Sunlight controlled coating solution in low radiation, preparation method and application

A technology of sunlight control and low radiation, applied in coatings, epoxy coatings, etc., can solve the problems of high toxicity, no mention of ultraviolet light control, no mention of it, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

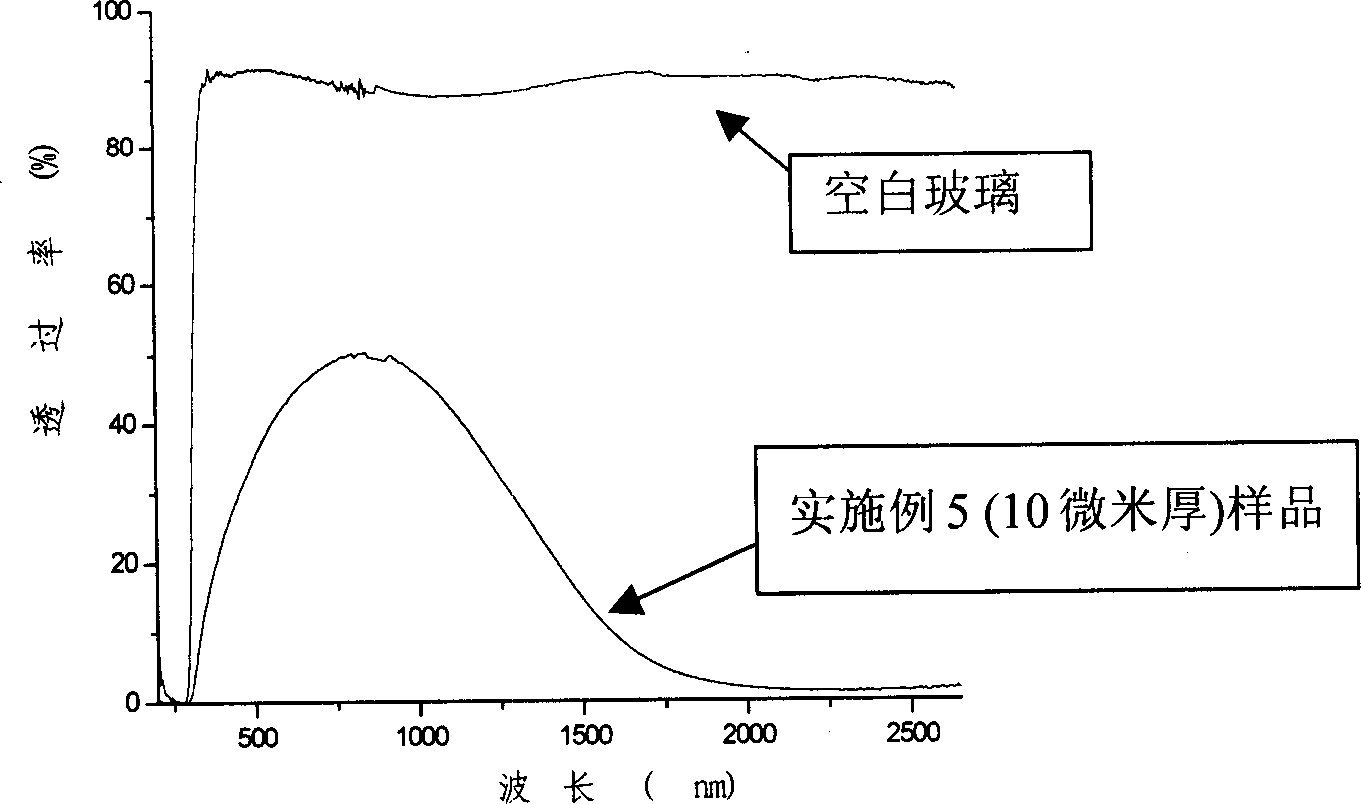

[0058] Under stirring, 80 grams of silicone-modified acrylic emulsions are added to the water slurry containing 100 grams of AZO (containing AZO 30wt%, the dispersant is water: the volume ratio of isopropanol is 2: 1, the average particle size of AZO nanoparticles 20nm), ultraviolet absorber UV-5316 grams, FC-432g, PVA (M average molecular weight 20000) 2 grams, mix uniformly, obtain sunlight control low radiation coating solution.

[0059] Apply the solution to a clean glass surface with a cotton swab, leave it at room temperature for 10 minutes, and then treat it at 150 degrees Celsius for 20 minutes for solar control low-e glass. Apply the solution on the PET film by roller coating, dry at 80°C for 1 hour, and stick it on the windows of automobiles and ships through pressure-sensitive adhesive, as an anti-ultraviolet and solar control low-emissivity film.

Embodiment 2

[0061] Preparation of solution A2:

[0062] In a container equipped with a stirring device, add 100 grams of 3-glycidyl etheroxypropyl trimethoxysilane, 50 grams of isopropanol, and add dropwise a mixture of 50 grams of water and 10 grams of 10 wt% hydrochloric acid under stirring. solution, stirred for 1 hour, added 2 g of 2-ethyl-4 methylimidazole, and stirred thoroughly. The silane coupling agent hydrolyzate-solution A2 was obtained for use.

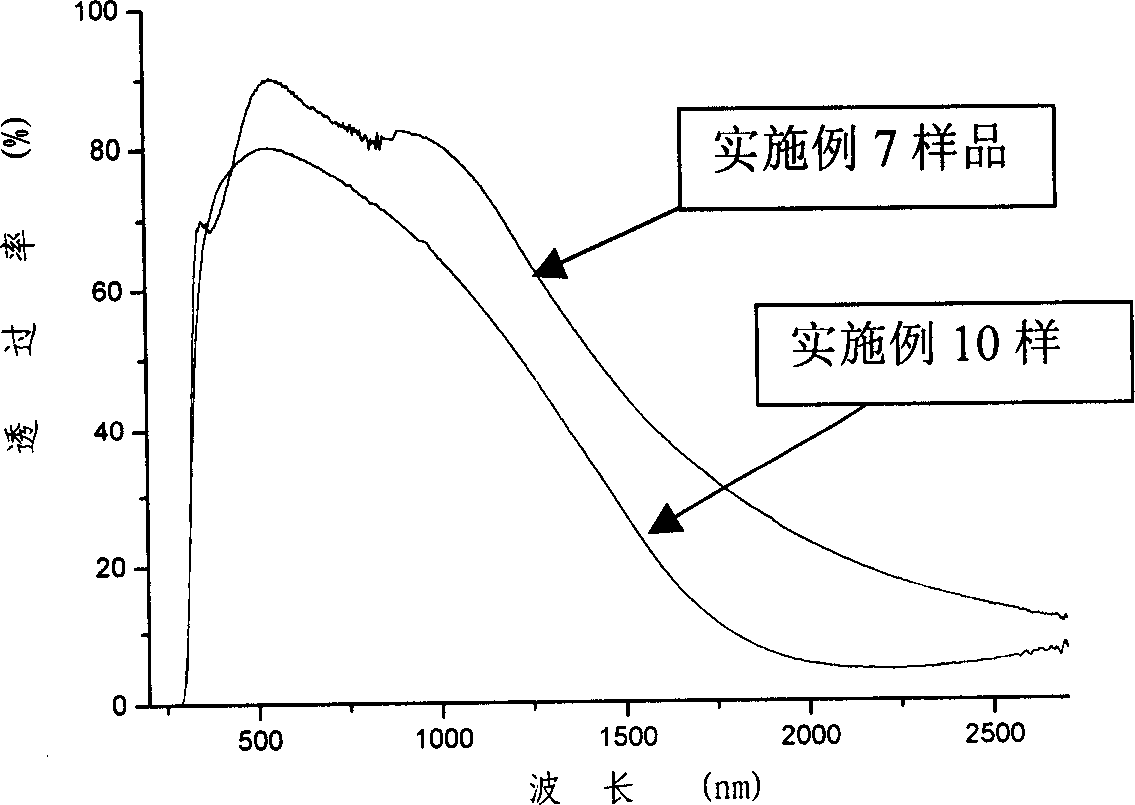

[0063] Preparation of solution B2:

[0064] Add 230 grams of solution A into the water slurry containing 50 grams of ATO (containing ATO 20wt%, dispersant is water: isopropanol volume ratio is 2: 1, and the average particle size of ATO nanoparticles is 20nm), then add polyurethane emulsion Baybond PU 400S 50 grams, UV absorber UVB-45 grams, TritonX-1005 grams, mix well. Solar control low-E coating solution B2 was obtained.

[0065] Apply the solution B2 to the clean glass surface and the PMMA surface with a cotton swab, and then t...

Embodiment 3

[0067] Prepare solution A3:

[0068] In a container equipped with a stirring device, add 30 grams of ethyl orthosilicate, 50 grams of vinyltrimethoxysilane, and 50 grams of ethanol, and add dropwise a mixed solution of 50 grams of water and 10 grams of 10 wt% nitric acid under stirring. After dropping, add 0.5 g of FC-129 (3M product) and continue to stir for 1 hour to obtain silane coupling agent hydrolyzate-solution A3 for use.

[0069] Prepare solution B3:

[0070] Nano-TiO 2 Water emulsion (containing TiO 2 30wt%, the average particle diameter is 20 nanometers, 50 grams of Zhongke Nano Technology Engineering Center Co., Ltd., join 25 grams of solution A1 and 10 minutes of propylene glycol, fully stir to obtain the ultraviolet absorber slurry-solution B3.

[0071] Prepare solution C3:

[0072] In reactor, add successively ITO water slurry (containing ITO 25wt%, dispersant is water: ethanol volume ratio is 1: 1, and the average particle size of ITO nanoparticle is 40nm)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com