Sunlight controlled transparent film in low radiation, prepartion method and application

A transparent film and sunlight control technology, which is applied in the field of organic polymer and nano-inorganic particle composite film, can solve the problems of limited application, achieve the effects of increasing heat preservation and energy saving, good transparency of visible light, and overcoming environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) The indium oxide nanopowder coarse product that buys 3wt% tin doping is mixed with DMF, cyclohexanone, butylamine, Tween 80 by the weight percentage of Table 1-1, and add diameter is 0.8 millimeters of oxide The zirconium microbeads are sand-milled to separate the zirconia beads, and a solution system in which tin-doped indium oxide particles are uniformly dispersed with an average particle diameter of 25 nanometers is obtained.

[0051] composition

weight percentage (%)

3wt% tin-doped indium oxide nanopowder coarse product

32.47

DMF

32.46

32.47

1.3

Tween 80

1.3

[0052] A solution system in which the above-mentioned tin-doped indium oxide is uniformly dispersed, polyvinyl chloride, vinyltrimethoxysilane, dioctyl phthalate, 2-(2'hydroxy-5'-methylphenyl)benzo Triazole, antioxidant CA and TPP are mixed according to the ratio of 2: 100: 2: 25: 1.5: 1.3: 0.5 by...

Embodiment 2

[0057] (1) Mix the purchased 18wt% tin-doped indium oxide nanopowder coarse product with the dispersion medium and dispersant in the ratio of Table 2-1, and carry out sand grinding with zirconia microbeads with a diameter of 0.8 mm to separate the oxide Zirconium beads to obtain a solution system in which tin-doped indium oxide particles have an average particle size of 80 nanometers and are uniformly dispersed.

[0058] composition

weight percentage (%)

18wt% tin-doped indium oxide crude product

31.85

31.85

31.85

Dodecanoic acid

1.27

span 80

3.18

[0059] A solution in which the above tin-doped indium oxide nanoparticles are uniformly dispersed, polyvinyl chloride, vinyltrimethoxysilane, dioctyl phthalate, 2-hydroxy-4-methoxybenzophenone, antioxidant Agent CA and TPP were mixed in a weight ratio of 6:100:2:30:1.5:1:0.5, and the volatile small molecule solvent was remo...

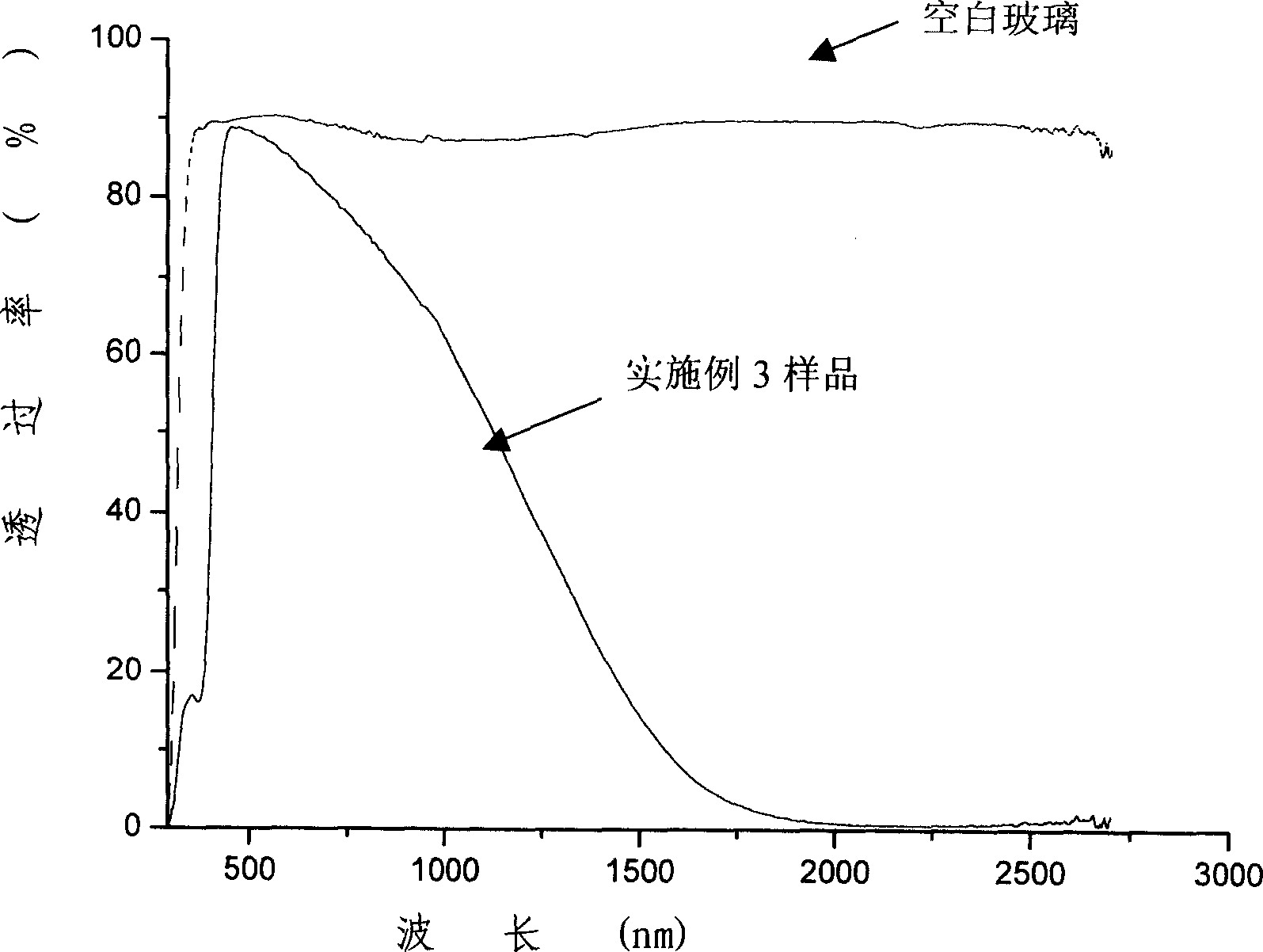

Embodiment 3

[0064] (1) make 7wt% antimony-doped tin oxide nanopowder rough product by oneself according to aforementioned document, this thick product mixes with the other composition of table 3-1 in the ratio shown, and be sand with the zirconia bead of 0.8 millimeters in diameter The grinding medium is sanded, and then the zirconia beads are separated to obtain a uniform dispersion of 7 wt% antimony-doped tin oxide nanoparticles, wherein the average particle size of the antimony-doped tin oxide particles is 50 nanometers. The above-mentioned antimony-doped tin oxide nanoparticles uniformly dispersed solution, polystyrene, vinyltrimethoxysilane, and epoxy soybean oil are mixed according to a weight ratio of 15:100:2:2:1.5, and then vacuum Remove the volatile small molecule solvent in the oven to obtain the masterbatch, the composition of which is shown in Table 3-2. The weight percent in Table 3-2 refers to the proportion of each component in the masterbatch.

[0065] compositi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com