Patents

Literature

54results about How to "Overcome the problem of easy shedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of NdFeB magnet with high coercivity

InactiveCN107578912AReduce machining costsSimple production processInductances/transformers/magnets manufactureMagnetic materialsMicrometerTerbium

The invention relates to a preparation method of an NdFeB magnet with high coercivity. The method includes the following steps that heavy rare earth powder is mixed with an anti-oxidizing agent, a binder and an organic solvent to prepare uniform slurry, wherein the heavy rare earth powder refers to one or a mixture of Dy, hydrogenated dysprosium, Tb and terbium hydride, the mass ratio of the heavyrare earth powder in the slurry is 40-80%, the mass ratio of the anti-oxidizing agent is 5-20%, the mass ratio of the binder is 2-10% and the balance organic solvent, and the anti-oxidizing agent refers to the anti-oxidizing agent containing fluorine; after the slurry covers the surface of a sintered magnet, the thickness of the slurry is controlled to 20-100 micrometers, and drying is then conducted; the dried magnet is then sintered, and aging treatment is conducted. The method can reduce the use amount of heavy rare earth powder such as Dy and Tb, meanwhile, the requirement of the grain boundary diffusion technology for the size of a product is met, the problem that fluoride and oxide coating powder is easy to fall off is solved, and the manufacturing process is simple.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL

Preparation method of sintered neodymium iron boron magnet

ActiveCN107026003APrevent the problem that the coating is easy to fall offImprove performanceInorganic material magnetismInductances/transformers/magnets manufactureOrganic solventAdhesive

The invention relates to a preparation method of a sintered neodymium iron boron magnet. The preparation method comprises the following steps: pretreating a sintered magnet R1-Fe-B-M; mixing heavy rare earth power with metal Ga, and then mixing with an organic solvent to prepare a sizing agent, wherein the content of the Ga in the mixed power is 0.5 wt% to 20 wt%, wherein the heavy rare earth is one or a compound of more of Dy, Tb, alloy of Dy and Tb and hydride of Dy or Tb; enabling the surface of the sintered magnet to be covered with the obtained sizing agent, and then carrying out grain boundary diffusion treatment after drying, wherein the thickness of the sizing agent on the surface of the magnet is 20 to 200 microns. According to the method disclosed by the invention, by using a self-bonding effect of the Ga in the sizing agent of the mixed powder, the problems that fluorides are directly coated and hydride powder is easy to fall off are solved, and the defect that the magnetic property is reduced caused by the fact that excess C and N, together with heavy rear earth, are permeated into the magnet due to an added adhesive is also overcome.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

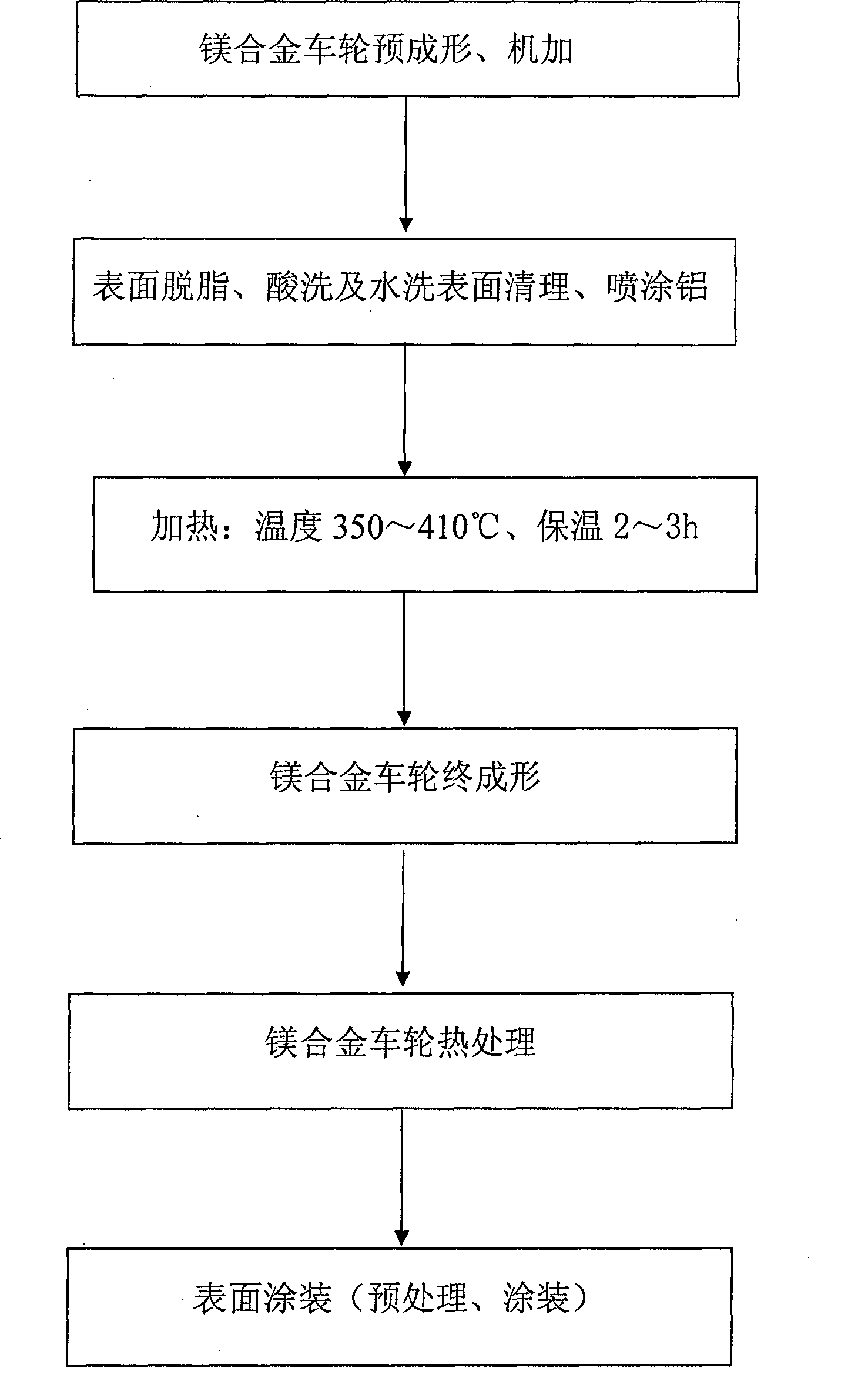

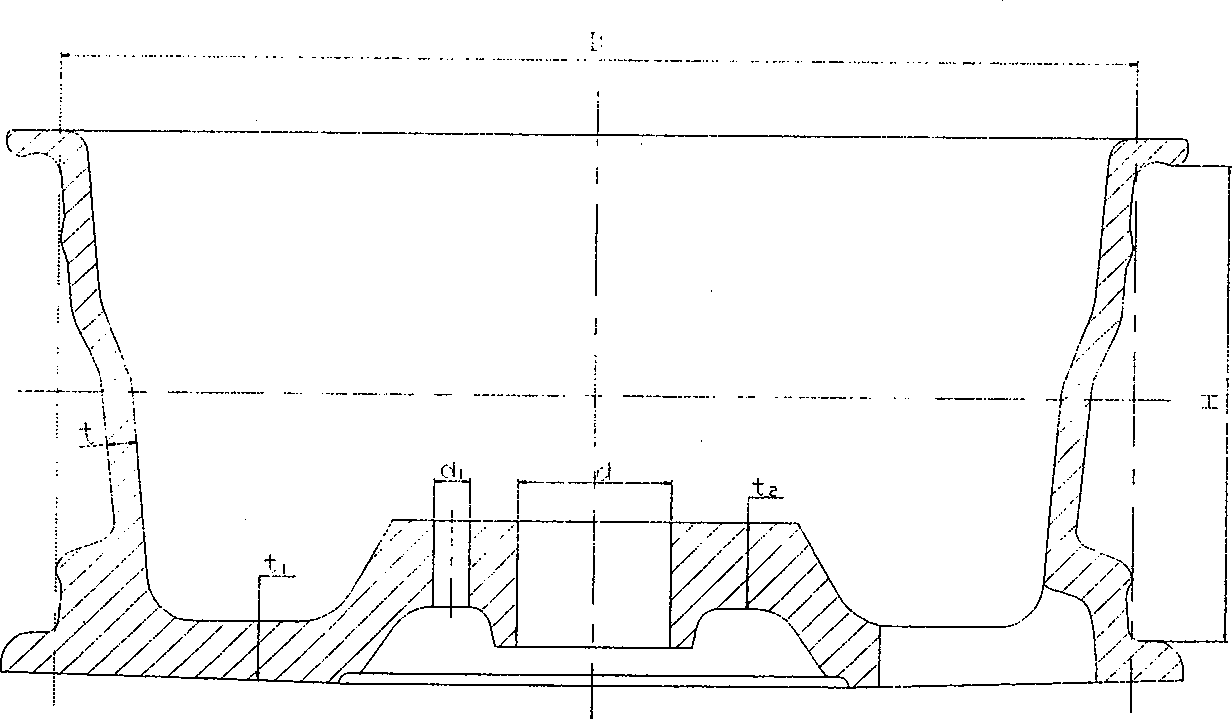

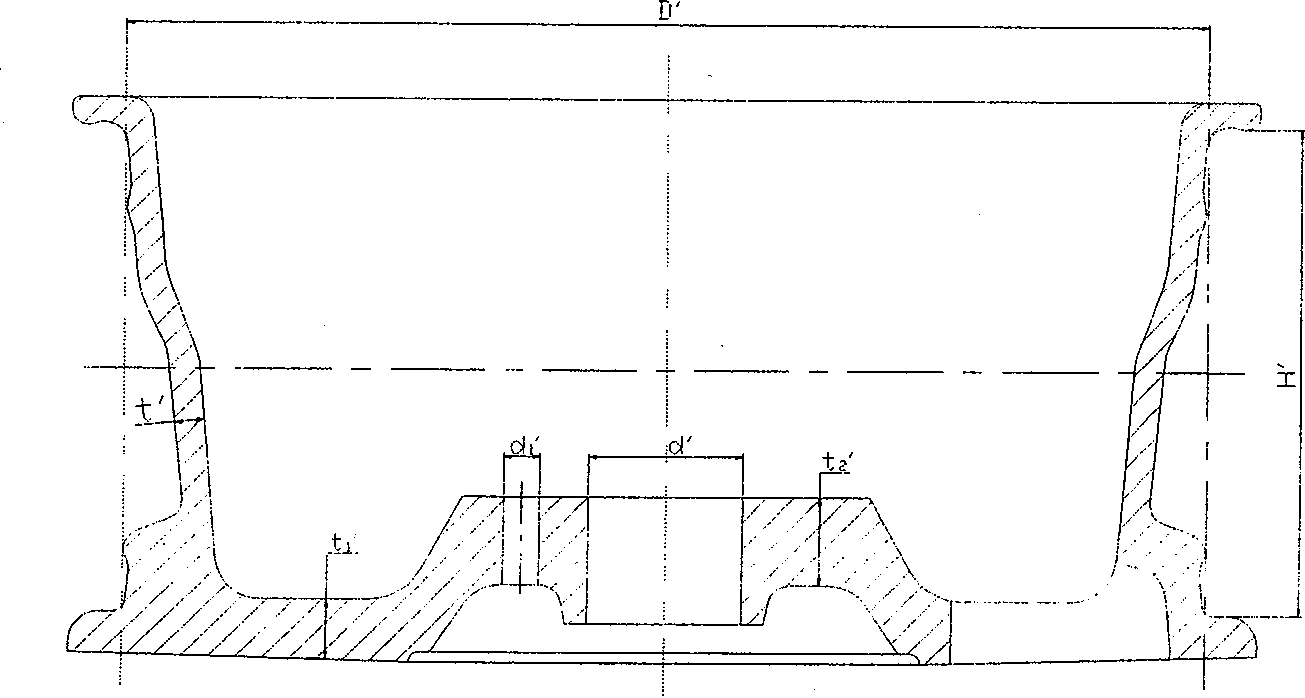

Magnesium alloy vehicle wheel surface treatment method and magnesium alloy vehicle wheel

InactiveCN101392380AImprove corrosion resistanceSolving Galvanic Corrosion ProblemsMolten spray coatingSurface finishingWork in process

The invention pertains to a surface treatment method of magnesium alloy wheels. The surface treatment method is characterized by the inclusion of preliminary shaping, machining, aluminium coating on the surface, heating and diffusion, final shaping, heat treatment and surface coating treatment, wherein, the preliminary shaping and the machining can provide a semi-product of a magnesium alloy wheel with a deflection left for the final shaping; after the aluminium coating on the surface and the heating and diffusion, a finished product of the magnesium alloy wheel can be obtained through the final shaping. Heating action during the procedure of the heating and diffusion and mechanical action during the procedure of deformation improve the bonding force of an aluminium coating and a magnesium alloy substrate as well as corrosion resistance of the magnesium alloy wheel, solve the problem of electrochemical corrosion of a bonding part and the problem that a coating with a common treatment method is liable to fall off, and do not reduce mechanical performance of materials of the magnesium alloy substrate with low production cost and no environmental pollution.

Owner:ZHONGBEI UNIV

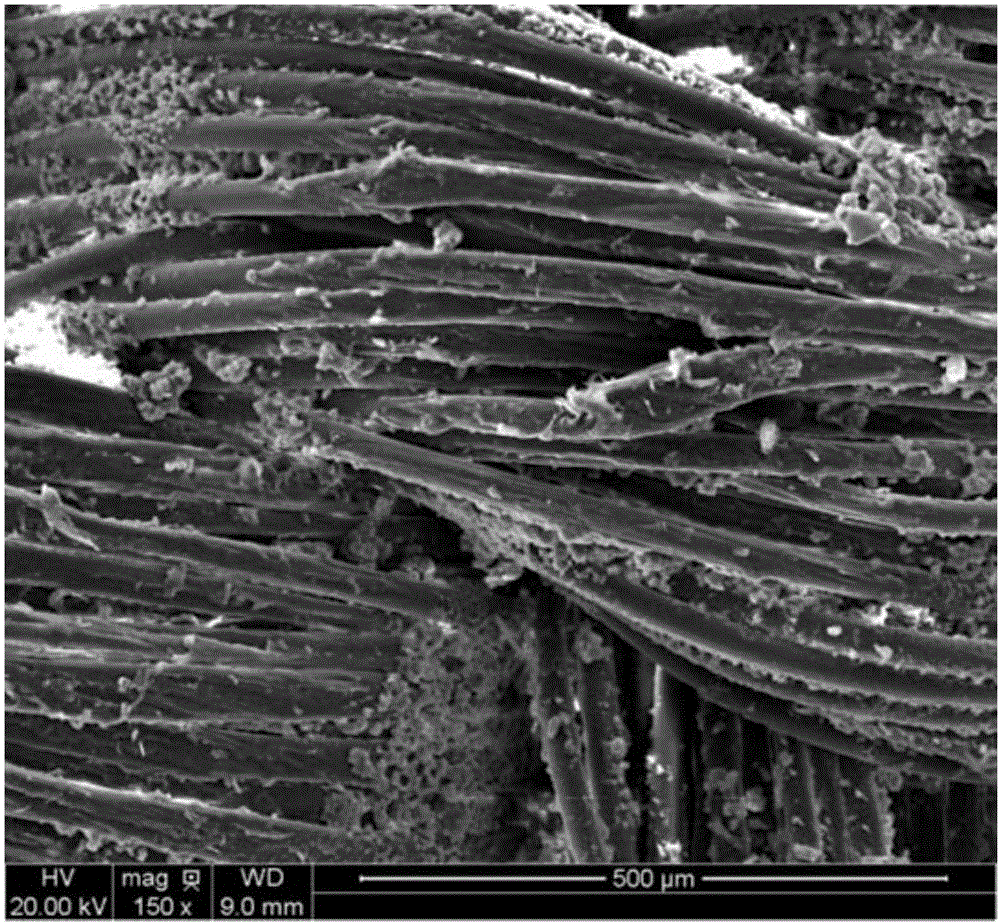

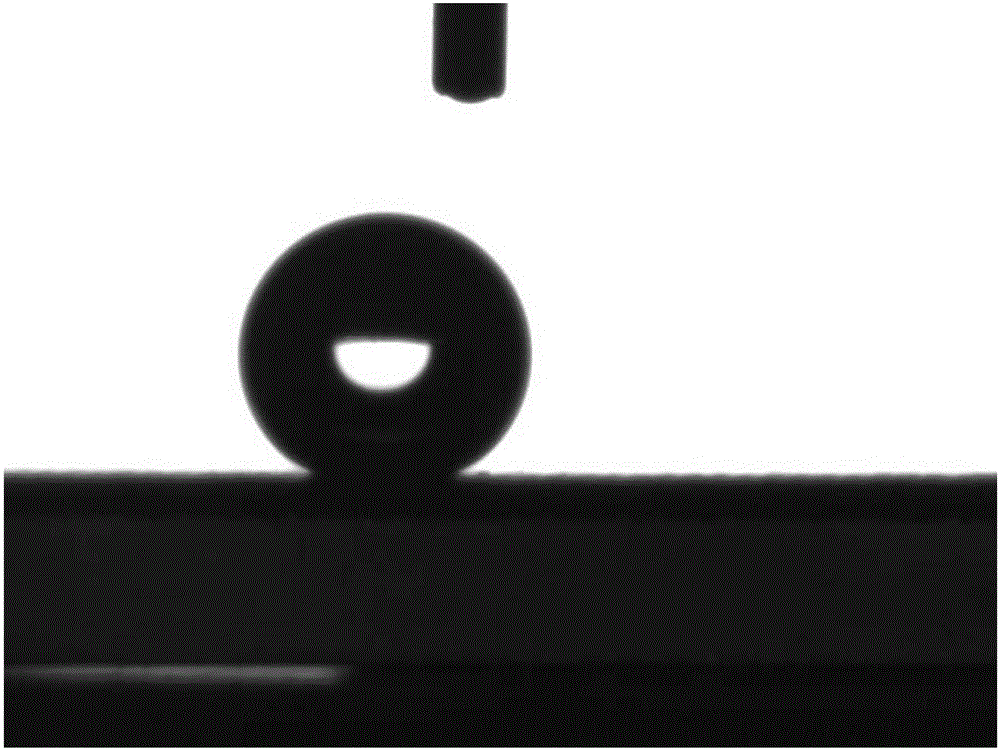

Wear-resistant, hydrophobic and lipophilic material, preparation method therefor and application of wear-resistant, hydrophobic and lipophilic material

ActiveCN106512480AAchieve hydrophobic and lipophilic effectOvercome the problem of easy sheddingNon-miscible liquid separationVegetable oilKerosene

The invention discloses a wear-resistant, hydrophobic and lipophilic material. According to the wear-resistant, hydrophobic and lipophilic material, a lipophilic substrate material is adopted, metal stearate is adhered to the surface of the substrate, and a wear-resistant and hydrophobic surface layer is formed on the surface of the substrate by using the hydrophobic characteristic of the metal stearate, so that wear-resistant, hydrophobic and lipophilic effects are achieved. The material is low in cost, has good hydrophobic characteristic and lipophilic characteristic and can be applied to oil-water separation technologies, and an oil-permeable and water-impermeable meshed membrane is achieved; and the material is applicable to the separation of water-insoluble organic solvents such as kerosene, gasoline, diesel, engine oil, toluene, dichloromethane, vegetable oil and petrol from water.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

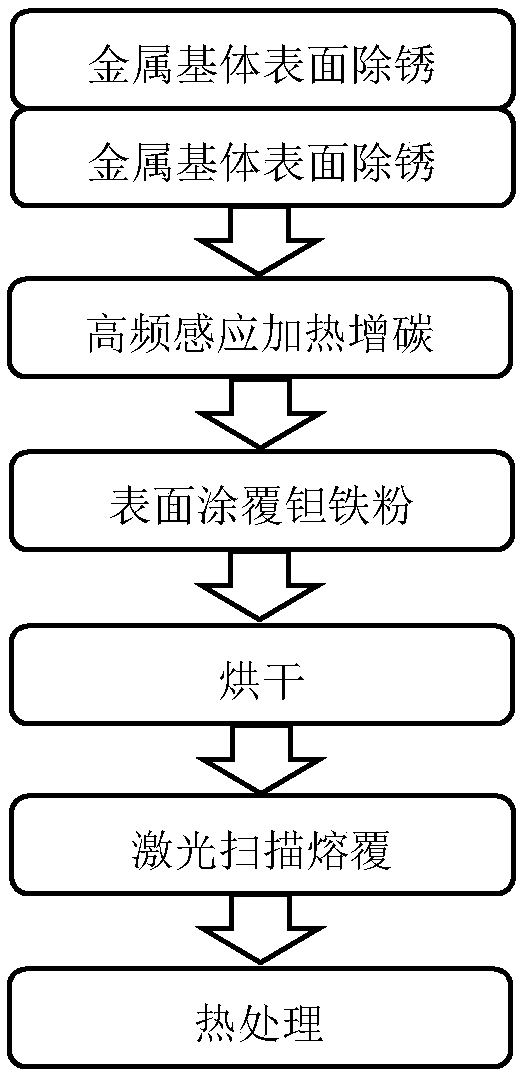

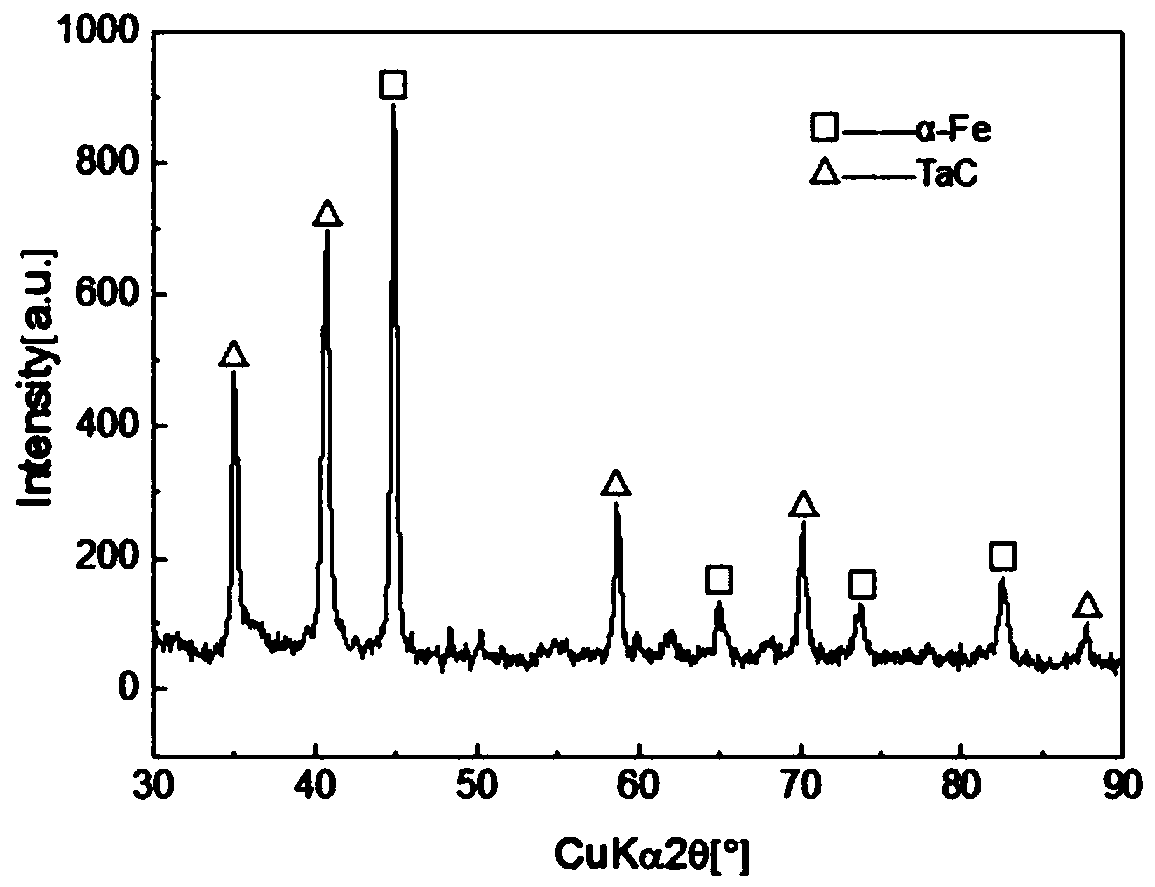

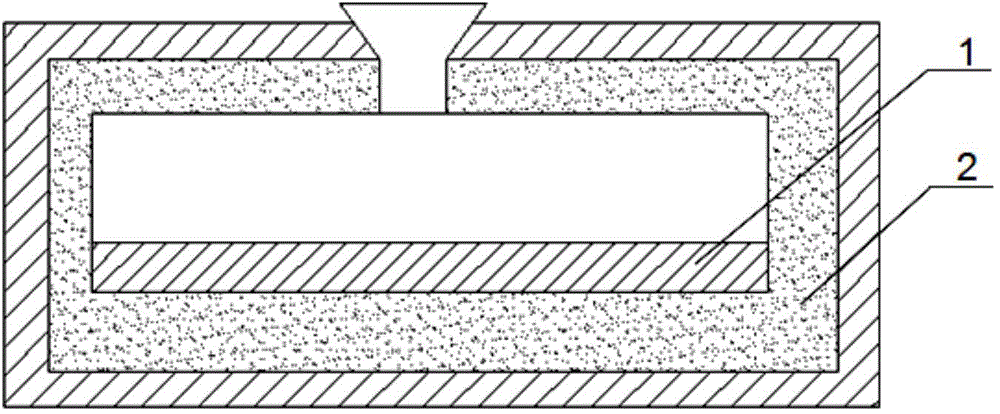

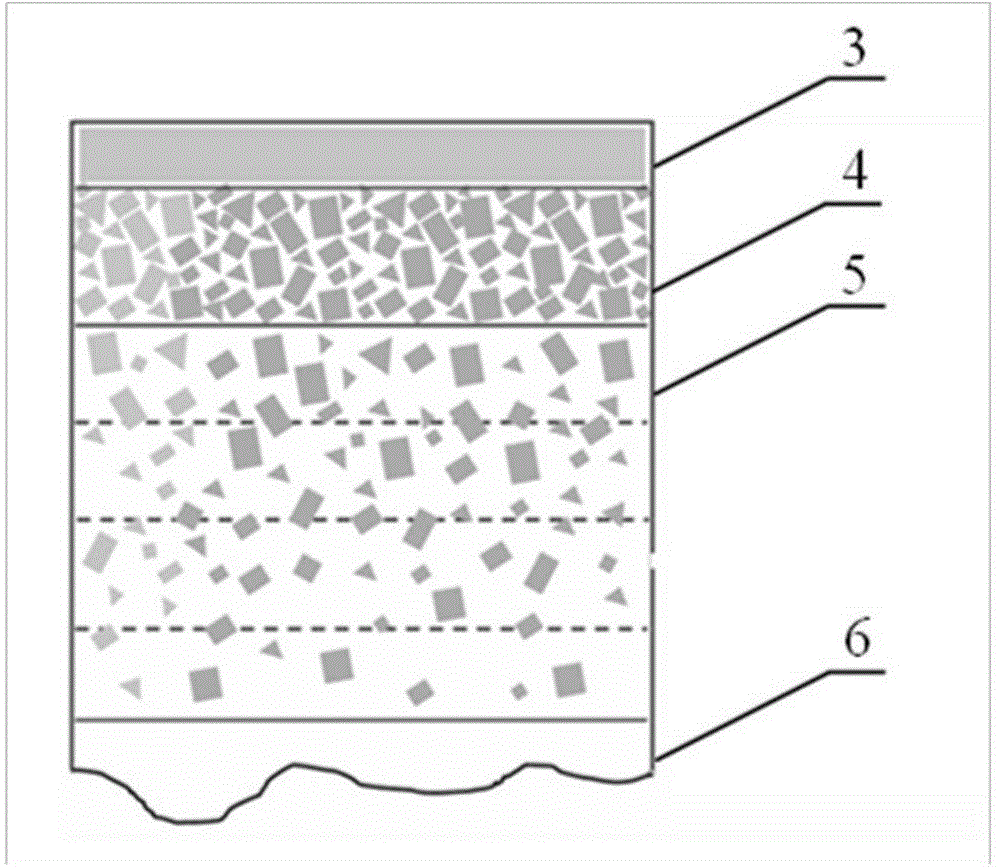

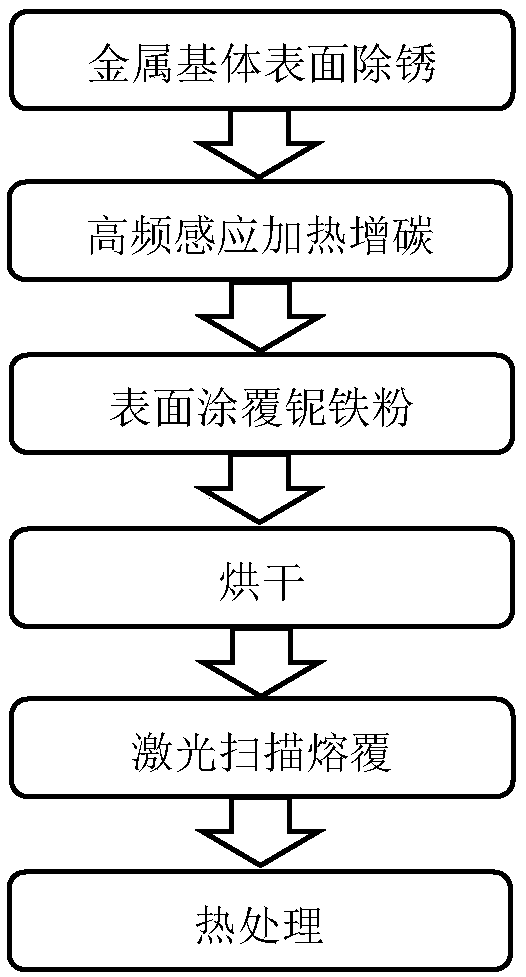

Tantalum carbide gradient composite coating layer and preparation method thereof

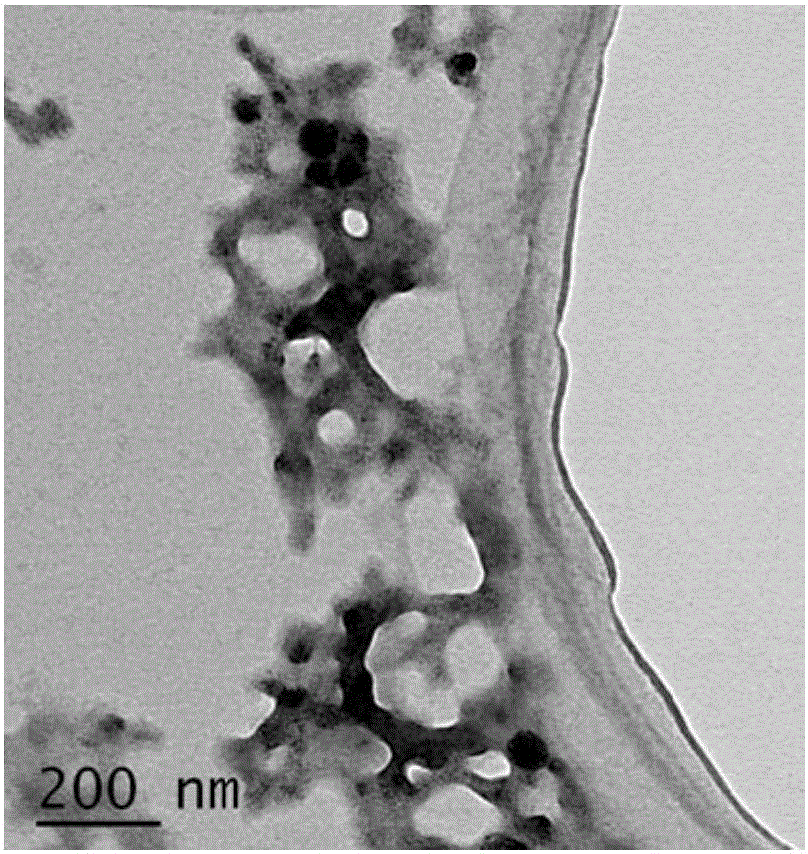

ActiveCN109252158AImprove mechanical propertiesOvercome the problem of easy sheddingSolid state diffusion coatingSuperimposed coating processMicro nanoWear resistant

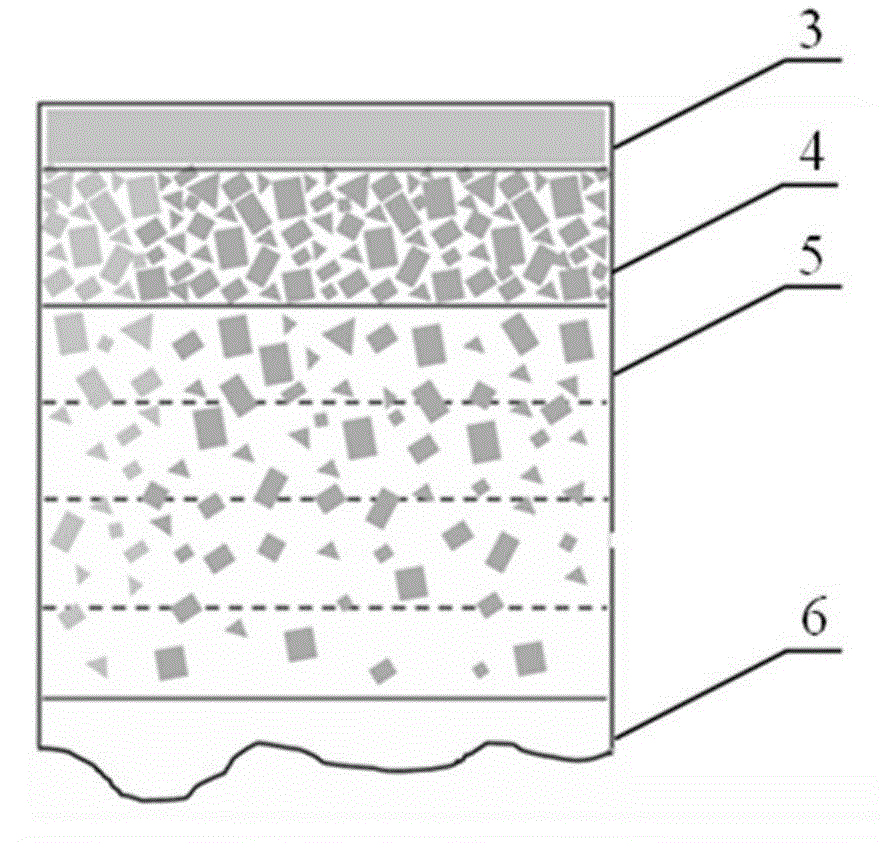

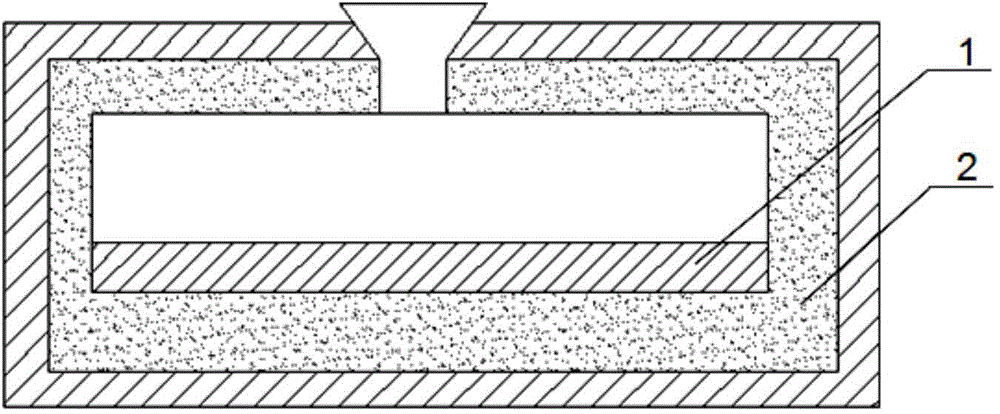

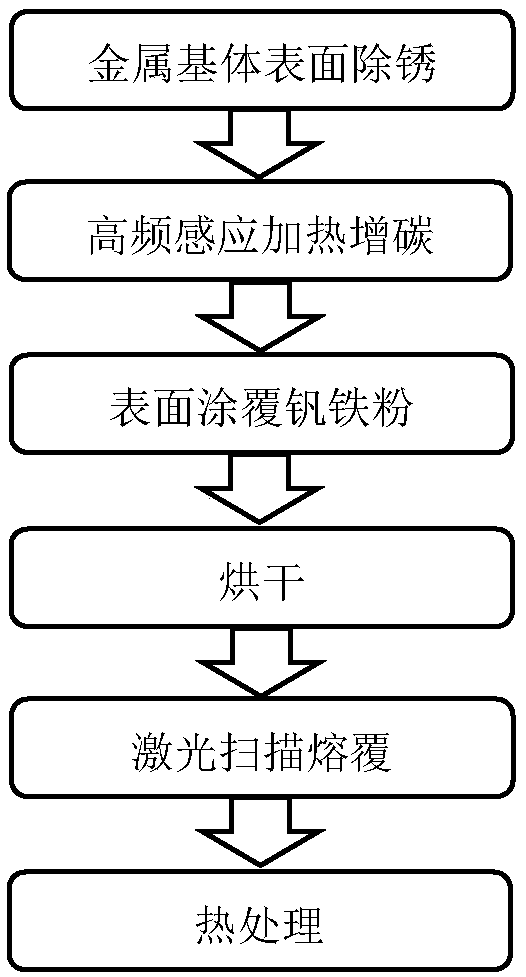

The invention discloses a tantalum carbide gradient composite coating layer and a preparation method thereof. The preparation method comprises the following steps: surface treatment of a metal substrate, preparation of a carburant, coating of the surface with the carburant and a thermal insulation coating layer, surface layer carburetting, conveying tantalum-iron powder to the surface of the metalsubstrate, pre-drying, laser scanning, multi-track-joined cladding, thermal insulation, and furnace cooling for obtaining the composite wear-resistant tantalum carbide coating layer on the surface ofthe metal substrate. The coating comprises a dense nano-TaC layer, a micro-nano and micro-TaC layer and a uniformly distributed TaC dispersion layer. The coating layer and the substrate are metallurgically bonded, and the bonding force is very strong, so the wear resistance of the surface of a low-carbon steel or low-carbon steel substrate is greatly improved.

Owner:XIAN UNVERSITY OF ARTS & SCI

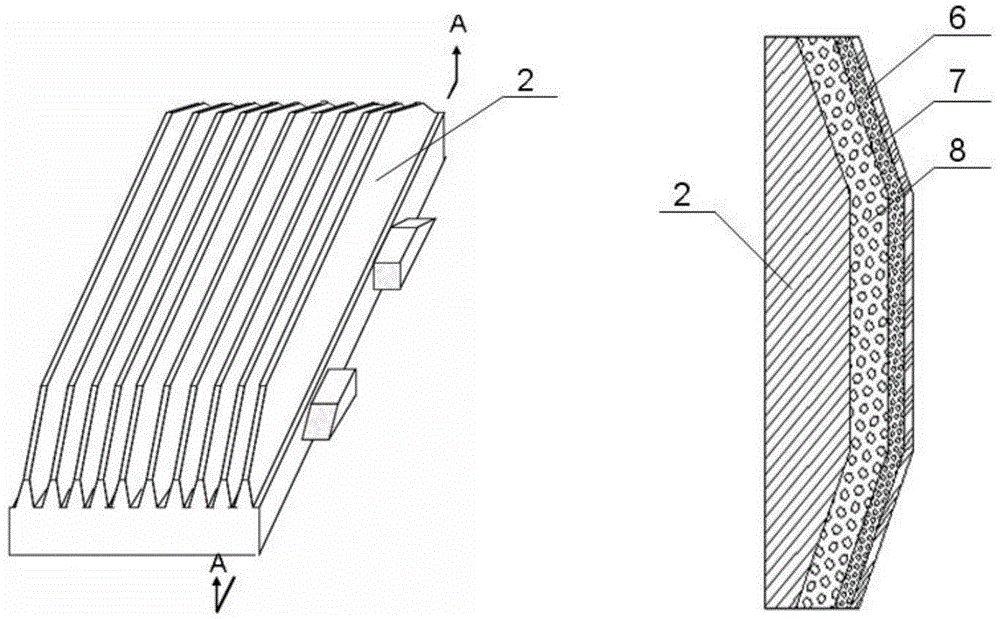

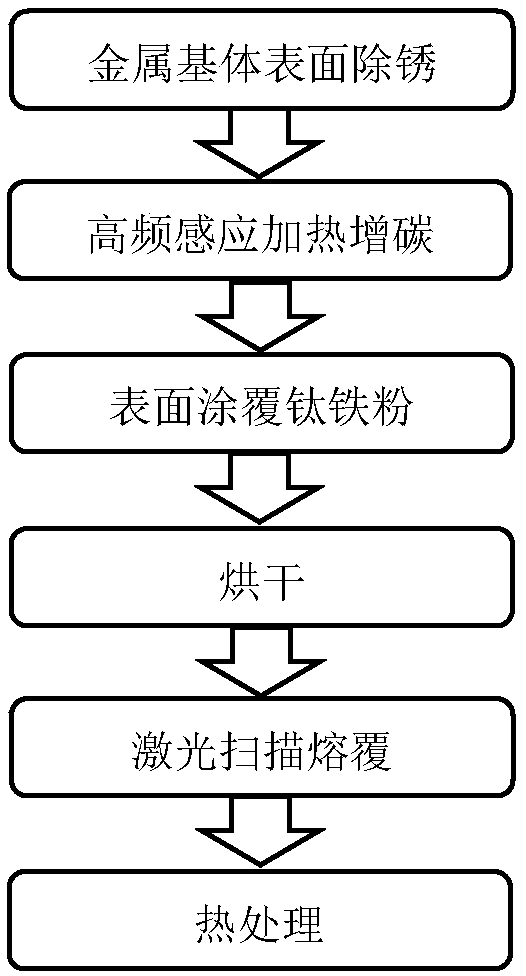

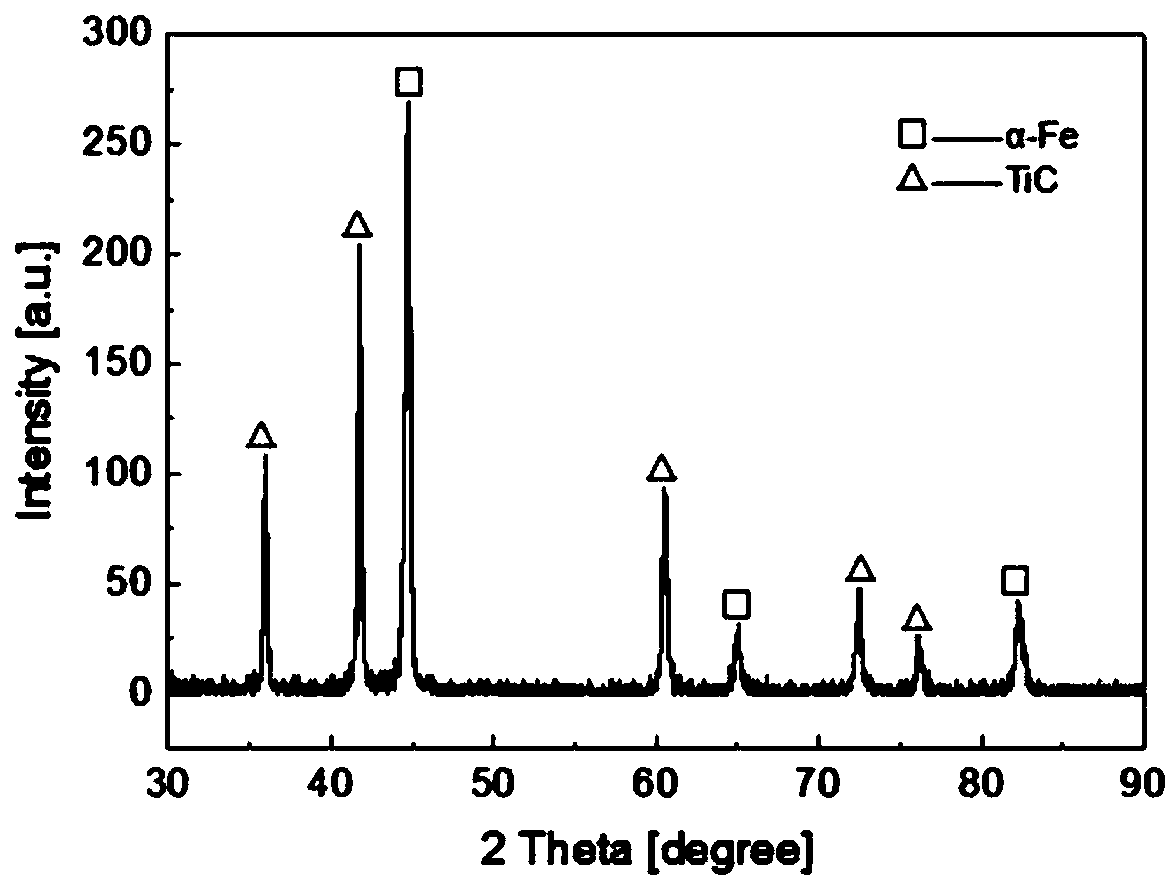

Wear resistant carbide coating layer and preparation method thereof

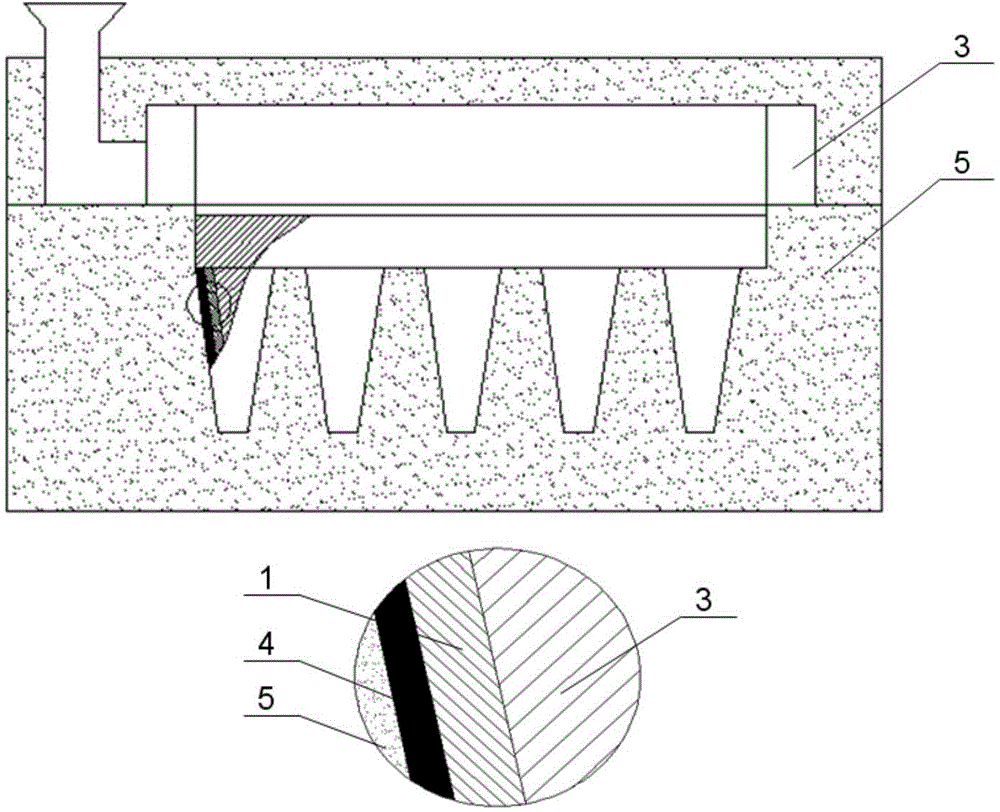

ActiveCN104525900AImprove mechanical propertiesOvercome the problem of easy sheddingSolid state diffusion coatingCarbide coatingWear resistant

The invention discloses a wear resistant carbide coating layer. The wear resistant carbide coating layer comprises a pseudo-single crystal phase TiC compact ceramic layer, and can further comprise a micron TiC ceramic layer and a fused layer of TiC and a matrix. The pseudo-single crystal phase TiC compact ceramic layer, the micron TiC ceramic layer and the fused layer of TiC and the matrix are gradiently distributed in sequence. The wear resistant carbide coating layer can be applied to the surface of a metal matrix. A metal matrix and titanium compound body obtained through casting is externally leaded in an external carbon source, and is heated and insulated to form the carbide coating layer on the surface of the metal matrix; and the coating layer and the matrix are metallurgically bonded, so that the binding force is strong, the problems of weak binding force and easy particle dropping due to traditional non-metallurgical bonding between hard particles and the metal matrix are overcome, and the surface wear resistance of the metal matrix is largely improved.

Owner:SUZHOU FURUTA AUTOMATION TECH

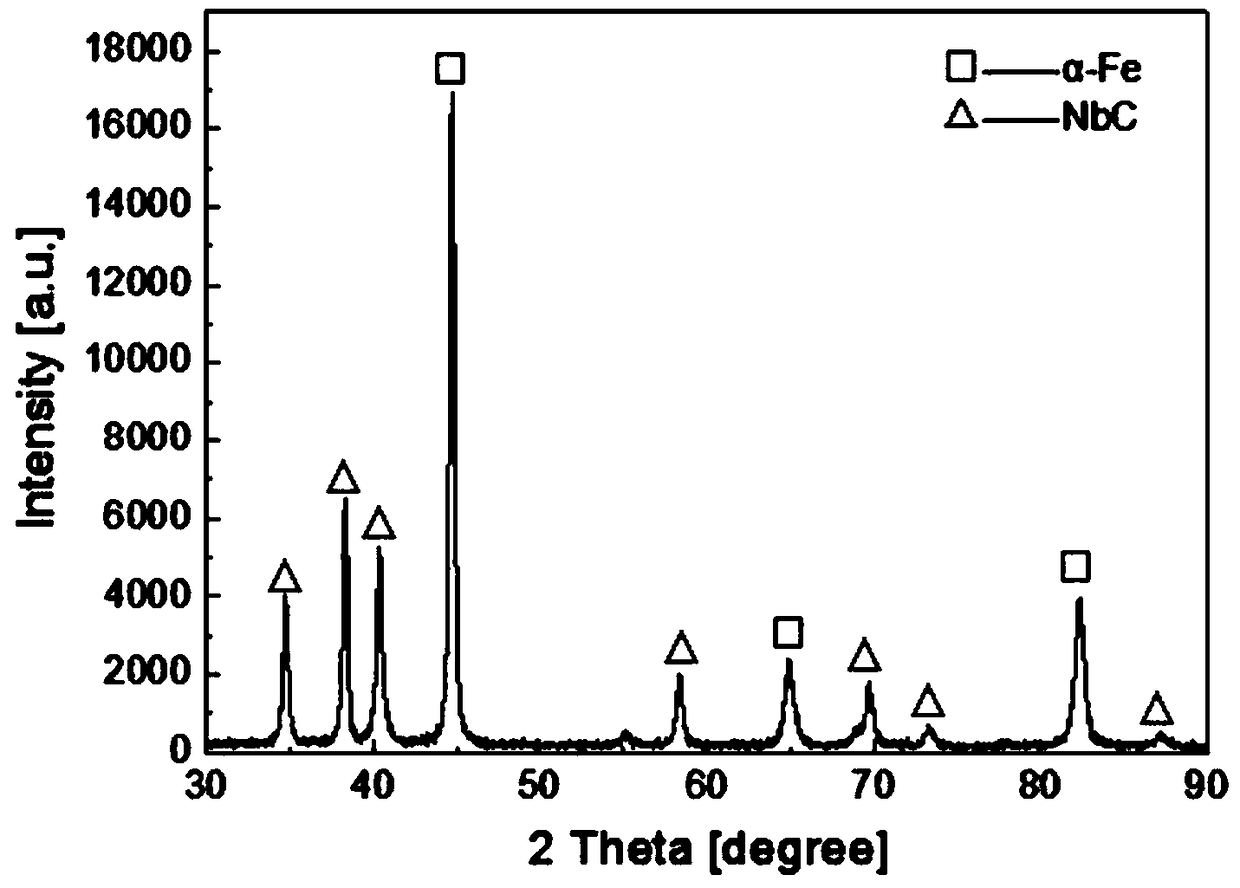

Niobium carbide gradient composite coating layer and preparation method thereof

ActiveCN109252159AImprove mechanical propertiesOvercome the problem that the binding force is weak and the particles are easy to fall offSolid state diffusion coatingSuperimposed coating processMicro nanoCarbide coating

The invention discloses a niobium carbide gradient composite coating layer and a preparation method thereof. The preparation method comprises the following steps: surface treatment of a metal substrate, preparation of a carburant, coating of the surface with the carburant and a thermal insulation coating layer, surface layer carburetting, conveying niobium-iron powder to the surface of the metal substrate, pre-drying, laser scanning, multi-track-joined cladding, thermal insulation, and furnace cooling for obtaining the composite wear-resistant niobium carbide coating layer on the surface of the metal substrate. The coating layer comprises a dense micro-nano and micro-NbC layer and a uniformly-distributed near-spherical and cuboidal NbC particle dispersion layer, and the uniformly-distributed near-spherical and cuboidal NbC particle dispersion layer is sequentially arranged in a gradient. The coating layer can be applied to the surface of the metal substrate. The carbide coating layer is formed on the surface of the metal substrate through introduction of an external carbon source to a metal substrate and vanadium complex, obtained through laser cladding, heating and thermal insulation, the coating layer and the substrate are metallurgically bonded, and the bonding force is very strong, so the wear resistance of the surface of the metal substrate is greatly improved.

Owner:XIAN UNVERSITY OF ARTS & SCI

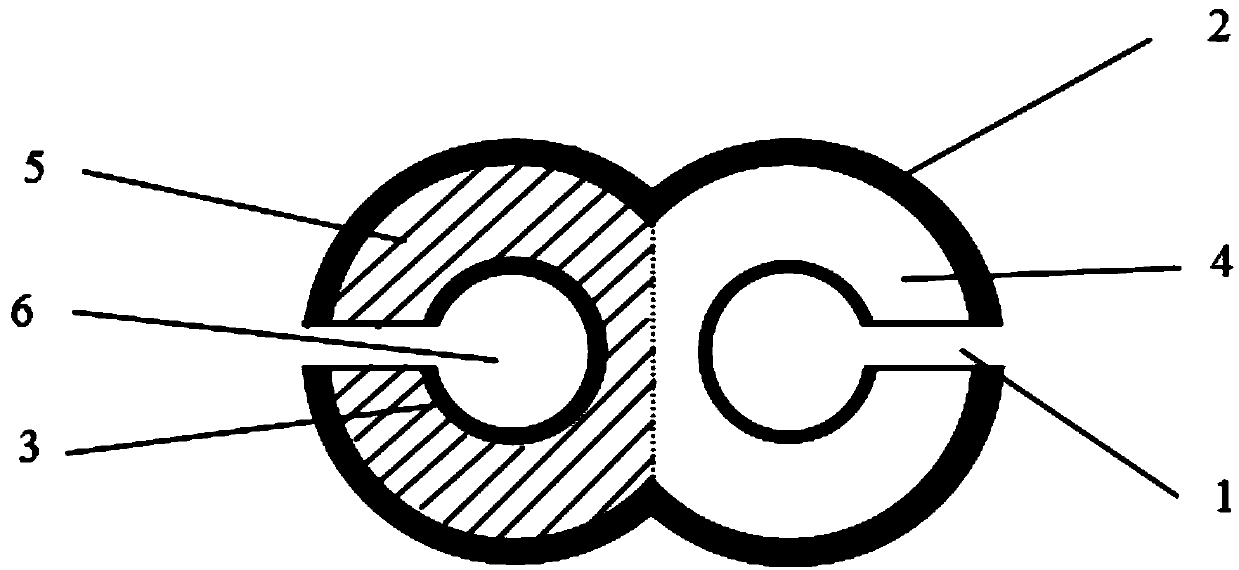

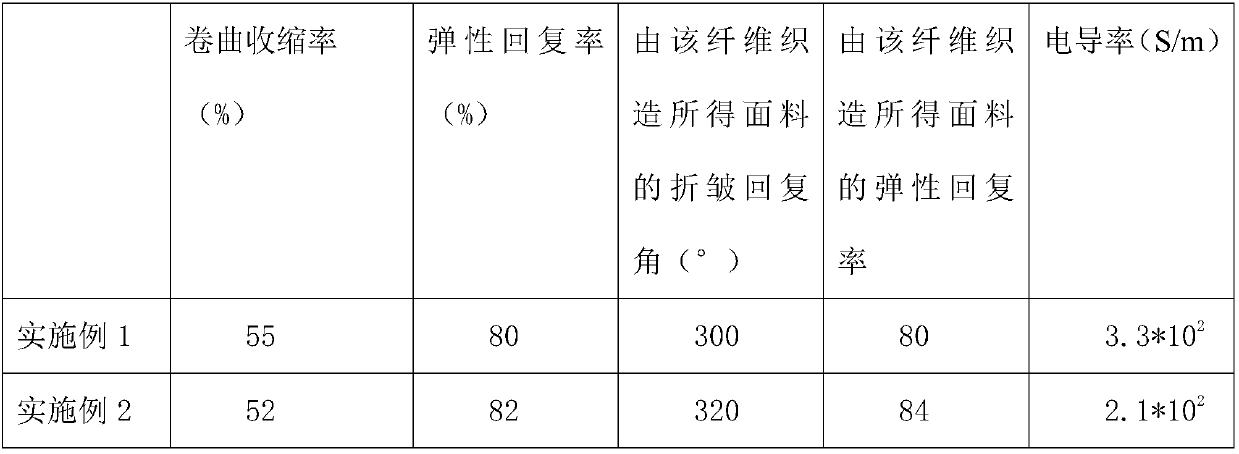

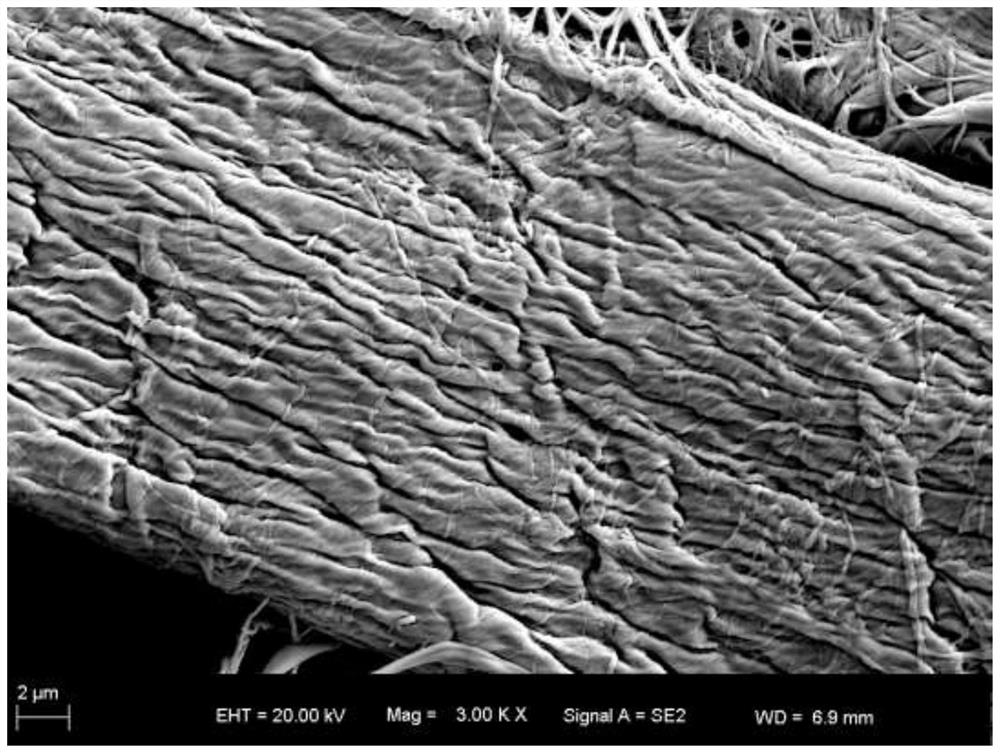

Conductive hollow double-ingredient parallel composite fiber and preparation method thereof

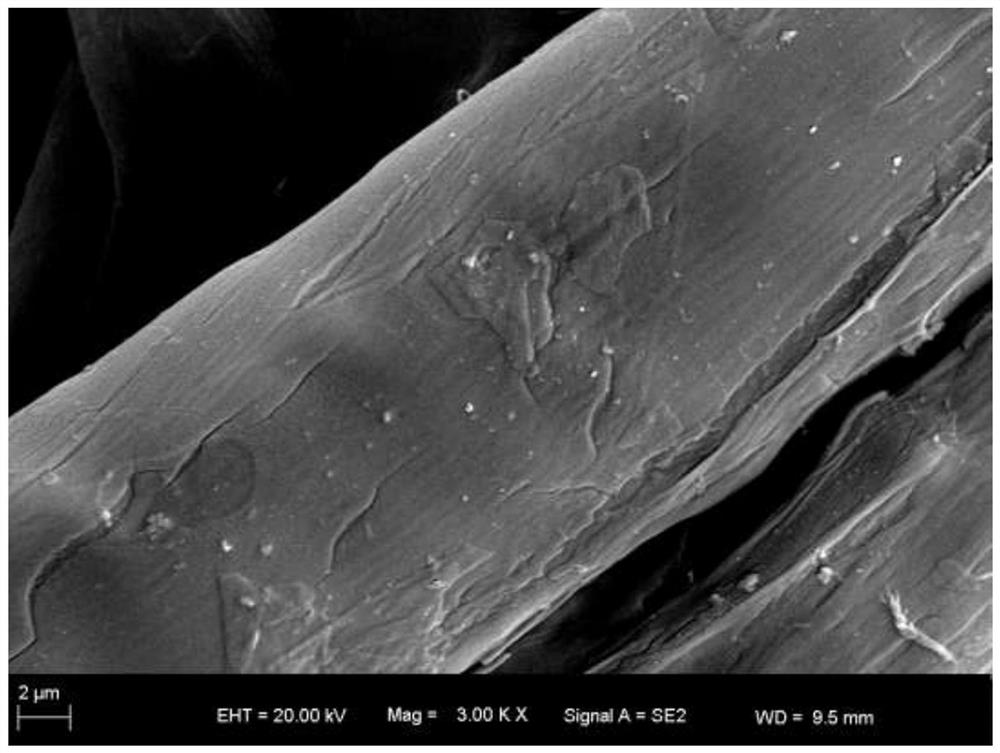

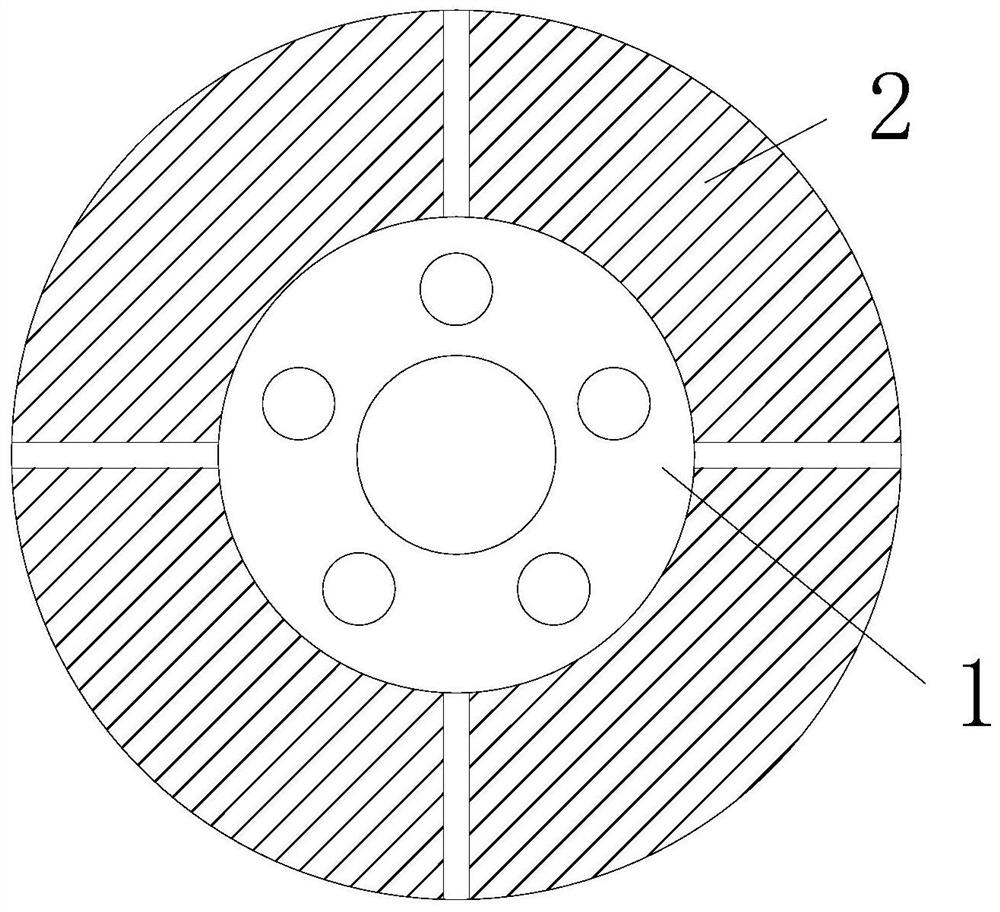

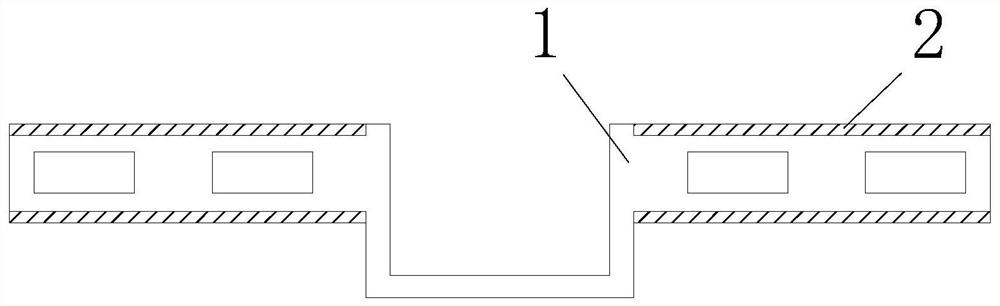

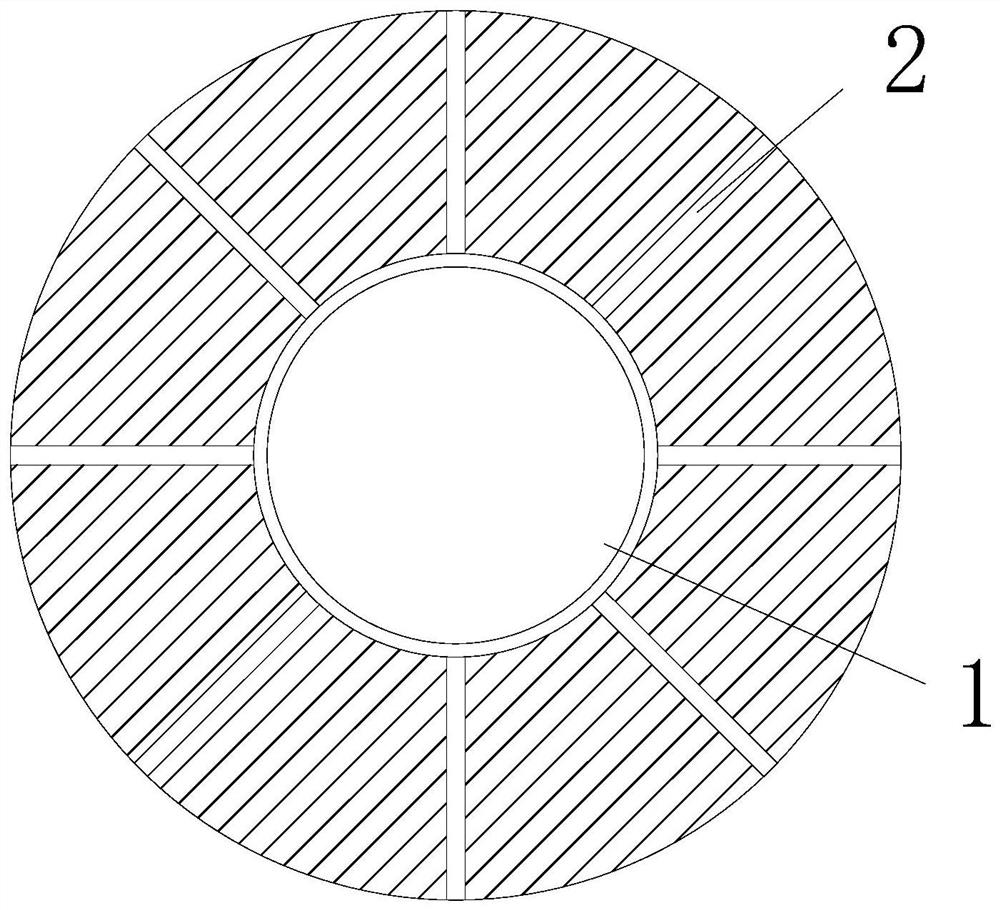

InactiveCN109518454AIncrease surface areaSolve the problem of easy falling offHollow filament manufactureMelt spinning methodsAdditive ingredientElectrical resistivity and conductivity

The invention relates to the technical field of synthetic fiber, in particular to a conductive hollow double-ingredient parallel composite fiber and a preparation method thereof. The composite fiber is formed by two ingredients of an ingredient A and an ingredient B in parallel; the double-ingredient cross section of the composite fiber is in a transverse eight shape or a dumbbell shape or a bielliptic shape or a double square shape or an I shape; hollow structures are respectively arranged in double ingredients of the composite fiber. The composite fiber and the preparation method have the advantages that the conductive hollow double-ingredient parallel composite fiber has inner and outer double conductive layers in parallel double conductive structures; due to the existence of the doubleconductive layers, a synergistic effect is achieved; the surface area of the conductive layer is greatly increased; high conductivity can be provided; the conductivity is 10 to 104S / m; the compositefiber hollow structure provides an inner conductive layer; the composite fiber is communicated with an outer opening in the drying process for contraction and closing, so that the problem that conductive particles attached on a conduction and coating electric layer at the inner surface of the composite fiber can easily fall off is solved.

Owner:LANGSHA KNITTING

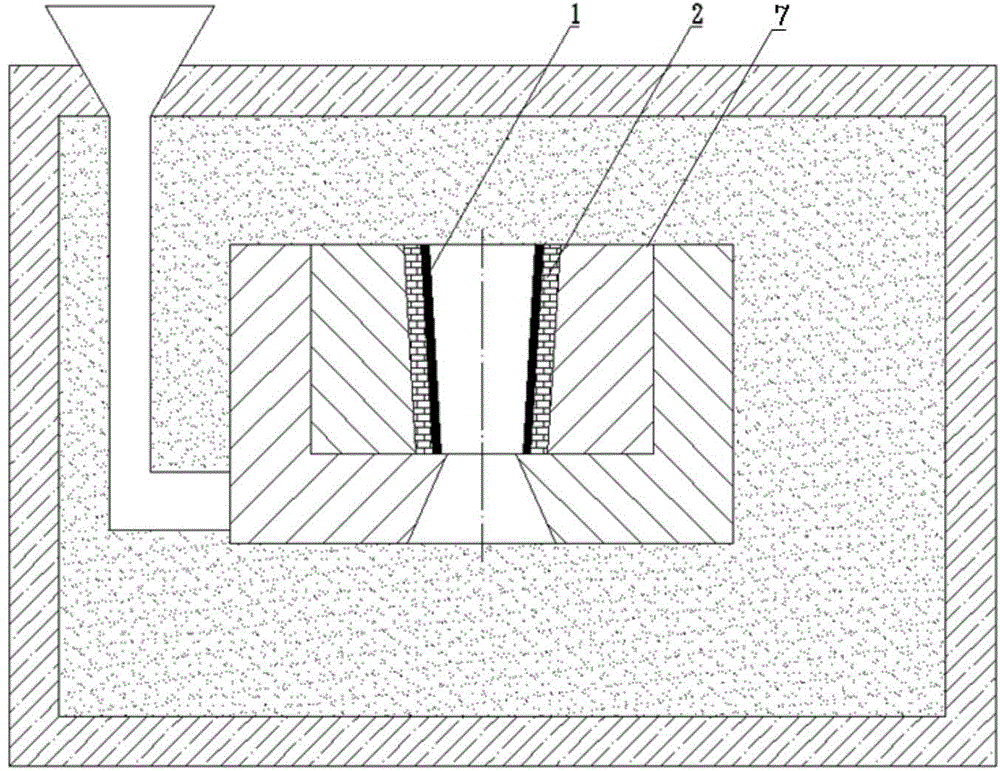

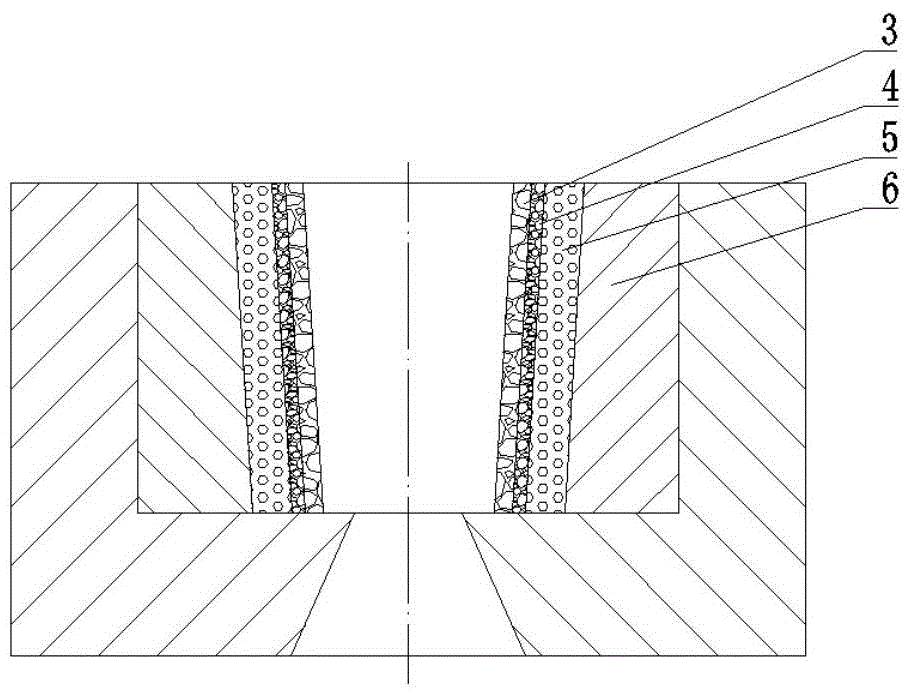

Wire drawing die and production method thereof

ActiveCN104525593AImprove mechanical propertiesOvercome the problem of easy sheddingDrawing diesCarbide coatingMicrometer

The invention discloses a wire drawing die and a production method thereof. The surface of each of work positions of the wire drawing die is provided with a carbide coating. The work positions of the upper surface and the lower surface of the wire drawing die are respectively provided with the carbide coating. A quasi monocrystalline TiC dense ceramic layer, a micrometer TiC ceramic layer and a TiC-matrix composite layer are sequentially distributed in a gradient manner from outside to inside, and are applied to the surface of carbon steel. The carbide coating can be applied to the surface of the carbon steel. The carbide coating is formed on the surface of the above matrix through the cast matrix-titanium complex, the introduction of an external carbon source, heating and heat insulation, the coating and the matrix are metallurgically bonded, and the bonding force is very strong, so the problems of non-metallurgic bonding between present hard particles and the steel substrate, very weak bonding force and easy shedding of the particles are overcome, and the wear resistance of the work surfaces of the wire drawing die is greatly improved.

Owner:XIAN UNIV OF TECH

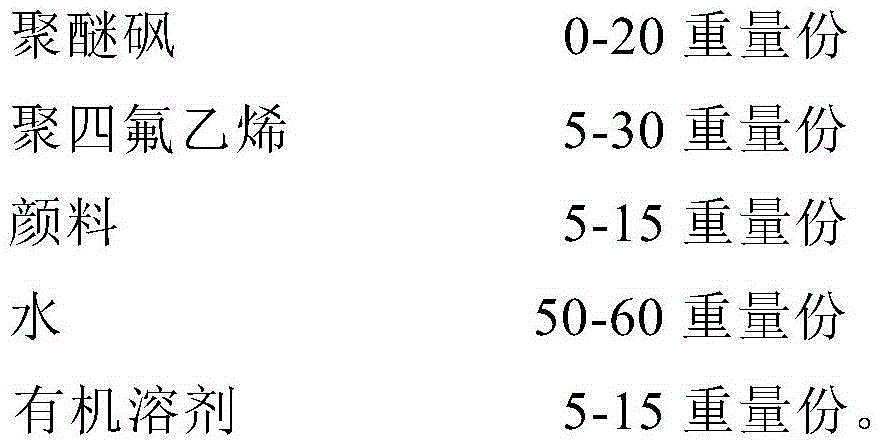

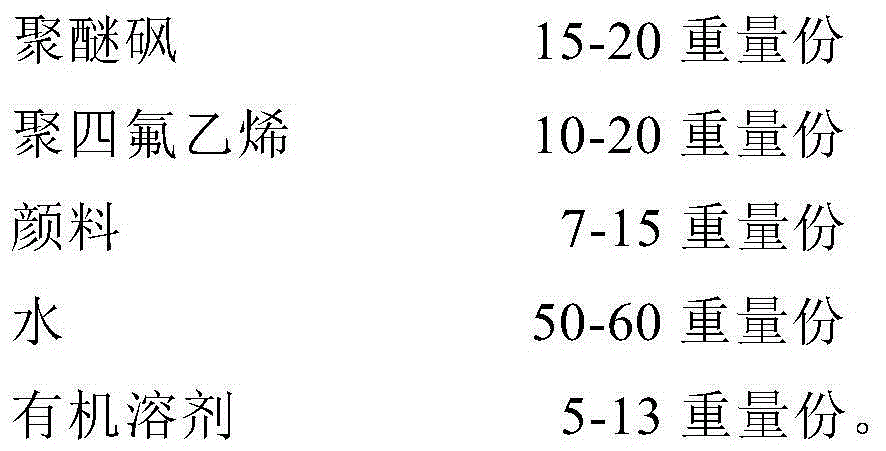

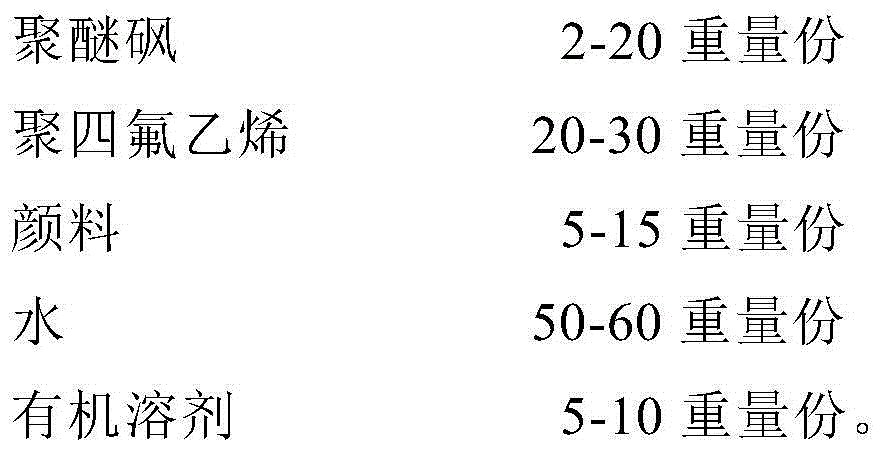

Aqueous anti-adhesion coating for iron substrate

The invention relates to an aqueous anti-adhesion coating. The coating contains polyethersulfone (PES), polytetrafluoroethylene, a pigment, water and a solvent. The aqueous anti-adhesion coating solves the problem of shedding of a film, and makes aqueous coatings be especially suitable for an iron substrate. The coating can be individually used to form the coating layer of an article, and also can be used to form any layer of a multilayer non-adhesion coating.

Owner:曾志玲

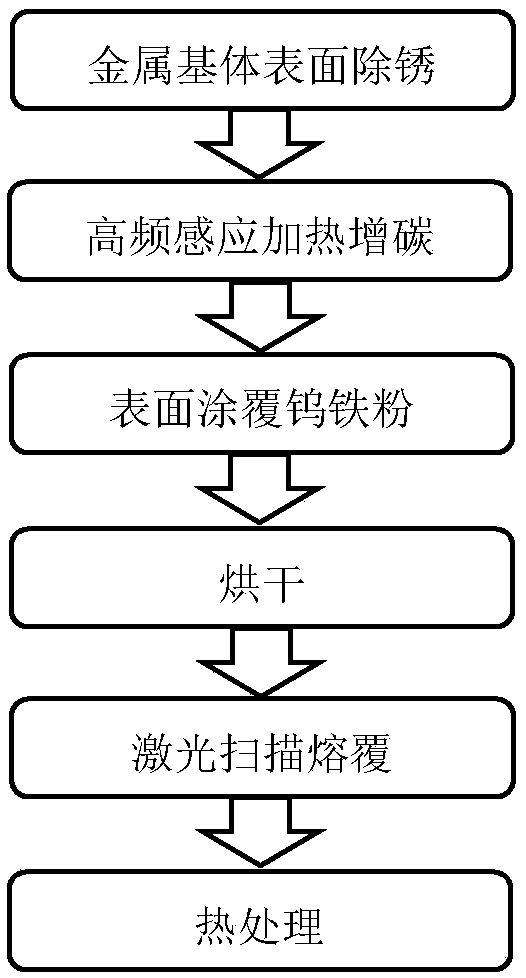

Tungsten carbide gradient composite coating and preparation method thereof

InactiveCN109023354AImprove mechanical propertiesOvercome the problem of easy sheddingSolid state diffusion coatingSuperimposed coating processCarbide coatingSurface layer

The invention discloses a tungsten carbide gradient composite coating and a preparation method thereof. The method comprises the steps: surface treatment is performed on a metal substrate; a carburantis prepared; the surface is coated with the carburant and a thermal insulation coating; surface layer recarburization is performed; a ferrotungsten powder is fed to the surface of the metal substrate; pre-drying laser scanning is performed; multi-pass lap welding is performed; heat preservation is performed; and cooling with the furnace is performed to obtain a composite wear-resistant tungsten carbide coating on the surface of the metal substrate. The coating is a tungsten carbide dense ceramic layer that can be applied to the surface of a low carbon steel or low carbon alloy steel substrate. A composite of the low carbon steel or low carbon alloy steel substrate and the ferrotungsten powder obtained by laser cladding is subjected to heating and heat preservation, thereby forming a carbide coating on the surface of the low carbon steel or low carbon alloy steel substrate; the coating and the substrate are subjected to metallurgical bonding; and the bonding force is large, greatly improving the wear resistance of the surface of low carbon steel or low carbon alloy steel substrate.

Owner:XIAN UNVERSITY OF ARTS & SCI

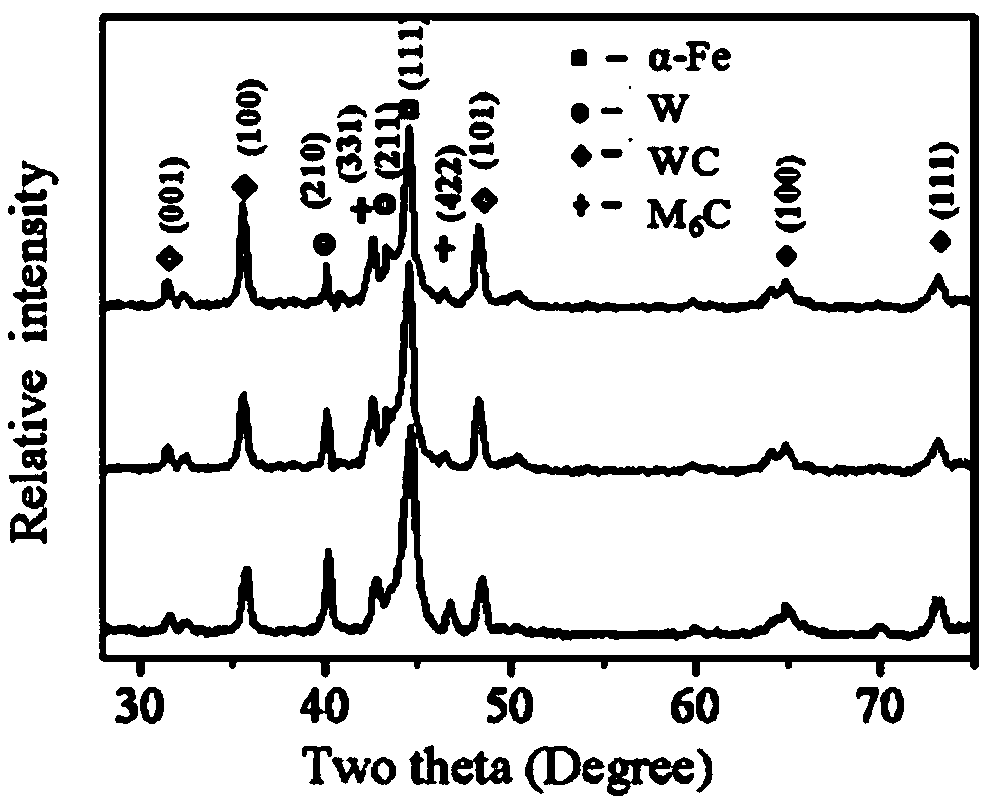

Wear resistant carbide coating and production method thereof

ActiveCN104532234AImprove mechanical propertiesOvercome the problem of easy sheddingMetallic material coating processesCarbide coatingWear resistant

A wear resistant carbide coating comprises a quasi monocrystalline phase WC dense ceramic layer, and further comprises a micrometer WC ceramic layer and a WC-substrate fusion layer. The quasi monocrystalline phase WC dense ceramic layer, the micrometer WC ceramic layer and the WC-substrate fusion layer are sequentially distributed in a gradient manner. The coating can be applied to the surface of the carbon steel. The carbide coating is formed on the surface of the carbon steel through the cast steel substrate and tungsten complex, the introduction of an external carbon source, heating and heat insulation, the coating and the substrate are metallurgically bonded, and the bonding force is very strong, so the problems of non-metallurgic bonding between present hard particles and the steel substrate, very weak bonding force and easy shedding of the particles are overcome, and the wear resistance of the surface of the carbon steel is greatly improved.

Owner:XIAN UNIV OF TECH

Vanadium carbide gradient composite coating and preparation method thereof

ActiveCN109055685AImprove mechanical propertiesOvercome the problem of easy sheddingMetallic material coating processesCarbide coatingWear resistant

The invention discloses a vanadium carbide gradient composite coating and a preparation method thereof. The metal matrix surface is treated, a carburant is prepared, the metal matrix surface is coatedwith the carburant and a thermal insulation coating, surface carburization is carried out, ferrovanadium powder is sent to the metal matrix surface, pre-drying laser scanning is carried out, multi-channel overlap cladding is carried out, heat preservation is carried out, while-furnace cooling is carried out, and the composite wear resistant vanadium carbide coating on the metal matrix surface isobtained. The coating includes a composite zone of granular-shaped and short rod-shaped carbide and a matrix, and can further includes a composite zone of granular-shaped and chrysanthemum-shaped carbide and the matrix, a composite zone of granular-shaped secondary carbide and the matrix, and a ferrite zone with less carbon and vanadium contents, the composite zone of the granular-shaped and shortrod-shaped carbide and the matrix, the composite zone of the granular-shaped and chrysanthemum-shaped carbide and the matrix, the composite zone of the granular-shaped secondary carbide and the matrix and the ferrite zone with the less carbon and vanadium contents are successively distributed in gradient, and can be applied to the metal matrix surface. According to the vanadium carbide gradient composite coating and the preparation method thereof, a complex of a metal matrix and vanadium is obtained by casting, external carbon sources are externally introduced, heating and heat preservation are carried out, and a carbide coating is formed on the metal matrix surface; and the coating is metallurgical bonded to the matrix, the binding force is high, and the wear resistant property of the metal matrix surface is greatly improved.

Owner:XIAN UNVERSITY OF ARTS & SCI

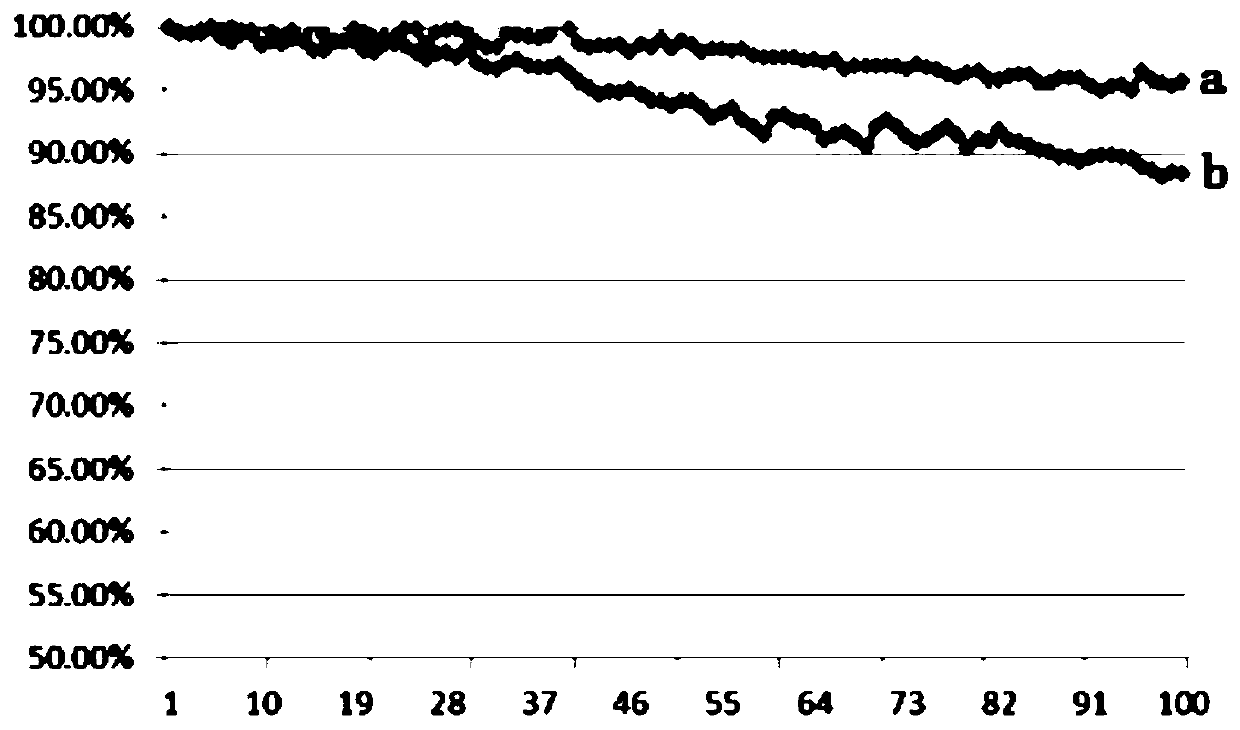

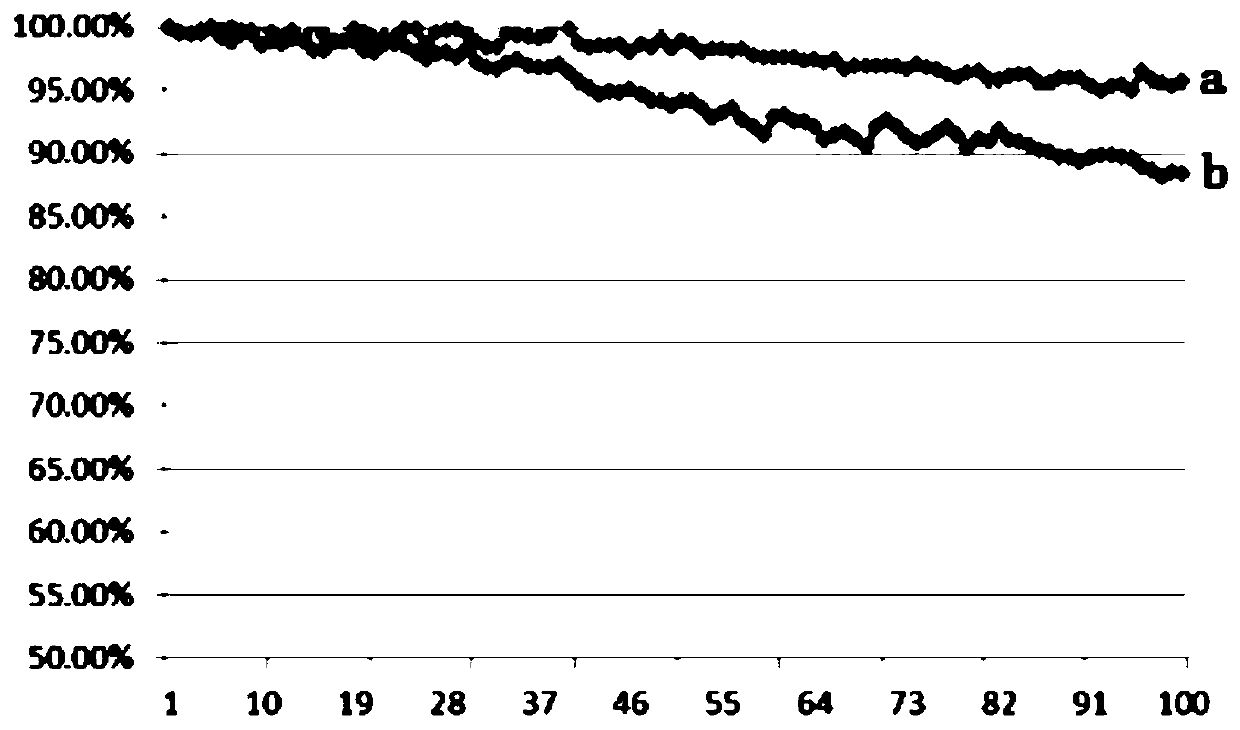

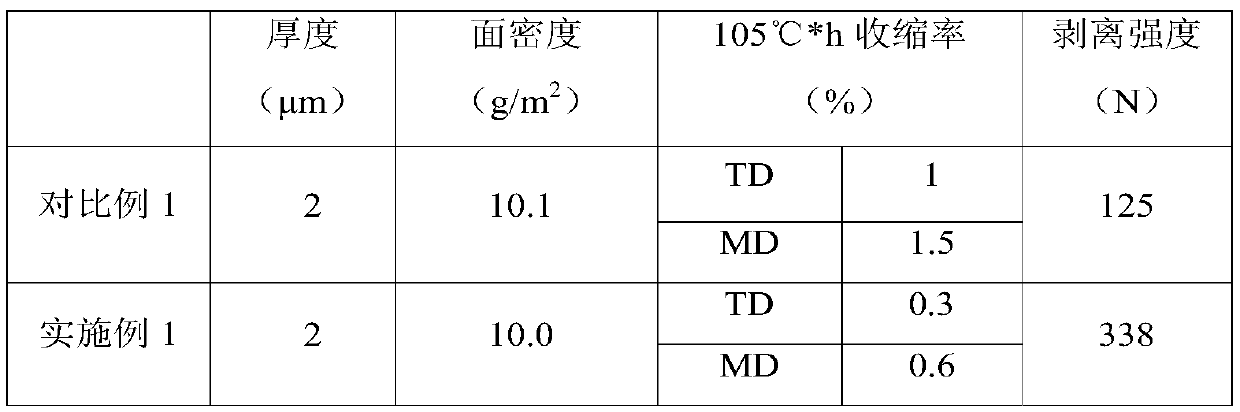

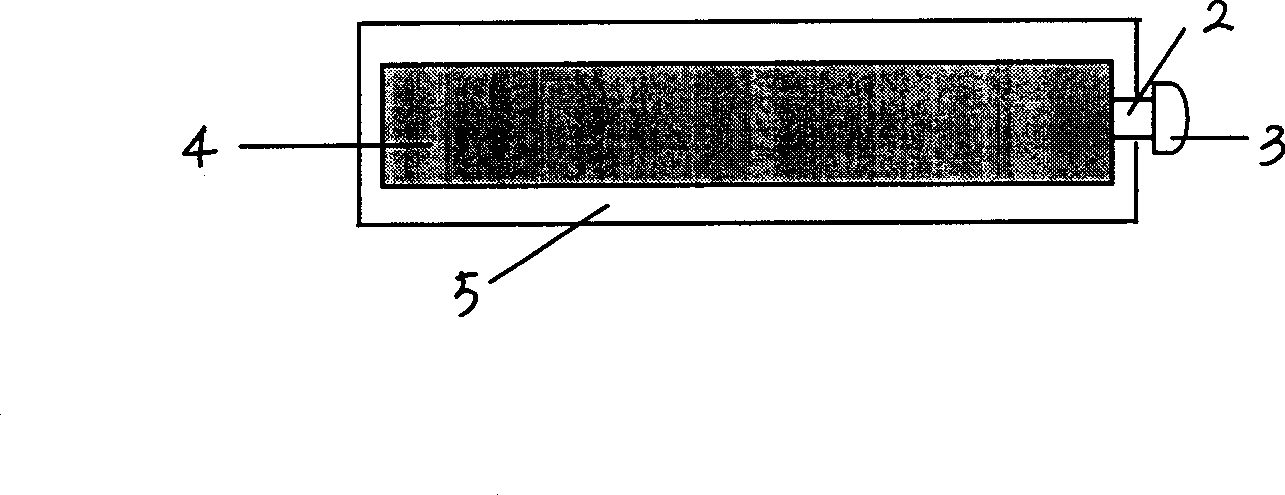

Chemically-modified lithium battery diaphragm and preparation method thereof

InactiveCN109713200ALow heat shrinkageOvercome the problem of easy sheddingSecondary cellsCell component detailsSilicon dioxideSilica membrane

The invention discloses a chemically-modified lithium battery diaphragm and a preparation method thereof, and belongs to the field of lithium batteries. The preparation method of the chemically-modified lithium battery diaphragm comprises the following steps: activating the surface of a PE film to form a C = O group on the surface of the PE film; and forming a silicon dioxide film on the surface of the activated PE film. The preparation method is simple in process, convenient to operate and suitable for large-scale production. In addition, the invention also relates to the lithium battery diaphragm prepared by the preparation method. The chemically-modified lithium battery diaphragm solves the problem that the coating of the diaphragm is easy to fall off, the thermal shrinkage rate of thediaphragm is reduced, and the cycle performance is improved.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

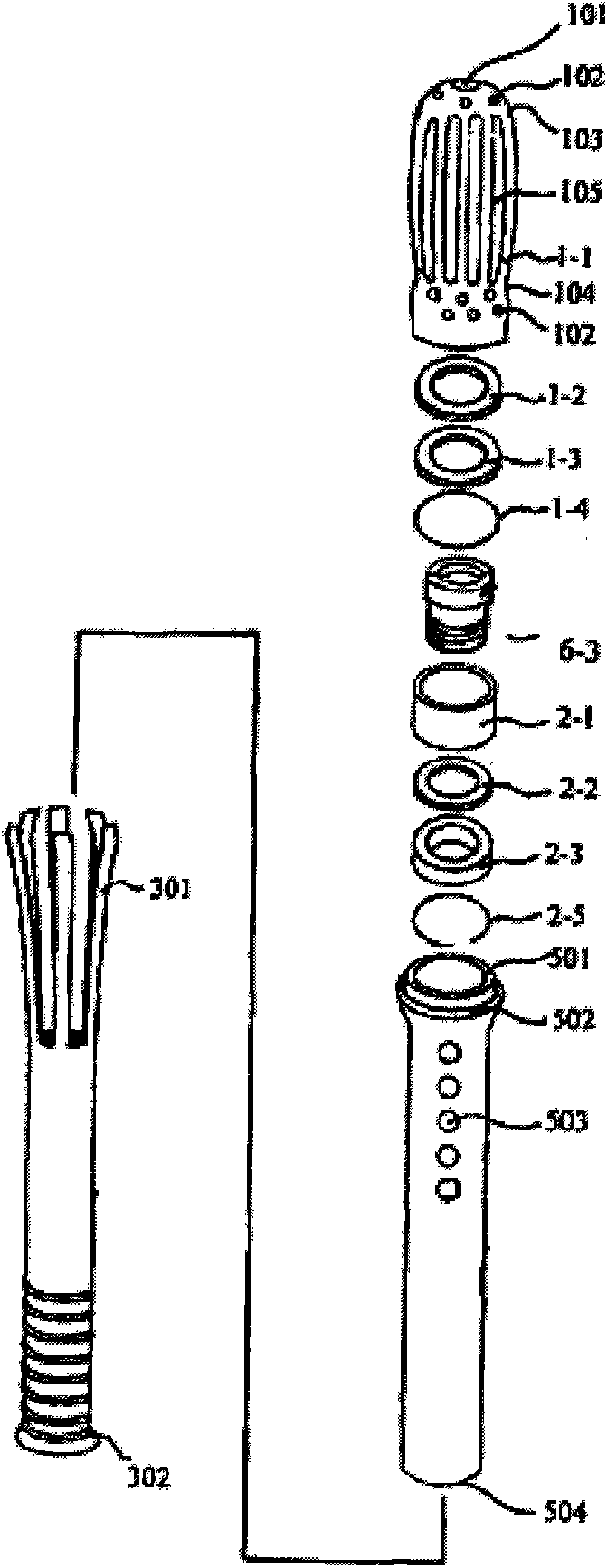

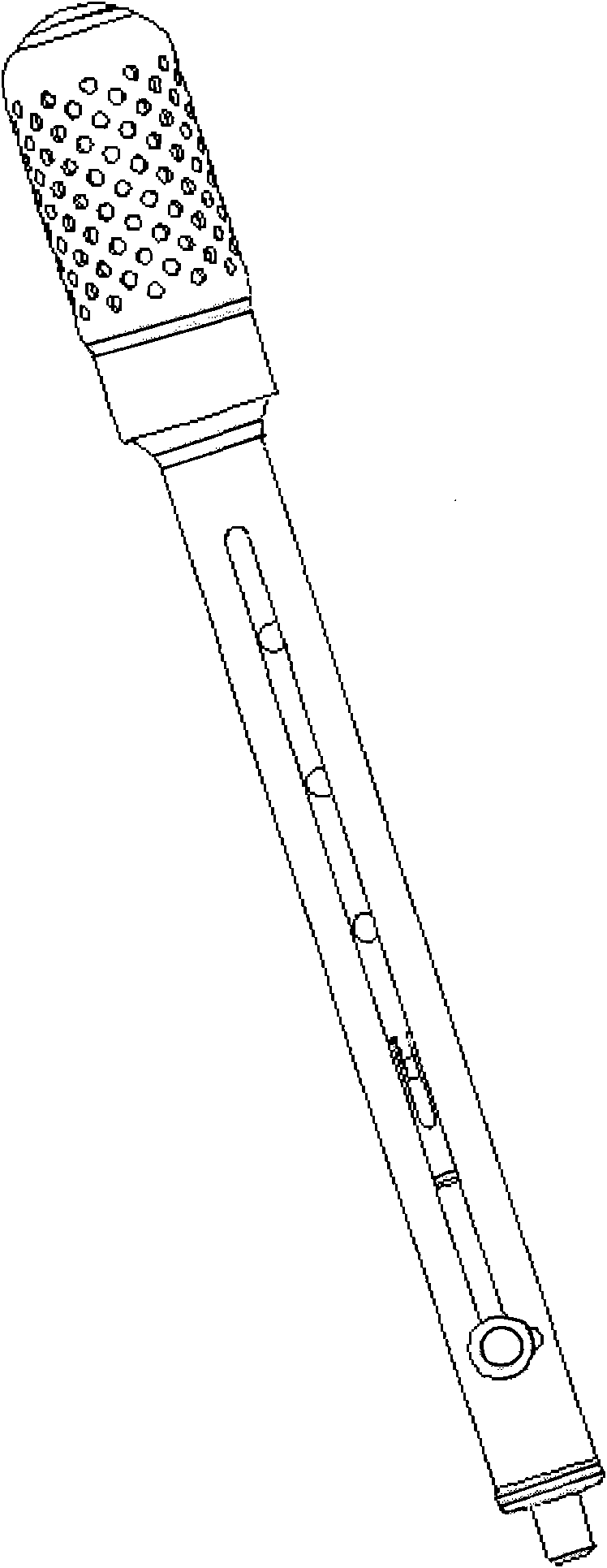

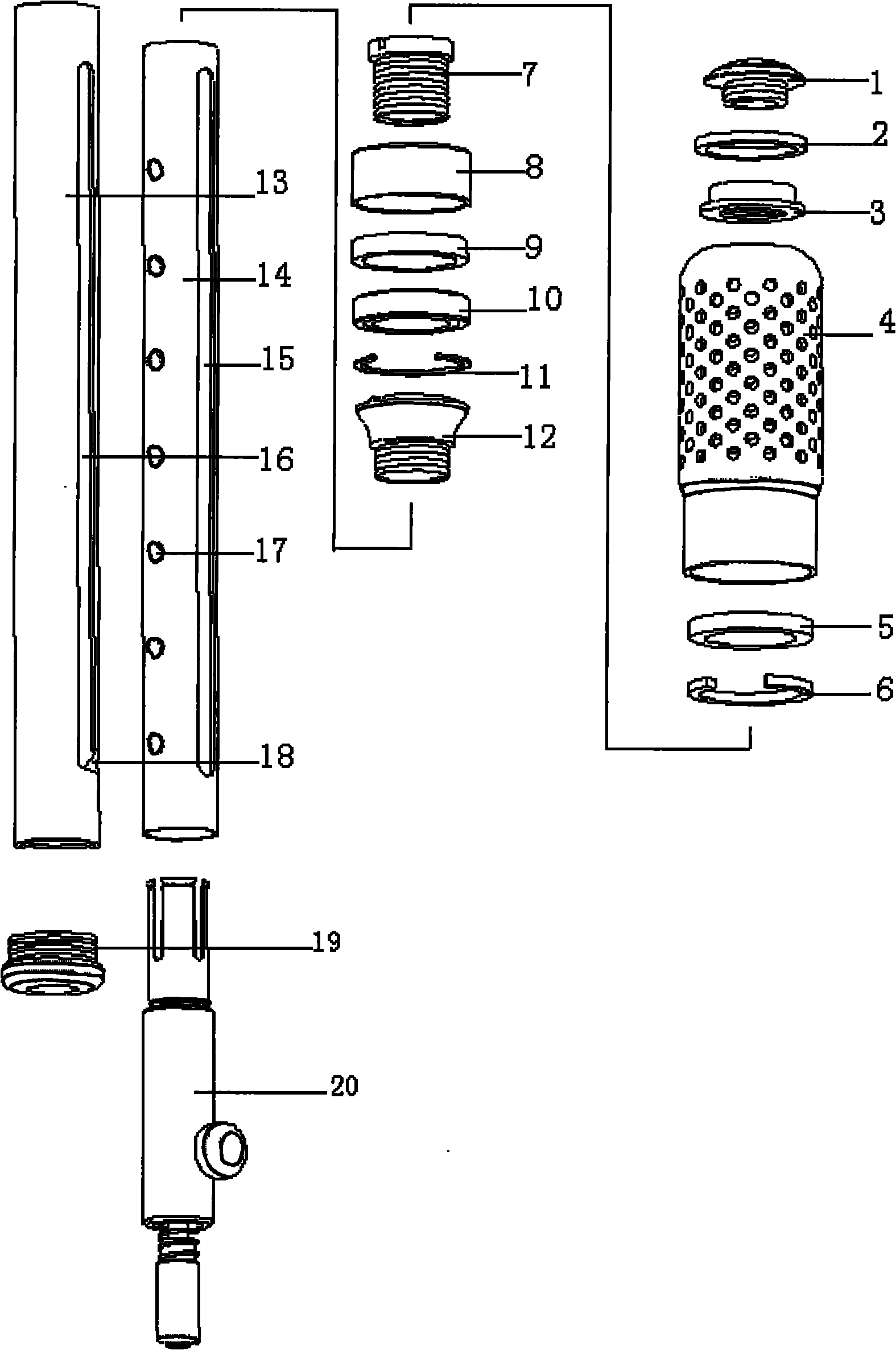

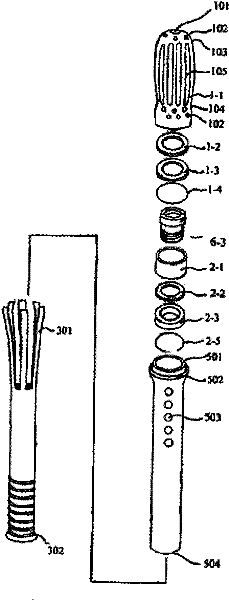

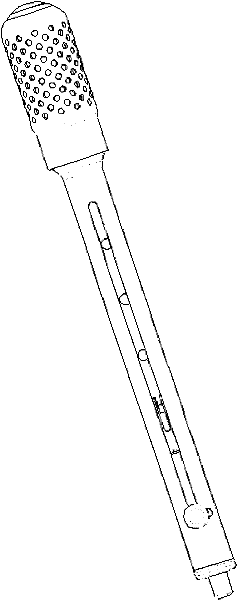

Warming moxibustion bar for activating collaterals by fragrant magnetic therapy

InactiveCN101780008AFlexible control positionEasy to replaceDevices for heating/cooling reflex pointsElectrotherapyEngineeringMoxibustion

The invention relates to a warming moxibustion bar for activating collaterals by fragrant magnetic therapy, which comprises a warming moxibustion head component, a connecting component and a swath clamp component, wherein the swath clamp component comprises an inner tube, a threaded connector, an outer tube and a push rod assembly, wherein a groove is arranged along the longitudinal direction of one side of the wall of the inner tube, and a positioning hole is arranged along the longitudinal direction of the other side; one end of the threaded connector is used for connecting with the connecting component; a groove corresponding to the groove of the inner tube is arranged along the longitudinal direction of the wall of the outer tube, the upper end of the outer tube is connected with the other end of the threaded connector, and a thread cap is arranged at the lower end of the outer tube; and the push rod assembly is used for pushing the swath placed in the inner tube along the grooves arranged on the inner tube and the outer tube to adjust the position of the swath in the warming moxibustion head component, and the push rod assembly is positioned through the positioning hole.

Owner:温宗金

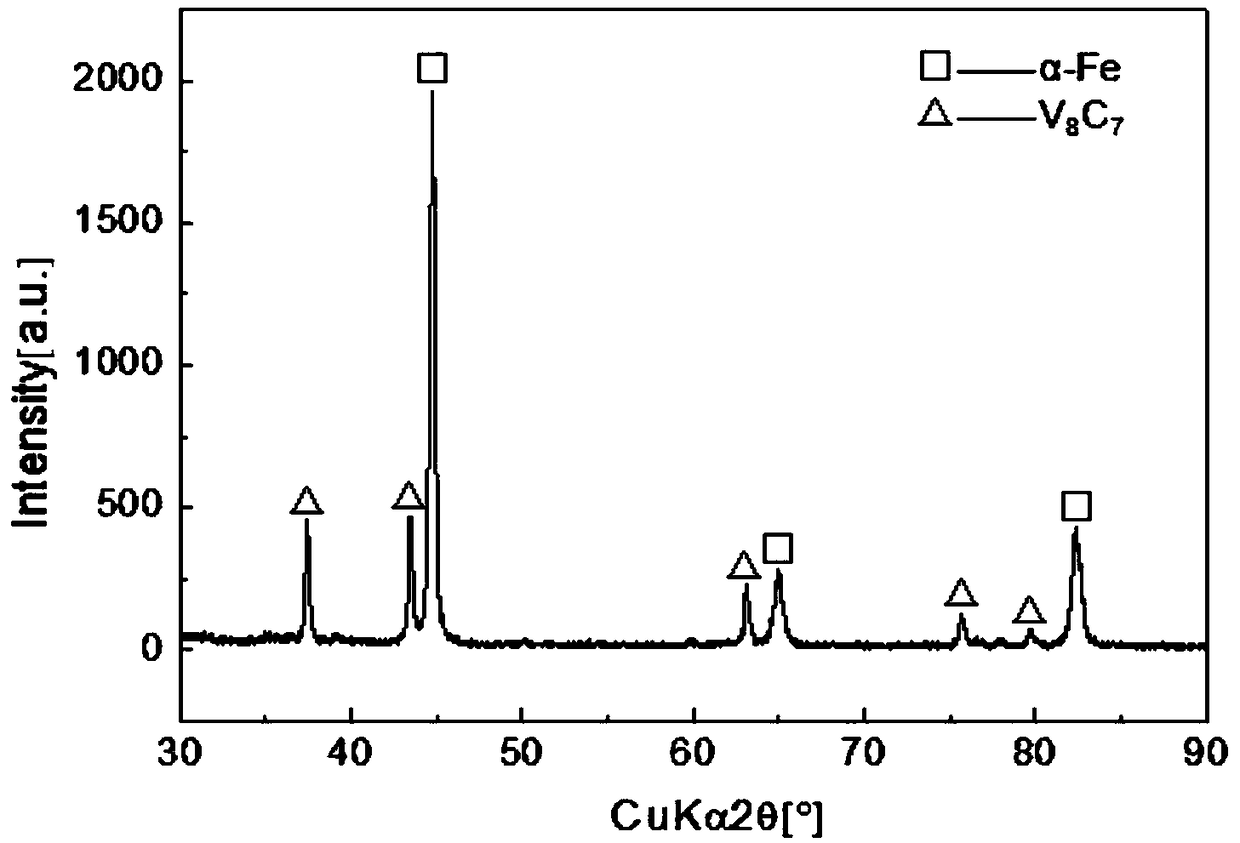

Jaw plate and production method thereof

ActiveCN104525299AImprove mechanical propertiesApparent quasi-single crystal structureGrain treatmentsMetal substrateMicrometer

The invention provides a jaw plate and a production method thereof. The work surface of the jaw plate contacting with a material is provided with a carbide coating The surface of the jaw plate is provided with the carbide coating. The carbide coating includes a V2C dense ceramic layer, and further includes a micrometer V8C7 dense ceramic layer and a V8C7-substrate fusion layer. The V2C dense ceramic layer, the micrometer V8C7 dense ceramic layer and the V8C7-substrate fusion layer are distributed in a gradient manner. The carbide coating can be applied to the surface of high manganese steel. The coating and the substrate are metallurgically bonded, and the bonding force is strong, so the problems of non-metallurgical bonding between present hard particles and a metal substrate, weak bonding force and easy shedding of the particles are overcome, and the wear resistance of the work surface of the jaw plate is greatly improved.

Owner:XIAN UNIV OF TECH

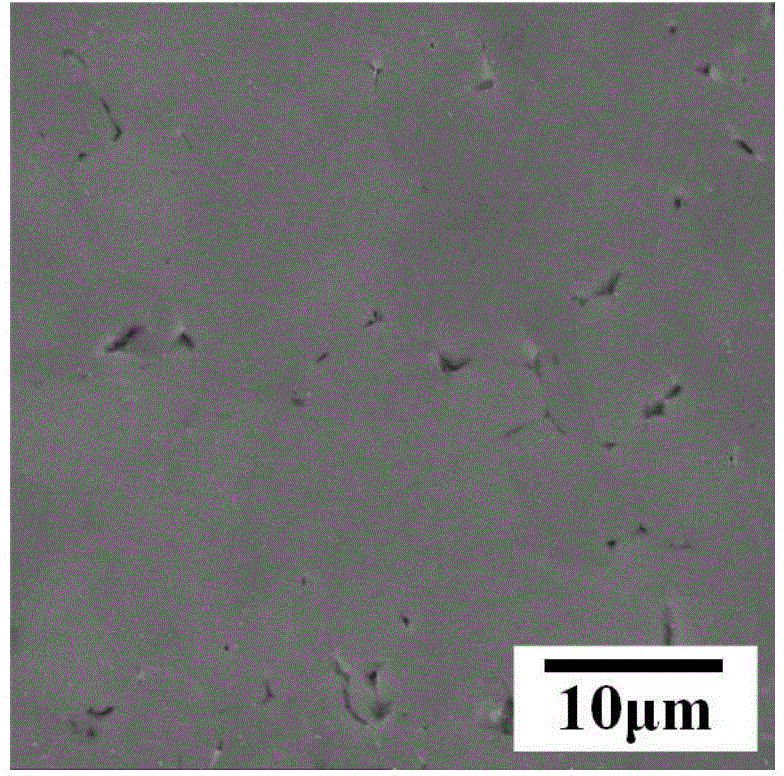

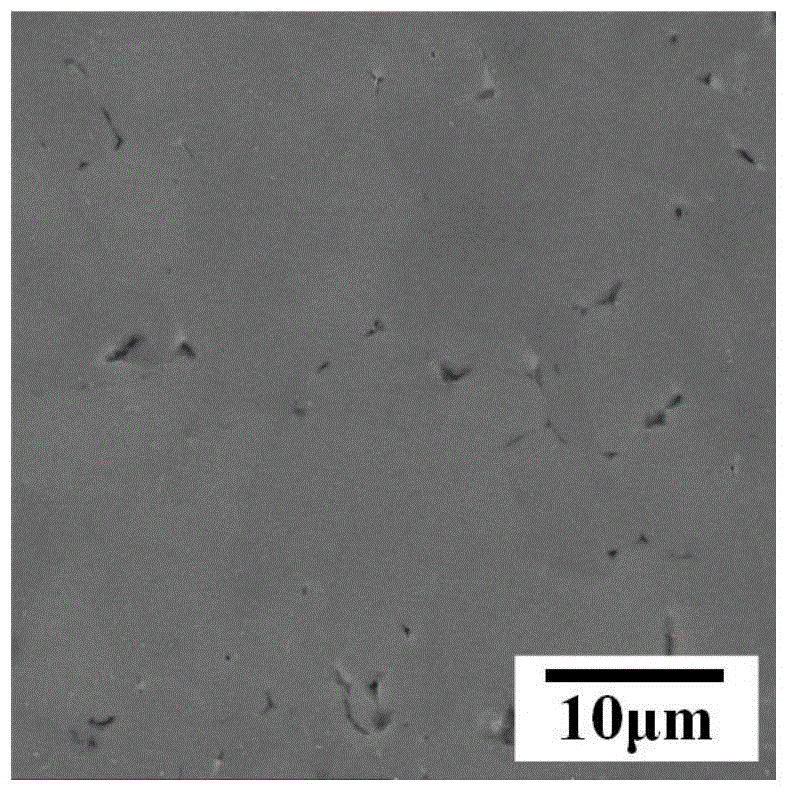

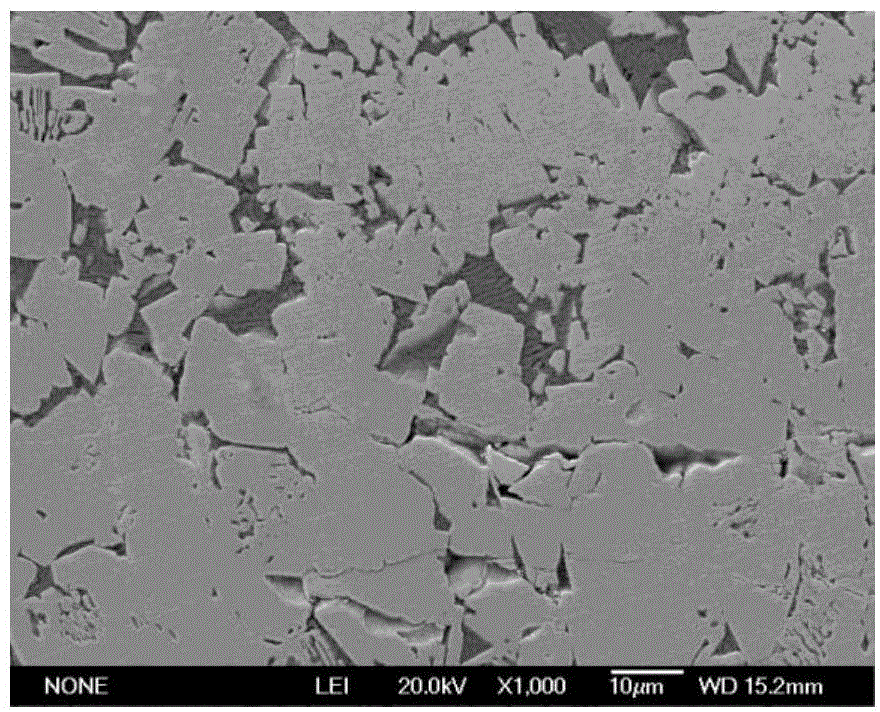

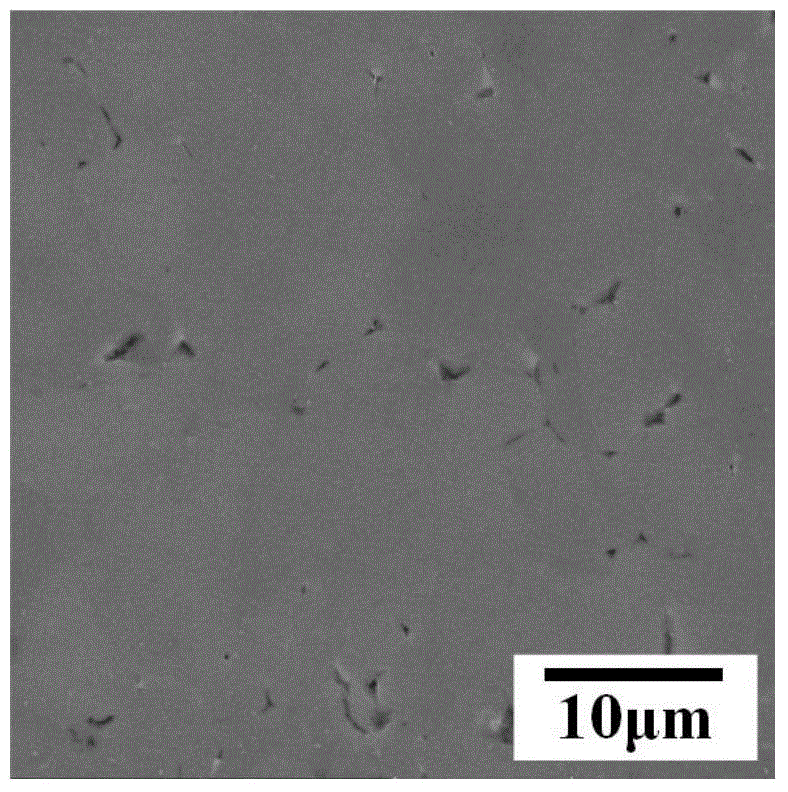

High-density titanium carbide composite wear-resisting coating and preparation method thereof

InactiveCN109112534AImprove mechanical propertiesOvercome the problem of easy sheddingSolid state diffusion coatingCarbide coatingThermal insulation

The invention discloses a high-density titanium carbide composite coating and a preparation method thereof. The preparation method comprises the following steps: treating the surface of a metal matrix, preparing a recarburizing agent, smearing the recarburizing agent and a thermal insulation coating on the surface, recarburizing a surface layer, sending ferrotitanium powder onto the surface of themetal matrix, pre-drying, laser scanning, performing multi-step laser overlapping cladding, preserving the heat, cooling along with the furnace, and obtaining the composite wear-resisting titanium carbide coating on the surface of the metal matrix. The coating consists of a great amount of gray reinforcing phase particles TiC and little gray white iron matrix; and the reinforcing phase particlesTiC are uniformly distributed and are uniform in shape and are in a square or spherical shape, and have no apparent sharp angle and edges and corners. The metal matrix and titanium complex obtained byvirtue of casting is provided with an outer carbon source to be heated and thermally preserved, so that a carbide coating is formed on the surface of the metal matrix, the coating is metallurgicallycombined with the matrix, the binding force is high, and the wear resistance of the metal matrix surface is greatly improved.

Owner:XIAN UNVERSITY OF ARTS & SCI

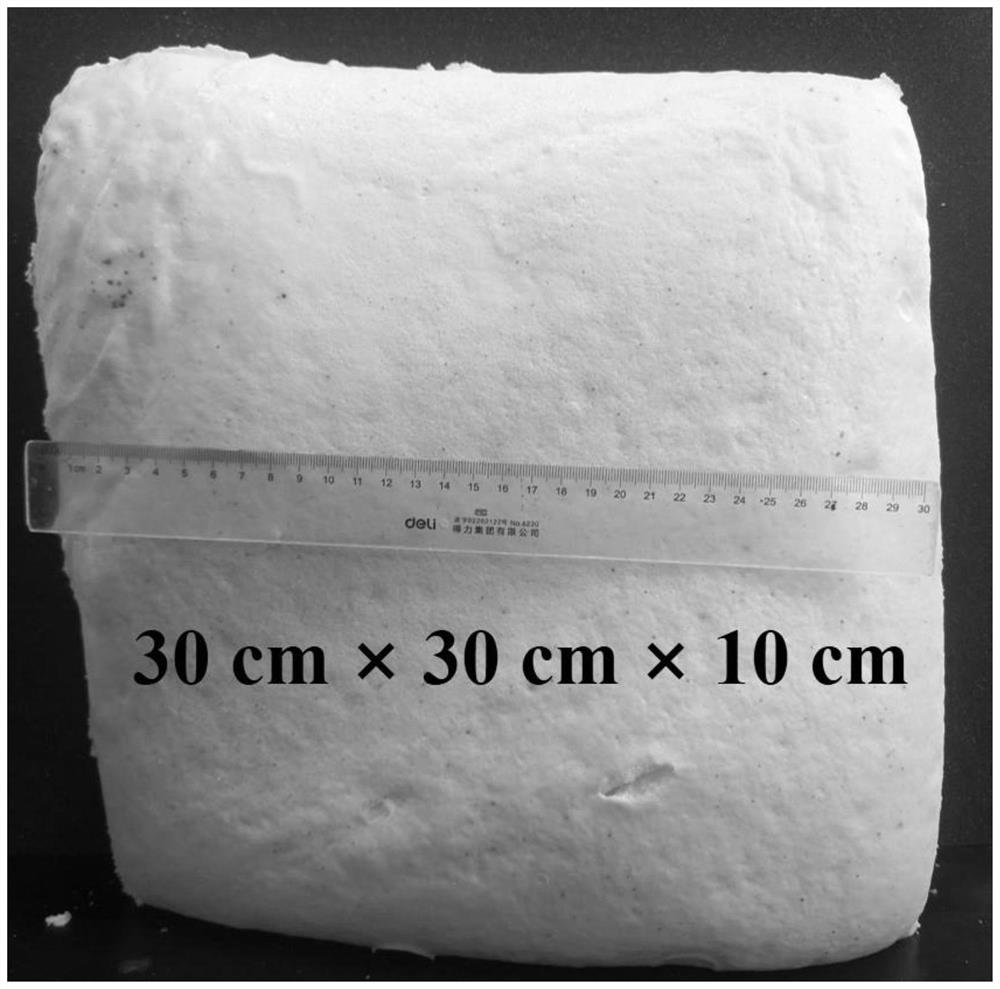

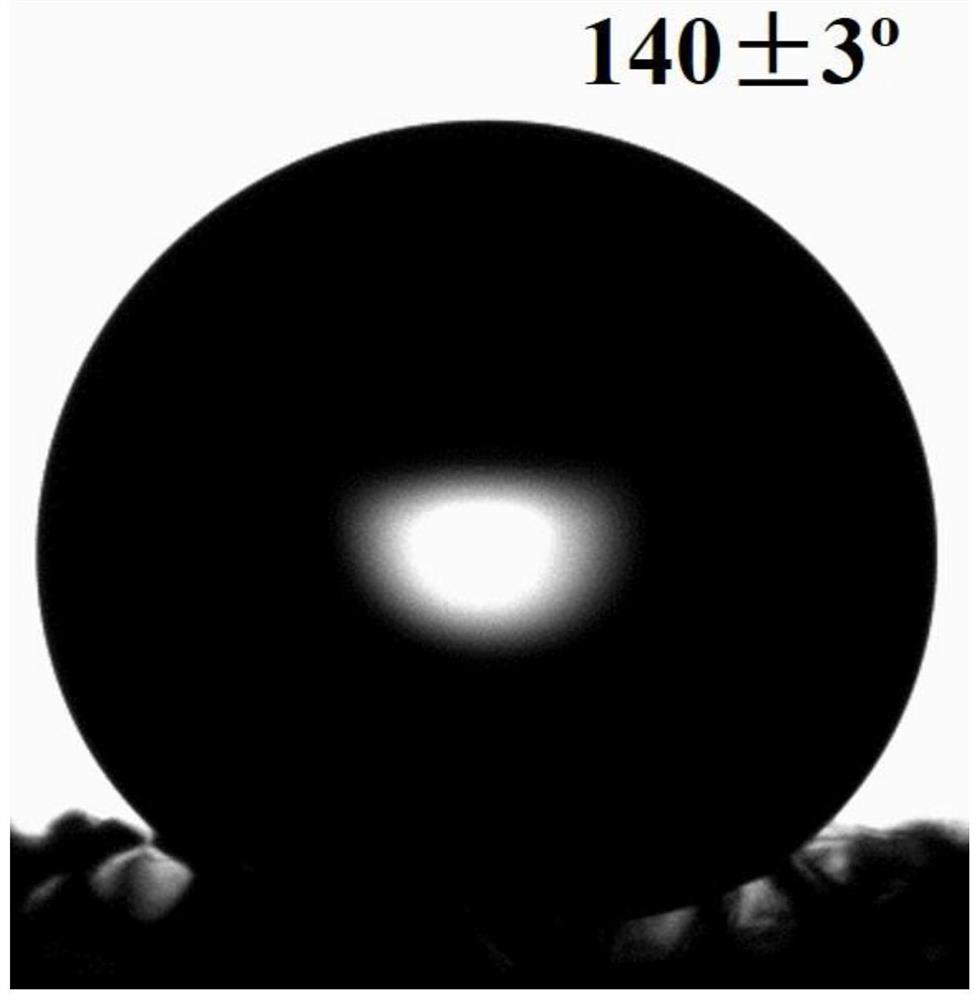

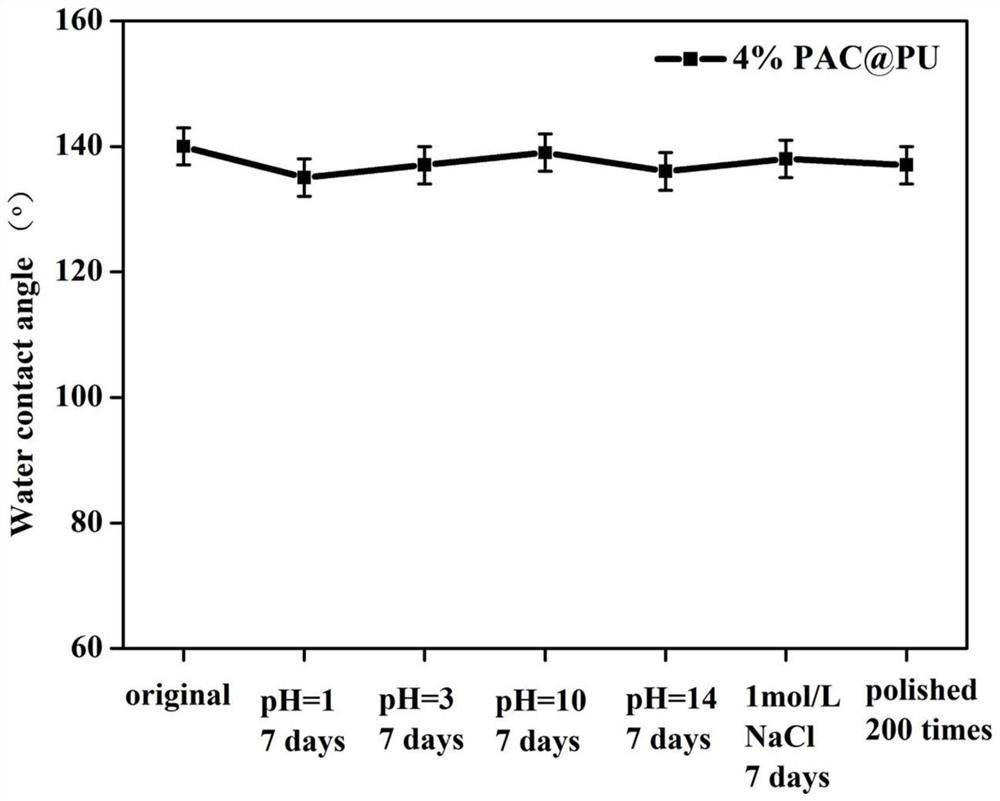

Composite polyurethane foam emulsion separation material, and preparation method and application thereof

ActiveCN113072677AOvercome the problem of easy sheddingEfficient separationLiquid separationAluminium chloridePolymer science

The invention discloses a composite polyurethane foam emulsion separation material. The separation material is polyaluminum chloride in-situ composite polyurethane foam. The separation material is prepared from polyether polyol, a catalyst, a foaming agent, a foam stabilizer, isocyanate and polyaluminum chloride. The preparation method of the separation material adopts a quick foaming method, and comprises the following steps: adding commercial polyaluminum chloride into a polyurethane foam synthesis raw material, and uniformly dispersing the polyaluminum chloride into the foam synthesis raw material by stirring; and foaming and naturally curing to obtain the emulsion separation material. The preparation method is simple in process, short in period, mild in condition, green and environment-friendly, and easy for large-scale production and application. The emulsion separation material of the polyaluminum chloride in-situ composite polyurethane foam has excellent hydrophobicity and stable physical and chemical properties; and the efficient separation efficiency on oil-in-water type emulsification is realized, and the wide application prospect is realized in the field of oily sewage treatment.

Owner:SOUTHWEST PETROLEUM UNIV

Wire-drawing die and manufacturing method thereof

ActiveCN104588616AImprove mechanical propertiesOvercome the problem of easy sheddingDrawing diesCarbide coatingMicrometer

The invention discloses a wire-drawing die. Carbide coatings are arranged on the surfaces of work portions. The invention further provides a manufacturing method of the wire-drawing die. The work portions of the upper surface and the lower surface of the wire-drawing die are provided with the carbide coatings. A pseudo-single crystal WC compact ceramic layer, a micrometer WC ceramic layer and a composite layer of WC and a base body are distributed from outside to inside sequentially in a gradient mode and are applied to the surfaces of carbon steel. The base body and a tungsten composite body are obtained in a casting mode, an external carbon source is introduced, heating and heat preservation are carried out, and therefore the carbide coatings are formed on the surfaces of the base body. The coatings and the base body are combined in a metallurgy mode, the combination force is high, the problems in the prior art that hard particles and the base body are combined in a non-metallurgy mode, the combination force is weak, and particles are prone to falling off are solved, and the abrasion resistance of the work surface of the wire-drawing die is largely improved.

Owner:XIAN UNIV OF TECH

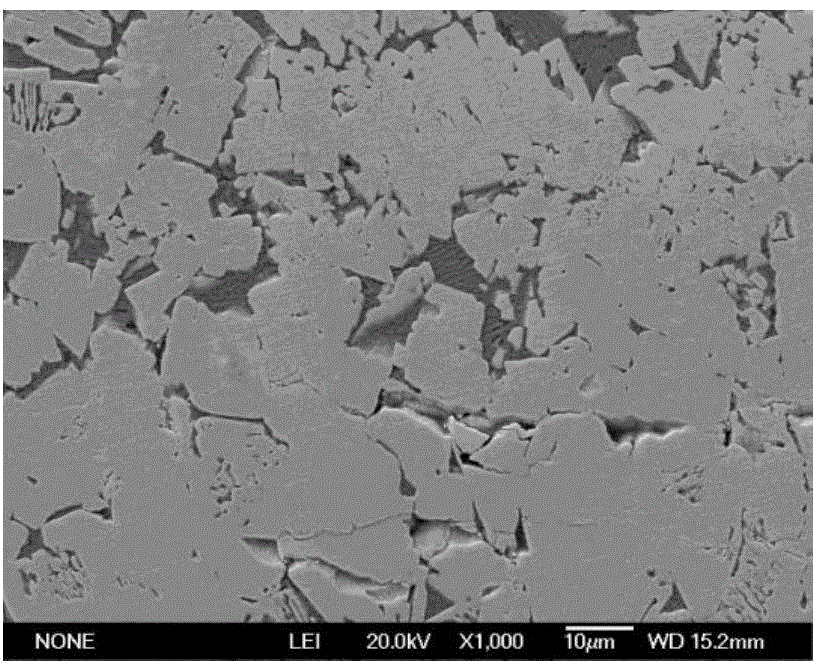

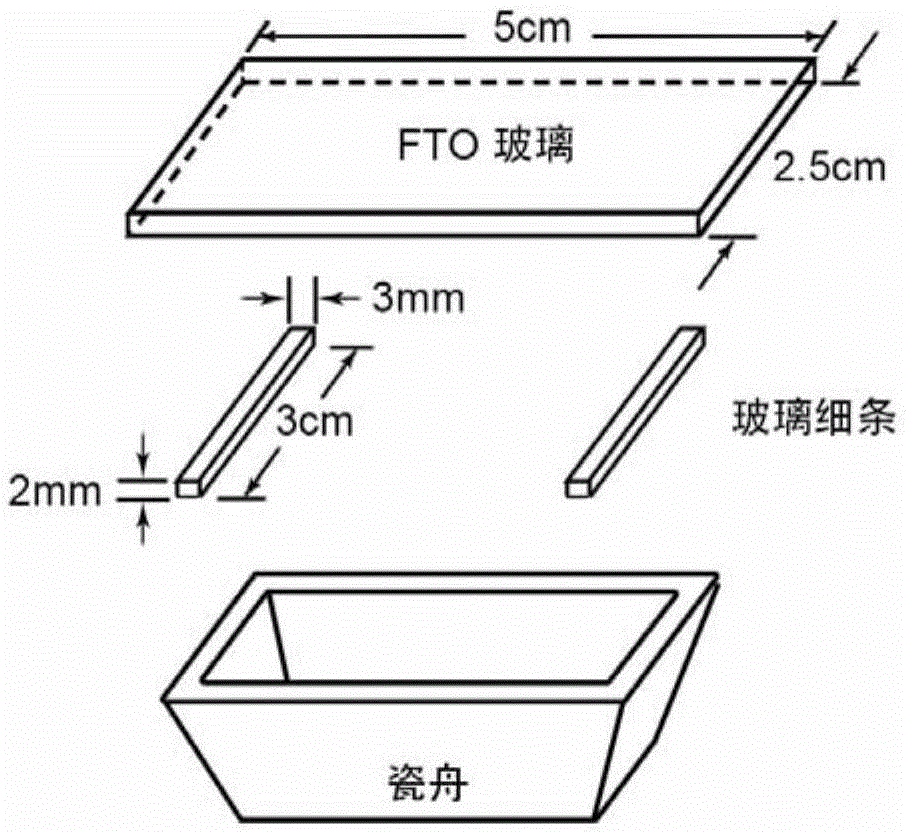

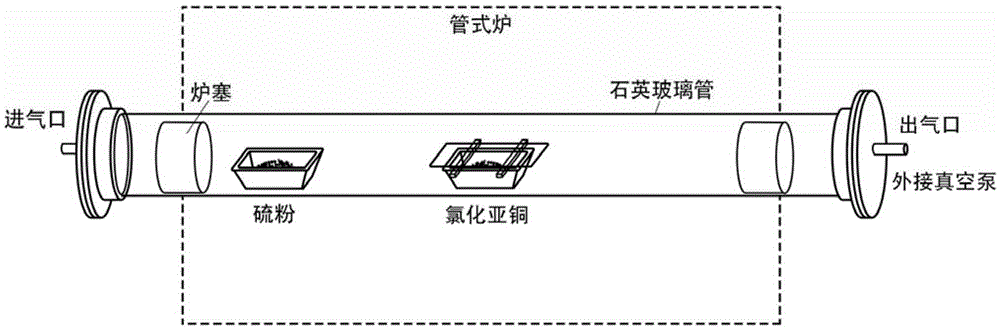

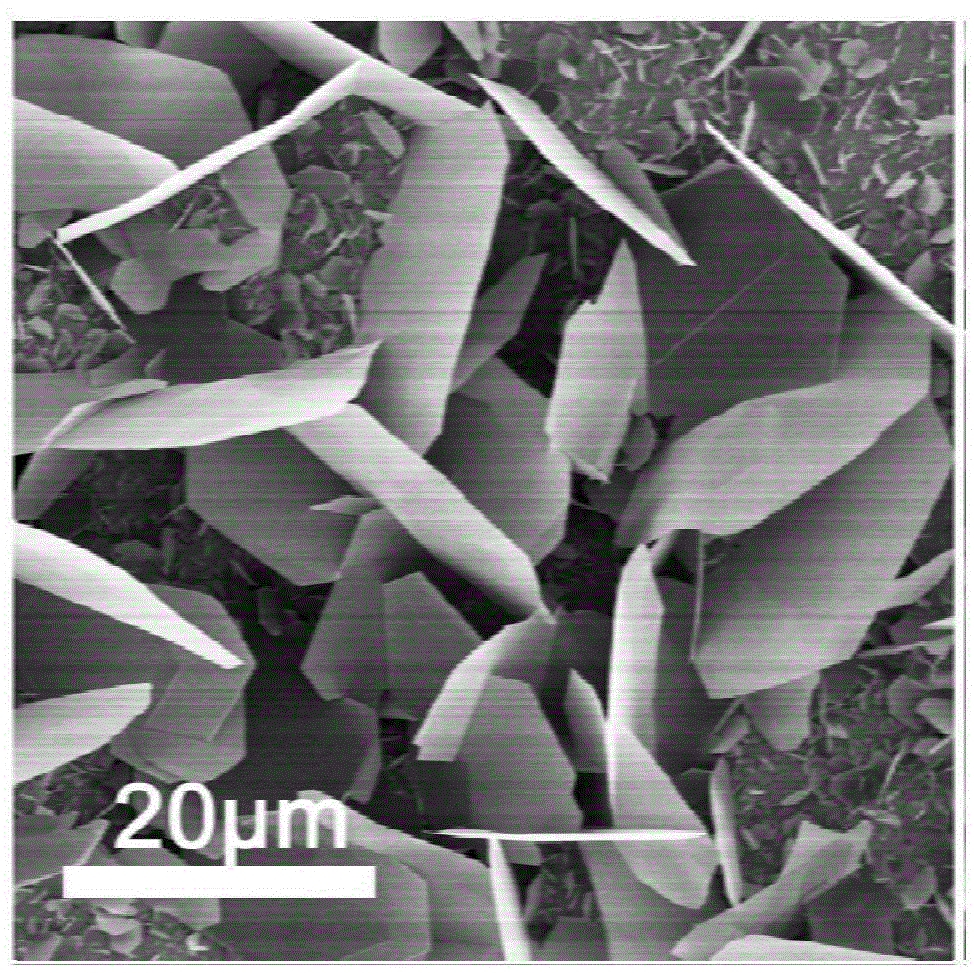

Method for synthesizing copper-zinc-tin-sulfur nano-sheet array by two-step method

InactiveCN105384357AOvercome the problem of easy sheddingSmall sizeCoatingsTwo stepZinc Acetate Dihydrate

The invention discloses a method for synthesizing a copper-zinc-tin-sulfur nano-sheet array by a two-step method. The method comprises the following steps that: FTO glass is used as a substrate, and two porcelain boats are respectively filled with powdered sulfur and cuprous chloride, and are put into a vacuum tube furnace; the vacuum tube furnace is vacuumized to a high-vacuum state at negative 101kPa, is washed for three times with argon, and is set to be 300 DEG C; the substrate is taken out after the reaction is finished, is put into the liner of a reaction kettle, is added with a reaction liquid (zinc acetate dihydrate and stannic chloride dihydrate are dissolved in triethylene glycol, the mass ratio of the solutes is 1 to 1, and the concentration of each solute is 1.75g / L), and is put in the steel bushing of the reaction kettle; the reaction kettle is put in a constant temperature oven, and is insulated for 40 hours at 205 DEG C; and the substrate is washed with ethanol after reaction to obtain the copper-zinc-tin-sulfur nano-sheet array. According to the method, the original process for preparing a cuprous chloride film and a subsequent sulfurizing process are integrated into one step, the problem that a product easily falls off can be solved, the repeatability can be improved, and the process cycle is shortend; and the size of a single sheet in the sheet array can be 20[mu]m, the sheet size can be controlled, and the synthesizing method is successfully improved.

Owner:TIANJIN UNIV

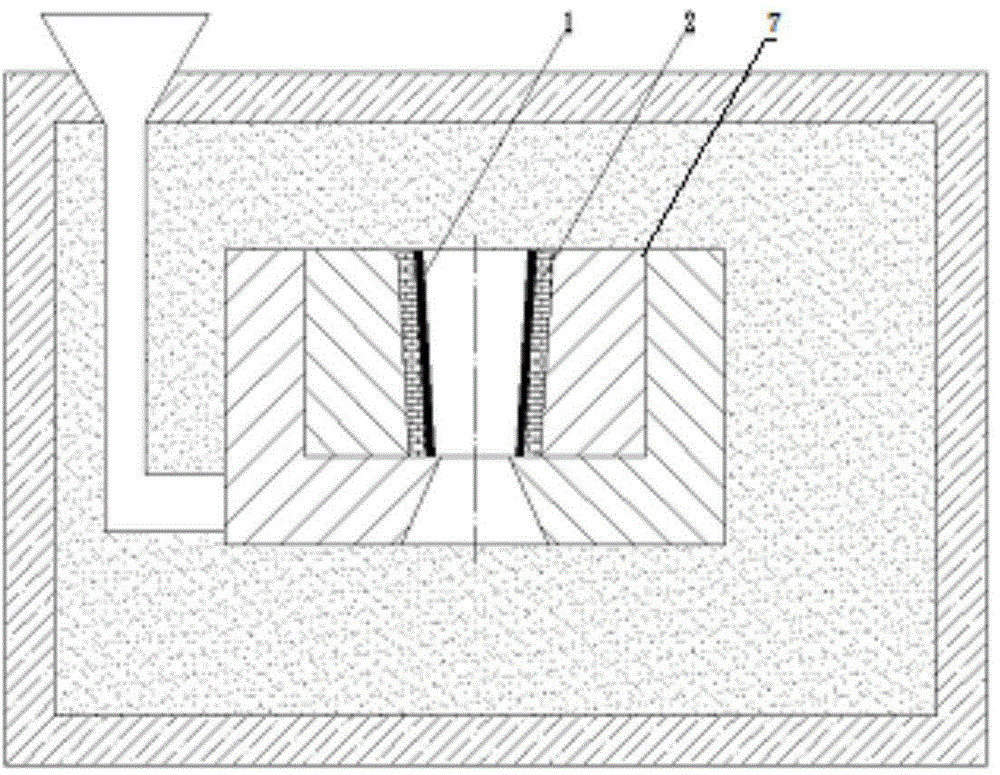

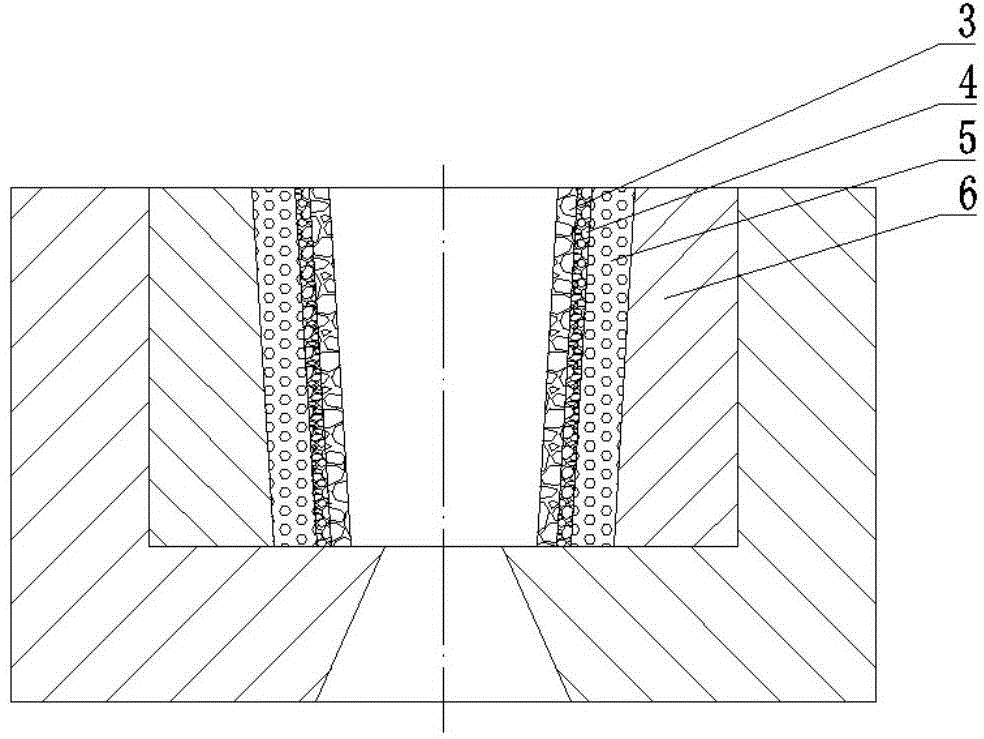

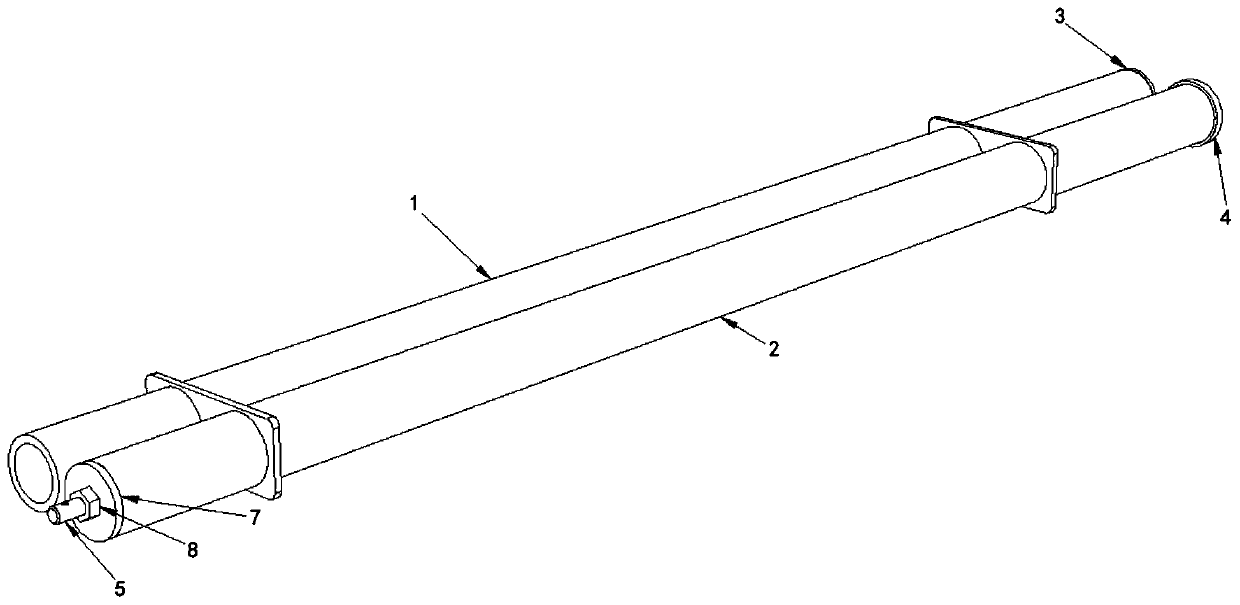

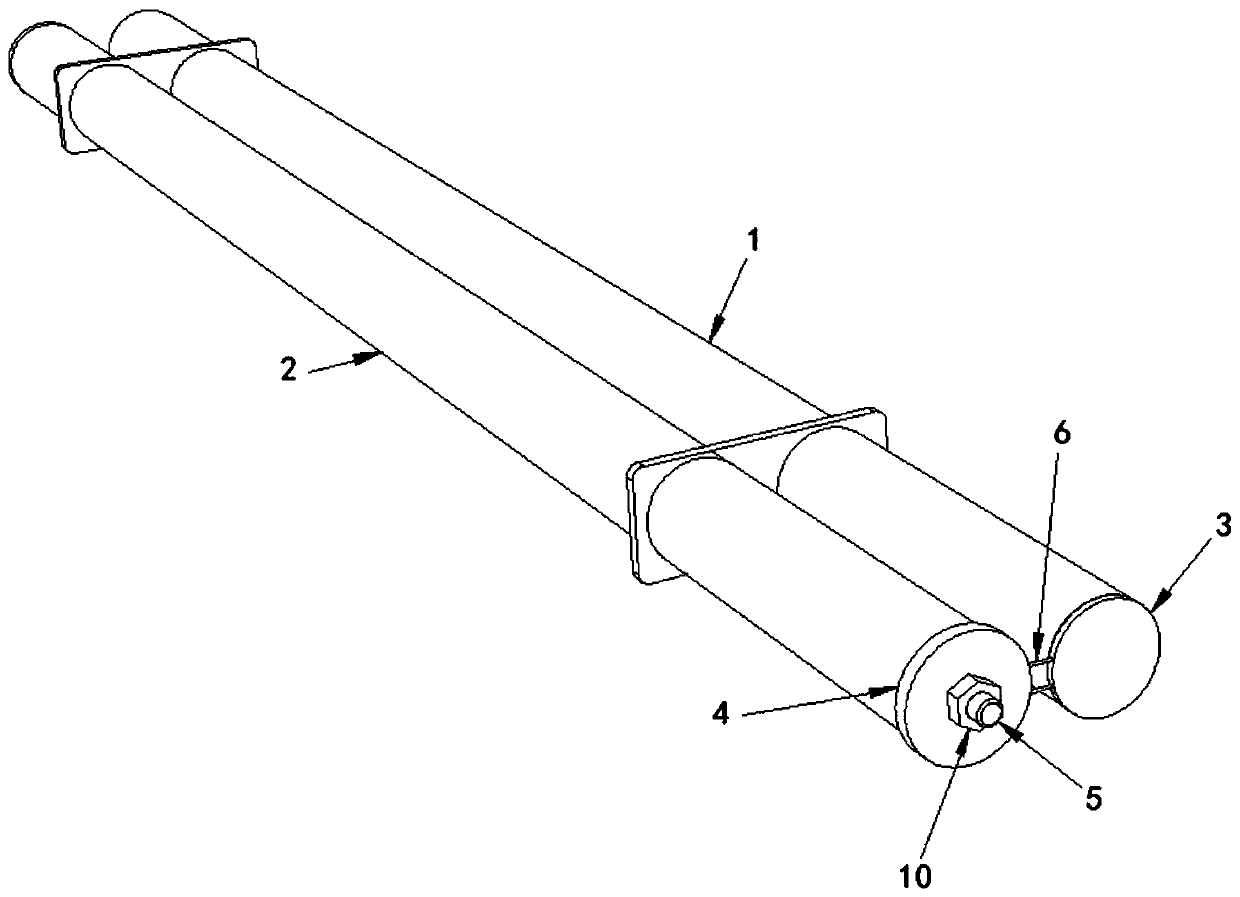

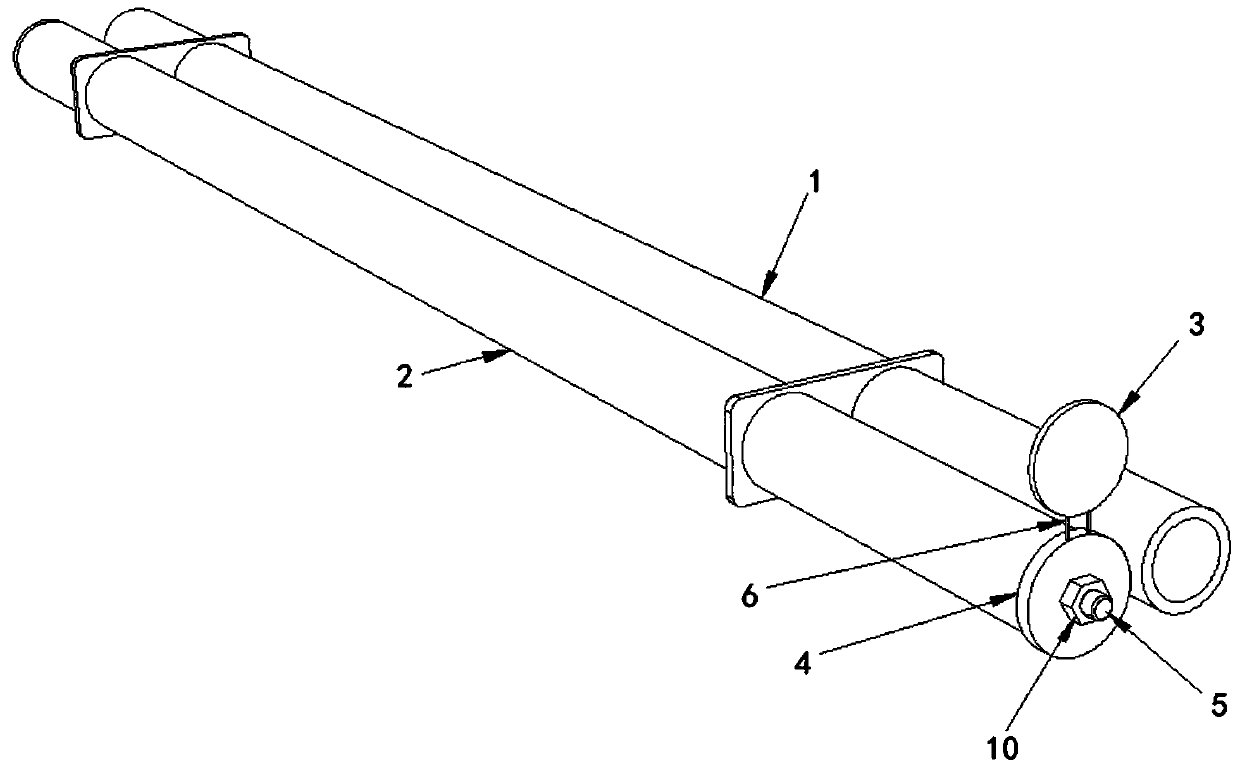

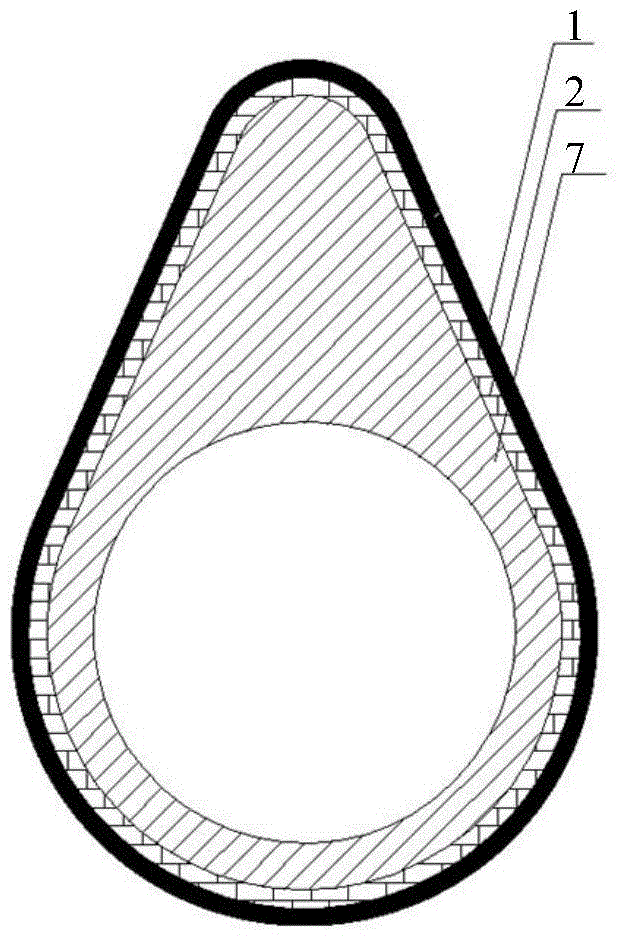

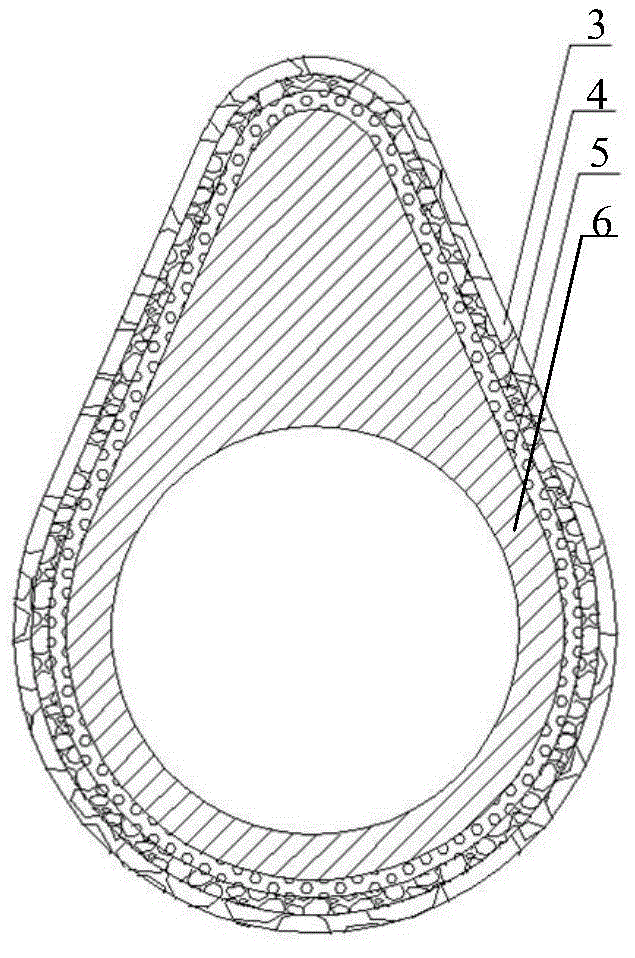

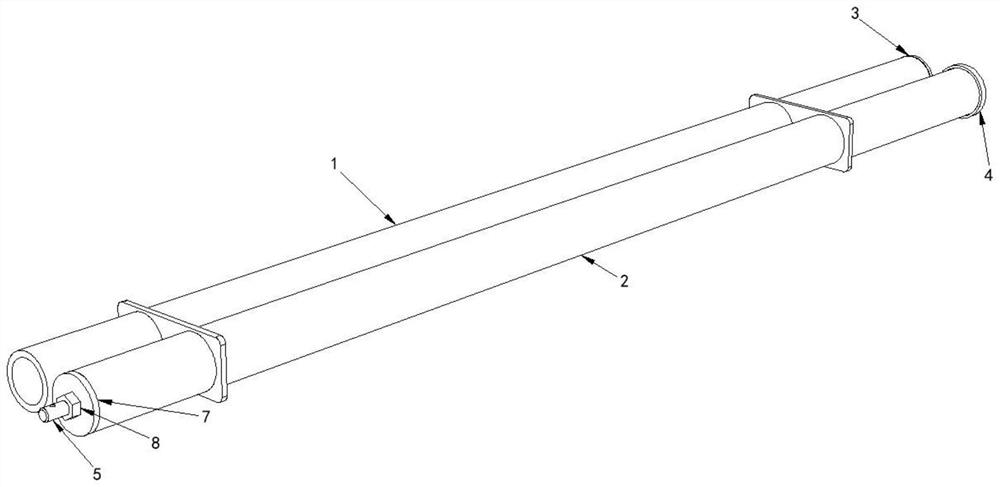

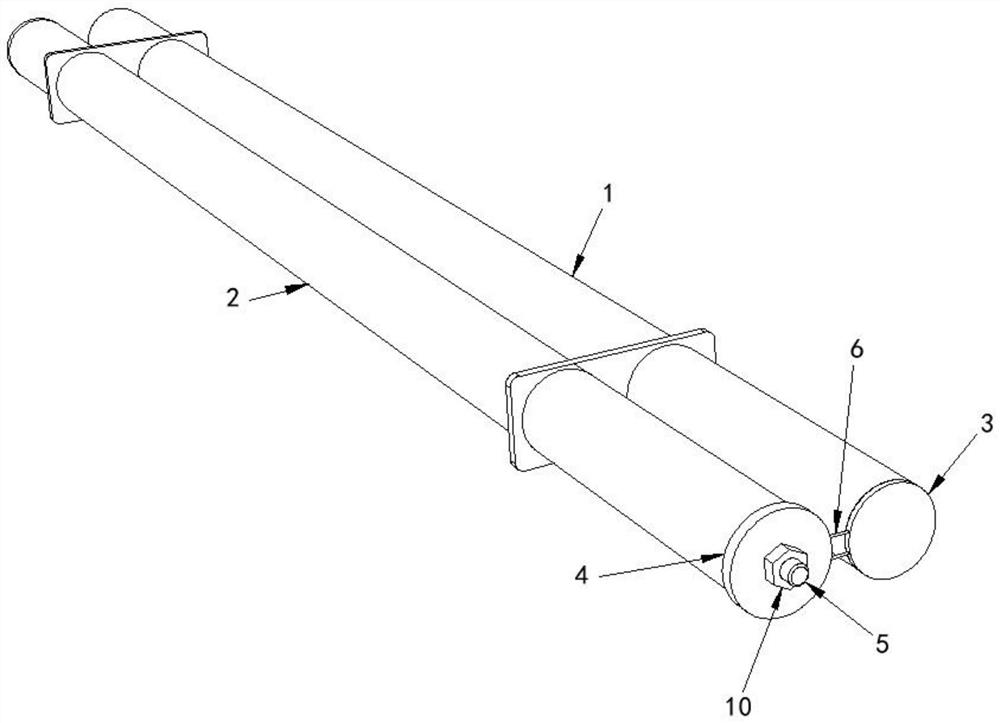

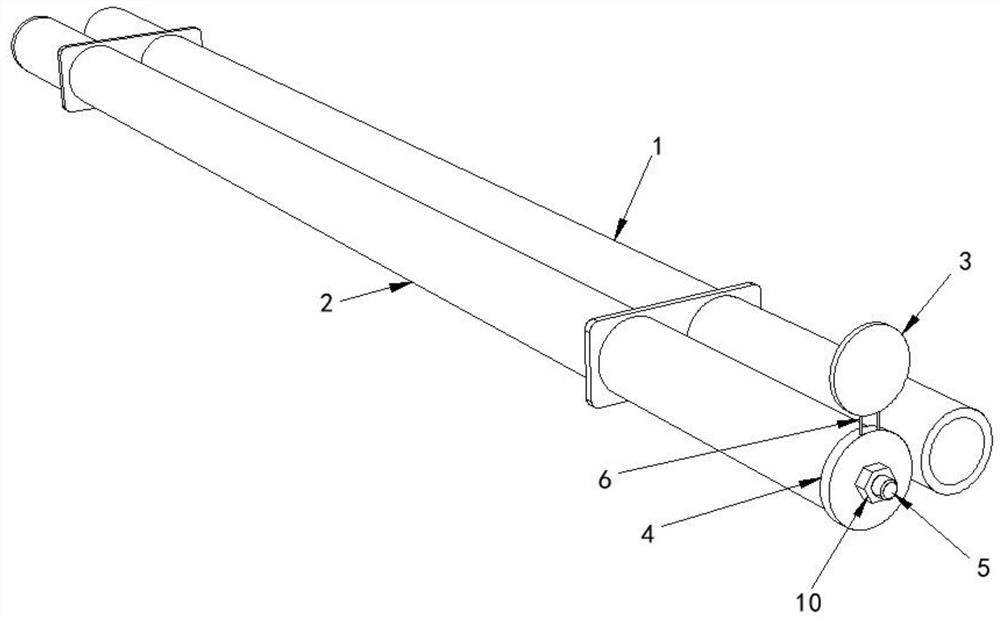

Double-pipe type shield tail grouting device

ActiveCN110805456AExtended service lifePrevent backflowUnderground chambersTunnel liningEngineeringStructural engineering

The invention discloses a double-pipe type shield tail grouting device. The device comprises a main pipe, an auxiliary pipe, a main end cover, an auxiliary end cover, a long rod and a connecting rod.The main pipe and the auxiliary pipe are both installed at the shield tail of a shield tunneling machine, and the main pipe and the auxiliary pipe are parallel. The auxiliary end cover covers the pipetail of the auxiliary pipe, the main end cover is coaxial with the main pipe, the two ends of the connecting rod are connected with the side face of the main end cover and the side face of the auxiliary end cover respectively, and the main end cover and the auxiliary end cover are located on the same plane. The long rod is located in the auxiliary pipe and is coaxial with the auxiliary pipe, a first end of the long rod goes beyond the pipe head of the auxiliary pipe, a second end of the long rod is fixedly connected with the auxiliary end cover, and the long rod can drive the auxiliary end cover to rotate. According to the double-pipe type shield tail grouting device, the long rod is arranged in the auxiliary pipe, and a constructor rotates the auxiliary end cover and the main end cover by using the long rod, so that the main end cover can be controlled to close the pipe tail of the main pipe, slurry is prevented from flowing back to the main pipe during shutdown of the shield tunneling machine, the main pipe has higher anti-blocking capability, and the service life of the main pipe is prolonged.

Owner:中建八局轨道交通建设有限公司

Engine cam and manufacturing method thereof

ActiveCN104525914AImprove mechanical propertiesOvercome the problem of easy sheddingCamsLayered productsCarbide coatingThermal insulation

The invention discloses an engine cam with a carbide coating on the surface of a working part, and provides a manufacturing method of the engine cam. The engine cam has a carbide coating on the surface of the working part thereof. A pseudo-single crystal WC compact ceramic layer, a micron WC ceramic layer and a fusion layer of WC and a substrate are in gradient distribution successively from outside to inside, and are applied to the surface of carbon steel. According to the engine cam and the manufacturing method of the present invention, a complex of the substrate and tungsten is obtained by casting, an external carbon source is introduced, and heating and thermal insulation are performed, so that the carbide coating is formed on the surface of the substrate. The coating is in metallurgical binding with the substrate, the binding force is very strong, the problems that the hard particles in the prior art are in non-metallurgical binding with the carbon steel substrate, the binding force is very weak and the particles are easy to fall off are solved, and the wear resistant property of the working surface of the engine cam is greatly increased.

Owner:XIAN UNIV OF TECH

Preparation method of super-hydrophilic/underwater super-oleophobic filter paper

ActiveCN112982030ASolve efficiency problemsSolve corrosivePhysical paper treatmentFiltration separationUltraviolet lightsFilter paper

The invention discloses a preparation method of super-hydrophilic / underwater super-oleophobic filter paper. The preparation method is specifically implemented according to the following steps: step 1, preparing SiO2 sol; step 2, coating the SiO2 gel on the surface of the filter paper through dipping, centrifuging and drying treatment in sequence at room temperature; and step 3, converting the SiO2 gel layer on the surface of the filter paper into a hydrophilic SiO2 ceramic layer by adopting ultraviolet light degradation combined with a low-temperature heat treatment process, thereby completing the preparation of the super-hydrophilic / underwater super-oleophobic filter paper. The problems that in the prior art, the filter paper is low in separation efficiency, poor in corrosion resistance and poor in recycling performance in oil-water separation are solved.

Owner:陕西鸿鑫耐斯环保科技有限公司

Aluminum alloy/aluminum alloy-ceramic combined automobile brake disc and preparation method thereof

PendingCN113930645AStrength easyHigh bonding strengthBraking discsFurnace typesMotor vehicle partAluminium alloy

The invention discloses an aluminum alloy / aluminum alloy-ceramic combined automobile brake disc, and belongs to the technical field of automobile part composite materials. The automobile brake disc has the characteristics of light weight, high safety and good wear resistance. The automobile brake disc comprises a brake disc body and a wear-resistant layer imbedded on a brake surface of the brake disc body, the brake disc body is made of an aluminum alloy base material, the aluminum alloy base material is composed of, by weight, 70-92% of aluminum, 0.1-8% of silicon, 0.1-2.6% of copper, 0.1-3.0% of magnesium, 0.1-6% of zinc, 0.1-0.5% of manganese, 0.1-0.5% of chromium, 0-0.5% of nickel, 0.1-0.5% of erbium and 0.1-0.5% of zirconium, and the wear-resistant layer consists of the following materials of 70-95% of an aluminum alloy matrix and 5-30% of a ceramic phase. The invention further discloses a preparation method of the aluminum alloy / aluminum alloy-ceramic combined automobile brake disc.

Owner:YULIN NORMAL UNIVERSITY

Aromatherapy meridians-activating magnetic therapy warming moxibustion stick

InactiveCN101822615BFlexible control positionOvercome the problem of easy sheddingDevices for heating/cooling reflex pointsElectrotherapyAromatherapyEngineering

The invention discloses an aromatherapy meridians-activating magnetic therapy warming moxibustion stick, which comprises a warming moxibustion head assembly, a connecting assembly and a swath clamp assembly. The swath clamp assembly comprises an inner tube, a screw connector, an outer wall and a push rod assembly, wherein one side of the wall of the inner tube is longitudinally provided with a groove, while the other side is provided with a positioning hole along the longitudinal direction; one end of the screw joint is connected with the connecting assembly; the wall of the outer tube is longitudinally provided with a groove corresponding to the groove of the inner tube, the upper end of the outer tube is connected with the other end of the screw connector, and the lower end of the outertube is closed; and the push rod assembly is used for pushing a swath placed in the inner tube along the grooves formed on the inner tube and the outer tube to adjust the position of the swath in the warming moxibustion head assembly, and the push rod assembly is positioned through a positioning hole.

Owner:温宗金

Liquid-phase sandwich nanometer colloid particle laser protective materials

InactiveCN1300602CGlare confinement effectGood visible light transparencyOptical partsOptical elementsLead nitrateTetrahydrofuran

A laser protective plate is prepared by injecting solution of nano-glue particles into sandwich of two pieces of glasses. The nano-glue particles solution is prepared as the follows: silver nitrate or either of silver nitrate and lead nitrate together with thioacetanilide are dissolved in one or combined solvent of water, alcohol, glycol, benzene, pyridine and tetrahydrofuran with using one of polyvinyl pyridine, vinyl pyridinedone and polyvinyl alcohol as the stabilizer.

Owner:ELECTRONICS ENG COLLEGE PLA

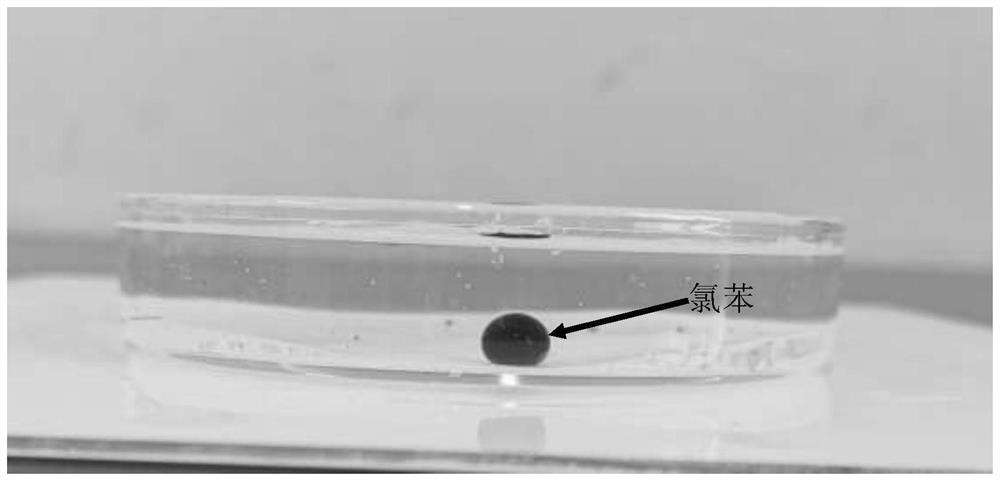

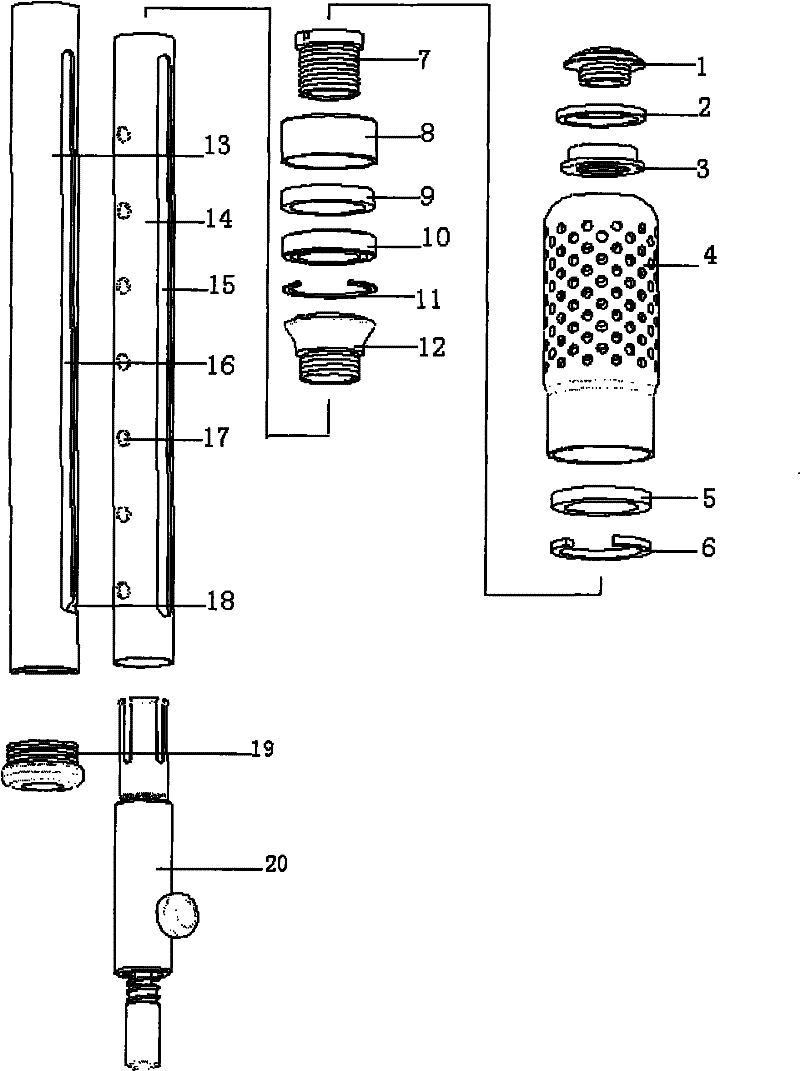

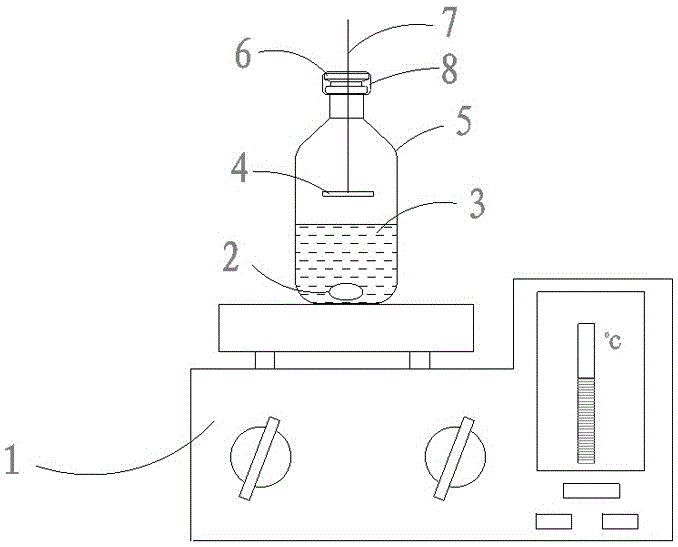

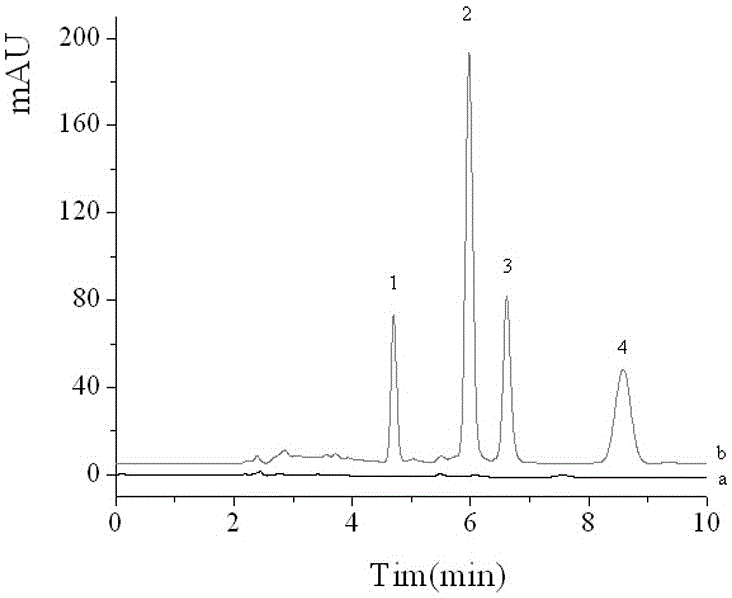

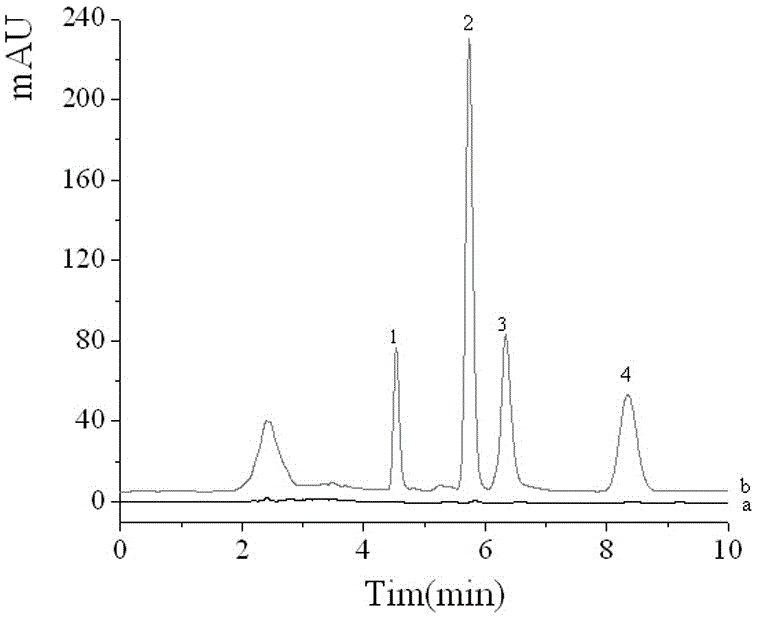

Membrane headspace solvent microextraction method and device

InactiveCN103293042BOvercome the problem of easy falling off of direct suspensionOvercome the problem of easy sheddingPreparing sample for investigationTarget analysisFiber

The invention discloses a method and a device for micro-extracting a filter membrane headspace solvent. The method comprises the following steps of: soaking a cut fiber filter membrane into an extracting solvent to enable the micropores of the filter membrane to be fully filled with the solvent; putting the filter membrane fully filled with the solvent above sample solution, and extracting the volatile target analyte; after that, taking out the filter membrane, and dissolving the target analyte on the filter membrane by a solvent; finally, analyzing and measuring. The device is simple; the materials are easily available; the method is convenient to operate, easy to master, rapid, less in dosage of organic solvent, high in enhancement factor and low in cost; therefore, the method and the device are suitable for separating and enriching trace volatile target analyte or matter which can be transformed into the volatile target analyte in different physical states of complex samples such as environment, food, organisms, traditional Chinese medicine, etc.

Owner:SHANXI MEDICAL UNIV

A double-pipe shield tail grouting device

ActiveCN110805456BImprove sealingAvoid enteringUnderground chambersTunnel liningStructural engineeringSlurry

The invention discloses a double-pipe type shield tail grouting device. The device comprises a main pipe, an auxiliary pipe, a main end cover, an auxiliary end cover, a long rod and a connecting rod.The main pipe and the auxiliary pipe are both installed at the shield tail of a shield tunneling machine, and the main pipe and the auxiliary pipe are parallel. The auxiliary end cover covers the pipetail of the auxiliary pipe, the main end cover is coaxial with the main pipe, the two ends of the connecting rod are connected with the side face of the main end cover and the side face of the auxiliary end cover respectively, and the main end cover and the auxiliary end cover are located on the same plane. The long rod is located in the auxiliary pipe and is coaxial with the auxiliary pipe, a first end of the long rod goes beyond the pipe head of the auxiliary pipe, a second end of the long rod is fixedly connected with the auxiliary end cover, and the long rod can drive the auxiliary end cover to rotate. According to the double-pipe type shield tail grouting device, the long rod is arranged in the auxiliary pipe, and a constructor rotates the auxiliary end cover and the main end cover by using the long rod, so that the main end cover can be controlled to close the pipe tail of the main pipe, slurry is prevented from flowing back to the main pipe during shutdown of the shield tunneling machine, the main pipe has higher anti-blocking capability, and the service life of the main pipe is prolonged.

Owner:中建八局轨道交通建设有限公司

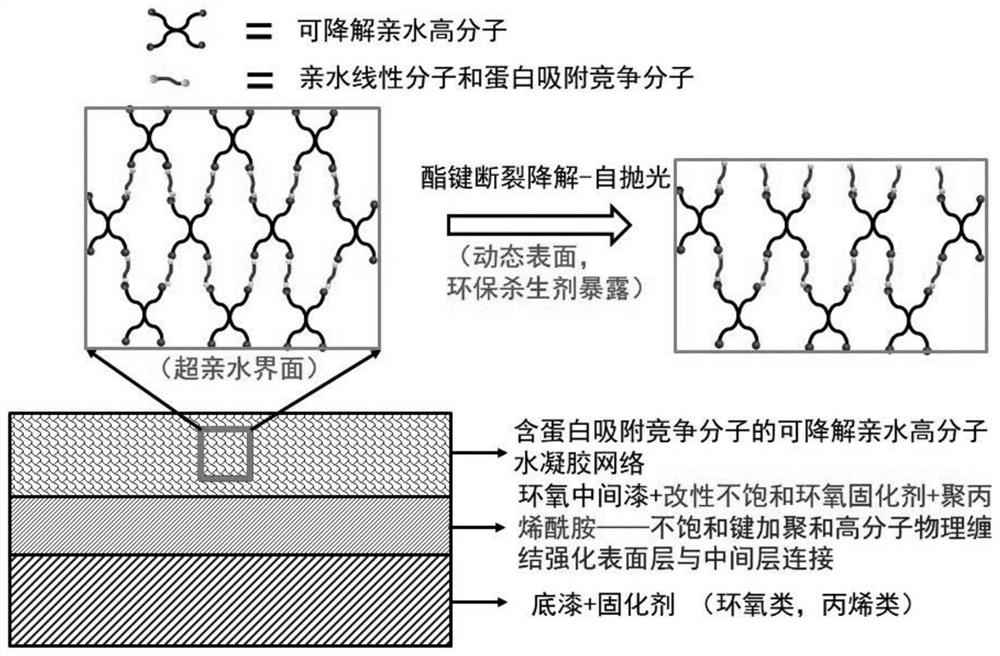

A kind of bionic antifouling paint and its preparation method and application

ActiveCN111187531BAnti-fouling long-lastingAvoid adsorptionAntifouling/underwater paintsPaints with biocidesLacquerBiological adhesion

The invention discloses a novel bionic antifouling coating and its preparation method and application. The novel bionic antifouling coating based on the hydrophilic polymer skeleton surface antifouling coating and the modified intermediate paint curing agent can be widely used to prevent Protein, polysaccharide adsorption, marine fouling biological adhesion, etc., are suitable for the prevention and control of various marine or river biofouling.

Owner:苏州银炙新材料科技有限公司

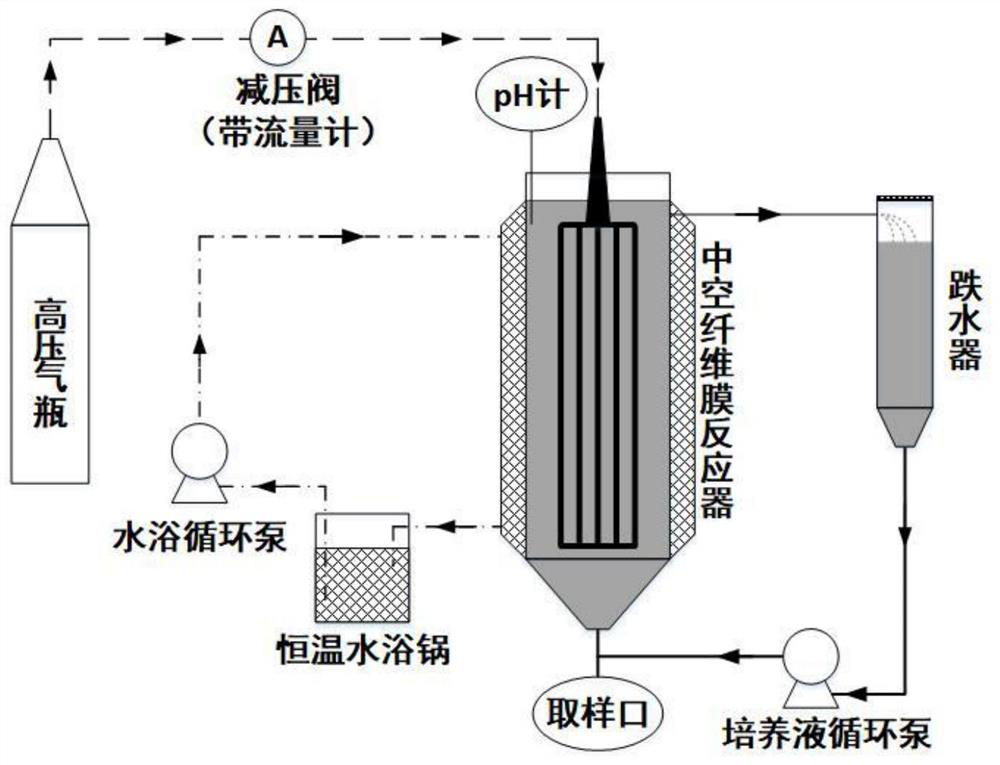

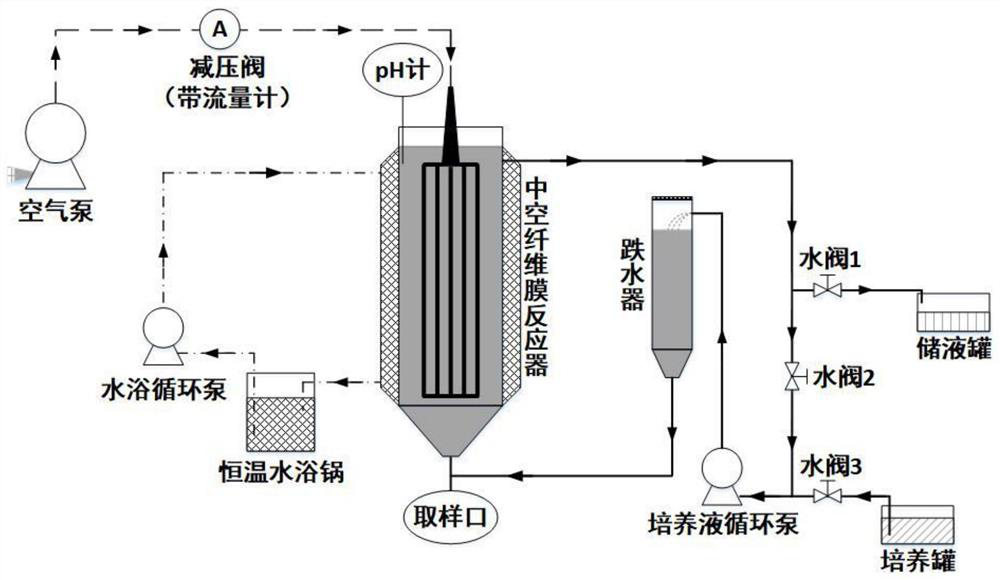

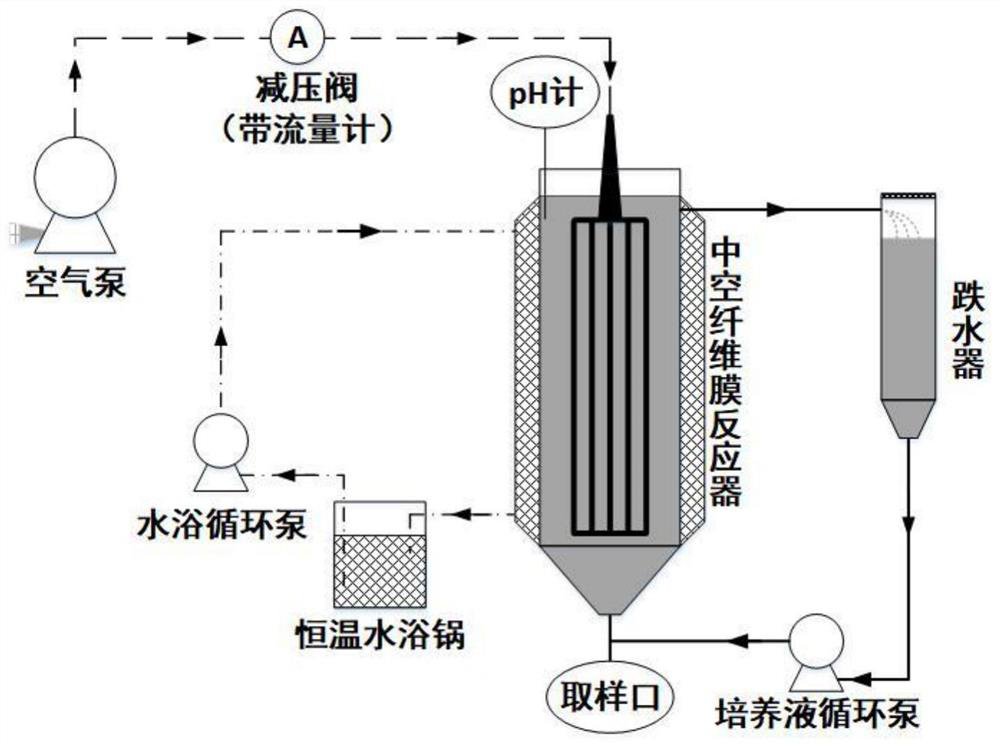

A method for enriching Thiobacillus ferrooxidans with a hollow fiber membrane to form a biofilm, a hollow fiber membrane reactor and its application

ActiveCN110117564BReduced operating requirementsReduce management costsBioreactor/fermenter combinationsBiological substance pretreatmentsThiobacillus ferrooxidansIron sulfate

The invention discloses a method for forming a biological membrane by enriching thiobacillus ferrooxidans by using a hollow fiber membrane, a hollow fiber membrane reactor and application. The methodincludes the steps that a reaction system with the hollow fiber membrane reactor as a core is built, a culture medium and an inoculation body are added, and thiobacillus ferrooxidans enrichment culture is carried out to form the biological membrane; mixed gas containing hydrogen is supplied to the surface of the membrane by the hollow fiber membrane reactor through bubble-free gas output; the temperature of the hollow fiber membrane reactor is stabilized at 25-35 DEG C through water bath heating; after several days of operation, a culture solution is discharged through a sampling port, and thehollow fiber membrane reactor with the membrane surface enriched with the thiobacillus ferrooxidans biological membrane is obtained; the hollow fiber membrane reactor enriched with the biological membrane can be used for generating an iron sulfate solution and schwertmannite. The method realizes separation of thiobacillus ferrooxidans culture and utilization, can achieve culture / utilization circulation, and solves the problem that the culture solution cannot be repeatedly used.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com