Patents

Literature

1067 results about "Dispersed media" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A dispersed medium consists of two media that do not mix. More specifically, it contains discrete elements of one medium which are dispersed in a continuous second medium. The two media can be of very different nature. In particular, they can be a gas, a liquid or a solid.

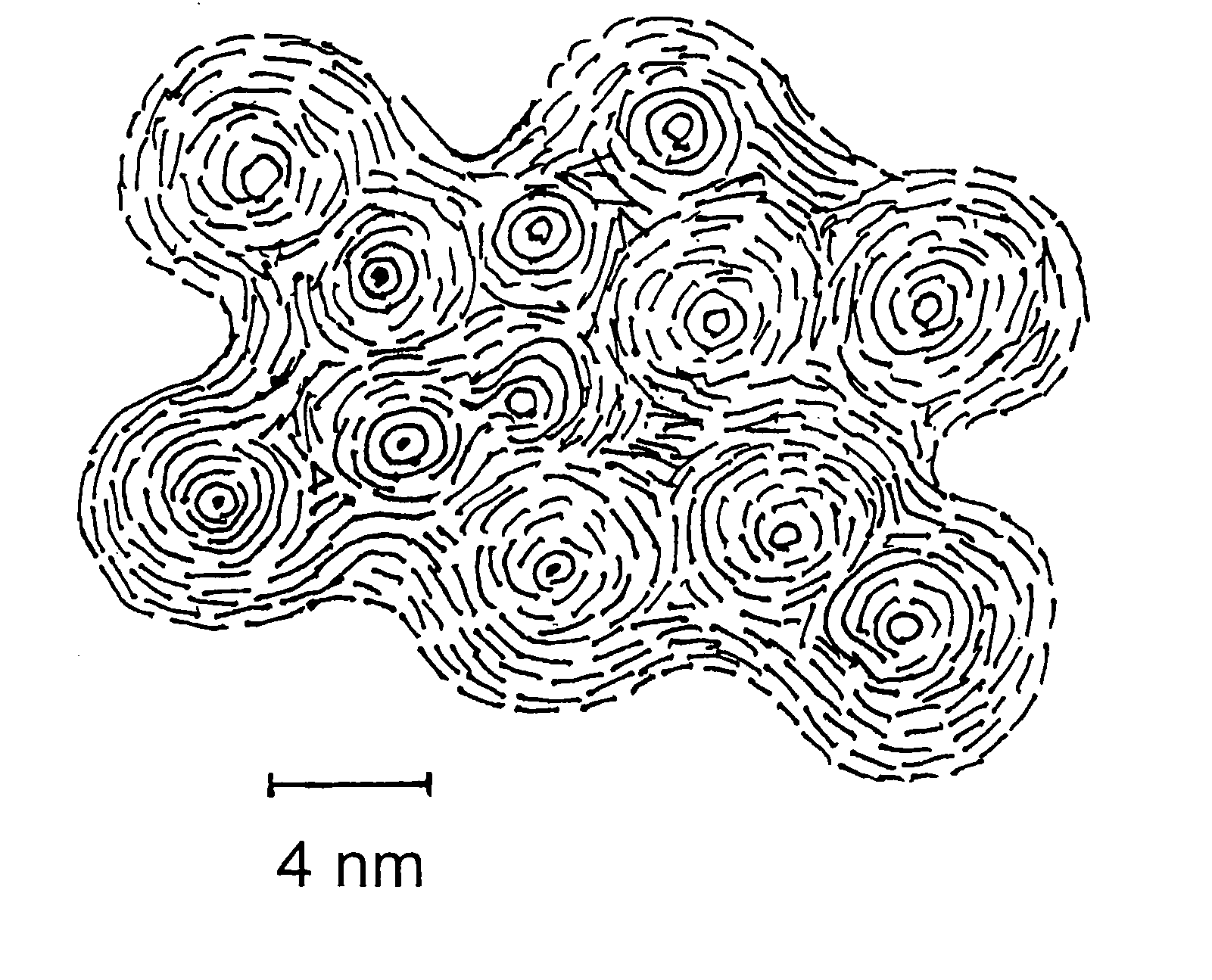

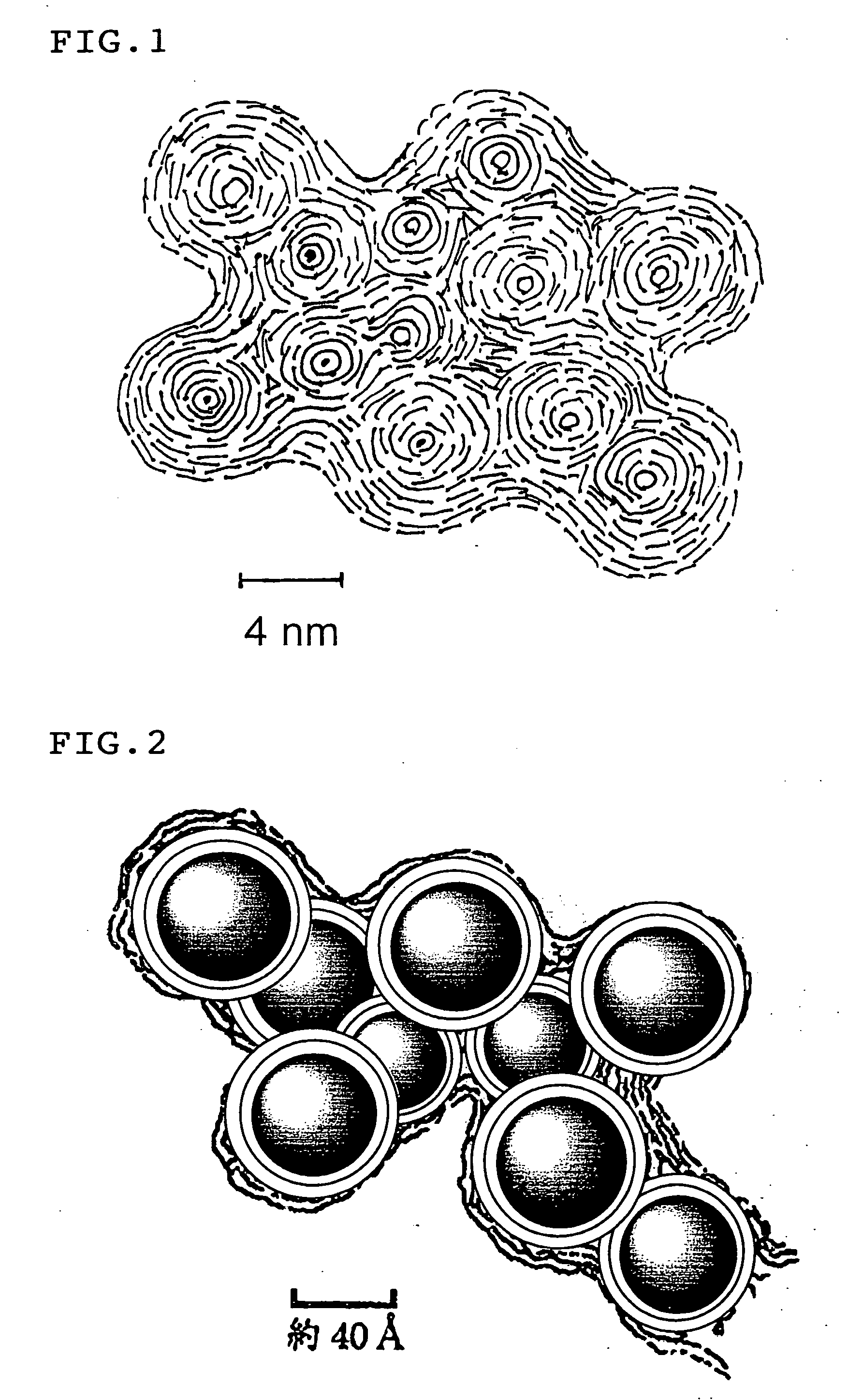

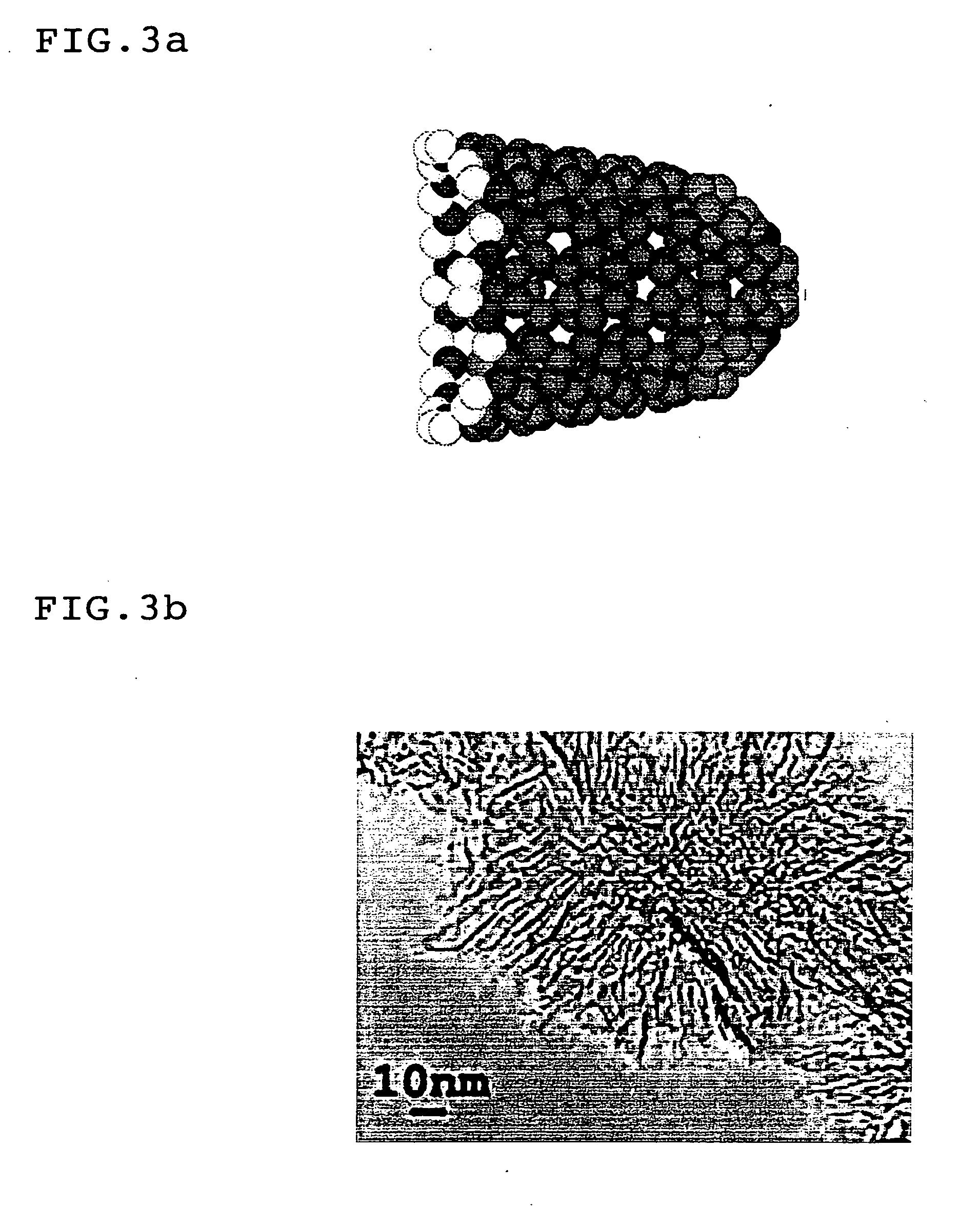

Ultra-dispersed nanocarbon and method for preparing the same

InactiveUS20050008560A1Avoid reorganizationMaterial nanotechnologyPigmenting treatmentDispersed mediaHigh energy

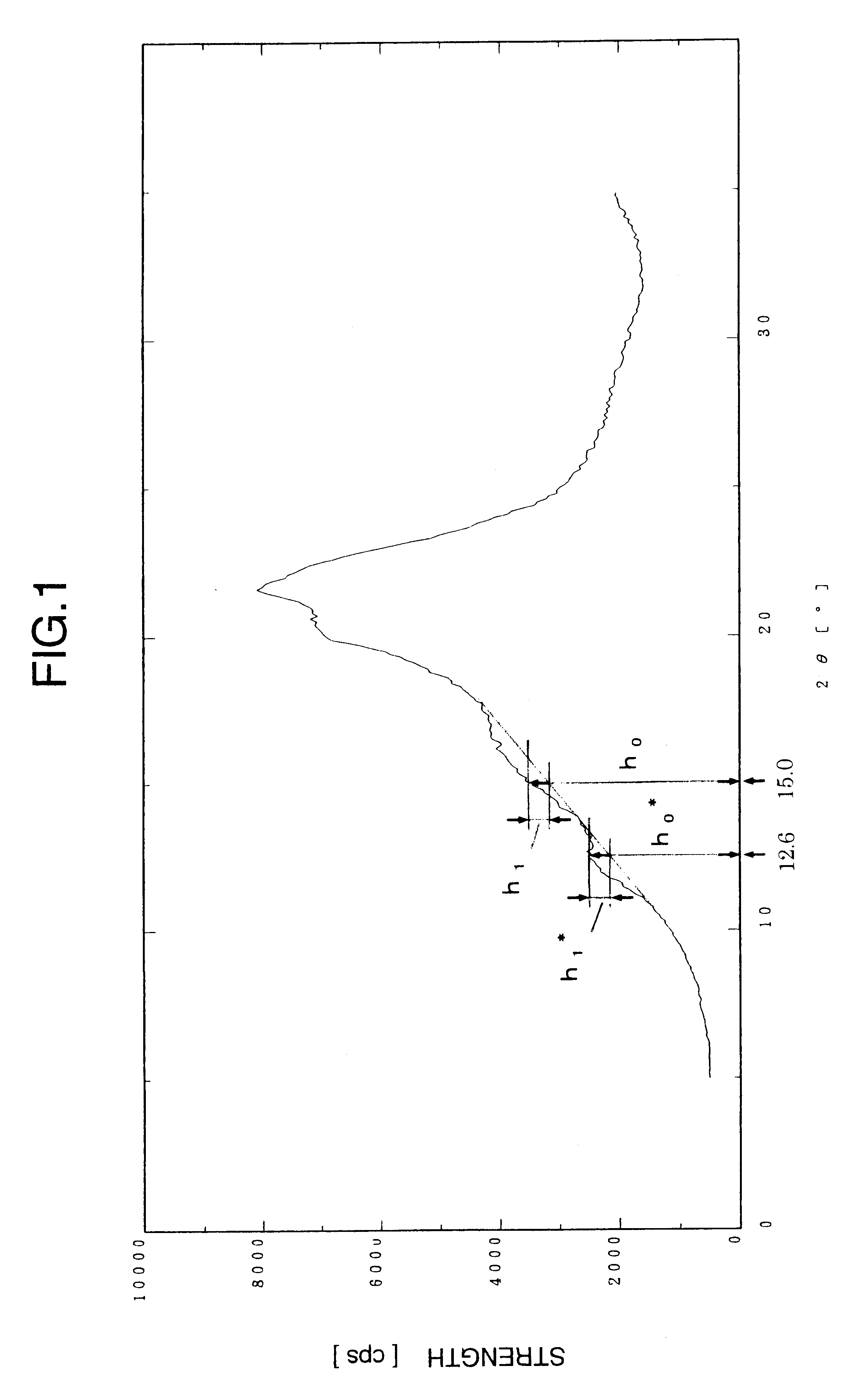

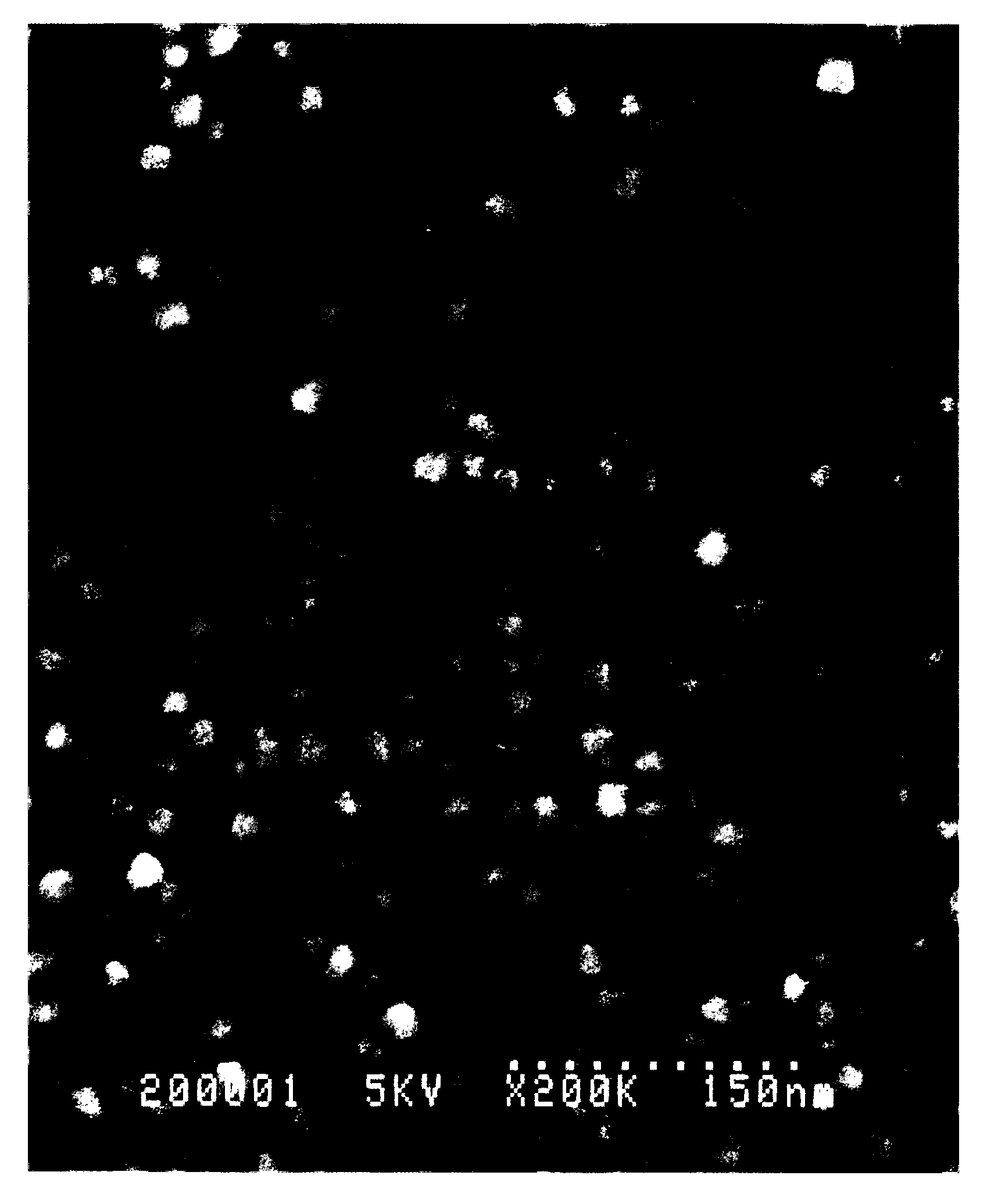

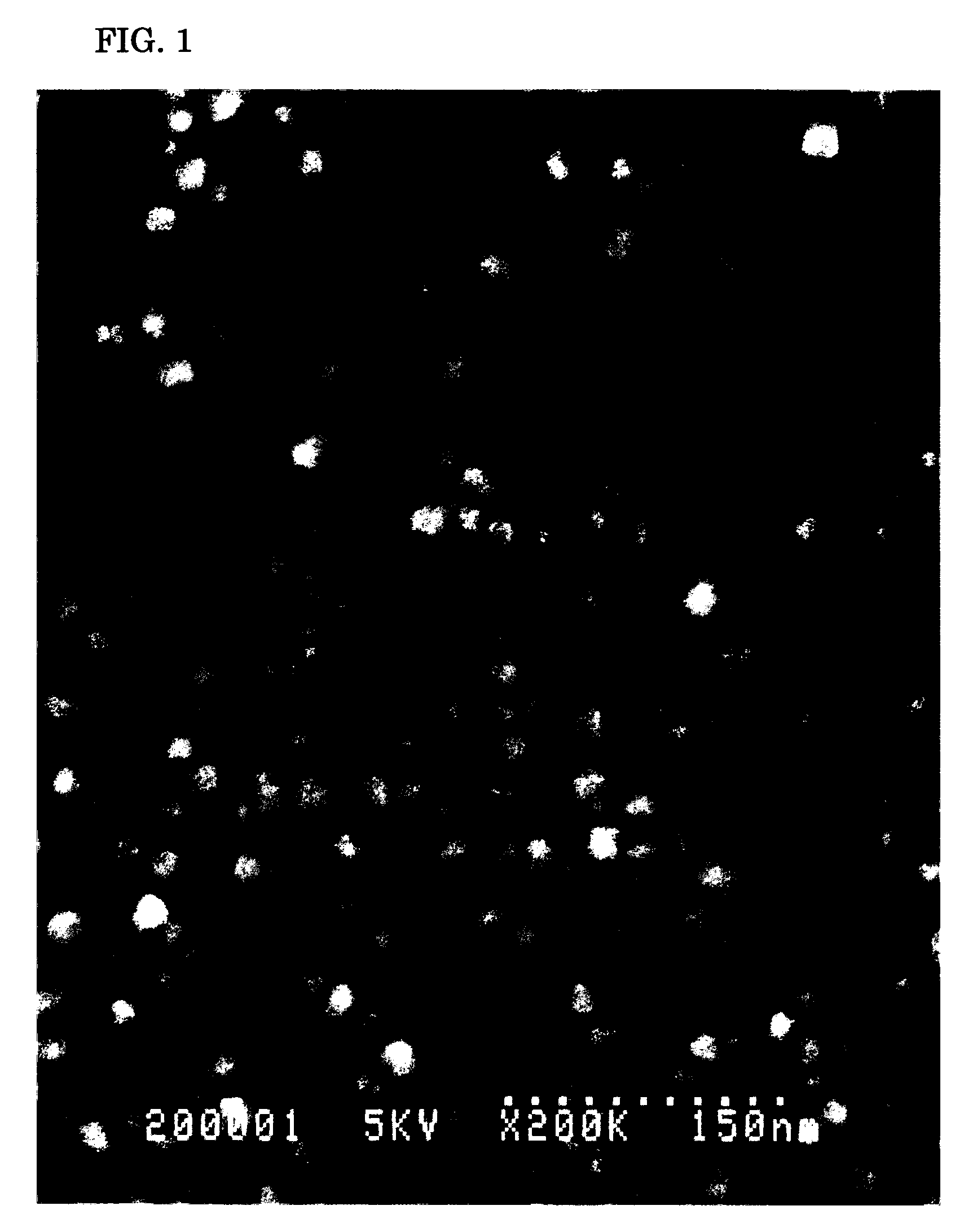

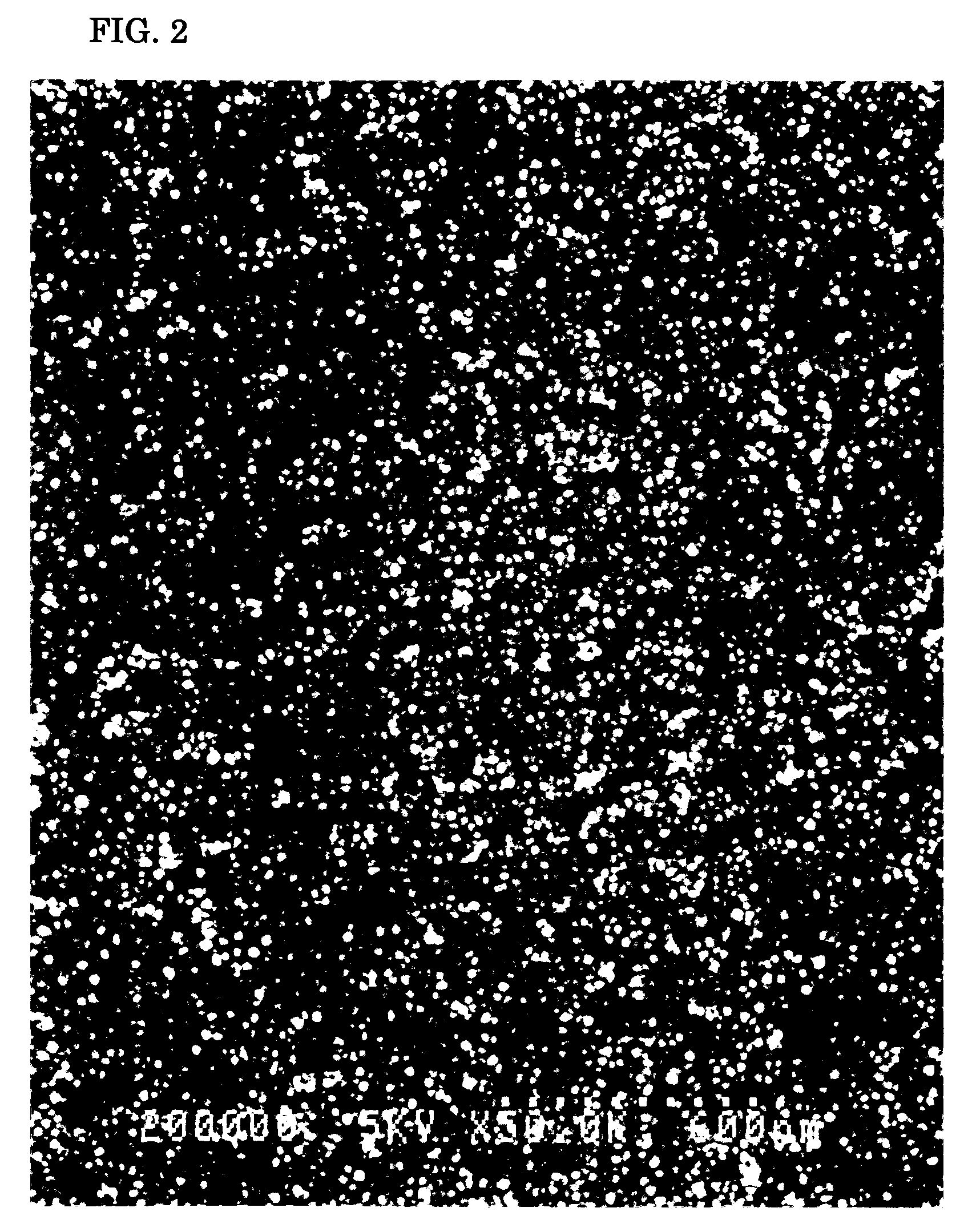

Ultradispersed ones of primary particles of nanometer-sized carbon are obtained by applying a wet-type milling method and / or a wet dispersion method to an aggregate structure of the primary particles to overcome van der Waals forces, by which forces the primary particles are held together to form the aggregate structure, whereby the ultradispersed primary particles are obtained in a colloidal dispersion on a large-scale basis at low cost without using any additive. In a method of manufacturing the ultradispersed primary particles, the wet-type milling method is carried out in a ball mill, preferably in combination with a high-energy ultrasonic-wave process carried out in a dispersing medium such as pure water, whereby a colloidal solution or slurry with a low-concentration of the primary particles ultradispersed in the dispersing medium is obtained.

Owner:FUTABA CORPORATION +2

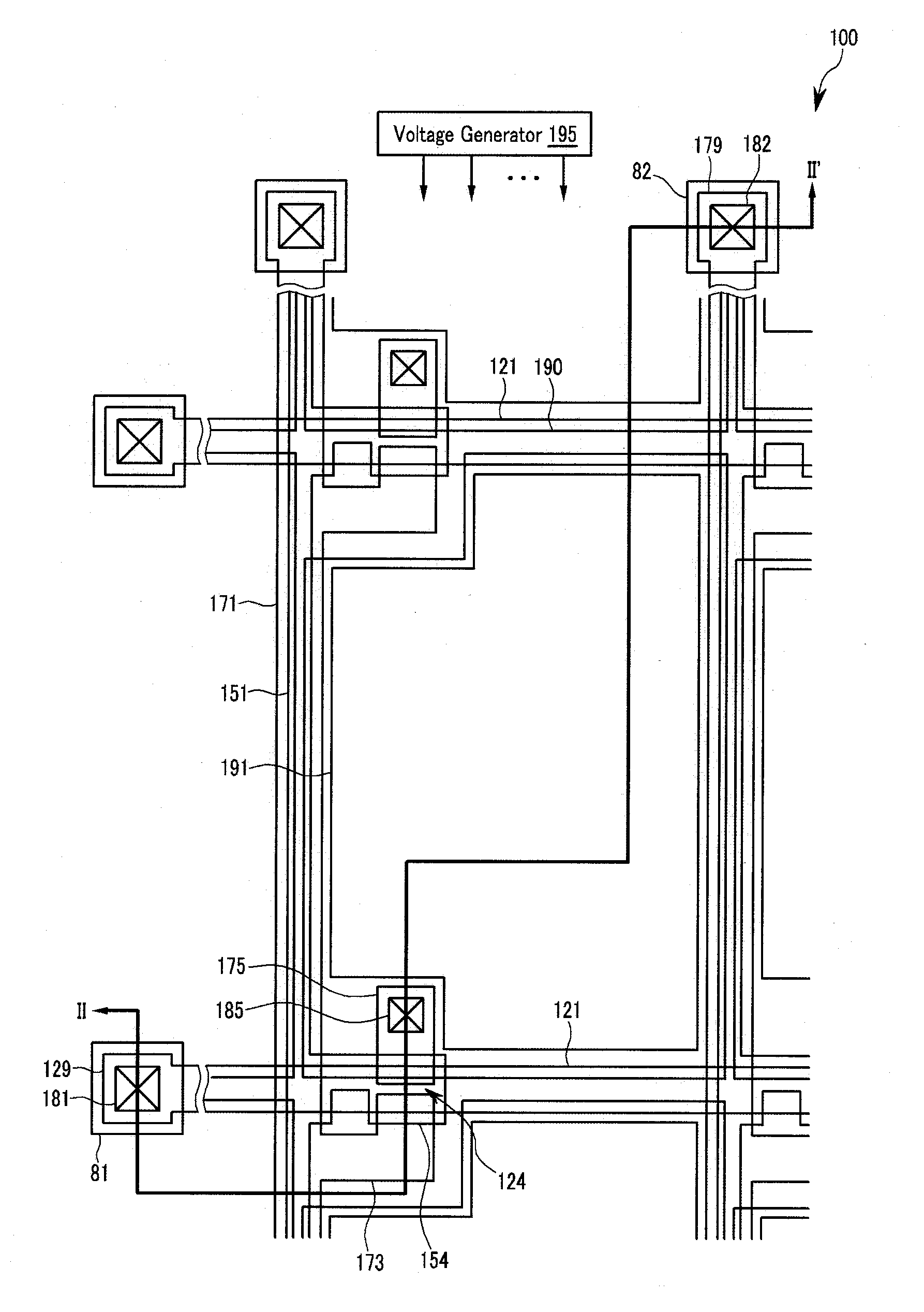

Electrophoretic display and method for driving thereof

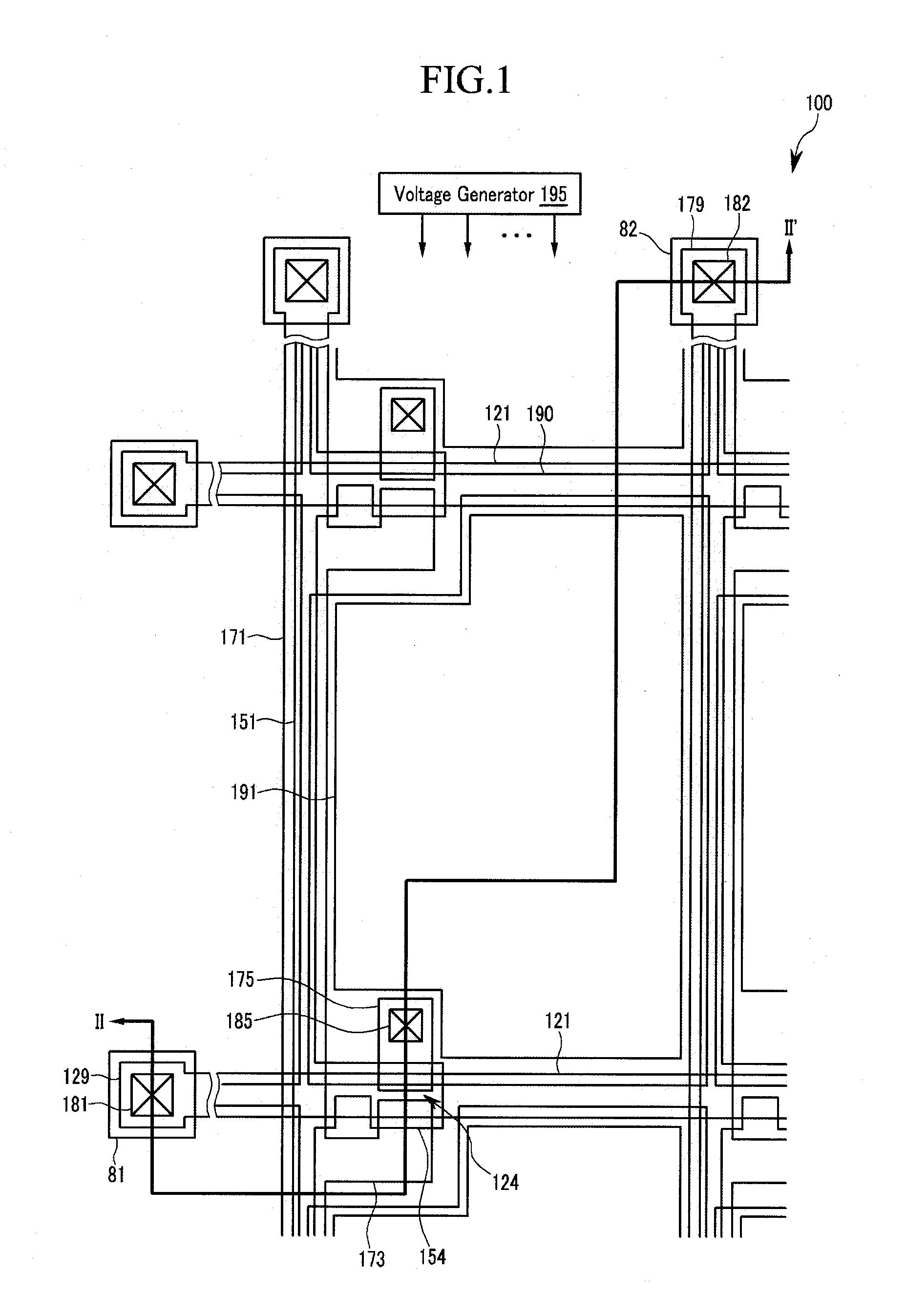

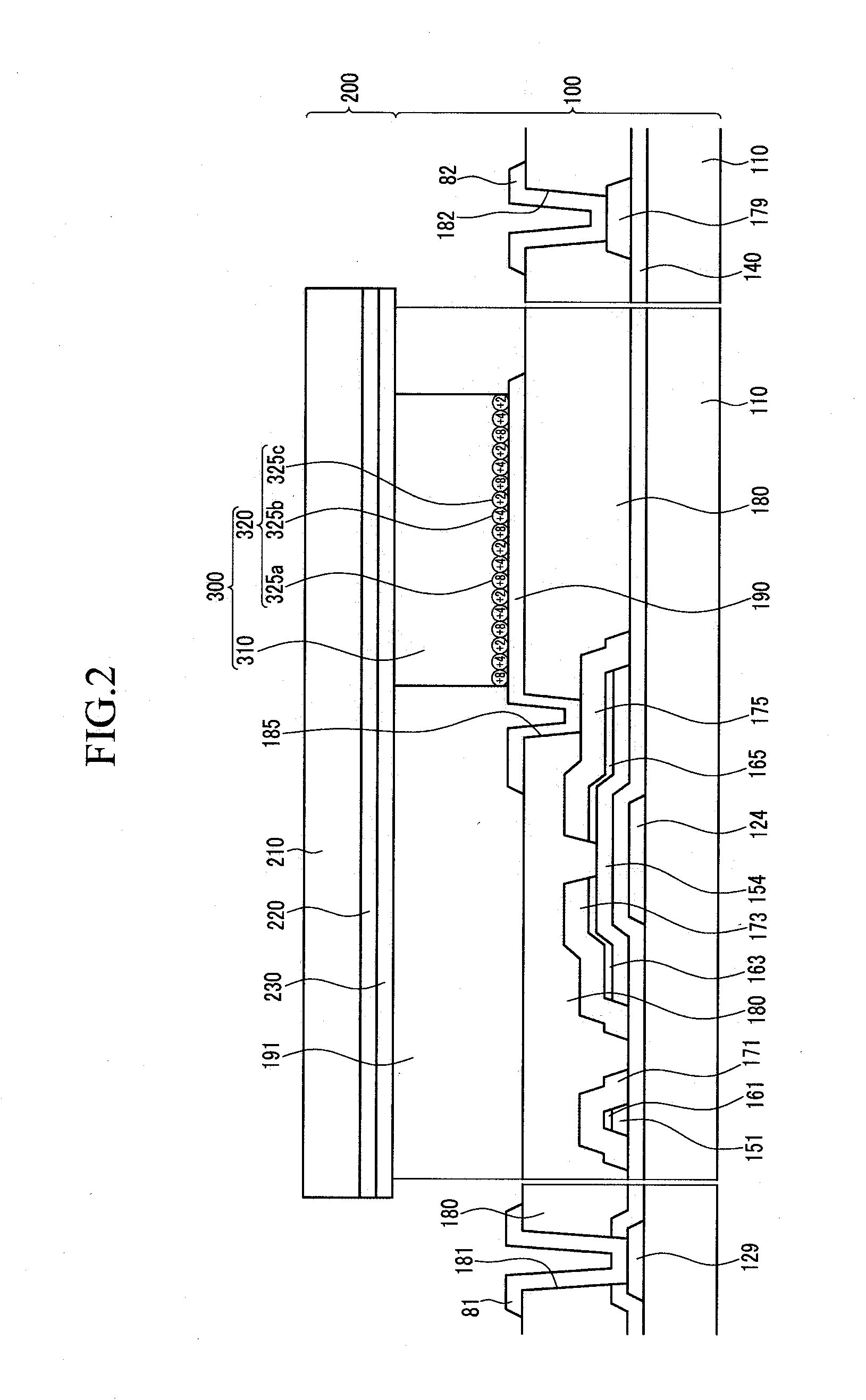

An electrophoretic display and a method for driving thereof are disclosed. Some embodiments provide an electrophoretic display comprising: (a) a first electrode; (b) a second electrode; (c) an electrophoretic member between the first and second electrodes, the electrophoretic member comprising: first particles each of which carries a first charge, second particles each of which carries a second charge, and third particles each of which carries a third charge, the first, second and third charges being different from each other; and a dispersion medium for distributing the first, second and third particles. The electrophoretic display comprises circuitry for applying at least six different driving voltages between the first and second electrodes for selectively moving the first, second and third particles relative to at least the first electrode to display different colors. Accordingly, many colors can be represented.

Owner:SAMSUNG ELECTRONICS CO LTD

Cellulose dispersion

InactiveUS6541627B1Good dispersionImprove stabilitySugar derivativesCellulose coatingsCelluloseDispersion stability

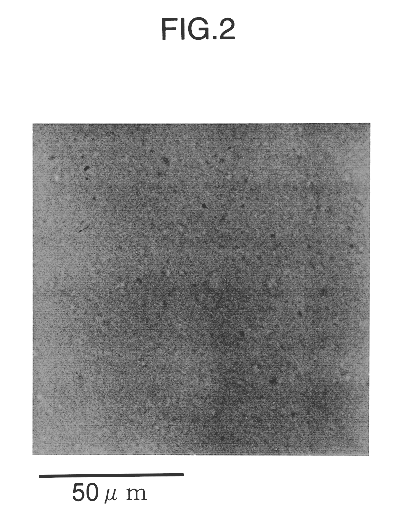

A cellulose dispersion which is a dispersion comprising a dispersing medium and a cellulose having a fraction of cellulose I type crystal component of not more than 0.1 and a fraction of cellulose II type crystal component of not more than 0.4 and in which the average particle diameter of the constitutive cellulose is not more than 5 mum. A cellulose particulate and a cellulose composite particulate which have an average particle diameter of 0.2 to 20 mum, a ratio of long diameter (L) to short diameter (D) observed through a scanning electron microscope (L / D) of not more than 1.2 and a coefficient of aggregation of 1.0 to 3.0. The present invention provides a cellulose dispersion which has an excellent effect such as dispersion stability or the like and is high in transparency. Moreover, it provides a cellulose particulate and a cellulose composite particulate which have such performances as no rough feel, excellent rolling properties, high dispersibility and the like.

Owner:ASAHI KASEI KK

Metal oxide dispersion

ActiveUS20050069648A1Low costLess resourcesMolten spray coatingPhotosensitive materialsDispersed mediaMaterials science

The present invention relates to a metal oxide dispersion, which can form a metal thin film onto a substrate by heat treatment at a low temperature, wherein a metal oxide having a particle diameter of less than 200 nm is dispersed in the dispersion medium. By heat treating the dispersion after applying it onto a substrate, a metal thin film is formed.

Owner:ASAHI KASEI KK

Metallic colloidal solution and inkjet-use metallic ink

InactiveUS20050189520A1Easy to handleUniform particle sizeLiquid surface applicatorsConductive materialWater basedOrganic solvent

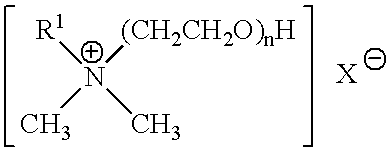

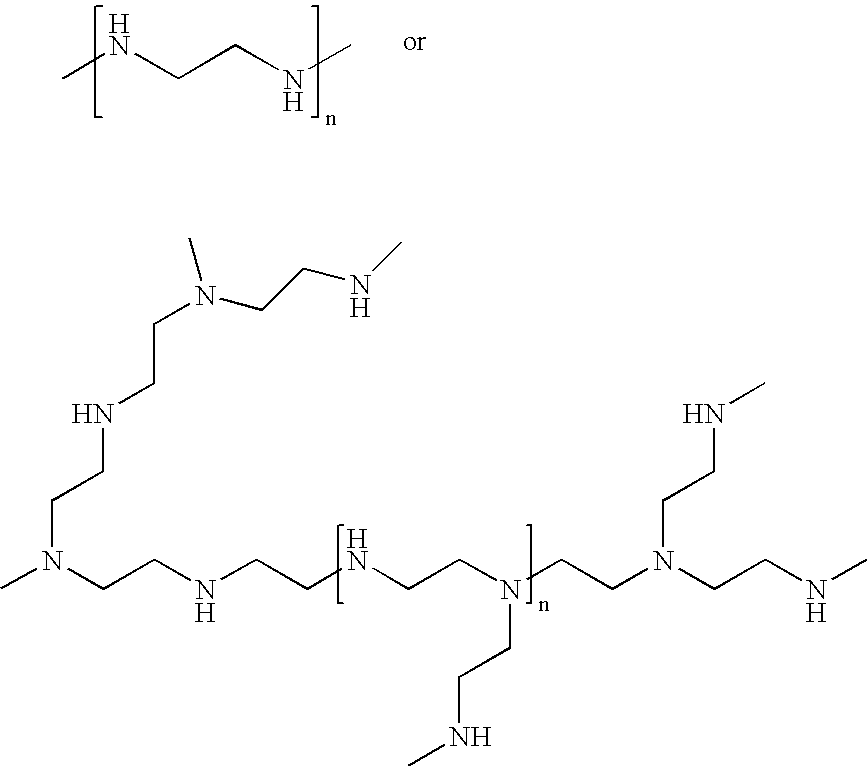

A metallic colloidal solution (a) includes a water-based dispersion medium that is easy in handling with regard to safety and environment and metallic particles having a uniform particle diameter and being excellent in properties such as conductivity and (b) has properties suitable for various printing methods and ink-applying methods. In addition, an inkjet-use metallic ink incorporating the metallic colloidal solution has properties suitable for the inkjet printing method. The metallic particles are deposited by reducing metallic ions in water and have a primary-particle diameter of at most 200 nm. The dispersion medium is made of a mixed solvent of water and a water-soluble organic solvent. The metallic particles are dispersed in the dispersion medium under the presence of a dispersant having a molecular weight of 200 to 30,000.

Owner:SUMITOMO ELECTRIC IND LTD

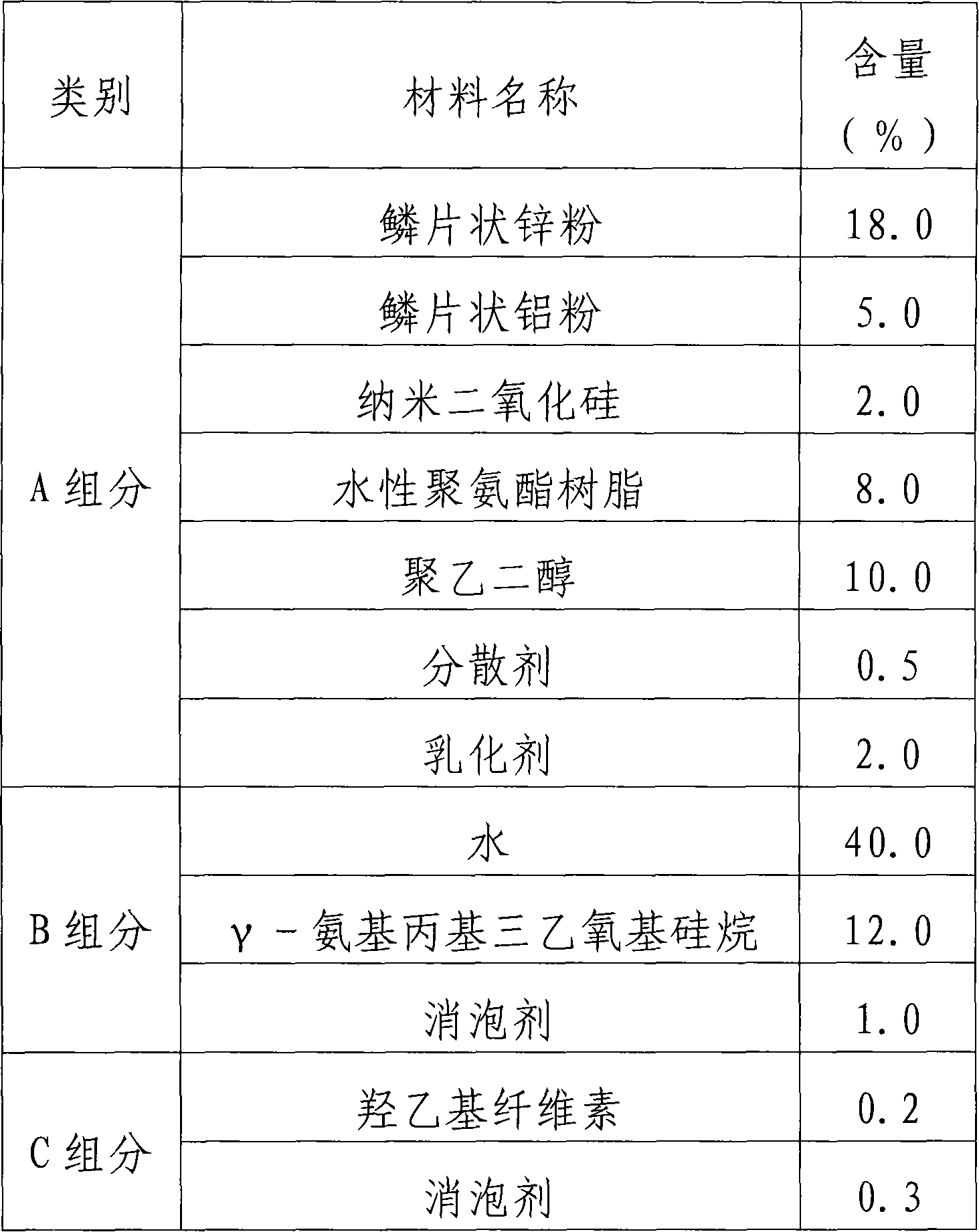

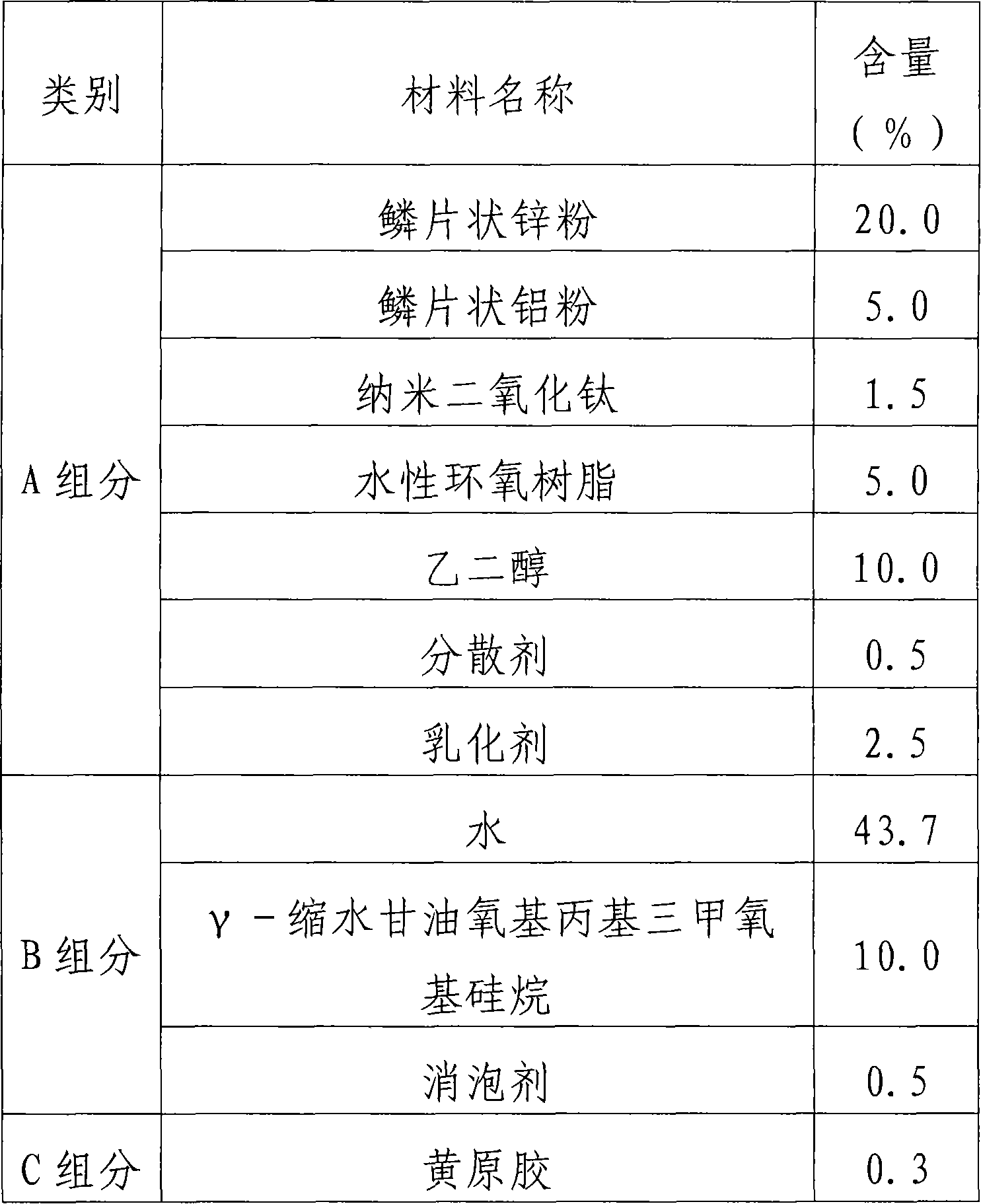

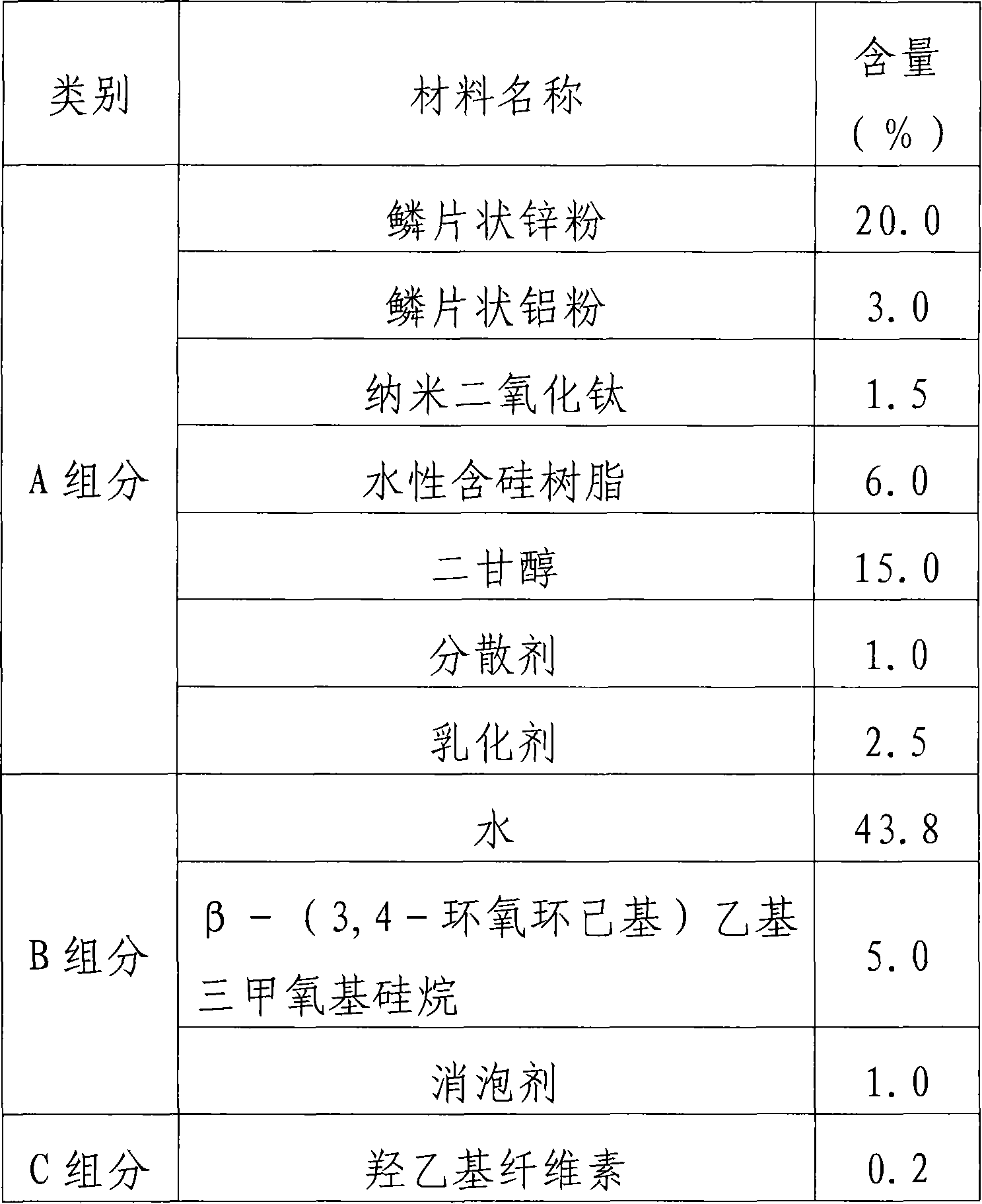

Hydrophilic nano zinc based composite coating

InactiveCN101613559AStrong weather resistanceNo pollution in the processAnti-corrosive paintsPolyurea/polyurethane coatingsSilanesSolvent

The invention belongs to the technical field of chemical engineering coatings and particularly relates to a hydrophilic nano zinc based composite coating used for preventing corrosion on the surfaces of the metal parts. The coating comprises an emulsifier, a dispersant, an antifoaming agent, scaly metallic powder, nano oxides, a silane coupler, an alcohol-type solvent, a high-molecule organic material, a thickener and 30.0 to 60.0 percent of water serving as a disperse medium. The coating can be coated by spraying, brushing, soaking and soaking-centrifugal coating and other methods, and the coating can be formed by being roasted at a temperature of about 200 DEG C for 20 minutes. Neutral salt spray corrosion resistant tests show that the neutral salt spray corrosion resistant time is more than 800h, the binding force is proved to be above level 4 (by an adhesive band test). The coating has the advantages of environmental pollution prevention, excellent metallic corrosion resistant property, economy and practicability and convenient use; and moreover, the coating can be widely used for the corrosion resistant treatment of the surface of metal parts made of iron, aluminum, copper and magnesium alloy and the like, particularly the corrosion resistant treatment of metal parts with complex geometric shapes.

Owner:YUNNAN GREAT IND DEV

Water epoxy paint for ground floor and its mfg. process and construction technology

The invention relates to a water epoxy ground floor coating and its making method and constructing process, where one component is low-molecular weight liquid-state epoxy resin assorted with active diluter in a proper proportion, and the other component is a dispersoid with hydrophilic curing agent as the principal thing, containing water-borne curing agent, water, acid-resistant wearable color filler, various auxiliaries, etc. and its producing method is simple and mainly includes mechanical dispersing and mixing; it does need to clean paint-covered surface as used on humid basal surface; the paint film has excellent properties of oily products and unilateral permeability. It uses water as dispersing medium, has no VOC, safe and environmental-protection.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

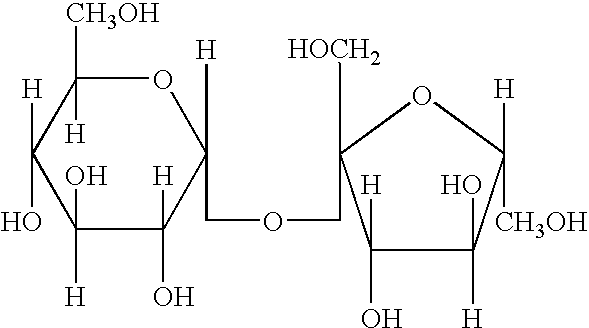

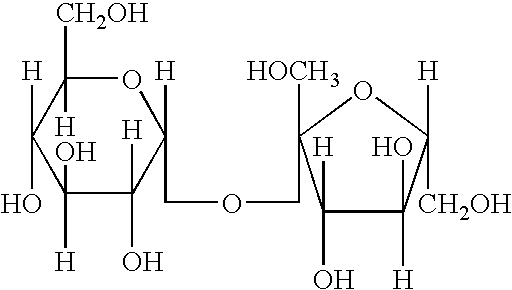

Fabric care compositions

InactiveUS20060276370A1Cationic surface-active compoundsNon-ionic surface-active compoundsDispersed mediaWrinkle reduction

A fabric care composition and process for using the composition to treat fabrics are provided. The fabric care composition comprises a sucrose ester, a cationic polysaccharide and a dispersing medium, wherein the charge density of the cationic polysaccharide is from about 0.05 to about 5.5 meq / gram. Optionally, deposition agents and adjunct materials may also be included. The present compositions are used to treat fabrics to impart one or more of the following benefits tot eh treated fabrics: improved fabric softness, wrinkle reduction after drying, ease of ironing, in-wear shape retention, fabric elasticity, fabric tensile strength, fabric tear strength, and / or color protection.

Owner:THE PROCTER & GAMBLE COMPANY

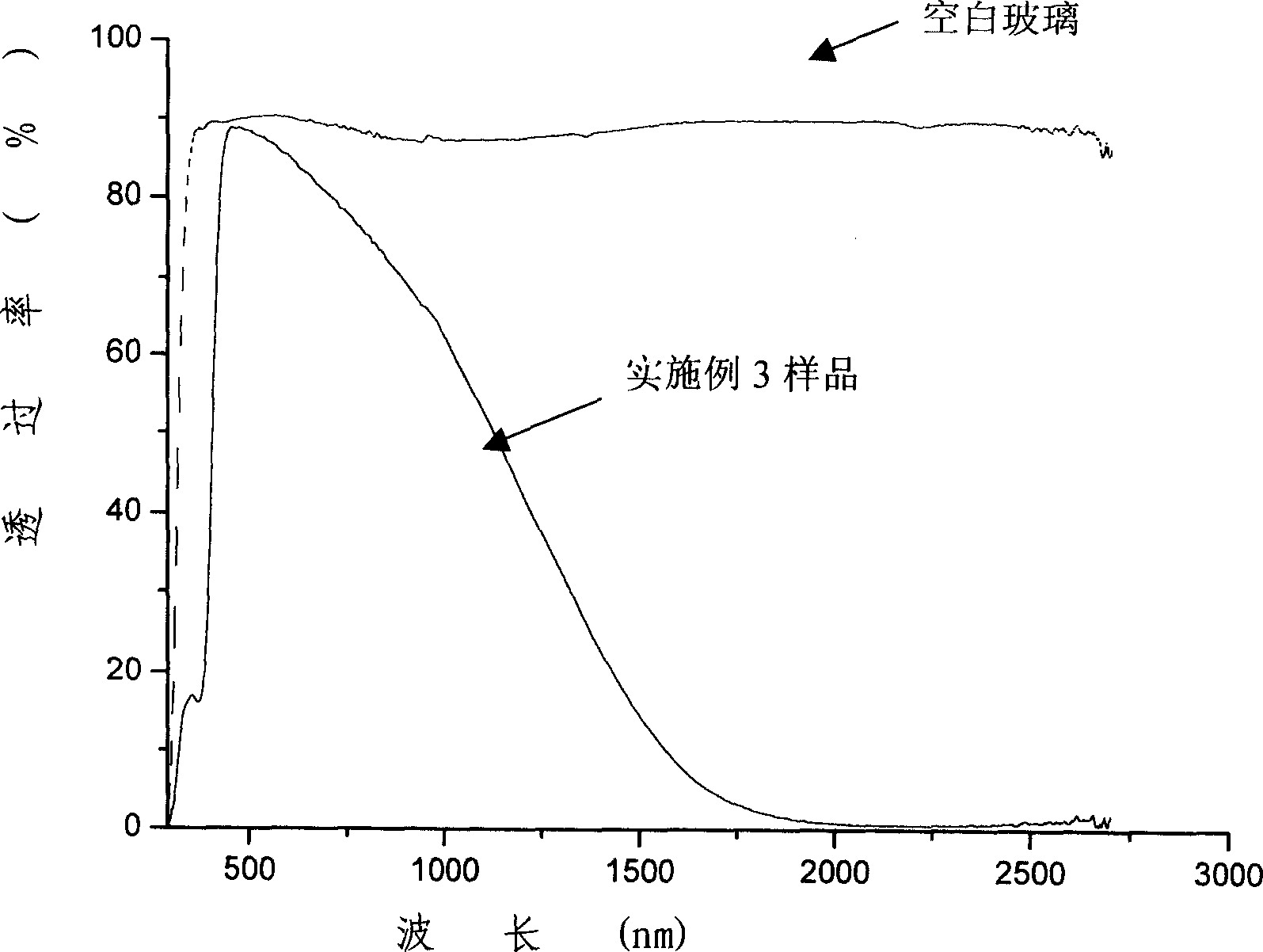

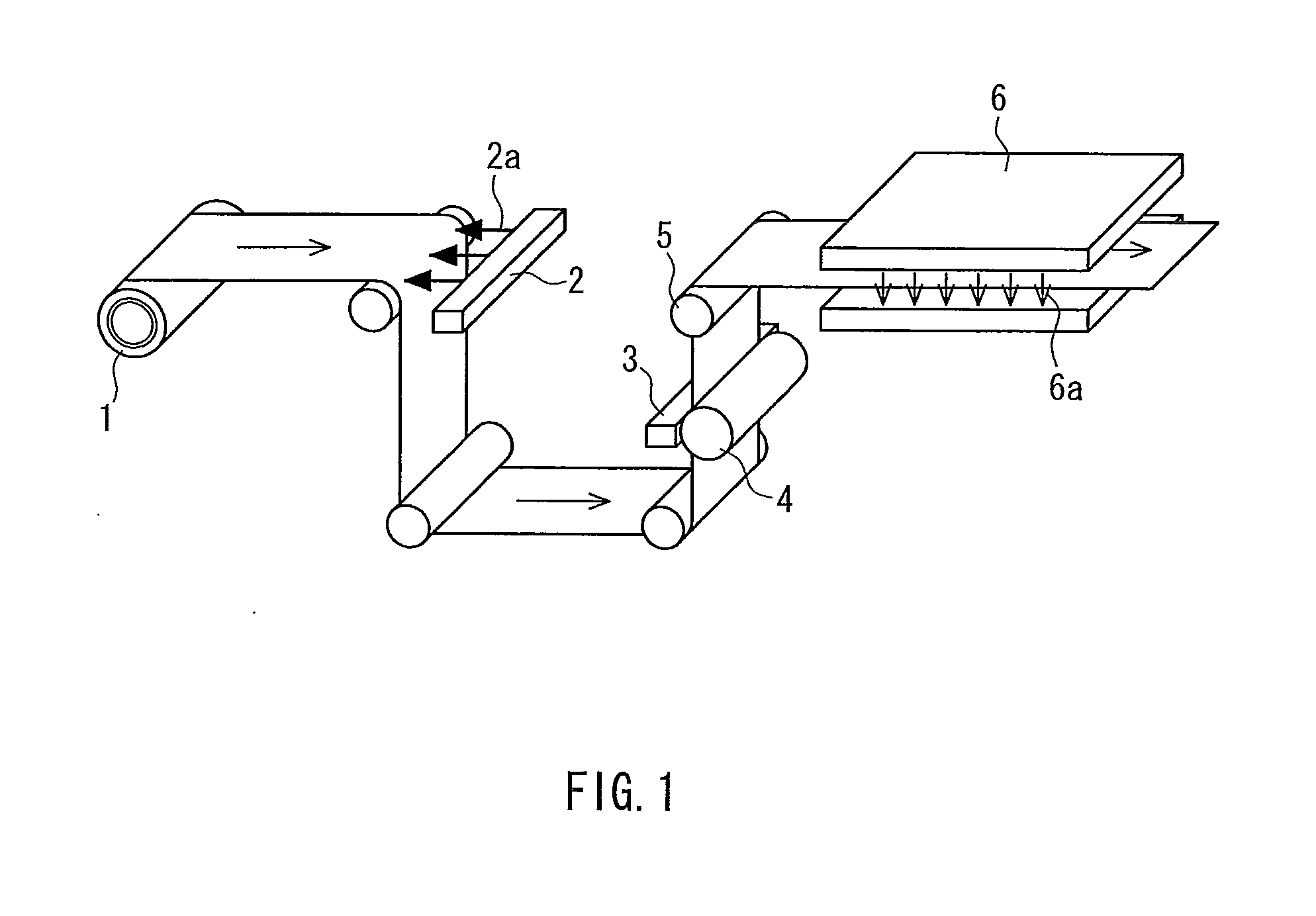

Sunlight controlled transparent film in low radiation, prepartion method and application

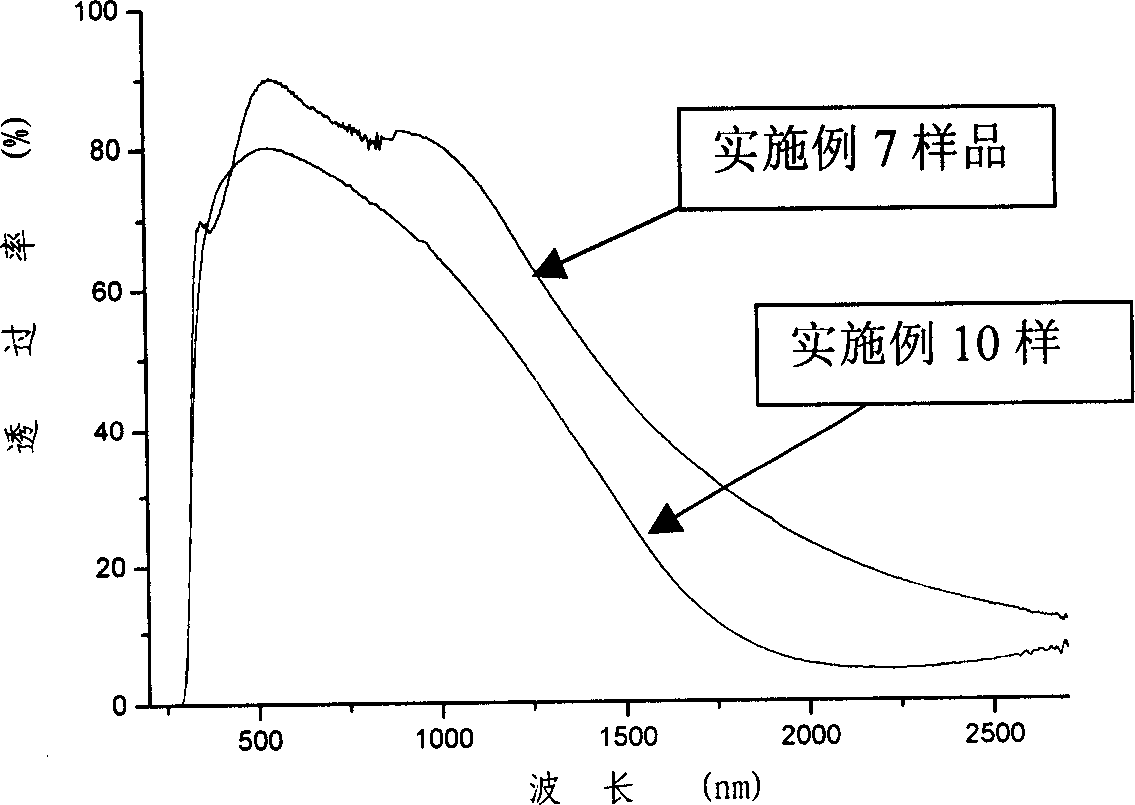

InactiveCN1916057AGood visible light transparencyPrevent penetrationDispersed mediaMetal oxide nanoparticles

This invention relates to a method for preparing low-radiation heat-insulating transparent film for controlling sunlight. The film is composed of: organic polymer 70-99.9 wt. %, doping metal oxide nanoparticles 0.1-30 wt. % and adjuvant 0-29.9 wt. %. The method comprises: (1) uniformly dispersing the doping metal oxide nanoparticles into a dispersing medium, mixing with the organic polymer and the adjuvant, and drying to obtain master batches; (2) plasticizing, smelting or extruding and blowing, calendaring, stretching, extruding and casting to obtain the film. The film can be used as the coating film for architecture glass, automobile window and ship window, and has such advantages as high visible-light permeability, good sunlight obstructing effect, good anti-electrostatic effect, and good electromagnetic radiation resistance.

Owner:长春迪高实业有限公司

Slurry for forming insulating layer, separator for electrochemical device, method for producing the same, and electrochemical device

InactiveUS20100221965A1Excellent heat resistanceHigh reliabilityCosmetic preparationsToilet preparationsElectrochemistryMaterials science

A slurry for forming an insulating layer of the present invention includes heat-resistant insulating fine particles, a thickening agent, and a dispersion medium. The insulating fine particles are dispersed in the dispersion medium. The slurry for forming an insulating layer has a viscosity of 5 to 500 mPa·s. The proportion of particles with a particle size of 1 μm or less in the insulating fine particles is 30 vol % or more and the proportion of particles with a particles size of 3 μm or more in the insulating fine particles is 10 vol % or less. An electrochemical device of the present invention includes a separator for an electrochemical device of the present invention that is produced using the slurry for forming an electrochemical device of the present invention.

Owner:HITACHT MAXELL LTD

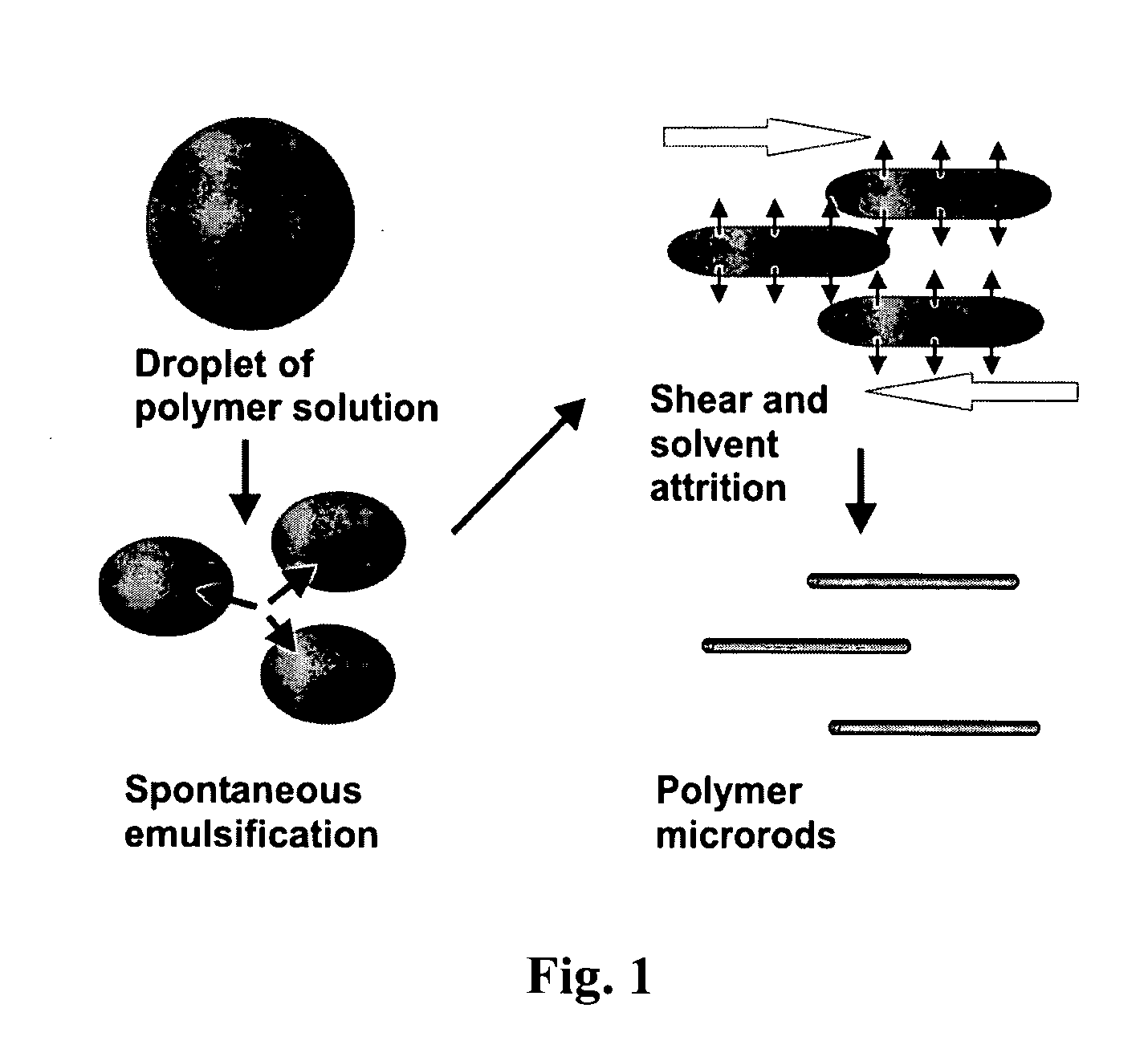

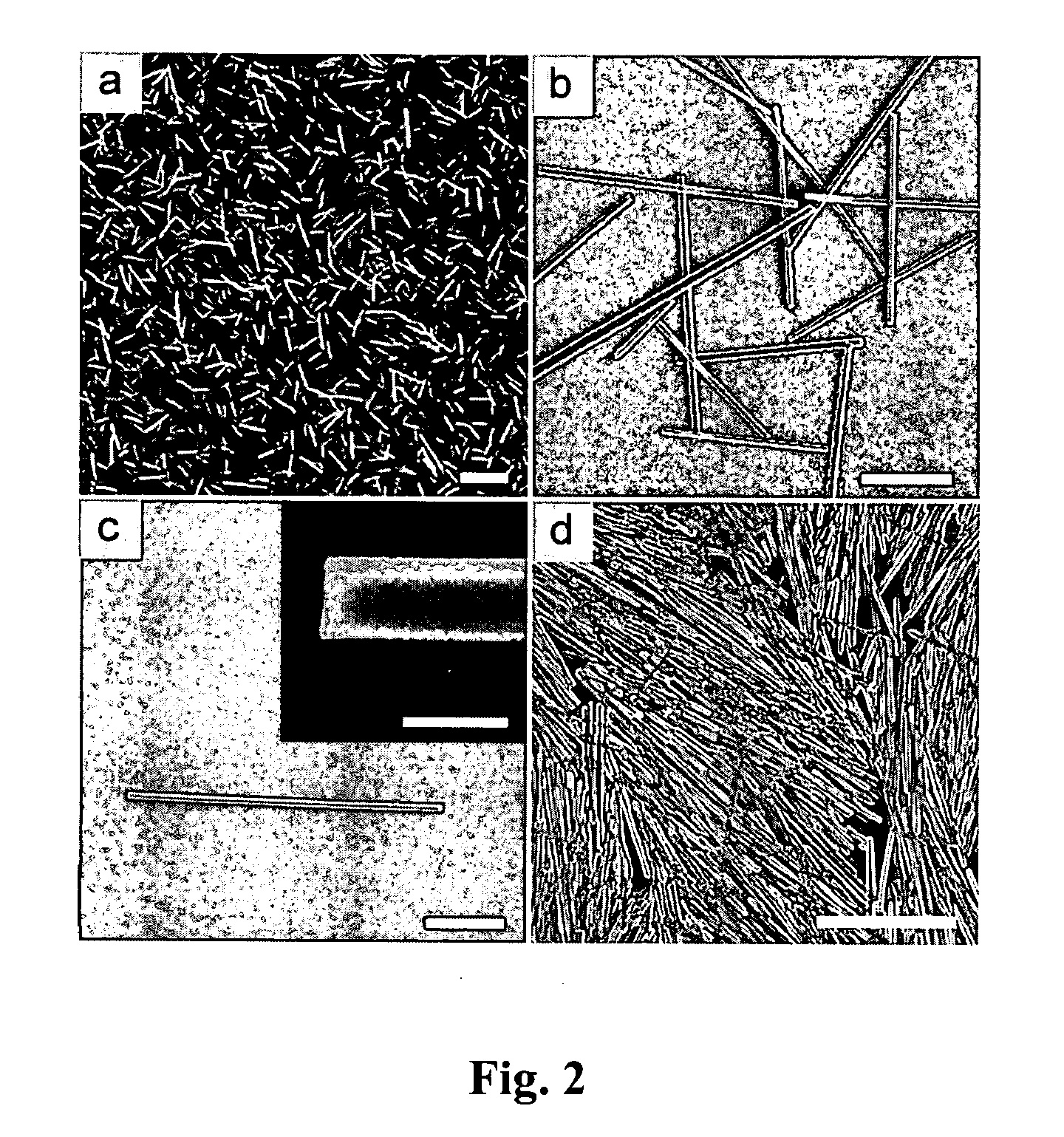

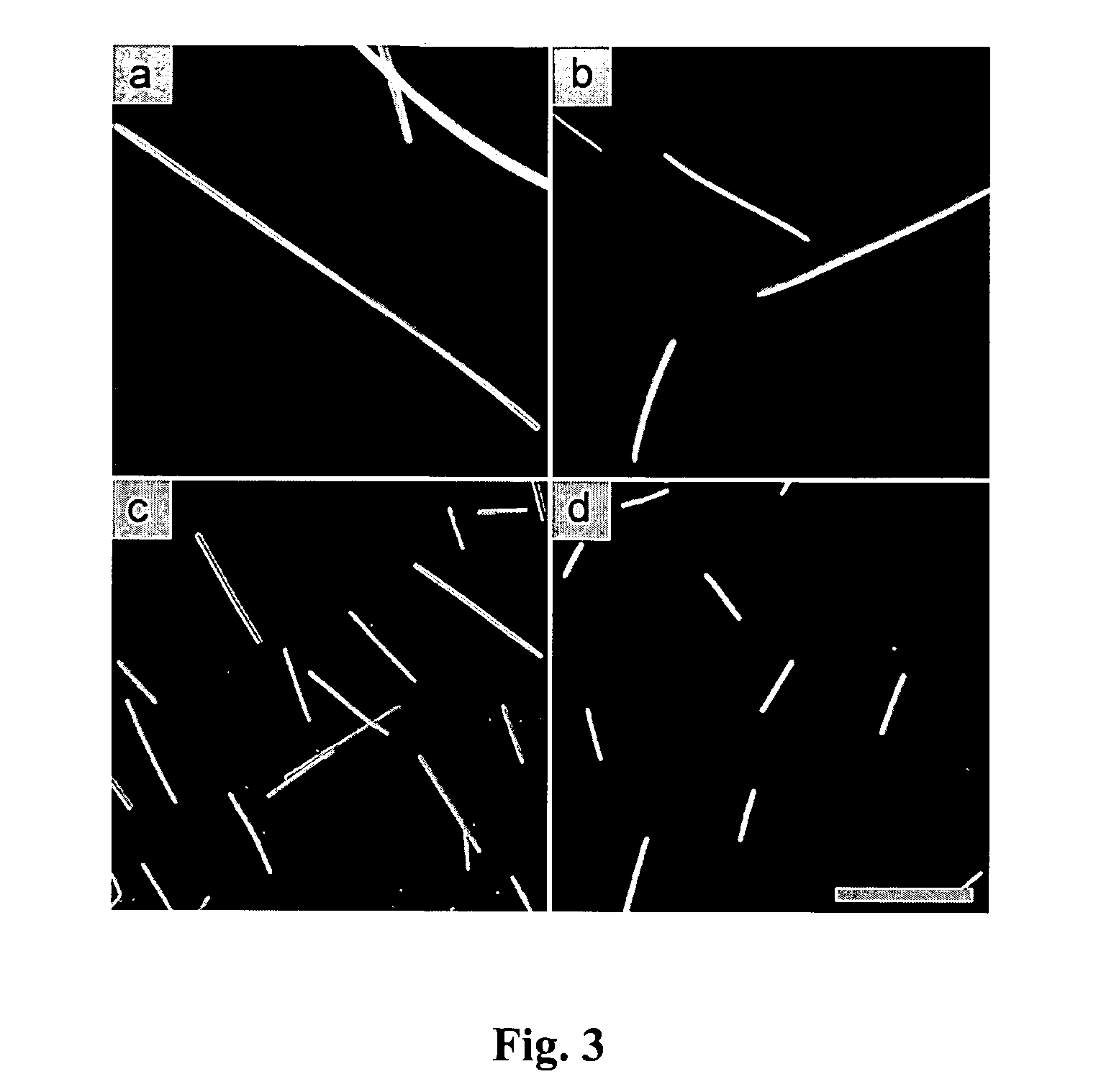

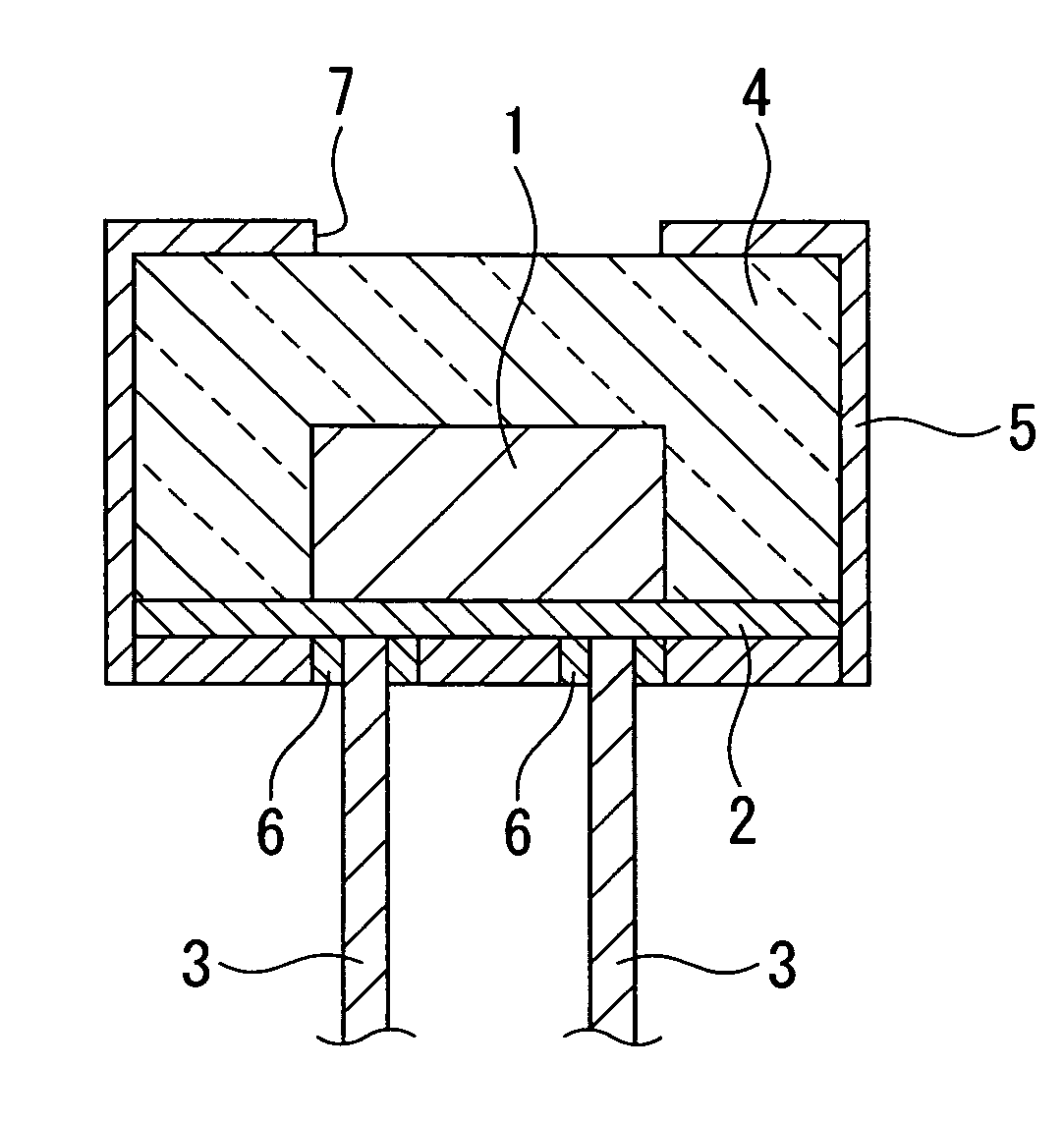

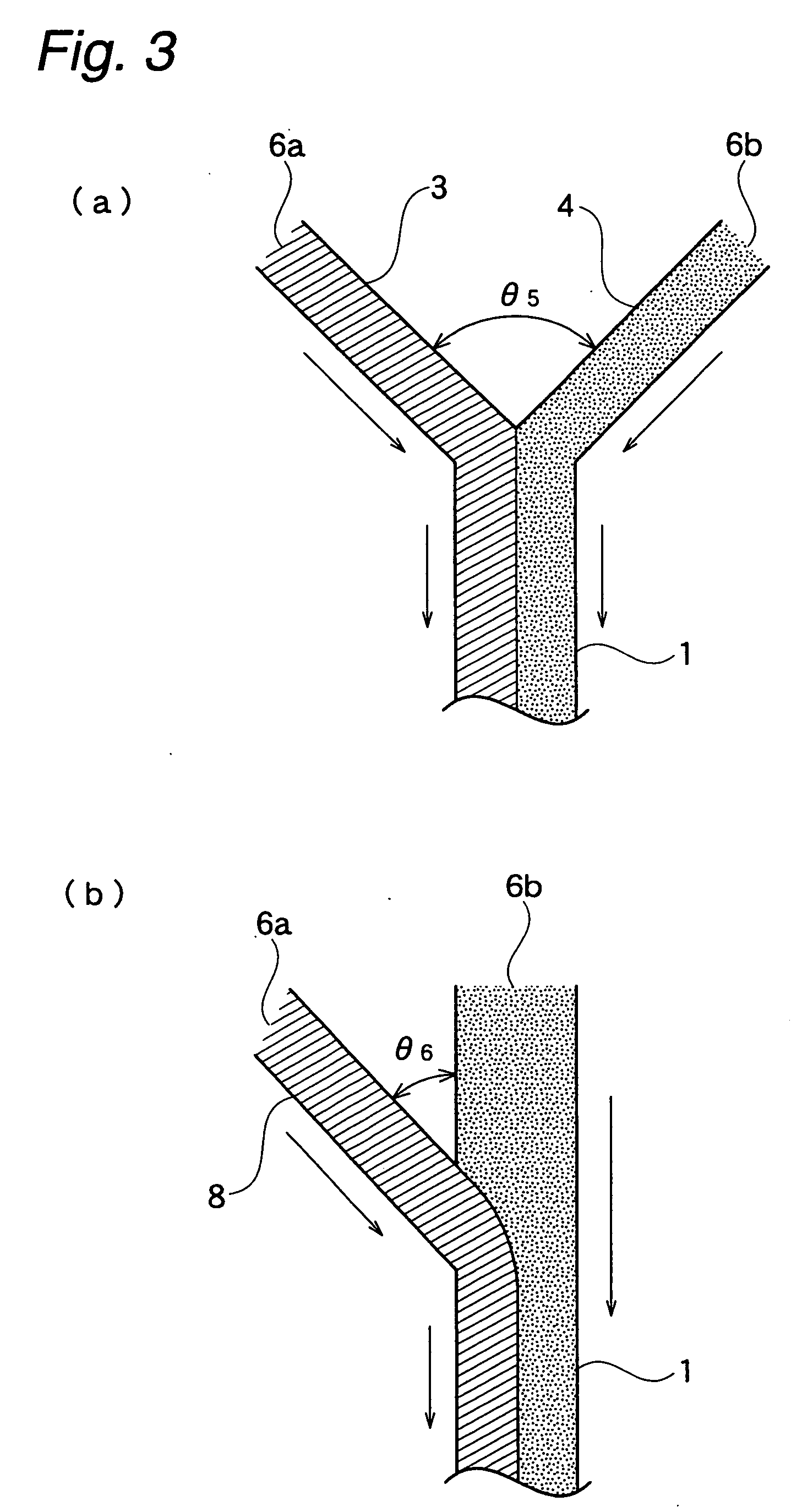

Process for preparing microrods using liquid-liquid dispersion

ActiveUS20060063882A1Large aspect ratioSimple methodBiocideOrganic active ingredientsPolymer scienceDispersed media

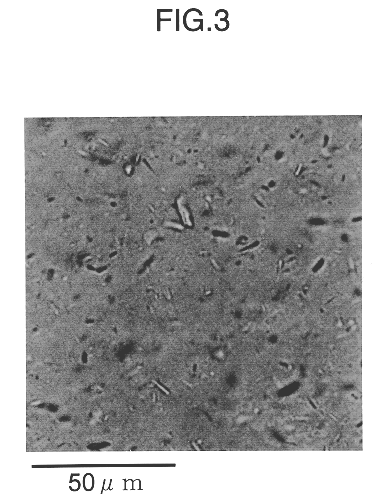

The invention provides a method for forming polymer microrods, the method including the steps of providing a polymer solution comprising a polymer dissolved in a first solvent; providing a dispersion medium comprising a second solvent, wherein the first solvent and the second solvent are miscible or partially soluble in each other, and wherein the polymer is insoluble in the second solvent; adding the polymer solution to the dispersion medium to form a dispersed phase of polymer solution droplets within the dispersion medium; and introducing a shear stress to the dispersion medium and dispersed polymer solution droplets for a time and at a shear rate sufficient to elongate the polymer solution droplets to form microrods and solidify the microrods by attrition of the polymer solvent into the dispersion medium.

Owner:NORTH CAROLINA STATE UNIV

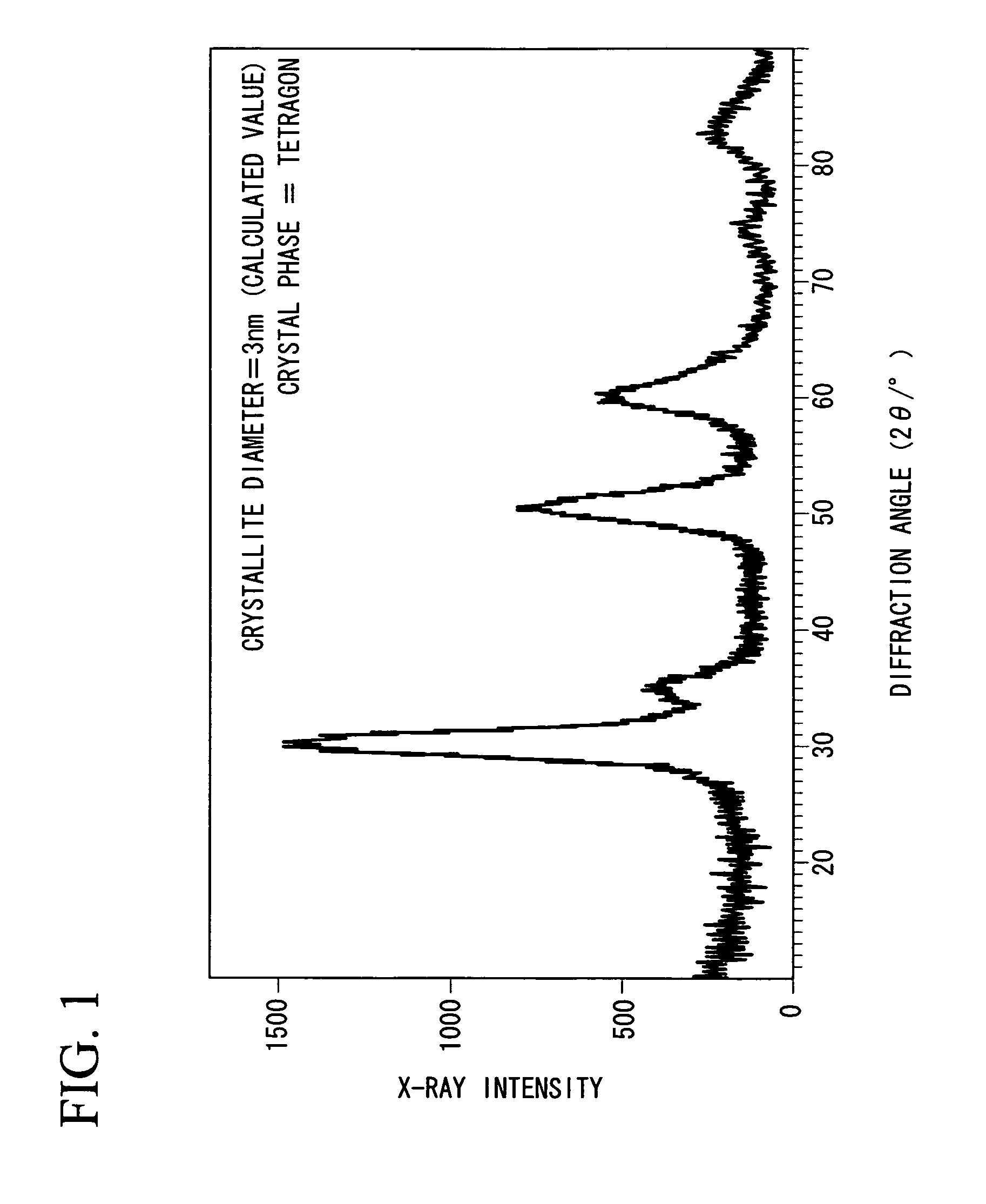

Transparent Inorganic Oxide Dispersion and Iorganic Oxide Particle-Containing Resin Composition, Composition for Sealing Light Emitting Element and Light Emitting element, Hard Coat Film and Optical Functional Film and Optical Component, and Method for Producing Inorganic Oxide Pariticle-Containing Resin

InactiveUS20090140284A1High refractive indexExcellent mechanical propertiesMixing methodsSemiconductor/solid-state device detailsDispersed mediaOrganic Oxide

The present invention provides a transparent inorganic oxide dispersion which makes it possible to improve the refractive index and mechanical characteristics and to maintain transparency by modifying the surface of inorganic oxide particles with a surface modifier having one or more reactive functional groups; and an inorganic oxide particle-containing resin composition in which the transparent inorganic oxide dispersion and a resin are compositely integrated by the polymerization reaction, a composition for sealing a light emitting element, a light emitting element, and a method for producing an inorganic oxide particle-containing resin composition; and a hard coat film which has high transparency and makes it possible to improve a refractive index and tenacity, an optical functional film, an optical lens and an optical component. The transparent inorganic oxide dispersion of the present invention comprises inorganic oxide particles which have a surface modified with a surface modifier having one or more reactive functional groups and have a disperse particle diameter of 1 nm or more and 20 nm or less, and a disperse medium, wherein the surface modifier is one or more kinds selected from the group consisting of a silane coupling agent, a modified silicone, and a surfactant.

Owner:SUMITOMO OSAKA CEMENT CO LTD

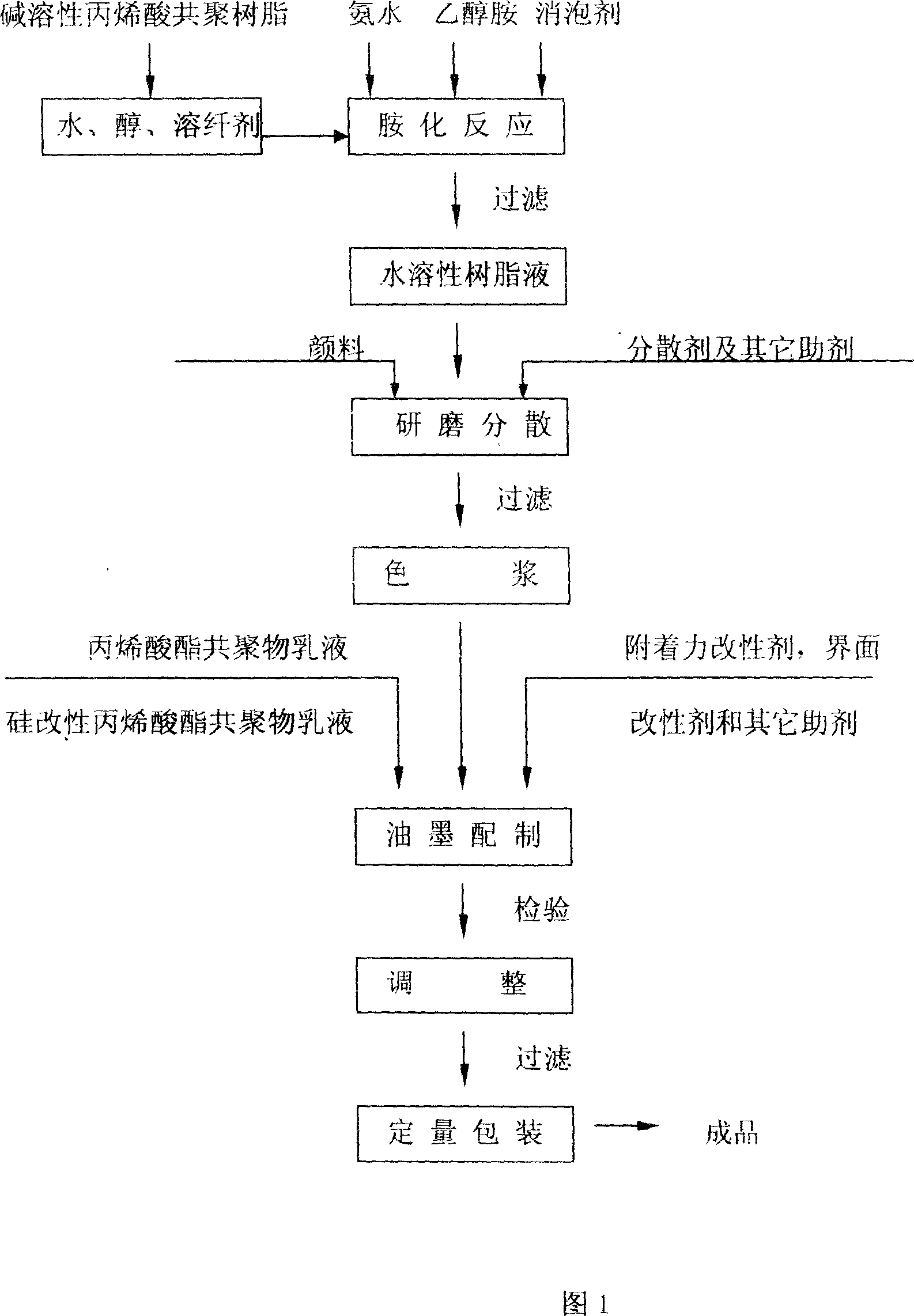

Plastic-film water intaglio printing ink

InactiveCN101029194AImprove adhesion fastnessImprove stabilityInksOther printing apparatusEmulsionDispersed media

A water plastic-film intaglio printing ink consists of alkali soluble acrylic copolymer, low-Tg value acrylate copolymer emulsion, high-Tg value acrylate copolymer emulsion, silicon modified acrylate copolymer emulsion as grinding dispersing medium and filming medium. Adhesion modifier, interface modifier and other various accessories are added into ink and the ink can be produced proportionally for red ink, yellow ink, blue ink, black ink and other-color inks. It has bright color, better saturation degree, alkali-resistance and dispersion.

Owner:BEIJINGYINGKEFAN CHEM PRODS

Phosphorus-contained flame-retarding nano-class ethanediol polyterephthalate/laminated silicate composition and its preparing process and application

InactiveCN1396206AImprove mechanical propertiesMeet practical requirementsFiberDimethyl terephthalate

A P-contained flame-retarding ethanediol polyterephthalate / laminar silicate composition is prepared from dimethyl terephthalate (or terephthalic acid), ethanediol, laminar silicate, P-contained flame retardant, intercalator, dispersing medium and catalyst. Its advantages are high mechanical properties and refractory nature, and simple preparing process.

Owner:SICHUAN UNIV

Conductive Ink

InactiveUS20080134936A1Improve adhesionLower resistanceMaterial nanotechnologyTransportation and packagingPolymer scienceDispersed media

It is an object of the present invention to provide a conductive ink which enables to form a circuit or the like having excellent adhesion to a substrate and to form a conductor having high film density and low electric resistance. In order to attain the object, a conductive ink comprising metal powder or metal oxide powder dispersed in a dispersion medium, which is characterized in that the dispersion medium contains a metal salt or a metal oxide as a film density improver for increasing film density of a conductor formed by using the conductive ink is adopted. A main solvent constituting the dispersion medium is selected from one or a combination of two or more selected from the group consisting of water, alcohols, glycols and saturated hydrocarbons having a boiling point of 300 deg. C. or less at normal pressure.

Owner:MITSUI MINING & SMELTING CO LTD

Material and applications therefor

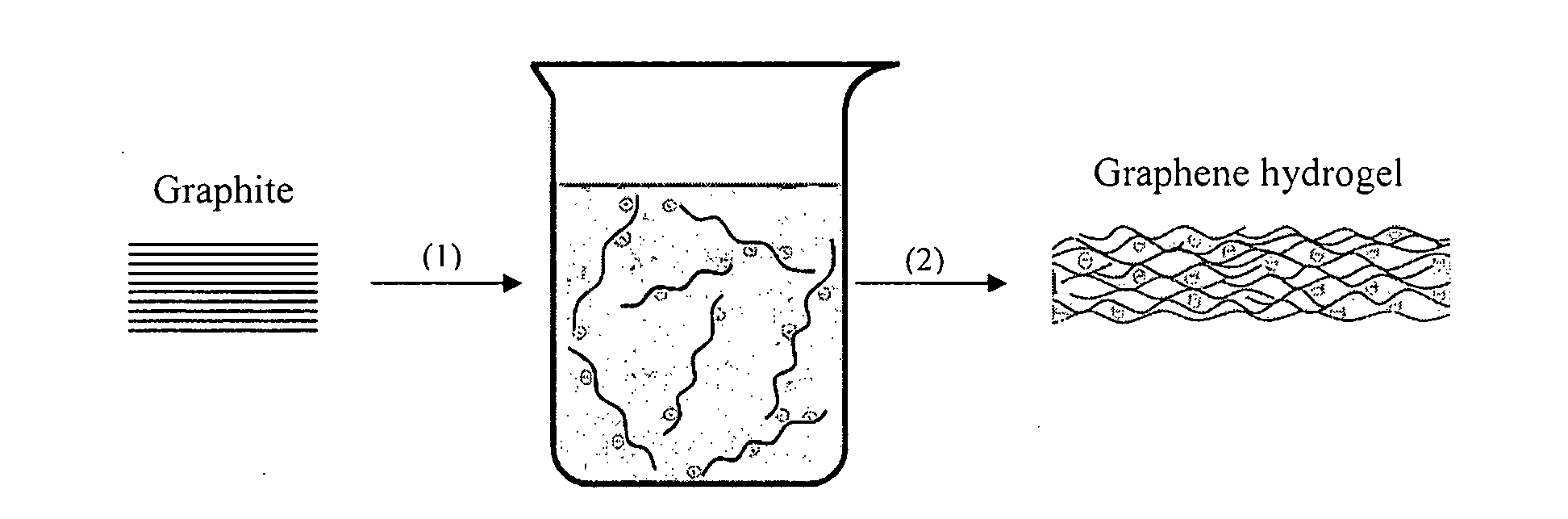

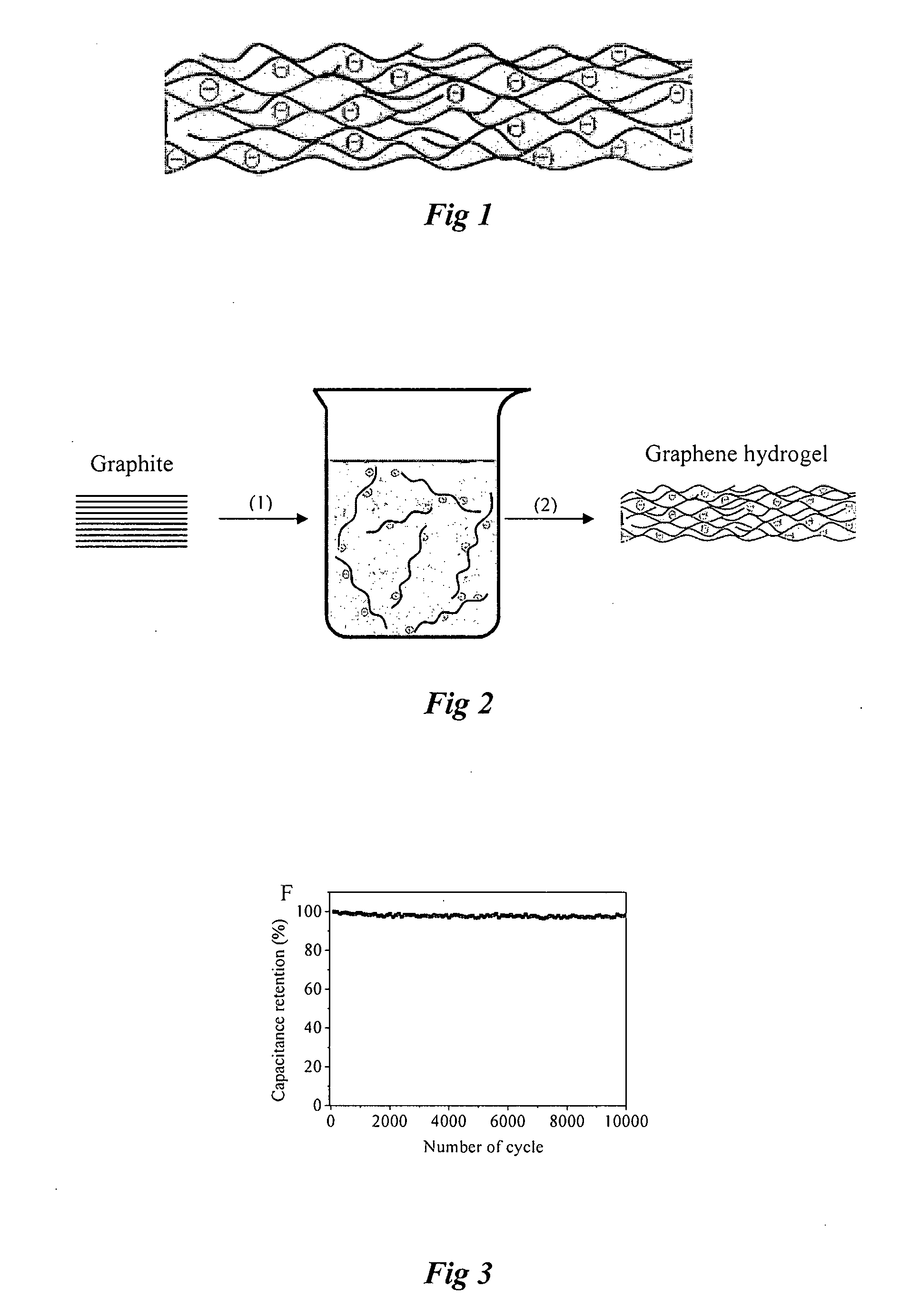

ActiveUS20130180912A1Increase temperatureLarge inter-sheet spacingMaterial nanotechnologyCarbon compoundsPolymer scienceDispersed media

A gel film or an isolated gel film comprising sheets of graphene or chemically converted graphene at least partially separated by a dispersion medium, such as water, and arranged in a substantially planar manner to form an electrically conductive matrix.

Owner:MONASH UNIV

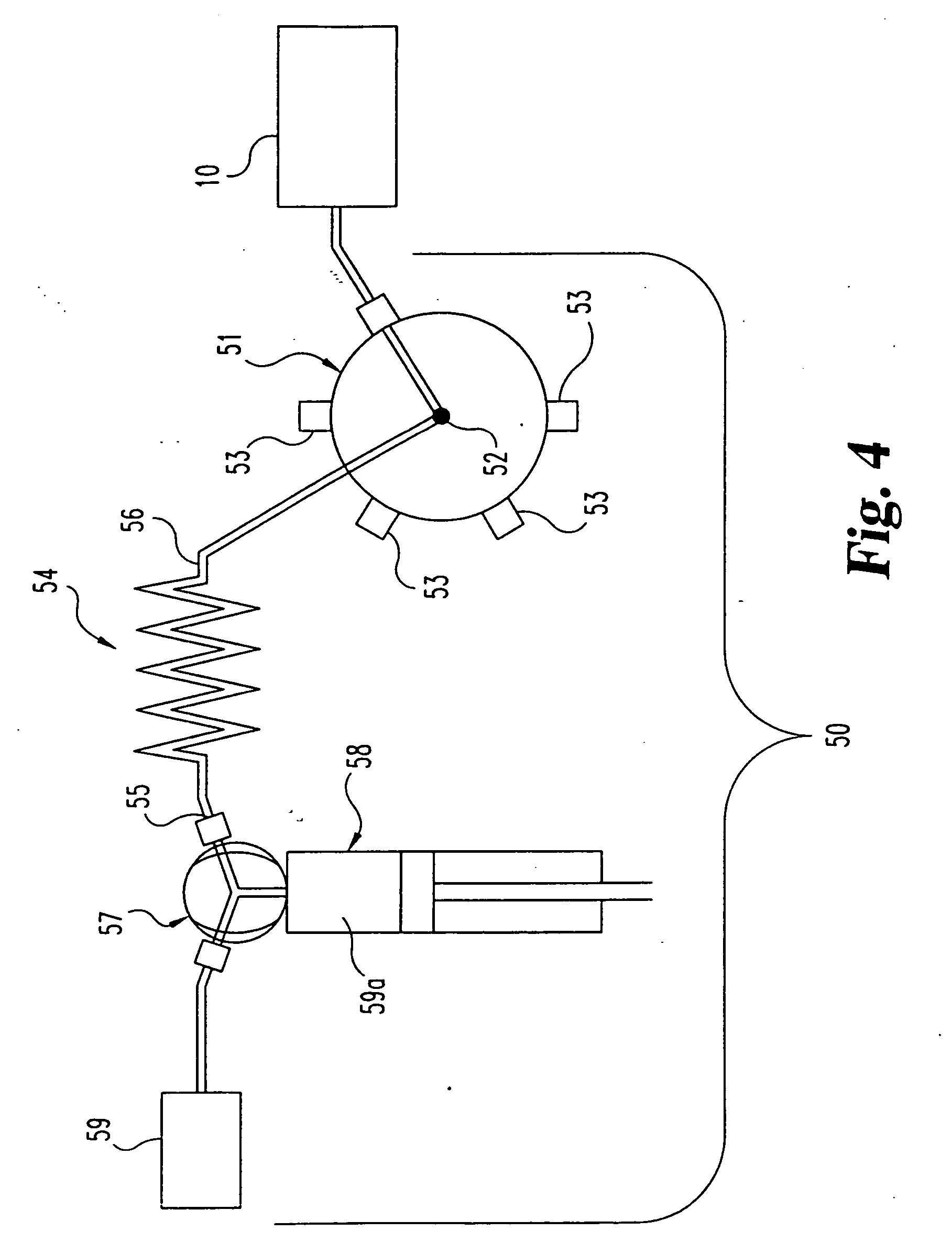

Flow-controlled magnetic particle manipulation

InactiveUS20070105163A1Increase flow rateIncrease concentrationBioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic markerChemical physics

Inventive methods and apparatus are useful for collecting magnetic materials in one or more magnetic fields and resuspending the particles into a dispersion medium, and optionally repeating collection / resuspension one or more times in the same or a different medium, by controlling the direction and rate of fluid flow through a fluid flow path. The methods provide for contacting derivatized particles with test samples and reagents, removal of excess reagent, washing of magnetic material, and resuspension for analysis, among other uses. The methods are applicable to a wide variety of chemical and biological materials that are susceptible to magnetic labeling, including, for example, cells, viruses, oligonucleotides, proteins, hormones, receptor-ligand complexes, environmental contaminants and the like.

Owner:BATTELLE MEMORIAL INST

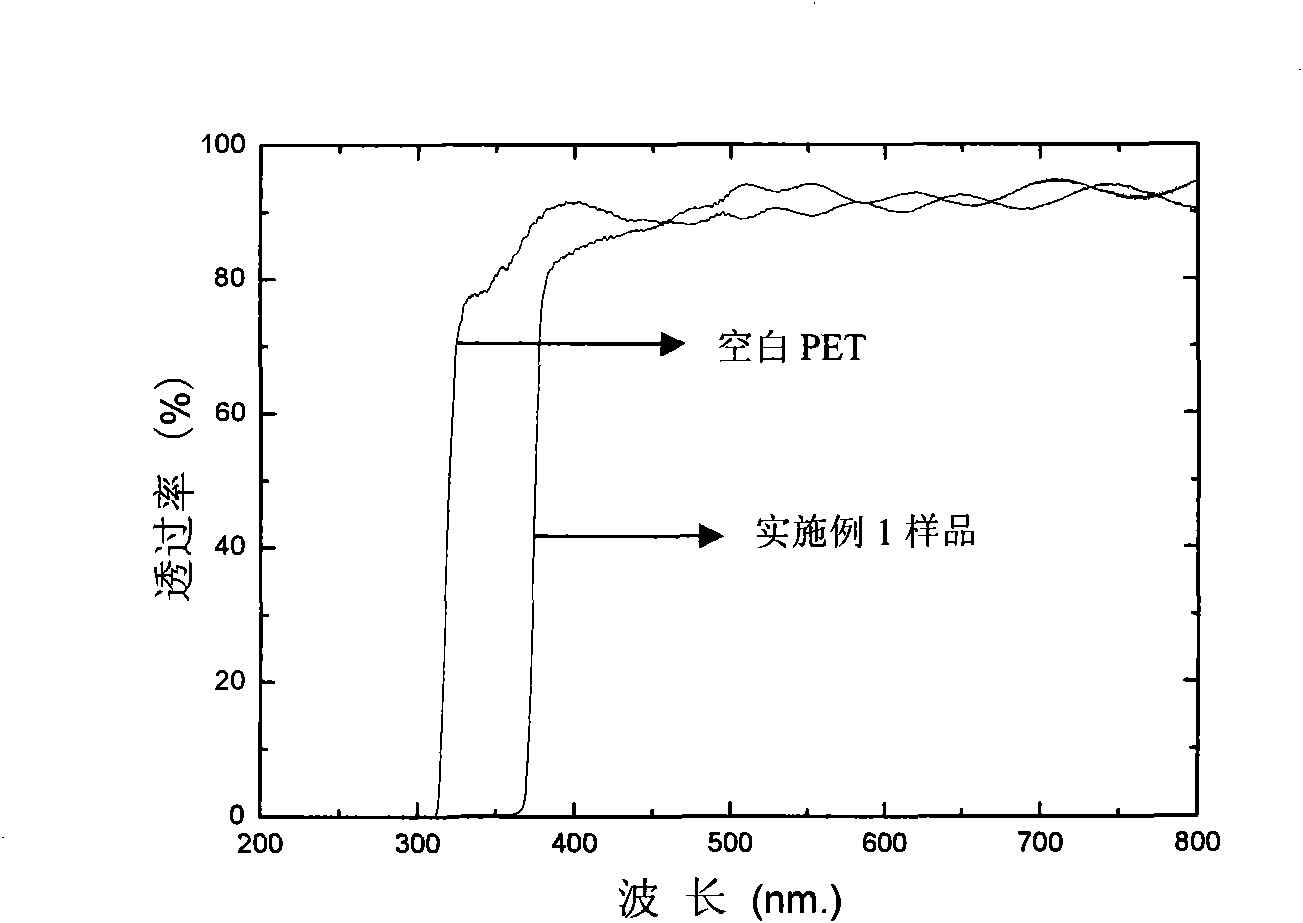

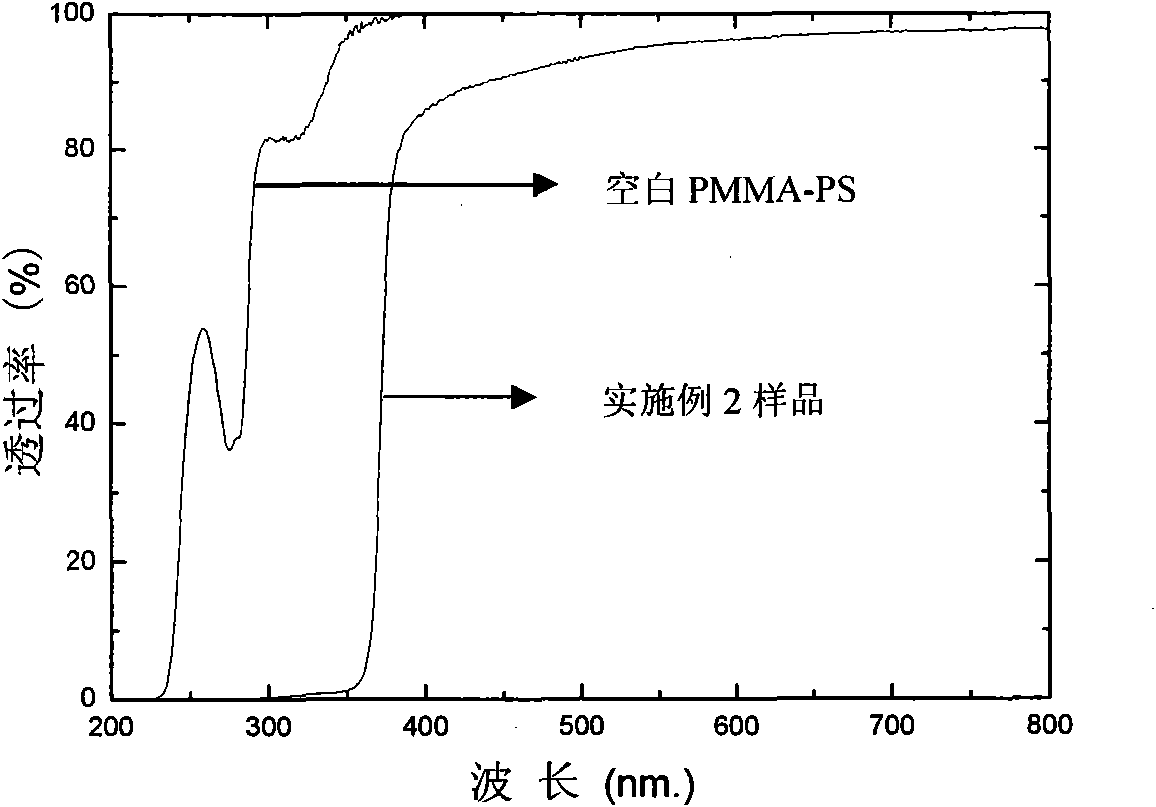

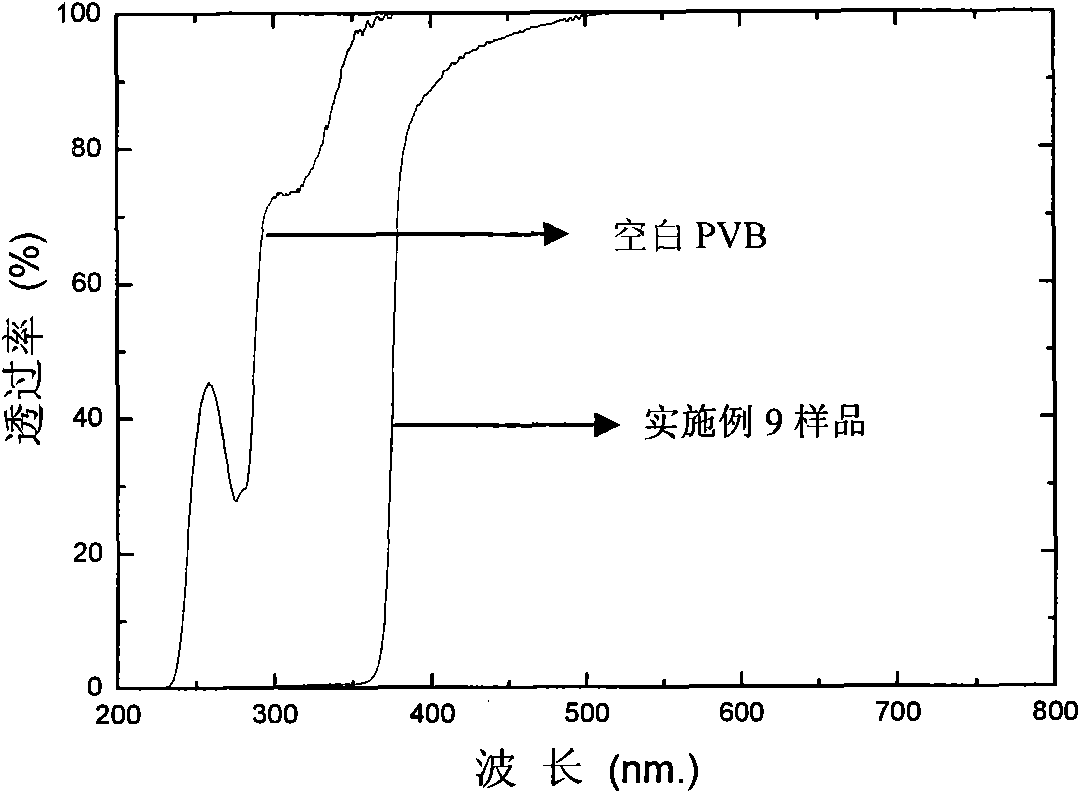

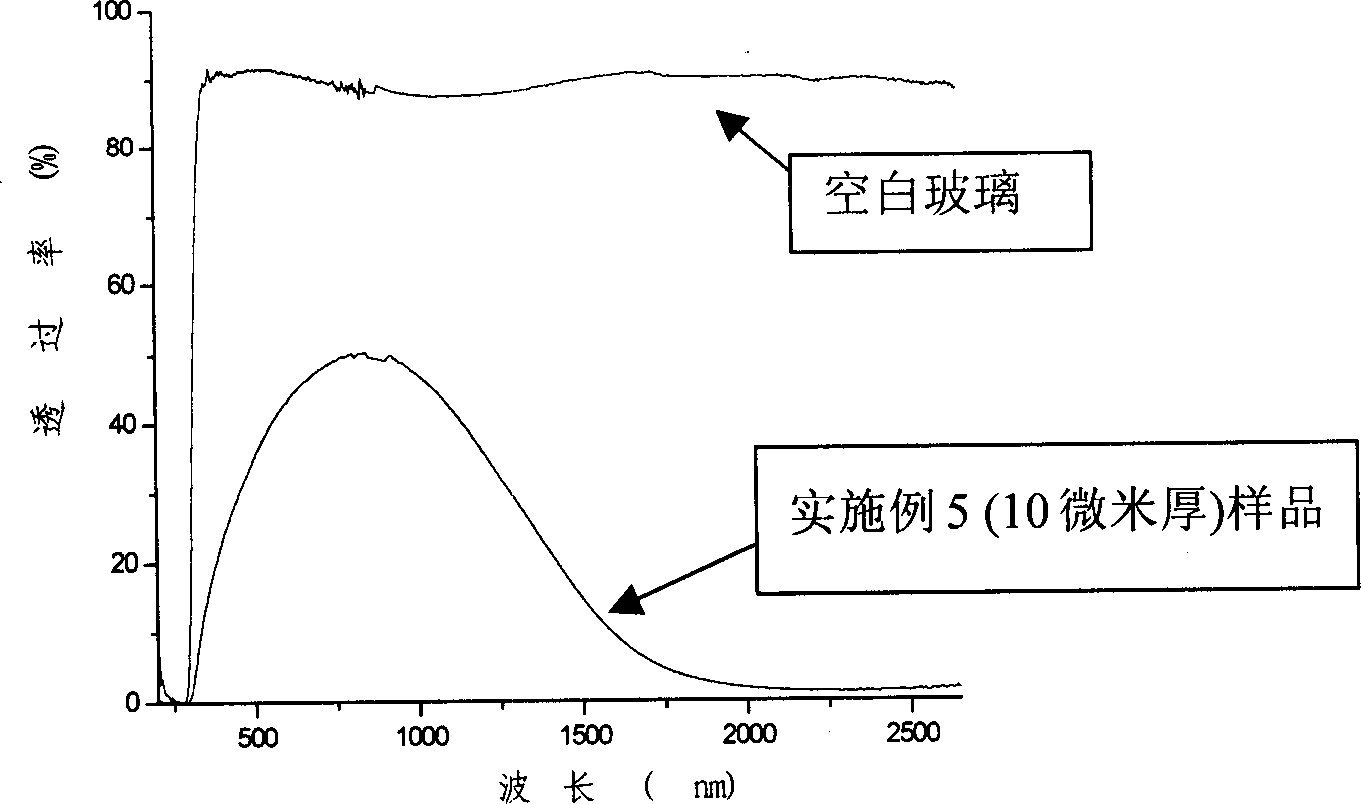

Highly-transparent ultraviolet-resistant energy-saving film and preparation method thereof

The invention relates to a highly-transparent ultraviolet-resistant energy-saving film and a preparation method thereof, belonging to the field of composite films synthesized by compounding polymer and inorganic nano-particles and aiming at overcoming the defects that the prior film has low visible light transmission and high production cost. The highly-transparent ultraviolet-resistant energy-saving film comprises the following components by the weight percent: 50-99.8 of organic polymer, 0.2-50 of metal-oxide nano-particles and 0-39.9 of polymer auxiliary agent. The highly-transparent ultraviolet-resistant energy-saving film is prepared by a solution mixing method or a solution-melting mixing method; with the solution mixing method, the organic polymer and the metal-oxide nano-particles are dispersed in dispersing medium to prepare film preparing stock solution, and the film preparing stock solution is used for preparing the energy-saving film on a substrate; with the solution-melting mixing method, the mixture of the organic polymer and the metal-oxide nano-particles is dried to prepare master batch, and the master bath is mixed with the organic polymer and the polymer auxiliary agent to prepare the energy-saving film. The highly-transparent ultraviolet-resistant energy-saving film has high visible light transmission, good ultraviolet resistance and energy-saving effect, simple preparation process and low cost, thereby being suitable for industrial production.

Owner:BEIJING UNIV OF CHEM TECH +1

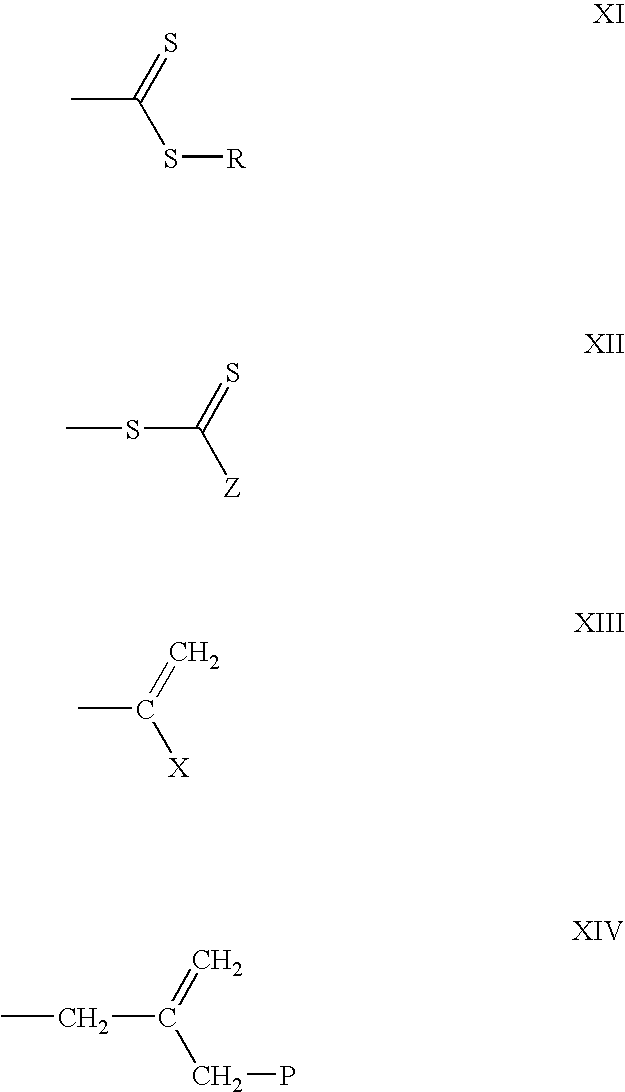

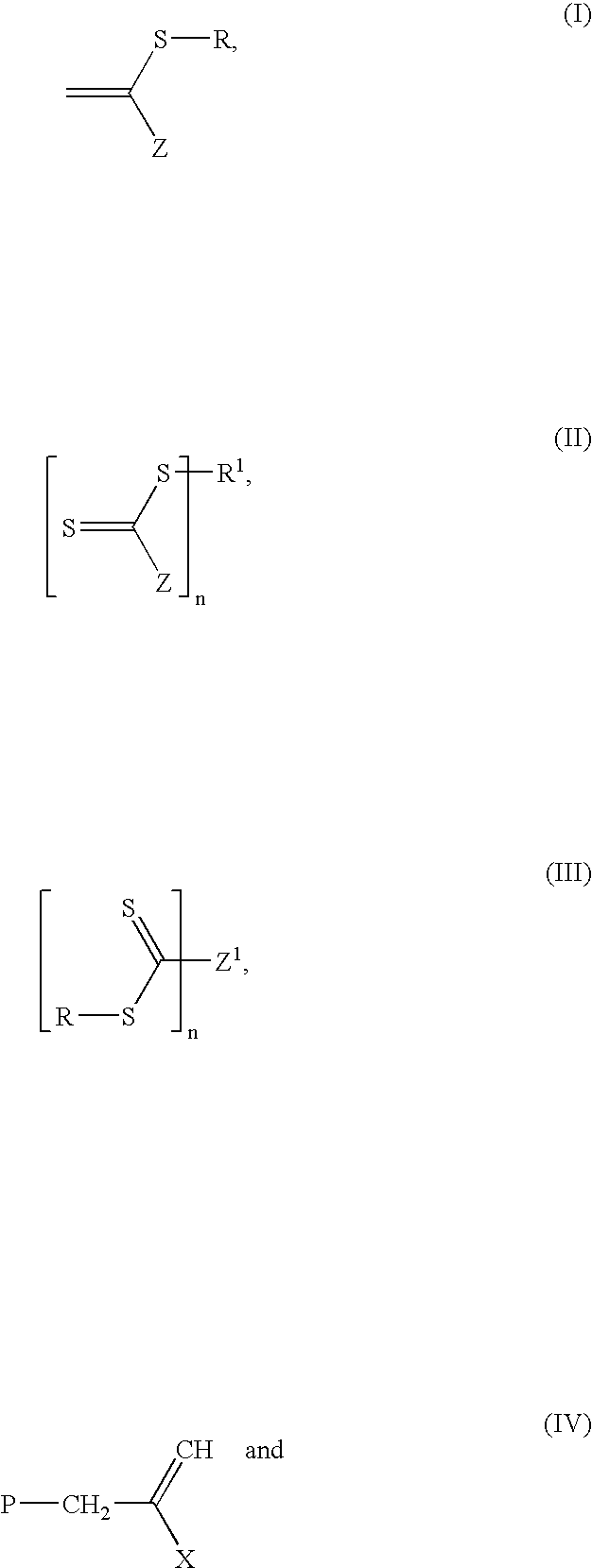

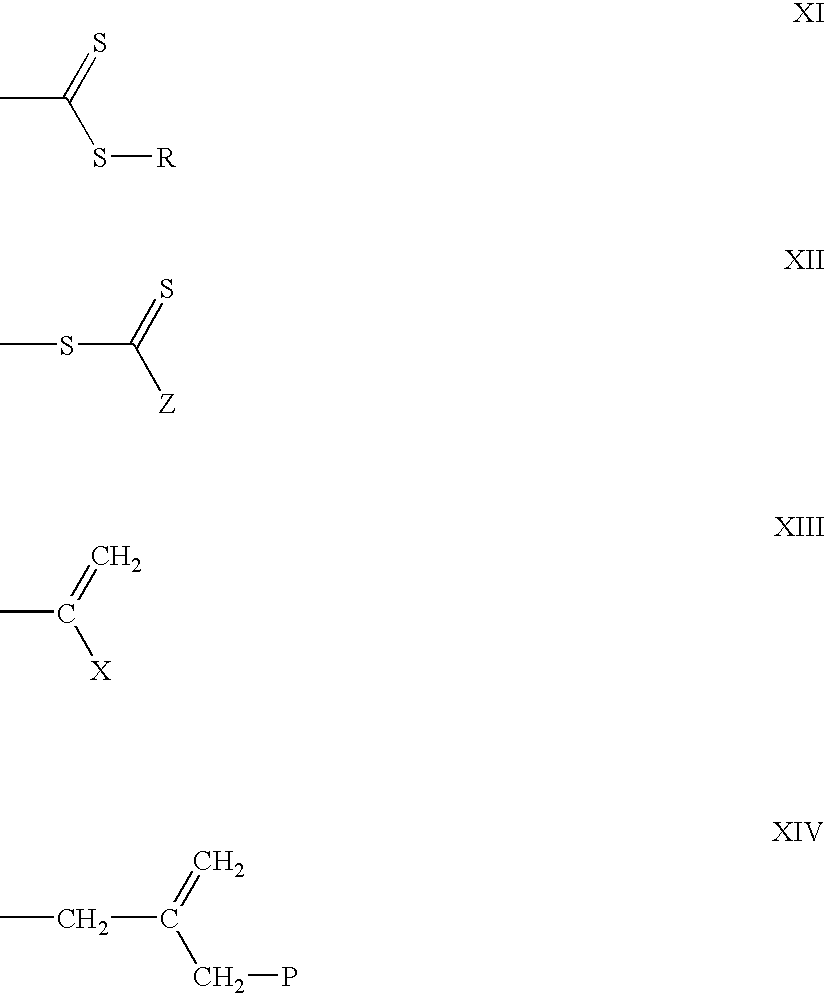

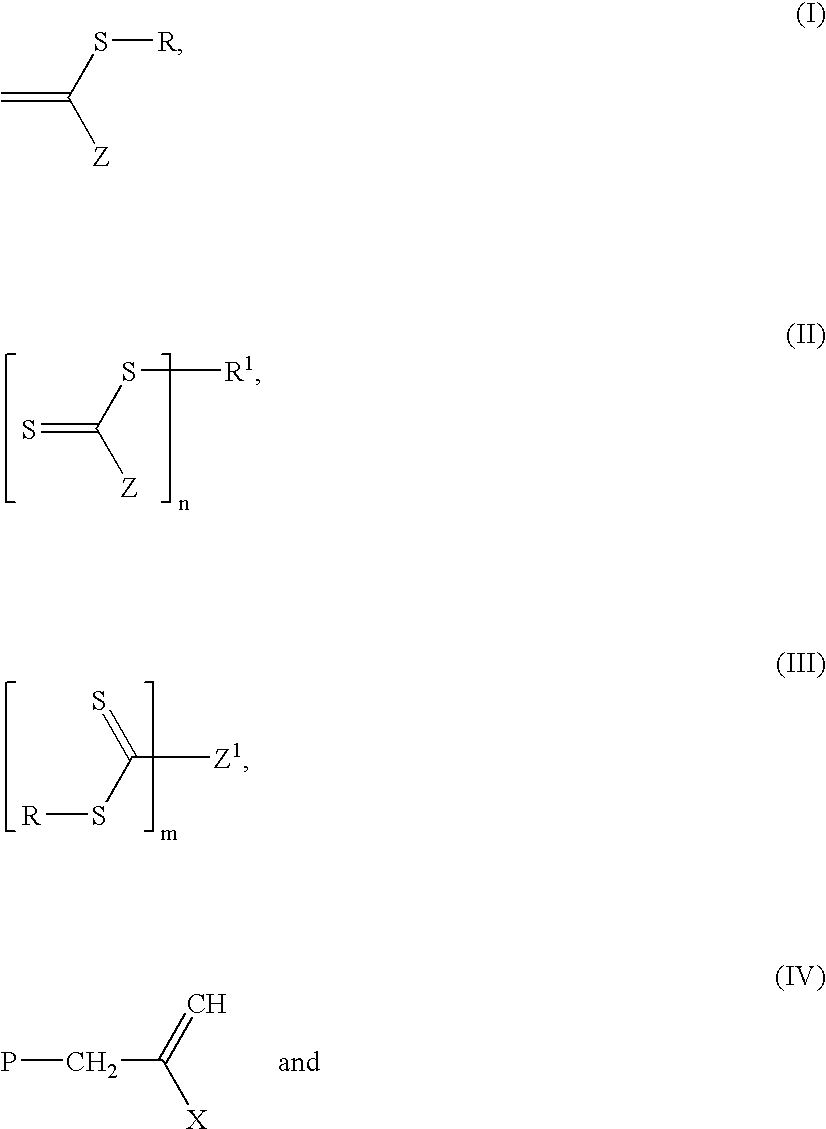

Process of microgel synthesis and products produced therefrom

The invention provides in one aspect a process for preparing a microgel by RAFT polymerizing in the presence of a RAFT chain transfer agent, one or more solvophobic monomers and one or more solvophilic monomers to form one or more block copolymers comprising one or more solvophobic blocks and one or more solvophilic blocks wherein the solvophobic block is insoluble in a dispersing medium and the solvophilic block is soluble in the dispersing medium. The block copolymer is dispersed in the dispersing medium to form micelles, which is then stabilized to form the microgel. The dispersing medium can be aqueous or lipophilic. The method of the present invention also permits one to encapsulate a wide variety of materials, such as pigments, dye molecules, and aluminum flakes used in metallized paints.

Owner:COMMONWEALTH SCI & IND RES ORG

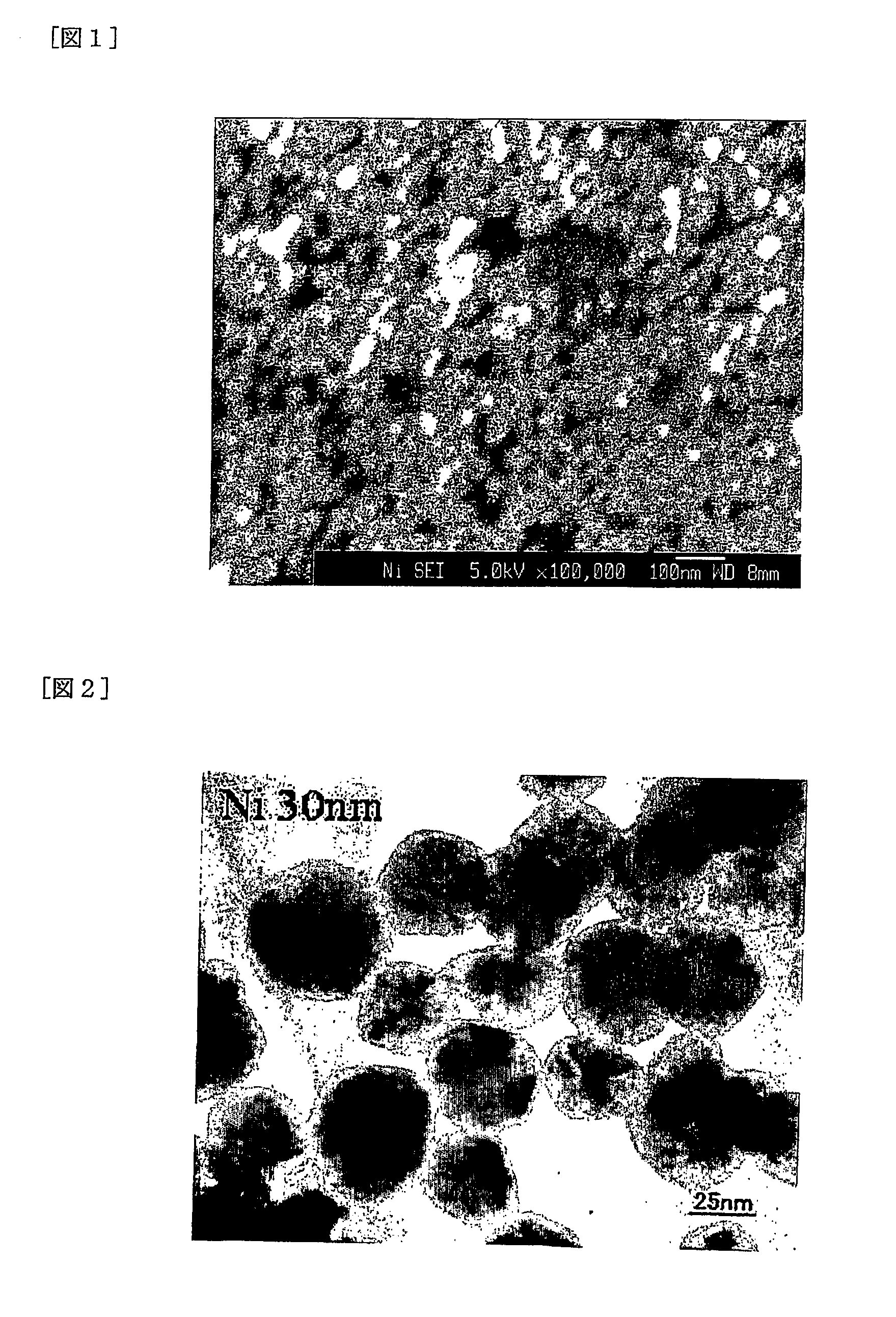

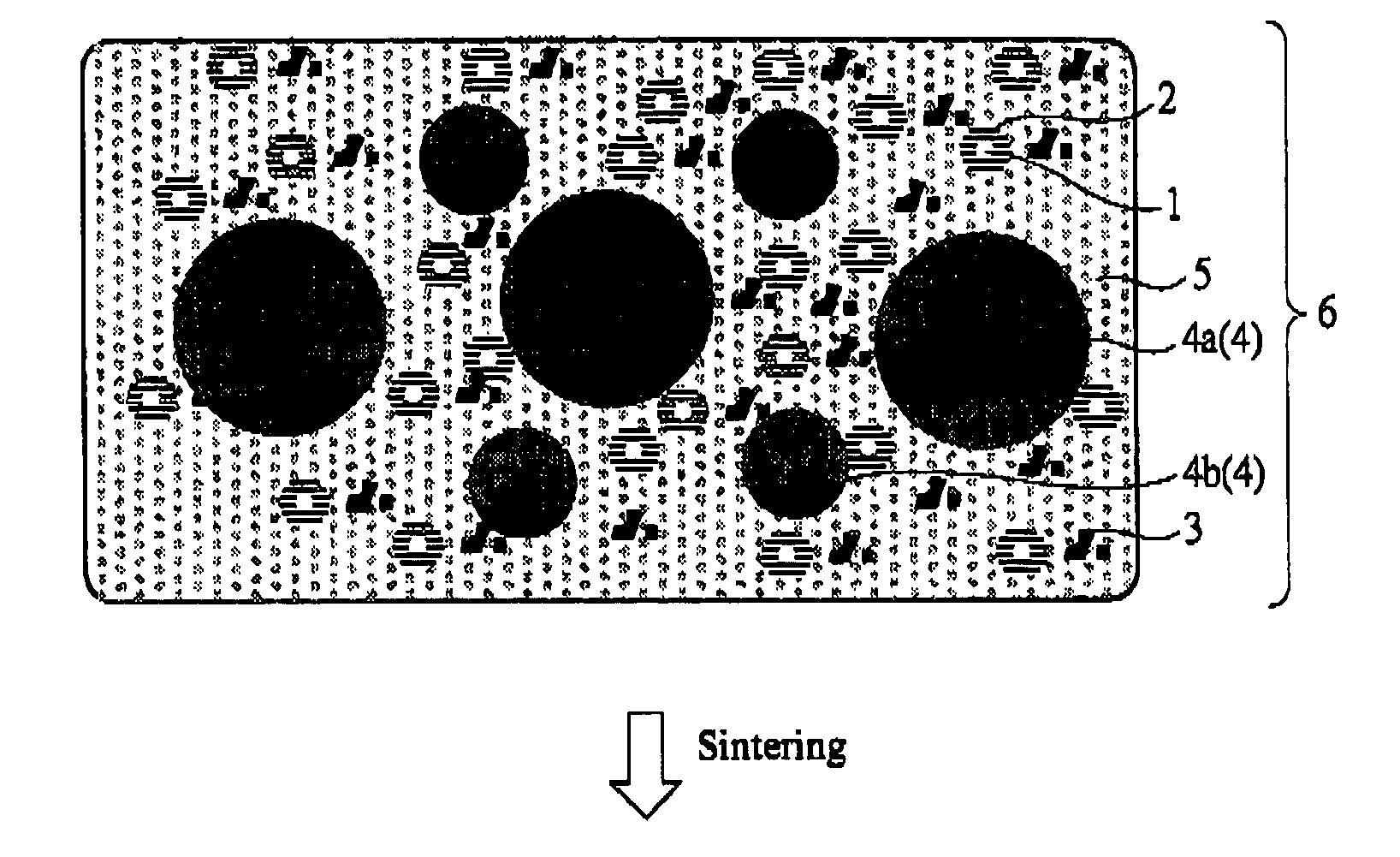

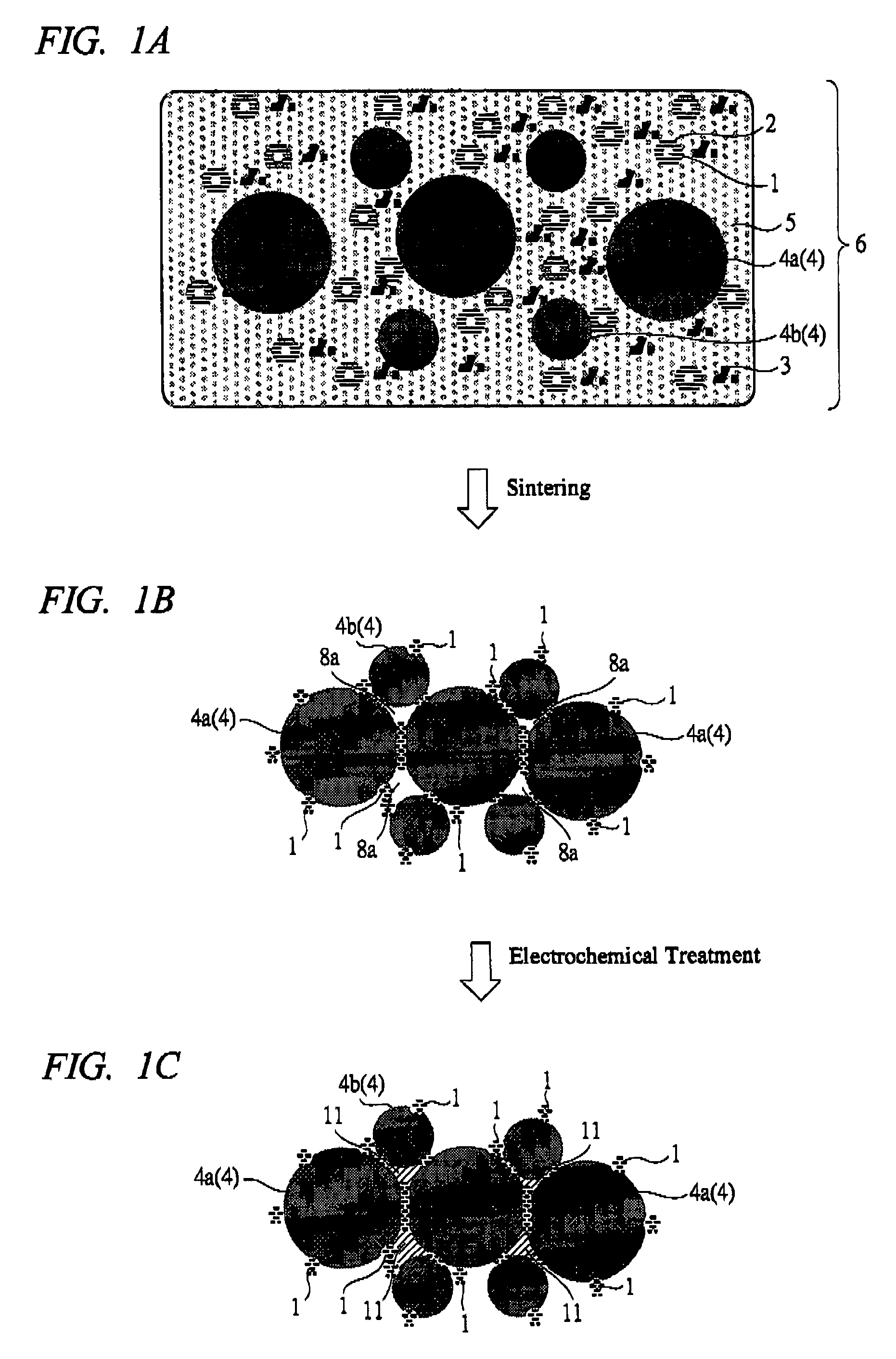

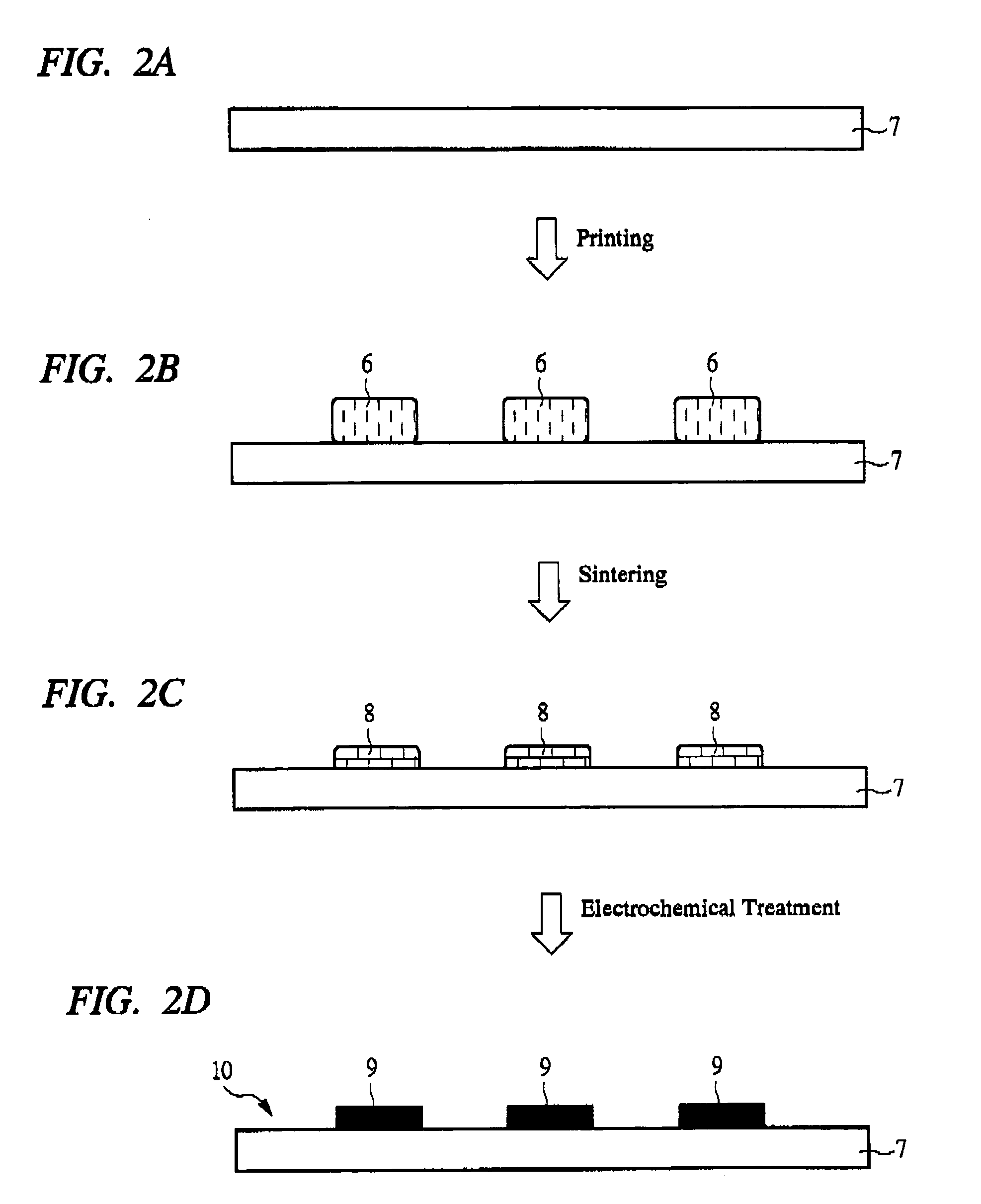

Compound for forming wiring conductor, fabrication method of circuit board using the same and circuit board

InactiveUS20050207930A1Electrical resistance formed at the wiring conductor portion can be reducedHigh strengthMaterial nanotechnologyConductive materialScreen printingSimple Organic Compounds

The present invention sufficiently secures conductor component content ratio in wiring formed on a multilayer circuit board and increases reliability by fabricating the multilayer circuit board by steps of drawing wiring precursor patterns containing a paste of compound for forming wiring conductor containing (a) superfine metal particles (metal nanoparticles) whose average particle size is 1-10 nm; (b) an organic coating compound coated on the surface of the superfine metal particle in the film thickness of 1-10 nm; (c) a latent reactive organic compound reacting with the organic coating compound in the range of 100-250° C., (d) metal particles whose average particle size is 0.5-10 μm, and (e) dispersion medium that stably disperses components (a) through (d) on a substrate by screen printing, sintering by heating the patterns to 100-250° C., and electrochemically treating the patterns to allow the conductor to deposit in a desired cross-sectional area in the inside.

Owner:HITACHI CABLE

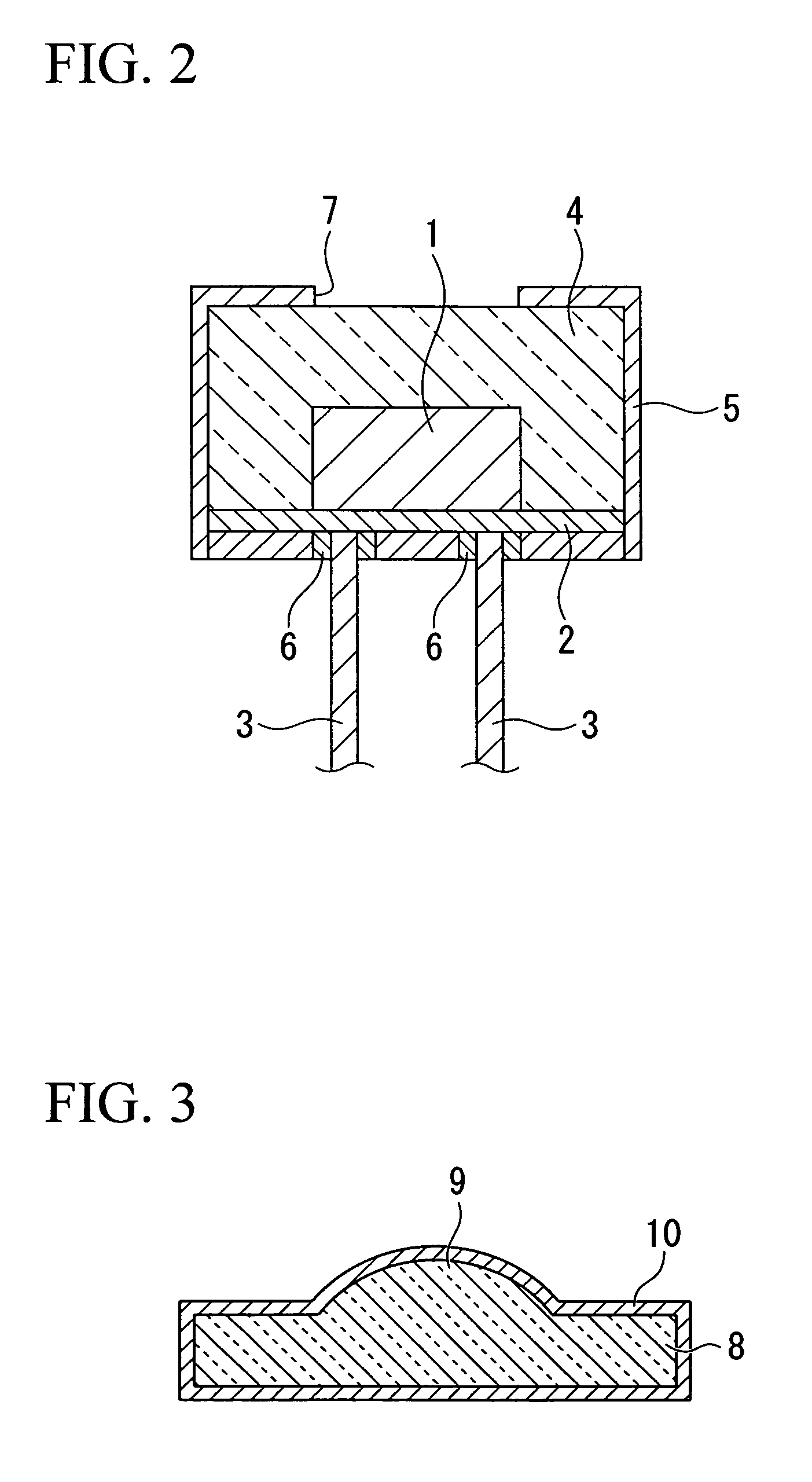

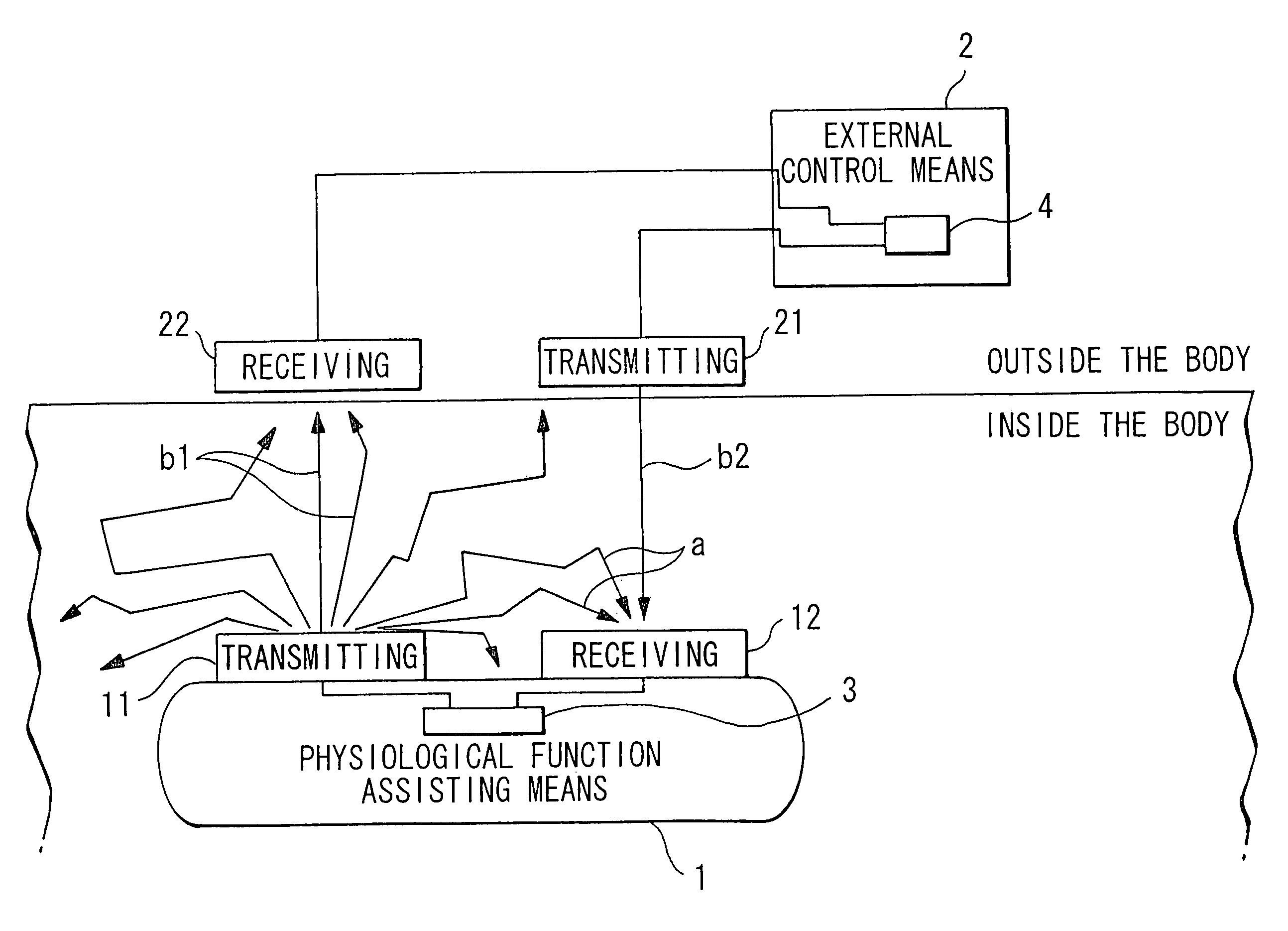

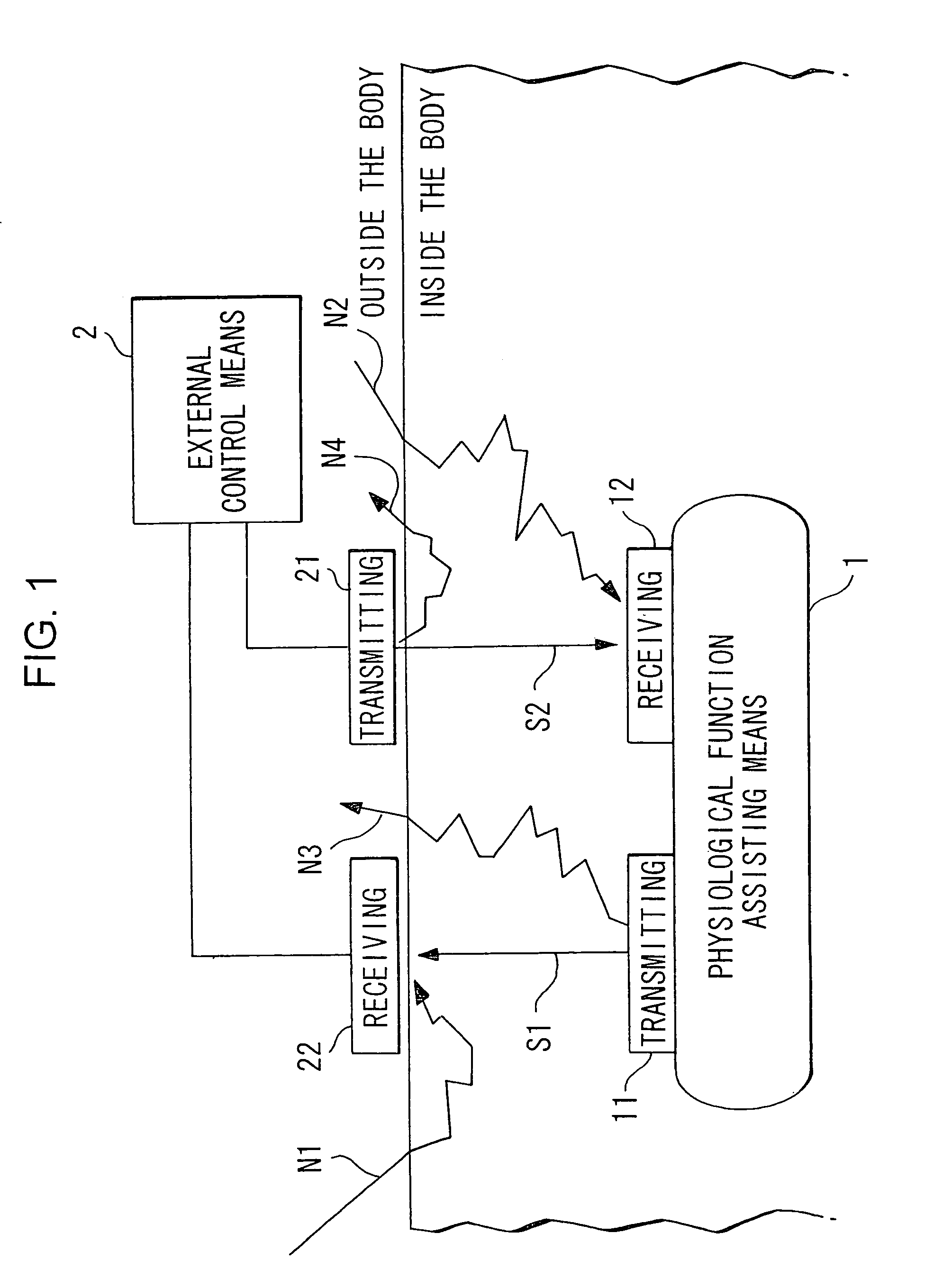

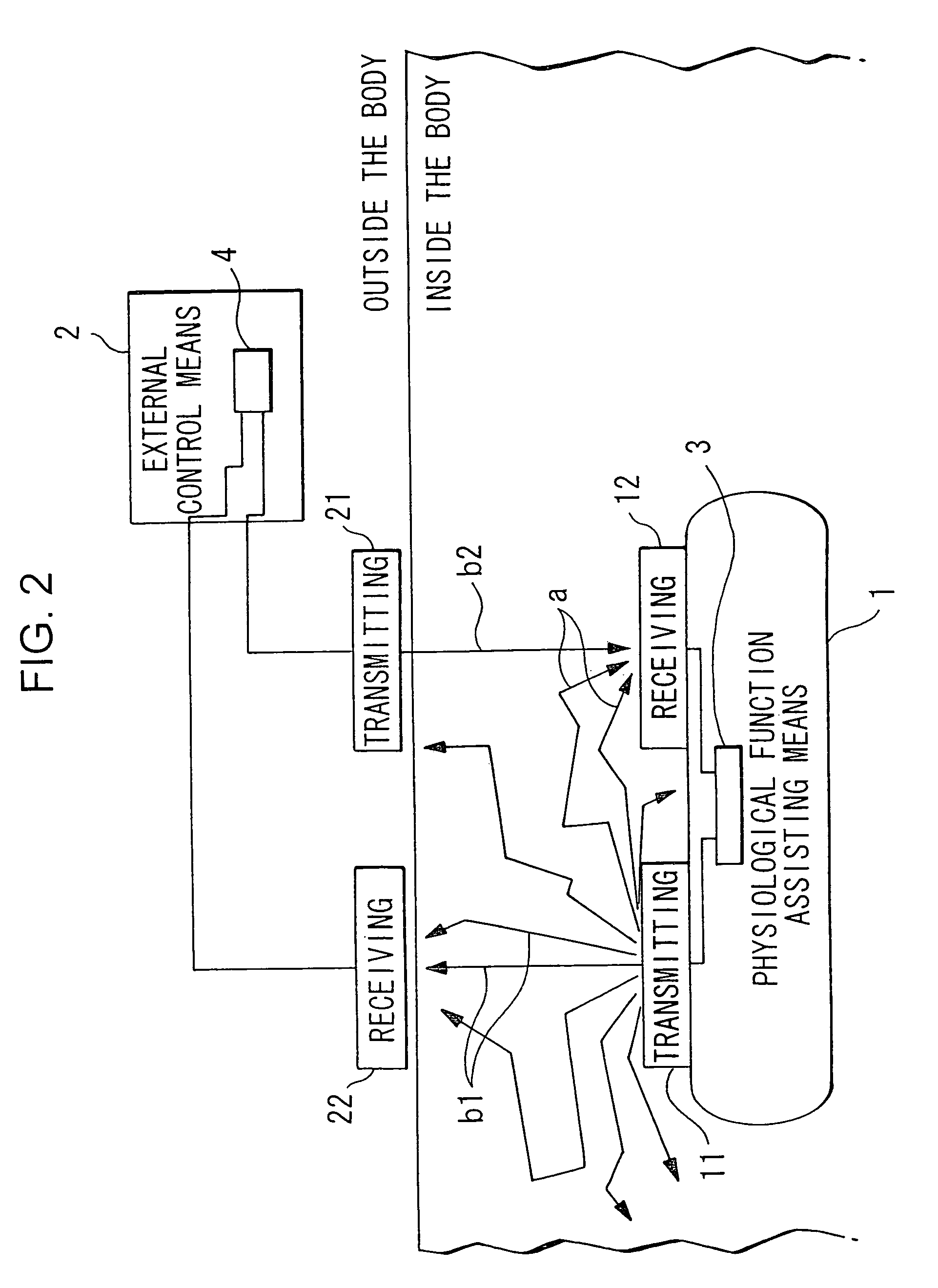

Polarized light communication device, transmitter, laser, polarized light communication device for physiological use, reflected light detector and pulse wave detecting device

InactiveUS6999685B1The overall impact is smallSmall dampingPolarisation multiplex systemsLaser active region structureDispersed mediaEngineering

A physiological function assisting device 1 is embedded in the body, and is provided with a transmitter 11 and receiver 12 for communicating with an external controller 2. External controller 2 controls embedded physiological function assisting device 1 from the outside. External controller 2 is provided with a transmitter 21 and receiver 22 for communicating with physiological function assisting device 1. Transmitters 11,21 modulate the plane of polarization of laser light, and emit the result as a transmission signal. Receivers 12,22 selectively receive light of a specific polarization state. Receivers 12,22 respectively output electric signals corresponding to the polarization state (polarization angle or ellipticity) of the received light. As a result, full duplex communications between a strongly dispersing medium like the human body and the outside is possible, while the power consumed by the internal device can be reduced.

Owner:SEIKO EPSON CORP

Sunlight controlled coating solution in low radiation, preparation method and application

A low-radiation aqueous solution able to be coated on the surface of glass for controlling sunlight contains at least one kind of metal oxide doped nanoparticles, high-molecular filming material, and dispersing medium chosen from water, the mixture of water and alcohol, and the mixture of water, alcohol and ester.

Owner:长春迪高实业有限公司

Uv-shielding silicone coating composition and coated article

ActiveUS20100221557A1Solve the lack of durabilitySolve the lack of resistanceLayered productsCoatingsUltravioletSolvent

A UV-shielding silicone coating composition comprises (A) a dispersion in a dispersing medium of composite zinc oxide nanoparticles which are obtained by coating zinc oxide nanoparticles with an oxide or hydroxide of Al, Si, Zr or Sn, the dispersion having a photocatalytic degradability of up to 25%, (B) a silicone resin, (C) a curing catalyst, and (D) a solvent, the solids content of composite zinc oxide nanoparticle dispersion (A) being 1 to 50% by weight based on silicone resin (B). The composition is transparent to visible light, mar resistant, UV-shielding, weatherable, and durable.

Owner:SHIN ETSU CHEM IND CO LTD

Fabric care compositions comprising polyol based fabric care materials and deposition agents

InactiveUS20060058214A1Organic detergent compounding agentsSurface-active detergent compositionsDispersed mediaPolyol

A composition comprises polyol-based fabric care materials, particularly esterified saccharides. The composition further comprises deposition agents, dispersing medium, and optional adjunct ingredients. The compositions of the present invention are used to treat fabrics to provide one or more of the following benefits: fabric softness, wrinkle reduction after drying, ease of ironing, in-wear shape retention, fabric elasticity, fabric tensile strength, fabric tear strength, and color protection. Various products containing the composition and methods for using the composition are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

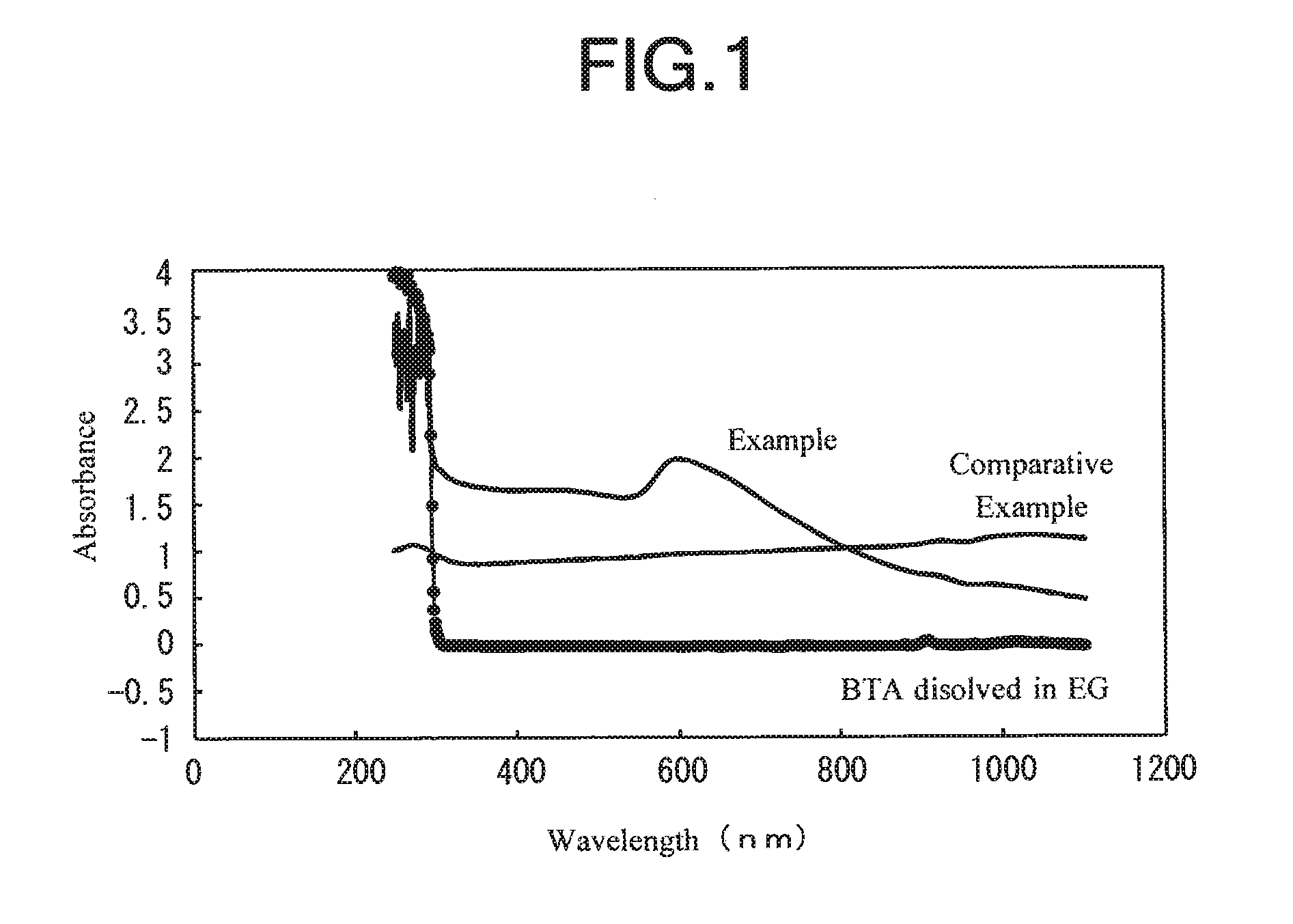

Copper particle dispersing solution and method for producing conductive film using same

InactiveUS20160346838A1Improve conductivityTransportation and packagingMetal-working apparatusScreen printingLight irradiation

A copper particle dispersing solution obtained by dispersing fine copper particles having an average particle diameter of 1 to 100 nm, each of the fine copper particles being coated with an azole compound, such as benzotriazole, and coarse copper particles having an average particle diameter of 0.3 to 20 μm in a dispersing medium, such as ethylene glycol, so as to cause the total amount of the fine copper particles and coarse copper particles to be 50 to 90% by weight and so as to cause the ratio of the weight of the fine copper particles to the weight of the coarse copper particles to be in the range of from 1:9 to 5:5, is applied on a substrate by screen printing or flexographic printing to be preliminary-fired with vacuum drying, and then, fired with light irradiation by irradiating light having a wavelength of 200 to 800 nm at a pulse period of 100 to 3000 μm and a pulse voltage of 1600 to 3600 V, to form a conductive film on the substrate.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

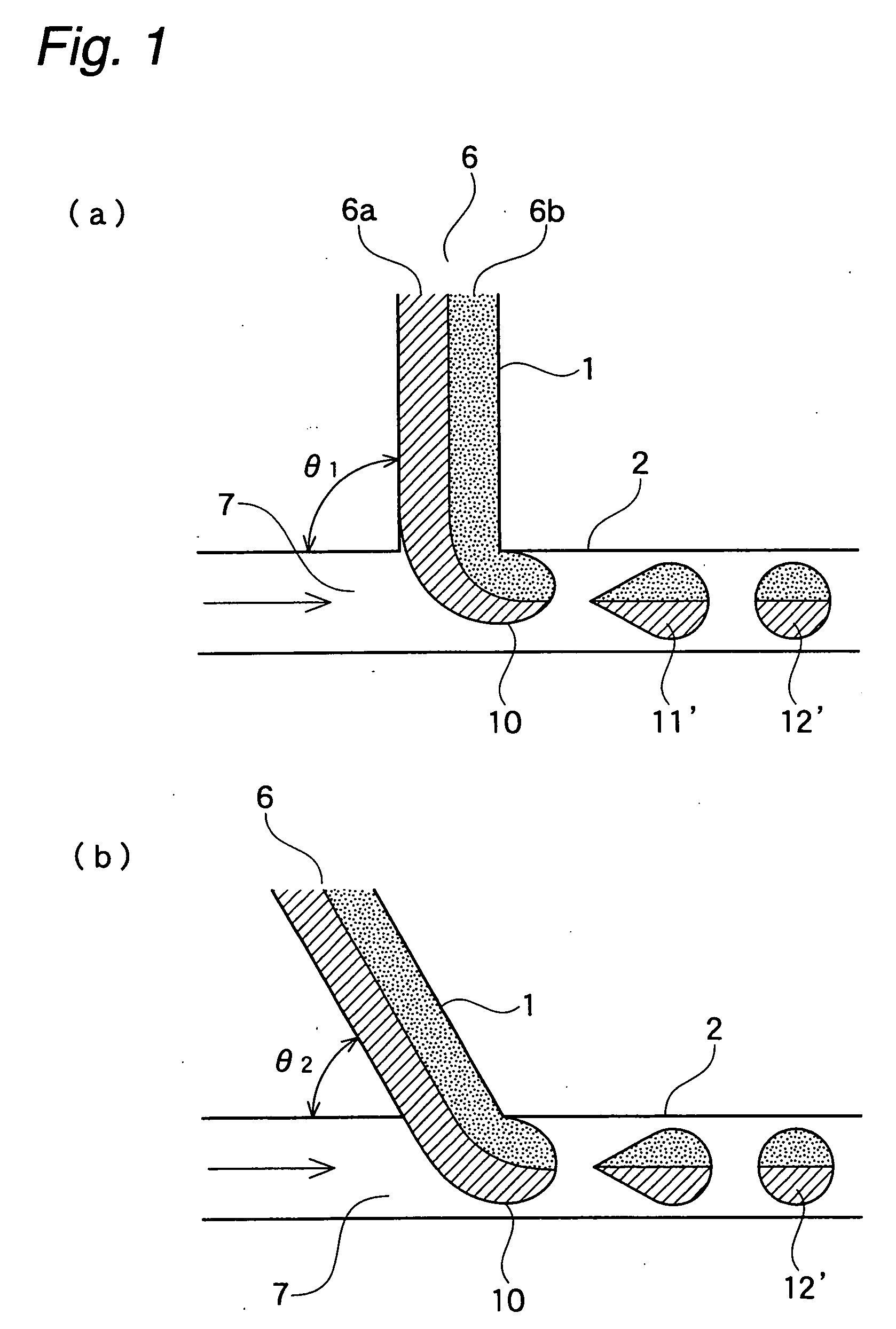

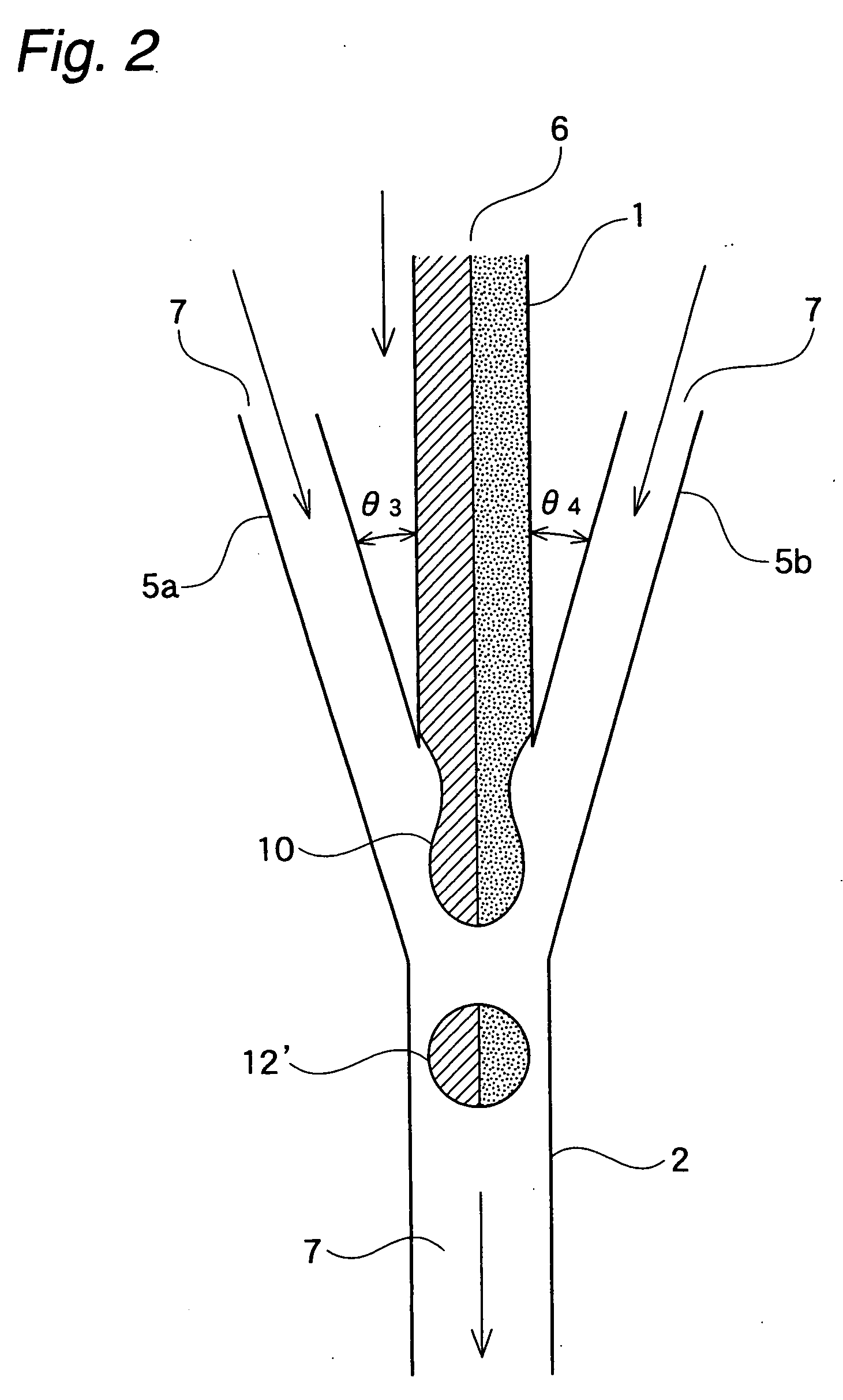

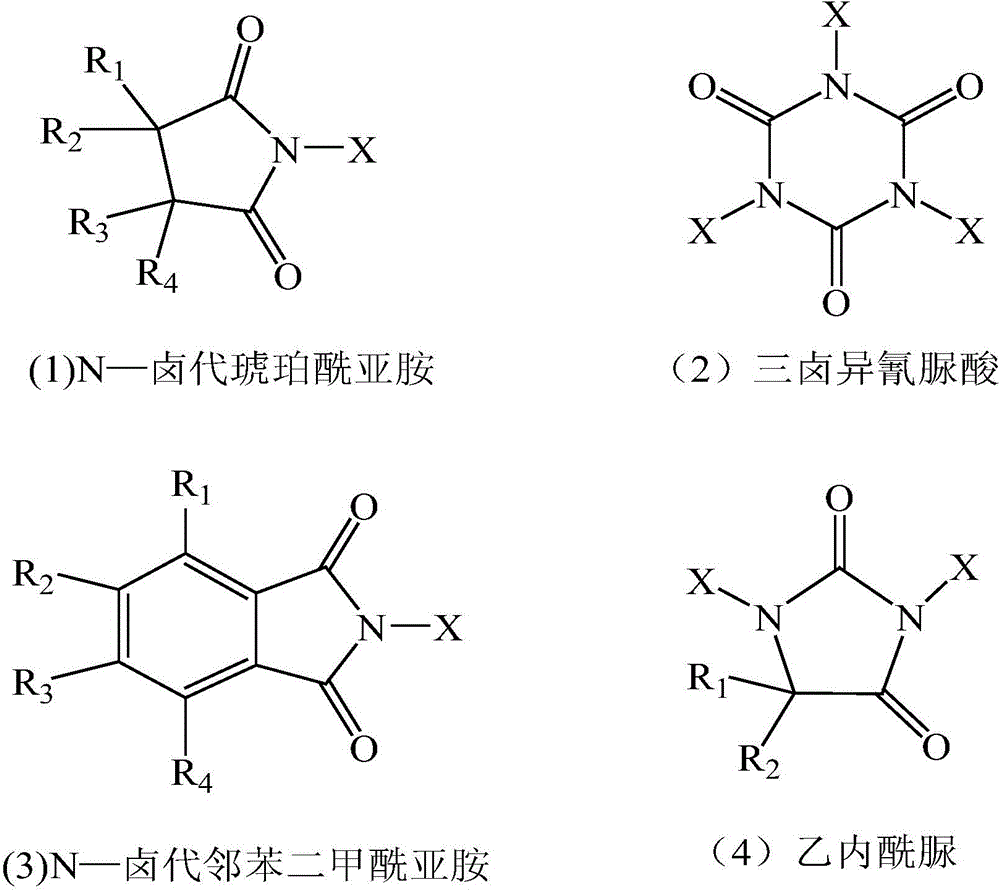

Process for microchannel production of colorred spherical grain and microchannel production apparatus for use therein

InactiveUS20060014894A1Easy transferSimple wayOther chemical processesMixing methodsDispersed mediaViewpoints

Monodisperse colored spherical particles each having two separated color regions of two hues, that is, two-colored spherical particles, useful, for example, for displays of characters, graphics, images and the like, the two hues being for reverse display in terms of electricity and magnetism from the viewpoint of good suitability for display are provided. In the production process and the apparatus for producing the colored spherical polymer particles, microchannels are utilized including a first microchannel through which a colored continuous phase comprising a color dye / pigment dispersed in a fluid dispersing medium containing a polymerizable resin component and having colored phases of different hues is transferred, and a second microchannel through which a spheroidizing disperse phase flows. The process and apparatus spheroidizes the discharged colored continuous phase having two hues and cures the polymerizable resin component in the colored continuous phase, whereby colored spherical polymer particles are formed.

Owner:SOKEN CHEM & ENG CO LTD +2

Water dispersible nanometer avicel, its prep.and colloid therefrom

The nanometer microcrystal cellulose powder is surface modified nanometer microcrystal cellulose with added hydrophilic colloid in the amount of 5-150 wt% of nanometer microcrystal cellulose and has grain size of 6.3-100 nanometers. During its preparation, hydrophilic colloid is dispersed homogeneously into water dispersed medium of surface modified nanometer microcrystal cellulose and the mixture is then dried and crushed. The nanometer microcrystal cellulose is easy to be water dispersed to form colloid, which is homogeneous and high in gluing strength and has the small size of microcrystal cellulose maintained, so that it has wide and unique application foreground in food production, medicine, papermaking, textile, new material preparation and other fields.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

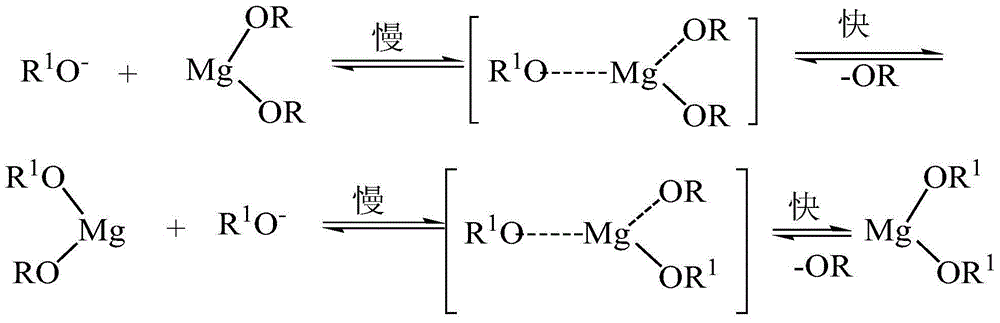

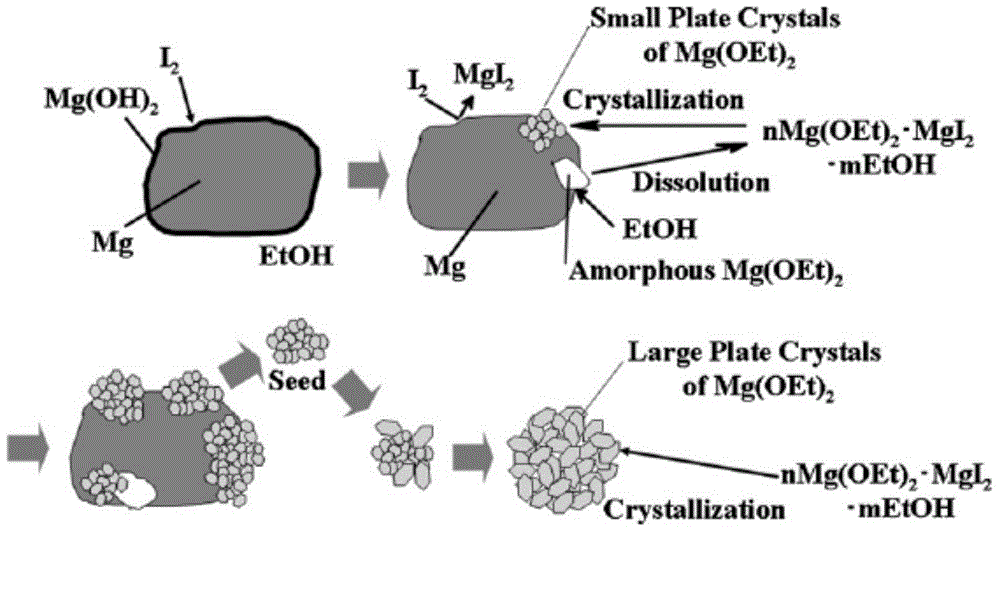

Preparation method and applications of alkoxyl magnesium carrier

The invention relates to a preparation method and applications of an alkoxyl magnesium carrier. The preparation method is used for preparing an olefin polymerization catalyst alkoxyl magnesium carrier. The alkoxyl magnesium carrier comprises the following components: magnesium powder, an initiator, a cross-linking agent, a unitary organic alcohol, a dispersing agent and a dispersing medium according to mole ratio of 1 to (0.00001-0.1) to (0.0001-0.5) to (2-100) to (0.05-50) to (1-100). The involved alkoxyl magnesium carrier is good in particle morphology, high in bulk density, and high in mechanical strength. A catalyst prepared by the carrier is used for preparing an olefin polymerization catalyst, the catalyst is high in activity, good in hydrogen regulation performance and good in copolymerization performance, and the polymer is low in the powder content, low in wax content, and good in particle morphology; the involved catalyst is used for ethylene homopolymerization, copolymerization of ethylene and alpha-olefin, or ethylene and polar alkene monomer, propylene homopolymerization, propylene and alpha-olefin copolymerization or propylene and polar alkene monomer copolymerization.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of high-toughness boride-carbide composite ceramic

A preparation method of a high-toughness boride-carbide composite ceramic relates to a preparation method of a boride-carbide composite ceramic and solves the problems that in the conventional preparation of the boride-carbide composite ceramic, due to high sintering temperature and high sintering pressure, the preparation cost is high and the prepared boride-carbide composite ceramic is poor in mechanical property and fracture toughness. The preparation method of the high-toughness boride-carbide composite ceramic comprises the following steps : adding a dispersing medium into boride and carbide; uniformly mixing the dispersing medium, the boride and the carbide; pressing the mixture into a blank material; and sintering the blank material in a two-section pressure-free sintering way at alow temperature and a high temperature sequentially. The sizes and the distribution of grain crystals in the boride-carbide composite ceramic which is prepared under the low-temperature pressure-freeconditions are uniform; the fracture toughness is as high as 5.0-13MPa.m<-1 / 2>; and the bending strength is as high as 400-1000 MPa; the boride-carbide composite ceramic with excellent comprehensive mechanical property can be prepared; the preparation cost is reduced; and the application range is widened.

Owner:吉林长玉特陶新材料技术股份有限公司

Process of microgel synthesis and products produced therefrom

The invention provides in one aspect a process for preparing a microgel by RAFT polymerizing in the presence of a RAFT chain transfer agent, one or more solvophobic monomers and one or more solvophilic monomers to form one or more block copolymers comprising one or more solvophobic blocks and one or more solvophilic blocks wherein the solvophobic block is insoluble in a dispersing medium and the solvophilic block is soluble in the dispersing medium. The block copolymer is dispersed in the dispersing medium to form micelles, which is then stabilized to form the microgel. The dispersing medium can be aqueous or lipophilic. The method of the present invention also permits one to encapsulate a wide variety of materials, such as pigments, dye molecules, and aluminum flakes used in metallized paints.

Owner:COMMONWEALTH SCI & IND RES ORG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com