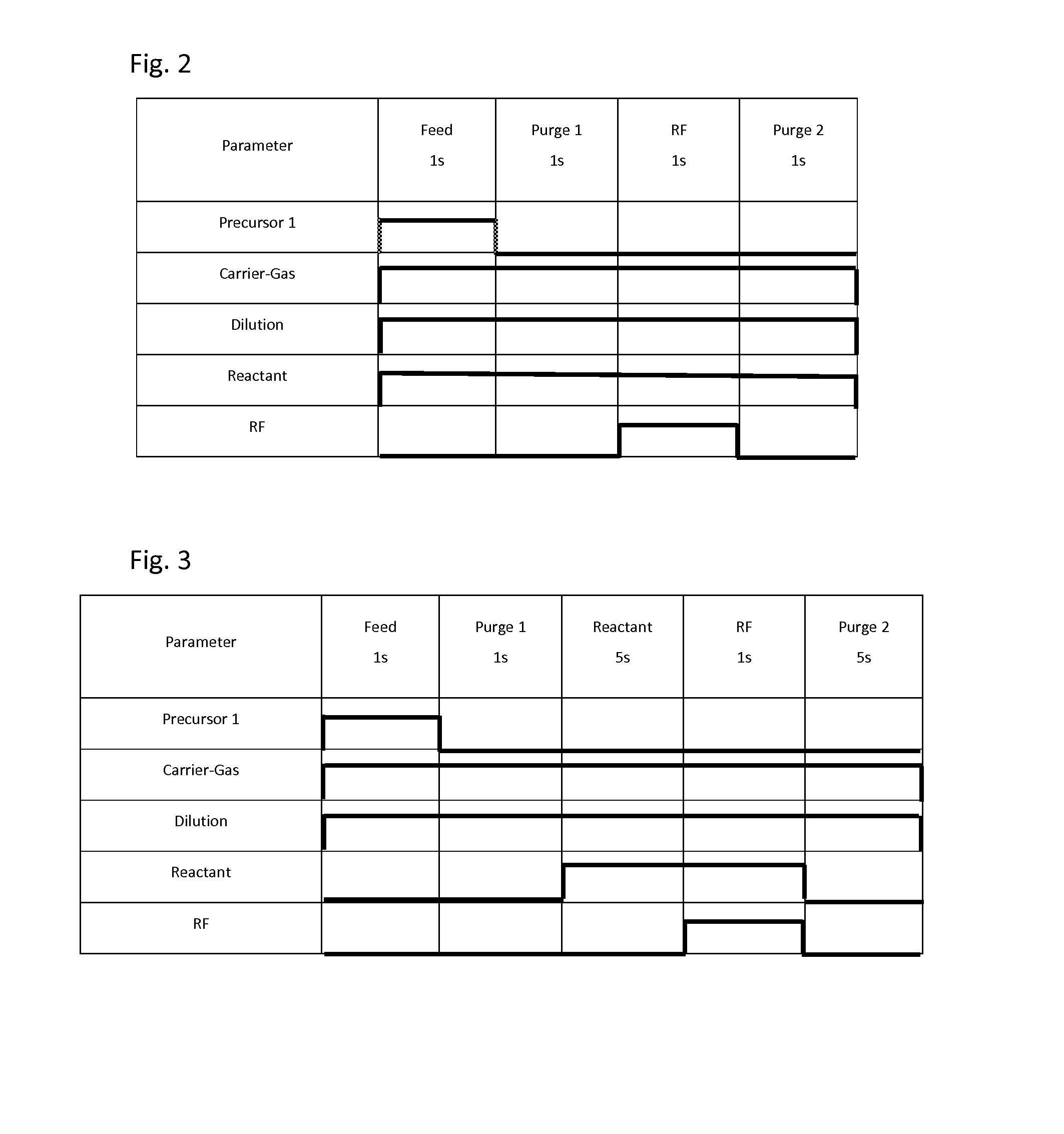

Method for depositing metal-containing film using particle-reduction step

InactiveUS20160168699A1Reduce surface roughnessSolve the lack of resistanceChemical vapor deposition coatingPlasma techniqueAMINO BASENitride

A method for forming a metal oxide or nitride film on a substrate by plasma-enhanced atomic layer deposition (PEALD), includes: introducing an amino-based metal precursor in a pulse to a reaction space where a substrate is placed, using a carrier gas; and continuously introducing a reactant gas to the reaction space; applying RF power in a pulse to the reaction space wherein the pulse of the precursor and the pulse of RF power do not overlap, wherein conducted is at least either step (a) comprising passing the carrier gas through a purifier for reducing impurities before mixing the carrier gas with the precursor, or step (b) introducing the reactant gas at a flow rate such that a partial pressure of the reactant gas relative to the total gas flow provided in the reaction space is 15% or less.

Owner:ASM IP HLDG BV

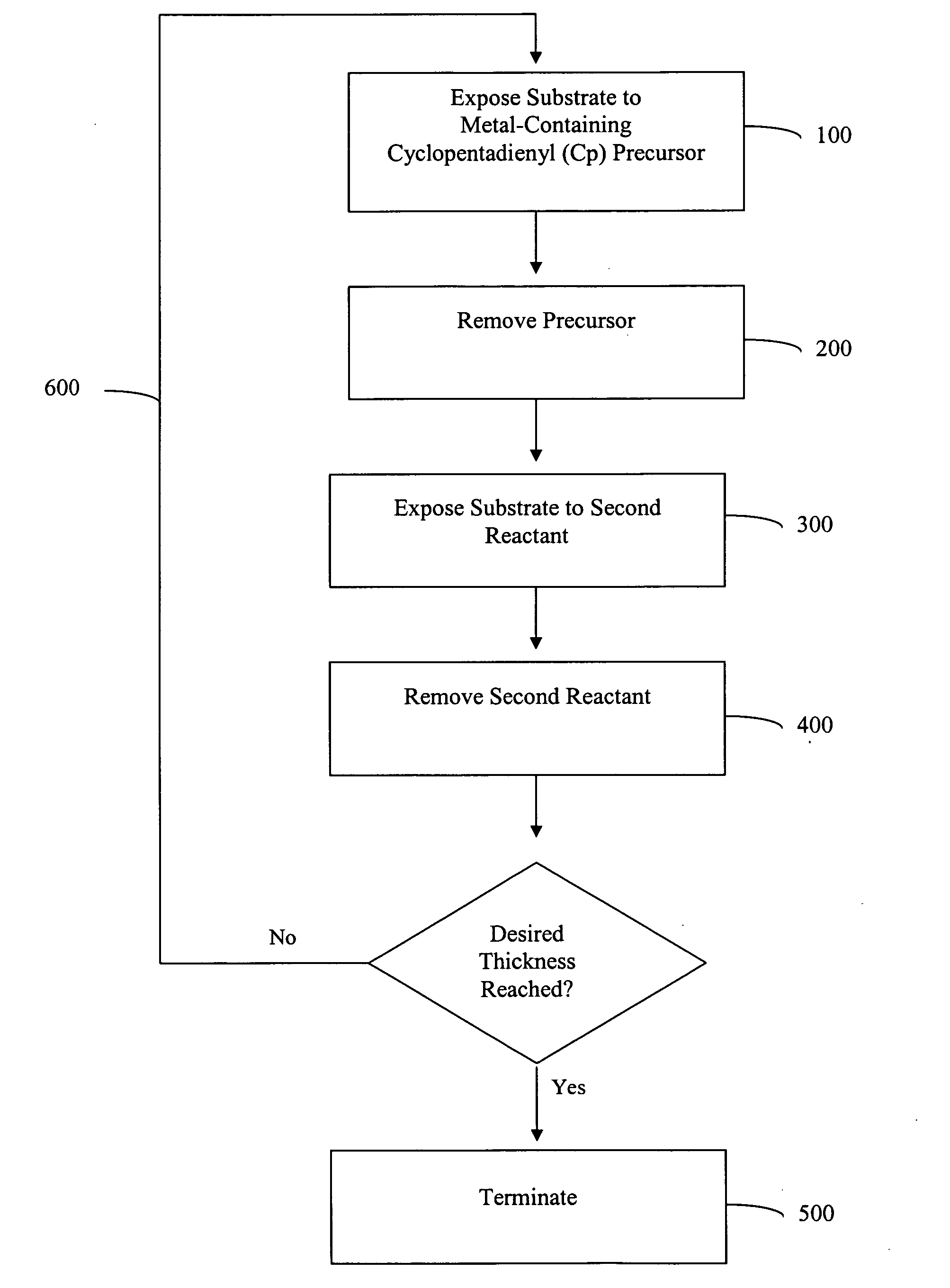

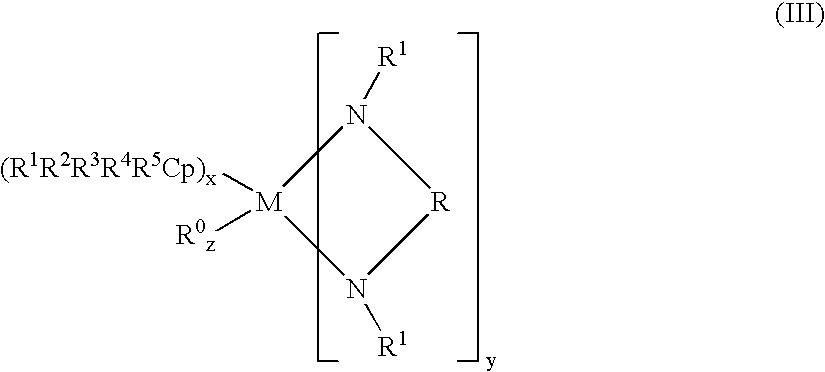

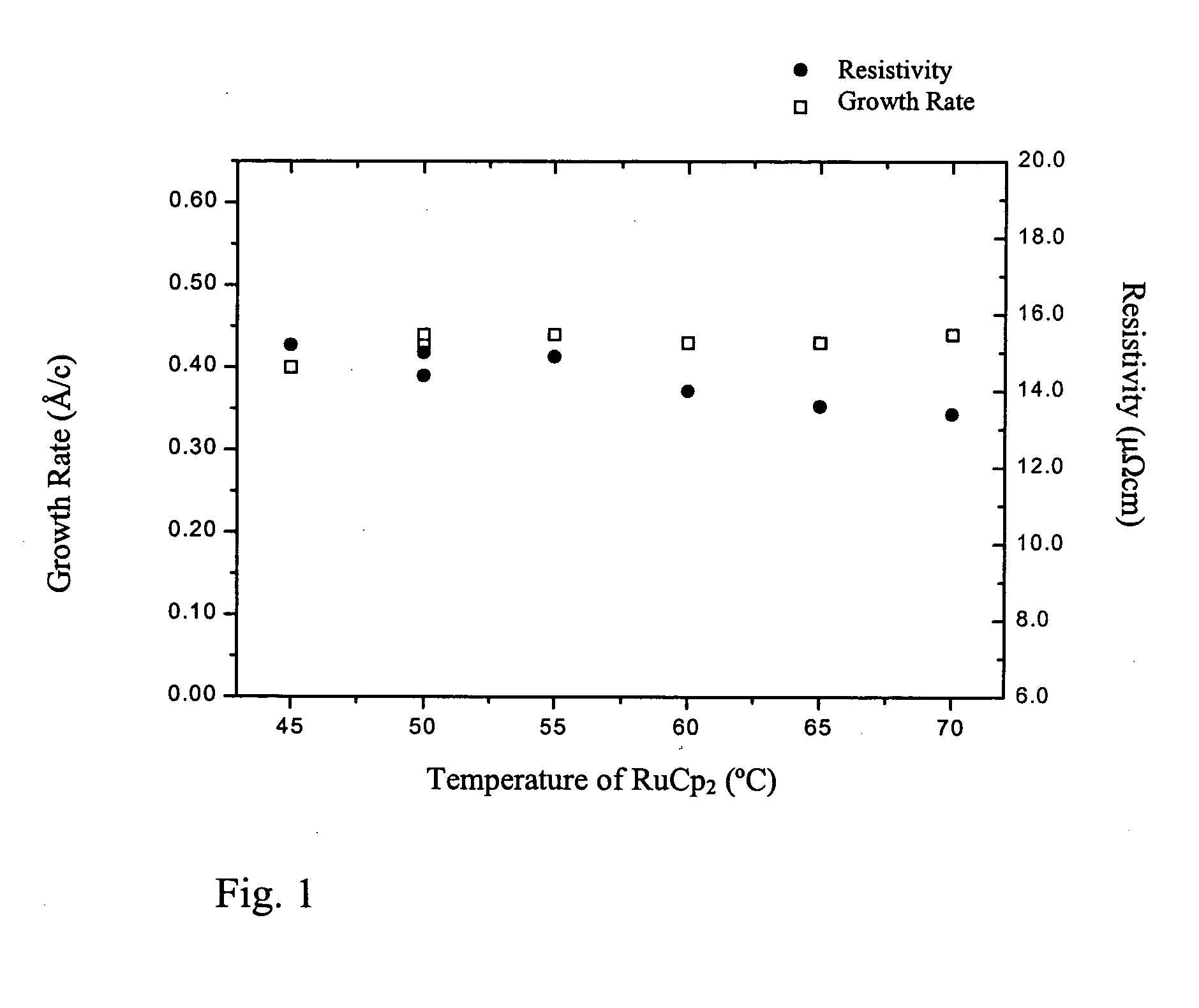

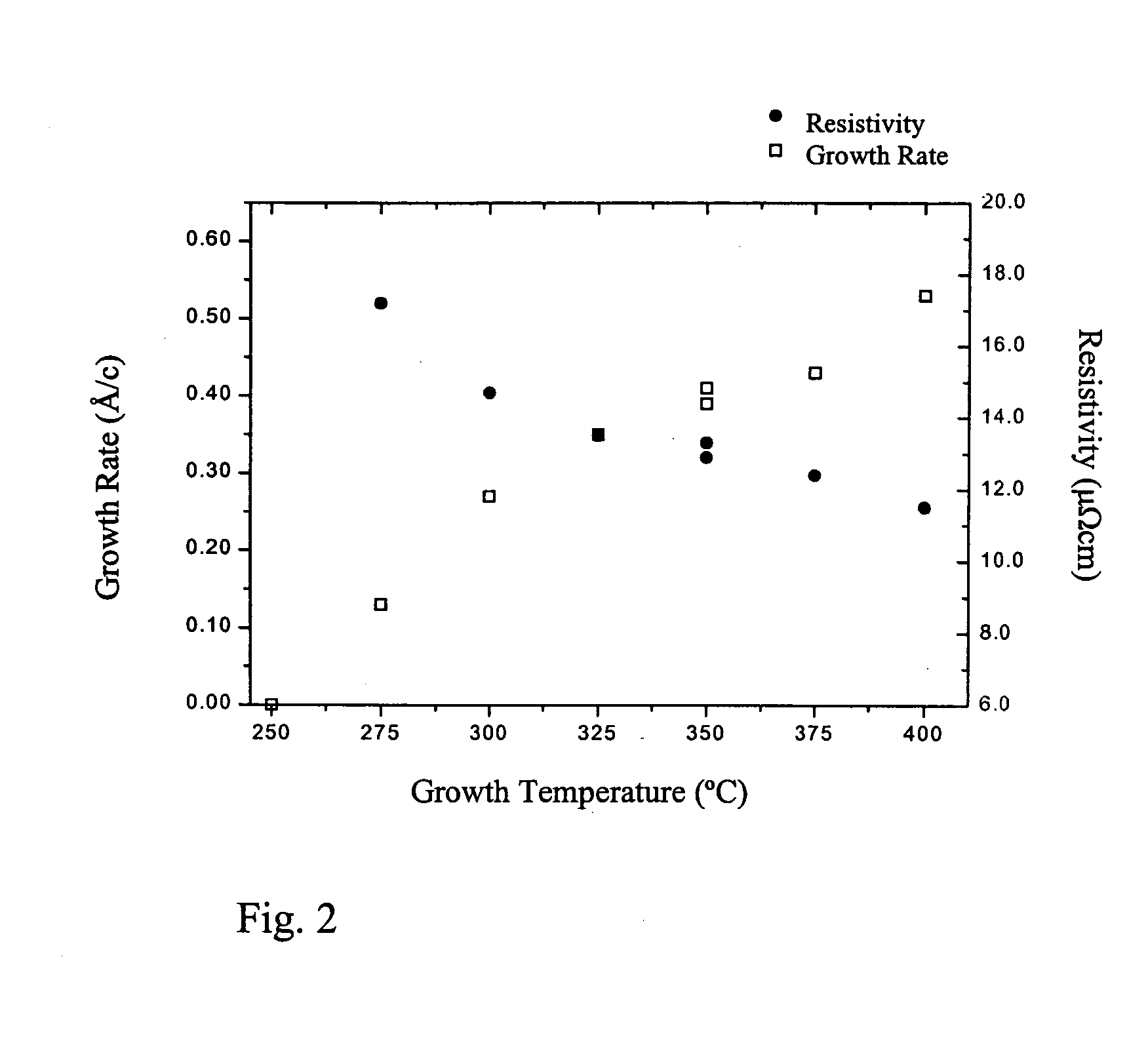

ALD of metal-containing films using cyclopentadienyl compounds

Atomic layer deposition (ALD) type processes for producing metal containing thin films comprise feeding into a reaction space vapor phase pulses of metal containing cyclopentadienyl precursors as a metal source material. In preferred embodiments the metal containing cyclopentadienyl reactant comprises a metal atom that is not directly bonded to an oxygen or halide atom. In other embodiments the metal atom is bonded to a cyclopentadienyl compound and separately bonded to at least one ligand via a nitrogen atom. In still other embodiments the metal containing cyclopentadienyl compound comprises a nitrogen-bridged ligand.

Owner:ASM IP HLDG BV

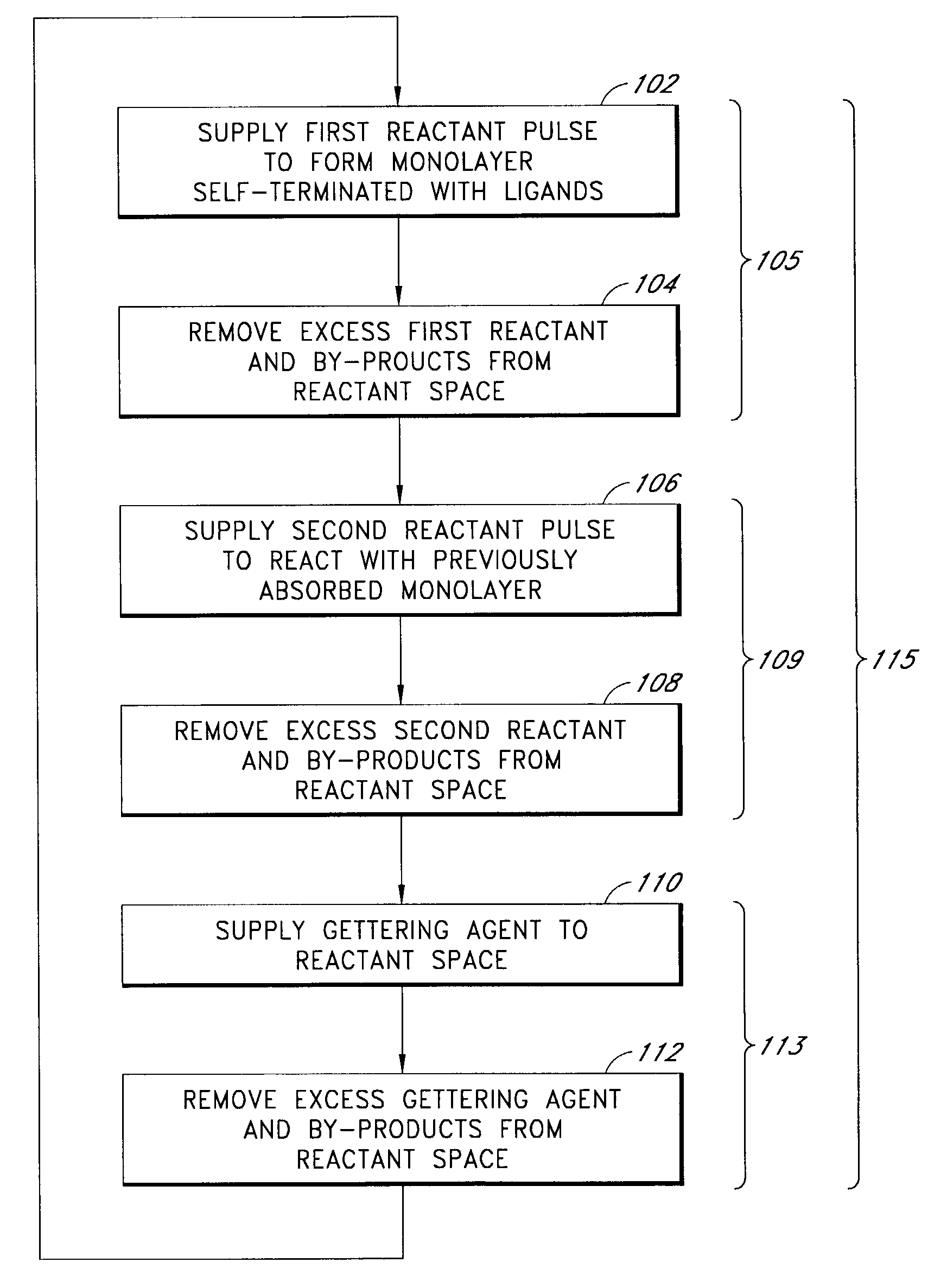

Metal nitride deposition by ALD with reduction pulse

The present methods provide tools for growing conformal metal thin films, including metal nitride, metal carbide and metal nitride carbide thin films. In particular, methods are provided for growing such films from aggressive chemicals. The amount of corrosive chemical compounds, such as hydrogen halides, is reduced during the deposition of transition metal, transition metal carbide, transition metal nitride and transition metal nitride carbide thin films on various surfaces, such as metals and oxides. Getter compounds protect surfaces sensitive to hydrogen halides and ammonium halides, such as aluminum, copper, silicon oxide and the layers being deposited, against corrosion. Nanolaminate structures incorporating metallic thin films, and methods for forming the same, are also disclosed.

Owner:ASM INTERNATIONAL

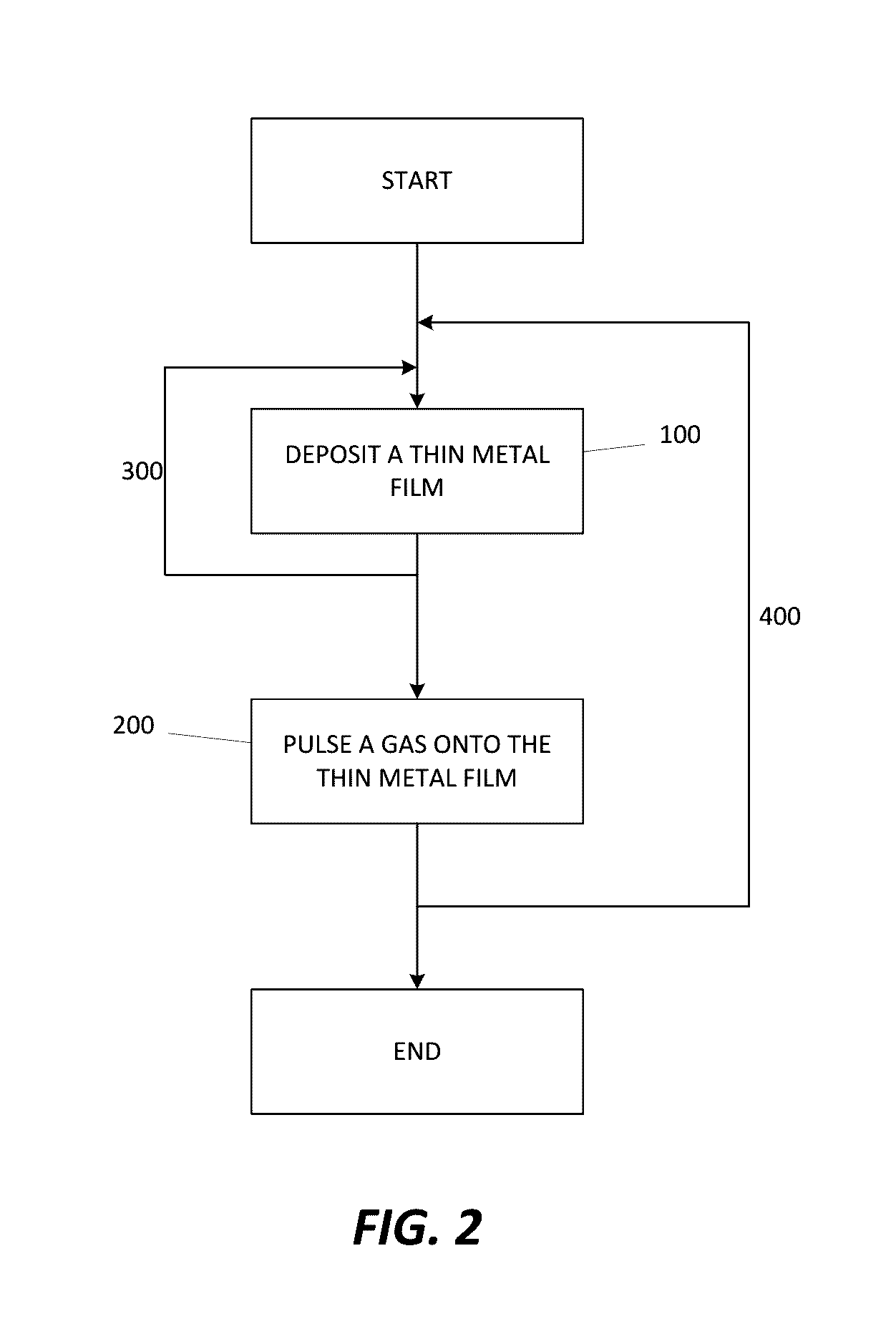

Formation of boron-doped titanium metal films with high work function

ActiveUS20170025280A1Solid-state devicesSemiconductor/solid-state device manufacturingTitanium metalWork function

A method for forming a Boron doped metallic film, such as Titanium Boron Nitride, is disclosed. The method allows for creation of the metallic film with a high work function and low resistivity, while limiting the increase in effective oxide thickness. The method comprises a thin metallic layer deposition step as well as a Boron-based gas pulse step. The Boron-based gas pulse deposits Boron and allows for the removal of excess halogens within the metallic film. The steps may be repeated in order to achieve a desired thickness of the metallic film.

Owner:ASM IP HLDG BV

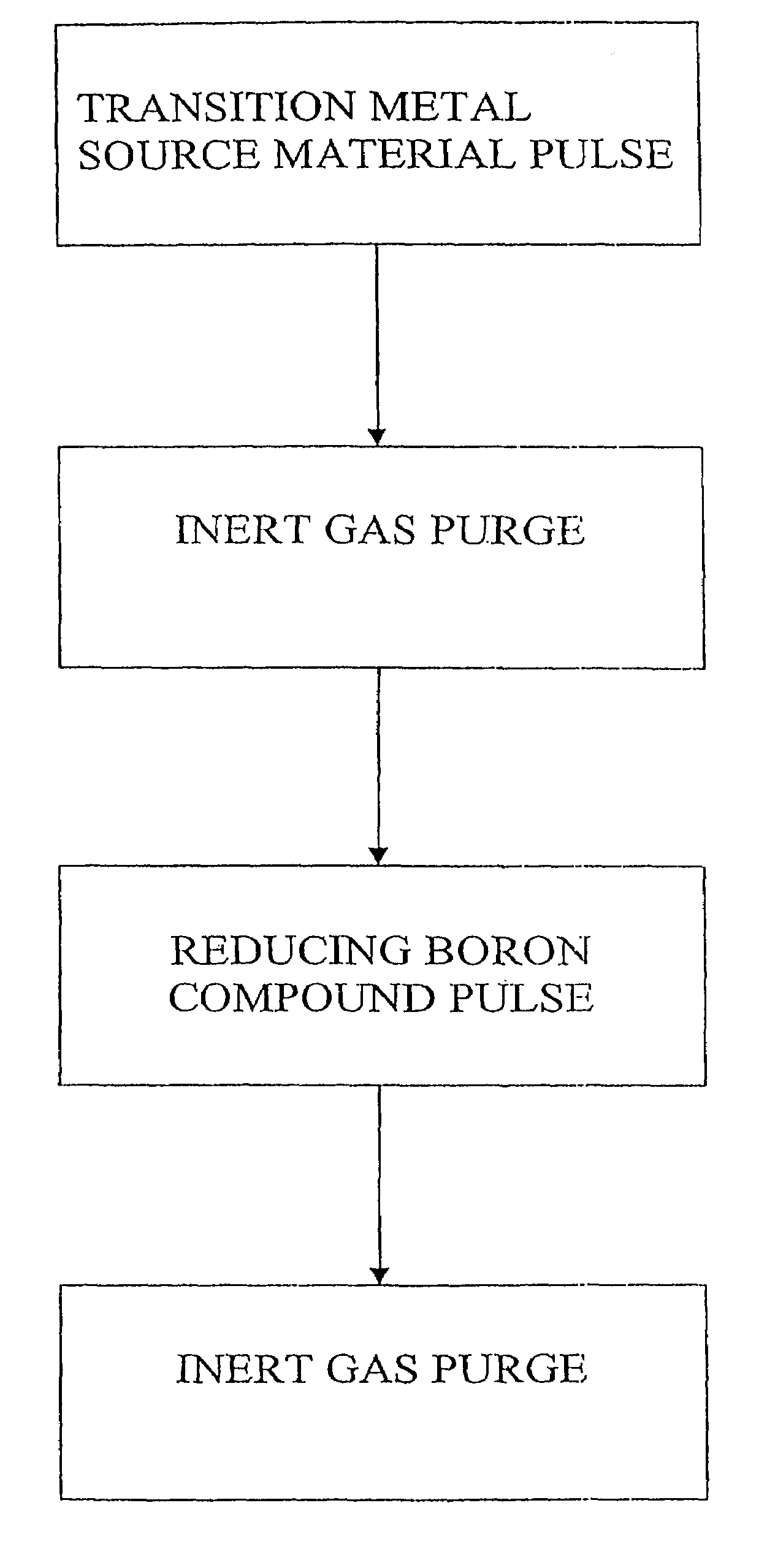

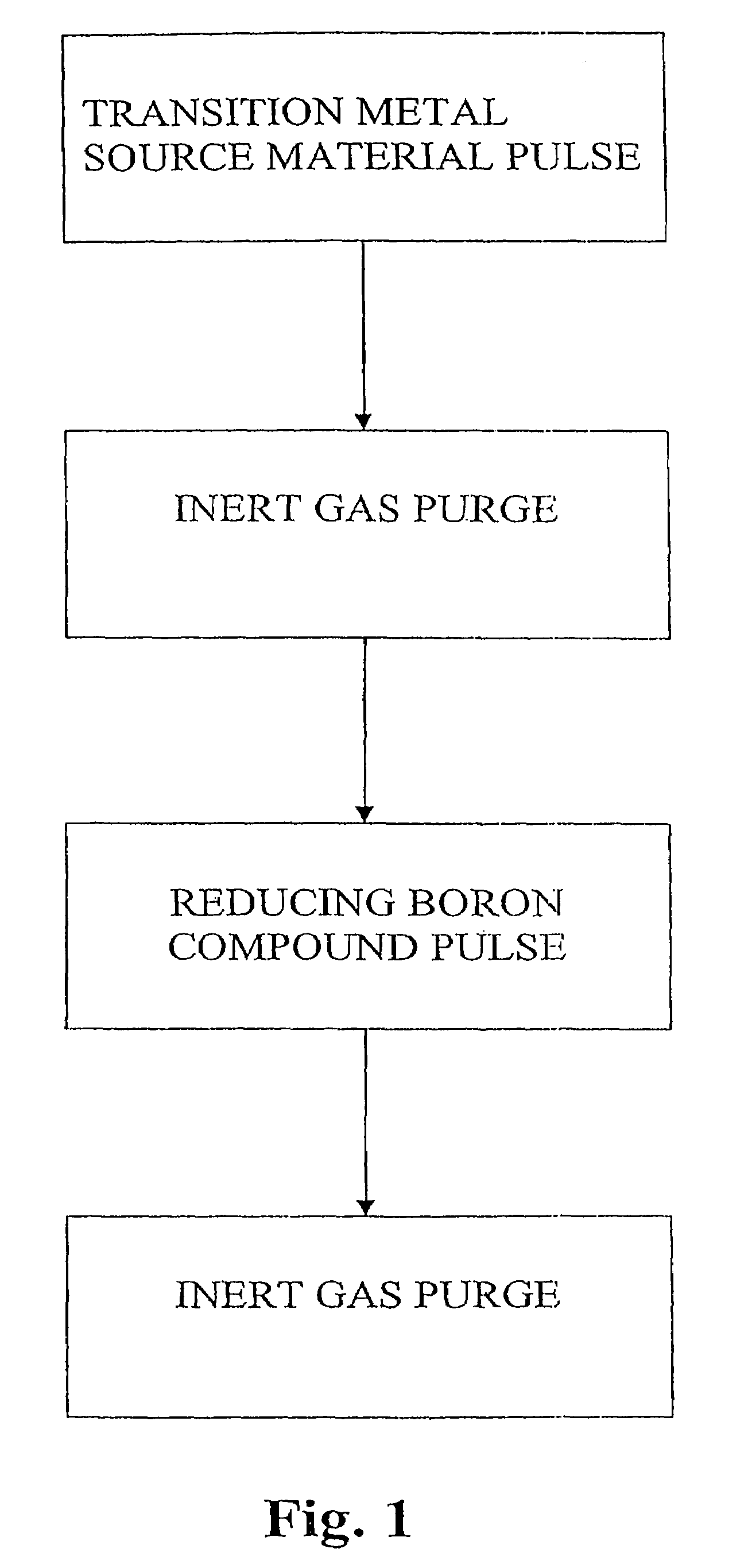

Production of elemental films using a boron-containing reducing agent

InactiveUS7144809B2Polycrystalline material growthSemiconductor/solid-state device detailsElectricityGas phase

The present invention relates generally to depositing elemental thin films. In particular, the invention concerns a method of growing elemental metal thin films by Atomic Layer Deposition (ALD) using a boron compound as a reducing agent. In a preferred embodiment the method comprises introducing vapor phase pulses of at least one metal source compound and at least one boron source compound into a reaction space that contains a substrate on which the metal thin film is to be deposited. Preferably the boron compound is capable of reducing the adsorbed portion of the metal source compound into its elemental electrical state.

Owner:ASM INTERNATIONAL

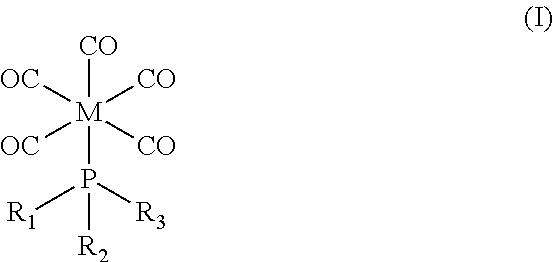

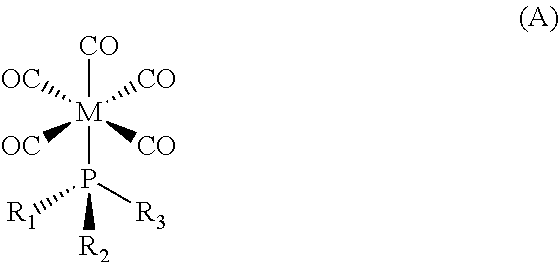

Deposition of Molybdenum Thin Films Using A Molybdenum Carbonyl Precursor

ActiveUS20190003050A1Thin film depositionChemical vapor deposition coatingMetal thin filmCarbonyl group

Transition metal precursors are disclosed herein along with methods of using these precursors to deposit metal thin films. Advantageous properties of these precursors and methods are also disclosed, as well as superior films that can be achieved with the precursors and methods.

Owner:MERCK PATENT GMBH

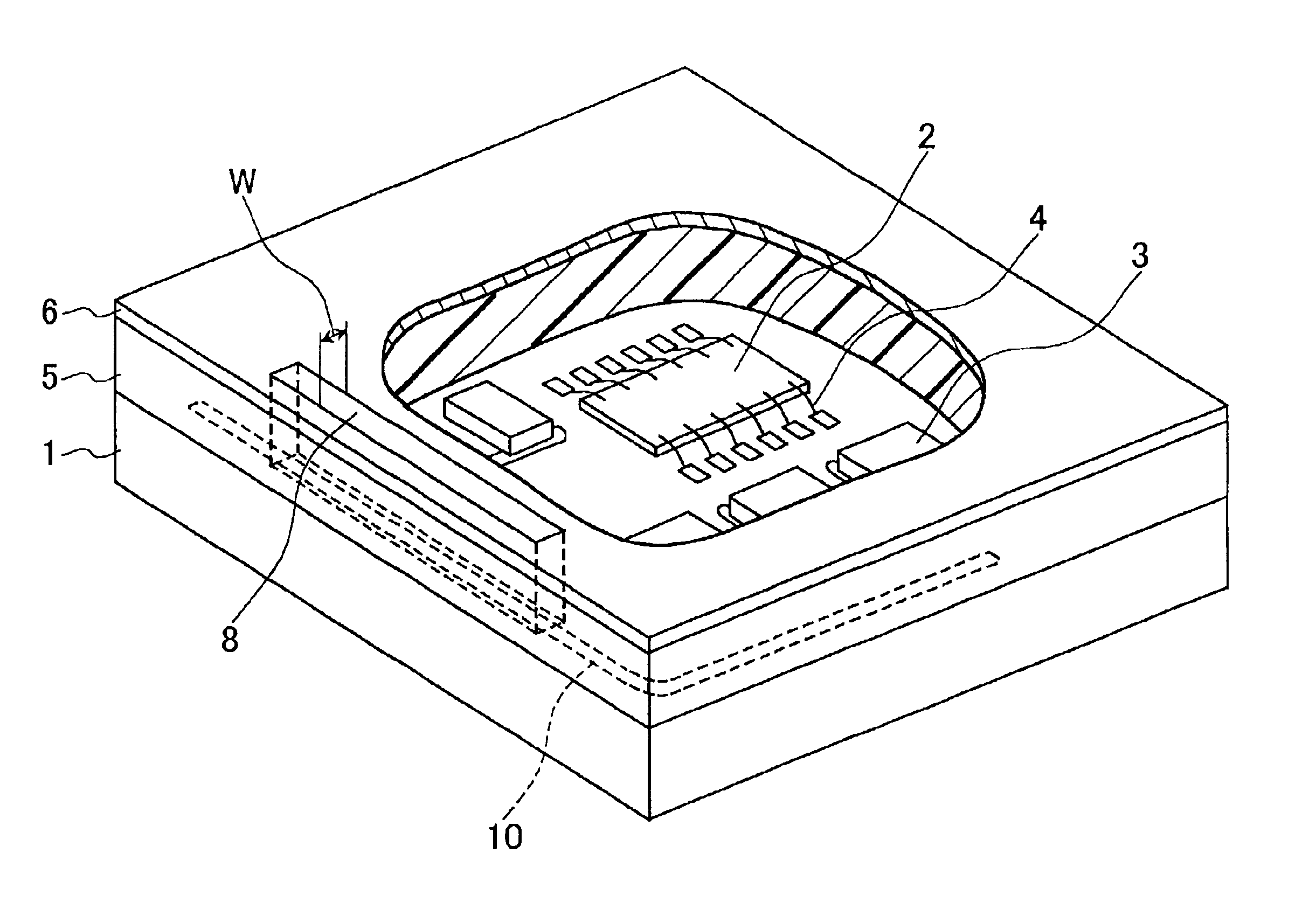

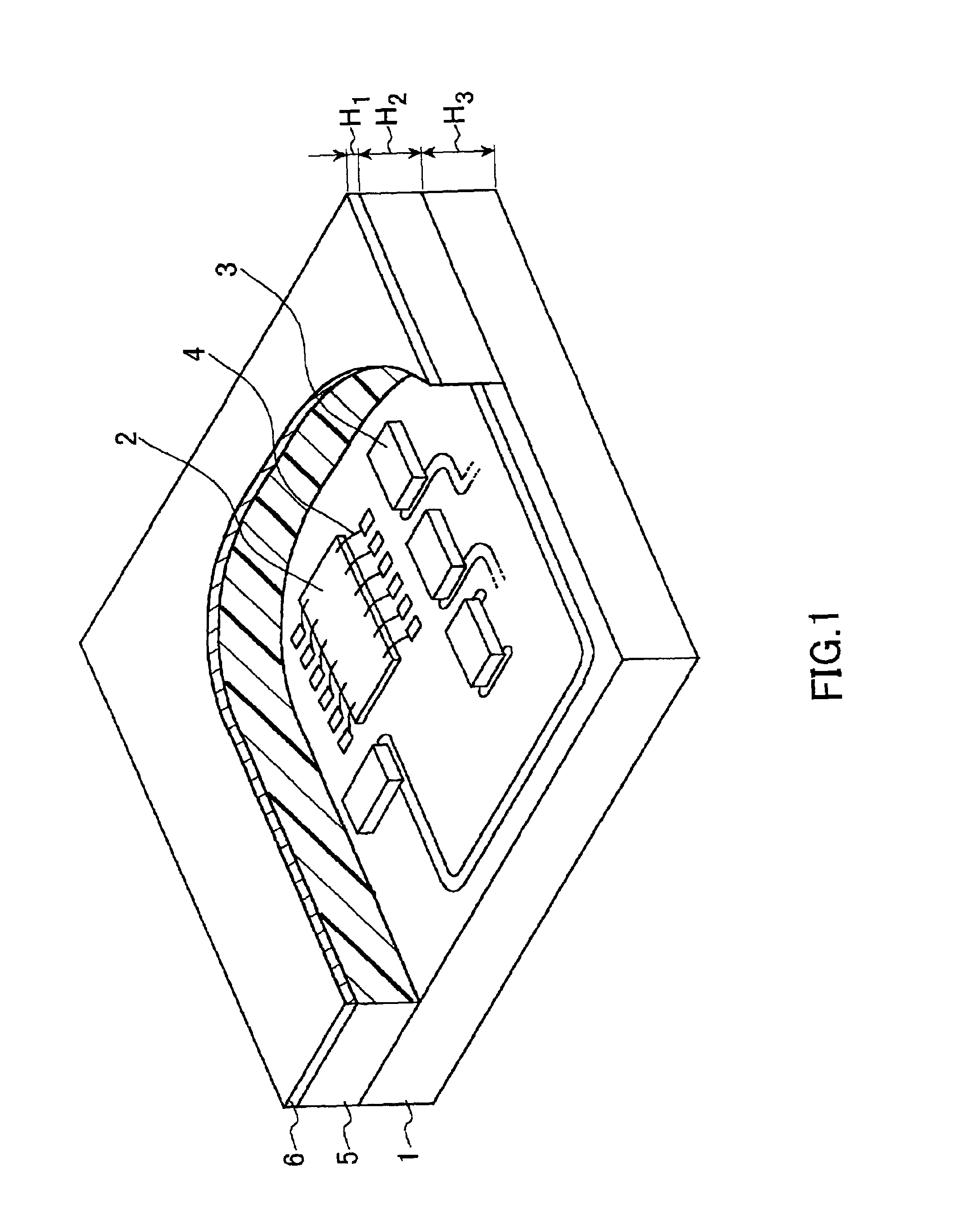

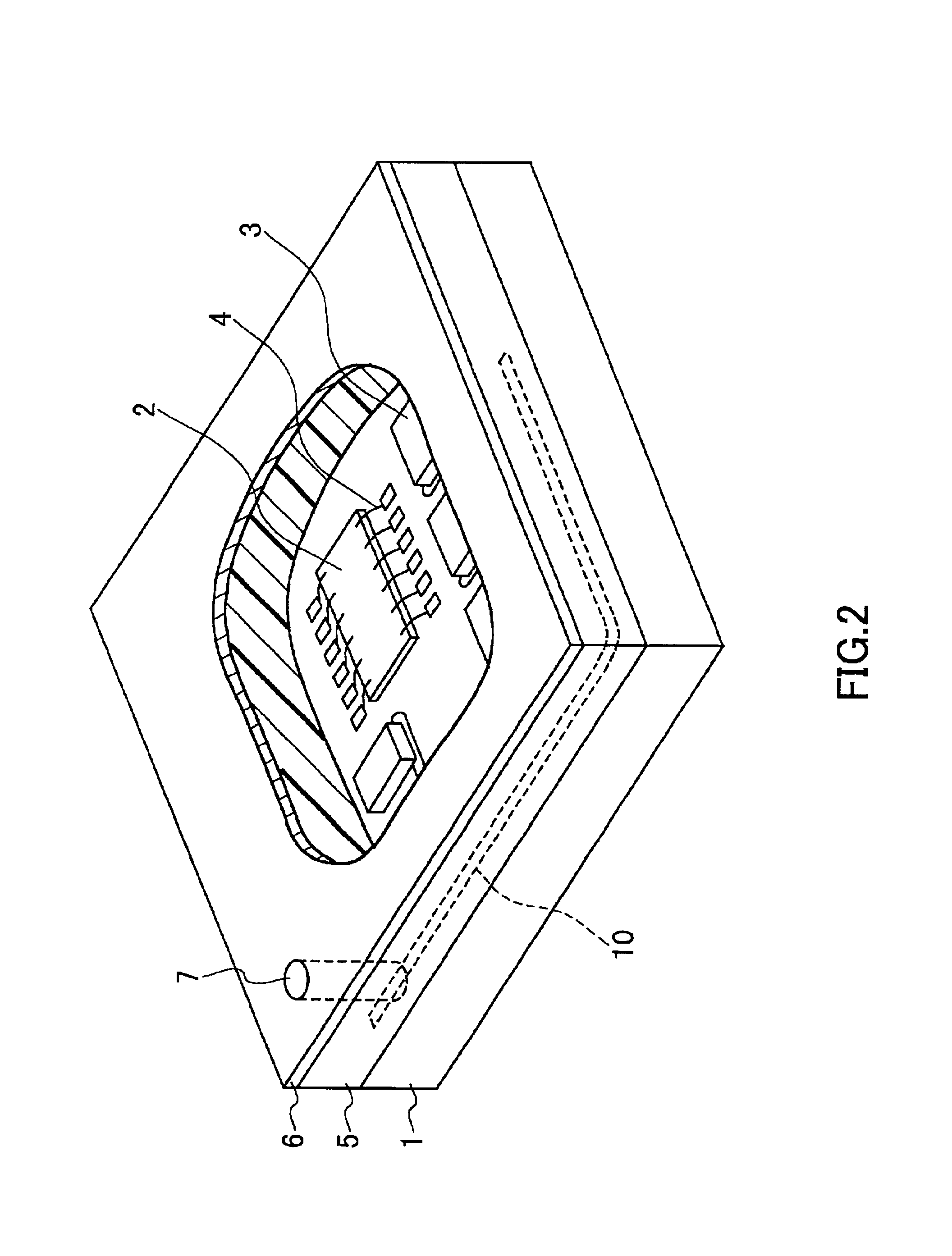

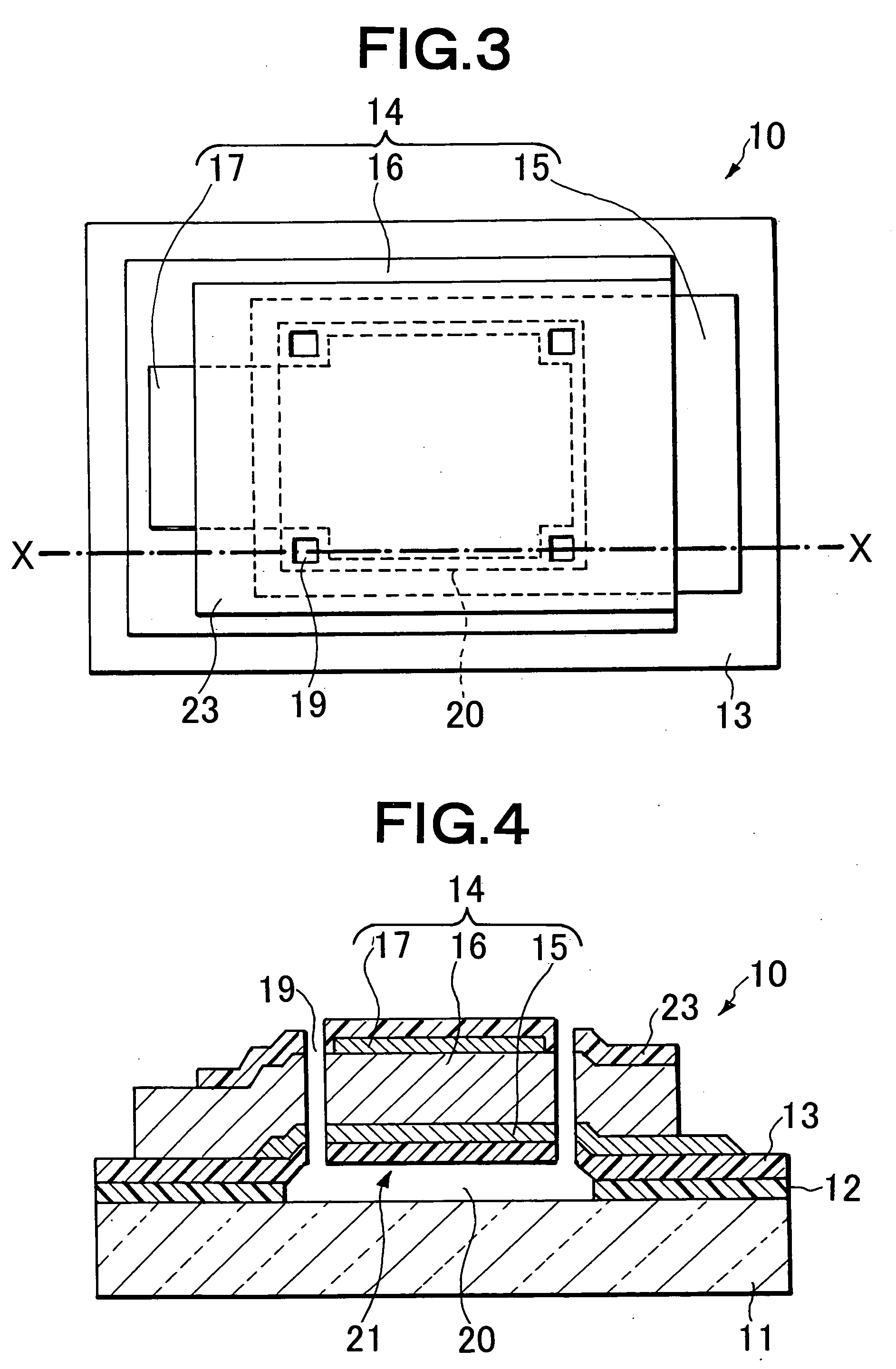

High-frequency module and method for manufacturing the same

InactiveUS7081661B2Reduce electromagnetic influencePliability problemMagnetic/electric field screeningSemiconductor/solid-state device detailsEngineeringElectronic component

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

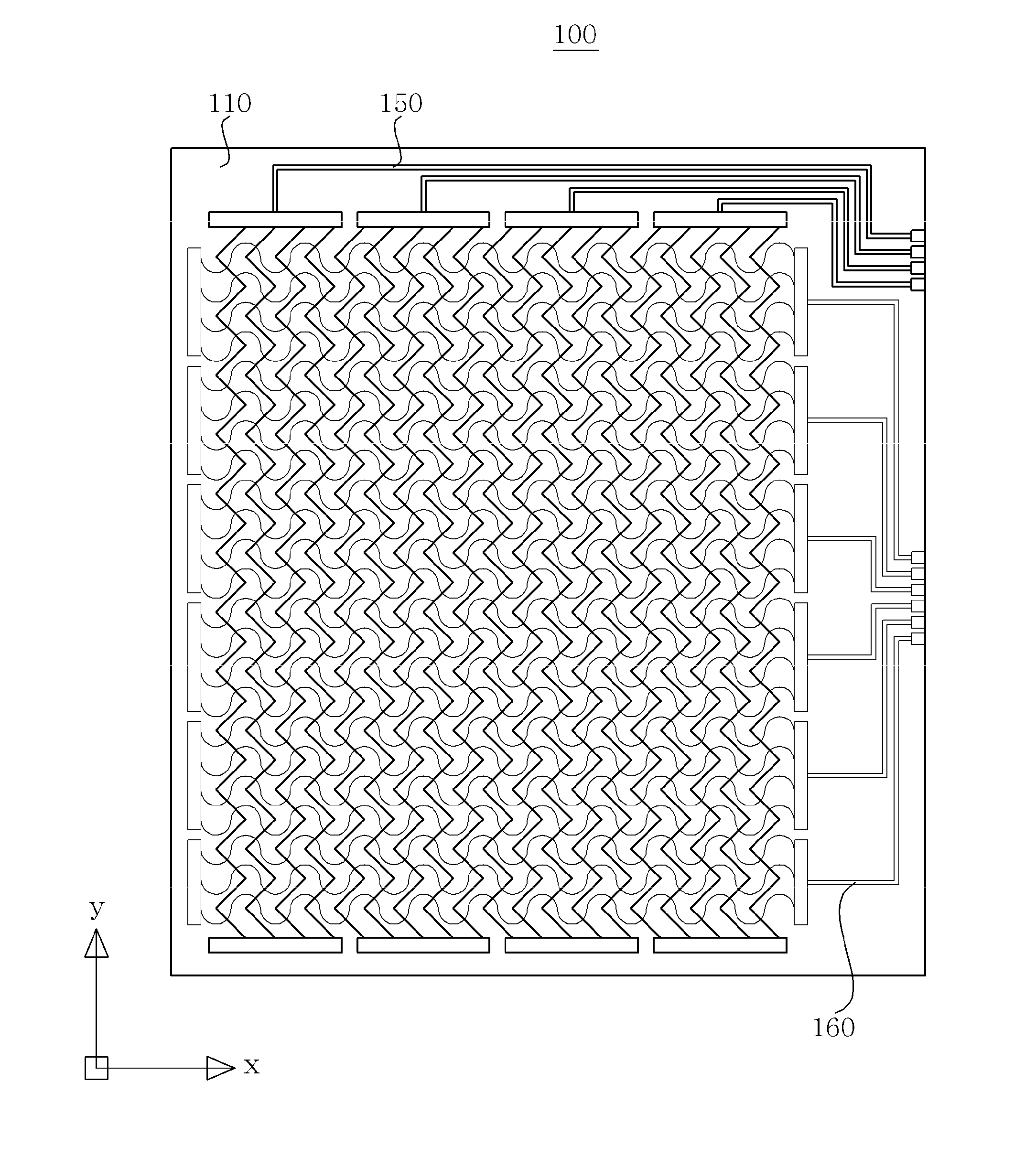

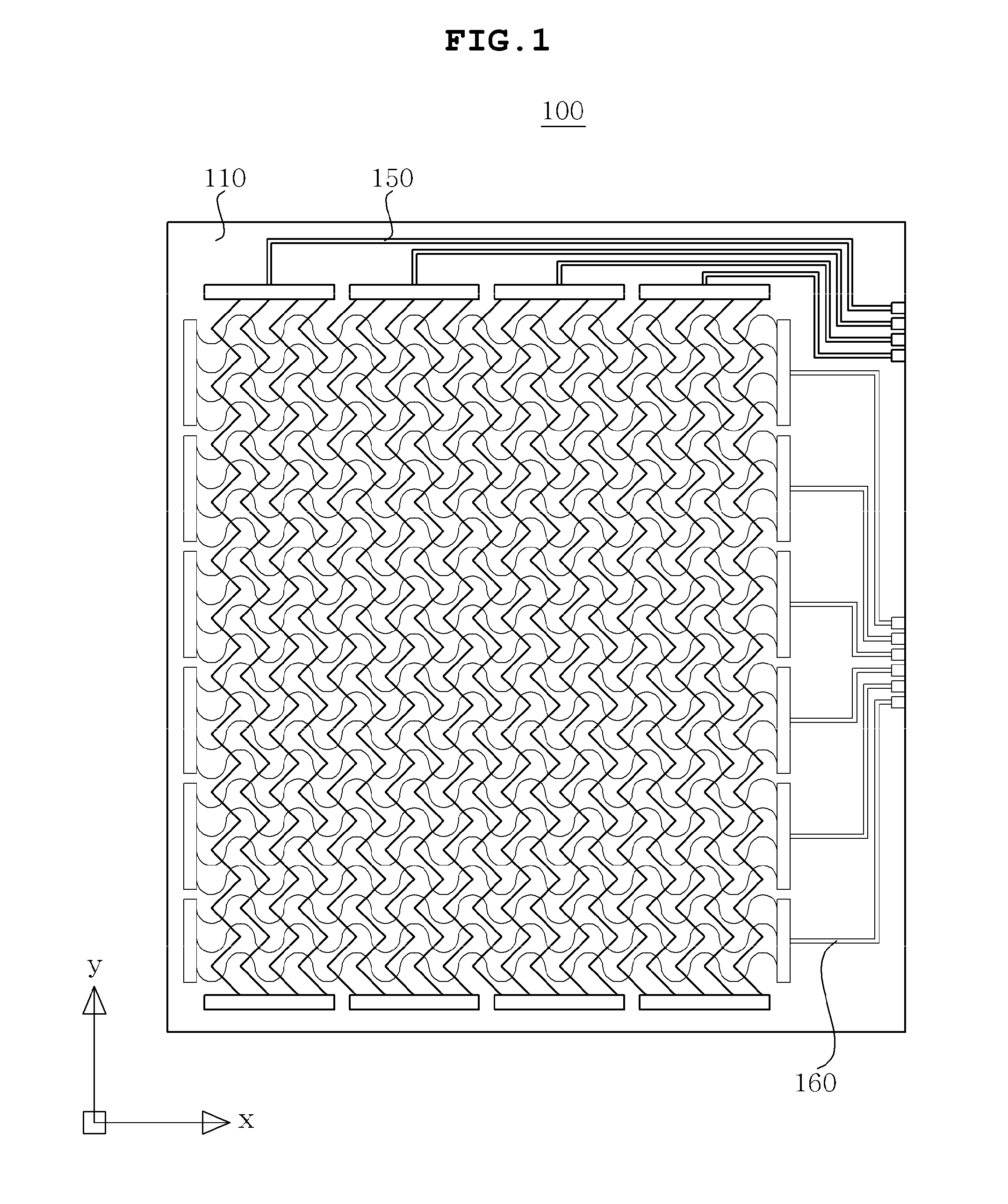

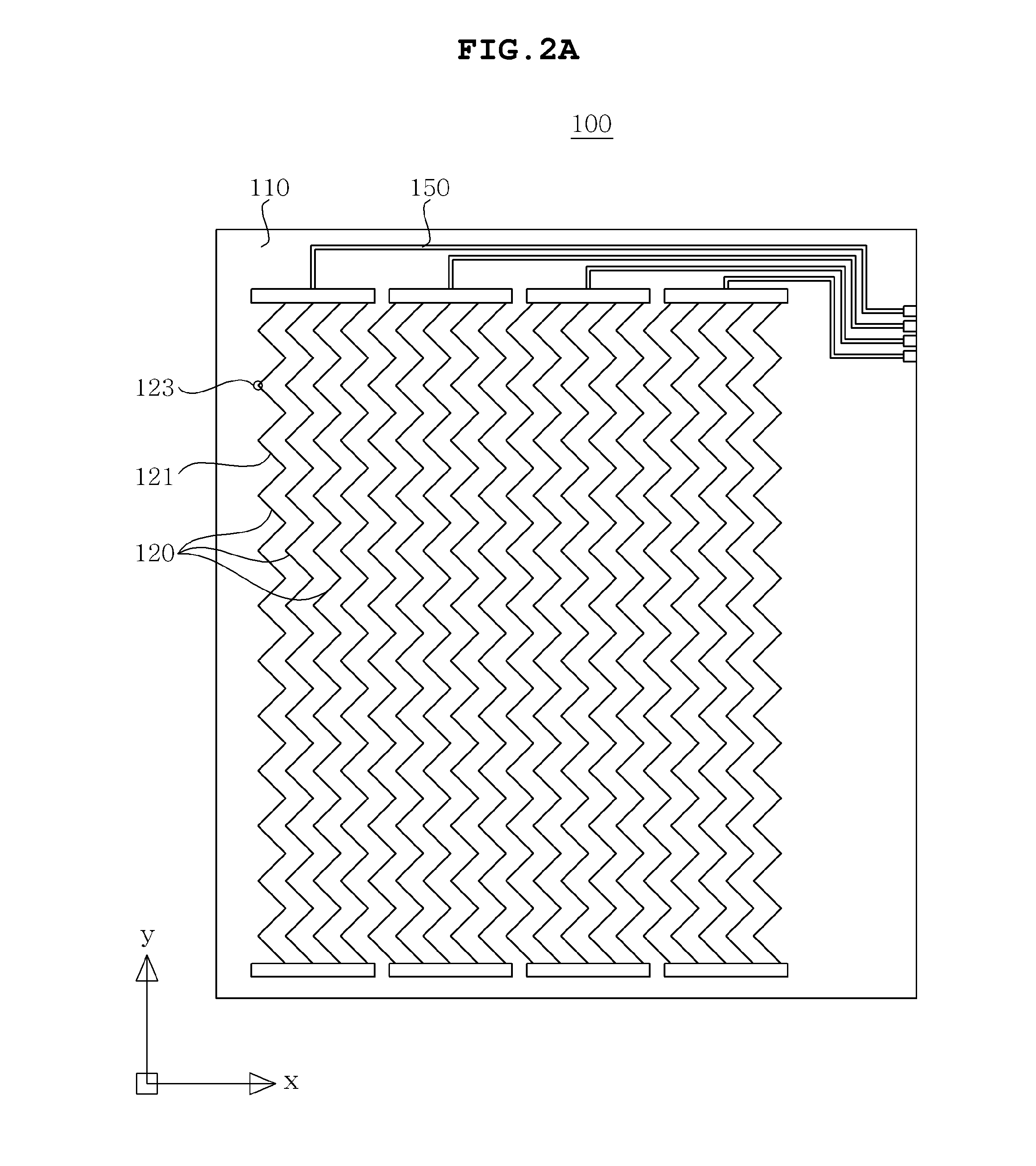

Touch panel

InactiveUS20130063371A1Depletion problemInput/output processes for data processingVisibilityOptoelectronics

Disclosed herein is a structure of a touch panel capable of solving a depletion problem of resources used for a transparent conductive layer, in particular, improving a moiré phenomenon occurring during a image projection process when a metal electrode in a mesh shape is formed on both surfaces of the transparent substrate, by replacing ITO and forming electrodes using a metal thin film on which fine patterns are formed. Exemplary embodiments of the present invention can improve the moiré phenomenon occurring due to overlapping lines between the top and bottom metal electrodes on the transparent substrate during the image projection process and can improve the visibility by minimizing overlapping lines between the metal electrode formed on the transparent substrate and the pixel grid or the black matrix formed on the color filter.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Magnetoresistive element and magnetic head

A magnetic transducing element in which a ferromagnetic tunneling junction film, including first and second ferromagnetic layers and an insulating layer are enclosed between the ferromagnetic layers, and a nonmagnetic metal thin film is inserted between the second ferromagnetic layer and the insulating layer, is formed on a substrate.

Owner:WESTERN DIGITAL TECH INC

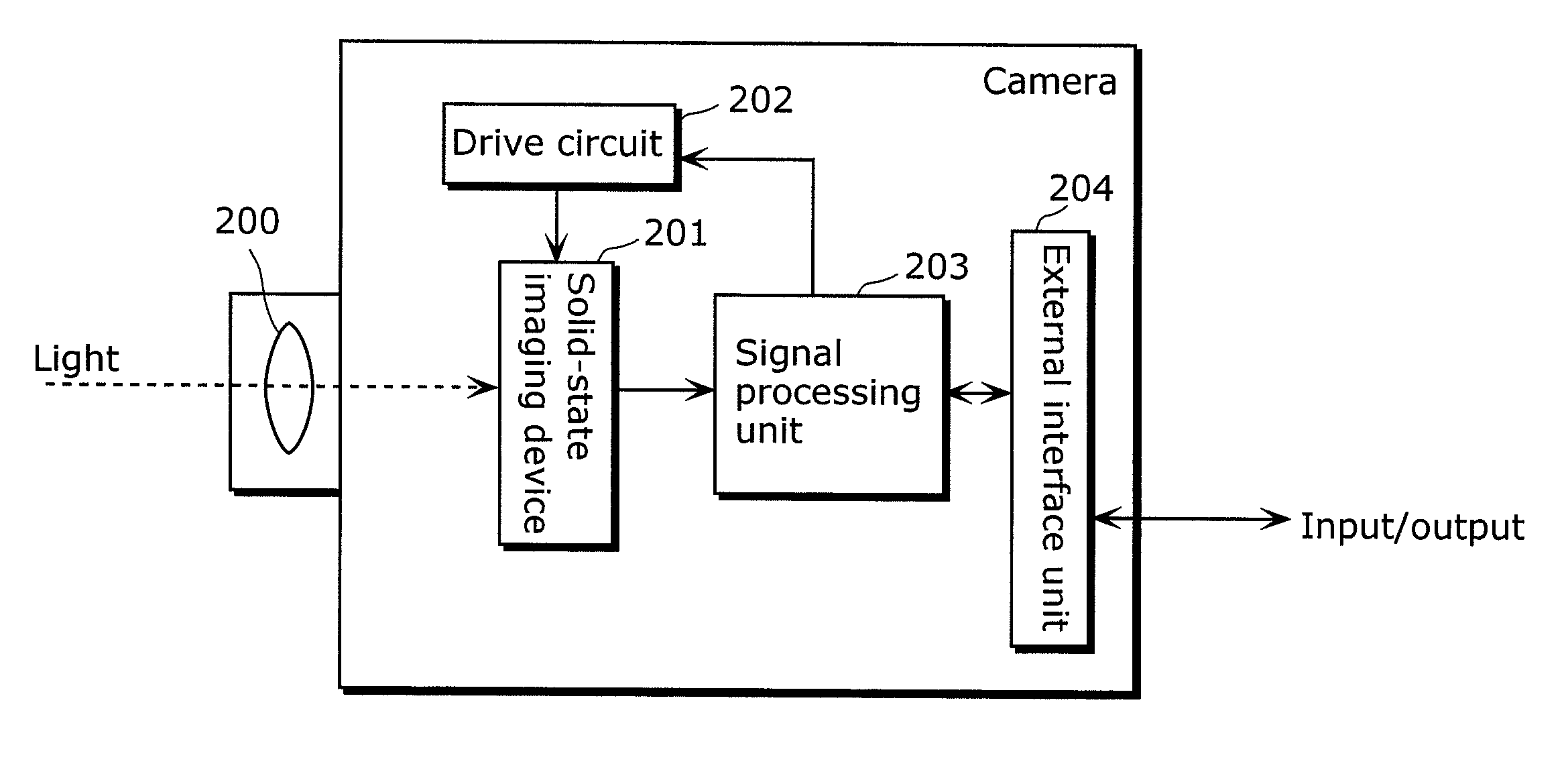

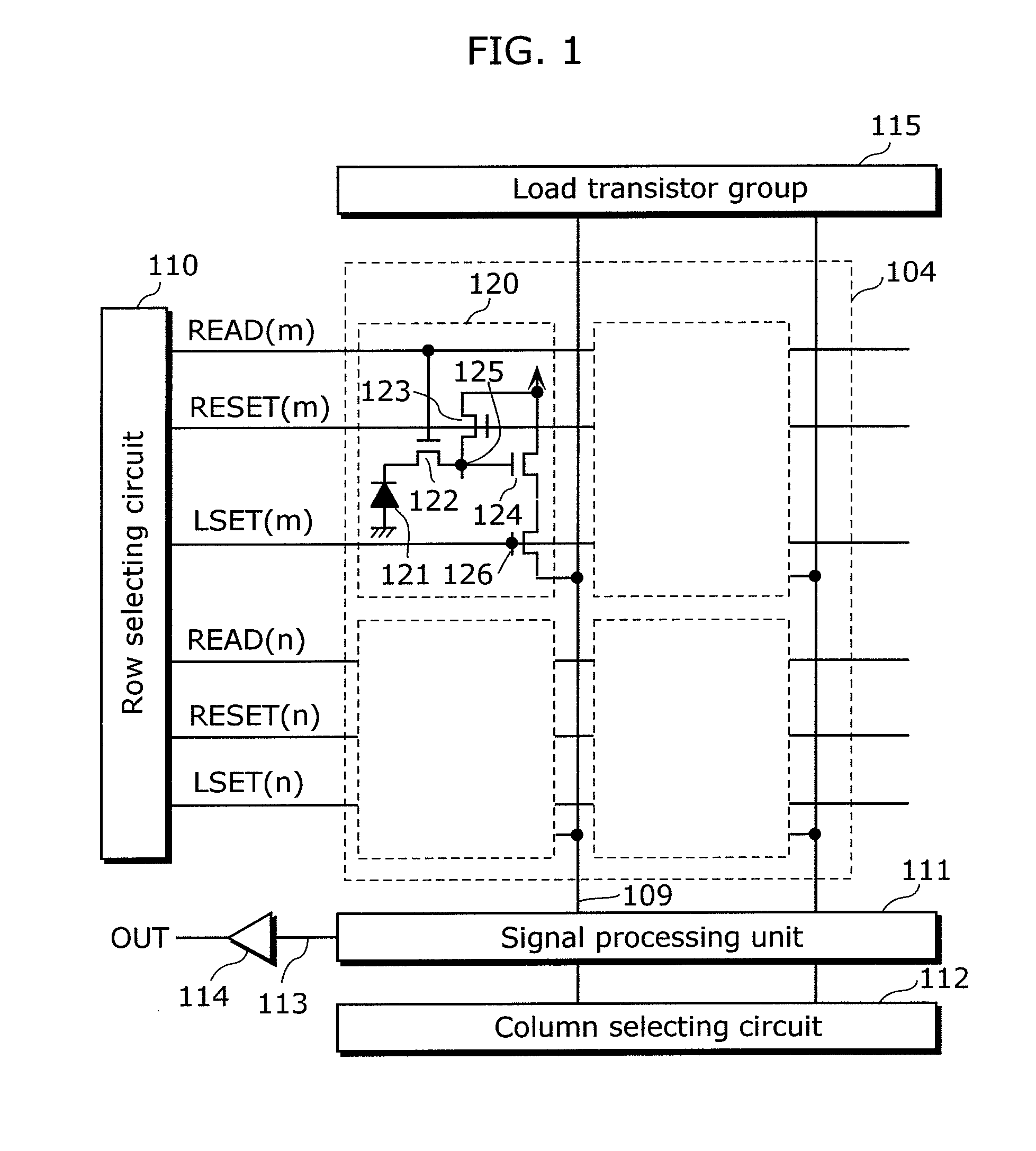

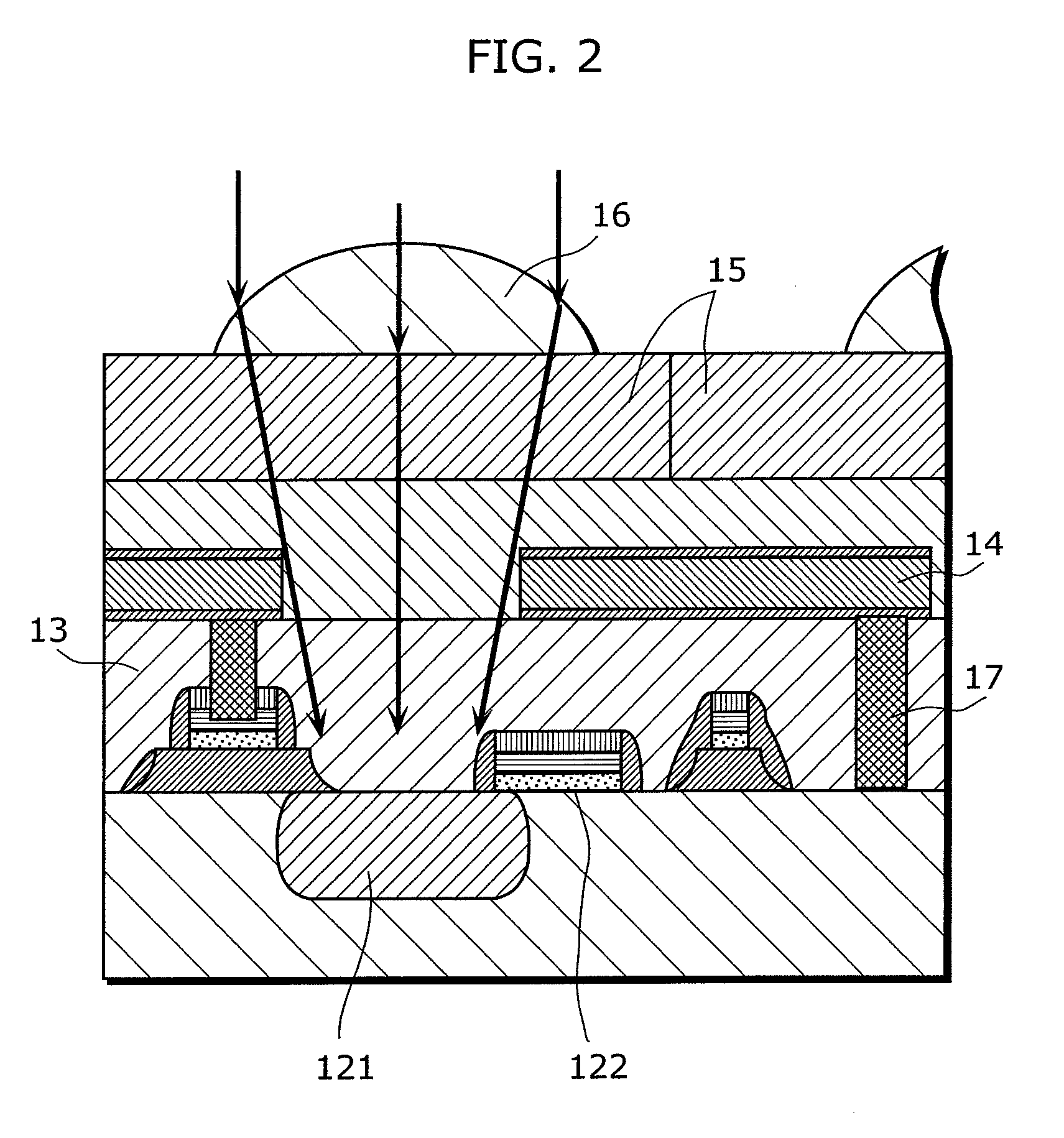

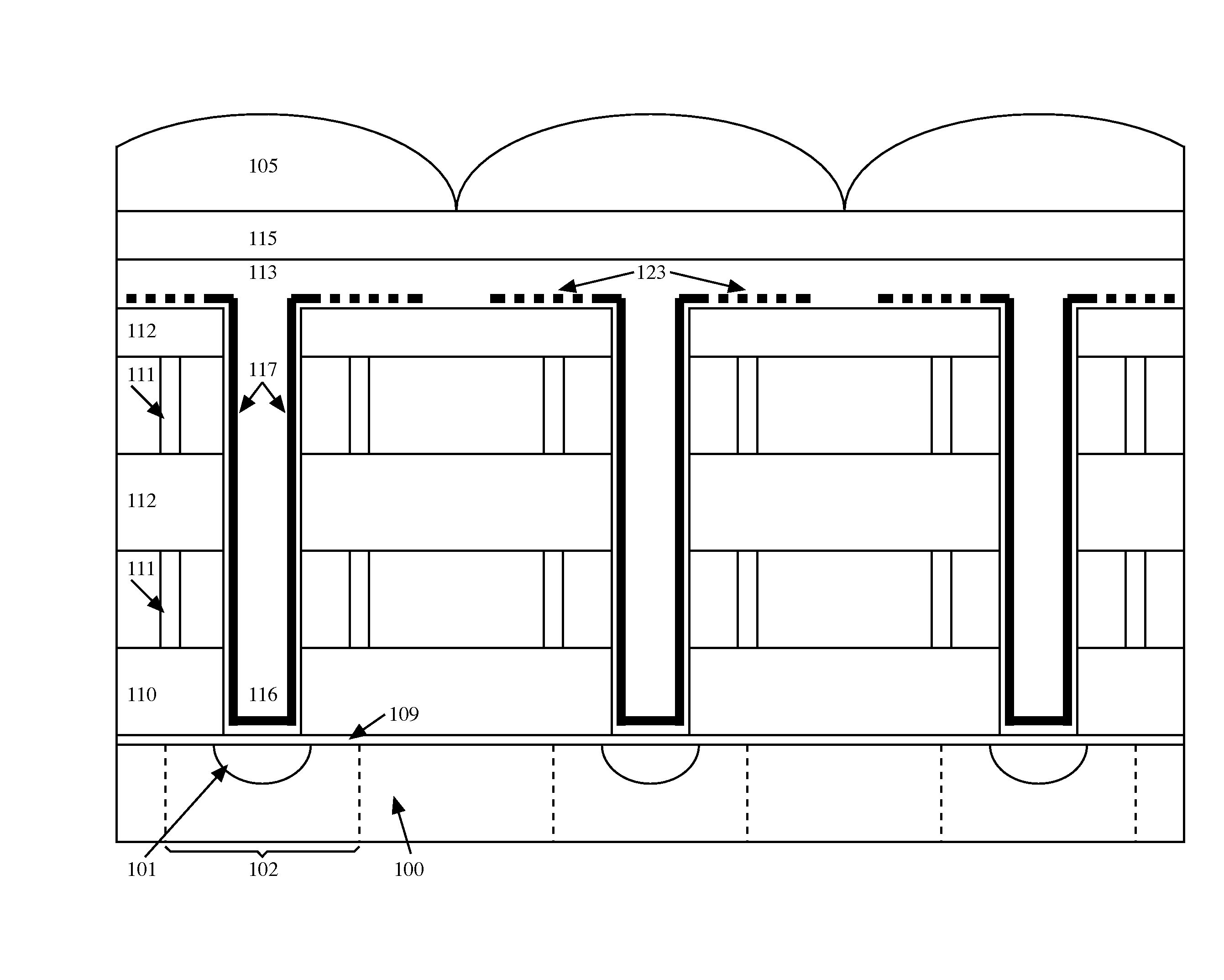

Solid-state imaging device and camera using the same

InactiveUS20080170143A1Improve picture qualityHigh sensitivityTelevision system detailsTelevision system scanning detailsLength waveScale down

The object of the present invention is to provide a solid-state imaging device equipped with a color filter which is highly durable, inexpensive to manufacture, and adaptable to the scaling down of pixels, and a camera using the solid-state imaging device. The solid-state imaging device includes a photodiode, and a metal optical filter formed above the photodiode, which allows light of a desired wavelength to be transmitted. The metal optical filter is made of a metal thin film in which plural cylinder-shaped apertures are periodically arrayed. The size of each of the apertures is smaller than the desired wavelength, and an inter-aperture distance between a predetermined aperture and an aperture adjacent to the predetermined aperture is shorter than the desired wavelength.

Owner:PANASONIC CORP

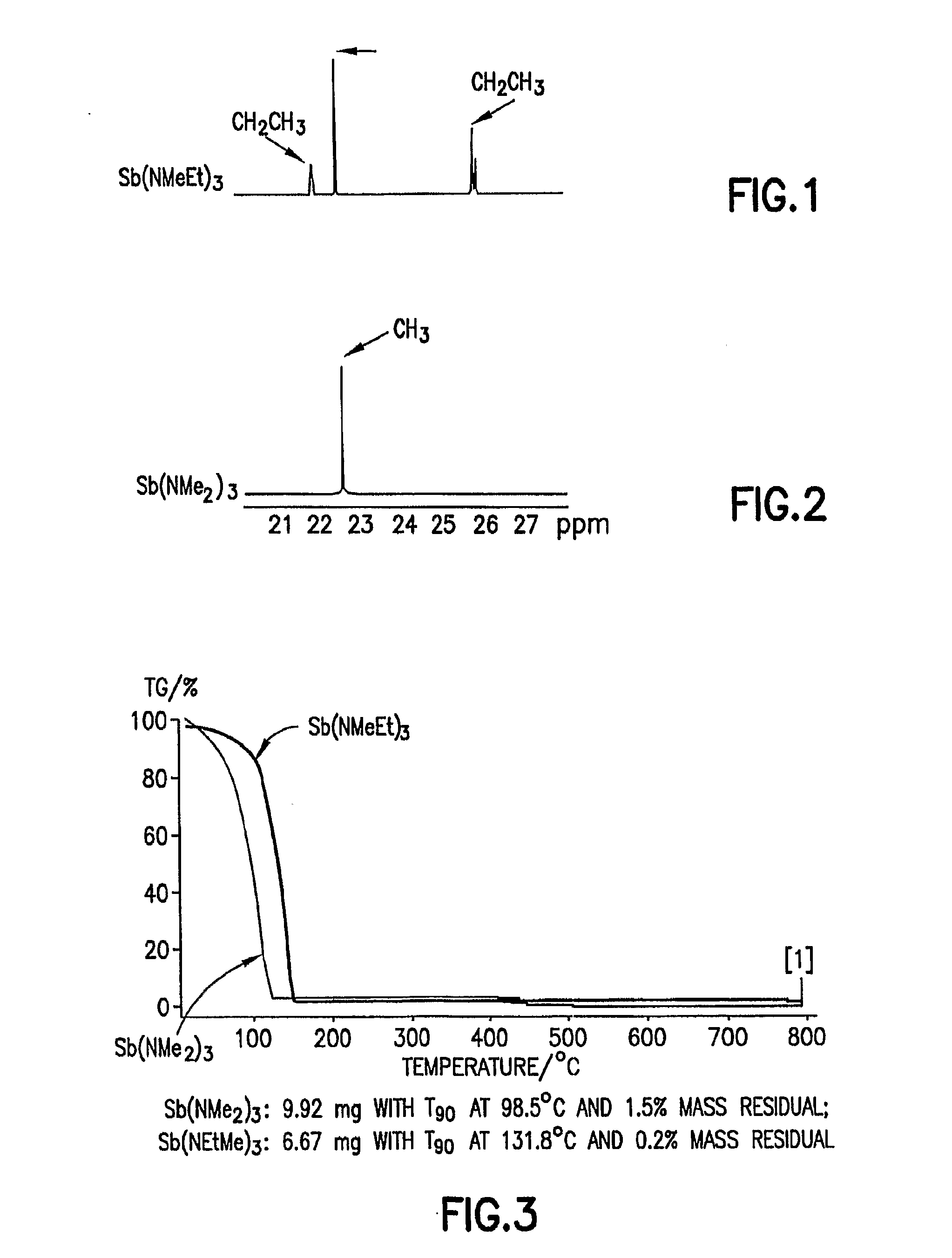

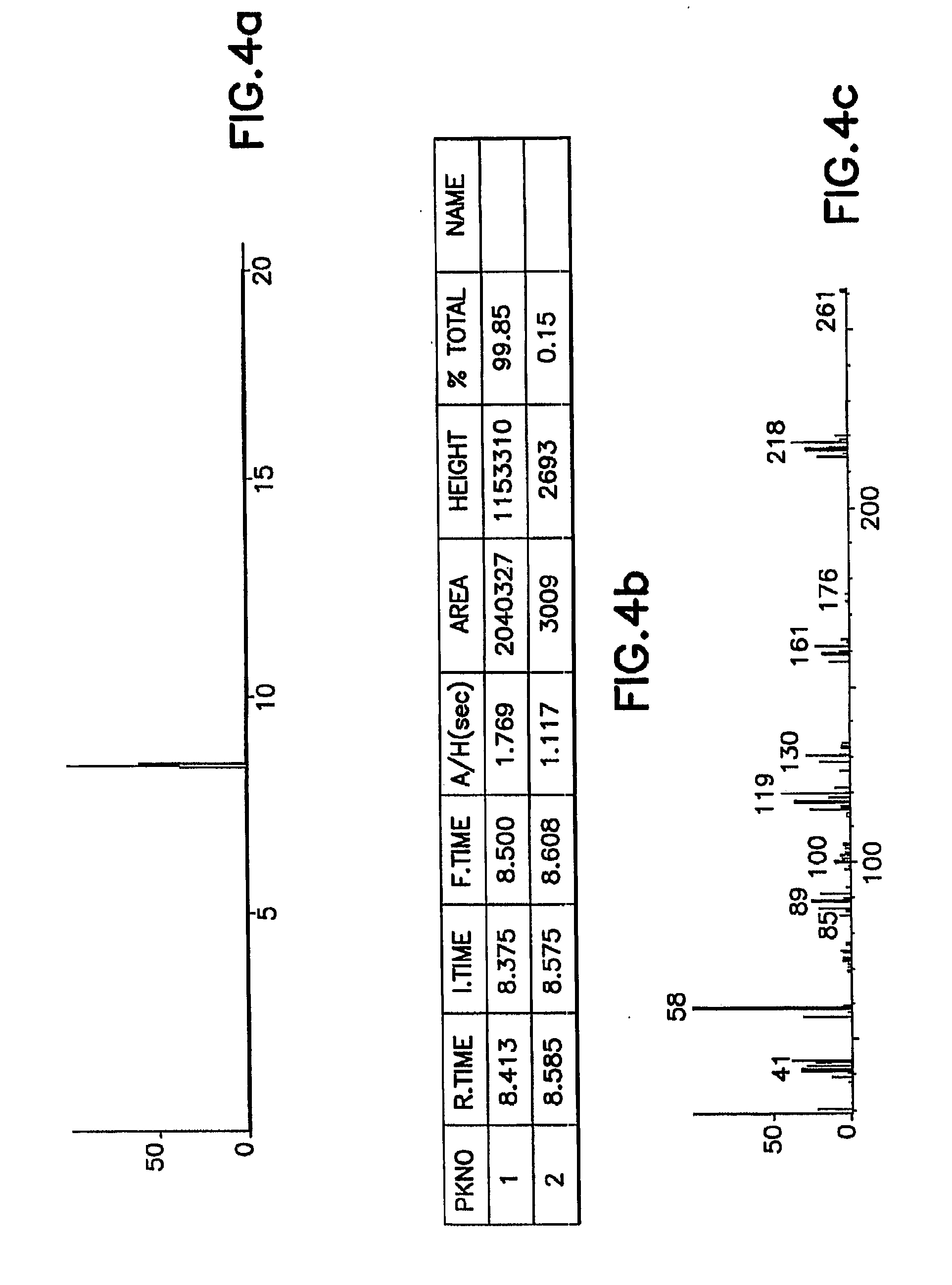

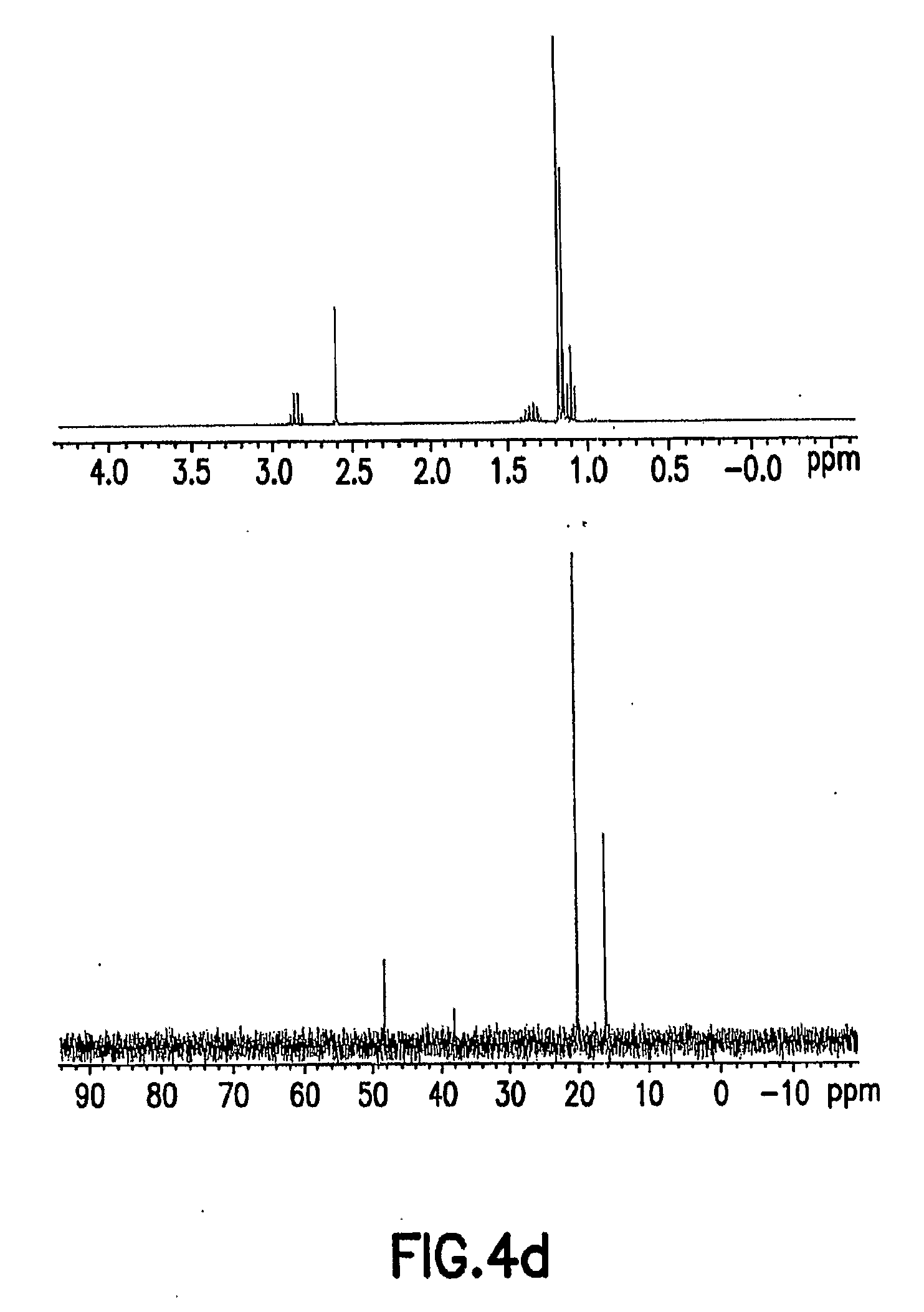

Antimony and germanium complexes useful for cvd/ald of metal thin films

ActiveUS20090305458A1Group 4/14 organic compounds without C-metal linkagesGermanium organic compoundsPhase-change memoryTe element

Antimony, germanium and tellurium precursors useful for CVD / ALD of corresponding metal-containing thin films are described, along with compositions including such precursors, methods of making such precursors, and films and microelectronic device products manufactured using such precursors, as well as corresponding manufacturing methods. The precursors of the invention are useful for forming germanium-antimony-tellurium (GST) films and microelectronic device products, such as phase change memory devices, including such films.

Owner:ENTEGRIS INC

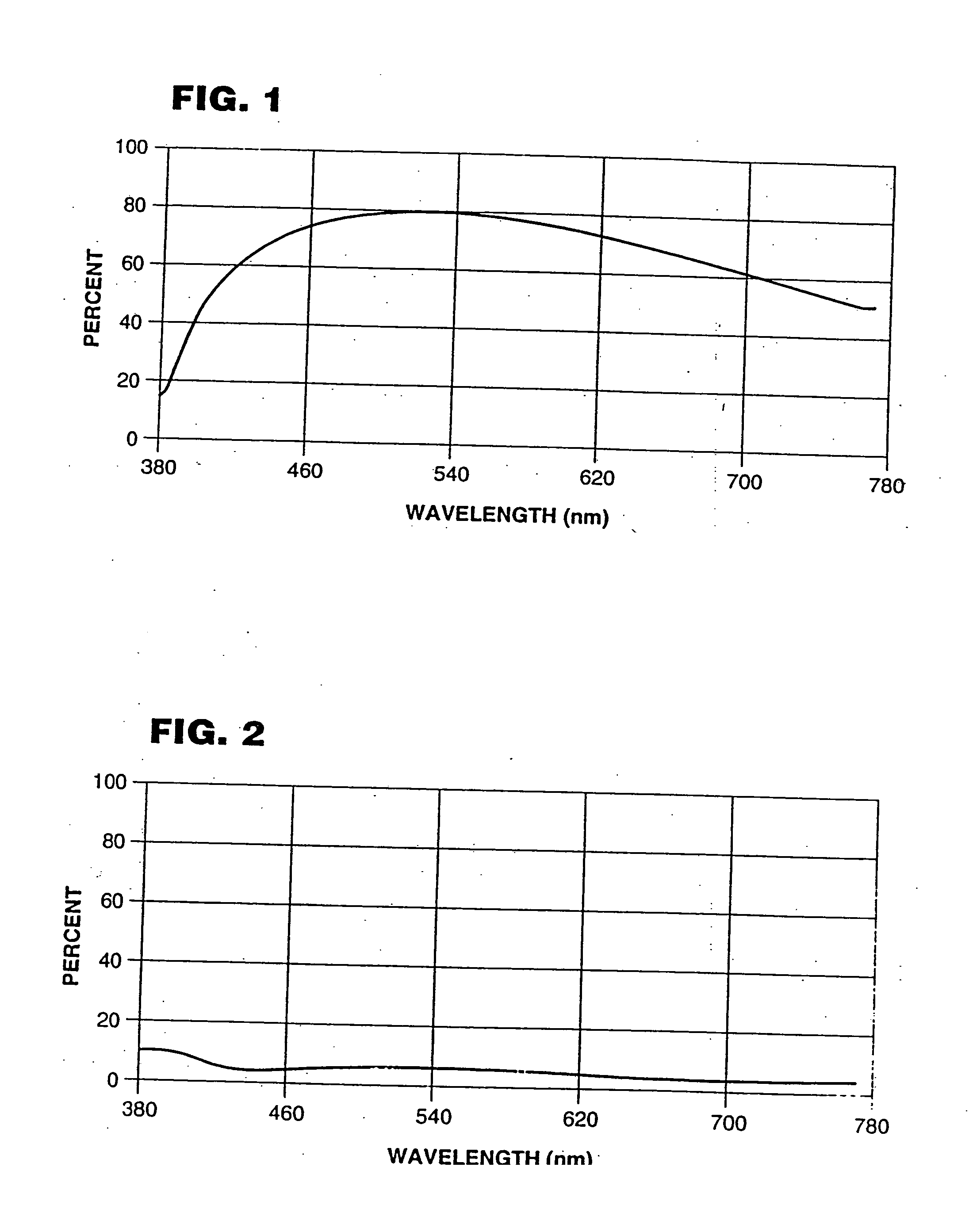

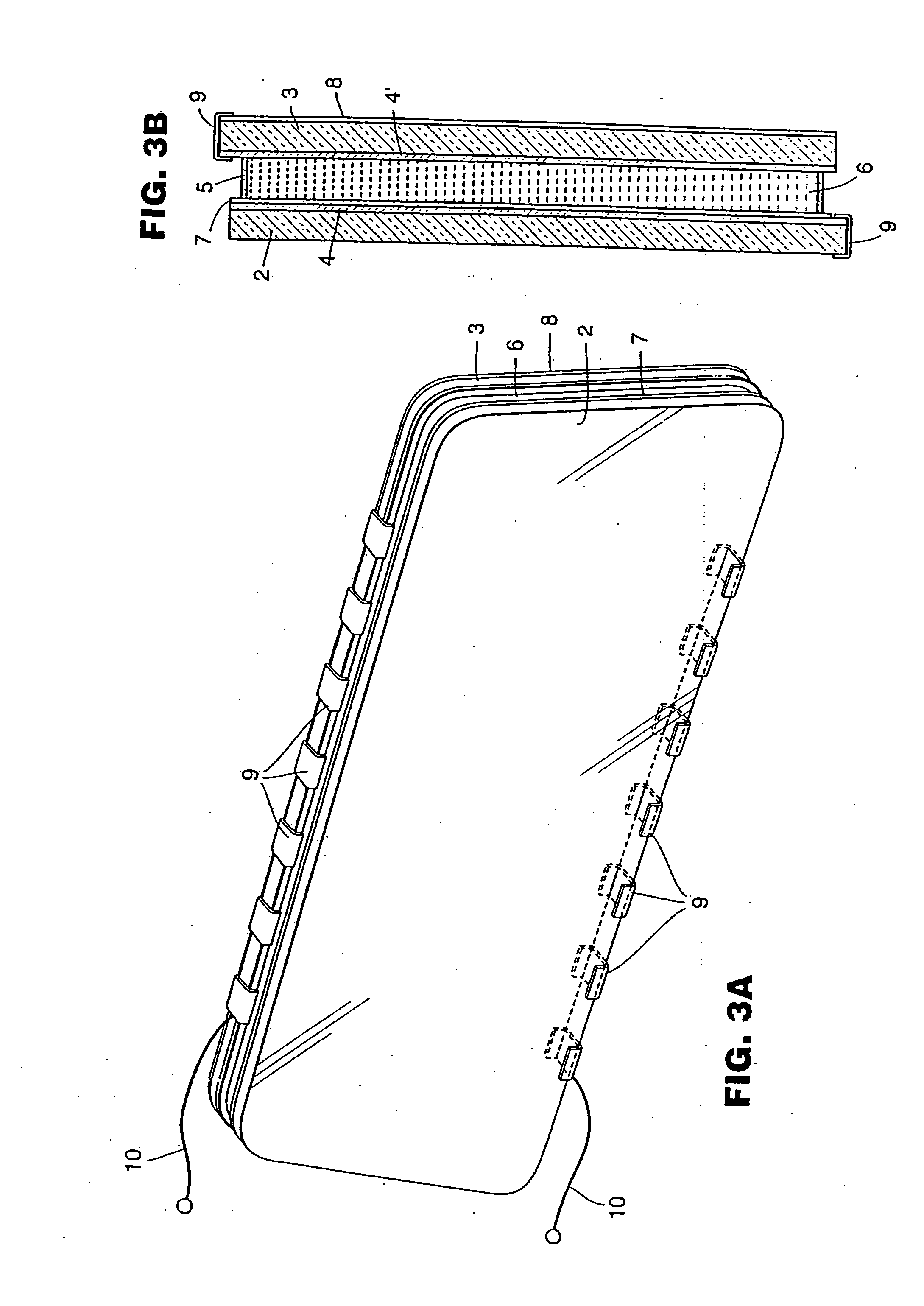

Signal mirror system for a vehicle

InactiveUS20070183066A1Reduce material costsGood optical performanceMirrorsAntiglare equipmentDisplay deviceLight reflectance

A signal mirror system for a vehicle includes a reflective mirror element comprising a semitransparent nondichroic mirror reflector coated onto a light-transmitting substrate. The visible light transmission through the reflective mirror element is in the range of from about 1% visible light transmission to about 30% visible light transmission and the visible light reflectance is in the range from 40% visible light reflectance to 80% visible light reflectance for visible light incident upon the front side of the reflective mirror element. The reflective mirror element exhibits substantial non-spectral selectivity in its reflectance. The semitransparent nondichroic reflector comprises a metal thin film layer. A turn signal display, preferably having at least one light emitting diode, is disposed to the rear of the reflective mirror element and configured so it emits light emitted that passes through the semitransparent mirror reflector to be viewed by a viewer viewing from the front of said reflective mirror element with a display luminance of at least about 30 foot lamberts.

Owner:DONNELLY CORP

Aluminum nitride thin film, composite film containing the same and piezoelectric thin film resonator using the same

ActiveUS20070080611A1Improve featuresHigh crystallinityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesRocking curveComposite film

A piezoelectric thin film resonator has a substrate and a piezoelectric layered structure including a lower electrode, piezoelectric aluminum nitride thin film with c-axis orientation and upper electrode formed on the substrate in this order. The lower electrode are made of a metal thin film including a layer containing ruthenium as a major component having a full-width half maximum (FWHM) of a rocking curve of a (0002) diffraction peak of ruthenium of 3.0° or less. The piezoelectric aluminum nitride thin film formed on the lower electrode has a full-width half maximum (FWHM) of a rocking curve of a (0002) diffraction peak of 2.0° or less.

Owner:MEMS SOLUTIONS INC

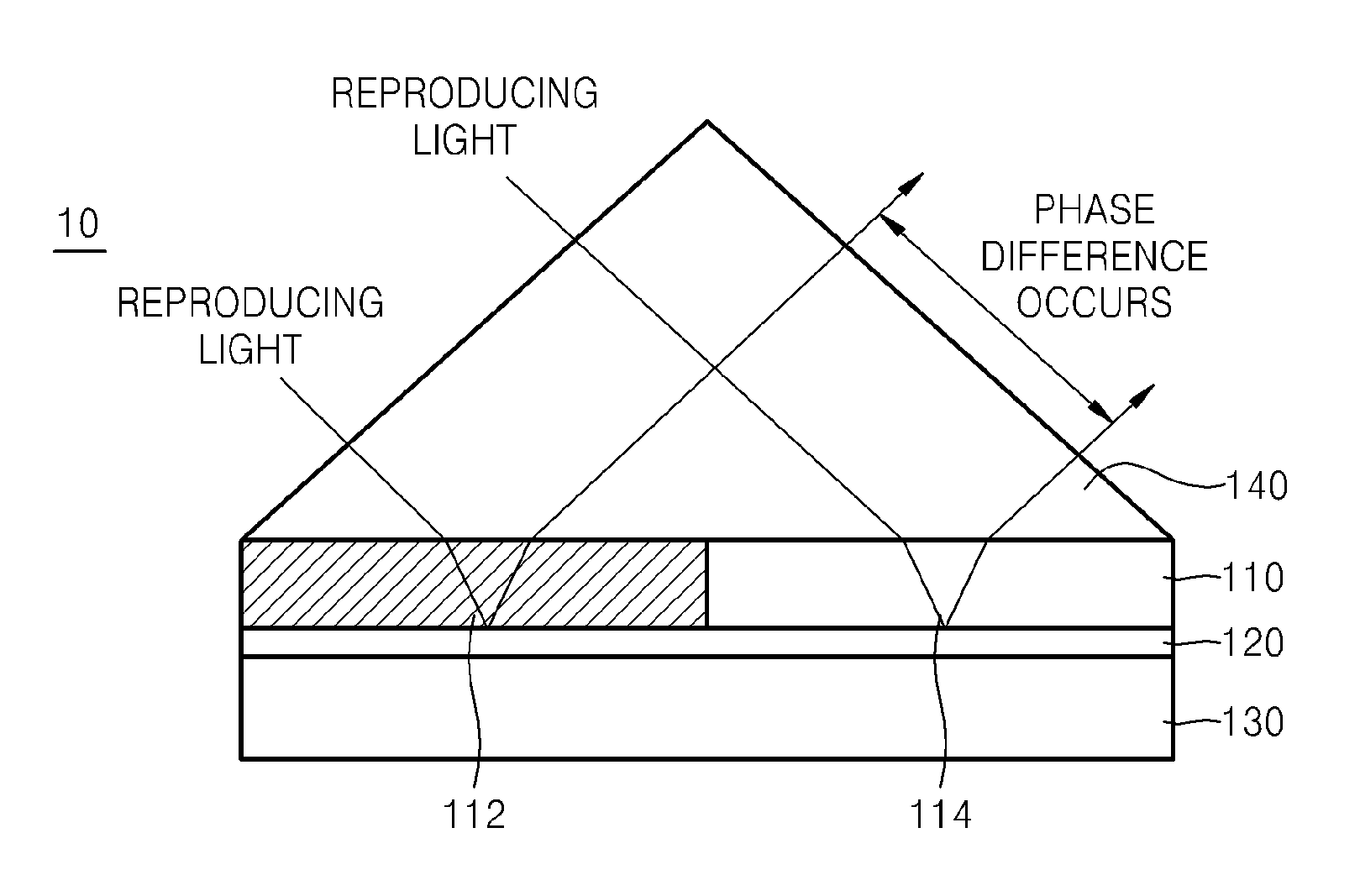

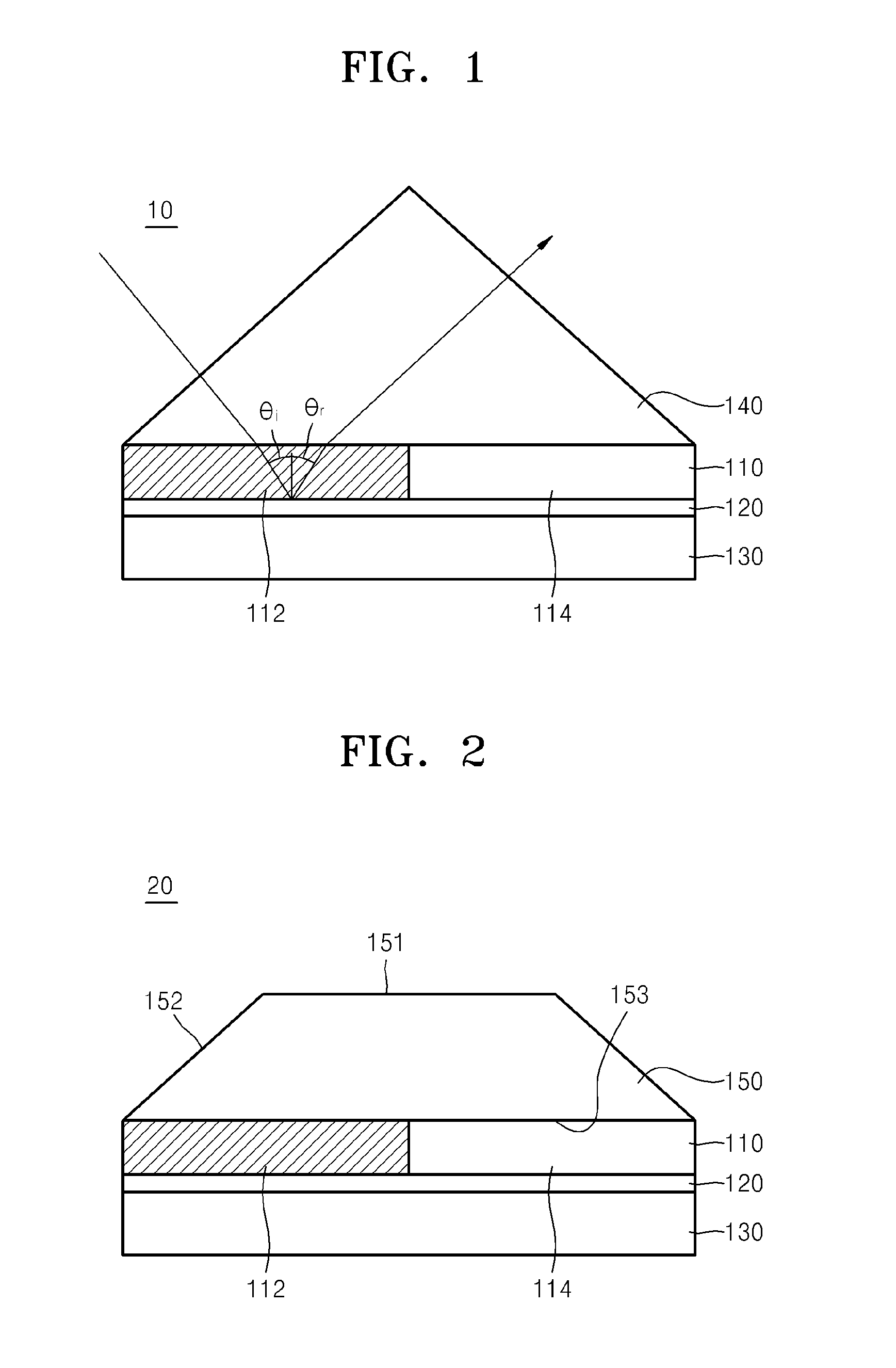

Spatial light modulators, holographic 3-dimensional display apparatuses including the spatial light modulators, and methods of modulating spatial light

ActiveUS20130094069A1Active addressable light modulatorNon-linear opticsSpatial light modulatorPhase difference

A spatial light modulator may include a refraction layer including first and second regions with refractive indices different from each other; and / or a metal thin film on a lower face of the refraction layer configured to generate surface plasmons due to light incident on the metal thin film via the refraction layer. When first light is incident on the refraction layer, a phase difference between light reflected by the first and second regions may occur. A spatial light modulator may include a metal thin film and a refraction layer on the metal thin film. The refraction layer may include a first region with a first refractive index and a second region with a second refractive index different from the first refractive index. When first light is incident on the refraction layer, there may be a phase difference between light reflected from the first and second regions.

Owner:SAMSUNG ELECTRONICS CO LTD

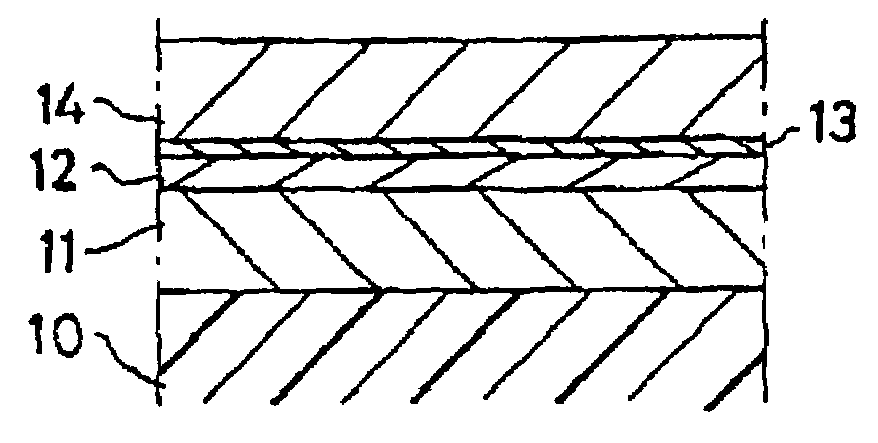

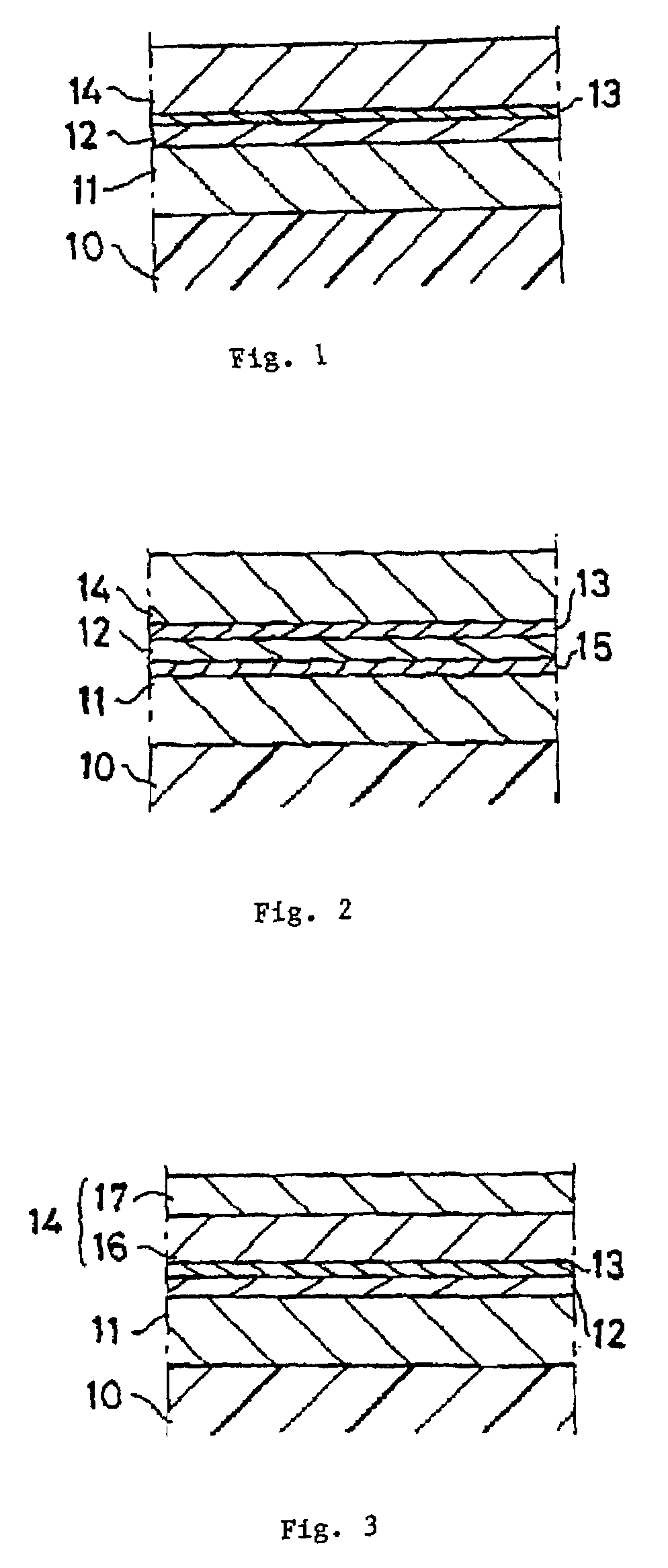

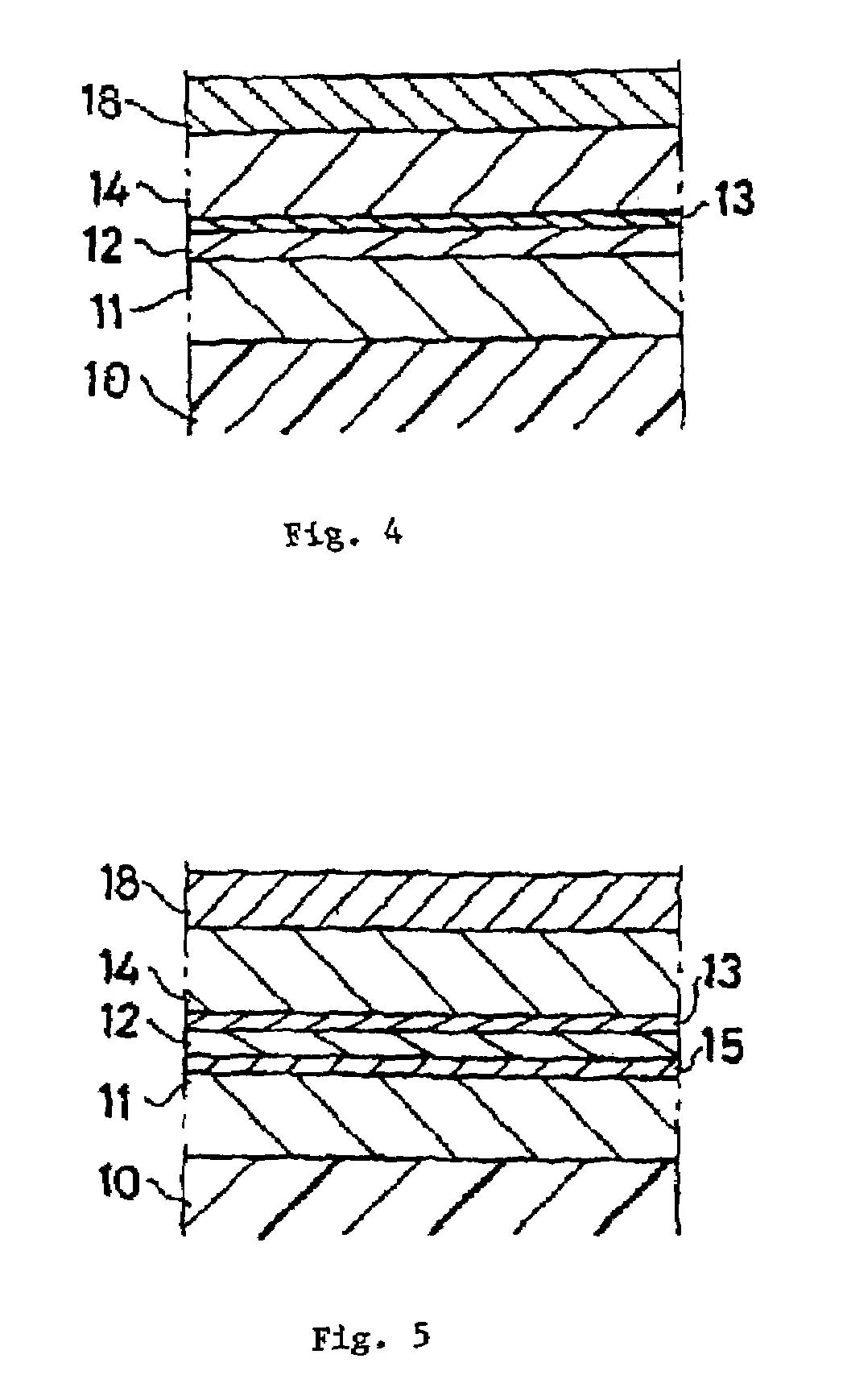

Multilayer thin film

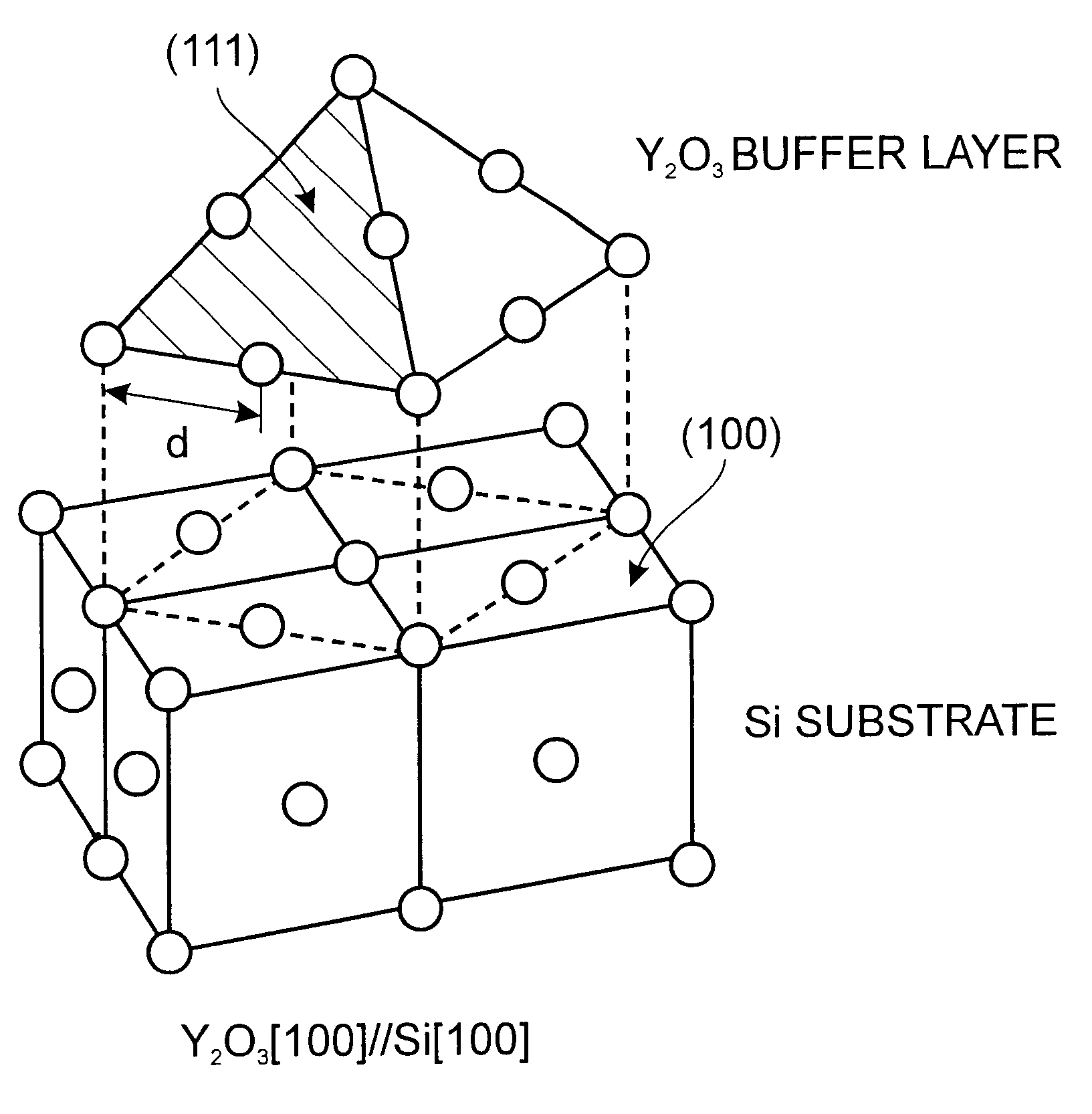

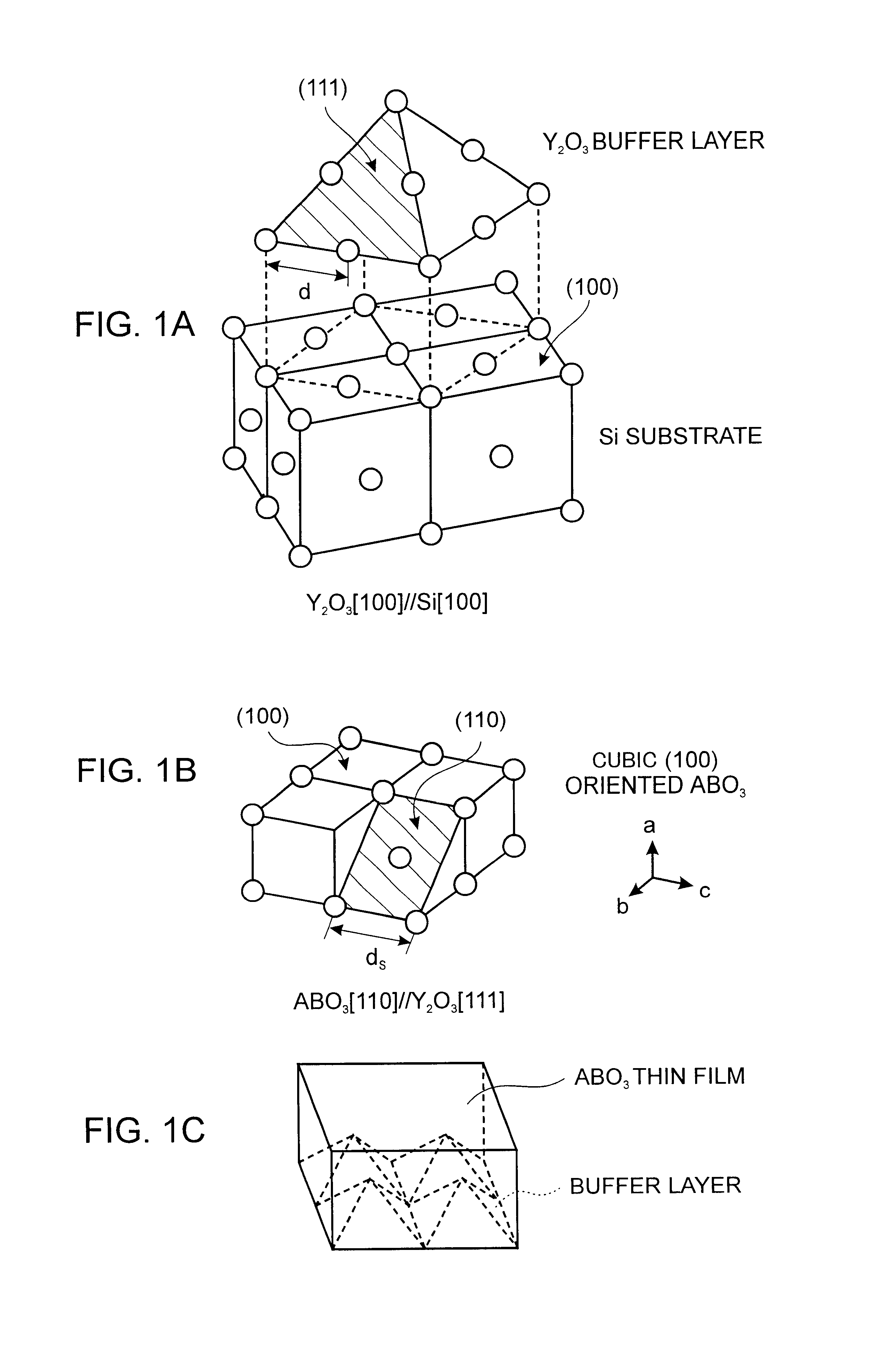

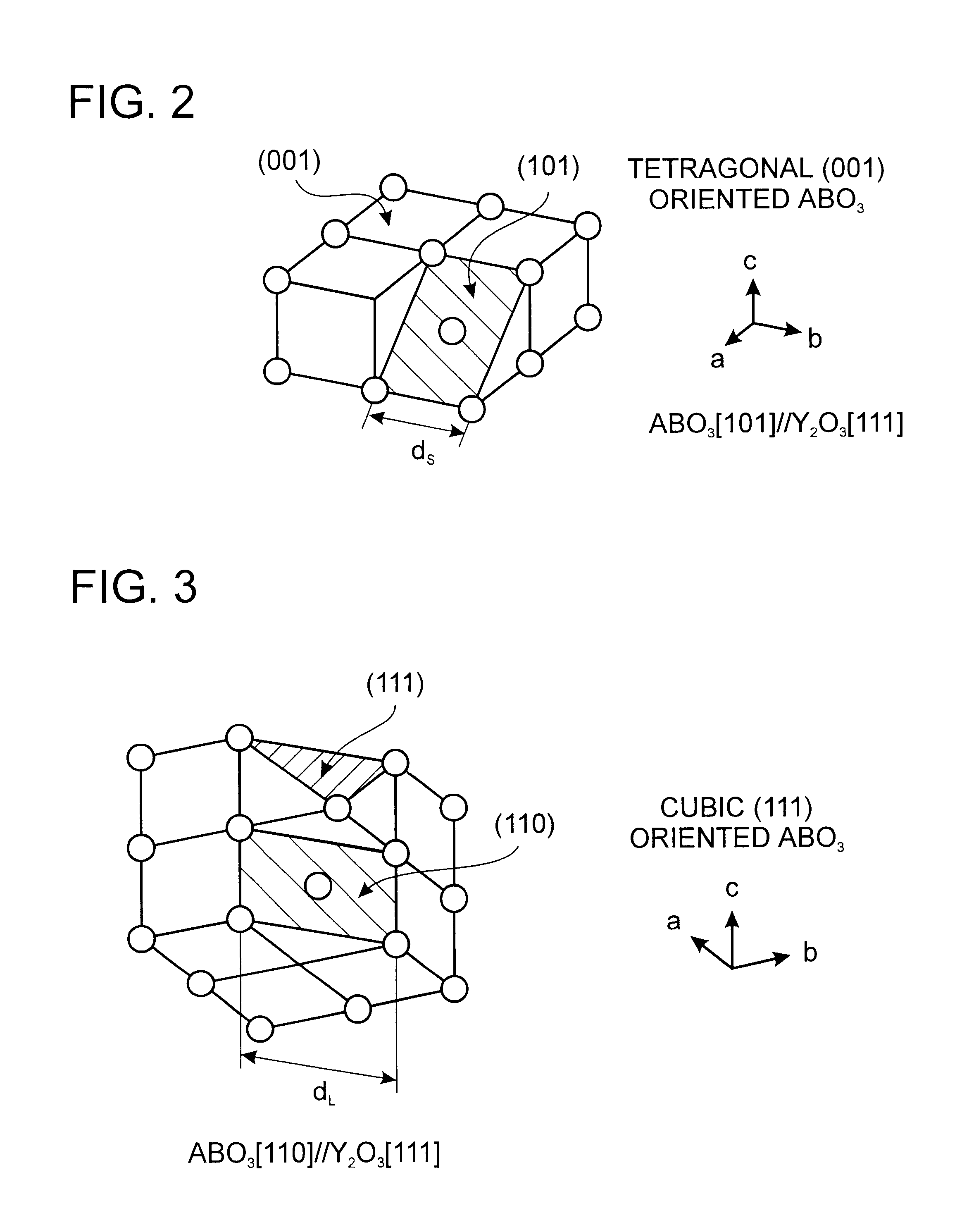

InactiveUS6258459B1High crystallinityIncrease the buffer functionSemiconductor/solid-state device detailsSolid-state devicesCrystallinityMaterials science

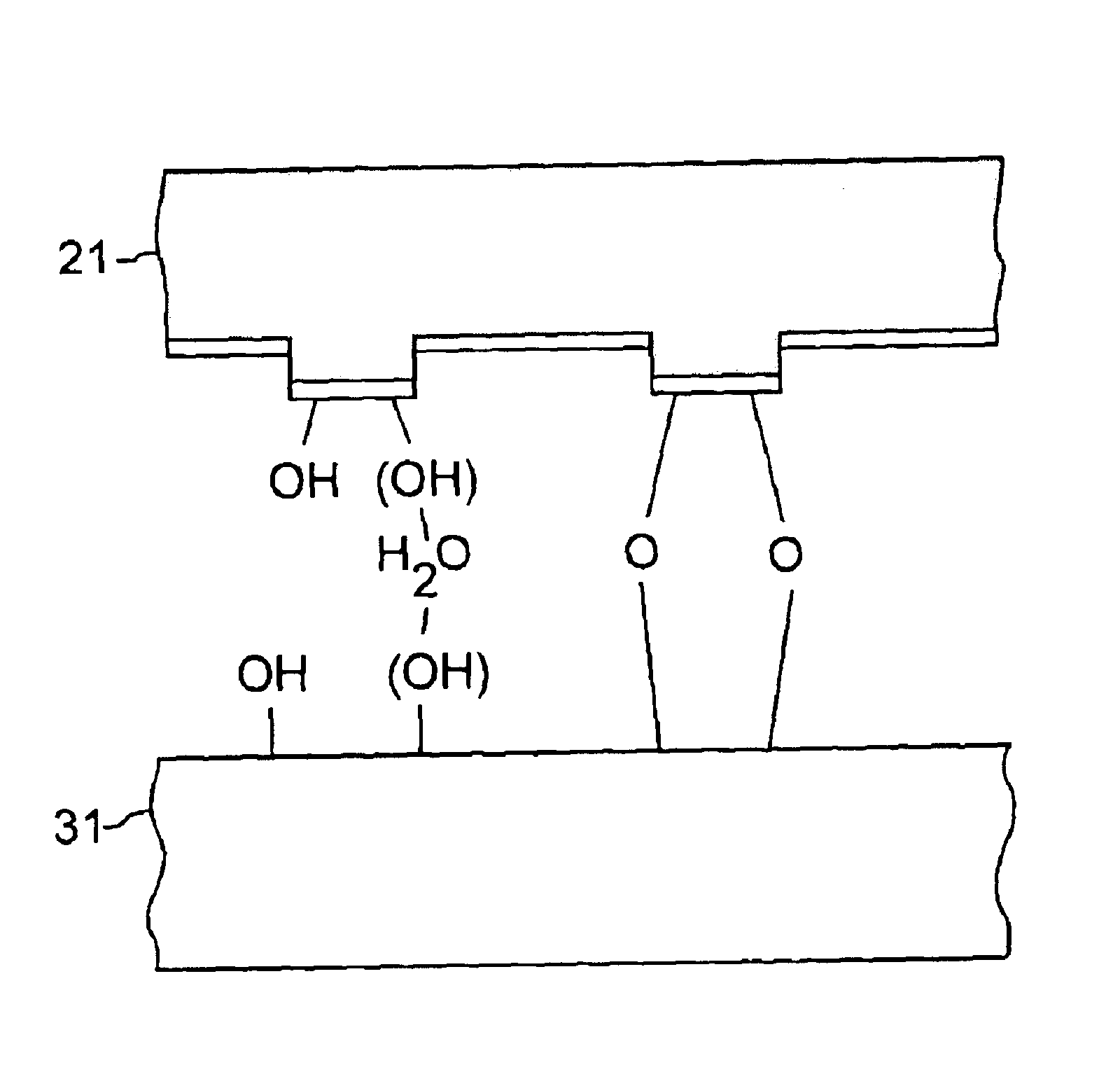

The first object of the invention is to provide means that enables a perovskite oxide thin film having (100) orientation, (001) orientation or (111) orientation to be easily obtained, and the second object of the invention is to provide a multilayer thin film comprising a unidirectionally oriented metal thin film of good crystallinity. The multilayer thin film according to the first embodiment of the invention comprises a buffer layer and a perovskite oxide thin film present thereon. The interface between the buffer layer and the perovskite oxide thin film is made up of a {111} facet plane. Substantially parallel to the facet plane there is present a {110} face of a cubic, rhombohedral, tetragonal or orthorhombic crystal of the perovskite oxide thin film, a {101} face of the tetragonal or orthorhombic crystal or a {011} face of the orthorhombic crystal. The multilayer thin film according to the second embodiment of the invention comprises a metal thin film that is a cubic (100) unidirectionally oriented epitaxial film, and a buffer layer where a {111} facet plane is present on the interface of the buffer layer in contact with the metal thin film.

Owner:SNAPTRACK

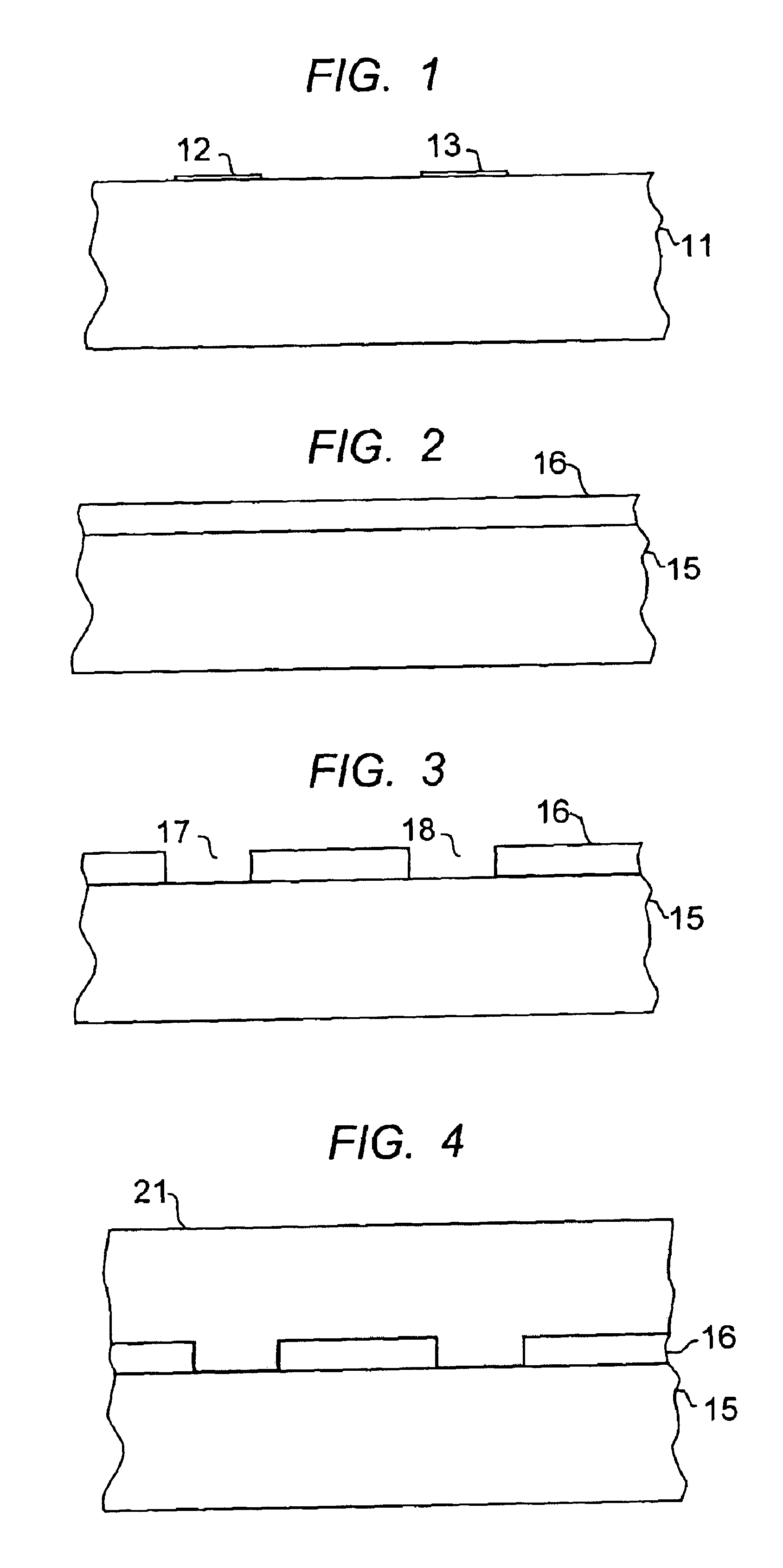

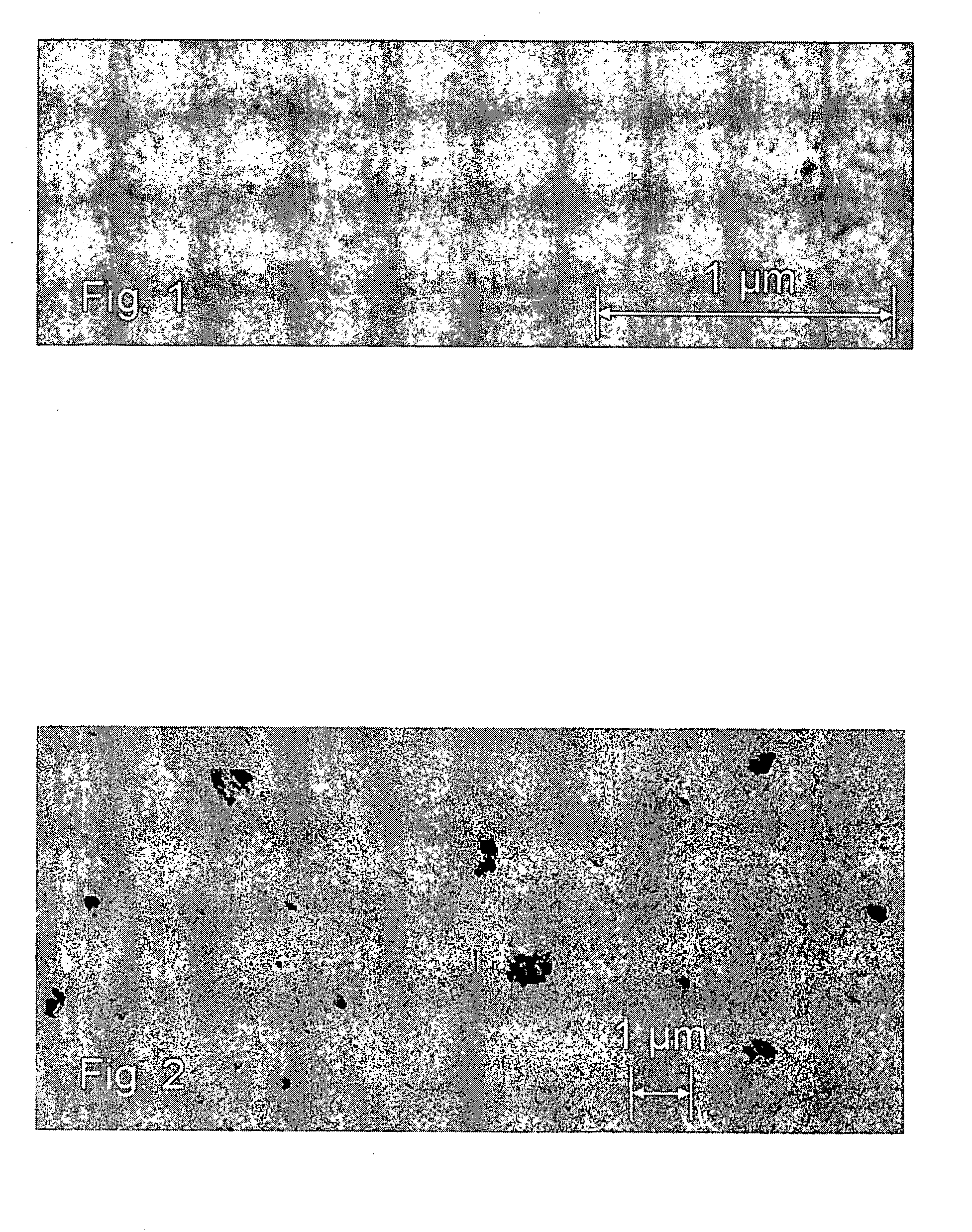

Forming nanoscale patterned thin film metal layers

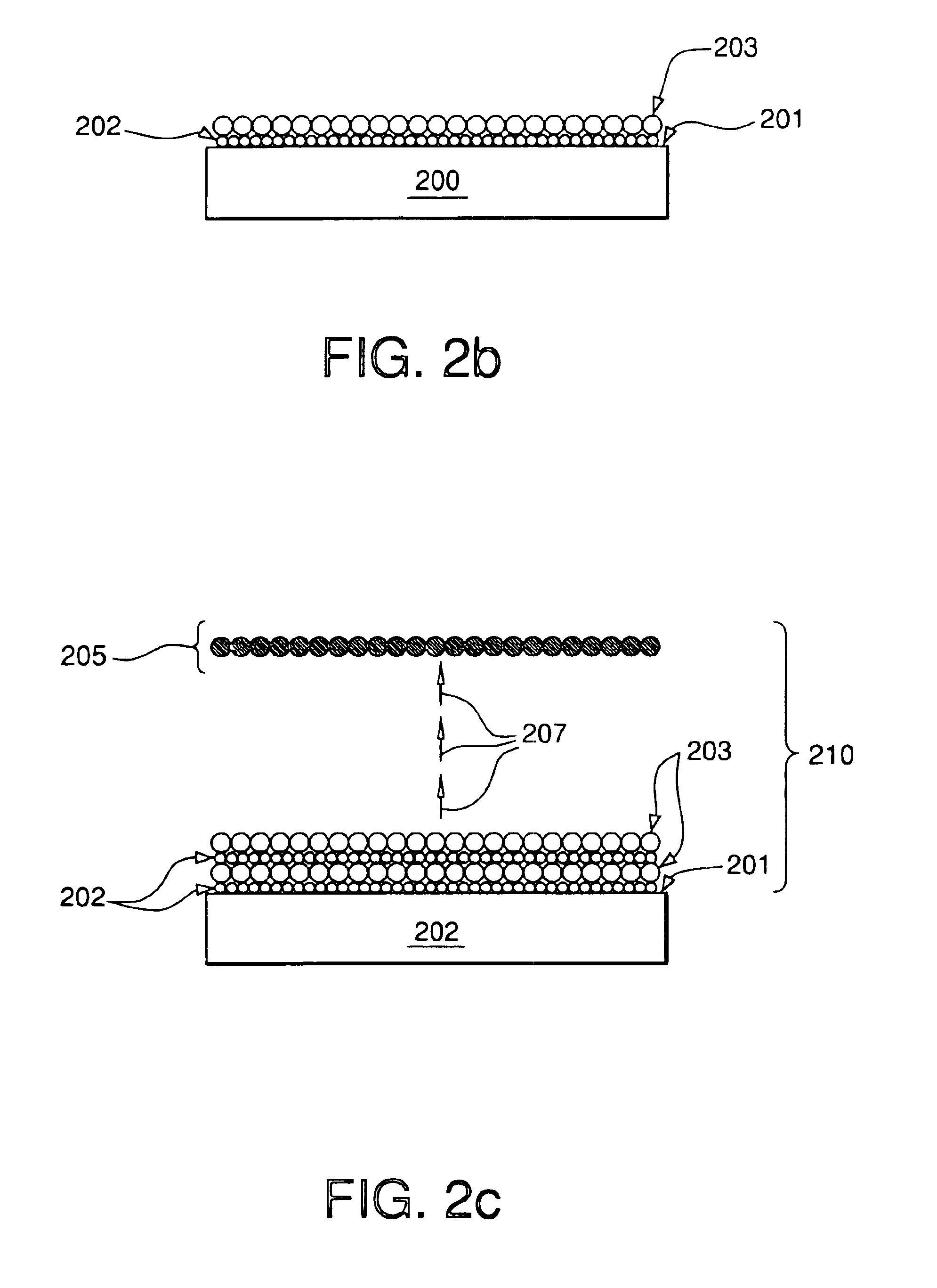

The specification describes a contact printing technique for forming patterns of thin films with nanometer resolution over large areas. The procedure, termed here “nanotransfer printing (nTP)”, relies on tailored surface chemistries for transferring thin films, typically metal films, from the raised regions of a stamp to a substrate when these two elements are brought into intimate physical contact. This technique is purely additive, it is fast (<15 s contact times), and the printing occurs in a single processing step at room temperature in open air. nTP is capable of producing patterns with a wide range of features with sizes down to ˜100 nm, and edge resolution better than 25 nm. Electrical contacts and interconnects have been fabricated for high performance organic thin film transistors (TFTs) and complementary inverter circuits, to demonstrate one of the many potential applications for nTP.

Owner:ALCATEL-LUCENT USA INC +1

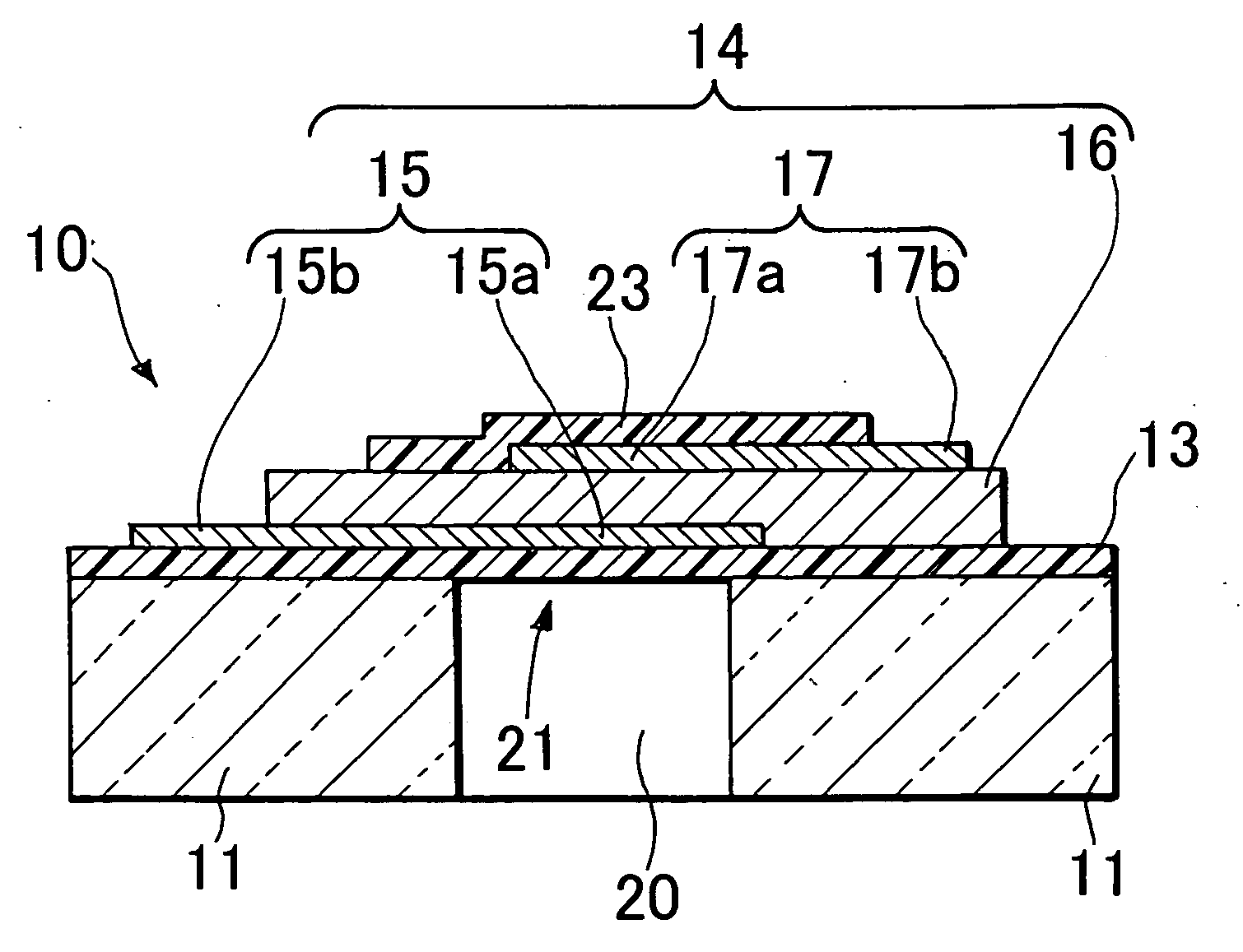

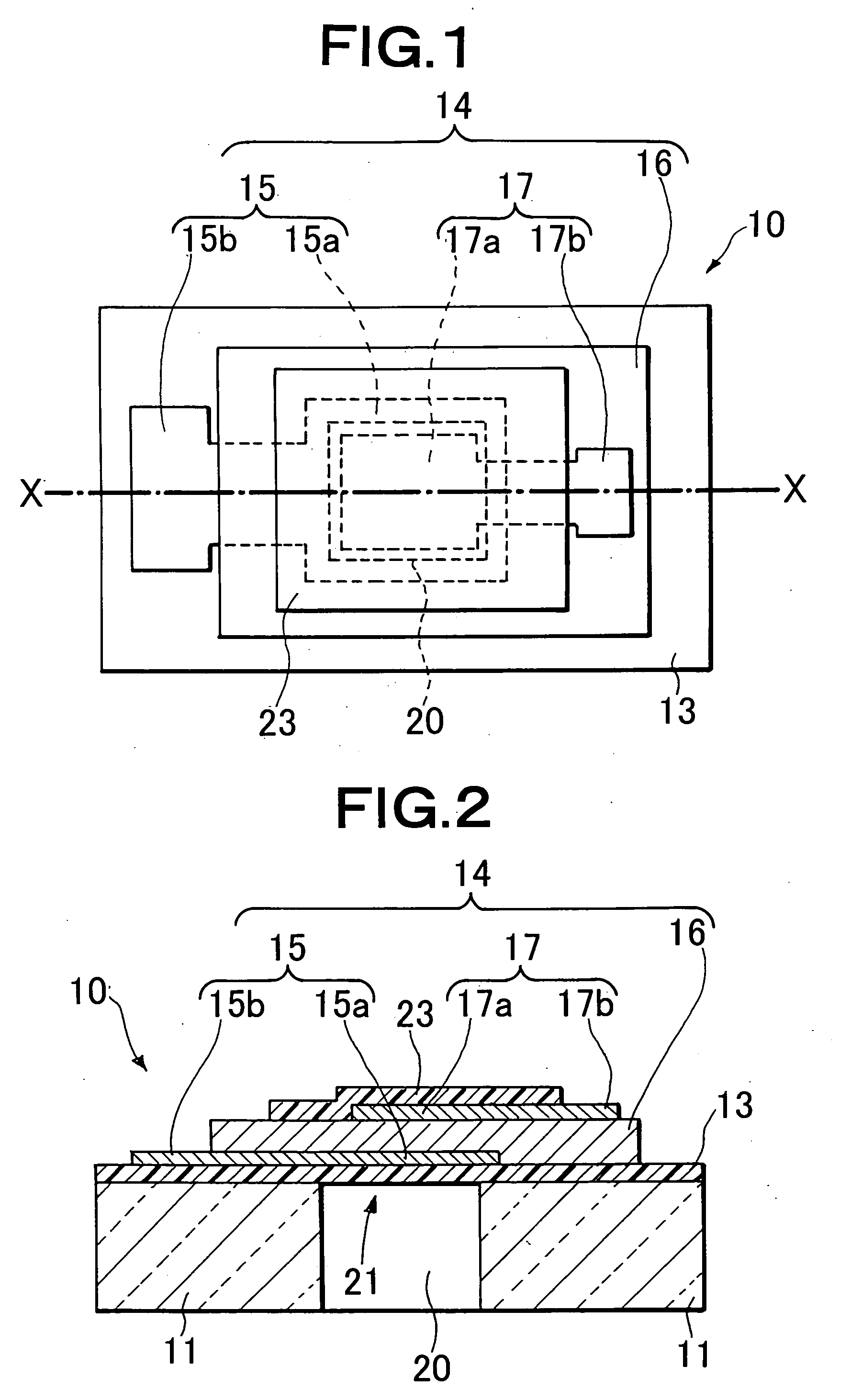

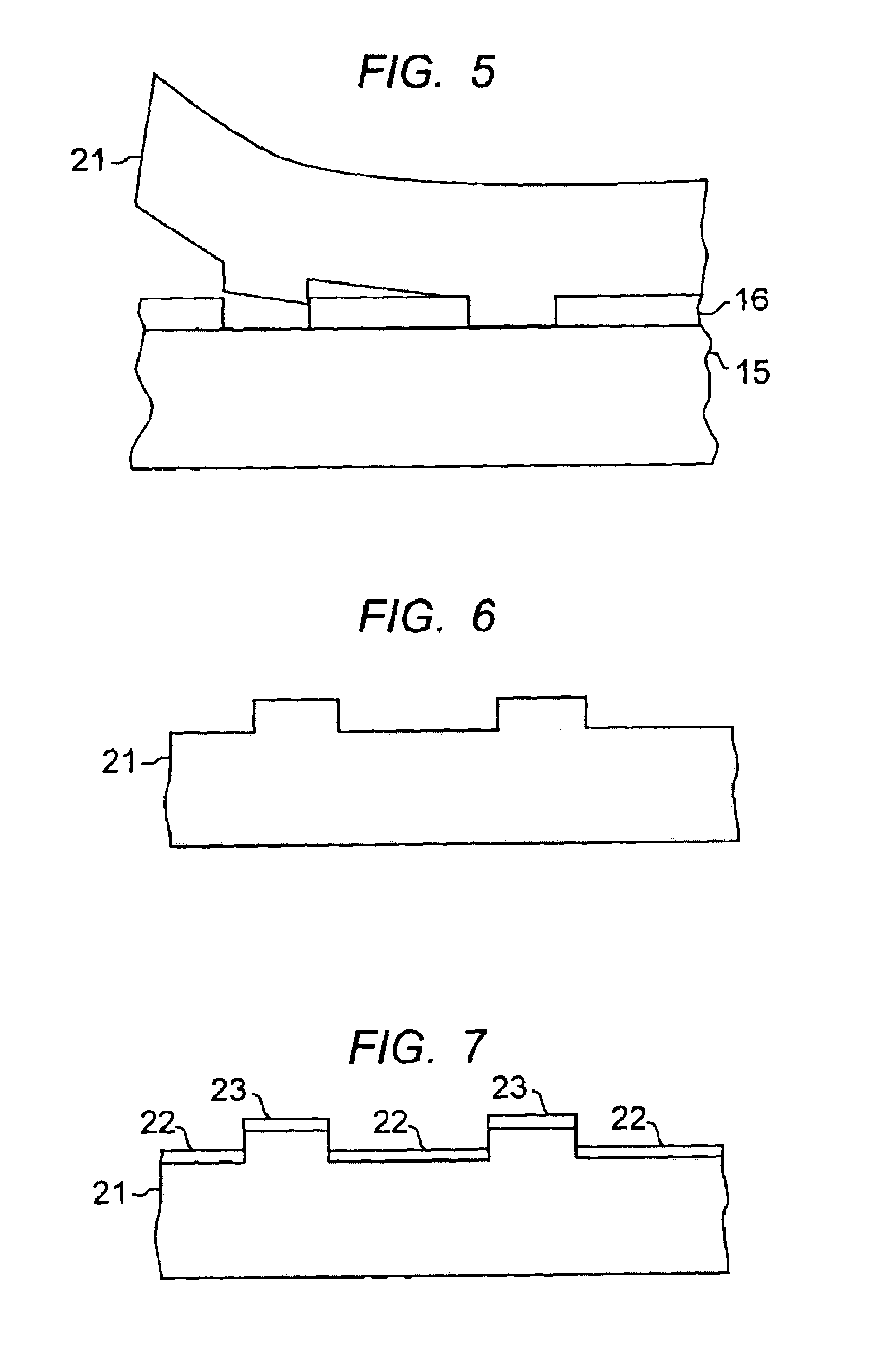

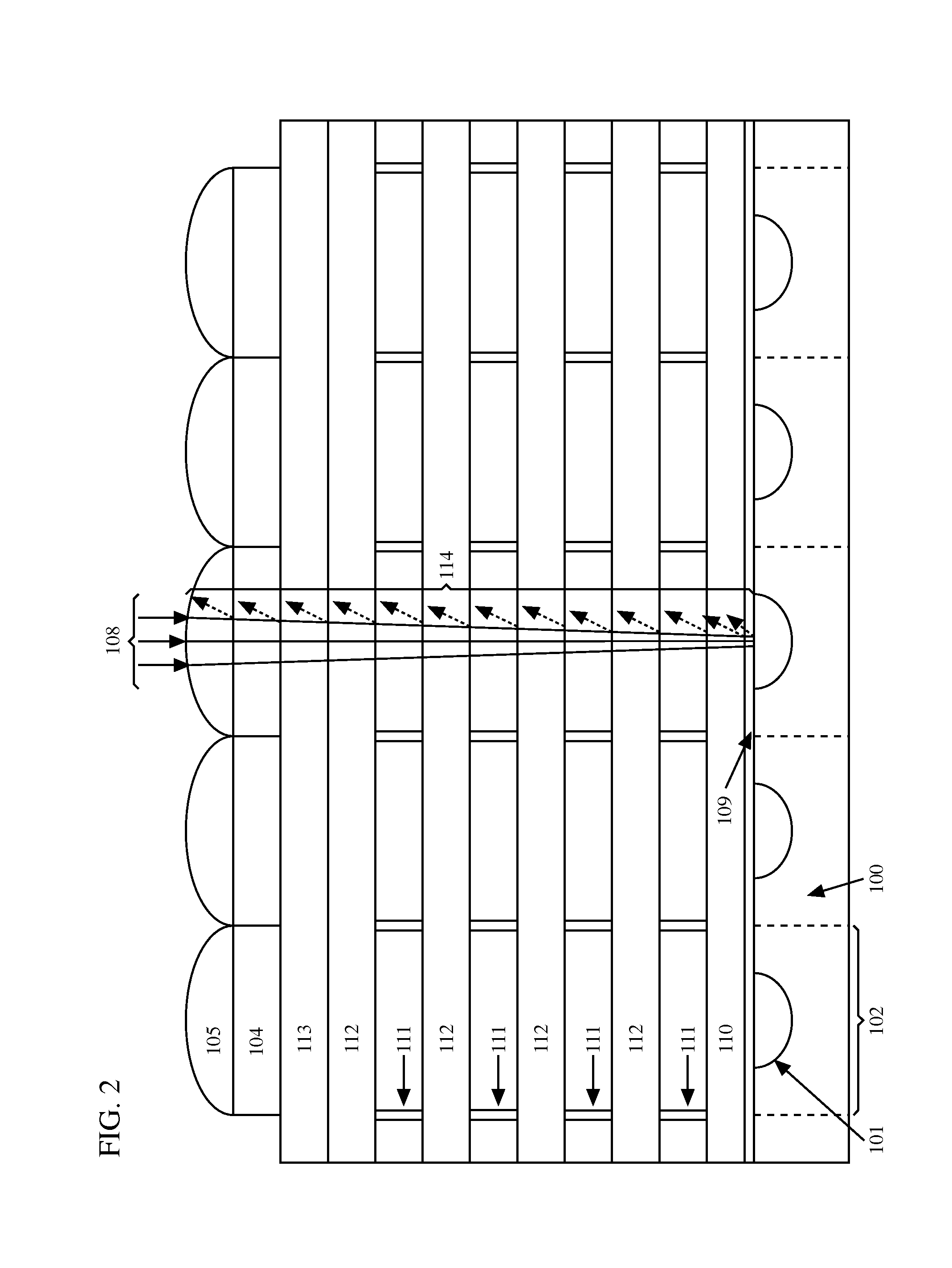

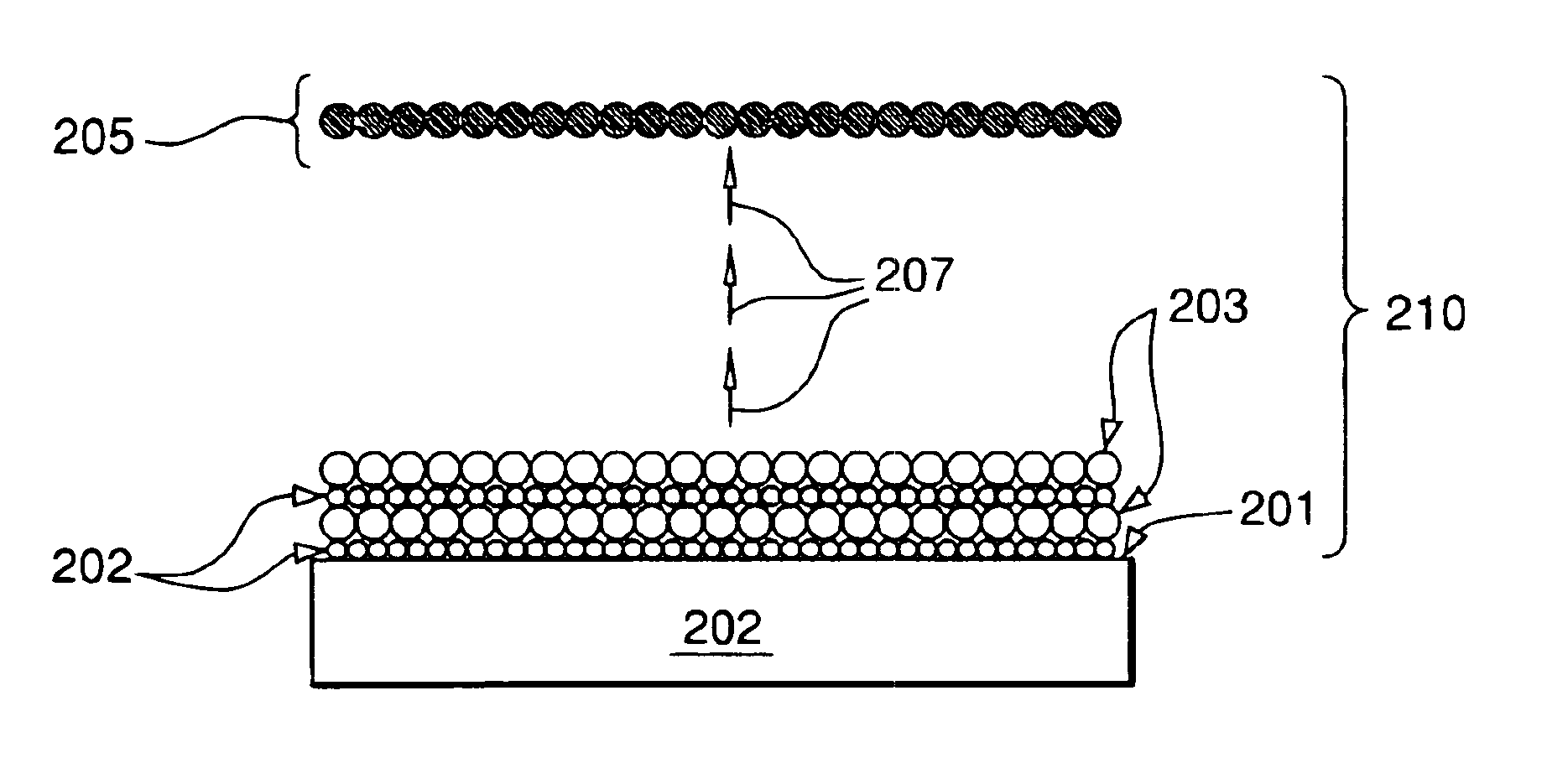

Photonic Via Waveguide for Pixel Arrays

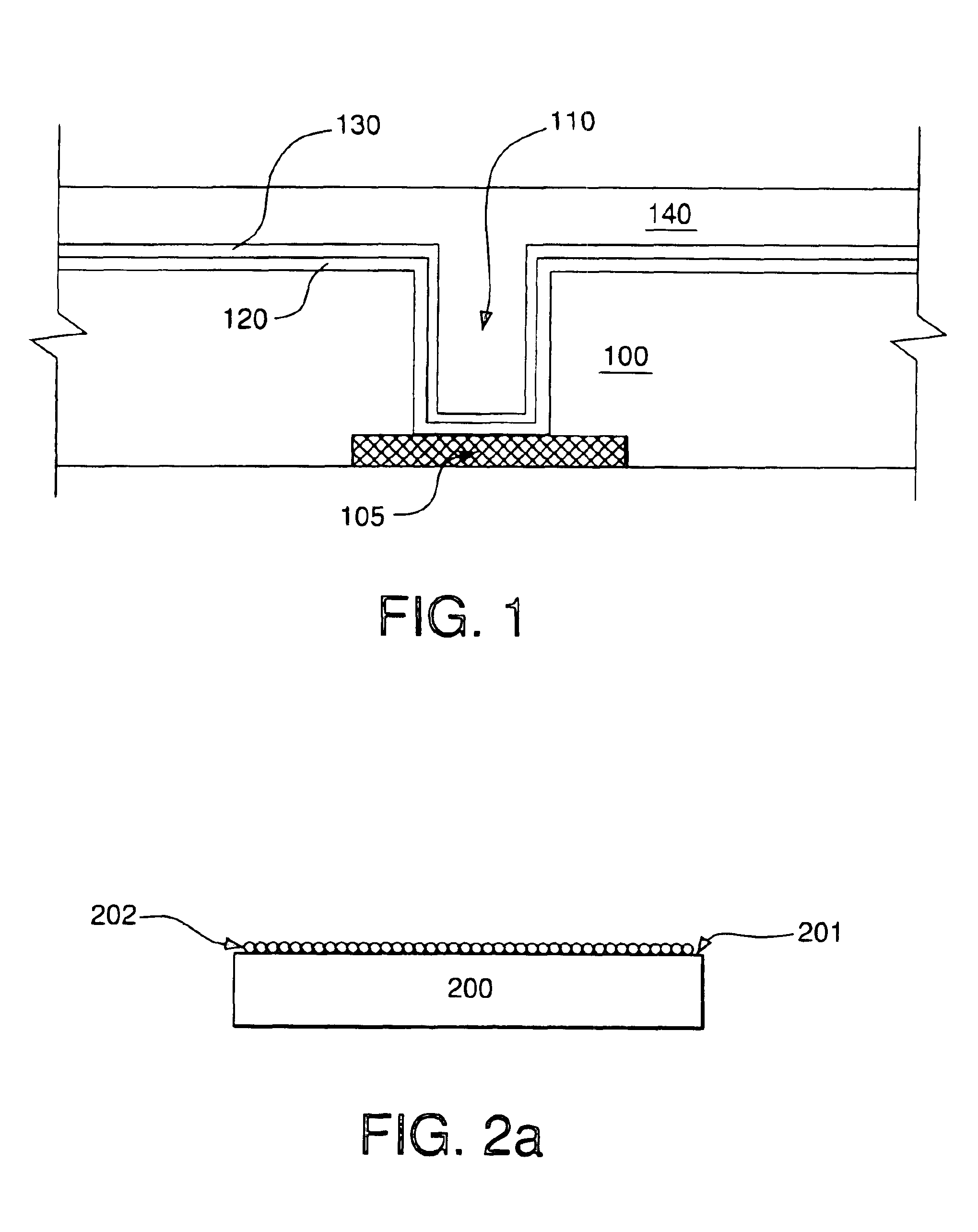

Photonic passive structure to couple and guide light between photonic active devices (101), such as photo-diodes, light emitting devices and light-valves, which may be arranged into 2D arrays, and the top of the metallization layer stack (110,111,112) interconnecting said devices, with said photonic passive structure comprising a hole (116) between the near surface of said photonic active Ndevices and the top of said metallization stack, said hole being filled with a dielectric (113) having embedded metal films (117) and in which the embedded metal thin films are connected to a planar perforated metal film (123,124) formed on top of the metallization stack.

Owner:QUANTUM SEMICON

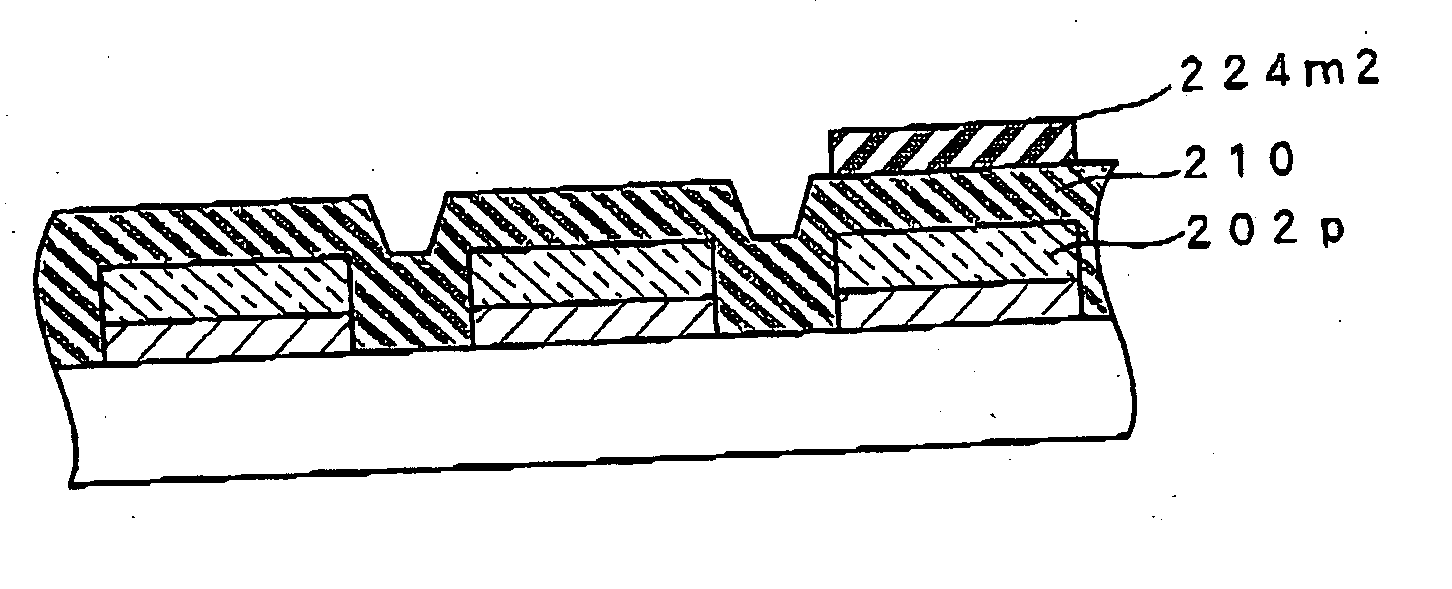

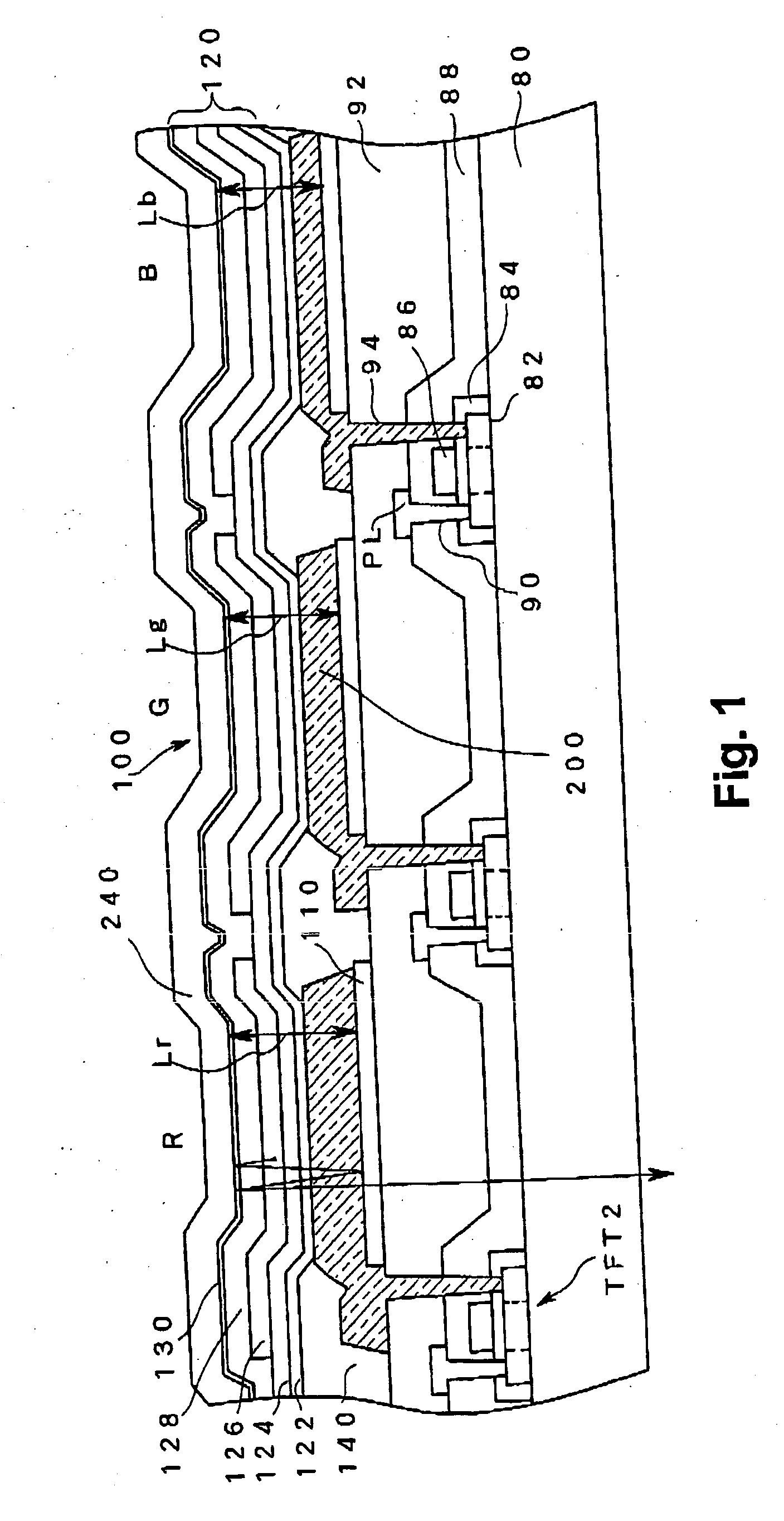

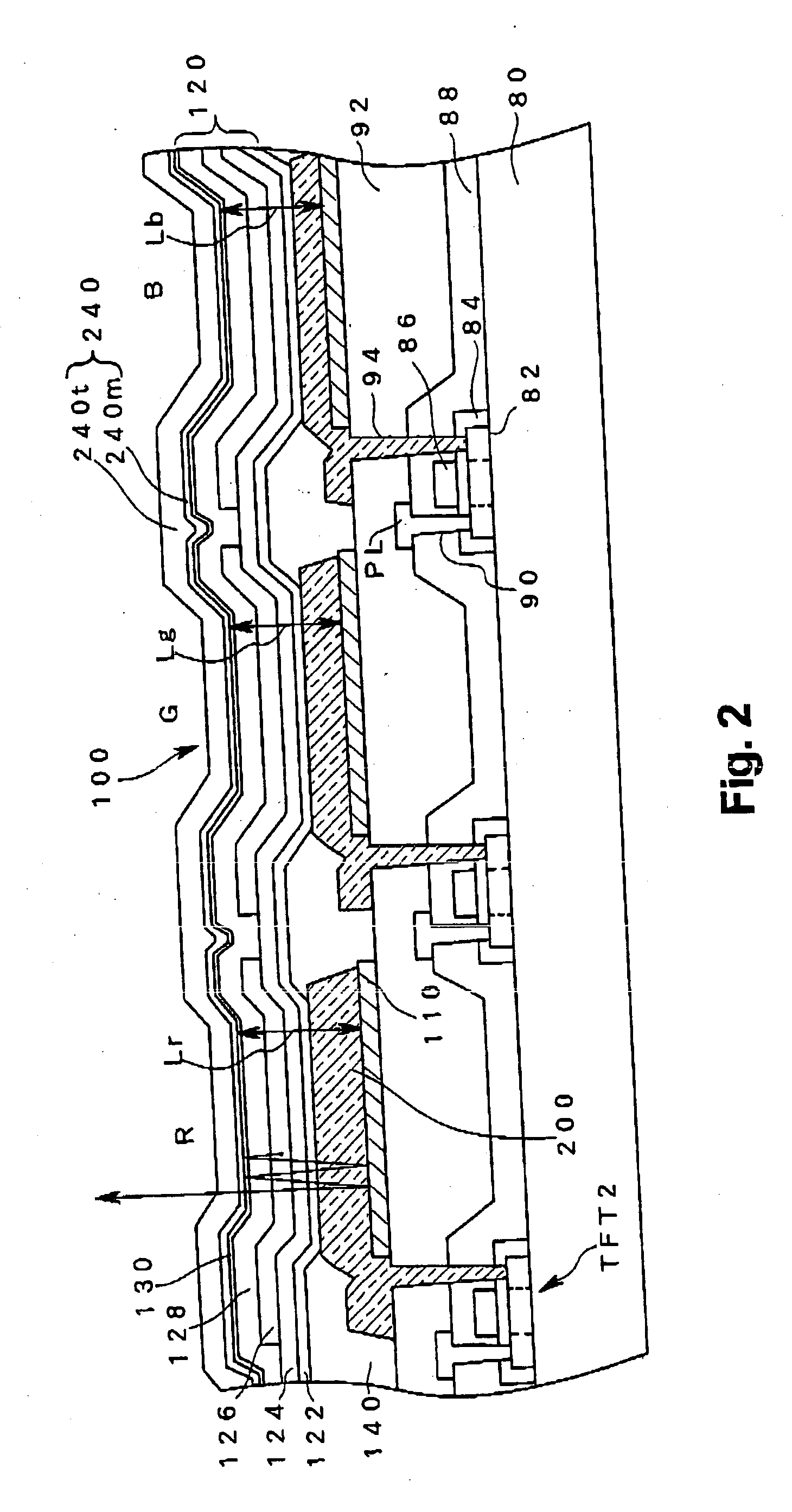

Method for manufacturing display device

ActiveUS20050142976A1Easily and accurately formedHigh positioning accuracyElectroluminescent light sourcesSolid-state devicesDisplay deviceLength wave

A display device having a plurality of pixels and which realizes a color display with emitted light of at least two wavelengths wherein each pixel has a microresonator structure between a lower reflective film formed on a side near a substrate and an upper reflective film formed above the lower reflective film with an organic light emitting element layer therebetween. The lower reflective film is made of a metal thin film and a conductive resonator spacer layer which functions as a first electrode is provided between the lower reflective film and the organic light emitting element layer. A thickness of the conductive resonator spacer layer is changed by changing a number of layers or a number of remaining layers of transparent conductive metal oxide layers made of ITO corresponding to pixels of different light emission wavelengths. An amorphous ITO layer at an upper layer is selectively removed from above a polycrystalline ITO layer at a lower layer using the polycrystalline ITO layer as an etching stopper so that the thickness is changed corresponding to the thickness of the ITO layer to be formed and not removed. Light obtained in the organic light emitting element layer is intensified by the microresonator structure in which the optical length is adjusted by the conductive resonator spacer layer and is emitted to the outside.

Owner:SANYO ELECTRIC CO LTD

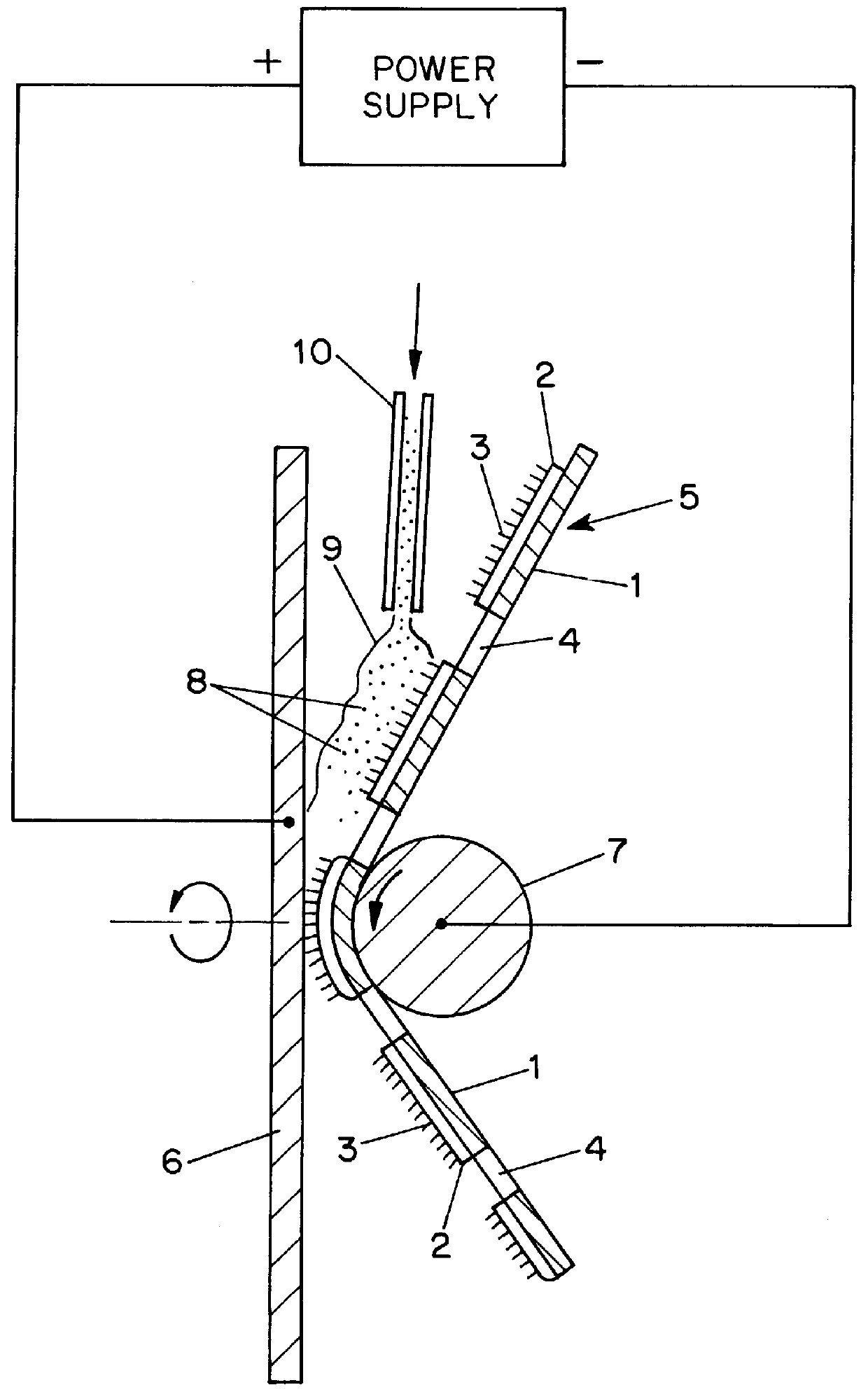

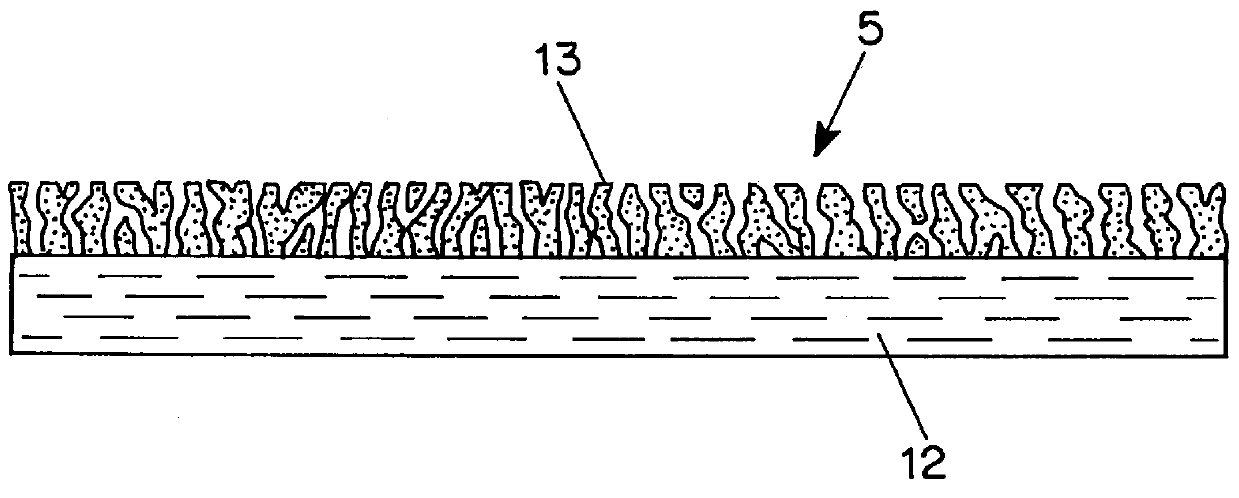

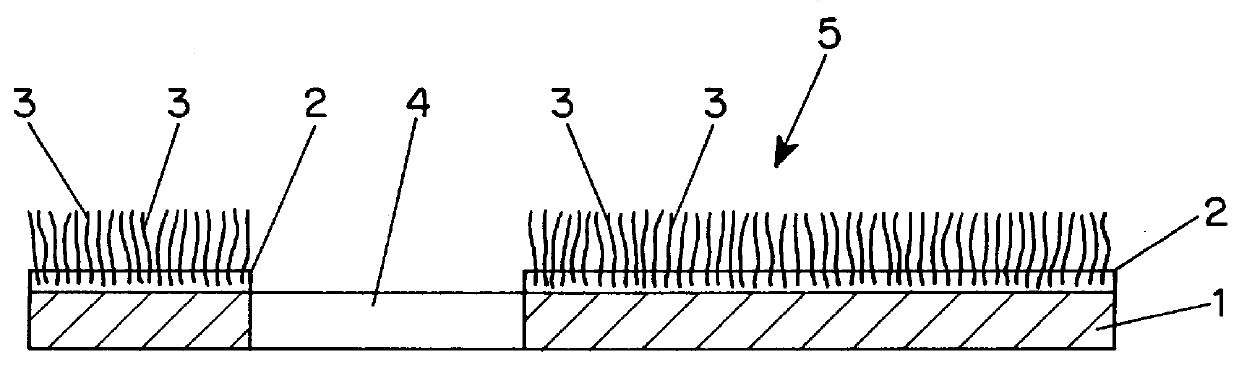

Combination electrolytic polishing and abrasive super-finishing method

InactiveUS6074284AHigh surface finishEfficient supplyBelt grinding machinesAbrasion apparatusFiberElectrolytic agent

An abrasive super-finishing method for workpieces, such as metallic thin-film magnetic discs, employs a polishing / texturing material having a backing, such as synthetic resin film or woven material or non-woven cloth, and a layer which can hold abrasive grains on the backing, such as flocked fibre or a porous polymer foam, on one surface of the backing. An electrolytic solution in which abrasive grains are suspended is supplied to the polishing / texturing material to conduct polishing or texturing of the workpiece surfaces. The workpiece is connected to an anode and a pressure roller or a cathode bar is connected to a cathode. A voltage is applied between the workpiece and the pressure roller or cathode bar to conduct simultaneously electrolytic polishing and abrasive polishing / texturing.

Owner:UNIQUE TECH INT PTE

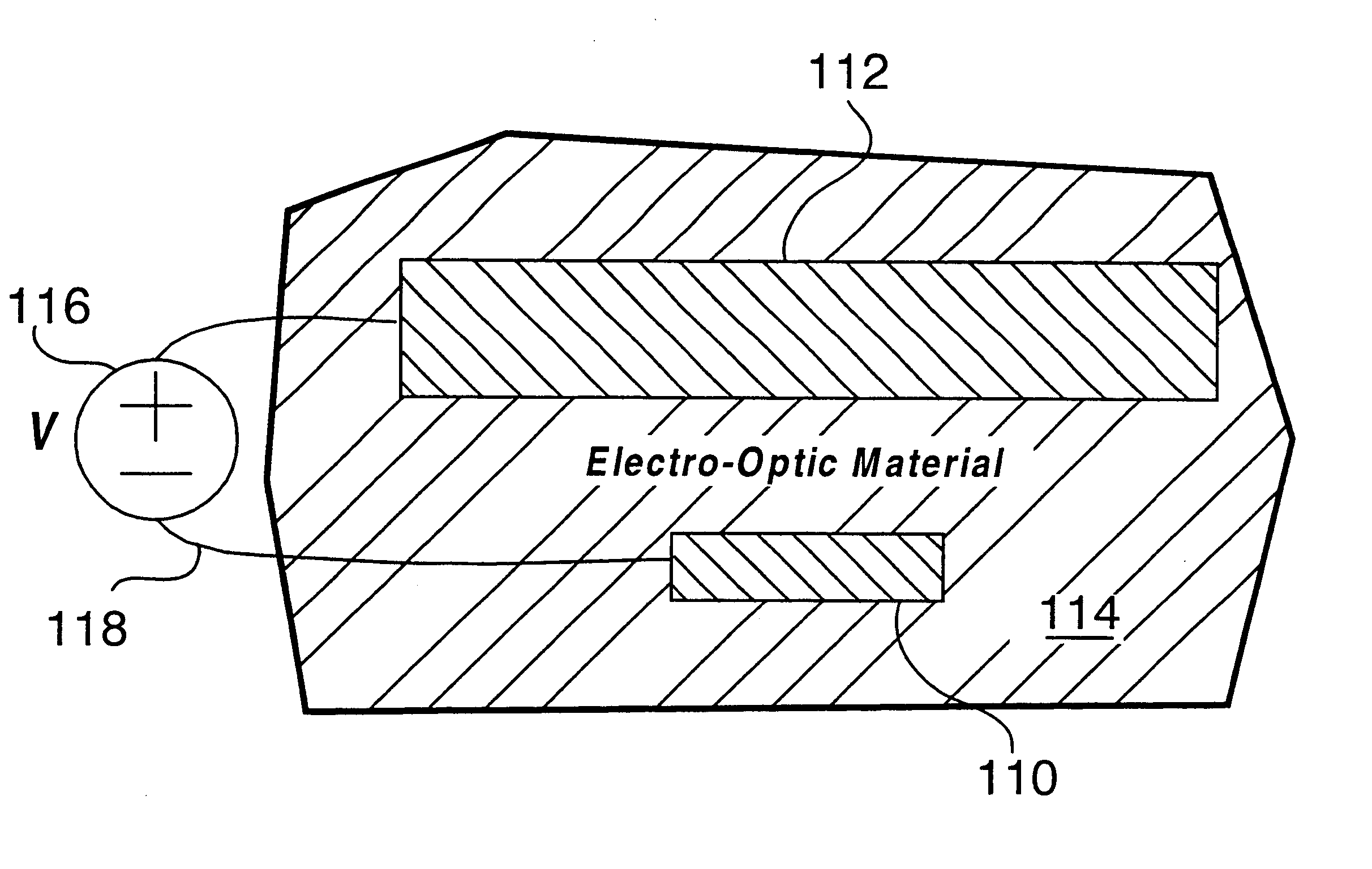

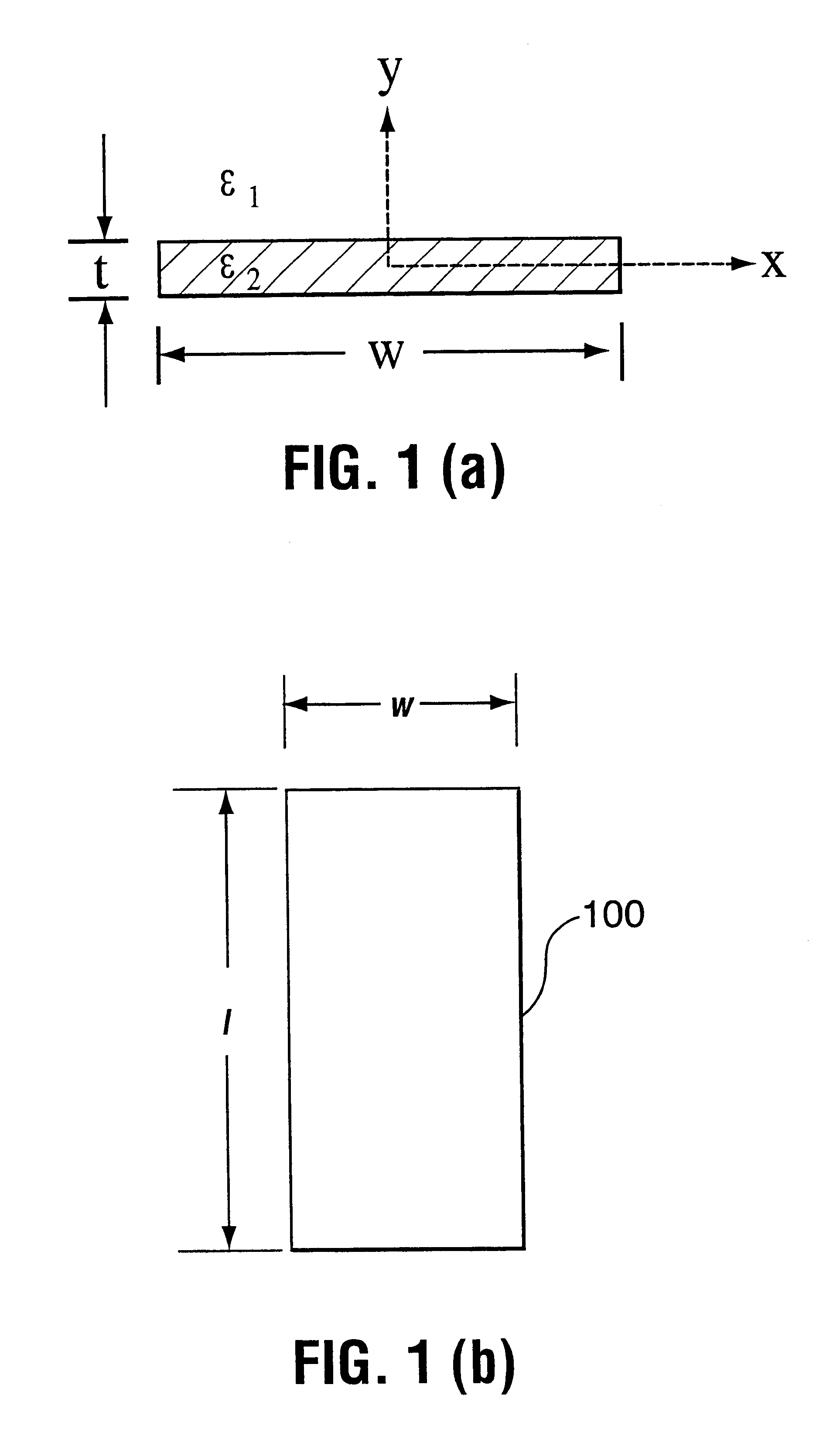

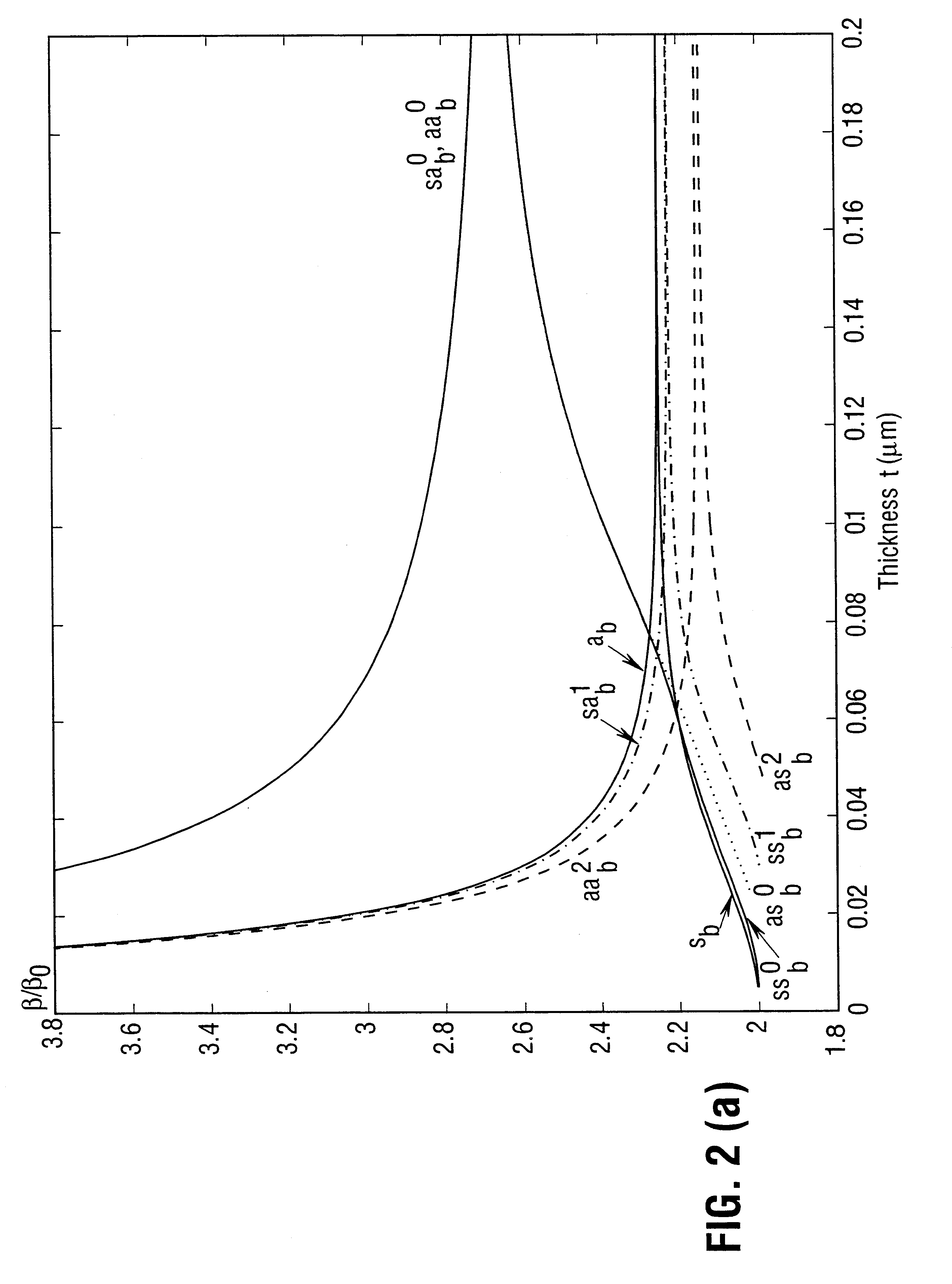

Optical waveguide structures

InactiveUS6614960B2Optical resonator shape and constructionRecord information storageUltrasound attenuationElectricity

Waveguide structures comprising a thin lossy metal film of finite width embedded in an infinite homogeneous dielectric support purely bound electromagnetic modes of propagation low mode power attenuation in the neighbourhood of 10 to 0.1 dB / cm is achievable at optical communications wavelengths, with even lower values being possible. Carefully selecting the film's thickness and width can make this mode the only long-ranging one supported. In addition, the mode can have a field distribution that renders it excitable using an end-fire approach. The finite-width metal film waveguide may be used for applications requiring short propagation distances and 2-D field confinement in the transverse plane, enabling various devices to be constructed, such as couplers, splitters, modulators, interferometers, switches and periodic structures. Under certain conditions, an asymmetric structure can support a long-ranging mode having a field distribution that is suitable to excitation using an end-fire technique.

Owner:UNIVERSITY OF OTTAWA

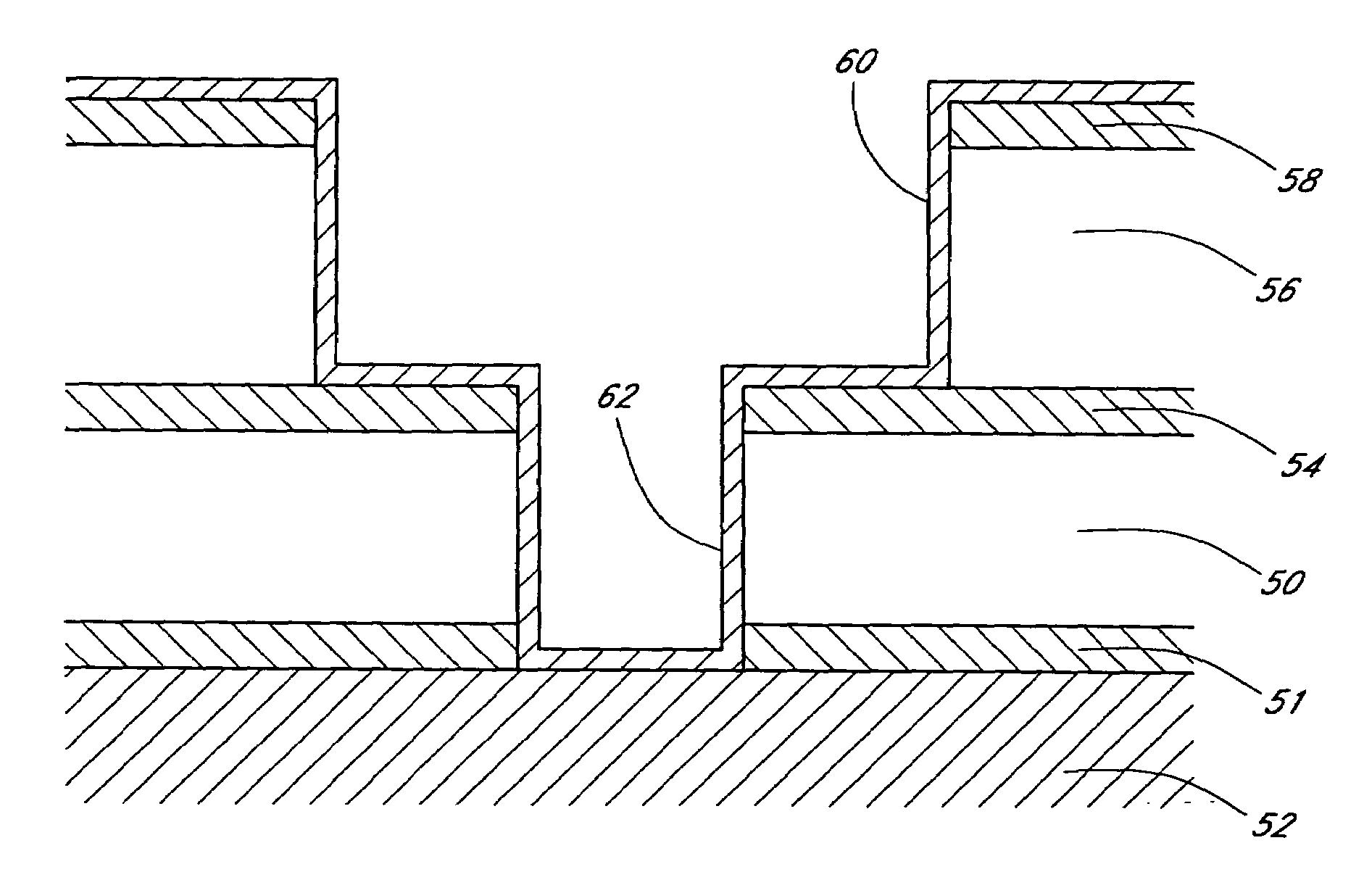

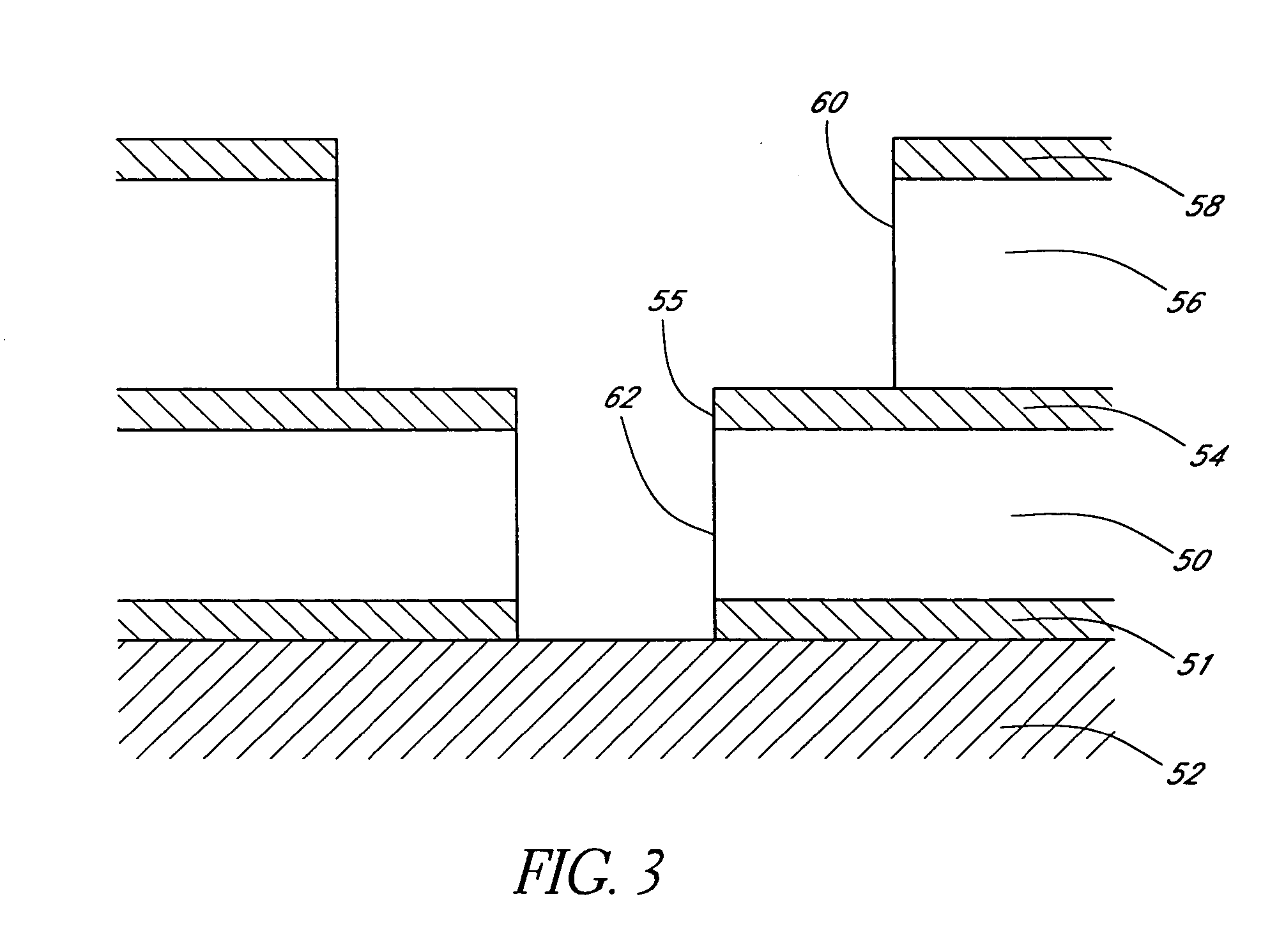

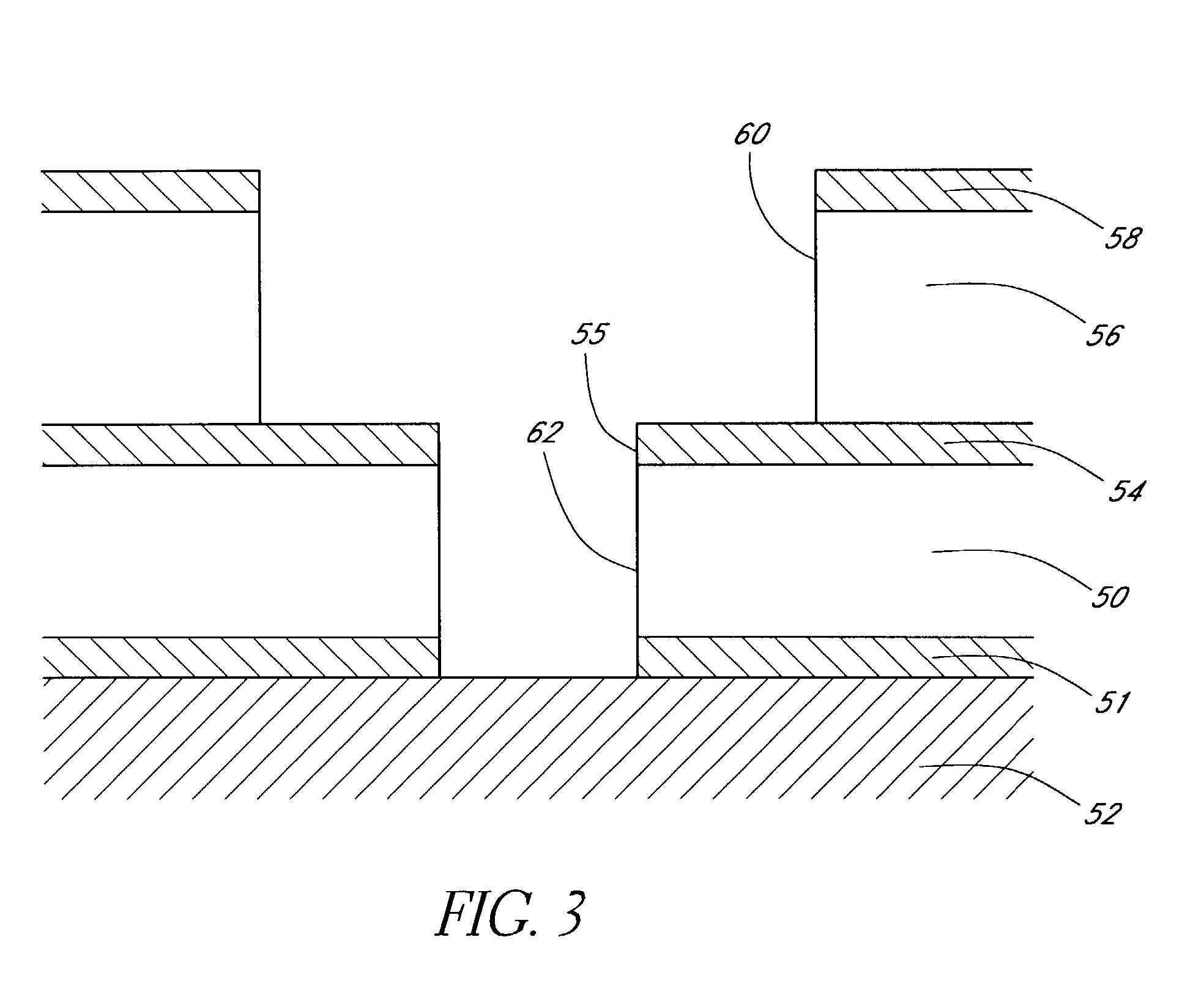

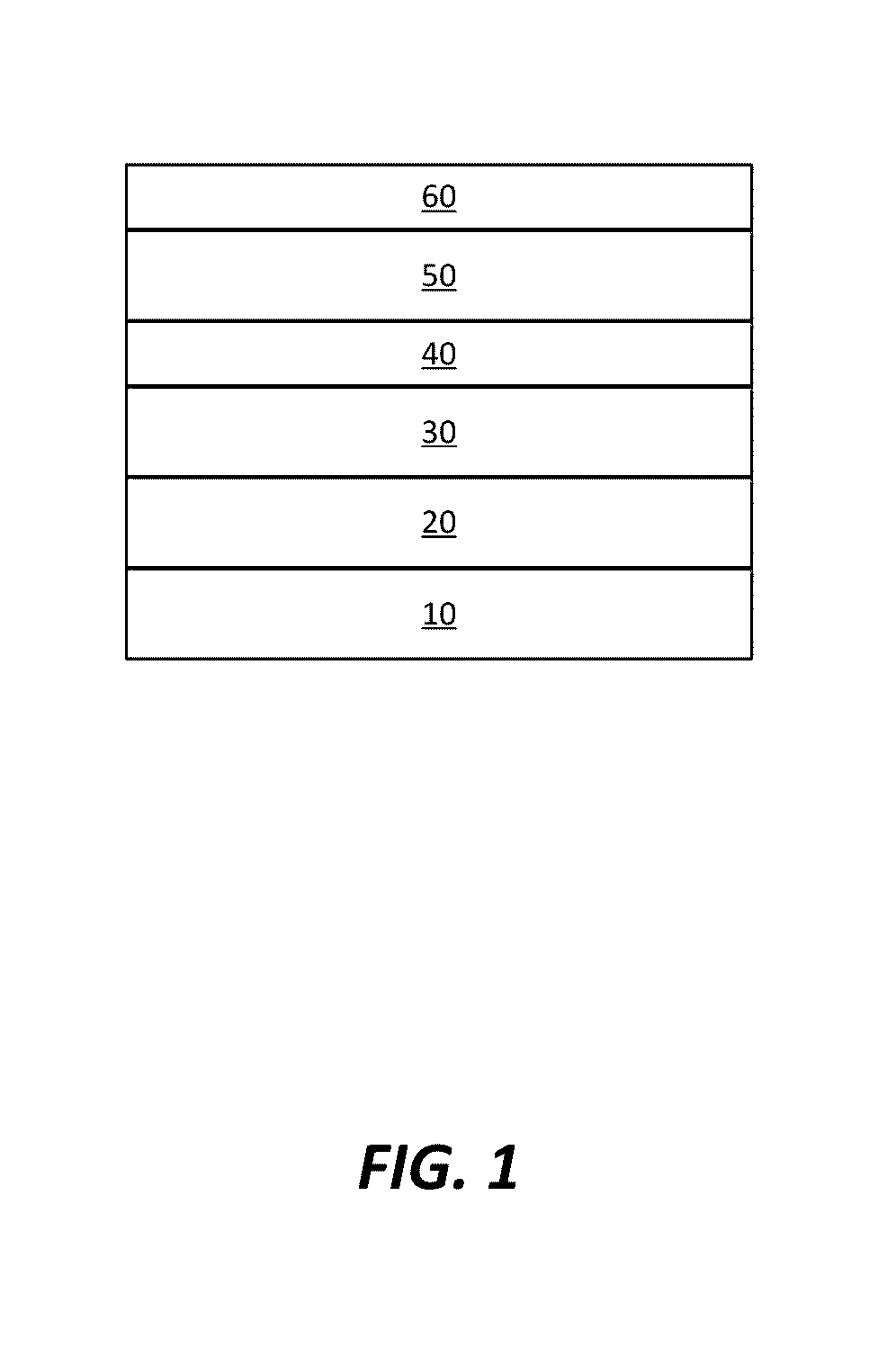

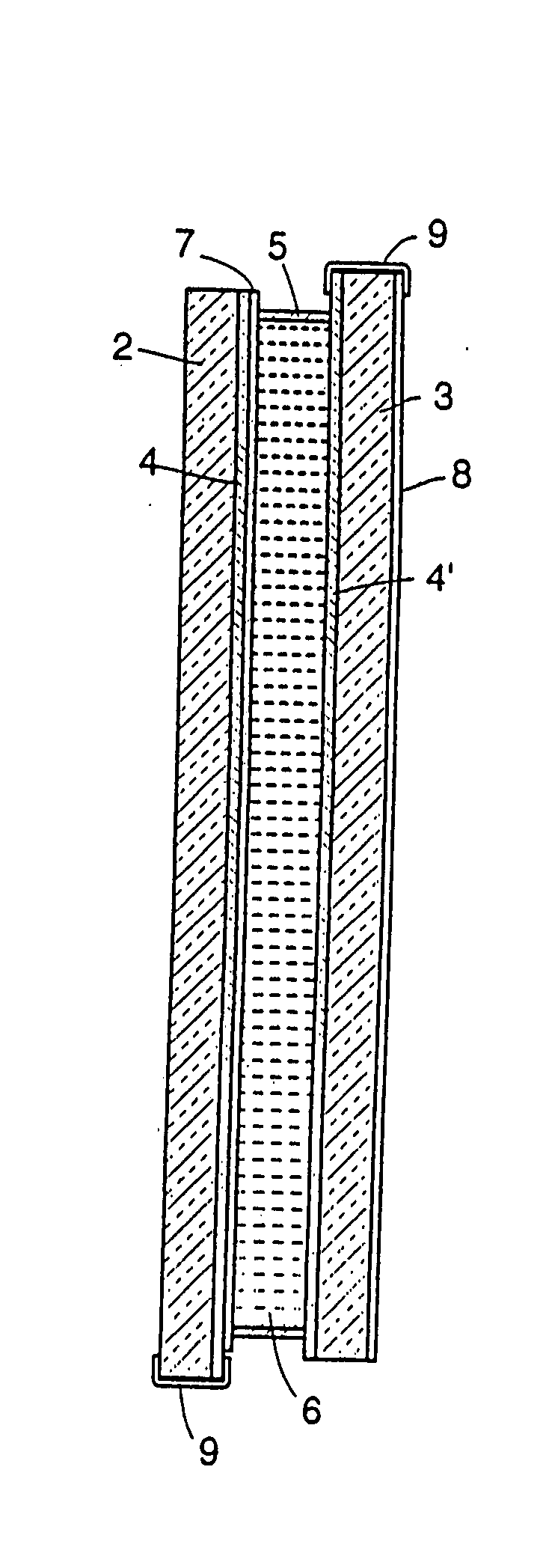

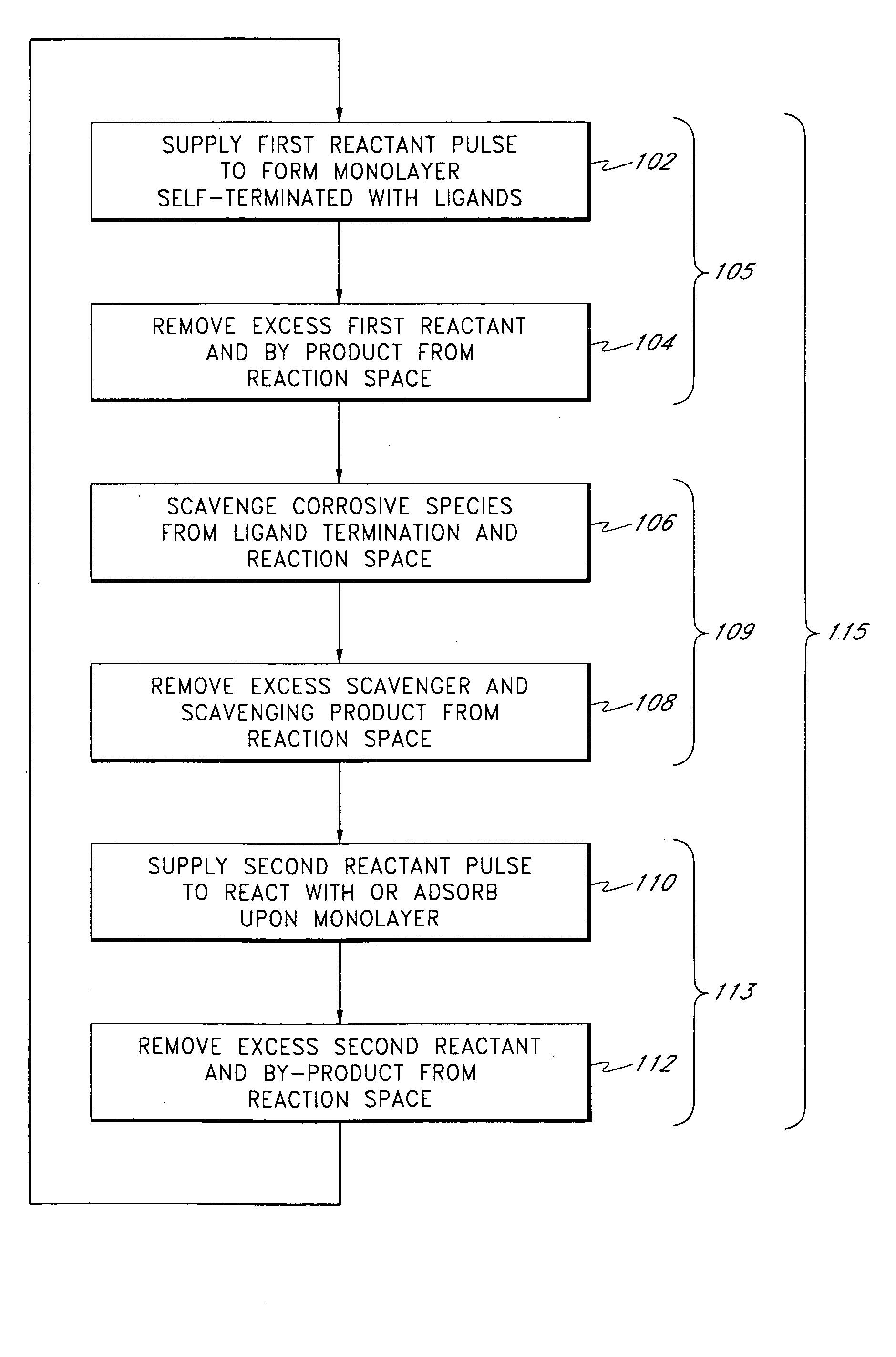

Method for depositing nanolaminate thin films on sensitive surfaces

InactiveUS20050106877A1Polycrystalline material growthSemiconductor/solid-state device manufacturingHydrogen halideCorrosive chemical

The present method provides tools for growing conformal metal nitride, metal carbide and metal thin films, and nanolaminate structures incorporating these films, from aggressive chemicals. The amount of corrosive chemical compounds, such as hydrogen halides, is reduced during the deposition of transition metal, transition metal carbide and transition metal nitride thin films on various surfaces, such as metals and oxides. Getter compounds protect surfaces sensitive to hydrogen halides and ammonium halides, such as aluminum, copper, silicon oxide and the layers being deposited, against corrosion. Nanolaminate structures (20) incorporating metal nitrides, such as titanium nitride (30) and tungsten nitride (40), and metal carbides, and methods for forming the same, are also disclosed.

Owner:ASM INTERNATIONAL

Process for producing metal thin films by ALD

InactiveUS20050020060A1Promote nucleationGood film uniformityNanomagnetismSolid-state devicesHigh elevationSurface structure

The invention relates generally to processes for producing electrically conductive noble metal thin films on a substrate by atomic layer deposition. According to one embodiment of the invention a substrate with a surface is provided in a reaction chamber and a vaporised precursor of a noble metal is pulsed into the reaction chamber. By contacting the vaporised precursor with the surface of the substrate, no more than about a molecular layer of the metal precursor is formed on the substrate. In a next step, a pulse of molecular oxygen-containing gas is provided in the reaction chamber, where the oxygen reacts with the precursor on the substrate. Thus, high-quality metal thin films can be deposited by utilising reactions between the metal precursor and oxygen. In one embodiment, electrically conductive layers are deposited in structures that have high aspect ratio vias and trenches, local high elevation areas or other similar surface structures that make the surface rough.

Owner:ASM INTERNATIONAL

Metal oxide dispersion

ActiveUS20050069648A1Low costLess resourcesMolten spray coatingPhotosensitive materialsDispersed mediaMaterials science

The present invention relates to a metal oxide dispersion, which can form a metal thin film onto a substrate by heat treatment at a low temperature, wherein a metal oxide having a particle diameter of less than 200 nm is dispersed in the dispersion medium. By heat treating the dispersion after applying it onto a substrate, a metal thin film is formed.

Owner:ASAHI KASEI KK

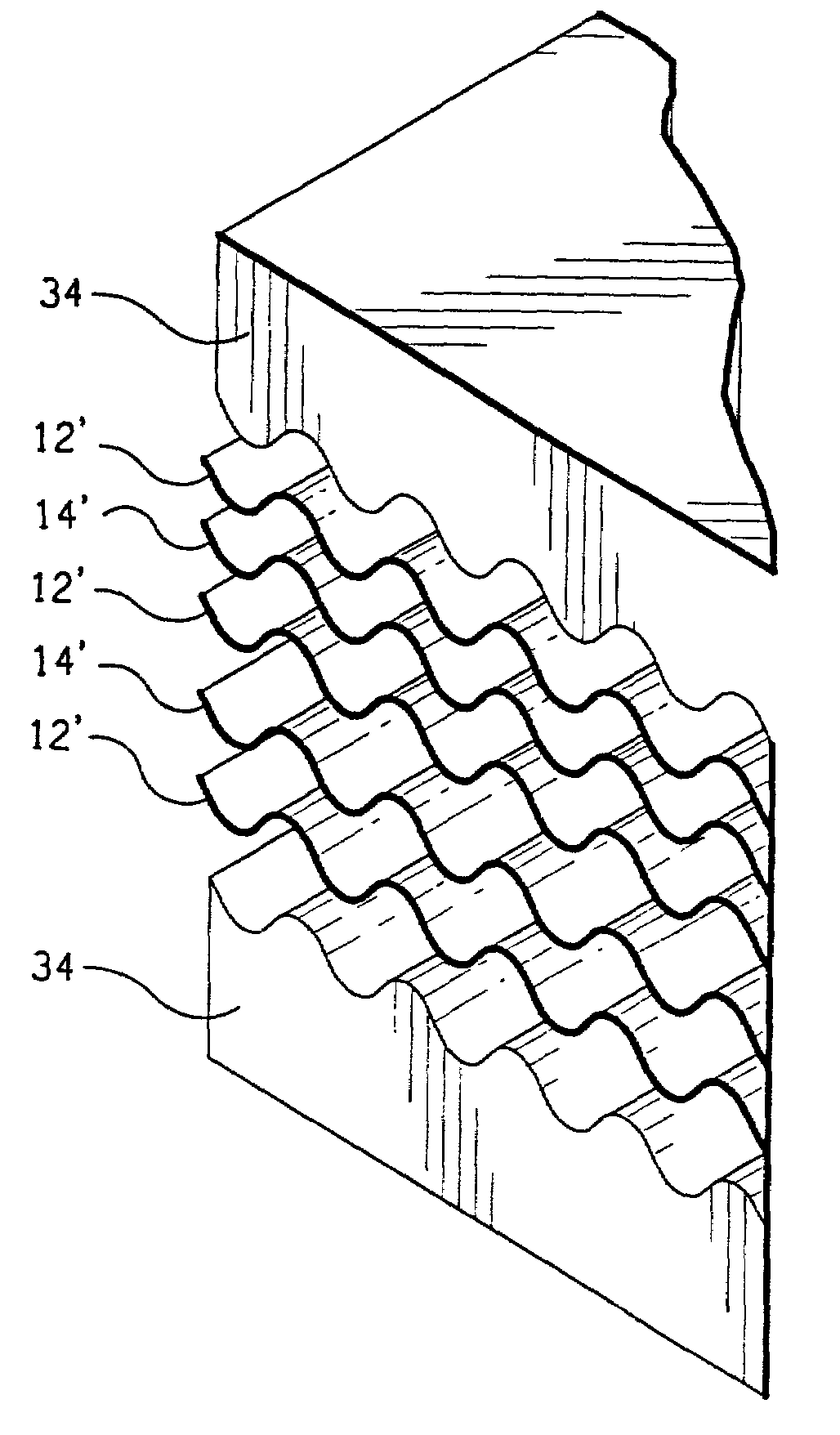

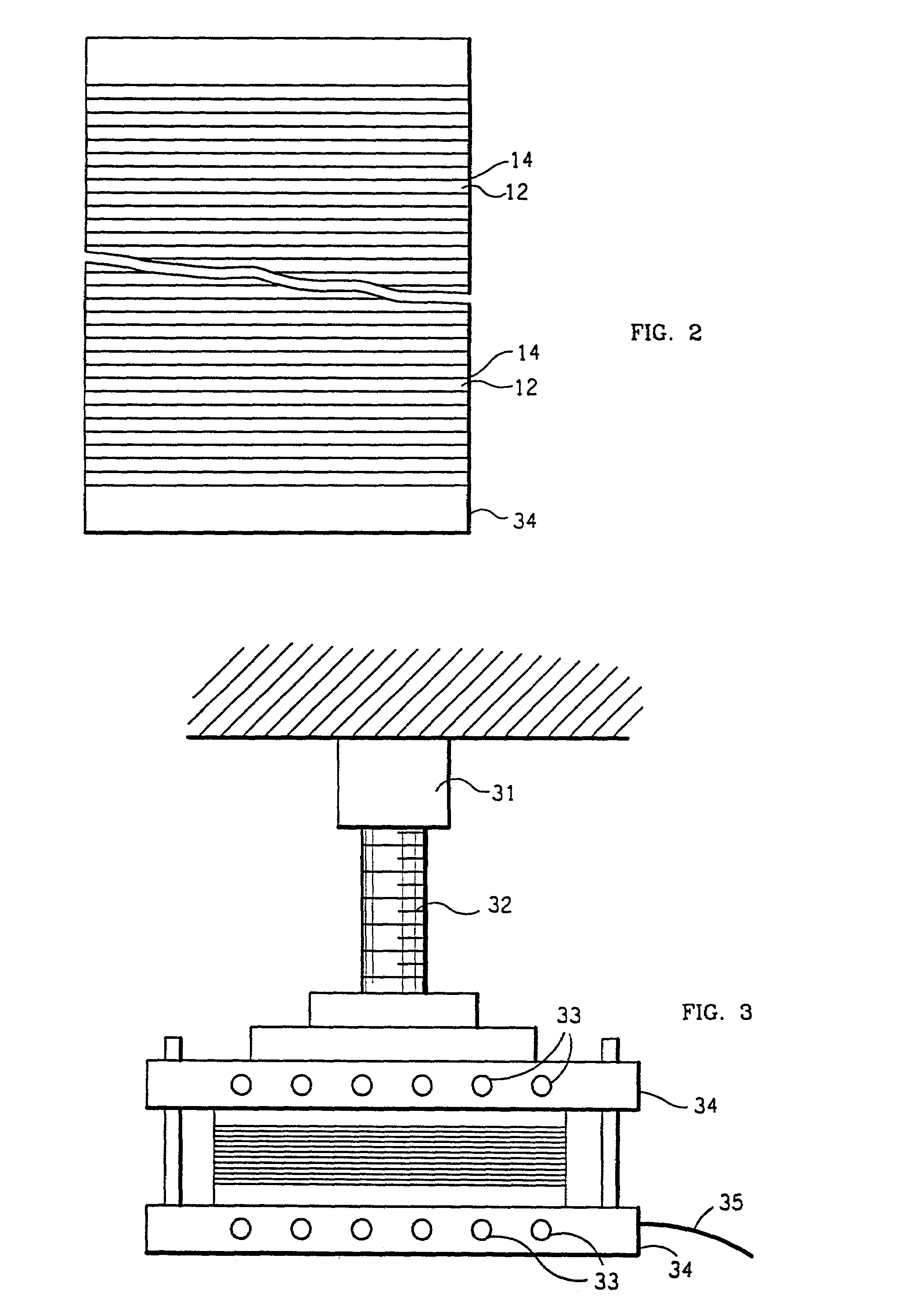

Fabrication of interleaved metallic and intermetallic composite laminate materials

InactiveUS7188559B1Well formedLimit cracking and fracturingWeapon componentsDomestic articlesGramComposite laminates

Typically 20–40 films of a tough first metal, normally 0.1–1.0 mm thick films of titanium, nickel, vanadium, and / or steel (iron) and alloys thereof, interleaved with a like number of films of a second metal, normally 0.1–1.0 mm thick films of aluminum or alloys thereof, are pressed together in a stack at less than 6 MPa and normally at various pressures 2–4 MPa while being gradually heated in the presence of atmospheric gases to 600–800° C. over a period of, typically, 10+ hours until the second metal is completely compounded; forming thus a metallic-intermetallic laminate composite material having (i) tough first-metal layers separated by (ii) hard, Vickers microhardness of 400 kg / mm2+, intermetallic regions consisting of an intermetallic compound of the first and the second metals. The resulting composite material is inexpensive, lightweight with a density of typically 3 to 4.5 grams / cubic centimeter, and very hard and very tough to serve as, among other applications, lightweight armor. Upon projectile impact (i) the hard intermetallic, ceramic-like, layers are confined by the tough metal layers while (ii) cracking and fracturing is blunted and channeled in directions orthogonal to the axis of impact.

Owner:RGT UNIV OF CALIFORNIA

Process for atomic layer deposition of metal films

InactiveUS6869876B2Satisfies needSemiconductor/solid-state device manufacturingSolid state diffusion coatingHalogenMetal halides

In the present invention, a metal halide film is grown which is then reduced to the metal film rather than growing the metal film directly on the substrate surface. In certain embodiments, a metal halide film is grown from at least two precursors: a halogen-containing precursor and a metal-containing precursor. The metal halide film is then exposed to a reducing agent to form the metal film. In certain preferred embodiments, the metal halide film is exposed to the reducing agent prior to the completion of the growing step.

Owner:AIR PROD & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com